Diking method through filling sludge and curing agent into mold bags

A curing agent and mold bag technology, which is used in dikes, coastline protection, dams and other directions, can solve the problems of prolonging construction time, increasing construction difficulty, and reducing costs, and achieves the effect of improving construction efficiency, reducing construction difficulty and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

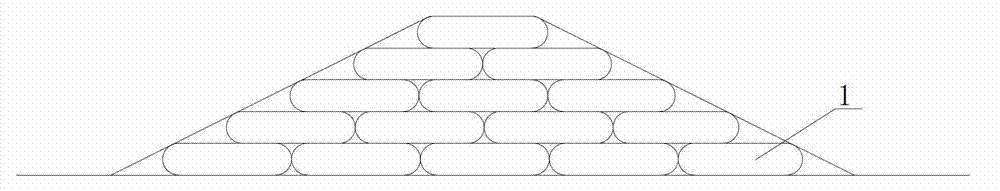

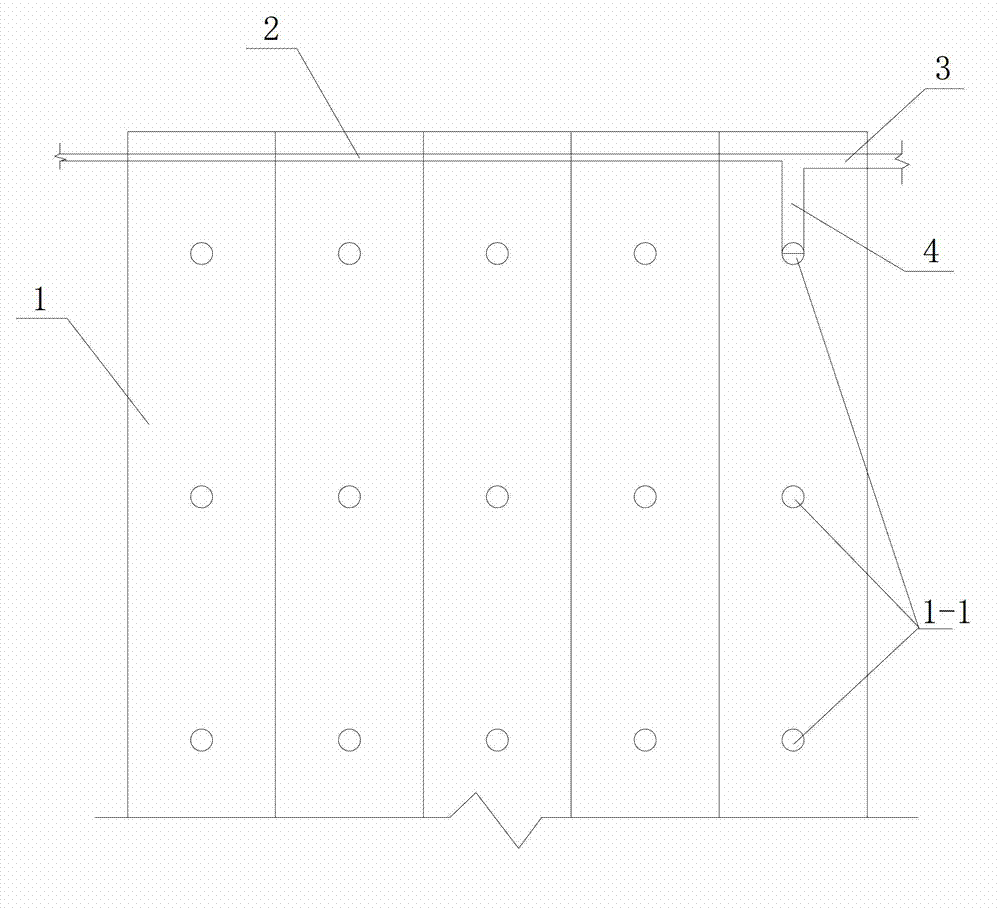

[0017] Such as Figure 1 to Figure 2 As shown, the embankment method of the present embodiment mold bag filling mud mixed with solidifying agent comprises the following steps:

[0018] The first step is to lay a layer of permeable filling mold bag 1 with filling port 1-1 on the target tidal flat surface;

[0019] The second step is to pump the curing agent slurry and sludge into the filling mold bag 1 through the curing agent pipeline 2 and the mud pipeline 3 through the filling port 1-1 until the mold bag 1 is filled;

[0020] The 3rd step, static filling mold bag 1, until the silt in the bag is consolidated;

[0021] The fourth step is to lay the next layer of filling mold bag 1 above the layer of filling mold bag 1, and then repeat the second and third steps;

[0022] The fifth step is to lay the subsequent layers of mold bags 1 sequentially according to the fourth step, and to consolidate the silt therein until reaching the design height.

[0023] In the second step, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com