Patents

Literature

2401results about How to "Improve replacement efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

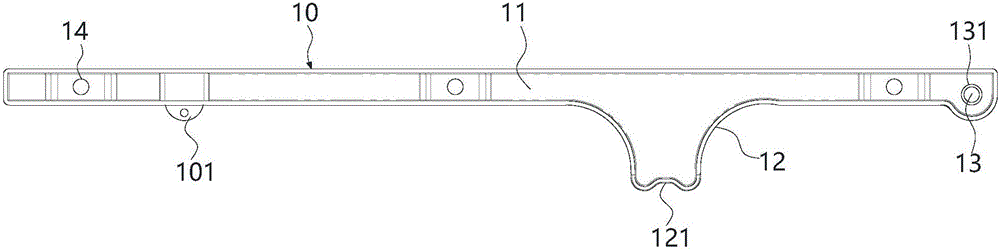

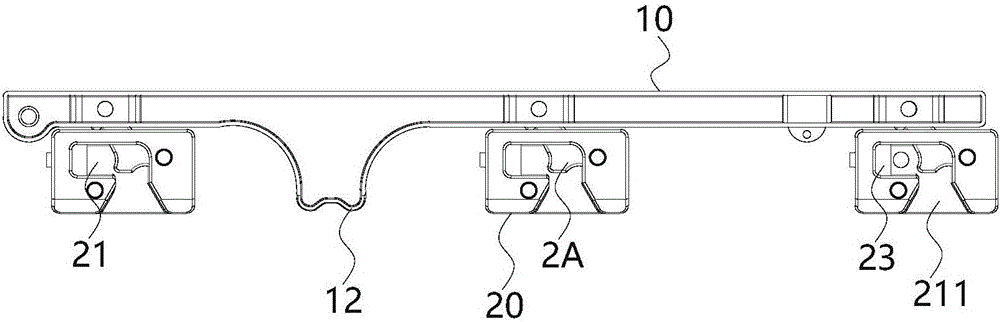

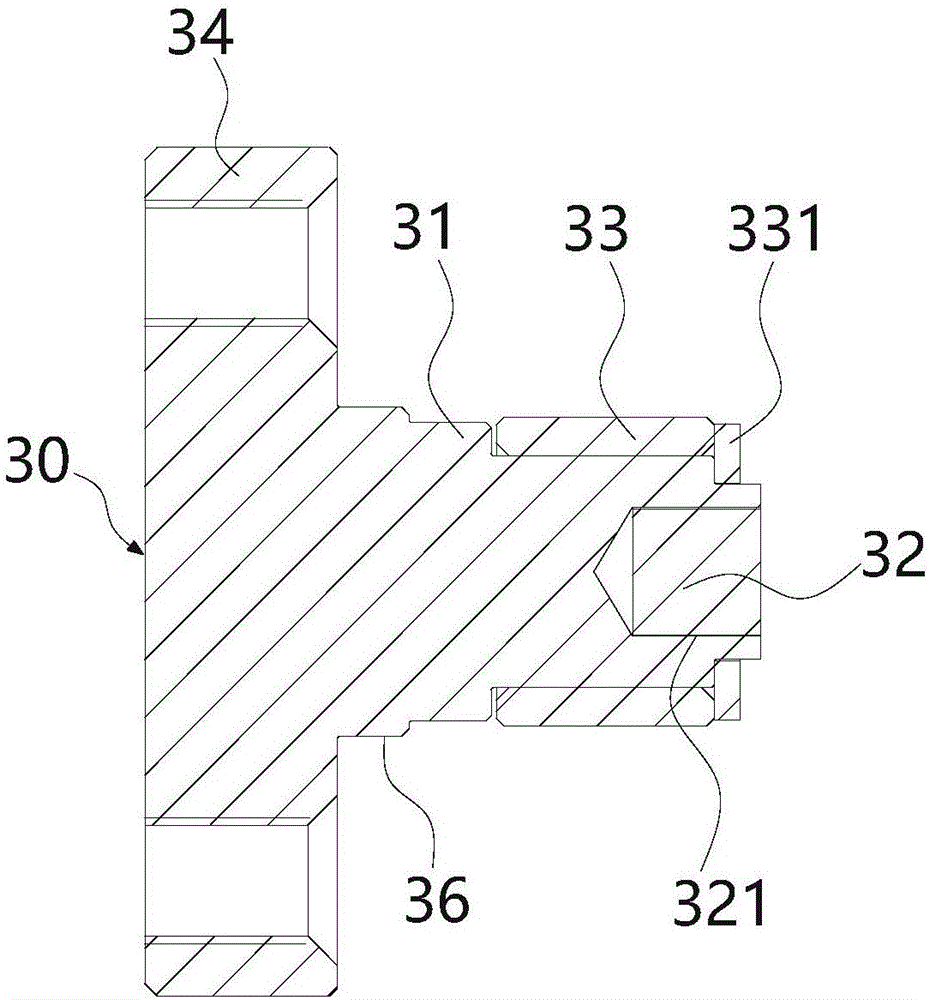

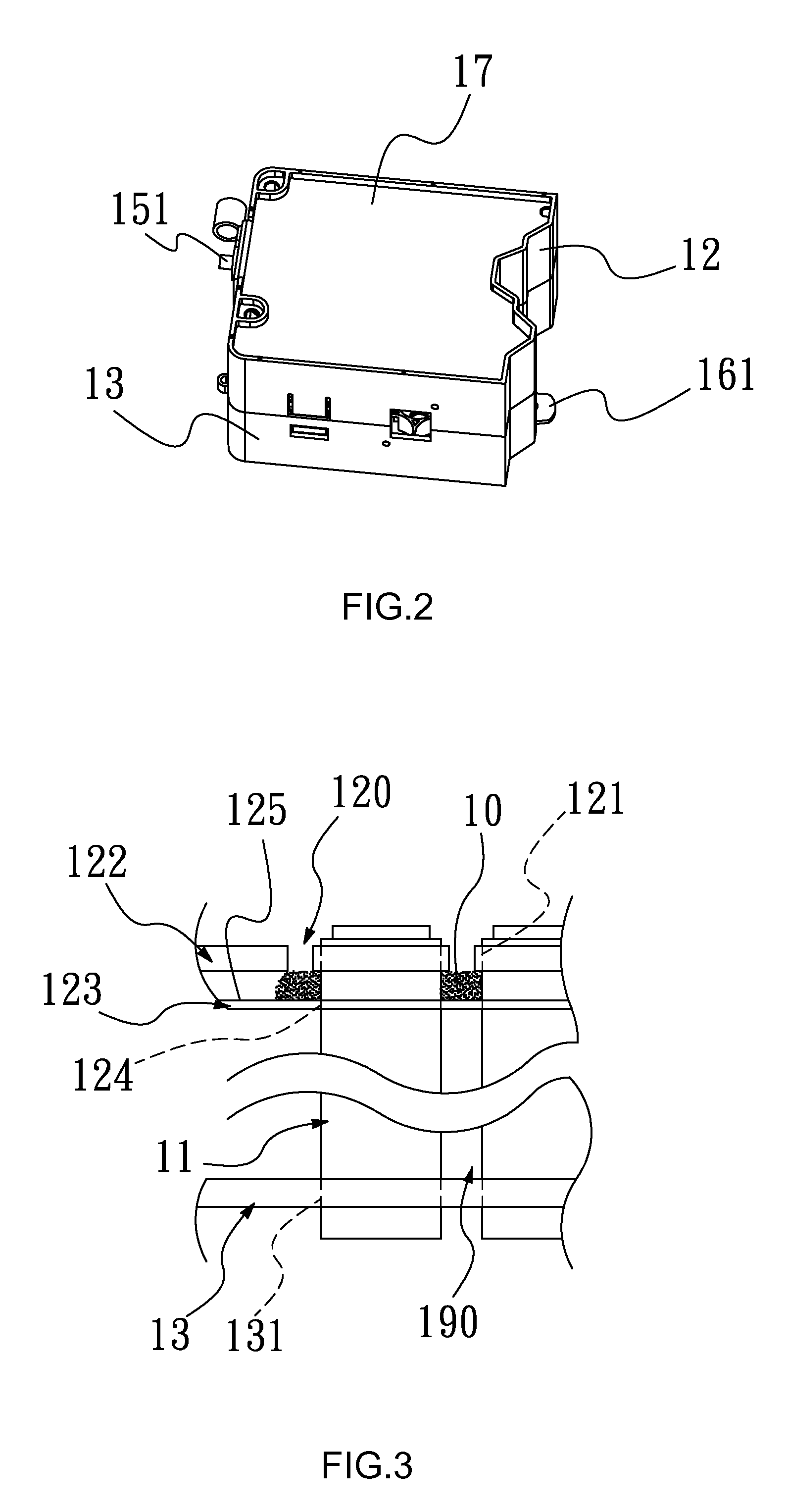

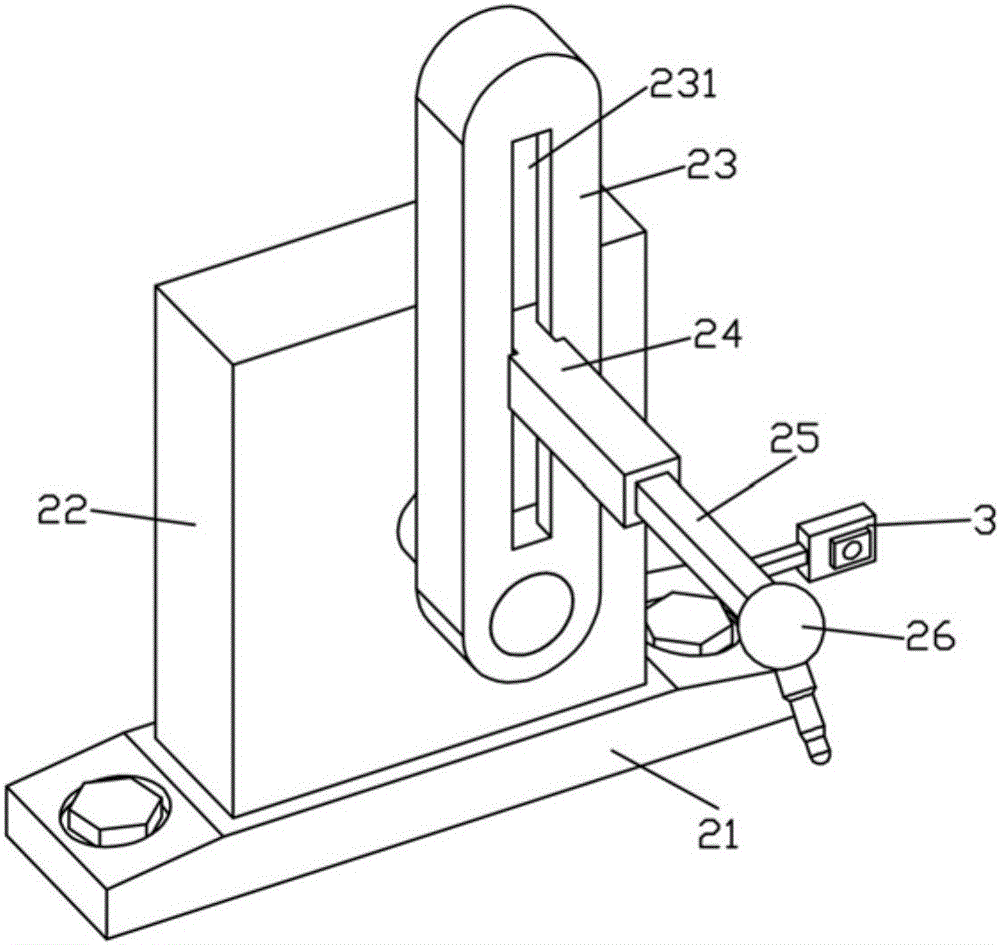

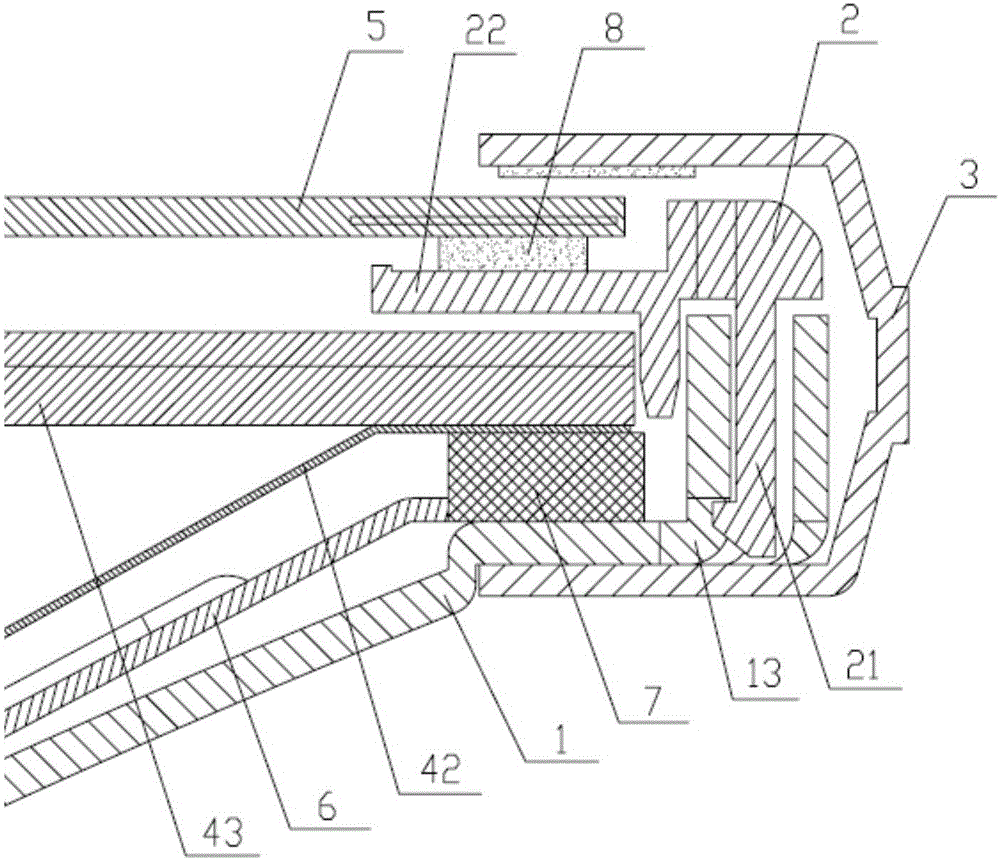

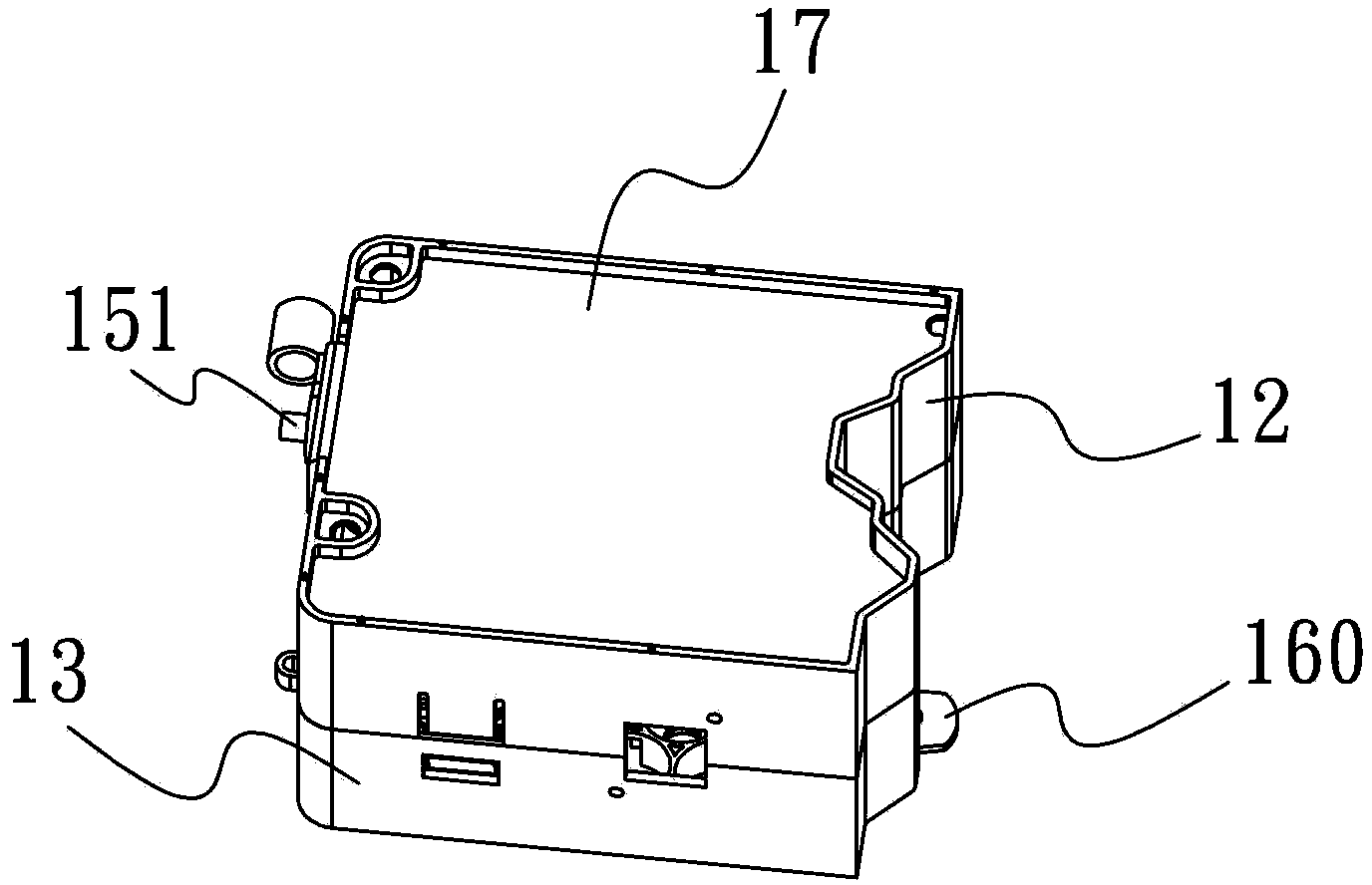

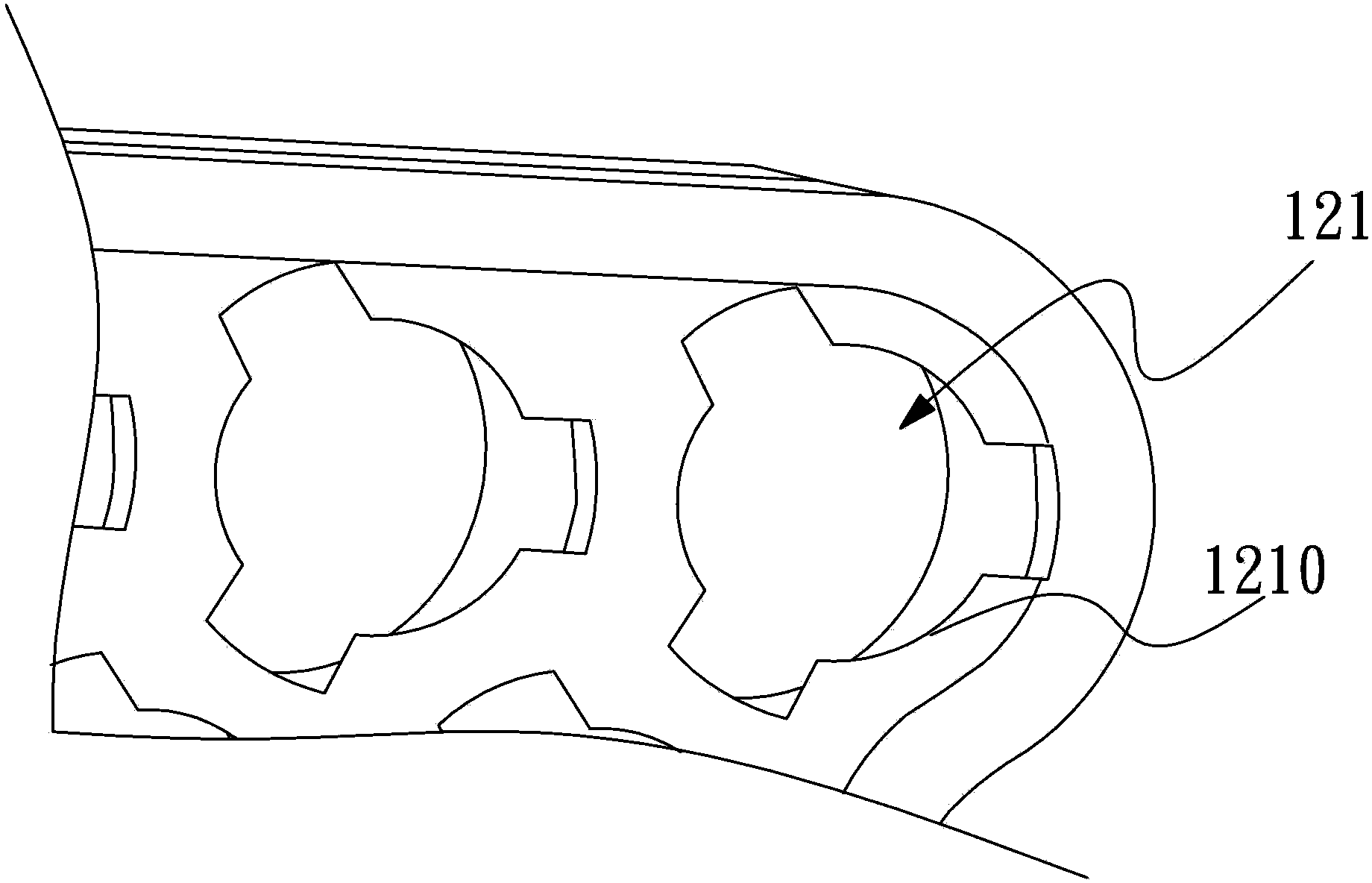

Locking device and electric automobile

ActiveCN106427514AImprove installation efficiencyImprove disassembly efficiencyCharging stationsElectric propulsion mountingEngineeringMechanical engineering

Owner:SHANGHAI DIANBA NEW ENERGY RESOURCES SCI & TECH

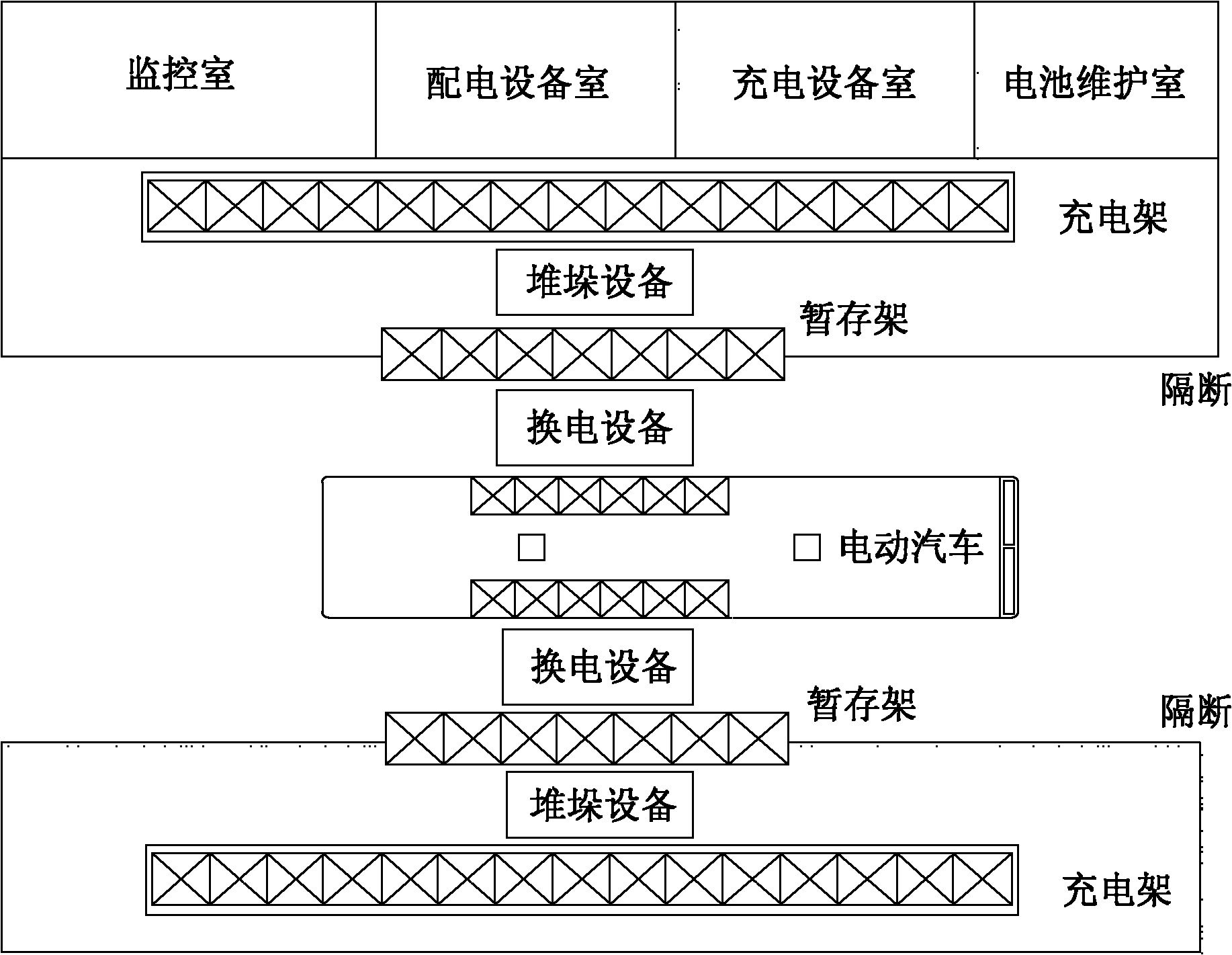

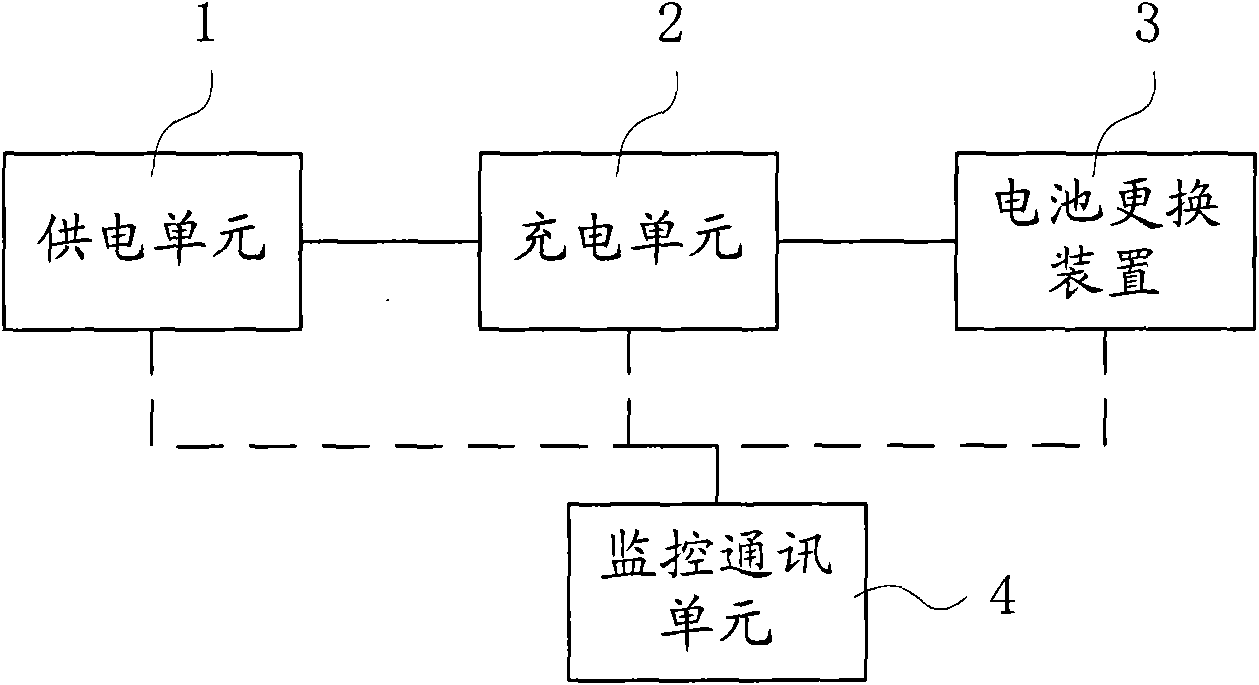

Battery replacing system and battery replacing method of electromobile battery replacing station

ActiveCN102152776AImprove replacement efficiencyIncrease in sizeCharging stationsElectric propulsion mountingElectricityElectrical battery

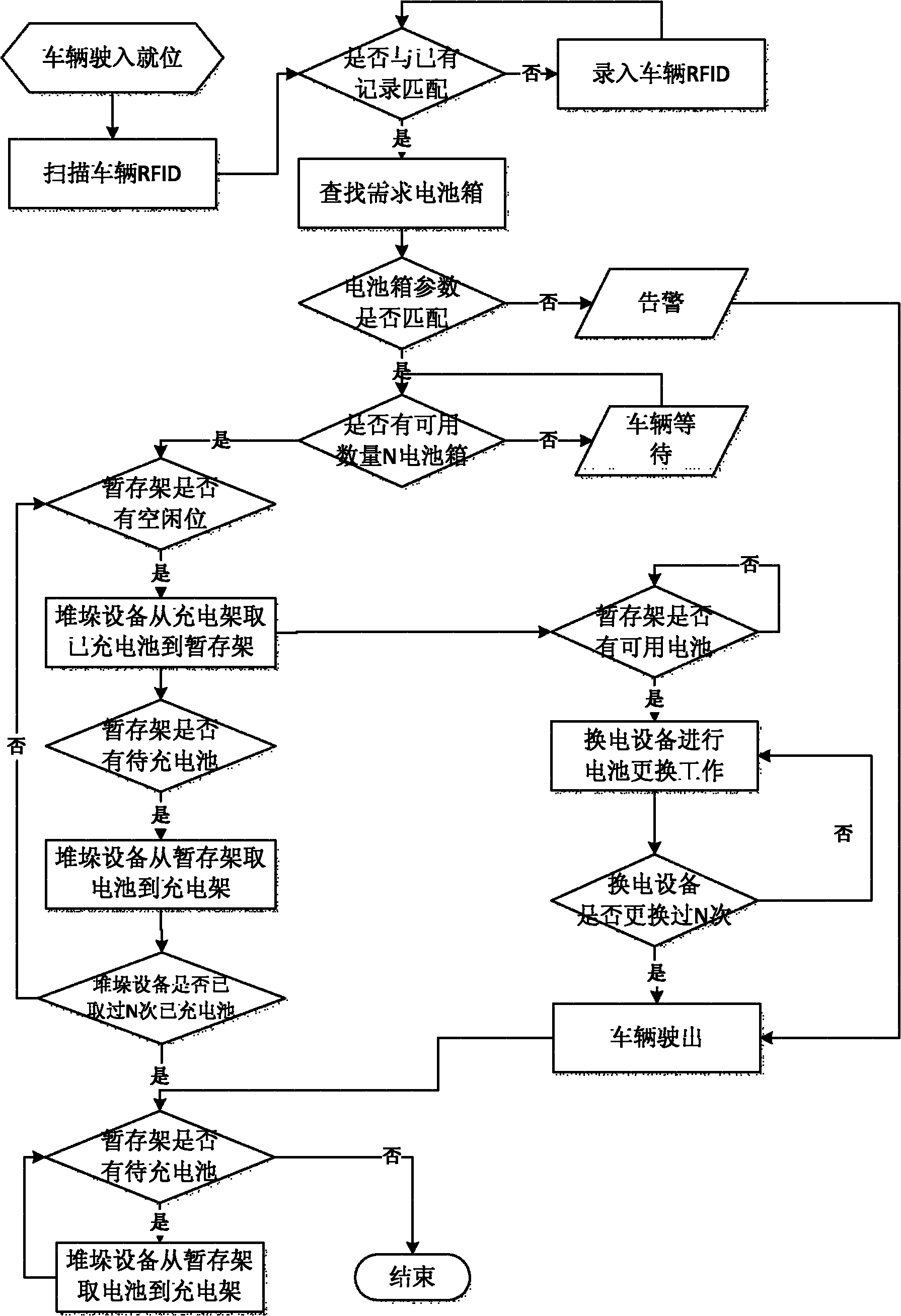

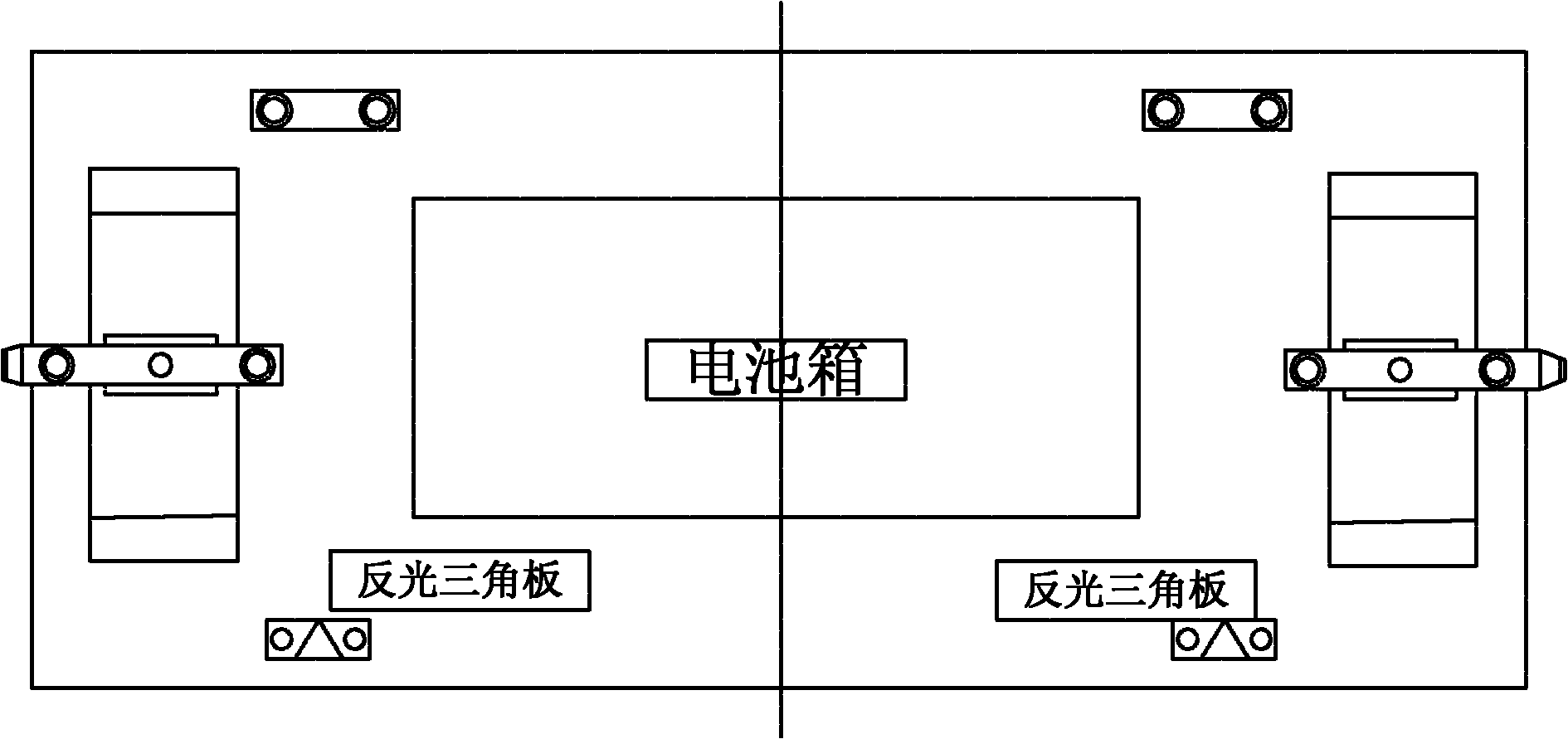

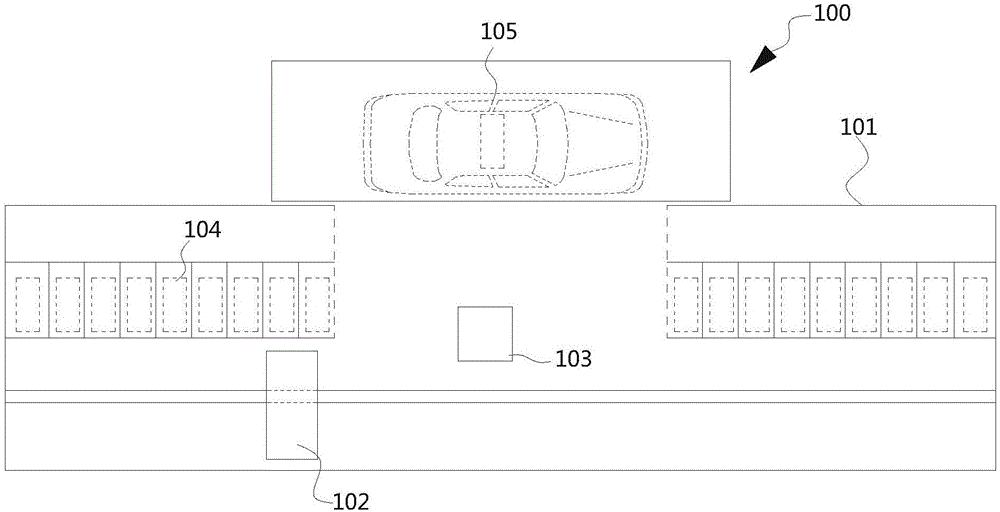

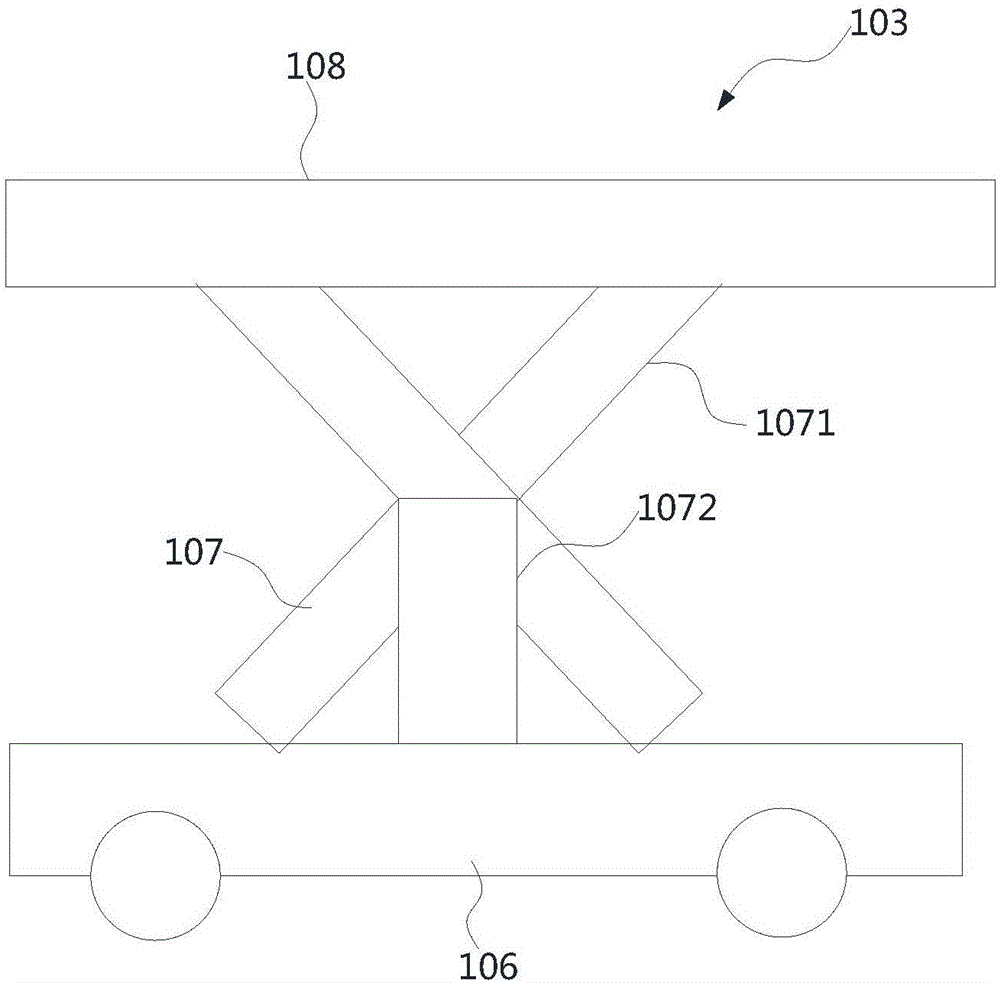

The invention discloses a battery replacing system of an electromobile battery replacing station. The battery replacing system comprises a charging rack, stacking equipment, a temporary storage rack, electric-switching equipment and a charger system. The battery replacing system is characterized in that: the stacking equipment is used for carrying batteries between the charging rack and the temporary storage rack; the electric-switching equipment is used for carrying the batteries between the temporary storage rack and the electomobile; the stacking equipment has translation, hoisting and loading / unloading functions and is used for carrying the batteries between the charging rack and the temporary storage rack; and the electric-switching equipment has translation, hoisting, rotating, inclination angle adjustment and loading / unloading functions, and is used for carrying the batteries between the temporary storage rack and an electromobile. Accurate positioning of a battery box by the electric-switching equipment is realized in a way that a self-carried laser transducer scans a light-reflecting triangular panel arranged on an electromobile battery box frame. Due to the different designs of the charging rack and the temporary storage rack, the stacking equipment and the electric-switching equipment coordinately work together, and then the electromobile battery replacing efficiency is effectively improved.

Owner:NARI TECH CO LTD +4

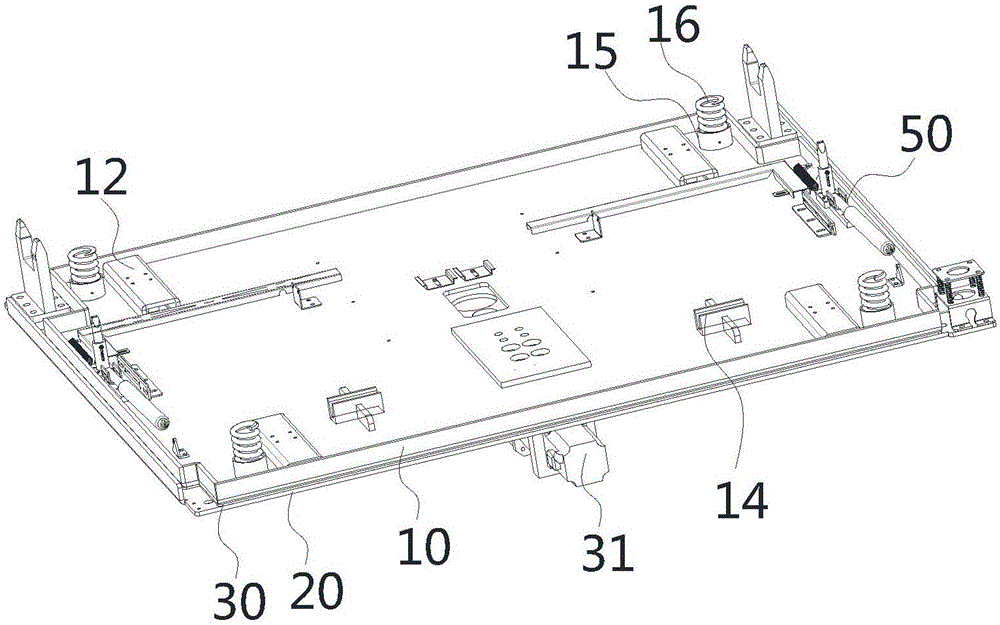

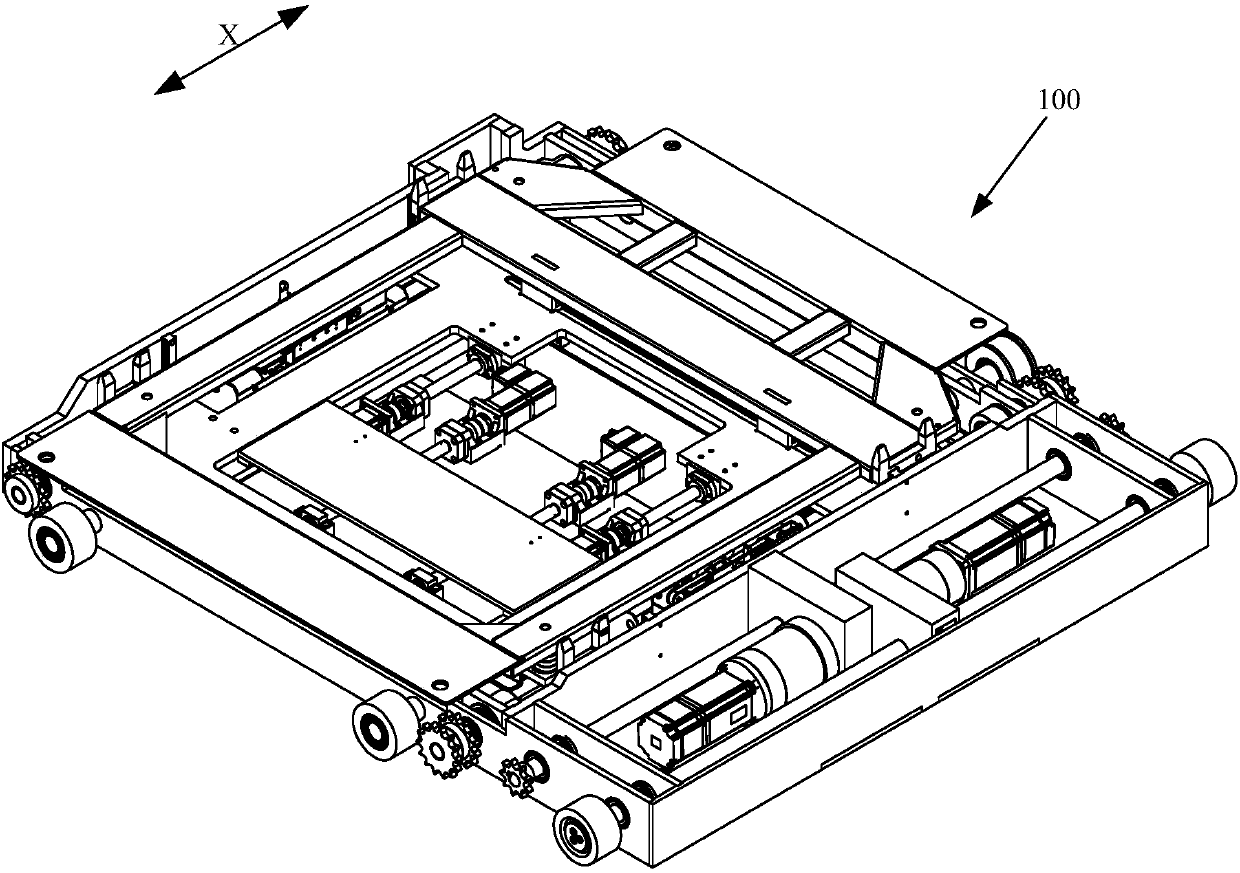

Electricity replacing platform for replacing batteries of electromobiles and electricity replacing mobile platform and rapid replacing system

ActiveCN106740725AImprove replacement efficiencyNo human intervention requiredCharging stationsElectric propulsion mountingElectricityAutomotive battery

The invention provides an electricity replacing platform for replacing batteries of electromobiles and an electricity replacing mobile platform and a rapid replacing system. The electricity replacing platform for replacing batteries of electromobiles comprises an upper board used for bearing the replaced batteries; an unlocking device mounted on the upper surface of the upper board and used for unlocking a battery locking device mounted on the electromobile; and a mobile drive device mounted in connection with the upper board through the drive output end and used for driving the upper board to move in a horizontal direction. According to the electricity replacing platform, the batteries locked on the bottom of the electromobile can be unlocked by utilizing the unlocking device, the unlocking point of the battery locking device is automatically aligned, and the automatic unlocking is achieved in the moving process, the whole process is completely automated, manual interference is not necessary, and the replacing efficiency of batteries can be increased. Additionally, the angle of the upper board relative to the battery unlocking position can be adjusted through the mobile drive device, thus under the condition that the whole battery replacing mobile platform is not moved, the unlocking point of the batteries is automatically adapted, and the unlocking efficiency is further increased.

Owner:SHANGHAI DIANBA NEW ENERGY RESOURCES SCI & TECH

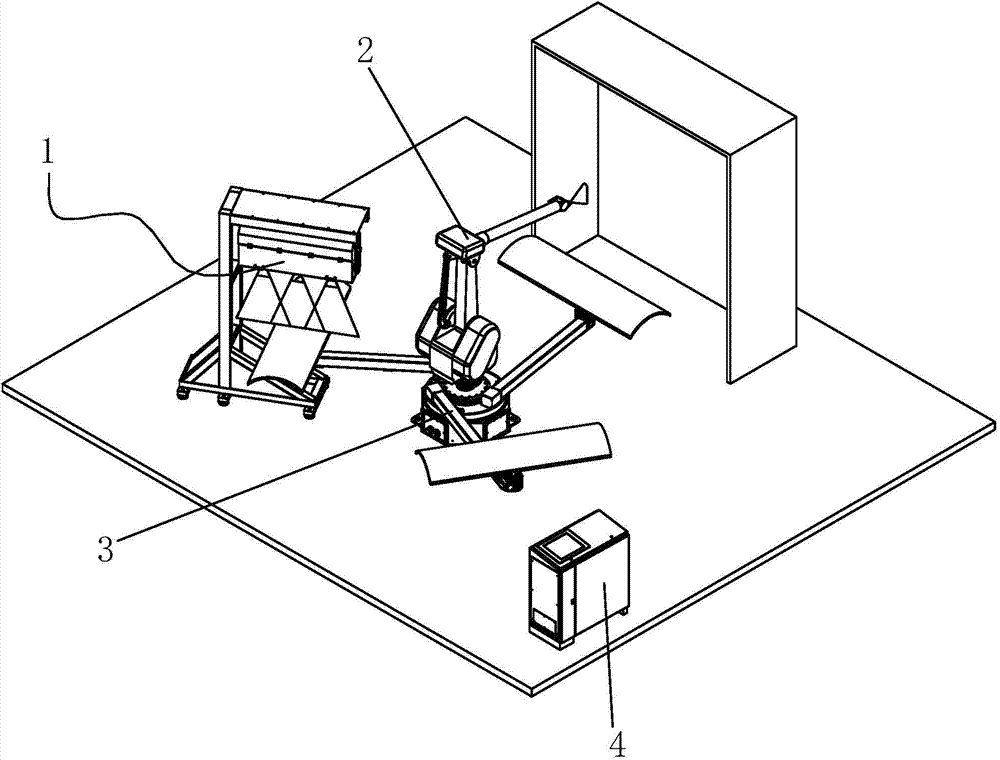

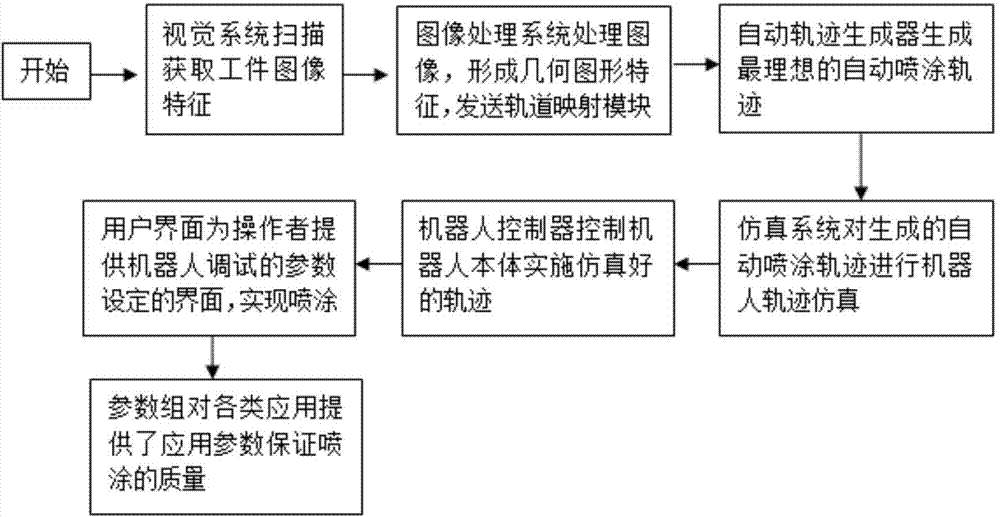

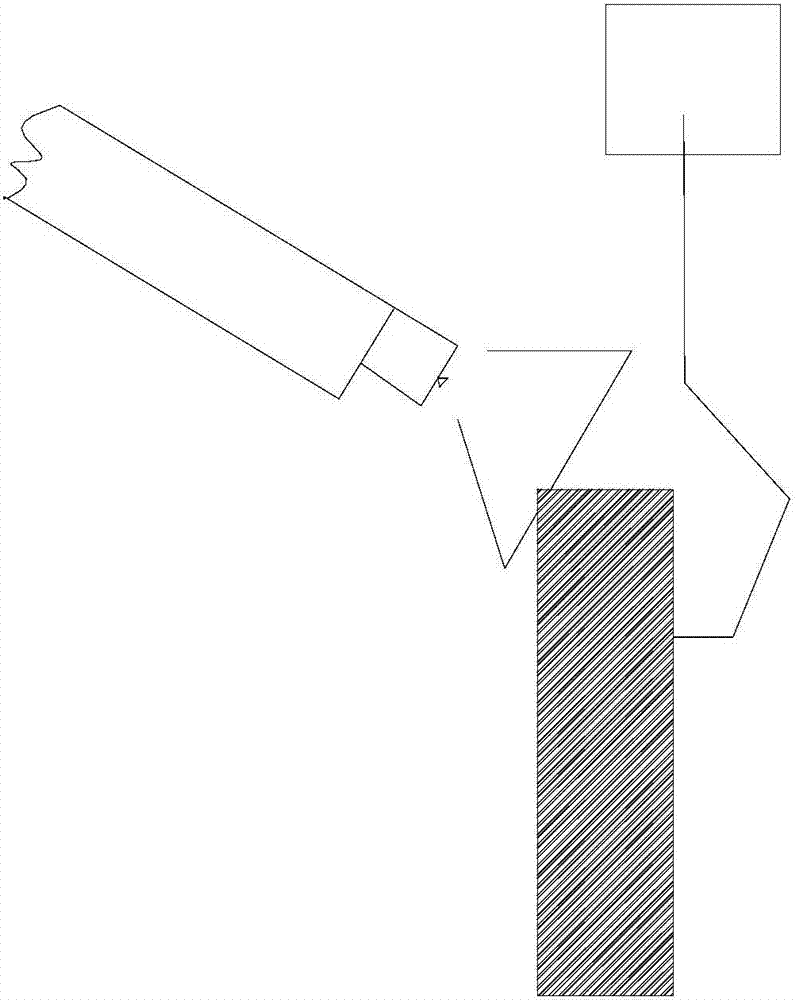

Control method of robot automatic spraying system

The invention discloses a control method for a robot automatic spraying system. The control method of the robot automatic spraying system comprises the following steps of (1) acquiring feature data of a workpiece to be sprayed; (2) processing acquired data by using an image processing system; (3) automatically generating a track; (4) simulating; (5) controlling a user interface; (6) determining a spraying parameter; and (7) performing spraying. The control method of the robot automatic spraying system has the advantages of high automation degree, high machining precision, wide application range and the like. Different workpiece spraying tracks can be generated automatically, the operation difficulty of a user is reduced, the traditional manual programming on single different-model workpieces to be sprayed is replaced, consumed time on spraying is shortened, and the production efficiency is improved.

Owner:希美埃(芜湖)机器人技术有限公司

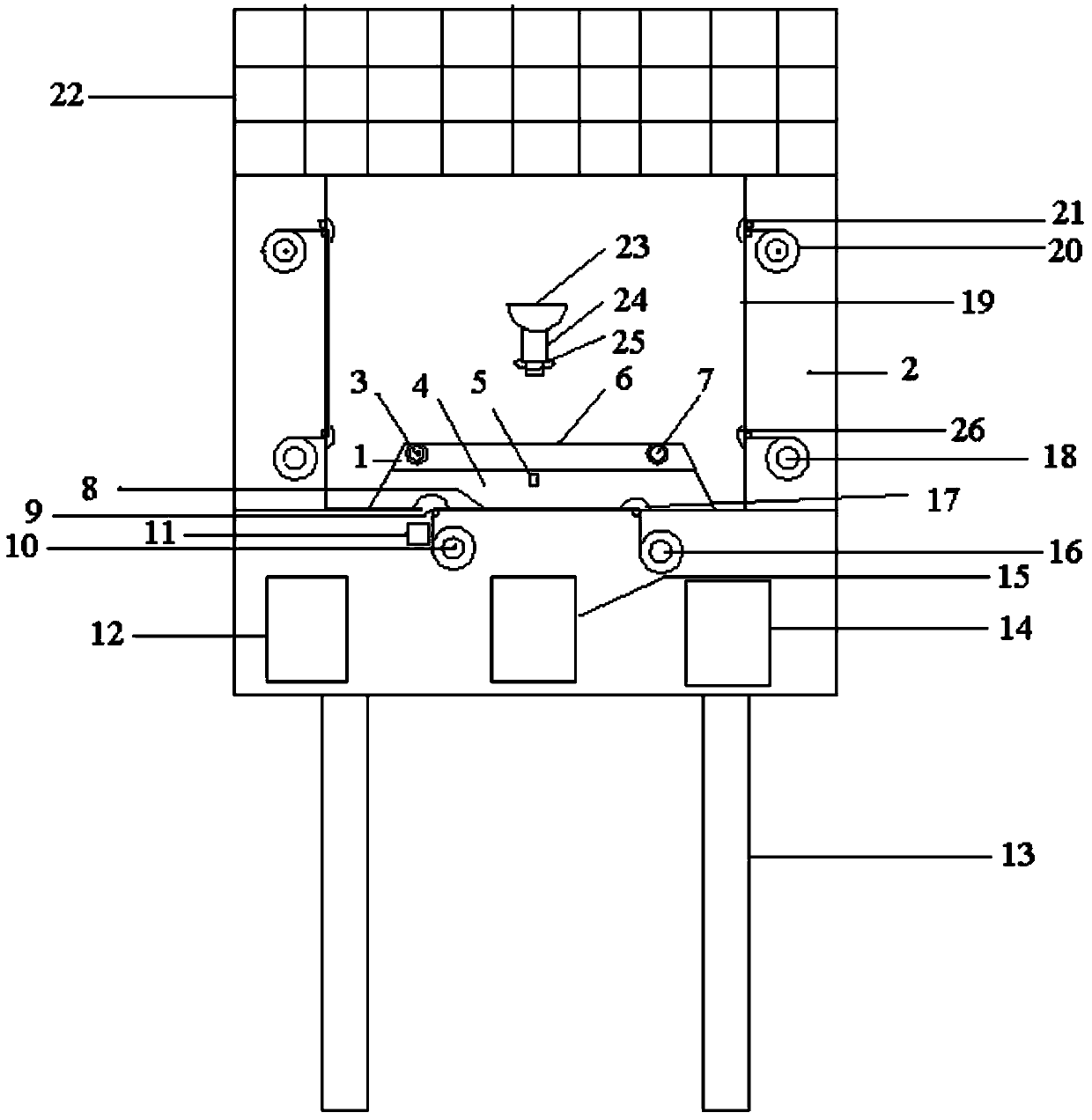

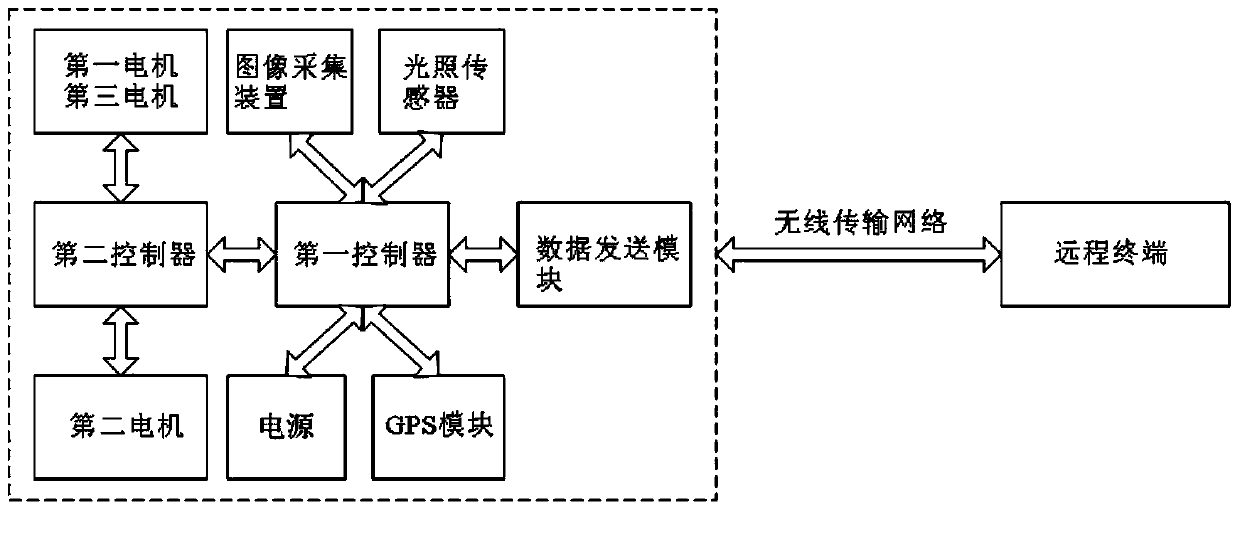

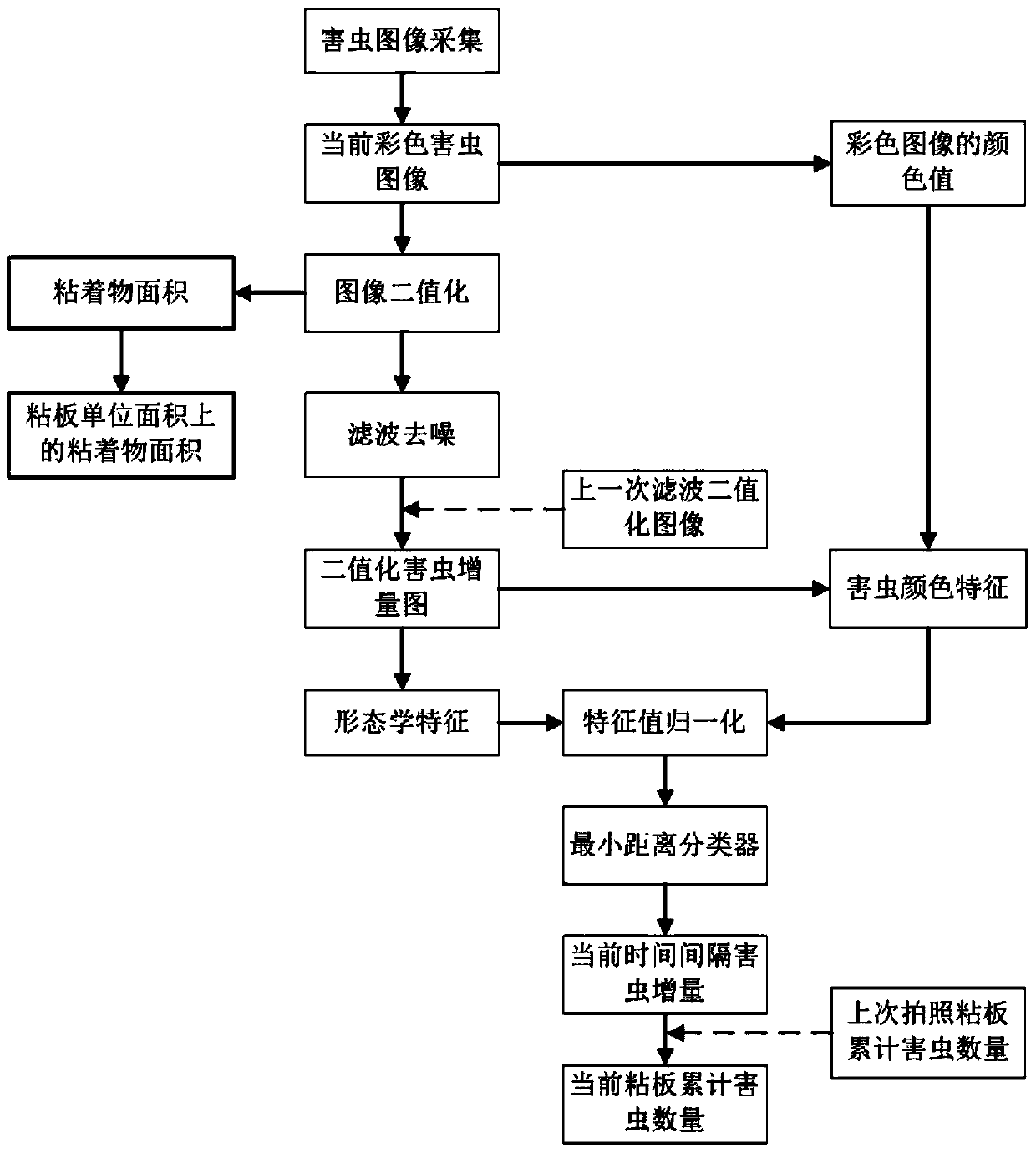

Pest monitoring system capable of automatically replacing pest sticky board and monitoring method

ActiveCN104186449ARealize automatic replacementImprove replacement efficiencyInsect catchers and killersMonitoring systemComputer science

The invention discloses a pest monitoring system capable of automatically replacing a pest sticky board and a monitoring method. The system comprises a trapping device, an image collecting device and a processing control device, wherein the trapping device is located in the center of the pest monitoring system; the image collecting device is located in the center of the trapping device and used for collecting an image of the pest sticky board of the trapping device; the processing control device is respectively connected with the trapping device and the image collecting device, and is used for automatically replacing the pest sticky board by controlling the trapping device when the area of attached objects on the pest sticky board in a unit area exceeds a preset threshold value or preset time is up. According to the system, the image of the pest sticky board is obtained and the number of pests and the area of the attached objects are obtained after the image of the pest sticky board is processed and analyzed; the pest sticky board is automatically replaced through control of a motor or the motor is controlled to work through timing so that the pest sticky board can be automatically replaced; the system is simple in structure and easy to operate and replacement efficiency of the pest sticky board is improved.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

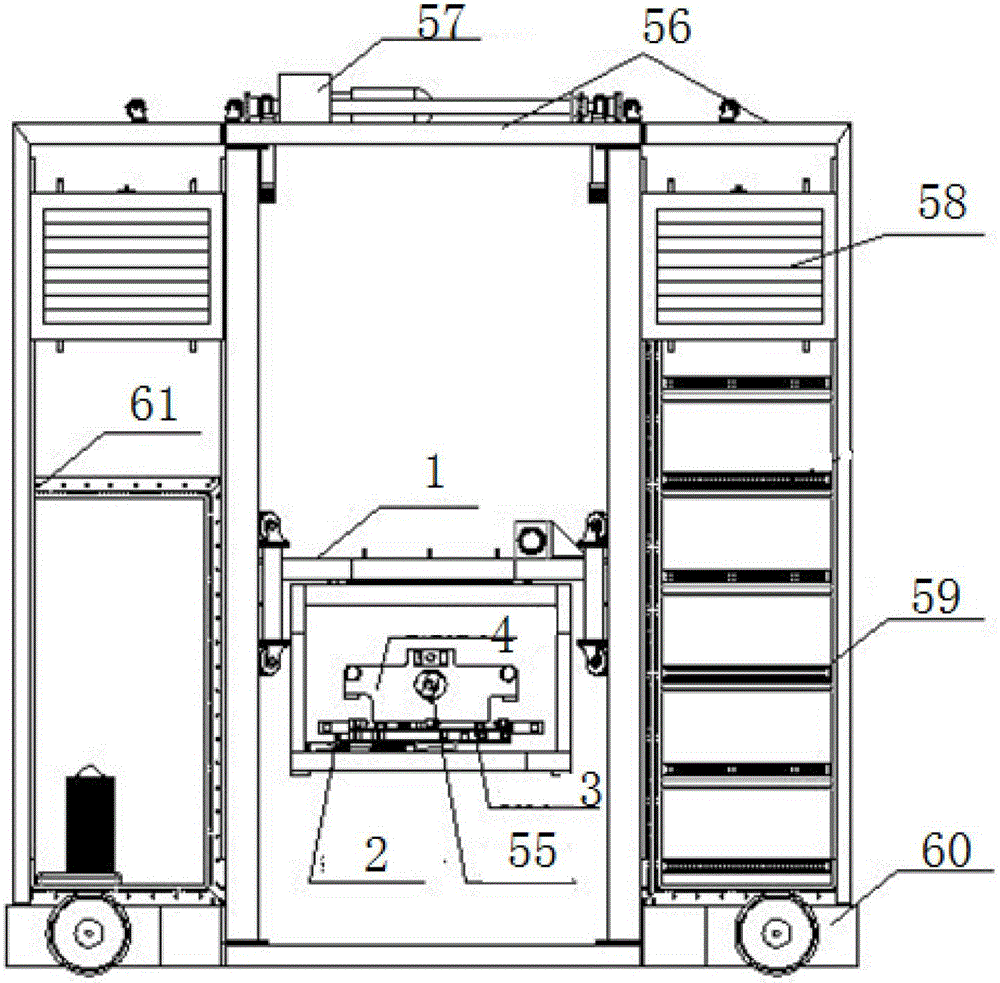

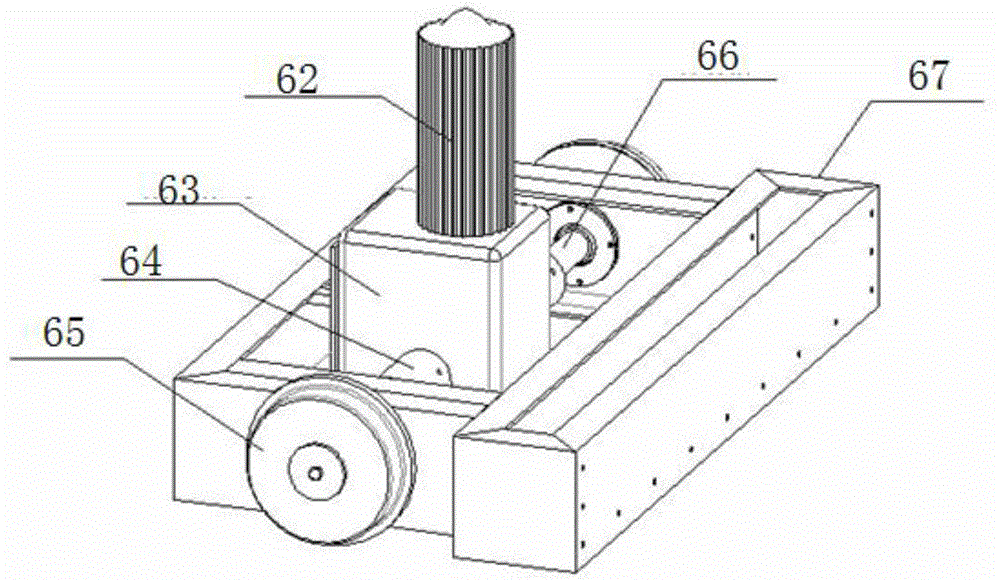

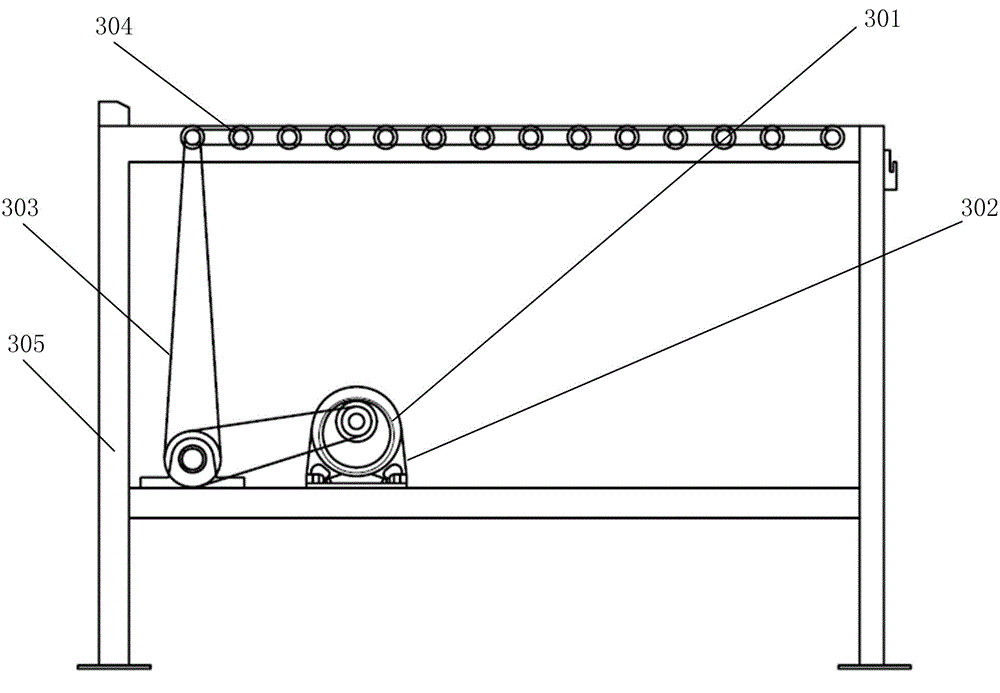

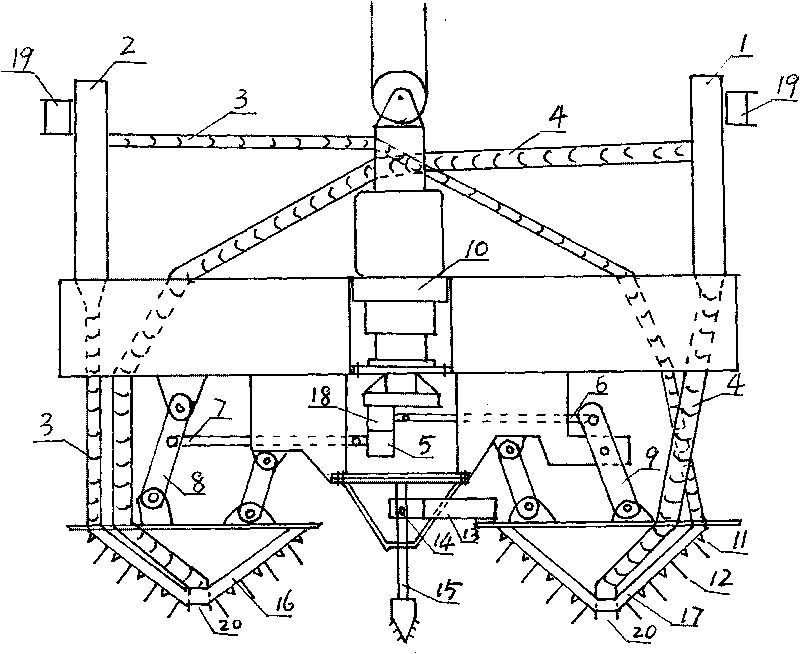

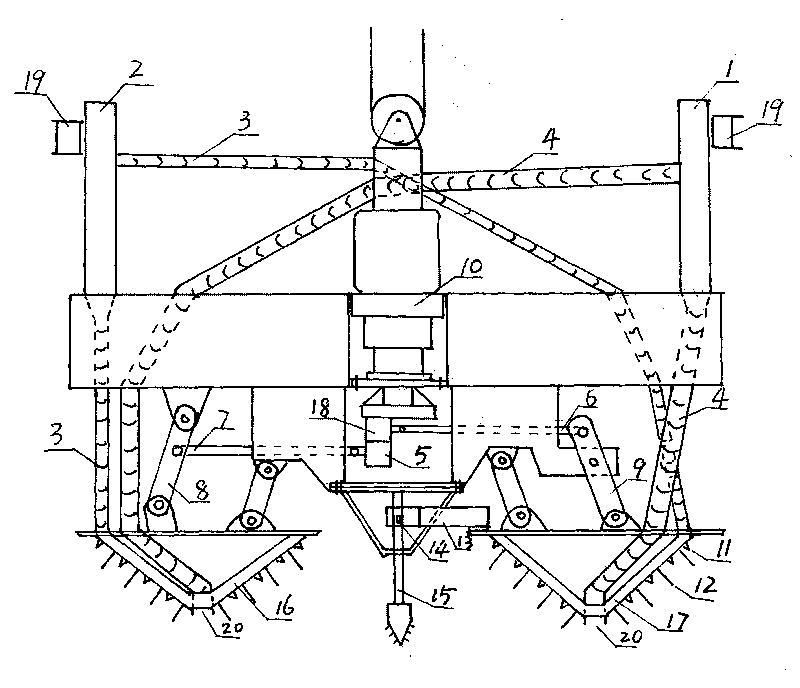

Electric commercial vehicle battery box single-trip replacement robot

ActiveCN103144615AShort work scheduleShorten battery replacement timeElectric propulsion mountingElectric/fluid circuitElectricityCommercial vehicle

The invention relates to an electric commercial vehicle battery box single-trip replacement robot which has the advantages of reducing the land occupation because the size of a replacement robot is effectively reduced, and being easily matched with an electric bus because an installing mode of a battery replacement device in the existing replacement robot is changed into a suspension installing mode. The electric commercial vehicle battery box single-trip replacement robot comprises a frame assembly, wherein the frame assembly is arranged on a walking assembly, a temporary storage rack is arranged at one side of the frame assembly, a control cabinet is arranged at the other side of the frame assembly, a lifting transmission assembly is arranged at the top of the frame assembly and is connected with a lifting assembly and also connected with a balance weight assembly, an objective table assembly capable of rotating in situ is suspended at the lower part of the lifting assembly, a fork assembly and a battery push handle assembly are arranged at the bottom of the objective table assembly, V-shaped wheel sets matched with a rectangular steel upright of a replacement robot frame are arranged at four corners of the lifting assembly, an objective table assembly rotating drive device is arranged on the lifting assembly, and a limit device is arranged on the objective table assembly.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

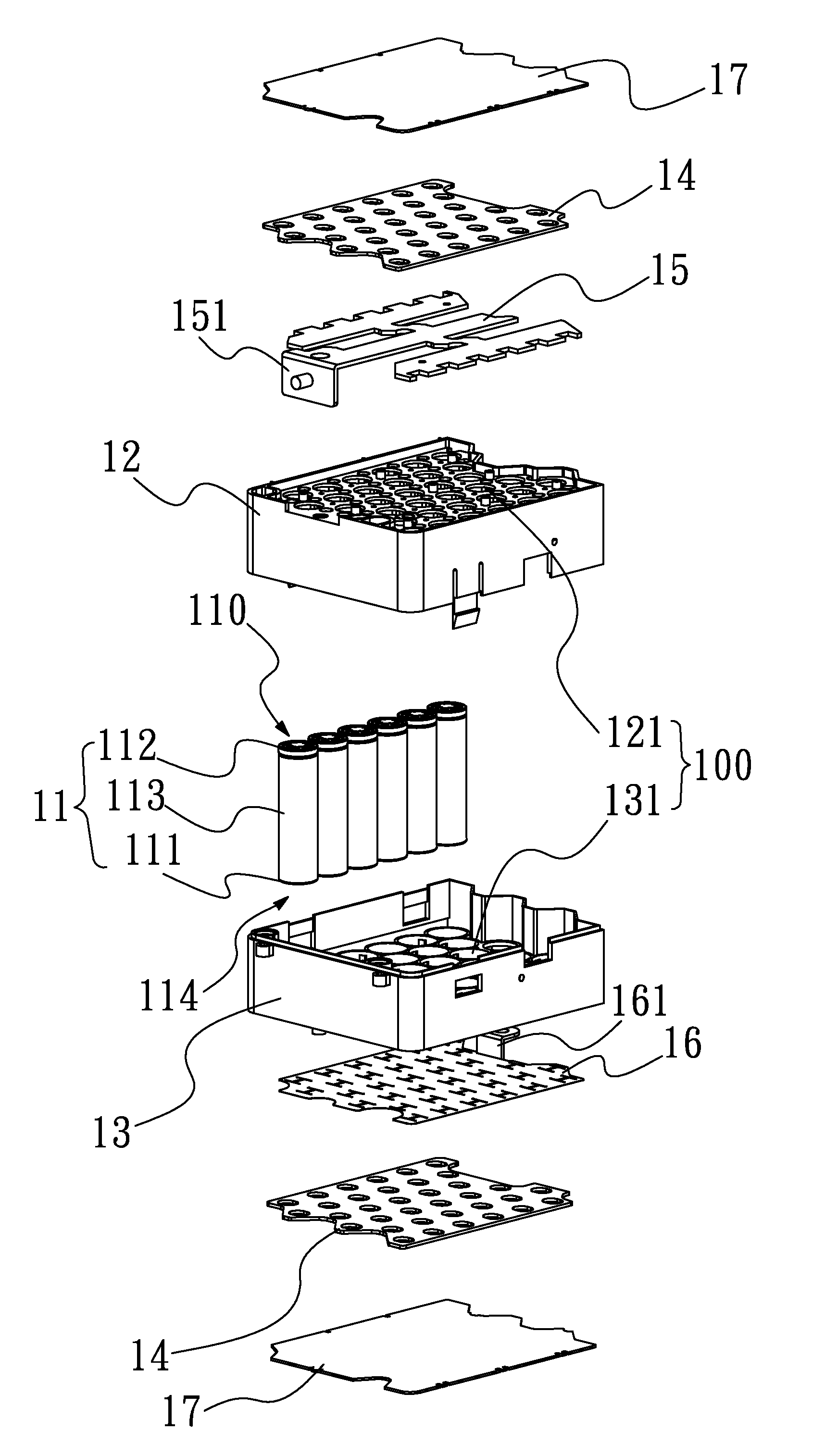

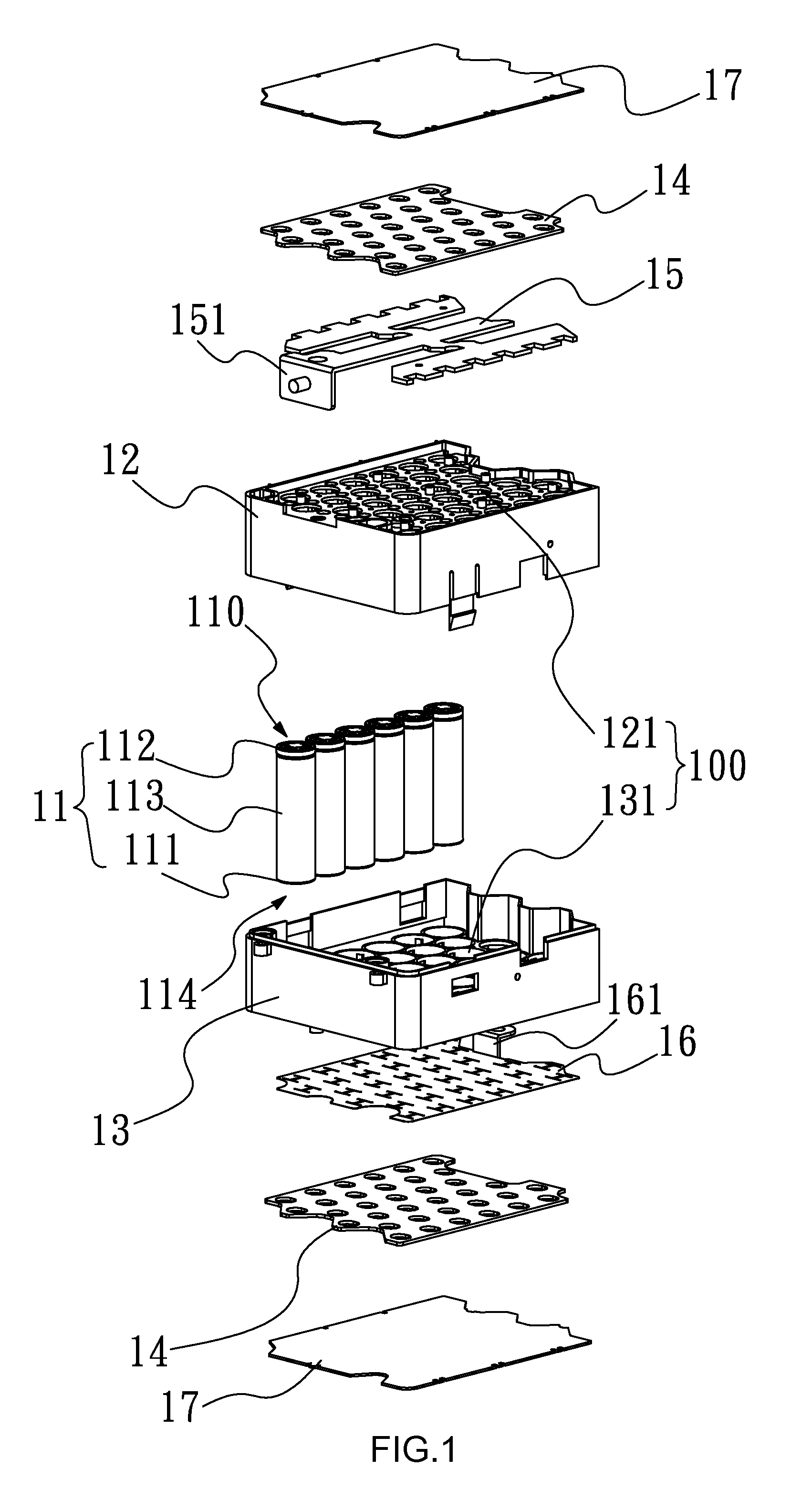

Battery assembly with adhesive stop mechanism

ActiveUS20140065455A1Improve cooling efficiencyImprove cooling effectSecondary cellsCell component detailsEngineeringBattery cell

A battery assembly provided with an adhesive stop mechanism is disclosed. The battery assembly includes multiple battery cells, a primary retaining frame, a secondary retaining frame, two common electrodes and a bonding layer. The primary and second retaining frames are combined together to constitute accommodation chambers for housing the battery cells. The primary retaining frame includes an outer deck and a shallow deck, wherein the outer deck is formed with adhesive application pores and the shallow deck is formed with stop portions corresponding to the adhesive application pores. The adhesive composition applied through the adhesive application pores is confined by the stop portions and subsequently cured into a bonding layer that firmly holds the battery cells within the accommodation chambers.

Owner:ATIEVA USA INC

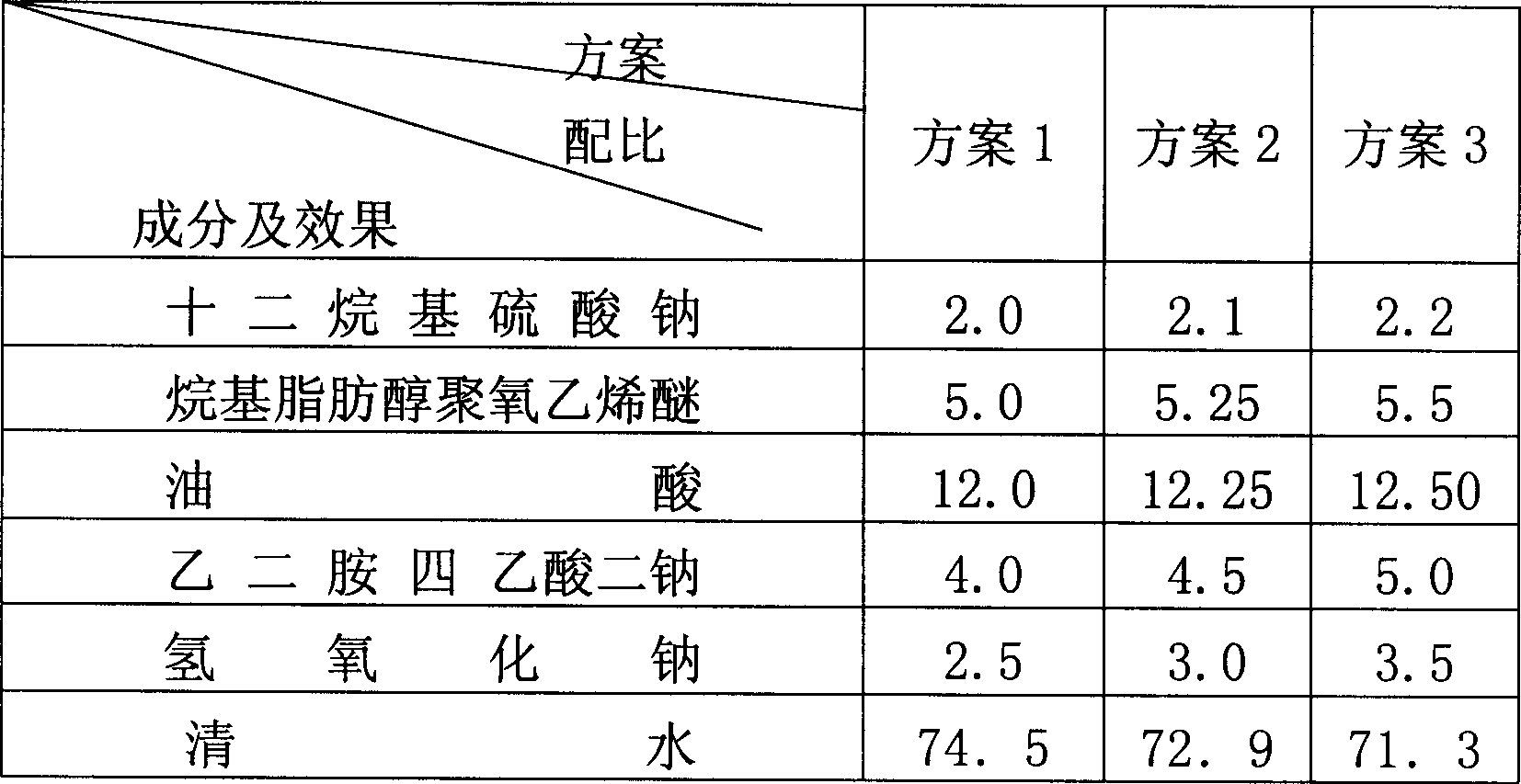

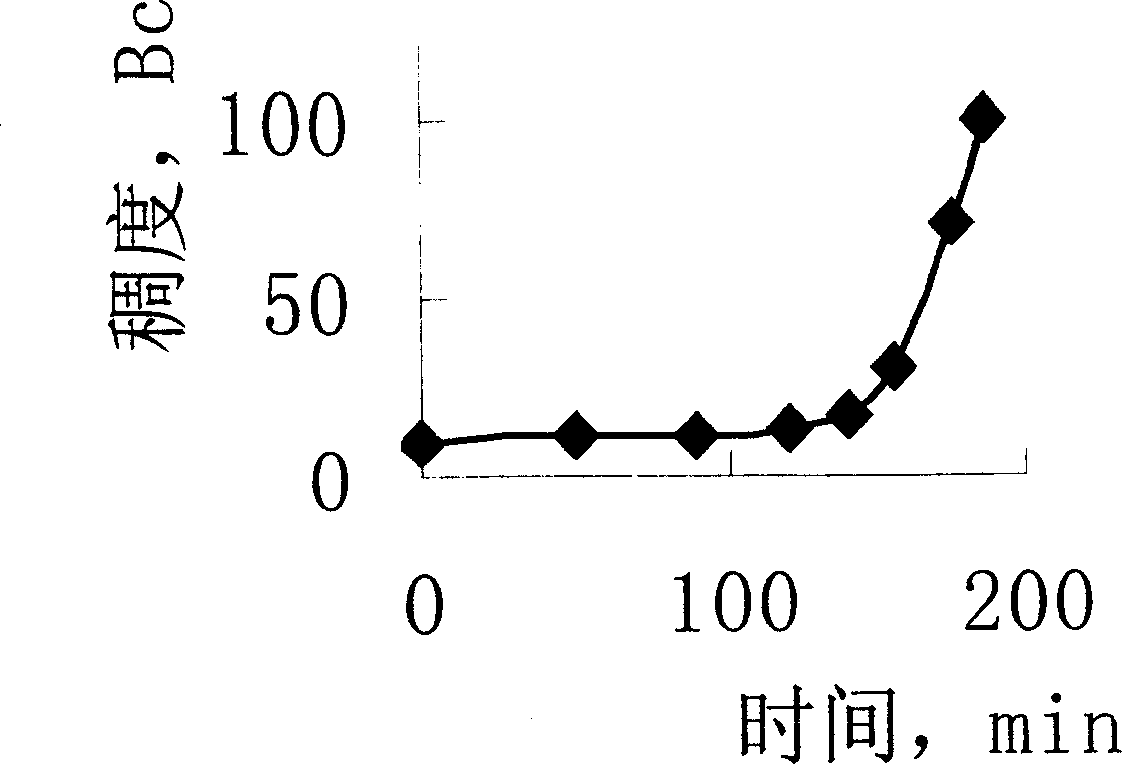

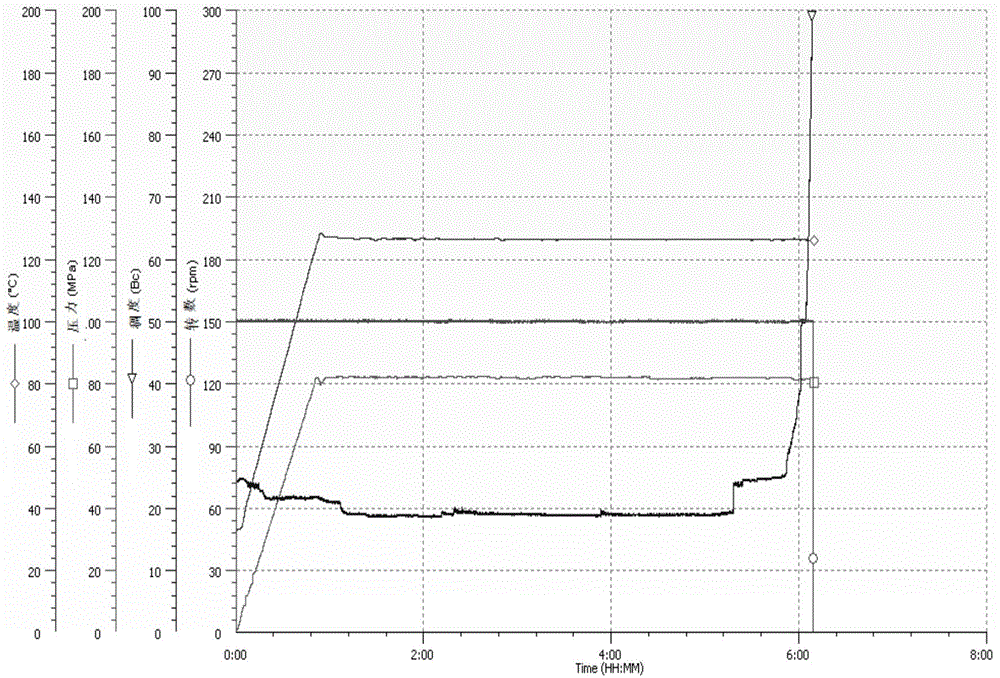

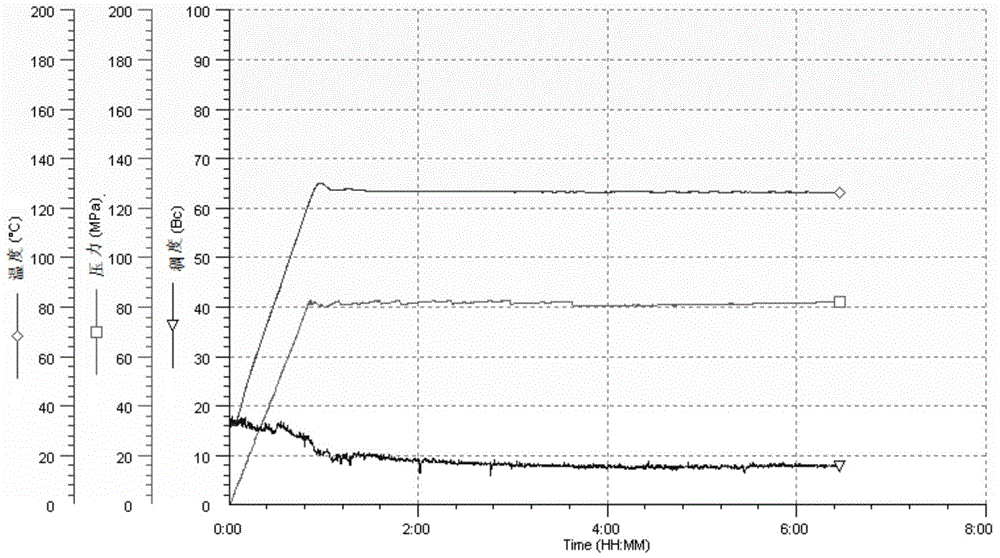

Oil-based mud flushing liquor and preparation method thereof

The invention refers to an oil rinse liquid for mud and the manufacturing method. It resolves the problem that the second interface cementation is bad. Its character lies in: add 2.5-3.5 shares sodium hydroxide and 4.0-5.0 shares ethyl diamine fourthacetic acid to clean water and blend to make them dissolve completely, then add 12.0-12.5 share oleic acid and blend for 20-30 minutes, add 2.0-2.2 shares dideakly natrium sulphate and 5.0-5.5 shares alkyl fatty ethanol poly-oxy ethene aether and blend for 55-65 minutes, finally add in the organic silicon anti-foamer. It can change the "oil wet" into "water wet", improve the cementation of cement interface and enhance the quality of fixing mine.

Owner:DAQING PETROLEUM ADMINISTRATION

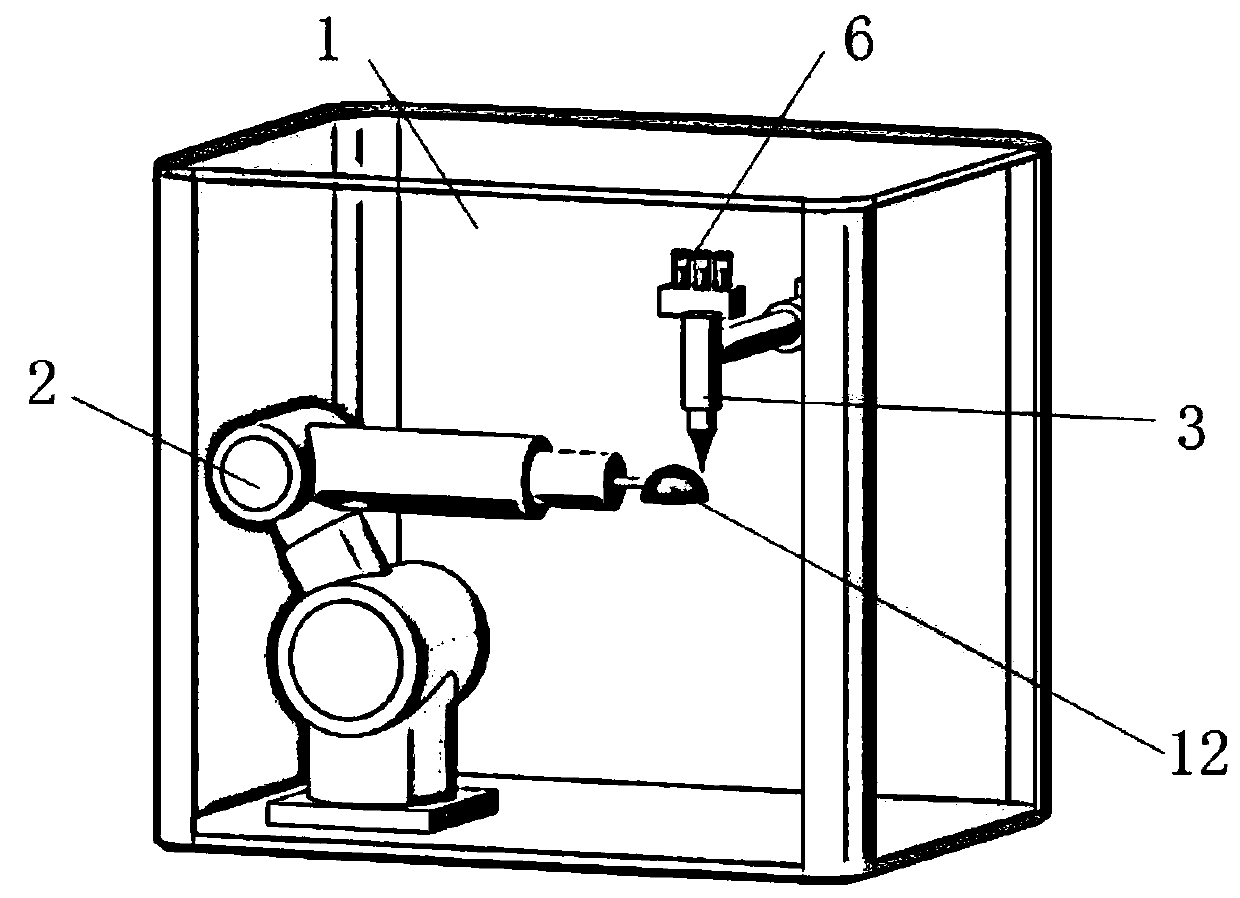

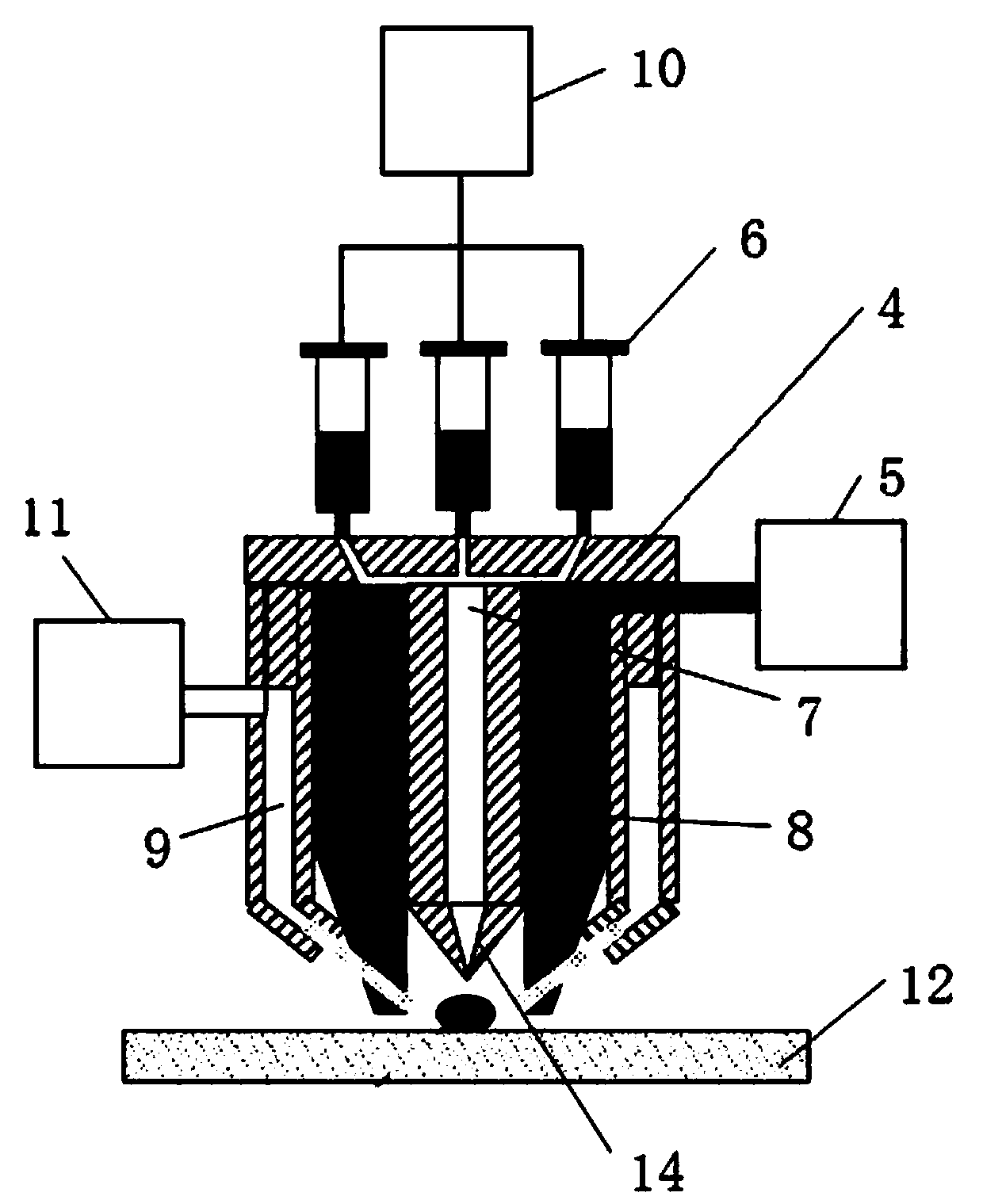

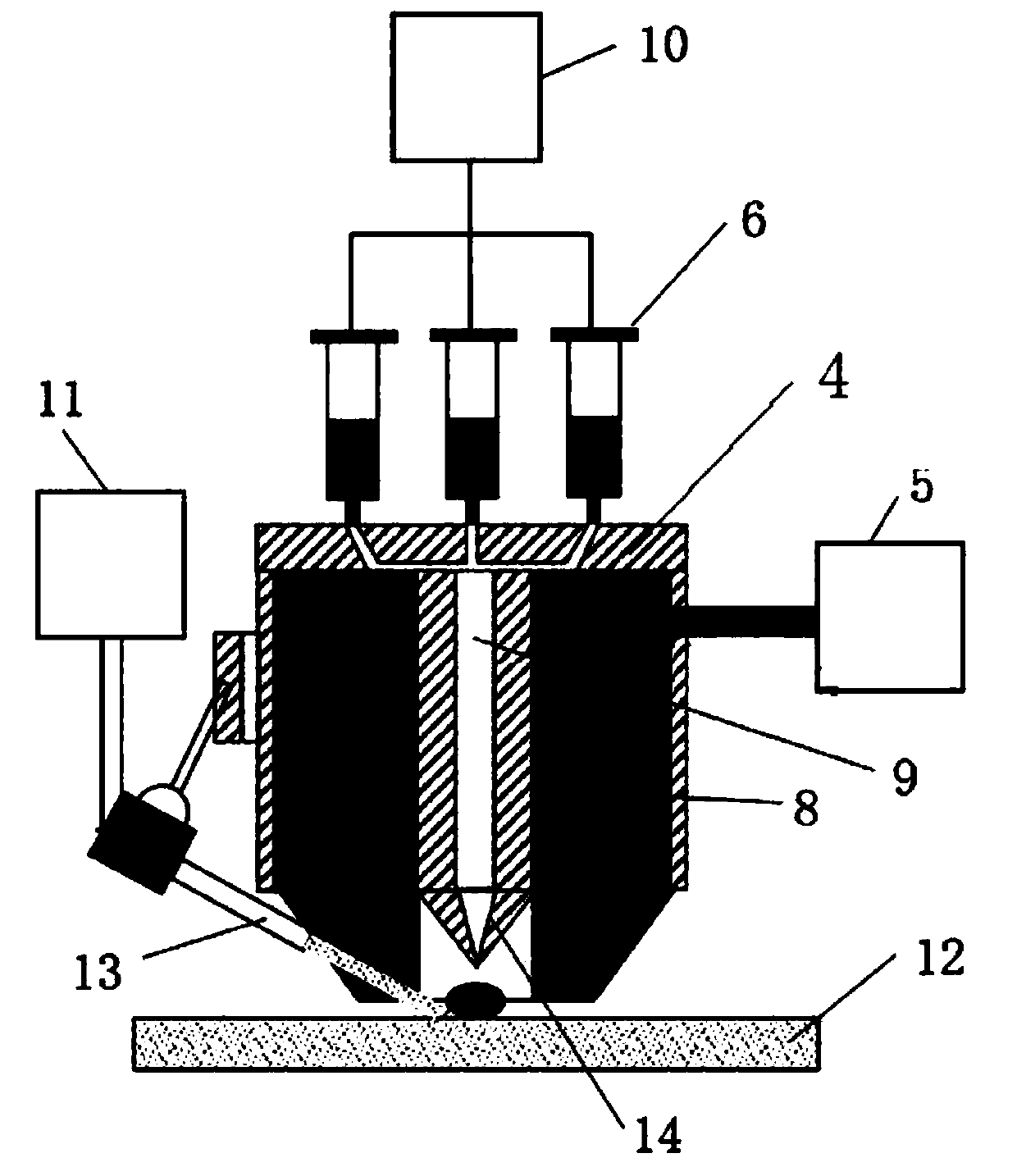

Multi-material laser direct writing conformal system and method

InactiveCN104260360ALarge adjustment rangeHigh repeat positioning accuracyMulti materialControl system

The invention discloses a multi-material laser direct writing conformal system and a method. The system comprises a vacuum seal case, a multi-joint mechanical arm, a multi-material laser direct writing head and a control system for controlling the constituent parts, wherein the mechanical arm and the laser direct writing head are arranged in the vacuum seal case; the laser direct writing head comprises a direct writing head body, a laser and at least two groups of material cylinders; a material channel and a laser focusing channel communicated with the laser and the material cylinders respectively are arranged on the direct writing head body; and the at least two groups of material cylinders are arranged on the direct writing head body in parallel. A particular process is as follows: the mechanical arm drives a workpiece to move along a set path; a material controller selects the corresponding material cylinders; a discharge head delivers and allows materials to be attached to the surface of the workpiece; and at the same time, laser light emitted from the laser focusing channel carries out solidifying or sintering forming on the attached materials. According to the invention, a control process is simple, the forming precision is high, continuous production is achieved, and production efficiency is improved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

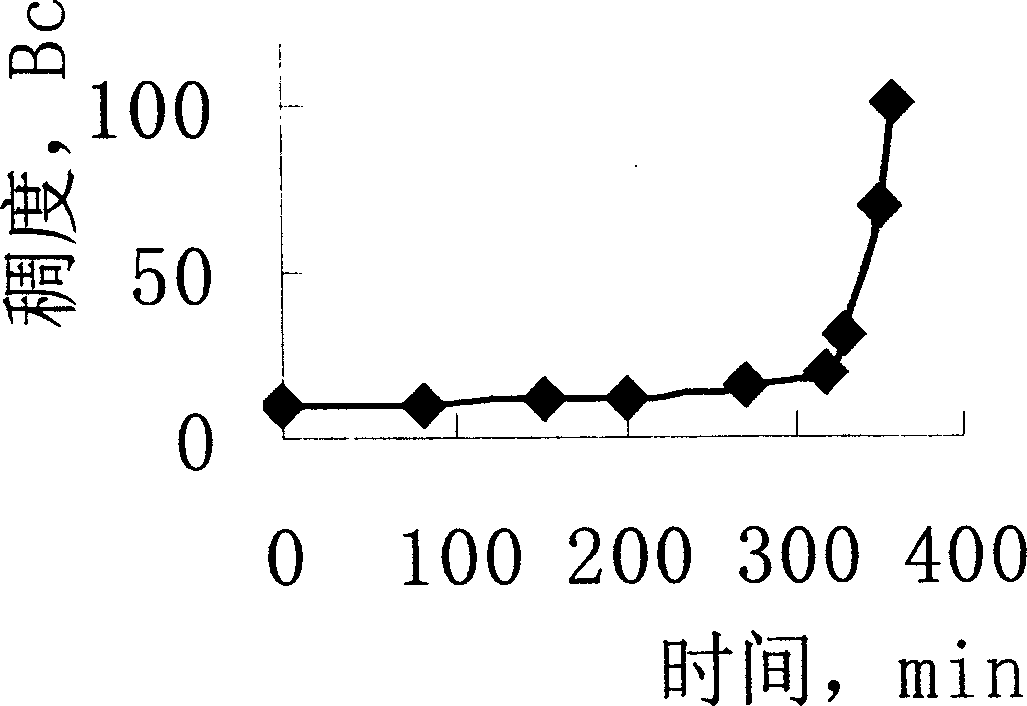

Oil well cement inhibiting agent

ActiveCN101368091AImprove performanceSuitable for a wide temperature rangeDrilling compositionWater qualityCarboxylic acid

The invention relates to a retarder for cement paste used in petroleum drilling, completion or well cementing operation, which comprises two components. The two components are a multipolymer containing carboxylic acid groups accounting for 60 to 90 portions by weight and an organic phosphonic acid and salts thereof accounting for 10 to 40 portions by weight. The average relative molecular mass of the multipolymer containing carboxylic acid groups is 2,000 to 20,000. The applicable temperature scope of the cement retarder is wide, and the cement retarder can be applied at high temperature, medium and low temperatures. The applicable temperature scope ranges from 30 DEG C to 230 DEG C. The cement retarder can be matched with various additives and is very compatible, which is applicable for oil well cement of various grades. The retarder can resist salt well, which is applicable for fresh water, brine, seawater, concentrated water and so on. The retarder can be widely applied in various shallow holes, moderate-depth holes, deep holes and superdeep holes. An excess amount of retarder is not sensitive in brine and seawater; the construction safety is ensured; the retarder does not adversely affect the strength development of cement.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

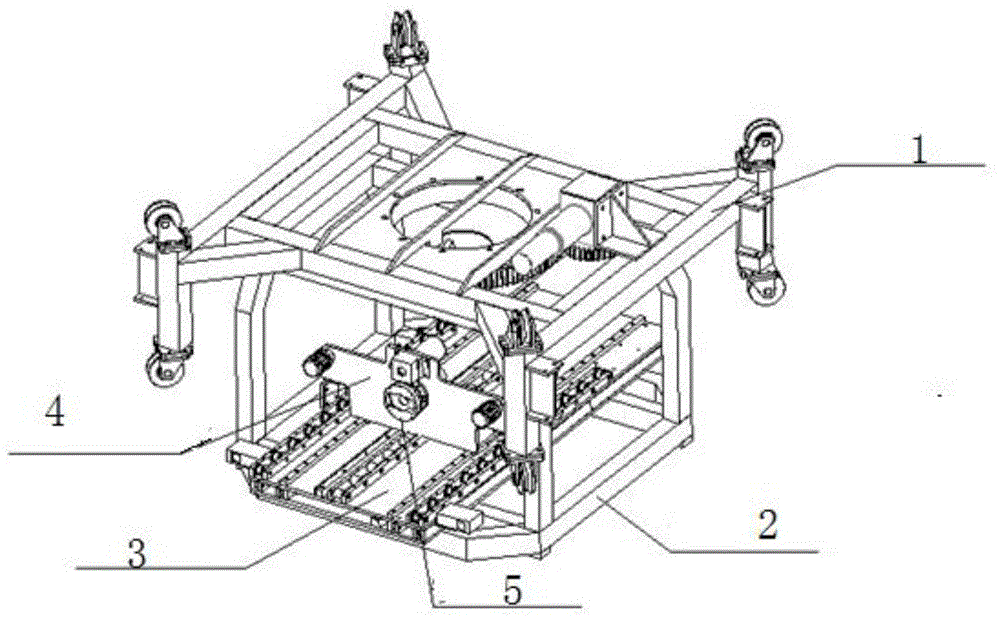

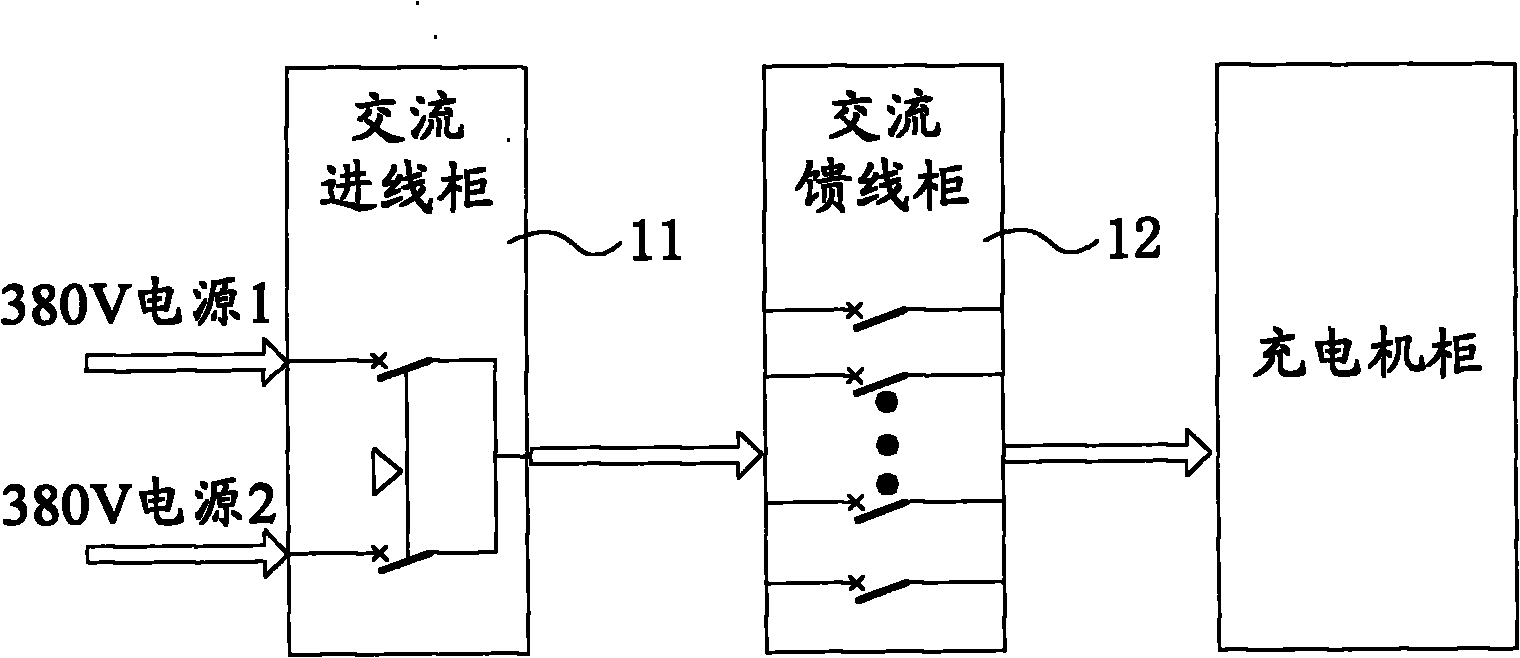

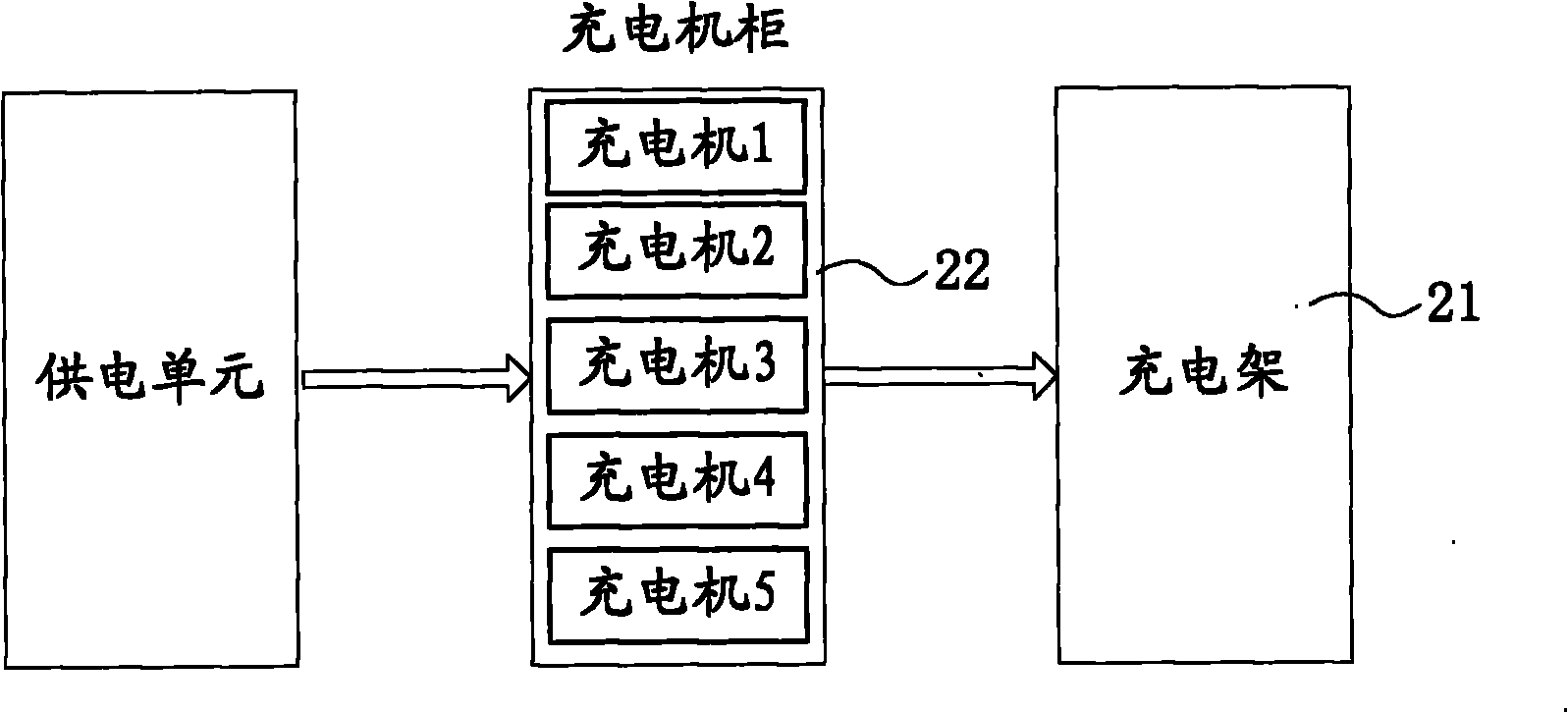

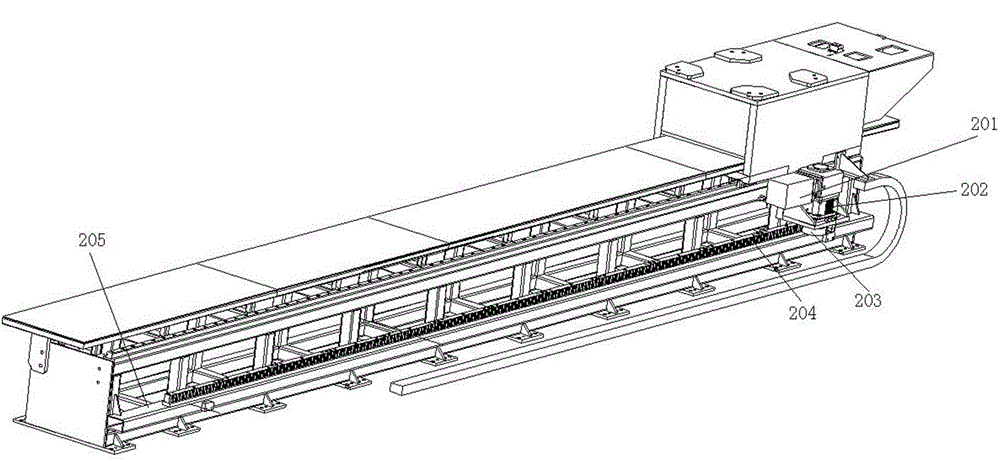

Battery changing device for commercial electric vehicle and electric conversion system

ActiveCN102040010AImprove replacement efficiencyShort replacement cycleCosmonautic condition simulationsCharging stationsElectricityElectrical battery

The invention relates to a battery changing device for a commercial electric vehicle. The device comprises a main frame, a positioning mechanism, a rotating mechanism, a lateral displacement mechanism and a push mechanism, wherein the positioning mechanism consists of a vertical positioning mechanism and a horizontal positioning mechanism; the vertical positioning mechanism is arranged in the main frame, and the horizontal positioning mechanism is arranged on the lower part of the main frame; the rotating mechanism is arranged on the lower part of the vertical positioning mechanism; the lateral displacement mechanism is arranged on the rotating mechanism; and the push mechanism is arranged on the lateral displacement mechanism. The invention also relates to an electric conversion system comprising the battery changing device. The battery changing device can automatically change a battery pack of the electric commercial vehicle; the process of assembling and disassembling the whole battery pack is completed by the battery changing device, is convenient, and has short changing time; the efficiency of battery changing is improved, so multiple times of battery changing can be completed in a unit time, the period of battery changing is shorter, a charger can charge electricity more sufficiently and has higher utilization.

Owner:STATE GRID CORP OF CHINA +1

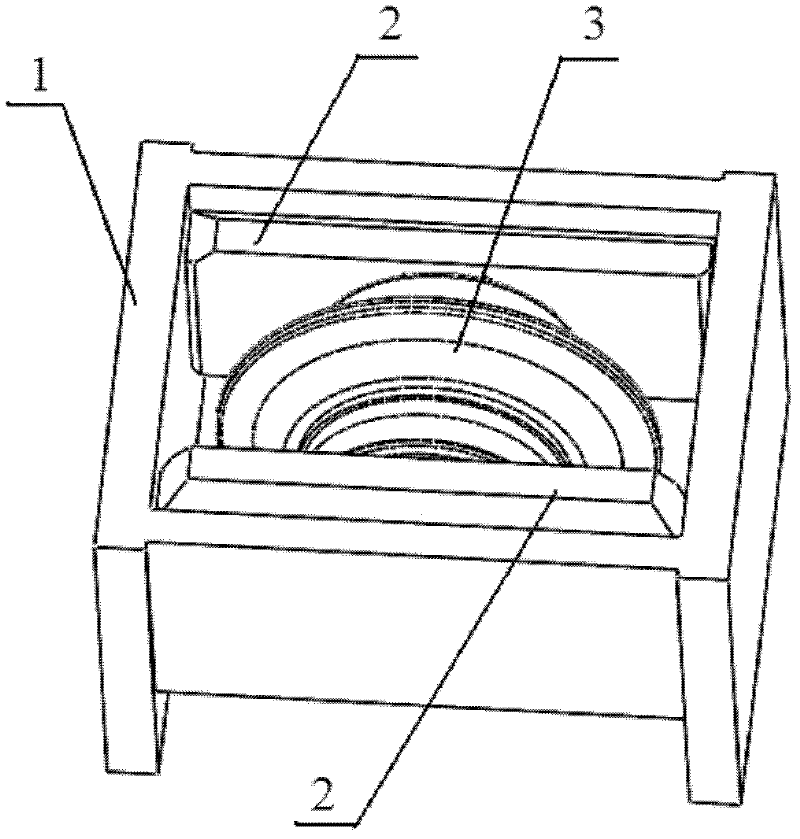

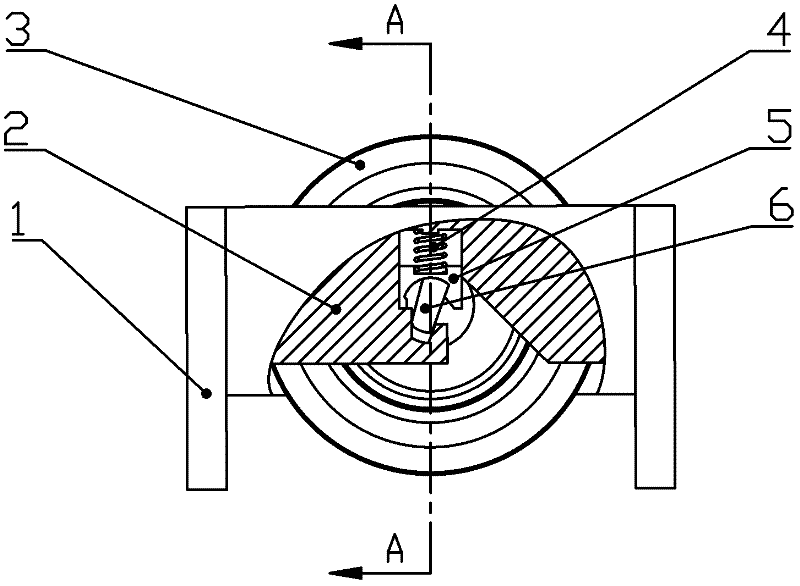

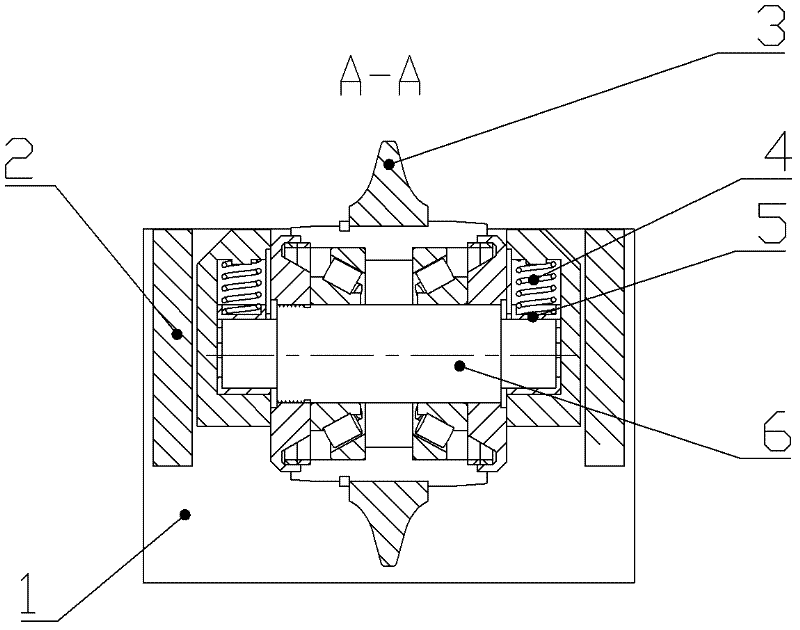

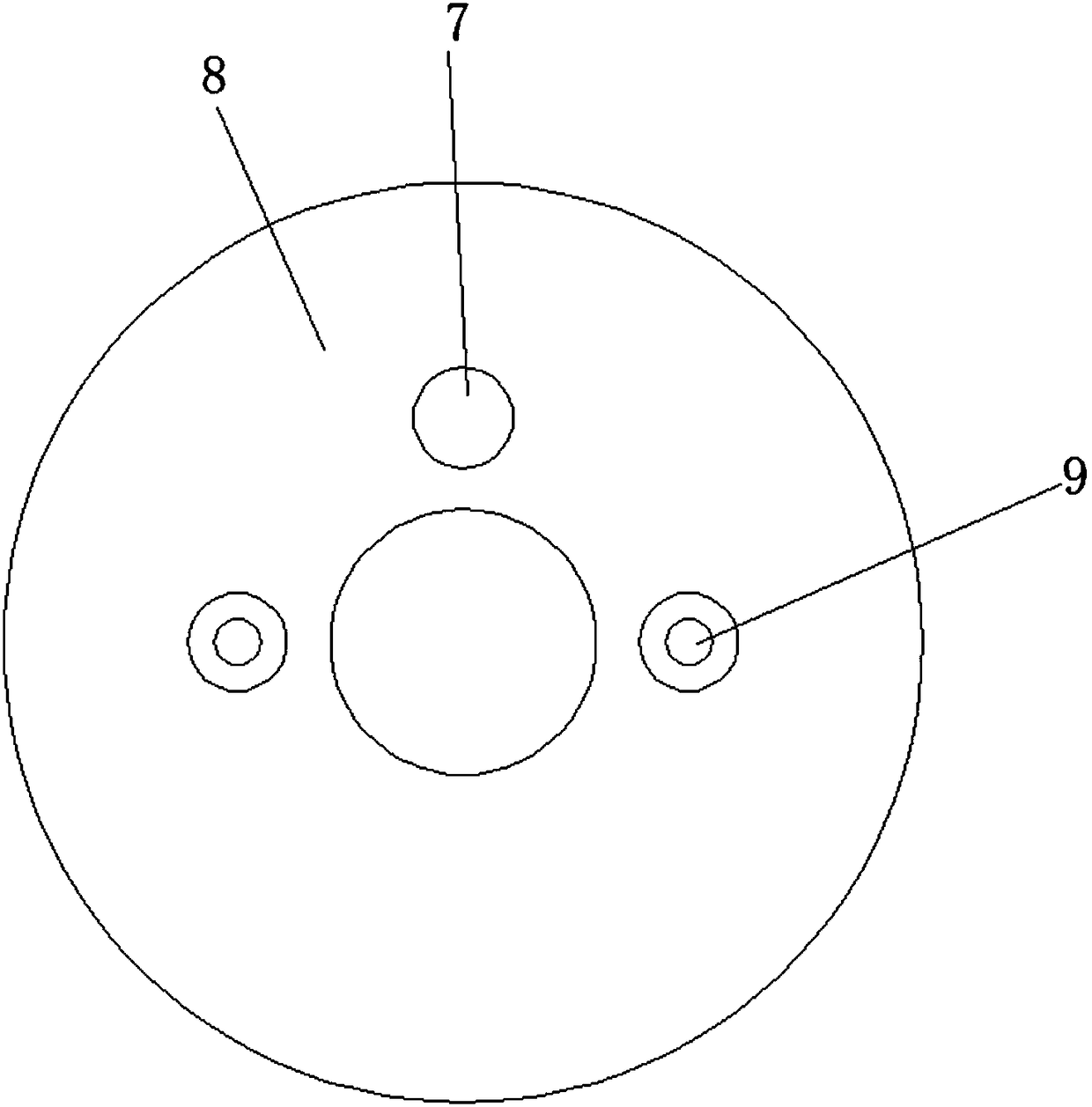

Mounting structure of disc hob

The invention discloses a mounting structure of a disc hob, which comprises a hob shaft support frame, hob shaft bases and a fixed cover plate. Two shaft ends of a hob center shaft are both processed by flat milling to form a flat shaft head with an inclined surface. The hob shaft support frame is a rectangular frame, the inner sides of the two opposite side upright plates of the hob shaft support frame are respectively fixedly provided with one hob shaft base in a connecting manner, an open groove is arranged on the inner side surface of each hob shaft base from bottom to top, a pressure spring, a limit slider and a trapezoid shaft base groove are arranged in the open groove from top to bottom, the bottom of the limit slider is an arc surface with a concave bottom, and a shaft base hole is formed between the arc surface with a concave top and the trapezoid shaft base groove. The side below the open groove is provided with an inclined surface, and an inclined channel is formed from the inclined surface to the opening. The flat shaft head of the disc hob center shaft is matched with the shaft base hole. According to the invention, the disc hob can be conveniently and quickly mounted, and space is widened for the further application of an automation technology. The invention has good application prospects.

Owner:TIANJIN UNIV

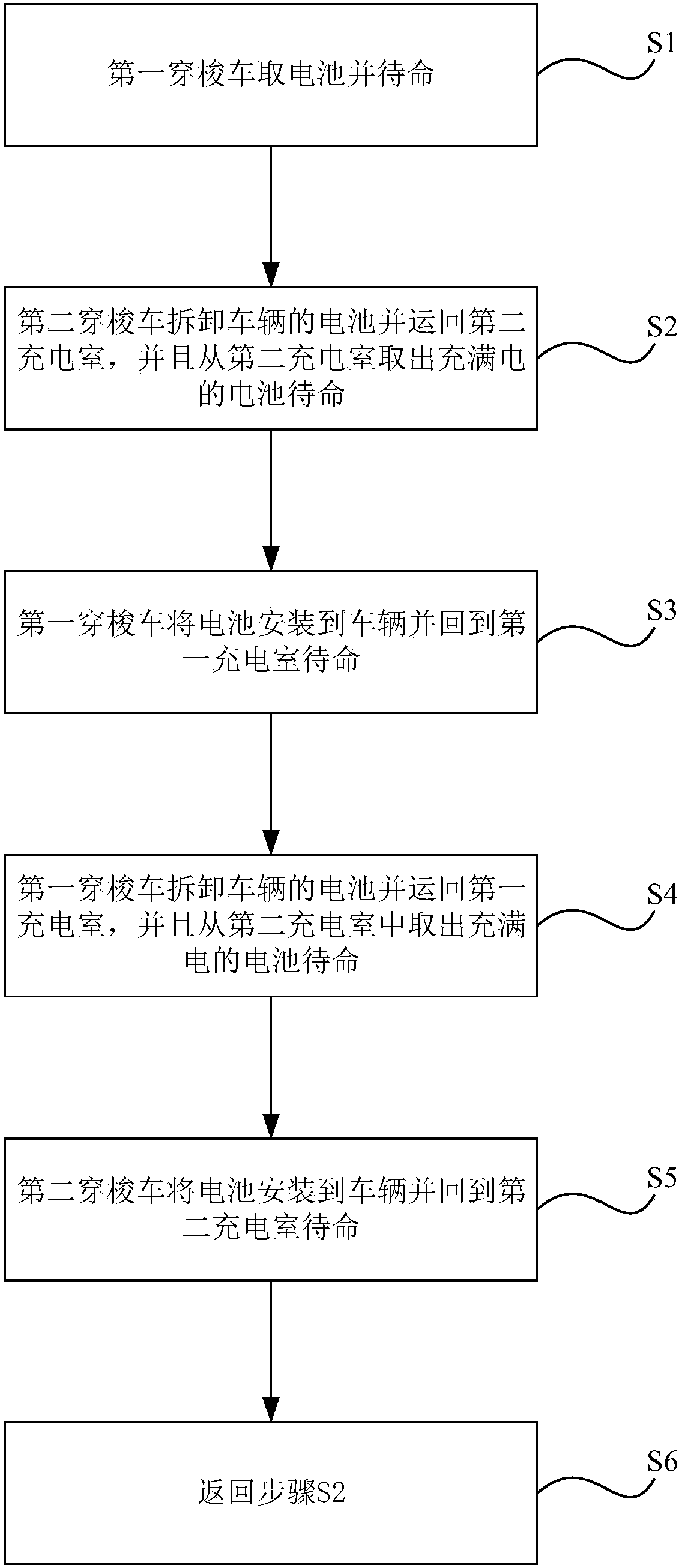

Battery replacement station and control method thereof

PendingCN109849861AImprove replacement efficiencyReduce waiting timeCircuit monitoring/indicationCharging stationsElectricityElectrical battery

The invention discloses a battery replacement station and a control method thereof. The battery replacement station comprises the following structures: a first charging chamber and a second charging chamber; a first battery replacing platform located between the first charging chamber and the second charging chamber; a first shuttle vehicle and a second shuttle vehicle respectively move back and forth between the first charging chamber, the second charging chamber and the first battery replacing platform; and a control unit that is electrically connected with the first shuttle vehicle and thesecond shuttle vehicle; the control unit is used for controlling the first shuttle vehicle and the second shuttle vehicle to perform the following operations: when the same vehicle on the first battery replacing platform is operated, if the first shuttle vehicle performs one operation of battery disassembly and battery assembly, the second shuttle vehicle performs the other operation of battery disassembly and battery assembly. According to the battery replacement station and the control method thereof, through alternate operations of the first shuttle vehicle and the second shuttle vehicle, the waiting time for battery replacement of the vehicle is shortened, and the battery replacement efficiency of the battery replacement station is improved.

Owner:SHANGHAI DIANBA NEW ENERGY RESOURCES SCI & TECH +1

Method for recovering crude oil from a subterranean formation

InactiveUS20090023618A1Easy extractionReduce adsorptionOrganic detergent compounding agentsAnionic surface-active compoundsPhysical chemistryOrganic phosphorus

Owner:RHODIA OPERATIONS SAS

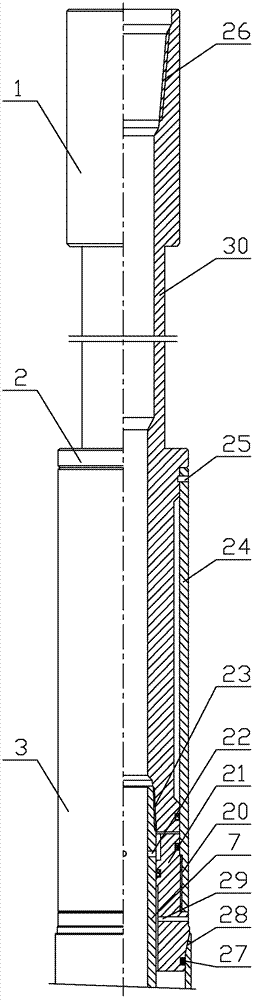

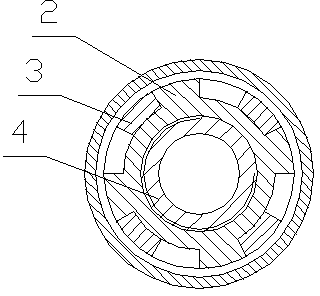

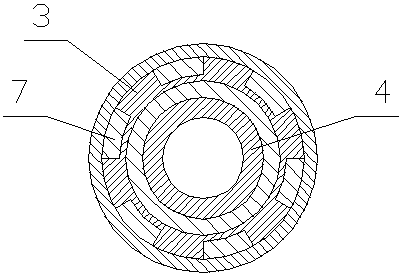

Replaceable prestressed anchor bolt device and mounting and replacement construction method thereof

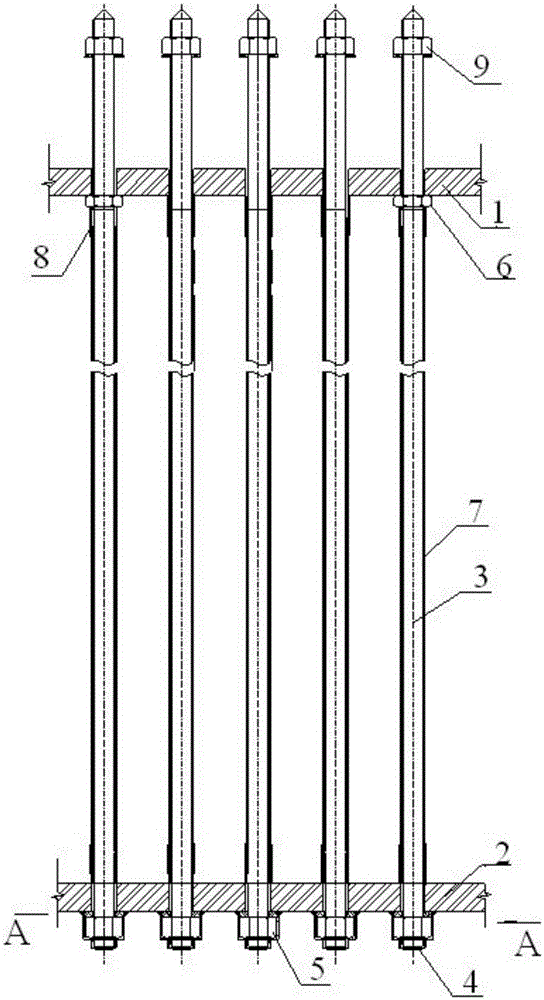

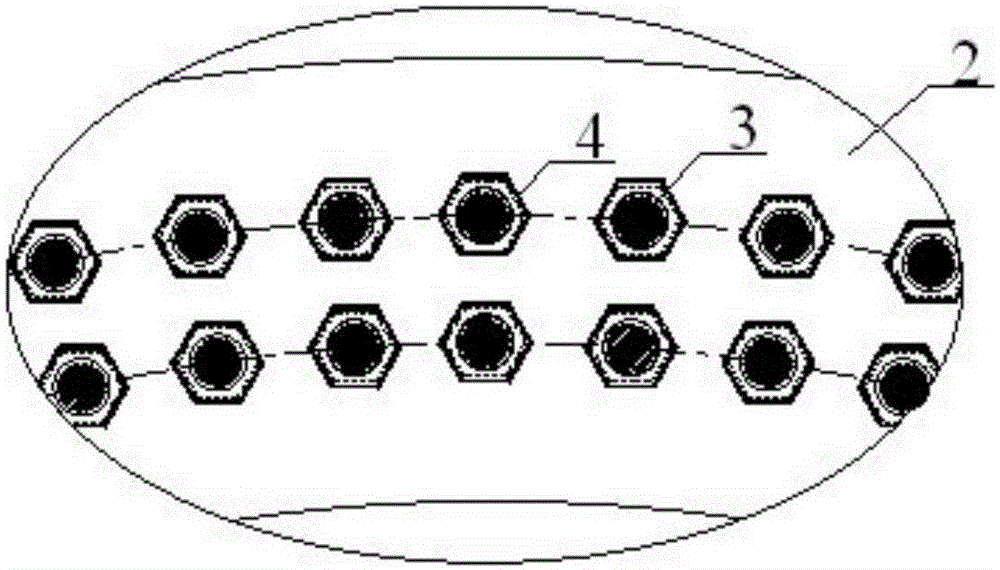

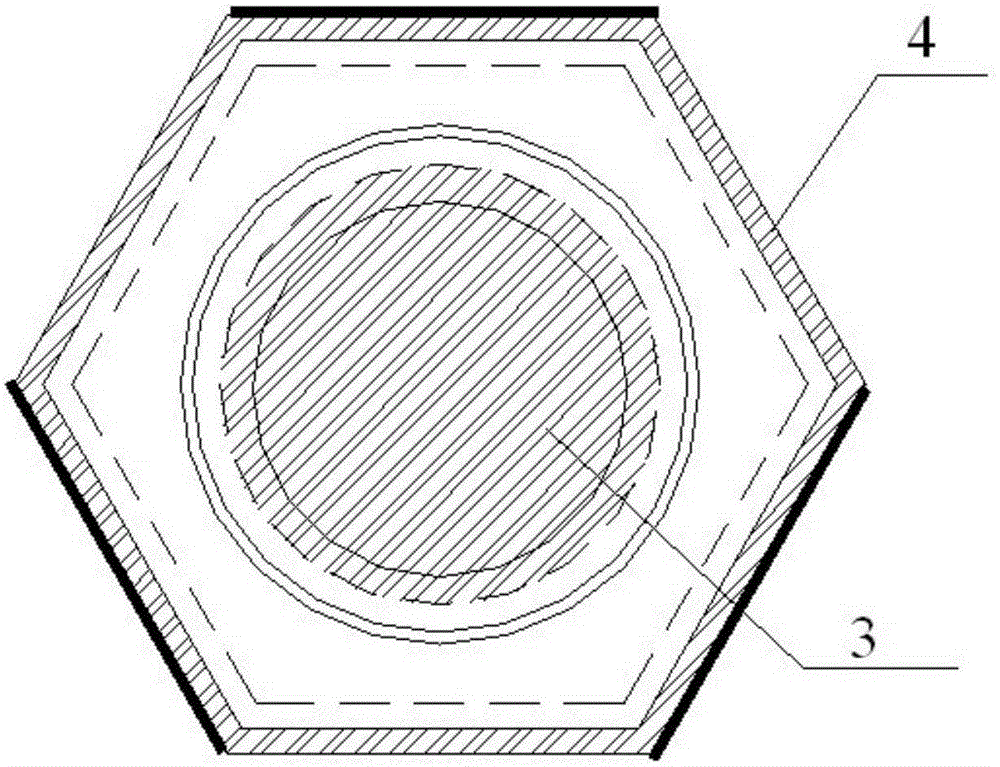

ActiveCN105155571AReasonable structural designAvoid the influence of forceFoundation engineeringMaterial resourcesAnchor bolt

The invention discloses a replaceable prestressed anchor bolt device. The replaceable prestressed anchor bolt device comprises an upper anchor plate (1), a lower anchor plate (2), anchor bolts (3) connected with the upper anchor plate (1) and the lower anchor plate (2) and plastic casing pipes (7) arranged on the peripheries of the anchor bolts (3) in a sleeving manner. The upper ends and the lower ends of the plastic casing pipes (7) are shrunk and sealed by thermal shrinkable sleeves (8). Nonmetal leveling nuts (6) are arranged on the thermal shrinkable sleeves (8) at the upper ends of the plastic casing pipes (7), and upper nuts (9) are arranged at the tops of the anchor bolts (3). The bottoms of the anchor bolts (3) and bottom sealing assemblies (4) are fixed. The replaceable prestressed anchor bolt device is reasonable in structural design, each anchor bolt can be freely replaced after a concrete foundation is completed or a fan runs, and a large amount of manpower and a large number of material resources can be saved; replacement cost is low, and efficiency is high; and many defects in the prior art can be overcome.

Owner:JIANGSU JINHAI NEW ENERGY TECH +1

Anti-pollution high efficiency isolation liquid and preparing method

The present invention relates to anti-pollution high efficiency isolating liquid for shaft wall cementing operation and its preparation process. The isolating liquid is compounded through adding suspension stabilizer, water reducing agent, tackifier, diluent, viscosity and shearing force increasing agent, weight additive and pH regulator in certain weight proportion into water. One compounding process is a water base process through throwing the said components successively into water in a slurry tank apparatus. One other compounding process is one dry mixture process in a cementing tank apparatus. The isolating liquid has flexible compounding process, high anti-pollution capacity and effective eliminating effect on well wall interface pollutant.

Owner:SOUTHWEST PETROLEUM UNIV

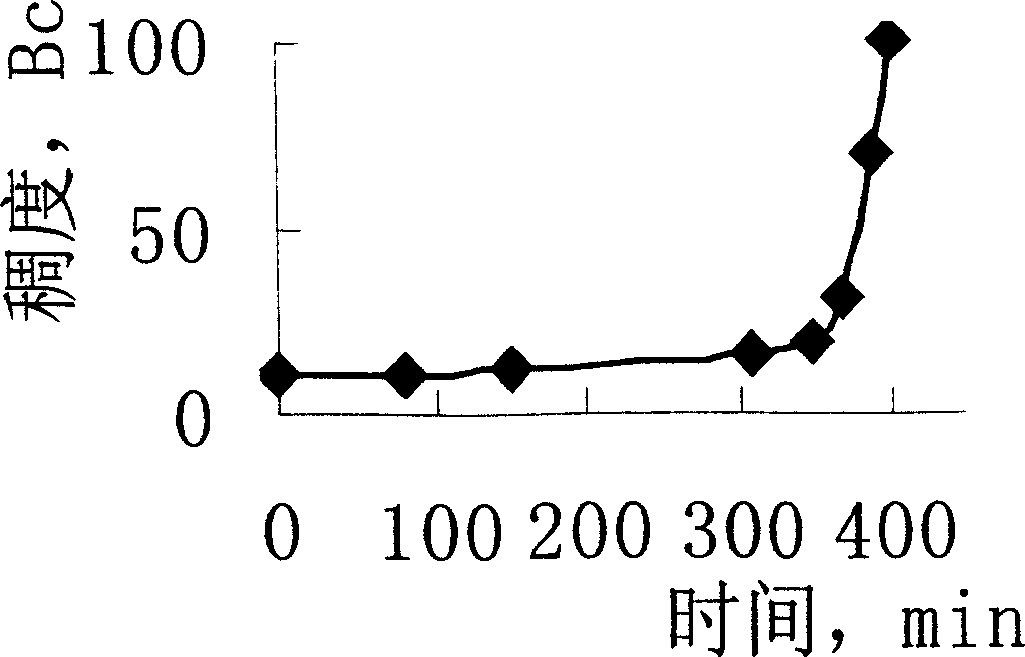

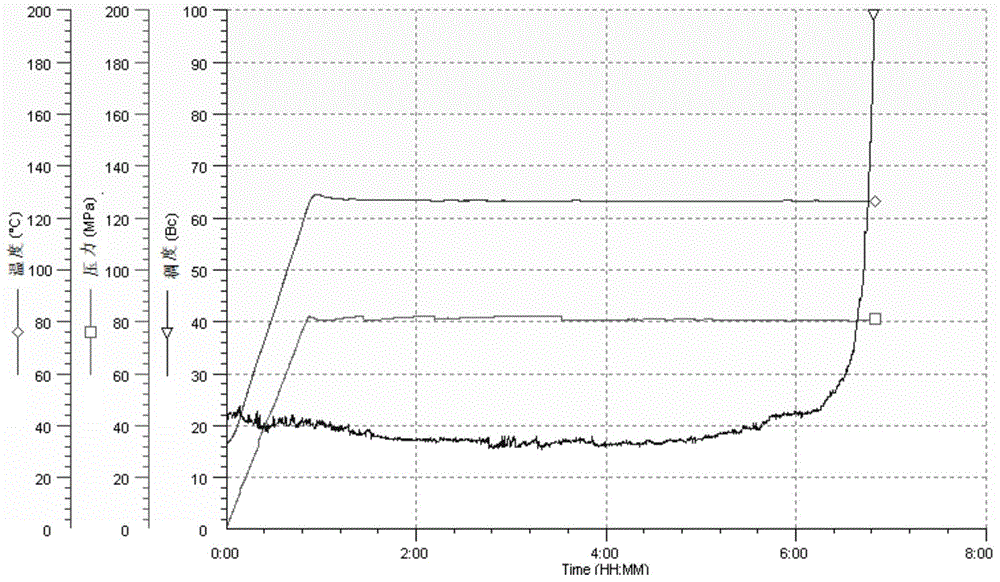

High temperature resistant well-cementing spacer fluid and preparation method thereof

ActiveCN104449606AGood thickeningGood suspensionDrilling compositionSodium BentoniteSuspending Agents

The invention relates to a high temperature resistant well-cementing spacer fluid and a preparation method thereof. The spacer fluid consists of: 100 parts by weight of fresh water, 2-8 parts by weight of a suspending agent, 2-10 parts by weight of a diluents, 25-400 parts by weight of a weighting agent, and 1-15 parts by weight of a flushing agent. Specifically, the suspending agent is composed of 100 parts by weight of OCMA bentonite, 2 parts by weight of hydroxypropyl guar gum and 8 parts by weight of xanthan gum; the diluent is composed of 100 parts by weight of sodium lignin sulfonate and 20 parts by weight of sulfonated tannin; the flushing agent consists of 40 parts by weight of fatty alcohol-polyoxyethylene ether, 40 parts by weight of triethanolamine oleate and 20 parts by weight of sodium tripolyphosphate; and the weighting material is barite. The spacer fluid has stable performance under 180DEG C high temperature condition, still has good rheological performance under the premise of ensuring the system good suspension stability, is compatible with conventional cement slurry and drilling fluid systems, improves the rheological properties of drilling fluid, enhances the displacement efficiency, and reinforces the cementation quality of a cement ring with a well cementation first interface and a second interface.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

Intelligent welding robot

ActiveCN105855769AImprove replacement efficiencyMeet welding needsWelding/cutting auxillary devicesAuxillary welding devicesProgrammable logic controllerDisplay device

The invention discloses an intelligent welding robot which comprises a pair of opposite welding fixtures, a welding manipulator, a CCD (charge coupled device) camera and a control mechanism. The welding fixtures, the welding manipulator and the CCD camera are electrically connected with the control mechanism, the welding manipulator is positioned between the two opposite welding fixtures, the CCD camera is positioned on the upper portion of the welding manipulator, the control mechanism comprises an upper computer, a PLC (programmable logic controller) and a display, the welding fixtures and the welding manipulator can act under the constant control of the PLC, the CCD camera can move along with the welding manipulator and can photograph workpieces in welding procedures, the workpieces can be fixedly firmly grasped by the welding fixtures in the welding procedures, and welding operation can be carried out on the workpieces by the welding manipulator. The intelligent welding robot has the advantages that the intelligent welding robot is provided with the two structurally identical welding fixtures, the workpiece changing efficiency can be improved by the two welding fixtures, welding requirements of the welding manipulator can be met, and the welding efficiency can be greatly improved.

Owner:江门市盛誉金属制品有限公司

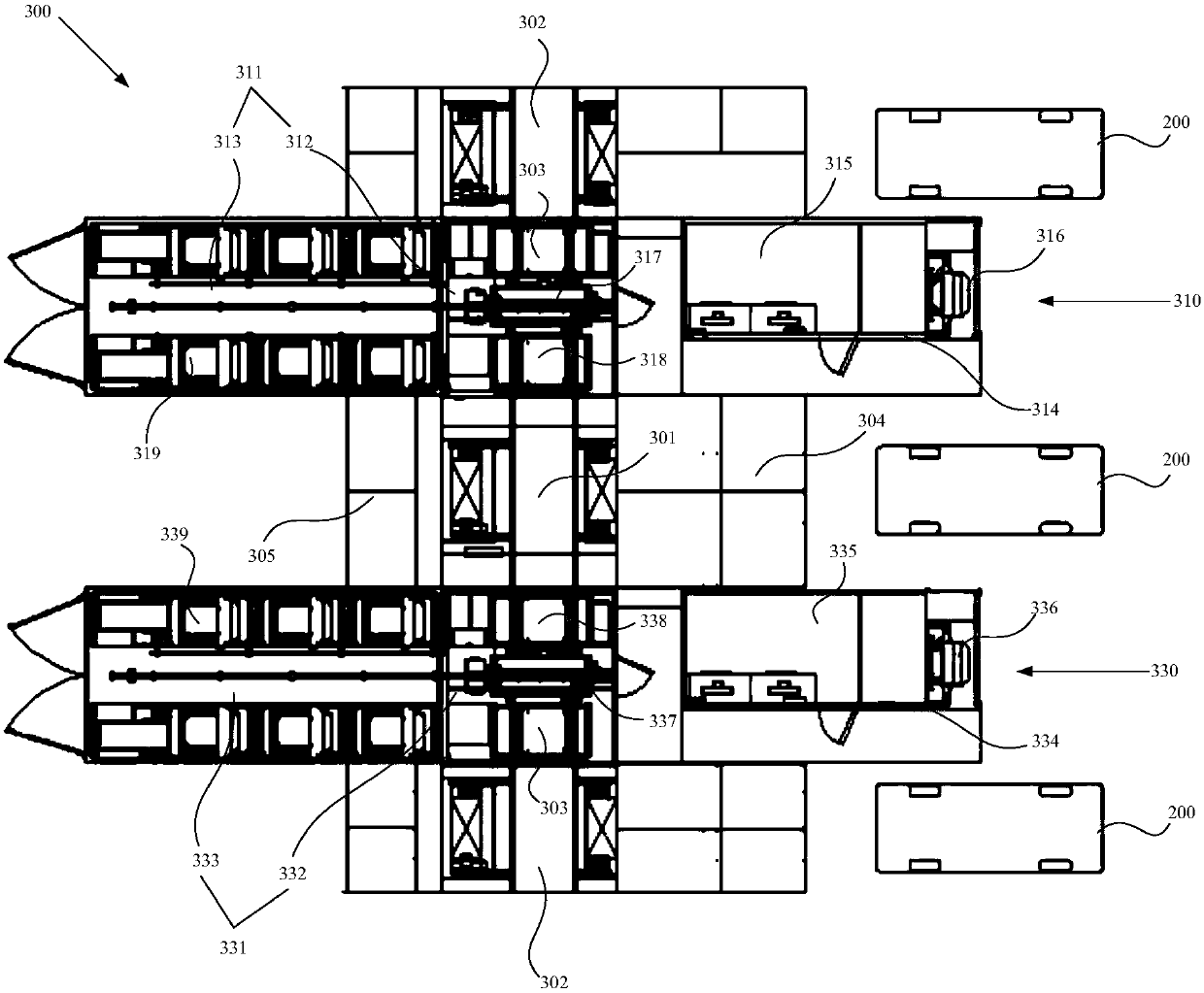

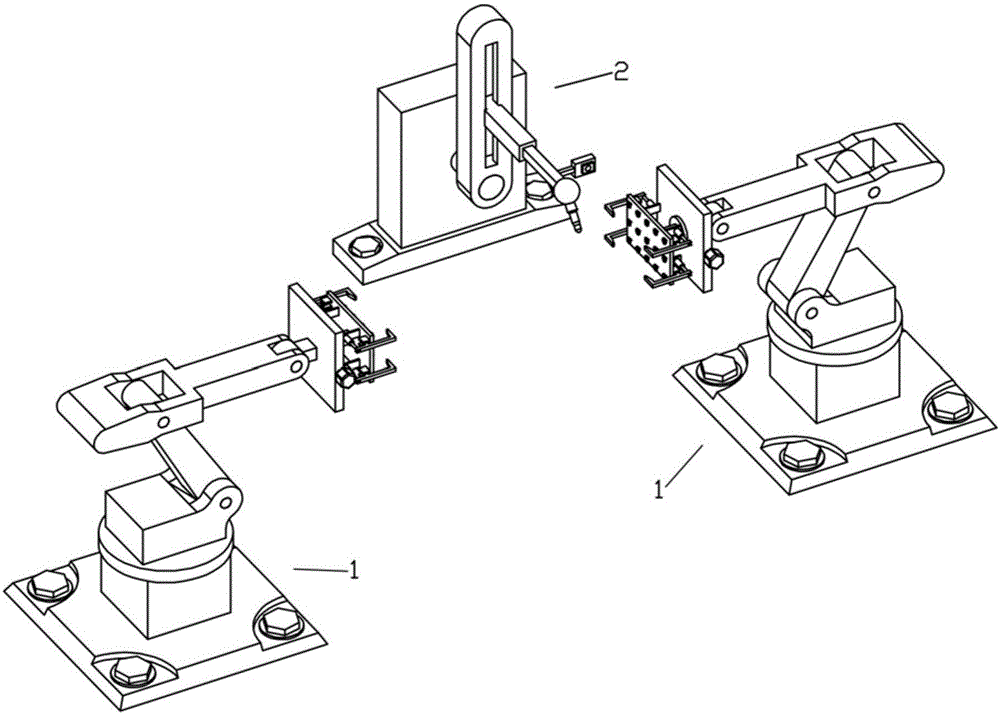

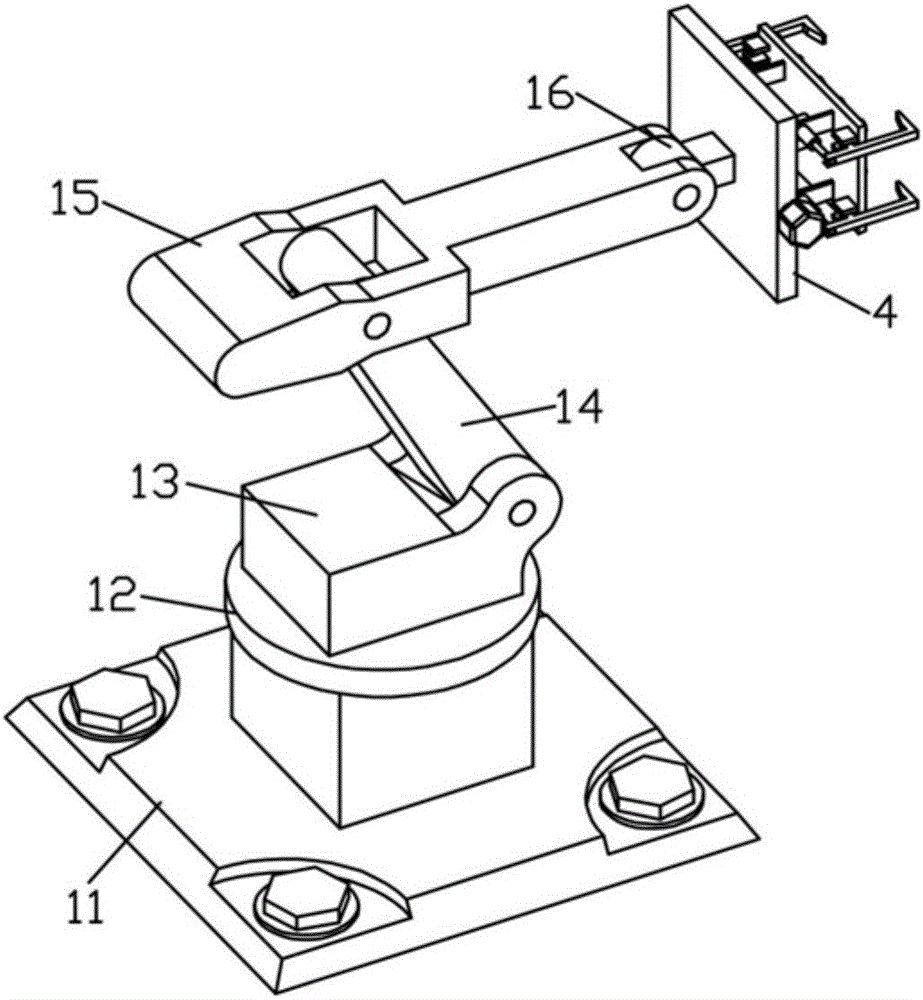

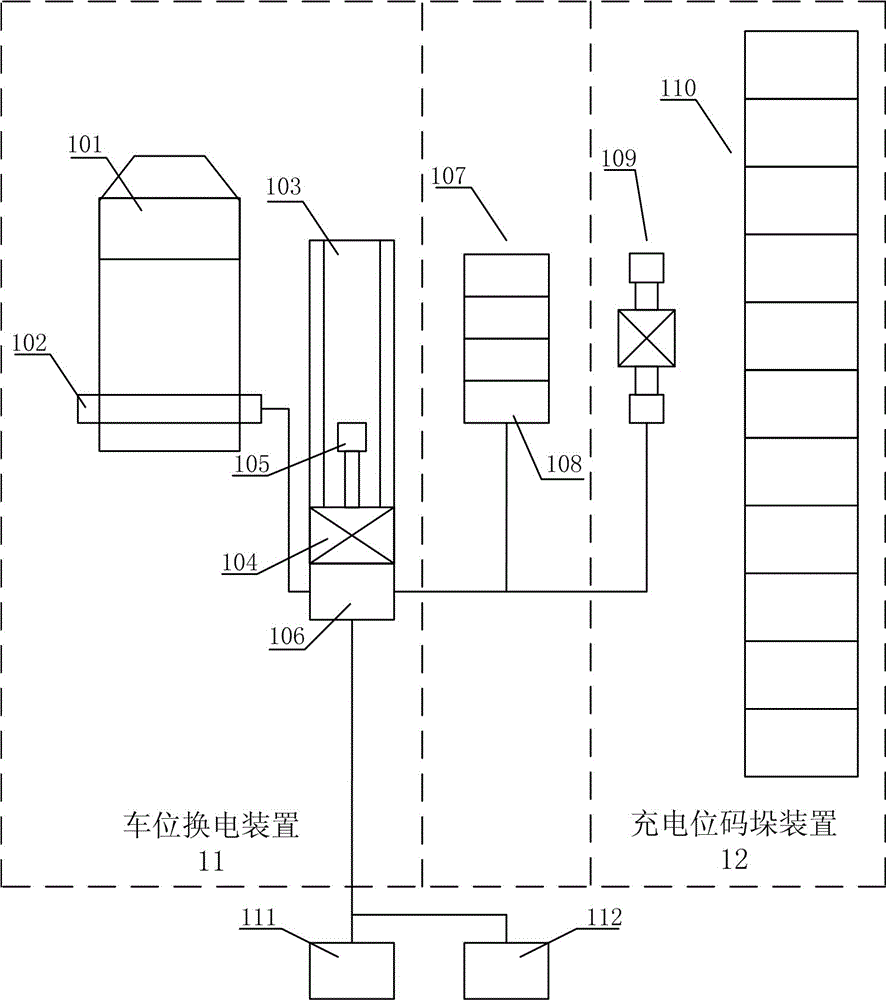

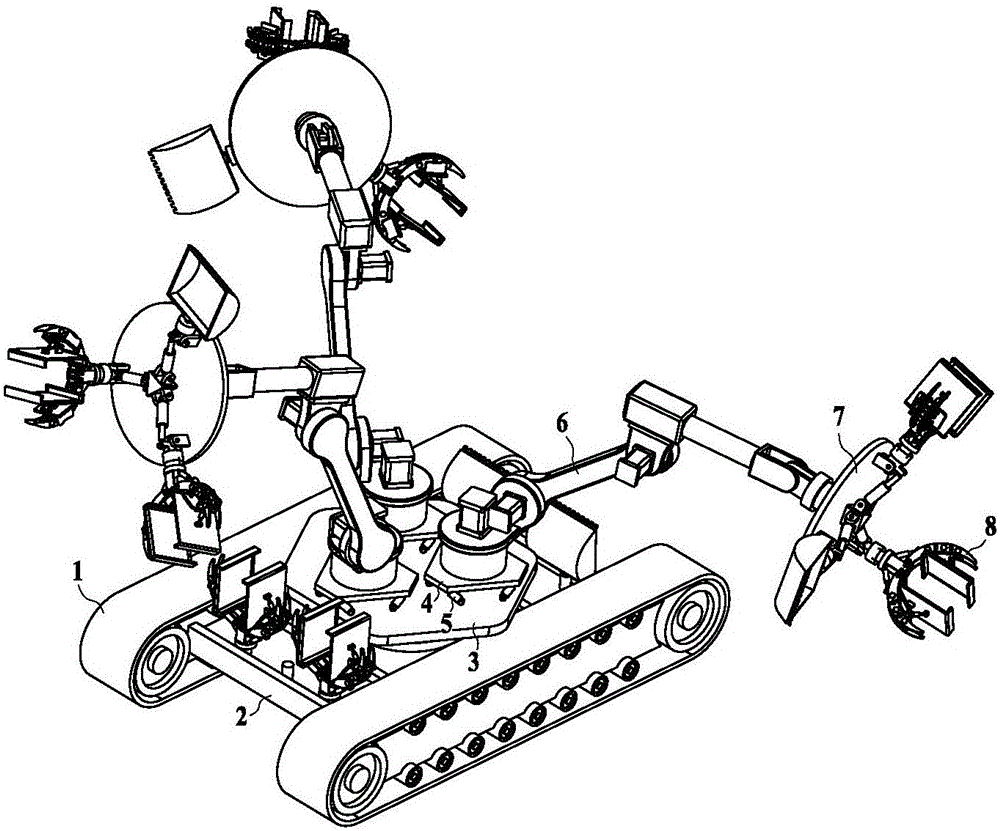

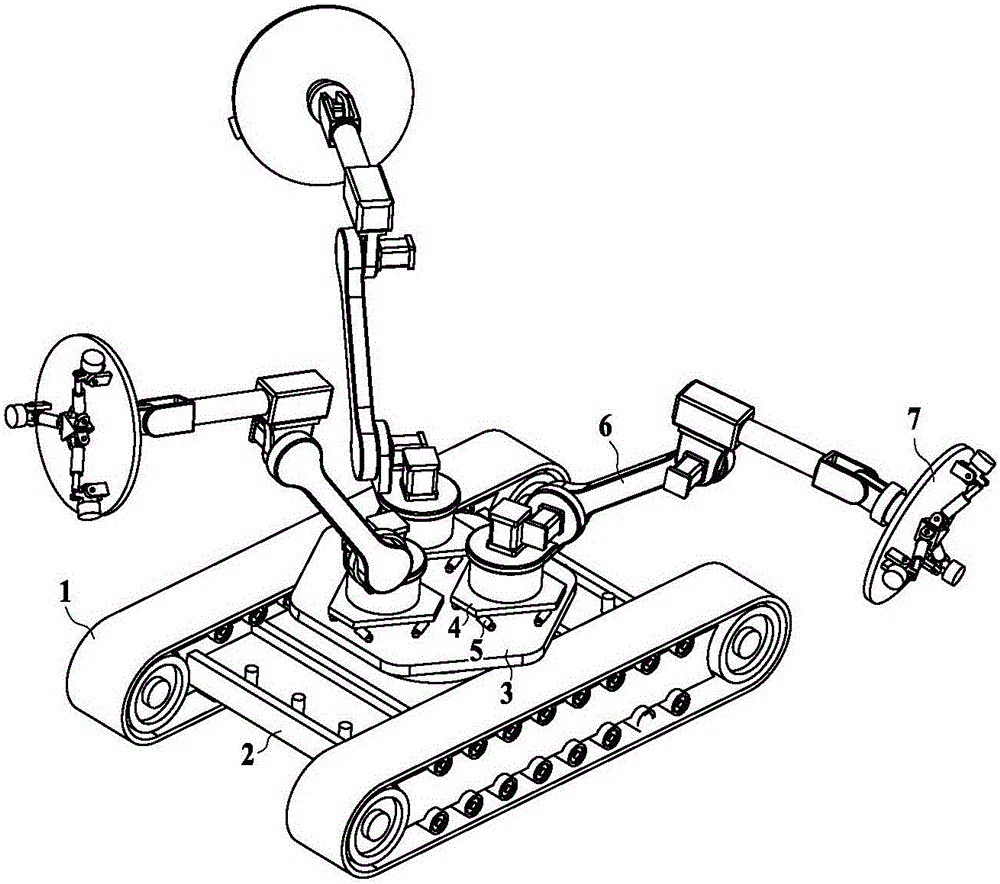

System for automatically replacing batteries by using robot and method thereof

InactiveCN102941842AImprove replacement efficiencyRealize fully automatic operationElectric propulsion mountingElectric/fluid circuitElectrical batteryAutomotive engineering

The invention provides a system for automatically replacing batteries by using a robot. The system comprises a vehicle position battery transfer device, a transport mechanism, a charging position stacking device and a system control unit. The vehicle position battery transfer device is used for transporting the batteries between an electric vehicle and the transport mechanism, the transport mechanism is used for placing charged batteries and to-be-charged batteries, the charging position stacking device is used for transporting the batteries between a charging bin rack and the transport mechanism, and the system control unit is used for controlling the operations of the vehicle position battery transfer device, the transport mechanism and the charging position stacking device. A method for automatically replacing batteries by using a robot is also disclosed. The method comprises the following steps: transporting the batteries between the transport mechanism and the charging bin rack through the stacking device, and transporting the batteries between the electric vehicle and the transport mechanism through the vehicle position battery transfer device. The battery automatic replacement system and method thereof can ensure full automatic operation of replacing the batteries of the electric vehicle and increase the efficiency of battery replacement.

Owner:YASKAWA SHOUGANG ROBOT CO LTD

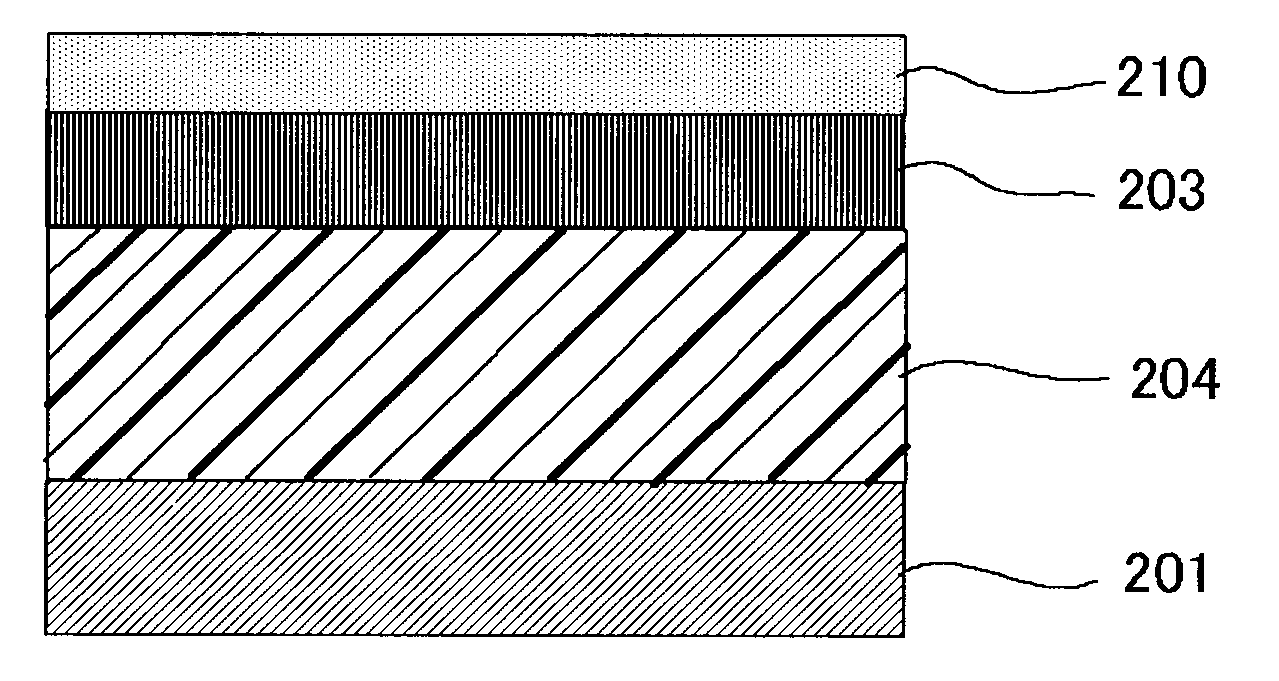

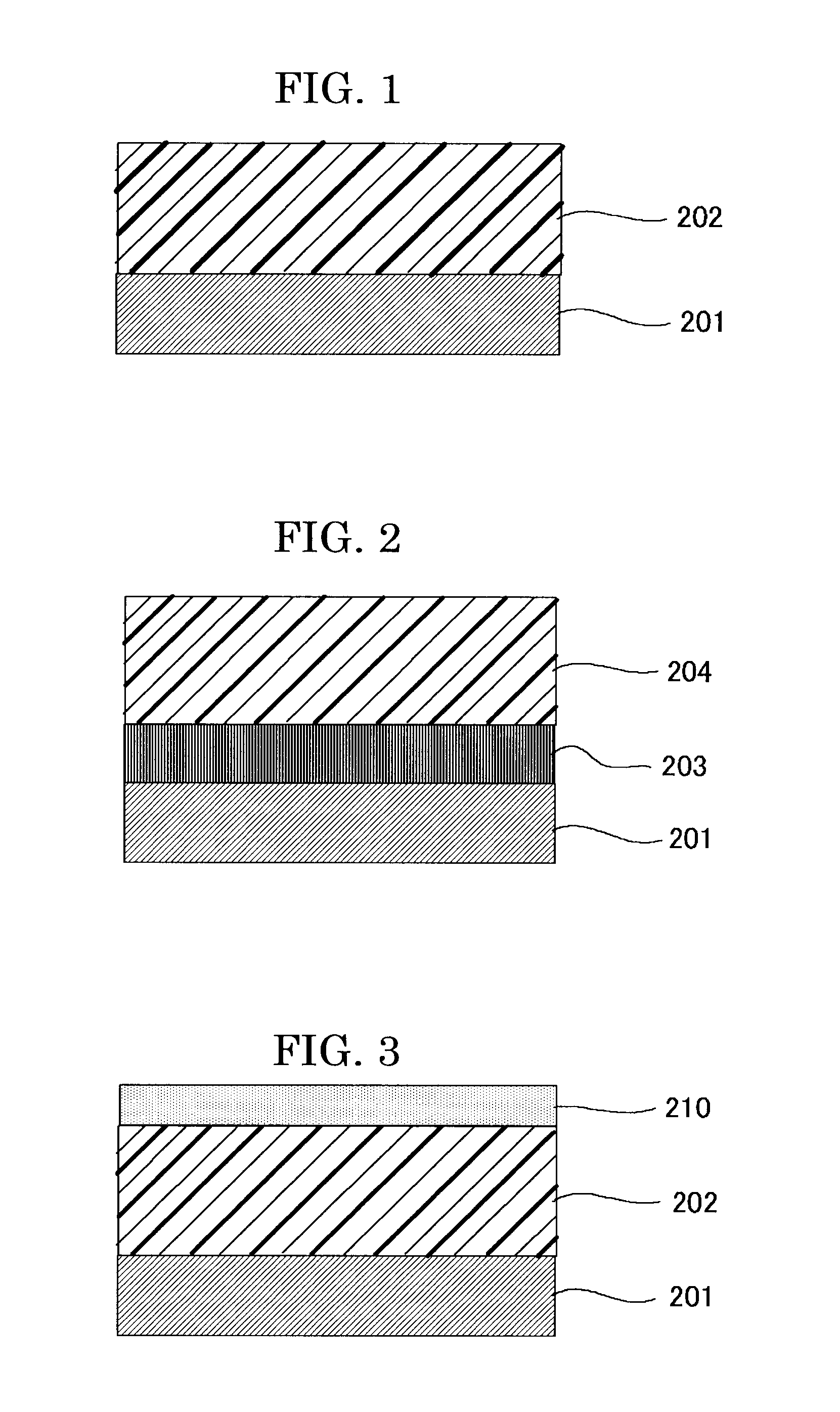

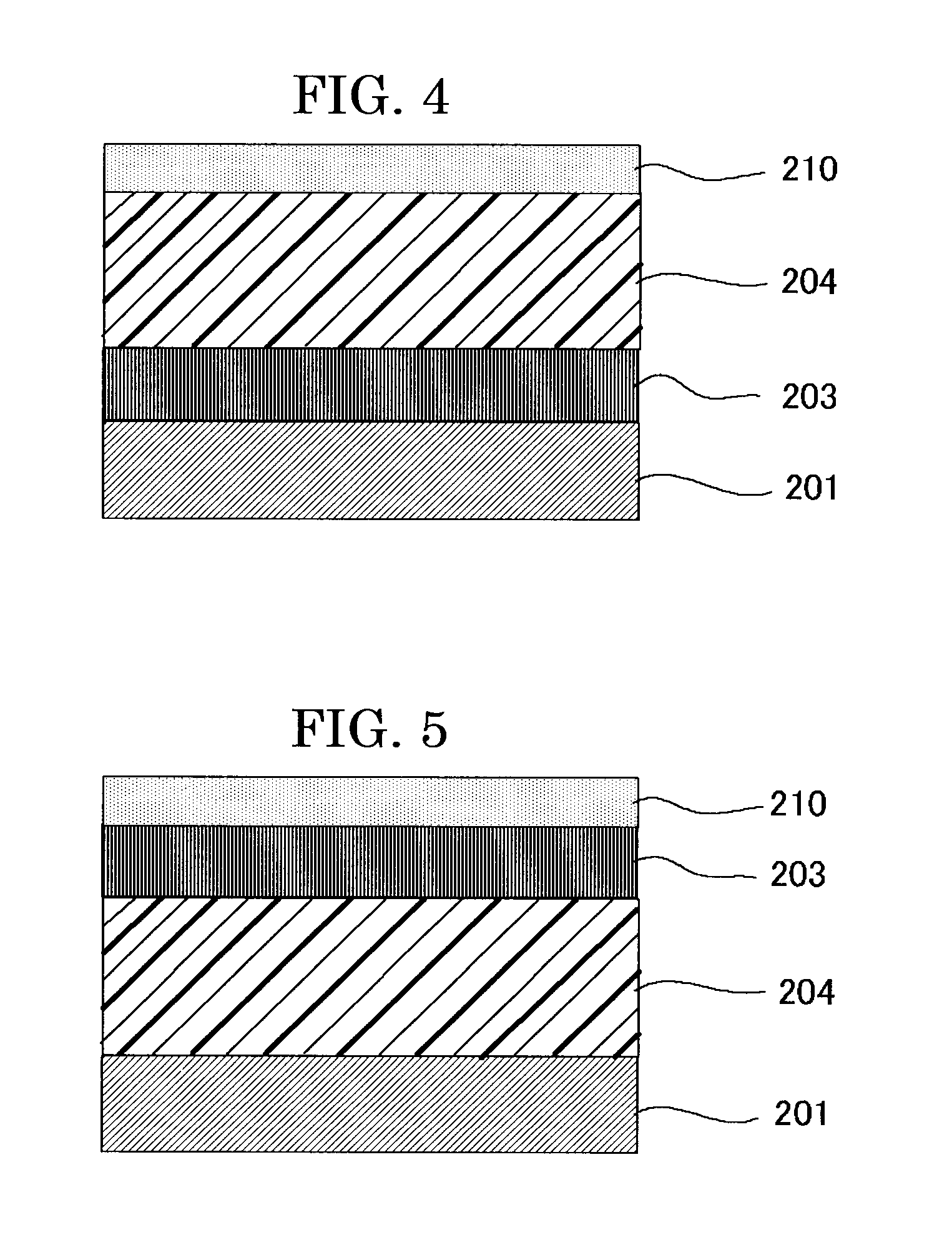

Image forming apparatus, image forming method, and process cartridge

InactiveUS20080112742A1Avoid it happening againMolding stabilityElectrographic process apparatusCorona dischargeElectricityElectrical conductor

The present invention provides an image forming apparatus which has high durability and allows for preventing occurrence of image blur and suppressing image degradation caused by a reduction in image density near a charging unit used under a high-humidity condition and stably forming high-quality images even when repetitively used for a long hours. To this end, the image forming apparatus has at least an electrophotographic photoconductor, a corona discharge type charging unit in a non-contact manner, an exposing unit, a developing unit, a transfer unit, a cleaning unit and a lubricant providing unit, wherein the outermost surface layer of the electrophotographic photoconductor contains at least a filler and an amine compound having a specific structure, the lubricant providing unit has a lubricant supplying unit configured to supply a lubricant onto the electrophotographic photoconductor and a lubricant applying unit configured to apply the supplied lubricant over the electrophotographic photoconductor surface.

Owner:RICOH KK

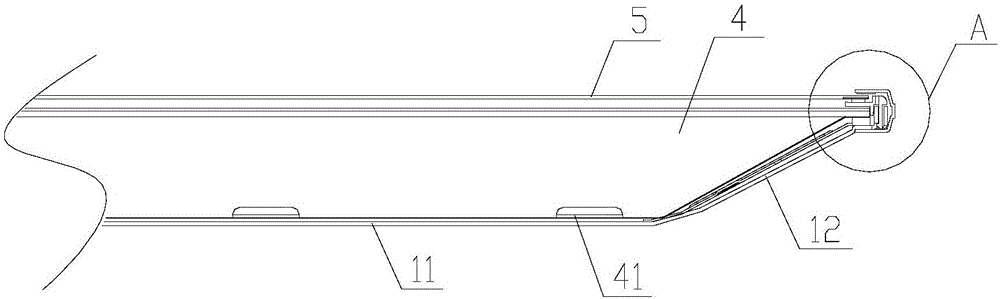

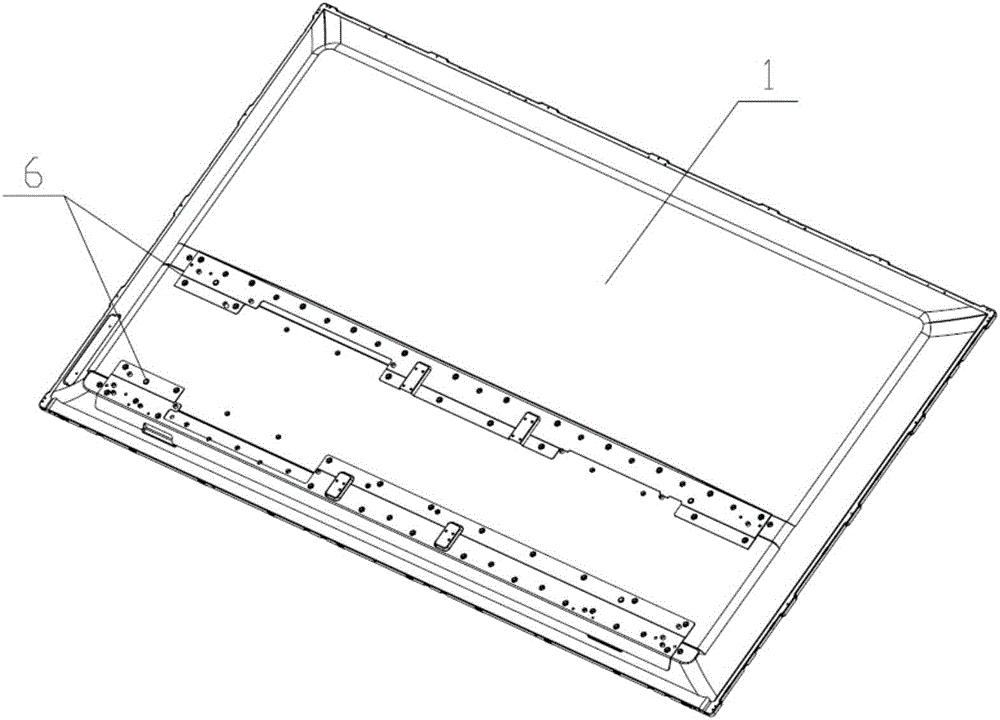

Direct type liquid-crystal display device

The invention discloses a direct type liquid-crystal display device and relates to the technical field of electronic and electrical products. The direct type liquid-crystal display device comprises a back plate, a middle frame, a front frame, a backlight module and a display screen, wherein the back plate comprises a base plate and side plates, the middle frame is installed on the side plates through fasteners and clamping tables, a supporting plate is further arranged on the middle frame, the backlight module is embedded between the supporting plate and the back plate, the front frame covers the outer side of the back plate and the outer side of the middle frame, and the display screen is embedded between the front frame and the supporting plate. A reinforcing plate is further fixed to the back plate, clamping hooks are arranged on the reinforcing plate, the backlight module comprises lamp strips, the lamp strips are provided with clamping holes, and the clamping hooks are matched with the clamping holes to fix the lamp strips on the reinforcing plate. The strength of the back plate is improved by arranging the reinforcing plate on the back plate, back plate damage during lamp strip installation is avoided, the size of the back plate is decreased, and the production cost is saved. In addition, the lamp strips and the reinforcing plate are connected through the clamping hooks and the clamping holes, mounting and dismounting are convenient, the assembly time is saved, and the lamp strip mounting and changing efficiency is improved.

Owner:洪鸿莎

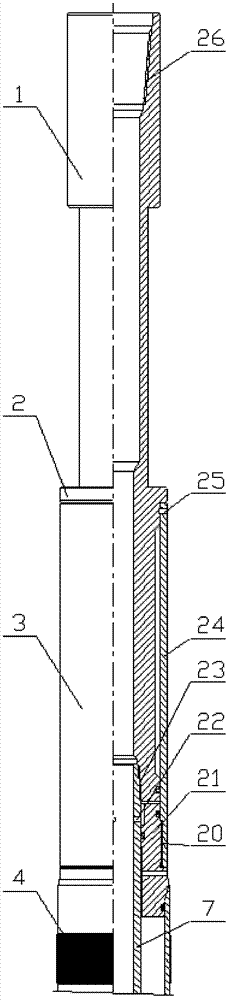

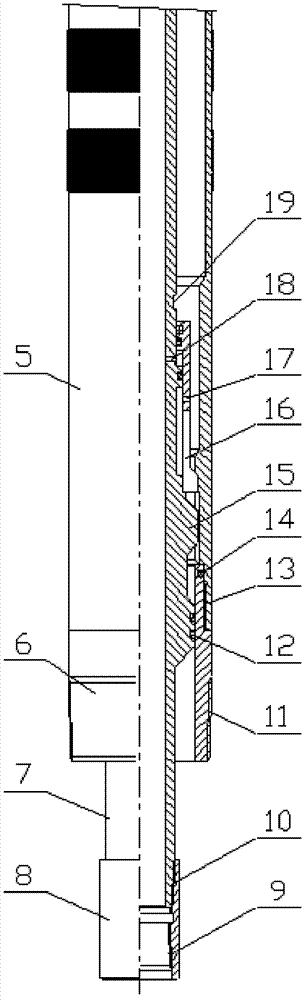

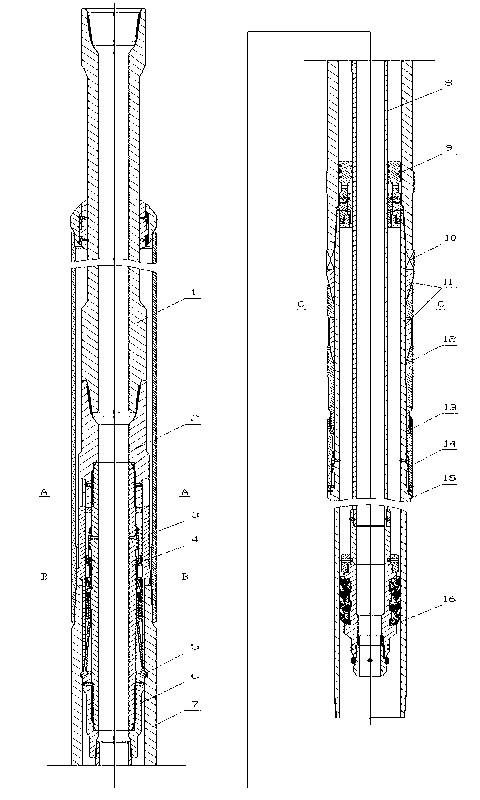

Expansion-type rotatable tail pipe hanger

The invention provides an expansion-type rotatable tail pipe hanger and belongs to the field of oil gas well fixation. The expansion-type rotatable tail pipe hanger comprises a hanger body and a feeding tool system, wherein the hanger body is an expandable metal tubing, a group of triangle-shaped annular protrusions are formed on the outer surface of an expansion section of the hanger body, annular rubber sections are vulcanized between every two adjacent triangle-shaped annular protrusions, and the diameter of each annular rubber section is larger than the outer diameter of top portion of each triangle-shaped annular protrusion. Rotation of a tail pipe can be realized, tripping-in capability and cement slurry displacement efficiency of the tail pipe are improved, sit-hanging and seal-separating functions of the hanger are realized via a hydraulic expansion hanger body. By the aid of the expansion-type rotatable tail pipe hanger, construction requirements on tail pipe cementation of an oil gas well can be met, and the technical difficulties like complex structure, many potential construction safety hazards and hardness in guaranteeing well cementation quality of a slip-type hanger are overcome. Operation process is simplified, tail pipe cementation quality is improved, risk is reduced, and cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Double-saw slot sawing machine

InactiveCN101705702ASimple structurePowerfulArtificial islandsSoil-shifting machines/dredgersMachine toolWater spray

The invention discloses a double-saw slot sawing machine comprising a water inlet tube (2), a water inlet rubber (3), a sand suction tube (1) and a sand suction rubber tube (4), wherein the water inlet rubber (3) respectively supplies water to two groups of saw blades, and the sand suction rubber tube (4) adsorbs sand to two groups of saw blades. A diving reduction box (10) is positioned in the middle of the slot sawing machine; an eccentric shaft is installed below the diving reduction box and is provided with an upper sealed axle sleeve (18) and a lower sealed axle sleeve (5); two axle sleeves are respectively connected with a left connecting rod (7) and a right connecting rod (6), wherein the connecting rod (7) is hinged with the middle of a swing arm (8), and the connecting rod (6) is hinged with the upper end of a swing arm (9); a drill point (15) capable of rotating from left to right is positioned on the top center of the slot sawing machine between a shifting fork and two shifting needles; two triangle tool rests (16) and (17) are respectively positioned on the left and the right of the lower end of the slot sawing machine; inclined saw blades (12) are evenly distributed according to certain length on the bottom of the tool rest; a water spray nozzle (11) is positioned between each two saw blades. The invention is a special machine tool for building underground impervious walls.

Owner:南通同旭贸易有限公司

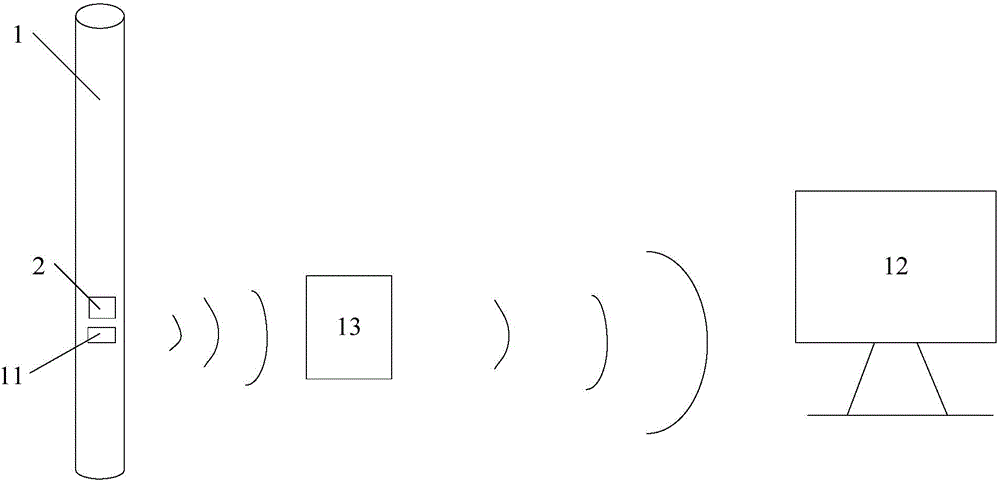

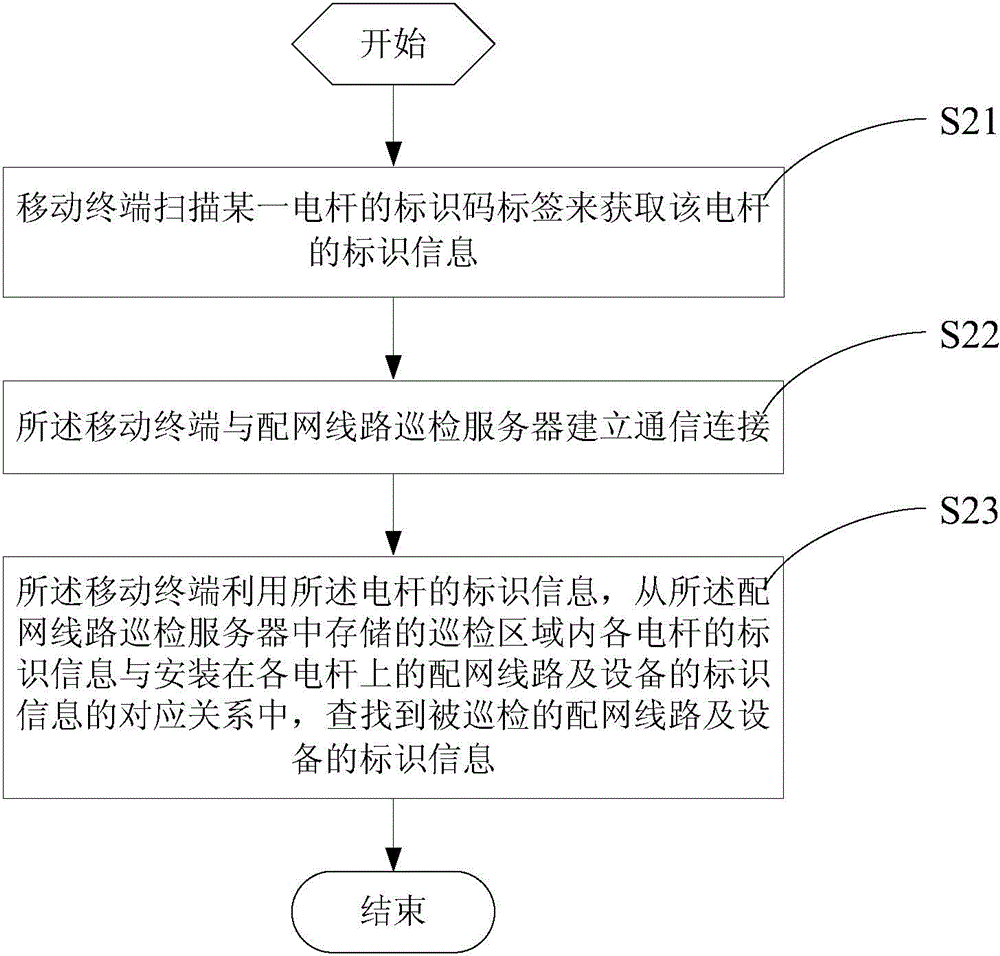

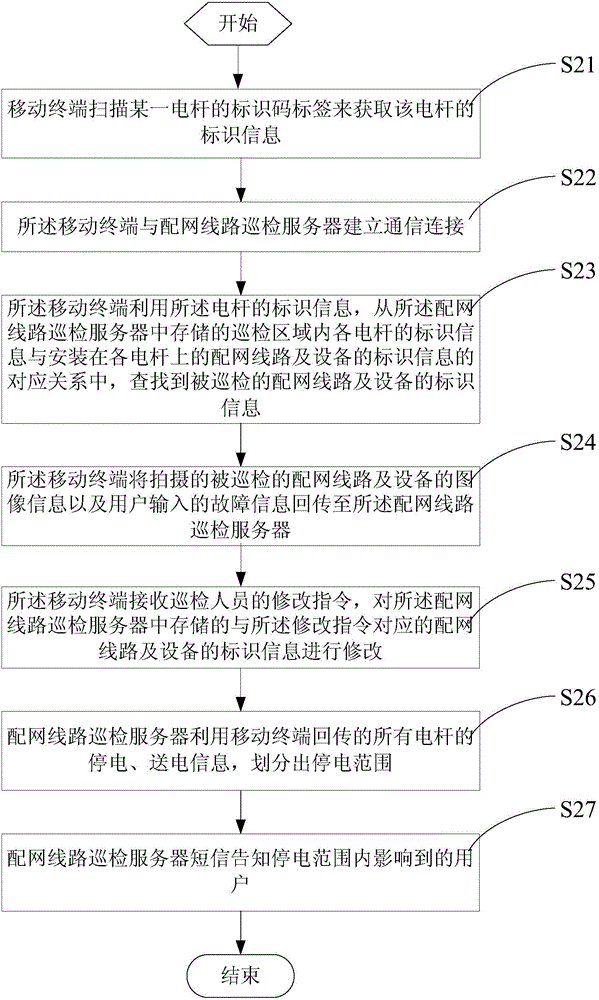

Electric power distribution network line as well as equipment inspection method and equipment inspection system

InactiveCN104103098AAvoid mismatchAccurate graspChecking time patrolsElectric power distributionIndustrial engineering

The invention discloses an electric power distribution network line as well as an equipment inspection method and an equipment inspection system. According to the method and the system, an inspector can scan the identification code labels of electrical poles through a mobile terminal to quickly recognize the label information of the electric rods; when connection is established between the mobile terminal and a distribution network line inspection server, through the label information of the electric pole, from the corresponding relation of the label information stored by the distribution network line inspection server, and the label information of the distribution network line and the equipment mounted on each electric pole, the label information of the inspected distribution network line and the equipment can be found out, and as a result, the detailed information of the inspected distribution network line and the equipment is mastered accurately, the problem that a distribution device carried is not matched with the inspected distribution network equipment to be replaced on site is solved, the replacing efficiency is further improved, and the working process is accelerated.

Owner:STATE GRID CORP OF CHINA +4

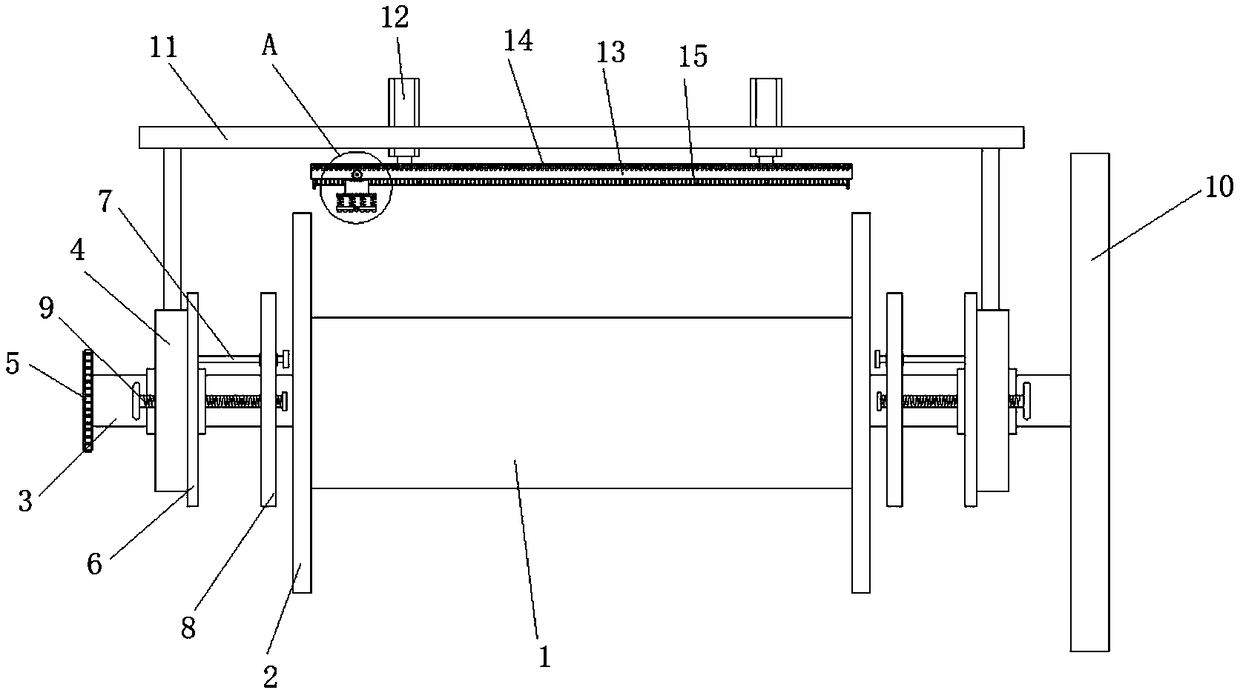

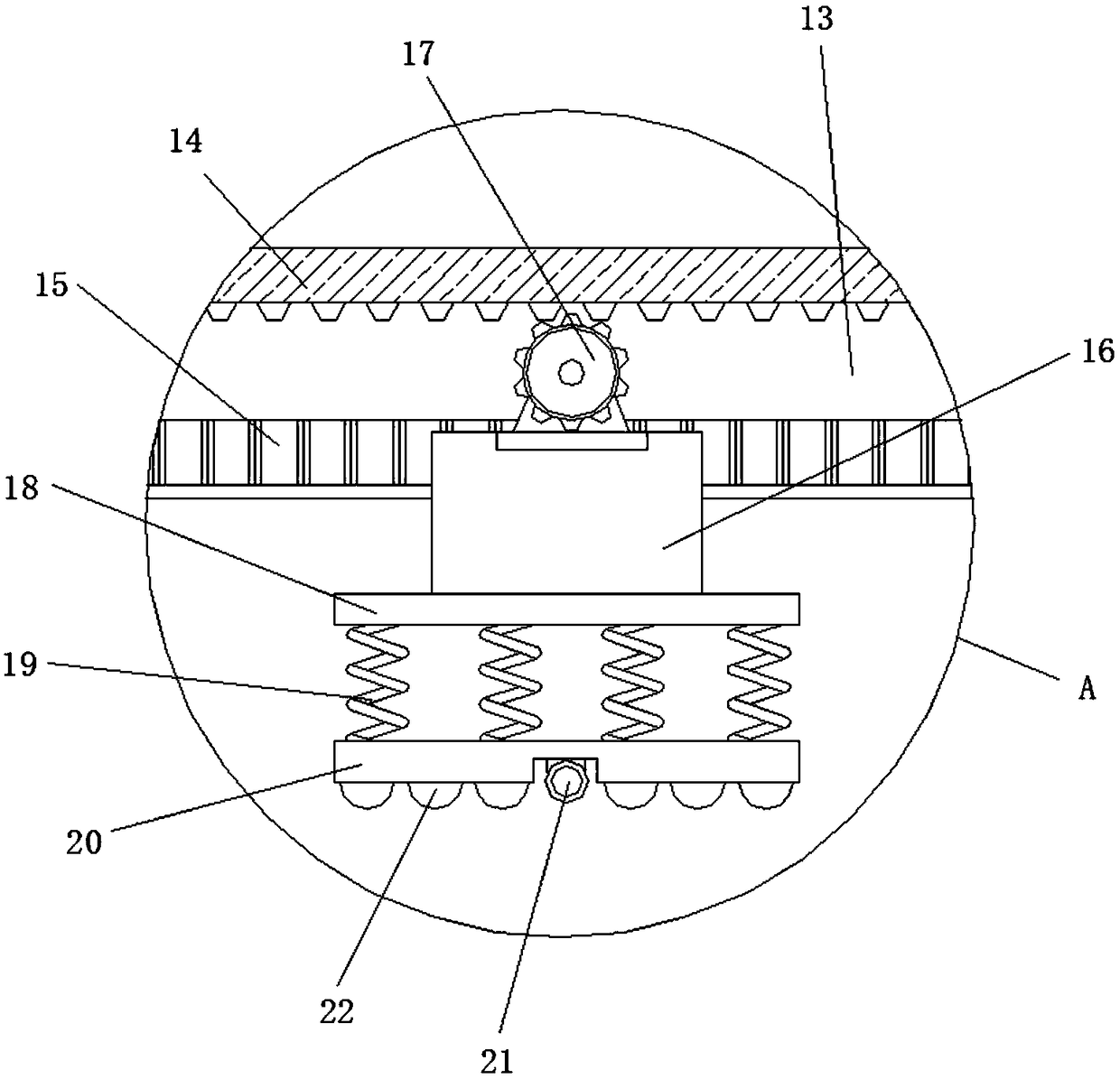

Textile winding roller

ActiveCN108178025AInstalled and disassembledImprove replacement efficiencyFilament handlingYarnGear wheel

The invention discloses a textile winding roller comprising a winding roller body. The two ends of the winding roller body are both provided with limiting plates. The circle centers of the sides, faraway from each other, of the two limiting plates are each fixedly connected with one end of a supporting shaft. The end, far away from the corresponding limiting plate, of one supporting shaft is fixedly provided with a transmission gear. The transmission gear is meshed with an output shaft of a drive motor on a spinning machine. The end, far away from the limiting plate, of the other supporting shaft is fixedly connected with a supporting disk. The supporting disk is parallel to the corresponding limiting plate. The middle sections of the two supporting shafts are provided with supporting blocks through bearings. The textile winding roller is novel in design and convenient and rapid to use, the winding roller body is fixedly installed on a machine frame of the spinning machine through a connection mechanism, installation is firm, and disassembly is convenient and rapid; and a yarn carding device can tightly press the yarn during carding, so that the winding amount of a single windingroller body is improved, frequent replacement of the winding roller is avoided, and the work efficiency of the spinning machine is improved.

Owner:安徽海洋网业有限公司

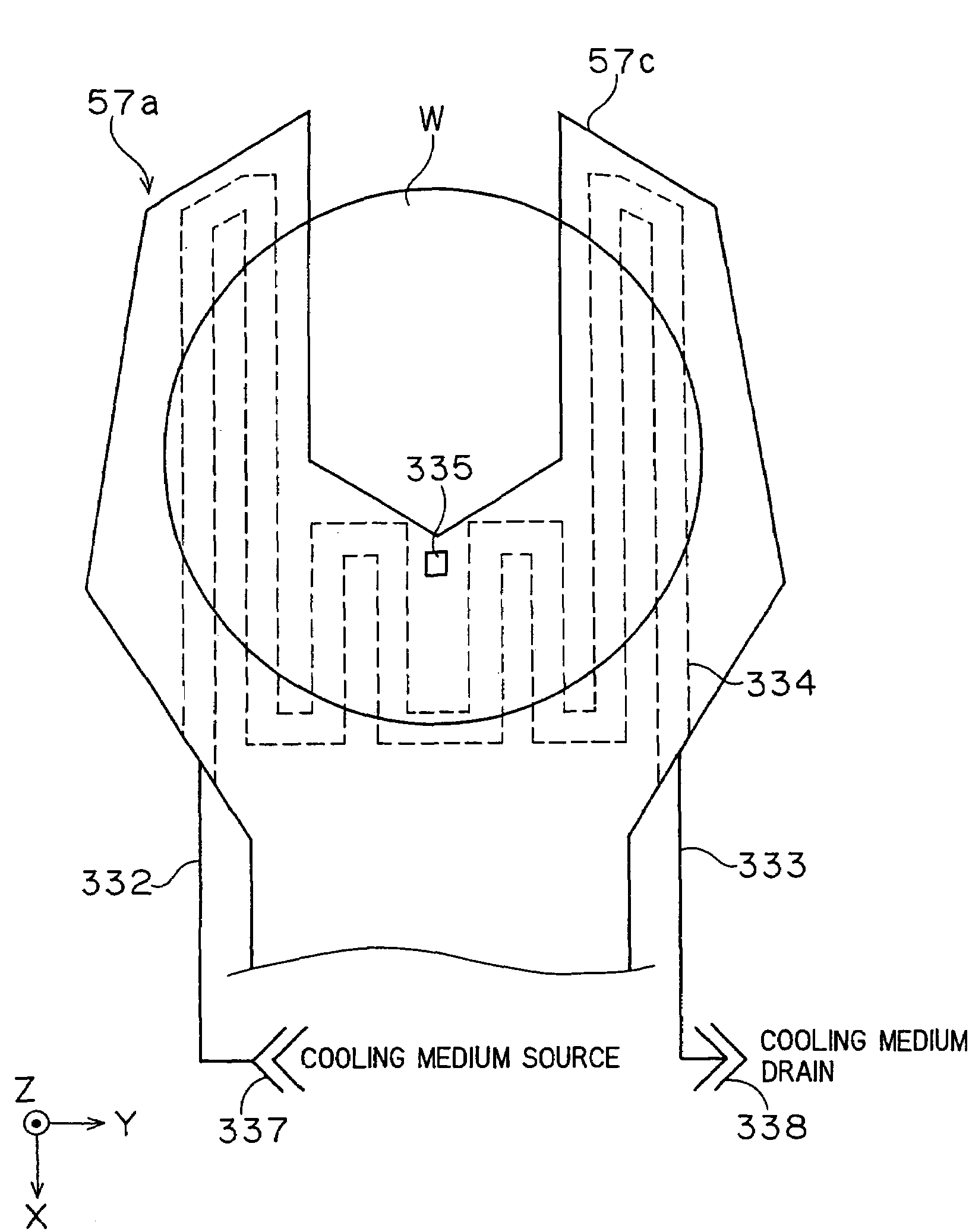

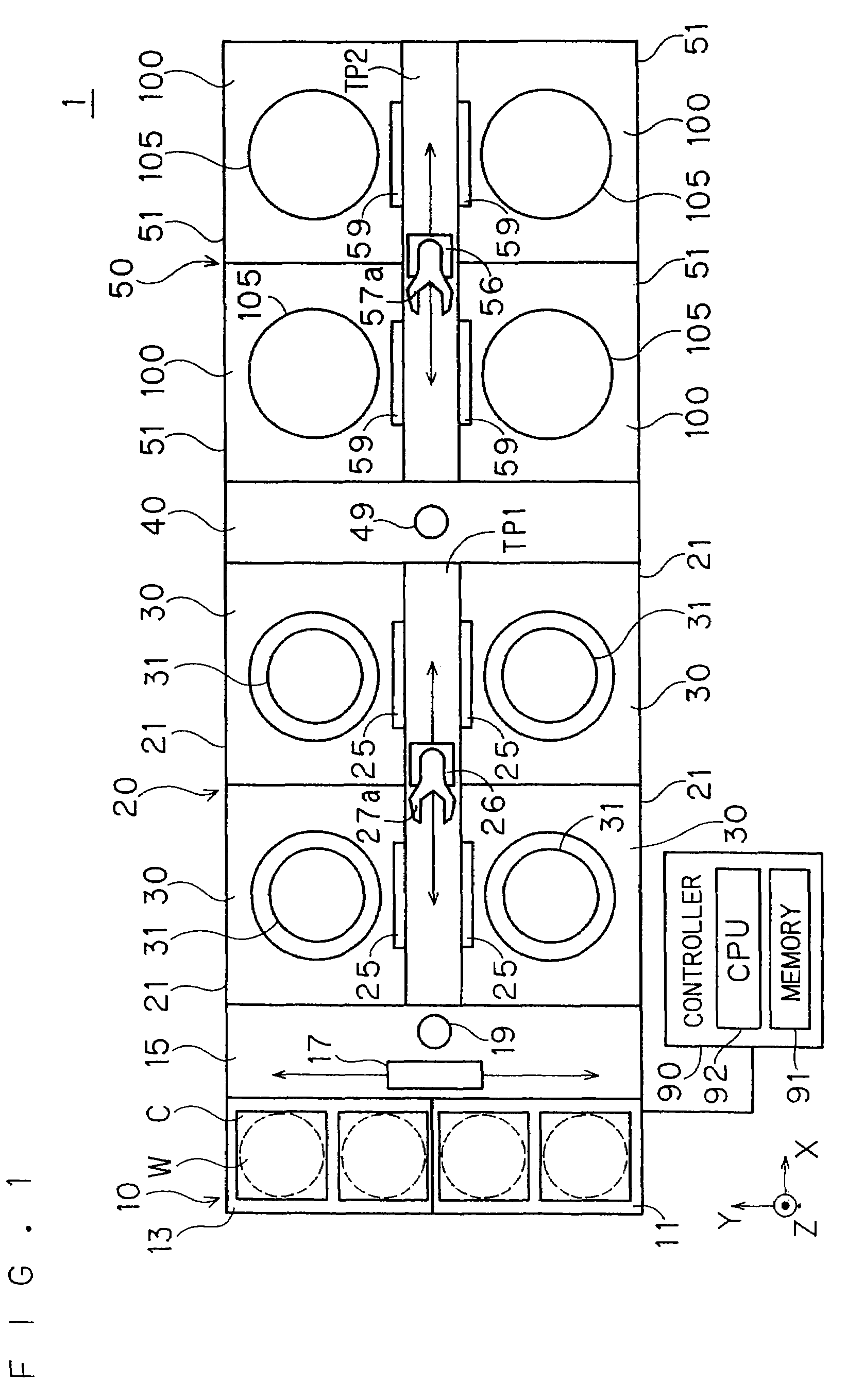

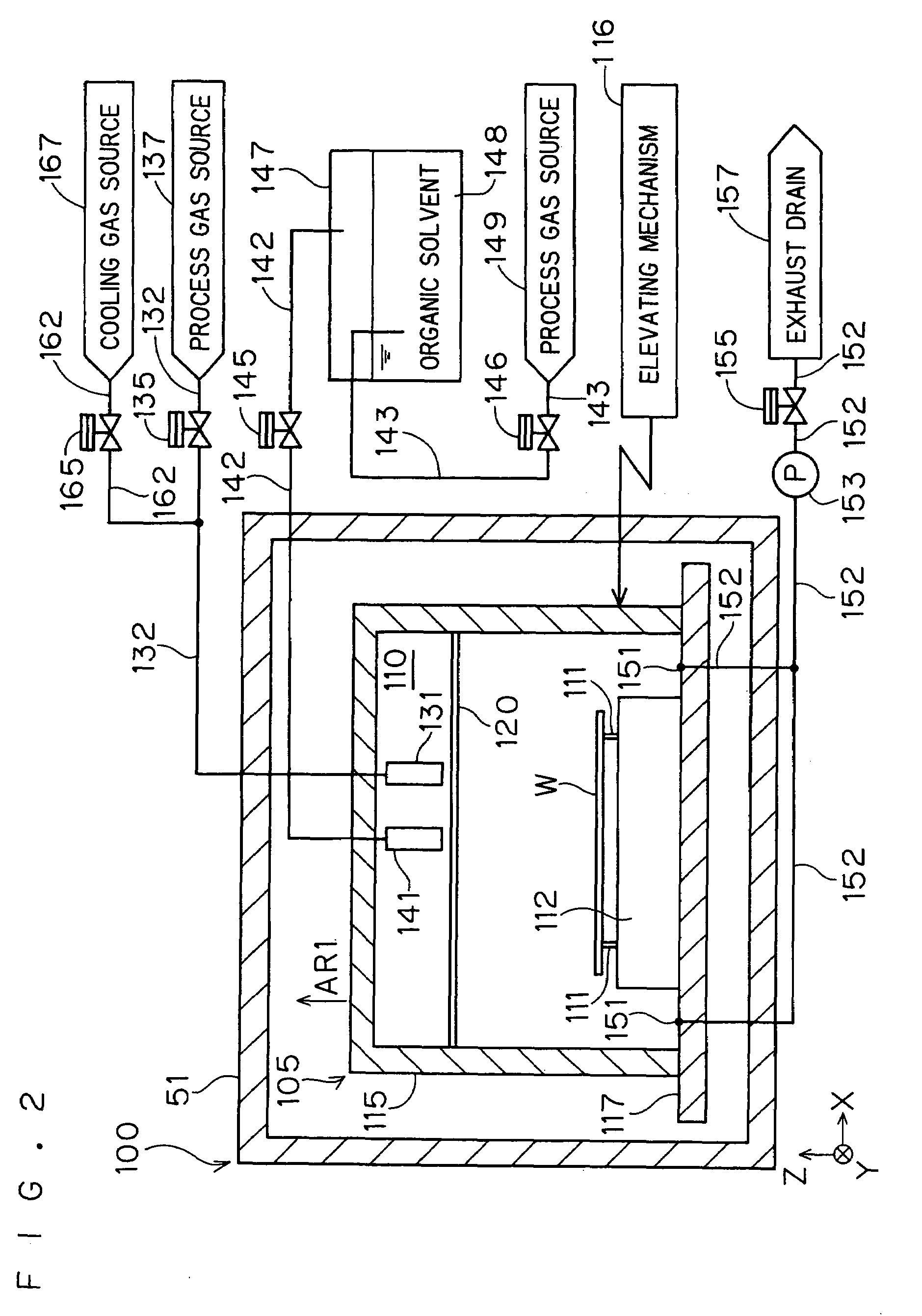

Substrate processing apparatus for drying substrate

InactiveUS7418970B2Reliable dryingImprove replacement efficiencyDrying solid materials without heatDrying gas arrangementsOrganic solventProduct gas

A substrate processing apparatus includes a container in which a heating plate, a discharge nozzle for discharging a vapor of organic solvent, and a discharge nozzle for supplying a process gas and a cooling gas are provided. A pump in communication with an exhaust outlet of the container exhausts an atmosphere from the container to reduce pressure in the container. Therefore, the substrate processing apparatus is capable of performing (1) the process of drying a substrate in a reduced-pressure atmosphere by the use of the vapor of organic solvent, and (2) the process of drying the substrate in the reduced-pressure atmosphere by heating, to thereby efficiently dry the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

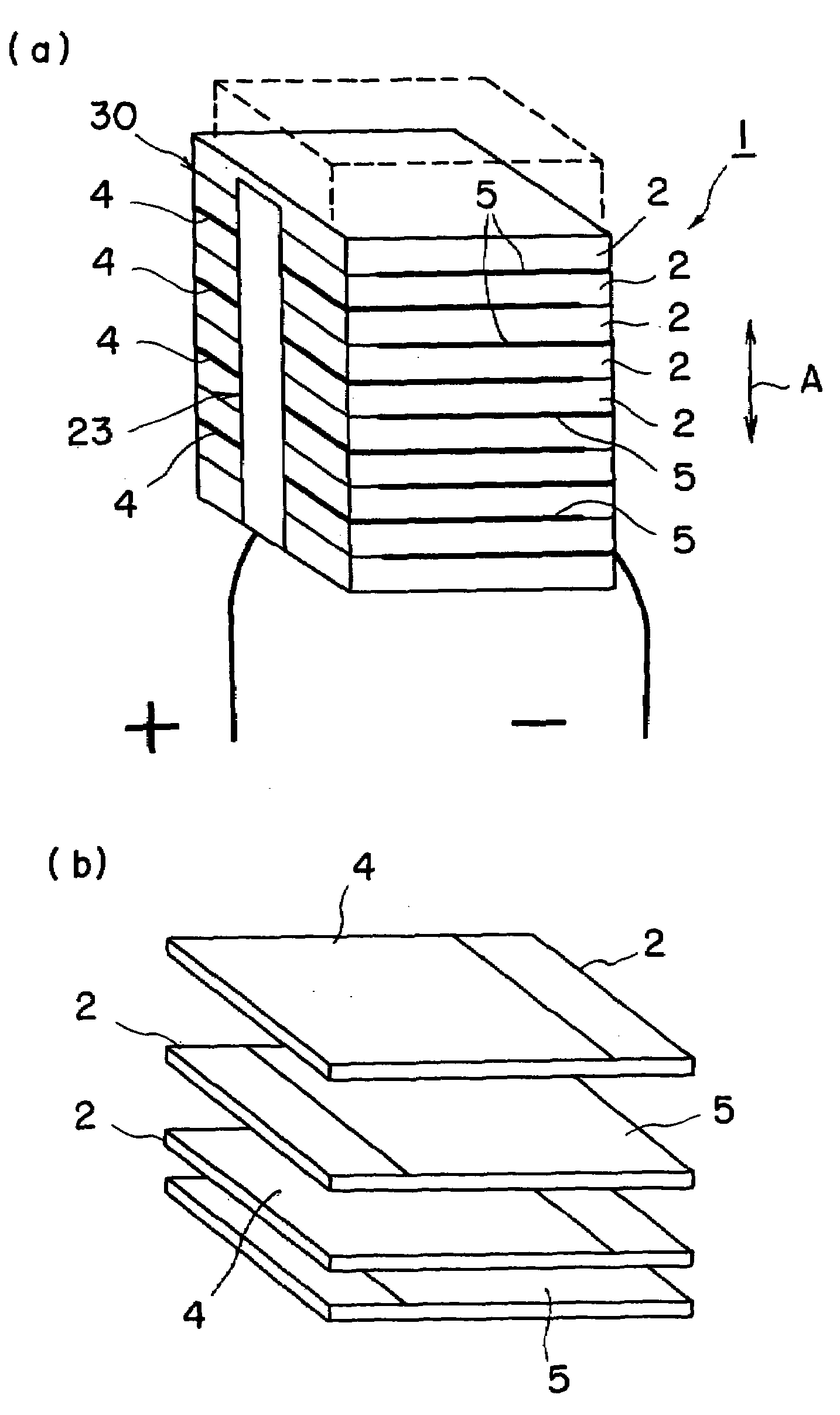

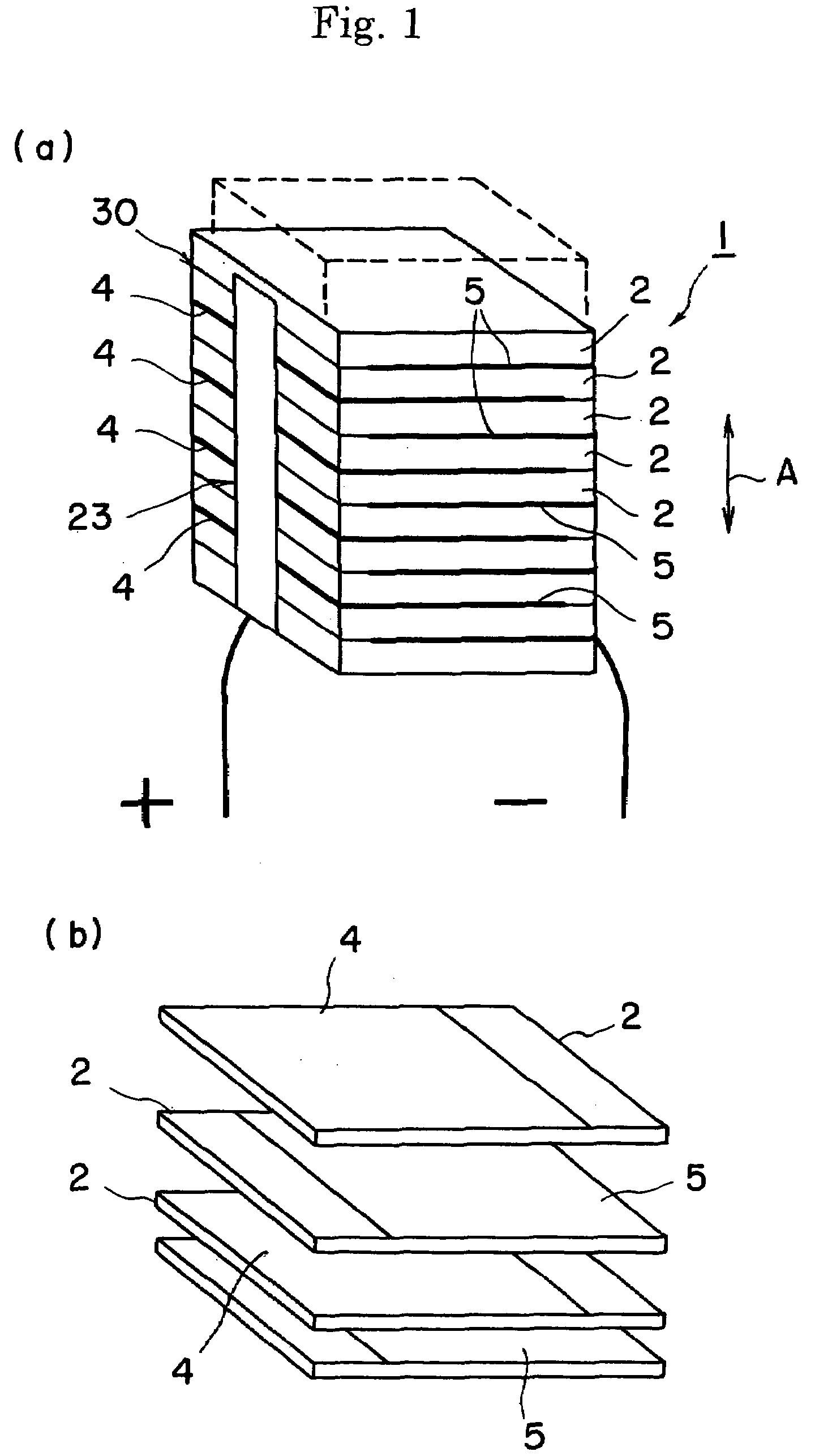

Multilayer piezoelectric devices and method of producing same

InactiveUS20070164639A1Increase displacementIncreased durabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringElectrical and Electronics engineering

A multilayer piezoelectric device has a laminated body 1 having piezoelectric layers 2 laminated in the direction of a given axis “A” and internal electrode layers 4, 5 each disposed between two respective neighboring piezoelectric layers 2. The device further has a underlying layer 3 disposed on a side of the laminated body 1 and electrically connected to the internal electrode layers 4, 5, a first conductive reinforcing layer 10 joined to the underlying layer 3, a second conductive reinforcing layer 11 joined to the first conductive reinforcing layer 10, and a conductive joining material 9 joining the underlying layer 3 to the first conductive reinforcing layer 10. The second conductive reinforcing layer 11 is not directly joined by means of the conductive joining material 9.

Owner:NGK INSULATORS LTD

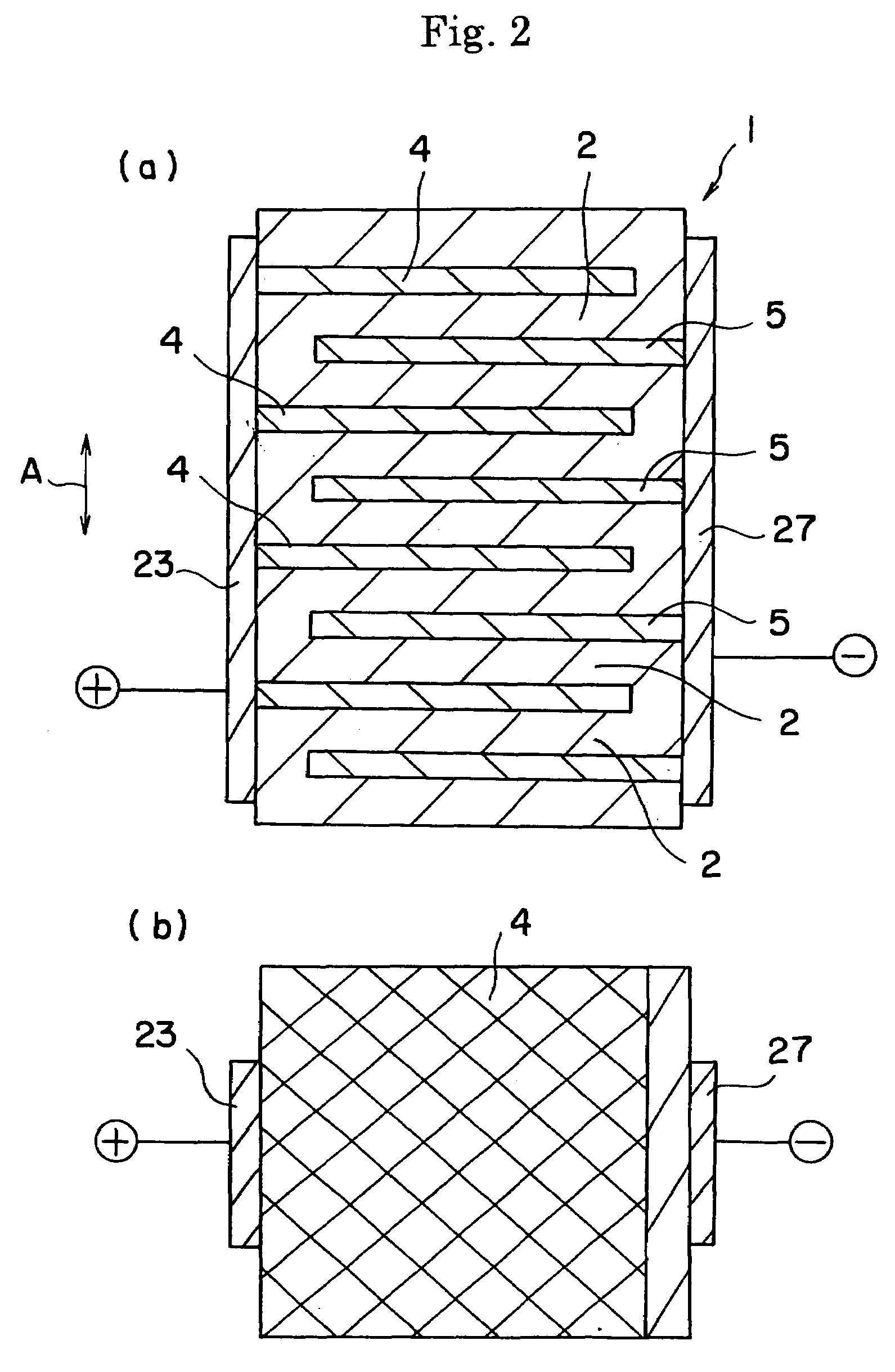

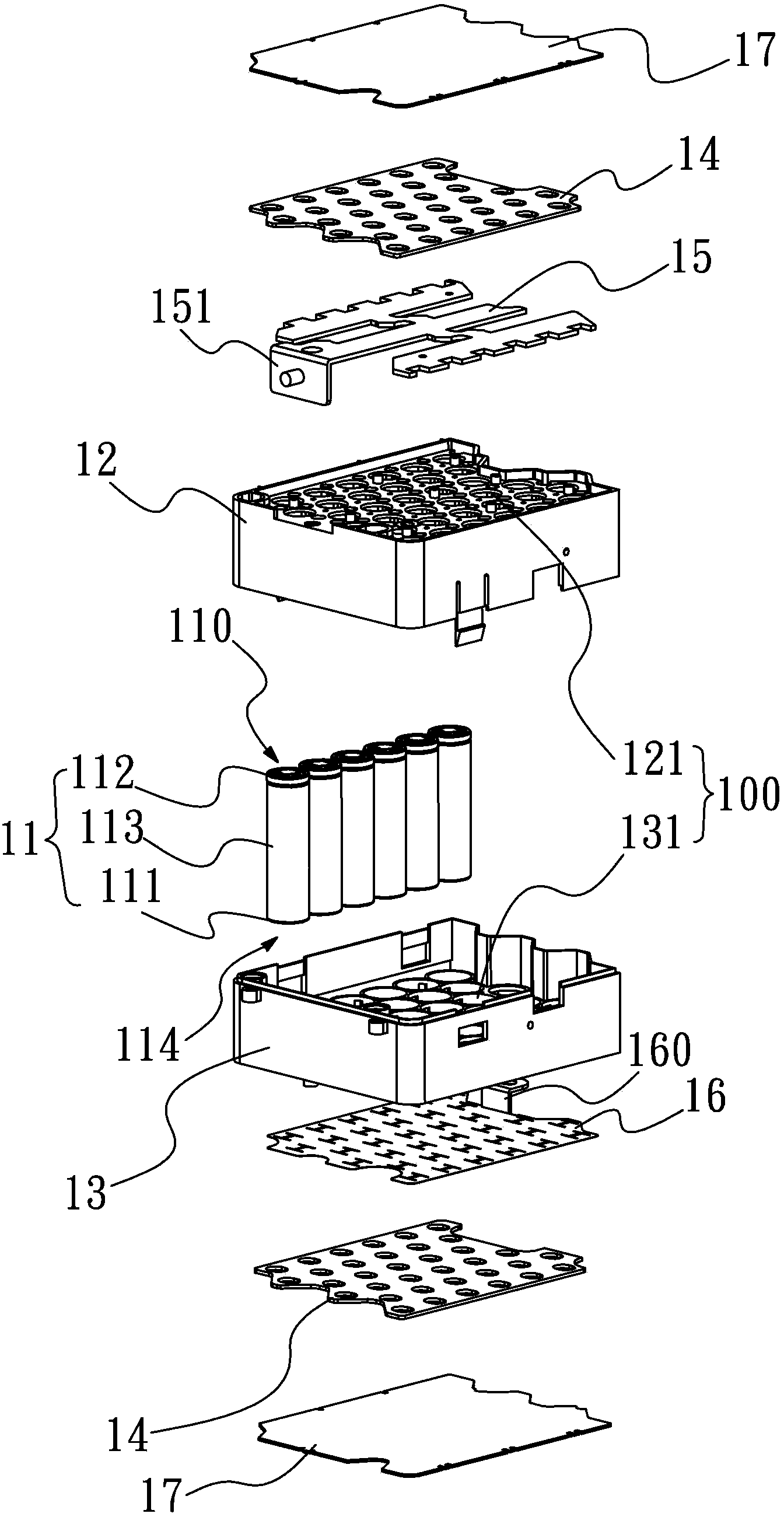

High-heat-conduction battery module having battery cores, and assembling method thereof

ActiveCN103390762AImprove cooling efficiencyWill not easily cause fall offFinal product manufactureSecondary cells manufactureFixed frameEngineering

The invention relates to a high-heat-conduction battery module having battery cores, and an assembling method thereof. The high-heat-conduction battery module comprises battery cores, a primary fixing frame, an auxiliary fixing frame, common electrodes and a heat dissipating device, the primary fixing frame and the auxiliary fixing frame are combined to form a plurality of accommodating tanks for accommodating the battery cores, the battery cores are stably clamped by an interference projection which forms an integral body together with the primary fixing frame and the auxiliary fixing frame, and after the battery cores are assembled in the accommodating tanks, two electrodes of each of the battery cores are guided to a corresponding common electrode, and the heat dissipating device is combined with the primary fixing frame and / or the auxiliary fixing frame to force the tops and / or the bottoms of the battery cores to the heat dissipating device in order to stably fix the battery cores in the accommodating tanks by the interference projection and the heat dissipating device and increase the heat dissipating efficacies of the battery cores.

Owner:阿提瓦公司

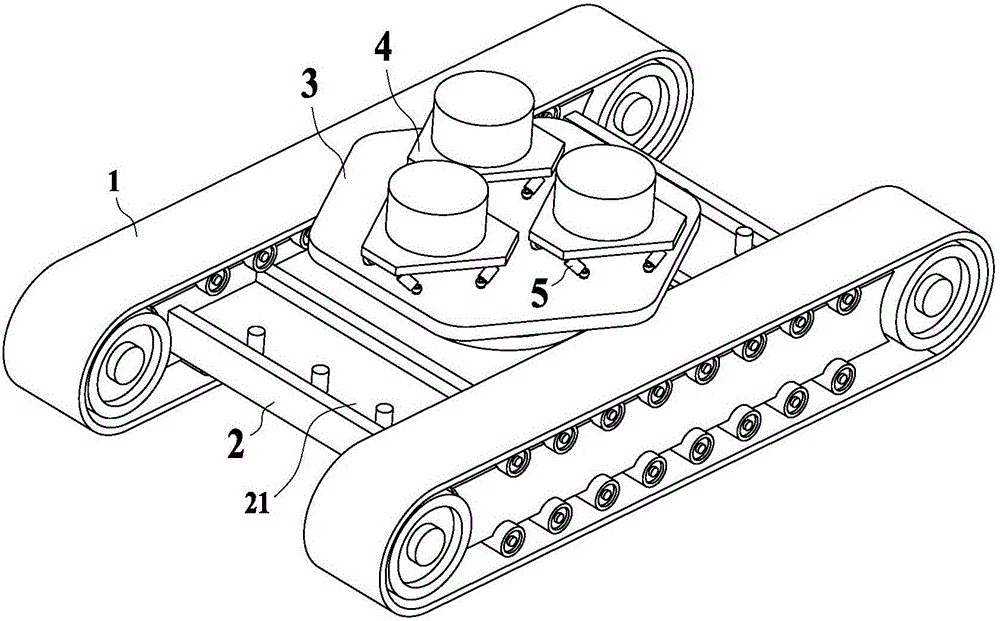

Multifunctional palletizing robot based on Stewart parallel connection platform

ActiveCN105690362AImprove palletizing efficiencyReduce labor intensityProgramme-controlled manipulatorJointsRotary stageEngineering

The invention relates to the field of robots, in particular to a multifunctional palletizing robot based on a Stewart parallel connection platform. The multifunctional palletizing robot comprises caterpillar band travelling mechanisms, a chassis, a rotating table, fine tuning tables, fine tuning air cylinders, mechanical arms, gripping devices and gripping hands; the caterpillar band travelling mechanisms are located on the two sides of the chassis, the rotating table is located in the middle portion of the chassis, the fine tuning tables are located at the upper end of the rotating table, the fine tuning air cylinders are located between the rotating table and the fine tuning tables, the mechanical arms are located at the upper ends of the fine tuning tables, and the gripping devices are located at the ends of the mechanical arms; the rotating table, the fine tuning air cylinders and the fine tuning tables form the Stewart parallel connection platform; and the number of the mechanical arms is three, the number of the gripping devices is three, and the three gripping devices are installed on the three mechanical arms. The multifunctional palletizing robot is high in palletizing efficiency, manual gripping hand replacement is replaced, and the labor intensity of workers is reduced; and in addition, the accuracy for replacing the gripping hands, gripping objects and palletizing the objects is high, and damage to the objects is greatly reduced.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

Mechanical-hydraulic double-acting release rotary tail pipe hanger

The invention discloses a mechanical-hydraulic double-acting release rotary tail pipe hanger, and belongs to the technical field of manufacturing downhole tools for oil and gas well cementing operations in oil and gas development. The mechanical-hydraulic double-acting release rotary tail pipe hanger comprises a short drill pipe, an upper joint, a release mechanism, a double male joint, a male and female joint and a lower joint. The short drill pipe, the upper joint, the double male joint and the lower joint are connected in a threaded manner from up to down sequentially. The mechanical-hydraulic double-acting release rotary tail pipe hanger further comprises a loading mechanism comprising a hanger set hydraulic cylinder, a light-load bearing, conjoined twin slips, a conjoined twin cone, a heavy-duty bearing and a central pipe. The hanger set hydraulic cylinder, the light-duty bearing, the conjoined twin slips, the conjoined twin cone and the heavy-duty bearing are arranged on the central pipe from down to up sequentially. The central pipe is connected at the lower end of the male and female joint. The heavy-duty bearing is arranged between the male and female joint and the conjoined twin cone. By the aid of the mechanical-hydraulic double-acting release rotary tail pipe hanger, a tail pipe can rotate when the a tube pillar enters, after the hanger is set and is separated from a releasing release, the slips and the bearings bear the hanger, and functions of rotating and well cementing of a heavy-duty tail pipe is realized.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com