Patents

Literature

51results about How to "Reliable drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

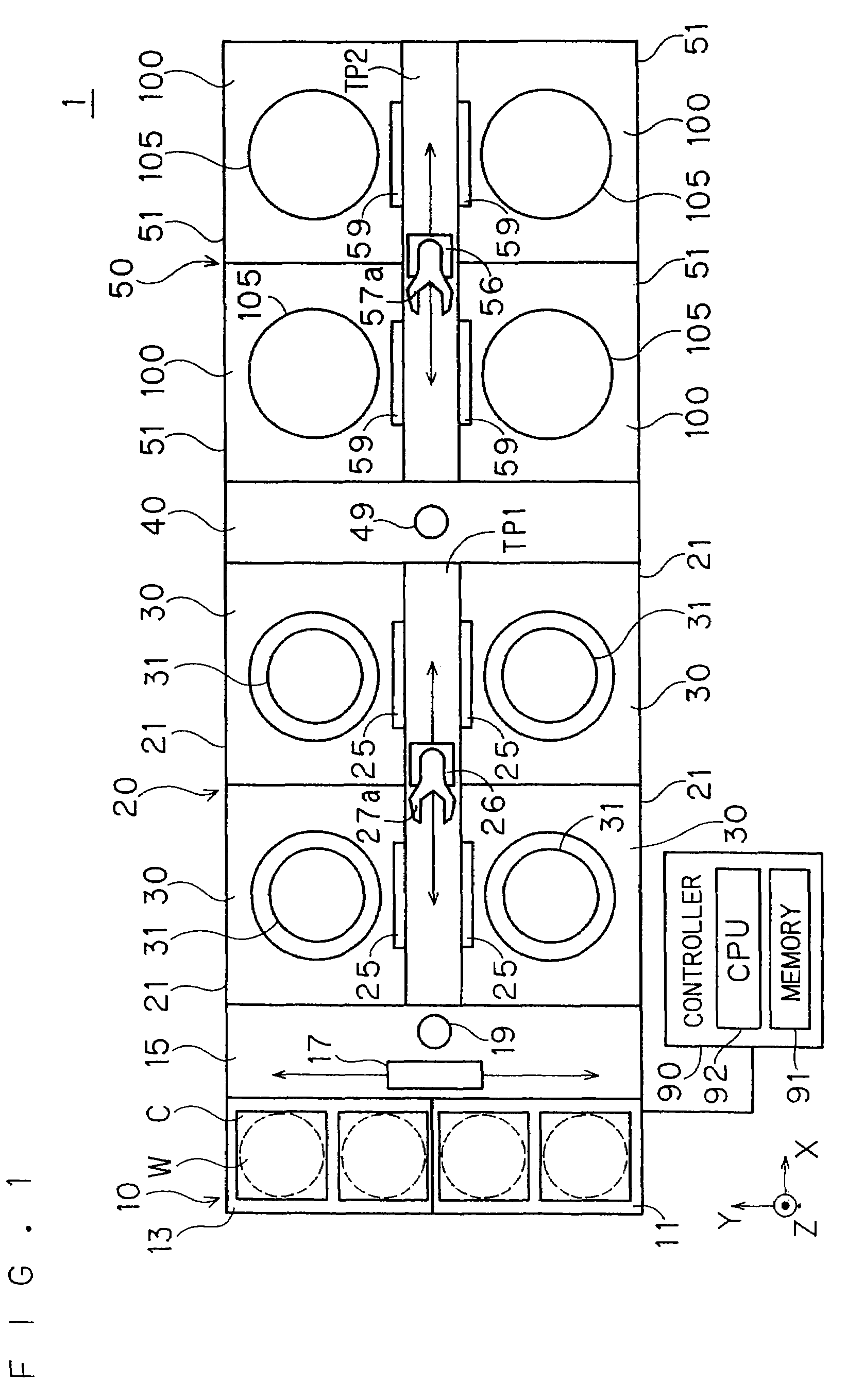

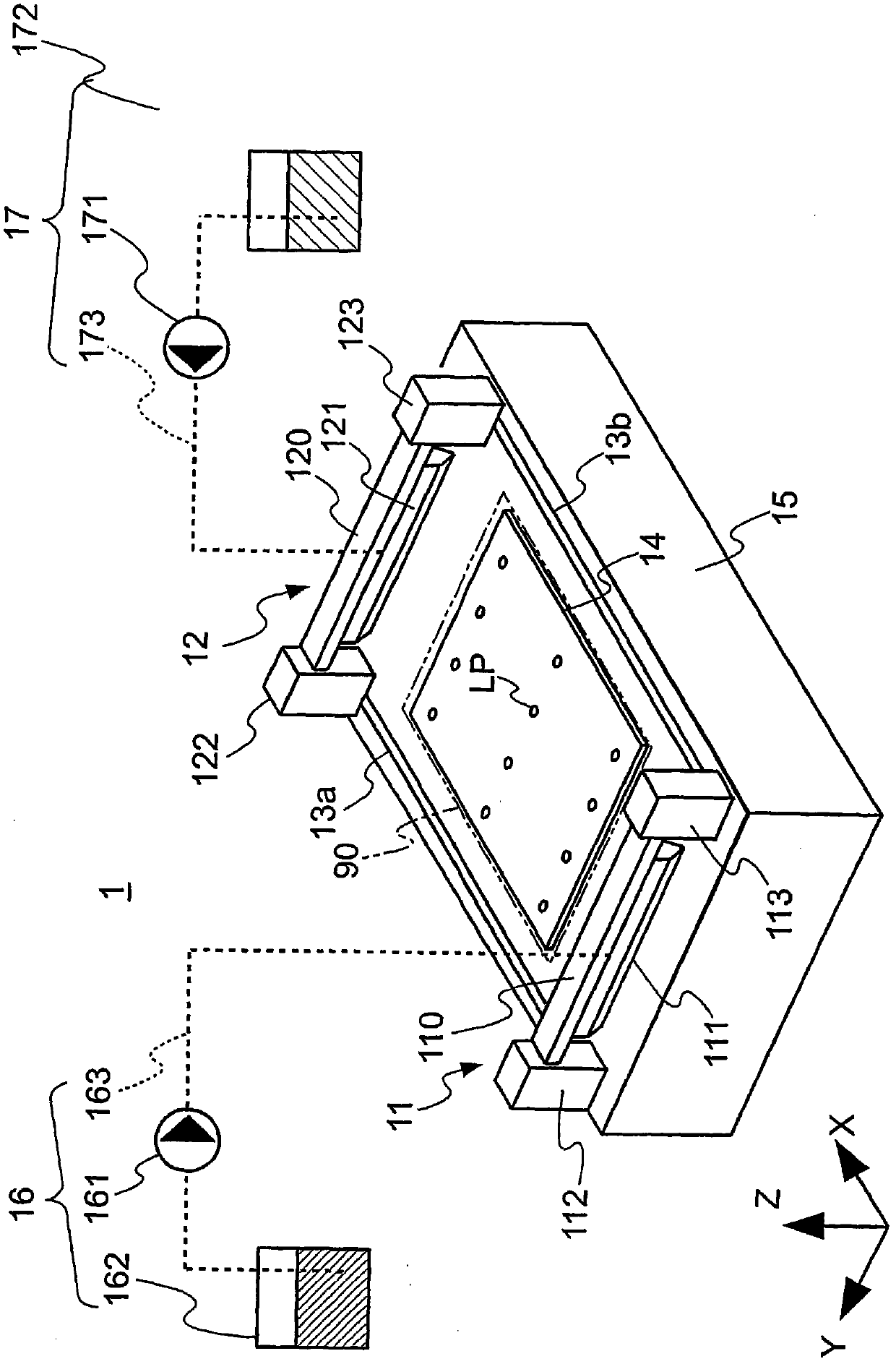

Substrate Processing Method and Substrate Processing Apparatus

ActiveUS20070223342A1Reliable dryingReduce consumptionDrying solid materials without heatDecorative surface effectsEngineeringInert gas

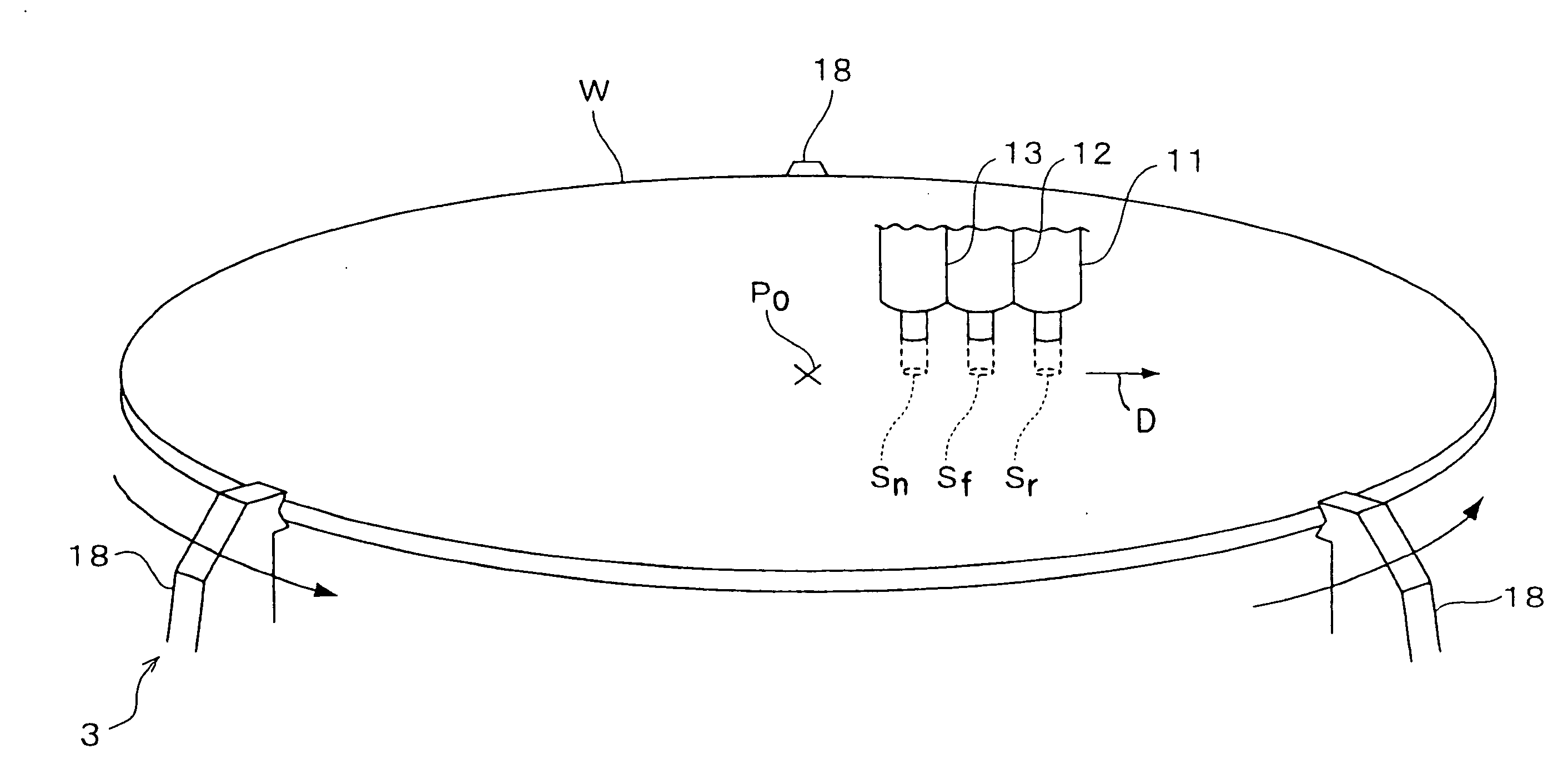

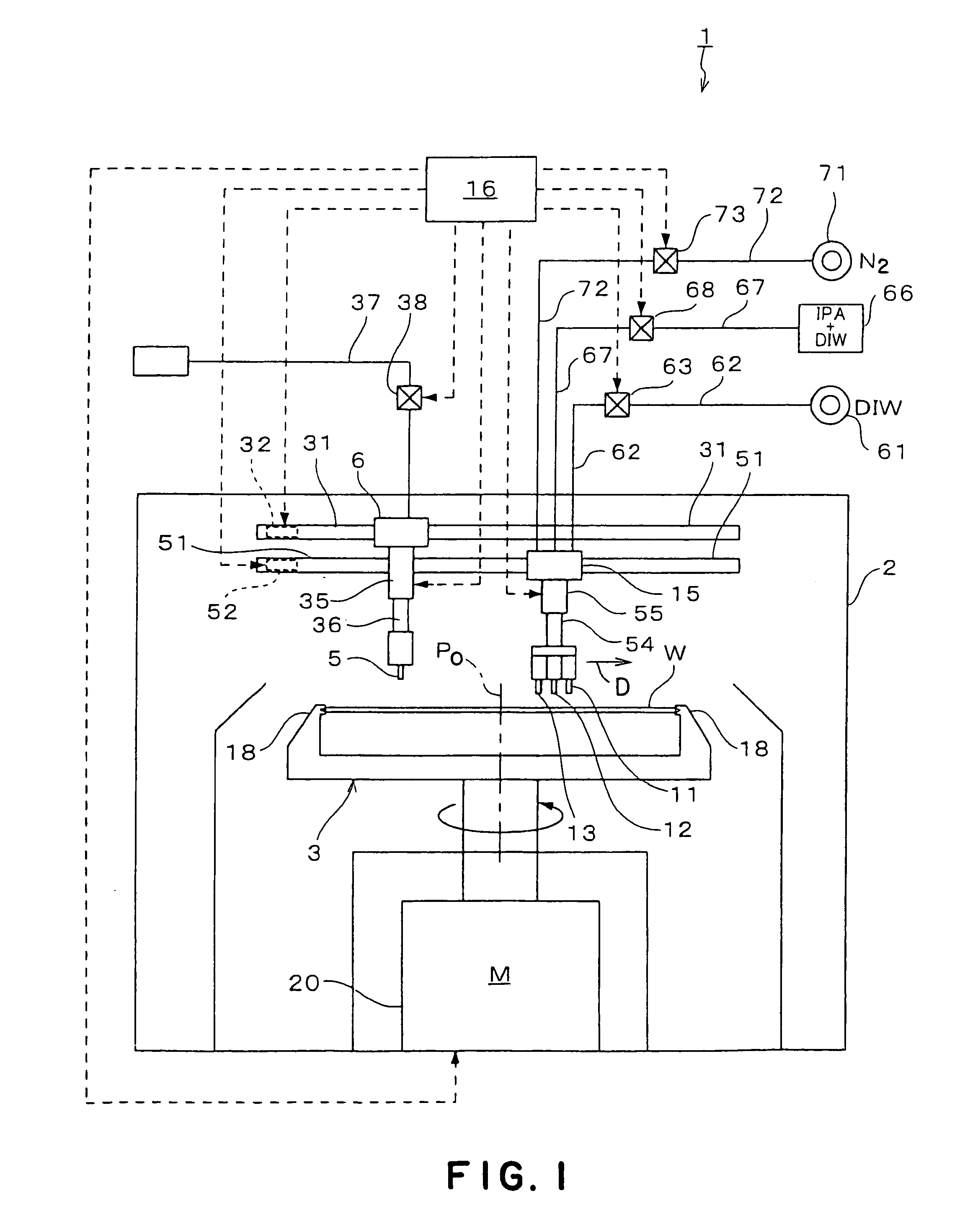

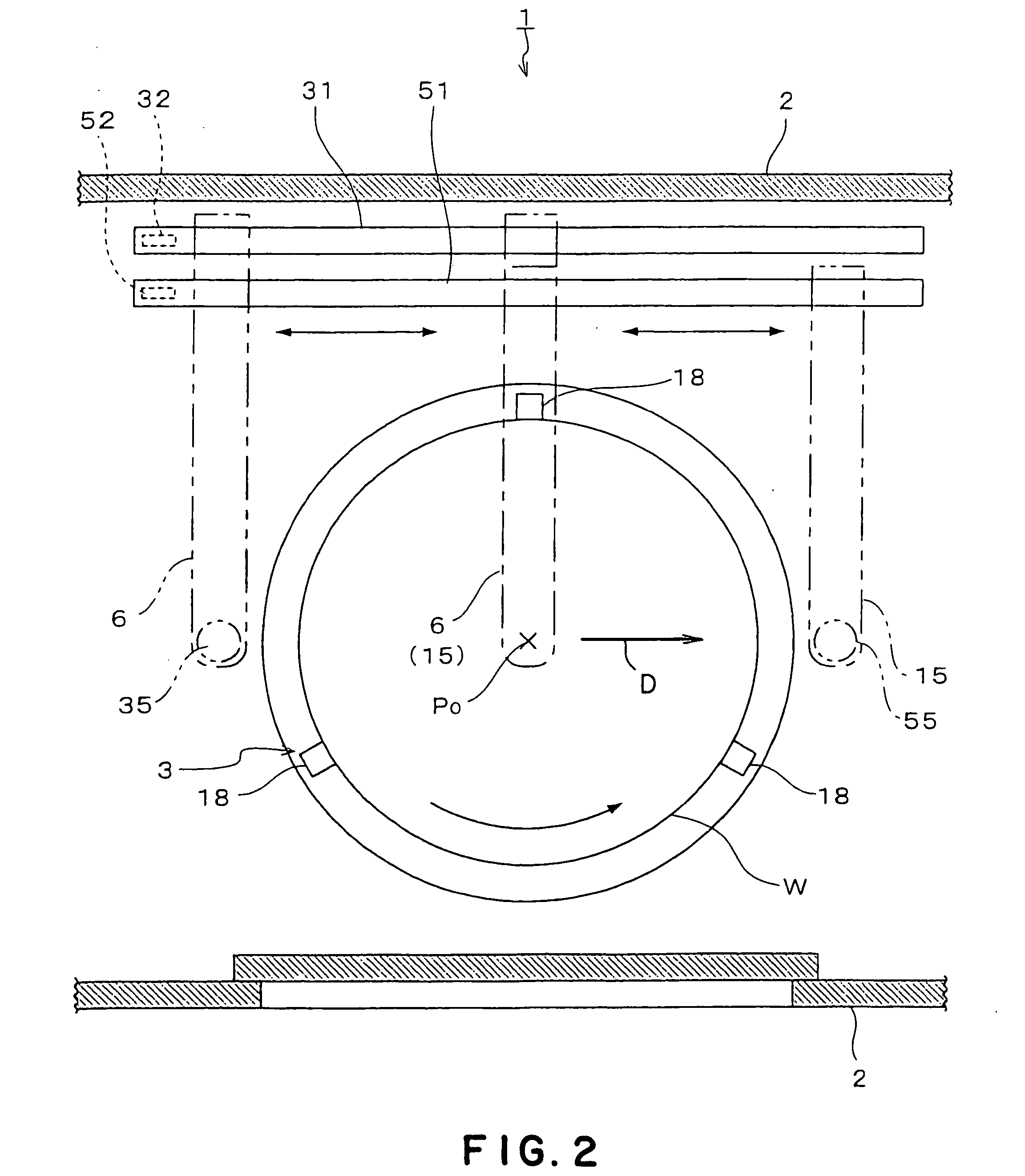

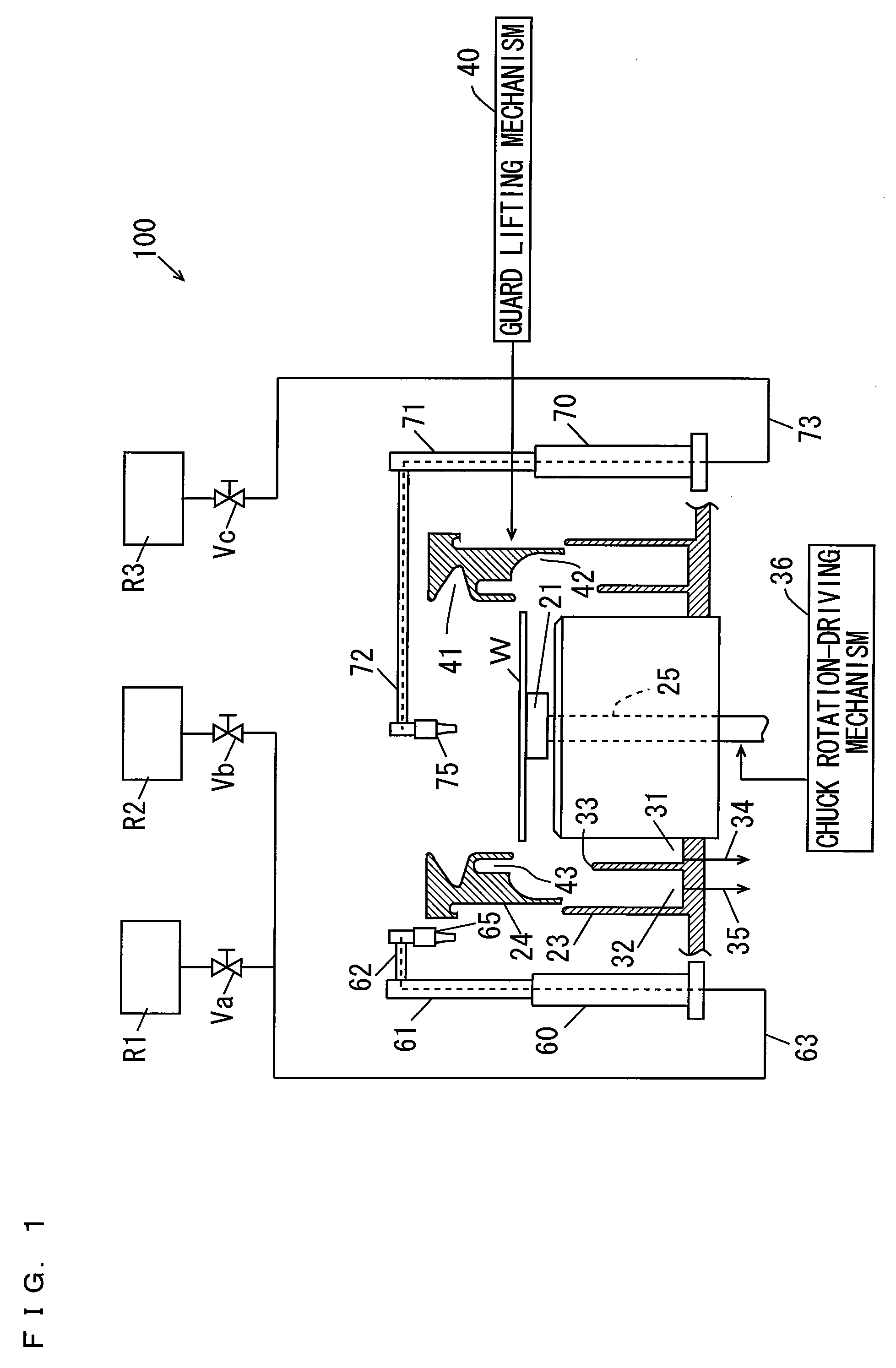

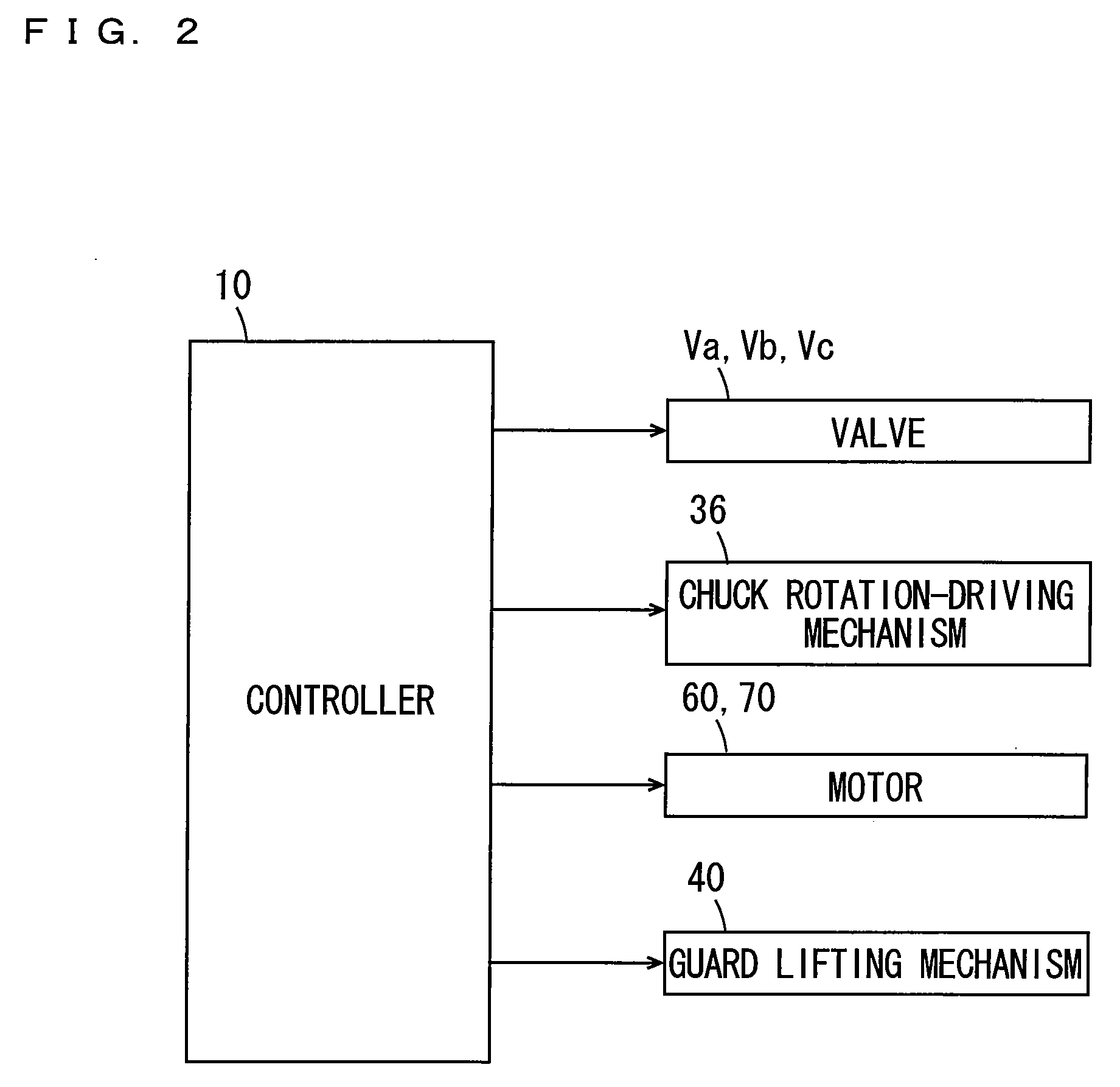

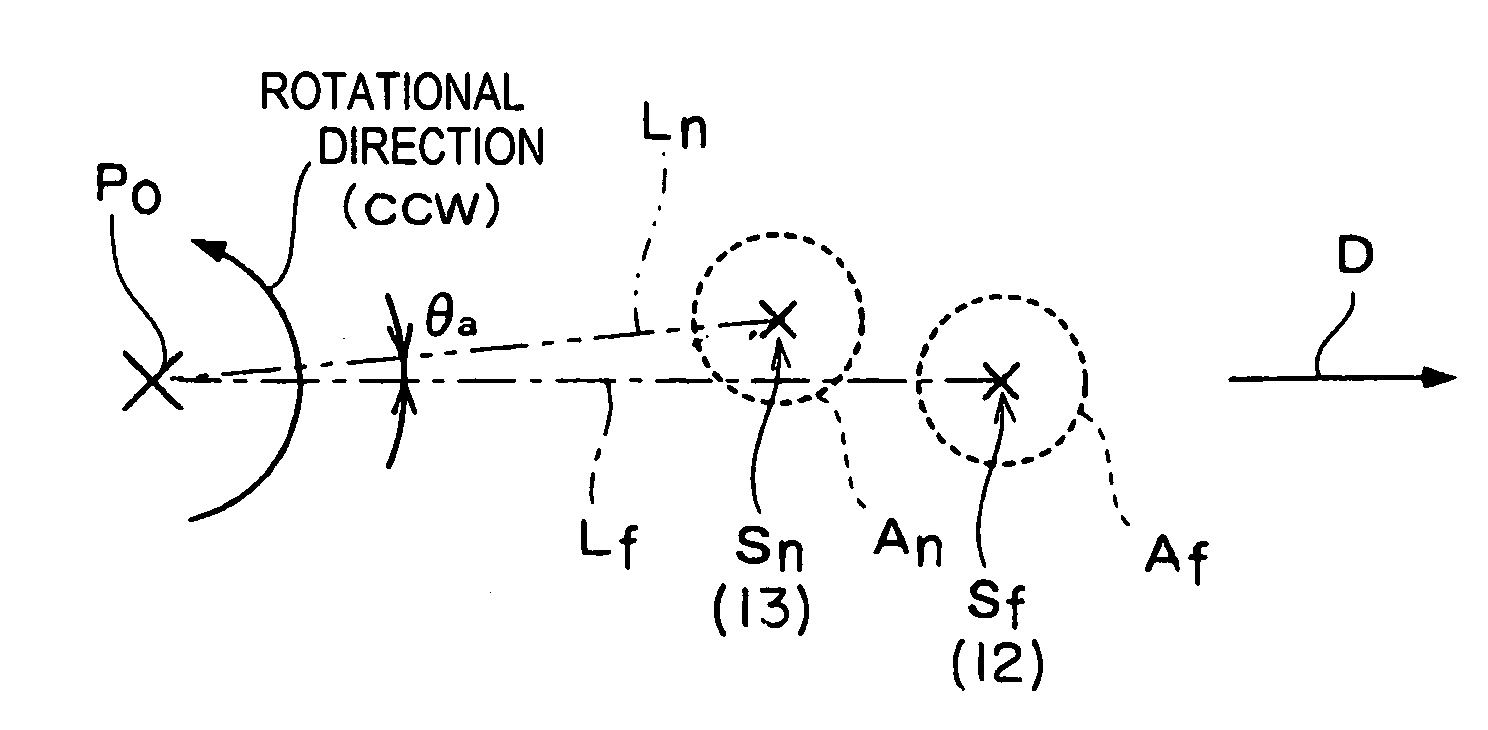

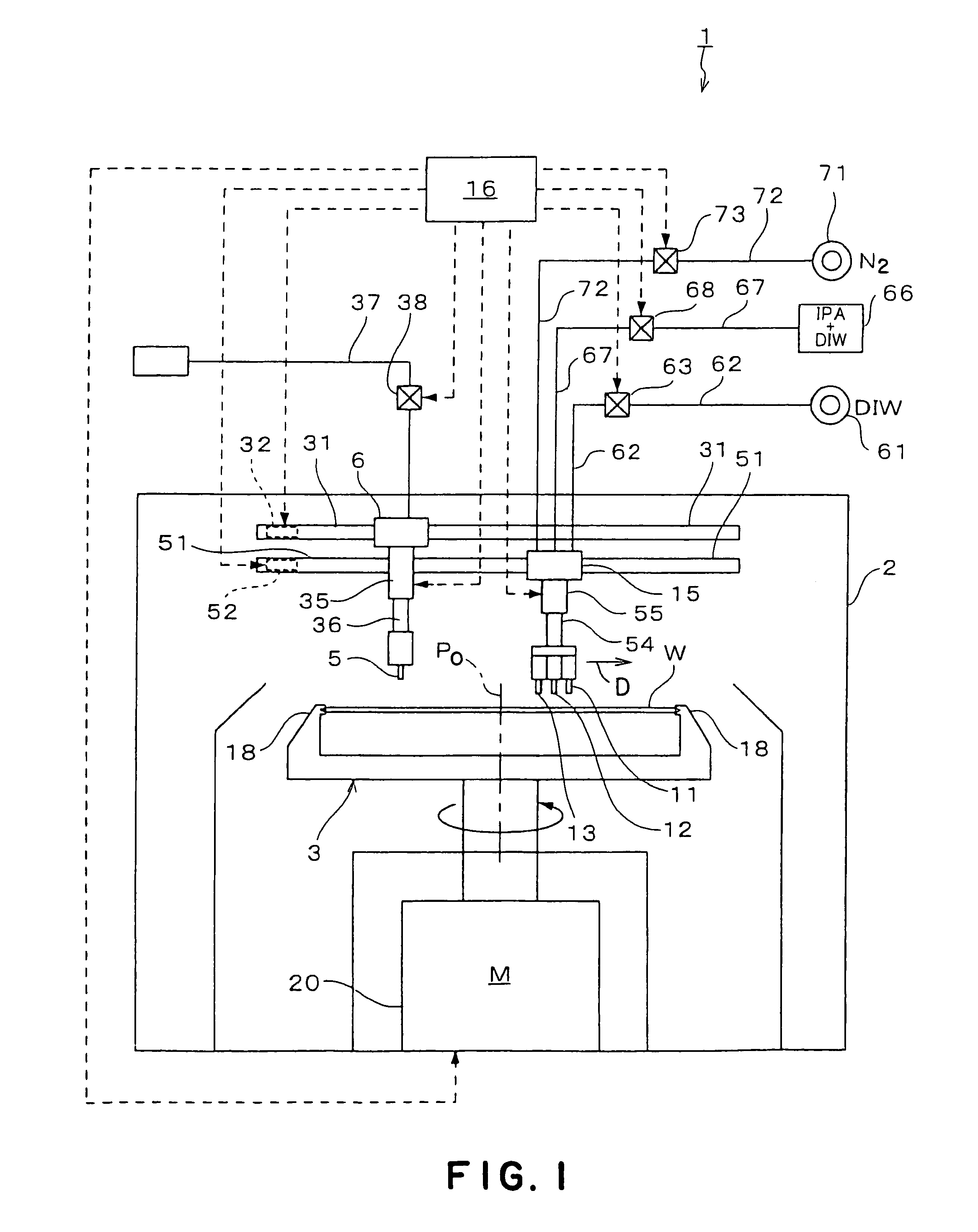

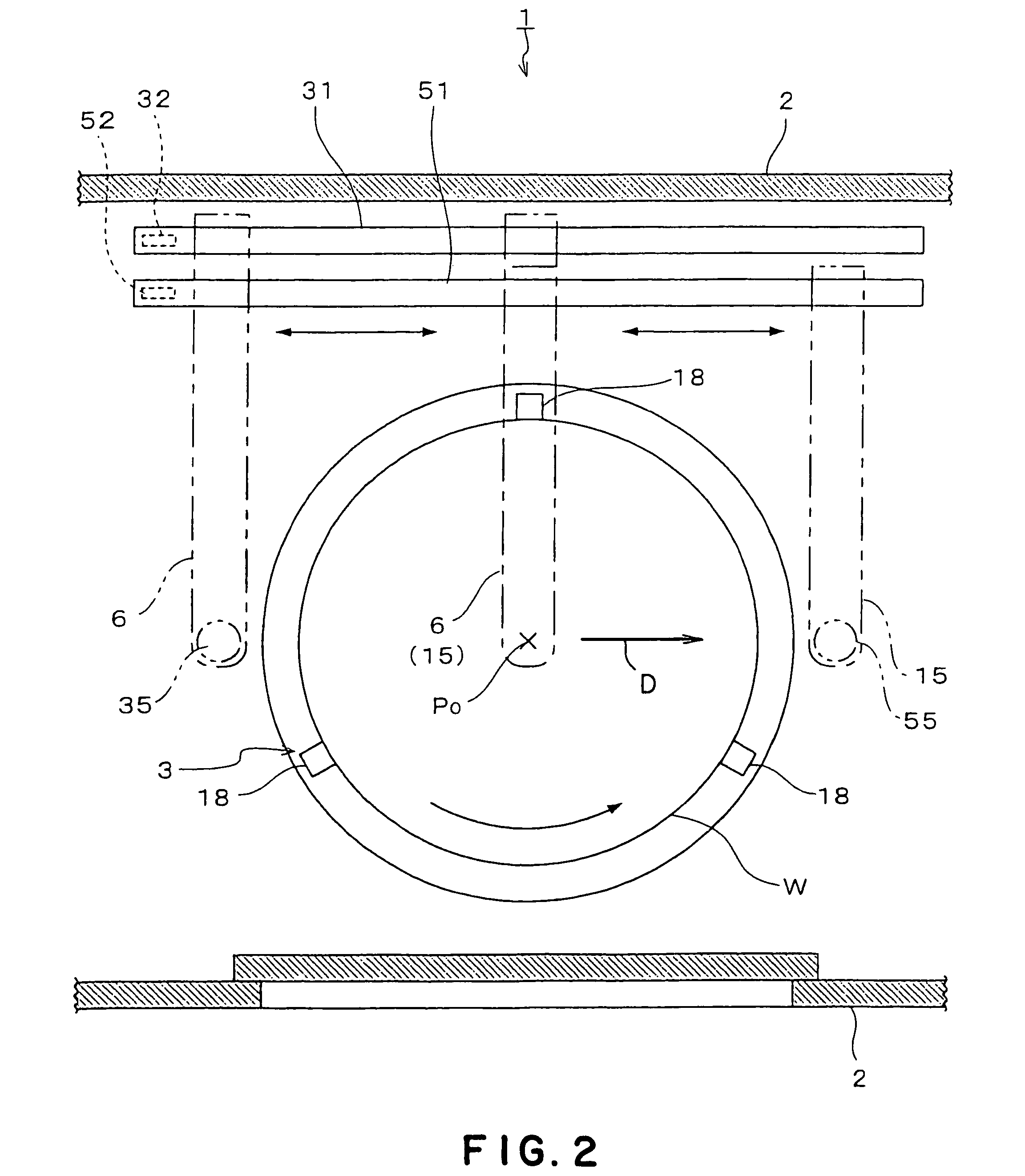

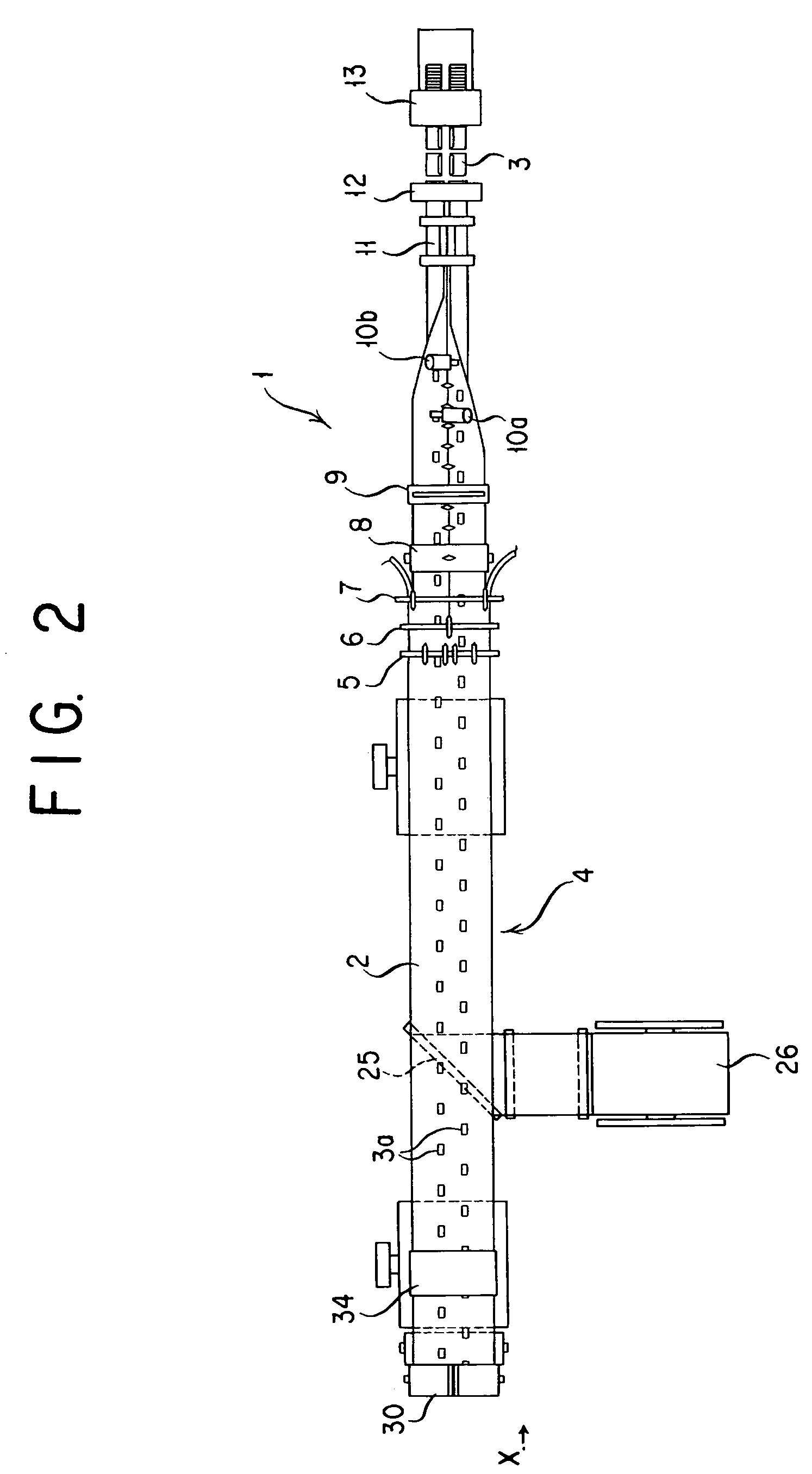

A substrate processing apparatus according to the present invention is provided with a spin chuck (3) that holds a substrate (W) and rotates the same. A process liquid supply system (11, . . . ) is disposed to supply a process liquid to the substrate rotated by the spin chuck. There are disposed a fluid nozzle (12) that supplies to the substrate a drying fluid having a higher volatility than that of the process liquid, and an inert gas nozzle (13) that supplies an inert gas to the substrate. A nozzle moving mechanism (15, 52, . . . ) is disposed that moves the nozzles (12, 13) radially outward relative to a rotational center (Po) of the substrate, while maintaining the inert gas nozzle nearer to the rotational center of the substrate than the fluid nozzle.

Owner:TOKYO ELECTRON LTD

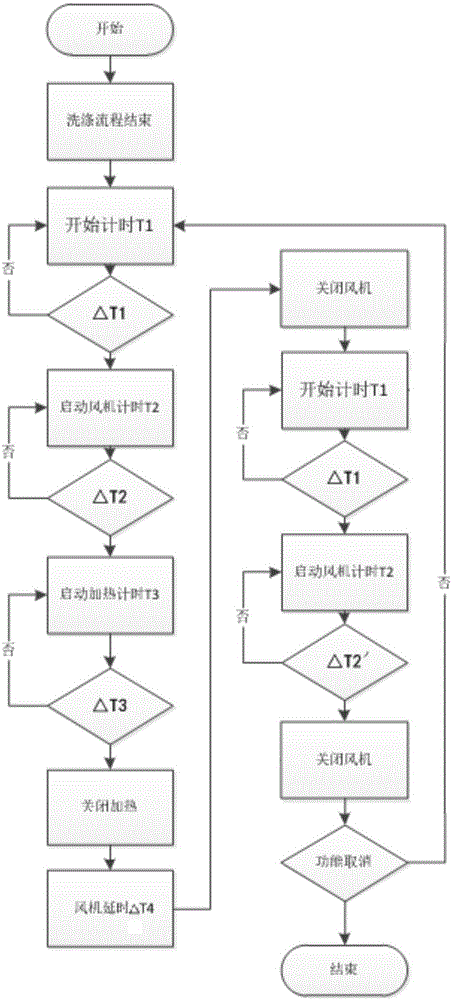

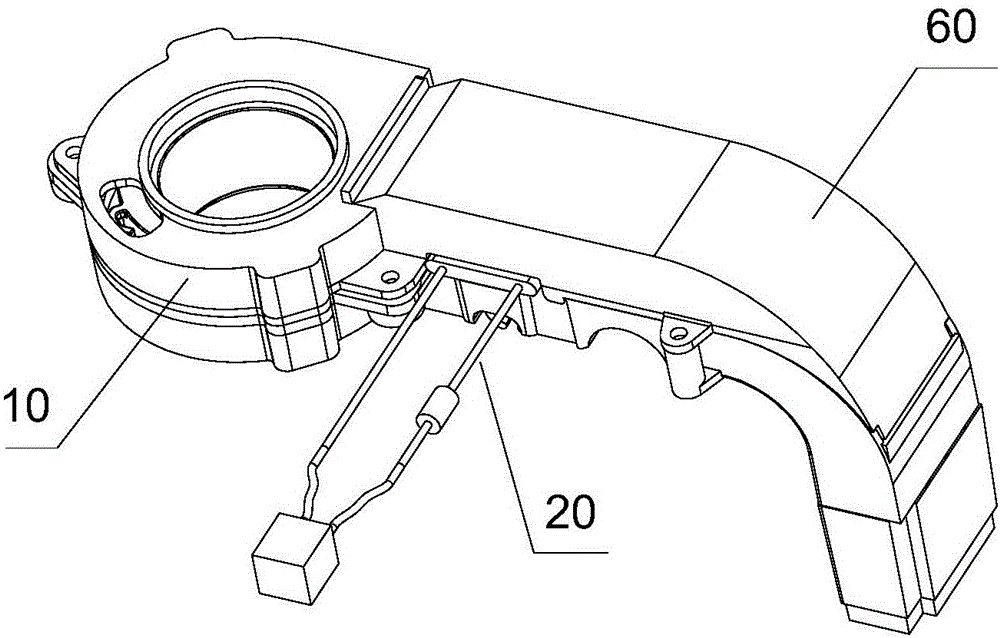

Drying device of bowl washing machine and drying control method of bowl washing machine

InactiveCN105832263AEfficient dryingReliable dryingTableware washing/rinsing machine detailsCleaning equipmentCold airEngineering

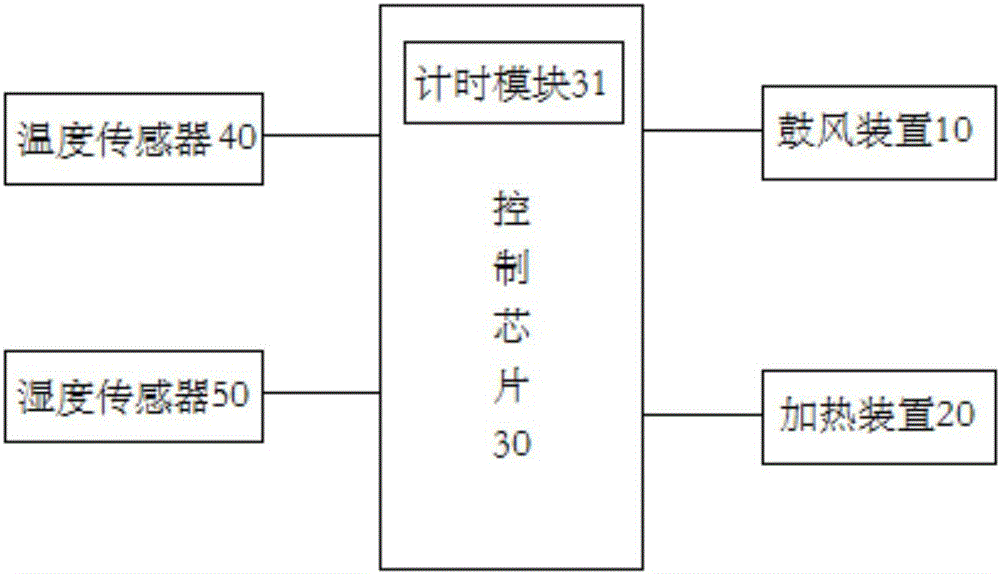

The invention provides a drying device of a bowl washing machine and a drying control method of the bowl washing machine. The drying device comprises an inner liner, a blower device, a heating device and a control chip, wherein the inner liner is used for containing tableware; the blower device comprises a blower passage and a blower; the blower passage is communicated with the inner liner; the blower is communicated with the blower passage and is used for blowing air into the inner liner; the heating device is used for heating the air in the blowing passage; and the control chip is electrically connected with the blowing device and the heating device, is used for controlling the blowing device to be electrified to work, and is also used for controlling the heating device to realize the discontinuous electrification work when the blower device is electrified to work. The goal of discontinuously and alternately blowing cold air and hot air into the inner liner for a long time can be achieved by controlling the blower device and the heating device to be discontinuously electrified to work via the control chip, so that no bacterium and no peculiar smell are generated inside the machine for a long time. Therefore the drying device and the drying method have the advantages that the drying effect is good; the anti-bacterial and peculiar smell prevention effects are realized; and the user experience is good.

Owner:JOYOUNG CO LTD

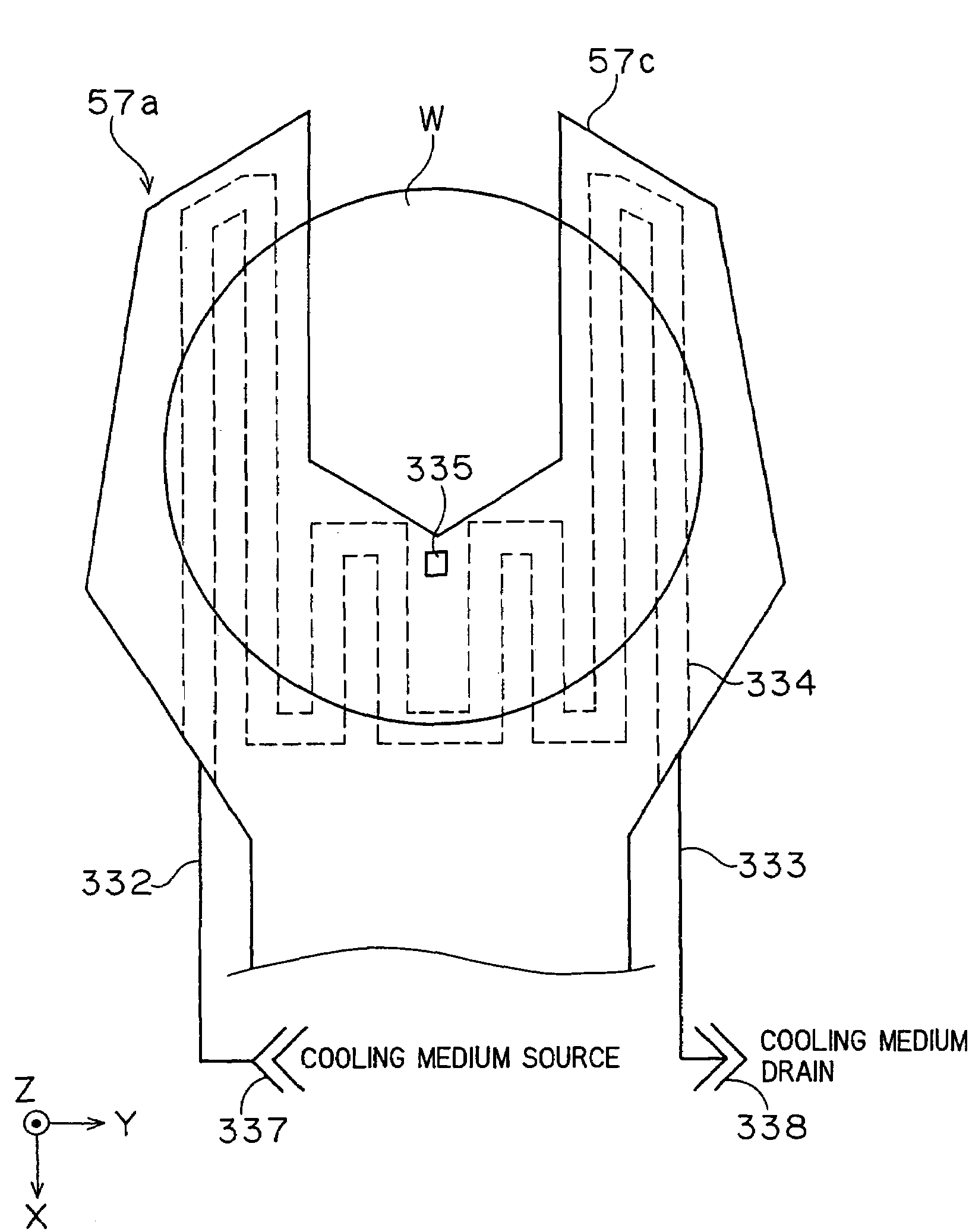

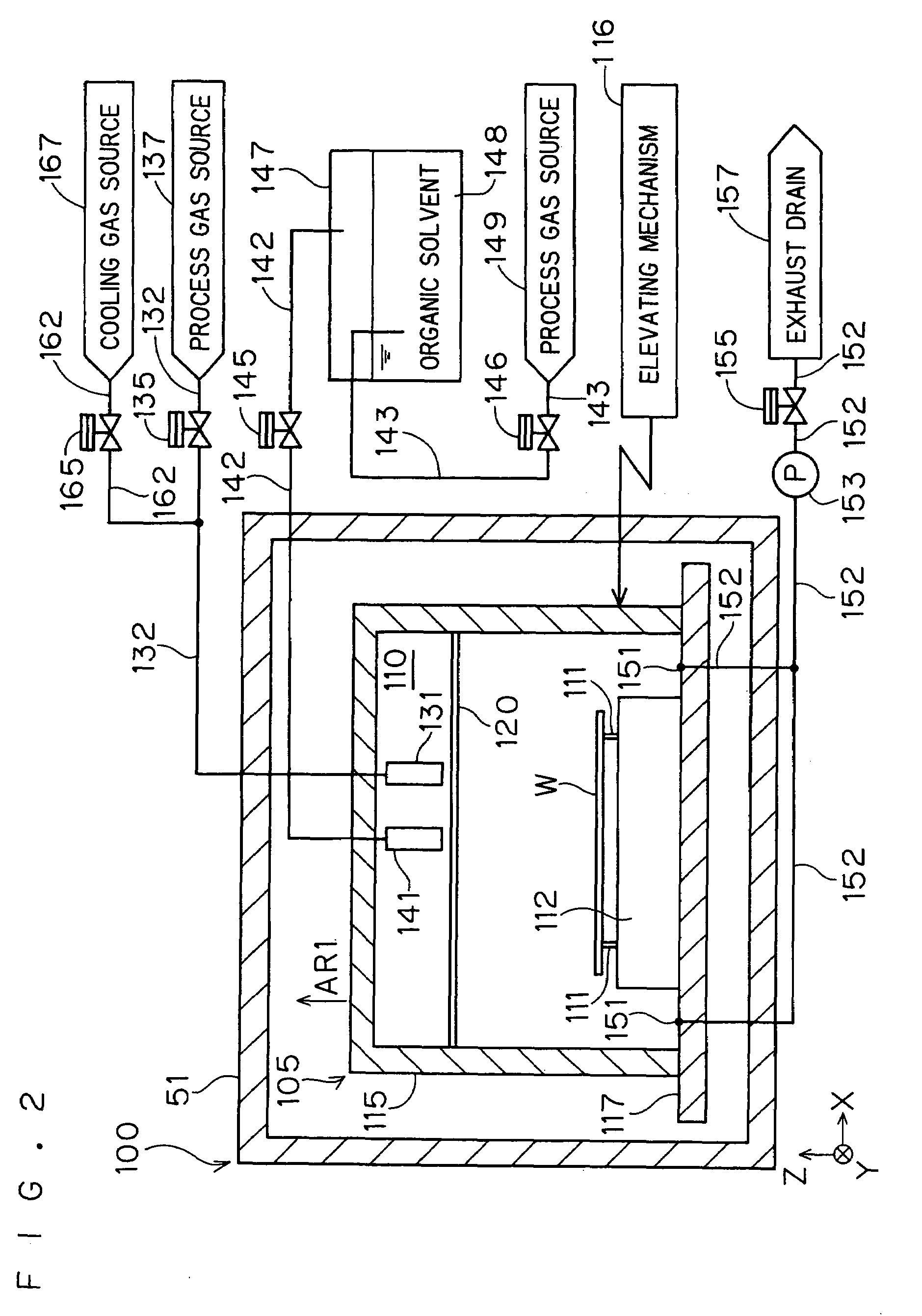

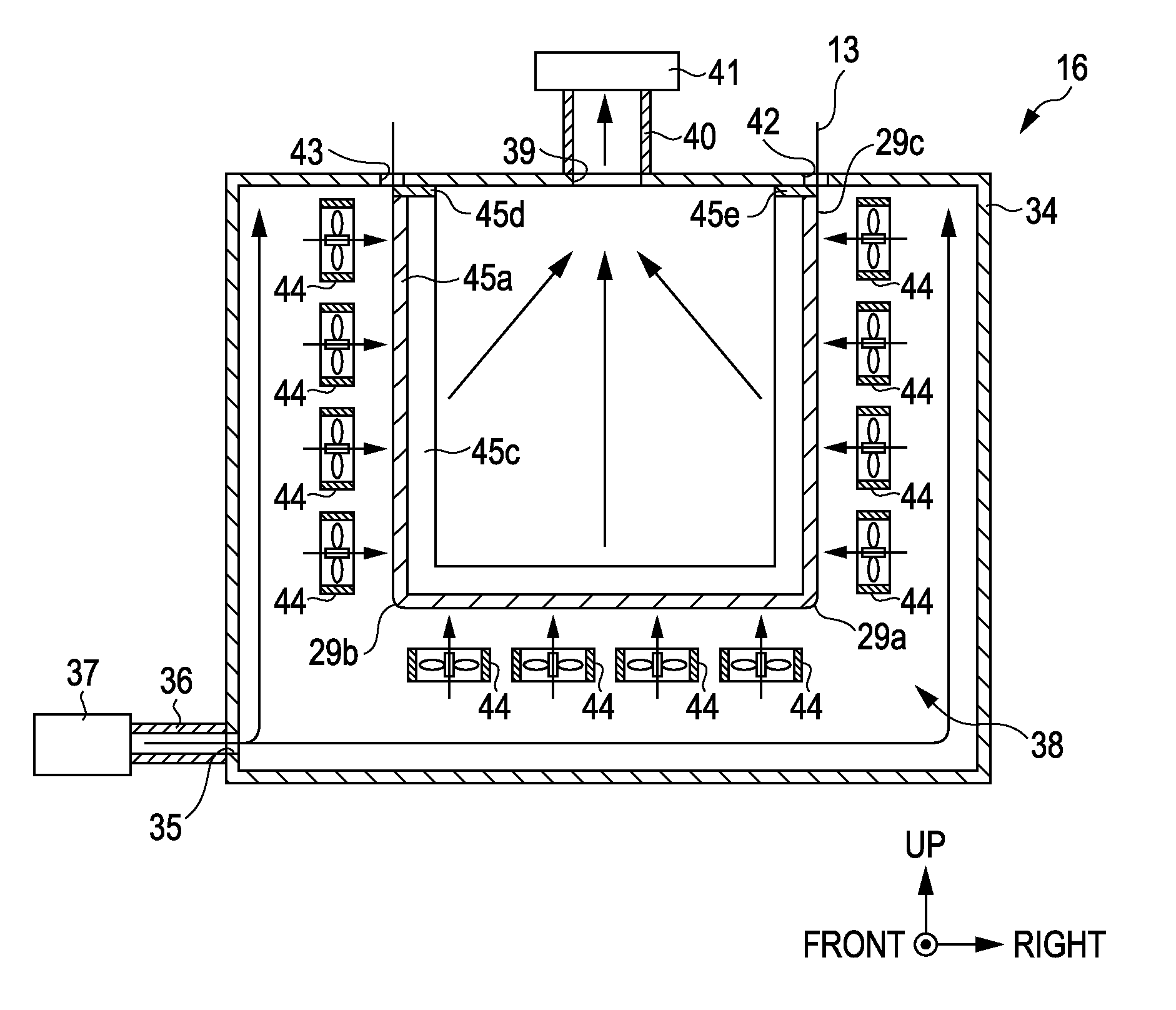

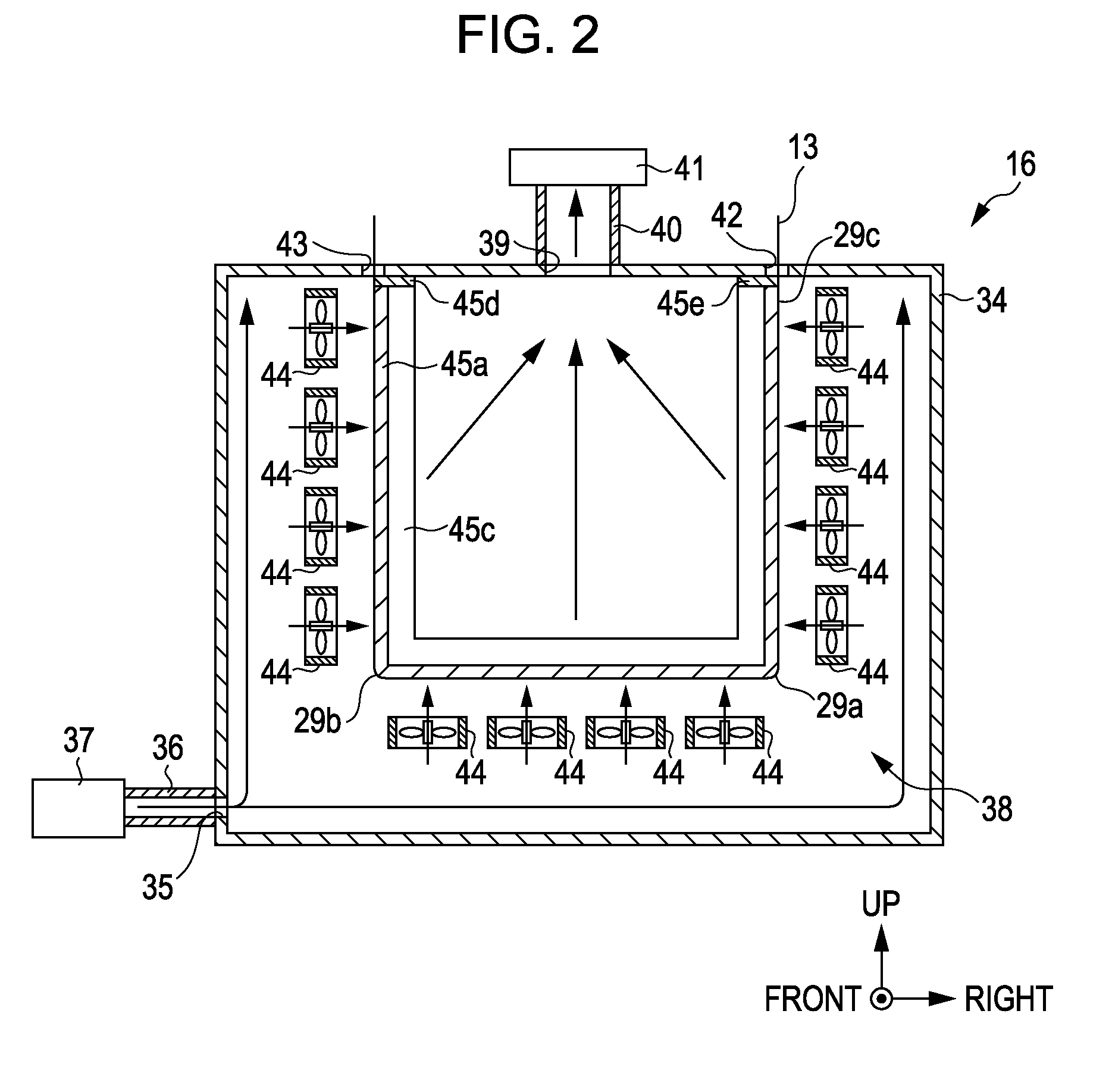

Substrate processing apparatus for drying substrate

InactiveUS7418970B2Reliable dryingImprove replacement efficiencyDrying solid materials without heatDrying gas arrangementsOrganic solventProduct gas

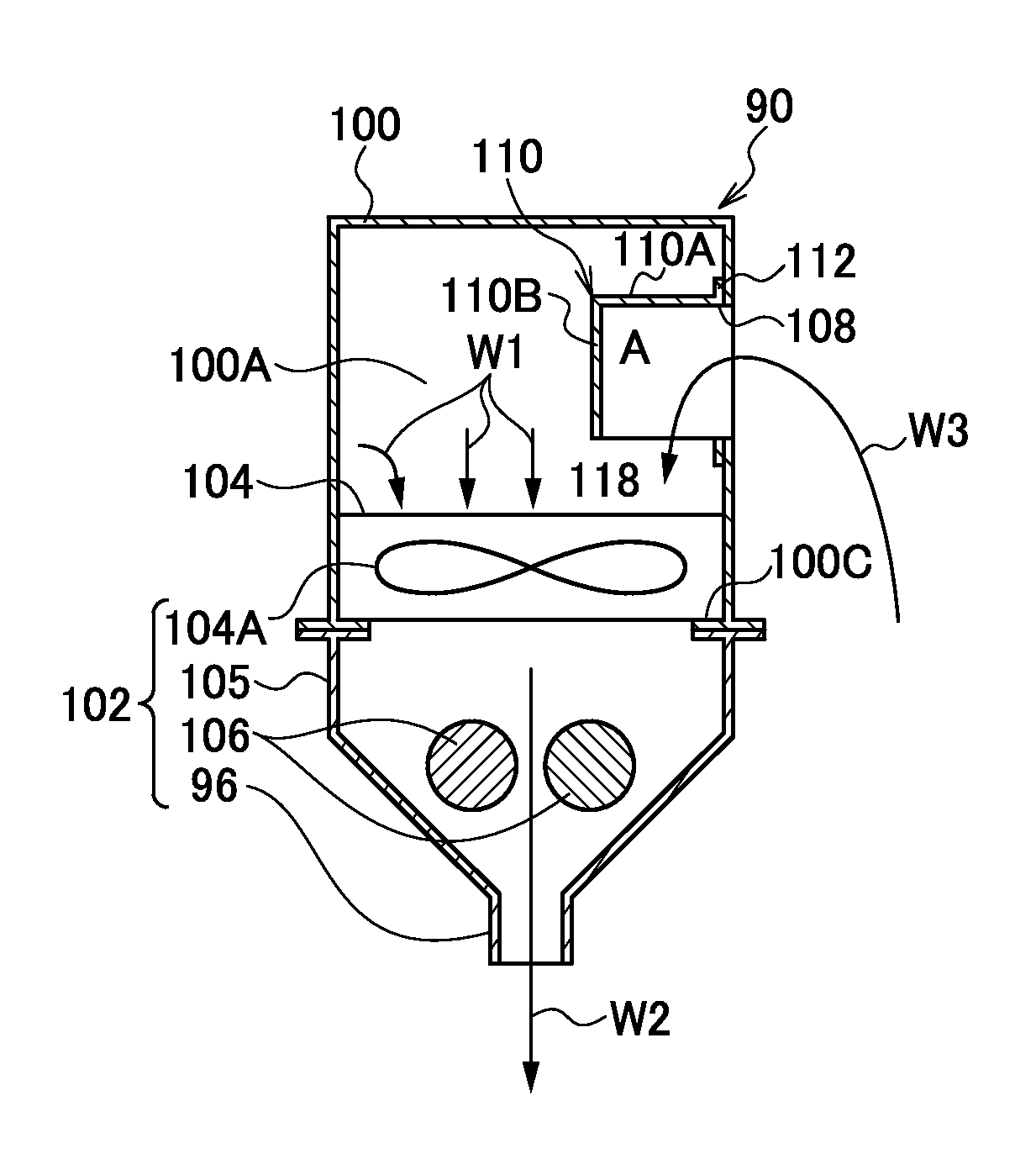

A substrate processing apparatus includes a container in which a heating plate, a discharge nozzle for discharging a vapor of organic solvent, and a discharge nozzle for supplying a process gas and a cooling gas are provided. A pump in communication with an exhaust outlet of the container exhausts an atmosphere from the container to reduce pressure in the container. Therefore, the substrate processing apparatus is capable of performing (1) the process of drying a substrate in a reduced-pressure atmosphere by the use of the vapor of organic solvent, and (2) the process of drying the substrate in the reduced-pressure atmosphere by heating, to thereby efficiently dry the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

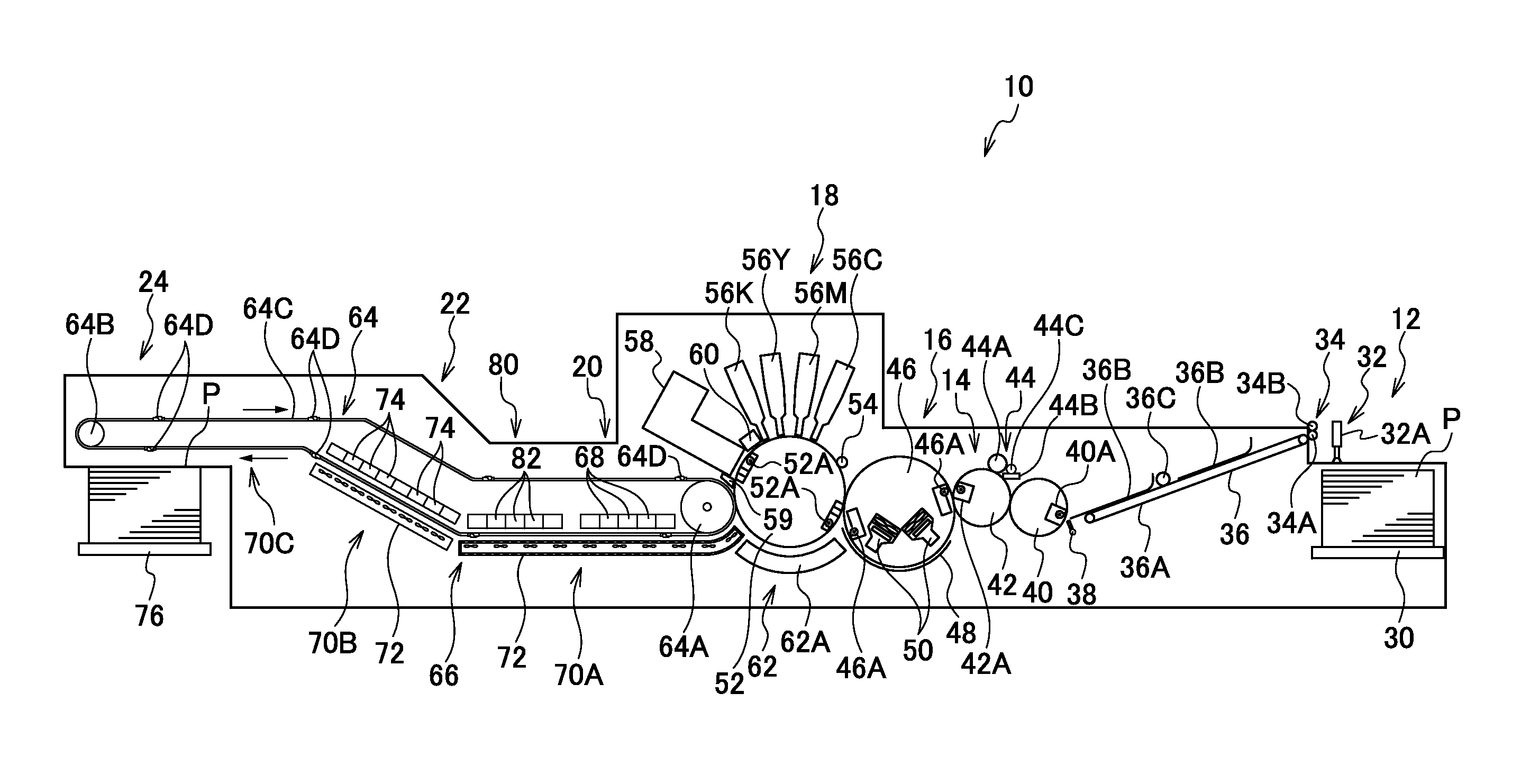

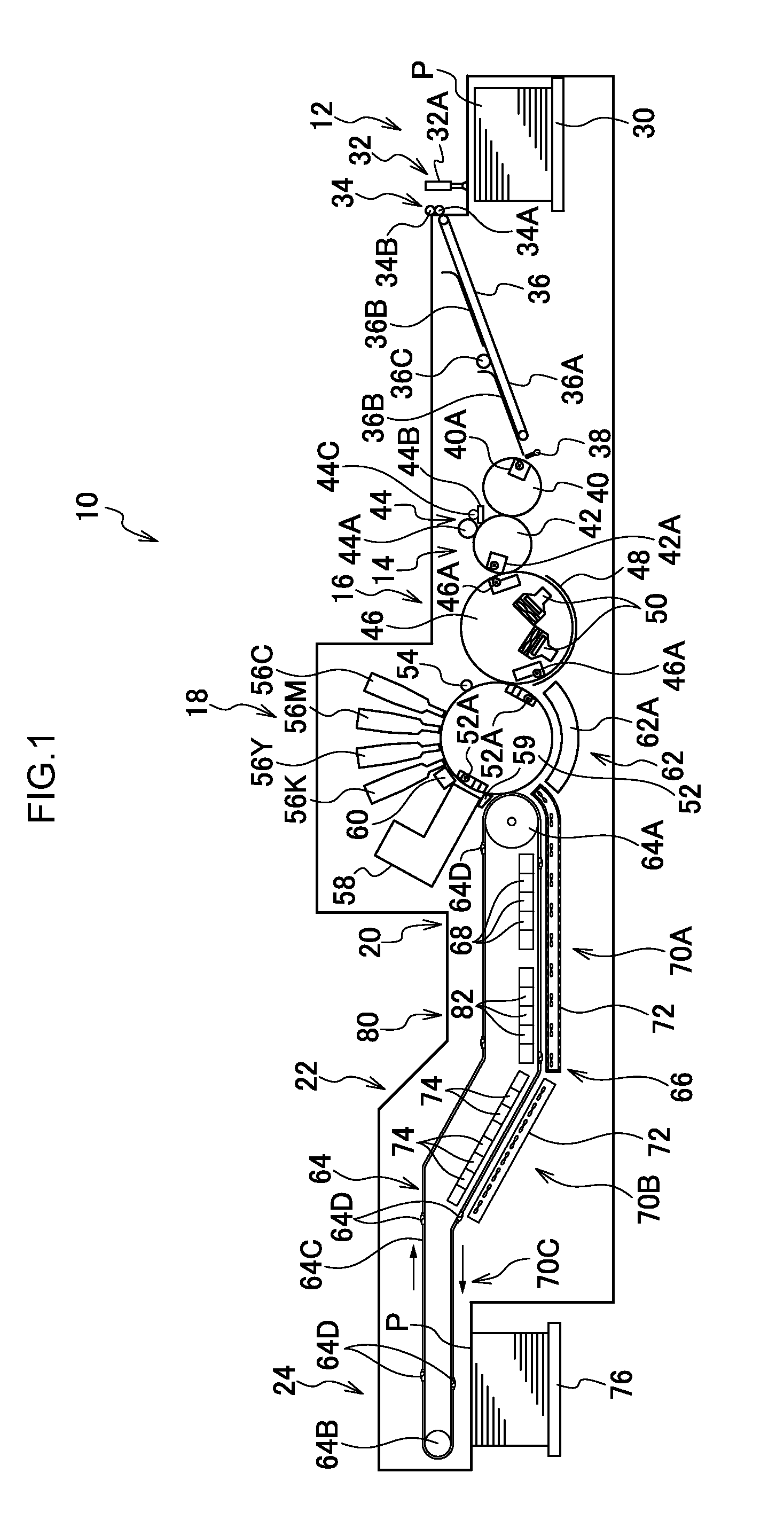

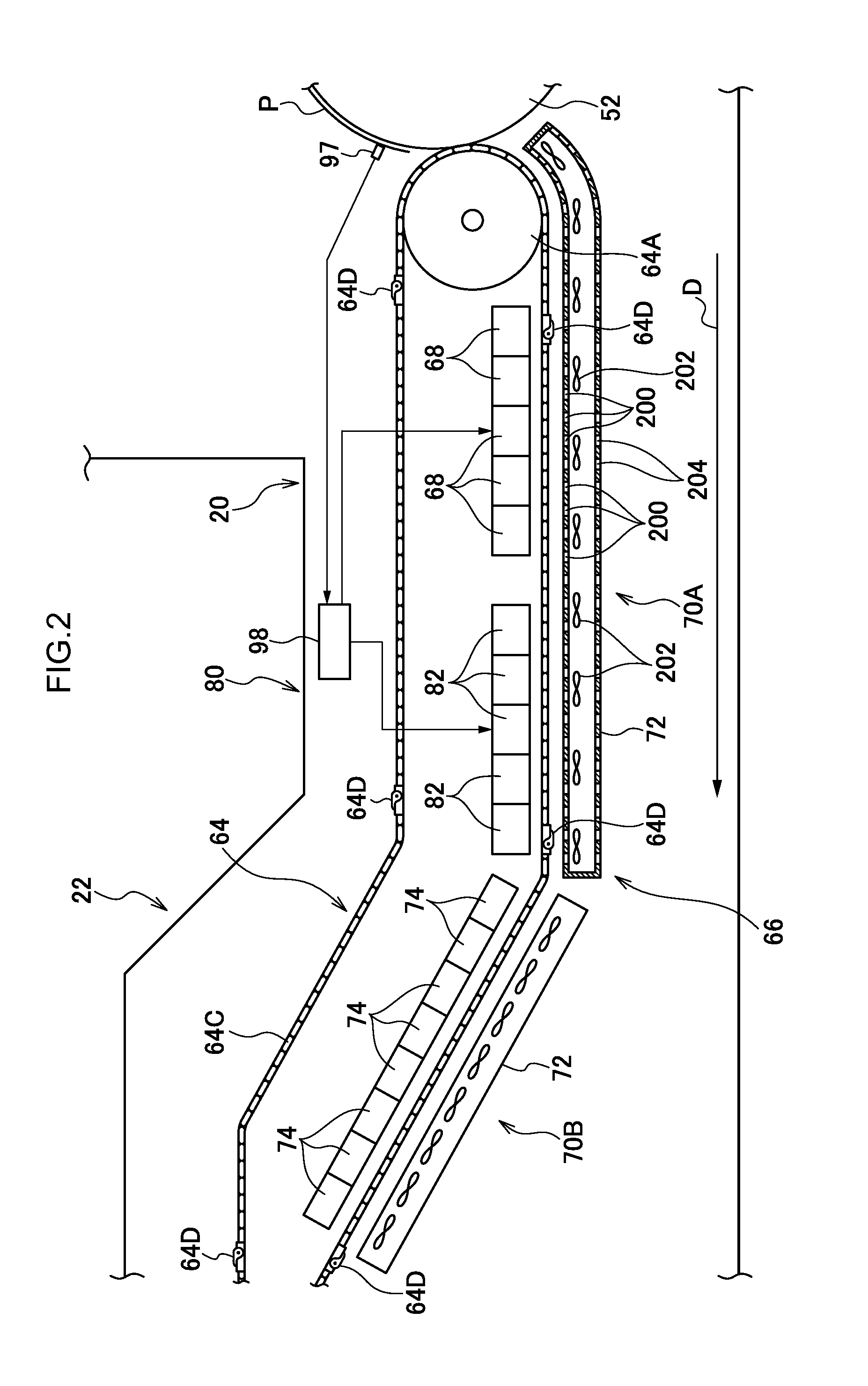

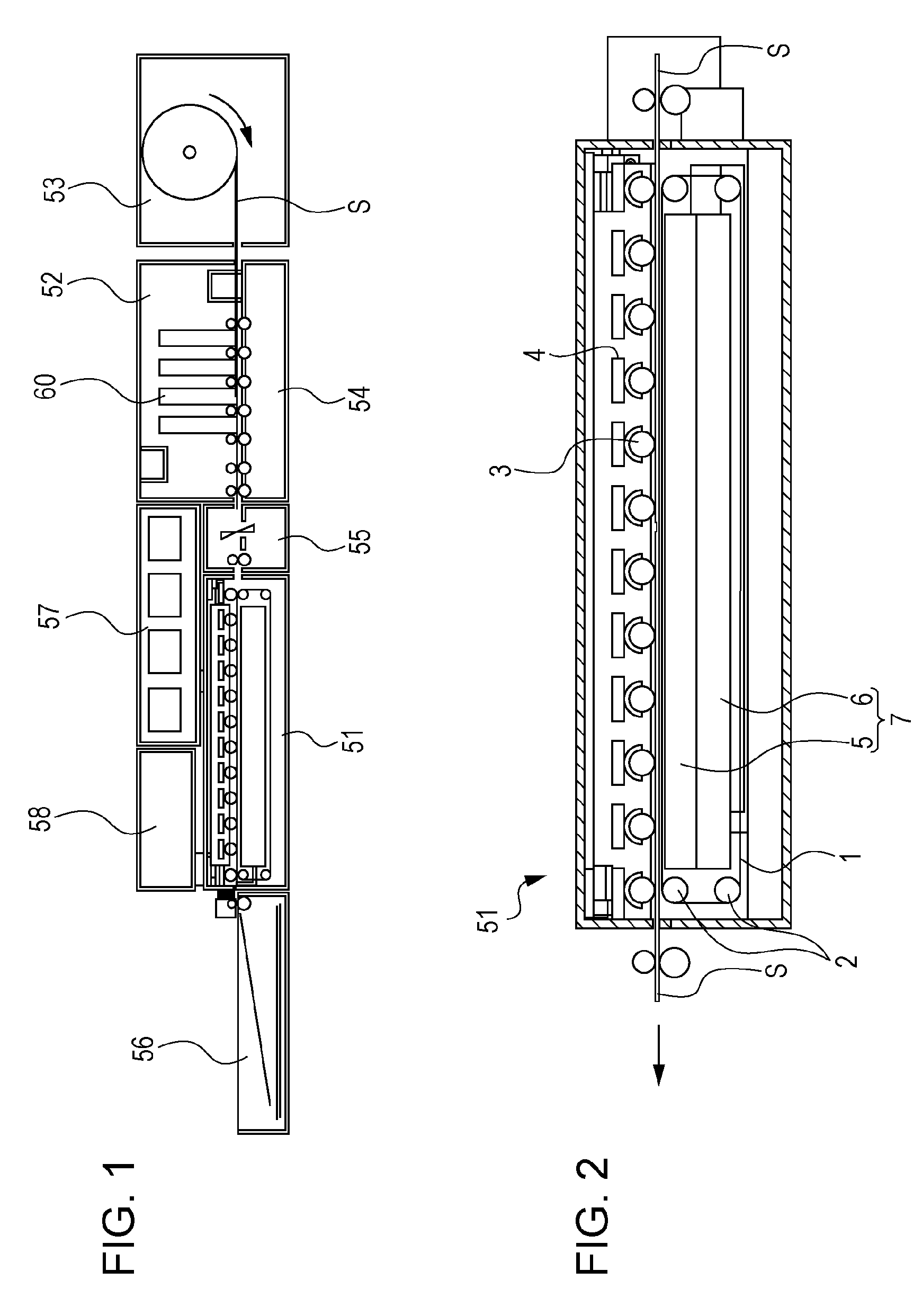

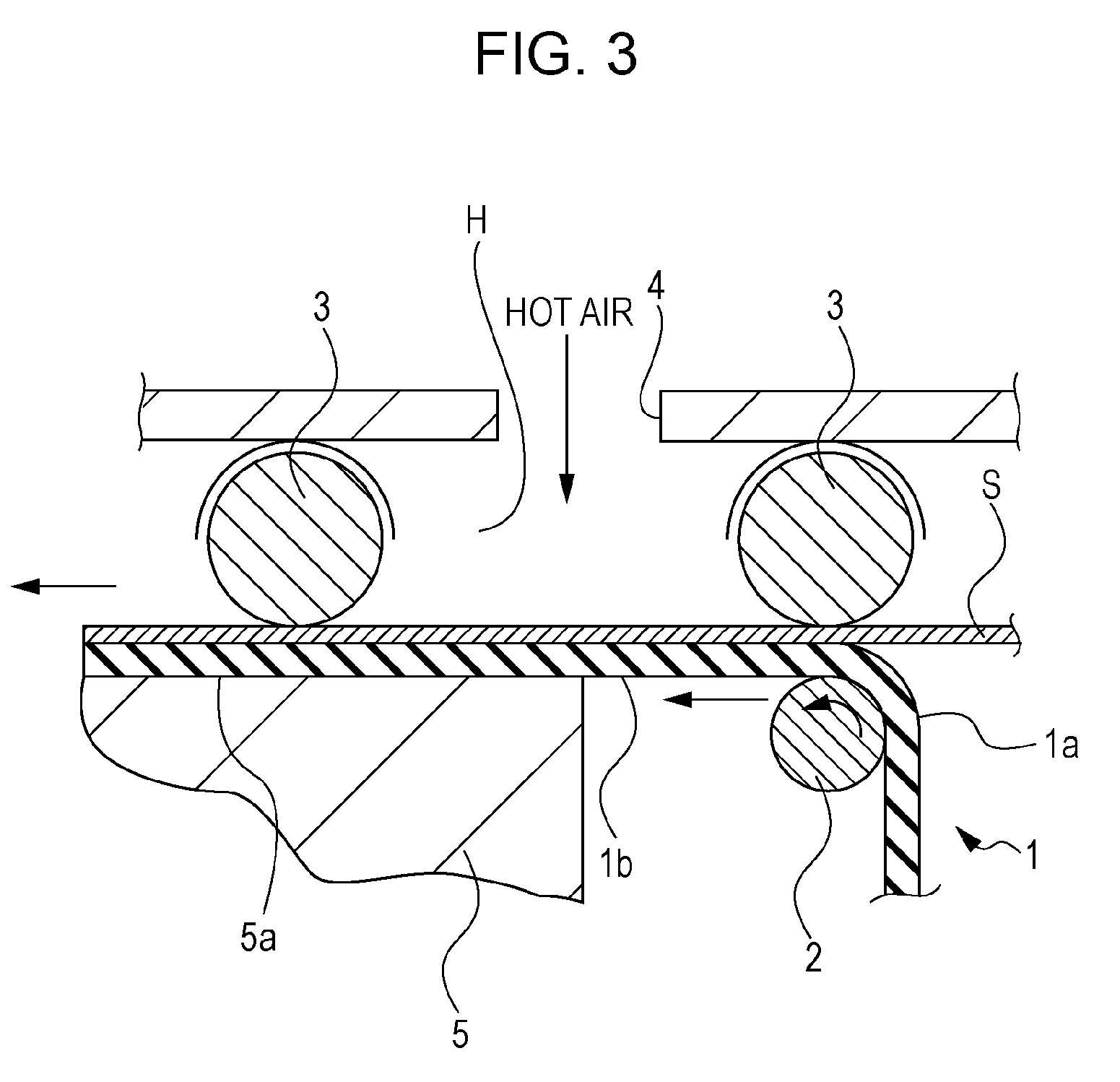

Drying device and image forming apparatus

ActiveUS20130194367A1Decreasing airflow rateImprove energy efficiencyDrying gas arrangementsDrying machines with progressive movementsRecording mediaAirflow

There is provided a drying device including: an airflow path extending in a direction intersecting with a conveyance path of a recording medium; an external air intake section that introduces external air into the airflow path; and a heating and blowing section provided to the airflow path that heats external air introduced into the airflow path and blows drying air onto a front face of the recording medium being conveyed on the conveyance path.

Owner:FUJIFILM CORP

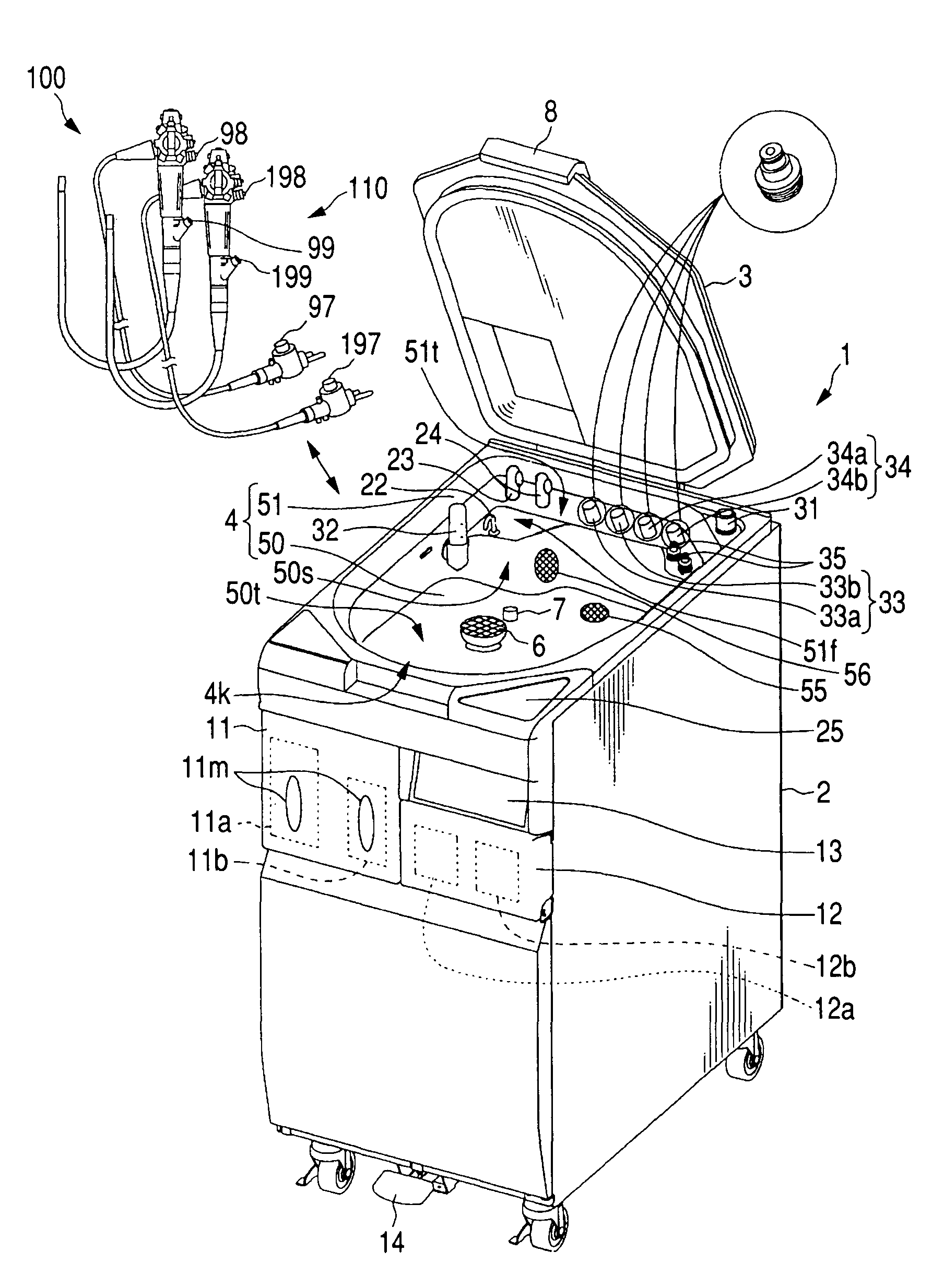

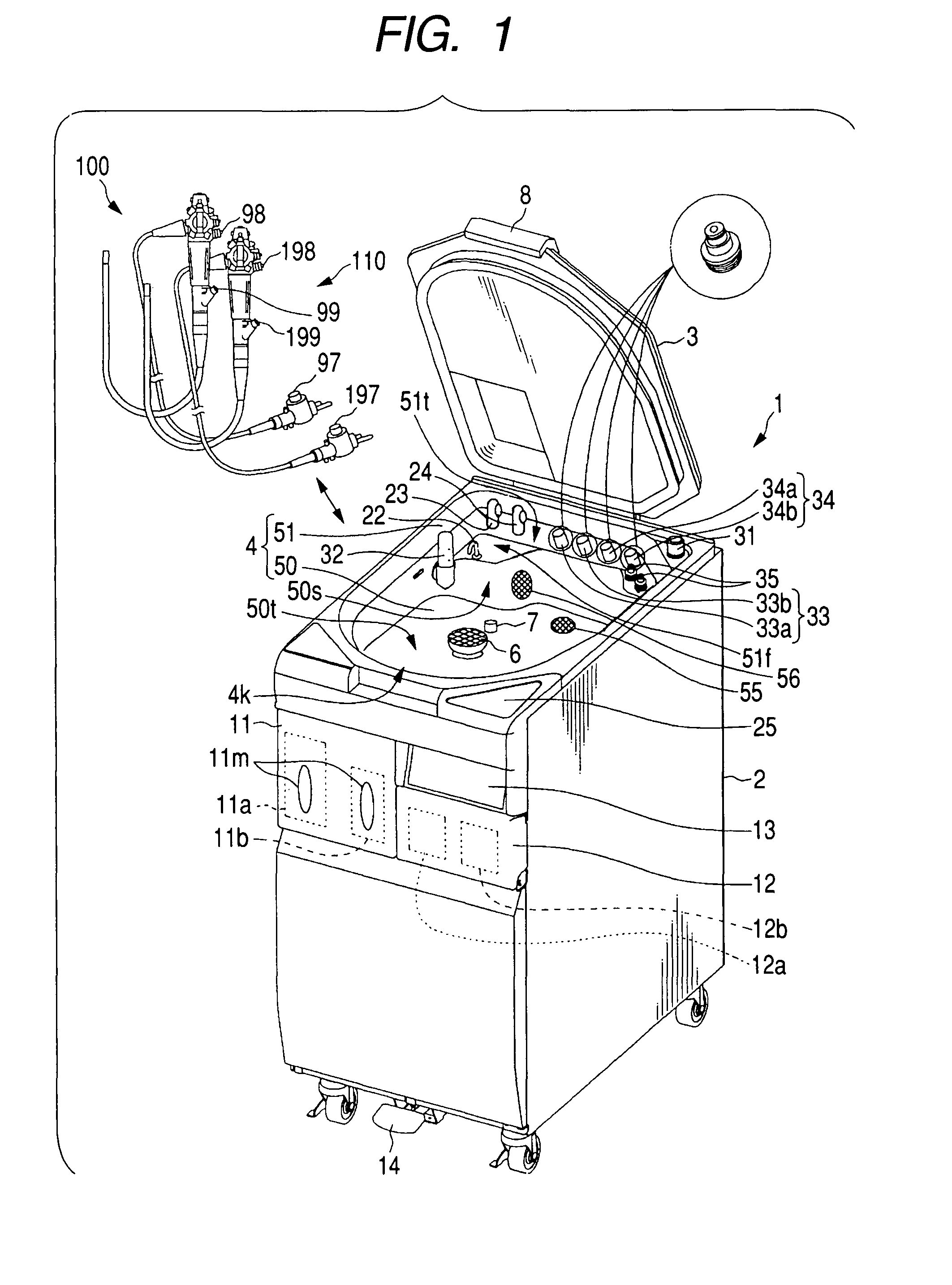

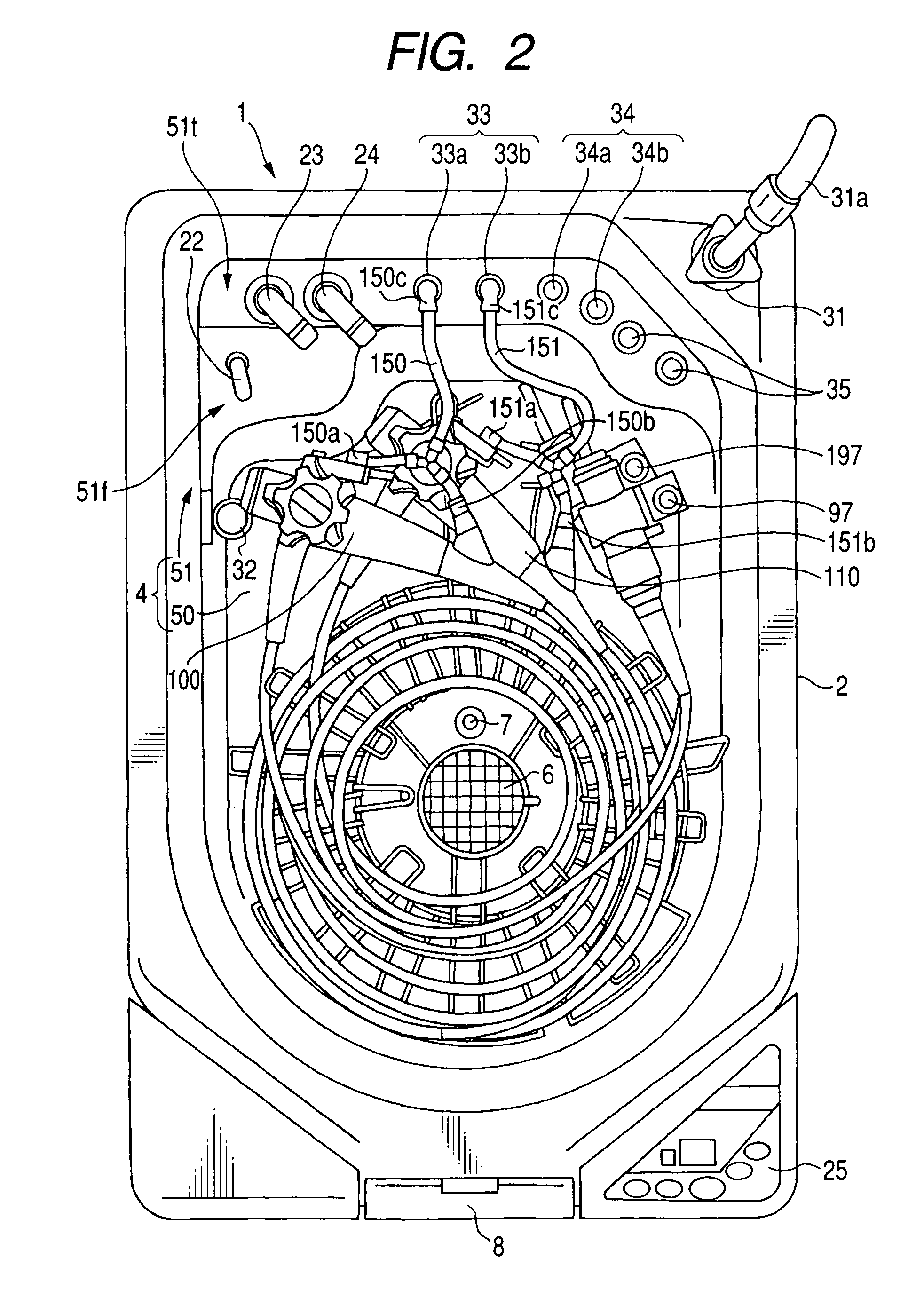

Method for dewatering endoscope channels

An apparatus washes / disinfects, at a time, a plurality of endoscopes having a plurality of channels with different diameters, and dewaters the channels at a time. For the dewatering, the apparatus includes plural ports for receiving air supply, and a plurality of tubes for connecting between each of the plurality of ports and each of the plurality of channels in each of the plurality of endoscopes. The apparatus also includes an on-off valve for intermittently supply air to the ports, and a control unit for opening / closing the valve a plurality of times at a predetermined ratio. Water droplets remaining in a large-diameter channel are mainly moved by wind pressure of continuously flowing air while the valve is open, and discharged. Water droplets in a smaller-diameter channel are mainly moved by hammer effect of high-pressure air caused while the valve is closed, and discharged. The valve opening / closing is repeated for complete dewatering.

Owner:OLYMPUS CORP

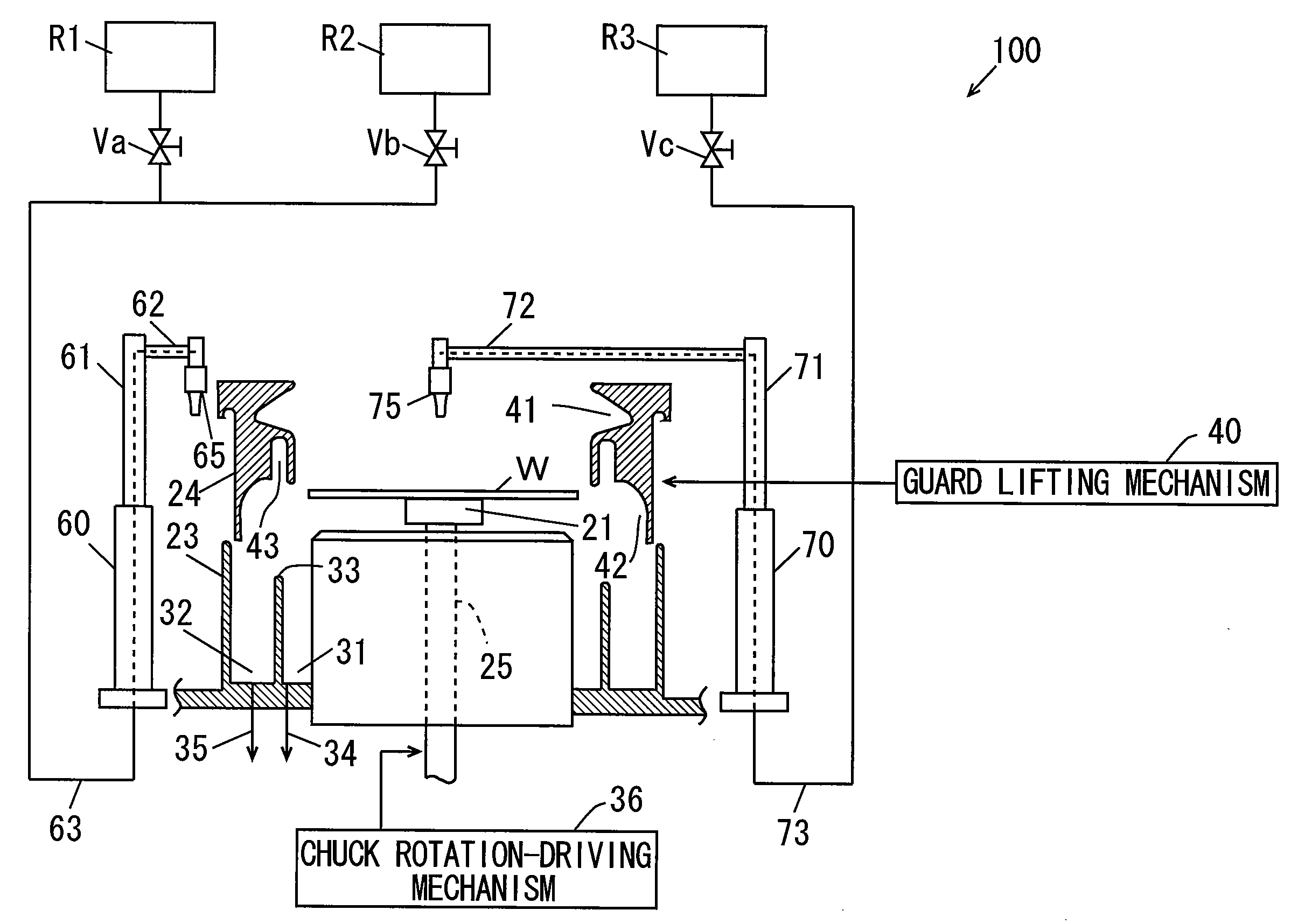

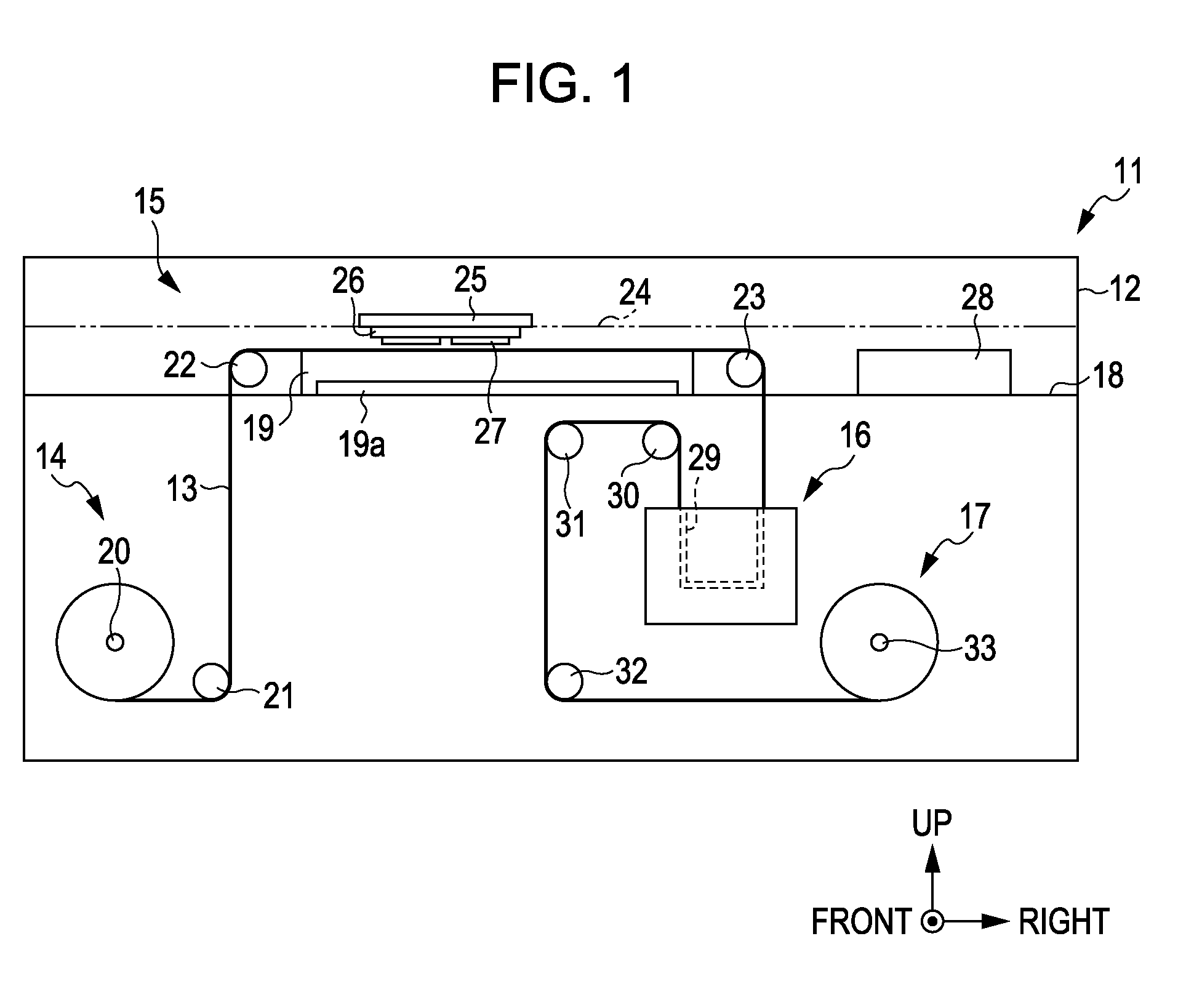

Multi-speed substrate processing apparatus and substrate processing method

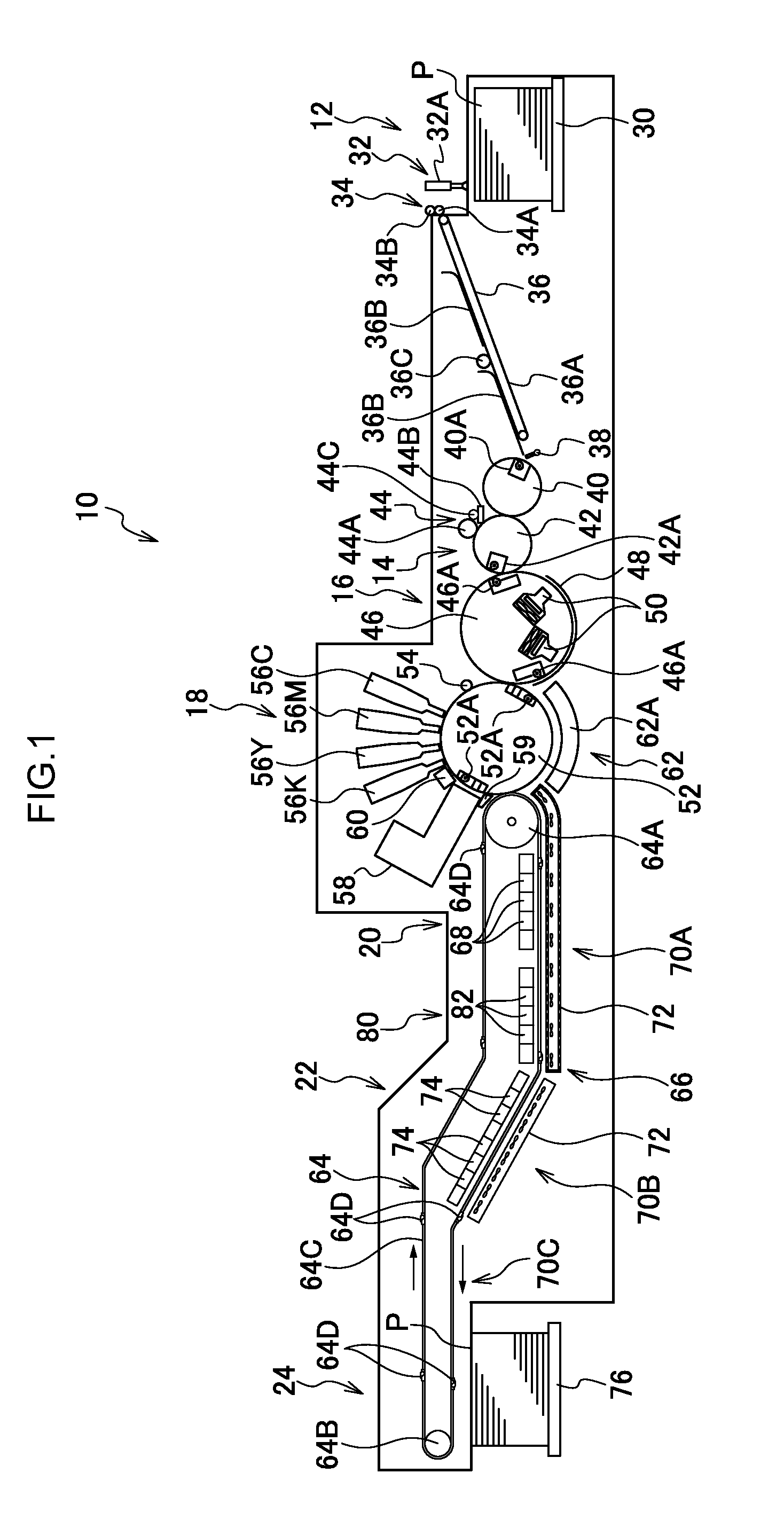

ActiveUS20090071940A1Avoid formingReliable dryingDecorative surface effectsPhotomechanical apparatusLiquid layerProduct gas

After a development liquid on a substrate is washed away with a rinse liquid, the rotational speed of the substrate is reduced, so that a liquid layer of the rinse liquid is formed over a top surface of the substrate. Thereafter, the rotational speed of the substrate is increased. The increase in the rotational speed of the substrate causes a centrifugal force to be slightly greater than tension, thereby causing the liquid layer to be held on the substrate with the thickness thereof in its peripheral portion increased and the thickness thereof at the center thereof decreased. Then, gas is discharged toward the center of the liquid layer from a gas supply nozzle, so that a hole is formed at the center of the liquid layer. This causes tension that is balanced with a centrifugal force exerted on the peripheral portion of the liquid layer to disappear. Furthermore, the rotational speed of the substrate is further increased while the gas is discharged. Thus, the liquid layer moves outward from the substrate.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

Substrate processing method and substrate processing apparatus

ActiveUS8337659B2Reliable dryingReduce consumptionDrying solid materials without heatDecorative surface effectsSpinsEngineering

A substrate processing apparatus according to the present invention is provided with a spin chuck (3) that holds a substrate (W) and rotates the same. A process liquid supply system (11, . . . ) is disposed to supply a process liquid to the substrate rotated by the spin chuck. There are disposed a fluid nozzle (12) that supplies to the substrate a drying fluid having a higher volatility than that of the process liquid, and an inert gas nozzle (13) that supplies an inert gas to the substrate. A nozzle moving mechanism (15, 52, . . . ) is disposed that moves the nozzles (12, 13) radially outward relative to a rotational center (Po) of the substrate, while maintaining the inert gas nozzle nearer to the rotational center of the substrate than the fluid nozzle.

Owner:TOKYO ELECTRON LTD

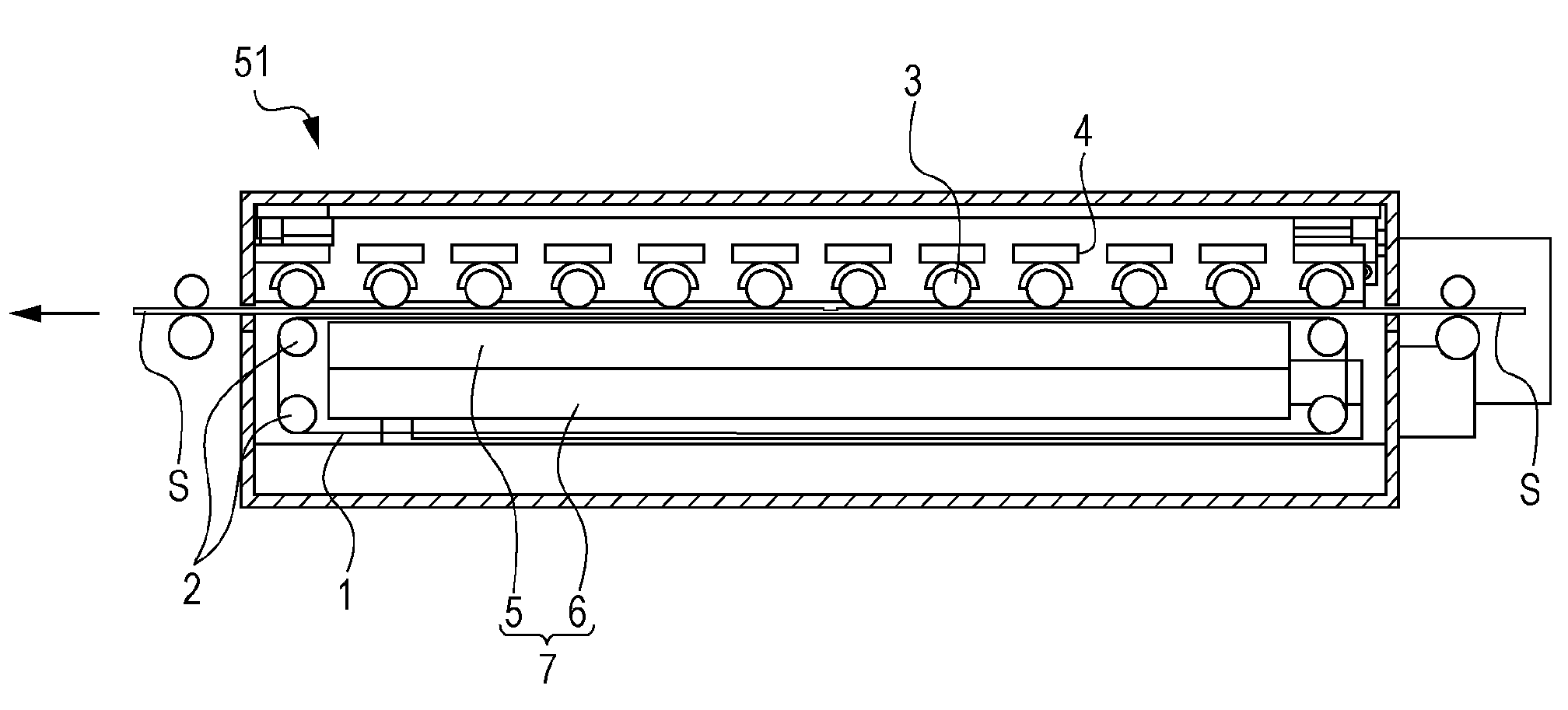

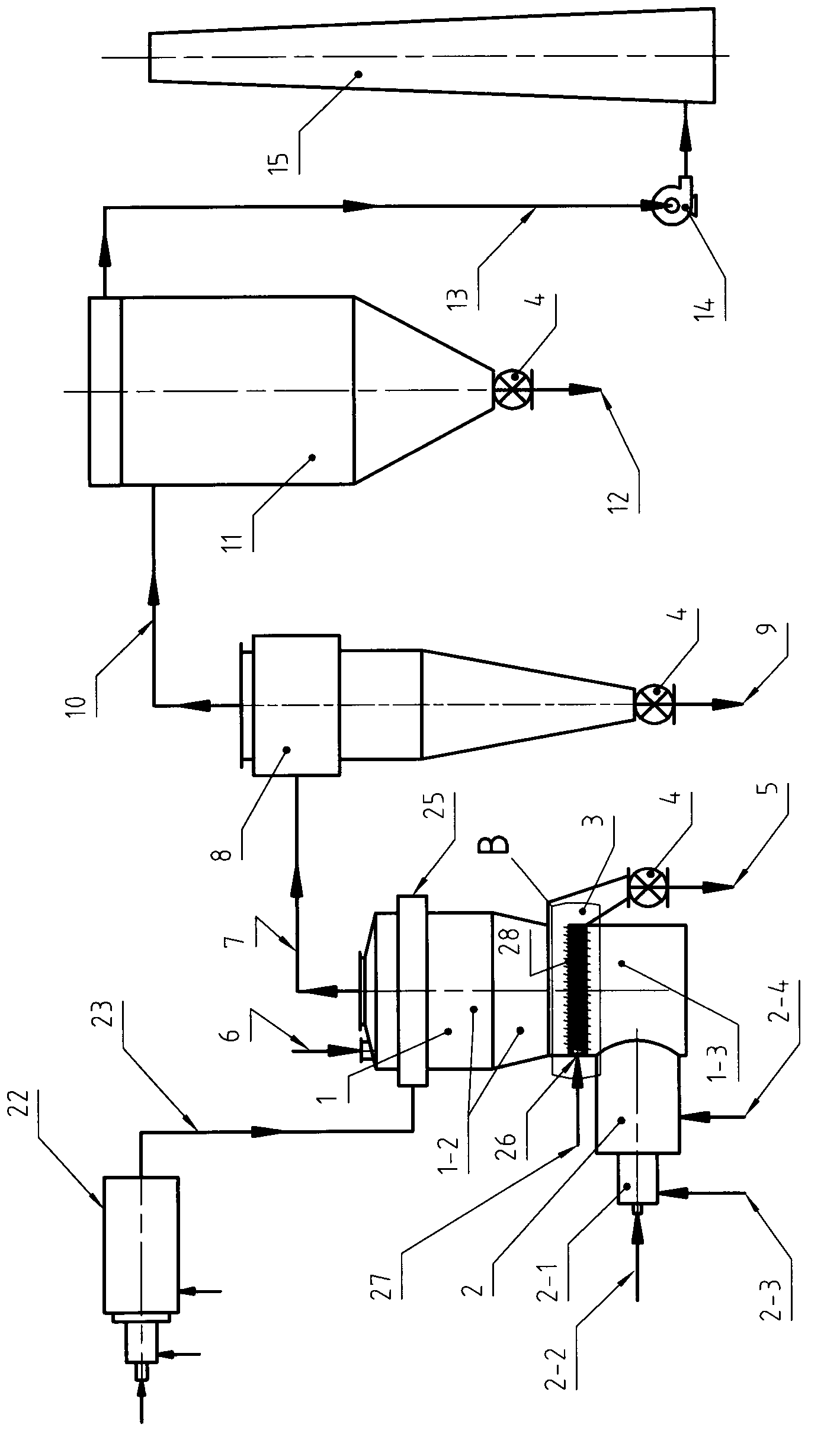

Lignite pre-drying process and lignite pre-drying device

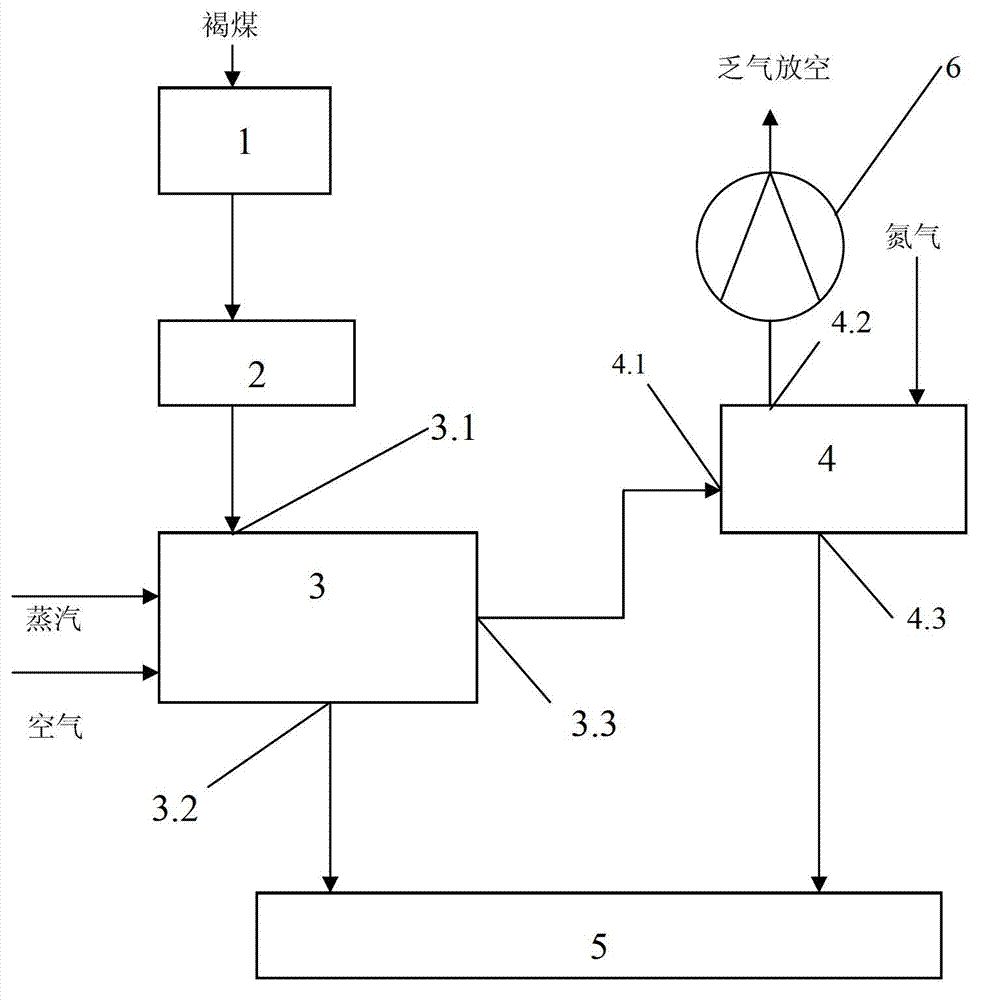

InactiveCN103047836AImprove efficiencyReduce moisture contentDrying gas arrangementsDrying machines with non-progressive movementsGranularityProcess engineering

The invention discloses a lignite pre-drying process and a lignite pre-drying device which solve the problems of poor 'dewatering' and dedusting effects and no large-scale industrial application caused by direct-contact heat transfer of the prior art. The technical scheme includes that the process includes that lignite with the granularity smaller than 13mm is fed into a drying tube of a tube drier via a lignite inlet of the tube drier, and meanwhile, a heat source serving as a drying medium is fed to the outside of the drying tube of the tube drier, so that lignite in the drying tube and the heat source outside the drying tube are subjected to indirect heat exchange, and dried lignite is discharged via a lignite outlet; and exhaust with dust and generated by feeding of the lignite in the drying tube is mixed with steam generated after lignite drying to form tail gas, the tail gas enters a bag filter via a tail gas outlet to be filtered and separated, lignite dust collected after separation is discharged via a dust outlet of the bag filter, and the tail gas is discharge by an induced draft fan via a tail gas outlet of the bag filter. The lignite pre-drying process is simple, good in dewatering effect, safe, reliable and suitable for large-scale industrial application, and tail gas emission reaches the standards.

Owner:WUHUAN ENG

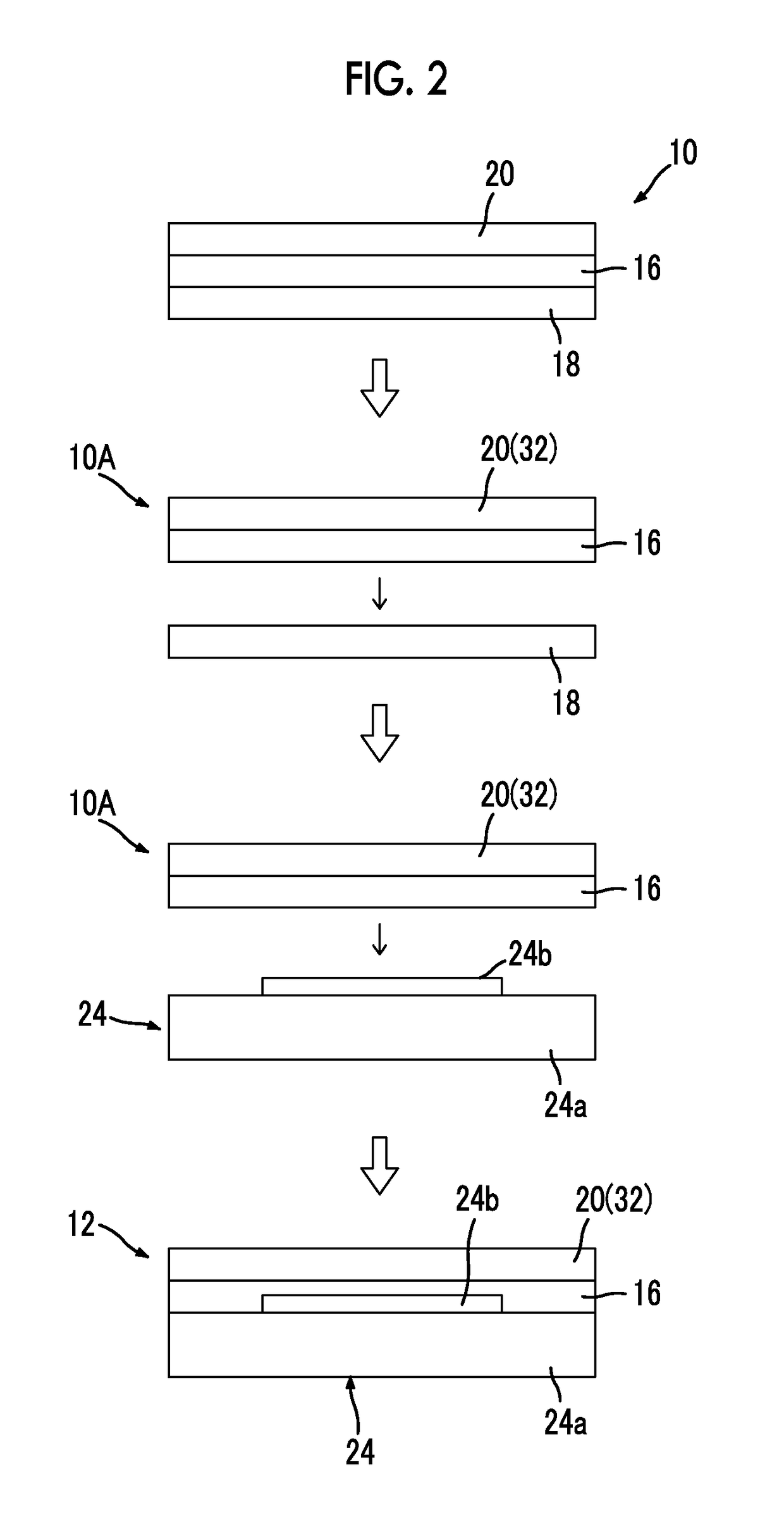

Method of manufacturing electronic device and composite film

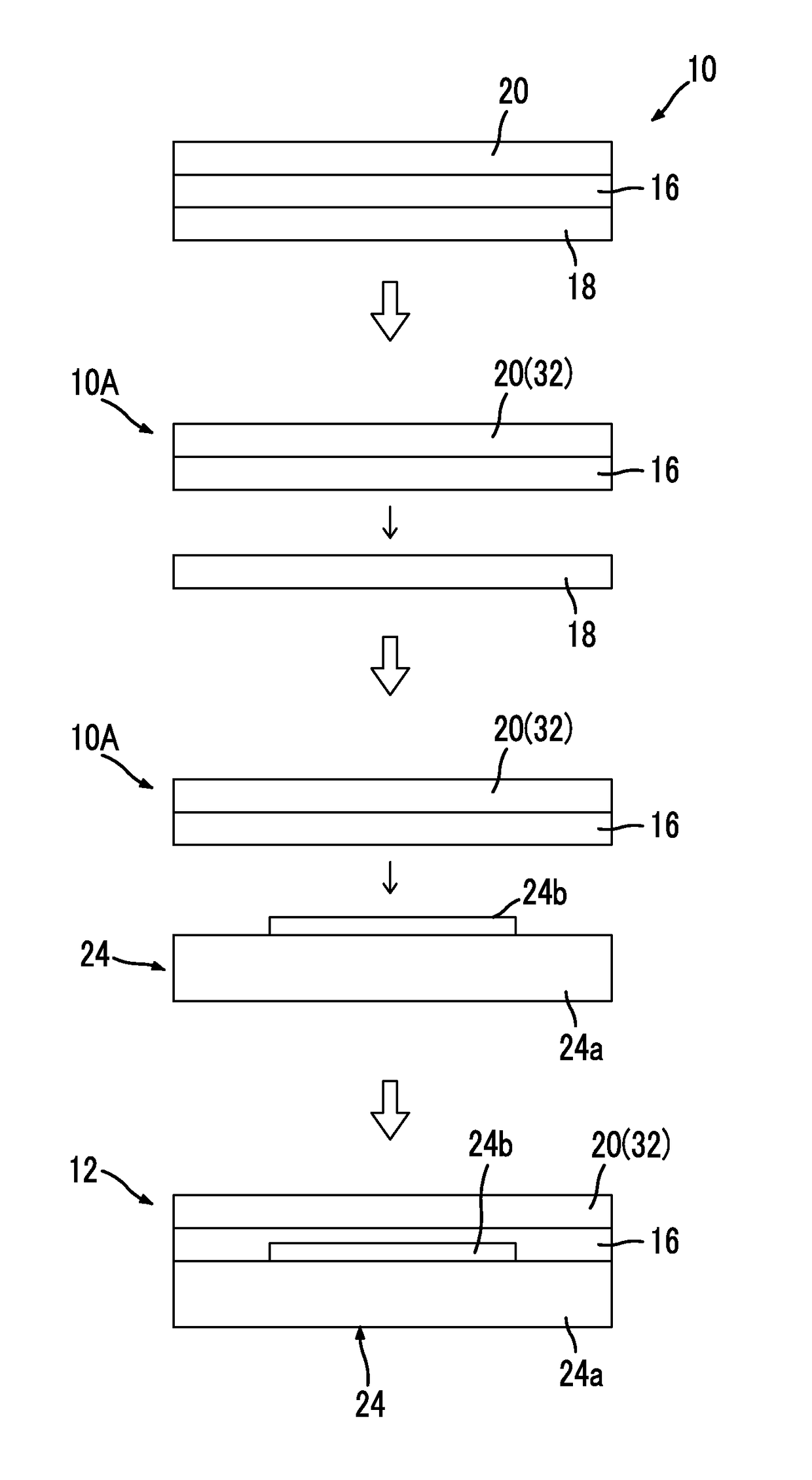

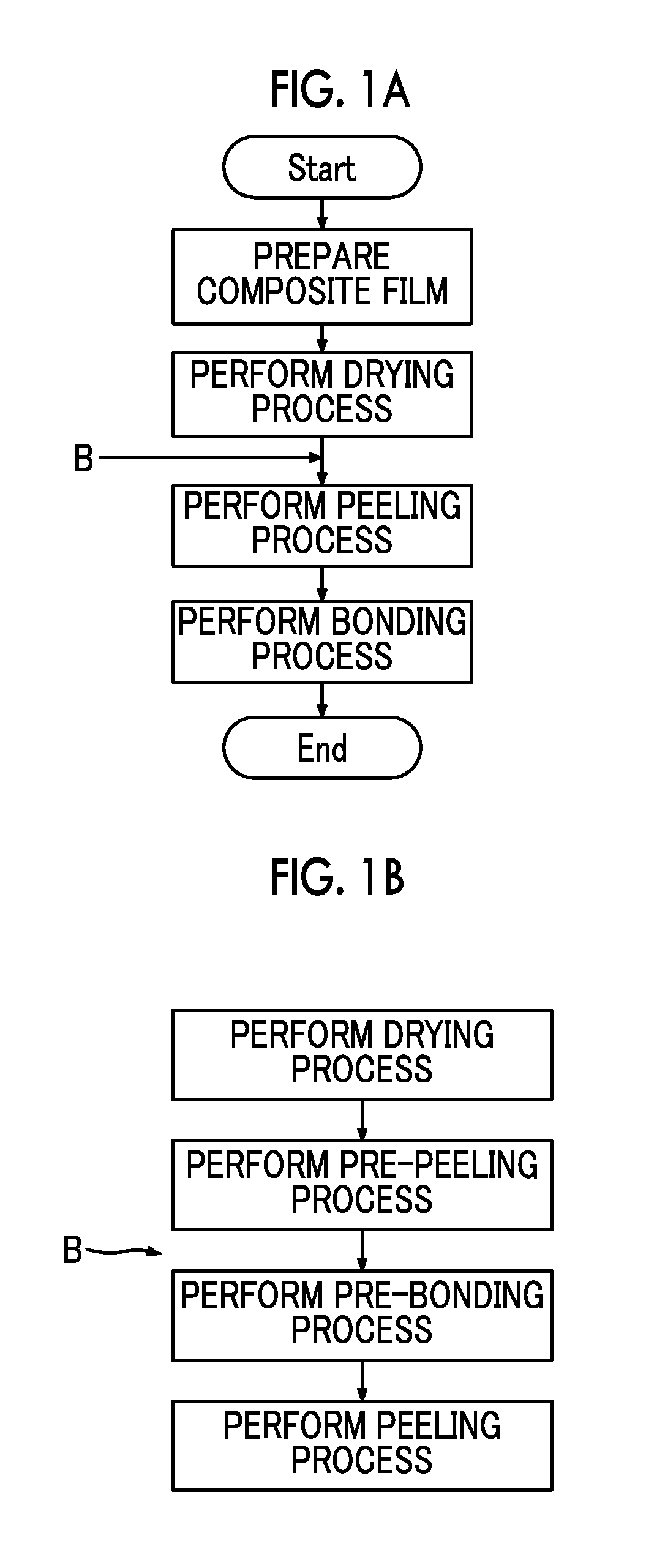

InactiveUS20170100926A1Increase in production cost can be suppressedDeterioration of the electronic deviceSolid-state devicesSemiconductor/solid-state device manufacturingComposite filmDevice form

Provided is a method of manufacturing an electronic device including: drying a pressure sensitive adhesive layer of a composite film which has the pressure sensitive adhesive layer; and a first film and a second film bonded to each surface of the pressure sensitive adhesive layer and in which a moisture vapor transmission rate of the first film at a temperature of 40° C. and a relative humidity of 90% is 100 g / (m2·day) or greater; peeling the first film from the composite film in which the pressure sensitive adhesive layer is dried; and bonding the composite film from which the first film is peeled to an electronic device. In this manner, deterioration of the electronic device due to moisture can be prevented during the manufacture of a laminated electronic device formed by sealing the electronic device with a gas barrier film or the like.

Owner:FUJIFILM CORP

Recording apparatus

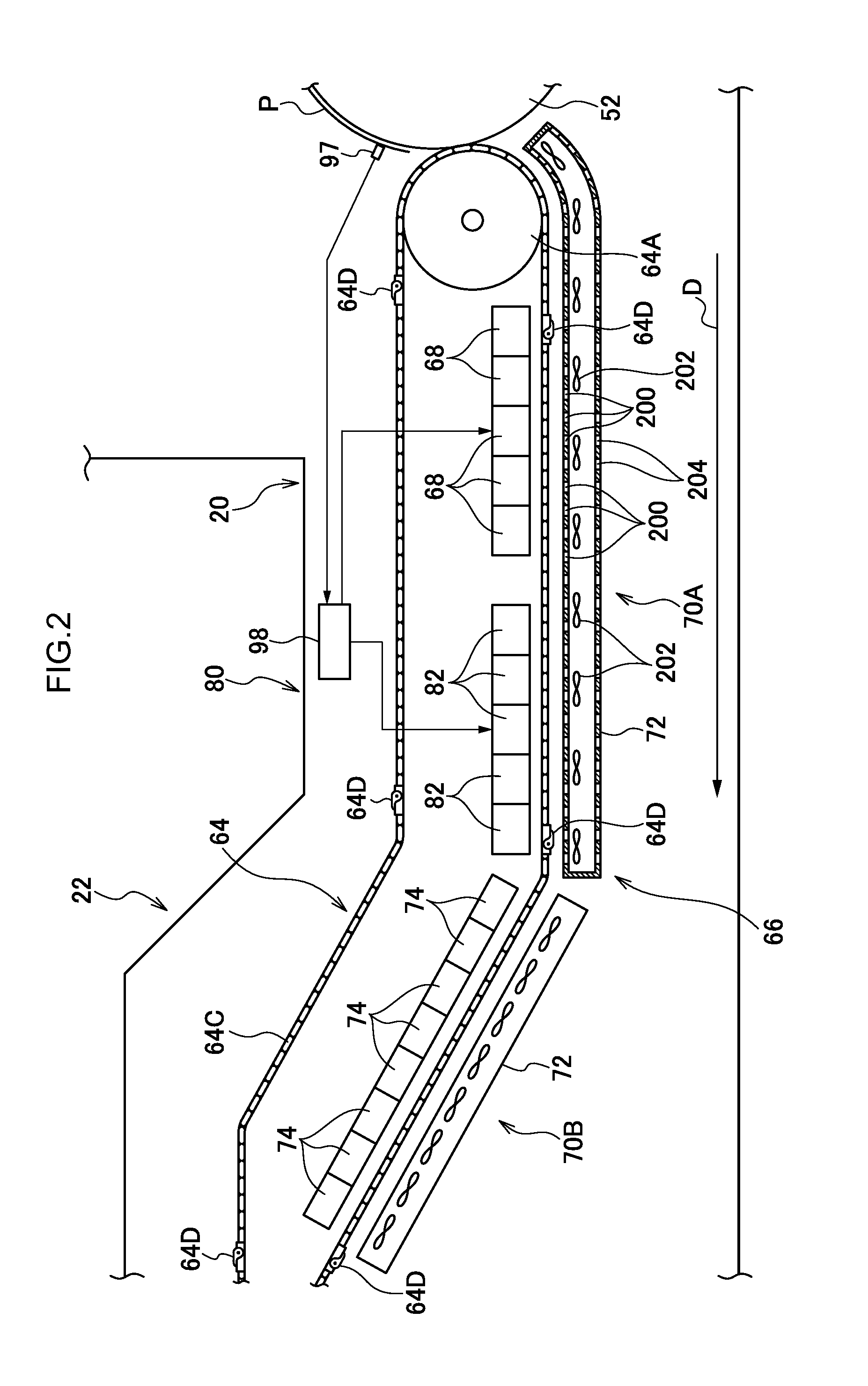

ActiveUS20110050823A1Little resistanceIncrease transport distanceOther printing apparatusEngineeringRecording media

A recording apparatus includes a transport unit that intermittently transports an elongated recording medium from an upstream side to a downstream side as the lengthwise direction of the recording medium moves along a transport path. A recording unit adheres a recording material to the recording medium when the recording medium is stopped in a midstream position of the transport path. A drying unit downstream from the recording unit heats and dries the recording material. A contact member has a contact surface continuous contact with the surface of the recording medium opposite the surface thereof to which the recording material is adhered, from the time when the recording medium enters into the drying unit to the time when the recording medium is discharged from the drying unit. The contact member forms the transport path with the contact surface having at least one bent section in the drying unit.

Owner:SEIKO EPSON CORP

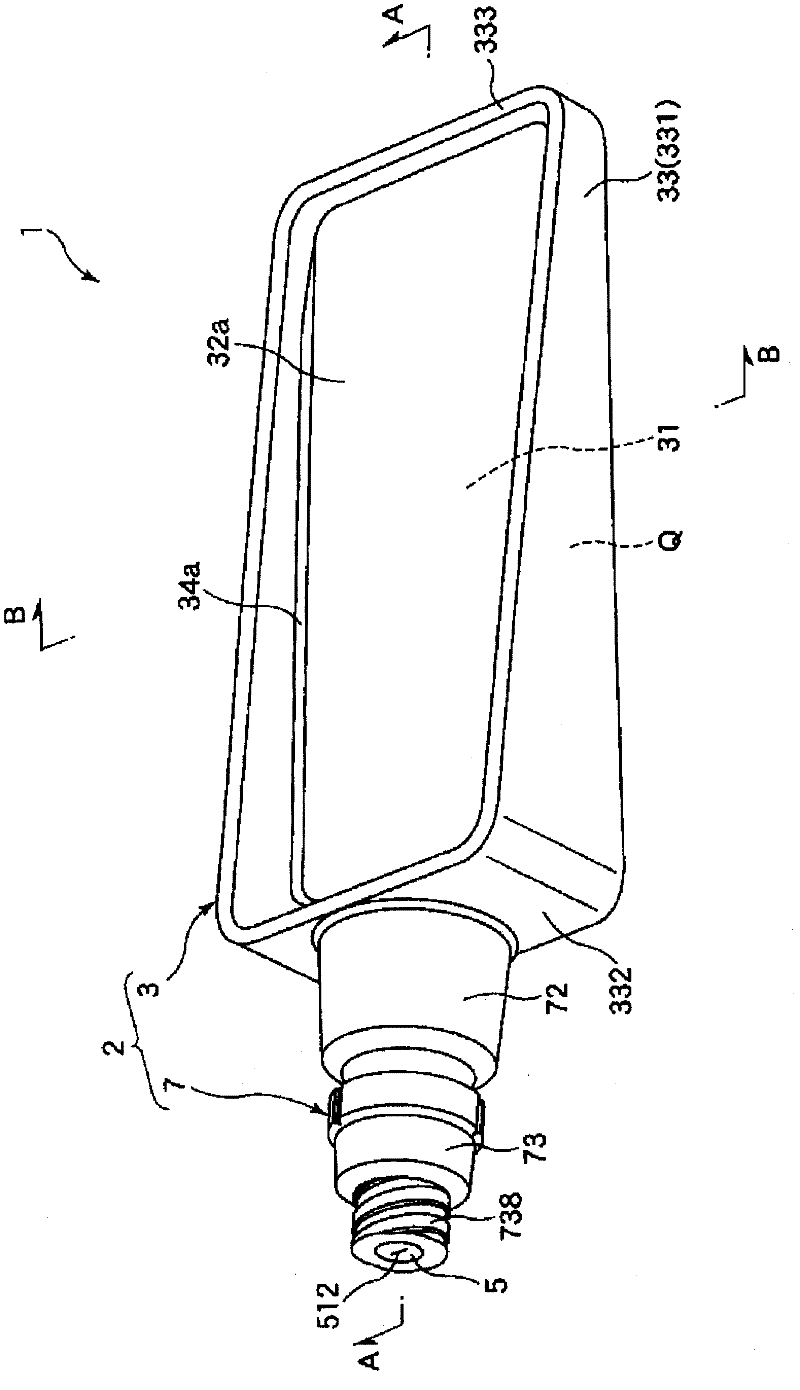

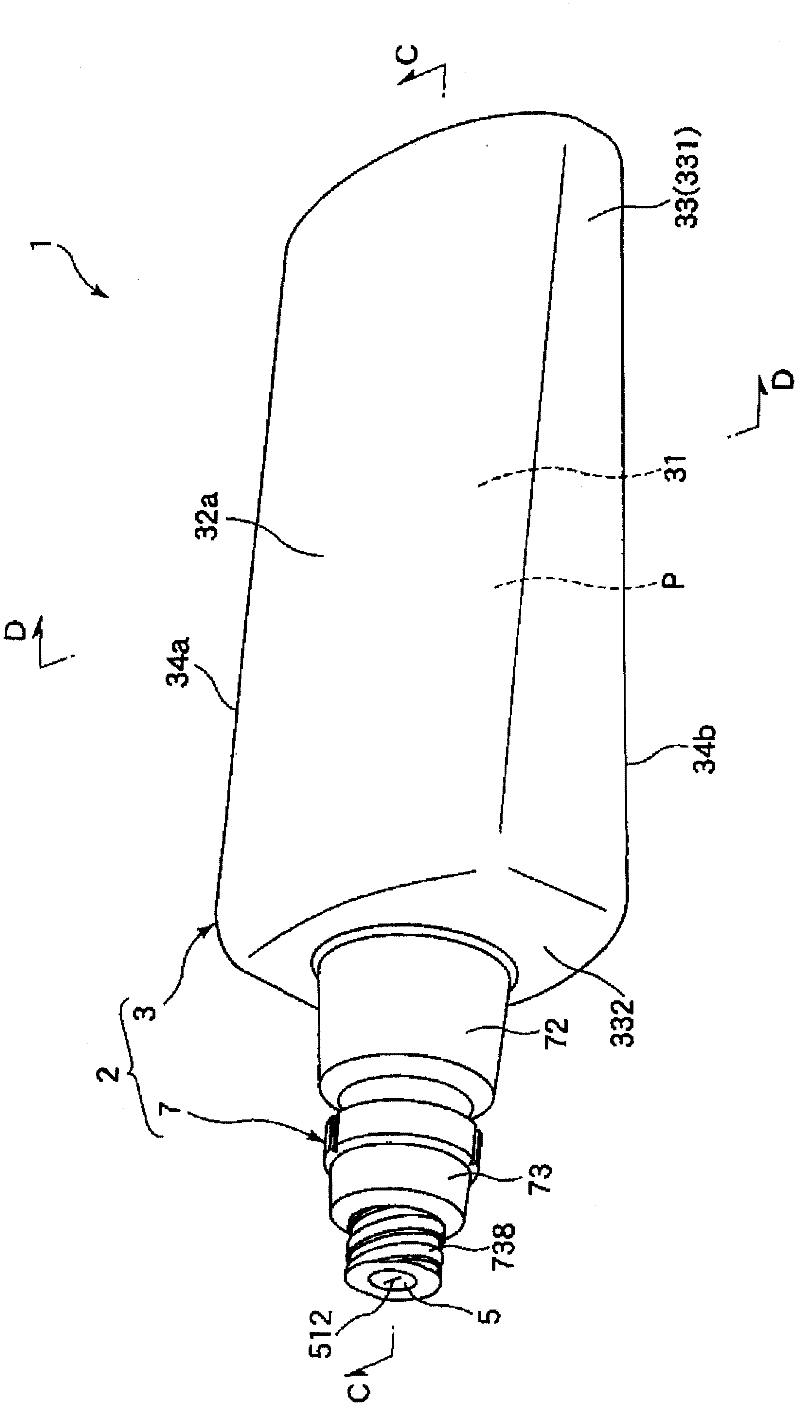

Medication-containing container

InactiveCN102131486AReliable dryingPharmaceutical containersPharmaceutical product form changeEngineeringMechanical engineering

Owner:TERUMO KK

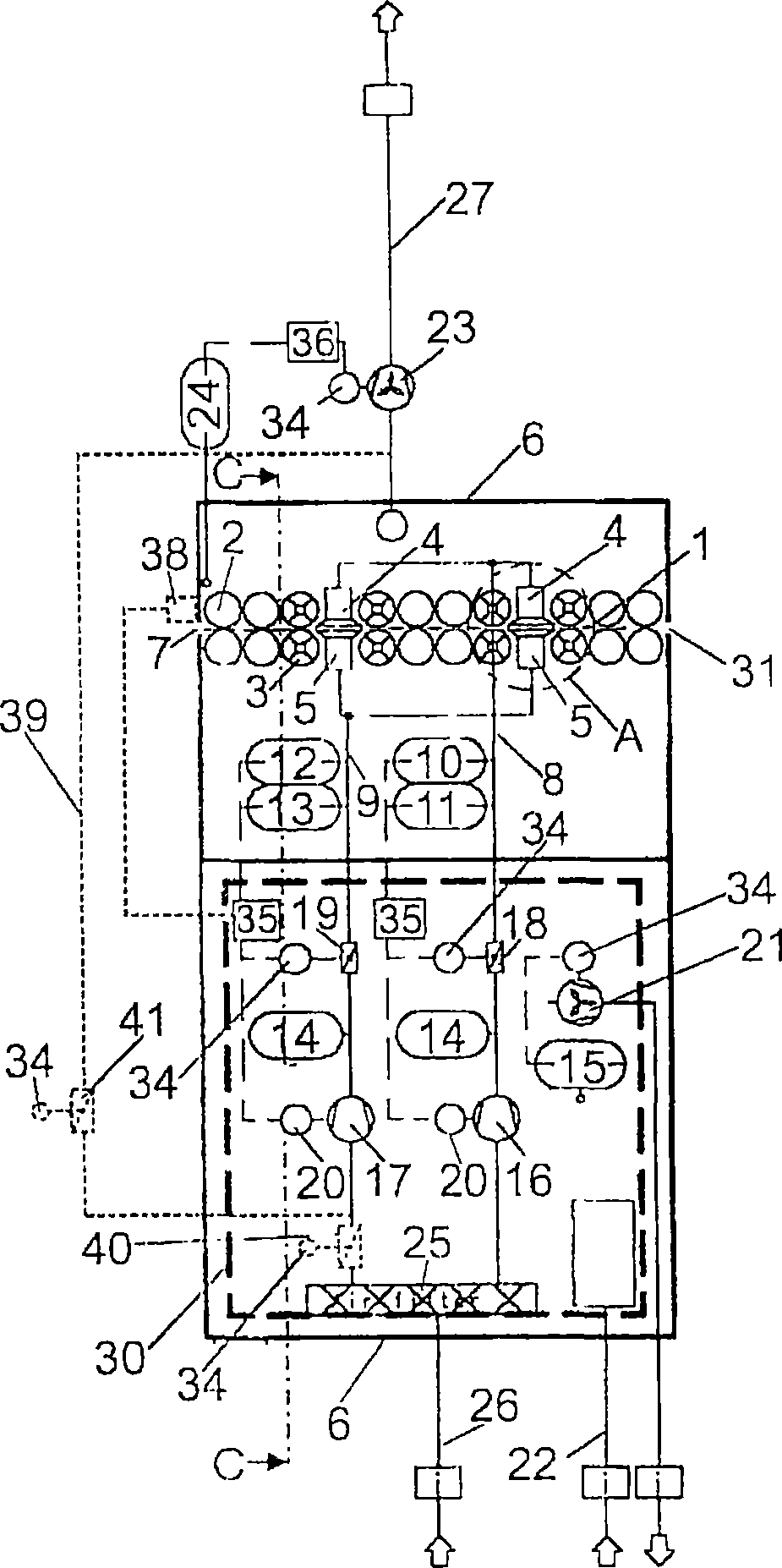

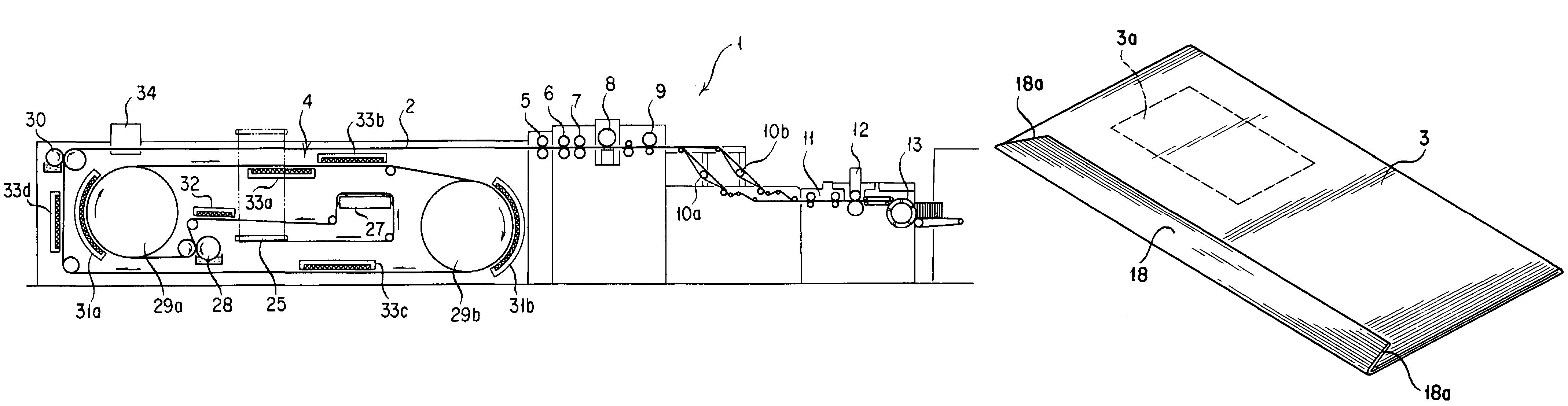

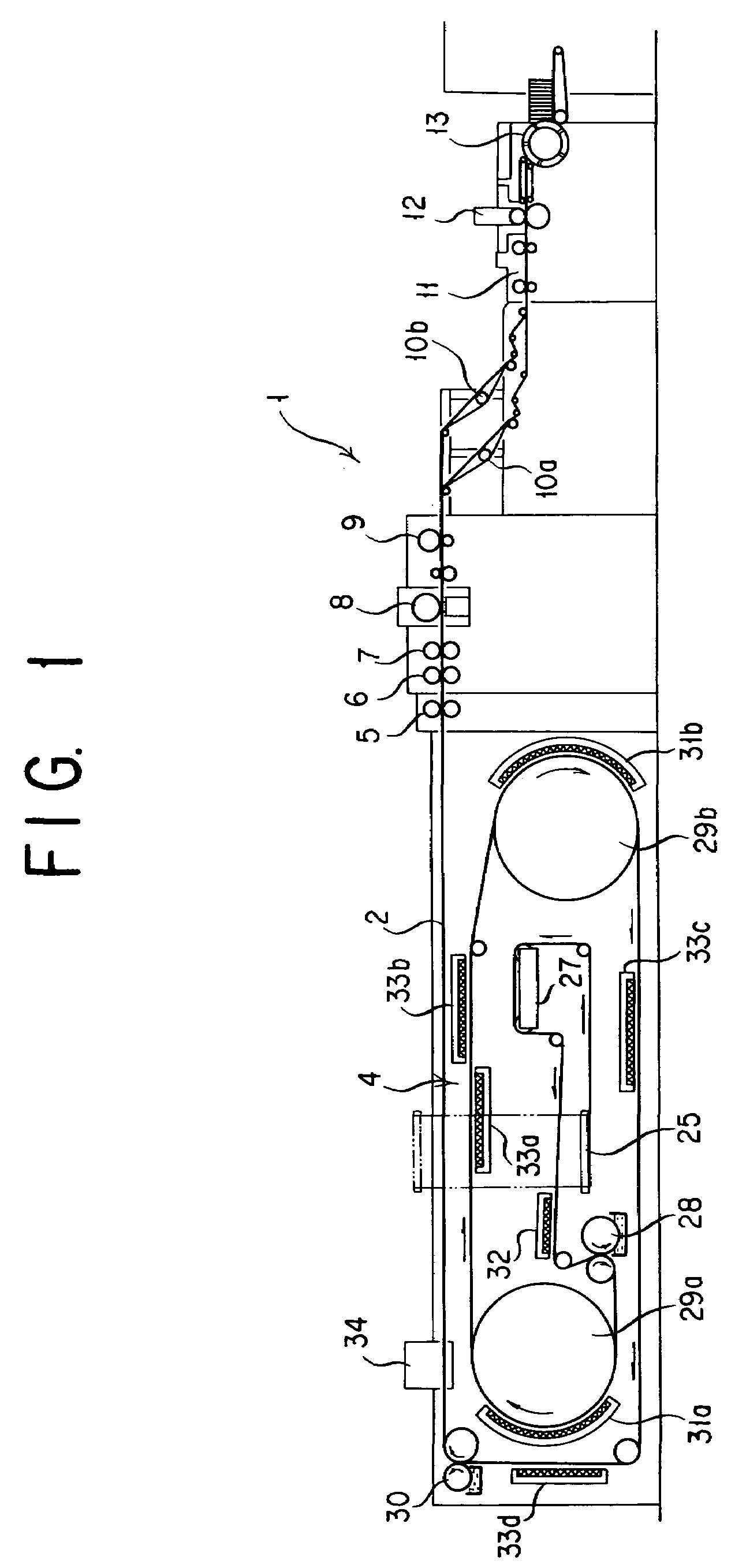

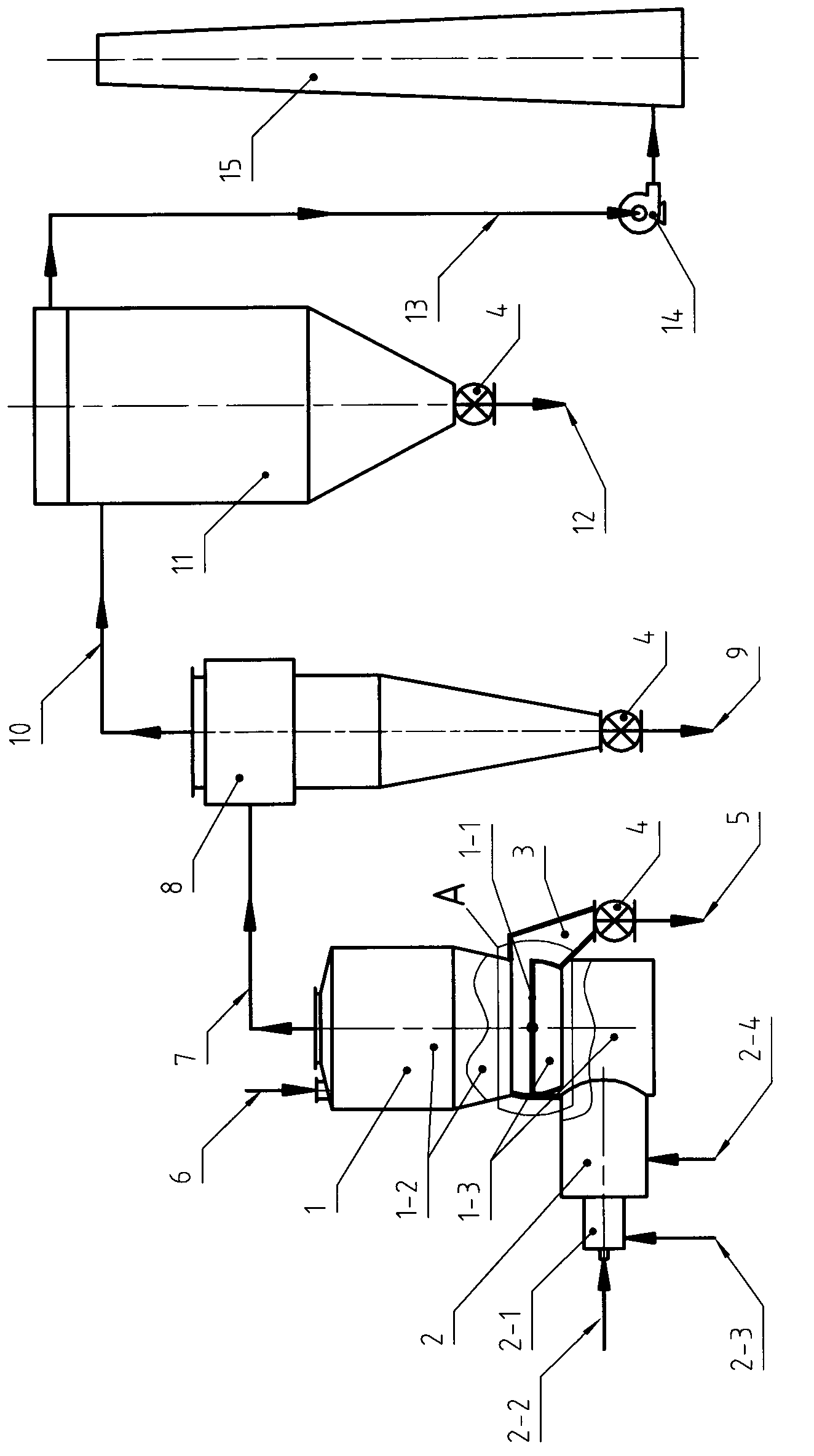

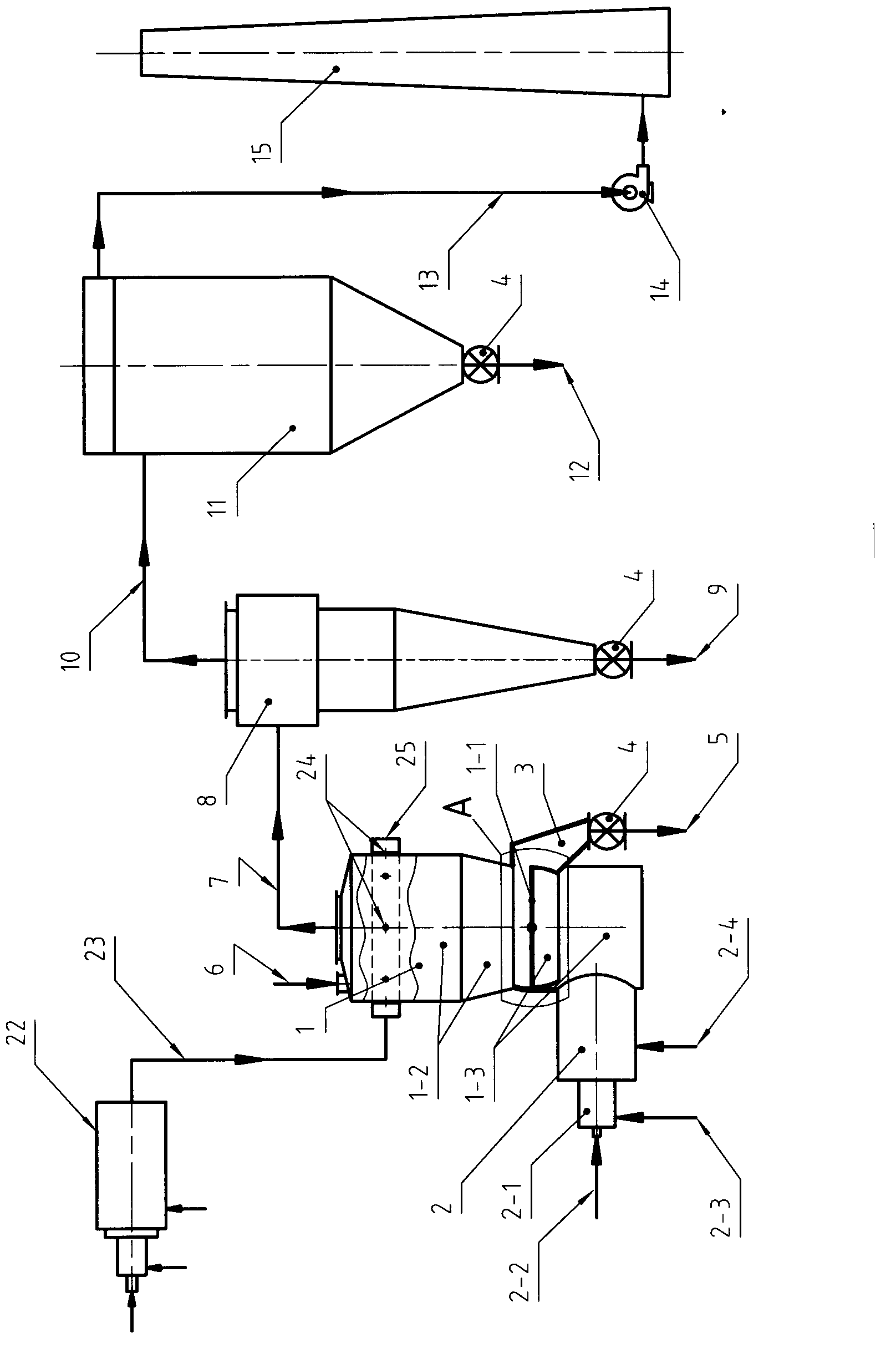

Method of and apparatus for making window envelopes

InactiveUS20060100082A1Rapid productionReliable dryingEnvelopes/bags making machineryBoxes/cartons making machineryPulp and paper industryWater soluble

Disclosed are a method and an apparatus designed to make a window envelope rapidly using a water-soluble clarifying agent without causing an inconvenience in its window area. Upstream of an envelope making stage wherein a continuous paper while traveling along a continuous path of travel is successively folded, pasted and cut to form an envelope, a water-soluble clarifying agent is applied to an area on the continuous paper that is designed to become the transparent window in the envelope and the continuous paper carrying the clarifying agent is wound on a plurality of drying cylinders so that its surface carrying the clarifying agent faces outwards to dry the clarifying agent while holding the surface of paper carrying the clarifying agent out of contact with the drying cylinders.

Owner:MIYAKOSHI PRINTING MACHINERY +1

Device and method for drying a treated product

ActiveCN1867805AGently dryReliable dryingDrying solid materials with heatDrying gas arrangementsProcess engineeringProduct gas

The invention relates to a device and to a corresponding method which is used to dry a treated product (1). Said device comprises transport means (3) which are used to transport the treated product (1) along a conveyor belt. Gas outlet devices (4, 5) which are disposed in an opposite manner are arranged above the conveyor belt. A gaseous drying medium is guided by blowing means to the gas outlets in a separate manner via supply pipes (8, 9). Pressure allocated to a respective gas outlet device (4, 5) is detected and a gas flow associated with the gas outlet device (4, 5) is controlled by control means according to said pressure.

Owner:ATOTECH DEUT GMBH

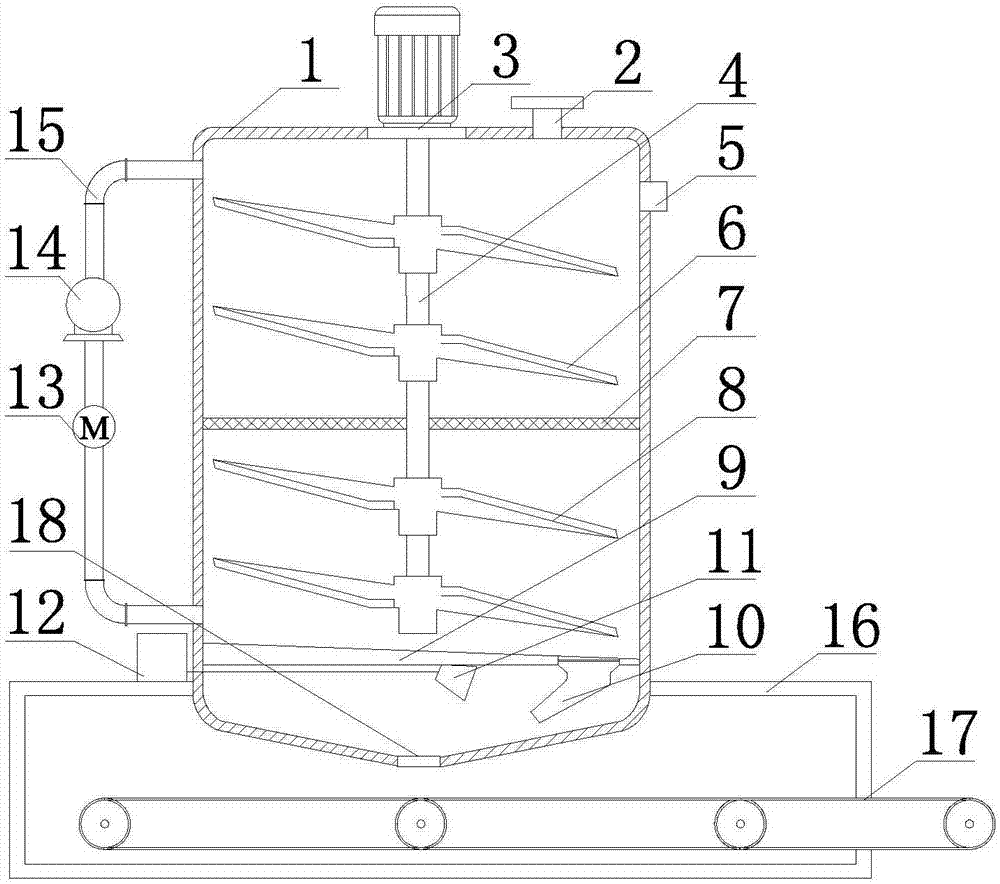

Color master batch drying device

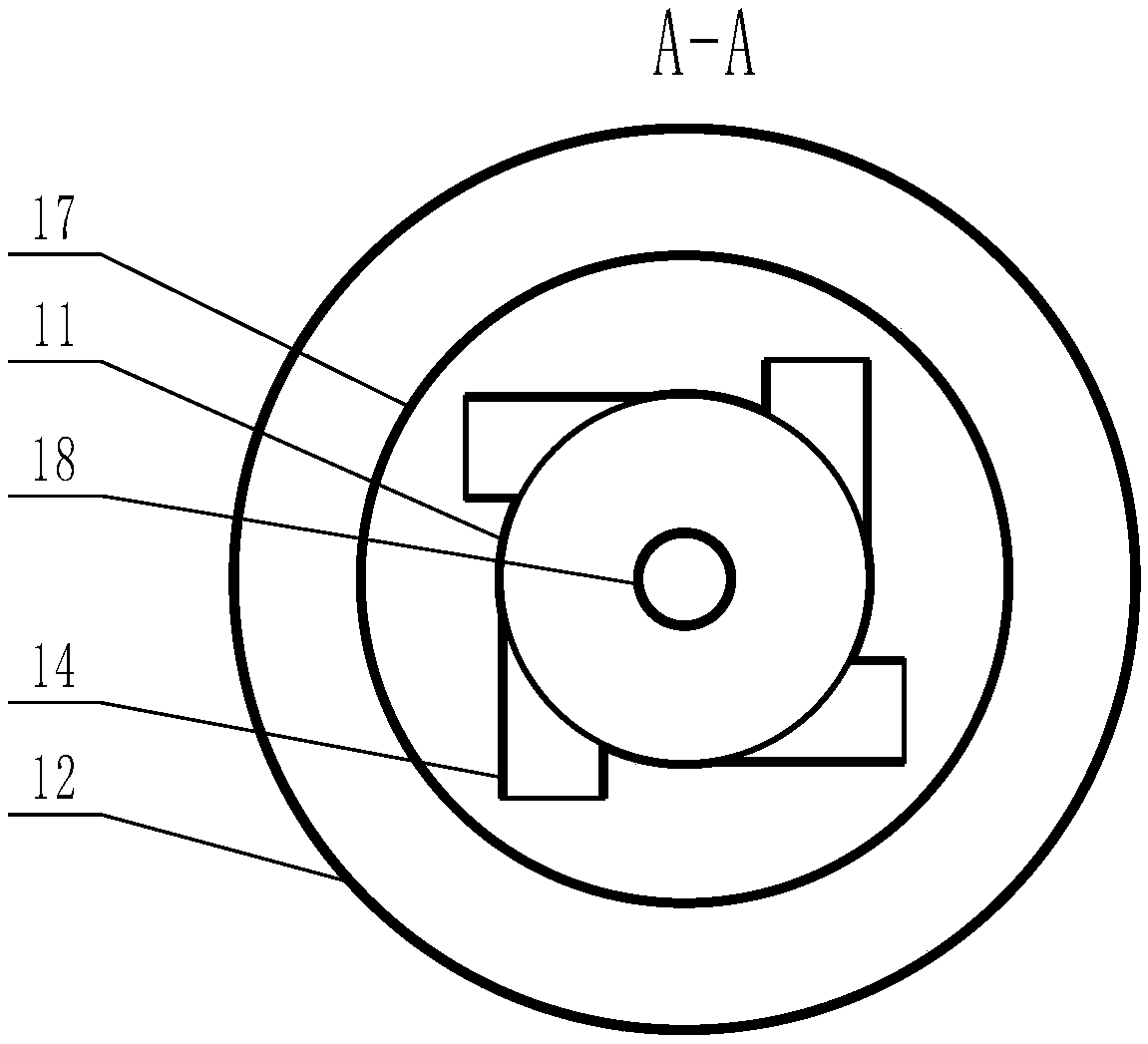

The invention relates to a color master batch drying device which can be used for performing multi-time drying treatment on color master batch, is high in drying efficiency, and is reliable in dryingeffect, and the dried color master batch is free of inferior-quality products with moisture exceeding the standards. A drying box is sequentially divided into an upper drying room, a middle drying room and a lower drying room from top to bottom by a filter screen and a baffle plate; a motor is arranged on the top of the drying box; the output shaft of the motor is in driving connection with a mainshaft which is vertically arranged; one end of the main shaft extends downwards from the upper drying room, and extends into the middle drying room after passing through the filter screen; a hot aircirculating mechanism is further arranged on the drying box; the hot air circulating mechanism comprises a fan, an electric heating box and a hot air tube; an air inlet of the hot air tube communicates with the upper drying room; an air outlet of the hot air tube communicates with the lower drying room; both the electric heating box and the fan are arranged on the hot air tube; the working surfaceof the baffle plate is an inclined surface; the lower end of the baffle plate is equipped with a discharge hole; an electric control valve is arranged in the discharge hole; an air flue is arranged in the lower drying room; and an air feeder is arranged on the air flue.

Owner:天津市春夏科技有限公司

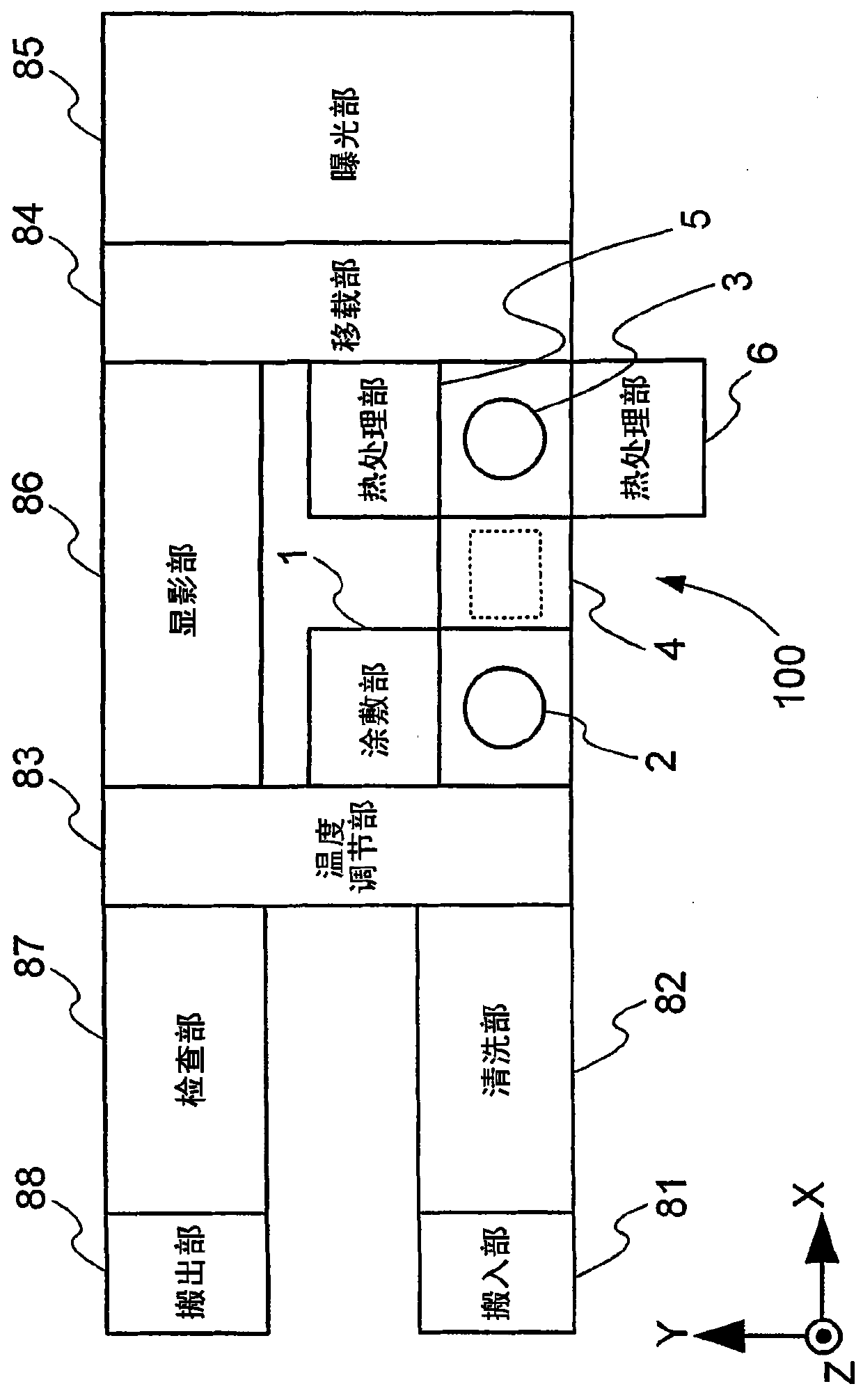

Substrate processing device

InactiveCN102166559AIncrease the number of sheets processedPrevent growing upLiquid surface applicatorsSemiconductor/solid-state device manufacturingLiquid layerEngineering

The invention provides a substrate processing device, which shortens device length and inhibits the declining of processing amount. When a plurality of coating liquid layers are disposed on the substrate, a plurality of coating devices and drying devices are disposed in a serial connection based on the laminating amount of the target layer, thereby the length of the device will be increased. The substrate processing device is provided with a moving unit in a manner of being able to access to the coating part and the drying part and moves the substrate completing the coating process to the drying part. The substrate after completing the regulated drying process is removed to the coating part for coating, thereby the length of the device can be prevented from increasing. A standby part is disposed at the drying part in a manner of lamination, and a mechanism enabling the substrate completing the heating process at the downstream to return to the standby part, thereby the processing efficiency of the substrate is further improved.

Owner:DAINIPPON SCREEN MTG CO LTD

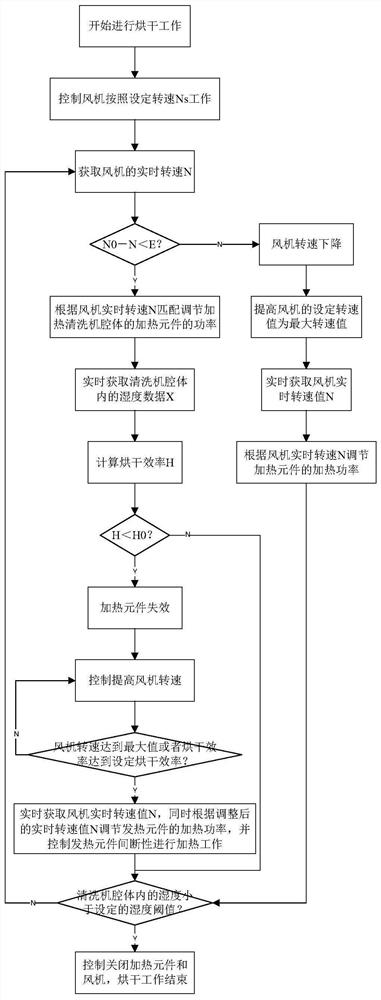

Cleaning machine drying method and cleaning machine applying same

ActiveCN112842218AKeep working at full capacityExtended service lifeKitchenware cleanersDrying gas arrangementsProcess engineeringManufacturing engineering

The invention relates to a cleaning machine drying method which comprises the steps that after drying work is started, a fan blowing air into a cleaning machine cavity is controlled to work according to the set rotating speed, meanwhile, the real-time rotating speed of the fan and humidity data in the cleaning machine cavity are obtained in real time, and then the current drying efficiency is calculated according to the humidity data; the current real-time rotating speed of the fan is compared with the set rotating speed, the current drying efficiency is compared with the set drying efficiency, and the heating power of the heating element or the rotating speed of the fan is adjusted according to the comparison result. According to the cleaning machine drying method, safe work of a heating element can be guaranteed, and the optimal drying efficiency can be guaranteed. The invention further relates to a cleaning machine applying the method, the dry burning risk is low, and the cost is low.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Apparatus for making window envelopes

InactiveUS7326164B2Rapid productionReliable dryingEnvelopes/bags making machineryBoxes/cartons making machineryWater solublePulp and paper industry

Disclosed are a method and an apparatus designed to make a window envelope rapidly using a water-soluble clarifying agent without causing an inconvenience in its window area. Upstream of an envelope making stage wherein a continuous paper while traveling along a continuous path of travel is successively folded, pasted and cut to form an envelope, a water-soluble clarifying agent is applied to an area on the continuous paper that is designed to become the transparent window in the envelope and the continuous paper carrying the clarifying agent is wound on a plurality of drying cylinders so that its surface carrying the clarifying agent faces outwards to dry the clarifying agent while holding the surface of paper carrying the clarifying agent out of contact with the drying cylinders.

Owner:MIYAKOSHI PRINTING MACHINERY +1

Drying device and image forming apparatus

InactiveUS9163876B2Increase contentImprove energy efficiencyDrying gas arrangementsDrying machines with progressive movementsPartial heatingRecording media

There is provided a drying device including: an airflow path extending in a direction intersecting with a conveyance path of a recording medium; an external air intake section that introduces external air into the airflow path; and a heating and blowing section provided to the airflow path that heats external air introduced into the airflow path and blows drying air onto a front face of the recording medium being conveyed on the conveyance path.

Owner:FUJIFILM CORP

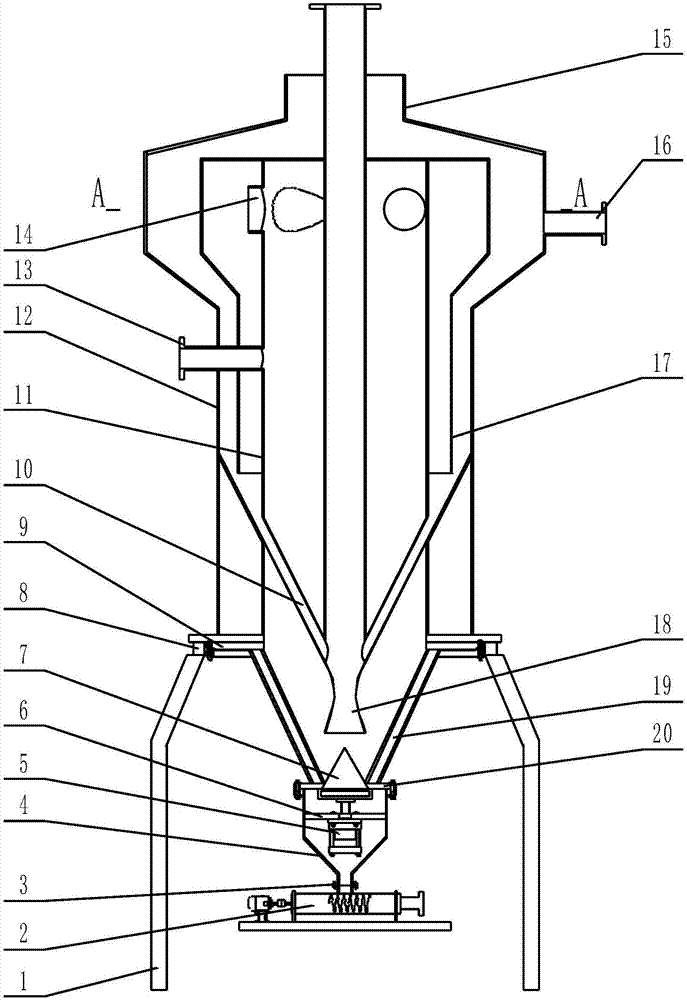

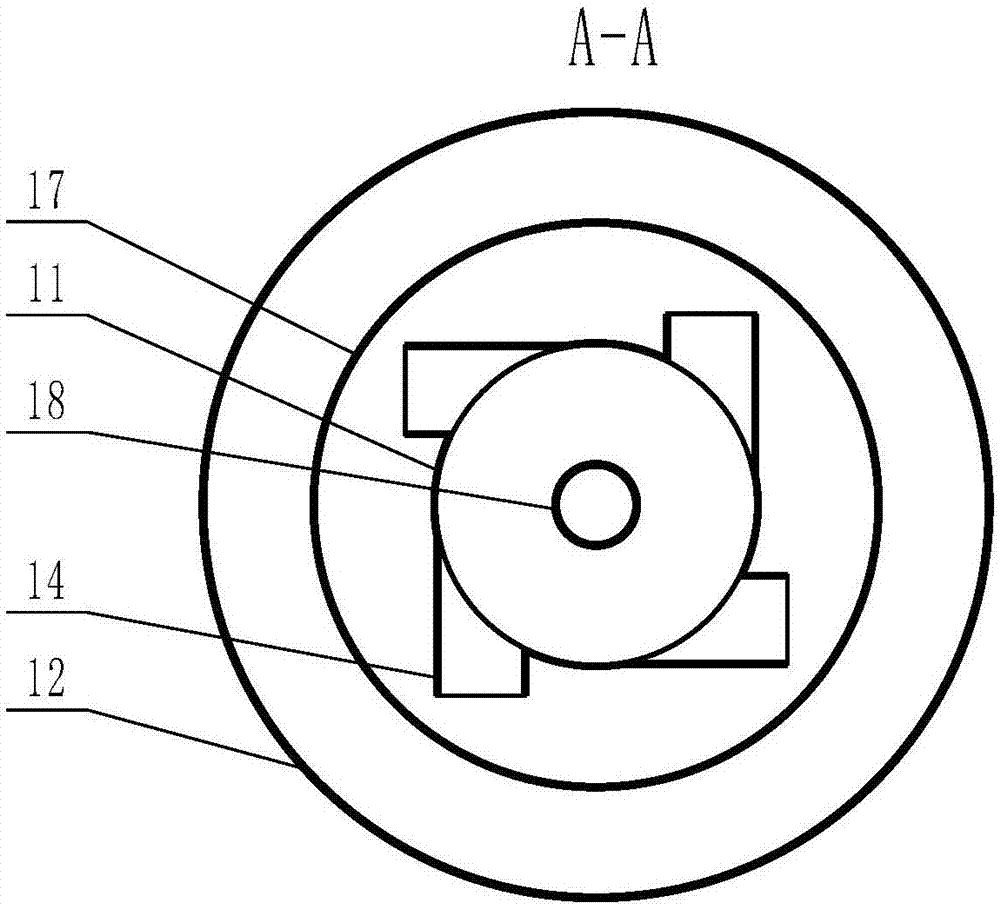

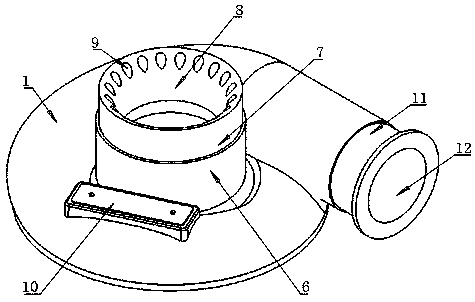

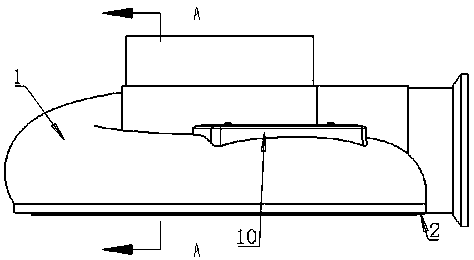

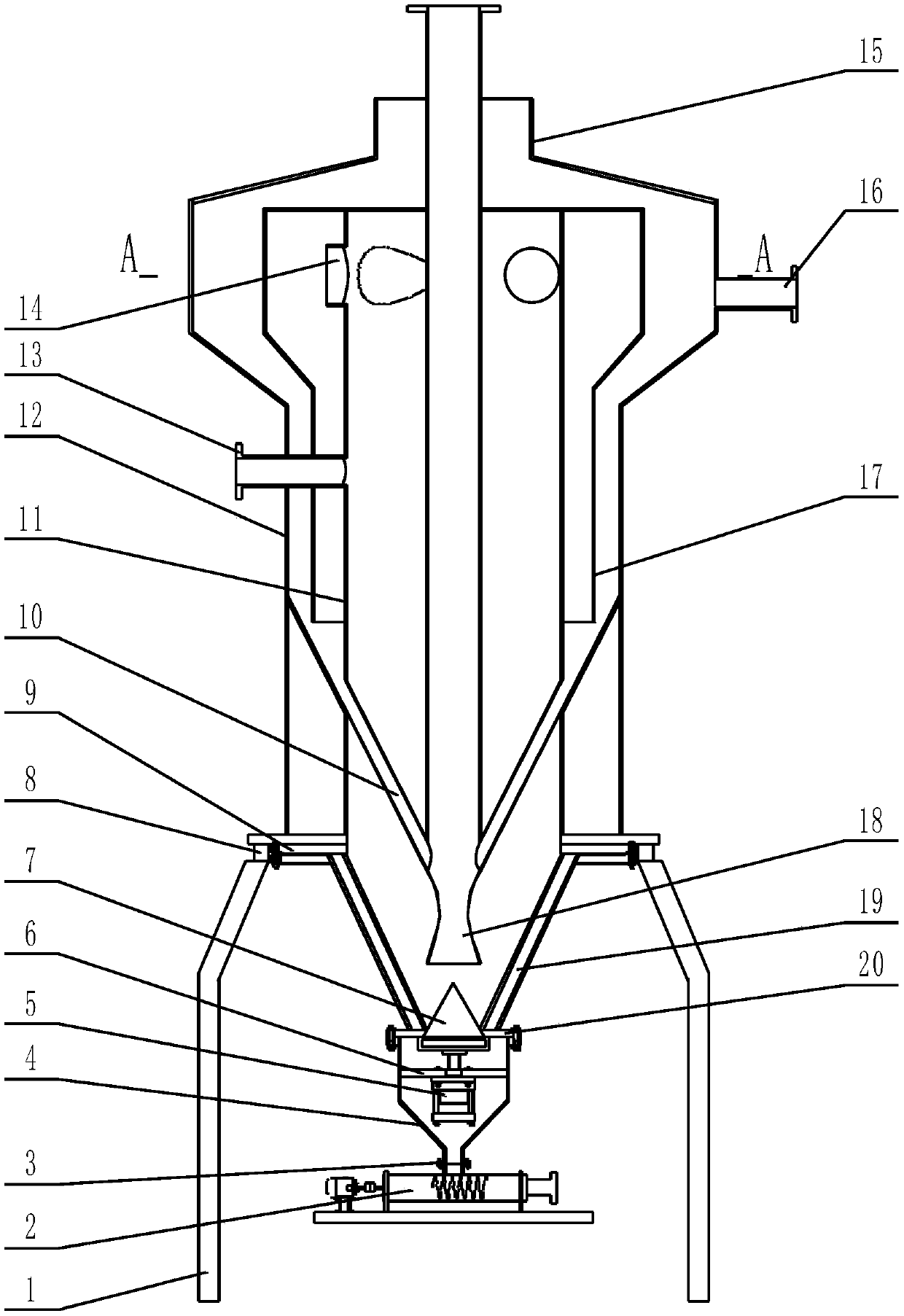

Flow-washing-type battery material dryer free of screen cloth

ActiveCN107514894AGood insulation effectEasy to transport materialsDrying gas arrangementsPistonAirflow

The invention relates to a flow-washing-type battery material dryer free of a screen cloth. The flow-washing-type battery material dryer free of the screen cloth is characterized in that the dryer comprises a support, a spiral material feeder, a first flange plate, a discharging pipe, an air cylinder, a material dropping plate, a sealing piston, a weighing device, a second flange plate, a Venturi branched tube, an airflow tank, a return air tank, a feeding pipe, a cyclone air outlet pipe, an air return pipe, a vacuum pumping pipe, a reflux tank, a Venturi tube and a third flange plate; the airflow tank comprises an upper airflow tank section and a lower airflow tank section, and the upper airflow tank section and the lower airflow tank section communicate with each other; the reflux tank is arranged at the outer side of the upper portion of the upper airflow tank section in a sleeving mode; the upper end of a space between the reflux tank and the upper airflow tank section is closed, and the lower end of the space is opened; and the reflux tank is of a cylinder structure with the cross section circle variable. According to the flow-washing-type battery material dryer, the return air tank, the reflux tank, the airflow tank and the Venturi tube are sequentially nested from outside to inside, so that the heat preservation effect of the dryer is made good; and moreover, heat is transmitted between the multiple layers of the pipes, after all layers of pipe walls are heated by hot air, the heat can be radiated outwards from the pipe walls, and powder drying is accelerated.

Owner:HEBEI UNIV OF TECH +1

Special catalyst drying device with detection function

PendingCN108050818AFast dryingReliable dryingDrying machines with progressive movementsDrying solid materialsDry structureEngineering

The invention relates to the technical field of catalyst drying equipment, in particular to a special catalyst drying device with a detection function. According to the adopted technical scheme, the special catalyst drying device comprises a spiral body drying structure; a spiral cavity with the cylindrical section is formed in a body of the body drying structure; a drying agent filling structureconnecting plane is arranged at the lower end of the body drying structure; a concentrically-distributed sealing connecting structure is arranged at the center position of the drying agent filling structure connecting plane; a drying agent conveying opening is formed in the center position of the sealing connecting structure and communicates with the spiral cavity in the body of the body drying structure; and a connecting supporting seat integrally formed with the upper end of the body drying structure is arranged above the center position of the drying agent conveying opening. The special catalyst drying device has the advantages that a catalyst can be thoroughly dried at a time, the drying speed of the catalyst is higher, the drying effect is more reliable, greater convenience is achieved in the use process, and the drying cost of the catalyst is lower.

Owner:JIANGSU SANJI IND

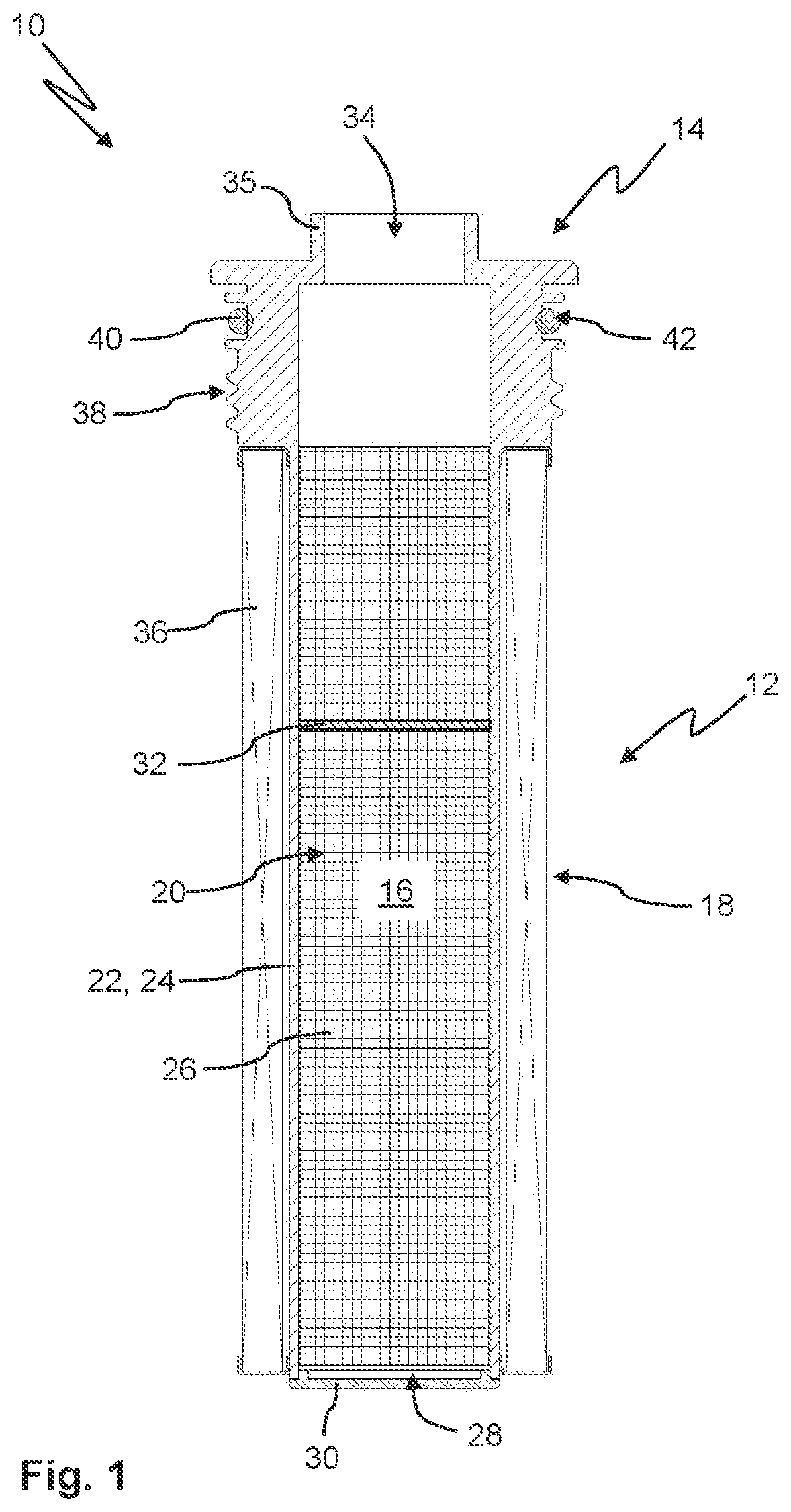

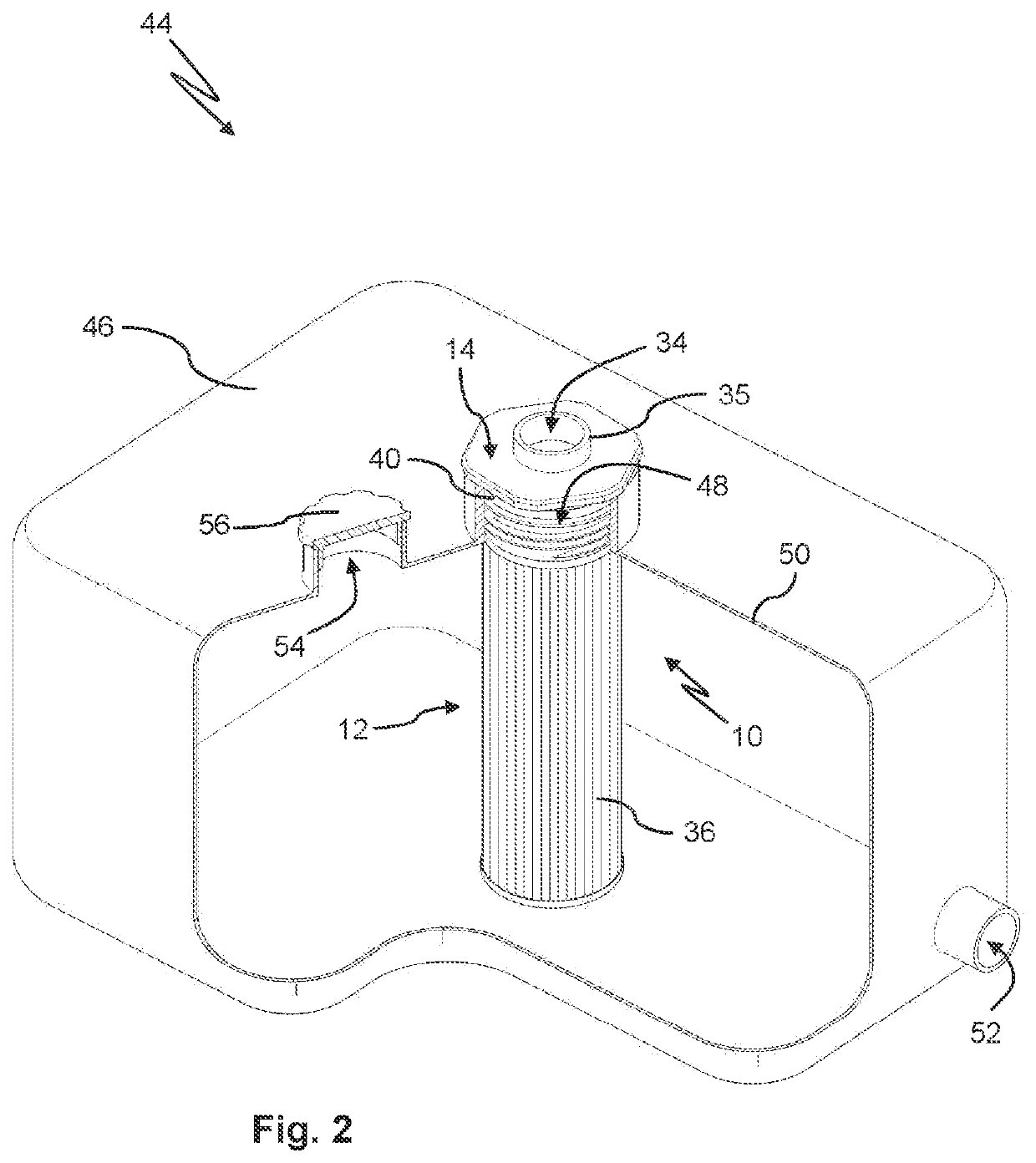

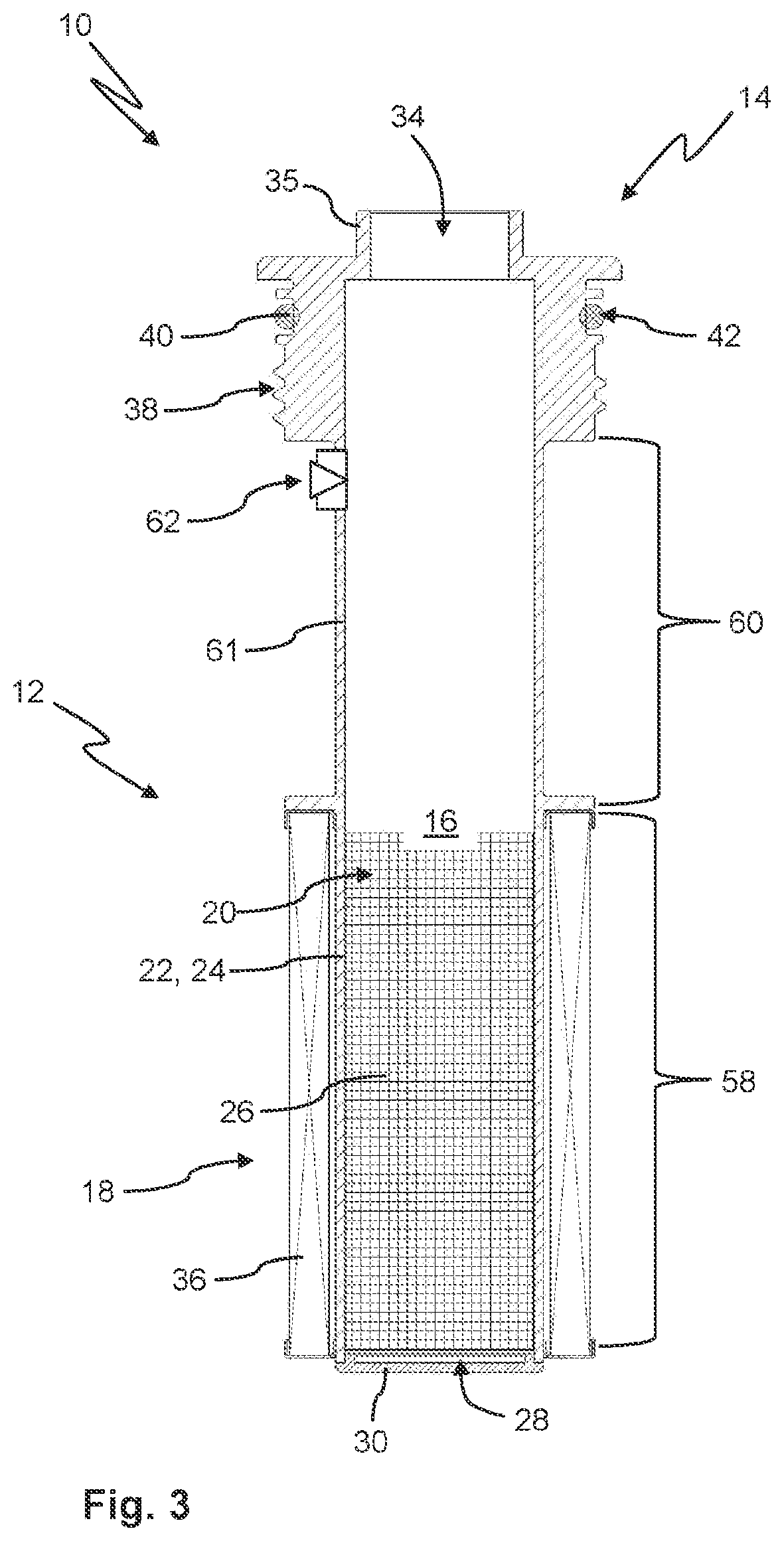

Dryer Cartridge, Drying System, and Use Thereof

PendingUS20210252425A1Reliable removal of waterReliable removalGas treatmentNon-fuel substance addition to fuelEngineeringMechanical engineering

A dryer cartridge for removal of water from a liquid is provided with a cartridge body having a receiving chamber and a cartridge body wall delimiting the receiving chamber at least in sections thereof, wherein the cartridge body wall allows the liquid to flow through. A drying agent is arranged in the receiving chamber. A connection head is provided that can fasten the dryer cartridge in an opening of a housing wall of a device for receiving the liquid. The connection head has a connection opening and the connection opening connects in fluid communication the receiving chamber to an environment of the cartridge body. A drying system is provided with a device for receiving the liquid and with the dryer cartridge that can be fastened to an opening of a housing wall of a device for receiving the liquid.

Owner:MANN HUMMEL GMBH

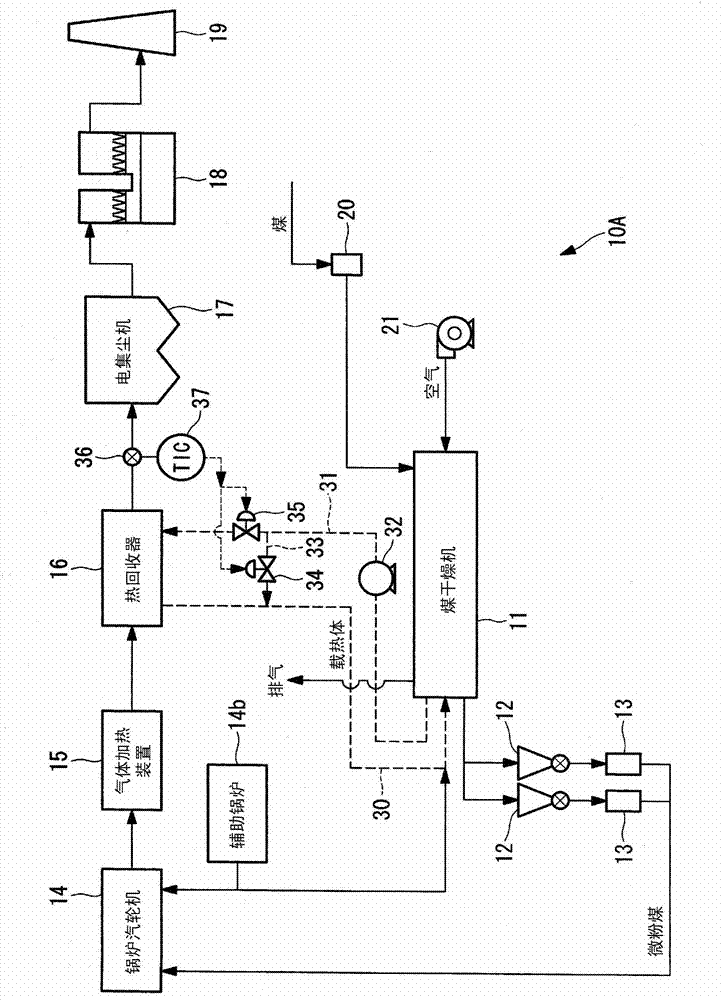

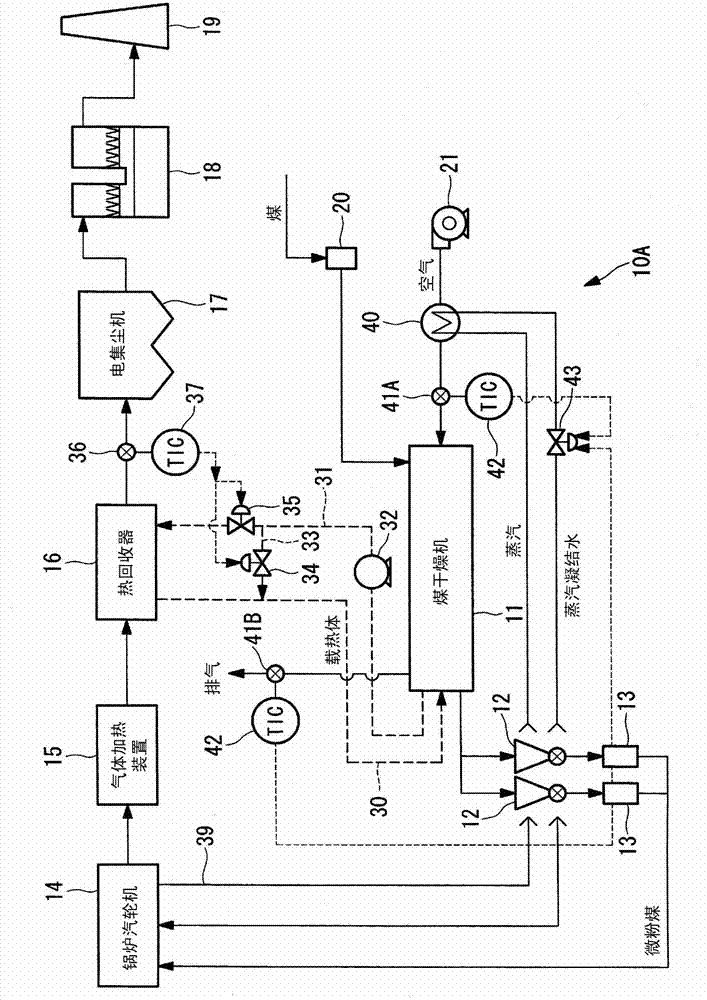

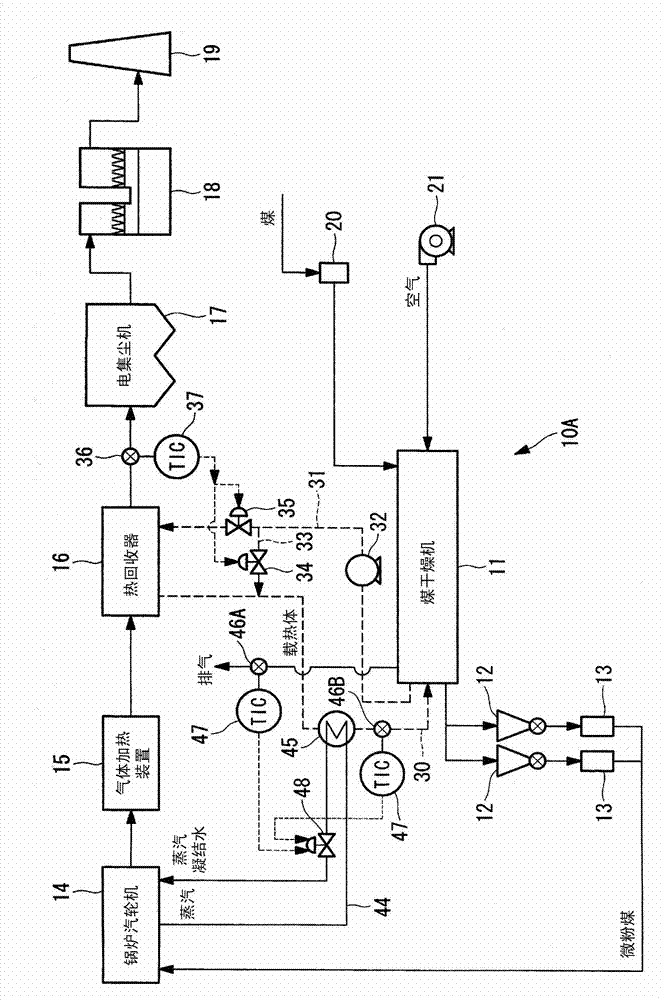

Coal-fired boiler facilities and coal drying method in coal-fired boiler facilities

ActiveCN104508376AInhibitionLow efficiencyElectrostatic separationSolid fuel pretreatmentCombustionProcess engineering

Coal is properly dried and the efficiency of a boiler is increased while suppressing any reduction in efficiency of the boiler and the generation of hydrocarbon gas components. Employed are a coal dryer that dries coal, a boiler in which the coal that is dried in the coal dryer is mixed with air for combustion and burned, an air heater that heats the air for combustion that is supplied to the boiler using combustion exhaust gas discharged from the boiler, a precipitator that collects dust included in the combustion exhaust gas, a desulfurization plant that performs a desulfurization process on the combustion exhaust gas, and heat recovery equipment that heats a heating medium using the combustion exhaust gas. The coal dryer dries the coal using the heat energy of the heating medium that has been heated in the heat recovery equipment.

Owner:MITSUBISHI HEAVY IND LTD

Drying apparatus and printing apparatus

ActiveUS8573764B2Insufficient and uneven drying can be avoidedIncrease speedOther printing apparatusEngineeringHeating element

Owner:CANON KK

Boiling type material drying method and special boiling kettle thereof

InactiveCN103673511AImprove space utilizationImprove productivityDrying solid materials with heatHearth type furnacesProcess engineeringUltimate tensile strength

The invention provides a boiling type material drying method and a special boiling kettle thereof, and belongs to the technical scheme of drying methods and drying equipment. The boiling type material drying method and the special boiling kettle thereof can increase the utilization rate of a drying space, improve drying intensity and productivity and improve controllability of a drying system. According to the technical scheme, the boiling type material drying method includes the step of arranging of a power device, a measuring and control device and a pipe network, and is characterized in that the boiling kettle is arranged so that materials can be dried in the boiling kettle in a boiling state, and a first material collecting device and a second material collecting device are arranged. The boiling type material drying method and the special boiling kettle thereof are suitable for the technical field of large-scale material drying.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

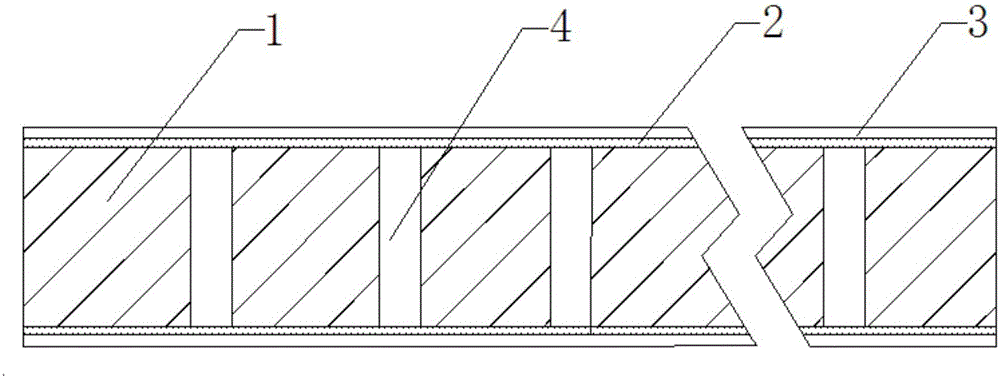

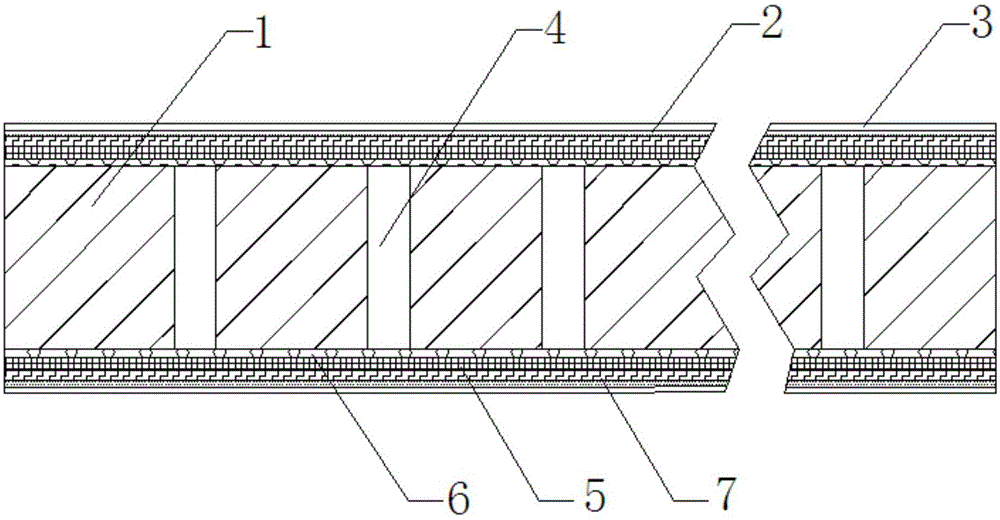

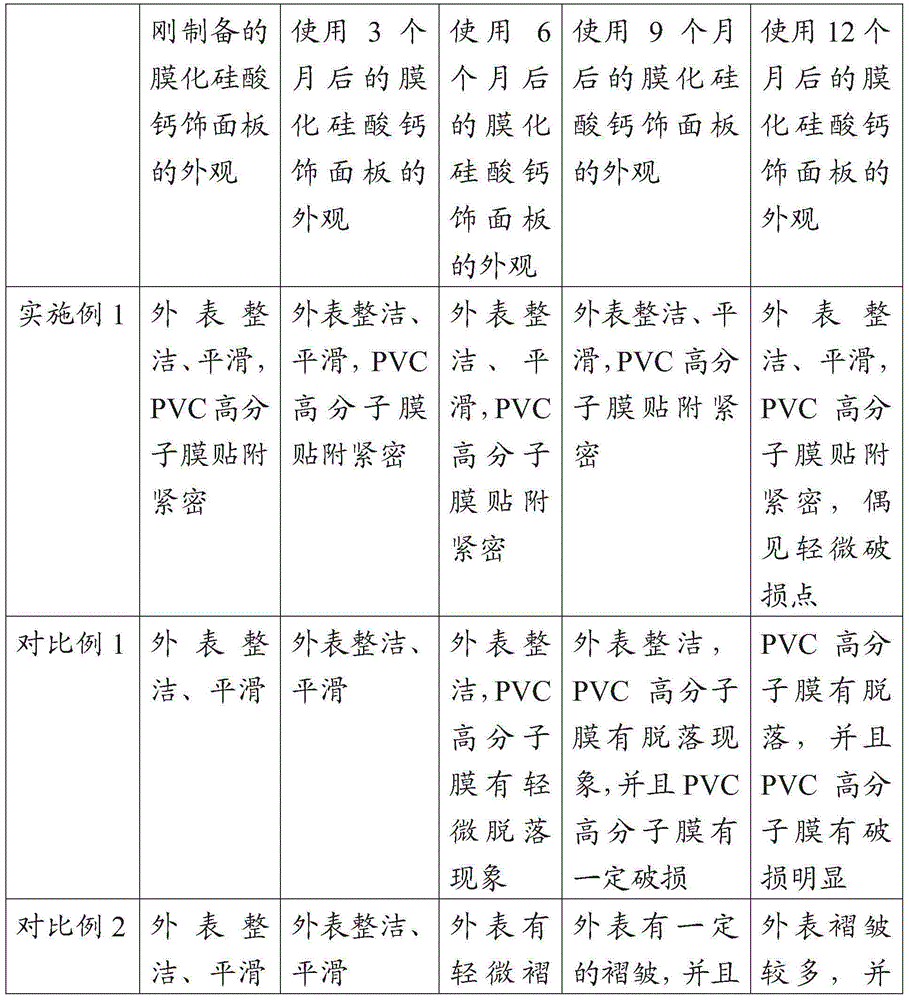

Membranization calcium silicate veneer and preparation method thereof

ActiveCN105064641AHigh strengthFlat surfaceCovering/liningsLamination ancillary operationsCalcium silicateChemical corrosion

The invention discloses a membranization calcium silicate veneer and a preparation method thereof. The membranization calcium silicate veneer comprises a calcium silicate board. A UV coating is arranged on at least one side of the calcium silicate board. A PVC high polymeric membrane is attached to the UV coating. The calcium silicate board is further evenly provided with a plurality of vent holes. The preparation method comprises the following steps that the vent holes are punched in the calcium silicate board; 2, at least one side of the calcium silicate board with the vent holes is coated with the UV coating to obtain the calcium silicate board coated with the UV coating; 3, the PVC high polymeric membrane is attached to the calcium silicate board coated with the UV coating. Due to the fact that the PVC high polymeric membrane is additionally arranged on the calcium silicate board, the surface is smooth, and bubbles are not likely to be generated; the strength is high, abrasion and chemical corrosion are resistant, cleaning is easy, and static electricity and moisture are prevented; due to the fact that the multiple vent holes are formed in the calcium silicate board, moisture prevention and sound insulation can be achieved.

Owner:GOLD MANTIS CONSTR DECORATION

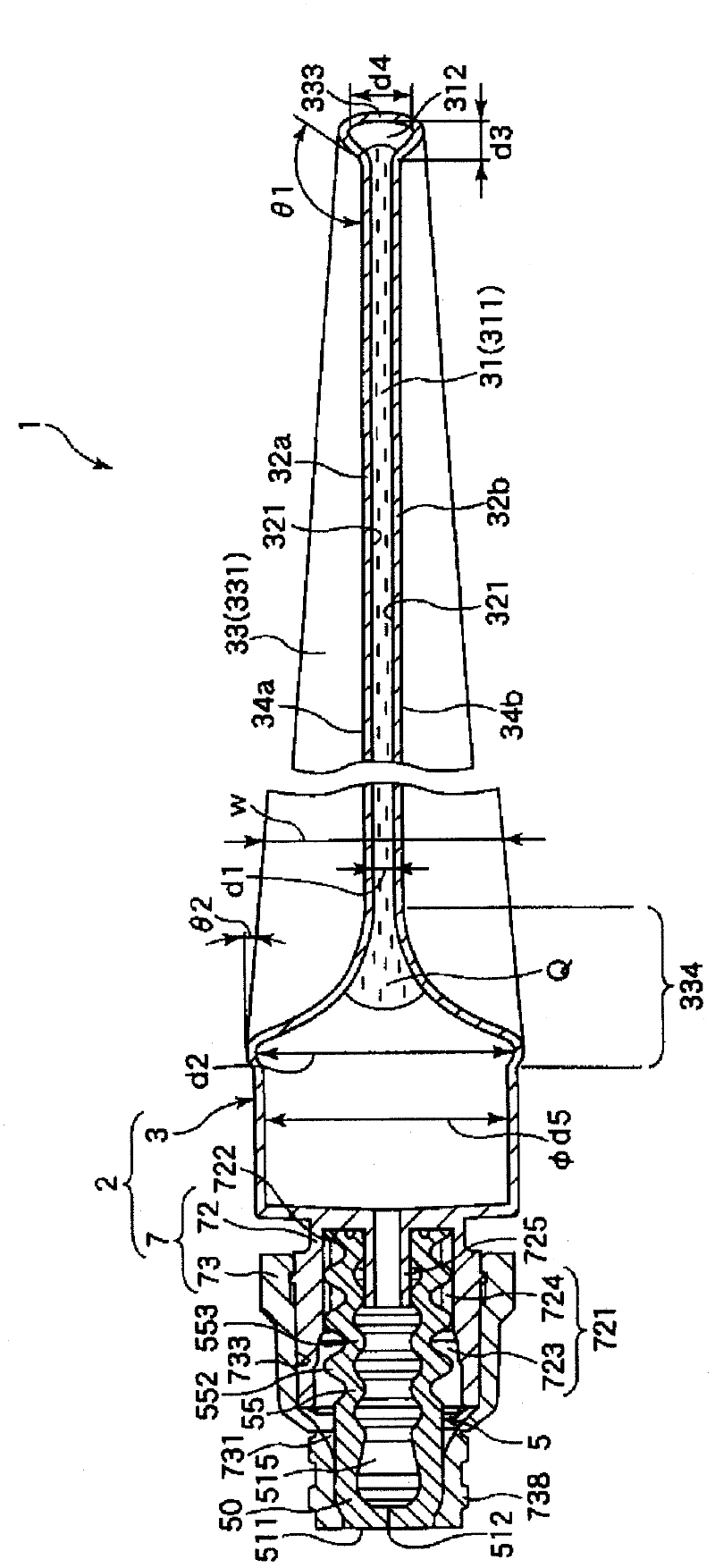

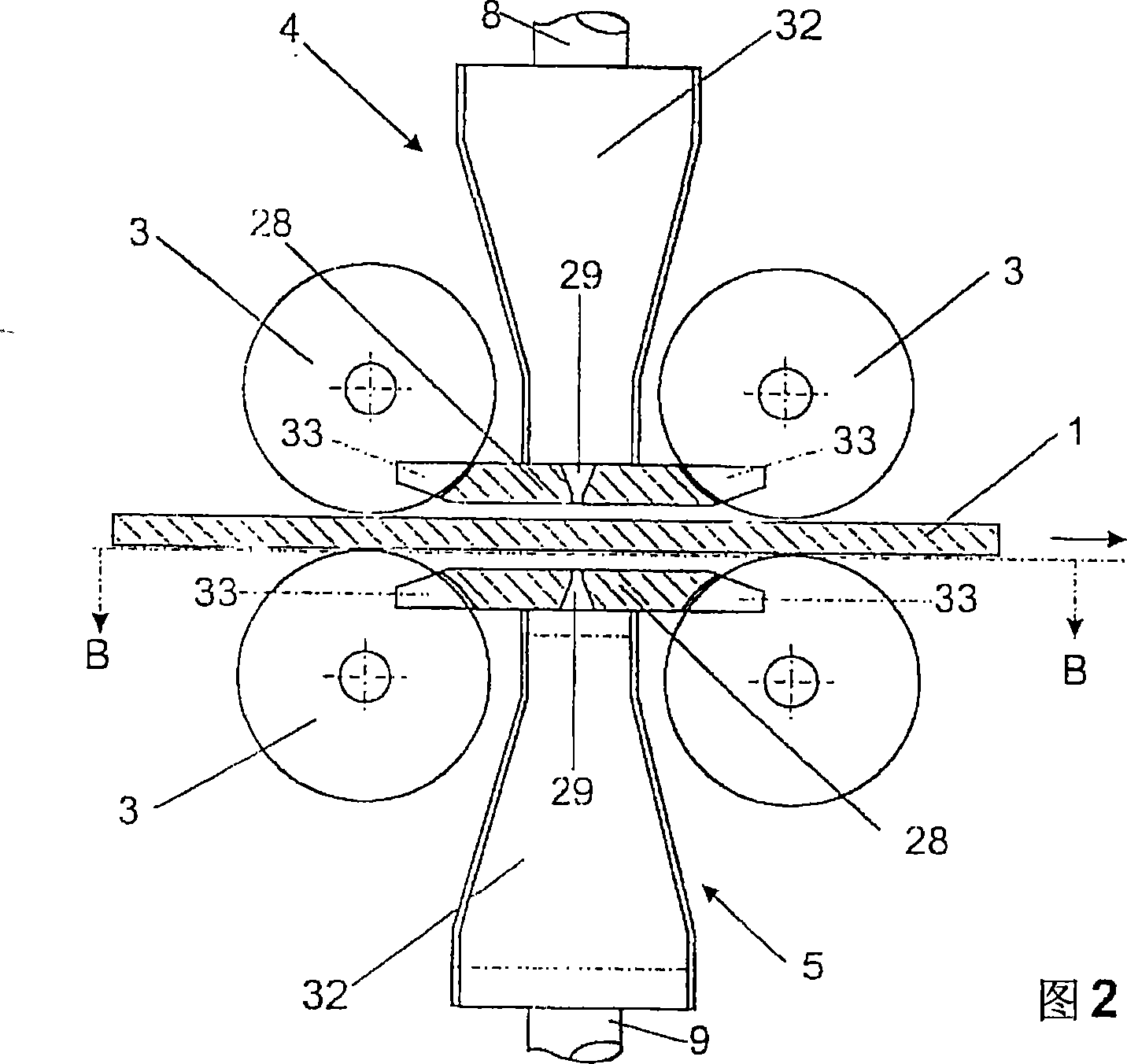

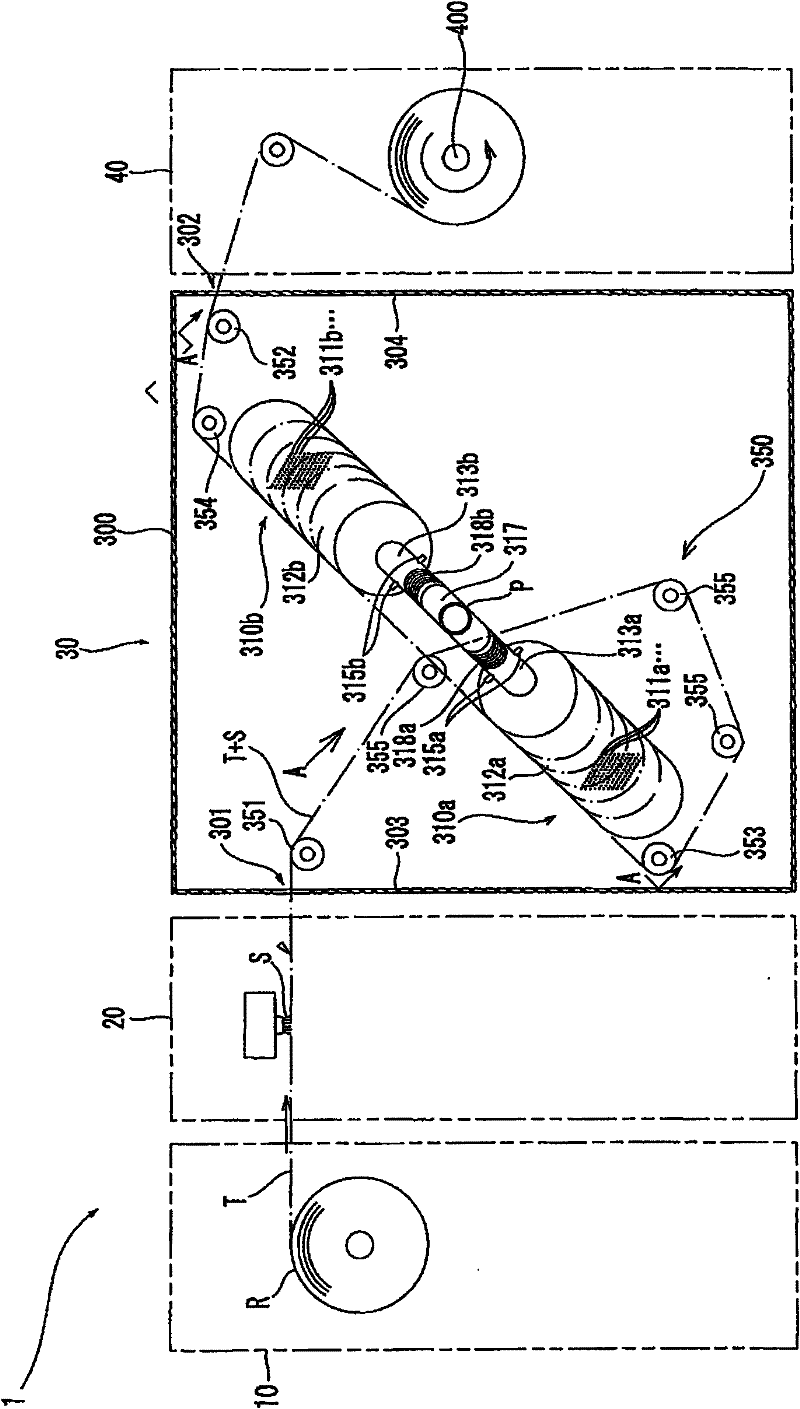

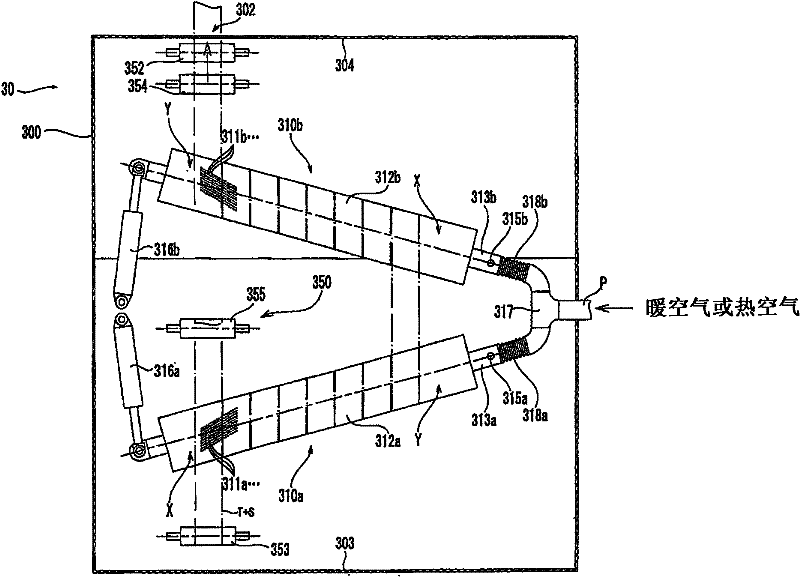

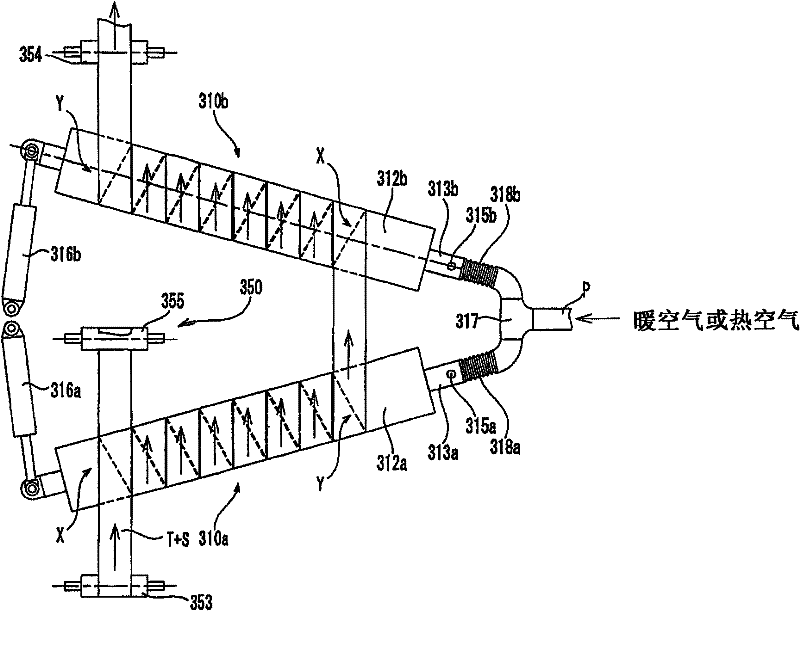

Drying apparatus for manufacturing pressure-sensitive adhesive tape

ActiveCN102161035AChange lengthReliable dryingPretreated surfacesDrying machines with progressive movementsEngineeringMechanical engineering

A drying apparatus for manufacturing a pressure-sensitive adhesive tape in which a pressure-sensitive adhesive layer is formed on a strip-shaped long tape base material is provided. The drying apparatus dries coating agent coated at least on one surface of the tape base material. The tape base material that is transferred in a lengthwise direction thereof is spirally wound around a cylinder body from one end side of the cylinder body to the other end side of the cylinder body in a slidable state. The cylinder body is formed with a plurality of air holes on an entire circumferential wall thereof, around which the tape base material is spirally wound, the air holes through which warm air or hot air flows from the inside of the cylinder body to the outside of the cylinder body. The drying apparatus for manufacturing the pressure-sensitive adhesive tape can reliably dry the coating agent on the tape base material without increasing the drying apparatus in size.

Owner:NITTO DENKO CORP

Screenless flow-through battery material dryer

The invention relates to a flow-washing-type battery material dryer free of a screen cloth. The flow-washing-type battery material dryer free of the screen cloth is characterized in that the dryer comprises a support, a spiral material feeder, a first flange plate, a discharging pipe, an air cylinder, a material dropping plate, a sealing piston, a weighing device, a second flange plate, a Venturi branched tube, an airflow tank, a return air tank, a feeding pipe, a cyclone air outlet pipe, an air return pipe, a vacuum pumping pipe, a reflux tank, a Venturi tube and a third flange plate; the airflow tank comprises an upper airflow tank section and a lower airflow tank section, and the upper airflow tank section and the lower airflow tank section communicate with each other; the reflux tank is arranged at the outer side of the upper portion of the upper airflow tank section in a sleeving mode; the upper end of a space between the reflux tank and the upper airflow tank section is closed, and the lower end of the space is opened; and the reflux tank is of a cylinder structure with the cross section circle variable. According to the flow-washing-type battery material dryer, the return air tank, the reflux tank, the airflow tank and the Venturi tube are sequentially nested from outside to inside, so that the heat preservation effect of the dryer is made good; and moreover, heat is transmitted between the multiple layers of the pipes, after all layers of pipe walls are heated by hot air, the heat can be radiated outwards from the pipe walls, and powder drying is accelerated.

Owner:HEBEI UNIV OF TECH +1

Flexible sterilization box with use of PTC

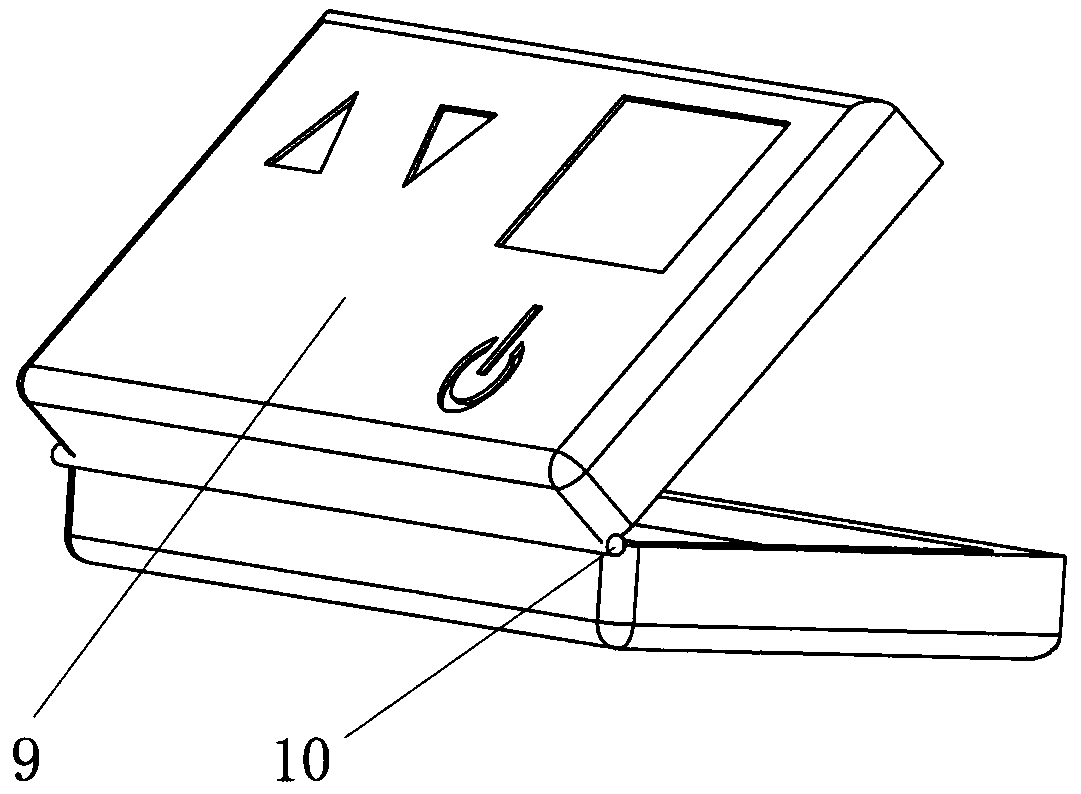

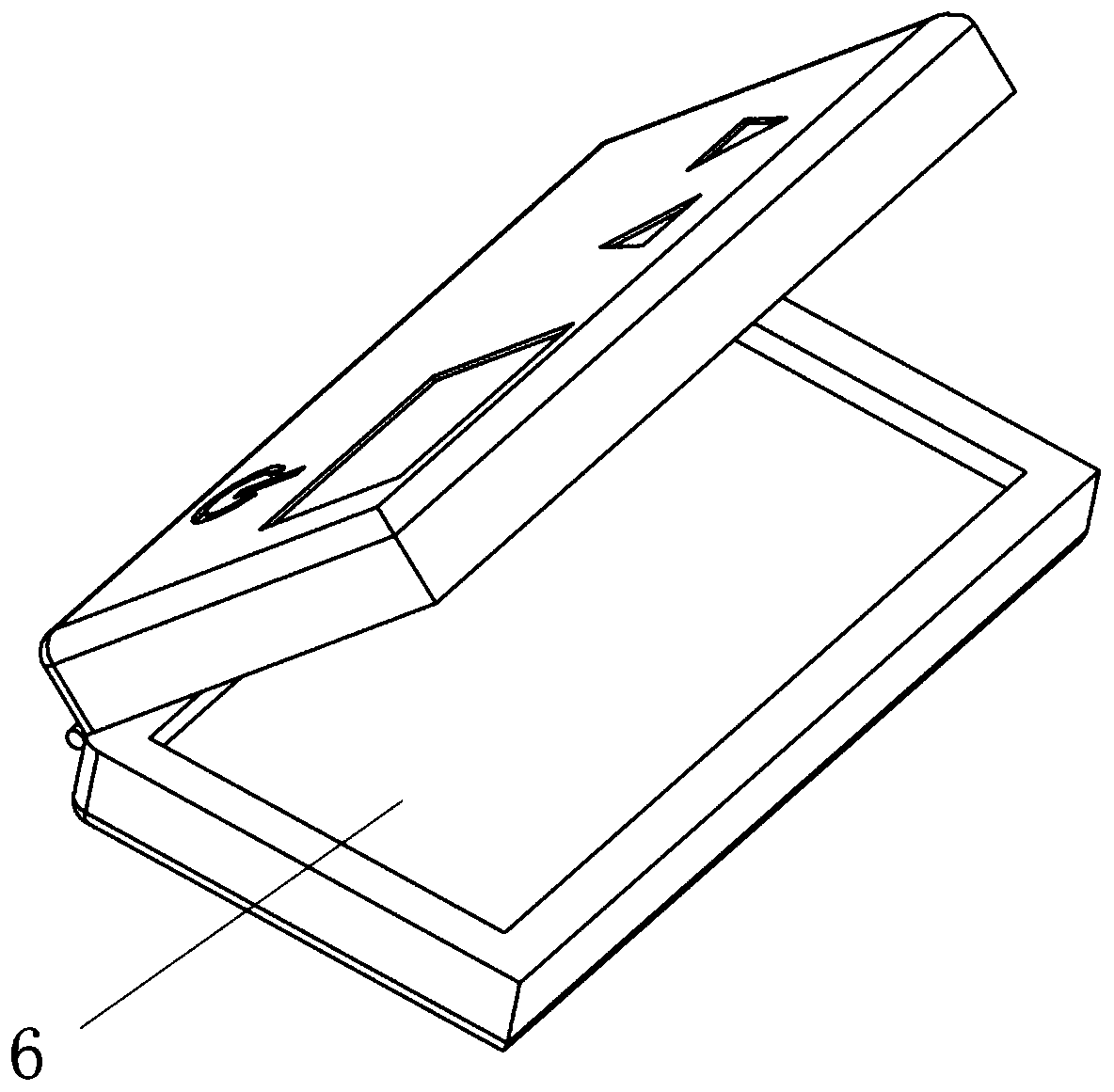

PendingCN111298144AEfficient exclusionReliable dryingLavatory sanitoryHeatTemperature controlBattery cell

Owner:董政

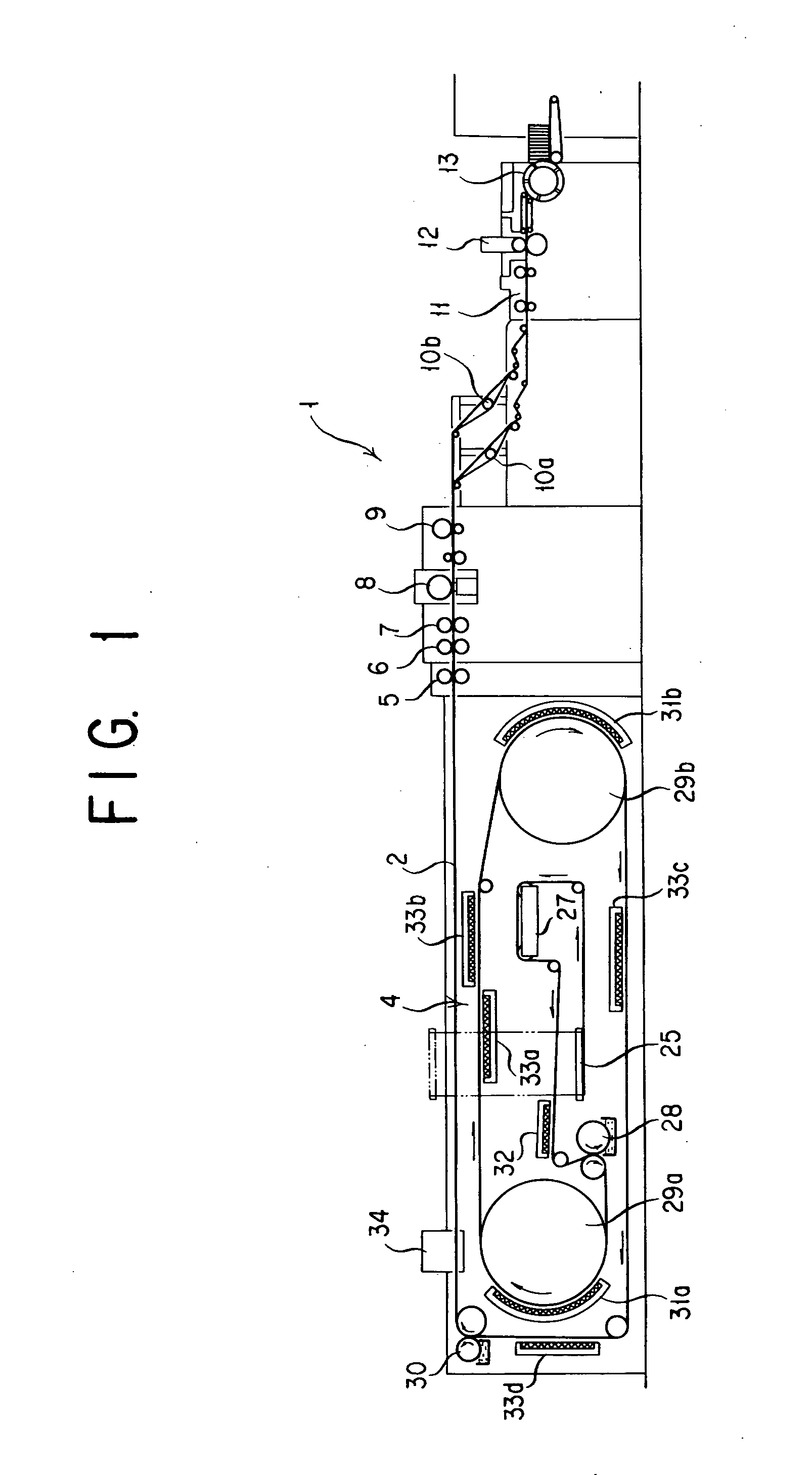

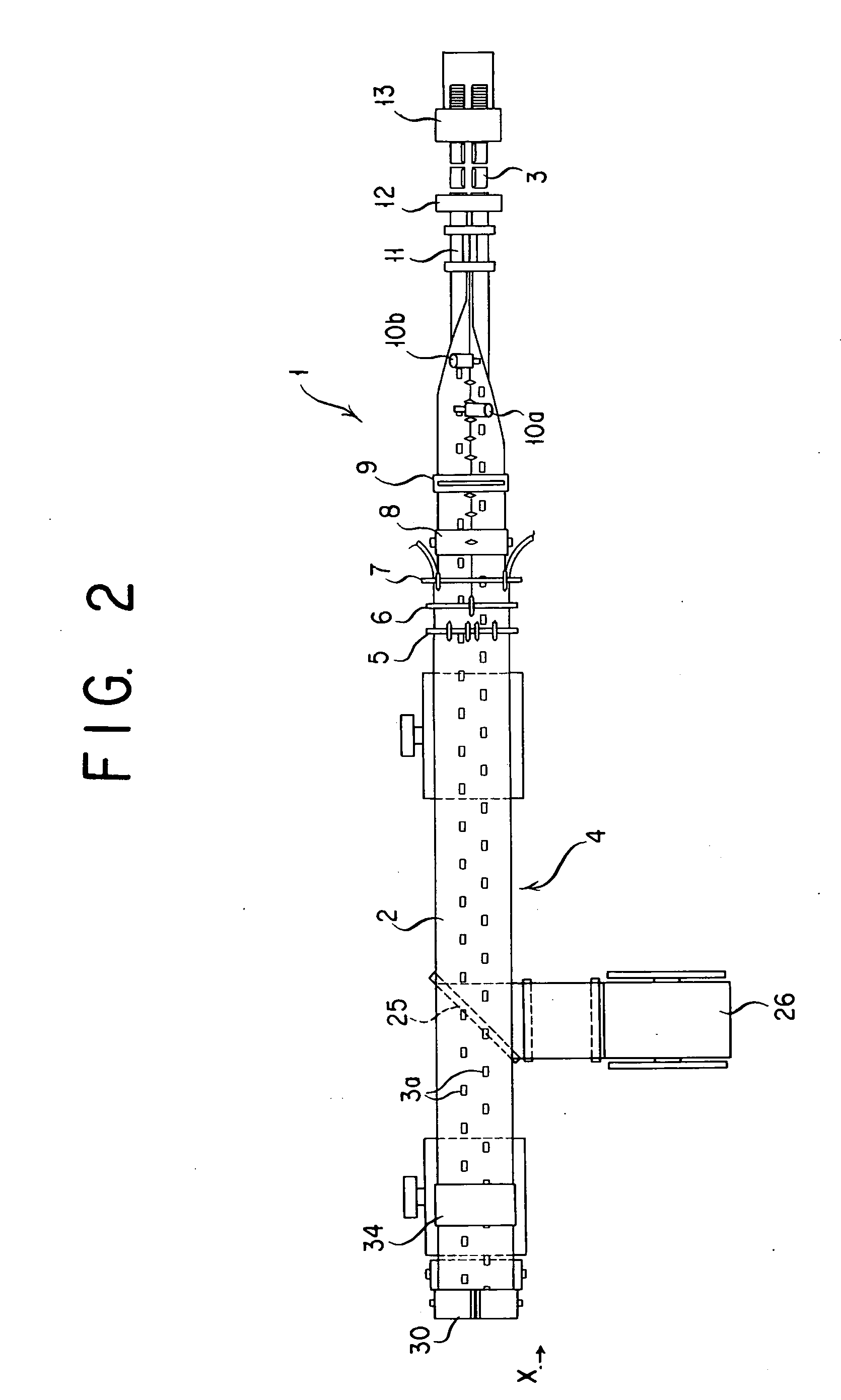

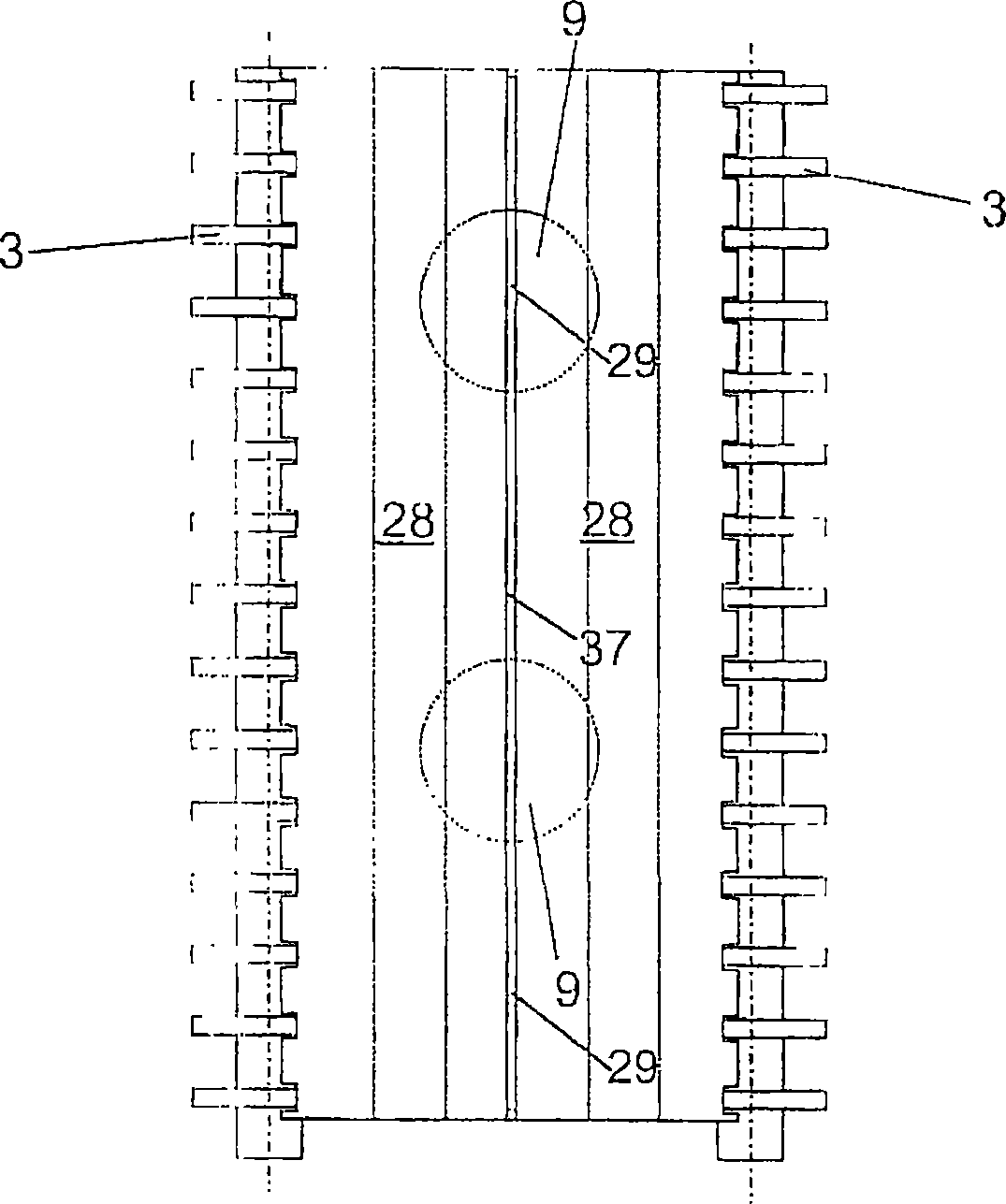

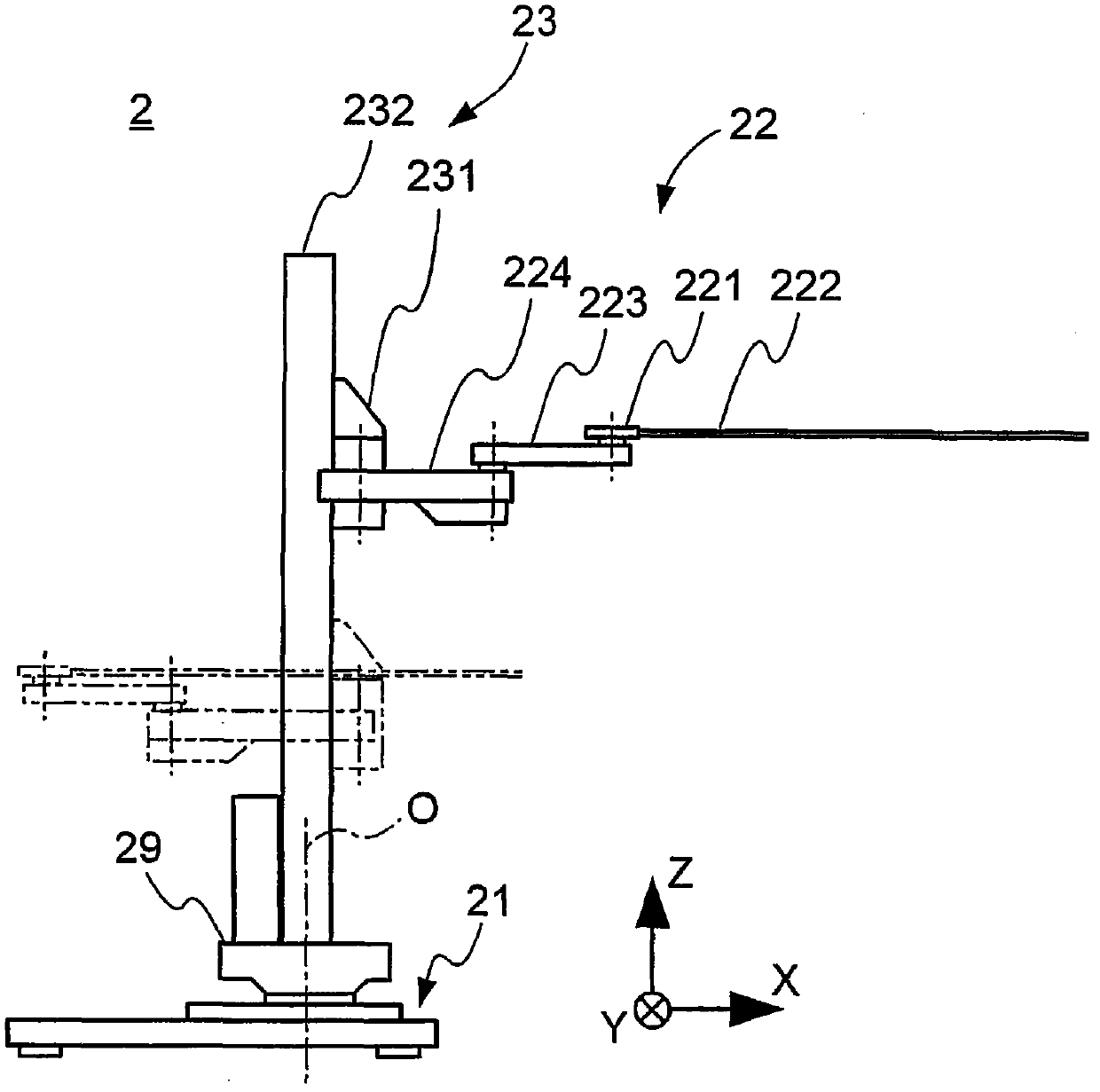

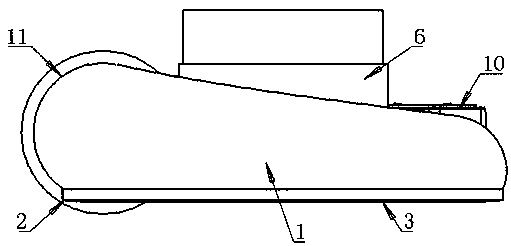

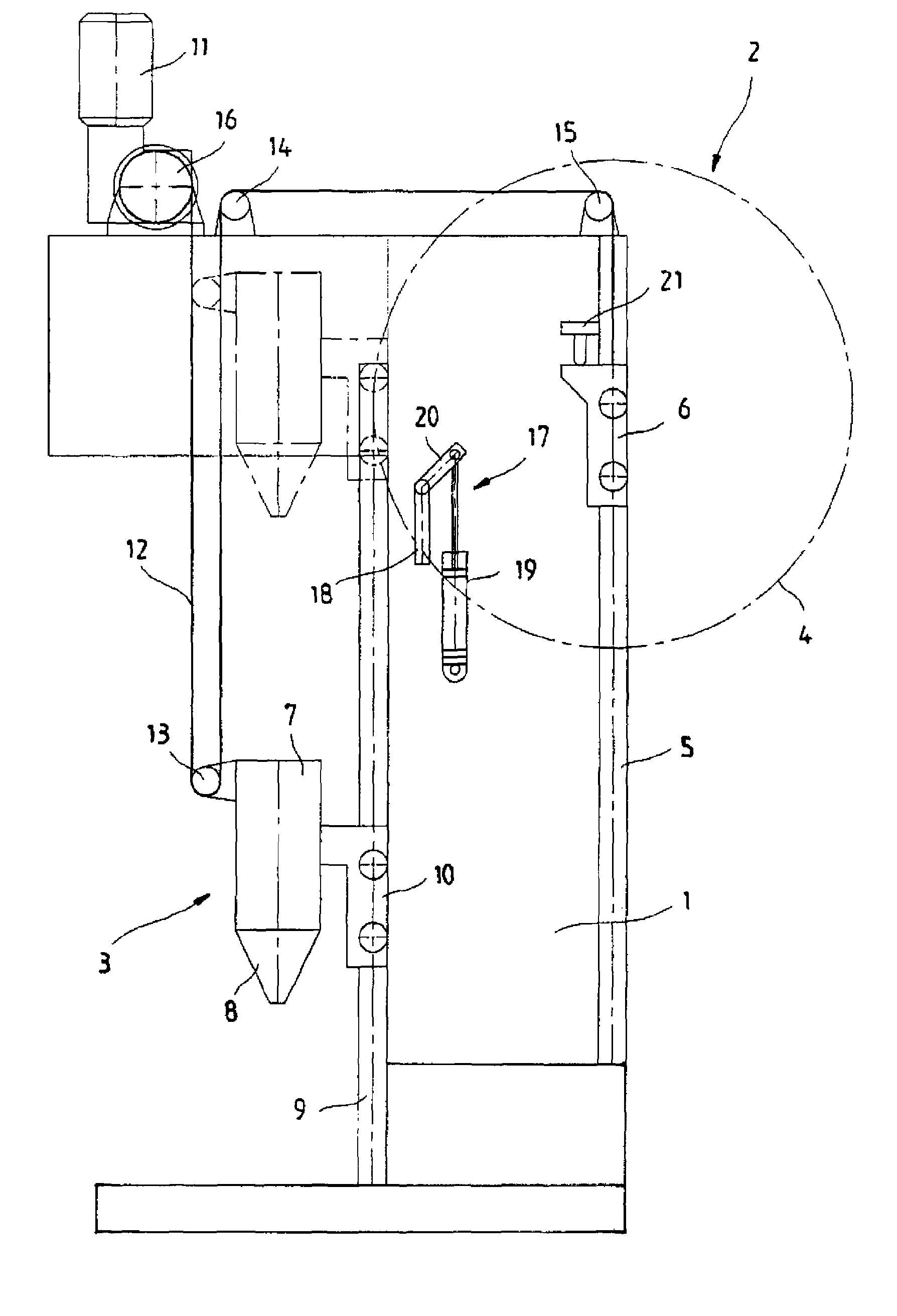

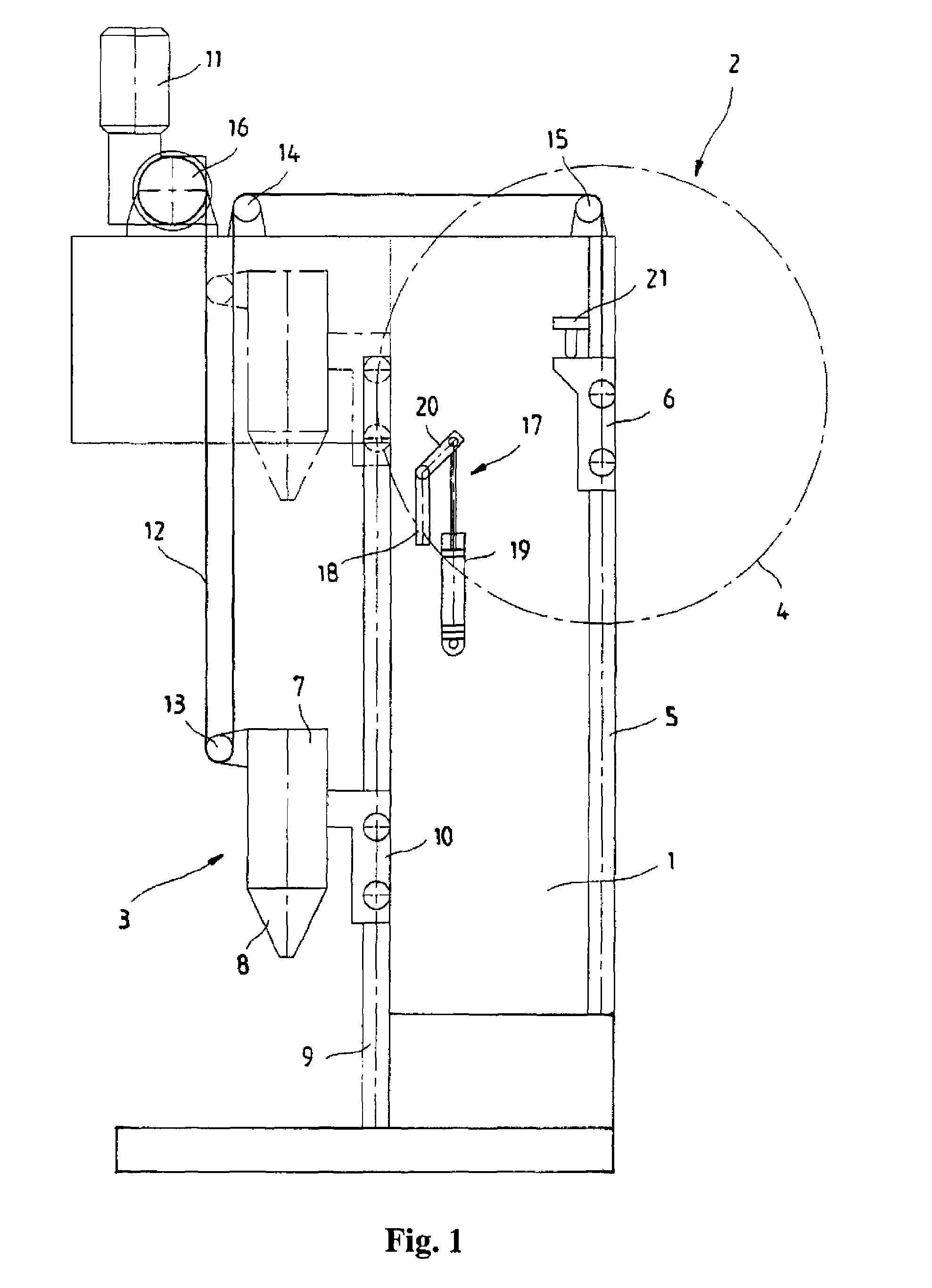

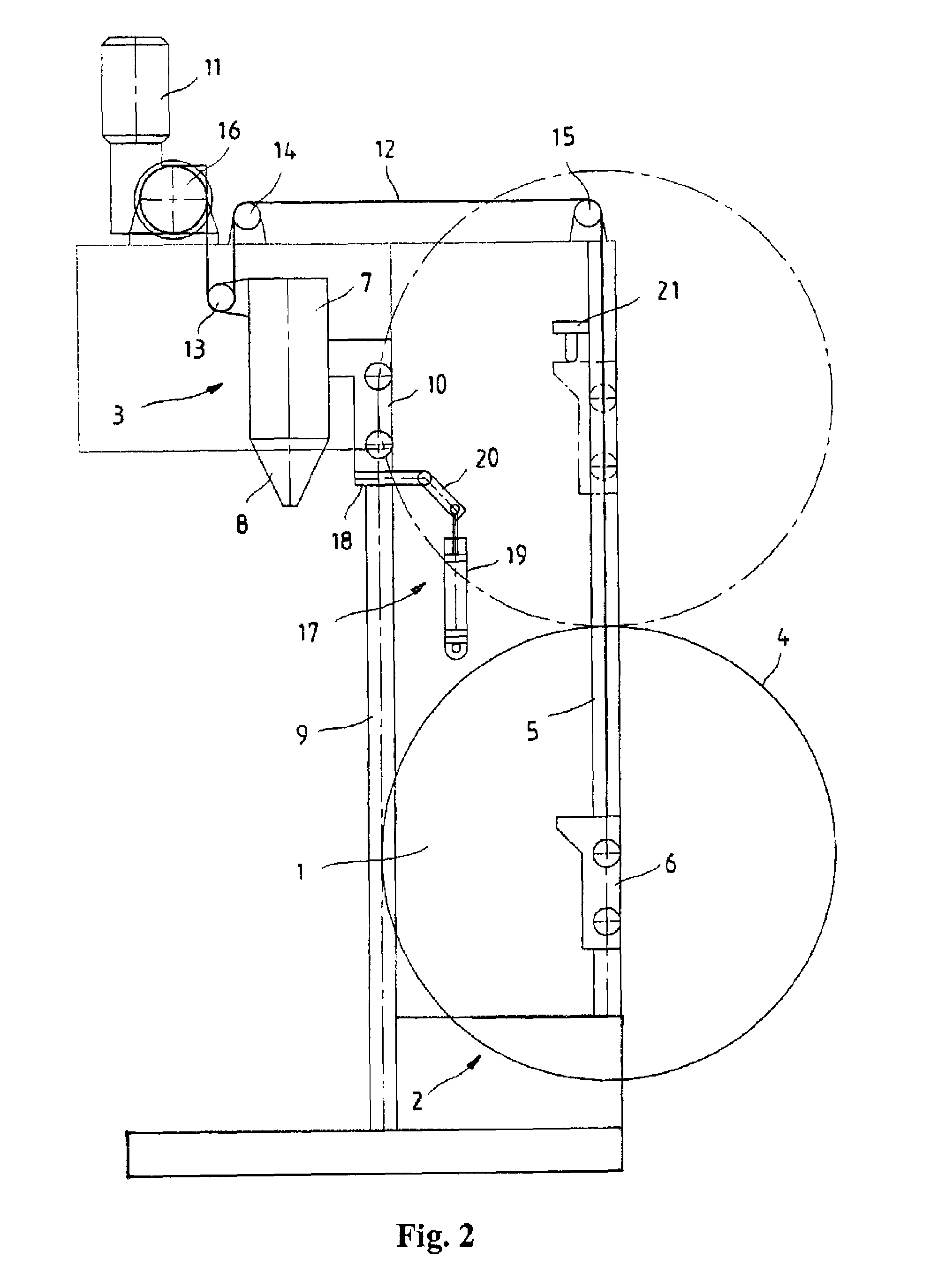

Vehicle wash system comprising a plurality of treatment units

InactiveUS8171945B2Reliable cleaningReliable dryingElectrostatic cleaningVehicle cleaning apparatusDrive motorEmbedded system

The invention relates to a vehicle wash system comprising a first treatment unit (2) arranged on a frame (1) so as to be height-adjustable and at least one second treatment unit (3) arranged on the frame (1) so as to be height-adjustable. In order to reduce the components required for driving and controlling the treatment units (2, 3) the latter are coupled to a common drive motor (11) via a traction mechanism drive (12, 13, 14, 15) for their mutual adjustment.

Owner:WASHTEC HLDG

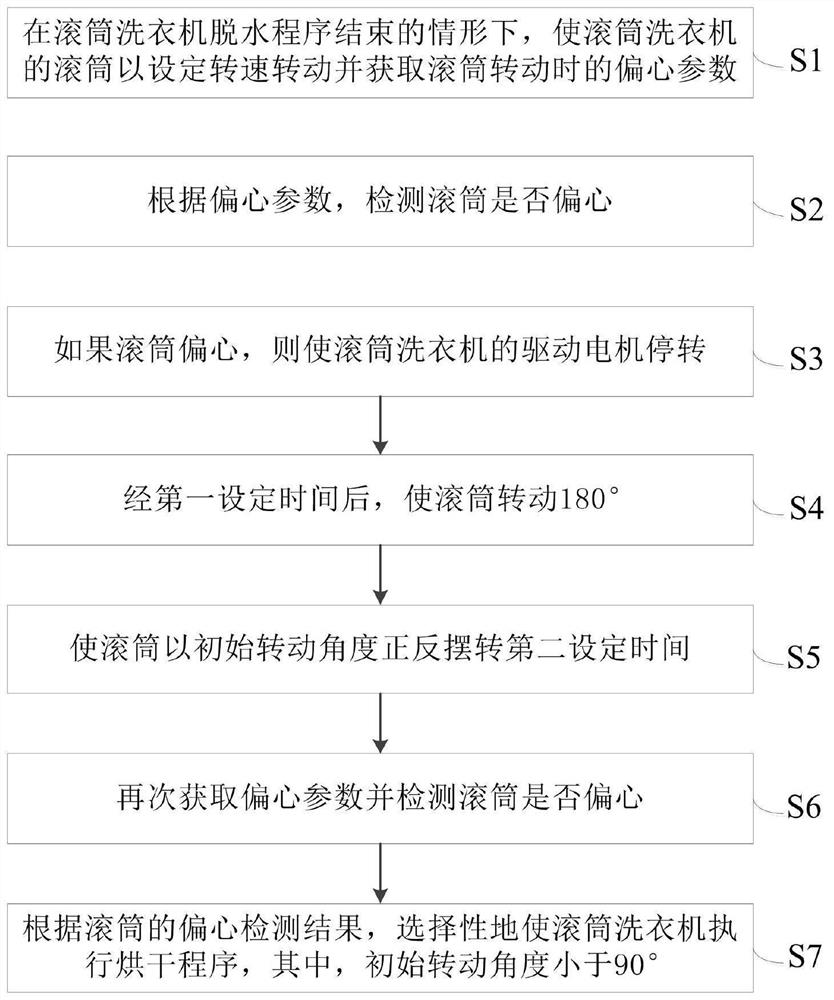

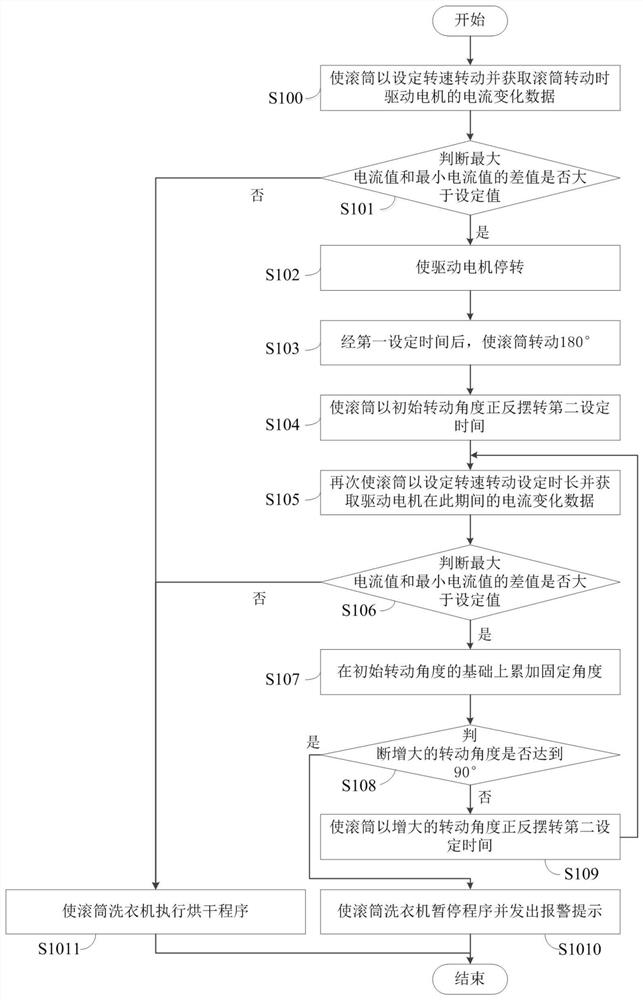

Control method of roller washing machine

PendingCN113136692ACounteract gravityCircumstances that weaken the trend of motionControl devices for washing apparatusTextiles and paperLaundry washing machineControl engineering

The invention belongs to the technical field of washing equipment, and particularly relates to a control method of a roller washing machine. The invention aims to solve the problem that the whole working time consumption and manual intervention work are increased because washings are easy to jam in the inner side wall area of a roller before an existing roller washing machine executes a drying procedure. According to the control method of the roller washing machine, the roller can be controlled to rotate by 180 degrees when the roller is eccentric after dewatering, then the roller is enabled to swing forwards and backwards by a small angle, and then washing balls are thrown out of the jamming position, so that the washing balls can be shaken to be scattered in the environment without jamming limitation; and through the addition of the self-gravity of the washing balls and the assistance of the small-angle shaking action of the roller, the washing balls generate a remarkable movement trend based on the inertia principle, so that the washing balls can be easily thrown down to the central area of the roller from the jamming position, the washing balls can be expanded in the whole internal space of the roller in the free environment without jamming, and the processing program of the roller washing machine is enabled to be automatic and coherent.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com