Patents

Literature

38 results about "Screenless" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Screenless video is any system for transmitting visual information from a video source without the use of a screen. Screenless computing systems can be divided into three groups: Visual Image, Retinal Direct, and Synaptic Interface.

Methods and Compositions for Screenless Completion

Methods are provided that include a method of a) placing a hydrojetting tool into a subterranean formation; b) introducing a jetting fluid that includes an aqueous base fluid, a stabilizing agent, and a cutting agent into the subterranean formation by use of the hydrojetting tool at a rate sufficient to create at least one fracture; c) introducing a slug fluid that includes an aqueous base fluid and a degradable diverting agent into an annulus formed between the hydrojetting tool and the subterranean formation; d) introducing a propping fluid that includes an aqueous base fluid and proppants coated with a consolidating agent into the annulus formed between the hydrojetting tool and the subterranean formation; and e) placing the proppants in the fracture.

Owner:HALLIBURTON ENERGY SERVICES INC

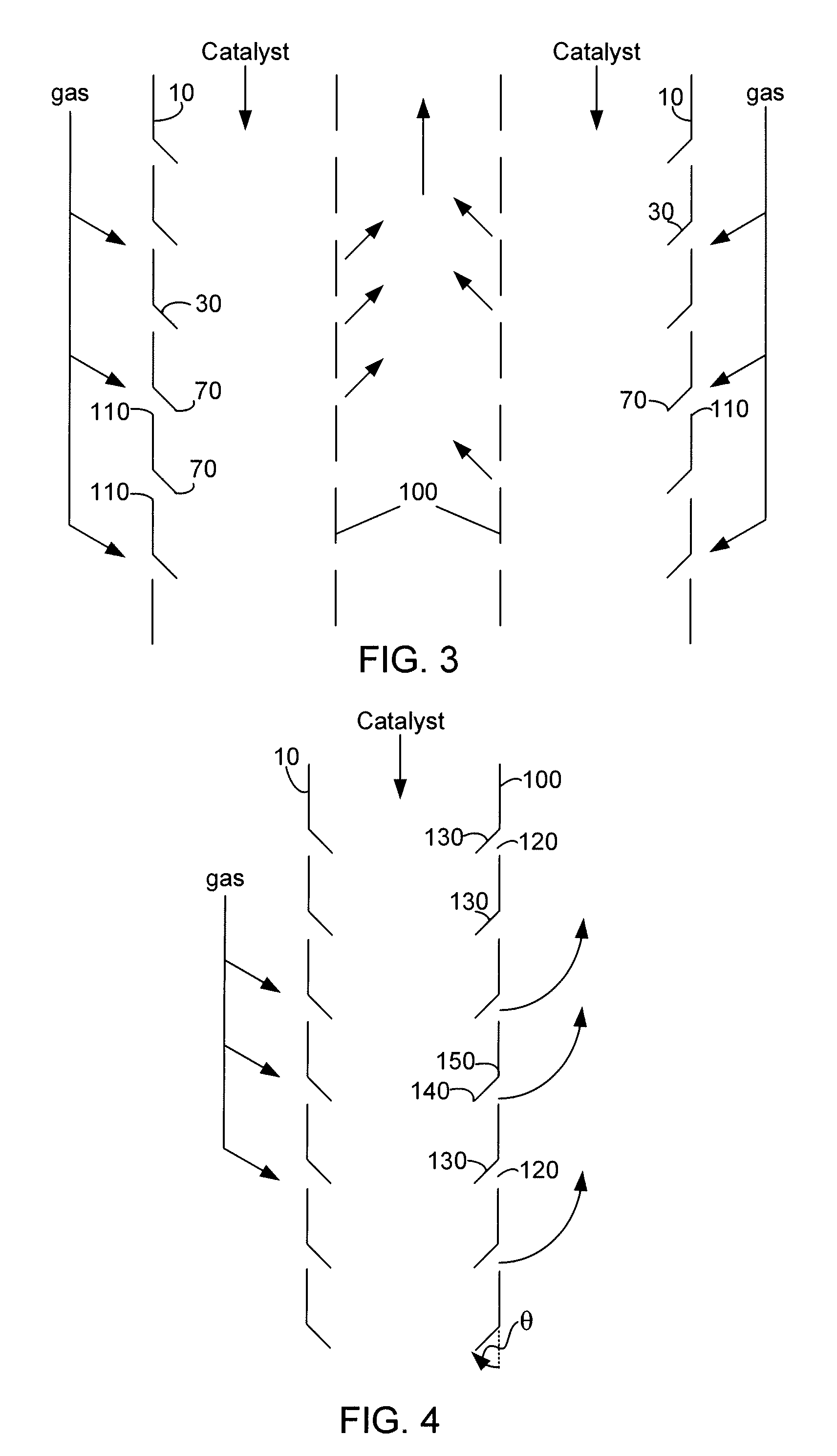

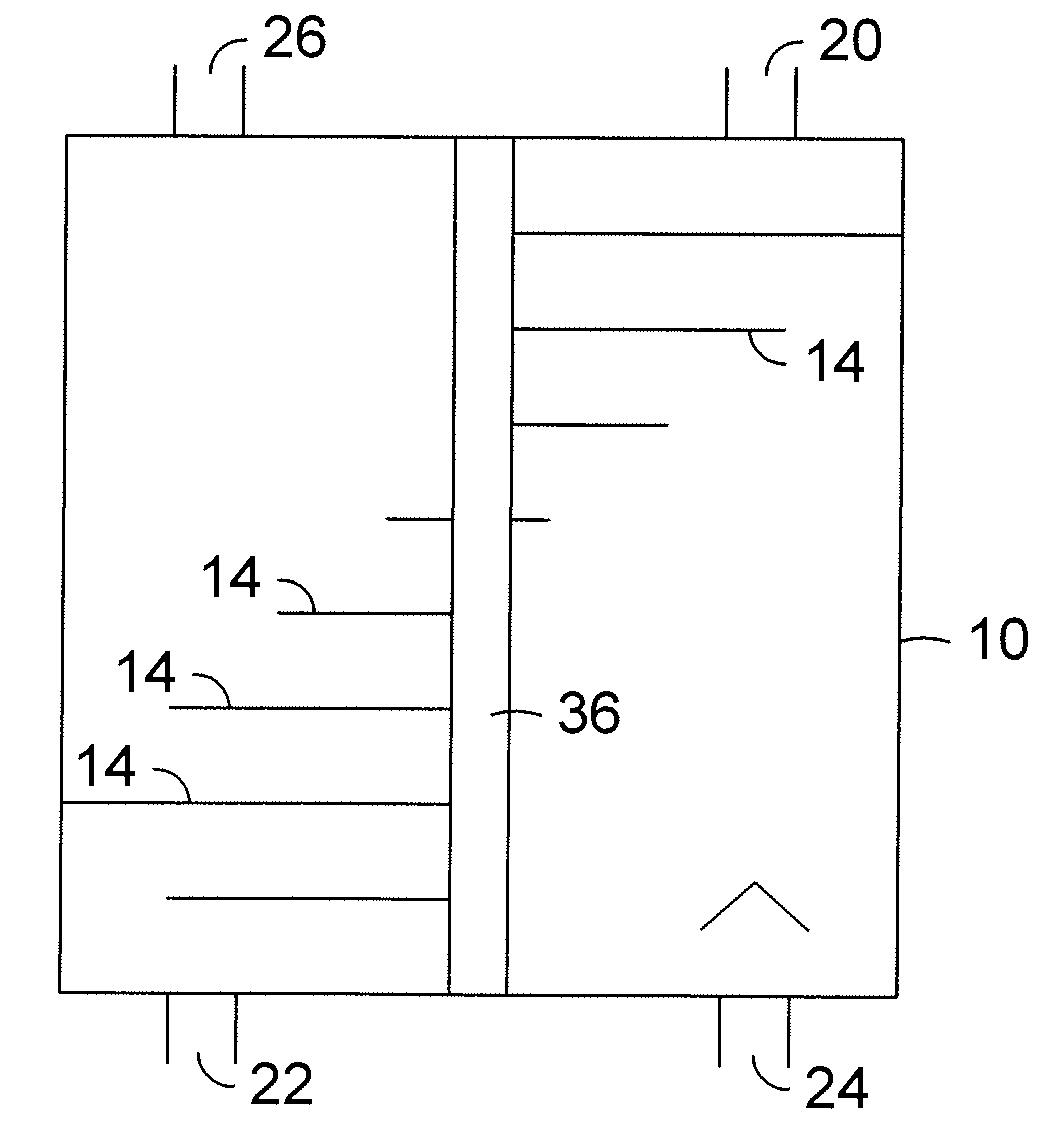

Secondary Containment for a Perforated Plate

ActiveUS20080219898A1Solve problemsGaseous chemical processesPhysical/chemical process catalystsScreenlessMechanical engineering

A secondary containment system is used with a screenless reactor. The secondary containment system includes a screen sized to prevent the passage of catalyst particles, and is affixed to the screenless reactor with supports to hold the screen a desired distance from the reactor.

Owner:UOP LLC

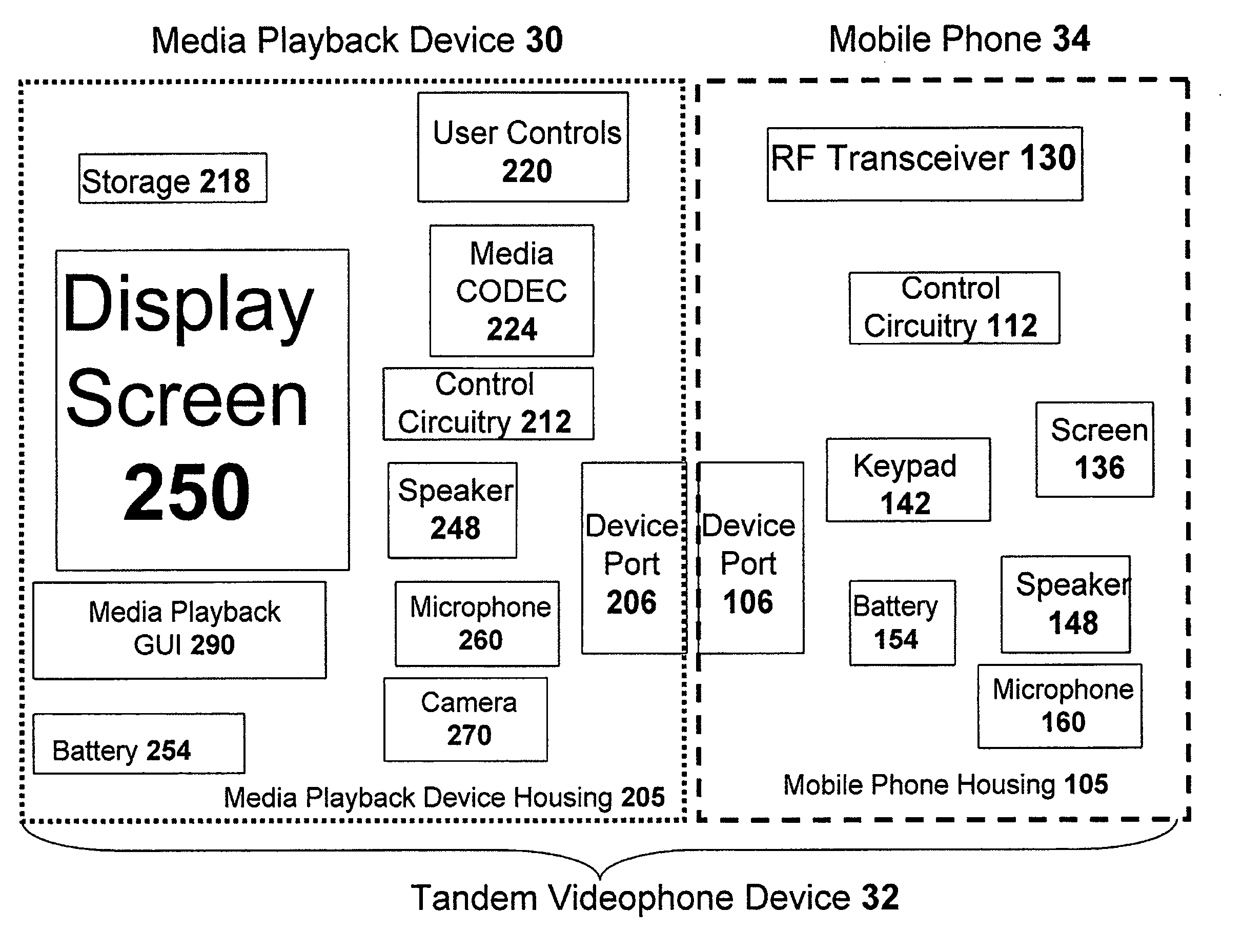

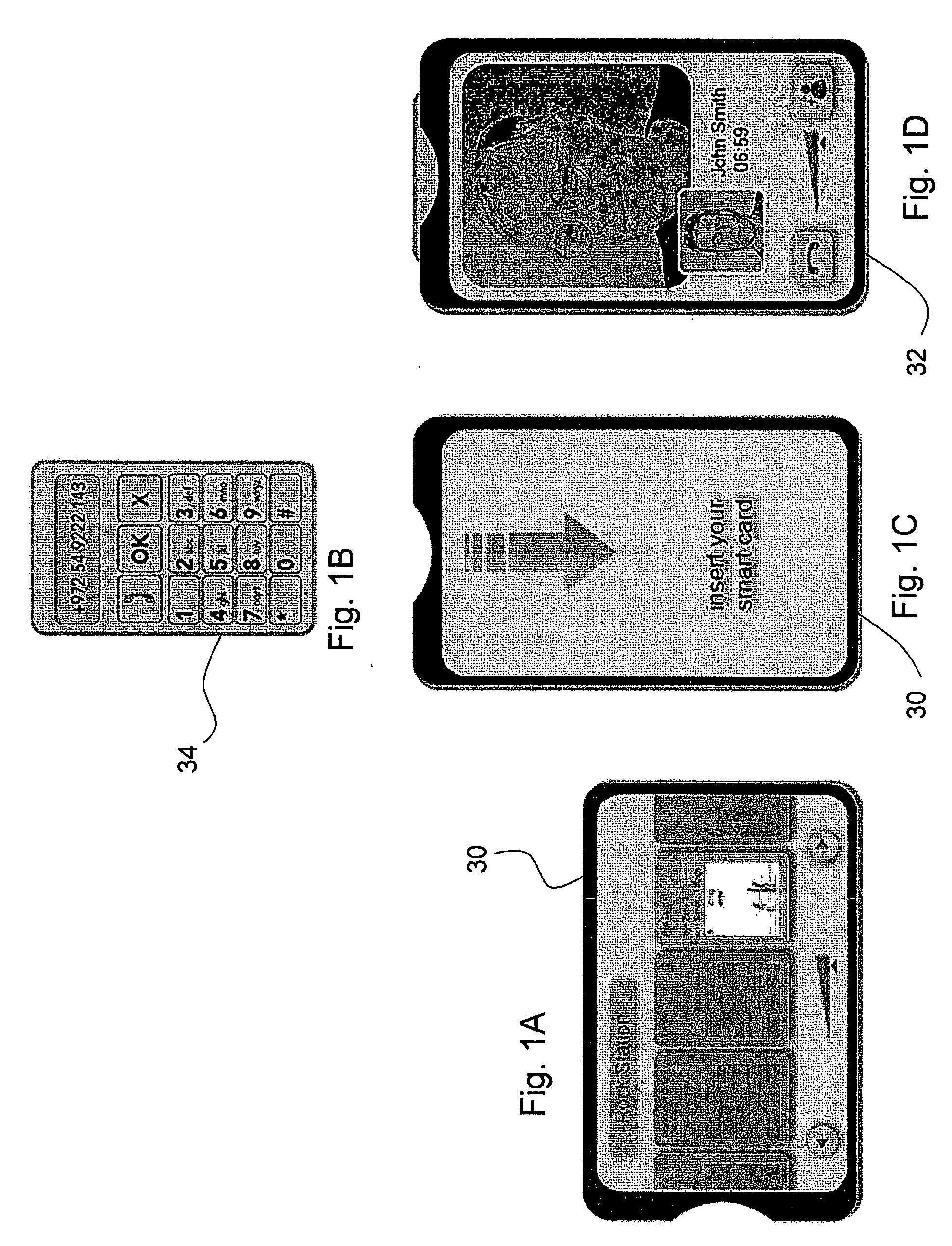

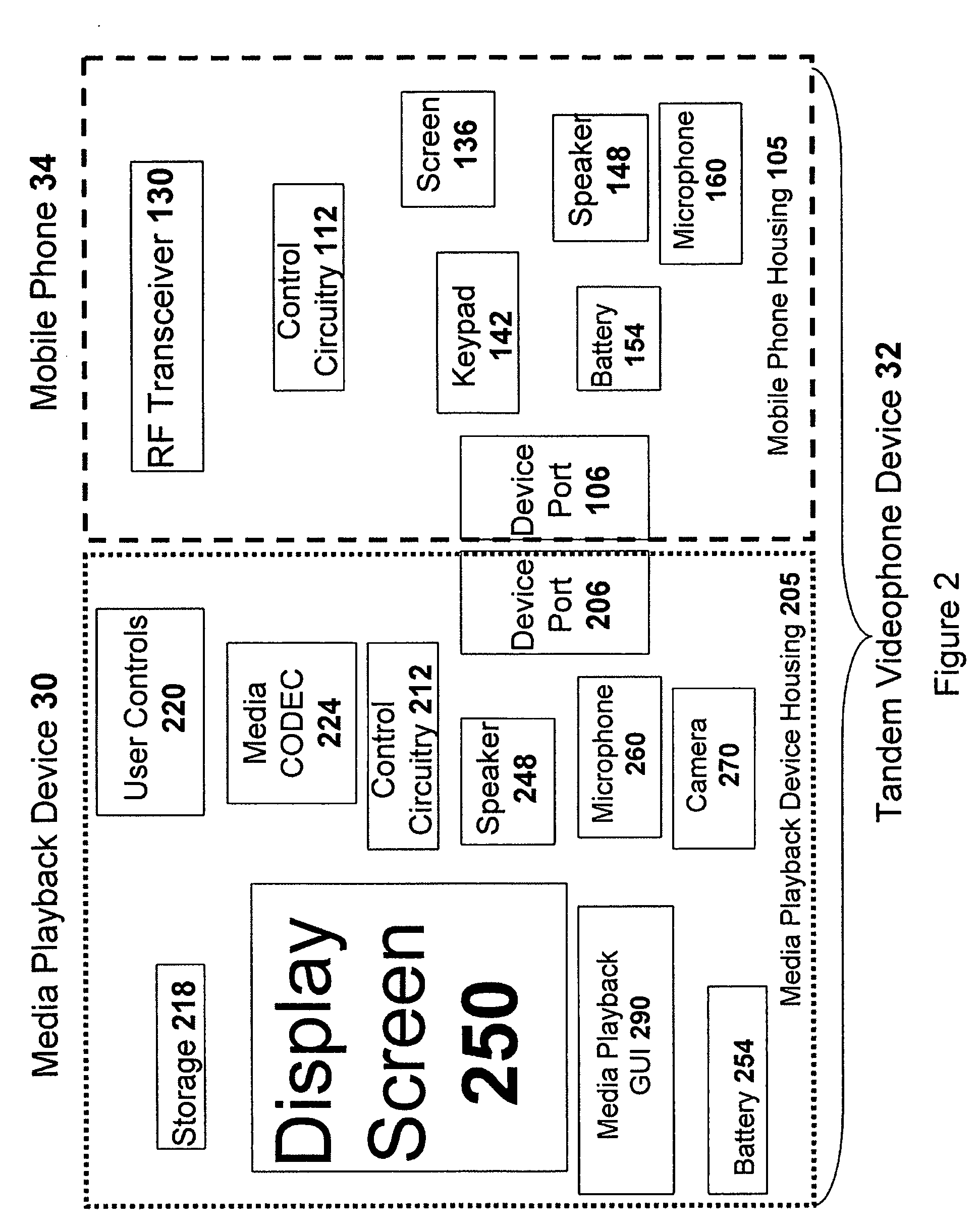

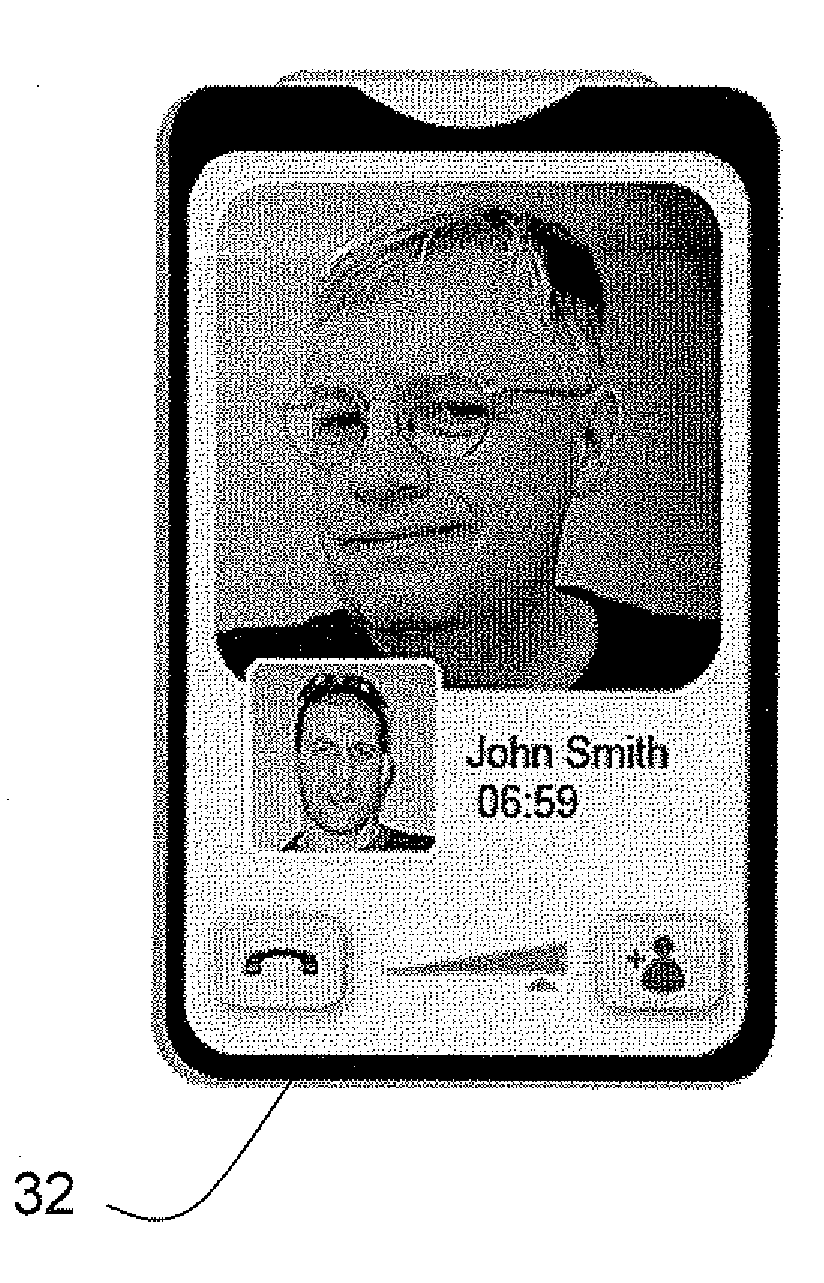

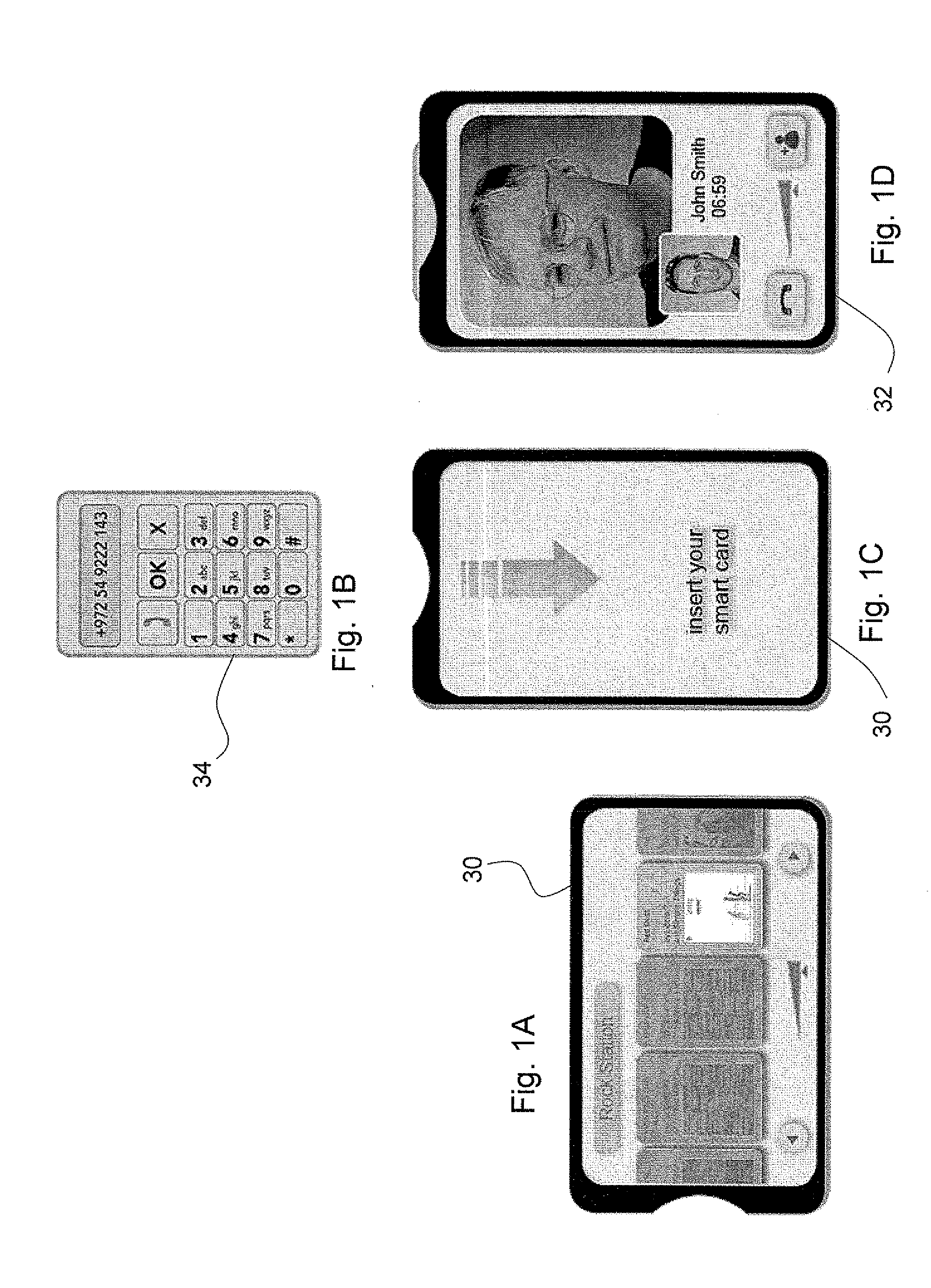

Synergetic tandem pocket device

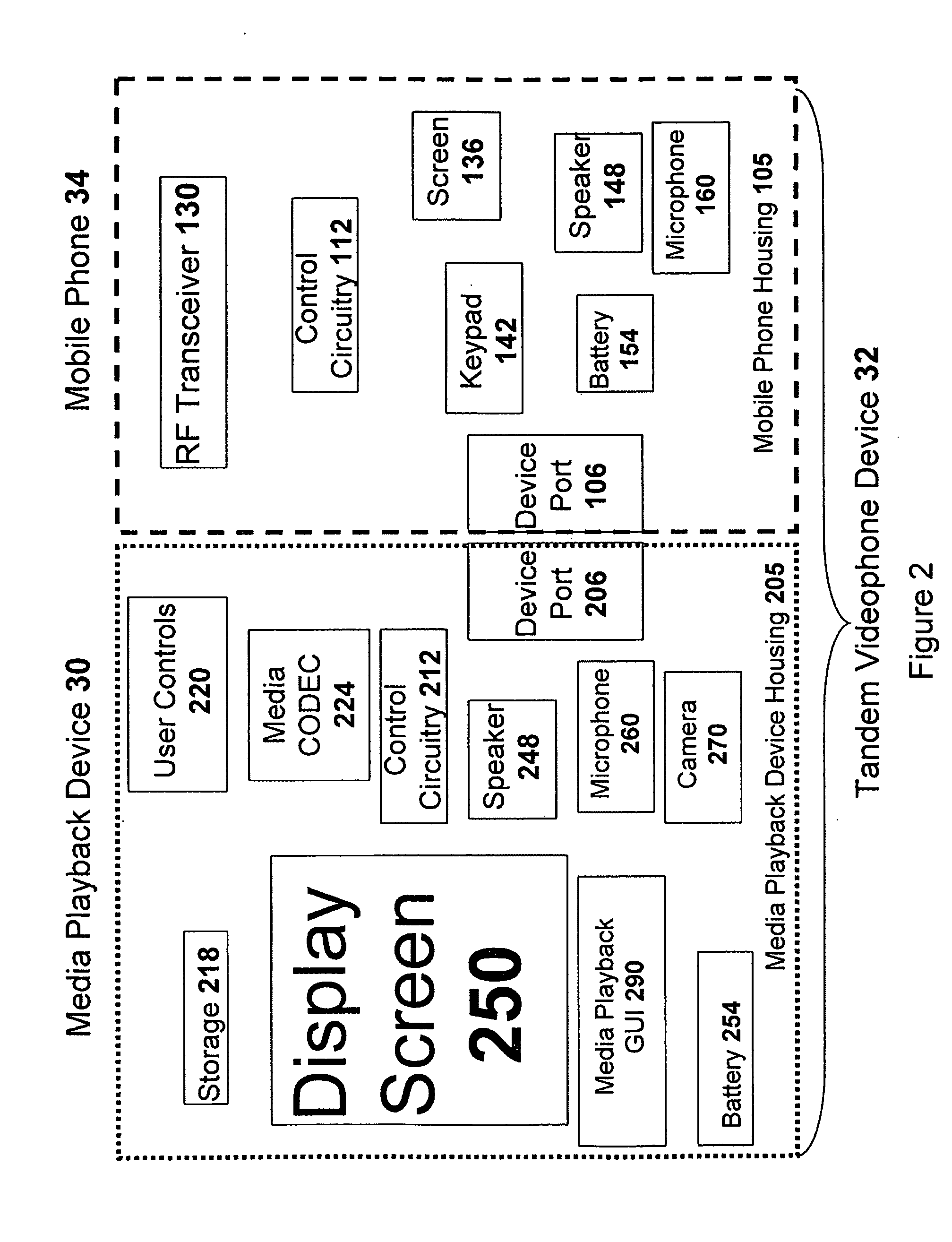

A videophone device including two units 30, 34 is disclosed. When decoupled from each other, the first unit is a mobile phone 34 (for example, a cellular phone or a VOIP phone) that provides voice telephony services, and the second unit 30 is a video playback device (for example, an MP4 player) that provides media playback services. When coupled to each other to form a ‘tandem device’32, the tandem device 32 is operative to provide video telephony services using an onboard CODEC 224 of the media playback device, a screen 250 of the media playback device, and an RF transceiver 130 of the mobile phone. Various packaging features are disclosed. A tandem device including a screenless GPS device 330 and a mobile phone is also disclosed herein.

Owner:SANDISK IL

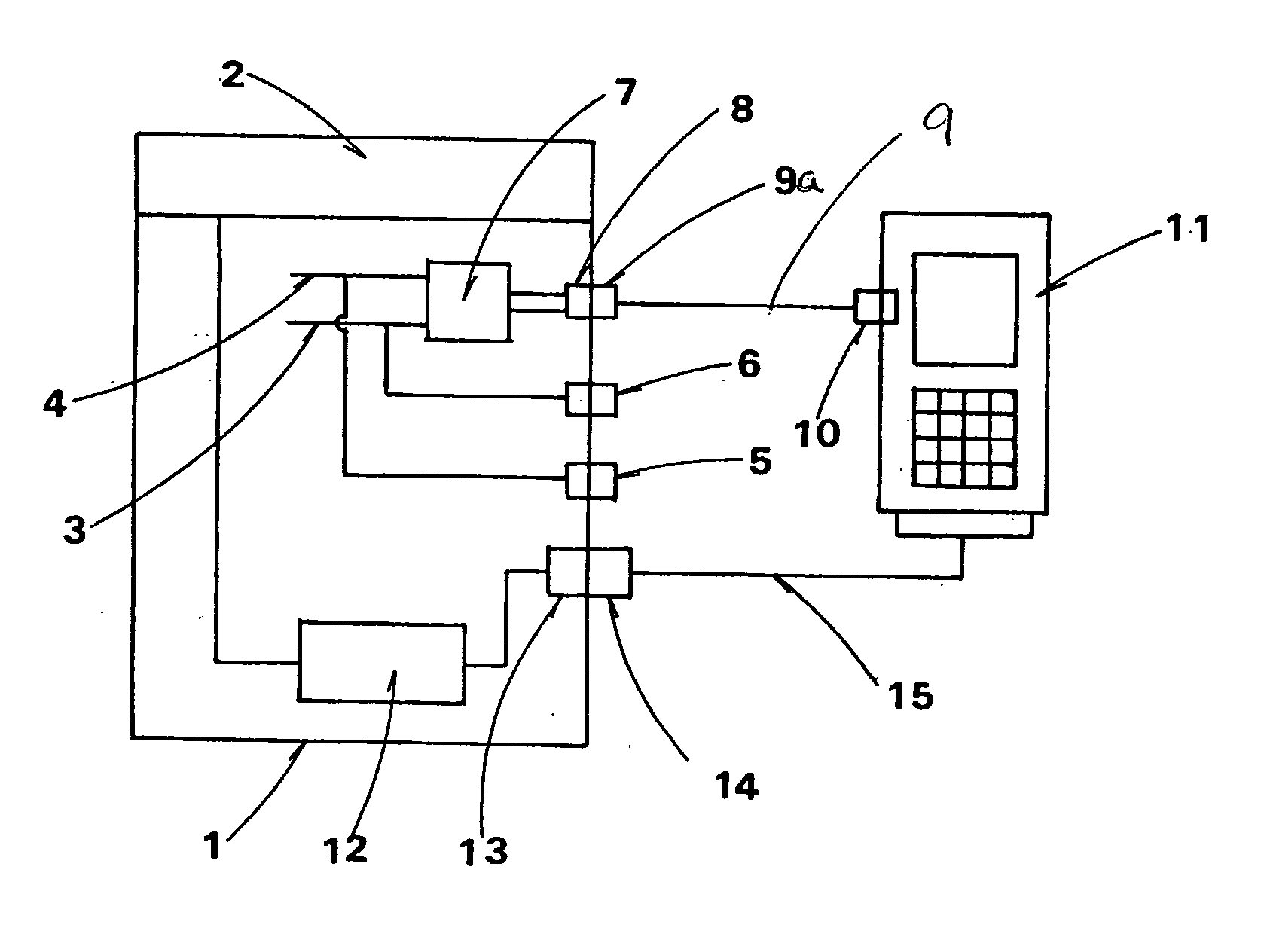

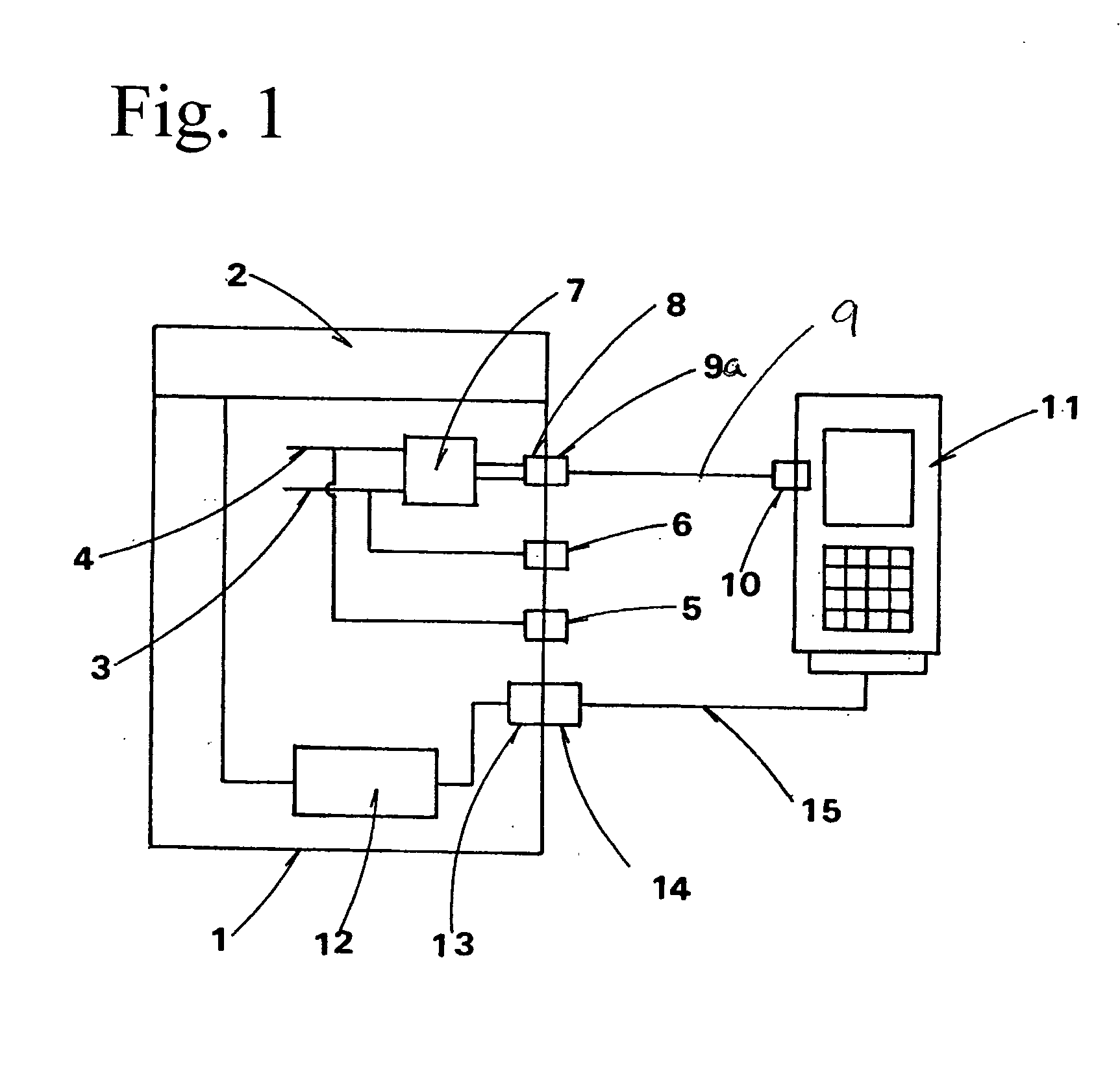

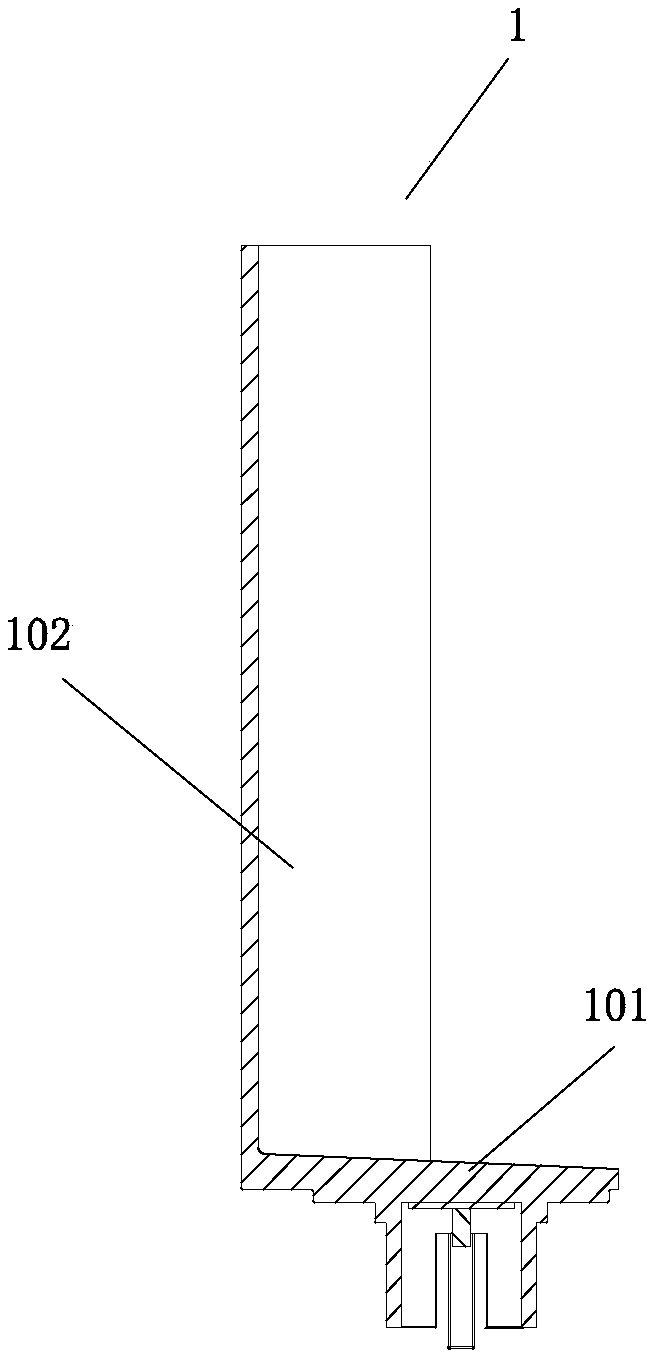

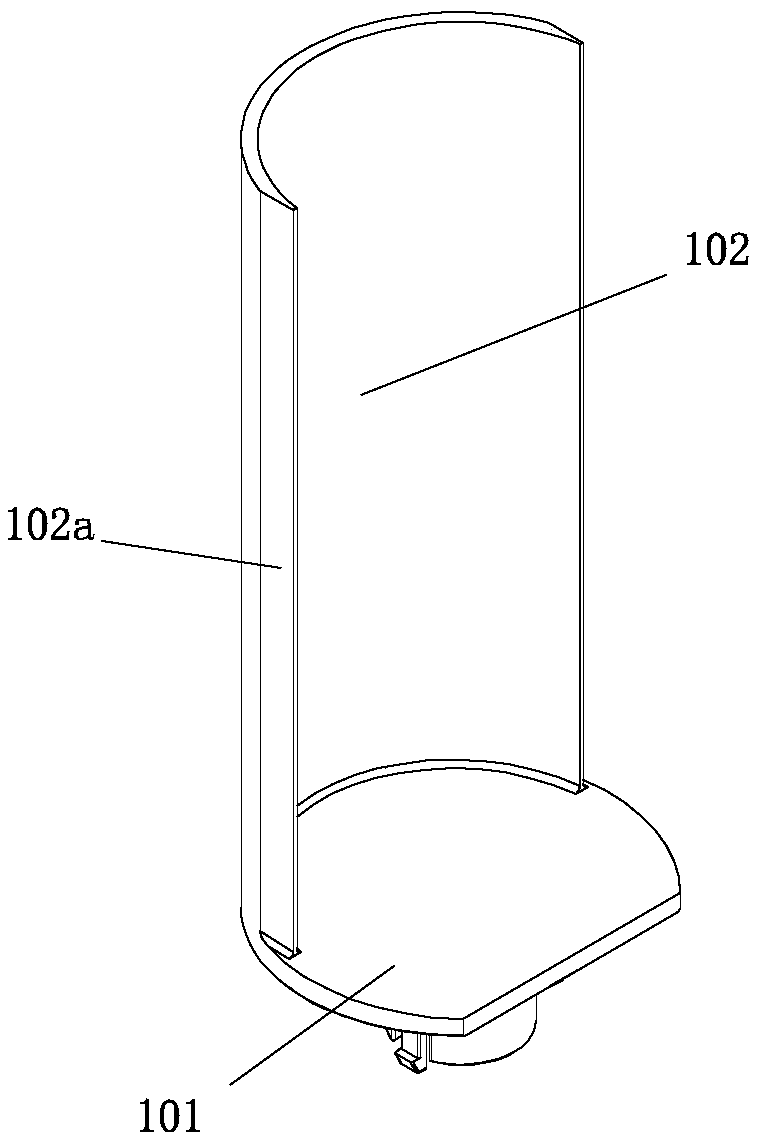

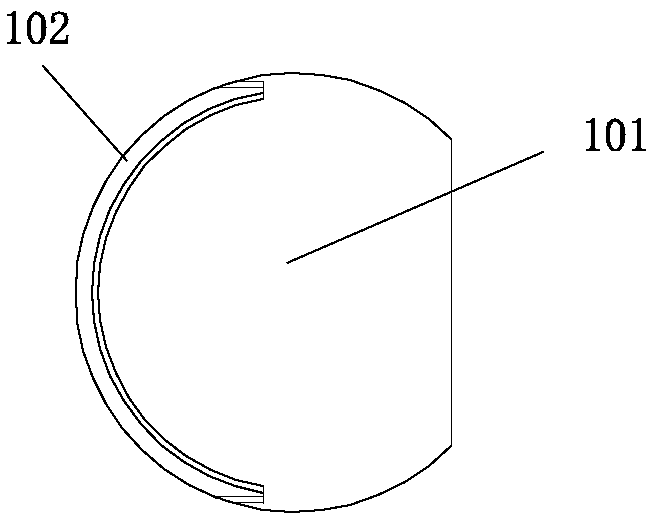

Small screenless portable DVD player having picture signal and sound signal combination terminal

InactiveUS20050201734A1Easily and conveniently be replayedSolve the real problemTelevision system detailsRecord information storageScreenlessCD player

A better way of replaying a video picture, using a small screenless portable DVD player, is disclosed. As a handy and easy way of charging a mobile telephone is also described by using the screen of the mobile telephone as a screen for a small screenless portable DVD player, and by connecting the small screenless portable DVD player with the mobile telephone with only one cable which transmits both picture signal and sound signal, use of the mobile to play DVDs is made easier. Moreover, by providing a USB terminal that provides electric power from the battery pack of the small screenless portable DVD player, on the side of the DVD player, and by charging electric power to the battery of the mobile telephone through this USB terminal, the mobile telephone is conveniently charged by the ordinarily larger battery of the DVD player.

Owner:KIMURA YOSHIAKI +3

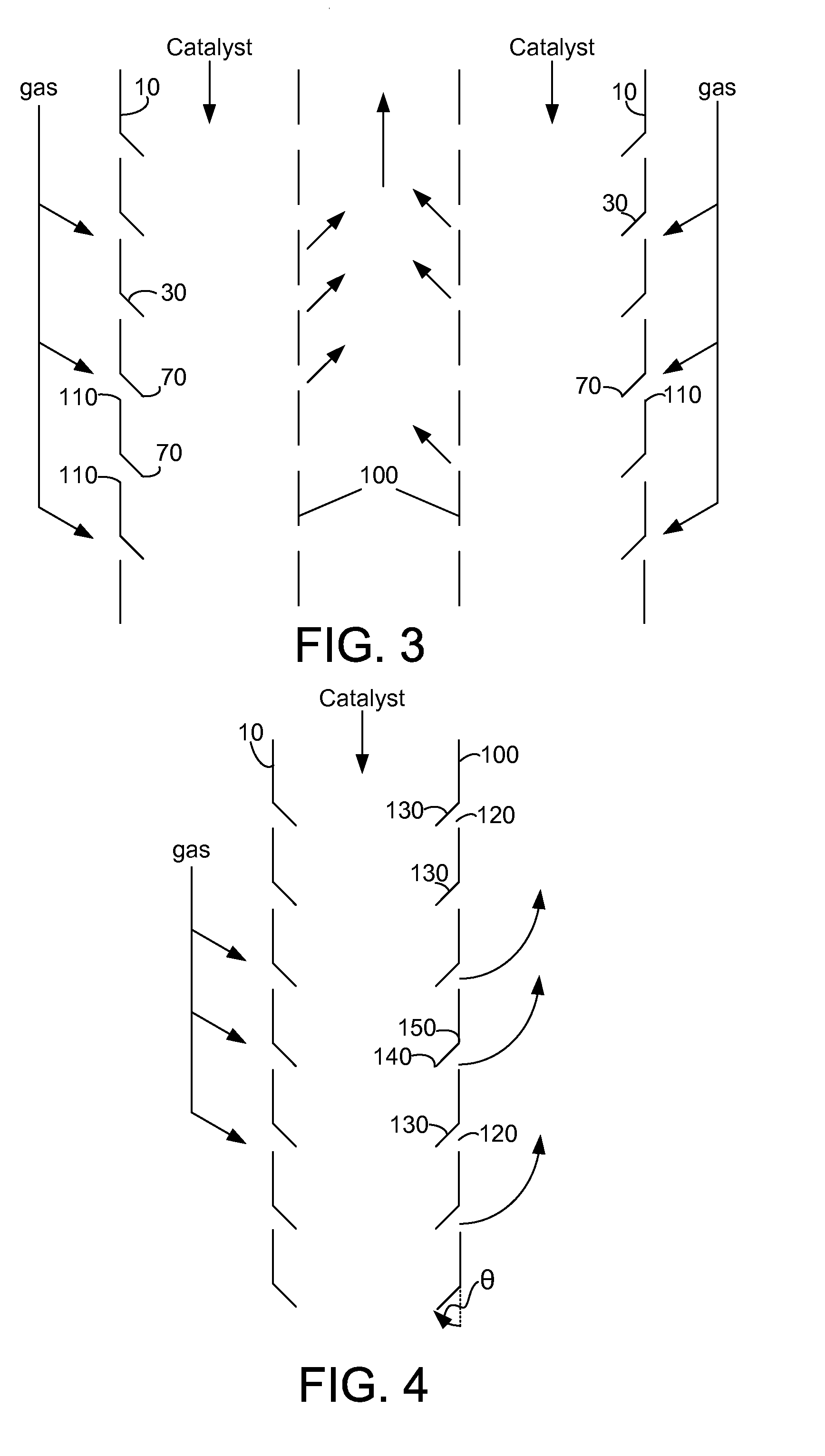

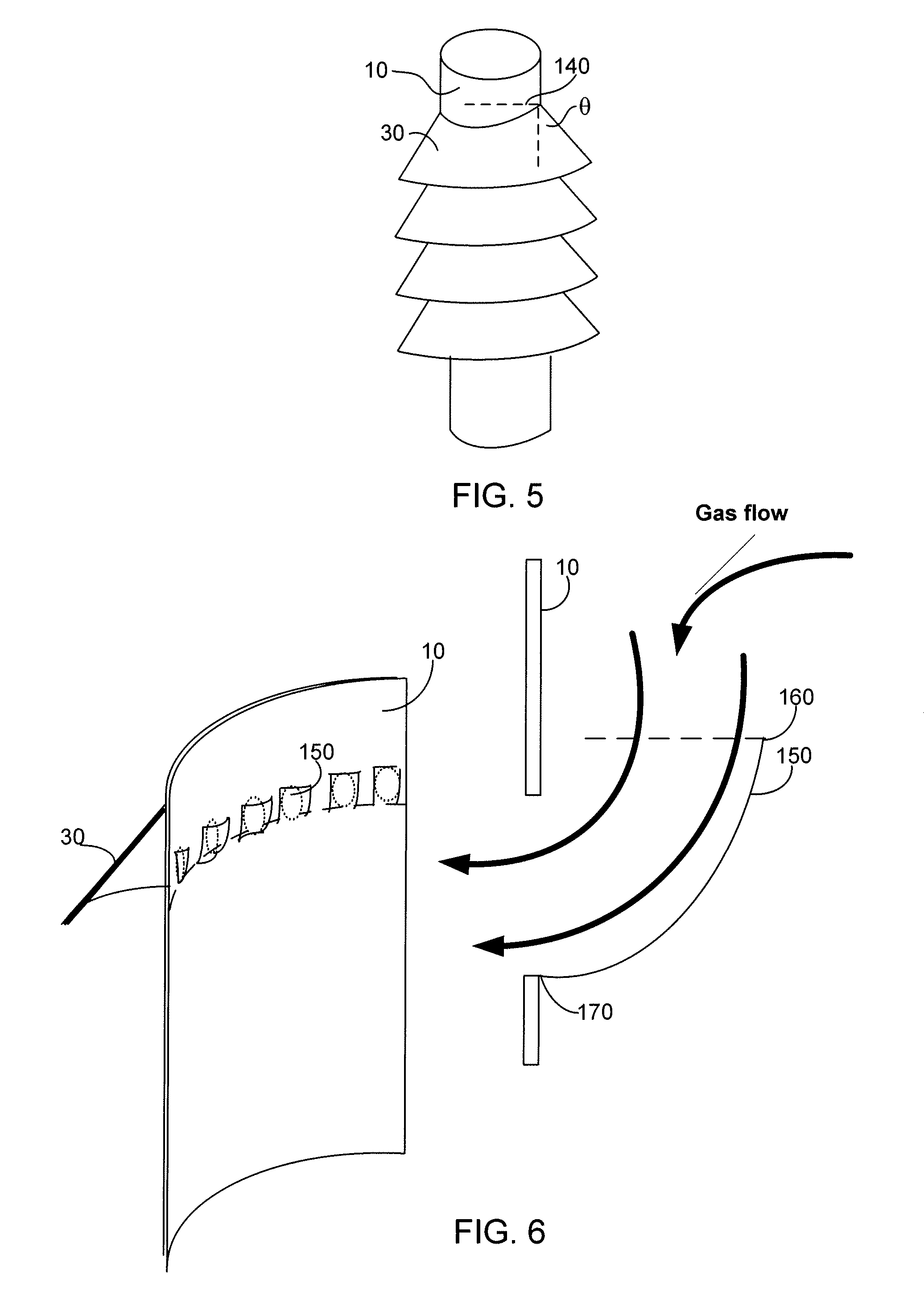

Conically shaped screenless internals for radial flow reactors

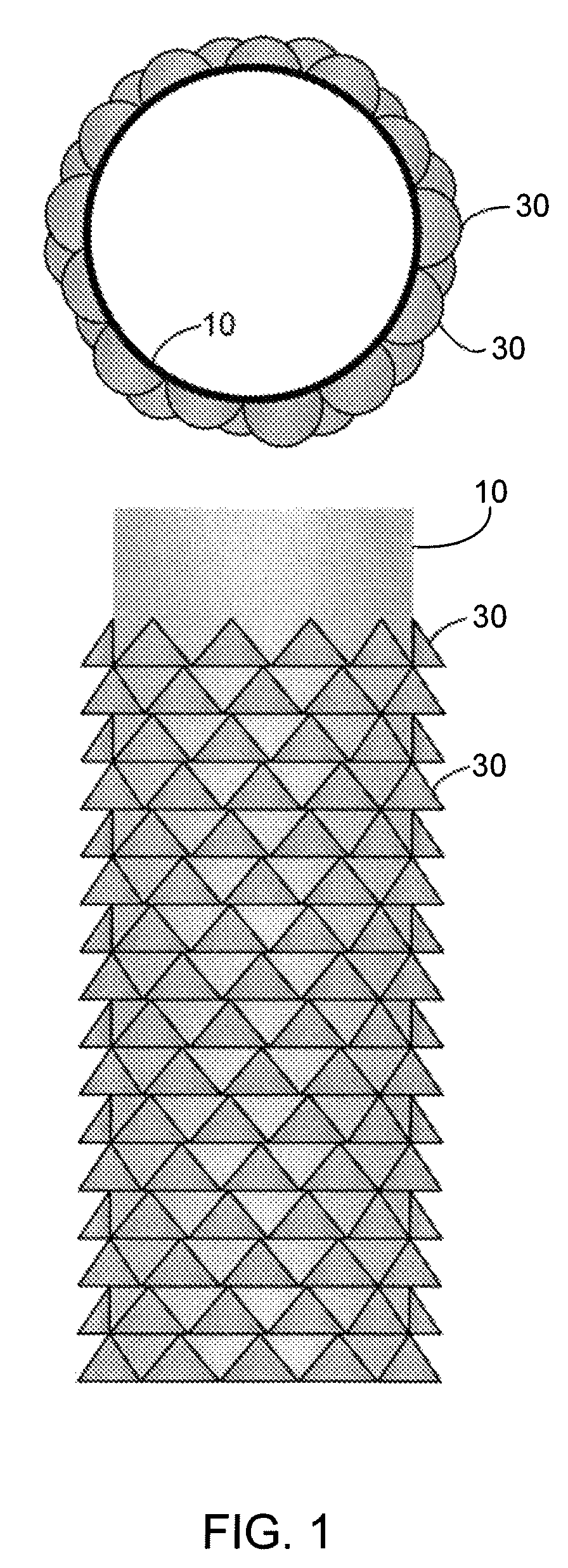

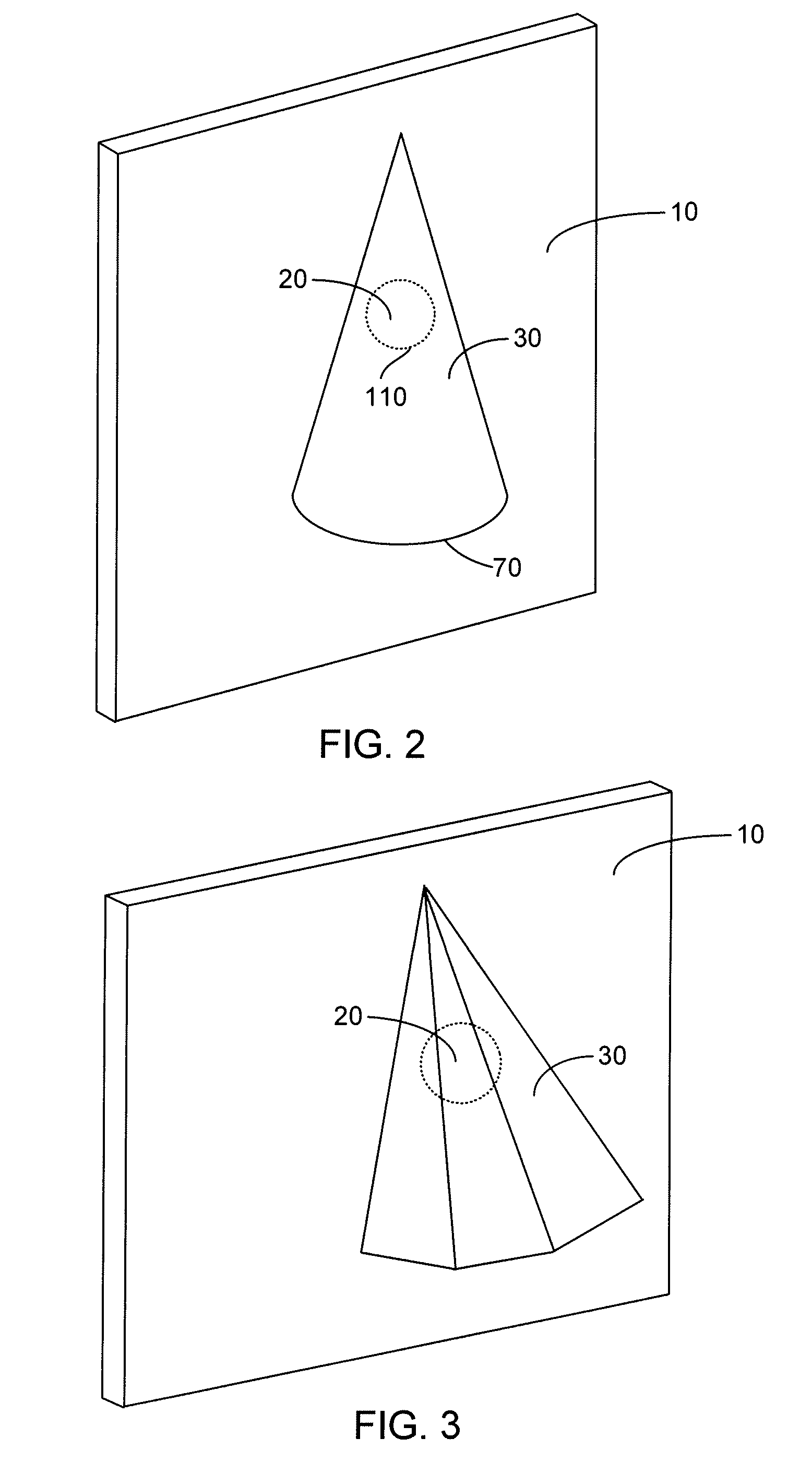

An apparatus for contacting a bed of particulate material with a cross flowing fluid, which maintains the bed of particulate material within a retention volume. The apparatus includes partitions for retaining particles, with apertures disposed within the partitions. The apertures are covered by shrouds that extend above the edges of the apertures to prevent solid particles from spilling through inlet apertures.

Owner:UOP LLC

Screenless processing technology for printing roller

The invention discloses a screenless processing technology for a printing roller. The screenless processing technology comprises the following steps of (1), a copper plating process, (2), a grinding and polishing process, (3), an engraving process and (4), a chromium plating process. By means of the technology, the problems that an existing pattern has the rich color level changes and not only has large color lumps with the deep color and high color density, but also has transition layers with the light color and gentle color, and when a color plate of one image data is engraved, unified parameters cannot be engraved at the same time are solved, the pattern with the same layer as an original engraving piece, the depth higher than that of the primary engraving and the higher thickness is formed, and the two-plate printing effect can be achieved through one printing roller for customers.

Owner:LONGYOU YUNSHEN PLATE MAKING CO LTD

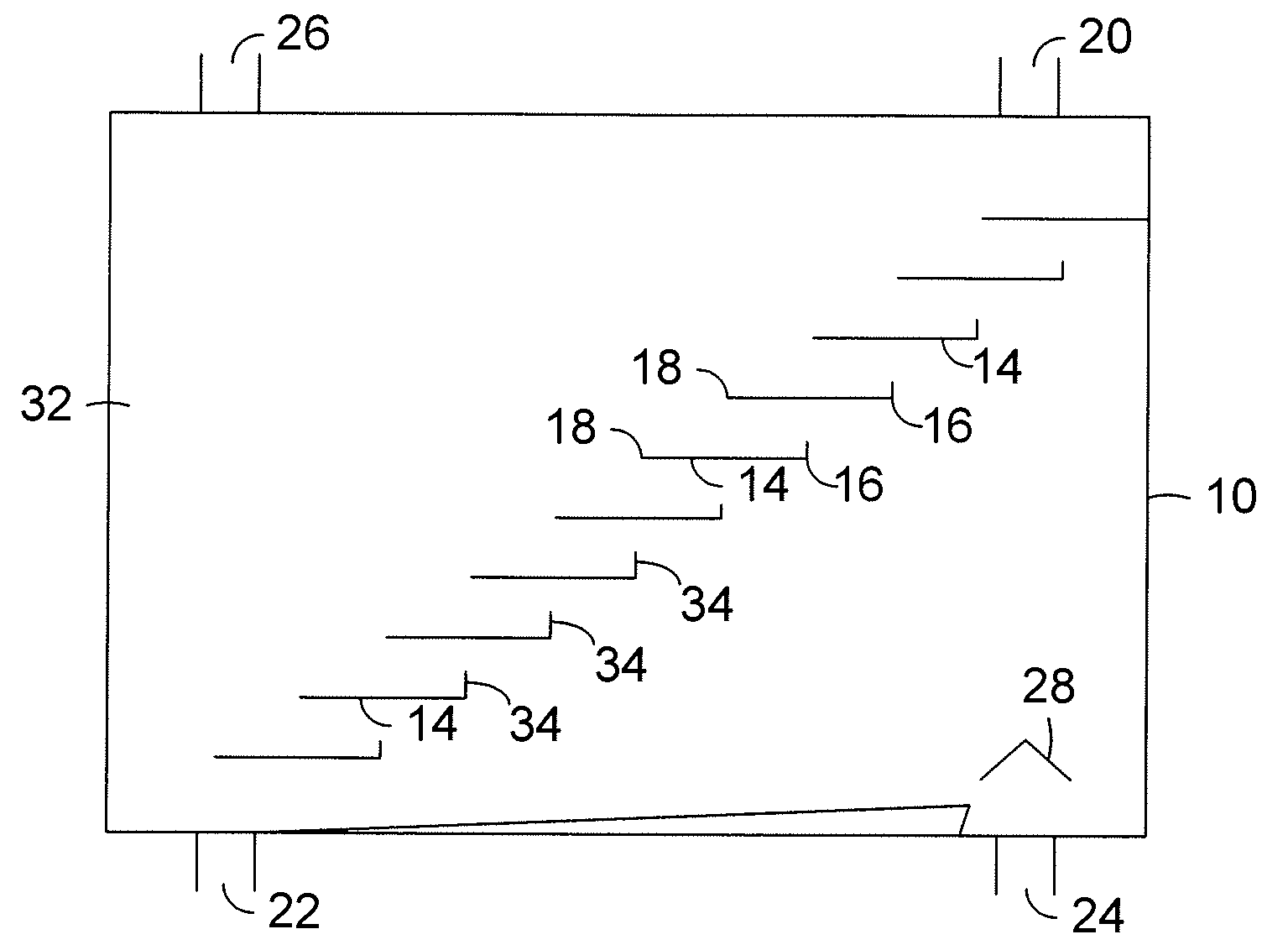

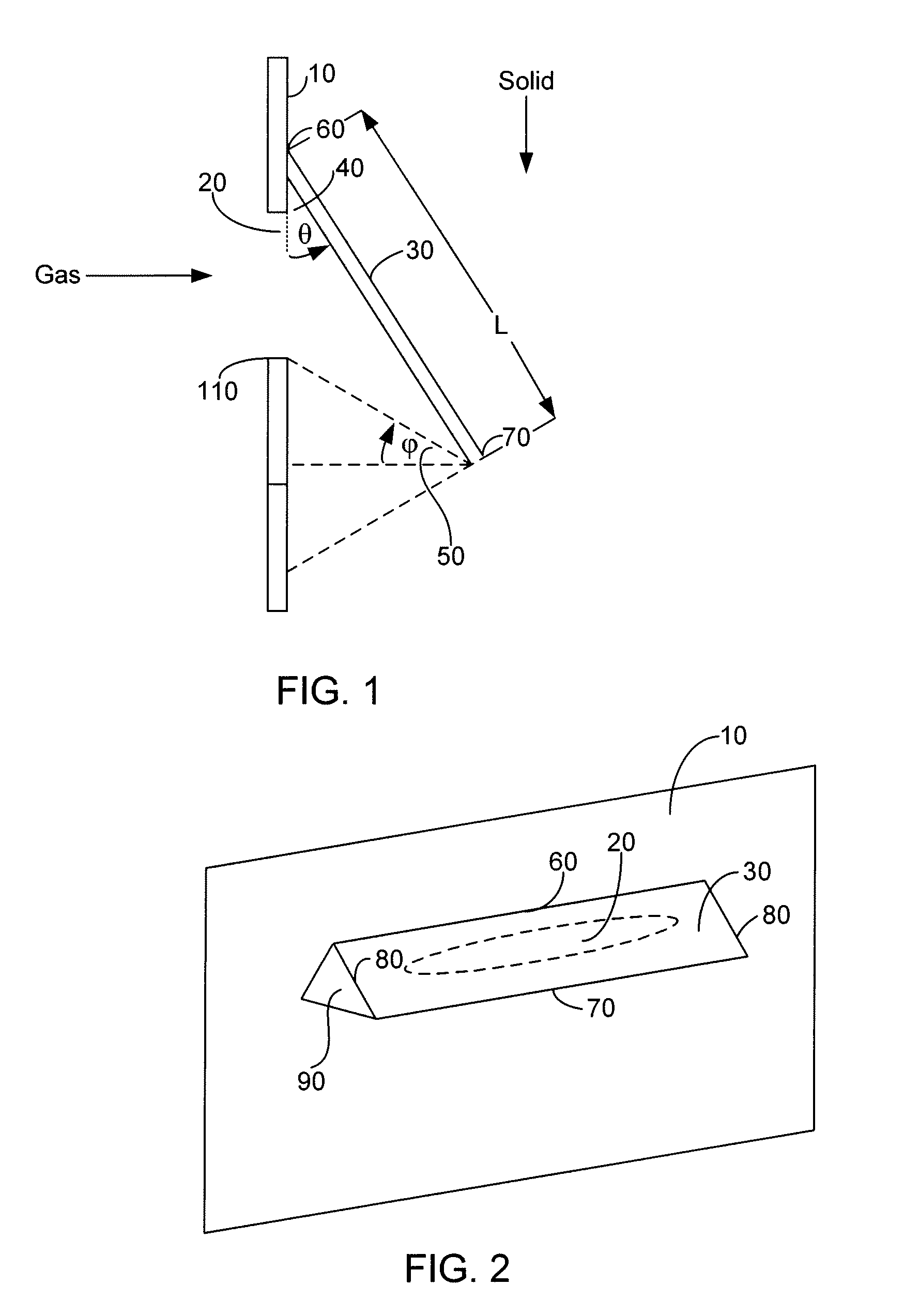

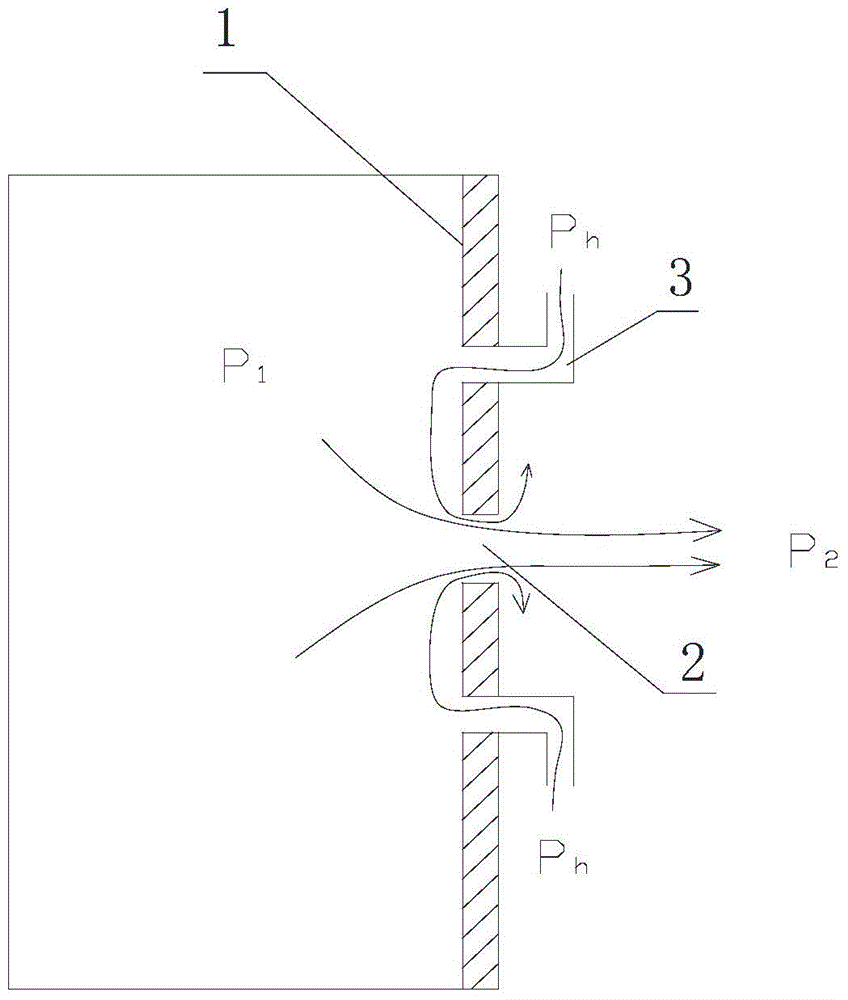

Screenless internals for radial flow reactors

An apparatus for contacting a bed of particulate material with a cross flowing fluid, which maintains the bed of particulate material within a retention volume. The apparatus includes partitions for retaining particles, with apertures disposed within the partitions. The apertures are covered by louvers that extend above the edges of the apertures to prevent solid particles from spilling through inlet apertures.

Owner:UOP LLC

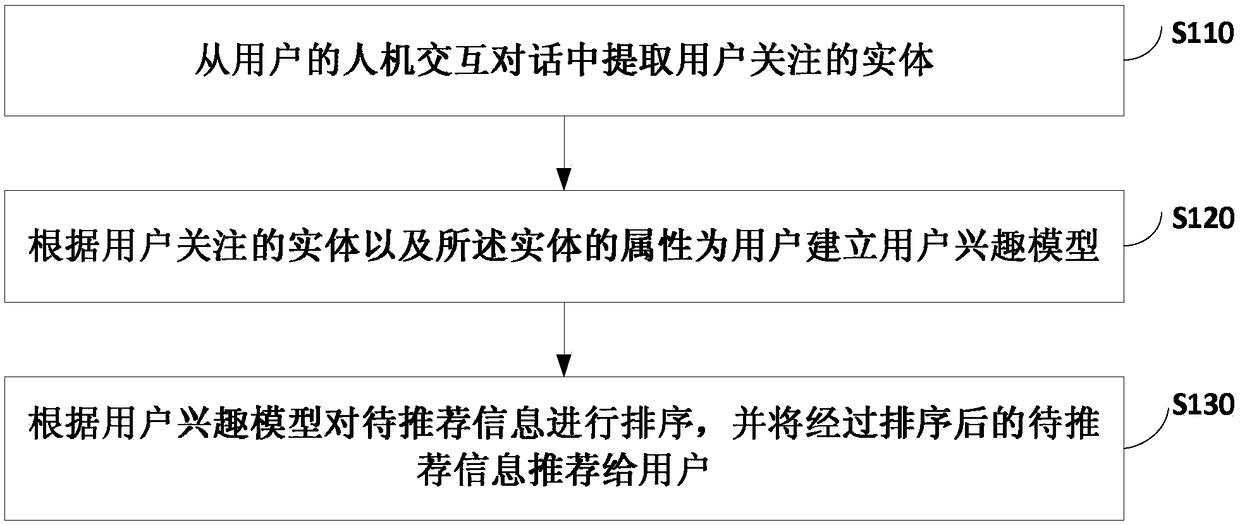

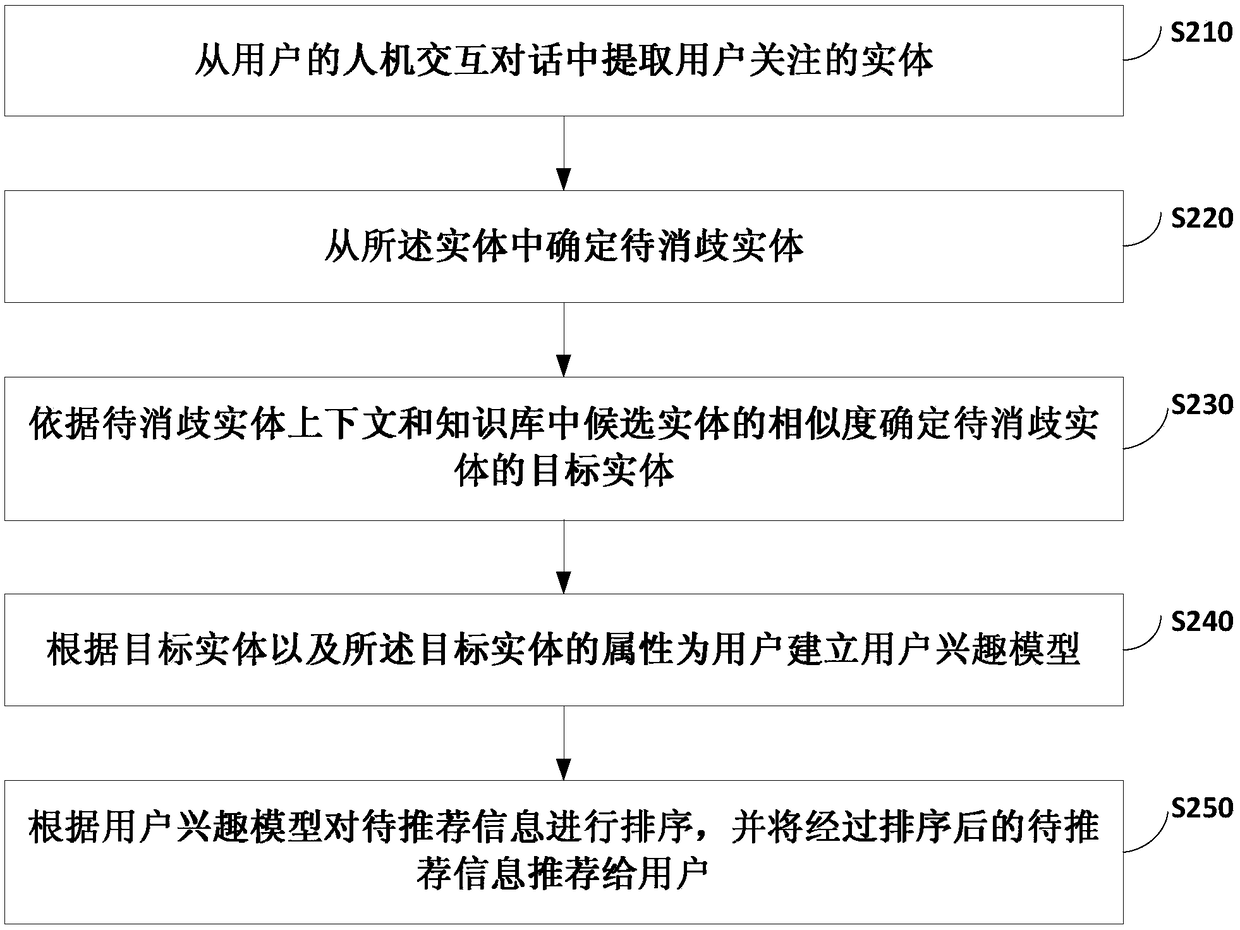

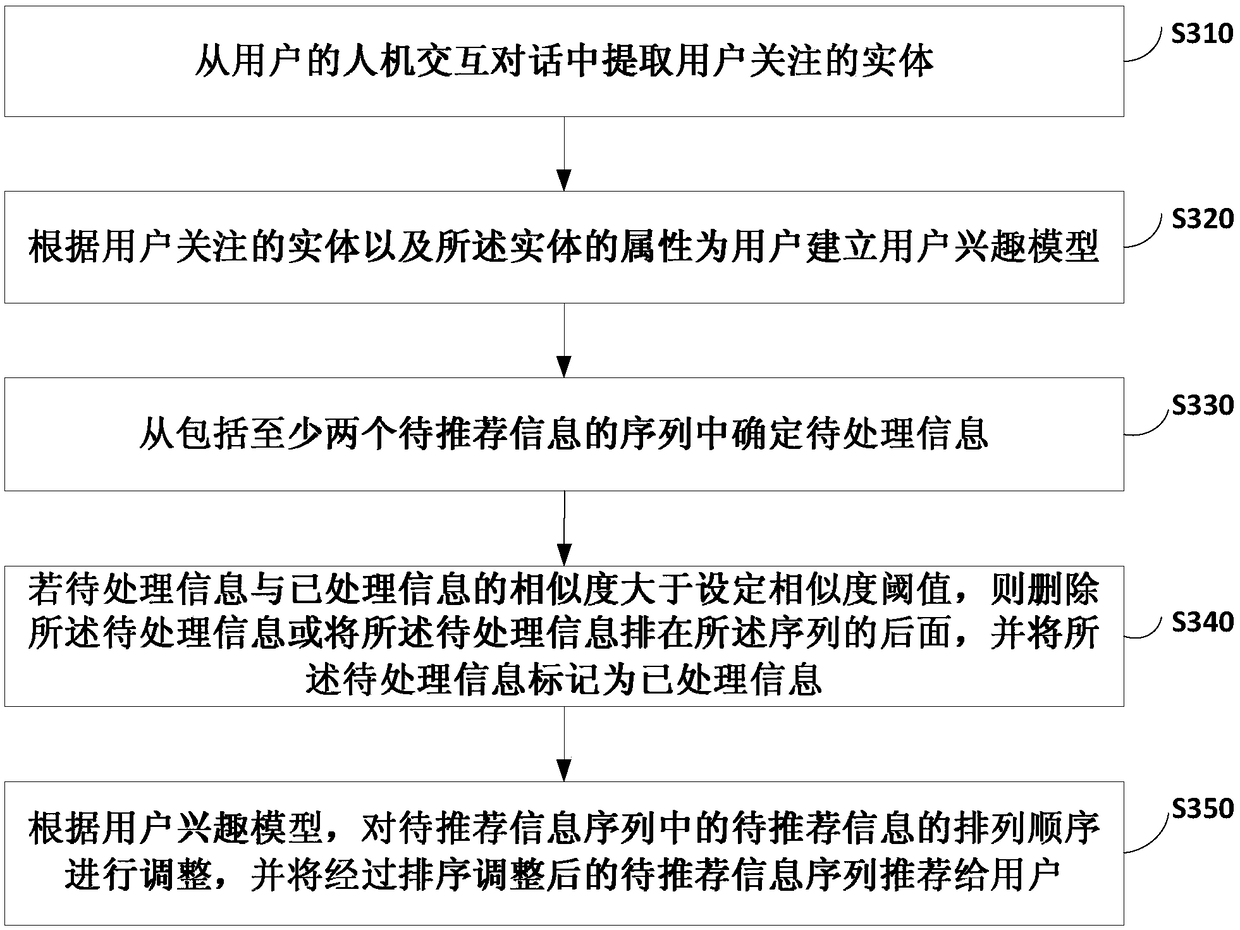

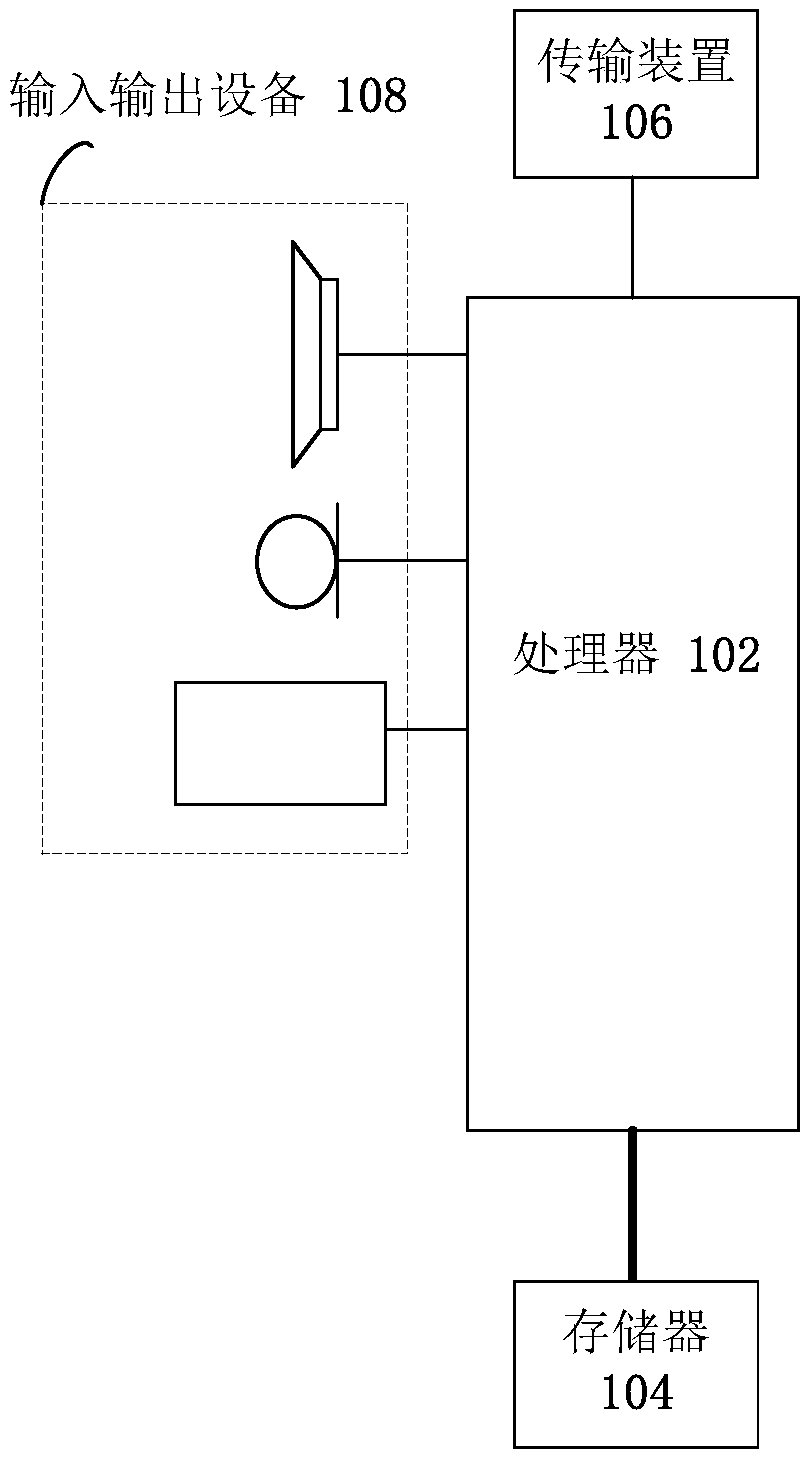

Information recommendation method, apparatus and device and medium

ActiveCN108920649AImprove experienceImprove receiving efficiencySpecial data processing applicationsInformation processingScreenless

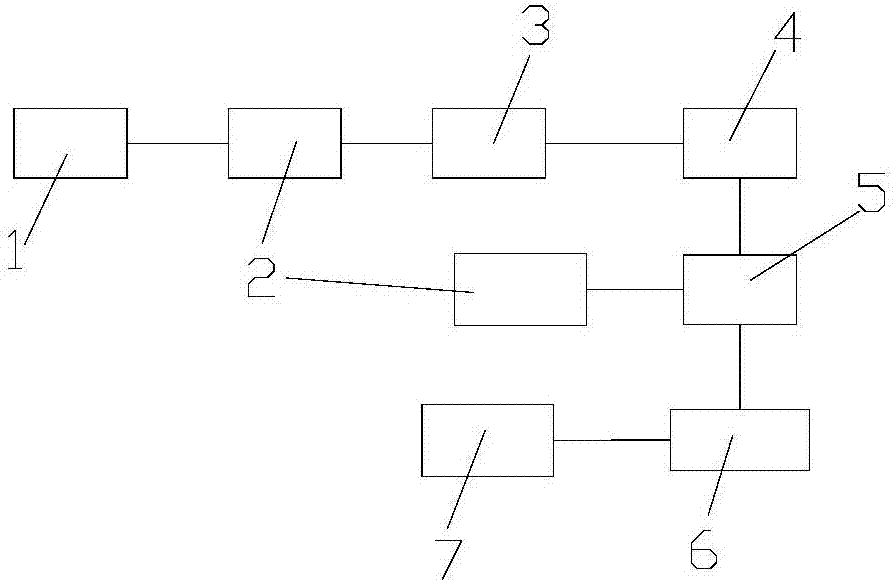

The embodiment of the invention discloses an information recommendation method, apparatus and device and a medium, and relates to an information processing technology. The method includes: extractingan entity that a user pays attention to from the user's human-computer interaction dialogue; establishing a user interest model for the user according to the entity that the user pays attention to andattributes of the entity; sorting to-be-recommended information according to the user interest model, and recommending the sorted to-be-recommended information to the user. According to the information recommendation method, apparatus and device and the medium, the sorting and tuning of the recommended content in a screenless environment are implemented.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

Methods of operating a synergetic tandem pocket device

A method of operating a communications system including a mobile phone and a media playback device is disclosed. When the mobile phone is uncoupled from the media playback device, voice telephony services are provided by the mobile phone using an onboard RF transceiver of the mobile phone. When the media playback device is uncoupled from mobile phone, media playback services are provided by the media playback device using an onboard CODEC and an onboard display screen of the media playback device. When the media playback device and the mobile phone are operatively coupled together to form a tandem device, video telephony services are provided by the tandem device using the RF transceiver of the mobile phone, the CODEC of the media playback device and the display screen of the media playback device. Methods of operating a GPS system including a screenless GPS device and a mobile phone are also disclosed herein.

Owner:SANDISK IL LTD

A new type of Internet screenless express cabinet system

ActiveCN104809818BImprove experienceLow costApparatus for meter-controlled dispensingTelecommunicationsScreenless

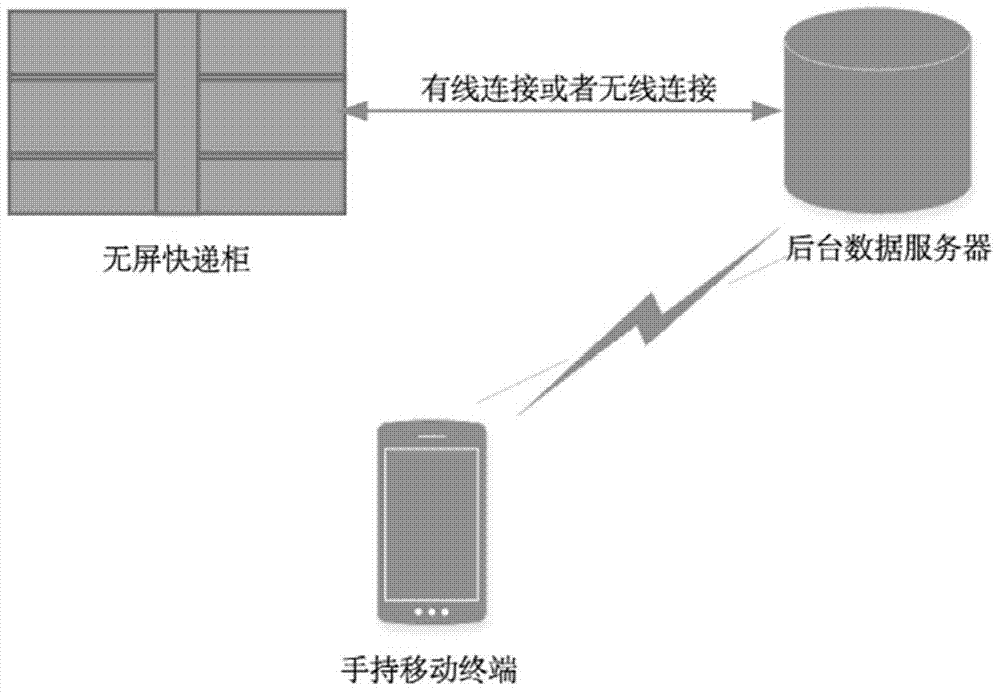

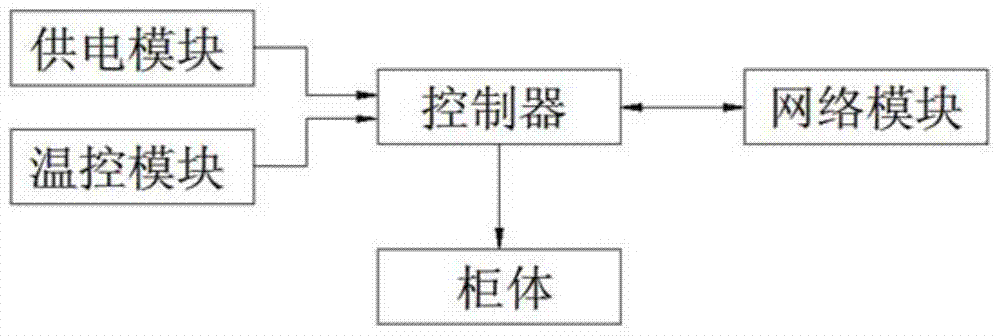

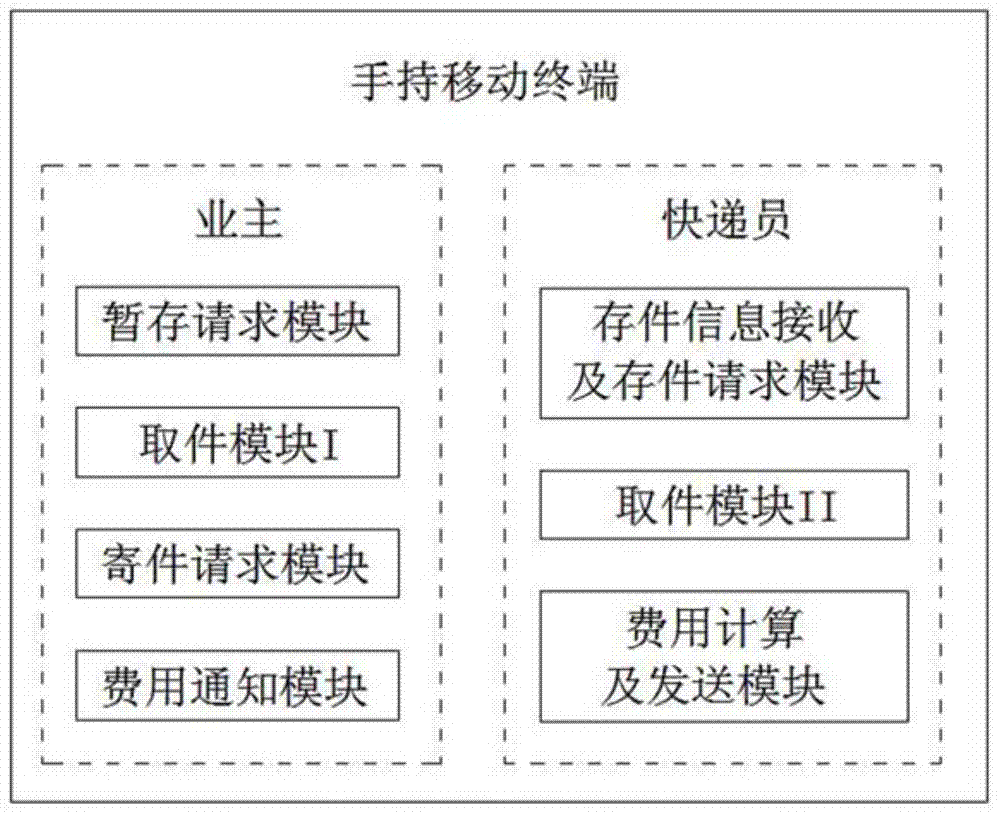

The invention discloses a novel internet screen-free express delivery cabinet system. The novel internet screen-free express delivery cabinet system comprises a screen-free express delivery cabinet, a handheld mobile terminal and a background server, wherein the screen-free express delivery cabinet is connected with the background server in a wired or wireless manner; the handheld mobile terminal accesses the background server in a wireless linkage manner; the background server receives a temporary storage or sending request from the handheld mobile terminal, then takes parameters from a background database and sends a message to the screen-free express delivery cabinet through a wired or wireless network; after receiving the message, the screen-free express delivery cabinet opens a corresponding grid to enable an owner or a courier to take an express item away or store the express item. The novel internet screen-free express delivery cabinet system has the benefits that a mobile internet technology is added, and the experience of a user is optimized; the screen-free express delivery cabinet is operated to be opened and closed by using the handheld mobile terminal, the environment limitation of an intelligent express delivery cabinet is broken, and the coverage temperature range is expanded to be minus 25 DEG C to 85 DEG C; compared with the conventional intelligent express delivery cabinet with a screen, the novel internet screen-free express delivery cabinet system has the advantages that the cost is lower, the total cost is reduced by about 40 percent, and the service life is longer.

Owner:北京安杰信息科技有限公司

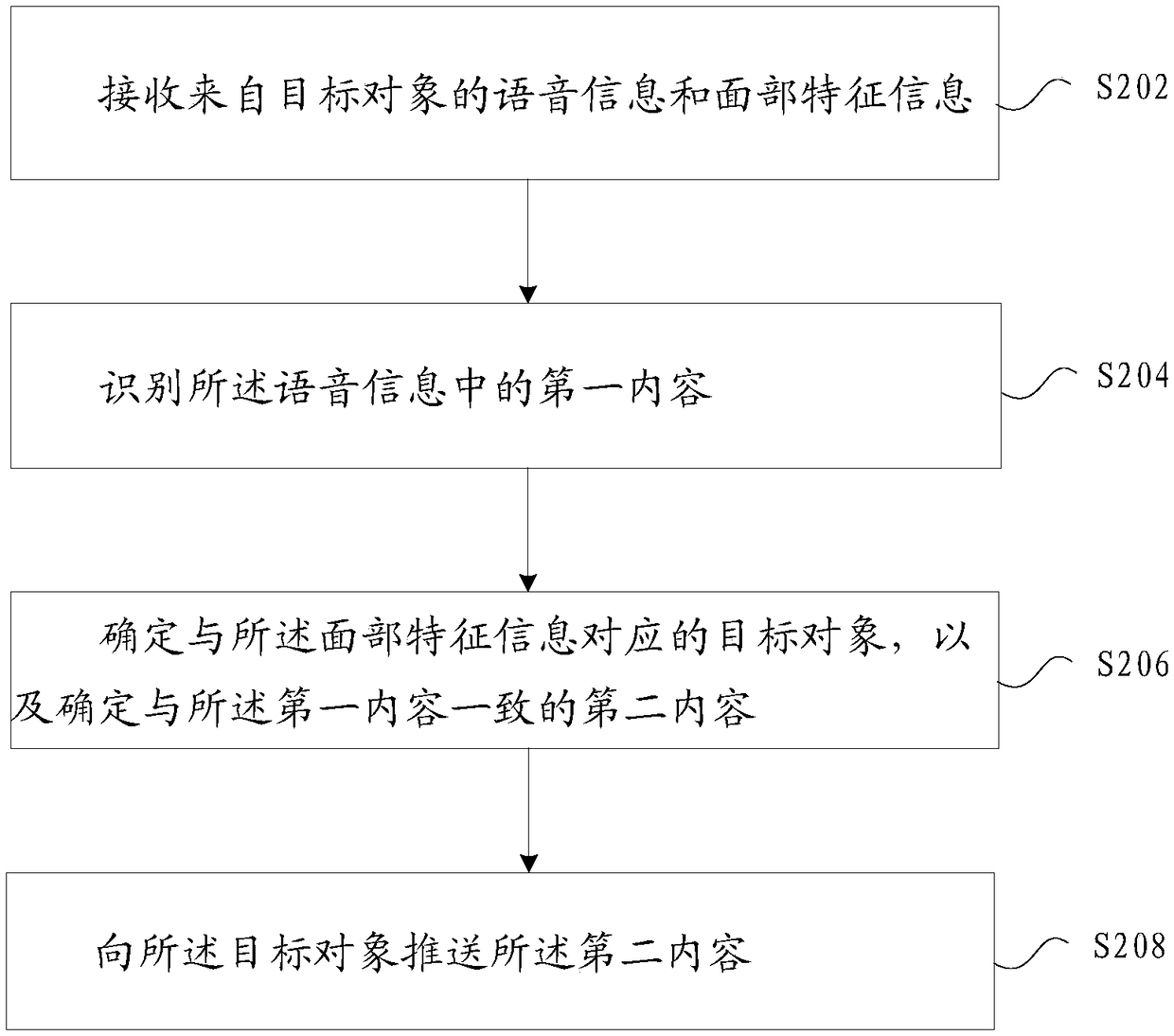

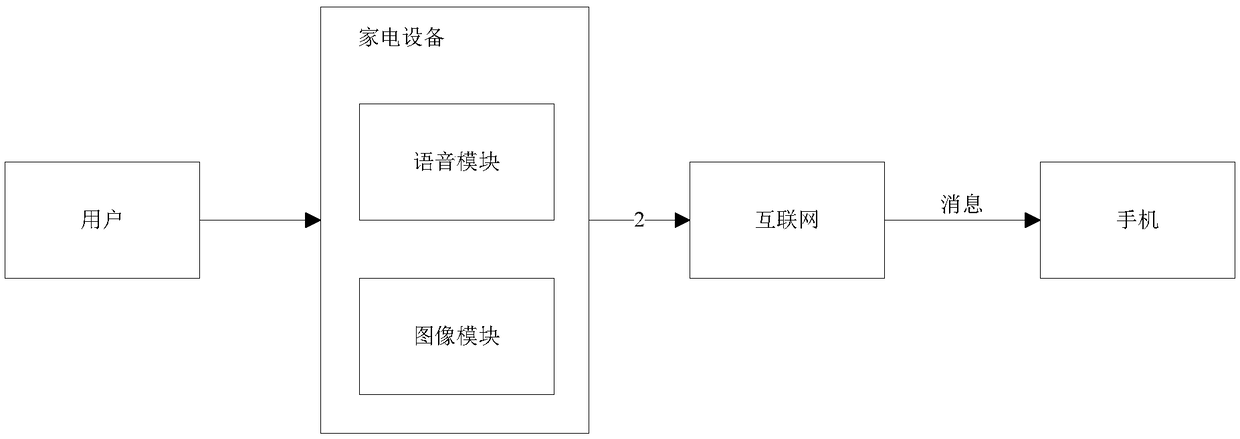

Information pushing method and device

ActiveCN109067883ASolve the problems displayedImprove experienceCharacter and pattern recognitionSpeech recognitionScreenlessSpeech sound

A method and apparatus for information pushing are provided, wherein the method comprises: receiving voice information and facial feature information from a target object, identifying a first contentin the speech information, determining a target object corresponding to the facial feature information, and determining a second content consistent with the first content, pushing the second content to the target object, by adoption of the technical scheme, the target object is searched by facial feature recognition, even if the device that currently performs facial feature information recognitionis screenless interactive, the invention also can display the content requested by the target object and the target object, solves the problem that the service content cannot be provided to the userwhen the screen-less interaction is carried out in the related technology, ensures the timely pushing of the information, increases the use range of the screen-less device, and improves the user experience.

Owner:GREE ELECTRIC APPLIANCES INC

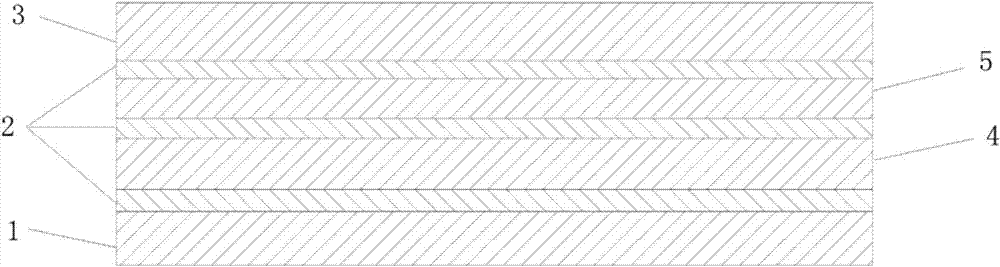

Screenless printing advertising cloth

InactiveCN104210203ATightly boundShorten the process strokeSynthetic resin layered productsScreenlessSurface layer

The invention relates to a screenless printing advertising cloth. The existing printing advertising cloth is poor in bonding fastness, and the production process of the existing printing advertising cloth is also complex, which results in relatively low yield. The screenless printing advertising cloth comprises a PVC surface layer and a PVC bottom layer; the screenless printing advertising cloth is characterized in that a PET film is arranged between the PVC surface layer and the PVC bottom layer, the PVC surface layer and the PVC bottom layer are pre-coated with a glue layer, and then the PVC surface layer and the PVC bottom layer both coated with the glue layer are fitted with the PET film by virtue of hot melting, and moreover, a PVC black film is additionally arranged between the PVC surface layer and the PVC bottom layer. The screenless printing advertising cloth has the advantages that the production process of the PET advertising material is effectively shortened and the processing steps for the PET film are reduced. The PET film is always kept flat without wrinkling during production and the rate of finished products is effectively increased.

Owner:ZHEJIANG GANGLONG NEW MATERIAL

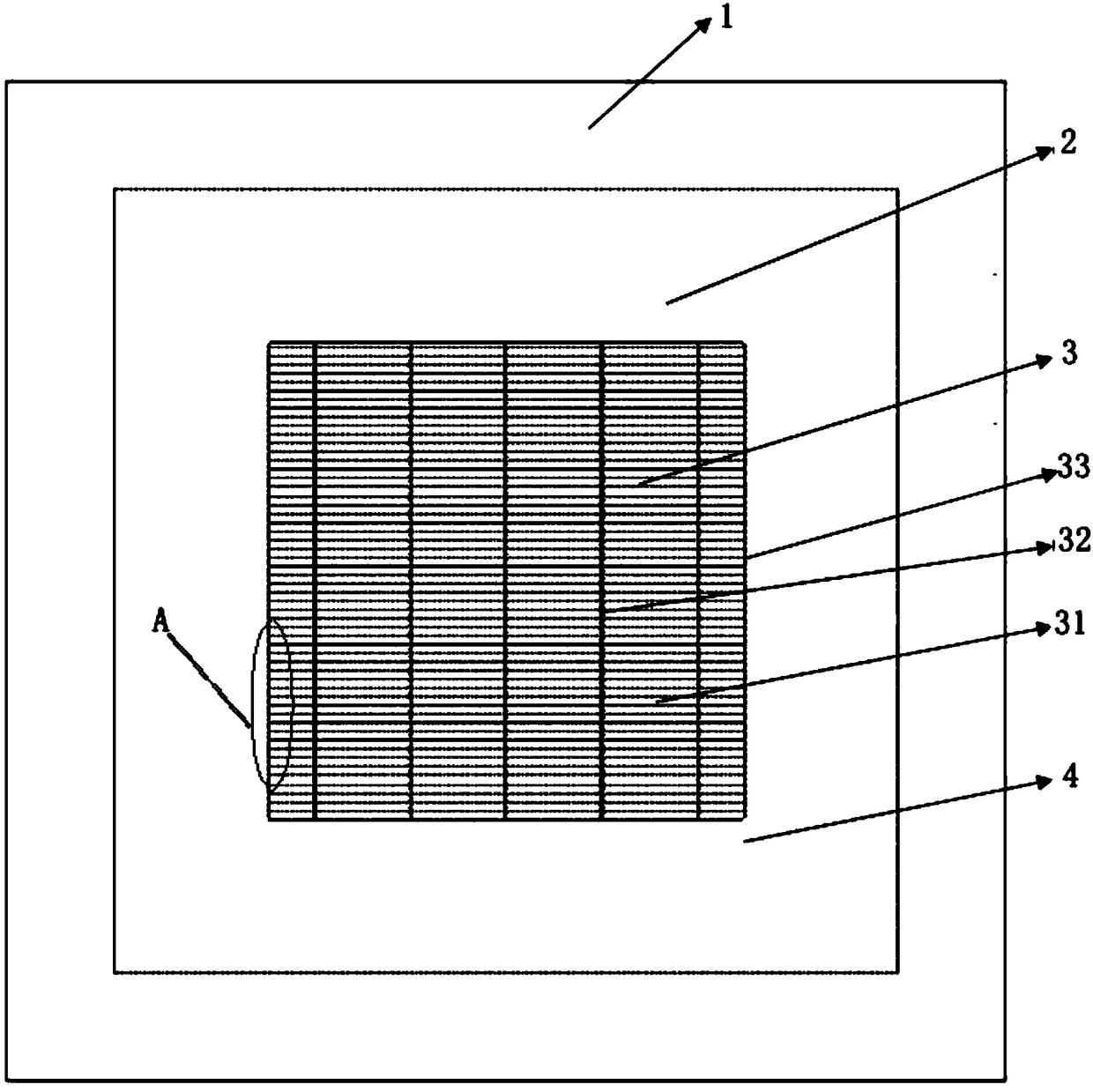

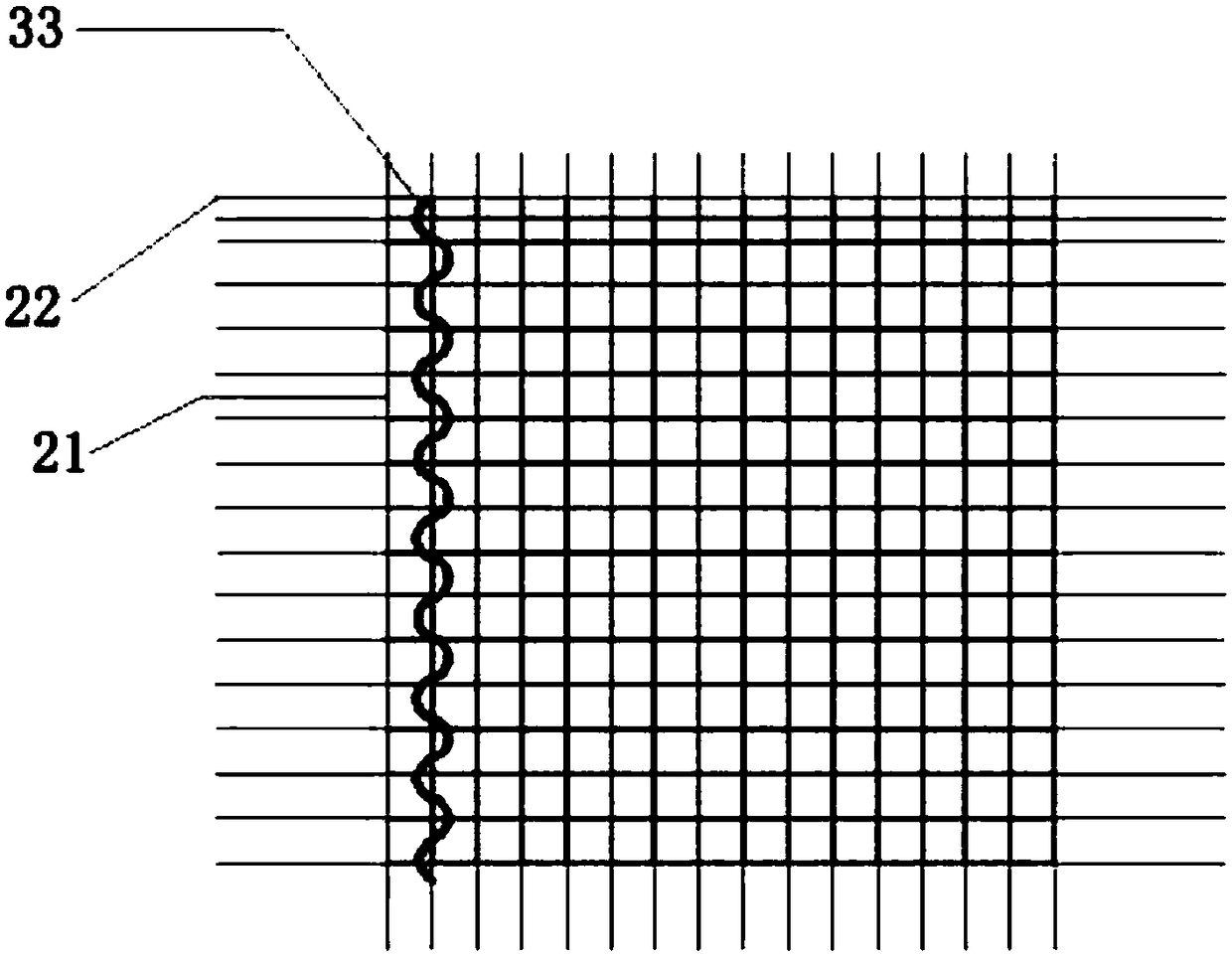

Screenless secondary printing method for positive electrode of crystalline silicon solar cell

InactiveCN109427919ALower transfer resistanceHigh aspect ratioPhotovoltaic energy generationSemiconductor devicesScreenlessSilicon solar cell

The present invention discloses a screenless secondary printing method for a positive electrode of a crystalline silicon solar cell. The method comprises that: a silk-screen printing machine is used to perform two times of printing of DP1 and DP2, wherein the sub-grid line is printed in the DP1, the main grid line and the sub-gate are printed in the DP2, and the silk-screen printing plate used forDP1 and DP2 printing is a screenless silk-screen printing late; the sub-grid line and the positioning points are printed onto the cell sheet by using the slurry through the DP1 screenless silk-screenprinting plate; four solid positioning points on the cell sheet is captured by using the HD camera, and the cell sheet is automatically adjusted to the appropriate position to achieve precise contrast with the alignment point on the DP2 screenless silk-screen printing plate; and the main grid line and the sub-grid line are printed onto the cell sheet by using the slurry through the DP2 screenlesssilk-screen printing plate. According to the method disclosed by the present invention, the limitations of the traditional printing process is broken through, the aspect ratio of the sub-grid printing is improved, the printing quality of the grid line is improved, and the electrical performance and the excellent product rate of the cell sheet are improved.

Owner:TONGWEI SOLAR ENERGY (CHENGDU) CO LID

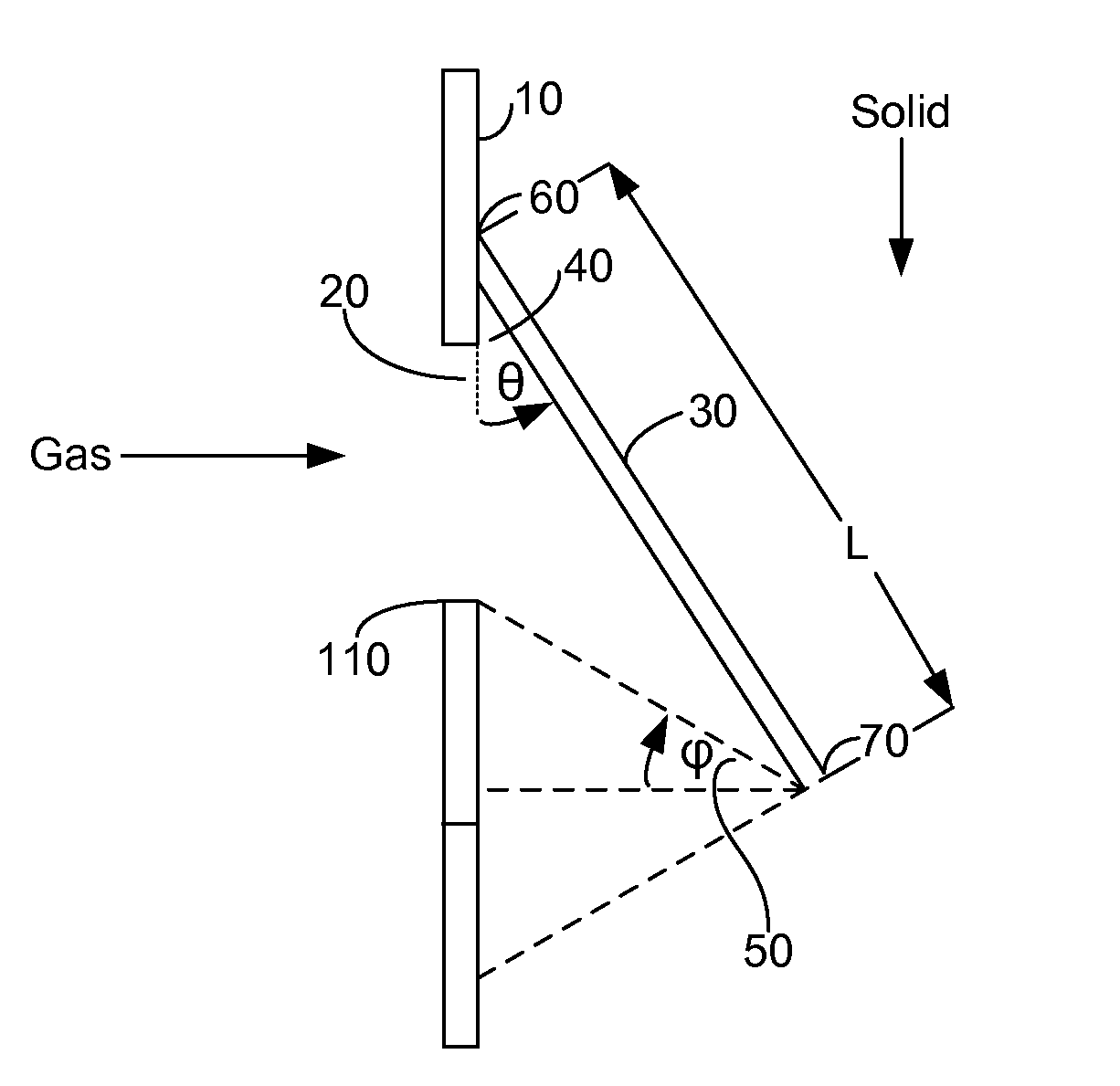

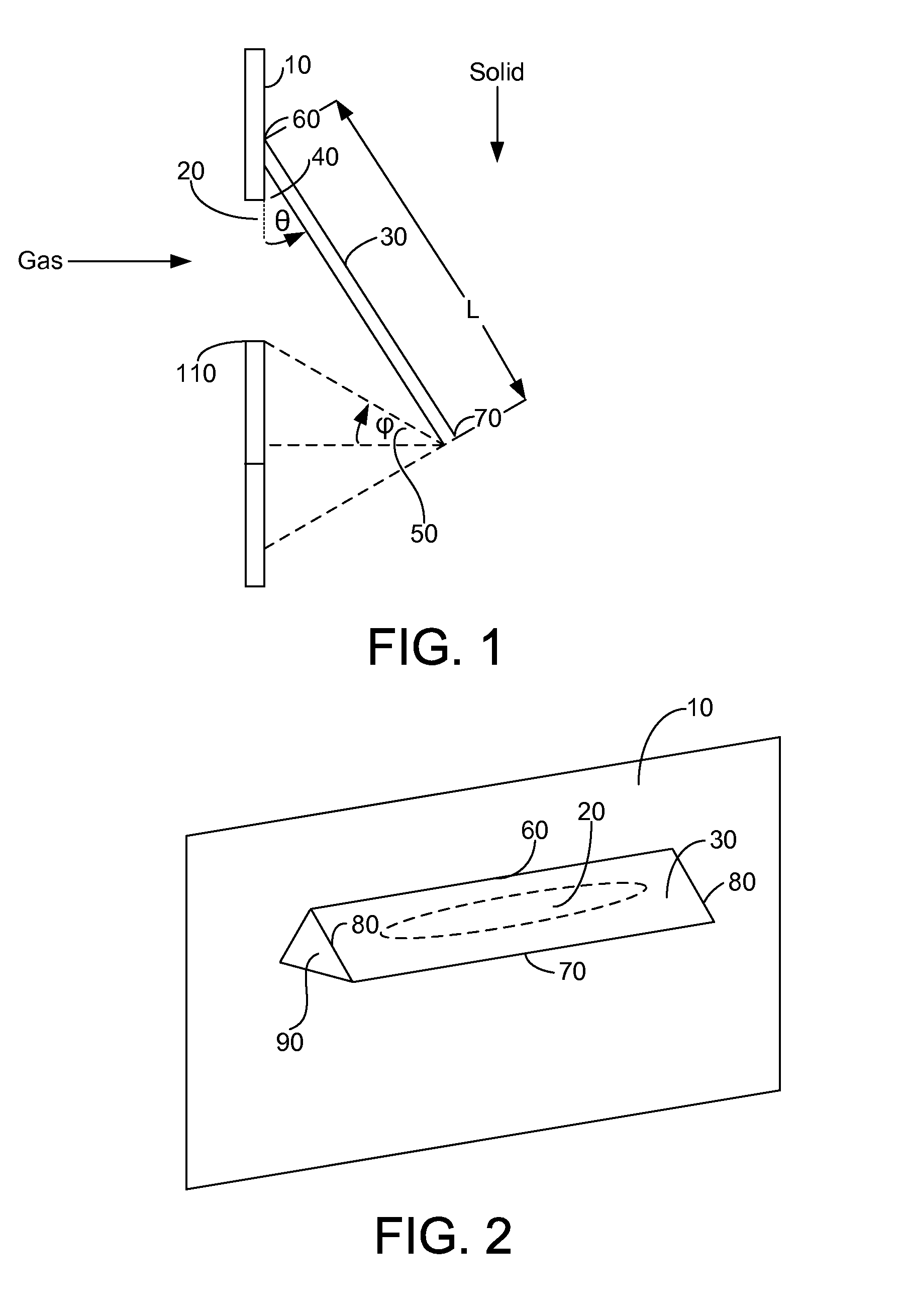

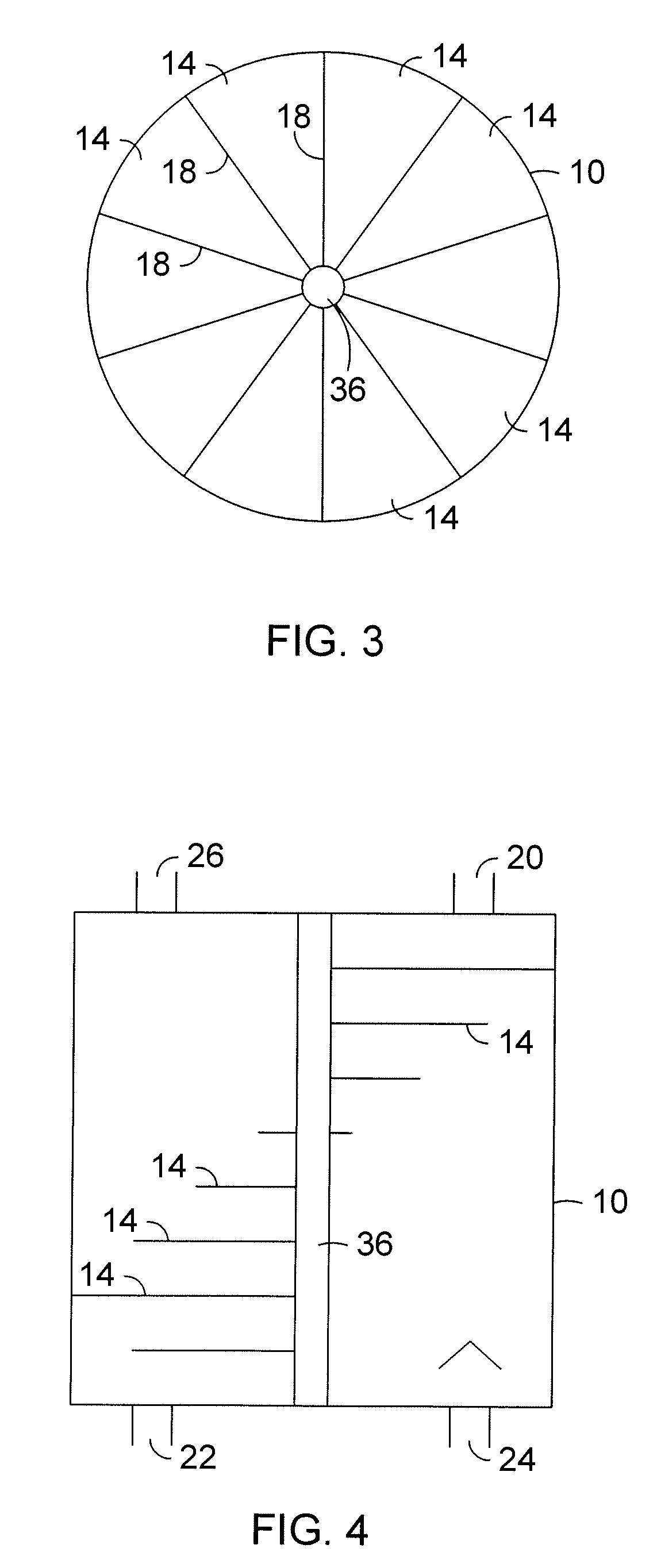

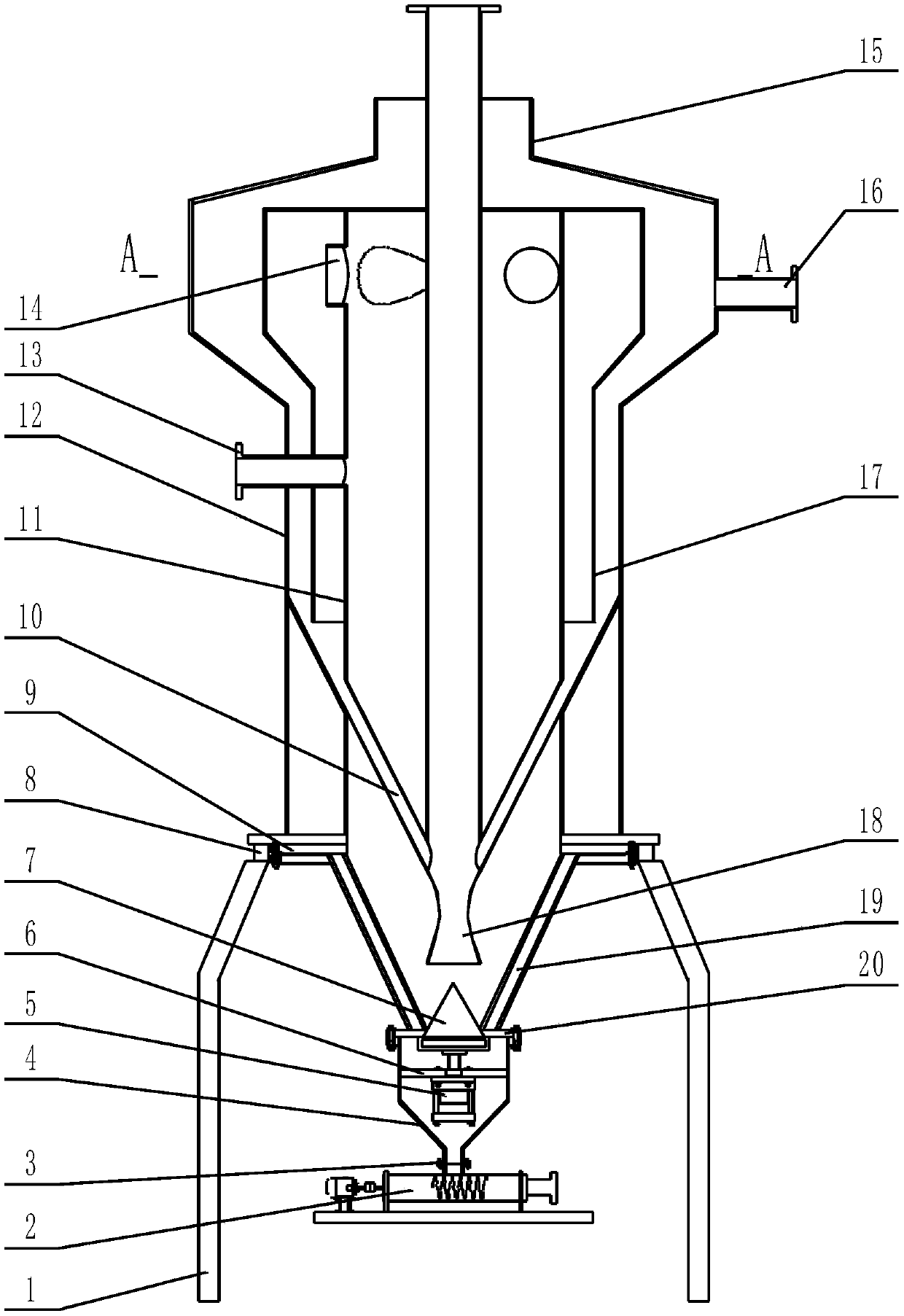

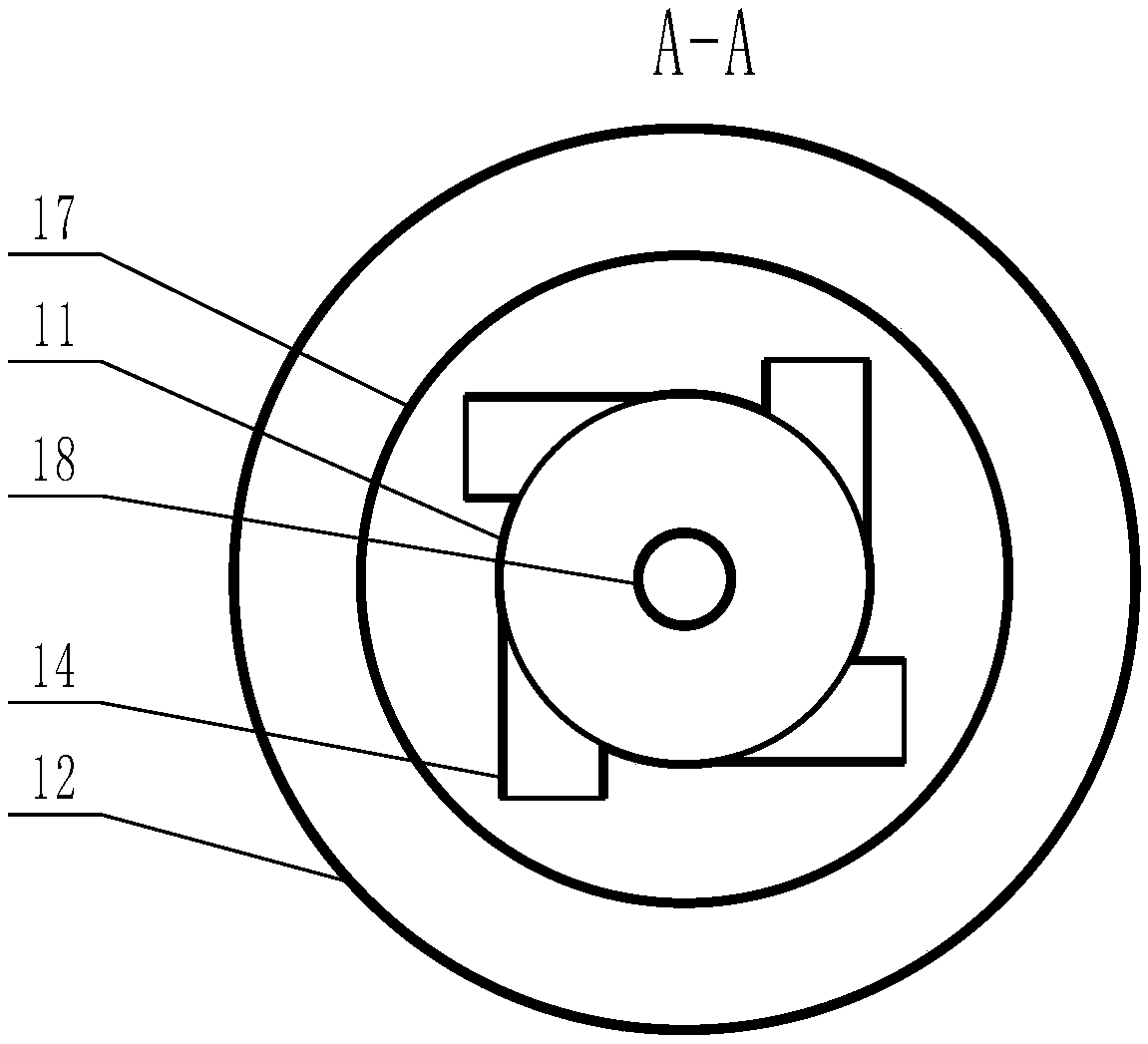

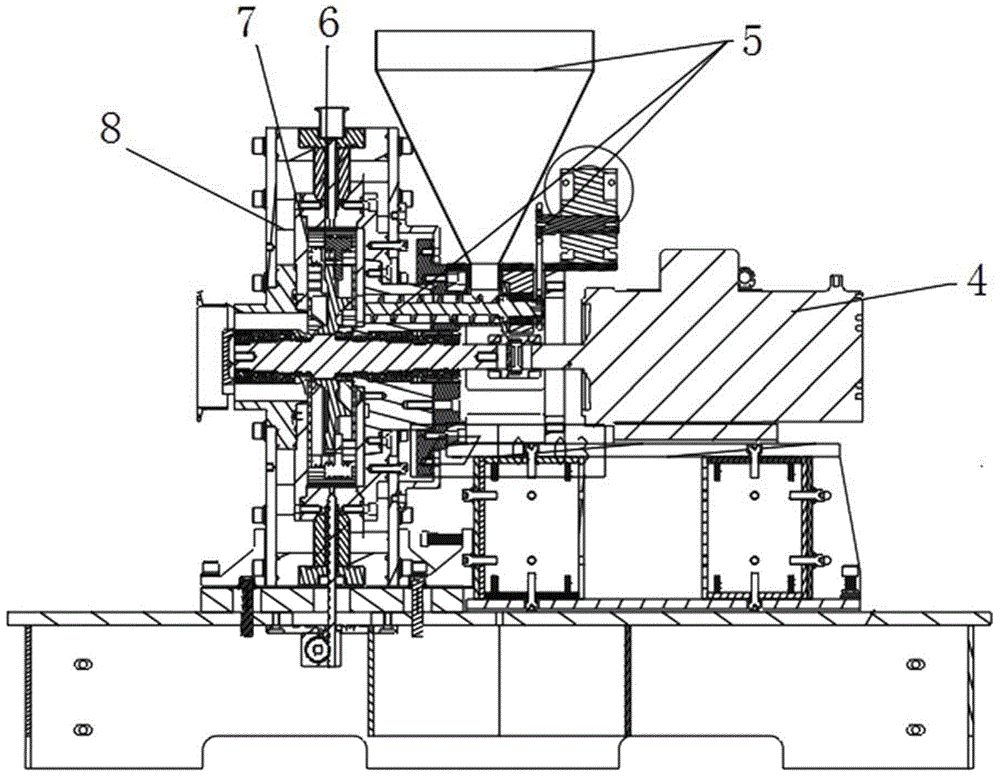

Screenless Reactor for Granular Moving Bed

ActiveUS20090130002A1Physical/chemical process catalystsLiquid degasificationScreenlessProcess engineering

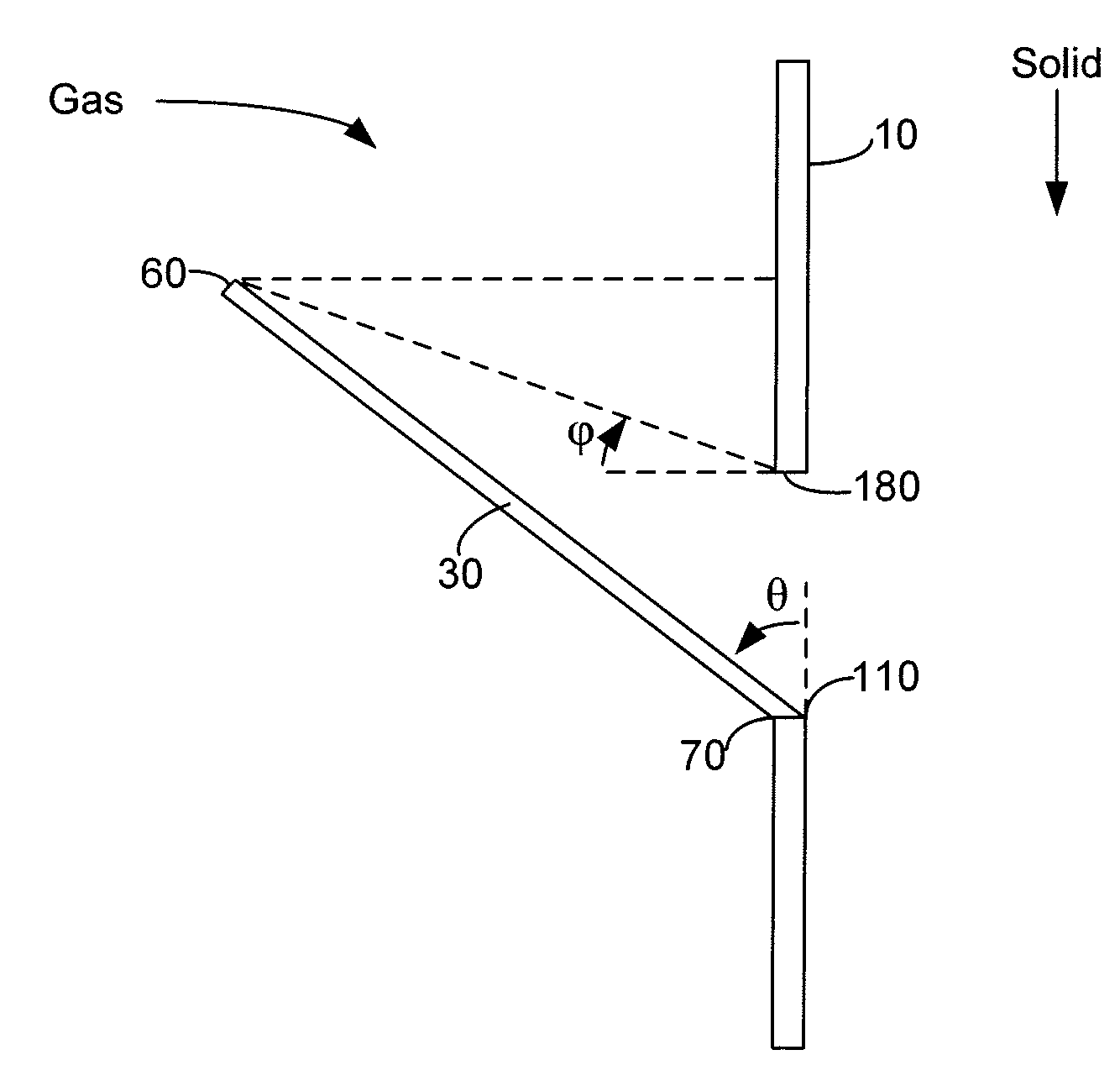

A screenless reactor design is presented. The reactor includes a series of overlapping vanes where solid catalyst can cascade down the vanes. Gas flows across the catalyst by flowing through the vanes contacting the catalyst and then disengaging from contact with the solid catalyst particles.

Owner:UOP LLC

Screenless Internals for Radial Flow Reactors

InactiveUS20080019886A1Physical/chemical process catalystsIsotope separationScreenlessSolid particle

An apparatus for contacting a bed of particulate material with a cross flowing fluid, which maintains the bed of particulate material within a retention volume. The apparatus includes partitions for retaining particles, with apertures disposed within the partitions. The apertures are covered by louvers that extend above the edges of the apertures to prevent solid particles from spilling through inlet apertures.

Owner:UOP LLC

Method for preparing PERC screenless printing single crystal solar cell sheet

InactiveCN109427920ALight attenuation (LID reductionReduced light decay (LID)Final product manufacturePhotovoltaic energy generationScreen printingScreenless

The present invention discloses a method for preparing a PERC (Passivated Emitter and Rear Cell) screenless printing single crystal solar cell sheet. A single crystal silicon wafer is used as a base material, and the PERC screenless printing single crystal solar cell sheet is prepared by the sequential steps of texture surface making, diffusion, etching, back passivation, anti-reflection film plating, laser grooving on the back surface, back electrode, back electric field and positive electrode printing, sintering, and light failure reduction. The step of back passivation is to plate Al2O3 andSiNX on the back surface of the silicon wafer; the step of the anti-reflection film plating is to plate the SiNX on the front side of the silicon wafer; and the step of the back electrode, back electric field, and positive electrode printing is to use silk-screen printing, and the positive electrode printing plate uses a screenless printing plate. According to the method for preparing the PERC screenless printing single crystal solar cell sheet provided by the present invention, the LID of the cell sheet can be reduced to around 1%, the power of the component product is improved, conversion efficiency is high, and both the grade and electrical properties are significantly improved.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID

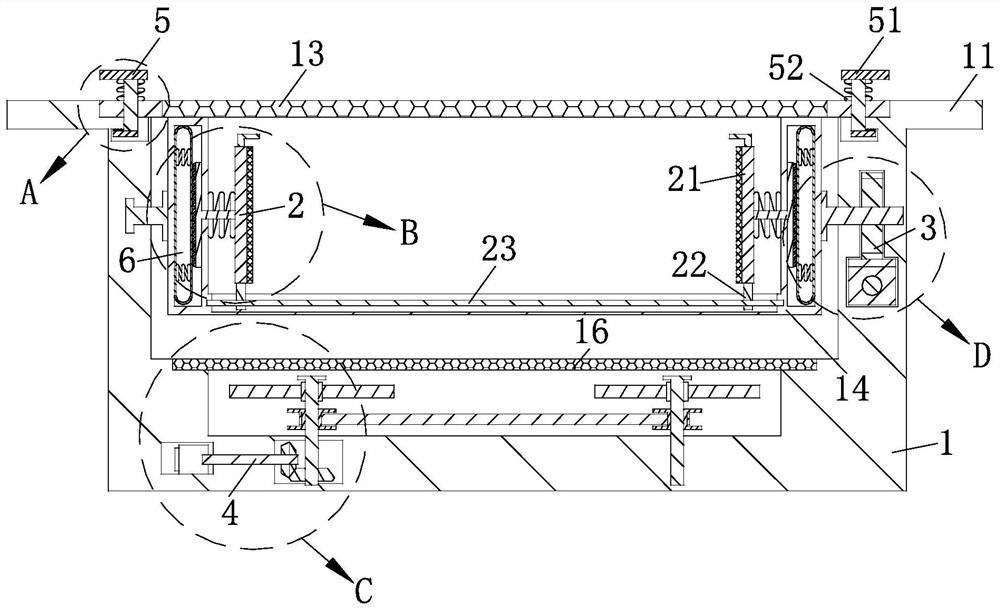

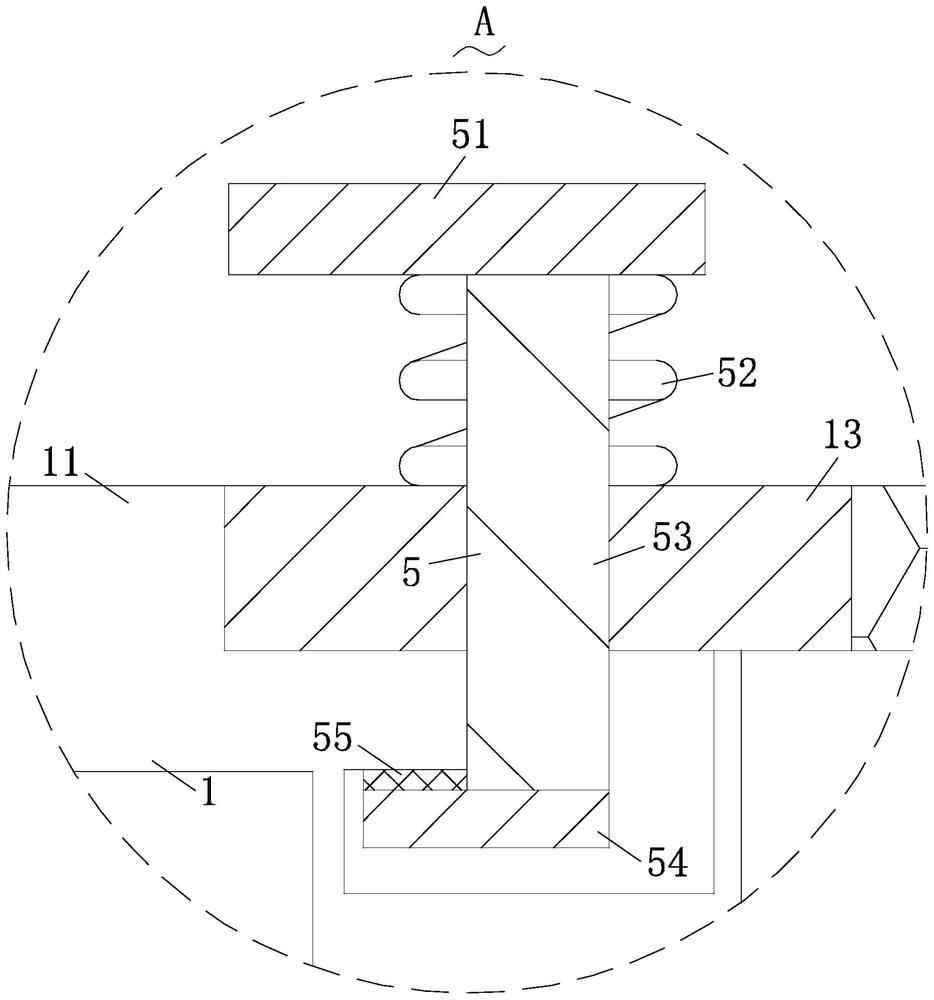

XY-type screenless self-service vending terminal and goods track position calibration method thereof

InactiveCN109544796AQuick calibrationImprove calibration efficiencyCoin-freed apparatus detailsApparatus for dispensing discrete articlesScreenlessComputer terminal

The invention discloses an XY-type screenless self-service vending terminal and a goods track position calibration method thereof. The self-service vending terminal is provided with an MCU, an XY-typegoods receiving mechanism and multiple rows of goods tracks. The XY-type goods receiving mechanism is connected with the MCU. The self-service vending terminal does not have a display screen. The method is characterized by comprising the following steps of: (1) association step: associating the self-service vending terminal with a calibration device; and (2) calibration step: maintaining the calibration device in communication with the self-service vending terminal; using the calibration device to control actions of the goods receiving mechanism of the self-service vending terminal to achievethe position calibration for the goods tracks. The XY-type screenless self-service vending terminal and the goods track position calibration method thereof are easy to implement and flexible.

Owner:HUNAN KIMMA INTELLIGENT EQUIP MFR

Screenless reactor for granular moving bed

ActiveUS7846402B2Physical/chemical process catalystsLiquid degasificationScreenlessProcess engineering

A screenless reactor design is presented. The reactor includes a series of overlapping vanes where solid catalyst can cascade down the vanes. Gas flows across the catalyst by flowing through the vanes contacting the catalyst and then disengaging from contact with the solid catalyst particles.

Owner:UOP LLC

Screenless flow-through battery material dryer

The invention relates to a flow-washing-type battery material dryer free of a screen cloth. The flow-washing-type battery material dryer free of the screen cloth is characterized in that the dryer comprises a support, a spiral material feeder, a first flange plate, a discharging pipe, an air cylinder, a material dropping plate, a sealing piston, a weighing device, a second flange plate, a Venturi branched tube, an airflow tank, a return air tank, a feeding pipe, a cyclone air outlet pipe, an air return pipe, a vacuum pumping pipe, a reflux tank, a Venturi tube and a third flange plate; the airflow tank comprises an upper airflow tank section and a lower airflow tank section, and the upper airflow tank section and the lower airflow tank section communicate with each other; the reflux tank is arranged at the outer side of the upper portion of the upper airflow tank section in a sleeving mode; the upper end of a space between the reflux tank and the upper airflow tank section is closed, and the lower end of the space is opened; and the reflux tank is of a cylinder structure with the cross section circle variable. According to the flow-washing-type battery material dryer, the return air tank, the reflux tank, the airflow tank and the Venturi tube are sequentially nested from outside to inside, so that the heat preservation effect of the dryer is made good; and moreover, heat is transmitted between the multiple layers of the pipes, after all layers of pipe walls are heated by hot air, the heat can be radiated outwards from the pipe walls, and powder drying is accelerated.

Owner:HEBEI UNIV OF TECH +1

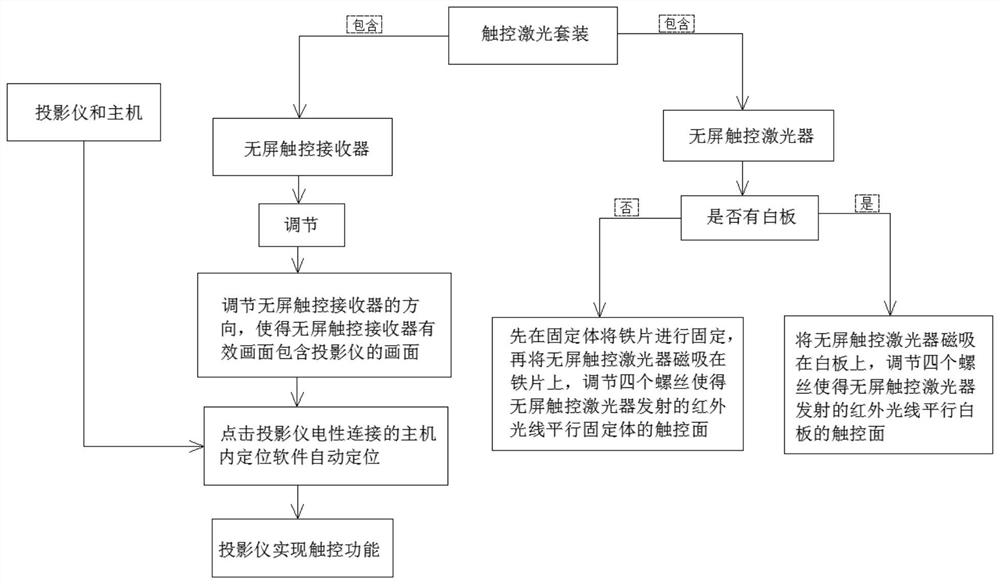

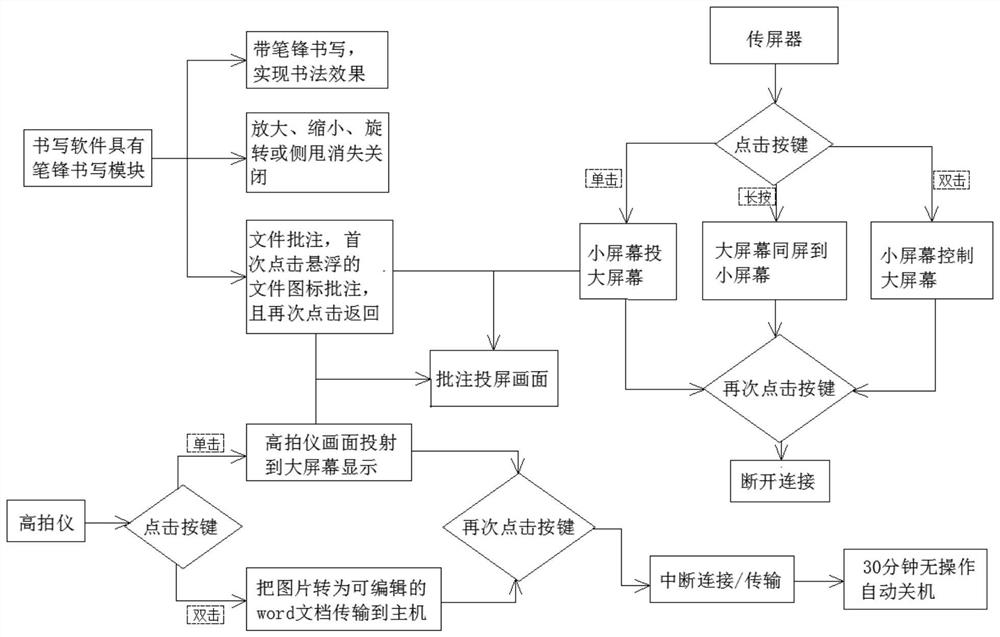

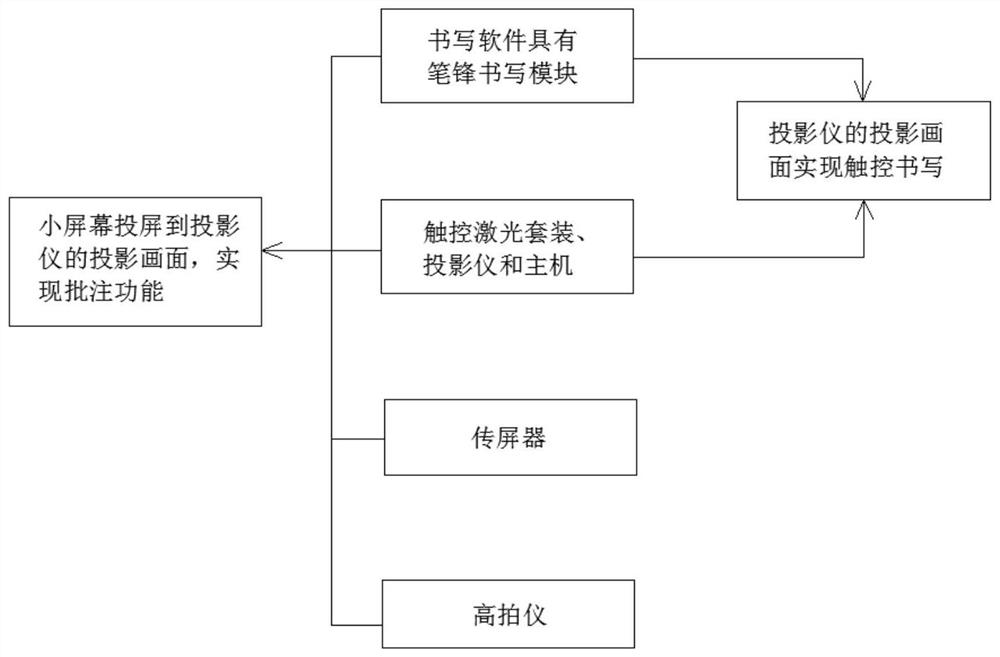

Smart touch projection system

ActiveCN110312114BSolve the incompatibilityImprove experienceProjectorsPicture reproducers using projection devicesComputer hardwareScreenless

The invention discloses an intelligent touch projection system, which includes a touch laser set and a projector used in cooperation with each other. The projection screen of the projector is located in the shooting area of the camera. Control receiver, the screenless touch laser is installed on a fixed body, the fixed body has a touch surface, the light emitted by the screenless touch laser is parallel to the touch surface, the screenless touch receiver receives the projection screen of the projector, and the host is installed There is a positioning software to touch the projection screen of the projector to operate the opening and disconnection between the screen transmitter and the projector. The writing software is installed in the main unit, and the information of the writing software is projected to the touch surface to solve the incompatibility of software and hardware products in the current market and provide customers with one-stop service.

Owner:深圳市云海易联电子有限公司

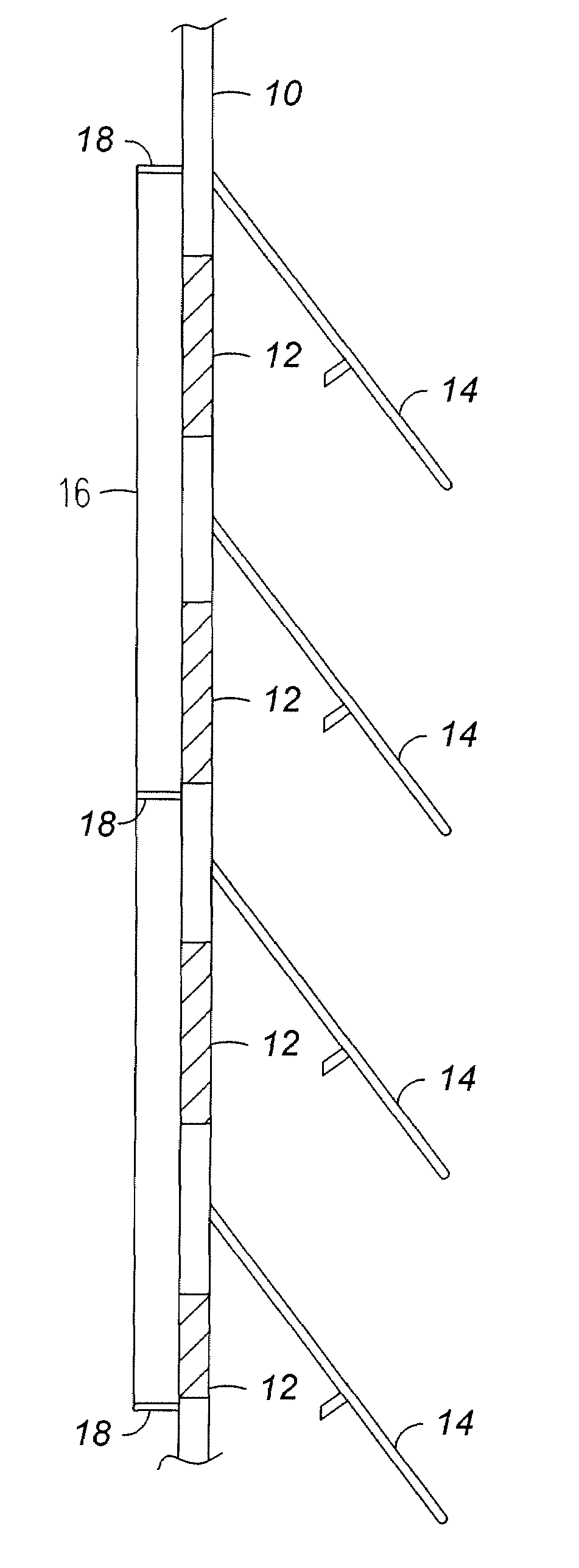

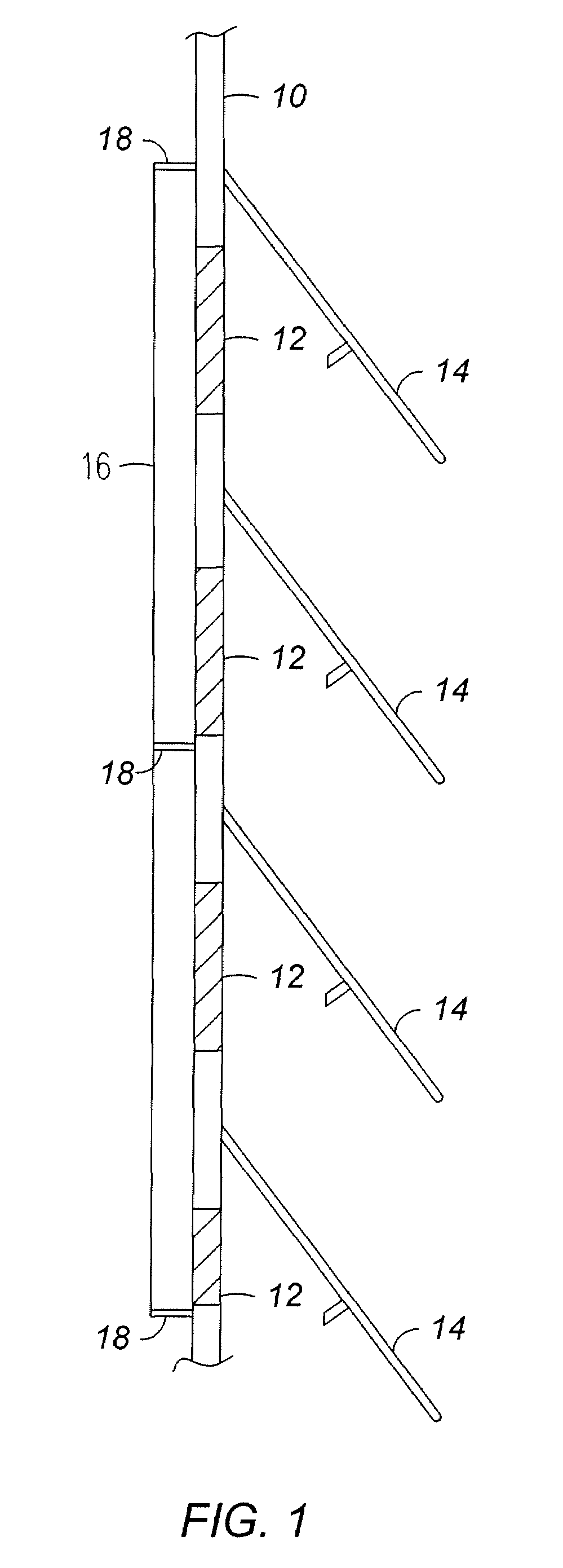

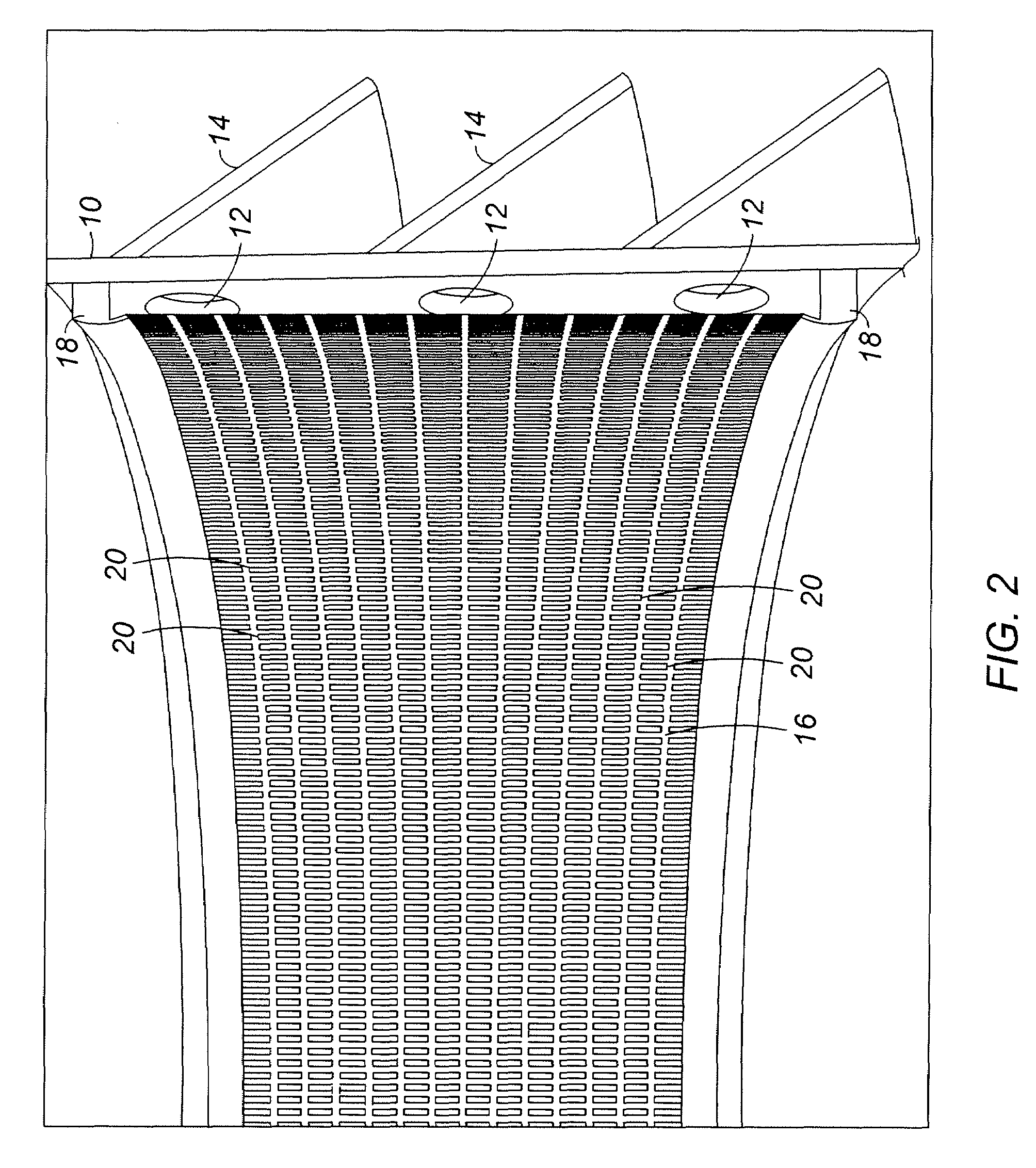

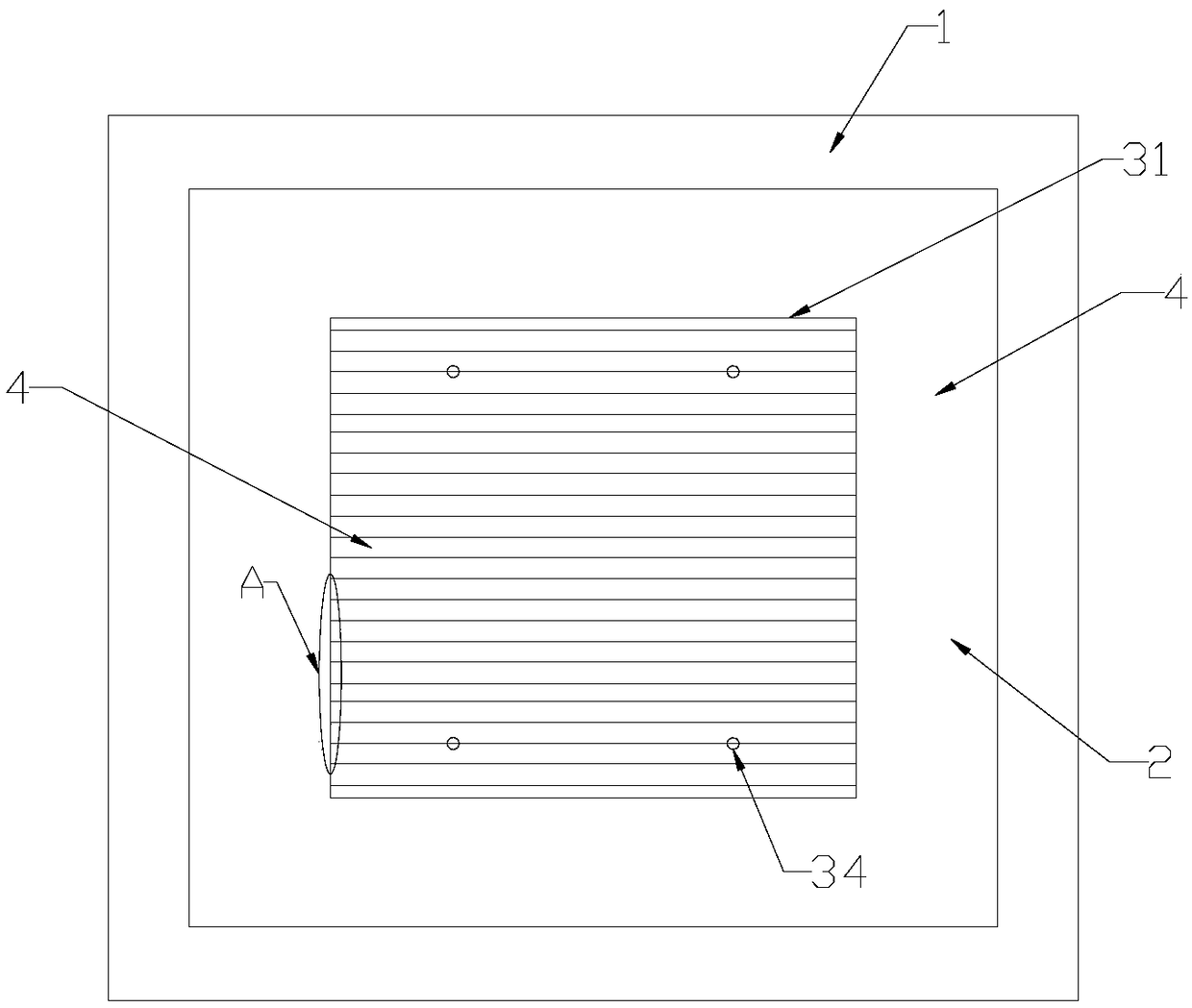

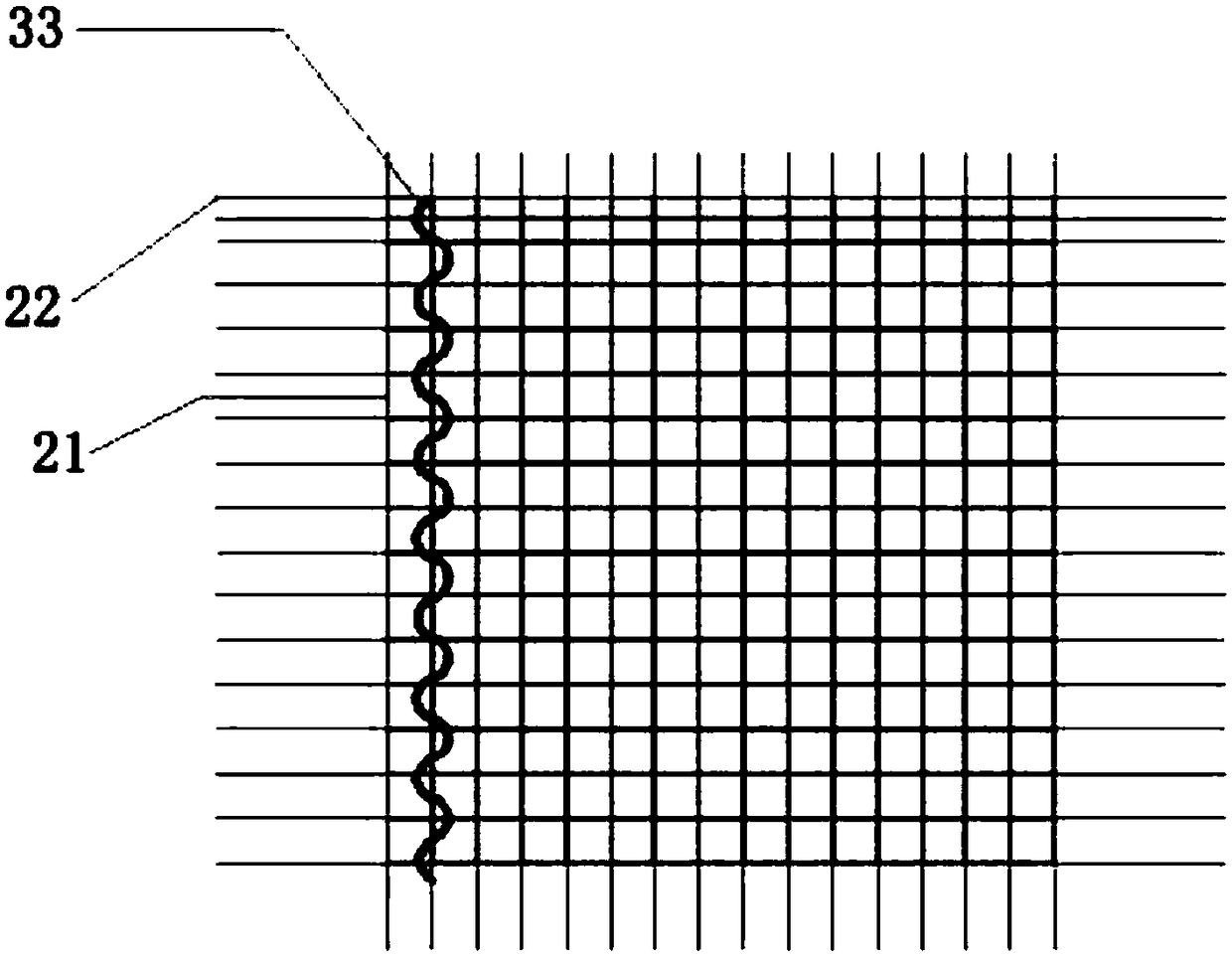

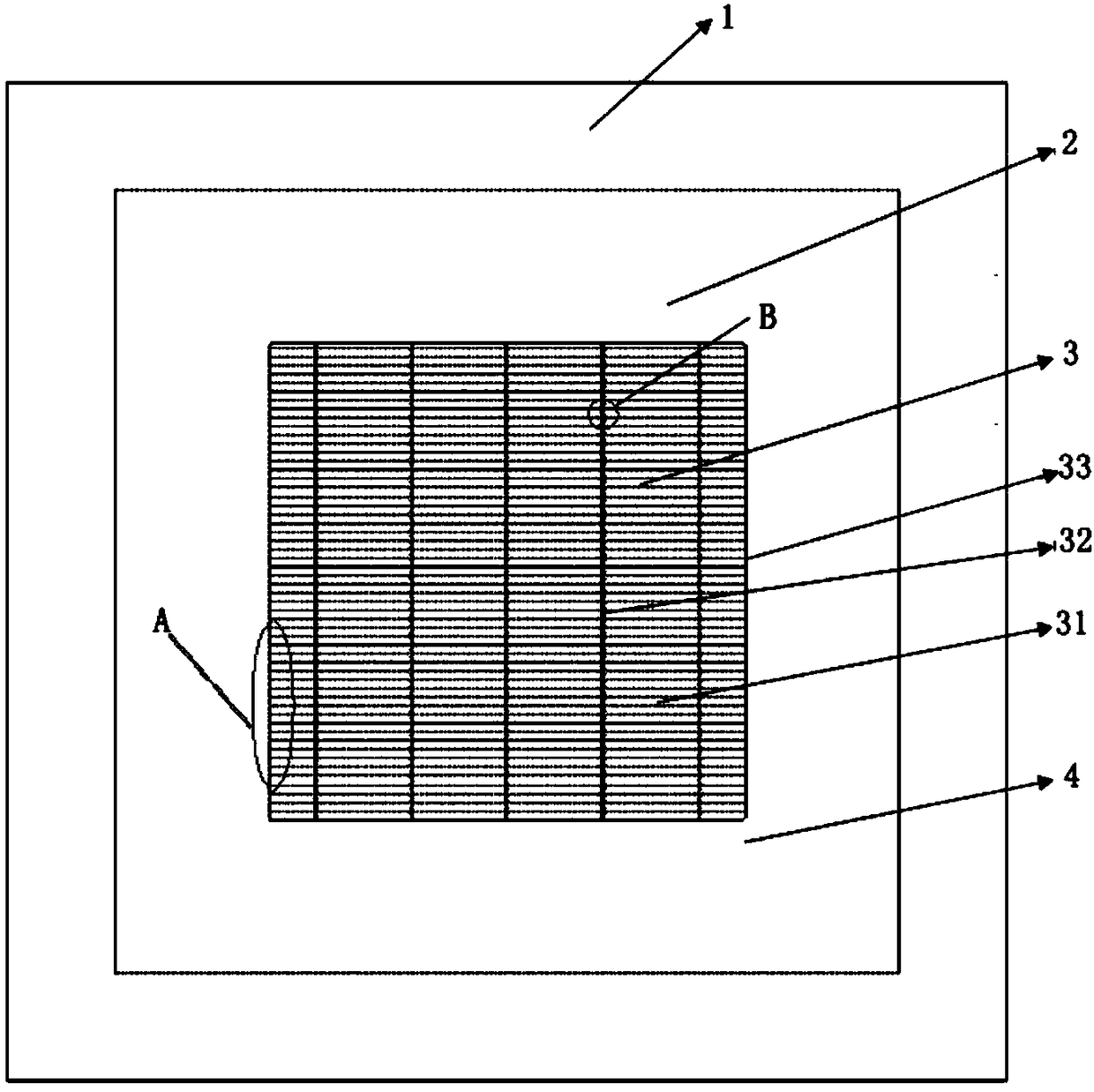

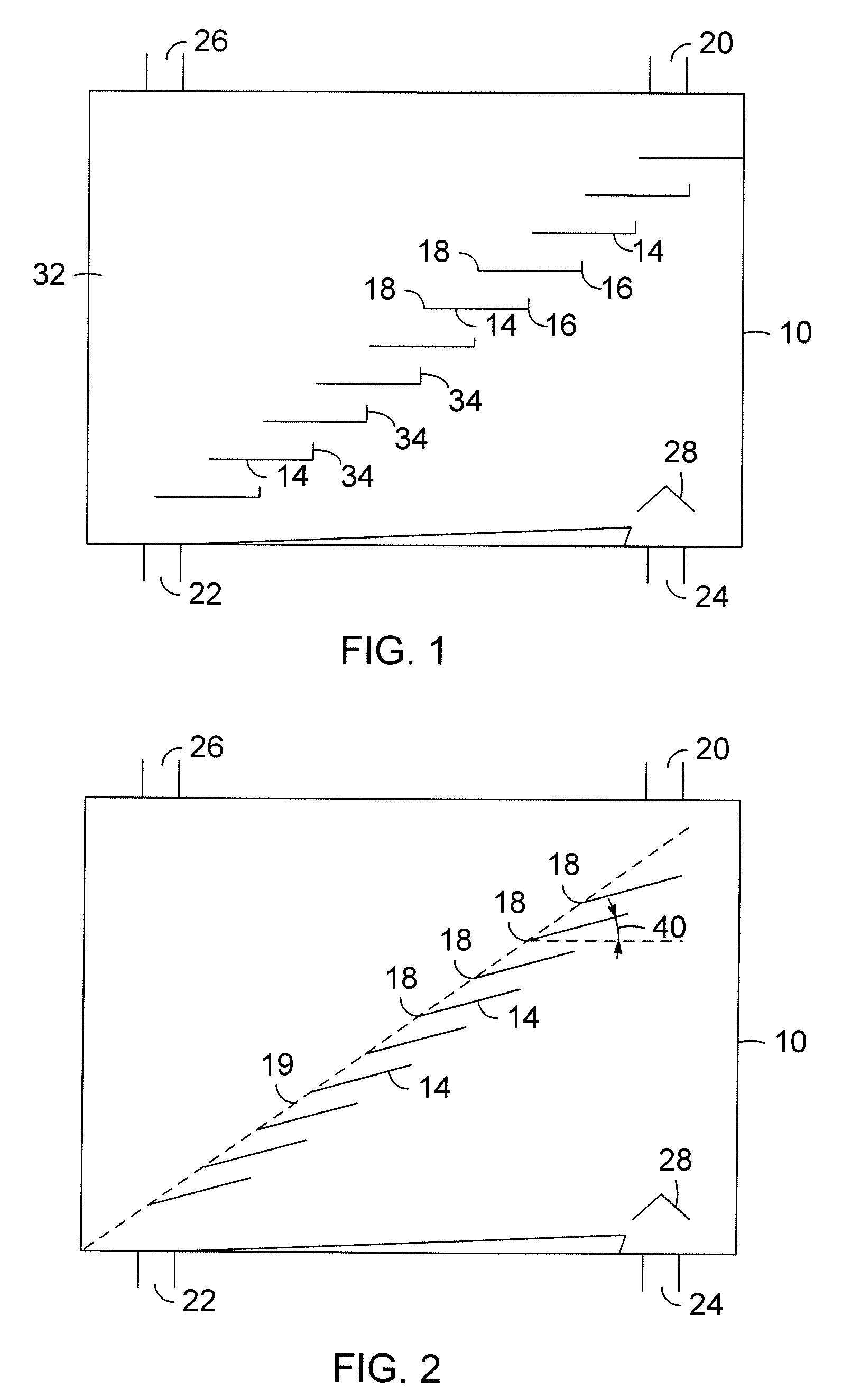

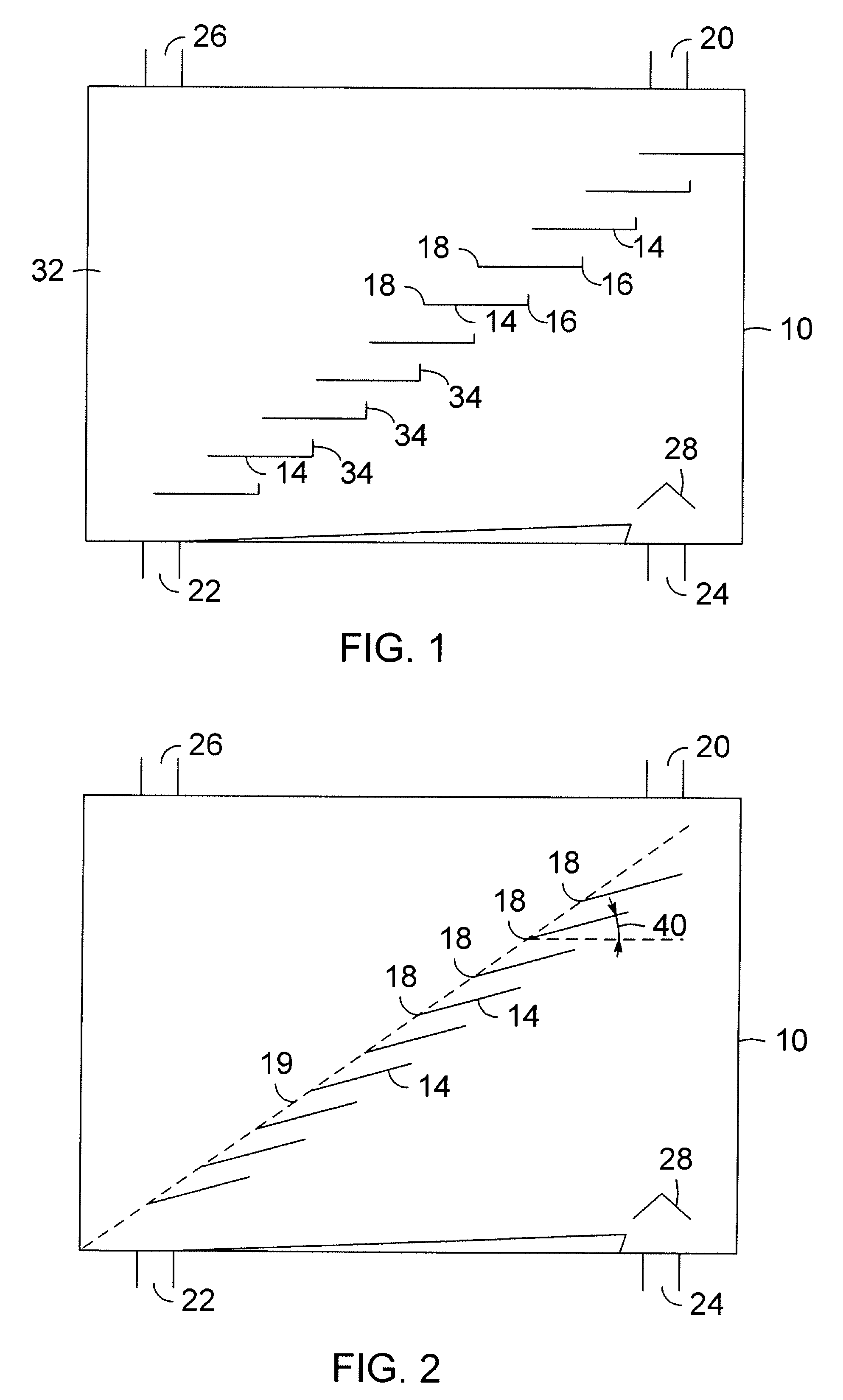

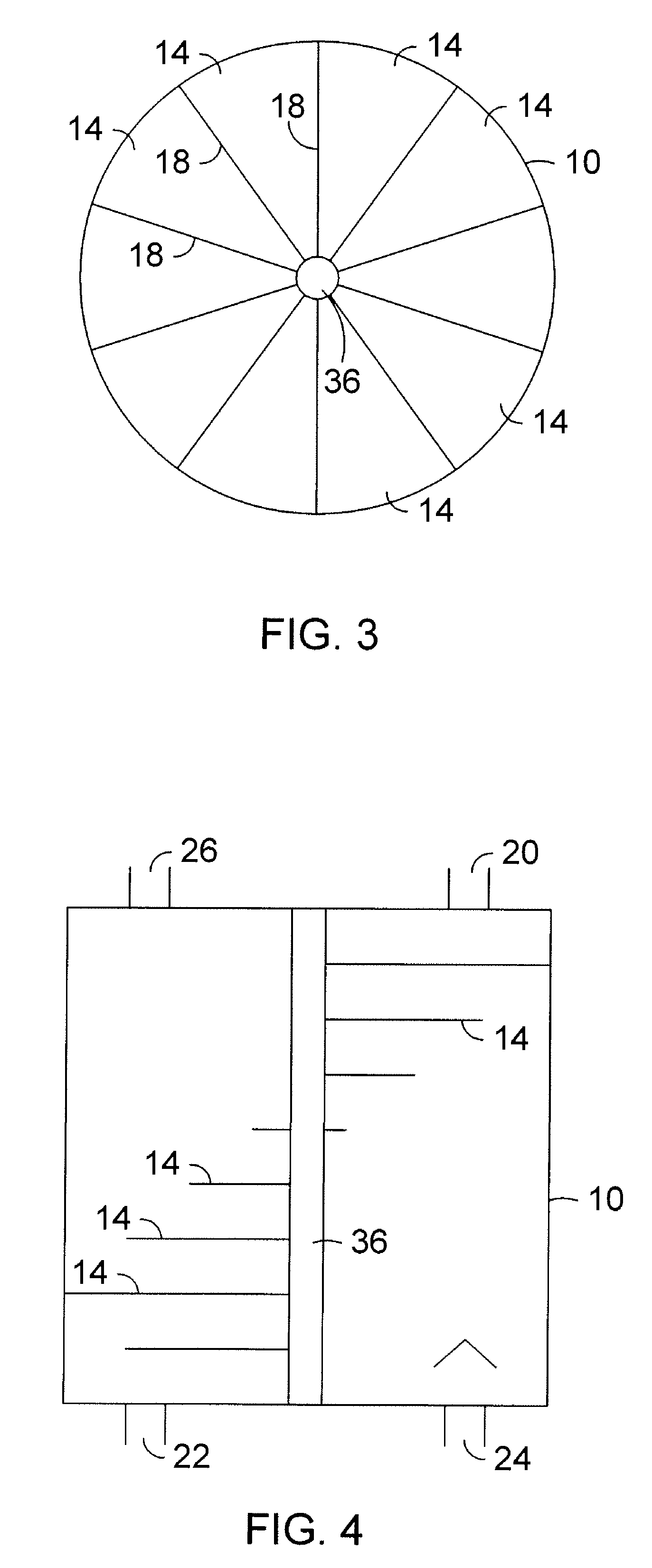

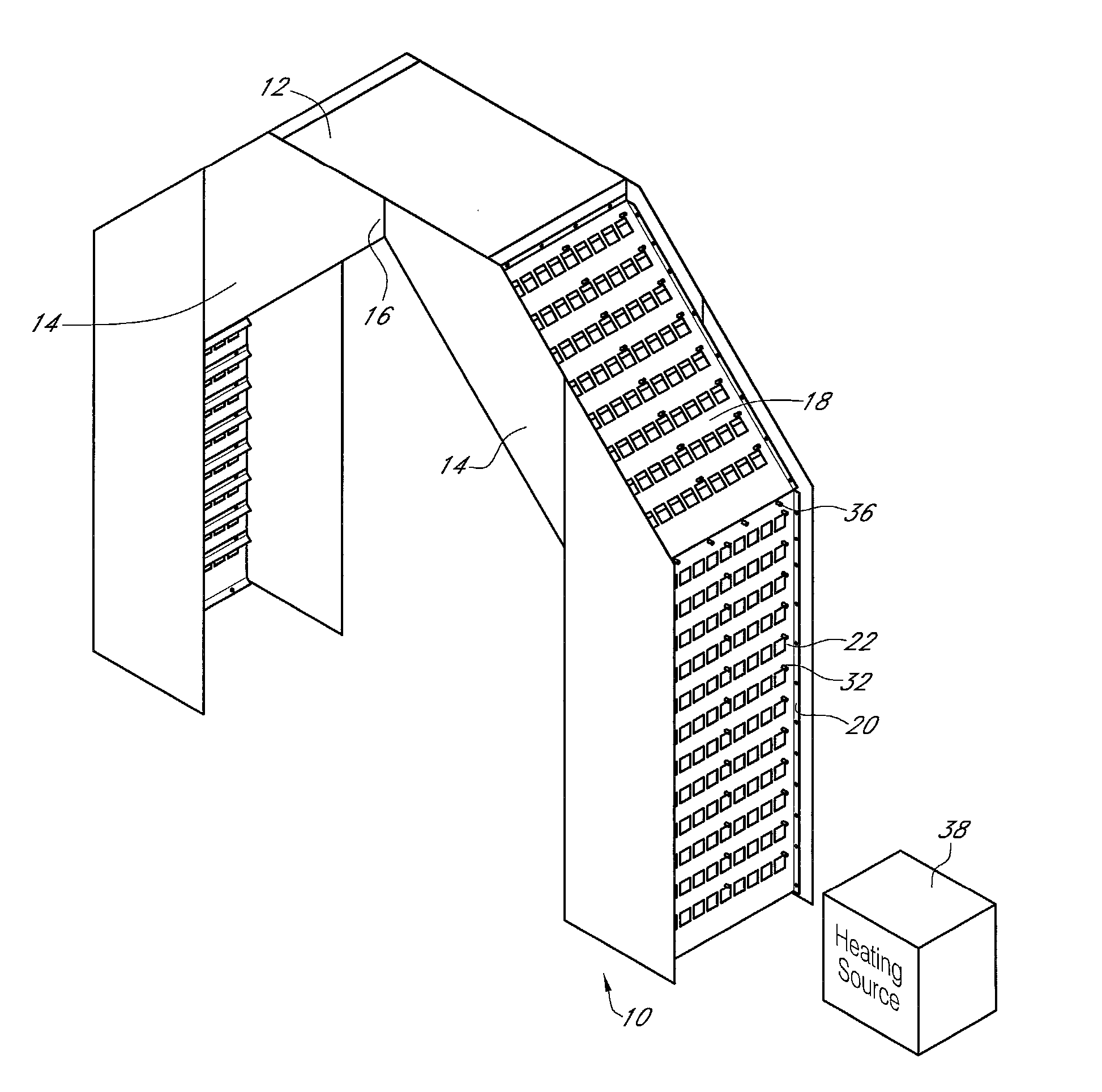

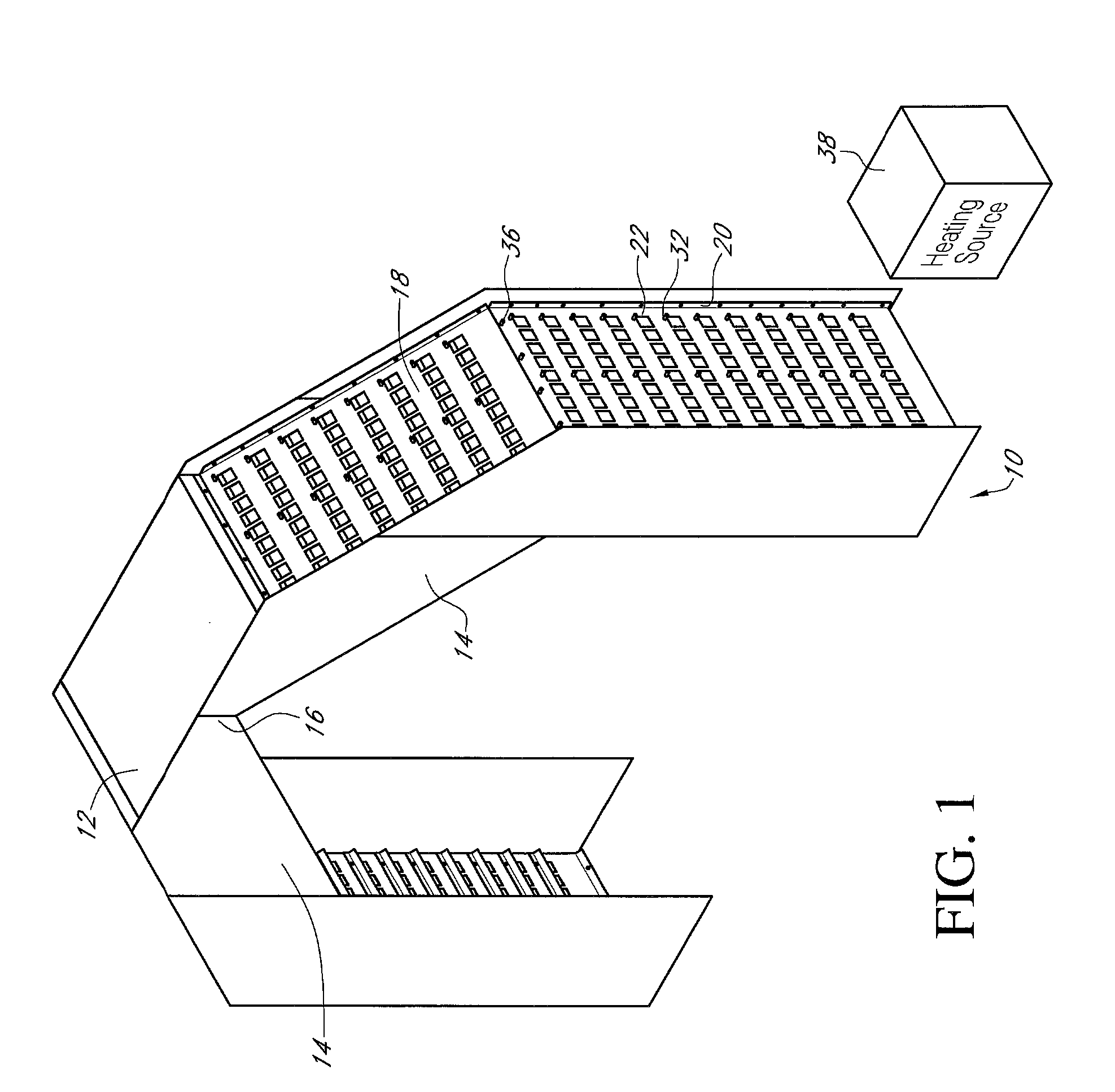

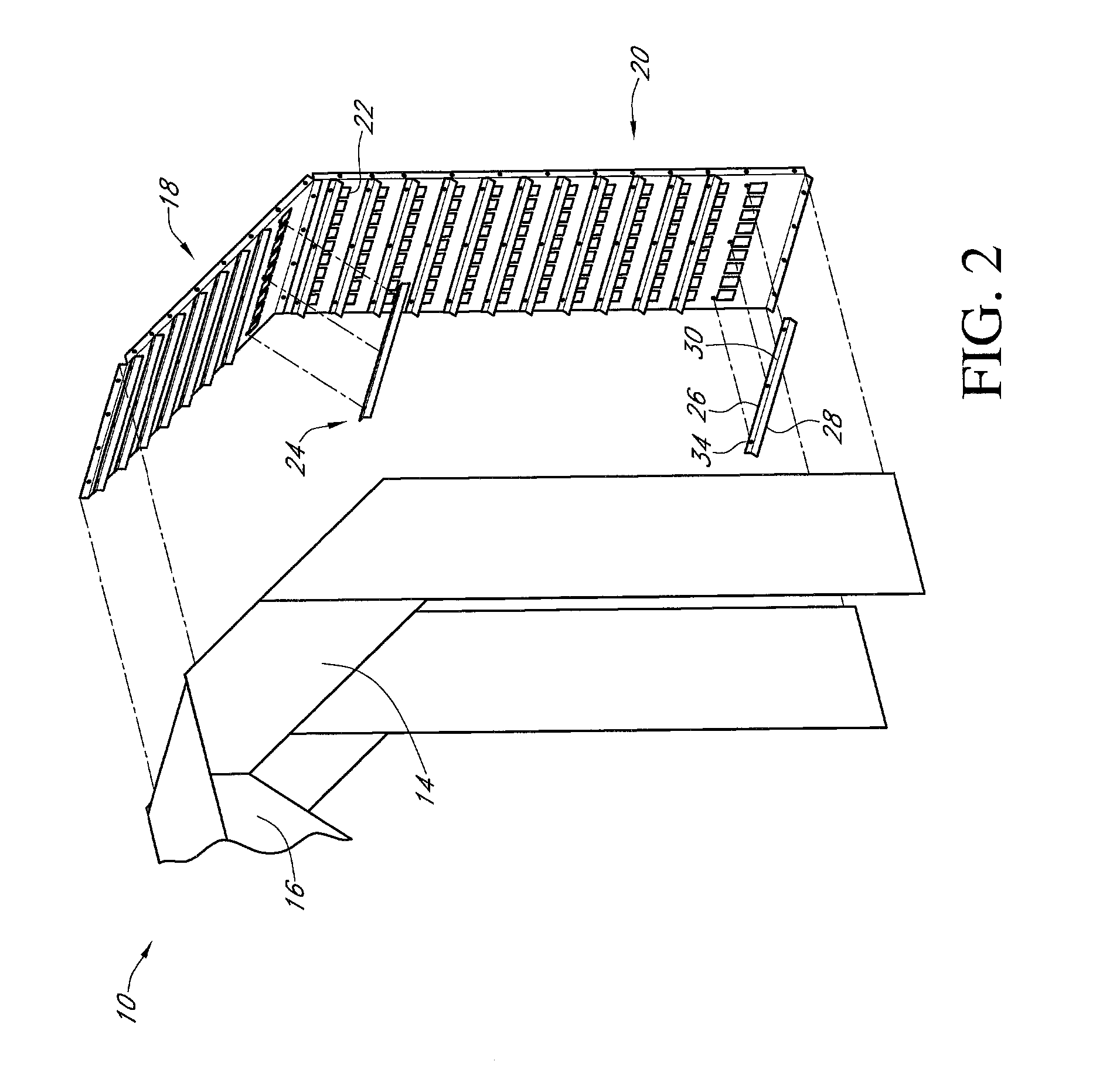

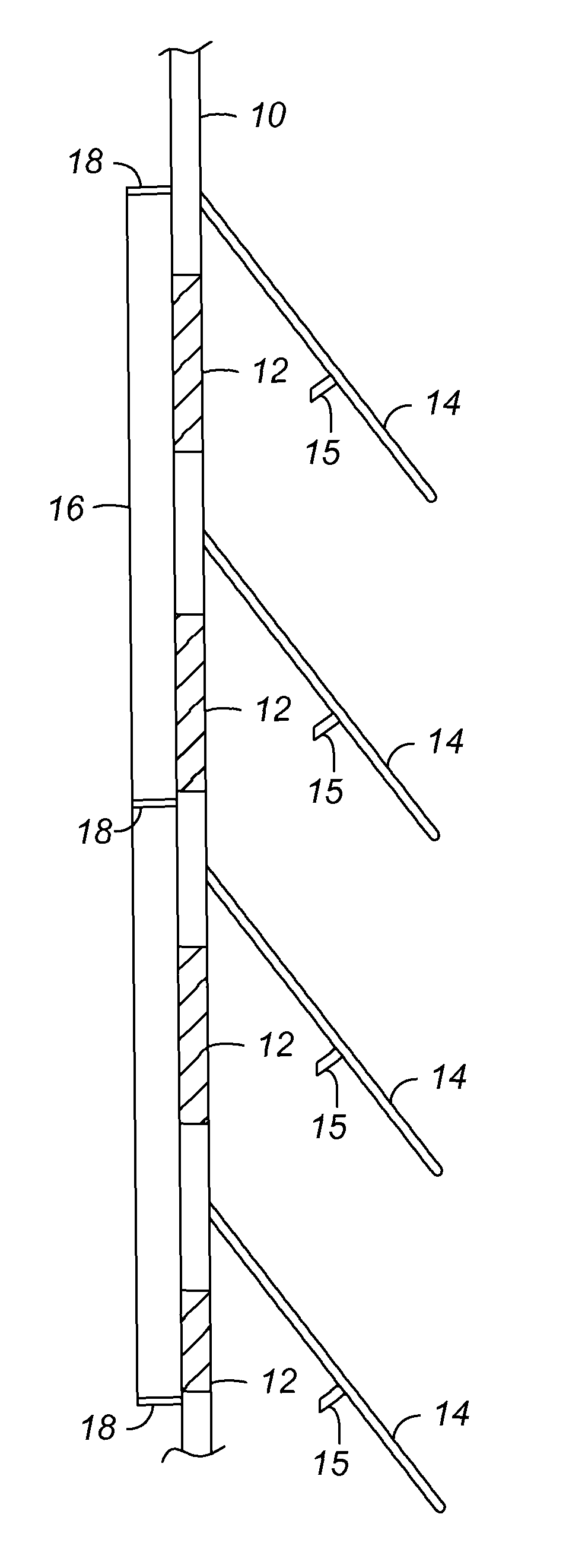

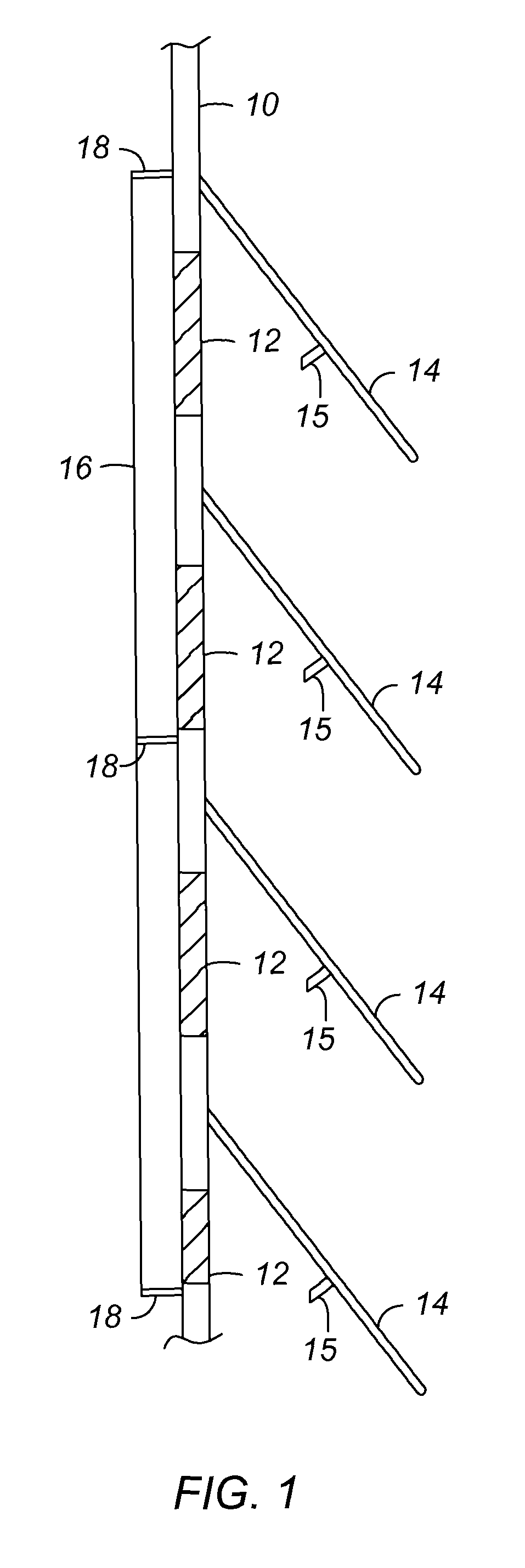

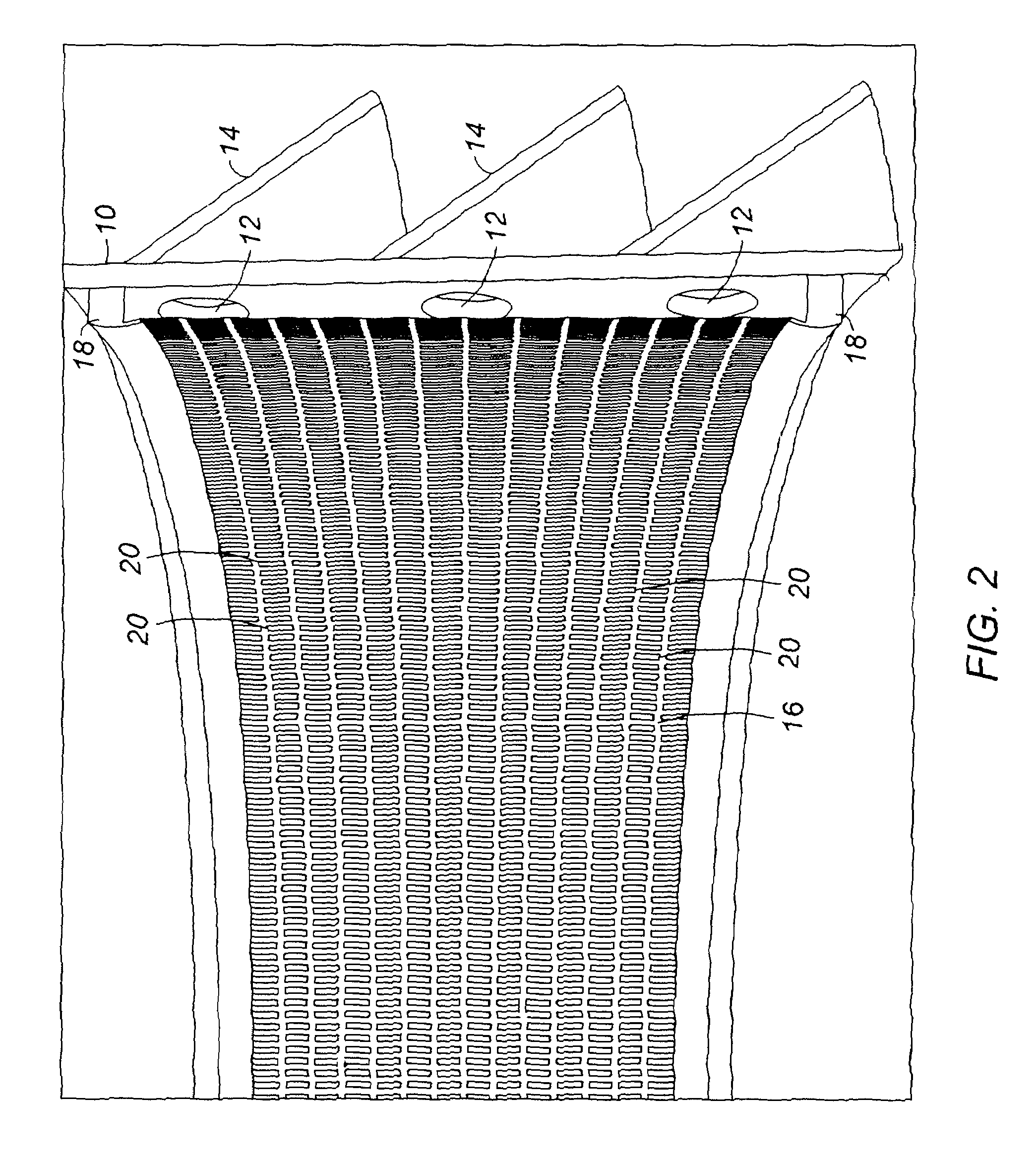

Screenless panels for a grain dryer

A plurality of screenless panels for a grain dryer having a plurality of cut outs to receive forced heated air from a heating system. The panels have a plurality of deflectors attached above the cut outs of the panels such that debris and grain fines is prevented from obstructing airflow. The deflectors have a connecting section and a deflecting section that is bent away from the connecting section along a bend line. The deflectors are connected to the panels by bolts placed through aligned apertures in the panels and deflectors.

Owner:SUKUP MFG

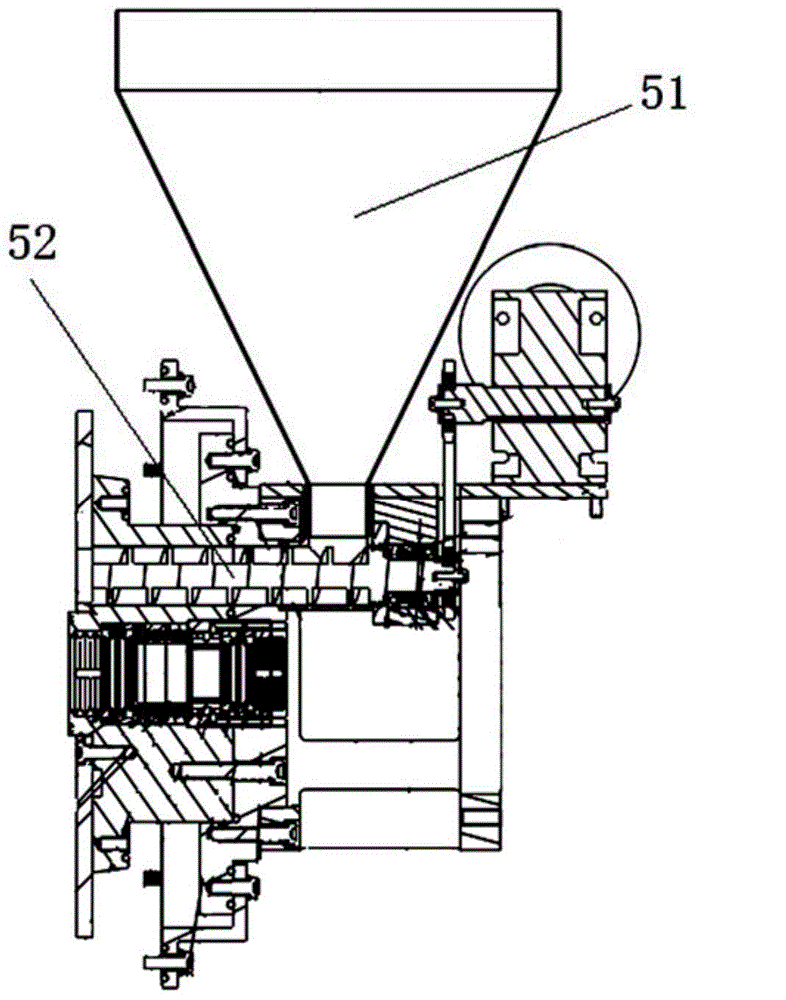

Discharging mechanism of energy-level molecular material cell tearing equipment and discharging method

InactiveCN104785184AAchieve sieve-free separationEnsure stabilityEnergy based chemical/physical/physico-chemical processesMicroballoon preparationNegative feedbackScreenless

The invention discloses a discharging mechanism of energy-level molecular material cell tearing equipment. The discharging mechanism is characterized by comprising a baffle, at least one material guide outlet penetrating through the baffle, and at least two negative feedback pressure adjusting holes formed in the periphery of the material guide outlet. During actual working, the baffle is arranged on an energy field cavity of the cell tearing equipment and serves as a side surface of the energy field cavity, and materials with large mass are thrown to the edge of the energy field cavity by centrifugal force under the action of centrifugal and centripetal forces in the energy field cavity; materials with small mass are collected to the center of the energy field cavity by the centripetal force under the action of a pressure difference, so that the materials are guided out and collected by the material guide outlet and screenless separation of the materials is realized. Particularly, when the materials are guided out, feedback air pressure is injected into the negative feedback pressure adjusting holes at the same time to effectively guarantee that the materials are guided out stably and uniformly.

Owner:广东如动纳米科技有限公司

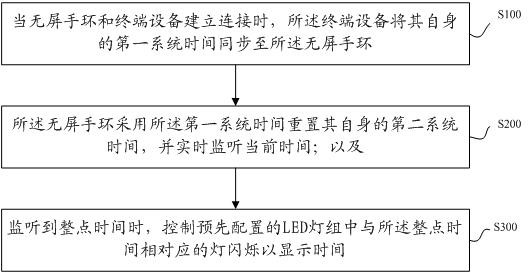

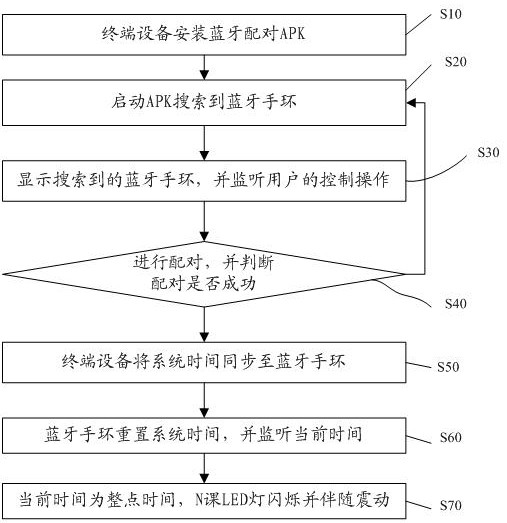

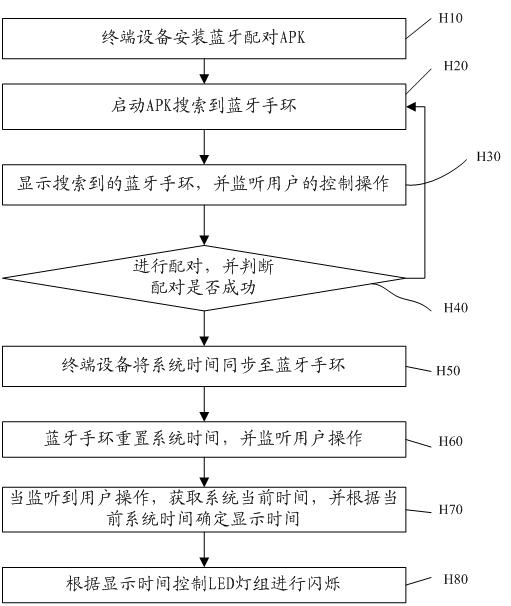

A method and system for controlling display time of a non-screen wristband

ActiveCN106658846BDisplay time withEasy to useElectrical apparatusElectroluminescent light sourcesScreenlessTerminal equipment

The invention discloses a method and system for controlling the display time of a non-screen wristband. The method includes that when a connection is established between the screenless wristband and a terminal device, the terminal device synchronizes its own first system time to the No-screen bracelet; the no-screen bracelet uses the first system time to reset its own second system time, and monitors the current time in real time; and when the hour is monitored, it controls the preconfigured LED lights The lights corresponding to said hour blink to show the time. In the present invention, the LED light group is arranged on the non-screen wristband, and the LED light group is controlled to perform corresponding display according to the monitored hourly time, so that the non-screen wristband has the function of displaying time, which brings convenience to users.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

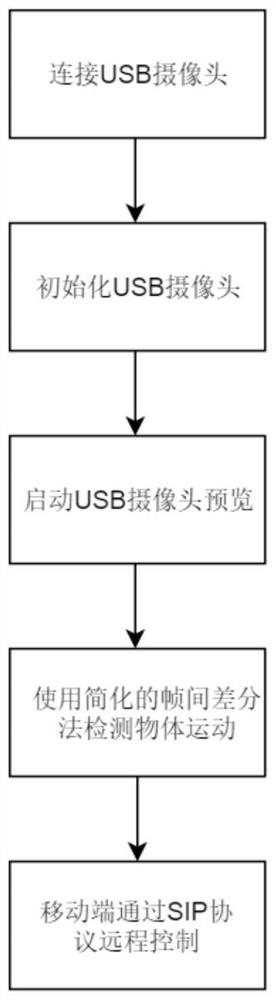

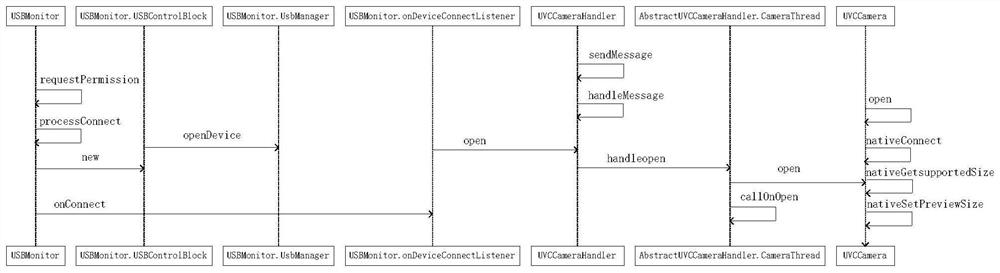

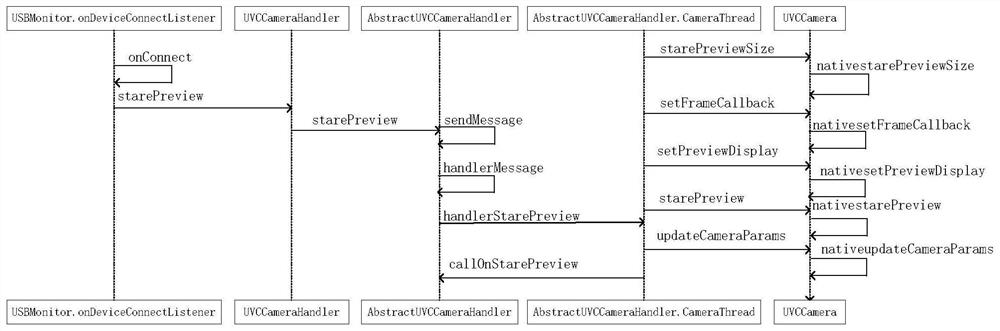

Method for realizing video monitoring and remote control of pet feeder

PendingCN111614866ADetection speedRealize the function of motion detectionTelevision system detailsColor television detailsSession Initiation ProtocolVideo monitoring

The invention relates to a method for realizing video monitoring and remote control of a pet feeder, and the method comprises the following steps: 1) connecting a USB camera to the pet feeder of an Android system which has no screen and cannot be operated by a user, and opening an Android studio; 2) initializing a USB camera in a main activity in the Android studio; 3) starting a USB camera to preview; 4) detecting object motion of each frame acquired by the USB camera by adopting a simplified inter-frame difference method; 5) enabling the mobile terminal to remotely control the equipment through an SIP protocol. The invention discloses a pet feeder with an Android system. The pet feeder is free of a screen and cannot be operated by a user. The universal serial bus camera is connected to apet feeder, a method for initializing the USB camera and a simplified inter-frame difference method are provided to achieve motion detection of an object, and then remote control over the pet feederis achieved on a mobile terminal through a session initiation protocol (SIP).

Owner:ZHEJIANG UNIV OF TECH

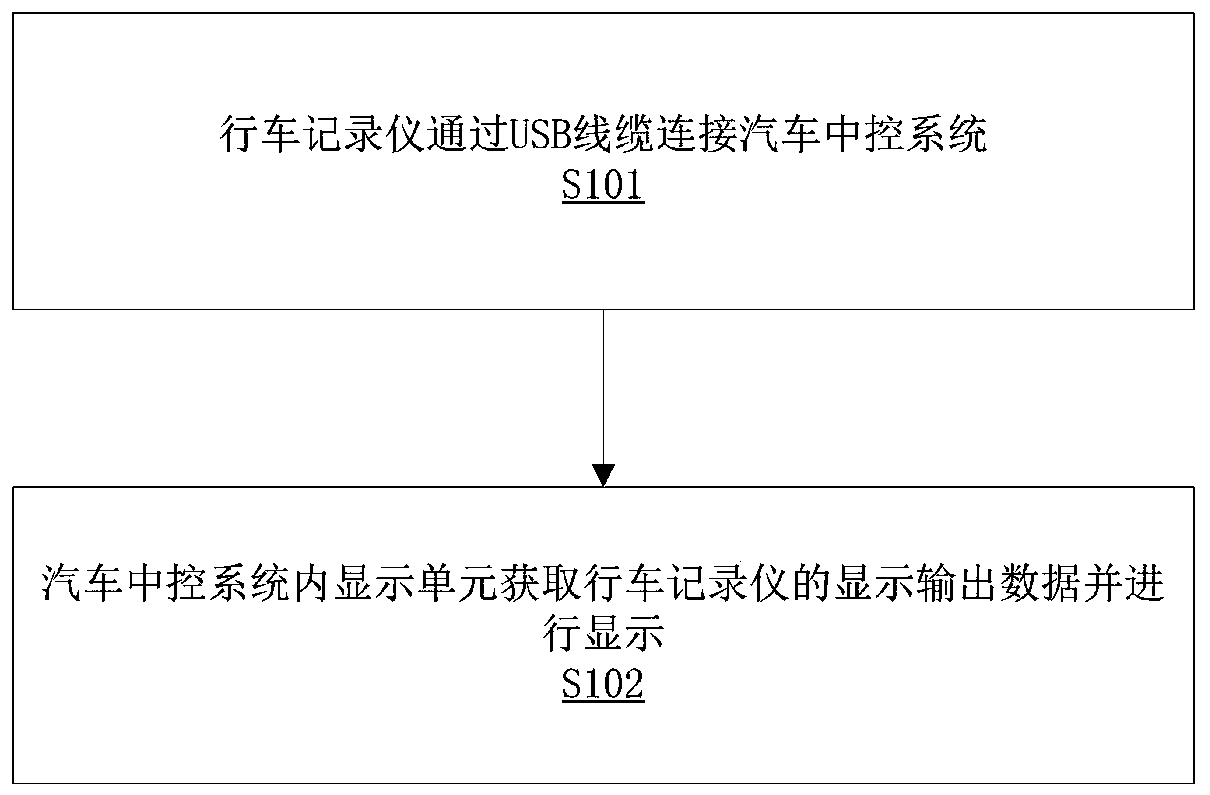

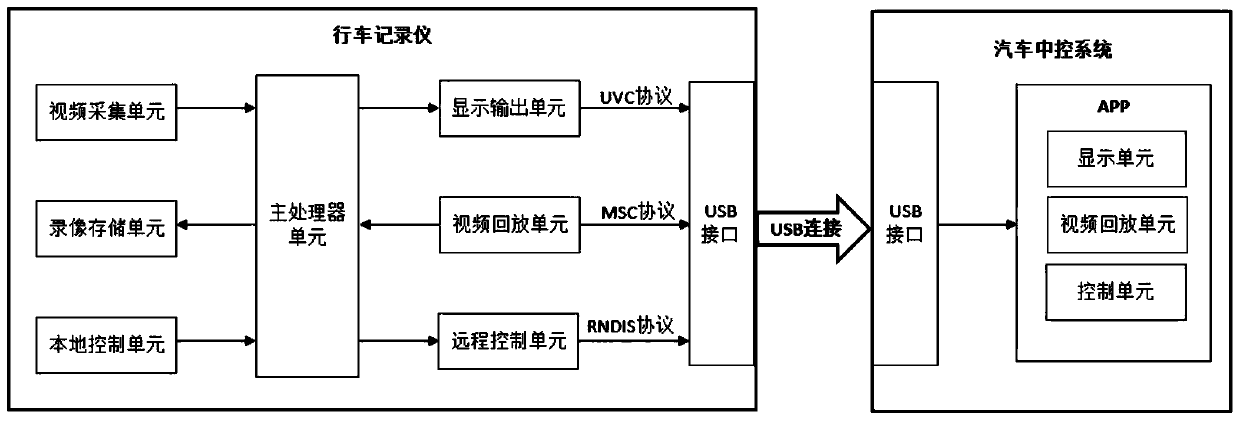

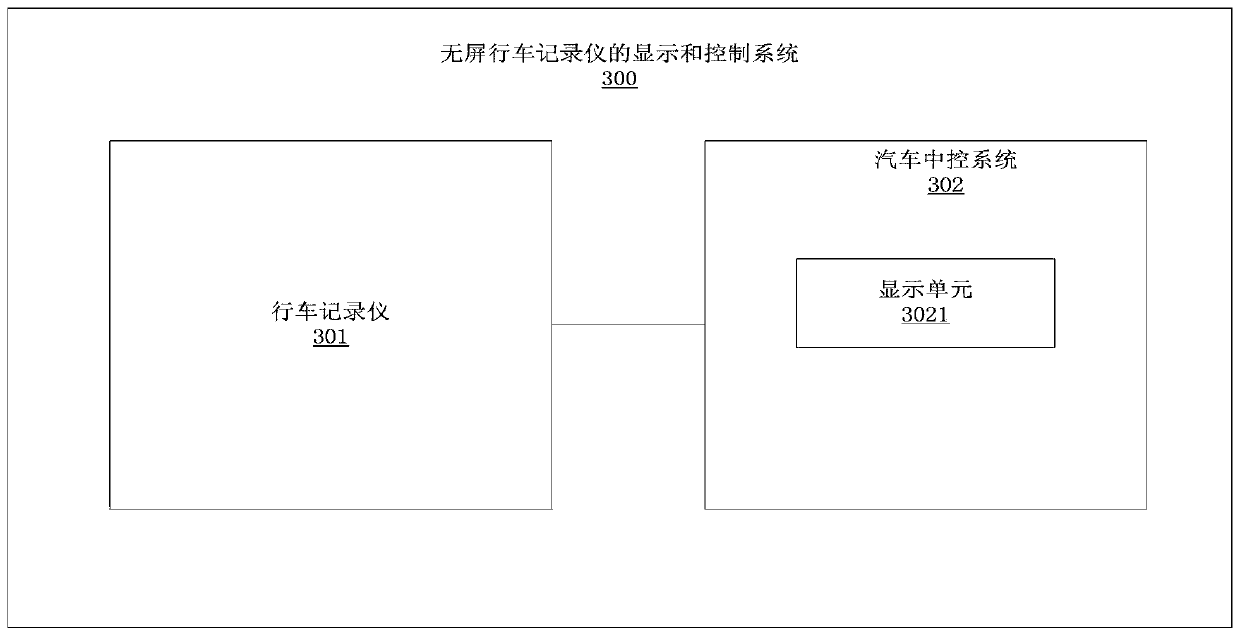

Display and control method and system for screenless driving recorder

InactiveCN110363881ALow costRegistering/indicating working of vehiclesDigital output to display deviceScreenlessControl system

The invention relates to the technical field of automobiles, and in particular to a display and control method and a display and control system for a screenless driving recorder. The display and control method of the screenless driving recorder comprises the steps that: the driving recorder is connected with an automobile central control system by means of a USB cable; and a display unit in the automobile central control system acquires display output data of the driving recorder and displays the data. The video data of the driving recorder can be viewed by means of the automobile central control system without the need of connecting a mobile phone additionally by means of WIFI, thus the limitations in use in the prior art are removed, and the driving recorder does not need to be equippedwith a WIFI module, thereby greatly saving the cost of the driving recorder.

Owner:FUZHOU ROCKCHIP SEMICON

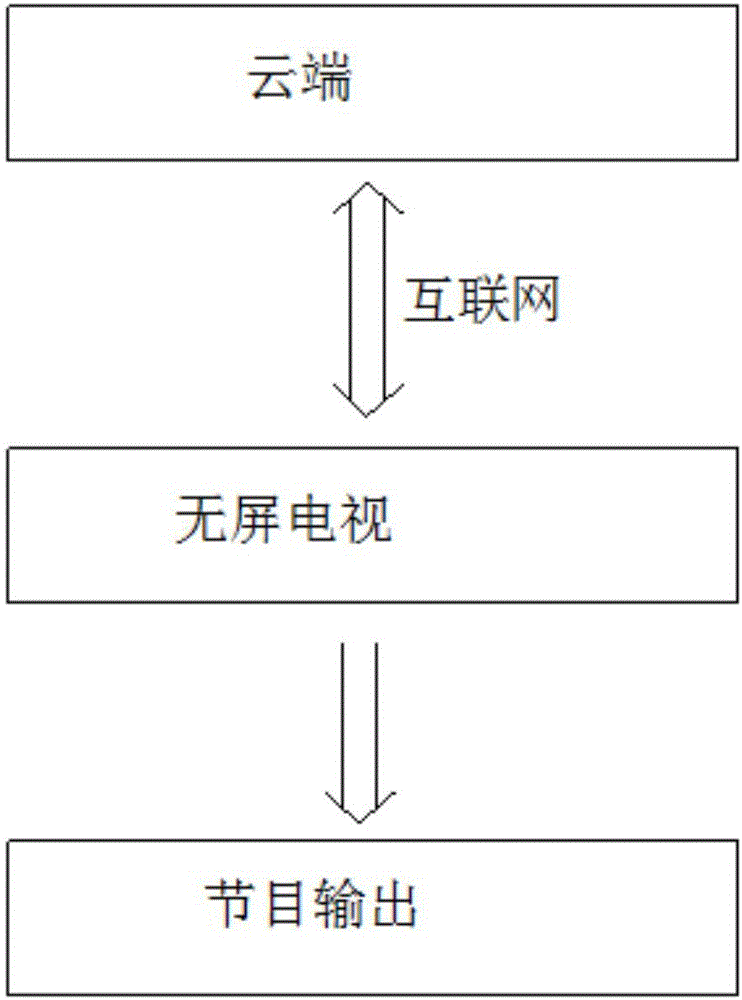

Screenless TV playback method based on cloud watching

InactiveCN106303594AApplicable viewing requirementsSave spaceSelective content distributionScreenlessOperating system

The invention discloses a screenless TV playback method based on cloud watching. The method comprises: a setting account of a screenless TV is created on a cloud end, and the setting account can store corresponding screenless TV storage content and parameters; when started, the screenless TV can read the storage content and the parameters of the screenless TV stored on the cloud end according to the setting account; and the screenless TV is configured according to the storage content and the parameters read from the cloud end and displays to audience. The audience can select TV program freely on the network, can customize the watching mode freely, and can set different watching modes. The method meets the watching demands of family members of different ages, so that watching TV can become a true enjoyment.

Owner:FOSHAN ZHANGYANG TECH CO LTD

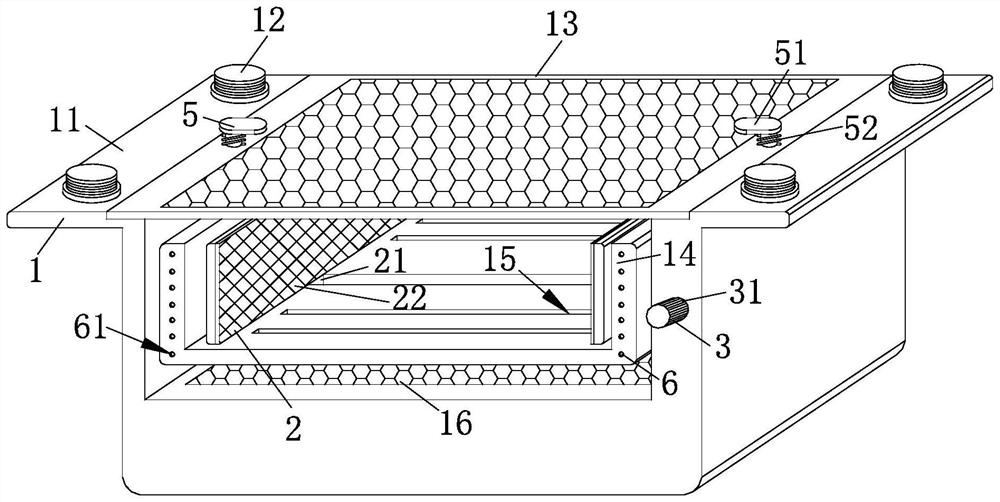

Screen-free projection device for intelligent teaching

InactiveCN112908047AImprove cooling effectEasy to useProjectorsElectrical appliancesScreenlessEngineering

The invention relates to the field of screen-free projection devices for intelligent teaching, in particular to a screen-free projection device for intelligent teaching. The projection device comprises a main body mechanism, a fixing mechanism, an adjusting mechanism, a heat dissipation mechanism, a limiting mechanism and a cleaning mechanism; the fixing mechanism is shifted, then the fixing mechanism clamps and fixes the side wall of a projector, the adjusting mechanism is rotated, then the adjusting mechanism adjusts the placing angle of the projector, and the tedious steps that an operator needs to reinstall the projector are reduced; the heat dissipation mechanism is started, so that the heat dissipation mechanism dissipates heat of the working projector when rotating; the limiting mechanism is pressed and rotated, so that the limiting mechanism is separated from the main body mechanism, an operator can conveniently mount and dismount the projector, and dust prevention of the main body mechanism is facilitated at the same time; and when the fixing mechanism slides, gas in the cleaning mechanism is discharged out of the main body mechanism, so that the main body mechanism is convenient to clean, and meanwhile, the pressure of the fixing mechanism is also convenient to release.

Owner:温州庆猫网络科技有限公司

Secondary containment for a perforated plate

ActiveUS7842258B2Gaseous chemical processesPhysical/chemical process catalystsScreenlessMechanical engineering

A secondary containment system is used with a screenless reactor. The secondary containment system includes a screen sized to prevent the passage of catalyst particles, and is affixed to the screenless reactor with supports to hold the screen a desired distance from the reactor.

Owner:UOP LLC

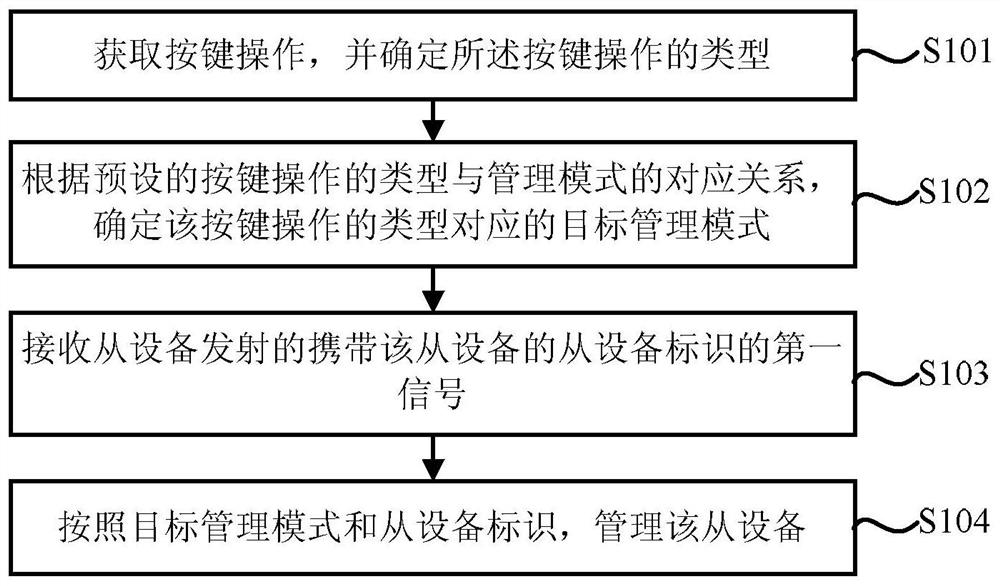

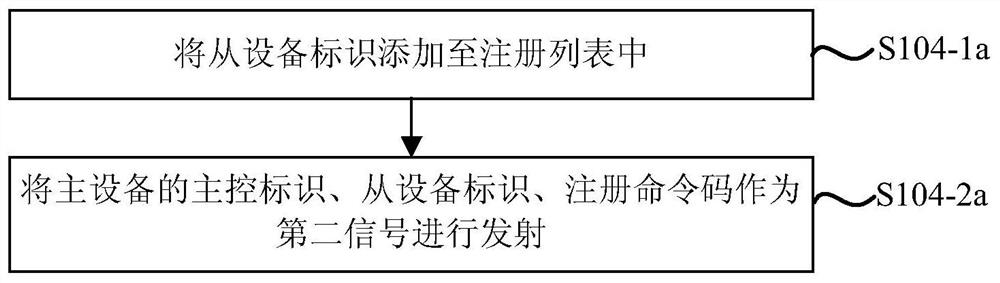

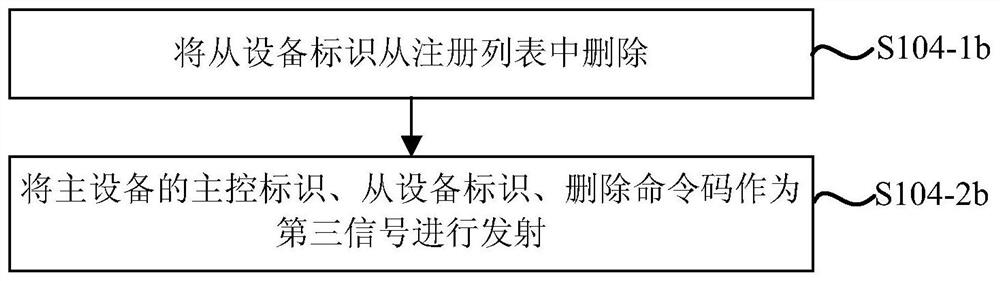

A device management method, device and system

ActiveCN110196671BRealize different managementTransmission systemsComputer controlKey pressingScreenless

Owner:HANGZHOU HIKVISION DIGITAL TECH

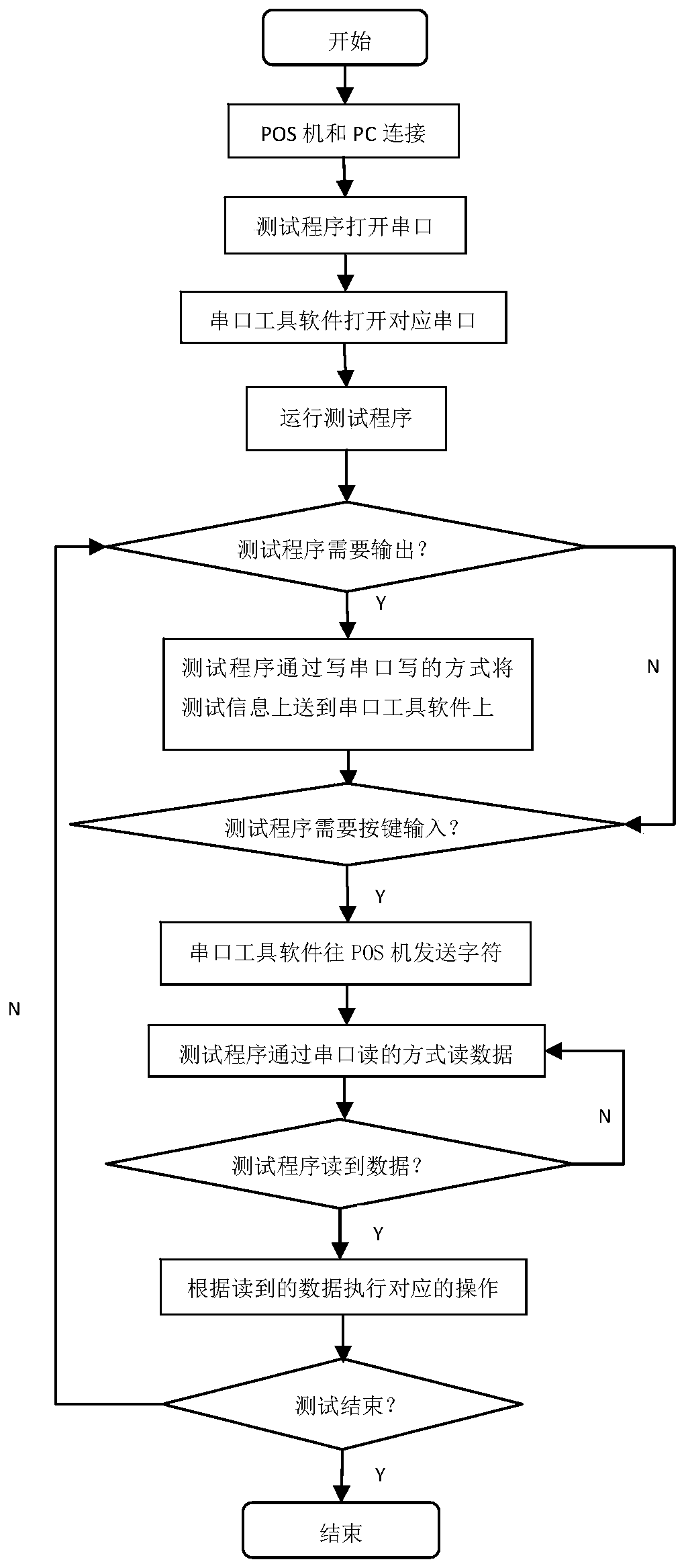

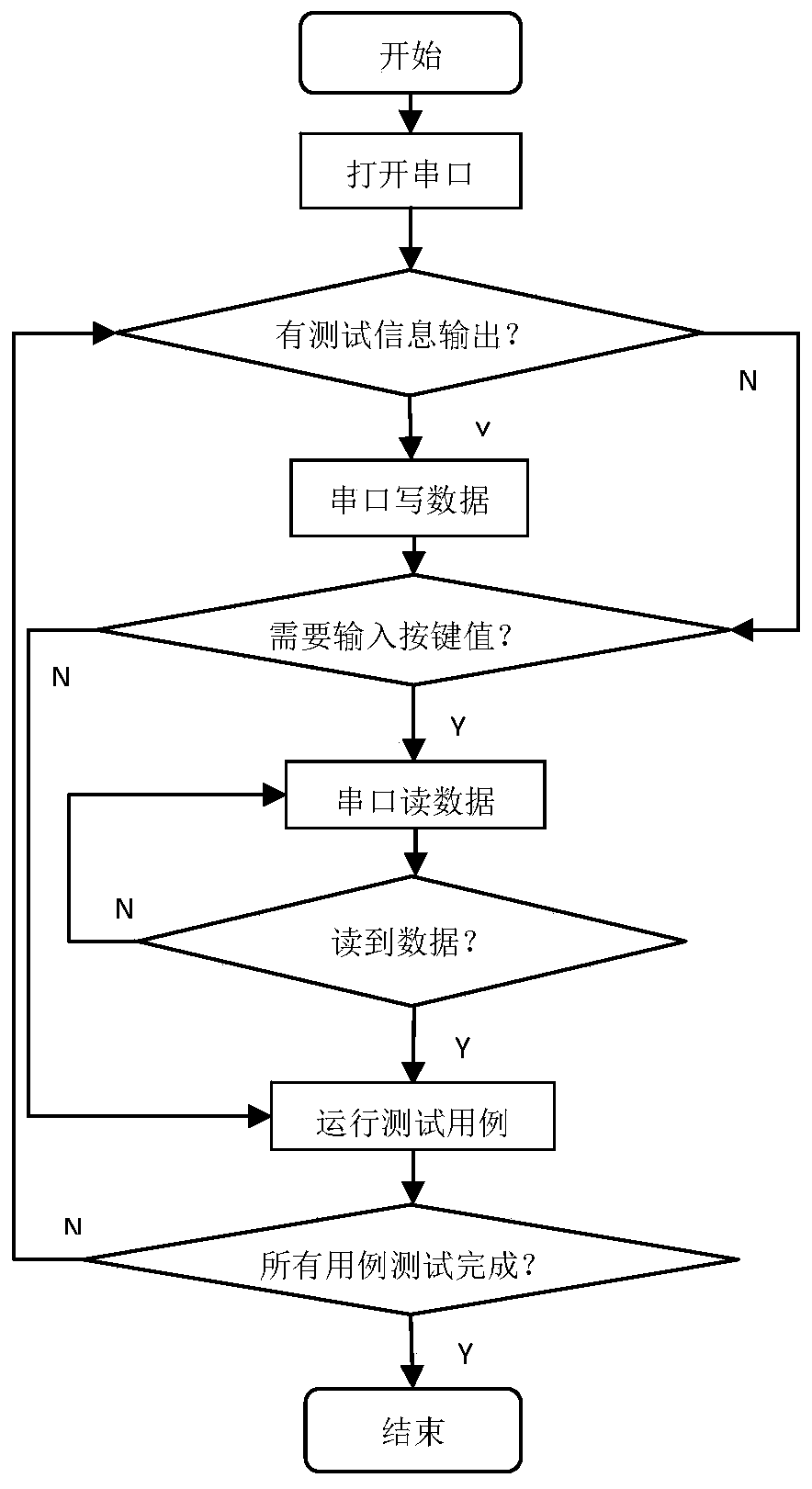

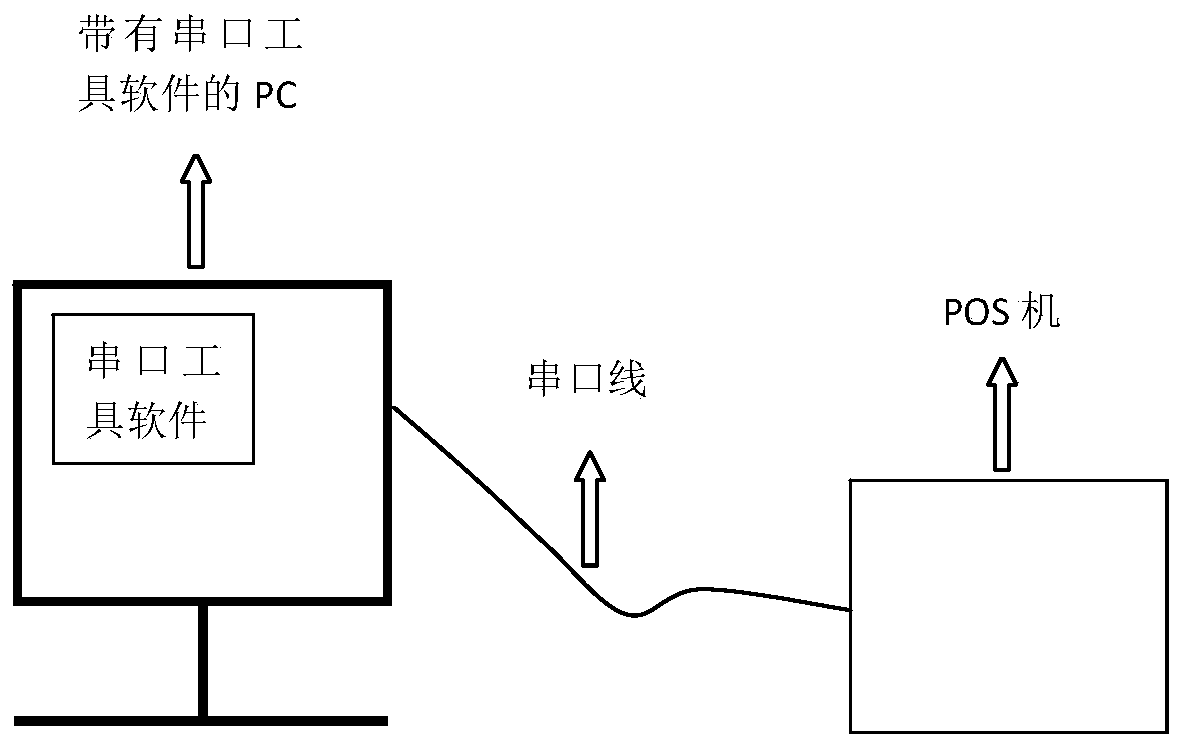

Method for testing keyboard-free and screen-free equipment

The invention relates to a method for testing keyboard-free and screen-free equipment. The method comprises the following steps: 1) physically connecting a POS machine with a PC through a serial portline; 2) running a test program, and executing an operation of opening the serial port by the test program; 3) opening serial port tool software, and opening a serial port; 4) when the test code needsto output the information, exeucting a serial port writing operation by the test program, and uploading a test result and the information required in the test process to an output display area of theserial port tool software; and (5) when key input is needed in the test process, inputting characters expected by the test program by the PC keyboard, sending the input characters to the POS machineby the serial port tool software, executing serial port reading operation by the POS terminal, and after the test program reads data, executing corresponding operation according to the read data.

Owner:FUJIAN NEWLAND PAYMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com