Method for preparing PERC screenless printing single crystal solar cell sheet

A solar cell technology without network junctions, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as light to attenuation, and achieve the effects of increasing power, improving conversion efficiency, and improving spectral response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments. It should be noted that the following preferred embodiments should not be regarded as limiting the present invention, and the protection scope of the present invention should be determined by the scope defined in the claims. For those skilled in the art, without departing from the spirit and scope of the present invention, some improvements and modifications can also be made, and these improvements and modifications should also be regarded as the protection scope of the present invention.

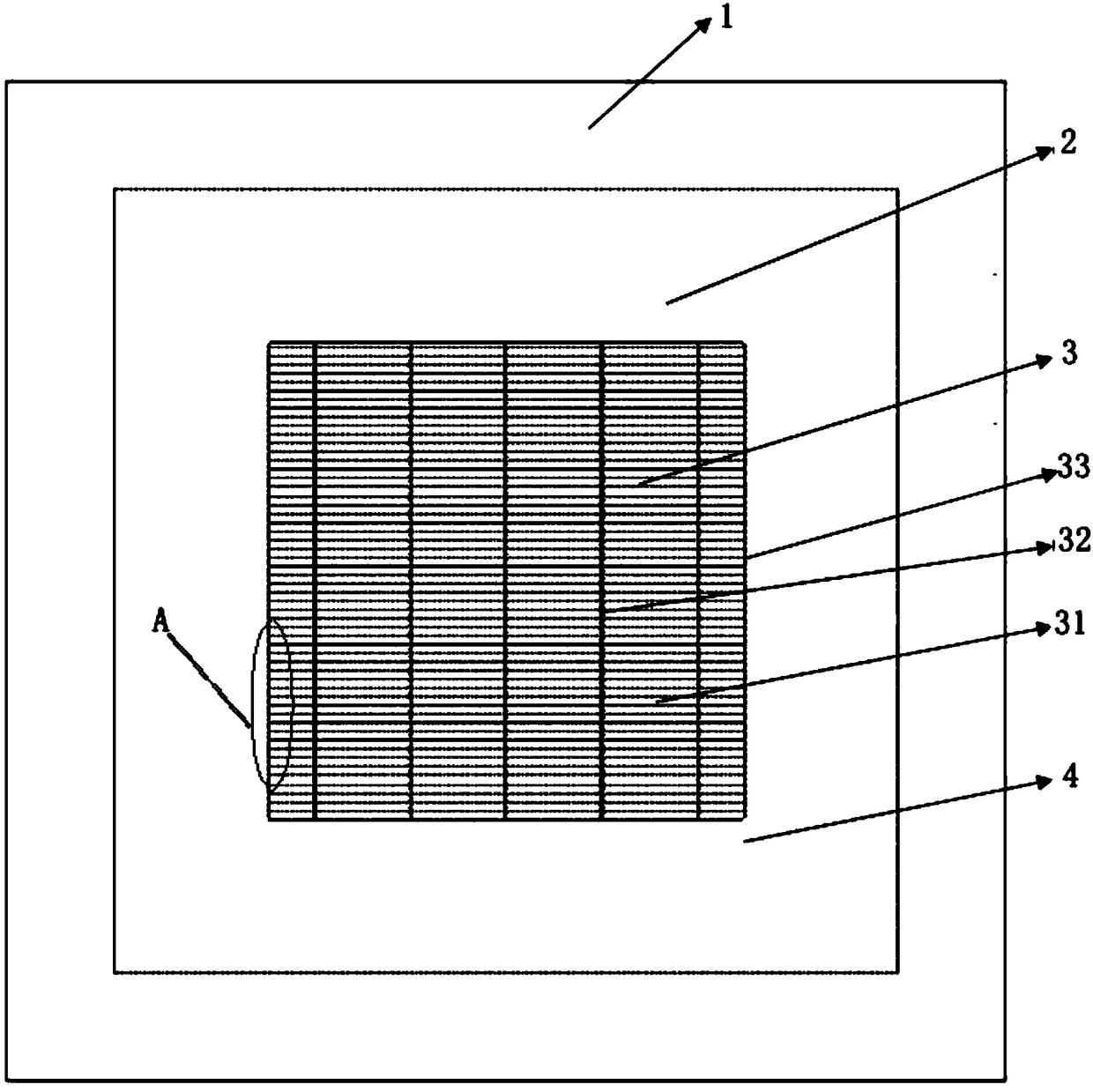

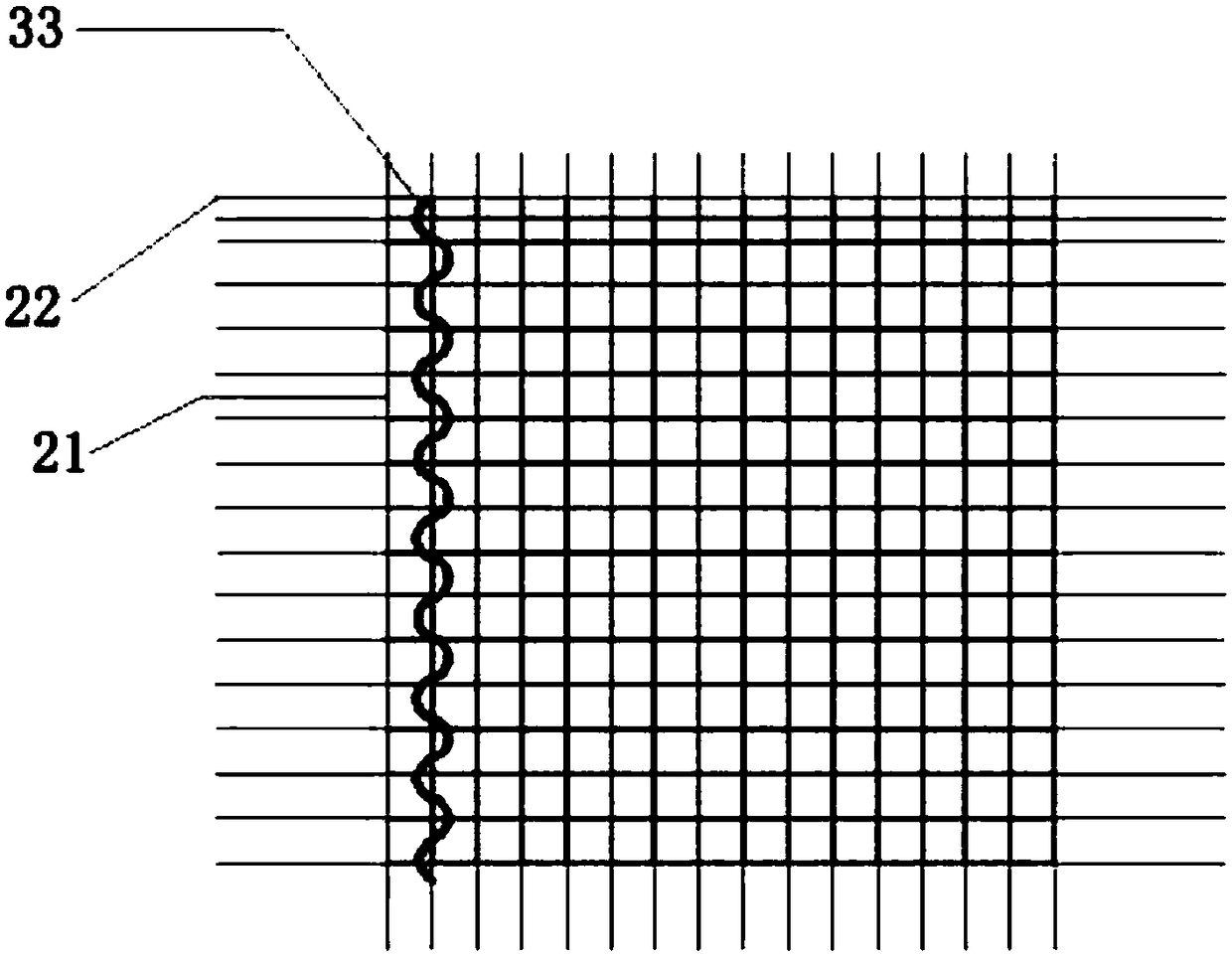

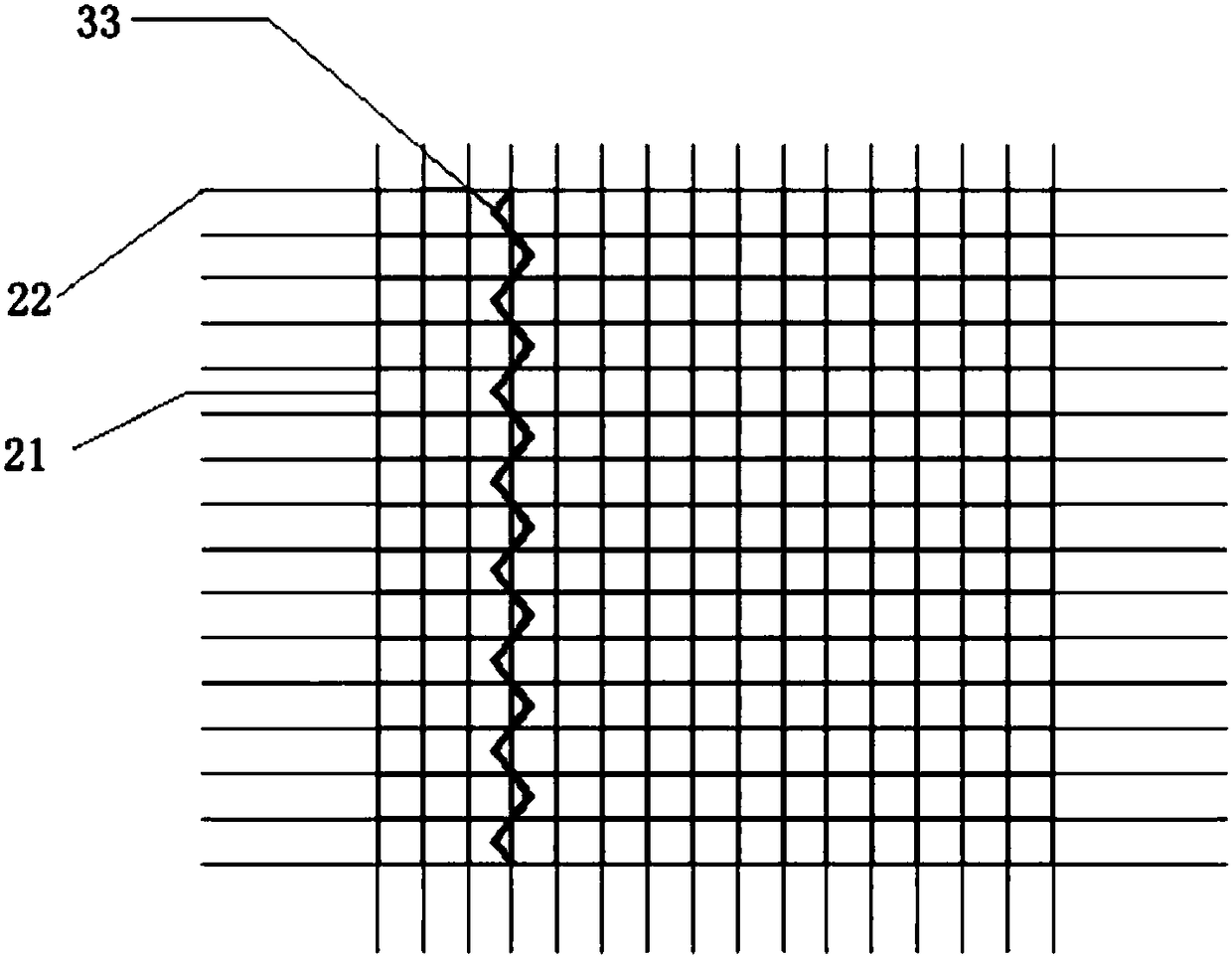

[0059] The invention provides a method for preparing a PERC grid-free printed monocrystalline solar cell, which uses a monocrystalline silicon wafer as a base material, comprising the following steps:

[0060] A. Texturing—The preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com