Liquid sensor and ice detector

a liquid sensor and detector technology, applied in liquid/fluent solid measurement, instruments, machines/engines, etc., can solve the problems of measuring reliably, requiring engine oil viscosity degradation, and devices susceptible to outside electrical and magnetic noise, so as to achieve the effect of reducing the cost of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

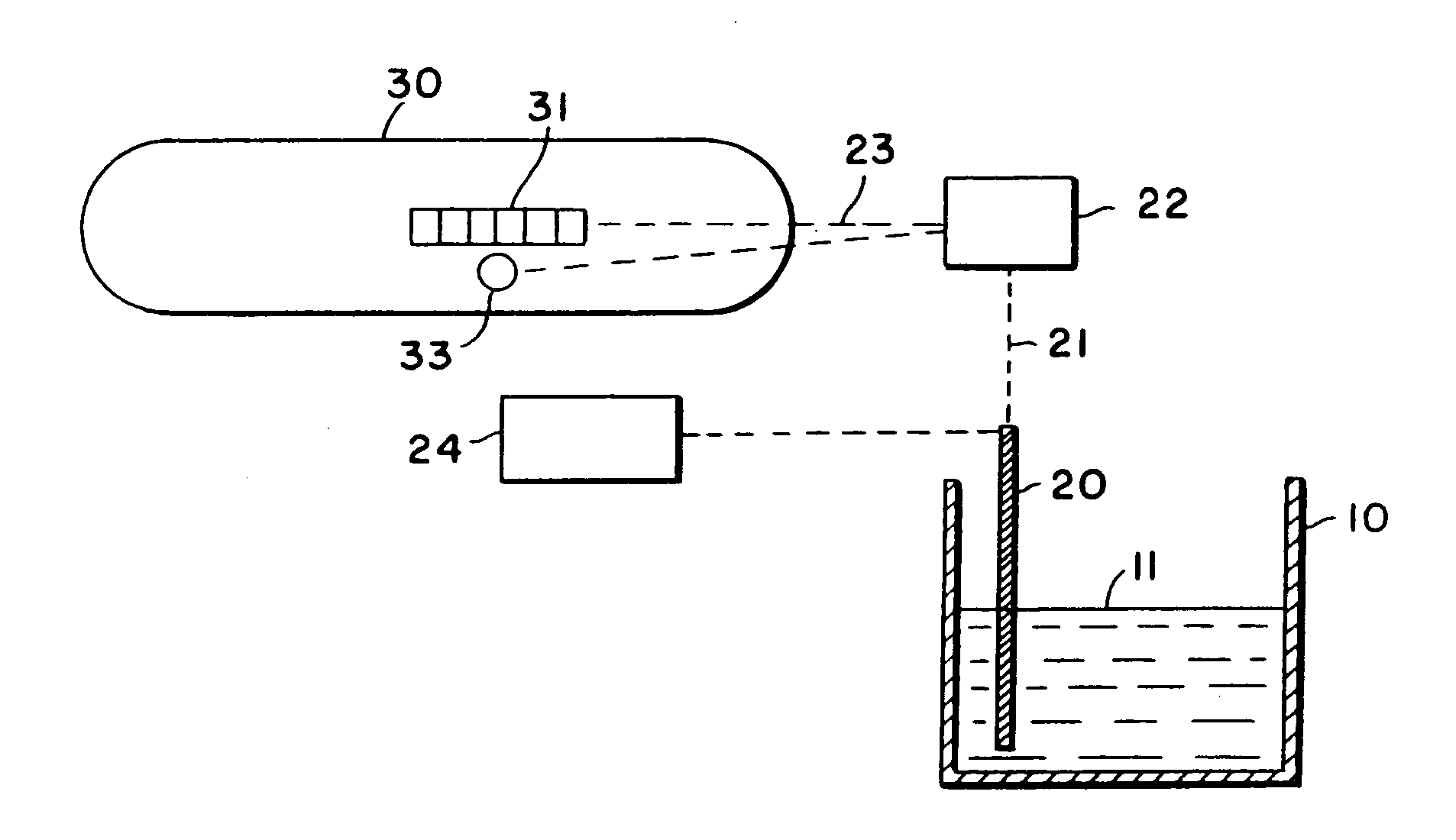

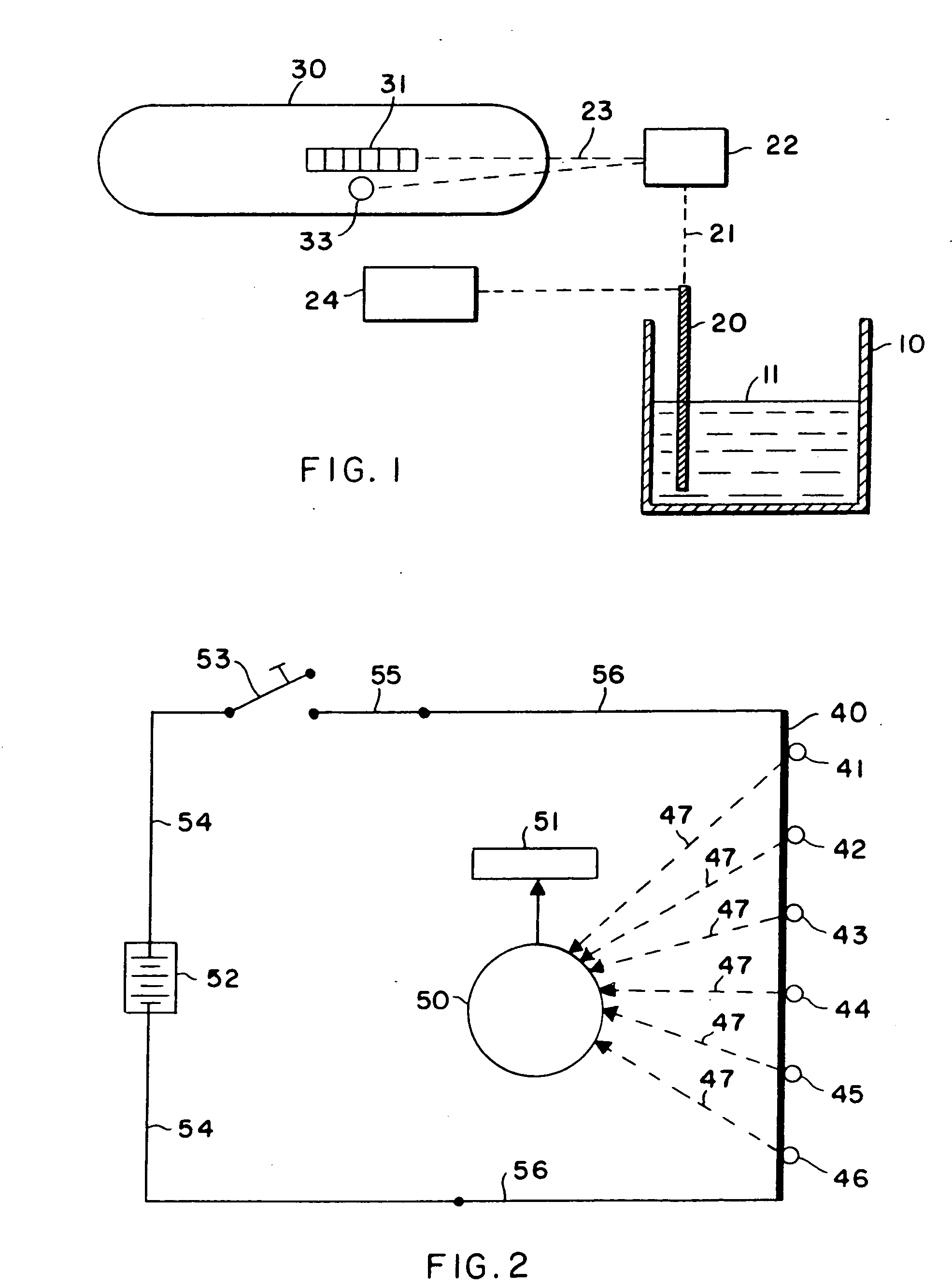

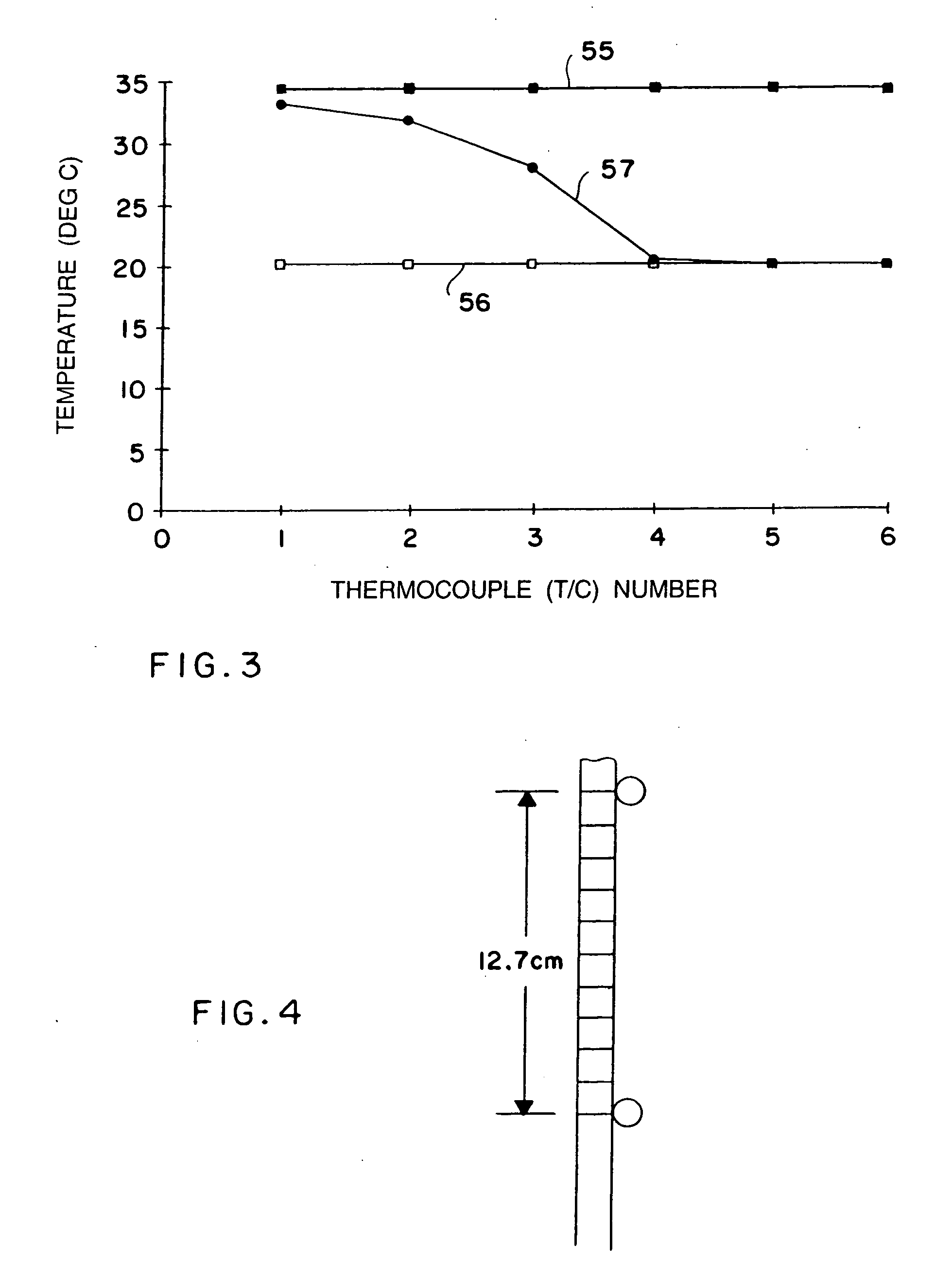

[0028] The present invention describes a new method and a new sensor that measure accurately the liquid level, absolute temperature, viscosity degradation and density and pressure of compressible fluid in a three dimensional liquid container. The method requires the development and use of a profile or a mode shape along an axis. The profile has three components. First, a horizontal line for the section of the sensor that is in liquid. Second, a horizontal line for the sensor section that is in the medium above the liquid. Third, a curved line that connects the two horizontal line. This curved line can be viewed as a wave shape. The curved line length is a fraction of the height of the liquid container. The point of intersection between the wave and the first horizontal line tracks the motion of the liquid level. The height of the first horizontal line, height of the second horizontal line or the changes in the slope and curvature of the curved line are used to determine accurately t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com