Patents

Literature

853 results about "Oil viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil Viscosity: Technically, the viscosity of an oil is a measure of the oils resistance to shear. Viscosity is more commonly known as resistance to flow.

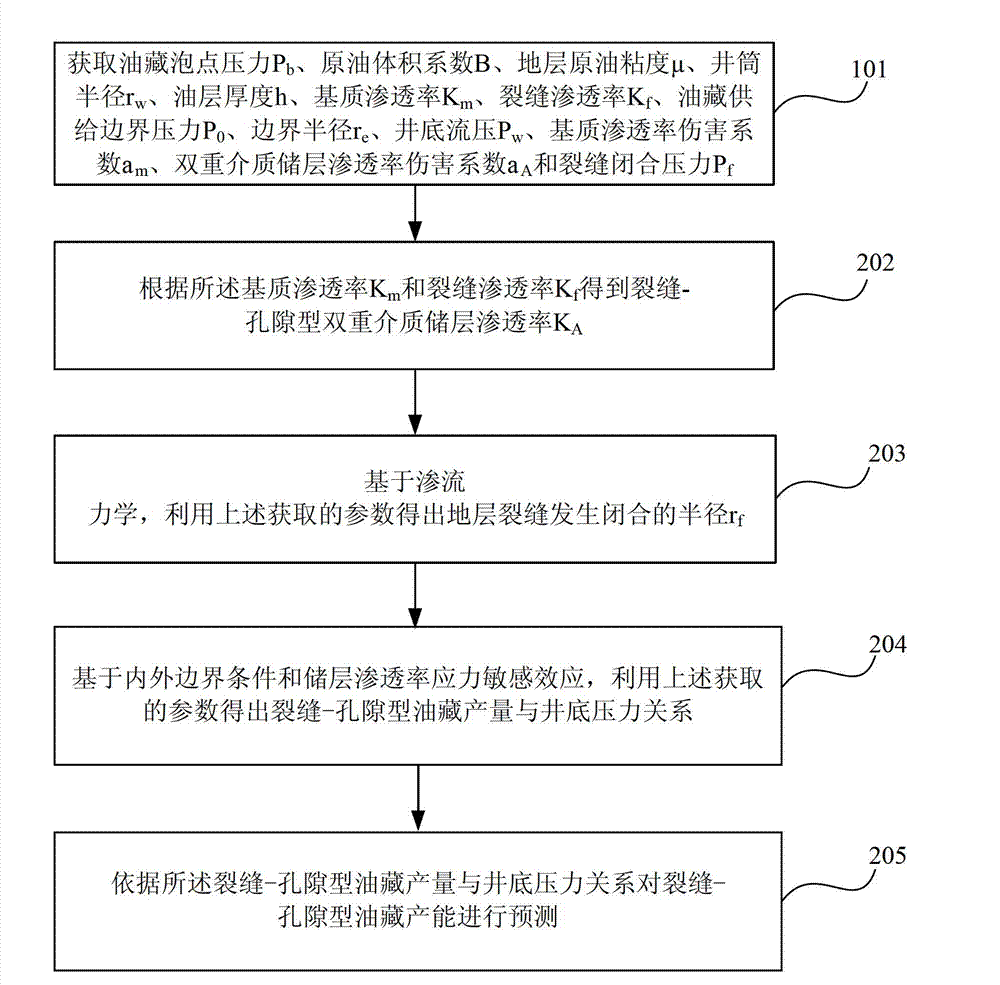

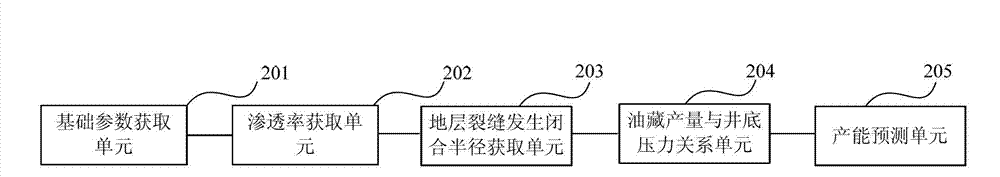

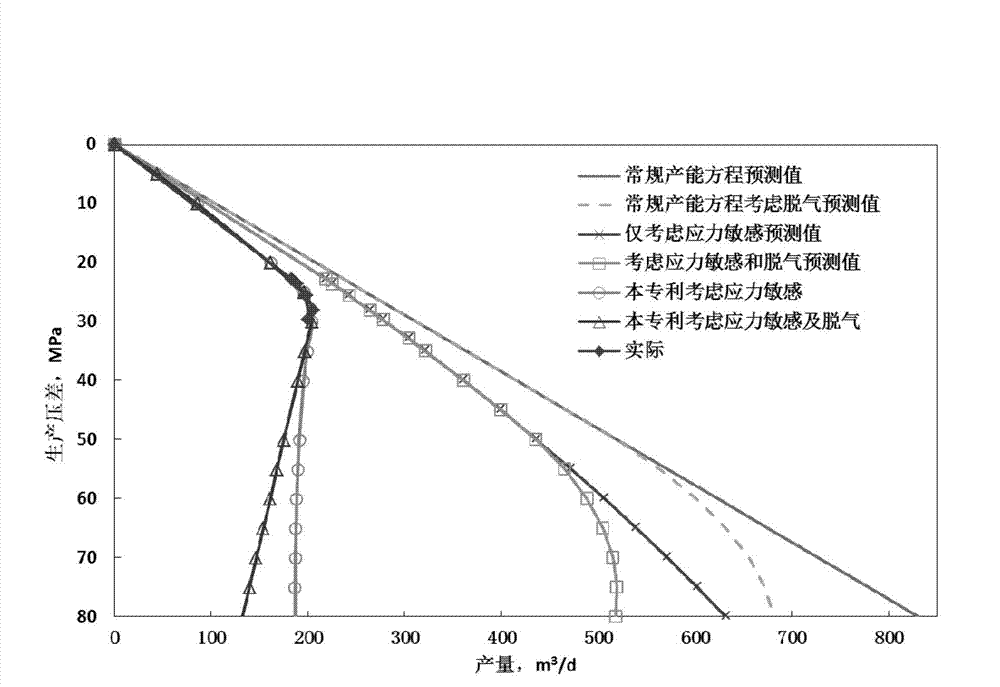

Method and device for predicting capacity of fissure-hole type oil deposit

ActiveCN102865059AForecast outputRich multi-media seepage theoryFluid removalDamage factorBottom pressure

The invention relates to a method and a device for predicting the capacity of a fissure-hole type oil deposit. The method includes the steps of acquiring oil deposit bubble point pressure Pb, a volumetric factor B, in-place oil viscosity mu, the shaft radius rw, the oil reservoir thickness h, matrix permeability Km, fissure permeability Kf, oil deposit supply boundary pressure Pe, the boundary radius re, shaft bottom flow pressure Pw, a matrix permeability damage factor alpha m, a double-medium reservoir permeability damage factor alpha A and fissure closing pressure Pf. Fissure-hole type double-medium reservoir permeability KA is obtained according to the matrix permeability Km and the fissure permeability Kf; on the basis of permeation fluid mechanics, the stratum fissure closed radius rf is obtained by the acquired parameters; on the basis of inner and outer boundary conditions and reservoir permeability stress sensitive effects, the relation between the capacity of the fissure-hole type oil deposit and shaft bottom pressure is obtained by the acquired parameters; and the capacity of the fissure-hole type oil deposit is predicted according to the relation between the capacity of the fissure-hole type oil deposit and the shaft bottom pressure.

Owner:PETROCHINA CO LTD

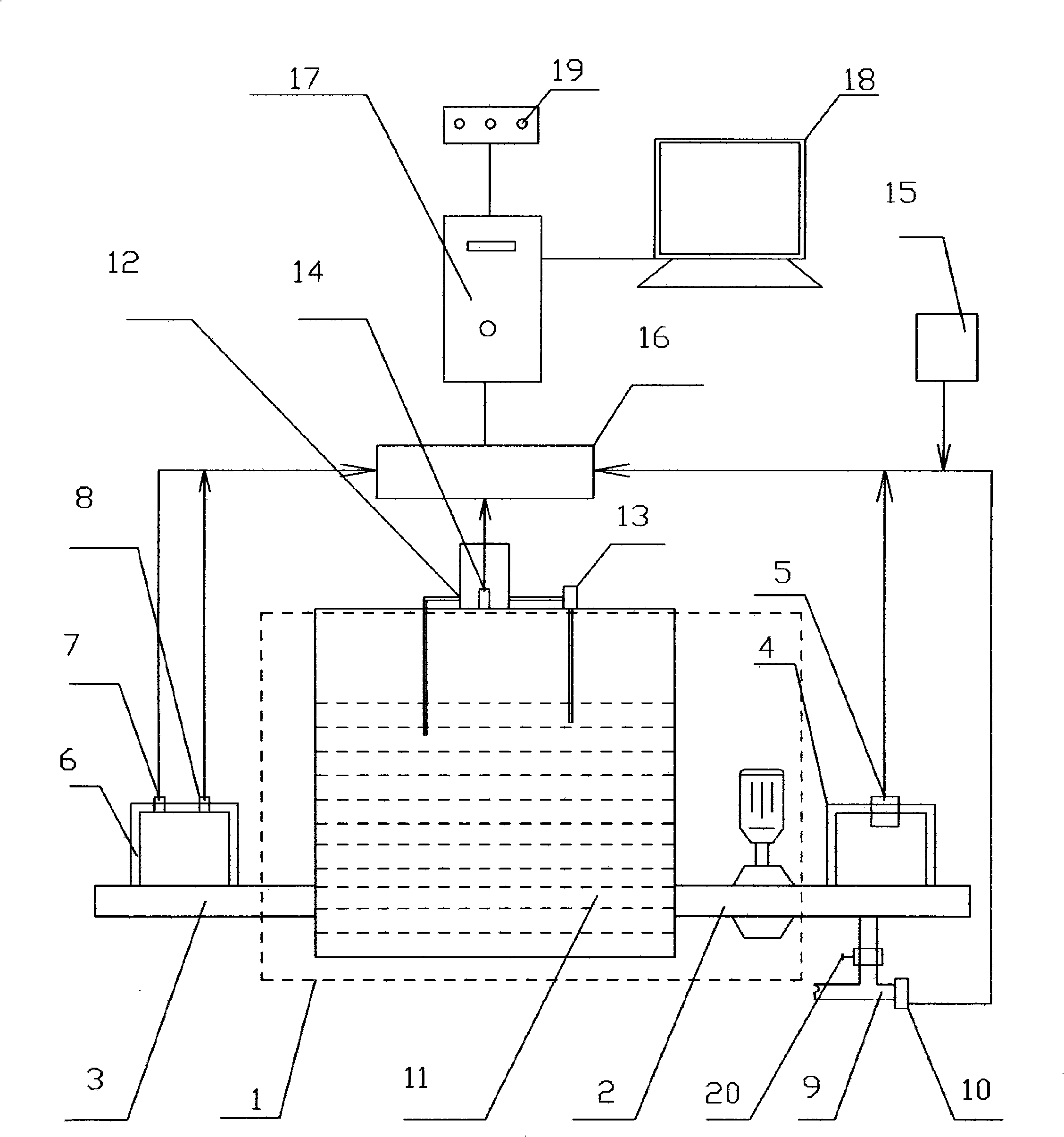

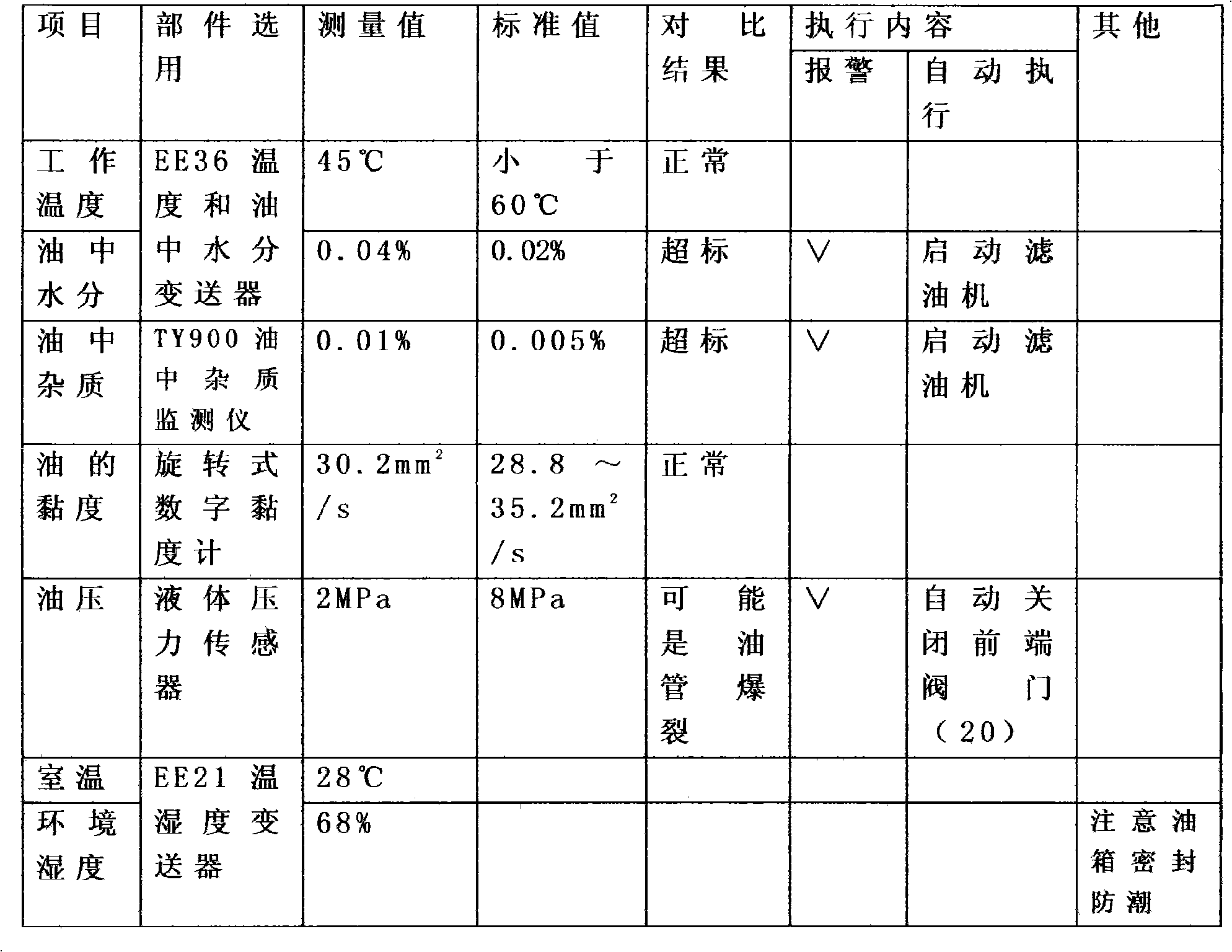

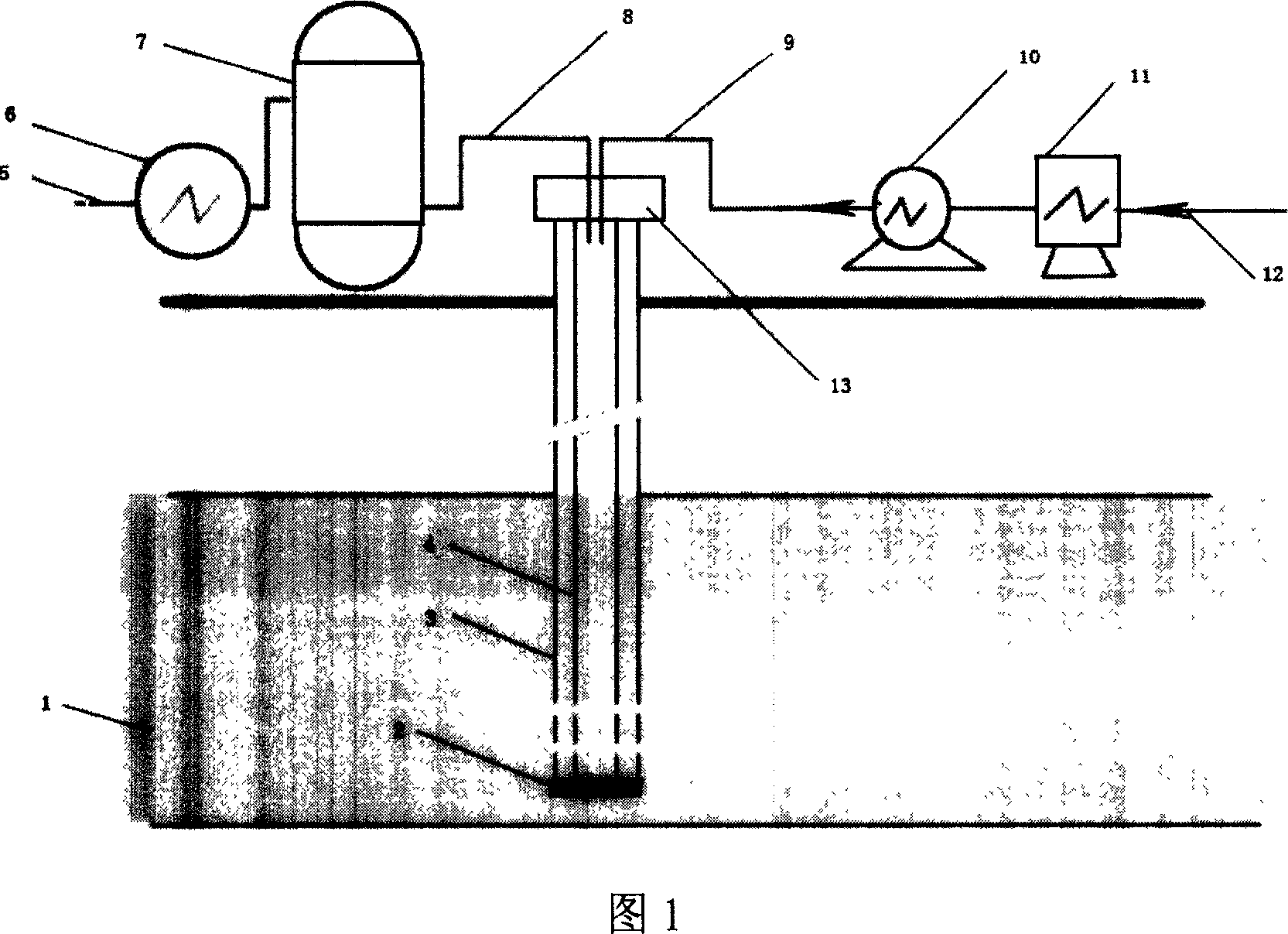

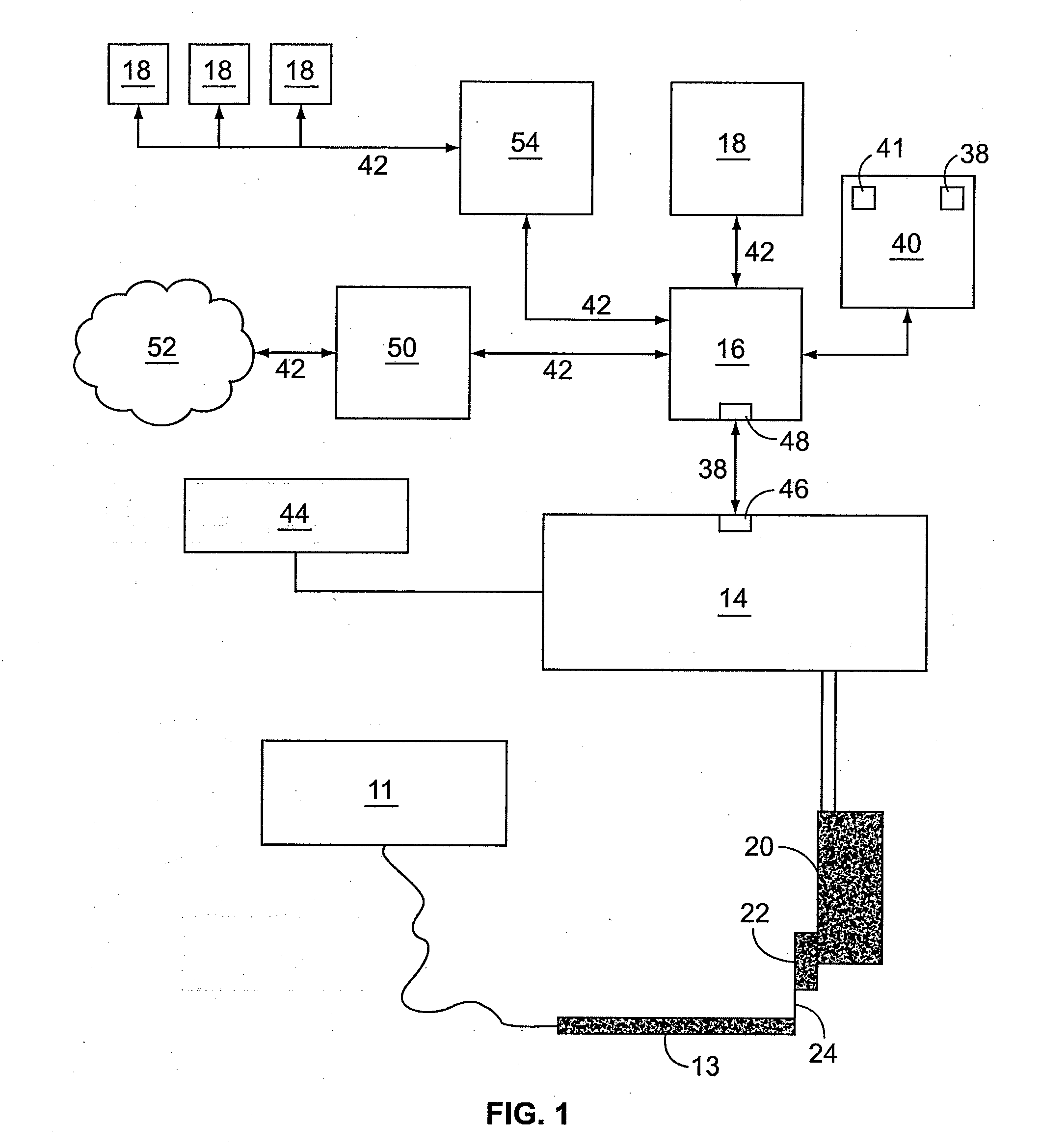

System and method for on-line monitoring hydraulic oil and lubricant oil conditions

InactiveCN101328917ATemperature measurement of flowing materialsLubrication elementsData acquisitionMonitoring system

The invention relates to an oil condition on-line monitoring system of hydraulic oil and lubricating oil, and is characterized in that the system consists of an oil condition detection and sensing system, an environment monitoring system, a data collection and conversion system, an operation procedure, a warning (caution) system and an automatic implementing system; a bypass and an oil storage chamber are arranged on an oil station; each monitoring unit is fixed to monitor an oil viscosity, a micro-moisture content, a temperature, impurity, a pressure and other parameters in real time; an actual measured value is compared with the set value; when the actual measured value excesses an allowed range, the system automatically warns or implements the functions of closing, self-locking, etc.

Owner:宁波天扬工业新技术有限公司

Inspissated oil emulsion viscidity reducer

ActiveCN1778862AStrong resistance to mineral saltHigh emulsifying colloidDrilling compositionPhosphateOil emulsion

A thickened oil emulsifying viscosity reducer consists of anion surface activator, non-ionic-anion surface activator, demulsifier and water in proportion by 1:0.1-50:0.01-20 and water content is 0.2-5000 times of the sum of a, b and c. Anion surface activator comprises sodium salt and calcium salt of petroleum sulfoacid salt methyl condensate and sulfonated lignin; non-ionic-anion surface activator is chosen organic phosphate salt, sulfuric ester salt , carboxylate and sulfosalt of alkylphenol or fatty alcohol-polyoxyethylene ether; demulsifier is copolymer of alkyl ammonium halide cation demulsifier, polyethylene glycol polyoxytrimethylene polylol ether non-ionic demulsifier or polyethylene glycol polyoxytrimethylene polyethylene polyamines block. It has strong emulsifying ability and low thickened oil viscosity,

Owner:CHINA PETROLEUM & CHEM CORP +1

Exploitation technique for disgorging thick oil by pouring air to assistant steam

The present invention provides a method for production of heavy oil reservoir. It is technically characterized by that in the cyclic steam injection and steam-flooding process it utilizes air injection to raise recovery efficiency and engineering benefits. Said method includes the following steps: after the oil well is drilled, making casing sand control completion of heavy oil reservoir so as to inhibit sand inflow in after-production; constructing artificial bottom hole so as to resist high-pressure produced by injecting steam and high-pressure air; after well completion injecting hot steam (above 200 deg.C), and injecting air into same oil reservoir, reducing heavy oil viscosity, then closing well, making crude oil and oxygen gas produce oxidation reaction; after the wellhead pressure is stabilized, opening well and making production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for reducing minimum miscible phase pressure between CO2 and crude oil of miscible phase displacement

The invention relates to a method for reducing the minimum miscible phase pressure between CO2 and crude oil of miscible phase displacement of CO2-containing oil deposits, overcoming the defect that the minimum miscible phase pressure between the CO2 and the crude oil is high, so CO2-containing miscible phase displacement cannot be achieved. In the technical scheme, surfactant slug is injected into an oil well at first, and when surfactants are dissolved in the in-place oil, the viscosity of the in-place oil is reduced to the viscosity range of the CO2-containing miscible phase displacement; and CO2 slug is injected under the pressure of 18.00-23.00 MPa, and since the surfactants injected at first can be dissolved in the supercritical CO2, the interface tension between a gas phase and an oil phase can be reduced rapidly due to the surfactants after injection of the CO2, the minimum miscible phase pressure between the CO2 and the crude oil can be reduced, the miscible phase can be achieved rapidly, and the miscible phase displacement can be realized. The invention has dual characteristics of reducing the viscosity and decreasing the minimum miscible phase pressure; the consumption of the surfactants and the cost are low; and the recovery rate of the crude oil is 5-14 percent higher than the recovery rate in the pure CO2 displacement under the same pressure.

Owner:SOUTHWEST PETROLEUM UNIV

Ethylene device quench oil viscosity reductant

InactiveCN101062880AEasy to useDoes not cause emulsificationHydrocarbon purification/separationHydrocarbonsVisbreakerLiquid viscosity

The invention discloses an ethylene device quench oil viscosity reductant in inhibiting liquid viscosity intensification technical domain, which is characterized by the following: comprising with inhibitor, disperser and metal deactivator; possessing the function of aggregation inhibition, aggregation prevention and metallic surface deactivation; decreasing erosion and incrustation of quench system device; possessing little adding quantity and good stability; non-generating side effect of oil water emulsion.

Owner:CHINA PETROLEUM & CHEM CORP +1

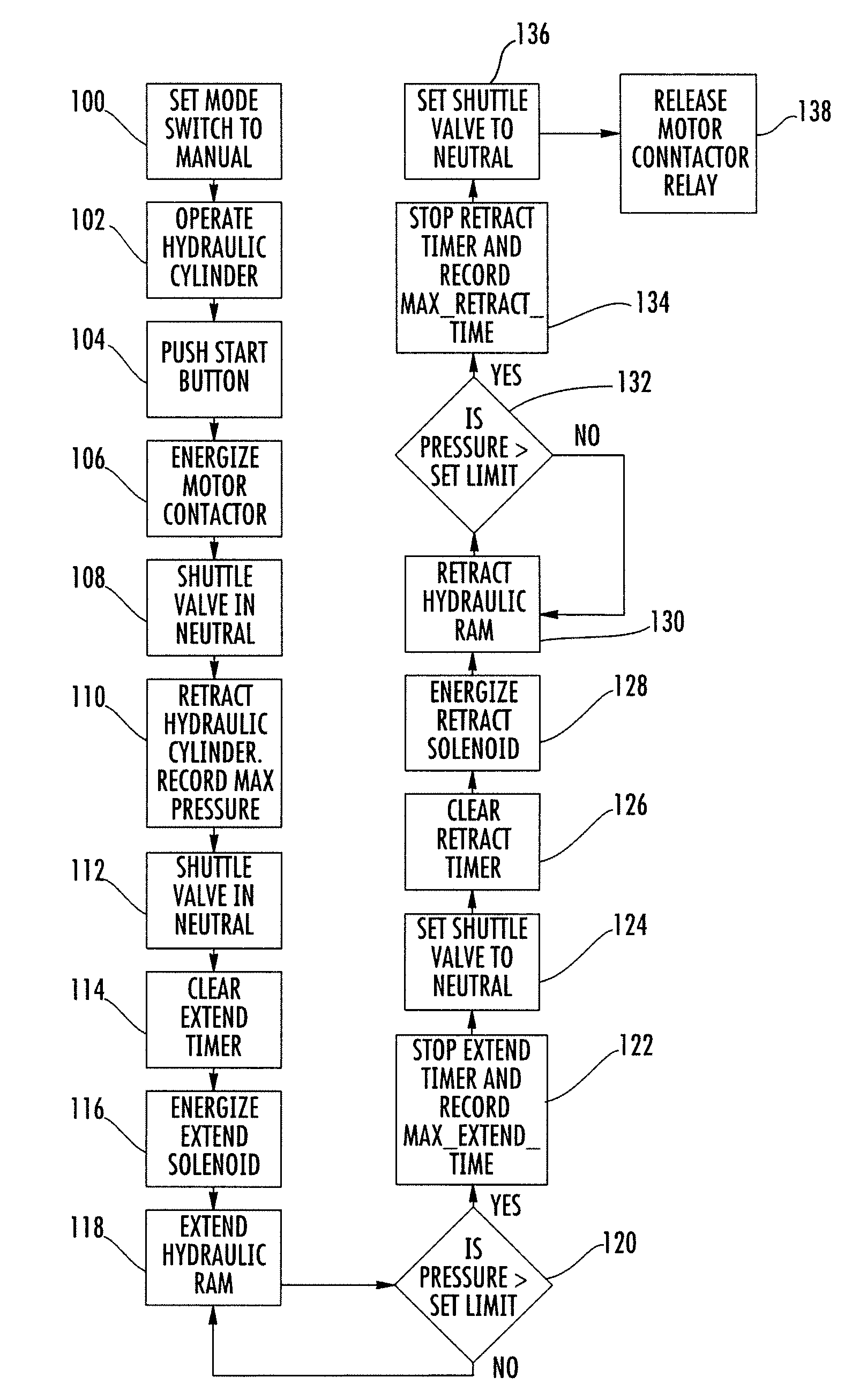

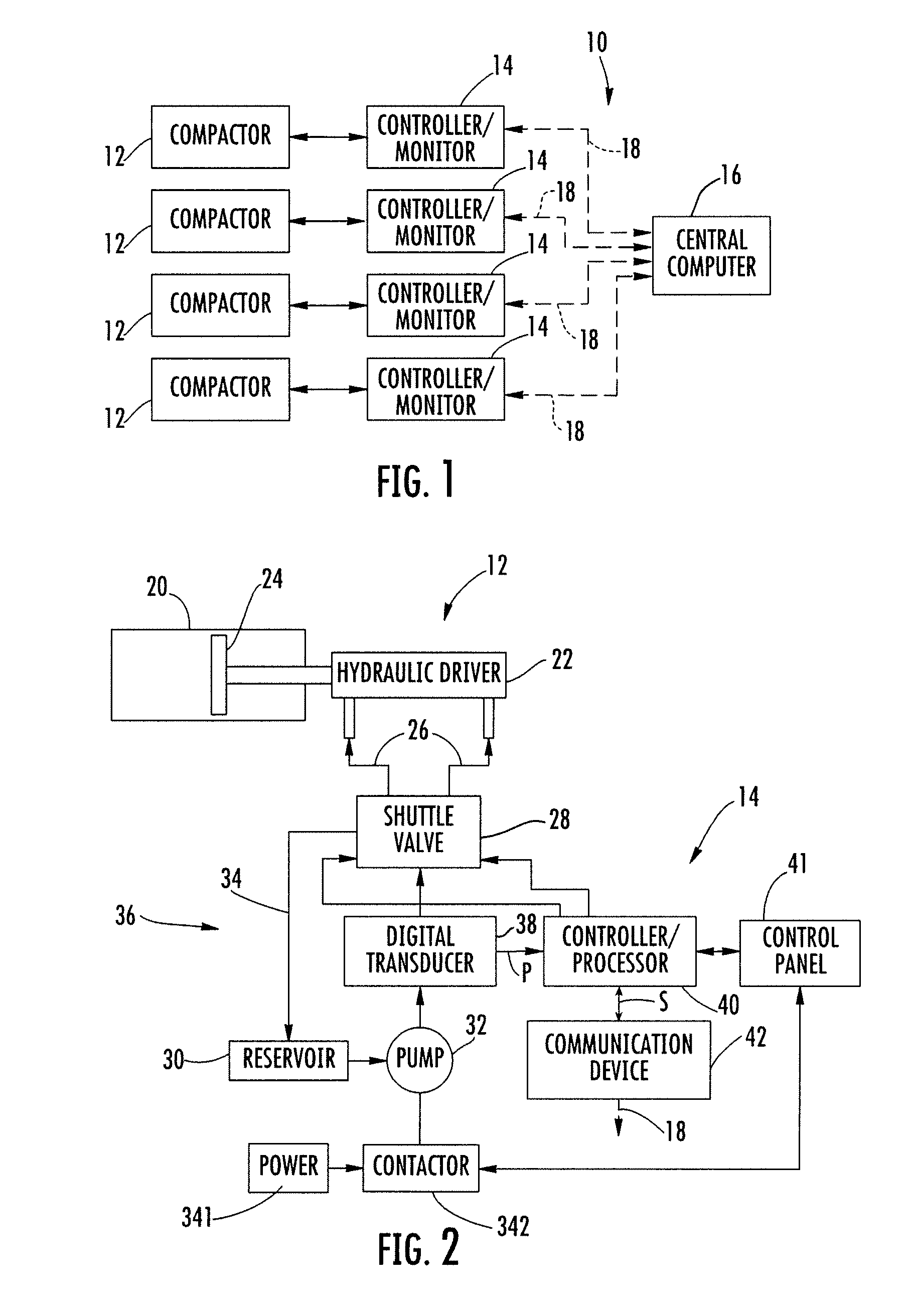

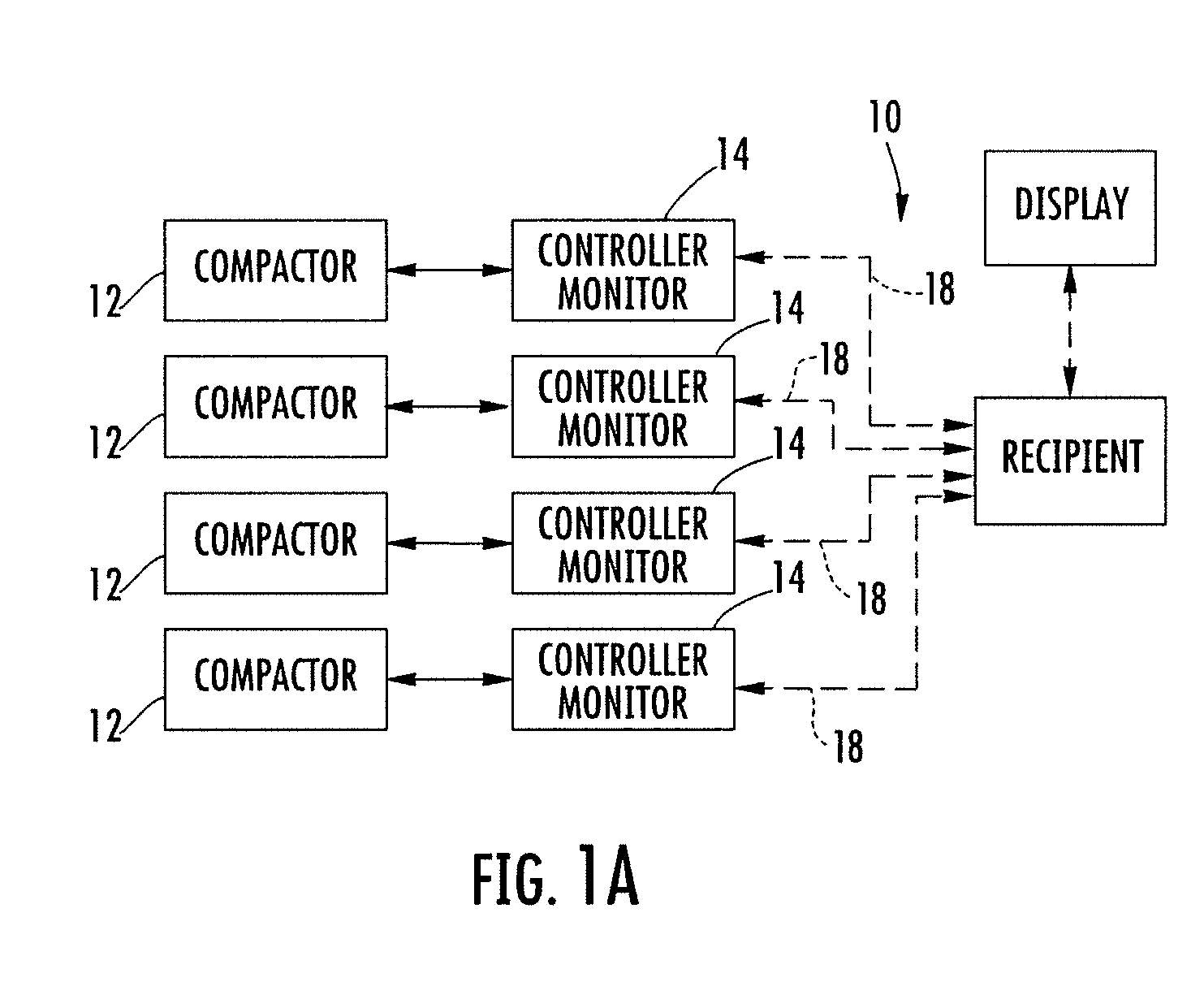

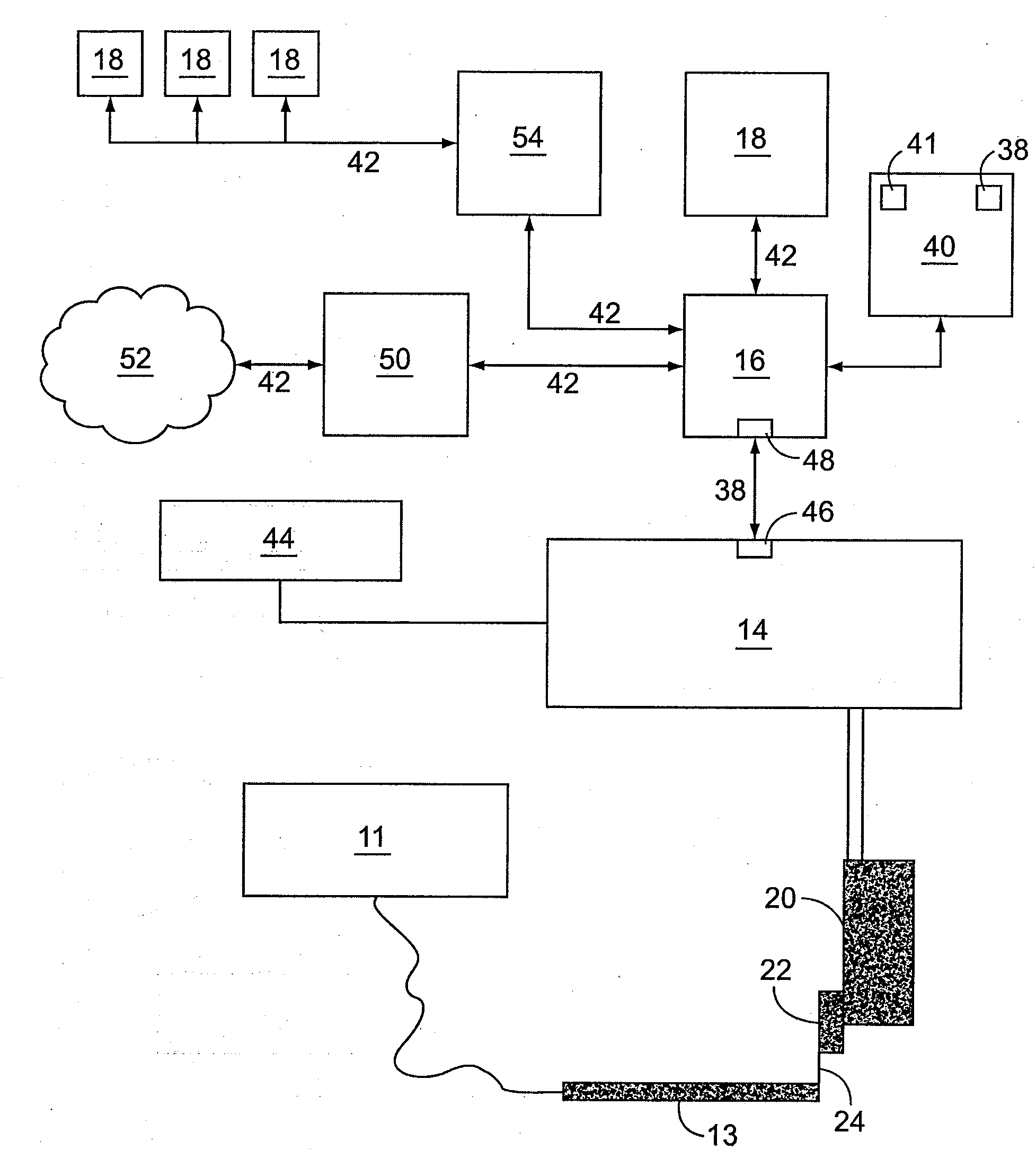

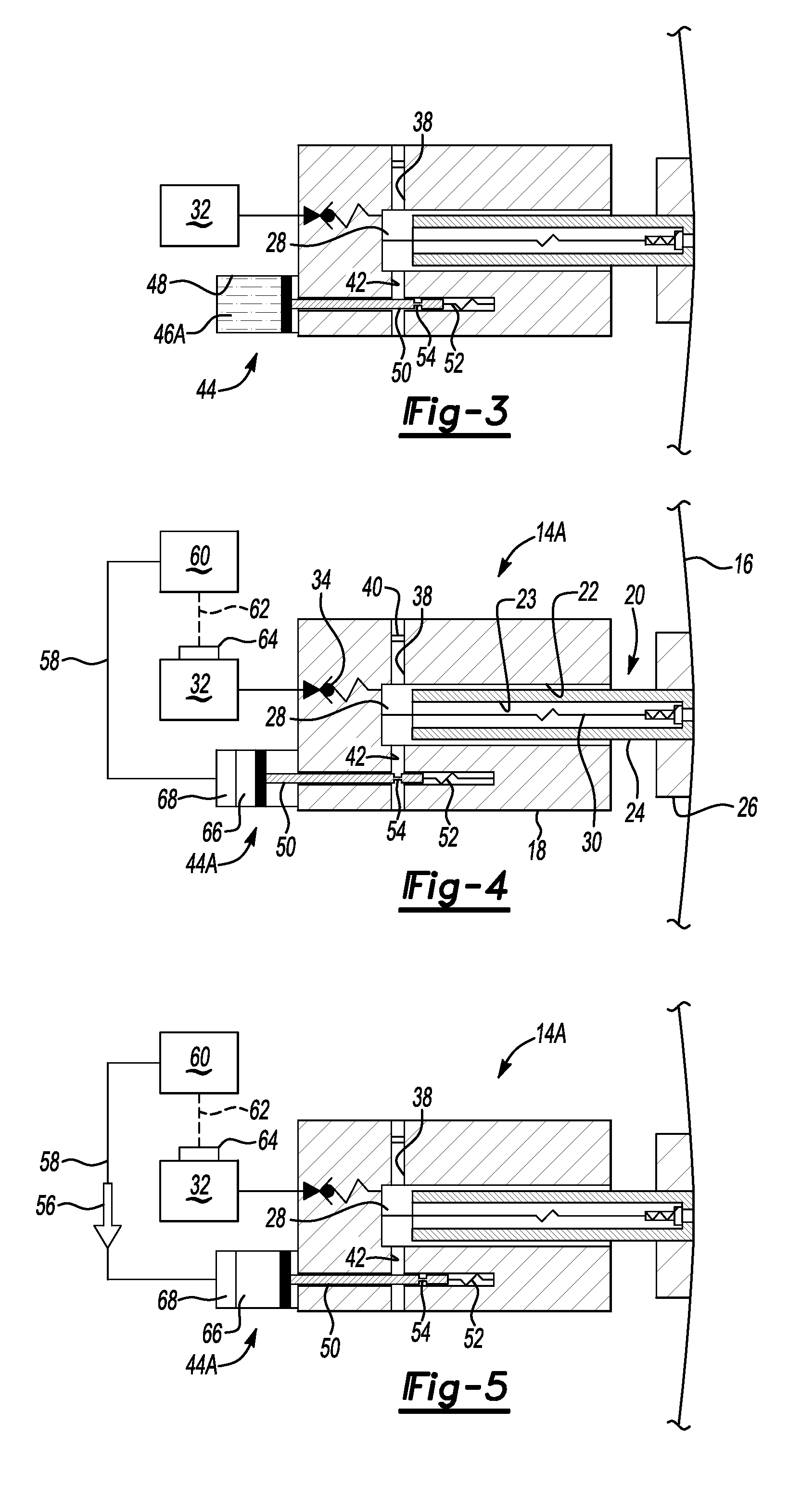

System and method for controlling compactor systems

ActiveUS7481160B1Easy to solveChange viscosityRotary clutchesFluid pressure measurement by mechanical elementsHydraulic ramOil viscosity

An integrated system for: complete waste compactor operational control; remote fullness monitoring; and, remote performance and maintenance diagnostics. Such diagnostic information is transferred wirelessly or otherwise to one or more recipients, so as to directly provide a critical warning in real time.The waste compactor controller / monitor system allows for periodic real-time oil viscosity measurements of the hydraulic fluid to account for changes in such viscosity. The system adjusts the timing of the compactor stroke to permit more efficient operation and inhibit damage to the hydraulic ram and / or container during use.

Owner:WASTE HARMONICS LLC

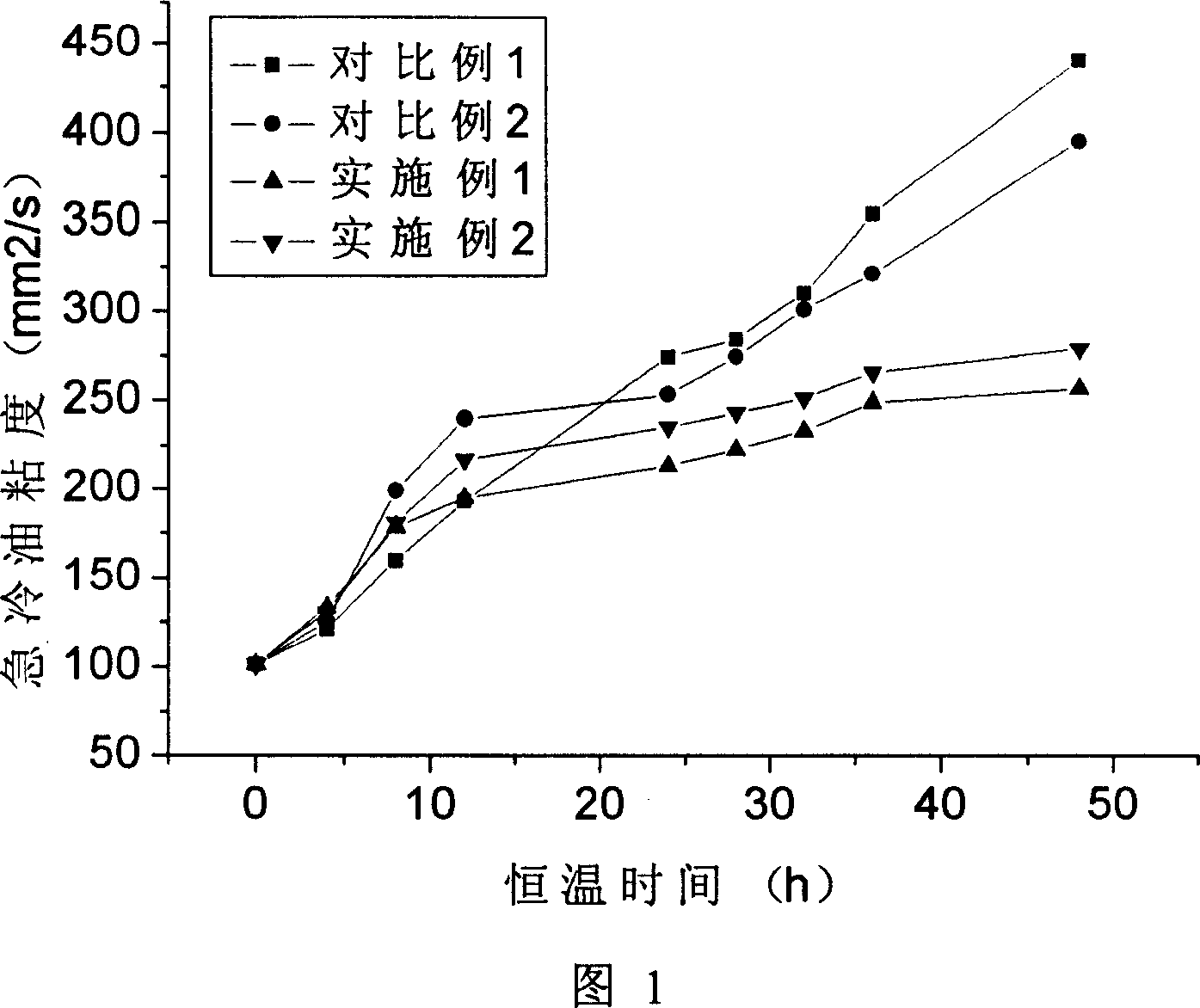

Thickened oil viscosity depressant as well as preparation method and application thereof

ActiveCN102719234AImprove liquidityUnique Viscosity ReductionDrilling compositionBoiling pointChain length

The invention discloses a thickened oil viscosity depressant as well as a preparation method and an application thereof. The viscosity depressant is obtained by carrying out aminolysis reaction on a terpolymer or a quadripolymer with an alkyl primary amine with the chain length of C12-C18, wherein the terpolymer is formed by three monomers including acrylate with the chain length of C18-C22, maleic anhydride and acrylic amide; the quadripolymer is formed by four monomers including the acrylate with the chain length of C18-C22, the maleic anhydride, styrene and the acrylic amide; and the number-average molecular weight of the viscosity depressant is 300-1000, the smelting point is 50-70 DEG C and the boiling point is 300-550 DEG C. The thickened oil viscosity depressant disclosed by the invention has unique viscosity depression and resistance reduction effects on thickened oil; by only adding 500-1000 ppm of the thickened oil viscosity depressant, the viscosity depression ratio of the thickened oil with the viscosity of 14000-24000 mPa s at 50 DEG C reaches up to 85%; and the thickened oil viscosity depressant has an obvious application effect and positive meanings.

Owner:SHANGHAI UNIV OF ENG SCI

Water-soluble thick oil viscosity reducer

InactiveCN101906295ALow viscosityReduce dosageDewatering/demulsification with chemical meansDrilling compositionPolyvinyl alcoholActive agent

The invention discloses a water-soluble thick oil viscosity reducer belonging to the technical field of emulsified viscosity reducers of viscous crude oil. The water-soluble thick oil viscosity reducer is prepared from the following components in parts by weight: 0.01-1.0 part of surface active agent, 0.01-1.0 part of dispersant and 0.01-0.6 part of demulsifier, wherein the surface active agent is a nonionic surface active agent selected from OP-10, TX100, Span80 and Tween80, the dispersant is a water-soluble polymer material selected from polyacrylamide, polyvinyl alcohol, guar gum and cellulose, and the demulsifier is a polyoxyethylene-polyoxypropylene segmented copolymer. The invention has good emulsifying and viscosity-reducing effects, the emulsified crude oil can be automatically demulsified to reach a dehydration rate over 95 percent, and the viscosity reducer has little consumption and low cost by adopting low-price materials.

Owner:SICHUAN HAIDUN PETROLEUM NEW TECH DEV

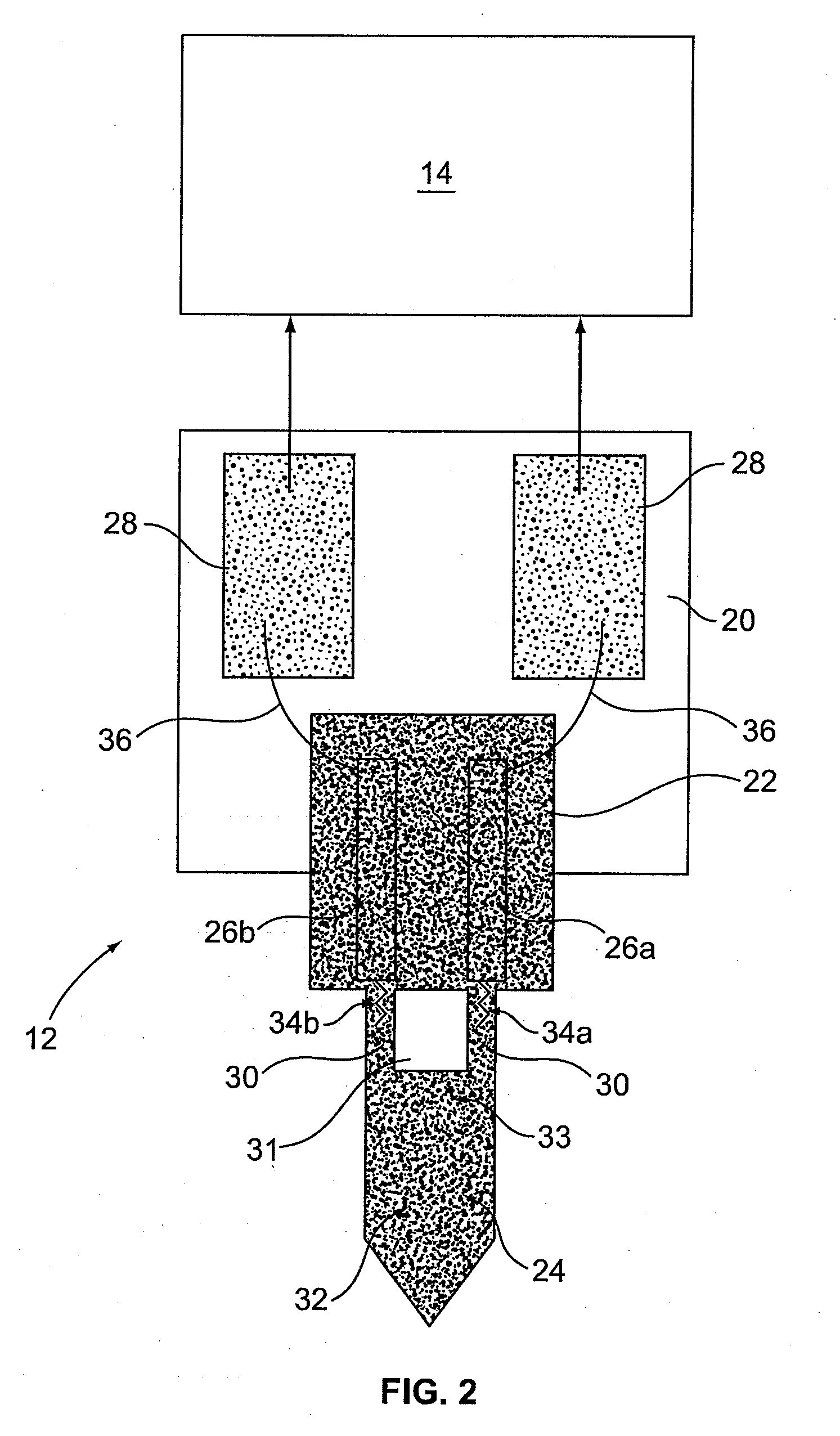

Petroleum viscosity measurement and communication system and method

InactiveUS20080289400A1Flow propertiesMaterial analysis by electric/magnetic meansElectricityElectrical resistance and conductance

The disclosure presents an apparatus and method for measuring viscosity of a lubricating oil. The apparatus has a piezo-resistive cantilever sensor for sensing a first oil viscosity parameter. The sensor has a cantilever having a pressure receiving portion for receiving pressure exerted by the lubricating oil as the lubricating oil comes into contact with the pressure receiving portion. The cantilever also has first and second resistive portions in electrical communication with a first lead and a second lead, respectively, which are in electrical communication with an electrical circuit amplification element, for creating an output signal indicative of a change in the resistive characteristics of the first and second resistive portions of the cantilever as the lubricating oil comes into contact with the pressure receiving portion. The output signal can be used for determining oil viscosity. A processor and memory compare the output signal value with a stored resistance value to provide information relating to the quality of the lubricating oil.

Owner:RICHMOND CHEM CORP

Method for manufacturing oil solubility thick oil thinner for thick oil pipe-line transportation

InactiveCN101245240AMeet flowable viscosity requirementsImprove low temperature fluidityPipeline systemsDrilling compositionSolubilityMethacrylate

The invention relates to the preparation method of oil-solute viscosity reducer used for the transportation of heavy oil tubes, which is characterized by comprising the following steps, first the preparation of the mixture of methacrylate with hydroxyl and dodecylbenzene sulfonic acid, second the preparation of acrylate high esters, third the preparation of oil-solute heavy oil viscosity reducer, according to the rate of the acrylate high esters : the mixture of methacrylate with hydroxyl and dodecylbenzene sulfonic acid equal to 1.0 to 4.5 ml : 1.0 to 7.5 ml, initiator ammonium persulfate, the mass fraction of which takes up 0.8 to 1.6 percent of the acrylate high esters and the mixture of methacrylate with hydroxyl and dodecylbenzene sulfonic acid, is added, the reaction is kept for 6 to 8 hours with the temperature of 70 DEG C, then the oil-solute heavy oil viscosity reducer can be got, the method is characterized by the good viscosity reducing effect, the simple process and the low cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

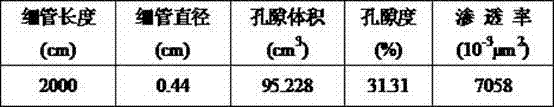

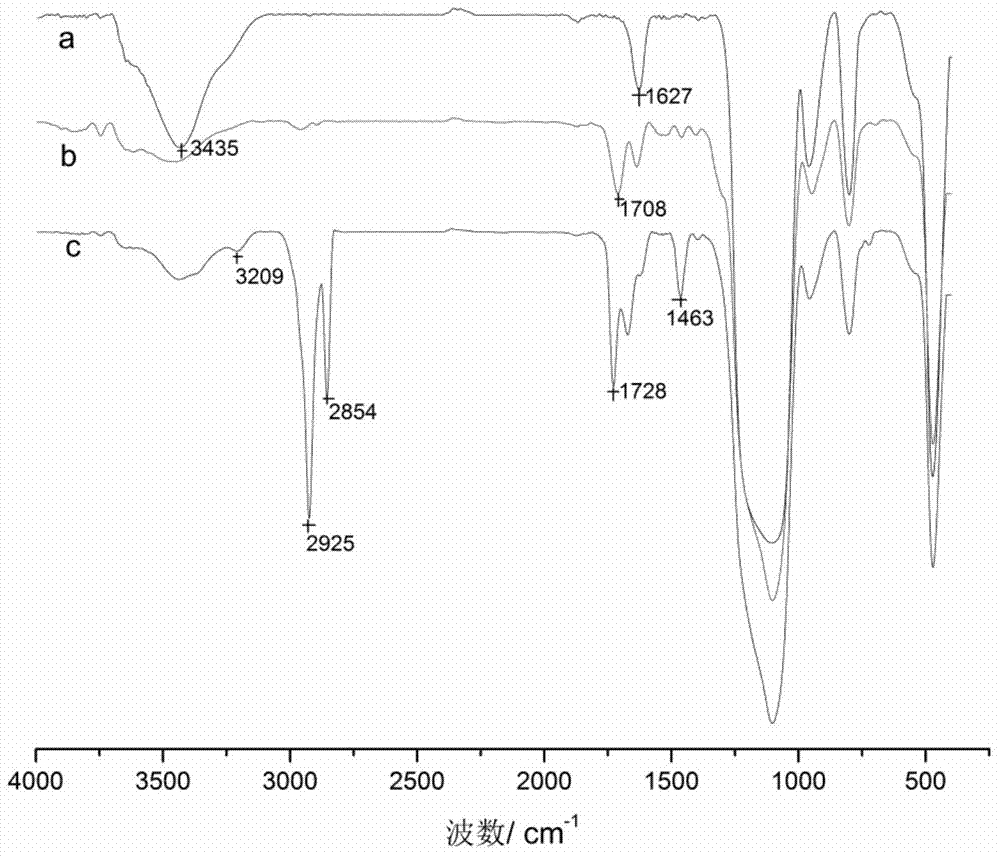

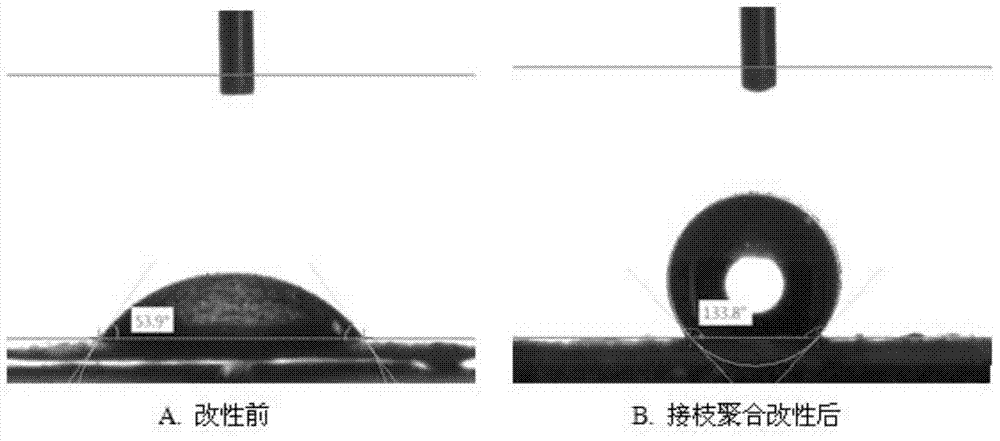

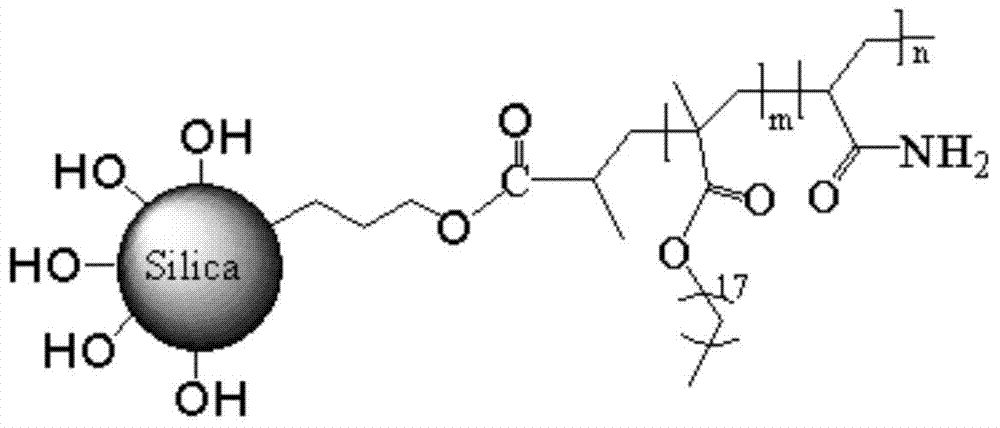

Nano SiO2 composite material thickened oil viscosity reducer and preparation method thereof

InactiveCN104327225AImprove hydrophobicityGood viscosity reduction effectDrilling compositionMaterials preparationNano sio2

The invention discloses a nano SiO2 composite material thickened oil viscosity reducer and a preparation method thereof, which belongs to the technical field of nano SiO2 composite material preparation and application thereof. The viscosity reducer is nano (polymethacrylate higher alcohol-acrylamide) / SiO2 composite material. The preparation method comprises the following steps: 1)pre-modifying the surface of the nano SiO2 by a silane coupling agent; and 2)performing graft copolymerization of (methyl)acrylate higher alcohol and acrylamide on the surface of nano SiO2 to obtain the (polymethacrylate higher alcohol-acrylamide) / SiO2 composite material powder. The nano viscosity reducer has the advantages of good viscosity reducing effect, low cost, simple production and no pollution during a cleaning process. Through the experiment, the viscosity reducing rate of the nano viscosity reducer to the high wax thickened oil at Daqing dandong station is 72.10% at 40 DEG C.

Owner:SHANDONG UNIV

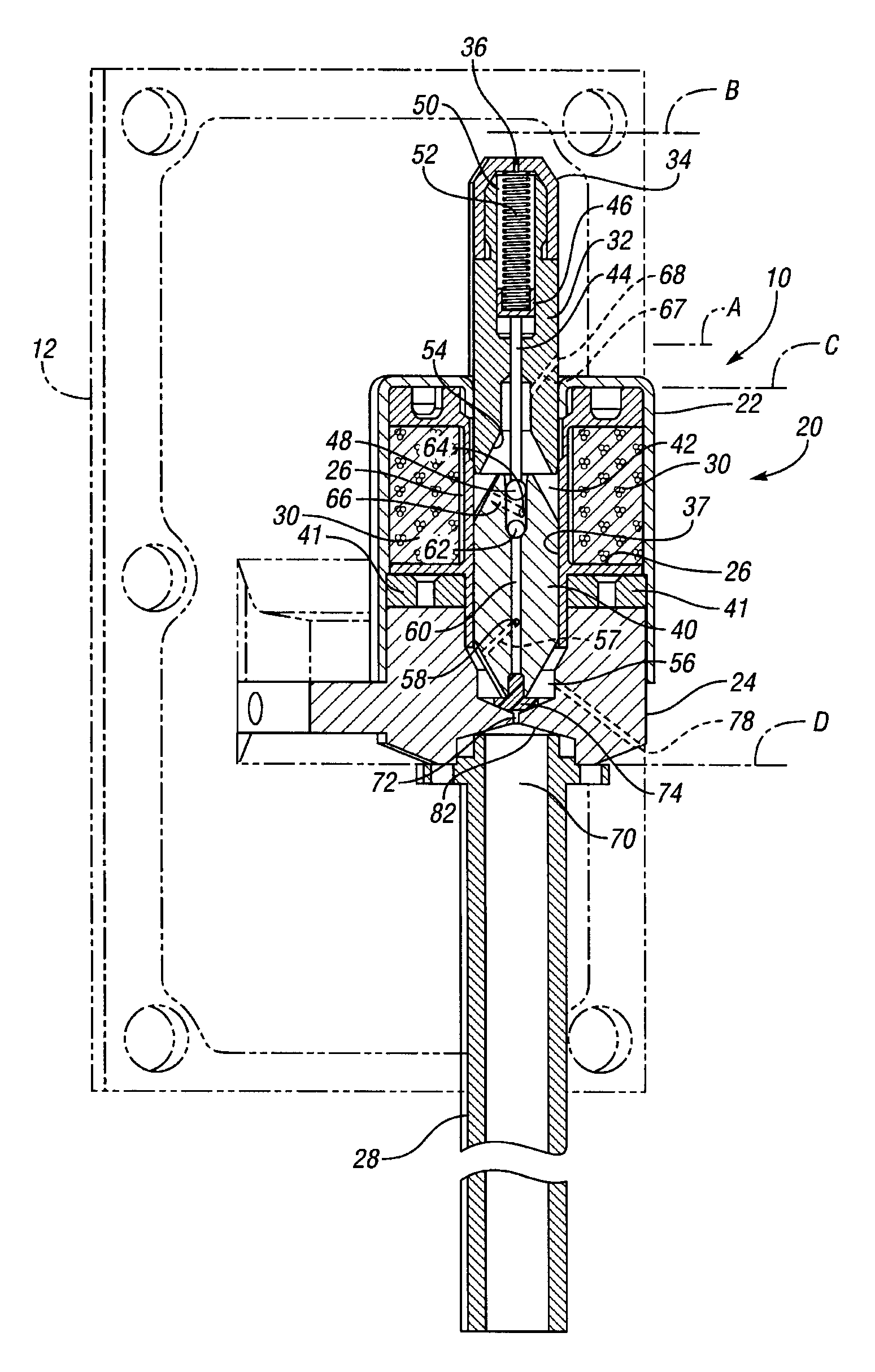

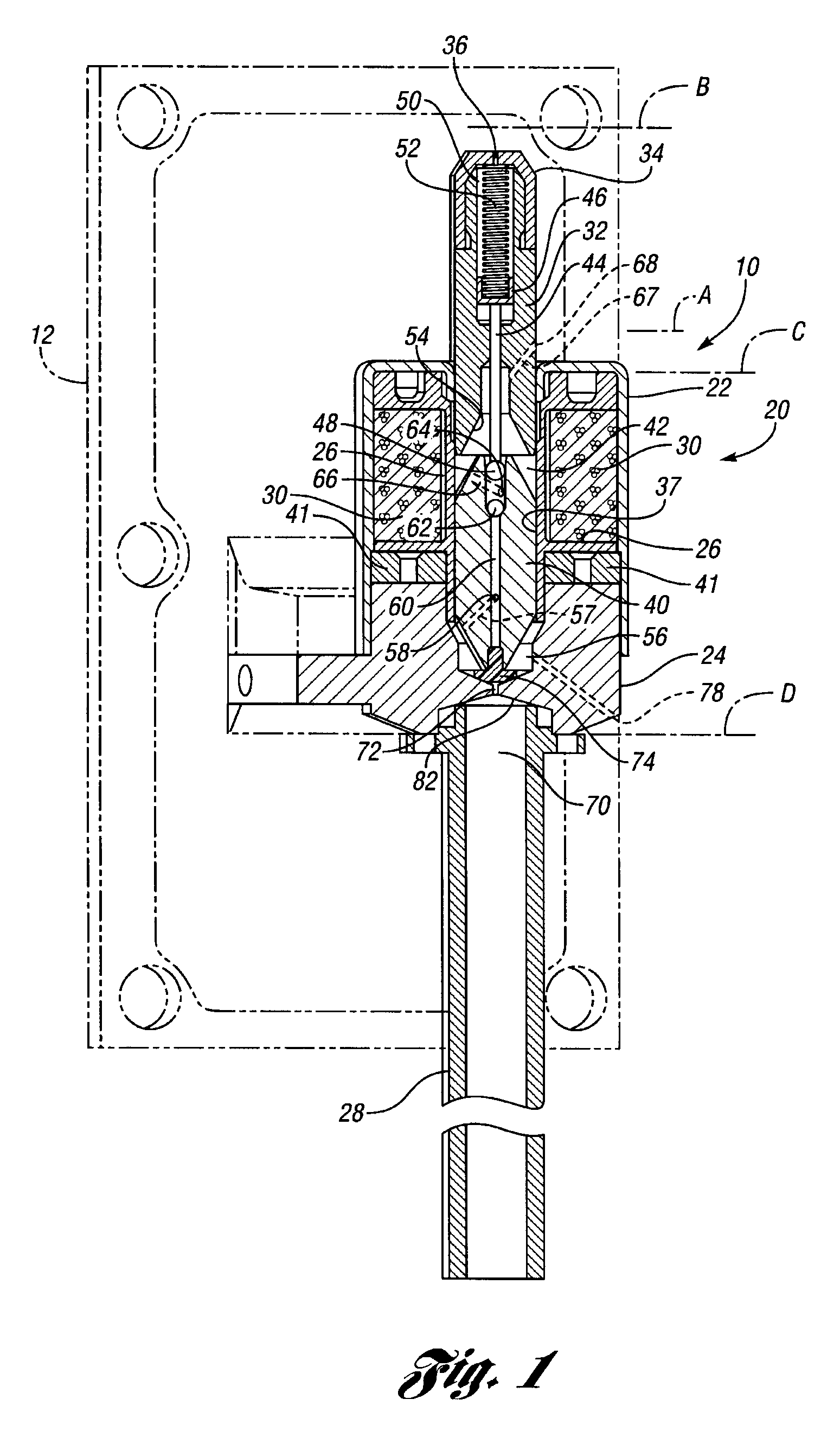

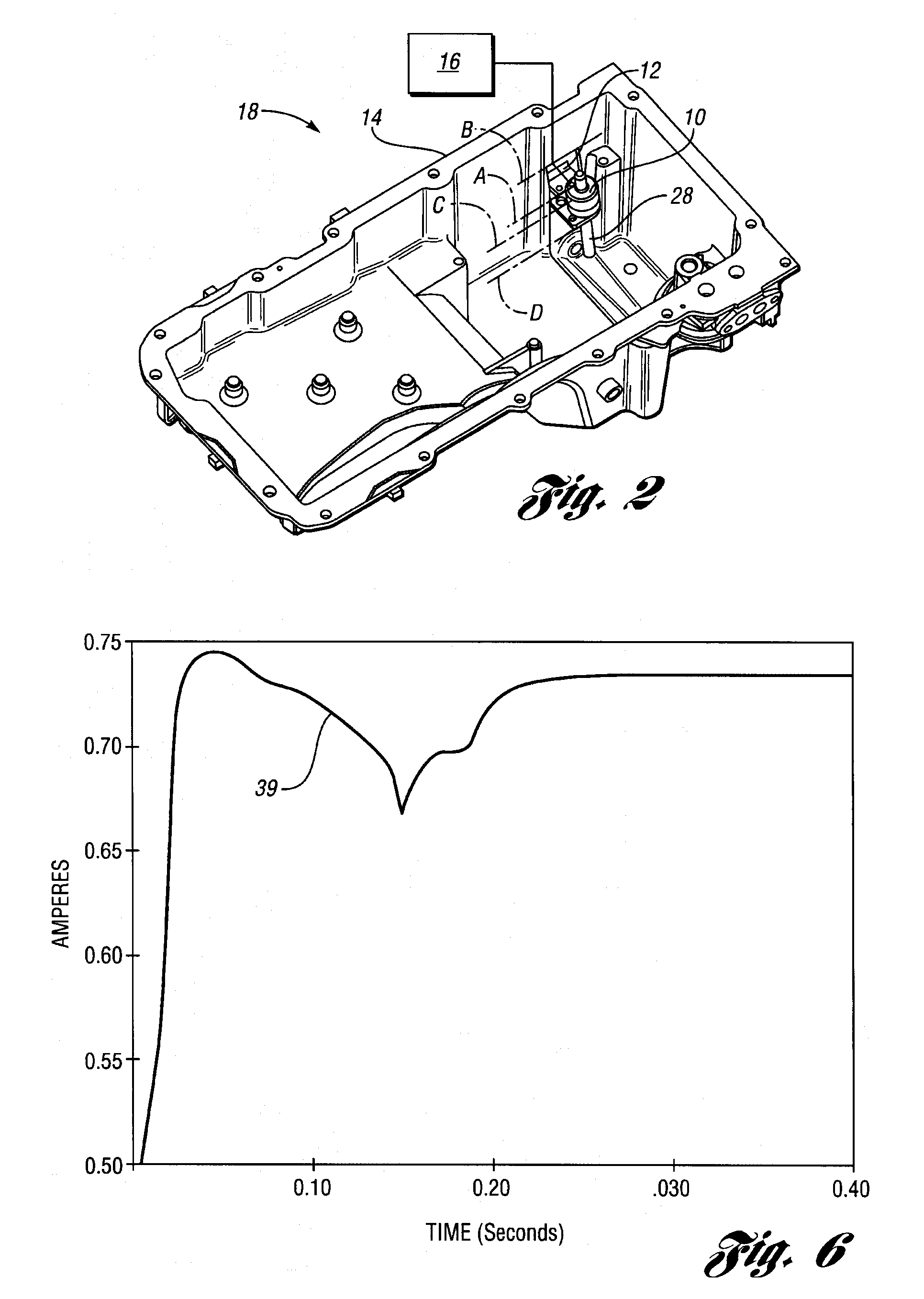

Integrated oil condition and level sensor

InactiveUS20080250851A1Accurate detectionIncrease currentFlow propertiesEngine testingLevel sensorOil viscosity

An oil condition and level sensor is provided that includes a solenoid body, a coil, an armature and a pole piece. The solenoid body defines an armature chamber between the armature and the pole piece. The armature is movable in the armature chamber in response to energizing of the coil. In an oil condition sensing system, the coil is operatively connected to a controller which can determine at least one of an oil temperature, oil viscosity, oil level, and an oil change occurrence. In one embodiment, four oil levels, including an overfill oil level and an excessively low oil level may be detected. The sensor is referred to as an integrated oil condition and level sensor as multiple sensing functions are integrated into one sensor.

Owner:EATON CORP

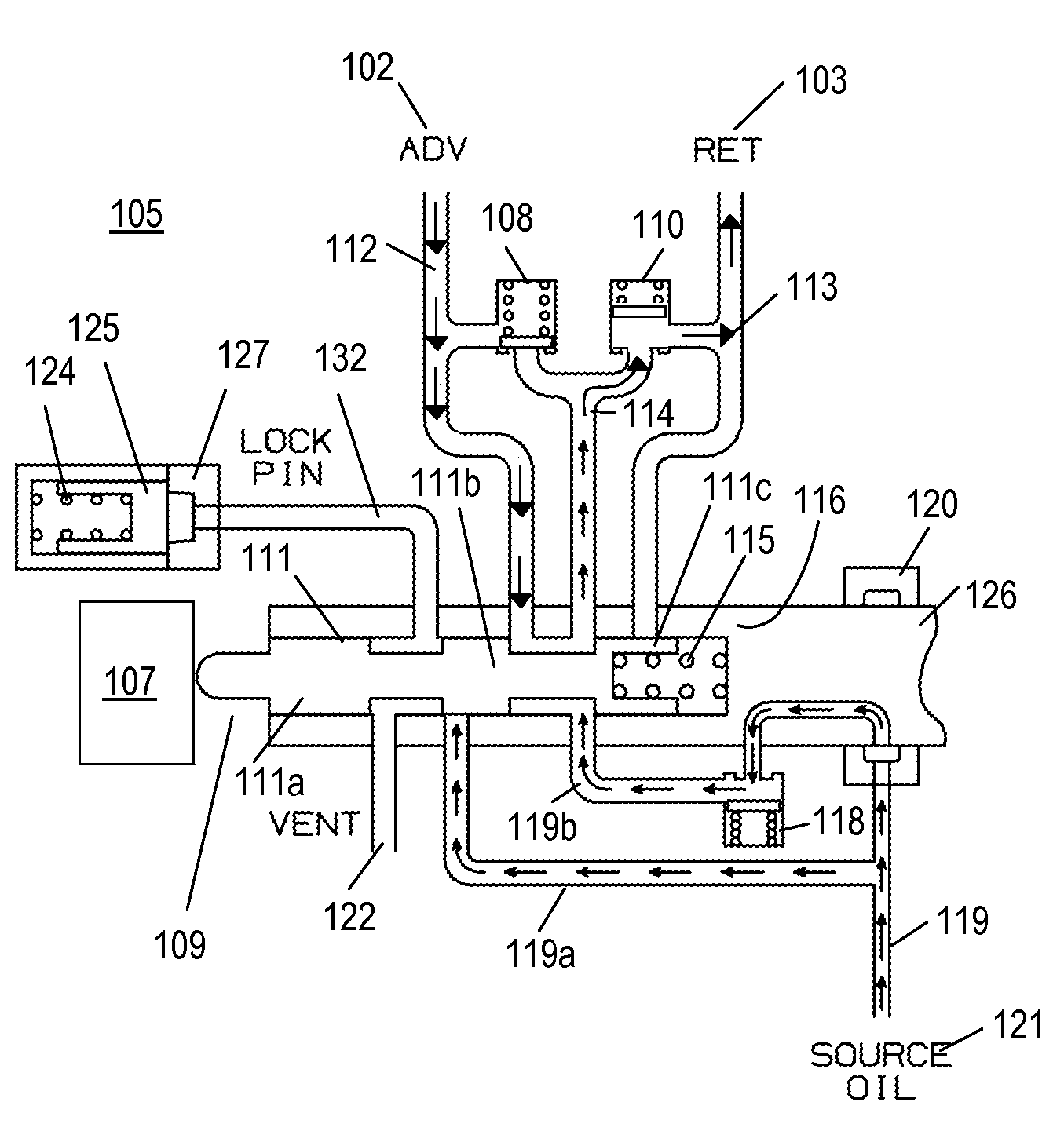

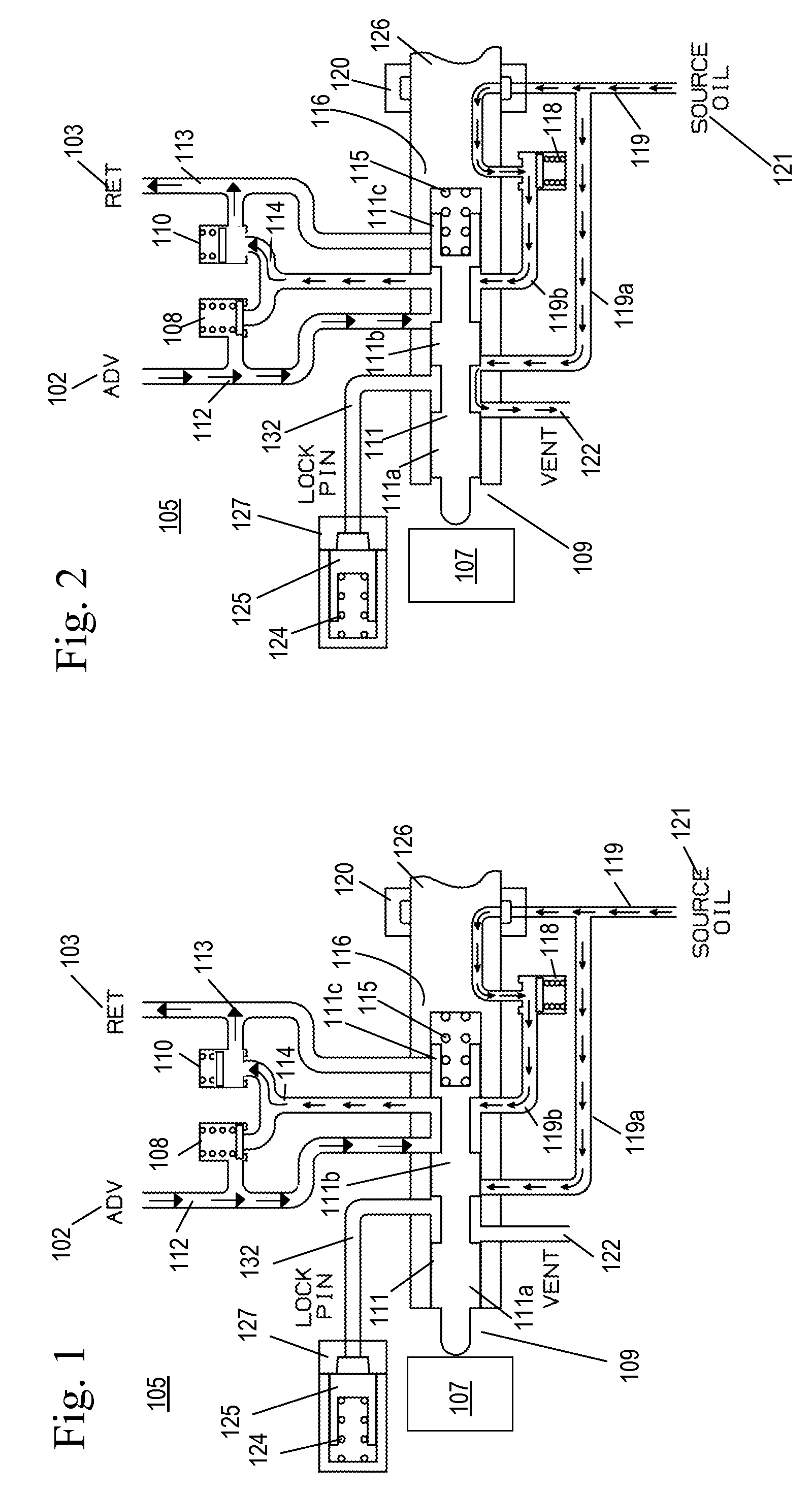

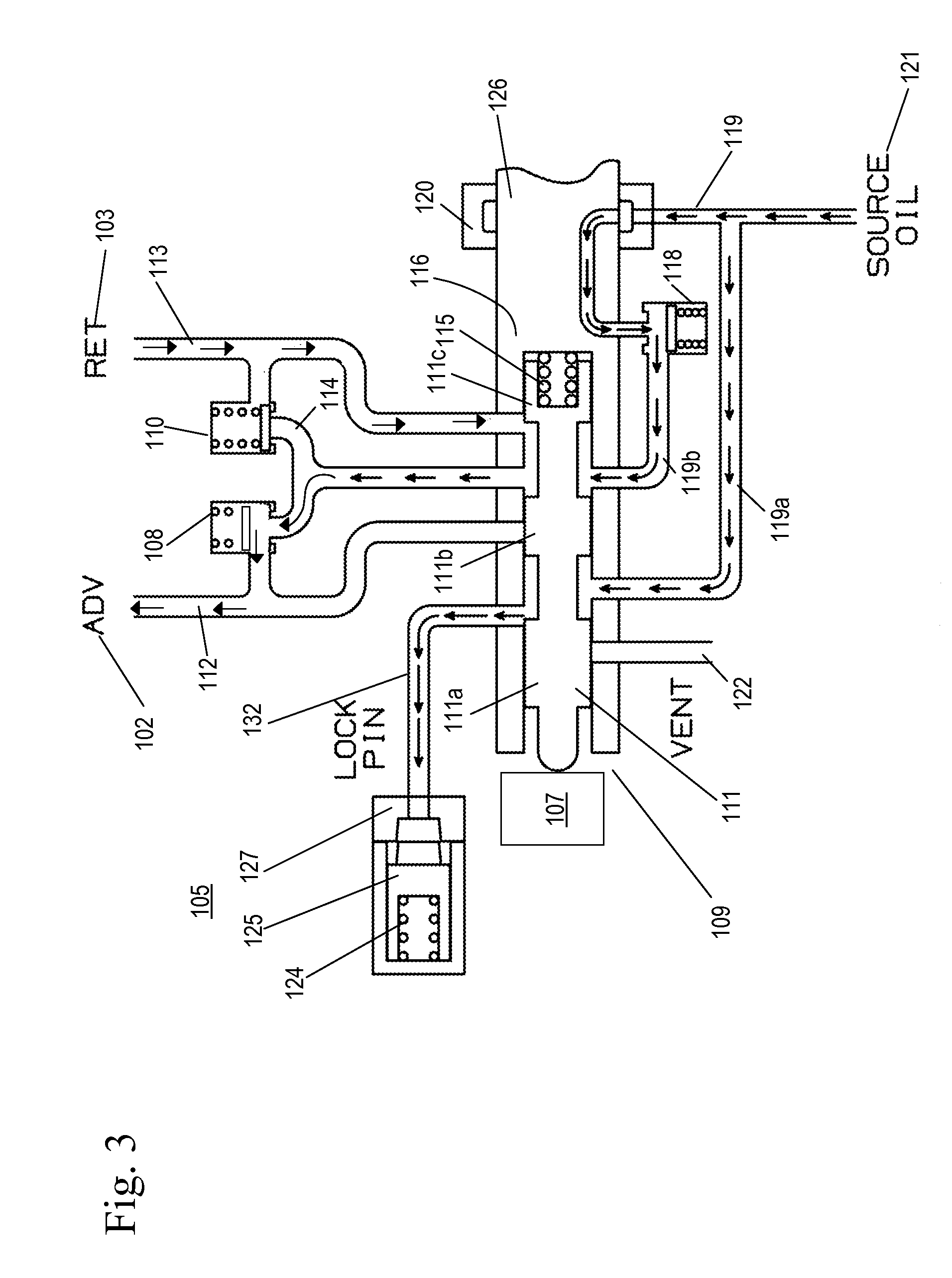

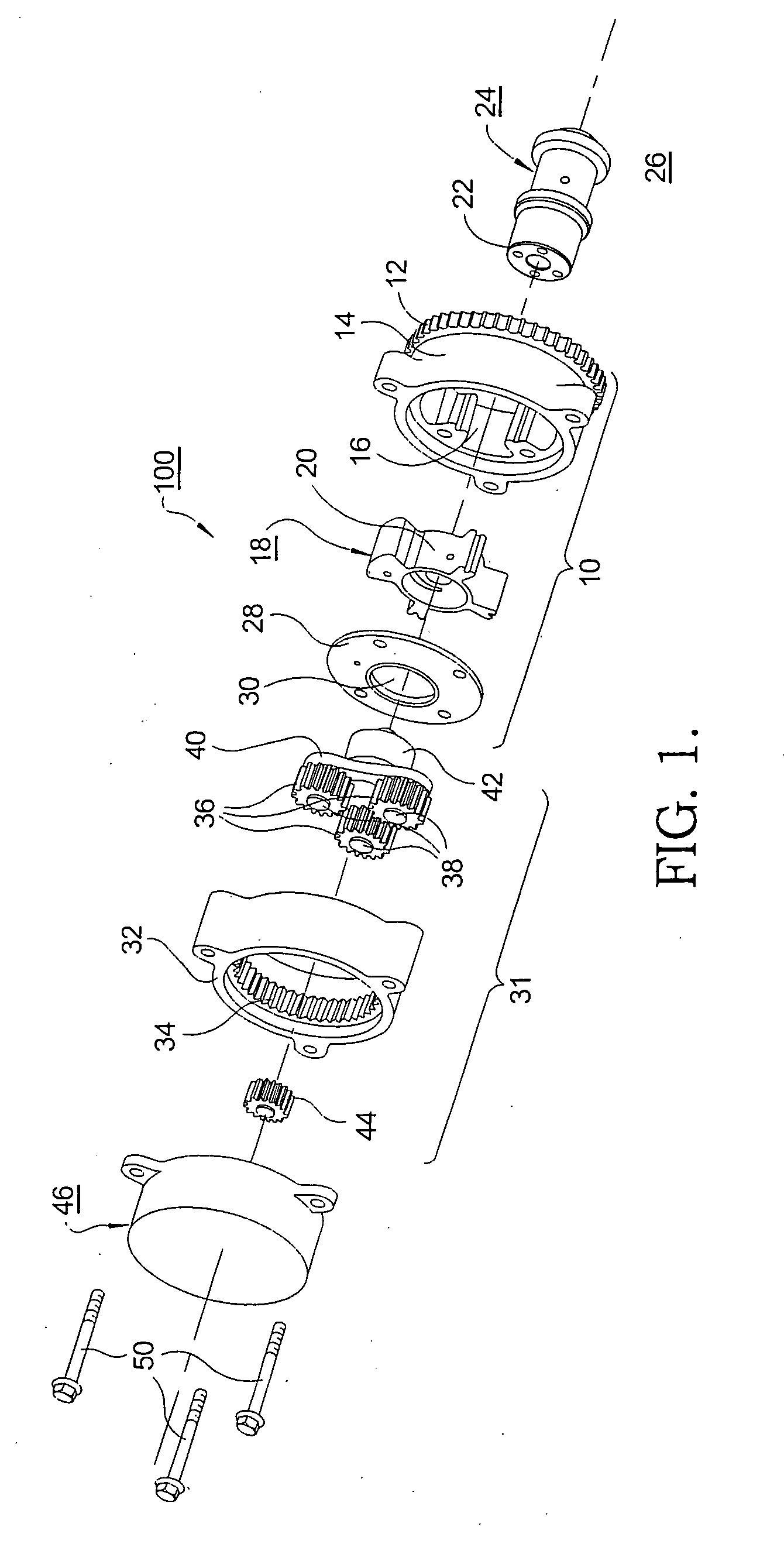

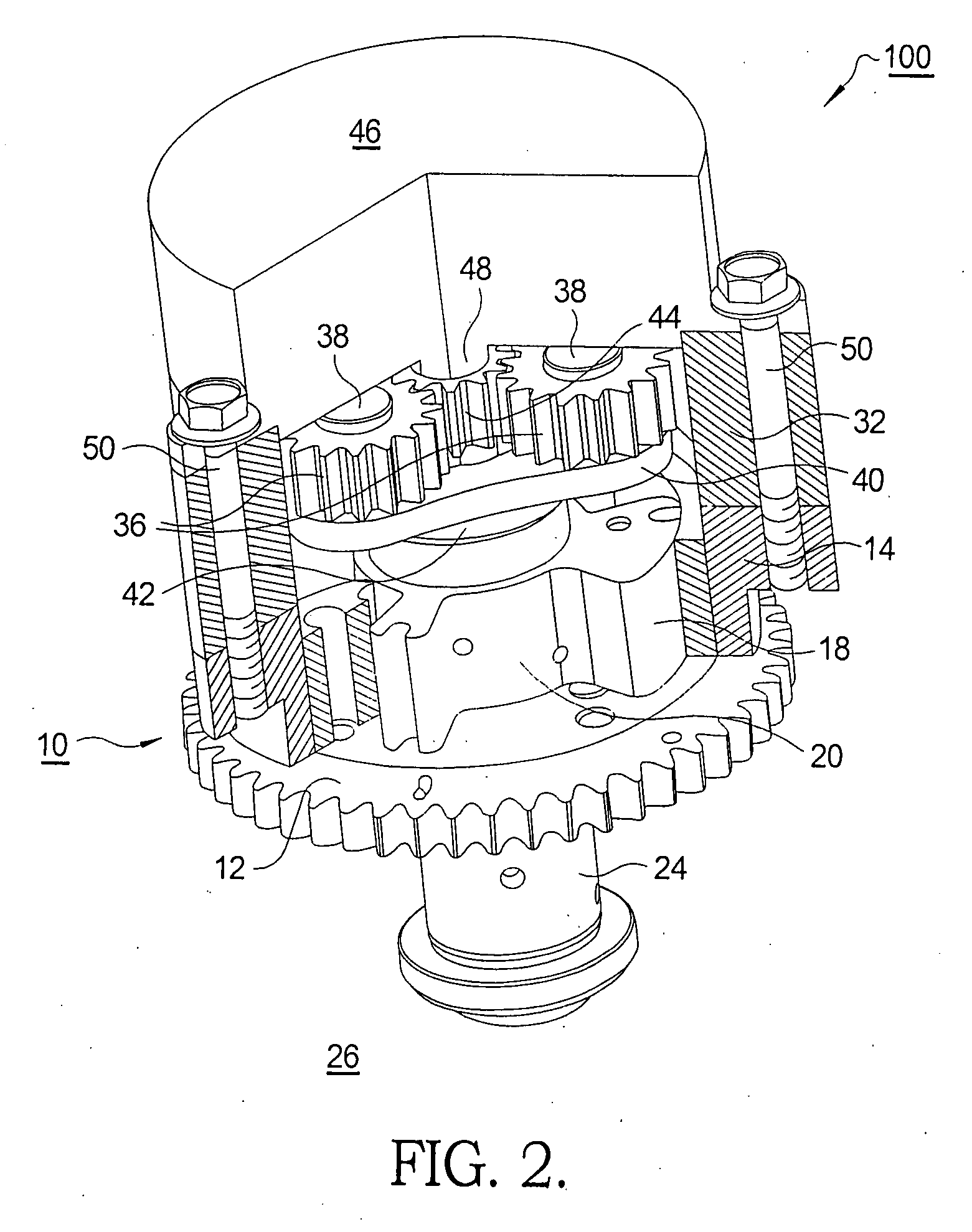

Venting mechanism to enhance warming of a varible cam timing mechanism

ActiveUS20100251981A1Shorten the timeLow viscosityMachines/enginesNon-mechanical valveOil viscosityCam

The present invention increases cold temperature oil flow through the variable cam timing (VCT) phaser to reduce the amount of time it takes to replace this oil with warmer low viscosity oil and thereby improve performance. Furthermore the oil flow through the VCT phaser is reduced once the oil temperature reaches the minimum operating temperature for the VCT phaser to operate and the VCT phaser is commanded to move from the park position. Therefore, the VCT phaser is charged with hot engine oil and is commanded to move from the parked position. The VCT phaser reduces oil flow through the phaser at high oil temperatures and low oil viscosity while adding the benefit of increased oil flow through the phaser at low oil temperatures and high oil viscosity to facilitate getting warmer oil into the VCT phaser sooner for increased VCT performance.

Owner:BORGWARNER INC

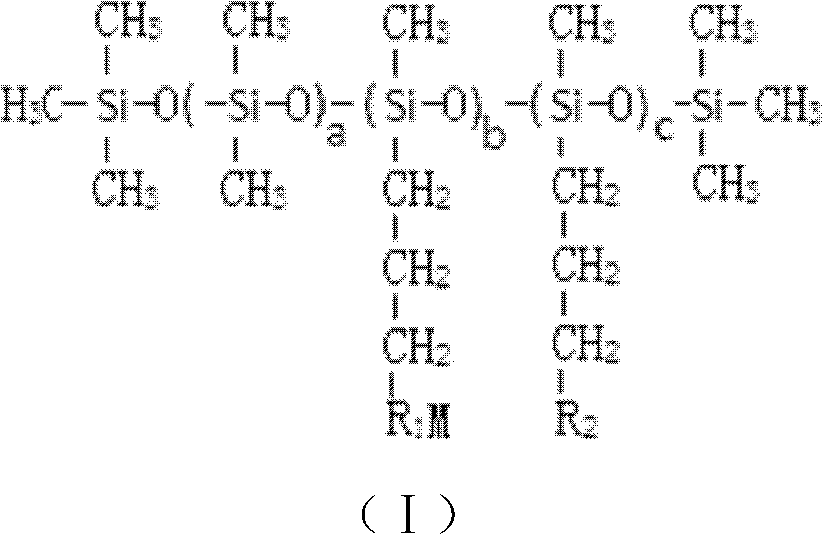

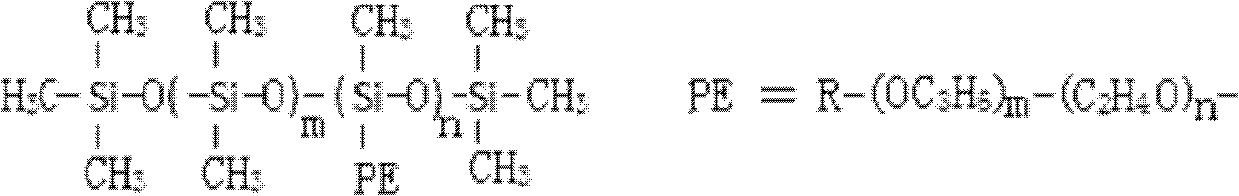

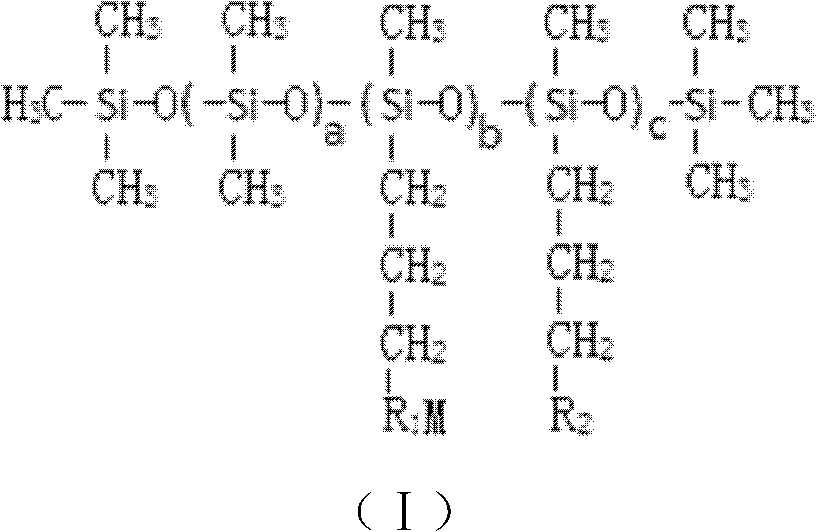

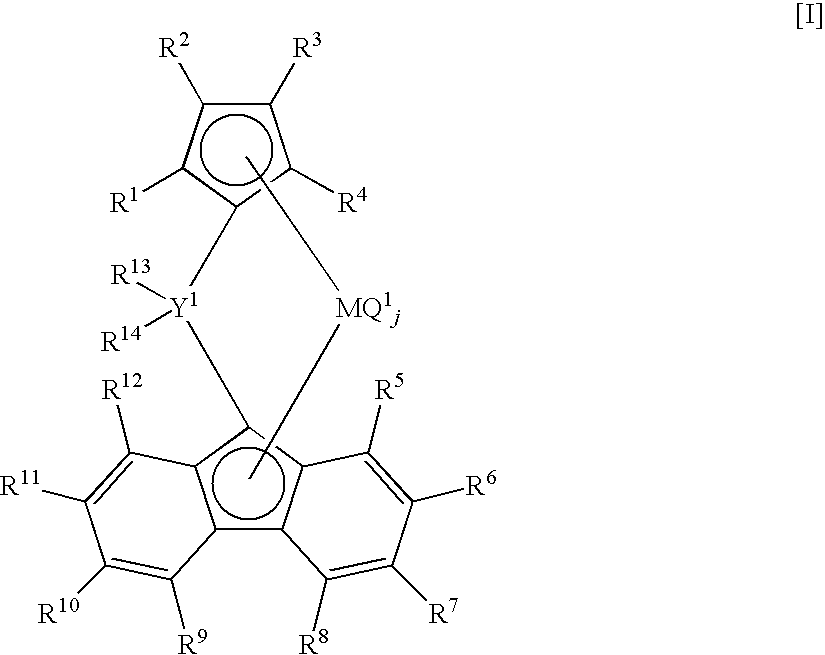

Comb-shaped modified polysiloxane anion water-base thick oil viscosity reducer and synthesizing method thereof

ActiveCN102516972AHigh affinityStrong dispersion viscosity reduction abilityDrilling compositionWater basedPolymer science

The invention discloses a comb-shaped modified polysiloxane anion water-based thick oil viscosity reducer and a synthesizing method thereof. In the viscosity reducer, a comb-shaped structure in which polydimethylsiloxane is taken as a main chain, long chain alkyl and a propylidene polypropylene oxide polyoxyethylene ether organic acid ester salt are taken as side chains is adopted, the side chains are connected through a Si-C chemical bond, and the viscosity reducer has high surface activity, high interface activity, high temperature resistance, high salt resistance, high hydrolysis property and large viscosity reducing capability on thick oil. The molecular structural general formula of the comb-shaped modified polysiloxane anion water-based thick oil viscosity reducer is shown as (I), wherein polydimethylsiloxane is taken as the main chain of a molecular structure; the long chain alkyl and the propylidene polypropylene oxide polyoxyethylene ether organic acid ester salt are taken as side chains; and the main chain is connected with the side chains through the Si-C chemical bond.

Owner:南京美思德新材料有限公司

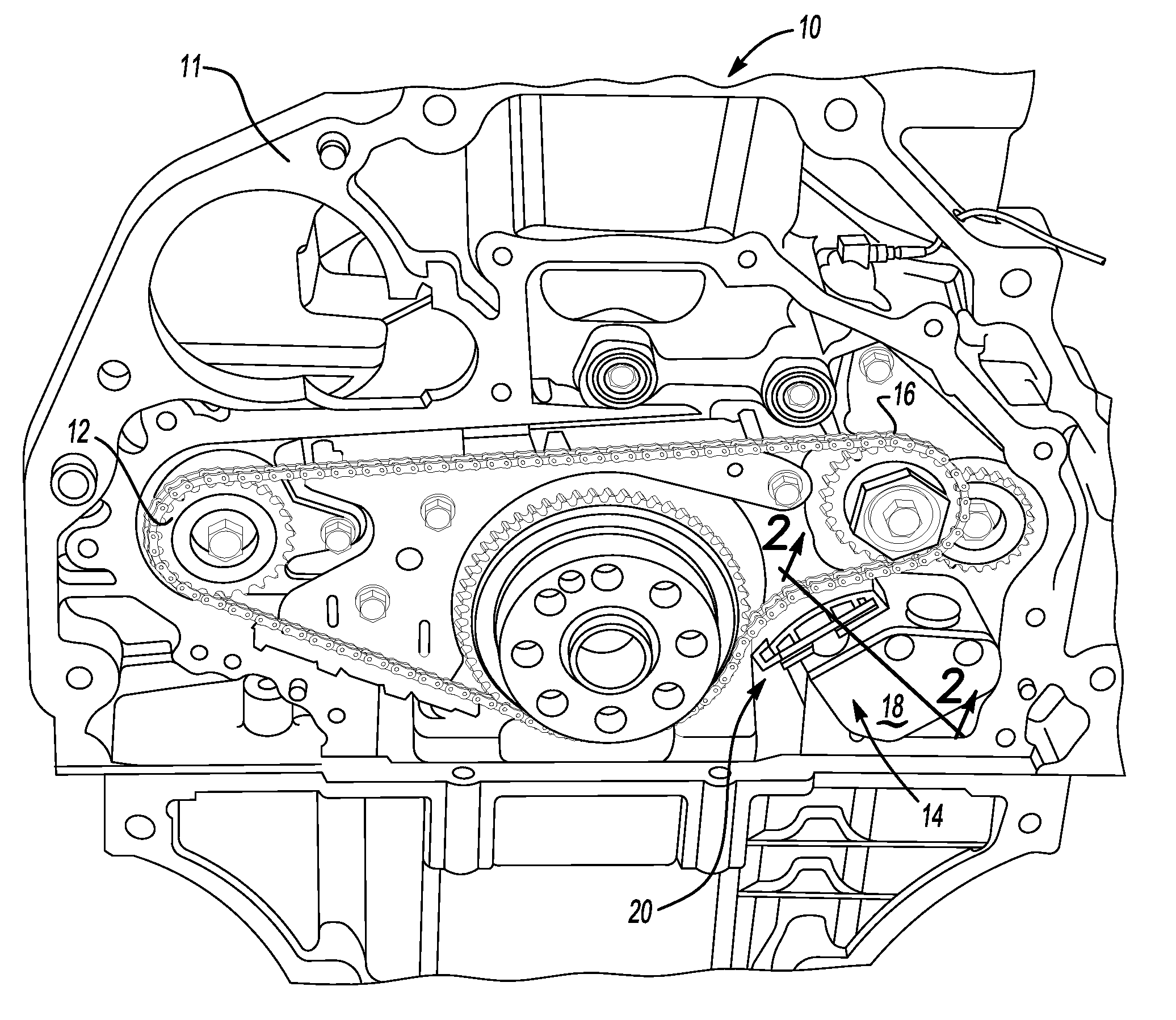

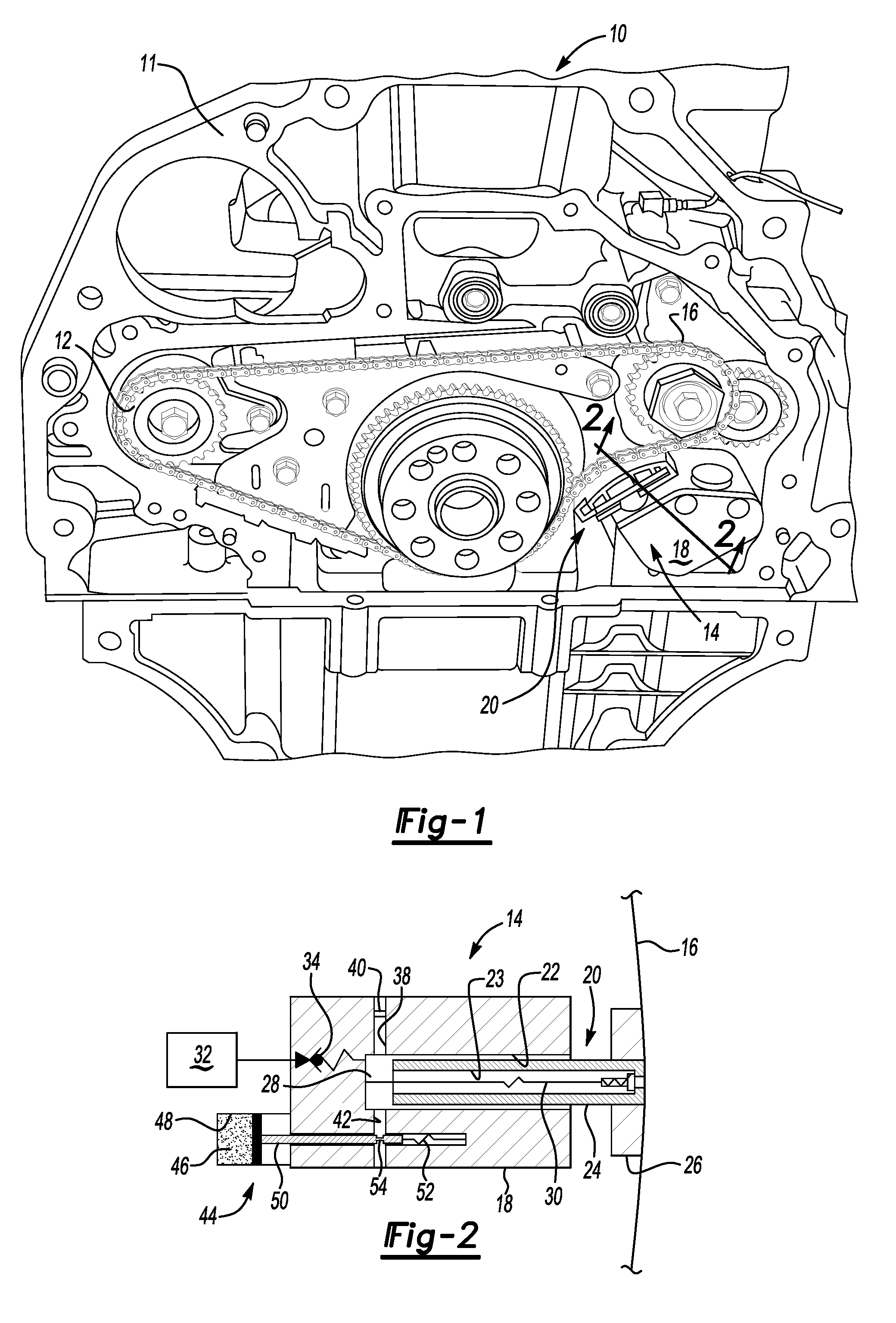

Chain Tensioning Apparatus with Temperature-Based Leakdown

An apparatus for tensioning a chain is provided that compensates for the affect of temperature on oil viscosity by providing, in addition to a continuously open oil leakage path, an additional leakage path open only at lower temperatures when oil is more viscous and leaks at a slower rate. Thus, overall oil leakage at lower temperatures is similar to that at higher temperatures, when the additional leakage path is closed, and the less viscous higher temperature oil leaks at a faster rate from the continuously open oil leakage path. Accordingly, the affect of temperature on hydraulic stiffness of the tensioner assembly is minimized.

Owner:GM GLOBAL TECH OPERATIONS LLC

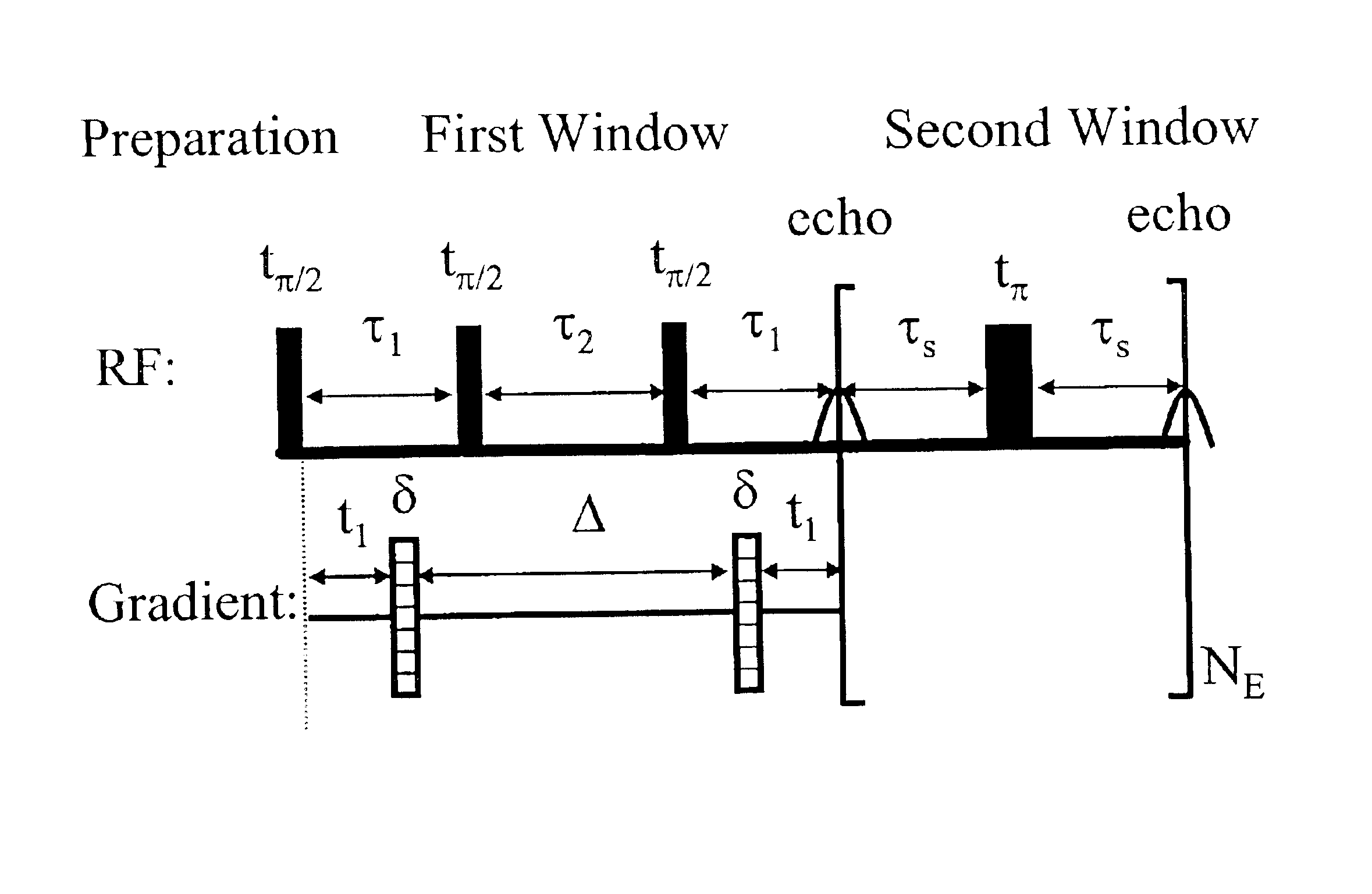

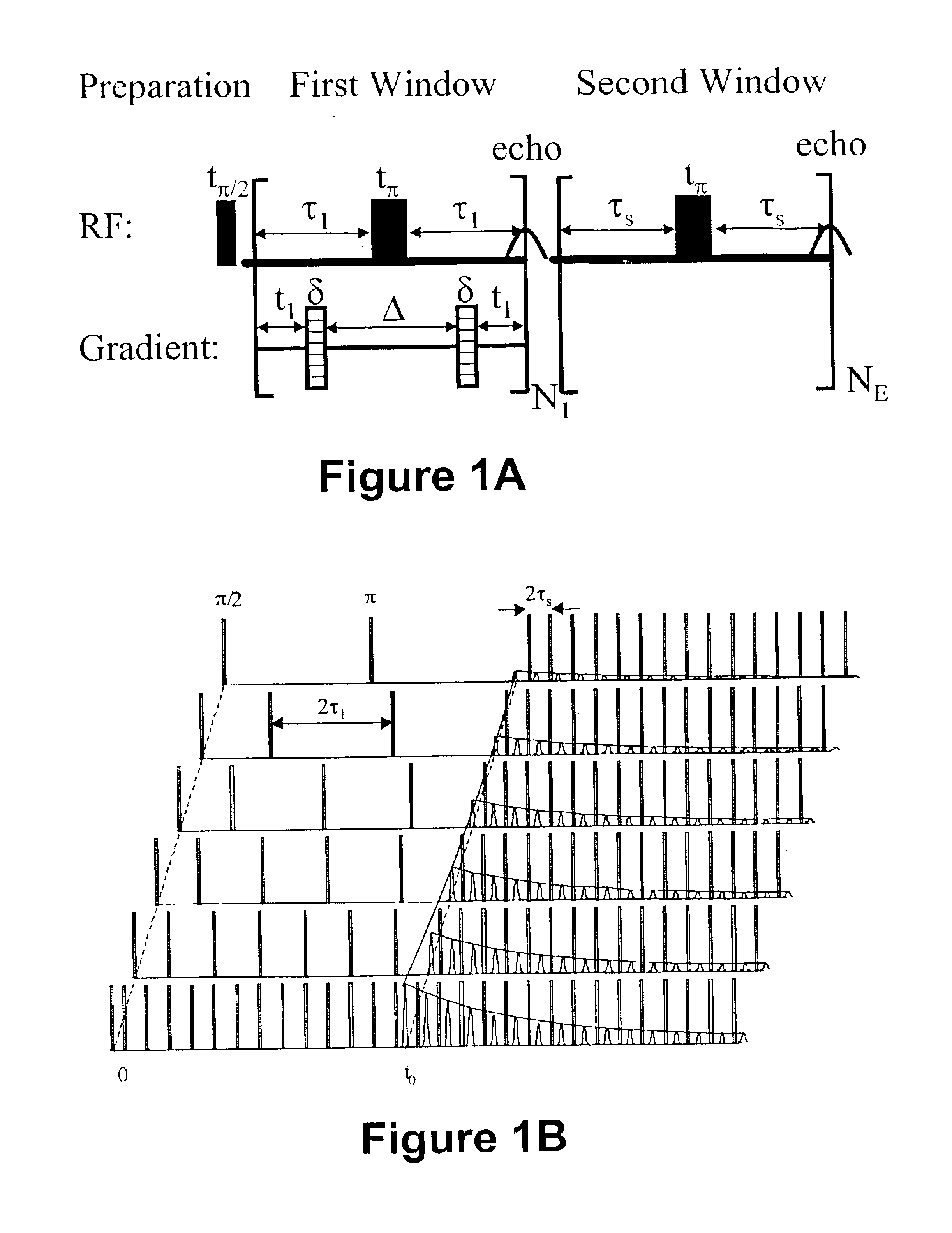

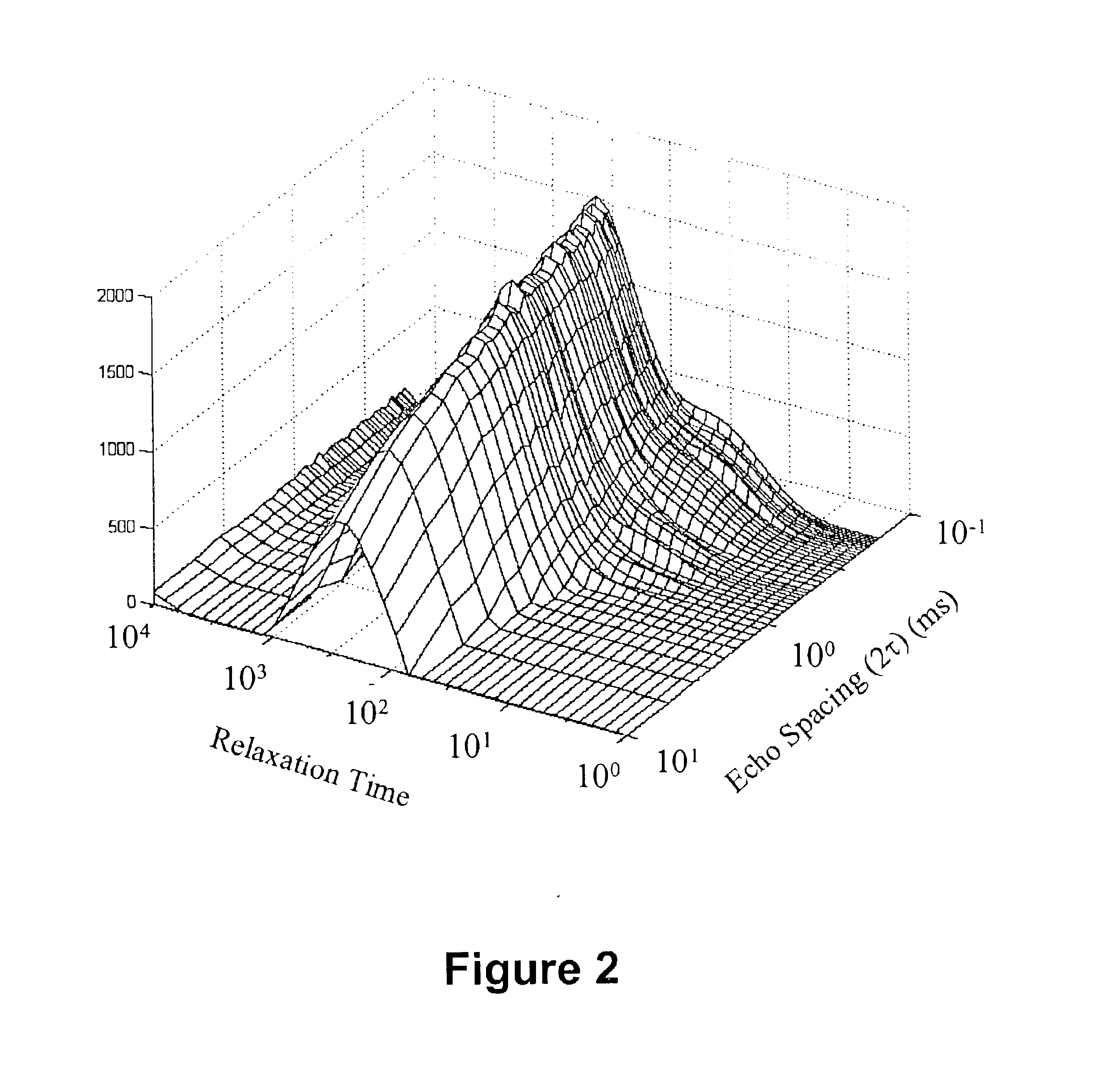

Methods of decoupling diffusion effects from relaxation times to determine properties of porous media containing fluids

InactiveUS6833698B2Remove and minimizes effectElectric/magnetic detection for well-loggingMaterial analysis by using resonancePore fluidPorous medium

Novel pulse sequences are used to probe the properties of porous media, such as are found in subterranean formations and core samples. This use allows diffusion effects to be uncoupled from the overall T2 relaxation time of the sample. Properties such as internal field gradient and distribution of diffusion coefficients may be determined. A series of pulse sequences are applied to the media to be evaluated. The series of pulse sequences include first and second windows. The first windows include pulse sequences have varying characteristics, such as increasing echo spacing, while the second windows preferably utilize similar pulse sequences which have very small echo spacing. Apparent internal field gradient distribution and apparent diffusion coefficient may be determined as a function of T2 relaxation time. These properties are readily visualized in a two-dimensional map with a first axis being the apparent internal field gradient or alternatively the diffusion coefficient of pore fluids, a second axis being the T2 relaxation times, and the vertical amplitudes being proportional to the proton population. Other properties which may be determined from use of this method include porosity, pore size distribution, oil and water saturation, oil viscosity, oil wettability, and permeability. Also, a method for determining and plotting a T1-MAS 2D spectrum is provided where T1 relaxation time and chemical shift are plotted on x,y axes while intensity of proton population is displayed along a third axis.

Owner:CHEVRONTEXACO US

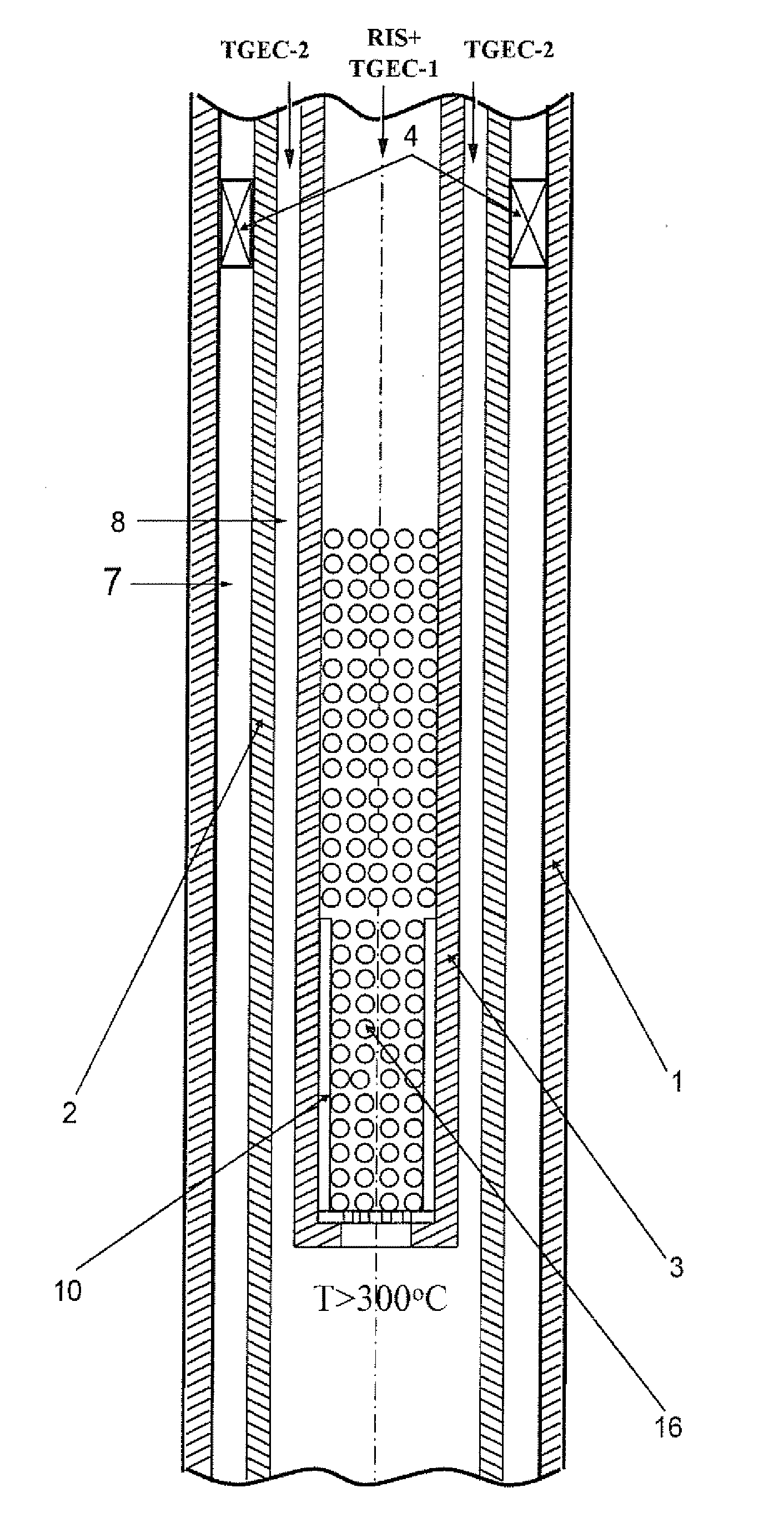

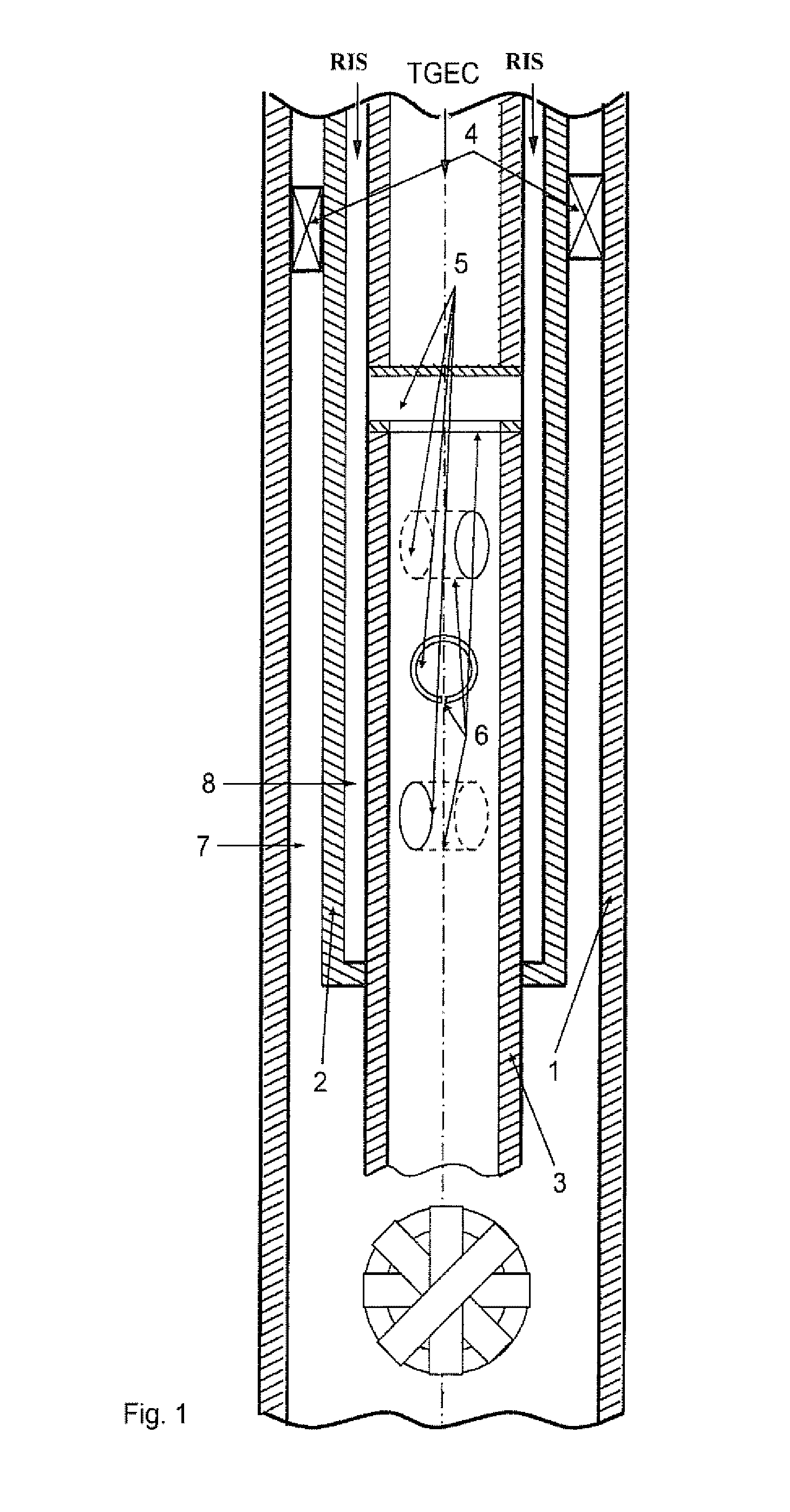

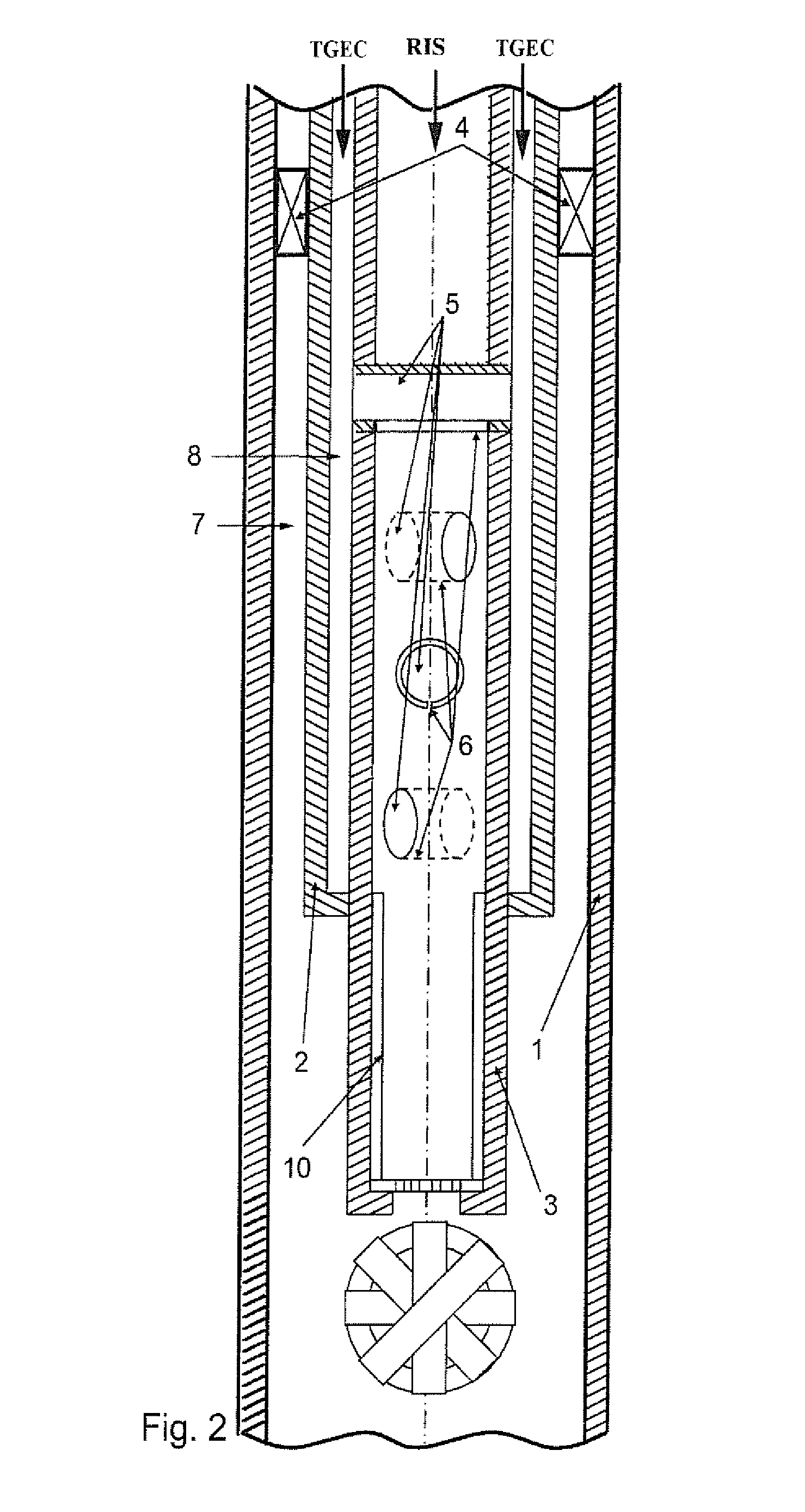

Gas evolving oil viscosity diminishing compositions for stimulating the productive layer of an oil reservoir

Owner:VISCOS ENERGY SERVICES

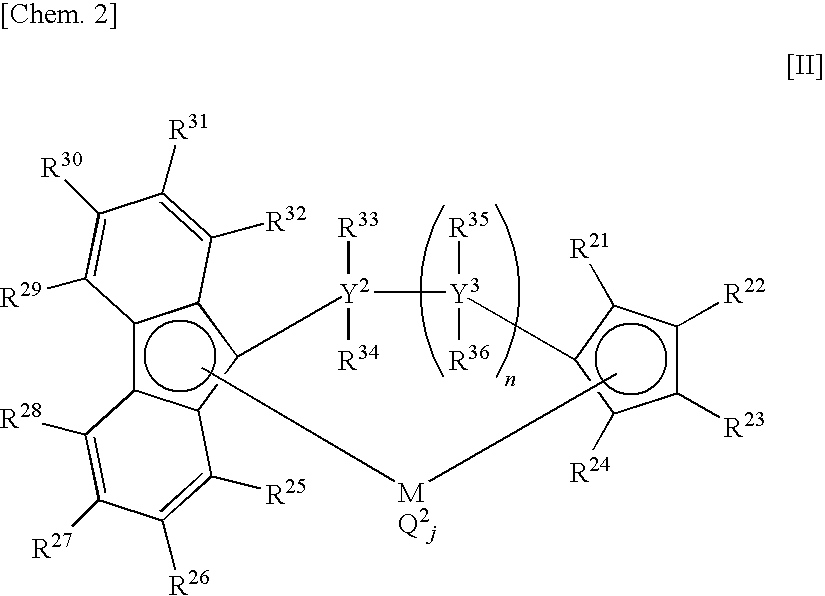

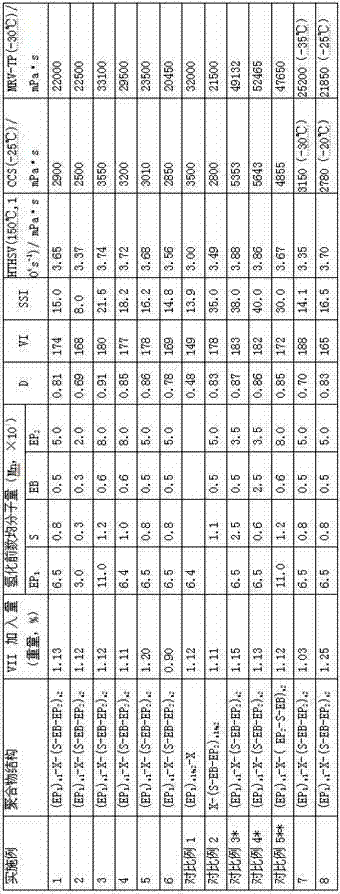

Copolymer, production process thereof, lubricating oil viscosity modifier, and lubricating oil composition

Copolymers when used as lubricating oil viscosity modifiers enable lubricating oils to show excellent low-temperature properties. Processes for producing the copolymers are disclosed. Lubricating oil viscosity modifiers and lubricating oil compositions contain the copolymers.A copolymer includes structural units derived from ethylene and structural units derived from a C3-20 α-olefin and satisfies the following requirements (1) to (8): (1) the melting point (Tm) according to DSC is in the range of 0 to 60° C.; (2) the melting point (Tm) and the density D (g / cm3) satisfy the equation: Tm≧1073×D−893; (3) Mw / Mn according to GPC is from 1.6 to 5.0; (4) the half-value width (ΔThalf) of a melting peak measured by DSC is not more than 90° C.; (5) the half-value width (ΔThalf) and the melting point (Tm) satisfy the equation: ΔThalf≦−0.71×Tm+101.4; (6) the heat of fusion (ΔH) as measured by DSC is not more than 60 J / g; (7) the crystallization temperature (Tc) measured by DSC is not more than 70° C.; (8) the heat of fusion (ΔH), the crystallization temperature (Tc), each measured by DSC and the crystallization temperature measured by a CRYSTAF method (Tcrystaf) satisfy the equation:Tc−Tcrystaf≧0.028×ΔH+25.3.

Owner:MITSUI CHEM INC

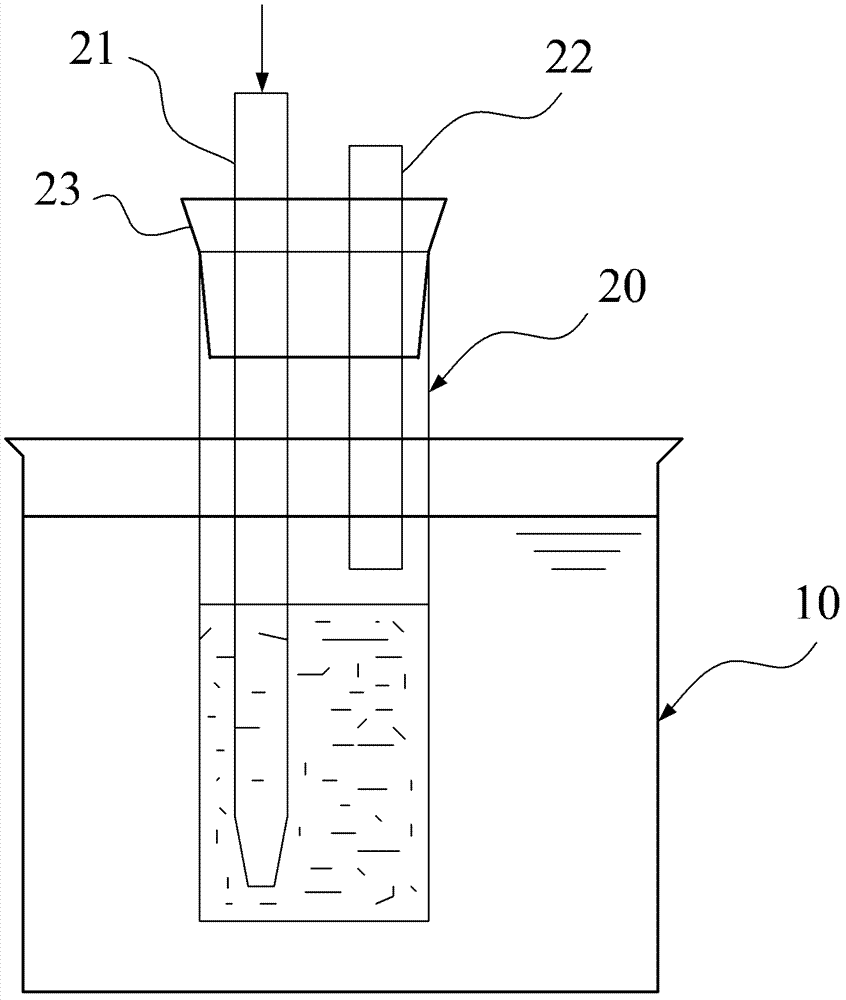

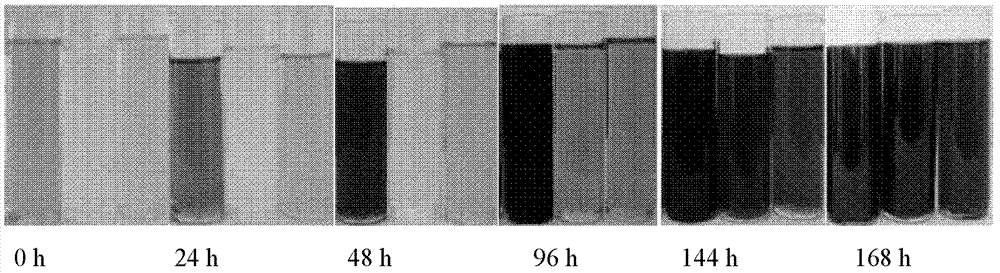

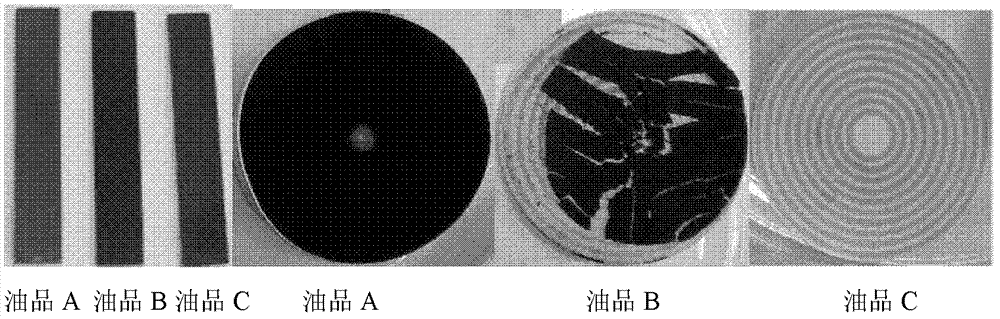

Rapid and comprehensive evaluation method of lubricant oil aging performance

ActiveCN103091476ARapid aging performance assessmentComprehensive aging performance evaluationMaterial testing goodsMetal catalystSludge

The present invention provides an evaluation method of lubricant oil aging performance. The method includes feeding air or oxygen with flow of 3-15L / h into the to-be-tested lubricant oil, under the conditions of oil temperature of 100-200 DEG C and metal catalyst, and then measuring aging performances including lubricant oil viscosity, color, acid value, demulsibility, pentane insolubles, copper corrosion, copper weight loss and sludge trend after 20-200 hours, and evaluating the lubricant oil aging performance according to the change of lubricant oil performances before and after the test. The evaluation method of lubricant oil aging performance helps to achieve rapid and comprehensive evaluation for oil.

Owner:CHINA PETROLEUM & CHEM CORP

Process for preparing blown vegetable oil

InactiveUS7262311B2Process economyLimit and eliminates yield lossFatty oils/acids recovery from wasteOrganic compound preparationVegetable oilOil viscosity

A method for partially refining a crude vegetable oil utilizing physical refining techniques is described. The crude vegetable oil is first degummed by either (1) allowing the crude oil to settle over a period of time, such as twenty days, so that the oil becomes stratified into at least two layers, wherein one layer comprises gums with low oil content and a second layer comprises oil containing only a fraction of the gums originally present and then separating the oil layer from the gum layer, or (2) heating the crude oil to a temperature of about 270-300° F. with agitation and then allowing the crude oil to settle for a period of time until the oil becomes stratified into the at least two layers. The degummed oil is then aerated and agitated while being maintained at a temperature of 170-180° F. for a time period sufficient to obtain a desired oil viscosity. The resulting partially refined oil is suitable for use in industrial applications such as the preparation of urethane foams.

Owner:SOUTH DAKOTA SOYBEAN PROCESSORS

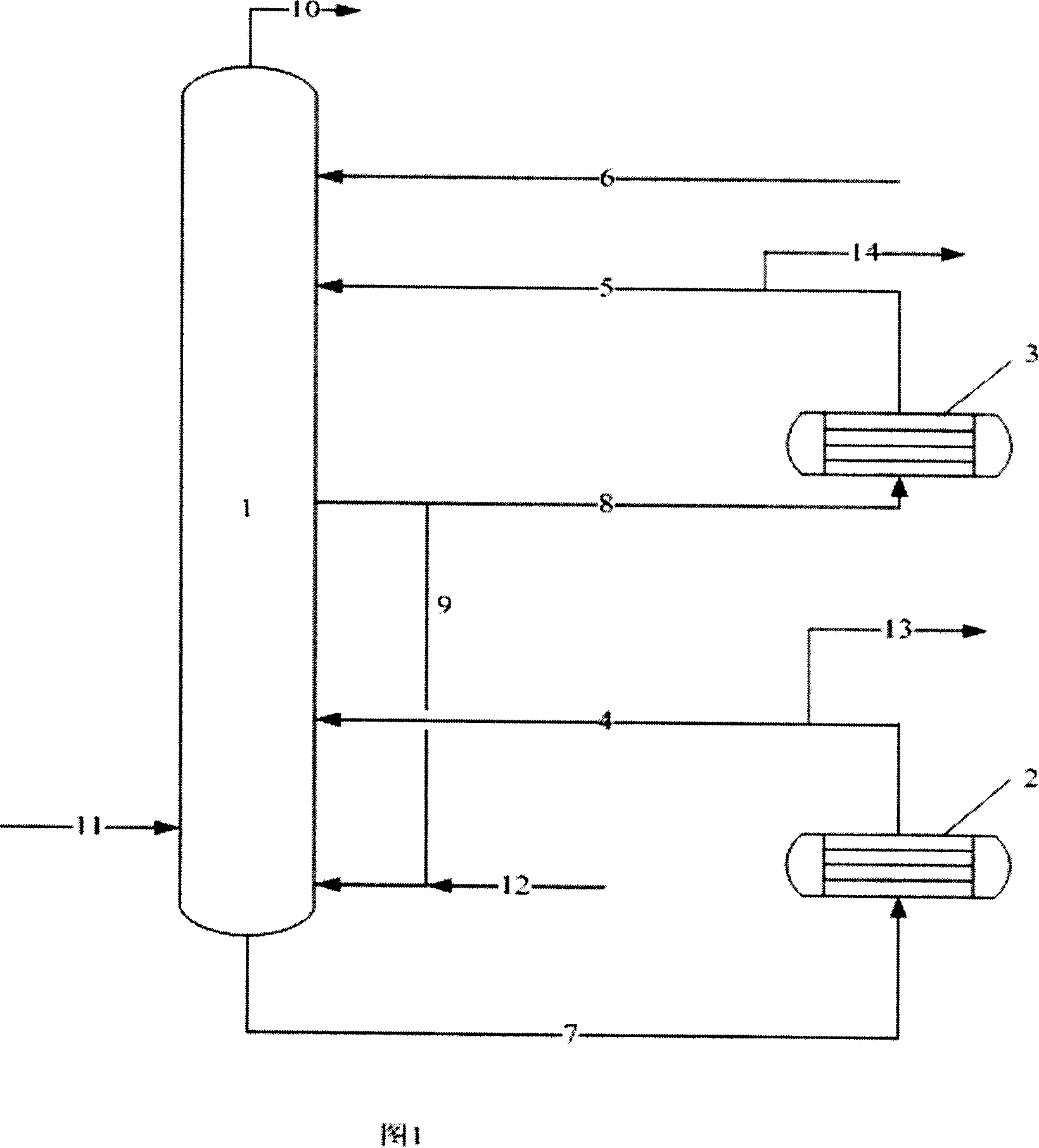

Method for reducing quenching-oil viscosity of ethene producer

ActiveCN101074184AAdjust injection volume at any timeIncrease temperatureHydrocarbon by hydrocarbon crackingGasolineOil viscosity

A method for breaking viscosity quenching oil of ethane apparatus is carried out by cooling pyrolysis gas from pyrolyzer, delivering it into oil-leaching tower bottom, separating from substances to form triple backflows, cooling by quenching oil at tower bottom, returning to oil-leaching tower partially, entering backflow gasoline at tower top into by pipeline, cooling substances from pyrolyzer and delivering into after system. It's stable, has high viscosity and saves energy resources.

Owner:PETROCHINA CO LTD

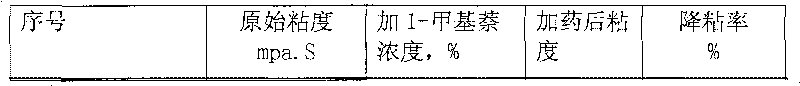

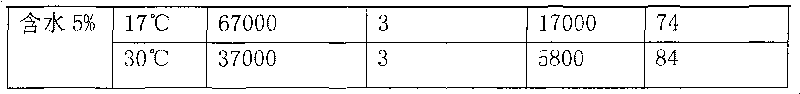

Application of methylnaphthalene in lowering viscosity of thickened oil

ActiveCN101717626ALow viscositySpeed up the flowFluid dynamicsFluid removalOil viscosityHigh surface

The invention discloses application of methylnaphthalene in lowering viscosity of thickened oil, which comprises application of 1-methylnaphthalene in lowering viscosity of thickened oil and the specific implementation steps, 2-methylnaphthalene in lowering viscosity of thickened oil and the specific implementation steps and mixed methylnaphthalene in lowering viscosity of thickened oil and the specific implementation steps. The invention enlarges the application method of methylnaphthalene, clearly demonstrates the specific application method of using methylnaphthalene to lower viscosity of thickened oil, solves the problems of great load and power consumption, frequent machinery accidents, high surface line return pressure, and the like of an oil extractor during extracting and outwards transporting thickened oil in the background art, and can effectively lower viscosity of thickened oil and reduce extraction and outward transportation cost of thickened oil.

Owner:盘锦河升大地石油科技有限公司

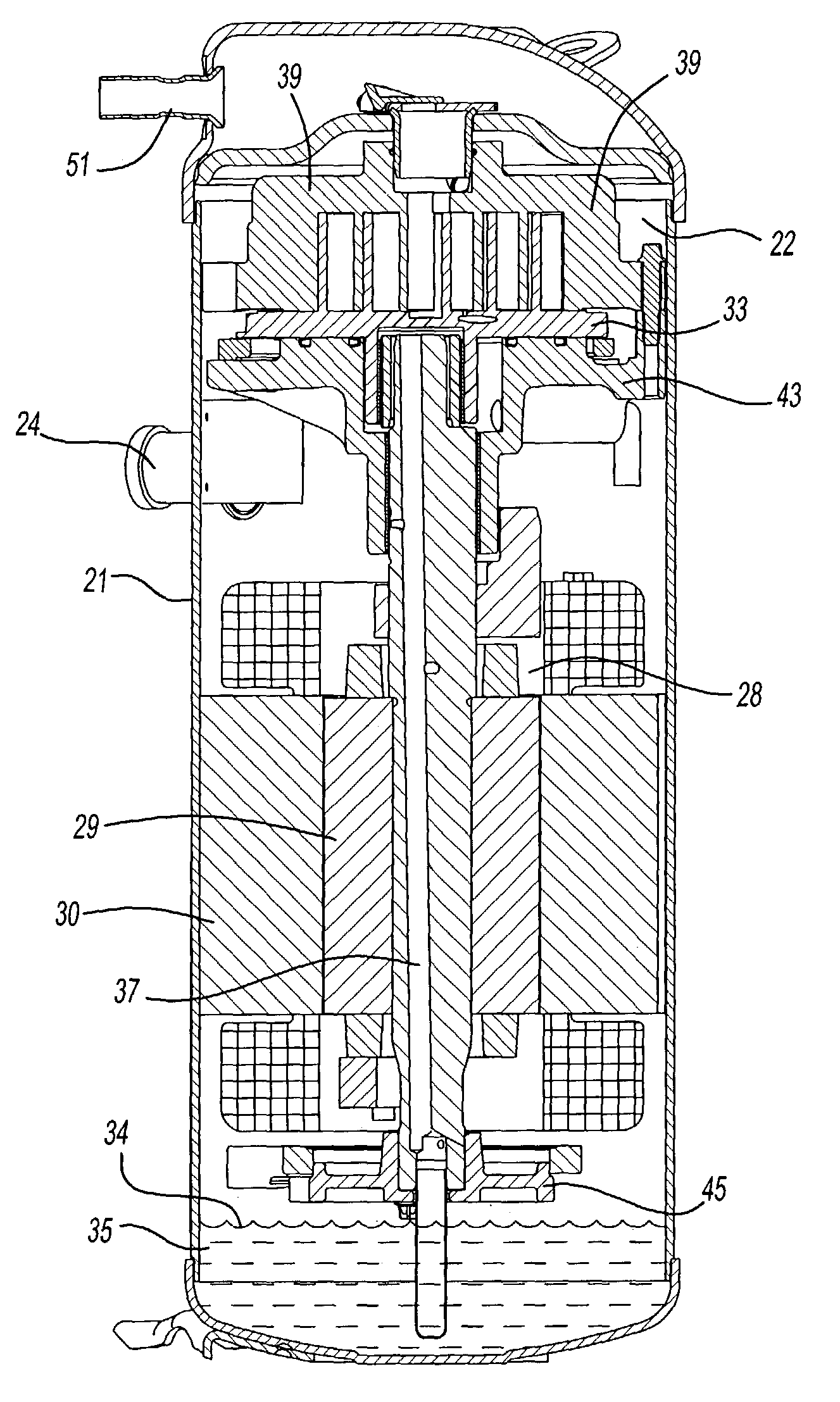

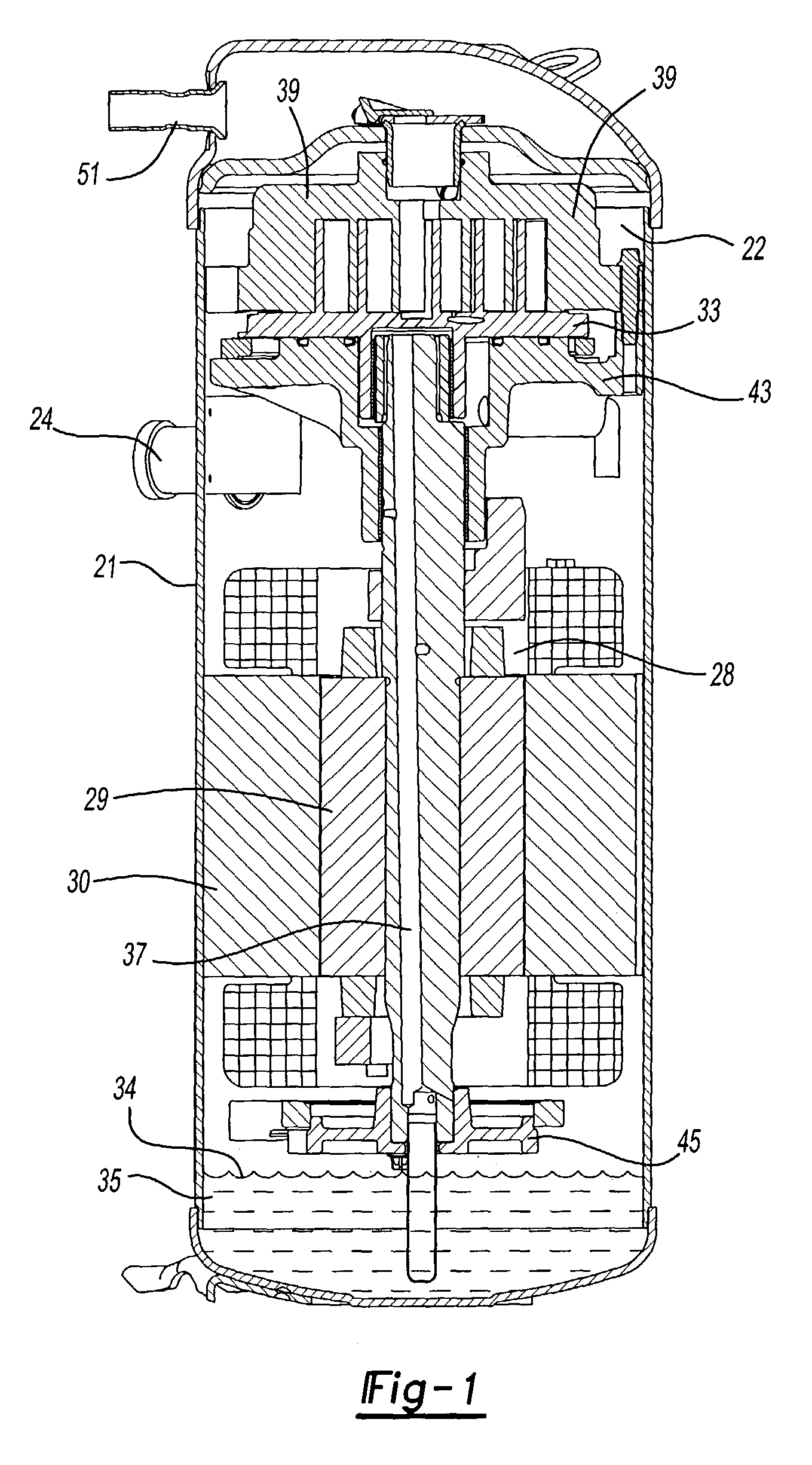

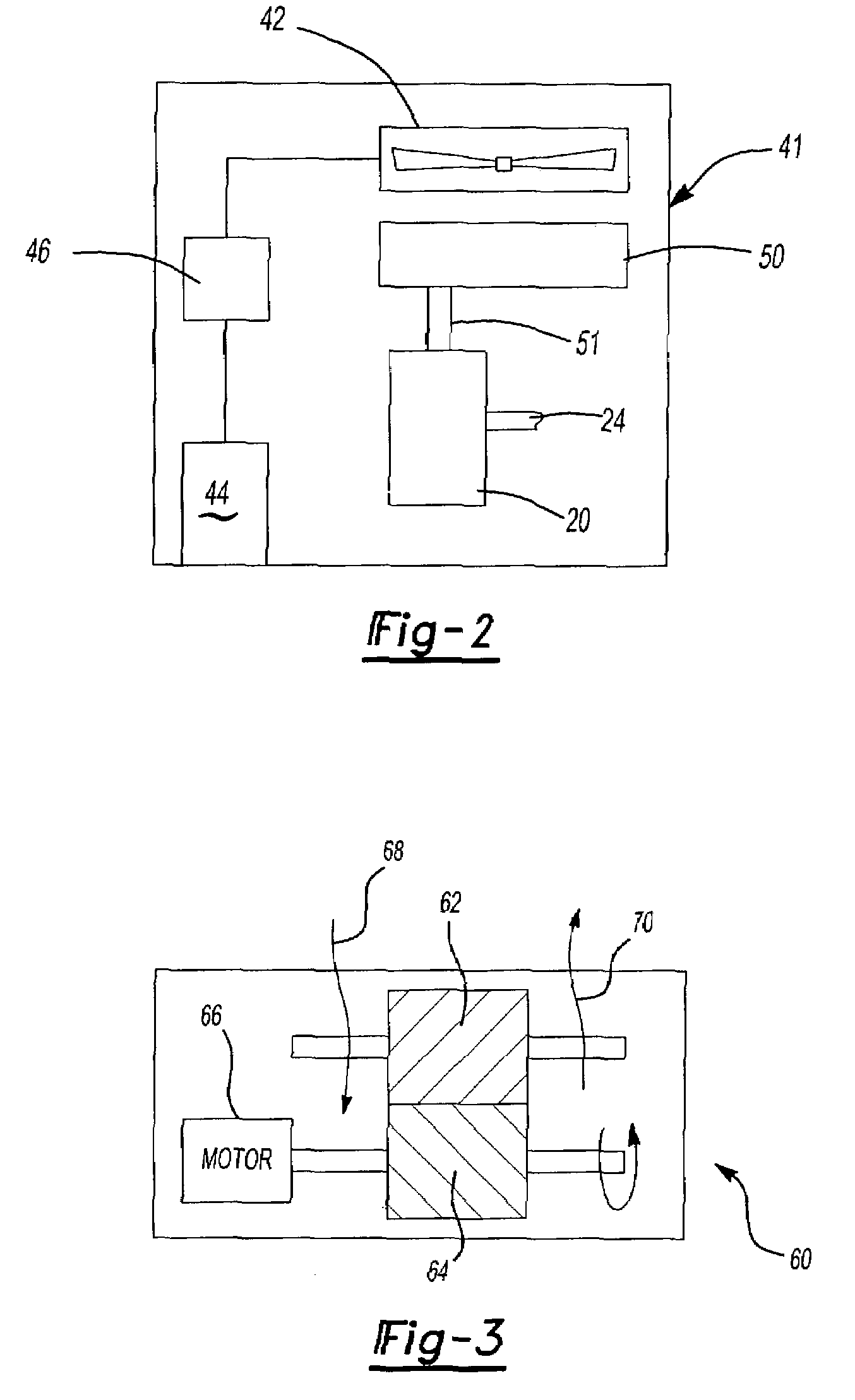

Short reverse rotation of compressor at startup

InactiveUS7290990B2Rotary/oscillating piston combinations for elastic fluidsFlexible member pumpsEngineeringBrief periods

In a method of operating a scroll or screw compressor at startup, the compressor is rotated in reverse for a brief period of time. The compressor is of a type that does not compress liquid when rotated in reverse. The purpose is to boil off the liquid refrigerant from the oil by heating and agitating the mixture of oil and refrigerant in the oil sump. This results in much more benign forward start as no refrigerant is drawn into the scroll compressor pump and the amount of oil pumped out of the compressor on start up is minimized. Also, the viscosity of oil is increased and lubrication of the bearings is improved. After a short period of time reverse rotation is stopped and the compressor can begin to be driven in the forward direction.

Owner:CARRIER CORP

Star polymer used as lubricating oil viscosity index improver, preparation method and application thereof

InactiveCN102731739AGood viscosity increasing effectImprove stabilityAdditivesPolystyreneOil viscosity

The invention discloses a star polymer used as a lubricating oil viscosity index improver, a preparation method of the star polymer and application of the star polymer. The star polymer has asymmetrical arms and consists of two different types of polymer arms, wherein the first type of polymer arm is a hydrogenation polyisoprene homopolymer, and the second type of polymer arm is a copolymer in a hydrogenation polyisoprene-hydrogenation polybutadiene-polystyrene block structure; and in the copolymer arm, the polystyrene section is close to the core of the star polymer, the hydrogenation polybutadiene section is in the middle of the arm, and the hydrogenation isoprene section is outside the arm. The structure of the star polymer contains 2-15% of polybutadiene block by weight, and at least a part of the polyisoprene block and the polybutadiene block in the structure of the start polymer is hydrogenated. The star polymer has an excellent tackifying effect and excellent shear resistance stability, and is lower in pumping viscosity and low-temperature start viscosity during blending of thickened engine oil, and crystal or gel cannot be formed in the engine oil by the star polymer.

Owner:FUYANG JINGLUE CHEM TECH

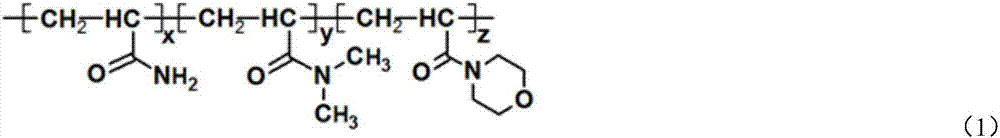

Preparation method of water-soluble anion polymer-type thickened oil viscosity reducer

ActiveCN107880214ARaw materials are cheap and easy to getSimple processDrilling compositionReduction rateEnd-group

The invention relates to a preparation method of a water-soluble anion polymer-type thickened oil viscosity reducer. The thickened oil viscosity reducer comprises a component A and a component B; thecomponent A is an acrylamide copolymer containing acryloyl morpholine blocks; the component B is an acrylamide copolymer containing active end groups. A thickened oil viscosity reducer solution is mixed with thickened oil; it is proved through viscosity reduction tests that when the dosage reaches 0.2 mg / mL, the viscosity reducer can achieve high-temperature stirred emulsification and viscosity reduction in pure water and salt water, the viscosity reduction rate is greater than 93%, and stirred demulsification is stopped at room temperature. The thickened oil emulsification viscosity reducer is obvious in viscosity reduction effect and high in environmental adaptability, the emulsification and viscosity reduction behaviors of the thickened oil viscosity reducer have temperature and shearing responsiveness, and convenience is provided for application and post-treatment in oil fields.

Owner:CHINA NAT OFFSHORE OIL CORP +2

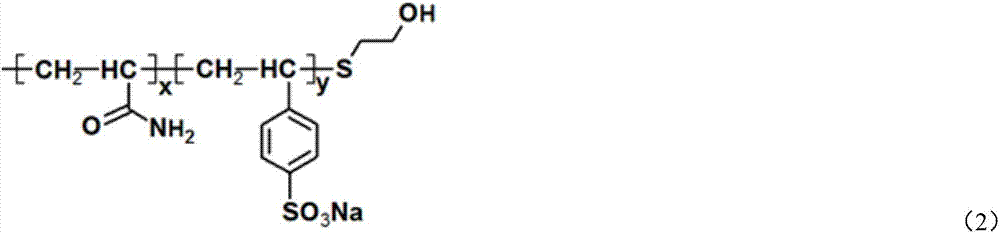

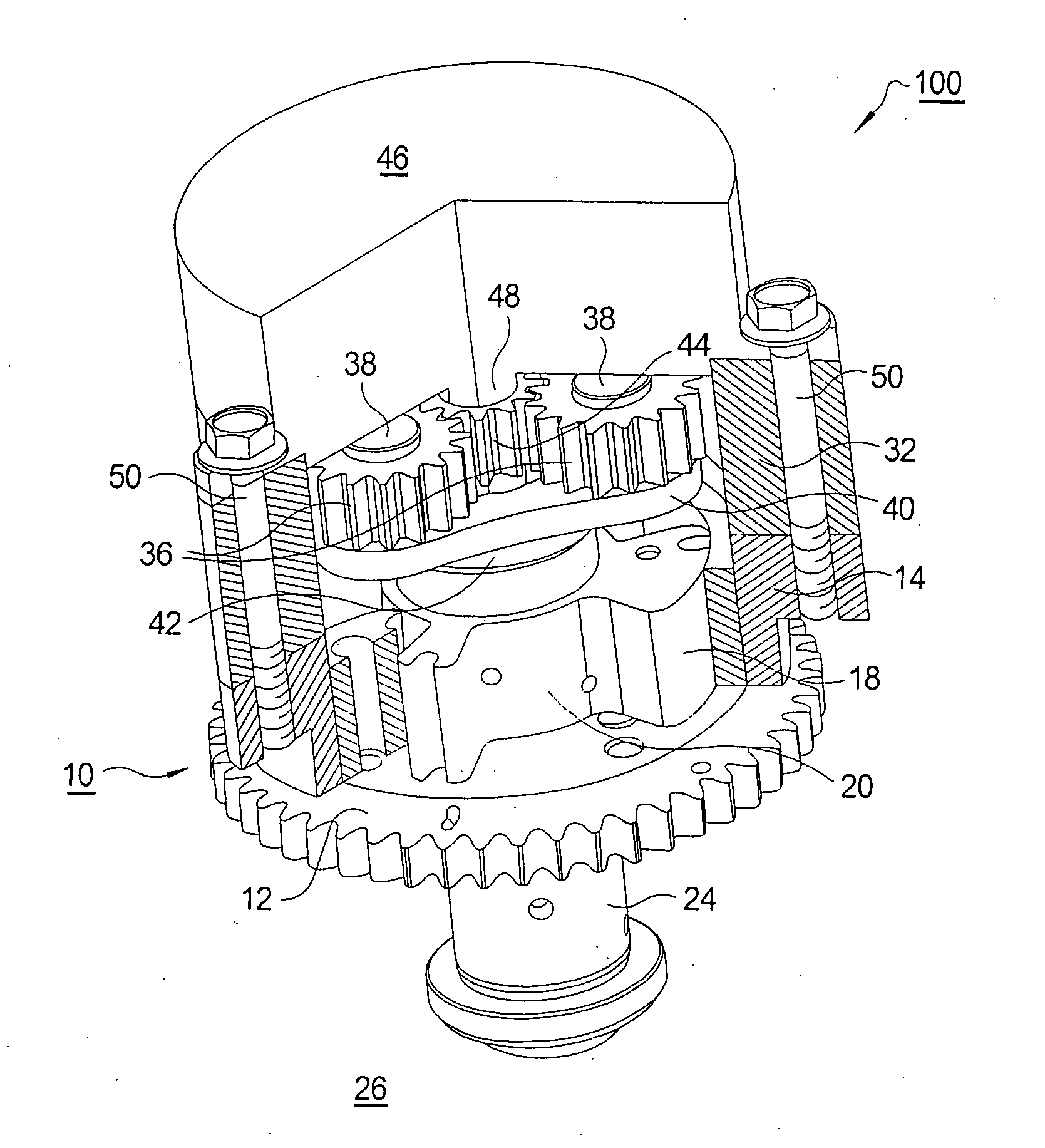

Electro-hydraulic hybrid camshaft phaser

InactiveUS20090120388A1Augments hydraulic actuationMachines/enginesNon-mechanical valveElectro hydraulicOil viscosity

A hybrid camshaft phaser comprising a conventional vane-type hydraulically-actuated phaser to which is coupled an electric motor and gear transmission. The transmission output shaft is coupled to the phaser rotor, optionally via an intermediate clutch mechanism. Under engine operating conditions in which the response of a hydraulic phaser is poor, the electric motor operates to augment the hydraulic actuation. Such conditions include at least low ambient temperatures at which oil viscosities are high, and high ambient temperatures and / or low engine speeds at which oil pressures are low. Preferably, at engine speeds above about 1500 rpm, the electric motor is de-energized.

Owner:DELPHI TECH INC

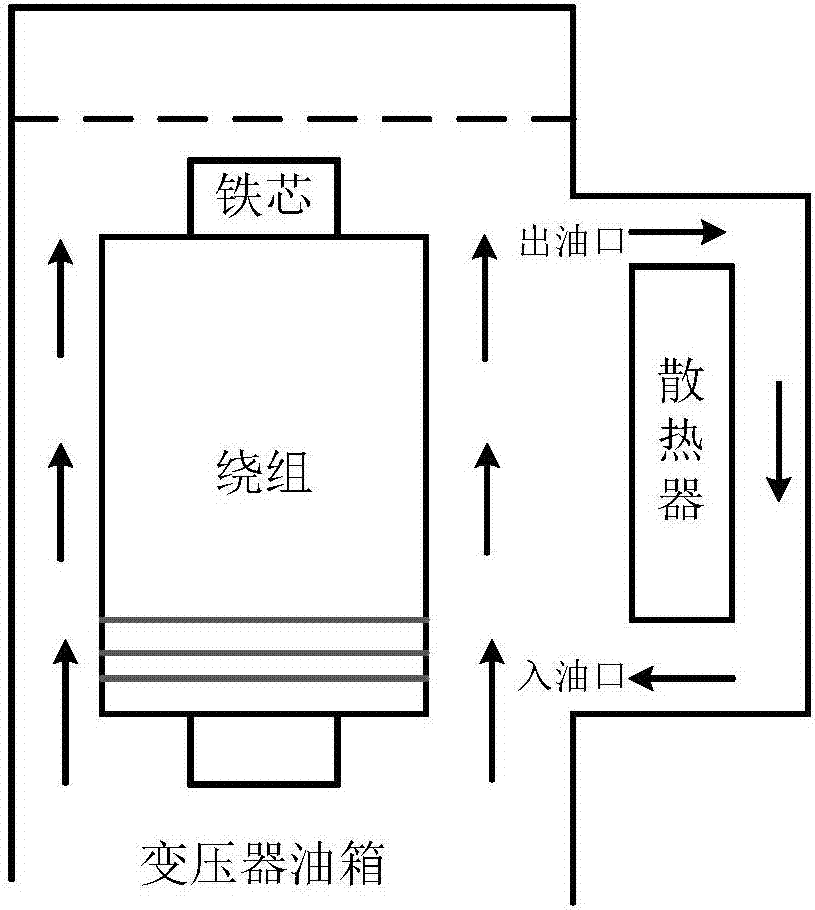

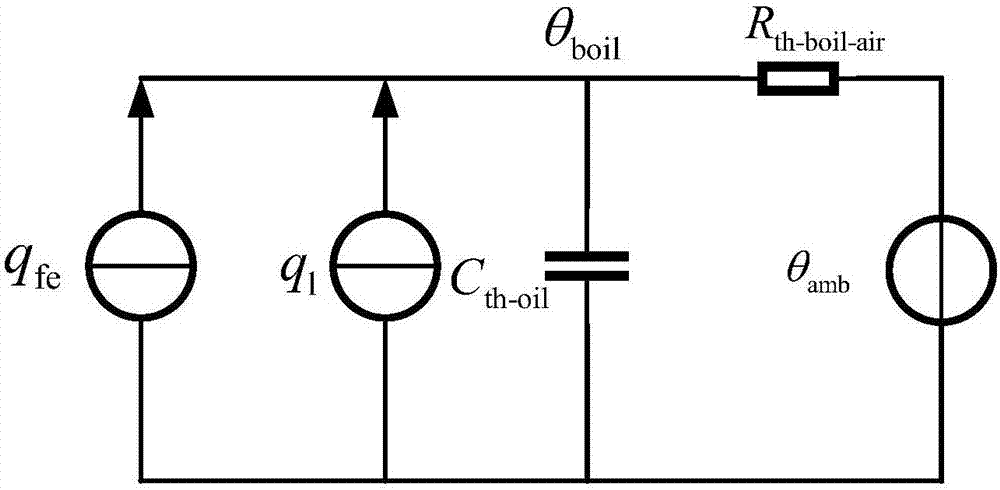

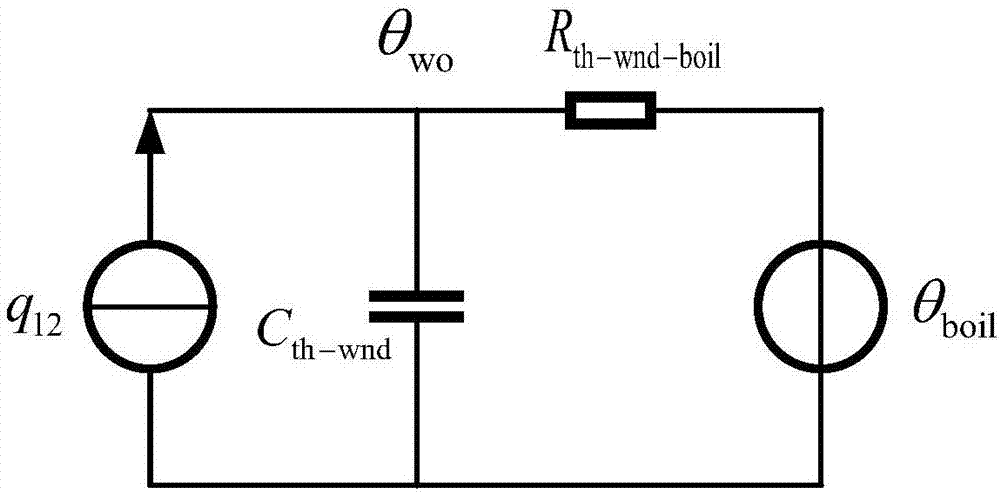

Oil-immersed transformer hot spot temperature evaluation method based on multi-parameter fusion

ActiveCN107063502AImprove dynamic response performanceAccurate responseThermometer applicationsCapacitanceDynamic equation

The invention discloses an oil-immersed transformer hot spot temperature evaluation method based on multi-parameter fusion. The oil-immersed transformer hot spot temperature evaluation method includes the following steps of (1) according to the process of heat transfer inside the transformer, clarifying the definition and calculation method of the hot spot heat source and hot oil area of the transformer, and reducing the calculation bias caused by taking the overall winding as the hot spot heat source; (2) correcting the algorithm of the hot oil area thermal capacitance Cwo and the hot spot thermal capacitance Chs, and improving the accuracy of the time constant tau wo and the winding time constant tau hs and the dynamic response capability of the calculation model; and (3) establishing the dynamic calculation equation of hot spot temperature by considering the influence of time-varying ambient temperature and time-varying load on the hot spot temperature. When the dynamic equation of the model is deduced, the temperature characteristics of the load loss and oil viscosity are further considered, and the calculation result can more accurately reflect the temperature rise inside the transformer. The method can dynamically reflect the characteristics of the temperature change inside the transformer, and the calculation is simple and the accuracy is high.

Owner:HAINAN POWER GRID CO LTD ELECTRIC POWER RES INST +1

Method for extracting oil in steam stimulation in single well by combining microorganisms and CO2 in heavy oil well

ActiveCN104329066ALow viscosityReduce interfacial tensionFluid removalDrilling compositionProduction effectOil water

The invention belongs to the technical field of tertiary oil recovery and particularly relates to a method for extracting oil in single well steam stimulation by combining microorganisms and CO2 in the heavy oil well. The method comprises the following steps: (1) screening test oil wells; (2) screening microorganisms and nutrients thereof; (3) injecting the microorganisms and the nutrients thereof into the stratum of the test oil well; (4) injecting liquid CO2; (5) shutting the test oil well down; (6) opening the test oil well for production. The method disclosed by the invention has the advantage of wide application range and is simple in process implementation; oil well sand production and sleeve damage situations are avoided and the oil well utilization rate is high; the thickened oil viscosity can be greatly reduced, the oil-water interfacial tension is reduced, the stratum energy can be effectively replenished, the characteristics of long action period, remarkable enhanced production effect of oil, and the like are achieved, and therefore, the method is an economic and effective method for increasing the yield of the heavy oil well and can be widely applied to a single well steam stimulation technology of the heavy oil well.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing solid lubricant coating on copper base bearing bush

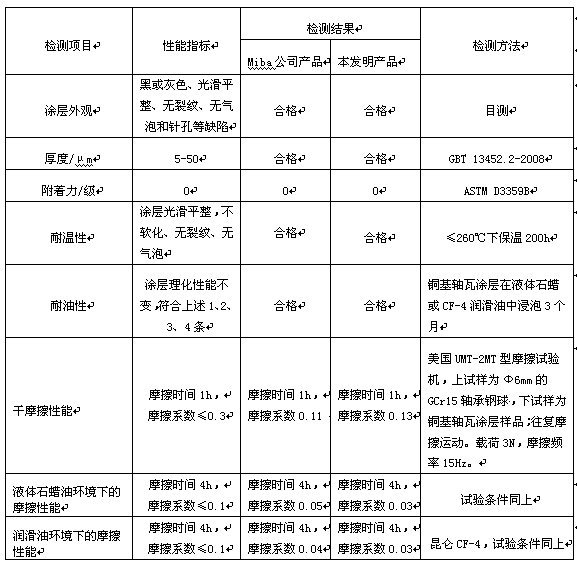

ActiveCN103849311AImprove the lubrication effectImprove bindingCoatingsLubricant compositionOil viscosityWear resistance

The invention discloses a method for preparing a solid lubricant coating on a copper base bearing bush. According to the invention, a selected suitable coating coats on the surface of the copper base bearing bush to form a curing coating. The coating has good adhesion with the metal copper alloy substrate, and can be used for a long time under 260 DEG C; and the coating has good lubricity, wear resistance and anti-copper sticking property, and can significantly reduce the friction coefficient of the alloy layer of the copper base bearing bush and reduce the phenomena of scratching, copper sticking and burnout of the copper base bearing bush and crankshaft under start and stop state, low machine oil viscosity state and oil free state, so as to improve wear resistance, emergency operation capability and service life of the copper base bearing bush.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com