Oil-immersed transformer hot spot temperature evaluation method based on multi-parameter fusion

A technology of oil-immersed transformers and hot spot temperature, which is applied to thermometers, heat measurement, and application of thermometers. It can solve problems such as calculation result errors, large calculation errors, and hot spot temperature rise deviations, so as to reduce calculation deviations and improve accuracy. The effect of speed and quick response ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

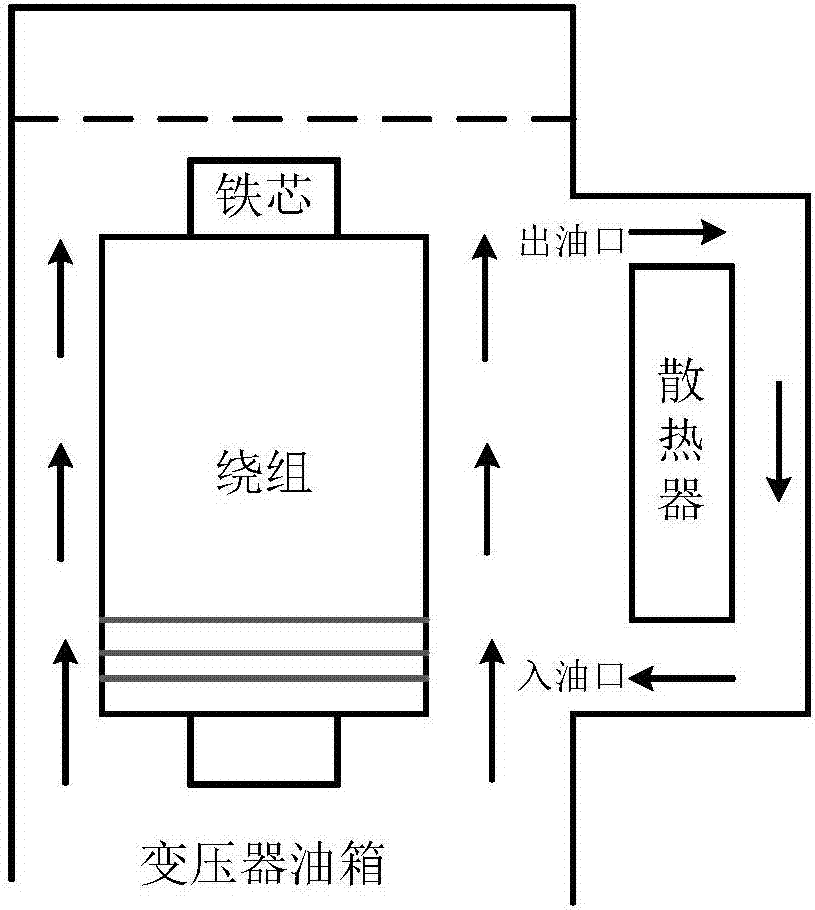

[0040] figure 1 It is the oil circulation flow diagram inside the oil-immersed transformer, which reflects the heat dissipation process inside the transformer. The heat generated on the transformer winding, iron core and various parts of the clamp is transferred to the radiator in the form of oil circulation, and then passed through the cooling device or nearby Emission of media into the external environment.

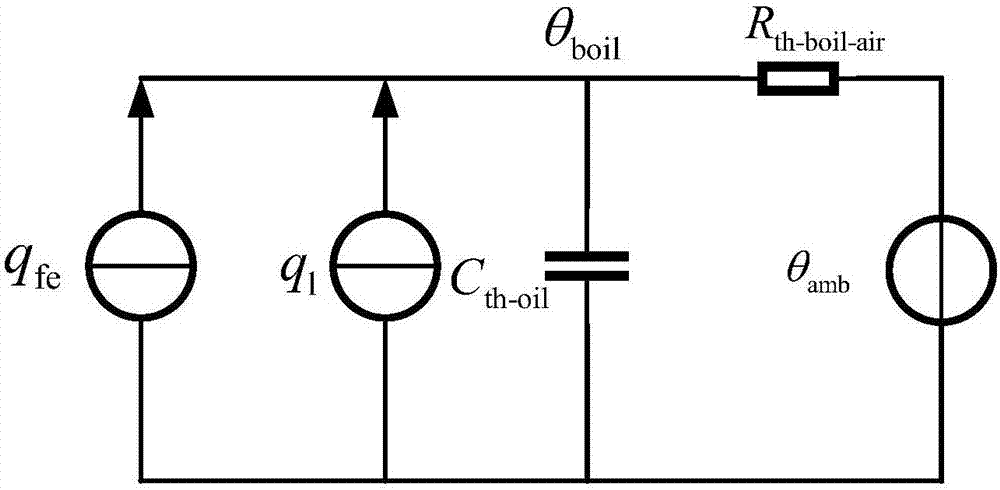

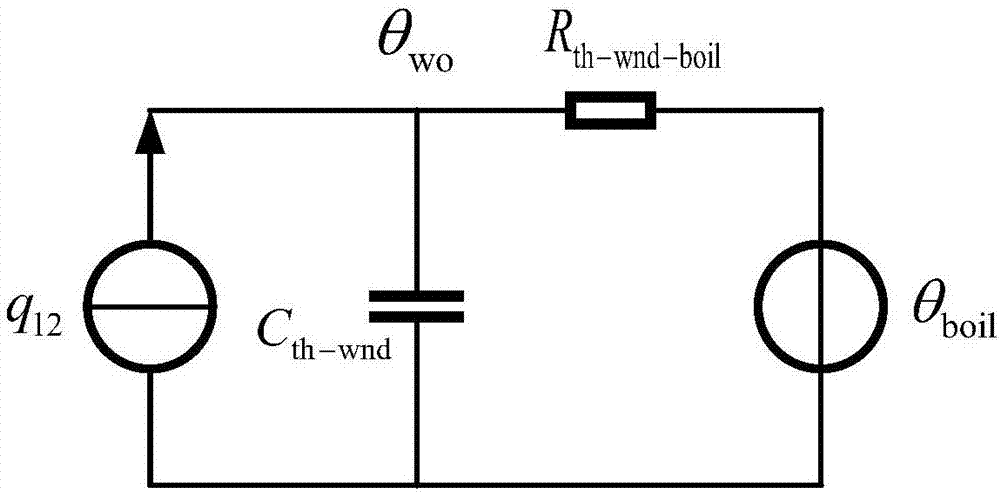

[0041] According to the internal heat transfer process and temperature rise mechanism of the transformer, a three-layer hot spot temperature estimation model based on the bottom oil temperature is established, namely the bottom oil-external environment model, the hot oil zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com