Patents

Literature

121 results about "Internal heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat transfer is a process by which internal energy from one substance transfers to another substance. Thermodynamics is the study of heat transfer and the changes that result from it. An understanding of heat transfer is crucial to analyzing a thermodynamic process, such as those that take place in heat engines and heat pumps.

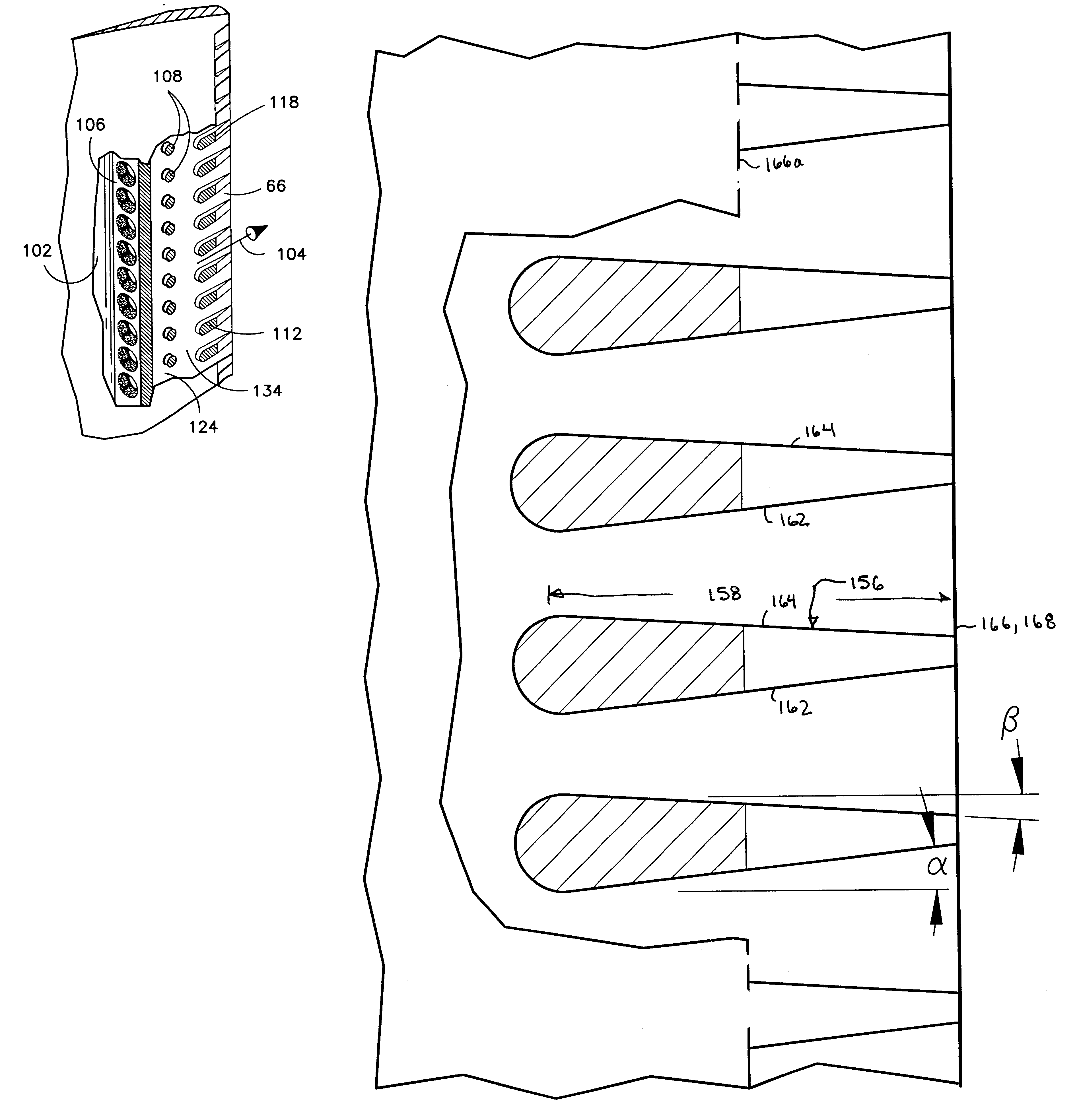

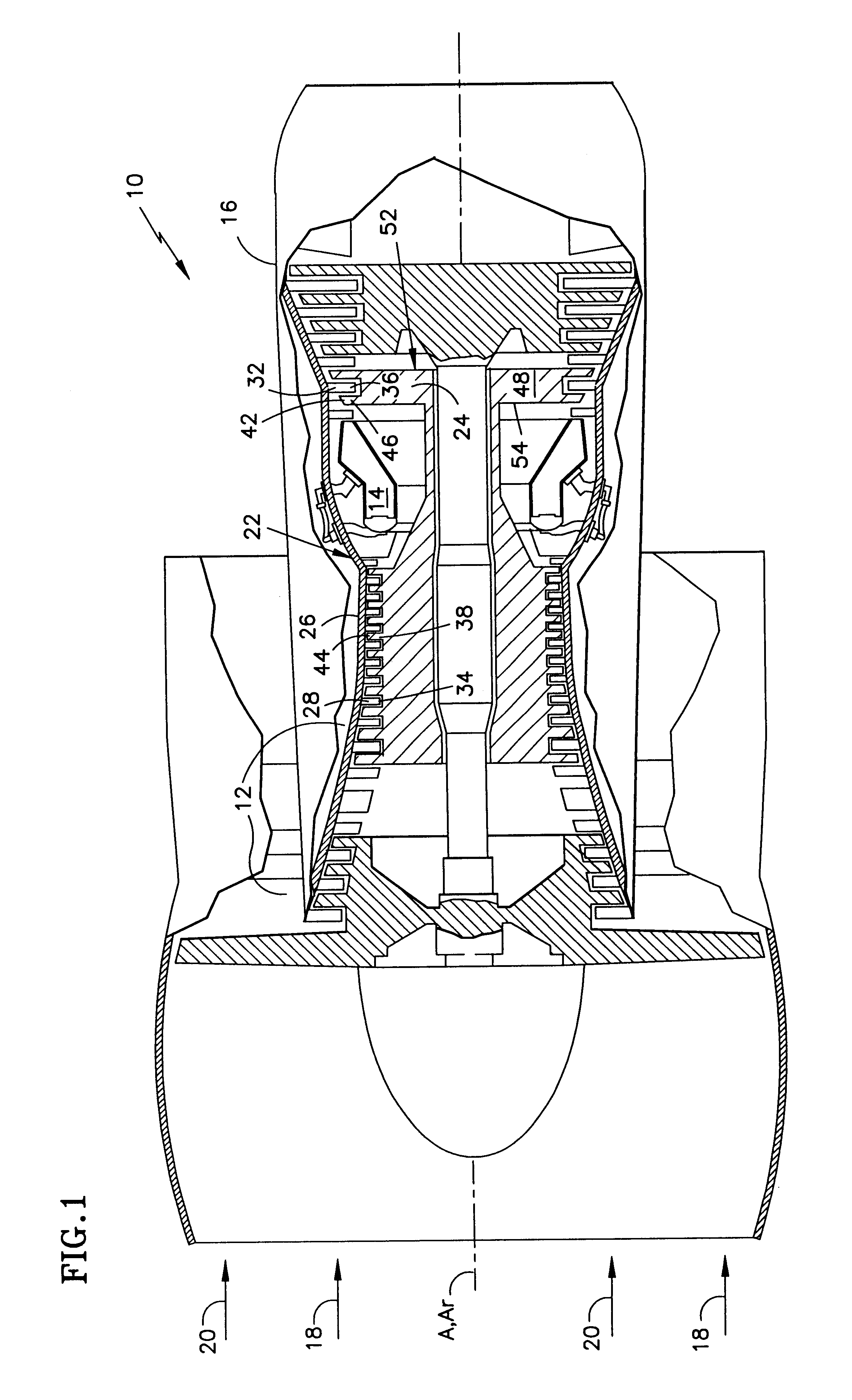

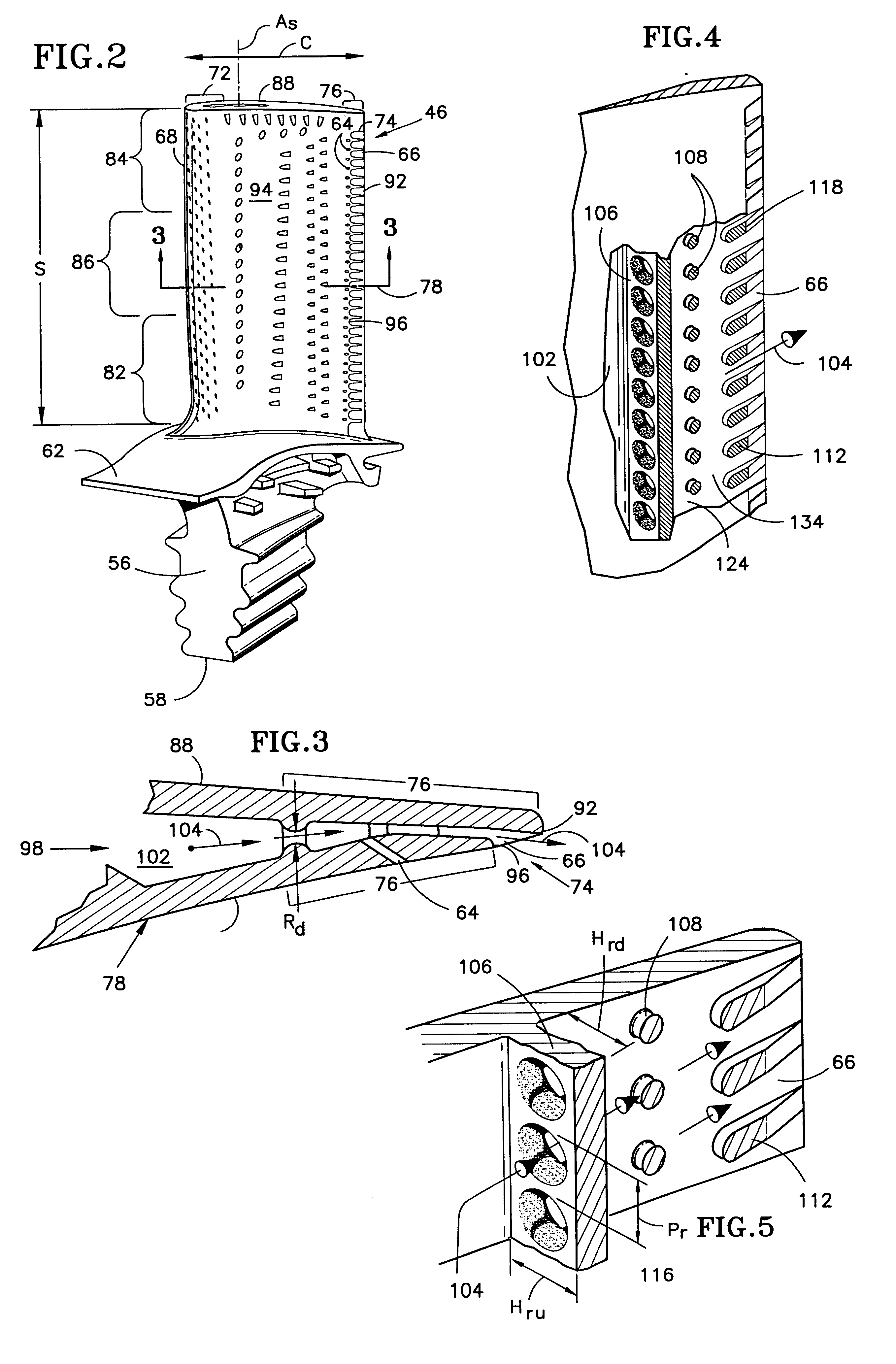

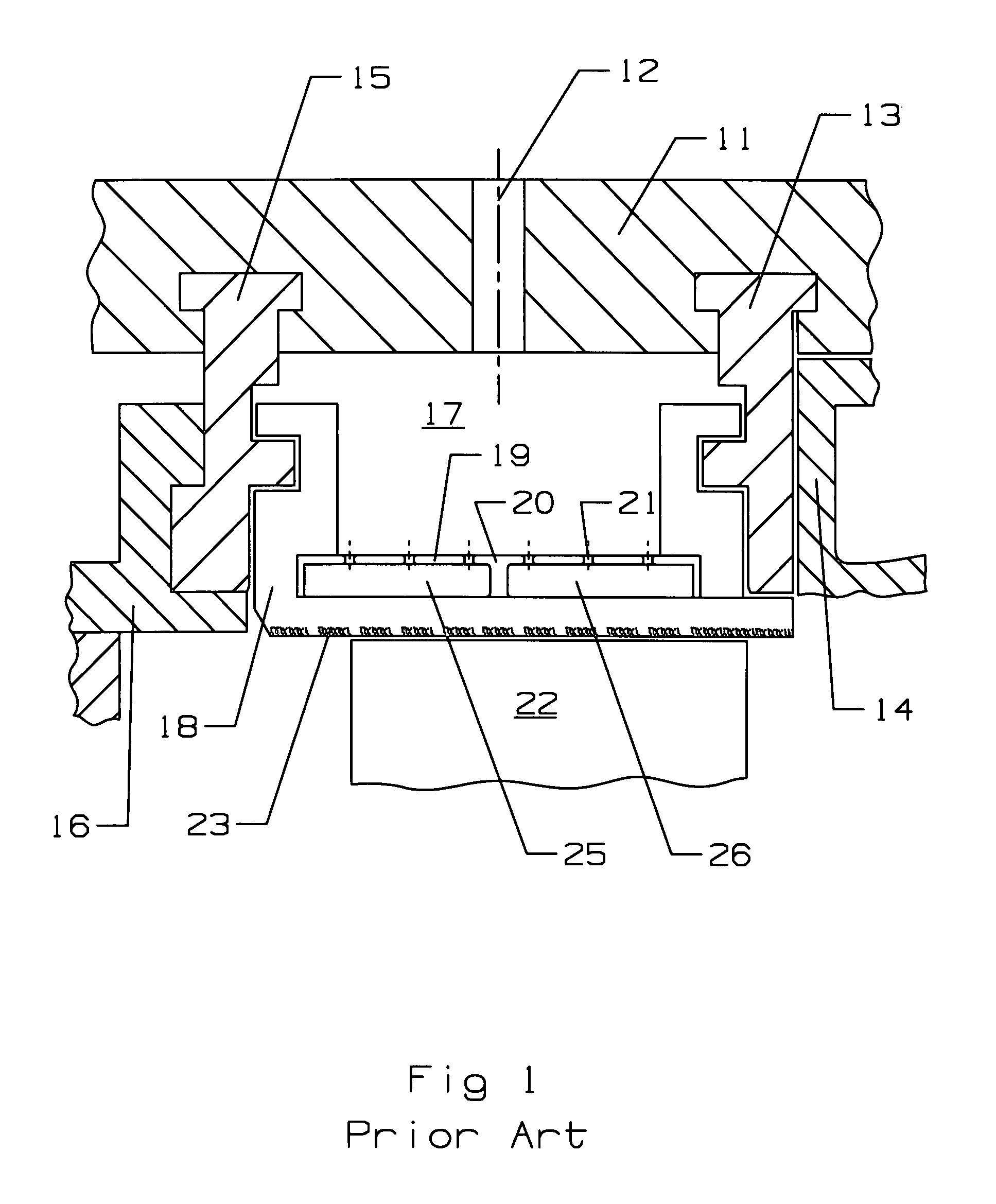

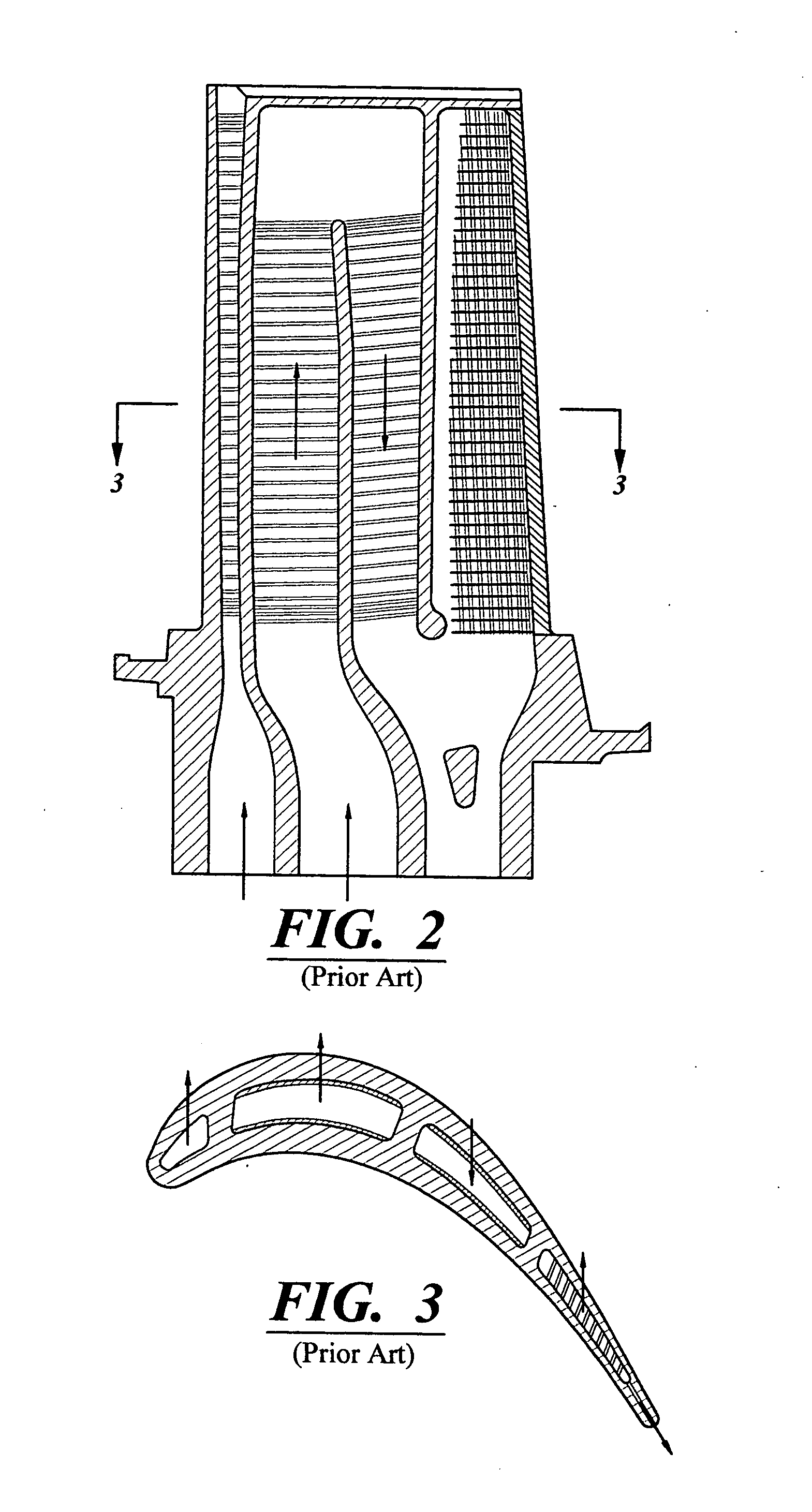

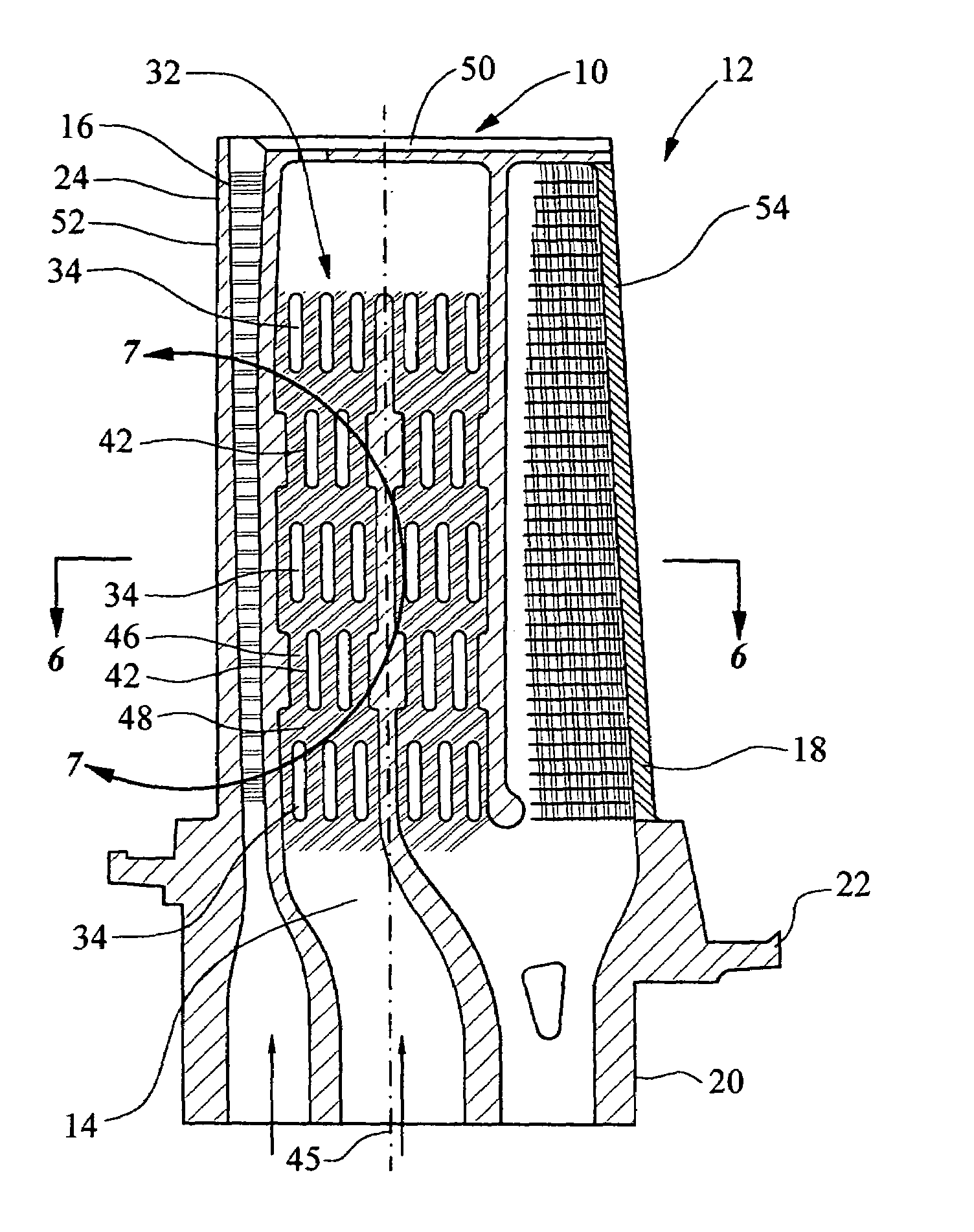

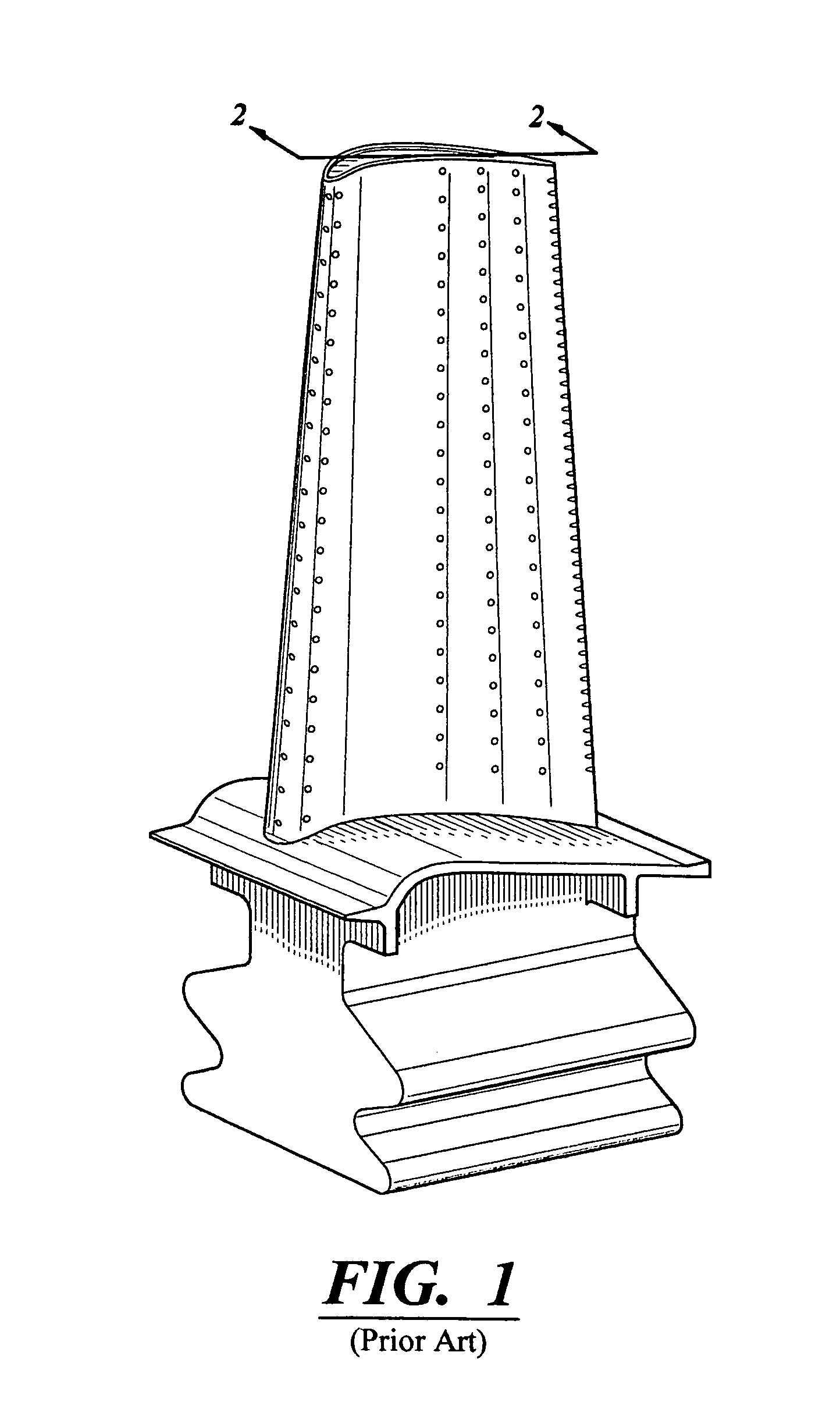

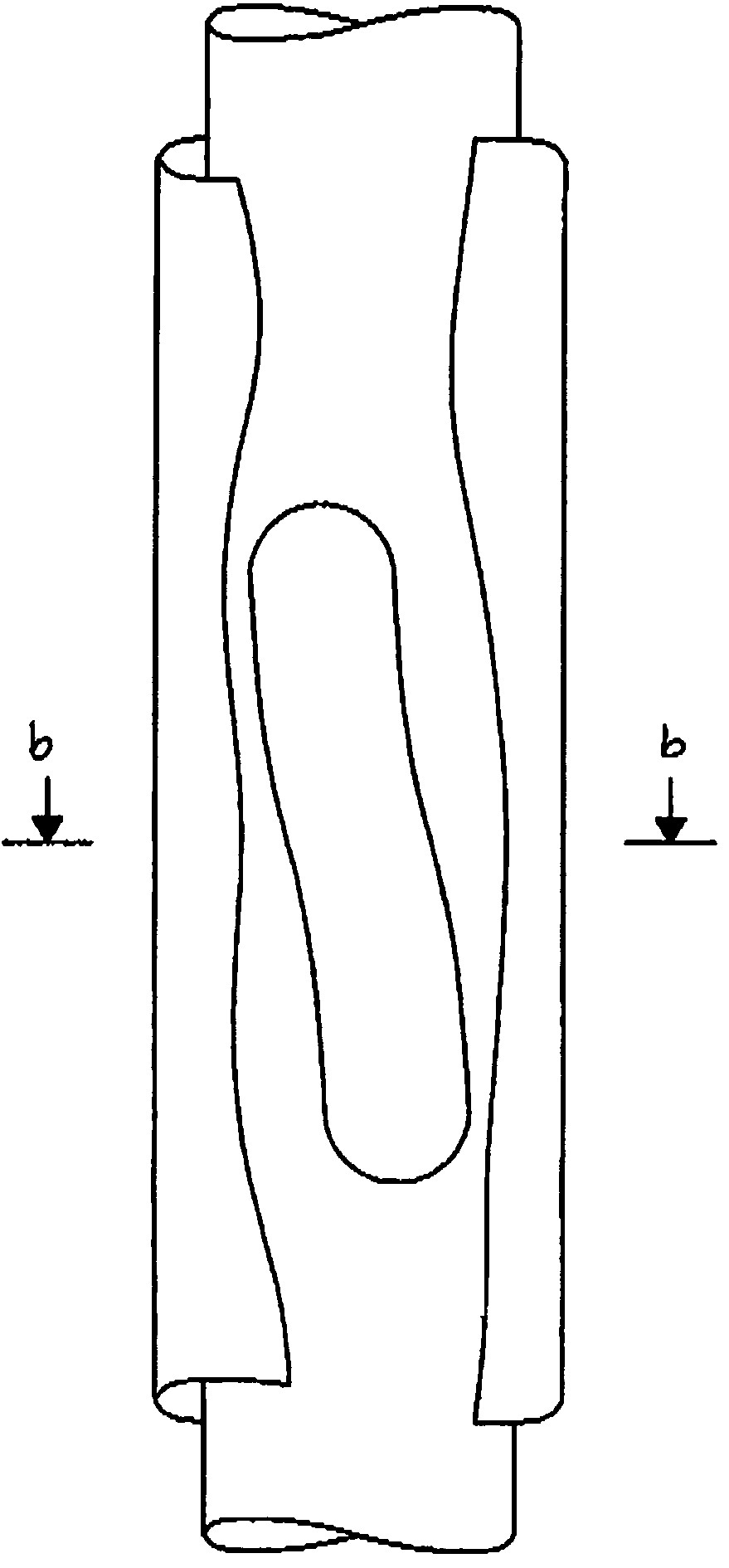

Coolable airfoil structure

InactiveUS6234754B1Durability and thermomechanical performanceIncreased durabilityPump componentsEngine fuctionsCastabilityInternal heat transfer

A coolable airfoil structure having internal heat transfer features through which cooling air is flowed under operative conditions is disclosed. Various construction details and features are developed which affect the castability and core strength during manufacture and strength and cooling effectiveness of the airfoil after manufacture. In one particular embodiment, the airfoil has a plurality of heat transfer members disposed in the rearmost section of the trailing edge region which comprises a single impingement rib, a single row of pedestals and a single row of chordwisely extending flow dividers.

Owner:UNITED TECH CORP

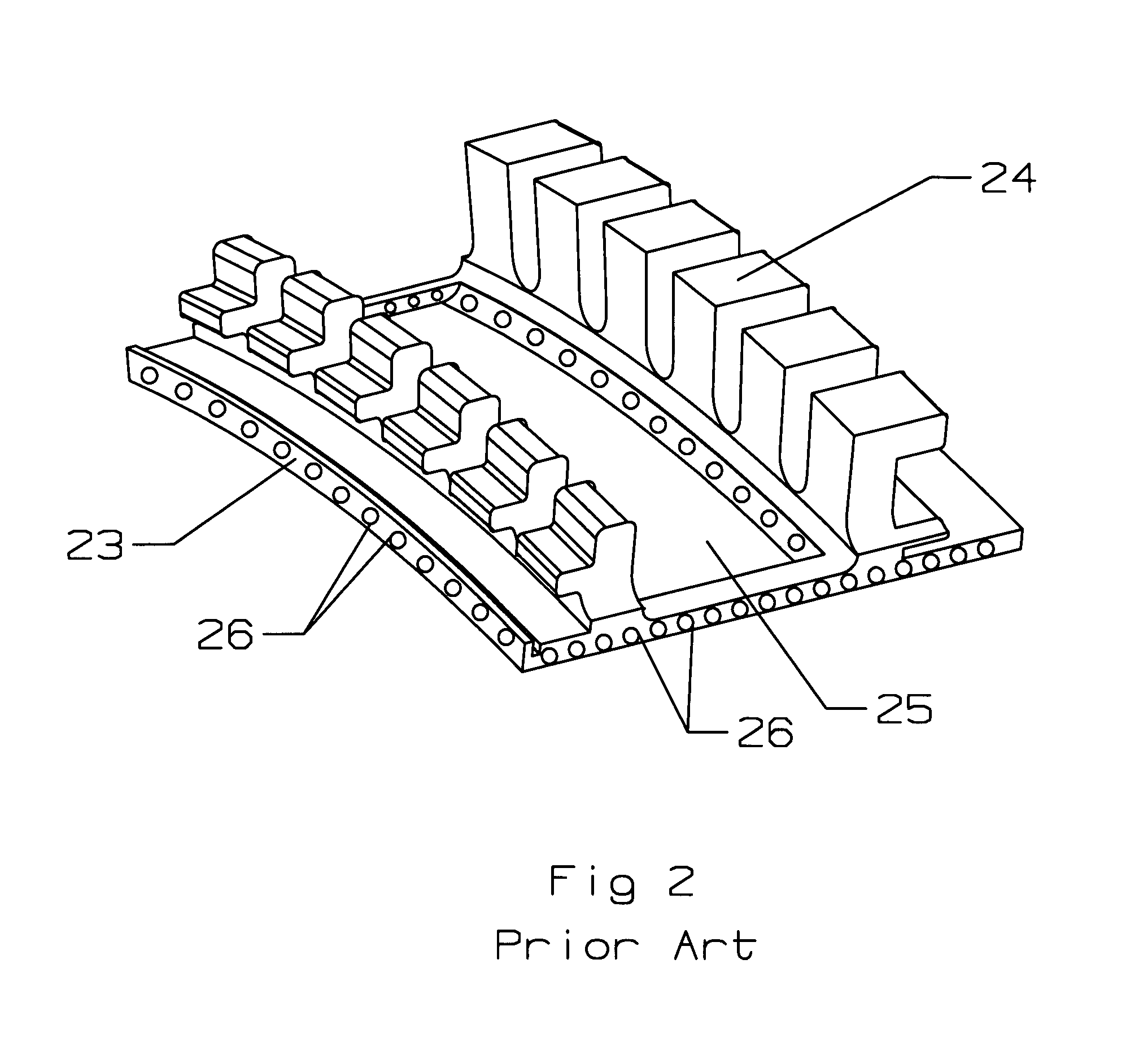

Turbine BOAS with edge cooling

A cooling hole having an inlet passage forming an inward spiral flow path and an outlet passage forming an outward spiral flow path in which the two paths are counter flowing in order to improve the heat transfer coefficient. The spiral cooling hole is used in a blade outer air seal (BOAS) for a turbine in which the edges of the shroud segments include a counter flowing micro serpentine flow cooling circuit with thin diffusion discharge cooling slots for the BOAS edges. The total BOAS cooling air is impingement from the BOAS cooling air manifold and metered through the impingement cooling holes to produce impingement cooling onto the backside of the BOAS. The spent cooling air is then channels into the multiple micro serpentine cooling flow circuits located around the four edges of the shroud segments. This cooling air then flows in a serpentine path through the horizontal serpentine flow channels and then discharged through the thin diffusion cooling slots as peripheral purge air for the mate faces as well as the spacing around the BOAS or shroud segments. Trip strips are used in the serpentine flow channels for the augmentation of internal heat transfer cooling capability. The micro serpentine flow cooling air circuits spaced around the four edges of the shroud segments are formed into the shroud segments during the casting process of the shroud segments.

Owner:FLORIDA TURBINE TECH

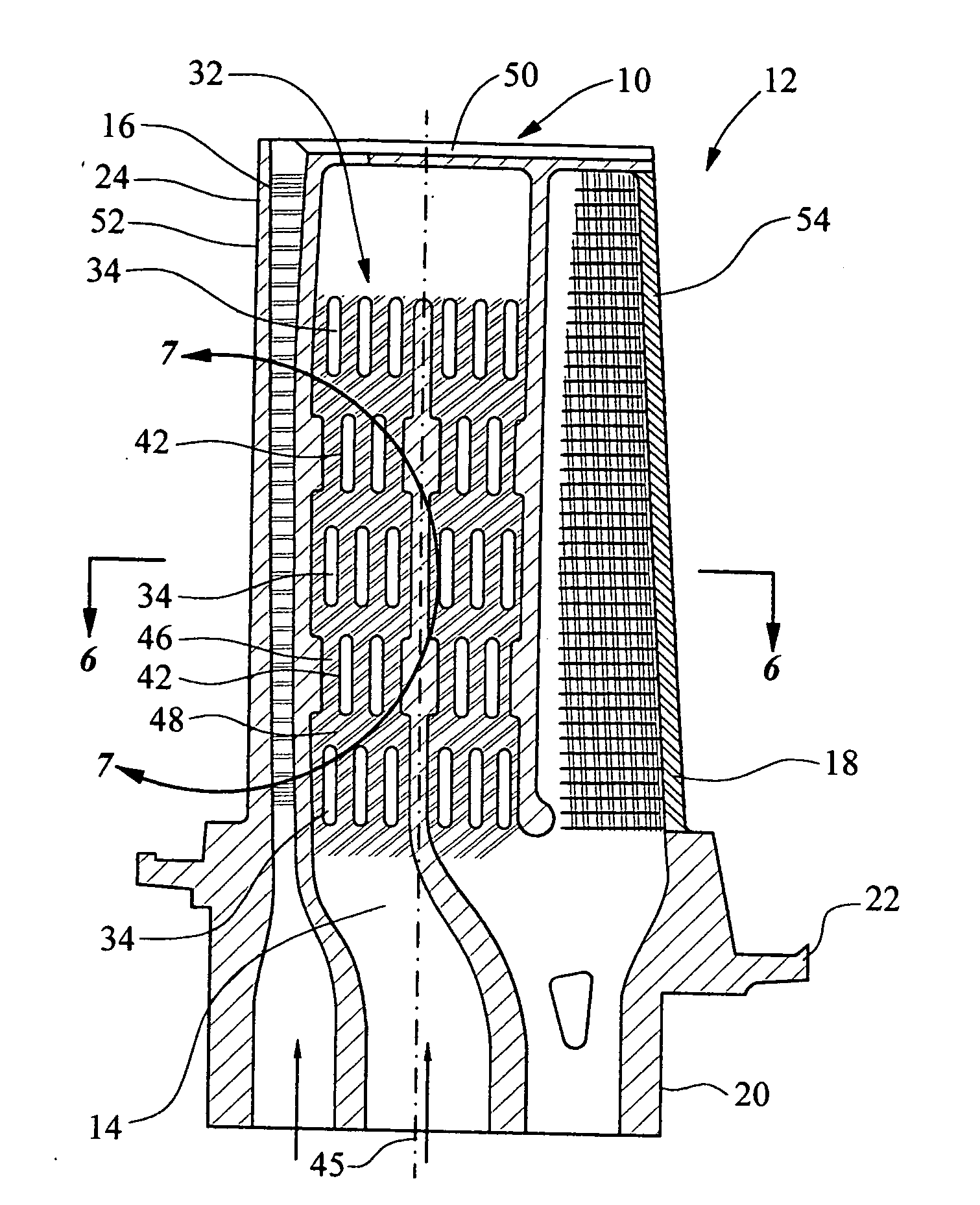

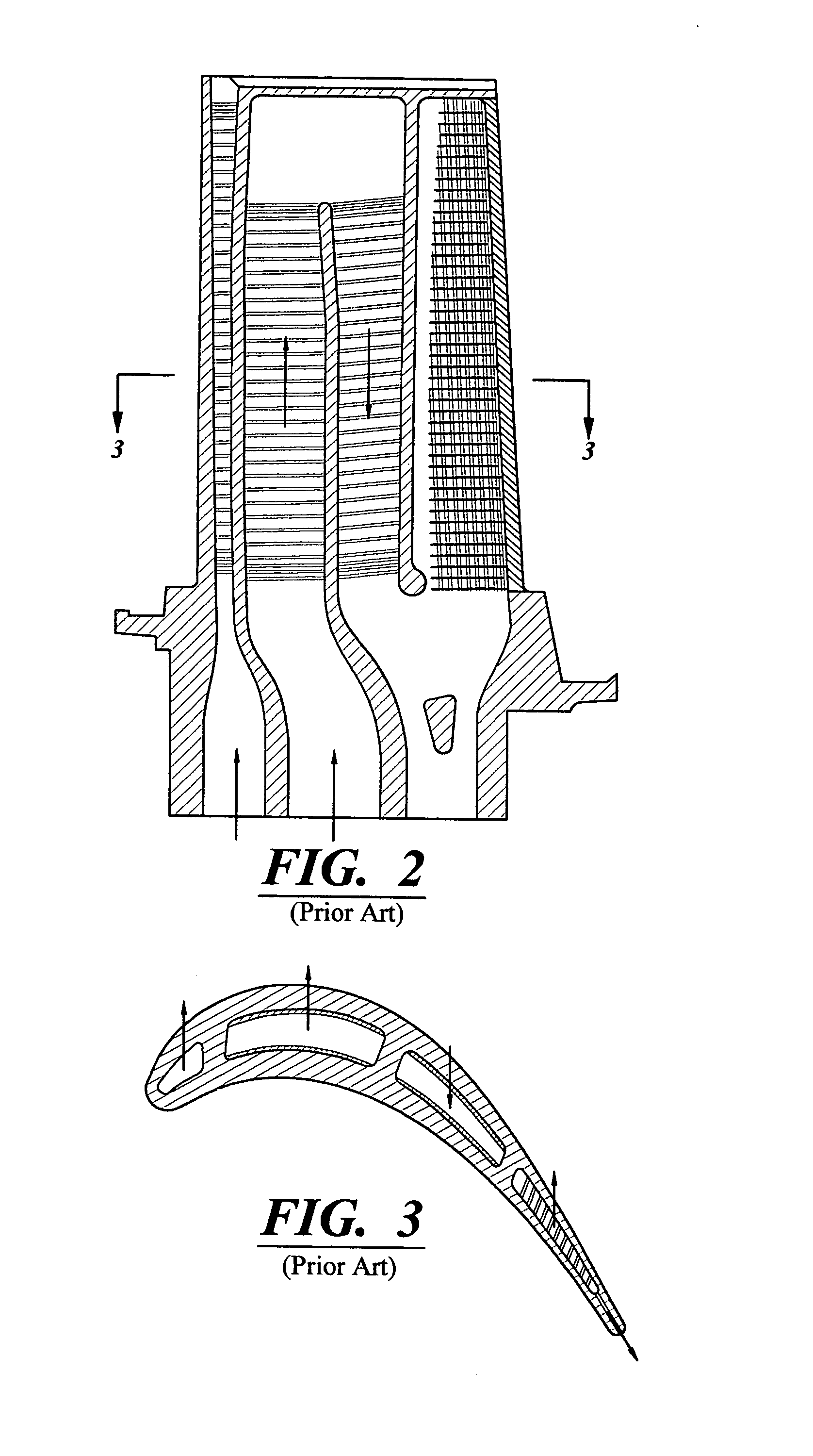

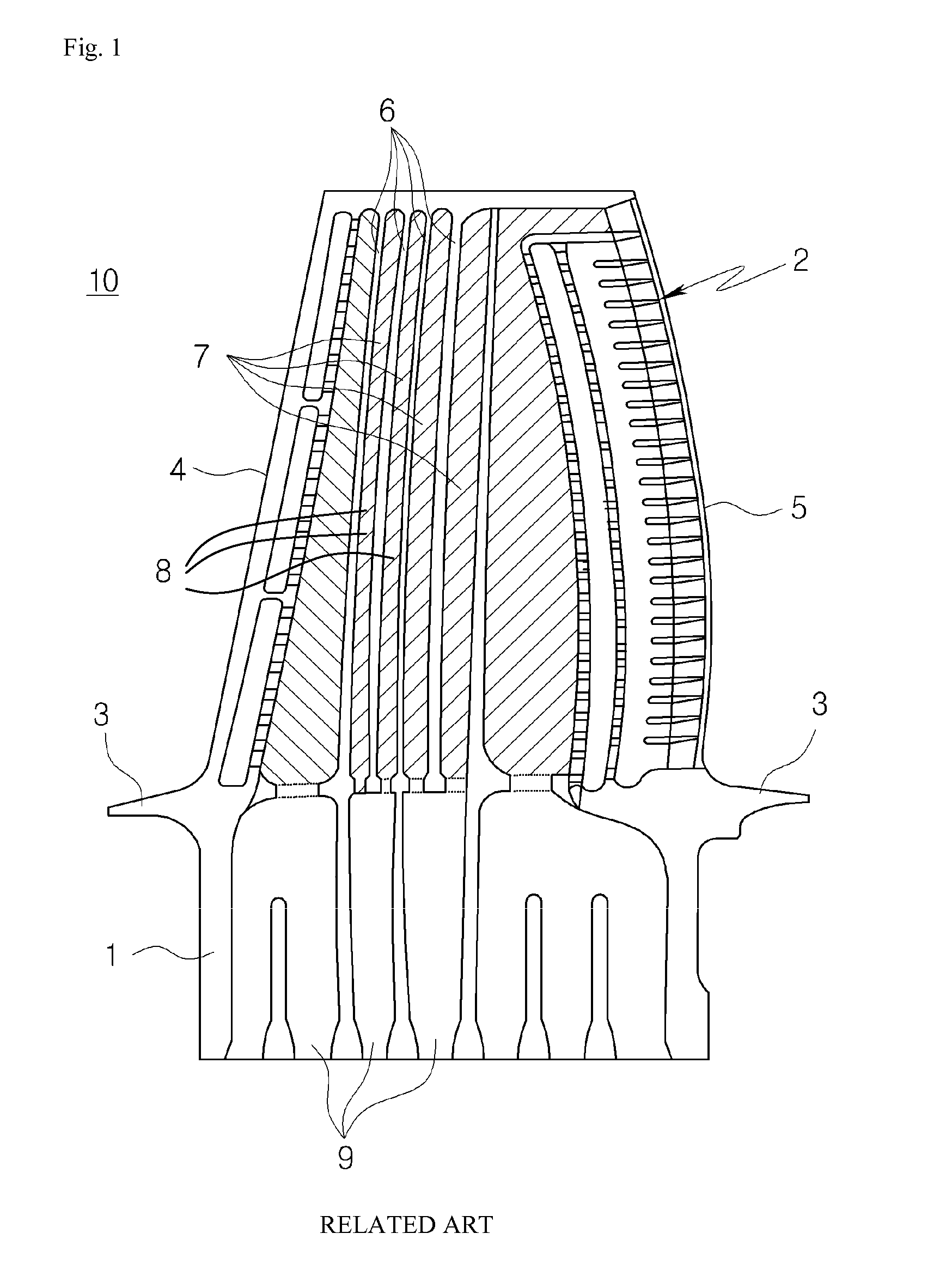

Cooling system including mini channels within a turbine blade of a turbine engine

InactiveUS20060153679A1Improve the overall coefficientInhibition formationPump componentsEngine fuctionsFully developedTurbine blade

A turbine blade for a turbine engine having a cooling system formed from one or more cooling channels having a plurality of mini channels. The cooling system may include first ribs forming a first passageway of mini channels in which the cross-sectional area of the cooling channel is reduced, thereby increasing the velocity of the cooling fluids and the internal heat transfer coefficient. The cooling system may also include second ribs forming a second passageway downstream from the first passageway a distance sufficient to prevent the formation of a fully developed boundary layer and allow the cooling fluids to fully expand after exiting the first passageway. The cooling channel may also include a plurality of protrusions extending from surfaces forming the cooling channel to create turbulence and prevent formation of a fully developed boundary layer.

Owner:SIEMENS ENERGY INC

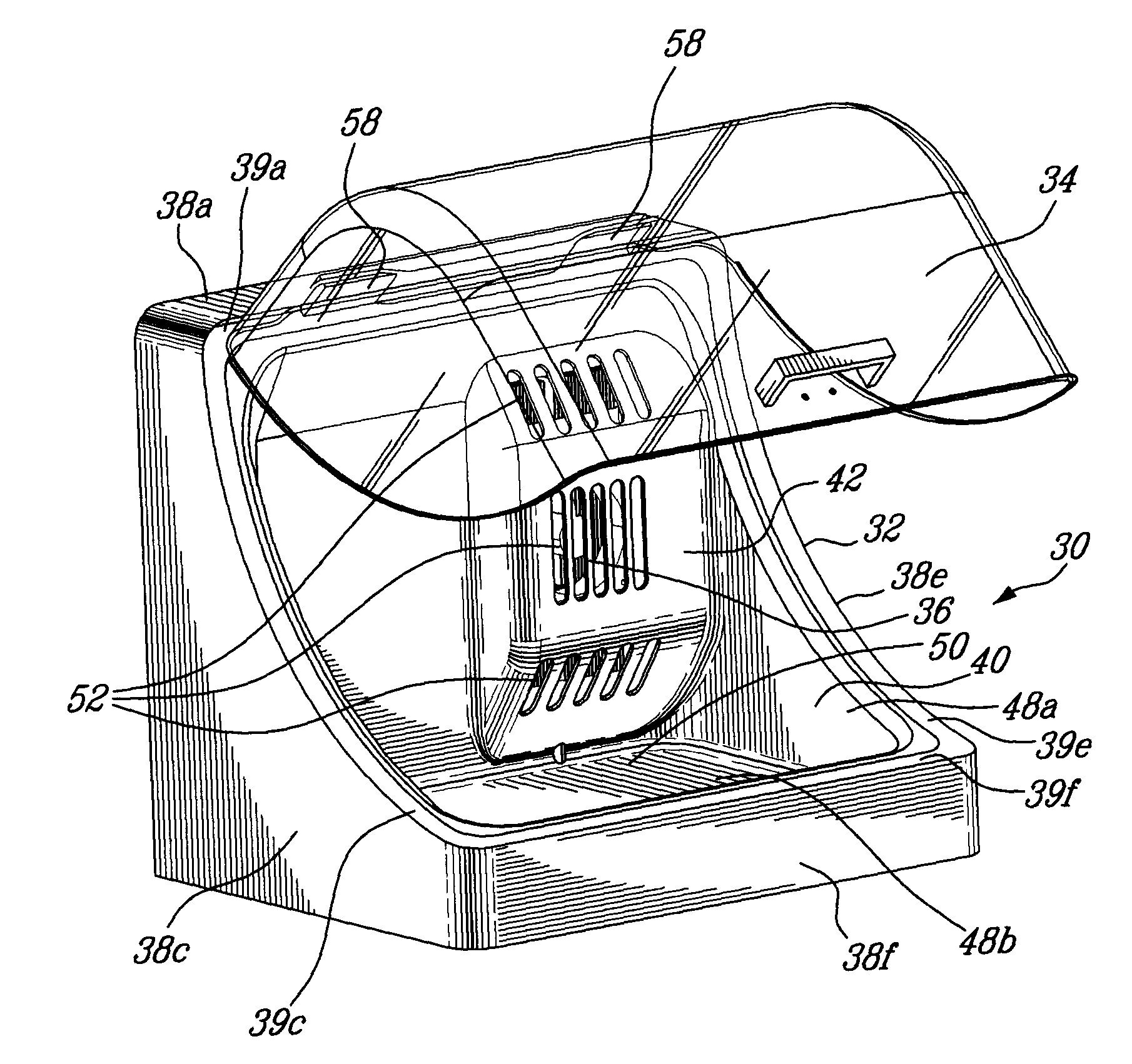

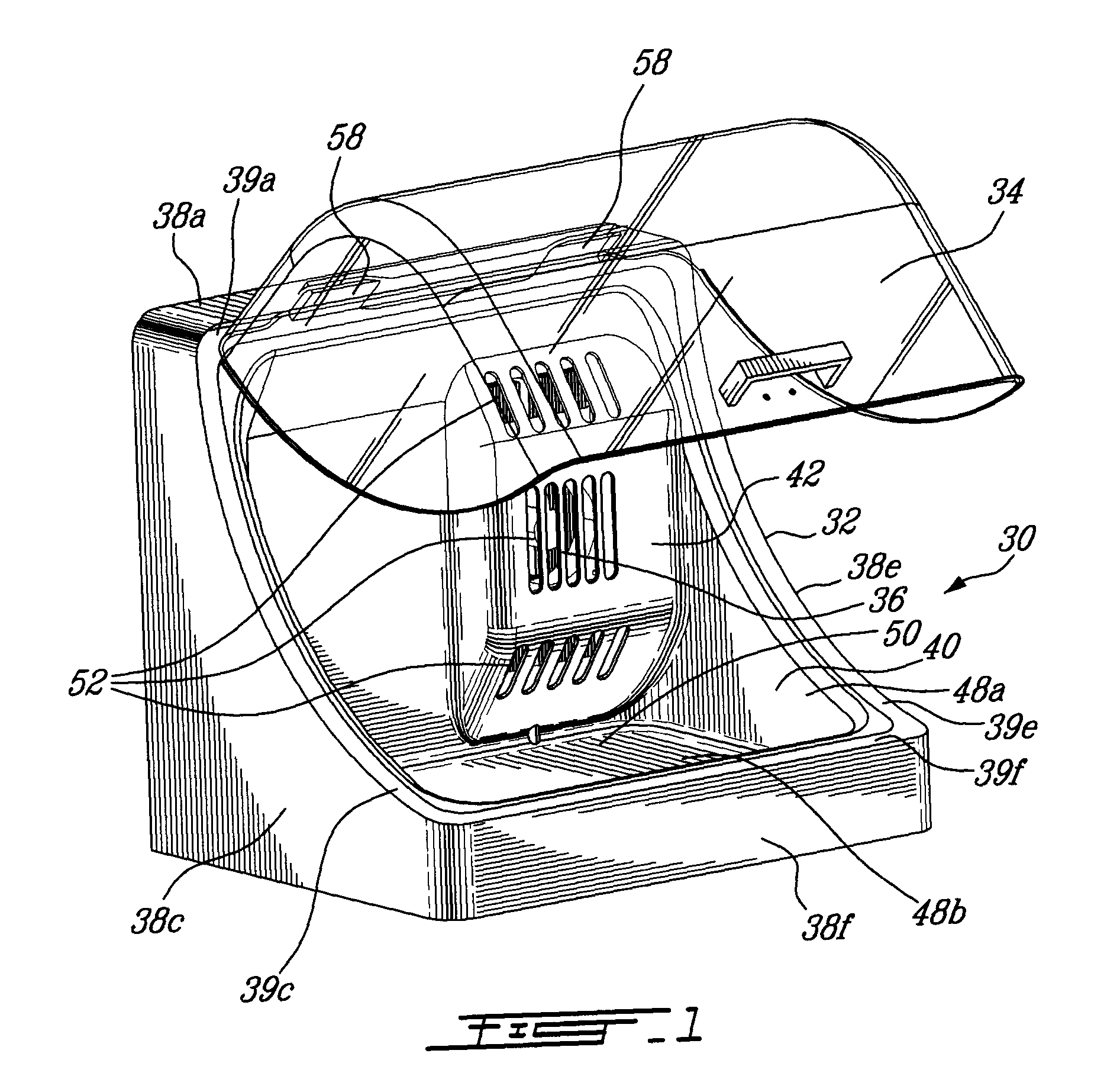

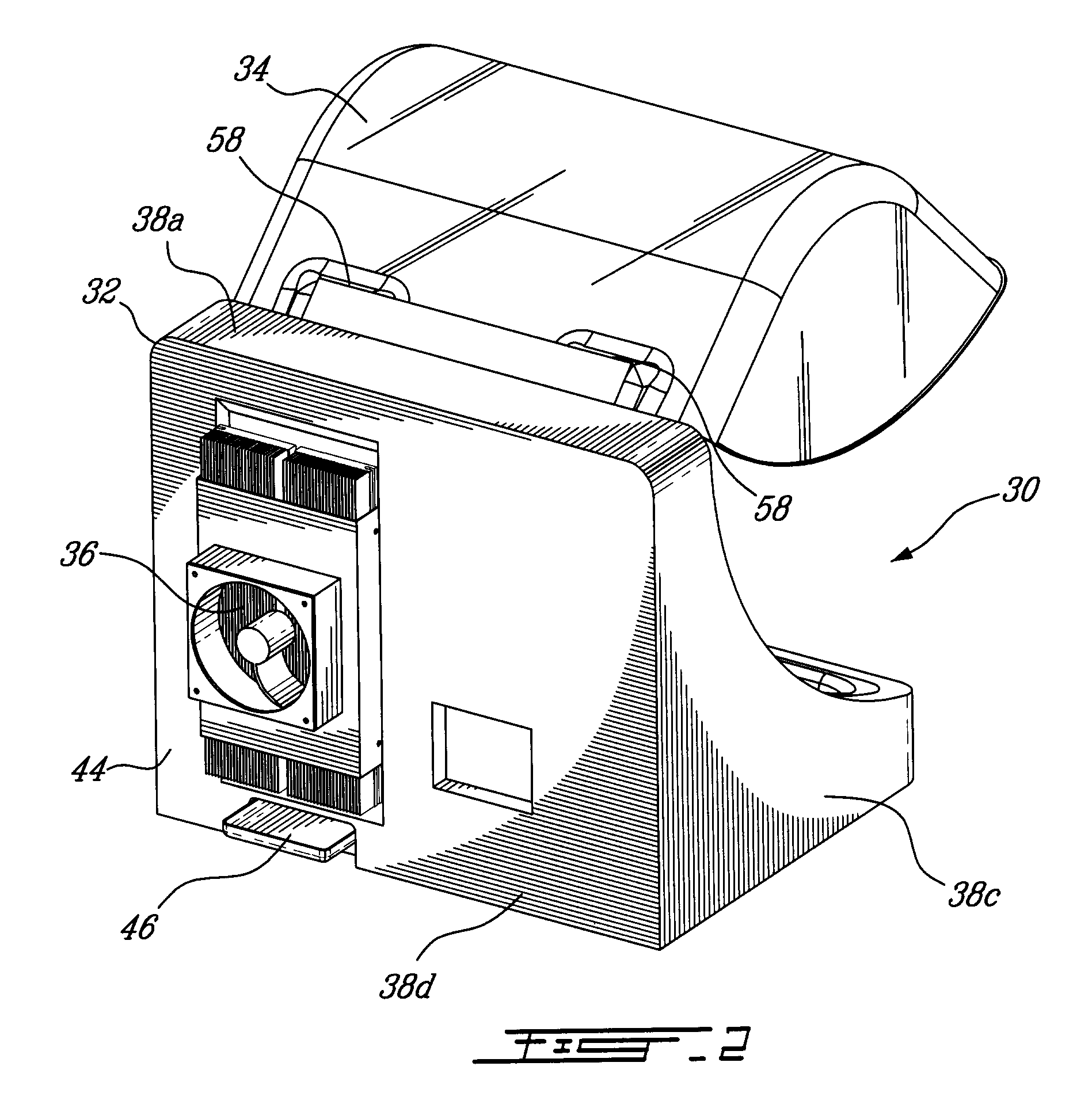

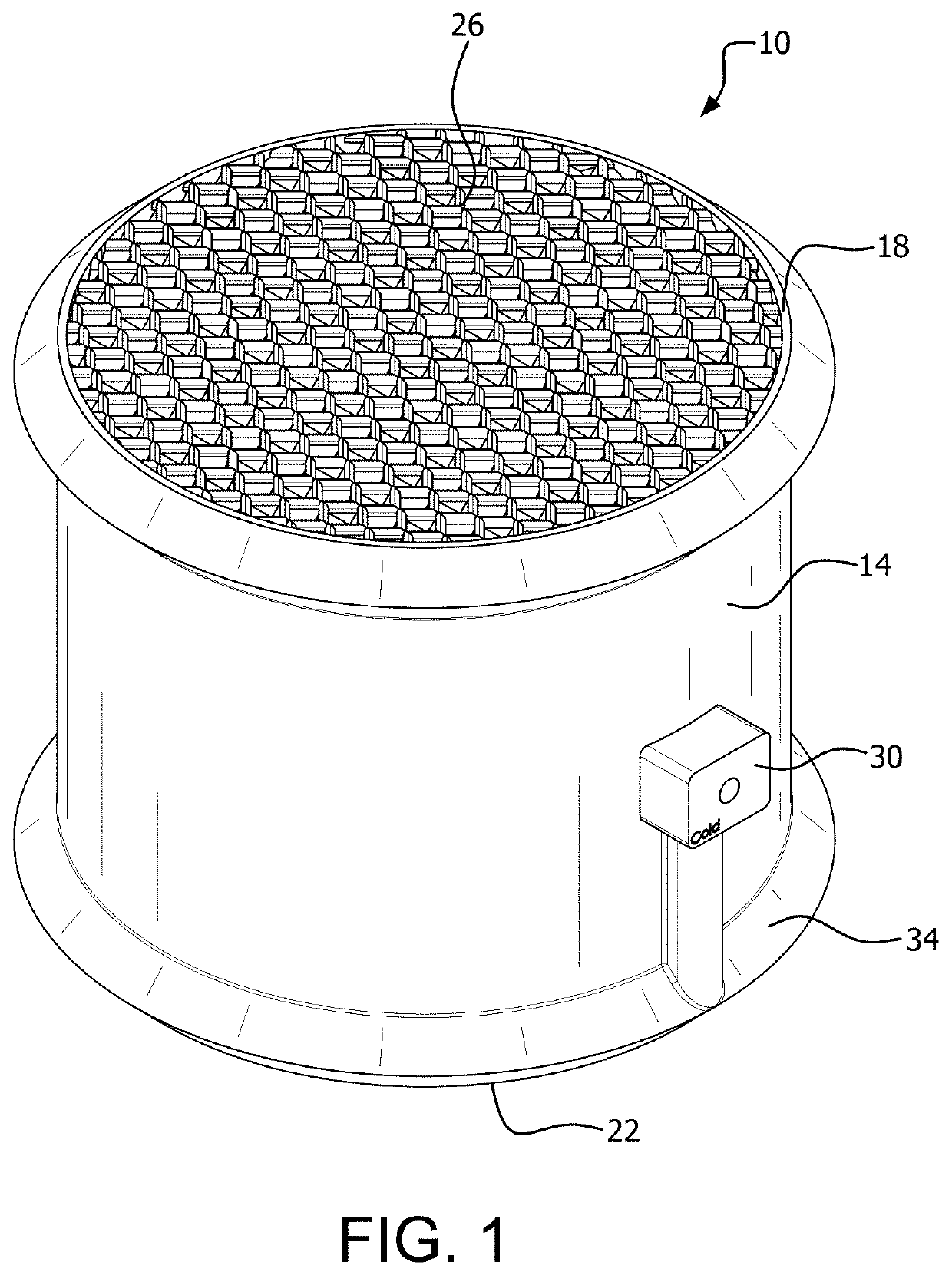

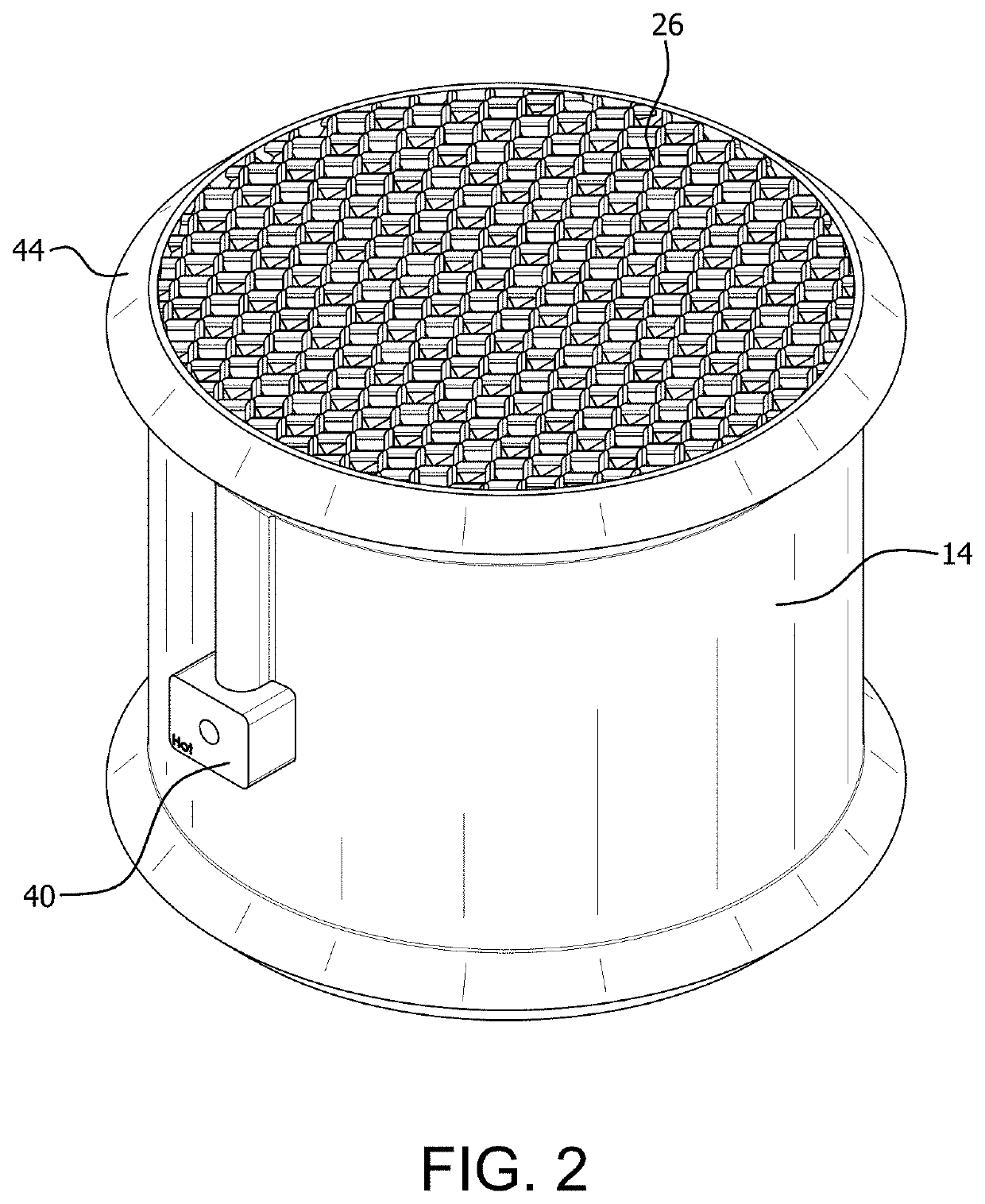

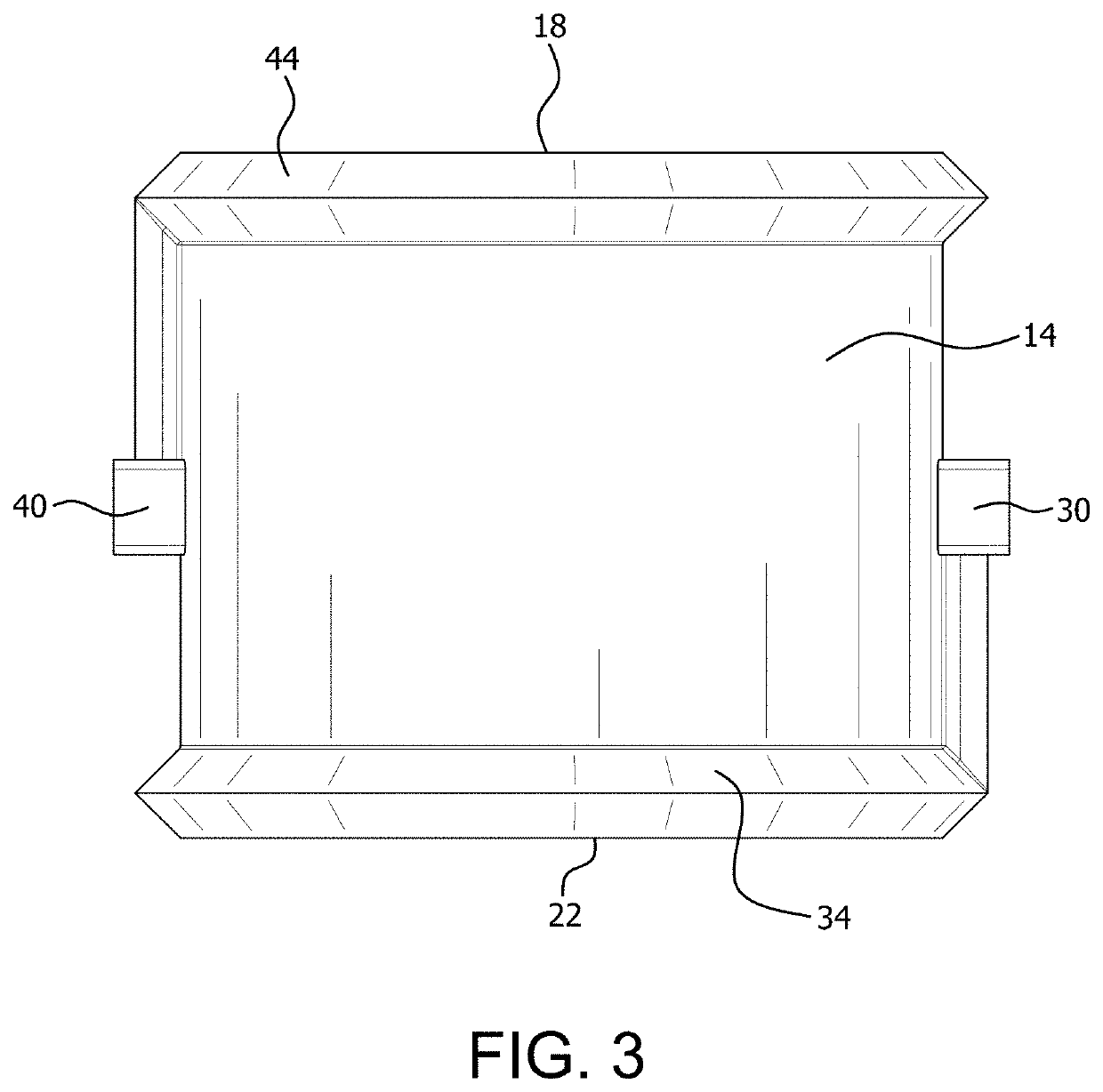

Portable temperature-controlled container

InactiveUS20090145138A1Easy to storeMinimal noiseShow cabinetsMachines using electric/magnetic effectsCold sideTemperature control

The present invention generally relates to containers and more specifically, to a portable temperature-controlled container. The temperature-controlled container is used for maintaining articles at a controlled temperature. The container includes a housing unit defining a storage chamber for receiving the articles, a cooling system mounted to the housing unit, wherein the cooling system includes a cold side assembly system in heat transfer communication with the interior of the chamber, a hot side assembly system in heat transfer communication with the outside of the storage chamber and a thermoelectric module supplied with an electrical power source.

Owner:SG PRODN

Cooling system including mini channels within a turbine blade of a turbine engine

InactiveUS7189060B2Reduce the cross-sectional areaImprove efficiencyPump componentsEngine fuctionsFully developedTurbine blade

A turbine blade for a turbine engine having a cooling system formed from one or more cooling channels having a plurality of mini channels. The cooling system may include first ribs forming a first passageway of mini channels in which the cross-sectional area of the cooling channel is reduced, thereby increasing the velocity of the cooling fluids and the internal heat transfer coefficient. The cooling system may also include second ribs forming a second passageway downstream from the first passageway a distance sufficient to prevent the formation of a fully developed boundary layer and allow the cooling fluids to fully expand after exiting the first passageway. The cooling channel may also include a plurality of protrusions extending from surfaces forming the cooling channel to create turbulence and prevent formation of a fully developed boundary layer.

Owner:SIEMENS ENERGY INC

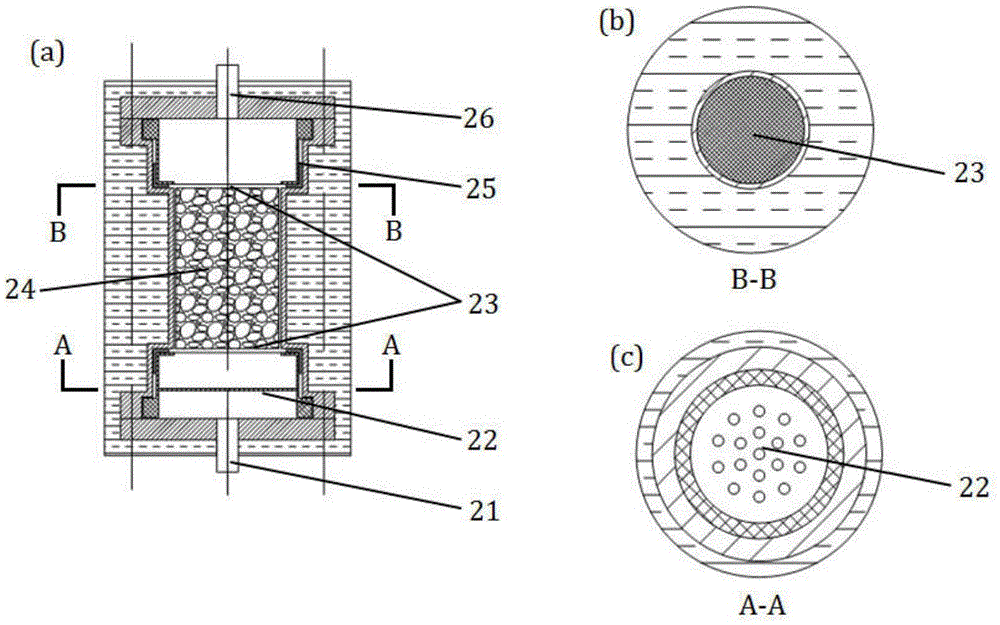

Heat transfer enhanced chemical heat storage device and heat storage system applying same

ActiveCN105651091AUniform temperatureImprove thermal efficiencyHeat storage plantsBuffer tankEngineering

A heat transfer enhanced chemical heat storage device in the technical field of heat storage comprises a plurality of heat storage units, a first gas buffer tank and a second gas buffer tank, wherein the first gas buffer tank and the second gas buffer tank are connected with gas inlet ends and outlets of the heat storage units respectively; each heat storage unit comprises an air distribution plate, a stainless-steel wire mesh, a heat storage medium and a bracket; the heat storage medium is wrapped in and fixed by the stainless-steel wire meshes; the stainless-steel wire meshes are fixed in the storage units through the brackets; and the air distribution plates are arranged between the corresponding gas inlet ends and the storage medium. The heat transfer enhanced chemical heat storage device can solve the problems of poor heat transfer performance in a powdery heat storage material and large temperature difference and low heat efficiency between a heat transfer medium and a reaction bed.

Owner:SHANGHAI JIAO TONG UNIV

Heat exchanging roll

InactiveUS6250376B1Reduce chanceOptimization mechanismDryer sectionCalendersInternal heat transferEngineering

A heat exchange roll. The roll includes a roll jacket, and a heat exchanger mounted inside the roll jacket. A supply mechanism controls an inflow and outflow of an external heat transfer fluid to a primary side of the heat exchanger. An internal heat transfer fluid has a fluid path between an inner portion of the roll jacket and a secondary side of the heat exchanger. A pump mechanism pumps the internal heat transfer fluid over the fluid path.

Owner:VOITH PATENT GMBH

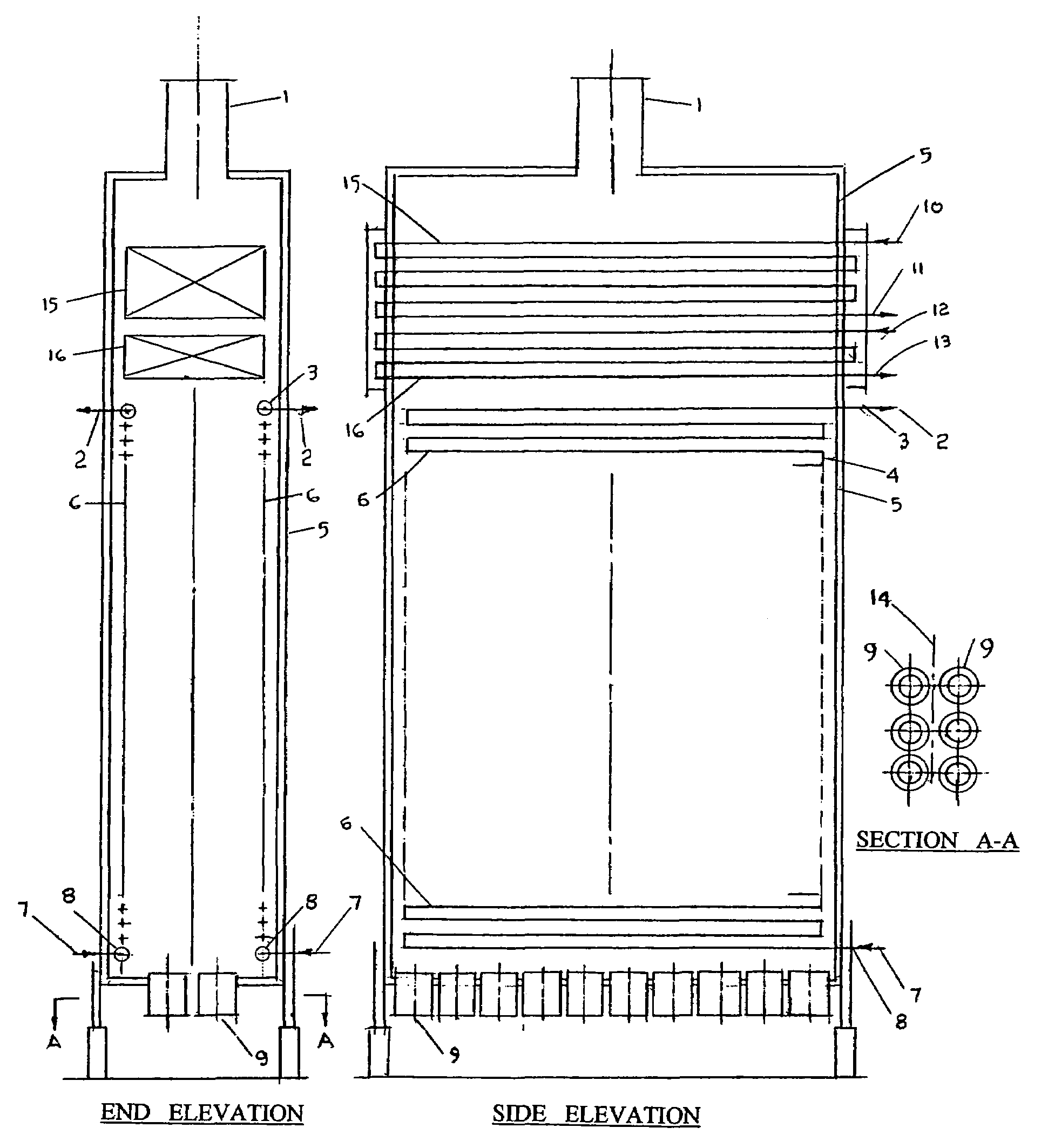

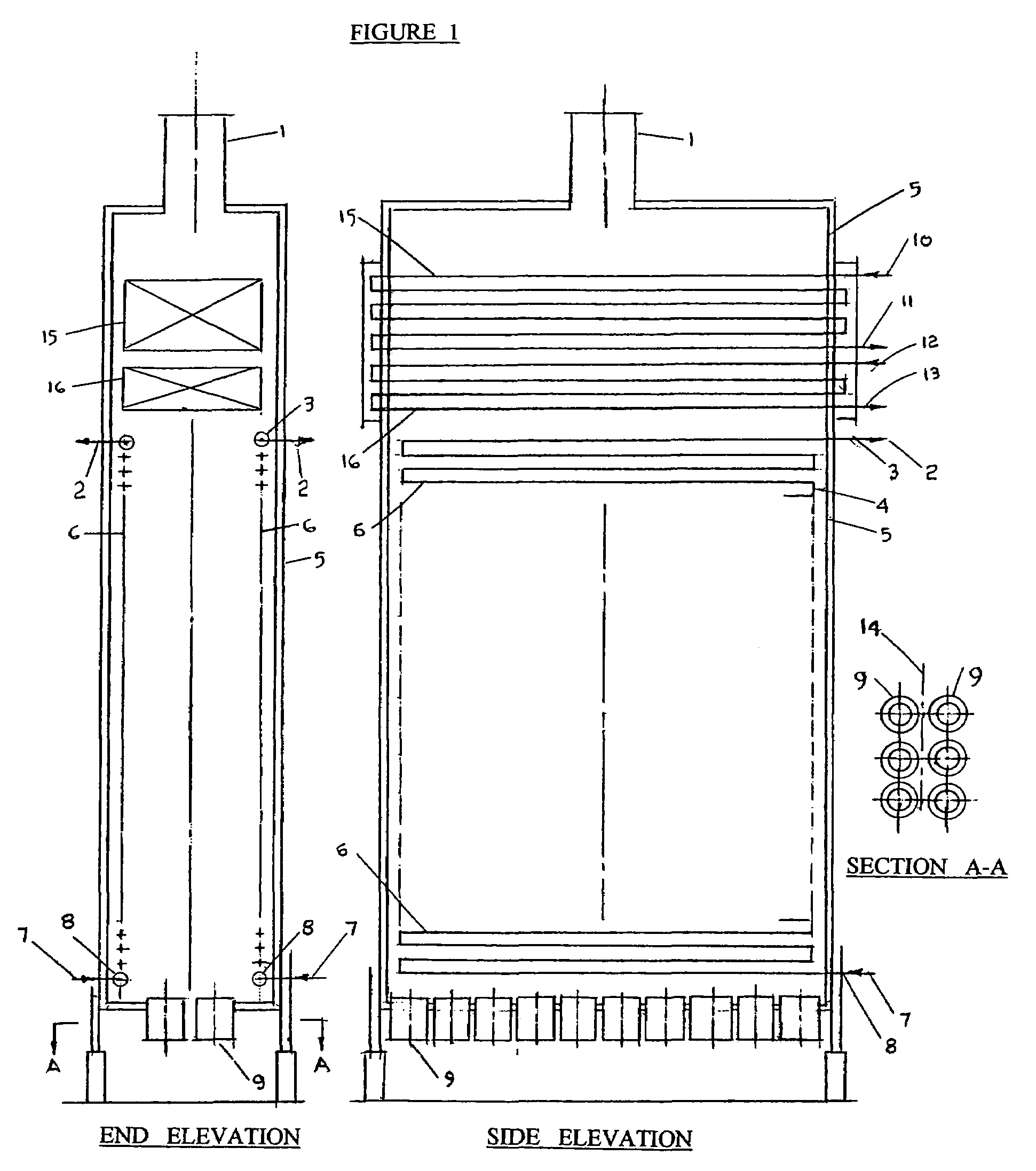

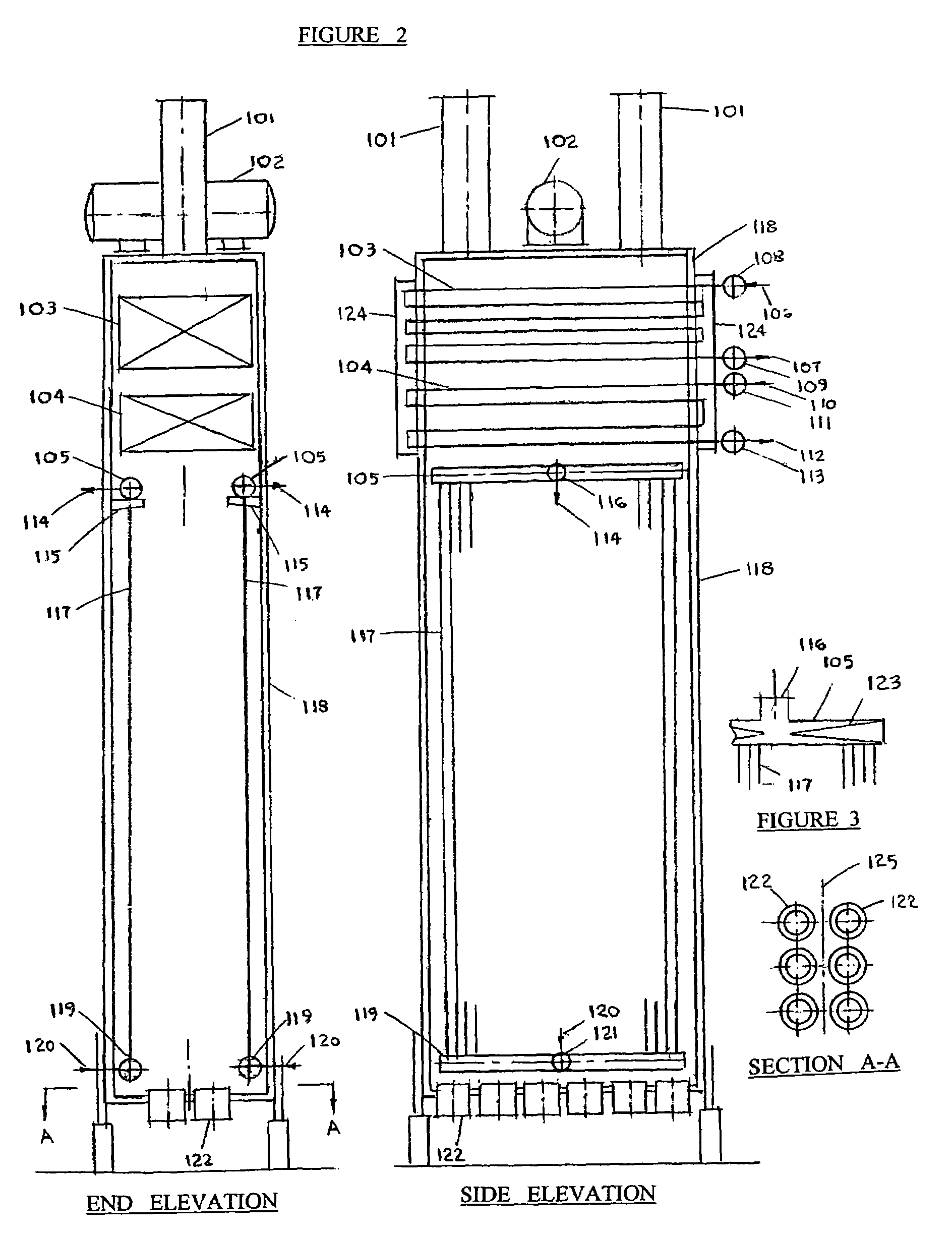

Reducing heat transfer surface area requirements of direct fired heaters without decreasing run length

InactiveUS7395785B1Small sizeLow costThermal non-catalytic crackingFurnace-tube steam boilersCombustion chamberContinuous flow

This invention relates to the design of direct fired heaters which consist of vertically oriented refractory lined enclosures containing tubular heat transfer elements, the elements partially surrounding a cluster of burners. The burners fire gaseous fuel and generate high temperature combustion products which allow for the transfer of heat, by radiation and convection, from the combustion products to the heat transfer elements and the continuous flow of process fluid contained therein. The transferred heat raises the temperature of the fluid from the design temperature at the inlet to the design temperature at the outlet, at a heat transfer rate commensurate with the temperature differential existing at any given location. The surface area requirements of the heat transfer elements and that of the enclosure surrounding the heat transfer elements is significantly reduced by limiting firebox recirculation of burner generated combustion products, thereby increasing overall temperature differentials and heat transfer rates between combustion products and process fluid. Gains in heating surface reduction are not accompanied by losses in heater run length because low process fluid temperatures and high inside heat transfer coefficients are provided, which minimize process fluid film temperature in areas where high heat transfer rates prevail.

Owner:CROSS ALAN

Plate type catalytic reactor

A plate type catalytic reactor in which components of a starting material gas react comprises a plurality of pairs of heat transfer plates, each pair being formed of two sheets of corrugated plates joined to each other and each pair having a plurality of interior heat transfer medium flow passages, that are arranged so that projected surface parts and recessed surface parts of the corrugated plates of adjacent heat transfer plates are opposed to each other and so that the plurality of pairs of corrugated plates placed in contiguous non-contacting relationship define a plurality of catalyst bed regions in which catalyst material is placed, each having an inlet for the flow of starting gas material and an outlet for the egress of reaction product, wherein the direction of flow of the heat transfer medium through the passages is perpendicular to the direction of flow of starting material gas through the plurality of catalyst regions.

Owner:MITSUBISHI CHEM CORP +1

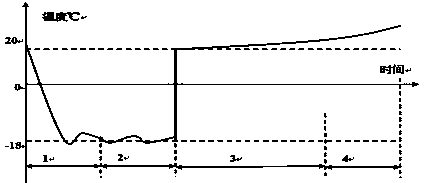

Refrigerator achieving intelligent heat pipe unfreezing

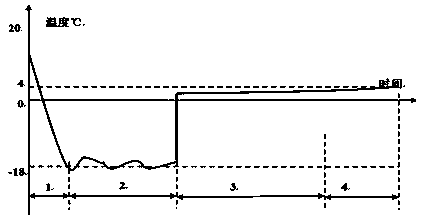

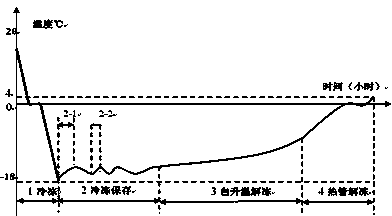

InactiveCN104165490AQuality improvementProtect healthLighting and heating apparatusDomestic refrigeratorsMicrocomputer systemIcebox

The invention discloses a refrigerator achieving intelligent heat pipe unfreezing and relates to the field of household appliances. According to an existing household refrigerator, the taste is affected and nutrition is lost due to rapid unfreezing of food, and manual operation is needed when food is unfrozen in refrigerating chambers. The refrigerator achieving intelligent heat pipe unfreezing achieves unfreezing in a preset mode by the utilization of a single-chip microcomputer control technology and a controlled heat pipe technology. The refrigerator achieving intelligent heat pipe unfreezing comprises a plurality of heat insulating freezing chambers the refrigerating chambers, the temperature of the freezing chambers and the temperature of the refrigerating chambers are controlled independently, the refrigerating chambers and the freezing chambers are connected through heat pipes, the heat pipes are provided with solenoid valves, and a single-chip microcomputer system controls the solenoid valves to operate or stop. When the heat pipes operate, heat transfer media in the heat pipes flow to the freezing chambers slowly by carrying heat of the refrigerating chambers, frozen food is unfrozen slowly within the time preset by a user, the amount of lost juice is reduced when the frozen food is unfrozen, and the nutrition and taste of food are reserved. Meanwhile, as the multiple independent heat insulating freezing chambers are provided and cold of the freezing chambers flows to the refrigerating chambers slowly, compared with the existing refrigerator, the refrigerator achieving intelligent heat pipe unfreezing can save more electric energy.

Owner:GUANGDONG OCEAN UNIVERSITY

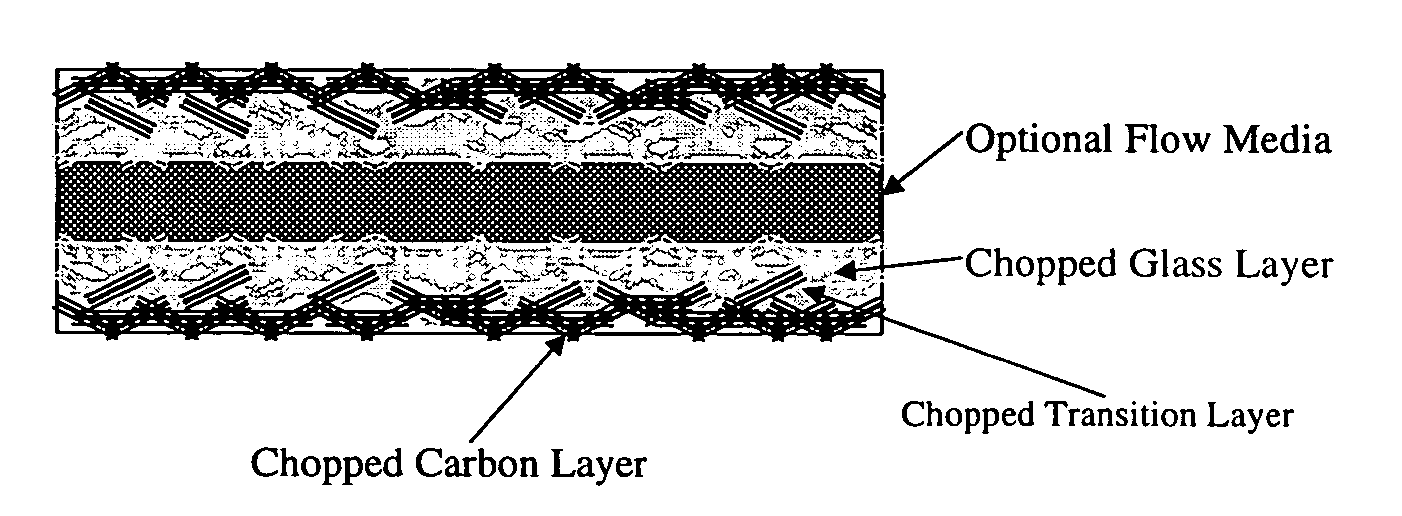

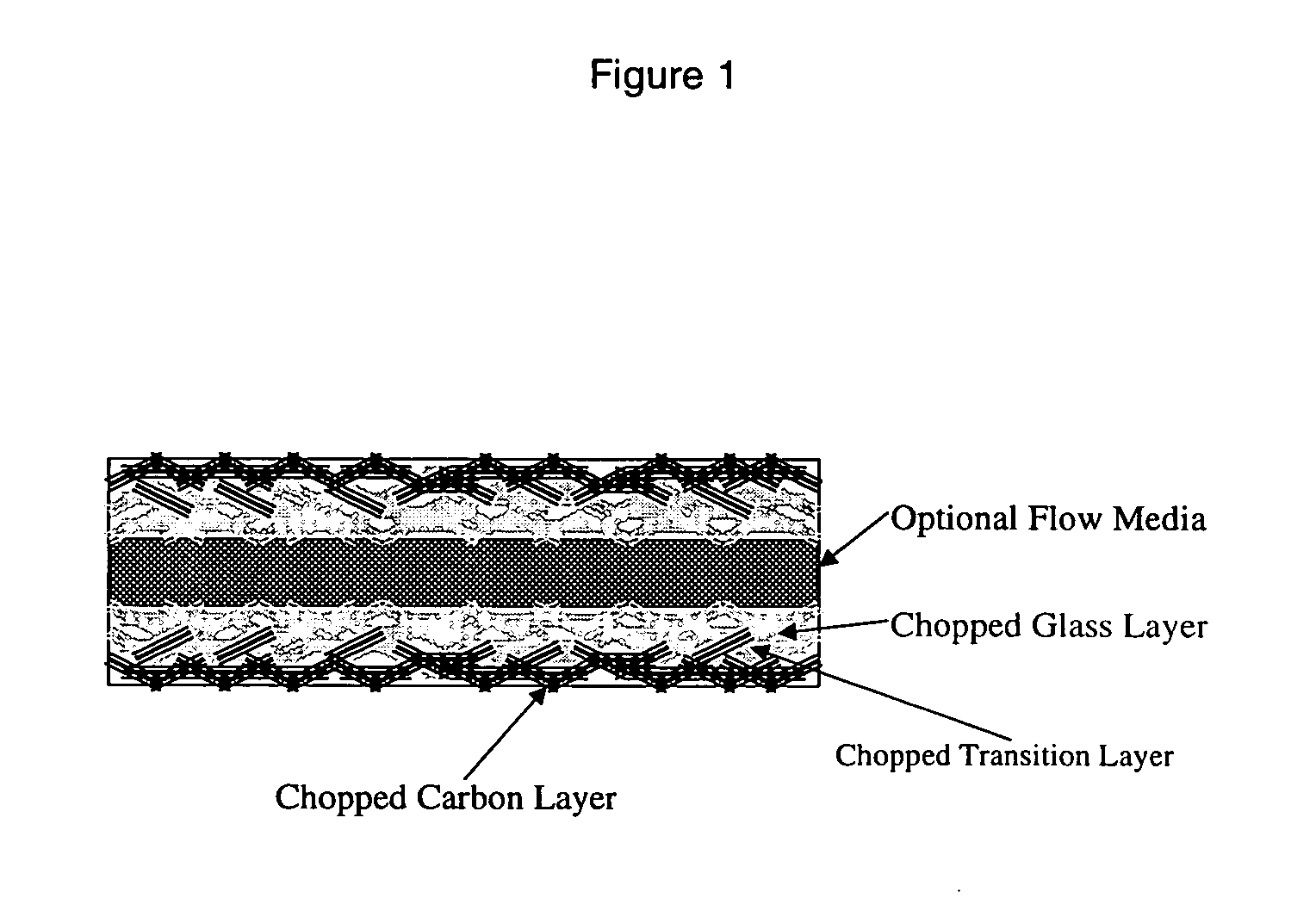

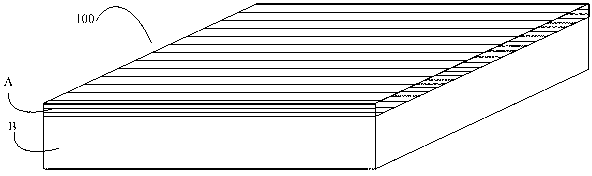

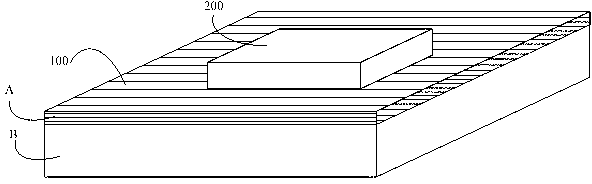

Composite materials and method of making

InactiveUS20070298236A1Reduce weightIncrease stiffnessSynthetic resin layered productsWood working apparatusPolyesterGlass fiber

A method for forming improved composite materials using a thermosetting polyester urethane hybrid resin, a closed cavity mold having an internal heat transfer mechanism used in this method, and the composite materials formed by this method having a hybrid of a carbon fiber layer and a fiberglass layer.

Owner:BATTELLE MEMORIAL INST

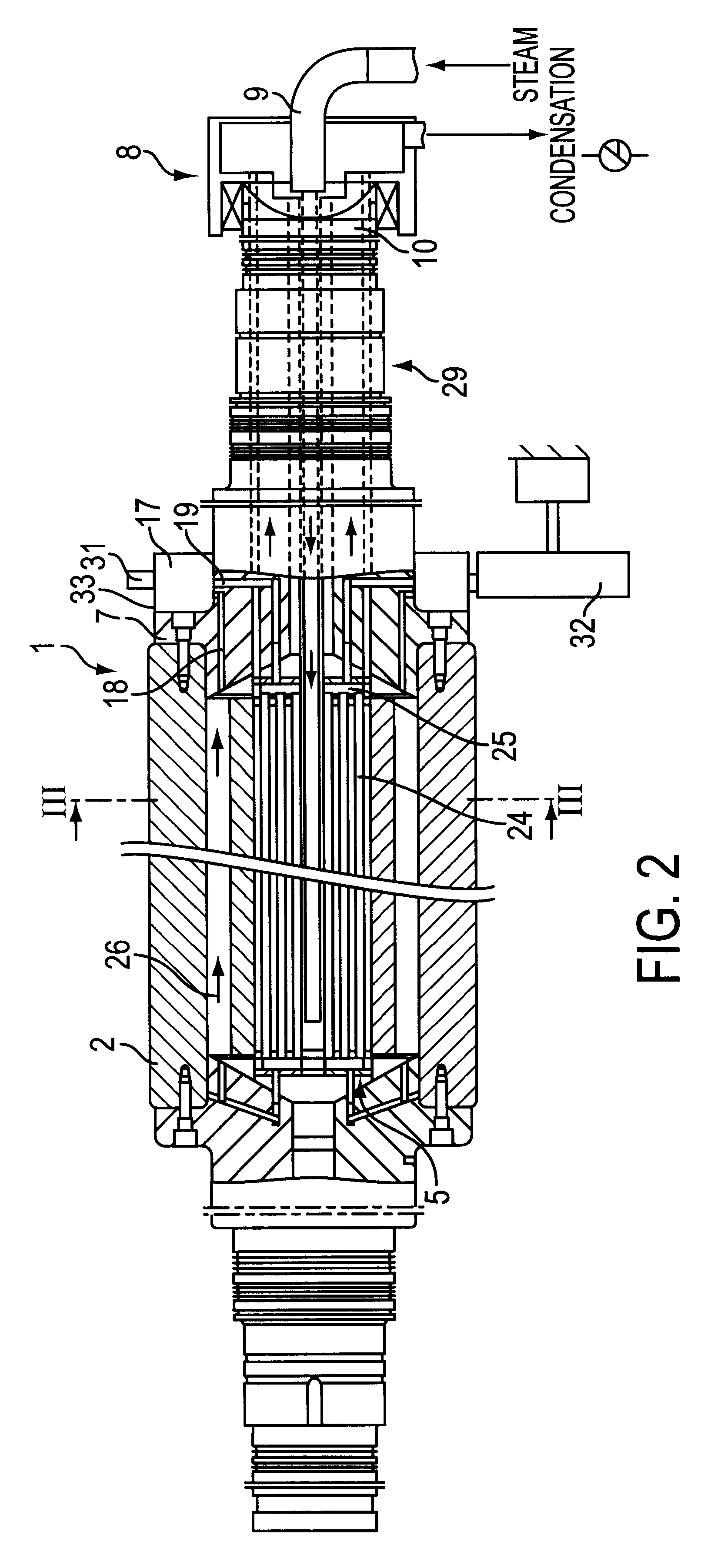

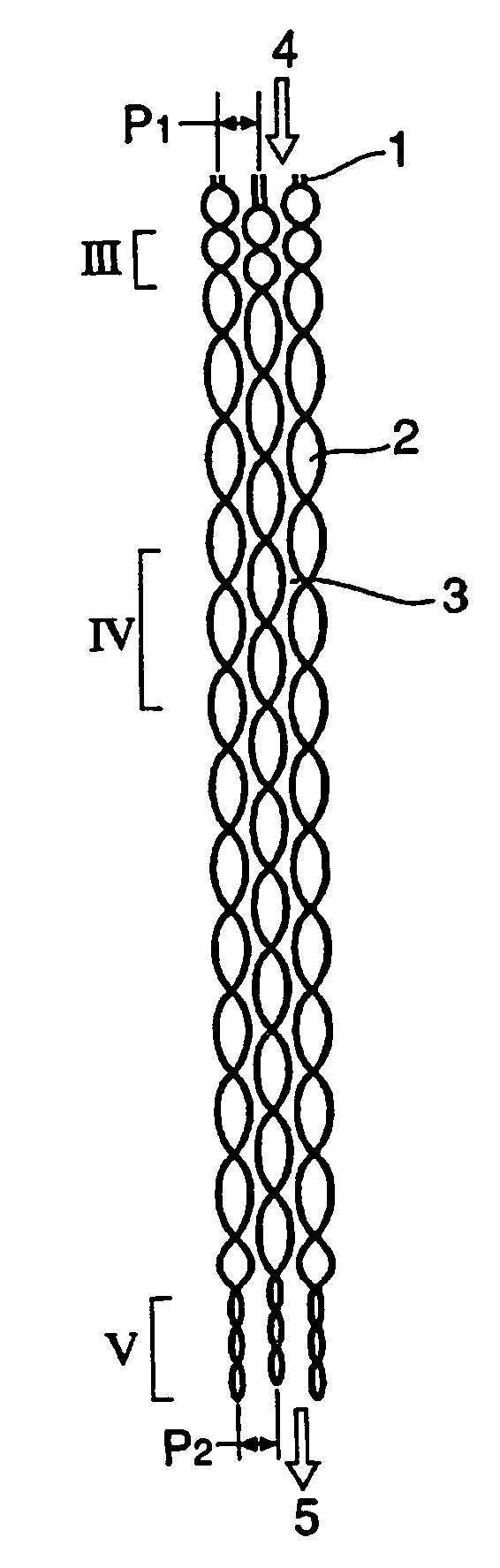

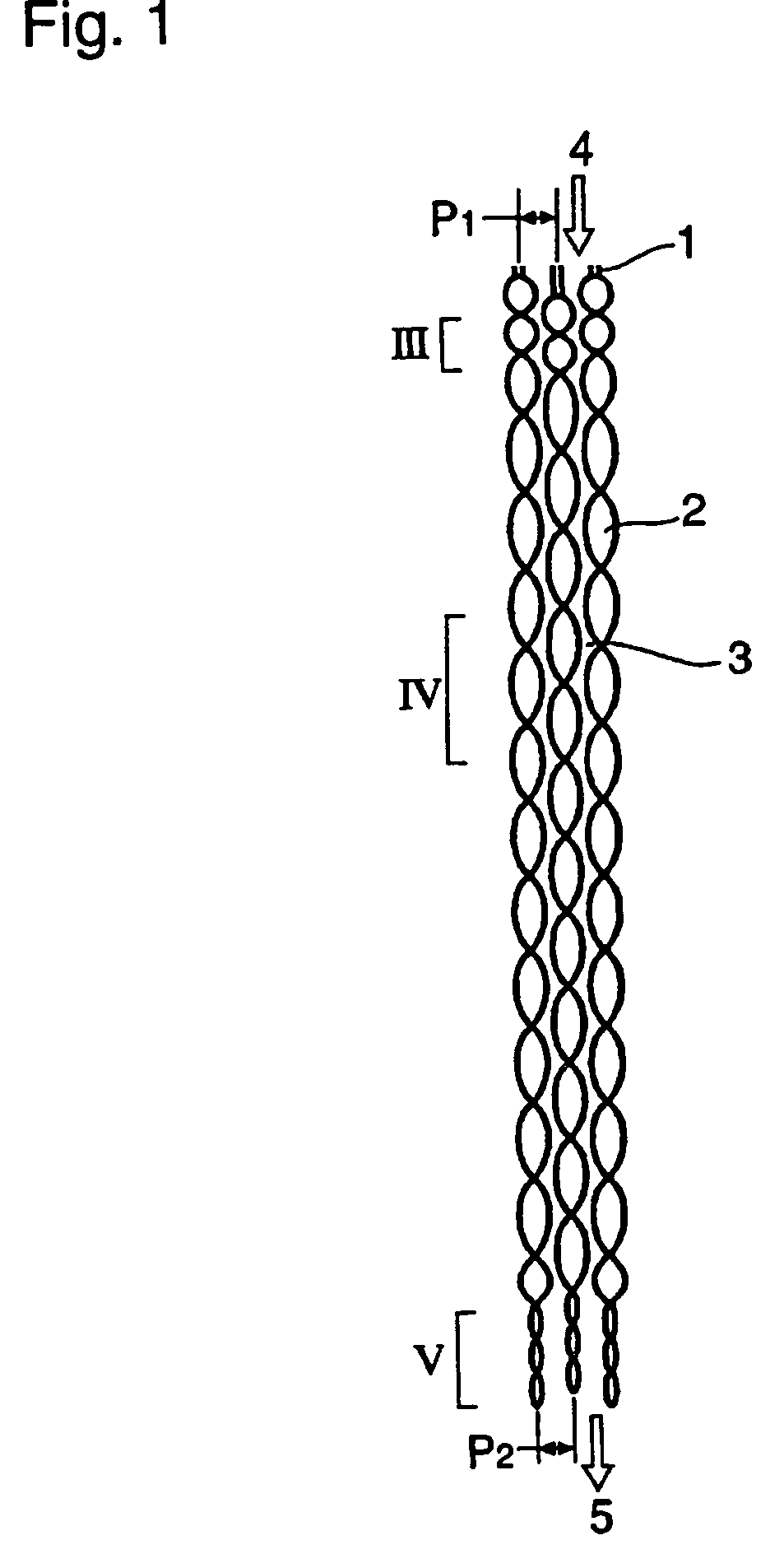

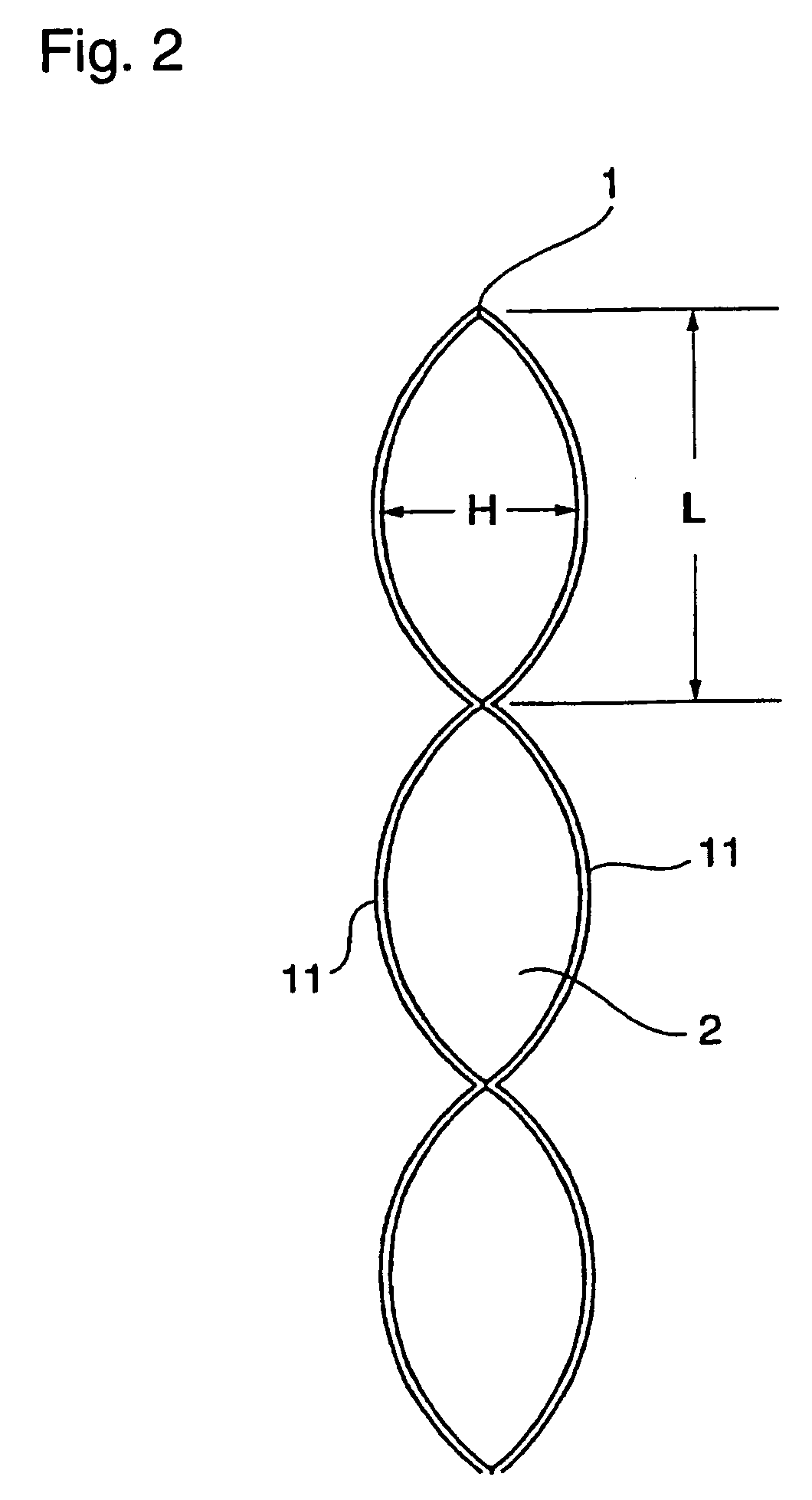

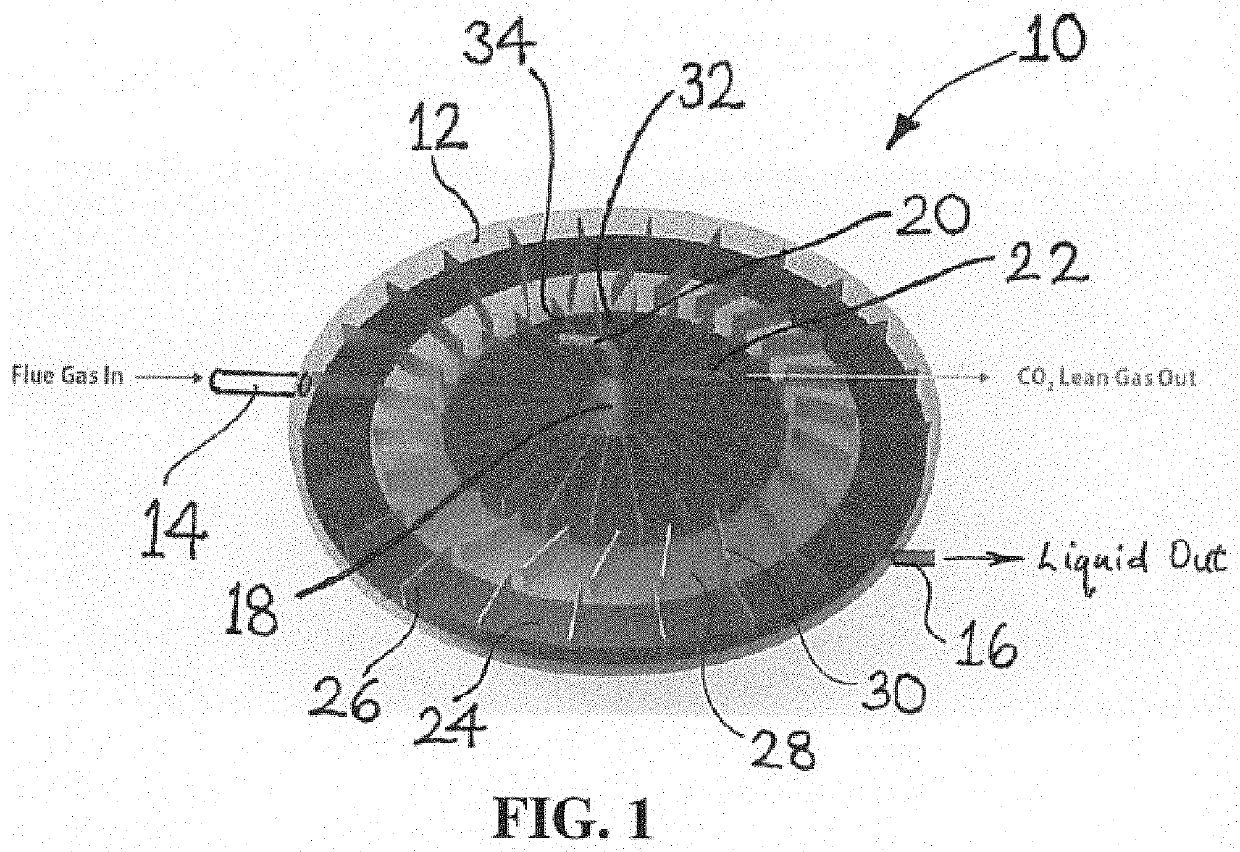

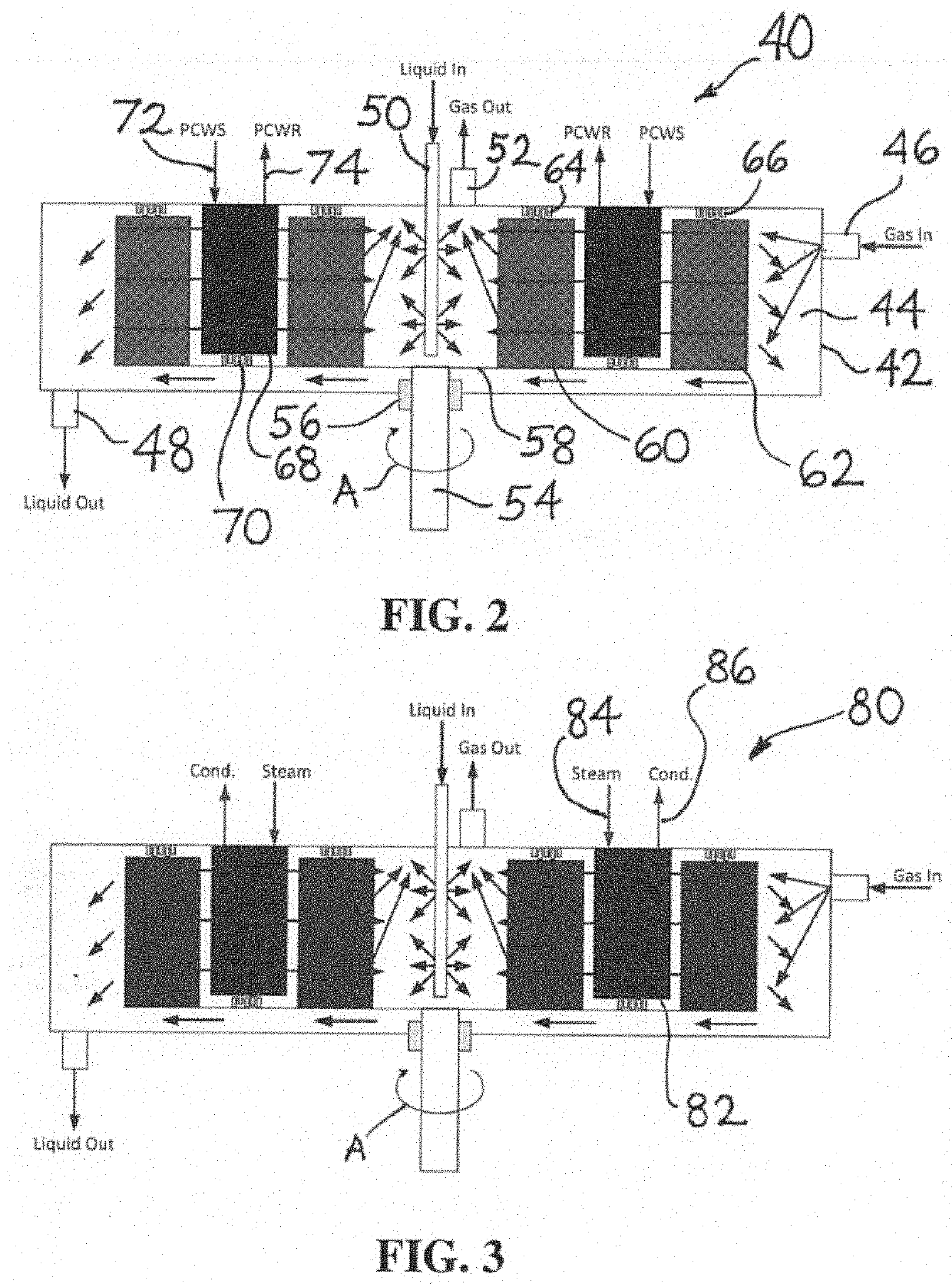

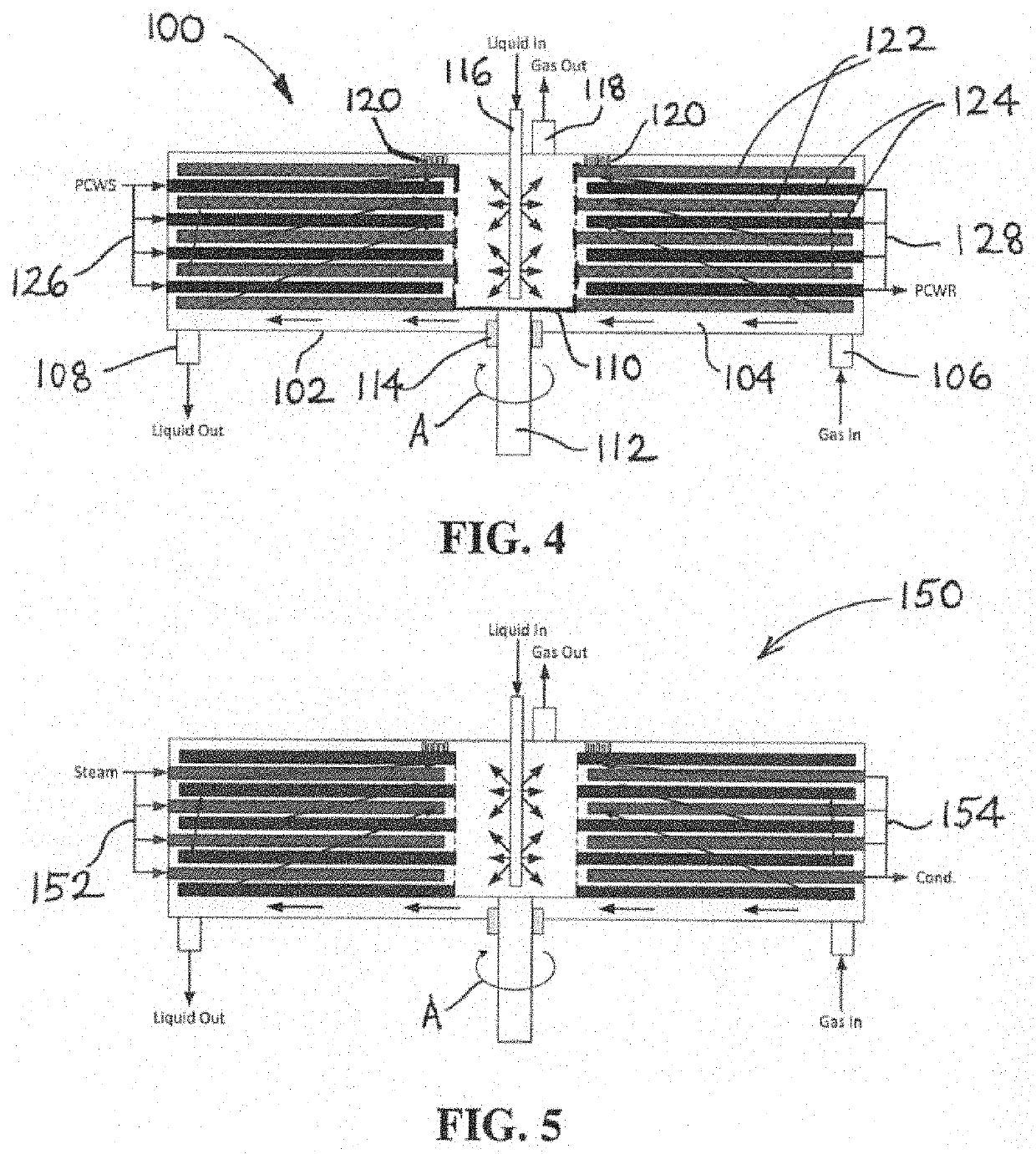

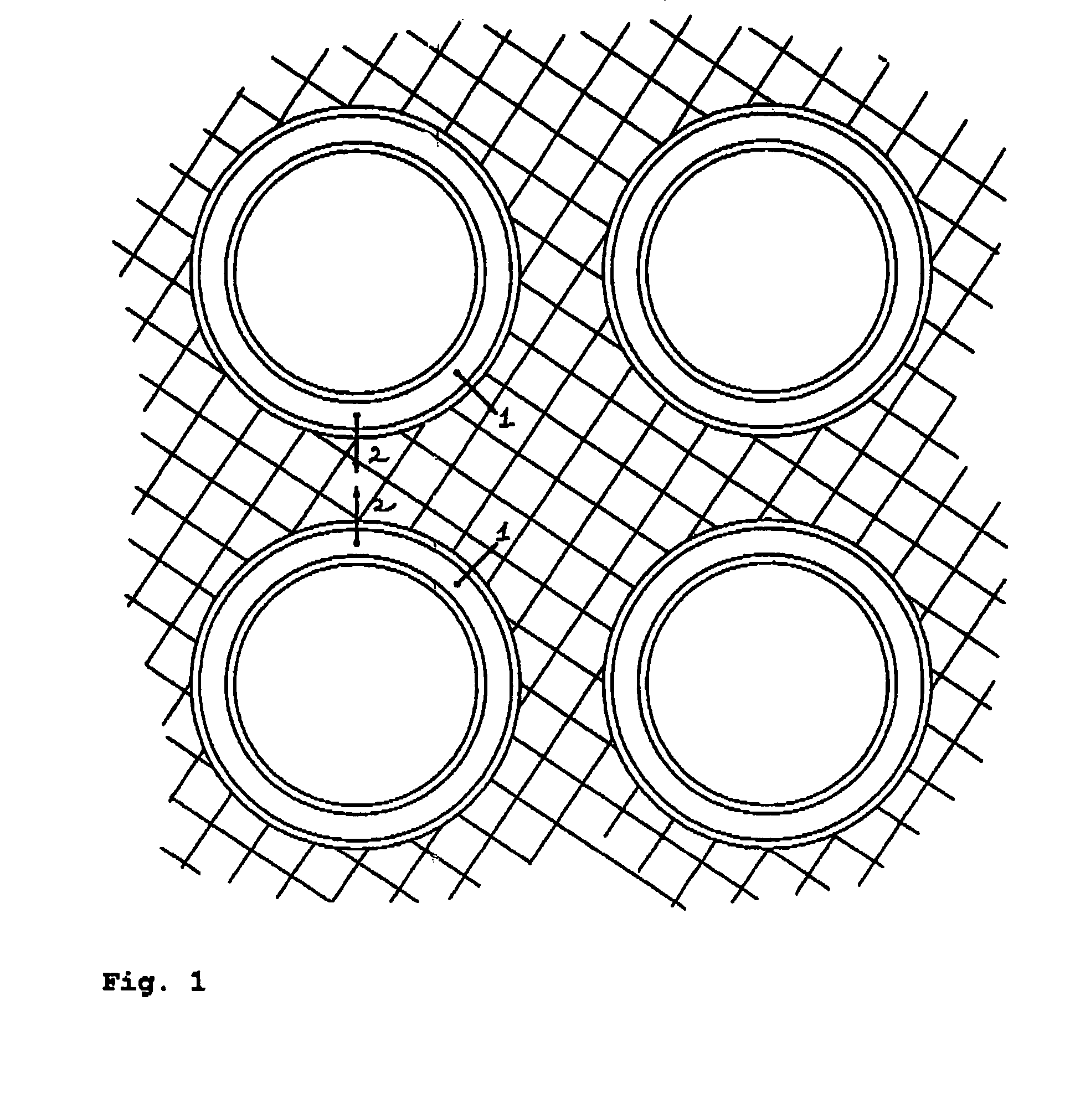

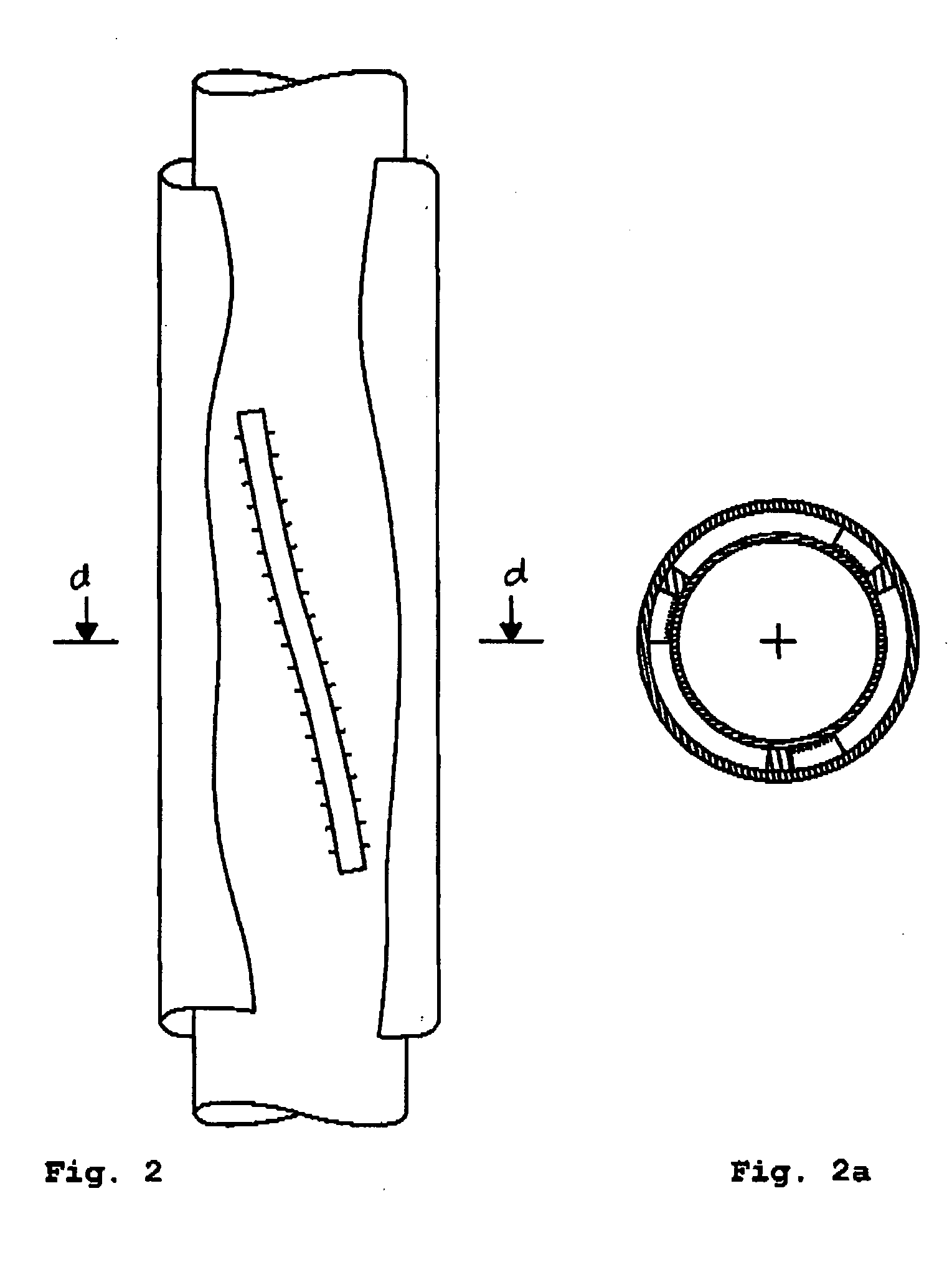

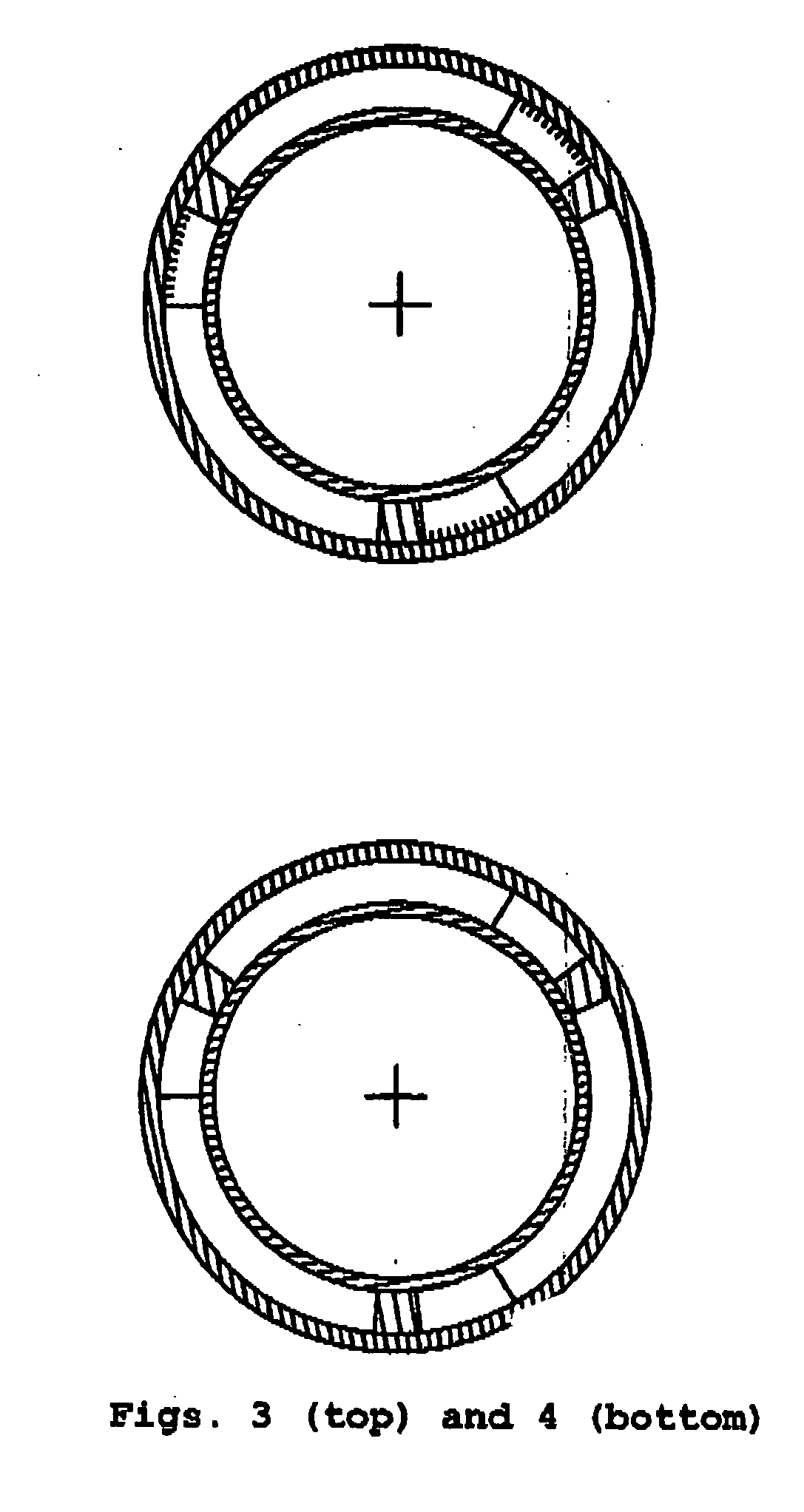

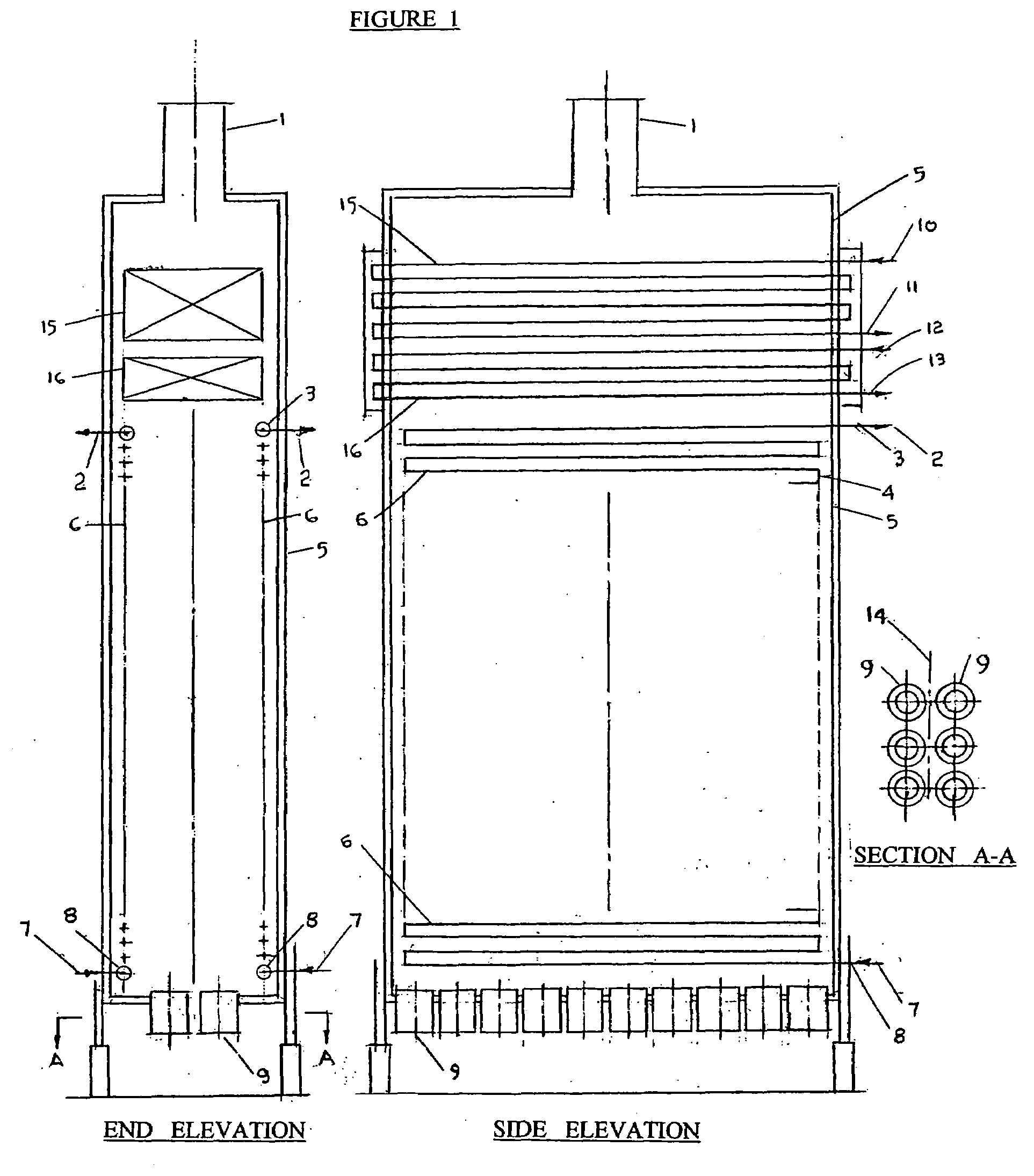

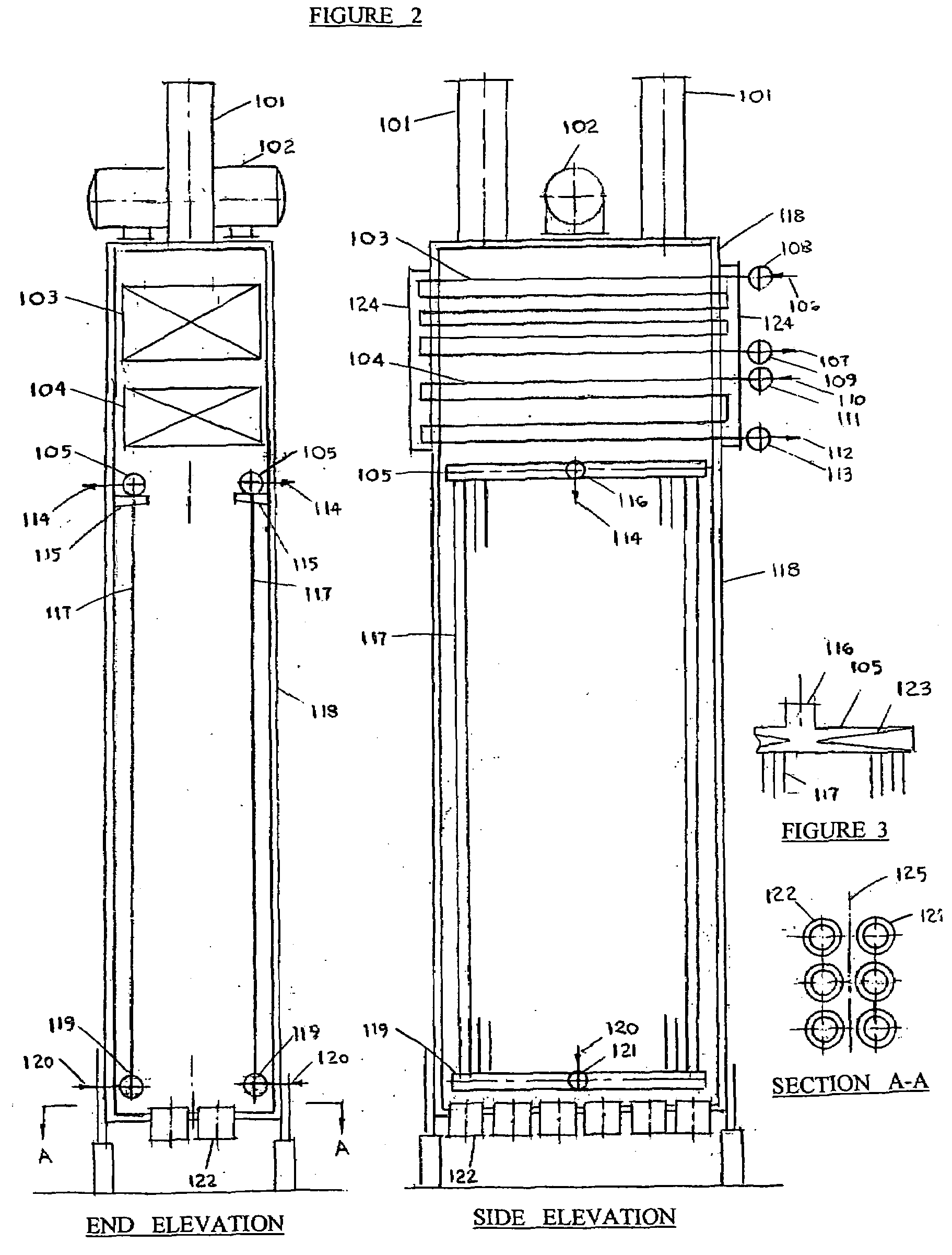

Rotating packed beds with internal heat transfer for absorption/regeneration applications

A gas-liquid contacting apparatus and method are described, in which at least one rotor assembly including packing is arranged in a contacting chamber containing at least one stator assembly including at least one heat exchanger arranged to thermally modulate the gas-liquid contacting so that each stator assembly is operatively arranged with each stator assembly to provide gas-liquid contacting at temperatures effective for mass exchange between the gas and liquid. The rotor and stator assemblies may be of annular shape, or may be of disk shape in a stacked array of rotor assemblies alternating with stator assemblies. Such apparatus and method are usefully employed for CO2 capture from CO2-containing flue gases such as combustion effluents from power generation plants.

Owner:RES TRIANGLE INST

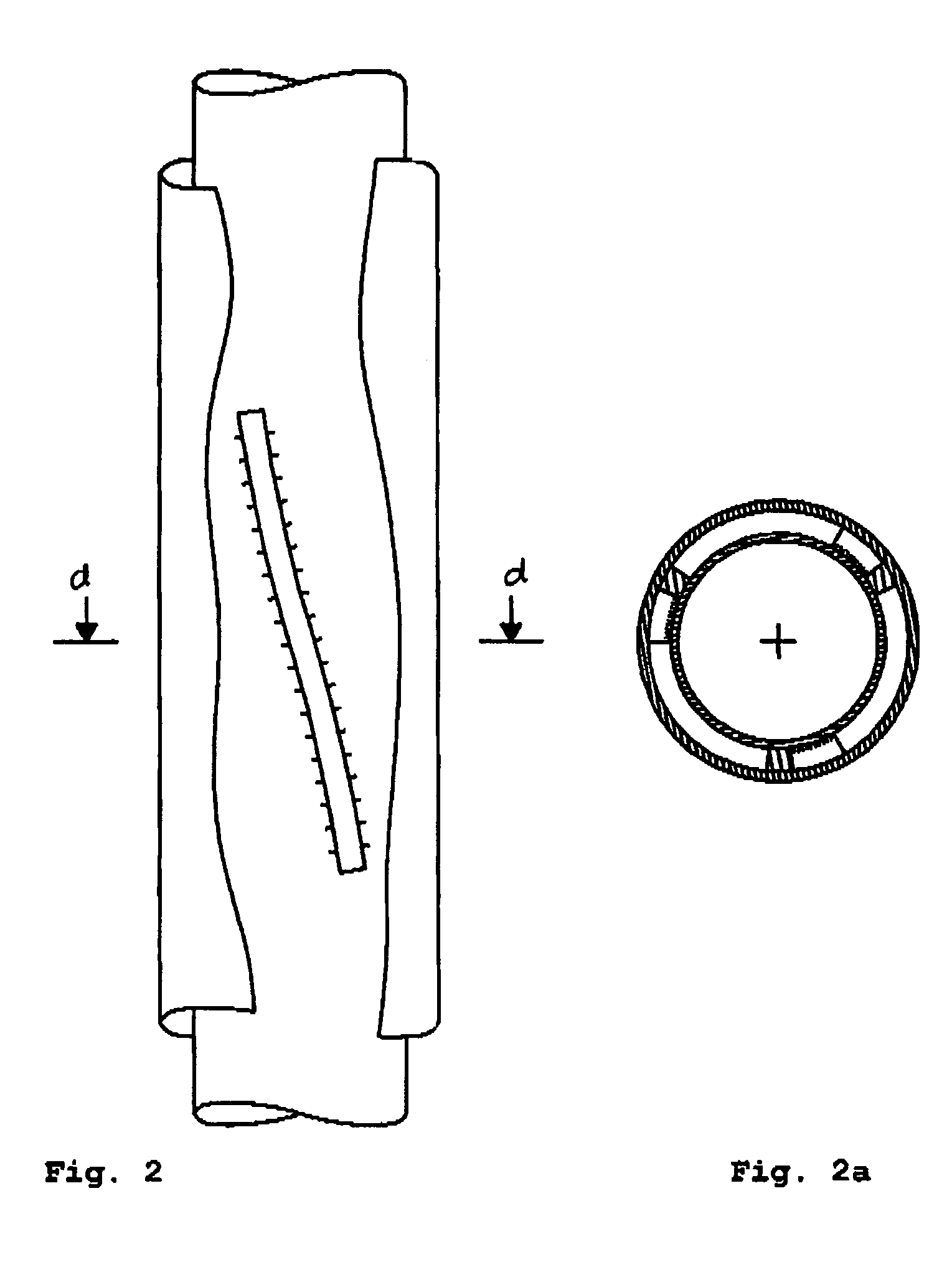

Heat exchange process and reactor

ActiveUS7780926B2Reduce temperature differenceSpacing meansHydrogenDouble wallInternal heat transfer

Process for carrying out heat exchange reactions comprising introducing a reactant stream into a bed of catalytic material placed outside at least one double walled heat transfer tube in a heat exchange reactor contacting the reactant stream with the catalytic material in indirect heat exchange with a heat transfer medium present in the annular volume of the at least one double walled heat transfer tube, the annular volume comprising one or more spacer elements creating a helical flow path of the heat transfer medium around the inner heat transfer tube of the at least one double walled heat transfer tube. The invention also includes a heat exchange reactor for carrying out the above reaction.

Owner:TOPSOE AS

Heat exchange process and reactor

ActiveUS20050265908A1Lowering and eliminating fluid temperature differenceReduce temperature differenceSpacing meansHydrogenInternal heat transferHeat transfer tube

Process for carrying out heat exchange reactions comprising introducing a reactant stream into a bed of catalytic material placed outside at least one double walled heat transfer tube in a heat exchange reactor contacting the reactant stream with the catalytic material in indirect heat exchange with a heat transfer medium present in the annular volume of the at least one double walled heat transfer tube, the annular volume comprising one or more spacer elements creating a helical flow path of the heat transfer medium around the inner heat transfer tube of the at least one double walled heat transfer tube. The invention also includes a heat exchange reactor for carrying out the above reaction.

Owner:HALDOR TOPSOE AS

Graphite block material and preparation method thereof

ActiveCN102795617AImprove performanceImprove heat transfer performanceGraphiteInternal heat transferGraphite

The invention discloses a graphite block material and a preparation method thereof. The graphite block material comprises two layers of graphite layer structures, wherein the first layer of graphite layer structure is anisotropic and arranged on the second layer of graphite layer structure; the relative high thermal conductive direction of the first layer of graphite layer structure is parallel to the surface of the second layer of graphite layer structure; and the two layers of graphite layer structures are carbonized to form a whole. The graphite block material is composed of two layers of graphite layer structures, the relative high thermal conductive direction of the first layer of the graphite layer structure is parallel to the surface of the second layer of the graphite layer structure, and the two layers of graphite layer structures are carbonized to form a whole, so that the two structures are almost in 'seamless' contact, the interface thermal resistance is very low, and the heat transfer effect is remarkable. According to the graphite block material, the two structures are arranged and burnt into a whole, so that the internal heat transfer effect of the graphite block material is good, and heat dispersing or heating performance is remarkable.

Owner:深圳石墨烯创新中心有限公司

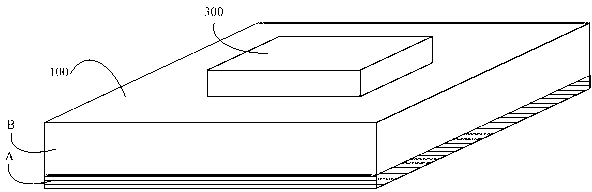

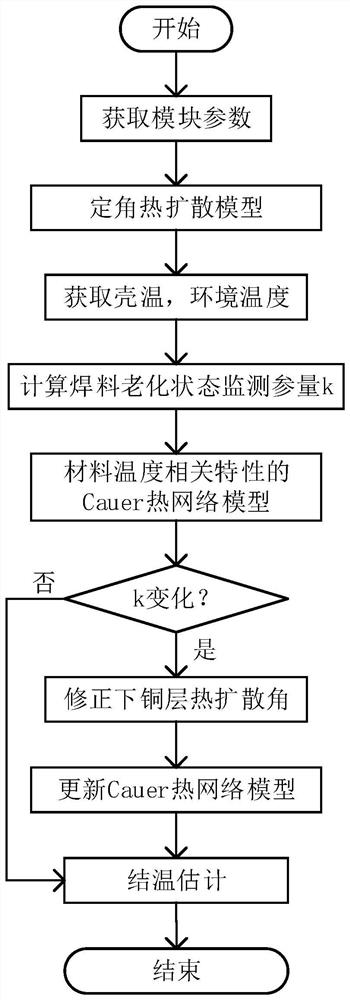

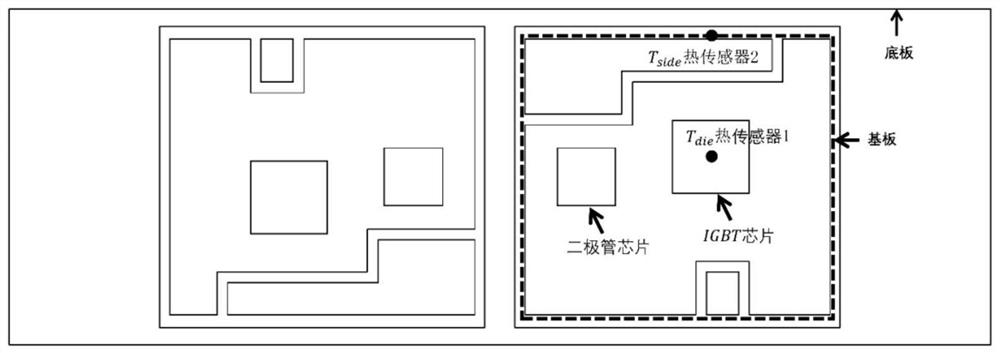

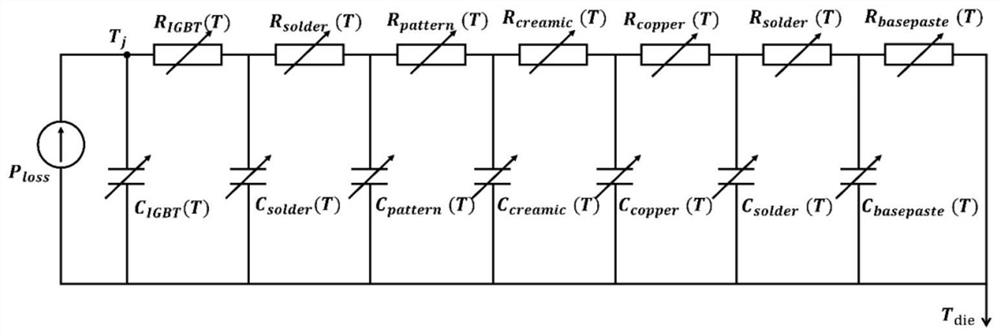

IGBT module junction temperature estimation method in solder aging state

ActiveCN111931402AResolving Heat Transfer Path Offset IssuesHigh precisionDesign optimisation/simulationSpecial data processing applicationsJunction temperatureProcess engineering

The invention relates to a method for estimating the junction temperature of an IGBT module in a solder aging state. The method comprises the steps that 1, geometric structure parameters and materialcharacteristic parameters of the IGBT module are acquired; 2, establishing a constant-angle thermal diffusion model based on the geometric parameters and the heat transfer performance; 3, collecting environment information of the IGBT module; 4, obtaining solder aging state monitoring parameters according to the environment information of the IGBT module; step 5, establishing a Caler thermal network model of IGBT module material temperature related characteristics; 6, quantifying the influence of solder aging on an internal heat transfer path through the aging monitoring parameters to obtain an actual heat transfer area, and updating the parameters of the thermal network model; and step 7, estimating the junction temperature of the IGBT module in real time based on the Cauer thermal network model and the feedback junction temperature. Compared with the prior art, the method has the advantages of being high in junction temperature estimation result precision, effectively improving evaluation precision and strategy rationality and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

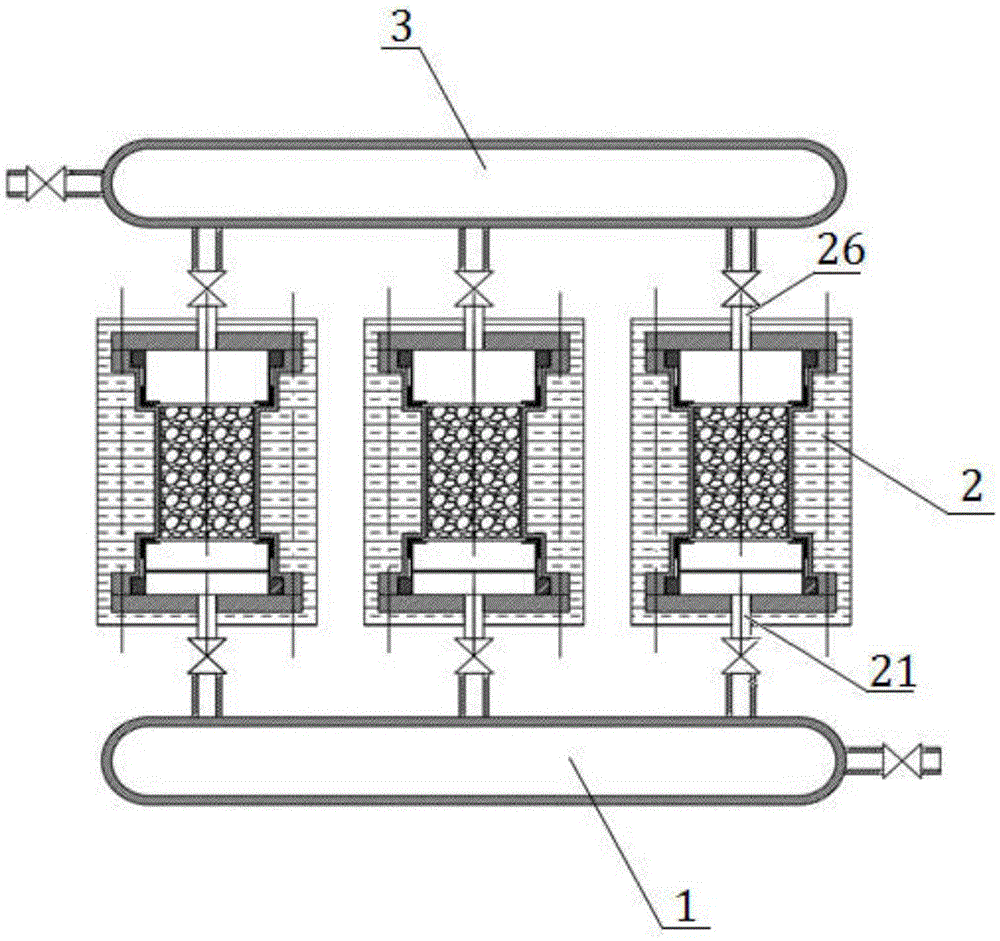

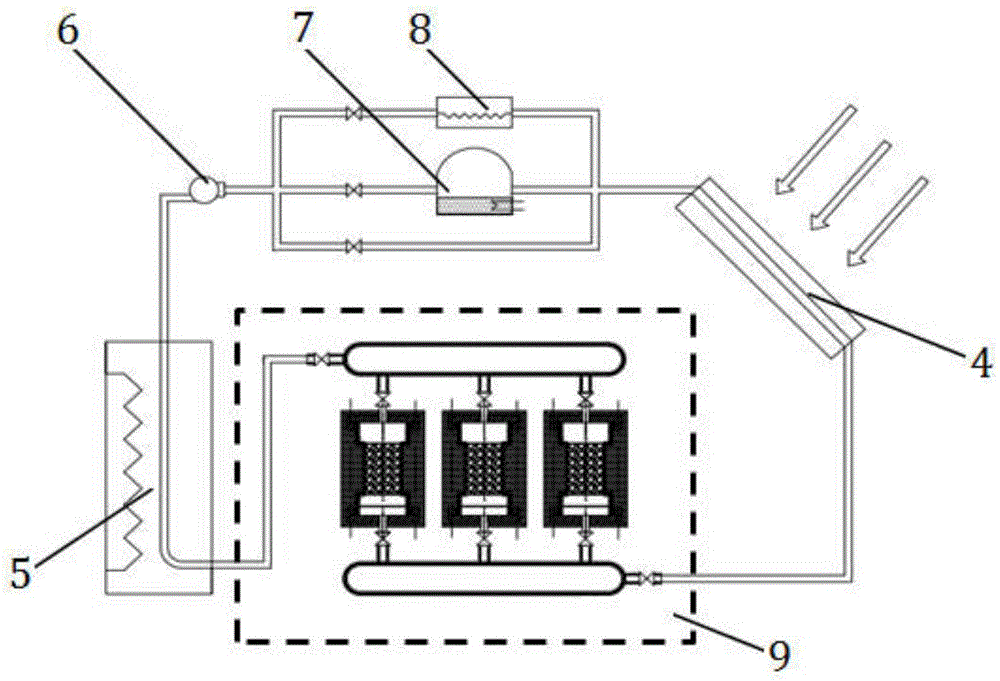

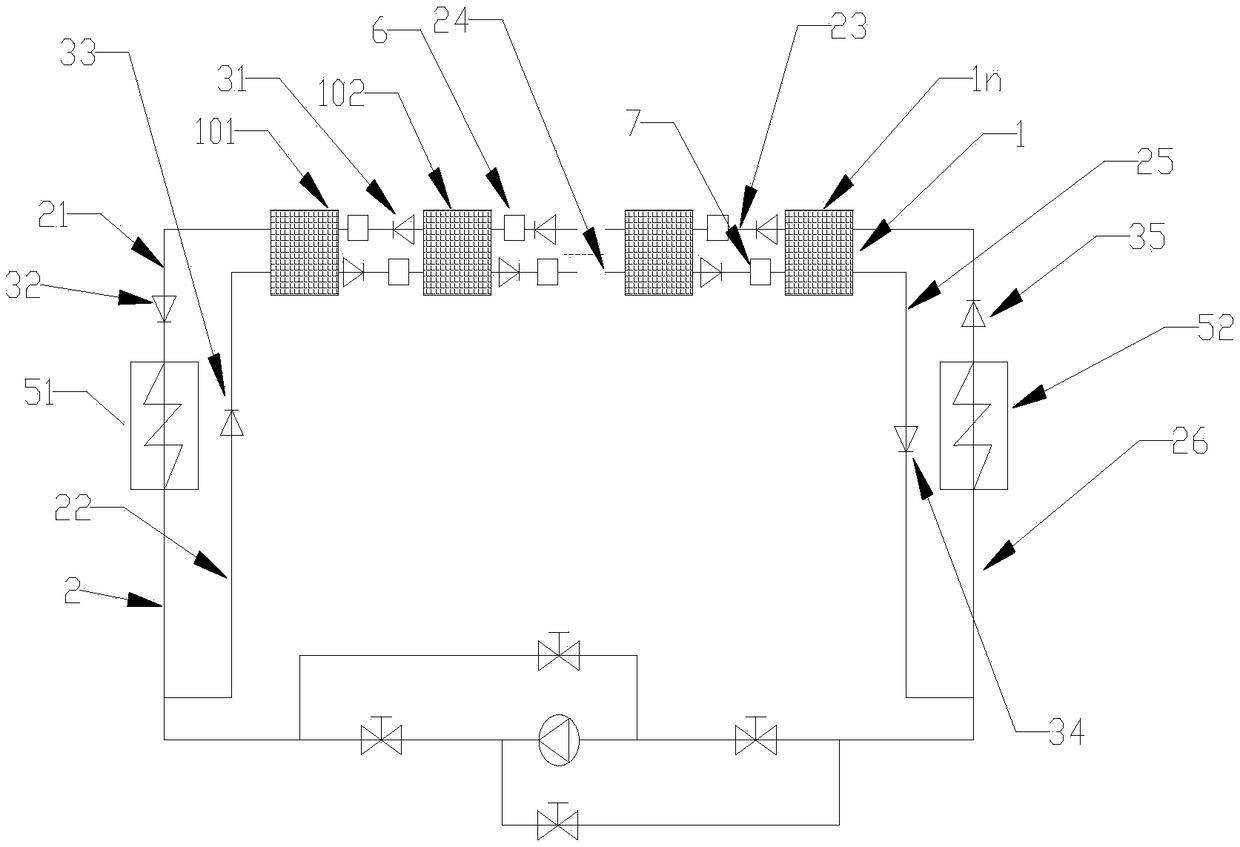

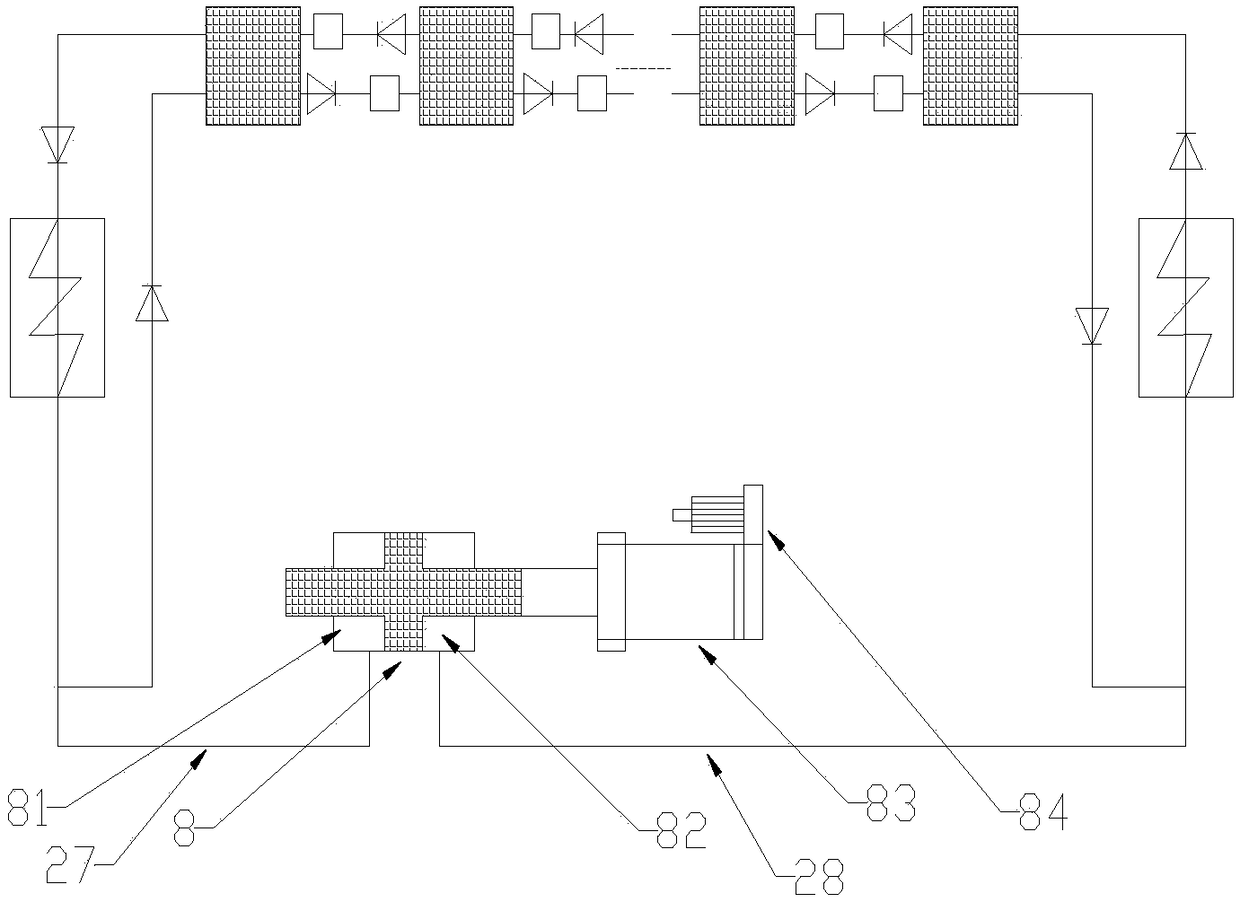

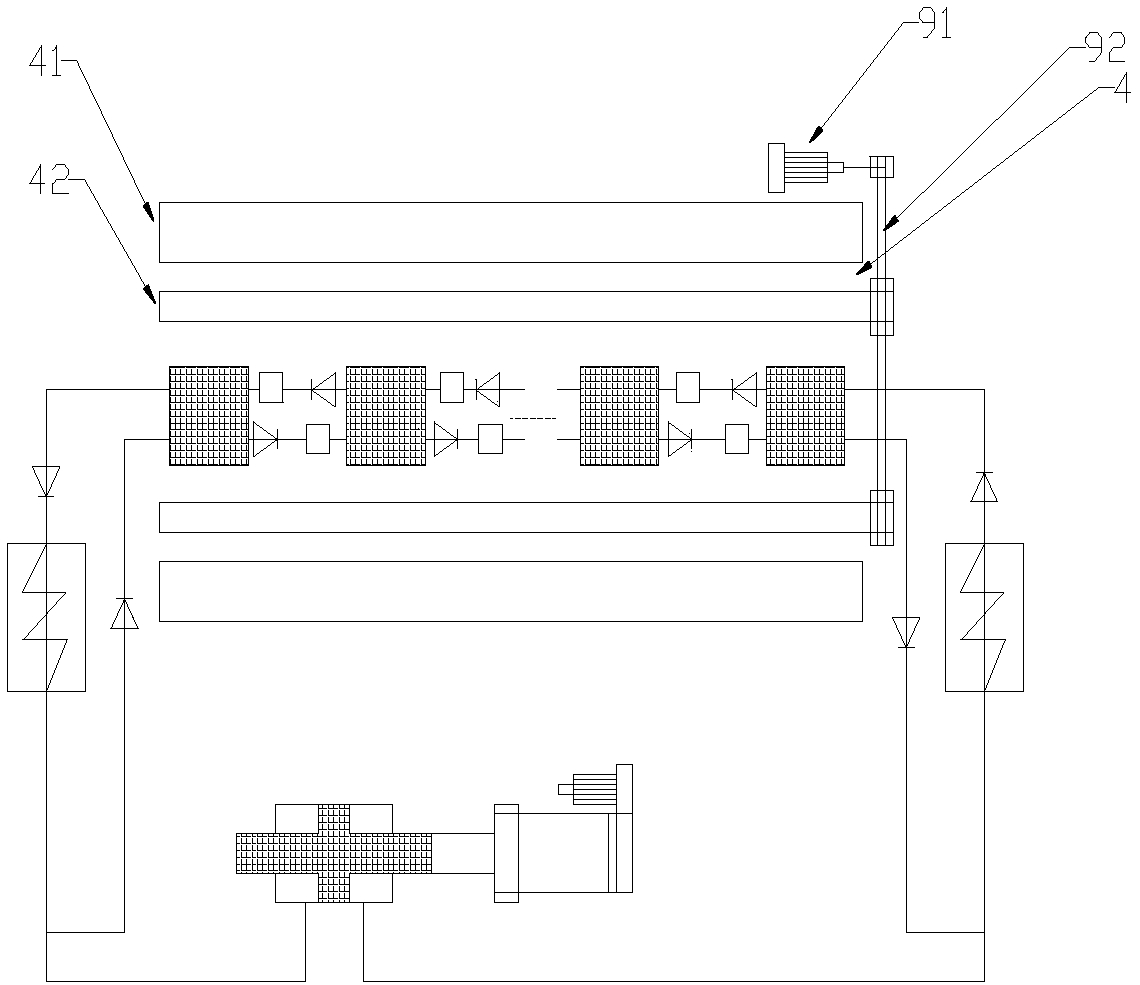

Magnetic refrigeration system of multistage magnetic regenerator

ActiveCN108413644ALarge temperature differenceReduce heat transferMachines using electric/magnetic effectsSustainable buildingsPlate heat exchangerEngineering

The invention provides a magnetic refrigeration system of a multistage magnetic regenerator. The magnetic refrigeration system comprises a magnetic body, a flow channel (2), a hot end heat exchanger (51), a cold end heat exchanger (52) and the multistage magnetic regenerator (1), wherein the multistage magnetic regenerator (1) comprises n magnetic regenerators (101,102,...1n) which are connected in series, n is an integer which is greater than 1, the first end of the multistage magnetic regenerator (1) are connected with an inlet and an outlet of the hot end heat exchanger (51) respectively through two flow channels (21, 22), and the second end of the multistage magnetic regenerator (1) are connected with an inlet and an outlet of the cold end heat exchanger (52) respectively through two flow channels (25, 26). The magnetic refrigeration system of the multistage magnetic regenerator has the advantage of high efficiency, the refrigeration loss caused by irreversible factors during backheating can be reduced, the refrigeration efficiency of fillers of the regenerators is fully improved, the internal heat transfer efficiency of the regenerators can be effectively improved, the large temperature span is established, and the enough refrigeration output of the system is guaranteed.

Owner:百慧科博(北京)科技有限公司

Reducing heat transfer surface area requirements of direct fired heaters without decreasing run length

InactiveUS20080173261A1Small sizeLow costThermal non-catalytic crackingFurnace-tube steam boilersEngineeringContinuous flow

This invention relates to the design of direct fired heaters which consist of vertically oriented refractory lined enclosures containing tubular heat transfer elements, the elements partially surrounding a cluster of burners. The burners fire gaseous fuel and generate high temperature combustion products which allow for the transfer of heat , by radiation and convection, from the combustion products to the heat transfer elements and the continuous flow of process fluid contained therein. The transferred heat raises the temperature of the fluid from the design temperature at the inlet to the design temperature at the outlet, at a heat transfer rate commensurate with the temperature differential existing at any given location. The surface area requirements of the heat transfer elements and that of the enclosure surrounding the heat transfer elements is significantly reduced by limiting top to bottom recirculation of burner generated combustion products, thereby increasing overall temperature differentials and heat transfer rates between combustion products and process fluid. Gains in heating surface reduction are not accompanied by losses in heater run length because low process fluid temperatures and high inside heat transfer coefficients are provided, which minimize process fluid film temperature in areas where high heat transfer rates prevail.

Owner:CROSS ALAN

Continuous heat transfer sulfur dioxide converter

The invention discloses a continuous heat transfer sulfur dioxide converter, which comprises a shell, and a catalyst layer in the shell, wherein the catalyst layer is supported by a grate; the shell below the grate is provided with a smoke outlet; a plurality of internal heat transfer pipes in rows are densely arranged in the catalyst layer; two ends of each heat transfer pipe penetrate the shell and are connected with a heat transfer header pipe; a great amount of heat released in reaction is transferred by the internal heat transfer pipes and is fully utilized; equipment is not corroded; the traditional conversion flow is simplified; and the equipment size is greatly reduced, and the occupied area is reduced.

Owner:YIXING CHEM INDSUTRY COMPLETE EQUIP

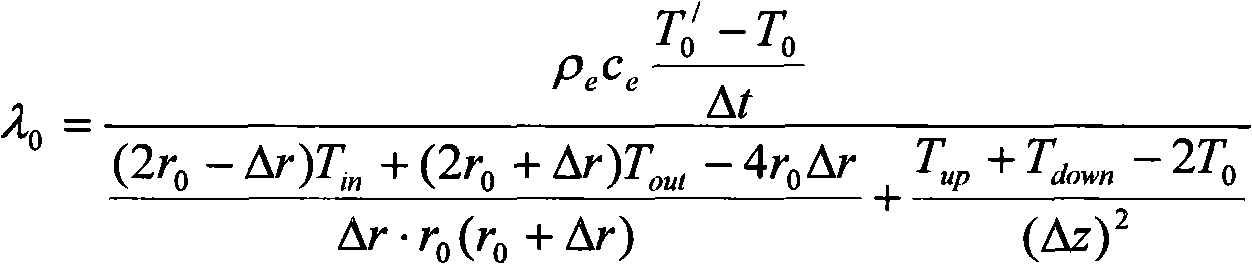

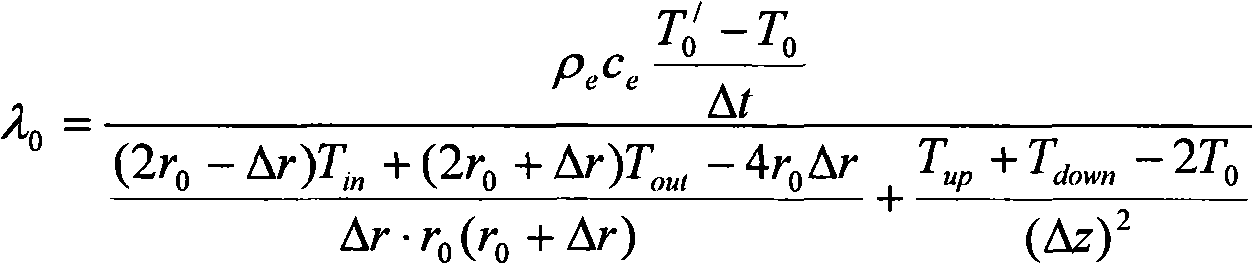

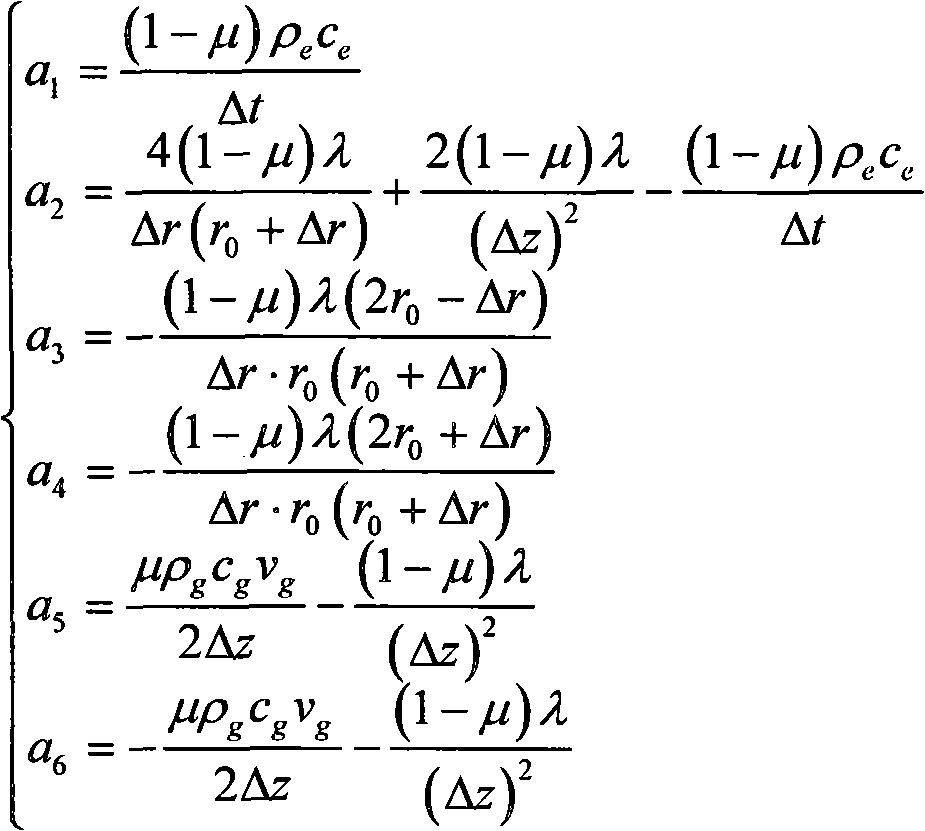

Determination method of oxidation heat liberation intensity of loose coal

InactiveCN101984349AShort test cycleGood repeatabilityMaterial heat developmentExothermic processEngineering

Provided is a determination method of oxidation heat liberation intensity of loose coal. Oxidation heat qic and conductivity factor lambada of loose coal are measured accurately based on the internal rule of heat and mass transfer of loose coal. The heat wire is placed at the center of the loose coal as the heat source and temperature measurement points and gas collection points are arranged inside the loose coal. The screened loose coal samples are loaded into a cylindrical heat insulation reaction container after the density and voidage thereof being measured. First, the loose coal samples are put in nitrogen atmosphere and heated until the temperature thereof reaches the predetermined value. Then the samples are left to cool naturally. The temperatures of temperature measurement points are collected continuously. Conductivity factor lambada of loose coal samples at different temperatures are calculated by the value of the factors of temperature, time, density, specific heat capacity and voidage. Then air is fed into the coal samples continuously. The temperatures of temperature measurement points and oxygen concentrations of the samples are monitored continuously during the cooling process. Finally, oxidation heat liberation intensity qic of loose coal samples at different temperatures are calculated by the value of the factors of temperature, conductivity factor, time, density, specific heat capacity, voidage and air flow meter. The experimental time is reduced and the obtained results are more accurate by utilizing the above method. As a result, the method is applicable to the measurement of exothermic process of coals.

Owner:CHINA UNIV OF MINING & TECH

Metal hydride hydrogen storage device

InactiveCN106813101AGood effectSimple structureVessel mounting detailsHydrogenInternal heat transferMetal foam

The invention provides a metal hydride hydrogen storage device. The metal hydride hydrogen storage device comprises a tank body, a ventilation pipeline in the tank body, a padding region and internal heat-transfer media in the padding region. The internal heat-transfer media are composed of foamed nickel with large porosity (60%-98%), and gaps of the foamed nickel contain hydrogen storage alloy powder. The metal hydride hydrogen storage device has the beneficial effects that storage positions are provided for hydrogen storage alloy powder by the gaps in the foamed nickel, the internal space of the tank body can be effectively utilized, the pressure caused by alloy powder volume expansion is reduced, and container deformation is avoided; the gaps of the foamed nickel are separated by metal nickel, and flowing accumulation of the alloy powder is avoided; the foamed nickel structure is used, the contact area between the alloy powder and hydrogen can be increased, and the efficiency of hydrogen absorbing and desorbing is improved; the contact area between the alloy powder and the metal foamed nickel is increased, and the conversion efficiency of heat is increased; and the foamed nickel is used as a skeleton structure, the tank body is simple in structure, the size is small, and hydrogen storage device is long in service life and safe.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

Multifunctional intensified reactor device with integrated heat and mass transfer

A packing device for mass and heat transfer with a subject fluid includes a housing having opposing ends, and subject fluid openings at each opposing end defining a subject fluid flow path for at least one subject fluid flowing through the packing device. A plurality of mass and heat transfer plates each include an interior heat exchange fluid channel disposed between interior heat transfer surfaces of the mass and heat transfer plates. A heat exchange fluid inlet and fluid outlet can supply and remove heat exchange fluid to the heat exchange fluid channels of the mass and heat transfer plates. The mass and heat transfer plates can be oriented to define there between fluid flow channels for the subject fluid. A method and system for mass and heat transfer with a subject fluid, and a method and system for the removal of CO2 from a gas stream are disclosed.

Owner:UT BATTELLE LLC

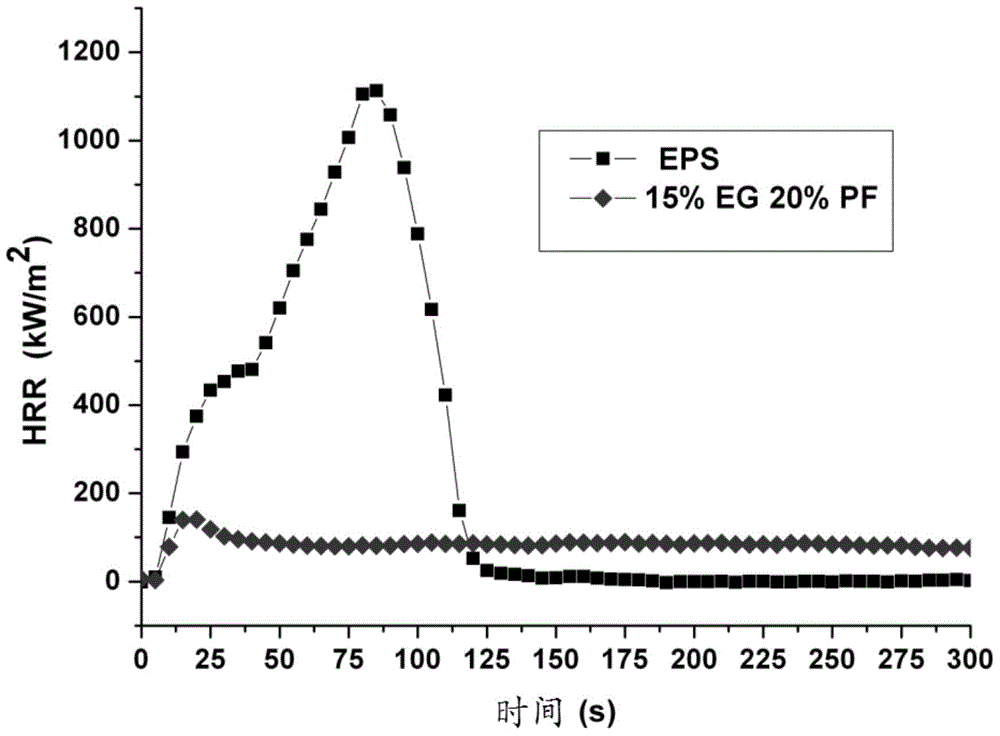

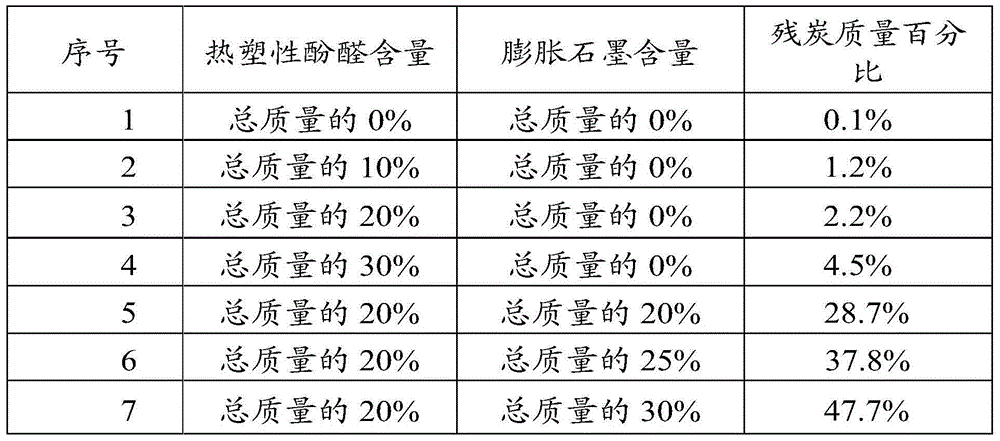

Polystyrene fire-retardant foam material and prepapration method thereof

InactiveCN104151729ASimple manufacturing methodIncrease carbon residueThermal insulationLimiting oxygen index

The invention relates to the field of polystyrene fire-retardant materials, and especially relates to a polystyrene fire-retardant foam material and a preparation method thereof. The polystyrene fire-retardant foam material is prepared from the raw materials of, by weight, 30-85% of expandable polystyrene particles, 5-40% of thermoplastic phenolic resin, and 10-50% of expansion graphite. According to the polystyrene fire-retardant foam material, when the added expansion graphite is heated, the volume thereof is rapidly increased, such that contact among pellets is inhibited. Also, expansion graphite has a good thermal insulation effect, such that internal heat transfer is reduced, polystyrene fire-retardant foam material pellet thermal degradation is inhibited, and material fire-retardant performance can be enhanced. The raw materials act synergetically. All the obtained polystyrene fire-retardant foam materials have limiting oxygen index values higher than 24%. The preparation method is simple and feasible, and cost is low. With the method, material fire-retardant property is effectively improved, and polystyrene fire-retardant foam material char residue amount is improved.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

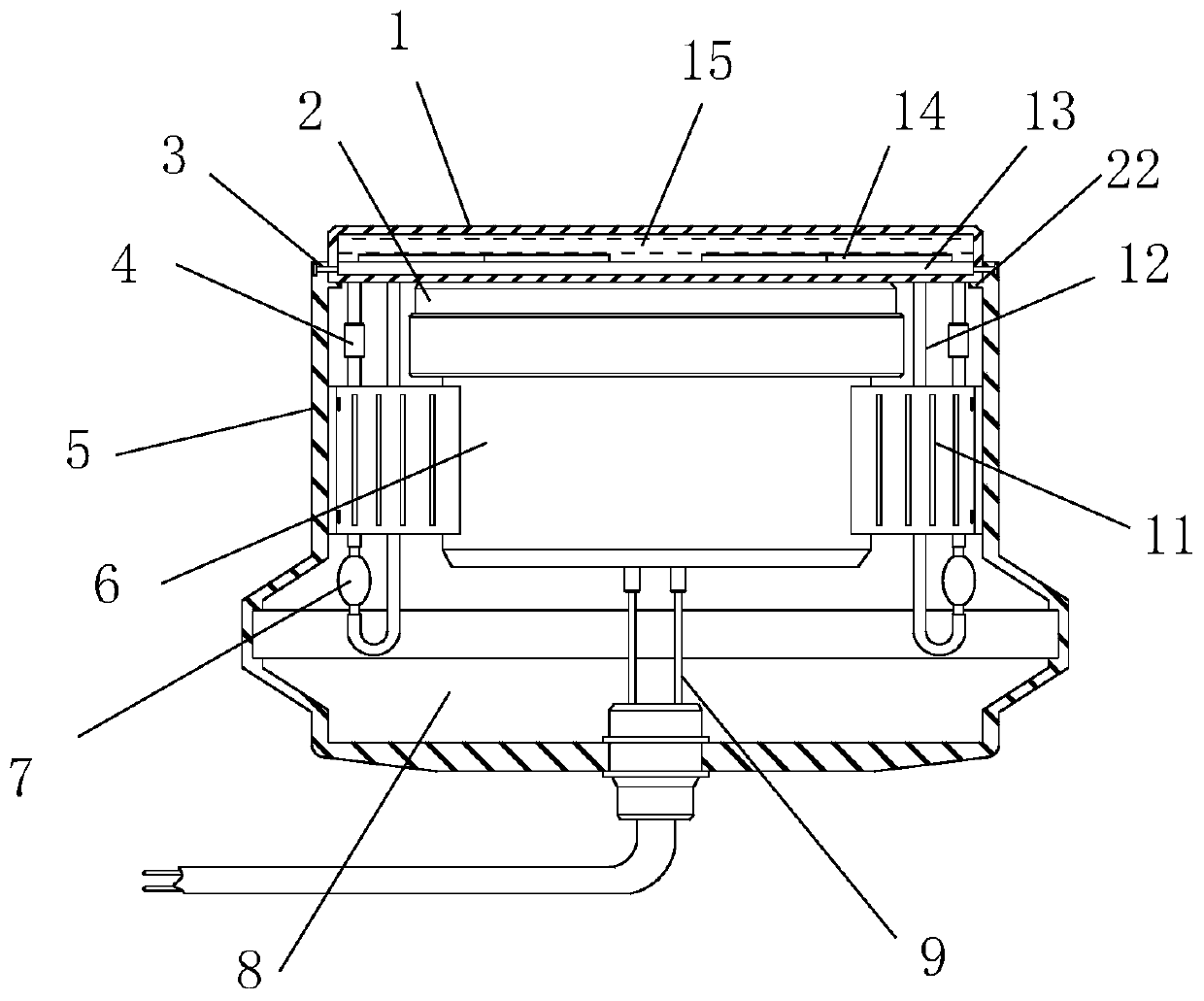

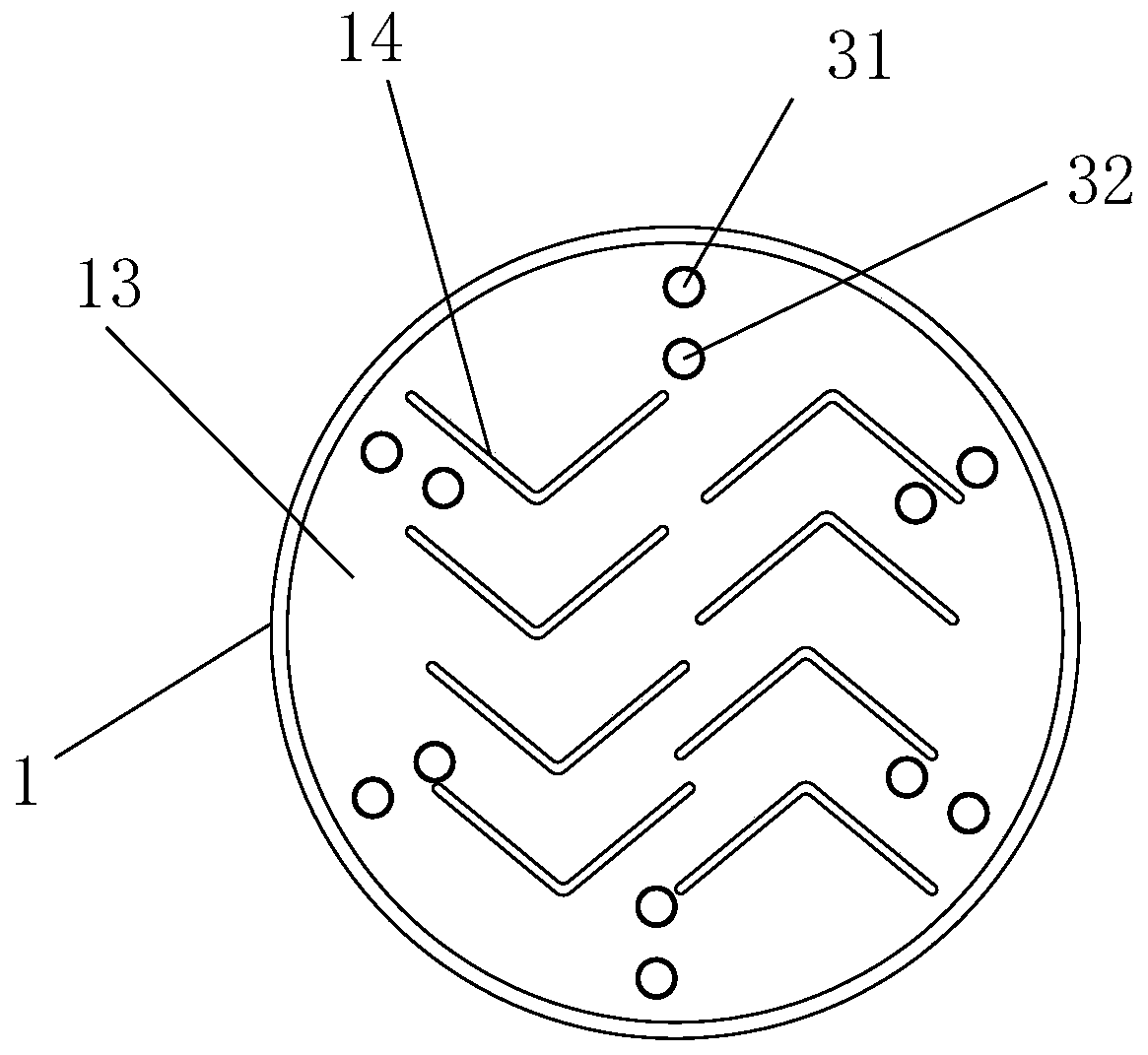

LED landscape buried light

ActiveCN110319394ATread softAdd bottom textureLighting heating/cooling arrangementsGlobesLight guideInternal heat transfer

The invention discloses an LED landscape buried lamp. the LED landscape buried lamp includes a buried lamp shell, the buried lamp shell is internally provided with a lamp body installation cavity, a lamp body is installed in the lamp body installation cavity, a lamp holder of the lamp body is directly opposite the opening end of the top face of the lamp body installation cavity, a light emitting panel is installed at the top opening end of the lamp body installation cavity, the light emitting panel is internally provided with a sealed medium cavity, a light guide plate is fixedly installed onthe bottom face of the medium cavity, the light emitting panel part is installed in the lamp body installation cavity and the top of the light emitting panel part protrudes from the top of the buriedlamp shell, more than one radiators are fixedly installed at the outer side ends of the lamp body, and the lamp body is fixedly installed on the inner wall face of the lamp body installation cavity through the more than one radiators. The LED landscape buried lamp can improve diversity of the irradiation angle of buried lamp light and can greatly improve the anti-slip performance at the same time,external force is used for allowing internal heat transfer, anti-slip and heat dissipation are integrated into one, the overall structure is simplified, design is more reasonable, and the appearanceis more artistic.

Owner:广州市升和电子有限公司

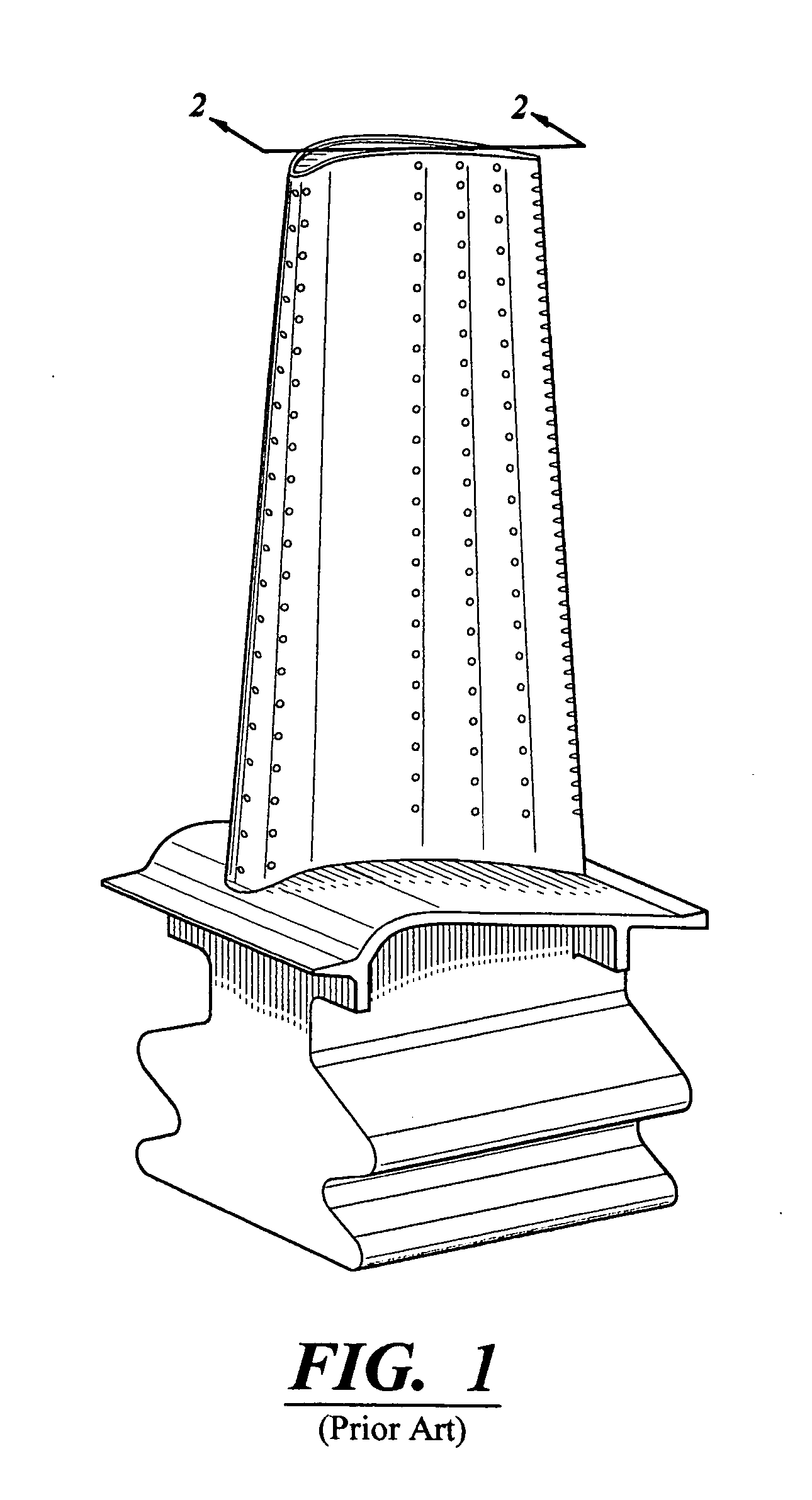

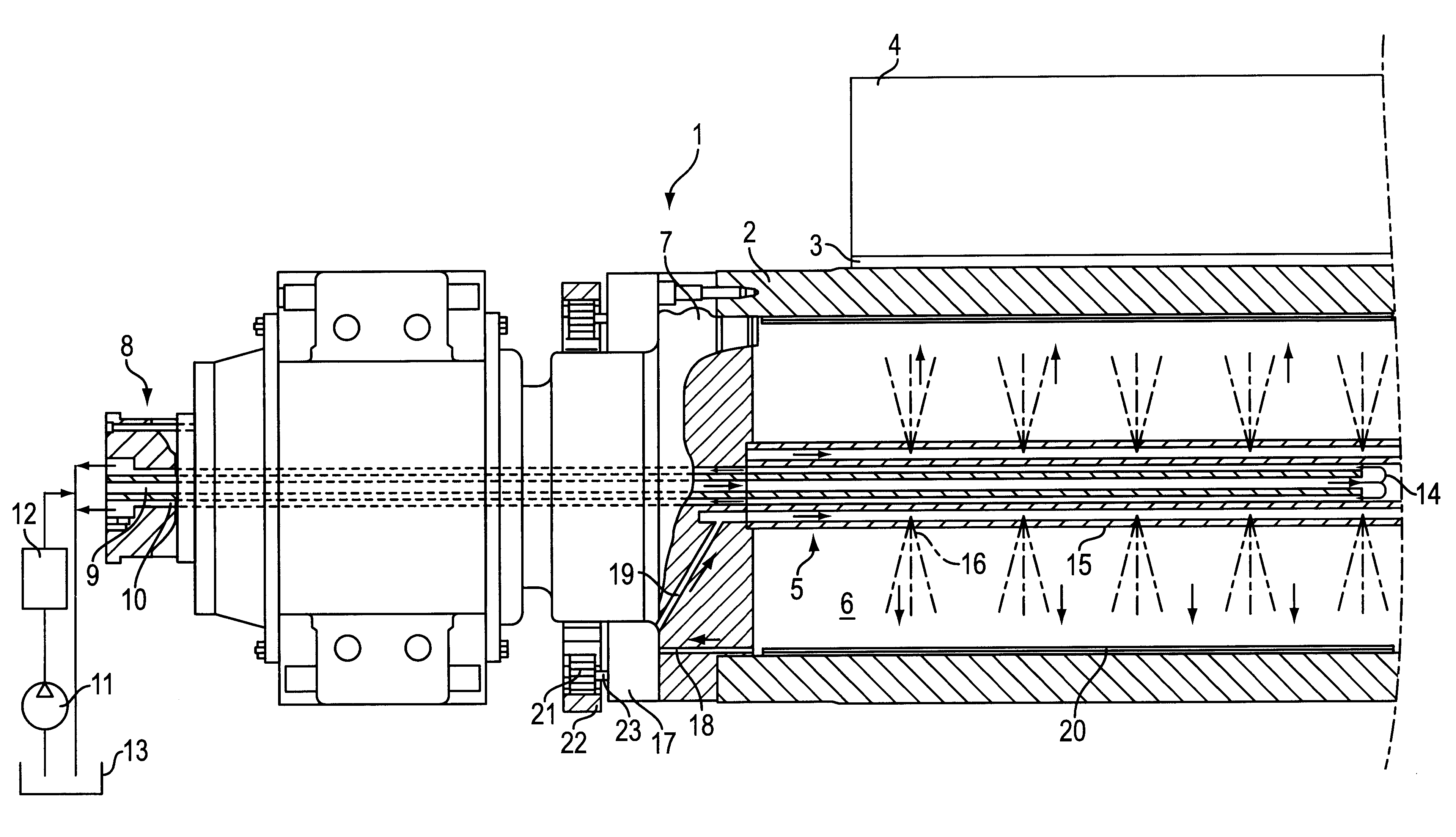

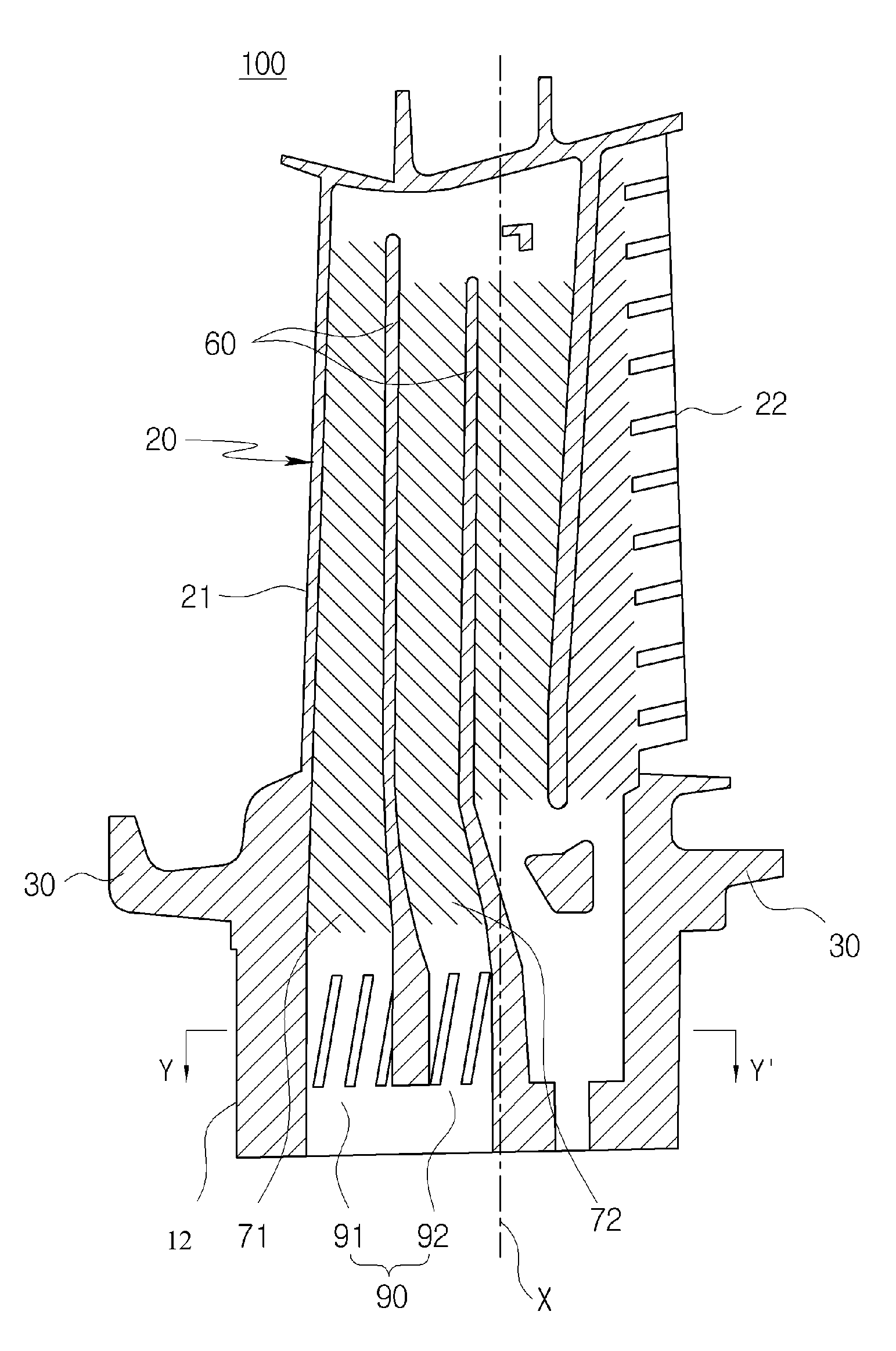

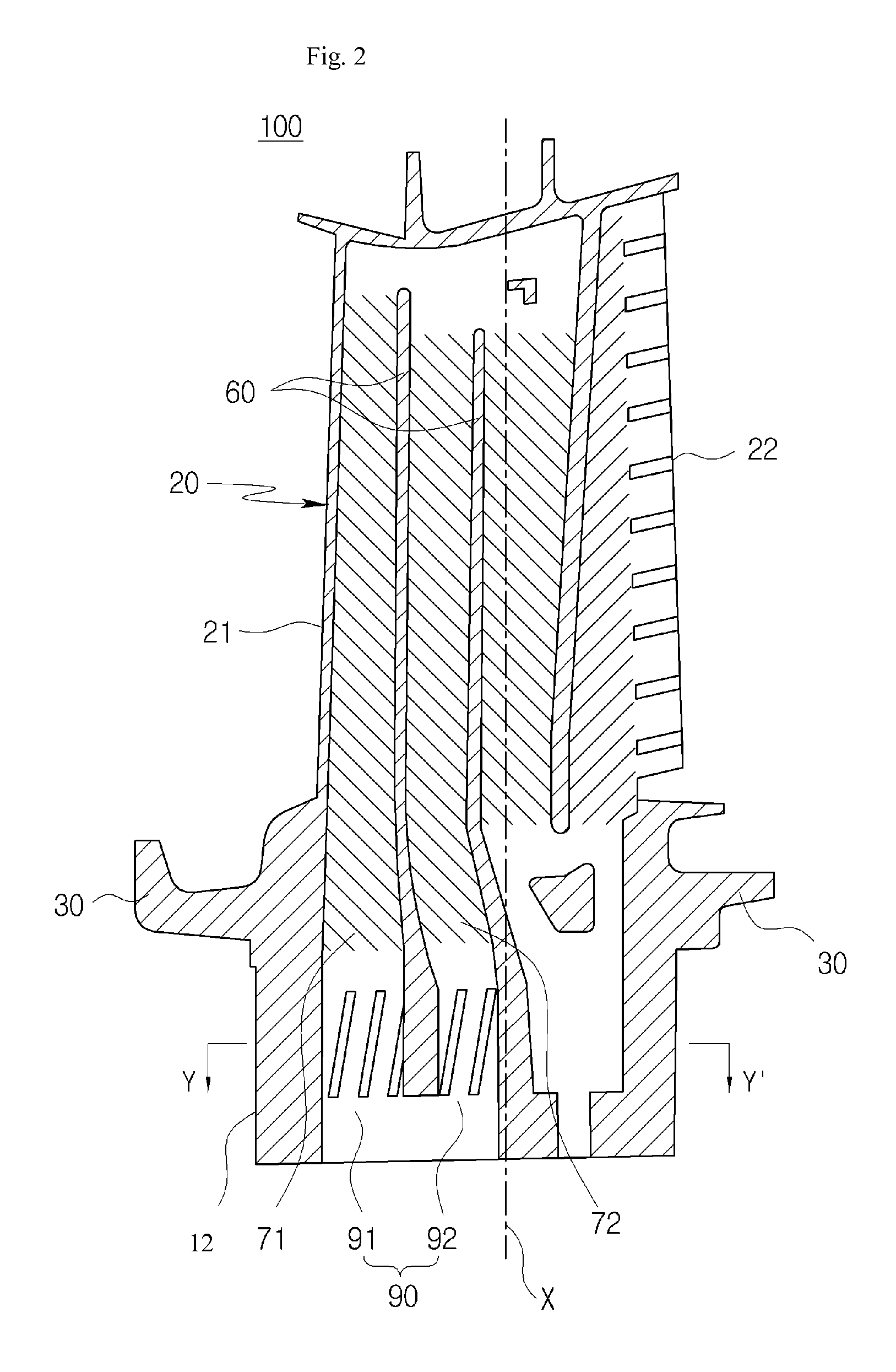

Turbine blade having swirling cooling channel and cooling method thereof

ActiveUS20150198049A1Improve cooling effectIncrease stiffnessPropellersRotary propellersTurbine bladeInternal heat transfer

A turbine blade includes a cooling channel through which cooling air is passed, and a swirl portion provided at an entrance of the cooling channel so as to form a swirl flow in the cooling air. The turbine blade may increase cooling performance of a root unit, improve the stiffness of the root unit, and increase the internal heat transfer efficiency of a blade unit.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

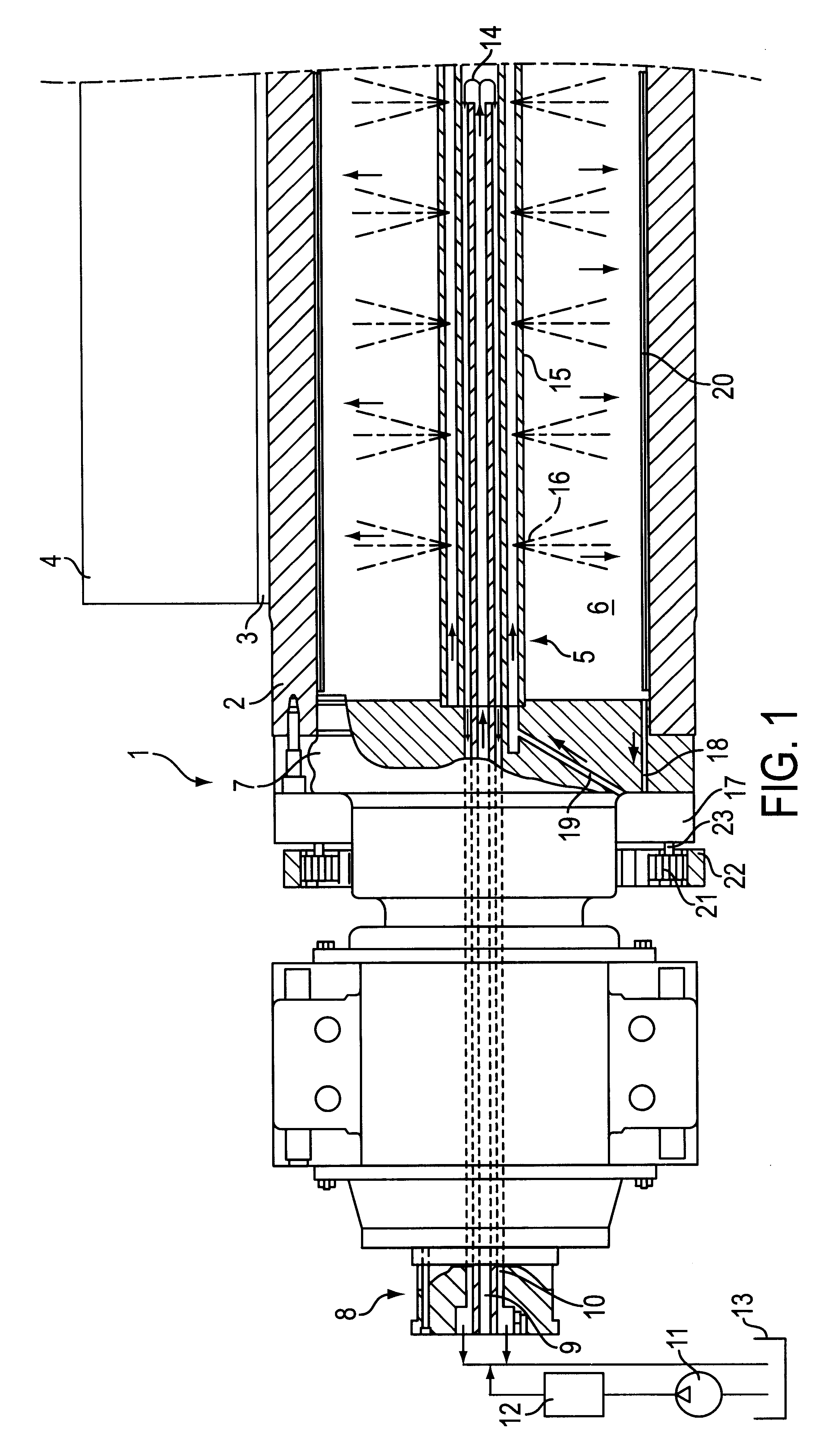

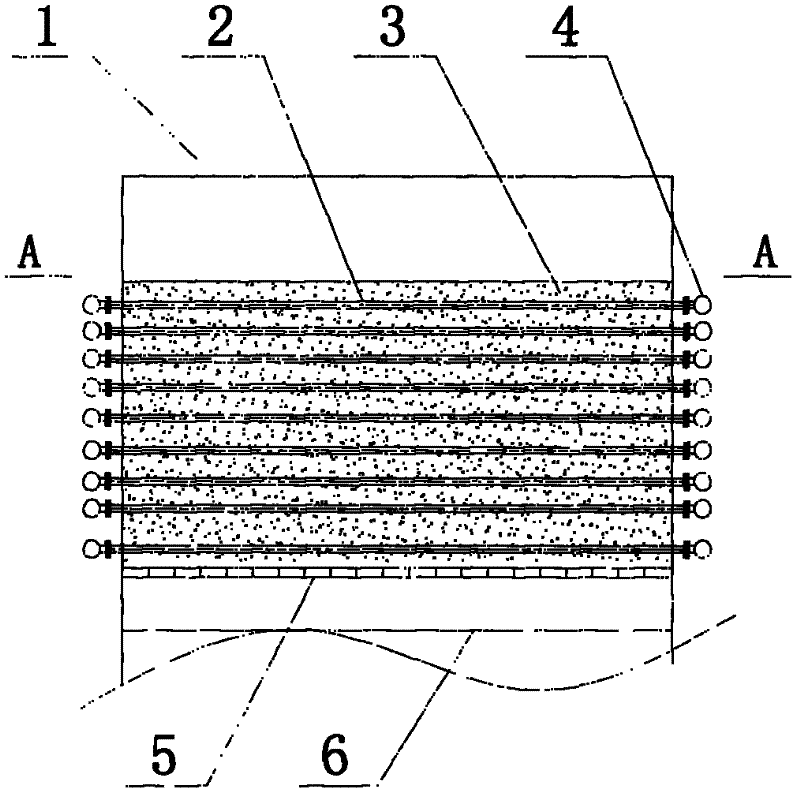

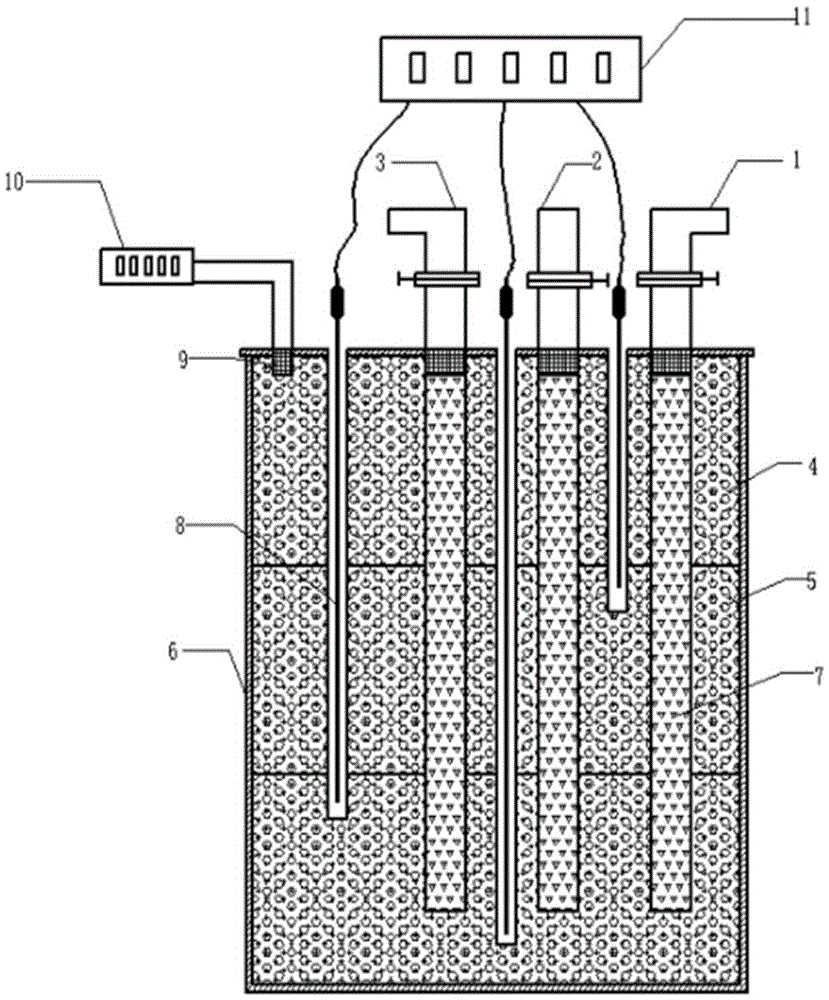

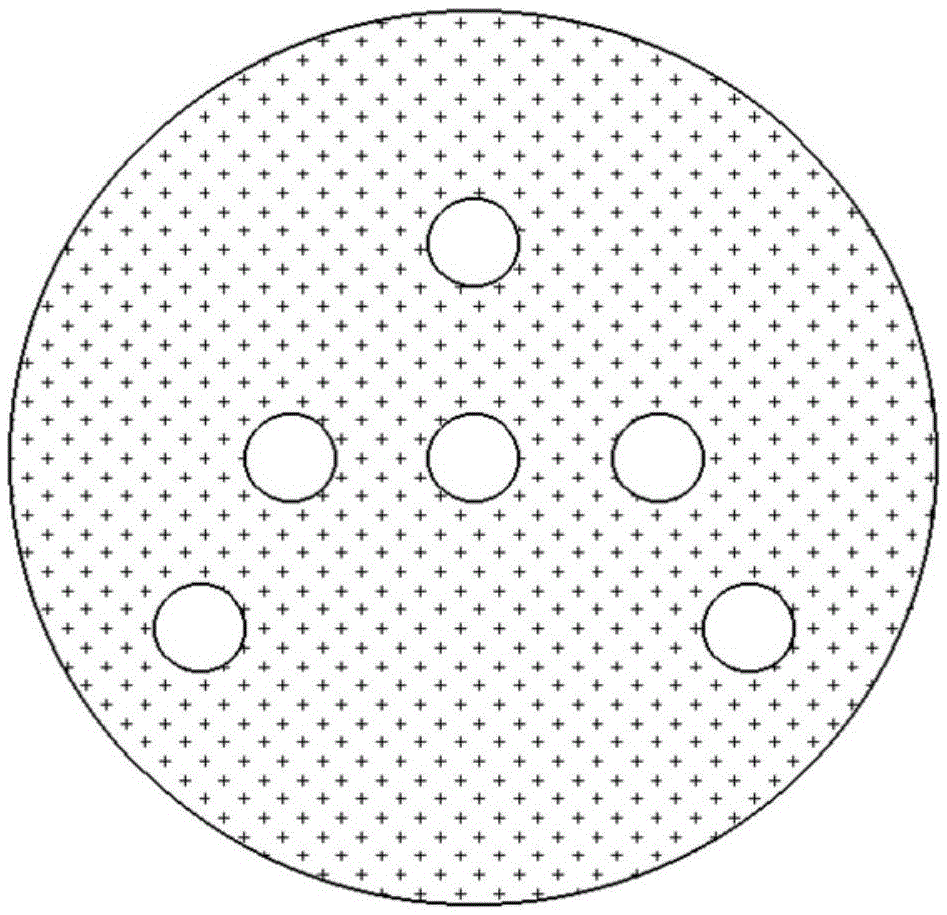

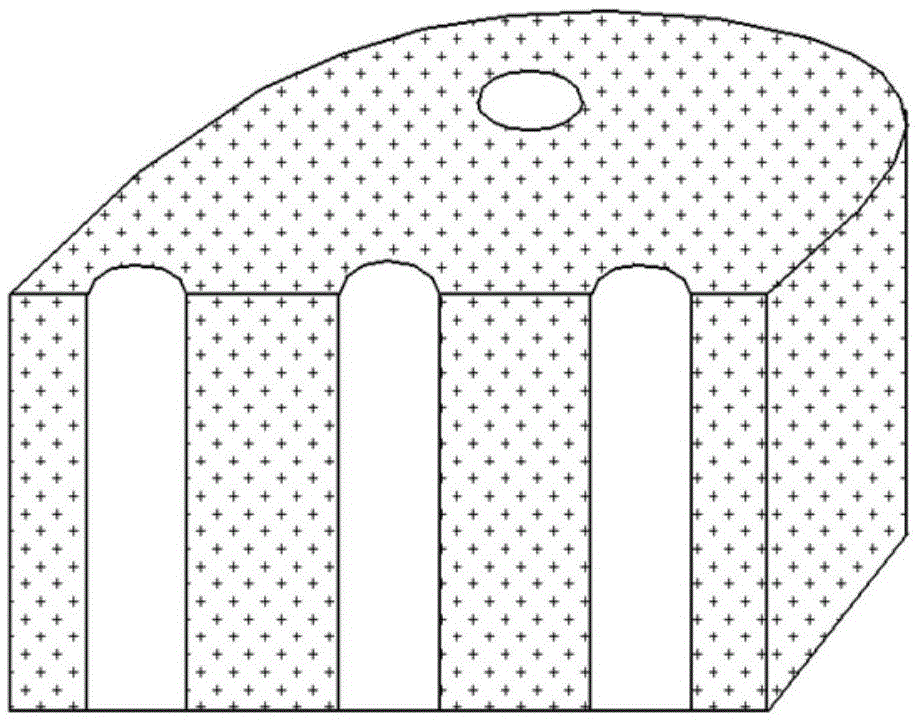

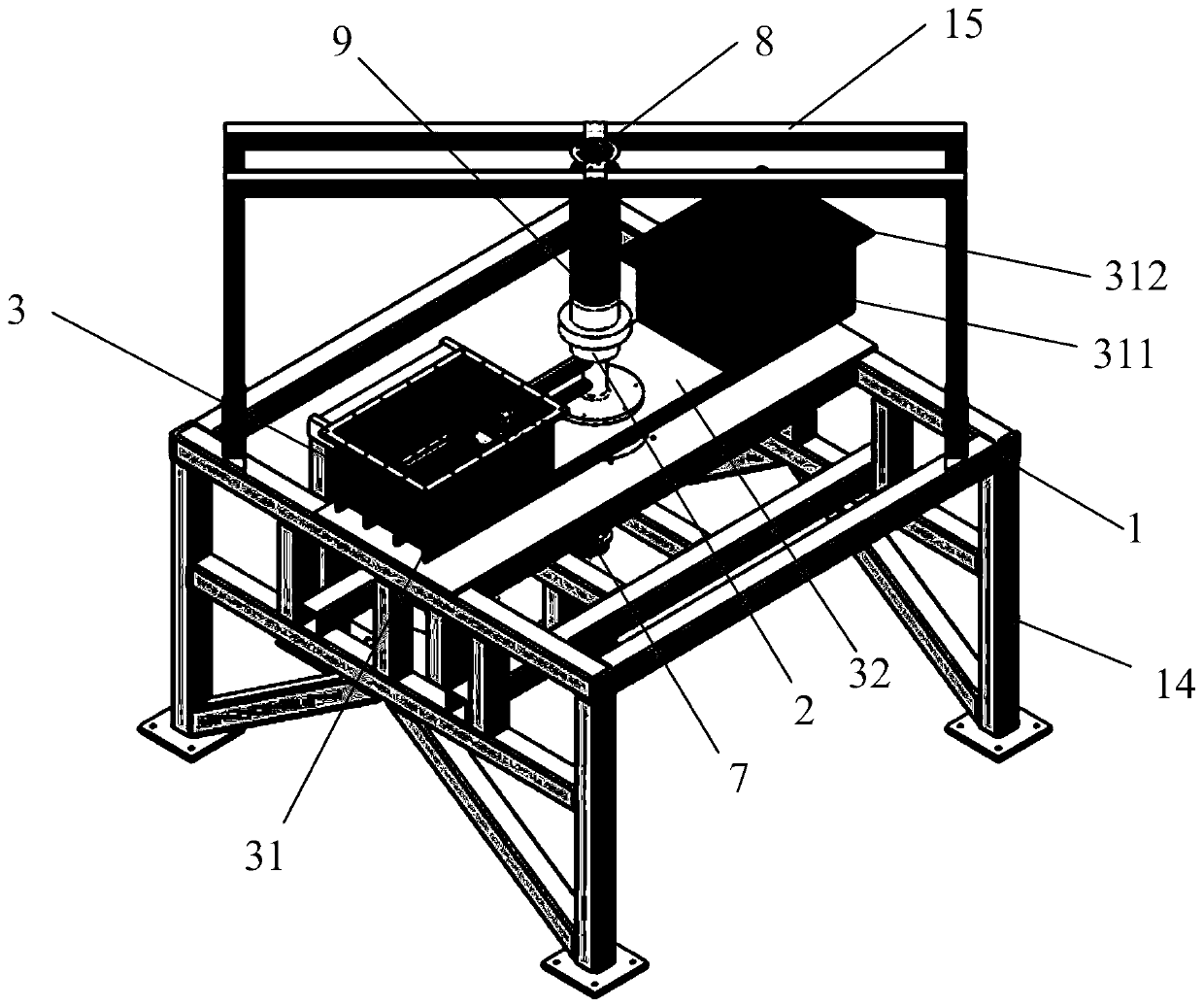

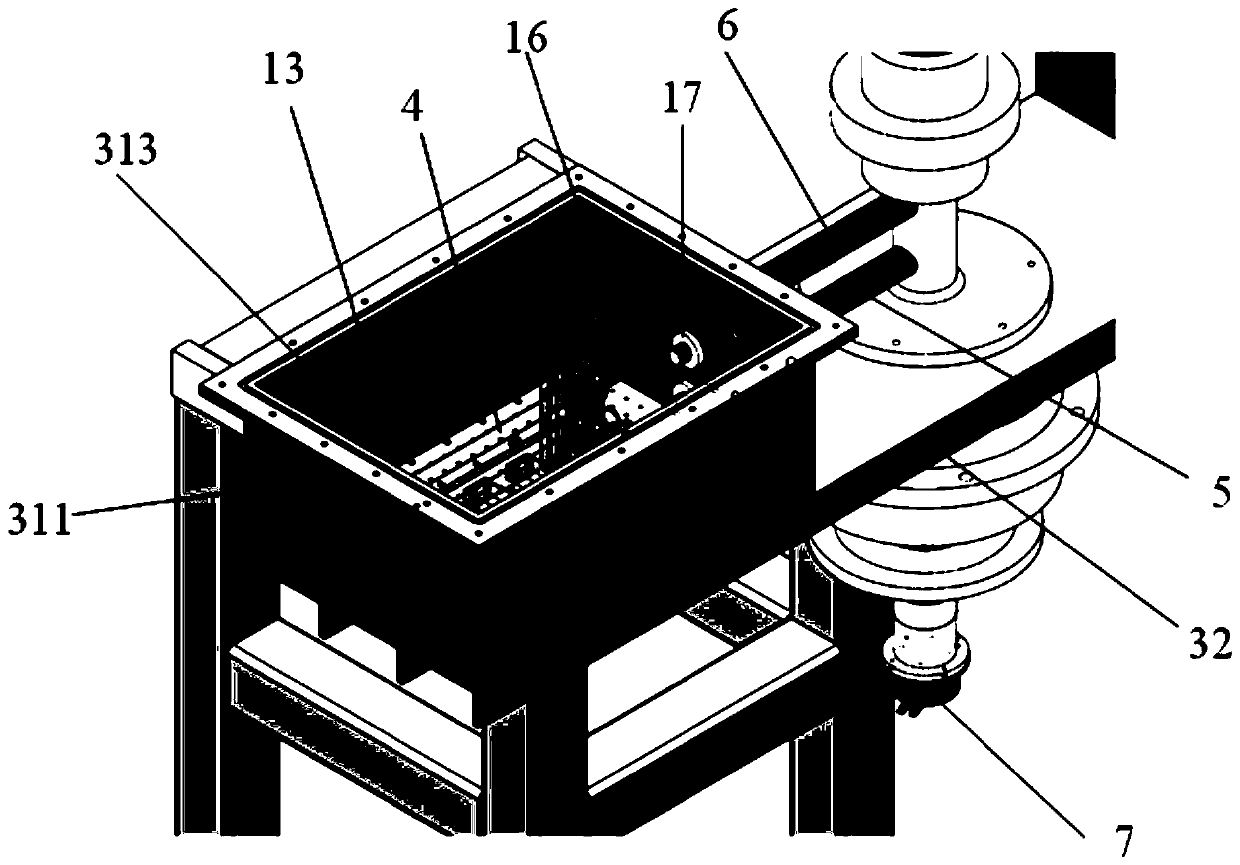

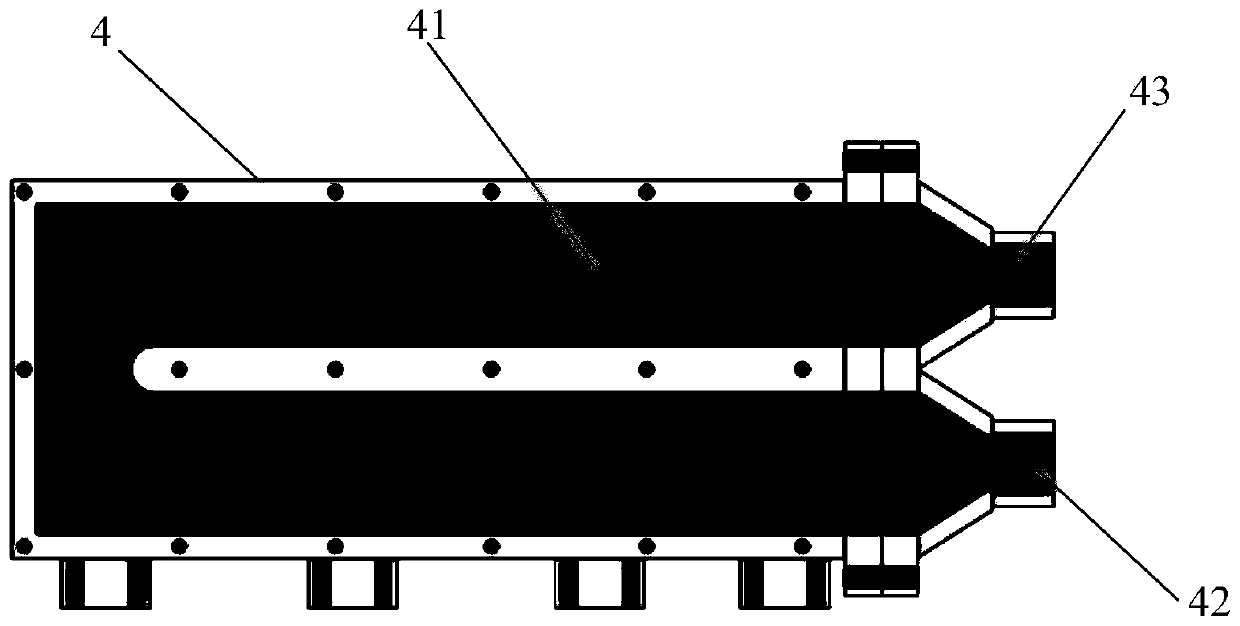

Modeling experiment device for heat transfer in moving blade of aviation gas turbine

ActiveCN110261433AReduce instabilityReduce mutual interferenceMaterial heat developmentAviationWireless transmission

The invention discloses a modeling experiment device for heat transfer in a moving blade of an aviation gas turbine. The modeling experiment device comprises an experiment rack, a rotating shaft, a compression chamber, a motor, a wireless transmission module and an experiment segment and a test assembly arranged in the compression chamber; the rotating shaft is vertically installed on the experiment rack and connected to the motor; the compression chamber is connected to the rotating shaft and can rotate around the rotating shaft; the experiment segment comprises a cooling channel which is communicated with an external air feed device, and the test assembly is used to obtain test data of the experiment segment; and the wireless transmission module is connected with the test assembly and used to control the test assembly and transmit the test data. Under the condition that characteristic criteria of cooling rotation in the moving blade of the aviation gas turbine are satisfied, the modeling experiment device can obtain heat transfer property data of the wall surface of an internal cooling channel of the experiment segment, and provide significant basic data for fine design of the moving blade of the aviation gas turbine.

Owner:XI AN JIAOTONG UNIV

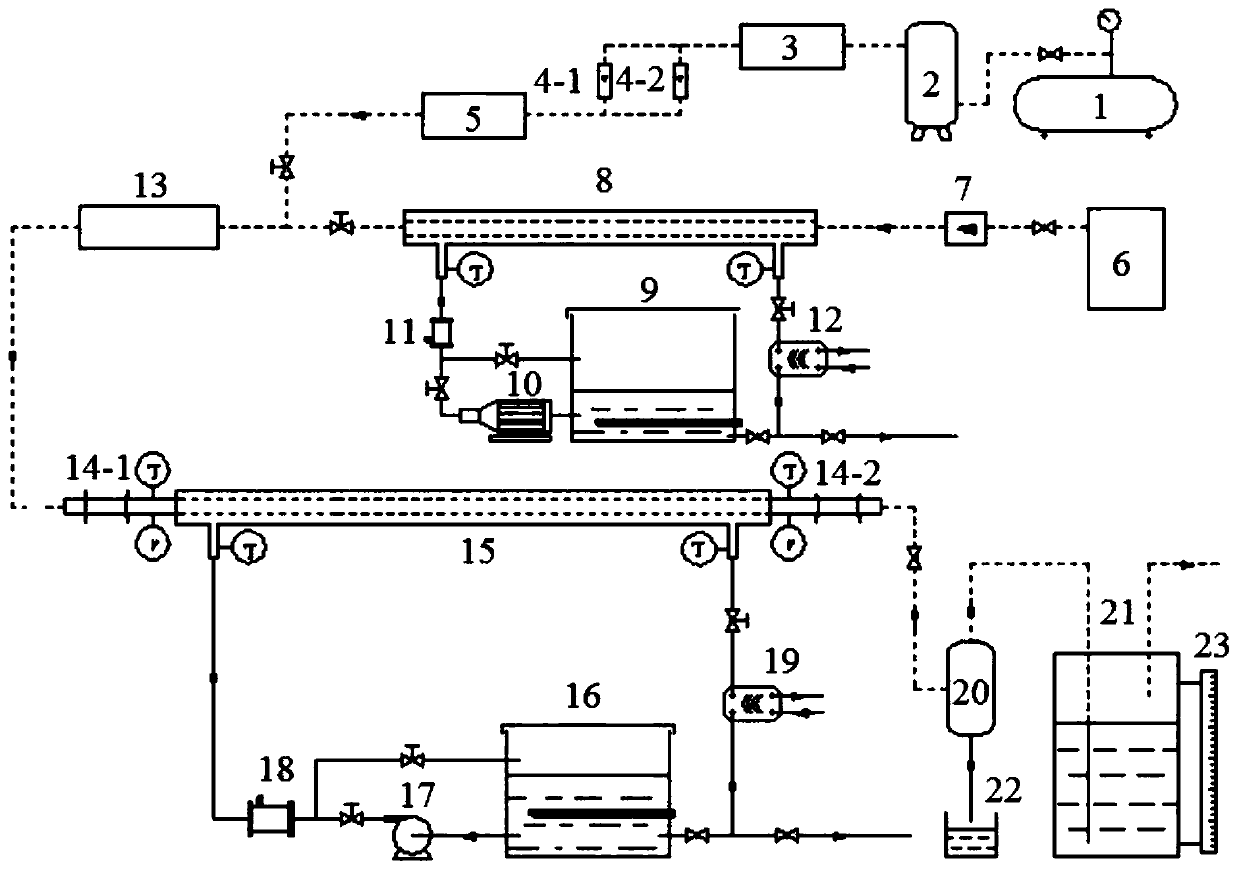

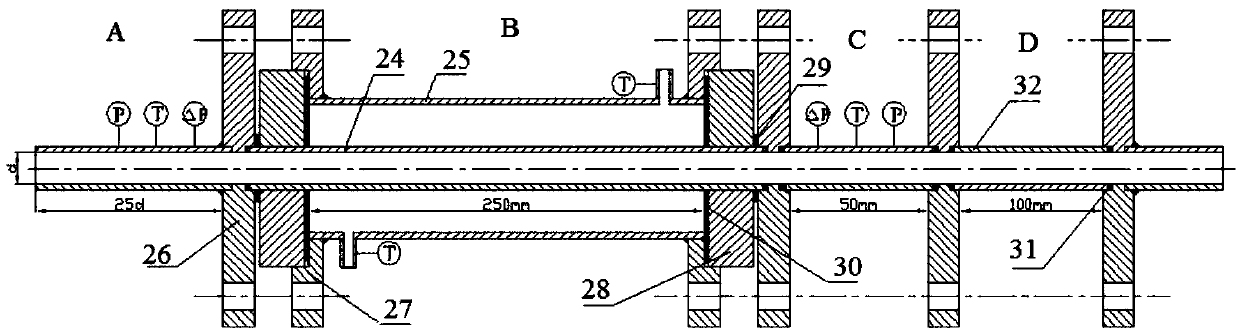

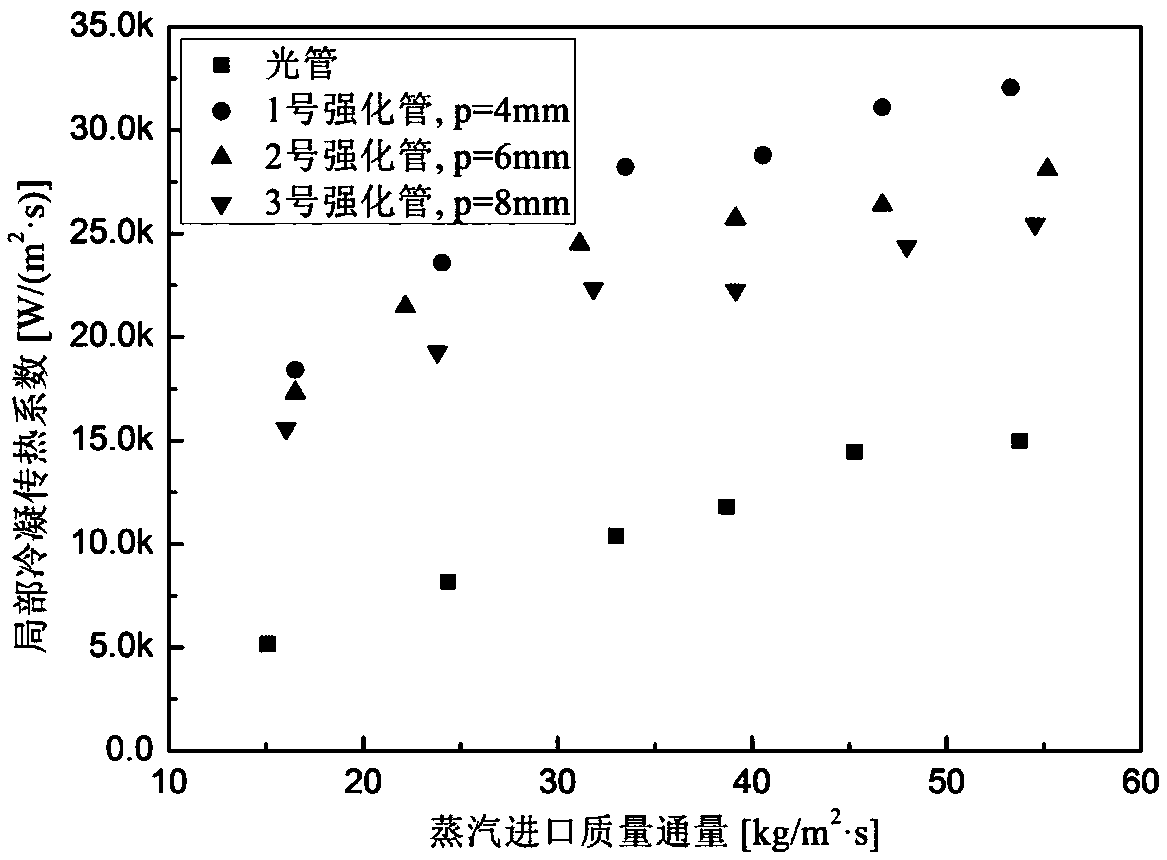

Device for evaluating internal condensation characteristic of enhanced heat transfer pipe

PendingCN109001249AAvoid temperature measurement problemsVerify accuracyMaterial heat developmentMaterial condensationGas heaterEnhanced heat transfer

The invention relates to a device for evaluating internal condensation characteristic of an enhanced heat transfer pipe. The device mainly comprises a steam system, a test section, a cold water takingsystem and a data acquisition system, and can evaluate the local condensation heat transfer and pressure drop characteristics of various kinds of steam or mixed gas in different enhanced heat transfer pipes. The steam system comprises a boiler, a precooler, an air compressor, a gas storage tank, a dryer, a gas heater and a static mixer, and can provide pure-component and multi-component steam orair-containing mixed gas needed by the test. The test section comprises a straight pipe measuring section, a condensation section, a measuring section and an observation section which are connected with one another sequentially; an inlet is connected with the steam system; and an outlet is connected with a gas and liquid separator. The two ends of an outer sleeve pipe of each of the precooler andthe test section are connected with one set of water cooling system in parallel. The internal heat transfer coefficient of the enhanced pipe is acquired through a thermal resistance separation method,and basis is provided for thermodynamic design of an efficient pipe shell type condenser.

Owner:SHANGHAI INST OF SPECIAL EQUIP INSPECTION & TECHN RES +1

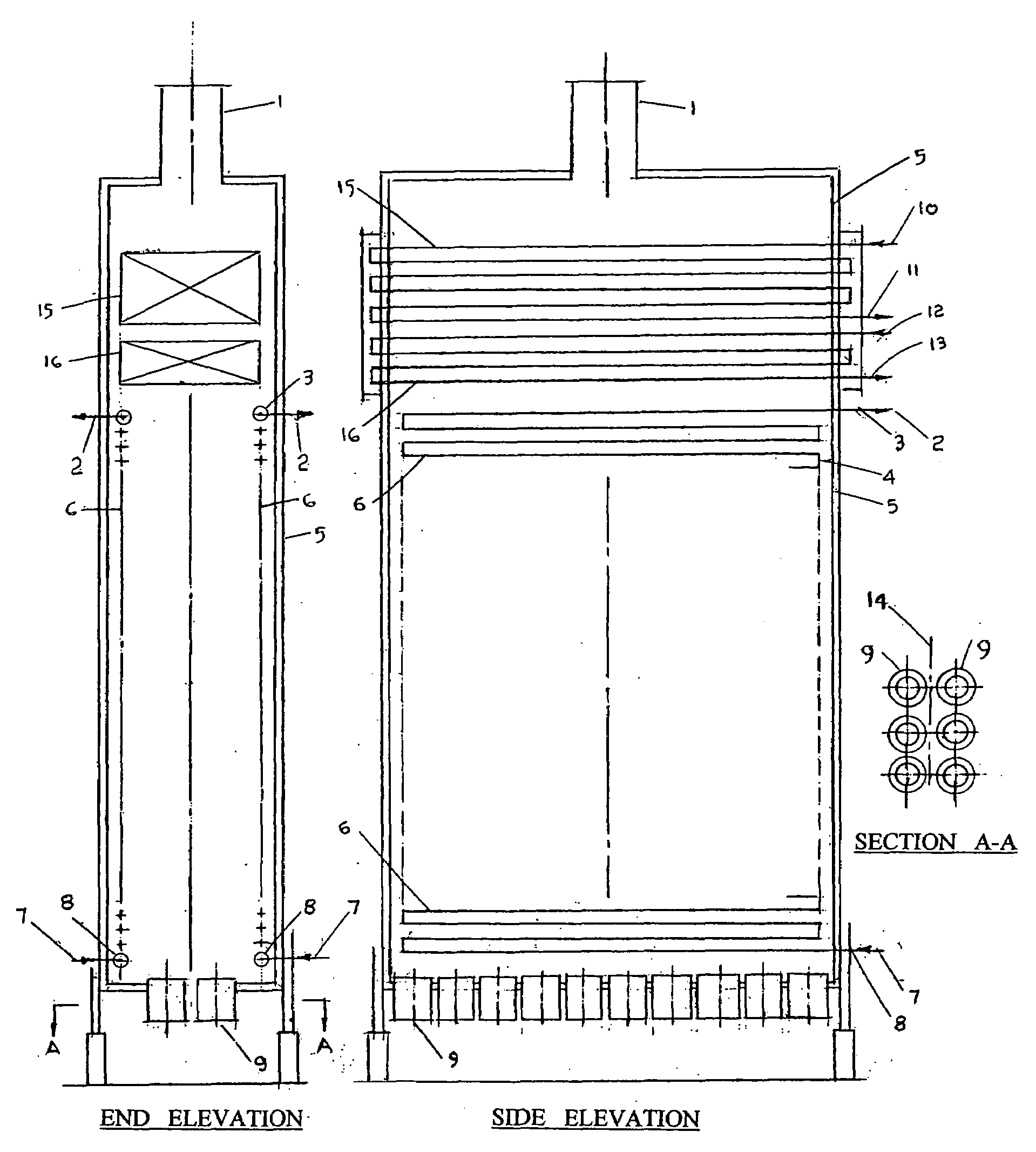

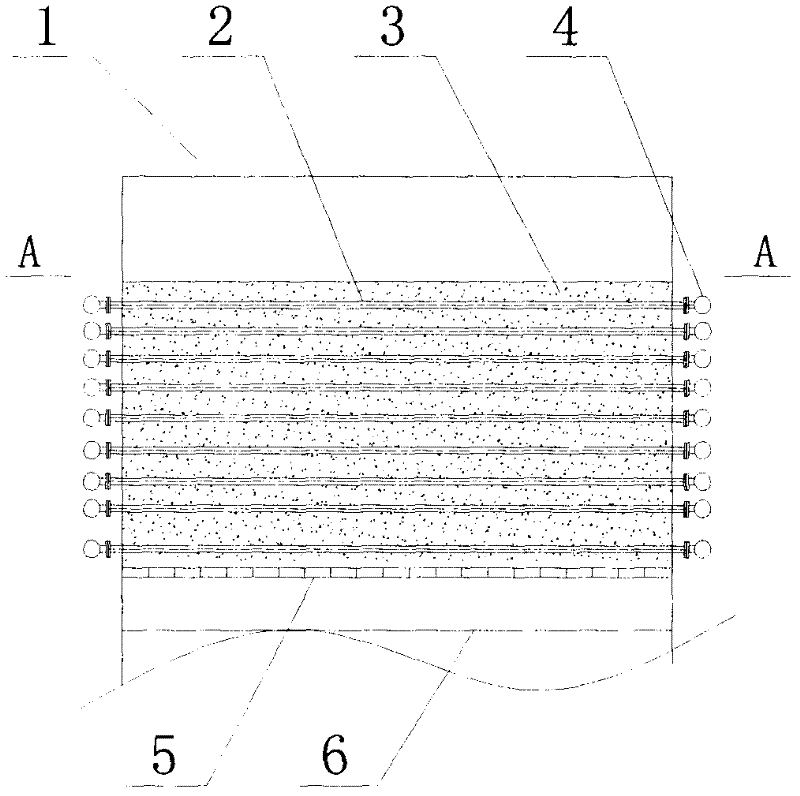

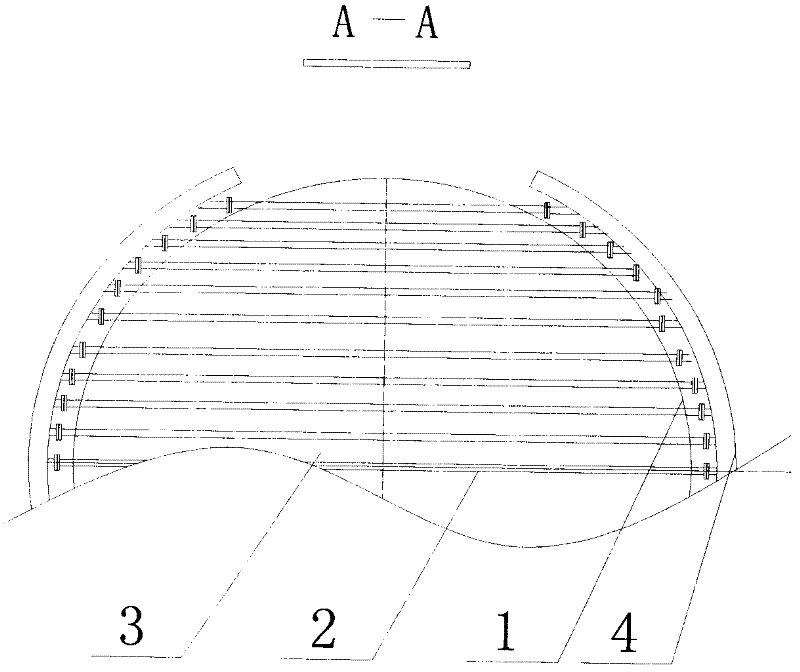

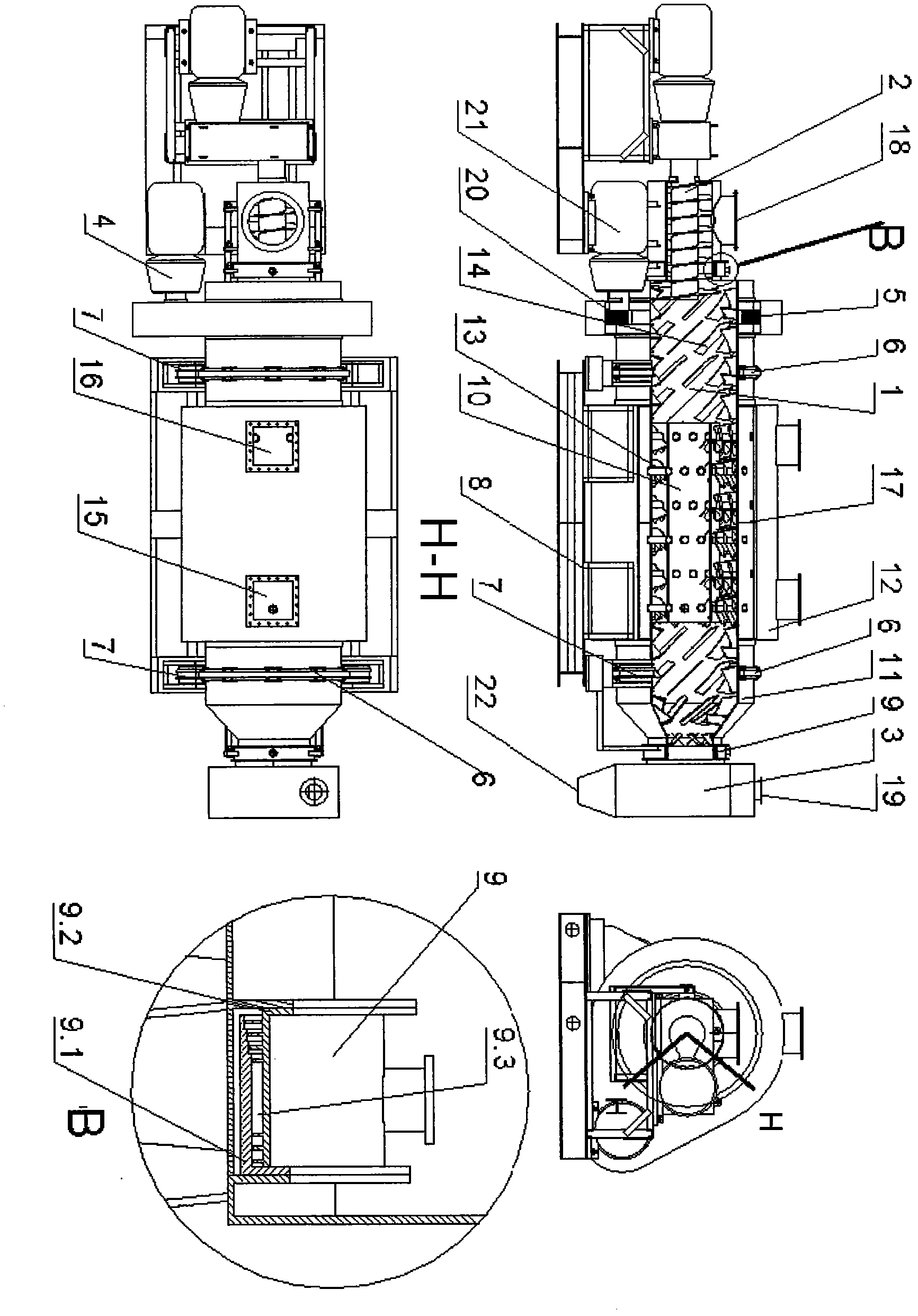

High-efficiency rotary type enhanced-drying pyrolyzing furnace

InactiveCN102636012AOvercome the disadvantages of only relying on the heat transfer of the outer cylinder wall of the cylinder bodyOvercome the disadvantages of heat transferDirect heating destructive distillationDrying chambers/containersEnhanced heat transferInternal heat transfer

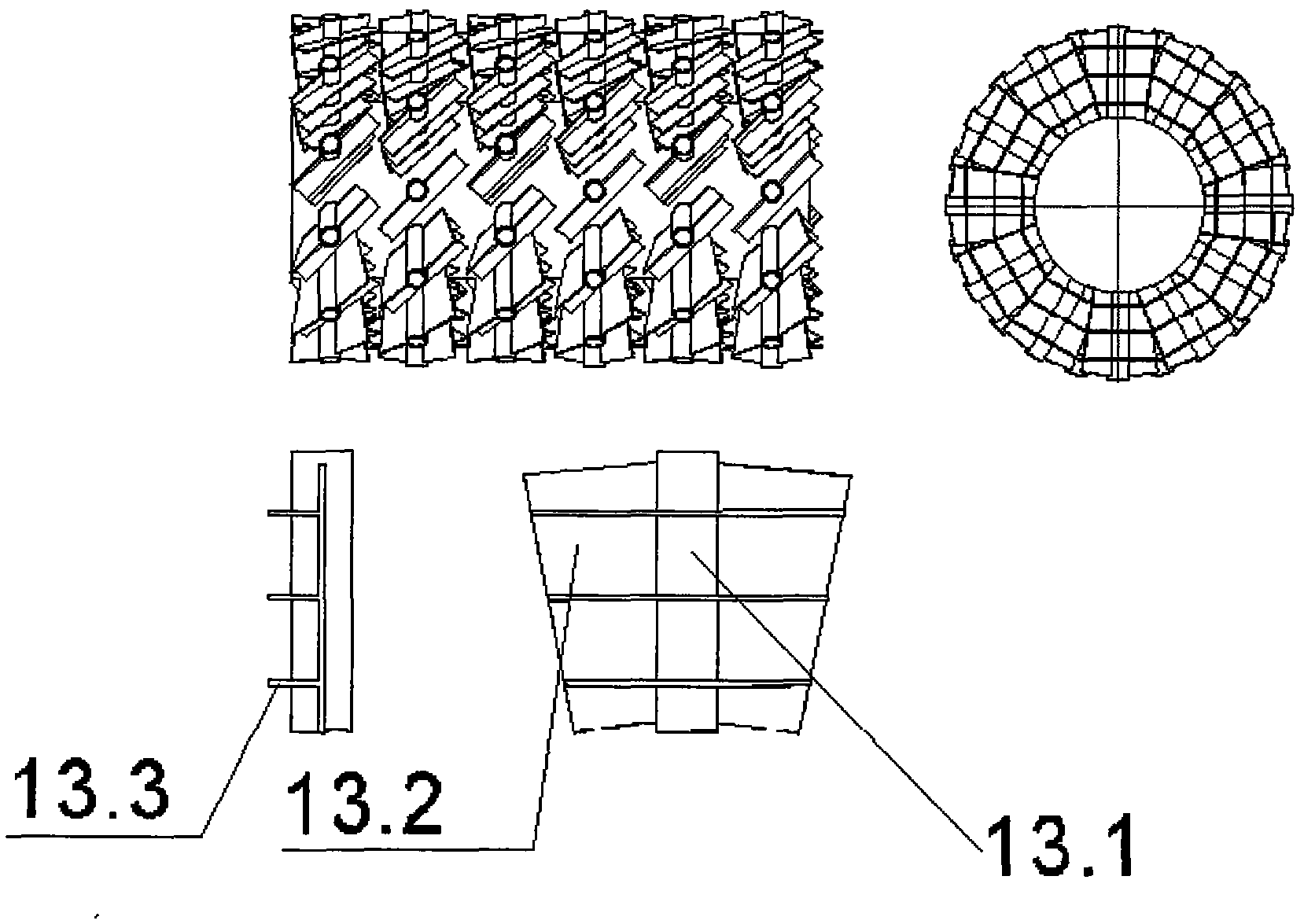

The invention relates to a high-efficiency rotary type enhanced-drying pyrolyzing furnace. The high-efficiency rotary type enhanced-drying pyrolyzing furnace comprises a drum body 1, a continuous feeding device 2, a continuous discharging device 3, a driving mechanism 4, a rotating gear 5, a supporting round rail 6, a supporting roller 7, a base 8, a sealing connection device 9, a hollow rotary shaft 9.1, a tooth-sealing shell 9.2, a middle cavity 9.3, a pipe cavity 10, an outer drum 11, a cavity body 12, a heat pipe component 13, a pipe (heat pipe) 13.1, fins 13.2, rib plates 13.3, a guide plate 14, a high-temperature cavity inlet 15, a low-temperature cavity outlet 16, a ring-shaped baffle 17, a material inlet 18, a pyrolysis gas outlet 19, a driving gear 20, a driving motor 21 and a solid-residue discharging port 22 and the like. The high-efficiency rotary type enhanced-drying pyrolyzing furnace has the advantages that the defects that the original rotary type drying pyrolyzing furnace realizes heat transfer only by the outer wall of the drum, is small in heat transfer area and can not realize internal heat transfer are overcome, the internal-external simultaneous heat transfer is realized, and an enhanced heat-transfer means is implemented inside, so that unit-volume production capacity of the rotary type drying pyrolyzing furnace is improved multiply; due to adoption of more-reliable and safer sealing connection device, the continuous feeding and continuous discharging of the rotary type drying pyrolyzing furnace can be realized, and safer and cleaner production can be realized; and compared with the original device, the installation and maintenance working is simplified, and the installation and maintenance cost can be saved.

Owner:宁波华德瑞环保科技有限公司

Heat dissipation device of sealed case and sealed case

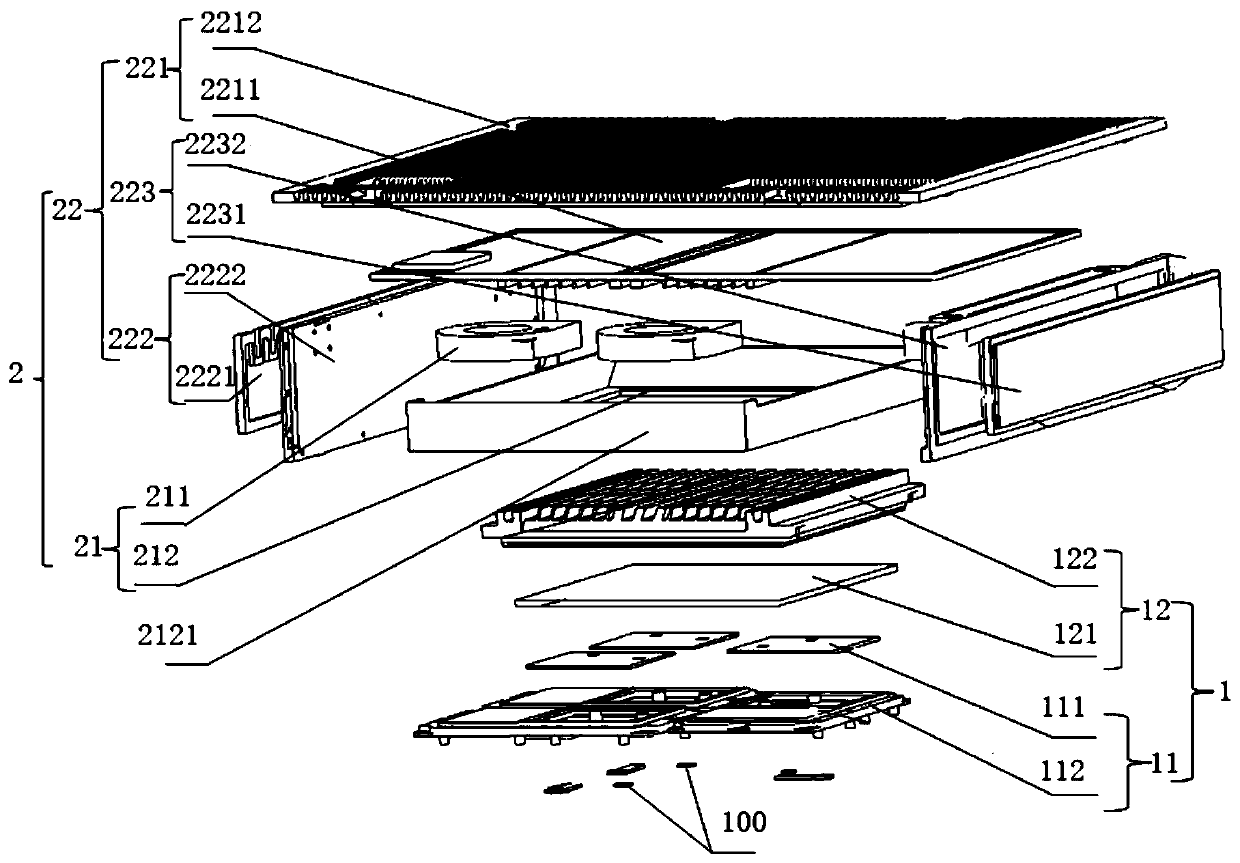

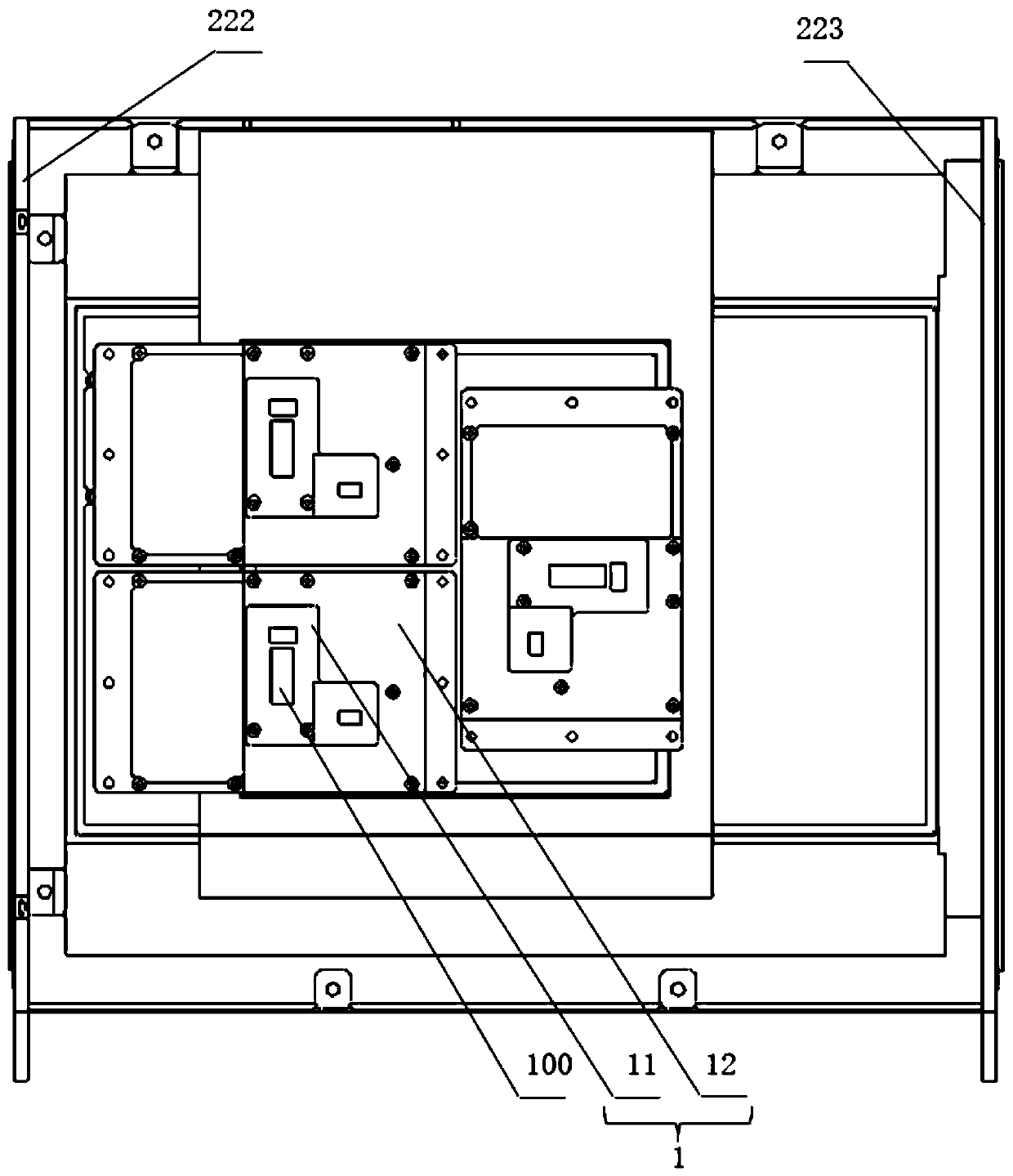

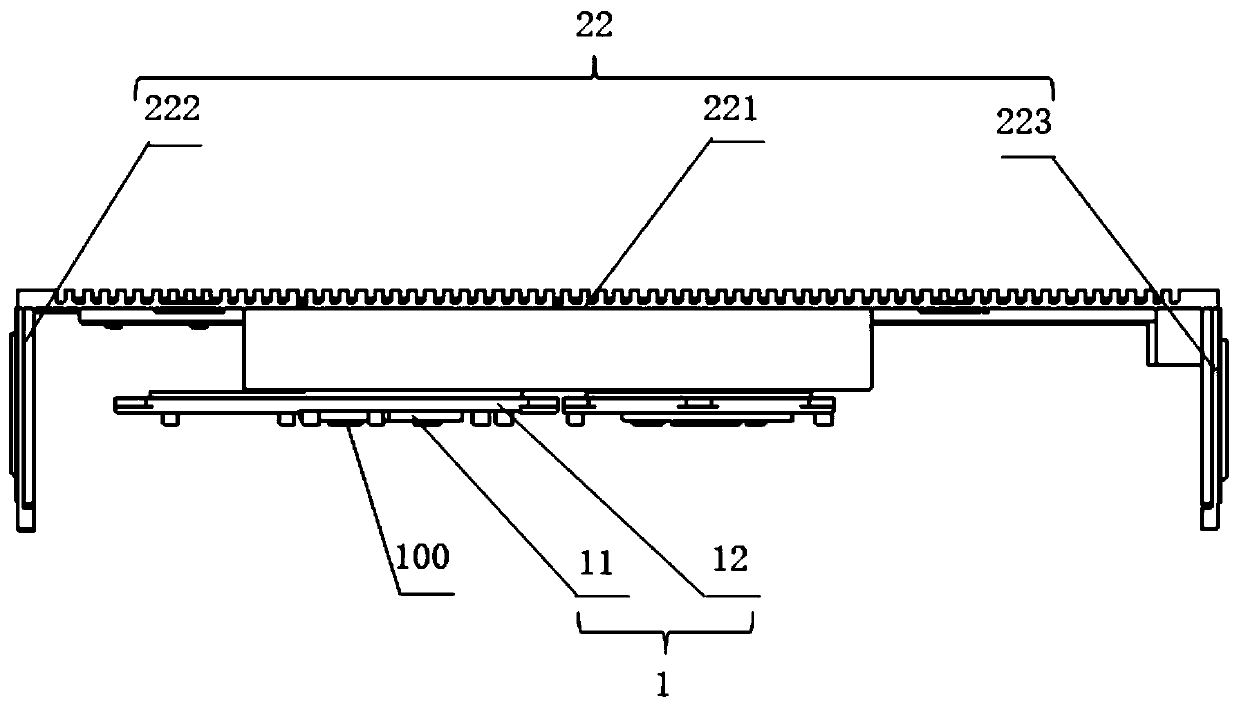

PendingCN110418557AIncreased cooling surface areaUniform surface temperatureHermetically-sealed casingsCooling/ventilation/heating modificationsTransfer systemButt joint

The invention relates to the technical field of heat dissipation, and discloses a heat dissipation device of a sealed case and the sealed case. The heat dissipation device, which is used to dissipatethe heat of heating electronic components installed in the case, includes an internal heat transfer system and an external heat transfer system. The internal heat transfer system is located in the sealed case and is in butt joint with the heating electronic components, and the heat generated by the heating electronic components can be transferred to the internal heat transfer system. The externalheat transfer system includes a blowing part and heat dissipation cover plates. The heat dissipation cover plates are all made of vapor chambers, and the blowing part is arranged on the inner side ofthe heat dissipation cover plates. The external heat transfer system is used to transfer the heat outside a sealed area to the outside air. The heat dissipation cover plates are connected with one another, can transfer heat to one another and are used to transfer heat to the outside air. The heat dissipation device of the sealed case in the invention has high heat dissipation efficiency, can reduce the internal temperature of the sealed case, improves the performance of the sealed case and increases the optional selectivity of the electronic components in the case.

Owner:KYLAND TECH CO LTD +1

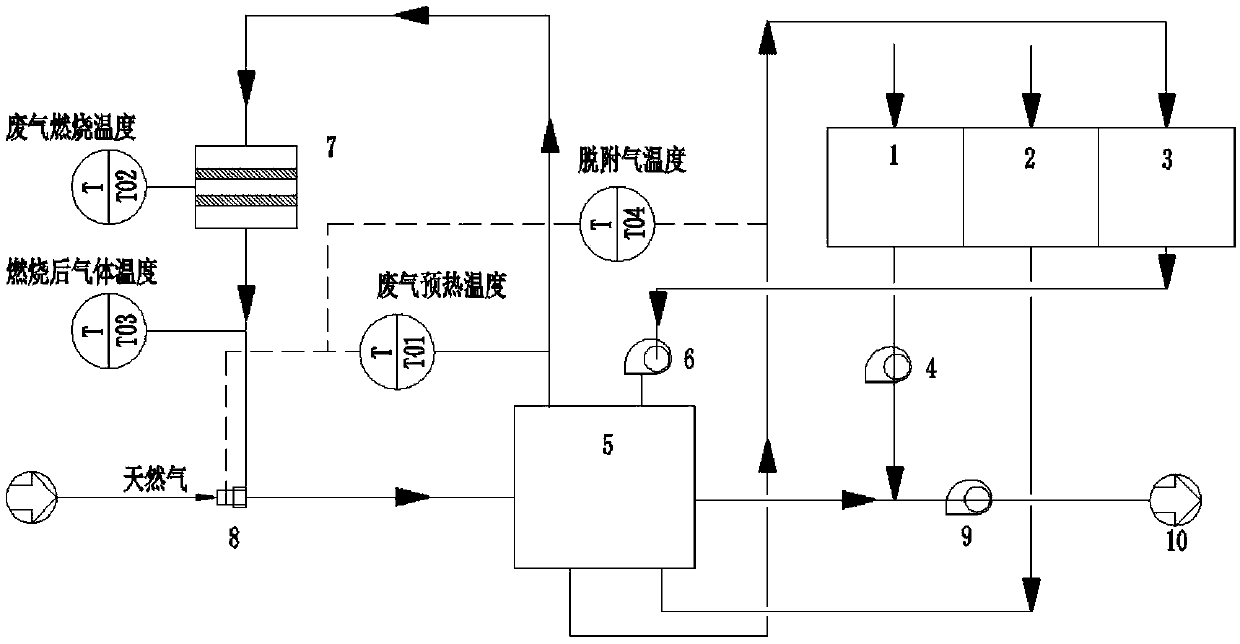

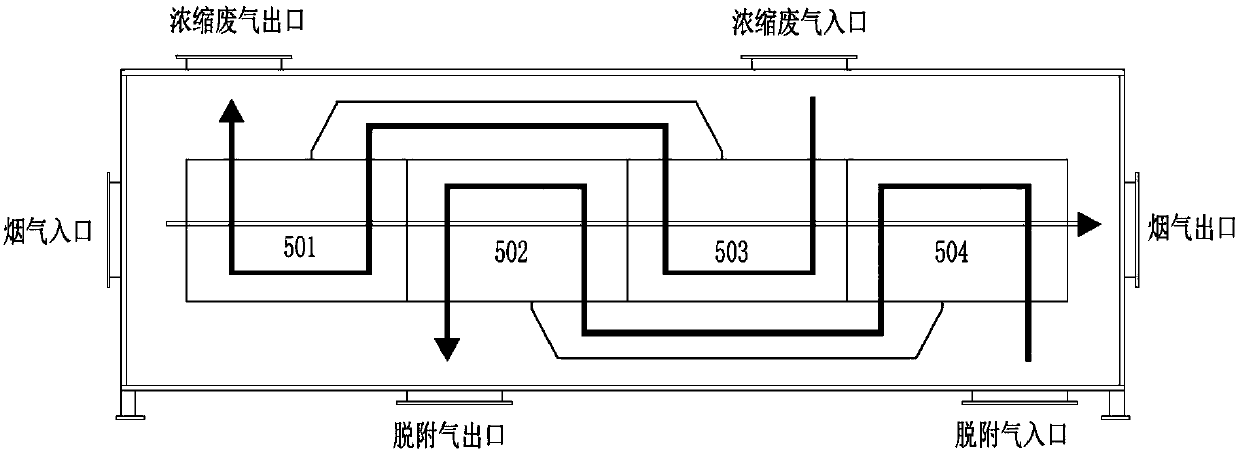

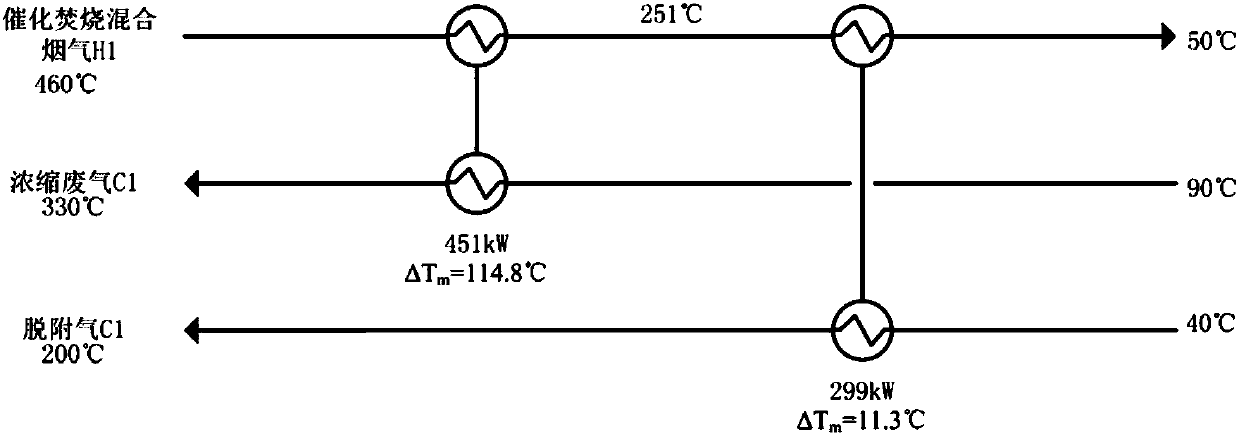

Optimized indirect catalytic combustion flue gas multistage heat exchange system and process

ActiveCN107830538AReduced activityReduce the likelihood of poisoningGas treatmentDispersed particle separationCombustorDesorption

The invention discloses an optimized indirect catalytic combustion flue gas multistage heat exchange system and process. The system comprises a catalyst bed, a natural gas combustor, a heat exchanger,an adsorption rotating wheel, an adsorption fan, a smoke exhaust fan and a desorption fan, wherein the heat exchanger is provided with four stages of heat exchange units according to a low and high-temperature level matching principle; the adsorption rotating wheel comprises an adsorption region, a purging region and a desorption region; another natural gas inlet and a combustor are arranged outside the catalyst bed; a pipeline of natural gas flue gas produced by combustion is communicated with a catalytic combustion waste gas pipeline to form a heat-side medium pipeline; after the natural gas flue gas and catalytic combustion flue gas are mixed, mixed gas enters the heat exchanger; concentrated waste gas and desorbed gas are respectively heated by the internal four stages of heat exchange units; after heat is recycled, the gas is discharged into a chimney. By use of a fine design of internal heat transfer units, a heat exchange process of fluid in the heat exchanger is optimized, andminimization of a heat exchange area is realized; and meanwhile, the life of a catalyst can be prolonged, and the system purification efficiency is improved.

Owner:南京宜热纵联环保科技溧阳有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com