Determination method of oxidation heat liberation intensity of loose coal

A determination method and technology of coal body, applied in the field of oxidation heat test, can solve the problems of difficulty in ensuring accuracy, high requirements, long experimental period, etc., and achieve the effect of good repeatability, ensuring accuracy, and short test period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

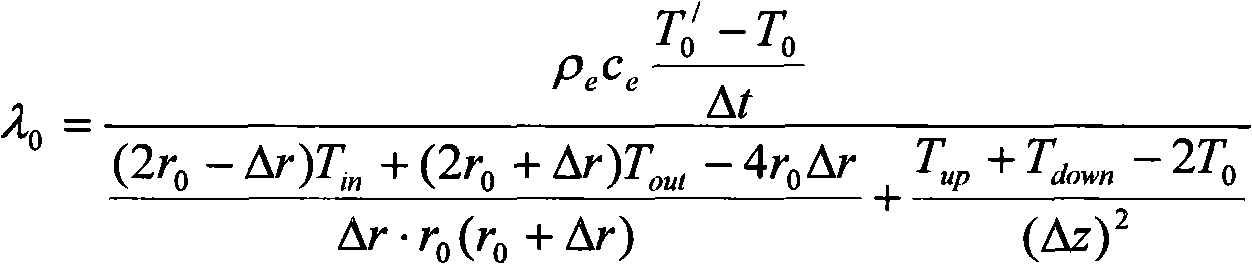

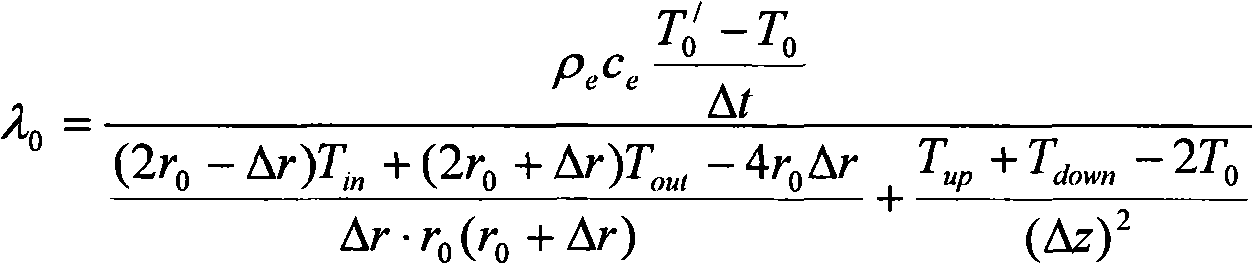

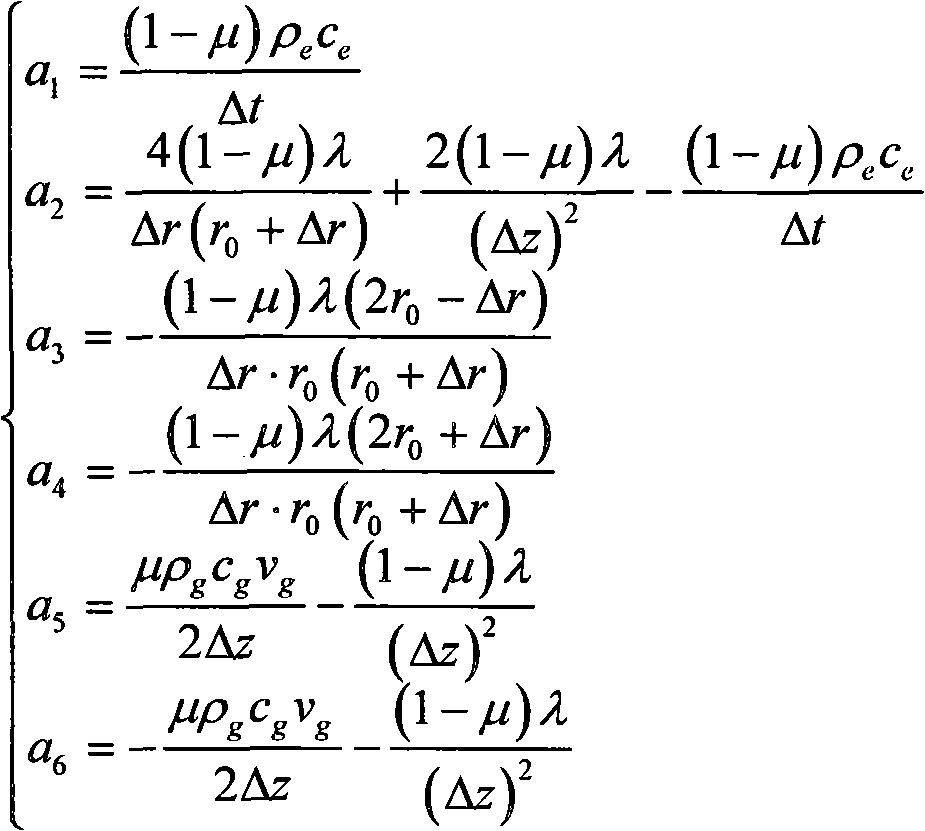

Method used

Image

Examples

Embodiment Construction

[0024] Take a coal mine as an example:

[0025] 1. Take fresh coal samples from a coal mine for crushing, and sieve them into coal samples with different particle sizes such as 0-1mm, 1-3mm or 3-6mm for batch testing;

[0026] 2. Arrange the hot wires along the axial center line in the adiabatic cylindrical reaction vessel, and arrange a row of temperature measuring points and gas sample measuring points on the same plane perpendicular to the hot wires at a distance of about 1cm, 2cm, and 3cm from the hot wires. The axial direction of the hot wires There are at least three rows of temperature measuring points and gas sample measuring points;

[0027] 3. Select a well-screened coal sample with a particle size range of 1-3mm, weigh it, take 80-100kg coal sample and put it into an adiabatic columnar reaction vessel, turn on the air supply control system, and continuously blow it at a speed of 0.005m / s Nitrogen gas is introduced into the coal body until the coal body is completel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com