Patents

Literature

1056 results about "Differential scanning calorimetry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

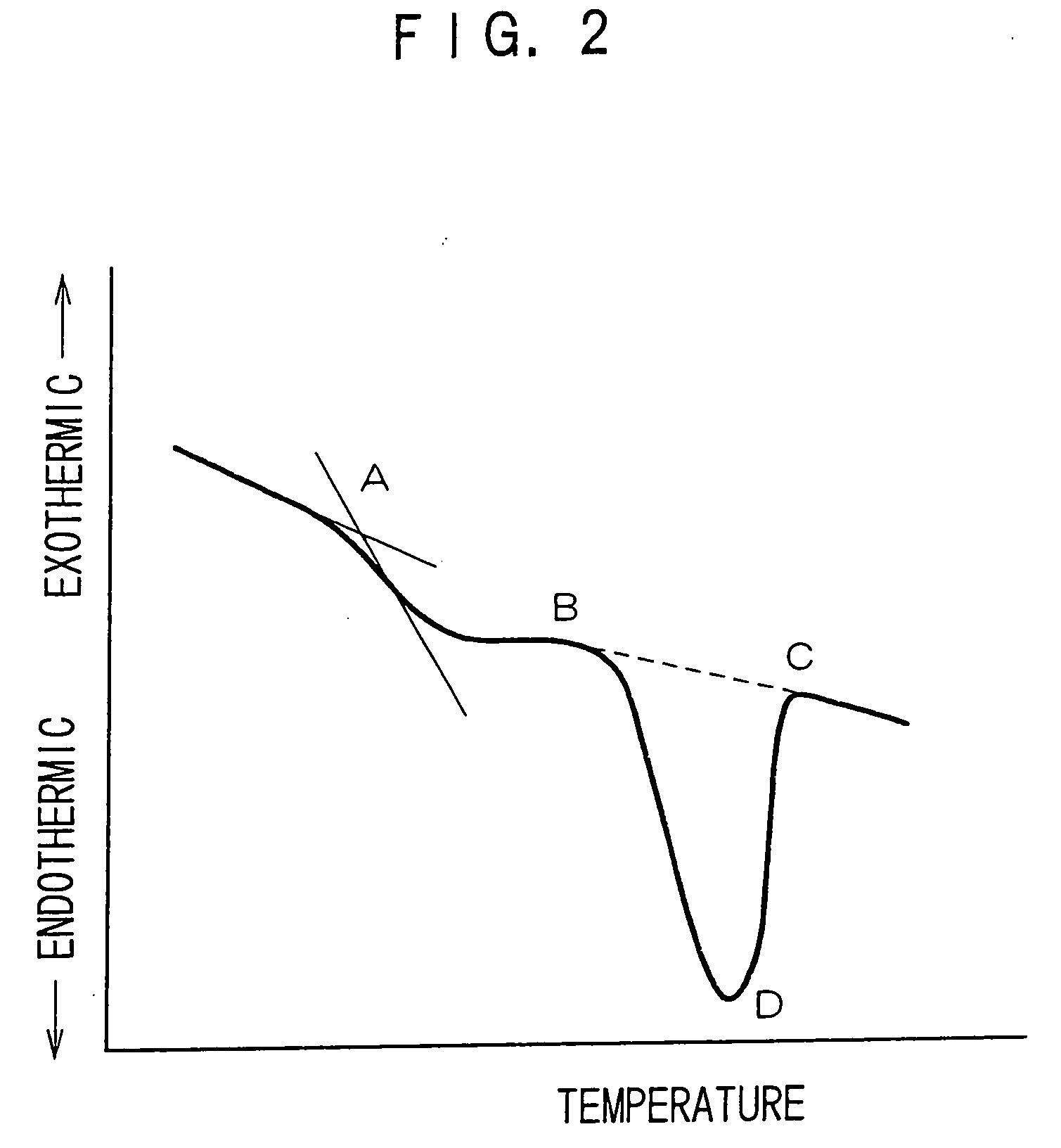

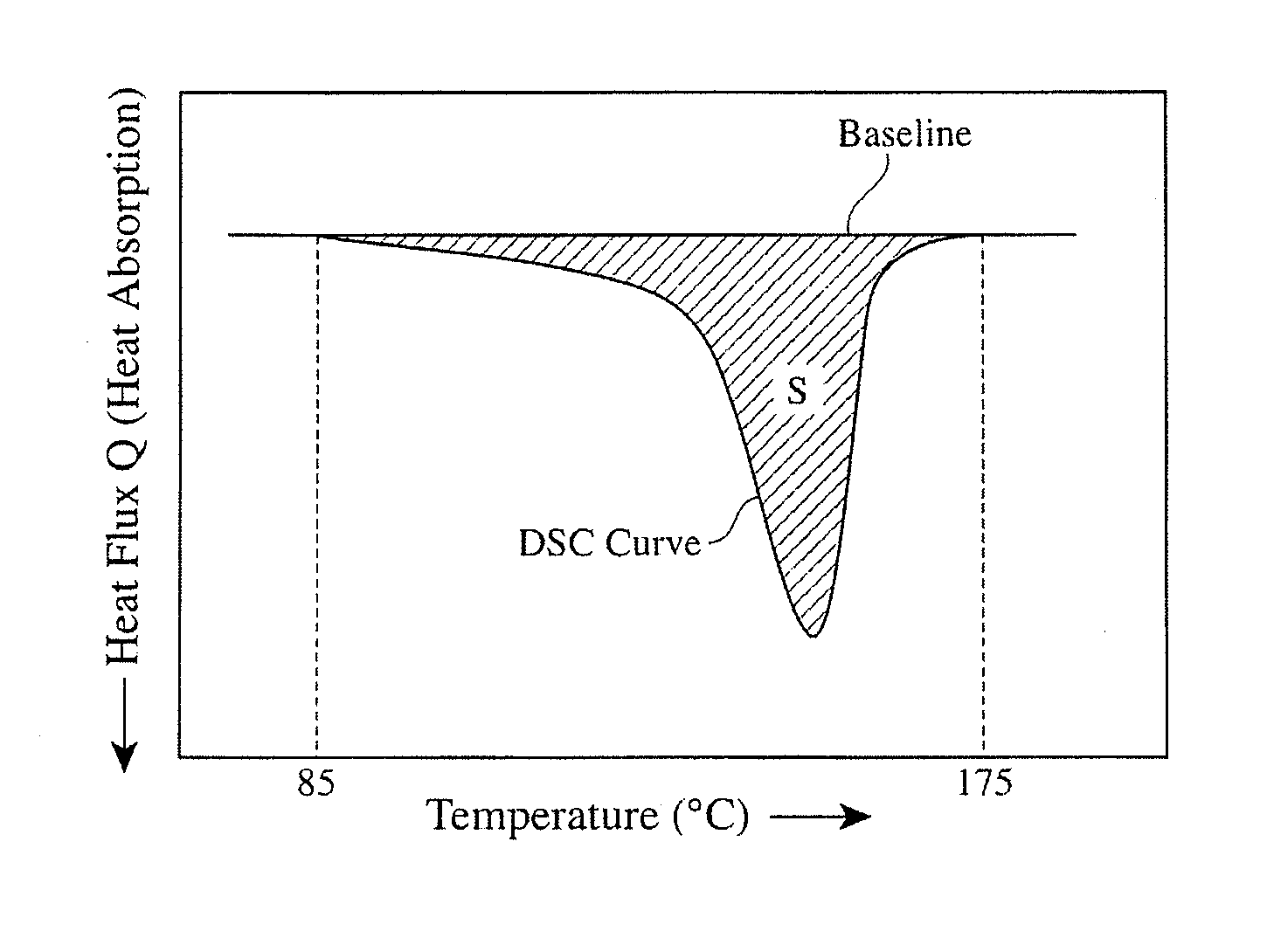

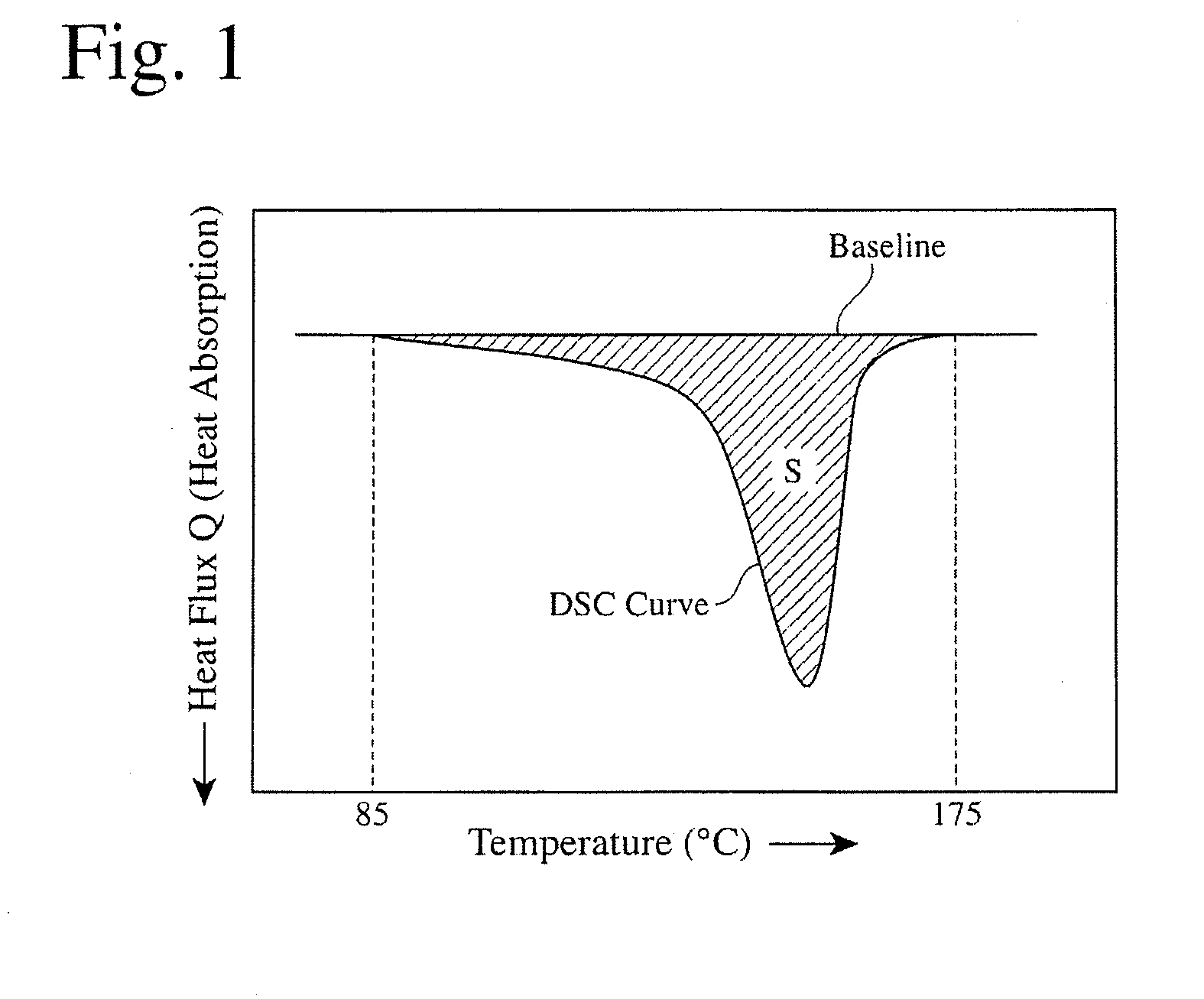

Differential scanning calorimetry, or DSC is a thermoanalytical technique in which the difference in the amount of heat required to increase the temperature of a sample and reference is measured as a function of temperature. Both the sample and reference are maintained at nearly the same temperature throughout the experiment. Generally, the temperature program for a DSC analysis is designed such that the sample holder temperature increases linearly as a function of time. The reference sample should have a well-defined heat capacity over the range of temperatures to be scanned.

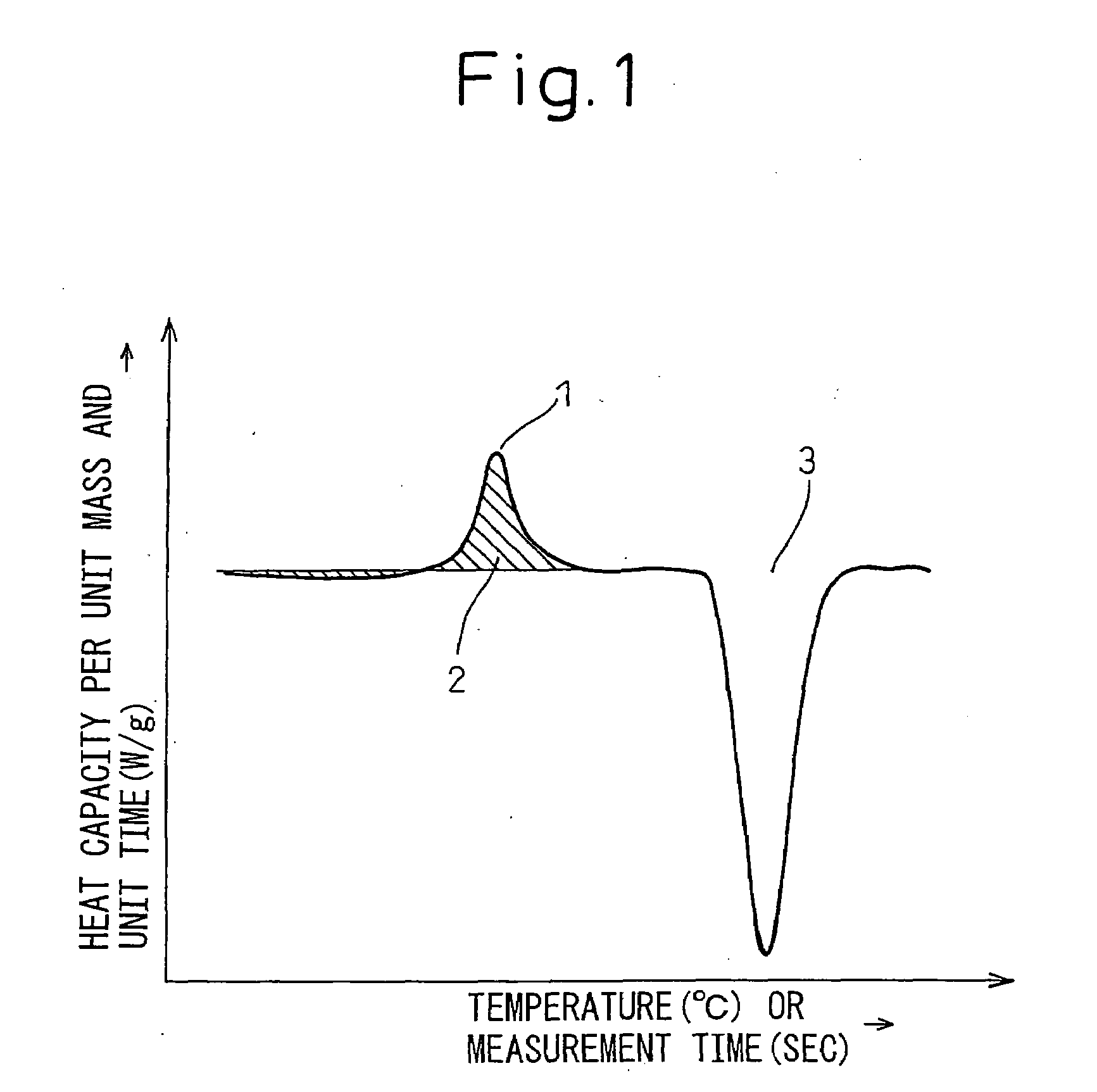

Toner, image forming method and process cartridge

InactiveUS20070026335A1DevelopersElectrographic processes using charge patternChemical structurePolyester

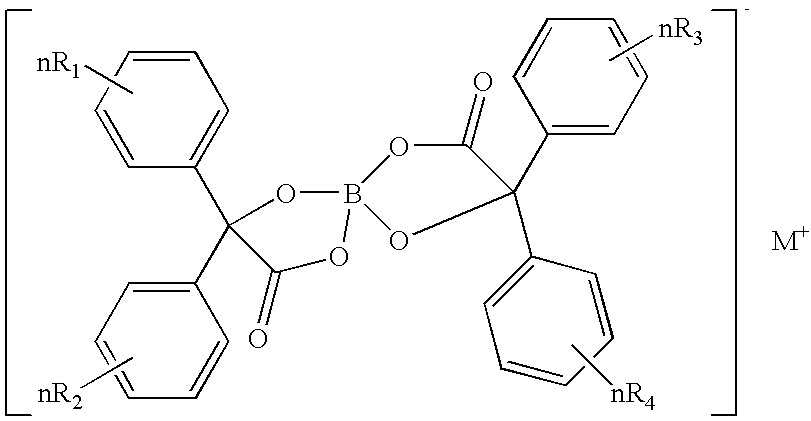

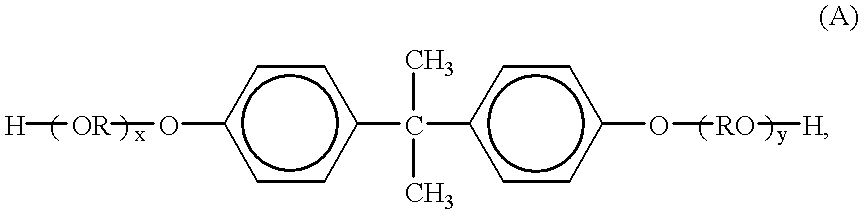

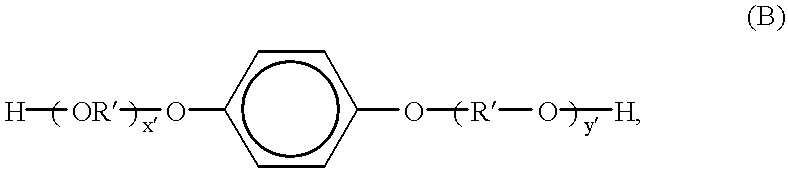

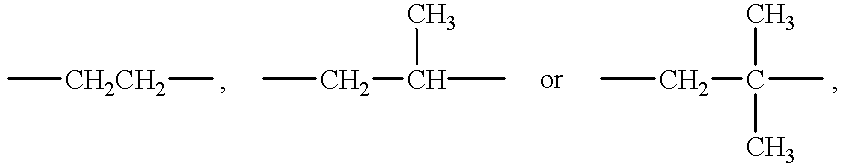

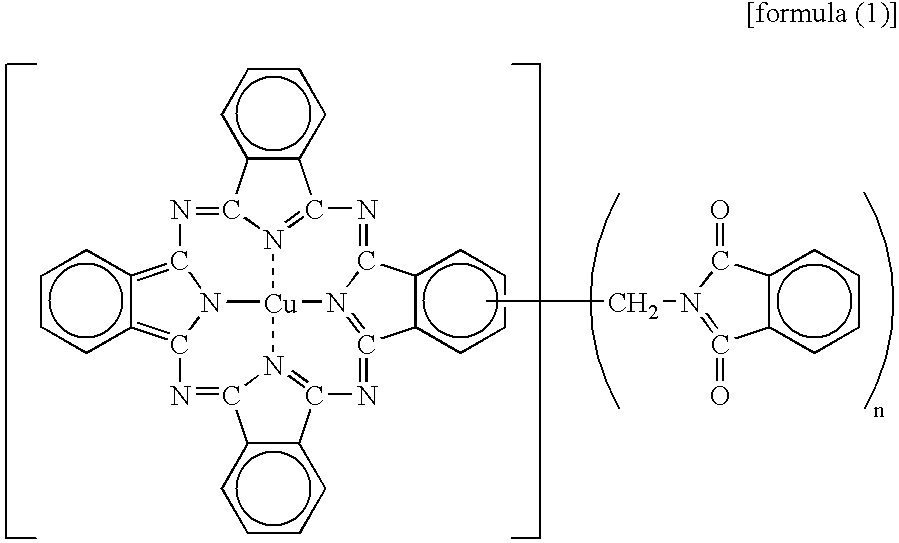

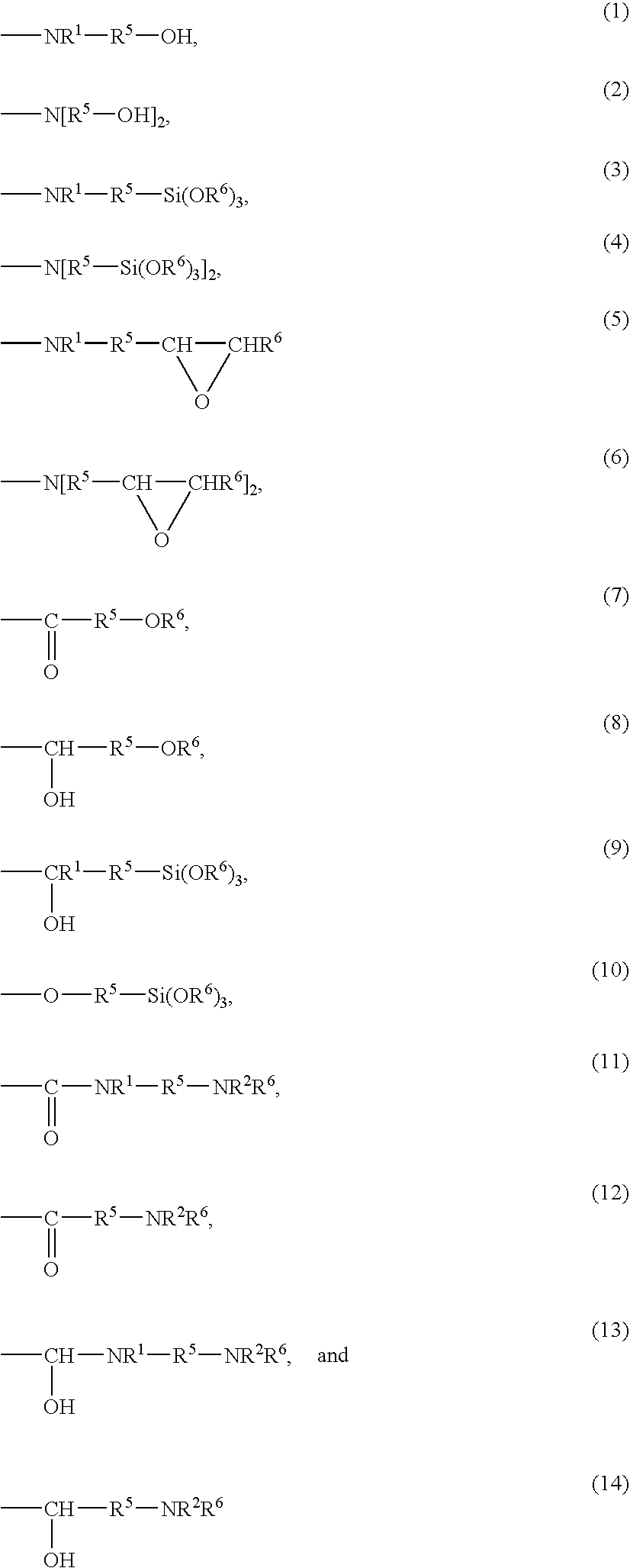

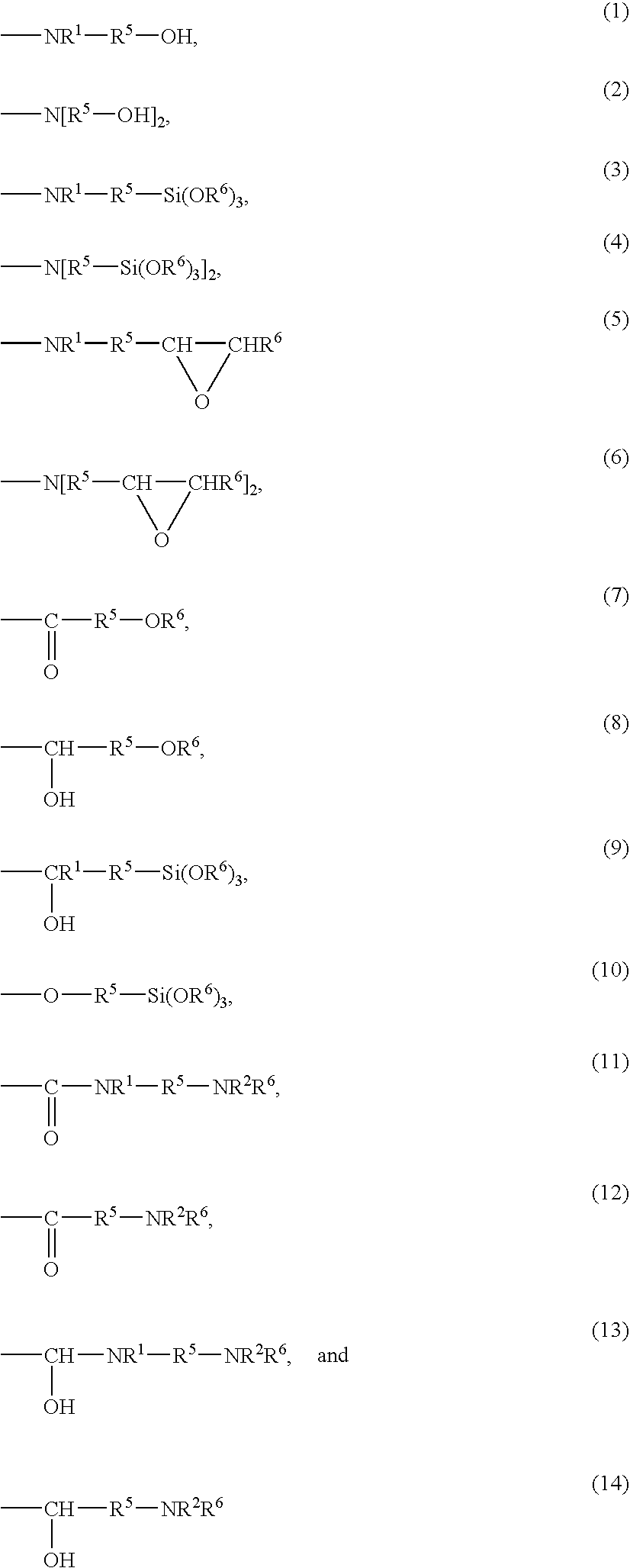

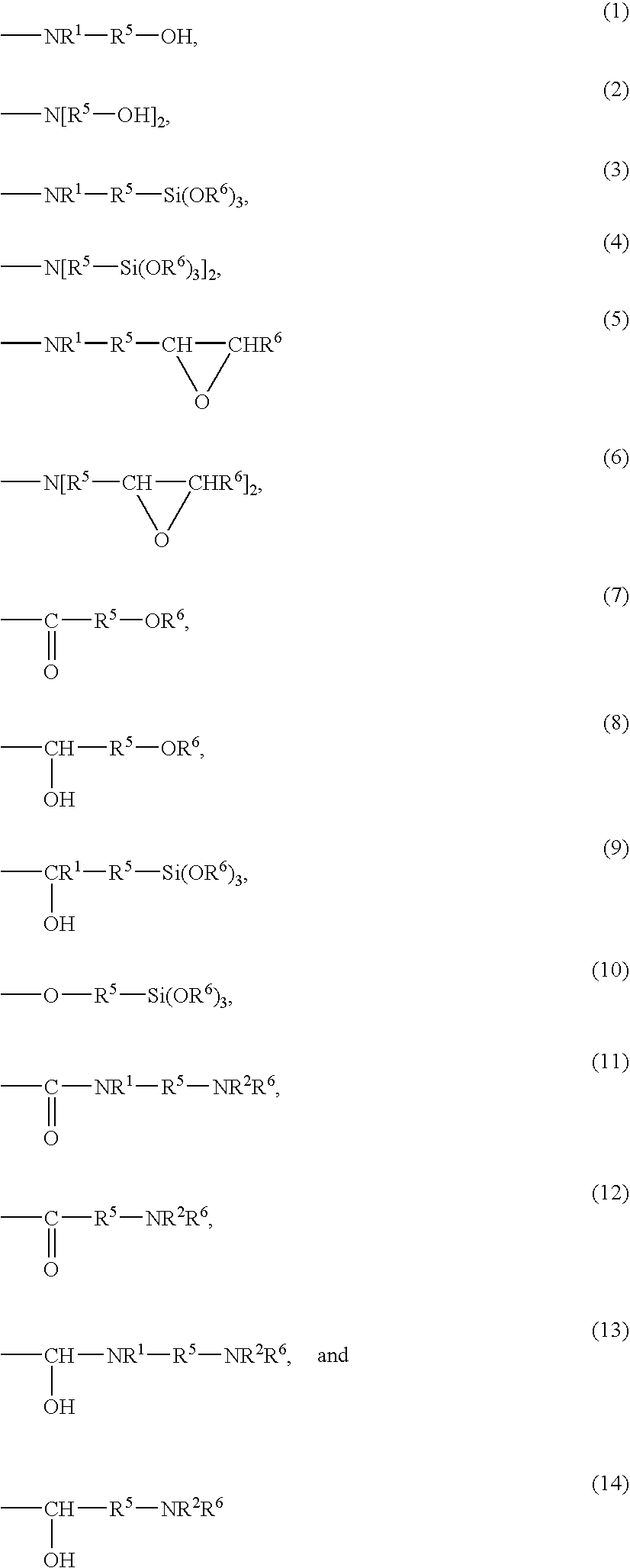

A toner containing a binder resin containing a resin having a polyester skeleton, a wax containing a hydrocarbon based wax, a colorant, and a charge controlling agent represented by the following chemical structure, wherein the toner has at least one endothermic peak in a range of from 60 to 80 ° C. when measured by a differential scanning calorimetry (DSC). In the chemical structure, M represents one of Li, Na and K, R1, R2, R3 and R4 each, independently, represent one of a hydrogen atom, an alkyl group having 1 to 4 carbon atoms, an alkoxy group having 1 to 4 carbon atoms, and a halogen atom, and n represents an integer of from 1 to 5, and when n is from 2 to 5, each of R1, R2, R3 and R4 can be different from the other.

Owner:RICOH KK

Toner

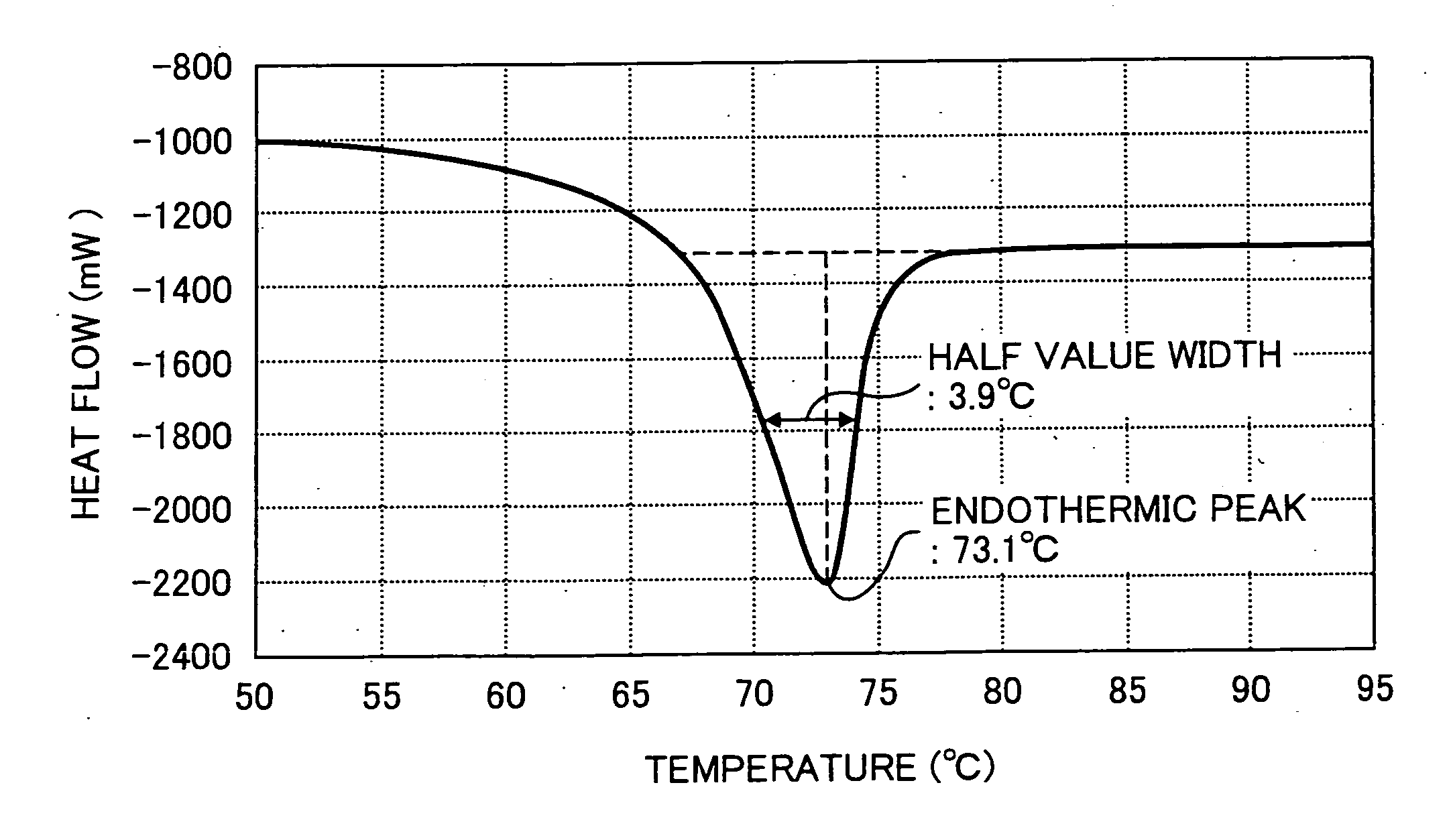

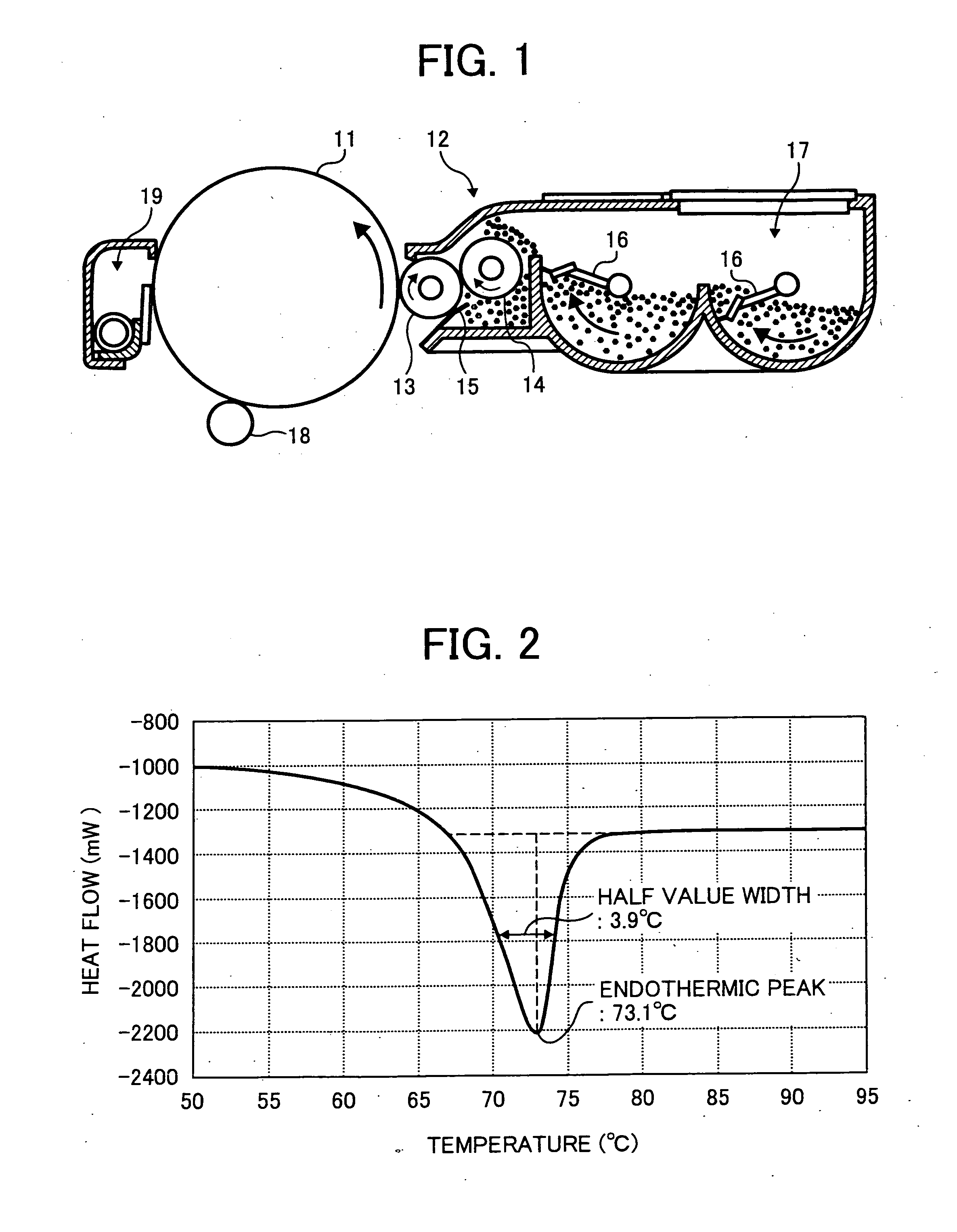

An electrophotographic toner is formed of a resinous composition including a binder resin and a wax (A). The wax (A) contains at least 92 wt. % thereof of n (normal)-paraffin comprising a plurality of n-paraffin species having different numbers of carbon atoms, and provides a DSC (differential scanning calorimetry)-heat-absorption curve exhibiting a maximum heat-absorption peak showing a peaktop temperature of 70-90° C. and a half-value width of at most 12° C. As a result of the n-paraffin-rich characteristic and the DSC-thermal characteristic, the wax can exhibit an improved fixability-improving effect without showing an excessive plasticizing effect, whereby the toner can exhibit good fixability as well as good flowability and storage stability.

Owner:CANON KK

Toner for developing electrostatic images, electrostatic image developer, and image-forming method

ActiveUS20060204880A1Superior in toner storage lifeSuperior in storage image stabilityDevelopersPolyester resinDifferential scanning calorimetry

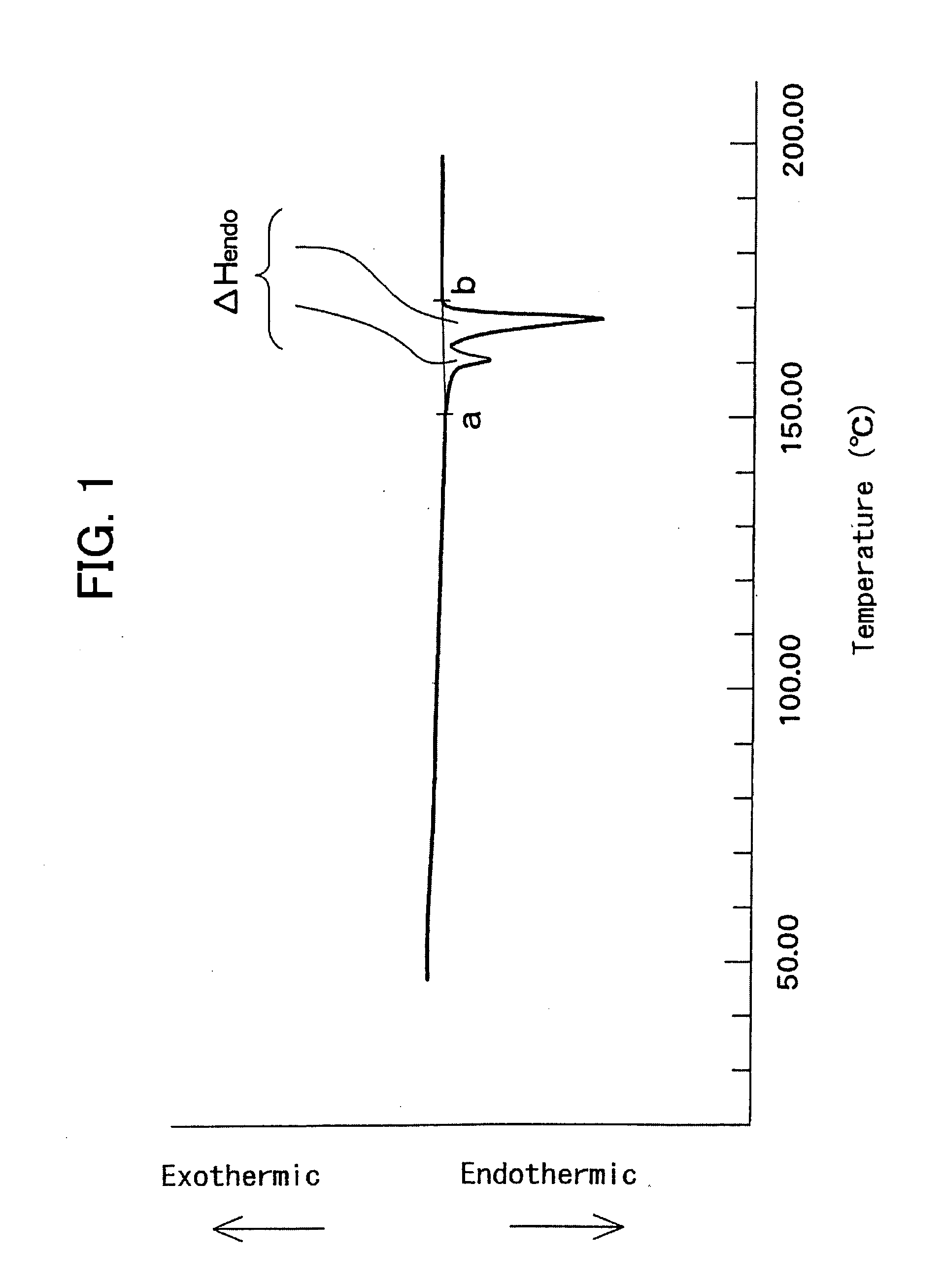

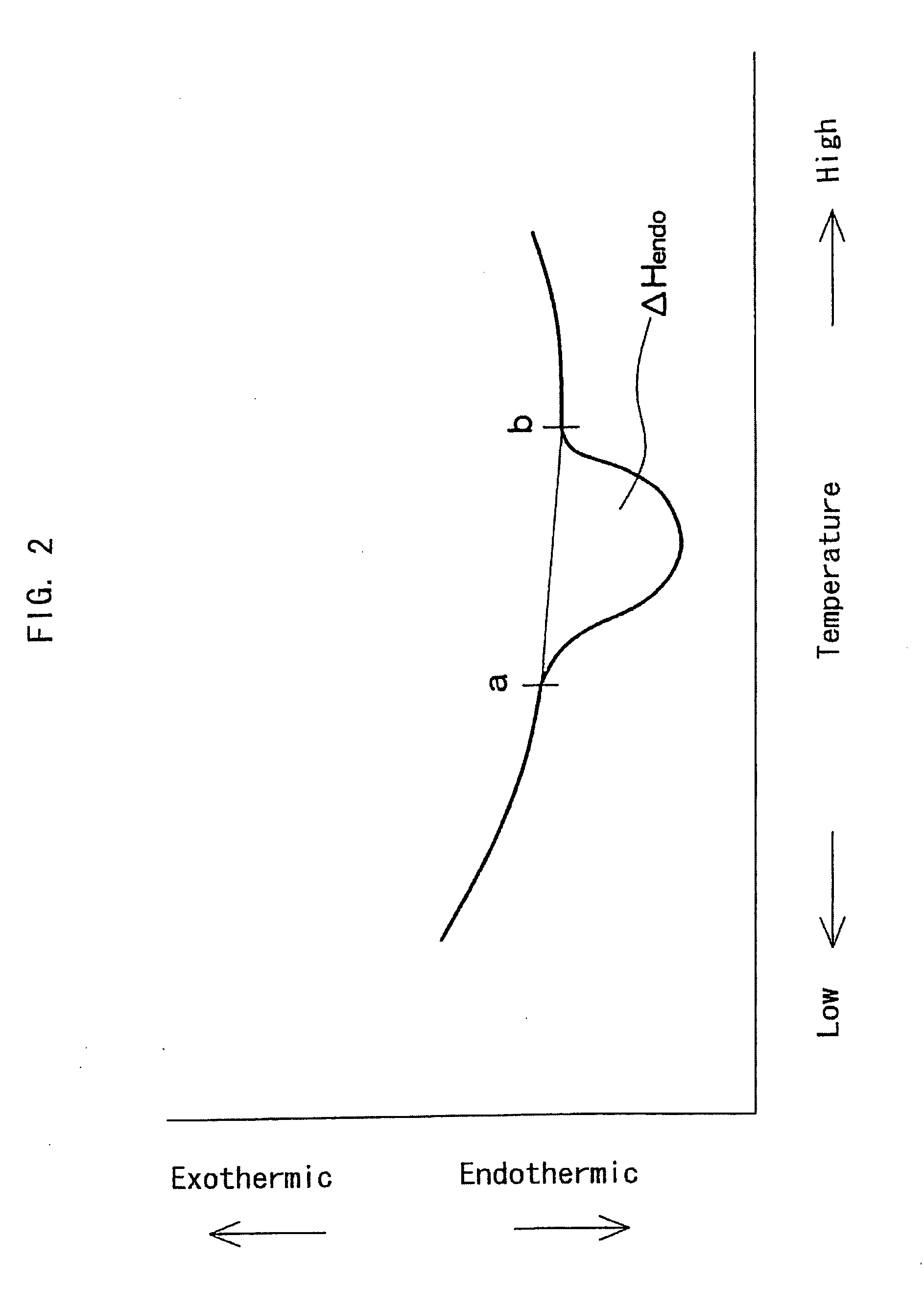

A toner for developing electrostatic images, comprising a binder resin and a colorant, the binder resin including a crystalline polyester resin and an amorphous resin. When, in differential scanning calorimetry of the toner according to ASTM D3418-8, the temperature of the endothermic peak derived from the crystalline polyester resin in a first heating process is defined as Tm1 (° C.), the endothermic quantity based on the endothermic peak in the first heating process is defined as ΔH1 (mW / g), and the endothermic quantity based on the endothermic peak in a second heating process is defined as ΔH2 (mW / g), Tm1 is 50 to 80° C, and ΔH1 and ΔH2 satisfy the relationship represented by the following Formula (1). When the softening temperature of the toner is defined as Tf1 / 2 (° C.), Tf1 / 2 is 85 to 135° C. Tm1 and Tf1 / 2 satisfy the relationship represented by the following Formula (2):0.35≦ΔH2 / ΔH1≦0.95 Formula (1)Tf1 / 2≦205−(1.4×Tm1) Formula (2).

Owner:FUJIFILM BUSINESS INNOVATION CORP

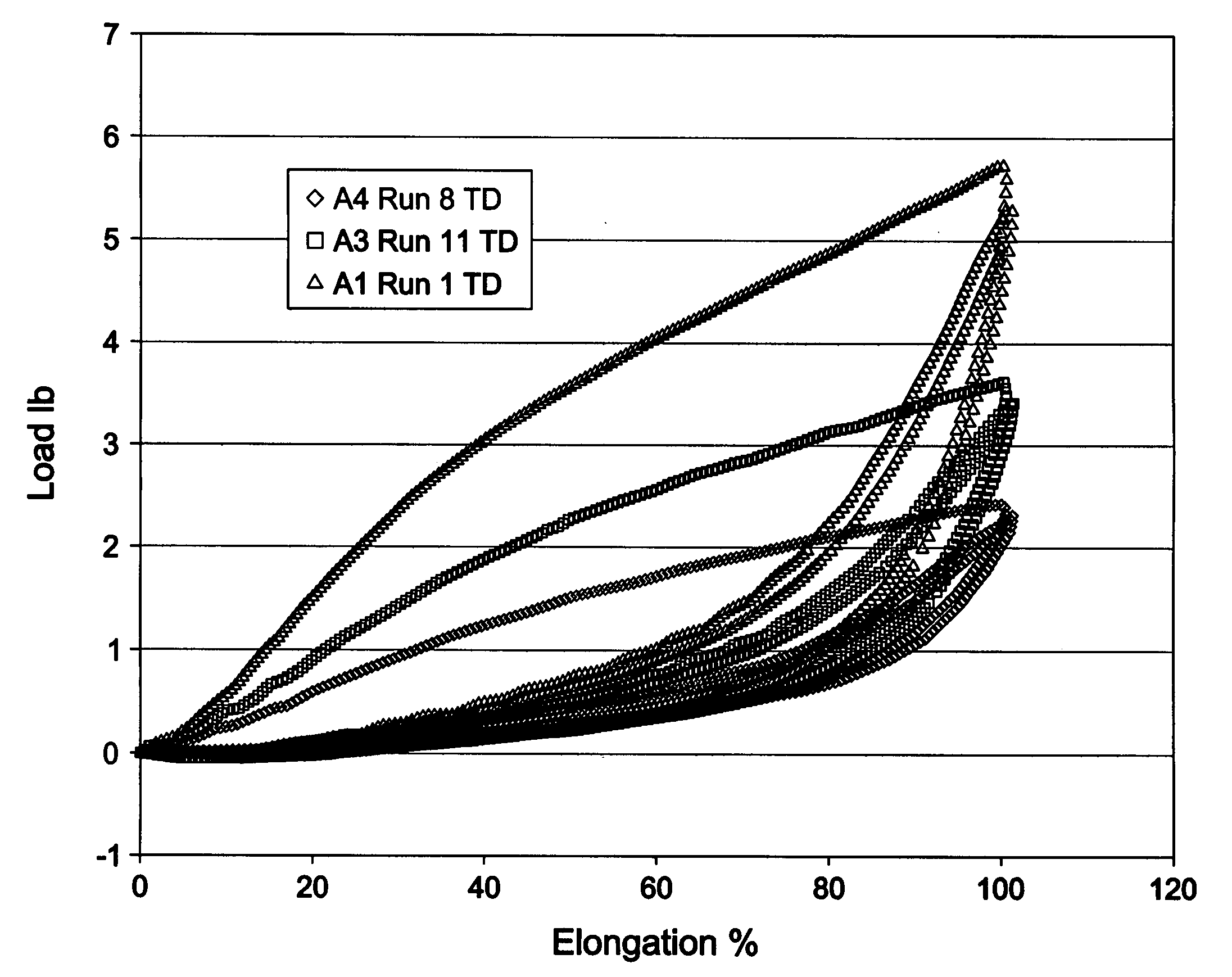

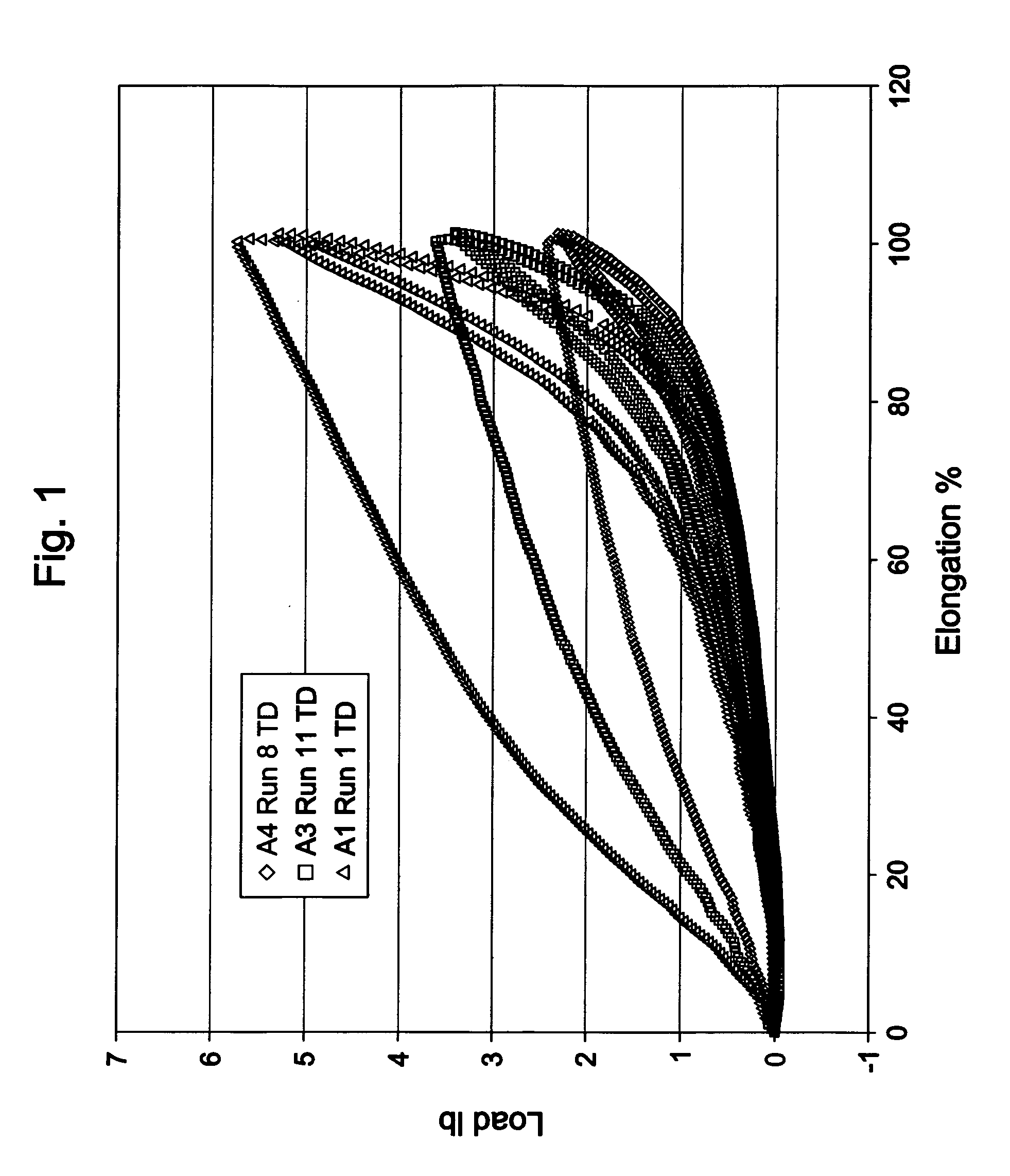

Spunbond fibers and fabrics from polyolefin blends

The invention described relates to a polyolefin blend composition suitable for spunbond fiber or filament compositions, and to fabric compositions and composite constructions therefrom, said blend comprising a) from 60-98 wt % of at least one random propylene copolymer having a comonomer content of from 8 to 25 wt % and a crystalline melting point (Tm) as determined by differential scanning calorimetry (DSC) of from about 40° C. to about 110° C.; and b) from 2-40 wt % of at least one substantially isotactic polypropylene homopolymer or copolymer comprising one or more C2 and / or C4-C8 comonomer, having a crystalline melting point (Tm) as determined by DSC greater than or equal to 120° C. The blends of the present invention typically have a melt flow rate (MFR) of from 100 g / 10min to about 500 g / 10min.

Owner:EXXONMOBIL CHEM PAT INC

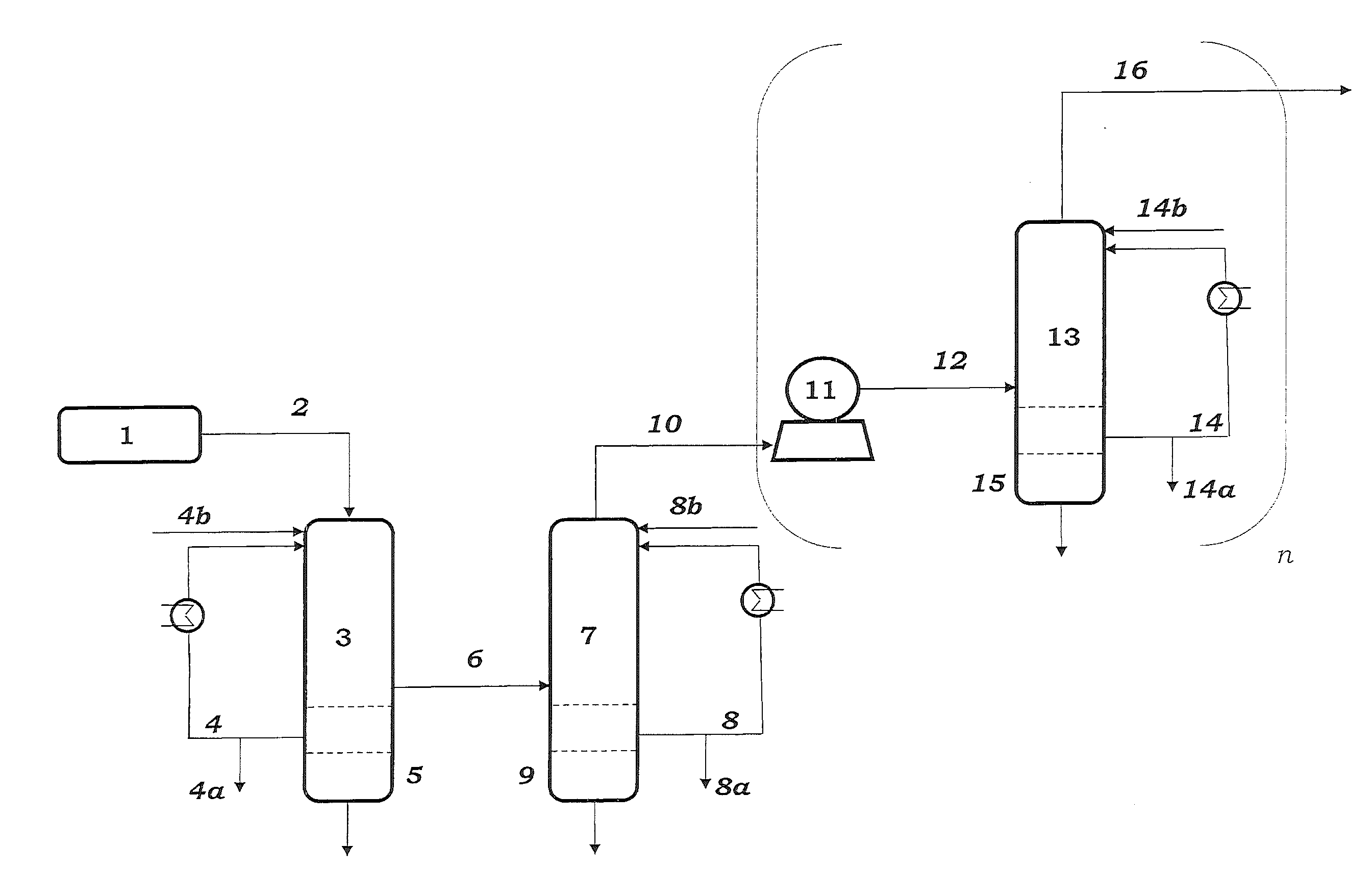

Process for Preparing Butadiene by Oxidative Dehydrogenation of N-Butenes with Monitoring of the Peroxide Content During Work-Up of the Product

InactiveUS20140200381A1Analysis using chemical indicatorsHydrocarbon by hydrogenationWater vaporDesorption

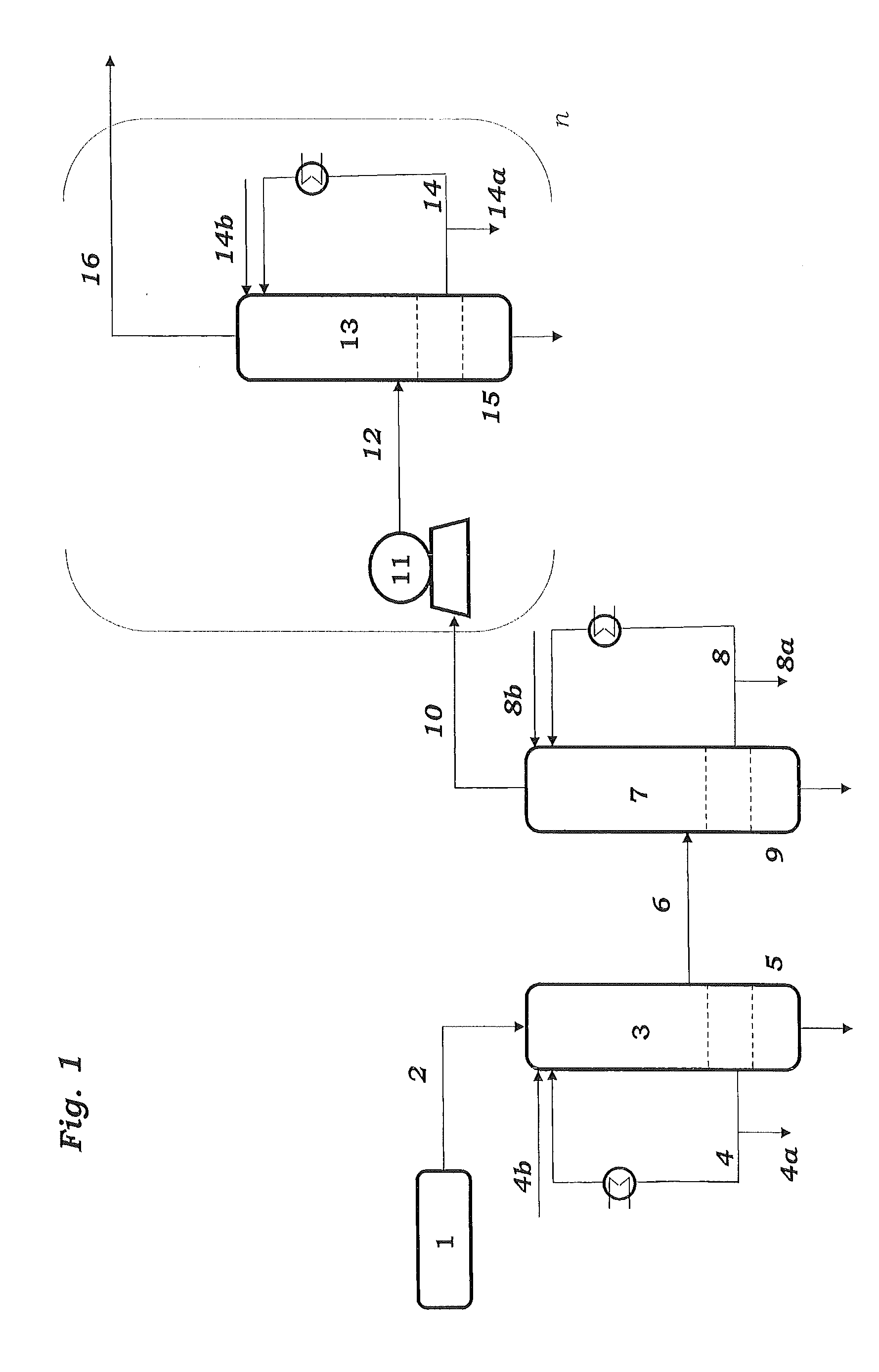

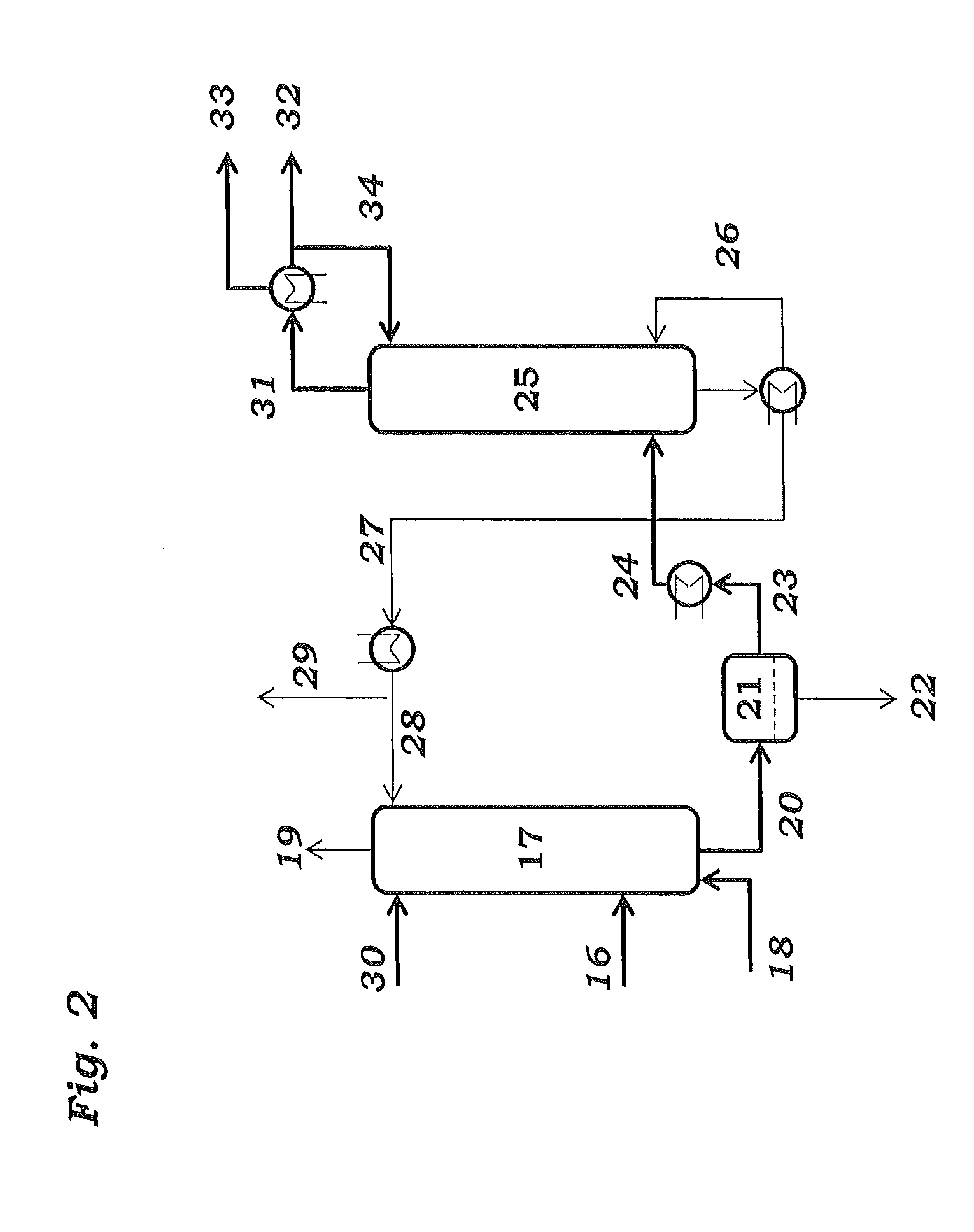

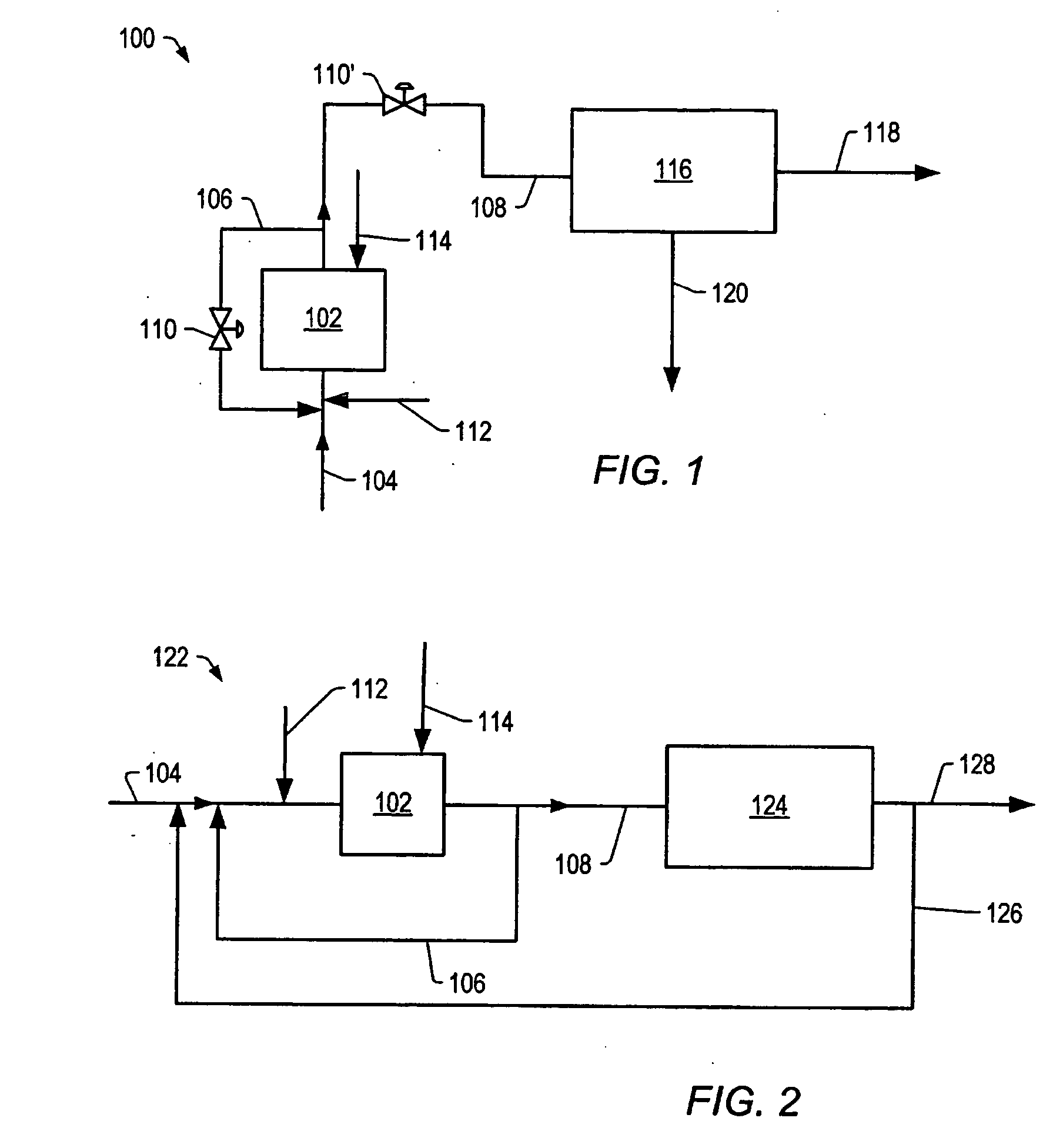

The invention relates to a process for preparing butadiene from n-butenes, which comprises the following steps:A) provision of a feed gas stream a comprising n-butenes;B) introduction of the feed gas stream a comprising n-butenes and an oxygen-comprising gas into at least one dehydrogenation zone and oxidative dehydrogenation of n-butenes to butadiene, giving a product gas stream b comprising butadiene, unreacted n-butenes, water vapor, oxygen, low-boiling hydrocarbons, possibly carbon oxides and possibly inert gases;C) cooling and compression of the product gas stream b in at least one cooling stage and at least one compression stage, with the product gas stream b being brought into contact with a circulated coolant to give at least one condensate stream c1 comprising water and a gas stream c2 comprising butadiene, n-butenes, water vapor, oxygen, low-boiling hydrocarbons, possibly carbon oxides and possibly inert gases;D) separation of incondensable and low-boiling gas constituents comprising oxygen, low-boiling hydrocarbons, possibly carbon oxides and possibly inert gases as gas stream d2 from the gas stream c2 by absorption of the C4-hydrocarbons comprising butadiene and n-butenes in a circulated absorption medium, giving an absorption medium stream loaded with C4-hydrocarbons and the gas stream d2, and subsequent desorption of the C4-hydrocarbons from the loaded absorption medium stream to give a C4 product gas stream d1;E) separation of the C4 product stream d1 by extractive distillation using a solvent which is selective for butadiene into a stream e1 comprising butadiene and the selective solvent and a stream e2 comprising n-butenes;F) distillation of the stream e1 comprising butadiene and the selective solvent to give a stream f1 consisting essentially of the selective solvent and a stream f2 comprising butadiene;where samples are taken from the circulated coolant in step C) and / or the circulated absorption medium in step D) and the peroxide content of the samples taken is determined by means of iodometry, differential scanning calorimetry (DSC) or microcalorimetry.

Owner:BASF AG

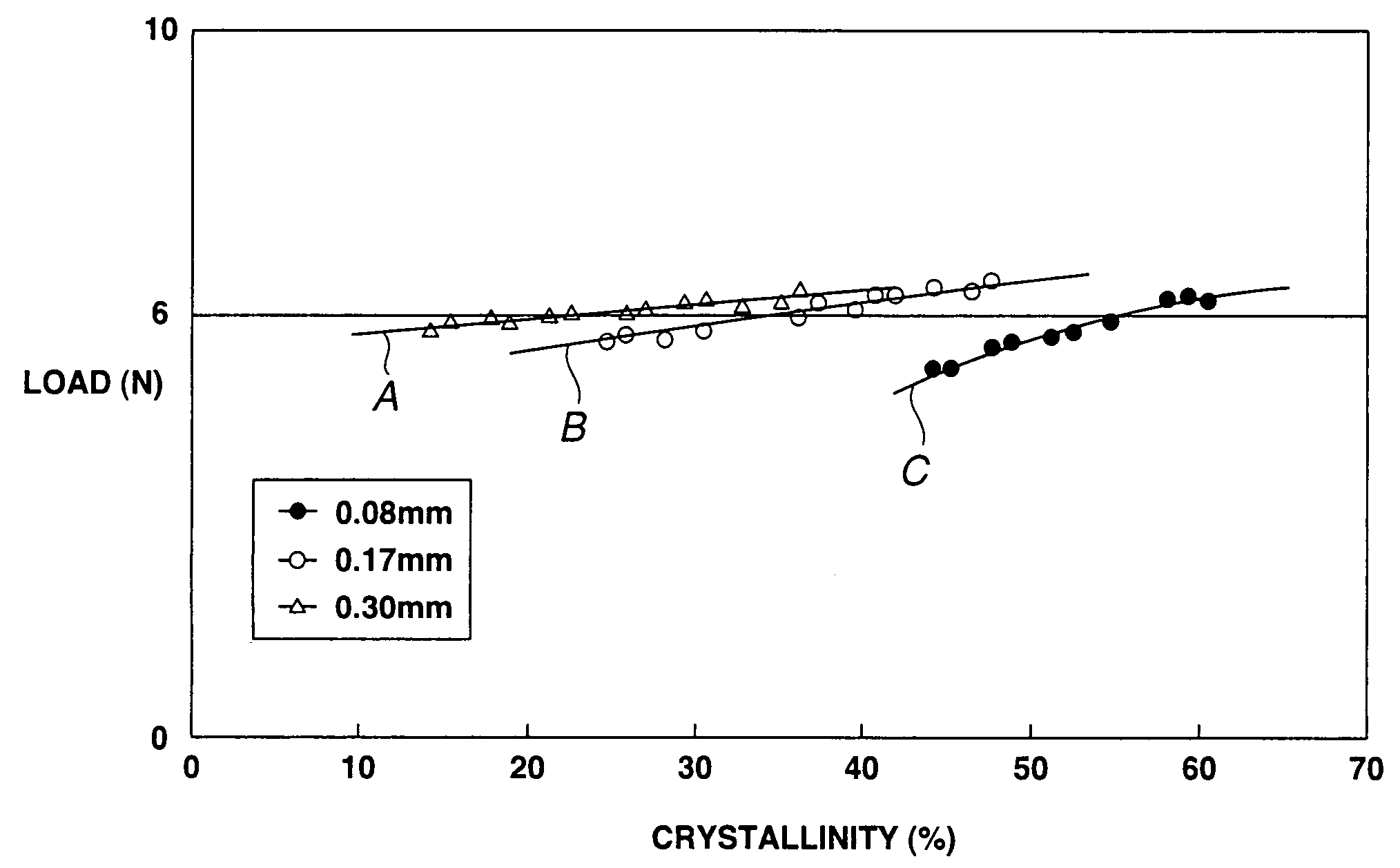

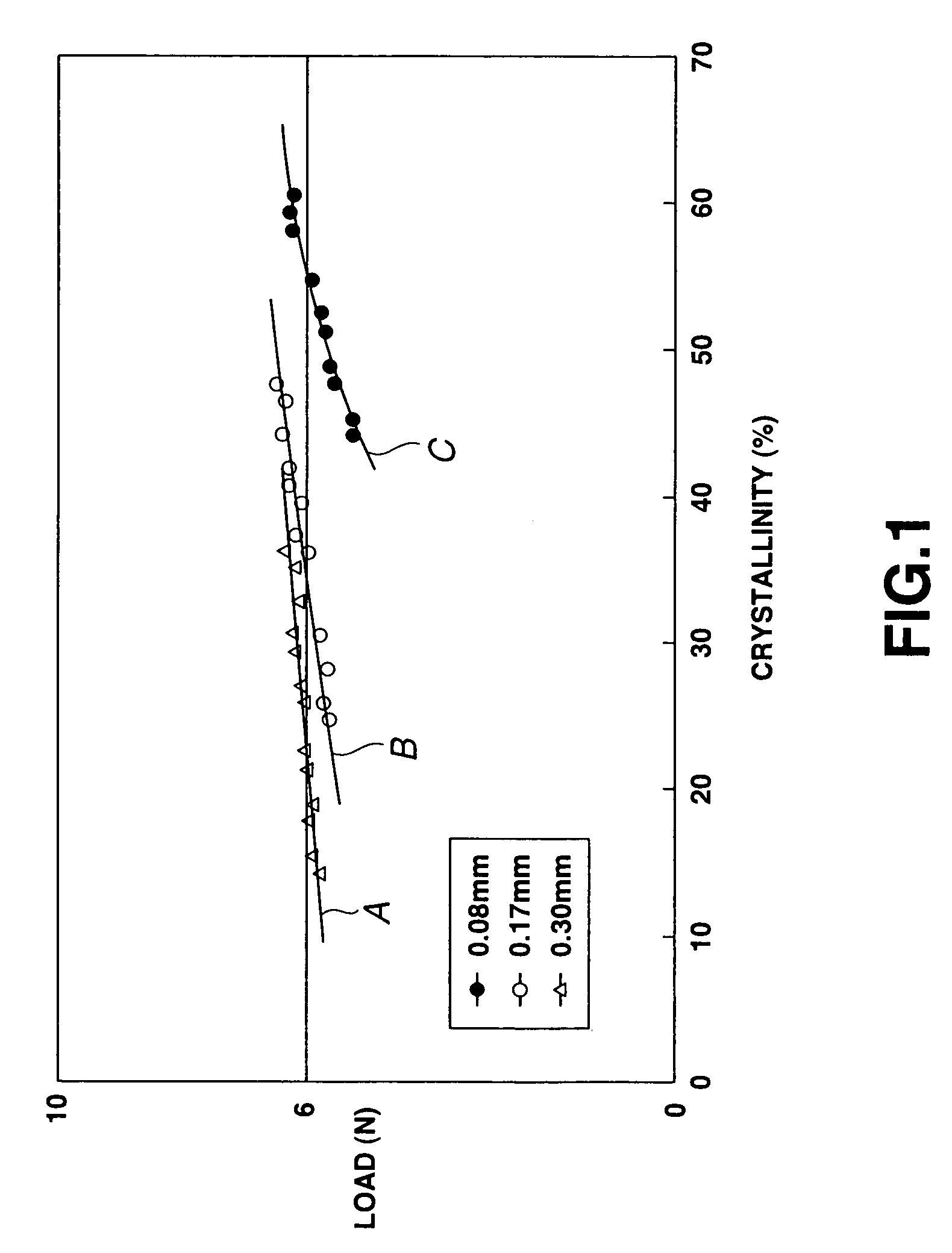

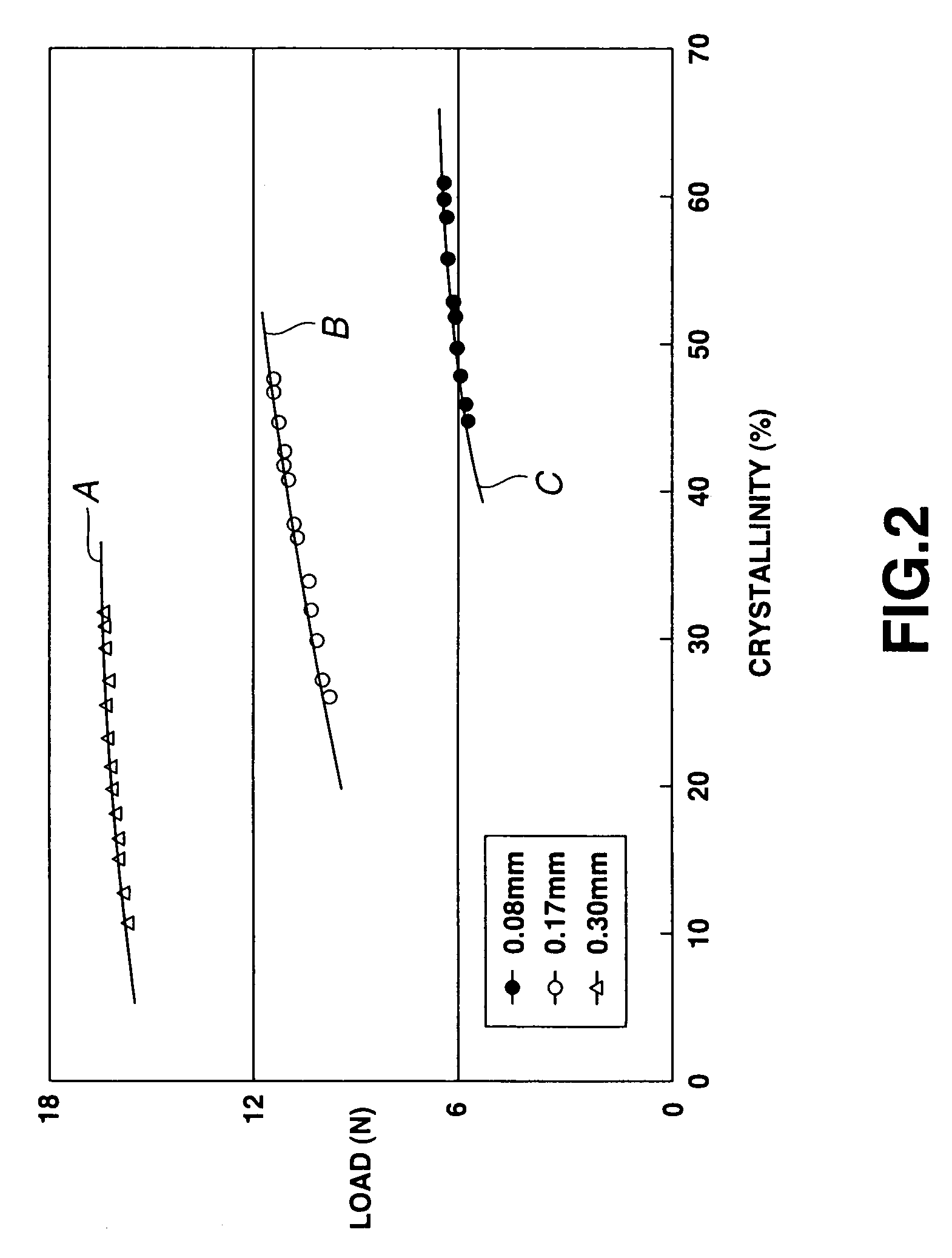

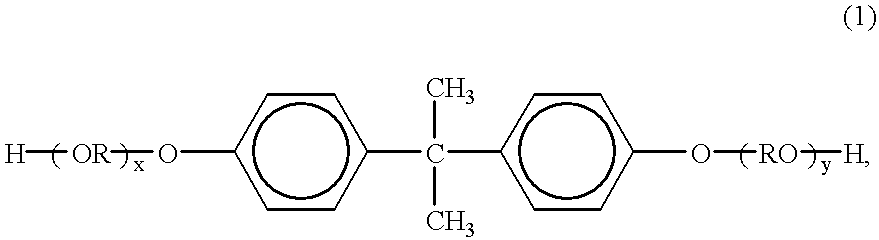

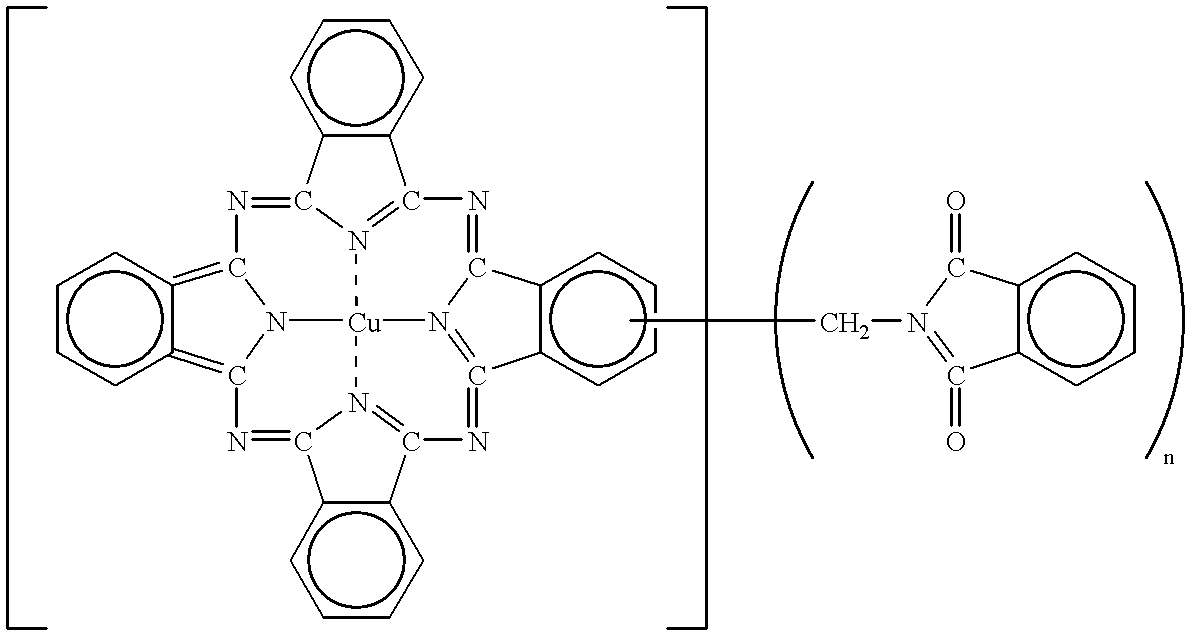

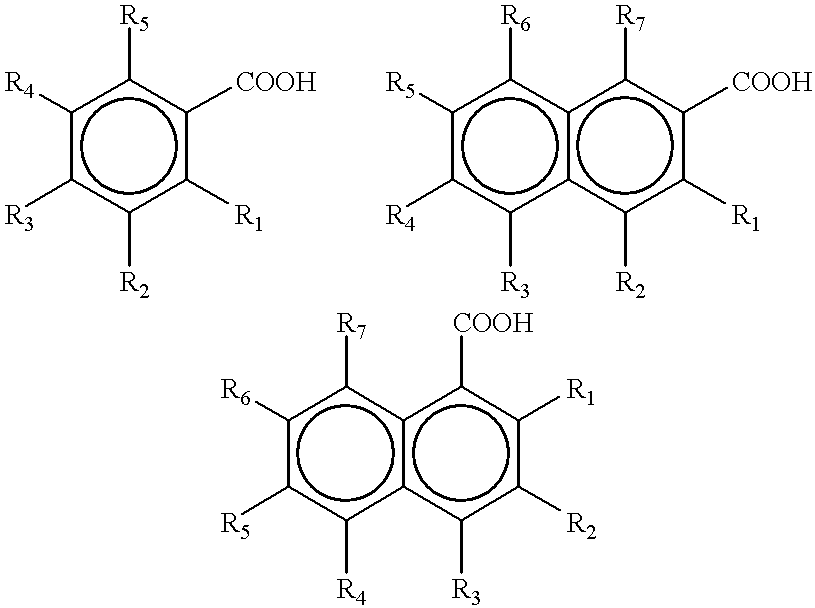

Linear material for blood vessel stent and blood vessel stent utilizing same

InactiveUS7070615B1Good antithrombotic propertiesImprove physical functionStentsSurgeryCoronary arteriesBlood vessel spasm

Owner:KYOTO MEDICAL PLANNING

Toner and full-color image forming method

InactiveUS6586147B2High transparencyExcellent low temperature fixabilityDevelopersElectrographic processes using charge patternWaxImage formation

A toner, particularly a color toner suitable for full-color image formation through a substantially oil-less heat-pressure fixing device, is formed from at least a binder resin, a colorant and a wax. The toner has viscoelasticity including: a storage modulus at 80° C. (G'80) in a range of 1x106-1x1010 dN / m2, storage moduli at temperatures of 120-180° C. (G'120-180) in a range of 5x103-1x106 dN / m2, and loss tangents (tan delta=G'' / G' as a ratio between G'' (loss modulus) and G' (storage molecules)) including a loss tangent at 180° C. (tan delta180) and a minimum of loss tangents over a temperature range of 120-180 ° C. (tan deltamin) satisfying 1<=tan delta180 / tan deltamin. The toner further exhibits a thermal behavior providing a heat-absorption curve according to differential scanning calorimetry (DSC) showing a maximum heat-absorption peak temperature in a range of 50-110° C. in a temperature range of 30-200° C.

Owner:CANON KK

LAYERED COMPOSITE MATERIALS HAVING THE COMPOSITION: (1-x-y)LiNiO2(xLi2Mn03)(yLiCoO2), AND SURFACE COATINGS THEREFOR

InactiveUS20120040247A1Improve discharge capacitySecondary cellsCeramic shaping apparatusX-rayCobalt

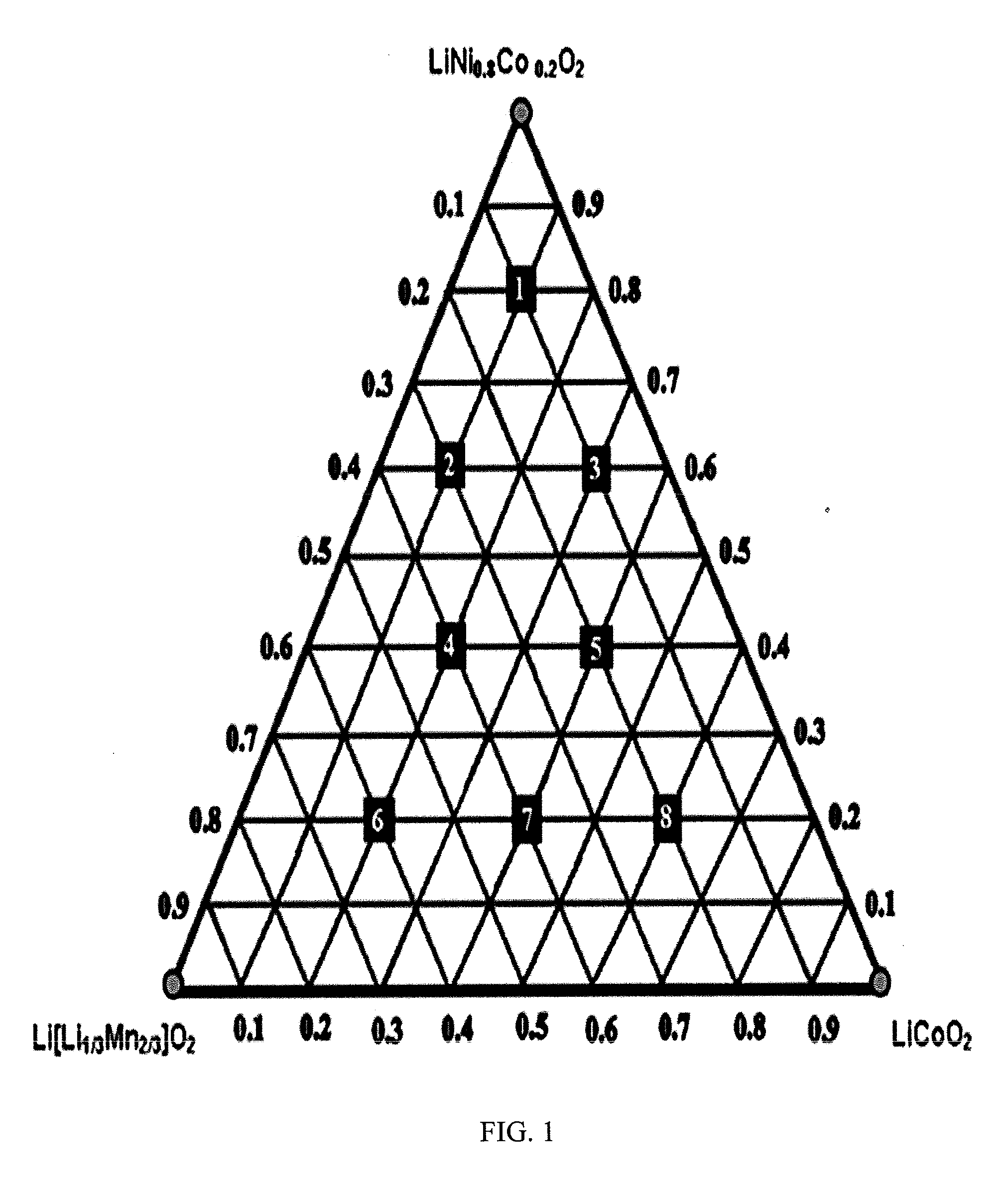

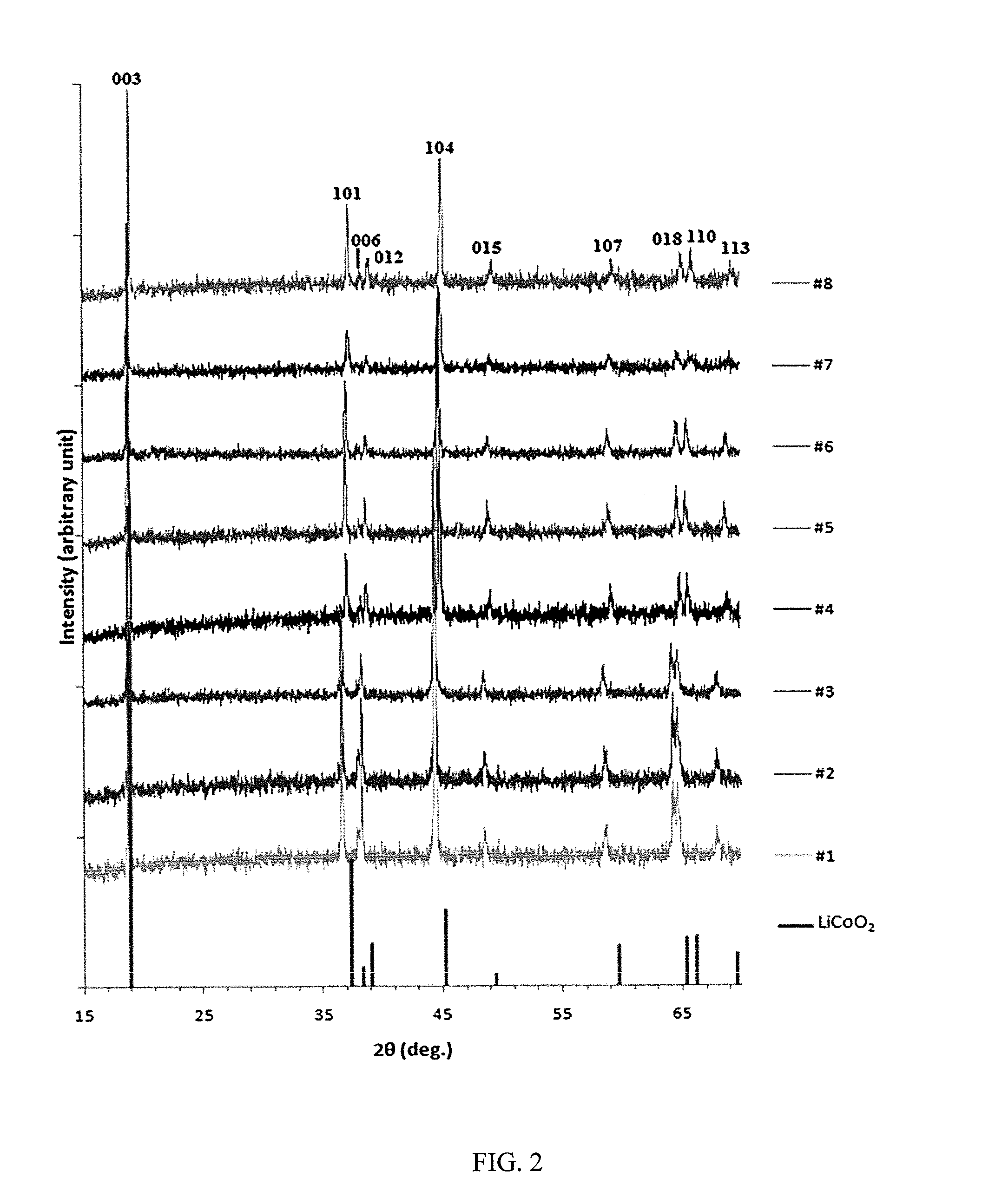

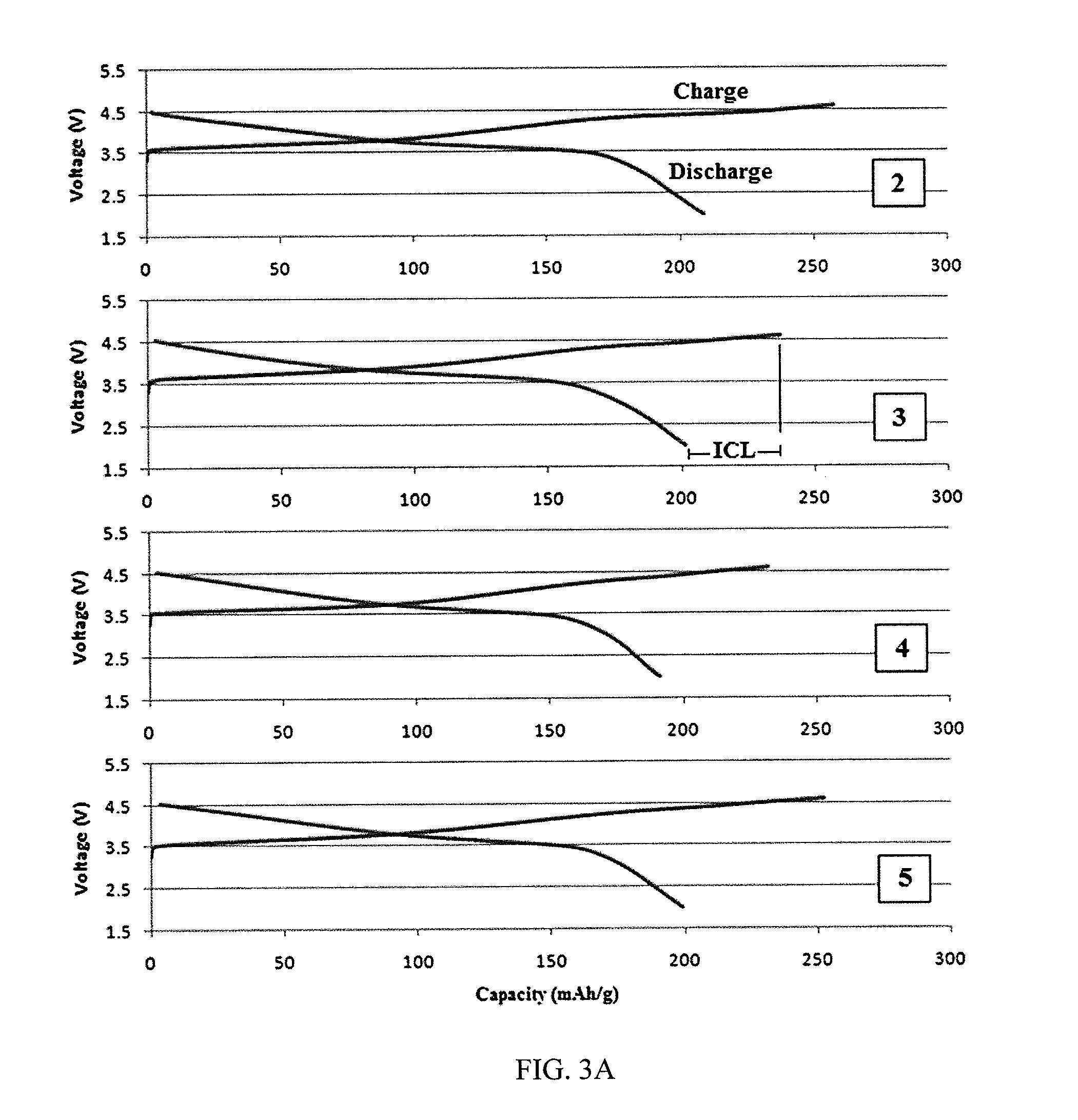

A straightforward and scalable solid-state synthesis at 975° C. used to generate cathode materials in the system Li(3+x)3Ni(1-x-y)CoyMn2x / 3O2 {a combination of LiNiO2, Li2MnO3, and LiCoO2 as (1-x-y)LiNiO2.xLi2MnO3.yLiCoO2} is described. Coatings for improving the characteristics of the cathode material are also described. A ternary composition diagram was used to select sample points, and compositions for testing were initially chosen in an arrangement conducive to mathematical modeling. X-ray diffraction (XRD) characterization showed the formation of an α-NaFeO2 structure, except in the region of compositions close to LiNiO2. Electrochemical testing revealed a wide range of electrochemical capacities with the highest capacities found in a region of high Li2MnO3 content. The highest capacity composition identified was Li1.222Mn0.444Ni0.167Co0.167O2 with a maximum initial discharge capacity of in the voltage range 4.6-2.0 V. Differential scanning calorimetry (DSC) testing on this material was promising as it showed an exothermic reaction of 0.2 W / g at 200° C. when tested up to 400° C. Cost for laboratory quantities of material yielded $1.49 / Ah, which is significantly lower than the cost of LiCoO2 due to the low cobalt content, and the straightforward synthesis. Li1.222Mn0.444Ni0.167Co0.167O2 is thought to be near optimum composition for the specified synthesis conditions, and shows excellent capacity and safety characteristics while leaving room for optimization in composition, synthesis conditions, and surface treatment.

Owner:COLORADO STATE UNIVERSITY

Encapsulated phase change materials in seed coatings

InactiveUS20090227451A1Good flexibilityIncrease productionBiocideFertilising methodsSeed dormancyPhase change

The present invention is directed to improved seed coatings which facilitate fall or early spring planting while maintaining seed dormancy until soil temperatures are appropriate for successful germination. The improved seed coatings contain encapsulated phase change materials within a polymeric shell which preserve the dormancy of the seed during early planting by slowing the rate at which the seed temperature rises in the event of a temperature spike thus preventing premature germination. The encapsulated phase change material is a material characterized by a solid / liquid or liquid / solid phase change which occurs at a temperature which ranges from about −5 to about 20° C., preferably between about 0 to about 19° C., most preferably between about 5 to about 15° C. The solid / liquid or liquid / solid phase change is further characterized by an effective enthalpy of fusion / crystallization for the solid-liquid / liquid-solid phase change equal to or greater than 20 J / g when determined by Differential Scanning Calorimetry.

Owner:CIBA CORP

Laminates comprising ionomer interlayers with low haze and high moisture resistance

A laminate comprises an ionomeric interlayer sheet which, in turn, comprises or is prepared from a sodium / zinc mixed ionomer that comprises carboxylate groups and a combination of counterions that consists essentially of sodium cations and zinc cations. The sodium / zinc mixed ionomer is the neutralization product of a precursor acid copolymer. The precursor acid copolymer comprises copolymerized units of an α-olefin and an α,β-ethylenically unsaturated carboxylic acid, and it has a melt flow rate of about 70 to about 1000 g / 10 min. In addition, the precursor acid copolymer, when neutralized to a level of about 40% to about 90%, and when comprising counterions that consist essentially of sodium ions, produces a sodium ionomer that has a freeze enthalpy that is not detectable or that is less than about 3.0 j / g, when determined by differential scanning calorimetry.

Owner:DOW GLOBAL TECH LLC

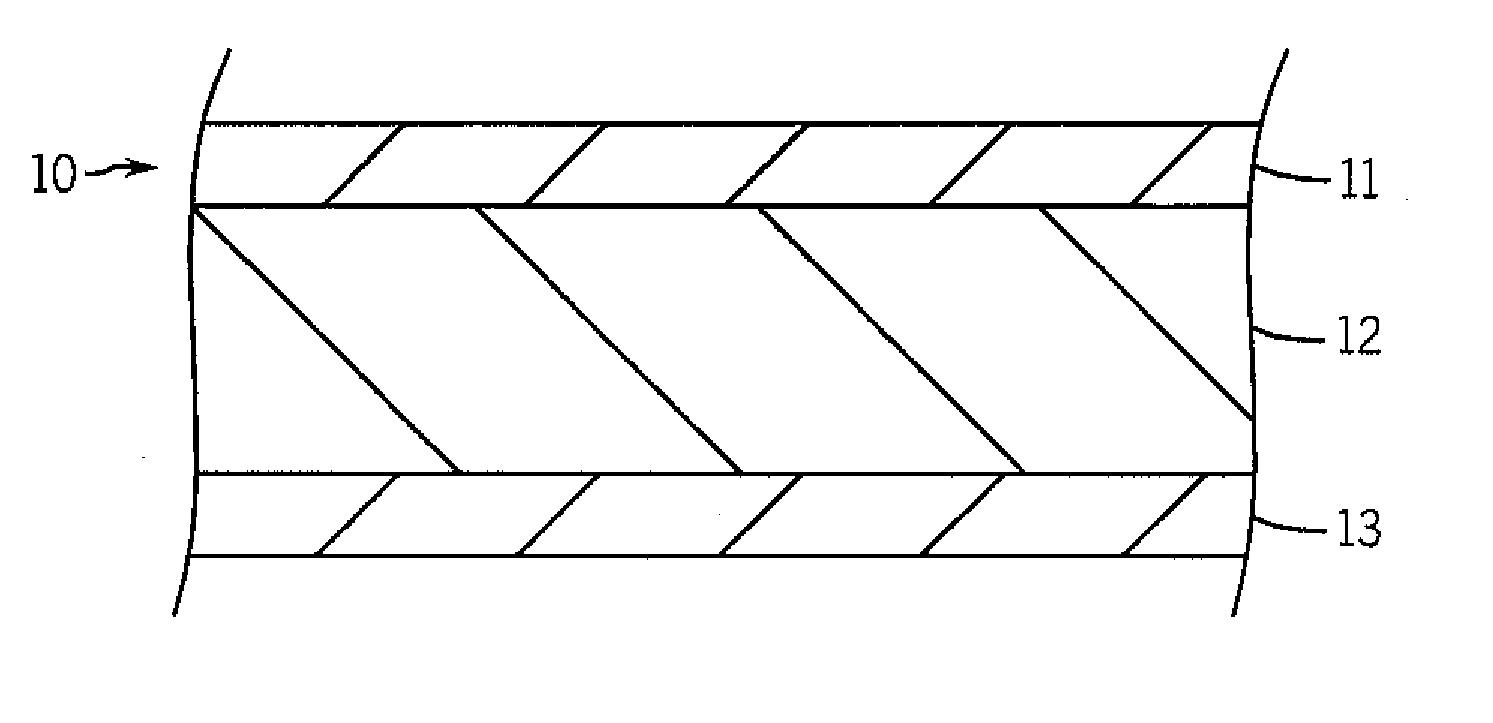

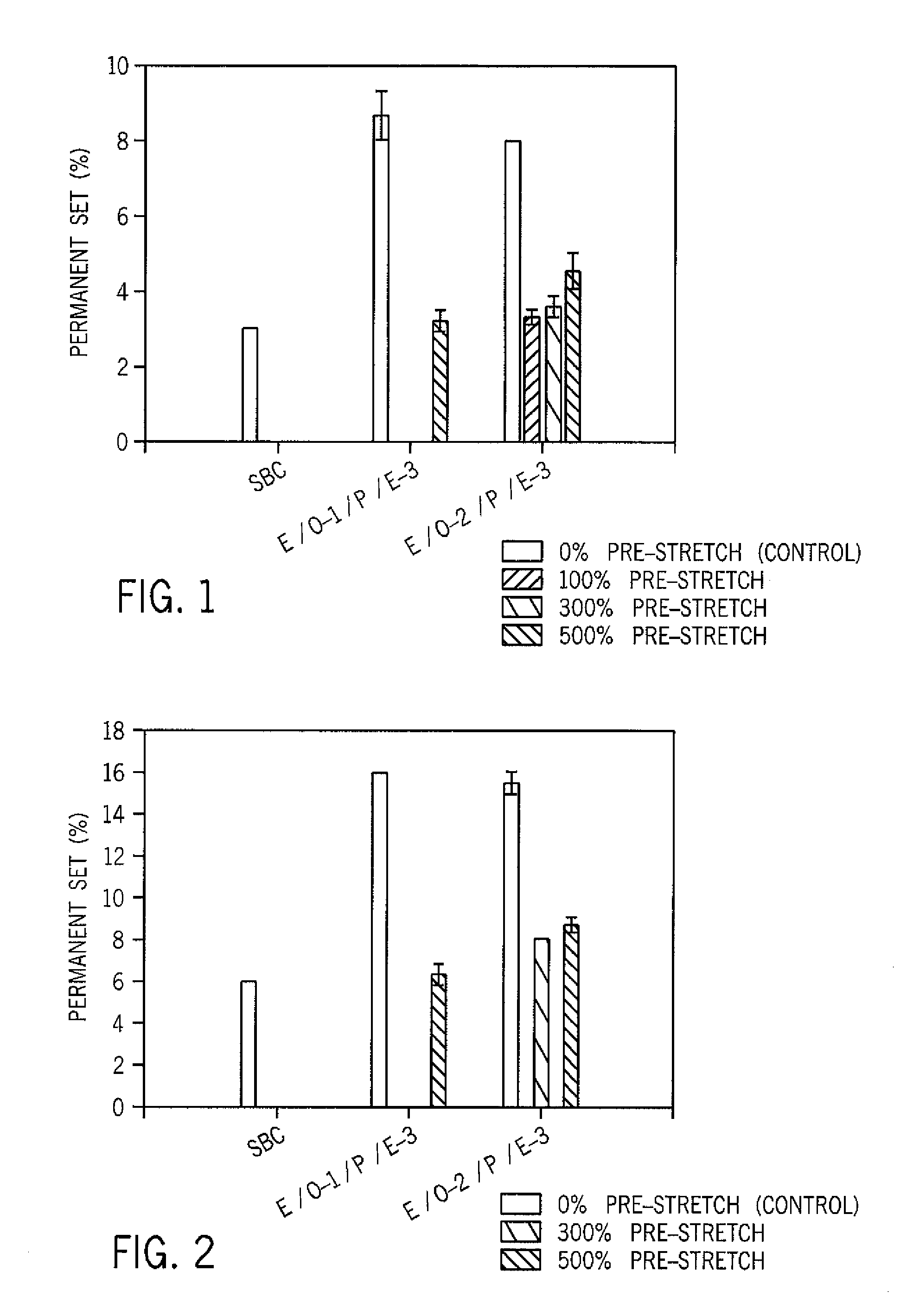

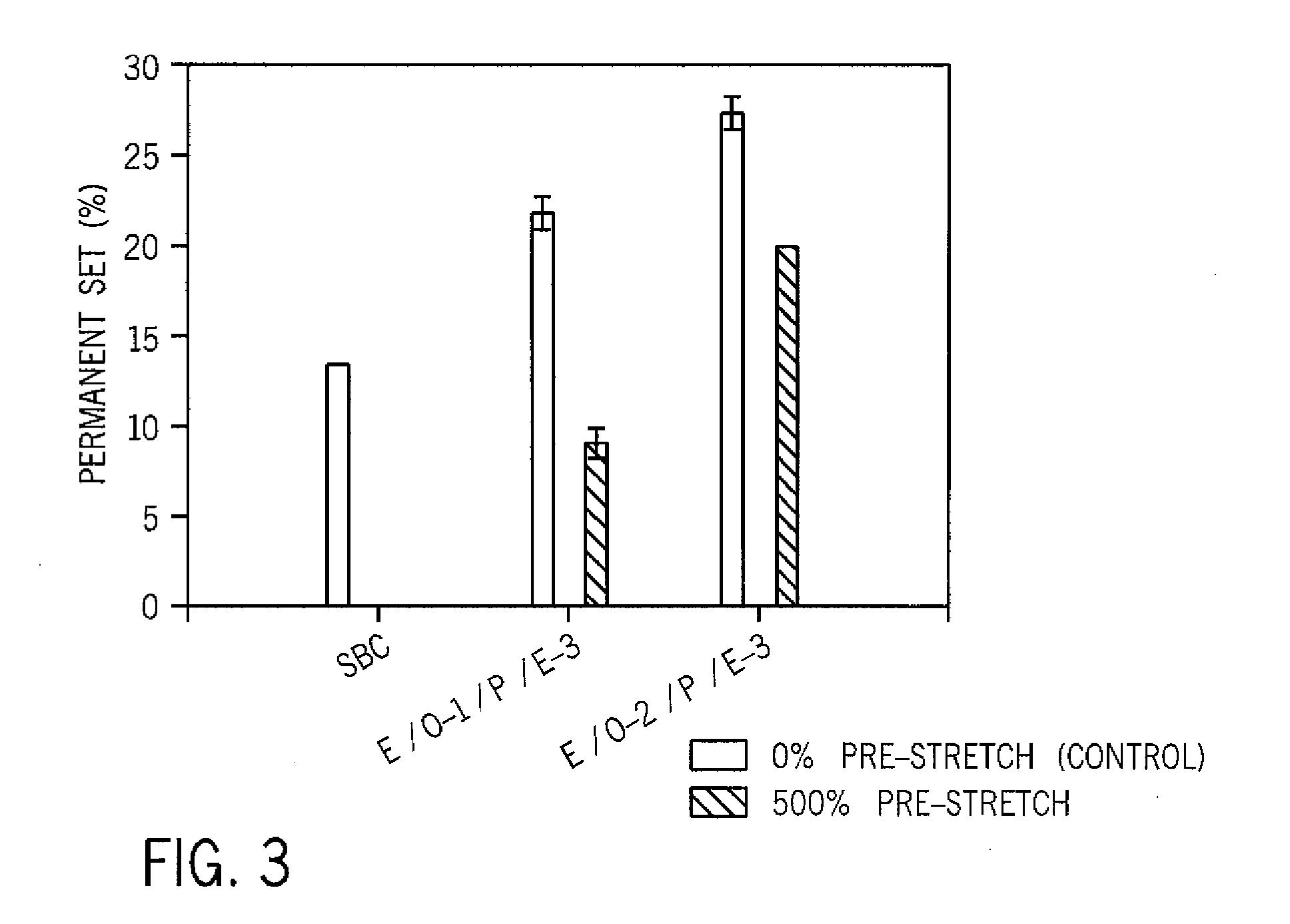

Multi-Layer, Pre-Stretched Elastic Articles

In one embodiment the invention is an article comprising at least two layers, a first or low crystallinity layer comprising a low crystallinity polymer and a second or high crystallinity layer comprising a high crystallinity polymer. The high crystallinity polymer has a melting point as determined by differential scanning calorimetry (DSC) that is about the same or within less than 25 C of the melting point of the low crystallinity polymer. The article is elongated at a temperature below the melting point of the low crystallinity polymer in at least one direction to an elongation of at least about 50% of its original length or width, to form a pre-stretched article. Preferably, the high crystallinity layer is capable of undergoing plastic deformation upon the elongation.

Owner:DOW GLOBAL TECH LLC

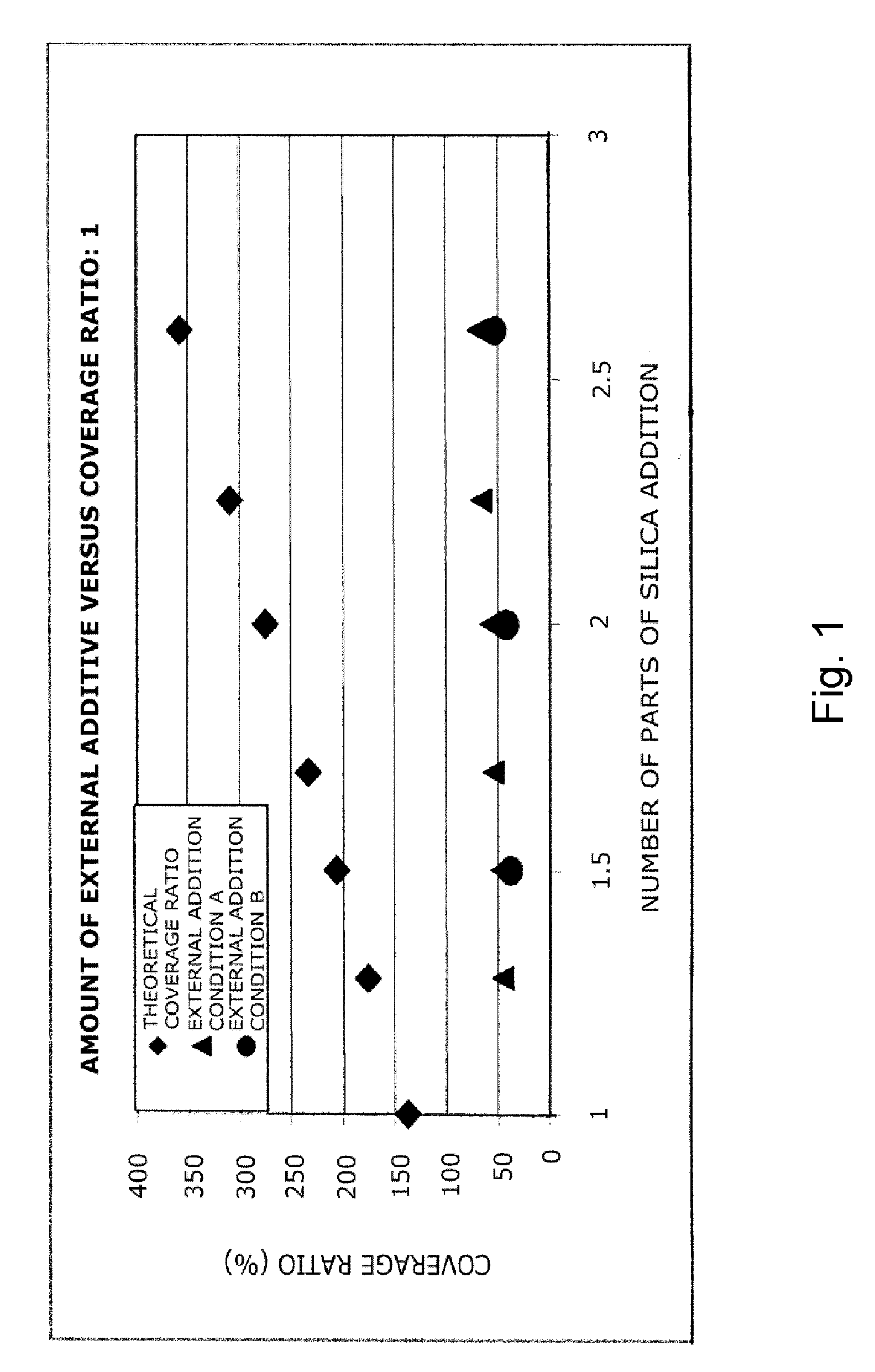

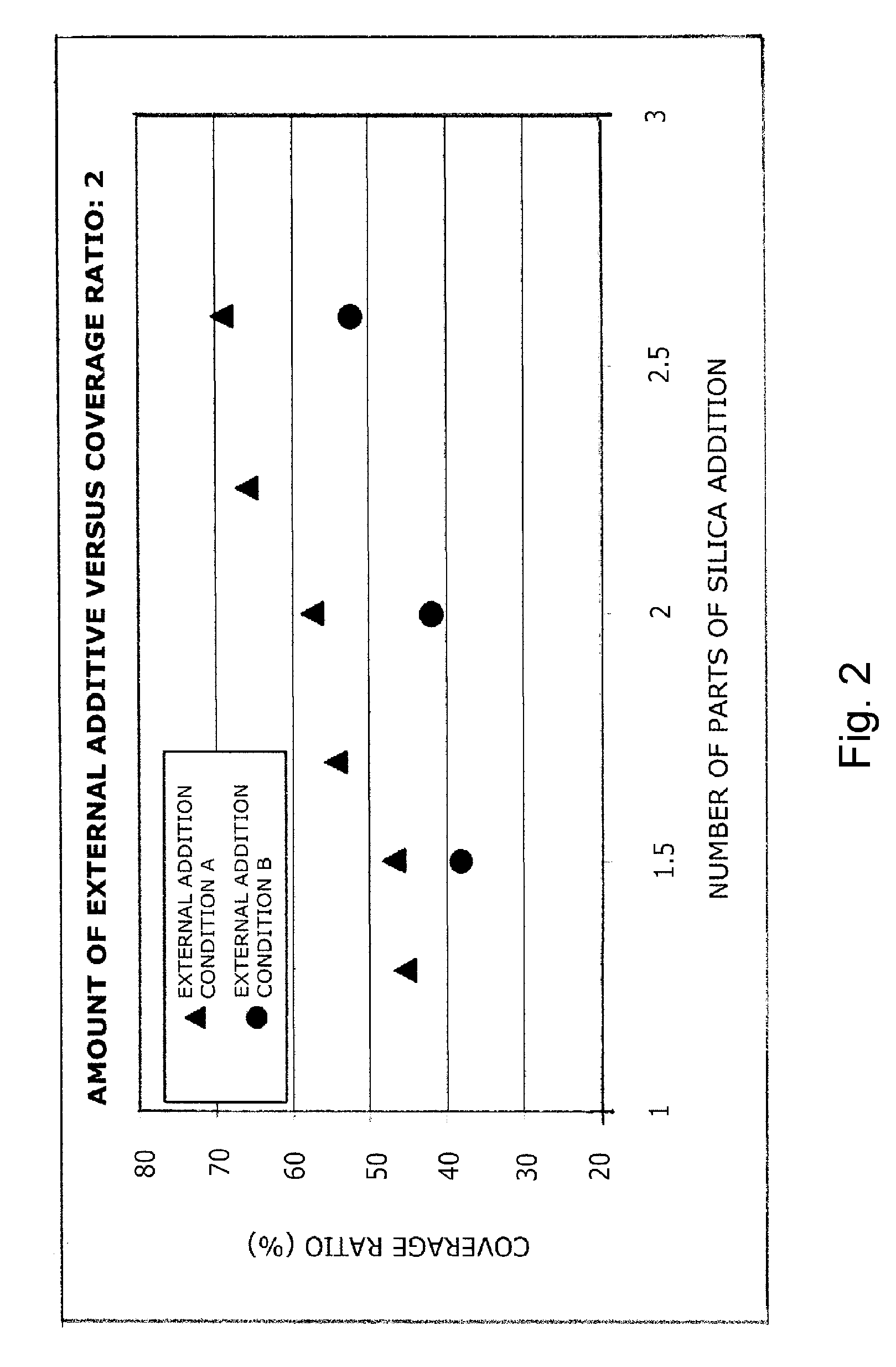

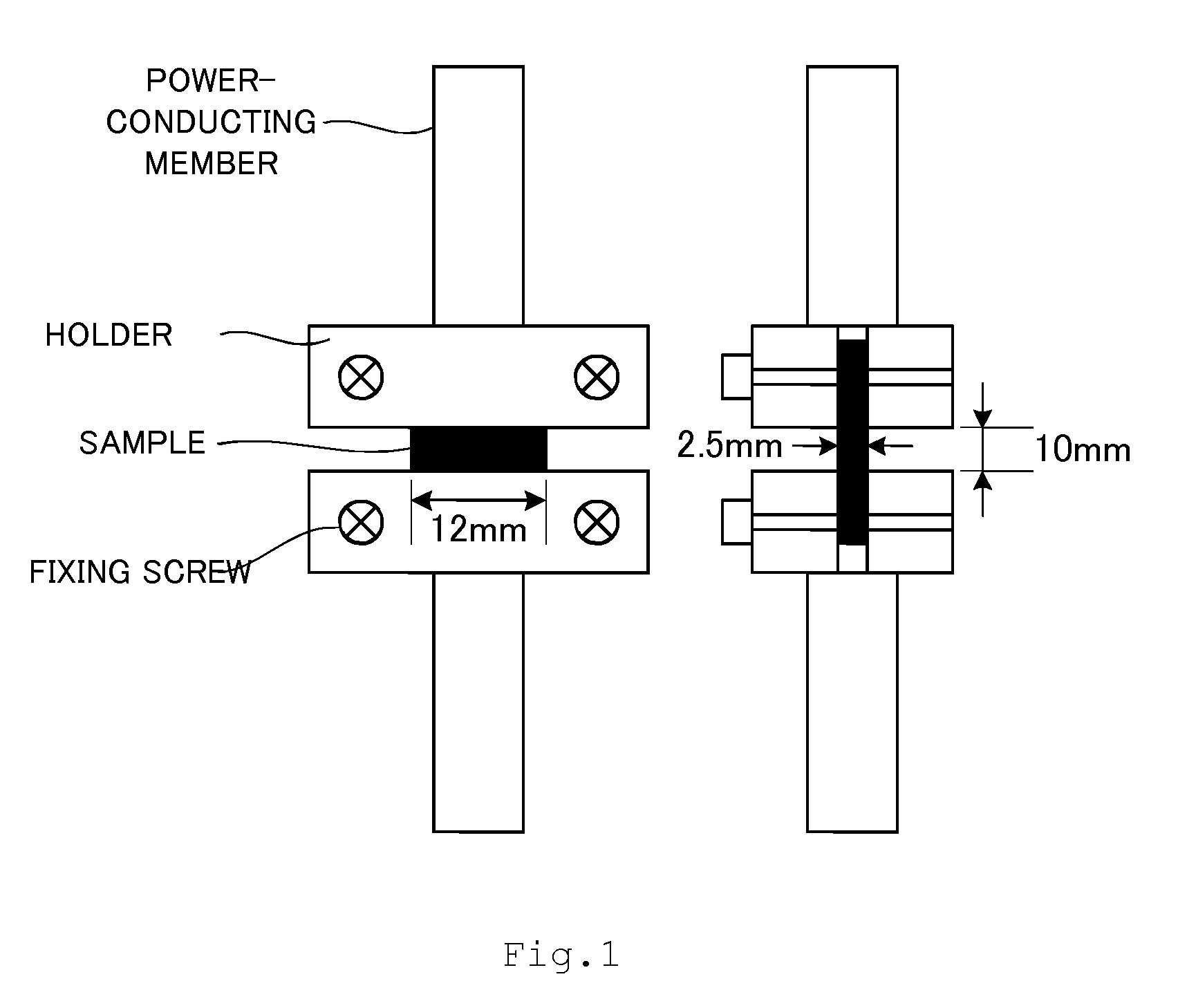

Magnetic toner

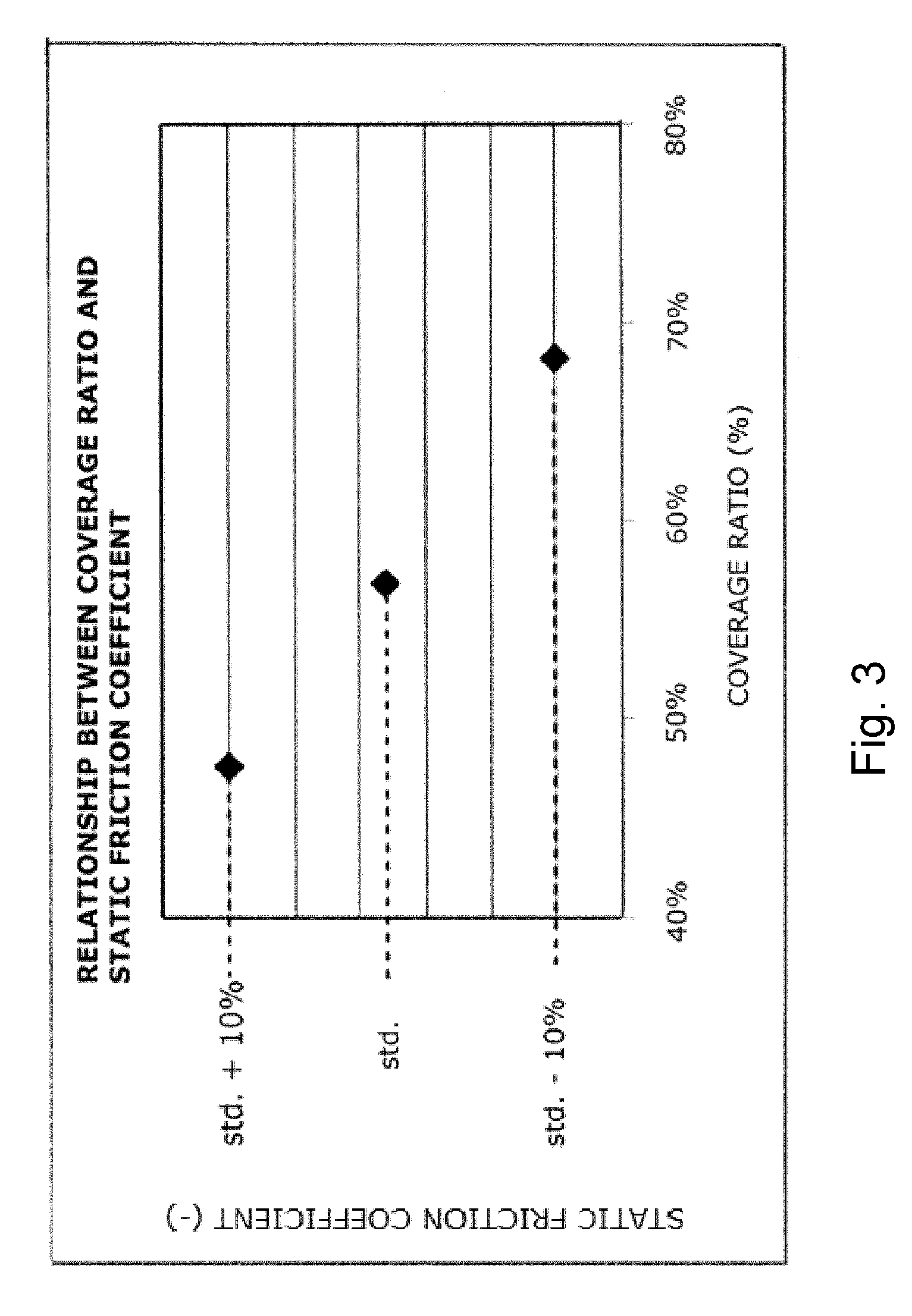

A magnetic toner is provided that exhibits an excellent electrostatic offset resistance both initially and after long-term use. The magnetic toner contains: magnetic toner particles containing a binder resin and a magnetic body; and inorganic fine particles present on the surface of the magnetic toner particles, wherein the inorganic fine particles present on the surface of the magnetic toner particles contain a prescribed metal oxide fine particle in a prescribed proportion; the magnetic toner has prescribed numerical value ranges for a coverage ratio A of the magnetic toner particle surface covered by the inorganic fine particles and for a coverage ratio B by the inorganic fine particles that are fixed to the magnetic toner particle surface; the magnetic toner particle contains a crystalline polyester; and measurement of the magnetic toner with a differential scanning calorimeter provides a characteristic differential scanning calorimetric curve.

Owner:CANON KK

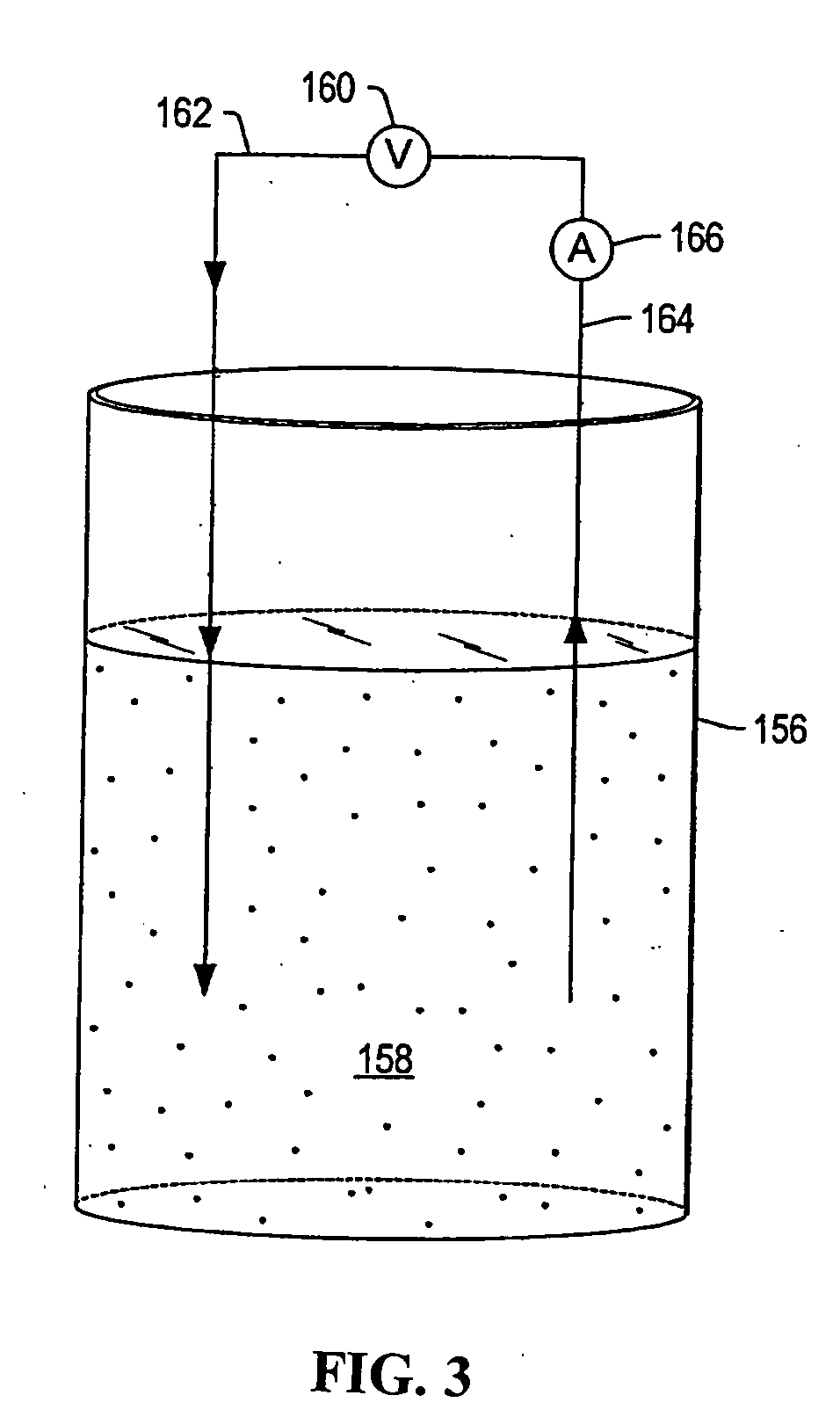

Reaction calorimeter and differential scanning calorimeter for the high-throughput synthesis, screening and characterization of combinatorial libraries

InactiveUS7033840B1Easily adapted to microscaleChemical analysis using catalysisChemical analysis using titrationReaction calorimeterHigh flux

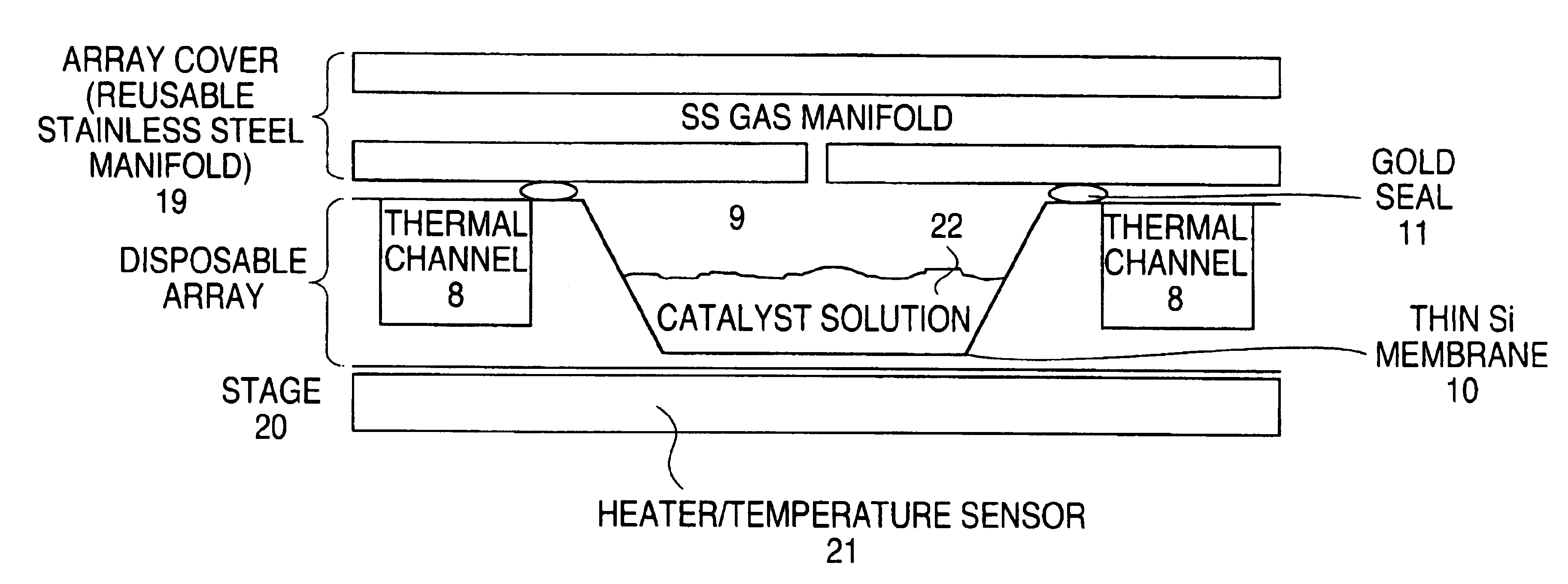

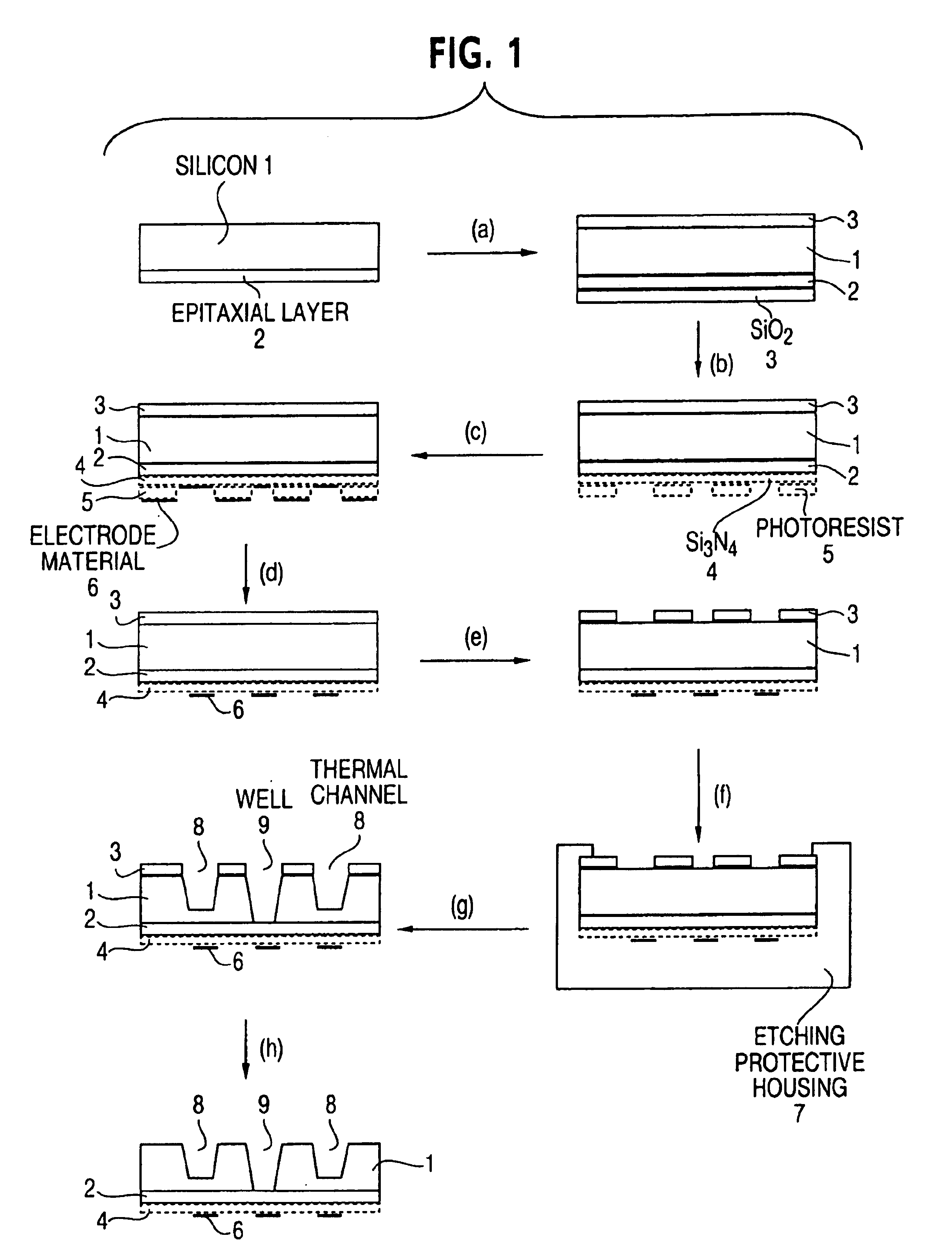

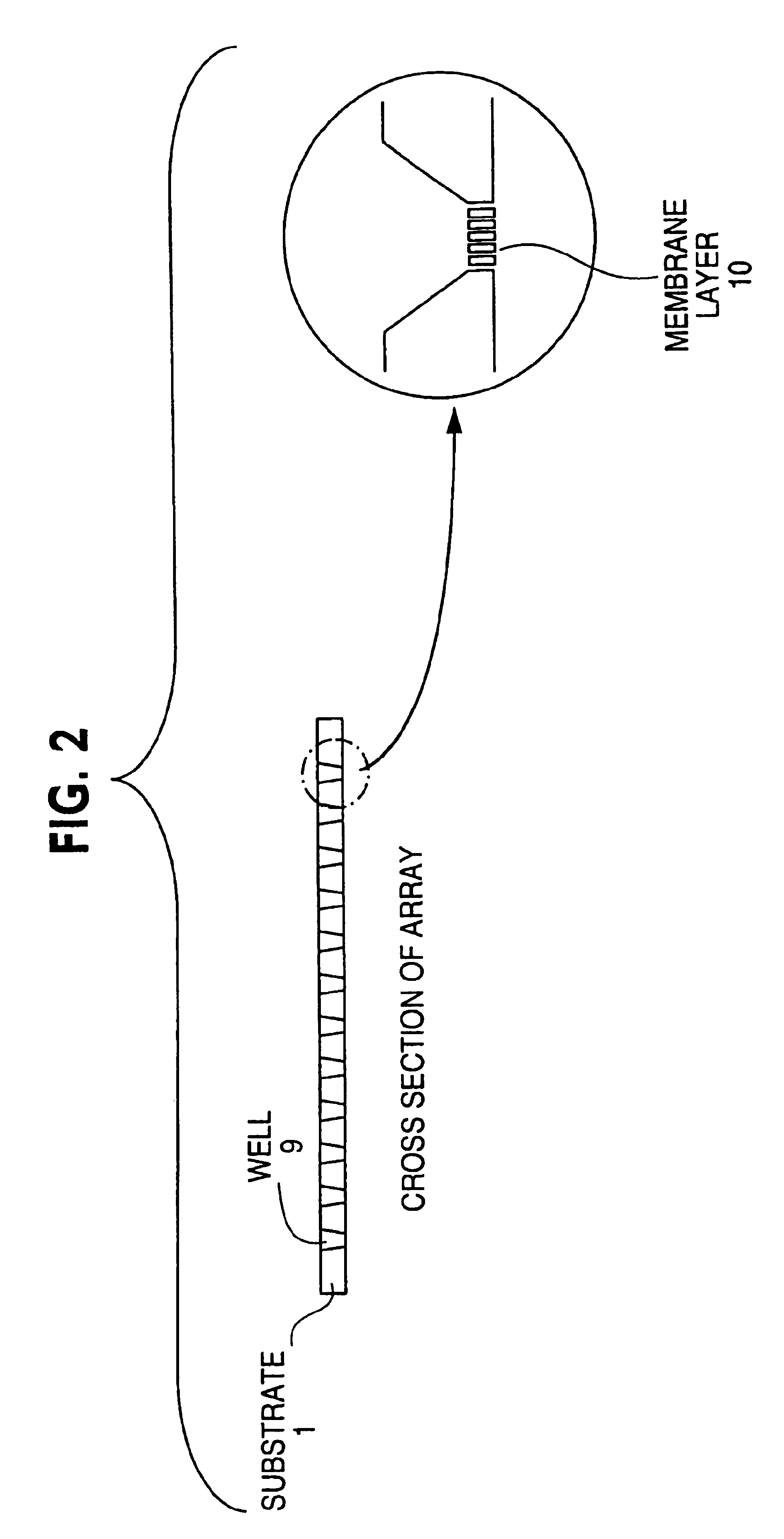

Workstation, apparatuses and methods for the high-throughput synthesis, screening and / or characterization of combinatorial libraries. The invention relates to an array, which permits various high-throughput methods for synthesis, screening and / or characterization in the same array, without requiring sample transfer from the array. In a preferred embodiment, the synthesis, screening, and / or characterization steps are carried out in a highly parallel fashion, where more than one compound is synthesized, screened, and / or characterized at the same time. The invention may be practiced at the microscale. The array may comprise thermal channels, for regulating the temperature of the wells in the array. The wells of the array may comprise a membrane, which is used in various screening and characterization methods. The invention also relates to a covered array, comprising the array and an array cover, as well as an apparatus comprising the array, which comprises the array, an array cover and a stage. The array, array cover, and the stage may be modified as required for a variety of synthesis and / or analysis techniques. The array is easily interchangeable between different analytical instruments, and in an embodiment, the invention relates to an automated workstation, where the array is transferred between different synthesis, screening, and characterization stations. The invention also relates to a variety of methods for synthesis, screening, and characterization, which are adapted for combinatorial chemistry. Any of the embodiments of the invention may be used either alone or taken in various combinations.

Owner:SRI INTERNATIONAL

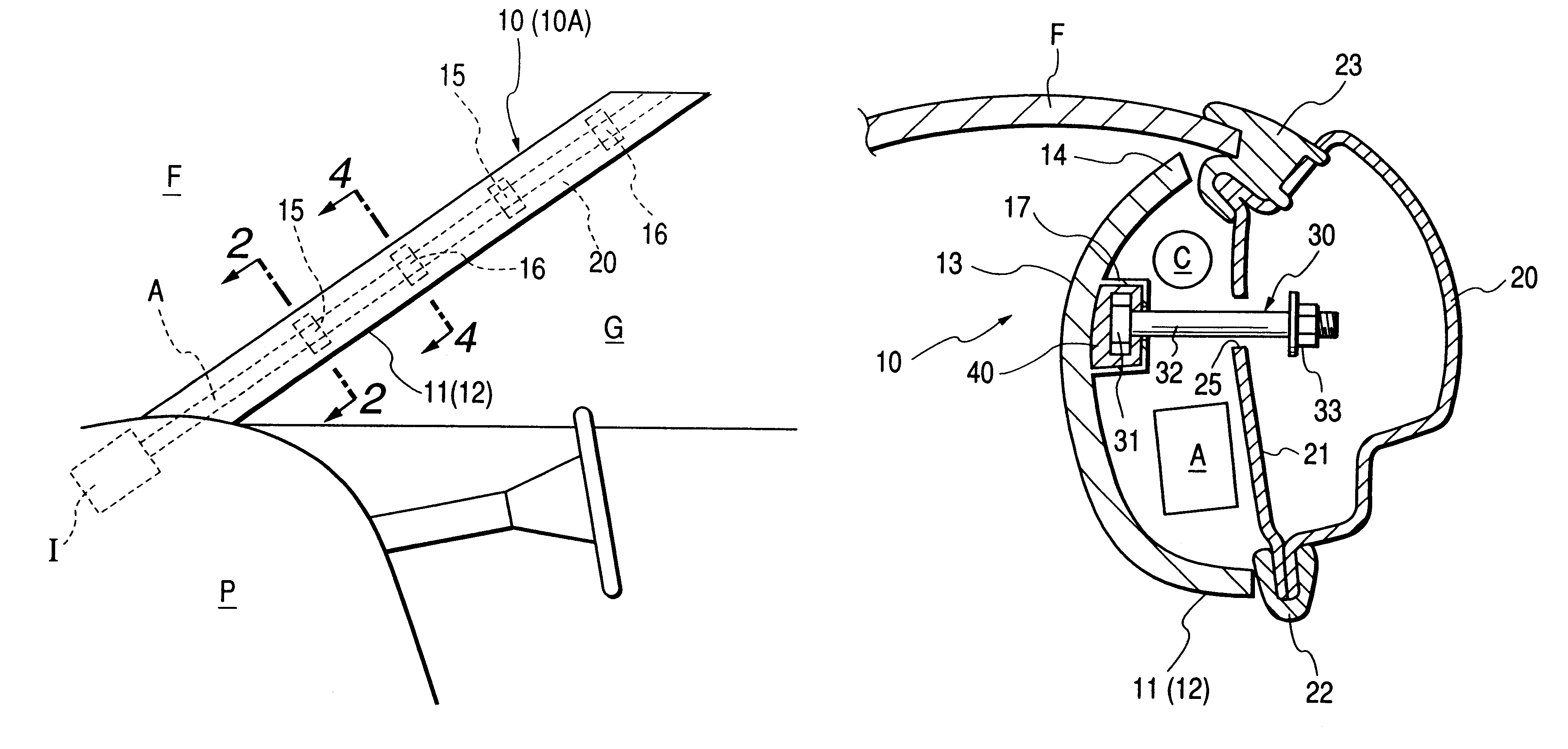

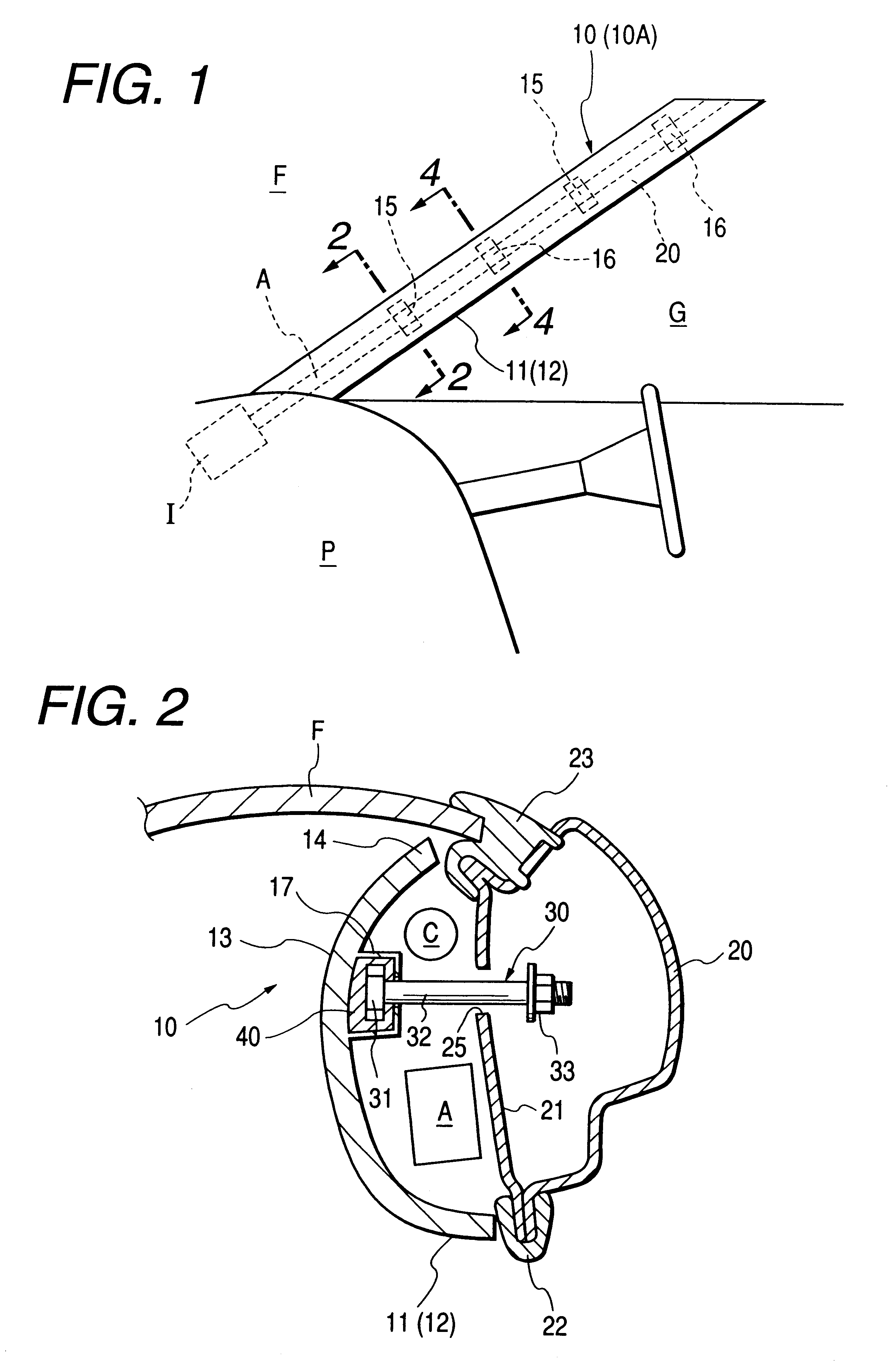

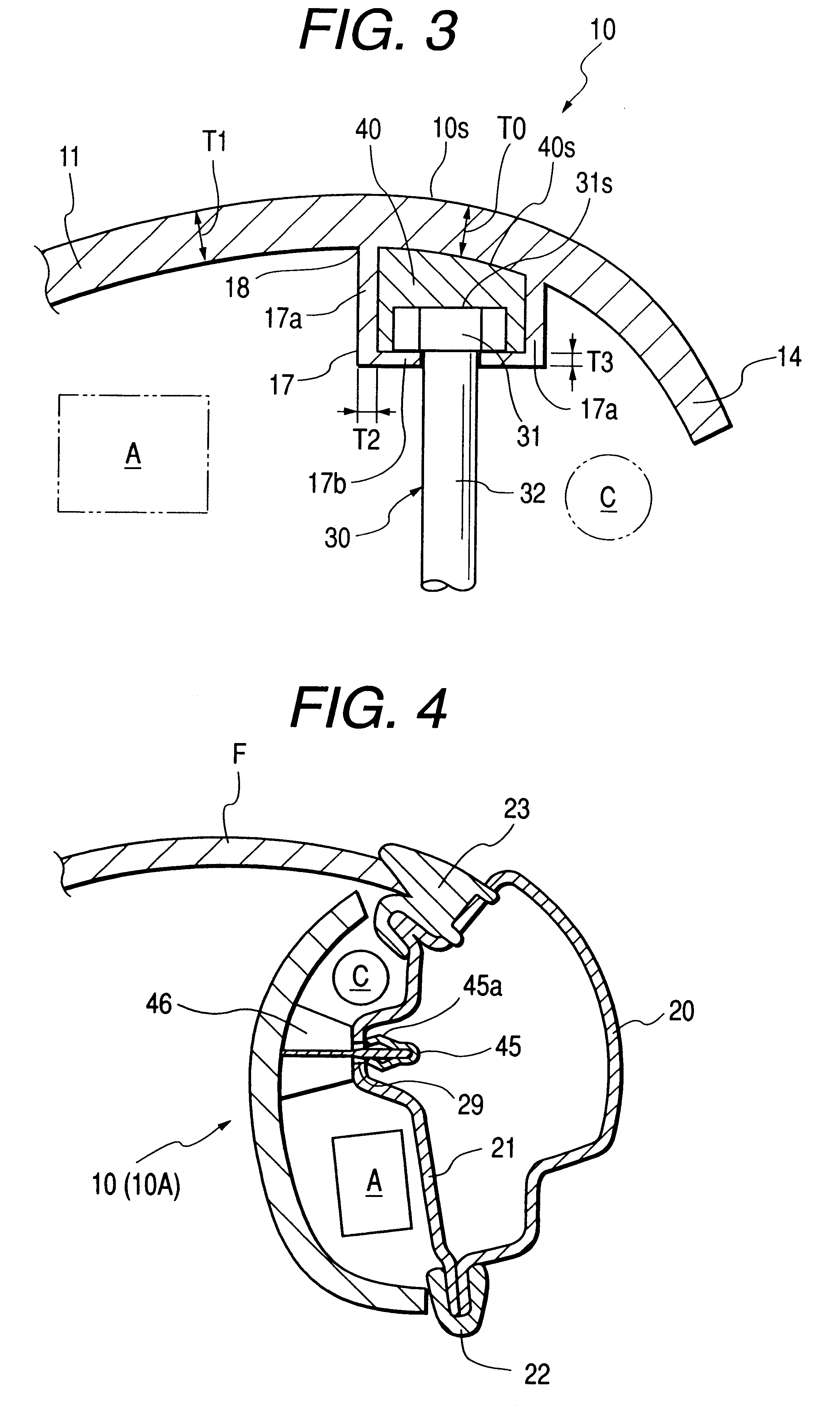

Pillar unit

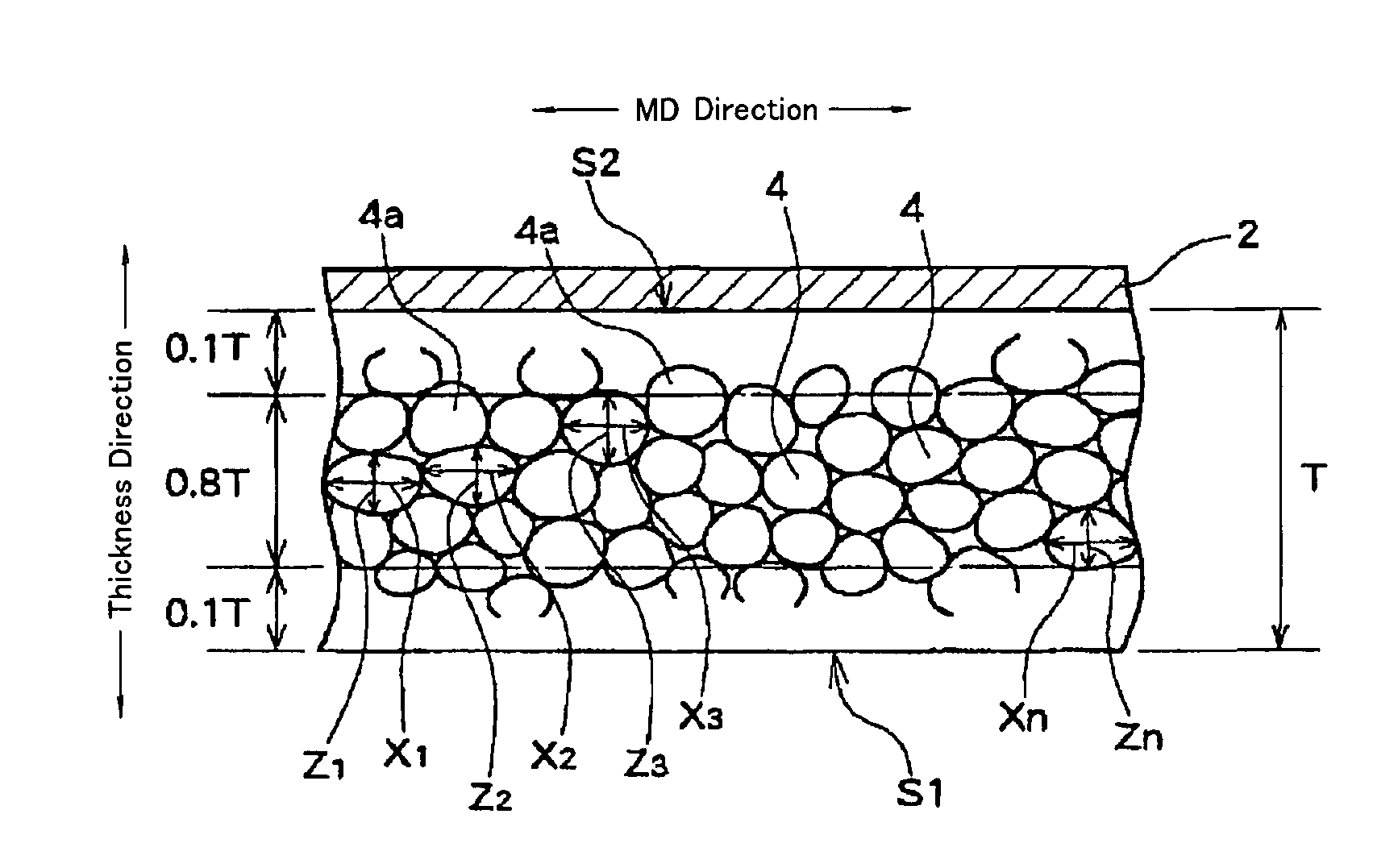

A structure for joining a pillar garnish including an air bag, incorporating: a pillar garnish 10 made of synthetic resin and having a reverse side from which a seat portion 17 projects into which a head 31 of a rod-shape fixing metal member 31 is embedded; and an engaging portion 33 formed at another end of the rod-shape fixing metal member and inserted and engaged into the inside portion of an engaging hole 25 of a pillar portion of the car body, wherein the head 31 of the rod-shape fixing metal member 30 is covered with a coating layer 40 made of synthetic resin to make the thickness of the pillar garnish surrounded by the side surface of the seat portion to be uniform, the resin for constituting the coating layer contains polyolefine by 40 wt % or greater and having the relationship between peak area S1 which indicates a heating value required to melt polypropylene and detected by differential scanning calorie measurement (DSC) and peak area S2 indicating a heating value required to melt a component which is melted at a temperature lower than the temperature at which polypropylene is melted, the relationship satisfying S2 / S1<½.

Owner:INOAC CORP

Multi-layer microporous polyolefin membrane and battery separator

ActiveUS20090274955A1Well-balanced propertyGood film formingMembranesSemi-permeable membranesSurface layerPolymer science

A multi-layer, microporous polyolefin membrane having at least three layers, which comprises first microporous layers made of a polyethylene resin for constituting at least both surface layers, and at least one second microporous layer comprising a polyethylene resin and polypropylene and disposed between both surface layers, the heat of fusion (ΔHm) of the polypropylene measured by differential scanning calorimetry being 90 J / g or more, and the polypropylene content in the second microporous layer being 50% or less by mass based on 100% by mass of the total of the polyethylene resin and the polypropylene.

Owner:TORAY IND INC

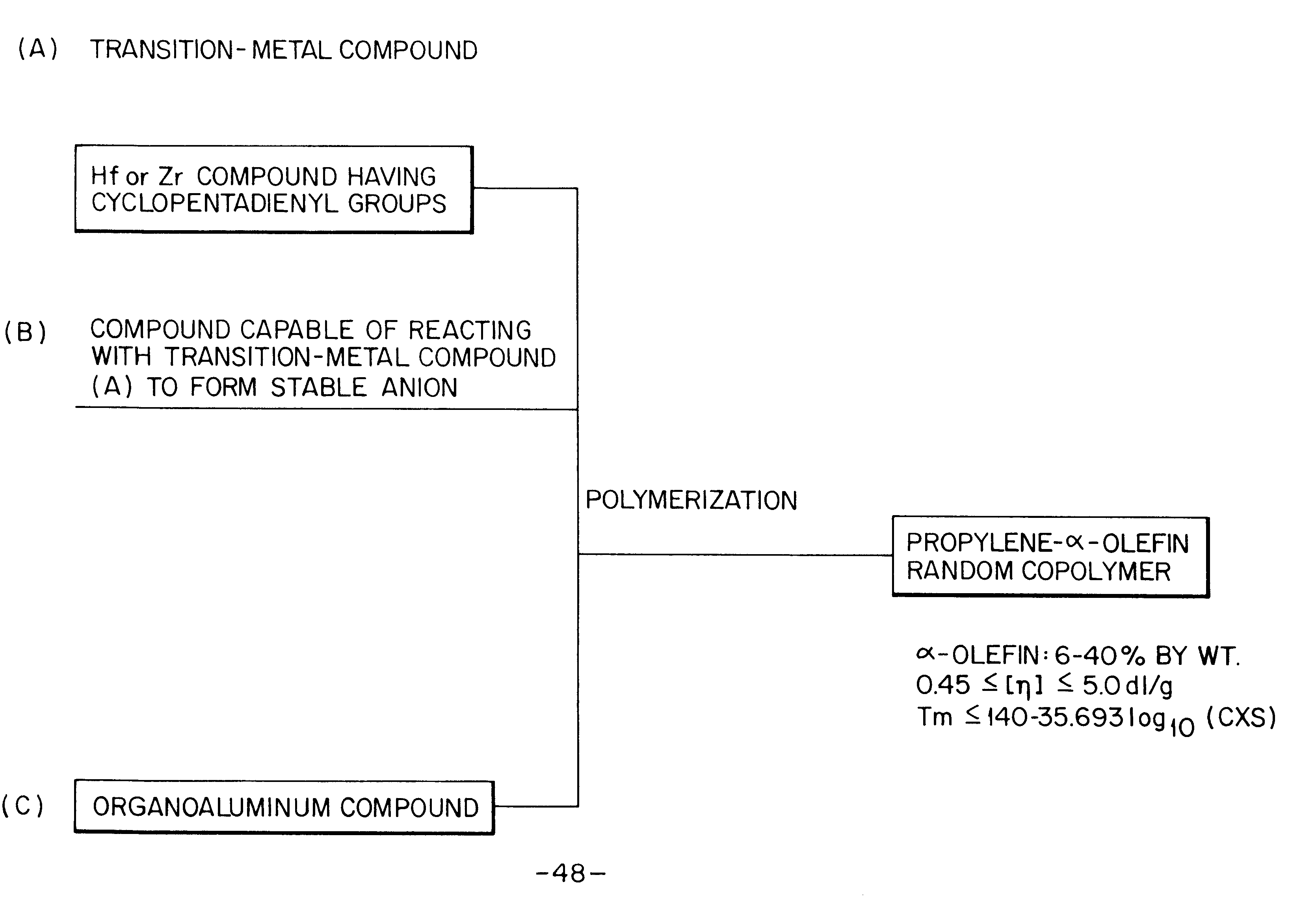

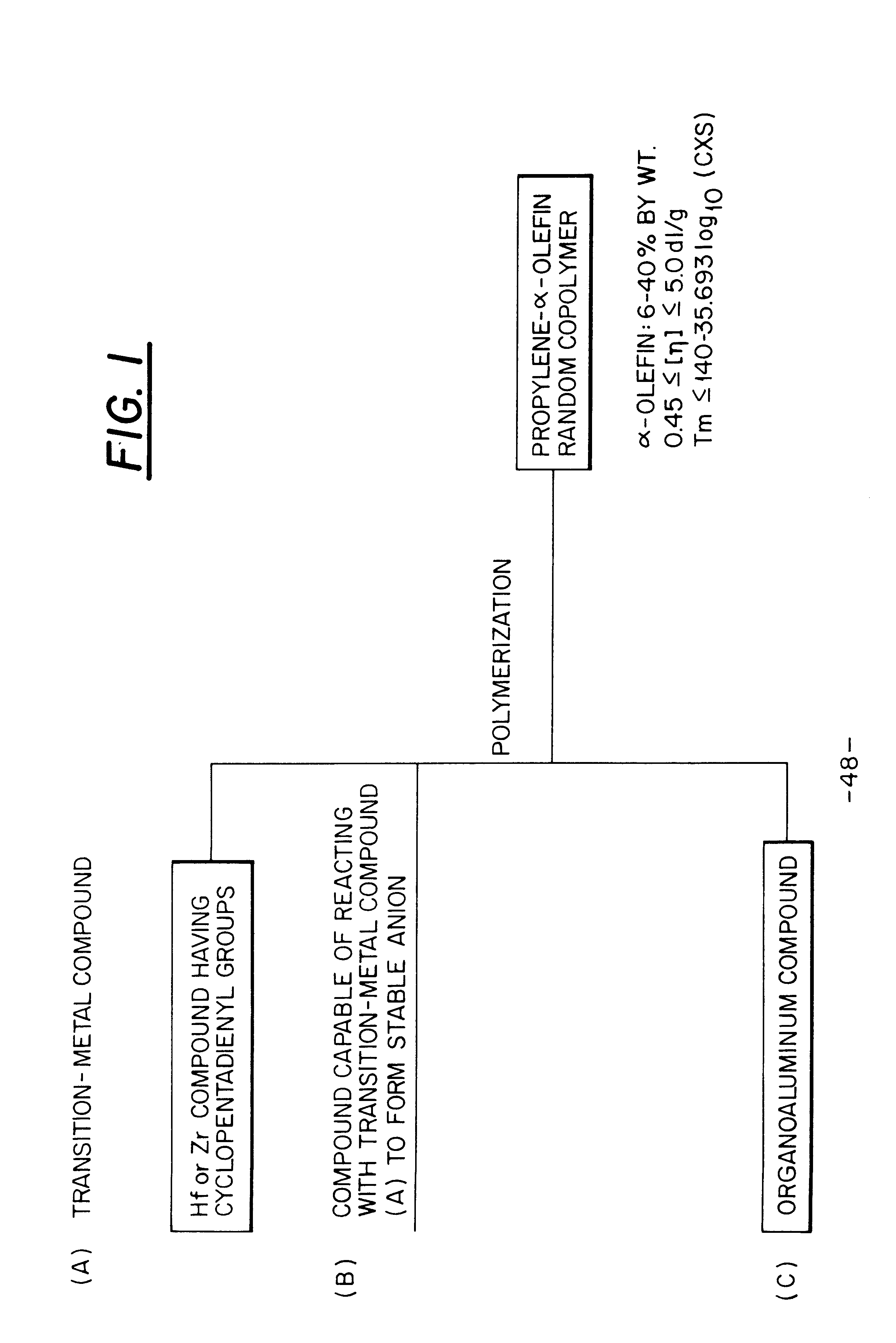

Propylene random copolymer and film laminate thereof

InactiveUS6214952B1Excellent blocking resistanceHigh transparencySynthetic resin layered productsThin material handlingElectricityTetralin

A propylene random copolymer and a film laminate thereof is described having excellent blocking resistance and transparency and substantially maintaining favorable low-temperature heat-sealing properties after corona discharge treatment. The propylene random copolymer of the invention includes a propylene component and an alpha-olefin component having 4 to 10 carbon atoms, wherein the content of the alpha-olefin component is in the range of about 6% to about 40% by weight, the intrinsic viscosity [eta] measured in tetralin at 135° C. is not lower than about 0.45 dl / g and not higher than about 5.0 dl / g, and the melting point (Tm) measured by a differential scanning calorimeter and the content of 20° C. xylene soluble fraction (CSX) fulfill a relationship of

Owner:SUMITOMO CHEM CO LTD

Toner and developer

ActiveUS20130059247A1Excellent low temperature fixabilityHot offset resistanceDevelopersVitrificationPolyester resin

To provide a toner, which contains: a non-crystalline polyester resin A obtained through a reaction between a non-linear chain reactive precursor and a curing agent, and having a glass transition temperature of −60° C. to 0° C.; a non-crystalline polyester resin B having a glass transition temperature of 40° C. to 70° C.; and a crystalline polyester resin C, wherein the toner has a glass transition temperature Tg1st of 20° C. to 40° C. as measured with first heating in differential scanning calorimetry (DSC).

Owner:RICOH KK

Method of decomposing polymer

InactiveUS20050148487A1Liquid hydrocarbon mixture productionDetergent powders/flakes/sheetsInorganic saltsLiquid product

Inventions described herein generally relate a process for contacting a polymeric feed with one or more inorganic salt catalysts to produce a total product comprising a liquid product and, in some embodiments, non-condensable gas. In some embodiments, the inorganic salt catalyst exhibits an emitted gas inflection of an emitted gas in a temperature range between 50° C. and 500° C., as determined by Temporal Analysis of Products. In some embodiments, the inorganic salt catalyst has a heat transition in a temperature range between 200° C. and 500° C., as determined by differential scanning calorimetry (DSC), at a rate of 10° C. per minute. Inventions described herein also generally relate to compositions that have novel combinations of components therein.

Owner:SHELL OIL CO

Toner

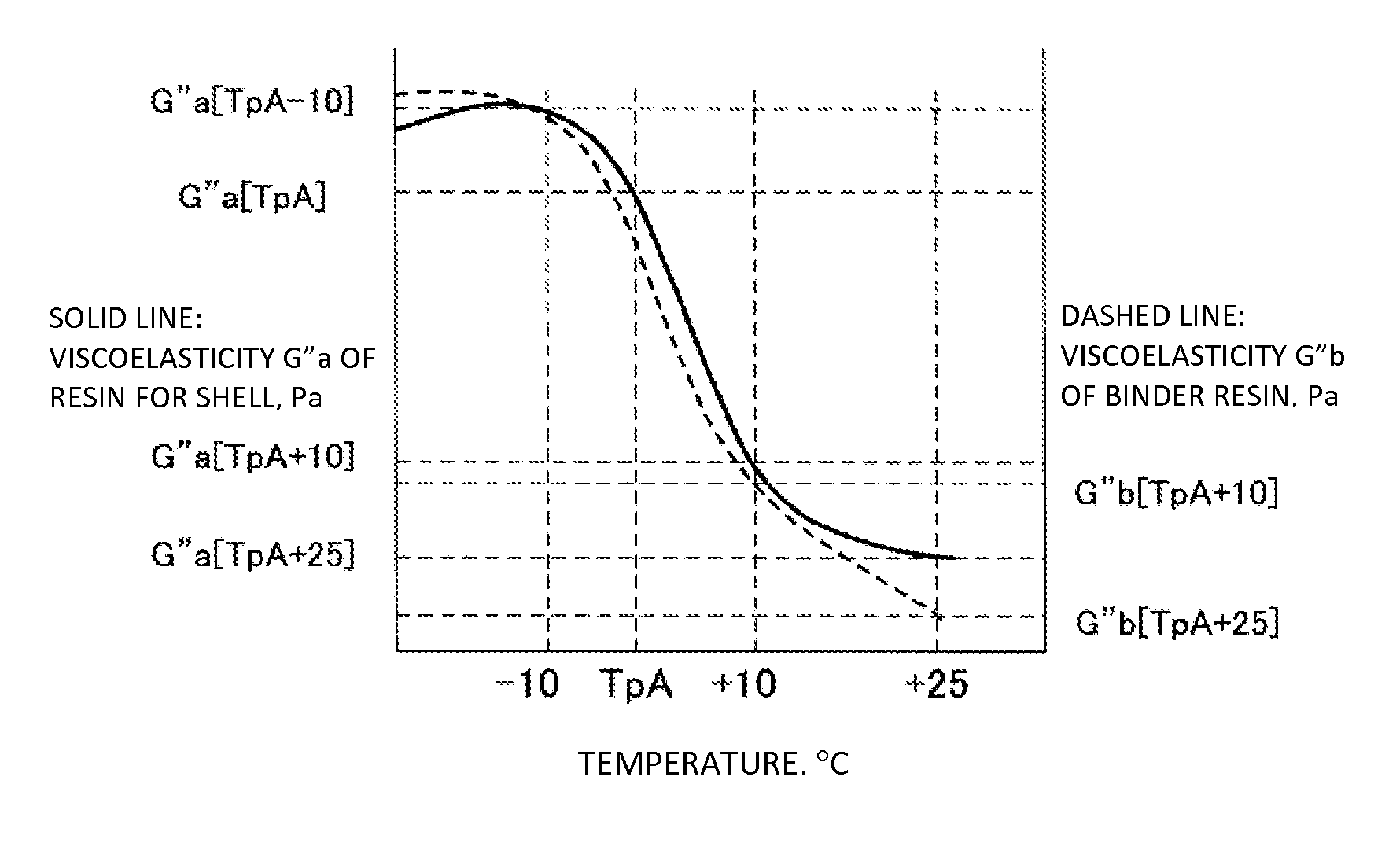

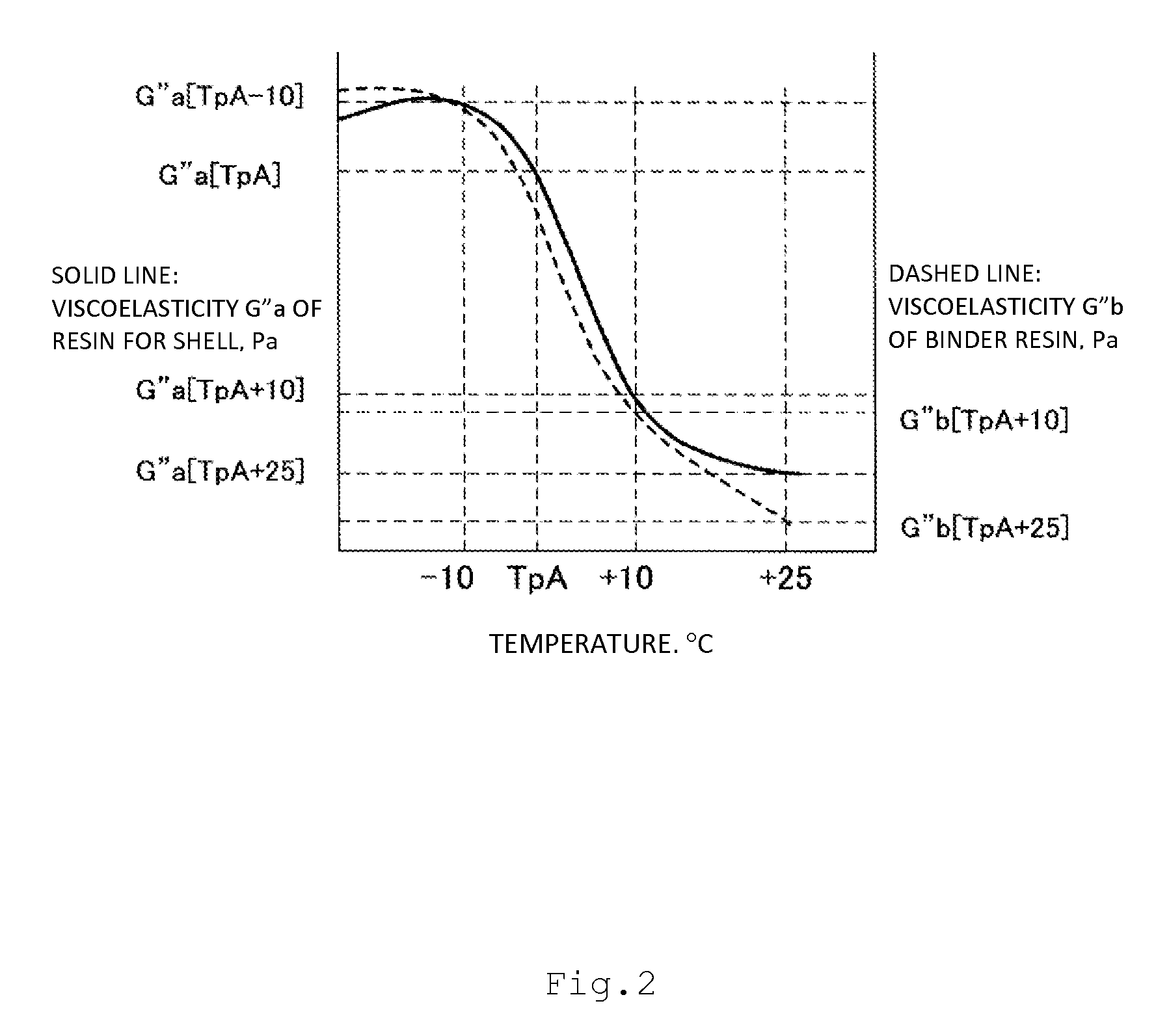

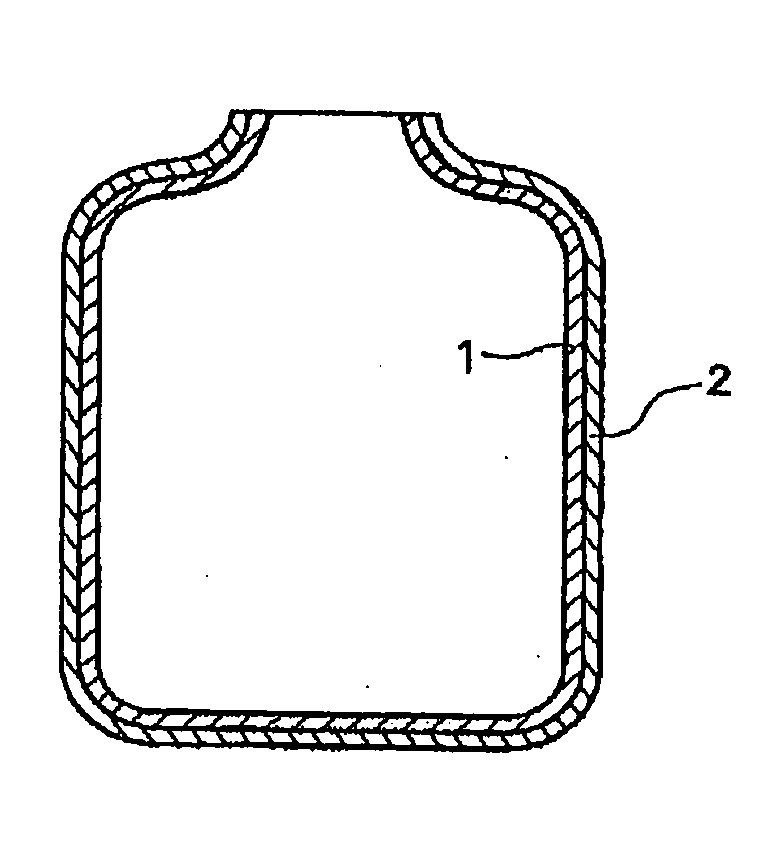

Provided is a toner having an excellent low-temperature fixability and hot offset resistance, a broad fixing temperature latitude in low-temperature areas to high-temperature areas, and a high heat-resistant storage stability. The toner includes toner particles having a core-shell structure in which a shell phase containing a resin A is formed on a core containing a binder resin, a colorant and a wax. In measurement of resin A by a differential scanning calorimetry (DSC), the peak temperature TpA (° C.) of a maximum endothermic peak in the first temperature rise is at least 55° C. but not more than 80° C. In measurement of a viscoelasticity of resin A, the loss elastic modulus at TpA−10 (° C.) is at least 1×107 Pa but not more than 1×108 Pa. In measurement of the viscoelasticity of resin A, the loss elastic moduli at TpA (° C.), TpA+10 (° C.) and TpA+25 (° C.) satisfy specific conditions.

Owner:CANON KK

Polylactic acid resin foamed molding and process for manufacturing the same

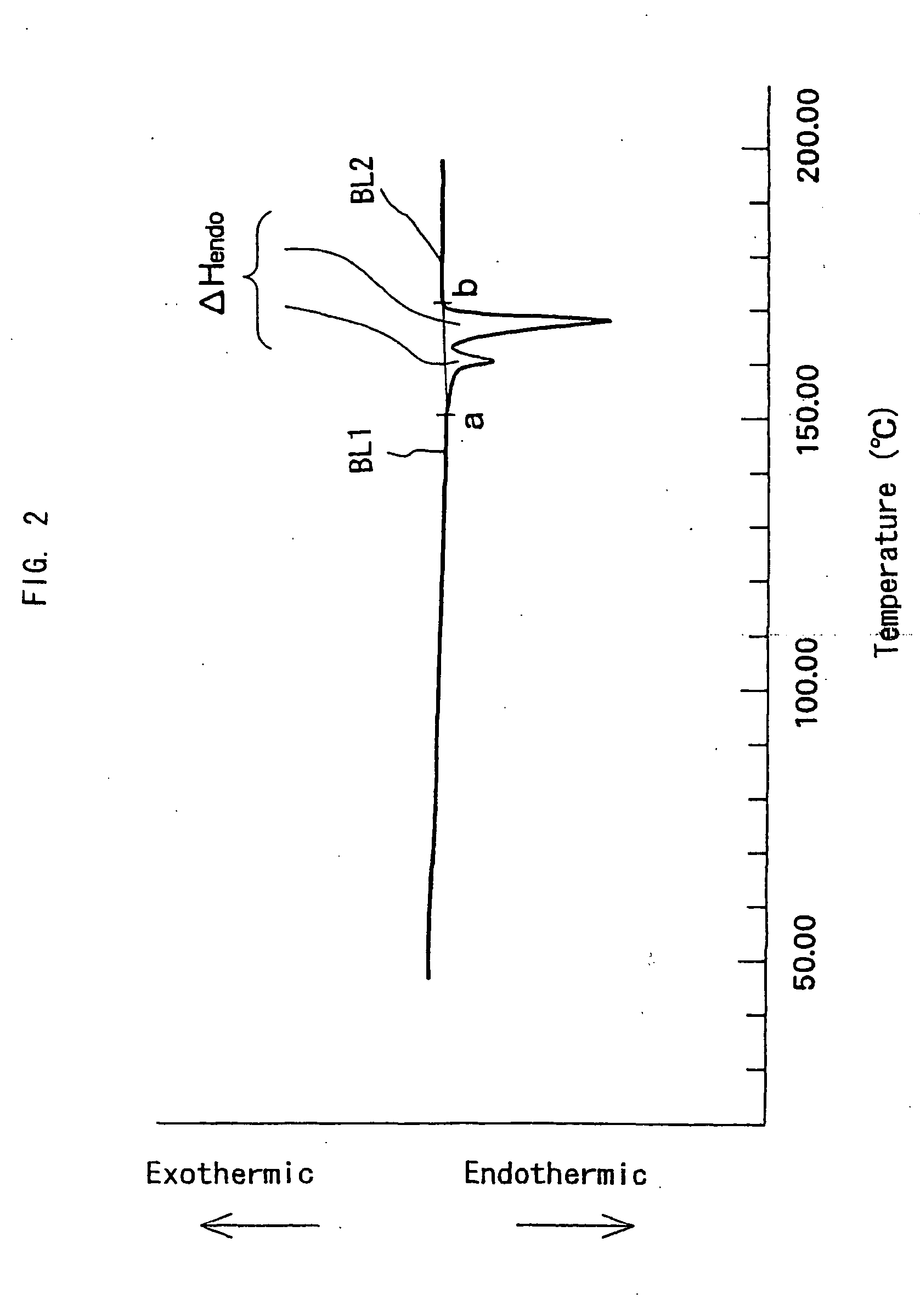

A polylactic acid resin foamed molding obtained by placing in a mold a cylindrical body having a foamed layer, which is formed by extruding a foamable molten resin composition prepared by kneading together a polylactic acid resin and a physical blowing agent from a die into a low-pressure zone, and molding it, wherein the molding's foamed layer constituting the foamed molding has a difference (ΔHendo:2° C. / min−ΔHexo:2° C. / min) between the endothermic calorific value (ΔHendo:2° C. / min) and the exothermic calorific value (ΔHexo:2° C. / min) obtained by heat flux differential scanning calorimetry (heating rate of 2° C, / min) of 10 J / g or more and a melt tension at 190° C. of 2 cN or more.

Owner:JSP CORP

Toner

Provided is toner which is excellent in developing property, transferring property, and fixing property, hardly affected by its surrounding, and has good endurance. The toner has a peak temperature of maximum endothermic peak in the range of 60 to 100° C. in an endothermic curve of differential scanning calorimetry (DSC) measurement;silica particles in the toner contain a titanium element; andthe silica particles satisfy the following expressions.0.7≦(Ia1 / Ib1)≦2.00.7≦(Ia2 / Ib2)≦2.0where Ia1 represents a maximum intensity in the case of 2θ=25.3 deg, Ib1 represents a mean intensity in the cases of 2θ=25.3 deg+2.0 deg. and of 2θ=25.3 deg.−2.0 deg., Ia2 represents a maximum intensity in the case of 2θ=27.5 deg and Ib2 represents a mean intensity in the cases of 2θ=27.5. deg+2.0 deg. and of 2θ=27.5 deg.−2.0 deg.

Owner:CANON KK

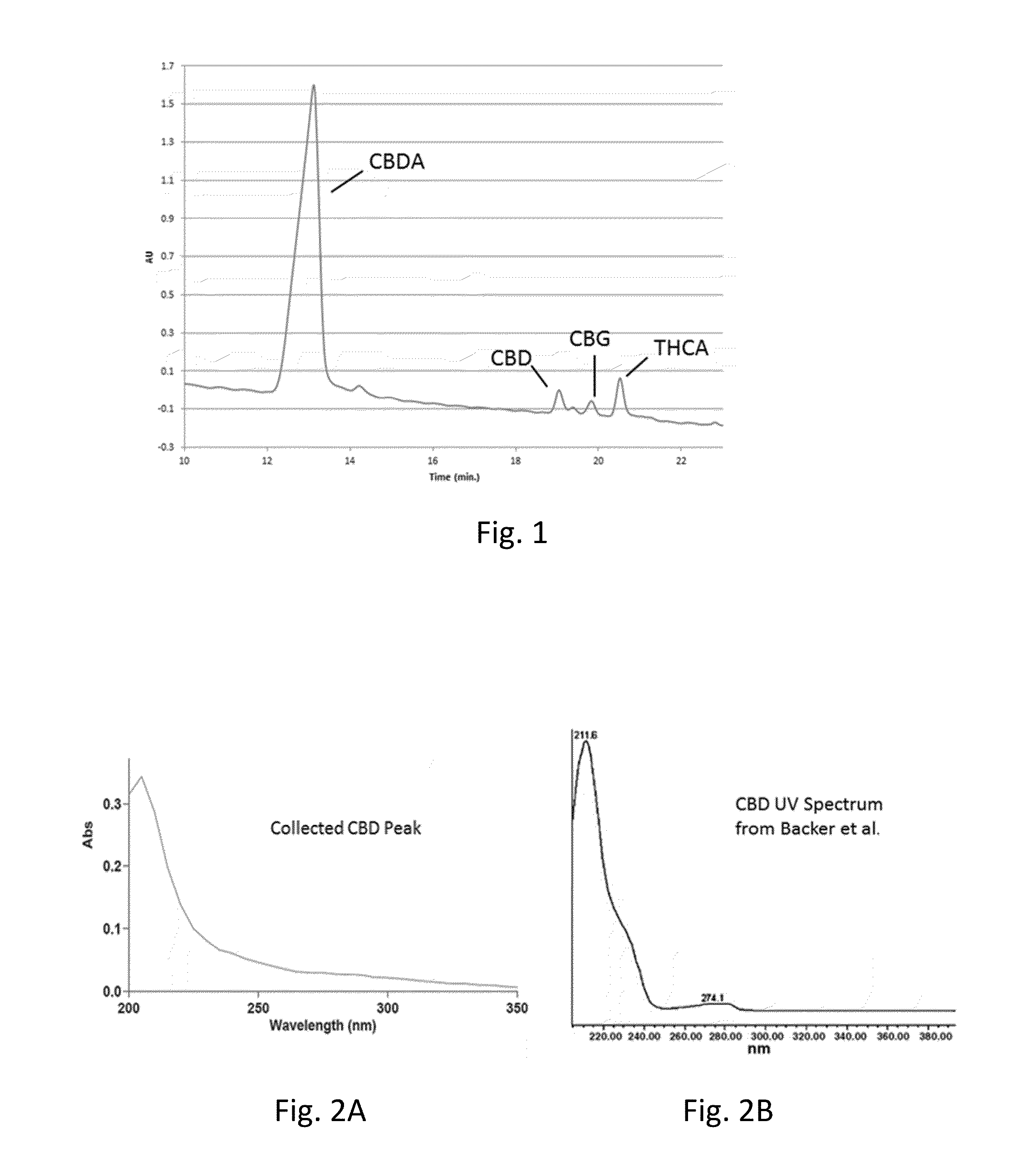

Purified cbd and cbda, and methods, compositions and products employing cbd or cbda

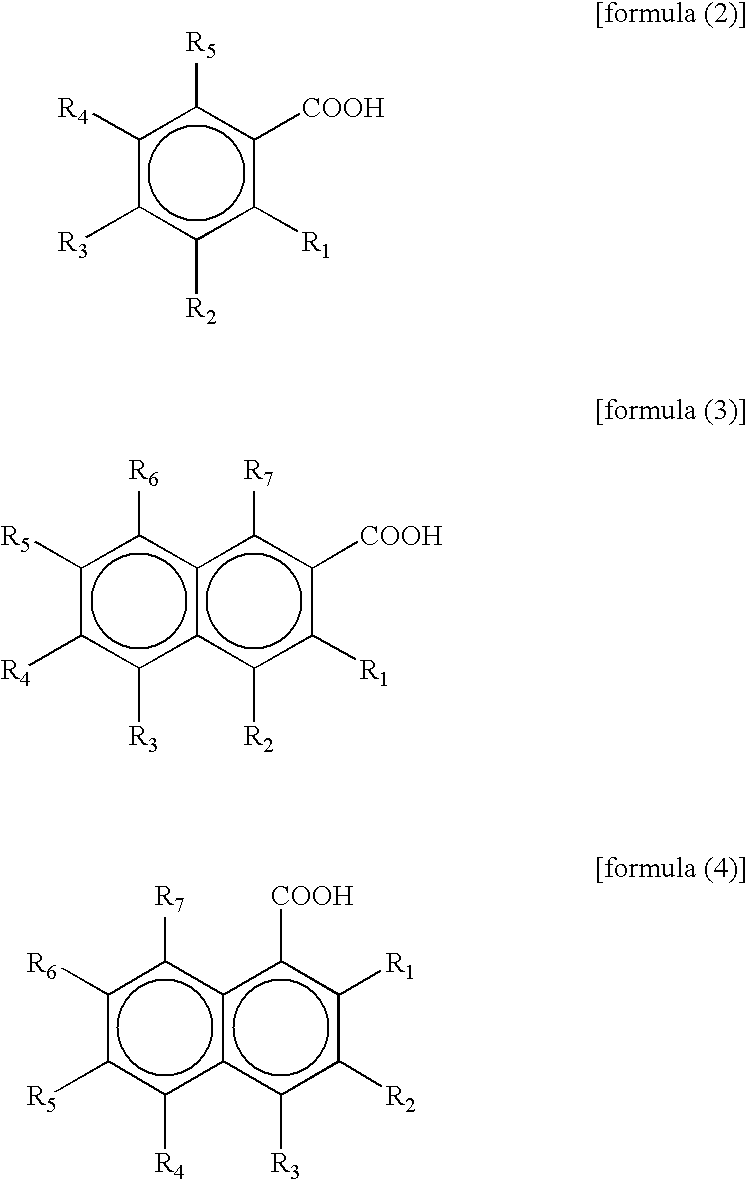

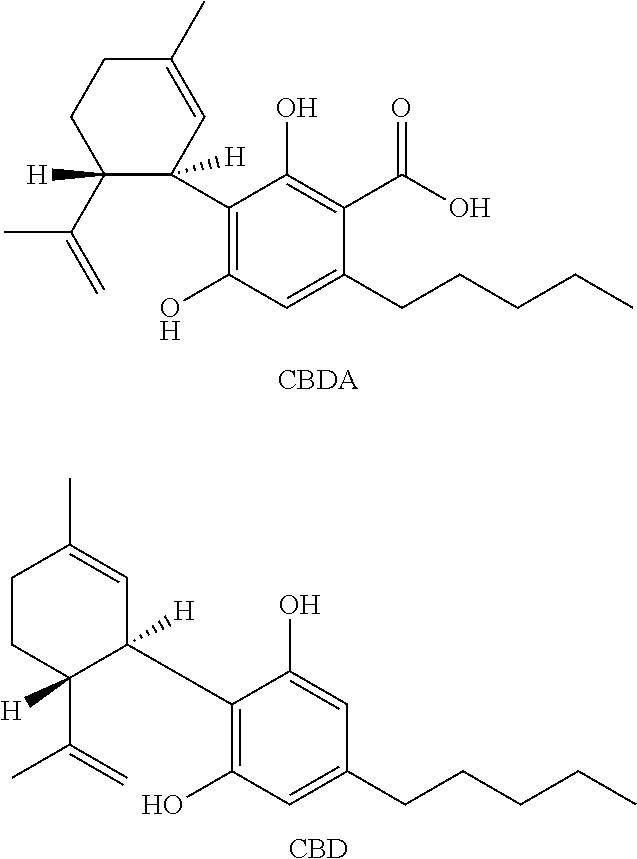

A purified cannabidiol (CBD) extract and / or cannabidiolic acid (CBDA) extract is isolated from industrial hemp and comprises less than 0.5 wt % organic impurities as measured by HPLC and 1H NMR spectroscopy exhibits no detectable peak at 4.07 ppm as measured by 1H NMR spectroscopy. The CBD and / or CBDA extract is in crystalline form. The CBD extract exhibits a melting point as measured by differential scanning calorimetry (DSC) of 69-70° C. Dry powder compositions comprise such extracts. Additional dry powder compositions comprise polyvinylpyrrolidone and an amorphous CBD extract. An adduct comprises CBD and / or CBDA bonded to a paramagnetic trivalent lanthanide (III) metal chelate.

Owner:COLORADO CAN LLC

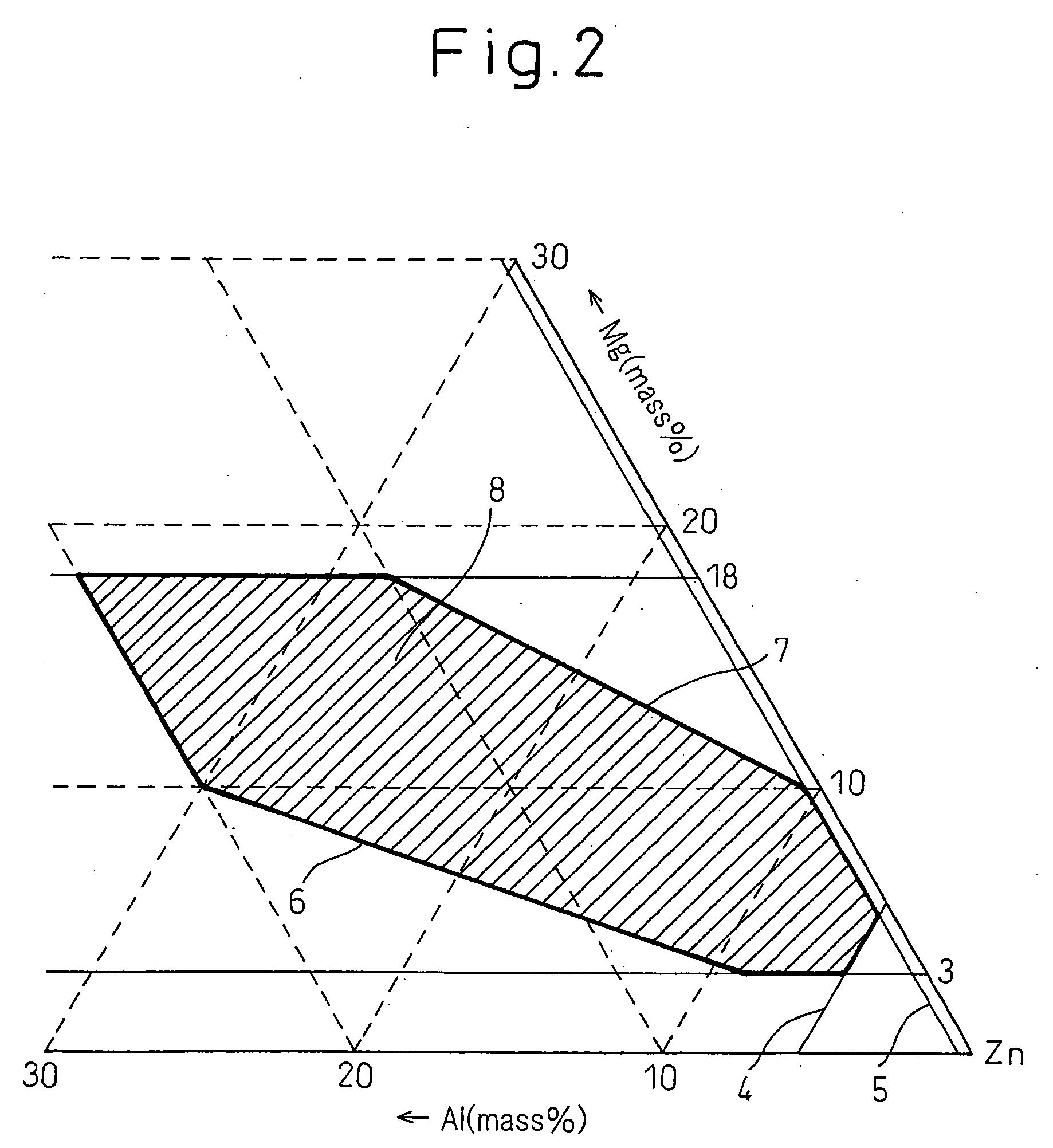

High Corrosion Resistance Hot dip Galvanized Steel Material

InactiveUS20090053555A1Improve corrosion resistanceSuppressing degradationHot-dipping/immersion processesThin material handlingAmorphous phaseAlloy

The present invention provides a high corrosion resistance hot dip galvannealed steel material comprised of a Zn-based hot dip plated steel material achieving both a higher corrosion resistance of the plated layer itself by the added elements and sacrificial protection of iron metal by the plated layer or workability free of degradation caused of formation of intermetallic compounds by added elements, that is, a high corrosion resistance hot dip Zn plated steel material characterized in that an alloy plated layer containing Zn: 35 mass % or more, preferably 40 mass % or more, contains a non-equilibrium phase having a heat capacity by differential scanning calorimetry of 1 J / g or more. Furthermore, 5% or more, preferably 50% or more in terms of vol % is an amorphous phase. The alloy layer may contain, by mass %, Mg: 1 to 60% and Al: 0.07 to 59%, may further contain one or more elements selected from Cr, Mn, Fe, Co, Ni, and Cu in a total of 0.1 to 10%, and may in addition contain one or more elements of 0.1 to 10% of La, 0.1 to 10% of Ce, 0.1 to 10% of Ca, 0.1 to 10% of Sn, 0.005 to 2% of P, and 0.02 to 7% of Si.

Owner:NIPPON STEEL CORP

Hydrogenated copolymer and composition thereof

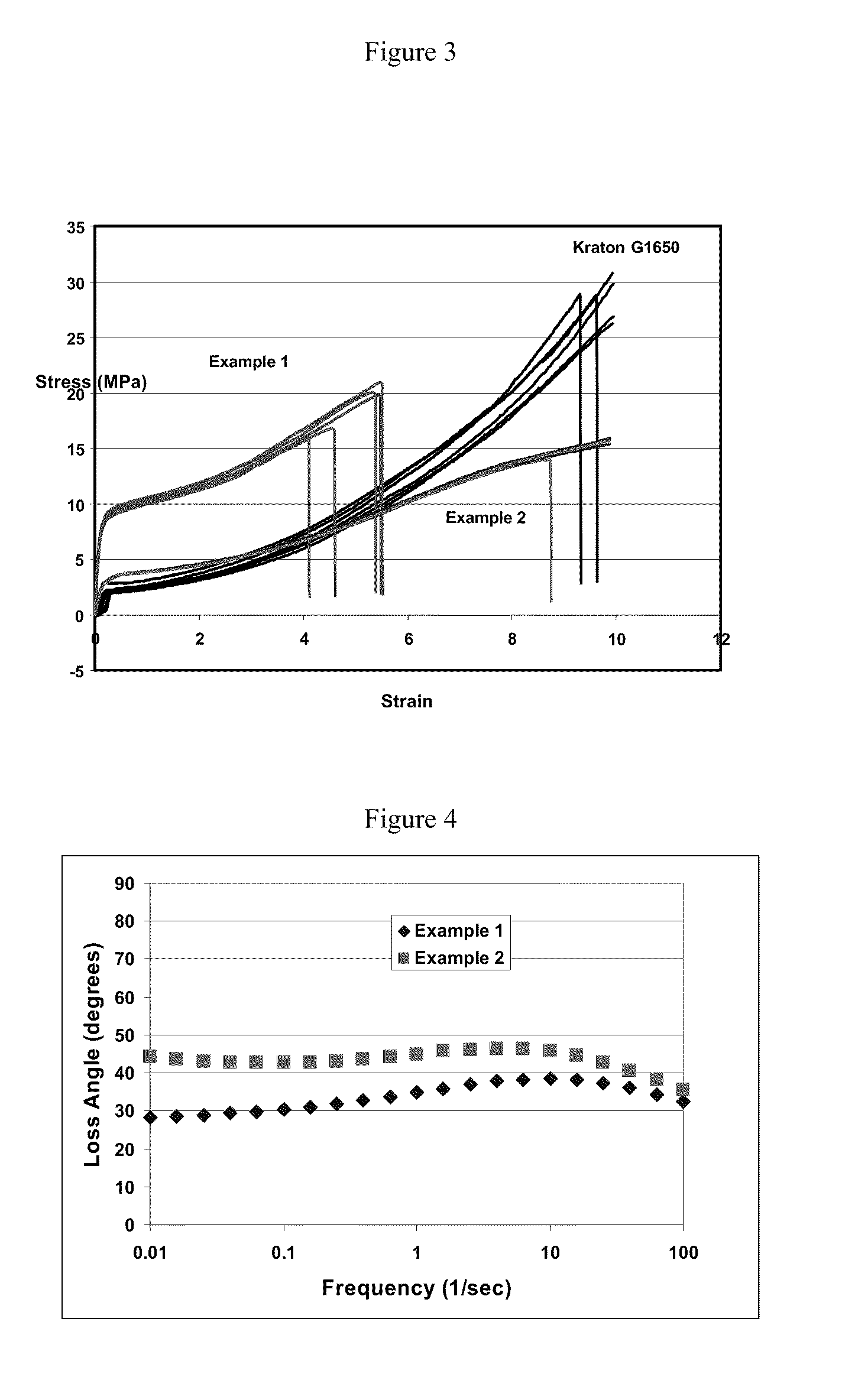

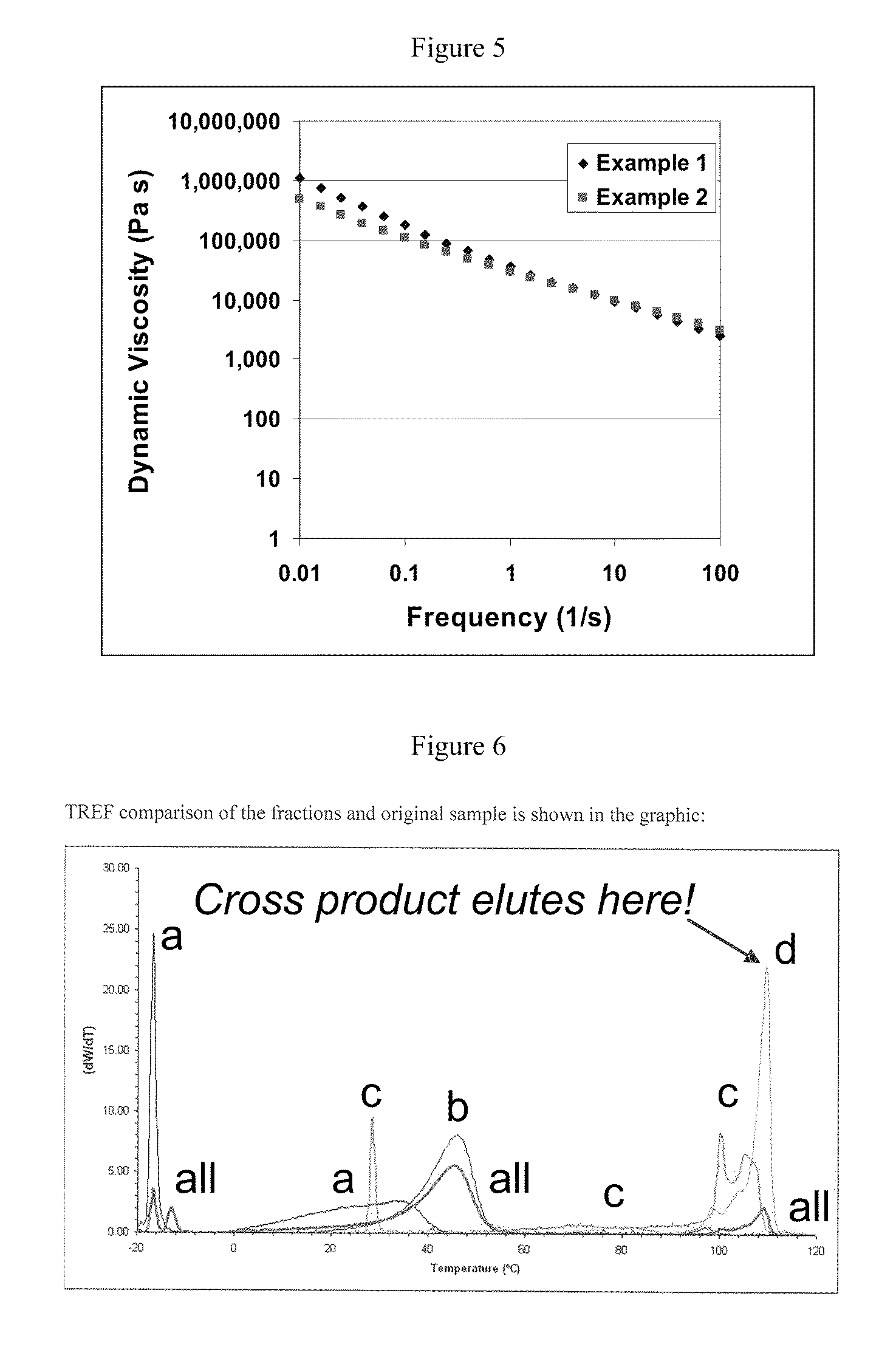

ActiveUS20050234193A1Maintain good propertiesImprove crosslinkabilitySpecial tyresPolymer scienceDynamic viscoelasticity

A hydrogenated copolymer obtained by hydrogenating an unhydrogenated copolymer comprising conjugated diene monomer units and vinyl aromatic monomer units, the hydrogenated copolymer containing at least one hydrogenated copolymer block (B) which is obtained by hydrogenating an unhydrogenated random copolymer block comprised of conjugated diene monomer units and vinyl aromatic monomer units, wherein the hydrogenated copolymer has the following characteristics: the hydrogenated copolymer has a content of the vinyl aromatic monomer units of from more than 40% by weight to less than 95% by weight; at least one peak of loss tangent (tan 8) is observed at −10 to 80° C. in a dynamic viscoelastic spectrum obtained with respect to the hydrogenated copolymer; and substantially no crystallization peak ascribed to the copolymer block (B) is observed at −20 to 80° C. in a differential scanning calorimetry (DSC) chart obtained with respect to the hydrogenated copolymer.

Owner:ASAHI KASEI CHEM CORP

Multi-Layerd Polylactic Acid Resin Foamed Body And Multi-Layered Polylactic Acid Resin Foamed Molded Article

ActiveUS20100028654A1Improve heat resistanceHigh mechanical strengthSynthetic resin layered productsThin material handlingHeat fluxHeat resistance

An object of the present invention is to provide a multi-layered polylactic acid resin foamed body of a crystalline polylactic acid resin which has good appearance and excellent mechanical strength such as bending strength and compressive strength and which is capable of being imparted with excellent heat resistance, and to provide a multi-layered polylactic acid resin foamed molded article having excellent appearance, heat resistance and mechanical strength.The multi-layered polylactic acid resin foamed body of the present invention is a laminate having a polylactic acid resin foamed layer and a thermoplastic resin layer provided at least one side of the foamed layer, wherein the foamed layer has a cell shape satisfying specific conditions, wherein the difference (ΔHendo:2° C. / min−ΔHexo:2° C. / min) between an endothermic calorific value (ΔHendo:2° C. / min) and an exothermic calorific value (ΔHexo:2° C. / min) of the foamed layer as measured by heat flux differential scanning calorimetry at a heating rate of 2° C. / min is less than 40 J / g, and wherein the endothermic calorific value (ΔHendo:2° C. / min) is at least 10 J / g and the exothermic calorific value (ΔHexo:2° C. / min) is at least 3 J / g.

Owner:JSP CORP

Toner and developer

InactiveUS20110223532A1Good combination of low-temperature fixabilityImprove bindingDevelopersPolyester resinDifferential scanning calorimetry

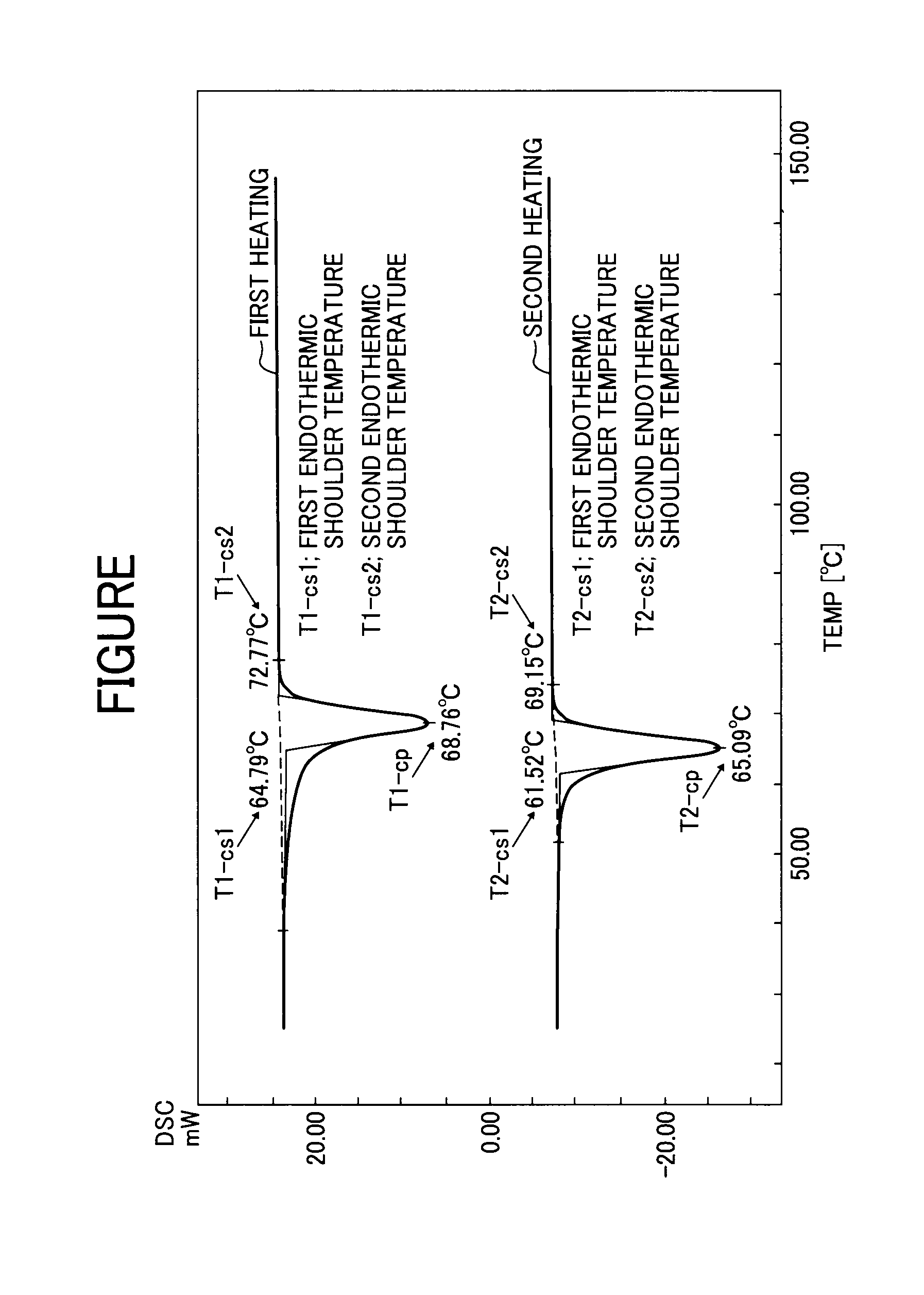

A toner, comprising a colorant, a crystalline polyester resin, and an amorphous polyester resin, in which the crystalline polyester resin satisfies the following relations:60≦(T2-cp)<80(T2-cs2)−(T2-cp)<10(T2-cp)−(T2-cs1)<10wherein (T2-cp) (° C.) represents an endothermic peak temperature, (T2-cs1) (° C.) represents a first endothermic shoulder temperature, and (T2-cs2) (° C.) represents a second endothermic shoulder temperature, each determined from a second heating in a differential scanning calorimetry.

Owner:RICOH KK

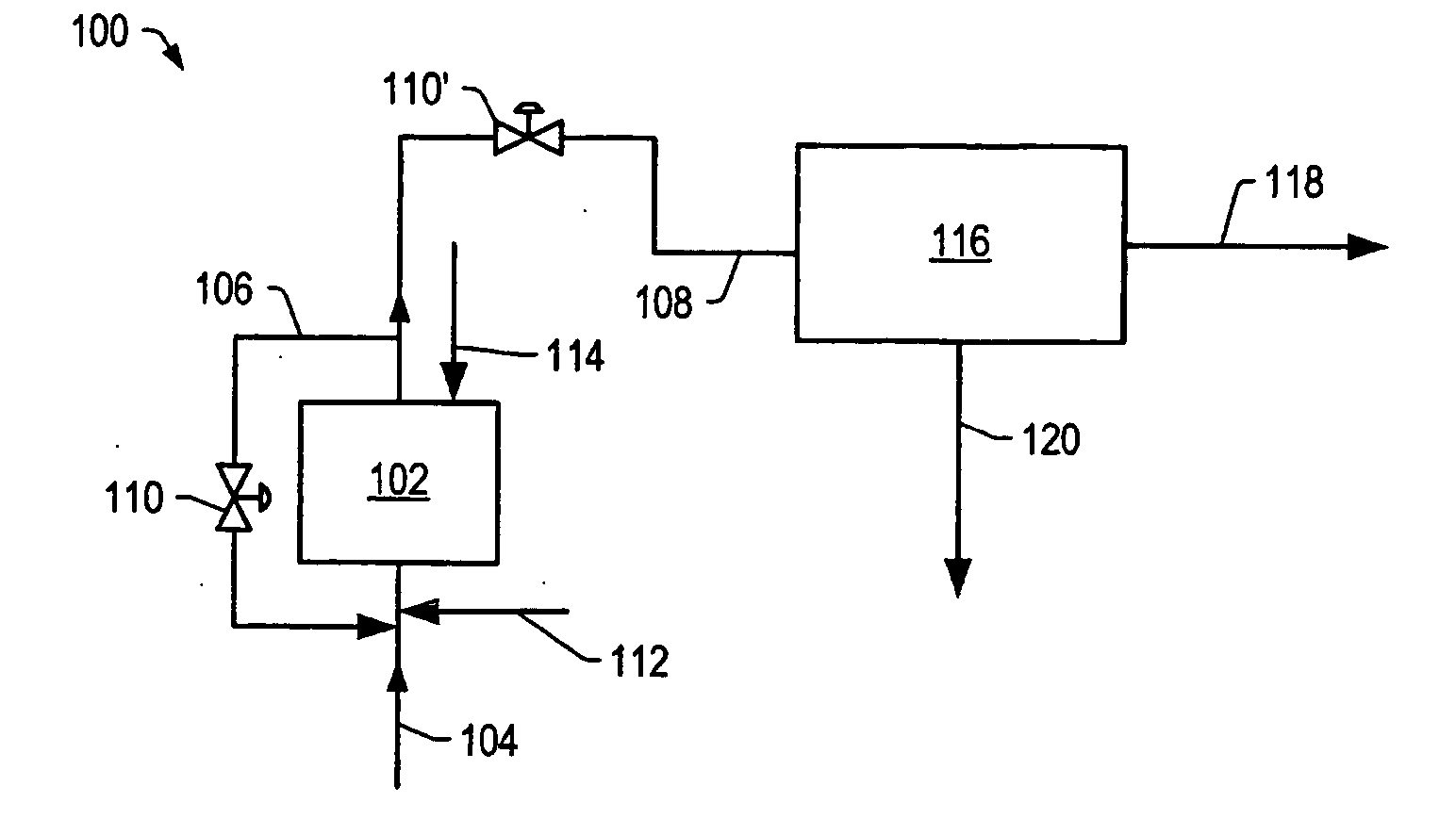

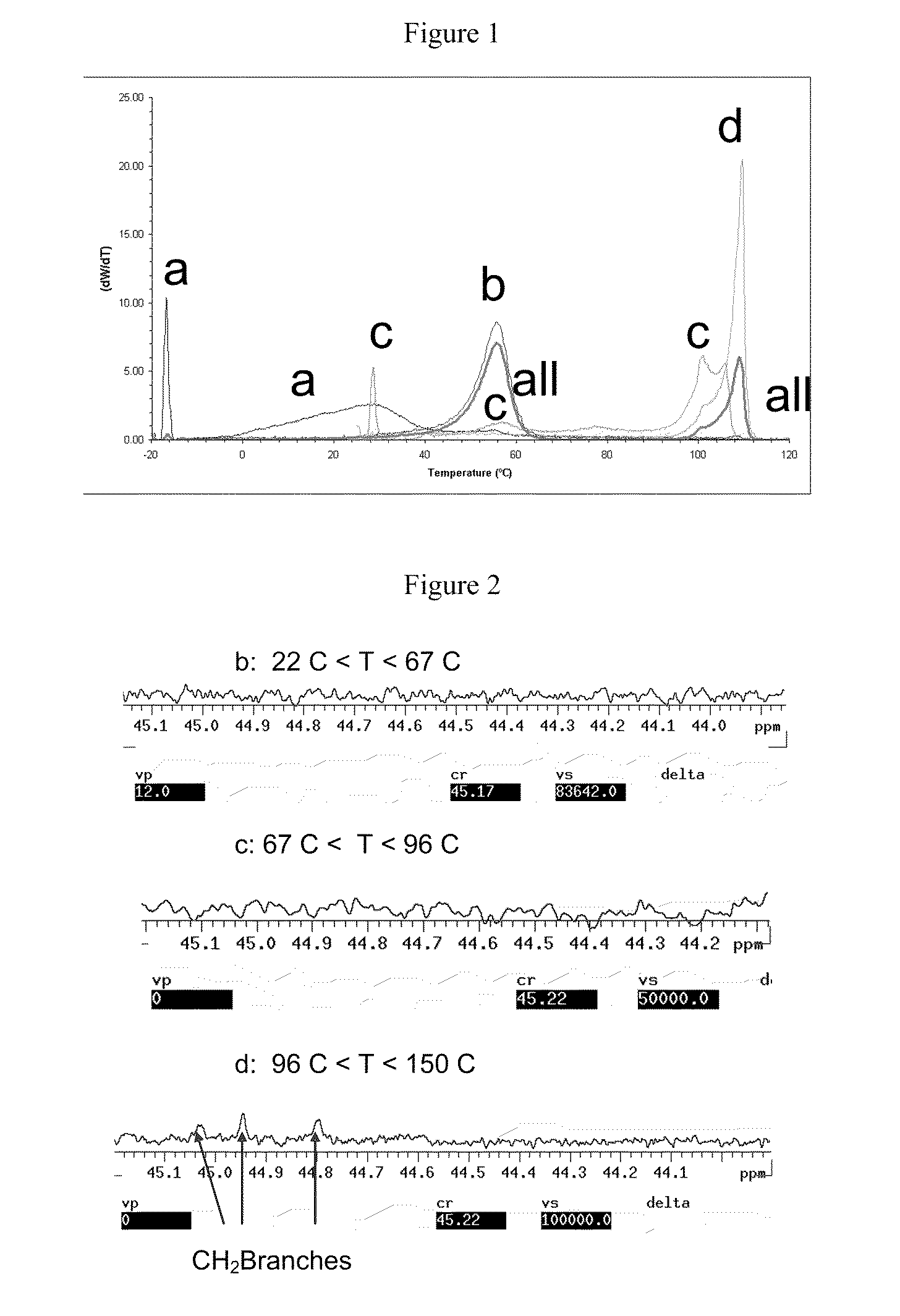

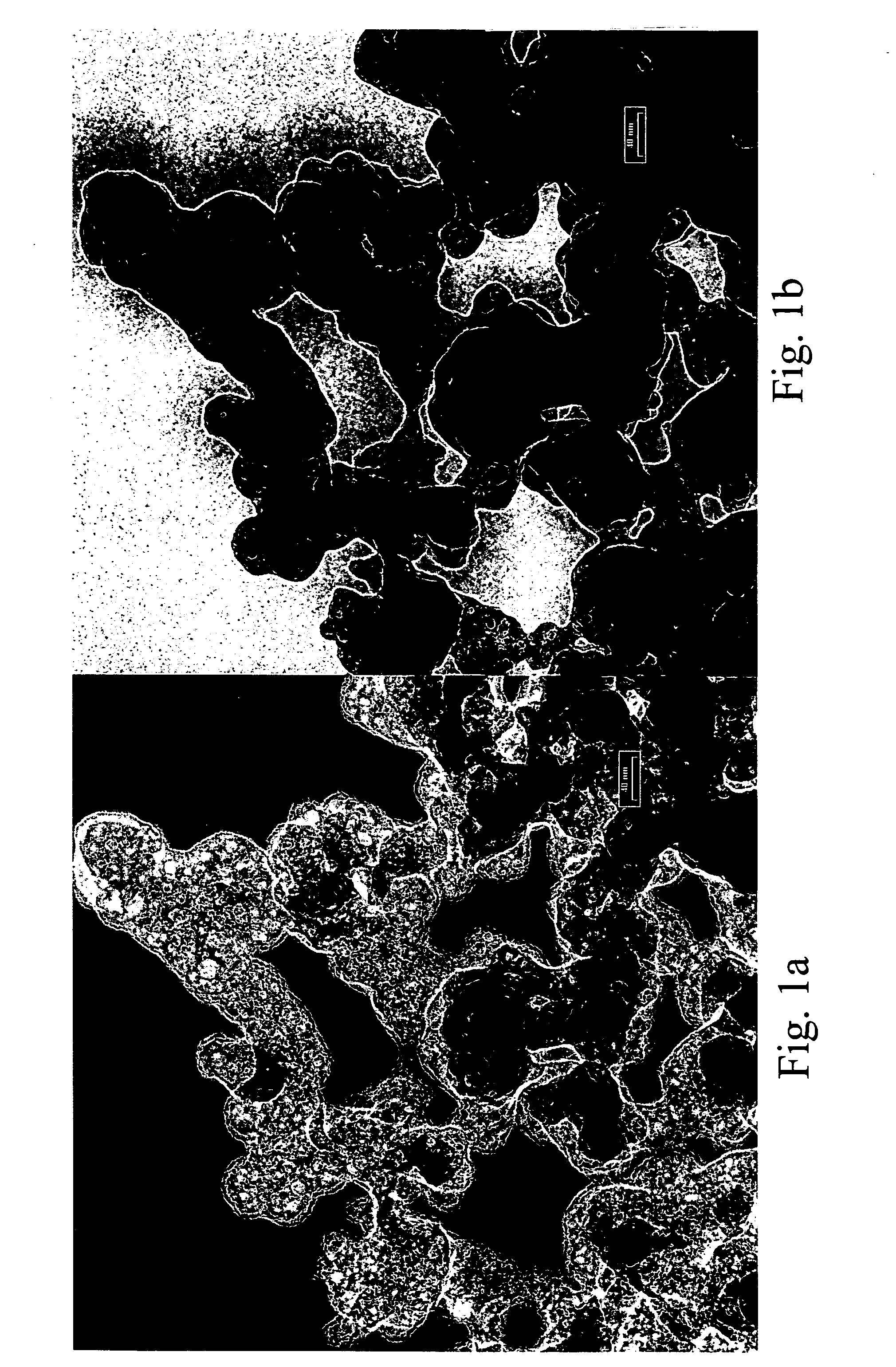

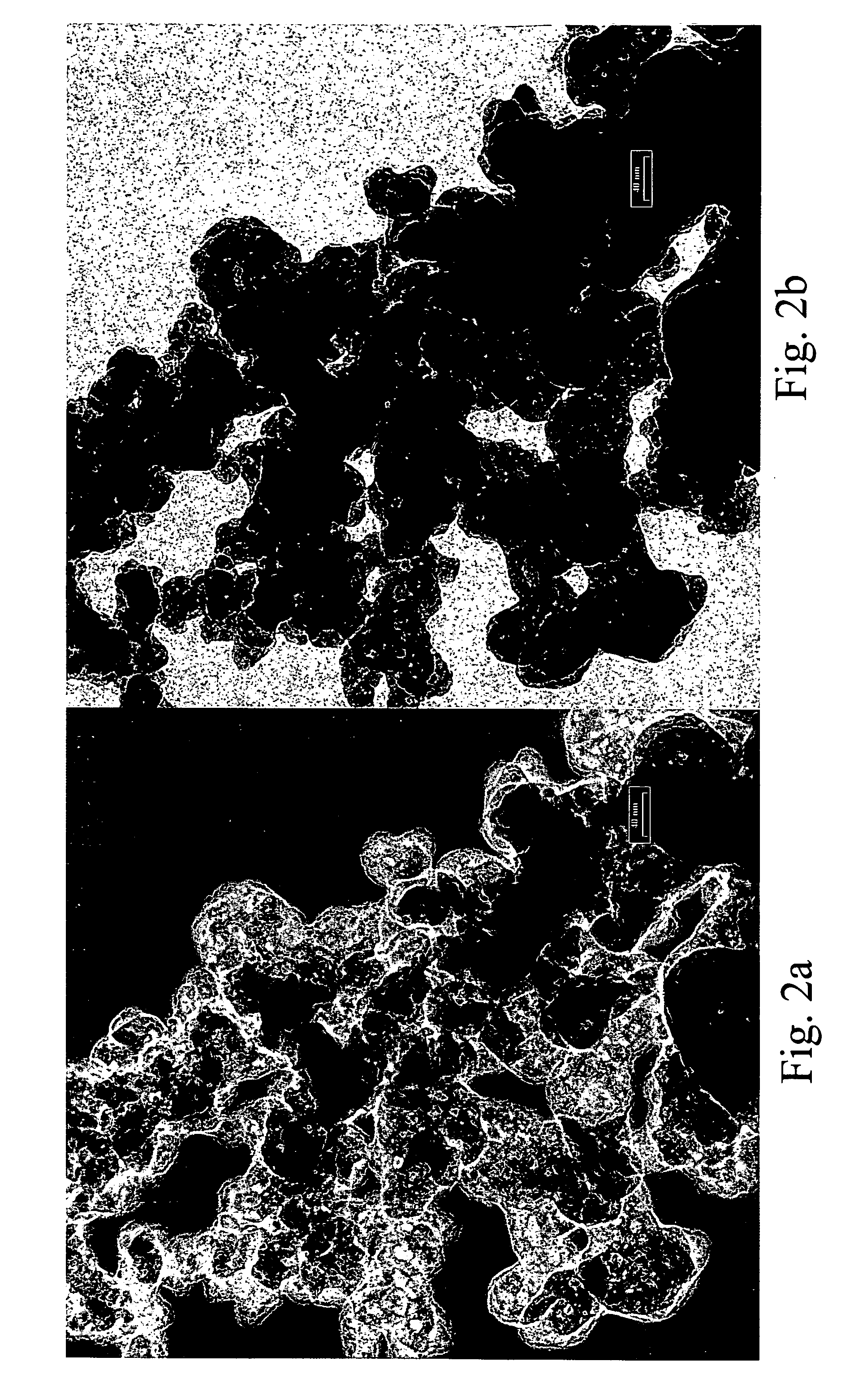

Heterogeneous In-Reactor Polymer Blends

An in-reactor polymer blend comprises (a) a propylene-containing first polymer; and (b) an ethylene-containing second polymer such that the polymer blend comprises between about 50 wt % and about 80 wt % units derived from ethylene and between about 50 wt % and about 20 wt % units derived from propylene. The blend is substantially free of dienes and the content of ethylene in the second polymer in the form of ethylene-ethylene-ethylene triads is at least 40%. The second polymer contains at least 0.1 branch having 8 or more carbon atoms per 10,000 carbons. In addition, the blend has a strain hardening index of at least 1.8, a shear thinning slope in the plot of log(dynamic viscosity) versus log(frequency) of less than −0.2 and exhibits at least two peaks when subjected to Differential Scanning Calorimetry (first melt) corresponding to a first melting point of at least 150° C. and a second melting point of at least 40° C. such that the difference between the first and second melting temperatures is at least 20° C.

Owner:EXXONMOBIL CHEM PAT INC

Aluminum phosphate, polyphosphate and metaphosphate particles and their use as pigments in paints and method of making same

An aluminum phosphate composition comprising aluminum phosphate, aluminum polyphosphate, aluminum metaphosphate, or a mixture thereof. The composisition may be characterized by, when in powder form, having particles wherein some of the particles have at least one or more voids per particle. In addition, the composition is characterized by exhibiting two endothermic peaks in Differential Scanning Calorimetry between about 90 degrees to about 250 degrees Celsius. The composition is also characterized by, when in powder form, having a dispersibility of at least 0.025 grams per 1.0 gram of water. The composition is made by a process comprising contacting phosphoric acid with aluminum sulfate and an alkaline solution to produce an aluminum phosphate based product; and optionally calcining the aluminum phosphate, polyphosphate or metaphosphate based product at an elevated temperature. The composition is useful in paints and as a substitute for titanium dioxide.

Owner:BUNGE AMORPHIC SOLUTIONS +1

Ionomer compositions with low haze and high moisture resistance and articles comprising the same

A sodium / zinc mixed ionomer comprises carboxylate groups and a combination of counterions that consists essentially of sodium cations and zinc cations. The sodium / zinc mixed ionomer is the neutralization product of a precursor acid copolymer. The precursor acid copolymer comprises copolymerized units of an α-olefin and an α,β-ethylenically unsaturated carboxylic acid, and it has a melt flow rate of about 10 to about 4000 g / 10 min. In addition, the precursor acid copolymer, when neutralized to a level of about 40% to about 90%, and when comprising counterions that consist essentially of sodium ions, produces a sodium ionomer that has a freeze enthalpy that is not detectable or that is less than about 3.0 j / g, when determined by differential scanning calorimetry. Further provided are articles comprising or prepared from the sodium / zinc mixed ionomer.

Owner:DOW GLOBAL TECH LLC

Adhesive material, pressure sensitive adhesive film and method of use thereof

InactiveUS20070172649A1Improve heat resistanceMaintain good propertiesLamination ancillary operationsLayered product treatmentSemiconductor materialsCompound (substance)

An adhesive material and a pressure sensitive adhesive film containing the same of the present invention are characterized in that they satisfy the following requirements (a) and (b). These adhesive material and pressure sensitive adhesive film of the present invention exhibit excellent stability against not only light and heat but also various chemicals. Consequently, they are suitable applications in surface protection uses, transport storage uses, heating treatment uses, grinding / polishing uses, cutting processing uses and transport / storage uses in the fields of electronic / semiconductor materials, optical / display materials and the like, where demands for performances and qualities are strict. The above requirements are: (a) an olefinic polymer is contained, and (b) by measurement according to a differential scanning calorimetry test, the melting temperature Tm is in the range of 80° C. to 180° C. and the heat of fusion ΔH is at least 1 J / g.

Owner:MITSUI CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com