Patents

Literature

524 results about "Shear thinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In rheology, shear thinning is the non-Newtonian behavior of fluids whose viscosity decreases under shear strain. It is sometimes considered synonymous for pseudoplastic behaviour, and is usually defined as excluding time-dependent effects, such as thixotropy. Shear-thinning behaviour is generally not seen in pure liquids with low molecular mass, or ideal solutions of small molecules like sucrose or sodium chloride, but is often seen in polymer solutions and molten polymers, and complex fluids and suspensions like ketchup, whipped cream, blood, paint, and nail polish.

Blends of temperature sensitive and anionic polymers for drug delivery

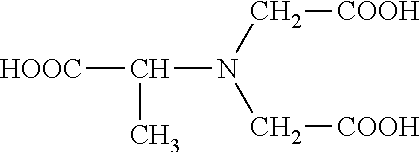

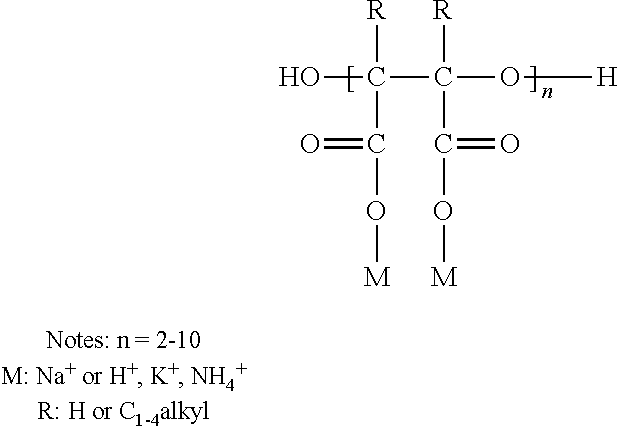

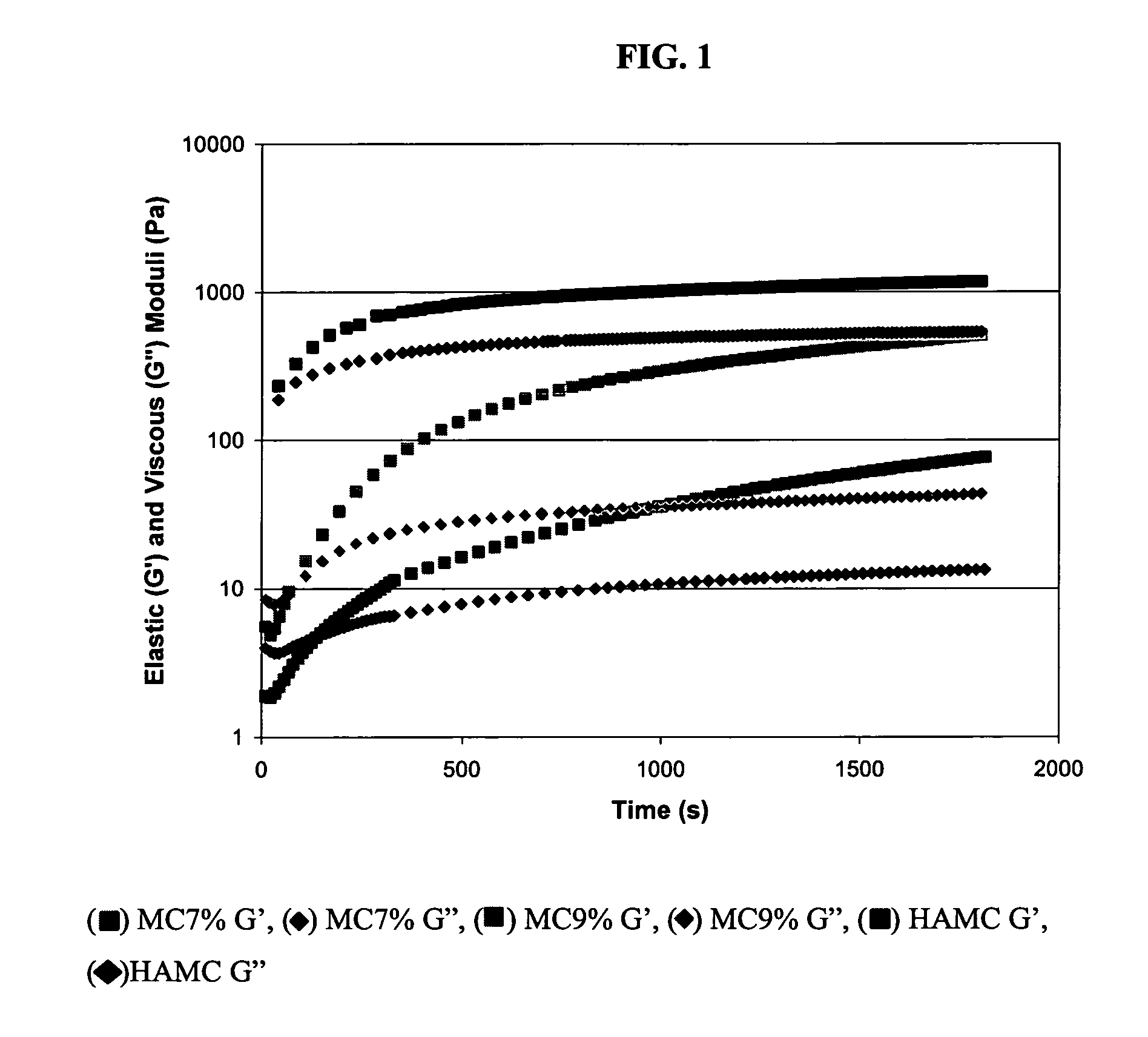

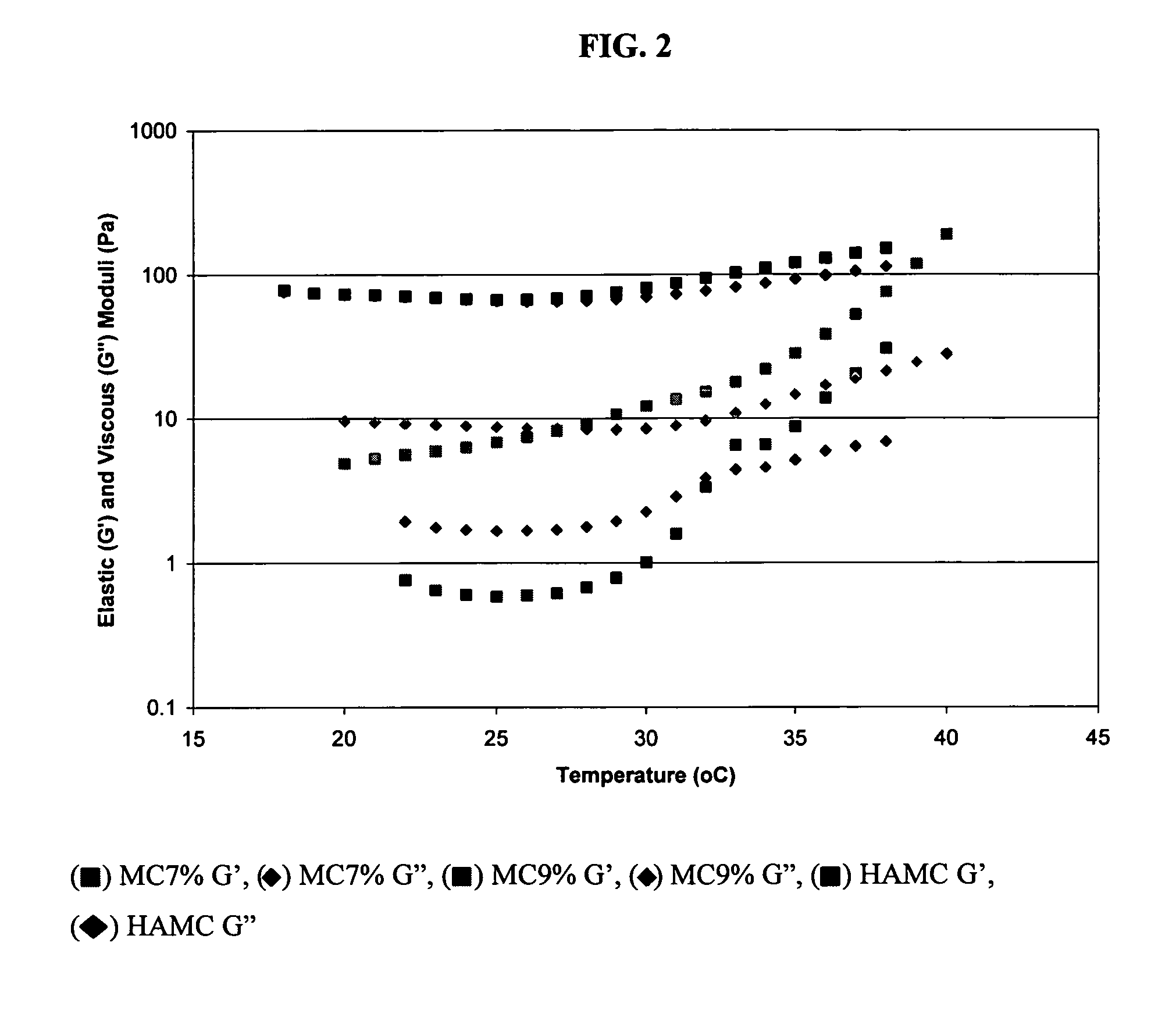

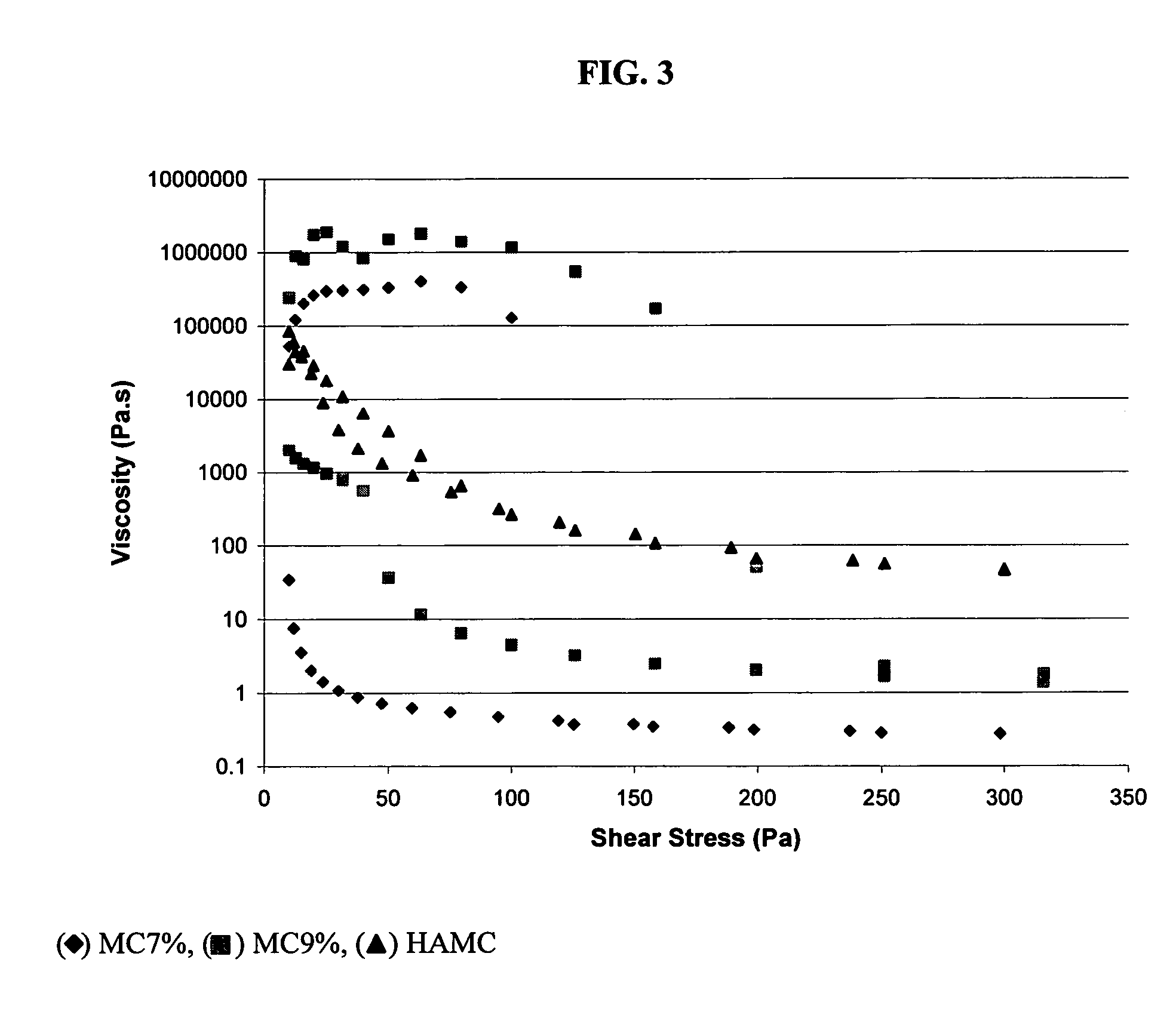

ActiveUS20060280797A1Faster rate of gellingDecrease gelling temperaturePowder deliveryOrganic active ingredientsRoom temperatureAnionic polymers

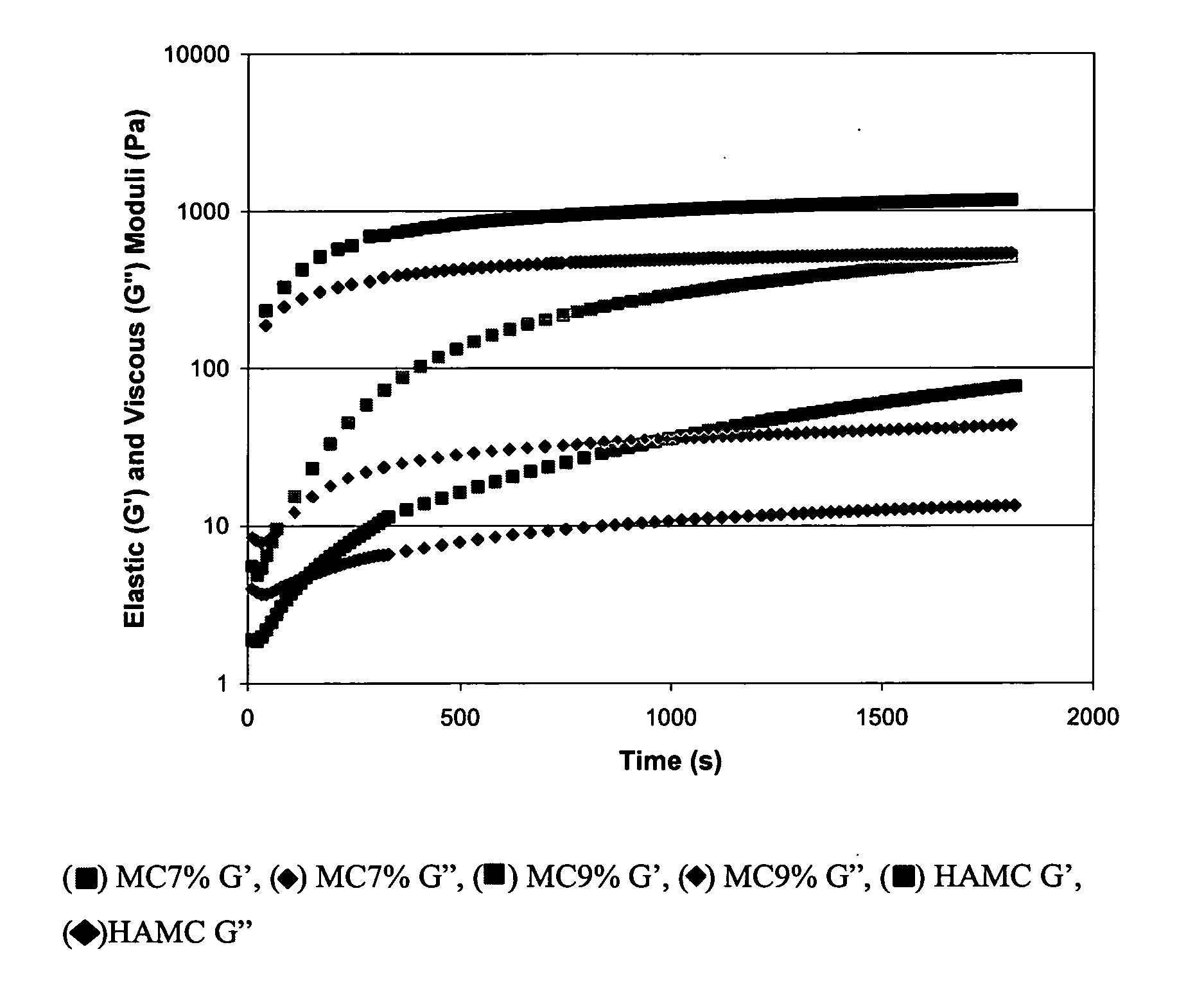

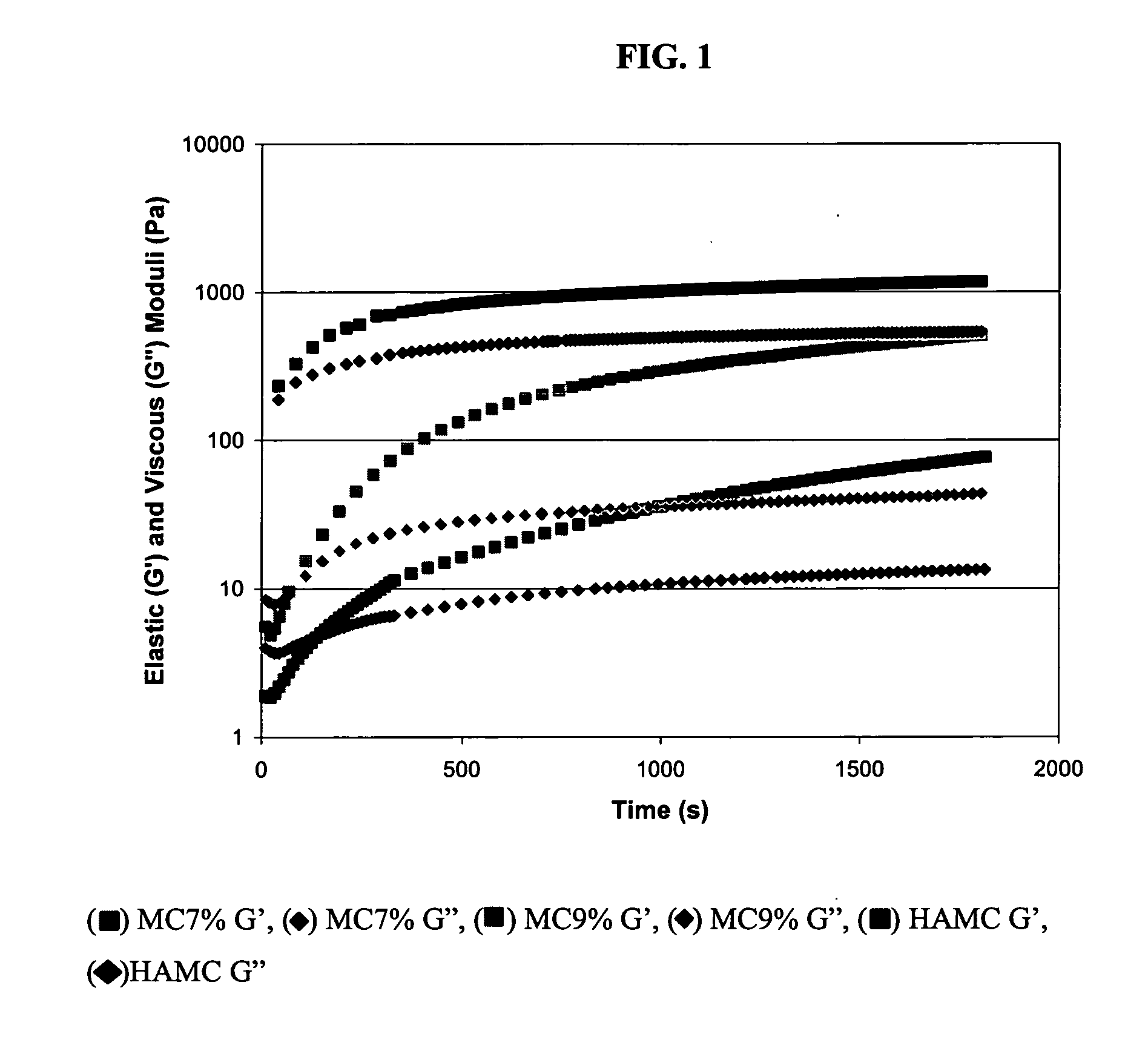

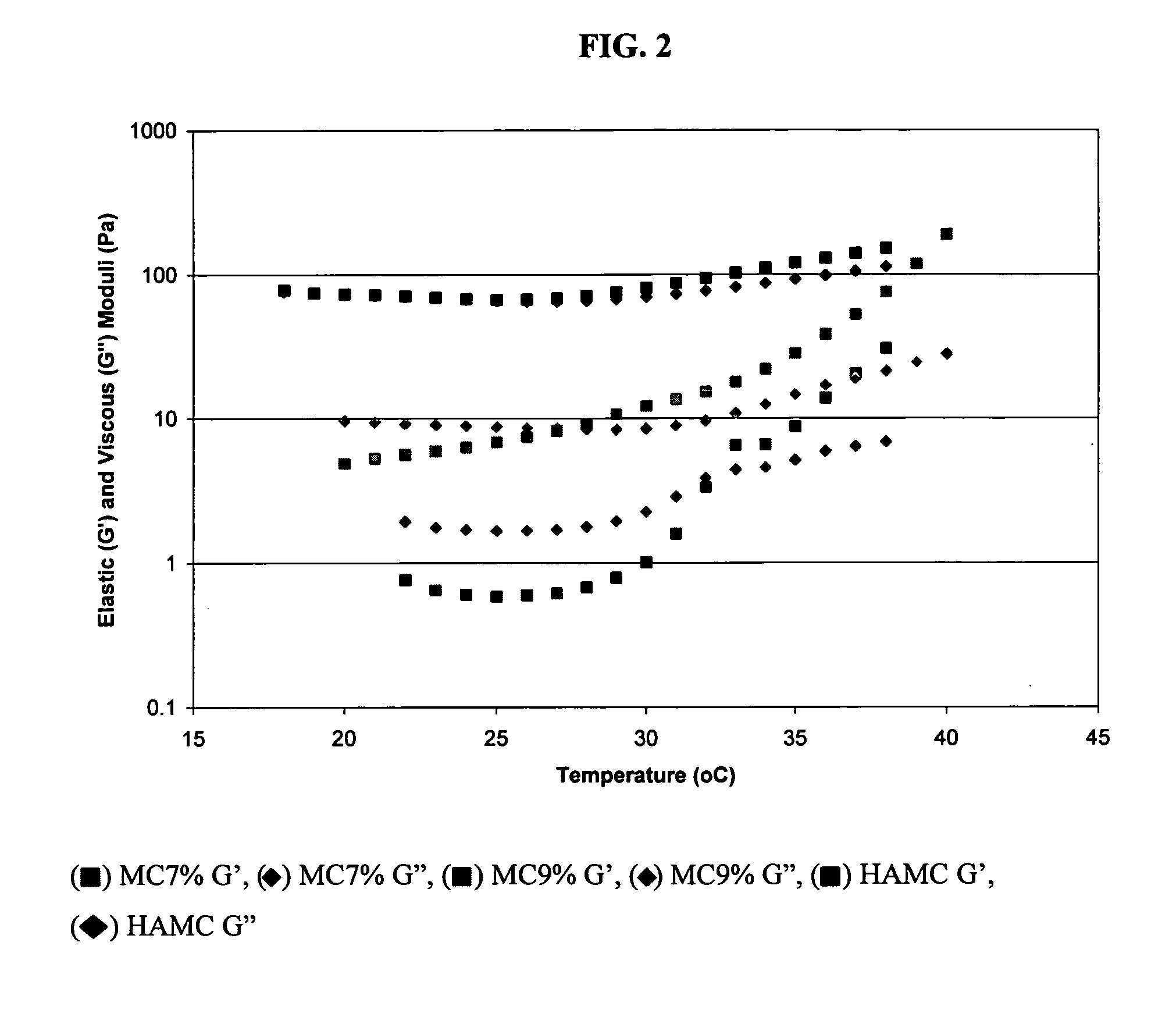

A physical blend of inverse thermal gelling and shear-thinning, thixotropic polymers that has a lower gelation temperature than the thermal gelling polymer alone is provided. The blend results in an injectable hydrogel that does not flow freely at room temperature, but is injectable due to its shear-thinning properties. The thermal-gelling properties of the polymer promote a more mechanically stable gel at body temperature than at room temperature. The polymer matrix gel has inherent therapeutic benefit and can also be used as a drug delivery vehicle for localized release of therapeutic agents.

Owner:SHOICHET MOLLY S +2

Viscous settable fluid for lost circulation in subterranean formations

A method of treating a well the method including the steps of: (A) forming a fluid including: (i) a shear-thinning aqueous liquid phase; and (ii) an inorganic setting material; wherein the fluid is shear-thinning, pumpable, and settable; and (B) introducing the fluid into the well.

Owner:HALLIBURTON ENERGY SERVICES INC

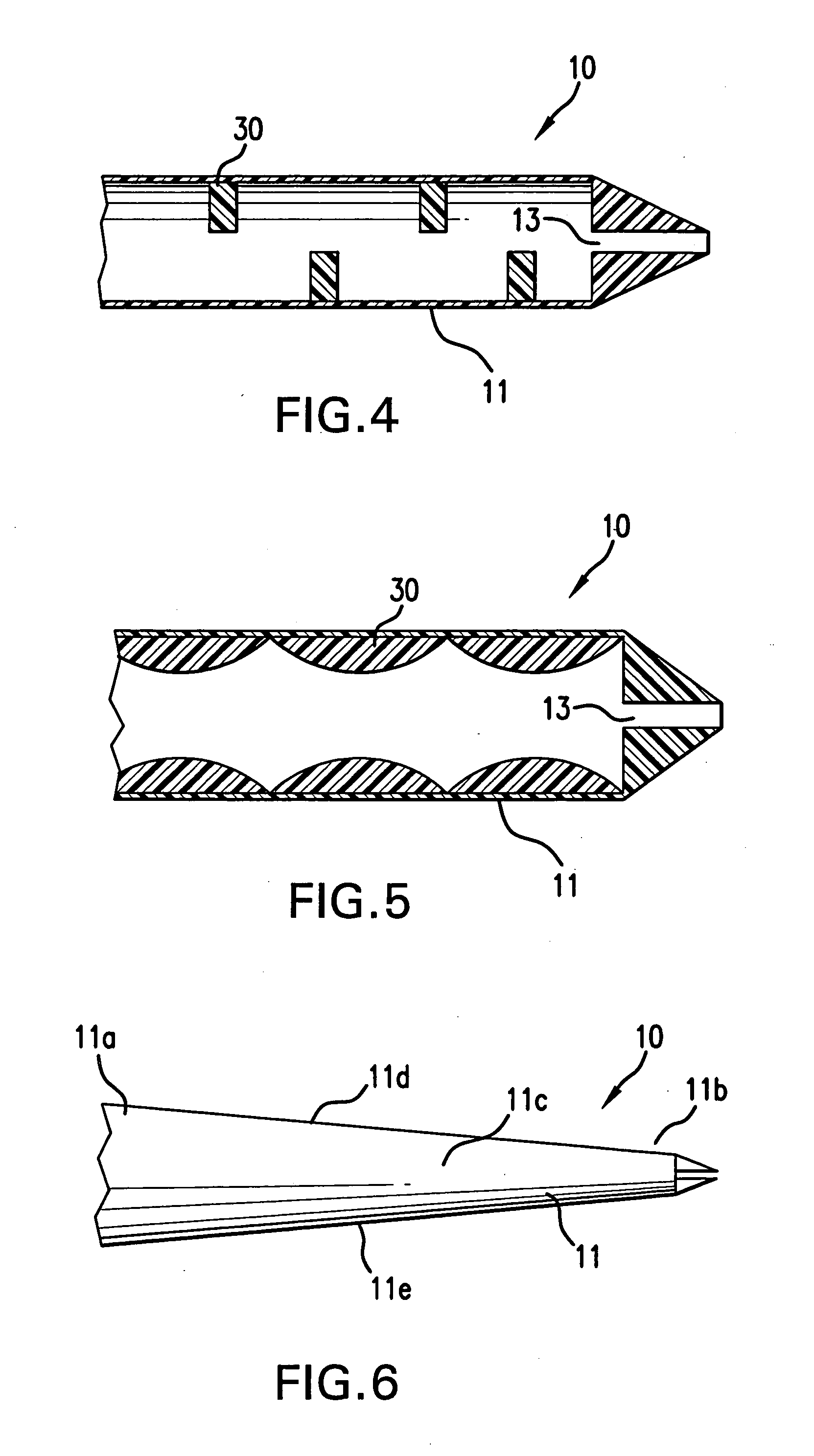

Multimodal polymer composition

A multimodal polymer composition for fiber optical cables and a fiber optical cable comprising the composition are disclosed. The composition is characterized in that it comprises a multimodal polyethylene with a density of 0.920-0.965 g / cm3 and a viscosity at a shear stress of 2.7 kPa (eta2.7kPa) of at least 150 kPa.s, said multimodal polyethylene comprising a low molecular weight (LMW) ethylene homo- or copolymer fraction and a high molecular weight (HMW) ethylene copolymer fraction, said multimodal polymer composition having a weight ratio of the LMW fraction to the HMW fraction of (35-55):(65-45). Preferably, the multimodal polyethylene is a bimodal polyethylene and has a shear thinning index (SHI), defined as the ratio of the viscosities at shear stresses of 2.7 and 210 kPa, respectively, of SHI2.7 / 210=20-150. Also, preferably, the multimodal polyethylene has a MFR5 of 0.1-2.0 g / 10 min and a melt strength at 190° C. of at least 4 g. The multimodal polymer composition is particularly useful as a material for slotted core elements of fiber optical cables of the slotted core type.

Owner:BOREALIS POLYMERS OY

Blends of temperature sensitive and anionic polymers for drug delivery

A physical blend of inverse thermal gelling and shear-thinning, thixotropic polymers that has a lower gelation temperature than the thermal gelling polymer alone is provided. The blend results in an injectable hydrogel that does not flow freely at room temperature, but is injectable due to its shear-thinning properties. The thermal-gelling properties of the polymer promote a more mechanically stable gel at body temperature than at room temperature. The polymer matrix gel has inherent therapeutic benefit and can also be used as a drug delivery vehicle for localized release of therapeutic agents.

Owner:SHOICHET MOLLY S +2

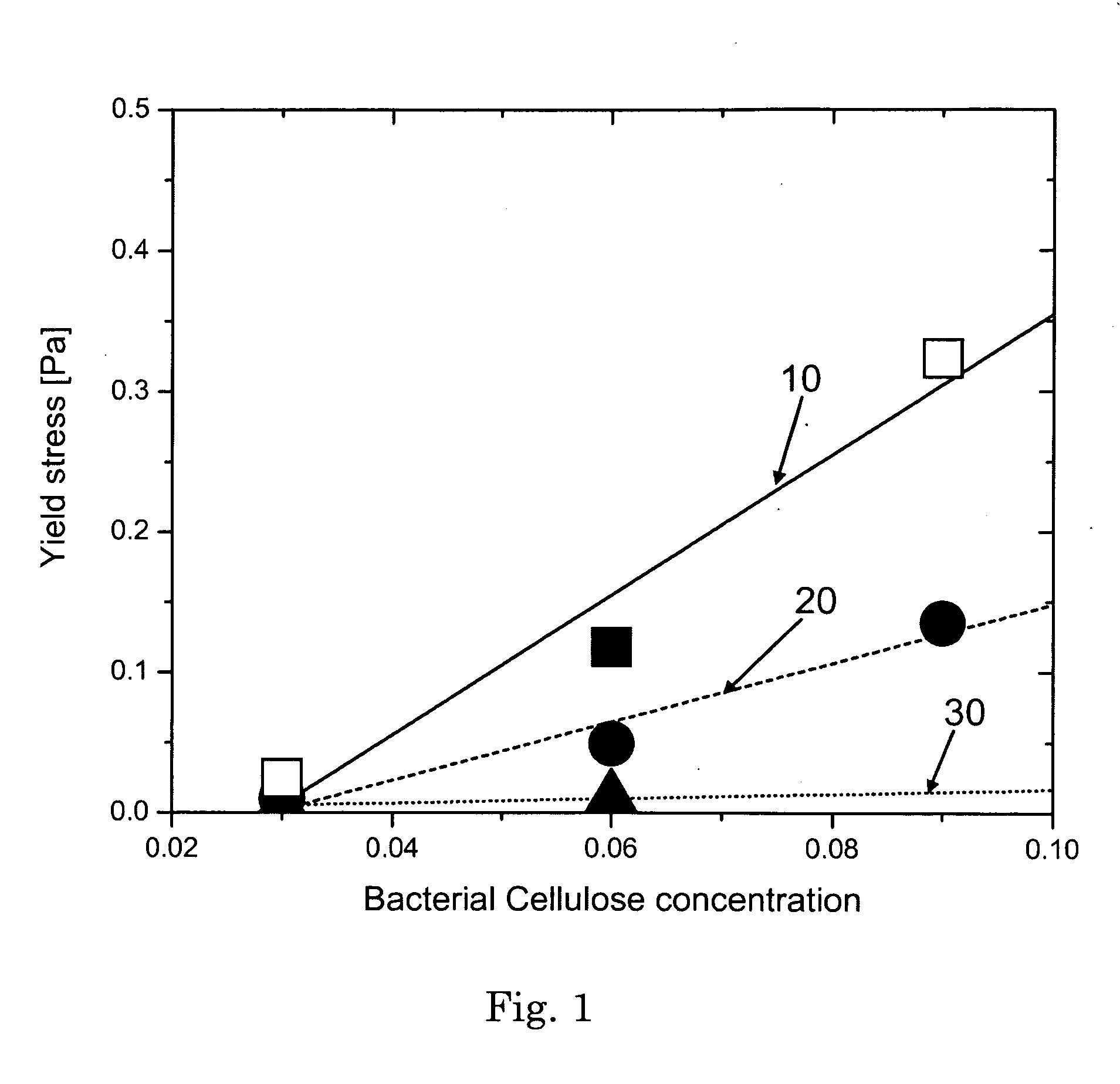

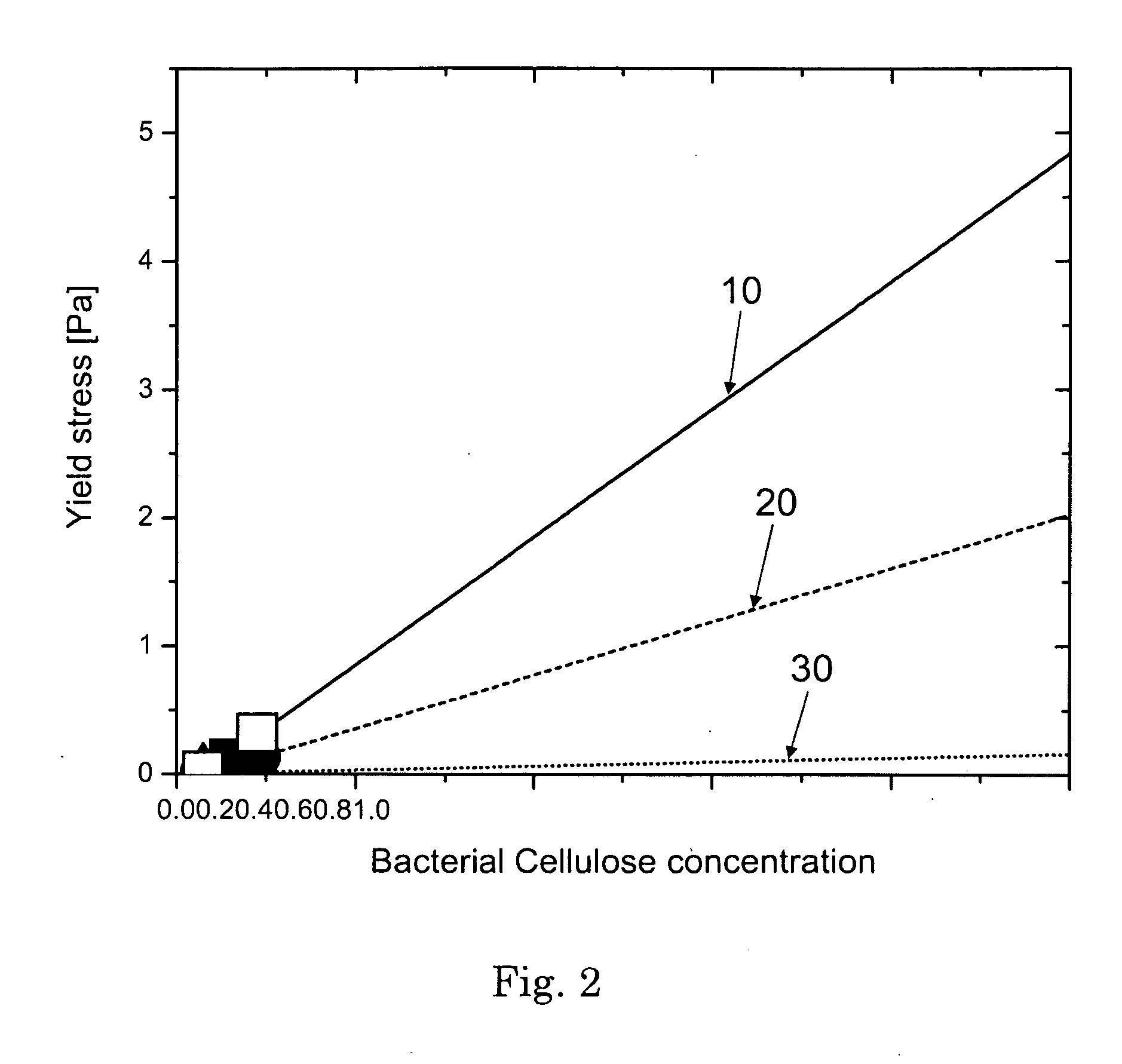

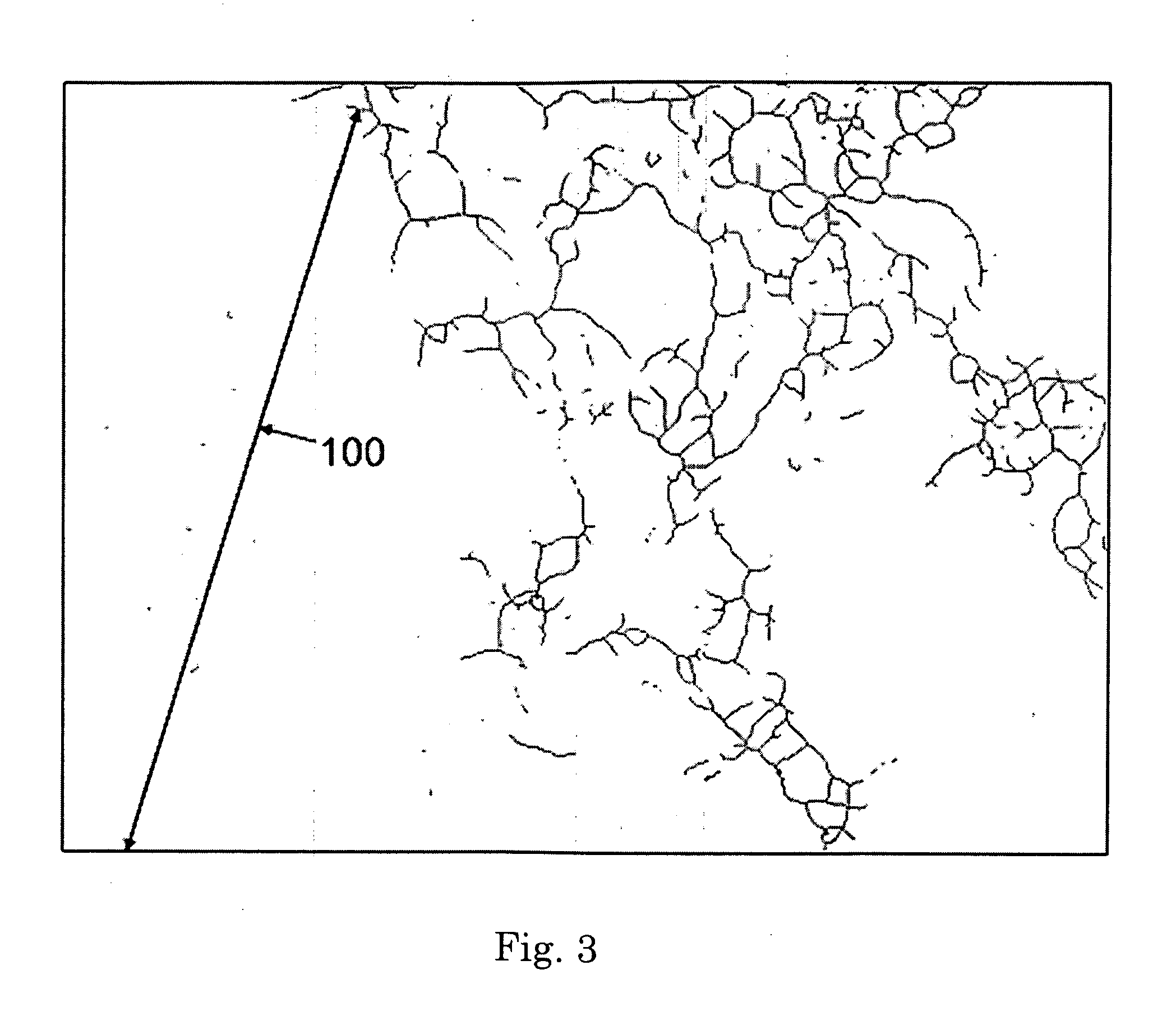

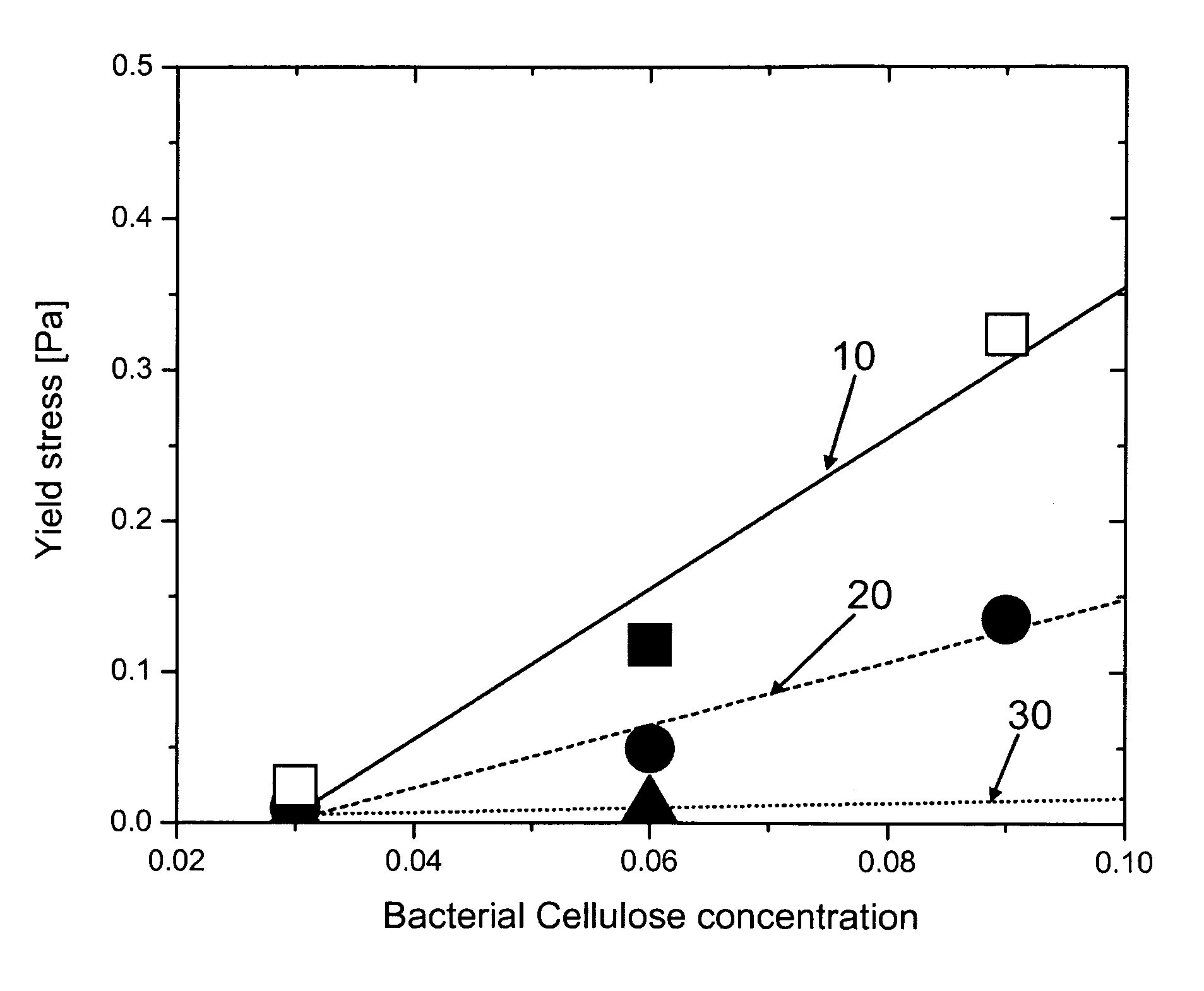

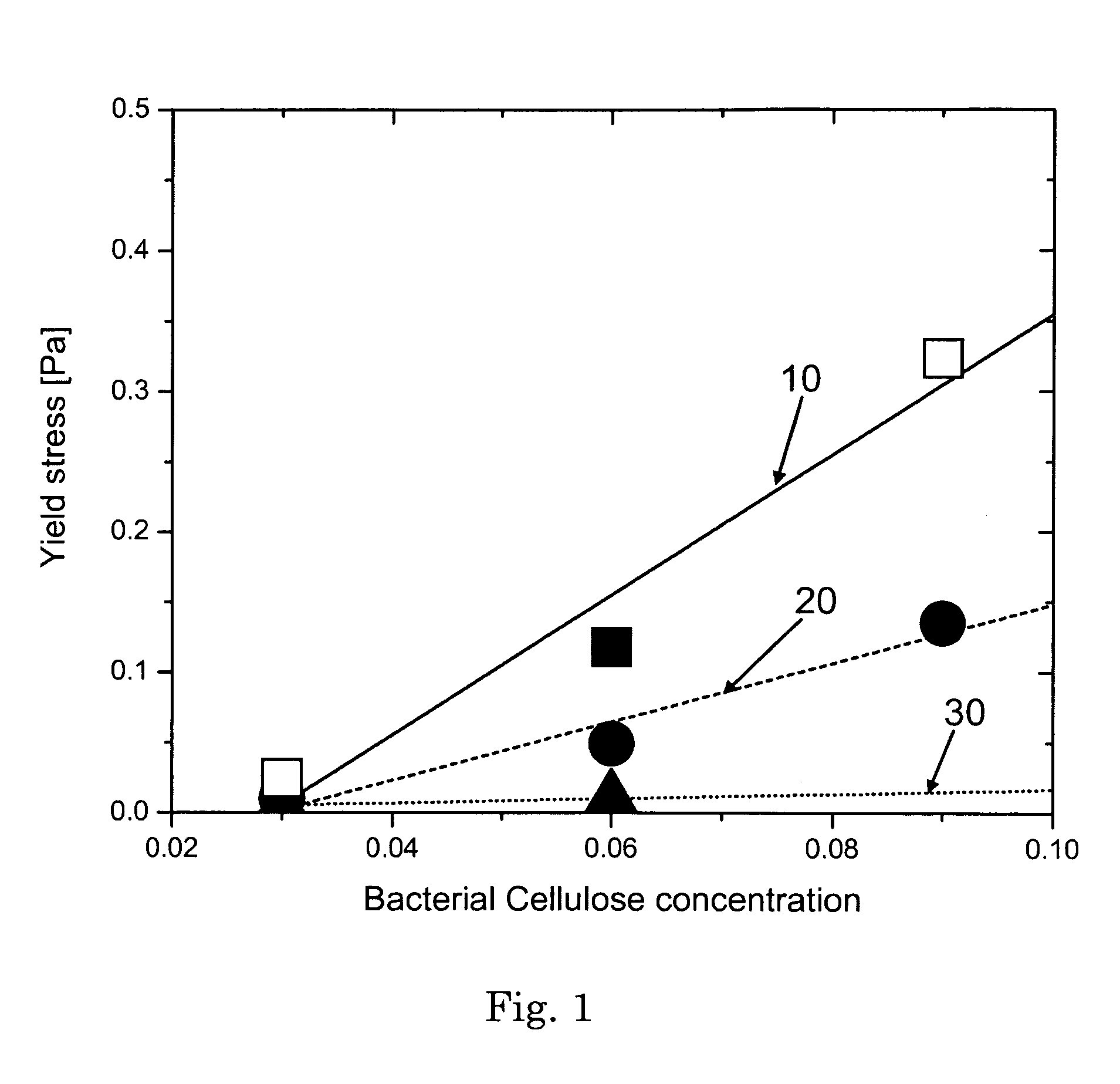

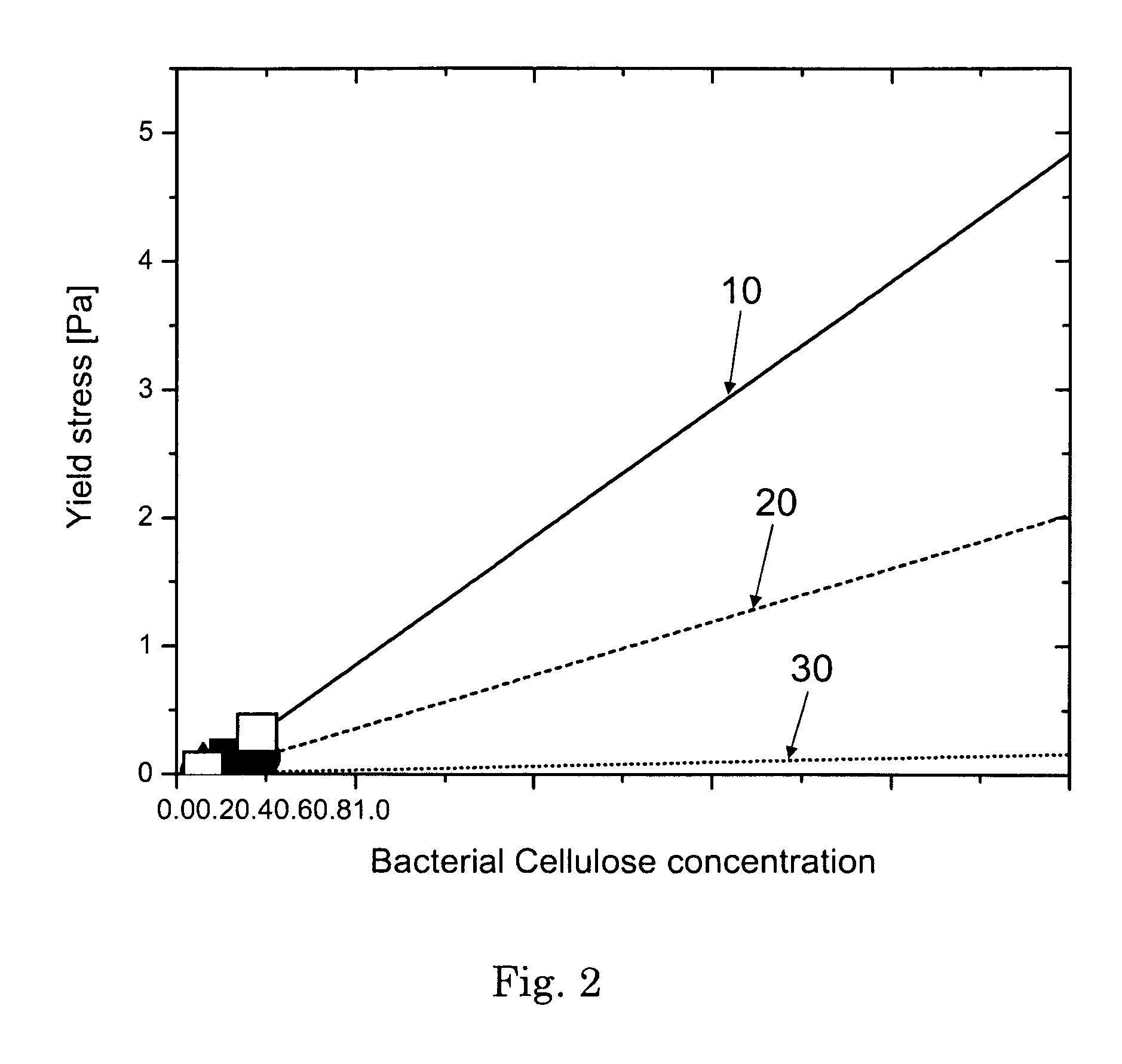

Liquid detergent composition comprising an external structuring system comprising a bacterial cellulose network

A structured liquid detergent composition in the form of a liquid matrix made up of an external structuring system of a bacterial cellulose network; water; and surfactant system including an anionic surfactant; a nonionic surfactant; a cationic surfactant; an ampholytic surfactant; a zwitterionic surfactant; or mixtures thereof, wherein said liquid matrix has a yield stress of from about 0.003 Pa to about 5.0 Pa at about 25° C. and provides suitable particle suspension capabilities and shear thinning characteristics.

Owner:THE PROCTER & GAMBLE COMPANY

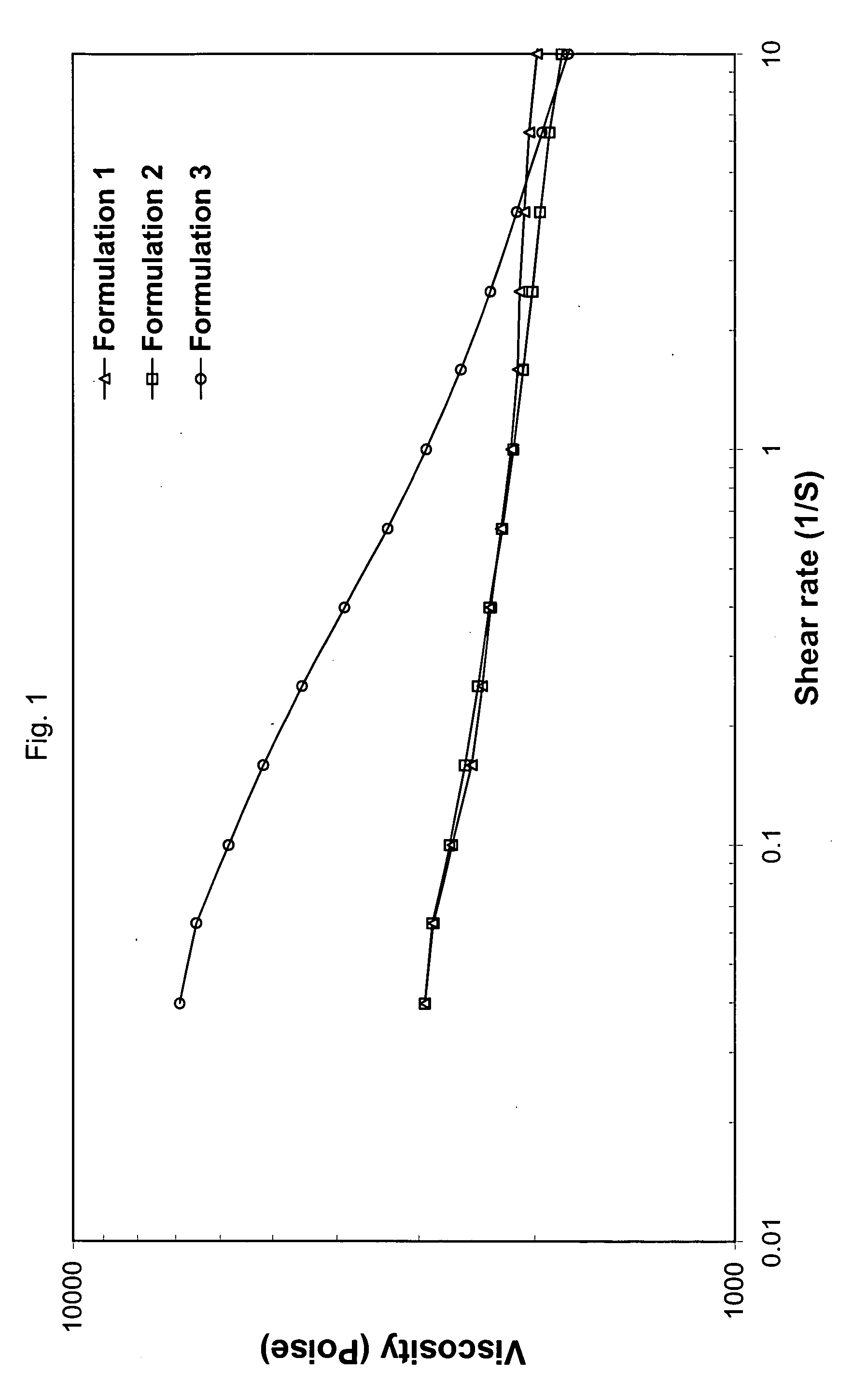

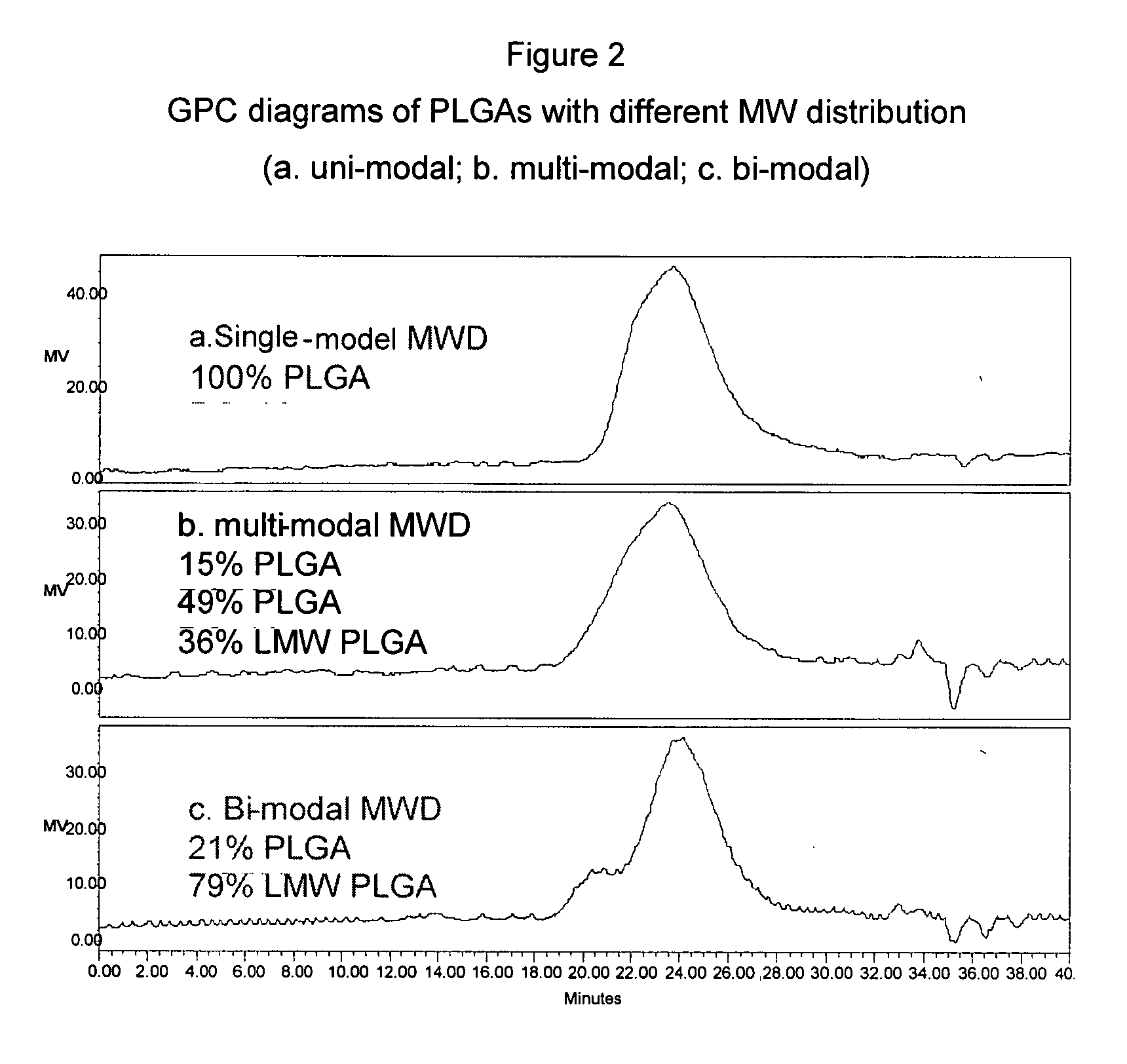

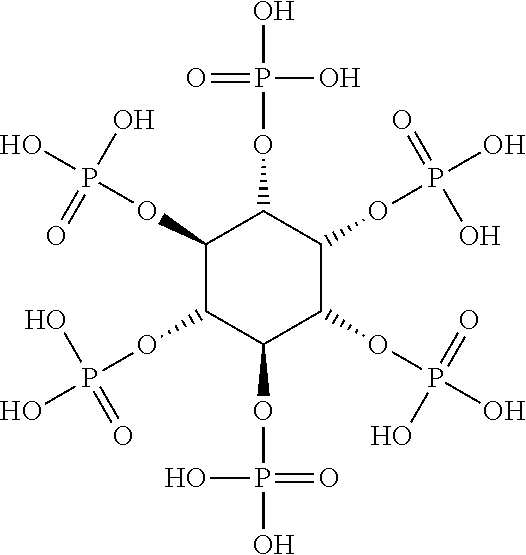

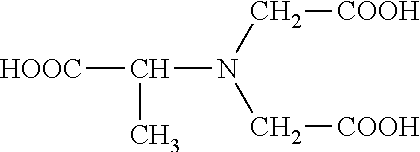

Injectable multimodal polymer depot compositions and uses thereof

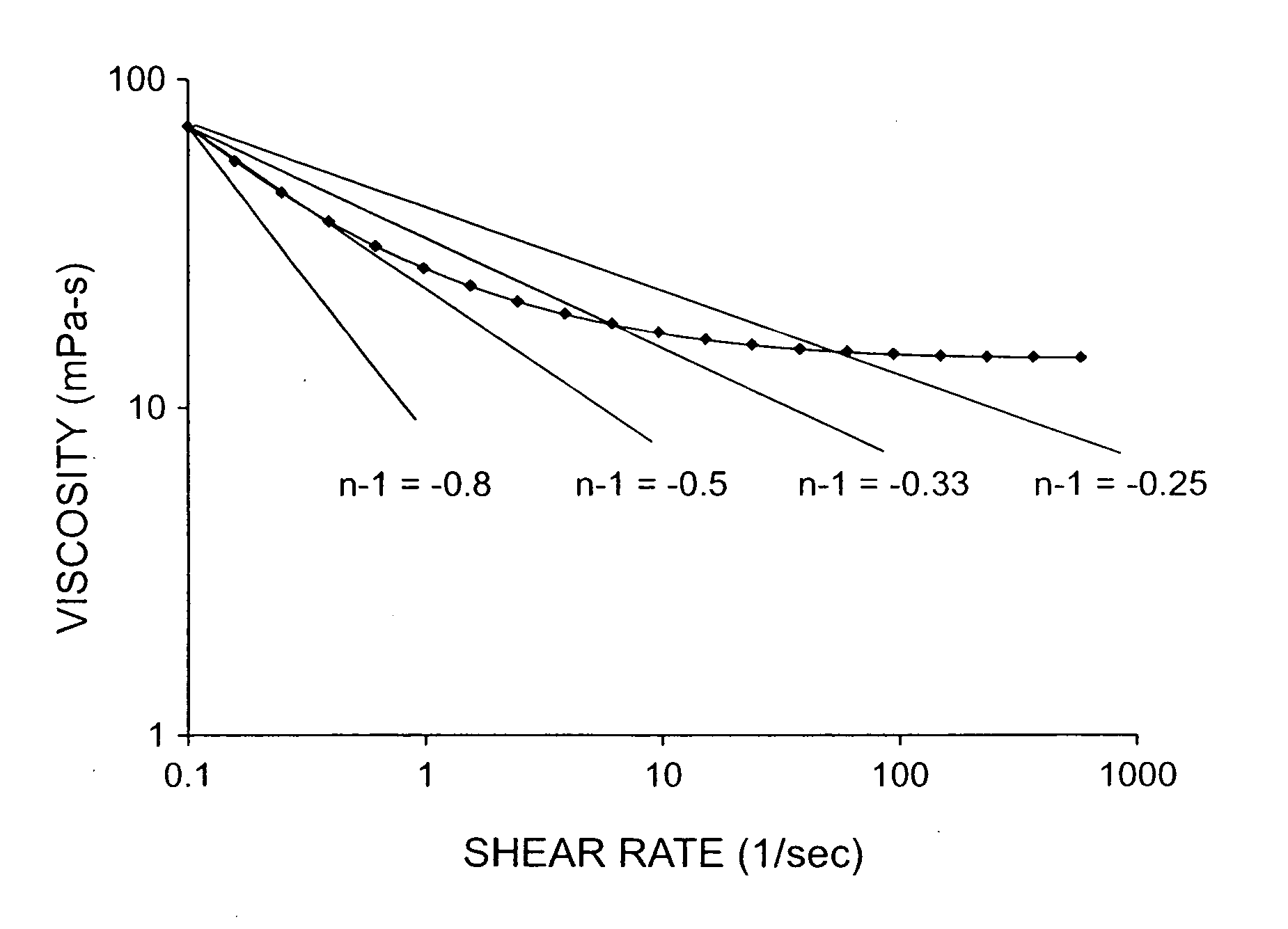

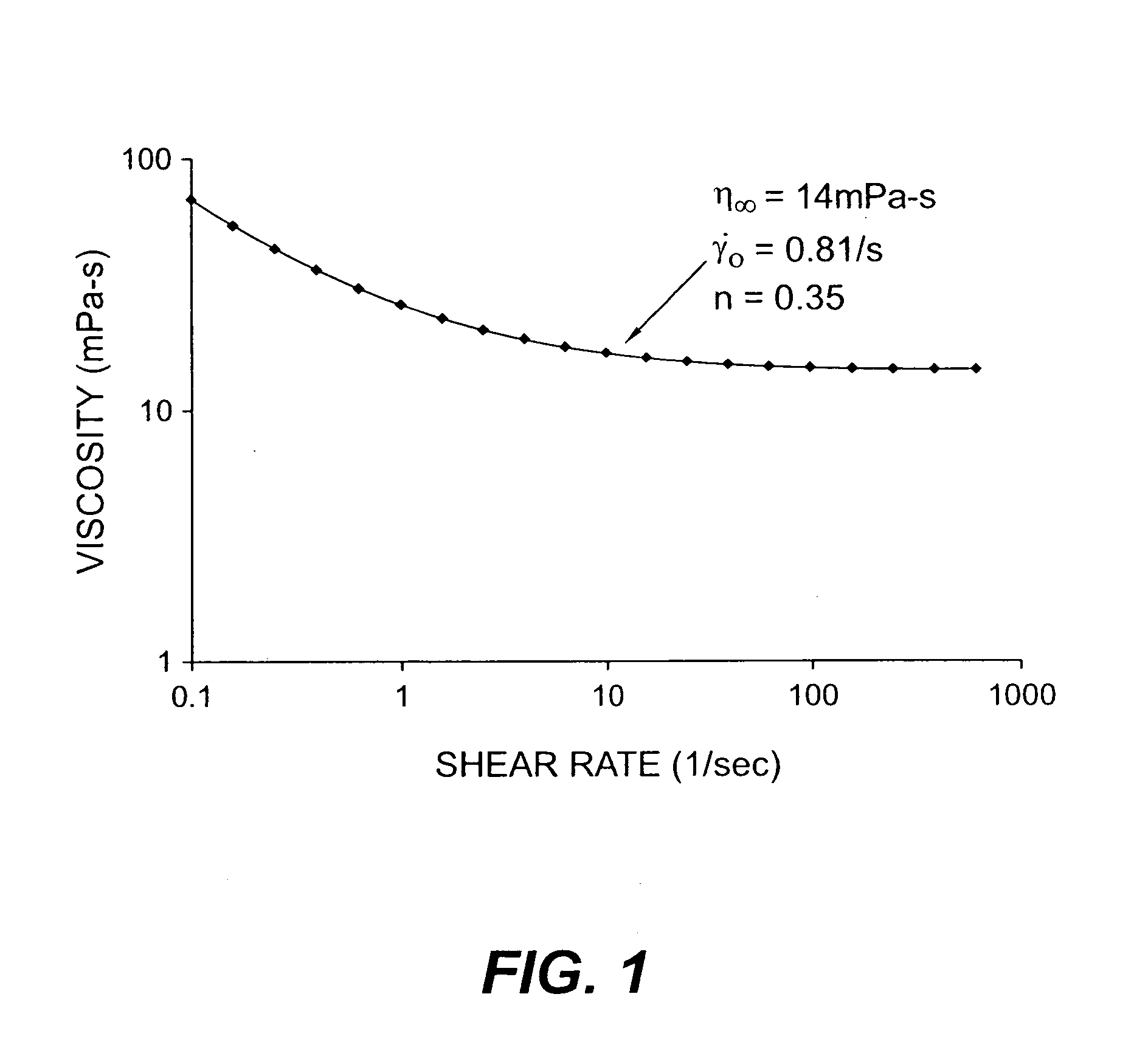

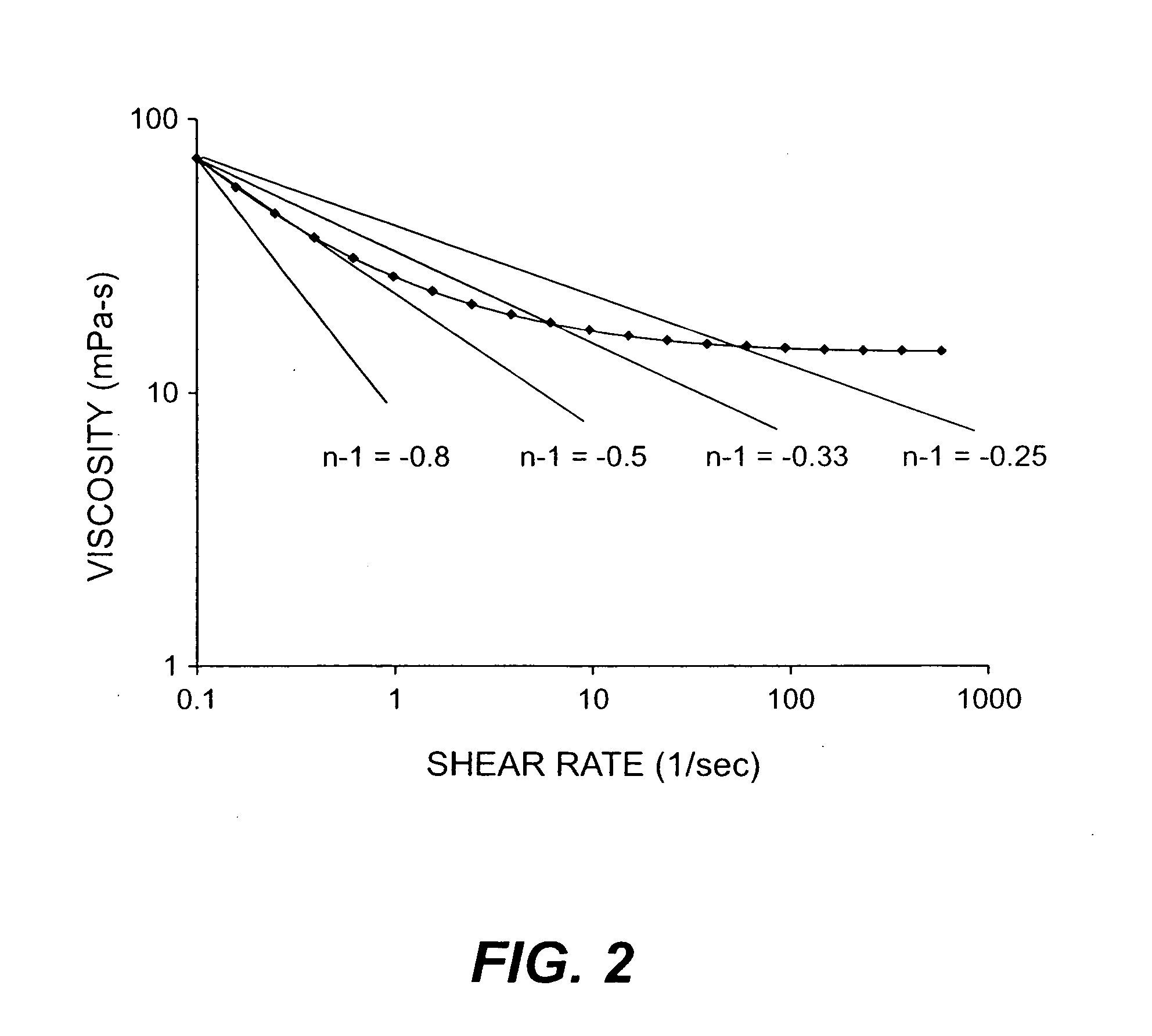

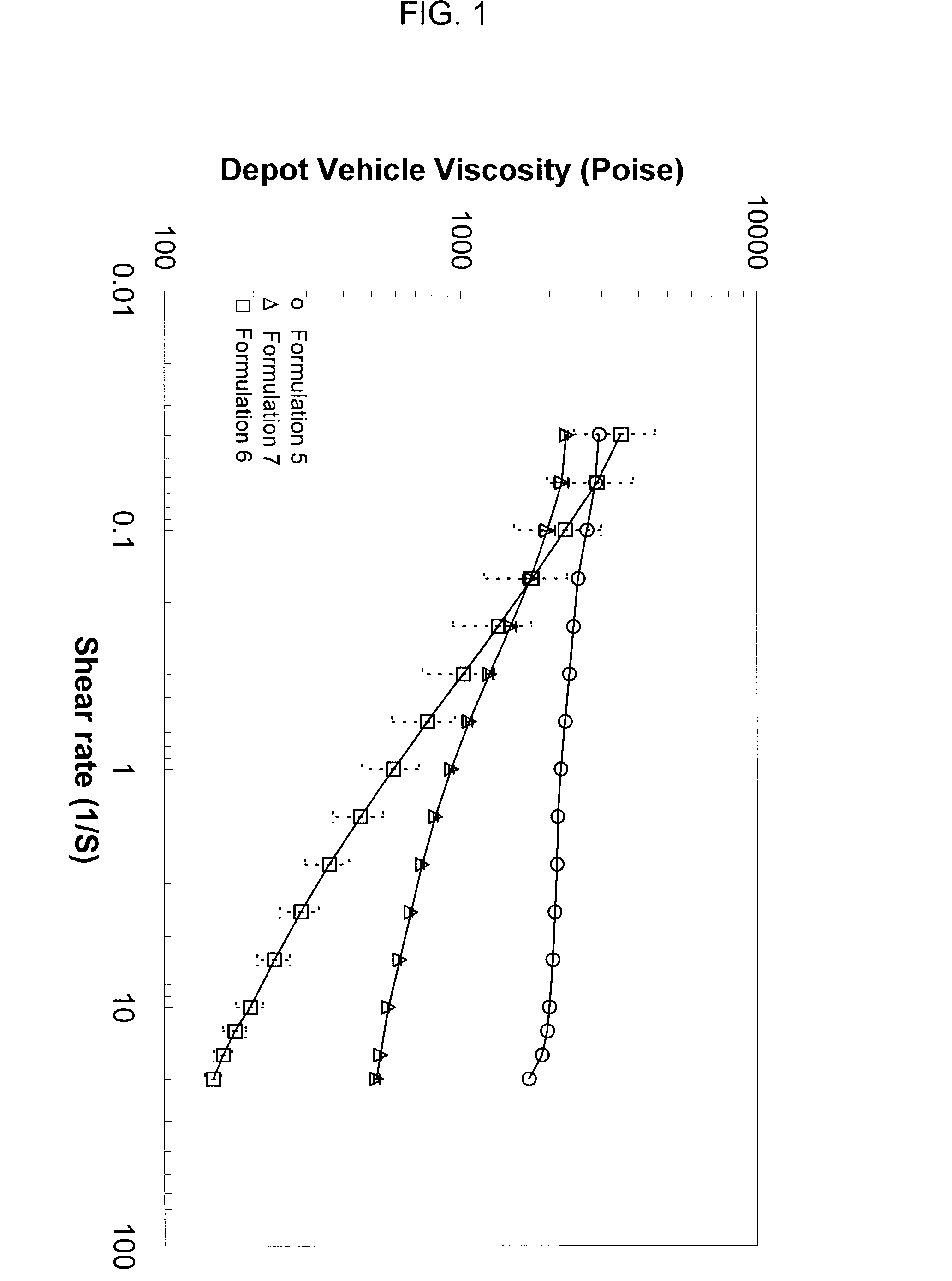

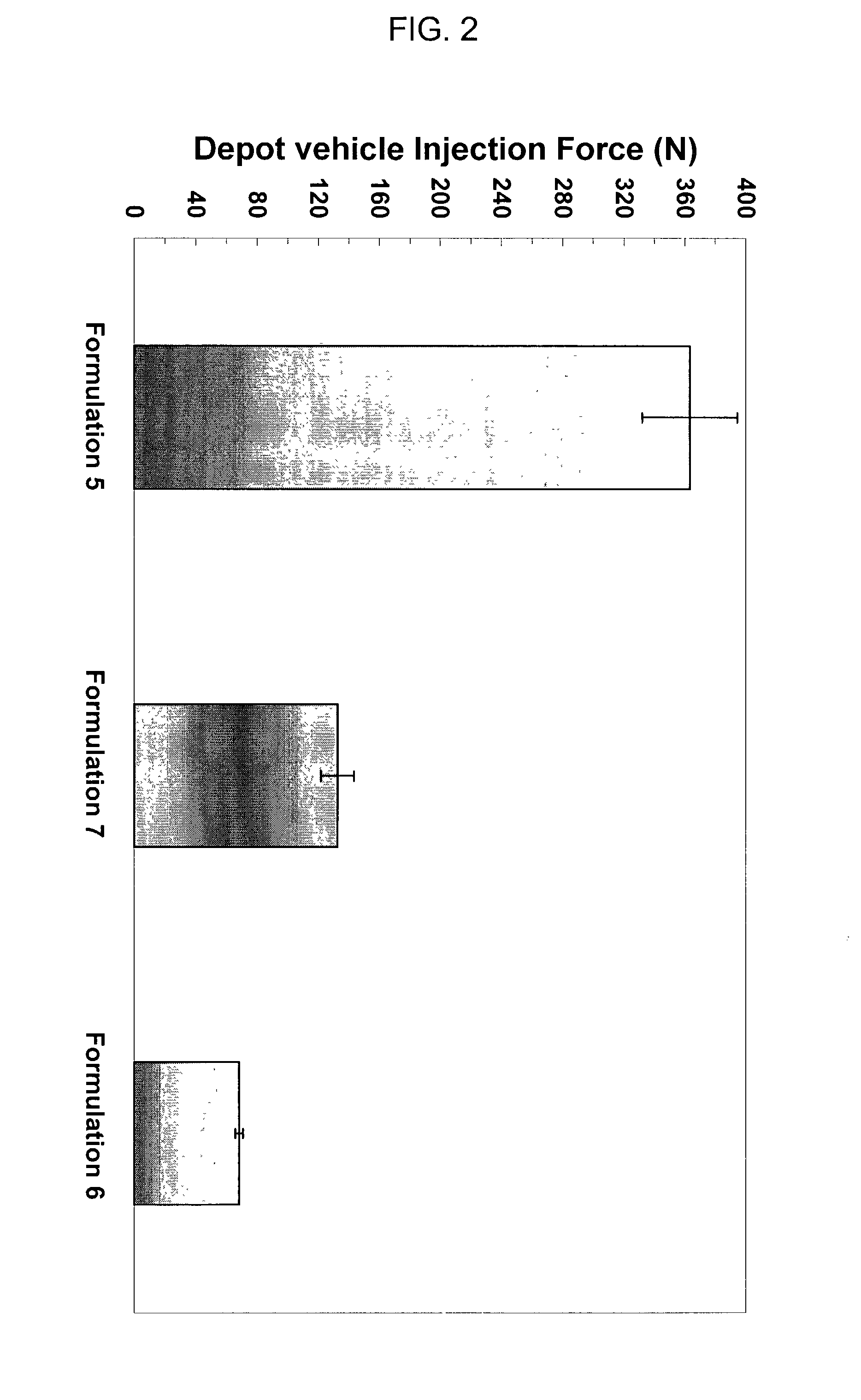

InactiveUS20040022859A1Effective distributionBeneficial agent loading ratePowder deliveryAerosol deliverySolventPolymer chemistry

Injectable depot compositions are provided that include a polymer matrix having a plurality of bioerodible, biocompatible polymers wherein wherein each polymer of the plurality of polymers has a specified weight average molecular weight; and the polymer matrix has a broad molecular weight distribution of the plurality of polymers; a solvent having a miscibility in water of less than or equal to 7 wt. % at 25° C., in an amount effective to plasticize the polymer and form a gel therewith; and a beneficial agent. The compositions are have substantially improved the shear thinning behavior and reduced injection force, rendering the compositions readily implanted beneath a patient's body surface by injection.

Owner:DURECT CORP

Viscous settable fluid for lost circulation in subterranean formations

A method of treating a well the method including the steps of: (A) forming a fluid including: (i) a shear-thinning aqueous liquid phase; and (ii) an inorganic setting material; wherein the fluid is shear-thinning, pumpable, and settable; and (B) introducing the fluid into the well.

Owner:HALLIBURTON ENERGY SERVICES INC

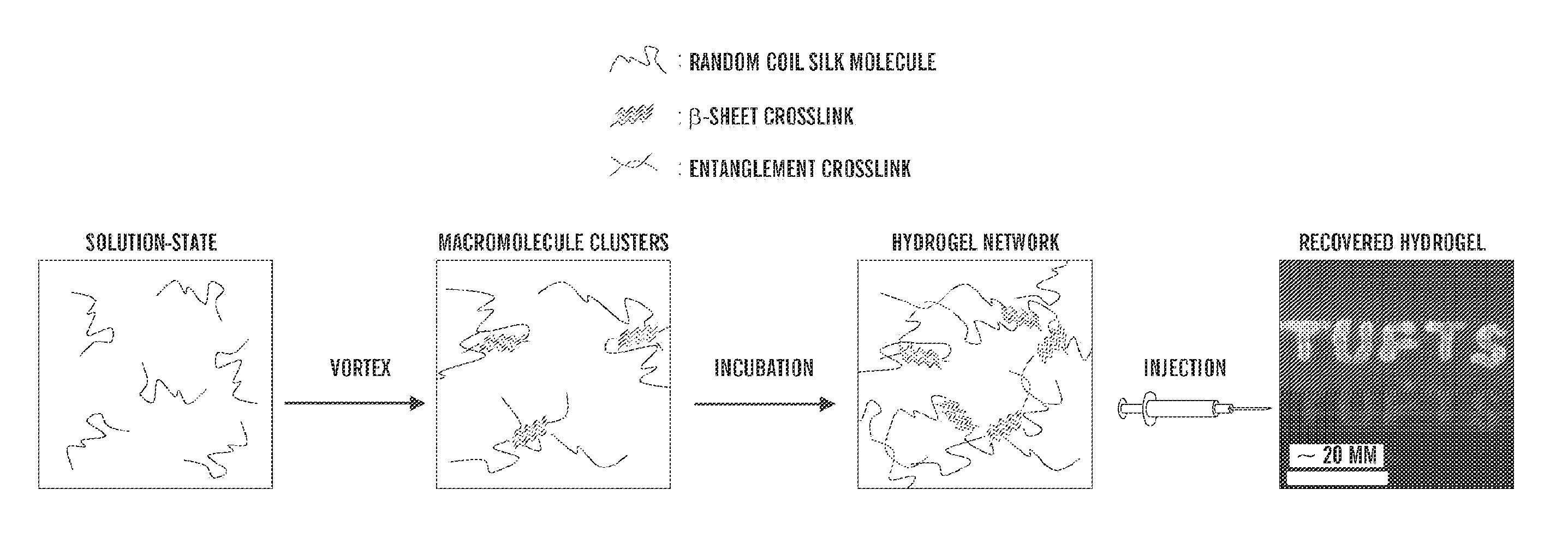

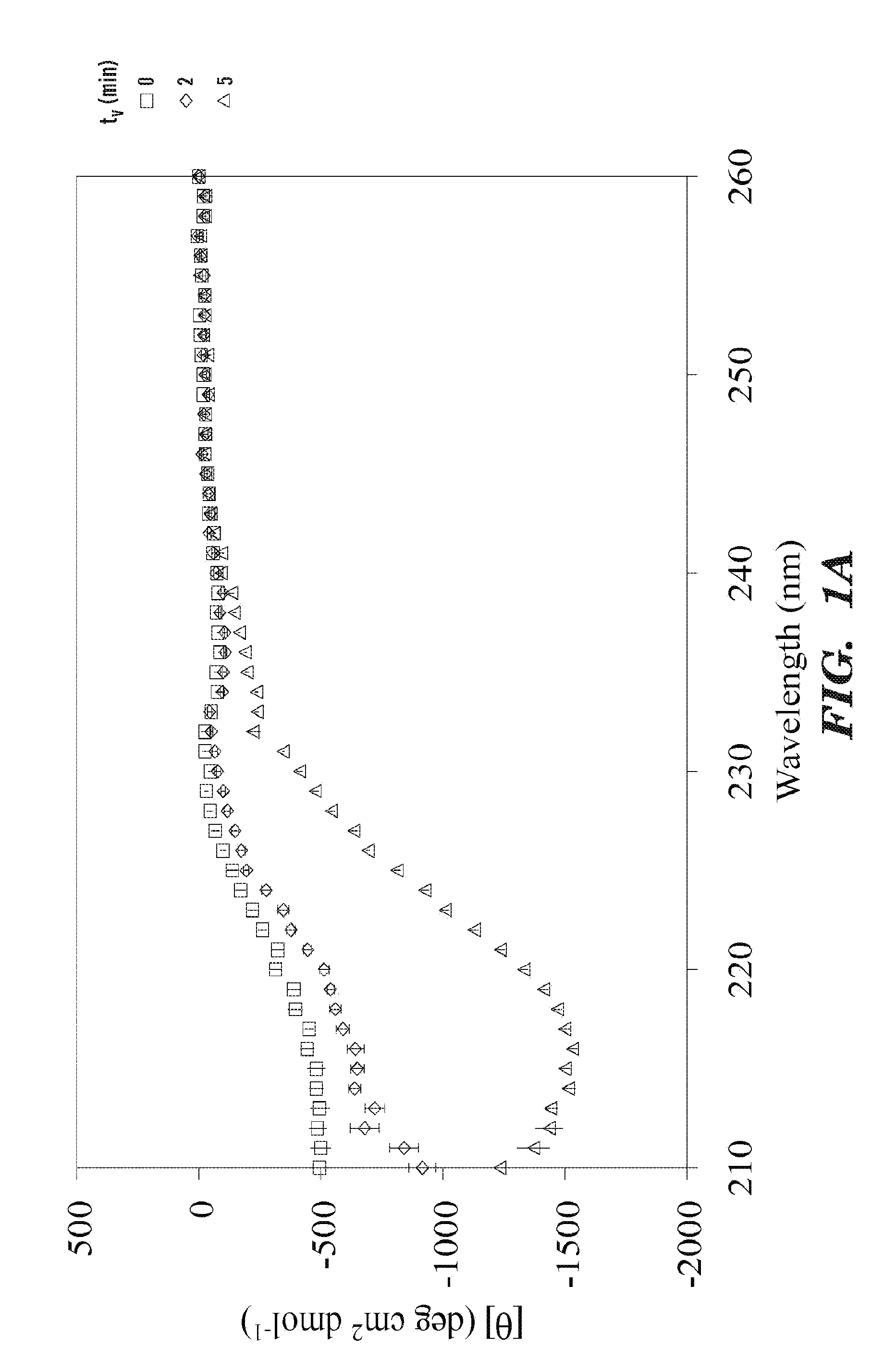

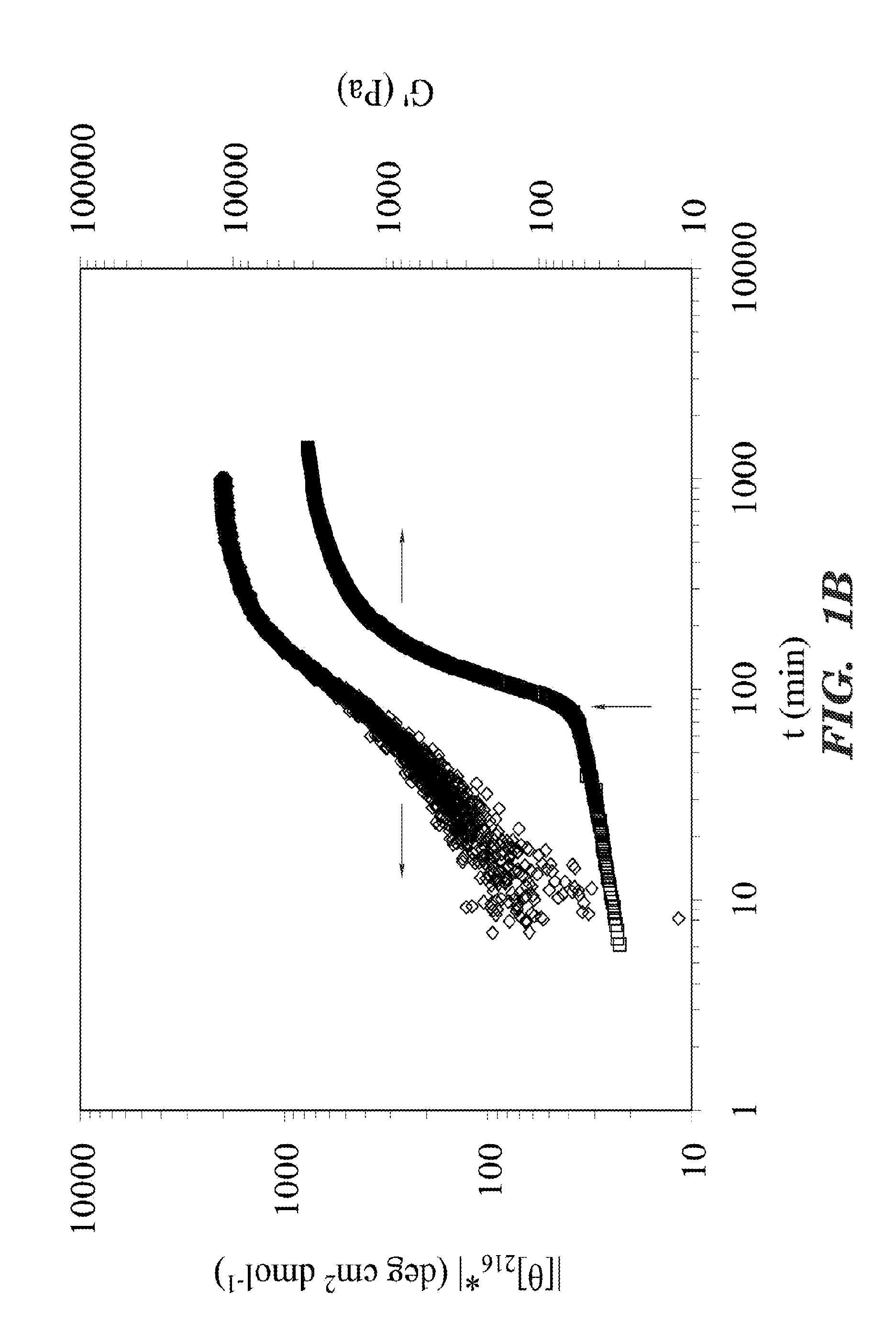

Vortex-induced silk fibroin gelation for encapsulation and delivery

The present invention provided for a novel process of forming silk fibroin gels, and controlling the rate of β-sheet formation and resulting hydrogelation kinetics, by vortex treatment of silk fibroin solution. In addition, the vortex treatment of the present invention provides a silk fibroin gel that may be reversibly shear-thinned, enabling the use of these approach for precise control of silk self-assembly, both spatially and temporally. Active agents, including biological materials, viable cells or therapeutic agents, can be encapsulated in the hydrogels formed from the processes, and be used as delivery vehicles. Hence, the present invention provide for methods for silk fibroin gelation that are useful for biotechnological applications such as encapsulation and delivery of active agents, cells, and bioactive molecules.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

Liquid detergent composition comprising an external structuring system comprising a bacterial cellulose network

A structured liquid detergent composition in the form of a liquid matrix made up of an external structuring system of a bacterial cellulose network; water; and surfactant system including an anionic surfactant; a nonionic surfactant; a cationic surfactant; an ampholytic surfactant; a zwitterionic surfactant; or mixtures thereof, wherein said liquid matrix has a yield stress of from about 0.003 Pa to about 5.0 Pa at about 25° C. and provides suitable particle suspension capabilities and shear thinning characteristics.

Owner:PROCTER & GAMBLE CO

Low pH structured surfactant compositions

An aqueous, low pH structured surfactant composition, contains, based on 100 parts by weight of the composition, from about 3 parts by weight to about 40 parts by weight of one or more anionic surfactants selected from anionic phosphate ester surfactants, anionic sulfonate surfactants, and anionic carboxylate surfactants, wherein the composition exhibits a pH of less than about 5, exhibits shear-thinning viscosity, and is capable of suspending water insoluble or partially water soluble components.

Owner:RHODIA OPERATIONS SAS

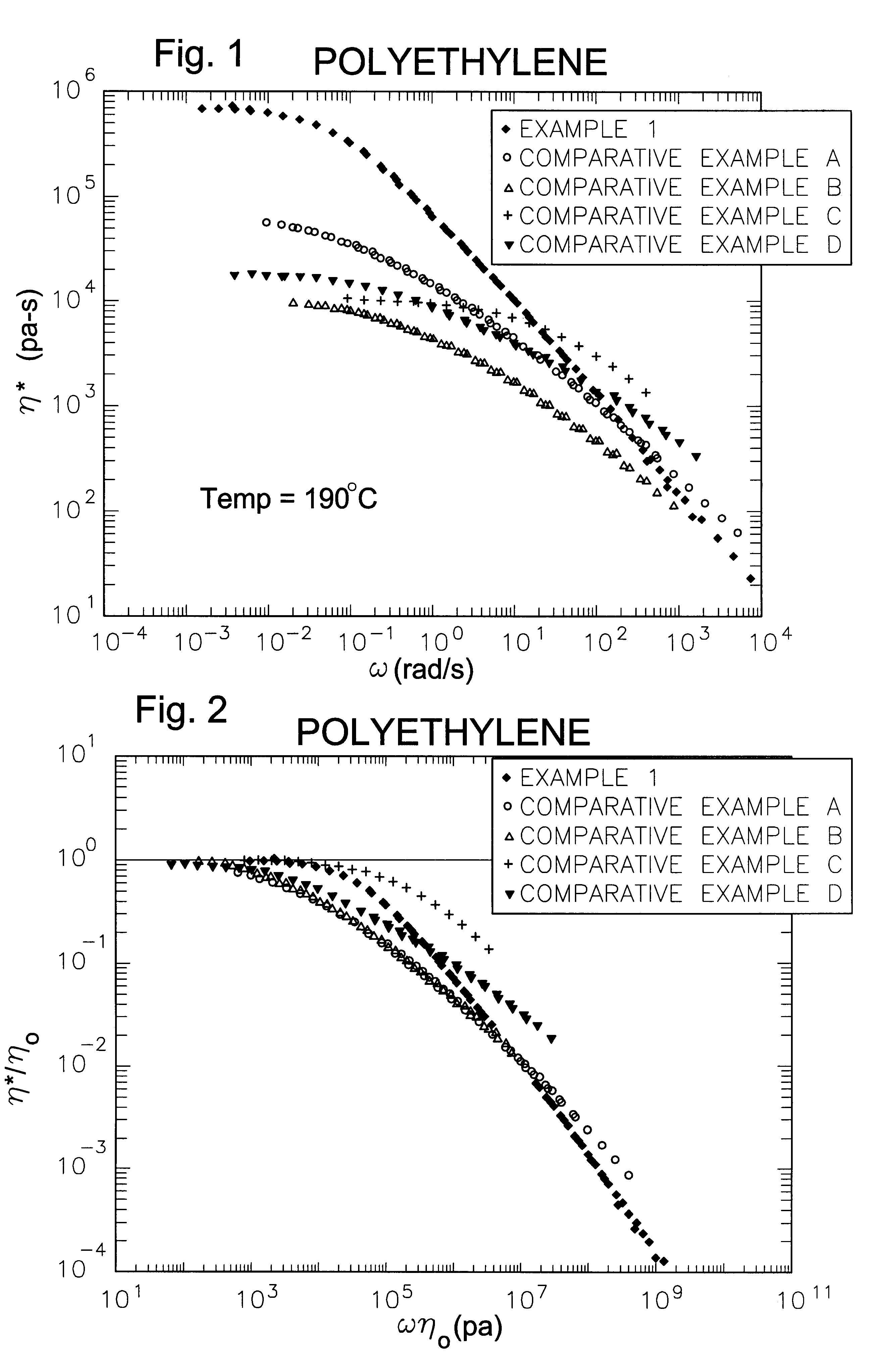

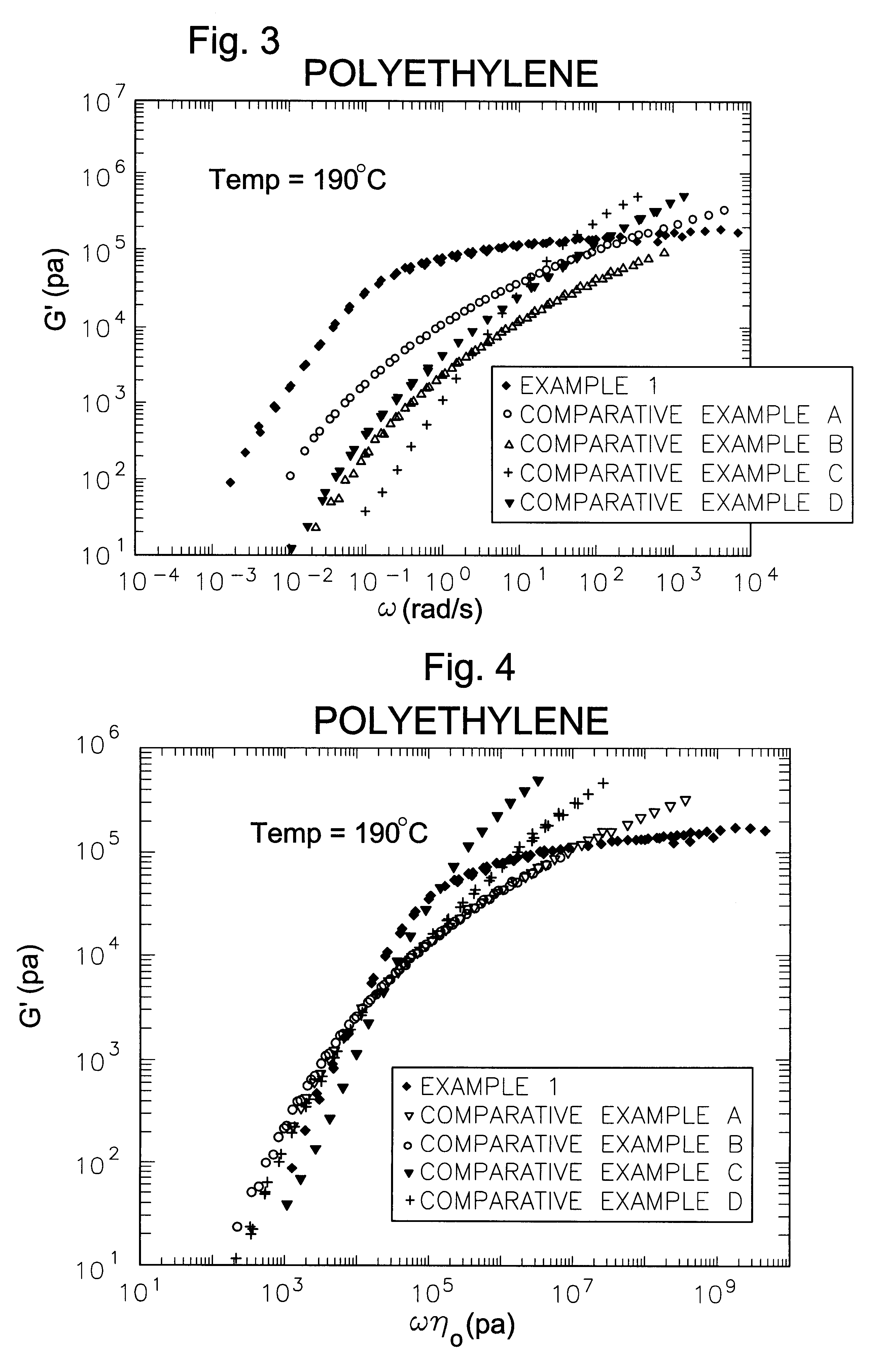

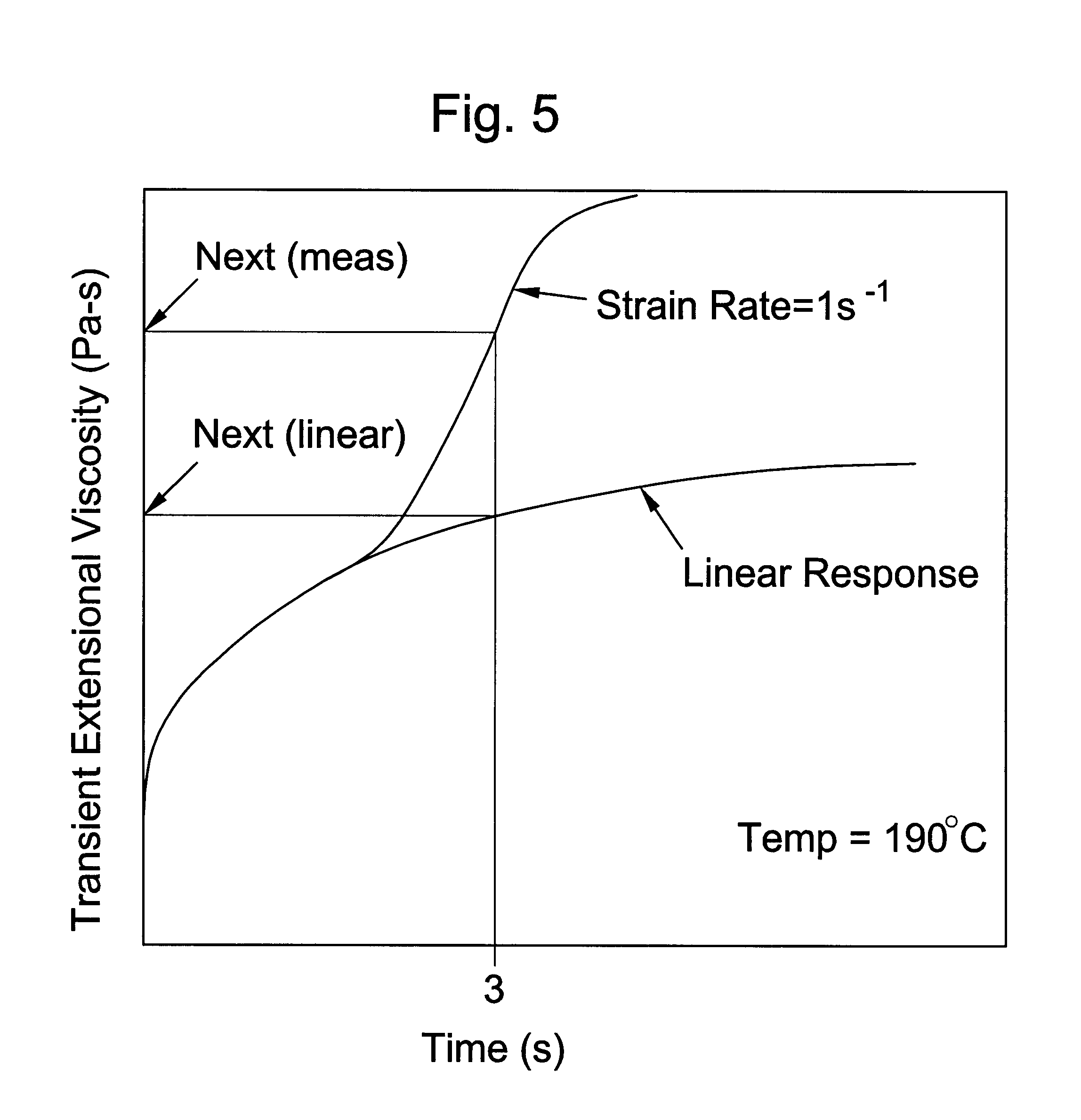

Processing olefin copolymers

The invention is directed to essentially saturated hydrocarbon polymer composition comprising essentially saturated hydrocarbon polymers having A) a backbone chain, B) a plurality of essentially hydrocarbyl sidechains connected to A), said sidechains each having a number-average molecular weight of from 2500 Daltons to 125,000 Daltons and a MWD by SEC of 1.0-3.5; and having A) a Newtonian limiting viscosity (eta0) at 190° C. at least 50% greater than that of a linear olefinic polymer of the same chemical composition and weight average molecular weight, preferably at least twice as great as that of said linear polymer, B) a ratio of the rubbery plateau modulus at 190° C. to that of a linear polymer of the same chemical composition less than 0.5, preferably <0.3, C) a ratio of the Newtonian limiting viscosity (eta0) to the absolute value of the complex viscosity in oscillatory shear (eta*)at 100 rad / sec at 190° C. of at least 5, and D) a ratio of the extensional viscosity measured at a strain rate of 1 sec-1, 190° C., and time=3 sec (i.e., a strain of 3) to that predicted by linear viscoelasticity at the same temperature and time of 2 or greater. Ethylene-butene prepared by anionic polymerization and hydrogenation illustrate and ethylene-hexene copolymers prepared by coordination polymerization illustrate the invention. The invention polymers exhibit improved processing characteristics in that the shear thinning behavior closely approaches that of ideal polymers and exhibit improved strain thickening.

Owner:EXXONMOBIL CHEM PAT INC

Polychromic ink composition depending on viewing angle

InactiveUS20020033117A1Coating obtainedImprove dispersion stabilityPigmenting treatmentInksPolymer chemistryPigment

A polychromic ink composition depending on viewing angle comprises 0.5 to 40% by weight of cholesteric liquid crystal polymer particles whose maximum particle diameter is 1 to 200 mum, 1.0 to 30.0% by weight of binder resins, 0.05 to 20% by weight of pigments with a deep-colored coloring matter whose average particle diameter is 0.01 to 0.5 mum, 0.01 to 5.0% by weight of a shear-thinning property imparting agent, and water with respect to the total amount of the ink composition.

Owner:SAKURA COLOR PRODUCTS CORPORATION

Gel laundry detergent composition

InactiveUS7297674B2Improve clarityHigh transparencySoap detergents with organic compounding agentsNon-ionic surface-active compoundsActive agentPolypropylene glycol

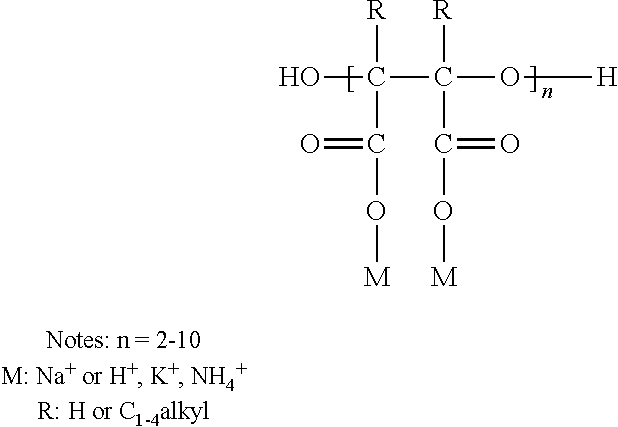

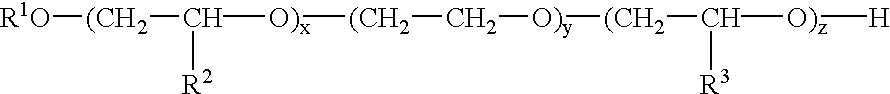

The present invention provides a shear thinning, transparent gel laundry detergent composition, comprising a surfactant system containing surfactant material selected from an anionic surfactant, a nonionic surfactant or a mixture thereof, and from 0.1 to 10% by weight of a clarity improving agent being a glycol dialkyl ether selected froma mono-or polyethylene glycol dialkyl ether having the formula(CpH2p+1)O—(CH2CH2O)n—(CqH2q+1), (I)a mono- or polypropylene glycol dialkyl ether having the formula(CpH2p+1)O—(CH2CH (CH3)O)n—(CqH2q+1), (II) and mixtures thereof,wherein p and q independently are integers in the range of from 1 to 5, and n is an integer in the range of from 1 to 50, preferably 1 to 10. It has been found that this gel laundry composition is highly transparent, such that particles can be suspended therein for improving visual appearance.

Owner:HENKEL IP & HOLDING GMBH

Viscosity modification of petroleum distillates

InactiveUS20030083209A1Suitable viscosityHigh viscosityCosmetic preparationsMake-upMaceralPressurized spray

A method for the thickening of mineral oil products, wherein the thickened mineral oil product exhibits shear-thinning so as to be applicable to a surface by non-pressurized spray mechanisms. The thickening agent added to the petroleum distillate comprises a thixotropic thickener chosen from the group consisting of mixtures comprising a triblock copolymer and a hydrocarbon oil, and N-Lauroyl glutamic acid di-n-butylamide.

Owner:SC JOHNSON & SON INC

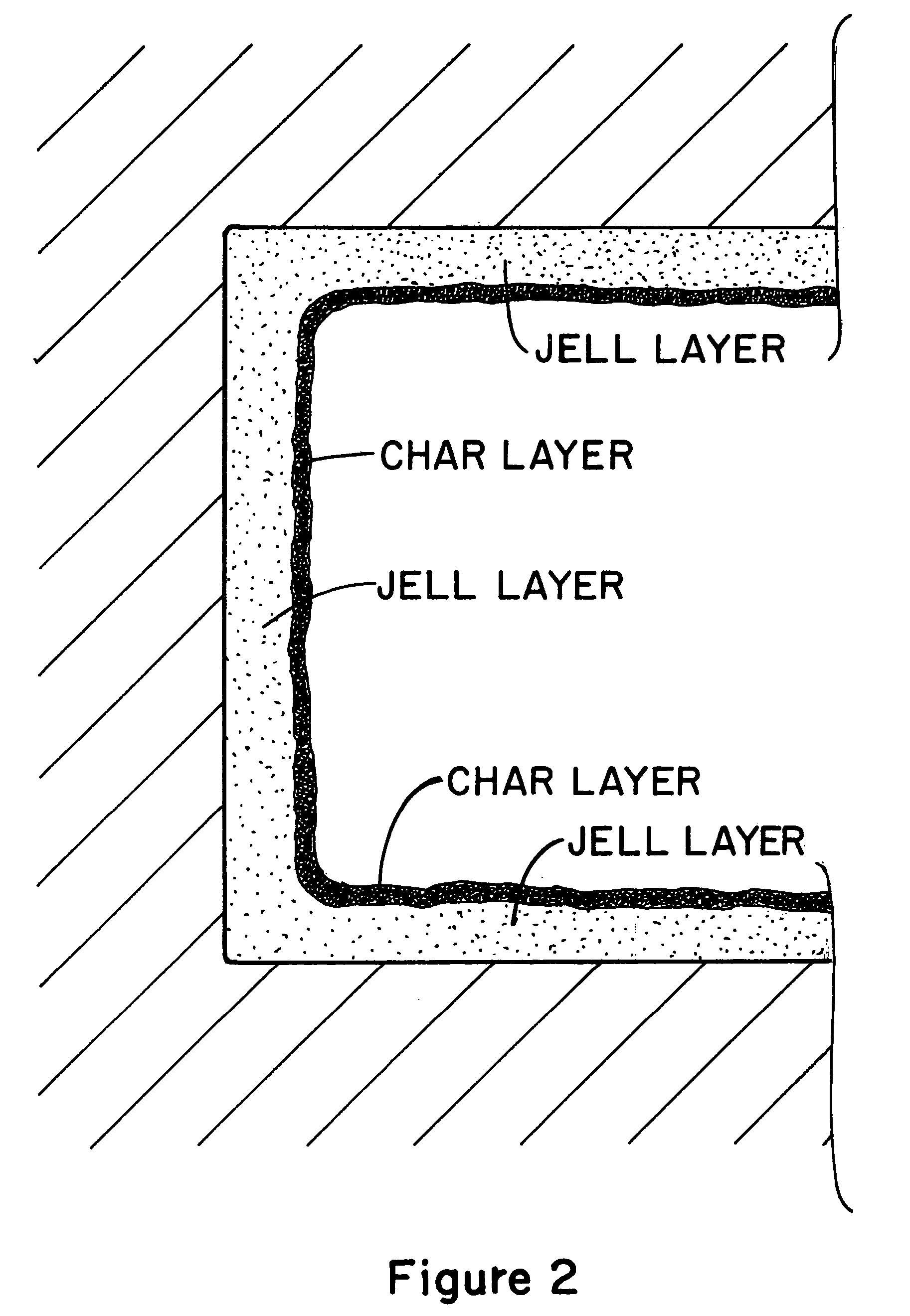

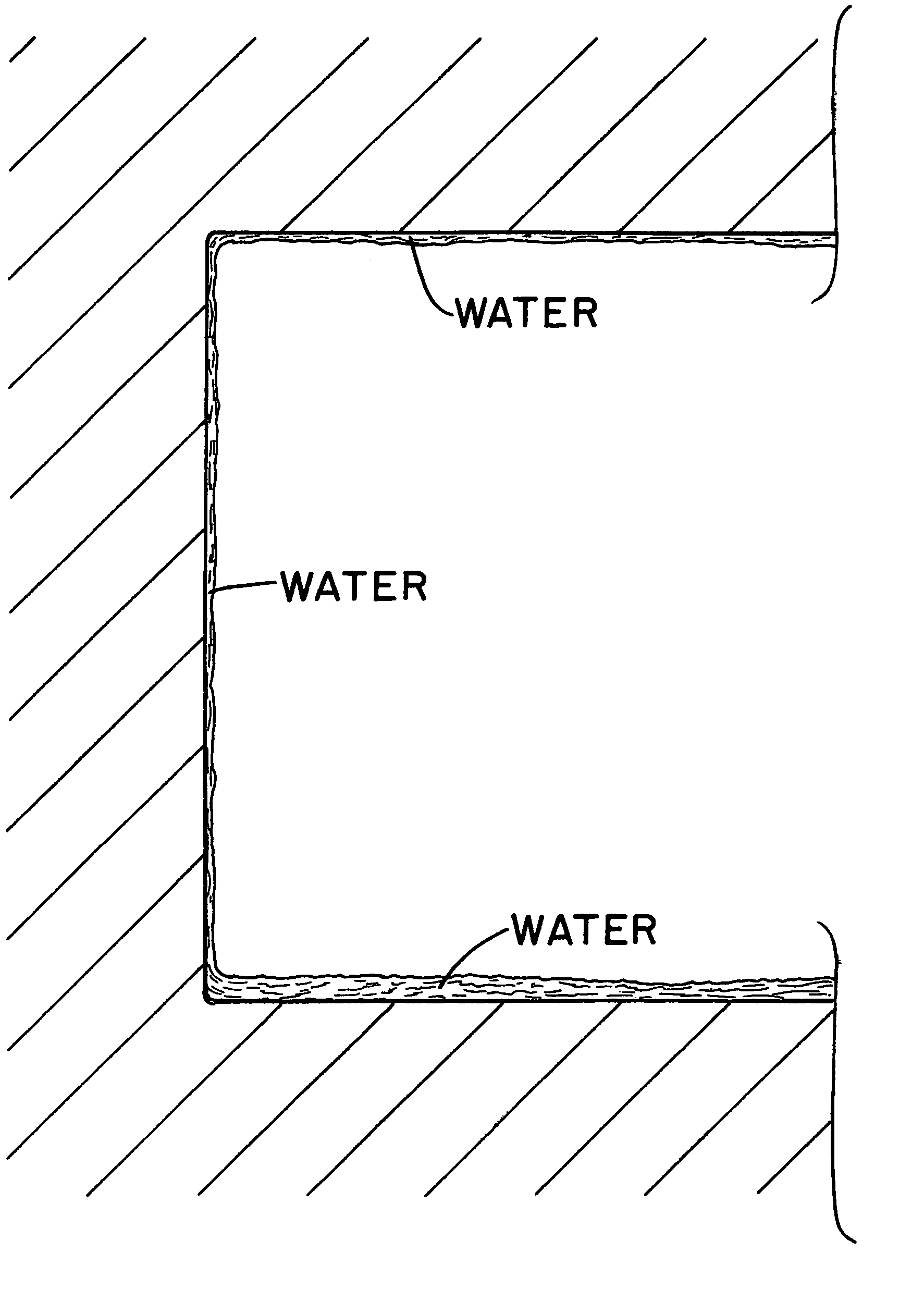

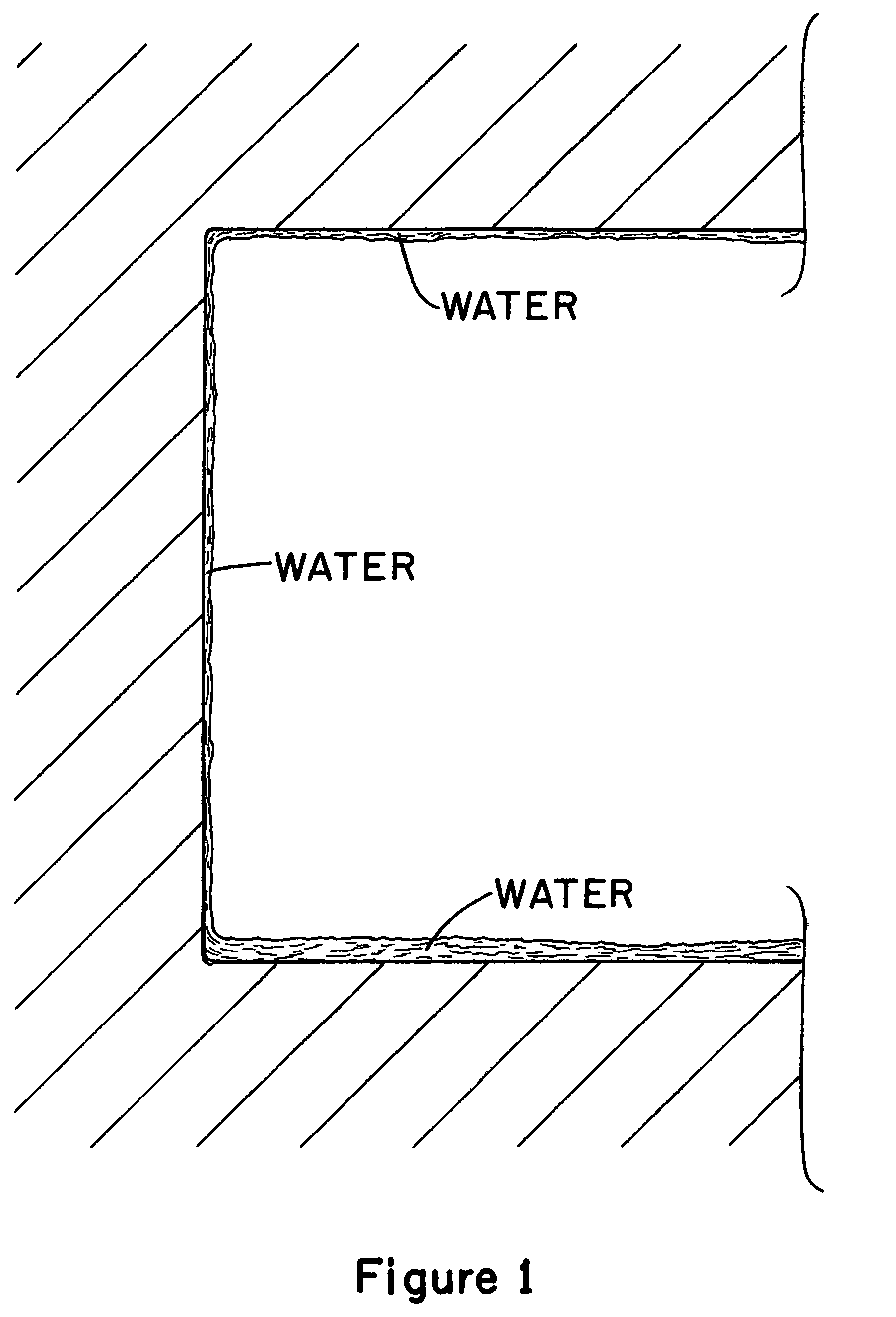

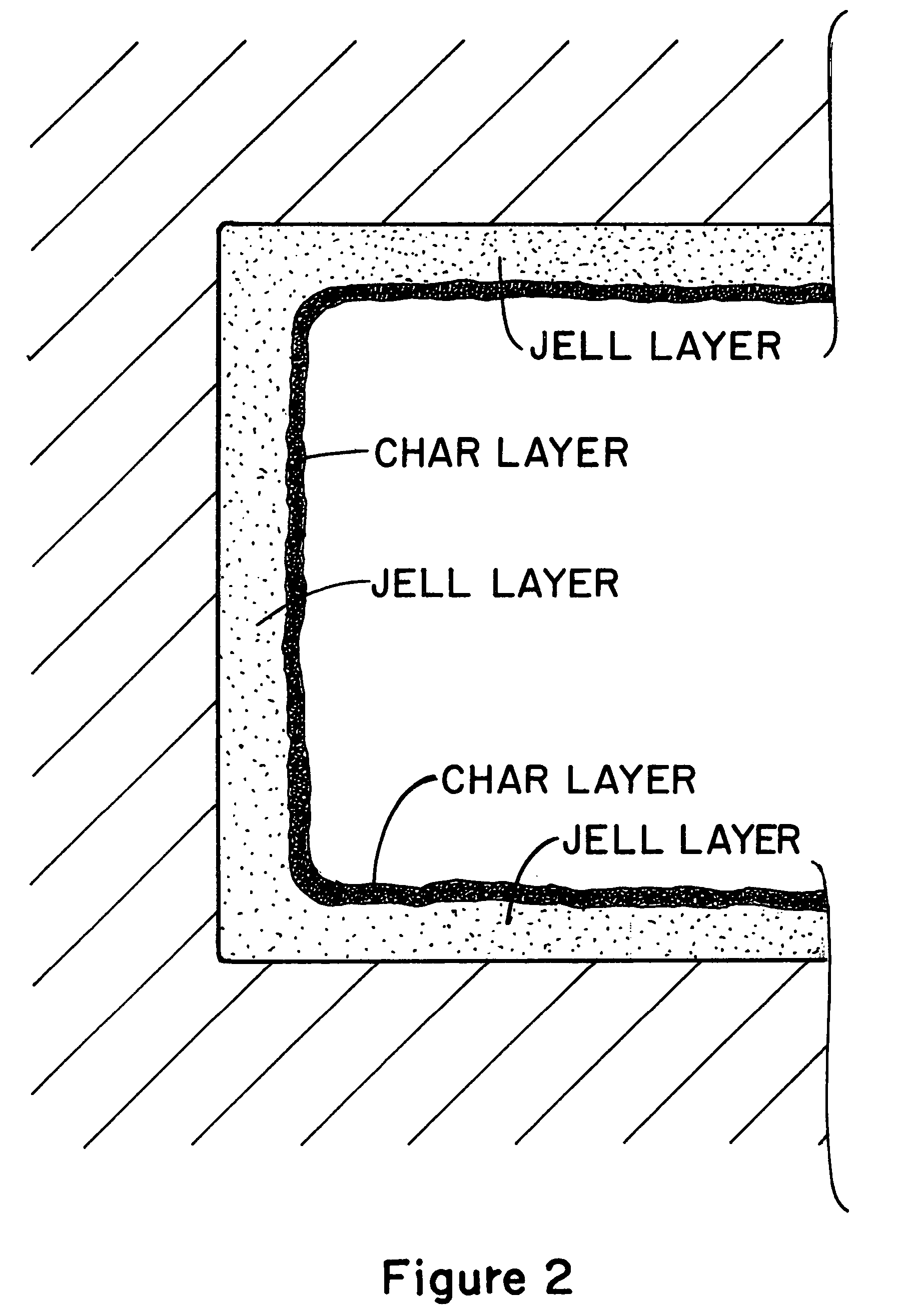

Composition inhibiting the expansion of fire, suppressing existing fire, and methods of manufacture and use thereof

InactiveUS20060076531A1Extended shelf lifeEasy to addFire rescueBoring toolsFoaming agentSuspending Agents

The invention relates to compositions that prevent expansion of a fire, suppress existing fire, as well as methods of preparing and using such compositions. The composition is comprised of water, pseudo-plastic high yield suspending agent and starch. Compositions may contain additional functional agents, such as rheological, wetting, foaming, coloring, chelating, antimicrobial and stabilizing agents. In the description of the present invention, all composition modifications are referred to as compositions. The composition, an augmentation of water, exhibits the characteristics of a sag resistant aqueous gel in the tank, but has shear thinning capacity, allowing the composition to be pumped or sprayed as easily as water. At the point of impact, when the sprayed composition is again at rest, it instantly reverts to a sag resistant aqueous gel. The composition also forms an intumescent, surface char layer upon contacting a fire. Foaming of the augmented composition on impact can be incorporated, which is advantageous for fighting petroleum fires.

Owner:EARTHCLEAN CORPRATION

High efficiency sunscreen composition particularly useful for wipes and sprays

InactiveUS20070178057A1Increase in shear-thinning indexHigh indexCosmetic preparationsToilet preparationsPolymer scienceOil phase

A sunscreen composition, either impregnating a wipe substrate or comprising a sunscreen spray, wherein the composition comprises an oil phase dispersed stably as emulsion droplets in a water phase that contains i) a booster for the sun protection factor (SPF), comprising a combination of water-dispersible particulate materials, one of which is smectite clay, and a water-soluble or water-dispersible phenolic polymer; and ii) a water-soluble or water-dispersible polymer having a weak acid group, a weight average molecular weight of 1,000-100,000 Dalton, and an anionic charge density of no less than 4 milliequivalent per gram of the polymer; the said sunscreen composition meeting the following specifications: i) the in-vivo sun protection factor (SPF) is ≧1.8 times the weight percent of the sunscreen active(s) contained therein, based on the weight of the sunscreen composition; and ii) the shear thinning index of the composition is greater by 5% or higher with the weak acid polymer contained therein than without the polymer, the shear thinning index being defined as the ratio of viscosities of the sunscreen composition at 0.5 rpm and 20 rpm, measured on a Brookfield RVT viscometer at 25 ° C., using spindle 7, after cooling the composition to room temperature and storing it at that temperature for about 24 hours.

Owner:AMCOL INTERNATIONAL CORPORATION

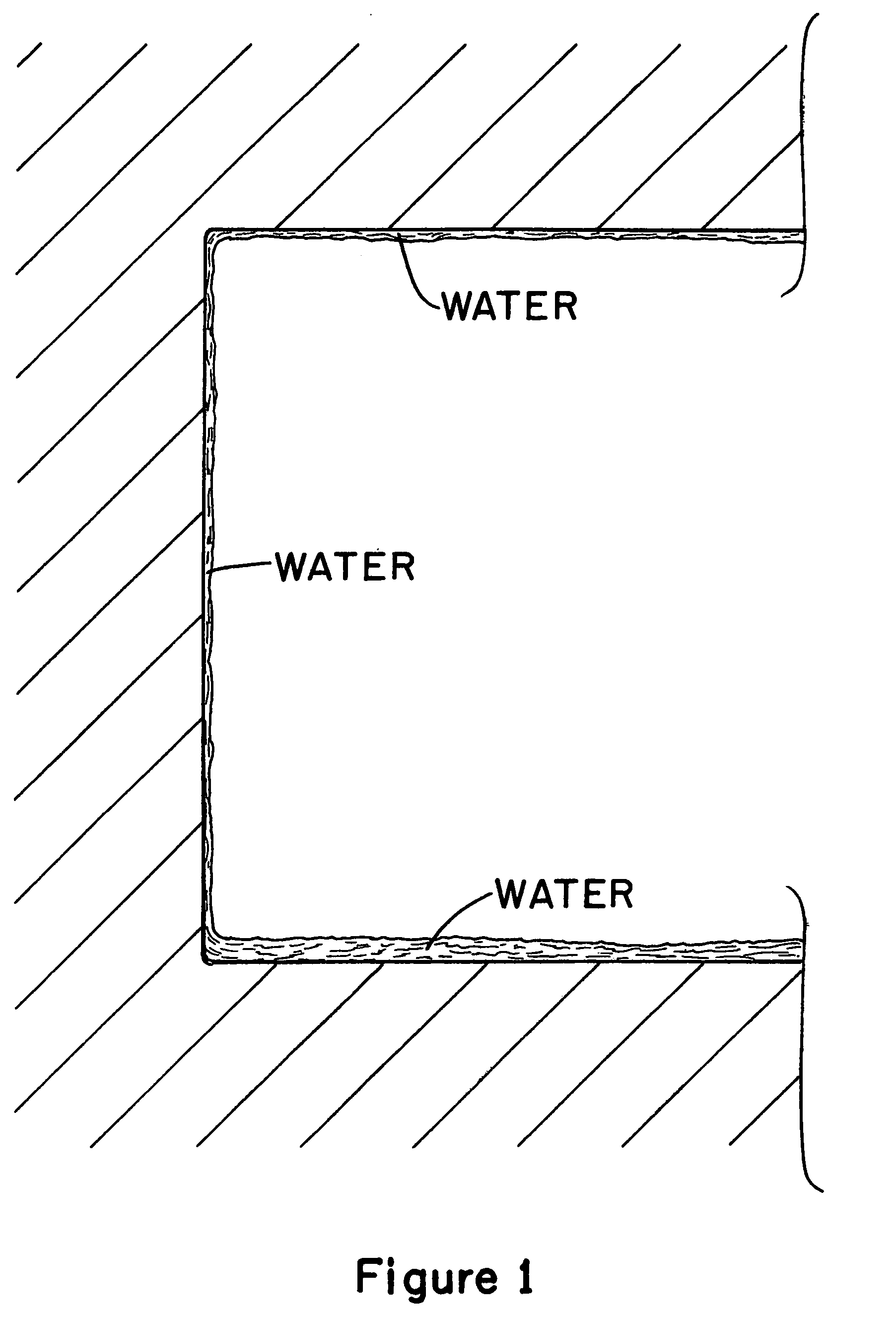

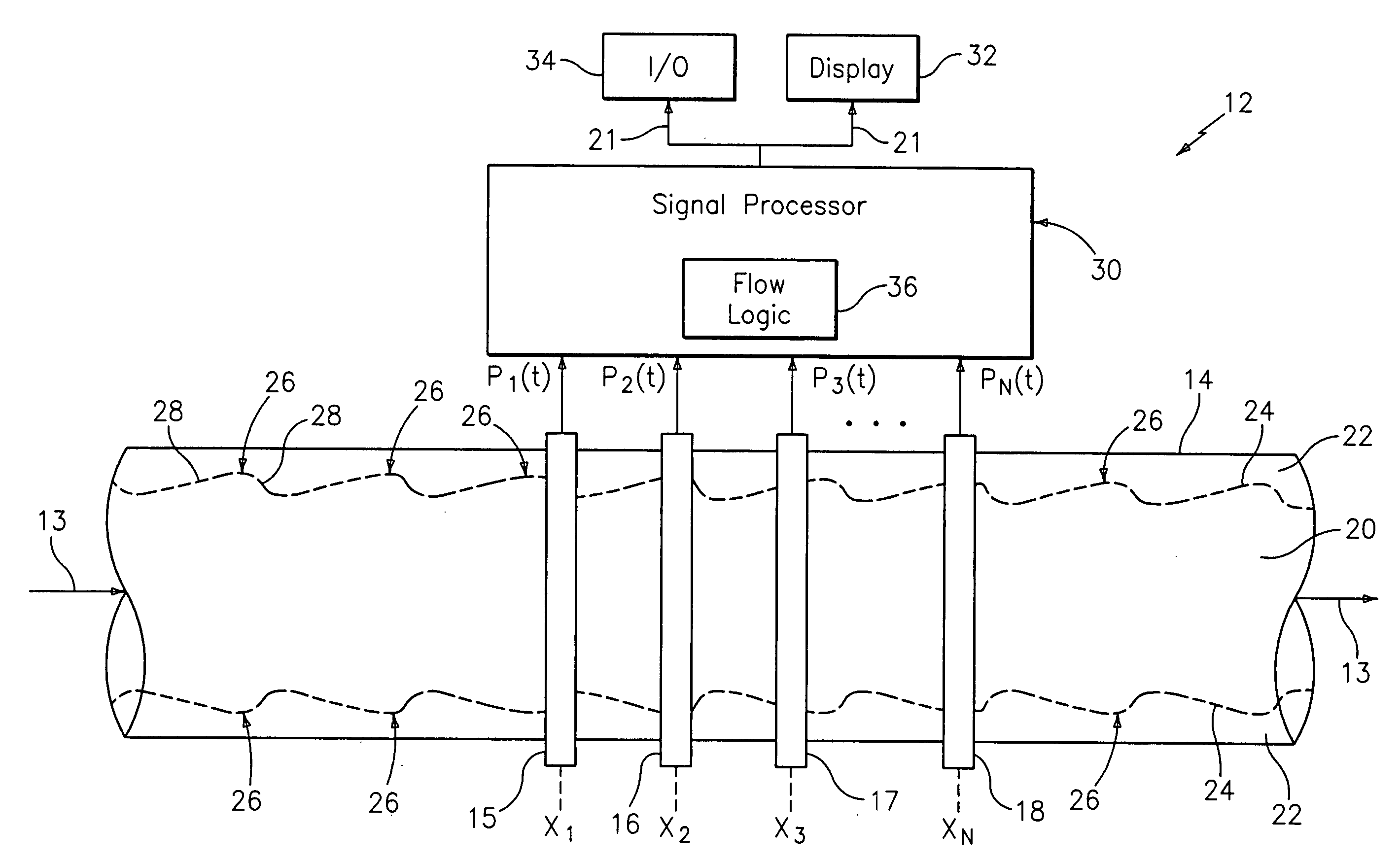

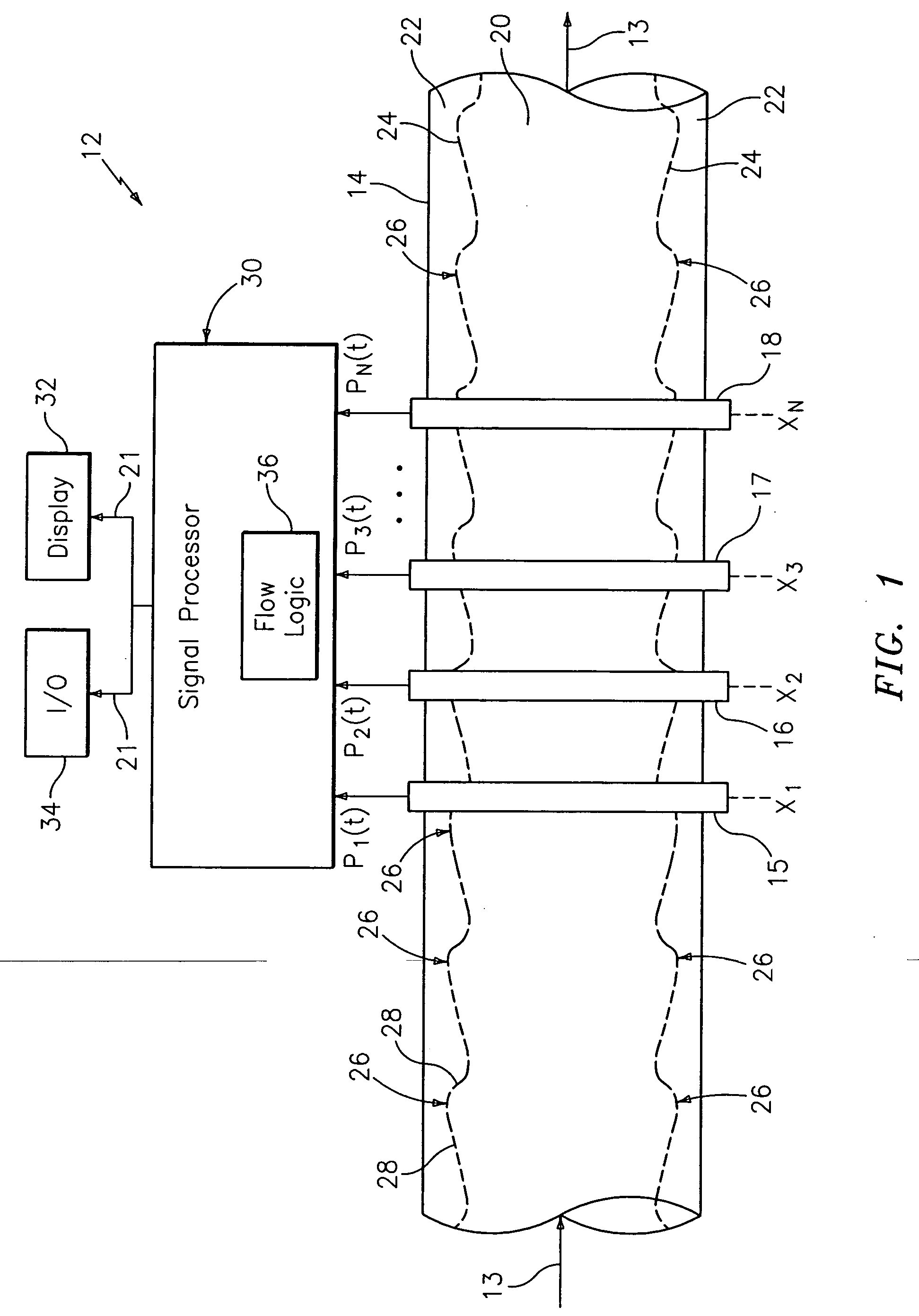

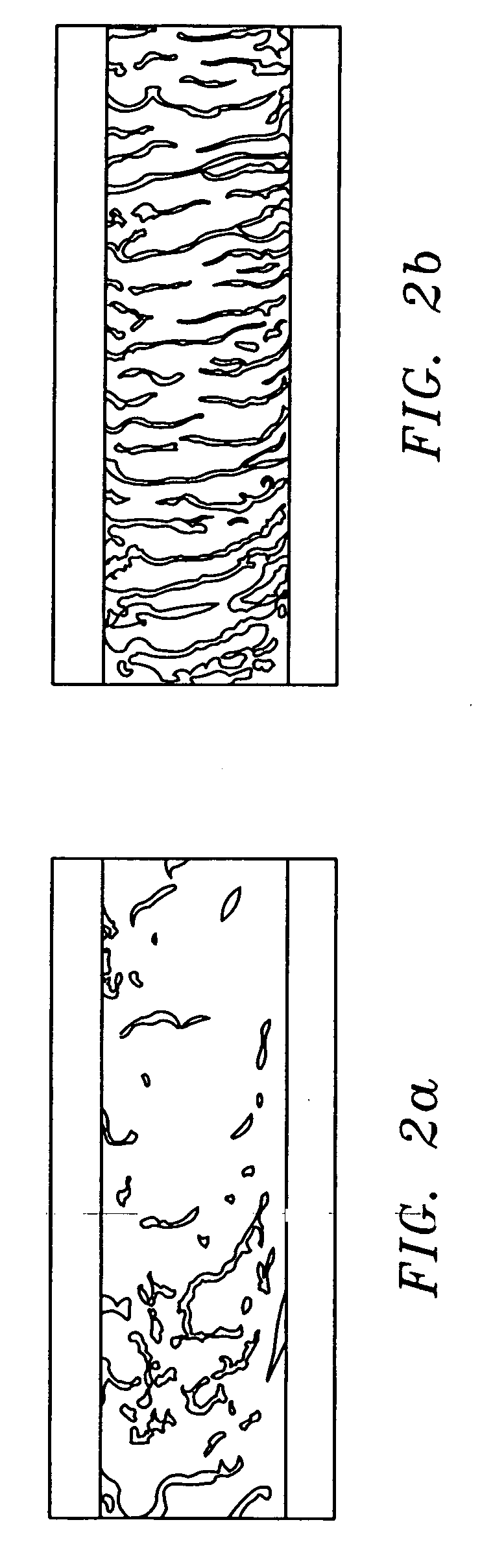

Method and apparatus for measuring characteristics of core-annular flow

ActiveUS20050033545A1Inflated body pressure measurementFluid pressure measurement by electric/magnetic elementsFiberEngineering

An apparatus and method are disclosed wherein at least one parameter associated with a core-annular flow (CAF) in a pipe is measured by sensing unsteady pressures associated with undulations formed at the interface of a core region and an annular region in the CAF at different axial locations along the pipe. The at least one parameter, which may include a flow velocity of the CAF, Mach number associated with the CAF, and a volumetric flow rate of the CAF, is determined using sensed unsteady pressures. The CAF may be developed from a shear thinning fluid, such as bitumen froth or from a wood pulp fiber suspension. Alternatively, the CAF may be developed from a lubricating fluid, such as water, and a fluid to be transported, such as oil, where the fluid to be transported forms the core region and the lubricating fluid forms the annular region.

Owner:CIDRA

Ink jet printing system for high speed/high quality printing

InactiveUS20070279467A1Measurement apparatus componentsInksHigh concentrationElectrical and Electronics engineering

In an ink jet printing apparatus for high speed / high quality printing, an ink jet ink having a high concentration of solids the range of about 20-70 wt. %, and exhibiting shear-thinning characteristics.

Owner:EASTMAN KODAK CO

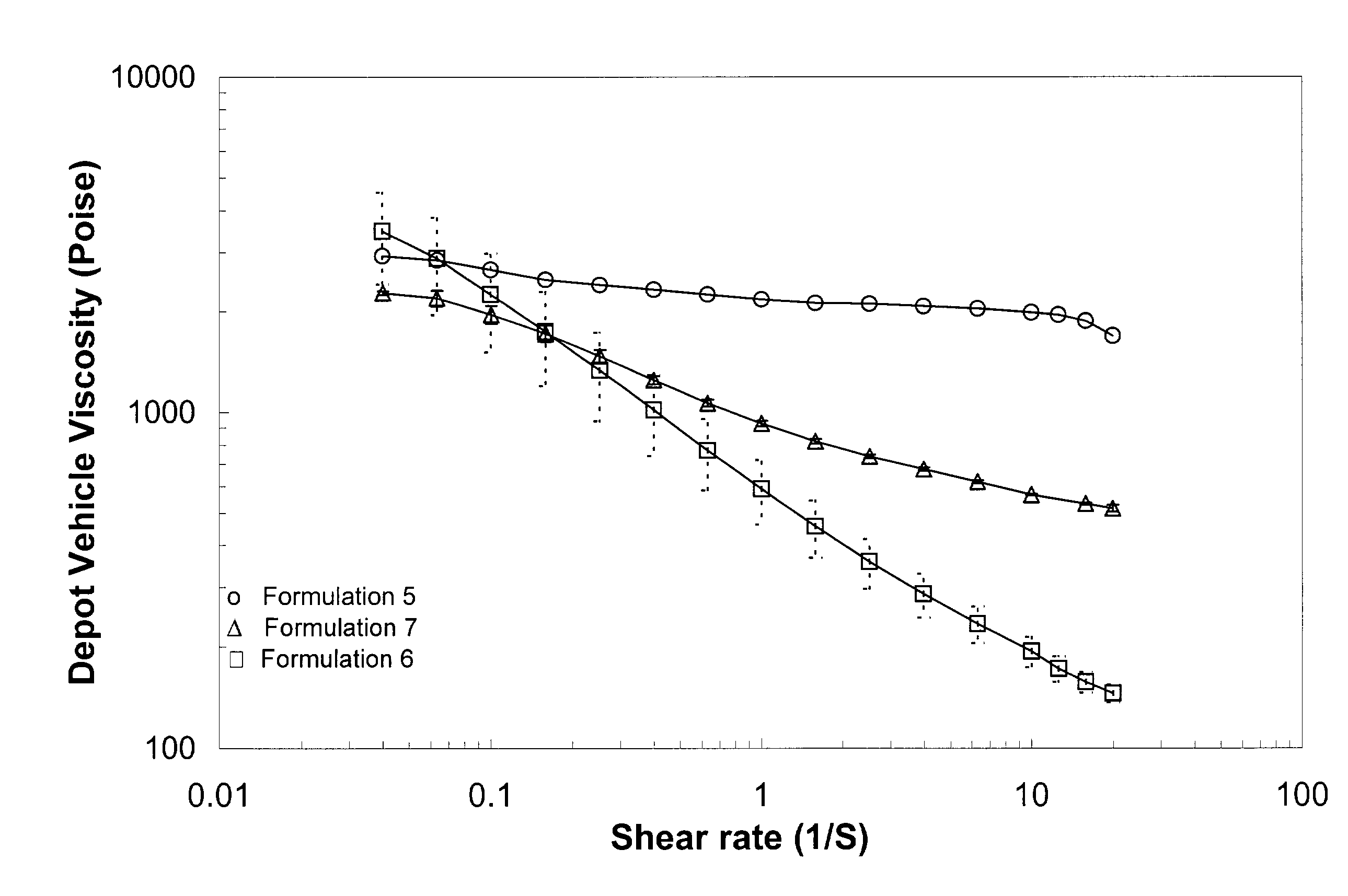

Catheter injectable depot compositions and uses thereof

InactiveUS7829109B2Improved shear thinning behaviorReduce injection forcePowder deliverySenses disorderMedicineAromatic alcohol

Catheter injectable depot compositions are provided that include a bioerodible, biocompatible polymer, a solvent having miscibility in water of less than or equal to 7 wt. % at 25° C., in an amount effective to plasticize the polymer and form a gel therewith, a thixotropic agent, and a beneficial agent. The solvent comprises an aromatic alcohol, an ester of an aromatic acid, an aromatic ketone, or mixtures thereof. The compositions have substantially improved shear thinning behavior and reduced injection force, rendering the compositions readily implanted beneath a patient's body surface by injection.

Owner:DURECT CORP

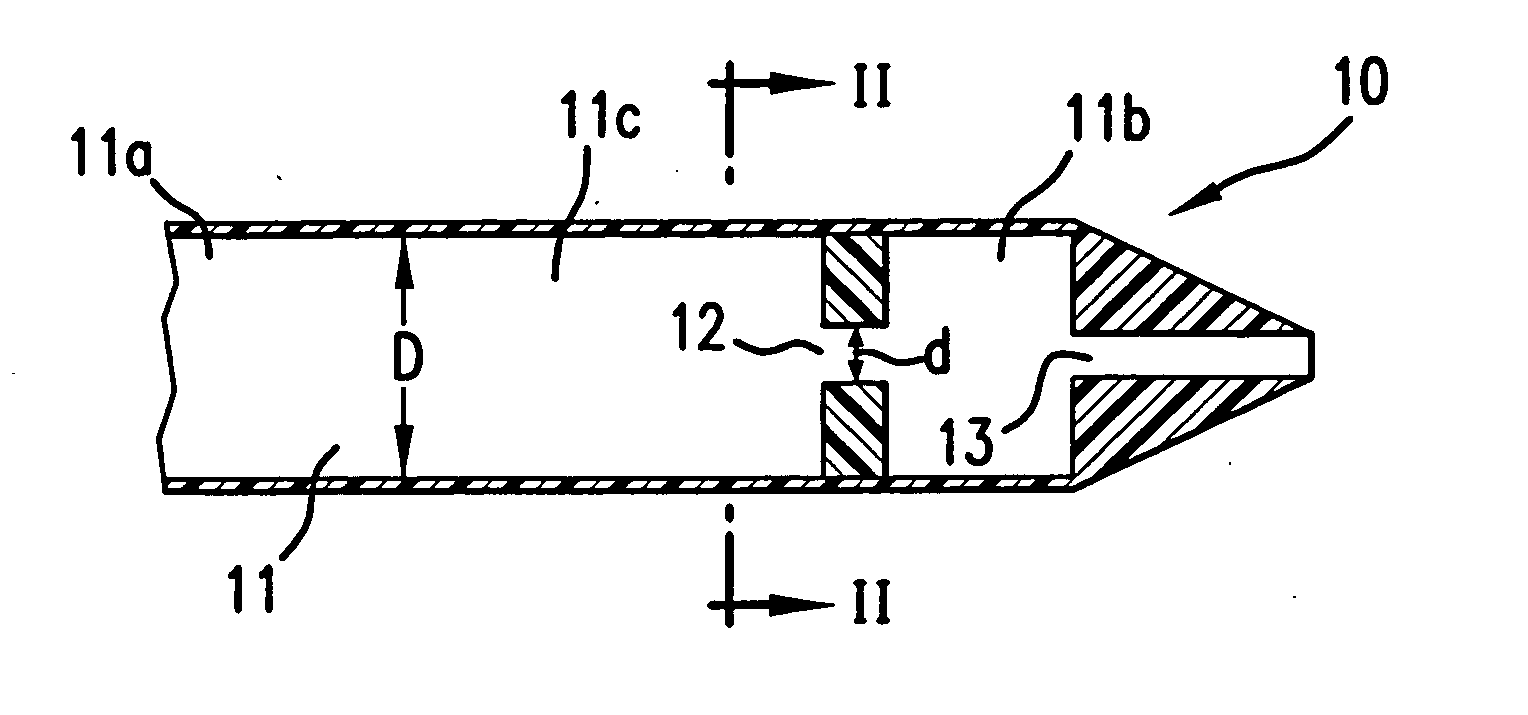

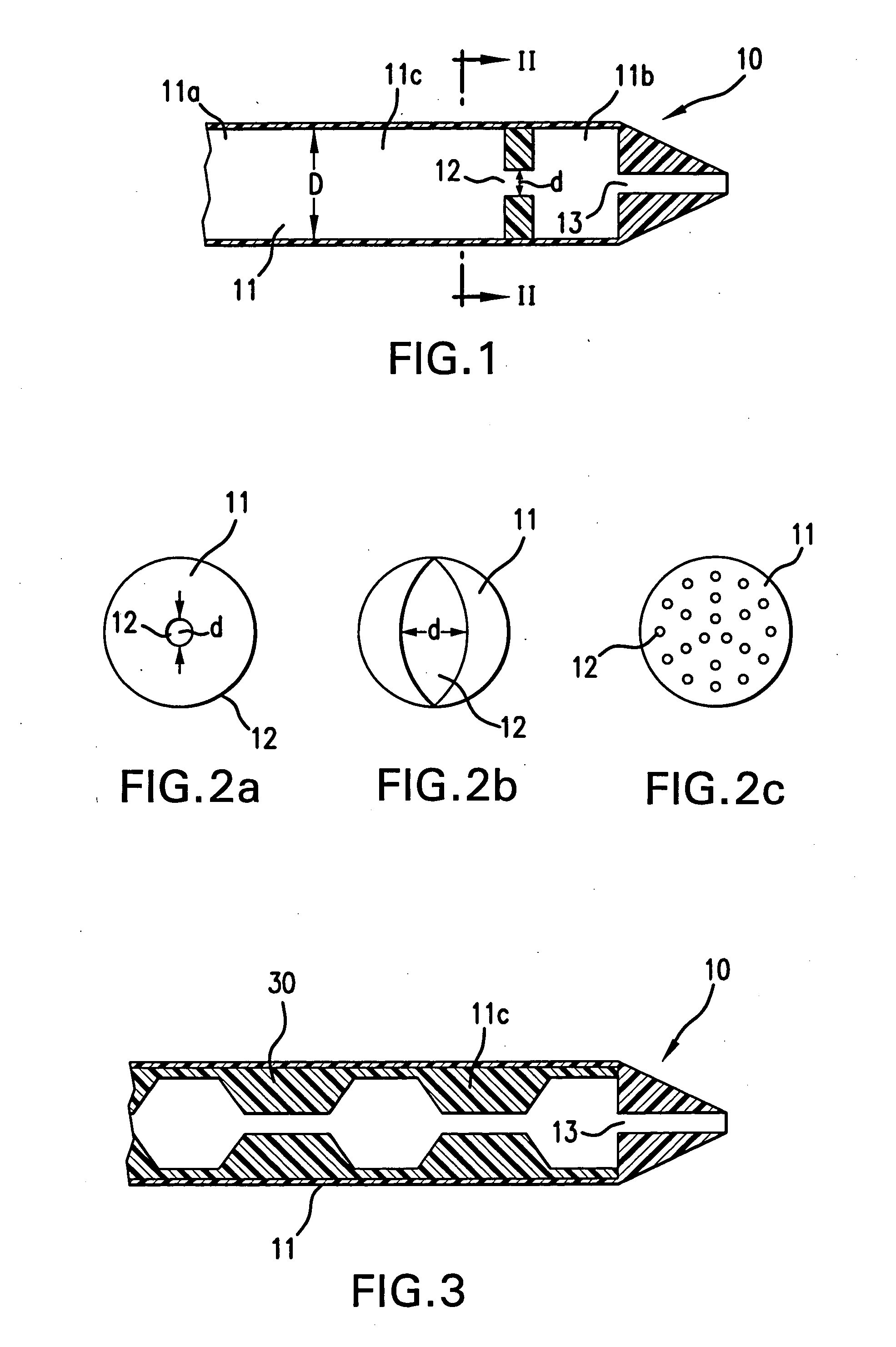

Device and method for direct delivery of a therapeutic using non-newtonian fluids

A device, system, and method for direct delivery of a therapeutic to a target site that utilizes the non-Newtonian characteristics of shear thinning and shear thickening to allow easy passage of a therapeutic through a delivery lumen yet facilitate retention of the therapeutic in the target site. The device, system, and method includes increasing the shear rate or shear stress of a non-Newtonian fluid having therapeutic properties thereby increasing or decreasing the viscosity of the non-Newtonian fluid.

Owner:BOSTON SCI SCIMED INC

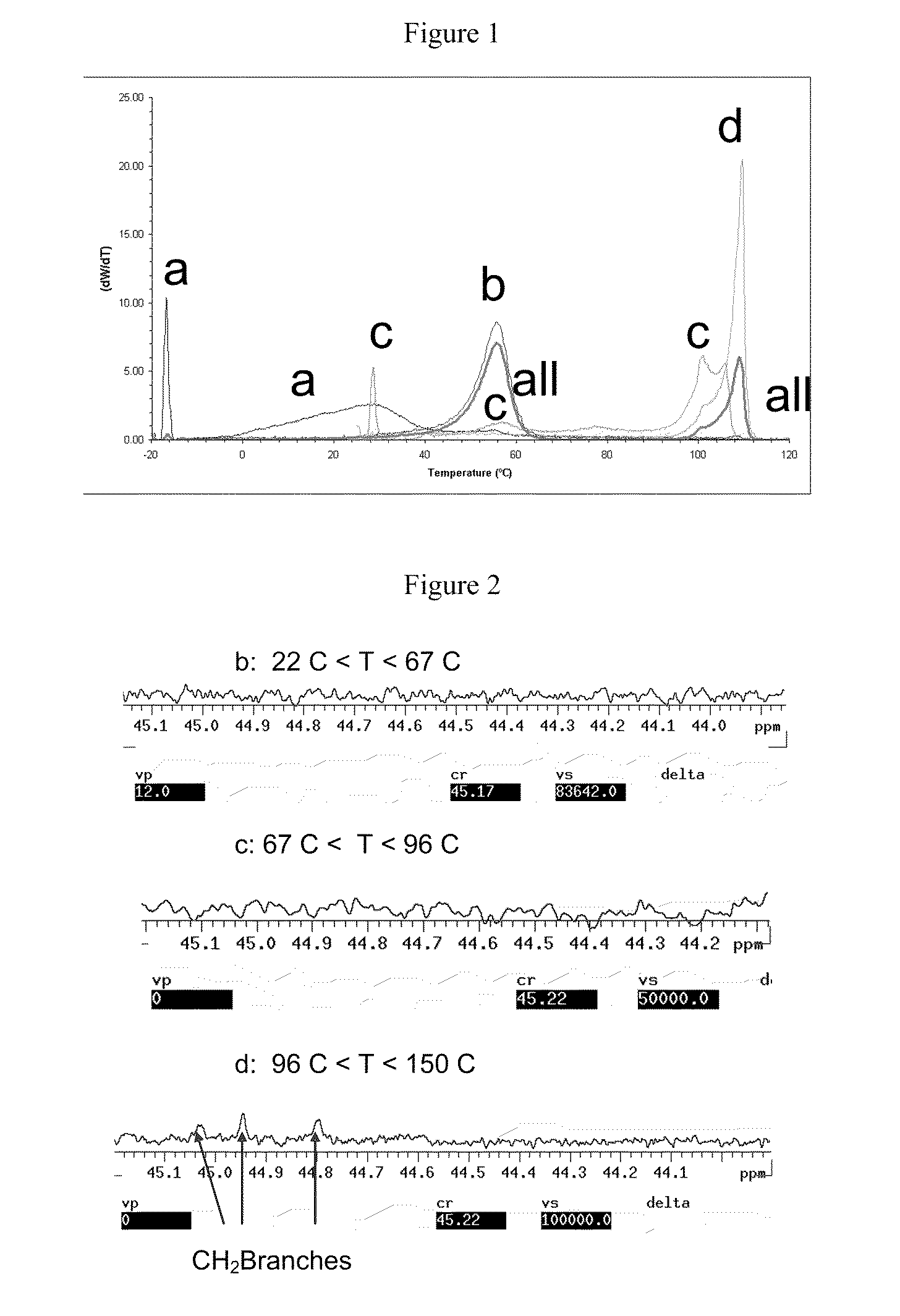

Heterogeneous In-Reactor Polymer Blends

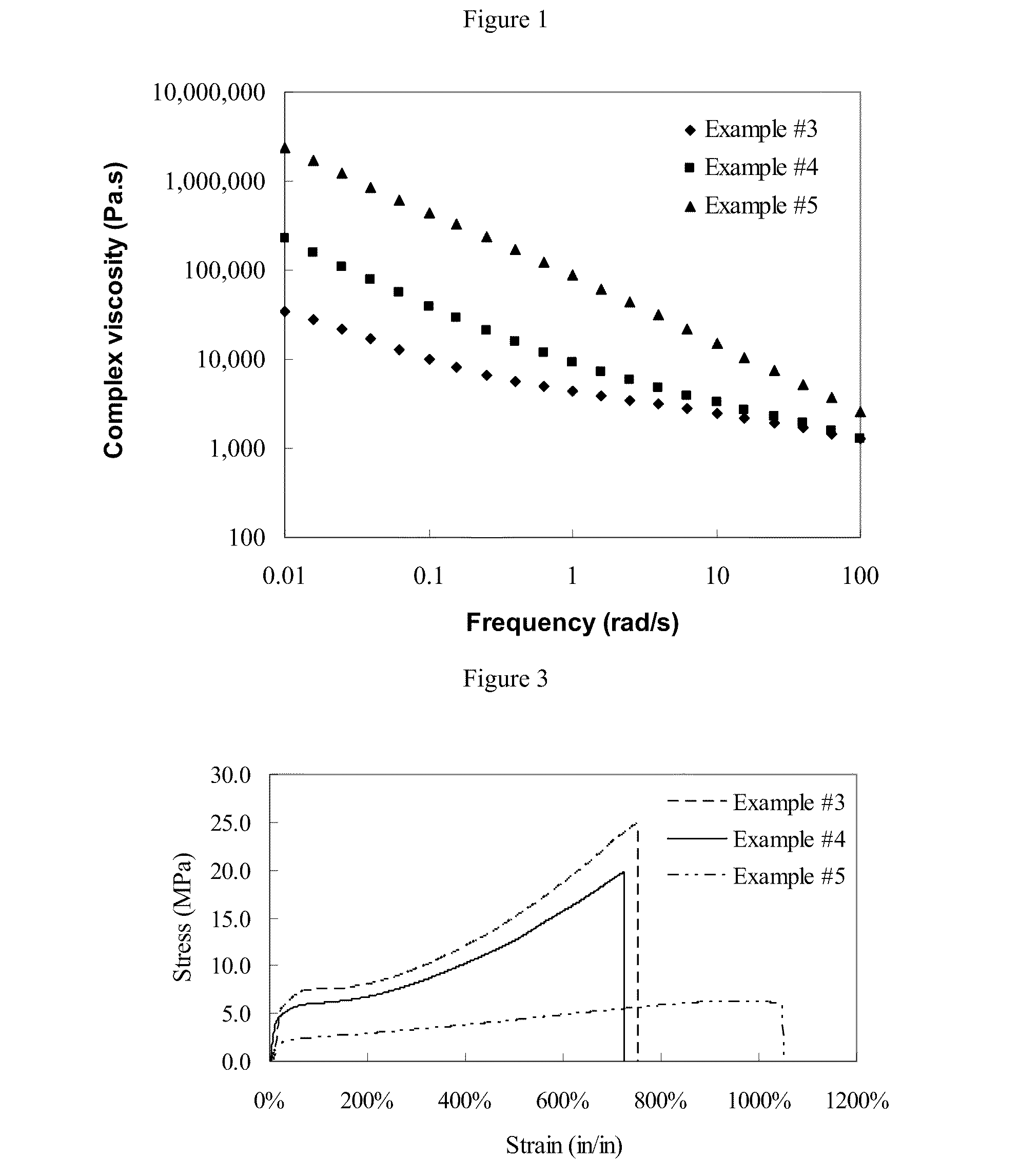

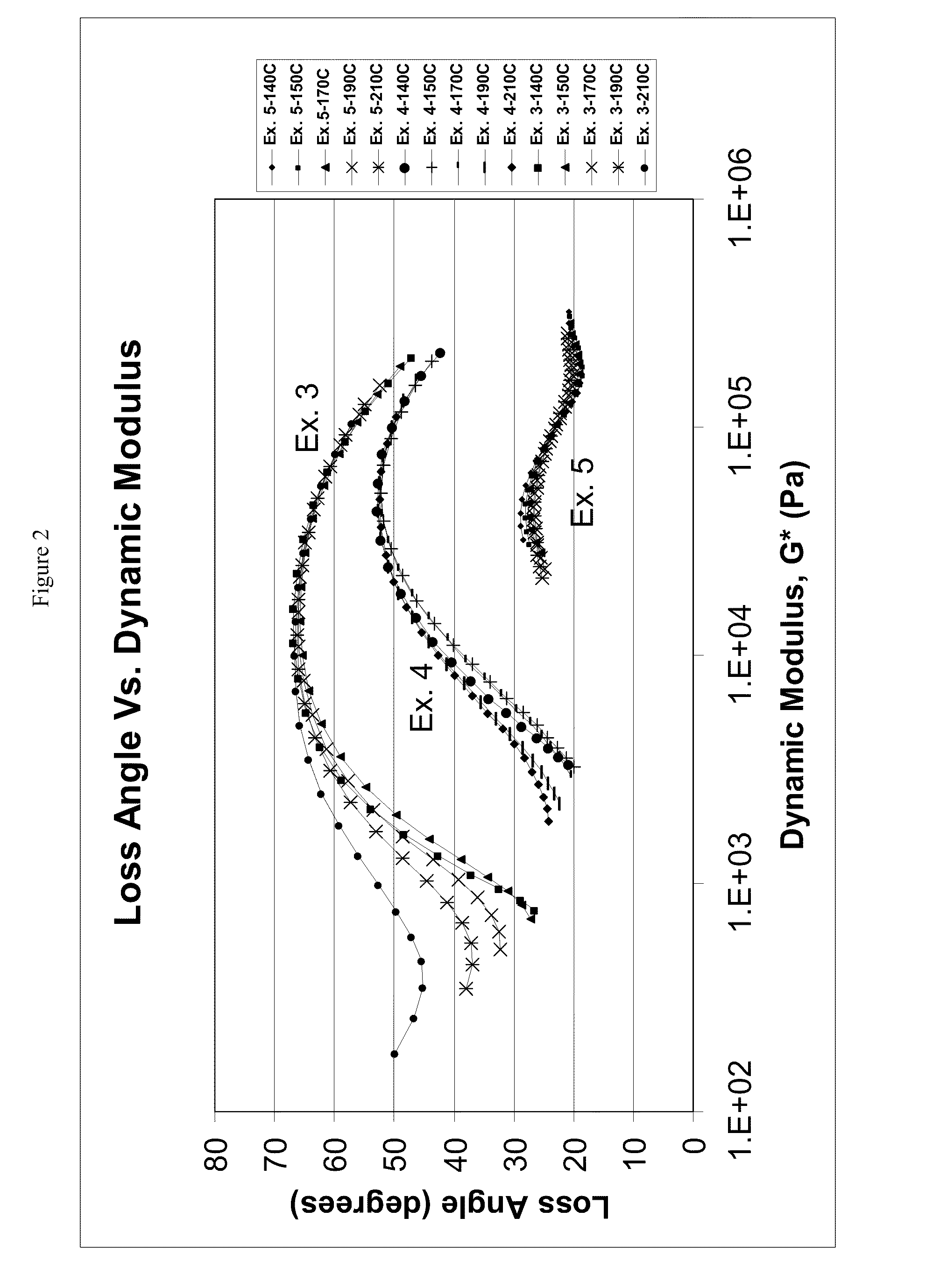

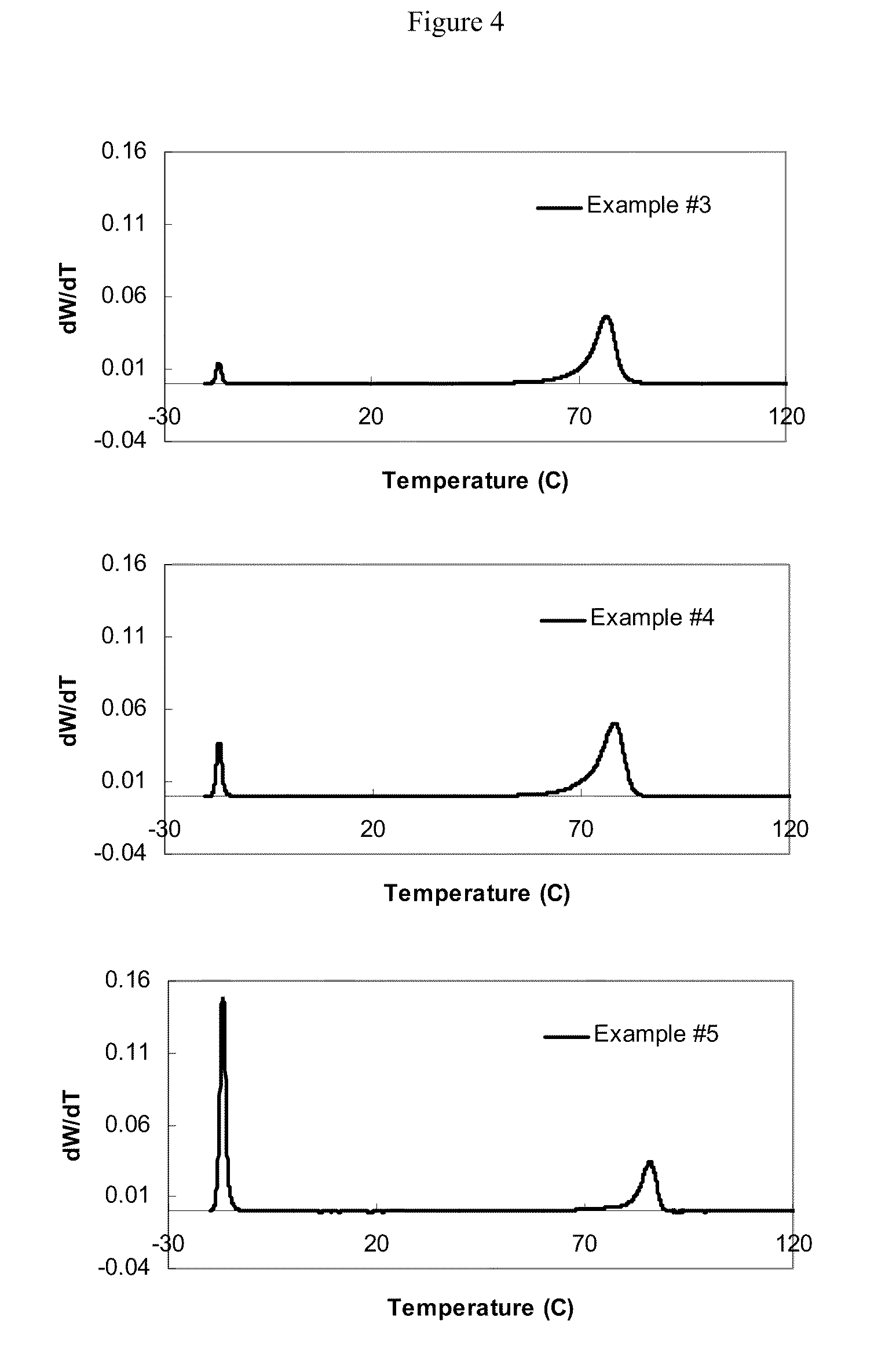

An in-reactor polymer blend comprises (a) a propylene-containing first polymer; and (b) an ethylene-containing second polymer such that the polymer blend comprises between about 50 wt % and about 80 wt % units derived from ethylene and between about 50 wt % and about 20 wt % units derived from propylene. The blend is substantially free of dienes and the content of ethylene in the second polymer in the form of ethylene-ethylene-ethylene triads is at least 40%. The second polymer contains at least 0.1 branch having 8 or more carbon atoms per 10,000 carbons. In addition, the blend has a strain hardening index of at least 1.8, a shear thinning slope in the plot of log(dynamic viscosity) versus log(frequency) of less than −0.2 and exhibits at least two peaks when subjected to Differential Scanning Calorimetry (first melt) corresponding to a first melting point of at least 150° C. and a second melting point of at least 40° C. such that the difference between the first and second melting temperatures is at least 20° C.

Owner:EXXONMOBIL CHEM PAT INC

Silicone compositions for producing elastomeric molded parts by means of ballistic methods

InactiveUS20180066115A1High-quality industrial productionAdditive manufacturing apparatus3D object support structuresPolymer sciencePtru catalyst

3D printing of curable silicone cam positions is made possible by employing a mixture of Si—H-functional silicon compounds and silicon compounds bearing aliphatically unsaturated groups, a hydrosilylation catalyst, and a combination of a reinforcing filler and a rheological agent containing polar groups, exhibiting shear thinning behavior.

Owner:WACKER CHEM GMBH

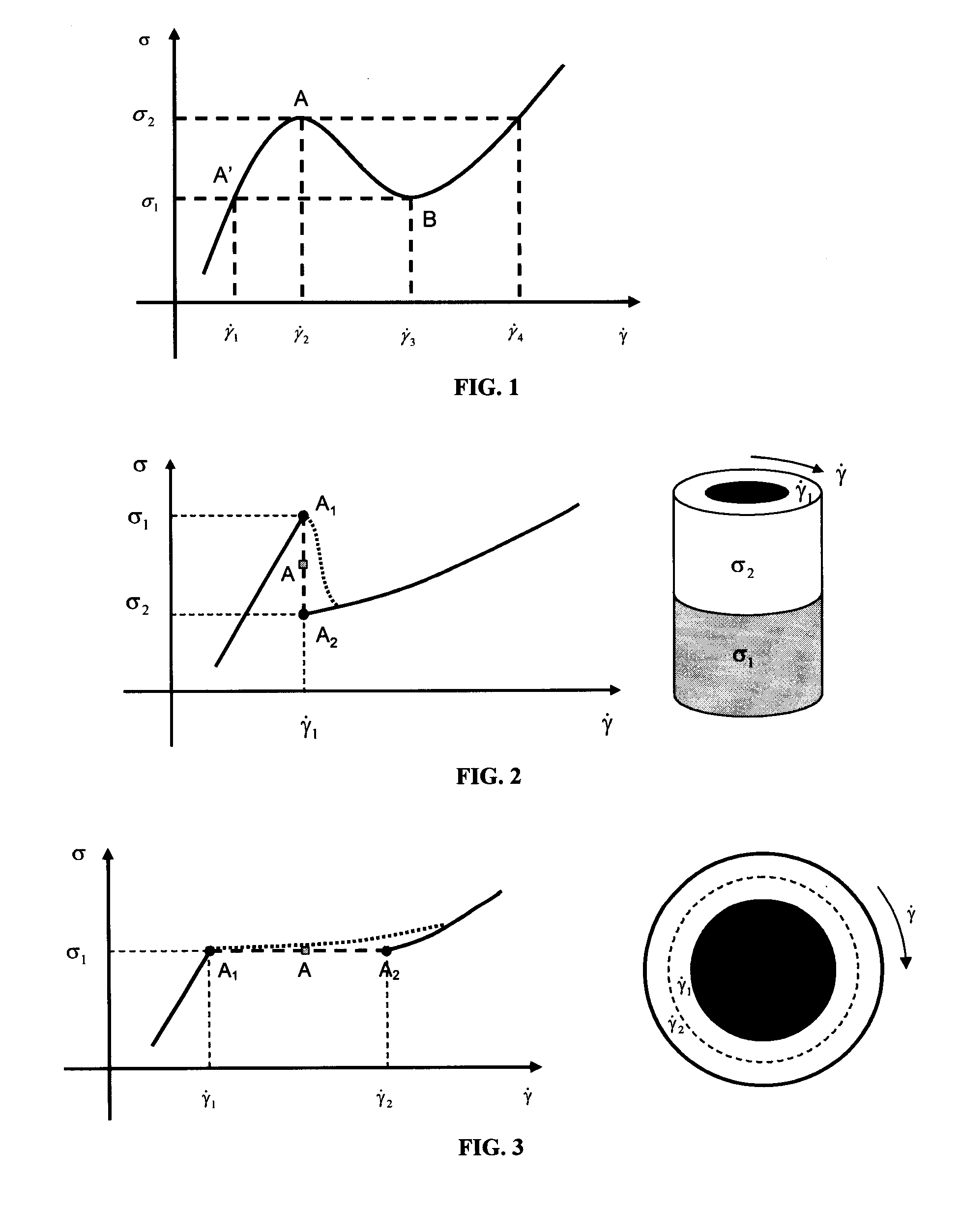

Rheology Controlled Heterogeneous Particle Placement in Hydraulic Fracturing

InactiveUS20080182762A1Easy to cleanMaintain conductivitySurveyFluid removalShear stressFracturing fluid

A method of treating a subterranean formation penetrated by a wellbore includes preparing a treatment fluid with shear thinning, non-monotonic rheological properties, injecting the treatment fluid into the subterranean formation, and inducing shear rate softening phase transition in the treatment fluid. The non-monotonic rheology properties can be such that in the relationship between shear stress (σ) versus strain rate ({dot over (γ)}), where {dot over (γ)}1<{dot over (γ)}2<{dot over (γ)}3<{dot over (γ)}4, the shear stress values are σ1<σ2σ3≦σ4, and σ3<σ2 The method can heterogeneously deposit proppant or solid acid in a fracture. A system to fracture a subterranean formation includes the fracturing fluid, a wellbore to inject the fracturing fluid to propagate a fracture in the formation, and a rate controller to inject the fracturing fluid into the subterranean formation at a minimum volumetric rate to provide a shear stress at an inlet to the fracture that exceeds σ2. The method and system can achieve heterogeneous particle placement with either proppant or solid acid.

Owner:SCHLUMBERGER TECH CORP

Method of increasing the low shear rate viscosity and shear thinning index of divalent cation-containing fluids and the fluids obtained thereby

Disclosed is a method of increasing the low shear rate viscosity and the shear thinning index of aqueous fluids containing a divalent cation salt, a crosslinked amylopectin starch which functions as both a viscosifier / suspending agent and as a fluid loss control additive, and a bridging agent, the fluids resulting from the method, and the use of the fluids in drilling a well, wherein the bridging agent is a sized particulate magnesium carbonate or a mixture of sized magnesium carbonate and sized calcium carbonate. The median (D.sub.50) particle size of the magnesium carbonate is from about 2 .mu.m to about 10 .mu.m. The weight ratio of calcium carbonate to magnesium carbonate is from about 70 / 30 to about 0 / 100.

Owner:TUCC TECH LLC +1

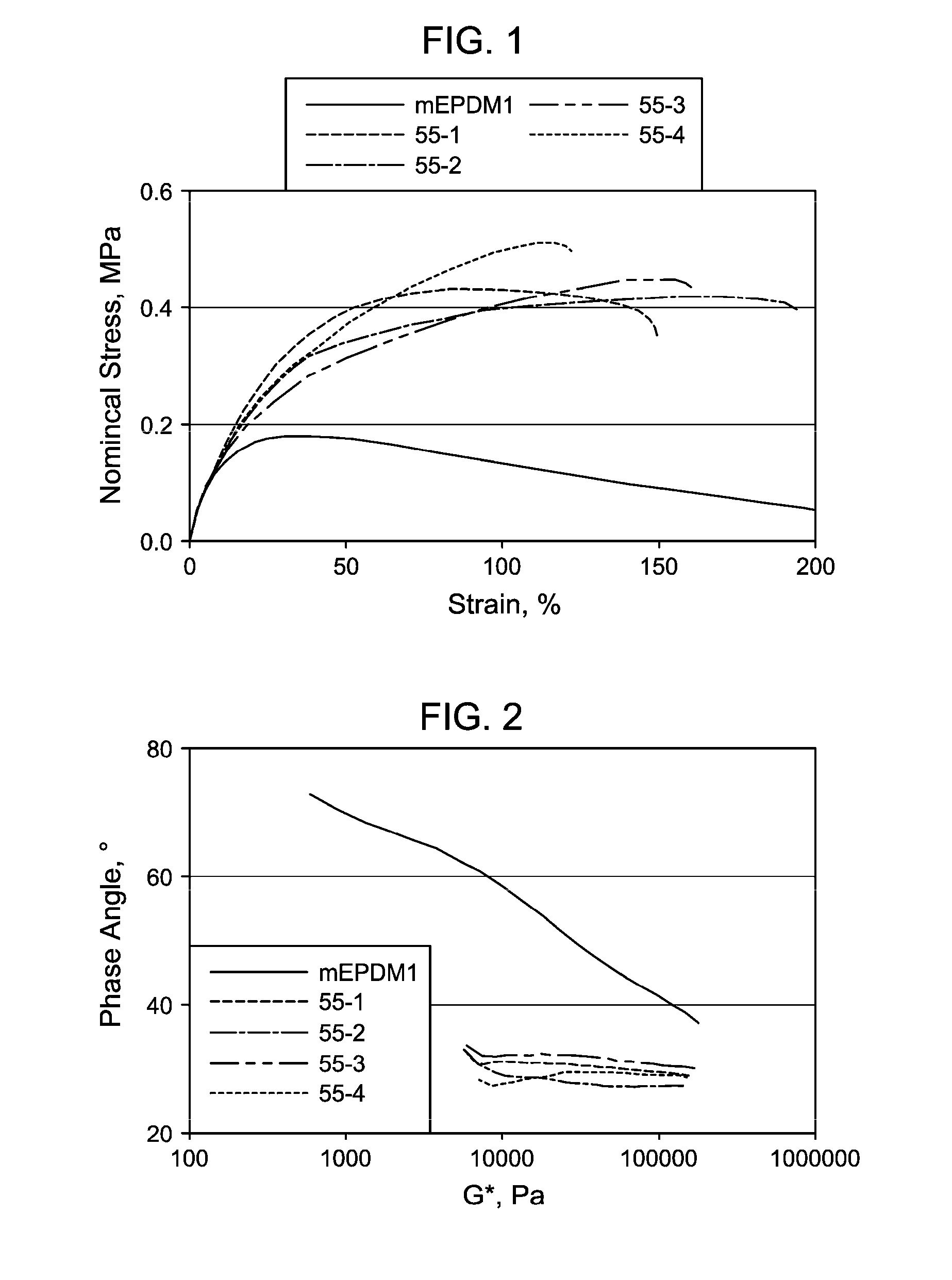

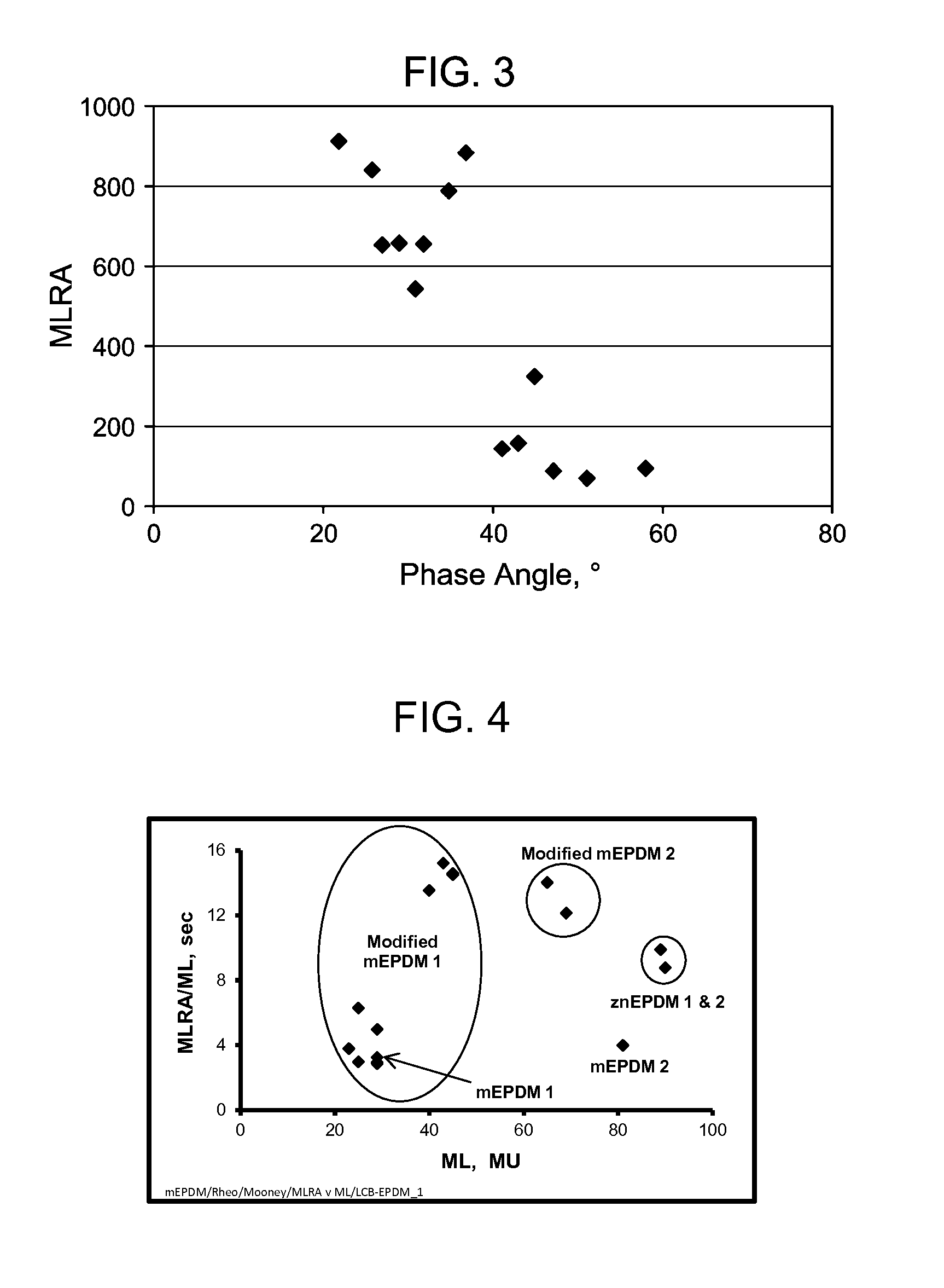

Long Chain Branched EPDM Compositions and Processes for Production Thereof

Highly branched compositions including: (i) from about 96 wt % to about 99.9 wt % metallocene catalyzed ethylene propylene diene derived units; and (ii) from about 0.1 wt % to about 4 wt % multifunctional monomer derived units, wherein the highly branched composition has: (a) a Mooney viscosity ML (1+4) at 125° C. of about 30 to 100 MU, (b) a Mooney relaxation area MLRA of about 100 to about 1000, (c) a branching index, g′(vis) of less than about 0.9, (d) a phase angle, δ, of less than about 55 degrees at a complex modulus of 10 kPa, measured at 190° C., and (e) a degree of shear thinning greater than about 0.95, measured at 190° C., are disclosed herein. Homogeneous blends including this composition are also described. Processes to make the highly branched composition and the homogeneous blend are also described herein.

Owner:EXXONMOBIL CHEM PAT INC

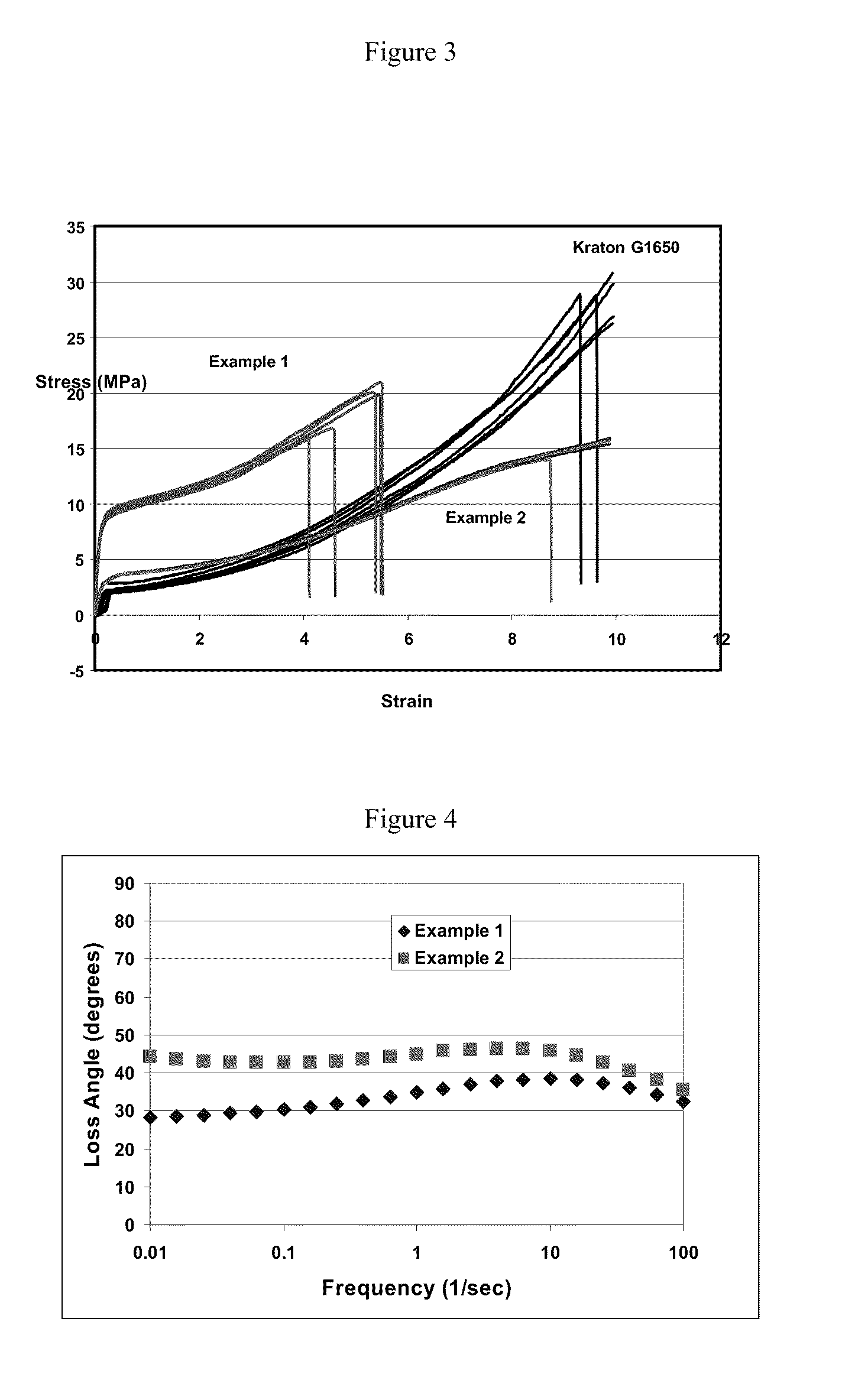

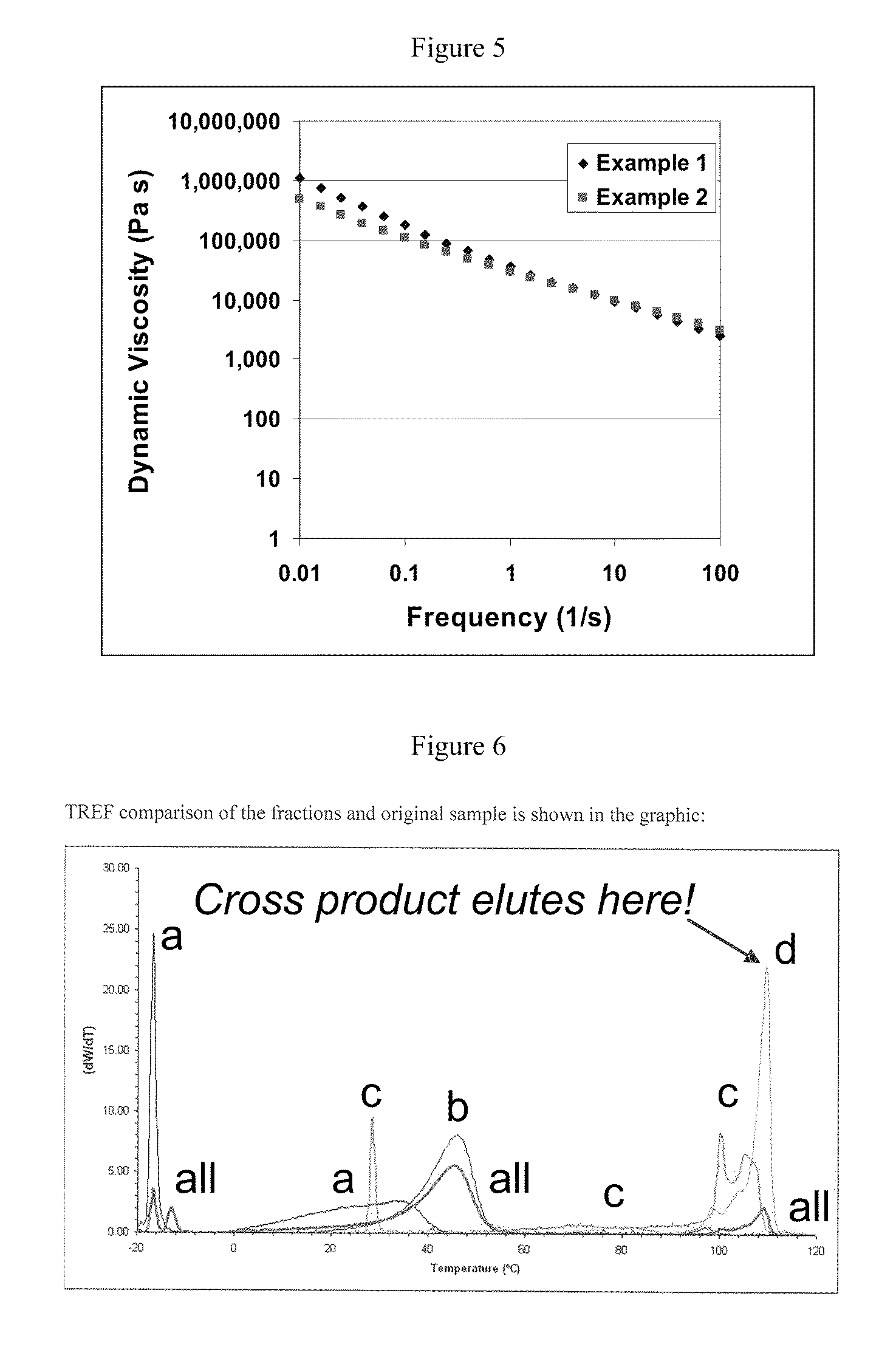

Thermoplastic Polyolefin Blends

This invention relates to a blend composition comprising: 1) a linear ethylene containing polymer, such as a LLDPE, a HDPE or the like; and at least 1 weight percent of an in-reactor polymer blend comprising: (a) a first ethylene containing polymer having a density of greater than 0.90 g / cm3 and a Mw of more than 20,000 g / mol; and (b) a second ethylene containing polymer having a density of less than 0.90 g / cm3, wherein the polymer blend has a Tm of at least 90° C. (DSC second melt), a density of less than 0.92 g / cm3, and the densities of the first and second polymers differ by at least 1%. Alternately the in-reactor polymer blend comprises: (a) a first ethylene polymer comprising 90 wt % to 100 wt % ethylene and from 0 wt % to less than 10 wt % comonomer, said first ethylene polymer component having density of greater than 0.920 g / cm3, an Mw of 20,000 g / mol or more; and (b) a second ethylene polymer comprising from 70 wt % to 90 wt % ethylene and 30 wt % to 10 wt % comonomer, said second ethylene polymer having a density of 0.910 g / cm3 or less, wherein the in-reactor polymer blend has one or more of the following characteristics: (a) at least 78 wt % ethylene; (b) a Tm of at least 100° C. over a density ranging from 0.84 to 0.92 g / cm3; (c) a elongation at break of 300% or more; (d) a strain hardening ratio M300 / M100 of at least 1.2; (e) a ratio of complex viscosity at 0.01 rad / s to the complex viscosity at 100 rad / s of at least 30; and (f) a shear thinning index of less than −0.2.

Owner:EXXONMOBIL CHEM PAT INC

Liquid dosing apparatus

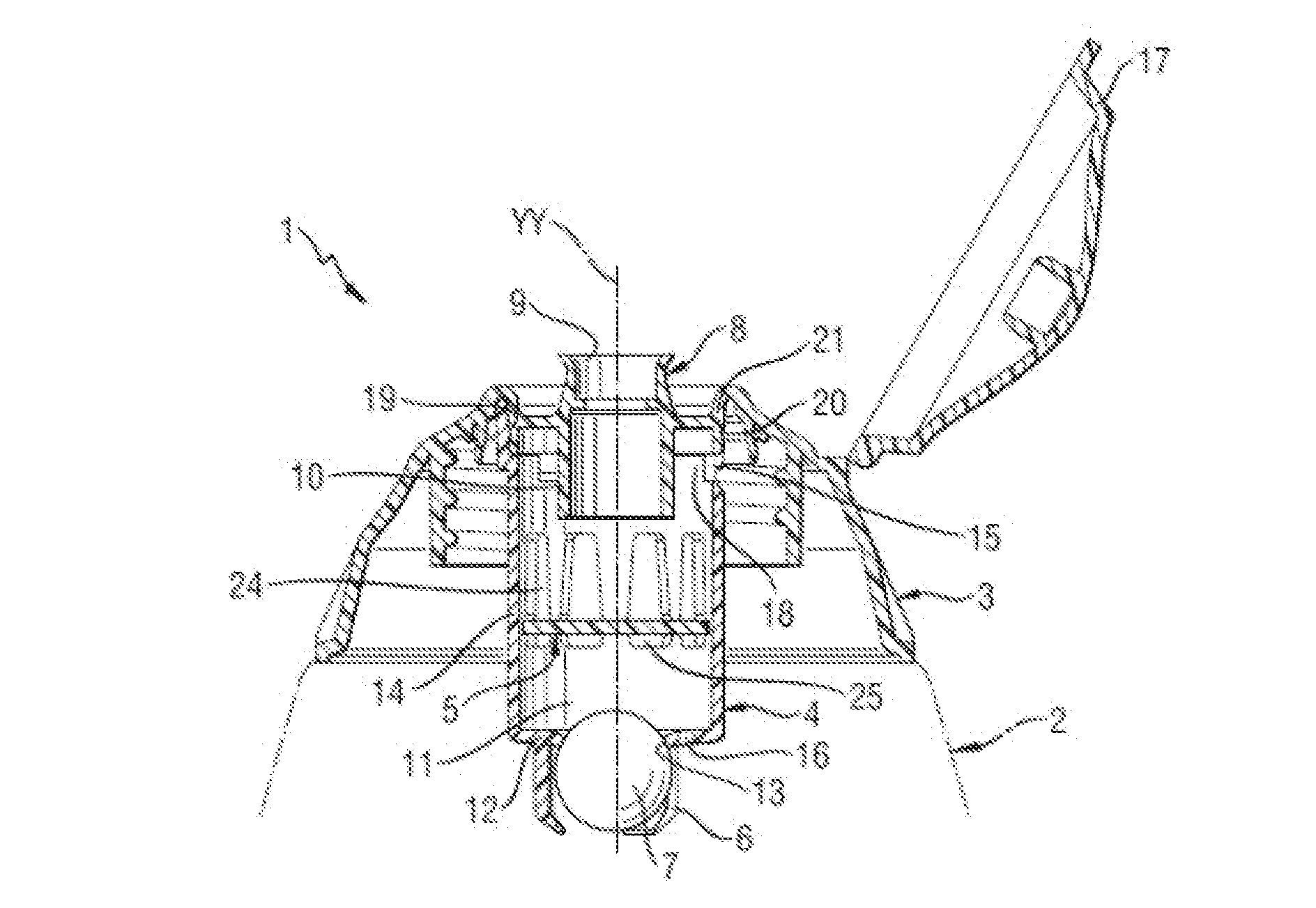

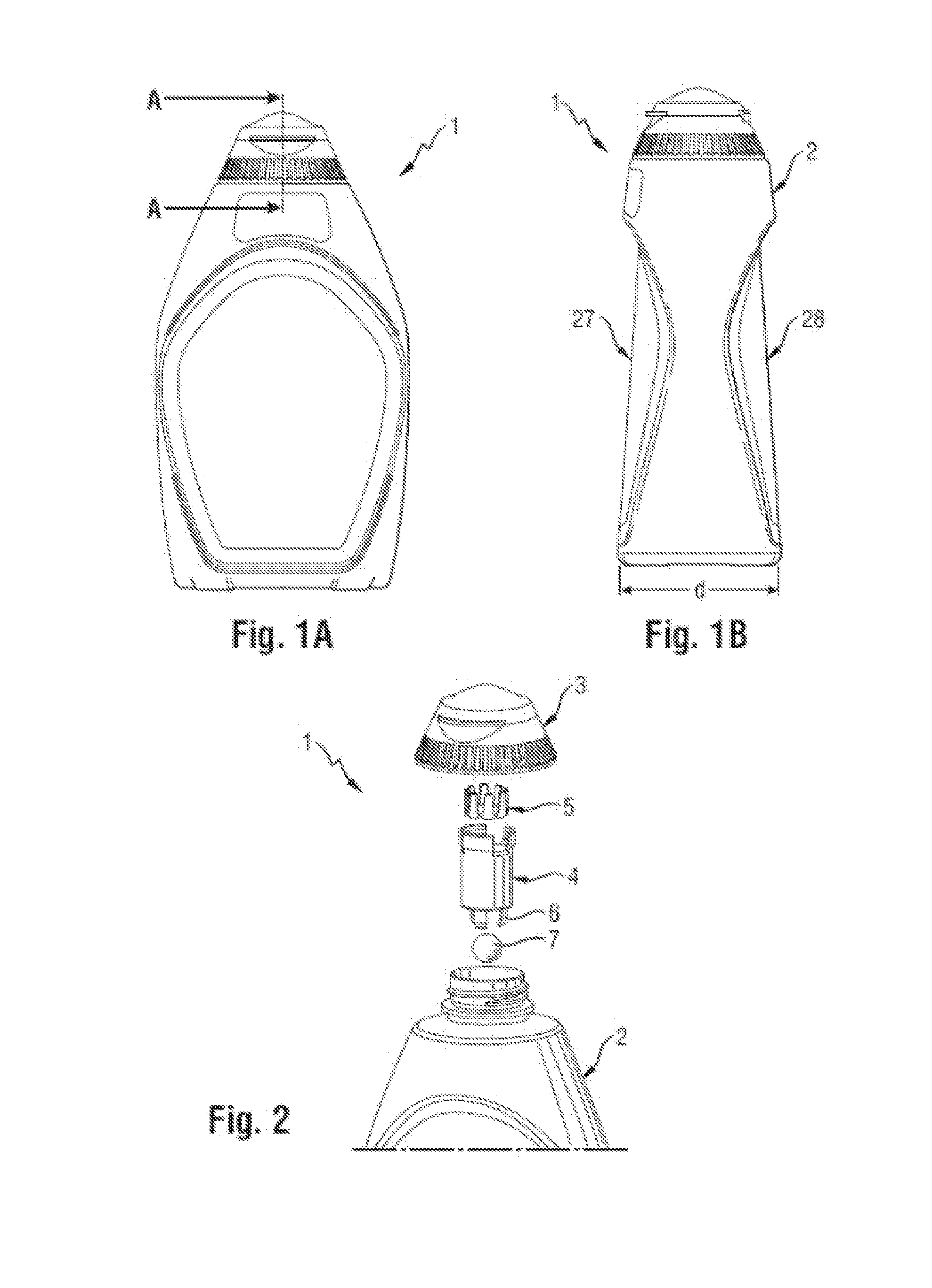

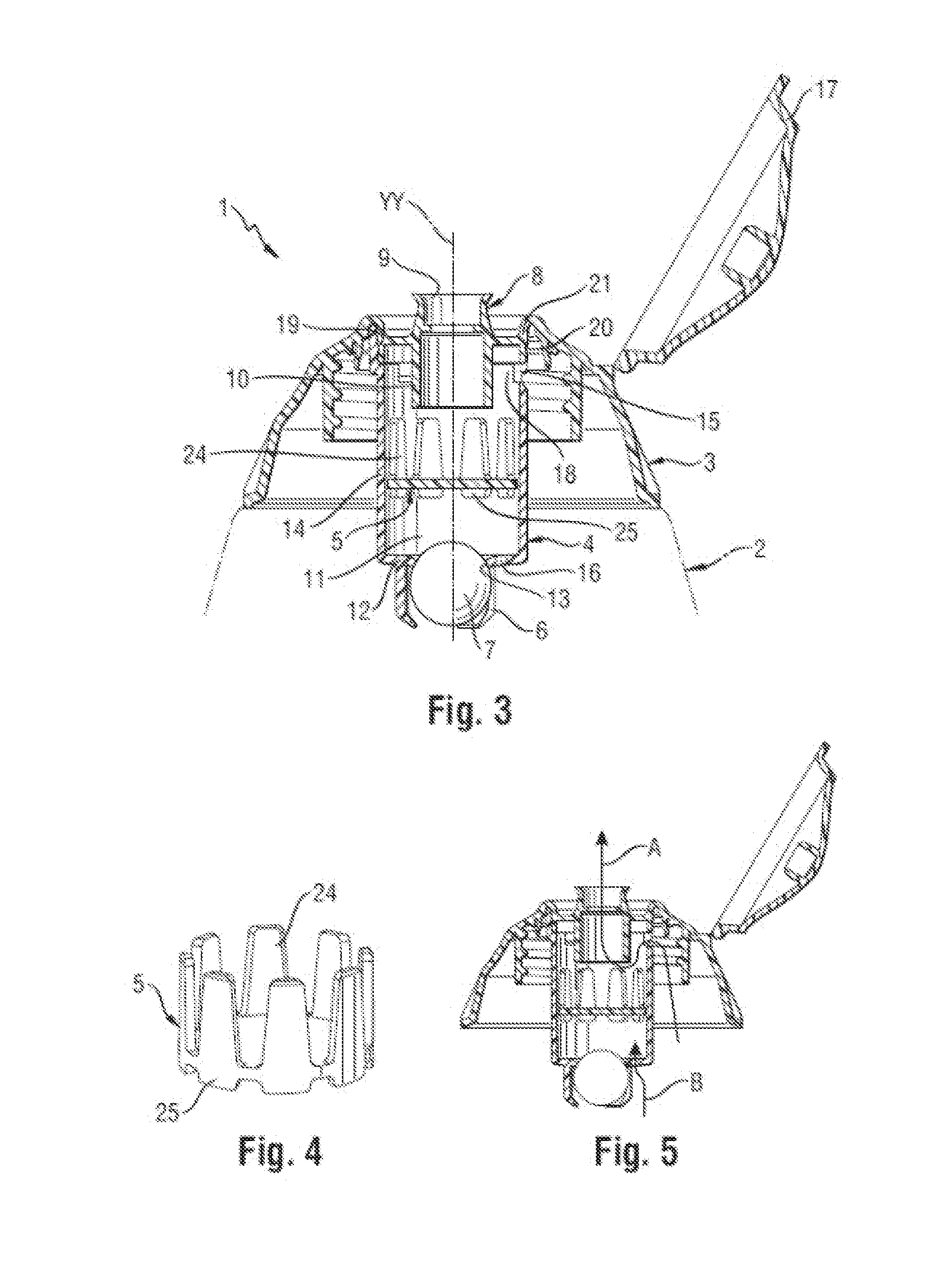

An apparatus and means of repeatedly dispensing controlled doses of liquid comprising a resiliently squeezable container for containing a liquid detergent composition; a cap operably connected to said container, the cap comprising a nozzle for expelling the liquid out of the container; a dosing chamber operably connected to the cap, wherein the dosing chamber comprises a base having a discharge opening therein, sidewalls extending upwardly along the perimeter of said base and at least one inlet opening located proximal the sidewalls; at least one timer aperture located proximal to the discharge opening; a plunger, provided in the dosing chamber and moveable relative to the chamber so as to advance upon squeezing of the container, up to a blocking position; a valve retaining means located below the base; a valve provided in the valve retaining mean wherein the valve is movable from an open position, allowing liquid flow through the discharge opening, and a closed position, where the valve blocks the discharge opening; wherein the liquid is a shear thinning liquid and the shear thinning liquid has a viscosity of greater than 150 mPa·s measured at 10 s−1 at 20° C.

Owner:THE PROCTER & GAMBLE COMPANY

Cleaning composition

InactiveUS20020169090A1Low viscosityHigh viscosityInorganic/elemental detergent compounding agentsSurface-active detergent compositionsSurface cleaningPre treatment

A hard-surface cleaning composition for removing cooked-, baked-, or burnt-on food soil from cookware and tableware, the composition comprising a soil swelling agent and a thickening system comprising synthetic smectite type clay thickening agent having an average platelet size of less than about 100 nm. The composition has shear thinning properties and can be used as pre-treatment prior to the dishwashing process. The composition provides excellent removal of polymerized grease from metal and glass substrates.

Owner:THE PROCTER & GAMBLE COMPANY

Composition inhibiting the expansion of fire, suppressing existing fire, and methods of manufacture and use thereof

InactiveUS7163642B2Easily pumped and sprayedInhibit swellingFire rescueBoring toolsSuspending AgentsPetroleum

The invention relates to compositions that prevent expansion of a fire, suppress existing fire, as well as methods of preparing and using such compositions. The composition is comprised of water, pseudo-plastic high yield suspending agent and starch. Compositions may contain additional functional agents, such as rheological, wetting, foaming, coloring, chelating, antimicrobial and stabilizing agents. In the description of the present invention, all composition modifications are referred to as compositions. The composition, an augmentation of water, exhibits the characteristics of a sag resistant aqueous gel in the tank, but has shear thinning capacity, allowing the composition to be pumped or sprayed as easily as water. At the point of impact, when the sprayed composition is again at rest, it instantly reverts to a sag resistant aqueous gel. The composition also forms an intumescent, surface char layer upon contacting a fire. Foaming of the augmented composition on impact can be incorporated, which is advantageous for fighting petroleum fires.

Owner:EARTHCLEAN CORPRATION

Highly viscous silicone compositions for producing elastomeric molded parts by means of ballistic generative methods

ActiveUS20180208797A1Additive manufacturing apparatus3D object support structuresPolymer scienceMelt flow index

Curable silicone rubber compositions of high viscosity can be ballistically printed if the melt flow index is within a defined shear thinning range and the viscosity is also within a defined range.

Owner:WACKER CHEM GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com