Patents

Literature

560 results about "Newtonian fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Newtonian fluid is a fluid in which the viscous stresses arising from its flow, at every point, are linearly correlated to the local strain rate—the rate of change of its deformation over time. That is equivalent to saying those forces are proportional to the rates of change of the fluid's velocity vector as one moves away from the point in question in various directions.

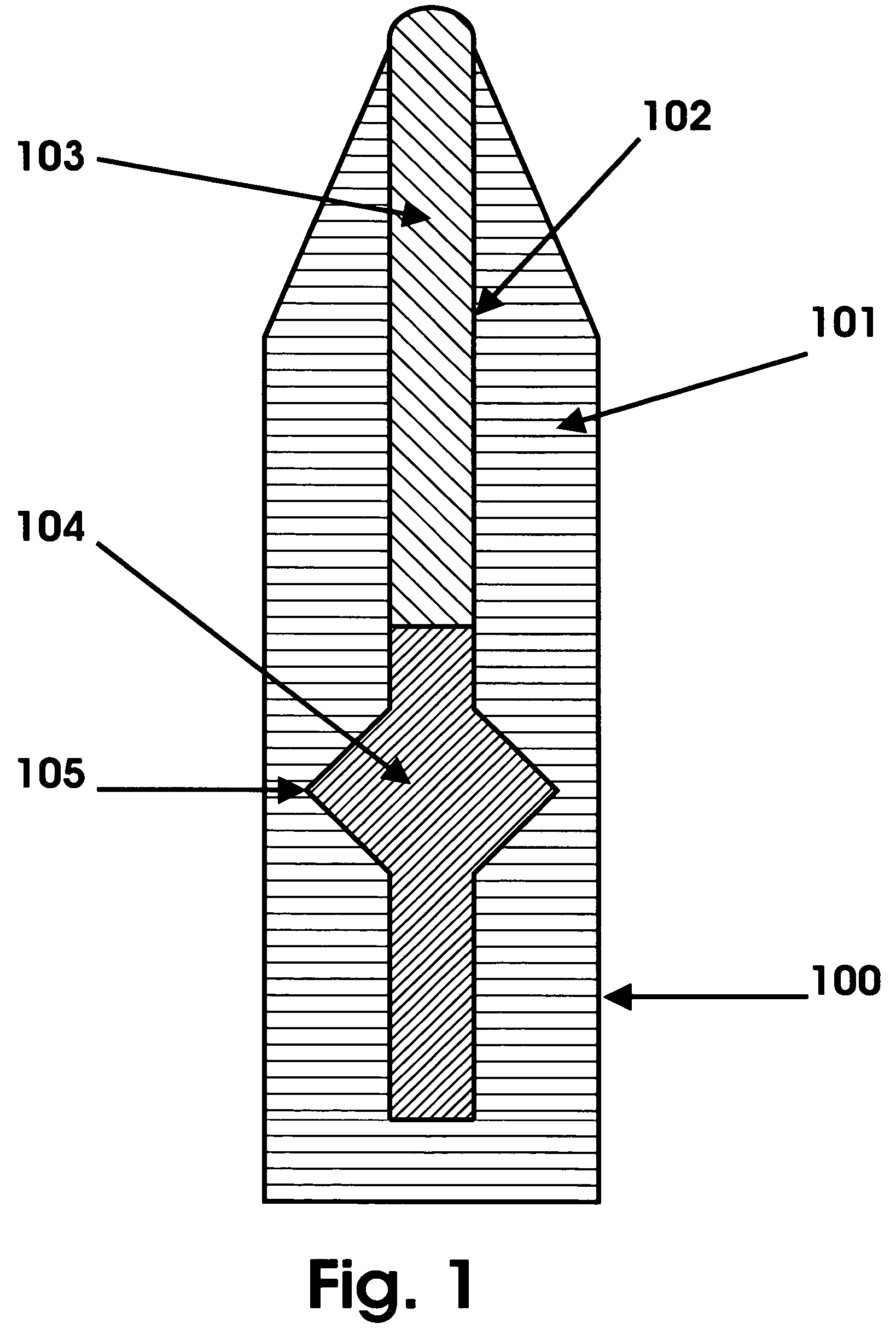

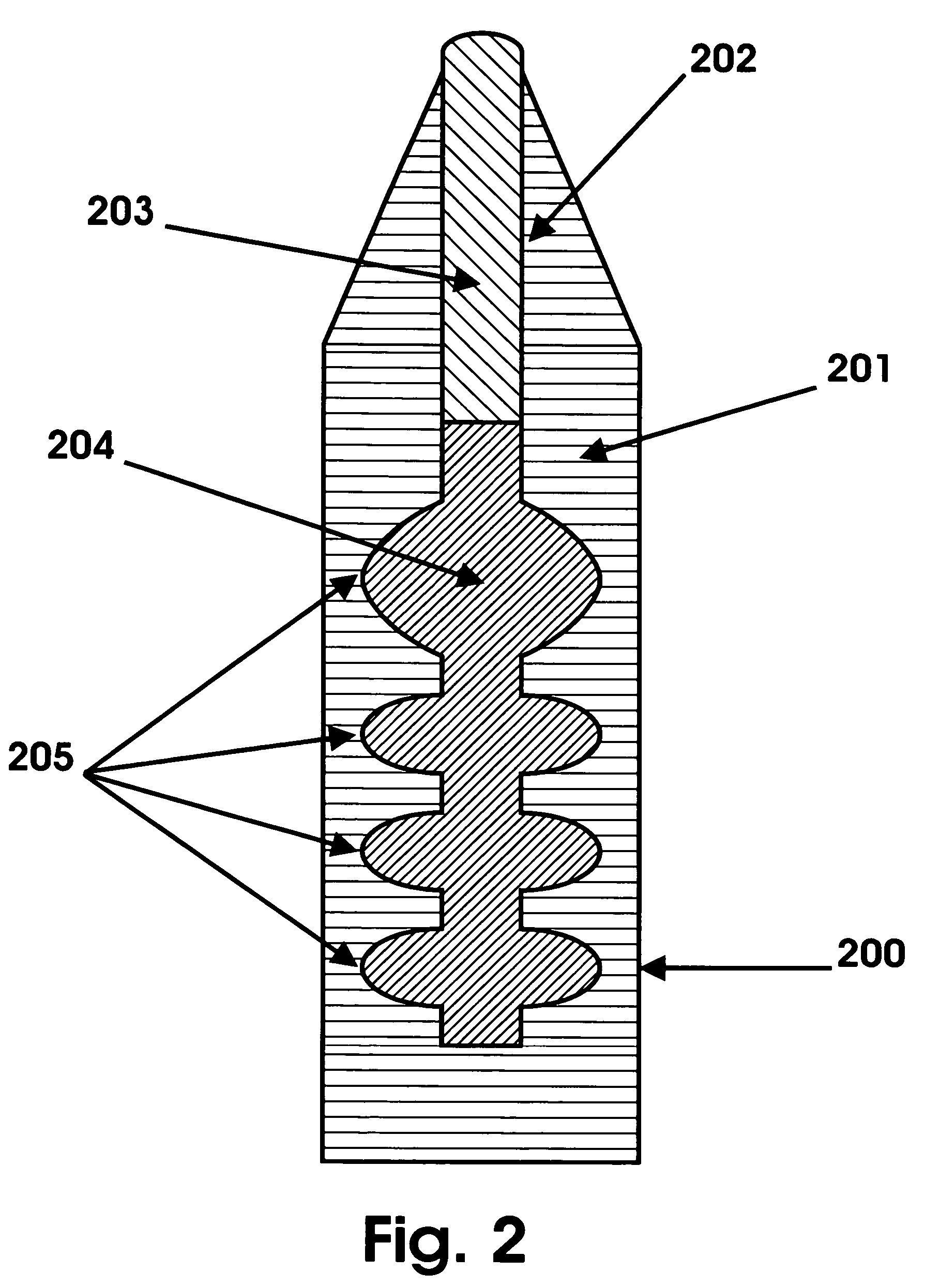

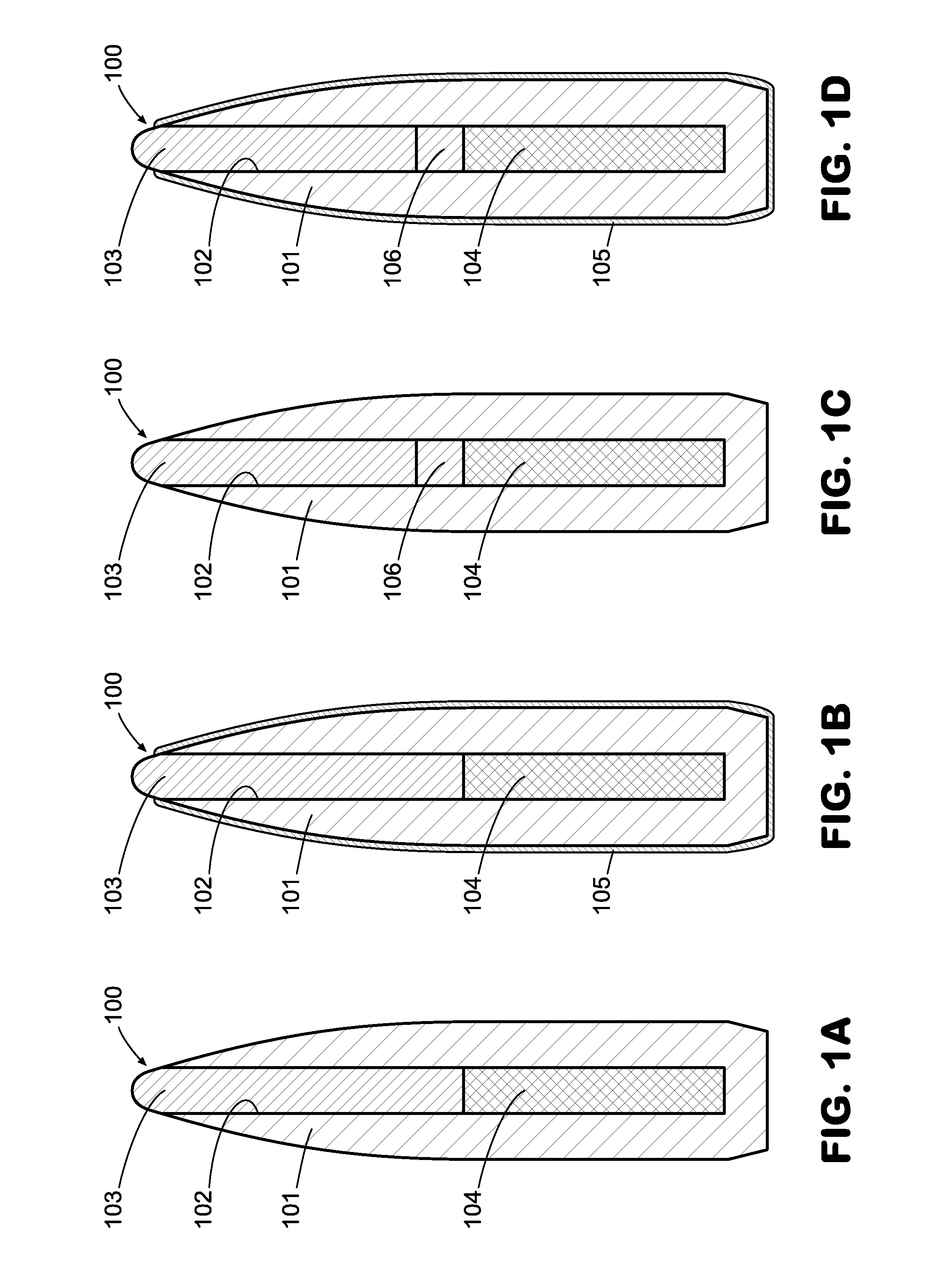

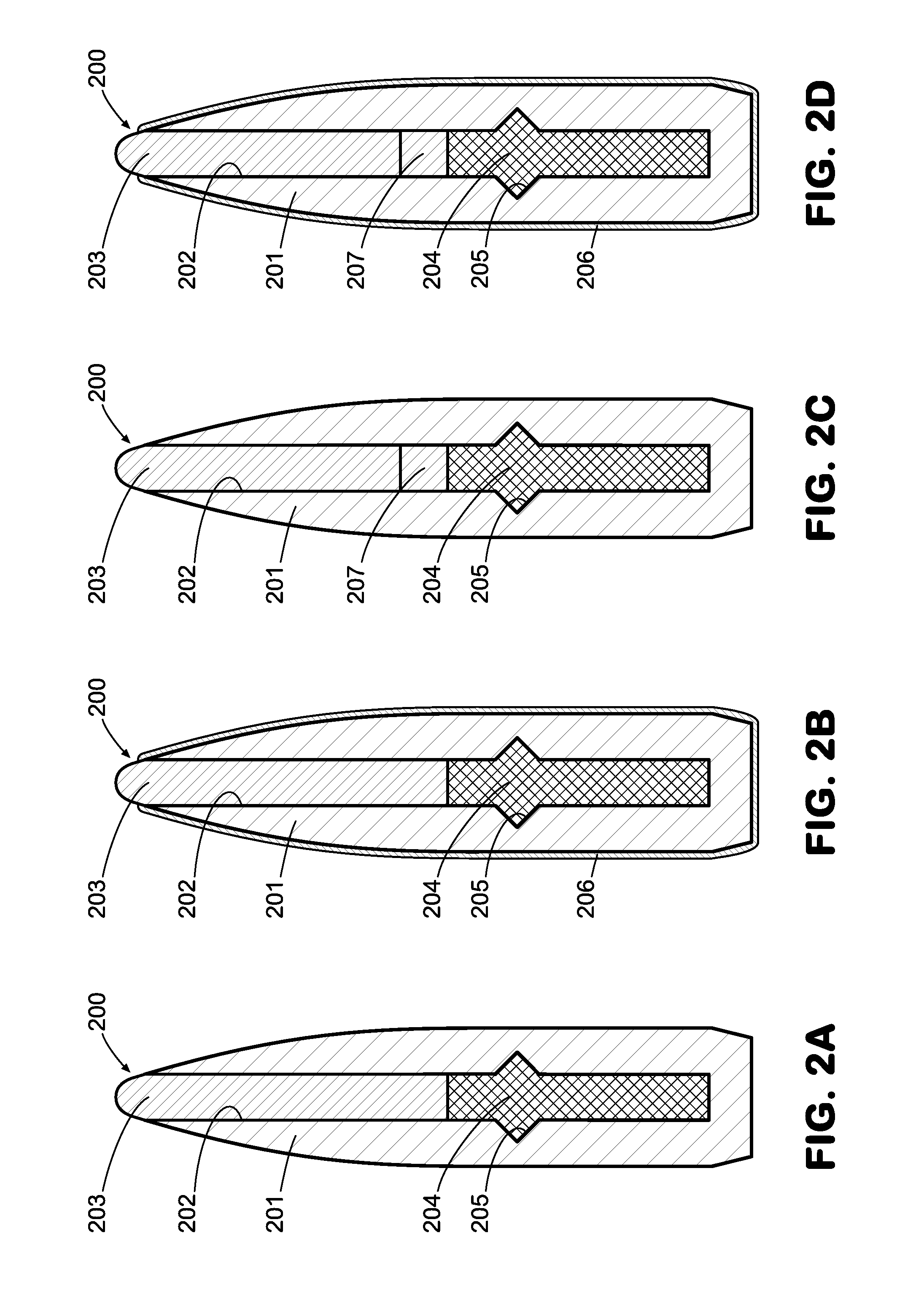

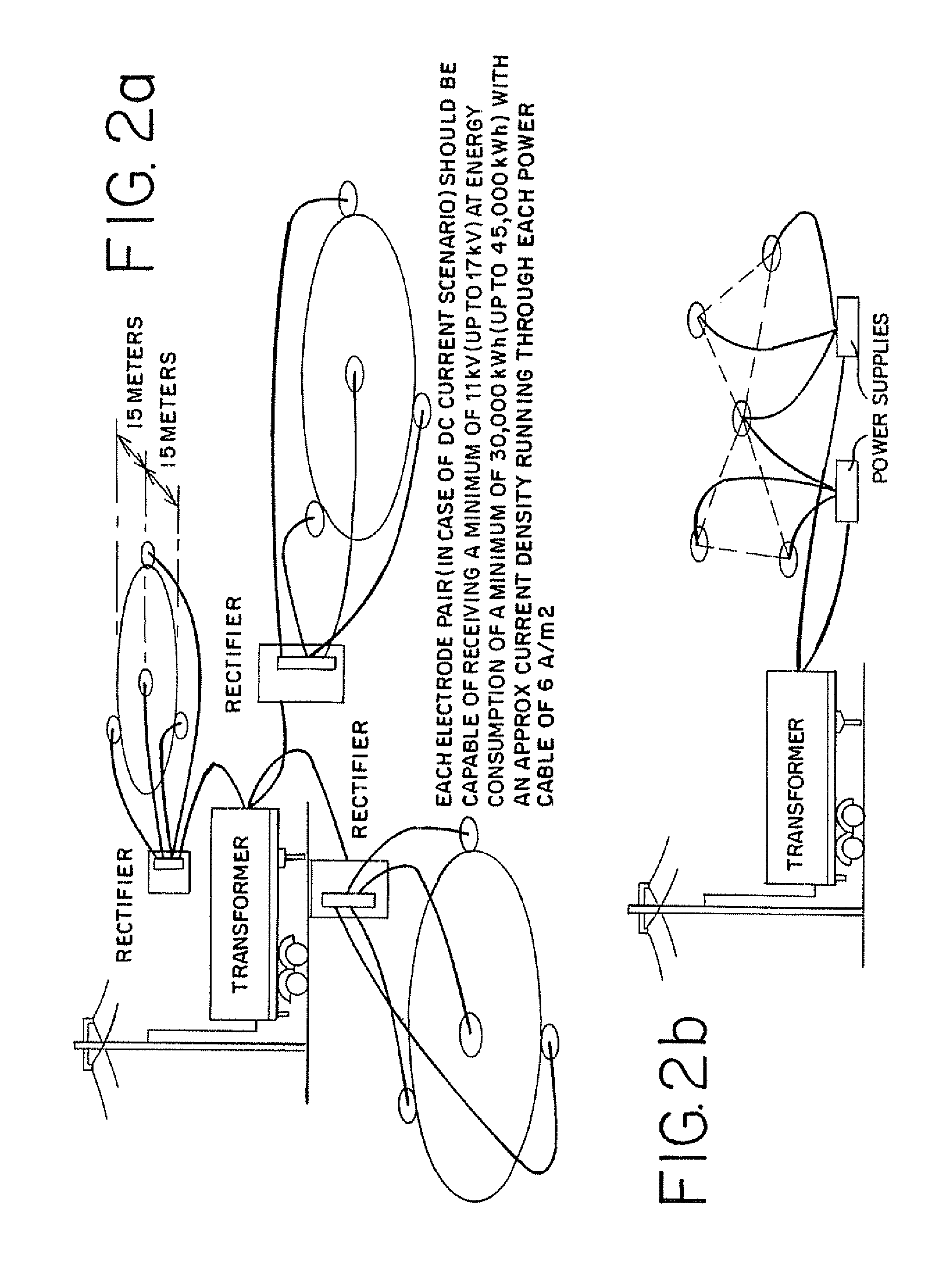

Expanding projectile

A projectile comprising a body having a channel, one or more recesses in the channel, a plunger in the channel, and a fluid in the channel is provided. When the projectile impacts a target, the plunger is driven down the channel, exerting a force on the fluid. The fluid, in turn, exerts fluidic pressure within the recesses, promoting rapid yet predictable expansion of the projectile. Another embodiment of the present invention provides a projectile utilizing a non-Newtonian fluid to optimize expansion of the projectile upon impacting a target.

Owner:JACKSON JASON STEWART

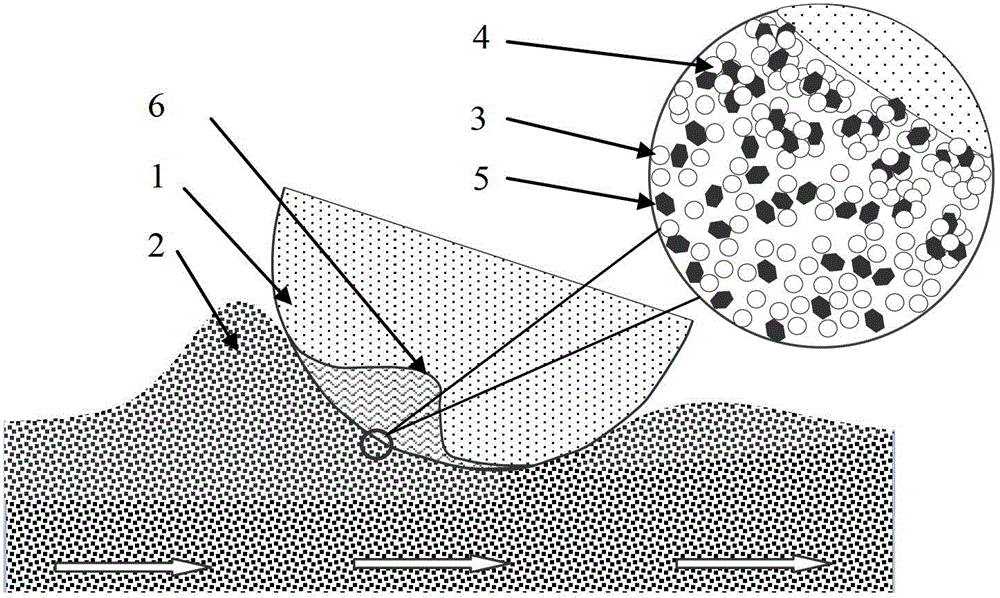

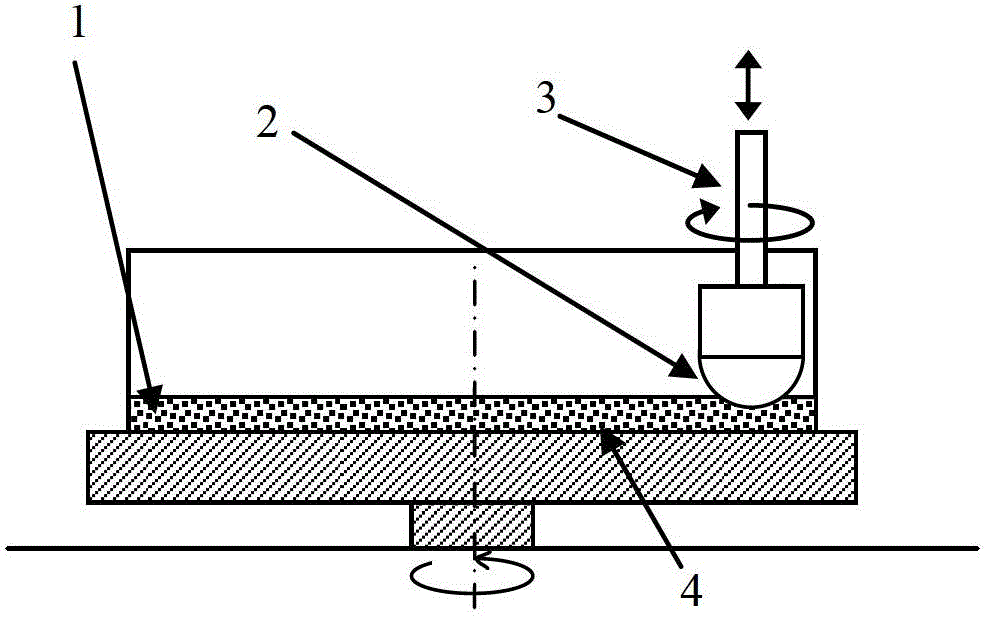

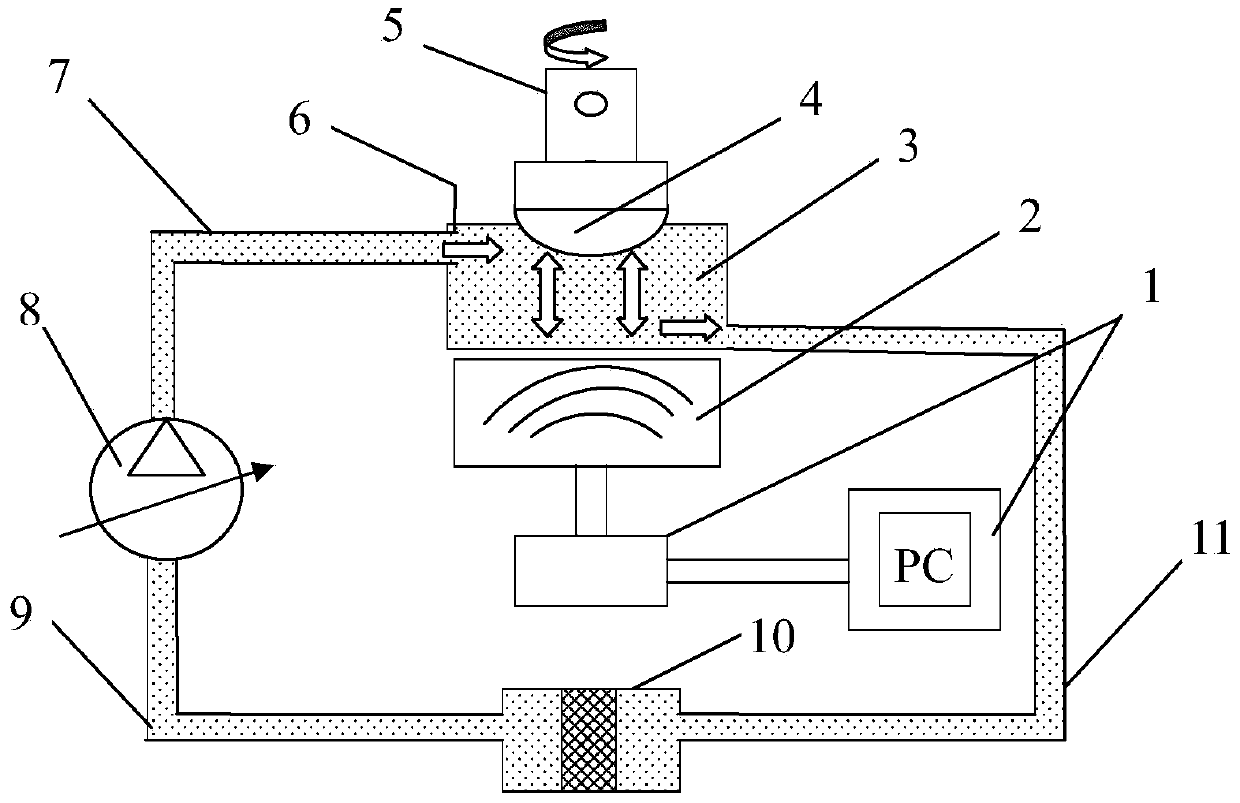

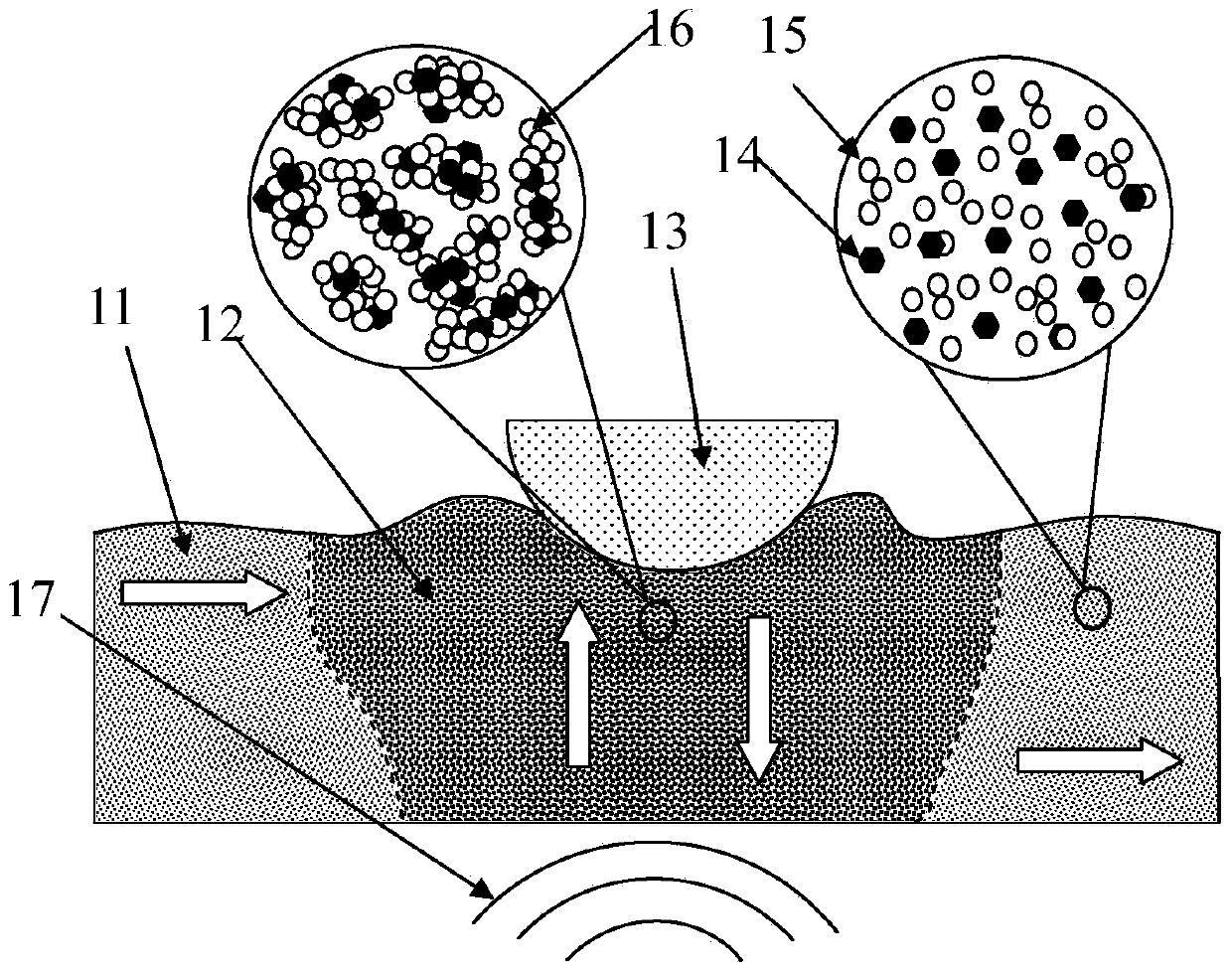

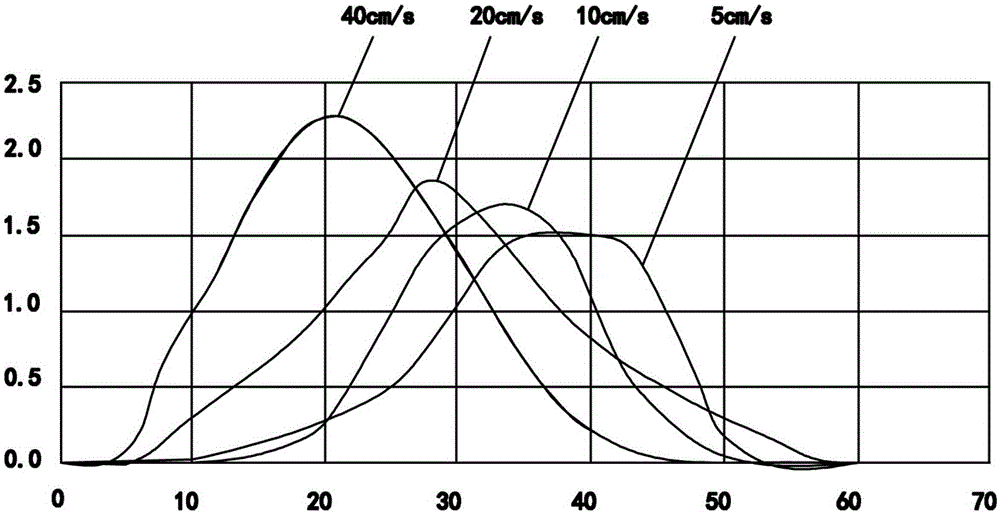

Ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect

ActiveCN102717325AImprove gripAvoid damagePolishing machinesOther chemical processesSocial benefitsSurface finish

The invention discloses an ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect. The method includes: adding abrasive particles or micropowder into non-Newtonian fluid with shear thickening effect to prepare non-Newtonian fluid polishing solution, wherein the non-Newtonian fluid accounts for 50%-90% of the mass of the polishing solution, the abrasive particles or the micropowder account for 10%-50% of the mass of the polishing solution, and the particle size of the abrasive particles or the micropowder ranges from 0.05 micrometer to 50 micrometers. Relative motion is generated between a workpiece and the polishing solution during polishing, shear thickening is generated at a contact portion of the polishing solution and the workpiece under shearing action, viscosity of the polishing solution in the contact area is increased to enhance holding force to the abrasive particles or the micropowder, and removal of workpiece surface materials is achieved under the micro cutting or chemical mechanical action of the adding abrasive particles or micropowder with polishing effect in the polishing solution on the workpiece, so that polishing of the workpiece surface is achieved. The ultra-precise curved surface finishing method based on the non-Newtonian fluid shear thickening effect can achieve efficient and high-quality polishing to various curved surfaces, in particular to complex curved surfaces and has great economic and social benefits.

Owner:ZHEJIANG UNIV OF TECH

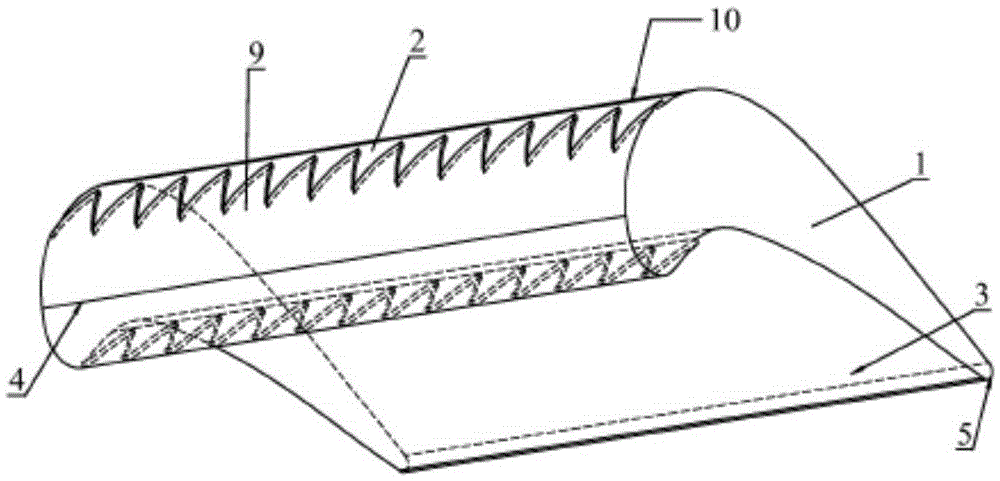

Energy efficiency improvements for turbomachinery

InactiveUS20160052621A1Reduce resistanceGood effectInfluencers by generating vorticesEngine manufactureProcess engineeringEnergy analysis

A method and apparatus are disclosed that allow Conformal Vortex Generator art to improve energy efficiency and control capabilities at many points in a turbomachine or device processing aero / hydrodynamic Newtonian fluid-flows.

Owner:IRELAND PETER +1

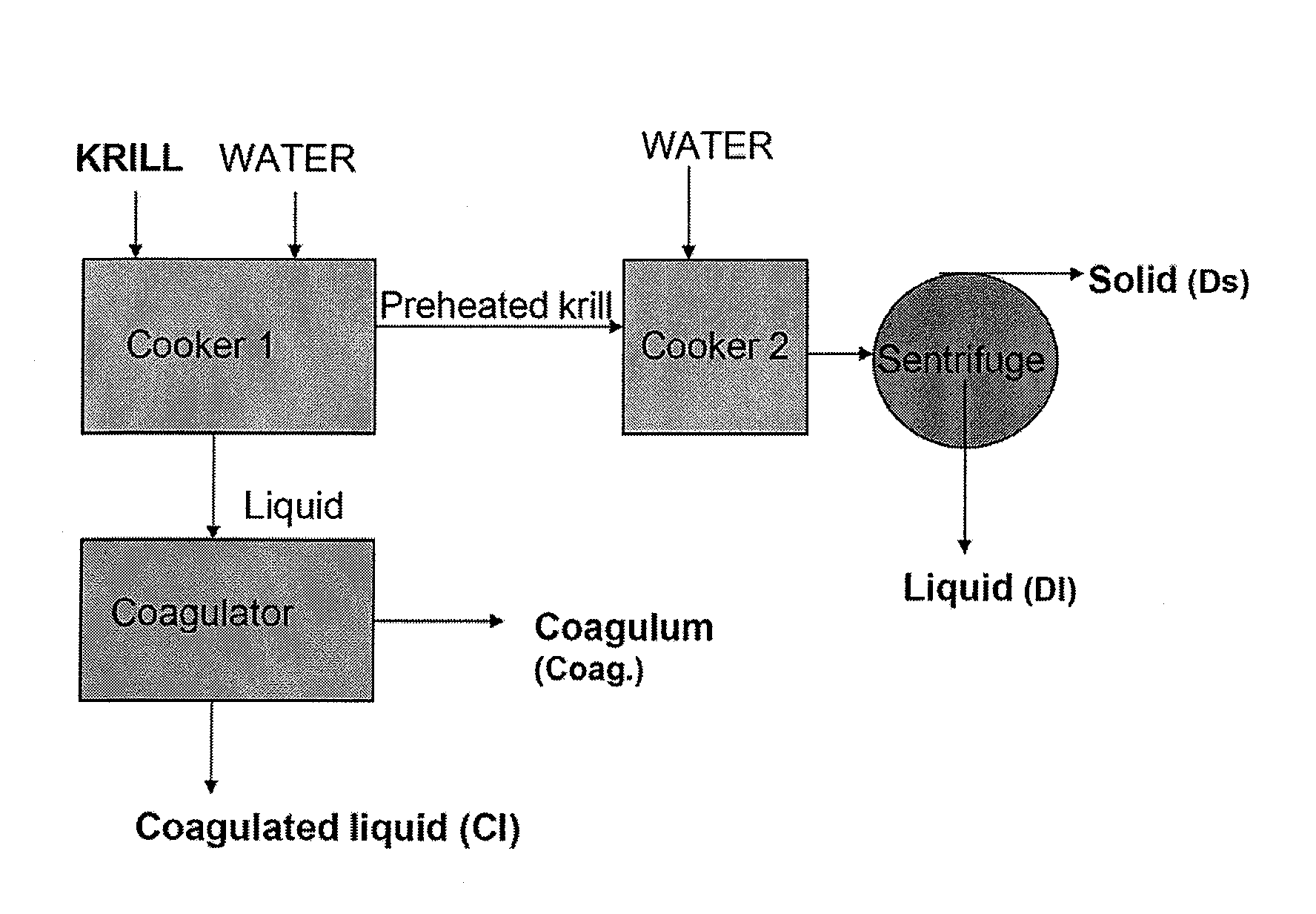

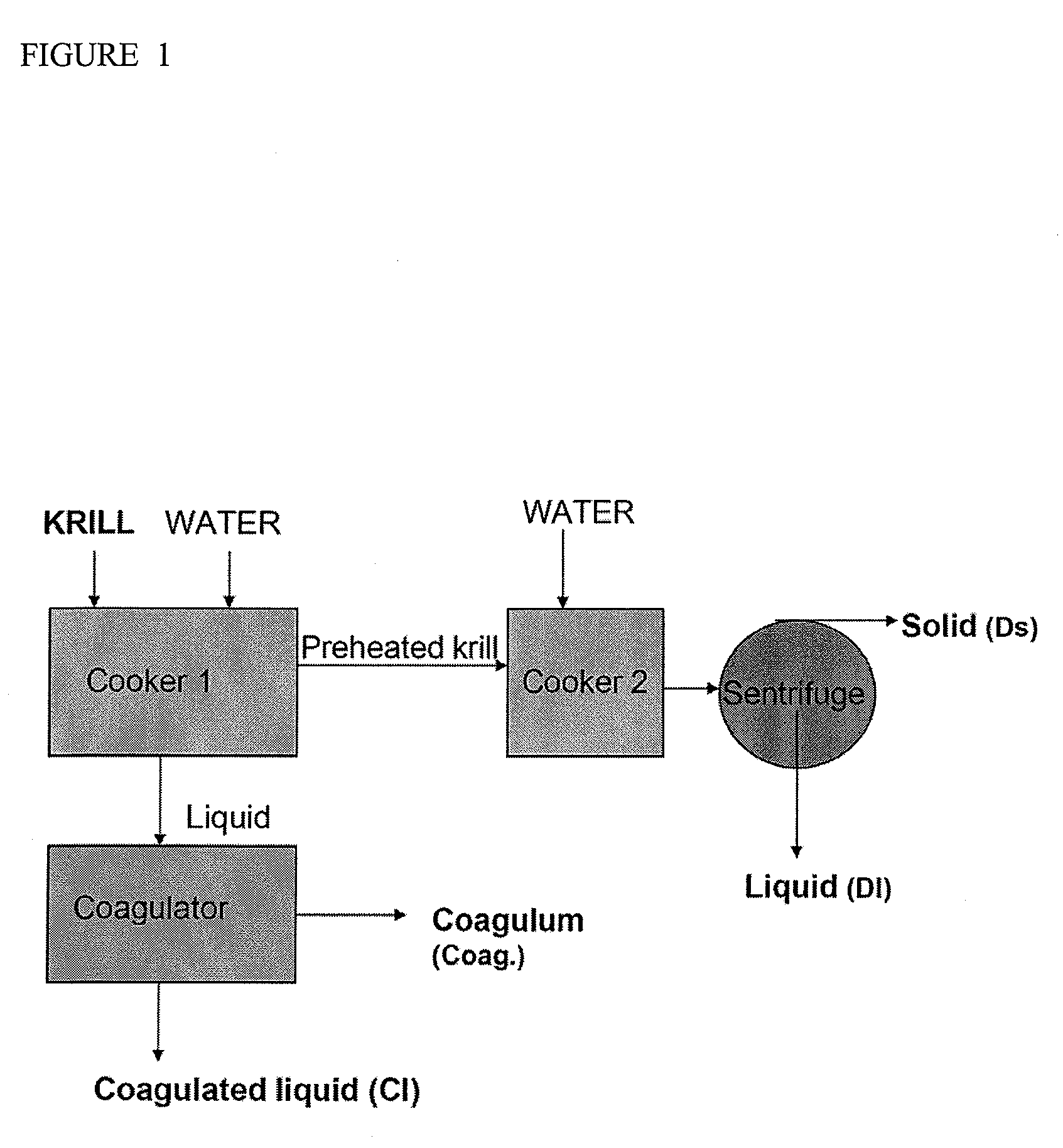

Low viscosity phospholipid compositions

InactiveUS20100226977A1Low viscosityImprove the level ofOrganic active ingredientsBiocideAstaxanthinBetaxanthins

The invention relates to processing crustaceans such as krill to oils comprising phospholipids that are Newtonian fluids and / or and have low viscosity, and in particular to the production of oils containing astaxanthin and phospholipids that show Newtonian fluidity and have a low viscosity.

Owner:AKER BIOMARINE ANTARCTIC

Efficiency improvements for flow control body and system shocks

InactiveUS20170137116A1Mitigate BL lossSolution to short lifeInfluencers by generating vorticesEngine manufactureMomentumEngineering

Methods and related apparatus embodiments are disclosed that allow novel Conformal Vortex Generator and / or Elastomeric Vortex Generator art to improve energy efficiency and control capabilities at many surface points of a body or object moving at speed in aero / hydrodynamic Newtonian fluids, by reducing; shock energy losses, surface flow turbulence, and / or momentum layer thicknesses.

Owner:IRELAND PETER +1

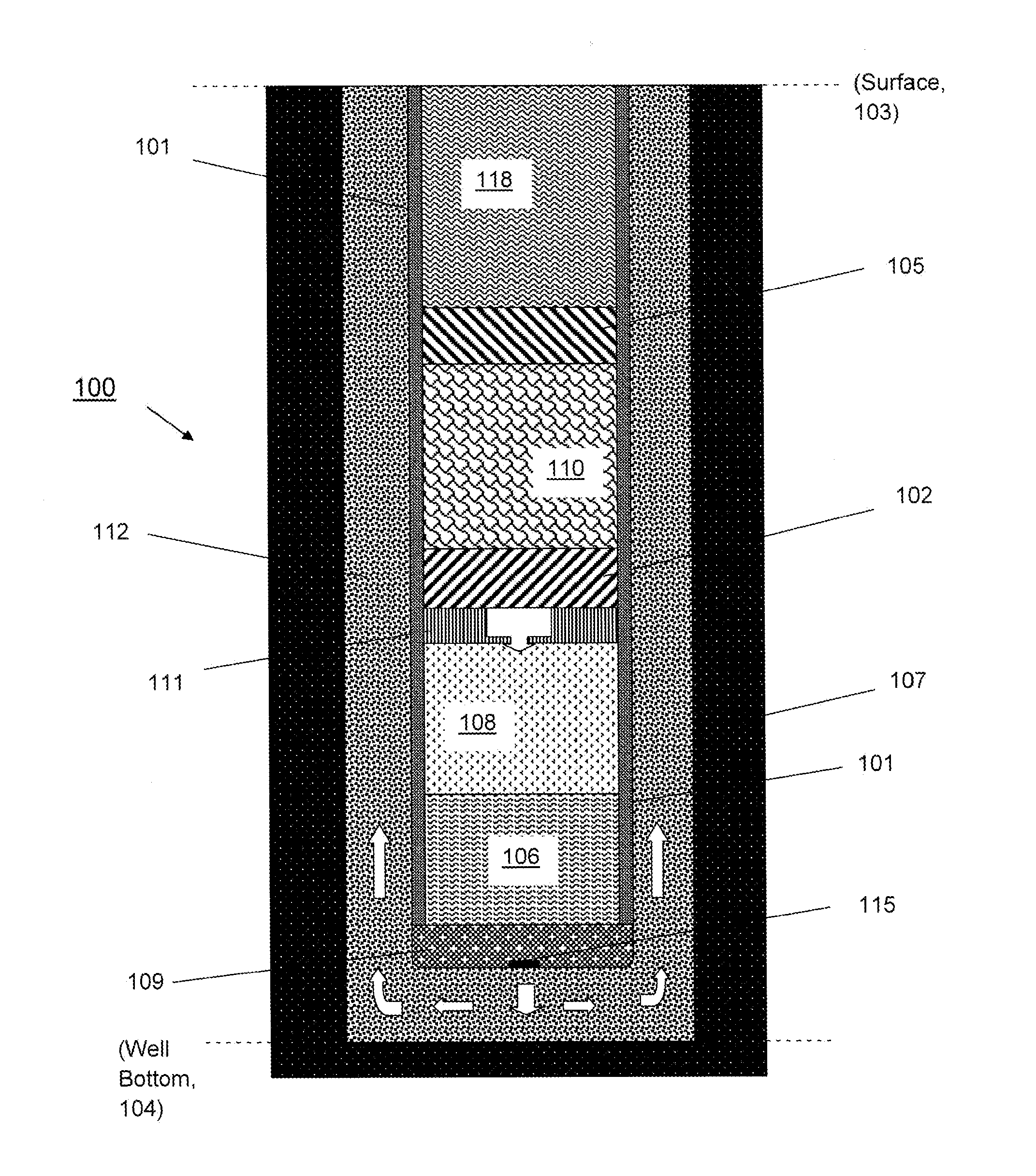

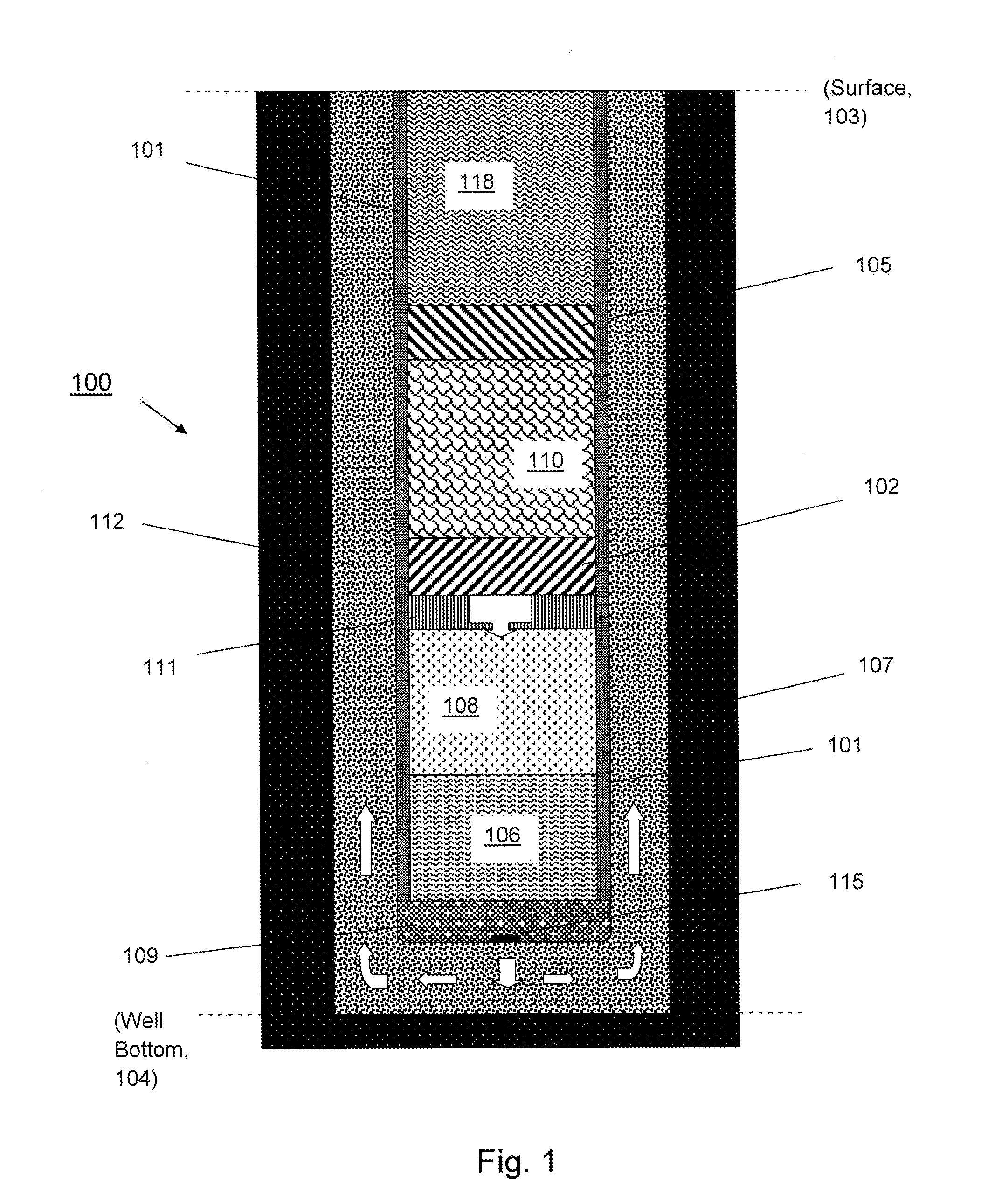

Nanoparticle-densified newtonian fluids for use as cementation spacer fluids and completion spacer fluids in oil and gas wells

The present invention is directed to methods for densifying cement spacer fluids for use in conjunction with drilling fluids and cement slurries for cementing operations involving oil and gas wells, wherein such densifying is done via the addition of nanoparticles to the spacer fluid. The present invention is also directed to analogous methods of densifying completion spacer fluids using nanoparticles, to Newtonian fluid compositions resulting from any such fluid densification, and to systems for implementing the use of such compositions in well cementing operations.

Owner:CHEVROU USA INC

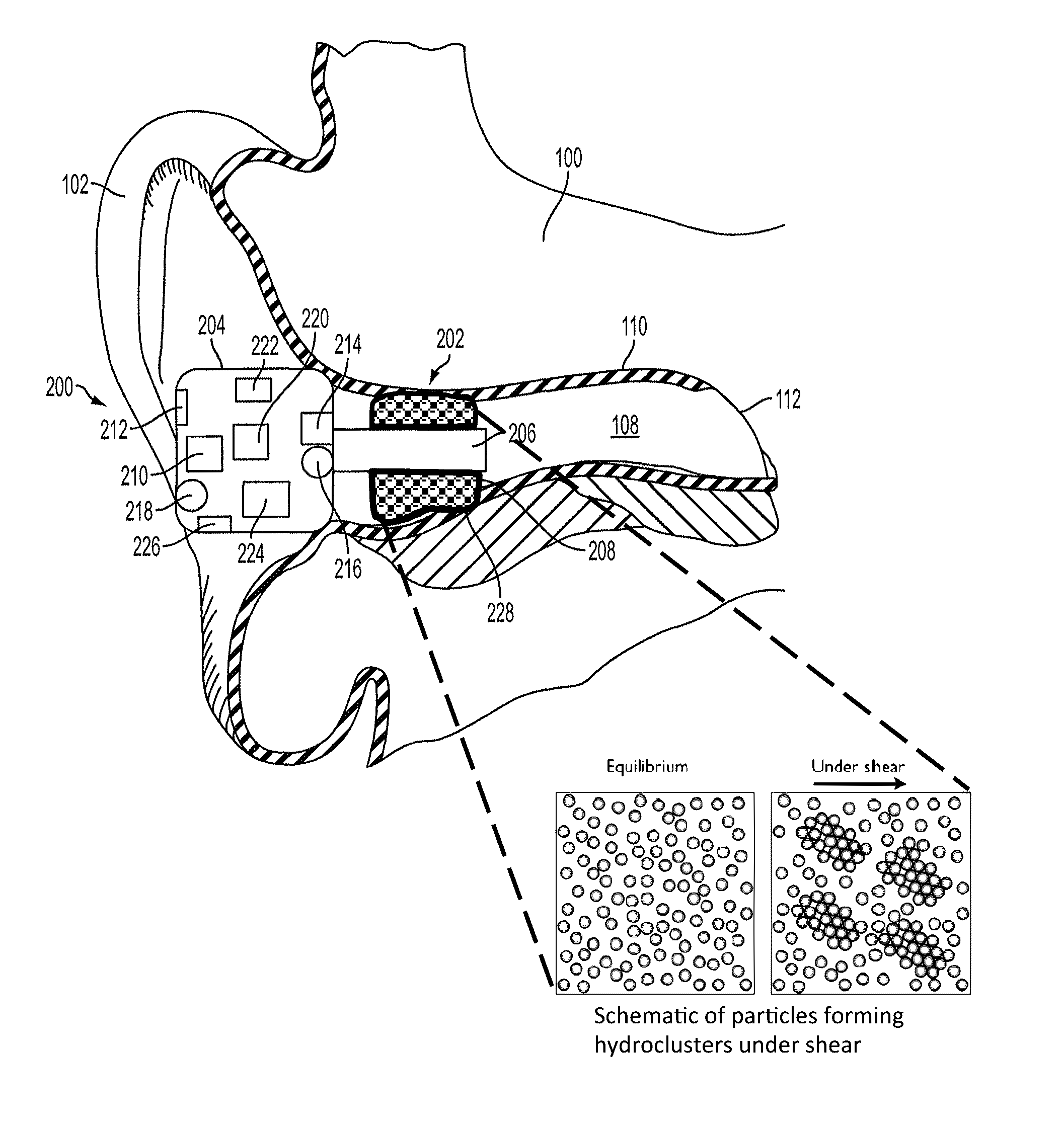

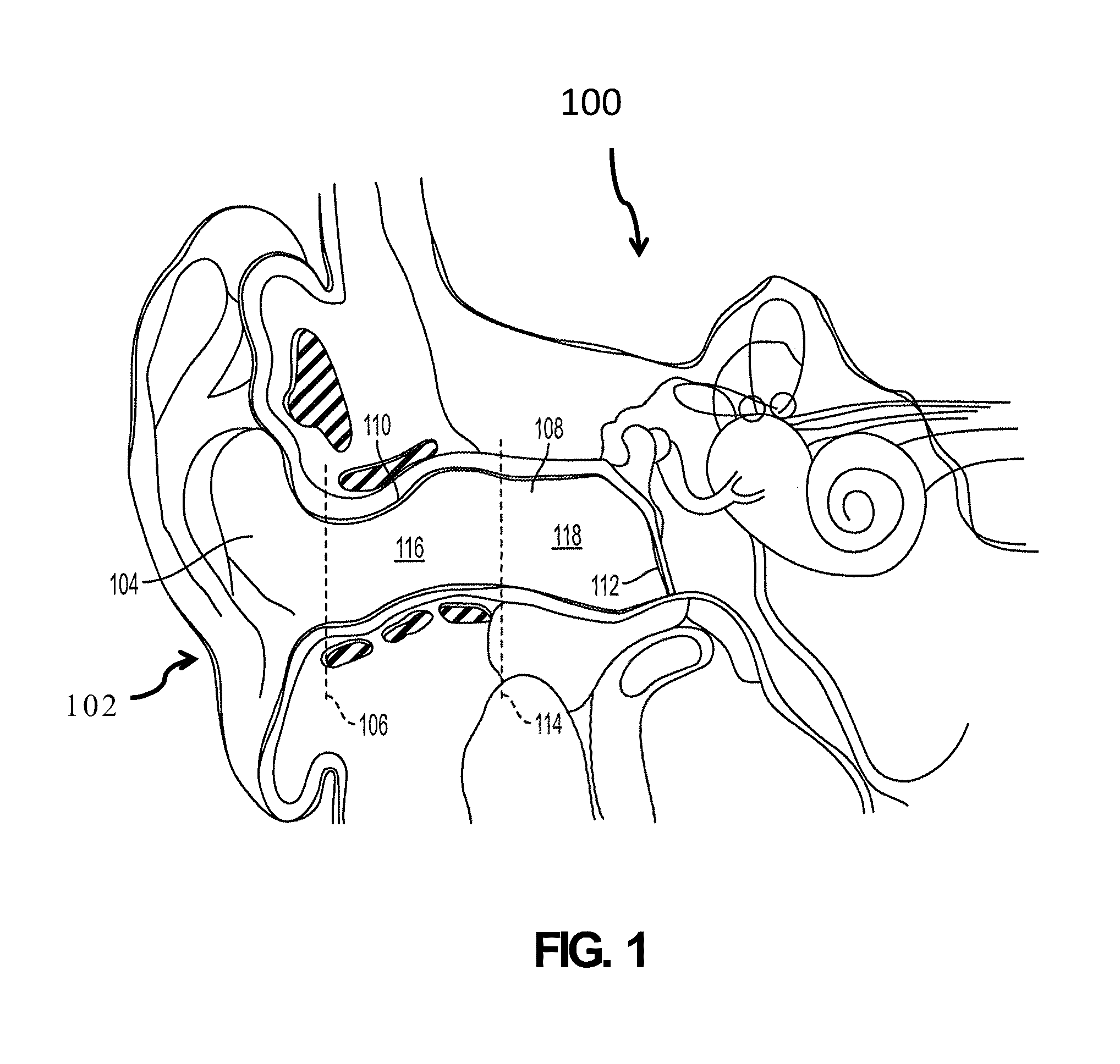

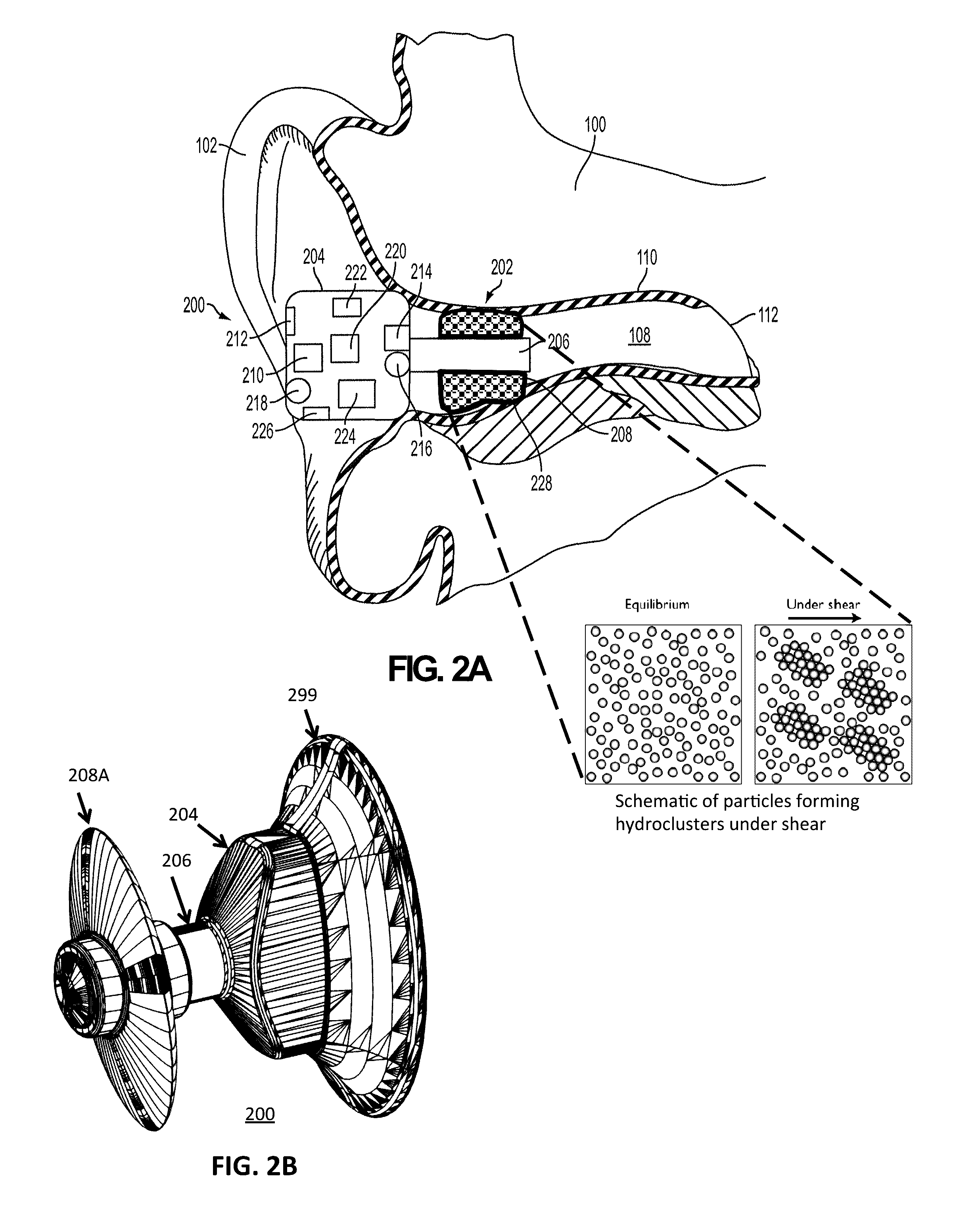

Methods and devices for attenuating sound in a conduit or chamber

ActiveUS20170040012A1Reduce decreaseIncreases its acoustical impendence (attenuationEarplugsIntra aural earpiecesUltrasound attenuationMedicine

Occlusion devices, earpiece devices and methods of forming occlusion devices are provided. An occlusion device is configured to occlude an ear canal, but other biological and non-biological conduits or chambers can be occluded using the devices and methods herein. The occlusion device includes an insertion element and at least one occluding member or element (which can be expandable) disposed on the insertion element. The occluding member is configured to receive a medium via the insertion element and is configured to expand, responsive to the medium, to contact the ear canal. Alternatively, the occluding member is made of a non-Newtonian fluid and can be enclosed by a balloon or not. Physical parameters of the occlusion device are selected to produce a predetermined sound attenuation characteristic over a frequency band. Use of a non-Newtonian fluid provides additional options or variables in customizing or designing a predetermined sound attenuation characteristic.

Owner:STATON TECHIYA LLC

Microfluidic autoregulator devices and arrays for operation with newtonian fluids

InactiveUS20070119510A1Expands potential complexityOperating means/releasing devices for valvesCircuit elementsAuto regulationControl flow

By use of the vias a microfluidic autoregulator is fabricated comprising an origin of a fluid, a sink for the fluid, a main flow channel coupling the origin and the sink, a valve communicated to the main flow channel to selectively control flow of fluid therethrough, and means dependent on flow through the main flow channel for creating a pressure differential across the valve to at least partially activate the valve to control flow of fluid through the main flow channel. The means for dependent on flow for creating a pressure differential comprises either a dead-end detour channel from the flow channel to the valve, or a loop channel fed back to the control chamber of the valve.

Owner:CALIFORNIA INST OF TECH

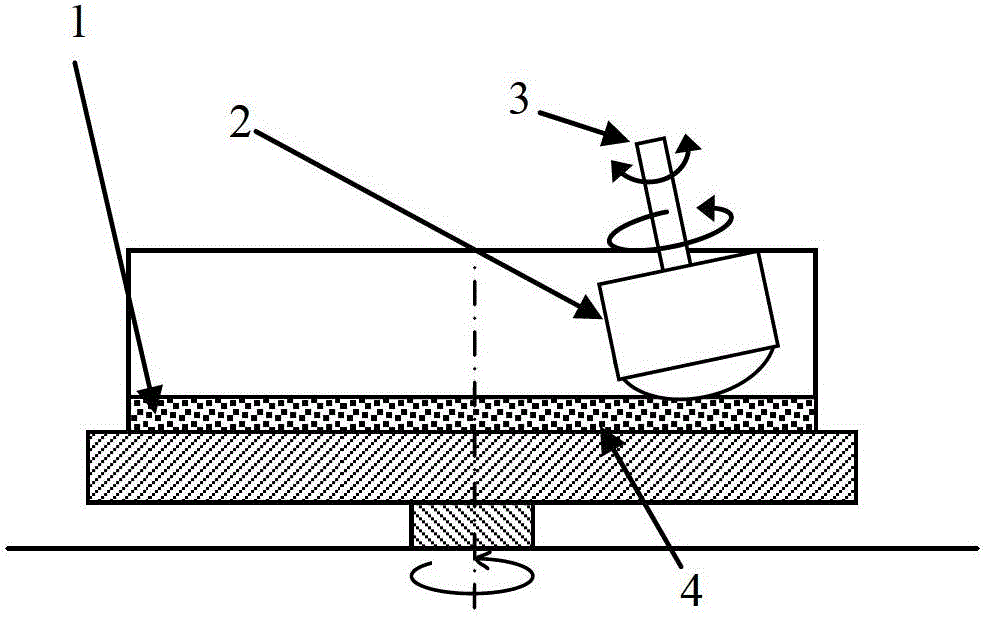

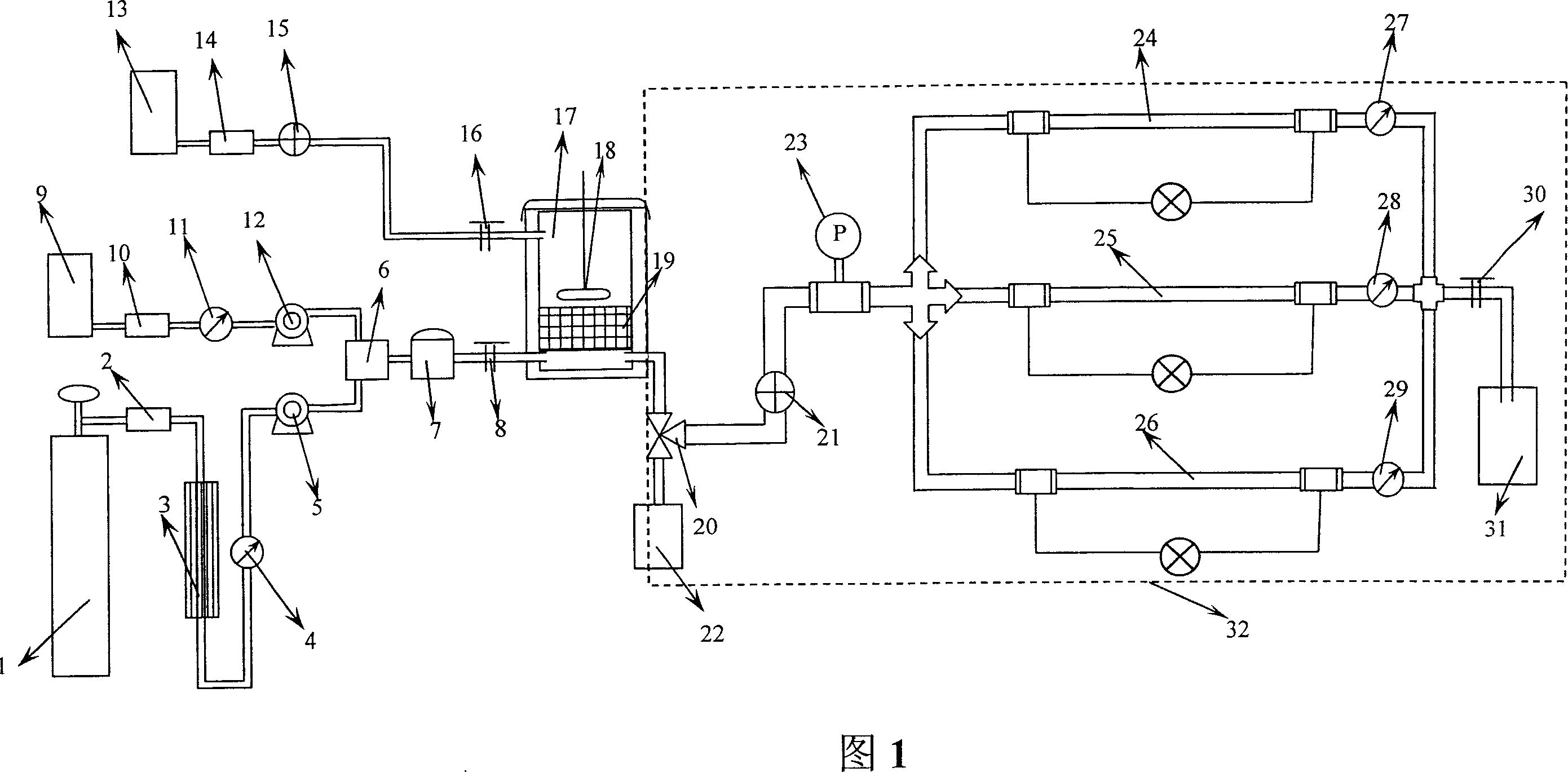

Ultrasonic control shear thickening and polishing method and device

An ultrasonic control shear thickening and polishing method comprises the following steps of 1 adding a non-Newtonian fluid polishing solution mixed with abrasive particles and having the shear thickening effect into a polishing pond and fixing a workpiece on a clamp, wherein the clamp is located above the polishing pond; 2 starting a polishing solution circulating system to enable the non-Newtonian fluid polishing solution to be circularly pumped out of the bottom of the polishing solution and fed into the upper portion of the polishing pond; 3 starting an ultrasonic wave generating device, and meanwhile setting the vibration frequency and vibration amplitude to enable the non-Newtonian fluid polishing solution in the polishing pond to rapidly vibrate and produce a strong shear thickening phenomenon; 4 adjusting the clamp to enable the workpiece to perform relative motion, wherein the abrasive particles having the polishing effect produce the micro-cutting effect or chemical mechanical effect on the workpiece to remove materials on the workpiece surface, and accordingly the workpiece surface polishing is achieved. The invention further provides an ultrasonic control shear thickening and polishing device. The ultrasonic control shear thickening and polishing method and device is high in polishing efficiency and low in cost.

Owner:ZHEJIANG UNIV OF TECH

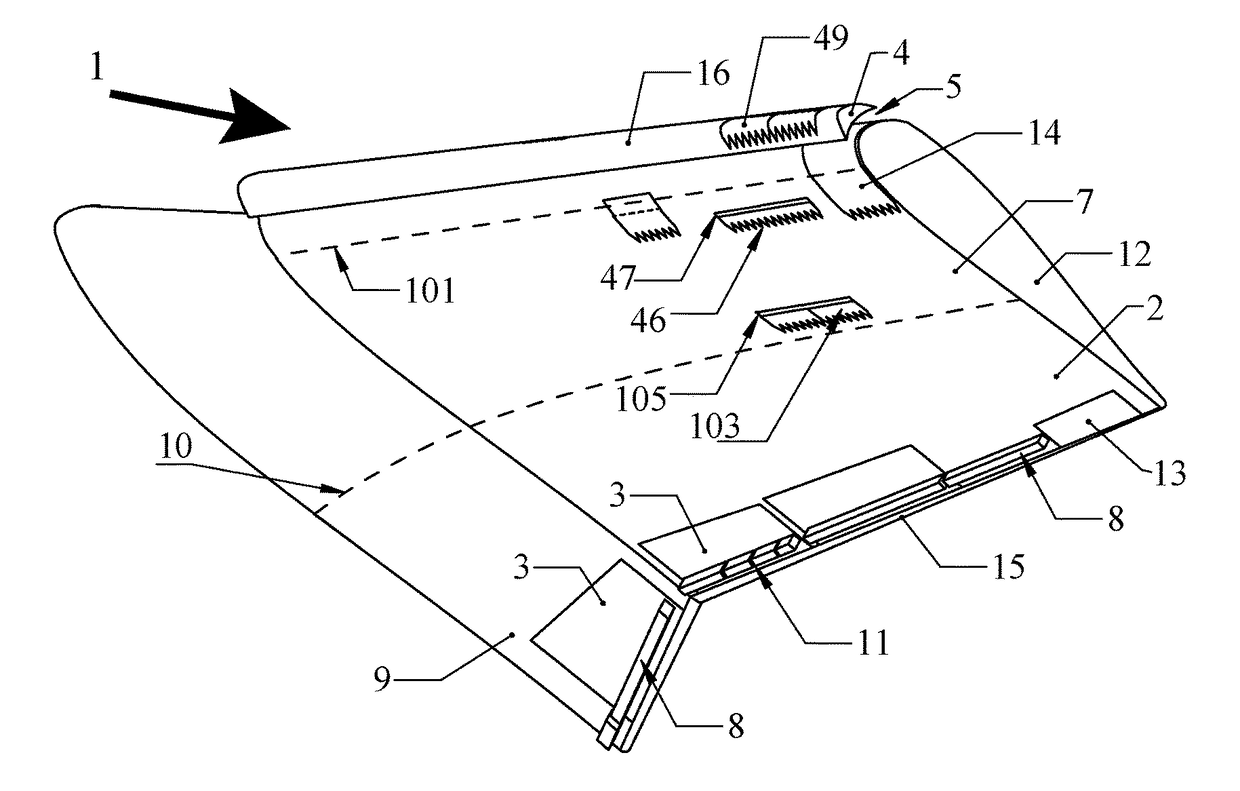

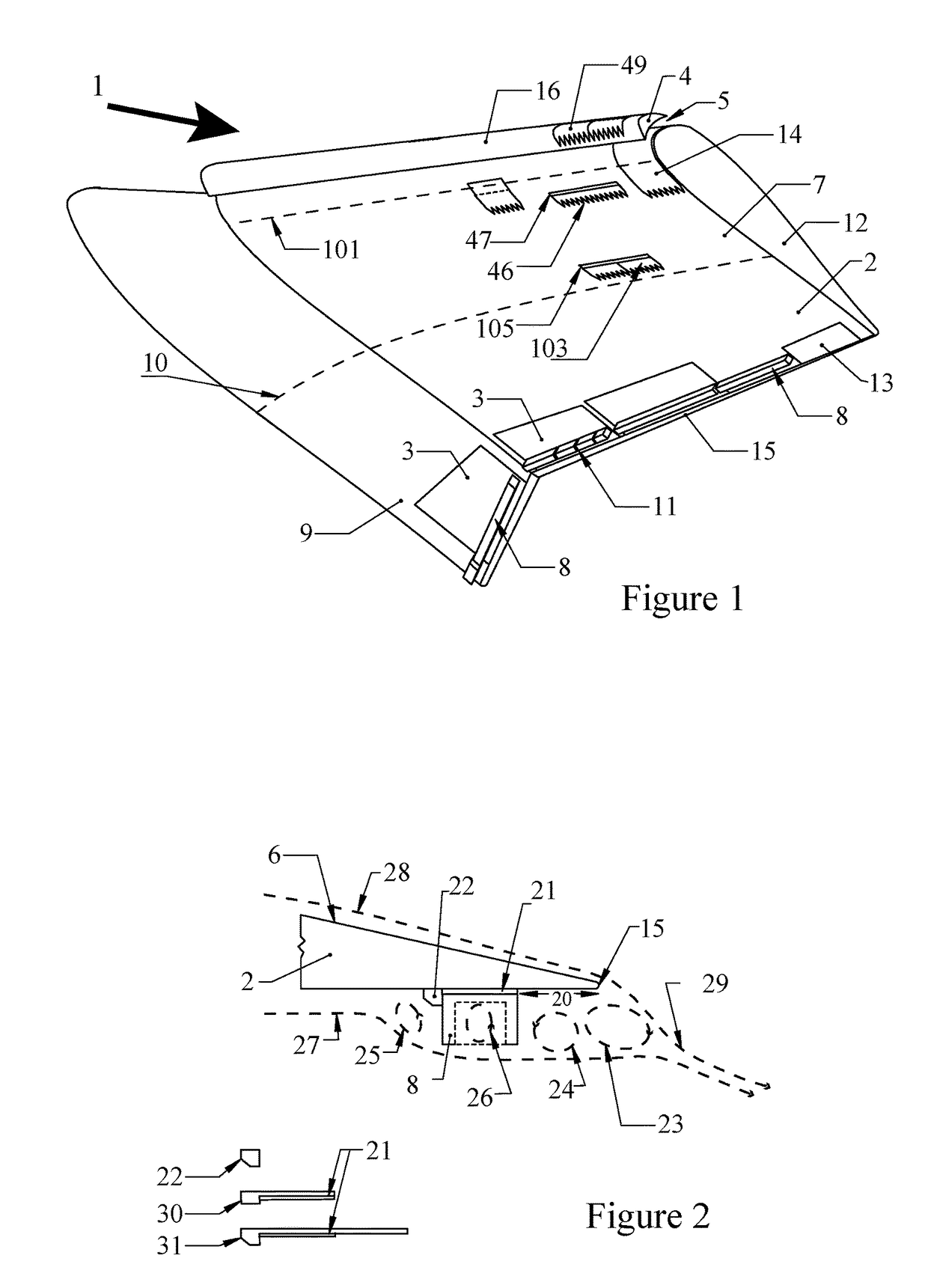

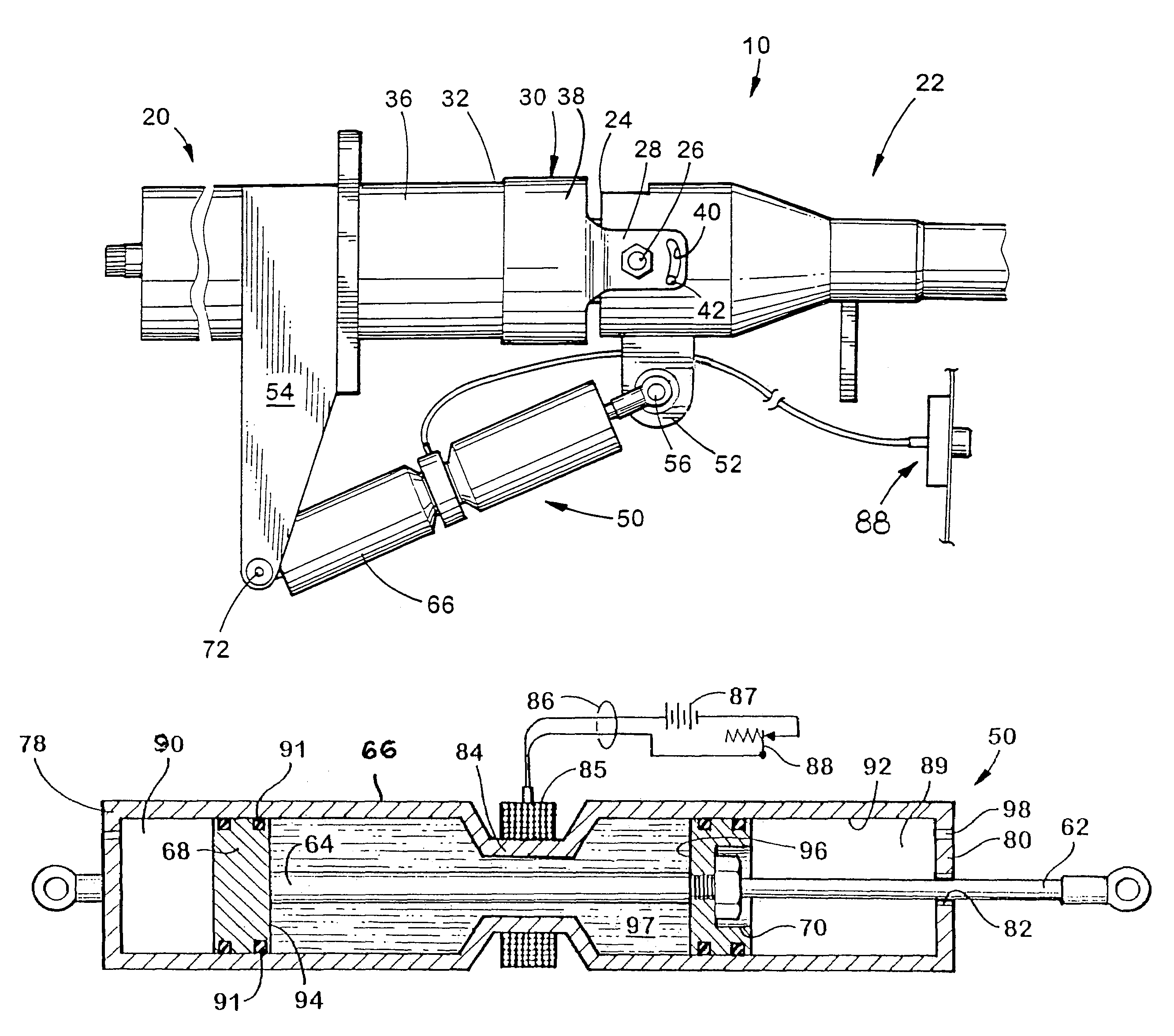

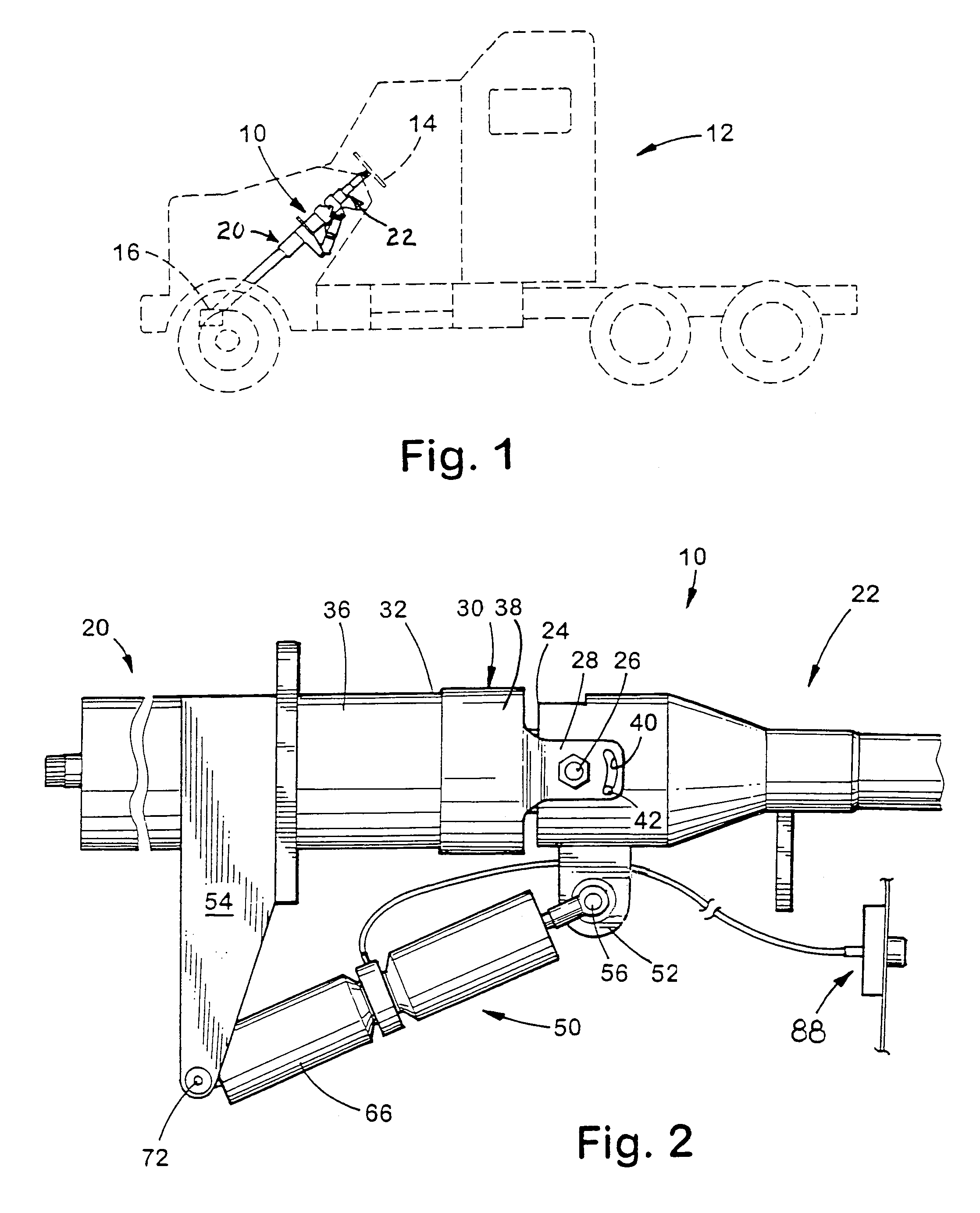

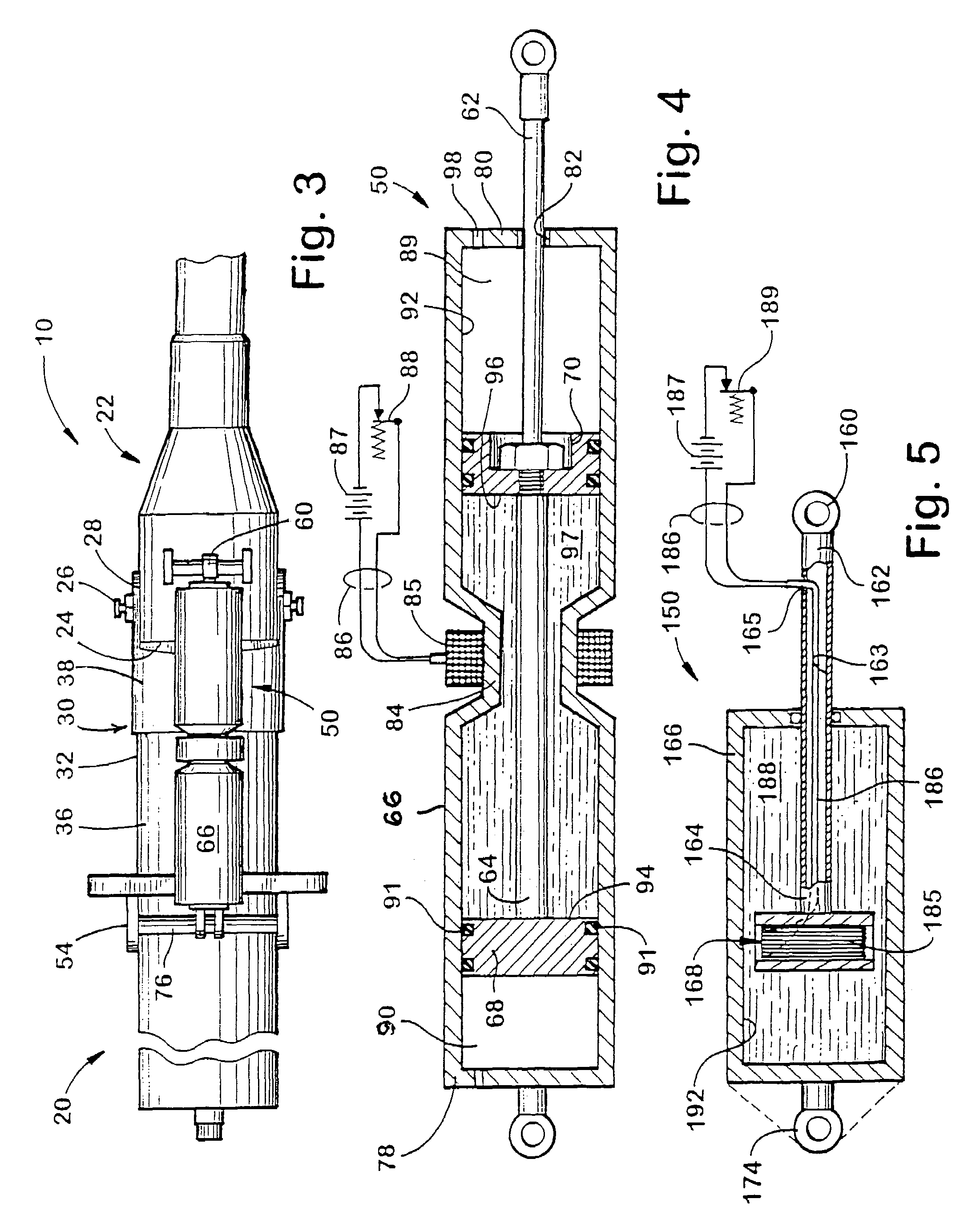

Non-newtonian flow fluid-locking mechanism for vehicles

InactiveUS7165786B1Shorten manufacturing timeLow costSpringsSteering columnsSteering columnUser input

An assembly is provided for fixing the position of an adjustable component (22) of a vehicle, comprising in combination a fixed reference frame (20) within the vehicle such as a dash or a firewall, an adjustable component (22) also disposed in the vehicle such as an adjustable steering column (10), pedals, or a seat. Interconnecting the fixed reference frame (20) and the adjustable component (22) is a fluid locking mechanism (50) which permits selective positioning of the adjustable component relative to the fixed reference frame (20) and holds the adjustable component (22) in position. The fluid locking mechanism (50) is preferably a non-Newtonian flow fluid locking mechanism which uses a magneto-rheological fluid (97) to fix the position of the adjustable component (22) in place once the desired position is selected. To provide additional safety for the vehicle occupants, the fluid locking mechanism may be controlled by an electrical microprocessor (556) or circuit which adjusts the locking strength of the fluid locking mechanism (50) based upon user inputs and dynamic events.

Owner:DOUGLAS AUTOTECH

Composite lithium base lubricant and its preparing method

ActiveCN1616612AGood mechanical stabilityGood colloidal stabilityBase-materialsLithium soapLithium hydroxide

The composite lithium-base lubricating grease consists of the following components: high alkality calcium sulfonate with calcium carbonate existing in calcite crystal and dispersed colloid particle form in 20-60 wt%; thickener comprising composite lithium soap in 3-15 wt%; and lubricating base oil in the rest amount. The preparation process of the lubricating grease includes mixing and heating Newtonian fluid high alkality calcium sulfonate, converting agent and base oil until thickening; adding C12-C24 fatty acid and auxiliary acid and producing saponification with lithium hydroxide aqua; heating to dewater and cooling to form grease. The composite lithium-base lubricating grease of the present invention has excellent mechanical stability, colloid stability, water resistance, rust resistance and high temperature use performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

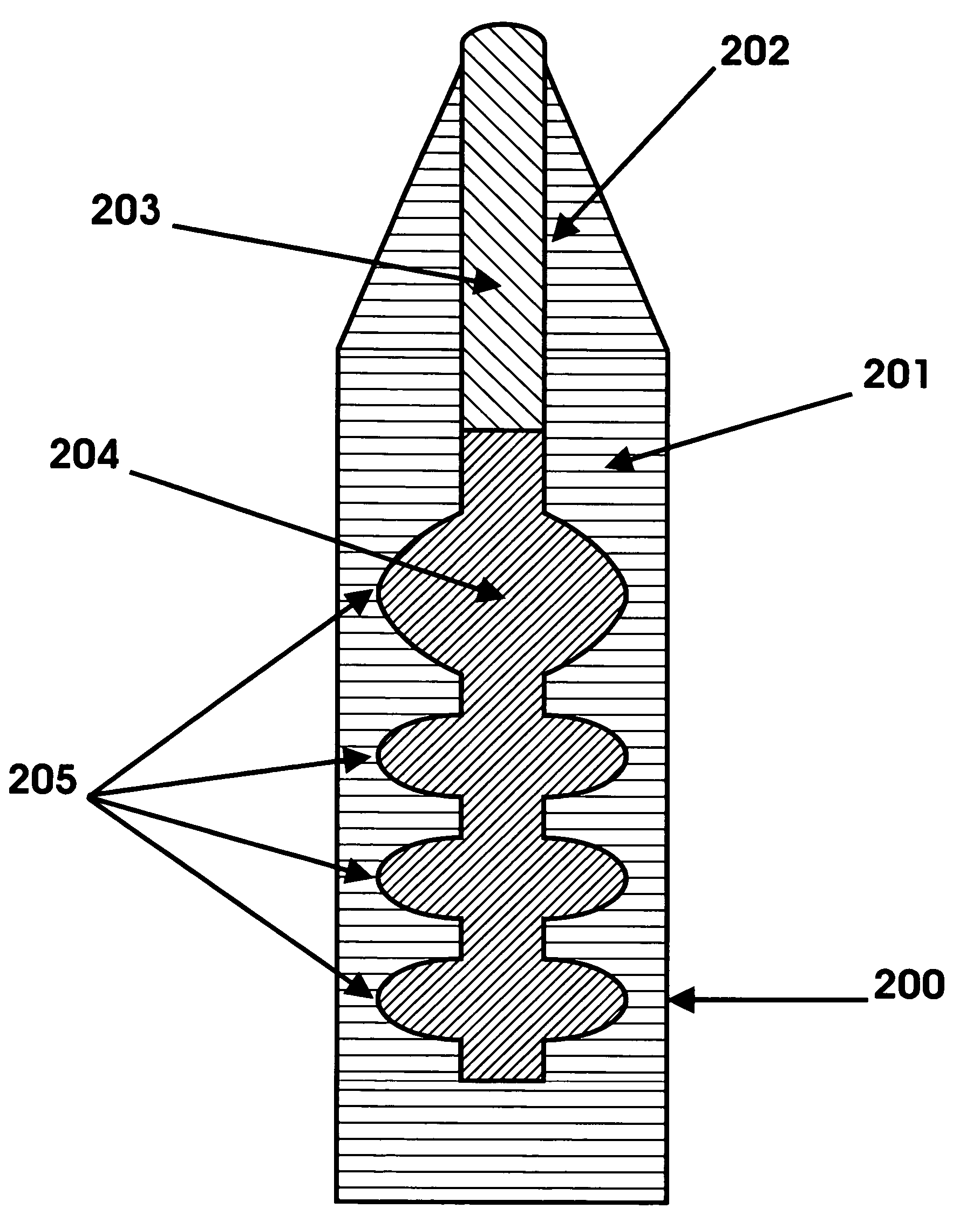

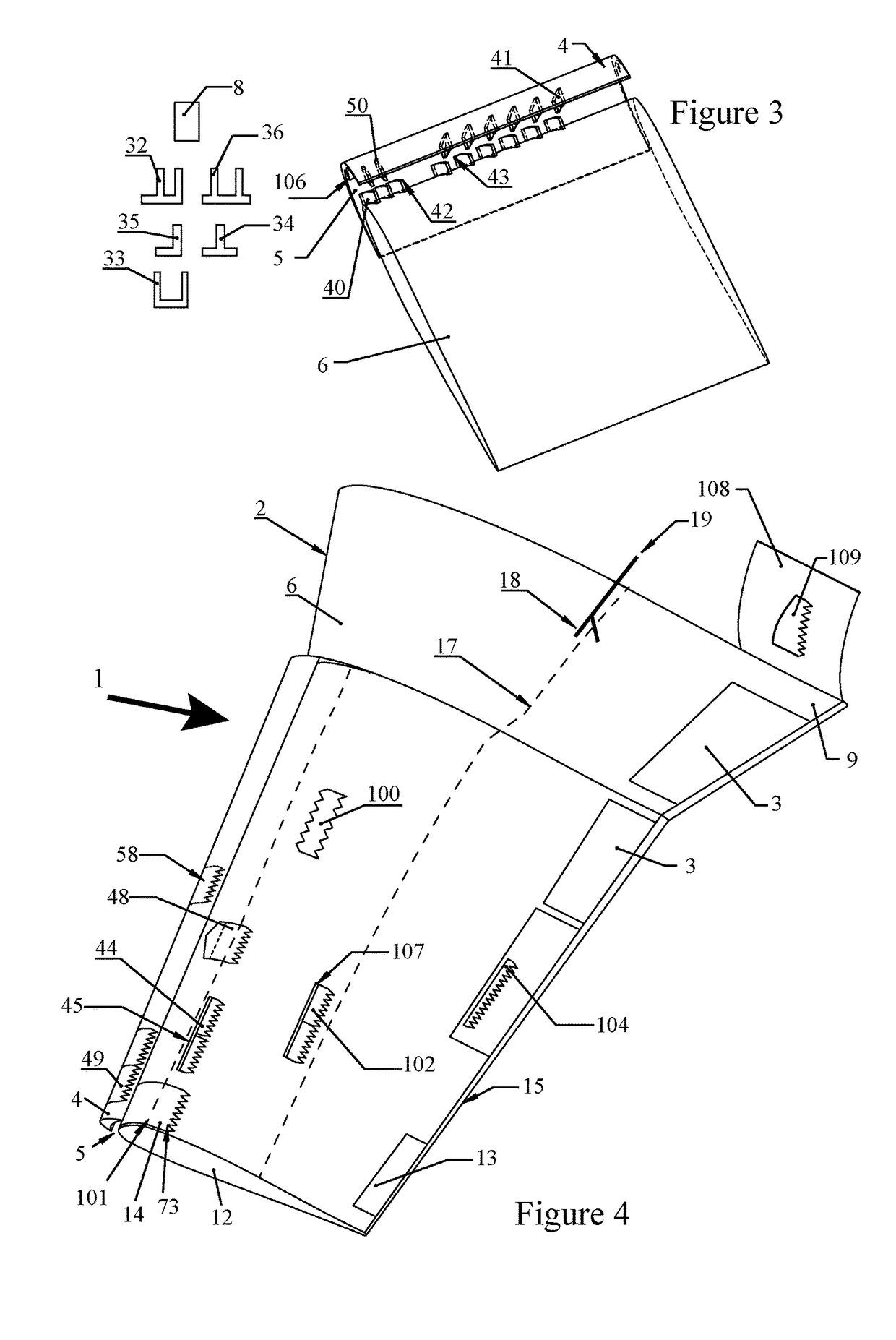

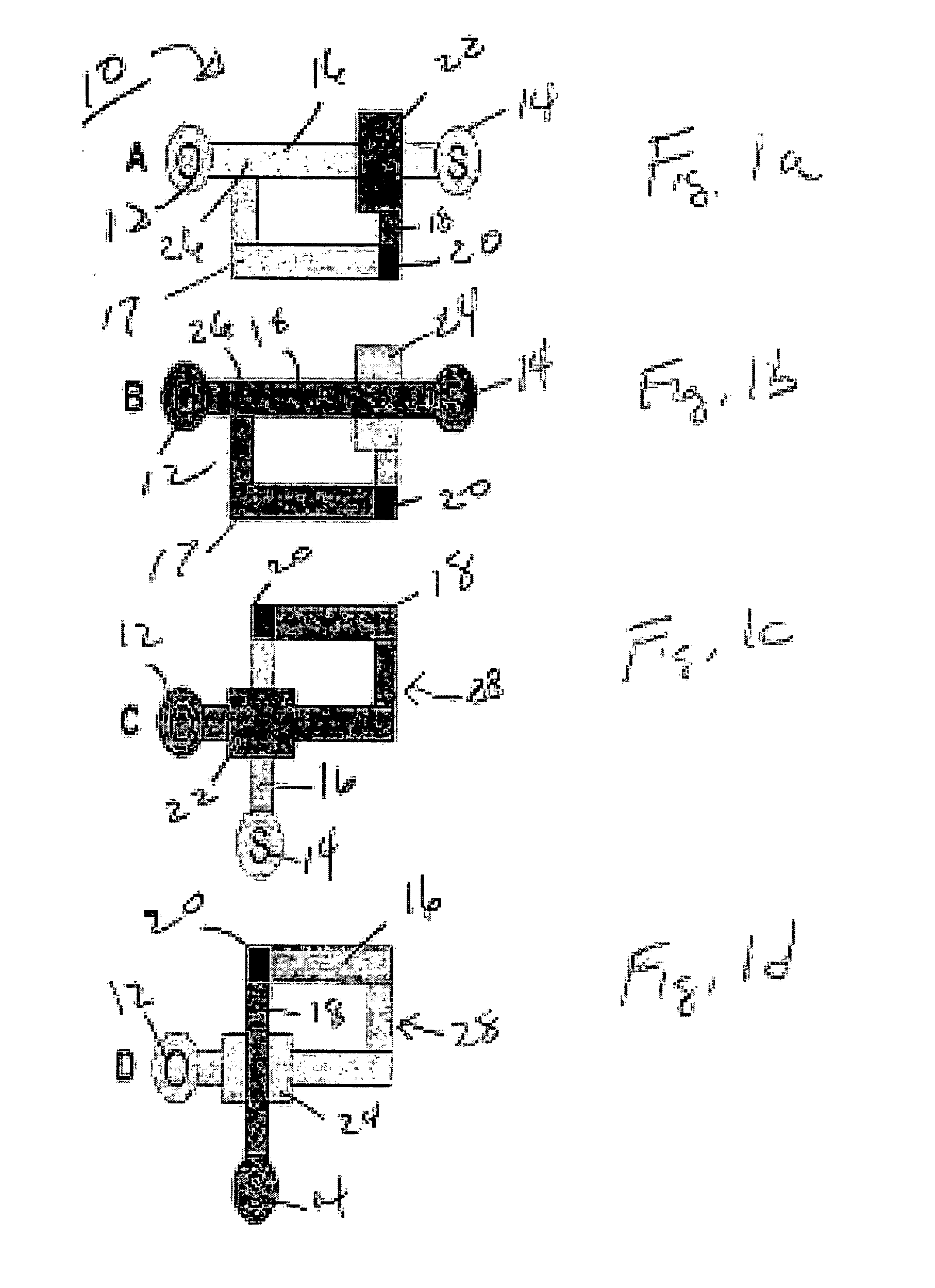

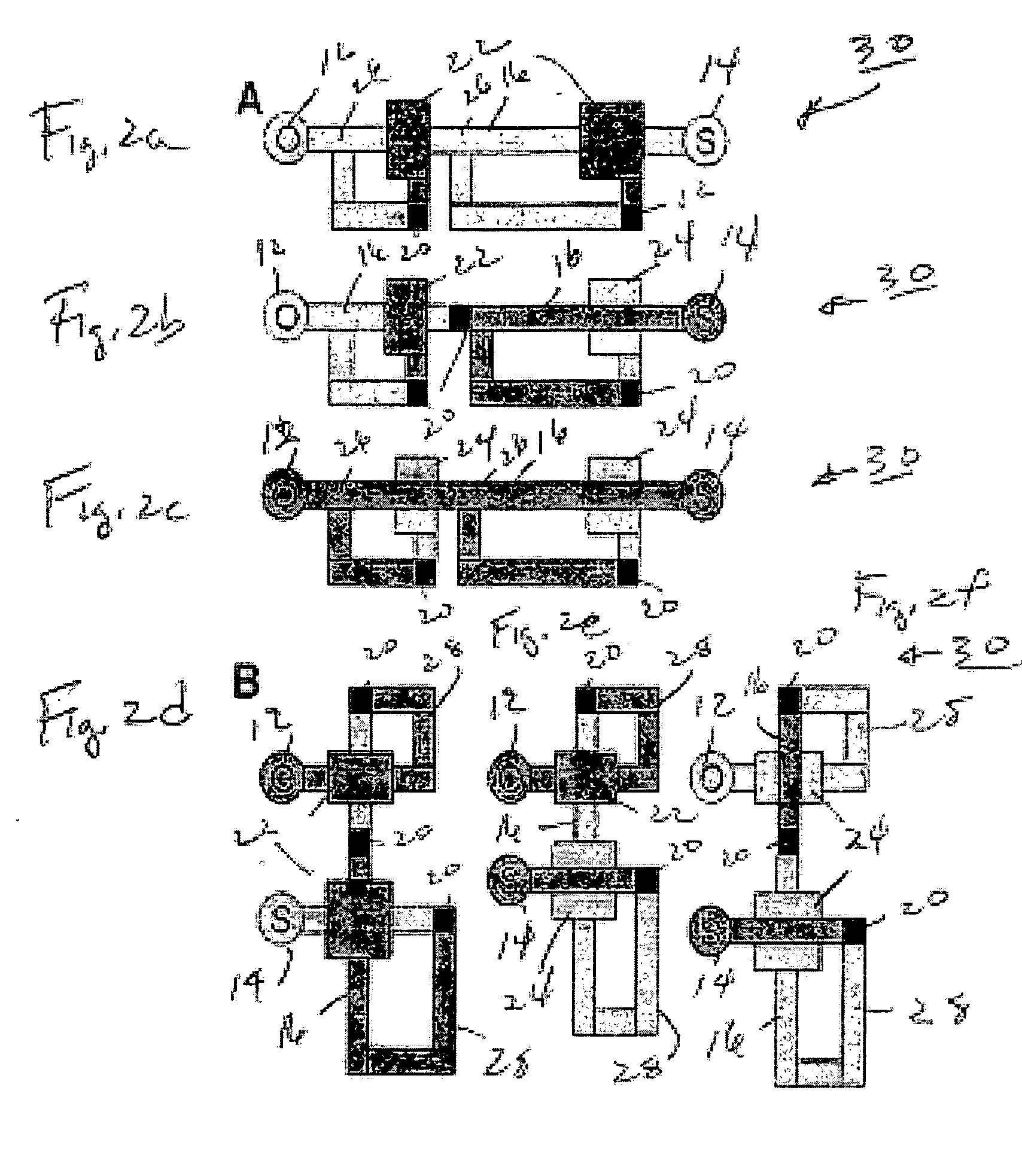

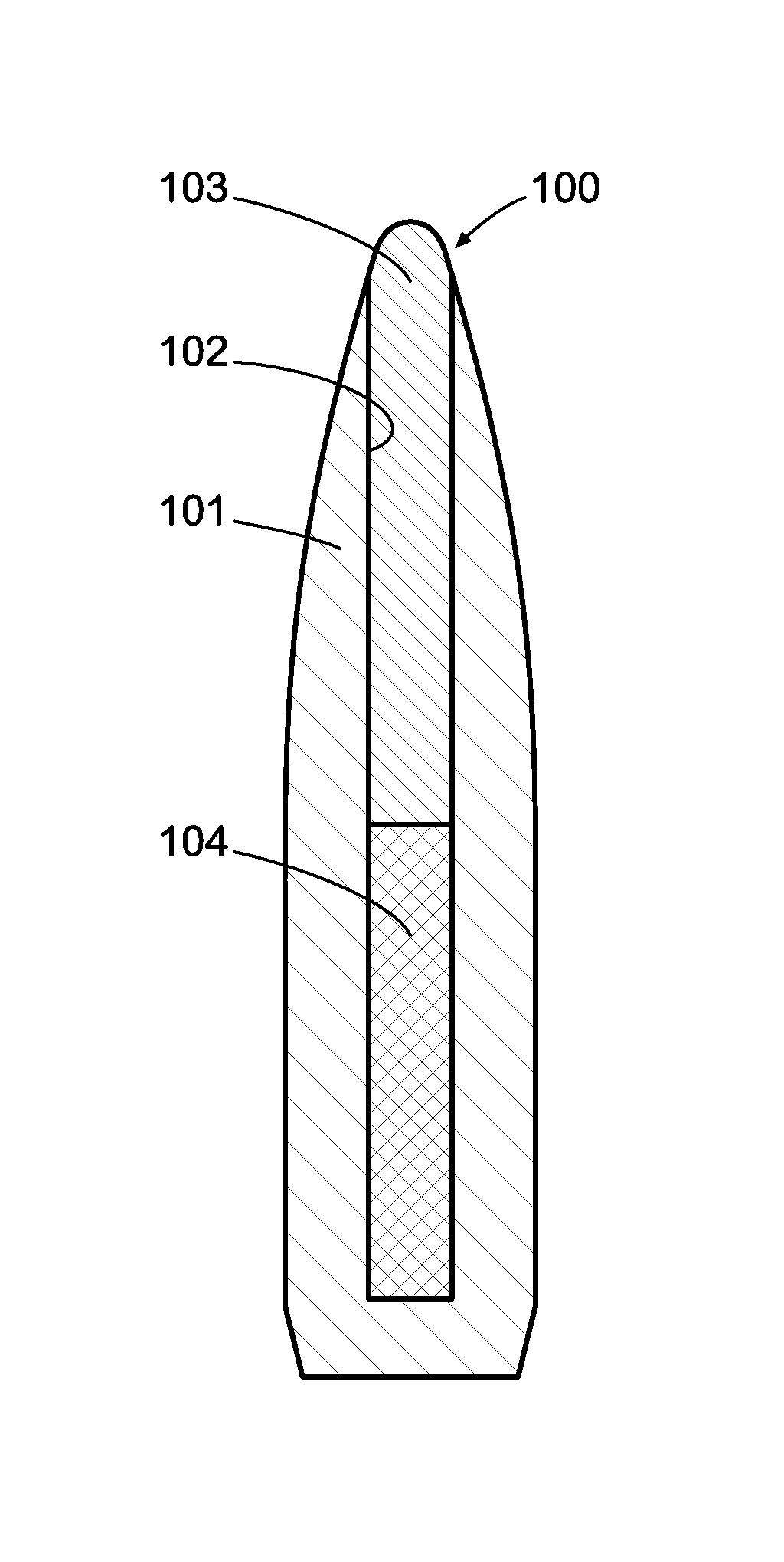

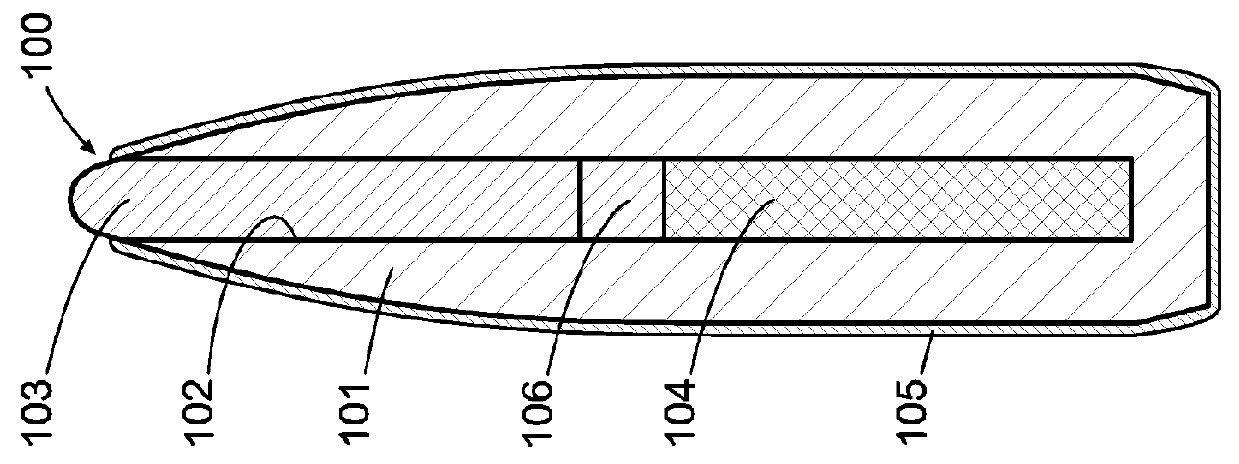

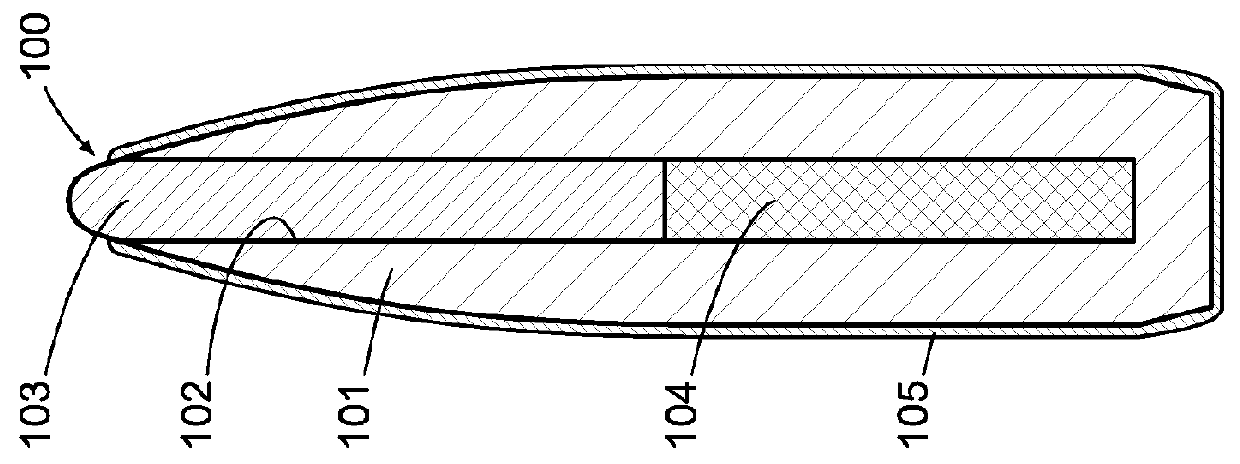

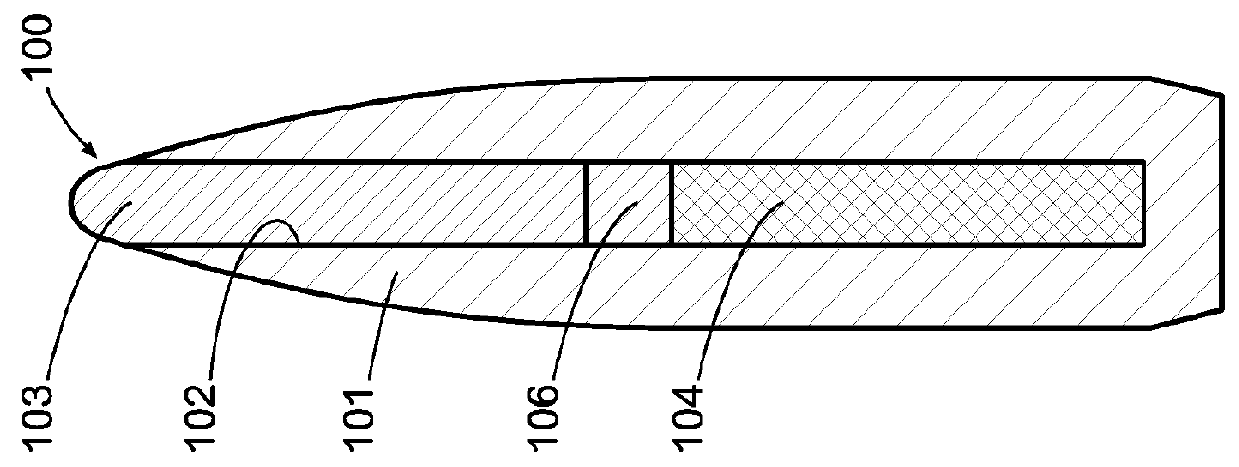

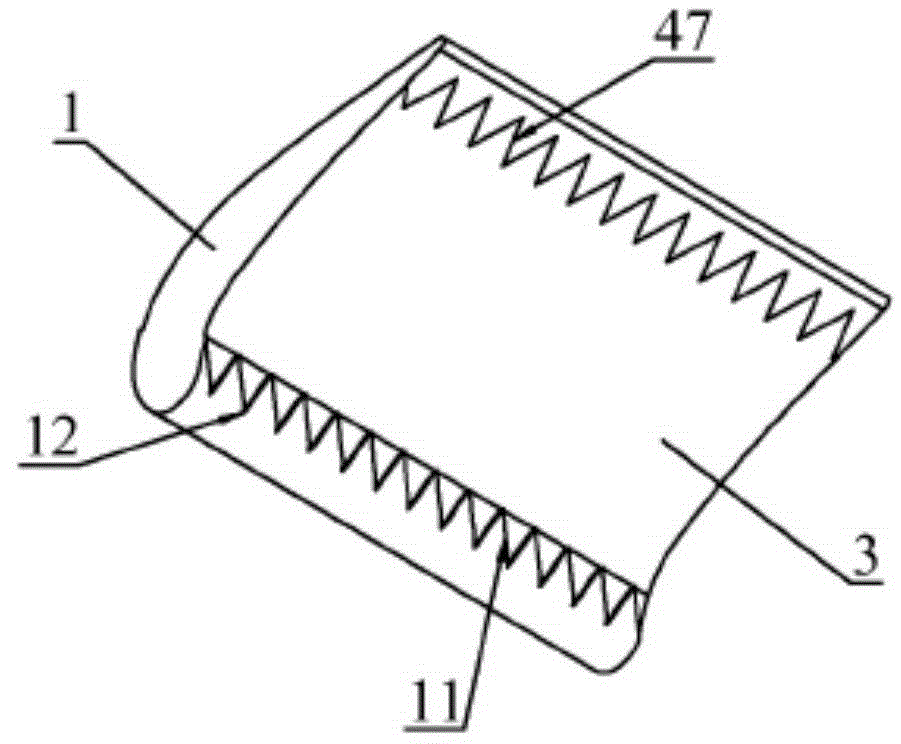

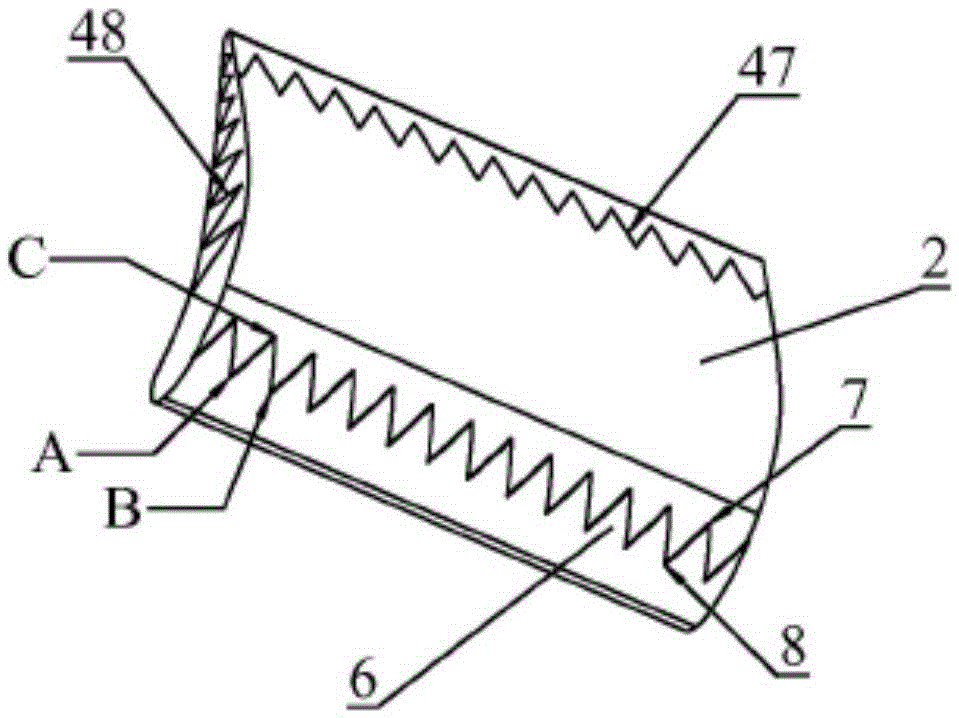

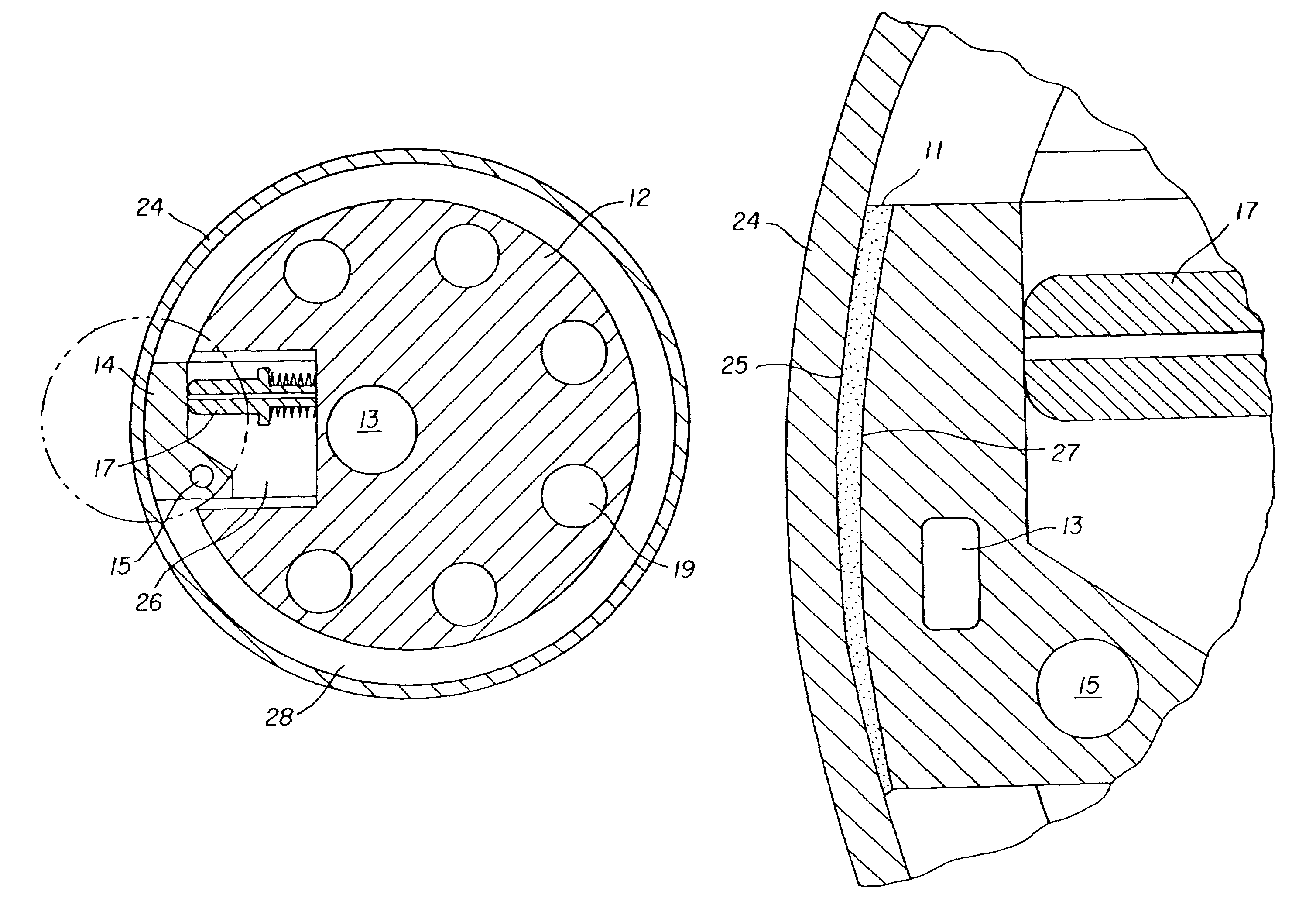

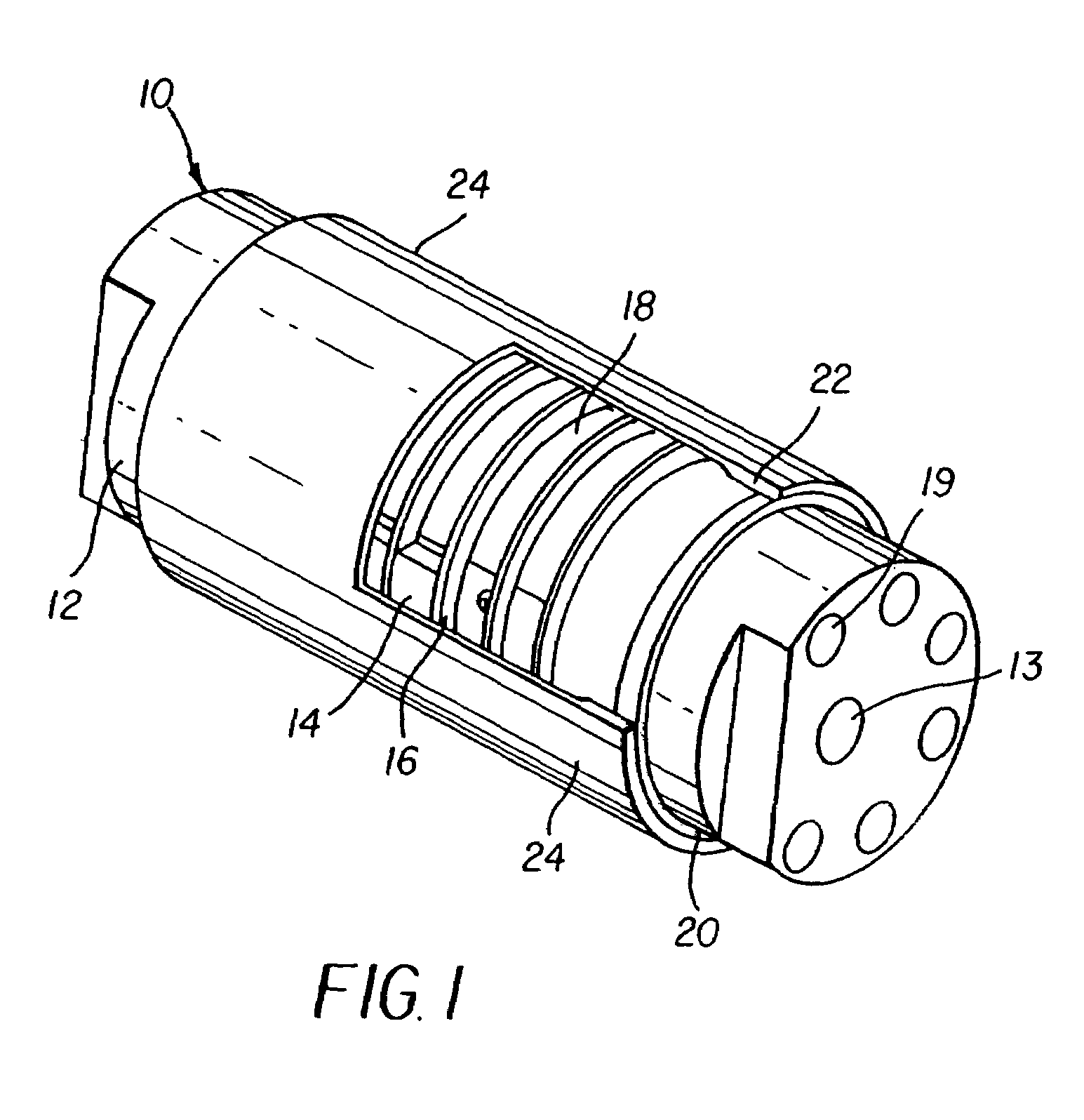

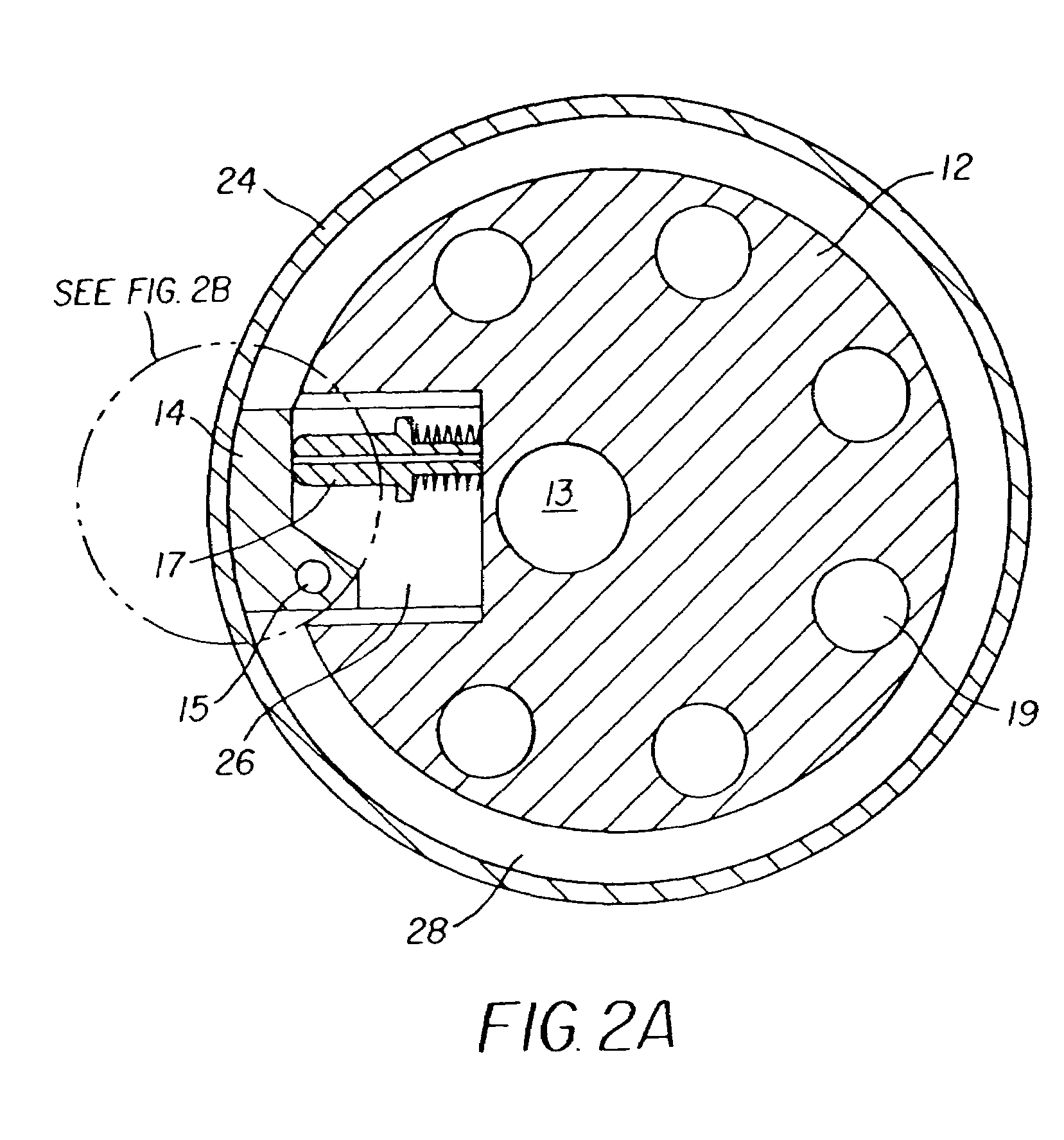

Non-newtonian projectile

ActiveUS7966937B1Pressure be exertAmmunition projectilesTraining ammunitionEngineeringNon-Newtonian fluid

A projectile is provided comprising a body with a channel that contains a non-Newtonian fluid. In various embodiments a plunger is located in the channel, wherein the plunger transmits a force to the non-Newtonian fluid upon interacting with a target, causing the non-Newtonian fluid to exert a pressure in the channel, and wherein the viscosity of the non-Newtonian fluid changes upon interacting with the target. By way of non-limiting example, the non-Newtonian fluid of embodiments of the present invention can comprise a shear-thickening fluid that increases its viscosity with at least the rate of shear upon interacting with the target.

Owner:JACKSON JASON STEWART

Crude oil pour point depressant and preparation method thereof

ActiveCN101845299ADosage is smallLarge range of pour point reductionDrilling compositionMaleic anhydrideWax

The invention discloses a crude oil pour point depressant, which is compounded by the following components in percentage by weight: 99.0 to 99.8 percent of quadripolymer, 0.1 to 0.5 percent of fumed silica, and 0.1 to 0.5 percent of nonionic fluorocarbon surfactant, wherein the quadripolymer is formed by polymerizing monomer higher alcohol acrylate, methylacrylic acid, maleic anhydride, and styrene. The crude oil pour point depressant has the advantages of small dosage, great pour point depression, excellent wax resistance effect, and the like. The experimental results prove that: the pour point depressant obviously lowers the condensation point of the crude oil, widens the Newton fluid temperature range of the crude oil, and reduces the viscosity at non-Newton fluid temperature. In the application of Jianghan oilfield, the freezing point of the crude oil can be reduced to 7 DEG C below zero from 25 DEG C by adding 0.025 mass percent of the pour point depressant, the reduction range is 32 DEG C, and the on-site using effect is good.

Owner:HUBEI UNIV +1

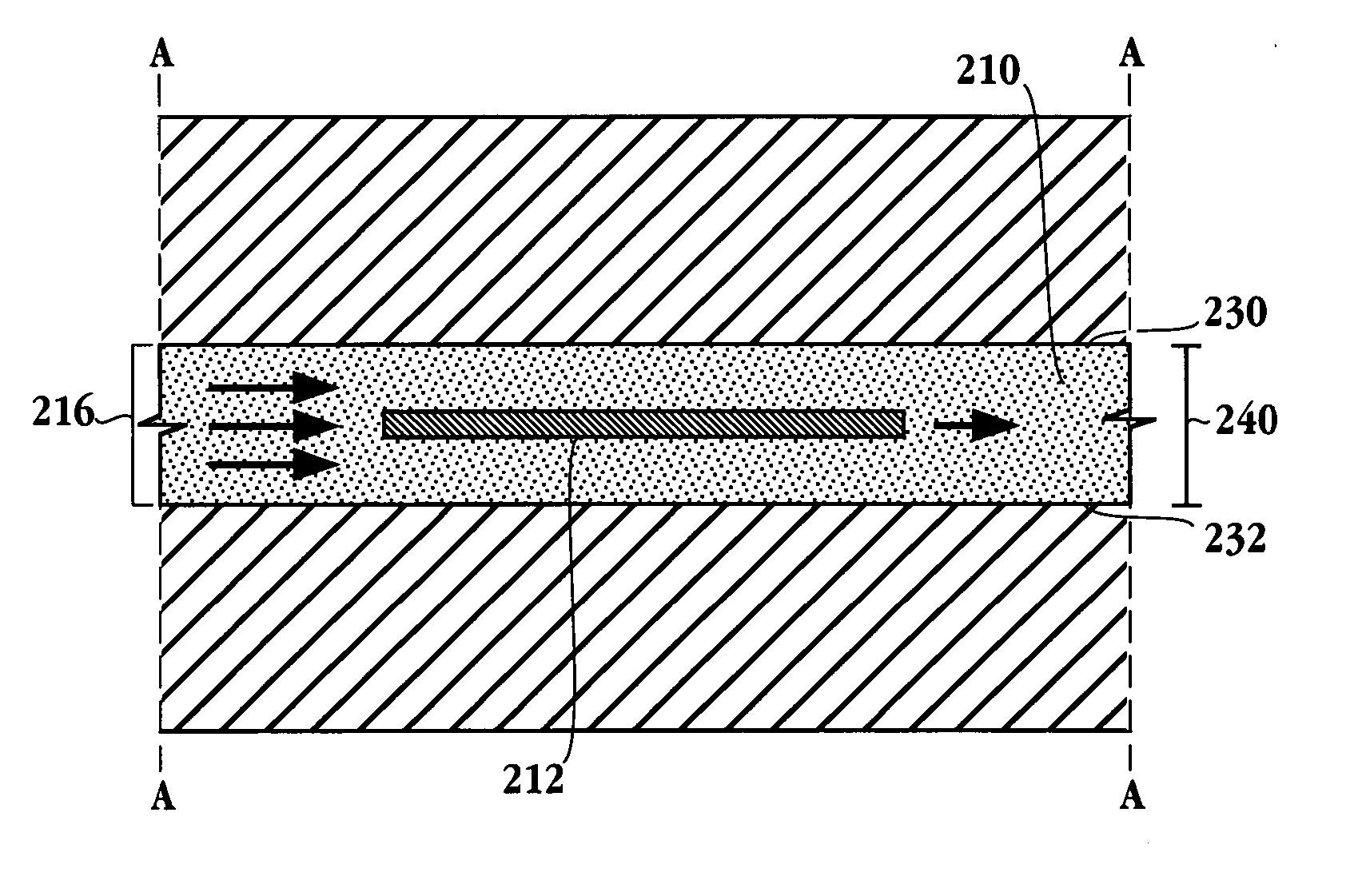

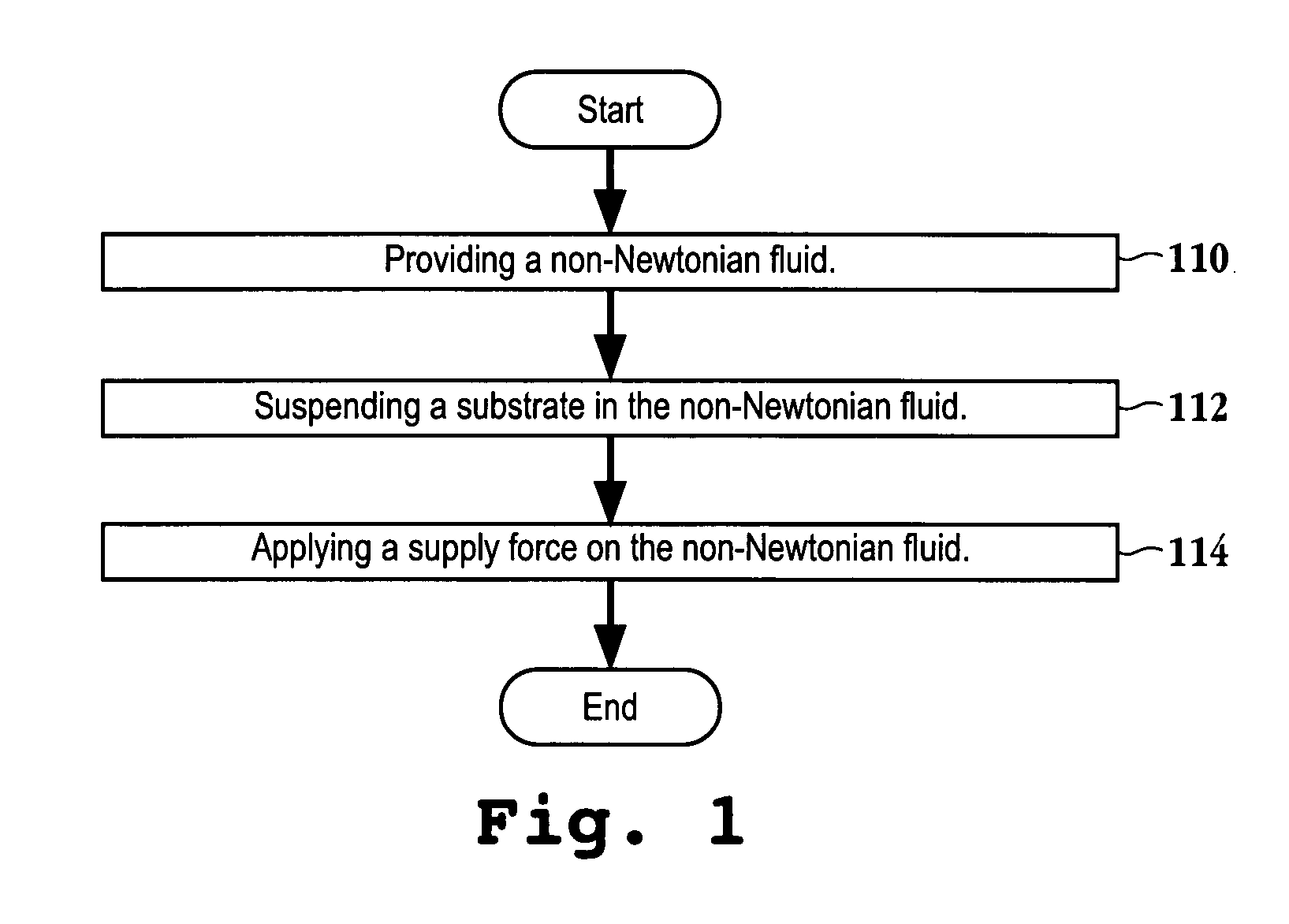

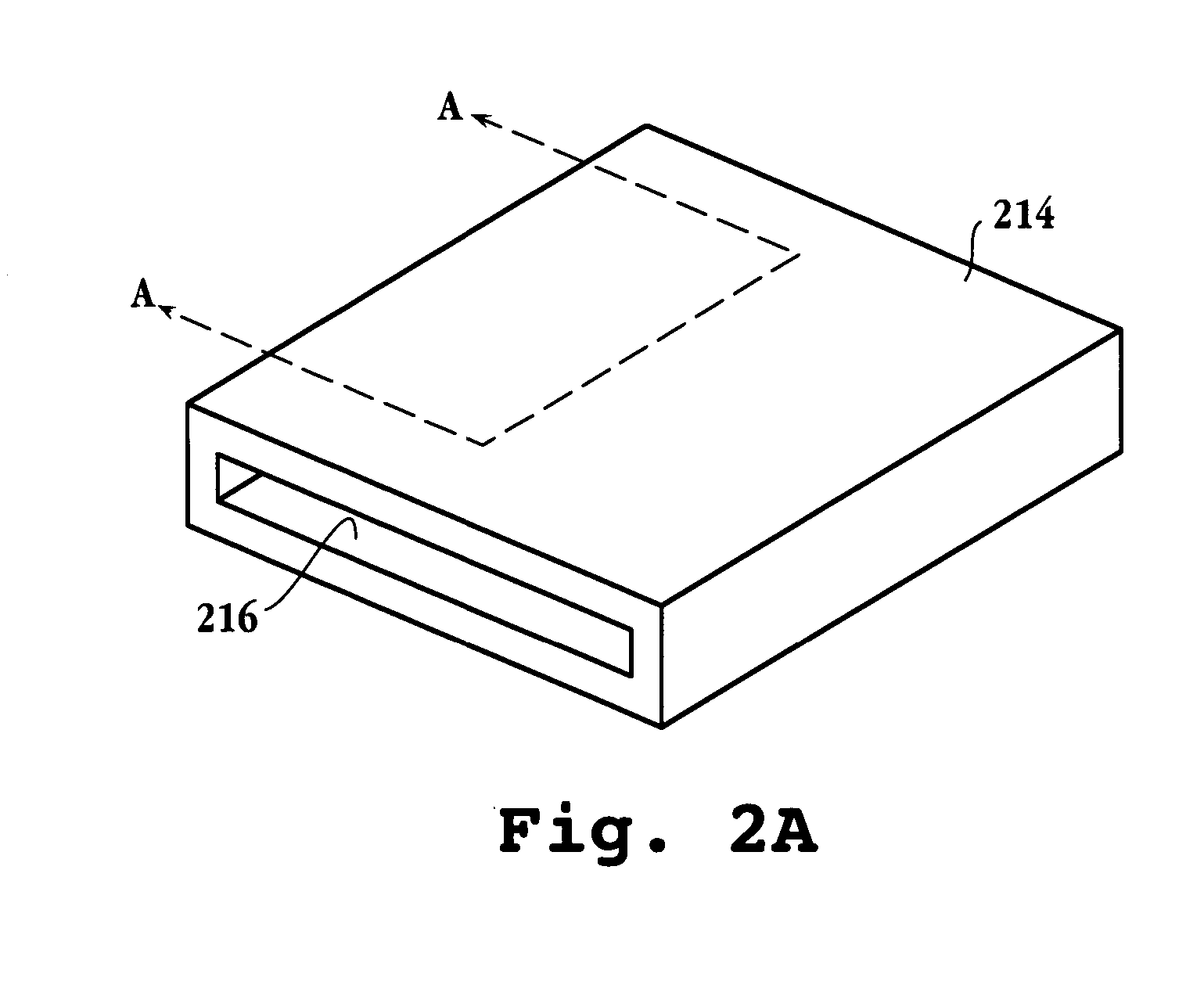

Method and apparatus for transporting a substrate using non-Newtonian fluid

InactiveUS20060285930A1Semiconductor/solid-state device manufacturingNon-mechanical conveyorsEngineeringMechanical engineering

A method for transporting a substrate is provided. In this method, a non-Newtonian fluid is provided and the substrate is suspended in the non-Newtonian fluid. The non-Newtonian fluid is capable of supporting the substrate. Thereafter, a supply force is applied on the non-Newtonian fluid to cause the non-Newtonian fluid to flow, whereby the flow is capable of moving the substrate along a direction of the flow. Apparatuses and systems for transporting the substrate using the non-Newtonian fluid also are described.

Owner:LAM RES CORP

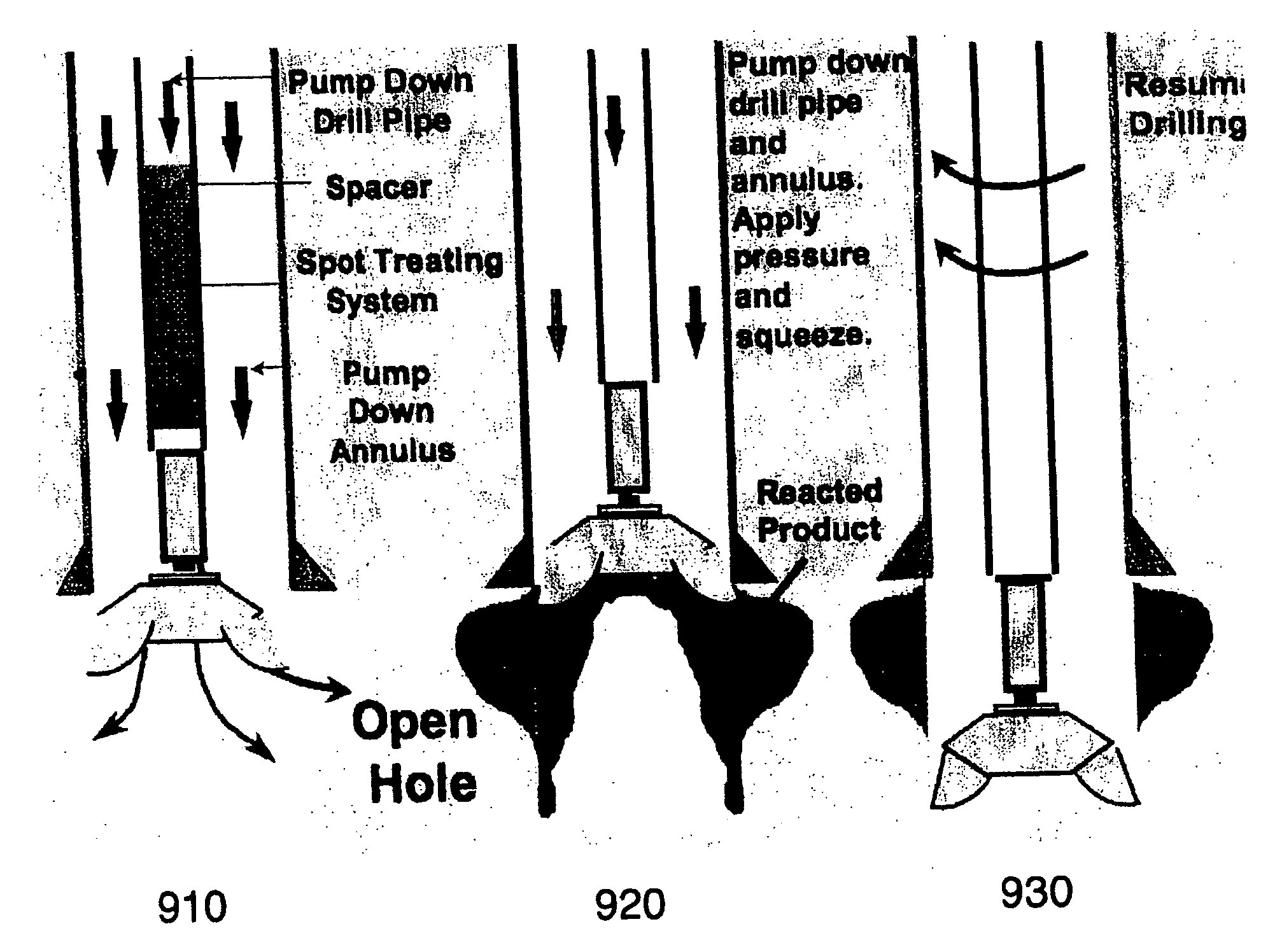

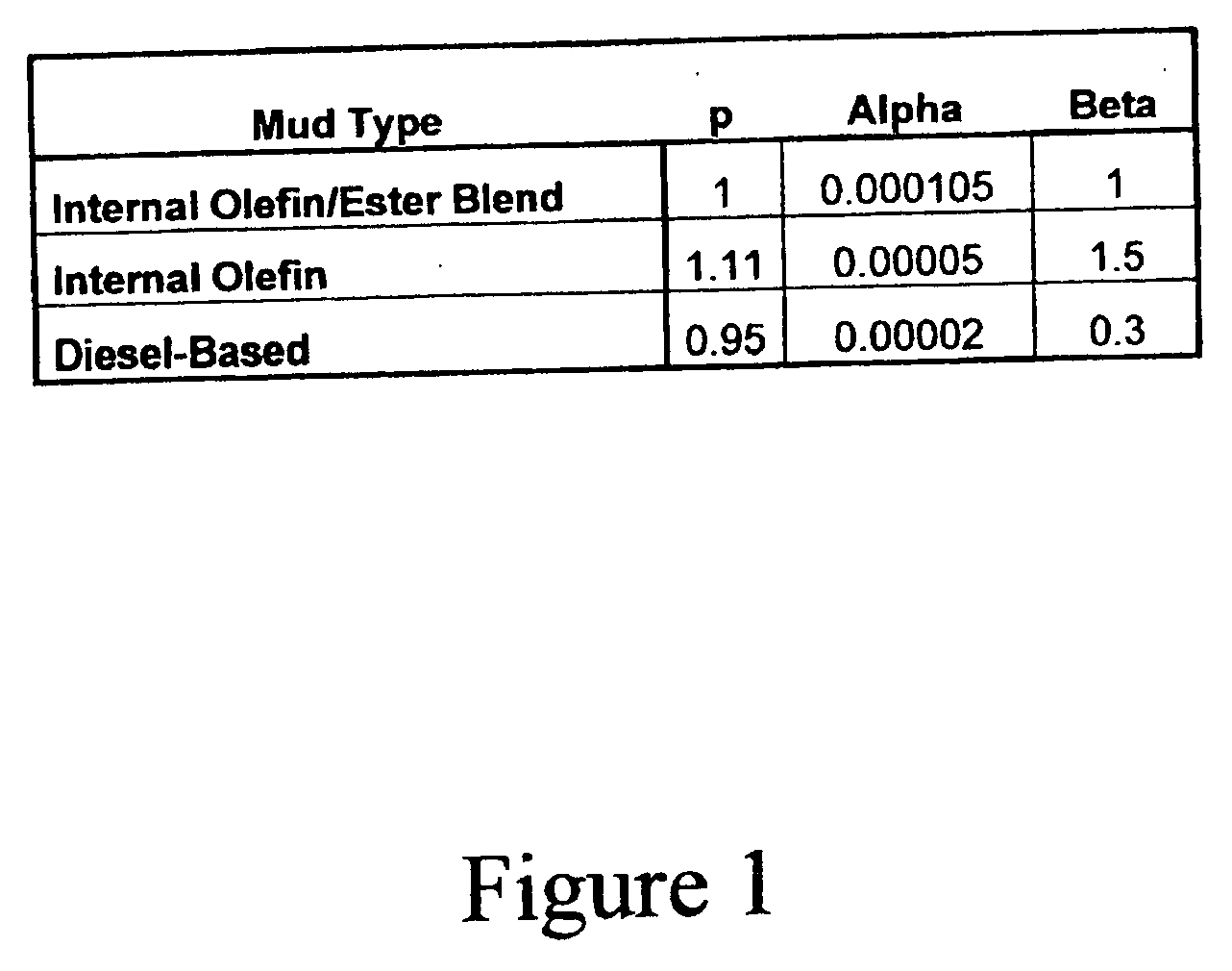

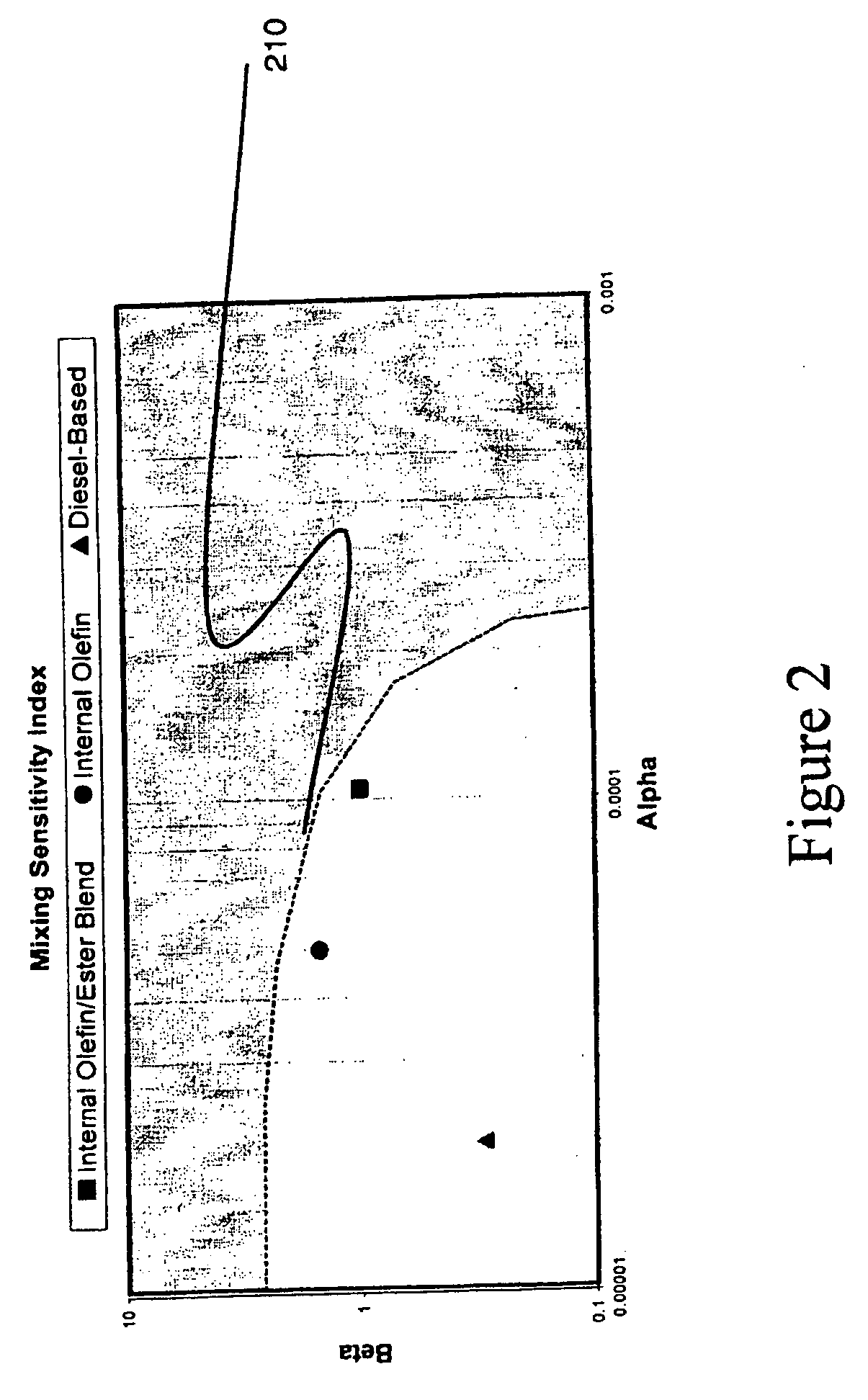

Mixing energy analysis of high-yielding non-newtonian fluids for severe lost circulation prevention

ActiveUS20070007006A1Minimize formation damageAvoid lostElectric/magnetic detection for well-loggingDrilling rodsCompound (substance)Engineering

Owner:HALLIBURTON ENERGY SERVICES INC

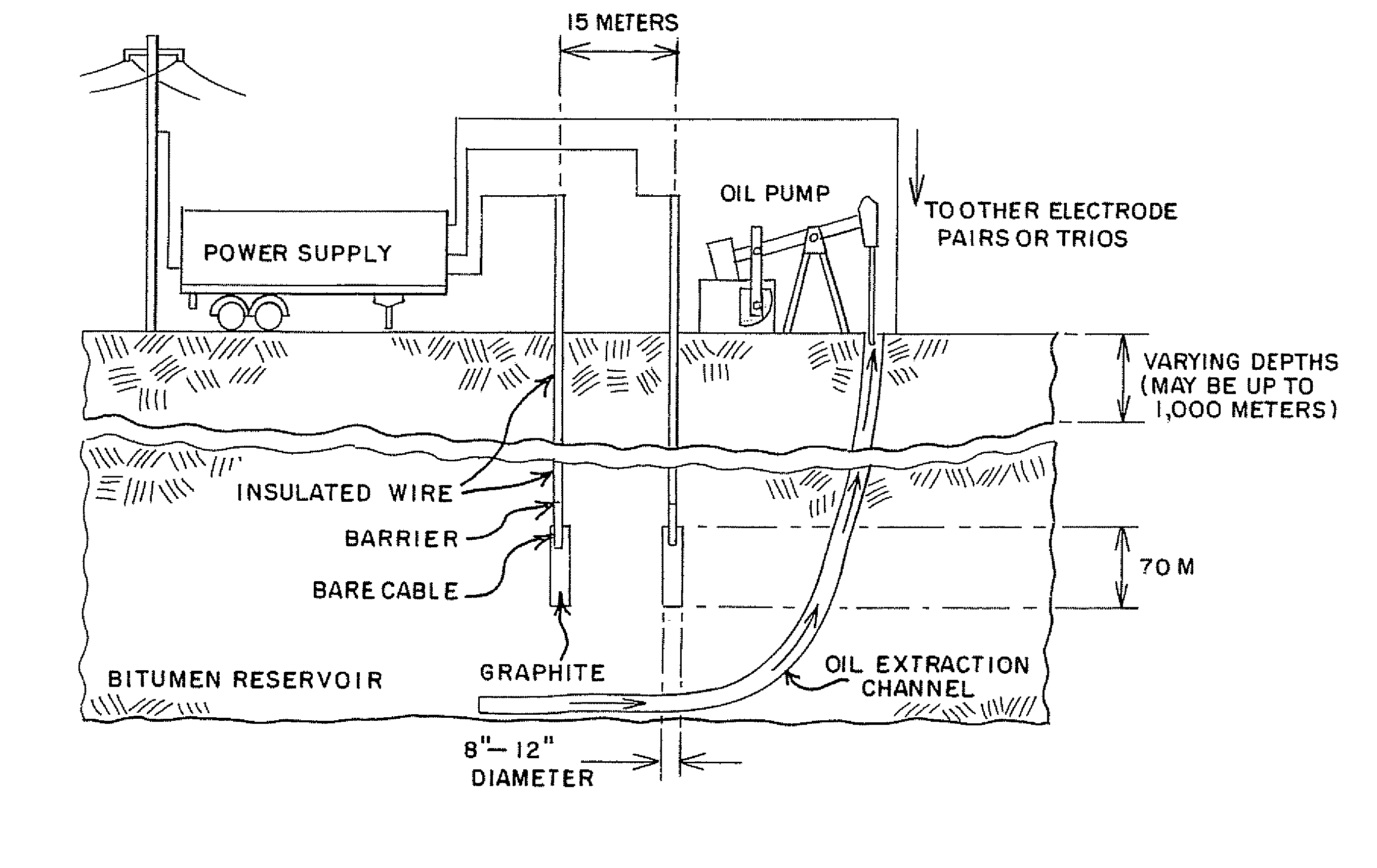

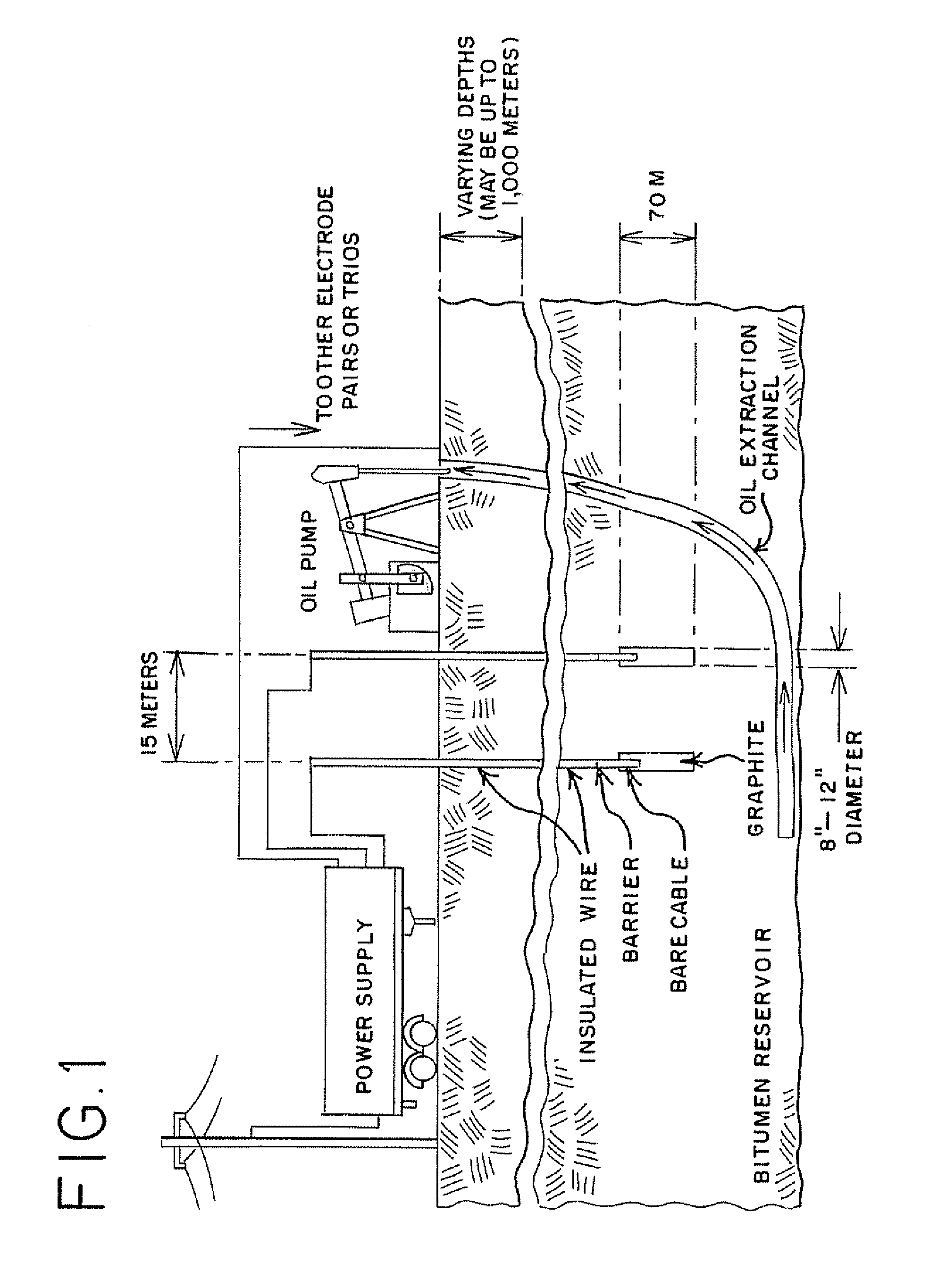

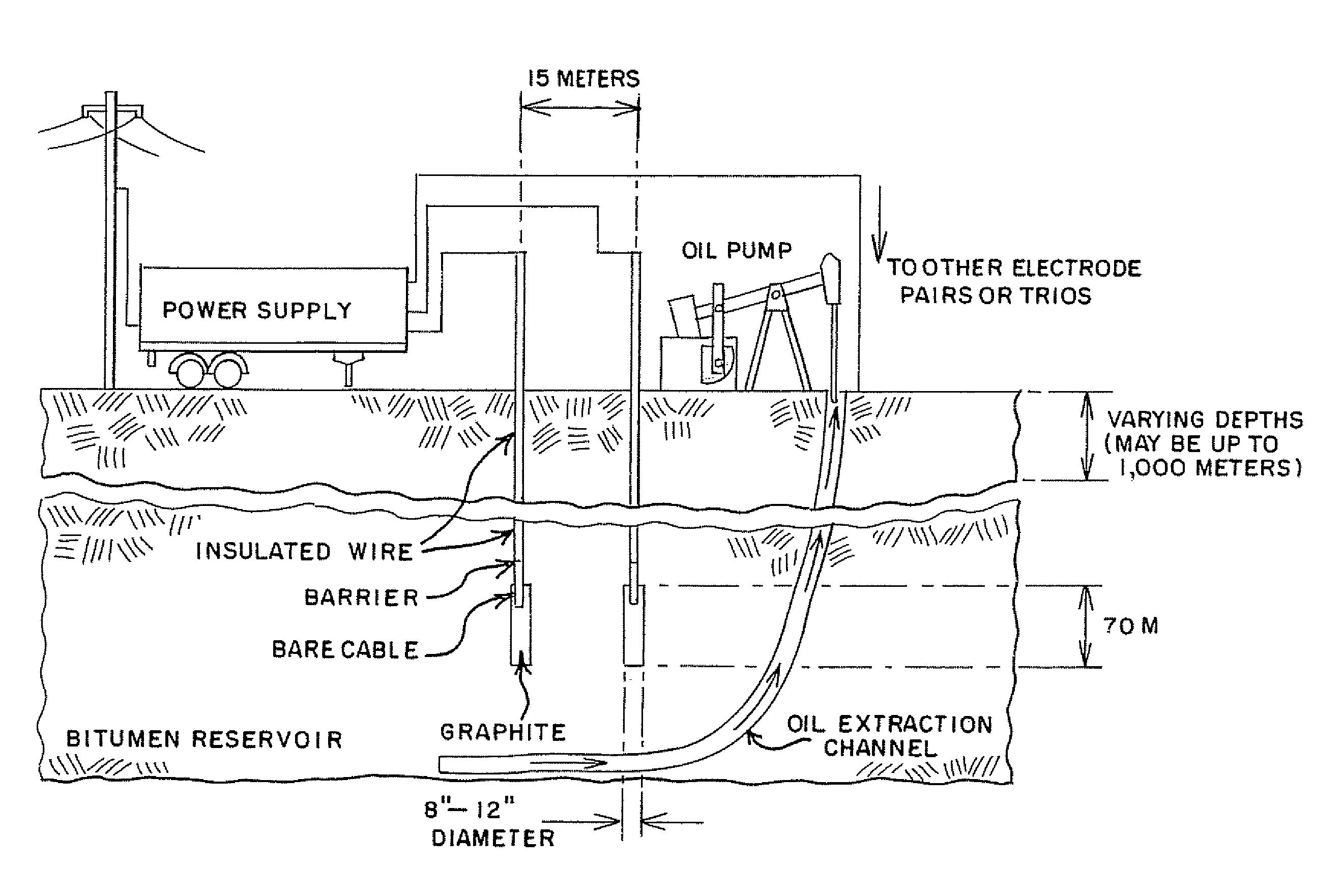

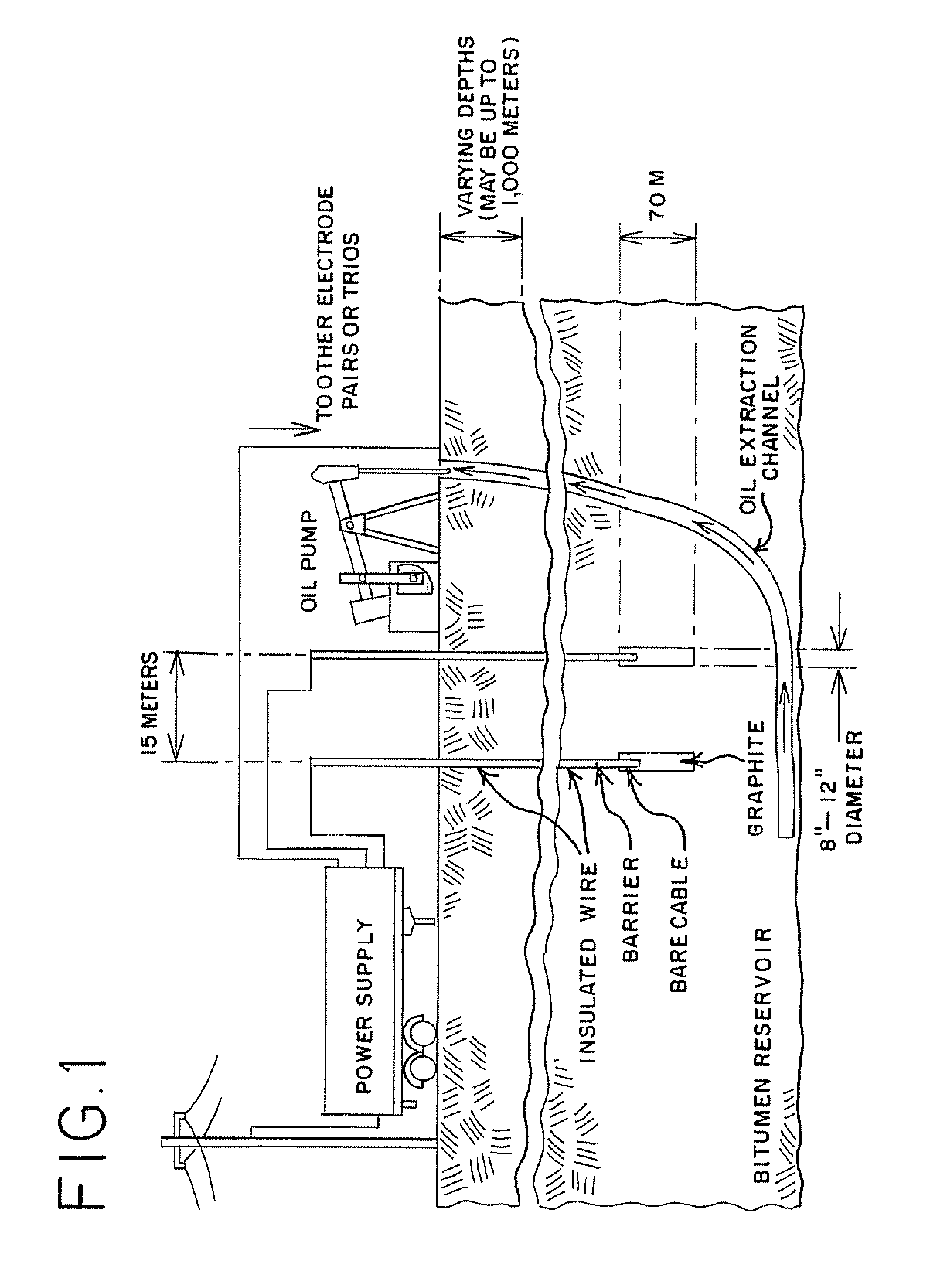

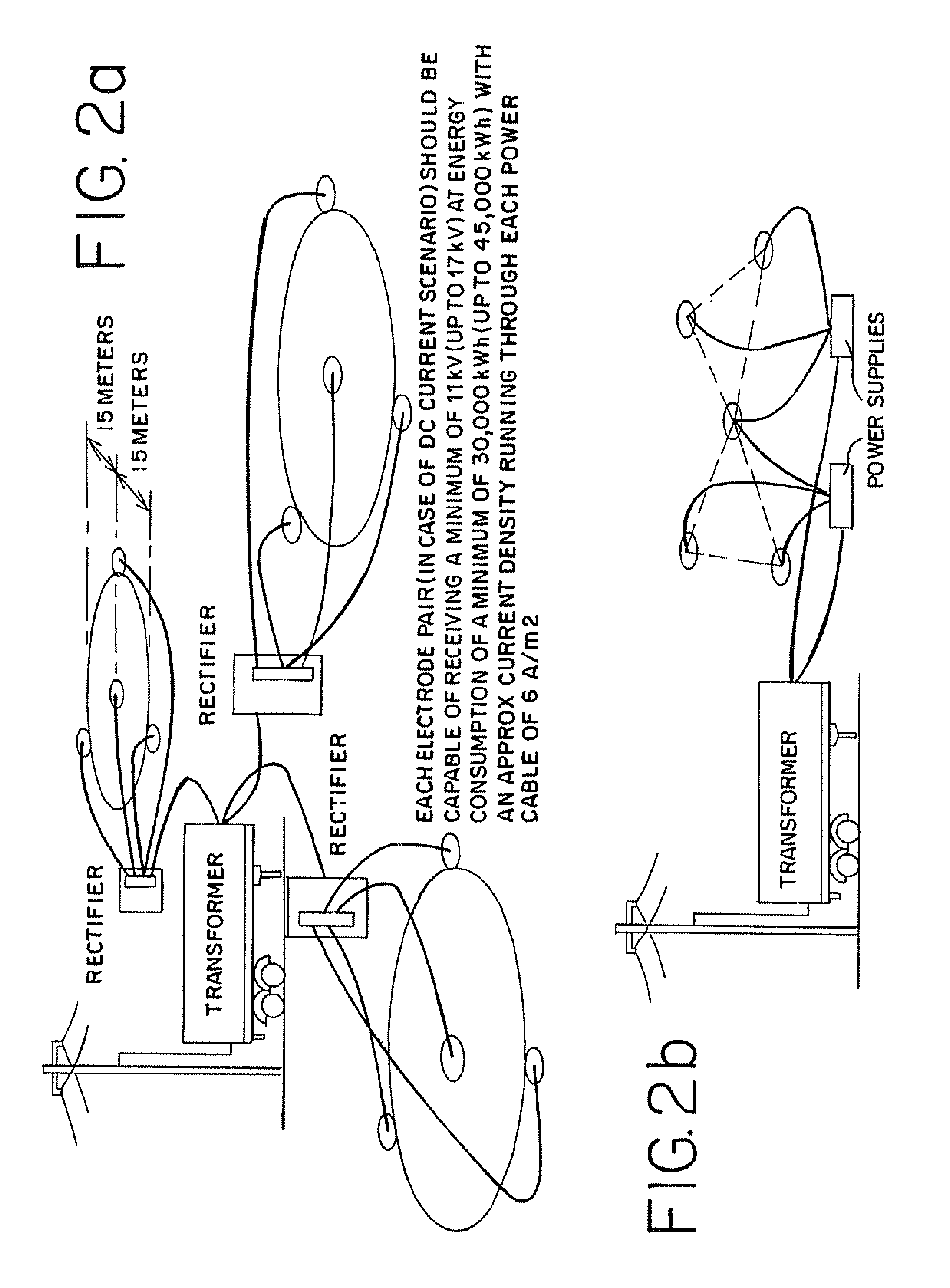

Methods for extracting oil from tar sand

Hydrocarbon containing formations can be processed using an in-situ liquefaction technique. This new technique embodies systematic temperature elevation applied to subsurface formation allowing recoverable hydrocarbons to reach a Newtonian fluid viscosity suitable for extraction.

Owner:SUPERIOR GRAPHITE CORPORATION

Non-newtonian projectile

A projectile is provided comprising a body with a channel that contains a non-Newtonian fluid. In various embodiments a plunger is located in the channel, wherein the plunger transmits a force to the non-Newtonian fluid upon interacting with a target, causing the non-Newtonian fluid to exert a pressure in the channel, and wherein the viscosity of the non-Newtonian fluid changes upon interacting with the target. By way of non-limiting example, the non-Newtonian fluid of embodiments of the present invention can comprise a shear-thickening fluid that increases its viscosity with at least the rate of shear upon interacting with the target.

Owner:JACKSON JASON STEWART

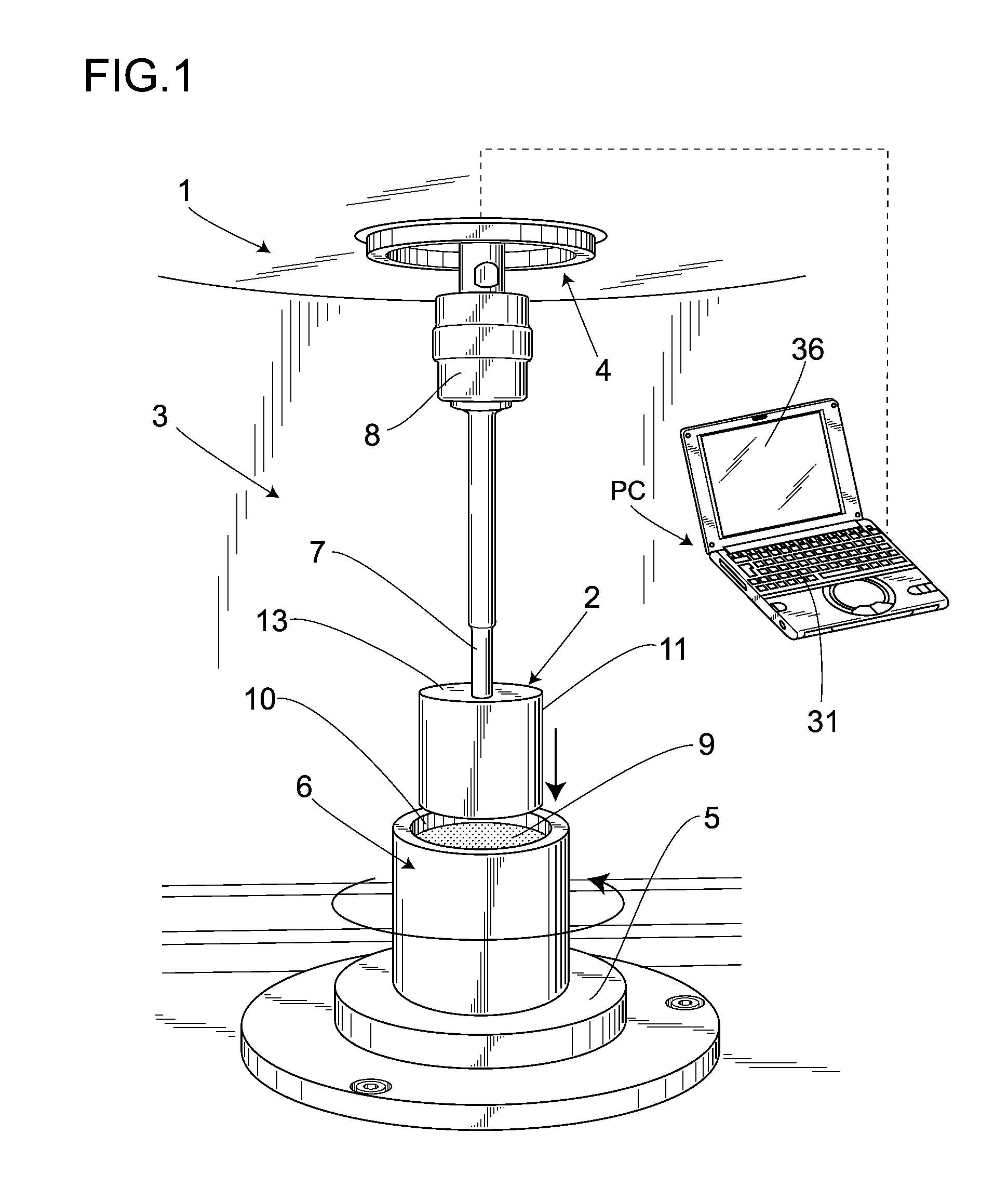

Rheological behavior mensuration instrument for system of supercutical fluid - polymer

A rheological performance analyzer of supercritical fluid-polymer system consists of polymer-supercritical fluid mixing unit and rheological performance analysis unit. It is featured as adding supercritical fluid unit based on thin tube rheological instrument for making it be able to be used to carry out analysis on rheological performance of polymer-supercritical fluid system.

Owner:ZHONGBEI UNIV

Methods for extracting oil from tar sand

Hydrocarbon containing formations can be processed using an in-situ liquefaction technique. This new technique embodies systematic temperature elevation applied to subsurface formation allowing recoverable hydrocarbons to reach a Newtonian fluid viscosity suitable for extraction.

Owner:SUPERIOR GRAPHITE CORPORATION

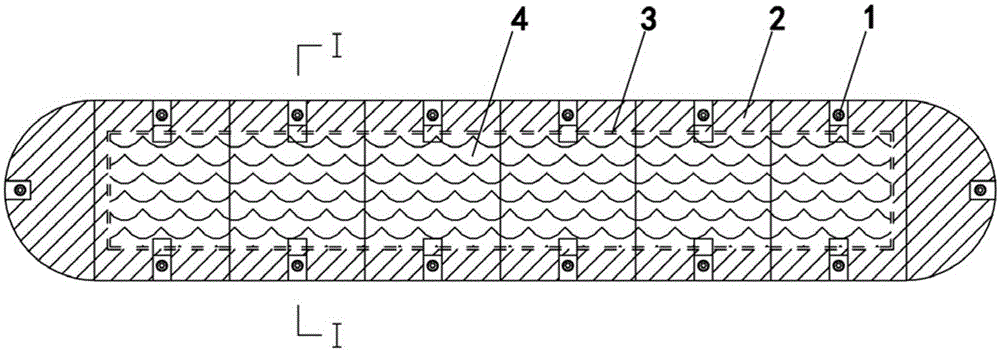

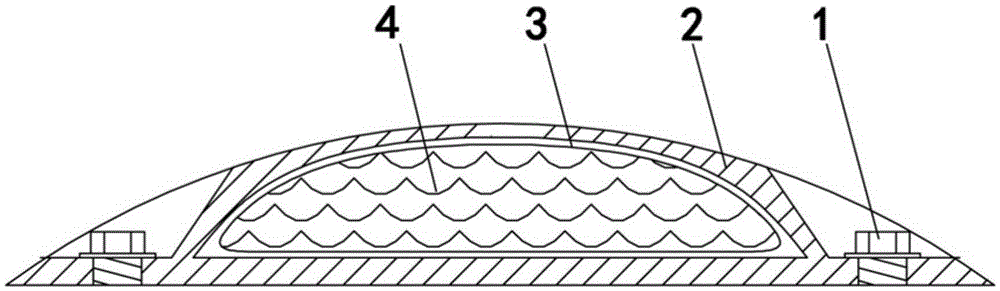

Settleable deceleration strip based on non-Newtonian fluid

InactiveCN105401537APass smoothlyReduce lossTraffic signalsRoad signsStructure of the EarthDual action

The invention relates to the technical field of traffic speed limitation and in particular relates to a settleable deceleration strip based on a non-Newtonian fluid. The settleable deceleration strip based on the non-Newtonian fluid comprises a deceleration strip; a non-Newtonian fluid filler is arranged at an inner layer of the deceleration strip; a soft rubber bag is arranged on an outer layer of the non-Newtonian fluid filler; a hard rubber protective cover is arranged on an outer layer of the soft rubber bag; the hard rubber protective cover is fixed on the floor through a plurality of fixing bolts. The settleable deceleration strip based on the non-Newtonian fluid has dual functions of limiting speeds of vehicles and protecting vehicles; besides, the settleable deceleration strip may settle when vehicles pass through the settleable deceleration strip at low speeds, such that the vehicles can smoothly pass through the settleable deceleration strip; as a result, the comfort of driving is enhanced and the wear of vehicles is reduced; besides, the settleable deceleration strip is simple in structure, ingenious in design and high in practicability.

Owner:WUHAN UNIV OF TECH

Energy efficiency improvements for turbomachinery

InactiveCN105307931ALower absolute dragReduce resistanceContinuous combustion chamberInfluencers by generating vorticesProcess engineeringEnergy analysis

A method and apparatus are disclosed that allow Conformal Vortex Generator art to improve energy efficiency and control capabilities at many points in a turbomachine or device processing aero / hydrodynamic Newtonian fluid-flows.

Owner:彼得·艾瑞兰德 +1

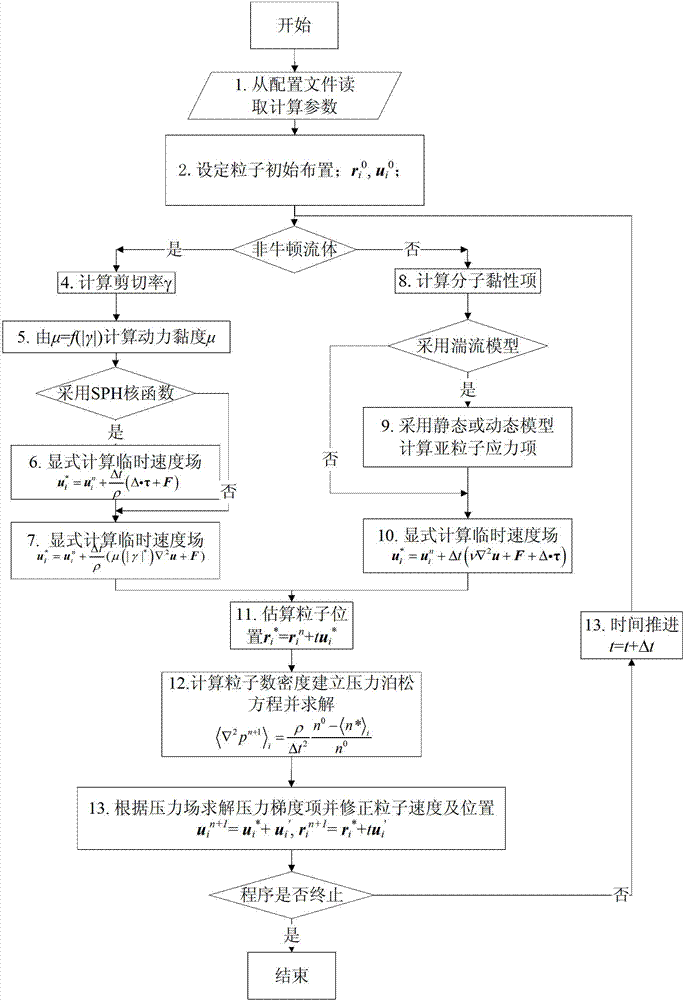

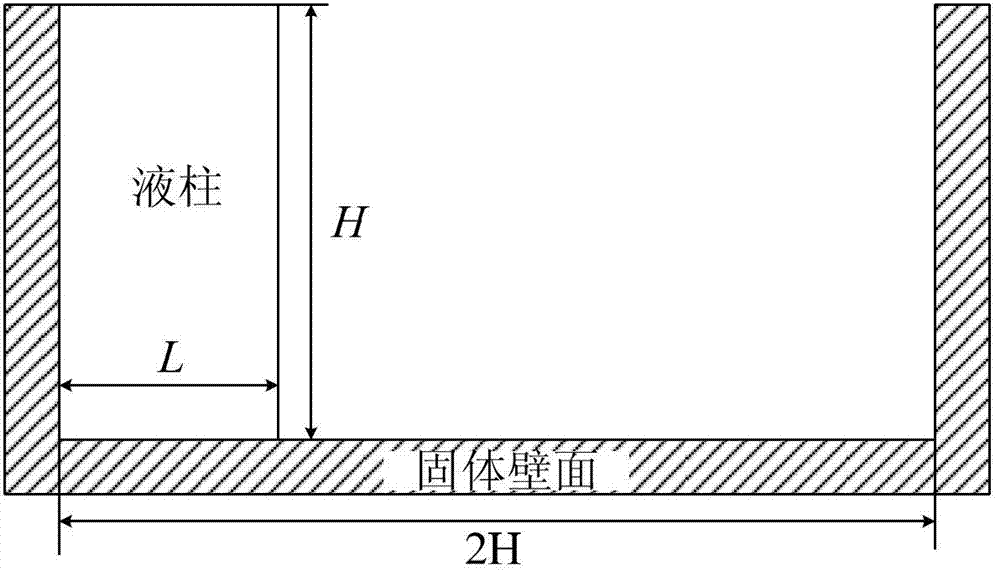

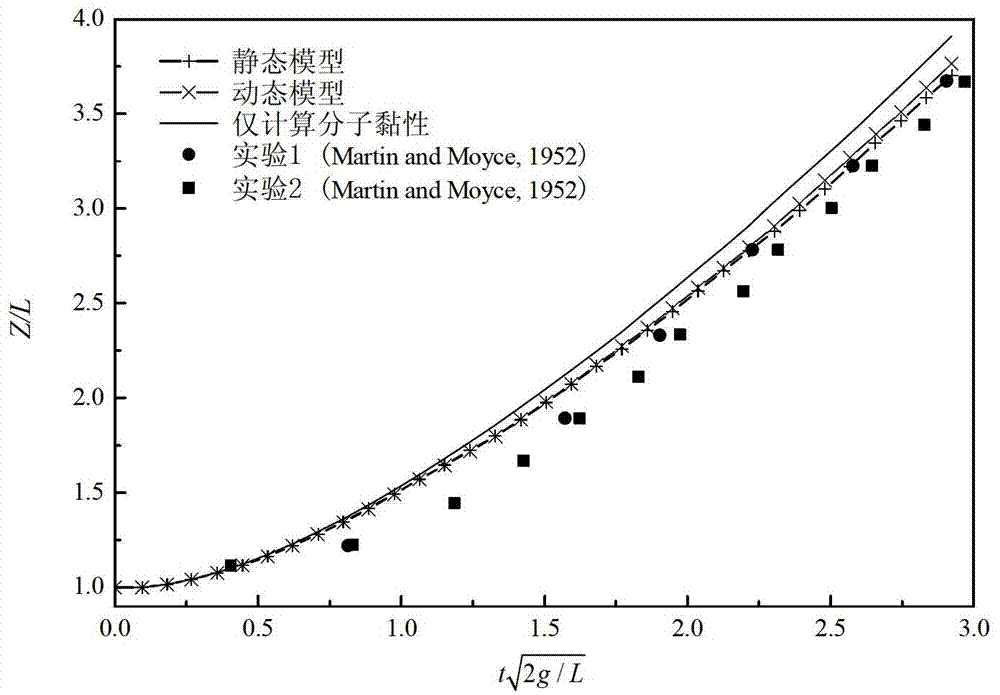

Establishment method for free surface flow model in moving particle semi-implicit algorithm

The invention provides an establishment method for a free surface flow model in a moving particle semi-implicit algorithm, comprising the following steps of: introducing a turbulence model which comprises a static Smagorinsky model and a dynamic Smagorinsky model in the form of Lagrange; treating a non-Newtonian fluid having a constitutive equation like mu = f(the absolute value ofgamma) by adopting a variable-viscosity Newtonian fluid model; and introducing a cubic spline kernel function, discretizing the shear stress of the non-Newtonian fluid by adopting the divergence discretization scheme of a smooth particle fluid dynamic method, and treating the free surface flow of the non-Newtonian fluid. According to the method provided by the invention, the sub-particle stress model of turbulence can be considered, and the method provided by the invention can be used for calculation for the non-Newtonian fluid.

Owner:江苏金洋造船有限公司

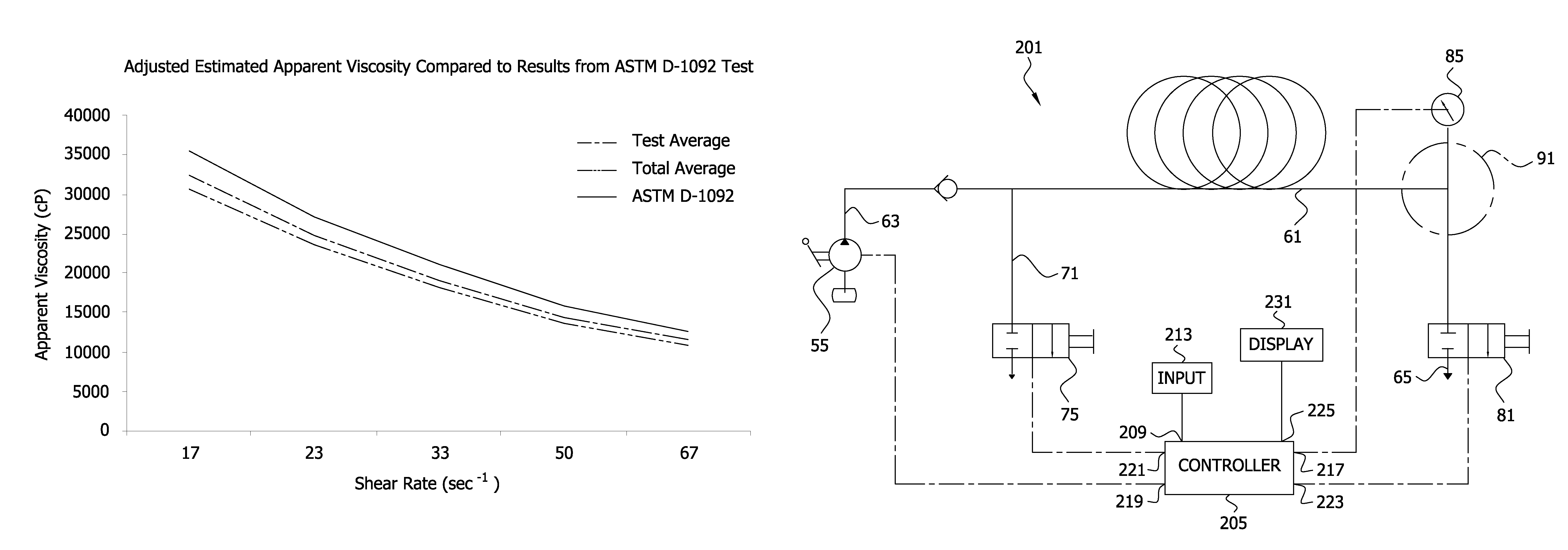

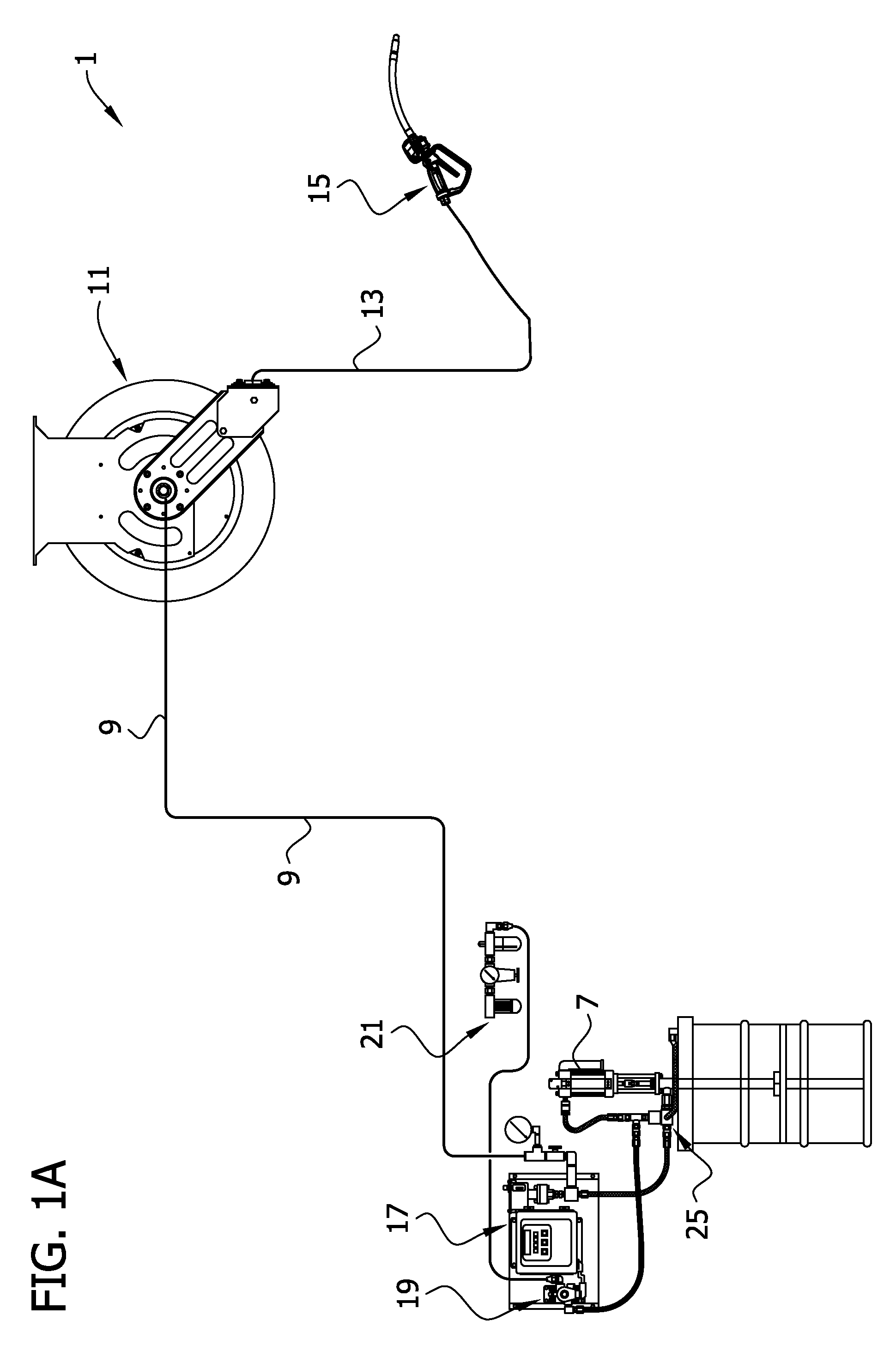

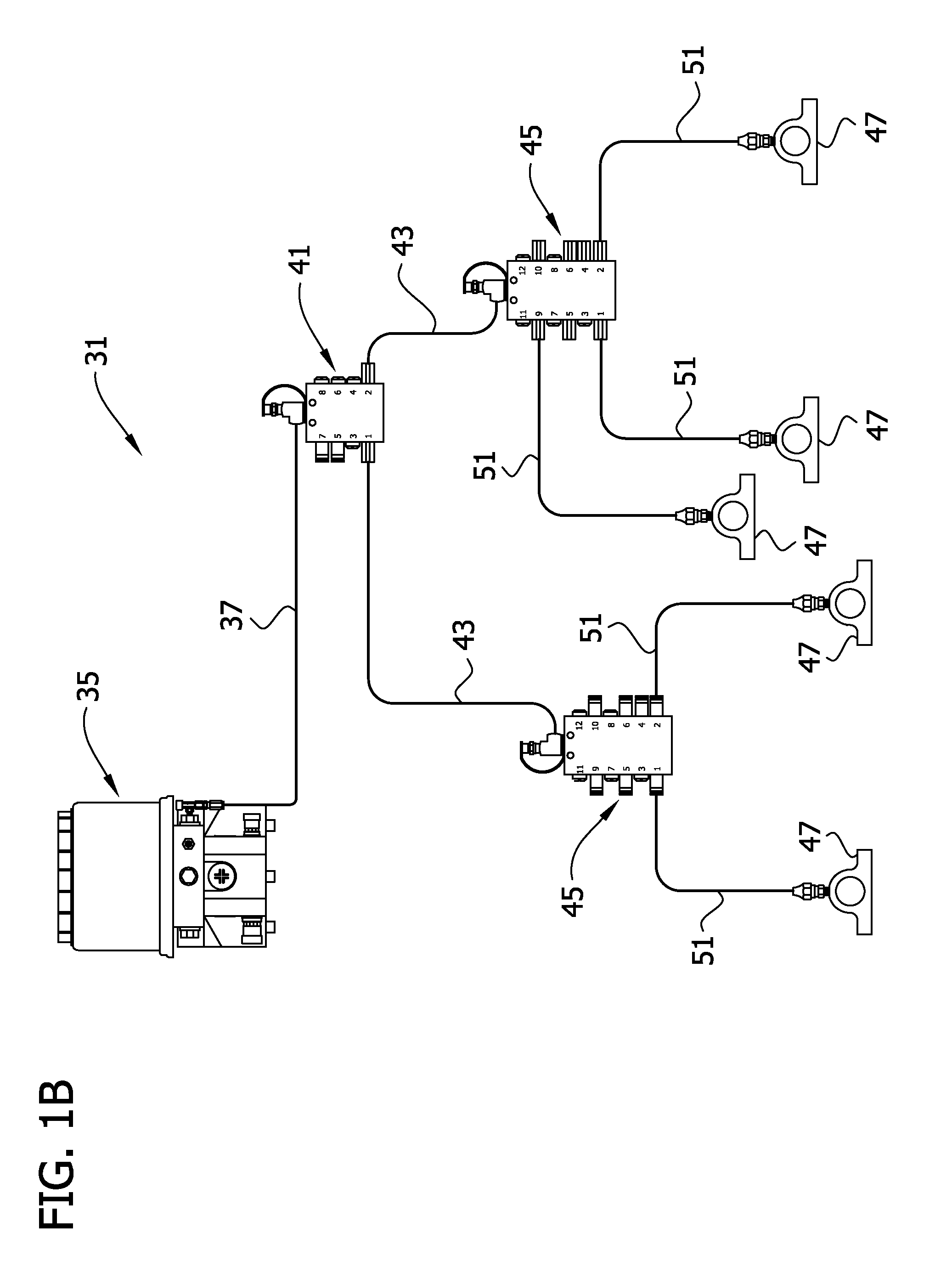

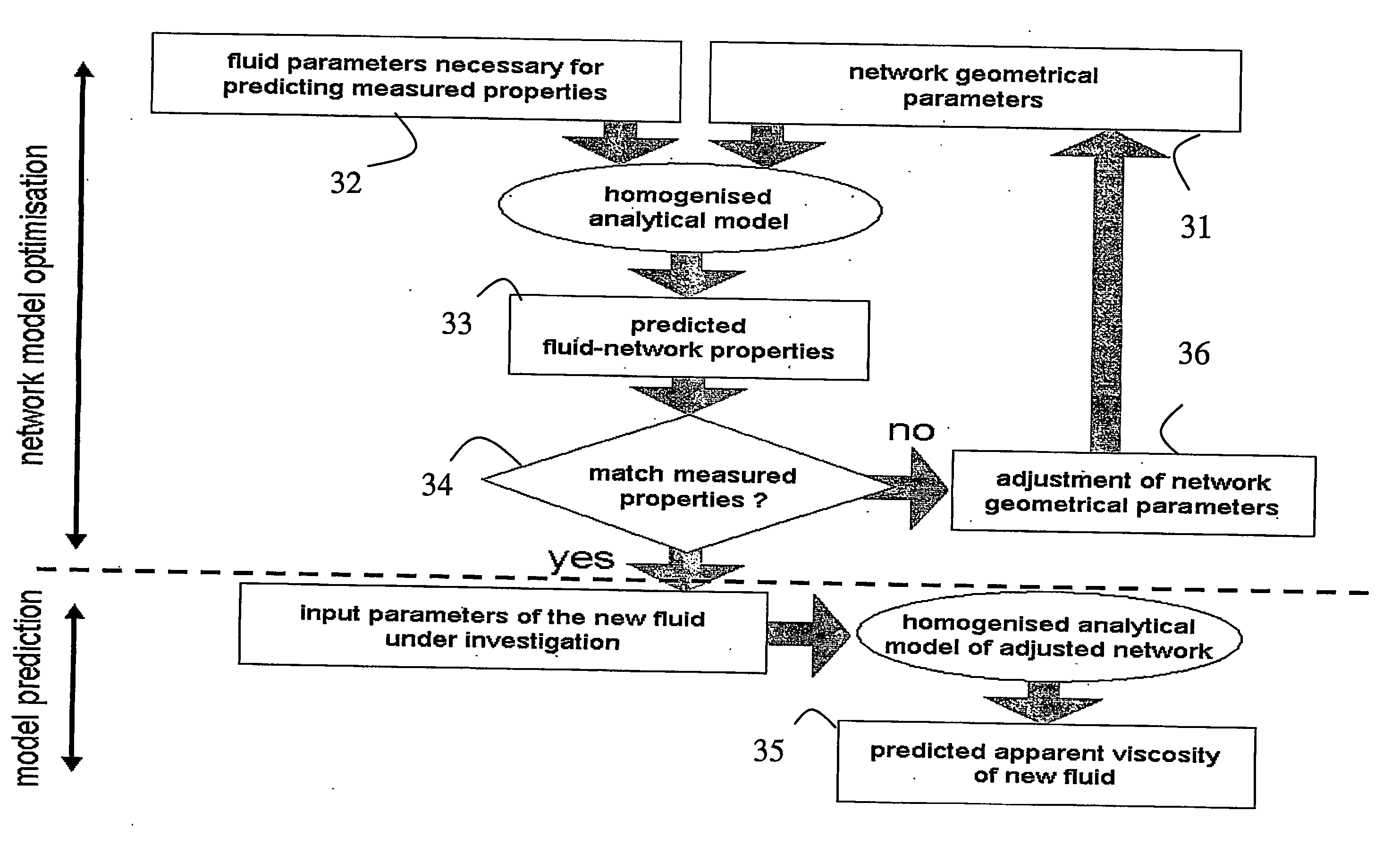

System and method for estimating apparent viscosity of a non-newtonian fluid

ActiveUS7980118B2Material analysis by optical meansFlow properties on non-Newtonian fluidsApparent viscosityNon-Newtonian fluid

Method and apparatus for estimating an apparent viscosity of a non-Newtonian fluid. The results may be used for selecting equipment for pumping systems.

Owner:LINCOLN INDUSTRIES CORP

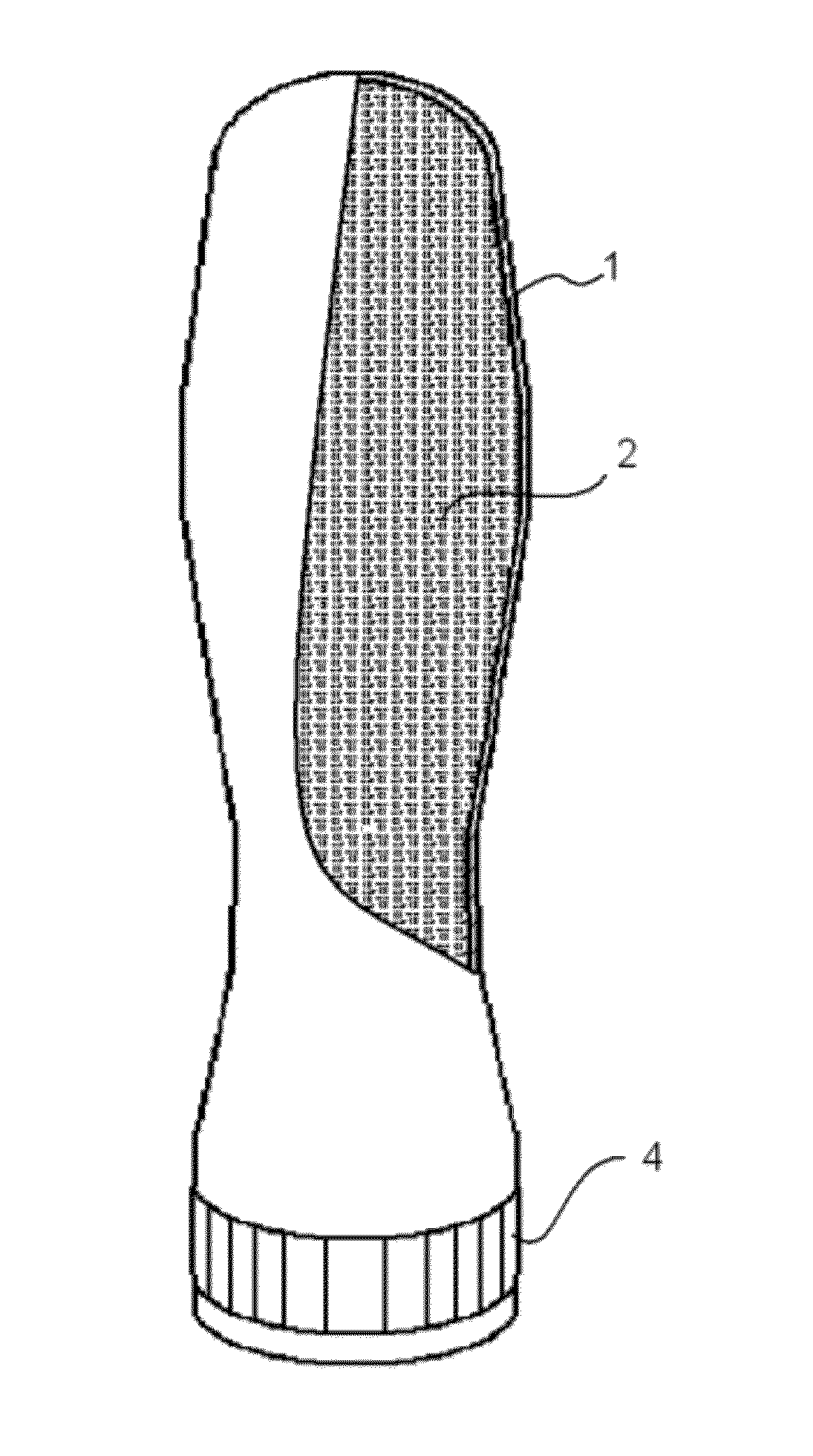

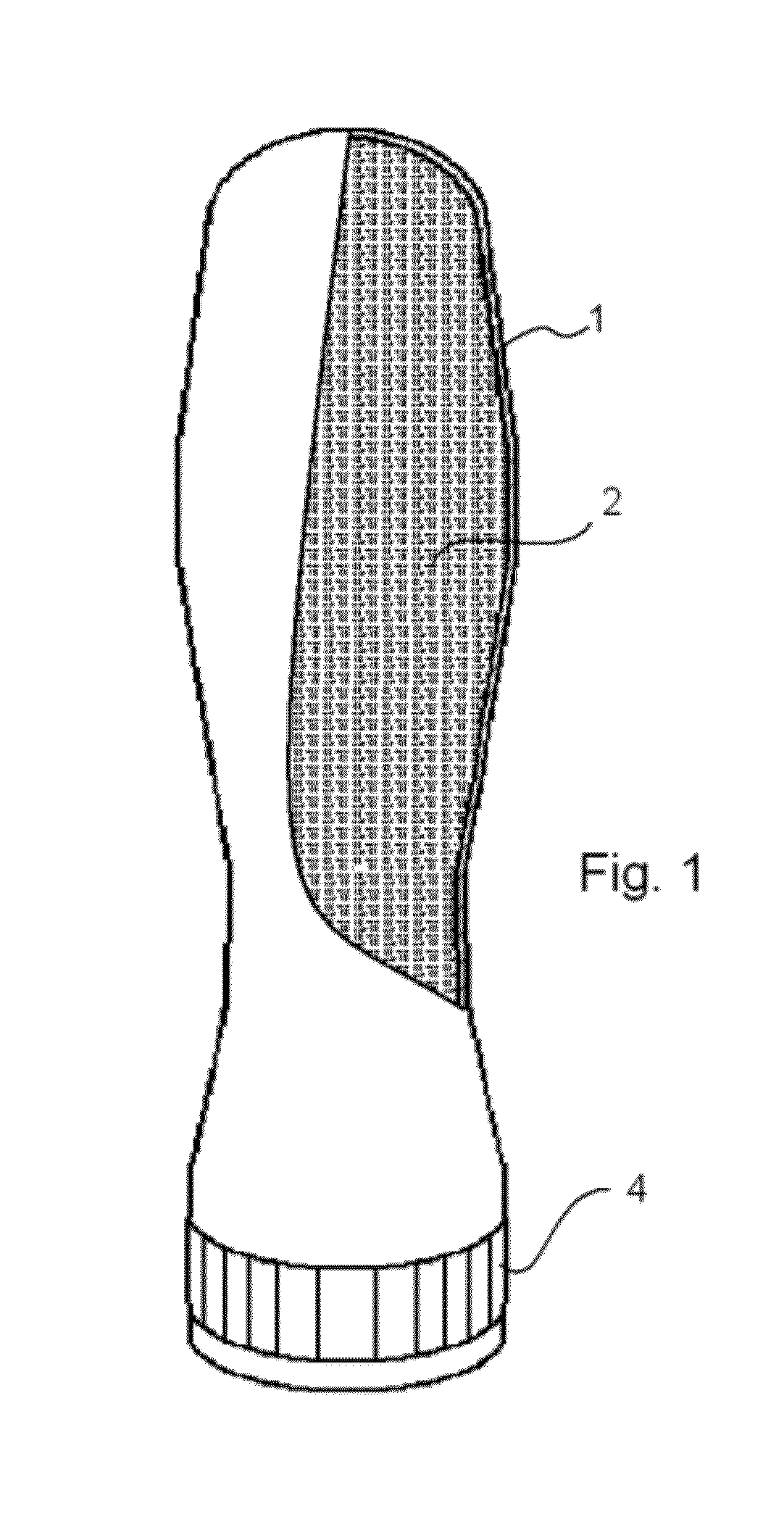

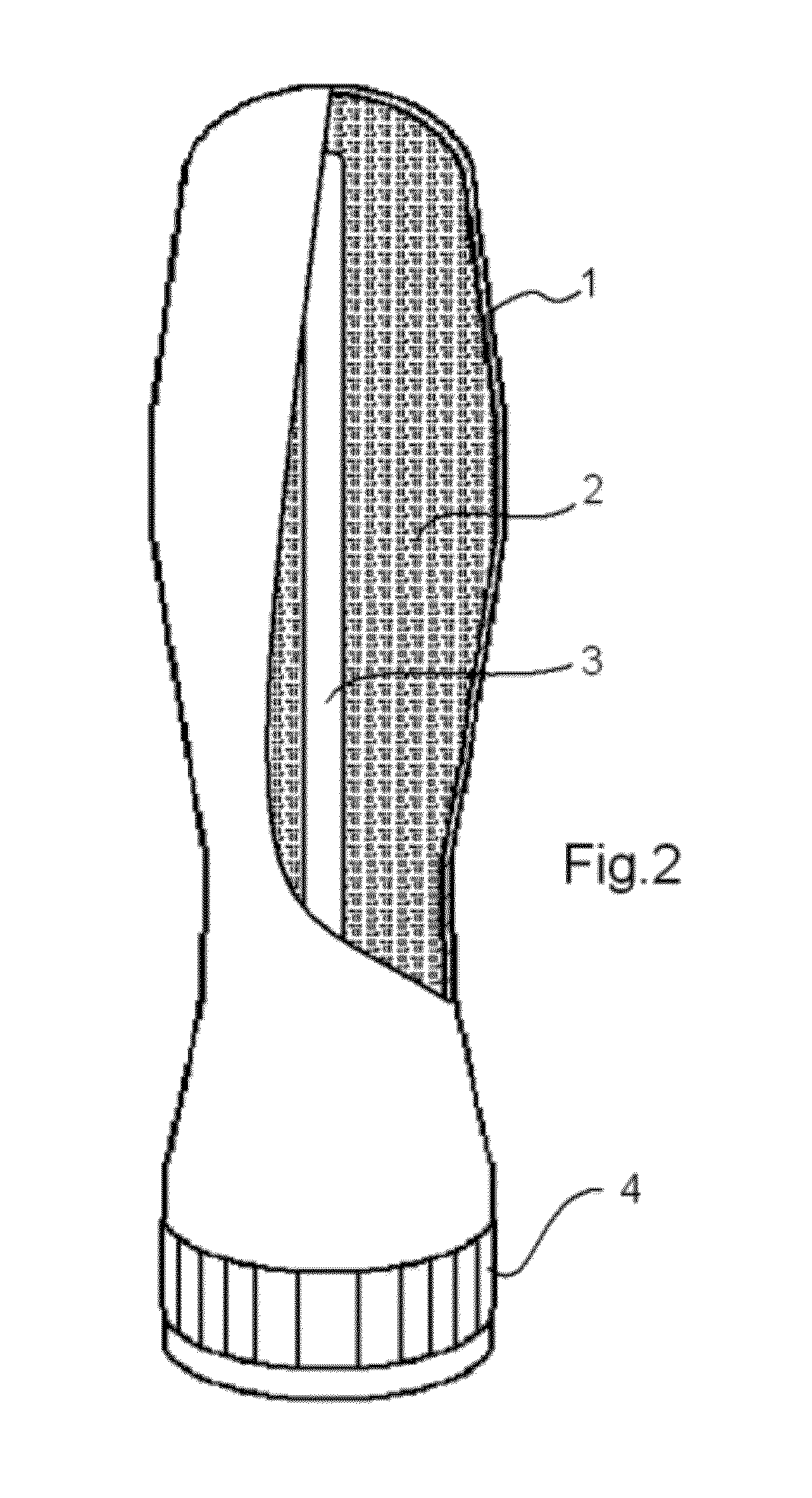

Dildo for sexual stimulation

The object of the invention relates to a dildo for sexual stimulation, comprising a tubular body (1) with a hollow structure made of a smooth material, such as silicone or rubber, having a shape and size similar to a penis, filled with a non-Newtonian fluid (2), the viscosity of which increases as the tension gradient applied thereto increases.

Owner:INNOVACIONES SOSTENIBLES DEL SUR S L U

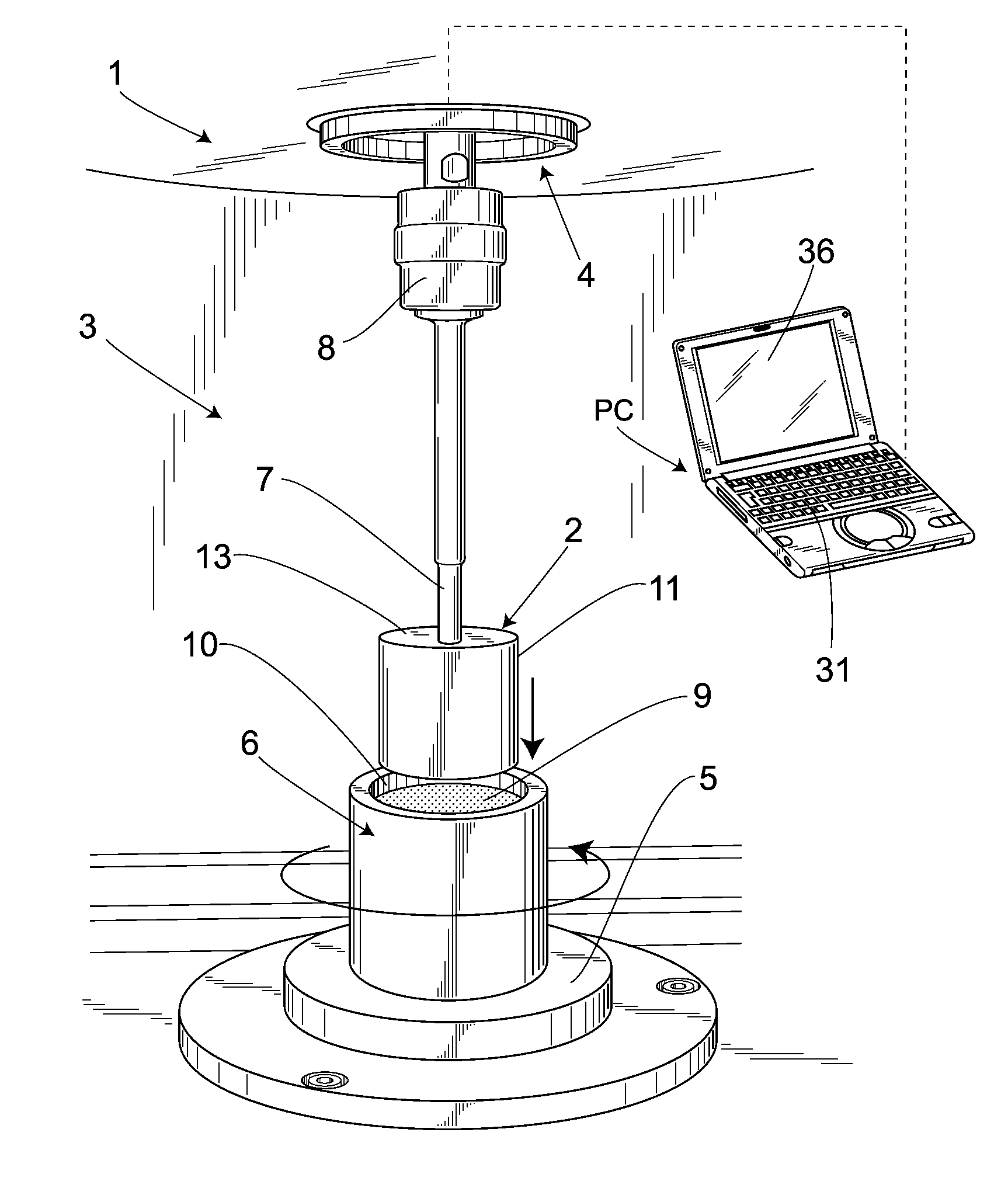

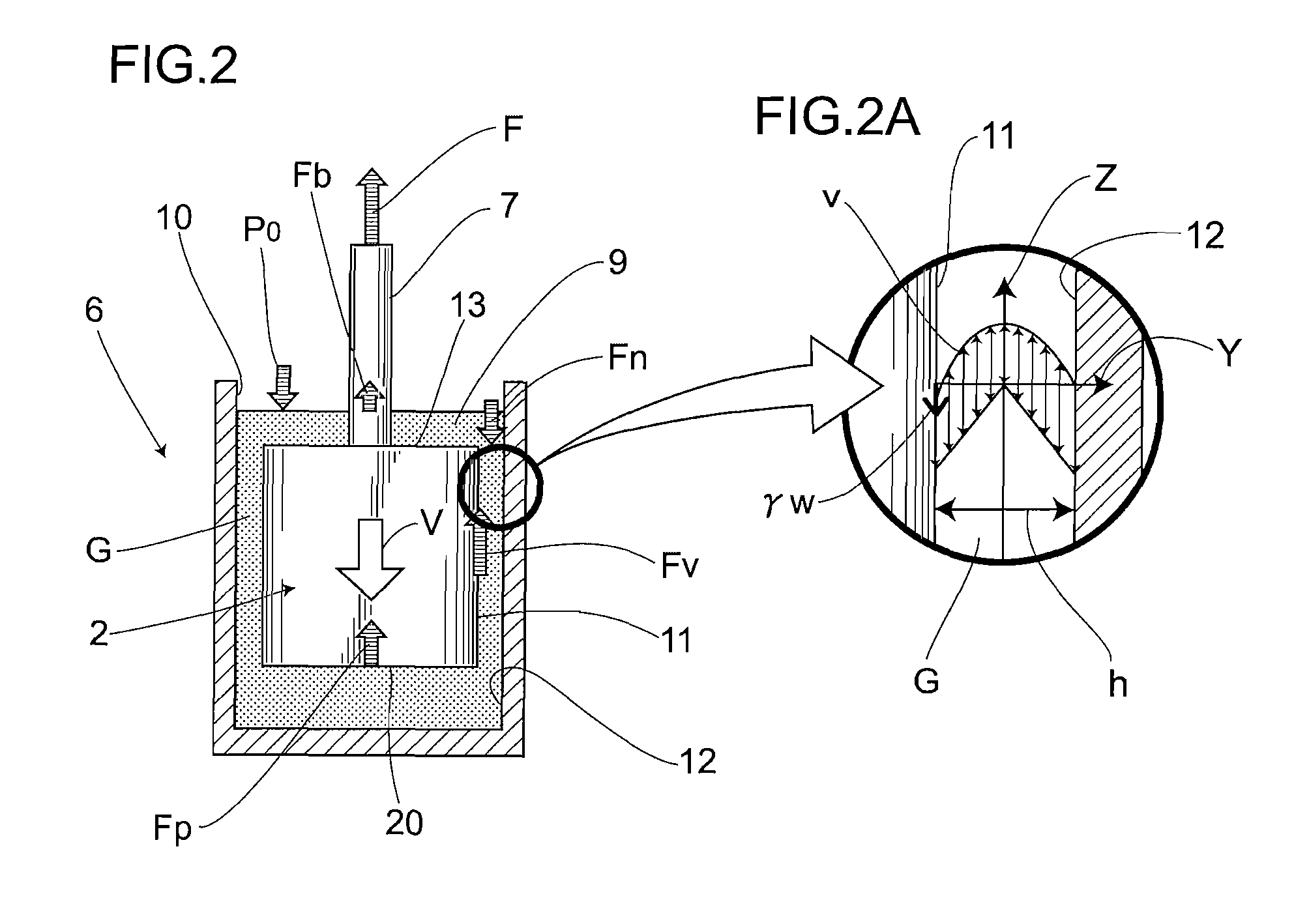

Fluid analysis method and fluid analysis device

InactiveUS20100274504A1Easy to analyzeFluid pressure measurement by mechanical elementsMachines/enginesEngineeringAnalysis method

There is provided a fluid analysis method and its device which are capable of easily analyzing a normal stress difference of a low-viscosity fluid in addition to that of a high-viscosity fluid. A shearing fluidity is applied to a non-Newtonian fluid within a lateral-side gap by pushing a cylindrical bob into a container. At that time, reactive force applied to the cylindrical bob is measured. Then, by practicing an arithmetic process in a given form using the reactive force and each of conditions input by a user, the normal stress difference of the low-viscosity non-Newtonian fluid which is hard to form in a solid state can be certainly determined. Thus, with respect to the low-viscosity non-Newtonian fluid in addition to the high-viscosity non-Newtonian fluid, the normal stress difference can be easily analyzed.

Owner:NAT UNIV CORP NAGAOKA UNIV TECH

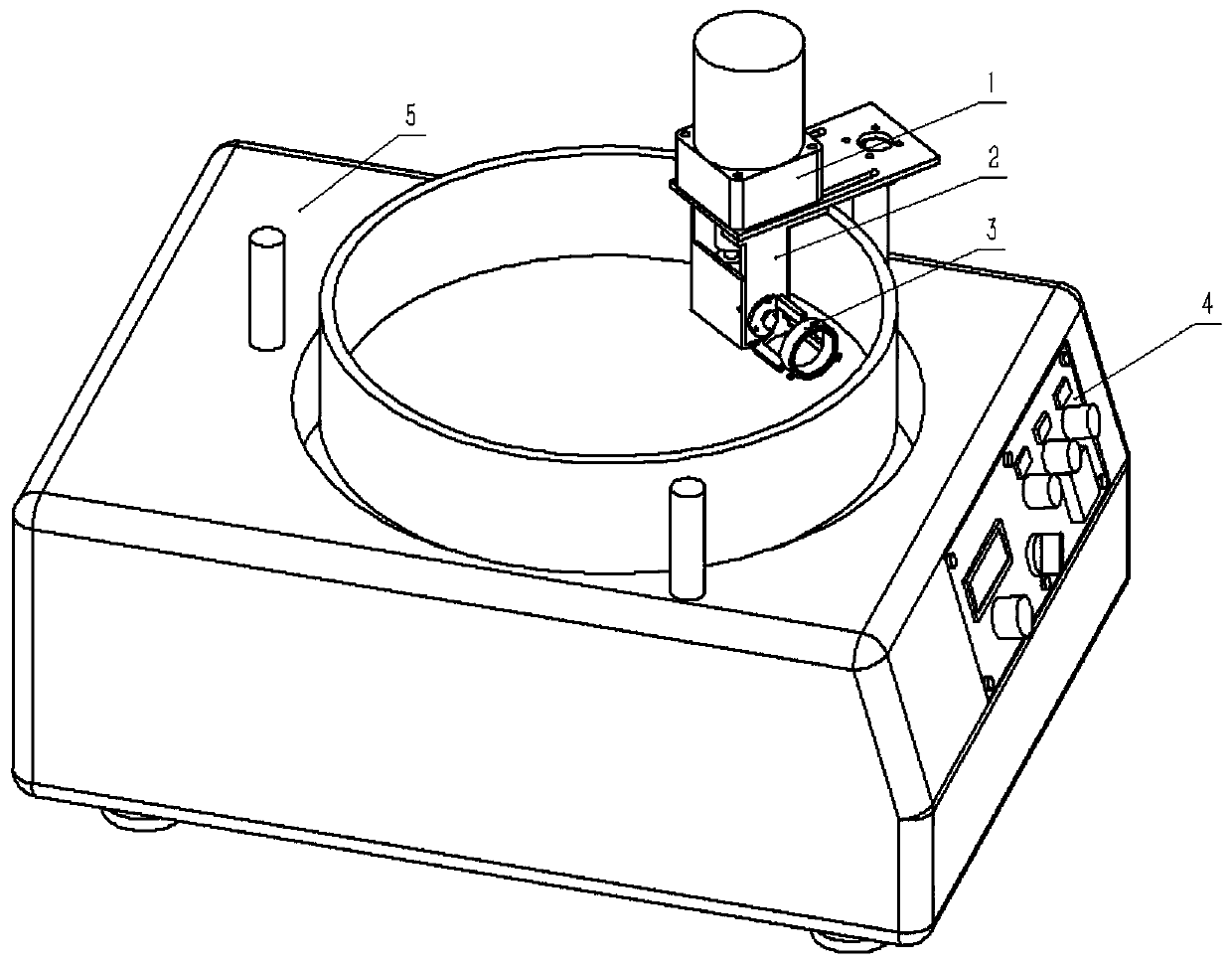

Ultra-precision flexible chemical mechanical polishing device and method for micro bearing core element

ActiveCN111216031AUltra-Precise Damage MachiningImprove surface qualityEdge grinding machinesPolishing machinesPolishingEngineering

The invention discloses an ultra-precision flexible chemical mechanical polishing device and method for a micro bearing core element. The core element comprises an inner ferrule, a retainer, a rollingbody and an outer ferrule. The polishing device comprises an element rotation module, an outer ferrule steering module, an element clamping module, a polishing liquid pool rotation module and a support. The element clamping module provides an inner ferrule clamp, a retainer clamp, a rolling body clamp and an outer ferrule clamp in a targeted manner. The polishing method comprises the steps of installing and debugging the polishing device, preparing flexible chemical mechanical polishing liquid, setting polishing process parameters, measuring the surface quality and conducting feedback. The flexible chemical mechanical polishing liquid comprises non-Newtonian fluid, 0.01-40 wt% of grinding particles, 0-10 wt% of an oxidizing agent, 0-10 wt% of a metal complexing agent, 0-5 wt% of a metal corrosion inhibitor and the balance water, and the pH value is 2.0 to 10.0. According to the ultra-precision flexible chemical mechanical polishing device and method, by optimizing the synergistic effect of the chemical reaction and the mechanical force of the force rheological effect, ultra-precision low-damage machining and complex curved surface shape-preserving machining of the surface of the core element can be achieved, and the device and method are green and environment-friendly.

Owner:SOUTHWEST JIAOTONG UNIV +1

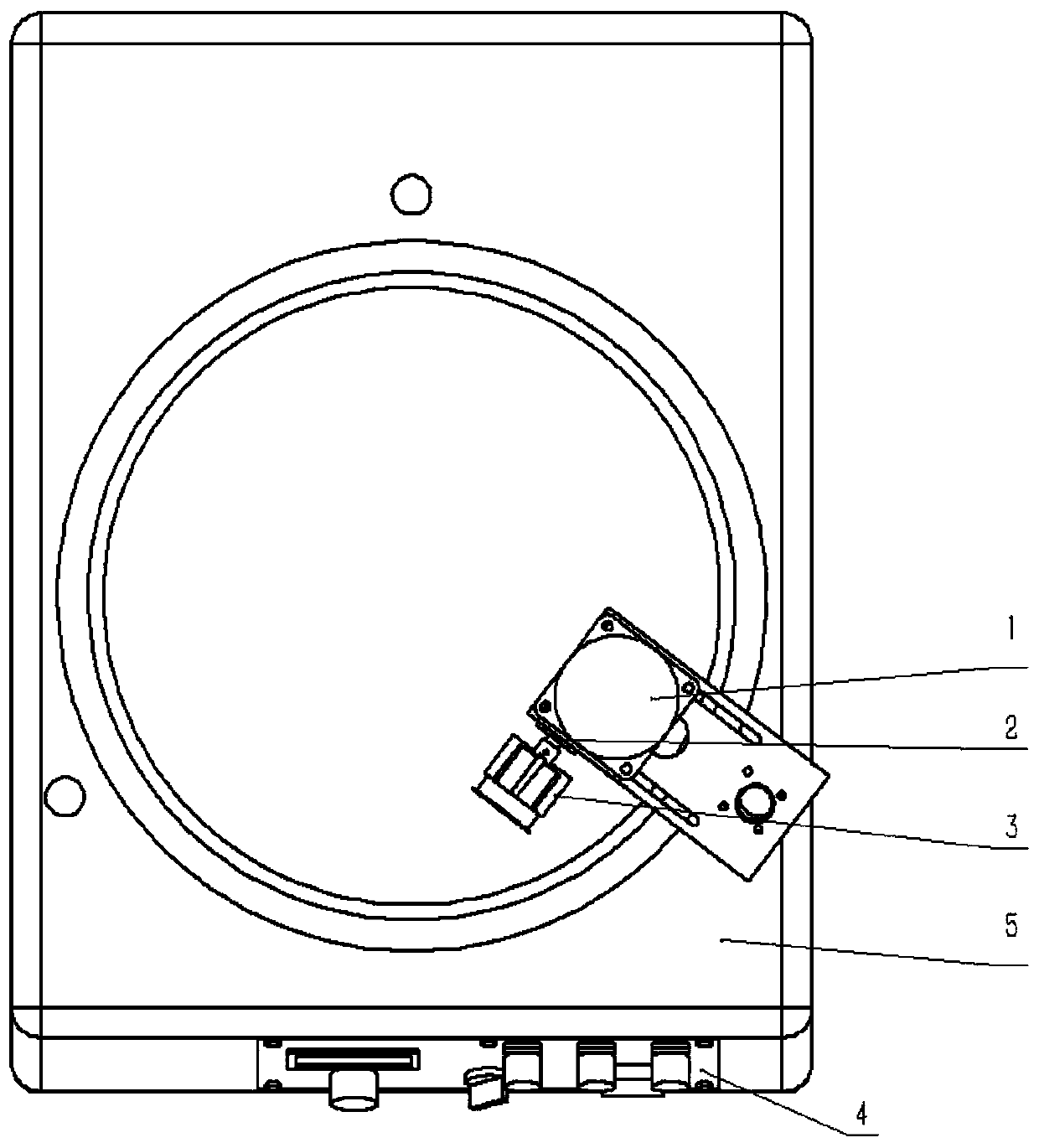

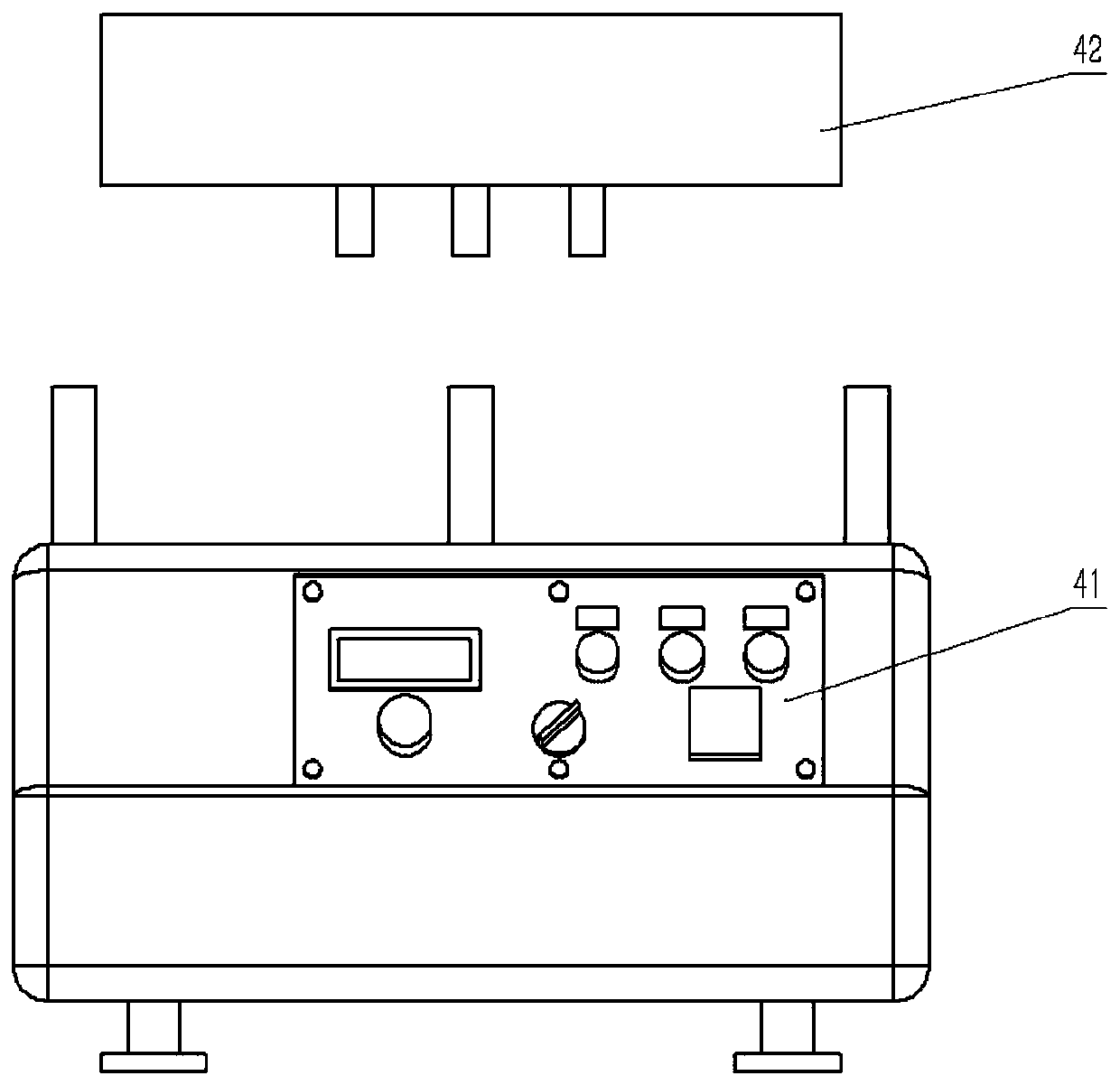

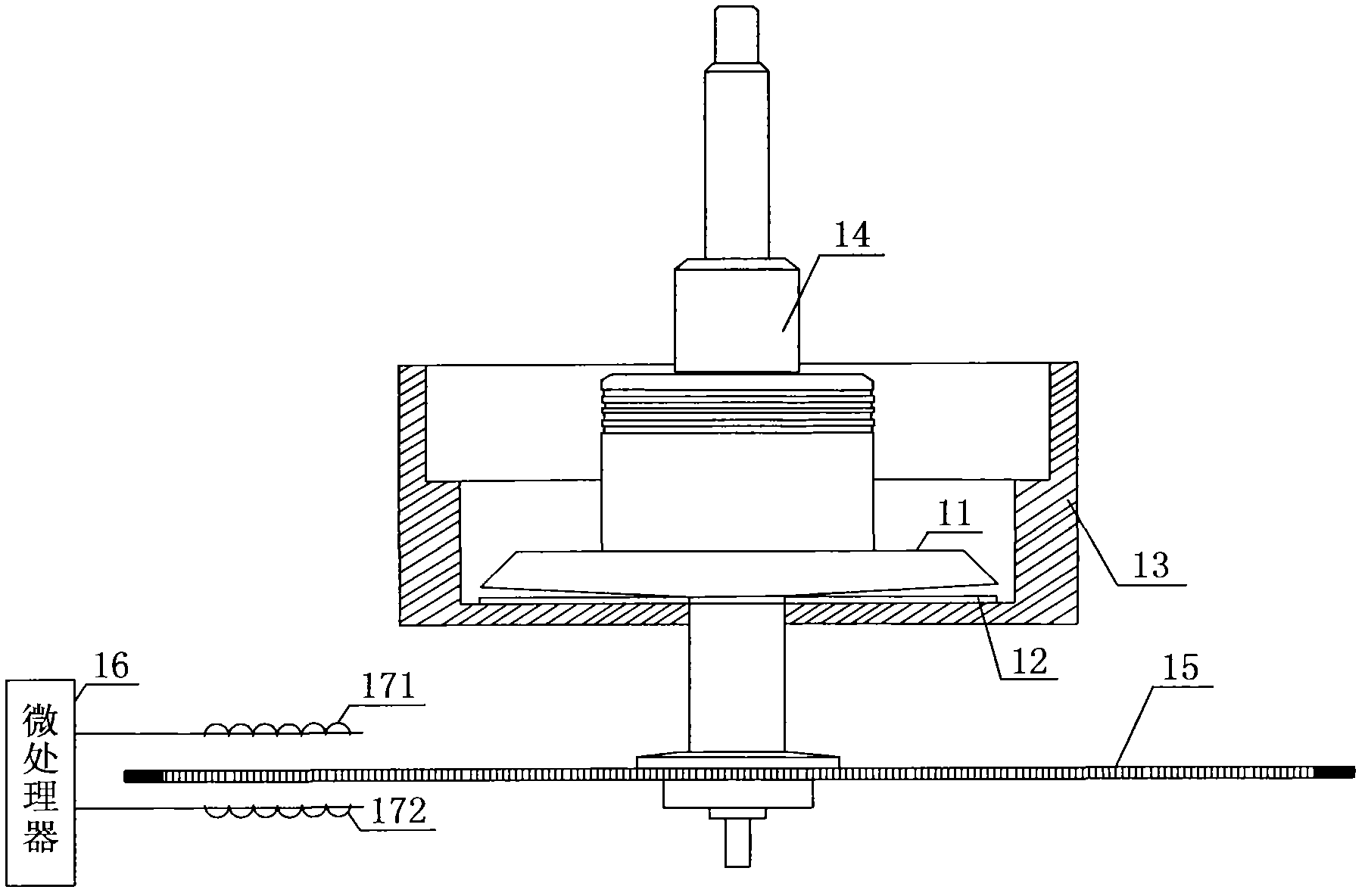

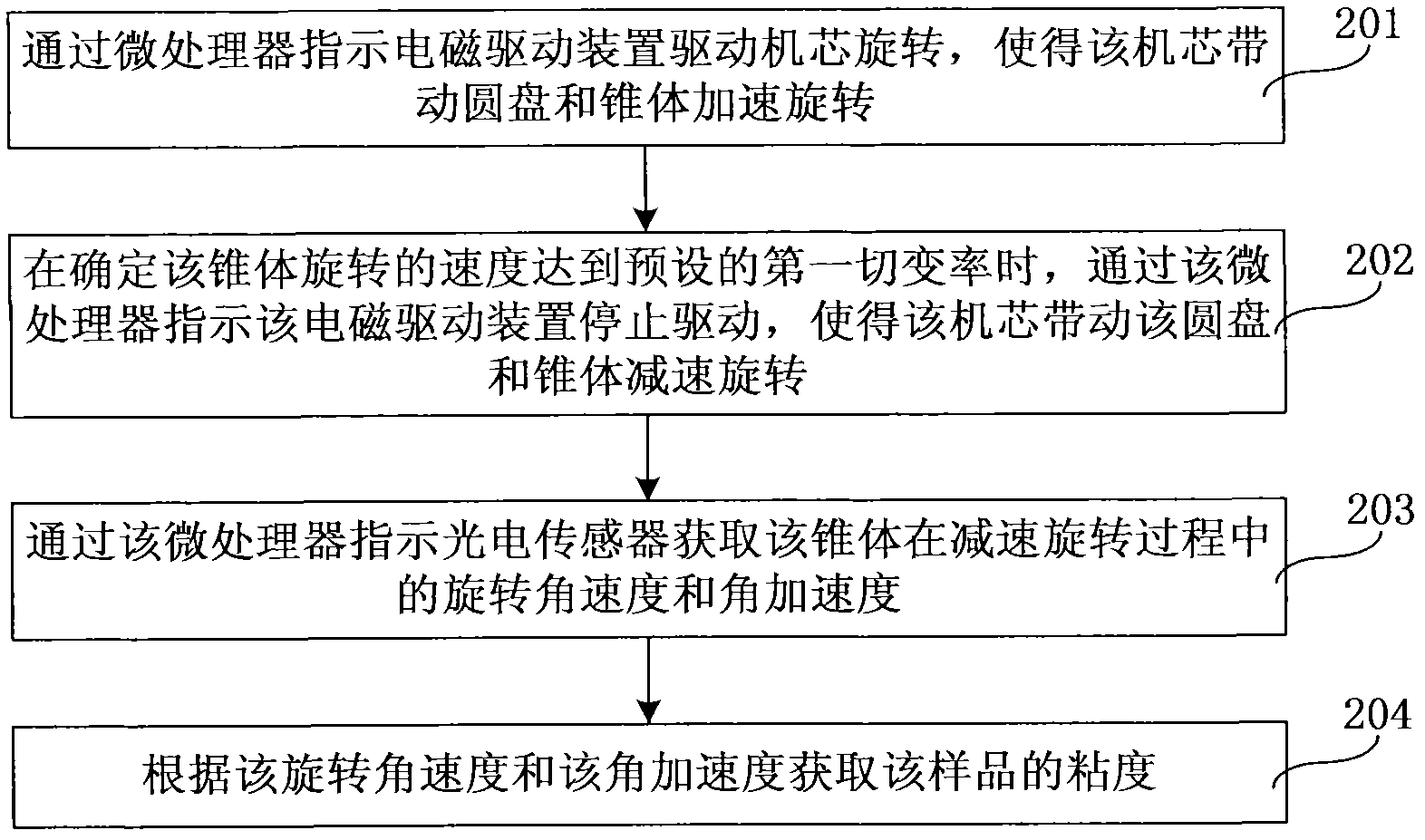

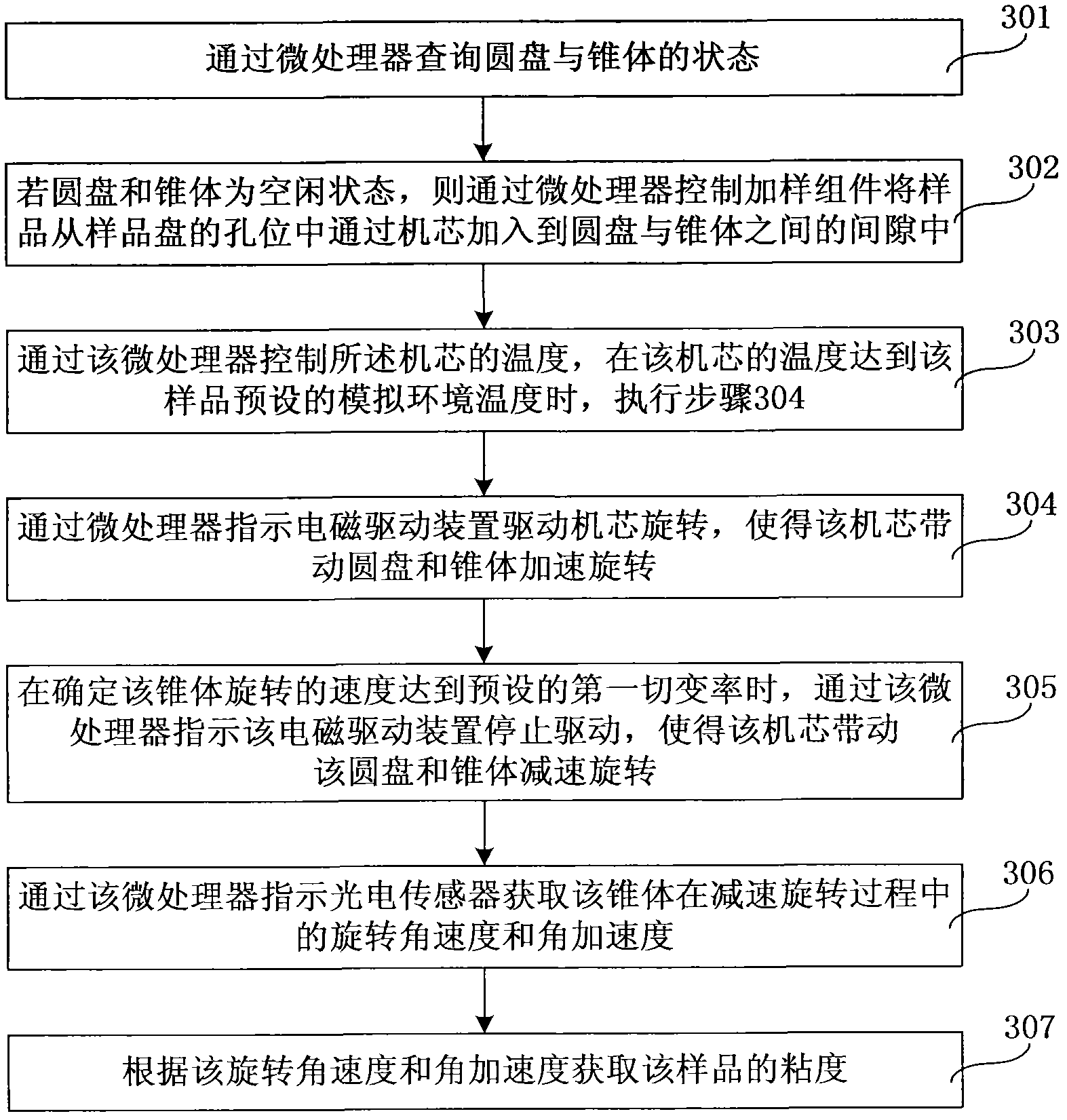

Blood viscosity acquiring method and system

The invention relates to a blood viscosity acquiring method and system. The method comprises the following steps: using a microprocessor to instruct an electromagnetic driving device to drive a cassette mechanism to rotate, thereby driving a disc and a cone to rotate at an accelerated speed by the cassette mechanism; using the microprocessor to instruct the electromagnetic driving device to stop driving when determining that the rotation speed of the cone reaches a preset first switching rate, thereby driving the disc and the cone to rotate at a decelerated speed by the cassette mechanism; using the microprocessor to instruct a photoelectric sensor to acquire the rotation angular velocity and the angular acceleration of the cone in the process of rotating at the decelerated speed; and acquiring the viscosity of the sample according to the rotation angular velocity and the angular acceleration. By using the embodiment of the invention, the influence on the viscosity of the sample caused by a frictional force generated between the electromagnetic driving device and the disc is avoided, the accuracy of the viscosity of the sample is increased, and the measurement for the viscosities of Newtonian fluid and non-Newtonian fluid under the condition of a determined switching rate is realized.

Owner:BEIJING SICCEEDER TECH CO LTD

Axially compliant pressure roller utilizing non-newtonian fluid

Owner:SKC HAAS DISPLAY FILMS CO LTD +1

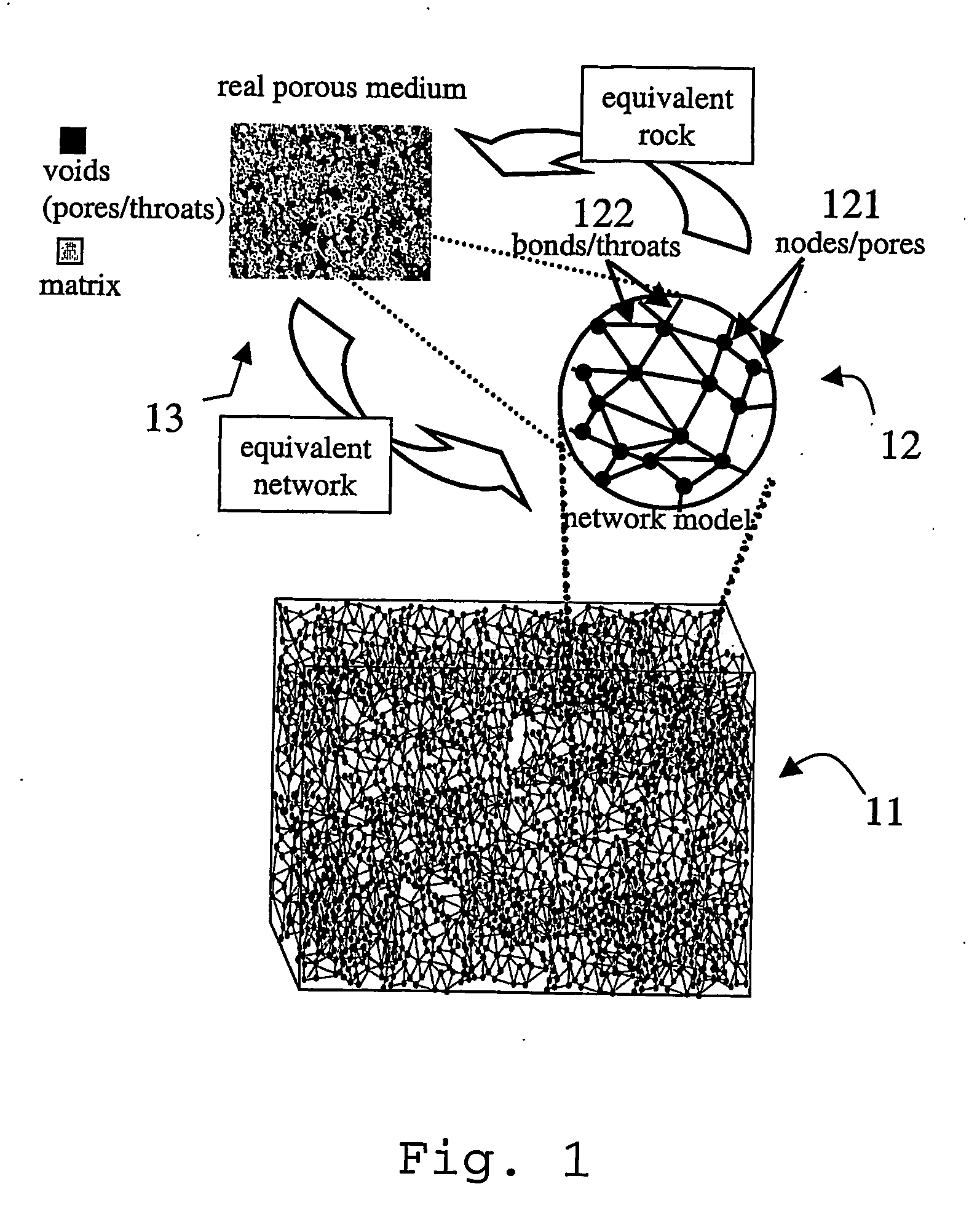

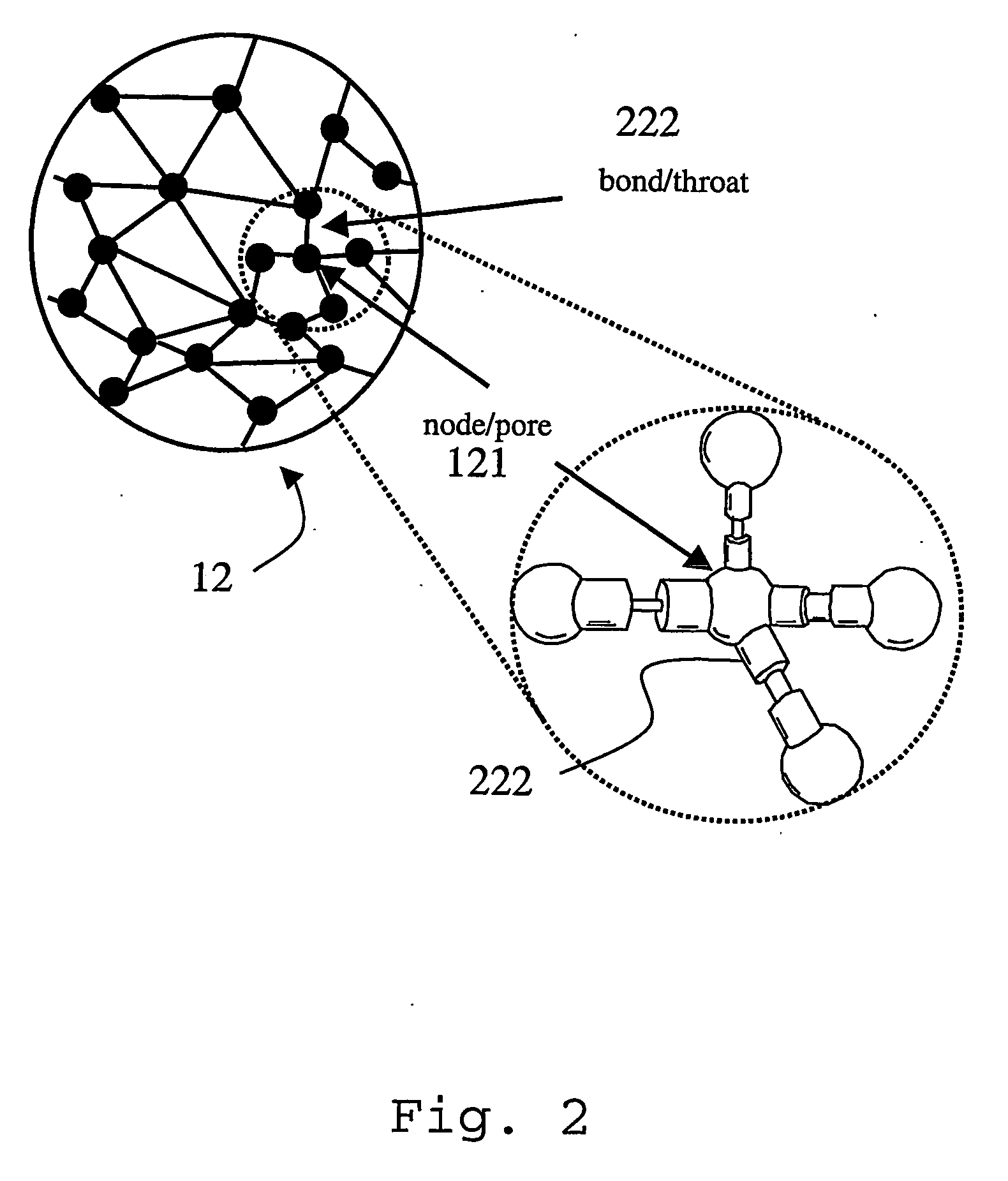

Method and system for predicting the apparent flow conductivity of a heterogeneous medium

The invention concerns a method and a system for predicting the apparent flow conductivity of a heterogeneous medium. According to the invention, the following steps are implemented:—choosing a flow conductivity element type with a given set of characteristic parameters;—determining equations for said flow in said element type;—determining a network statistics for said given set of characteristic parameters; and—performing a stochastic homogenisation of said equations, for said network statistics. The invention applies more particularly to the predicting of the apparent viscosity of non-Newtonian fluids in a heterogeneous porous medium.

Owner:SCHLUMBERGER TECH CORP

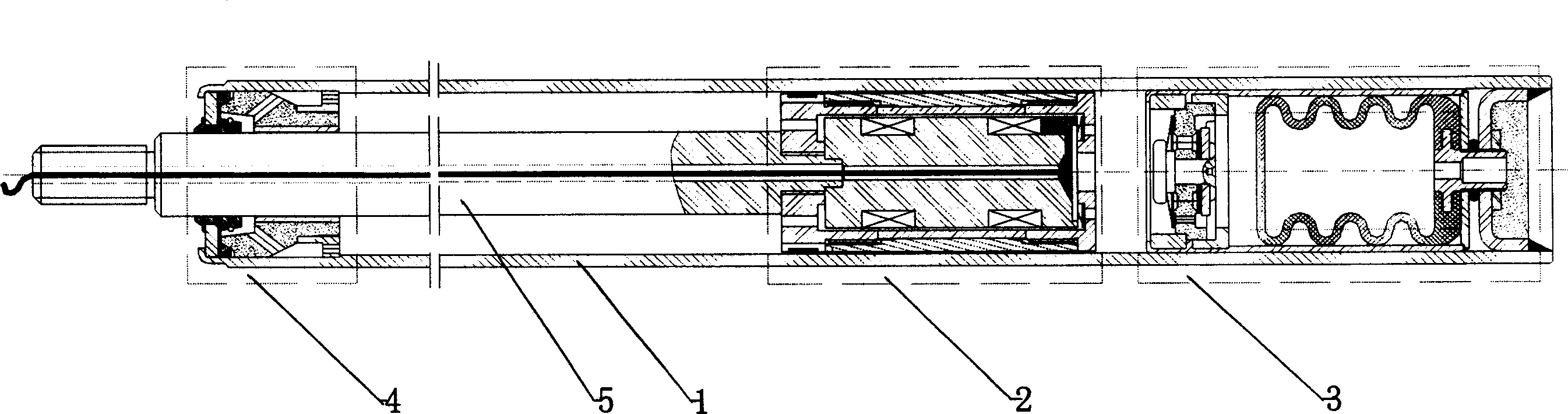

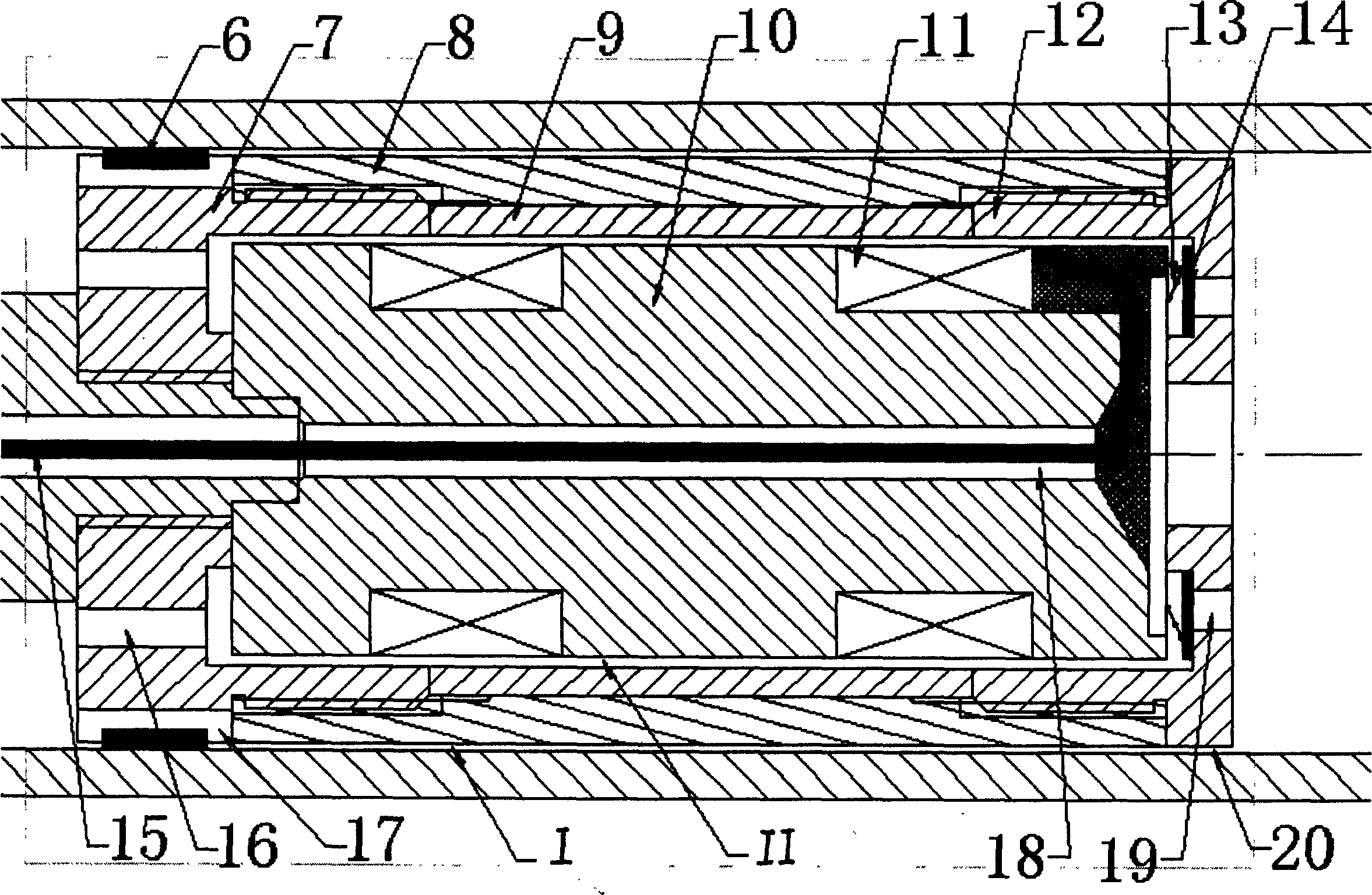

Double channel magnetic current damp variation device with recombination of mixing mode and flowing mode

InactiveCN1621707ANo compensation will occurNo problemNon-rotating vibration suppressionResilient suspensionsMagnetic currentSemi active

The composite mixed mode and flow mode double-channel magnetic rheologic damper includes work cylinder, piston type magnetic field generator, compensator and sealing unit. The piston type magnetic field generator has two flow channels, including the outer channel without magnetic field and operating in mixed mode and the inner channel inside magnetic field and operating in flow mode. The damper may operate in no outer exciting current state with relatively small damping and in large outer exciting current state with relatively great damping. This kind of double-channel structure makes the magnetic rheologic damper possess greatly lowered damping under the condition of no external magnetic field, has expanded dynamic regulation range and even suitable for the semi-active control of vehicle suspension.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com