Patents

Literature

46results about How to "No problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

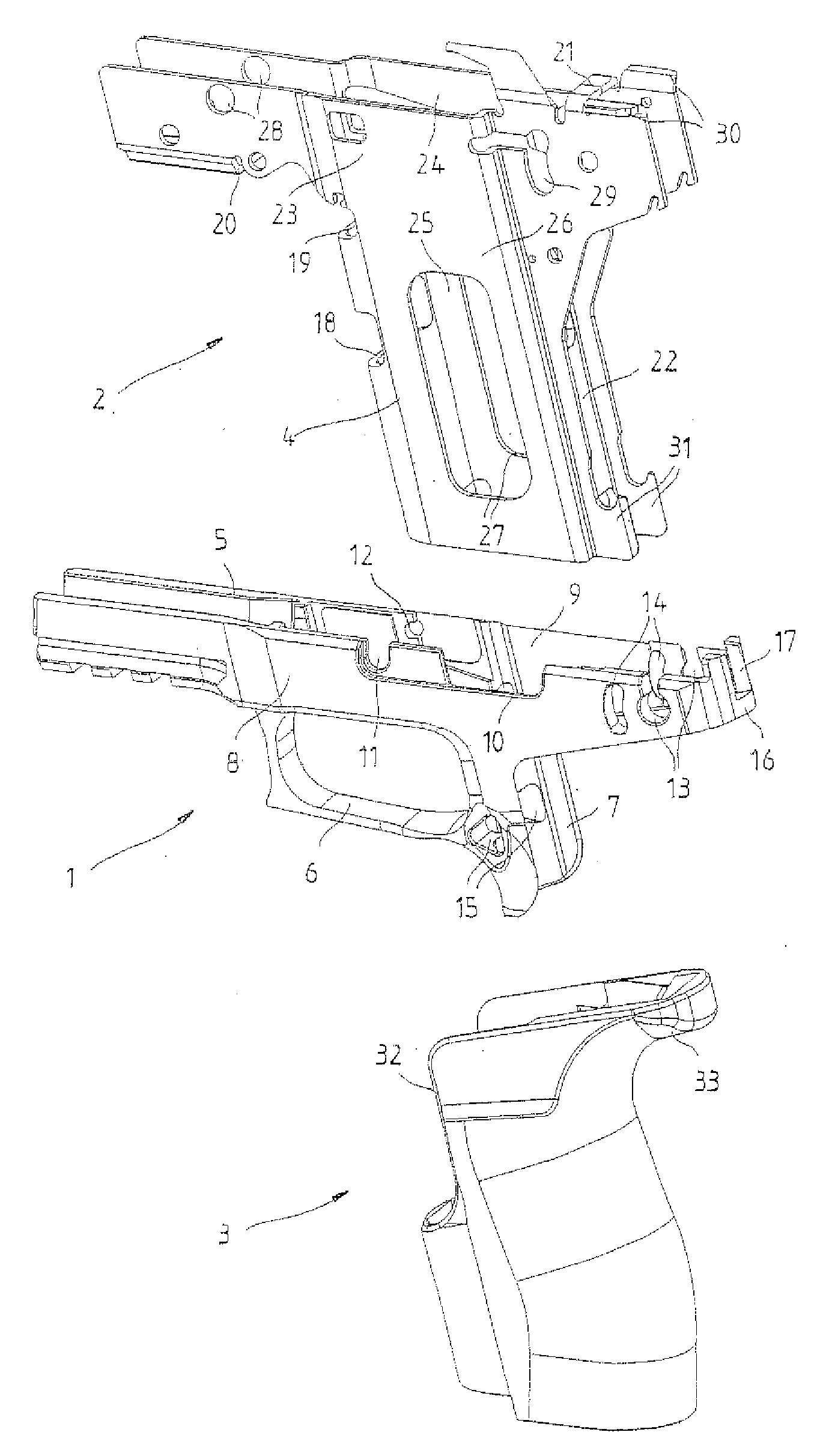

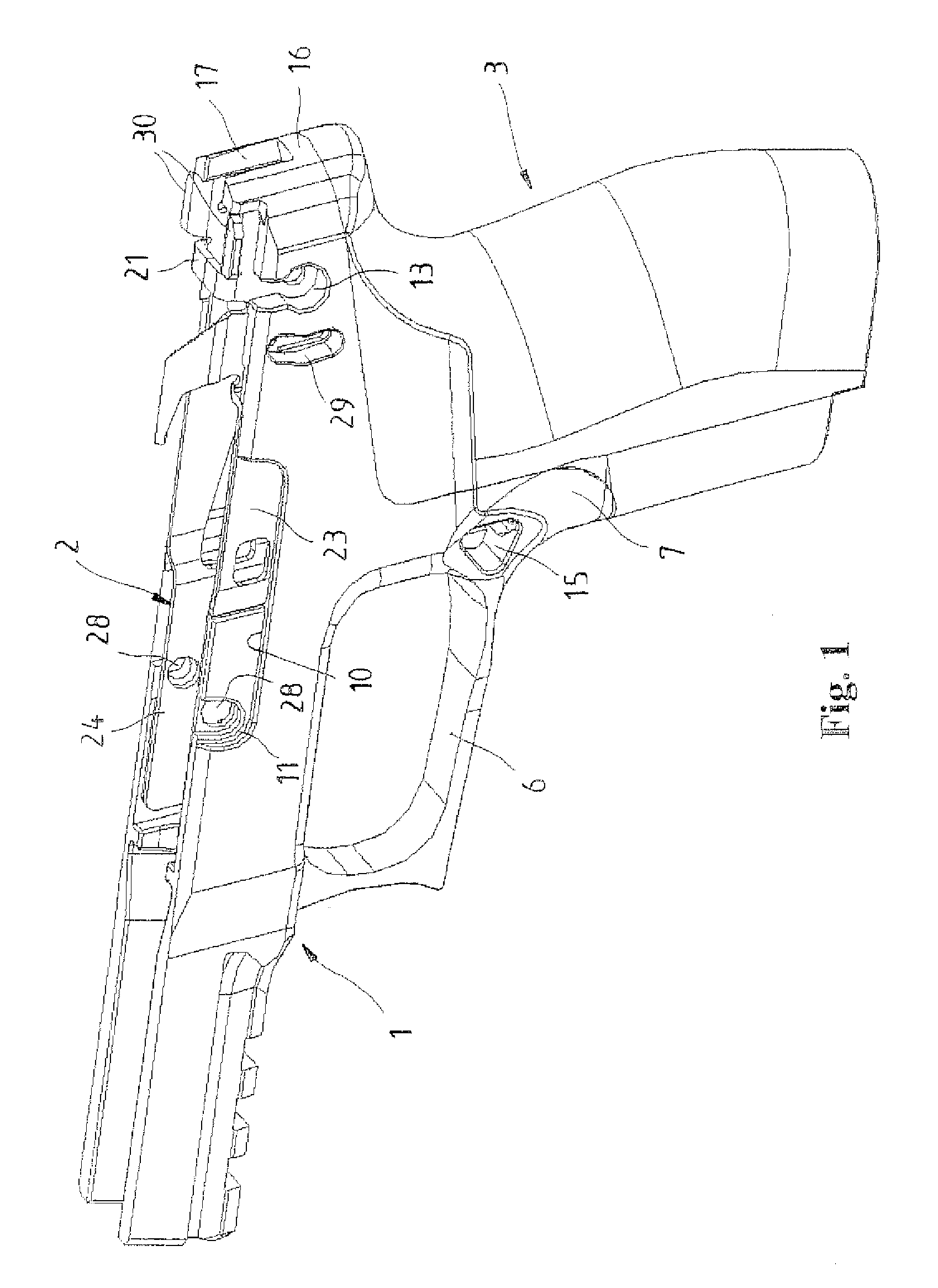

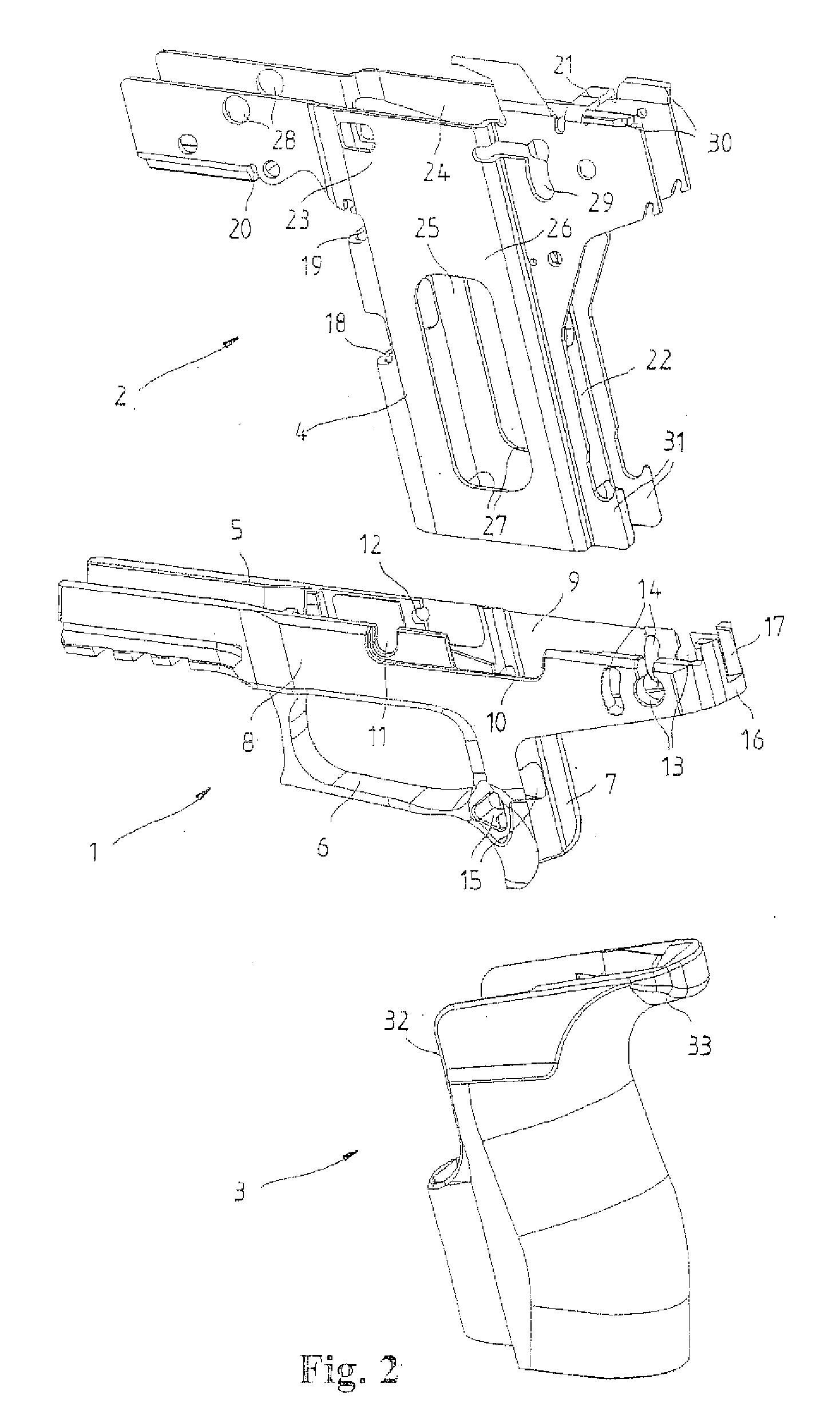

Grip for a handgun

InactiveUS20080060247A1Simple and cost-effective adaptationSimple and cost-effective to manufactureWeapon assembly/disassemblyBreech mechanismsEngineeringMechanical engineering

The invention relates to a grip for a handgun, in particular a pistol, having a grip module (1) made of plastic and a metal carrier element (2) that is insertable into said grip module (1). In order to enable a simple and cost-effective adaptation to the widest variety of demands of the marksman, a magazine shaft (4), projecting downward from the grip module (1) and onto which is slipped a grip shell module (3), is formed as a part of the carrier element (2).

Owner:T SWISS ARMS TECH

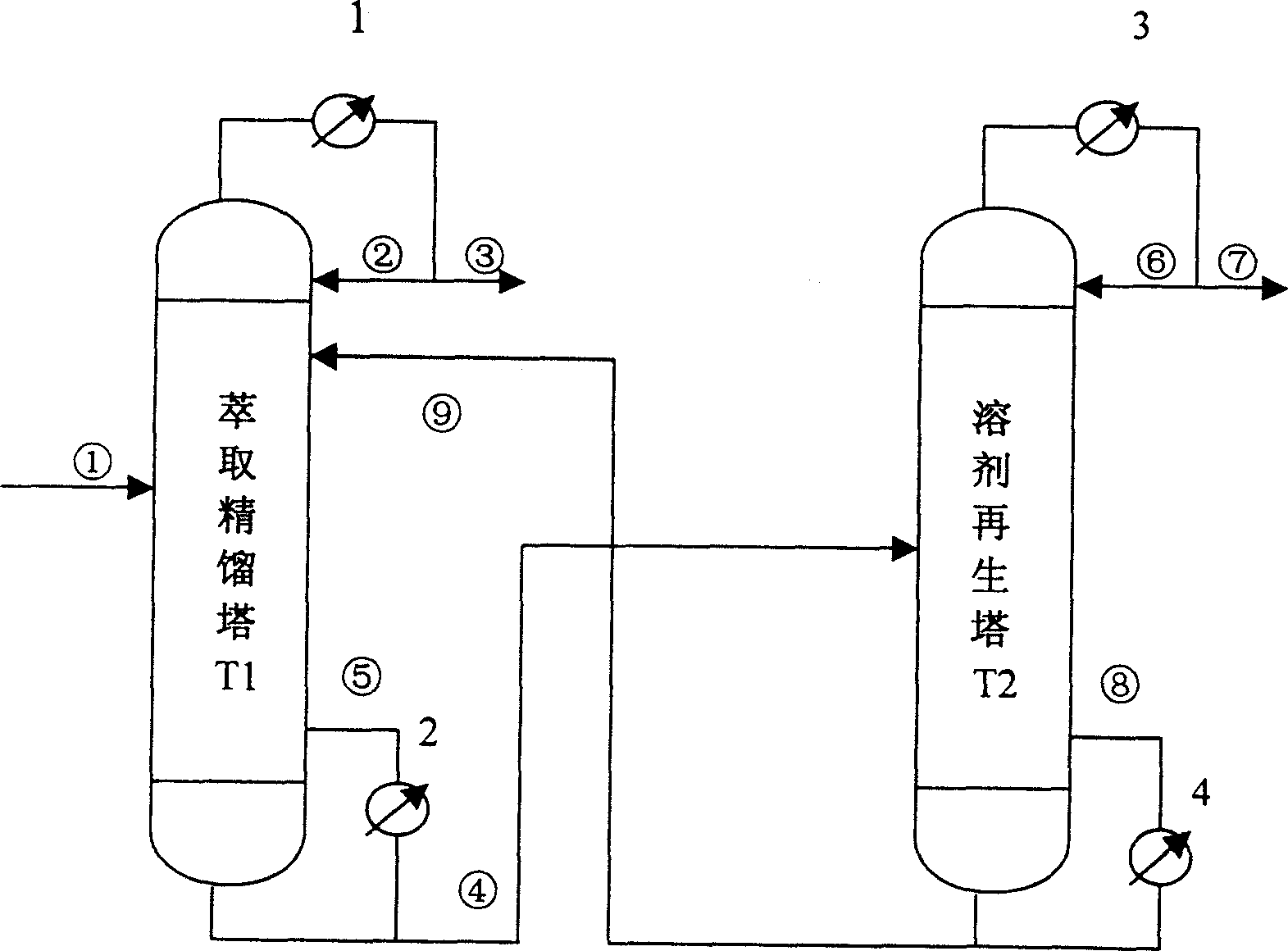

Extraction and rectification separation method for normal hexane and methyl cyclopentane

The extraction rectification separation method for normal hexane and methyl cyclopentane comprises: adding the industrial hexane and dimethyl phthalate into the tower with given ratio; after separation, there is high-purity normal hexane on tower top, solution and methyl cyclopentane on tower kettle; putting the material in kettle to solution for distillation with methyl cyclopentane on tower top for further refine; recycling the solution. Wherein, the ratio is 1:3~5. This invention has recycle ratio more than 90% with purity more than 98%, and has no pollution.

Owner:NANJING UNIV OF TECH

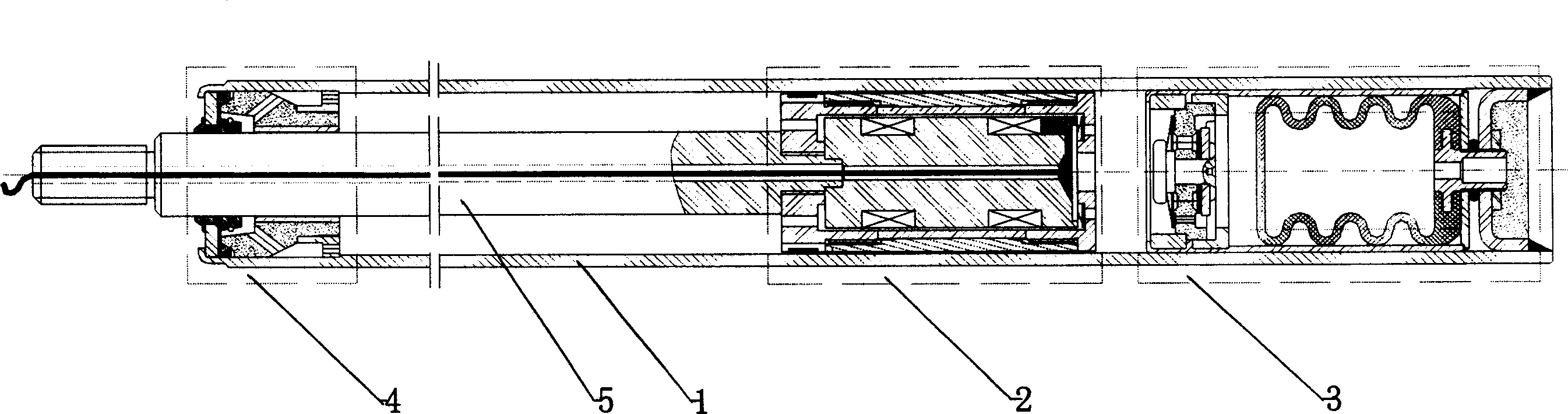

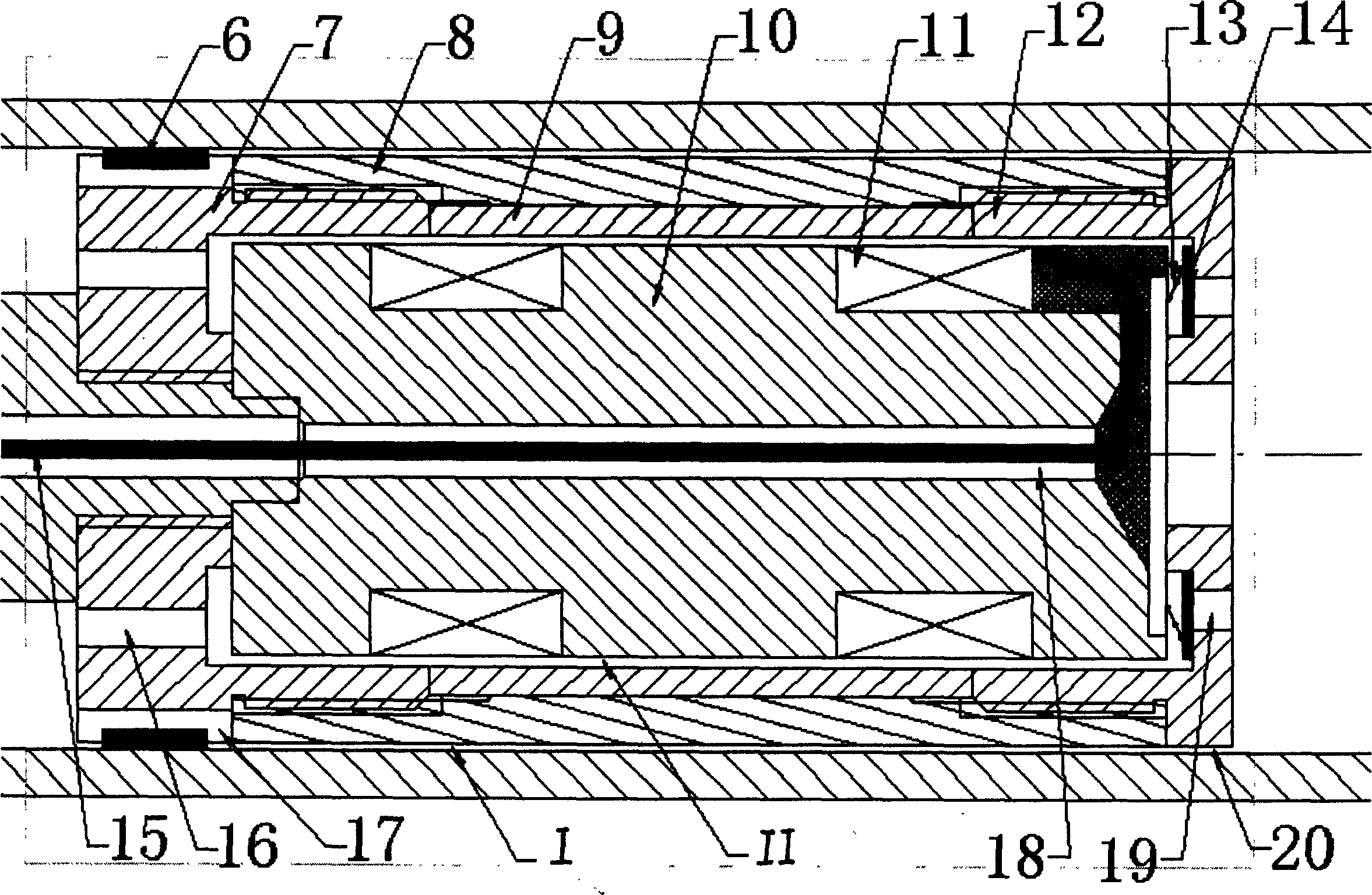

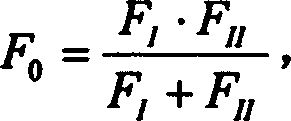

Double channel magnetic current damp variation device with recombination of mixing mode and flowing mode

InactiveCN1621707ANo compensation will occurNo problemNon-rotating vibration suppressionResilient suspensionsMagnetic currentSemi active

The composite mixed mode and flow mode double-channel magnetic rheologic damper includes work cylinder, piston type magnetic field generator, compensator and sealing unit. The piston type magnetic field generator has two flow channels, including the outer channel without magnetic field and operating in mixed mode and the inner channel inside magnetic field and operating in flow mode. The damper may operate in no outer exciting current state with relatively small damping and in large outer exciting current state with relatively great damping. This kind of double-channel structure makes the magnetic rheologic damper possess greatly lowered damping under the condition of no external magnetic field, has expanded dynamic regulation range and even suitable for the semi-active control of vehicle suspension.

Owner:CHONGQING UNIV

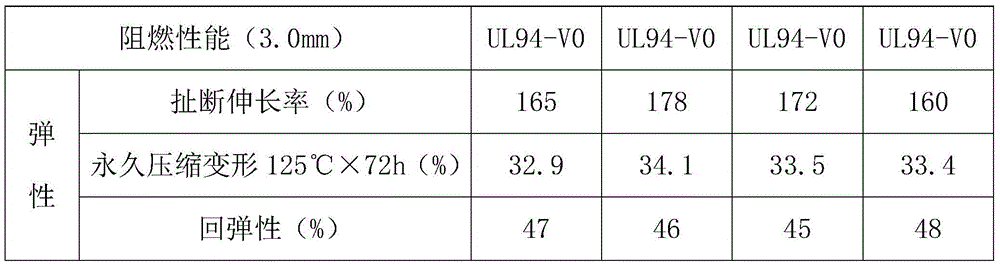

High-elasticity environmentally-friendly flame-retardant rubber material

The present invention discloses a high-elasticity environmentally-friendly flame-retardant rubber material comprising the raw materials of hydrogenated nitrile rubber, EPDM rubber, butadiene styrene rubber, vinyl chloride thermoplastic elastomers, ABS resin, di-tert-butyl peroxide DTBP, sulfur, divinylbenzene, accelerator DM, modified clay, carbon masterbatch, magnesium oxide, stearic acid, a modified flame retardant, polyphenyl ether, diisononyl phthalate DINP, antioxidant D-50, antioxidant SP and epoxy soybean oil. The high-elasticity environmentally-friendly flame-retardant rubber material has excellent flame retardant properties, and is halogen-free, low in toxicity, environmentally-friendly, good in elasticity and other mechanical properties and processing performances, and suitable for a variety of production and living areas.

Owner:宁国市开源橡塑汽车零部件有限公司

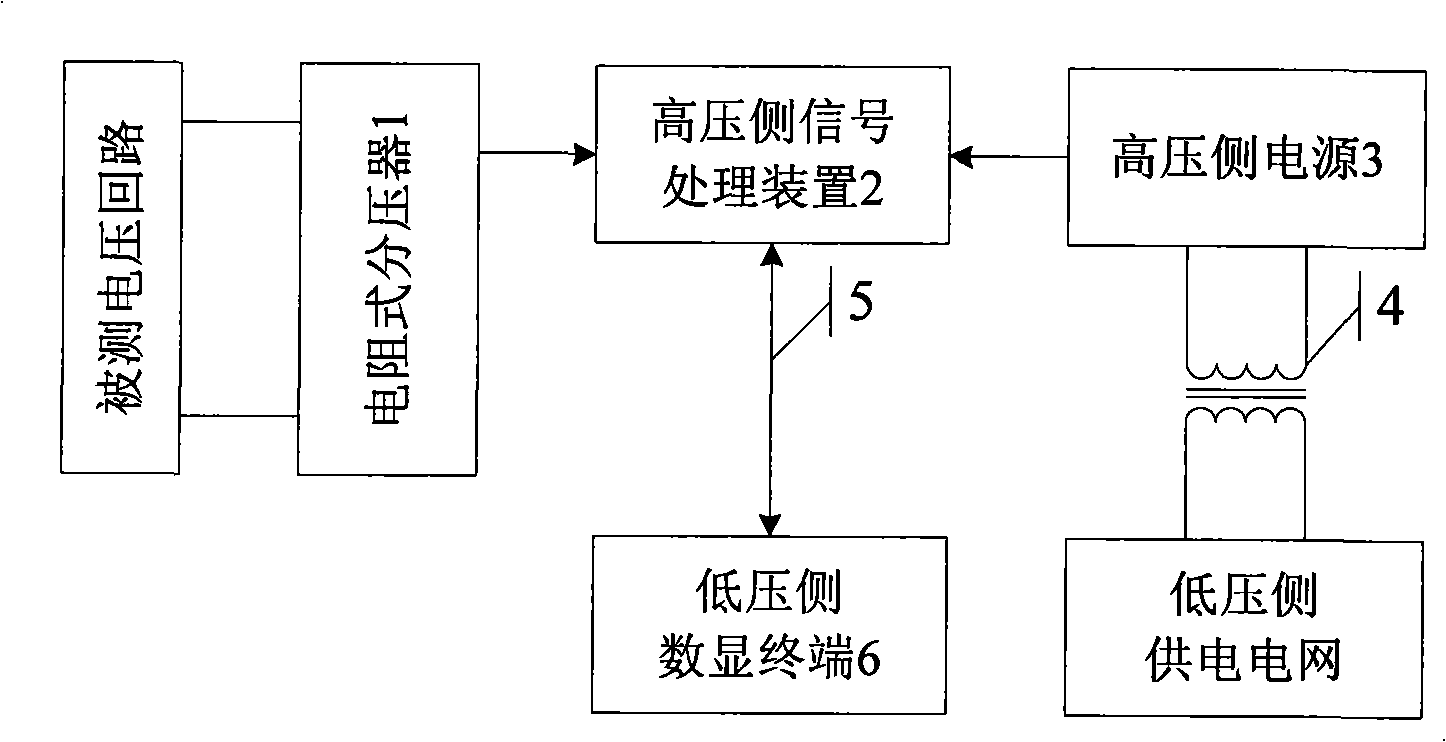

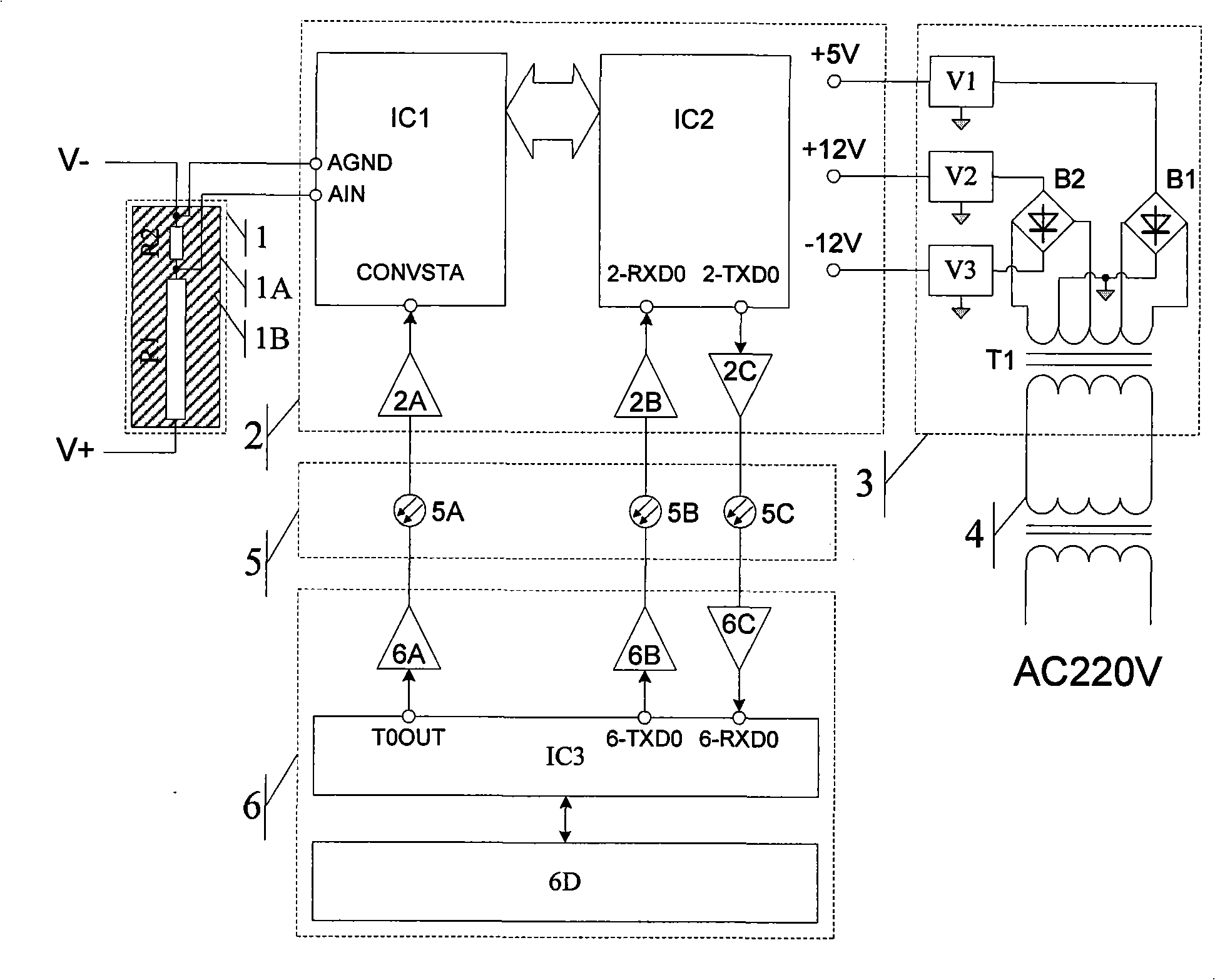

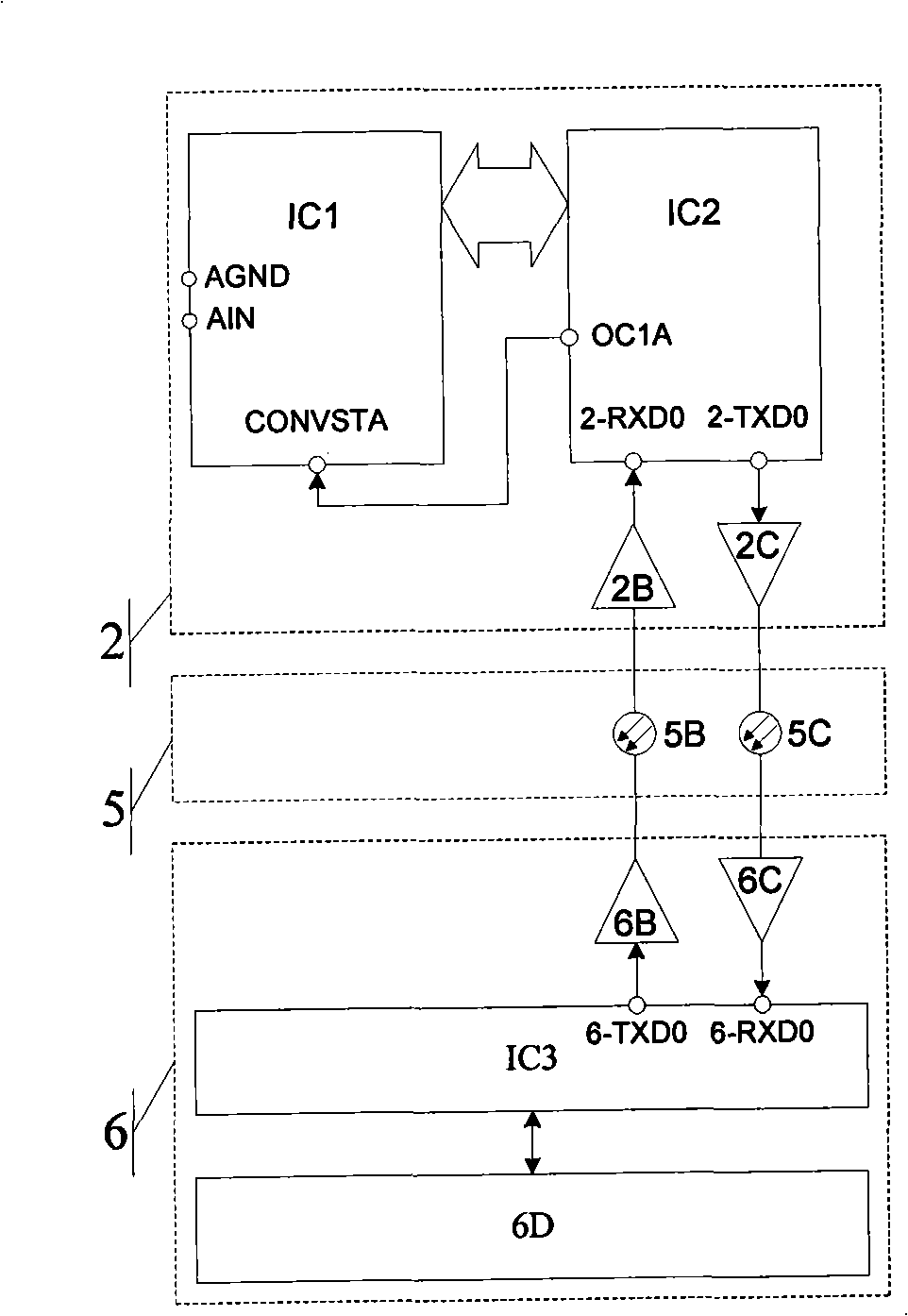

Wide band high voltage intelligent electric resistance partial pressure type voltage sensor

InactiveCN101285853AWide frequency response rangeWide effective test rangeTransformersVoltage/current isolationLow voltageTransformer

The invention discloses a broadband high-voltage intelligent resistance voltage-division voltage sensor, which consists of the following components: a resistance type voltage divider (1) used to pick voltage signal from a measured voltage circuit, a high-voltage side signal processing device (2) used to convert the analog voltage signal output from the resistance type voltage divider (1) into digital signal and carry out operation processing, a set of communication optical fibers (5) connecting the high-voltage side signal processing device (2) and a low-voltage side digital display terminal (6), a high-voltage side electric source (3) providing working electric source for the high-voltage side signal processing device (2) and a high-voltage isolating transformer (4) connecting the high-voltage side electric source (3) and a low-voltage side power supply electric network. The broadband high-voltage intelligent resistance voltage-division voltage sensor has wide frequency response scope, AC / DC commonality, wide effective testing scope, no magnetic saturation problem, high measuring precision, high voltage resistance, high linearity, low temperature drift, easy calibration and strong anti-interference capability, and is suitable to be used in places such as an electric motor manufacturing enterprise and an electric motor research and detection center, etc.

Owner:徐伟专

Method and device for predicting spectrum occupancy state based on neural network

ActiveCN103209417ANo problemSimple calculationBiological neural network modelsNetwork planningFrequency bandPrediction methods

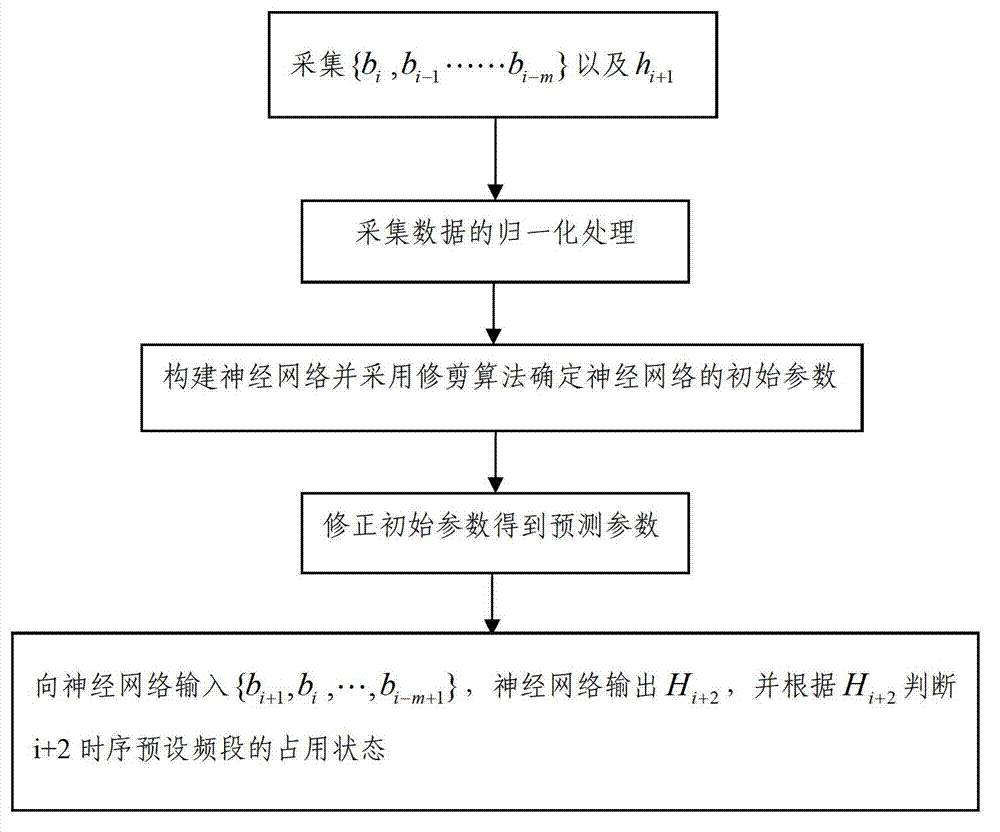

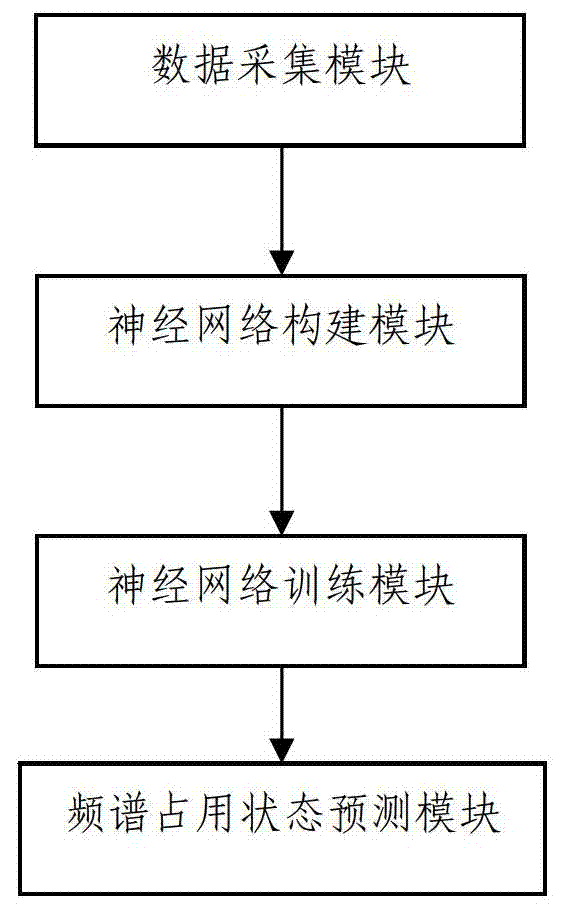

The invention discloses a method and a device for predicting a spectrum occupancy state based on a neural network. The method for predicting the spectrum occupancy state based on the neural network comprises the steps of S1: constructing the neural network and using a pruning algorithm to determine initial parameters of all layers and all neurons of the neural network; S2: inputting all elements in a set (bi, bi-1,..., bi-m) into the neural network, comparing an output result of the neural network with a representation variable hi+1 which represents the occupancy state of the preset frequency band of an (i+1) timing sequence, and correcting initial parameters to obtain predictive parameters according to the comparison result, wherein bi is the signal intensity of the preset frequency band of an i timing sequence, i is a positive integer, and m is a positive integer smaller than i; and S3: inputting all elements in a set (bi+1, bi,..., bi-m+1) into the neural network simultaneously, outputting a predictive representation variable Hi+2 which represents the occupancy state of the preset frequency band of an (i+2) timing sequence by the neural network, and judging the occupancy state of the preset frequency band of the (i+2) timing sequence according to the predictive representation variable Hi+2. The method has the advantages of being low in computation complexity and easy to implement.

Owner:BEIJING UNIV OF POSTS & TELECOMM

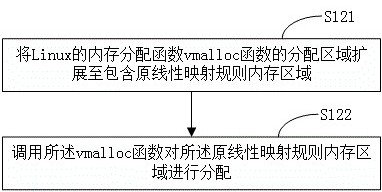

Method for avoiding Linux kernel memory fragmentation, device and computer storage medium

ActiveCN111813710ASolve FragmentationIncrease profitMemory adressing/allocation/relocationParallel computingPhysical address

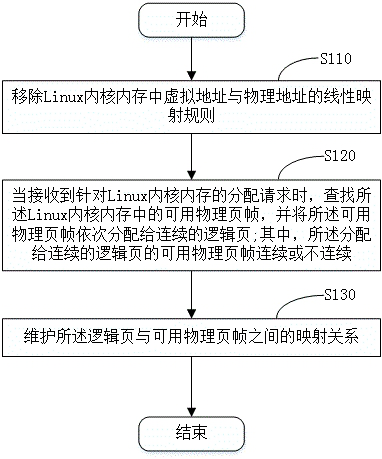

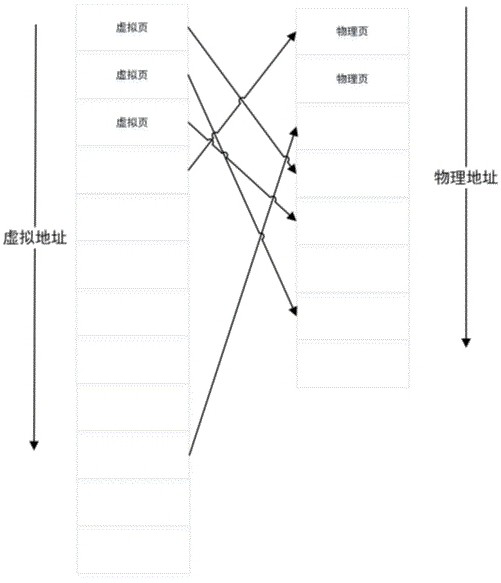

The invention discloses a method for avoiding Linux kernel memory fragmentation. The method comprises the following steps of: removing a linear mapping rule of a virtual address and a physical addressin a Linux kernel memory; under the condition that an allocation request for the Linux kernel memory is received, searching available physical page frames in the Linux kernel memory, and sequentiallyallocating the available physical page frames to continuous logic pages, the available physical page frames allocated to the continuous logic pages being continuous or discontinuous; and maintainingmapping relationships between the logic pages and the available physical page frames. And the problem of fragmentation of the Linux kernel memory is thoroughly solved. The technical effect of improving the utilization rate of the Linux kernel memory is achieved.

Owner:PENG CHENG LAB

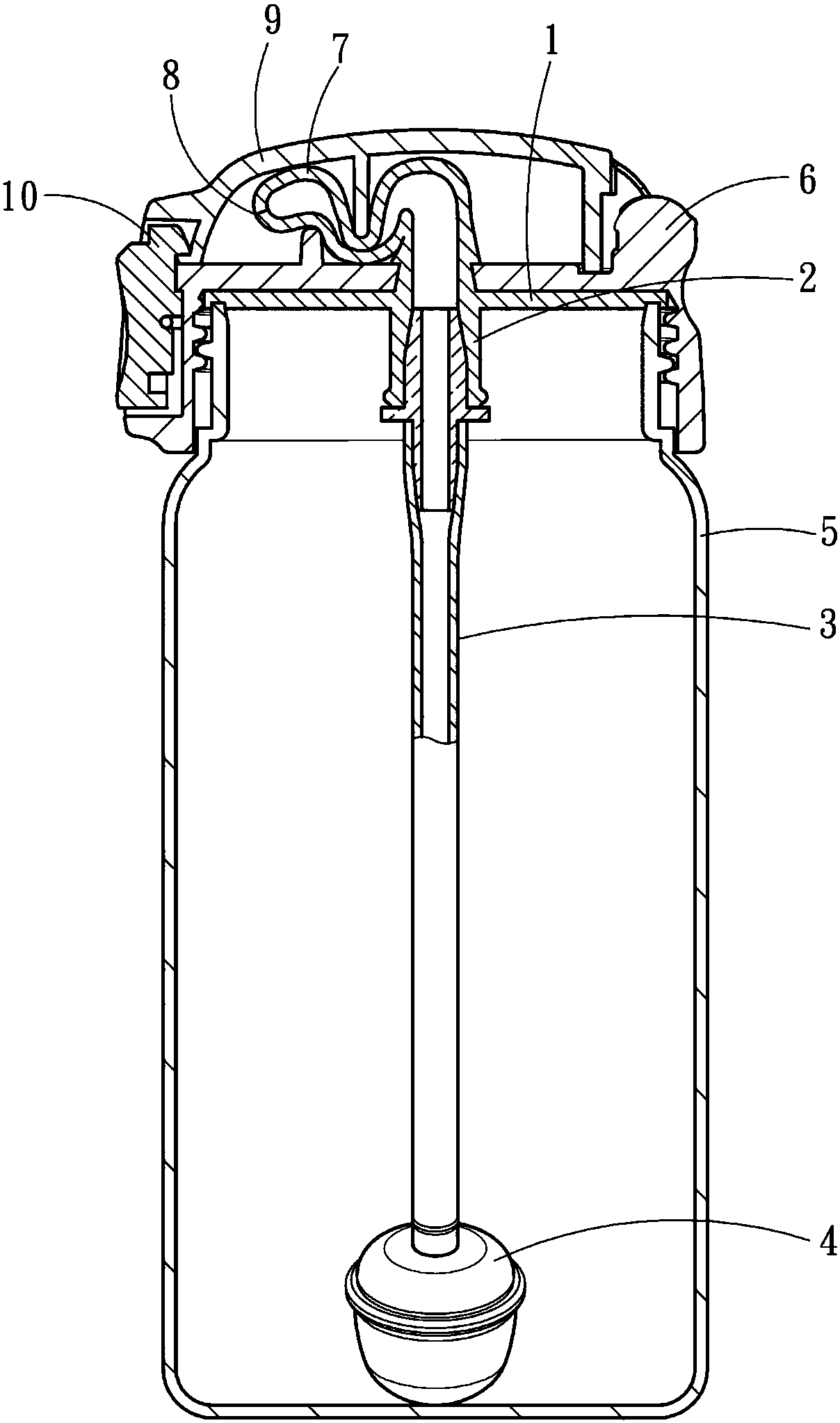

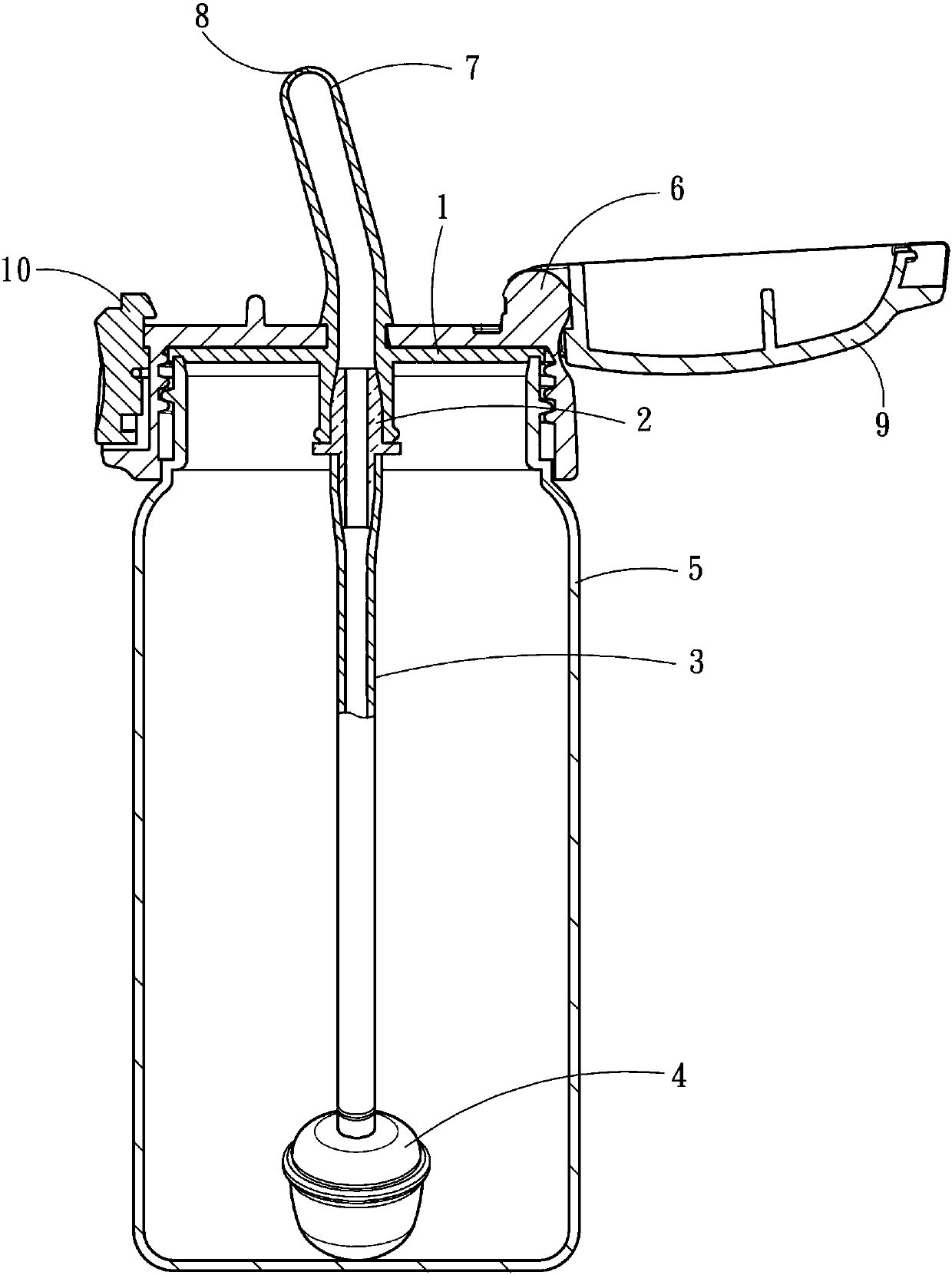

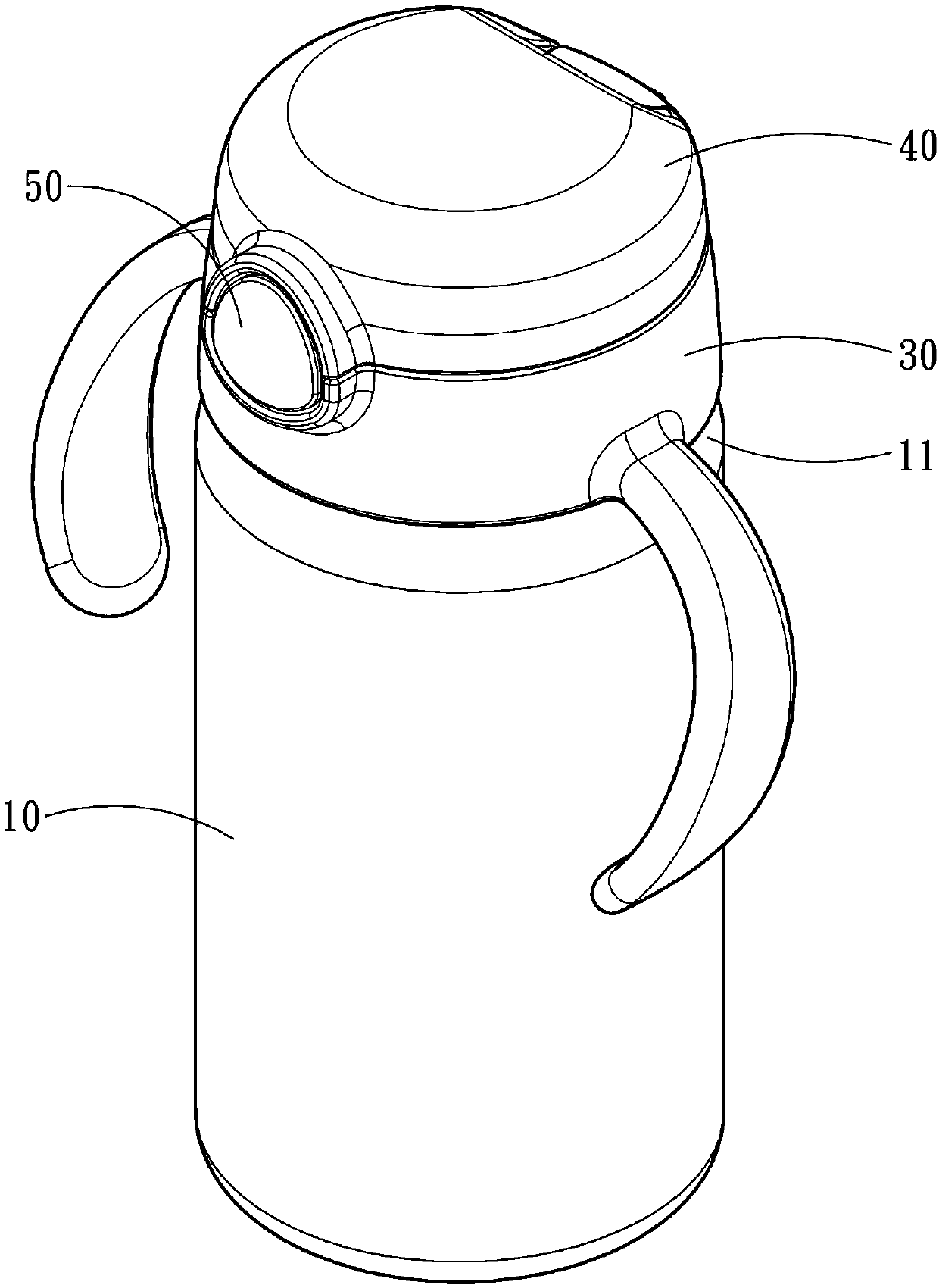

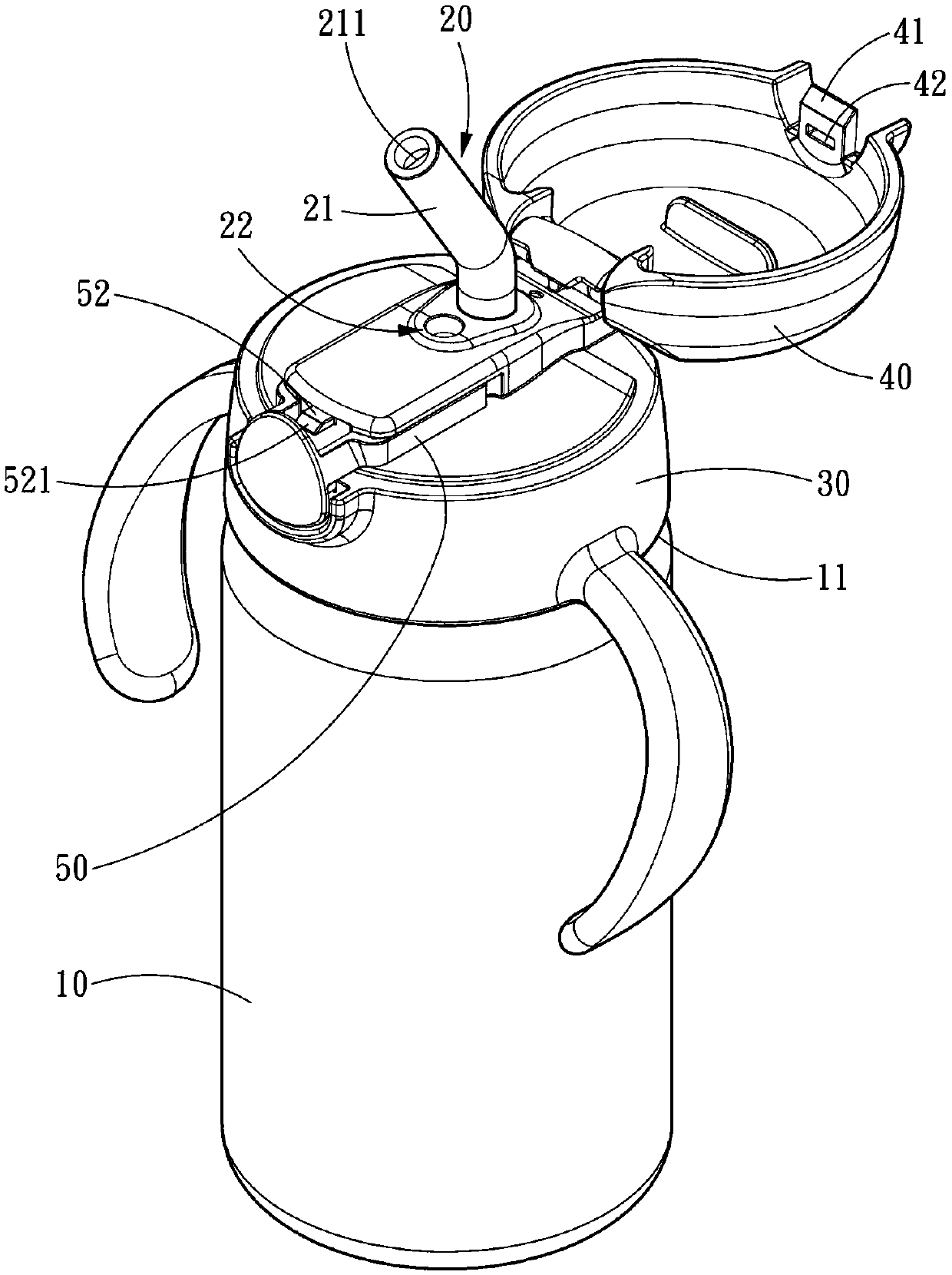

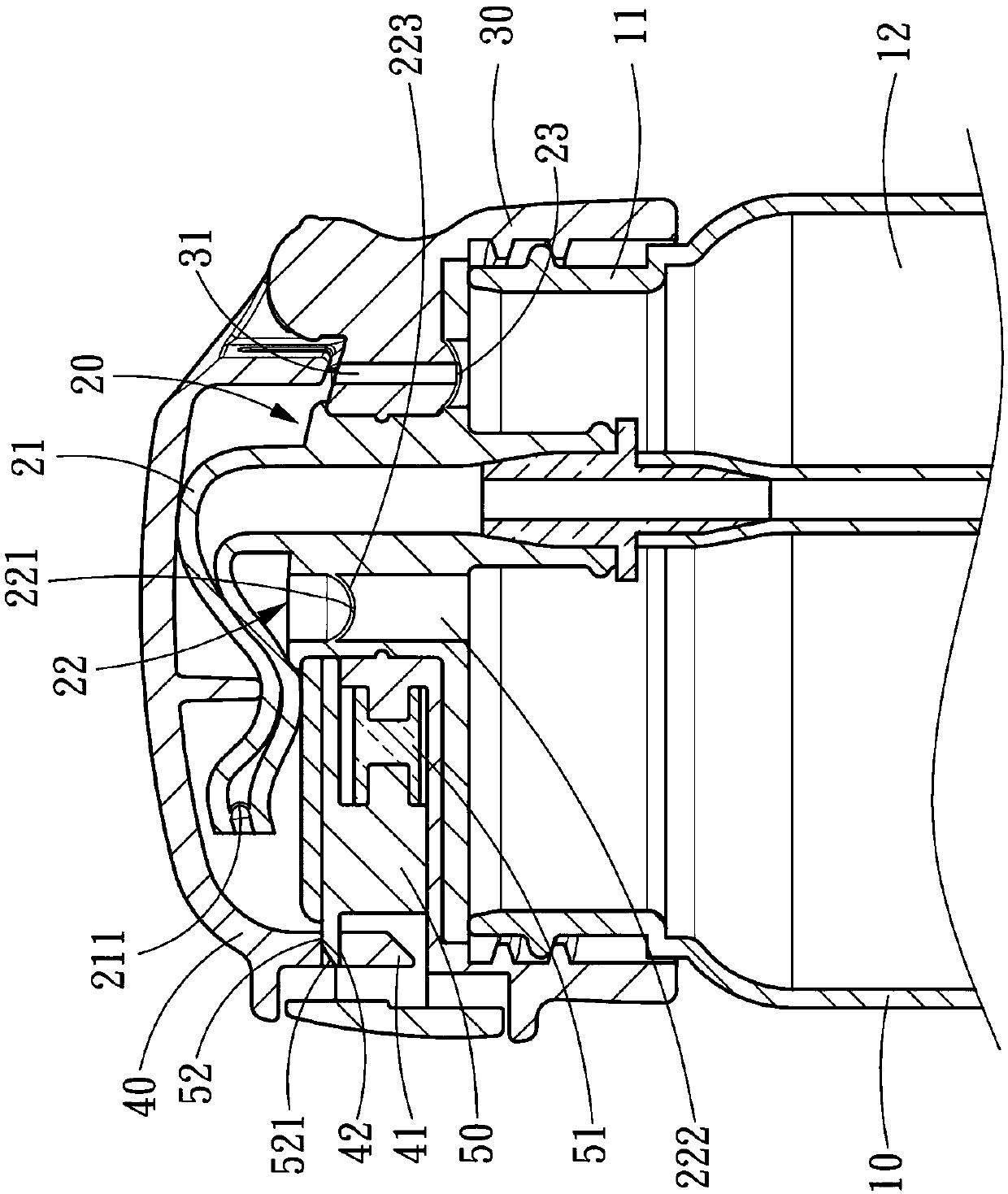

Kettle cover with pressure relief device

InactiveCN110664192APrevent sprayingConsistent internal and external pressureTravelling sacksDrinking vesselsPollutionFastener

The invention discloses a kettle cover with a pressure relief device. The kettle cover is arranged on a bottleneck of a kettle and comprises a kettle suction nozzle, a bottleneck cover, a fastener, anouter cover and an opening element, wherein the kettle suction nozzle is provided with a sucking part and a valve part, the valve part is provided with a pressure relief seam, the kettle suction nozzle is arranged on the bottleneck cover, and the sucking part and the valve part are exposed to the outer side; the bottleneck cover is locked on the bottleneck, the fastener is pivoted on the bottleneck cover, a traction element in contact with the valve part is integrally formed, one end of the outer cover is pivoted on the bottleneck cover, and the other end of the outer cover is fastened by thefastener and fixed on the other side of the bottleneck cover; the fastener inclines outwards under the linkage effect of the opening element and does not buckle the outer cover any longer, and meanwhile, the traction element drives the valve part to deform so as to open the pressure relief seam; and therefore, when a user presses the opening element to open the outer cover, the pressure relief seam can be simultaneously linked to be opened to relieve pressure, water in the kettle is prevented from being sprayed out of the sucking part due to the pressure, and dangers and environmental pollution can be avoided.

Owner:SONISON BABY PRODS

Feeding mechanism for assembling puncture type bare needle protection covers

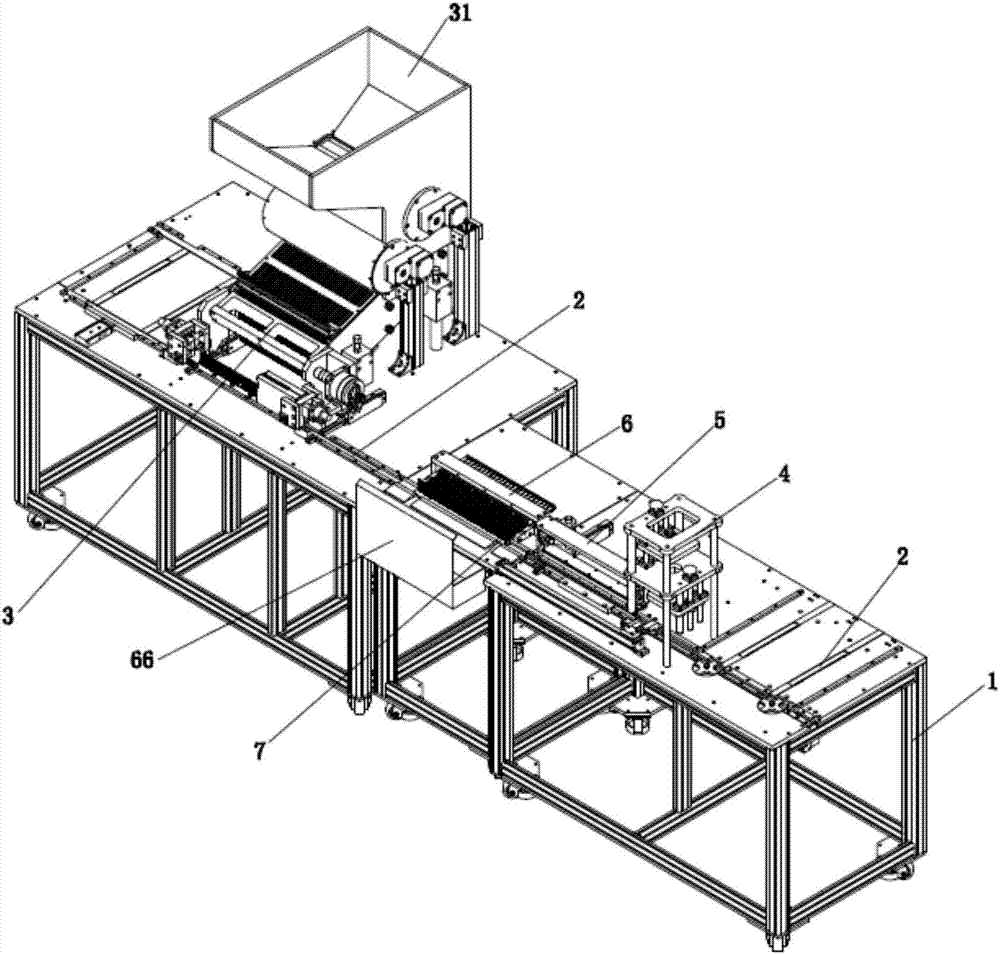

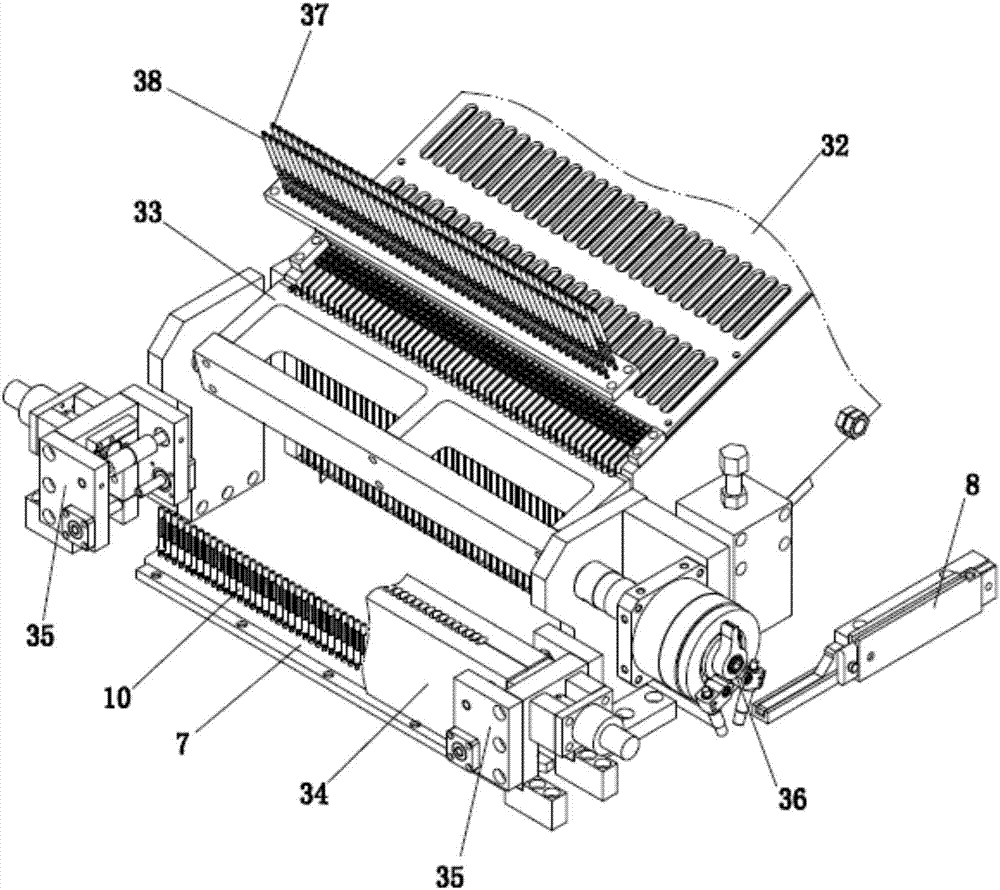

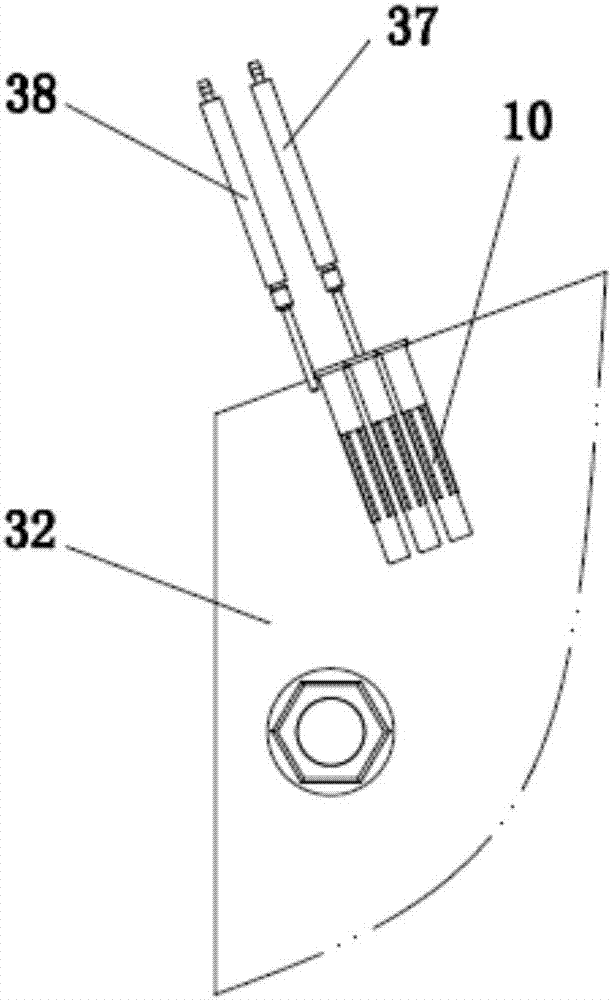

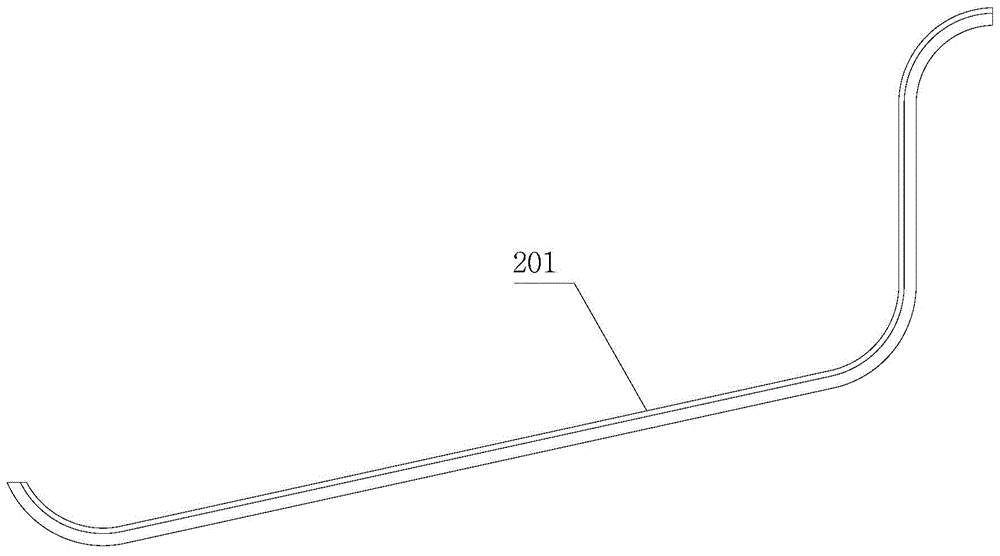

ActiveCN107009120AAvoid it happening againReduce generationControl devices for conveyorsMetal working apparatusStructural engineeringWorkbench

The invention discloses a feeding mechanism for assembling puncture type bare needle protection covers. The feeding mechanism comprises a workbench. A conveying mechanism used for moving a jig carrying needle seat and needle tube assemblies is arranged on the workbench. The feeding mechanism further comprises an image comparison device, an air blockage detection device, a defective product discharging device and a protection cover buckling device which are sequentially arranged in the conveying direction of the conveying mechanism. The protection cover buckling device is of a structure which can only buckle the protection covers on the residual needle seat and needle tube assemblies on the jig. According to the feeding mechanism for assembling the puncture type bare needle protection covers, the situation that jig movement is stopped due to the fact that the redundant protection covers fall onto the workbench is avoided, normal buckling of the protection covers of the needle seat and needle tube assemblies on the jig is guaranteed, work efficiency is improved, and defective products are greatly reduced.

Owner:江苏台正数控设备有限公司

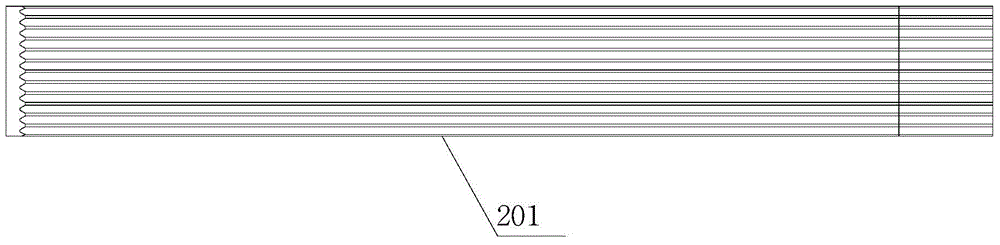

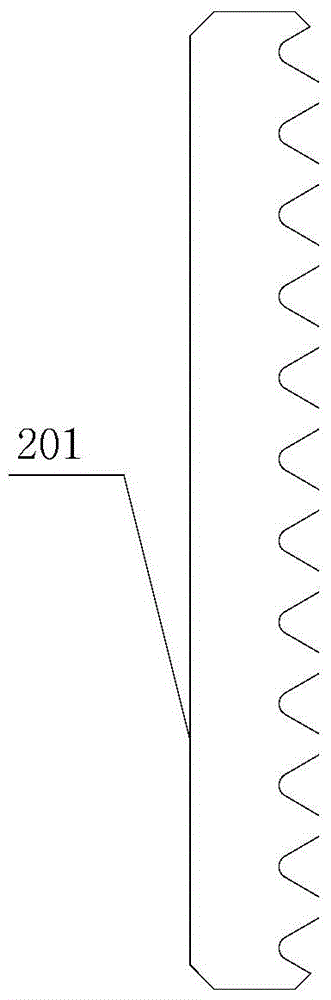

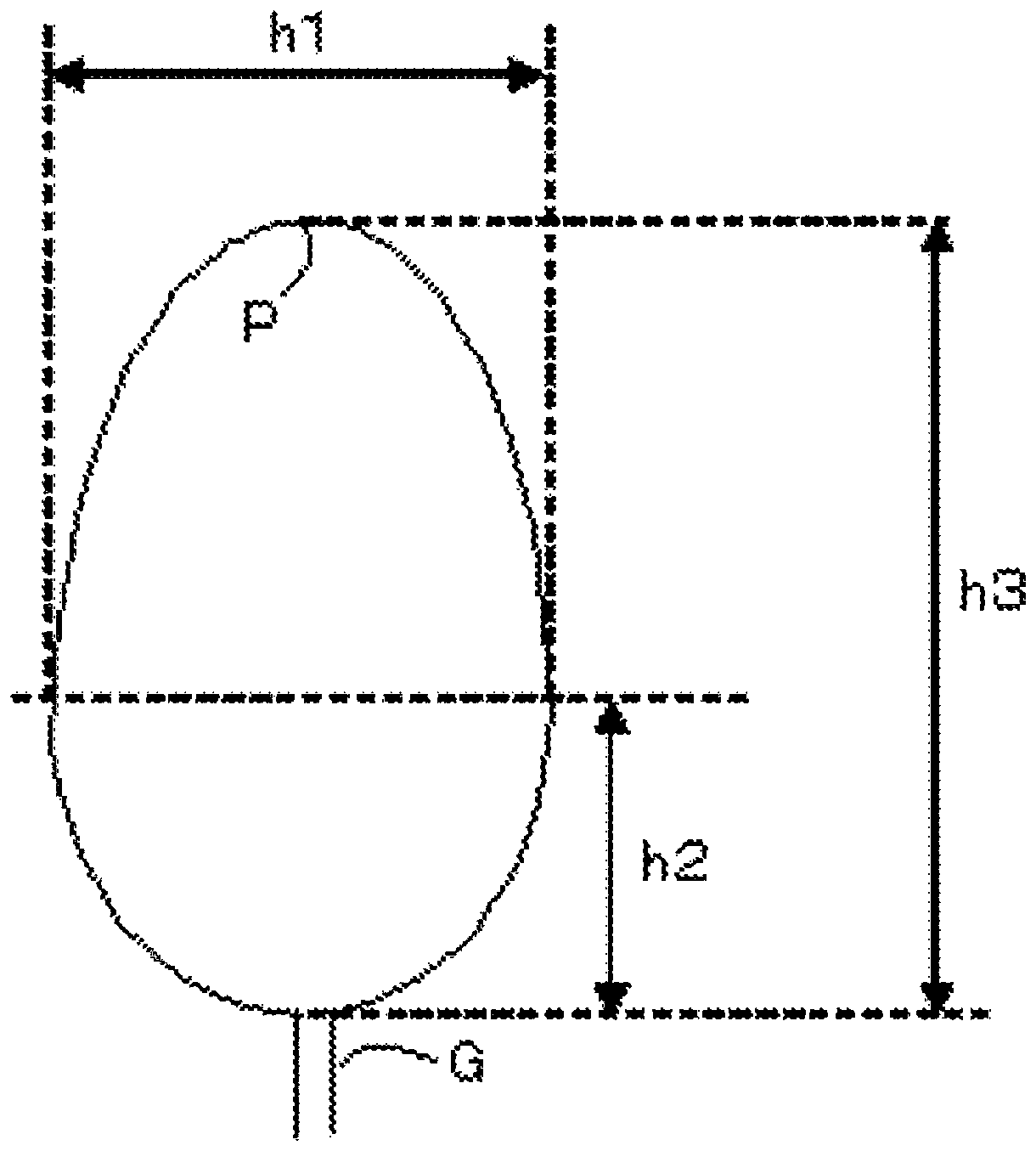

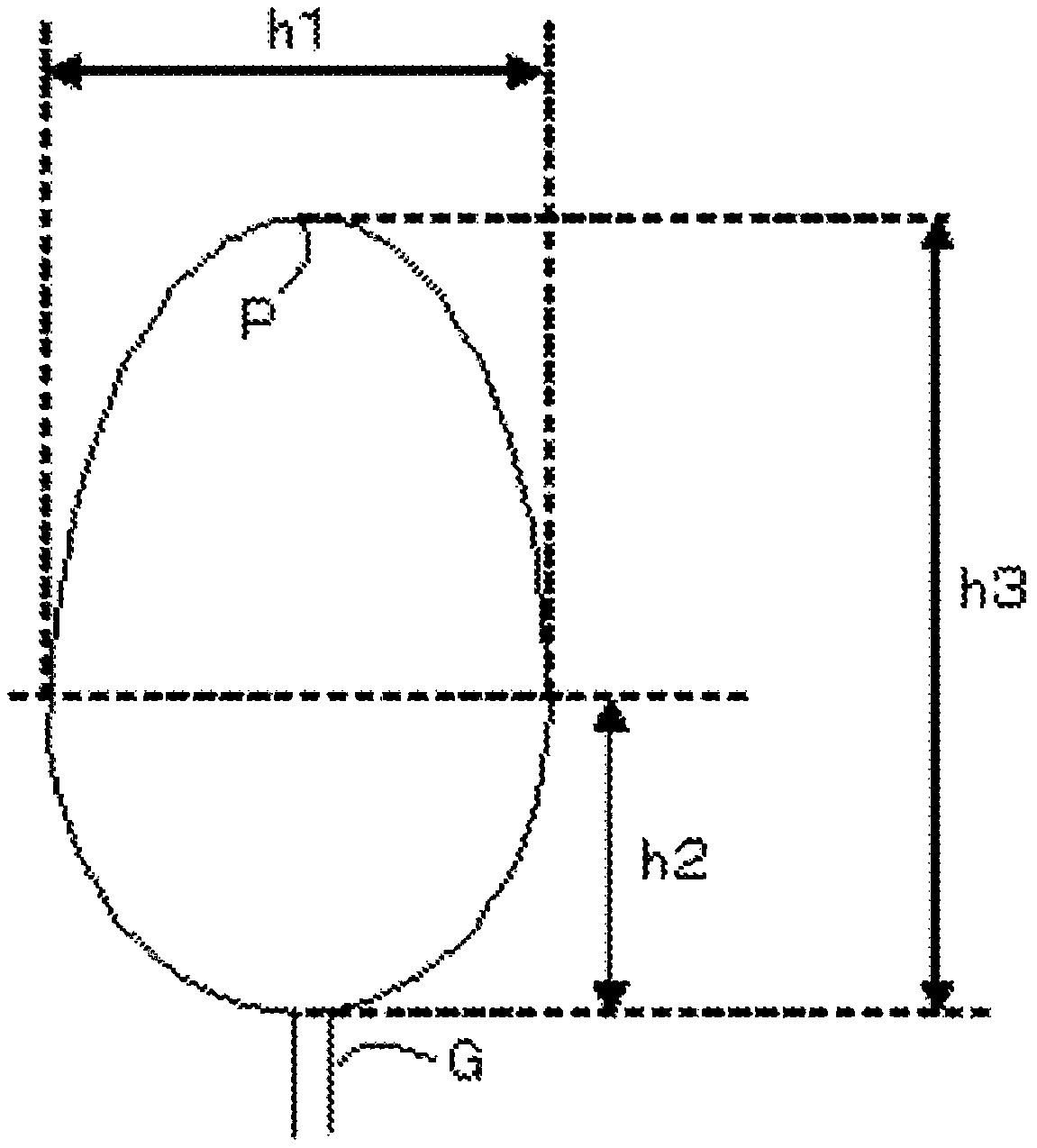

Shaping die for manufacture of gas turbine seals and manufacture process of gas turbine seals

The invention provides a shaping die for manufacture of gas turbine seals and a manufacture process of the gas turbine seals and belongs to the field of machining. The shaping die comprises a left moving core, a right moving core, a fixed die, guide posts and a base. The base is fixed on a base of a hydraulic press. The fixed die is fixed on the base. Left and right profiles of the fixed die match with a toothed surface profile of a seal; the fixed die is provided with teeth matching with those of the seal. The left moving core and the right moving core are disposed on two sides of the fixed die and fixed on a horizontal cylinder of the hydraulic press. The right surface profile of the left moving core and the left surface profile of the right moving core are matched with the smooth surface profile of the seal. The shaping die for manufacture of the gas turbine seals and the manufacture process of the gas turbine seals have the advantages that the inside and outside of the seal manufactured with the shaping die and by the manufacture process are free of flaw, the various specified requirements can be met, the shaping die and the manufacture process are fully adaptable to ultrahigh temperature and high pressure environments, and the seal never fails when a gas turbine operates.

Owner:SHANGHAI HAIYE ELECTROMECHANICAL EQUIP CO LTD

Polycarbonate resin composition

Owner:MITSUBISHI ENG PLASTICS CORP

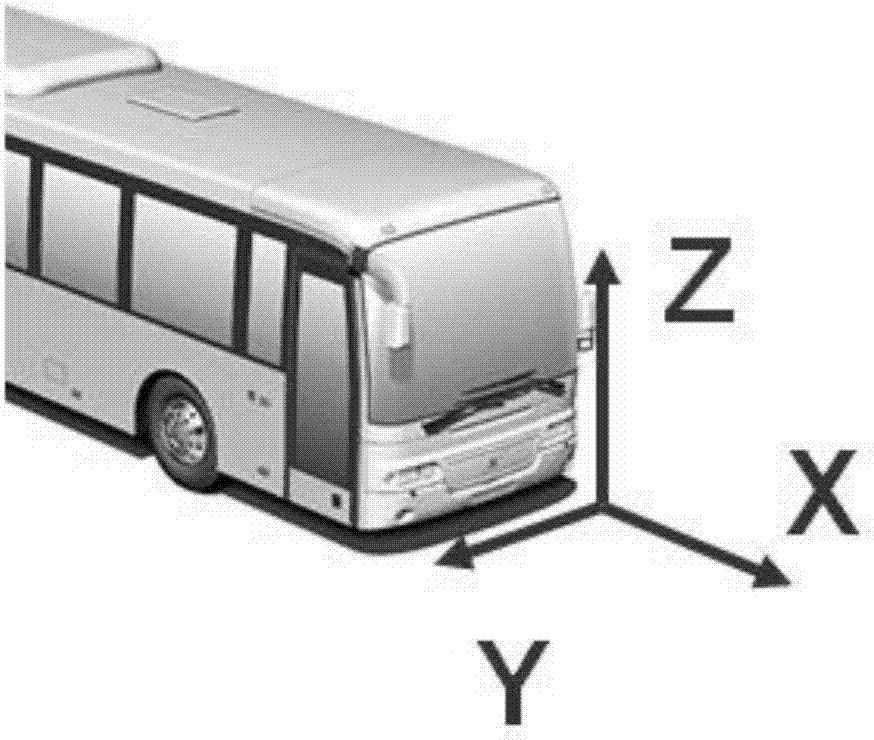

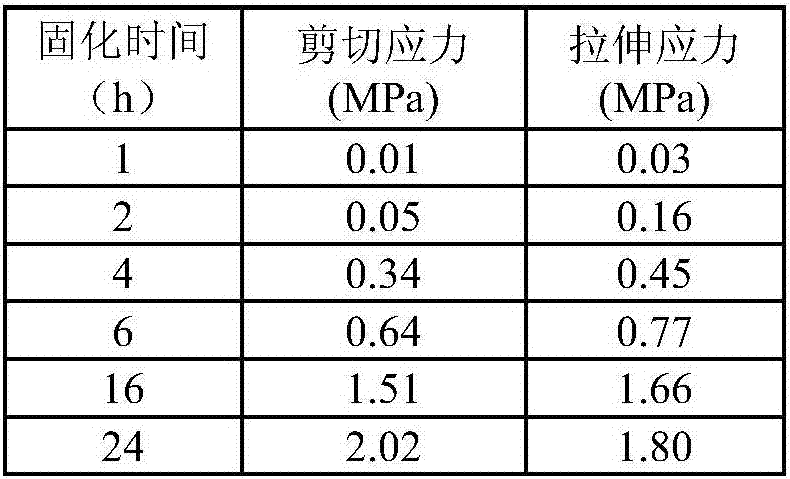

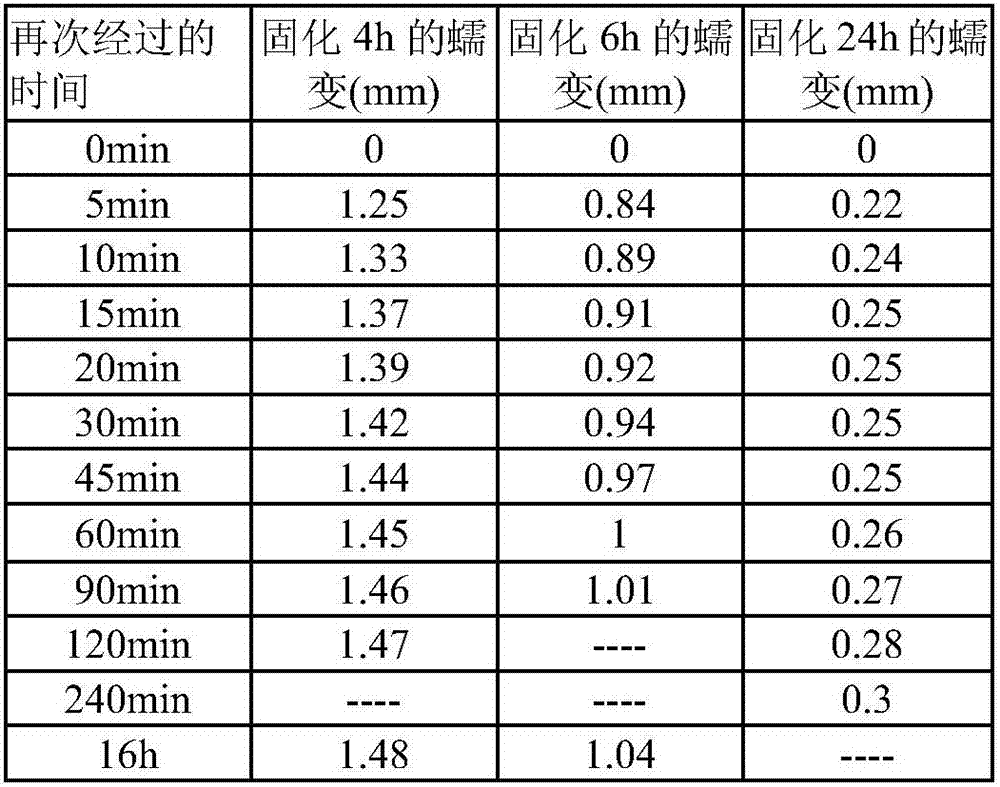

Method for determining safety handling time of cars and car production method

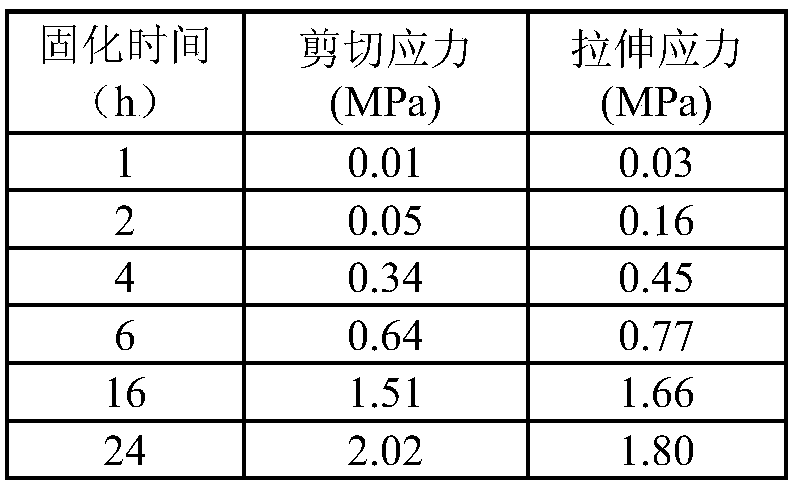

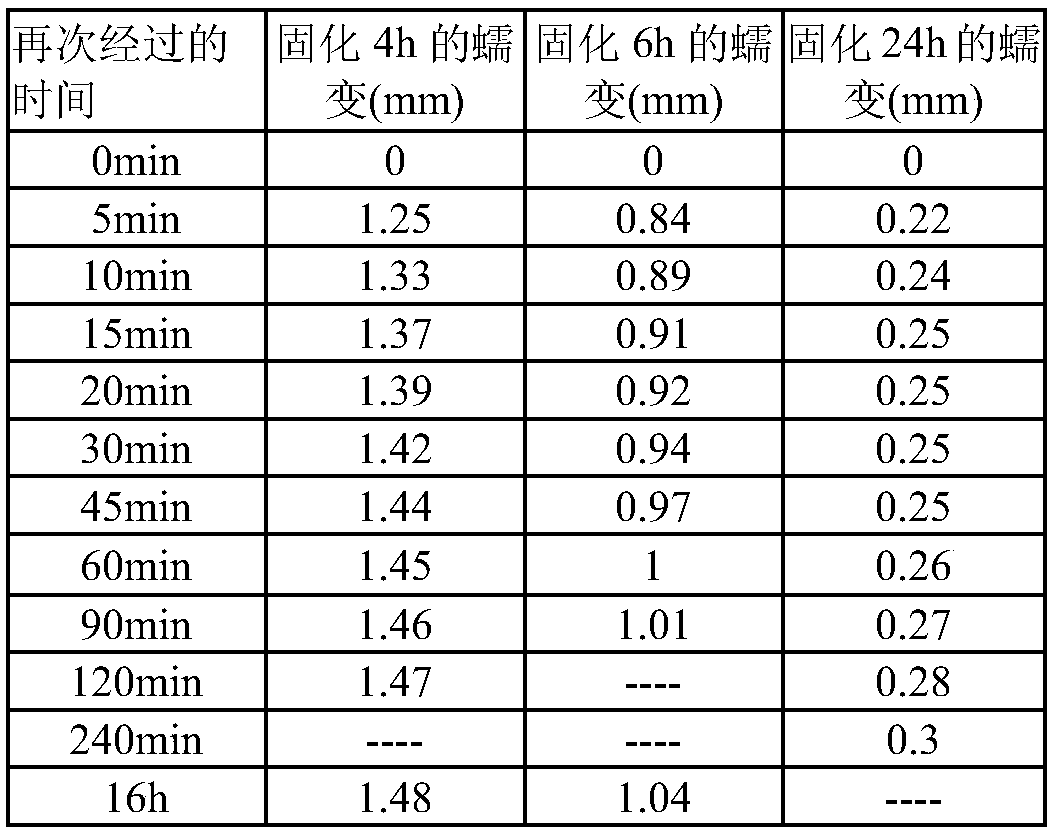

The invention provides a method for determining safety handling time of cars and a car production method and belongs to the technical field of car window bonding, aiming to overcome the failure in determining the safety handling time of the cars in the prior art. The car comprises a window bonded to a car body through a binder. The first stage of the safety handling time refers to the time from bonding the window to the car body until the beginning of the stage. The method includes calculating the maximum shear stress tau and the maximum tensile stress sigma of the window at the first stage according to the formula: tau=m<1>(1+f<2>)*g*f<1> / (L*w*f<3>), sigma=m<z>*g*f<1> / (L*w*f<3>), wherein L is the window circumference, w is the width of the window bonding region, m<1> is the window mass, and m<z> is the equivalent mass causing shear stress; determining the safety handling time of the stage according to tau and sigma and the preset bonding strength table, wherein the bonding strength table refers to a corresponding relationship table about curing time, shear strength and tensile strength of the binder on current conditions, the safety handling time refers to the minimum curing time, which allows the shear strength and the tensile strength respectively to be greater than or equal to the tau and the sigma, of the bonding strength table.

Owner:SIKA (CHINA) LTD

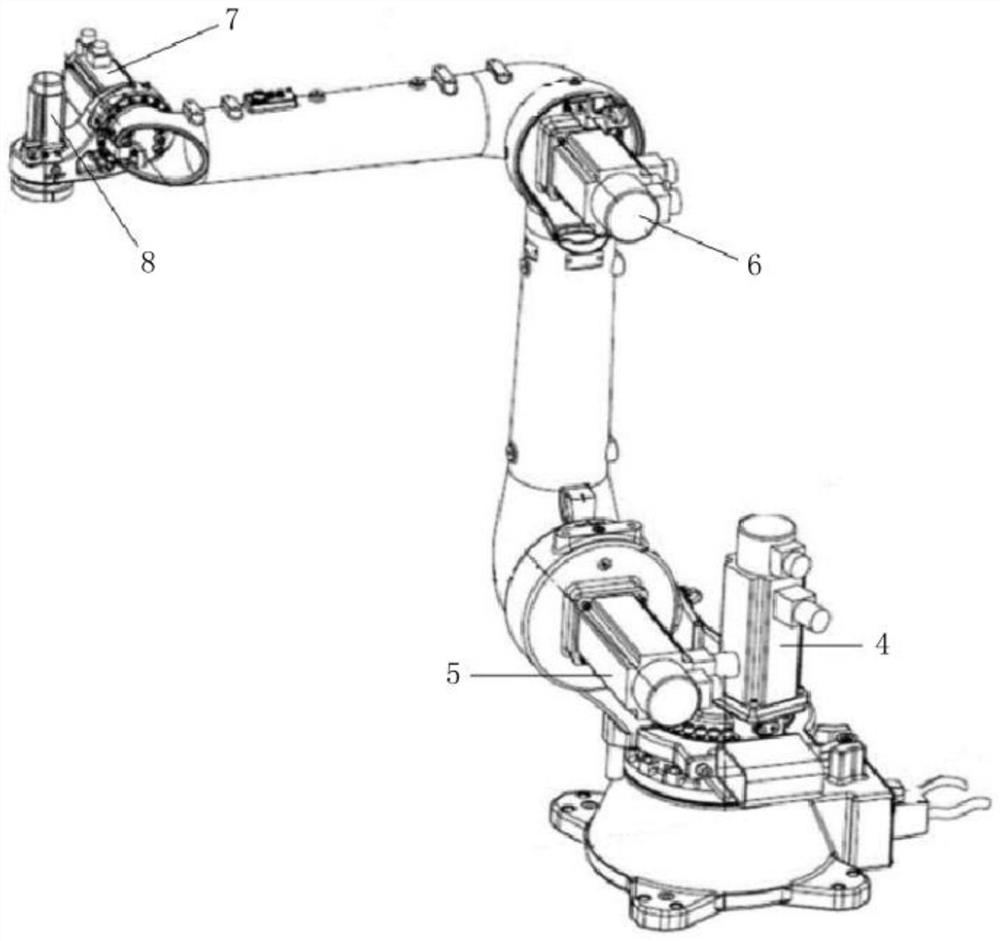

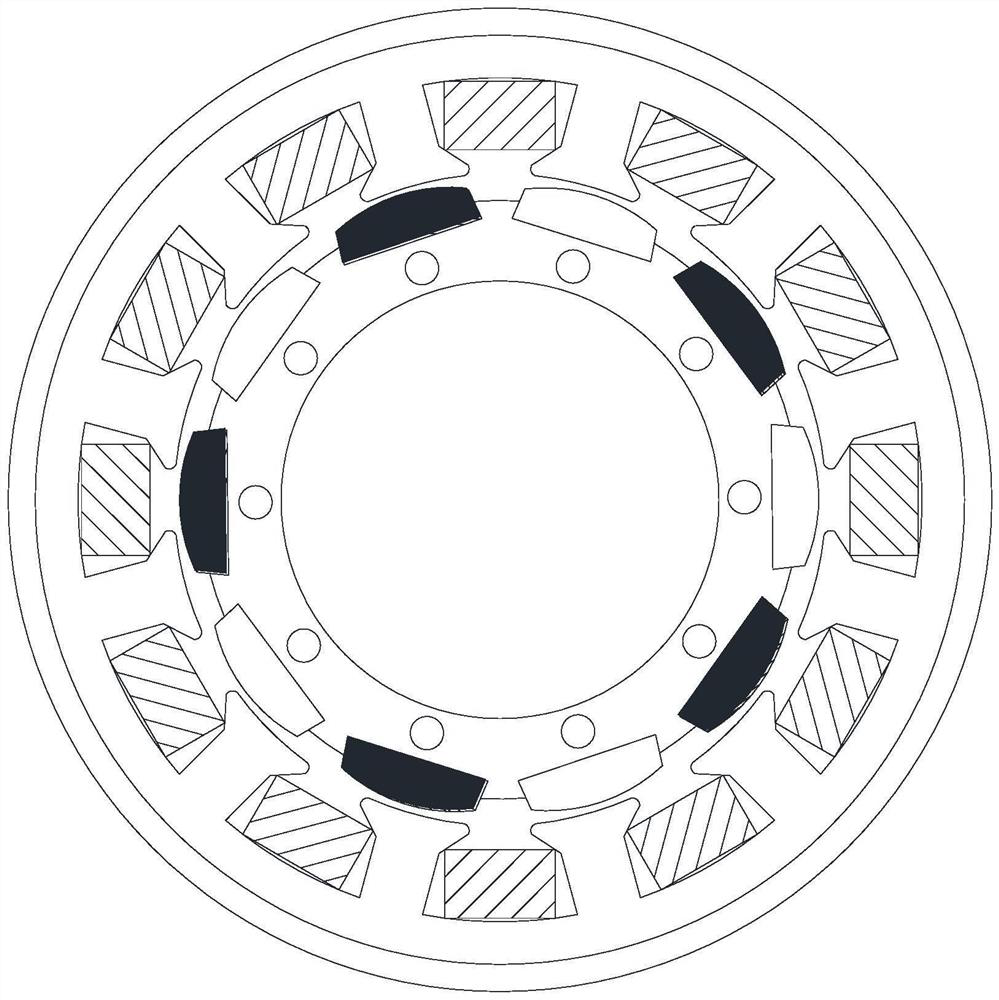

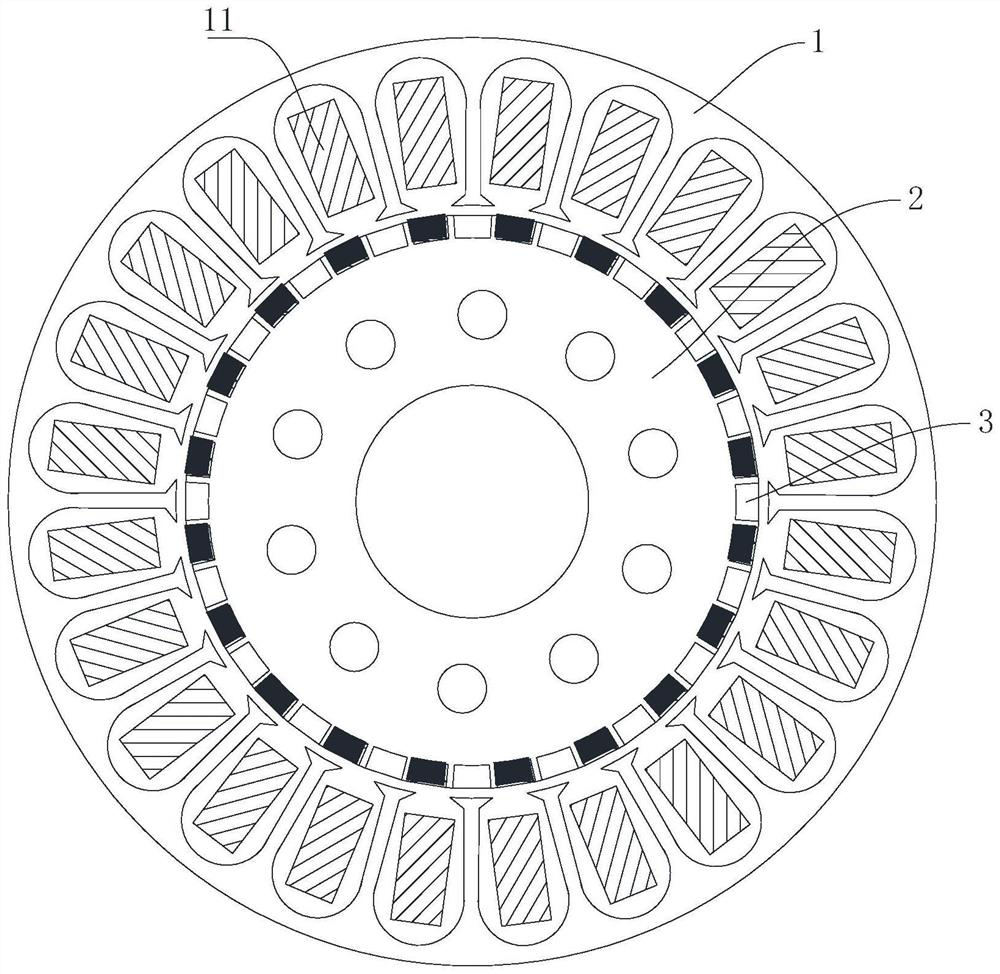

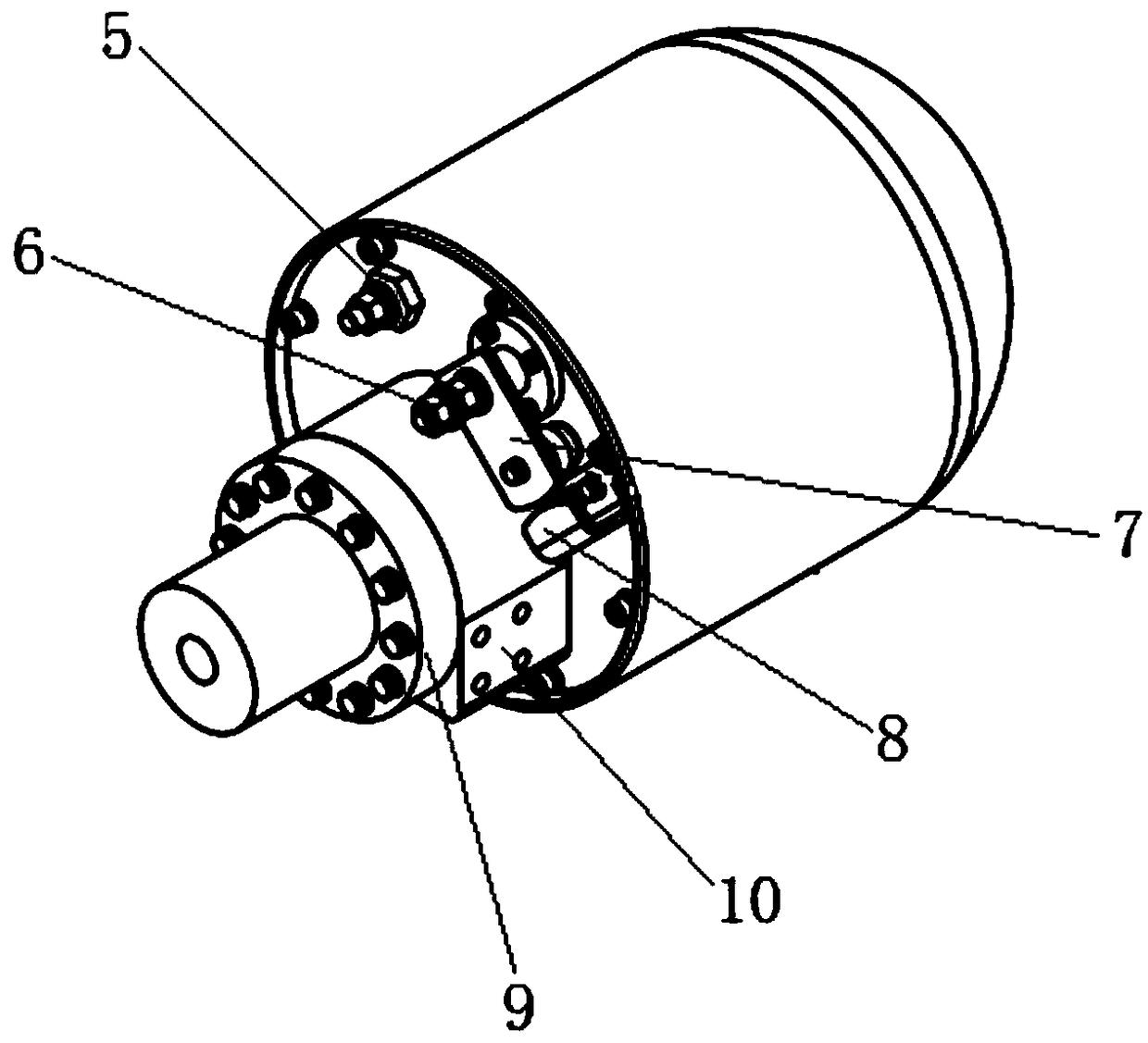

Magnetic field modulation motor magnetic circuit structure for robot arm joint

PendingCN114884235AEquivalent number of poles increasedReduce gear ratioProgramme-controlled manipulatorMagnetic circuit rotating partsReduction driveElectric machine

The invention discloses a magnetic field modulation motor magnetic circuit structure for a robot arm joint, and relates to the technical field of robots, more permanent magnets are adopted, more harmonic magnetic fields are generated through magnetic field modulation, although the harmonic magnetic fields cannot be seen, electromagnetic torque is actually generated to participate in the electromechanical energy conversion process, and the mechanical energy conversion efficiency is improved. Harmonic waves include third-order harmonic waves, fifth-order harmonic waves, seventh-order harmonic waves,... 2k + 1-order harmonic waves, generation of the harmonic waves actually enables the equivalent pole number of the motor to be increased, and therefore the rotating speed is reduced, electromagnetic speed reduction of a traditional servo motor can be achieved, the output rotating speed of a motor rotor shaft is reduced, torque is greatly improved, a speed reducer can be omitted, or the speed ratio of the speed reducer can be greatly reduced. Therefore, the technical threshold of mechanical manufacturing is reduced, low-speed direct drive and large-torque output of the motor are achieved, the transmission structure is greatly simplified, the weight of the transmission structure is reduced, and the dynamic response capacity and control precision of the system are improved.

Owner:ZHONGZHI NANJING ELECTRIC CO LTD

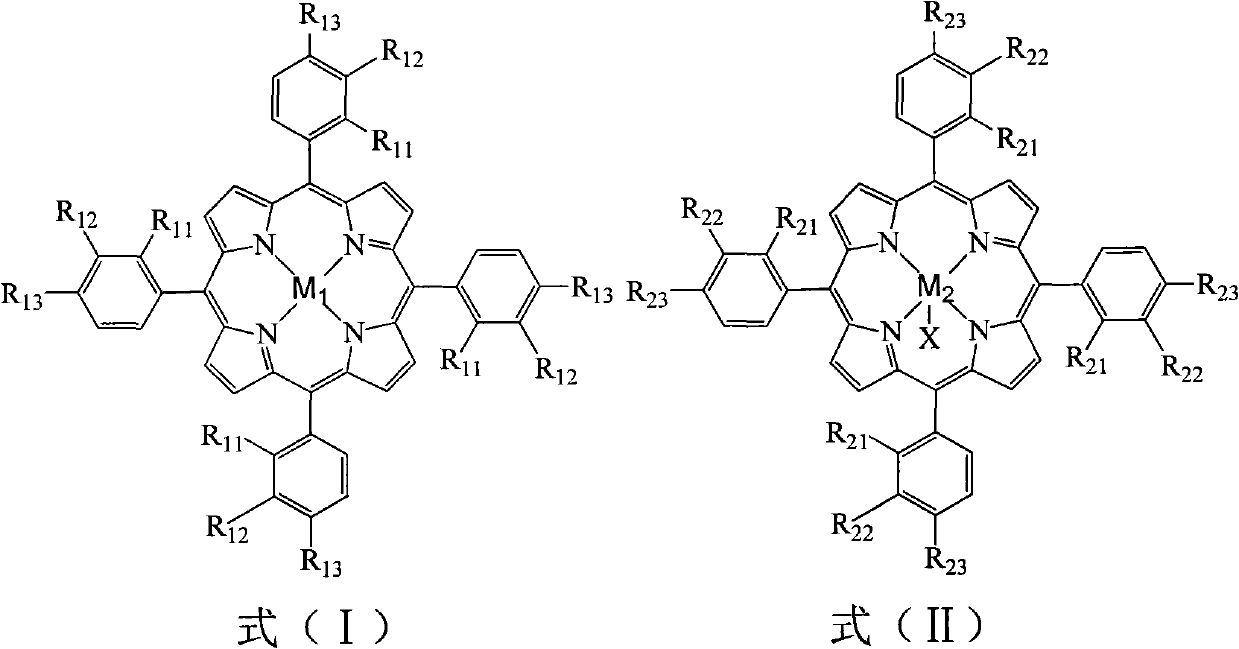

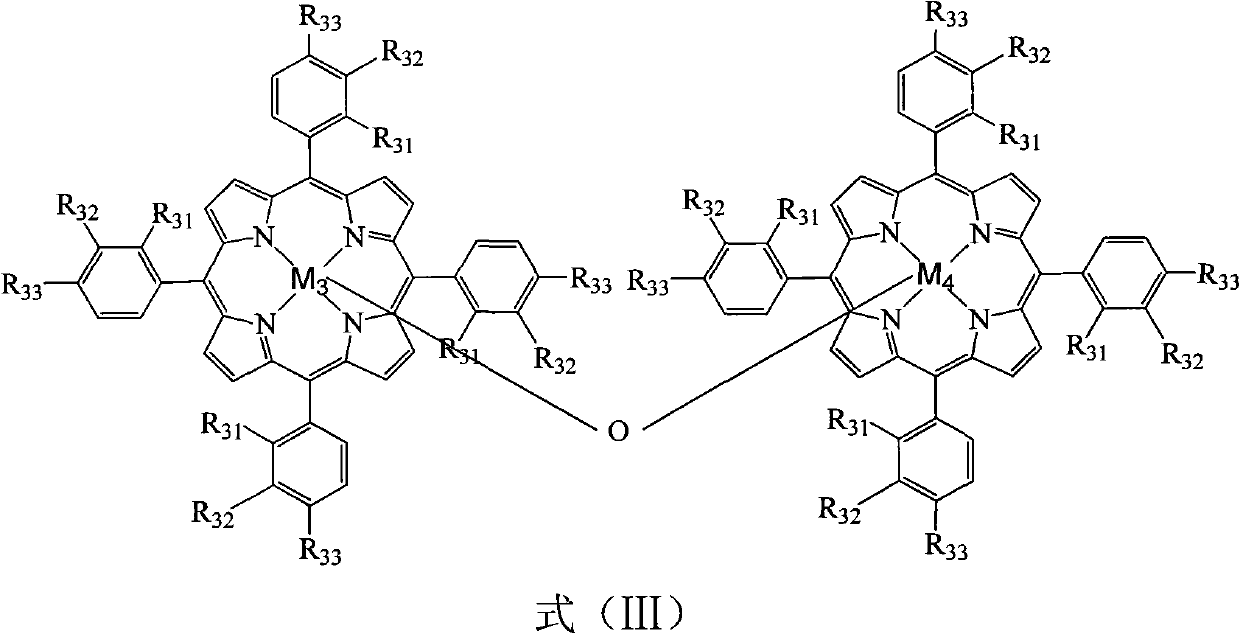

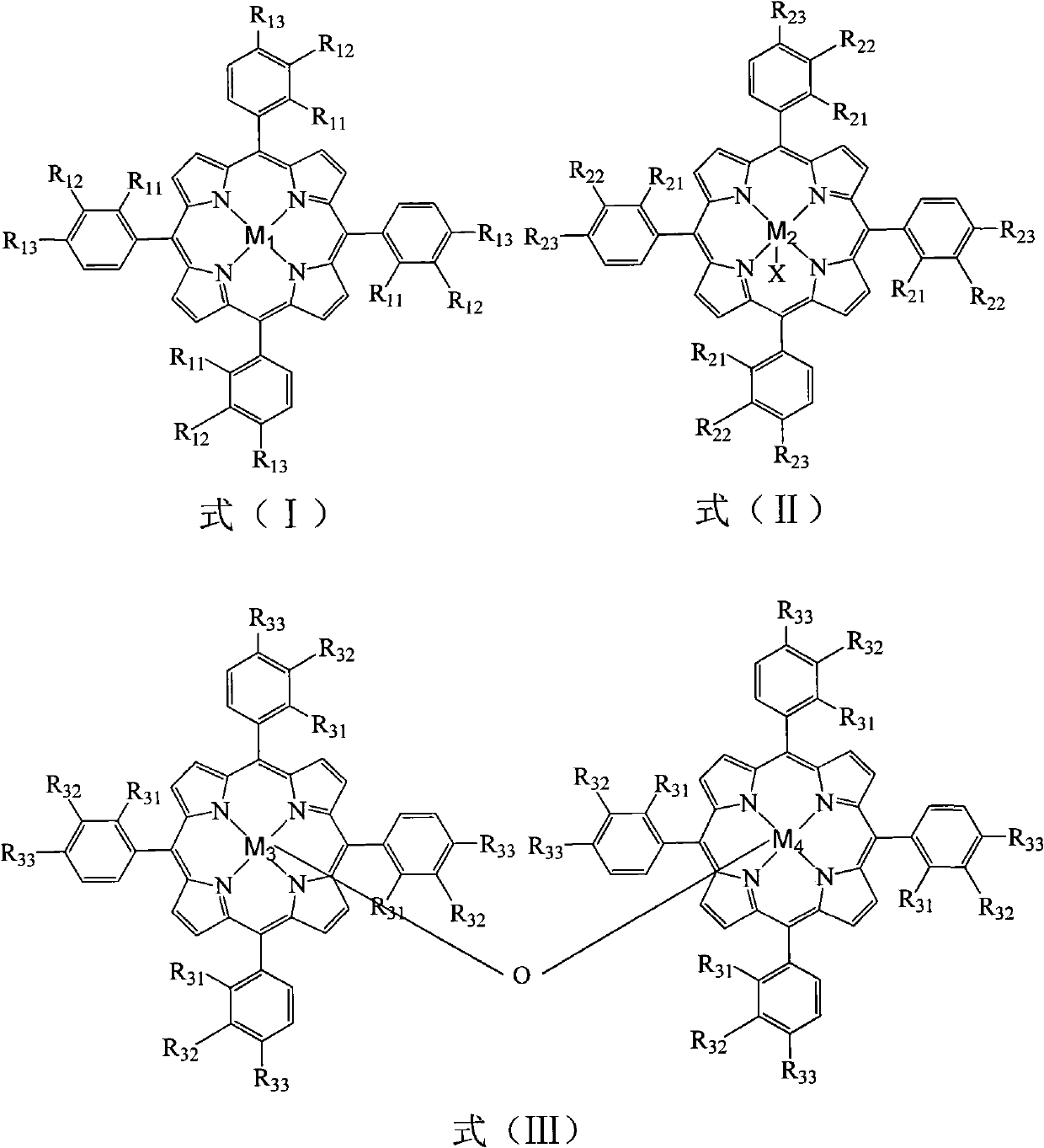

Method for preparing p-bromophenylacetone by biomimetic catalytic oxidation of p-bromoethylbenzene

InactiveCN101768067AHigh Chromatographic YieldShort reaction timeOrganic compound preparationCarbonyl compound preparationP-bromoacetophenoneBromine

The invention relates to a method for preparing p-bromophenylacetone by biomimetic catalytic oxidation of p-bromoethylbenzene, comprising the following steps of: taking p-bromoethylbenzene as raw material; selecting either of 1-30ppm mononuclear metal porphyrin and mu-oxo-dinuclear metal porphyrin or the both as a catalyst; introducing oxygen at the flow speed of 10 to 60mL / min under normal pressure without solvents; initiating reaction at 140 DEG C to 170 DEG C; and reacting for 6 to 16h at 80 DEG C to 120 DEG C to obtain the p-bromophenylacetone. The method uses the mode of high-temperaturequick initiation and low-temperature reaction, greatly shortens the initiation time of the reaction and the reaction time, improves the reaction efficiency, reduces the energy consumption and operation costs and improves the reaction safety.

Owner:BEIJING UNIV OF TECH

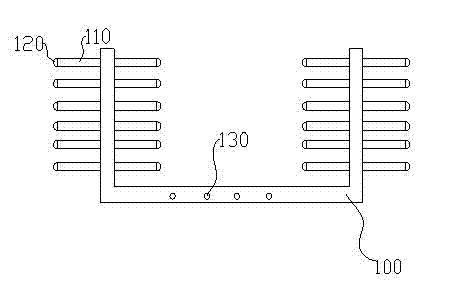

High-efficiency heat radiating fin

InactiveCN102858140AImprove cooling effectNo heat dissipationCooling/ventilation/heating modificationsHeat sinkMaterials science

The invention discloses a high-efficiency heat radiating fin. The high-efficiency heat radiating fin comprises a fin body, wherein the fin body is made of aluminum alloy and is formed by stamping; heat radiating fins are respectively arranged on two sides of the fin body; the space of every two heat radiating fins is equal; the top of each heat radiating fin is of a circular arc shape; a mounting hole is formed on the surface of each fin body; the mounting hole is formed by using a drilling milling machine; and the sizes of the mounting holes are identical. The high-efficiency heat radiating fin disclosed by the invention can be applied to a daily household appliance and can conveniently help the appliance dissipate heat; in addition, the high-efficiency heat radiating fin is made of aluminum alloy, and thus the production cost is saved, the production quality is improved and the simpleness and convenience in the actual mounting process are realized; the heat dissipating function is favorable, so that the problem caused by improper dissipation of the inside of the appliances can be solved; favorable practical performance and high flexibility are realized; and the high-efficiency heat radiating fin is a novel design scheme and facilitates the popularization and the use.

Owner:昆山铭佳利电子制品有限公司

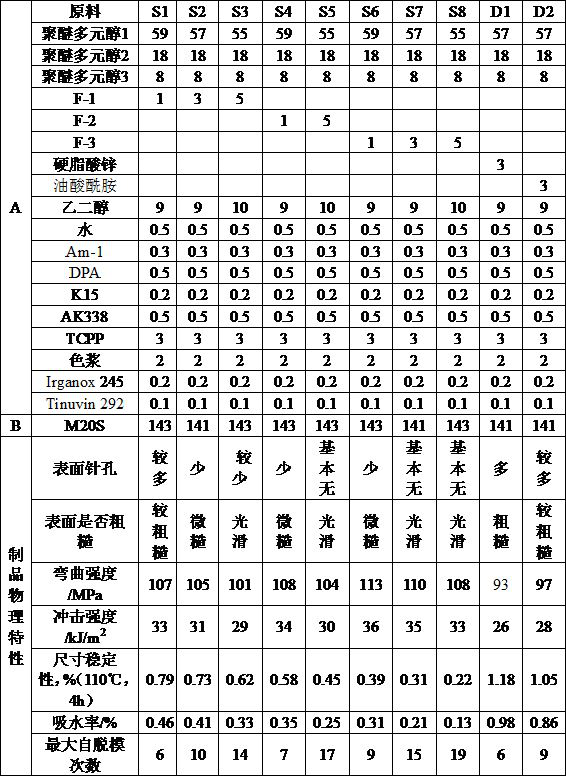

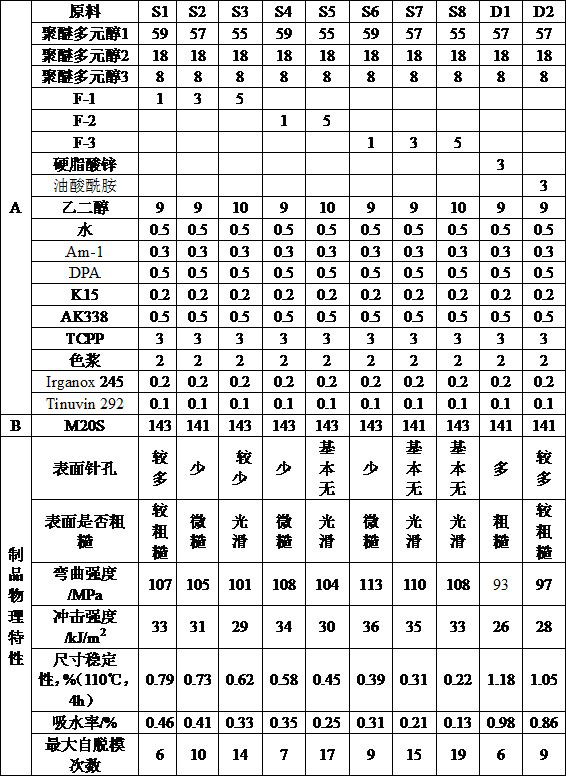

Polyurethane composition for high-surface-quality self-demolding automobile exterior trimming part material and application thereof

The invention discloses a polyurethane composition for a high-surface-quality self-demolding automobile exterior trimming part material and application thereof. The polyurethane composition comprises, in percentage by weight, a component A which comprises 50-60% of polyether polyol 1, 10-20% of polyether polyol 2, 5-10% of polyether polyol 3, 1-5% of a fluorosilicone modified amino compound, 5-10% of a chain extender, 0.2-2% of a foam stabilizer, 0.5-2% of a catalyst, 1-5% of a flame retardant and 0.2-1% of water. 0.5-3% of other additives are selectively added; the polyether polyol 1 takes cane sugar and glycerol as a mixed initiator, the hydroxyl value is 400-500mg KOH / g, and the polyether polyol 1 has six functional groups; the polyether polyol 2 takes glycerol as an initiator, the hydroxyl value is 400-500mg KOH / g, and the polyether polyol 2 has three functional groups; the polyether polyol 3 takes glycerol as an initiator, is grafted by epoxypropane and terminated by ethylene oxide, has a hydroxyl value of 33-37 mg KOH / g, and has three functional groups; and a component B is PAPI.

Owner:LIMING RES INST OF CHEM IND

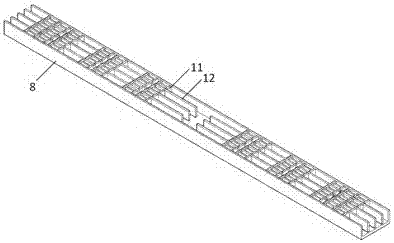

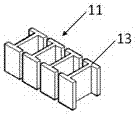

Motor power supply transfer wiring slot

The invention discloses a rotor power supply switching line slot. The motor power supply switching line slot comprises a box body provided with a detachable upper cover, wherein multiple groups of plug connecting holes are formed in the upper cover; multiple groups of parallel copper bar fixed parts are transversely arranged in the box body; each copper bar fixed part is formed by one row of four fixed blocks which have the same size and shape and H-shaped cross sections; and a copper bar which is vertically inserted is arranged in a gap between two adjacent fixed blocks. By applying the motor power supply switching line slot, line switching from normal racking to non-normal racking can be quickly realized, clipping of a motor lead can be effectively avoided, various problems caused by clipping of the lead cannot occur, the reliability of the power supply line is improved, and meanwhile, the motor switching line slot is applied, so that the non-normal test can be carried out at any safe distance, the occurrence of the human injury is avoided, the tester can operate conveniently, and the system testing requirements are met.

Owner:中国原子能工业有限公司

Air purification module

InactiveCN103585828AEffective disinfectionEfficient degradationDispersed particle filtrationRadiationFiltrationAir purification

The invention discloses an air purification module. The air purification module comprises a coarse filtration screen, a fine filtration screen, filter cotton and a modified nano-titanium dioxide foam metal filtration screen. The coarse filtration screen is used as a surface and the modified nano-titanium dioxide foam metal filtration screen is used as an inner layer. The fine filtration screen and the filter cotton are orderly arranged between the coarse filtration screen and the modified nano-titanium dioxide foam metal filtration screen from outside to inside. Compared with the prior art, the air purification module can realize effective sterilization, disinfection and organic pollutant degradation without energy consumption, has a low use cost, utilizes the purification screens recyclable after cleaning, prevents adsorption saturation, is convenient for maintenance, has high efficiency and has no toxic or side effect.

Owner:广州市阿波罗健康科技有限公司

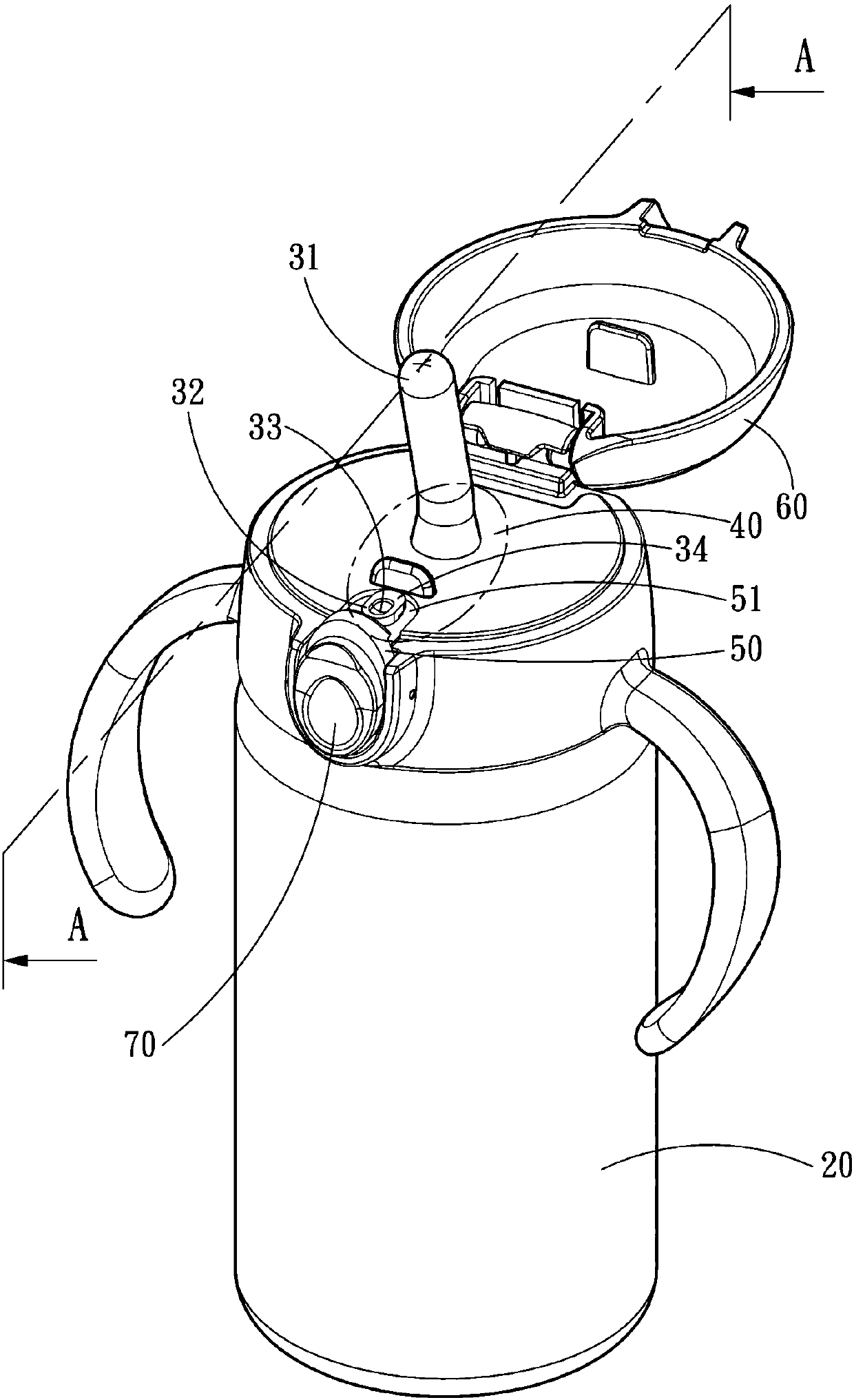

Kettle cover with pressure relief device

InactiveCN111493609APrevent sprayingAvoid pollutionDrinking vesselsEngineeringStructural engineering

The invention provides a kettle cover which comprises a water absorption element, a bottle cap, a water bottle cap and an opening element, wherein the water absorption element is provided with a waterabsorption head and an air leakage part; the air leakage part is provided with an air leakage valve; the water absorption element is arranged on the bottle cap; the water suction head and the air leakage part are exposed outwards; the bottle cap is locked on a bottle opening; the opening element is arranged on the bottle cap in a sliding and penetrating manner and is provided with an initial position and an acting position; one end of the kettle cover is pivoted to the bottle cover, the other end of the kettle cover is buckled and fixed by an opening element located at the initial position, and when the opening element is pressed to be located at the acting position, in order to enable the kettle cover to be separated from the opening element, the kettle cover is opened through elastic force of the water suction head, and meanwhile the opening element pushes the air leakage part to deform to enable the air leakage valve to be opened. Therefore, when a user presses the opening elementto open the kettle cover, the air leakage valve can be simultaneously linked to be opened to release pressure, water in the kettle is prevented from being sprayed out of the water suction head due topressure, and dangers and environmental pollution can be avoided.

Owner:SONISON BABY PRODS

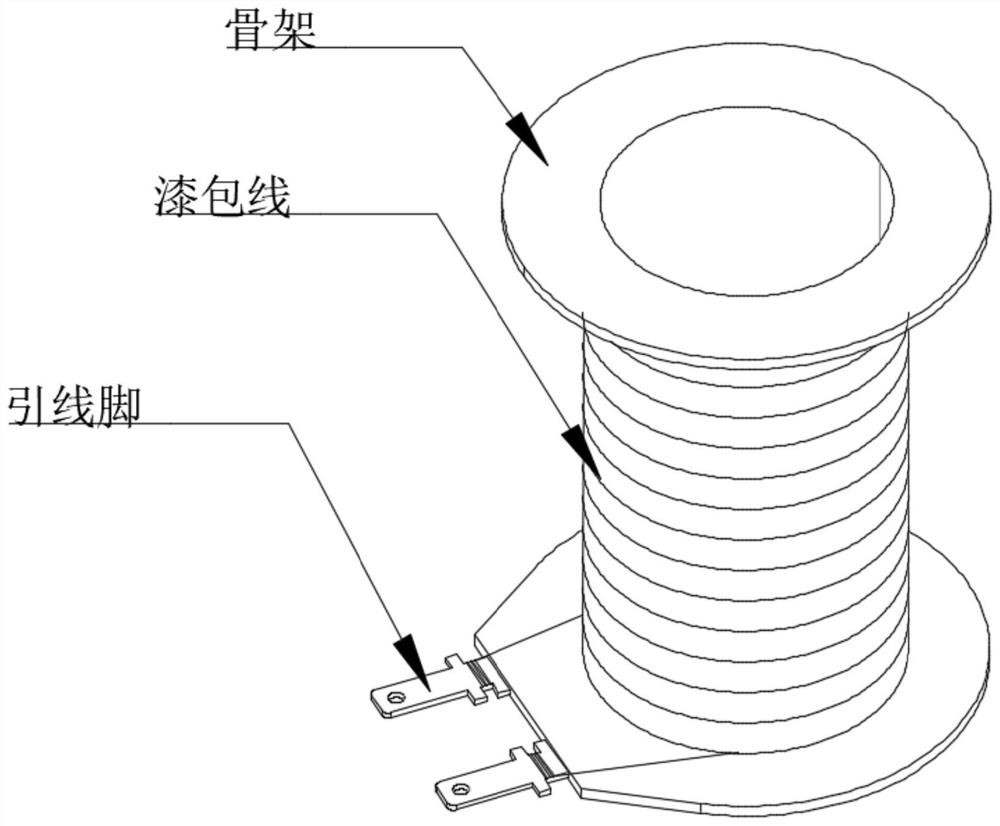

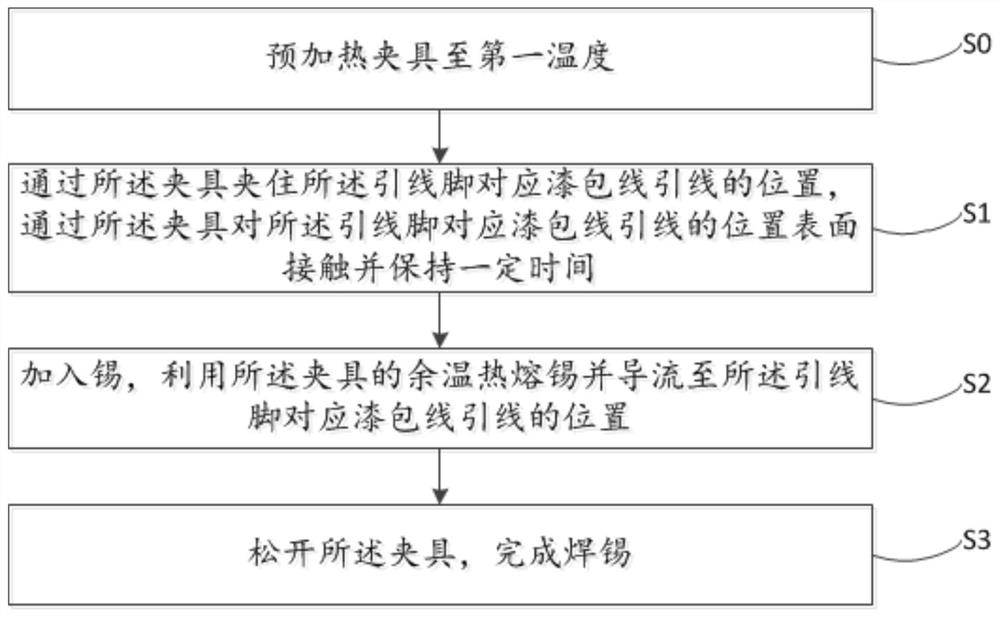

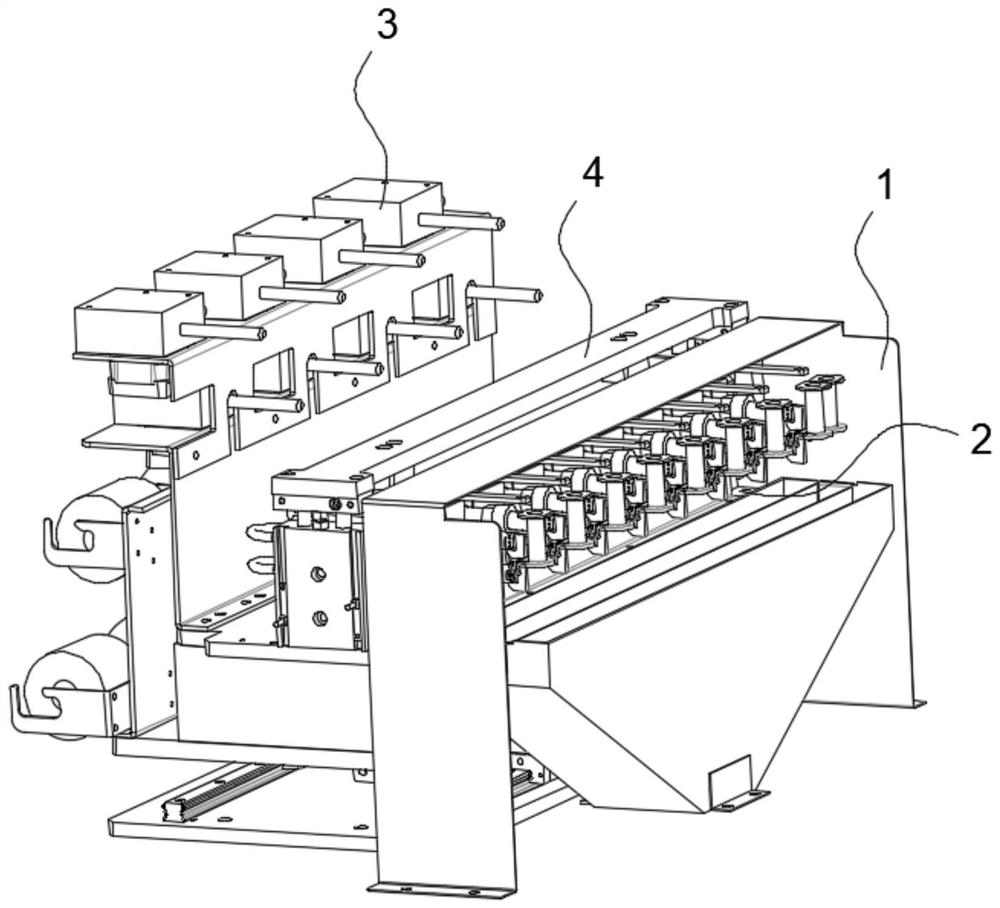

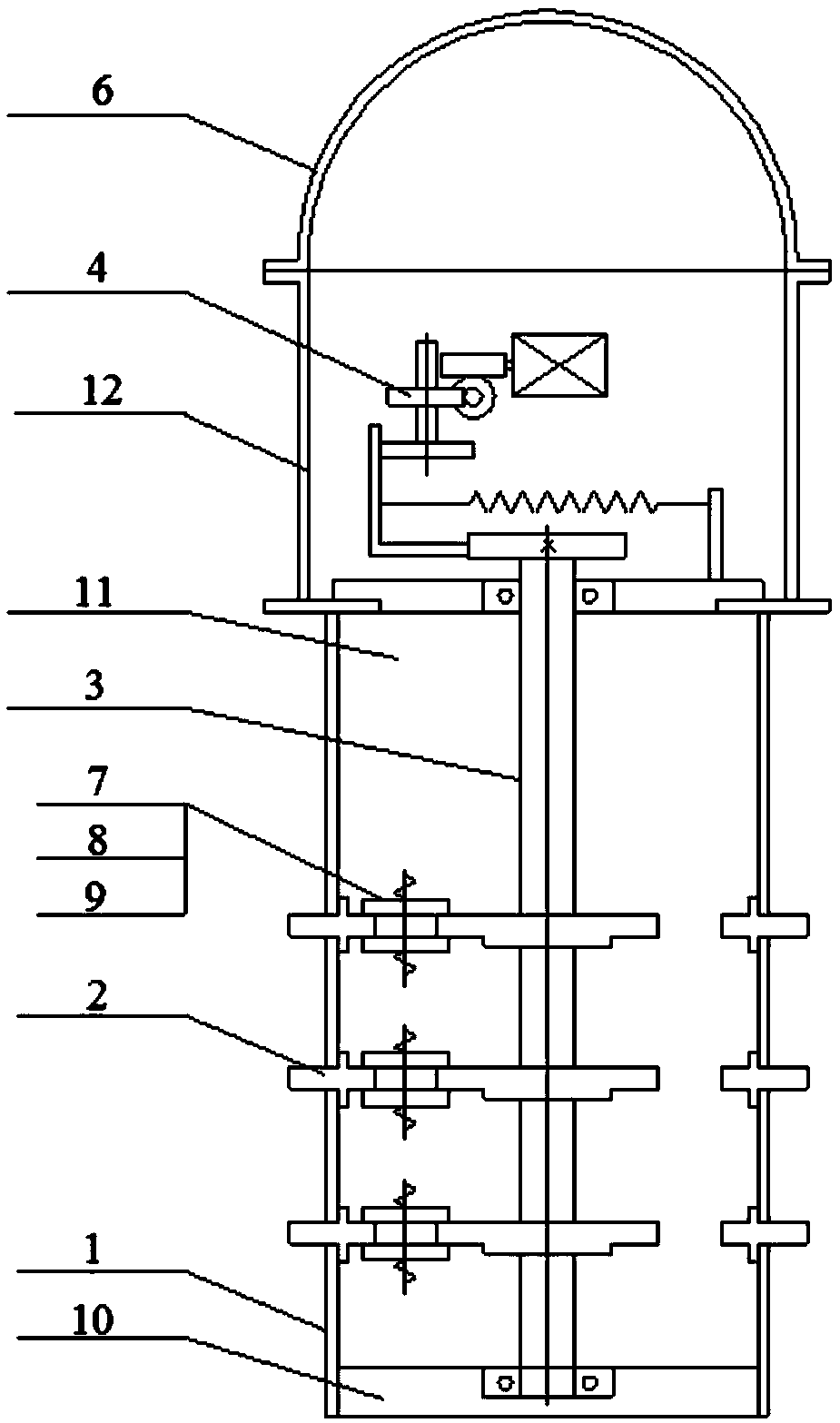

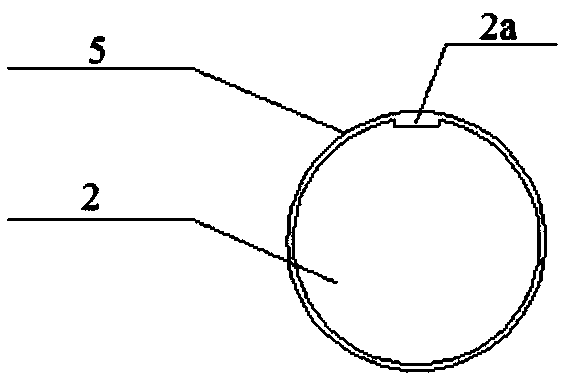

A control method of a soldering device for an enameled wire lead

ActiveCN113000961BIncrease brightnessShorten the gasification timeMetal working apparatusSolder feeding devicesTemperature controlEngineering

The invention relates to a method for controlling a soldering device for enameled wire leads, comprising the following steps: S1, providing a soldering device for enameled wire leads; S2, placing skeletons in parallel on the skeleton positioning mechanism; S3, controlling the heating mechanism to heat the fixture to The first temperature; S4, control the first driving cylinder to drive the clamp to close and hold one of the lead pins of the frame corresponding to the position of the enameled wire lead, and keep it for the first time; S5, control the reel to pull out the tin wire from the reel and send it Enter the tin feeding conduit, make the tin wire contact the clamping part, use the residual temperature of the clamping part to melt the tin and divert it to the position of the lead pin corresponding to the lead wire of the enameled wire; S6, control the first driving cylinder to drive the clamping part Loosen; S7, control the second driving cylinder to drive the mounting plate to move laterally, so that the clamping part corresponds to the position of the other lead pin of the frame corresponding to the lead wire of the enameled wire, and repeats steps S3-6.

Owner:厦门瑞熠自动化系统有限公司

Inflatable type on-load tap changer for transformer

PendingCN109545507AReduce maintenance workloadNo problemVariable inductancesTransformers/inductances detailsSulfur hexafluorideAgricultural engineering

The invention discloses an inflatable type on-load tap changer for a transformer. The on-load tap changer includes an insulating cylinder, fixed contacts, a main shaft, a drive mechanism, lubricants,an upper cover, switching contacts, transition resistors, transition contacts, a lower cover, an inflation space, and a drive mechanism shell; The inflatable type on-load tap changer fully utilizes non-flammability, good insulation performance and arc extinguishing performance of a sulfur hexafluoride (SF6) gas, and the on-load tap changer produced by the invention has the following characteristics of being not easy to catch fire and high in safety, being long in service life and repaor cycle, being small in land occupation area and convenient to install and operate, and being excellent in performance and reliable in operation.

Owner:张宏强

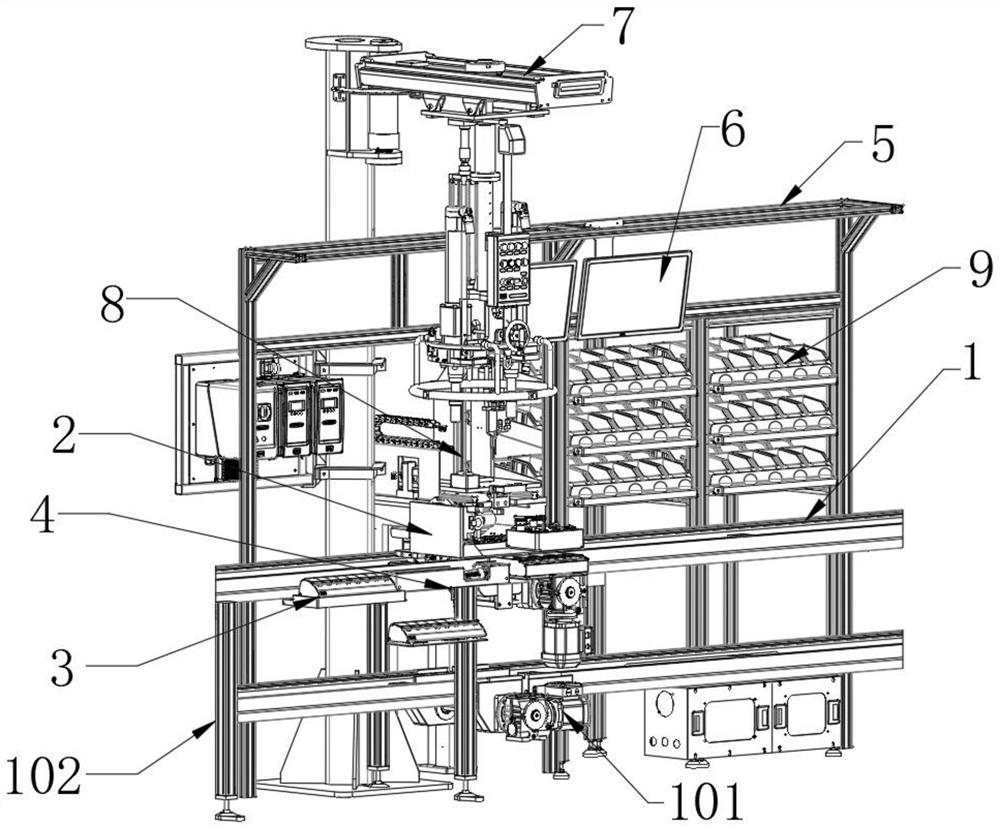

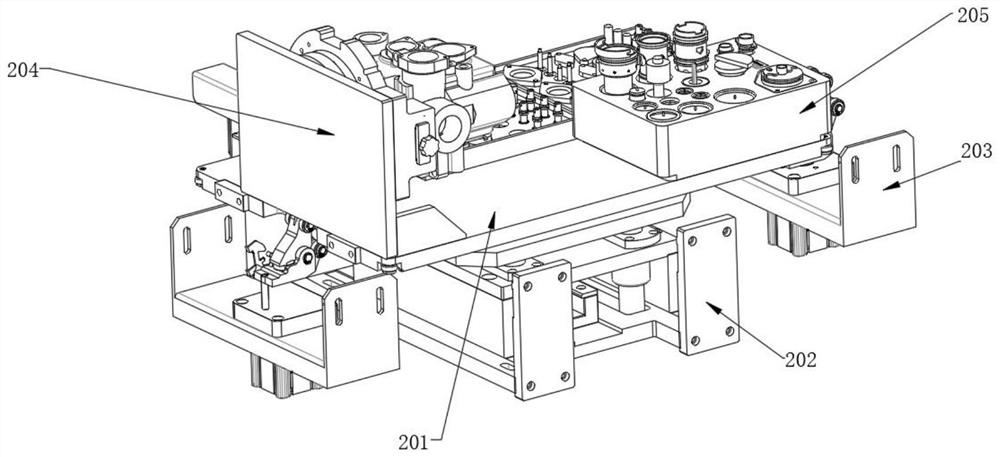

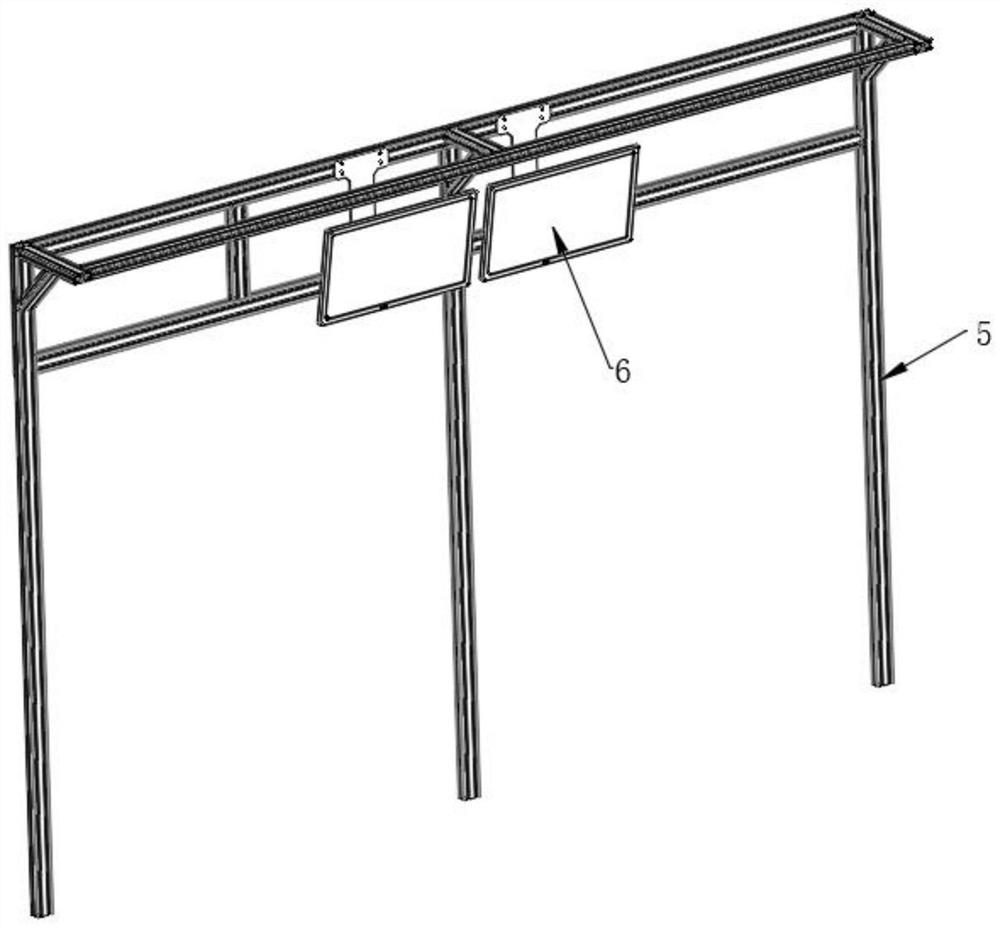

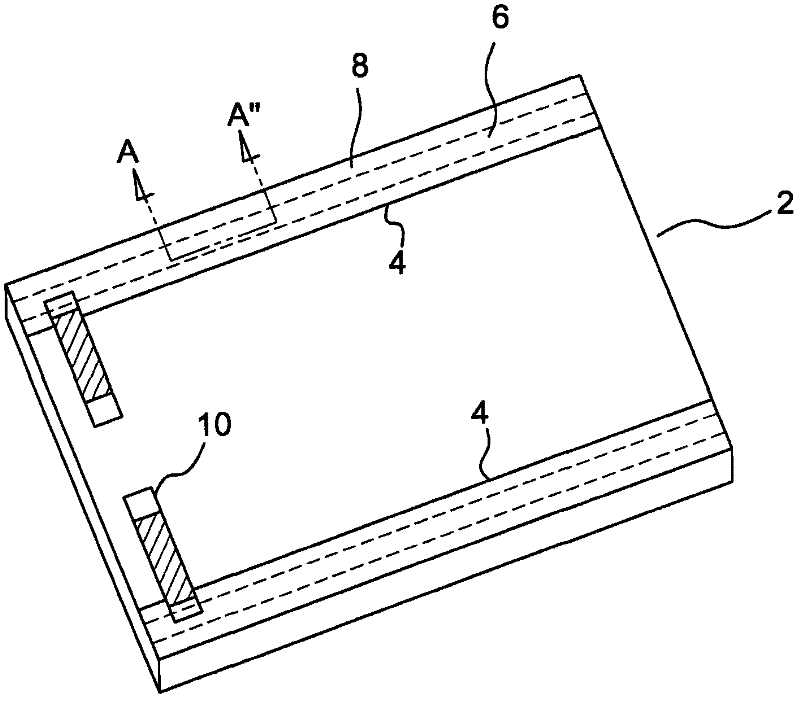

An intelligent material rack for engine production line

ActiveCN113184377BEasy to useEasy to operatePackaging vehiclesContainers for machinesProduction lineDisplay device

The invention discloses an intelligent material rack for an engine production line, comprising a product conveying device, a support frame is arranged on the lower side of the product conveying device, a driving device is connected to the outer side of the product conveying device, and a driving device is arranged on the upper side of the product conveying device The product positioning carrier, the outer side of the product conveying device is connected with a sleeve box, the left side of the sleeve box is provided with a charging screw gun box, the rear side of the product conveying device is provided with a bracket, and the lower side of the top of the bracket is connected with a A display, a height measuring device is arranged on the lower side of the display, an intelligent material rack is arranged on the right side of the height measuring device, and a screw gun is arranged on the left side of the height measuring device. The fluent strip at the bottom of the material rack is high in front and low in the back; the fluent strip on the upper side of the material rack is low in front and high in the back. The interior of the fluent strip is composed of multiple sets of pulleys. When in use, it is only necessary to load the material from the rear side, and take out the empty material box from the front end and place it on the fluent strip at the bottom. Easy to use and simple to operate.

Owner:西交思创智能科技(河北雄安)有限公司

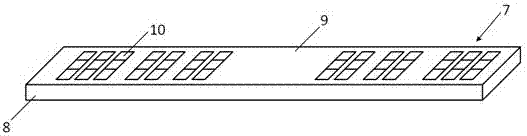

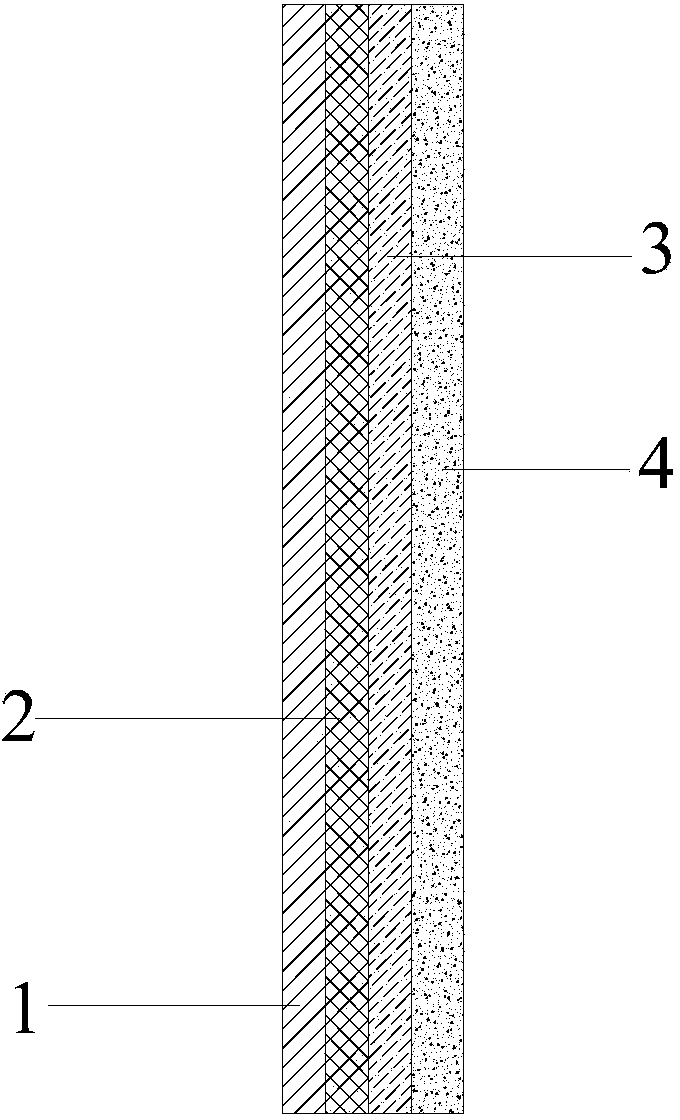

Process of electrically connecting electrodes of a photovoltaic panel

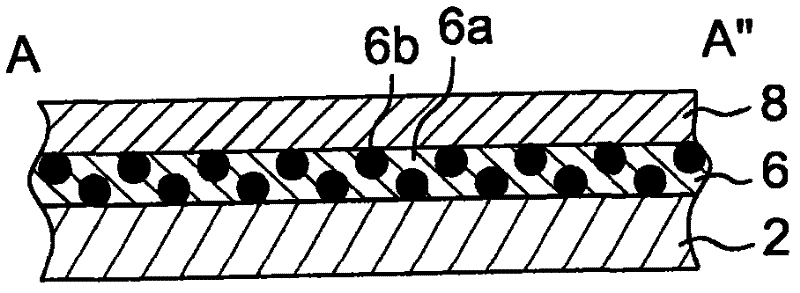

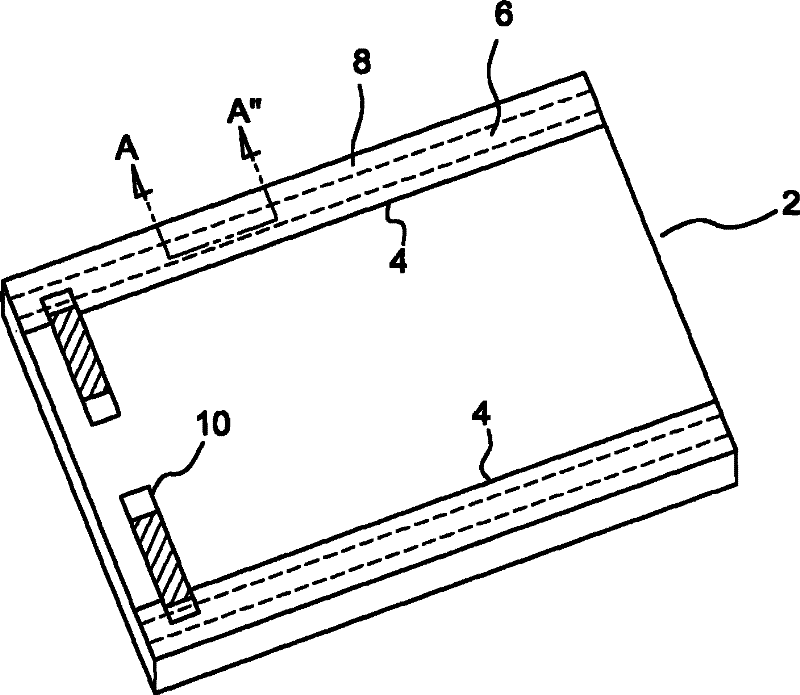

InactiveCN102194923AAvoid electrical connectionNo problemElectrical equipmentPhotovoltaic energy generationMetal stripsElectrical connection

A process of electrically connecting electrodes of a photovoltaic panel is provided, comprising: applying a conductive adhesive film on the electrodes of the photovoltaic panel, wherein the conductive adhesive film comprising an insulating adhesive layer and electrical conductive particles distributed in the insulating adhesive layer; providing a metal strip along the conductive adhesive film; and performing an electrical connection process between the metal strip and the electrodes via the conductive adhesive film.

Owner:DU PONT APOLLO

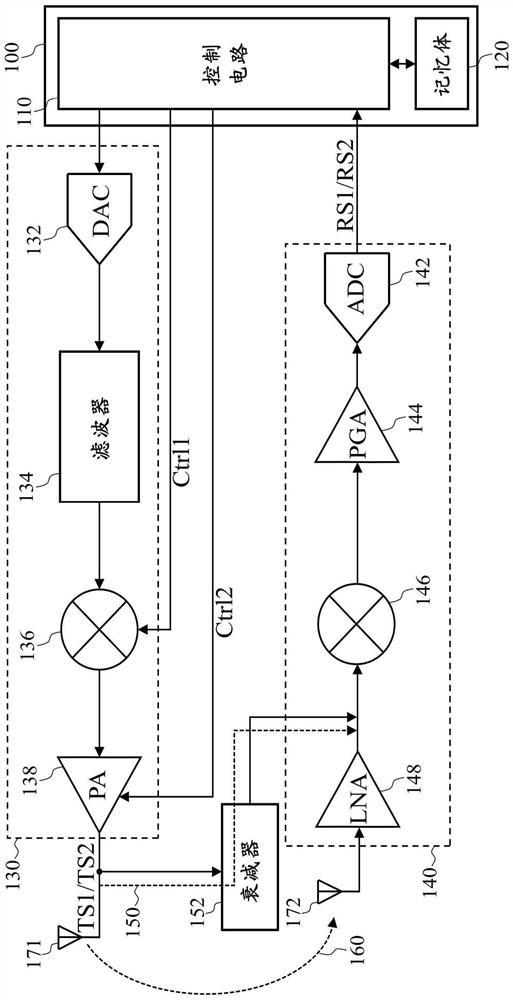

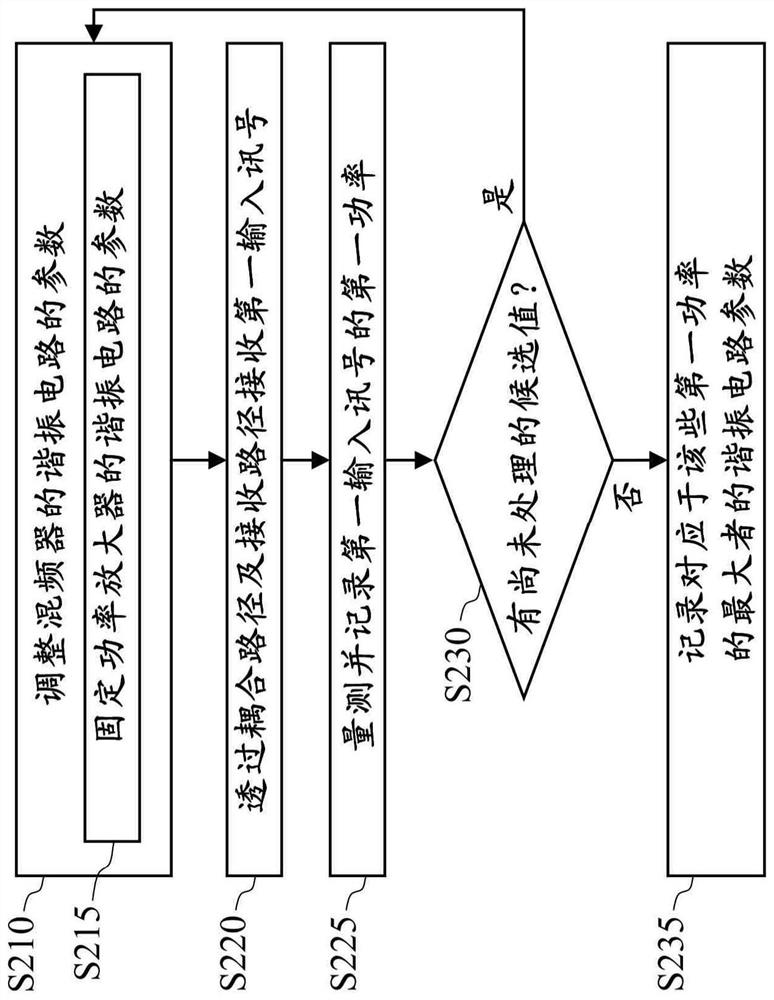

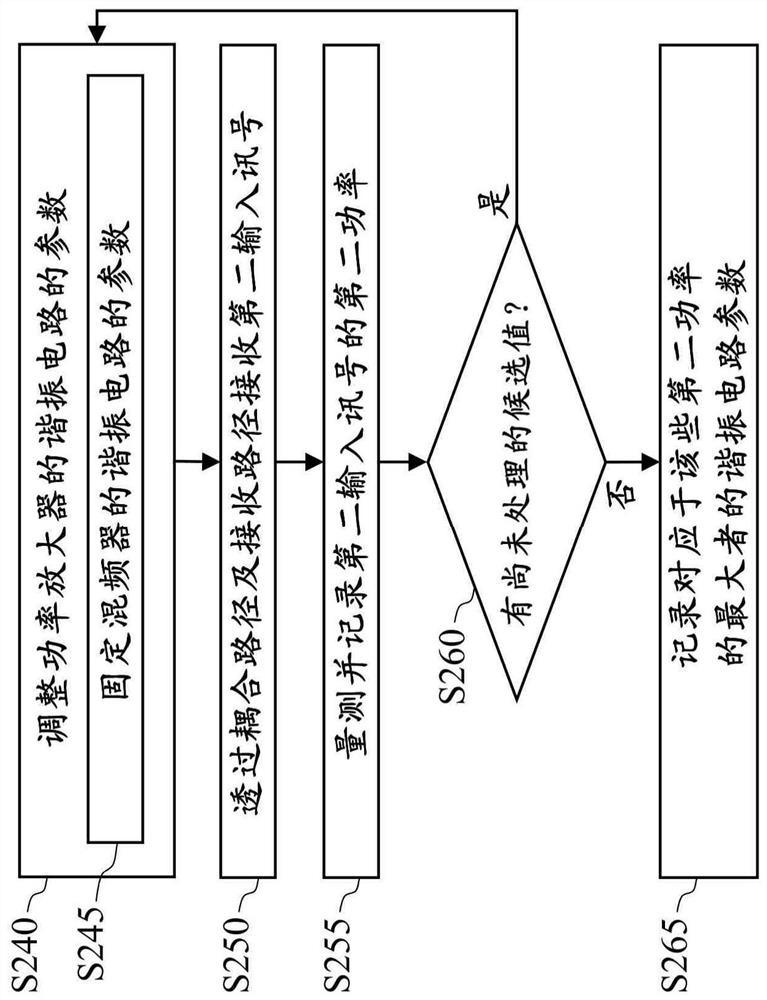

Correction method and correction circuit of wireless transceiver

The invention discloses a correction method and a correction circuit of a wireless transceiver. The wireless transceiver comprises a transmission path and a receiving path. The transmission path comprises a mixer. The correction method includes: (A) adjusting a first parameter of a first resonant circuit of the mixer; (B) receiving a first input signal through a coupling path and the receiving path; (C) measuring a first power of the first input signal; (D) repeating the steps (A) to (C) to obtain a plurality of first powers; and (E) finding out a first target parameter corresponding to the maximum one of the first powers.

Owner:REALTEK SEMICON CORP

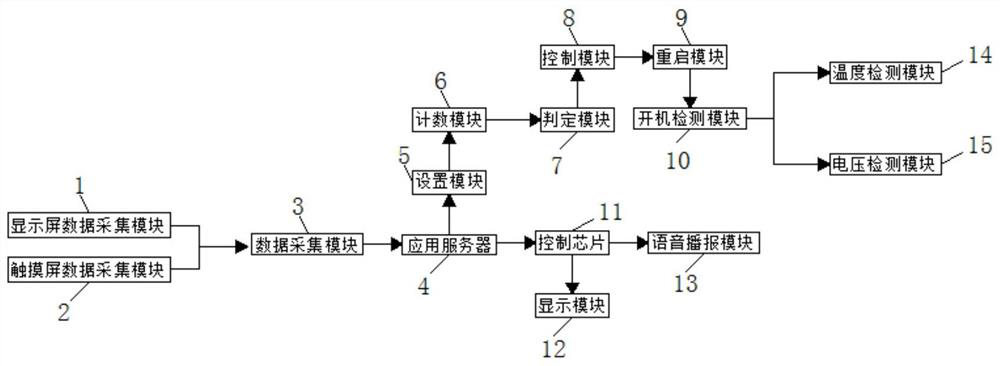

A Crash Detection System Based on Touch Screen and Display

ActiveCN107608811BReal-time monitoring of operating conditionsGuaranteed uptimeRedundant operation error correctionApplication serverData acquisition

The invention discloses a crash detection system based on a touch screen and a display screen. connection, the output end of the data transmission module is electrically connected to the input end of the application server, the output end of the application server is electrically connected to the input end of the setting module, the output end of the setting module is electrically connected to the input end of the counting module, and the output end of the counting module It is electrically connected with the input end of the judgment module. The crash detection system based on the touch screen and the display screen, through the cooperation between the display screen data acquisition module, the touch screen data acquisition module, the application server and the counting module, does not occupy system resources during detection, improves the operating speed of the mobile terminal, and The detection of the mobile terminal is more accurate than the watchdog timer.

Owner:河源市中源光电科技有限公司

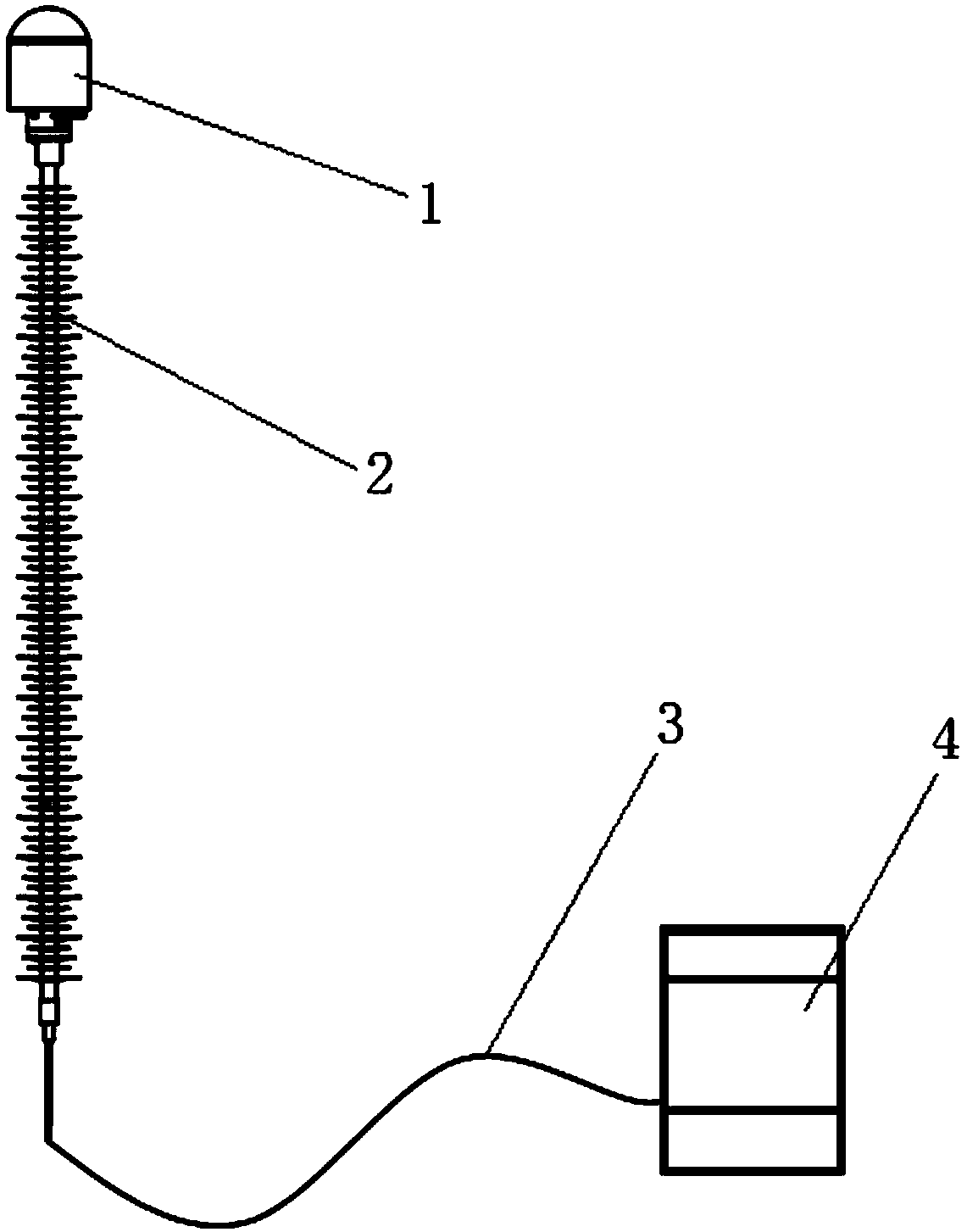

Unbalanced current measuring device

InactiveCN108802477AHigh sensitivityImprove environmental adaptabilityCurrent measurements onlyFiberMeasurement device

The invention discloses an unbalanced current measuring device. The unbalanced current measuring device comprises a primary optical sensing unit, a fiber optic insulator, a communication optical cableand a secondary data acquisition unit, wherein the neck of the primary optical sensing unit is fixed with a capacitor tower through a flange II; one end of the fiber optic insulator is fixed with thebottom of the primary optical sensing unit through a flange I and the flange II, and the other end of the fiber optic insulator is connected with the secondary data acquisition unit through the communication optical cable. The provided unbalanced current measuring device is simple and reliable in structure, convenient to construct and mount, better in stability, moderate in cost and suitable forlarge-scale popularization, and has great significance in development of ultra-high-voltage direct-current projects.

Owner:江苏鑫航电力设备工程有限公司

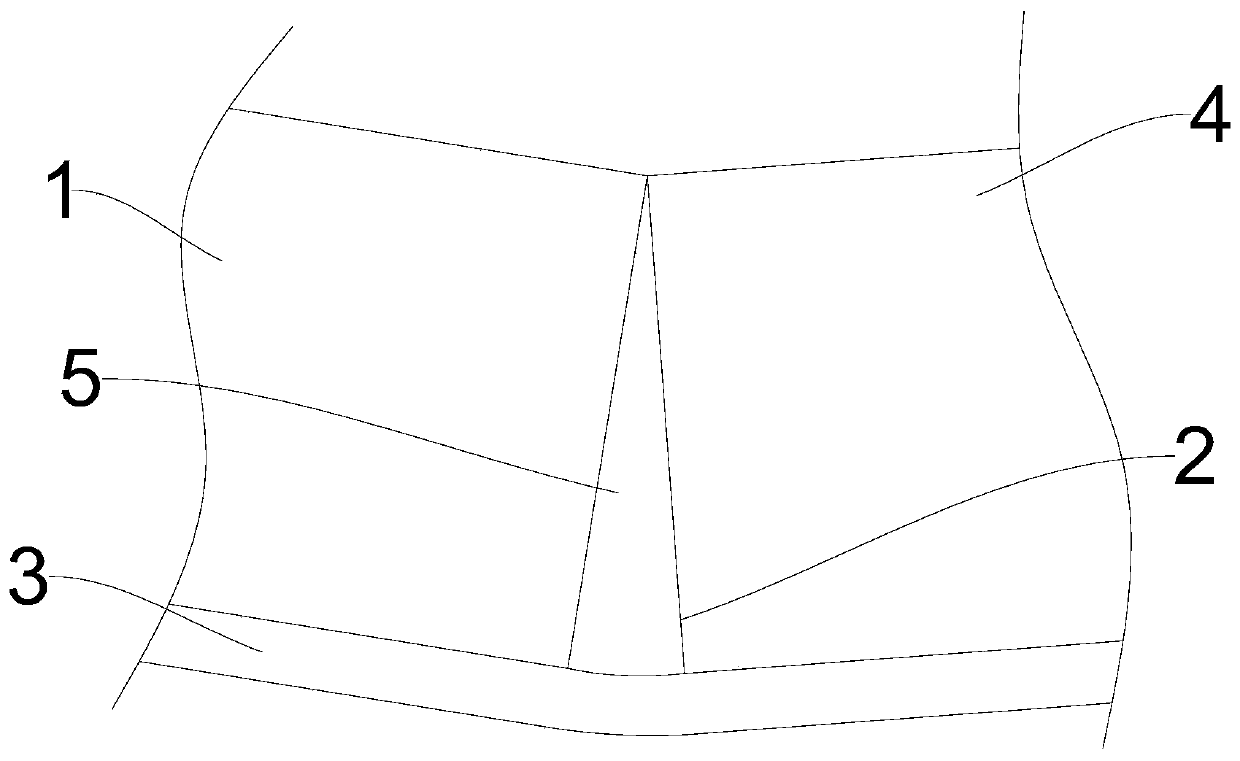

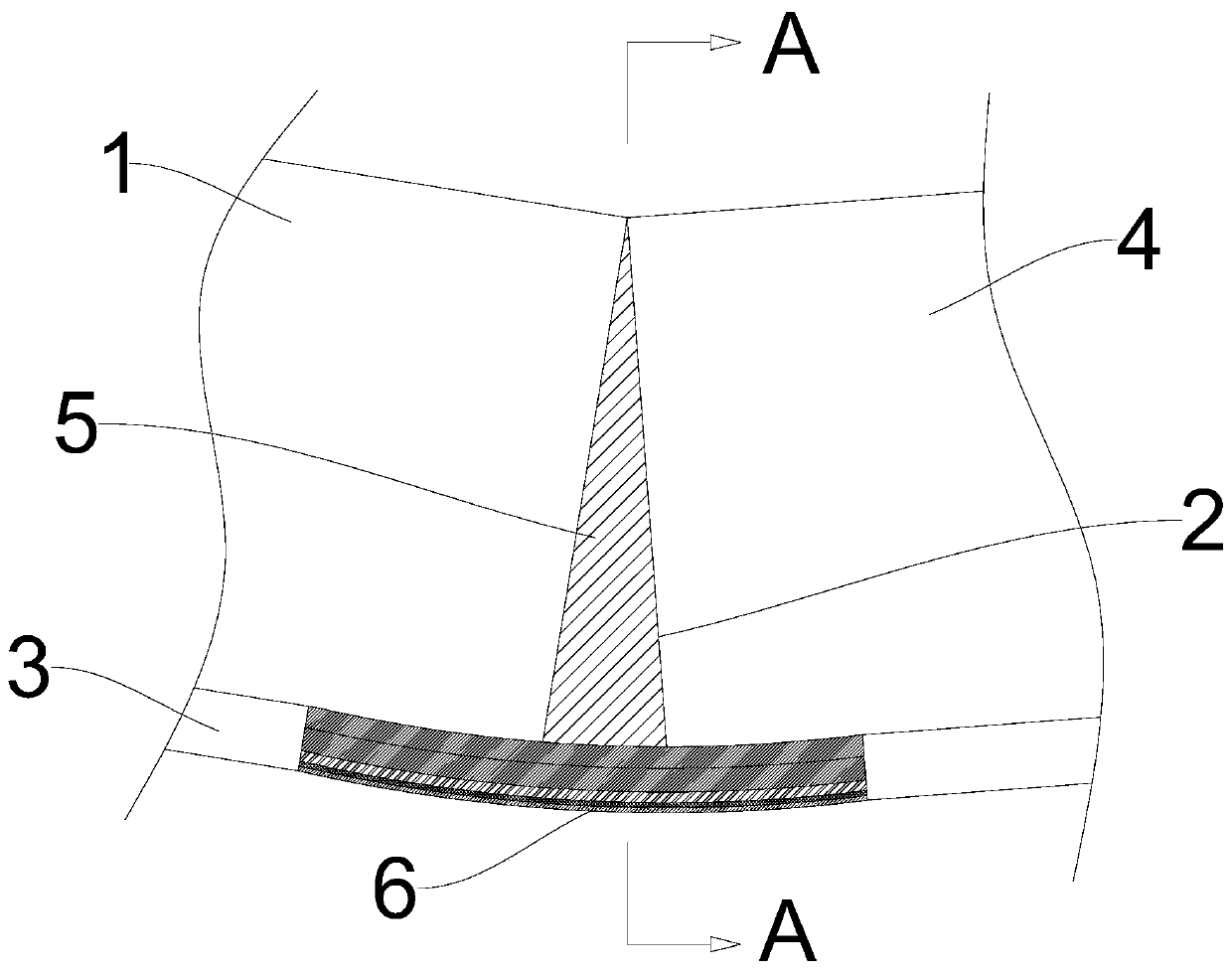

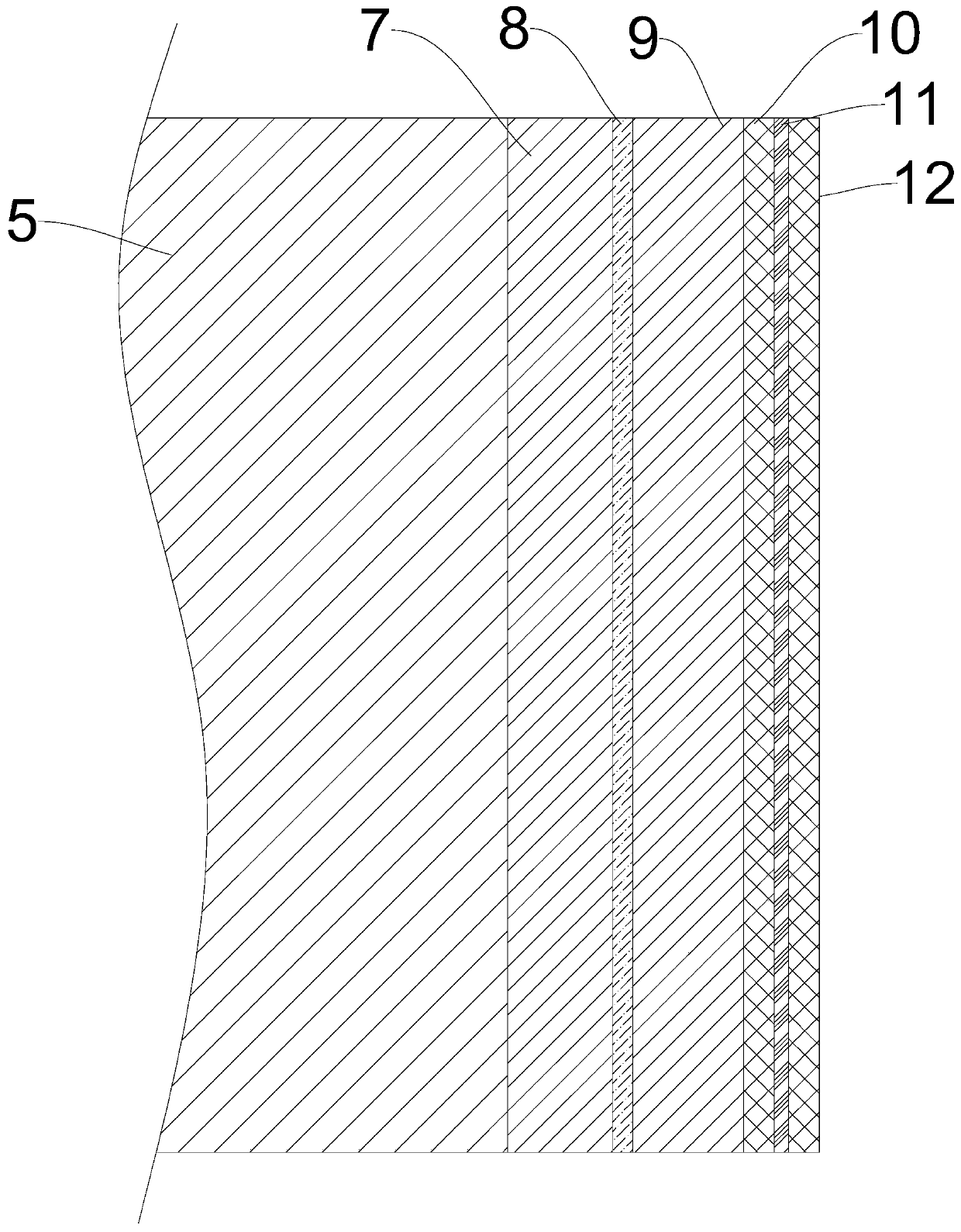

Method for repairing crack at jointing part of composite lightweight aggregate batten wall and a repairing layer thereof

InactiveCN110905228AImprove crack resistanceImprove appearance qualityBuilding repairsGlass fiberAggregate (composite)

The invention relates to a method for repairing a crack at a jointing part of a composite lightweight aggregate batten wall and belongs to the technical field of building decoration. The method comprises the following steps: treating a base course; brushing an interface agent; brushing a first layer of gypsum; paving an anti-cracking paper tape; brushing a second layer of gypsum; brushing a firstlayer of putty; paving alkali-resisting glass fiber gridding cloth; and brushing a second layer of putty to finish repairing the crack. With adoption of the method, the anti-cracking capacity at the jointing part between the composite lightweight aggregate battens is greatly enhanced, and the appearance quality of the composite lightweight aggregate batten wall is greatly improved.

Owner:GUIZHOU MINZU UNIV

Method for determining safe handling time for vehicles, vehicle production method

The invention provides a method for determining safety handling time of cars and a car production method and belongs to the technical field of car window bonding, aiming to overcome the failure in determining the safety handling time of the cars in the prior art. The car comprises a window bonded to a car body through a binder. The first stage of the safety handling time refers to the time from bonding the window to the car body until the beginning of the stage. The method includes calculating the maximum shear stress tau and the maximum tensile stress sigma of the window at the first stage according to the formula: tau=m<1>(1+f<2>)*g*f<1> / (L*w*f<3>), sigma=m<z>*g*f<1> / (L*w*f<3>), wherein L is the window circumference, w is the width of the window bonding region, m<1> is the window mass, and m<z> is the equivalent mass causing shear stress; determining the safety handling time of the stage according to tau and sigma and the preset bonding strength table, wherein the bonding strength table refers to a corresponding relationship table about curing time, shear strength and tensile strength of the binder on current conditions, the safety handling time refers to the minimum curing time, which allows the shear strength and the tensile strength respectively to be greater than or equal to the tau and the sigma, of the bonding strength table.

Owner:SIKA (CHINA) LTD

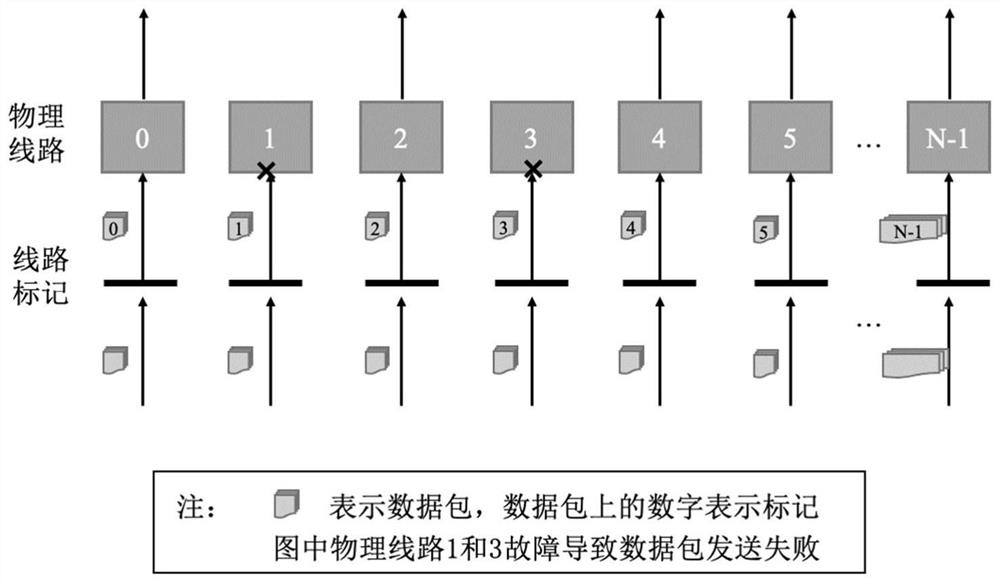

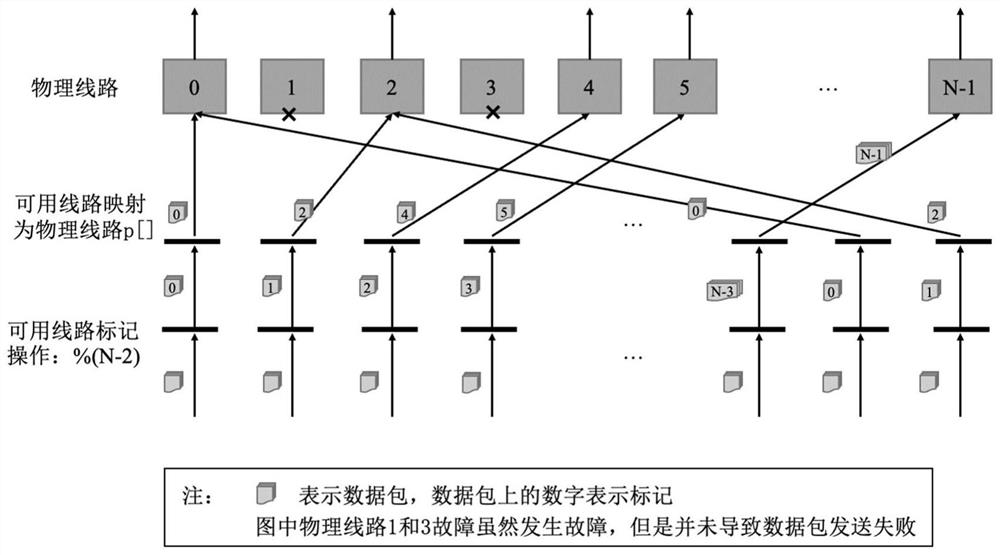

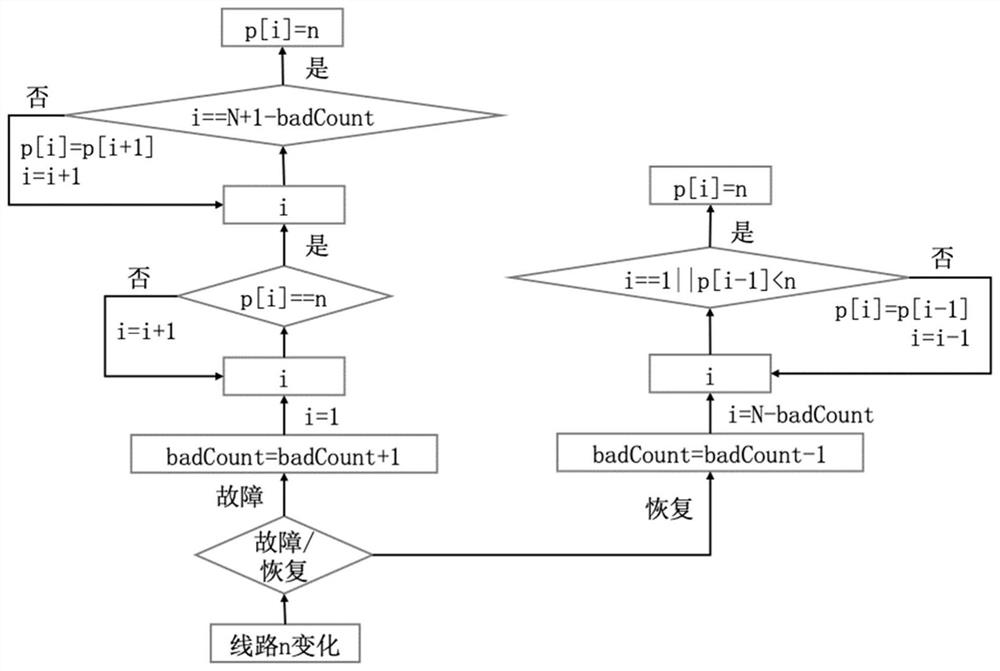

Method for adaptively adjusting lines in unstable multi-line scene and storage medium

The invention provides a method for adaptively adjusting a line in an unstable multi-line scene and a storage medium. The method comprises the following steps: defining two layers of marking rules on an OUTPUT chain of iptables, wherein the two layers of marking rules comprise setting a first rule corresponding to a first layer of mark of the line and setting a second rule corresponding to a second layer of mark of the line; after a first rule action is executed, an available line is selected and an fwmark is marked on the data packet, a second rule action is executed, a mapping relation is established between an available line mark and an actually available physical line mark, and a second fwmark is marked on the data packet; a program is set at an edge node to periodically execute adaptive logic, send a data packet to detect the availability of each physical line, select an available line when executing a first rule action, and select an actually available physical line when executing a second rule action, so as to adjust the pairing of the available line and the actually available physical line. Therefore, the dropped line can be automatically avoided after a part of the line of the network is dropped, and the connection of a new outbound station can be ensured on the premise that the existing network connection is not interrupted. Therefore, the problem of network obstruction of the upper-layer application is eliminated.

Owner:派欧云计算(上海)有限公司

A kind of high surface quality polyurethane composition for self-demolding automobile exterior trim material and its application

The invention discloses a high-surface-quality polyurethane composition for self-demolding automotive exterior trim materials and its application. It includes component A in terms of weight percentage: 50-60% polyether polyol 1, 10-20% polyether Polyol 2, 5-10% polyether polyol 3, 1-5% fluorosilicon modified amino compound, 5-10% chain extender, 0.2-2% foam stabilizer, 0.5-2% catalyst, 1~ 5% flame retardant, 0.2-1% water, optionally add 0.5-3% other additives; polyether polyol 1 is mixed with sucrose and glycerin as starter, hydroxyl value is 400-500mg KOH / g, 6-official ; Polyether polyol 2 uses glycerin as the initiator, the hydroxyl value is 400~500mg KOH / g, 3-official; Polyether polyol 3 uses glycerin as the initiator, grafted with propylene oxide, and capped with ethylene oxide , hydroxyl value 33~37 mg KOH / g, 3 official; B component is PAPI.

Owner:LIMING RES INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com