A control method of a soldering device for an enameled wire lead

An enameled wire lead wire and control method technology, which is applied to tin feeding devices, welding equipment, manufacturing tools, etc., can solve the problems of dull surface of solder joints, slow rise of tin liquid, and insurmountable immersion soldering, so as to prevent tin-copper fusion Difficult, improve brightness, avoid the effect of frying tin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

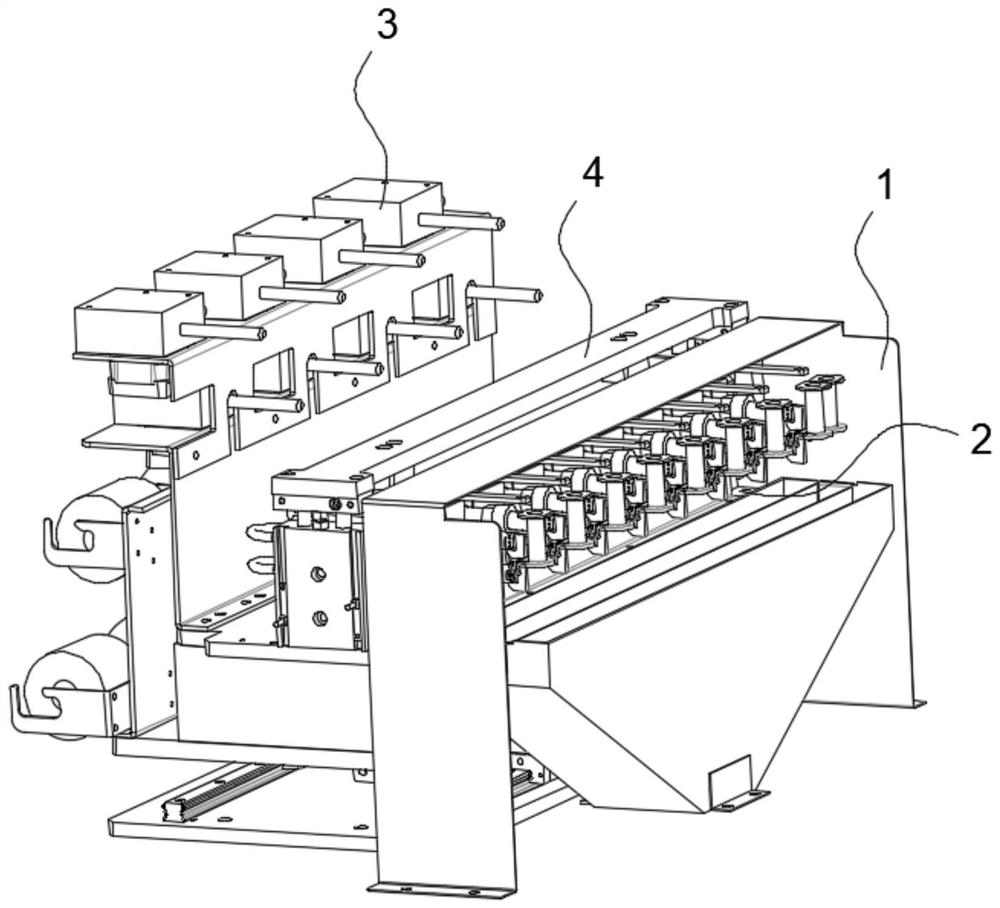

[0036] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

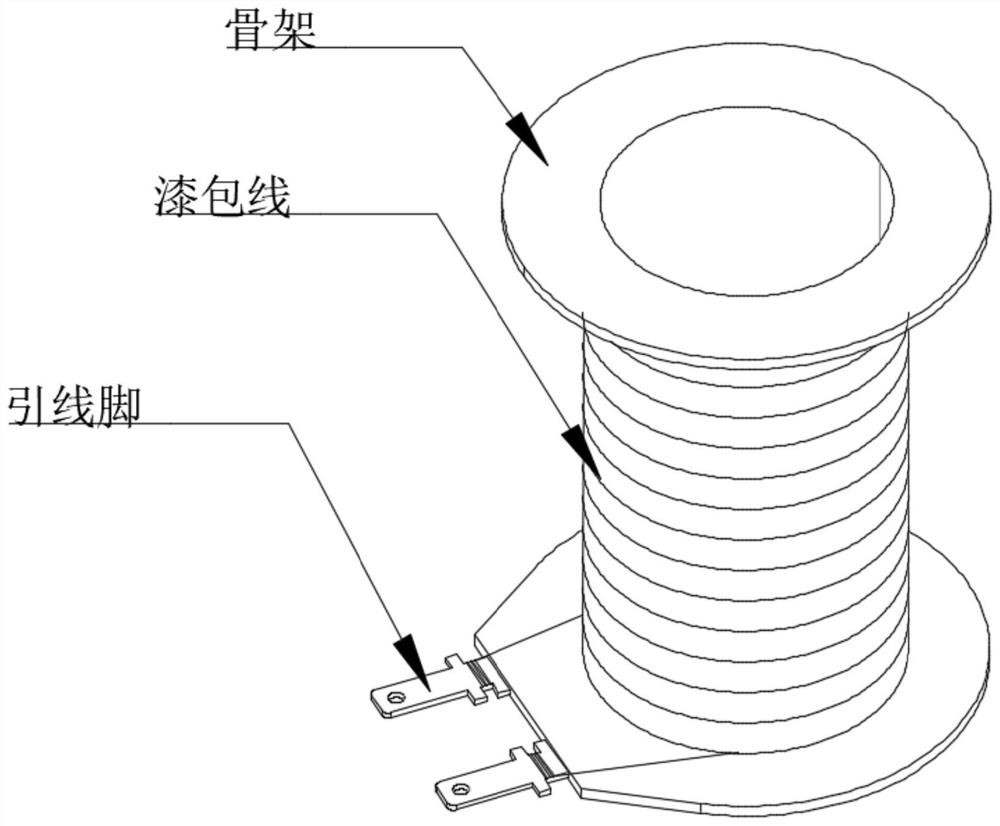

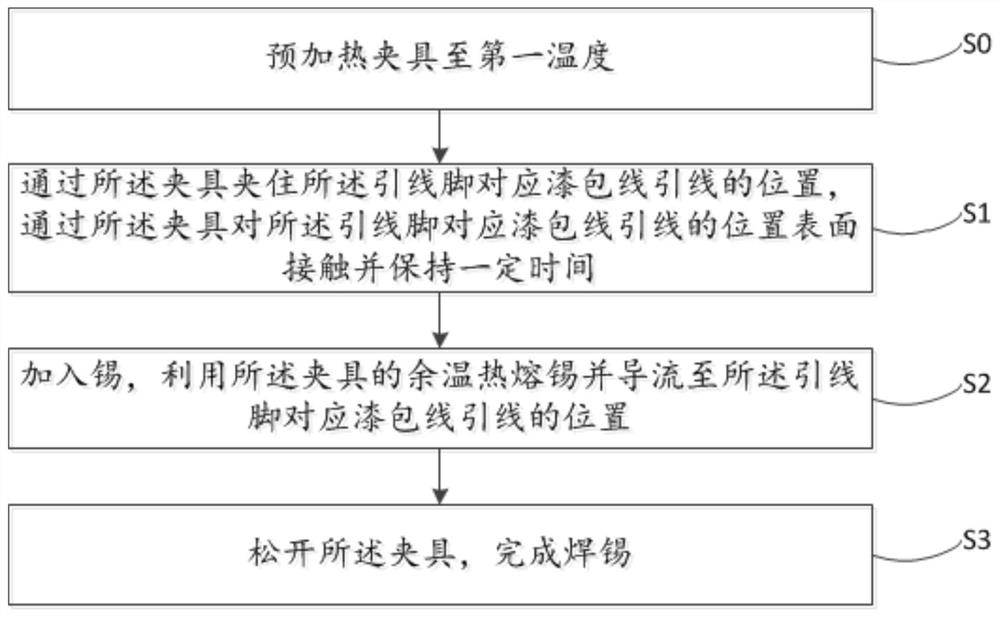

[0037] A method for soldering an enameled wire lead, wherein the enameled wire lead is wound around the end of the lead foot close to the skeleton, comprising the following steps:

[0038] S0, heat the fixture to the vaporization temperature of the paint film; specifically, in this embodiment, the fixture is preheated to 450°C, which is higher than the melting temperature of tin at 280°C, and at the same time, sufficient heat energy can be stored in the fixture without scalding the skeleton , In other embodiments, the fixture may also be preheated to 500° C., and in this embodiment, the fixture is made of metal, which has the functions of heat conduction and heat storage.

[0039] S1, using the clamp to clamp the position of the lead pin corresponding to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com