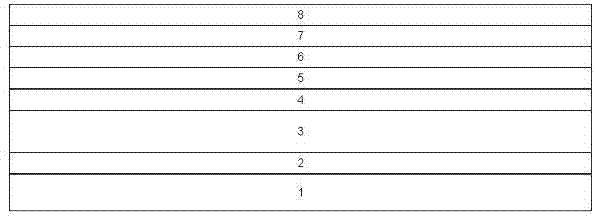

Patents

Literature

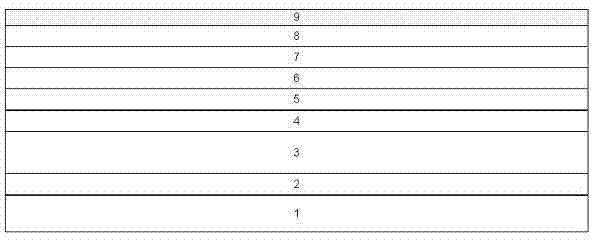

1131results about How to "Avoid Welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

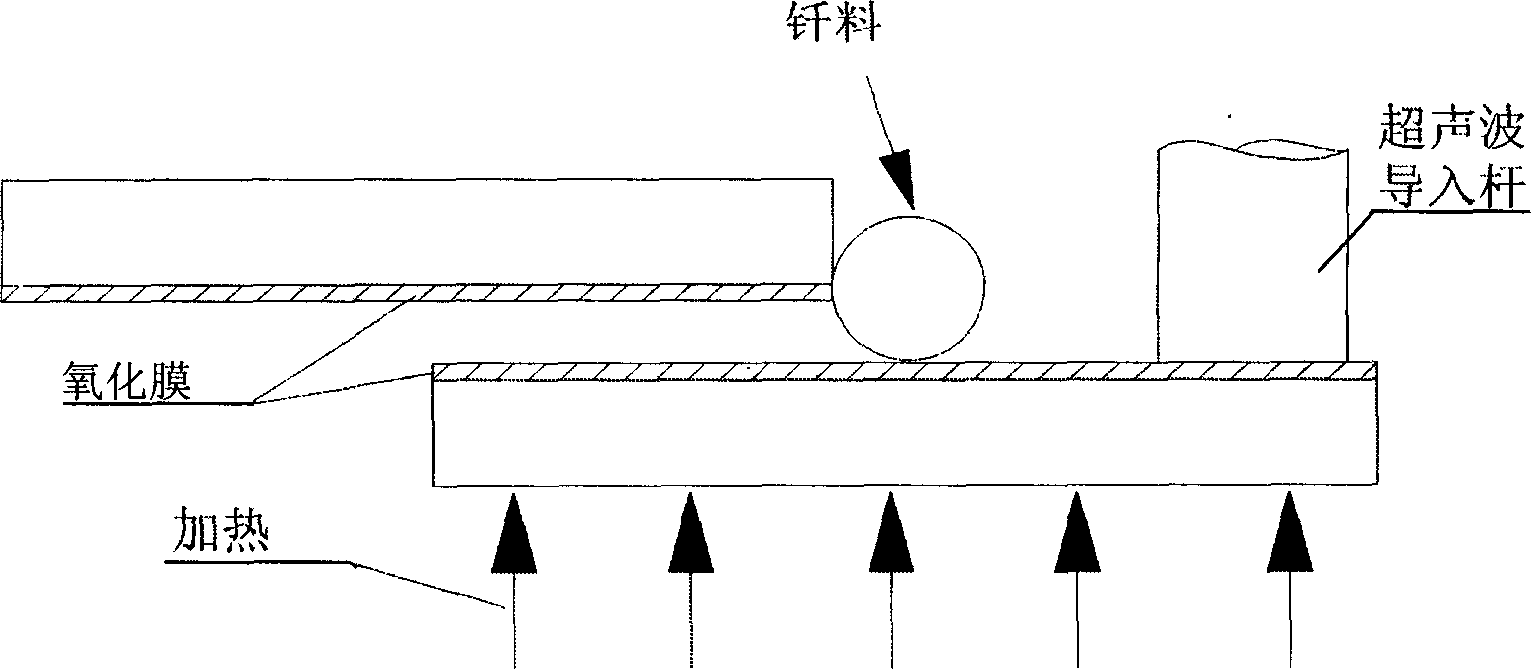

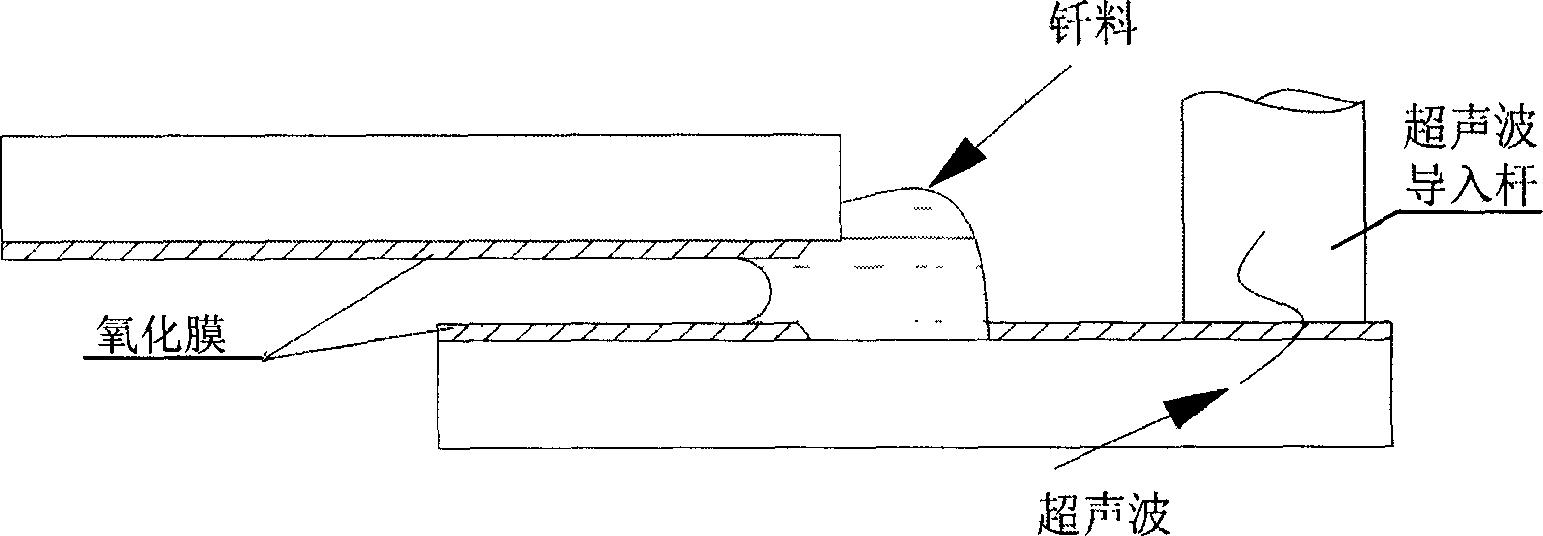

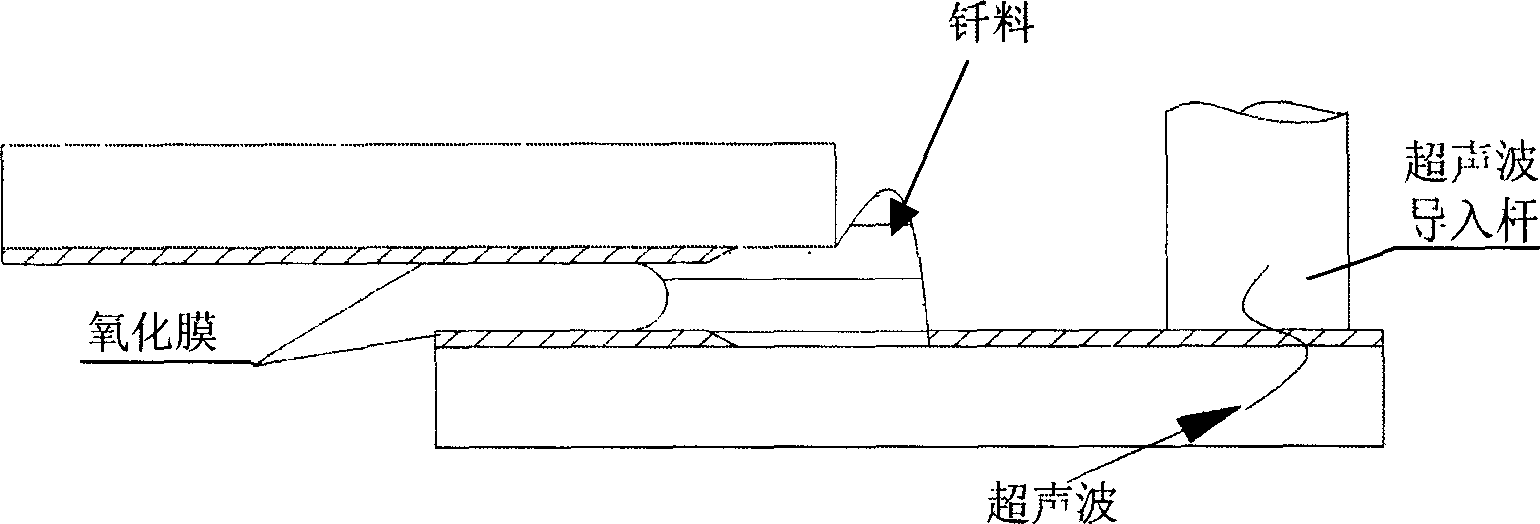

Aluminium base composite material ultrasonic wave fine welding method

InactiveCN1644291AAvoid WeldingEfficient weldingNon-electric welding apparatusUltrasonic vibrationMaterials science

An ultrasonic capillary welding method for the Al-base composite material includes such steps as arranging upper and lower parts to be welded in such manner that the gap between them is 10-300 microns, putting the flux close to lap end, heating to smelt the flux, holding the temp, pressing the ultrasonic head onto surface of the part to be welded, and applying ultrasonic vibration for 0.5-15 S. Its advantages are high welding quality, low welding temp, and high speed.

Owner:HARBIN INST OF TECH

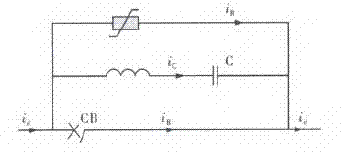

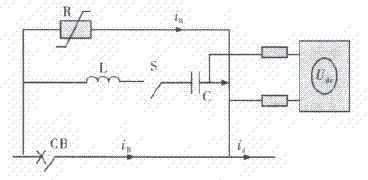

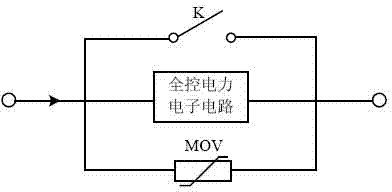

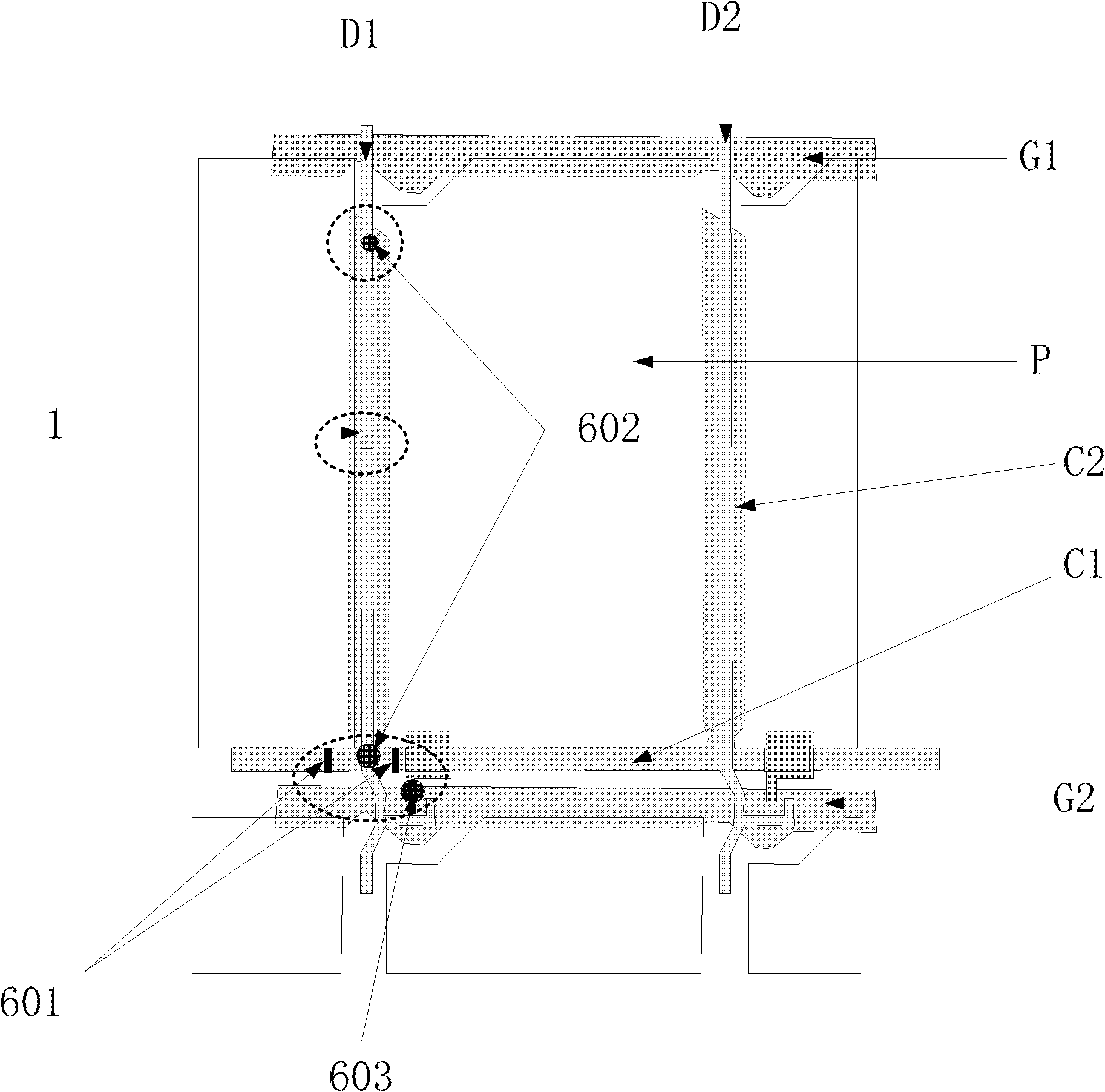

Multi-break hybrid direct current breaker

InactiveCN104242229APressure equalization improvementAvoid WeldingProtective switch detailsArrangements responsive to excess currentCapacitanceZero crossing

The invention discloses a multi-break hybrid direct current breaker. The multi-break hybrid direct current breaker comprises a main switch circuit, an oscillating circuit and an energy absorption circuit, wherein the main switch circuit is composed of three quick switches and three voltage equalizing circuits connected with the quick switches in parallel, the oscillating circuit is composed of thyristor valves T1-T4, a transformer, a capacitor and an inductor, and the absorption circuit is composed of a ZnO arrester. The multi-break hybrid direct current breaker is capable of bidirectionally and quickly breaking short circuit current in a direct current system in a non-arcing mode; the multi-break hybrid direct current breaker is low in conduction loss, low in cost, long in service life, strong in breaking ability, short in breaking time and low in implementation difficulty and improves the voltage equalization between breaks of each breaker so as to avoid the inconsistent braking voltage of each breaker due to breaking time difference; the circuit is faster and easier to reach a zero crossing point by means of active current injection.

Owner:STATE GRID CORP OF CHINA +1

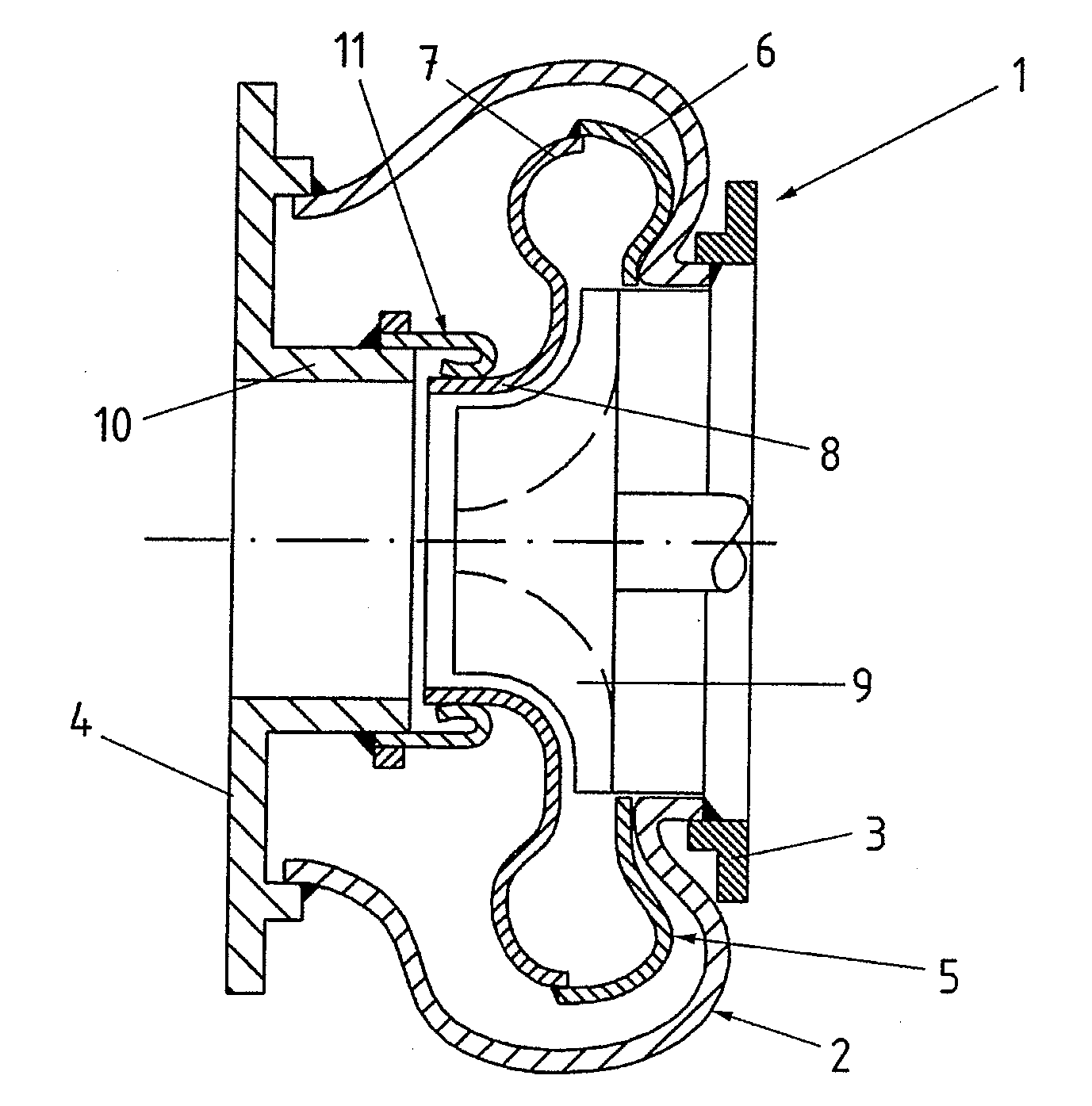

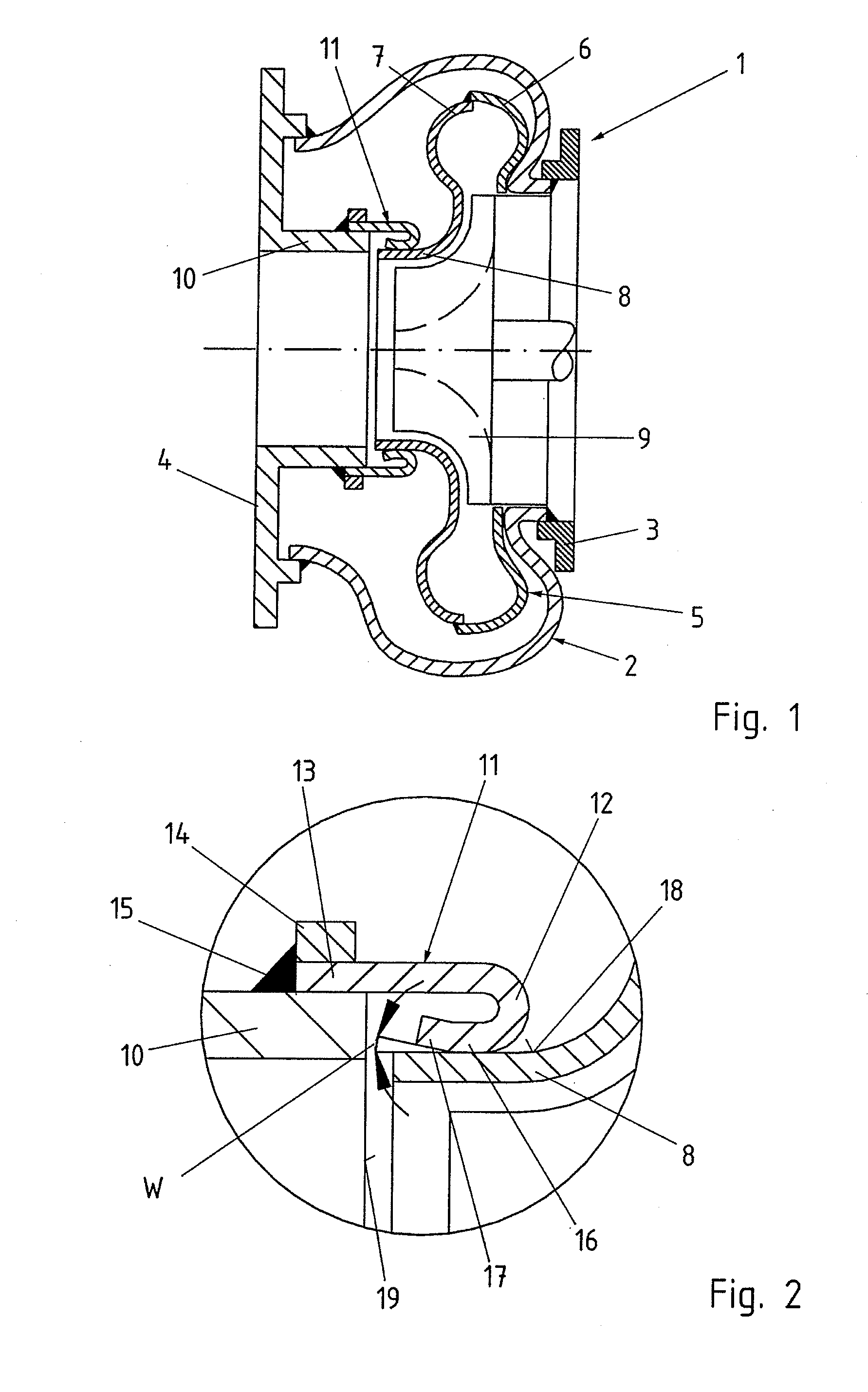

Turbine housing for gas turbochargers

InactiveUS20100316494A1Improve sealingSolve the thickerPump componentsCombustion enginesTurbochargerExhaust gas

A turbine housing for exhaust gas turbochargers includes an outlet pipe and an external housing connected therewith. A rotor housing is disposed in the external housing and has a pipe-shaped neck operably coupled with the outlet pipe and axially displaceable relative to the same. A separate sealing ring is positioned operably between the neck and the outlet pipe, supported by the outlet pipe, and has an inwardly turned sealing portion sealingly and slidingly engaging the neck to form a secure gas seal therebetween.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

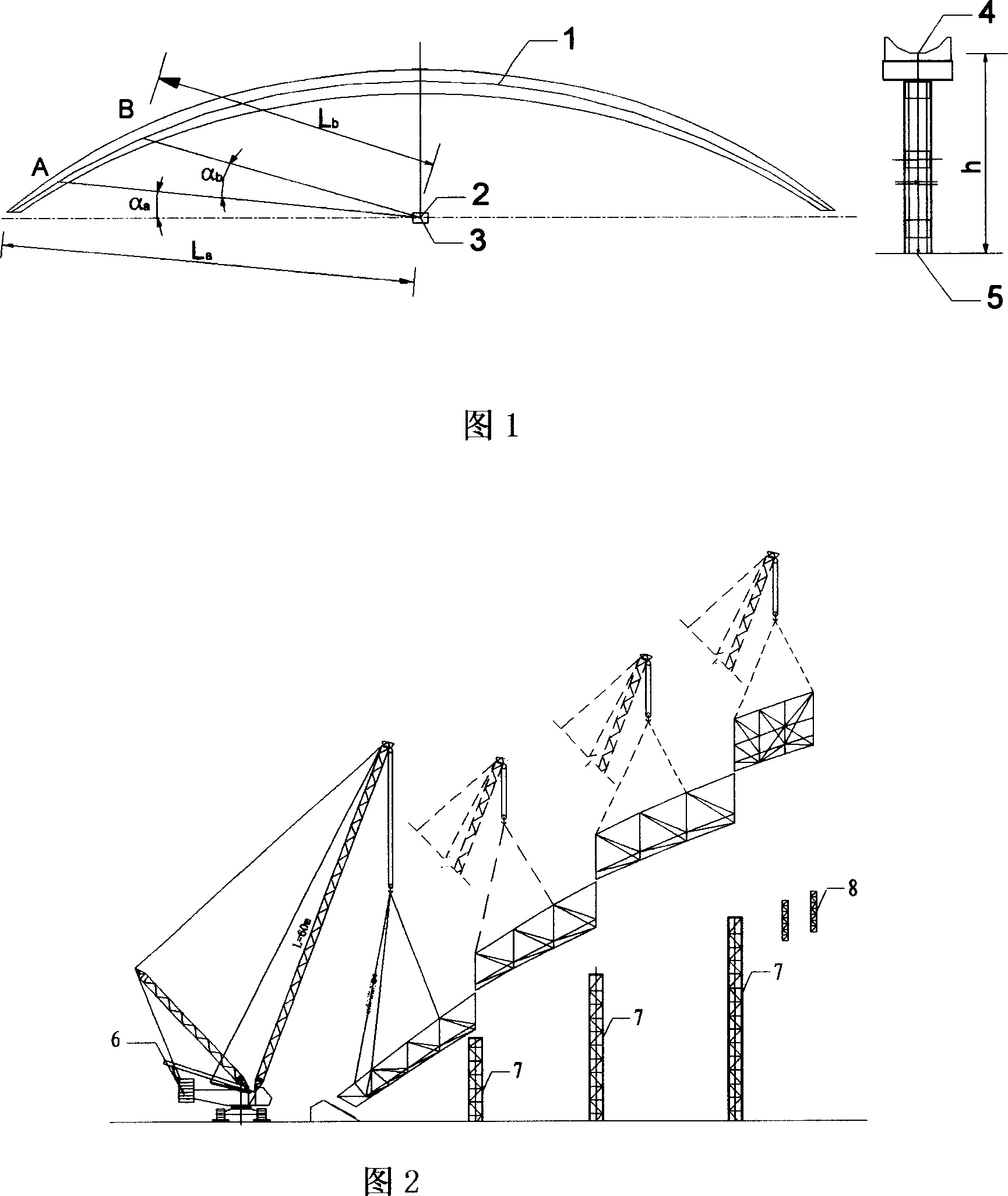

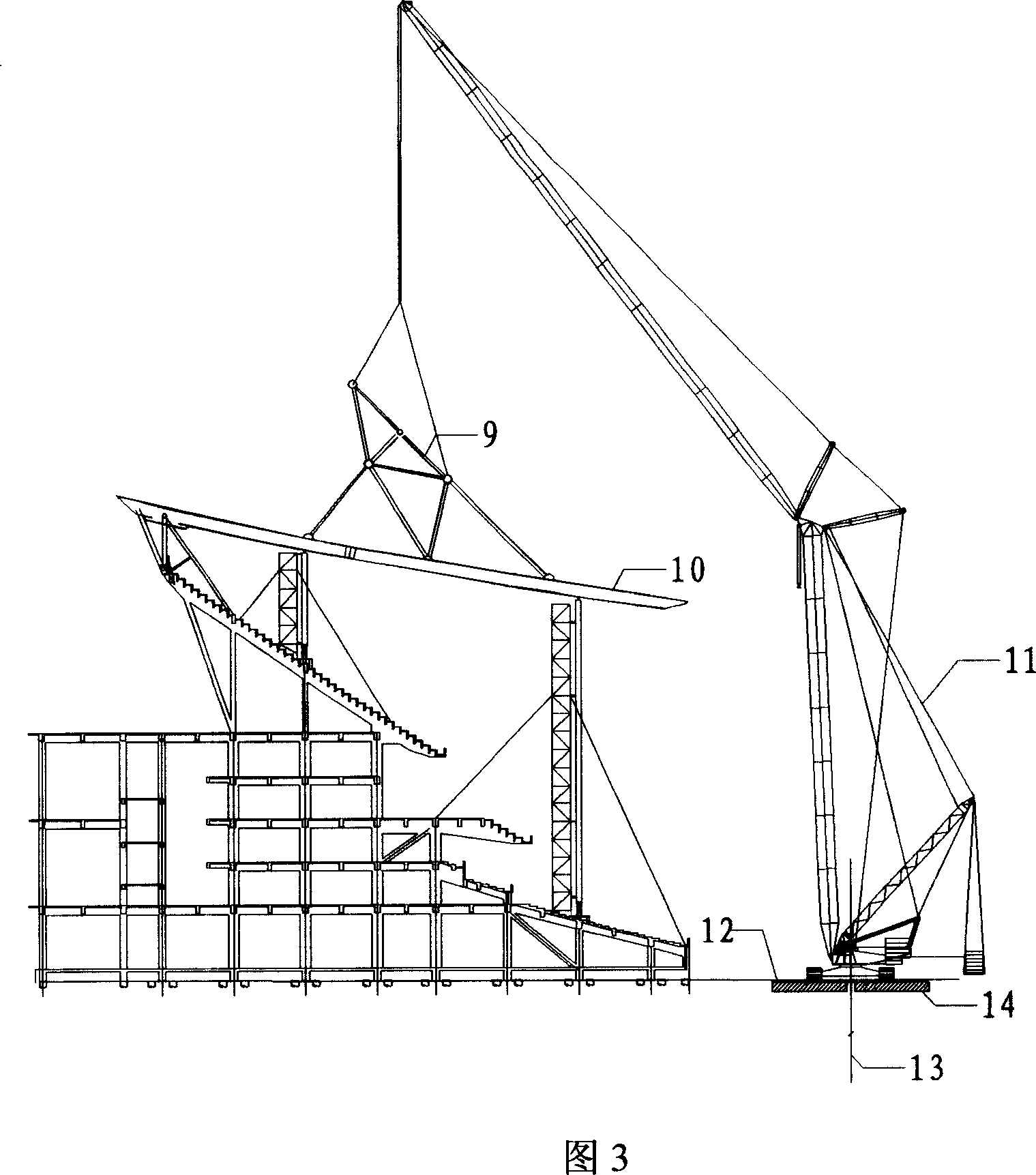

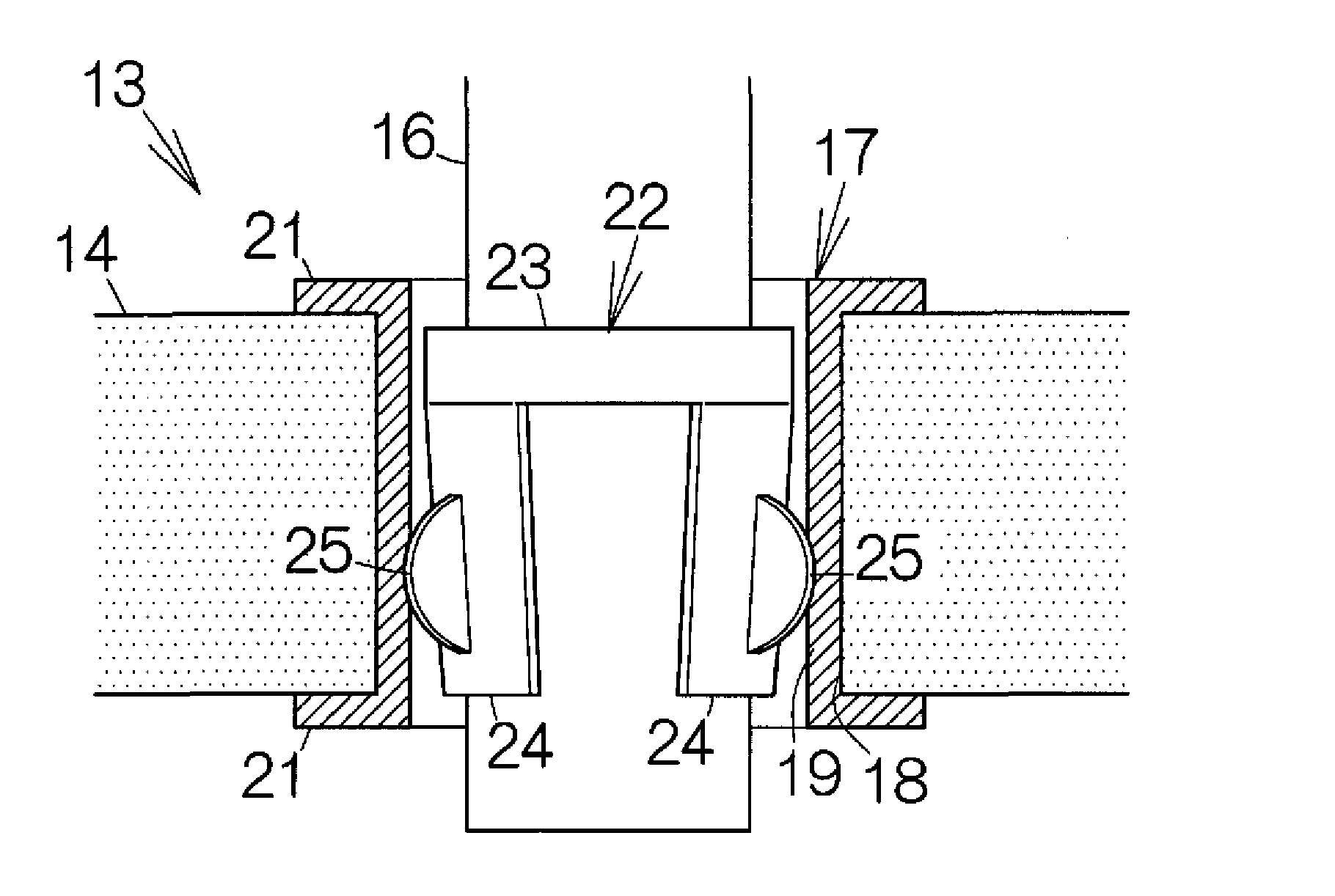

Super-span steel skew arch construction method

ActiveCN1978801AAvoid WeldingAvoid Welding StressArched structuresVaulted structuresArchitectural engineeringTotal station

The invention discloses super span steel skew arch construction method. Its feature is that it adopts molding bed support sectionalizing installation method which includes the following steps: dividing the super span steel skew arch into twenty one construction units; assembling each of them by horizontal type assembling method; laying off and locating supporting molding bed by total stations instrument; installing supporting molding bed; orderly installing the 1-4, 18-21 sections steel skew arch in roof covering, the 5-10, 12-17 sections out roof covering, the eleventh healing section in roof covering; removing the supporting molding bed. The invention can eliminate installing accumulative error, increase insurance coefficient for whole project to ensure steel skew arch healing successful at a time. The method can be used in large scale hall super span steel skew arch construction.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

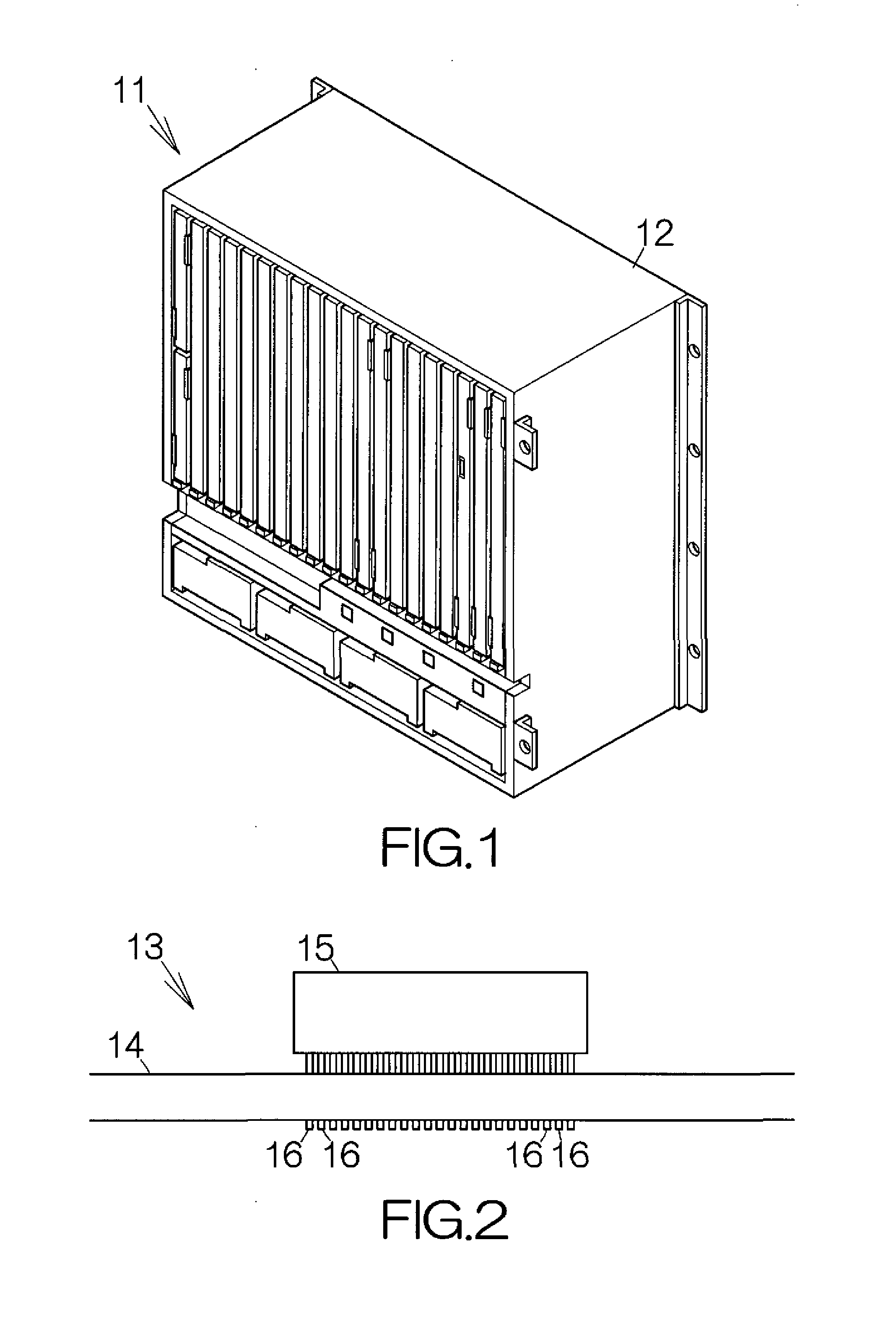

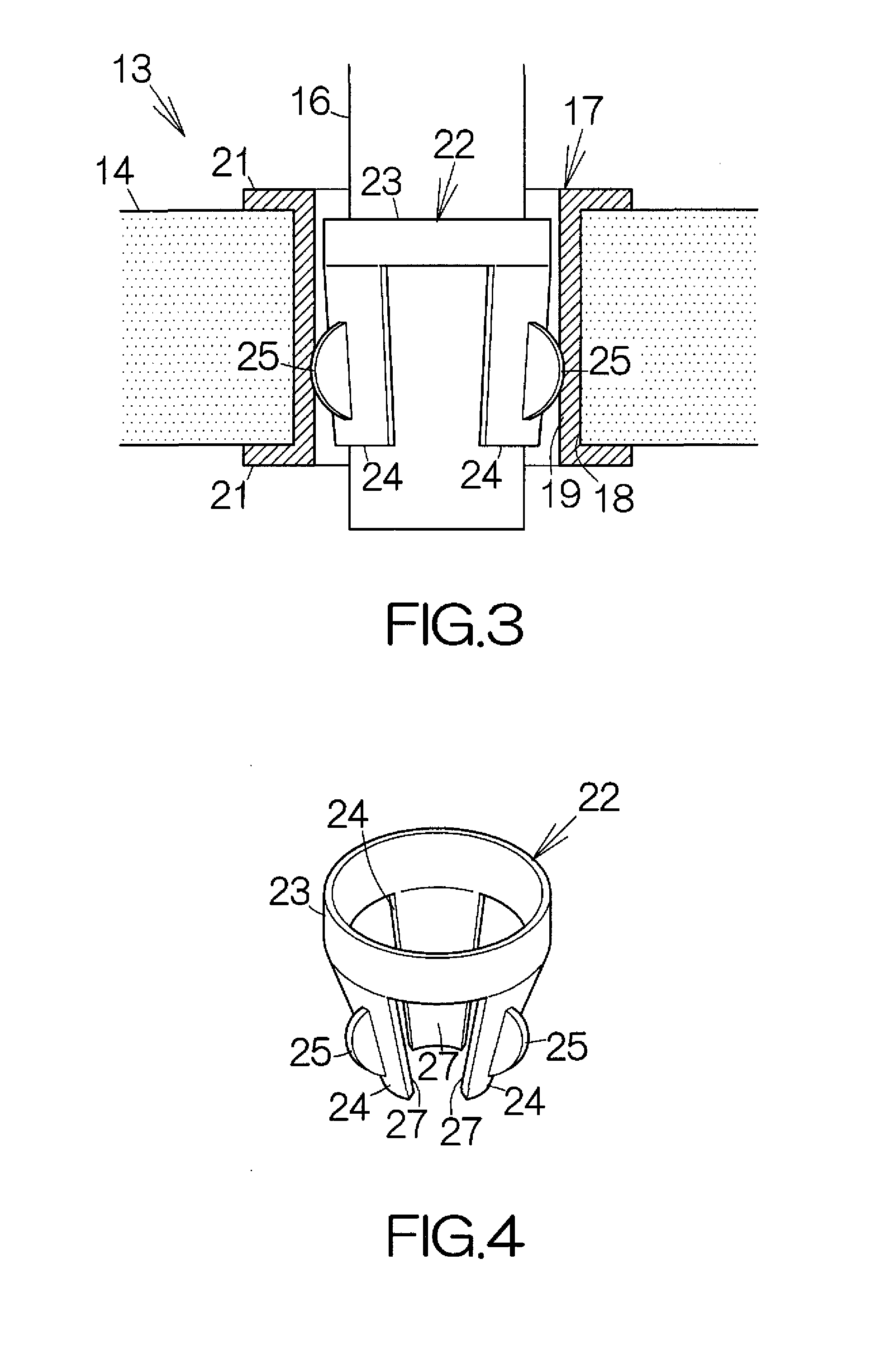

Connecting terminal for receiving lead terminal in printed wiring board

InactiveUS20080144301A1Avoid solderAvoid WeldingPrinted circuit aspectsPrinted circuit manufactureElectrically conductiveEngineering

Owner:FUJITSU LTD

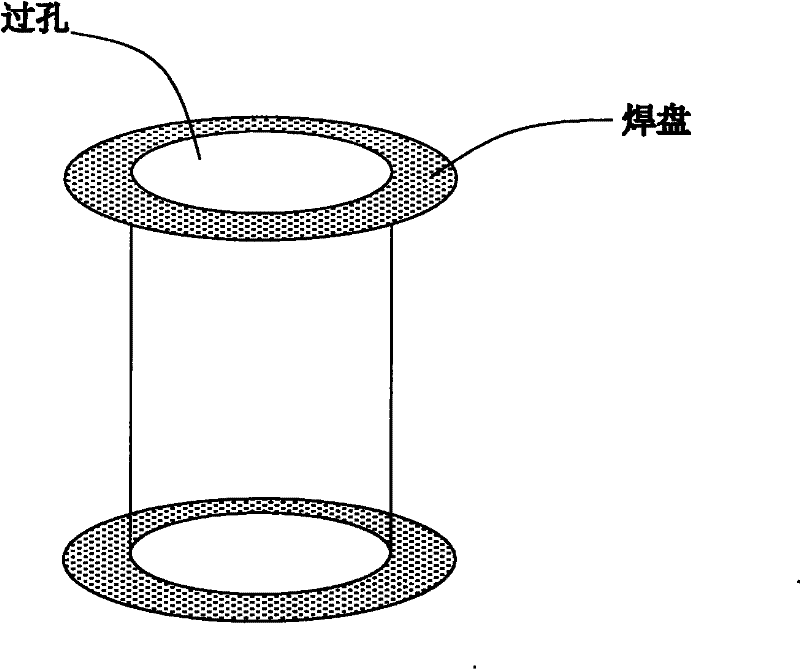

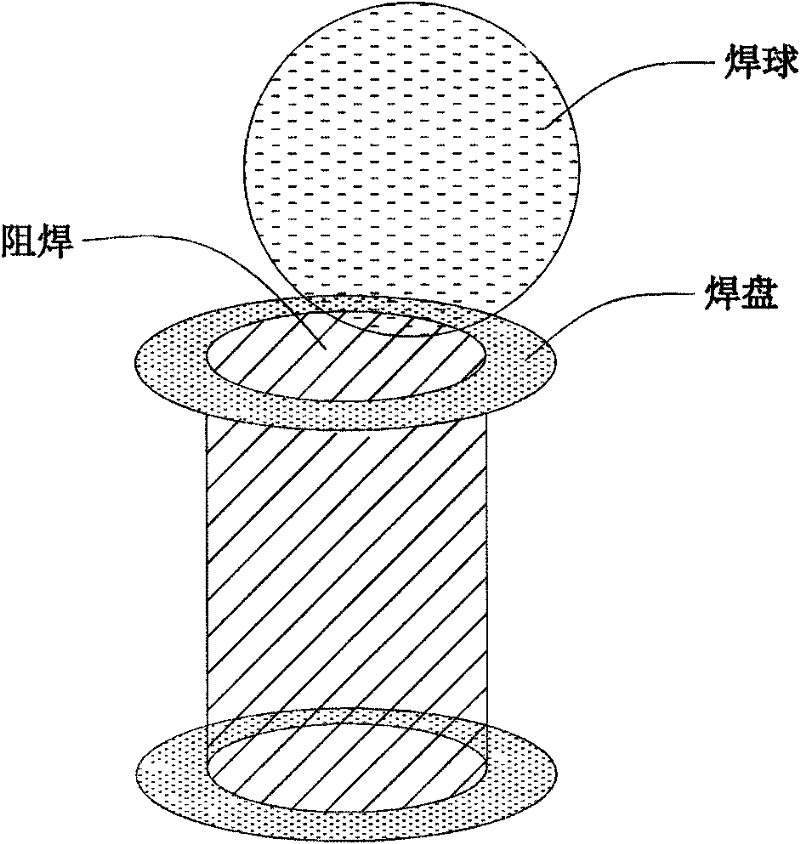

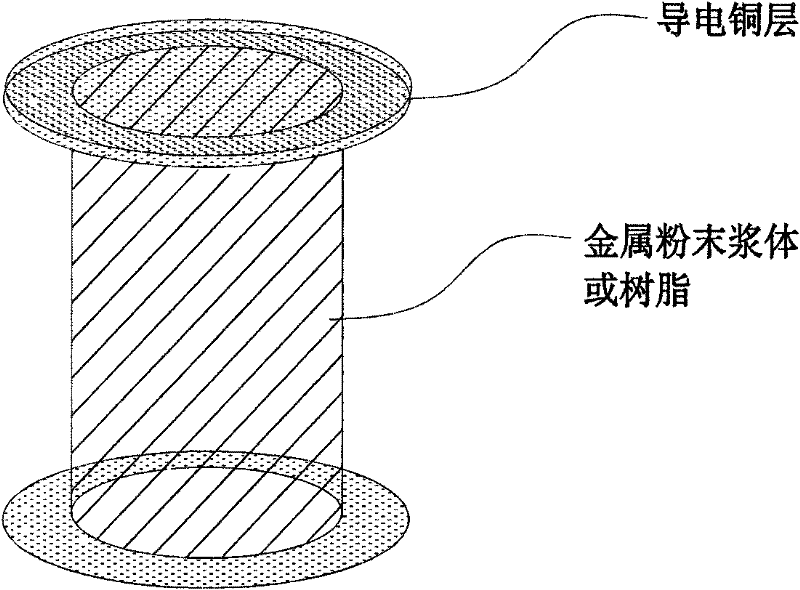

Manufacturing process of high-density printed board with holes in pads

ActiveCN102215641AIncrease contactAvoid WeldingPrinted element electric connection formationHigh densityElectrical conductor

The invention discloses a manufacturing process of a high-density printed board with holes in pads. The process is characterized by comprising the following steps: filling slurry in holes in pads formed in a welding plate of a circuit board, filling the holes in pads in the welding plate completely to form a solid body is formed; polishing, thus the slurry filled in the holes in pads on the welding plate of the whole circuit board is smooth, and forming the same plane with the adjacent conductor surface; and carrying out hole metallization and electroplating on hole walls of other non-holes in pads on the circuit board, thus a conductive copper layer is coated on the upper surface and the lower surface of the holes in pads filled with the slurry. When array welded balls or QFP (quad flat pack) pins and the like at the bottom part of a U-BGA (ball grid array) package appliance are connected with the welding plate of the holes in pads, the full contact with the welding plate can be ensured, and the problems of nonfarm welding and insufficient welding can be prevented form occurring.

Owner:SHENZHEN BOMIN ELECTRONICS

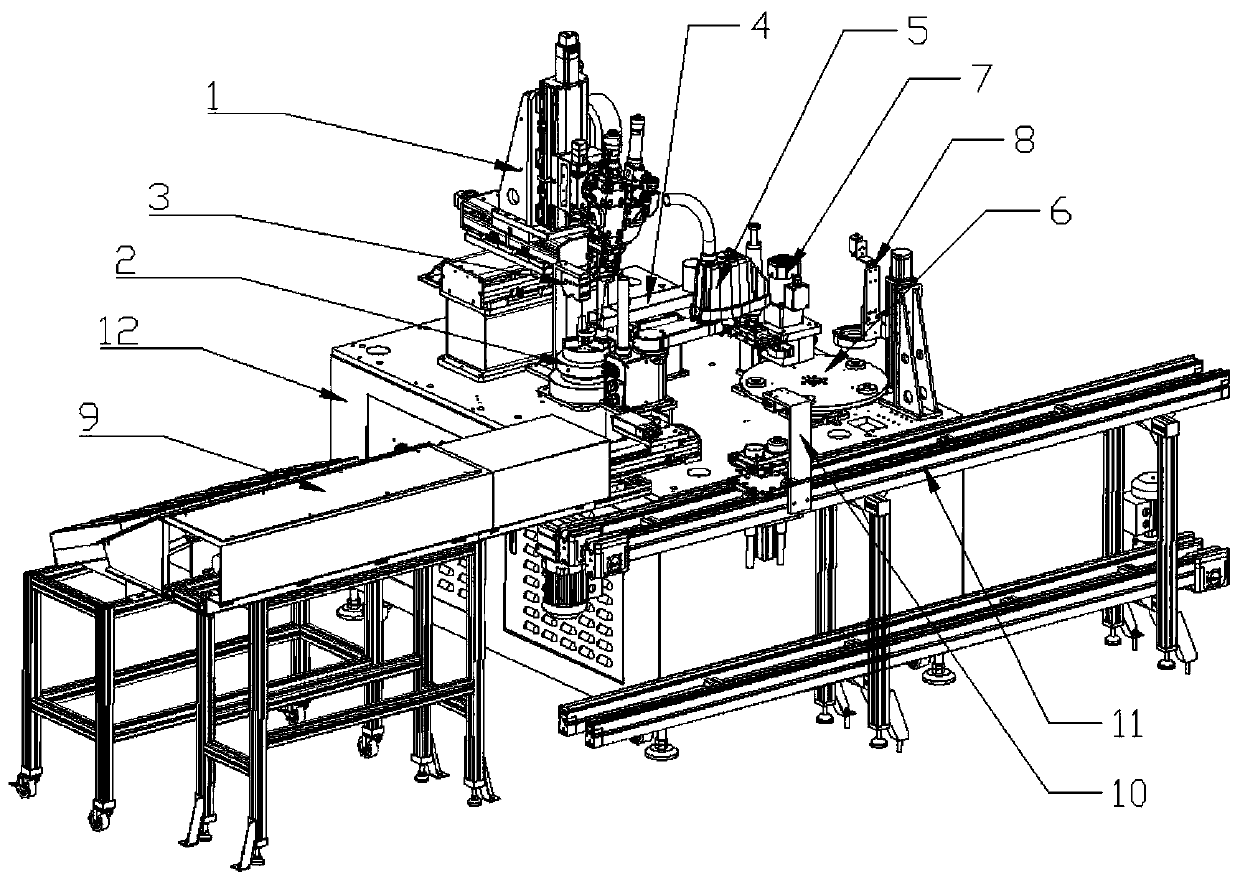

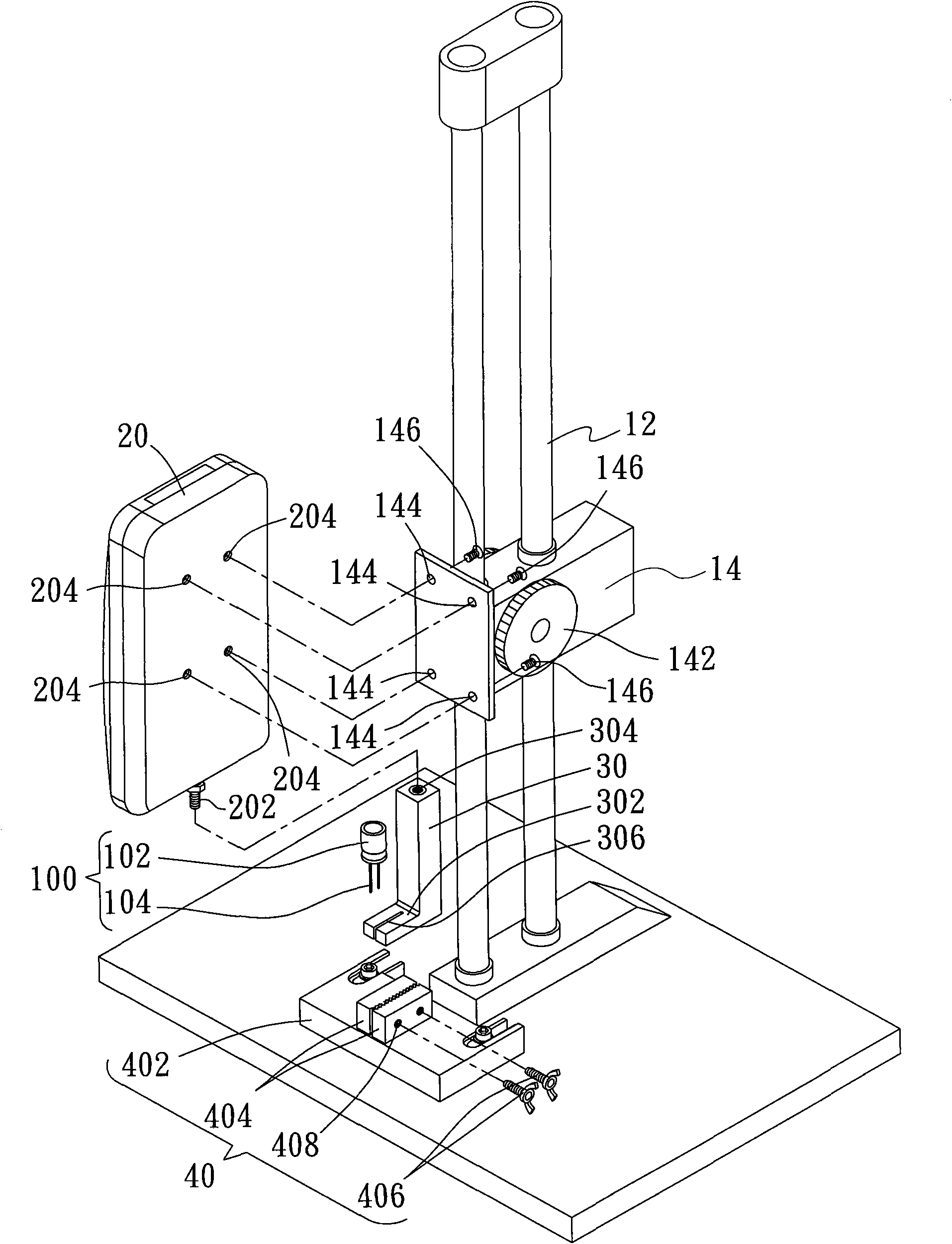

Automatic laser welding system

ActiveCN109822217AAdjustable angleAchieve precision clampingLaser beam welding apparatusThree dimensional shapeEngineering

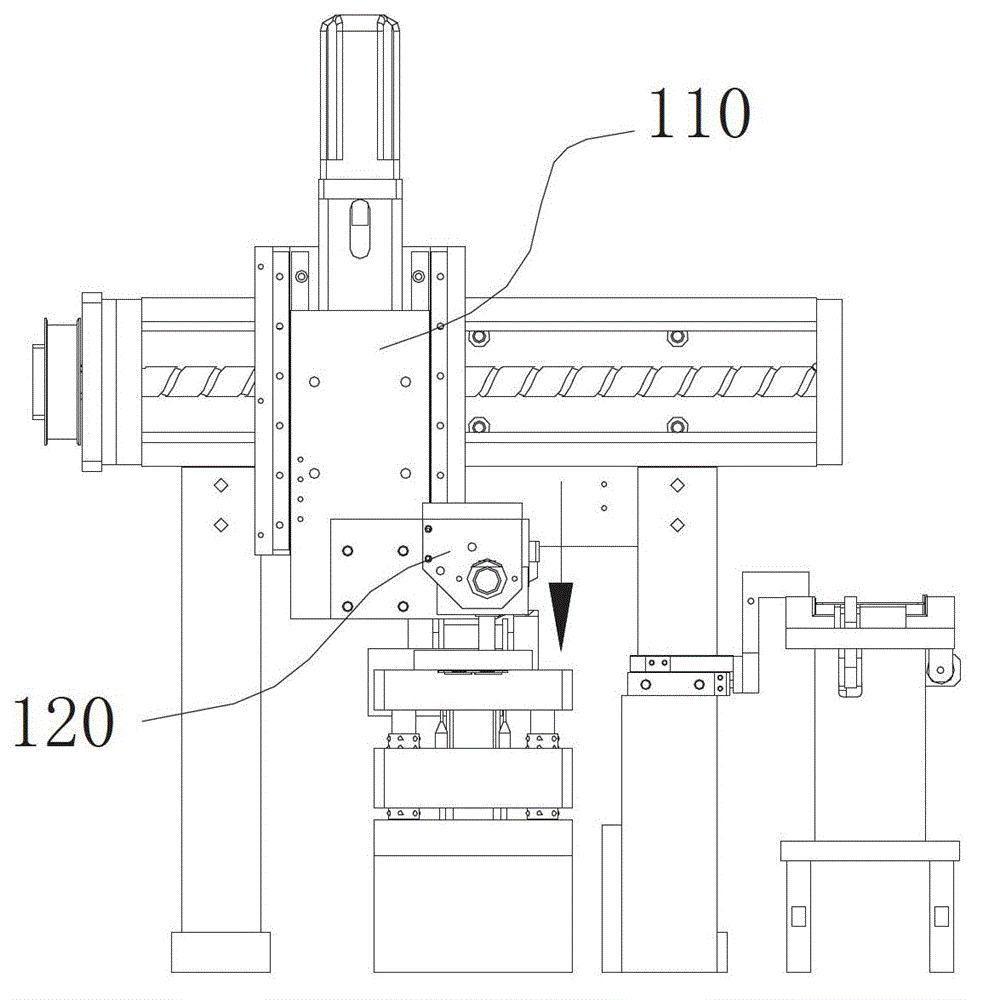

The invention provides an automatic laser welding system. The automatic laser welding system comprises a machine table, a laser welding head drive device, a tool clamp, a 3D detecting device, a smoke-extraction and dust-removal device, a mechanical hand loading and unloading device, a material rotary disc device, a wiping device, a 2D detecting device, a sorting device, a workpiece conveyor line and a code scanning device, wherein the welding head drive device drives the laser welding head to move or deflect; the tool clamp realizes clamping and rotating of the workpiece; the 3D detecting device detects a three-dimensional shape of a welding seam; the mechanical hand loading and unloading device is used for grabbing the workpiece to realize loading and unloading; the material rotary disc device is used for sequentially rotating the welded workpiece to a wiping station, a detecting station and an unloading station; the 2D detecting device is used for detecting a quality state of the surface of the welding seam; and the code scanning device is used for reading bar codes or two-dimensional codes which are matched with welding parameters to store. The automatic laser welding system hasthe characteristics of being capable of performing circumferential welding on the welding seam workpiece, automatically loading and unloading, welding, 3D / 2D detecting, sorting and the like, does notneed manual operation, is high in efficiency, and enables welding parameters to be corresponding to bar codes.

Owner:深圳市华天世纪激光科技有限公司

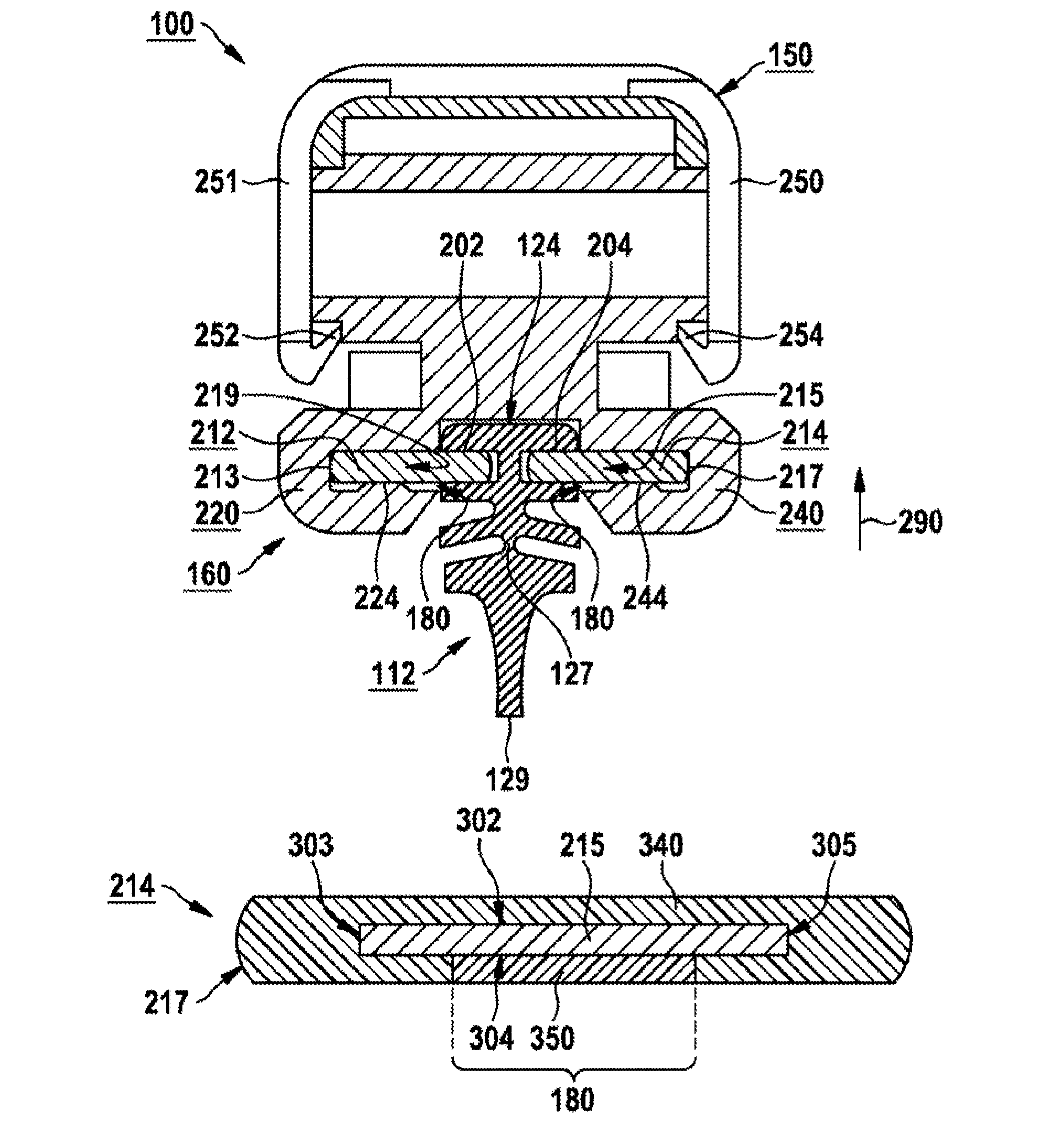

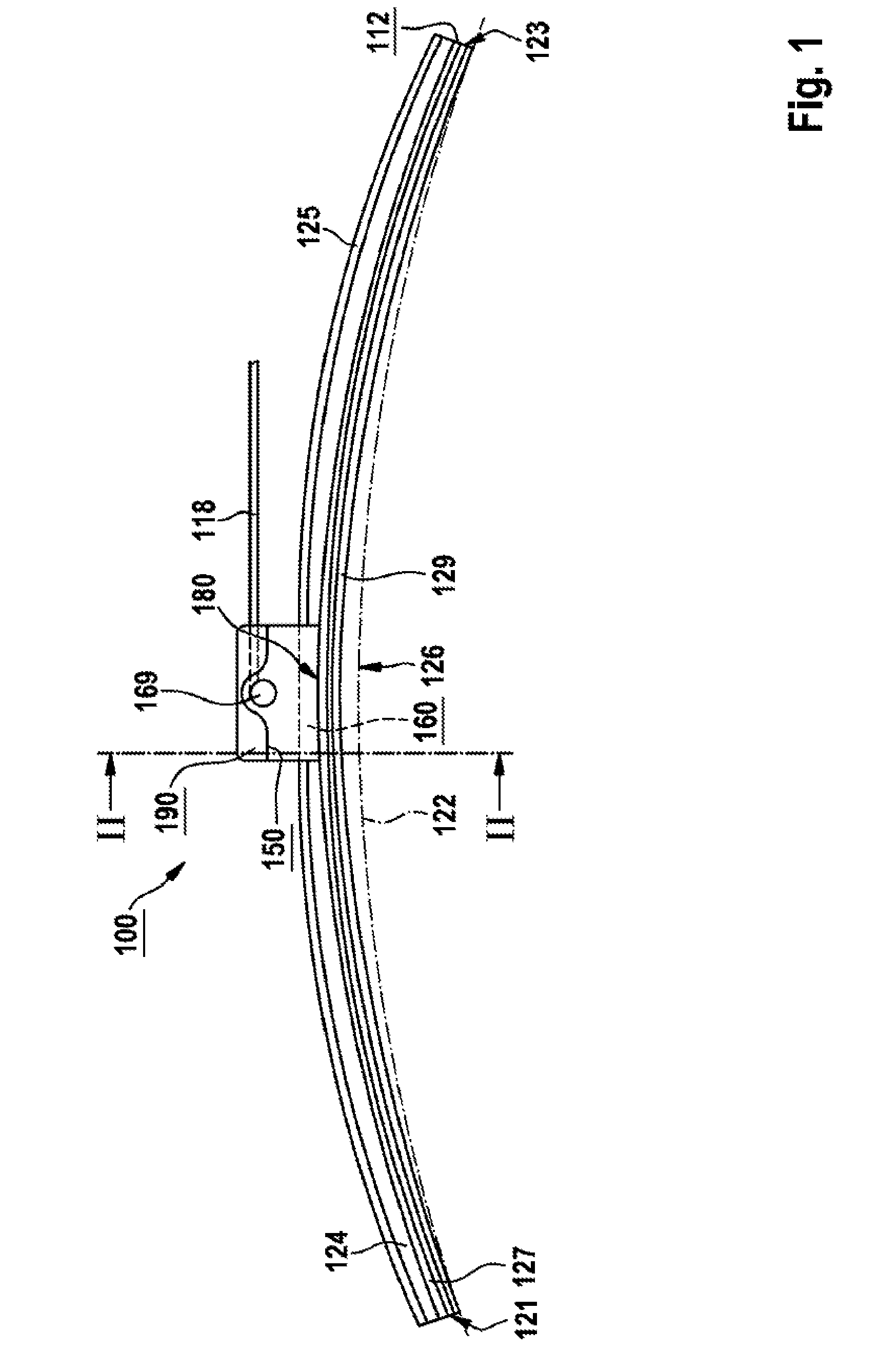

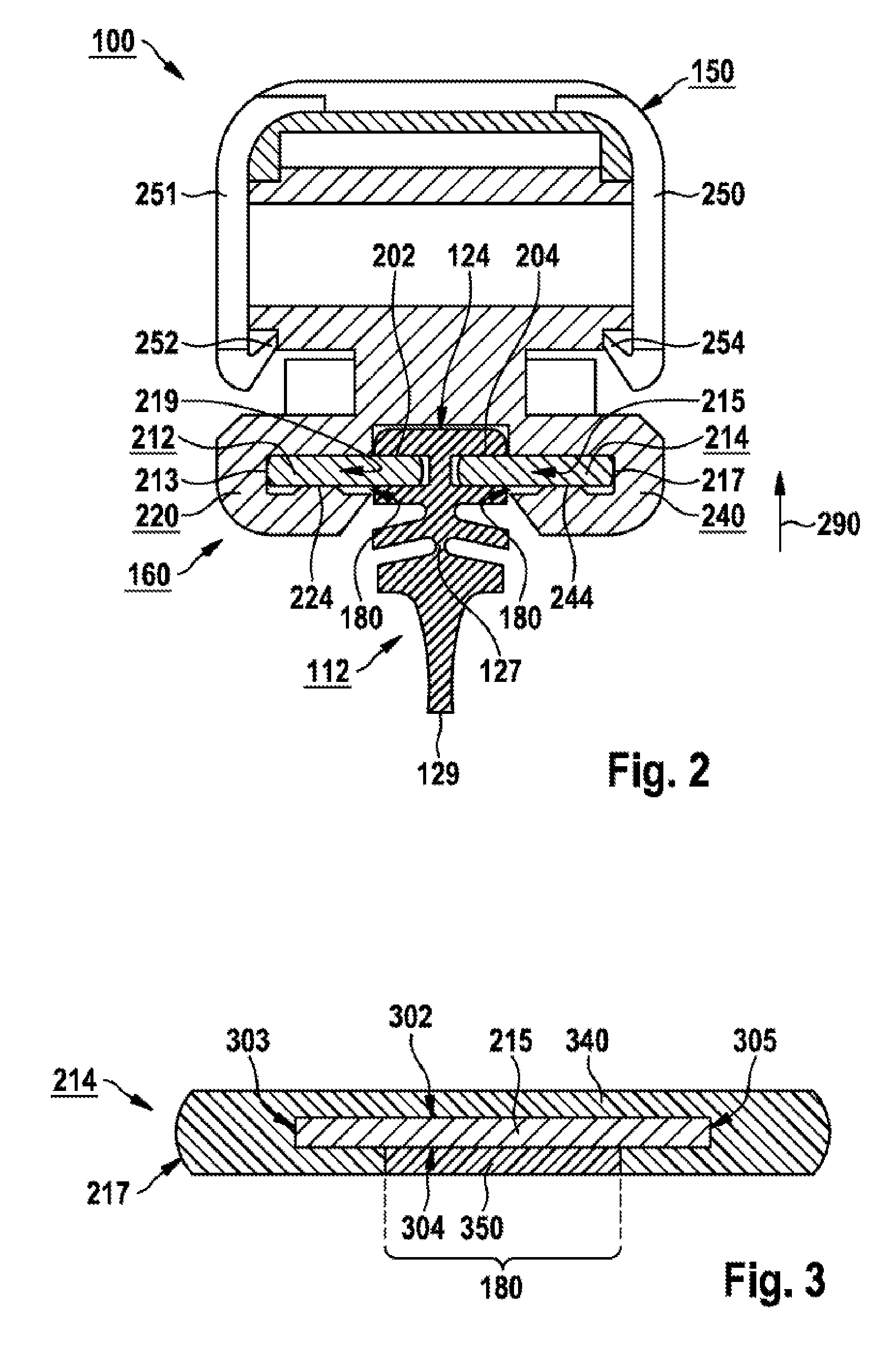

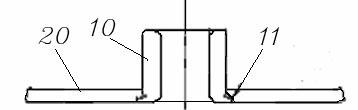

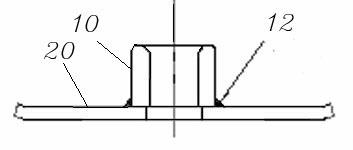

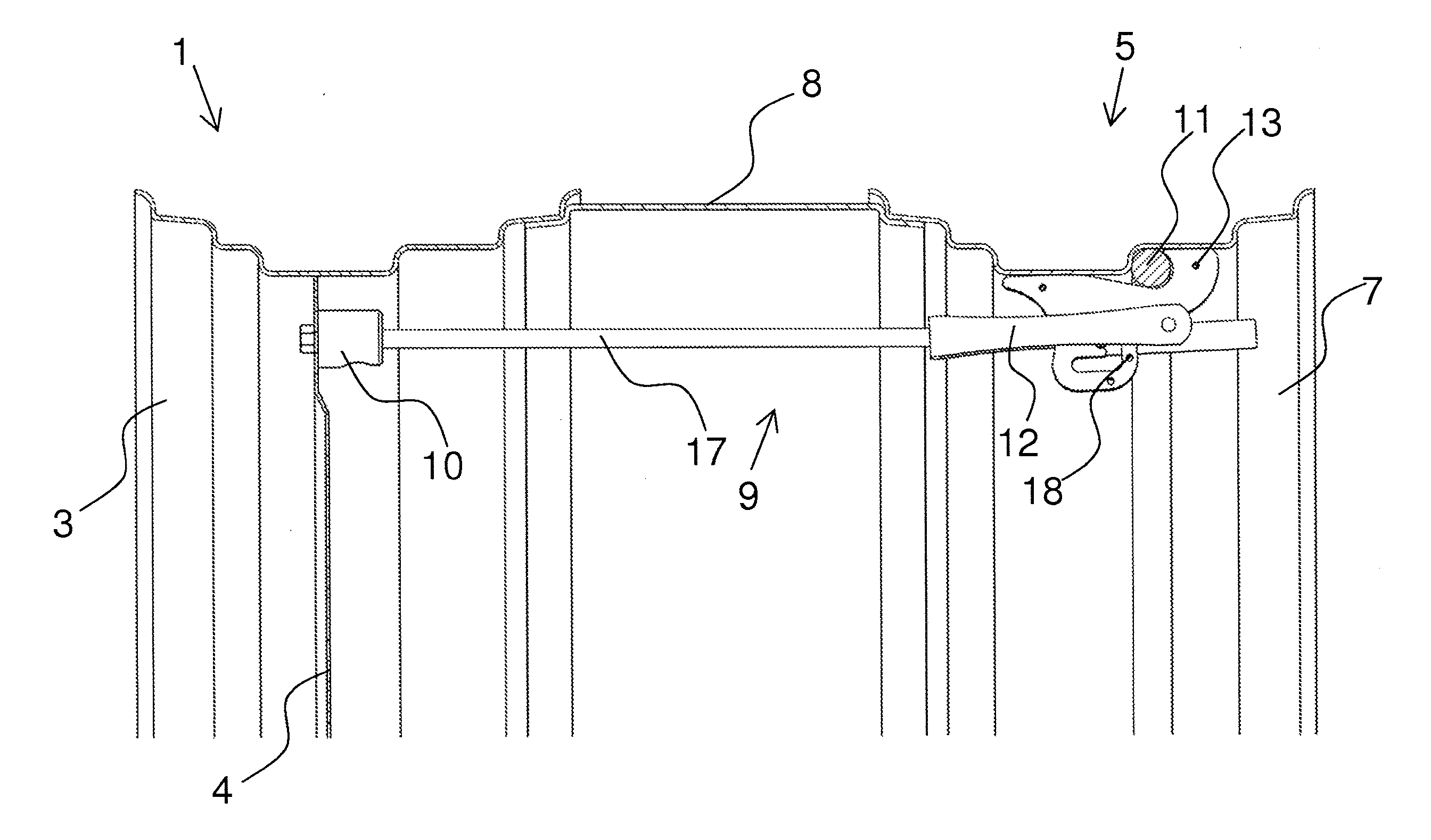

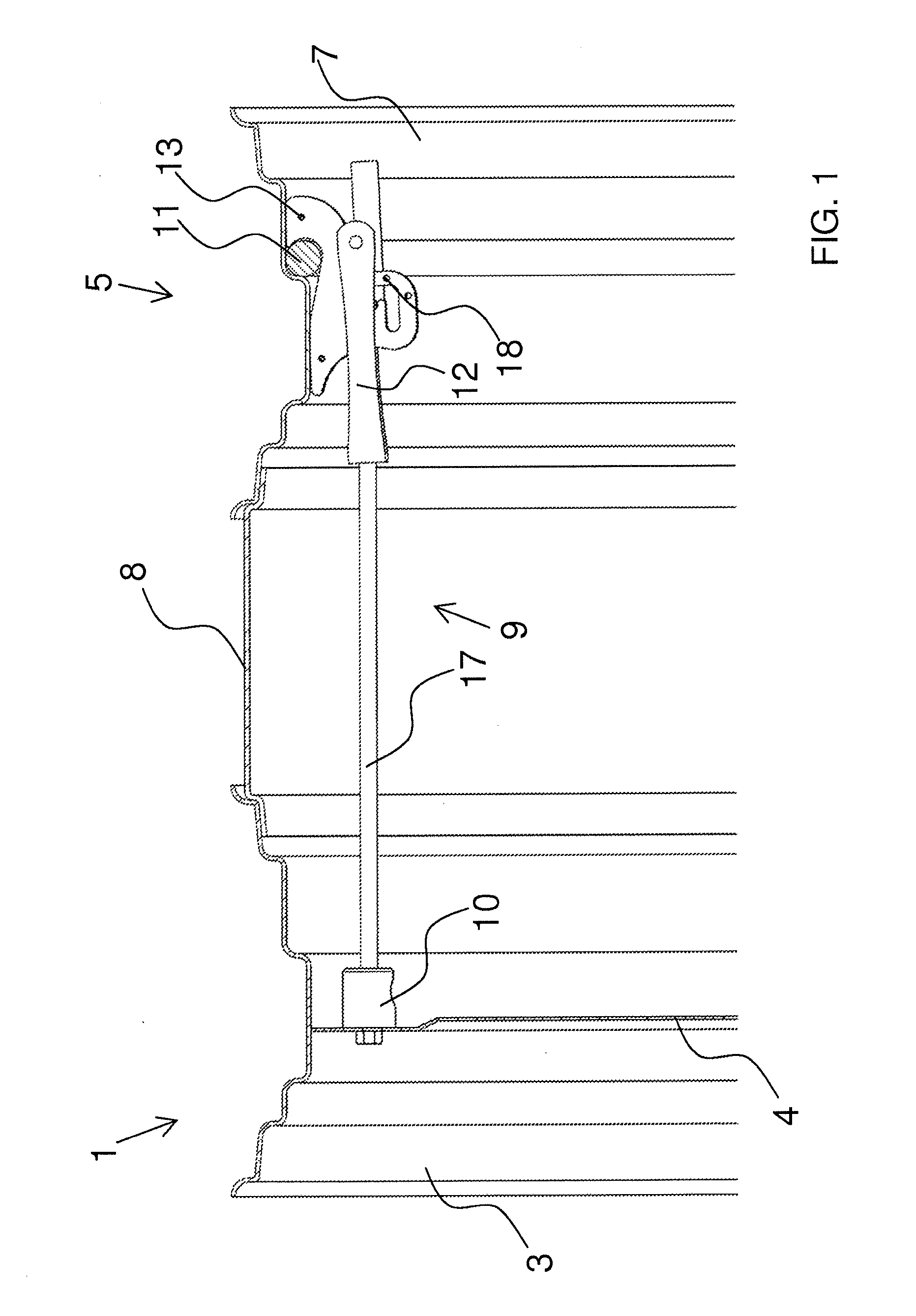

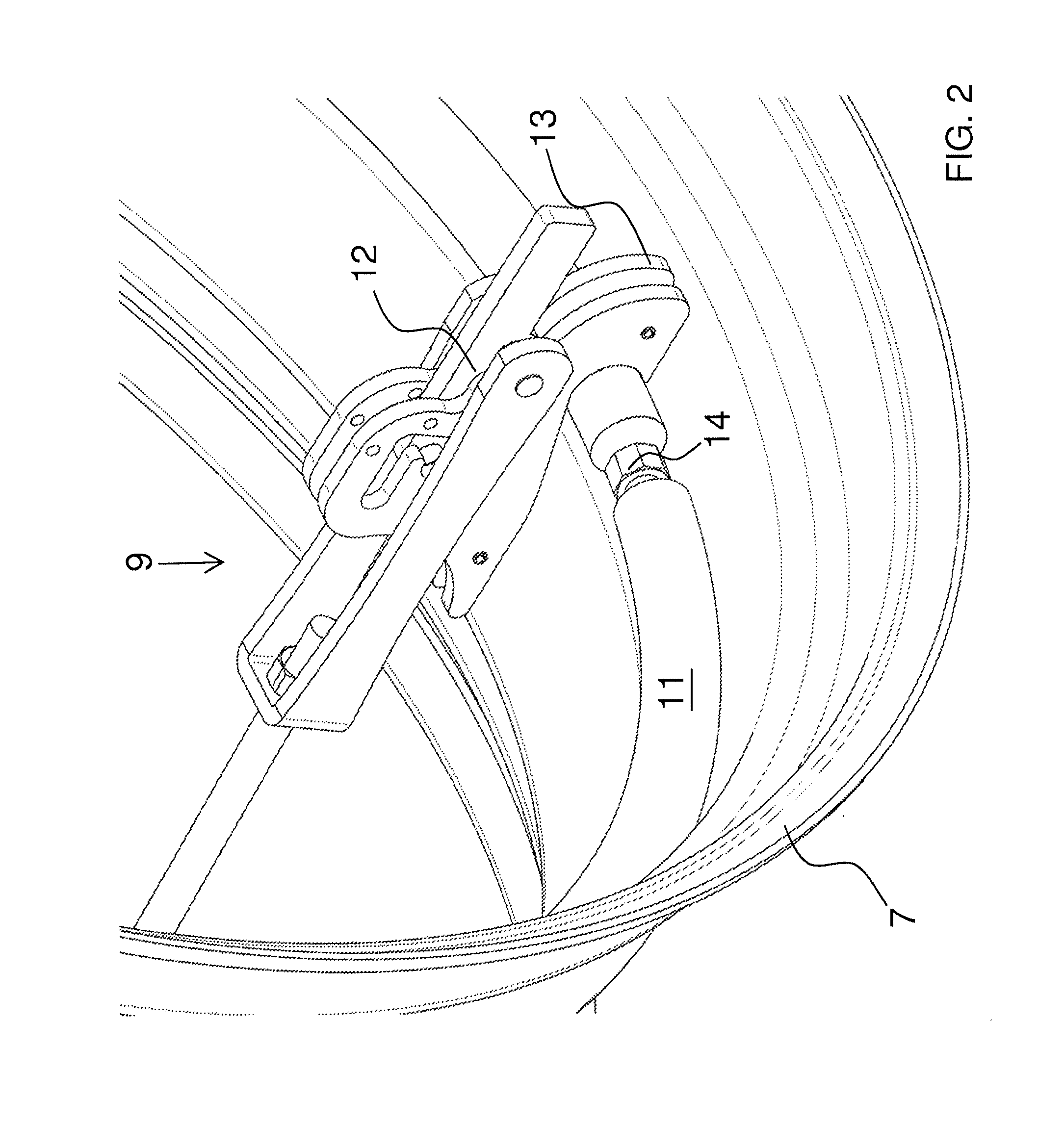

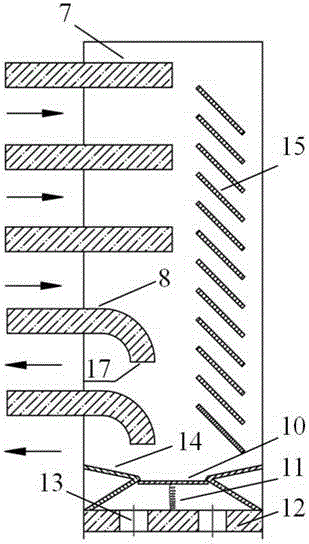

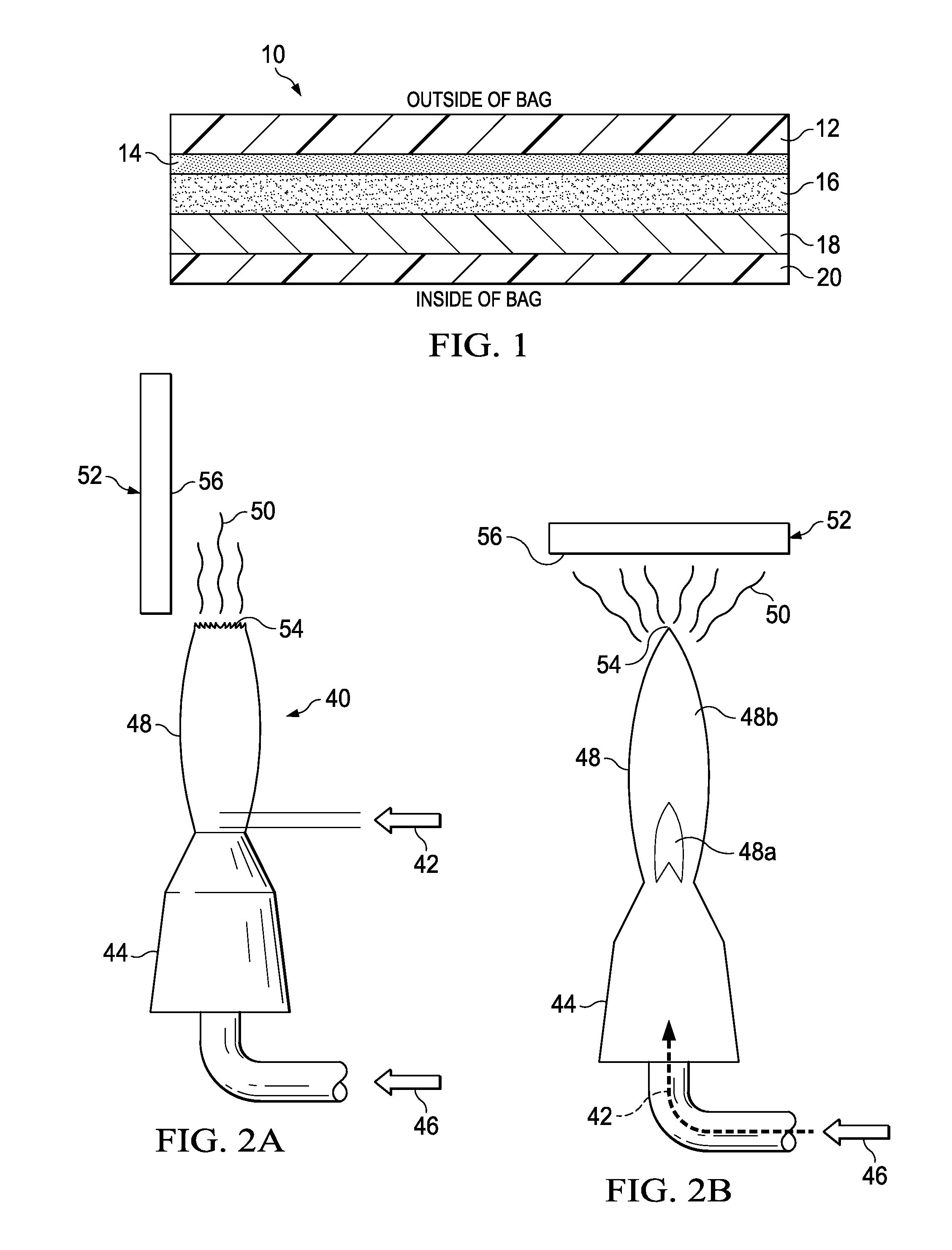

Wiper blade for a windshield wiper

In a wiper blade (100) for a windshield wiper, having a wiping strip (112) on which there is arranged at least one supporting rail (214) which has a spring element (215) provided with a plastic sheath (217), wherein the plastic sheath (217) is welded, at least in a predefined connecting region (180), to a base connecting device (160) which comprises thermoplastic material having a predefined melting point, the plastic sheath (217) comprises at least a first and a second thermoplastic material.

Owner:ROBERT BOSCH GMBH

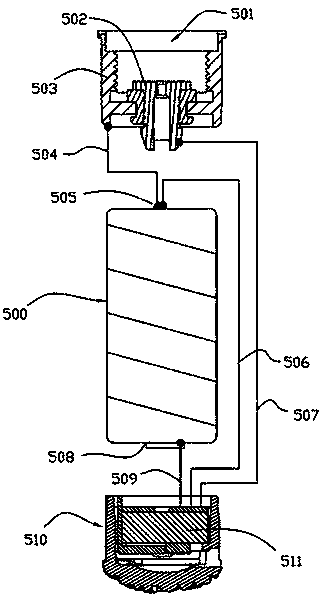

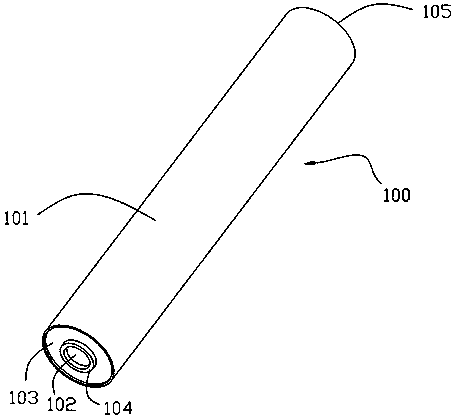

Electronic cigarette, battery device for electronic cigarette, power supply assembly and assembling method

InactiveCN103989255AAvoid welding wireImprove assembly efficiencyTobacco devicesCell component detailsElectrical batteryEngineering

The invention discloses an electronic cigarette, a battery device for the electronic cigarette, a power supply assembly and an assembling method. The battery device is provided with a plurality of power output ends, and comprises a packaging shell body with two ends, a cell unit is arranged in the packaging shell body, a first contact electrode and a second contact electrode which are connected with the positive electrode and the negative electrode of the cell unit respectively and are insulated with each other are arranged at one end of the packaging shell body, a third contact electrode is arranged at the other end of the packaging shell body, and the third contact electrode is in conductive connection with one of the first contact electrode and the second contact electrode. The power supply assembly comprises the battery device, a lampshade module, a connecting component and an outer shell, the lampshade module and the connecting component can be in direct conductive connection with the contact electrodes on the battery device from two ends, wires do not need to be welded, automated production can be met, and production efficiency is improved.

Owner:SHENZHEN FIRST UNION TECH CO LTD

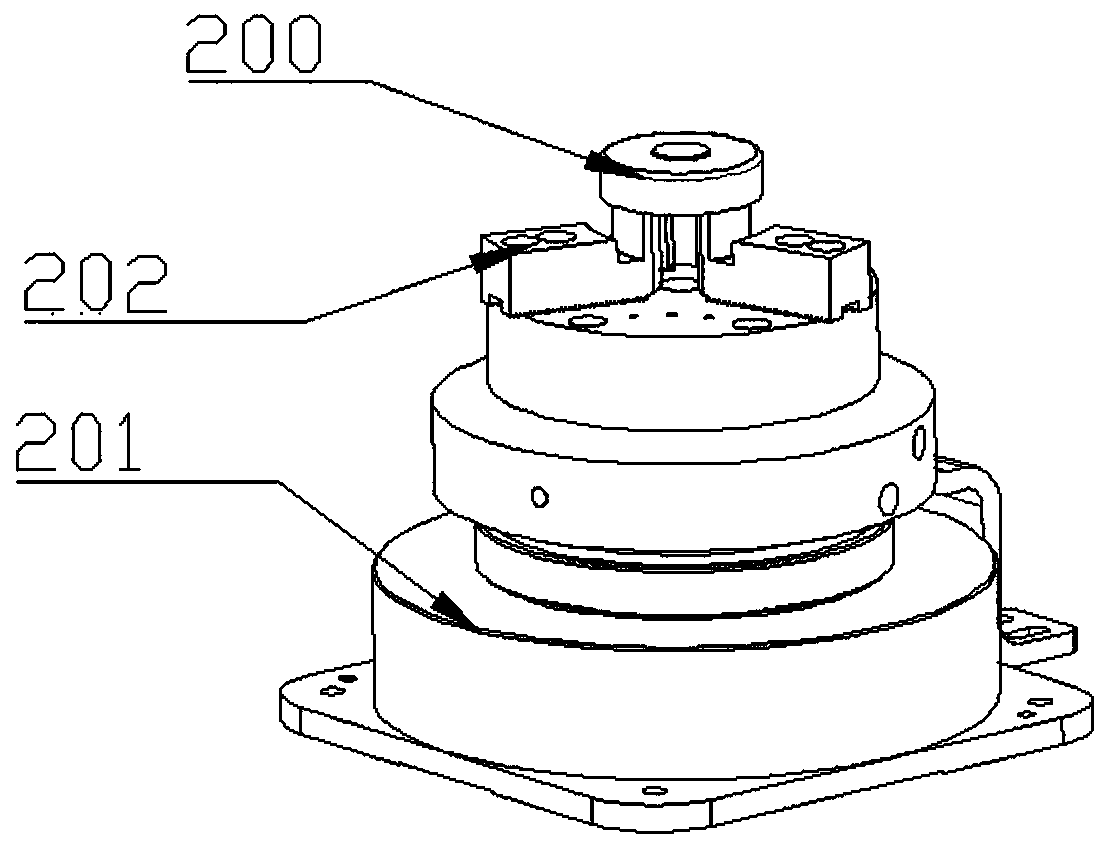

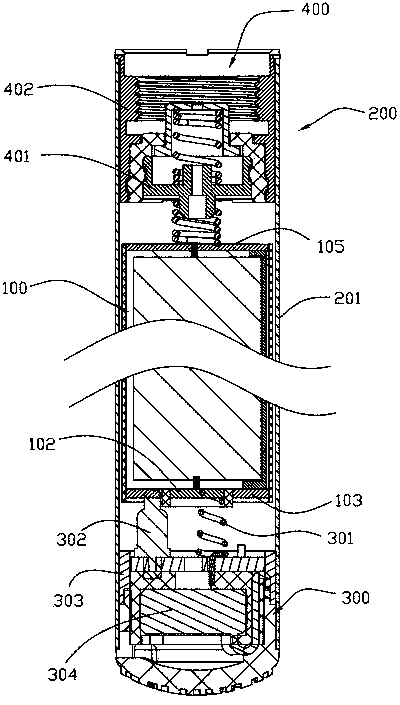

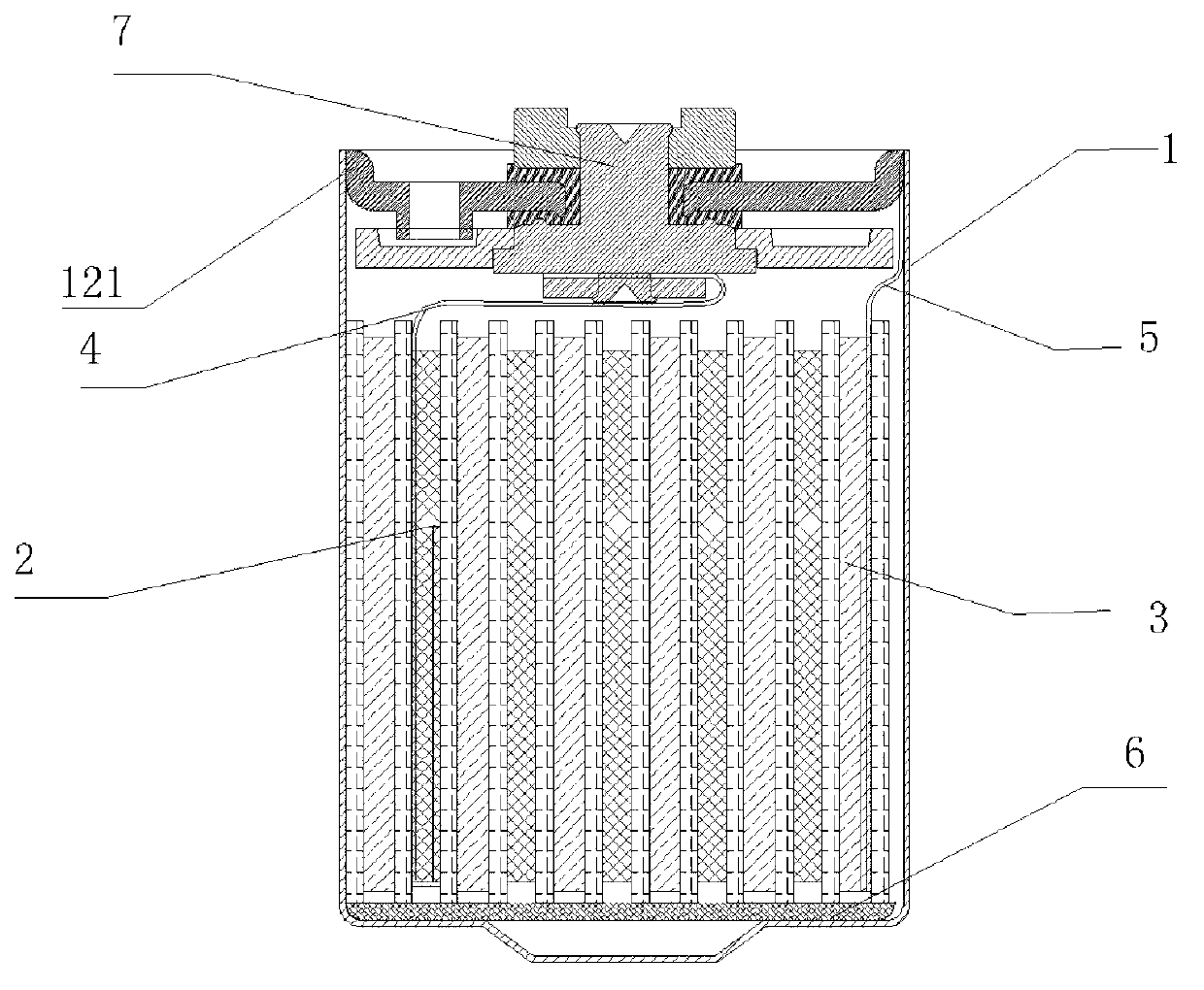

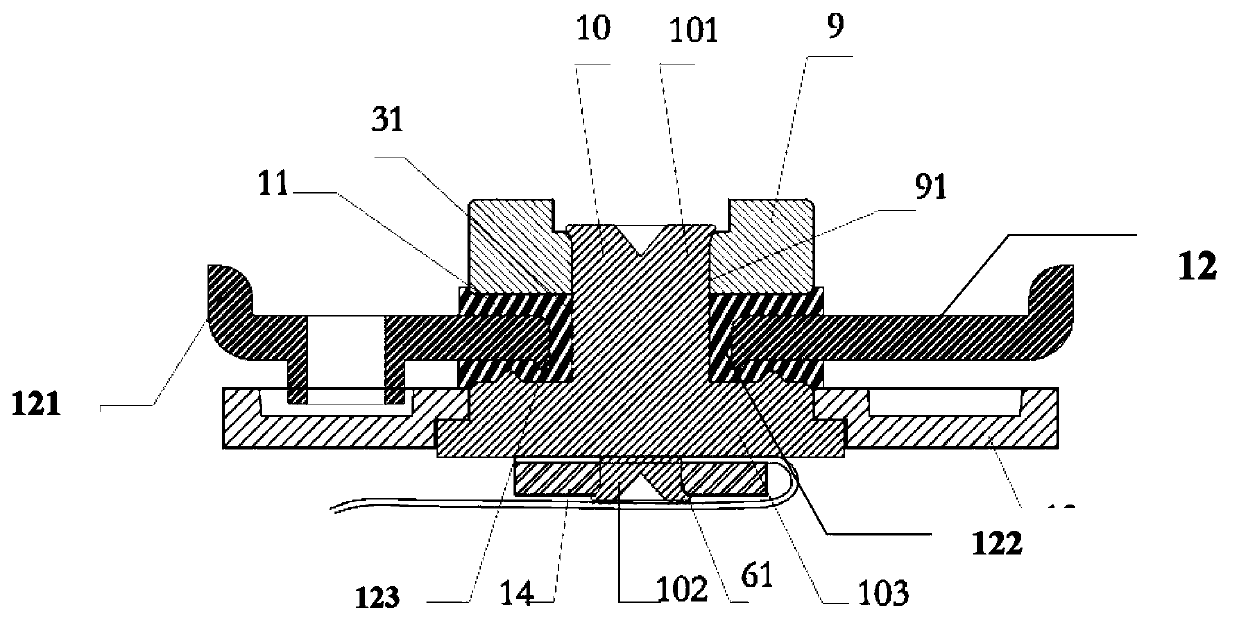

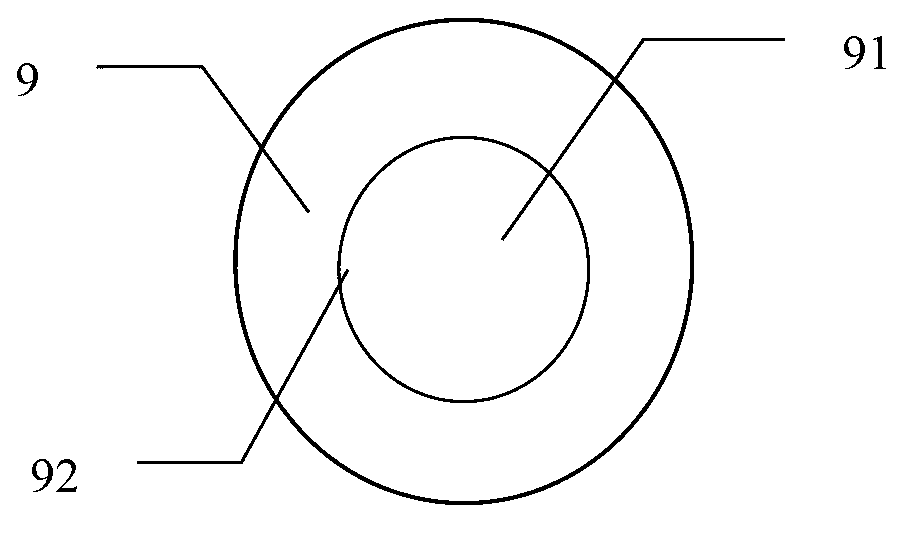

Cylinder battery capacitor

ActiveCN103137343AAvoid WeldingAvoid oversolderingCell component detailsHybrid cases/housings/encapsulationsEngineeringCapacitor

The invention relates to a cylinder battery capacitor. The cylinder battery capacitor comprises a cylinder shaped shell with an opening formed in the top end and the sealed bottom, electrode sets arranged inside the shell, wherein the electrode sets comprise positive electrode plates, negative electrode plates, positive electrode ears connected with the positive electrode plates and negative electrode ears connected with the negative electrode plates. The cylinder battery capacitor further comprises a seal assembly arranged on the top of the cylinder shaped shell and an insulation basement membrane arranged on the bottom of the cylinder shaped shell. The periphery of the battery capacitor is welded with the cylinder shaped shell and the negative electrode ears, and the bottom of the sealing assembly and the positive electrode ears are connected in a rivet joint mode. By arranging the seal assembly inside the battery capacitor and achieving a complete sealing of the battery capacitor in a rivet joint mode, seal performance of the battery capacitor is improved.

Owner:EVE ENERGY CO LTD

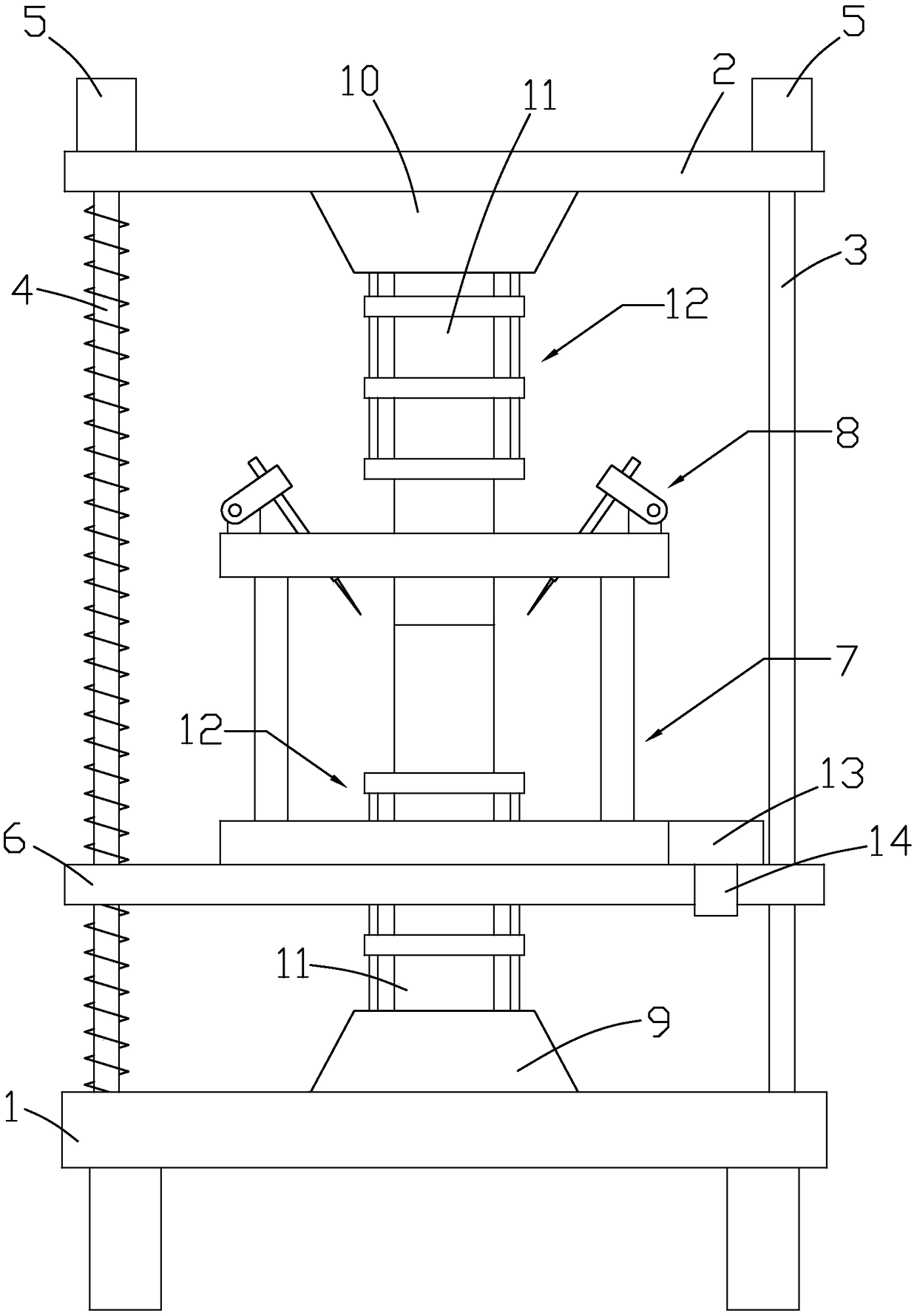

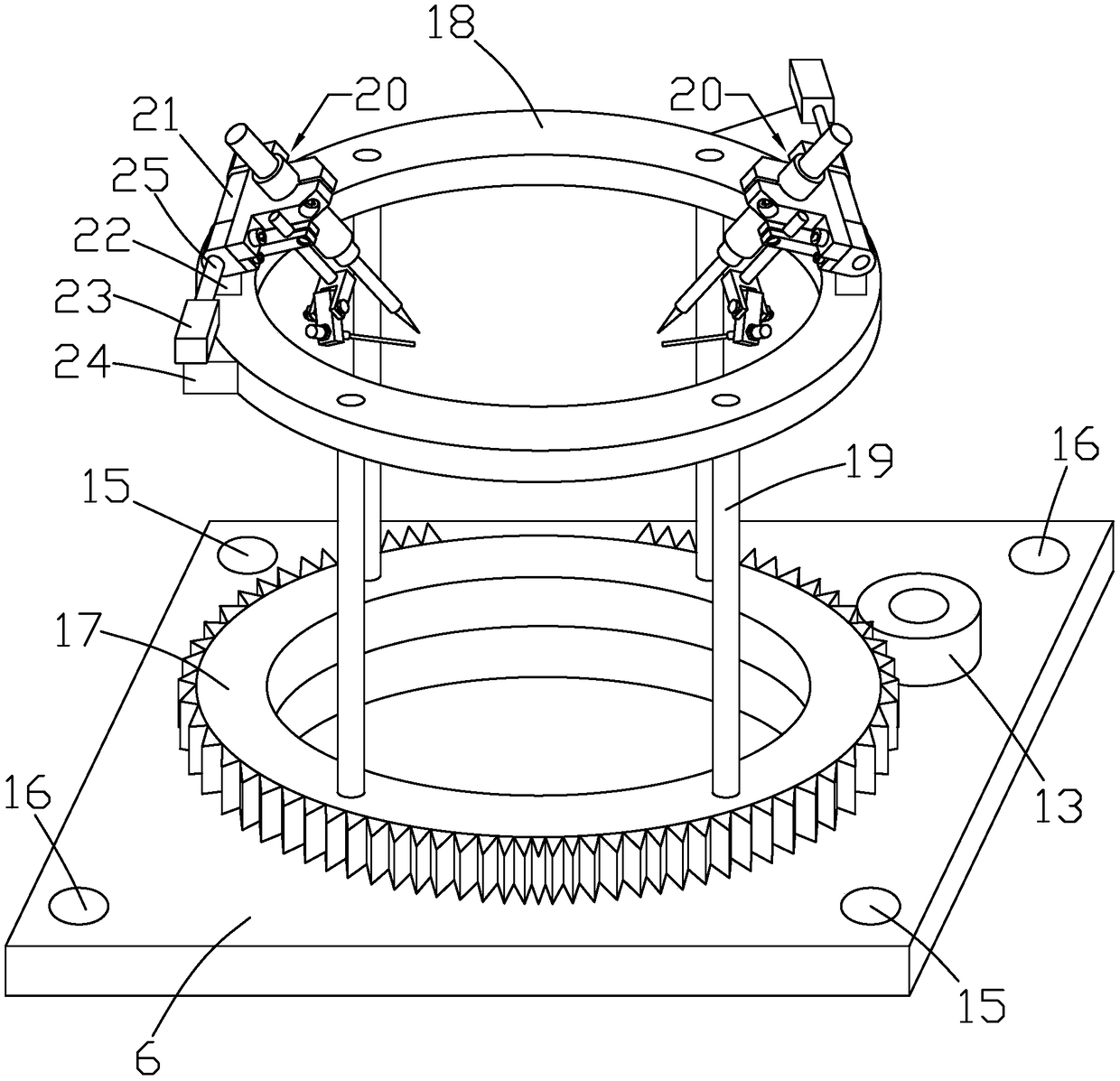

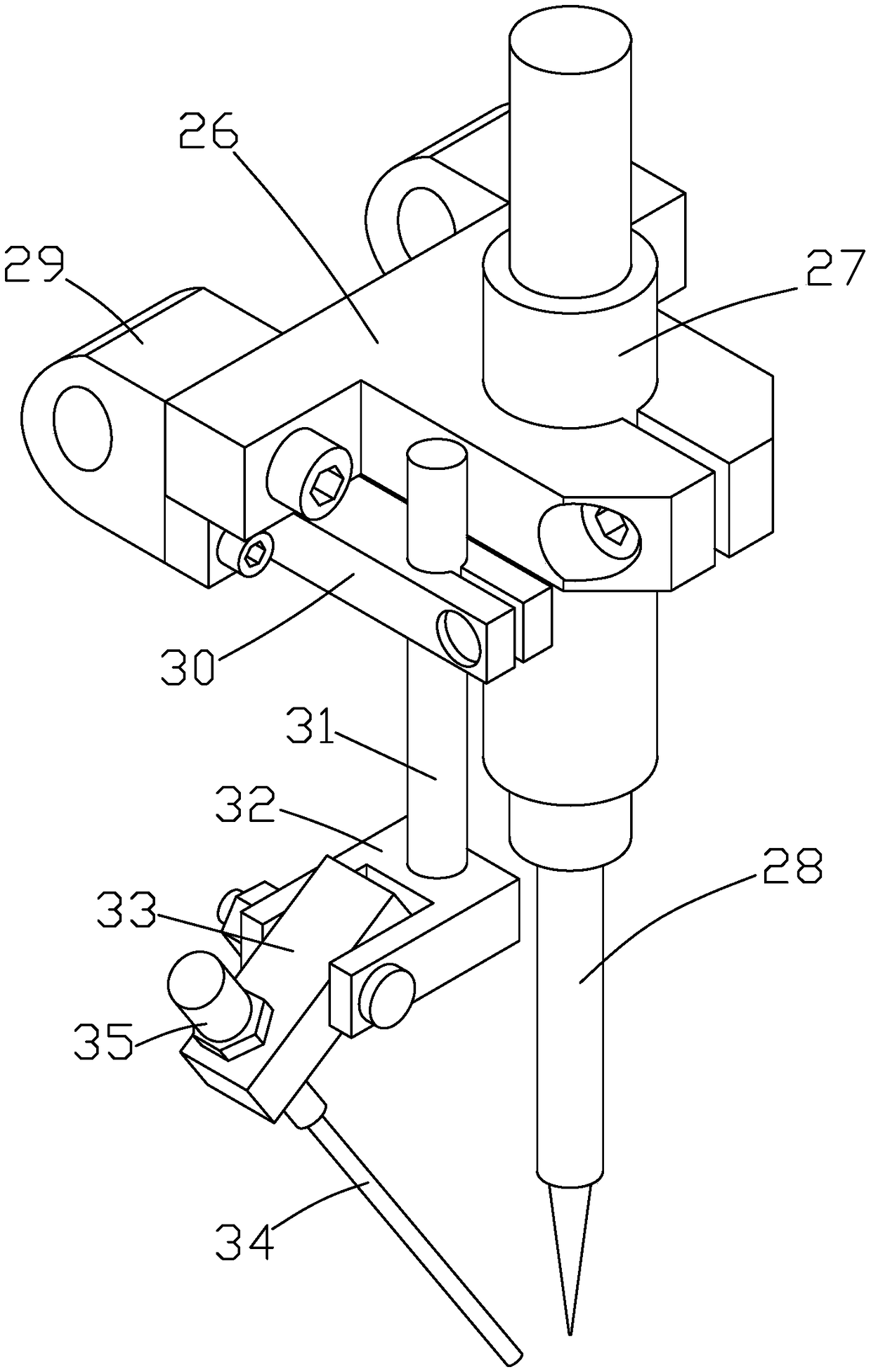

Welding device for pipeline sealing connection

ActiveCN109434341ASmooth rotationImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThreaded rod

The invention discloses a welding device for pipeline sealing connection. The welding device for pipeline sealing connection comprises a base, a locating plate, a rotating mechanism, a welding mechanism and clamping and locating mechanisms. The base is connected with the locating plate through a stand column and a threaded rod. First motors are arranged at the top end of the threaded rod, and a lifting plate is connected between the stand column and the threaded rod in a moving mode. The rotating mechanism is connected to the lifting plate in a rotating mode, and the welding mechanism is connected to the rotating mechanism. A lower locating platform and an upper locating platform are arranged on the top surface of the base and the bottom surface of the locating plate correspondingly, and the clamping and locating mechanisms are arranged on the lower locating platform and the upper locating platform. Two pipeline test pieces are limited in the upper clamping and locating mechanism and the lower clamping and locating mechanism correspondingly and located on the same vertical straight line. The welding device for pipeline sealing connection is simple in structure and high in practicability, can conduct clamping and locating operation on two pipelines in the up-and-down direction, and can also adjust the height and the position of a welding mechanism, the requirement for sealing welding of pipelines with different lengths is met, the practicability of the welding device is greatly improved, and the working range of the welding device is greatly broadened.

Owner:纳木博(常州)智能装备有限公司

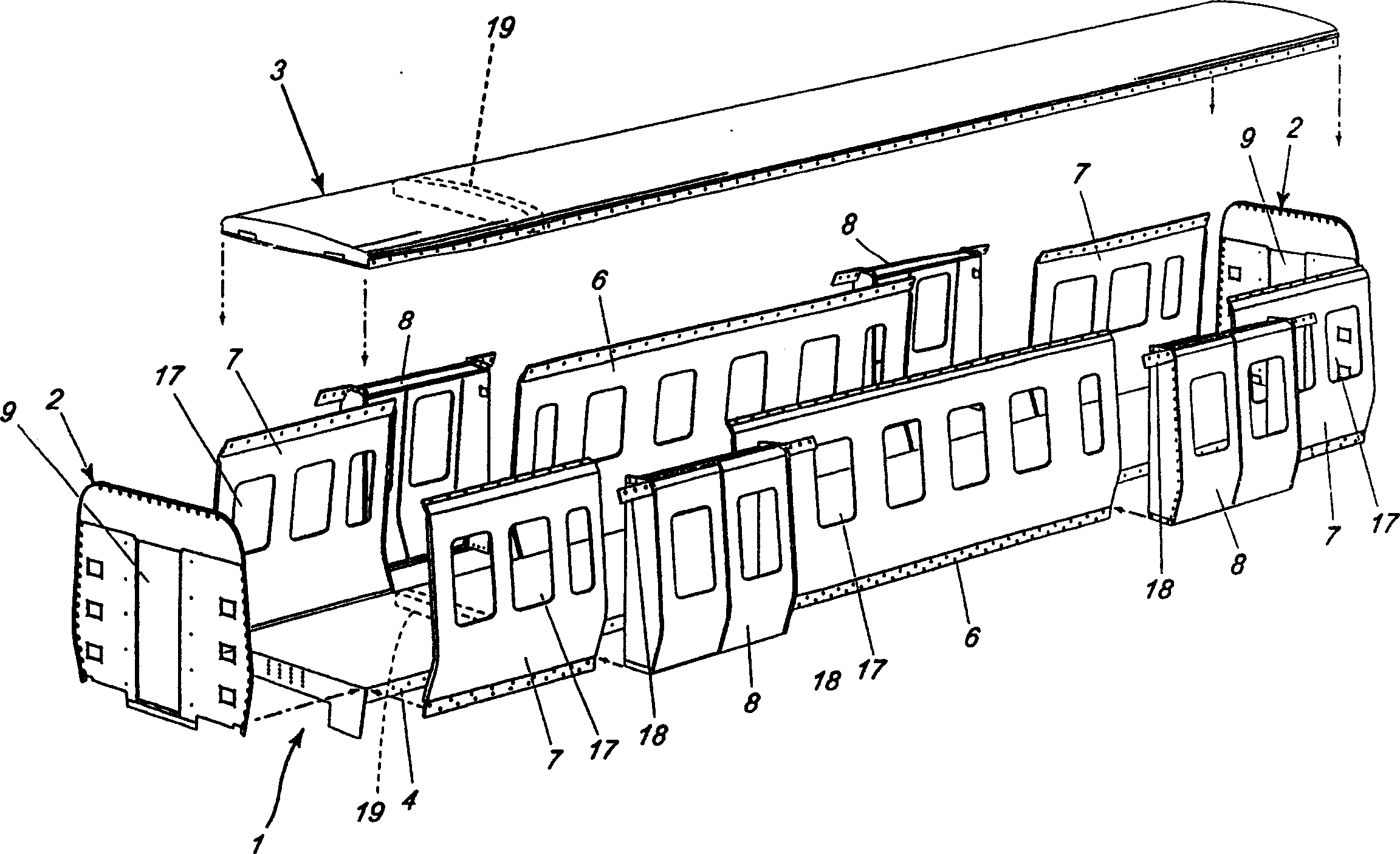

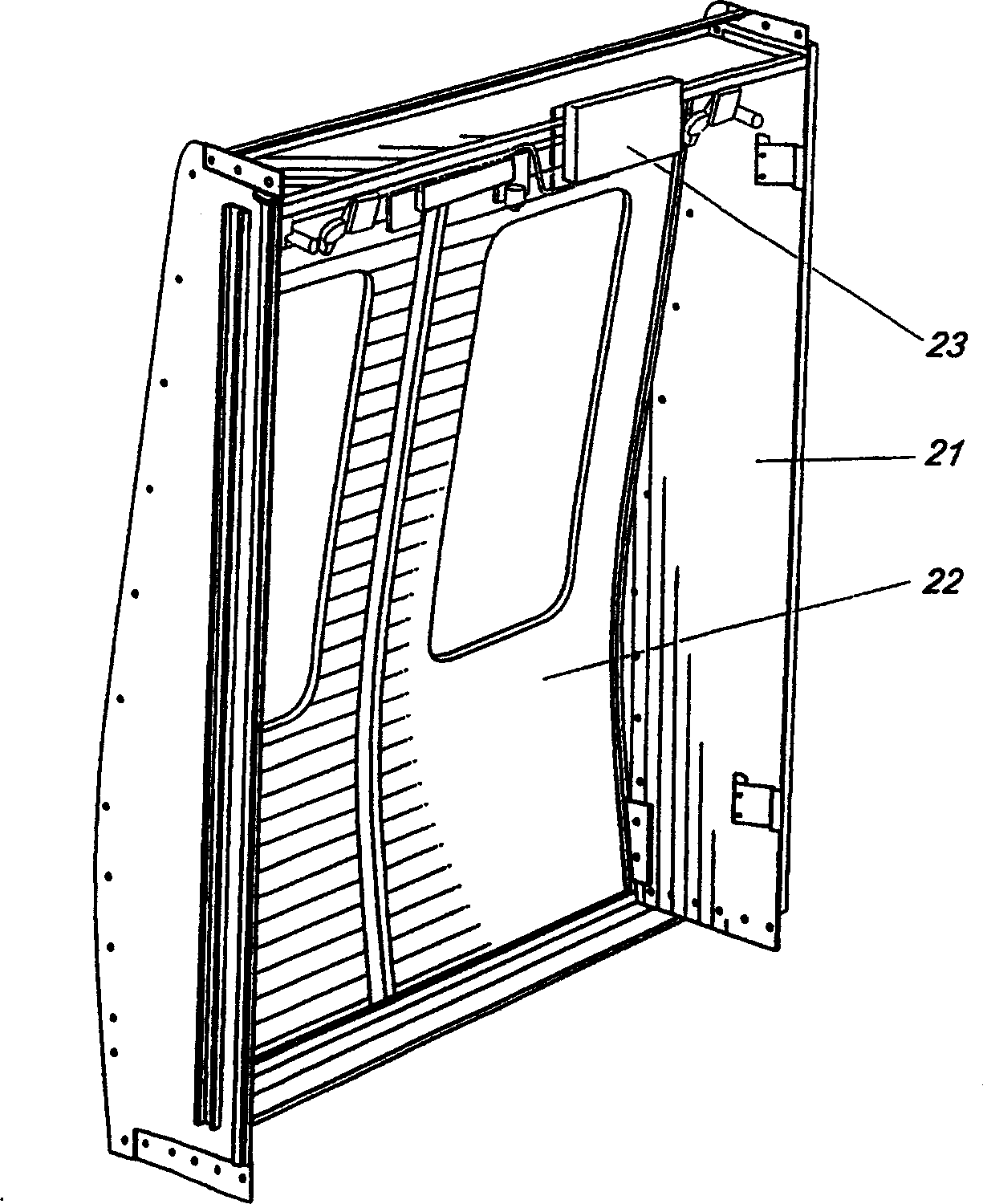

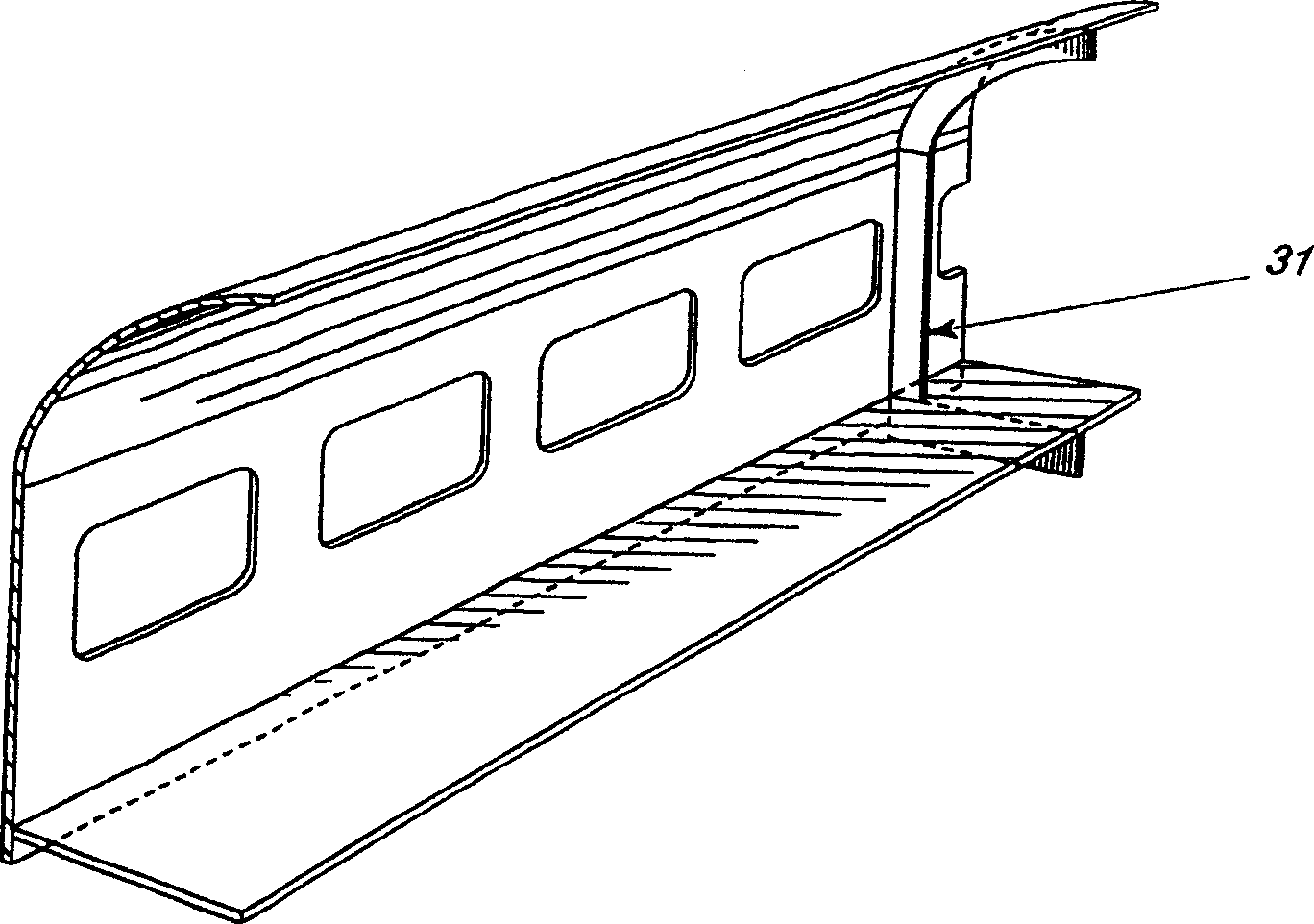

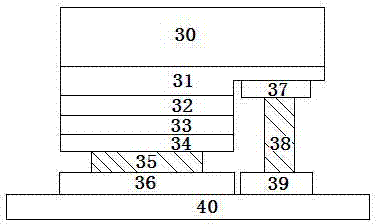

Rail vehicle carbody of modular construction

InactiveCN1489537AAvoid WeldingReduce weightAxle-box lubricationRailway bodiesModular constructionCar door

A carbody for a railbound vehicle of a modular construction comprising a floor module (1), a roof module (3), each forming single piece, self supporting structures, two end structures (2) and sides. The sides comprise vertical elements that are joint at the top to the roof module and at the bottom to the floor module and at the side to an adjoining vertical element or to an end structure. The vertical elements comprise wall modules (6, 7) and door modules (8). The door modules are self-supporting, structural parts mainly contributing to the cross-sectional strength of the vehicle, and the wall modules are thin, self-supporting structures and mainly contributes to the longitudinal strength of the vehicle. The door modules and said wall modules are the only structural parts of the sides. All joints are made with cold joining methods only.

Owner:BOMBARDIER TRANSPORTATION GMBH

Method for manufacturing inverted LED chip

InactiveCN102403425AImprove packaging yieldAvoid WeldingSemiconductor devicesOhmic contactLight reflection

Owner:俞国宏

Integral forming method for nut board

The invention relates to an integral forming method for a nut board, which comprises the steps of: A. firstly, stamping out a wide-aperture annular flanging with the same height as a nut on a motherboard at a time; B. secondly, tapering the inner diameter and the outer diameter of the annular flanging in a continuous stamping mode under the conditions that the height of the annular flanging is kept to be constant and the volume of the whole annular flanging is constant until the thickness of the annular flanging meets strength requirements; and C. finally, finishing and tapping the inner holeof the annular flanging so as to form the nut of the nut board. By adopting the technical proposal, the nut of the nut board formed by the integral forming method for a nut board in the invention avoids the problems of faulty riveting and faulty welding existing in riveting and welding, and has the advantages of high intensity and high pulling-out force resistance.

Owner:SHANGHAI HORNGSHIUE INDAL

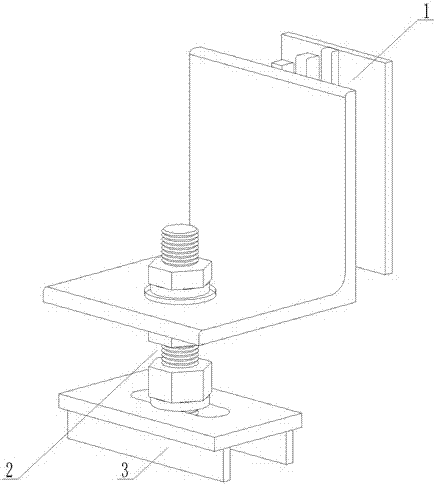

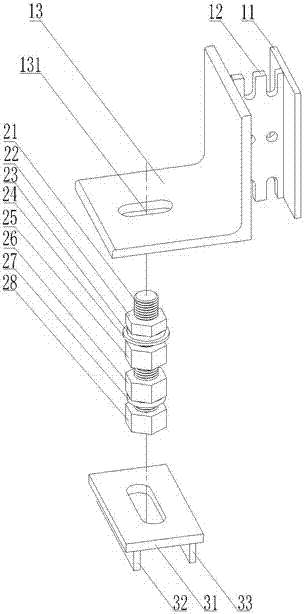

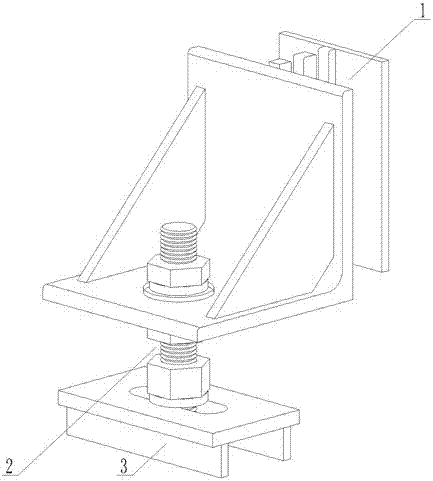

Point-supported PC wallboard connecting device

ActiveCN107143072ALow costReduce the difficulty of processing and manufacturingWallsEngineeringMechanical engineering

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

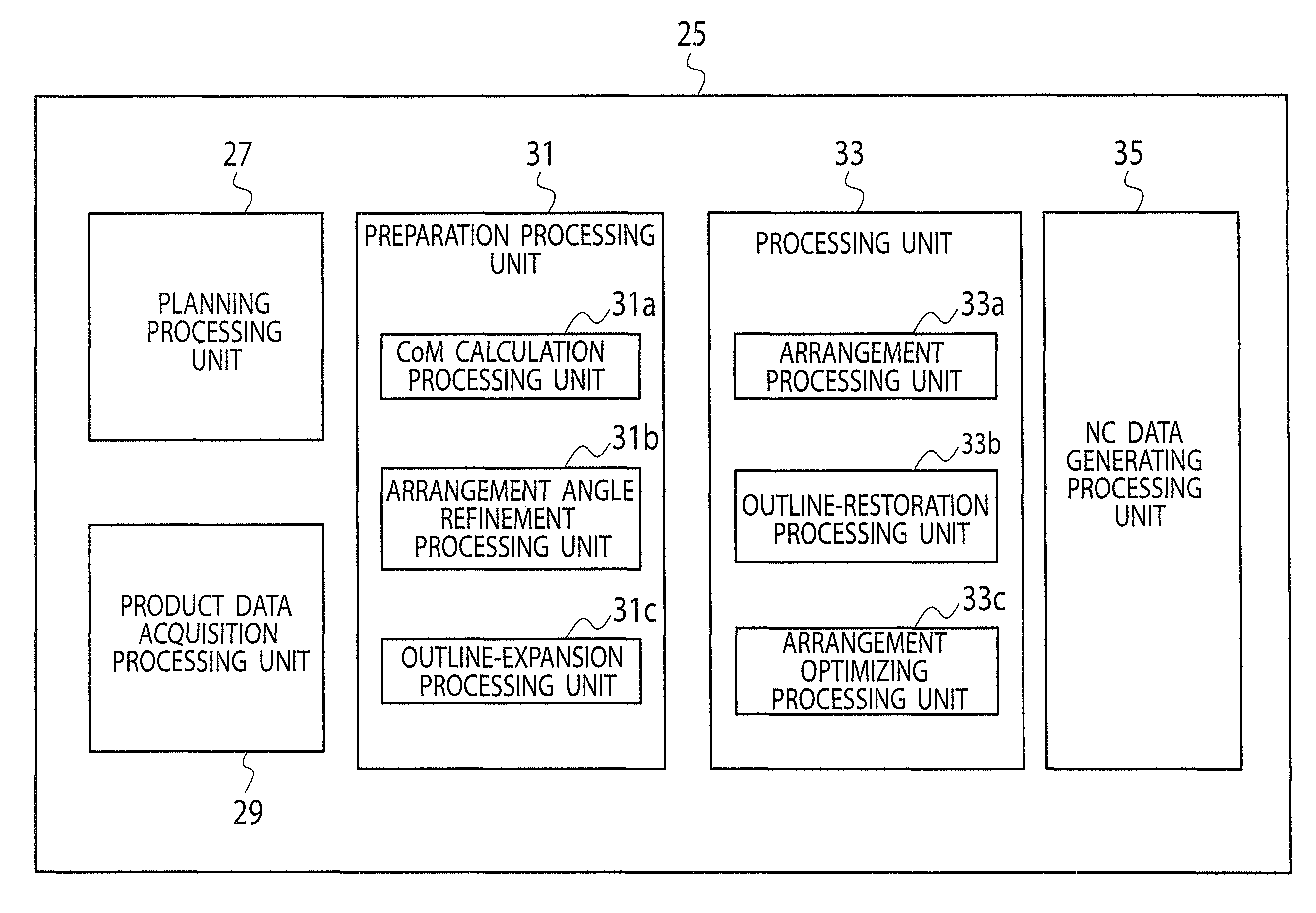

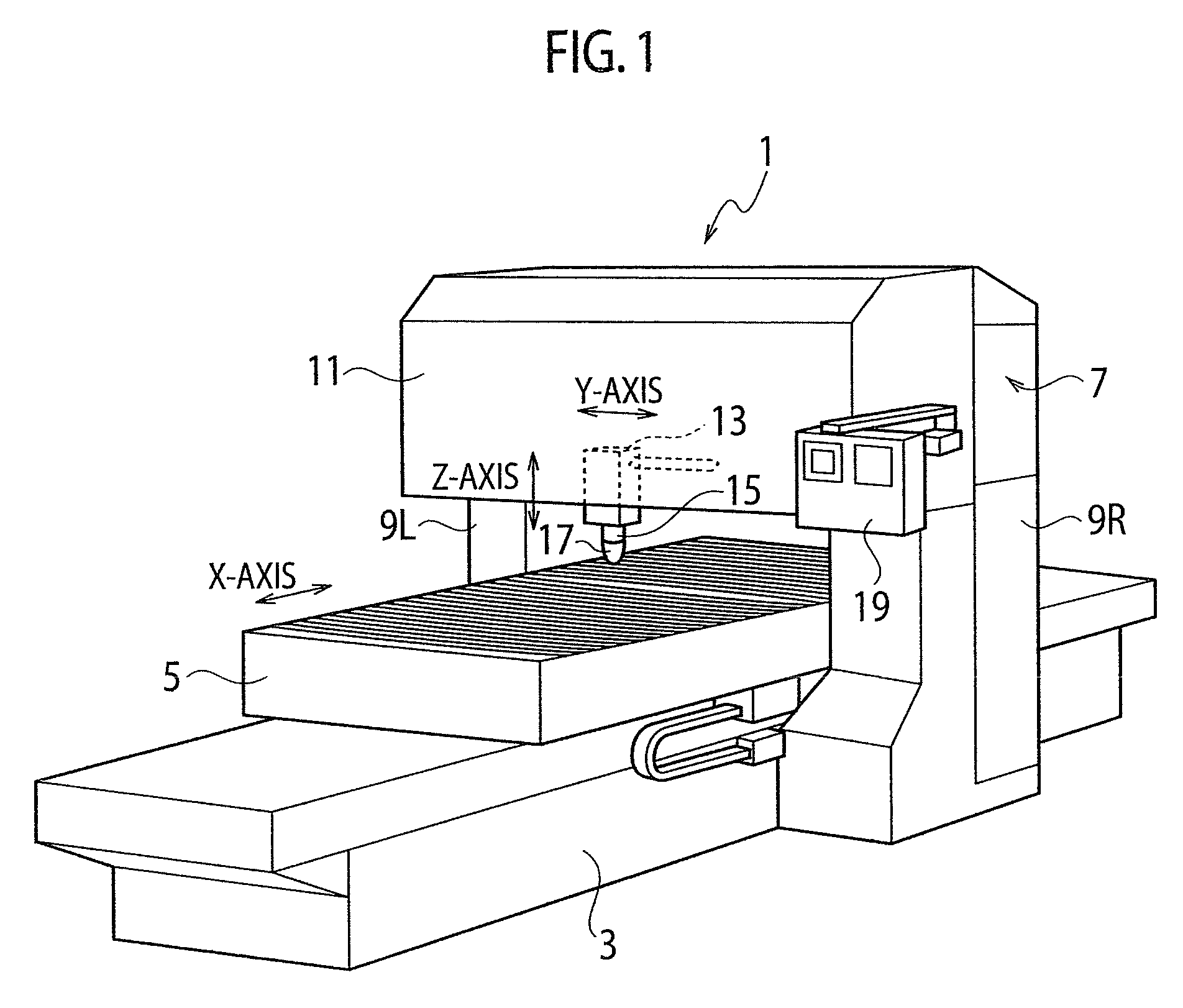

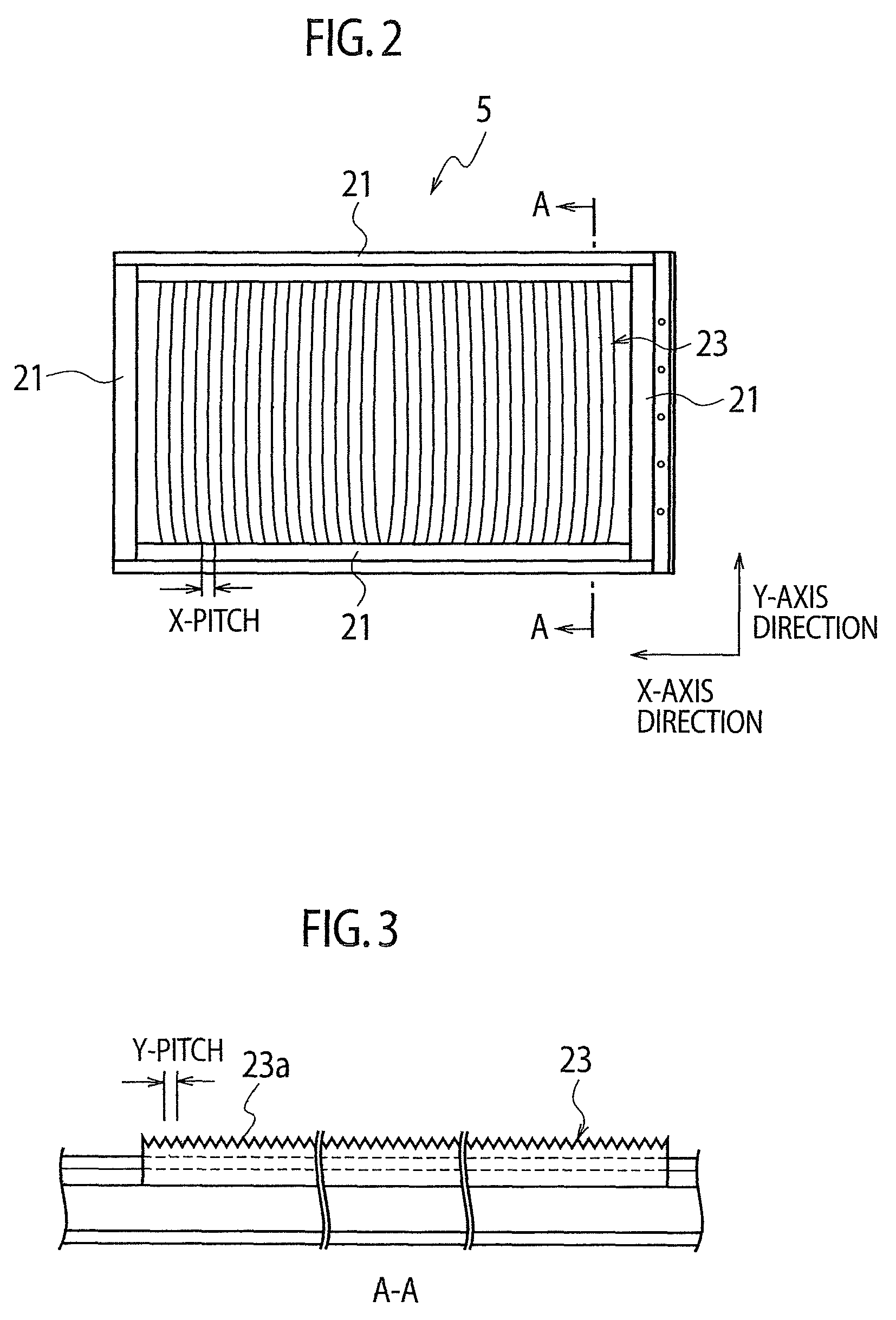

Nesting data generation device and nesting data generation method

InactiveUS9031688B2Done flawlessly and stablyGuaranteed uptimeProgramme controlComputer controlComputer scienceNested data

A nesting data generation device generates nesting data for cutting off a part from a work supported by plural support projections. The nesting data generation device includes a nesting data generating unit that generates the nesting data by arranging a geometry of the part on the work. The nesting data generating unit performs, upon arranging the geometry of the part on the work, an avoidance process for avoiding an impediment due to the support projections. According to the nesting data generation device, the part can be prevented from welding on the support projections and the support projections can be prevented from welding upon arranging the geometry on the work by considering positions of the support projections, so that a drop-off and an inclination of the cut part can be prevented.

Owner:AMADA CO LTD

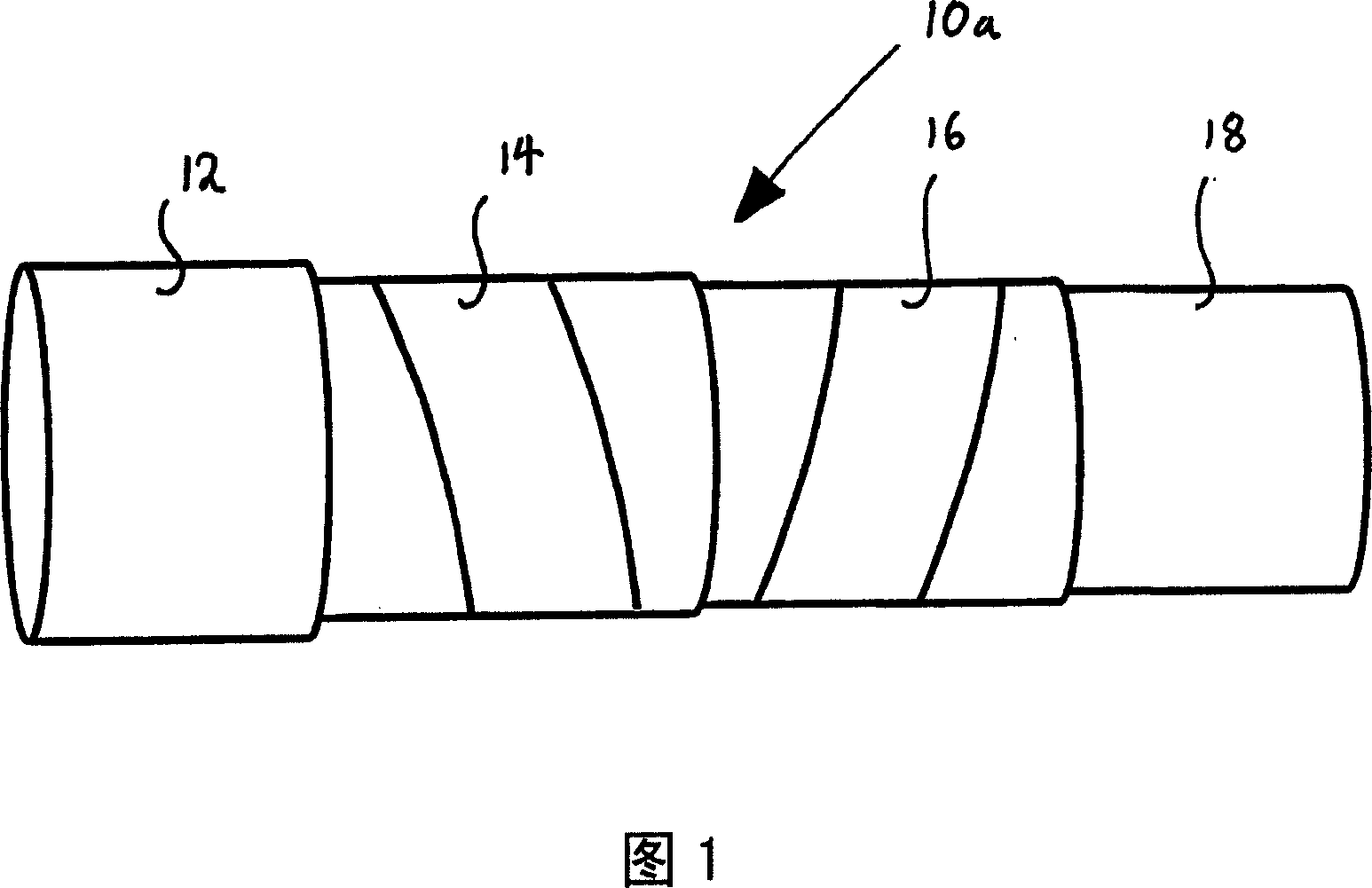

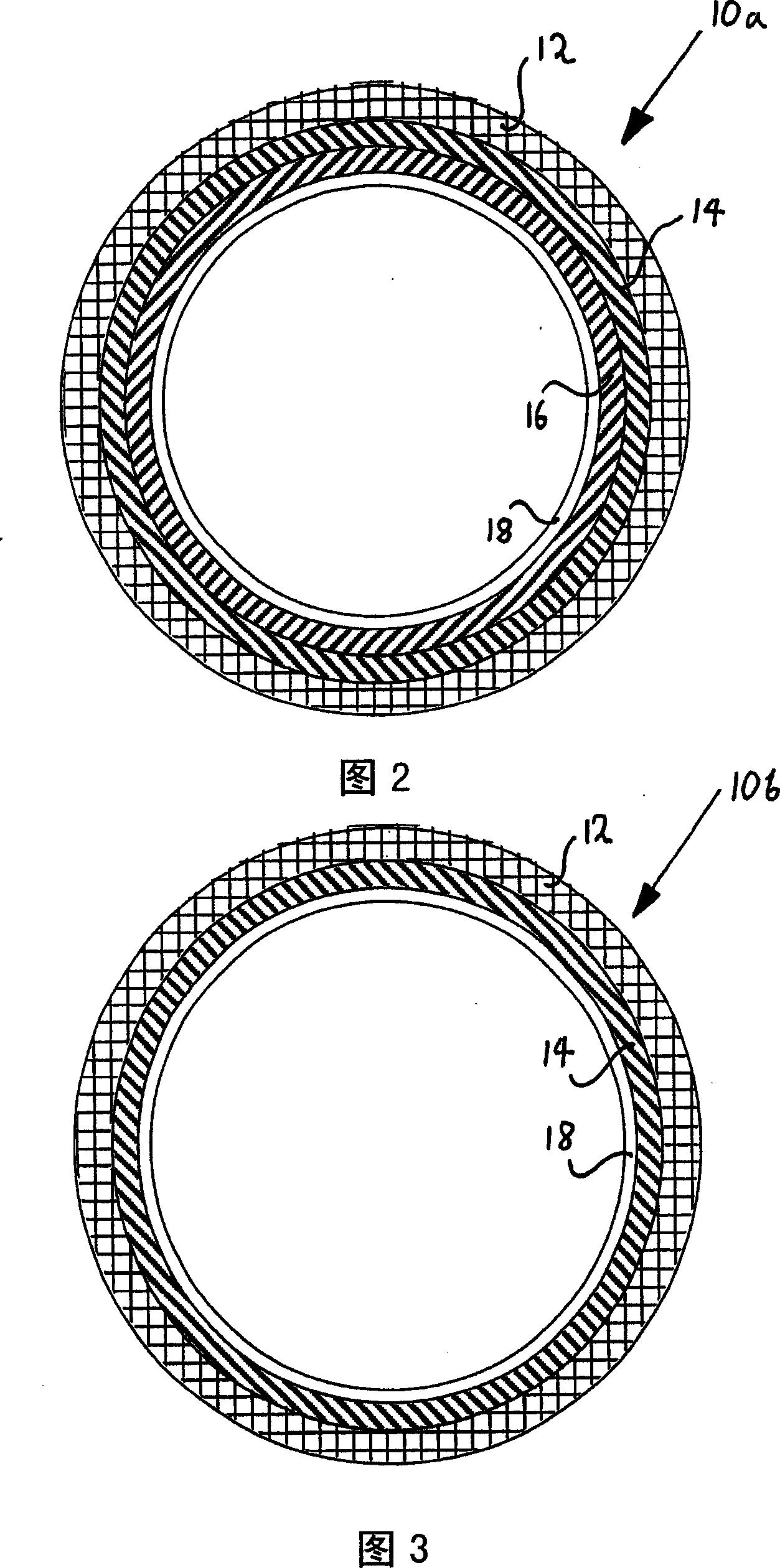

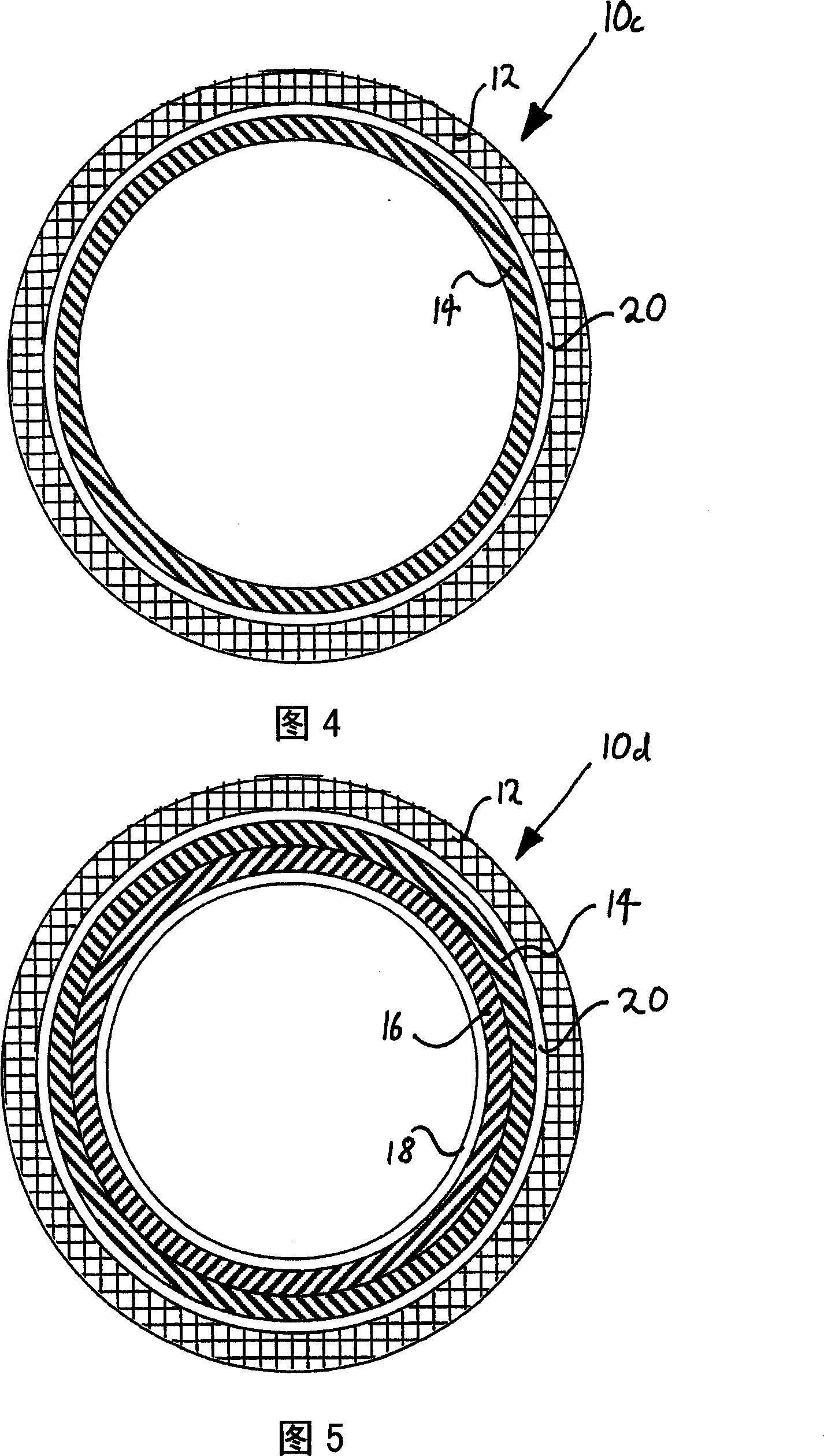

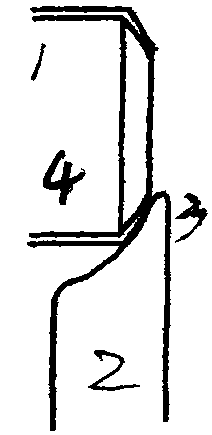

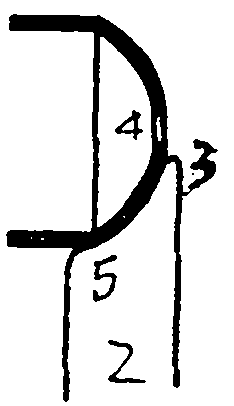

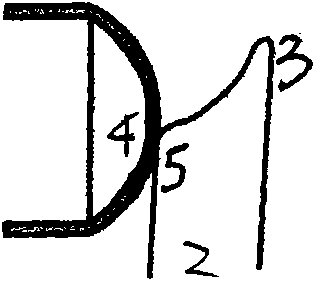

Composite pipe lining, method and apparatus for installing composite lining

A composite lining for a pipe comprising a structural layer for providing structural integrity and a containment layer for providing fluid impermeability. The structural layer comprising at least one strip of lining material arranged to form a substantially continuous lining within said pipe. A method for lining a pipe with said composite lining. A structure and method for testing the fluid integrity of said containment layer. Apparatus for installing said structural and containment layers in said pipe.

Owner:诺曼·怀斯特·贝拉米 +1

Port sealing process of heating container of electric water heater

The invention relates to a port sealing process of a heating container of an electric water heater, which comprises the following steps: first clamping a fixture for a red copper tube on a machine tool, adopting an edge-less cutter with an arc-shaped side on one end, slowly extruding the edge of the port of the red copper tube which rotates at high speed with the front end of the edge-less cutter so that the port of the red copper tube produces high temperature when rotating at high speed and having point-surface extrusion friction with the front end of the edge-less cutter, and enabling the port to close up inwards with the extension, pressing and stretching characteristics of red copper; forming a new port after the port of the red copper tube closes up inwards, extruding the new port with the arc-shaped end of the edge-less cutter, and so on, keeping closing up inwards until the port is gradually reduced and finally sealed in the center; and the port sealing process of the heating container of the electric water heater has the advantages of simple process, no seam and no welding, can well prevent welding and the oxidation of high-temperature melting points, can achieve attractive overall appearance, and is characterized by higher compressive strength, longer service life and the like.

Owner:陶镇铭 +1

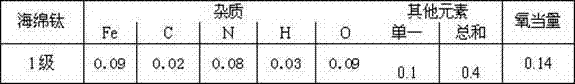

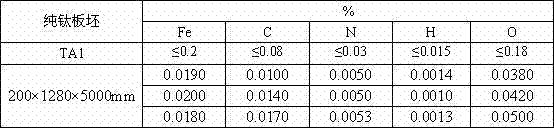

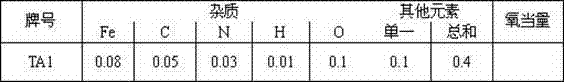

Method for producing titanium slabs efficiently

The invention discloses a method for producing titanium slabs efficiently. Electron beam cold hearth furnaces of six electron guns are used, raw materials of which components are selected are placed in bulk material feeders or bar material feeders of the electron beam cold hearth furnaces, smelting is conducted, then obtained cast ingots are cooled and are discharged out of the furnace, and finished products are obtained. According to the method, the raw materials in an original state are used directly for smelting, crushing of recycled materials, mixing of titanium sponge materials, electrode block pressing and electrode welding are avoided, slab ingots smelted through optimization design are two cast ingots of 200*1290*5000mm which are produced in one furnace, the weight is about 12 tons, and the slab ingots are not required to be smelted twice or to be forged can be used in rolling, so that the production flow and the production period are shortened, the production cost is reduced, and the efficiency is improved greatly.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

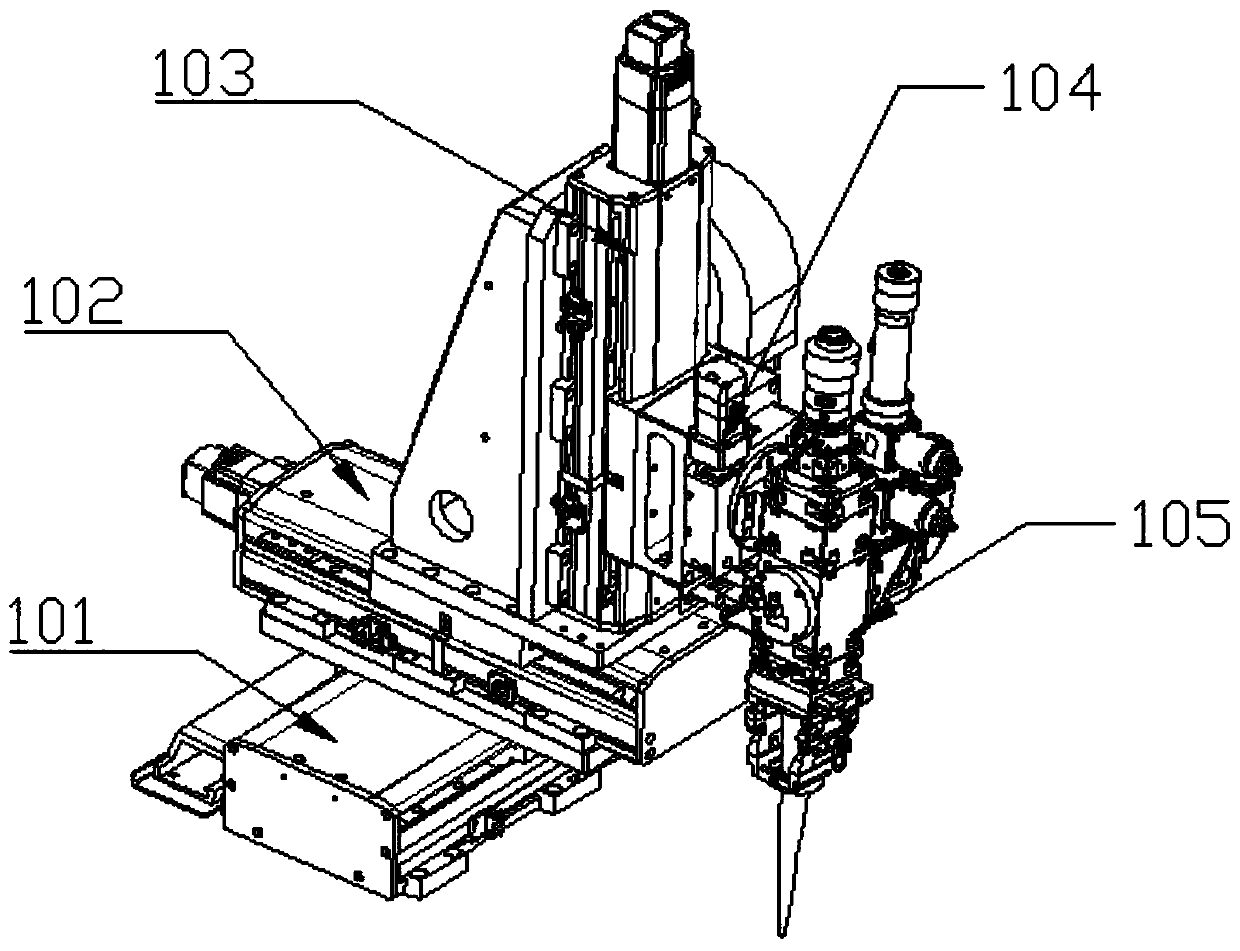

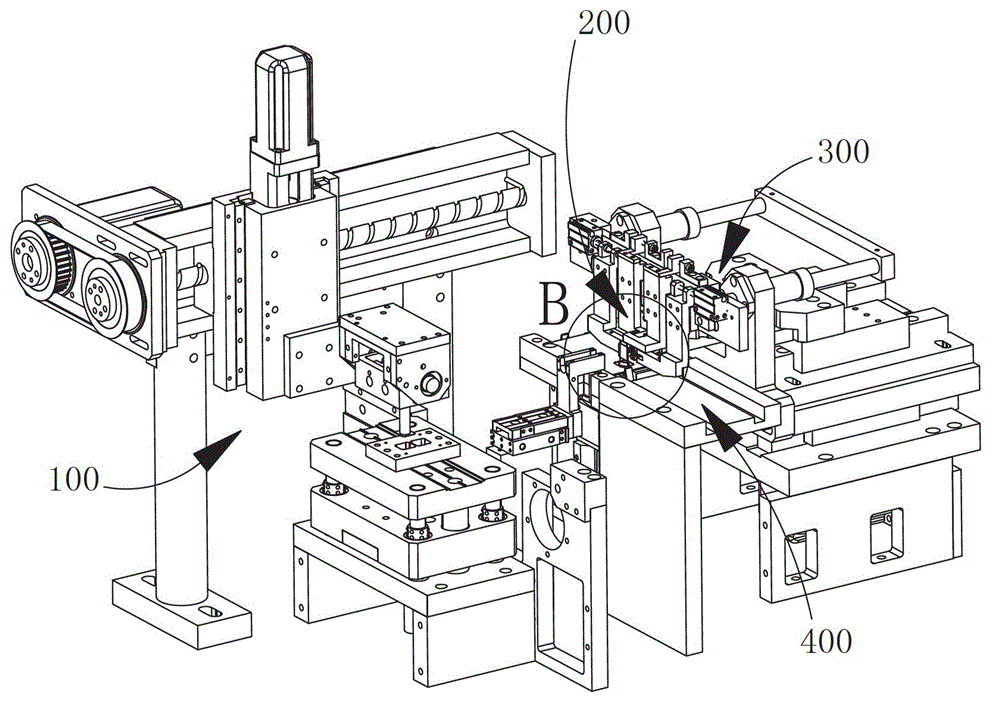

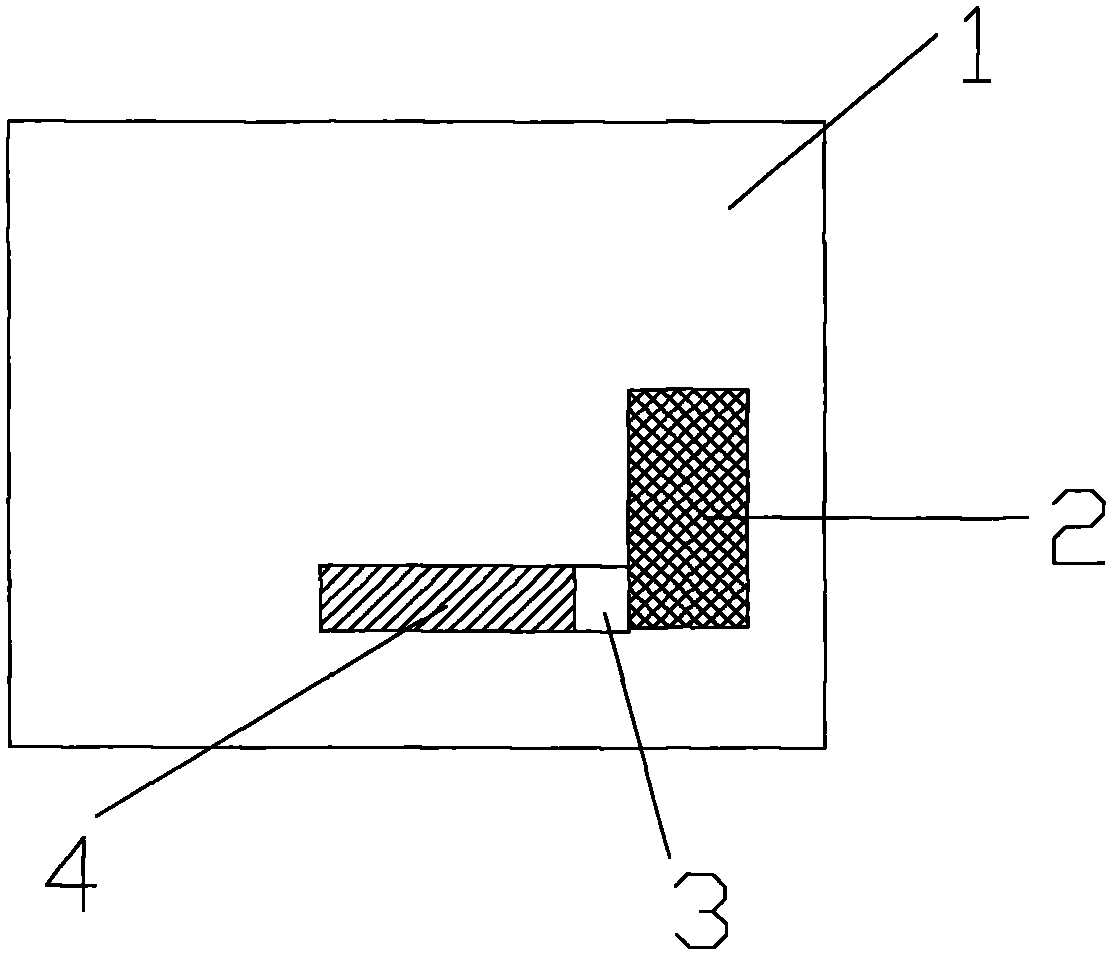

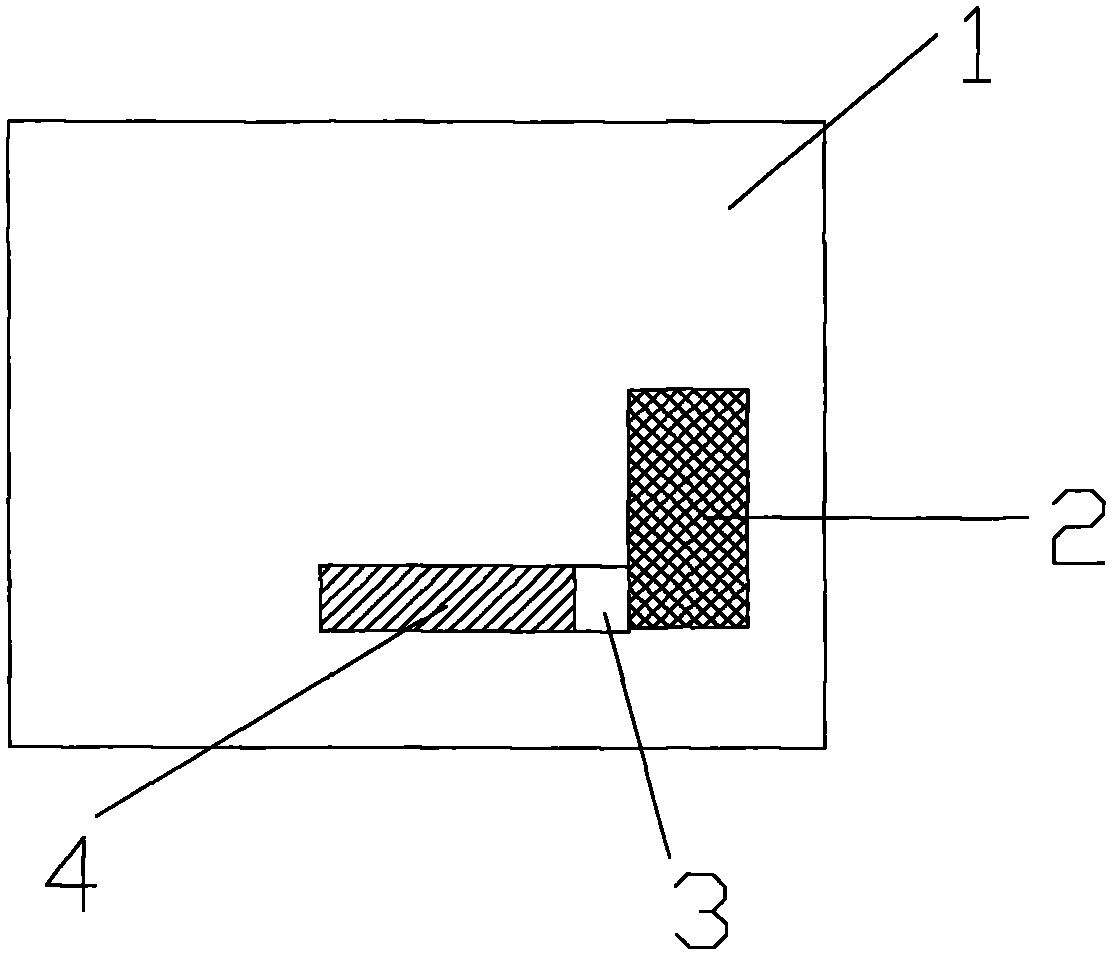

Chip welding method of dual-interface card and equipment thereof

InactiveCN103182577AImprove work efficiencyReduce labor intensitySoldering apparatusEngineeringElectrical and Electronics engineering

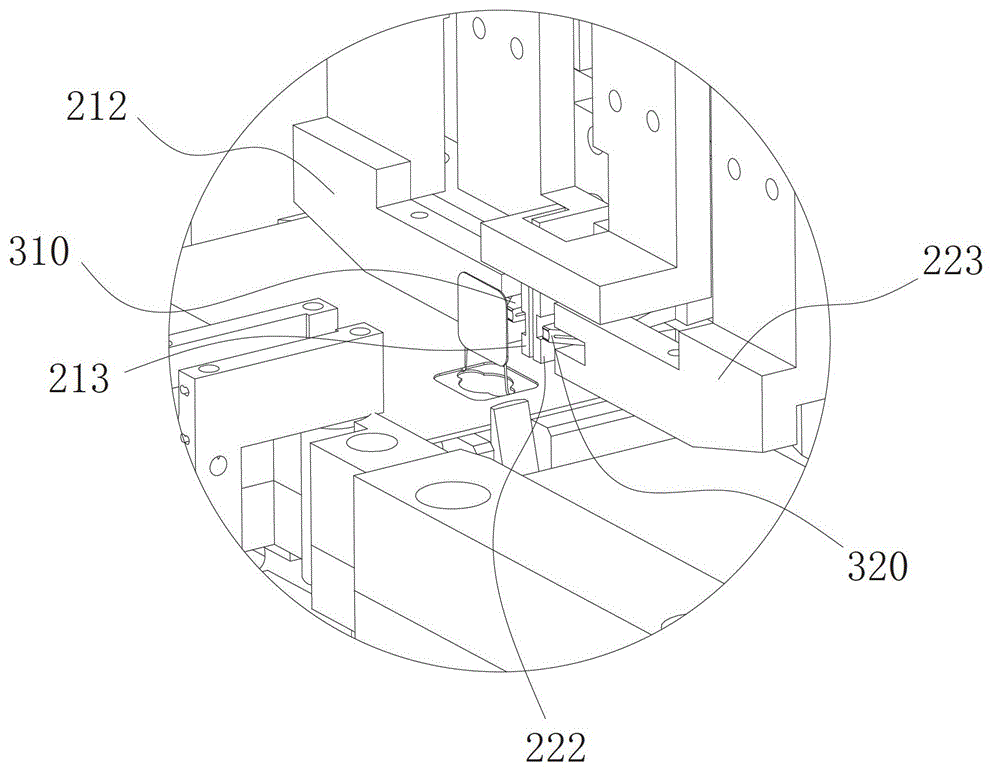

The invention discloses a chip welding method of a dual-interface card. The chip welding method of the dual-interface card comprises the following steps: 1, a card body is conveyed by a card body conveying device to a position on which the chip is to be welded, wherein the two ends of an antenna of the card body are at an erect state; and a chip pickup device picks up a chip and reaches the position on which the chip is to be welded to be welded; 2, an antenna clamping device clamps the two ends of the antenna at the same time and positions the antenna at the welded position of the chip; 3, a dual-touch welding head welds the two ends of the positioned antenna on the chip; and 4, after welding, all components return and the card body conveying device takes away the welded card body. The invention further discloses chip welding equipment of the dual-interface card for implementing the chip welding method of the dual-interface card. The chip welding equipment of the dual-interface card comprises the chip pickup device, the antenna clamping device, the card body conveying device and the dual-touch welding head, wherein the chip pickup device is arranged on one side of the antenna clamping device; and the dual-touch welding head is arranged on the other side of the antenna clamping device. By the chip welding method and the chip welding equipment, the two ends of the antenna can be welded on the chip by one step.

Owner:GUANGZHOU MINGSEN TECH CO LTD

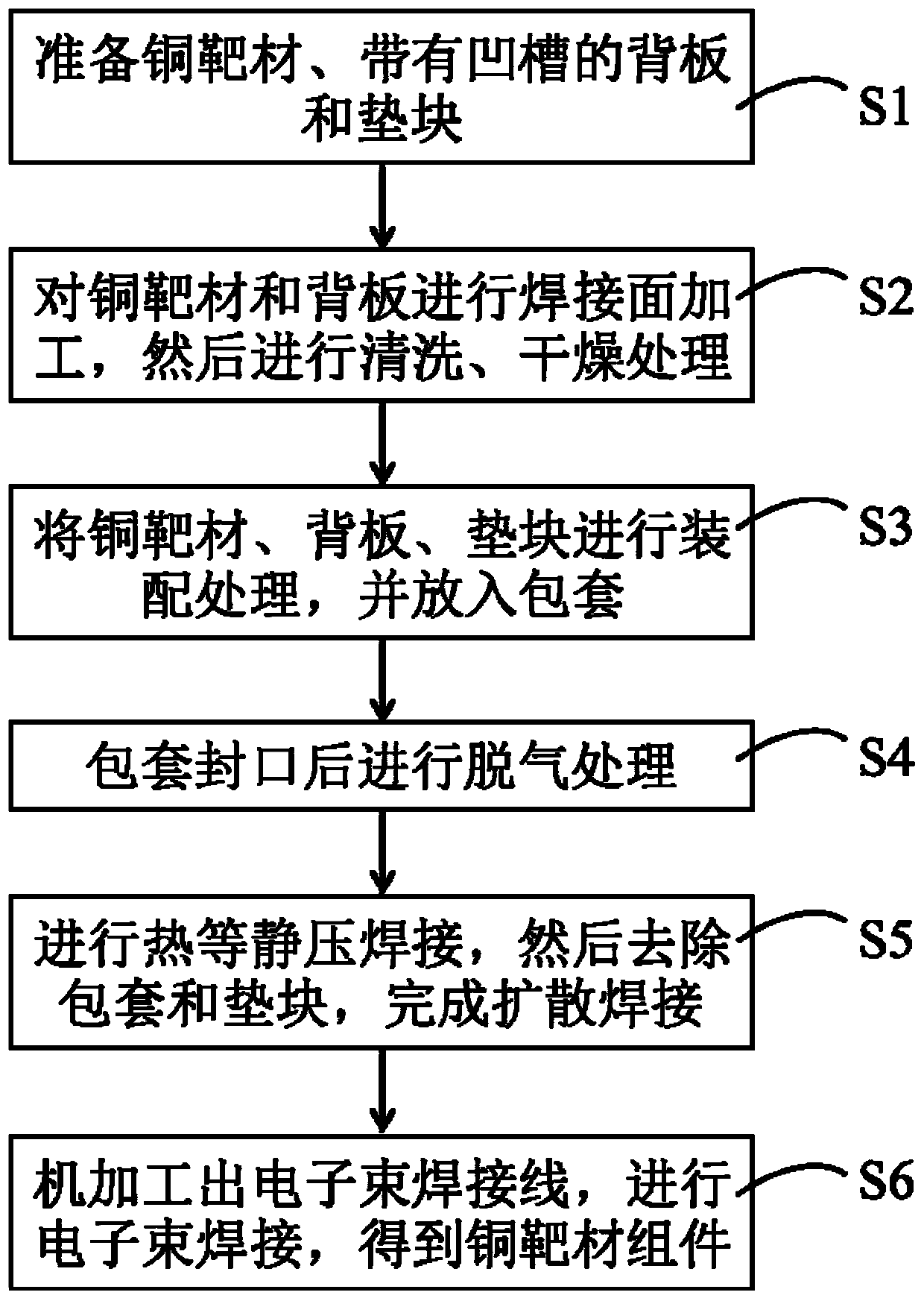

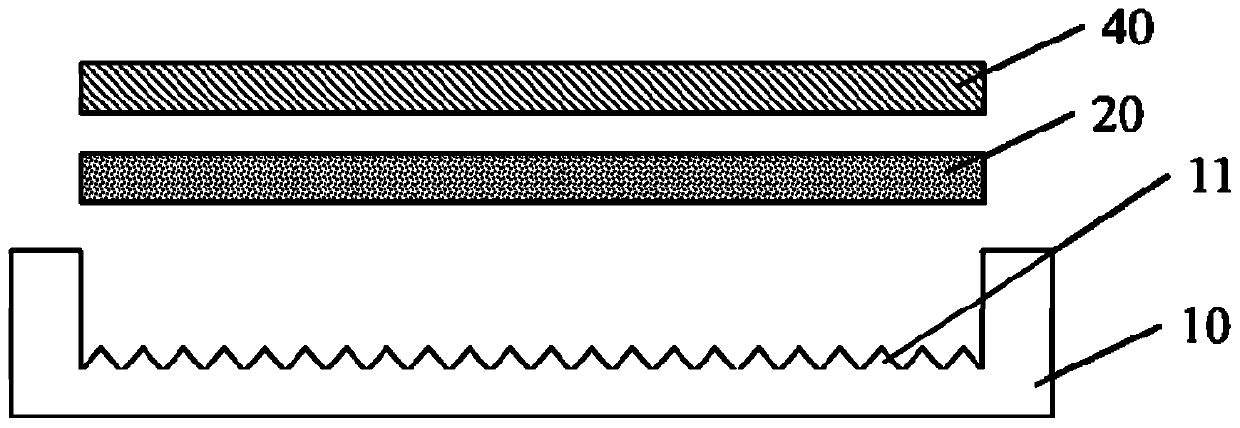

Diffusion welding method of copper target material and back plate

The invention relates to a diffusion welding method of a copper target material and a back plate. The diffusion welding method comprises the following steps that (1), the copper target material, the back plate and a cushion block, wherein the back plate is provided with a groove, and the areas of the copper target material and the cushion block are equal to the bottom area of the groove of the back plate; (2), the copper target material and the cushion block in the step (1) are sequentially put into the groove of the back plate to finish assembly treatment, and then a whole body is put into asheath; (3), the sheath obtained in the step (2) is sealed and then degassed; and (4), hot isostatic pressing welding is carried out on the sheath degassed in the step (3), and then the sheath and thecushion block are removed to finish diffusion welding of the copper target material and the back plate. According to the diffusion welding method, by improving an assembly structure of the copper target material and the back plate, the bonding degree of welding faces of the copper target material and the back plate is guaranteed, abnormal growth of crystal grains is effectively avoided, and particularly the phenomenon that the crystal grains are thick and large at the edge of the copper target material is avoided.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

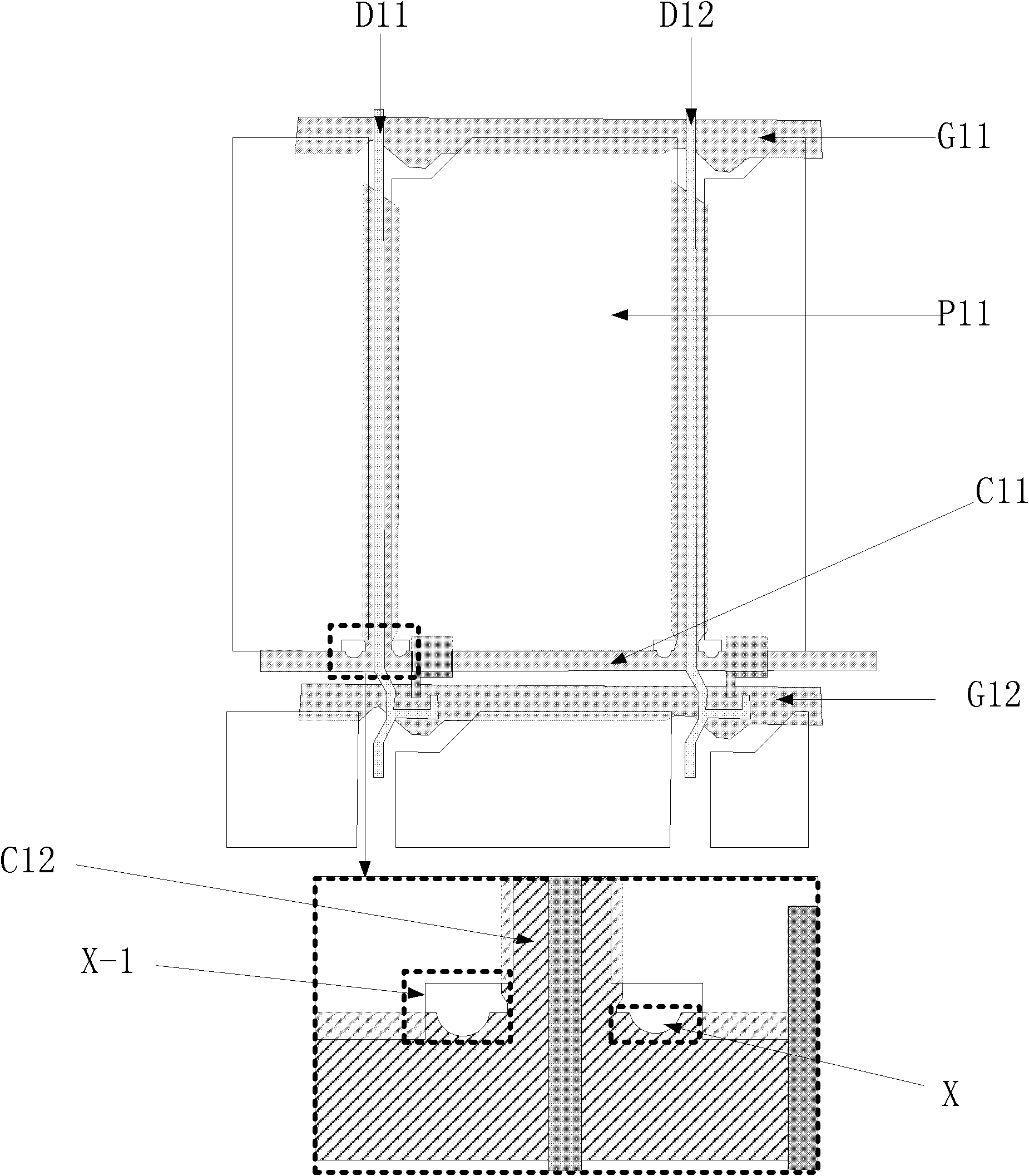

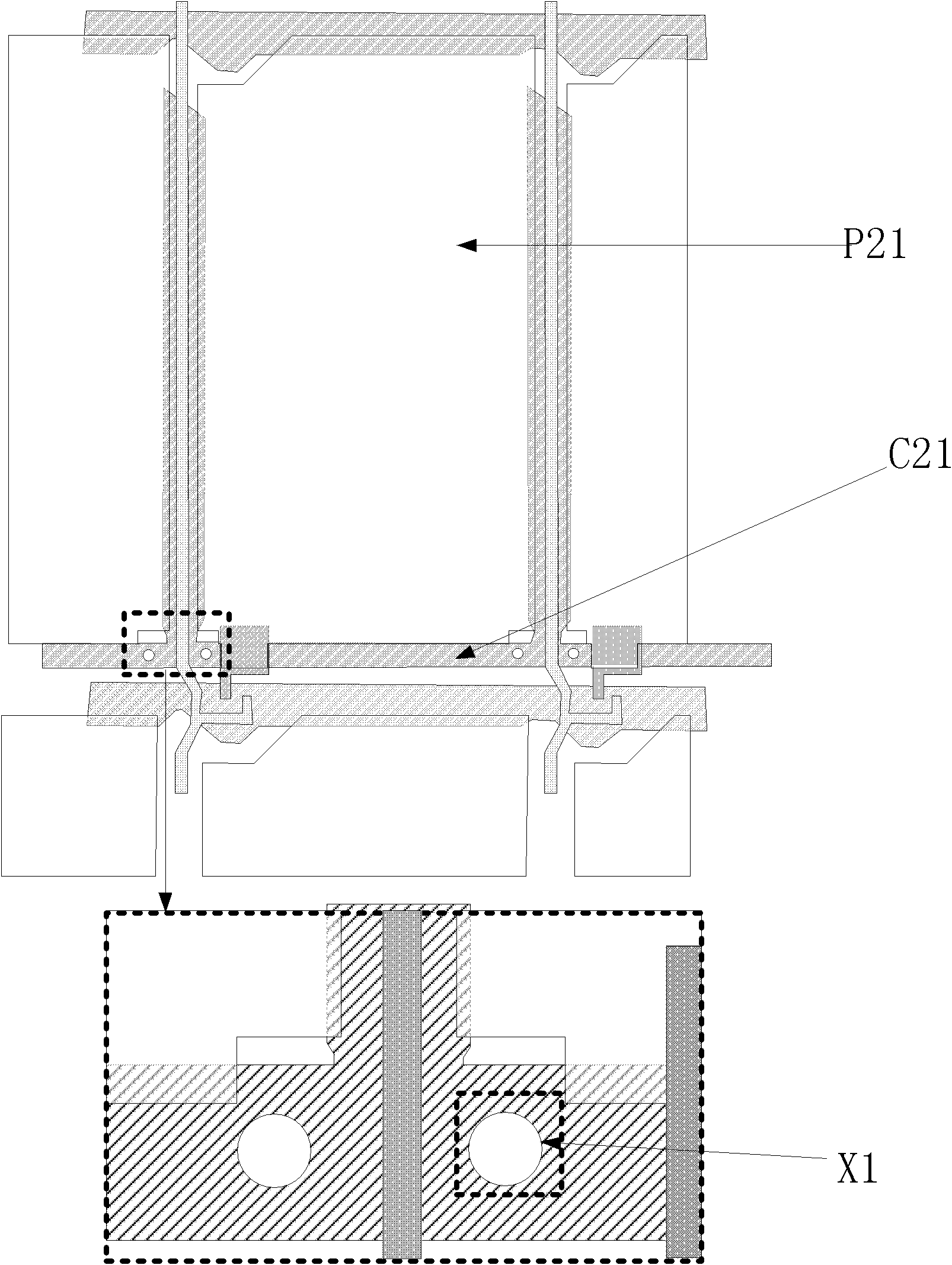

Thin film transistor liquid crystal display device and disconnected data line repairing method thereof

ActiveCN103135297AWon't touchAvoid WeldingSemiconductor/solid-state device manufacturingNon-linear opticsInsulation layerThin-film-transistor liquid-crystal display

The invention discloses a thin film transistor liquid crystal display device which comprises a substrate, a gate line, common lines, a gate insulation layer, a data line, a source electrode, a drain electrode and a pixel electrode. The common lines comprise a first common line arranged along a first direction and a second common line arranged along a second direction. Disconnection identifiers are arranged on the first common line, located on the two sides of the second common line and close to the second common line. A disconnection area notch is formed in the position, corresponding to the disconnection identifiers, of the pixel electrode. In the disconnection process of the first common line on the disconnection identifier positions, the pixel electrode is not touched. In the repairing process for the data line, the position needing to be cut off can be accurately judged, and due to the fact that the disconnection area notch is formed in the pixel electrode, the pixel electrode can be avoided according to the disconnection identifiers when the first common line is disconnected. The pixel electrode and the first common line are prevented from being welded together, and the success rate of repairing is further improved.

Owner:BEIHAI HKC OPTOELECTRONICS TECH CO LTD

Set of twin wheels

InactiveUS20110285195A1Need lessDisturbing overall impressionMultiple wheel assemblyEngineeringMechanical engineering

The present invention concerns a twin wheel set including twin wheel, intermediate ring and fixing means for coaxial mounting of the twin wheel set on a wheel of a vehicle, where twin wheel as well as vehicle wheel include a rim, preferably a steel rim with tyre. The new feature of the invention consist of the fixing means at least comprising an adjustable clamping ring, preferably a steel ring, for bearing on the rim periphery of the twin wheel at the side facing away from the vehicle wheel, preferably against at least one face on the inner peripheral area of the rim on a twin wheel. By using the outer side of the rim for contact with the adjustable clamping ring, there is achieved an independency of welding means thereon to which clamping devices are to be fixed on the twin wheel itself. By using a clamping ring which is not fixed to the twin wheel, a kind of universal clamping ring can be applied which possibly may be adapted to different sizes of twin wheels, and which therefore implies less need for keeping may different articles in stock at the producer.

Owner:TIRE TRADE DK

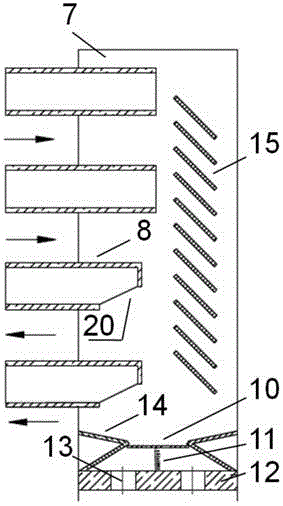

Multi-tube-row integrated header automatic adjusting dispensing condenser

ActiveCN105157441ASolve liquidity problemsSolve heat transferSteam/vapor condensersHeat exchanger casingsAuto regulationVapor–liquid separator

The invention discloses a multi-tube-row integrated header automatic adjusting dispensing condenser, comprising a first header, a second header, and heat exchange tubes. The header which is provided with an inlet pipe is provided with septums. The first header and the second header are internally provided with gas-liquid separators. The outlet tube segments of the heat exchange tubes extend into the cavity of the header, and the ends of the outlet tube segments bend downward. Or the outlet tube segments of the heat exchange tubes extend into the cavity of the header, and the outlet tube segments of the heat exchange tubes beveling downward from the diameter of the outlet tube segment and form bevel connections. Beneficial technical effects of the condenser are that heat transfer flowing performance of the condenser is improved, uniformity of working medium distribution is effectively improved, flow resistance is greatly reduced and high-efficiency heat exchange is maintained, a condensate liquid is prevented from being brought out of the headers, so as to greatly improve dispending effect of the headers on two ends, high-efficiency heat exchange flow state in tubes can be maintained on the tail of the condenser and under condition of lower area flow, and effect of enhancing heat transfer based on a dispensing condensing principle is improved.

Owner:广西高而美节能科技有限公司

Manufacturing method for metal semi-hole circuit board

InactiveCN103327753AAvoid WeldingReduce repair costsPrinted element electric connection formationTinningState of art

The invention discloses a manufacturing method for a metal semi-hole circuit board. According to the manufacturing method, after an outer layer graph of the circuit board is manufactured, graph electrolytic tinning treatment is carried out, tinning is carried out on the circuit graph and a drill hole needing to be protected, then a semi-hole is milled in the position of the drill hole, burr flashes are formed in the position of the hole opening after the semi-hole is milled, and then the etching treatment is carried out. As the circuit graph and the drill hole are protected by tinning, the burr flashes in the position of the hole opening are not tinned and can be etched off while the whole circuit graph and the drill hole are not influenced. Compared with the prior art, the manufacturing method is simple in process, avoids the problems of unsecured welding legs and cold solder joints occurring when follow-up welding is carried out on the circuit board, effectively solves the problem of production scrap, and lowers the maintenance cost and the scrap cost caused by the problem of the burr flashes.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

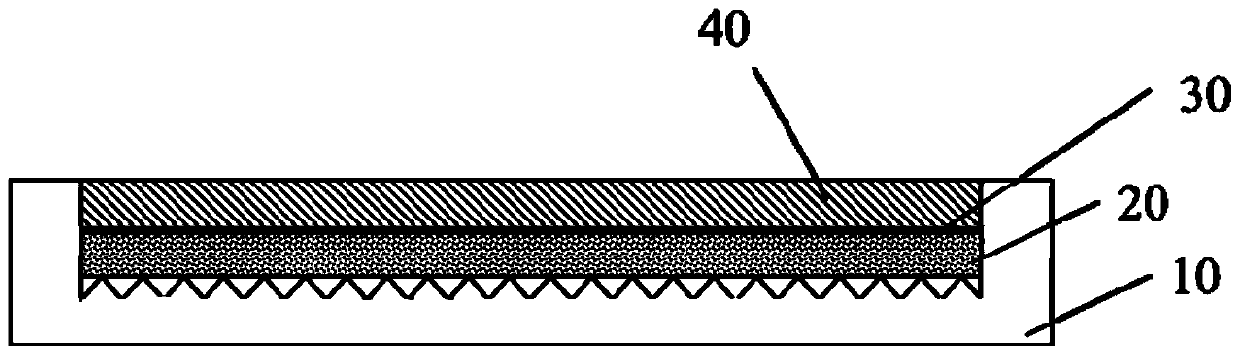

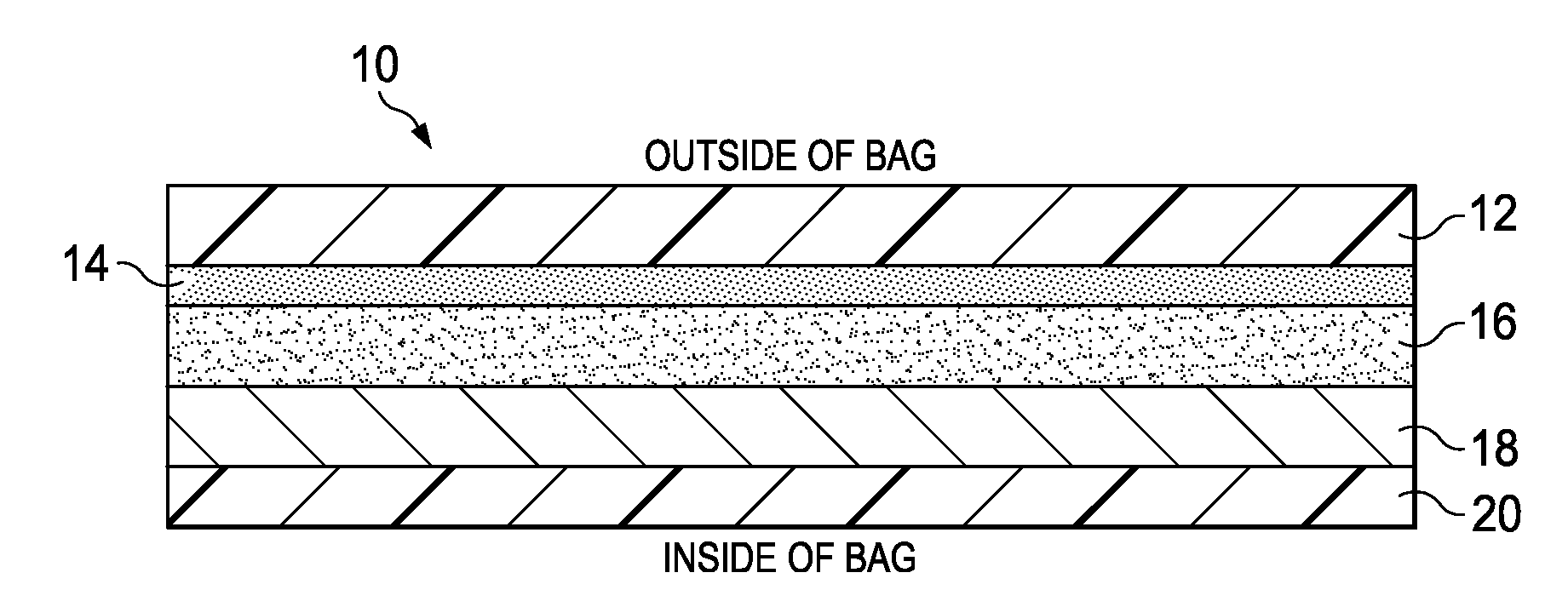

Inorganic nanocoating primed organic film

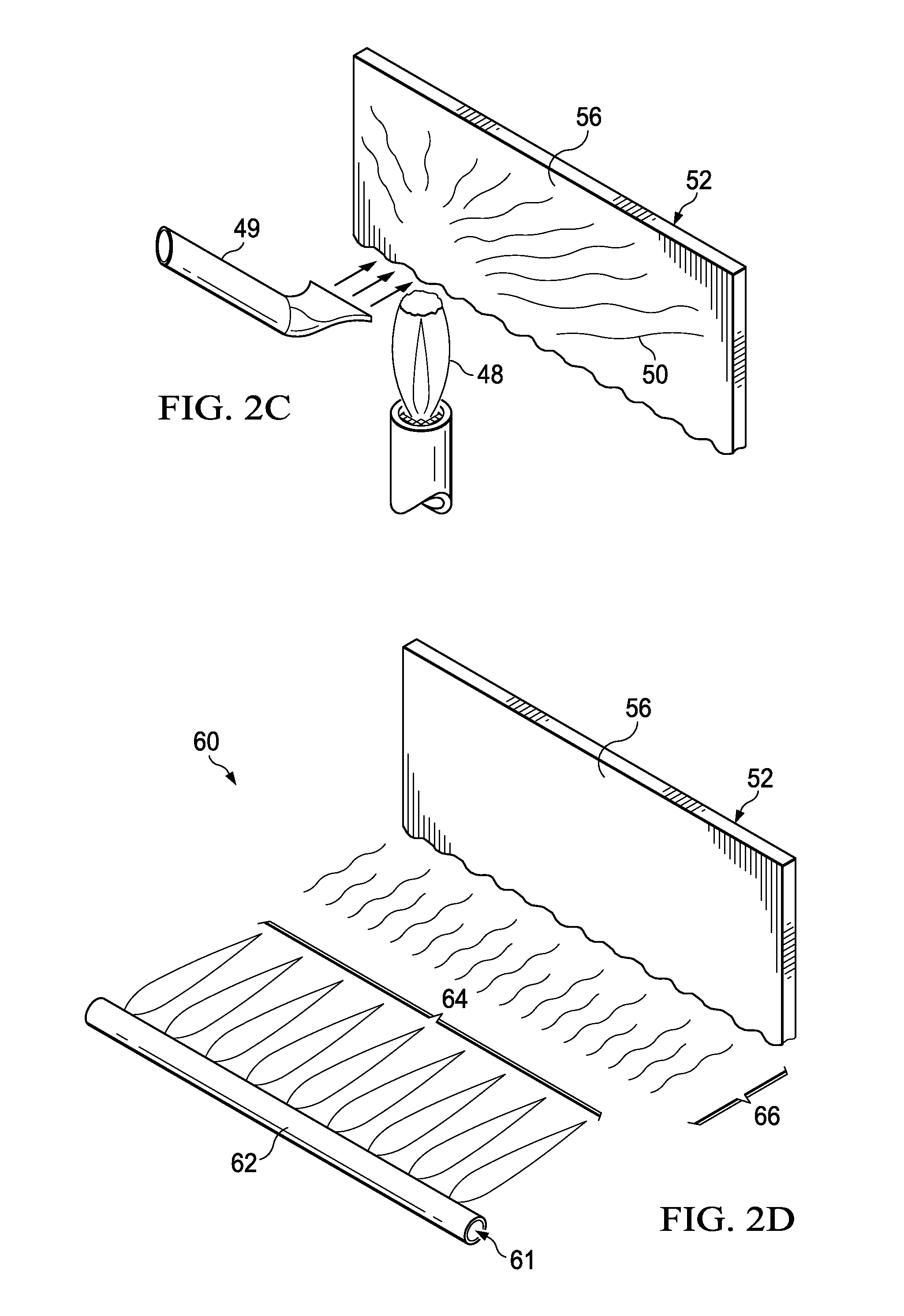

ActiveUS20130034667A1Avoid weldingDesired effectFibre treatmentVacuum evaporation coatingSurface energyNanometre

An inorganic nanolayer surface coated polymer film product is disclosed with enhancements such as improved metallization capability, low cost, low polymer additives and modifiers, improved recyclability, and good web properties. Also method for priming a flexible film substrate to enhance the reactivity or wettability of the substrate for metallization is disclosed. A substrate film is coated with one or more nanolayers of a metal or metal oxide applied by CCVD and / or PECVD at open atmosphere. The deposited coating acts to enhance the surface energy of the film substrate and to and reduce the surface gauge variation of the substrate or supporting film, thereby enhancing the wettability of the film substrate for metallization and / or to improve the anti-block characteristics of the film. The deposited coatings may also act as a barrier layer for lowering the permeability of light, gas and vapor transmission through the substrate.

Owner:PEPSICO INC +1

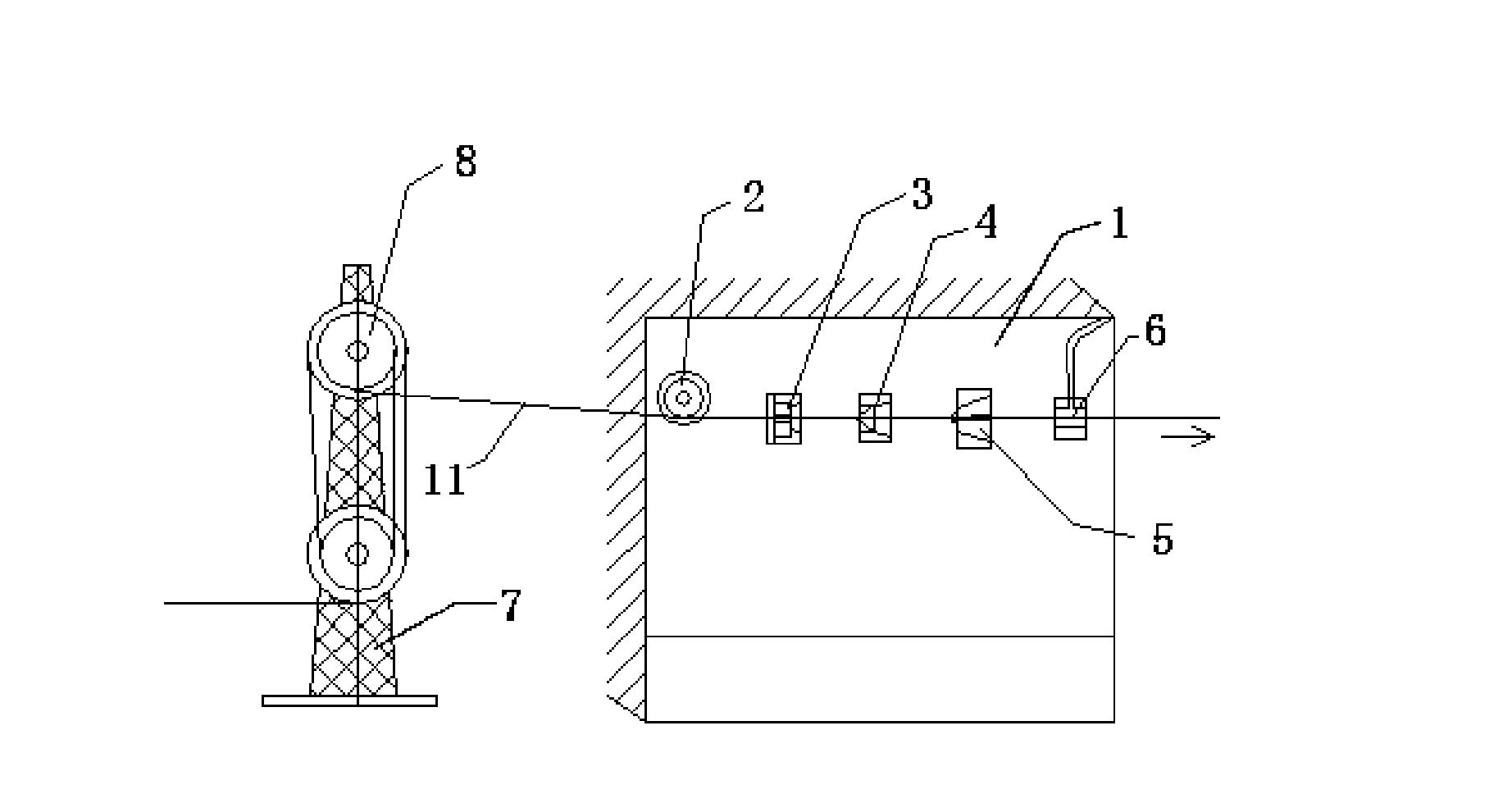

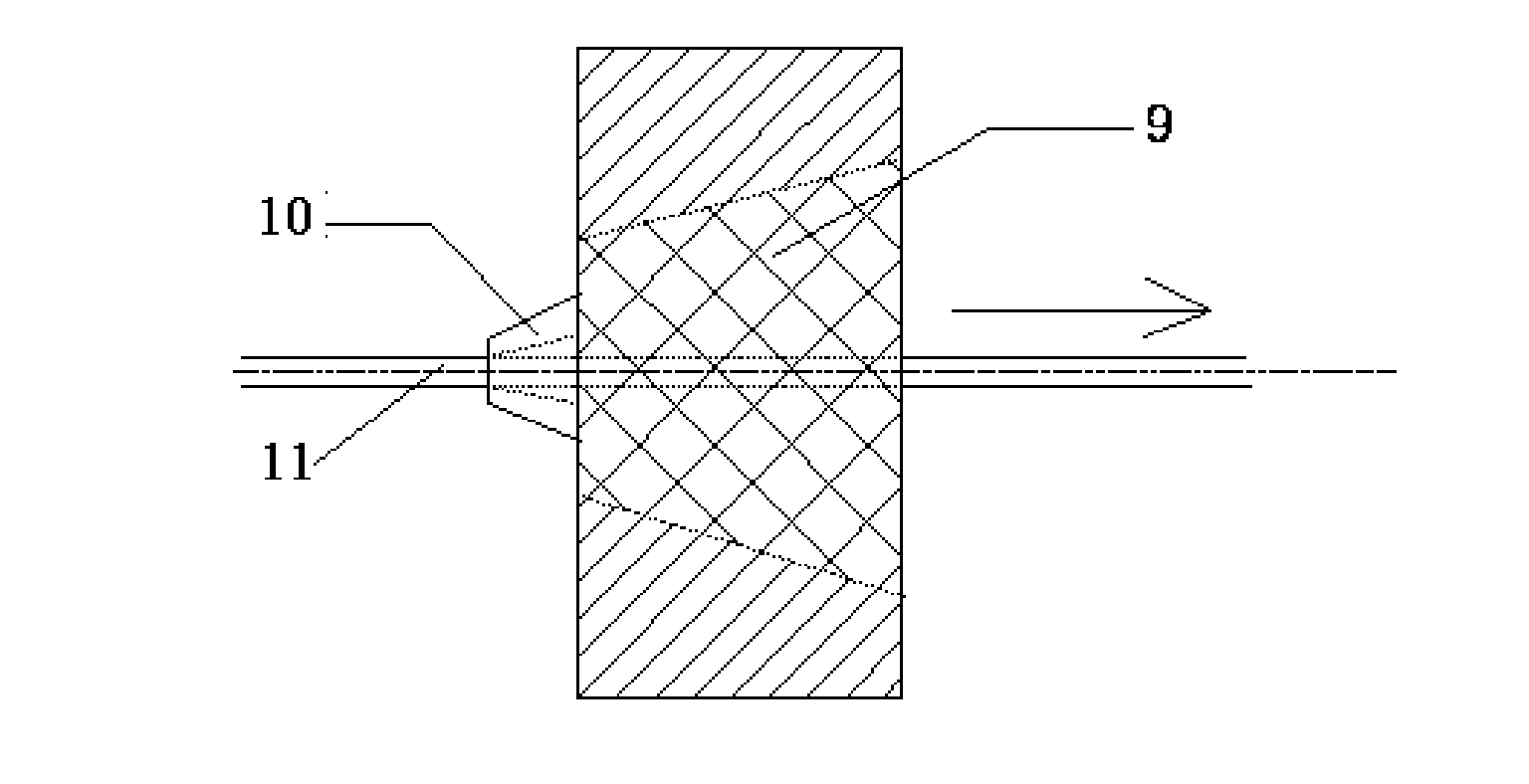

Aluminum alloy welding wire surface scraping method and device

ActiveCN101513699AGood surface finishPrevents dark spots and splattersWelding/cutting media/materialsSoldering mediaWeld seamSurface finishing

The invention relates to a metal welding wire manufacture method, especially to an aluminum alloy welding wire surface scraping method and device, which mainly solves problems in prior art that welding wire surface is treated by a chemical treatment method, because after chemical treatment, surface smoothness is deficient, block is easy to happen when conveying, simultaneously oil stain and chemical stain are remained on the surface, smoke is generated when the welding wire is used for welding, and black spot and splash phenomenon are appeared on and near weld seam. The method includes steps of line laying, positioning, wiping, crude scraping, fine scraping and cooling. The device includes a frame, and a positioning wheel, a wiping die, a crude scraping die, a fine scraping die and a cooling device which are connected in the frame.

Owner:杭州坤利焊接材料有限公司

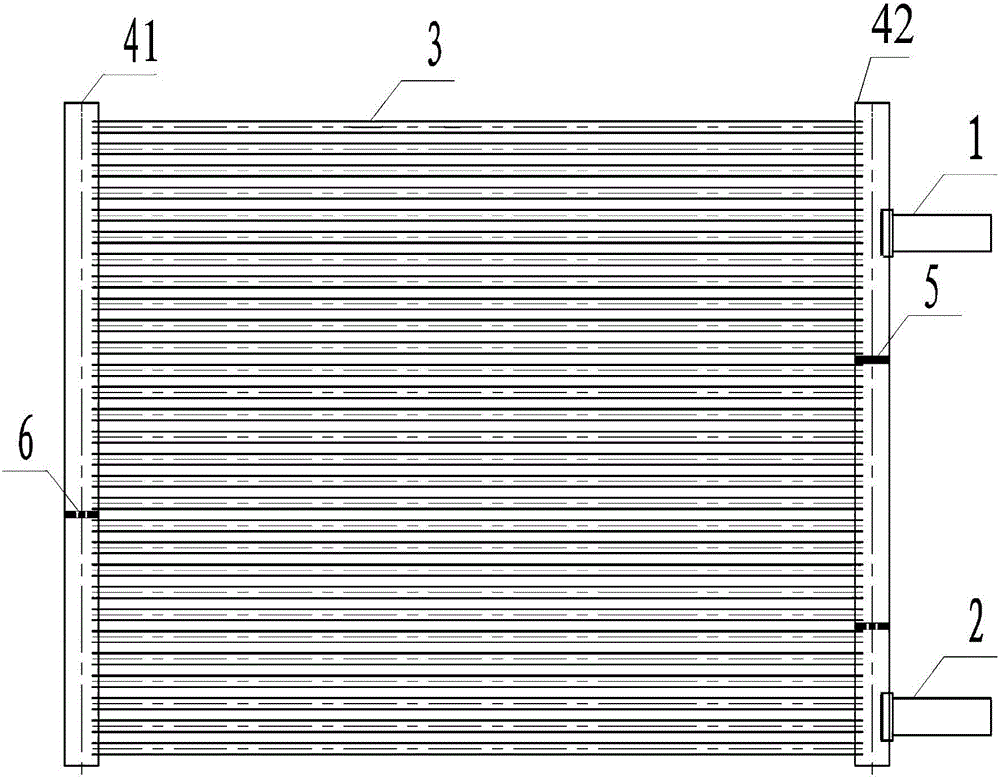

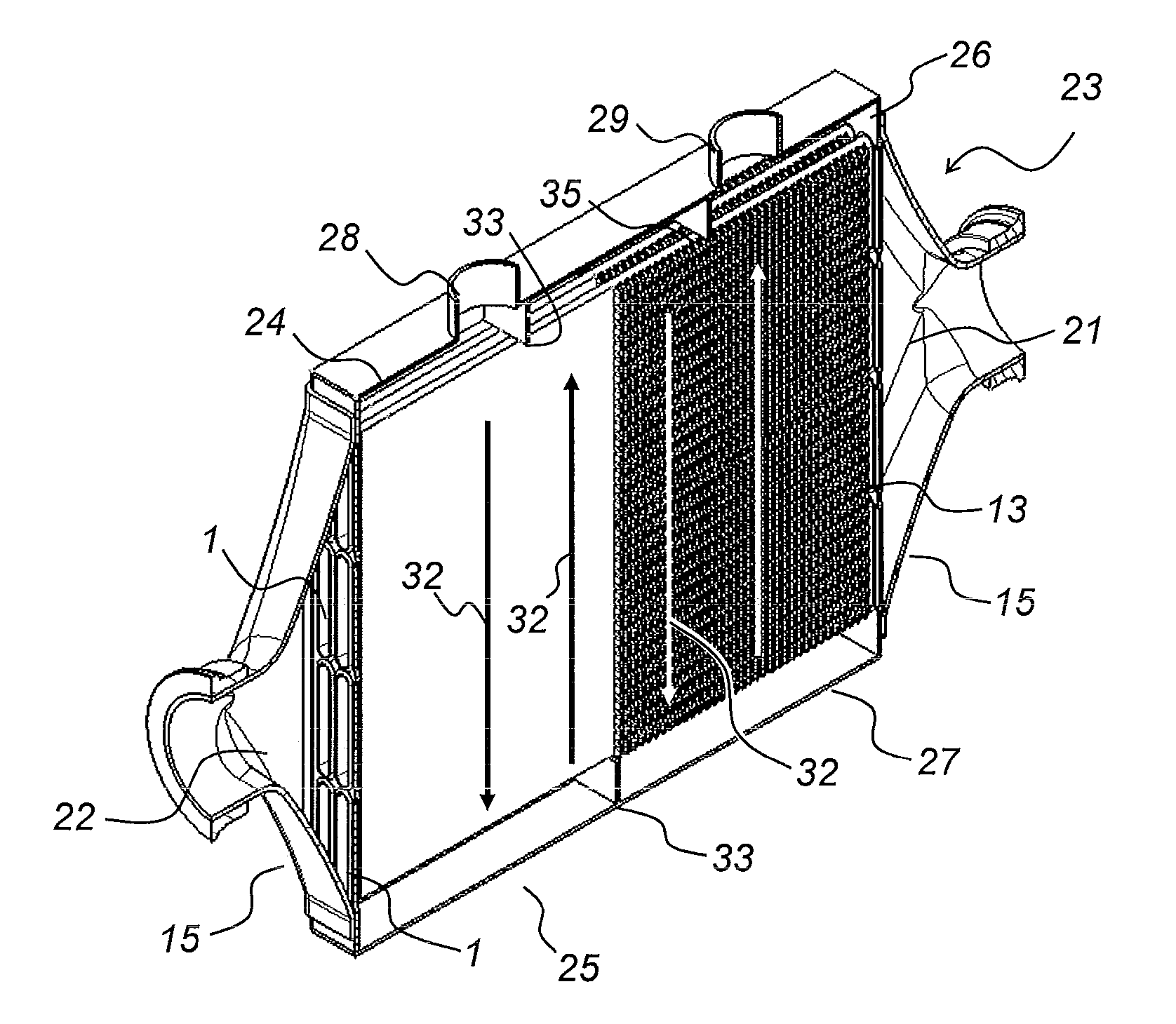

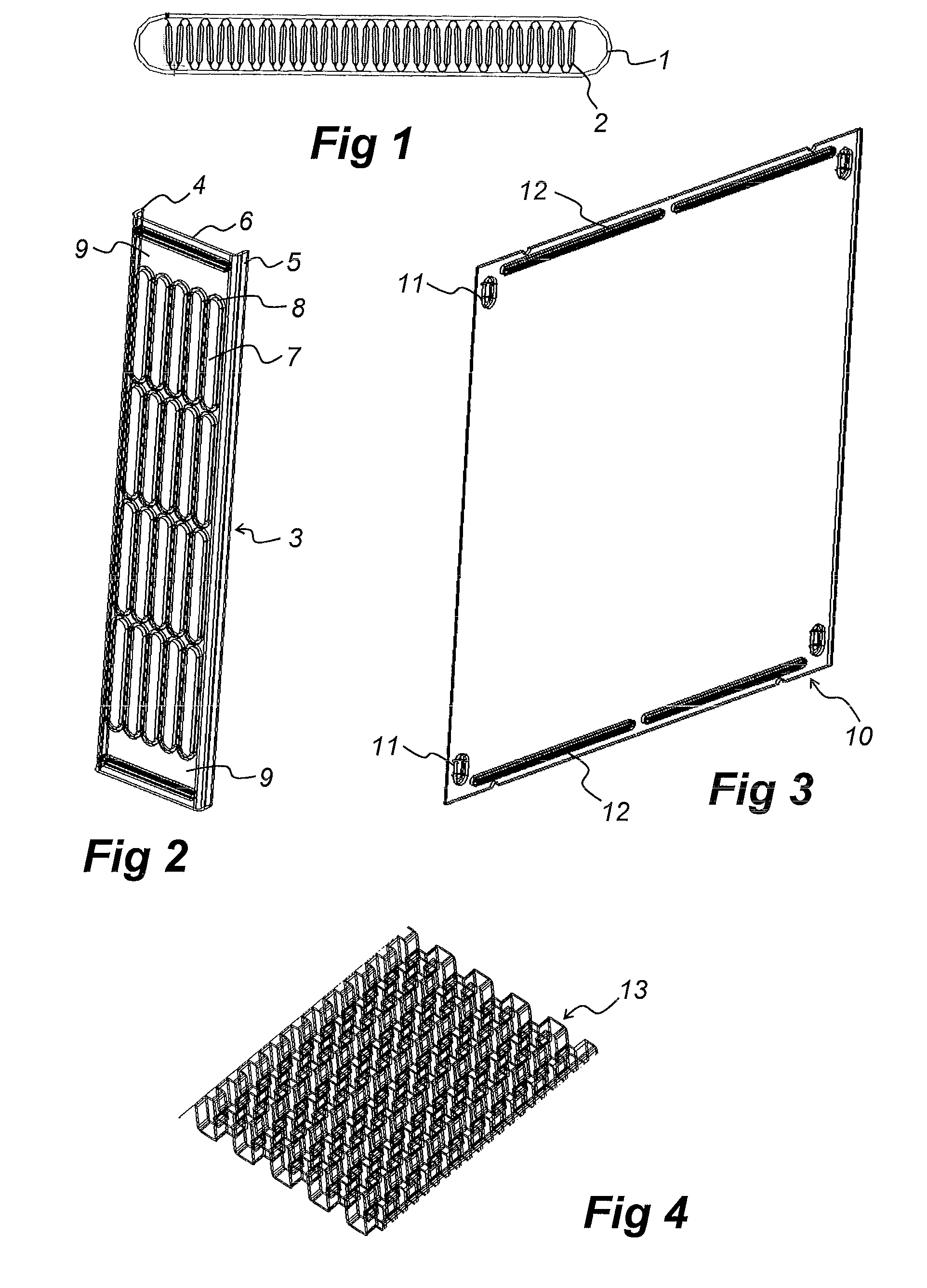

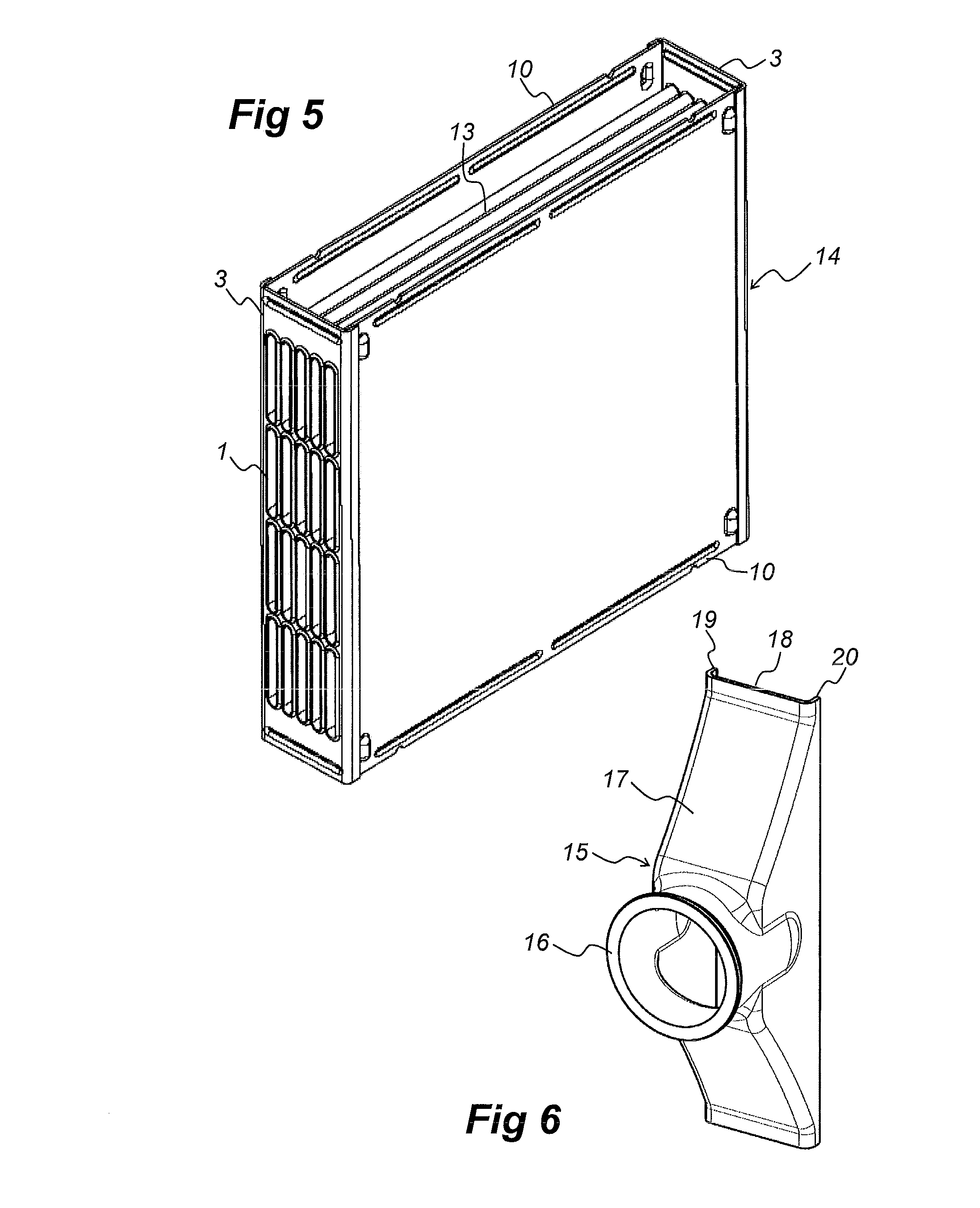

Heat exchanger and method of producing thereof

ActiveUS20100206534A1Easy to doPrecise supportCooking-vessel materialsInternal combustion piston enginesCopperFlange

The invention concerns a heat exchanger and a method of producing thereof. The heat exchanger comprises a coolant housing with two opposing wide side walls and two header plates of an inlet air tank and an outlet air tank, respectively. The header plates are channel-shaped with longitudinal flanges extending over and being brazed to the wide side walls. Tubes extend in parallel through said housing between the two header plates, said tubes being brazed to apertures in said header plates. The coolant housing has two opposing narrow side walls tightly fitting said wide side walls and said header plates and defining together with these wide side walls and header plates a first coolant tank and a second coolant tank opposing the first one. Each air tank comprises a cowling tightly fitting and being brazed to one of said header plates each and having an air inlet and an air outlet, respectively. At least one of said two side walls is welded to said wide side walls and said header plates thus enclosing said housing.

Owner:TITANX HLDG AB

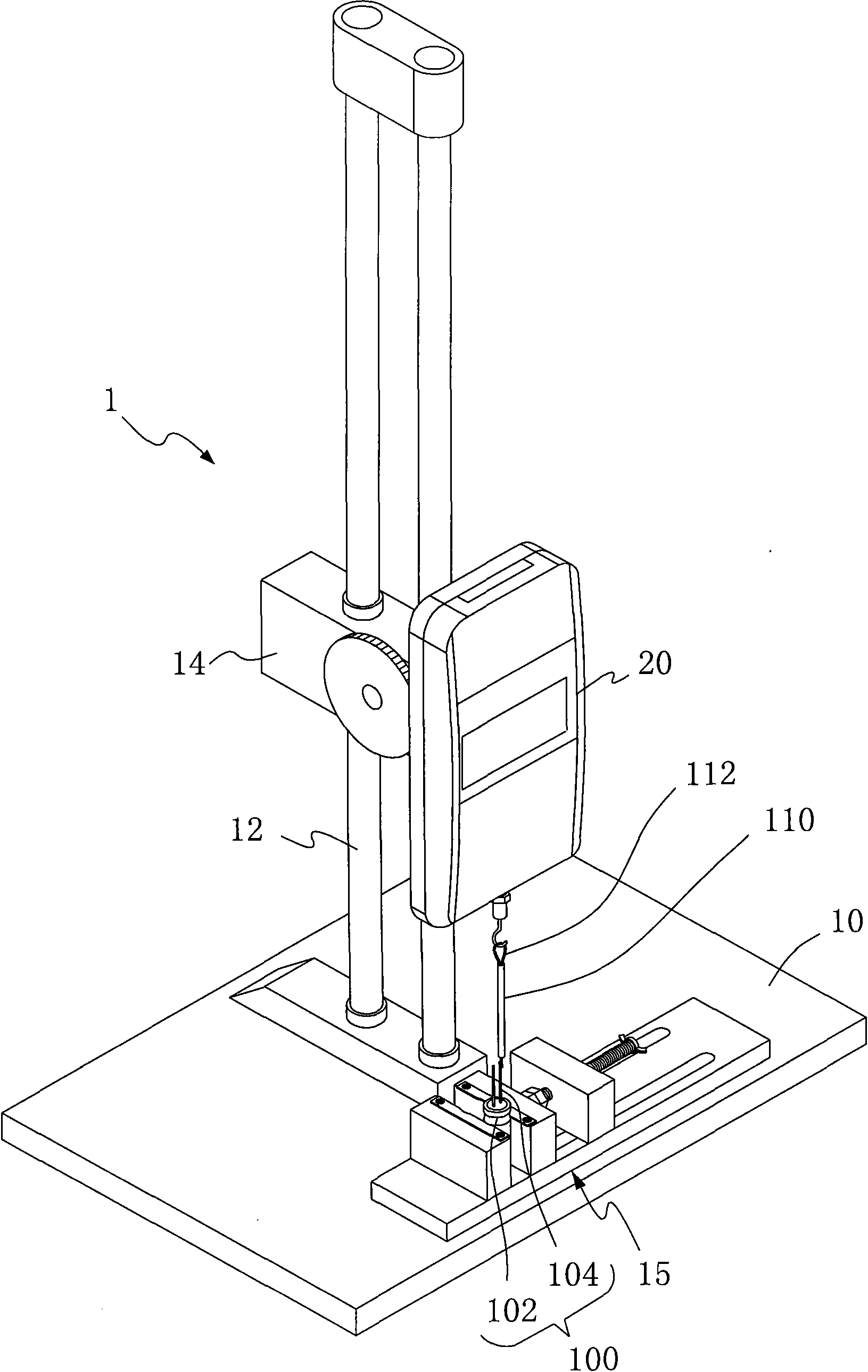

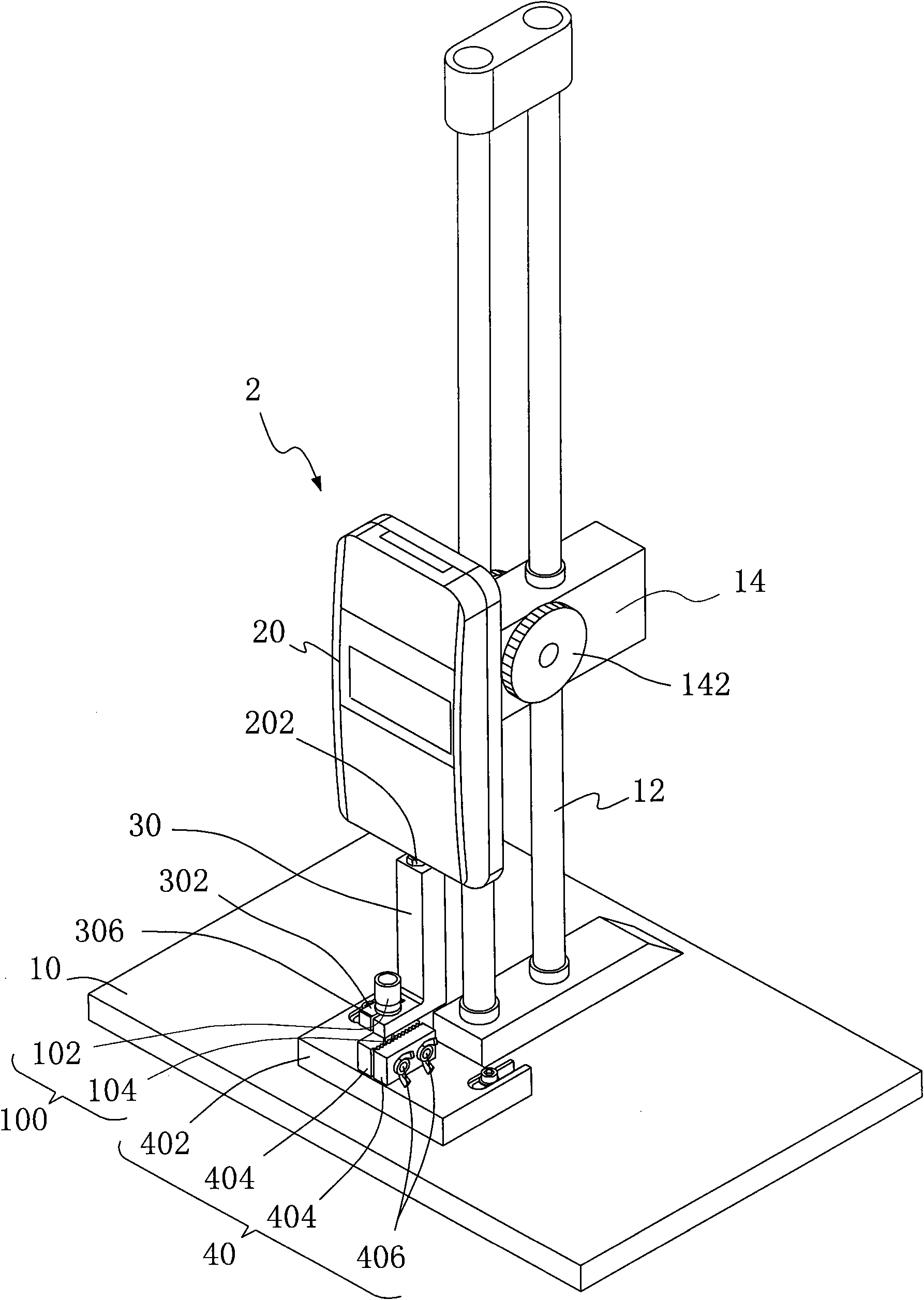

Tensile test device

InactiveCN102735540AEasy to operateReliable resultsMaterial strength using tensile/compressive forcesTest efficiencyPush and pull

The invention provides a tensile test device for tensile test of binding strength between an electronic component body and a pin. The device comprises a base, a push and pull dynamometer, a rack and a fixture. The base comprises a support frame and an installation part; the push and pull dynamometer is mounted on a mounting portion and contains an extension part; the rack is connected to the extension part, and is used for hanging the body and towards the exposed pin on the base; and the fixture is arranged on the base, right opposite to the rack and for clamping the pin. The invention can avoid electronic component body deformation caused by a known tensile test device and eliminate complex steps of welding and welding removal of the pin and a test wire, and can solve problems caused by component force in the test, thereby having the advantages of convenient operation, stable test process, improvement on test efficiency and reliability.

Owner:ASKEY TECH JIANGSU +1

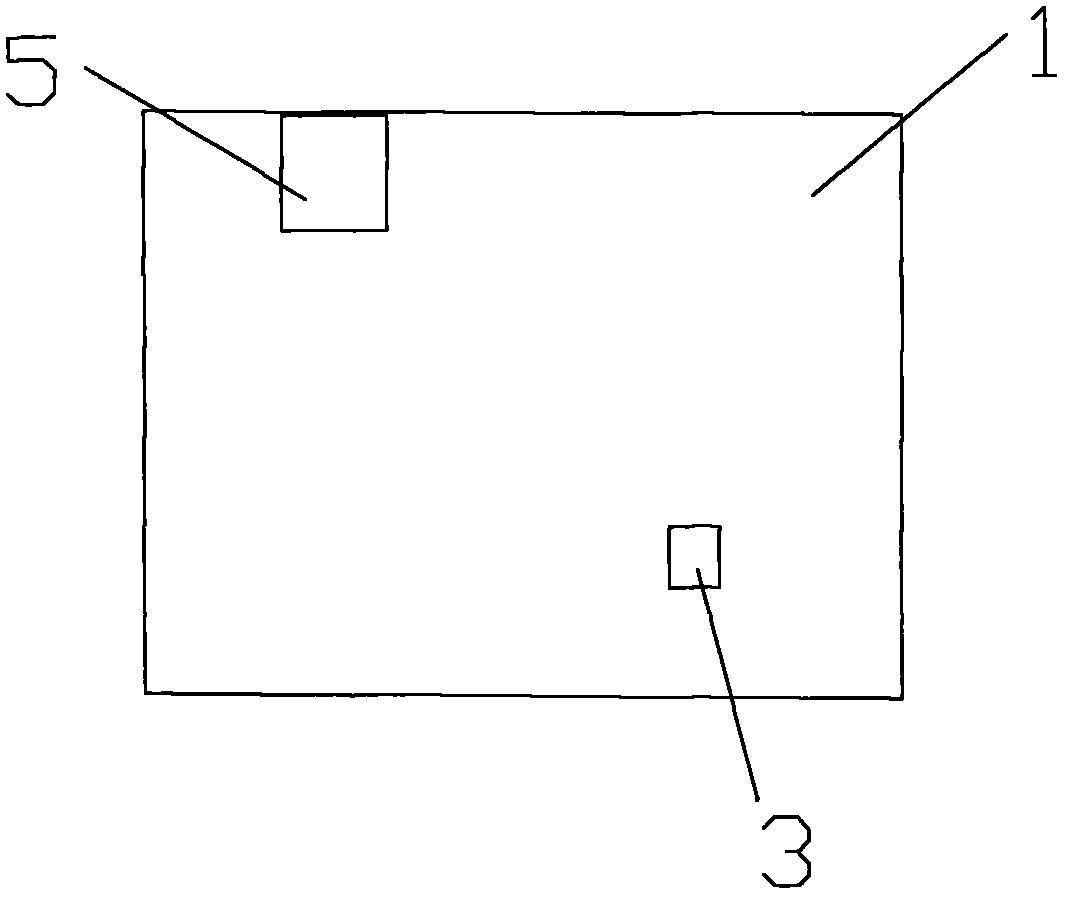

Spot soldering fixture and spot soldering process

InactiveCN102581458APrecise positioningHeight adjustableResistance welding apparatusEngineeringSoldering process

The invention belongs to the technical field of soldering, and particularly relates to a spot soldering fixture, which is used in a spot soldering process capable of avoiding pseudo soldering, false soldering and bursting, and is high in soldering efficiency. The spot soldering fixture comprises a fixture body, a cell storage area and a fuse storage area, and an avoidance hole is reserved between the cell storage area and the fuse storage area. Compared with the prior art, the spot soldering fixture has the advantages that a fuse and a metal strap can be effectively positioned, the height of a soldering pin can be adjusted, spot soldering quality can be improved, soldering reject ratio can be decreased, production efficiency can be improved, and cost can be saved. Besides, the invention further discloses the spot soldering process using the spot soldering fixture.

Owner:DONGGUAN NVT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com