Spot soldering fixture and spot soldering process

A fixture and spot welding technology, which is applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve the problems of difficult spot welding, low material utilization rate, and easy occurrence of defective products, so as to reduce the welding defect rate and improve Spot welding quality, the effect of improving the quality of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the examples and the accompanying drawings, but the implementation of the present invention is not limited thereto.

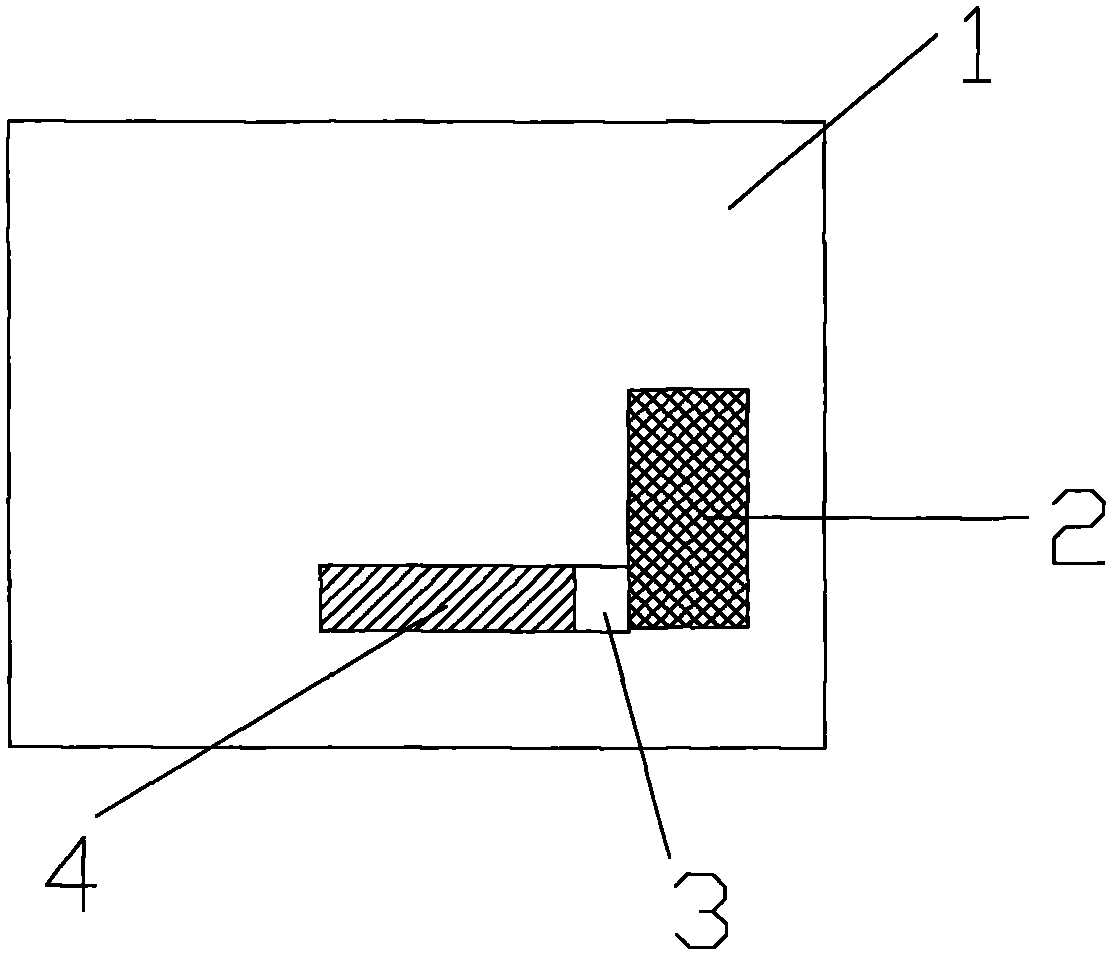

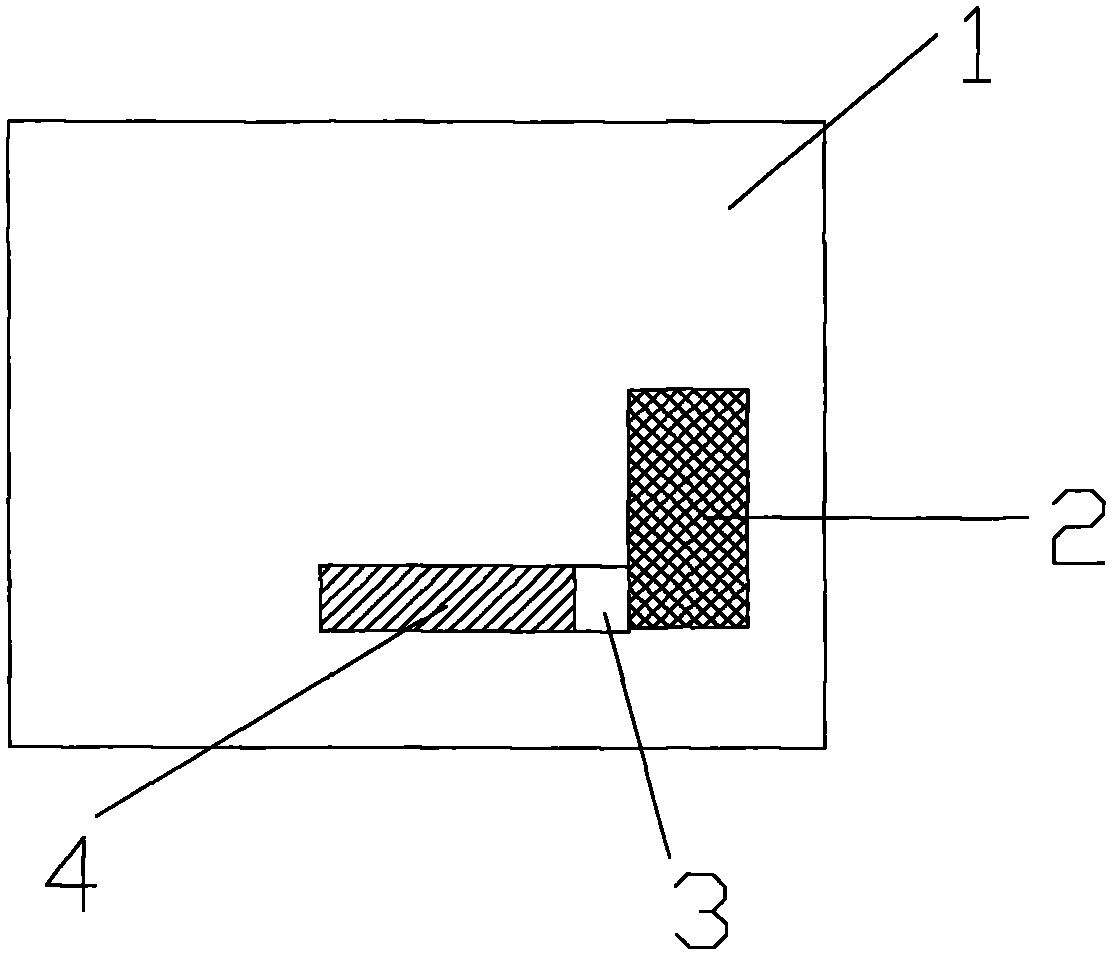

[0025] Such as figure 1 and 2 As shown, the spot welding jig of the present invention includes a jig body 1 and a cell placement area 2 and a fuse placement area 3 arranged on the jig body, and an arrangement between the cell placement area 2 and the fuse placement area 3 Have escape hole 4. The cell placement area 2 and the fuse placement area 3 are arranged vertically. The cell placement area 2 is a groove structure. The fuse placement area 3 is a groove structure. The electric core is provided with tabs made of aluminum-nickel composite tape.

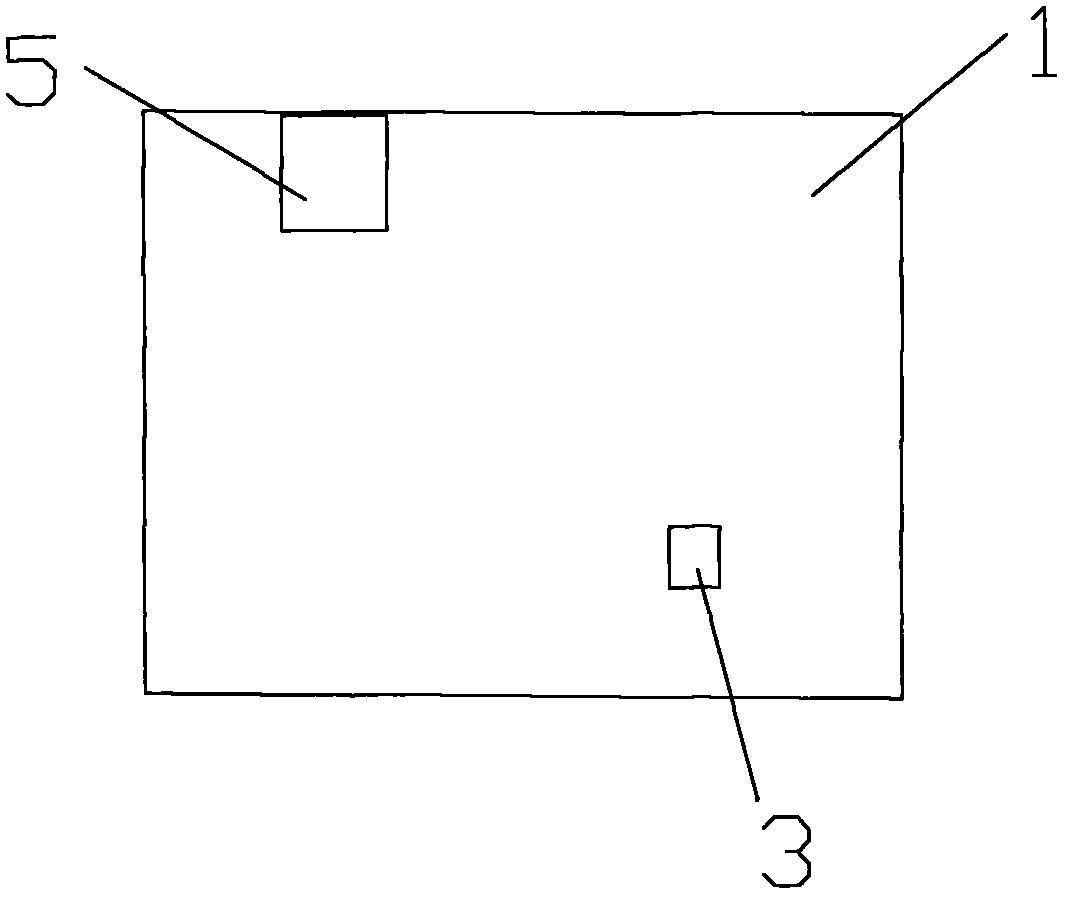

[0026] Depend on figure 2 It can be seen that the fixture main body 1 is also provided with an adjuster 5 for adjusting the height of the welding bottom needle.

[0027] When using this fixture for spot welding operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com