Patents

Literature

706 results about "Wave soldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wave soldering is a bulk soldering process used in the manufacture of printed circuit boards. The circuit board is passed over a pan of molten solder in which a pump produces an upwelling of solder that looks like a standing wave. As the circuit board makes contact with this wave, the components become soldered to the board. Wave soldering is used for both through-hole printed circuit assemblies, and surface mount. In the latter case, the components are glued onto the surface of a printed circuit board (PCB) by placement equipment, before being run through the molten solder wave. Wave soldering is mainly used in soldering of through hole components.

Wave soldering fixture

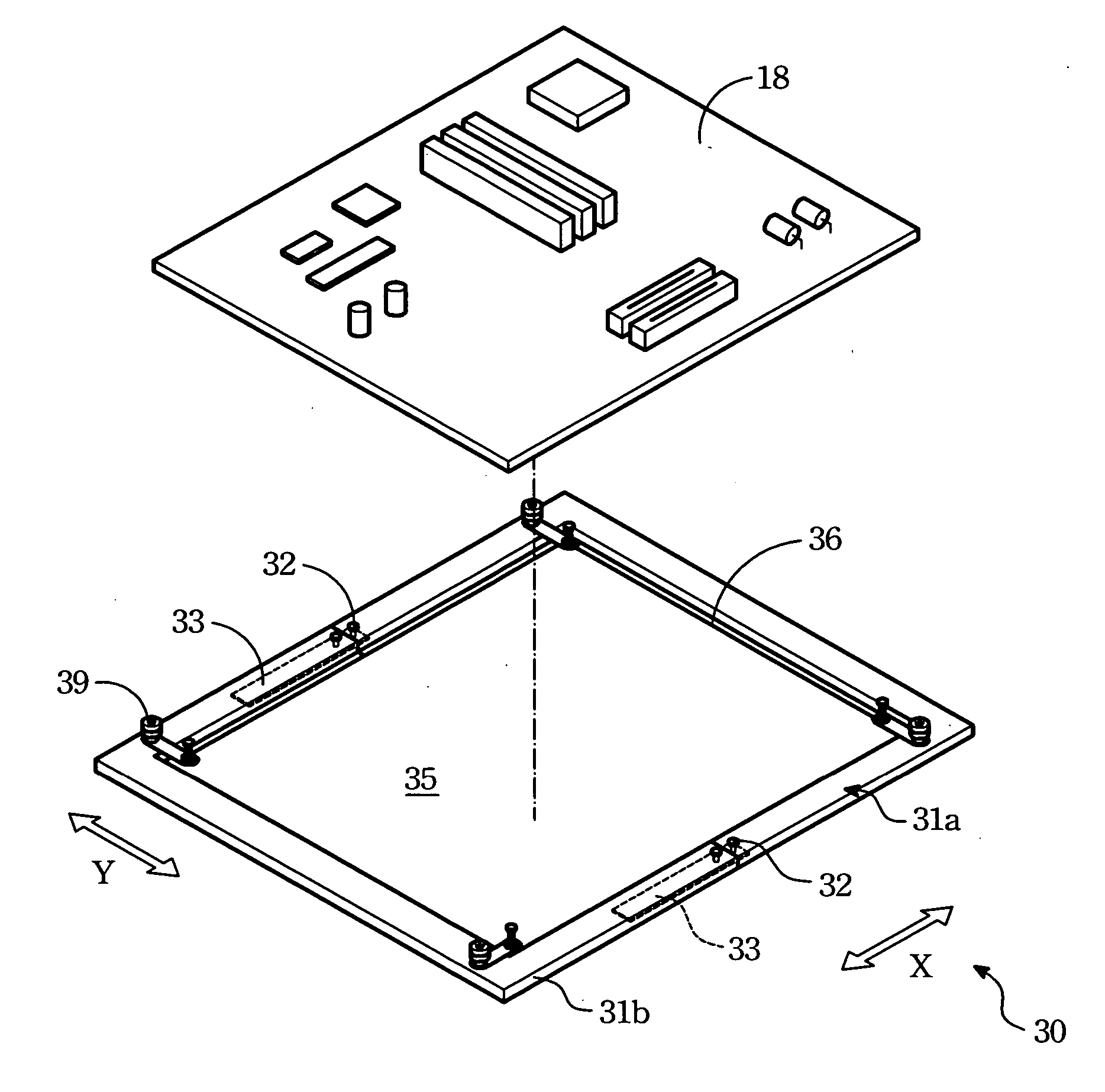

InactiveUS6237832B1Minimizing conductionMinimizing warpage/bowingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAluminum extrusion

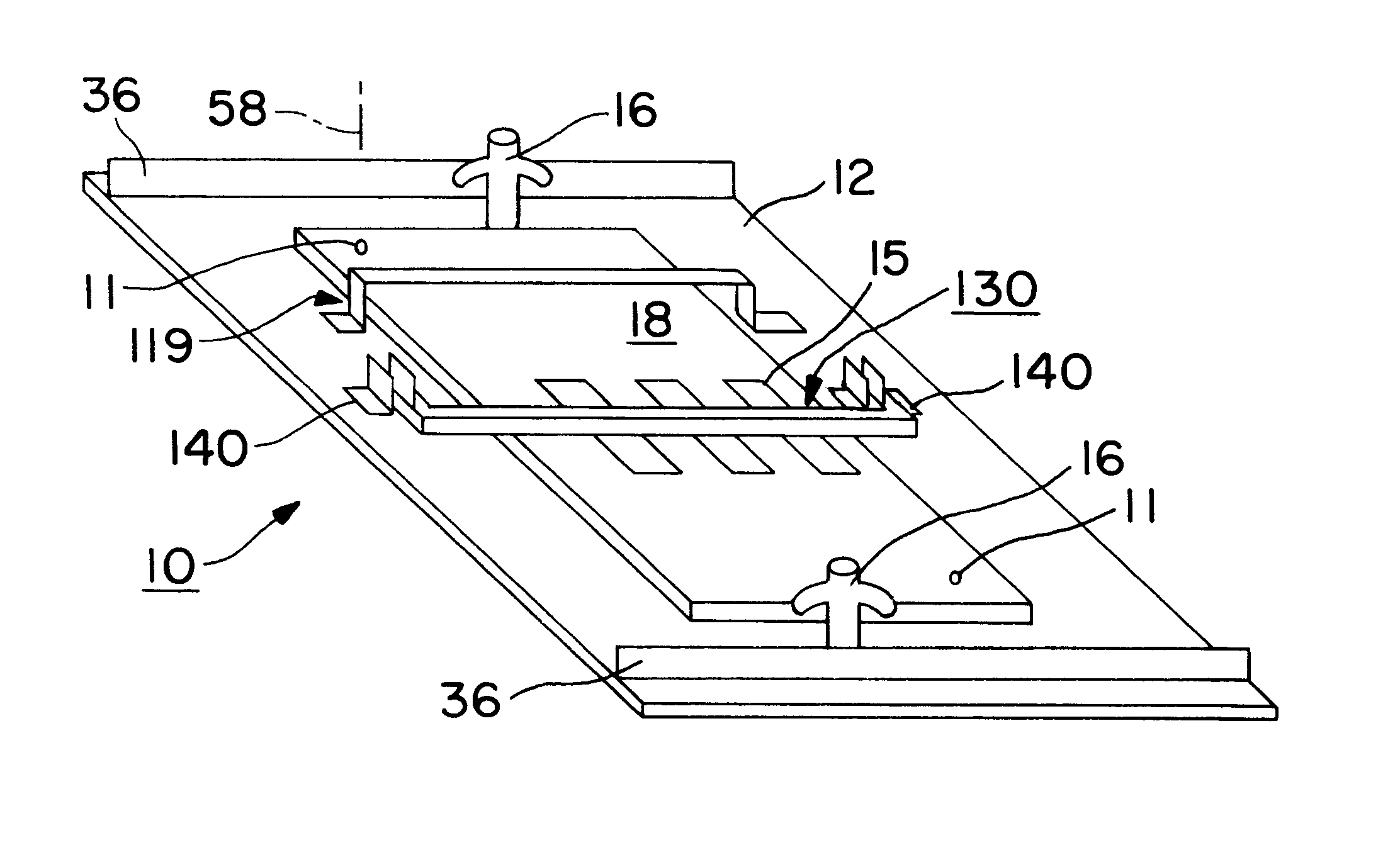

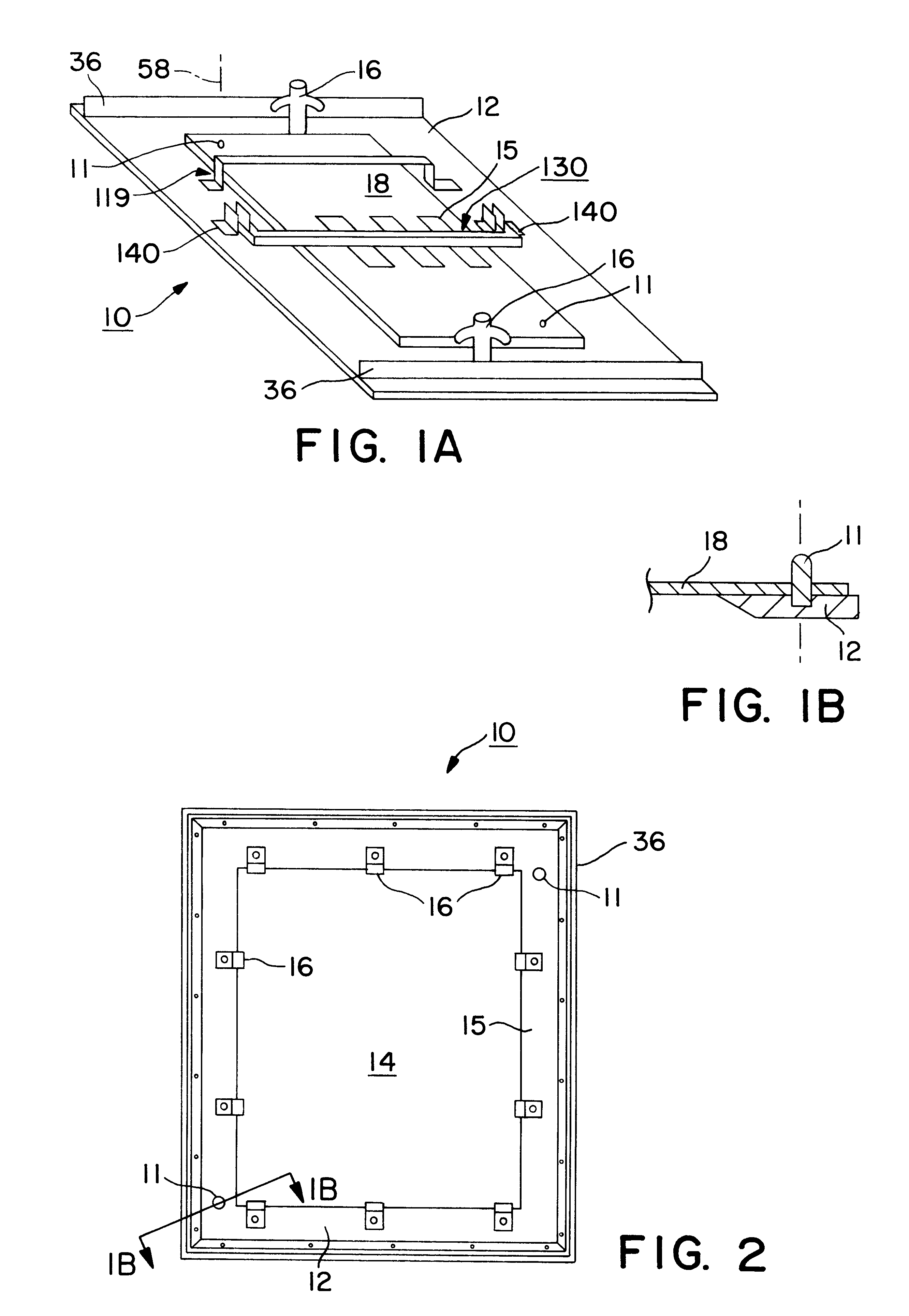

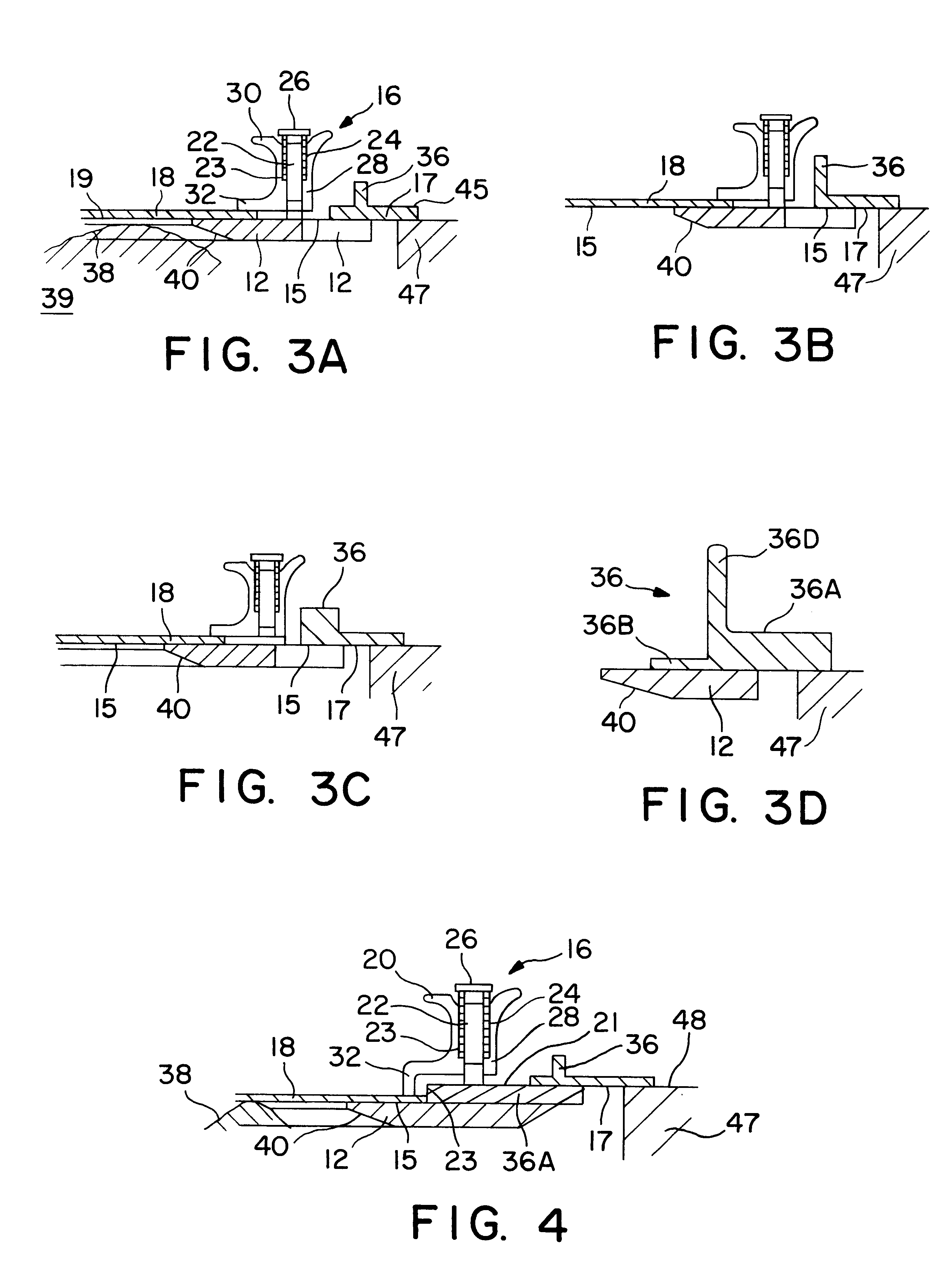

An apparatus used in a process for supporting a printed circuit board during a wave soldering operation including a frame with a frame opening in which a surface of the frame supports the board and also serves as a reference surface for vertically positioning the board above the solder pool. The board is secured against the reference surface with spring loaded clamps. Stiffeners preferably being an aluminum extrusion having a Tee or angle cross section is mounted along the outside edge of the reference surface of the frame and has a second reference surface facing in a direction opposite the reference surface of the frame. The second reference surface on the extrusion is accessible for support by a slide rail so that the height of the reference surface of the frame above the surface of the pool is independent of the thickness of the board or frame. A board support bar for minimizing warpage of the board from heat is disclosed as well as a hold down bar that secures components on the board so that they do not float away when contacted by the solder wave.

Owner:CHUNG HENRY

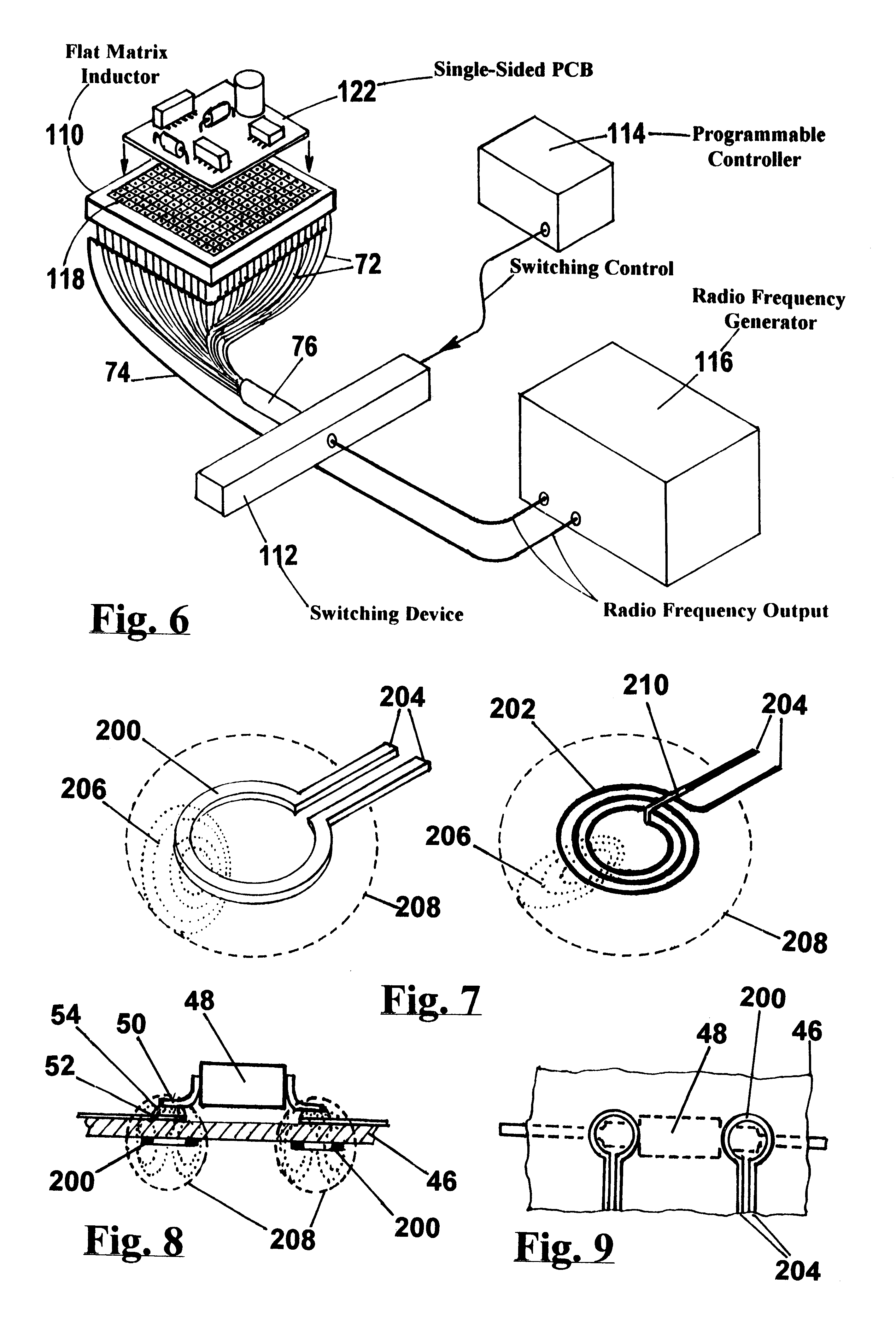

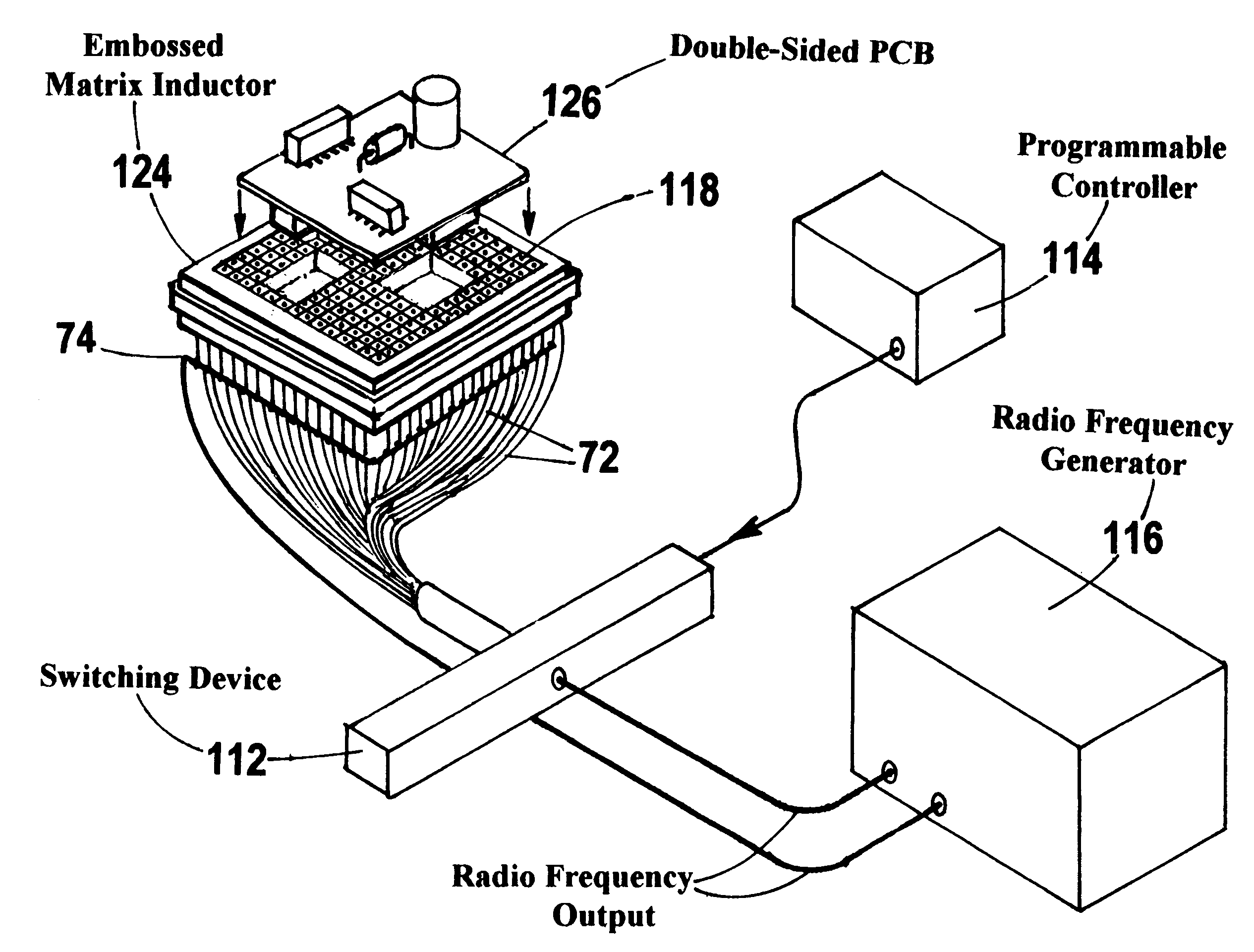

Inductive self-soldering printed circuit board

InactiveUS6229124B1Improve quality and reliabilityReduce formationPrinted circuit assemblingCoil arrangementsManufacturing technologyHeat sensitive

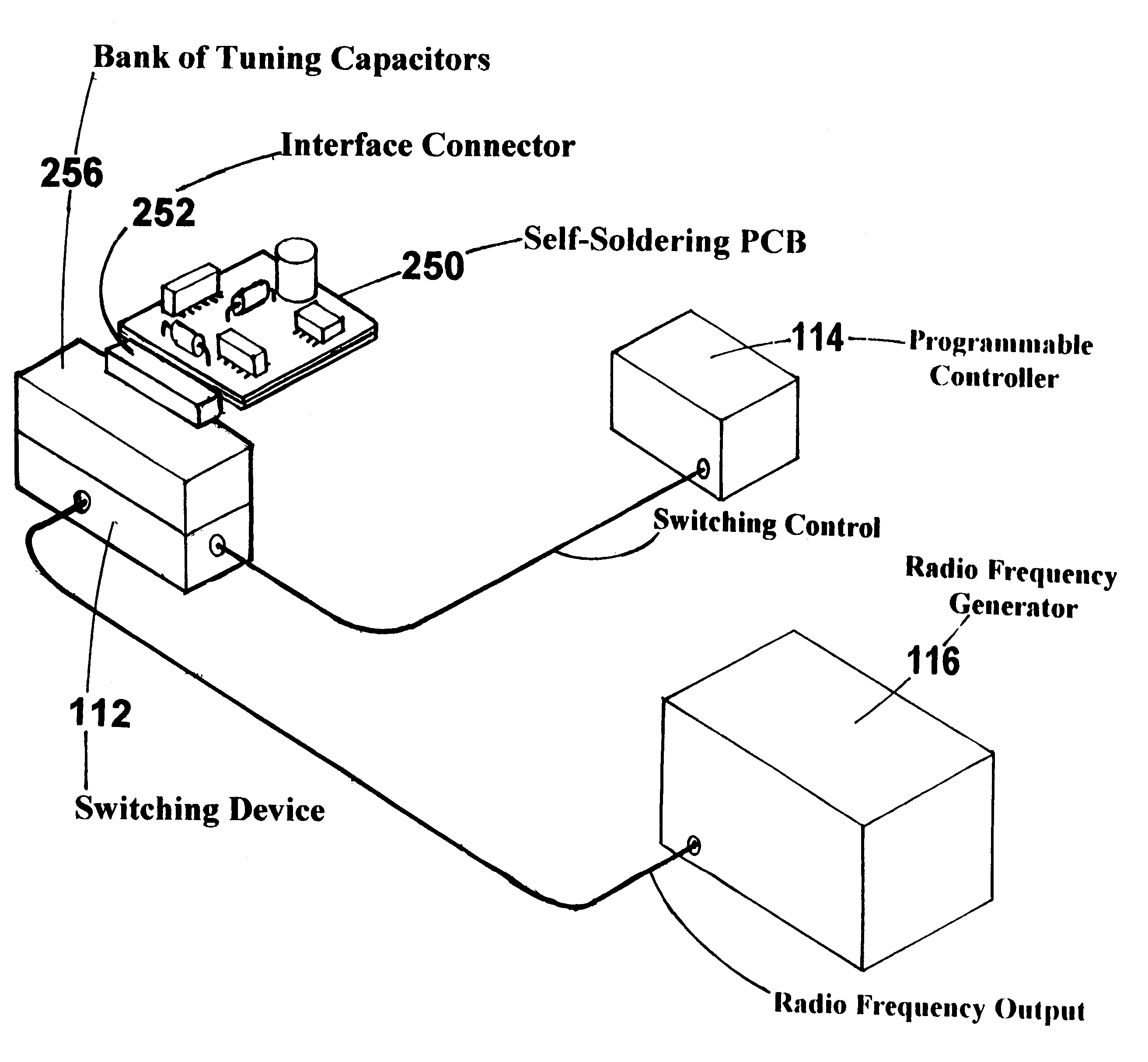

A new apparatus for inductively soldering surface-mount, straddle-mount and through-hole type electronic components into a self-soldering PCB (printed circuit board) in an automated fashion utilizing localized Electromagnetic Induction Heating (E.I.H.). Current manufacture technology for packaging electronic components depends on the reflow and wave soldering processes. Both processes heat up to relatively high temperatures the entire assembly, namely its PCB and all the electronic components being soldered into it. Such harsh high-temperature environment frequently causes components damage resulting in rejects and / or demanding rework. With this invention reflow oven and / or wave soldering equipment is not required. During a soldering operation only the leads and pads being soldered are heated but neither the body of said electronic components nor the dielectric material forming said self-soldering PCB and its interconnecting traces are heated. Because of this selectively localized inductive heating, the invention permits to reduce cost and improve the quality and reliability of manufactured products. The invention consumes about 200 times less energy than the reflow and wave soldering processes. This invention can readily be utilized to complement and / or supplement the reflow and wave soldering processes by providing selective inductive self-soldering of odd-form and / or heat-sensitive components. The invention also allows in-process, and in-situ, testing of soldered joints quality thus permitting rework before final assembly of a self-soldering PCB is completed. This invention also provides for a useful inductive de-soldering apparatus.

Owner:TRUCCO HORACIO ANDRES

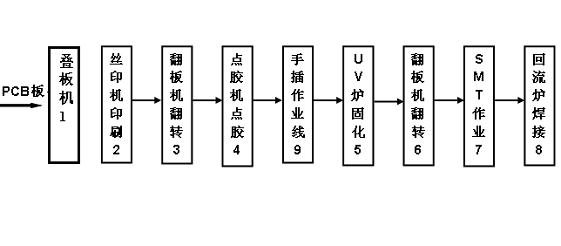

PCB (Printed Circuit Board) production line combining manual in process processing and paster processing

ActiveCN101977484AShorten production timeReduce turnoverPrinted circuit assemblingElectrical componentsProduction lineUV curing

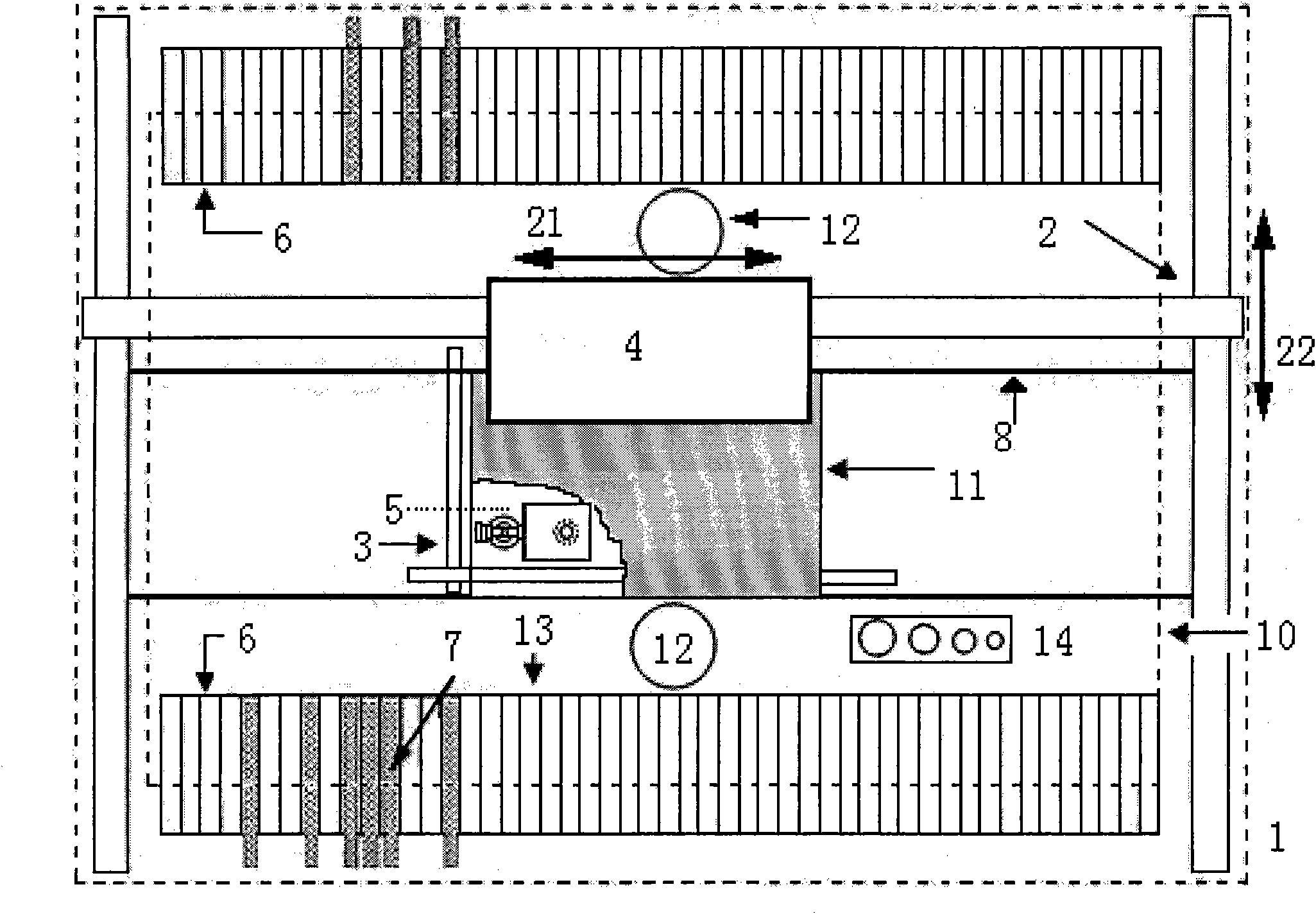

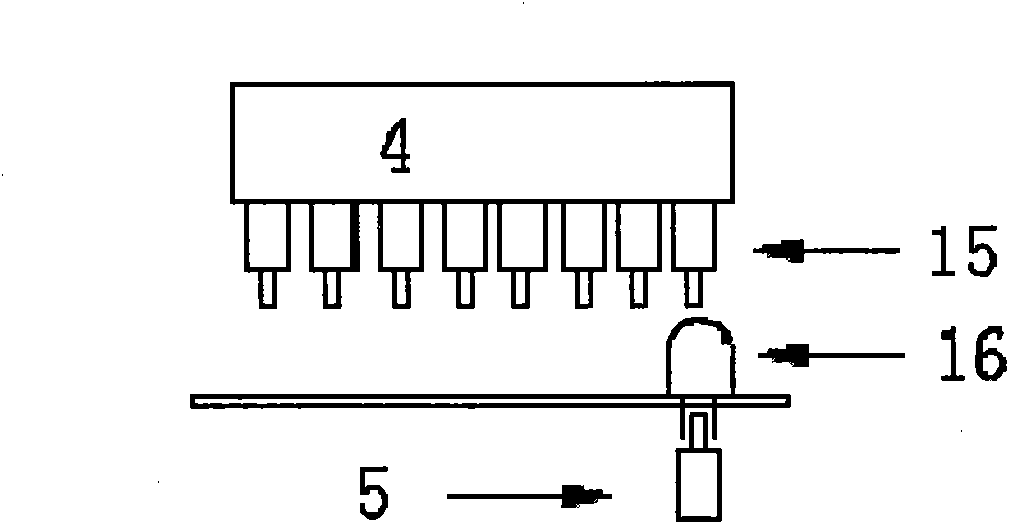

The invention discloses a PCB (Printed Circuit Board) production line combining a manual in process processing and paster processing, which is characterized by comprising a board feeding machine (1), a screen printing machine (2), as well as a first board overturning machine (3), an adhesive dispenser (4), a UV curing oven (5), a second board overturning machine (6), SMT (Surface Mounting Technology) equipment (7) and a reflow soldering heating curing oven (8). The first board overturning machine (3) is responsible for overturning a PCB subjected to low-temperature solder past printing of the screen printing machine (2) and then dispensing an adhesive, and after adhesive dispensing, a UV adhesive with a large long-pin device is cured under UV irradiation; after the PCB is overturned by the second board overturning machine, the step of paster production begins; and finally, PCB heating curing is finished in the reflow soldering heating curing oven (8). The invention combines SMT operation and manual in process operation together to realize a double-faced reflow soldering technology, solves the defects of traditional wave-soldering technology, and saves energy since reflow soldering is performed only twice and elements are heated twice.

Owner:NANJING PANDA ELECTRONICS MFG

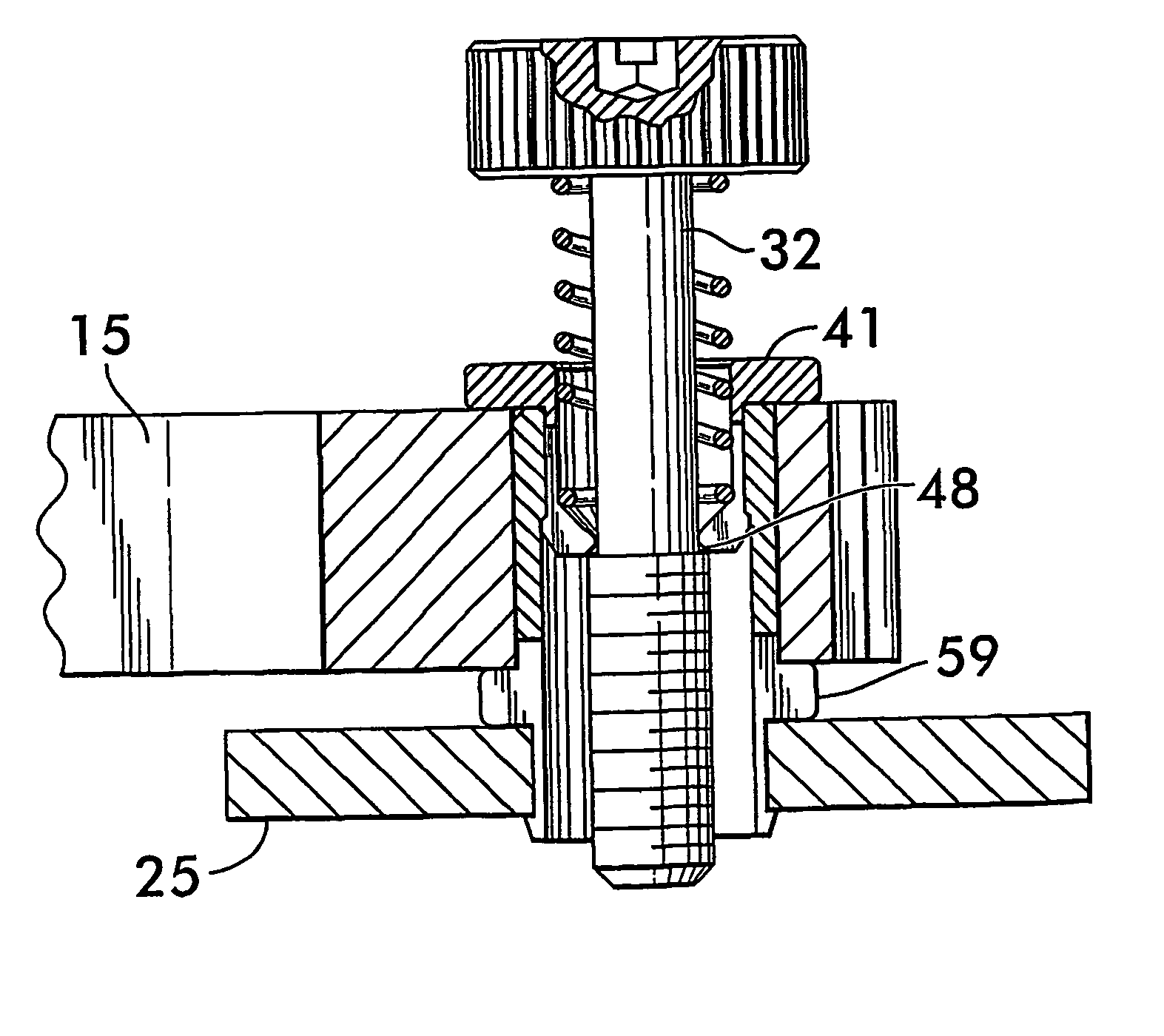

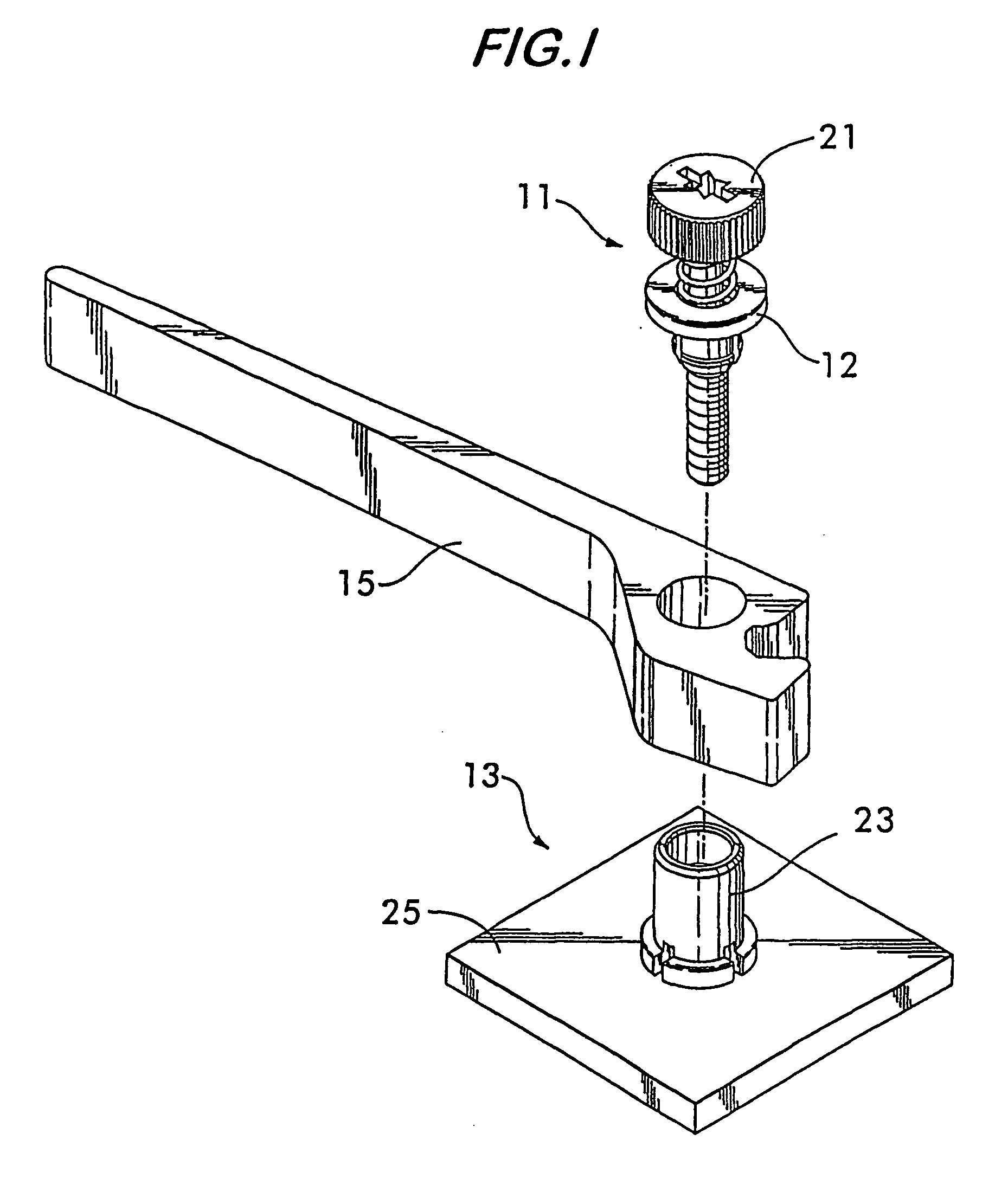

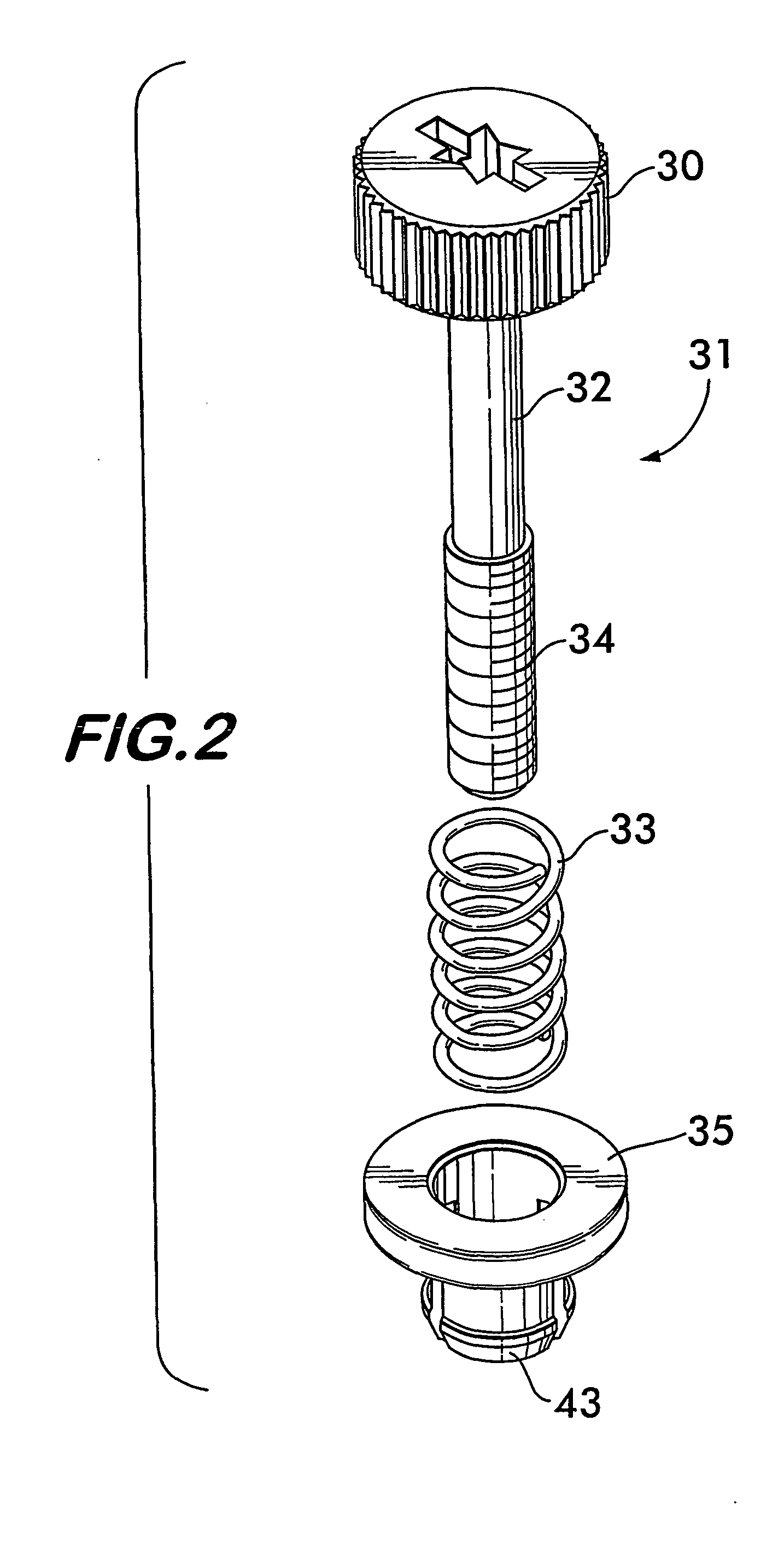

Two-part snap-together panel fastener

A two-part, snap-together captive panel fastener includes a ferrule portion and a screw sub-assembly which are attachable by snap fit. A locking mechanism prevents the unintended separation of the two components. The two-part structure of the present invention permits the ferrule which is preferably composed of a very hard and durable metal to be first wave-soldered to a printed circuit board with other elements of the board. Later, the screw sub-assembly can be snapped into the circuit board-mounted ferrule away for the harsh wave-soldering environment. The ferrule and screw retainer may further include cooperating outer flanges which captivate a pivoting structure such as a lever so that the panel fastener may not only be used to secure the attached panel to a sub-structure but may also affix other hardware to the panel.

Owner:PEM MANAGEMENT INC

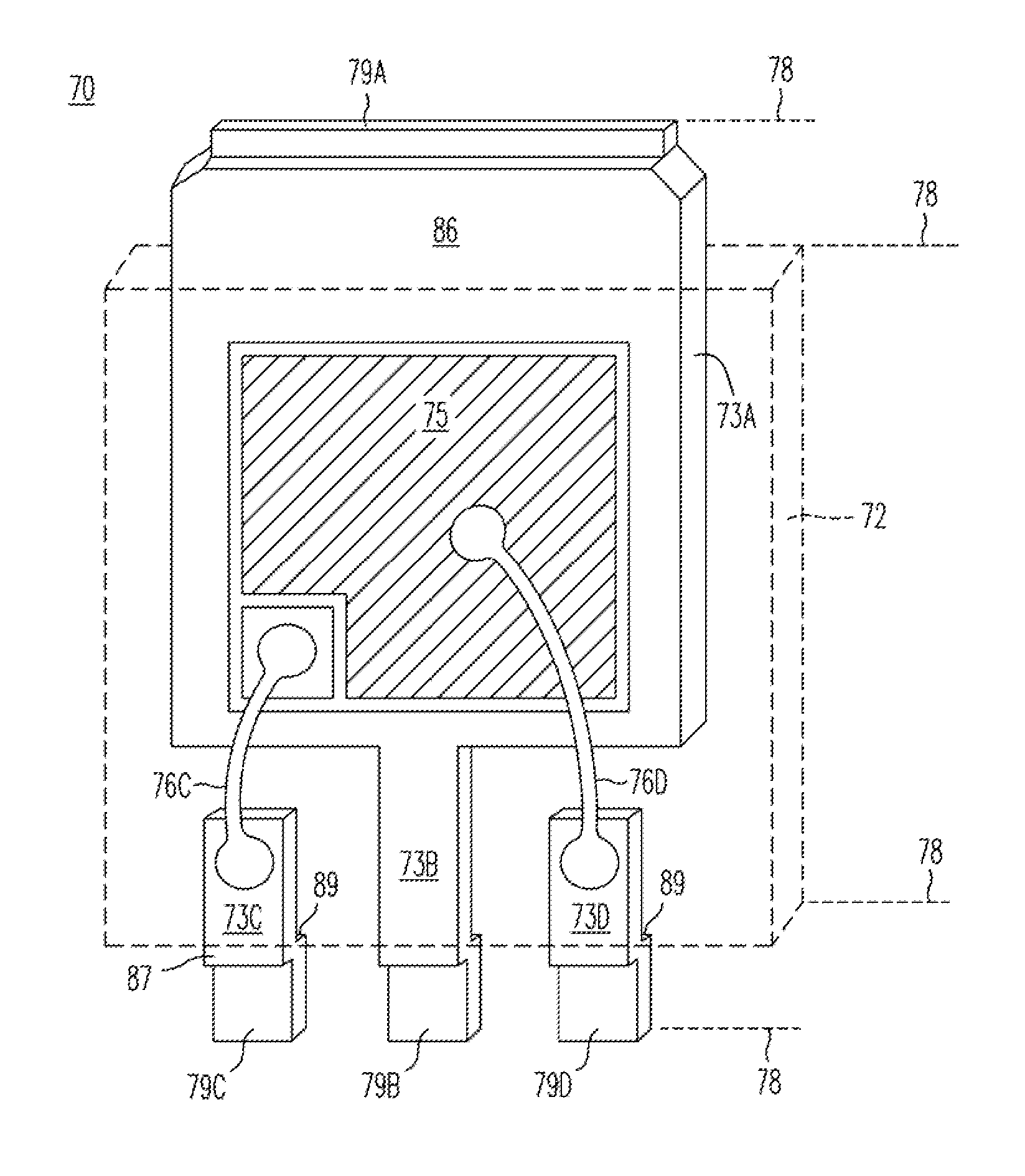

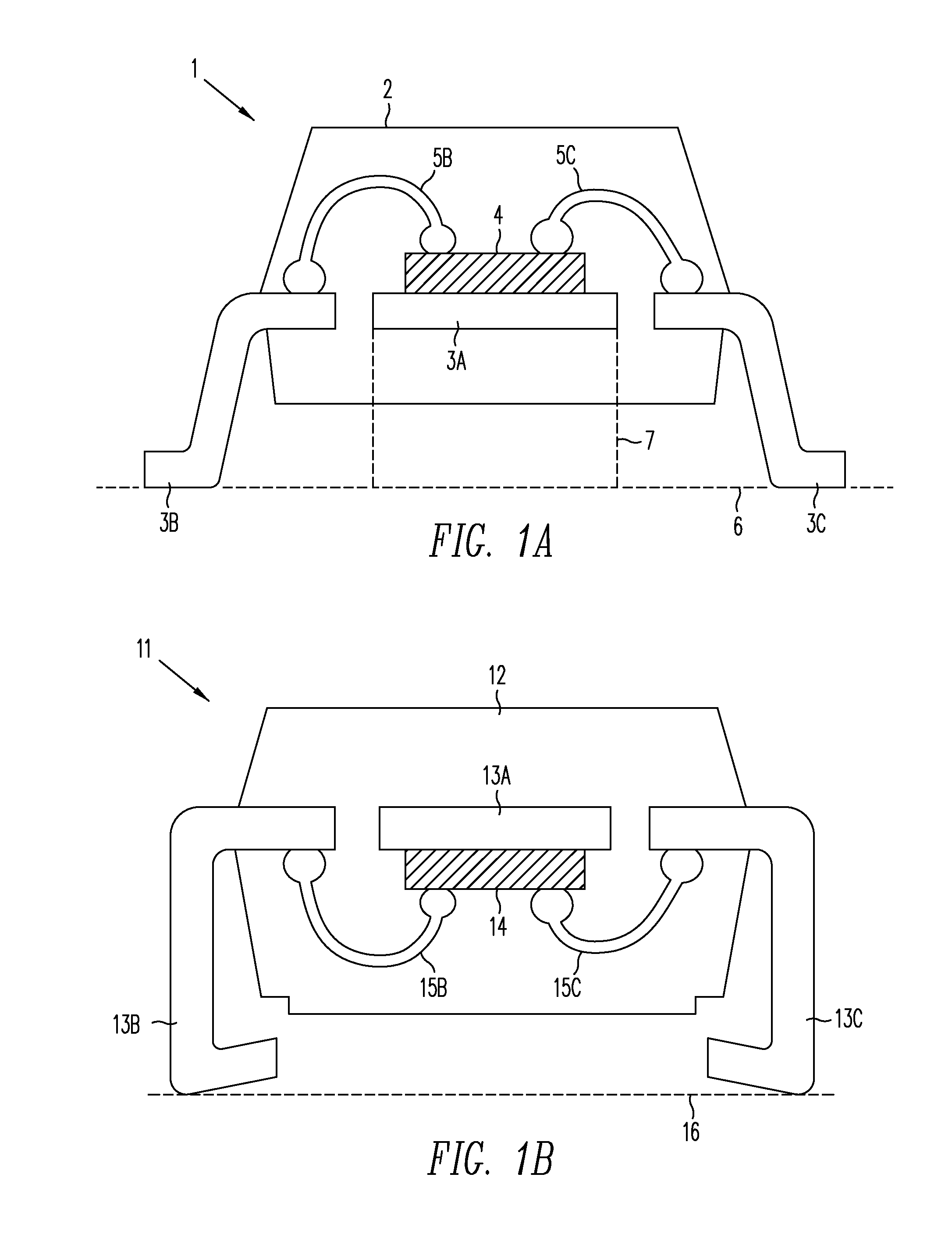

Low-Profile Footed Power Package

ActiveUS20150311144A1Good coplanarityCost-effective manufacturingSemiconductor/solid-state device detailsSolid-state devicesElectricityEngineering

A power package includes a heat tab extending from a die pad exposed on the underside of the package, which facilitates the removal of heat from the die to the PCB or other surface on which the package is mounted. The heat tab has a bottom surface coplanar with the flat bottom surface of the die pad and bottom surface of a lead. The lead includes a horizontal foot segment, a vertical columnar segment, and a horizontal cantilever segment facing the die pad. The heat tab may also have a foot. A die containing a power device is mounted on a top surface of the die pad and may be electrically connected to the lead using a bonding wire or clip. The die may be mounted on the die pad with an electrically conductive material, and the package may also include a lead that extends from the die pad and is thus electrically tied to the bottom of the die. The result is a package with a minimal footprint that is suitable for the technique known as “wave soldering” that is used in relatively low-cost printed circuit board assembly factories. Methods of fabricating the package are disclosed.

Owner:ADVENTIVE INT LTD

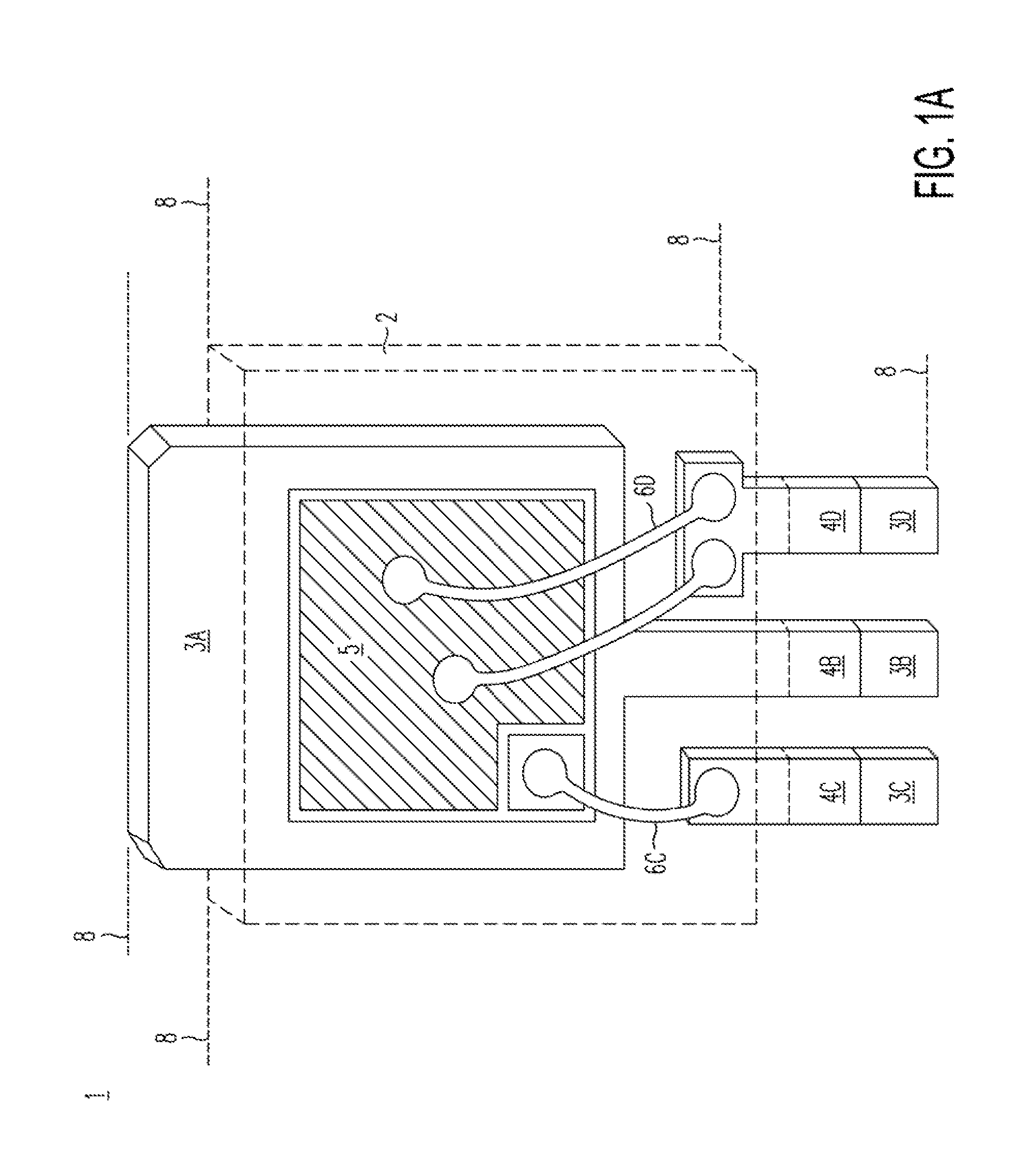

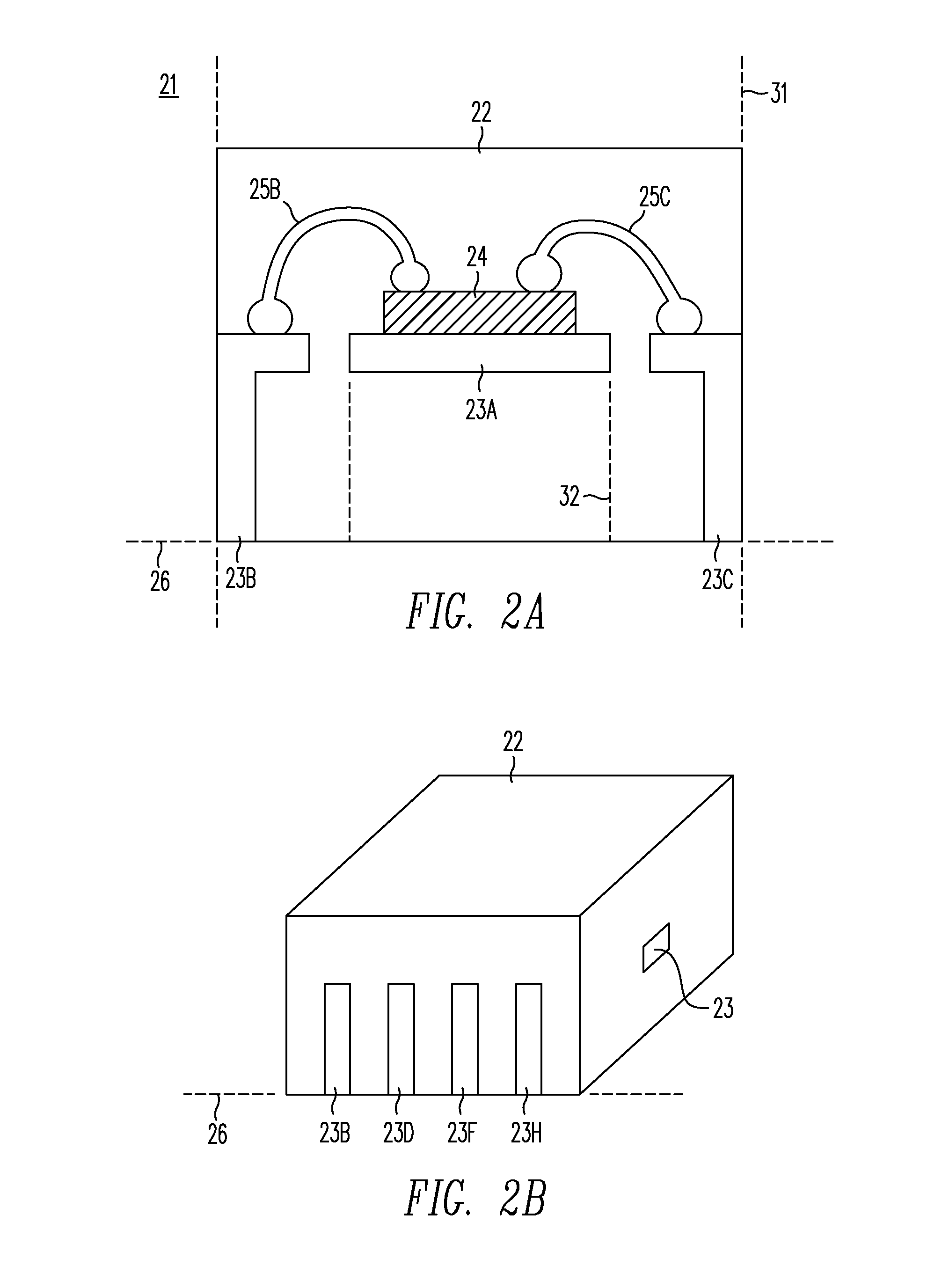

Low Profile Leaded Semiconductor Package

ActiveUS20140306330A1Not affectSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageWave soldering

In a semiconductor package a lead having a bottom surface coplanar with the flat bottom surface of the plastic body extends outward at the bottom of the vertical side surface of the plastic body. The result is a package with a minimal footprint that is suitable for the technique known as “wave soldering” that is used in relatively low-cost printed circuit board assembly factories. Methods of fabricating the package are disclosed.

Owner:ADVENTIVE INT LTD

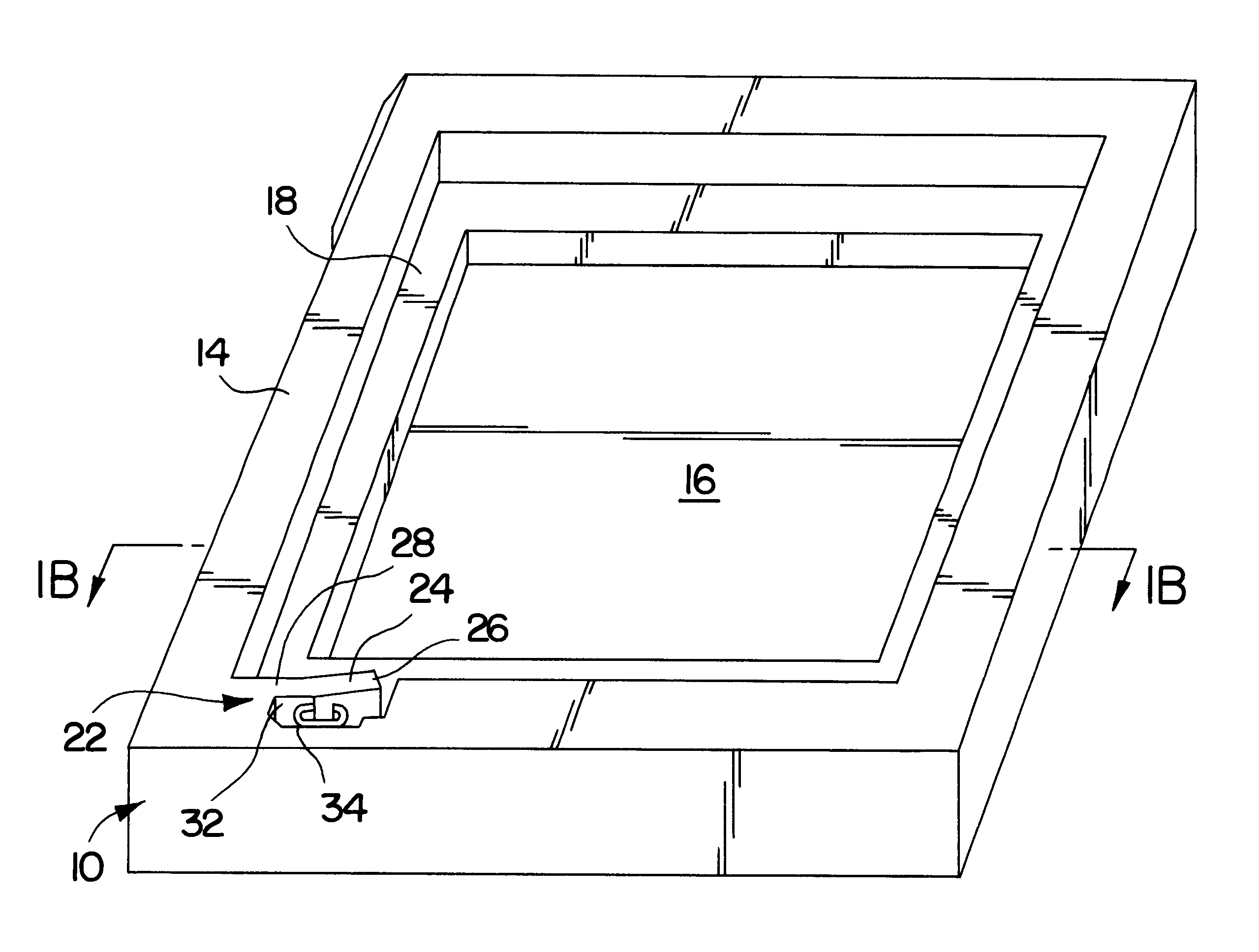

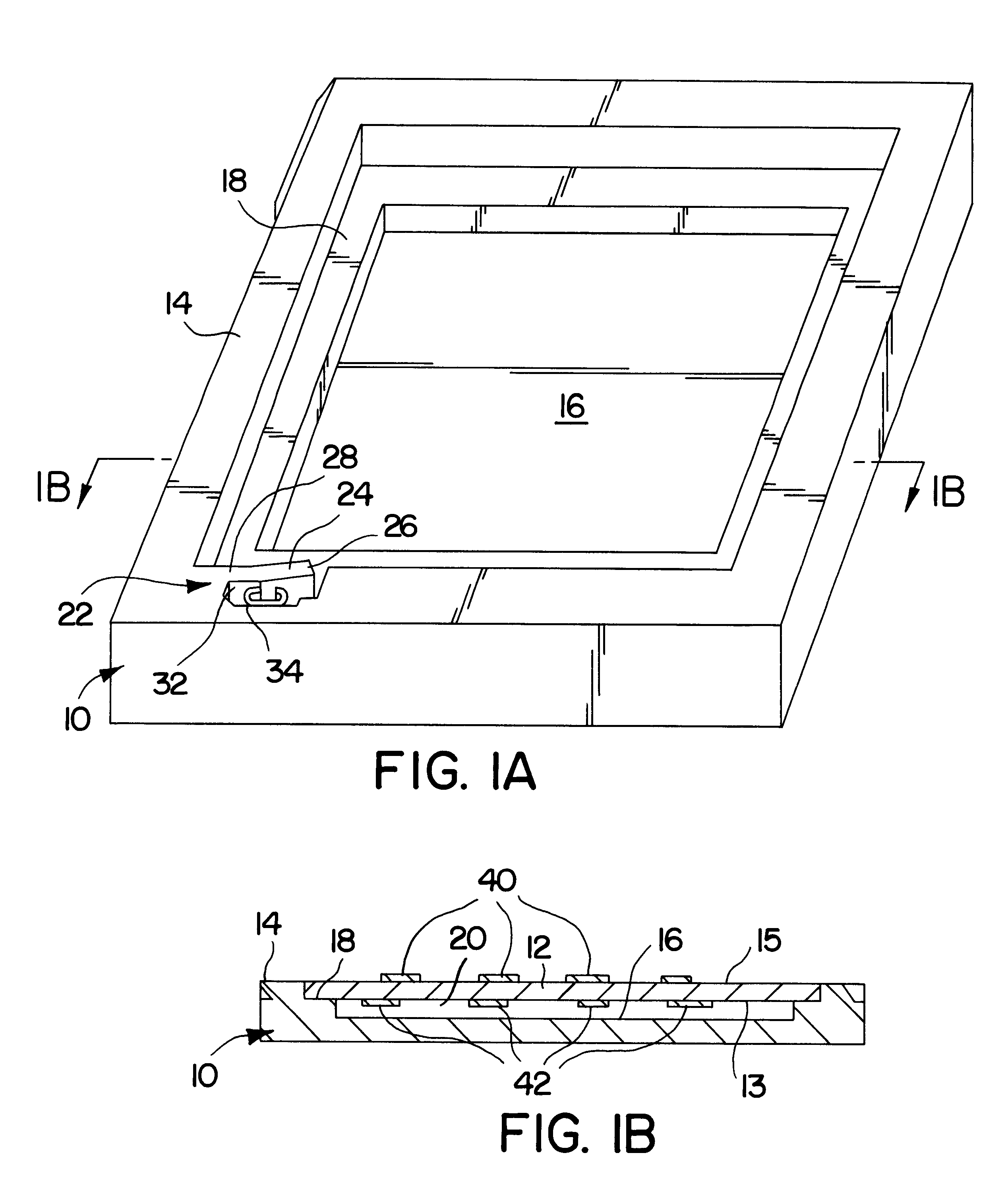

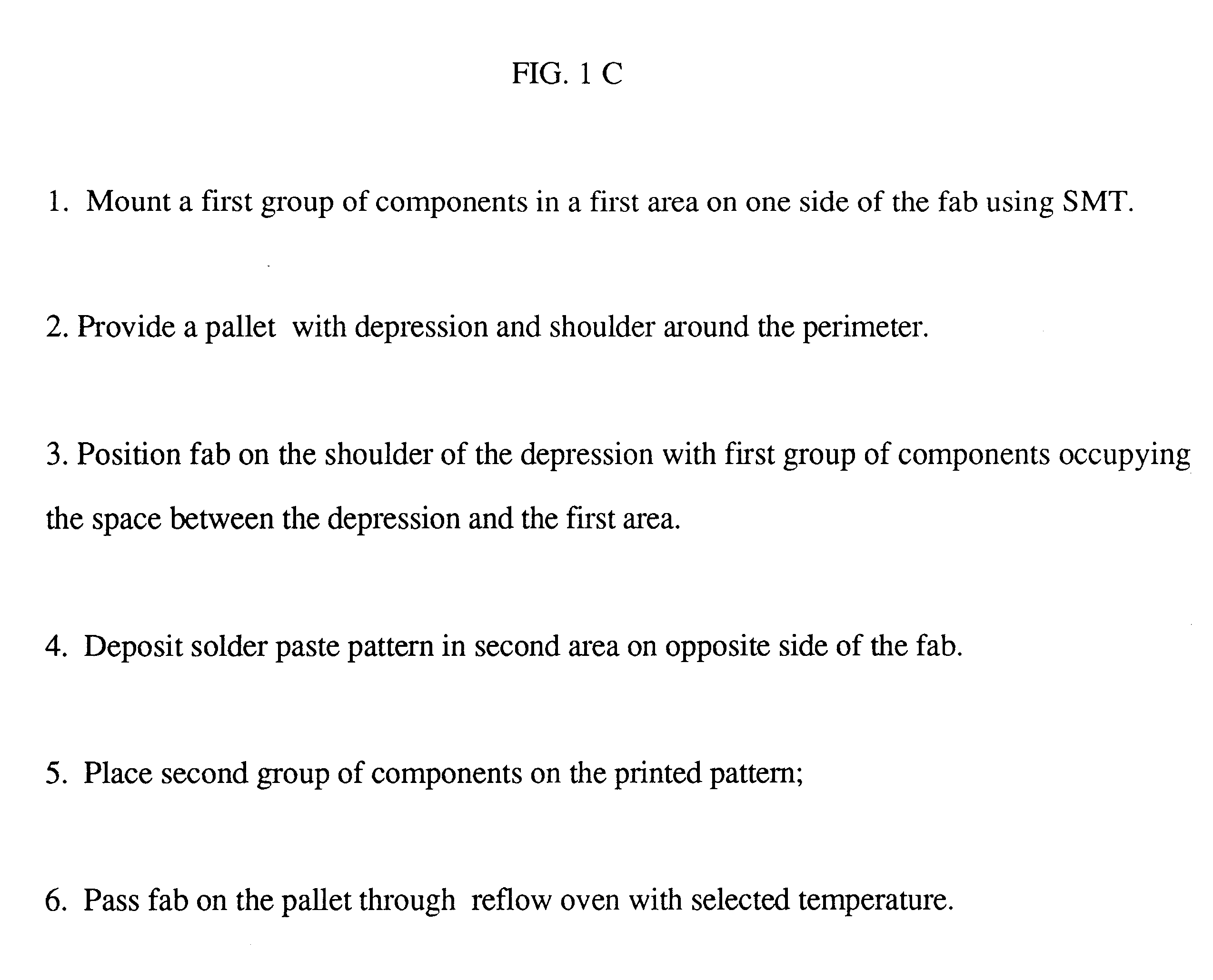

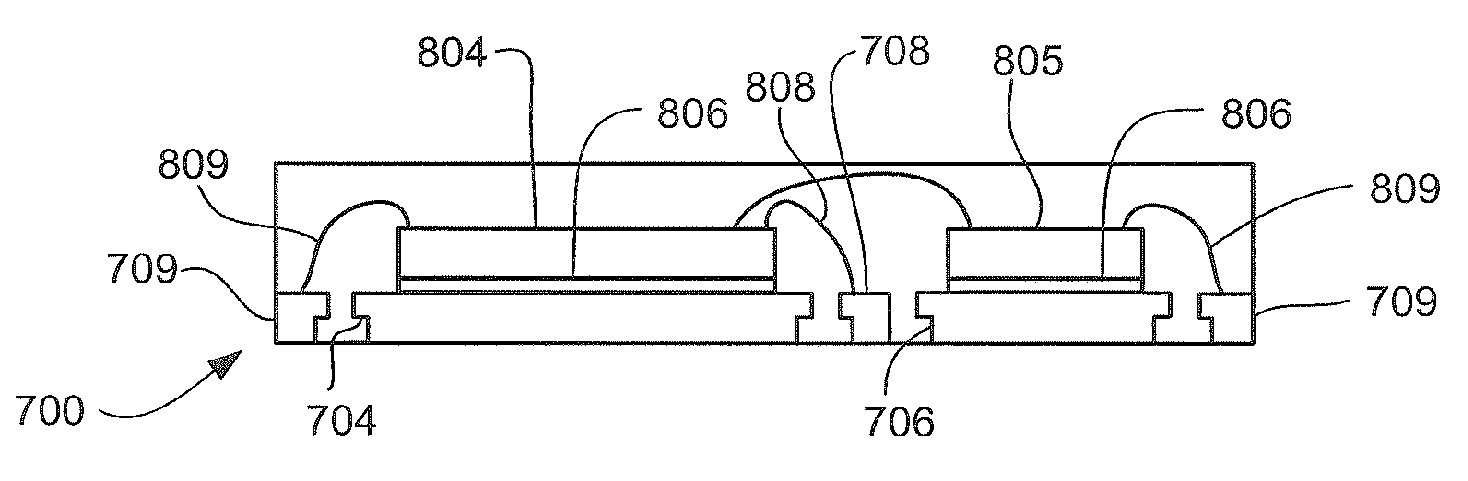

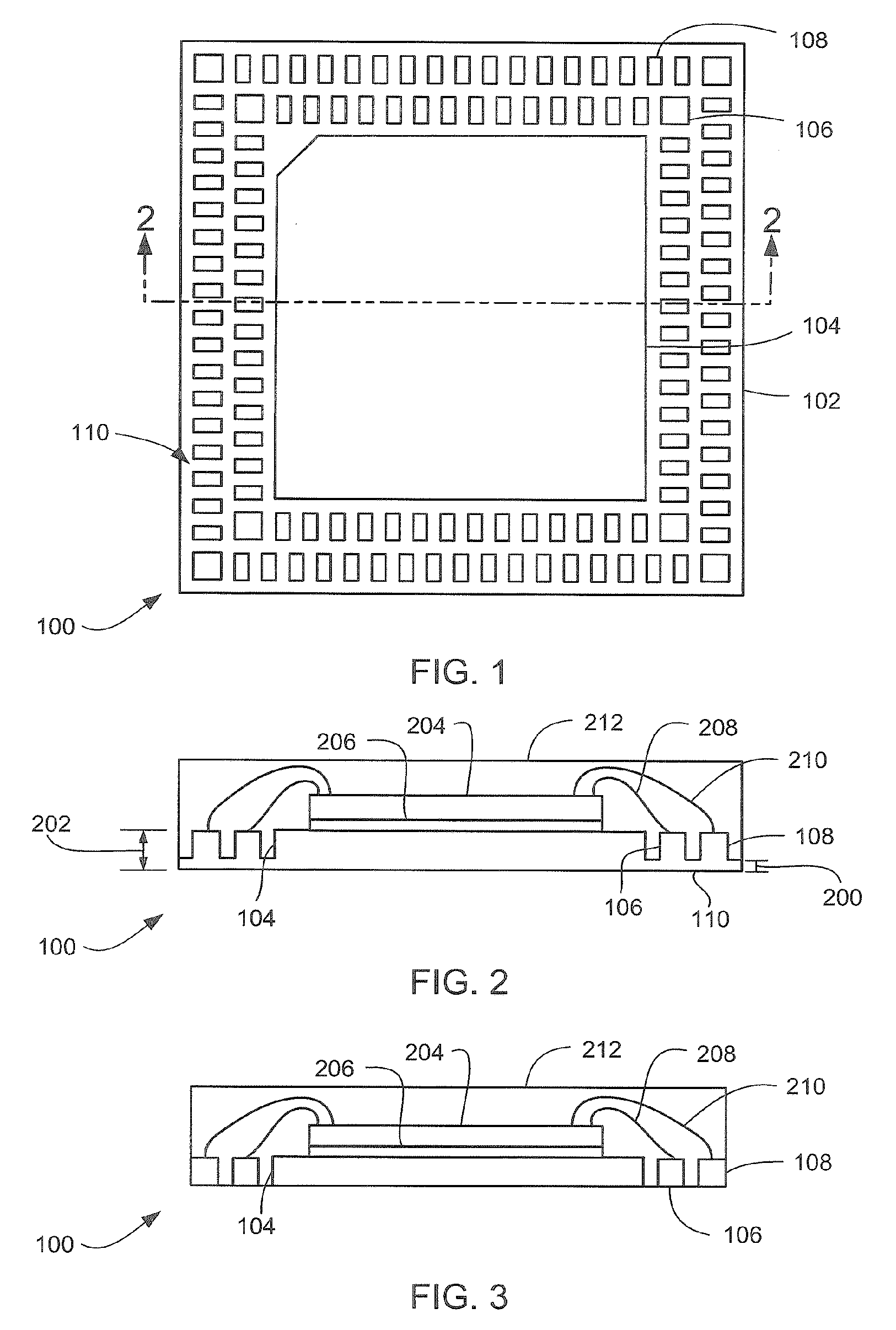

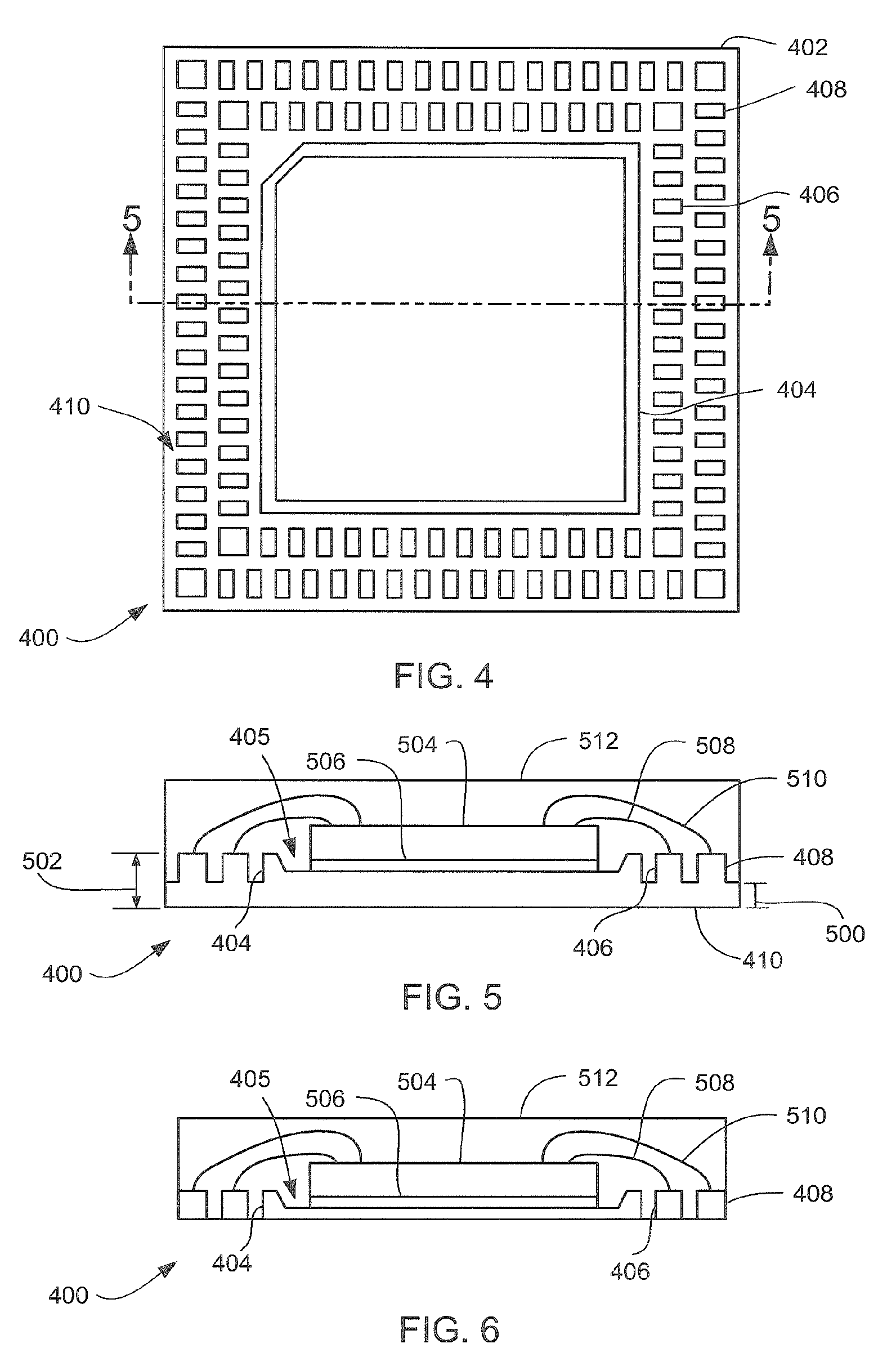

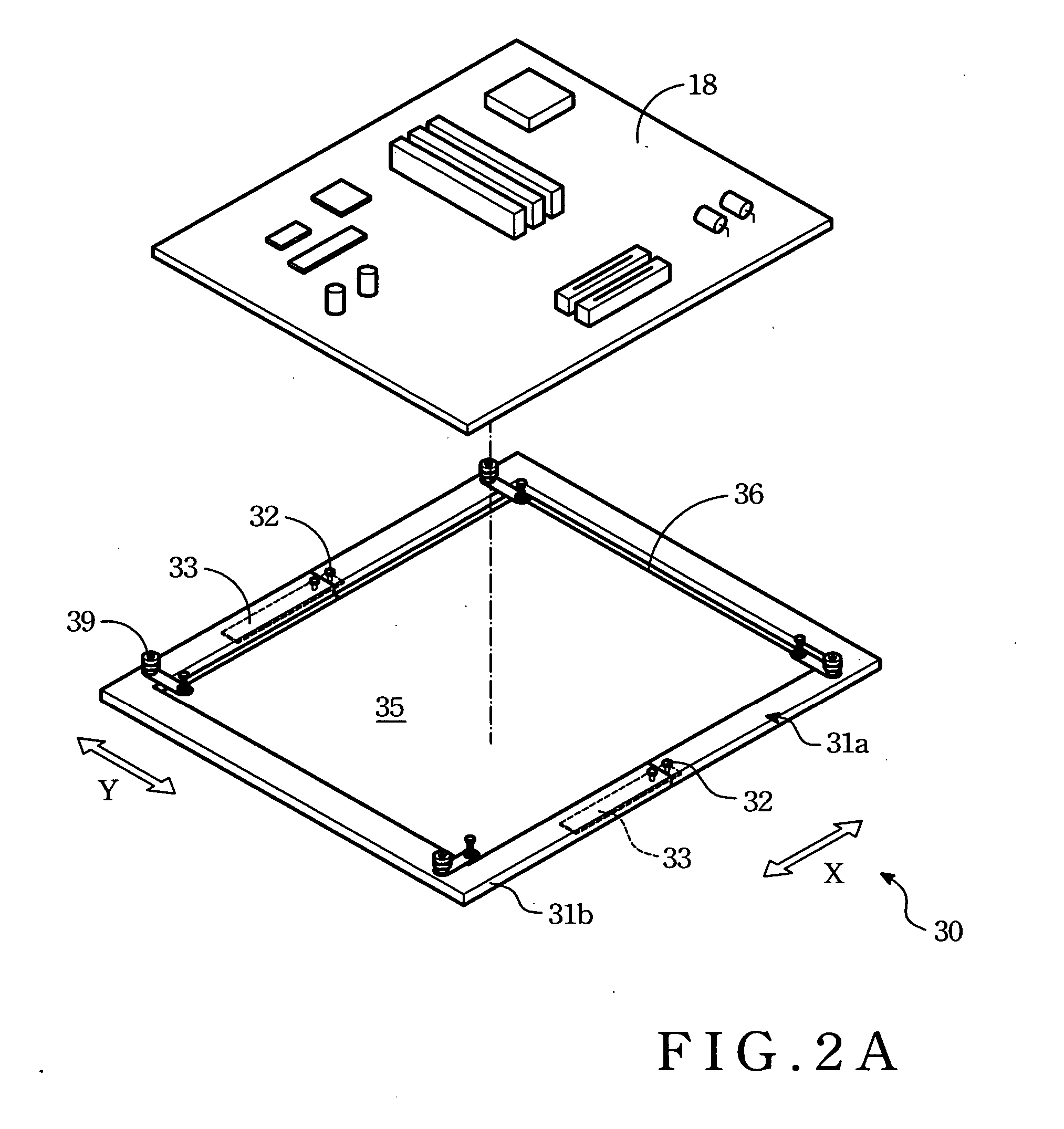

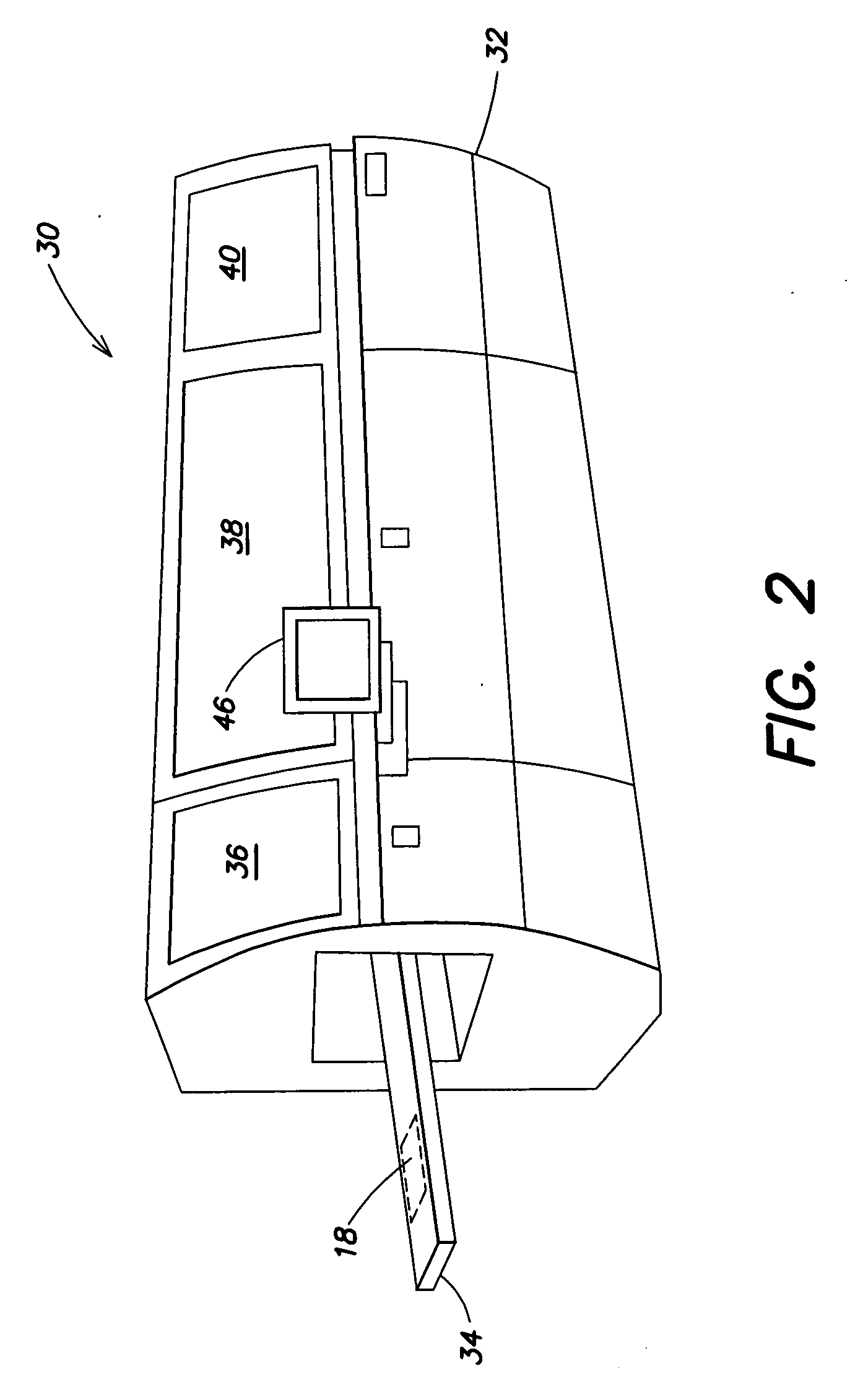

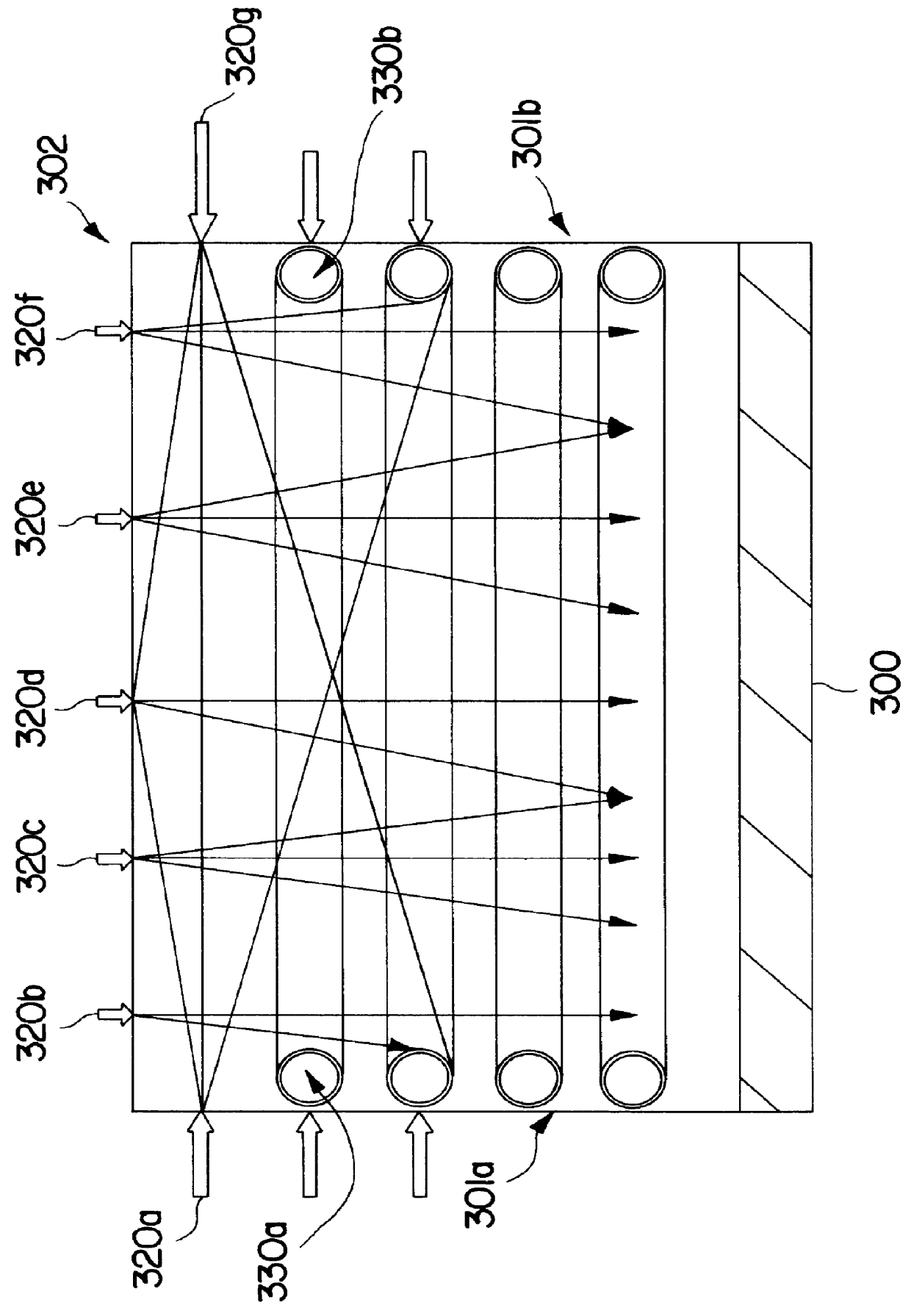

Pallet for combined surface mount and wave solder manufacture of printed ciruits

InactiveUS6267288B1Even heat distributionMinimize warpagePrinted circuit assemblingFinal product manufactureSurface mountingEngineering

A pallet for mounting components on a double sided PCB including a fab (panel) having a frame area surrounding a depression. A shoulder around the depression is dimensioned to support the fab. The fab is laid on the shoulder with the a group of components mounted in a previous reflow operation in the space between the depression and a first area of the fab. The print, pick and place and reflow operations are performed to mount a second group of components on the opposite side of the fab. The first area of the fab is shielded from the heat of the oven so that the first components do not separate from the fab during the second reflow step. Standoffs in the depression prevent sagging of the board. Another area of the pallet has a recessed area with cutouts for wave soldering components located on the third area of the fab.

Owner:CHUNG HENRY

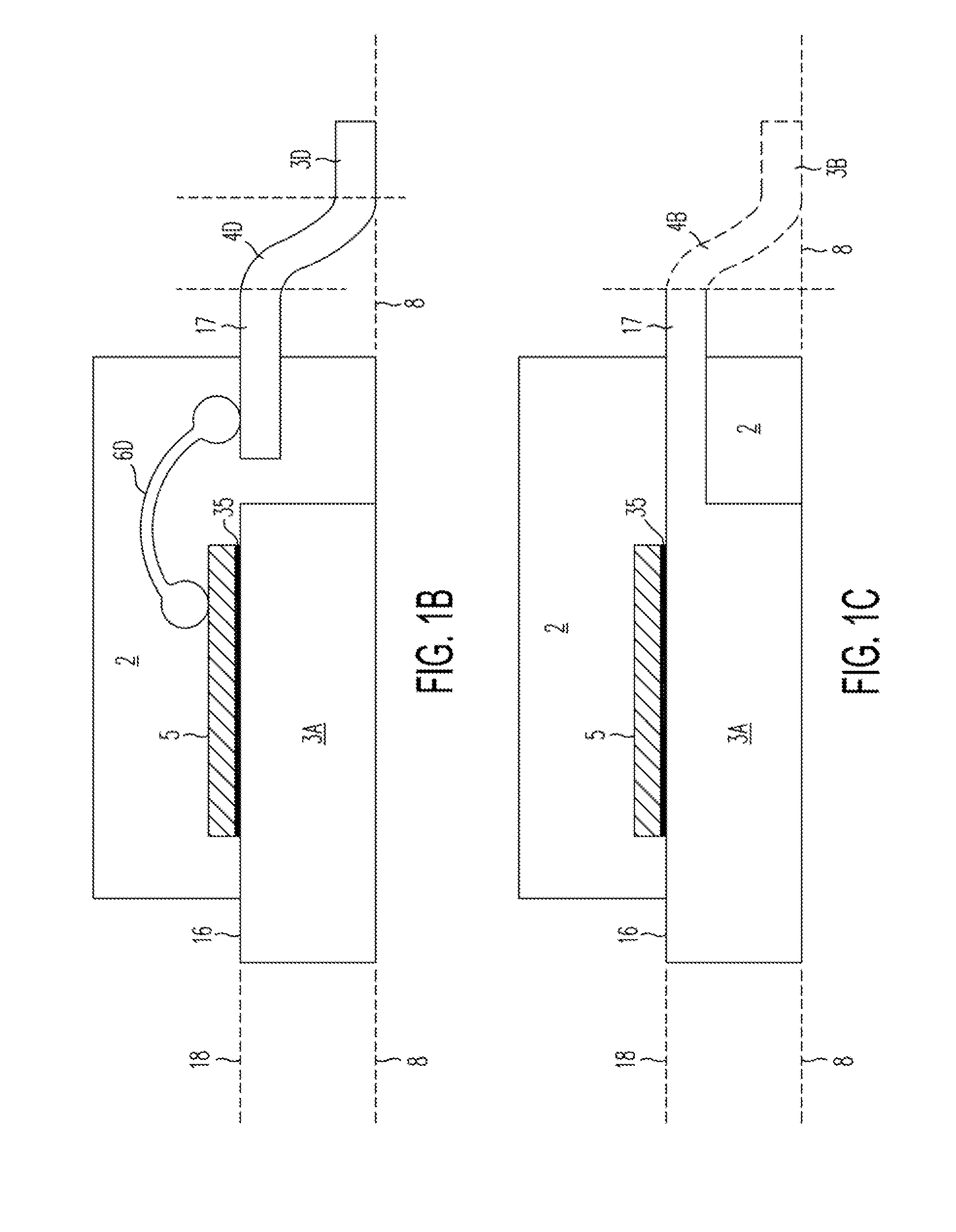

Integrated circuit package system using etched leadframe

ActiveUS20070085199A1Cost-effectiveSemiconductor/solid-state device detailsSolid-state devicesEngineeringSealant

An integrated circuit package system includes a conductive substrate. A heat sink and a plurality of leads are etched in the substrate to define a conductive film connecting the heat sink and the plurality of leads to maintain their spatial relationship. A die is attached to the heat sink and wire bonded to the plurality of leads. An encapsulant is formed over the die, the heat sink, and the plurality of leads. The conductive film is etched away to expose the encapsulant and the bottom surfaces of the heat sink and the plurality of leads. Wave soldering is used to form solder on at least the plurality of leads. Multiple heat sinks and hanging leads are provided.

Owner:STATS CHIPPAC LTD

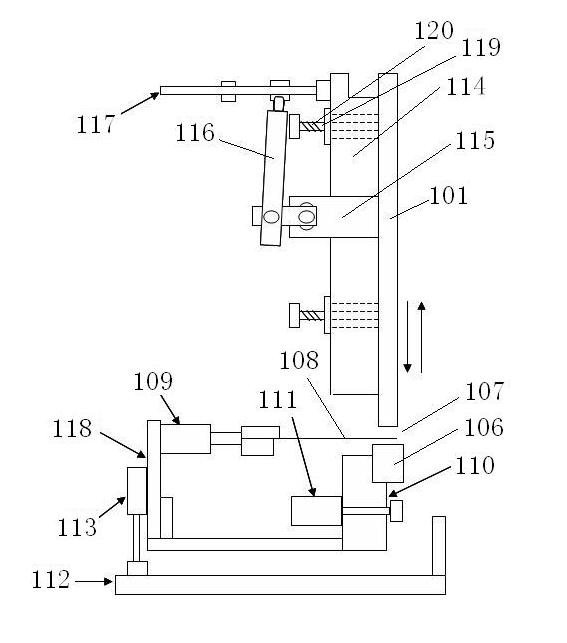

Full-automatic LED (Light Emitting Diode) and components mounting and inserting all-in-one machine and running method thereof

InactiveCN102065674AAchieve high efficiencyAchieve energy savingElectrical componentsSemiconductor devicesScreen printingControl system

The invention discloses a full-automatic LED (Light Emitting Diode) and components mounting and inserting all-in-one machine and a running method thereof. A foot striking mechanism moving platform, a foot striking mechanism and an LED suction nozzle are additionally arranged on the basis of the original mounter, the functions of a control system are updated, and two processes of mounting and inserting the components are combined, therefore, the full full-automatic LED and components mounting and inserting all-in-one machine is formed. The running method comprises the following steps of: determining the mounting and inserting position and the rotation angle of a mounting and inserting head according to the suction position deviation and the suction angle deviation of the components by the control system; and striking foot by the foot striking mechanism when inserting the LED by a mounting and inserting head mechanism so as to make a tube foot of the LED, which is exposed from the lowerpart of a PCB (Printed Circuit Board), bent and then fixed on the PCB to finish the assembly of the LED components. In the invention, the mounting process and the inserting process are integrated on one machine, and the traditional processes of silk-screen printing, mounting, reflow soldering, detecting to insert, wave-soldering and detecting are simplified; therefore, the invention has the advantages of high efficiency and energy conservation.

Owner:SOUTH CHINA UNIV OF TECH

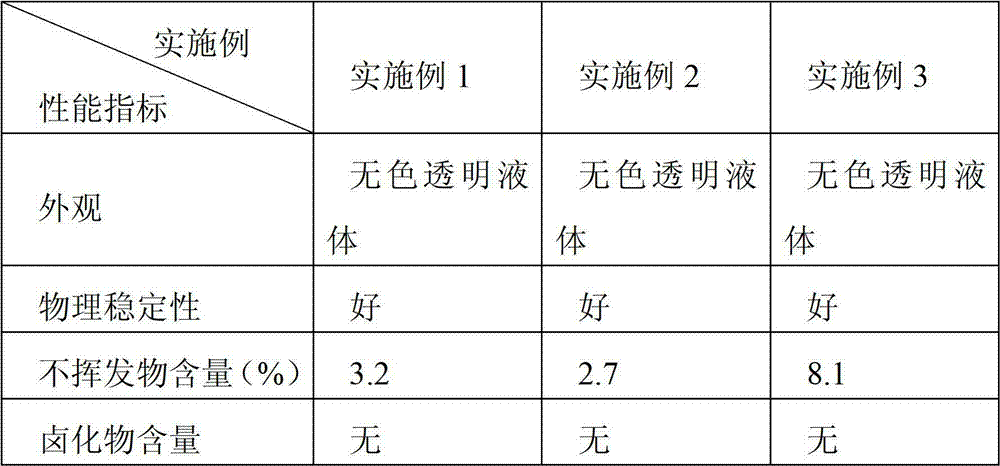

Soldering flux matched with lead-free solder

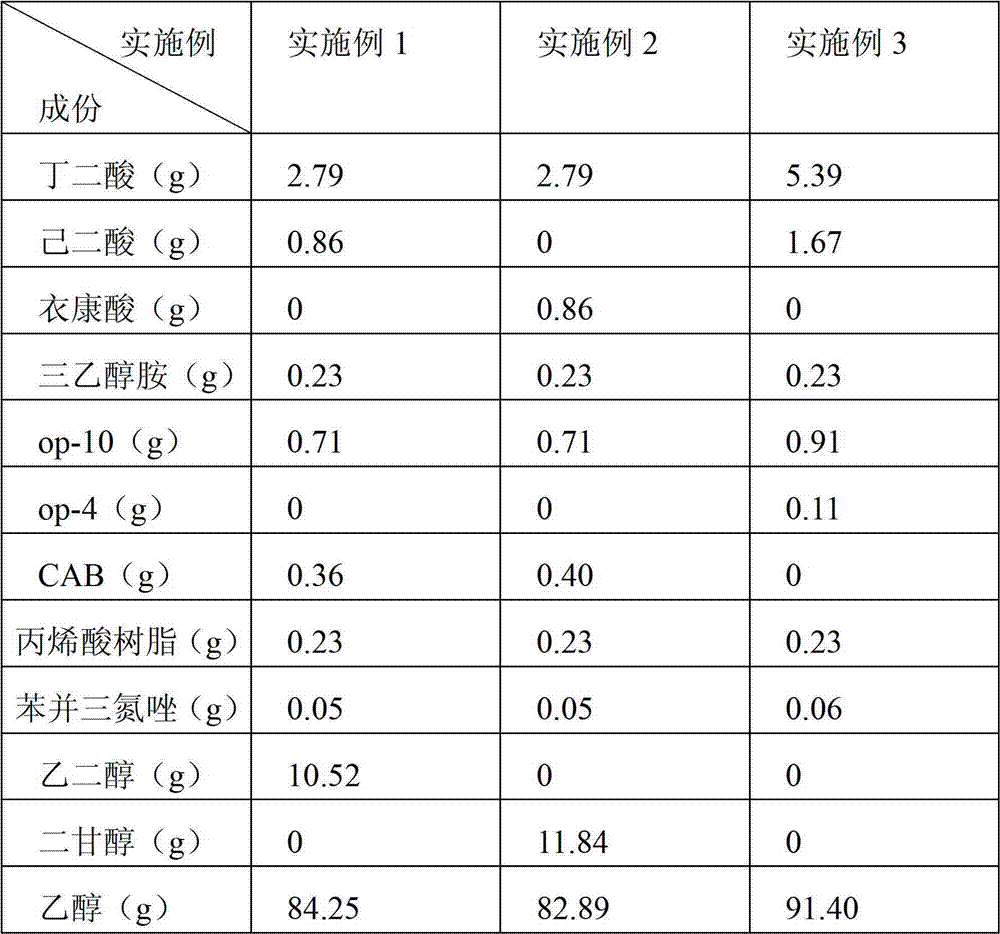

InactiveCN102825398ANothing producedNo splashWelding/cutting media/materialsSoldering mediaActive agentFilm-forming agent

Owner:BEIJING UNIV OF TECH

Lead-free solder with low copper dissolution

InactiveUS20070172381A1Minimize formation of oxideAdvantageously producedWelding/cutting media/materialsSoldering mediaDissolutionImpurity

Lead-free solder compositions suitable for joining electronic devices to printed wiring boards, which comprises by weight 0.2 to 0.9% copper, 0.006 to 0.07% nickel, 0.03 to 0.08% bismuth, less than 0.5% silver, less than 0.010% phosphorus, and a balance of tin and inevitable impurities. A solder composition embodying this invention finds particular application in automated wave-soldering machines where conventional lead-free solders dissolve excessive copper from printed wiring circuitry and component terminations.

Owner:KESTER

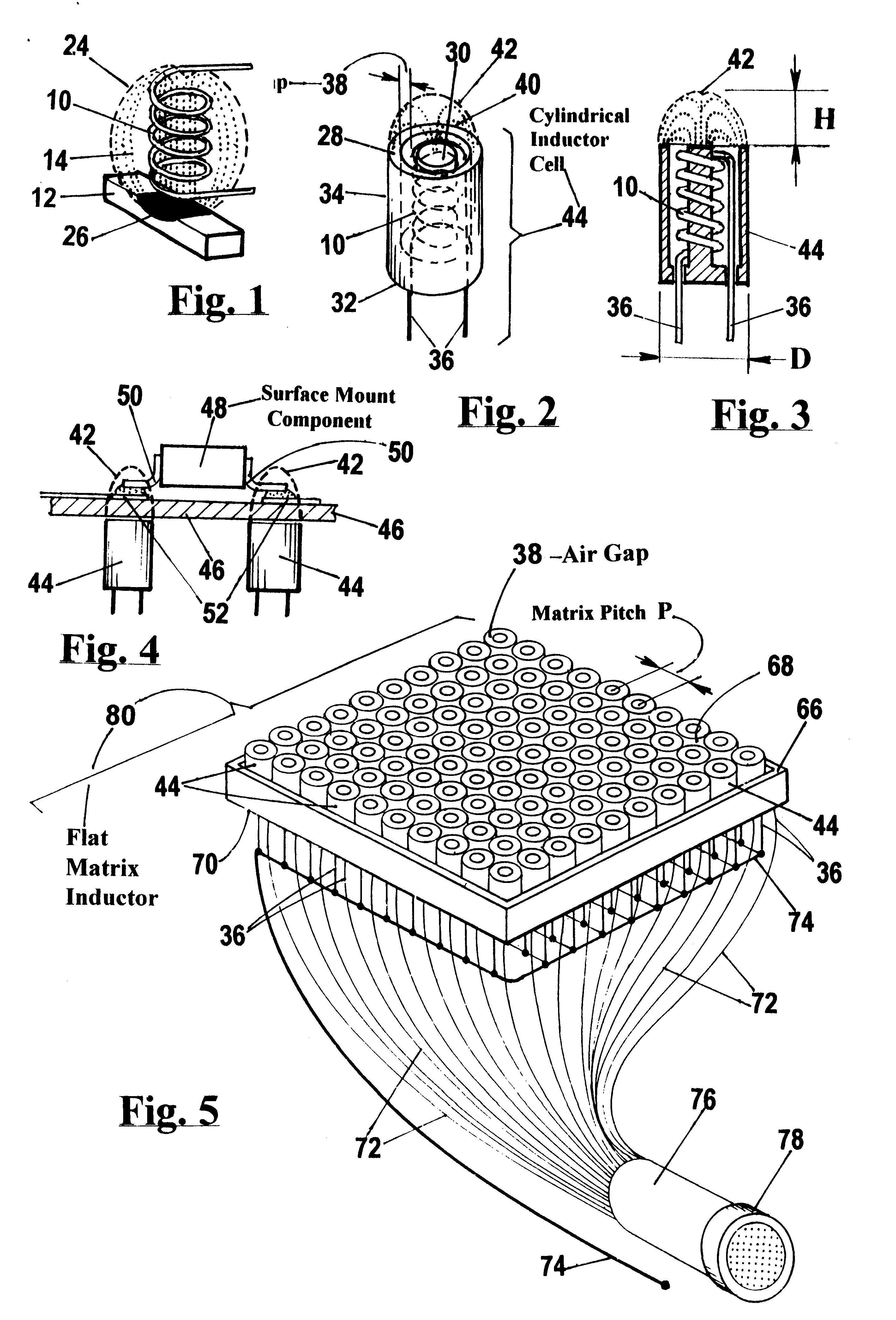

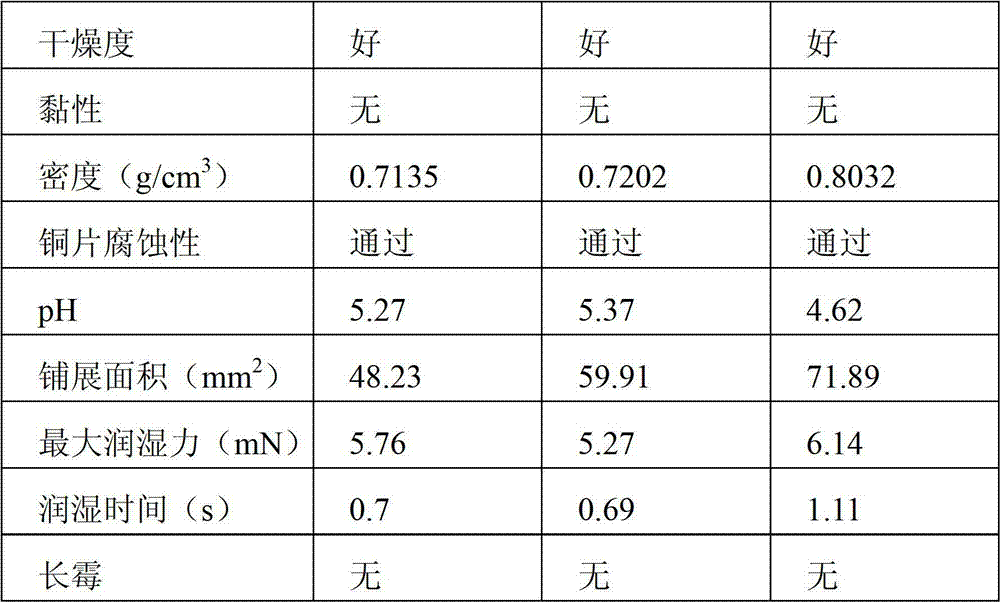

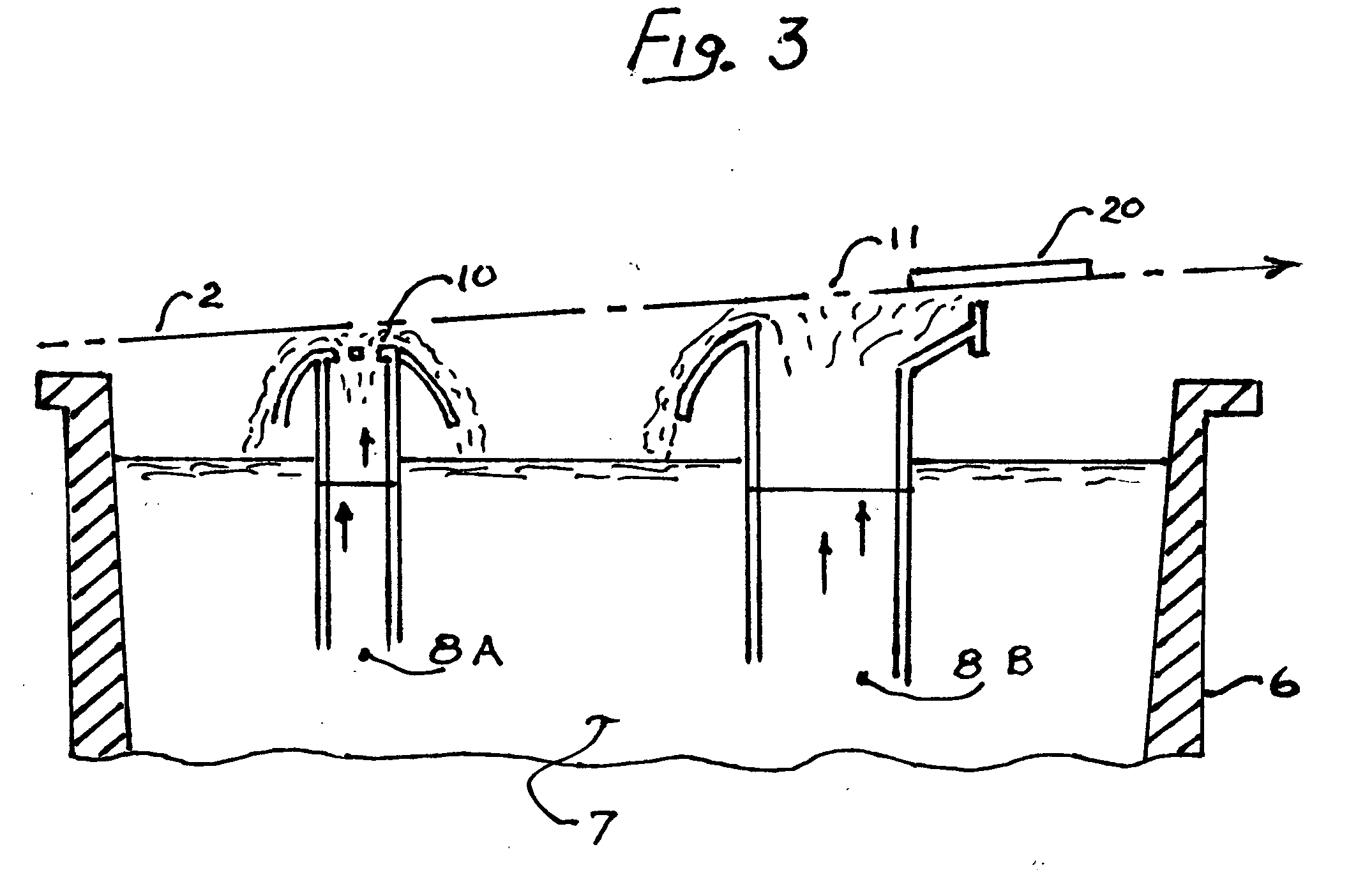

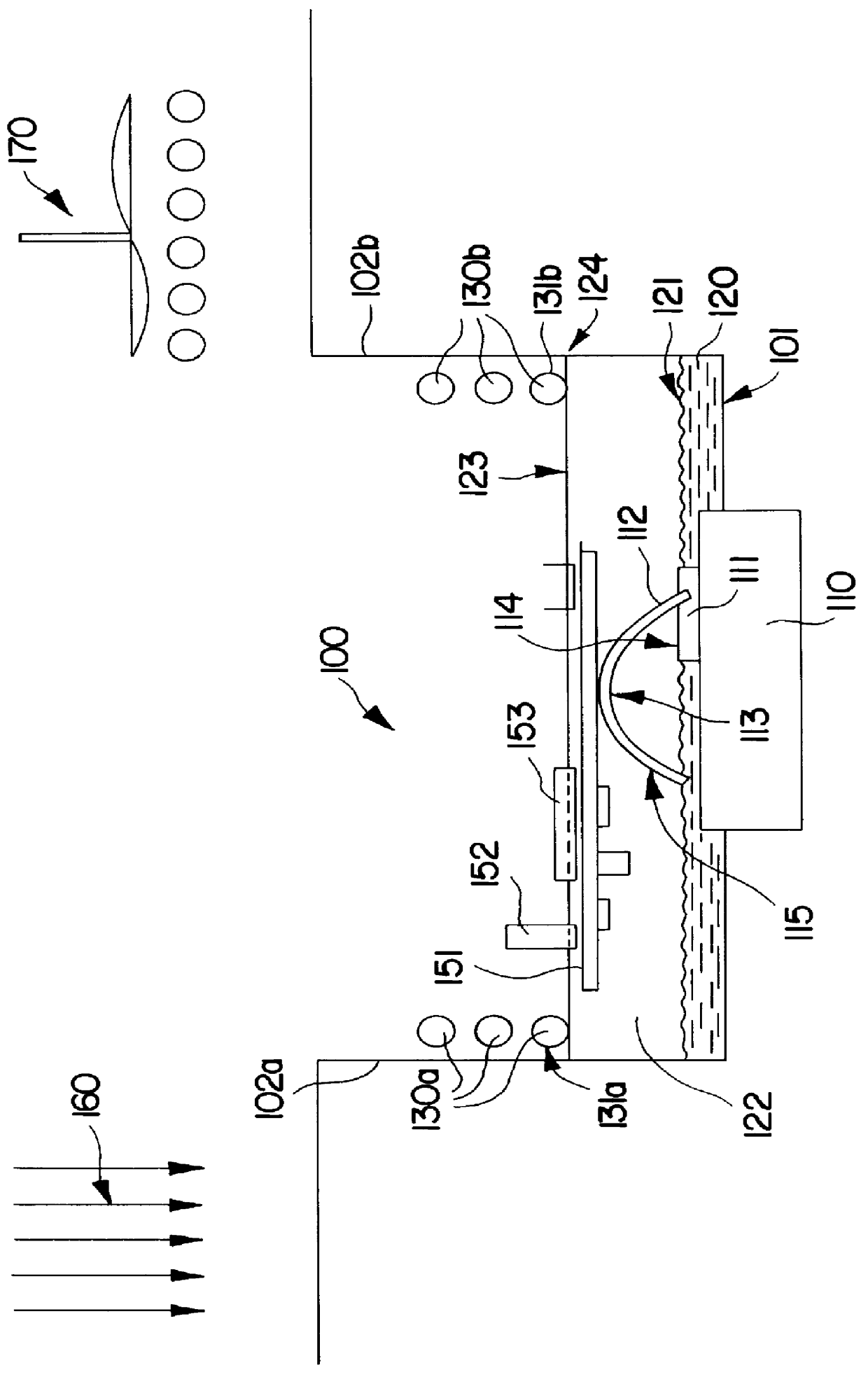

Matrix-inductor soldering apparatus and device

InactiveUS6188052B1Reduce manufactured-product costQuality improvementPrinted circuit assemblingLine/current collector detailsManufacturing technologySurface mounting

A new apparatus and process for soldering surface-mount and through-hole type electronic components into a printed circuit board (PCB) in an automated fashion utilizing localized electromagnetic induction heating. Current manufacture technology for packaging electronic components depends exclusively on the reflow and wave soldering processes. Both processes heat up to relatively high temperature the entire assembly, namely its PCB and all the electronic components been soldered into it. Such high temperature environment frequently causes components damage resulting in rejects and / or demanding rework. With this invention however, during a soldering operation only the leads and pads, or joints, being soldered are heated but neither the body, or casing, of said electronic components nor the dielectric material forming said PCB are heated. Because of this selectively localized heating, the invention permits to reduce cost and improve the quality and reliability of manufactured products. This invention consumes about 200 times less energy than the reflow and wave soldering processes. Also allows in-process, and in-situ, testing of soldered joints quality thus permitting rework before final assembly of a PCB is completed. This invention also provides for an useful de-soldering apparatus.

Owner:TRUCCO HORACIO ANDRES

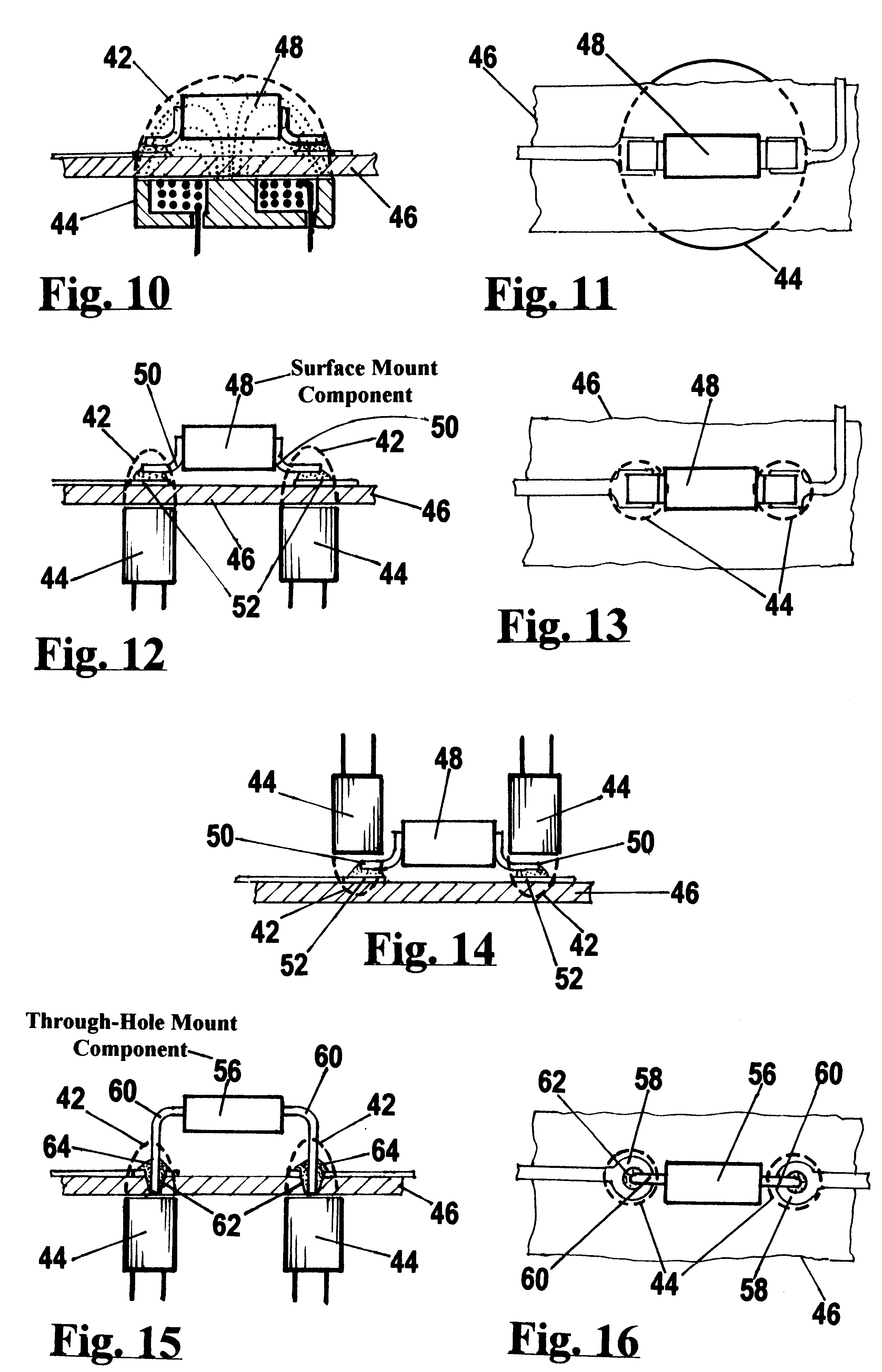

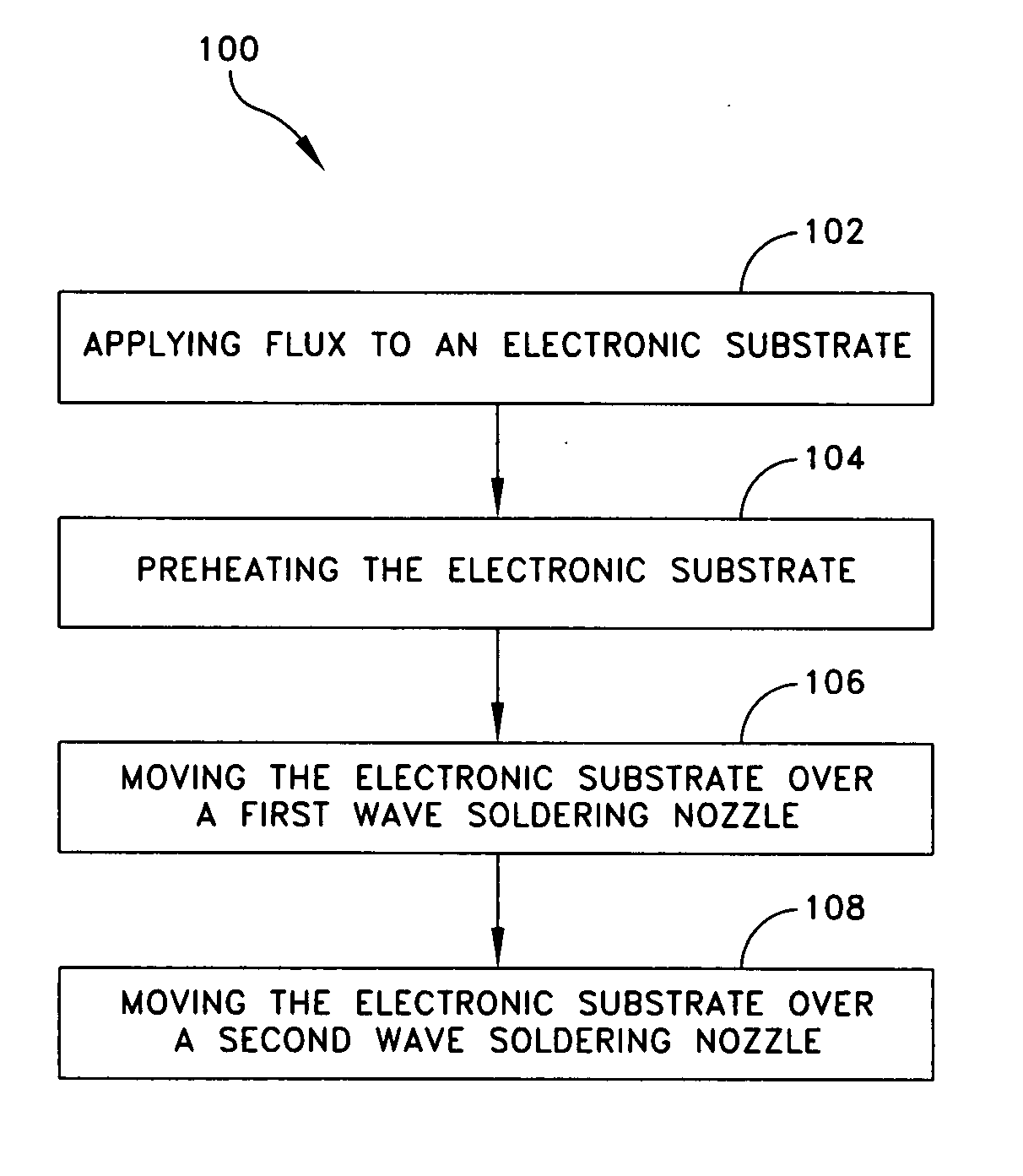

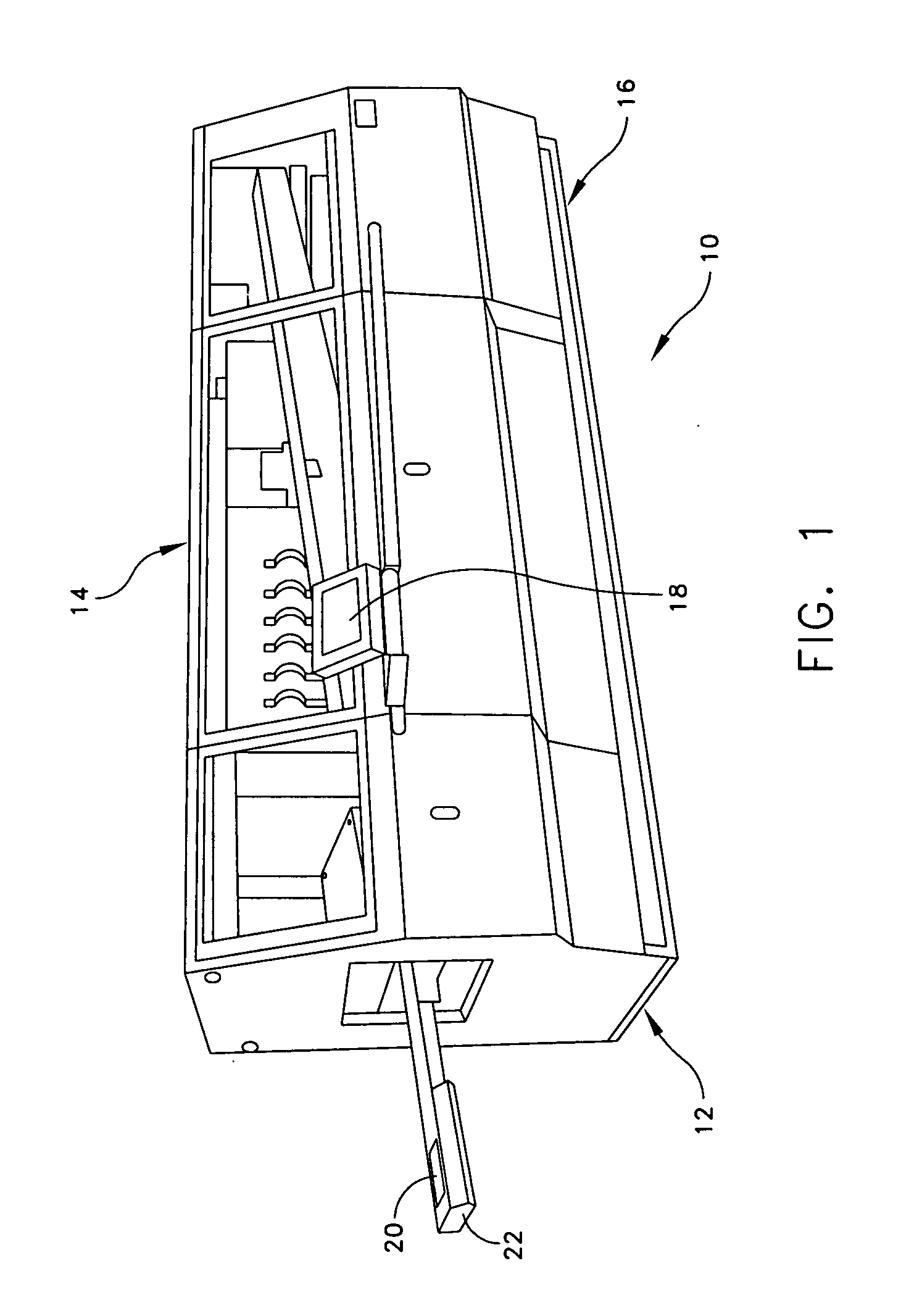

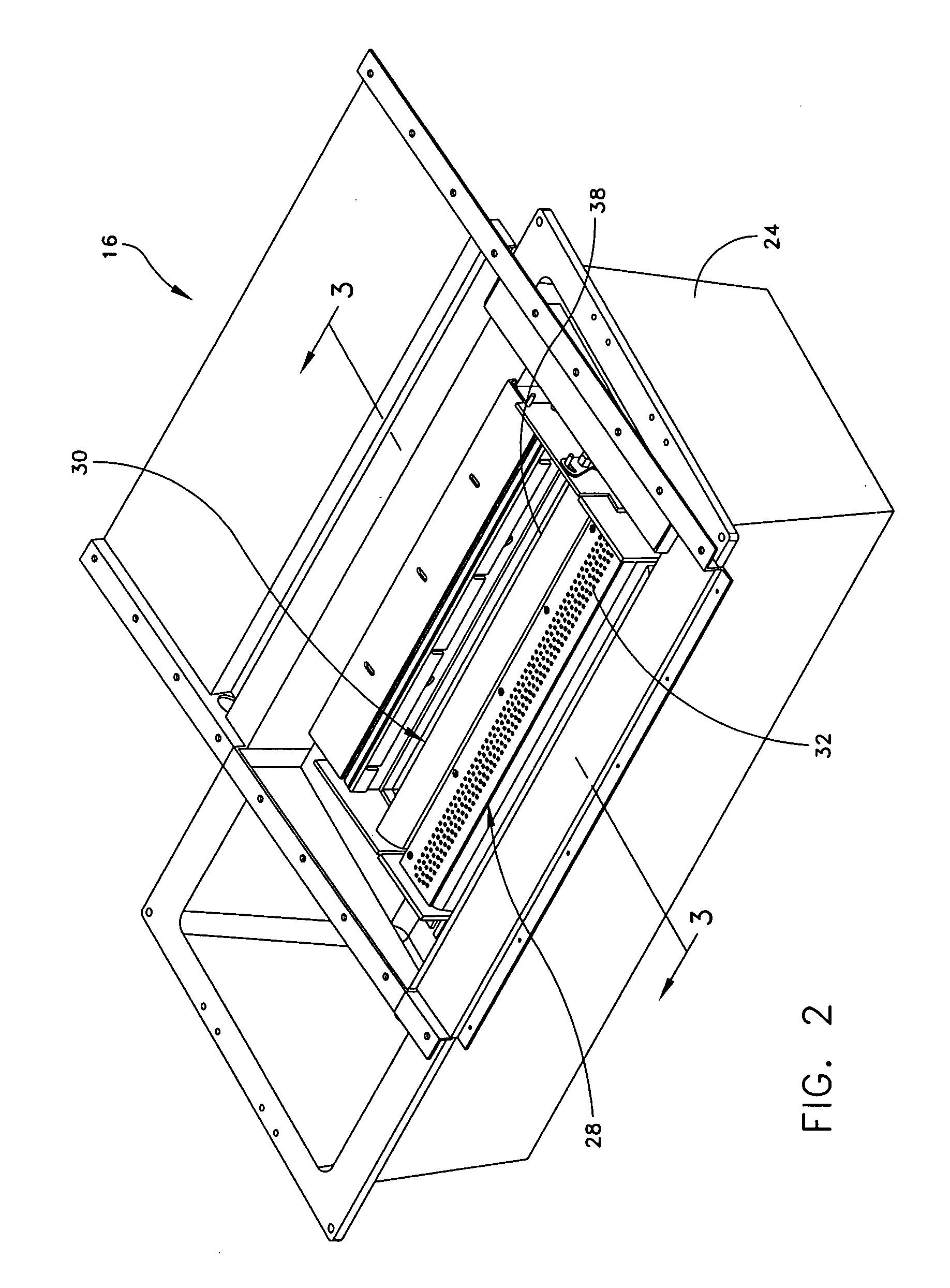

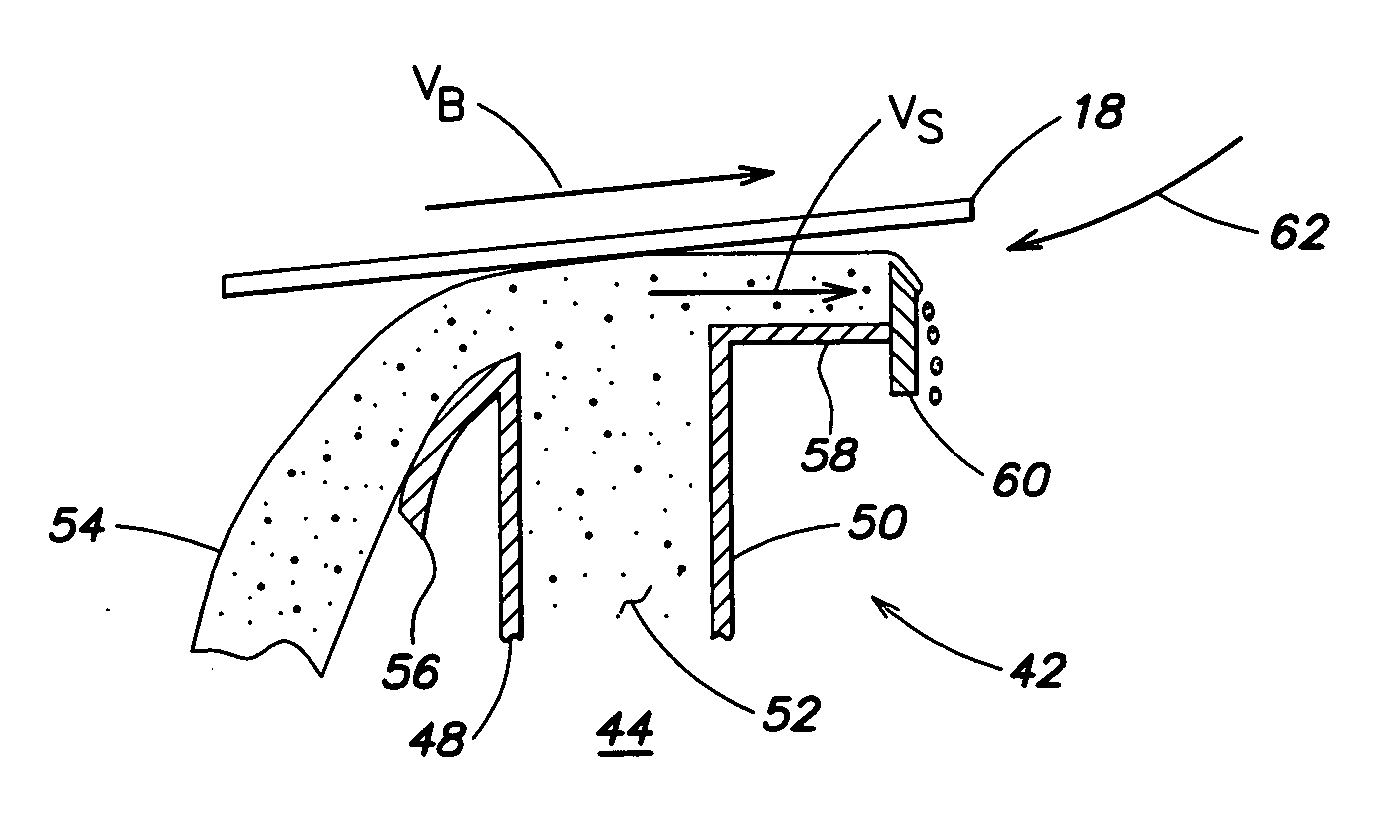

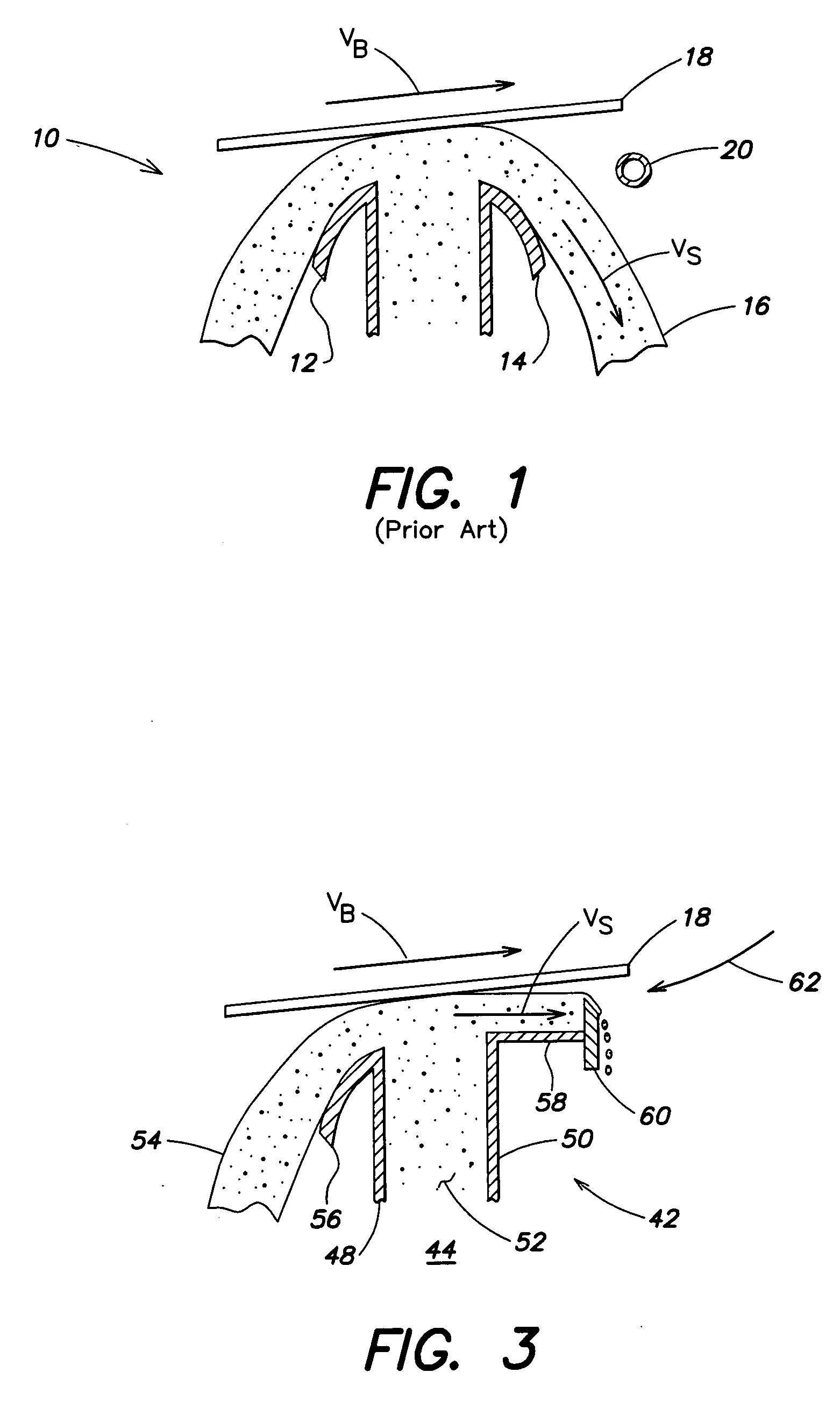

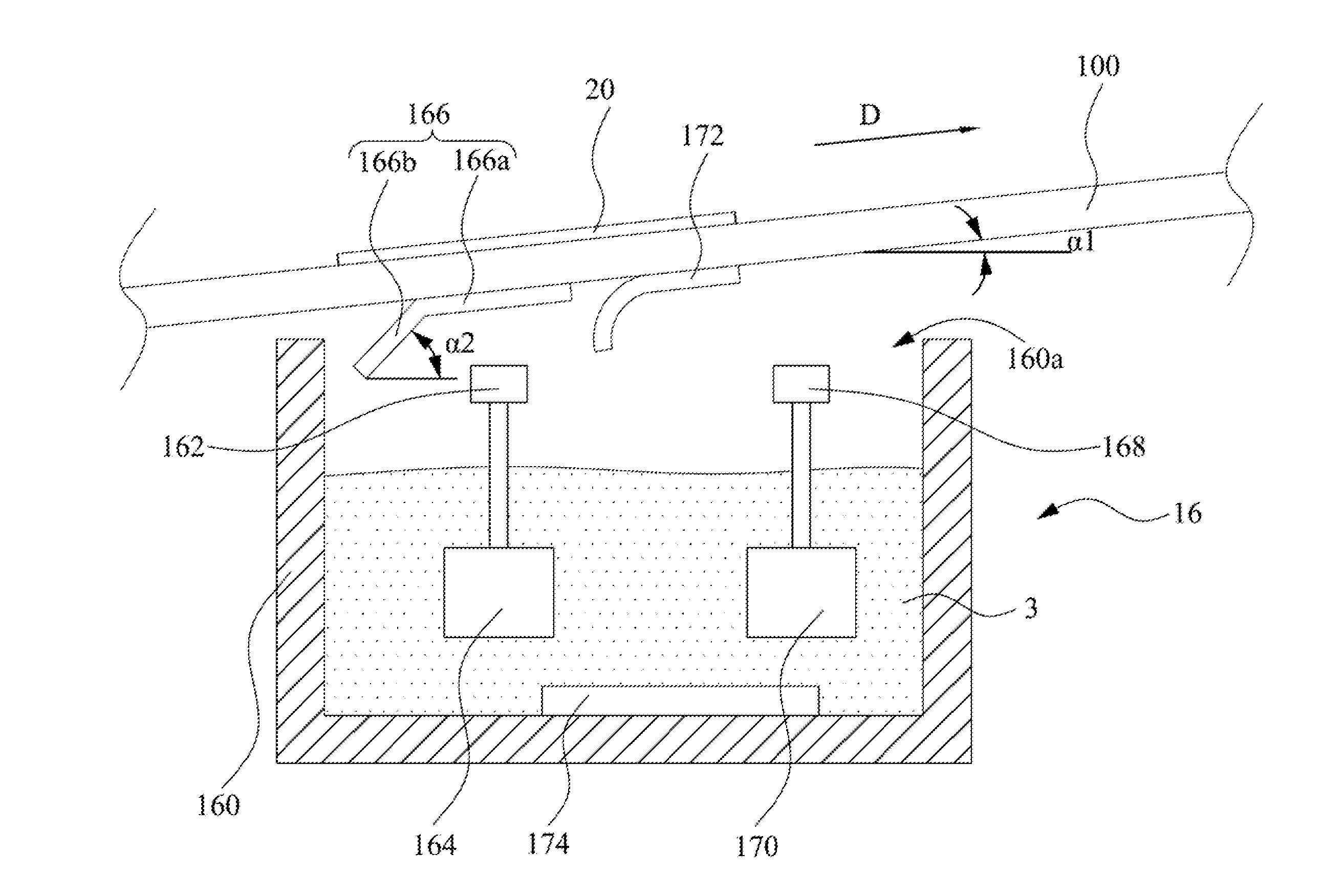

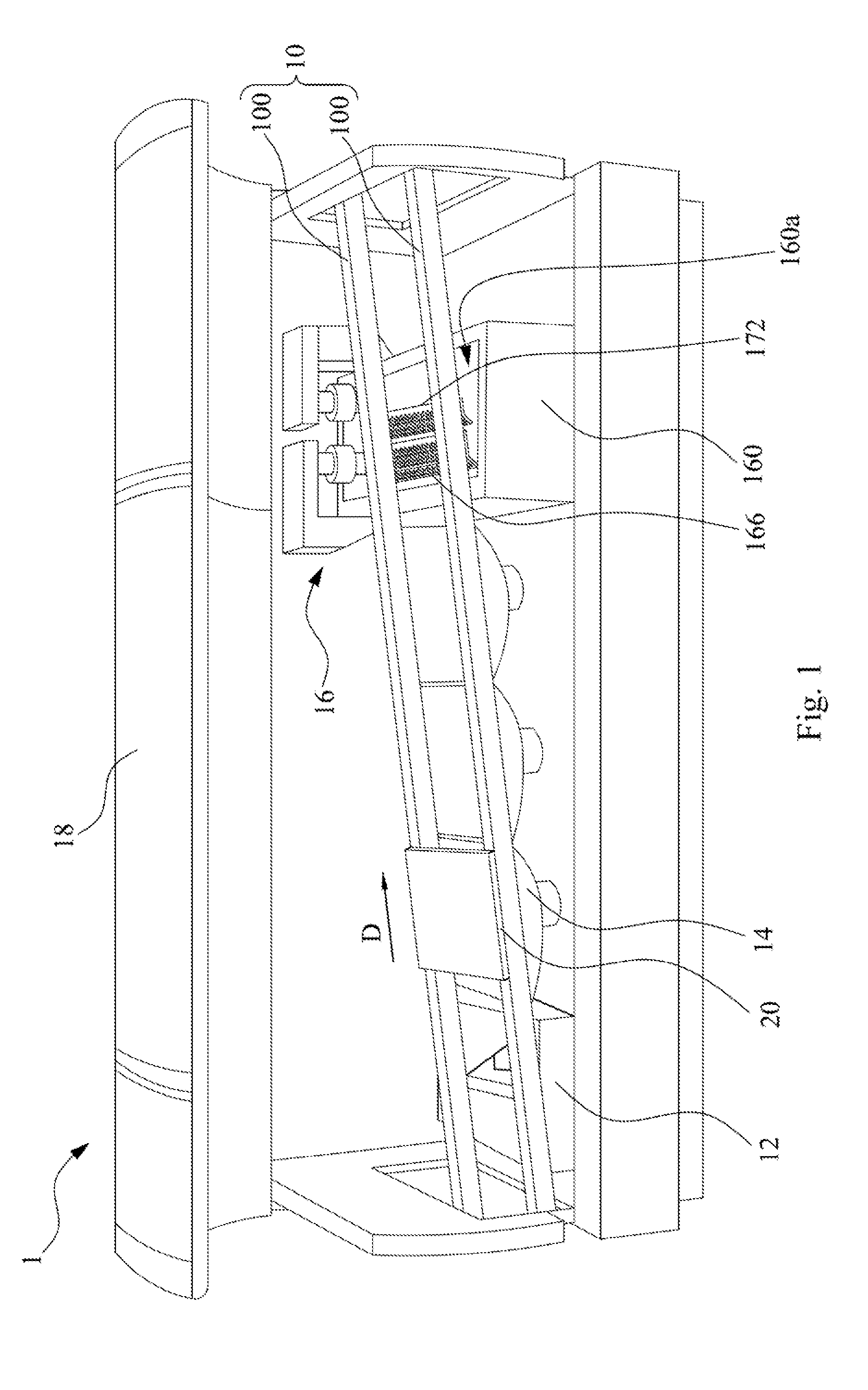

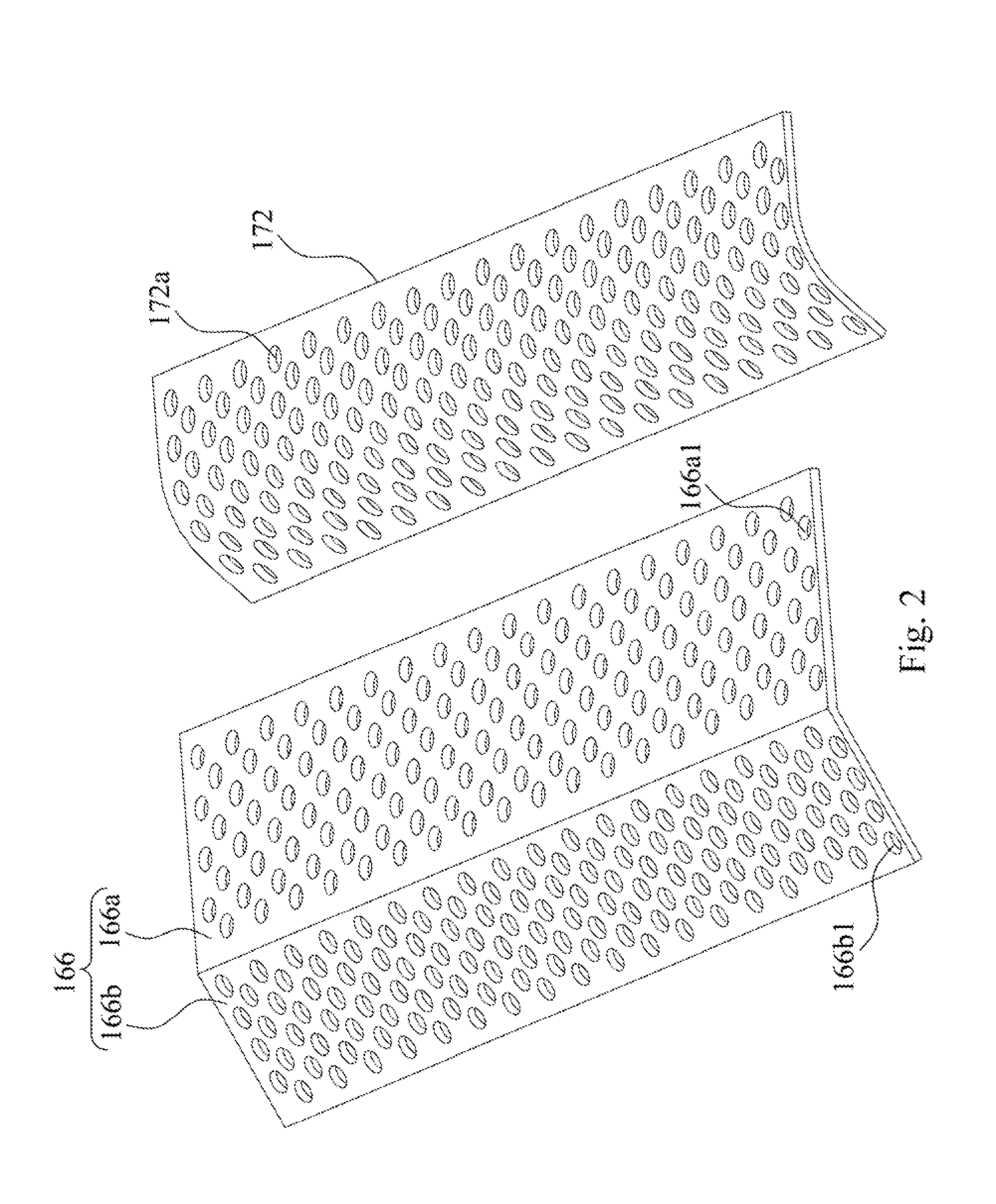

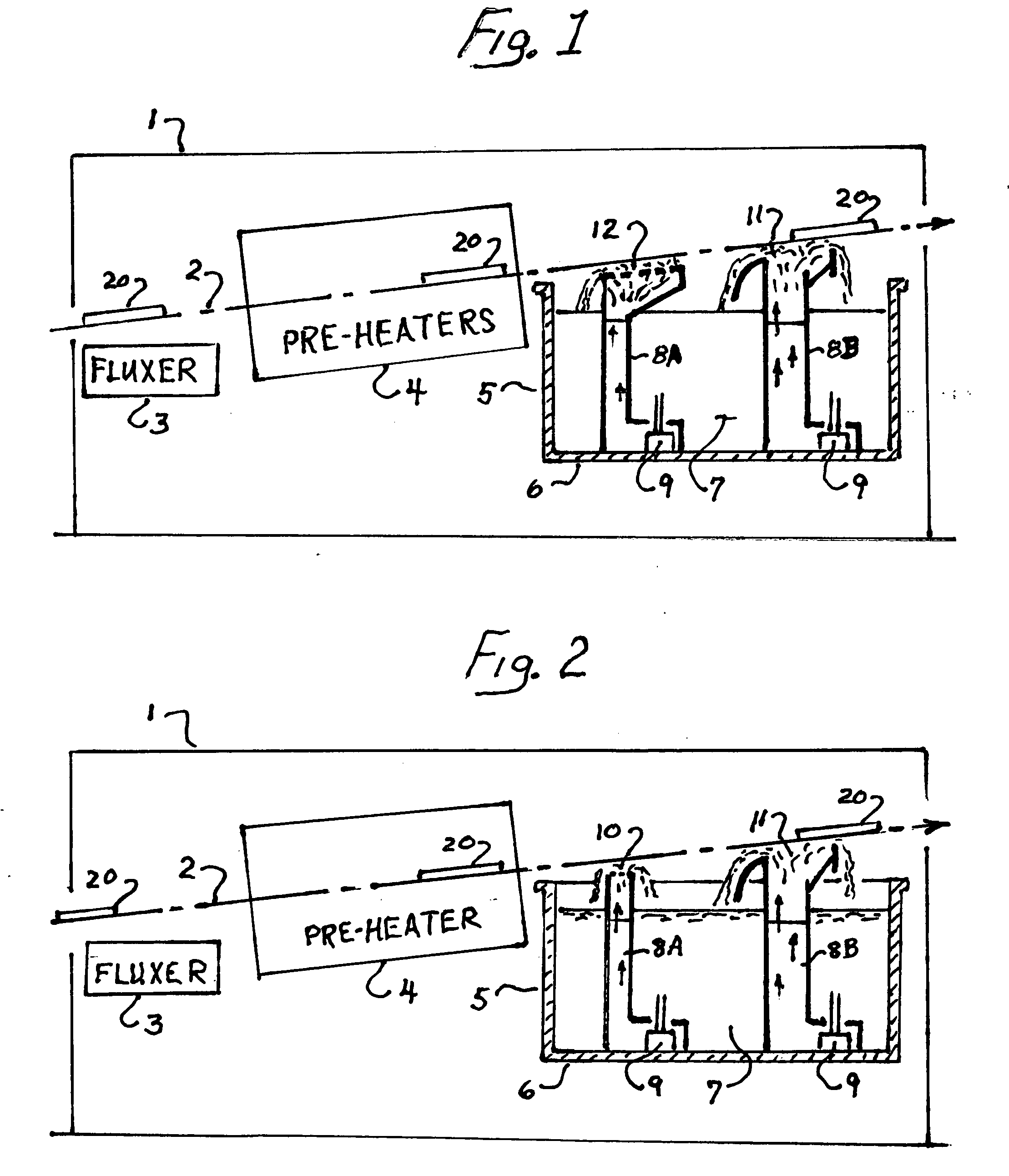

Method and apparatus for wave soldering an electronic substrate

A wave soldering apparatus includes a solder supply and a first wave soldering nozzle in fluid communication with the solder supply. The first wave soldering nozzle includes a flat plate having a plurality of square-shaped openings formed therein to generate a first solder wave. An inert system is configured to deliver an inert gas around the first solder wave. Other embodiments and methods of wave soldering are further disclosed.

Owner:ILLINOIS TOOL WORKS INC

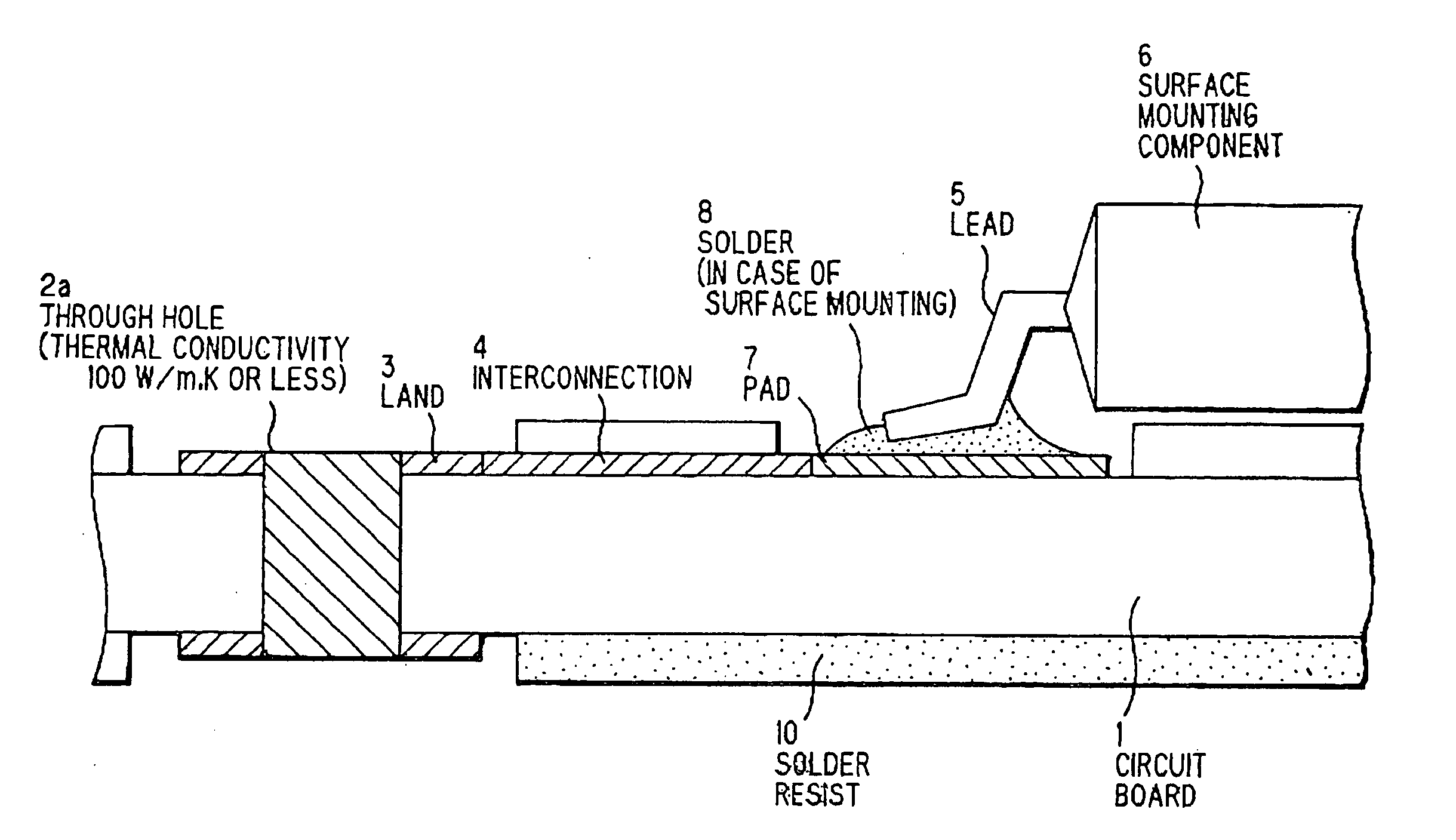

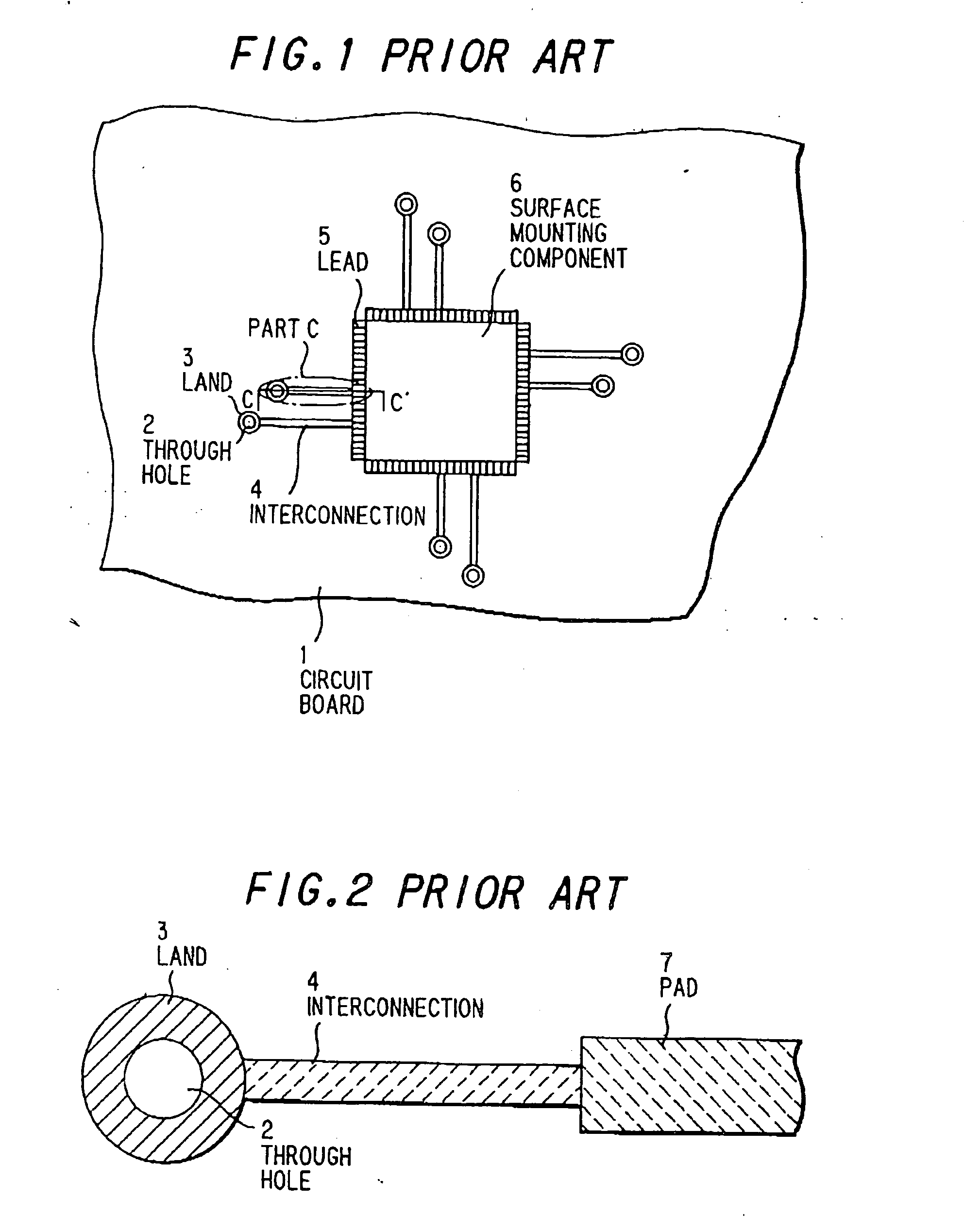

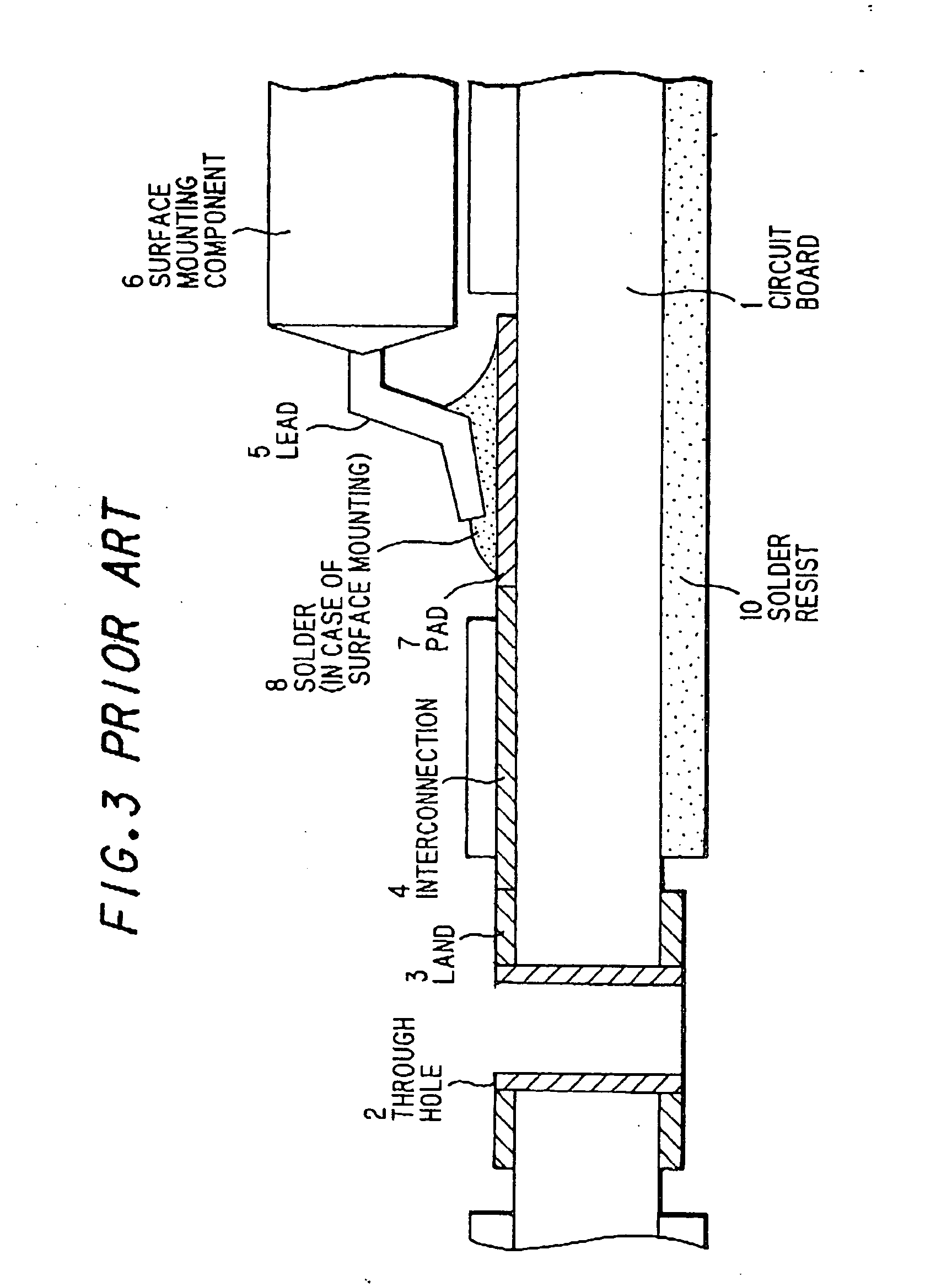

Circuit board, circuit board mounting method, and electronic device using the circuit board

A through hole 2 in a circuit board 1 and to be joined to a lead 5 in a surface mounting component 6 is prepared from a material such as nickel, and palladium having a thermal conductivity equal to or less than 100 W / m.K, the circuit board 1 involving a alloy layer composed of at least a member selected from elements of solder 8, a pad 7, and the lead 5 in a solder joined site of the lead 5 and the pad 7, whereby a quantity of heat transmitted to the joined site via the through hole 2 is reduced at the time when wave-soldering is applied to the back of the circuit board 1 after the surface mounting component 6 was mounted, so that the joined site is maintained at a temperature equal to or less than a melting point of the alloy layer, and hence, exfoliation in an interface of the joined site is prevented, and reliability in the joint of the lead 5 and the pad 7 is elevated.

Owner:NEC CORP

Dual additive soldering

Soldering with lead-free alloys is enhanced by use of two additives to a molten solder bath. One additive is an oxygen barrier fluid that floats on or envelops a bath. Another additive is an oxygen or metal oxide scavenger in the bath. Exemplary scavengers include metals with a higher free energy of oxide formation than oxide of tin, reducing gas, or an electrode immersed in the bath. The oxygen barrier may be an organic liquid, preferably polar in nature, which forms at least a monomolecular film over static surfaces of the bath. An exemplary soldering process is wave soldering of printed circuit boards.

Owner:MS2 TECH

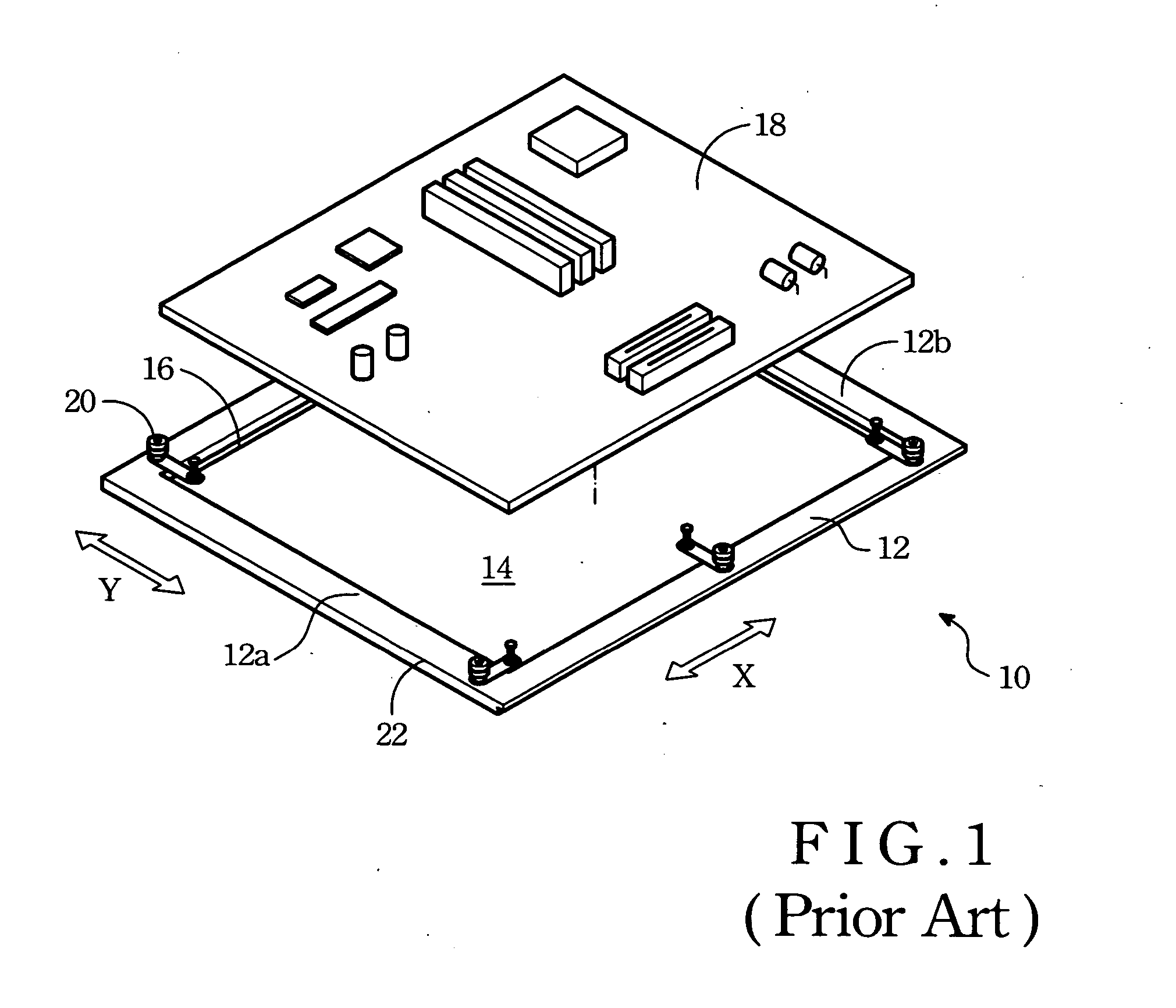

Adjustable frame fixture

InactiveUS20050067463A1Achieve fasteningWelding/cutting auxillary devicesAuxillary welding devicesTinFastener

An adjustable frame fixture aims to hold a printed-circuit board (PCB) to pass over a tin oven to process wave soldering. The fixture includes at least two side frames and at least two fasteners. The two side frames are coupled to form a holding dock. The positions of the two neighboring side frames are adjustable to form an area of different sizes to hold the PCB of different sizes. After the positions of the side frames have been adjusted, the fasteners are used to anchor and couple the side frames.

Owner:PEGATRON

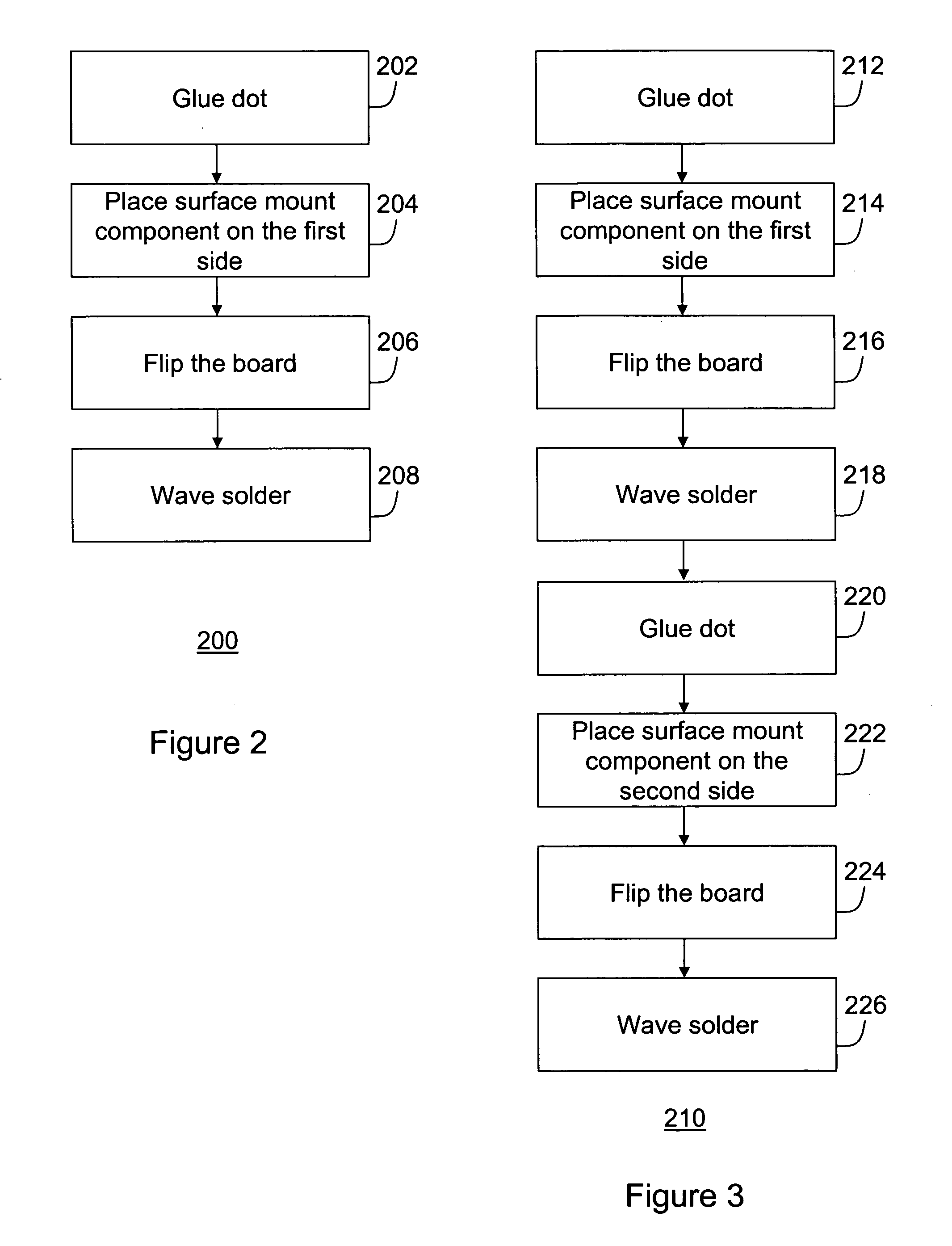

Methods and apparatus for assembling a printed circuit board

A method for manufacturing a printed circuit board includes providing a board including a plurality of electrical traces, a first surface, and a second surface opposite the first surface. The method further includes providing at least one surface mount component having a plurality of electrical terminals. The method also includes applying an adhesive on the first surface of the board, and adhering the surface mounting component to the first surface. The method also includes wave soldering the surface mount component on the first surface to the board to encapsulate at least a portion of the electrical terminals of the surface mount component with a lead-free solder.

Owner:HAIER US APPLIANCE SOLUTIONS INC

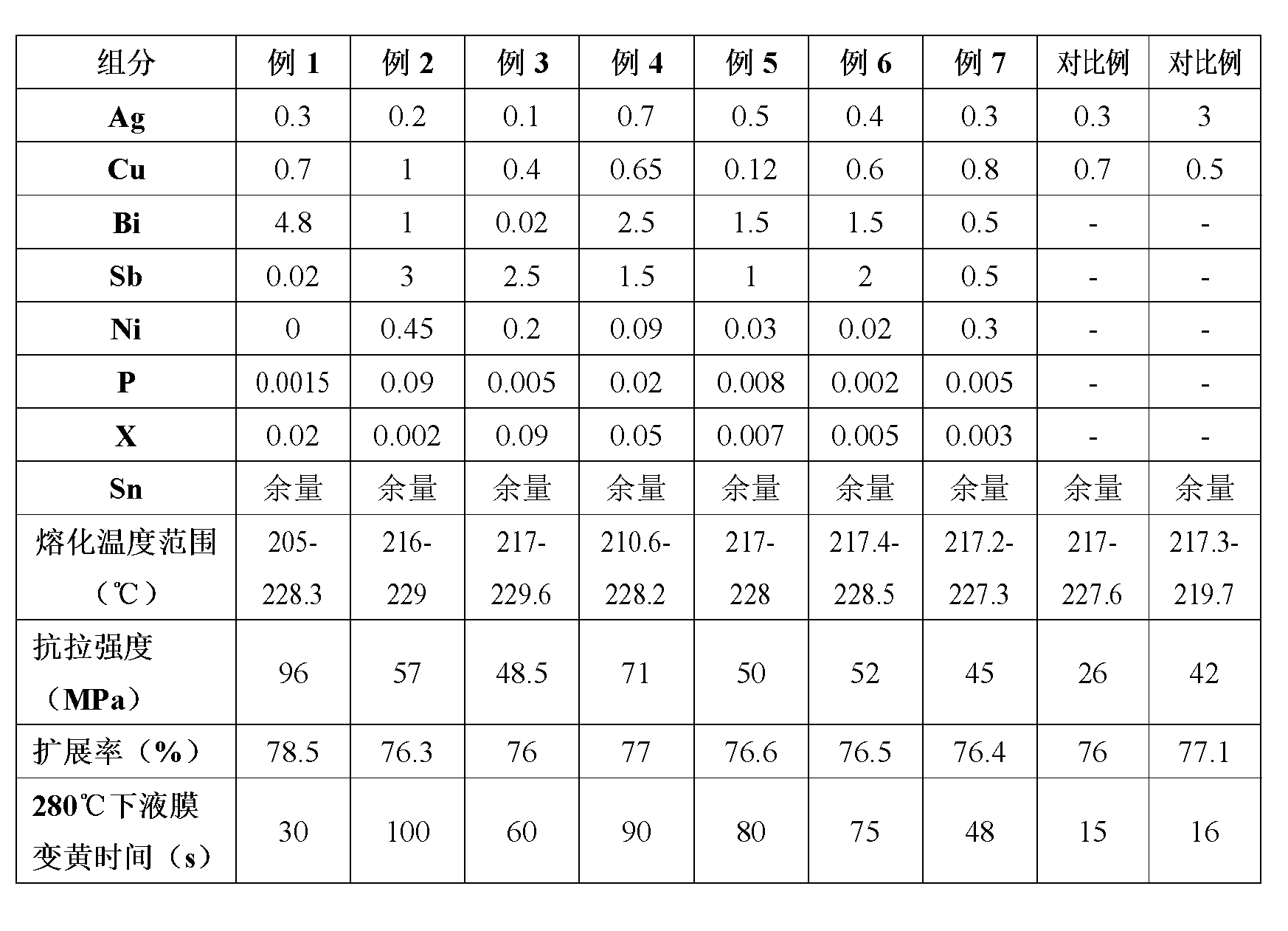

Low-silver lead-free soft solder

InactiveCN102699563ALow costImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaMisch metalRare earth

The invention discloses a low-silver lead-free soft solder, which is moderate in melting point, strong in tensile strength and low in cost. Based on the total weight of the solder, the solder contains 0.1 to 0.7 weight percent of Ag, 0.1 to 1.0 weight percent of Cu, 0.01 to 5 weight percent of Bi, 0.01 to 3 weight percent of Sb, 0 to 0.5 weight percent of Ni, 0.001 to 0.1 weight percent of P, 0.001 to 0.1 weight percent of X and the balance of Sn, wherein X is any one or combination of Ga, Ge and misch metal. The low-silver lead-free soft solder is applied to wave soldering, reflow soldering and manual soldering in the field of electronic and microelectronic packaging.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

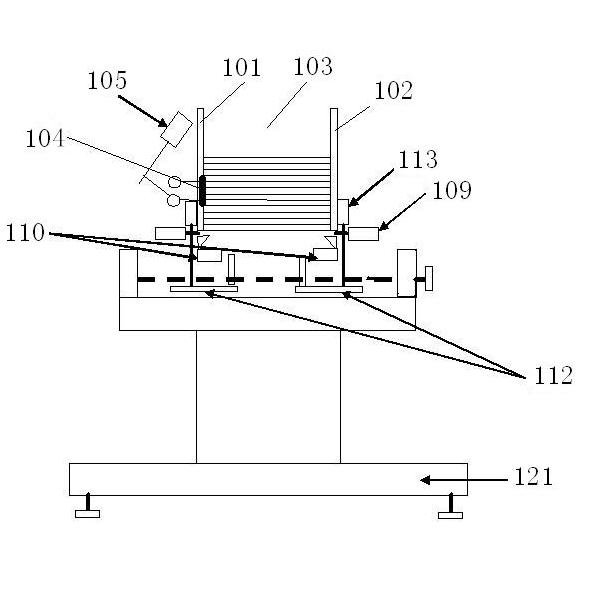

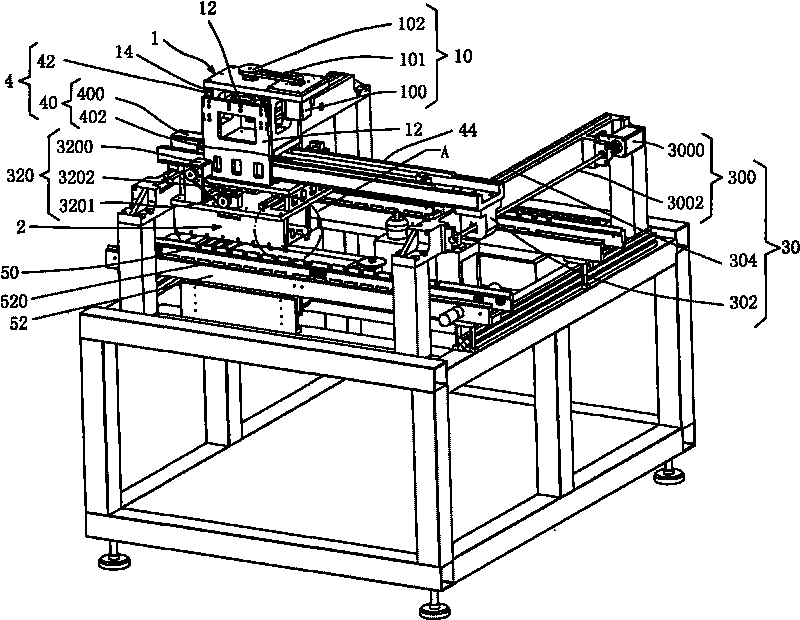

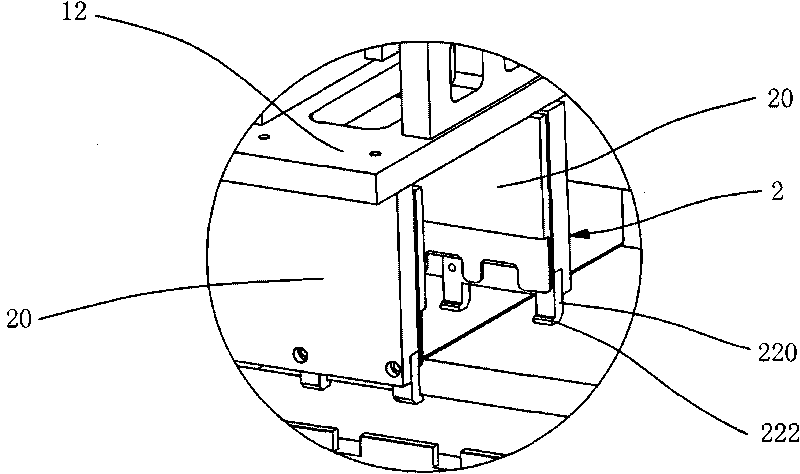

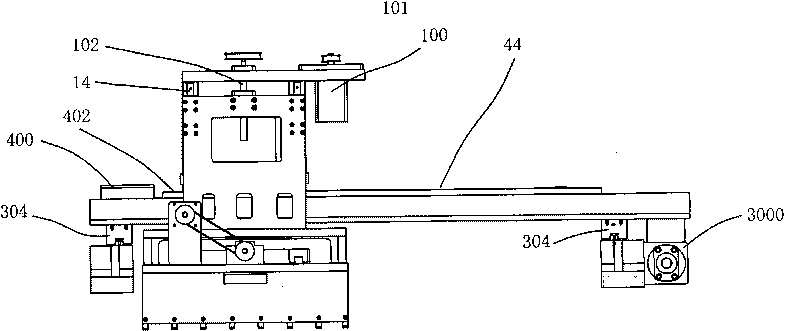

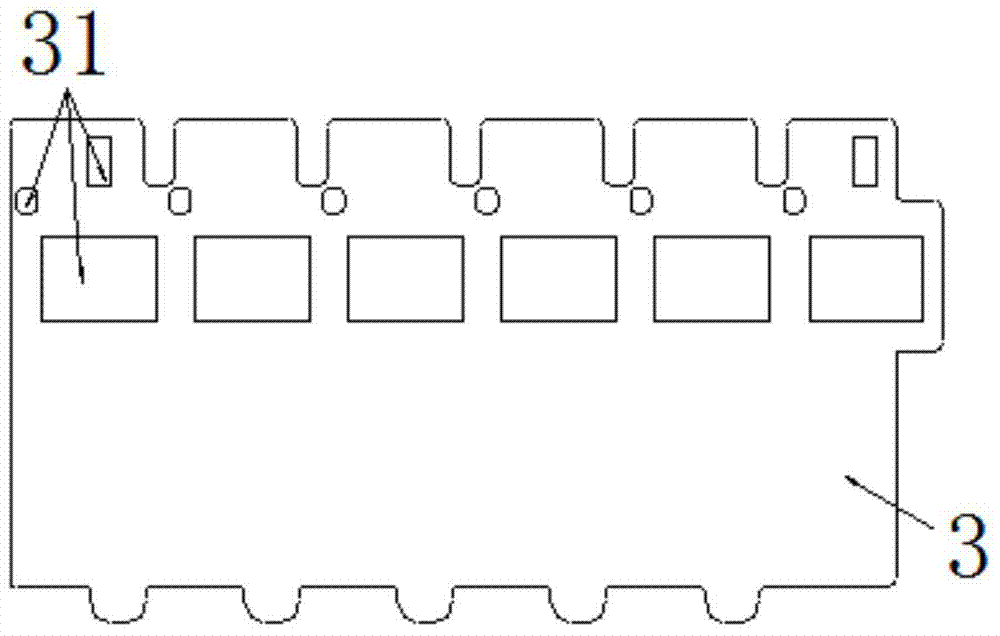

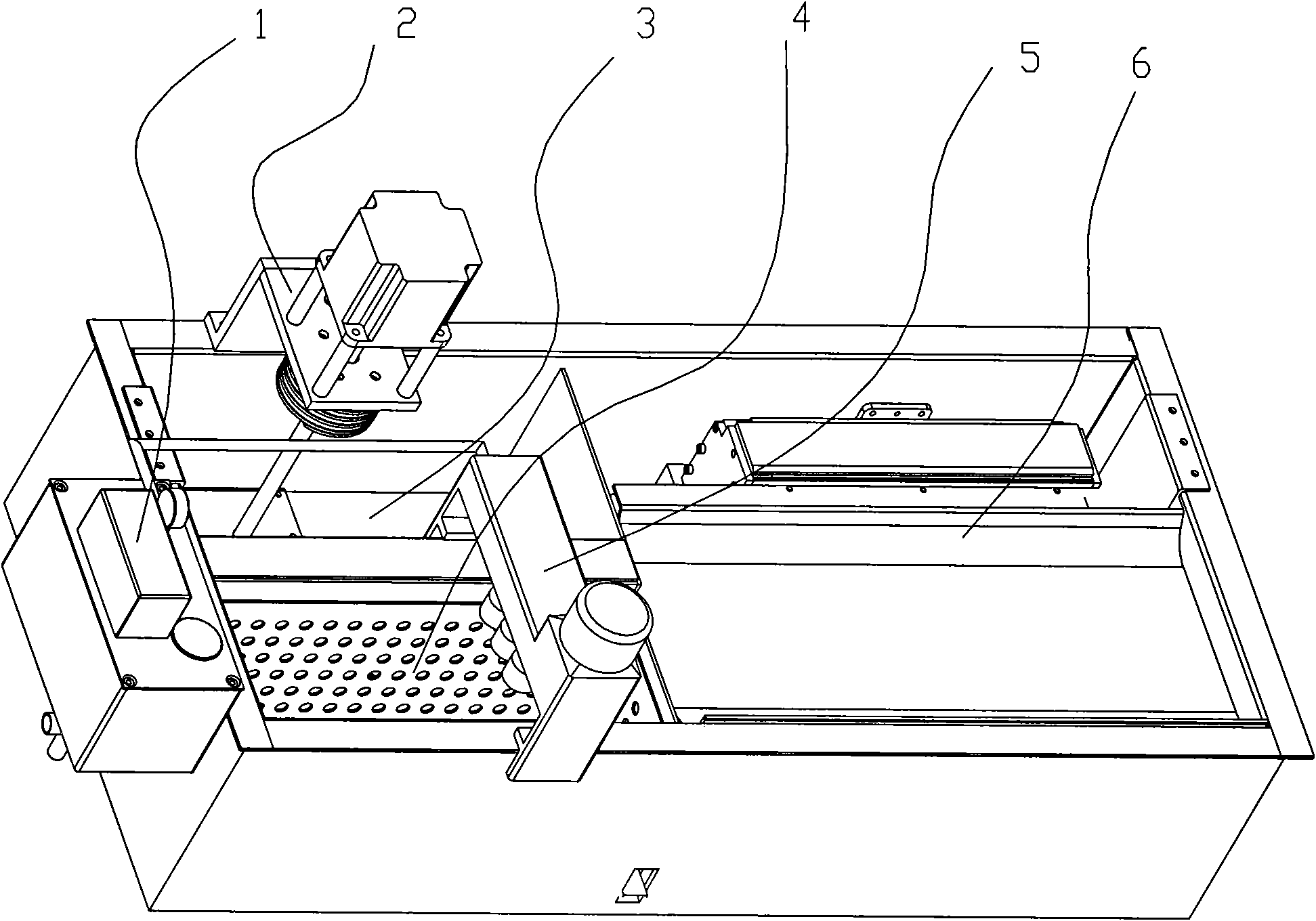

Wave-soldering unit and mechanical gripper thereof

InactiveCN101700593AWill not deformWon't hurtPrinted circuit assemblingGripping headsEngineeringGrippers

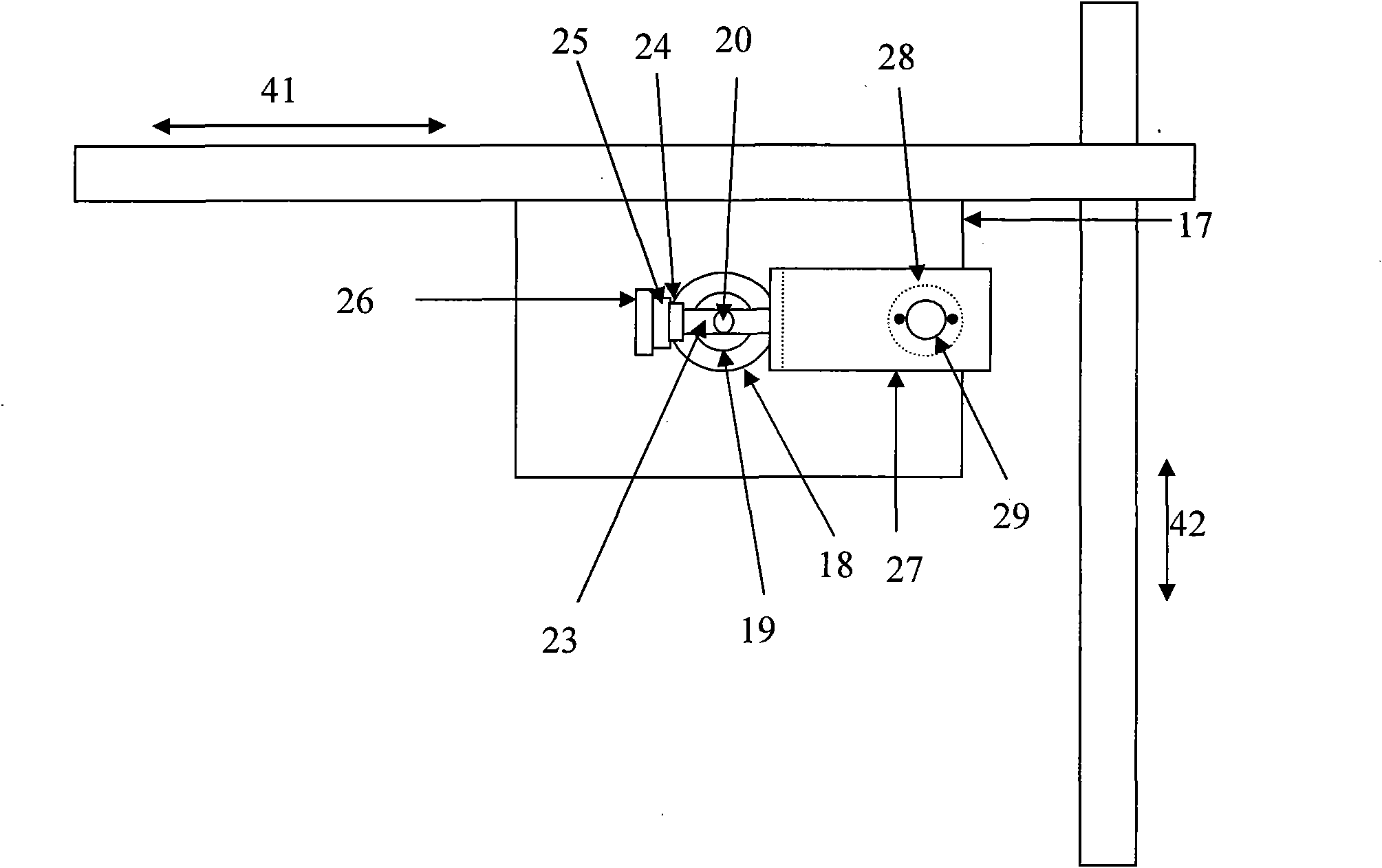

The invention relates to a mechanical gripper of a wave-soldering unit, comprising a lifting displacement device, and a pair of gripper bodies driven by the lifting displacement device to lift and an opening-closing system used for driving the gripper bodies to realize the opening-closing movement, wherein the lifting displacement device comprises a lifting power mechanism and a lifting substrate driven by the lifting power mechanism to lift along a lifting shaft; the two gripper bodies are arranged over against each other; each gripper body comprises a base and a pawn extending towards the direction of another gripper body from the bottom edge of the base so as to support a workpiece from the bottom. The pawn of the mechanical gripper is utilized to support the workpiece from the bottom of the workpiece when the mechanical gripper grabs the workpiece; and due to the fact that the workpiece does not need to be clamped from the edge of the workpiece, the workpiece can not deform or is damaged due to clamping force.

Owner:深圳市诺斯达科技有限公司

Wave solder nozzle

InactiveUS20060186183A1High trafficImproving flow of solderPrinted circuit manufactureWelding/cutting media/materialsAtmosphereSolder material

A wave solder nozzle is capable of delivering solder material to perform a wave soldering operation on a printed circuit board in an inert atmosphere. The wave solder nozzle includes a front plate and a back plate coupled to the front plate. The front plate and the back plate define a channel through which solder material flows. The nozzle further includes an exit trough extending from the back plate. The exit trough has a weir provided at one end of the exit trough. The exit trough is constructed and arranged to control the flow of solder material from the wave solder nozzle. A surface of the exit trough is wettable to improve the flow of solder material out of the wave solder nozzle. A method of improving the flow of solder material through the nozzle is also disclosed.

Owner:SPEEDLINE TECH

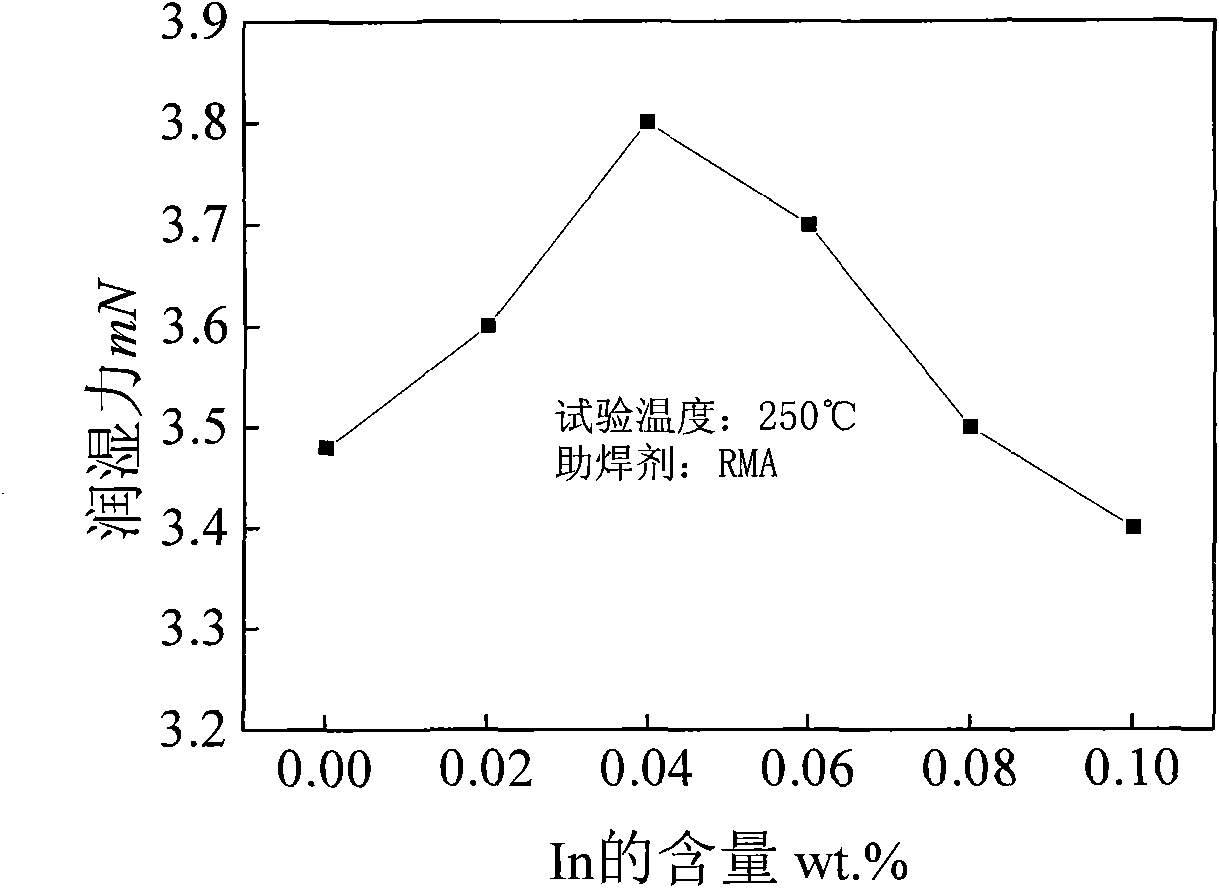

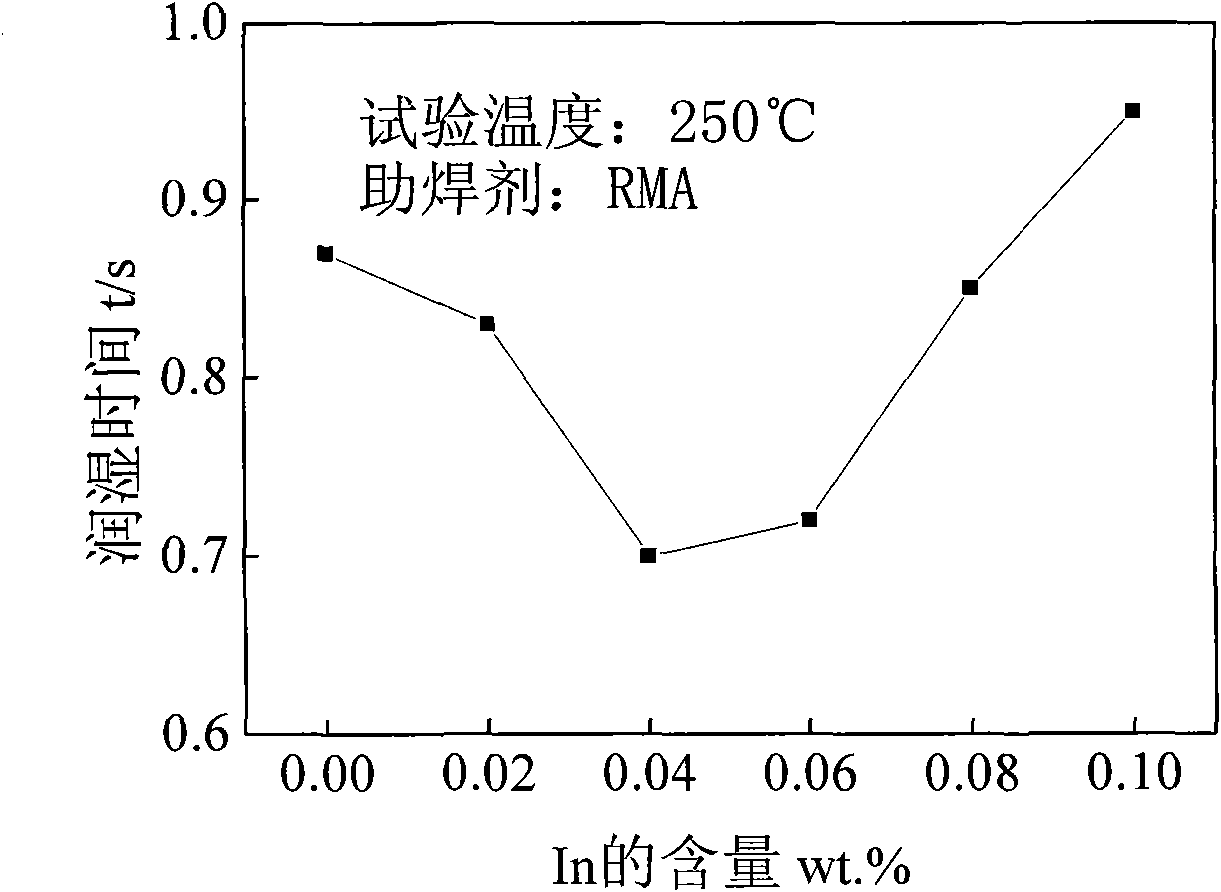

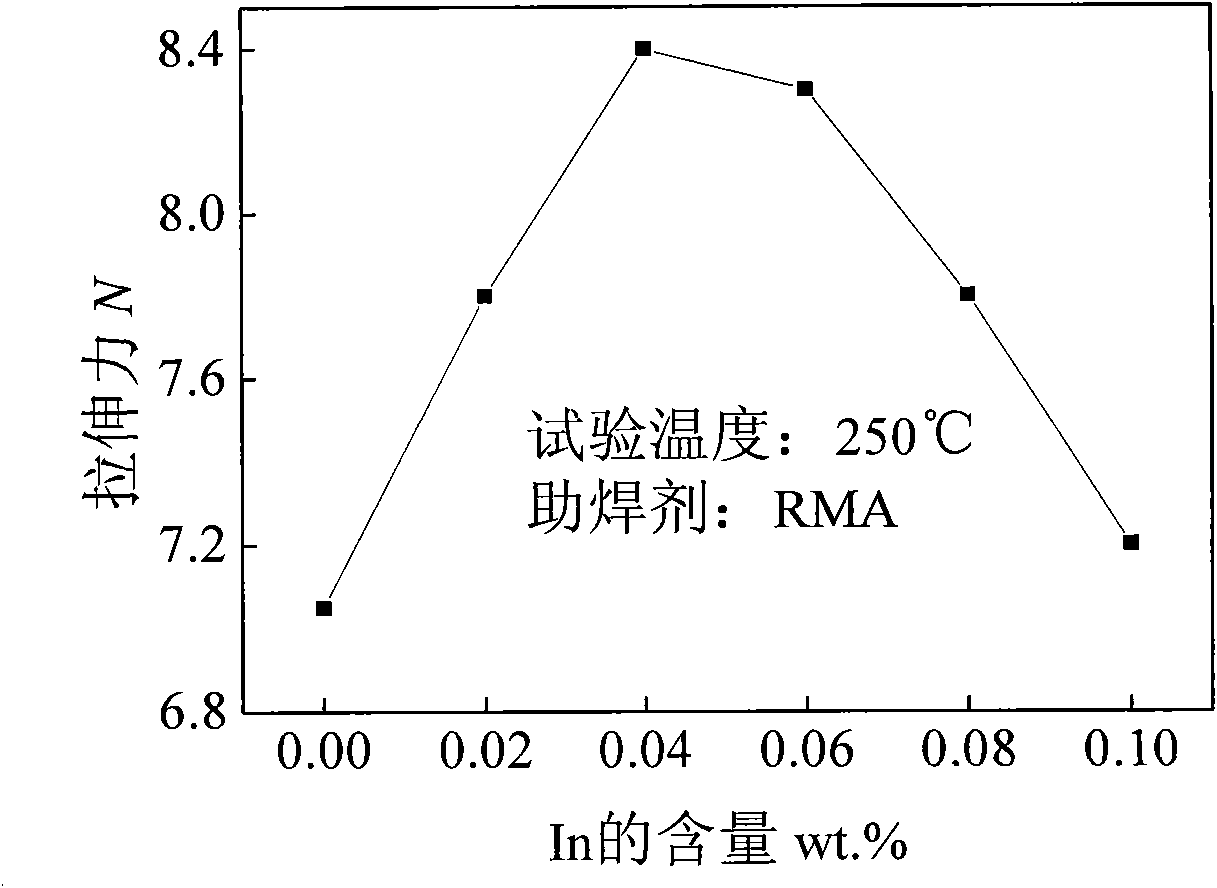

Sn-Ag-Cu lead-free solder containing Nd, Li, As and In

ActiveCN101579790AImprove wettabilityImprove creep resistanceWelding/cutting media/materialsSoldering mediaChemical compositionMetallic materials

The invention relates to a Sn-Ag-Cu lead-free solder containing Nd, Li, As and In, and belongs to soldering materials of metal materials. The solder comprises the following chemical compositions by mass percentage: 0.5 to 4.5 percent of Ag, 0.2 to 1.5 percent of Cu, 0.001 to 0.5 percent of Nd, 0.001 to 0.1 percent of Li, 0.001 to 0.1 percent of As, 0.001 to 0.1 percent of In, 0.001 to 0.1 percent of Pb, and the balance of Sn. The solder has excellent soldering performance (mainly including the wettability), and excellent mechanical property and creep resistant property, and is applicable to wave soldering, reflow soldering and other welding methods in the electronic industry.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

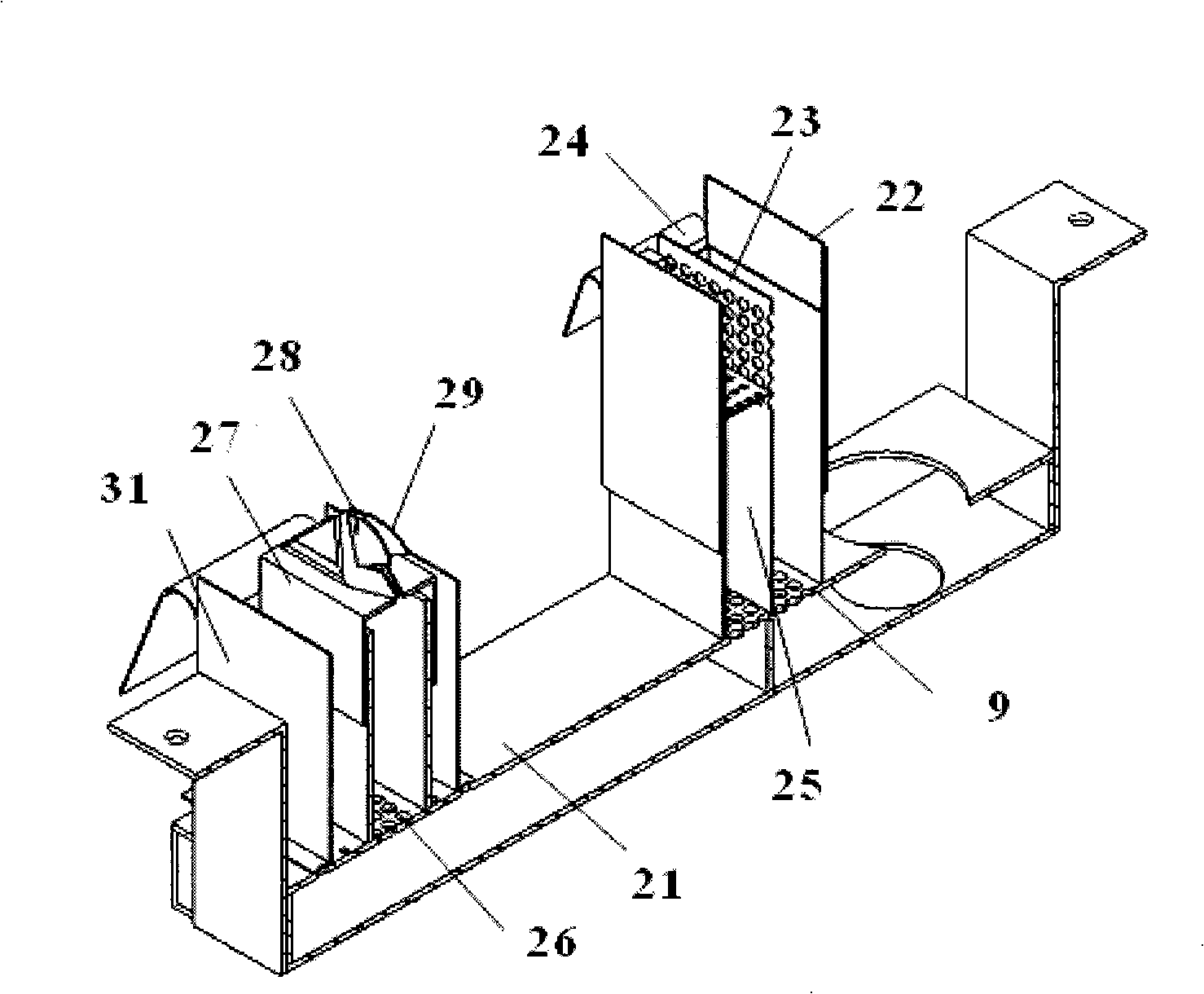

Automatic welding equipment

InactiveUS20140209661A1Reduce a phenomenon of sputtering the solderReduced impact strengthPrinted circuit manufactureSolder feeding devicesEngineeringWelding

Automatic welding equipment includes a wave soldering machine including a tank, a plurality of first nozzles, a first pump, and a first guide plate. The tank has an opening. The first nozzles and melted solder are disposed in the tank. The first pump is disposed in the tank for jetting the solder via the first nozzles. The first guide plate is located at the opening and includes a first plate portion and a second plate portion. The first plate portion is located over the first nozzles and has a plurality of first holes for passed through by the solder jetted from the first nozzles. The second plate portion, connected to the first plate portion, guides the solder to flow out of the first holes. The solder guided by the second plate portion passes through second holes of the second plate portion and returns into the tank.

Owner:INVENTEC CORP

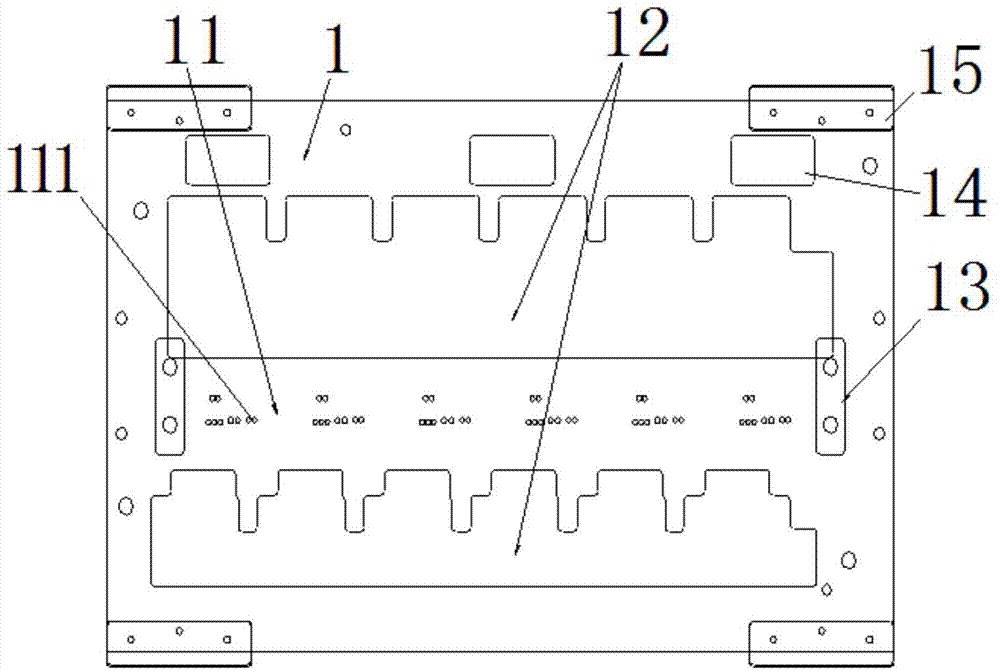

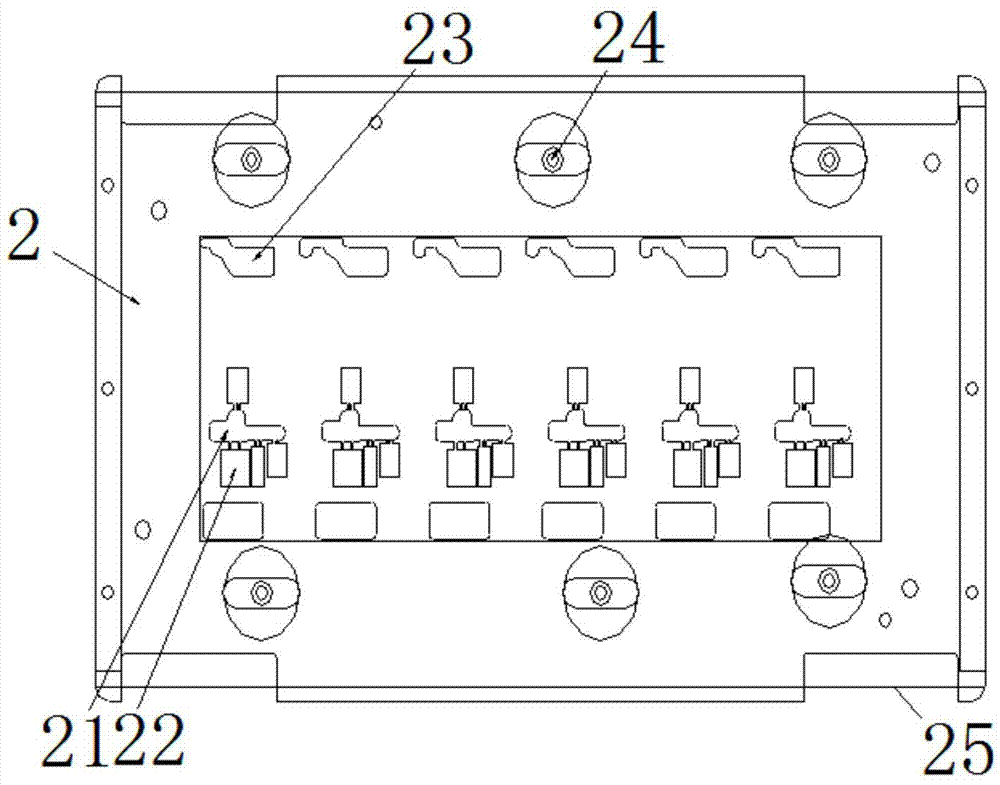

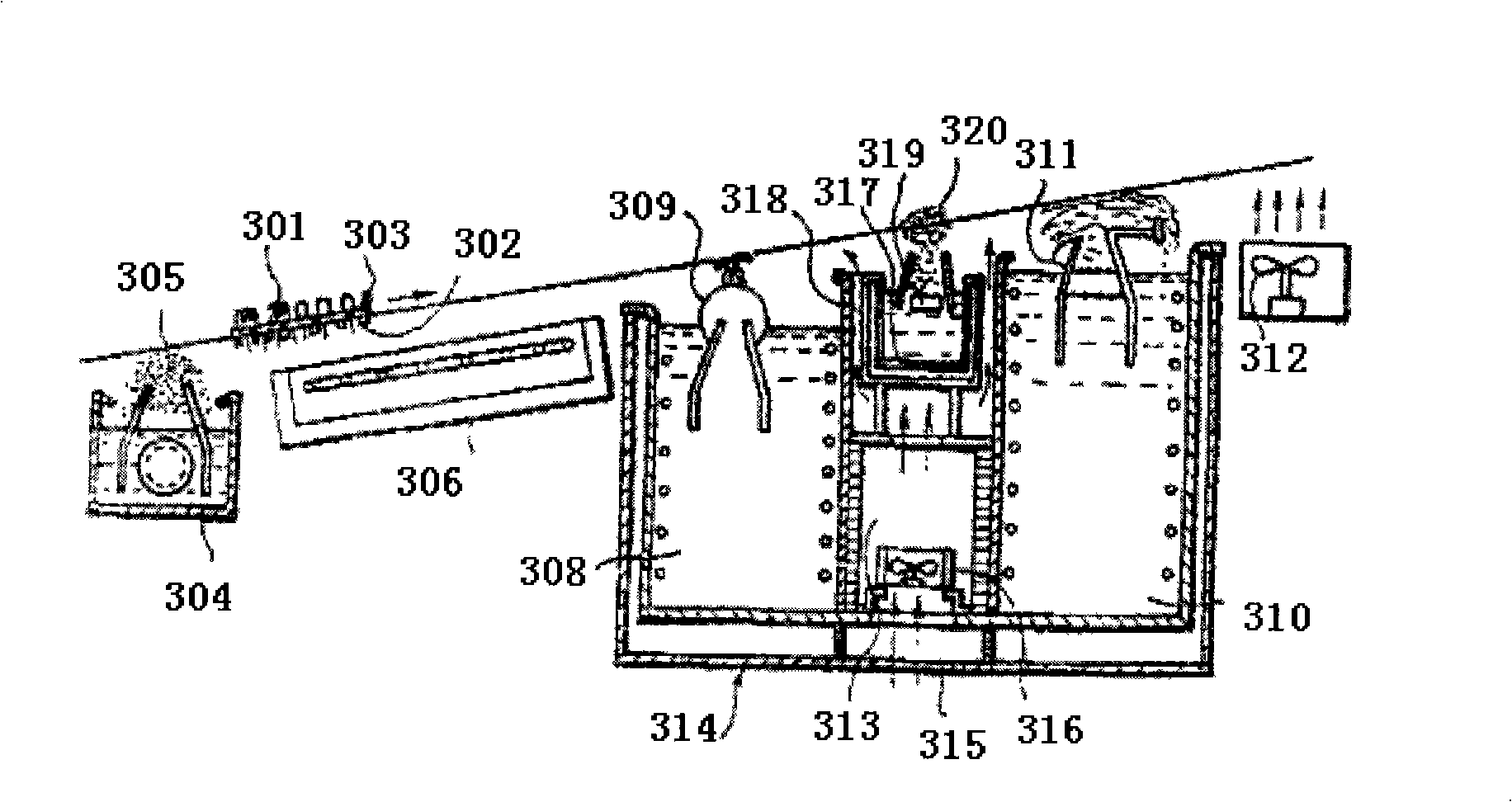

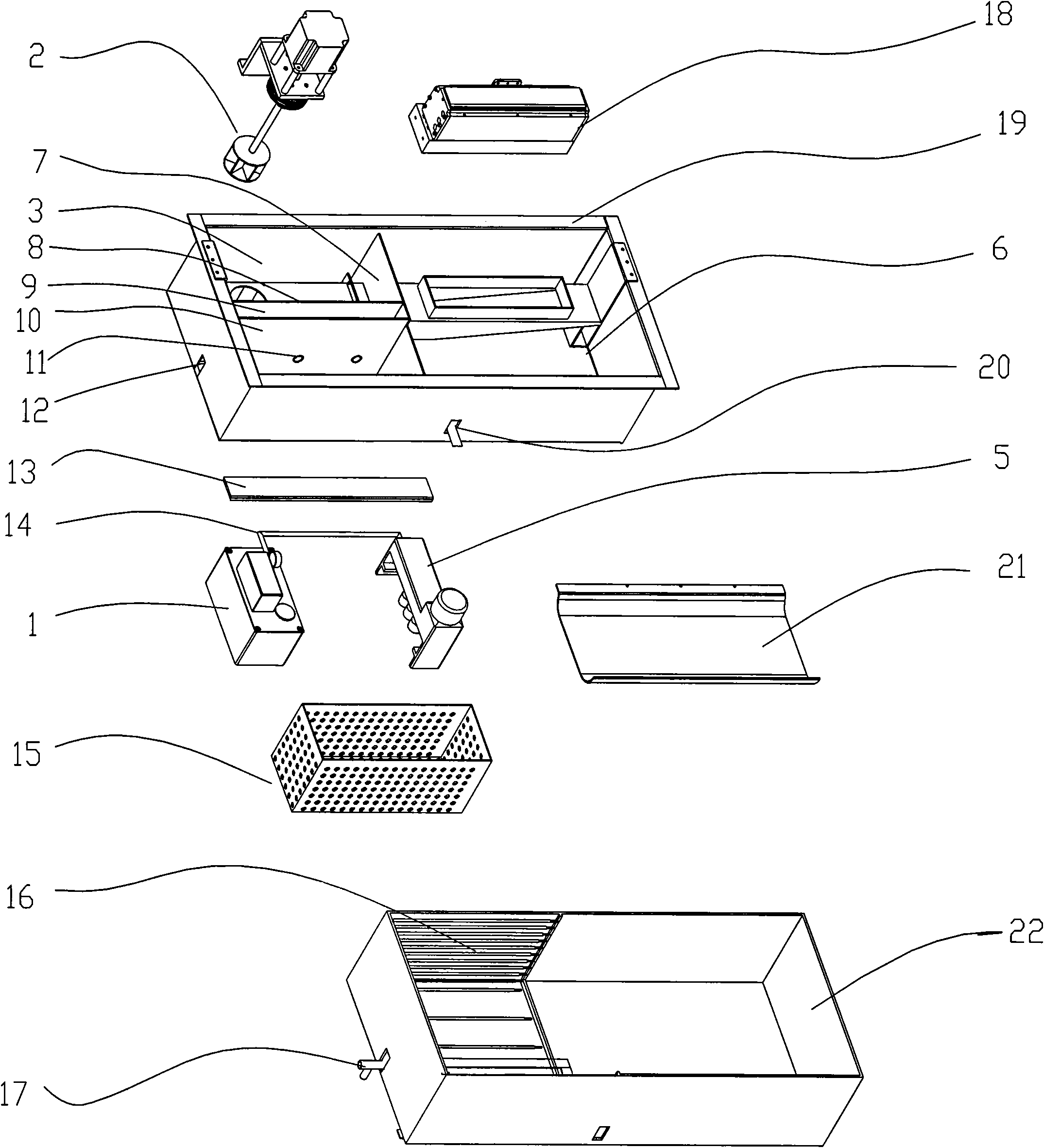

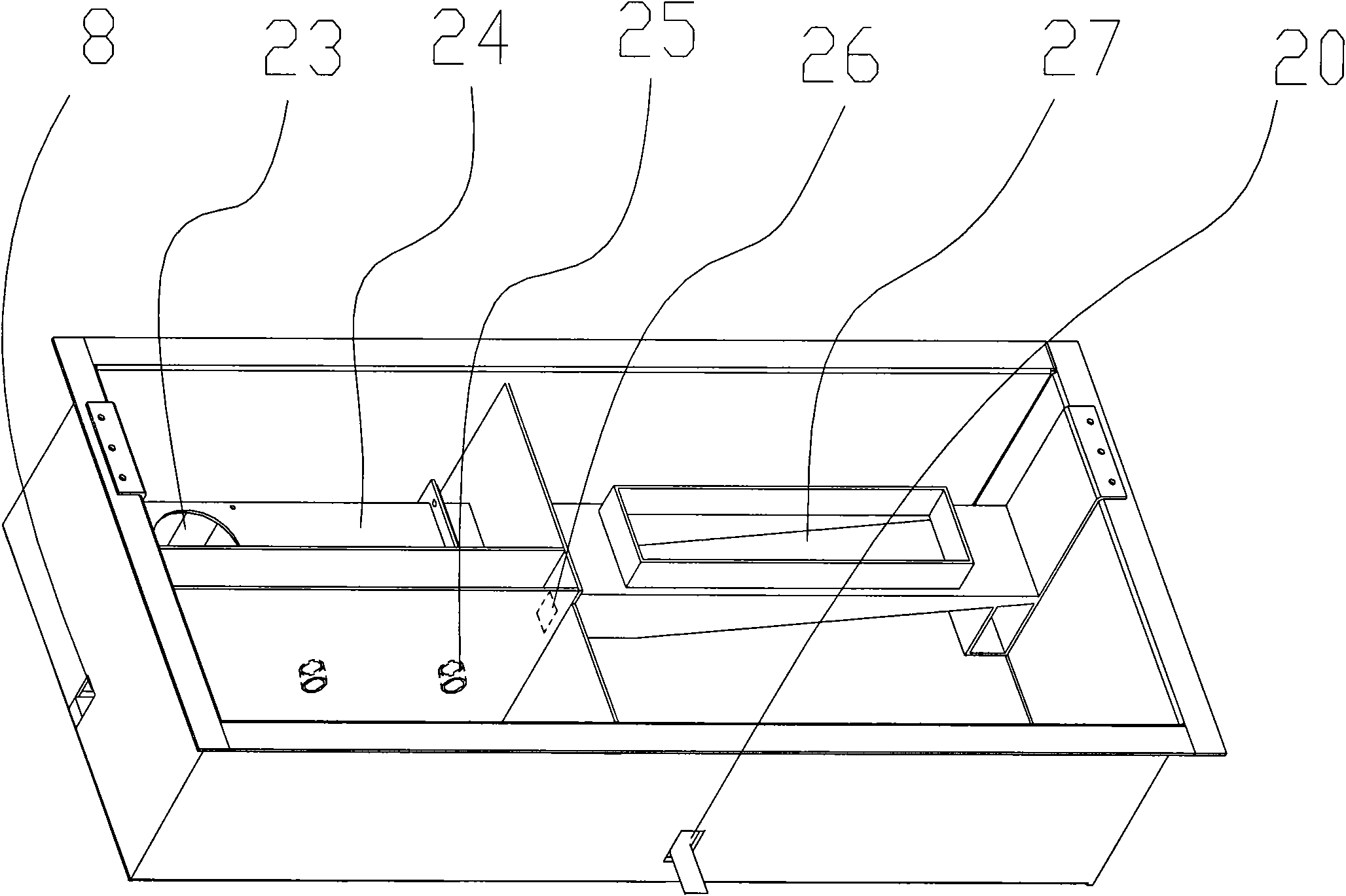

Plug-in welding process on PCB and welding carrier

ActiveCN103934537AImprove welding qualityImprove welding efficiencyPrinted circuit assemblingWelding/cutting auxillary devicesWelding processWave soldering

The invention discloses plug-in welding process on a PCB and a welding carrier. The welding process comprises the following steps: arranging the PCB on a carrier plate, wherein the board bottom of the PCB faces upwards, and the board face of the PCB faces downwards; inserting a horizontal type board bottom plug-in into the board bottom of the PCB; covering the carrier plate with the bottom plate, fixing the carrier plate to the bottom plate, covering a body of the board bottom plug-in with the bottom plate, locating a pin of the horizontal type board bottom plug-in in a welding hole in the bottom plate; turning over the carrier plate, wherein the bottom plate is below the carrier plate, inserting a board face plug-in into the board face of the PCB, extending a pin of the board face plug-in from the board bottom of the PCB, and locating the pin in a second welding hole in the bottom plate; covering the carrier plate with a cover plate, fixing the carrier plate to the cover plate, and pressing the board face plug-in through the cover plate; conducting wave-soldering at the positions of the first welding hole and the second welding hole corresponding to the board bottom of the PCB. The welding carrier comprises the carrier plate, the bottom plate and the cover plate, wherein the board face plug-in on the PCB is covered with the cover plate, and the cover plate is used for fixedly protecting the plug-in, so that the plug-in is fixed to the PCB with high quality through wave-soldering.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD

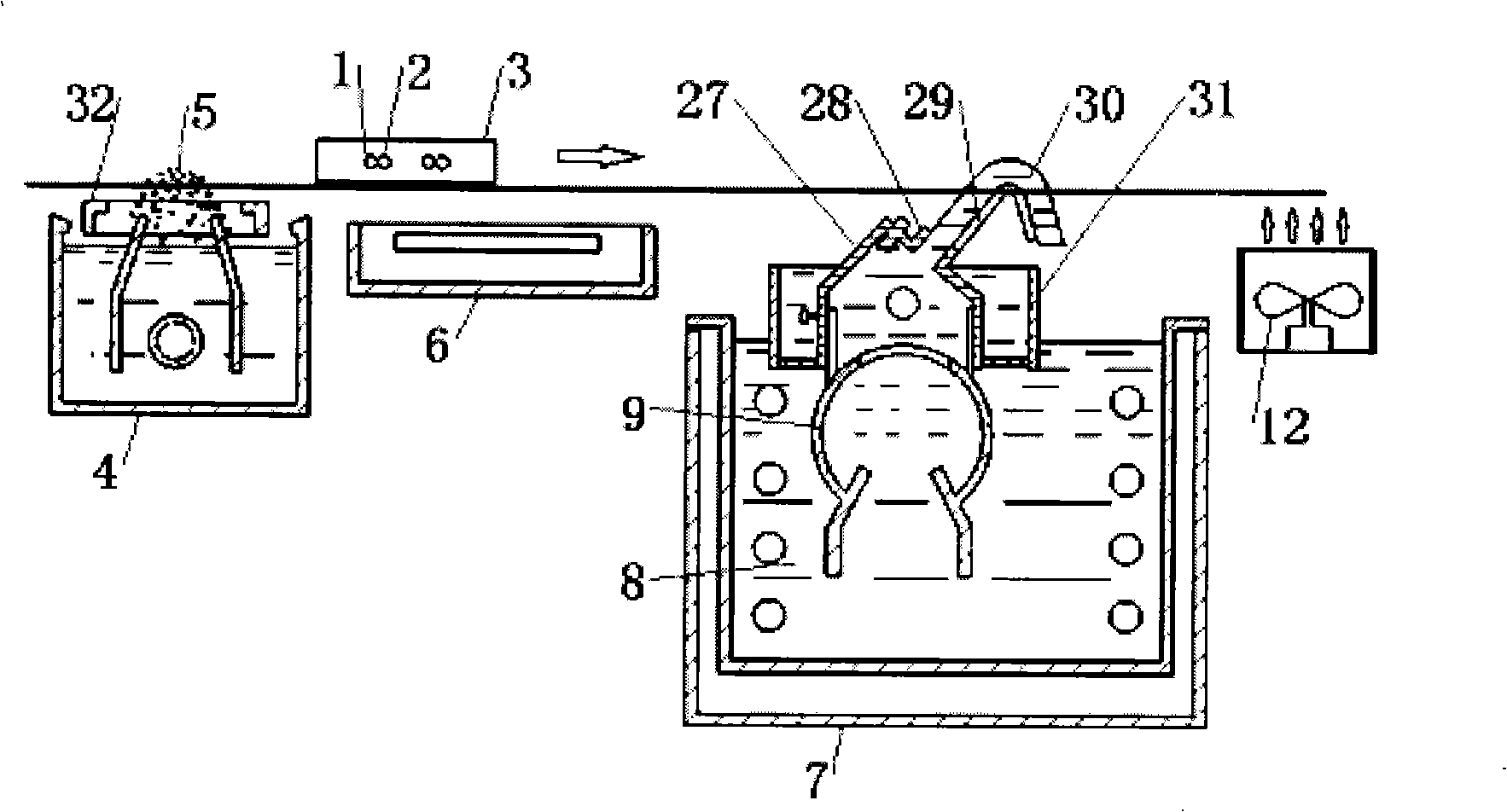

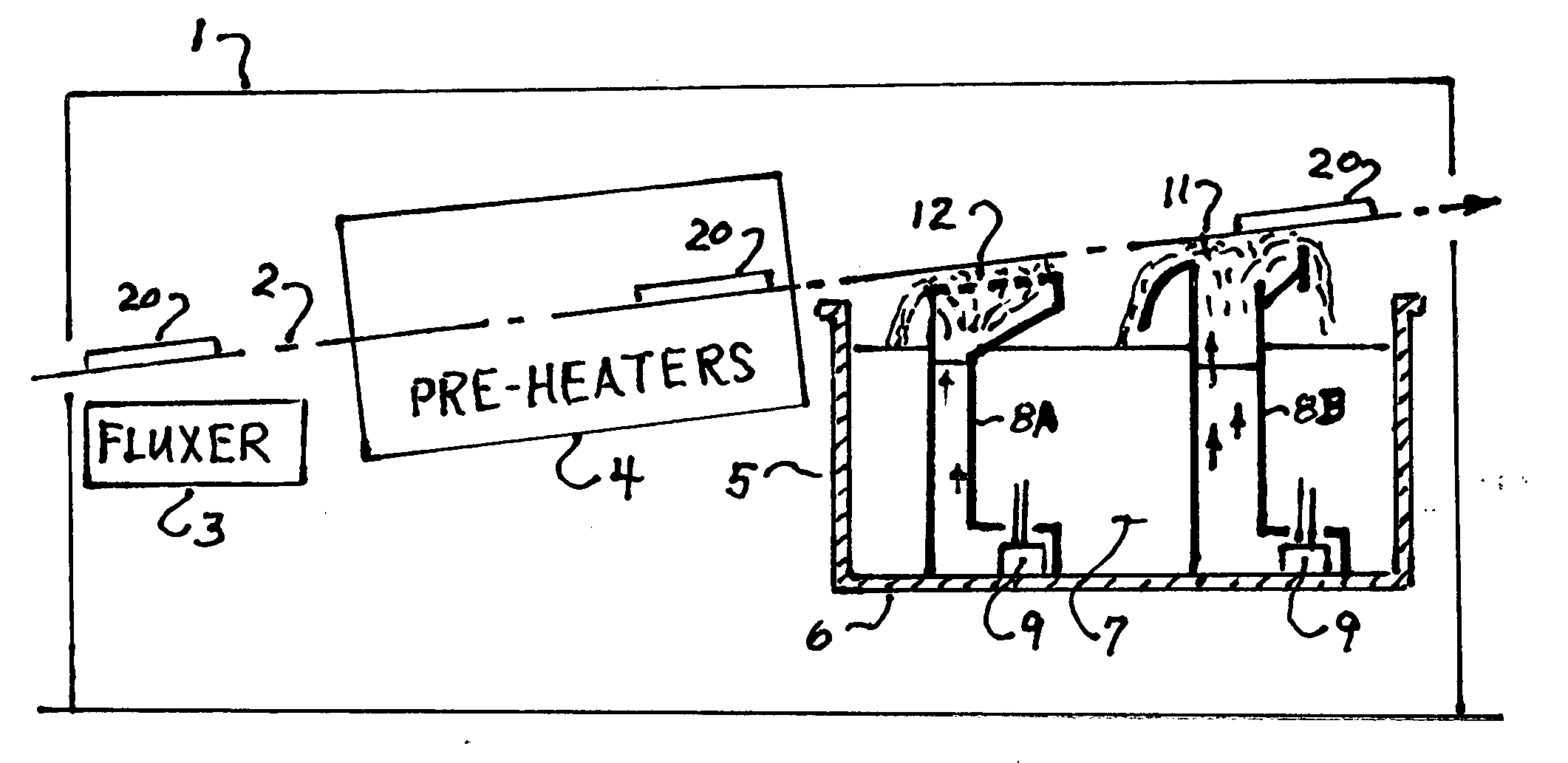

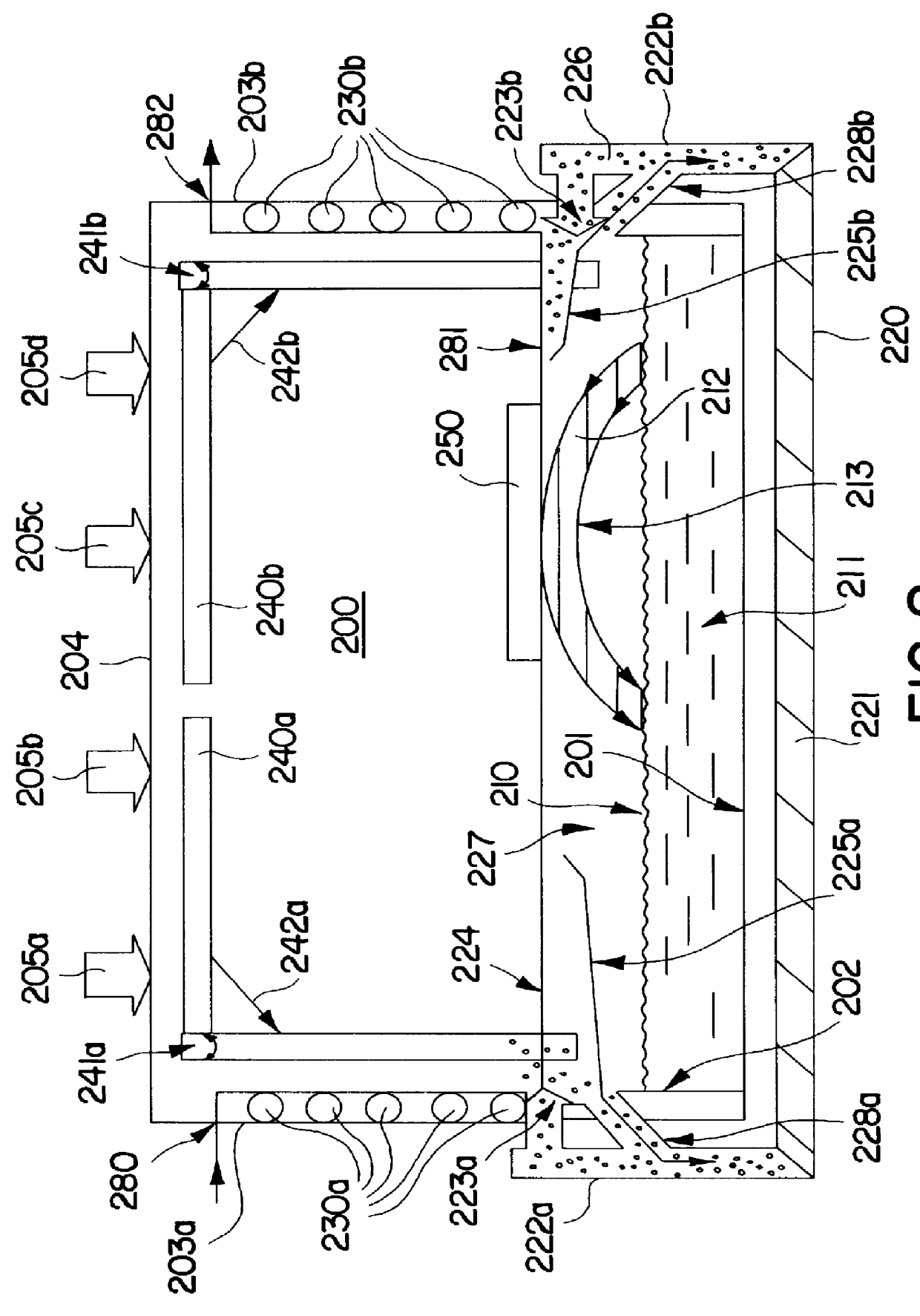

Reaction jet welding device and uses thereof

InactiveCN101293297AAchieve weldingRealize continuous weldingLine/current collector detailsMetal working apparatusWire rodEngineering

The invention discloses an injection stream welding plant and the application thereof. The injection stream welding plant comprises a clamp, a soldering flux generator, a preheater, a solder groove with a first-level spout, a voltage-stabilizing filter and a nozzle; the preheater is arranged downstream the soldering flux generator; the solder groove is located downstream the soldering flux generator; the voltage-stabilizing filter is positioned behind the solder groove and has an overflow cover and a second-level spout, wherein, an overflow baffle with adjustable height is arranged in the middle of the overflow cover; the nozzle is arranged on above the second-level spout and provided with a millimeter-level sized spout and a pair of nozzles which extend along the parabola trace of the solder stream, are arranged symmetrically in the shape of an inverted V and combined by blast baffles and form a millimeter-level section sized solder injection stream that hangs in the air to be exposed in the upper, left and right sides. The application of the injection stream welding plant of the invention is that the application of the wave-soldering welding technology is extended to the electronic product welding field of none-plane-type welding point arrangement between electronic wires and electronic elements beyond the plane-welding PCB welding field. The injection stream welding plant has the advantages of being capable of realizing consecutive welding and being used in the welding between none-plane electronic wires and electronic elements.

Owner:杨国金

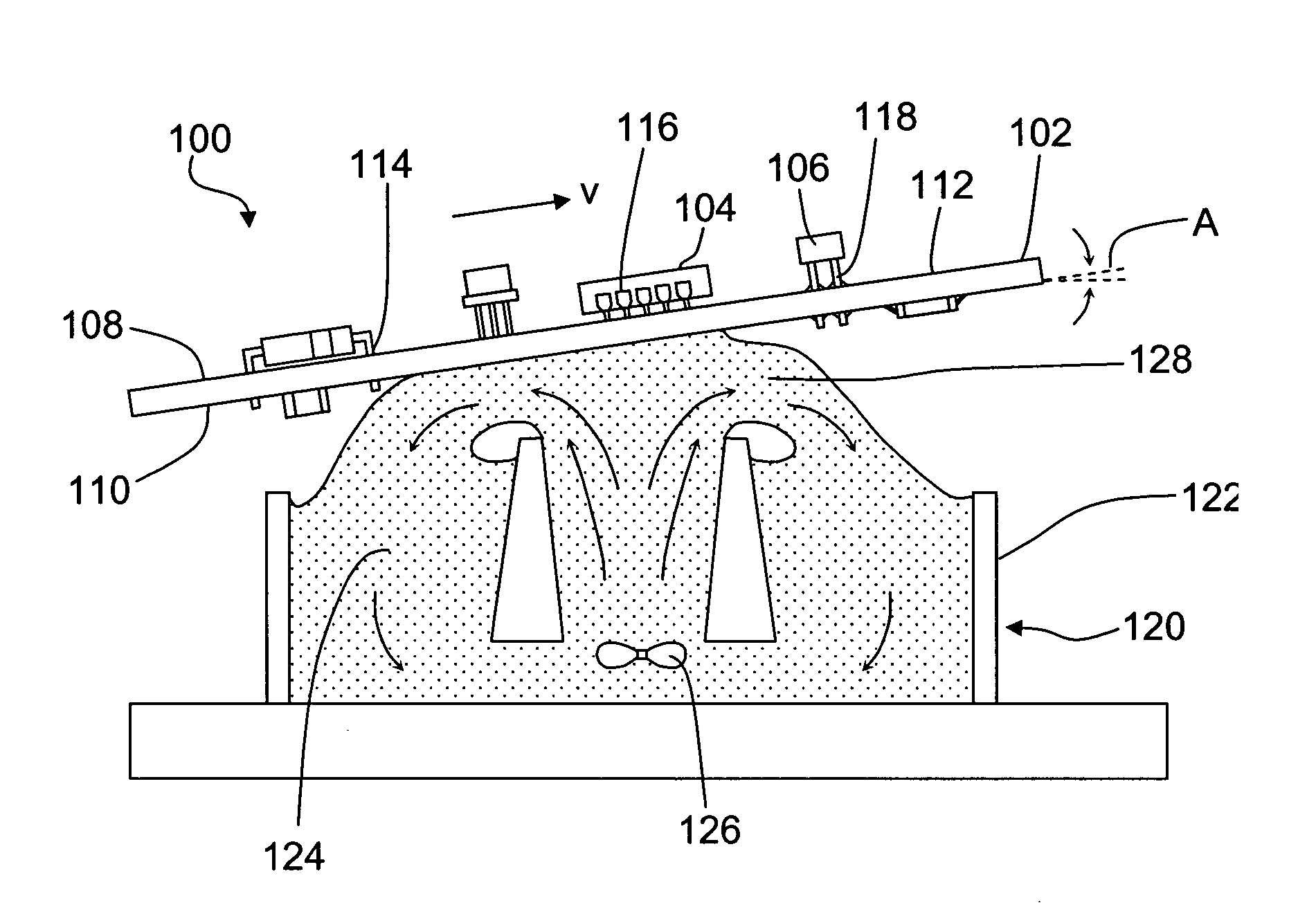

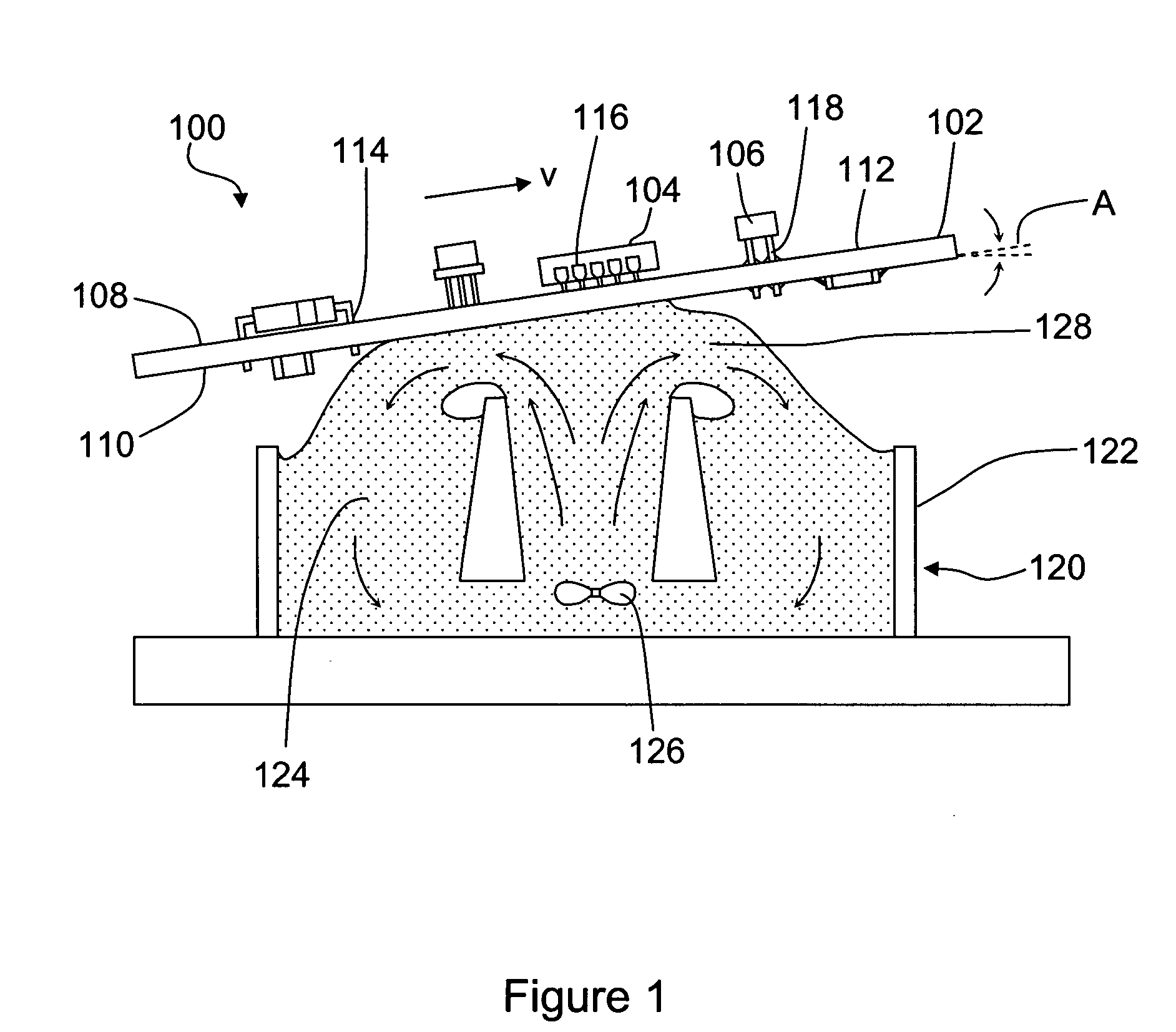

Wide wave apparatus for soldering an electronic assembly

InactiveUS20100065610A1Improve throughput speedReduce defectsSolder feeding devicesSpray nozzleWave form

Especially for but not limited to lead-free solder, the apparatus disclosed herein will provide better quality of wave soldered joints at a lower cost, without the addition of more equipment.The invention will form complete TH solder joints over the first wave soldering nozzle, not the second wave soldering nozzle which is current art. It specifically addresses the size and the shape of the holes in the first wave-forming nozzle.The first solder wave forming plate has hexagon shaped holes that reduce the incidence of holes being clogged and non-functional. There is a size gradient across the multiple rows of holes in the extended contact wave former that has the effect of creating a uniform solder pressure across the entire face of the nozzle. The result is higher solder pressure against the electronic substrate being soldered for a longer period of time than current art, allowing for faster formation of solder joints. This affects quality and thru-put.

Owner:SZYMANOWSKI RICHARD ANTHONY

Process and device for the wave or vapor-phase soldering of electronic units

InactiveUS6116497AHigh solder connectionGood precisionPrinted circuit assemblingSoldering apparatusGas phaseEngineering

PCT No. PCT / DE96 / 00968 Sec. 371 Date Dec. 12, 1997 Sec. 102(e) Date Dec. 12, 1997 PCT Filed May 24, 1996 PCT Pub. No. WO96 / 37330 PCT Pub. Date Nov. 28, 1996A method of and an apparatus for vapor phase / solder wave soldering contacts of electronic components including temperature sensitive portions in which the components while moving through a soldering chamber are only partially immersed in a saturated vapor whereas the contacts are wholly immersed in the vapor. A solder wave having a crest substantially coinciding with the components to be soldered is provided within the saturated vapor and a layer of an inert gas is provided above the vapor ceiling.

Owner:IBL LOTTECHN

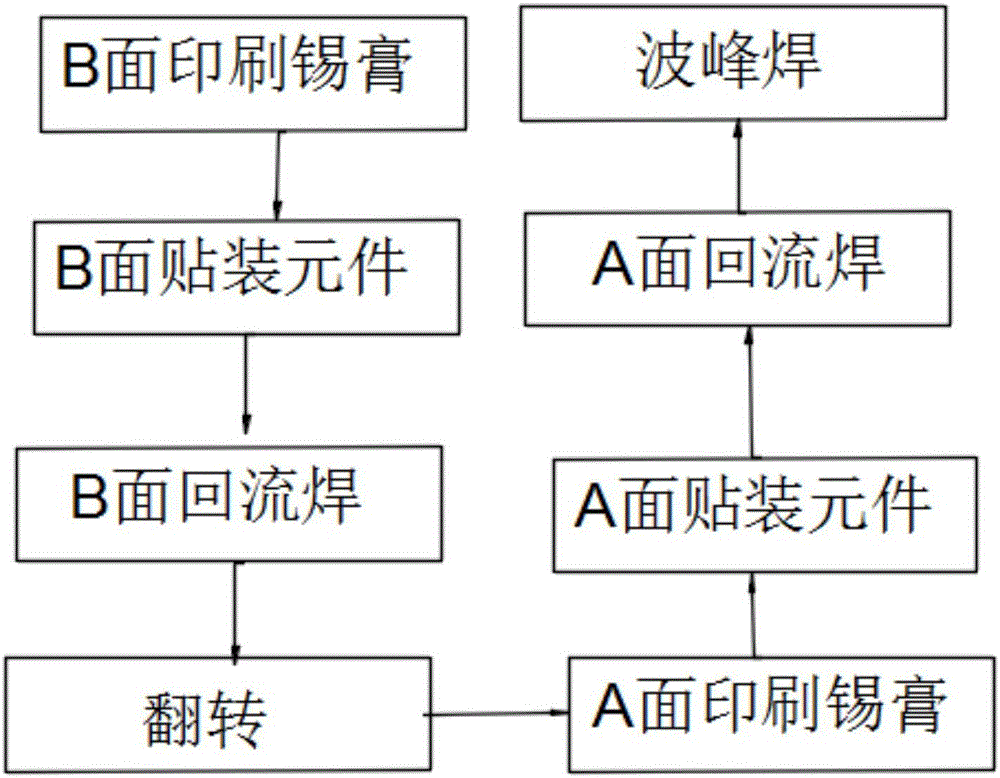

Hybrid surface-mounting process of double-side board

InactiveCN106413281ASimple processImprove pass ratePrinted circuit assemblingPrinted circuit aspectsSurface mountingEngineering

The invention discloses a hybrid surface-mounting process of a double-side board. The hybrid surface-mounting process comprises the steps of S1, printing tin paste on a B surface, in which the tin paste is printed on a bonding pad on the B surface of a PCB (Printed Circuit Board) under push of a scraper; S2, surface-mounting a component on the B surface, in which a surface-mounted component is accurately arranged on a fixed position of the B surface of the PCB; S3, performing reflow soldering on the B surface, in which quantity-controllable tin paste and a solvent are applied onto a surface to be connected, the component is placed on positions of the tin paste and the solvent, and the tin paste is molten by increasing a temperature and heating so that the surface-mounted component and the B surface of the PCB are firmly bonded; S4, performing turnover, in which the circuit board is turned over to complete printing of an A surface; S5, printing the tin paste on the A surface; S6, surface-mounting a component on the A surface; S7, performing reflow soldering on the A surface; and S8, performing wave soldering, in which molten soft welding material is sprayed by a power-driven pump or an electromagnetic pump to form a soldering material wave required by design so that a welding end or a pin of the component and the bonding pad of the printed circuit board are welded. The hybrid surface-mounting process of the double-side board is simple, the qualified rate of a product is high, and the curing speed is fast.

Owner:WUXI NASCH CONTROL & TEST TECH

Leadless solder

InactiveCN1460572ACompatibleImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaMetallurgyLow melting point

The composition of the leadless solder includes (wt%) 0.05-1.2% of Ag, 0.5-10% of Bi, 0.01-1.5% of Cu, 0.001-0.0009% of P, 0.002-0.8% of RE and the rest is Sn. It features low melting point, excellent resistance to oxidation and weldability, and is applicable of wave soldering, solder-dipping and reflow soldering of plug-in cards.

Owner:广州特铜电子材料有限公司

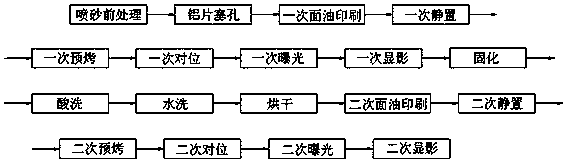

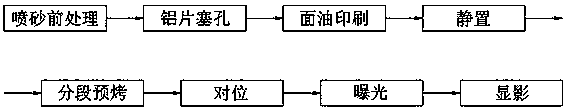

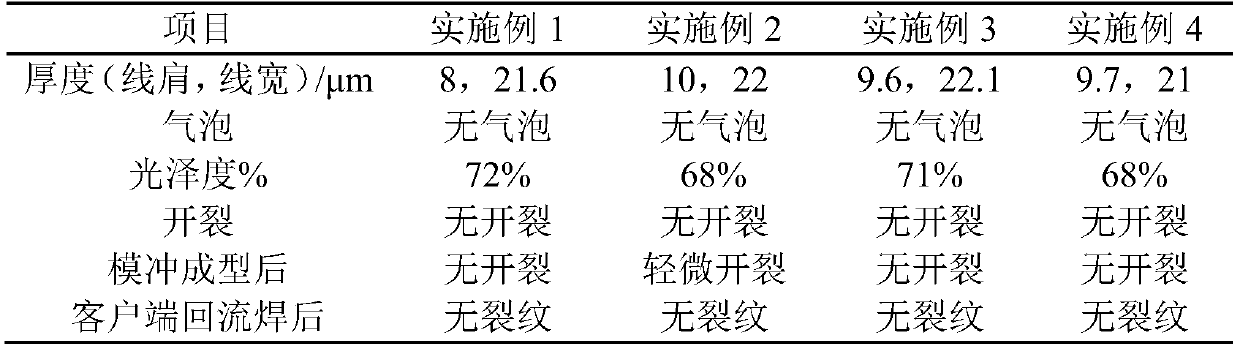

Ink silk-screen process of thick-copper white soldering resistant ink PCB

ActiveCN110267457AReduce multiple processesThe process takes a short timeNon-metallic protective coating applicationScreen printingPunching

The invention discloses an ink silk-screen process of a thick-copper white soldering resistant ink PCB. The silk-screen process comprises the following steps of S1, performing sand-blasting pre-processing on the thick-copper PCB to be silk-screened with soldering resistant ink, and performing plugging a conduction hole; S2, performing silk-screen printing of white soldering resistant ink, and allowing to stand; and S3, sequentially performing segmented pre-baking, alignment, exposure and developing, and completing ink silk-screen printing. According to the process, the white soldering resistant ink layer with a line shoulder thickness not lower than 7 micrometers can be completed on the thick-copper PCB by one-time silk-screen printing, the silk-screen process is improved, the silk-screen cost is reduced, and the problem that the ink layer is easy to crack during die punching is also prevented; moreover, by segmented pre-baking, the standing time after silk-screen is shorted, and the defect of white oil crack is also solved; and meanwhile, by controlling the energy of exposure and developing, the ink layer is maintained to be shiny, the developing is clear, and the defect that white oil crack is easily occurred after backflow welding or wave soldering at a client is effectively prevented.

Owner:惠州市联达金电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com