Reaction jet welding device and uses thereof

A technology of welding device and jet flow, which is applied in the directions of tin feeding device, auxiliary device, welding equipment, etc., can solve the problem that the application range cannot be expanded.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

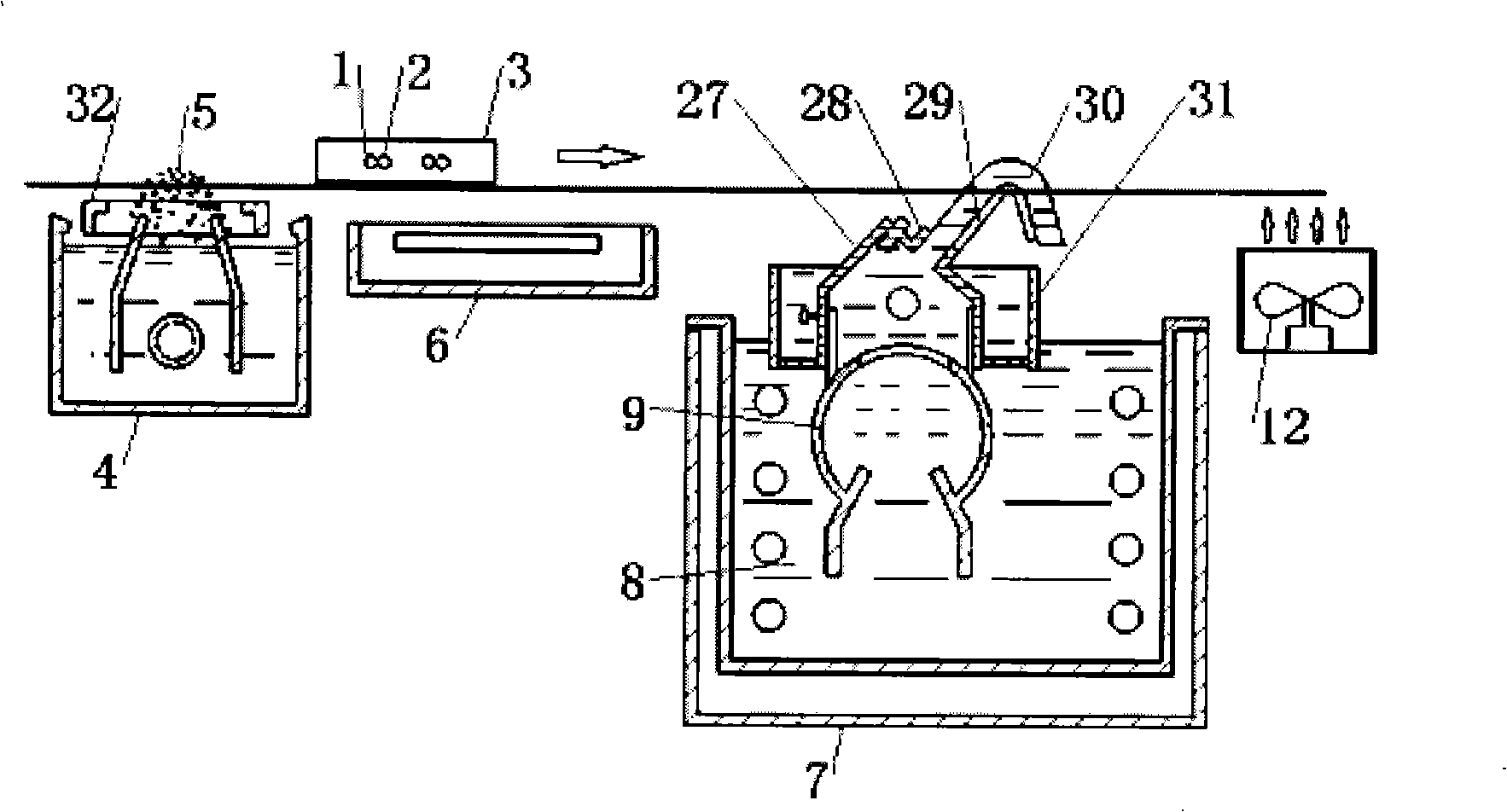

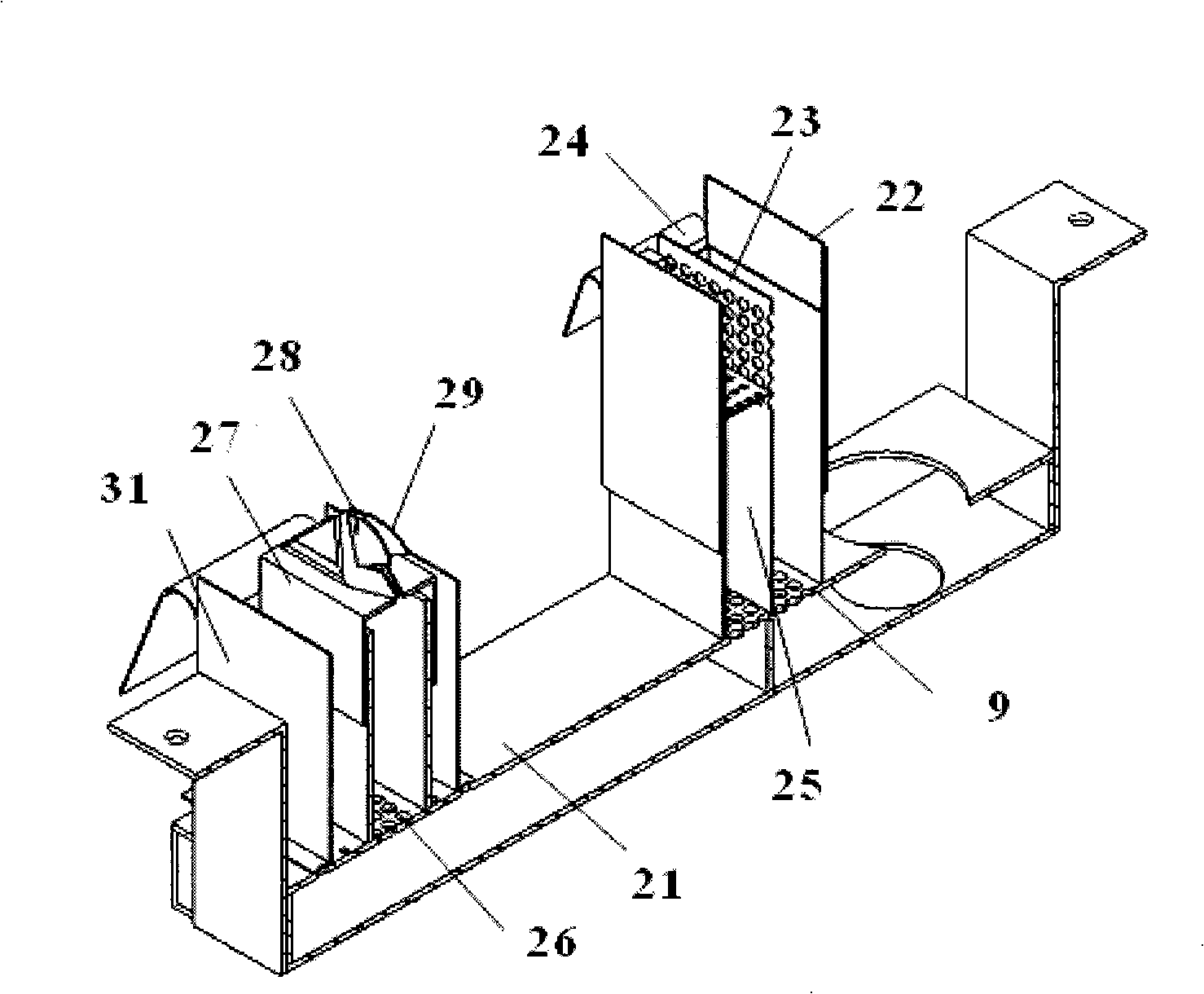

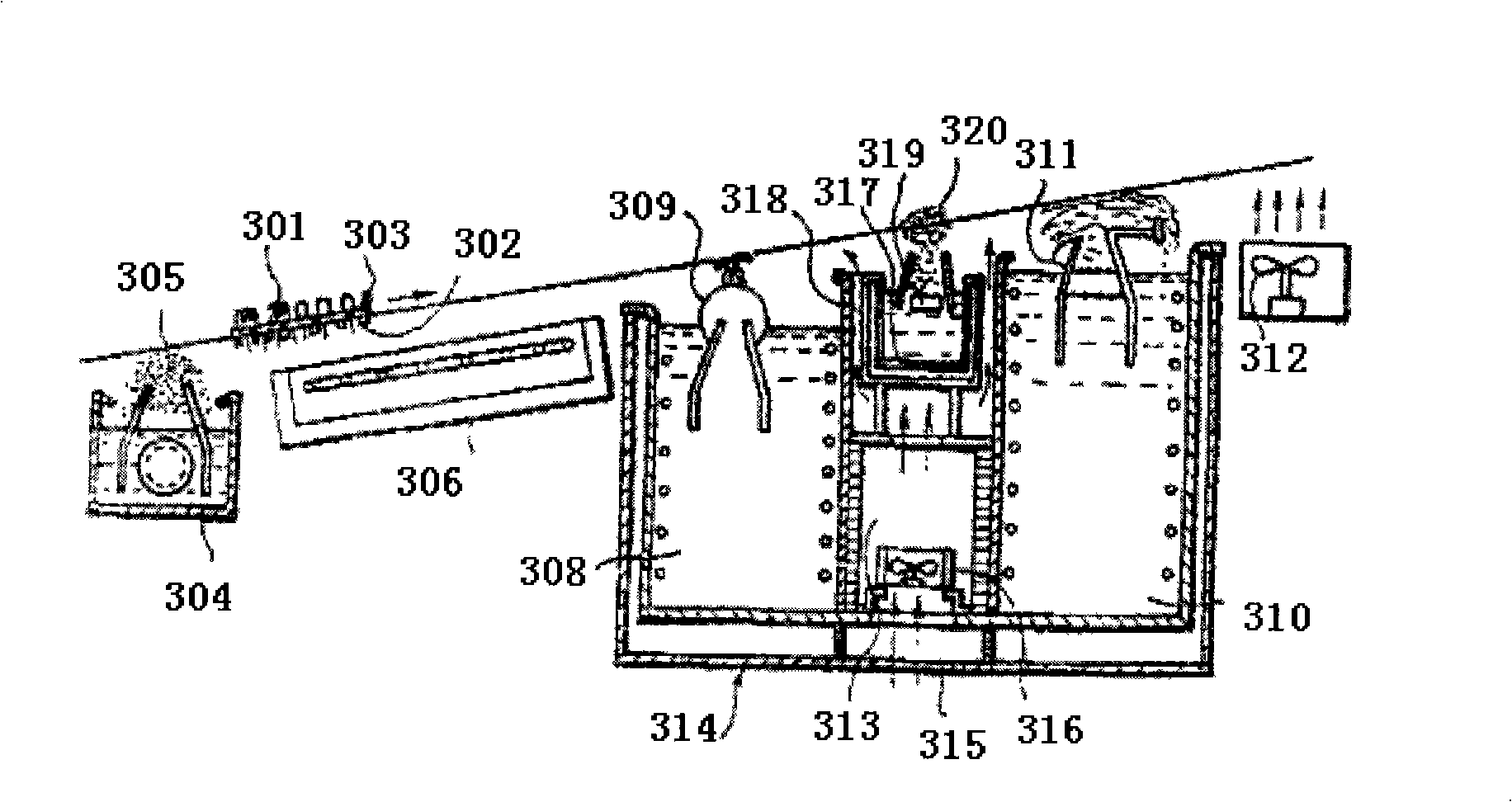

[0024]The jet welding device of the present invention is an improved welding device, including a fixture 3, a flux generator 4, a preheater 6, a flux tank 8 with a primary nozzle, a voltage stabilizing filter 21, and a nozzle 27; The preheater 6 is installed on the downstream of the flux generator 4 that applies the flux to the spot to be soldered; the flux tank 8 with a primary nozzle is located downstream of the above preheater; the voltage stabilizing filter 21 is located on the primary nozzle 9, There is an overflow cover 22 and a secondary spout 26 installed with an adjustable-height overflow baffle 23 in the middle; the nozzle 27 is installed above the above-mentioned secondary spout 26, and consists of a spout 28 with a millimeter size and a pair of spouts along the The deflectors 29 arranged symmetrically in the "eight" shape extended by the parabolic trajectory of the flux flow are combined to form a flux jet flow (ie, a millimeter-scale welding pool) 30 with the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com