Patents

Literature

1577 results about "Soldering iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A soldering iron is a hand tool used in soldering. It supplies heat to melt solder so that it can flow into the joint between two workpieces. A soldering iron is composed of a heated metal tip and an insulated handle. Heating is often achieved electrically, by passing an electric current (supplied through an electrical cord or battery cables) through a resistive heating element. Cordless irons can be heated by combustion of gas stored in a small tank, often using a catalytic heater rather than a flame. Simple irons less commonly used today than in the past were simply a large copper bit on a handle, heated in a flame.

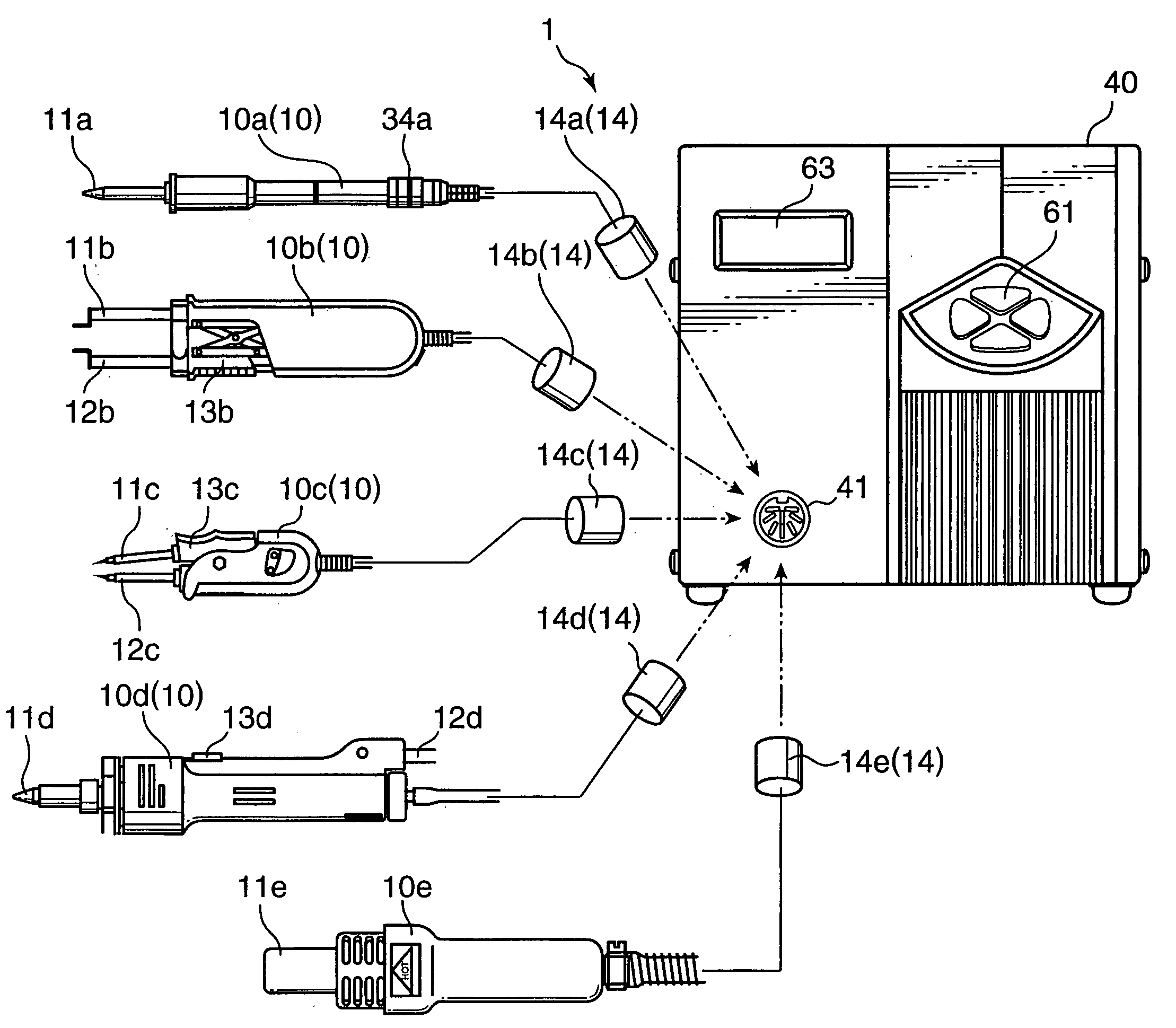

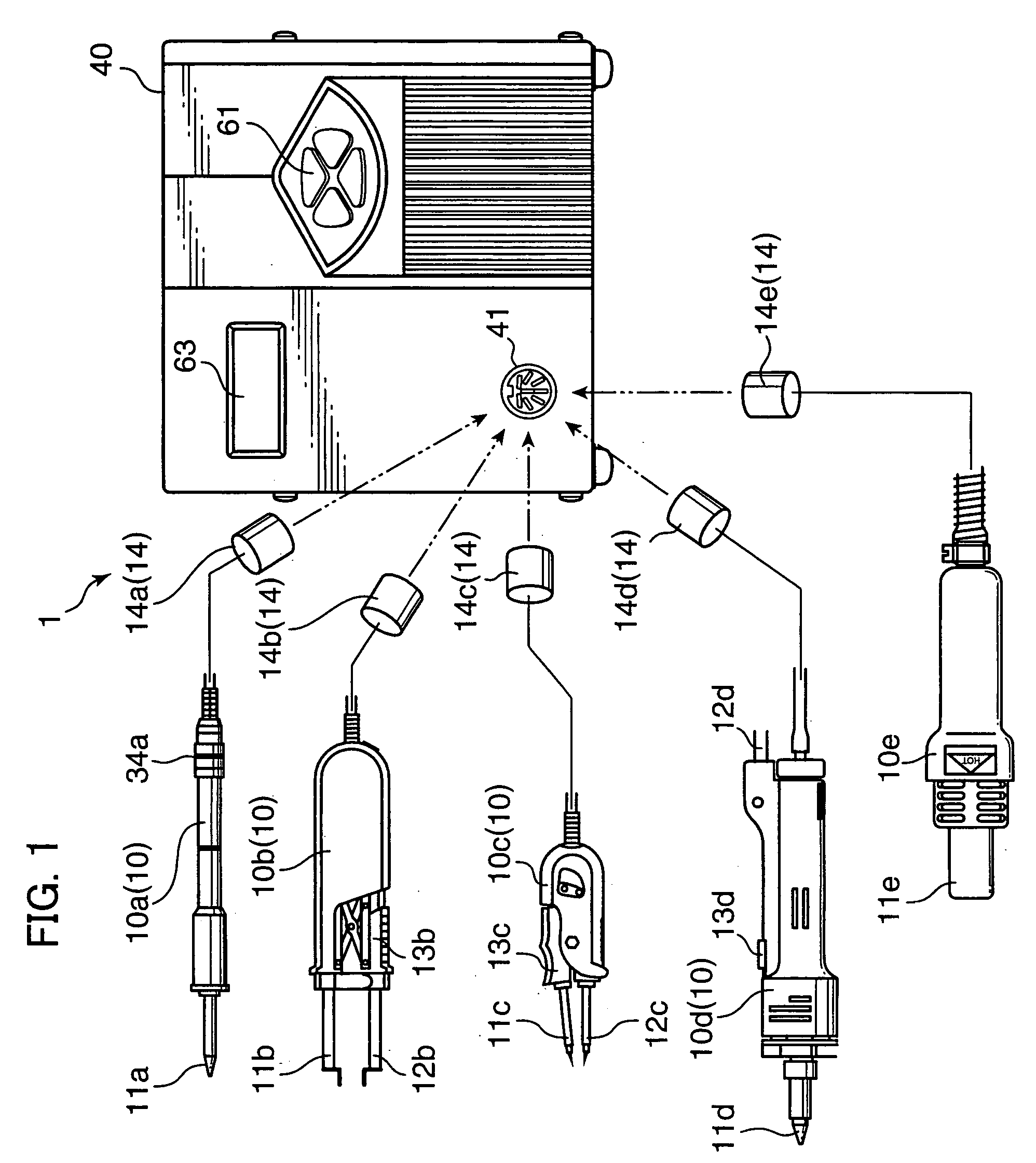

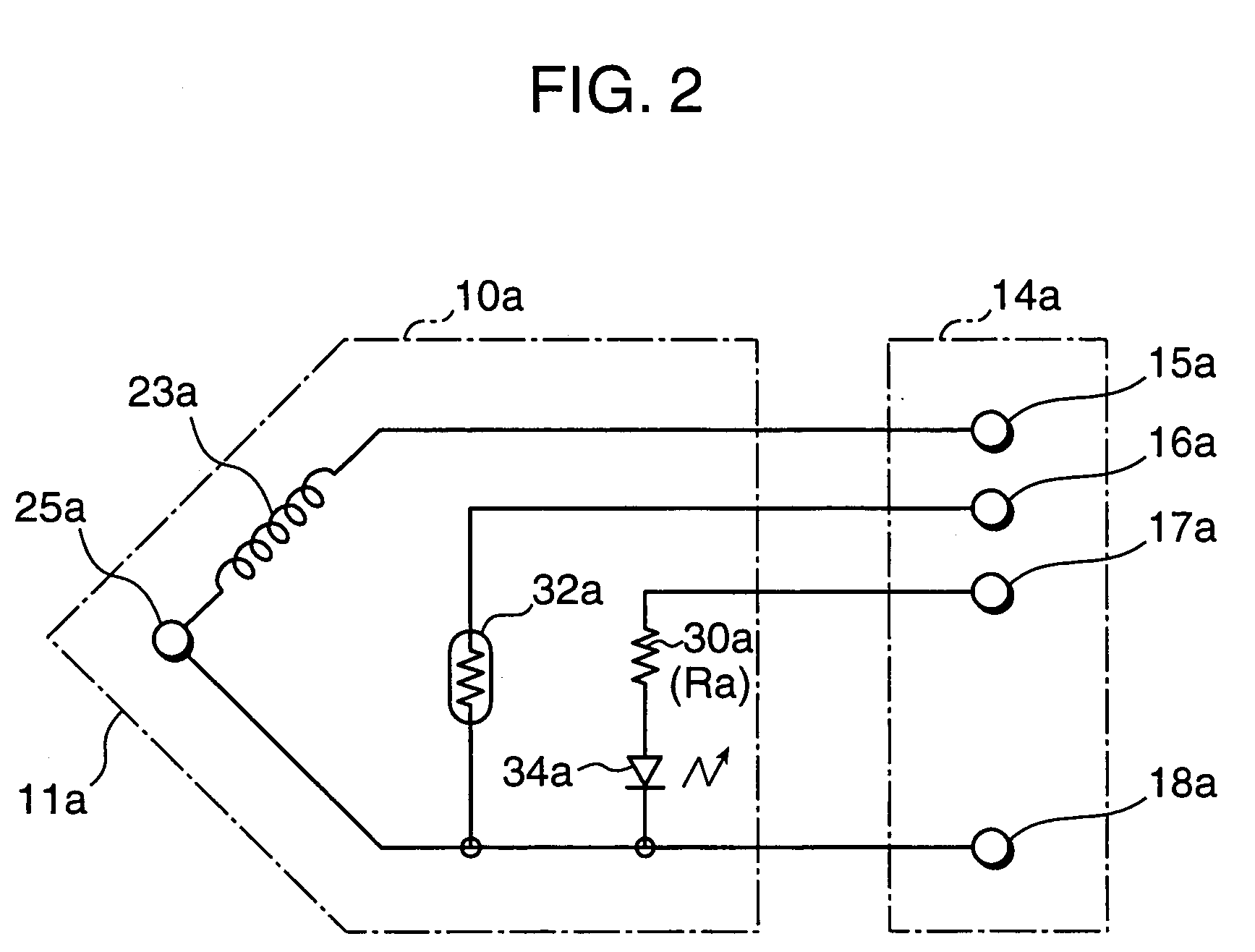

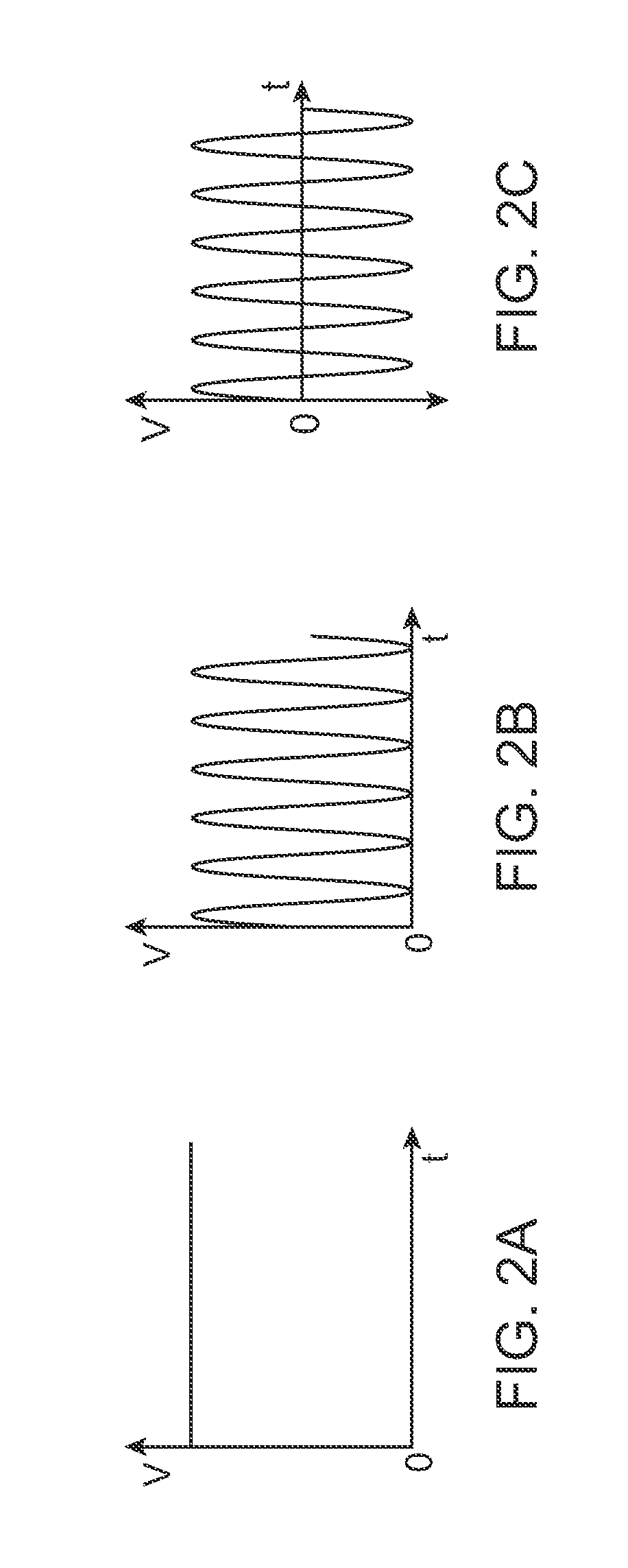

Temperature control system for solder handling devices and method for temperature control for those devices

InactiveUS20050121495A1Improve accuracyImprove reliabilityAutomatic control devicesPrecision positioning equipmentTemperature controlElectrical resistance and conductance

In a temperature control system for controlling a heating member or means of a solder handling device, a plurality of solder handling devices such as soldering iron, a heater tweezer, a solder sucker and a hot air blower are selectively coupled with a temperature controller which in turn identify the solder handling device connected thereto and controls temperature of the heater of the connected device with temperature control characteristic suitable for the device. Each solder handling device may have a resistor of which resistance value represents the type of the device so that the temperature controller identify the device by the resistance value.

Owner:HAKKO CO LTD

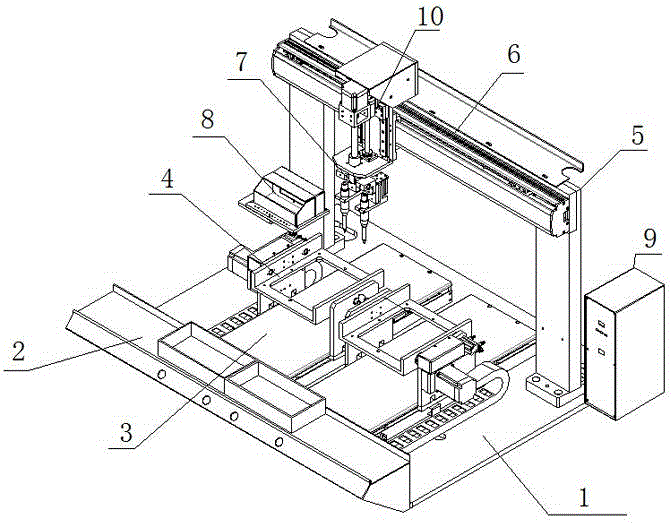

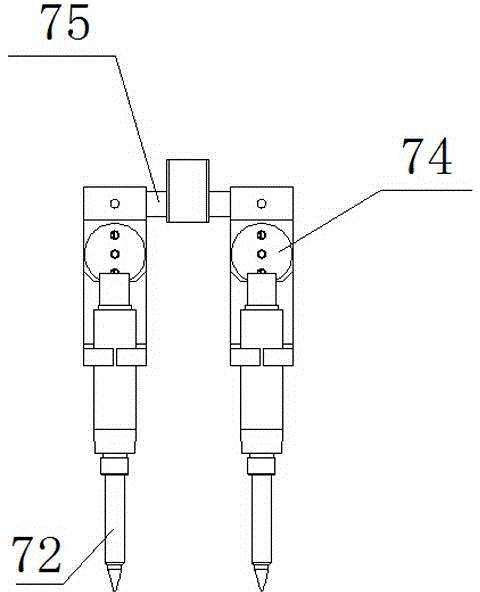

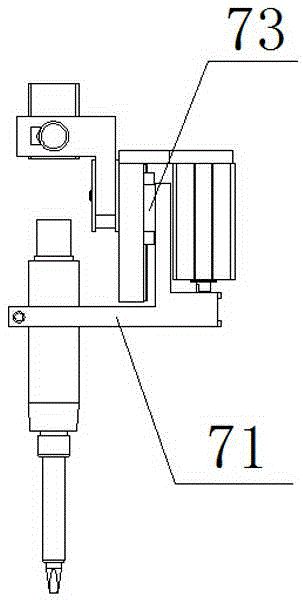

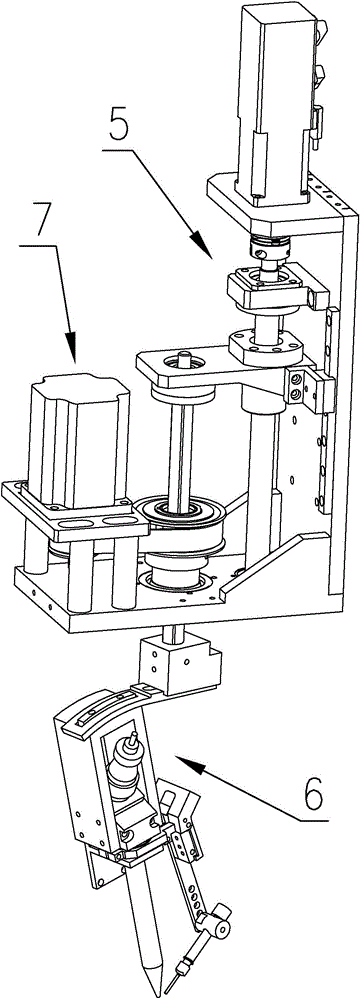

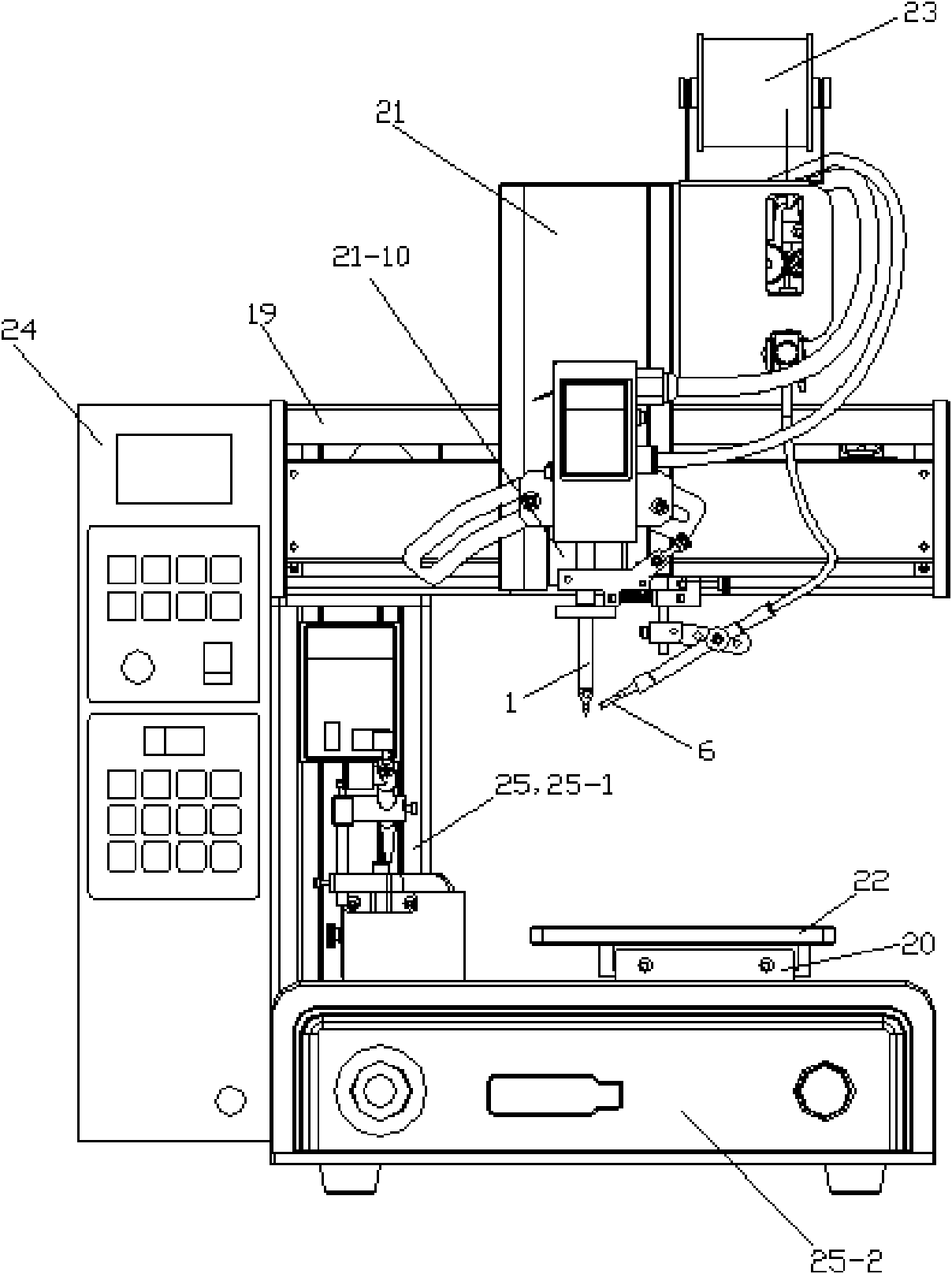

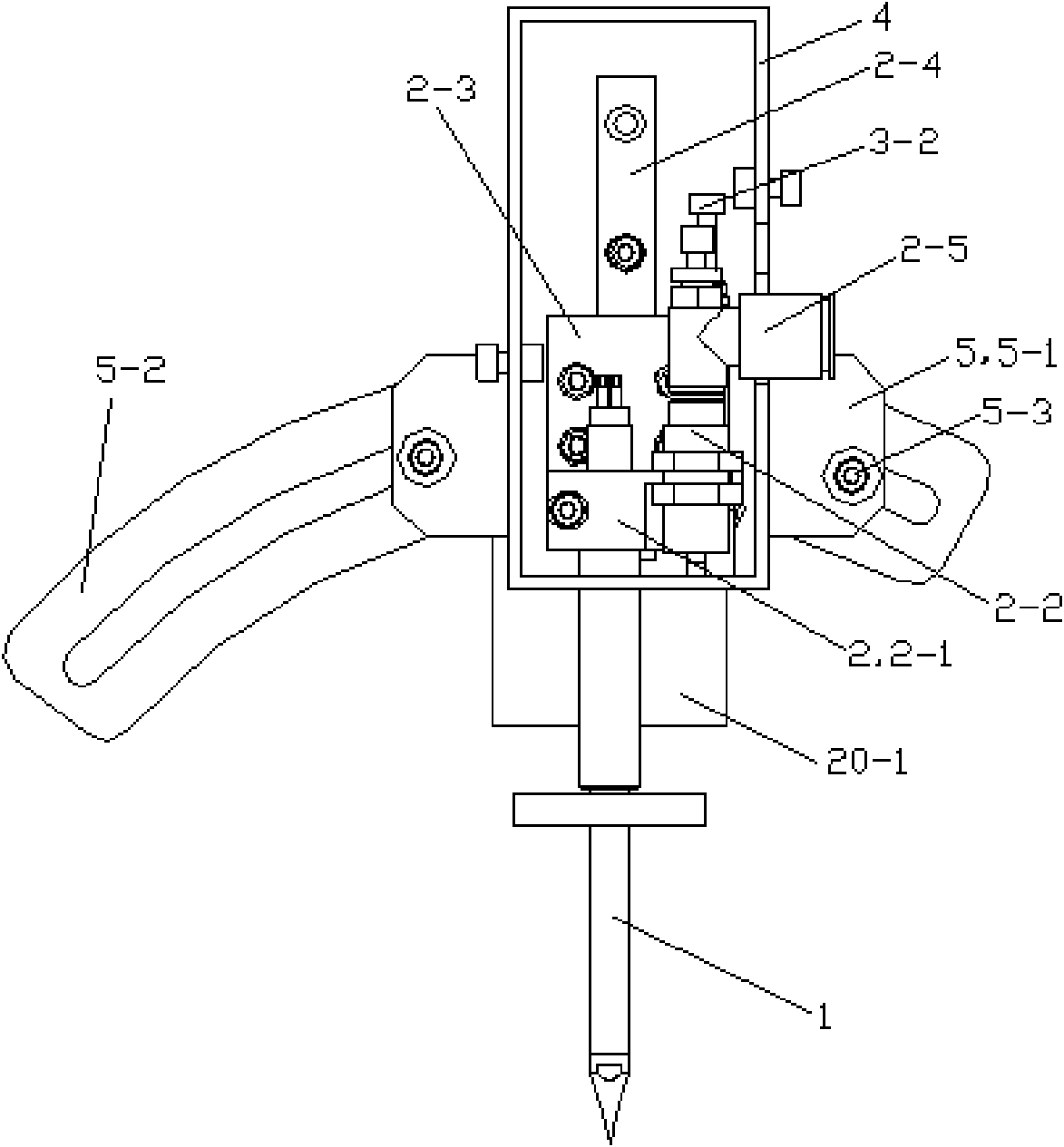

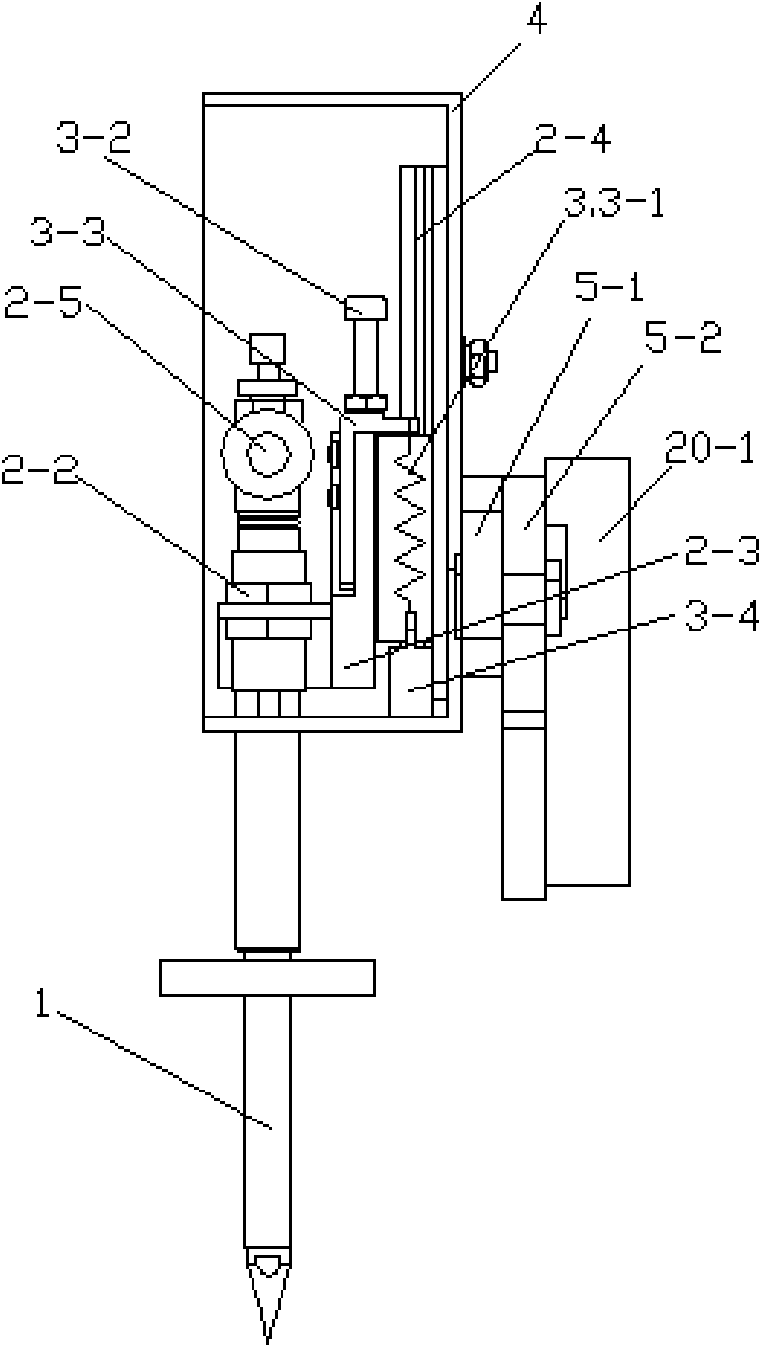

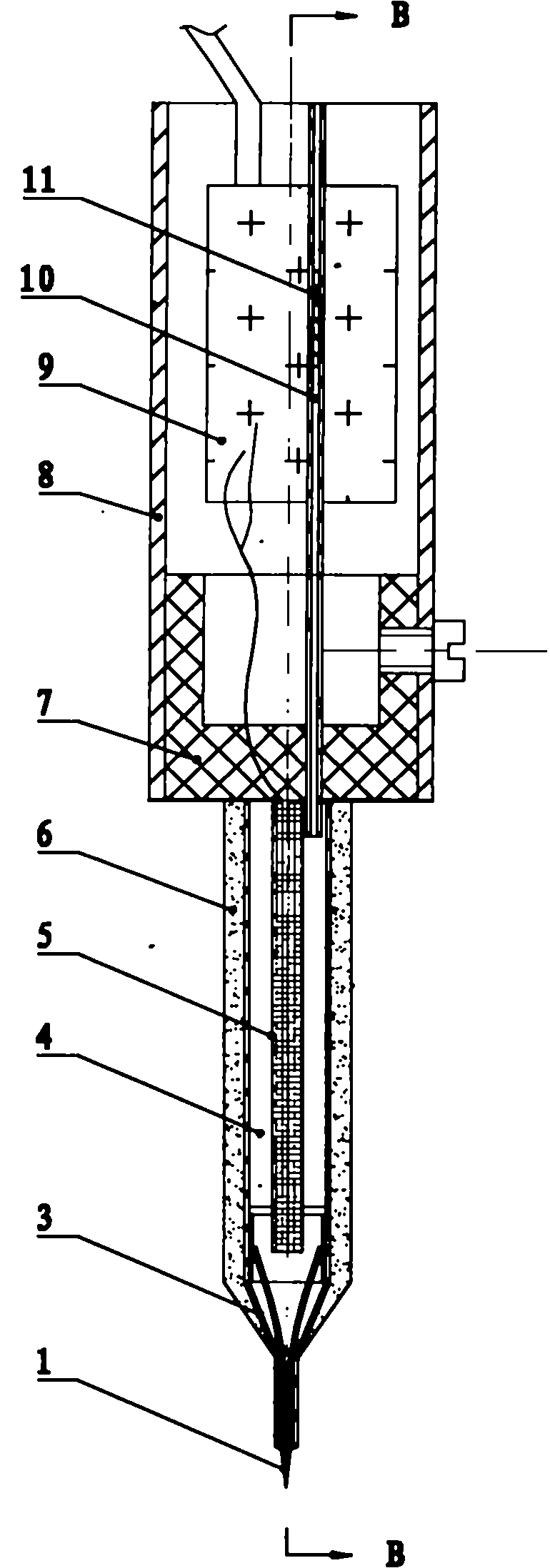

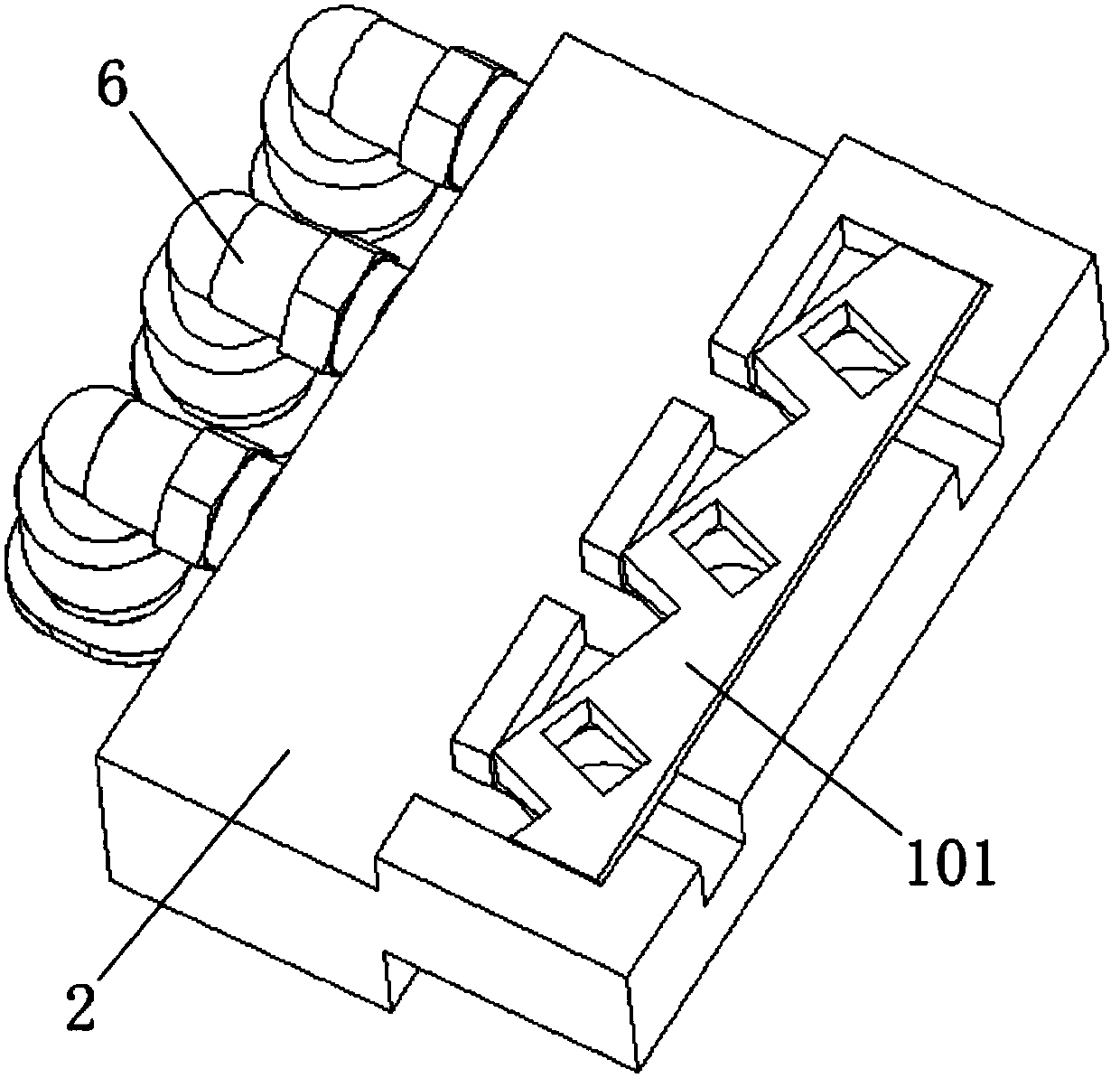

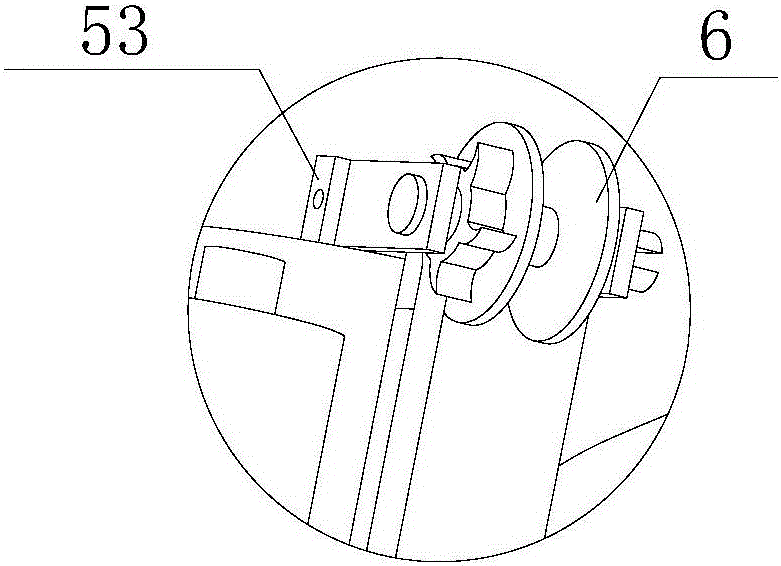

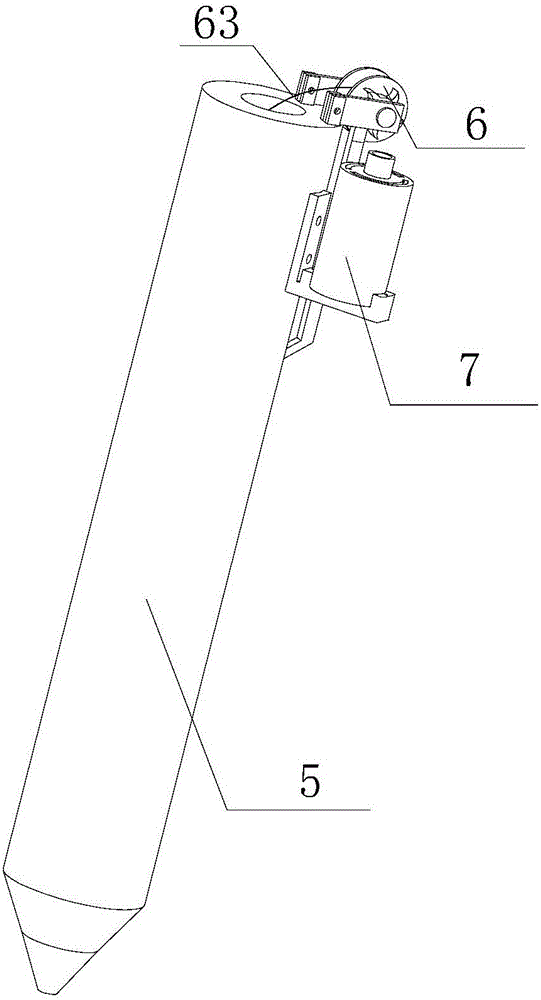

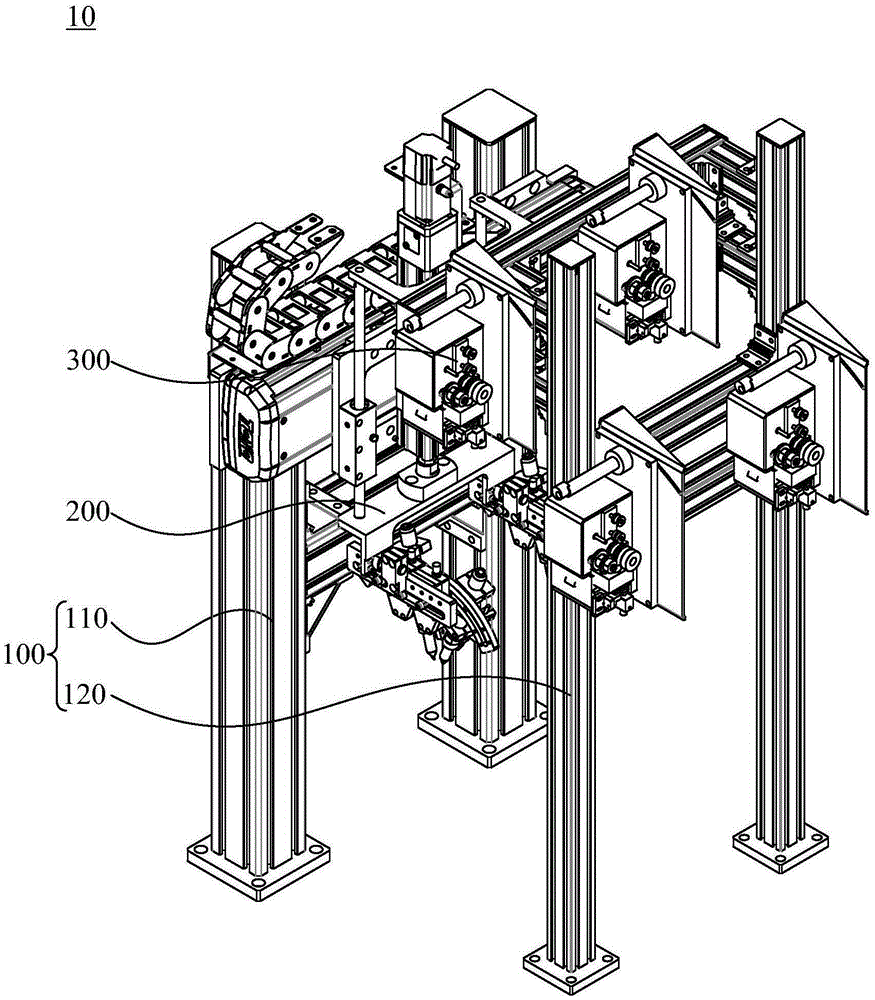

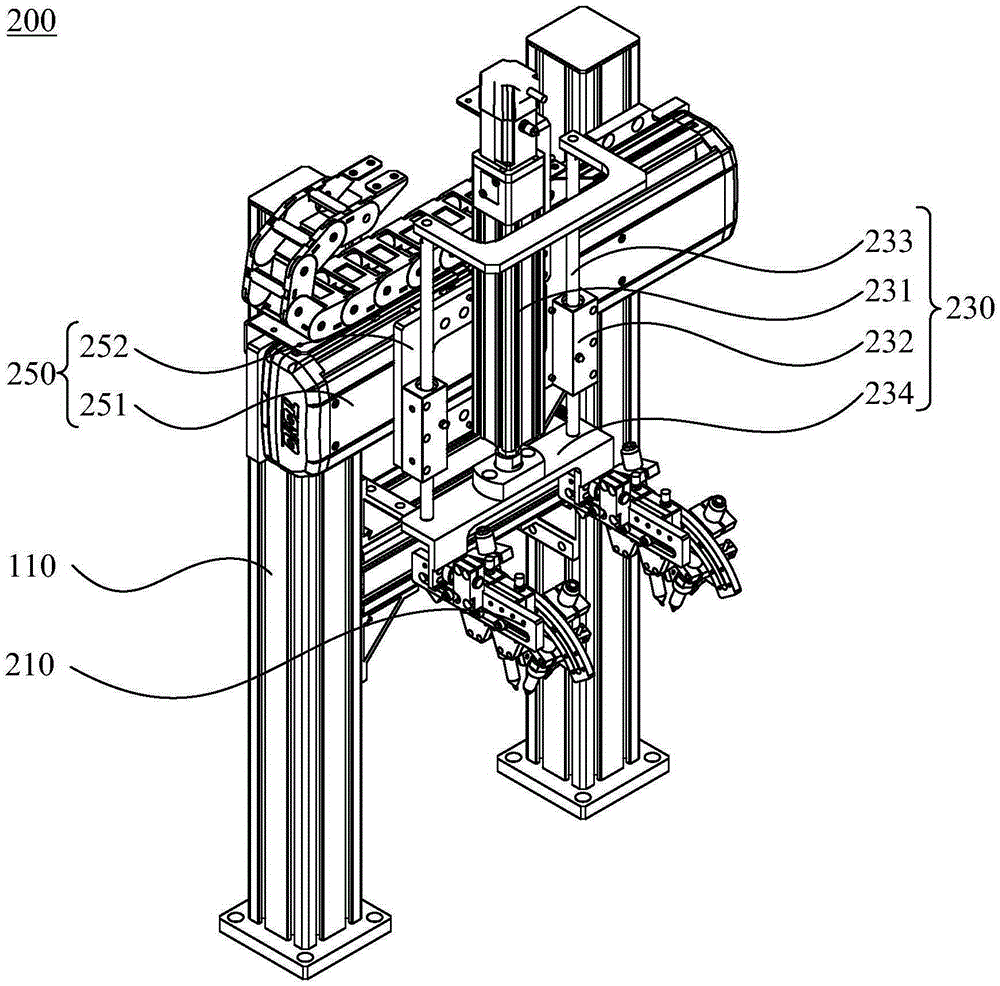

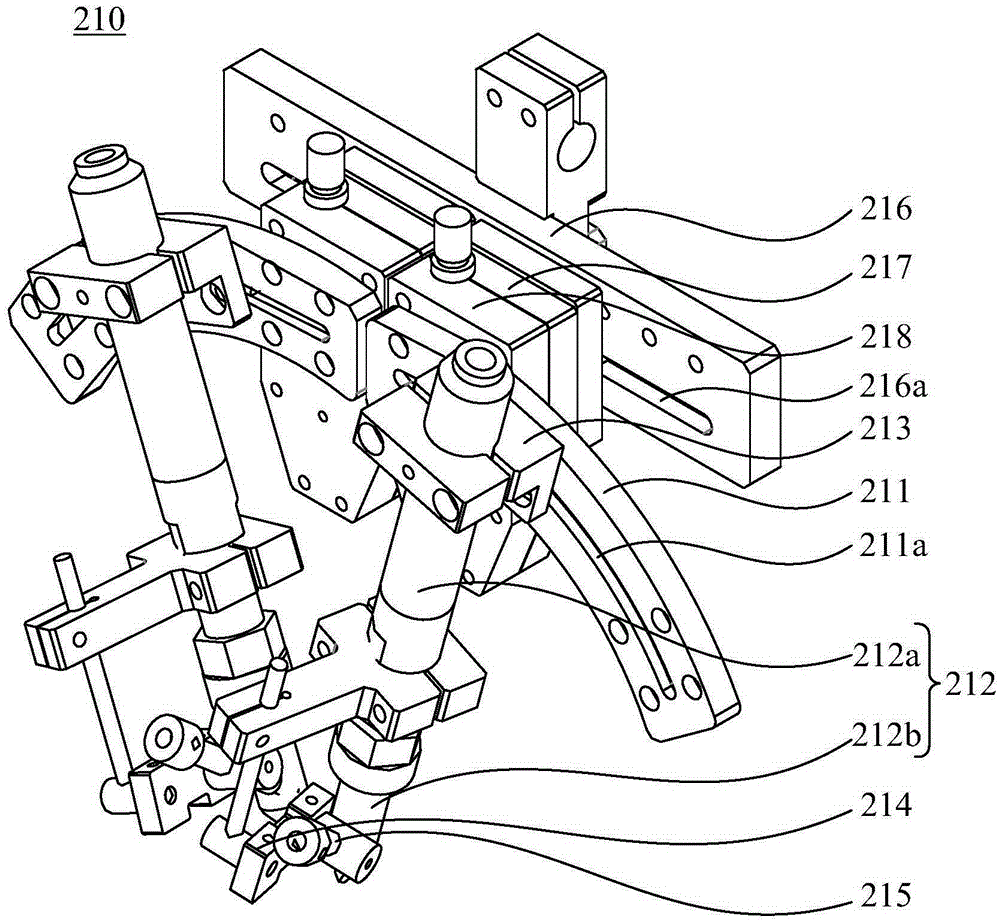

Multidirectional rotation working soldering tin machine capable of overturning jigs

ActiveCN104475900AImprove work efficiencyIncrease flexibilityHeating appliancesSoldering ironSlagTin

The invention relates to a multidirectional rotation working soldering tin machine capable of overturning jigs. The multidirectional rotation working soldering tin machine capable of overturning the jigs comprises a machine panel, a material station, Y-axis conveying mechanisms, overturning mechanisms, a welding bracket, an X-axis conveying mechanism, a multi-head independent control welding mechanism, a tin slag box, a welding station box, a soldering iron fixing block, a soldering iron, a sliding rail guide buffering assembly, a soldering iron left-and-right inclination angle regulating mechanism, a front-and-rear rotary regulating bracket and a soldering iron transfer cylinder. The multidirectional rotation working soldering tin machine capable of overturning the jigs can be used for determining to set the numbers of the overturning mechanisms and the Y-axis conveying mechanisms according to loading time and tin soldering time; by arranging more than one overturning mechanism paired with the Y-axis conveying mechanisms for use, a circuit board on which materials are loaded can be full-automatically overturned in a range of 180 degrees and the multi-head independent control welding mechanism can carry out non-stop tin soldering; the working efficiency is high; the working angle of the soldering iron in the random front-and-rear inclined direction can be regulated by the front-and-rear rotary regulating bracket; the working angle of the soldering iron in the random left-and-right inclined direction can be regulated by the soldering iron left-and-right inclination angle regulating mechanism; the multidirectional rotation working soldering tin machine capable of overturning the jigs has strong flexibility, has good effects and is low in cost.

Owner:DONGGUAN OKATA ELECTRONICS & TECH

Cantilever type automatic tin soldering device

InactiveCN104625290AImprove efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAssembly line

The invention provides a cantilever type automatic tin soldering device. The device comprises an X-axis movement module, a Y-axis movement module, a rack and a product conveying assembly line, wherein the product conveying assembly line is installed on the rack, the X-axis movement module is installed on the rack through a supporting plate, and the Y-axis movement module is installed on the X-axis movement module. The device further comprises a Z-axis lifting module, an iron welding assembly, an iron welding assembly rotating device and a soldering tin supplying device, wherein the Z-axis lifting module is installed on the Y-axis movement module through a supporting frame, the iron welding assembly rotating device is installed on the supporting frame, the iron welding assembly is installed on the iron welding assembly rotating device, the solder wire supplying device is installed on the supporting frame, products to be subjected to tin soldering are fed into the product conveying assembly line and positioned, the iron welding assembly rotating device drives the iron welding assembly to rotate to an assigned angle, the soldering tin supplying device is used for conveying soldering tin to the iron welding assembly, and the X-axis movement module, the Y-axis movement module and the Z-axis lifting module are combined to drive the iron welding assembly to an assigned position for tin soldering.

Owner:东莞新友智能科技有限公司

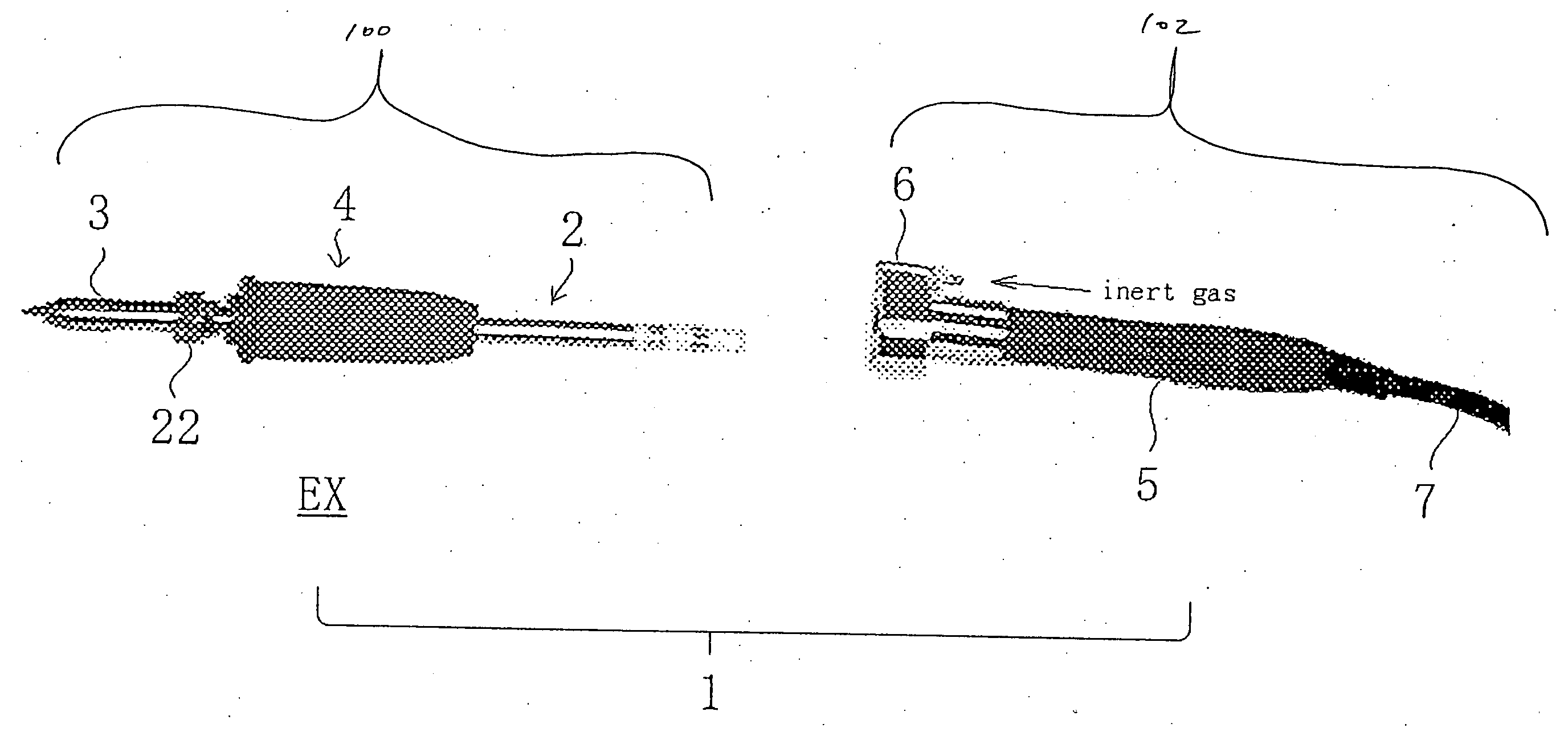

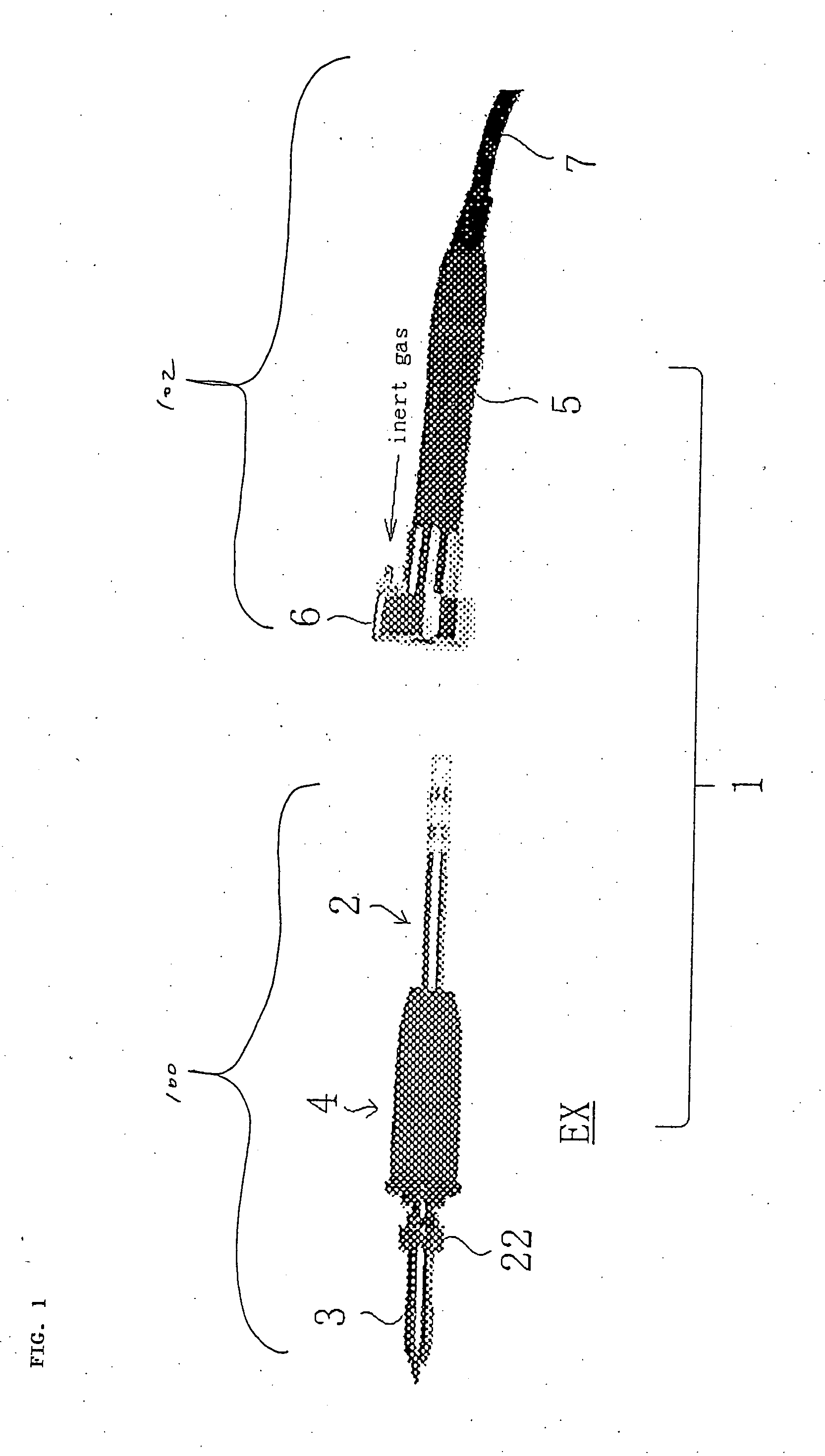

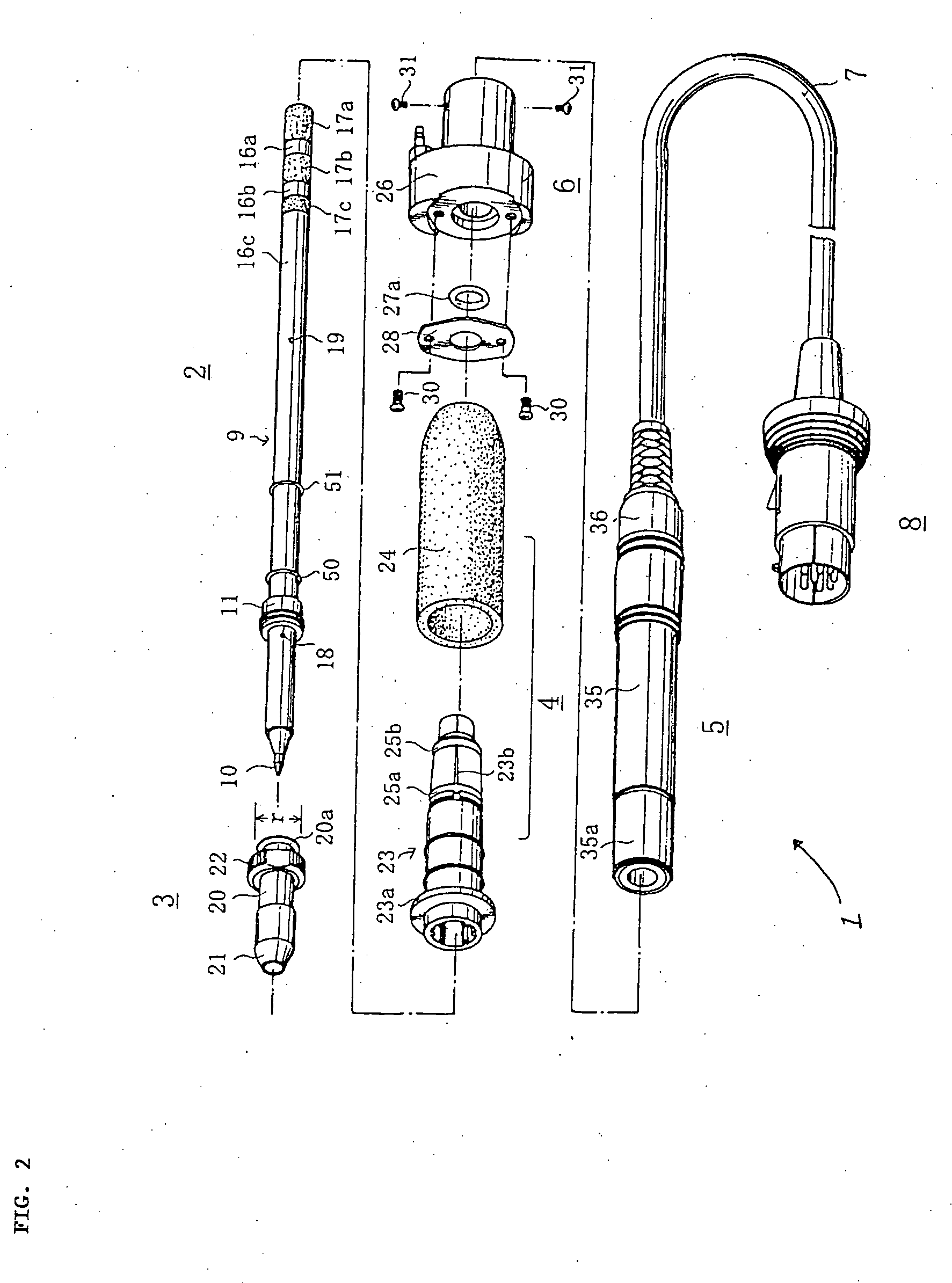

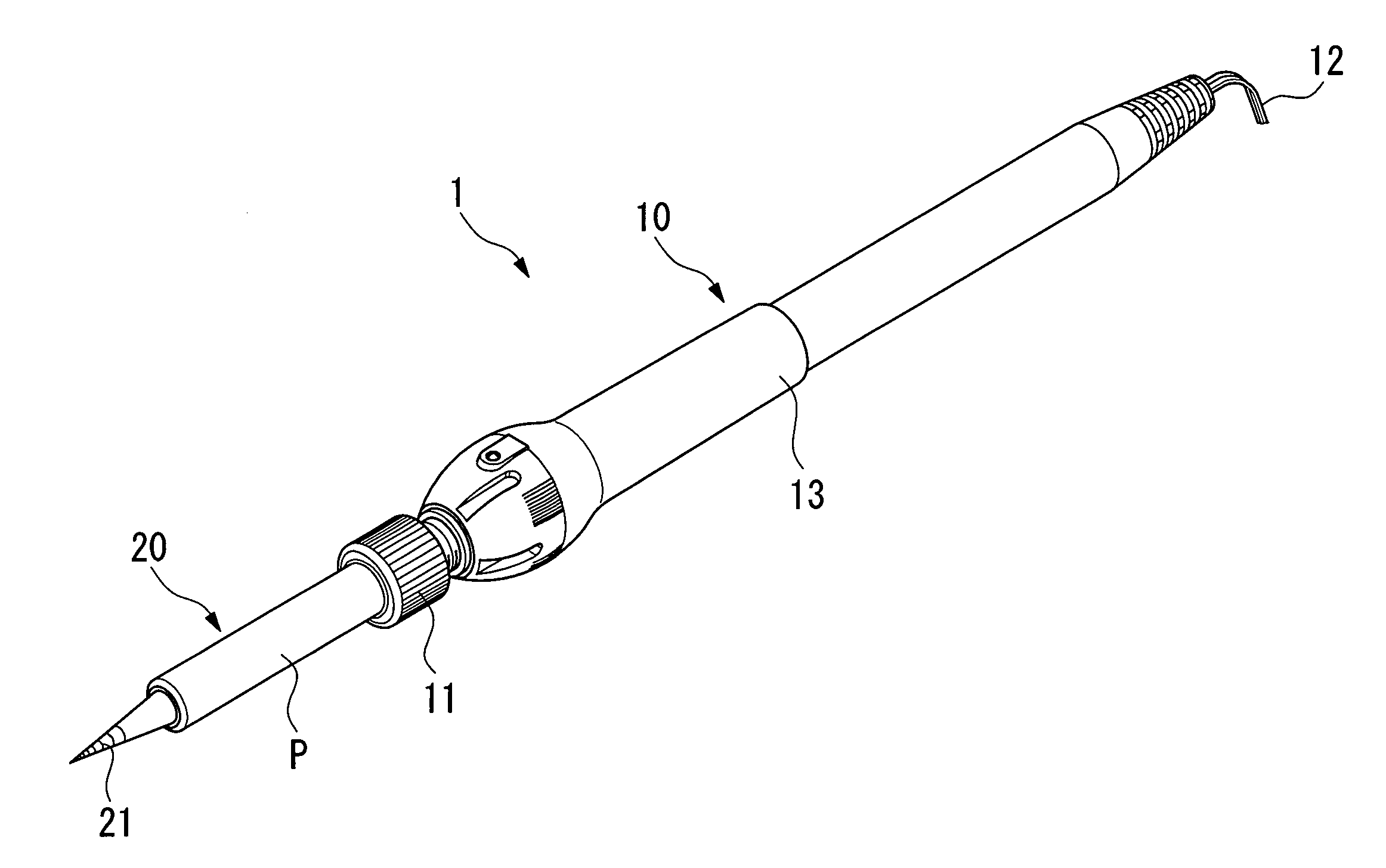

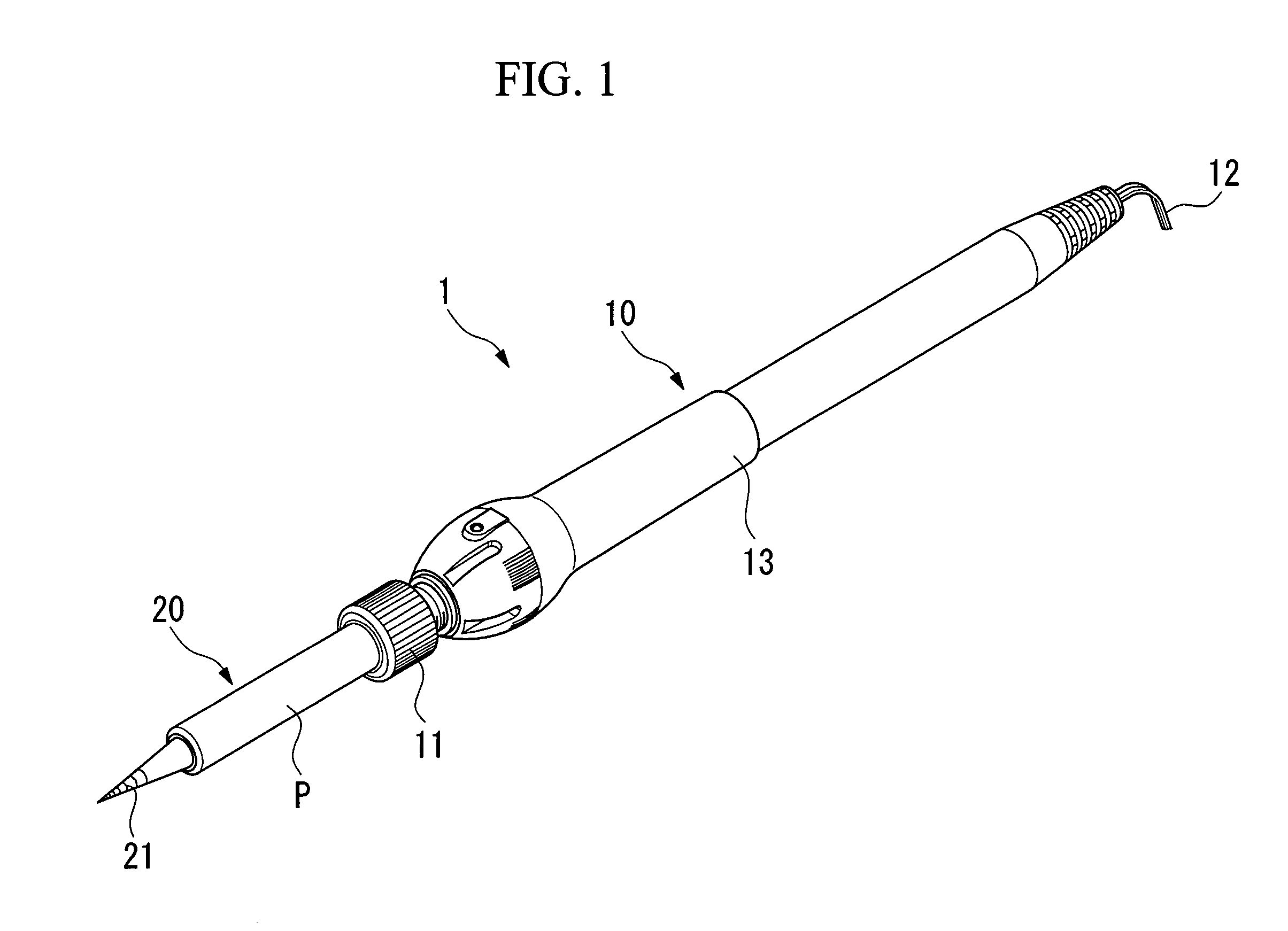

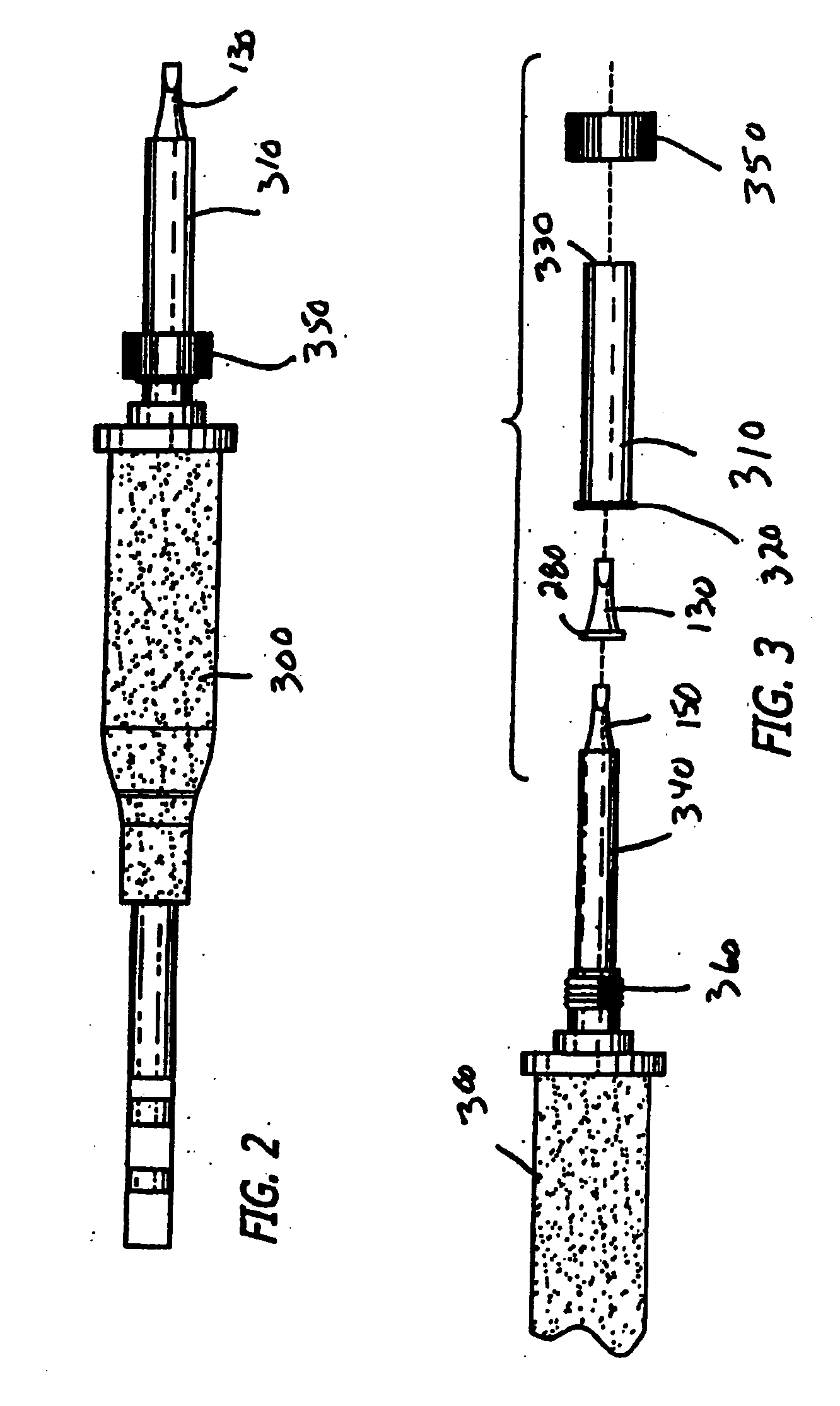

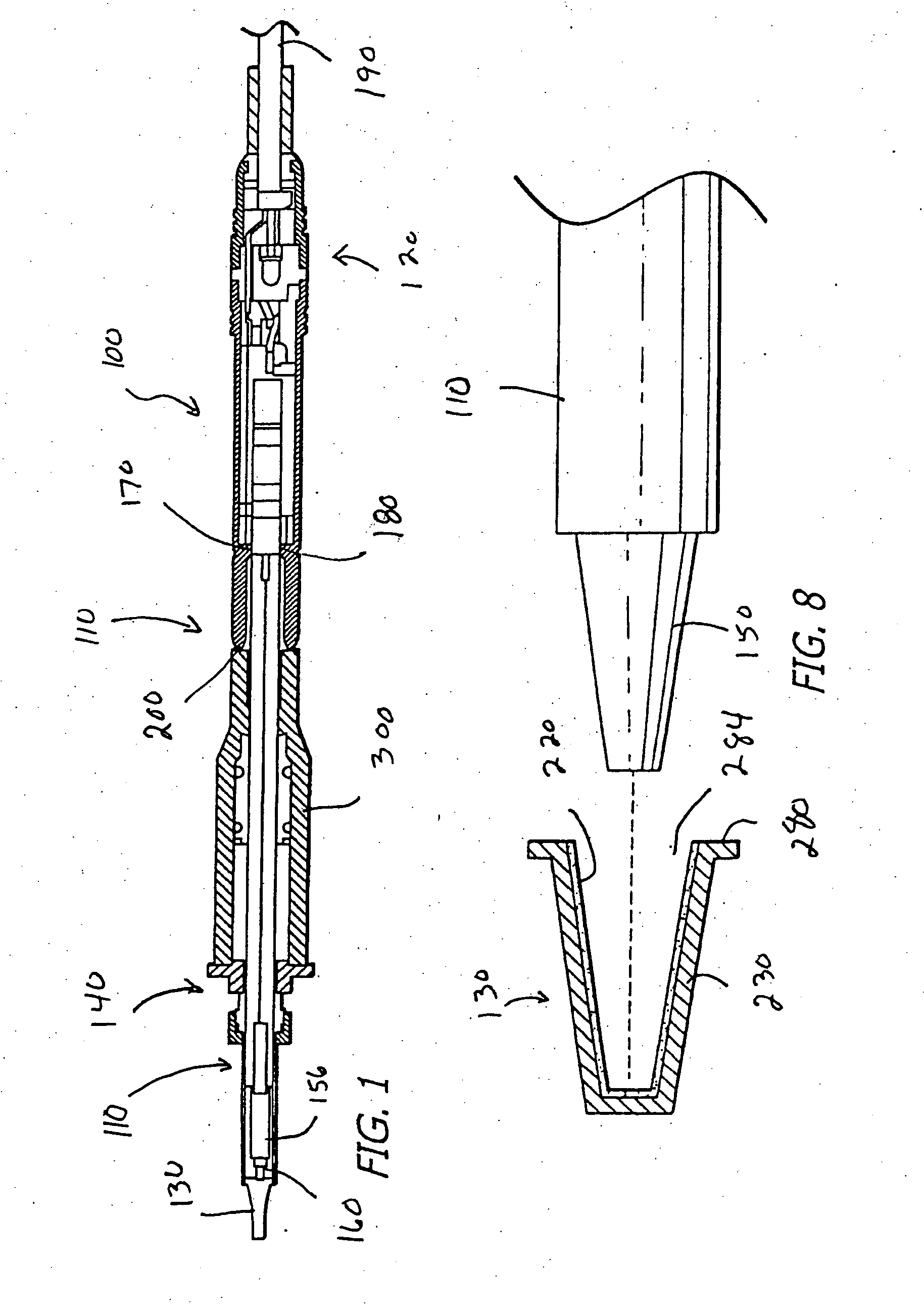

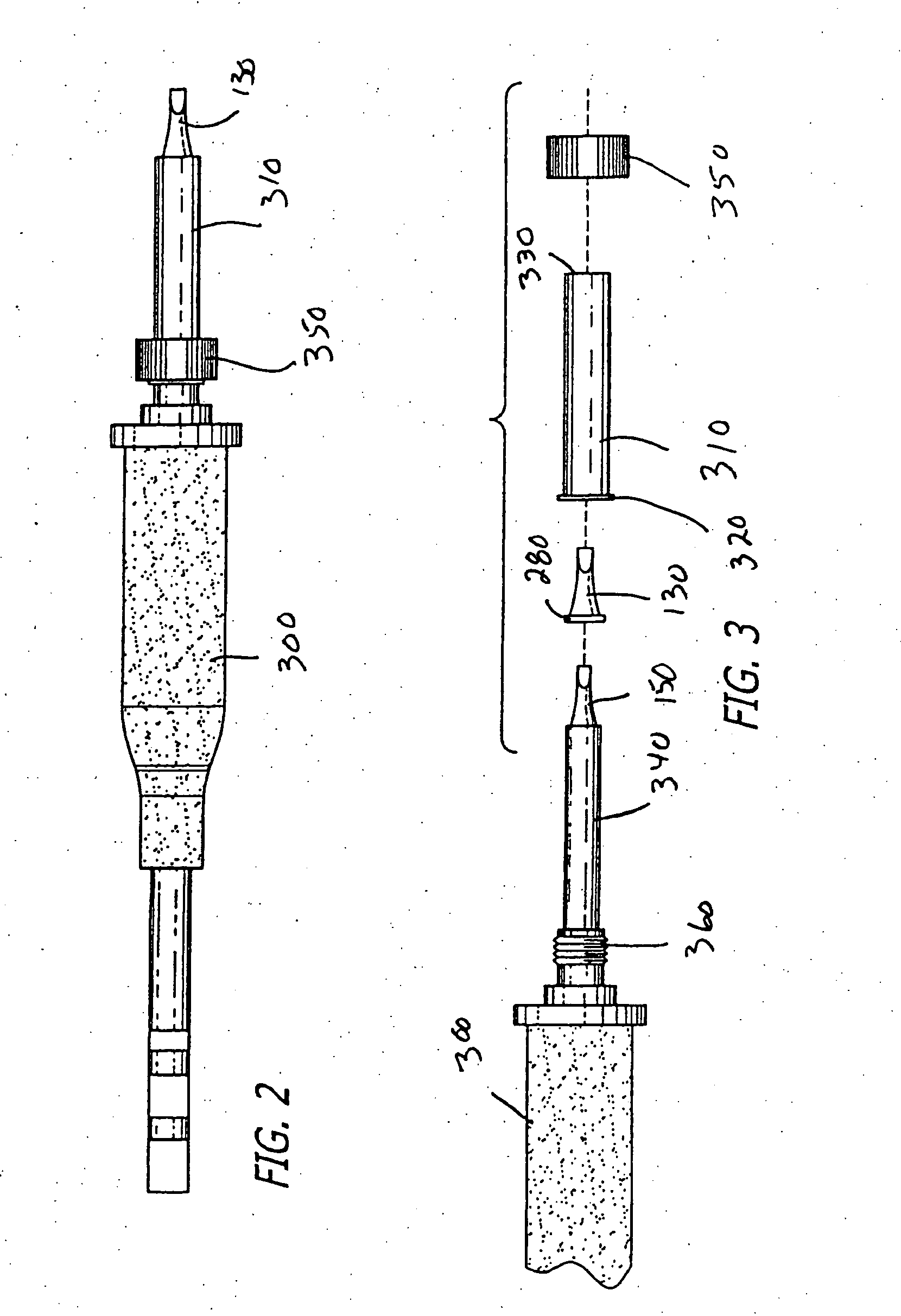

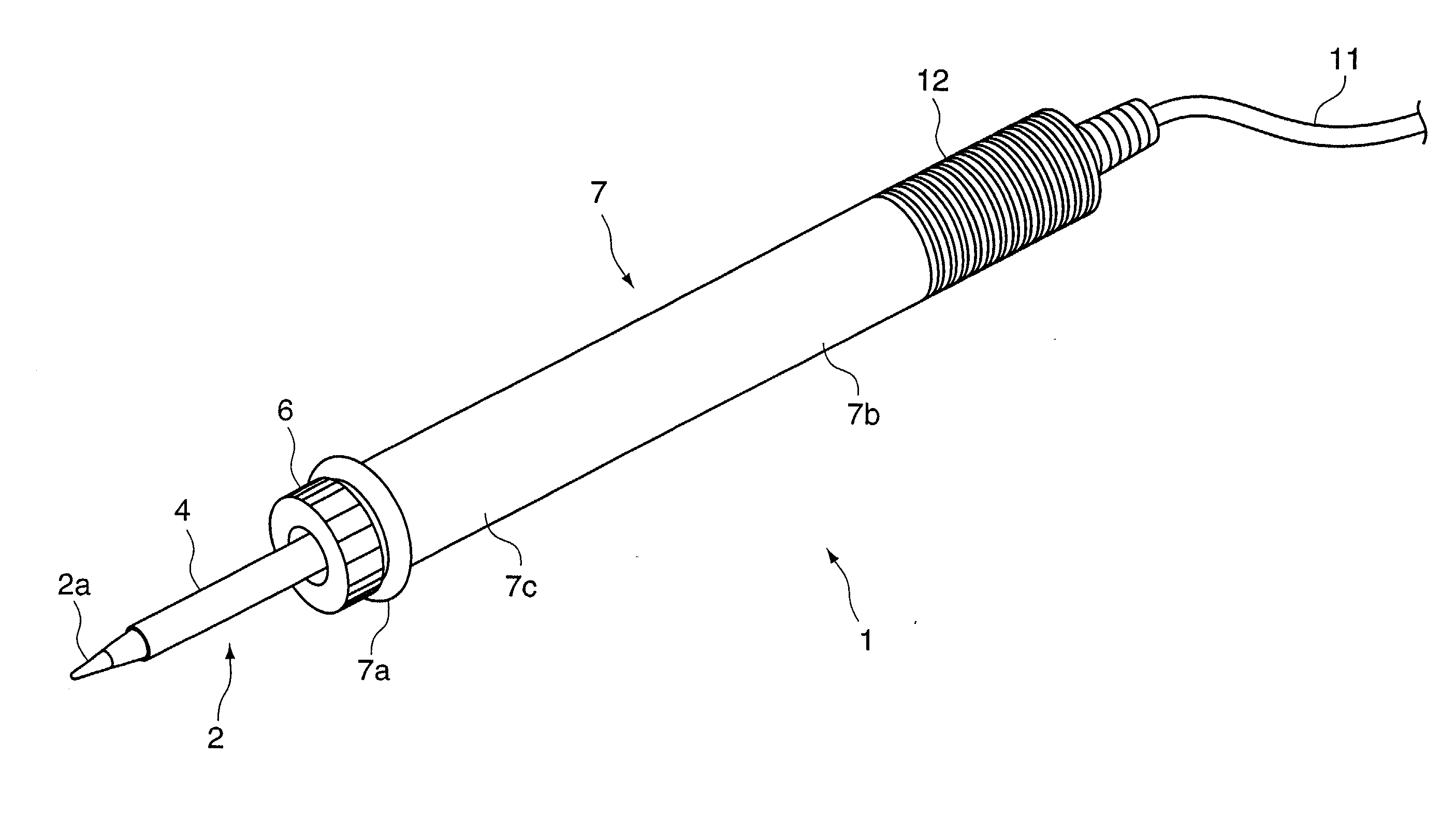

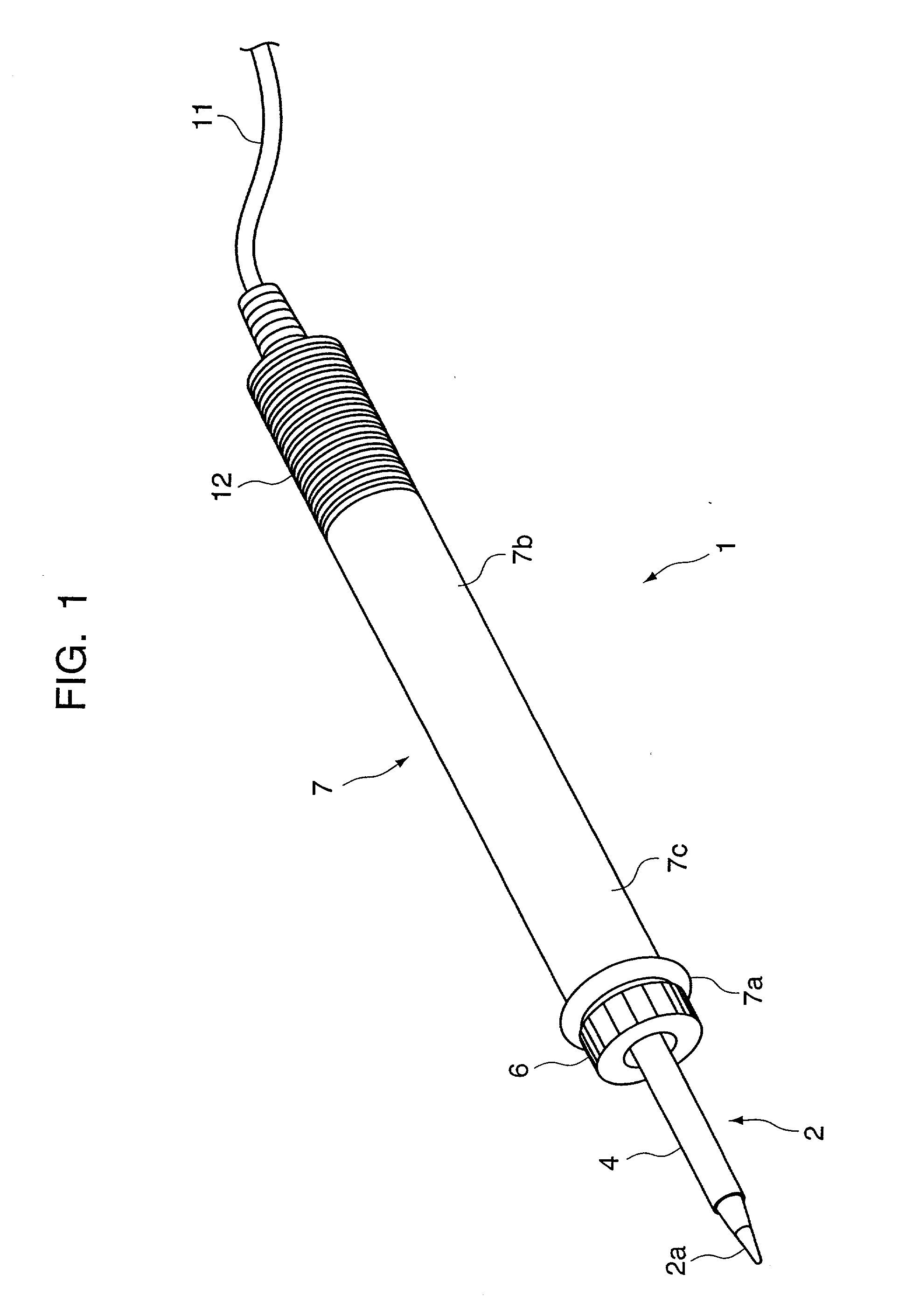

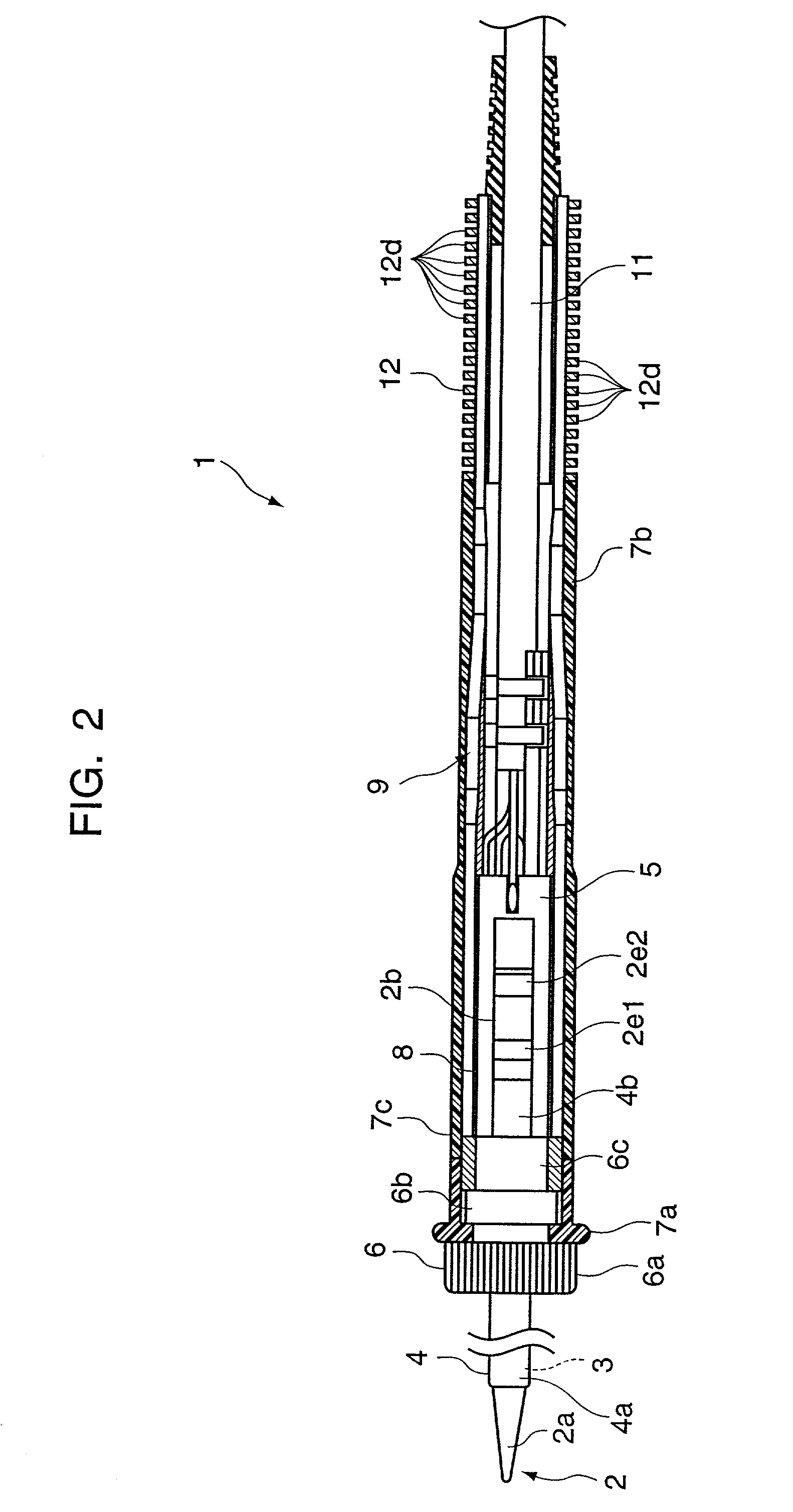

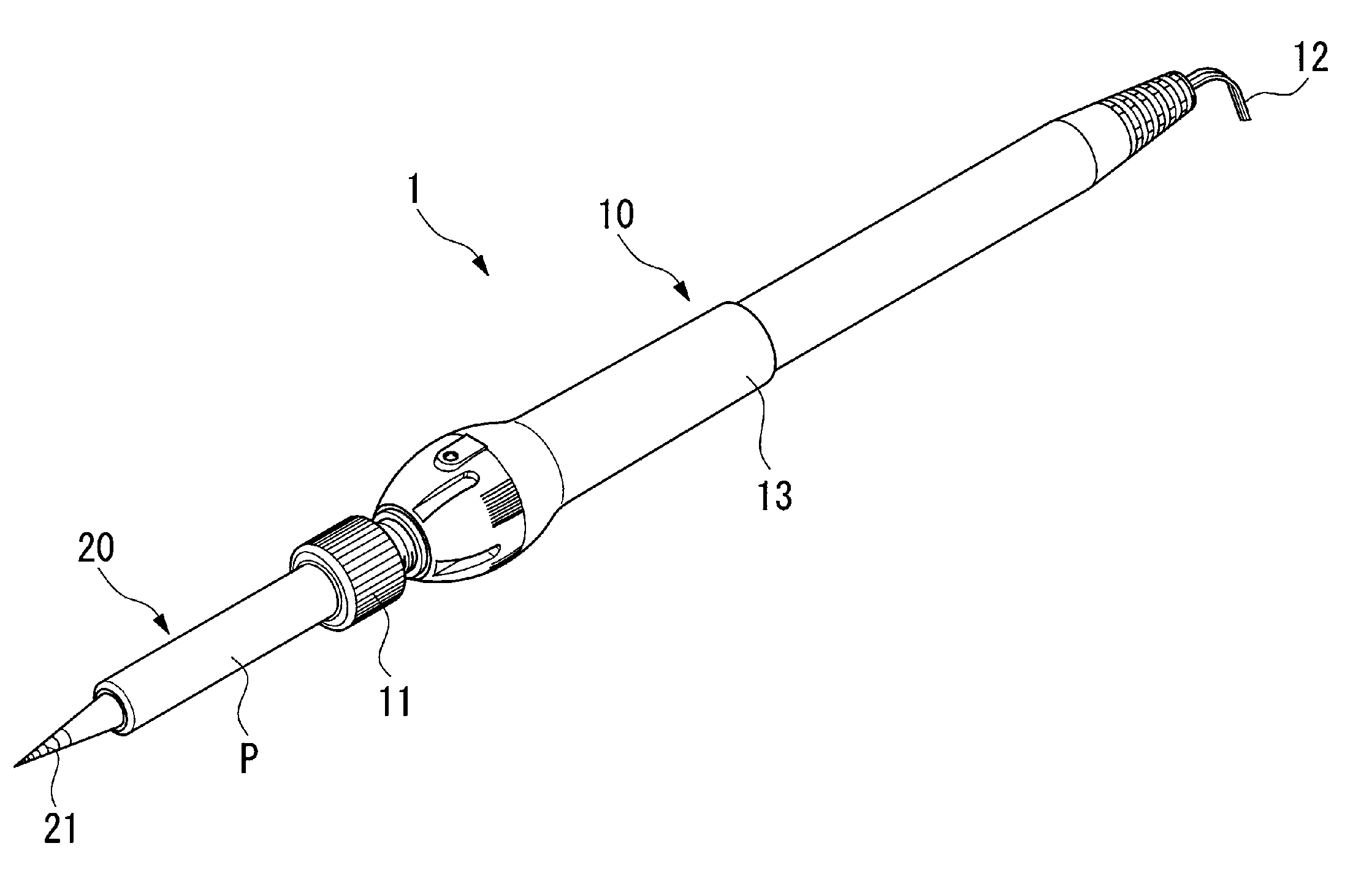

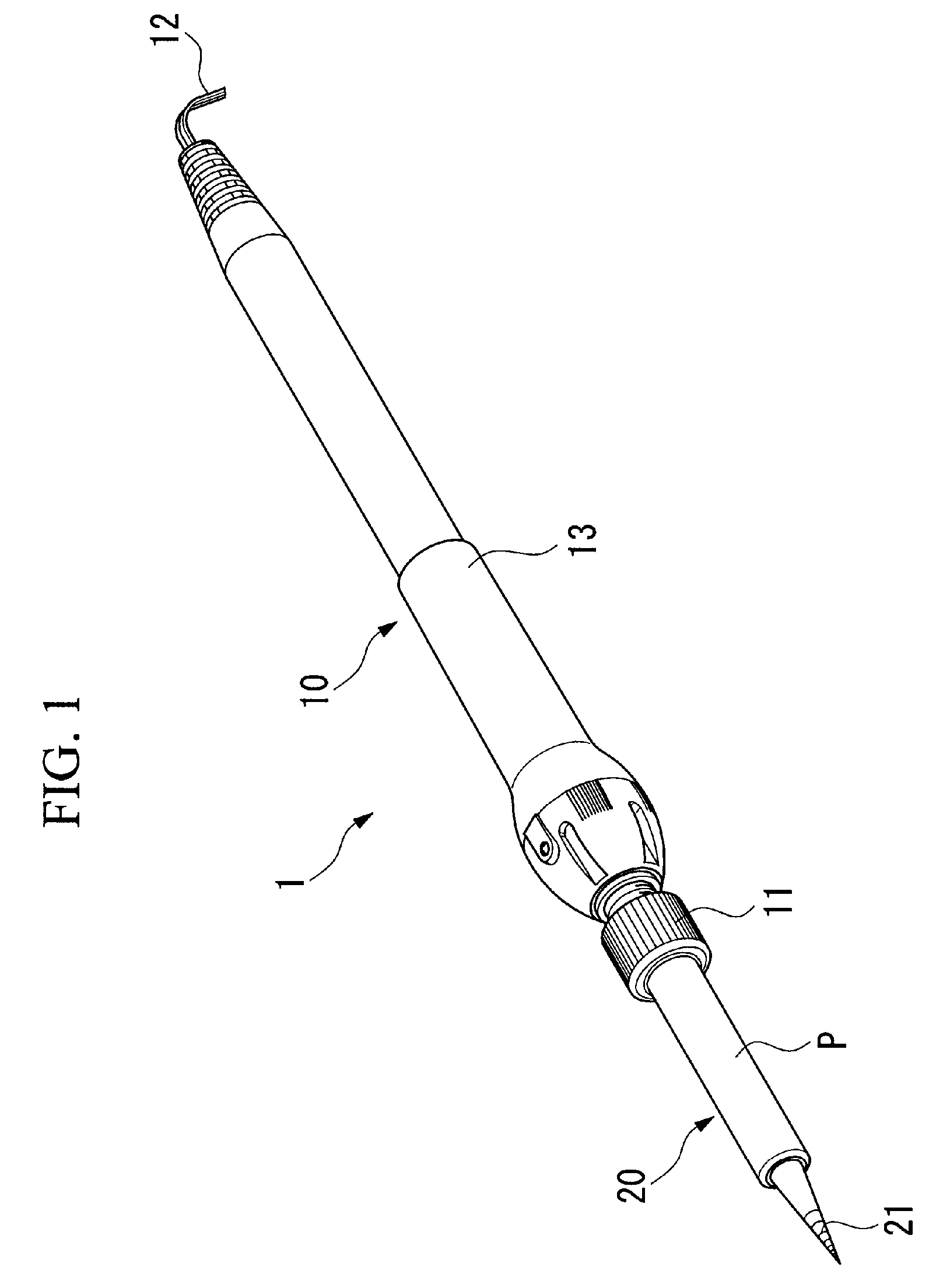

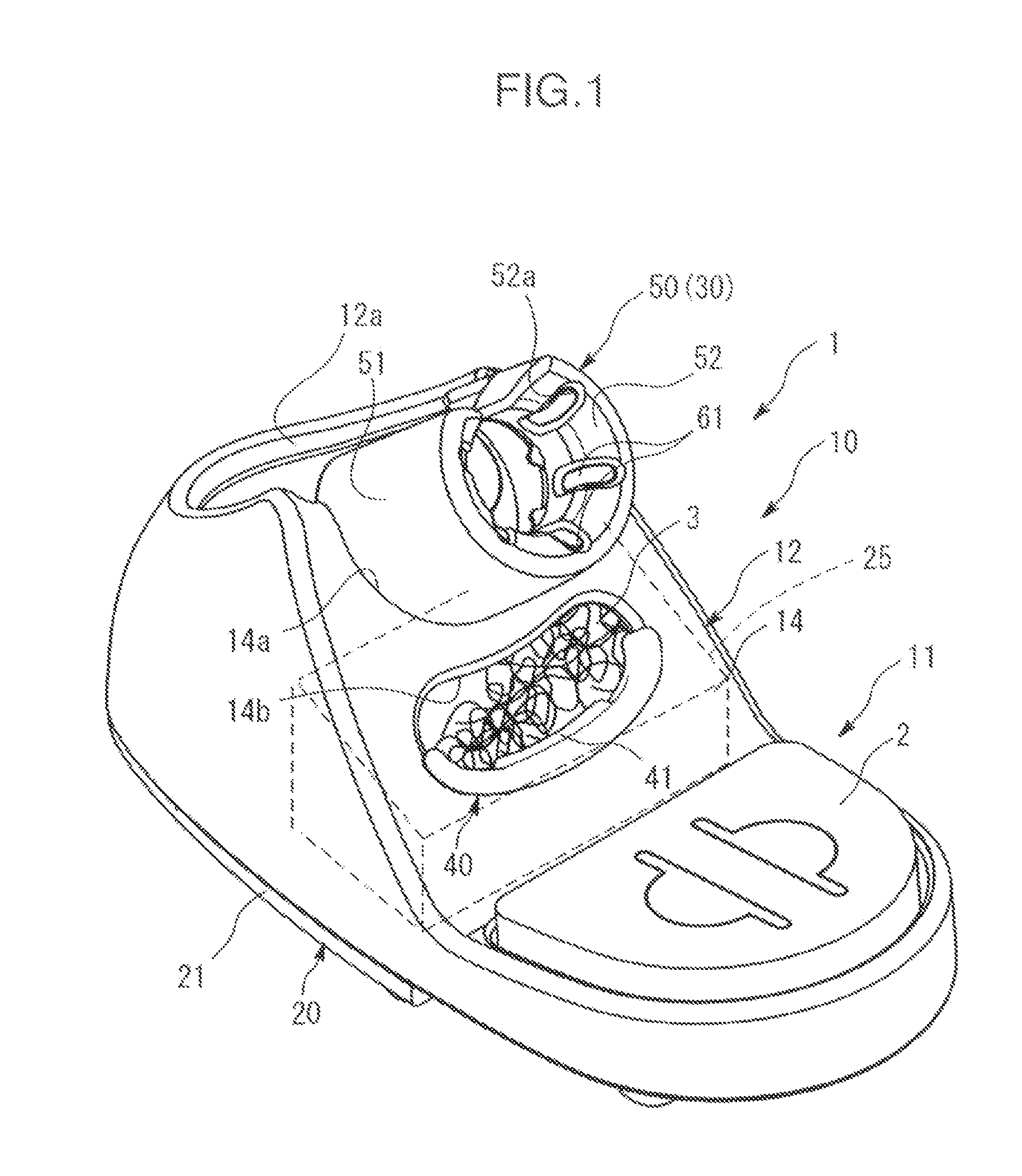

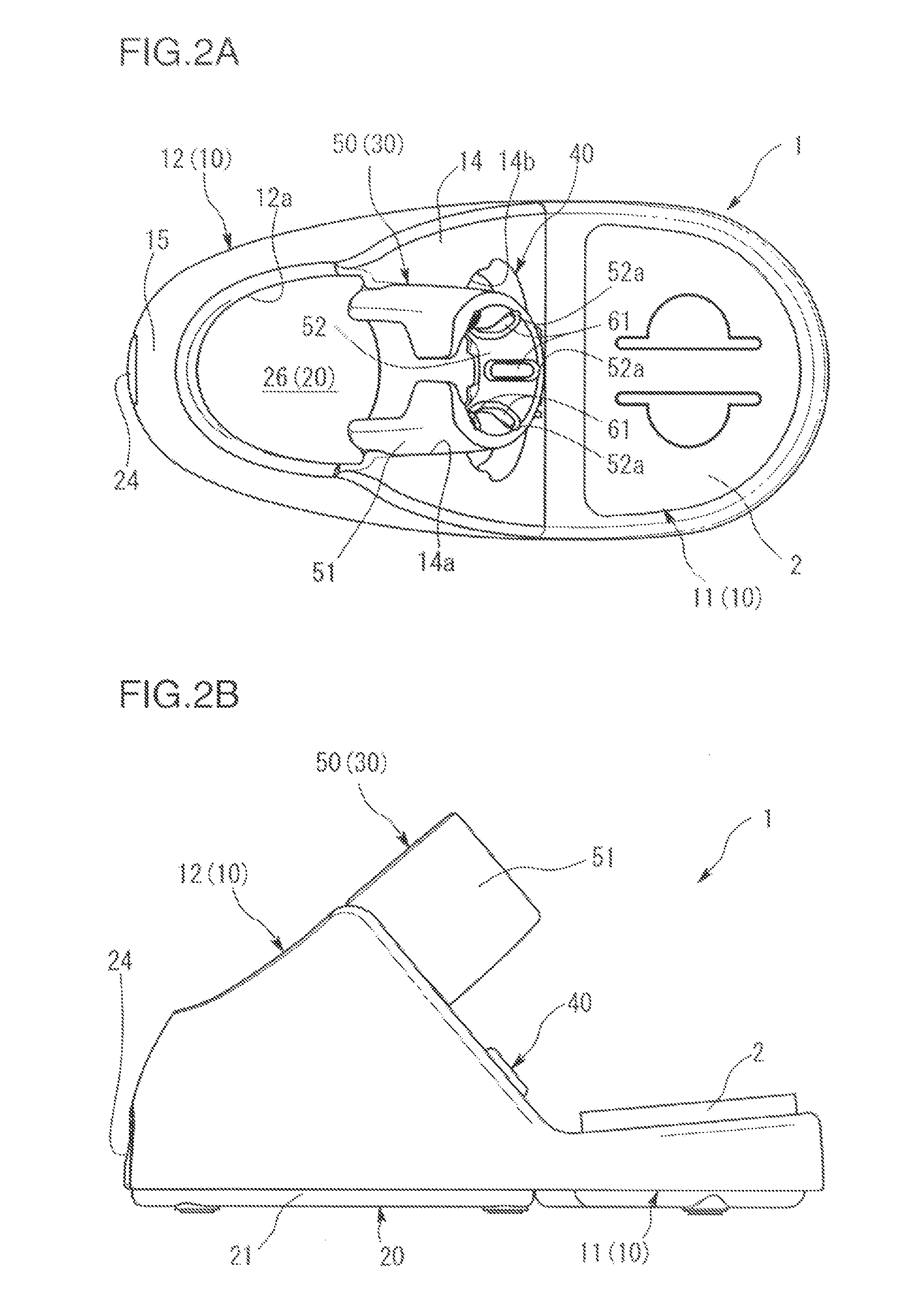

Cartridge-type soldering iron

ActiveUS20050092729A1Prevent oxidationGuaranteed to workHair dryingHeating element shapesEngineeringMechanical engineering

A soldering iron is configured to heat its tip and emit inert gas near the tip. This is accomplished by providing a heater cartridge having a heater pipe with a tip portion and a base portion. The heater pipe has a first hole in the tip portion and a second hole at the base portion. The heater pipe has a passage between the first and second holes so that gas can enter through the second hole and exit through the first hole. The heater cartridge has a grip handle between the tip and base portions of the heater pipe. The soldering iron has a handle base with a cavity adapted to receive the base portion of the heater pipe and at least a portion of the grip handle. The handle base is adapted to provide power and gas to the base portion of the heater pipe. The heater pipe transfers the power and gas from the base portion to the tip portion to heat the tip and emit gas near the tip. The cavity of the handle base is configured to substantially seal gaps between the grip handle and the handle base so that gas does not leak between the handle base and the grip handle.

Owner:HAKKO CO LTD

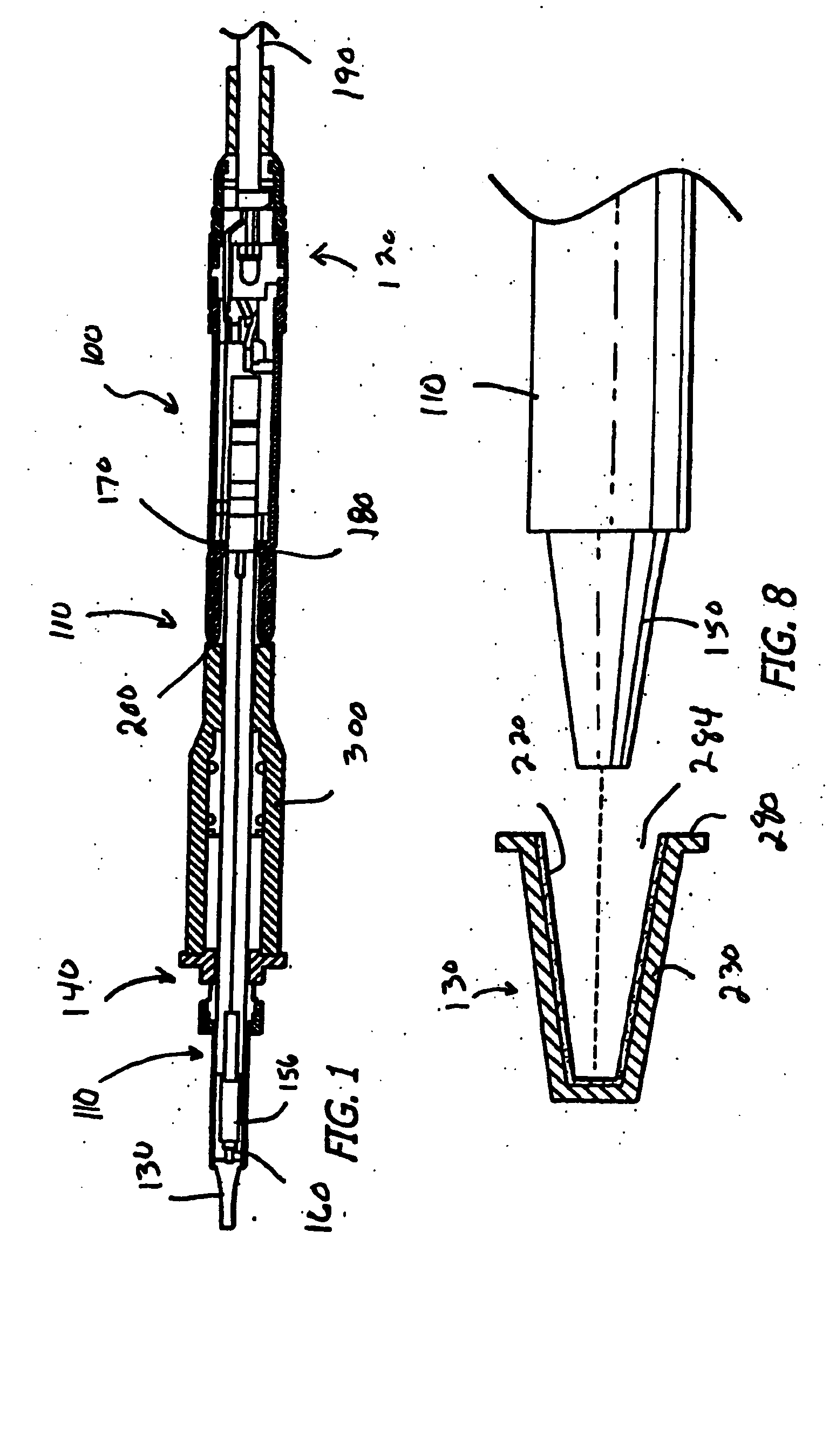

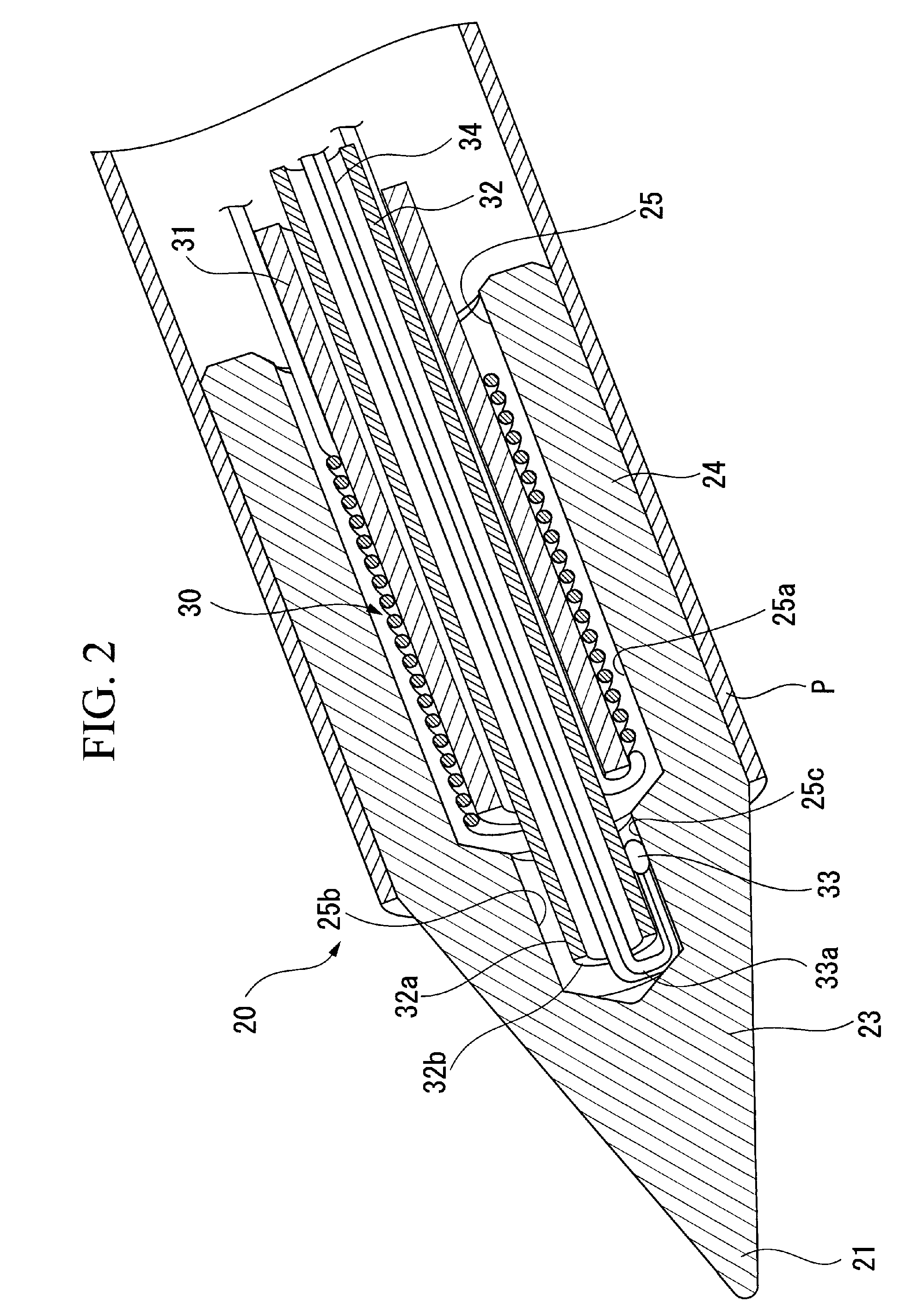

Soldering iron and method of manufacturing same

ActiveUS20060108345A1Heating fastIncrease heatHeating element shapesHeating appliancesBiomedical engineeringSoldering iron

A soldering iron provided with a soldering tip that melts solder at a distal end, having inside said soldering tip a substantially cylindrical insertion fit recess portion extending from a proximal end of the soldering tip to the distal end, opening at the proximal end, and a heater formed into a coil shape and whose surface is covered with an insulating oxide film being fittingly inserted into the insertion fit recess portion.

Owner:TAIYO ELECTRIC IND

Soldering iron tip with metal particle sintered member connected to heat conducting core

ActiveUS7030339B2Increase plate thicknessExtended processing timeHeating element shapesSoldering bitsCeramic coatingHeat conducting

A soldering iron tip having a copper or copper alloy core and a metal particle sintered member connected to the core to transfer heat therefrom to form a working soldering tip. The sintered member can be manufactured by powder metallurgy from a base material (iron, nickel and / or cobalt particles) and an additive (silicon, copper, silver, tin, boron and / or carbon particles) where needed. The sintered member can be formed as a cap which is fitted onto the working tip with a silver paste sandwiched therebetween, a brazing filler metal ring is positioned between an abutment shoulder and the cap, flux applied to the joint and the cap brazed into place. A metal, cermet or ceramic coating sprayed on the outer surface of the core, except for the (masked) working tip end, is not wettable by solder. An Ag—Al—Cu alloy coating layer in the rearwardly-disposed cavity improves heat conduction from the heater therein.

Owner:HAKKO CO LTD

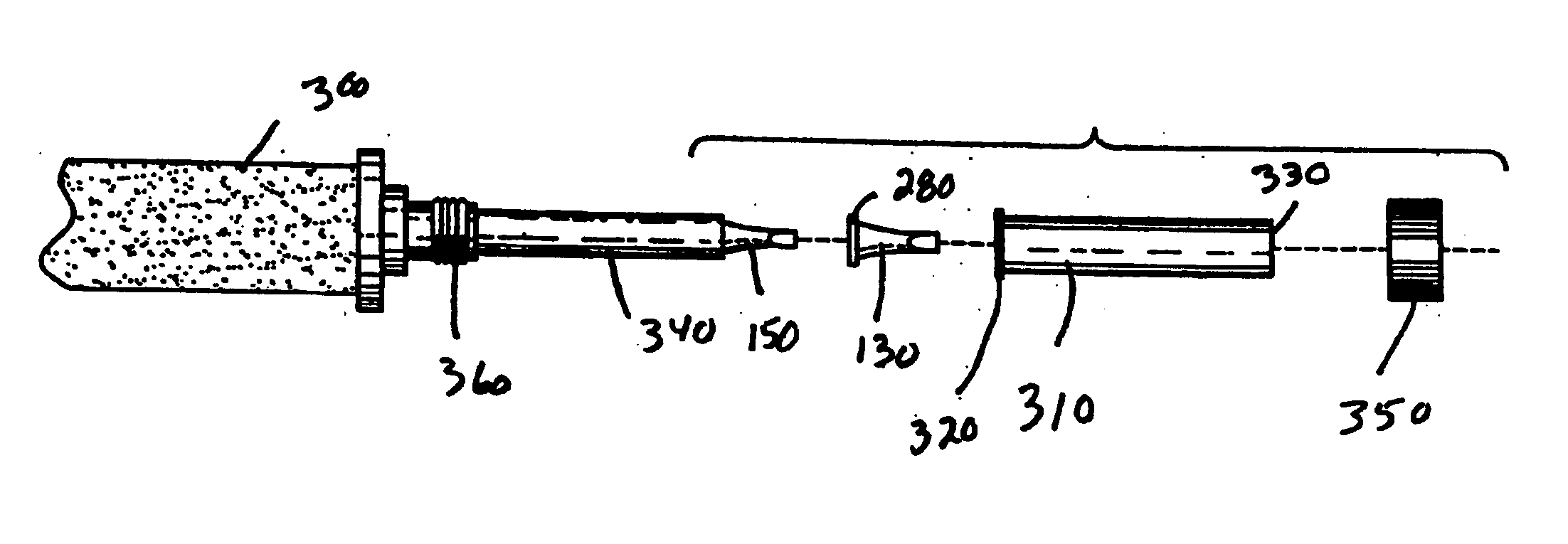

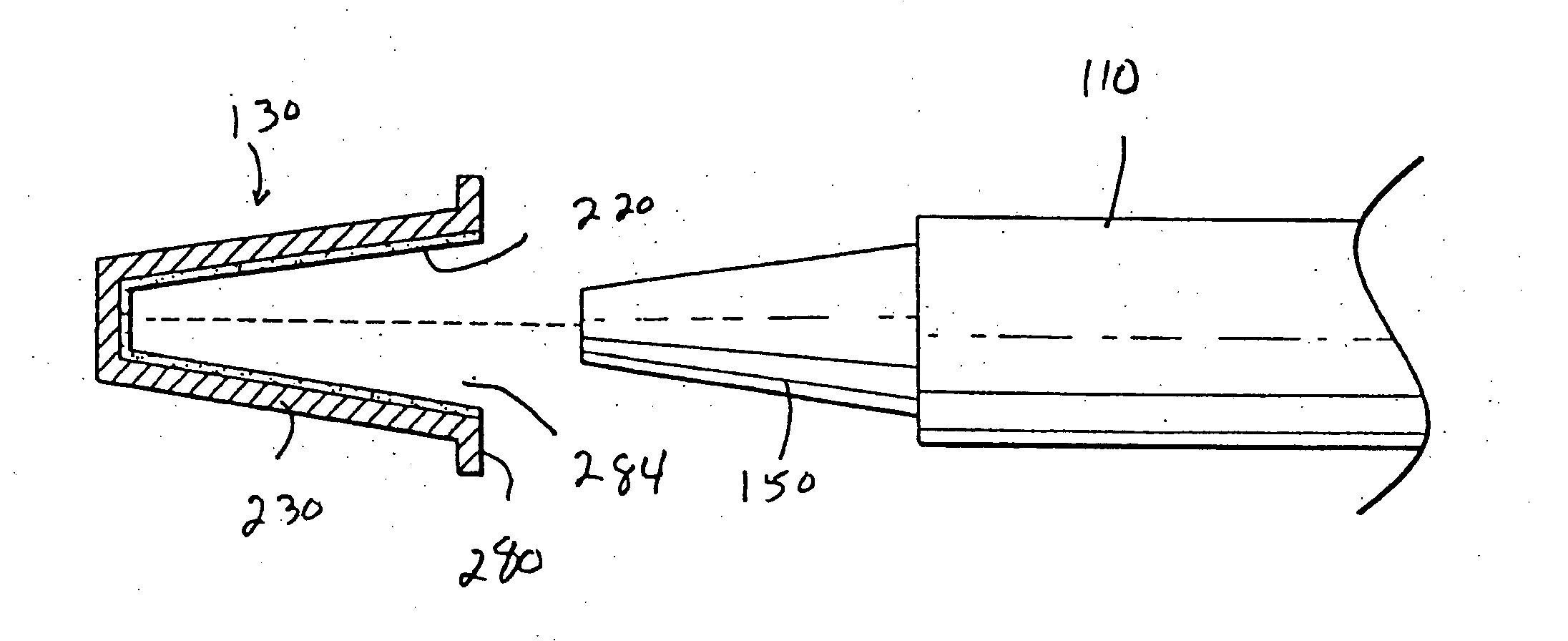

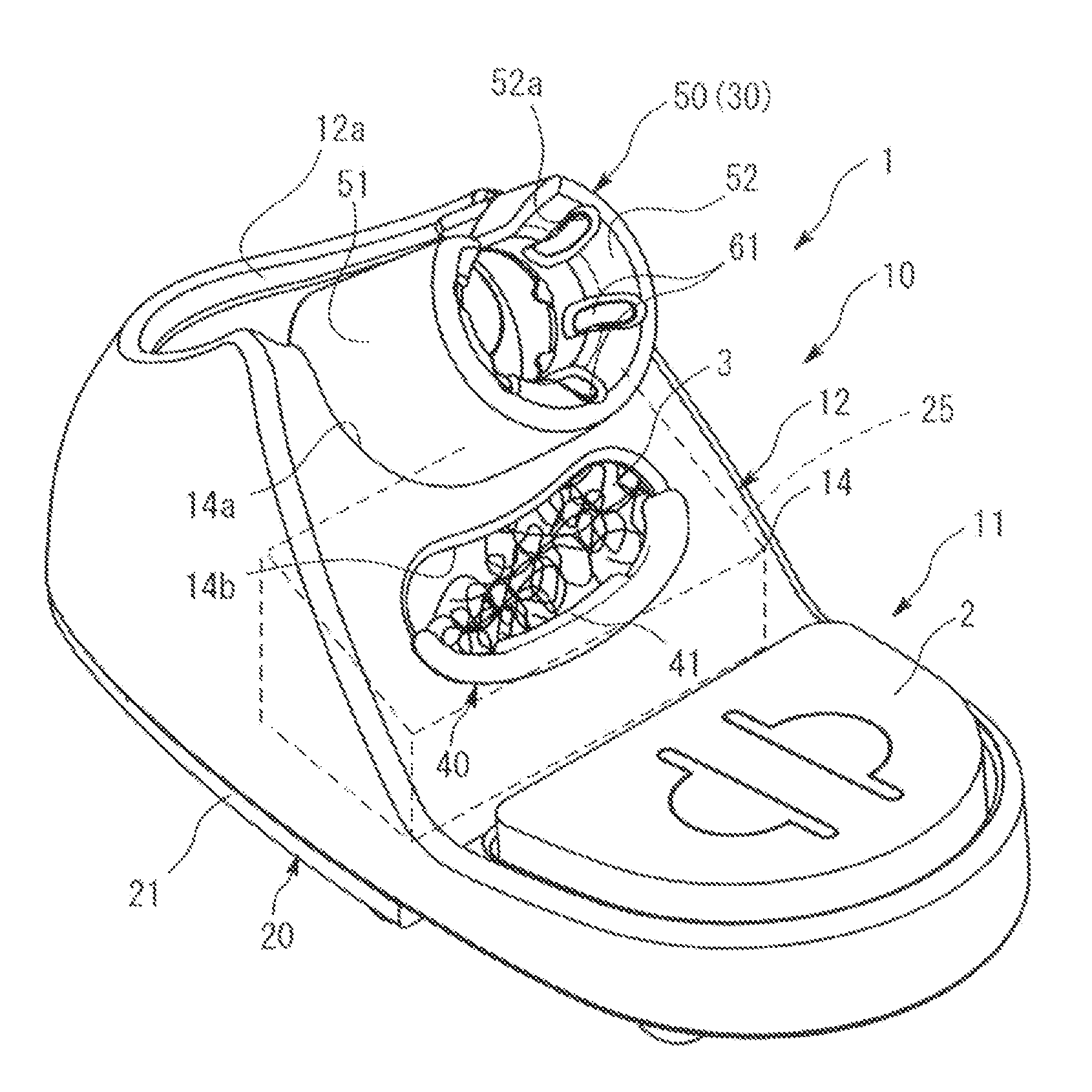

Soldering iron with replaceable tip

ActiveUS20060022018A1Improve thermal conductivityImprove the immunityHeating element shapesSoldering ironHeat conductingCoil spring

A soldering iron (and a desoldering iron) with a replaceable tip, which is releasably securable on the forward heat-conducting end of a soldering (or desoldering) iron heat assembly. The tip has a tapered heat conducting core in a tip cap. The face of the core can have a depression for mating engagement with a protrusion of the heat-conducting end. Also, the face can lie in the rear plane of the tip cap. An assembly which allows for the easy removal and application of a replacement tip can include a sleeve with tightening bolt, a coil spring sleeve, or a slotted compressible sleeve. The tip can thus be replaced after it has worn out, and the heat assembly unit need not be replaced until it has burnt out. Methods of manufacturing and using the tip are also disclosed.

Owner:HAKKO CO LTD

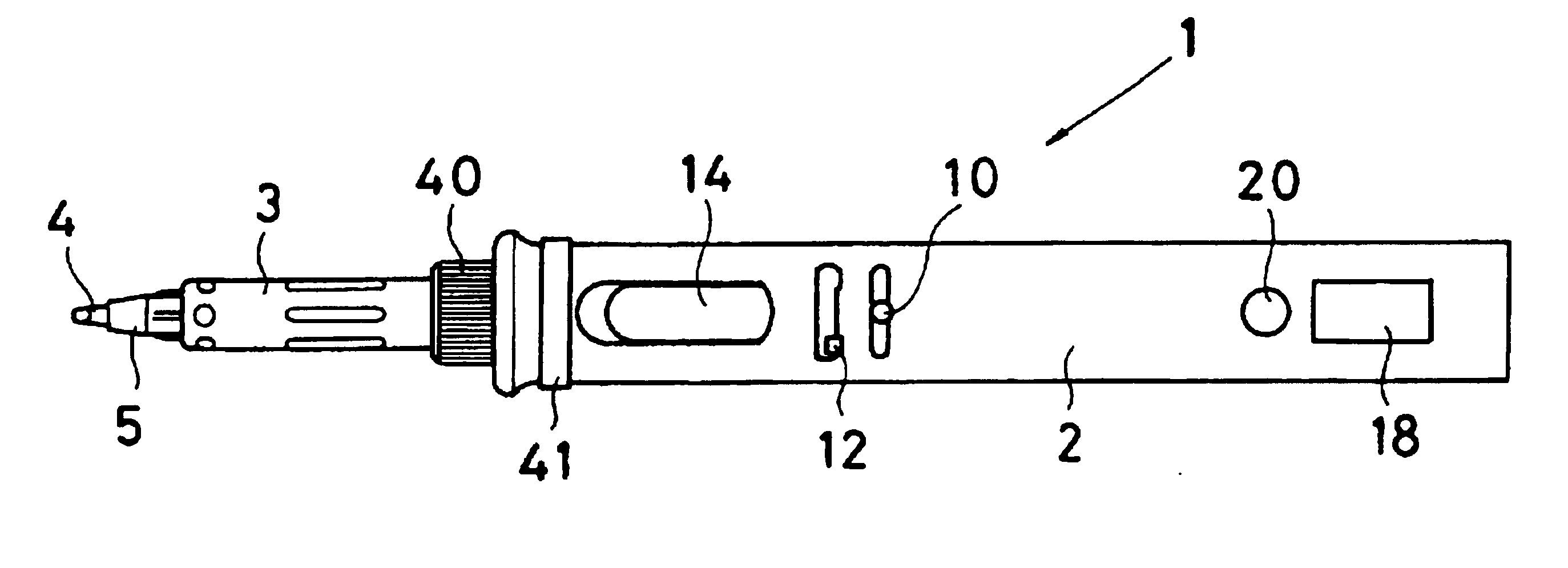

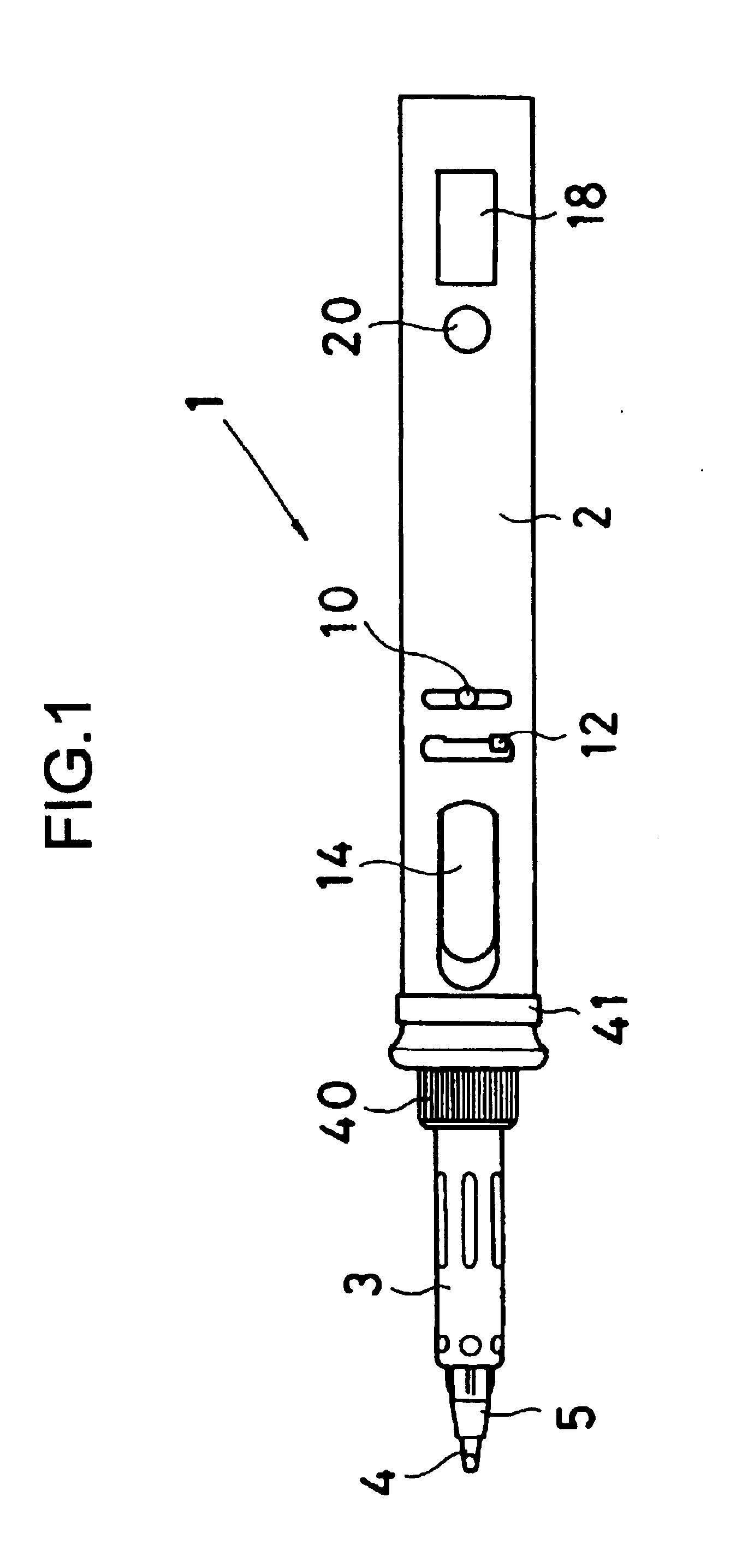

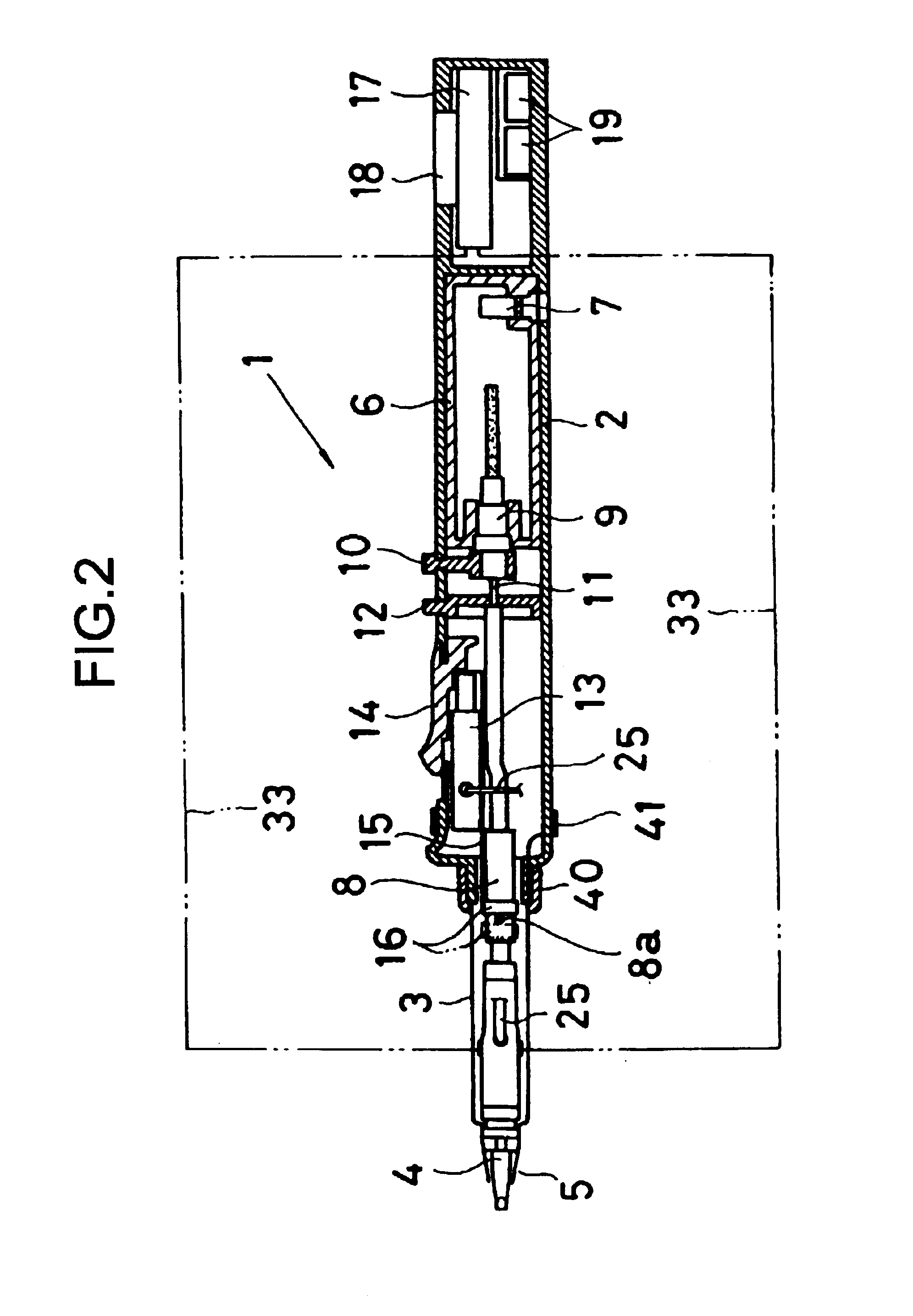

Soldering tool

InactiveUS6874671B2Prevent oxidationExtend working lifeHeating appliancesCombustion using catalytic materialElectricityEngineering

A soldering iron capable of eliminating static charges accumulated on an operator or materials to be soldered simply without using no particular charge elimination device, the soldering iron comprising a combustion catalyst for complete combustion of a gas mixture of a fuel gas and air, a soldering iron tip heated by the combustion catalyst, a gas conduit for exhausting a combustion exhaust gas from the combustion catalyst along the outer circumference of the soldering iron tip toward the top end, and an electric conduction mechanism for electrically connecting an operator for conducting soldering and the soldering iron tip, fuel gas combustion products which are ionized and forming steams upon catalytic combustion contributing to charge elimination.

Owner:NAKAJIMA DOKOSHO CO LTD

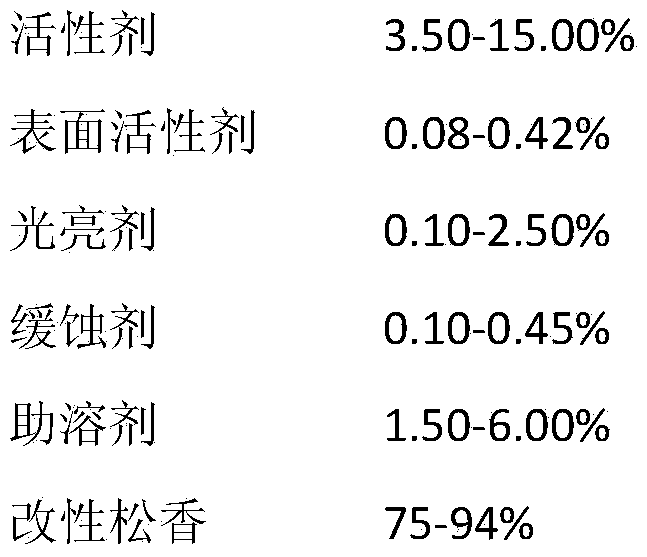

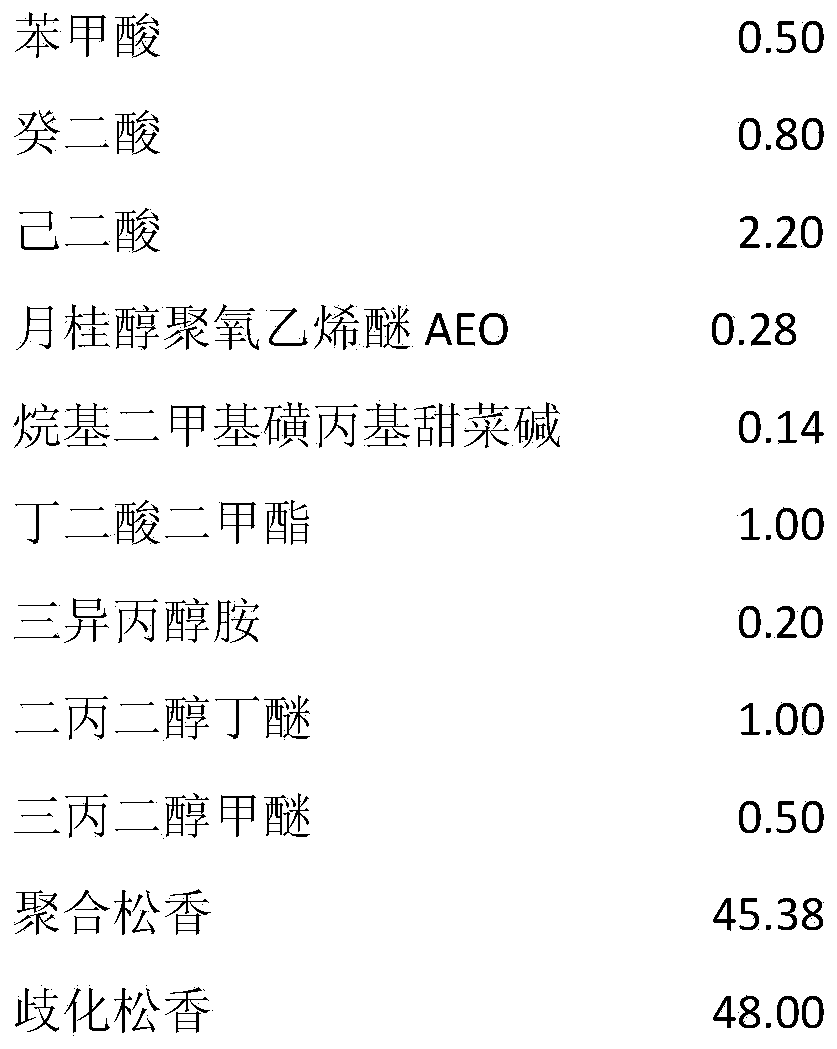

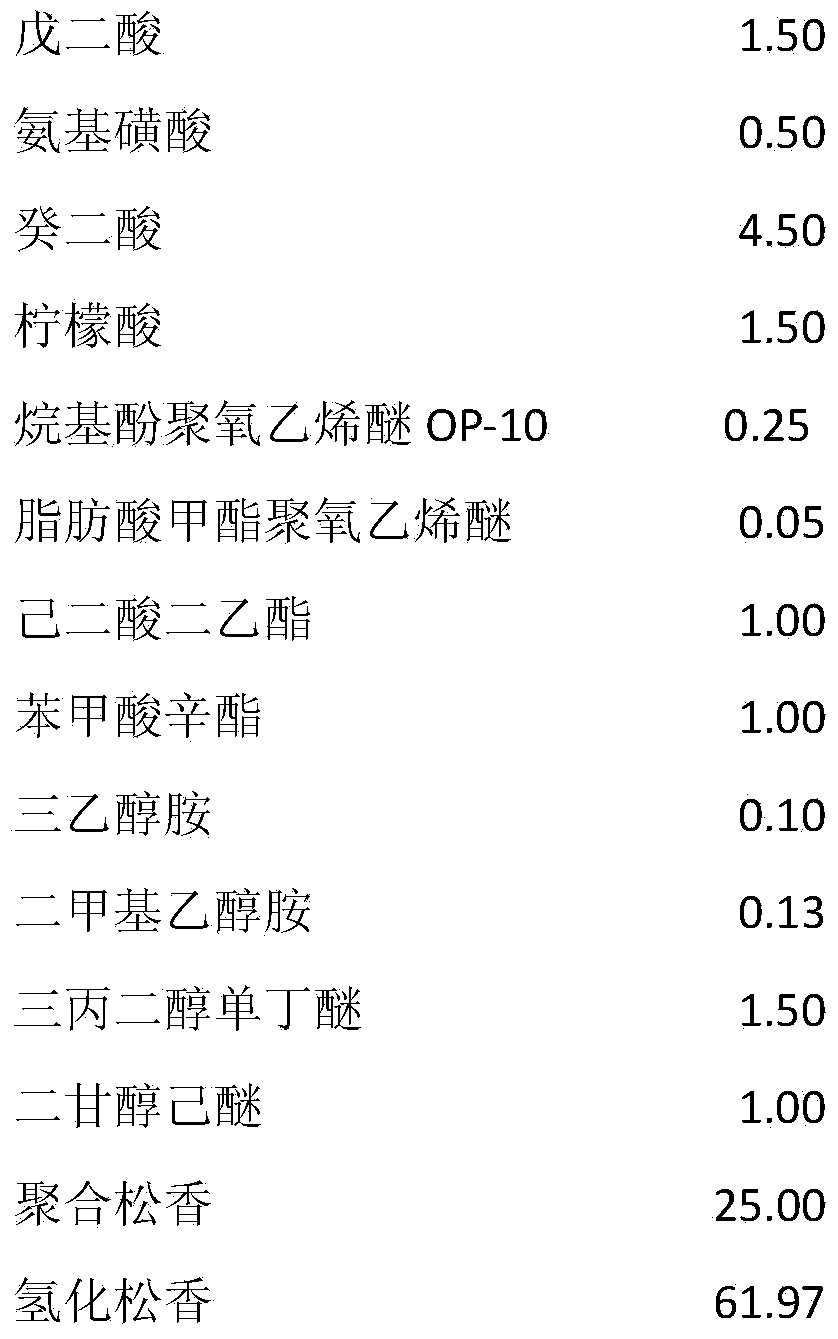

Abietyl-based soldering flux for halogen-free no-clean bright solder wire and preparation method thereof

InactiveCN104070308AIncrease brightnessGood specular reflection abilityWelding/cutting media/materialsSoldering mediaTinningElectricity

The invention discloses an abietyl-based soldering flux for a halogen-free no-clean bright solder wire and a preparation method thereof. The abietyl-based soldering flux comprises, by mass, raw materials including active agent 3.50-15.00%, surface active agent 0.08-0.42%, brightener 0.10-2.50%, corrosion inhibitor 0.10-0.45%, cosolvent 1.50-6.00% and the balance modified rosin. The ingredient proportion in the abietyl-based soldering flux is suitable for manufacture of lead-free solder wires containing the soldering flux in cores, and the soldering flux can be used for automatic welding or manual soldering iron welding. When the solder wire welding is adopted, the process stability is good, tinning speed is high, the splashing amount is small, the defects including continuous tinning, solder skips, insufficient solder, icicles and the like in the welding process can be decreased, welding spots are bright and full after welding, residues are few, the corrosivity is low, cleaning is not needed, and the surface electrical insulation property is excellent after the welded solder wires are placed for a long period of time.

Owner:SOUTH CHINA UNIV OF TECH

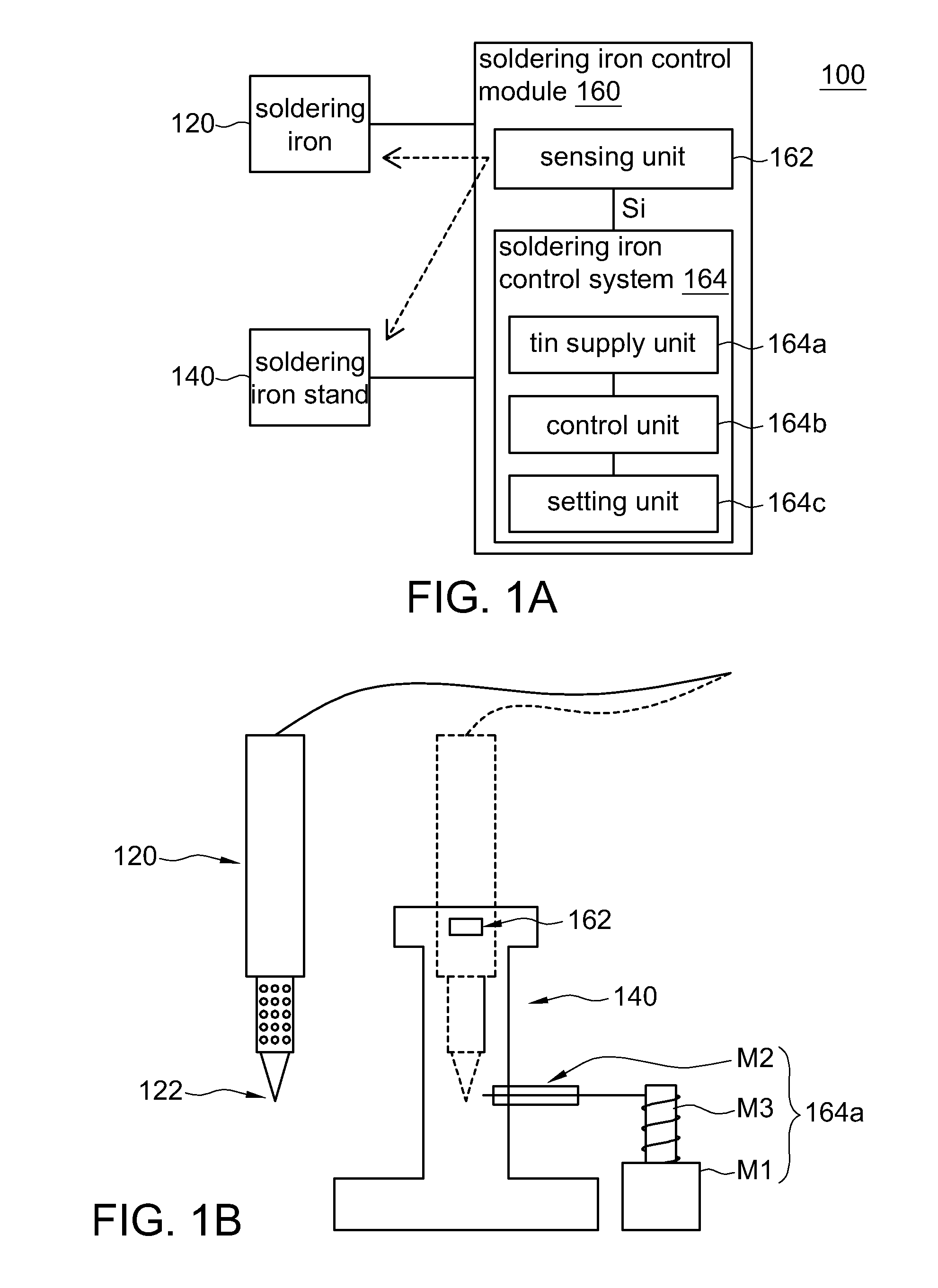

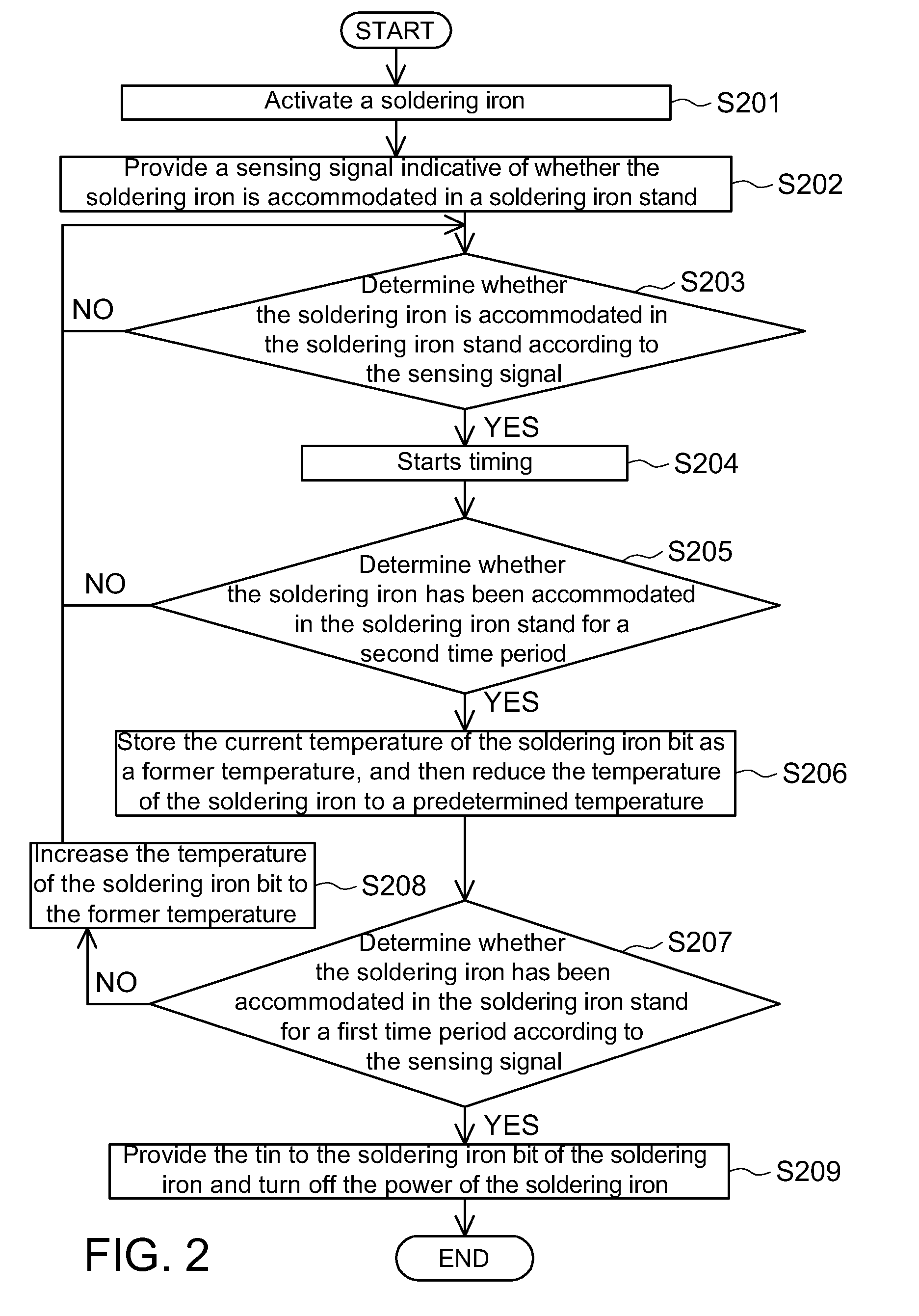

Soldering iron device, soldering iron control module and soldering control method thereof

InactiveUS20100084455A1Extend your lifeAutomatic control devicesPrecision positioning equipmentControl systemEngineering

A soldering iron control module applied to a soldering iron and a soldering iron stand is provided. The soldering iron stand accommodates the soldering iron which has a soldering iron bit. The soldering iron control module includes a sensing unit and a soldering iron control system. The sensing unit provides a sensing signal indicating whether the soldering iron is accommodated in the soldering iron stand. The soldering iron control system includes a tin supply unit and a control unit. The control unit determines whether the soldering iron has been accommodated in the soldering iron stand for a first time period according to the sensing signal. When the control unit determines that the soldering iron has been accommodated in the soldering iron stand for the first time period, the tin supply unit provides the tin to the soldering iron bit and the power of the soldering iron is turned off.

Owner:INVENTEC CORP

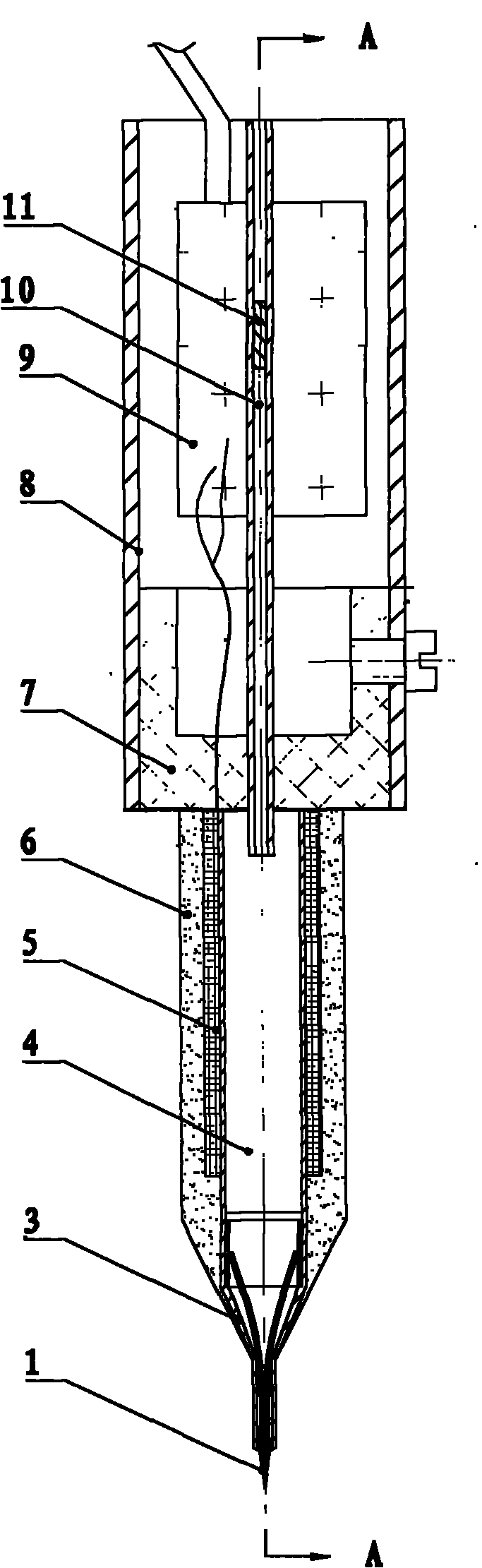

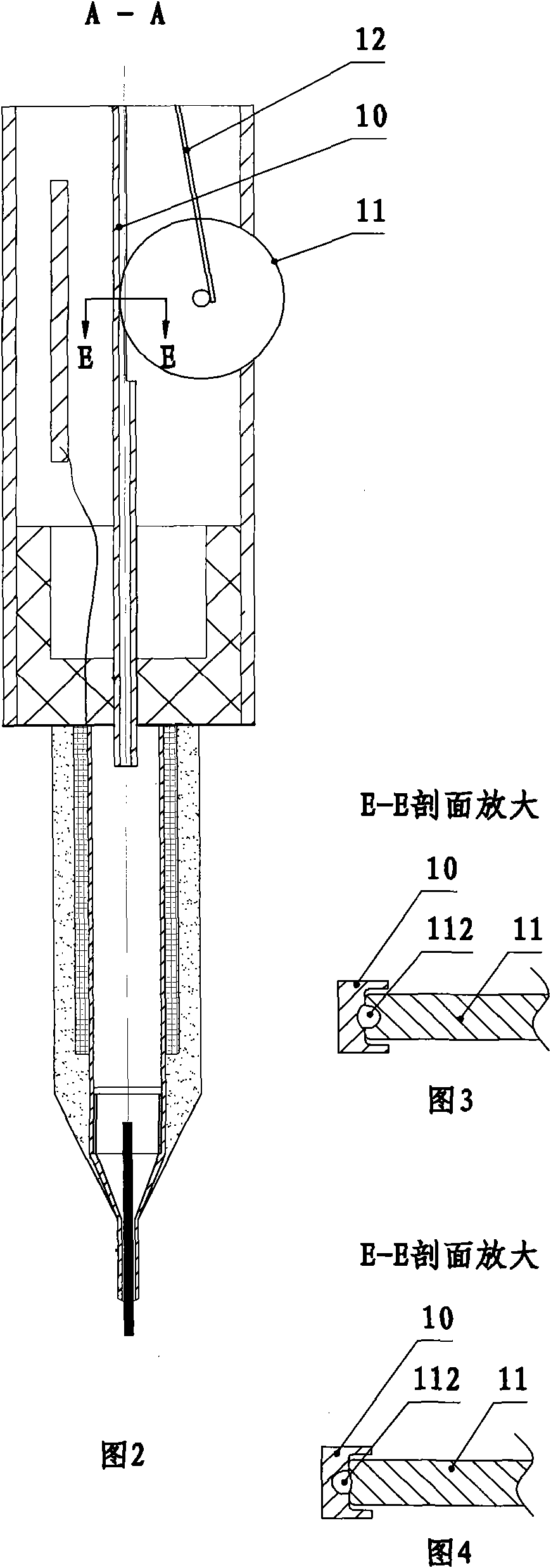

Press type automatic tin supply electric soldering iron

InactiveCN104526101AEasy to controlReal-time controlHeating appliancesSoldering ironInternal pressureElectronic industry

The invention relates to a press type automatic tin supply electric soldering iron which comprises a soldering iron head, a heating device, a tin melting device, a pressure piston and a handle device. The soldering iron head, the tin melting device and the pressure piston are combined together. Inner cavities of the soldering iron head, the tin melting device and the pressure piston are communicated and do not make contact with external air to form a closed inner cavity body. The heating device is mainly used for heating the soldering iron head and melting solid soldering tin in the tin melting cavity into molten tin. The tin melting cavity is mainly used for melting solid soldering tin. A inflator principle is adopted for the pressure piston, the internal pressure intensity can be changed by pushing a pressure rod, and therefore air flow is produced, and air is exhausted from an air outlet; the pressure rod is sleeved with a spring device which is used for making the electric soldering iron rapidly rotate back in a non-press state. The press type automatic tin supply electric soldering iron can be operated by one hand to control the amount of soldering tin, and can conduct automatic supply in real time and control the welding flow, effectively improve the welding efficiency in an electronic industry and save cost.

Owner:HUBEI UNIV OF TECH

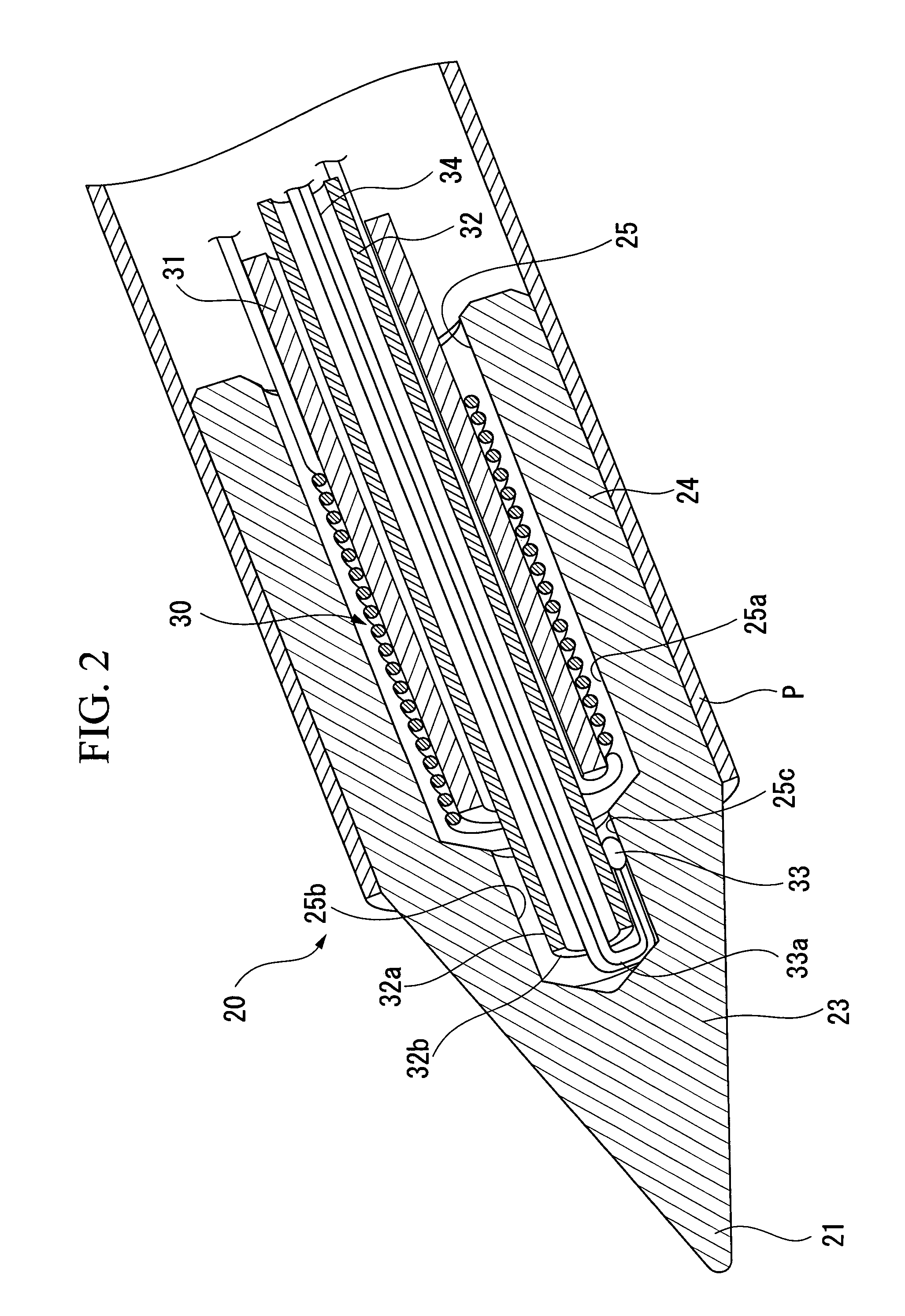

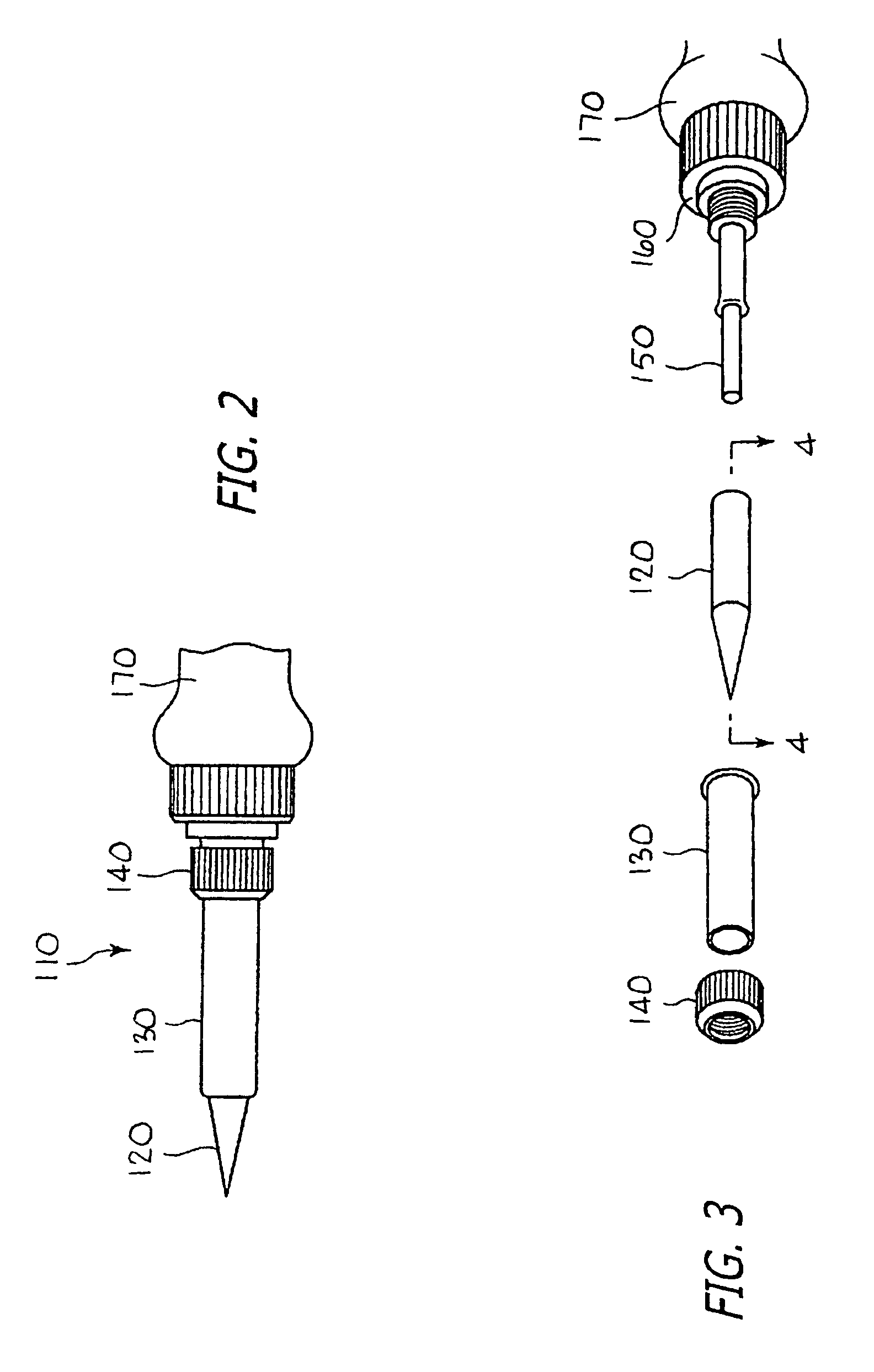

Soldering iron with replaceable tip cap

InactiveUS20050011876A1Improve thermal conductivityImprove the immunityHeating element shapesSoldering bitsConductive pasteHeat conducting

A soldering iron (and a desoldering iron) with a replaceable tip cap are herein disclosed. The replaceable tip cap is fitted on the forward heat-conducting core end of a soldering (or desoldering) iron heat assembly. Conductive paste, powder or a low melting temperature material such as solder, can be sandwiched between the tip cap and the forward end to improve heat conductivity therebetween. An assembly which allows for the easy removal and application of a replacement tip cap can include a sleeve with tightening bolt, a coil spring sleeve, or a slotted compressible sleeve. The tip cap can thus be replaced after it has worn out, and the heat assembly unit need not be replaced until it has burnt out.

Owner:HAKKO CO LTD

Soldering iron with heat pipe

InactiveUS20030146264A1Shorten the lengthLow costHeating element shapesHeating appliancesMechanical engineeringHeat pipe

A soldering iron comprises a tip end; a heater portion for electrically heating the tip end of the soldering iron; a holding portion provided at the rear end of the heater portion: a heat pipe structure provided in the holding portion; a first heat pipe holder for holding a frontal portion of the heat pipe structure to which heat generated at the heater portion is transferred; a second heat pipe holder for holding a rear part of the heat pipe structure; and a grip portion placed externally around the first heat pipe holder.

Owner:HAKKO CO LTD

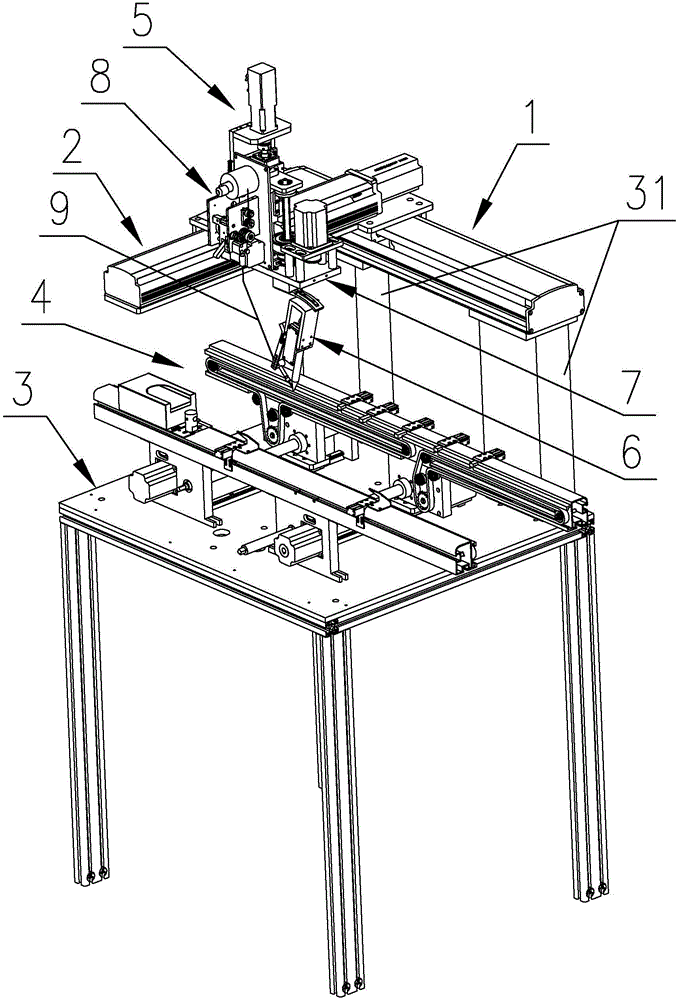

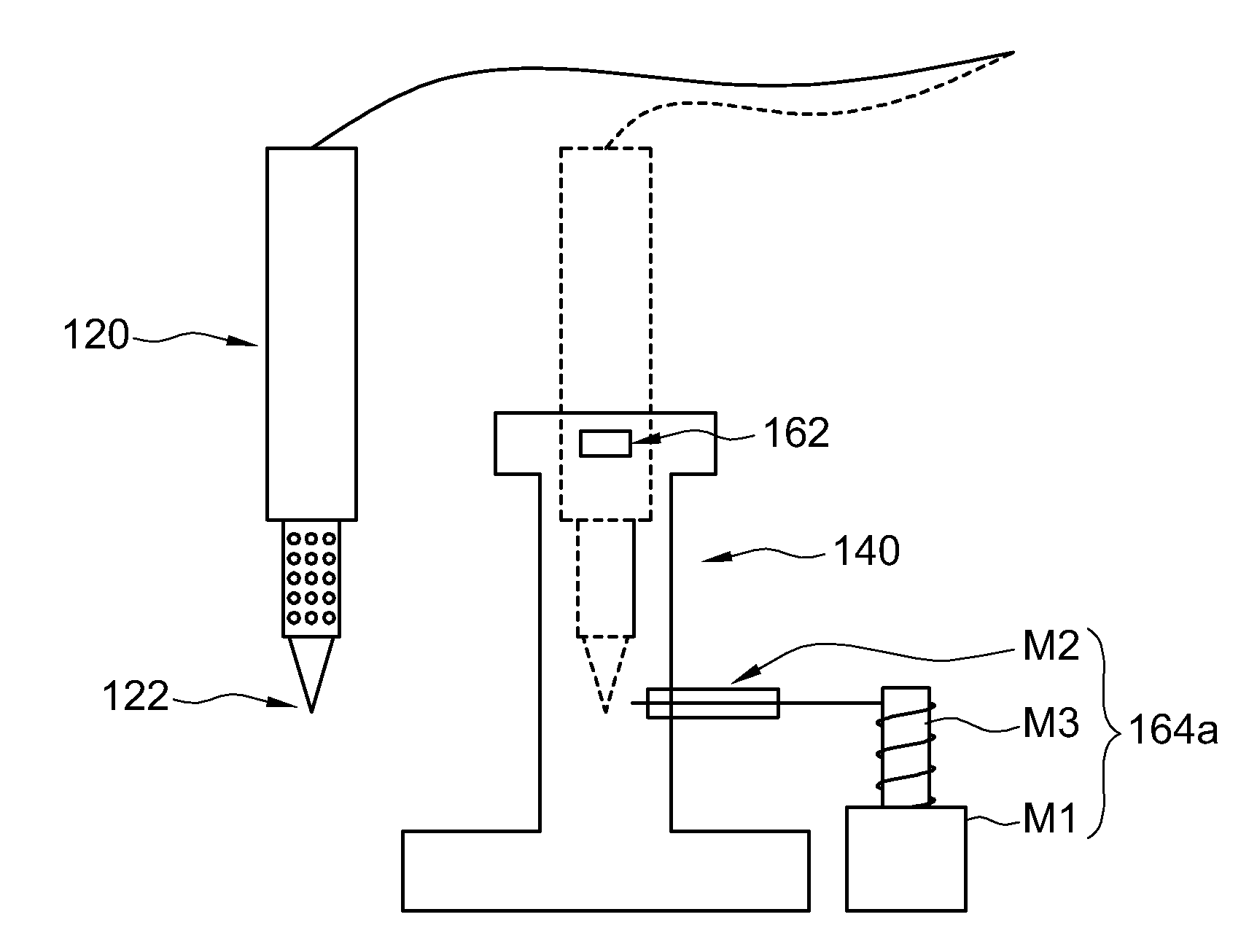

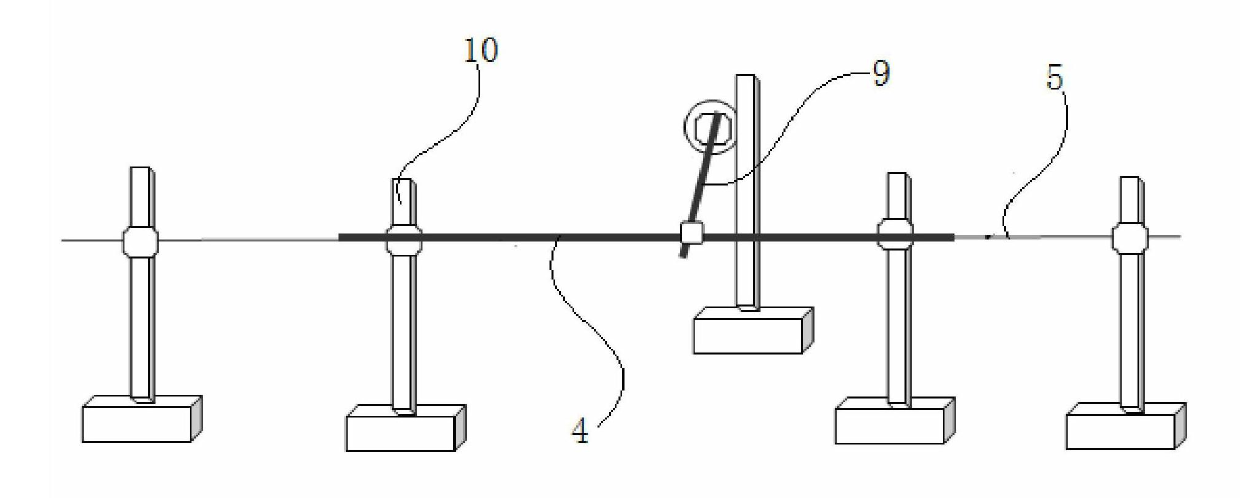

Automatic solder robot

ActiveCN102069255AExtended service lifeGuaranteed accuracyPrinted circuit assemblingWelding/soldering/cutting articlesSlide plateEngineering

The invention relates to an automatic solder robot comprising a soldering bit, an X-axis module, a Y-axis module, a Z-axis module, a carrying board, a wire feeding mechanism and an electric control box as well as a soldering bit motion mechanism and an accurate solder wire positioning mechanism. The soldering bit motion mechanism comprises a moving device which is connected with the soldering bit and comprises a connecting block, an air cylinder, a sliding plate and a linear sliding rail; the connecting block is used for connecting the upper end of the soldering bit with the cylinder body of the air cylinder together and connected with the sliding plate which is glidingly connected with the linear sliding rail; a solder wire nozzle of the accurate solder wire positioning mechanism is connected with the connecting block through a connecting rod, the connecting block is connected with a connecting shaft which is fixedly connected with a deflection block and is in rotating connection with an elevation block, a clamping block is connected with the elevation block and fixed at the upper end of the soldering bit, a horizontal adjusting screw is in rotating connection with the deflection block, and the front end of the horizontal adjusting screw is glidingly connected with the elevation block. The invention can accurately solder melted tin solder in a needed position and improve the efficiency, the product quality consistency and stability.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

Automatic tin supplying electric iron

The invention provides an automatic tin supplying electric iron and relates to the electric iron. The electric iron solves the problems of complicate structure, difficult control of soldering tin flow and inconvenient operation in the conventional automatic tin supplying electric iron. The automatic tin supplying electric iron comprises a heating device, a handle, a solder tip, a tin melting cavity and a wire feeding device. The tin melting cavity is positioned between the handle and the solder tip; the heating device is positioned inside or outside the tin melting cavity; the heating device is used for heating the tin melting cavity so as to melt soldering tin in the cavity; the wire feeding device is used for feeding soldering tin wires into the tin melting cavity; the outlet of the tin melting cavity is communicated with the inlet of the solder tip; and the solder tip can consist of a tin storing cavity and a tin discharging pipe, and can also consist of the tin storing cavity and a brush. The electric iron also comprises an elastic compression device. The automatic tin supplying electric iron has an external heating structure or an internal heating structure. The electric iron has the advantages of simple structure, low cost, convenient mass production and easy popularization.

Owner:张大理

Method for manufacturing wheat straw handicraft

InactiveCN101564963ANot afraid of moistureNot afraid of mildewDecorative surface effectsSpecial ornamental structuresBiotechnologyChange color

The invention relates to a method for manufacturing a handicraft, in particular to a method for manufacturing a wheat straw handicraft, which comprises the steps of: a. firing a green body with a shape the same as that of the handicraft; b. treating wheat straw raw materials: soaking the wheat straw in sterilizing lotion and soaking the wheat straw in water containing soda after being dried; fumigating the wheat straw with sulphur and then steaming the wheat straw in a pressure cooker or a steamer; bleaching and dyeing the wheat straw with oxydol and dye respectively; cleaving the wheat straw with a knife blade, back-scrolling the wheat straw and then placing the scrolled wheat straw for a certain time; spreading the scrolled wheat straw and scraping inner pulp; ironing the wheat straw into a plain film with an iron; and pressing the wheat straw plain film with a soldering iron to cause the plain film change color slightly; c. cleaving the wheat straw into filaments and cutting on the bias; or gluing the wheat straw into plain film; d. gluing the filaments and the plain films to the green body; and e. glazing the green body. The wheat straw handicraft manufactured by the method resists moisture, does not mildew or fade, can be preserved permanently, and presents stereo perception.

Owner:聂远征

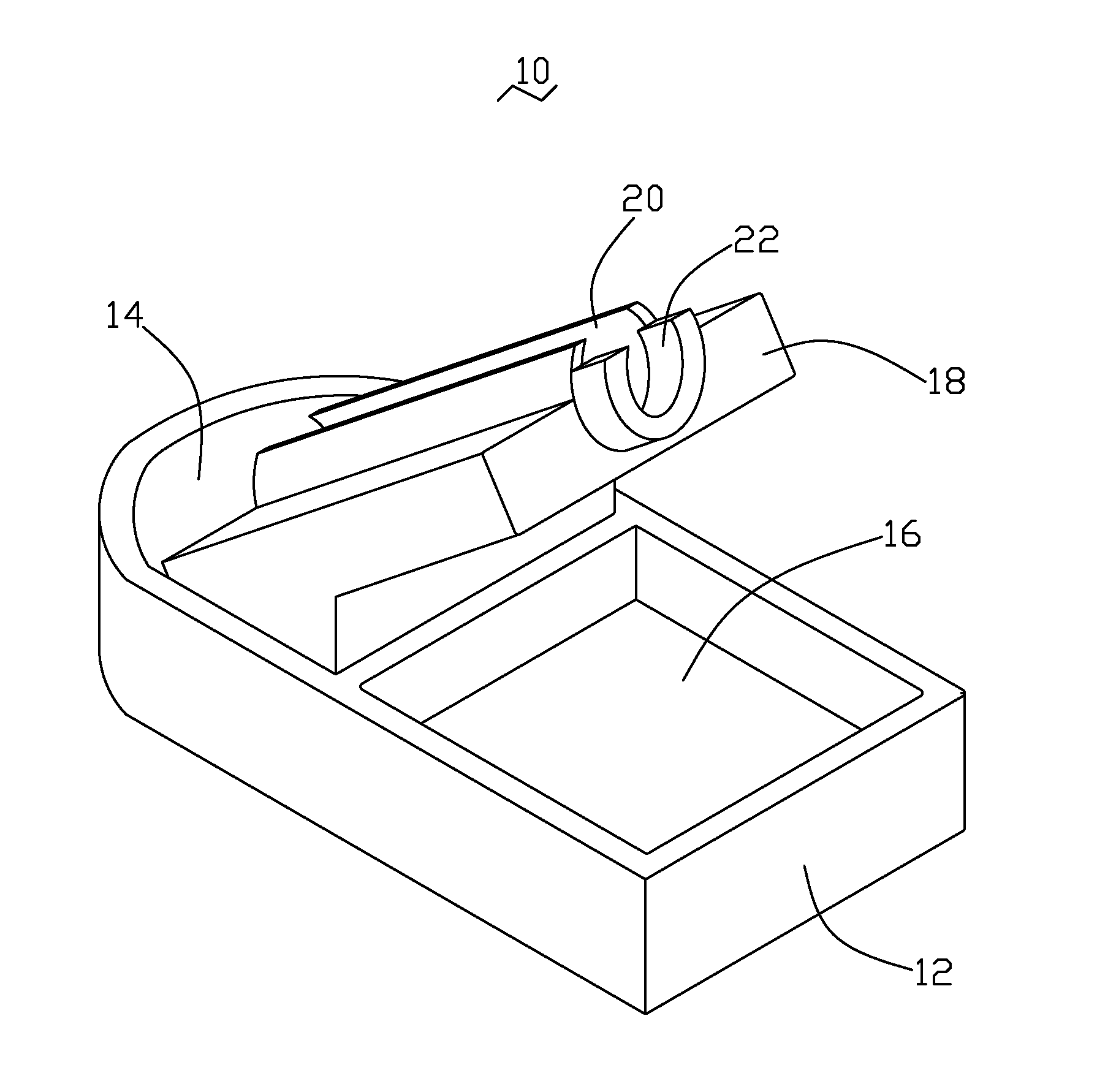

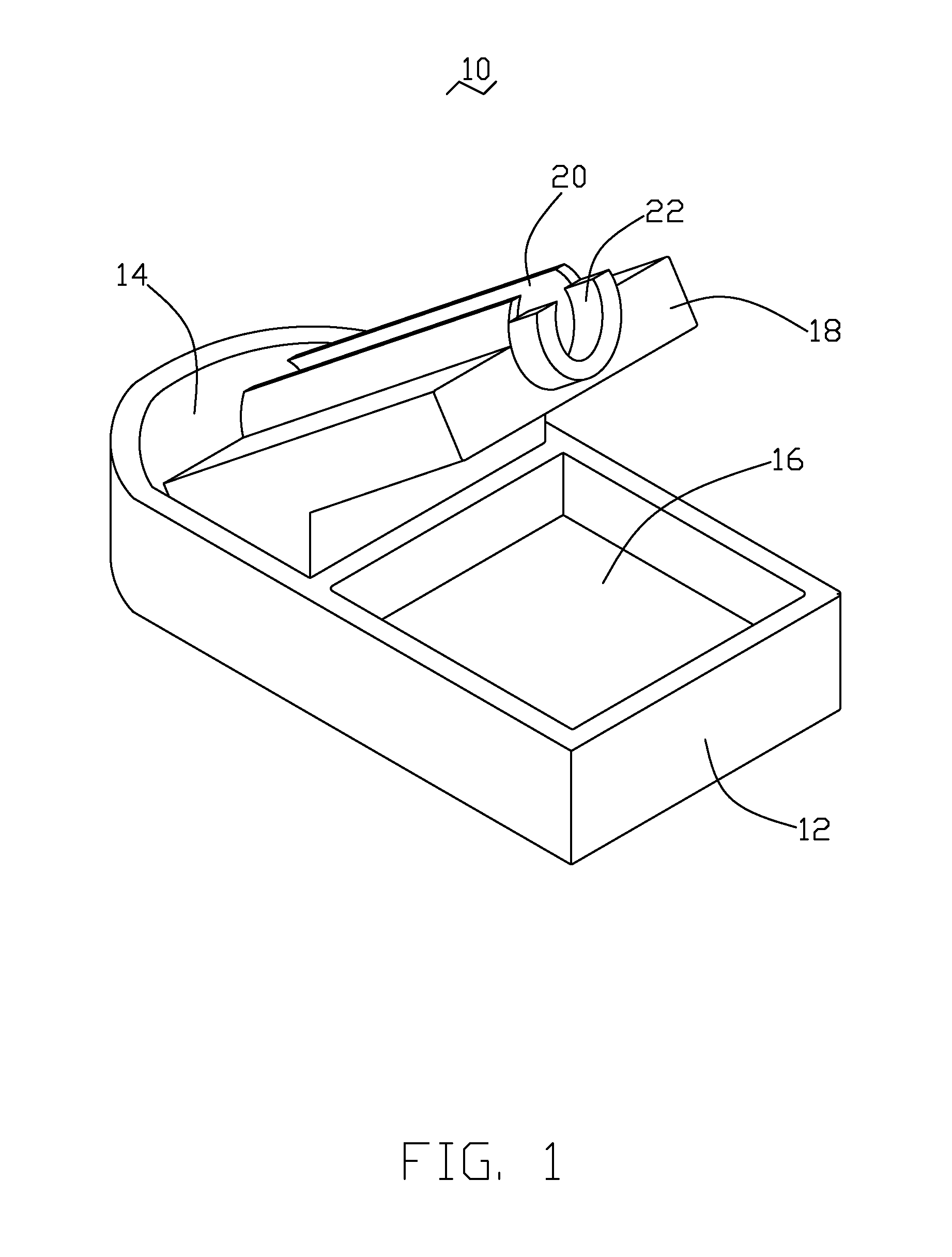

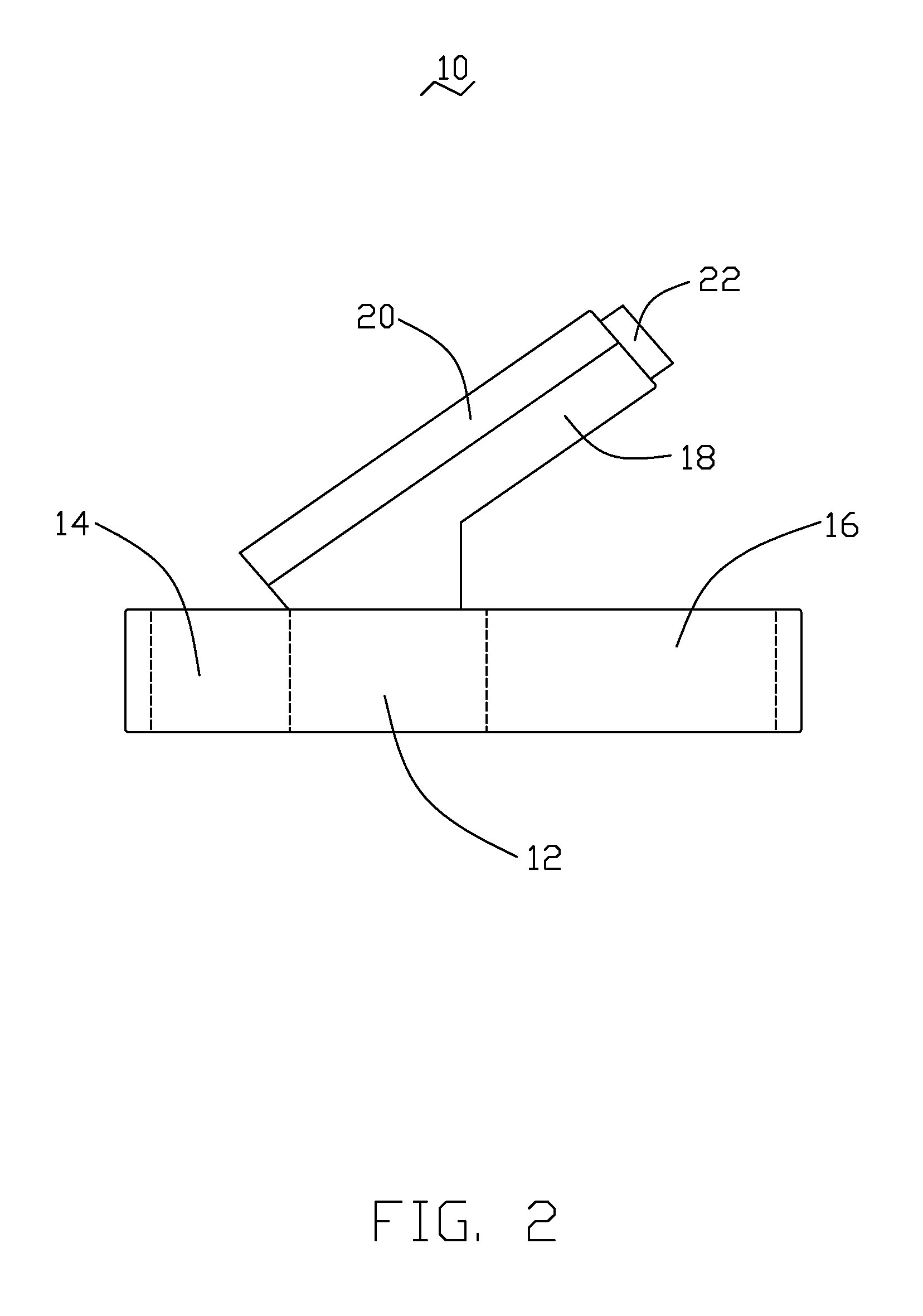

Stand for holding soldering iron

A stand configured for holding a soldering iron therein includes a base, and a supporting member extending slantingly and upwardly from the base. A reservoir is defined in one end of the base for receiving solder therein. A sponge holder sponge holder is defined in another end of the base for receiving a sponge. The supporting member defines a tube for receiving the soldering iron therein. When the soldering iron is holden in the tube of the supporting member, the tip of the soldering iron extends into the solder.

Owner:HON HAI PRECISION IND CO LTD

Multihead temperature control electric soldering iron

InactiveCN101704145AImprove work efficiencySave time at workSoldering ironTemperature controlEngineering

The invention provides a multihead temperature control electric soldering iron which comprises two or more soldering iron heads, heating cores, a connecting rod, a handle and a power supply wire, wherein the heating core is positioned in a cavity of each soldering iron head, and fixed screws are arranged on the soldering iron heads and used for fixing the heating cores and the soldering iron heads into a whole; both the heating cores and the soldering iron heads are fixed on the connecting rod; the connecting rod is fixed on the handle; a temperature control button is arranged on the surface of the handle, and a temperature control circuit is arranged in the temperature control button. The multihead temperature control electric soldering iron is characterized in that an adjusting disk is arranged between the soldering iron heads and the connecting rod; and the adjusting disk comprises a fixed knob and an adjusting knob. Because the multihead temperature control electric soldering iron is provided with a plurality of soldering iron heads, a plurality of pins can be welded or a plurality of elements on a circuit board are simultaneously disassembled according to the requirement, and the working efficiency is improved; and the invention shortens the working time of the electric soldering iron, reduces loss, prolongs the service life and simultaneously saves electric energy.

Owner:HAIAN QIRUI ELECTRONICS

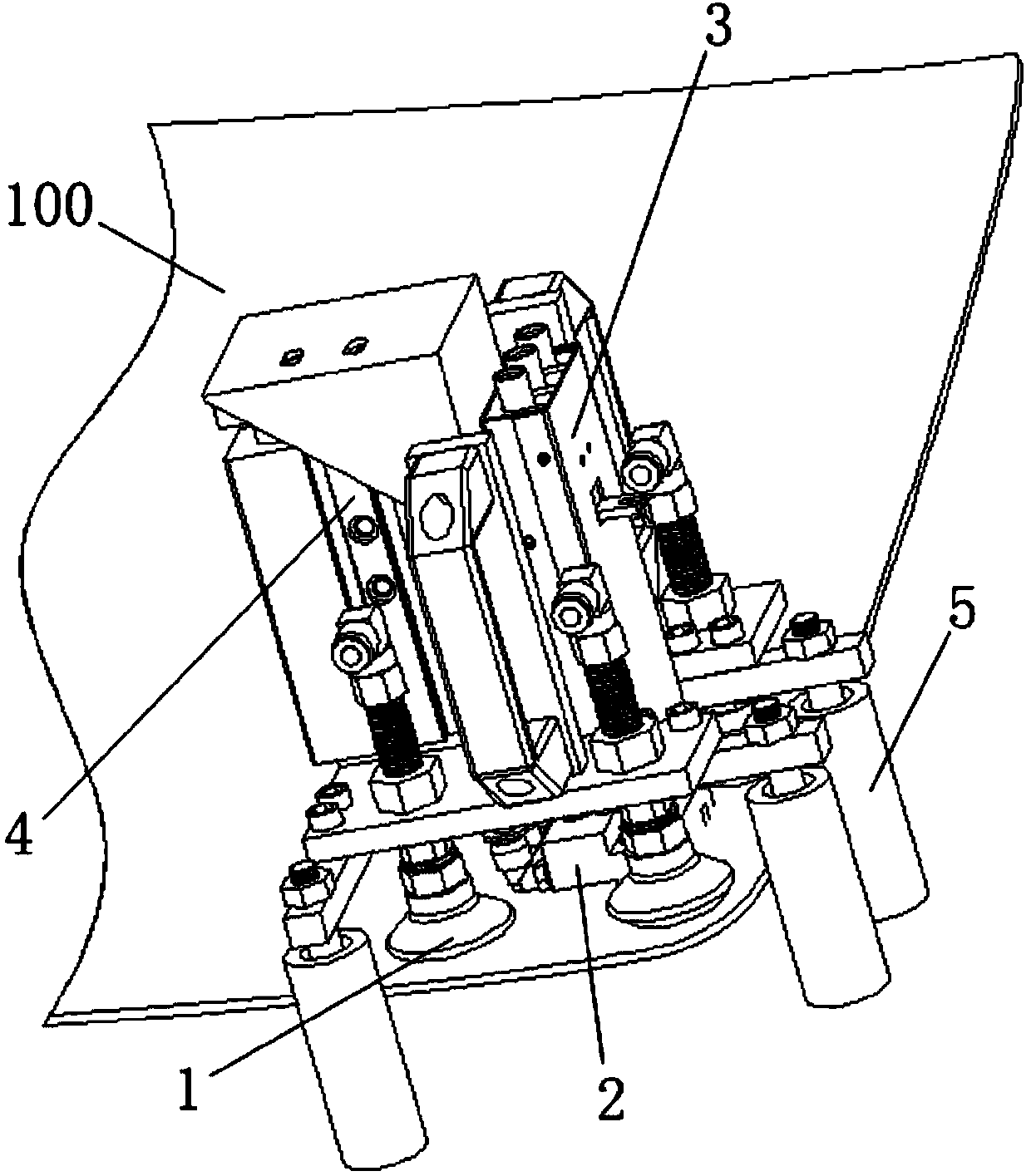

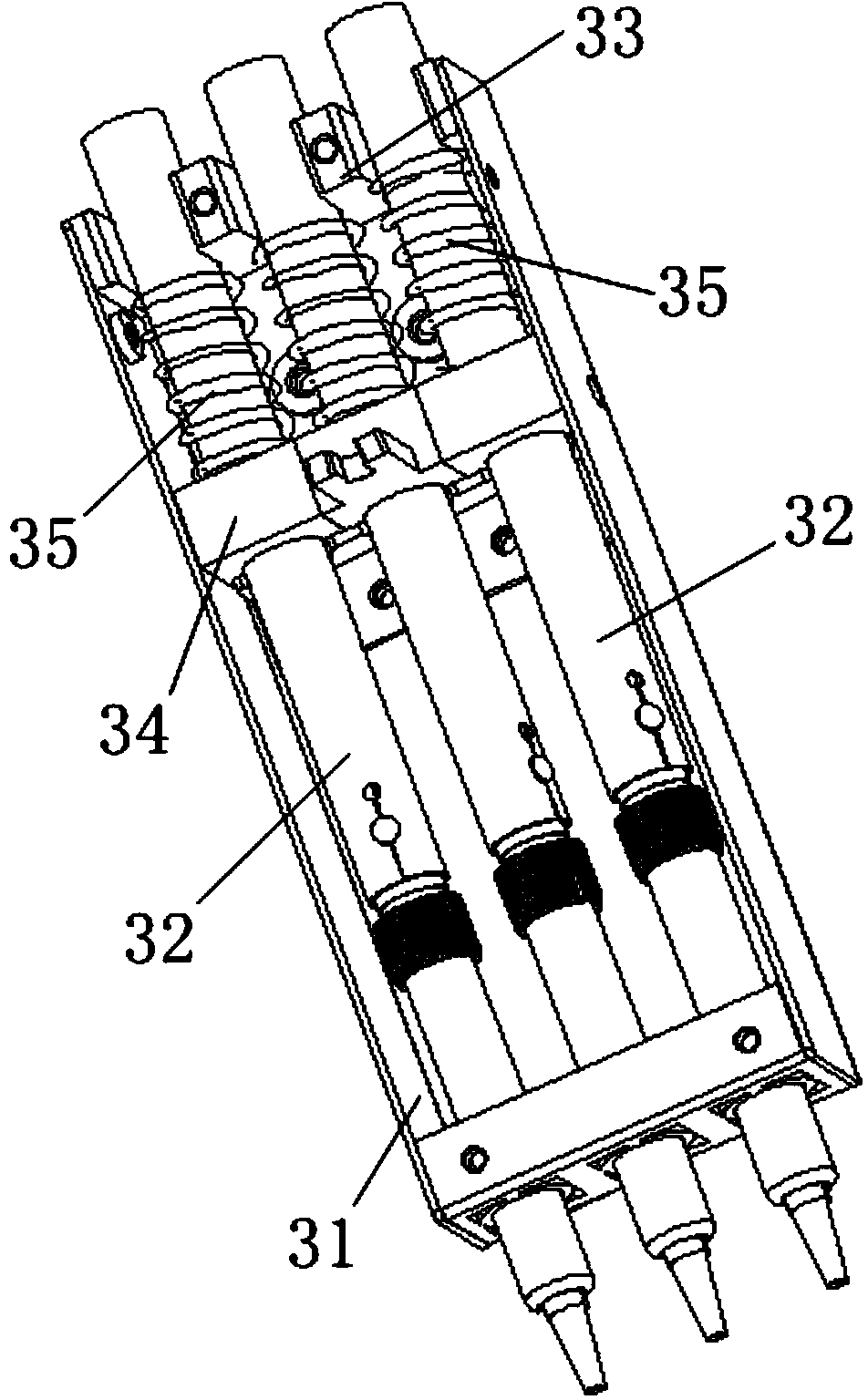

Device and method for welding antenna connector to automotive glass

ActiveCN103990882ASo as not to damageGuaranteed appearanceMetal working apparatusSoldering auxillary devicesEngineeringWeld strength

The invention relates to the field of automotive glass accessory machining, in particular to a device for welding an antenna connector to automotive glass. Meanwhile, the invention further provides a method for welding the antenna connector to automotive glass through the device. The device for welding the antenna connector to the automotive glass comprises a welding positioning mechanism, an accessory fixing mechanism, a welding mechanism and a driving mechanism, wherein the welding mechanism comprises a base, at least two electric soldering irons, a guide device and a fixed base. The device and method for welding the antenna connector to the automotive glass are applied to welding the antenna connector with double wiring harnesses or three wiring harness or multiple wiring harnesses, soldering tin on the antenna connector can be heated and fused in a heat conduction mode, and therefore welding can be completed under low pressure; plastic components on the antenna connector cannot be damaged, and appearance of the antenna connector is guaranteed; welding strength and welding stability can also be improved, and the device and method can be suitable for welding of the antenna connector as well as welding of a tongue piece and have the advantage of being wide in application range.

Owner:ZHENGZHOU FUYAO GLASS

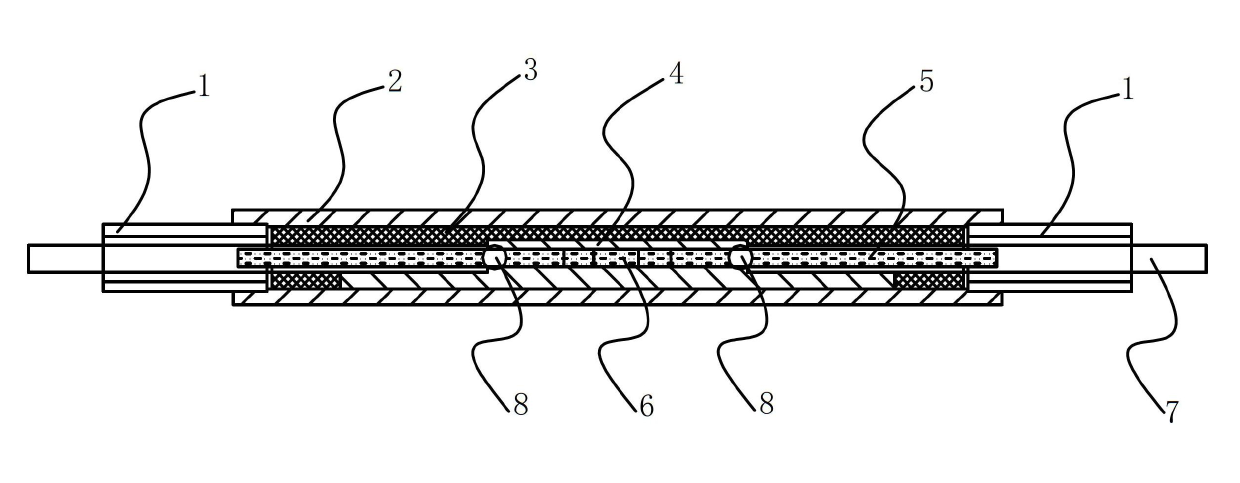

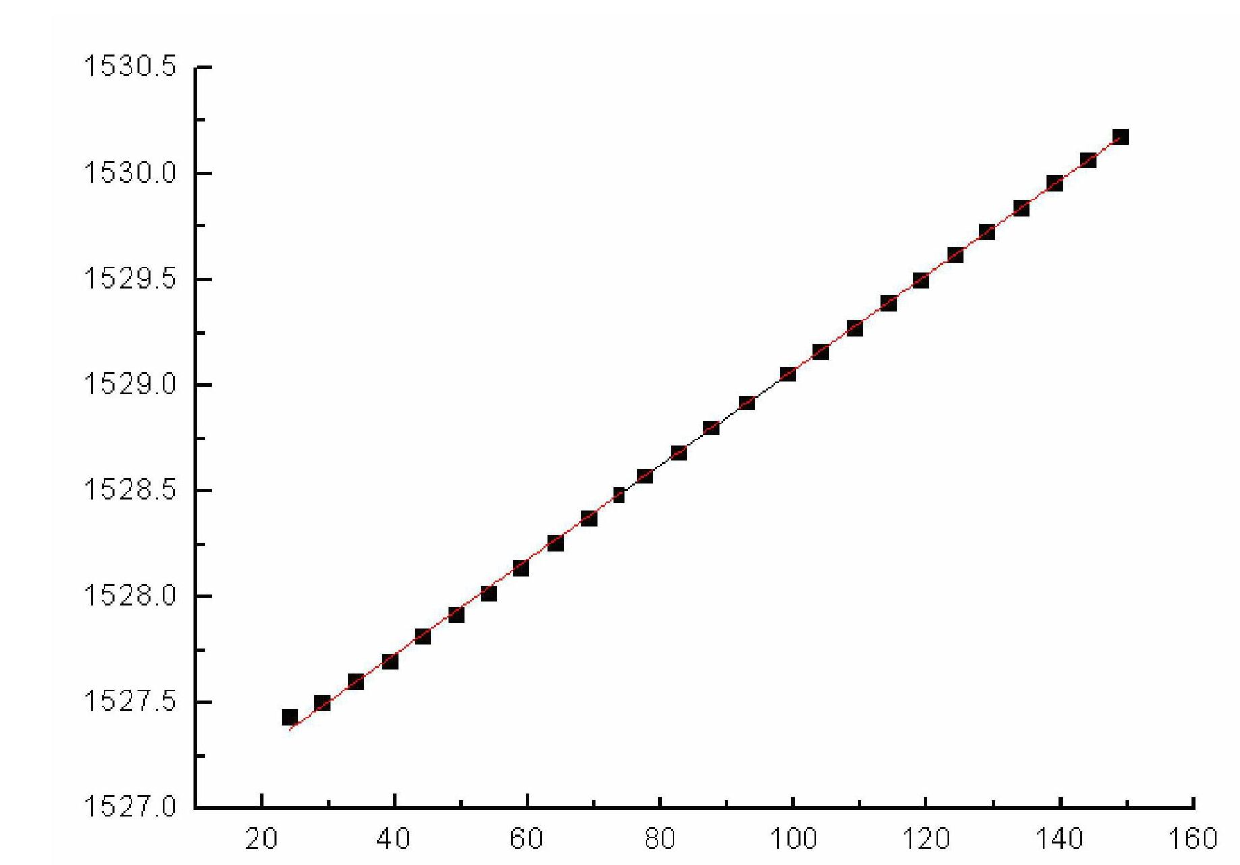

Low-temperature non-glue packaging process for FBG (fiber brag grating) high-temperature sensor

ActiveCN102636290ALow costLower operating temperatureThermometers using physical/chemical changesFiberGrating

The invention discloses a low-temperature non-glue packaging process for an FBG (fiber brag grating) high-temperature sensor. According to the process, a heat resisting fiber brag grating is sealed with a semi-cylindrical stainless steel pipe by a glass solder with a low melting point, the solder is heated by an electric soldering iron until fused, then, the solder is sealed with the fiber brag grating and the semi-cylindrical stainless steel pipe, due to the heat resisting characteristic of the heat resisting fiber brag grating with a polyimide coating, the fiber brag grating is protected and prevented from being broken off when being sealed, besides the characteristic of a traditional fiber brag grating temperature sensor, a novel packaging technology of the fiber brag grating sensor is provided, the non-glue packaging is hardly affected by stress or strain, the grating part is completely sealed and cannot be affected by ambient humidity, there is no need to worry about the aging problem or to carry out the metallization treatment, no laser welding is required, the cost is low, the operating temperature is low, the stability is high, and the structural process and the treatment process are simple.

Owner:SICHUAN GUANGSHENG IOT TECH CO LTD

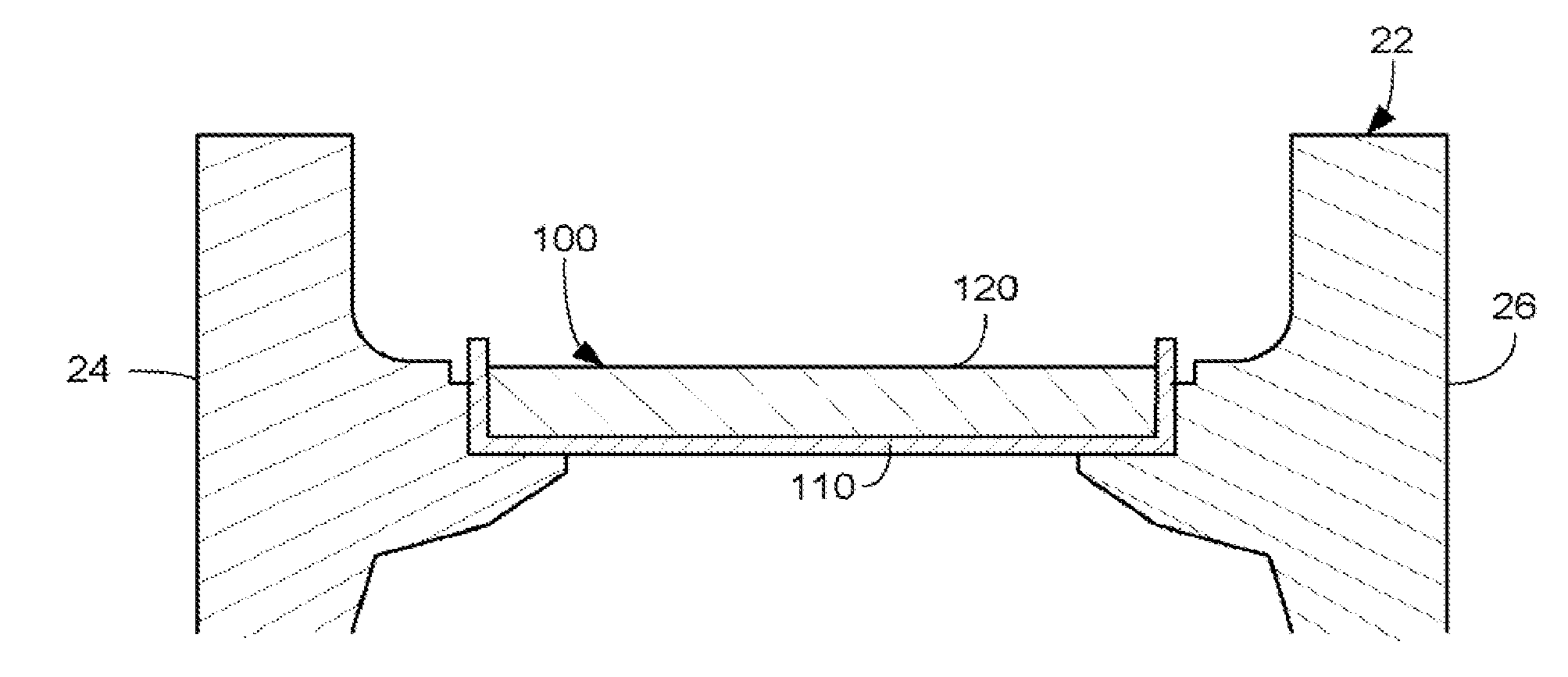

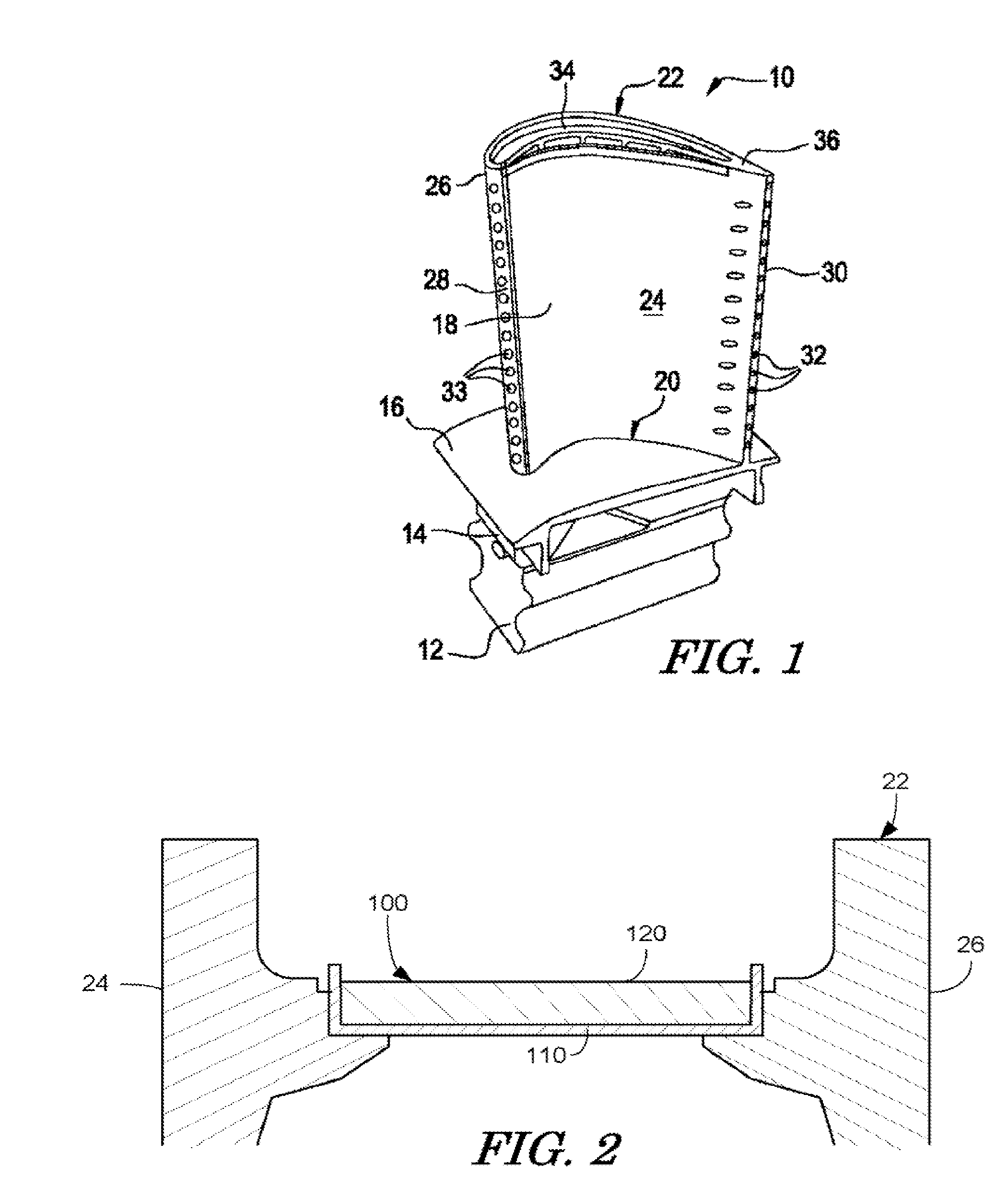

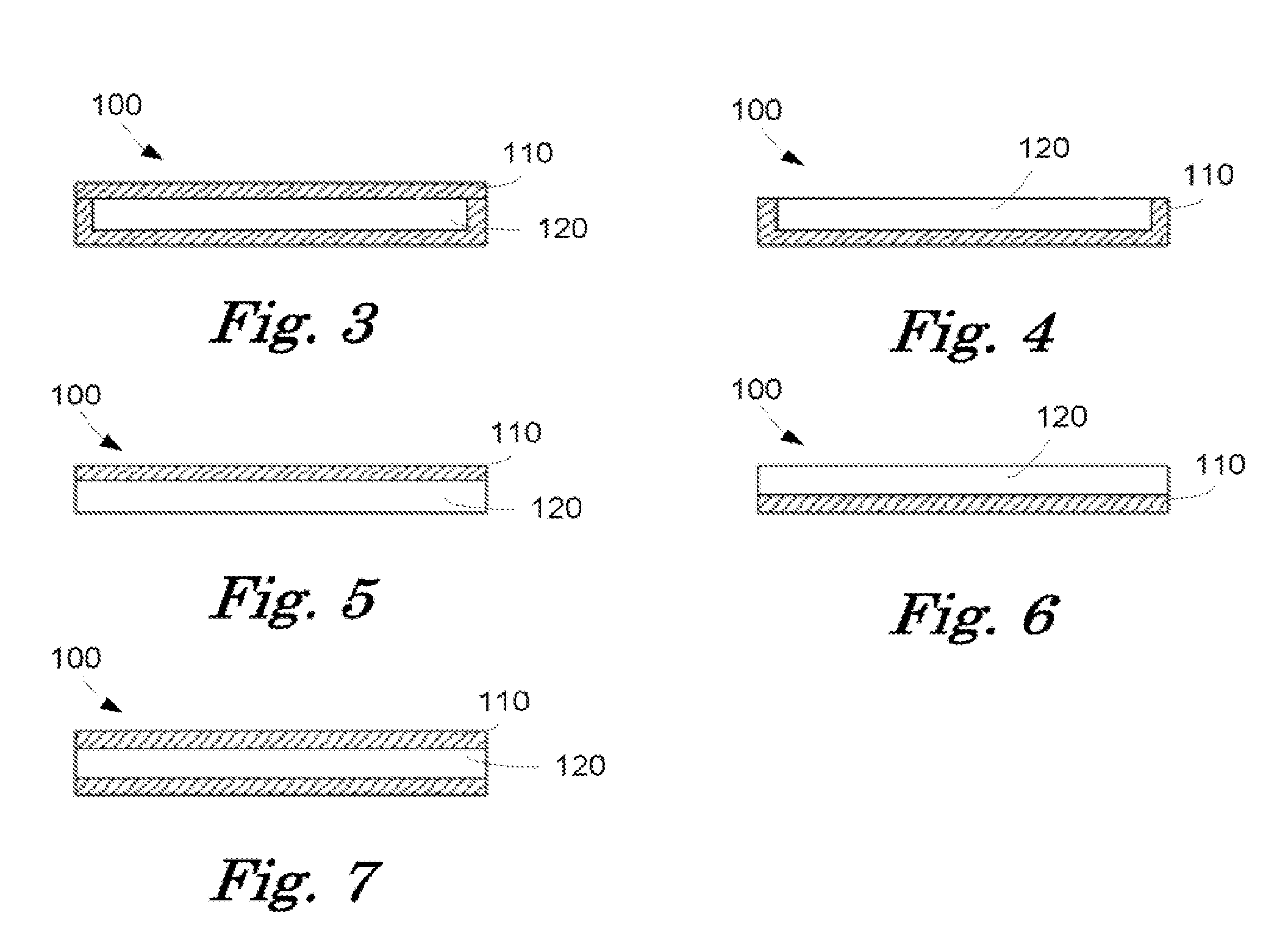

Bi-layer tip cap

A tip cap for use in a turbine bucket. The tip cap may include a shield of an oxidant resistant material and a cap positioned within the shield of a high strength material.

Owner:GENERAL ELECTRIC CO

Method for realizing welding of carbon fiber with metal

The invention discloses a method for realizing the welding of carbon fiber with metal, which comprises the following steps: slurry plating: stripping off the outer skin of a carbon fiber original wire head, and plating diluted copper slurry on the carbon fiber original wire head; curing: putting the slurry-plated carbon fiber original wire head in a constant temperature oven with the temperature of 130-150 DEG C for 25-35 minutes; tin plating: plating low-temperature soldering tin on the carbon fiber original wire head by using a low-temperature soldering iron; and welding: fast welding the carbon fiber original wire head with a metal wire by using a high-temperature soldering iron. The welding method provided by the invention enables the connection between the carbon fiber and the metal to be uniform, firm, and safe and reliable.

Owner:上海朝日低碳新能源有限公司

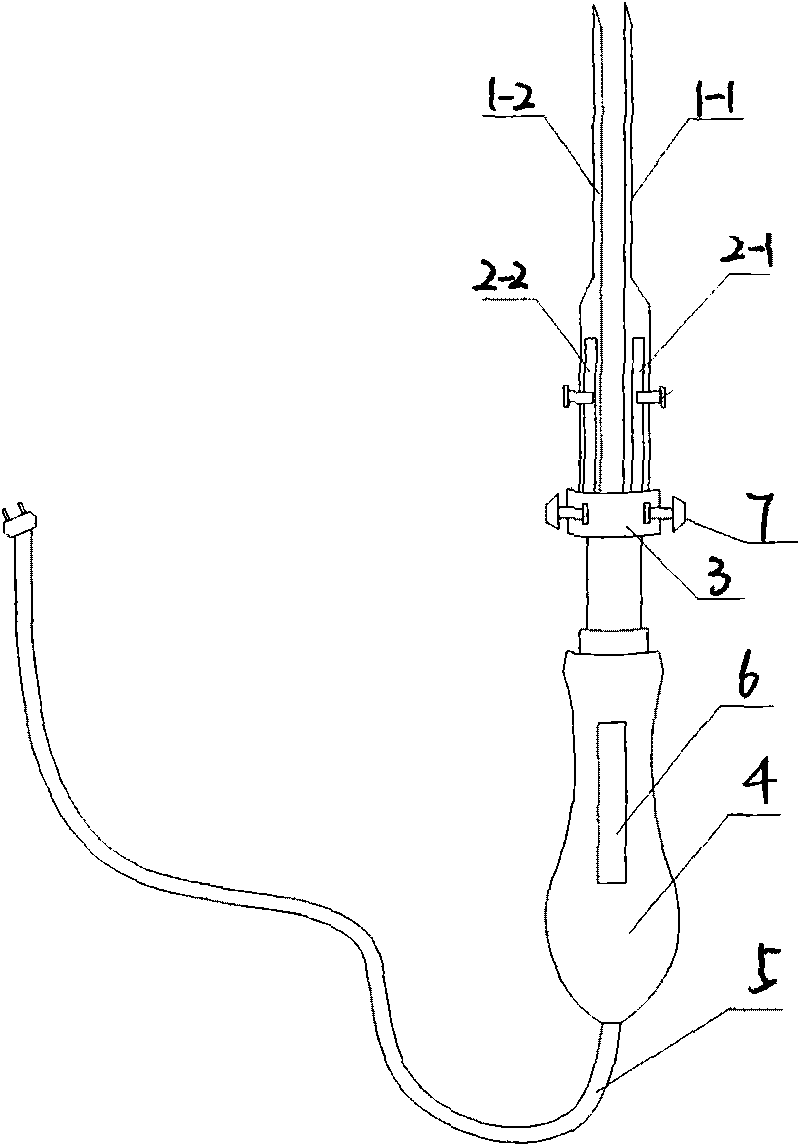

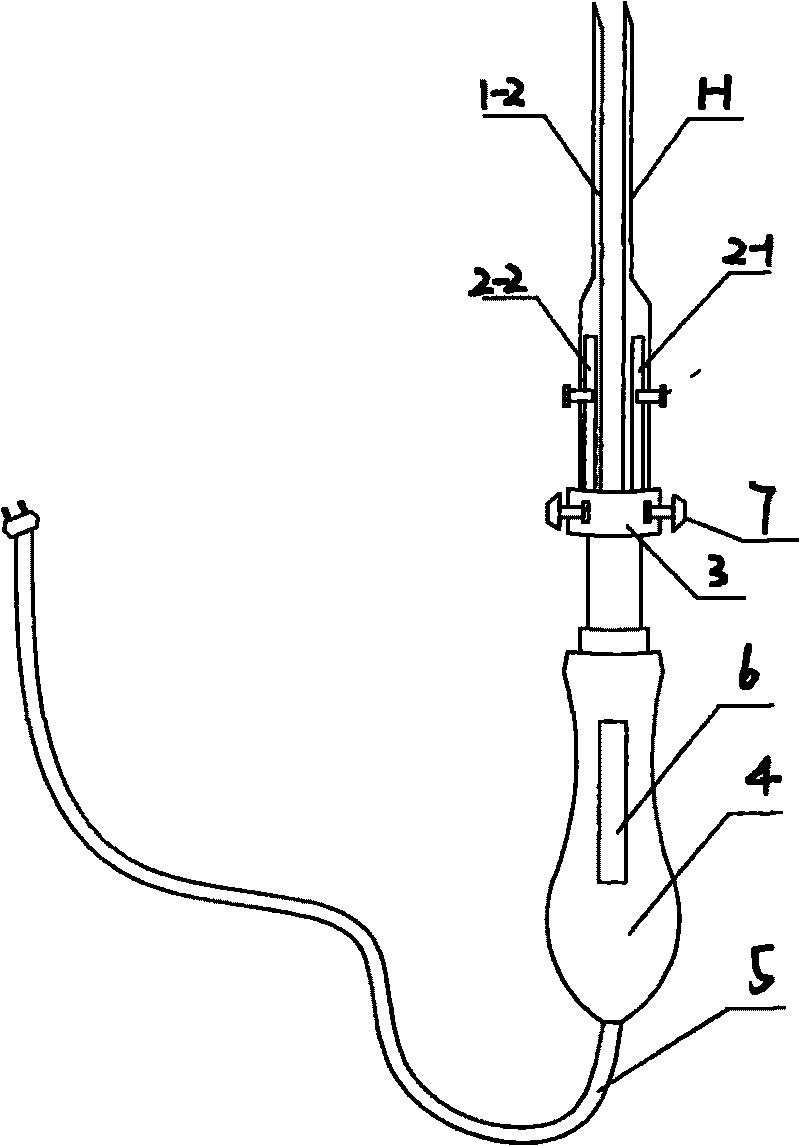

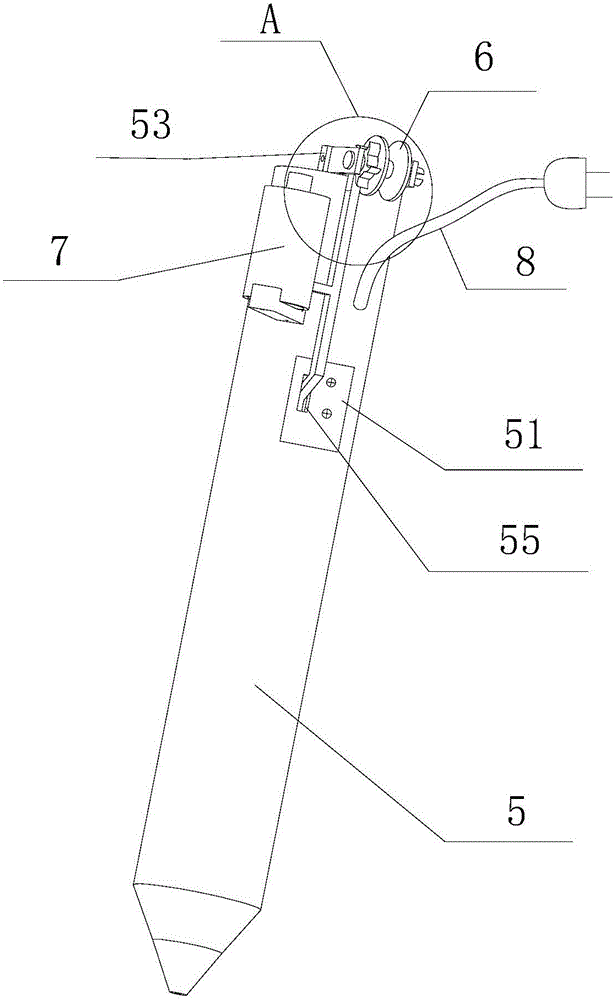

Pen type automatic soldering tin electric soldering iron

ActiveCN105033394AReduce welding labor intensityEasy to operateSoldering ironSolder feeding devicesPower switchingEngineering

The invention relates to a pen type automatic soldering tin electric soldering iron which comprises a barrel, a heating device, a control switch device and an automatic wire feeding device. The barrel comprises a sleeve, a hollow ceramic pipe located in the sleeve, and a heat preservation layer located between the hollow ceramic pipe and the sleeve. The control switch device and the automatic wire feeding device are adjacent and located on the upper portion of the sleeve. A power switch and the automatic wire feeding device of the electric soldering iron are designed to be in linkage control, and soldering operation can be achieved with one hand, so that the electric soldering iron is easy and convenient to operate. Through the automatic wire feeding device, the electric soldering iron has the properties of being short in soldering wire melting time, even in liquid soldering tin supply and the like, and the soldering labor intensity is lowered to a certain degree; and meanwhile soldering quality is improved.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

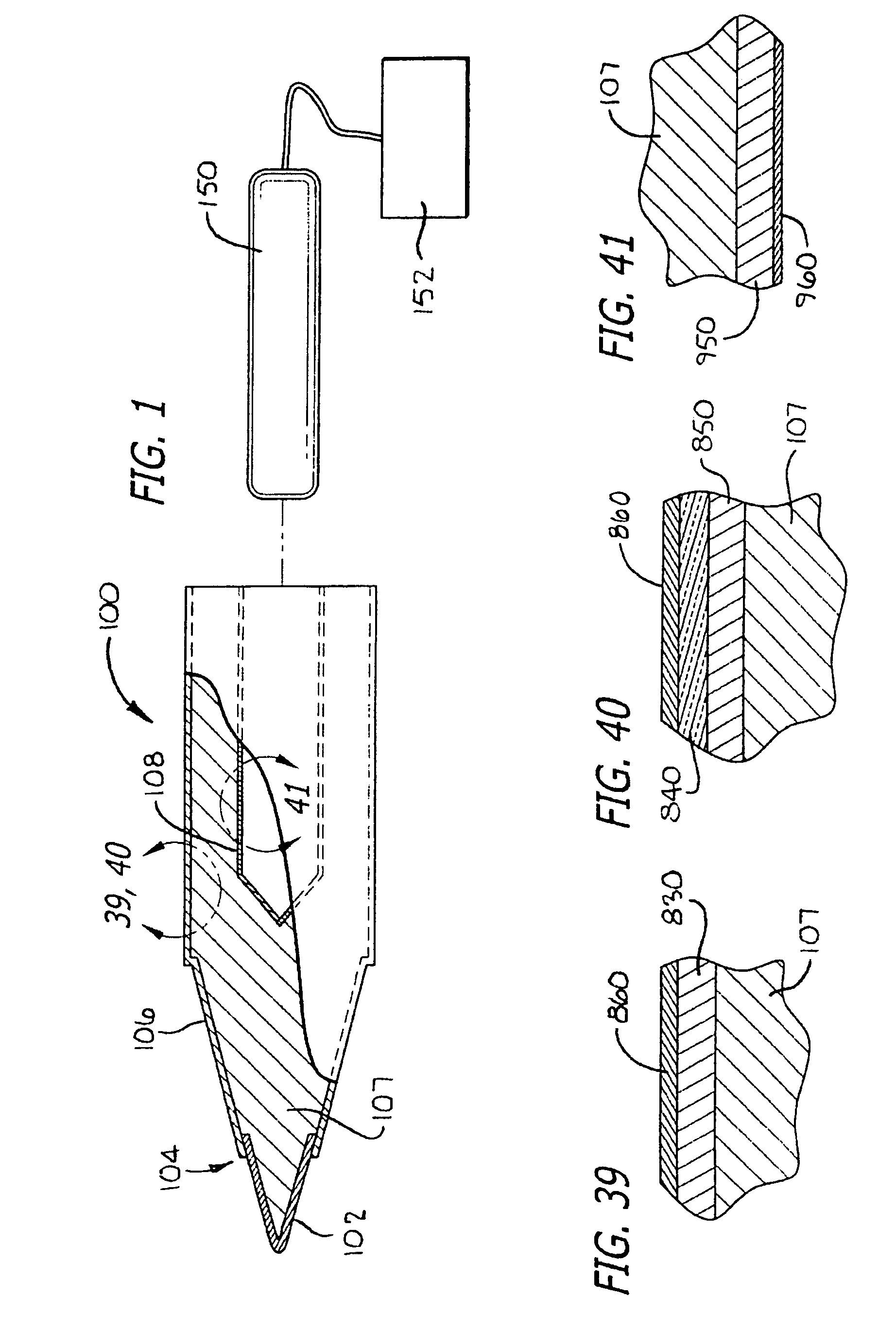

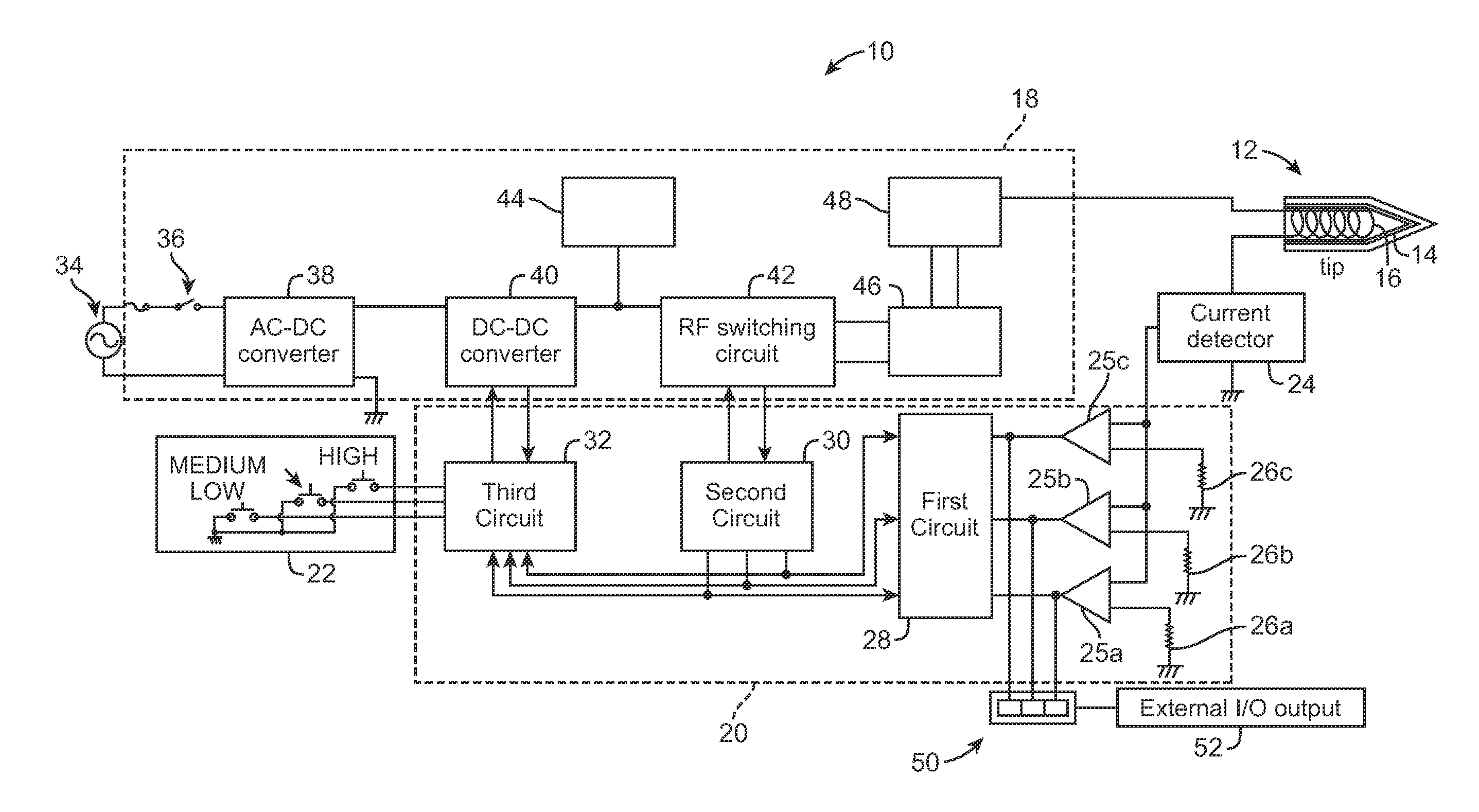

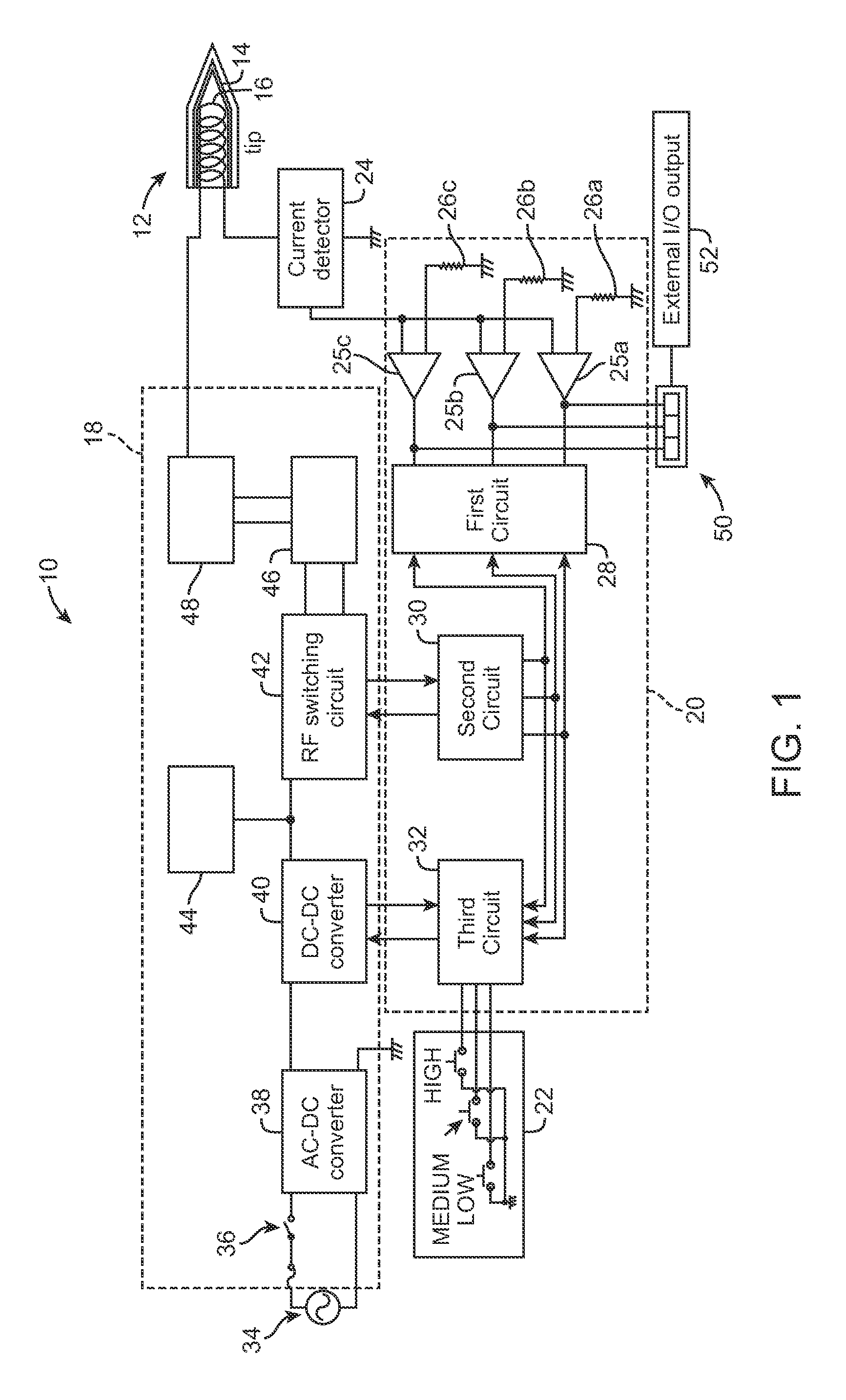

System and Method for Induction Heating of a Soldering Iron

A soldering iron system includes a power assembly that provides power to an induction heater at a variable voltage and a variable frequency. A control assembly adjusts the temperature of the heater in accordance with signals from a current detector coupled to the induction heater and a selection made by the user on an operating level selector.

Owner:HAKKO CO LTD

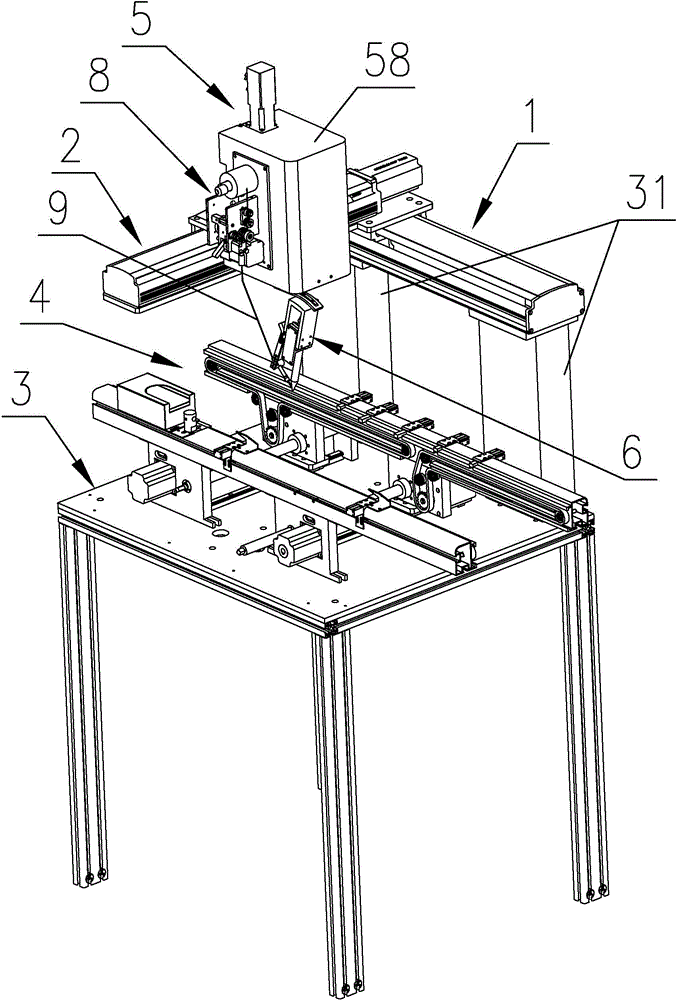

Tin soldering machine

InactiveCN105269108ARealize automatic tin feedingRealize automatic controlSoldering ironPrinted circuitsAutomatic controlEngineering

The invention relates to a tin soldering machine which comprises a rack, a soldering mechanism and tin wire feeding mechanisms. The soldering mechanism is installed on the rack and comprises electric soldering iron soldering assemblies, a vertical driving assembly and a horizontal driving assembly. The electric soldering iron soldering assemblies can be used for carrying out tin soldering on a workpiece and are installed on the vertical driving assembly. The vertical driving assembly can drive the electric soldering iron soldering assemblies to vertically move. The horizontal driving assembly is installed on the rack, and the vertical driving assembly is installed on the horizontal driving assembly. The horizontal driving assembly can drive the vertical driving assembly to slide horizontally. The tin wire feeding mechanisms are arranged on the rack and used for providing tin wires for the electric soldering iron soldering assemblies. According to the tin soldering machine, automatic tin feeding can be achieved through the tin wire feeding mechanisms, the tin wires and the workpiece can be automatically soldered through the soldering mechanism, the automatic tin soldering process is achieved under the coordination of the soldering mechanism and the tin feeding mechanisms, the tin soldering machine is combined with a production line to achieve automatic control, and the tin soldering efficiency and the soldering quality are improved.

Owner:SHENZHEN XUANSHUO INTELLIGENT MANUFACTURING TECHNOLOGY CO LTD

Method of manufacturing soldering iron

ActiveUS20080010808A1Small sizeEasy to useHeating element shapesHeating appliancesBiomedical engineeringSurface cover

A soldering iron provided with a soldering tip that melts solder at a distal end, having inside said soldering tip a substantially cylindrical insertion fit recess portion extending from a proximal end of the soldering tip to the distal end, opening at the proximal end, and a heater formed into a coil shape and whose surface is covered with an insulating oxide film being fittingly inserted into the insertion fit recess portion.

Owner:TAIYO ELECTRIC IND

Soldering iron stand

ActiveUS20100108827A1Easy to cleanEfficiently scrape off solder residueHand ironStands/trestlesEngineeringSoldering iron

A soldering iron stand comprises a stand base, and a soldering iron holder provided on an upper portion of the stand base and formed to have a curved surface for receiving thereon a soldering iron to be held by the stand base. The soldering iron holder has a plurality of recesses formed therein and arranged in a circumferential direction of the curved surface. Each of the recesses is provided with a heat-resistant elastic member.

Owner:HAKKO CO LTD

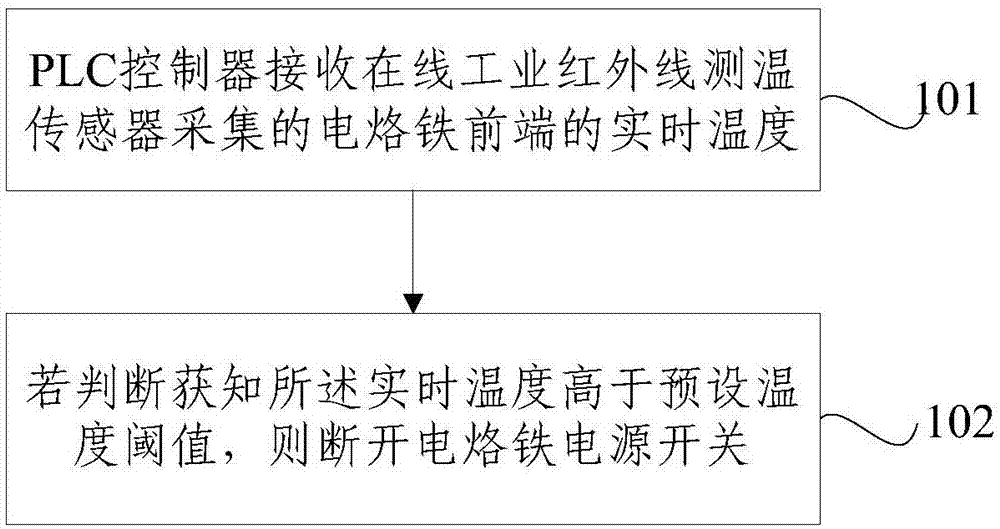

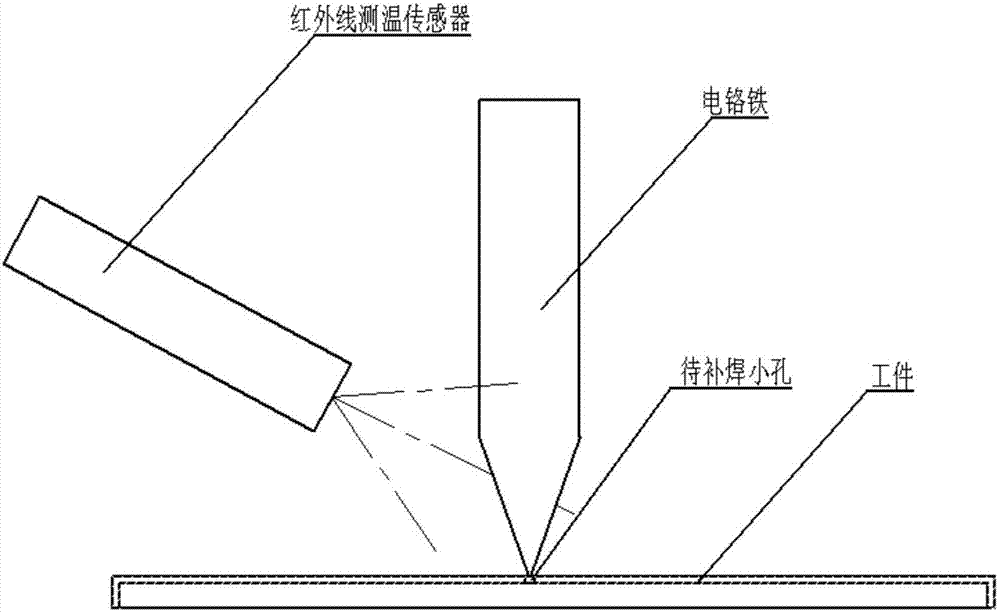

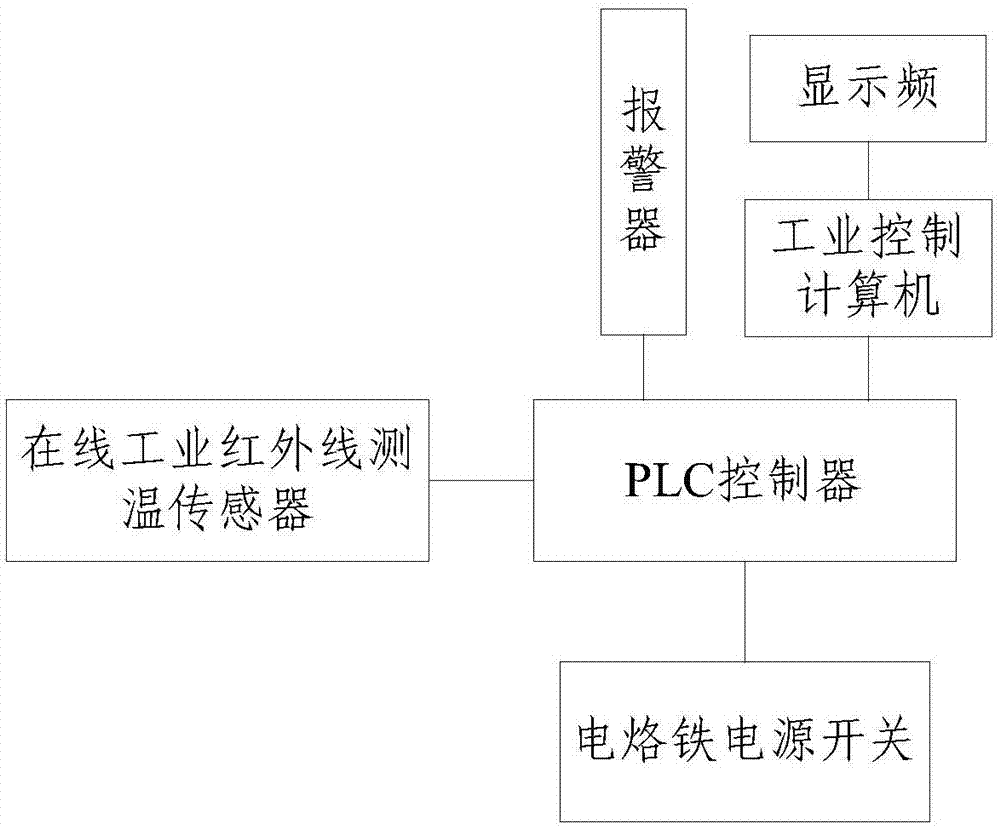

Welding temperature adjusting method and system

The invention provides a welding temperature adjusting method. The method comprises the steps that a PLC receives the real-time temperature of the front end of an electric soldering iron collected by an online industrial infrared temperature measuring sensor; and if the acquired real-time temperature is judged to be higher than a preset temperature threshold value, an electric soldering iron power switch is disconnected. The invention further provides a welding temperature adjusting system. The welding temperature adjusting system comprises the on-line industrial infrared temperature measuring sensor, the PLC and the electric soldering iron power switch. According to the welding temperature adjusting method and system, the real-time temperature of the front end of the electric soldering iron is compared with the preset temperature threshold value through the PLC, when the real-time temperature exceeds the preset temperature threshold value, the electric soldering iron power switch is disconnected, and therefore the welding over-temperature protection can be realized; the online industrial infrared temperature measuring sensor has the characteristics of being high in anti-interference capability and high in response speed, and therefore the real-time temperature of the electric soldering iron can be rapidly and accurately measured; and automatic and accurate welding can be realized, the welding efficiency can be improved, and the quality of welded products can be improved.

Owner:HUNAN JUNCHENG TECH

One-step forming manufacturing method of bracelet

The invention relates to a one-step forming manufacturing method of a bracelet, comprising the following steps of: enabling a manually carved water channel to pass through two designed bracelet silver frame accessories, forming a glue film with a wax injecting port in the middle of a surface through gluing pressure, and taking out silver frames; placing the glue film into a double-faced clamp plate with a through hole in the middle of the surface, injecting liquid wax, condensing and then taking out formed wax patterns, splicing the wax patterns together to form an integral bracelet wax pattern; repeating the front two steps to produce the bracelet wax pattern with multiple pattern types, and welding liquid wax channels of a plurality of bracelet wax patterns together by using an electric soldering iron; sleeving the plurality of bracelet wax patterns with iron bell models, injecting liquid gypsum, and carrying out vacuum condensation; placing the gypsum models into a high temperature furnace for thorough burning so as to form hollow gypsum models; placing the hollow gypsum models into an air suction machine, injecting liquid metal, cooling, and then forming; and smashing gypsum to obtain finished products. The method has the advantage that the bracelet is cast in one step, thereby not only saving time and cost, but also manufacturing bracelets with uniform patterns.

Owner:黄飞达

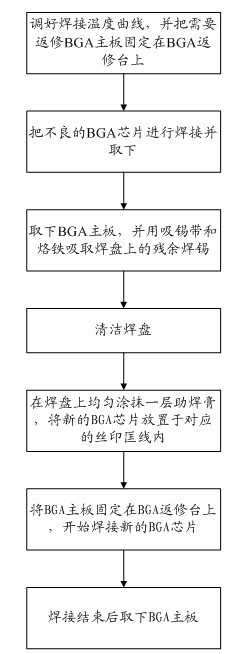

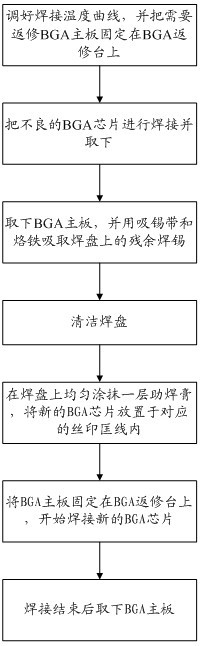

Method for removing residual solder tin from soldering-pan during repair and replacement of ball grid array (BGA) chip

InactiveCN102686044AImprove rework efficiencyImprove yield ratePrinted circuit assemblingScreen printingTemperature curve

The invention discloses a method for removing residual solder tin from a soldering-pan during the repair and replacement of a ball grid array (BGA) chip. The method comprises the following steps of: (a) well regulating a soldering temperature curve, and fixing a BGA mainboard to be repaired on a BGA repair station; (b) soldering a poor BGA chip, and taking the poor BGA chip down; (c) taking the BGA mainboard down, and sucking the residual solder tin from the soldering-pan by using a soldering wick and soldering iron; (d) cleaning the soldering-pan; (e) uniformly smearing a layer of flux paste on the soldering-pan, and placing a new BGA chip in a corresponding silk-screen printing frame wire; (f) fixing the BGA mainboard on the BGA repair station, and starting soldering the new BGA chip; and (g) after the soldering is finished, taking the BGA mainboard down. According to the method for removing the residual solder tin from the soldering-pan during the repair and replacement of the BGA chip, the residual solder tin can be effectively removed from the soldering-pan, the repair efficiency of the BGA chip is greatly improved, and the yield is also greatly improved.

Owner:JIANGSU LEMOTE TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com