Abietyl-based soldering flux for halogen-free no-clean bright solder wire and preparation method thereof

A no-clean, solder wire technology, used in welding equipment, welding media, manufacturing tools, etc., can solve the problems of not enough bright and beautiful surface of solder joints, low activity of halogen-free flux, and low corrosiveness of post-soldering residues. Achieve good specular reflection ability, improve surface insulation resistance after welding, and excellent surface insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

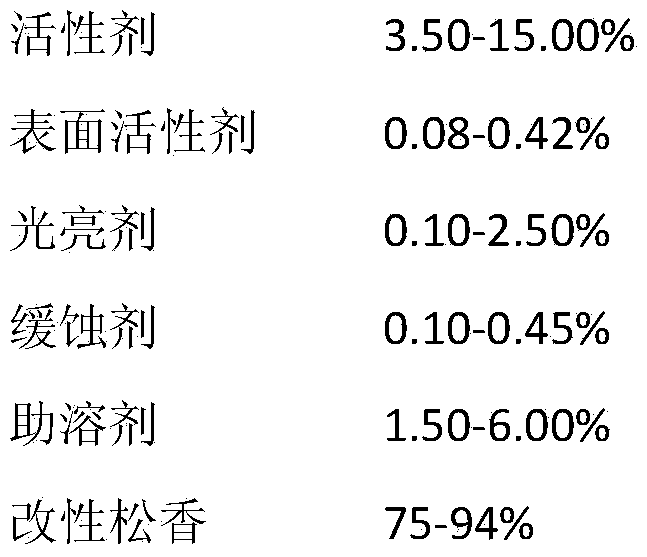

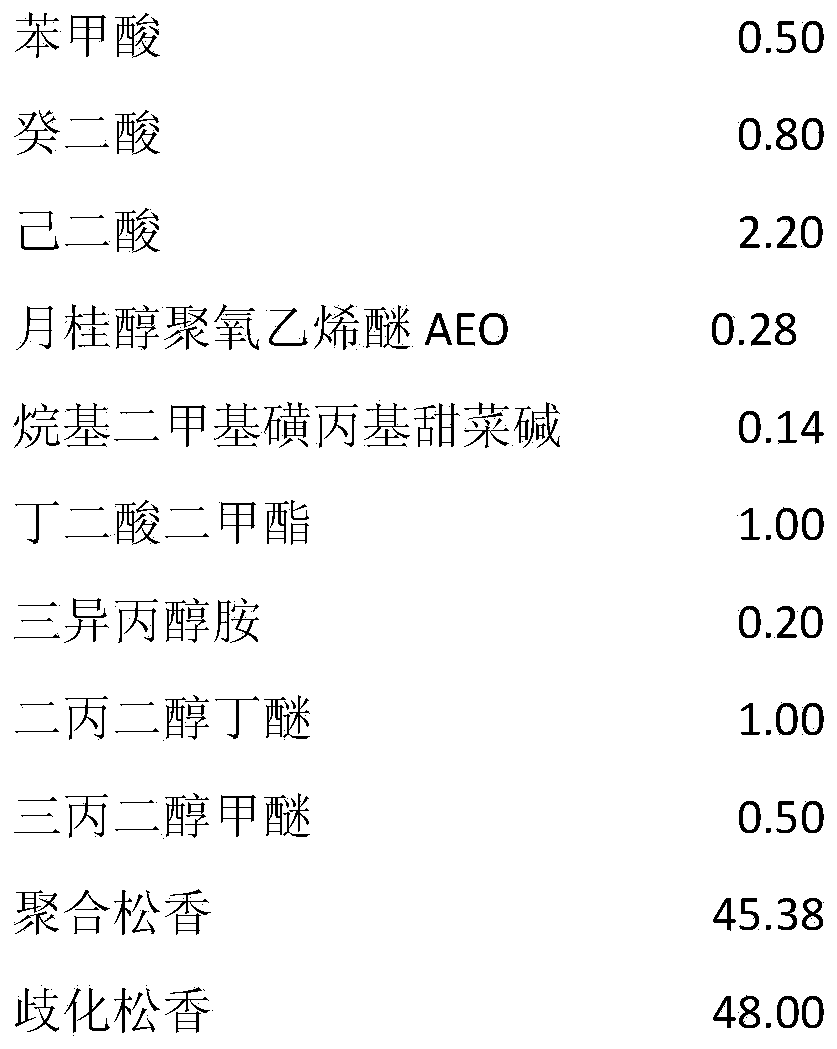

[0037] A rosin-based flux for halogen-free no-cleaning bright solder wire, the raw material formula components are as follows:

[0038]

[0039] Preparation method: put the polymerized rosin and disproportionated rosin into the reaction kettle, heat to 150±5°C, and stir continuously for 30 minutes; add the weighed dipropylene glycol butyl ether and tripropylene glycol methyl ether into the reaction kettle where the modified rosin is located , keep the heating temperature at 150±5°C, and continue to stir for 5 minutes; add benzoic acid, sebacic acid, adipic acid, lauryl polyoxyethylene ether AEO, alkyl dimethyl sulfopropyl betaine, dimethyl succinate Add the ester and triisopropanolamine to the reaction kettle where the modified rosin is located in sequence, keep the heating temperature at 150±5°C, and continue to stir for 30 minutes until the raw materials in the reaction kettle are fully dissolved and mixed uniformly; heat the resulting mixture in the reaction kettle After...

Embodiment 2

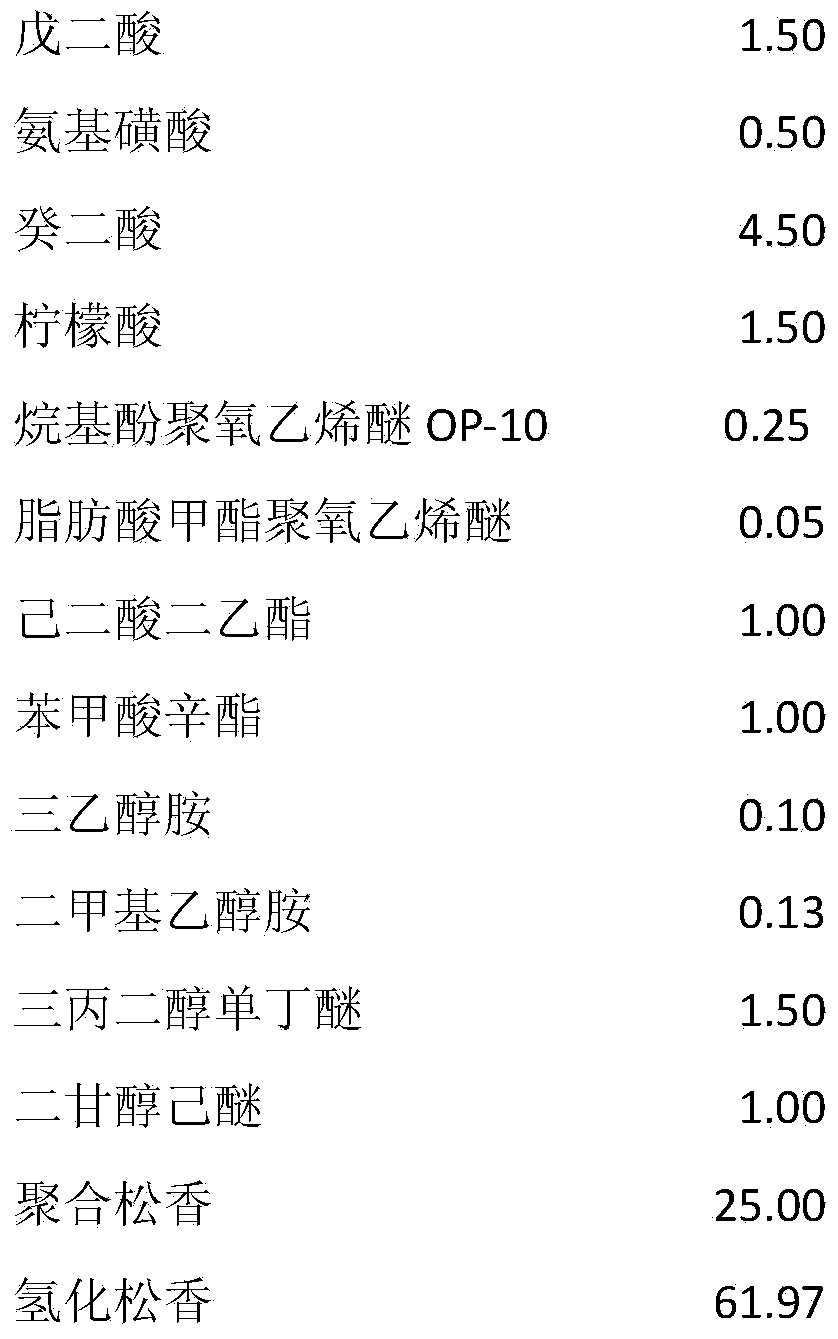

[0041] A rosin-based flux for halogen-free no-cleaning bright solder wire, the raw material formula components are as follows:

[0042]

[0043] Preparation method: Put the polymerized rosin and disproportionated rosin into the reaction kettle, heat to 150±5°C, and stir continuously for 30 minutes; add the weighed tripropylene glycol monobutyl ether and diethylene glycol hexyl ether to the reaction where the modified rosin is located In the kettle, keep the heating temperature at 150±5°C and continue to stir for 5 minutes; add glutaric acid, sulfamic acid, sebacic acid, citric acid, alkylphenol polyoxyethylene ether OP‐10, fatty acid methyl ester polyoxyethylene ether , diethyl adipate, octyl benzoate, triethanolamine and dimethylethanolamine are sequentially added to the reaction kettle where the modified rosin is located, and the heating temperature is maintained at 150±5°C, and the stirring is continued for 30 minutes until the raw materials in the reaction kettle are ful...

Embodiment 3

[0045] A rosin-based flux for halogen-free no-cleaning bright solder wire, the raw material formula components are as follows:

[0046]

[0047]

[0048] Preparation method: put hydrogenated rosin and disproportionated rosin into the reaction kettle, heat to 150±5°C, and stir continuously for 30 minutes; add the weighed tripropylene glycol monobutyl ether and diethylene glycol hexyl ether to the reaction where the modified rosin is located In the kettle, keep the heating temperature at 150±5°C and continue to stir for 5 minutes; add sulfosalicylic acid, hexadienoic acid, maleic acid, alkyl dimethyl betaine, alkyl dimethyl sulfoethyl betaine, Add diethyl adipate, dibutyl oxalate, diethanolamine and triethanolamine in sequence to the reaction kettle where the modified rosin is located, keep the heating temperature at 150±5°C, and continue stirring for 30 minutes until the raw materials in the reaction kettle are fully dissolved and mix uniformly; the mixture obtained by he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com