Patents

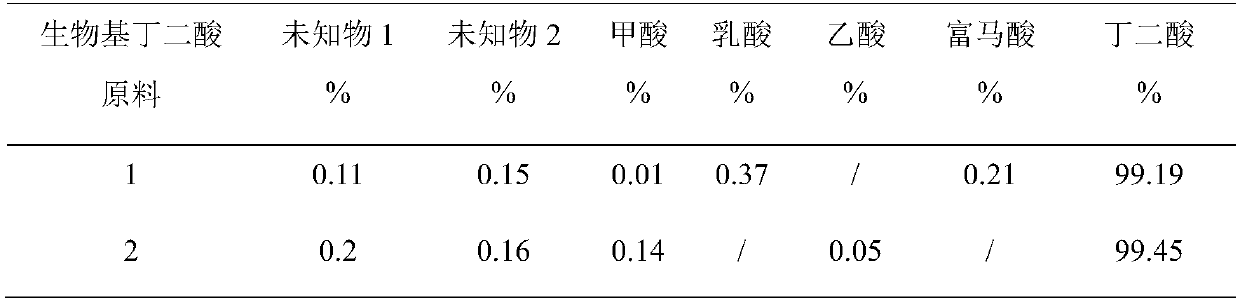

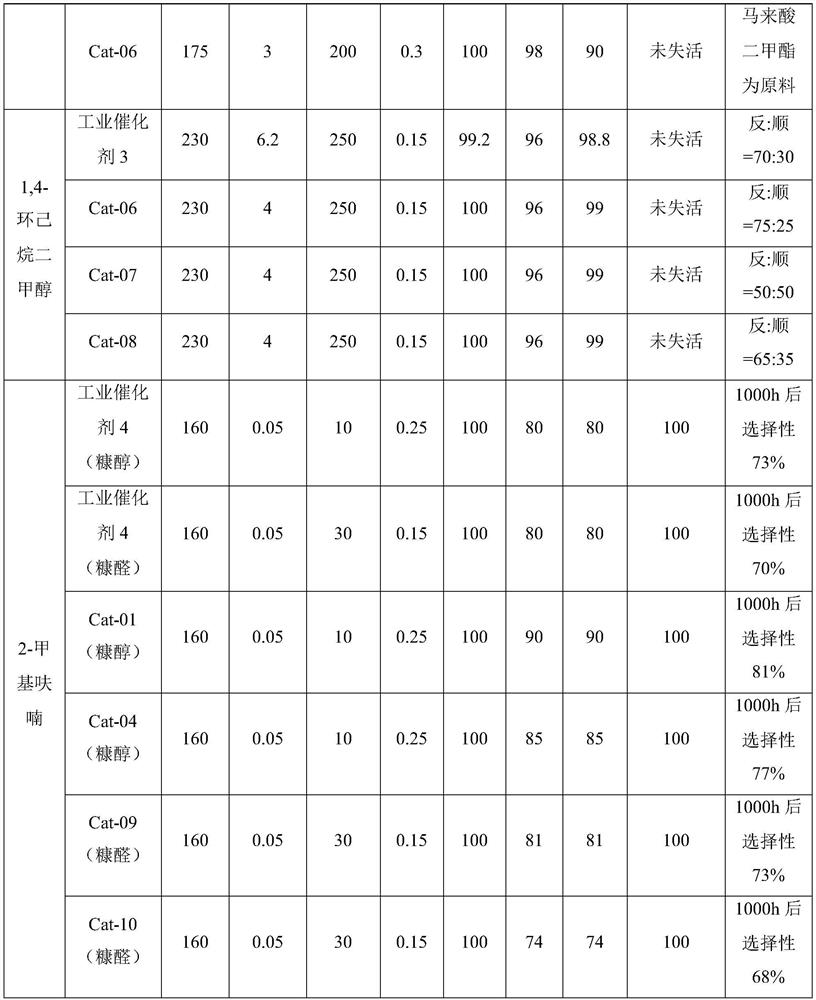

Literature

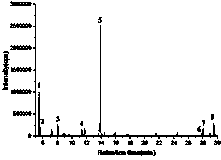

134 results about "Dimethyl succinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimethyl succinate is found in nuts. Dimethyl succinate is present in roasted filberts. Dimethyl succinate is a flavouring ingredient.

Catalyst that can be used in hydrotreatment, comprising metals of groups viii and VIB, and preparation with acetic acid and dialkyl succinate c1-c4

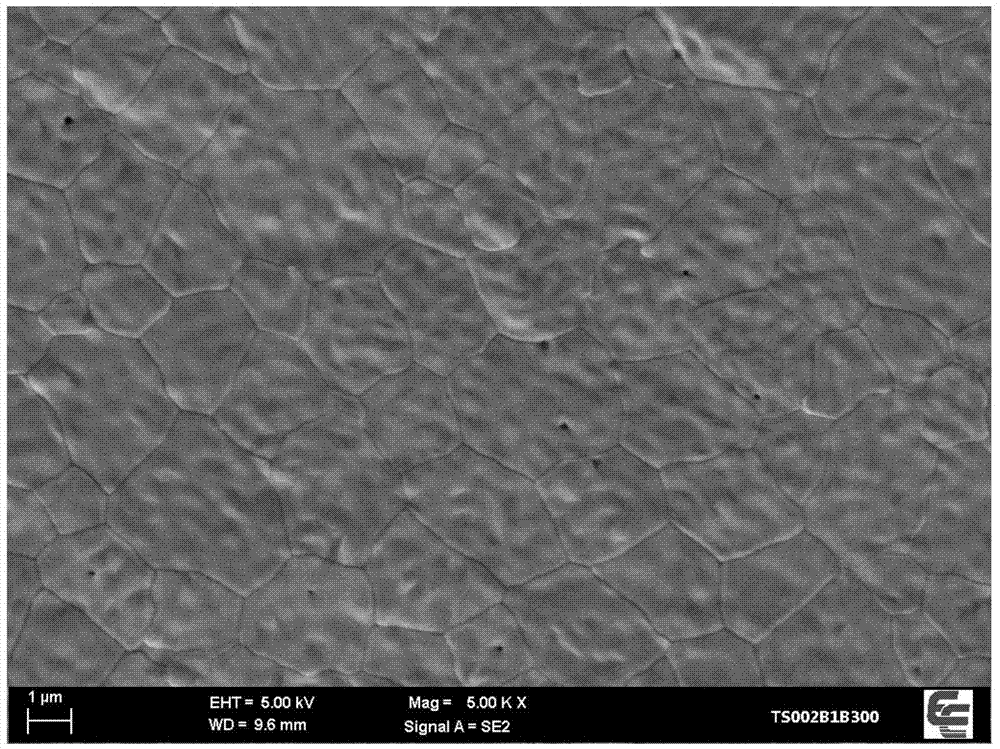

ActiveUS20130008829A1Improve catalytic performanceHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAcetic acidCobalt

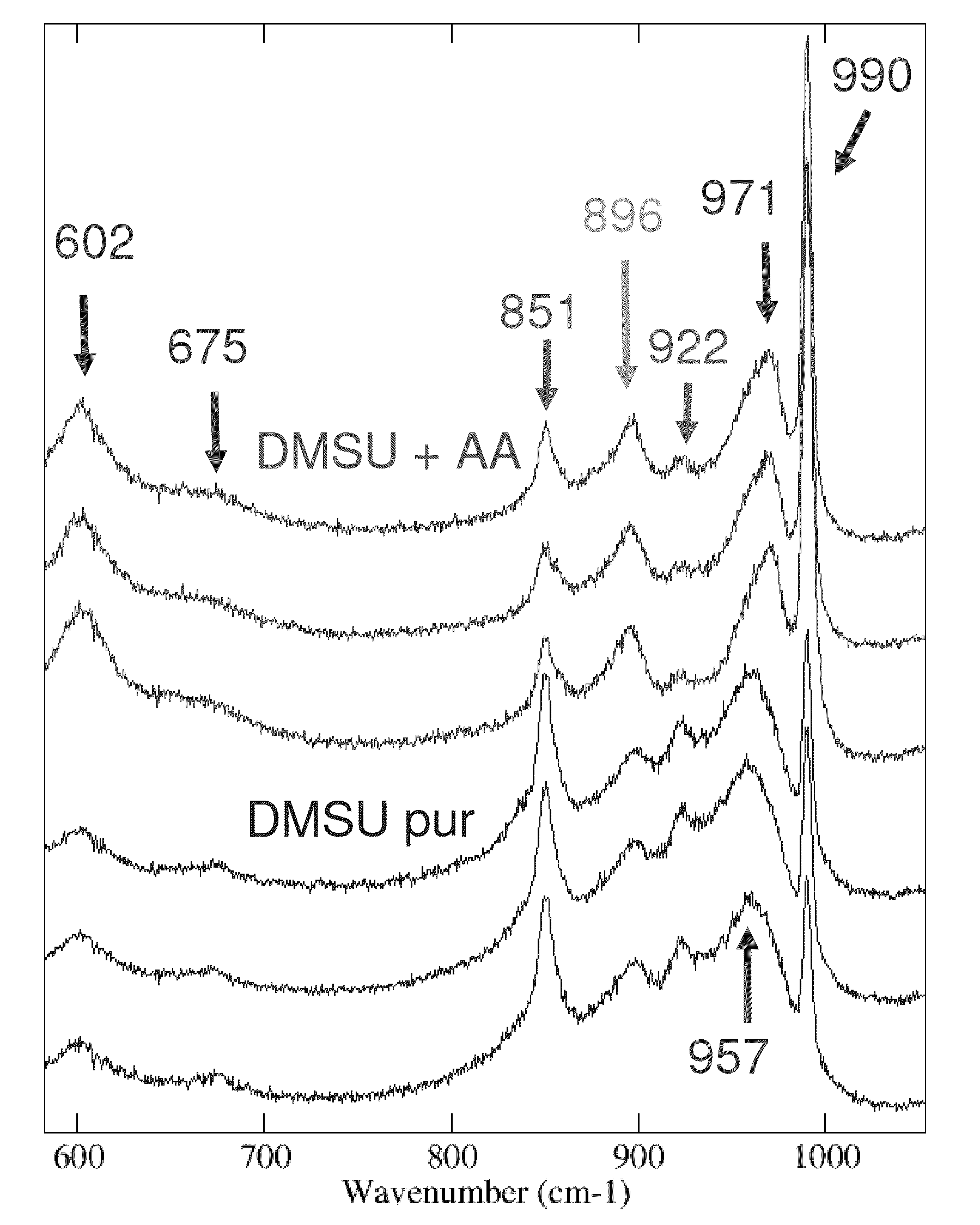

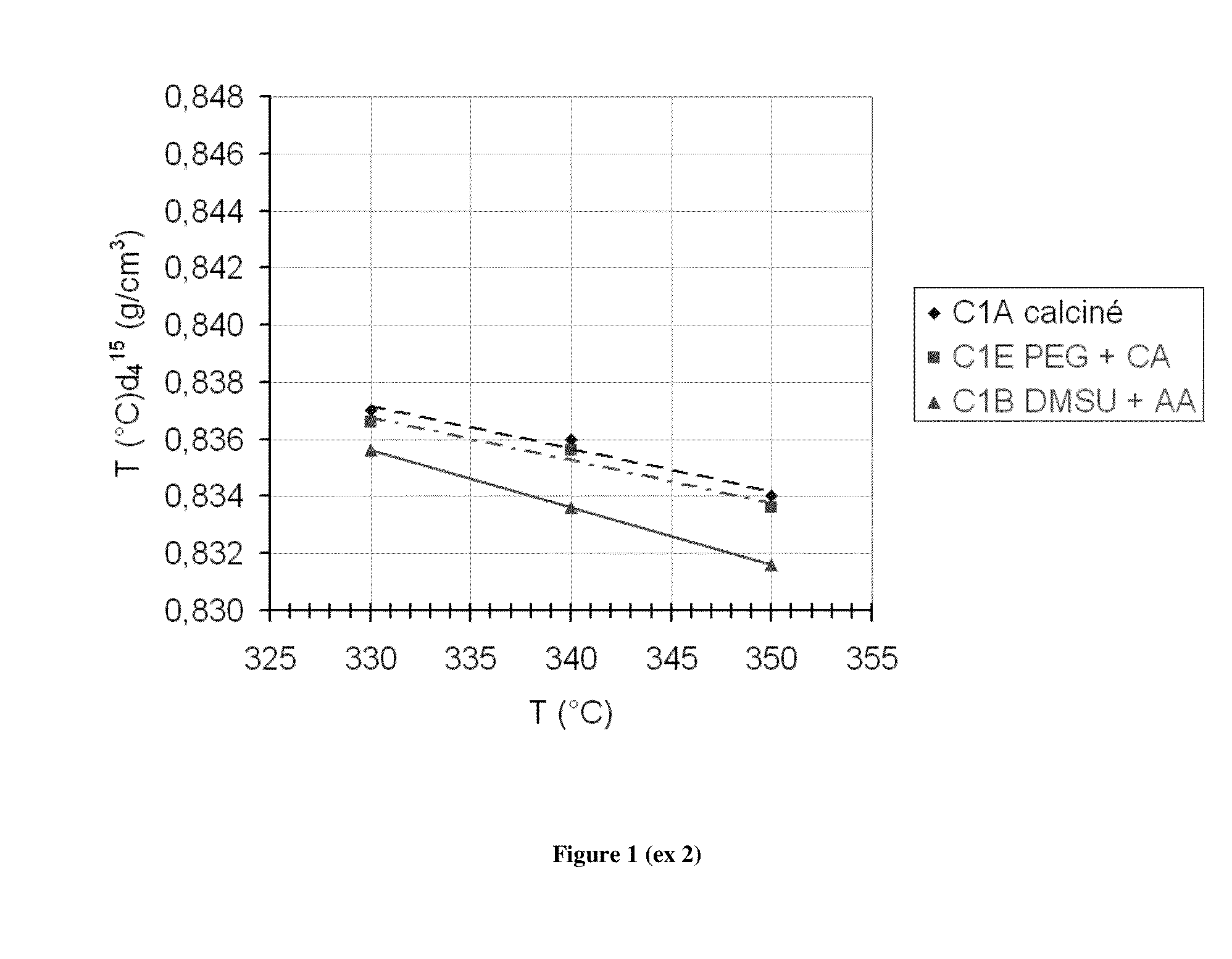

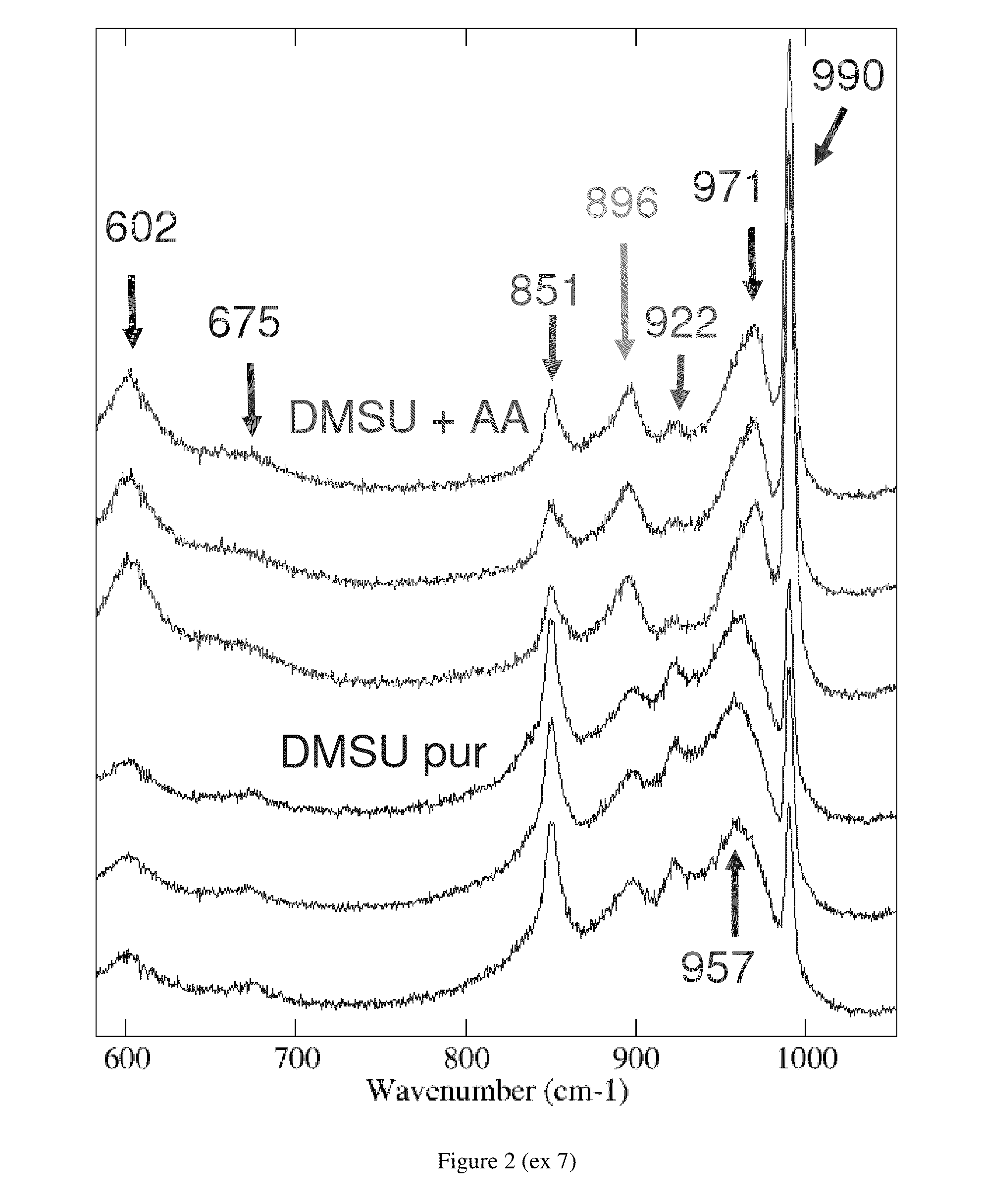

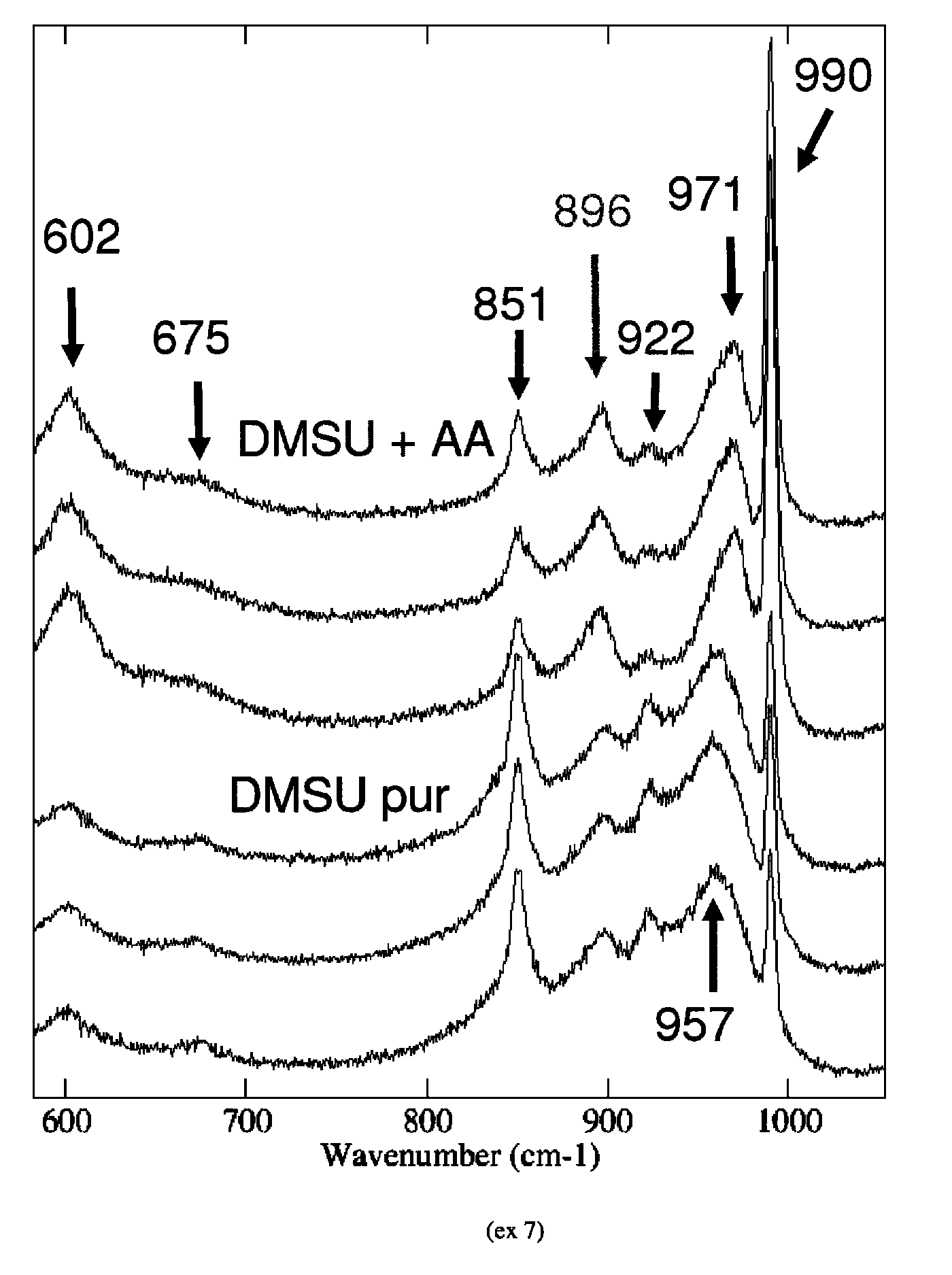

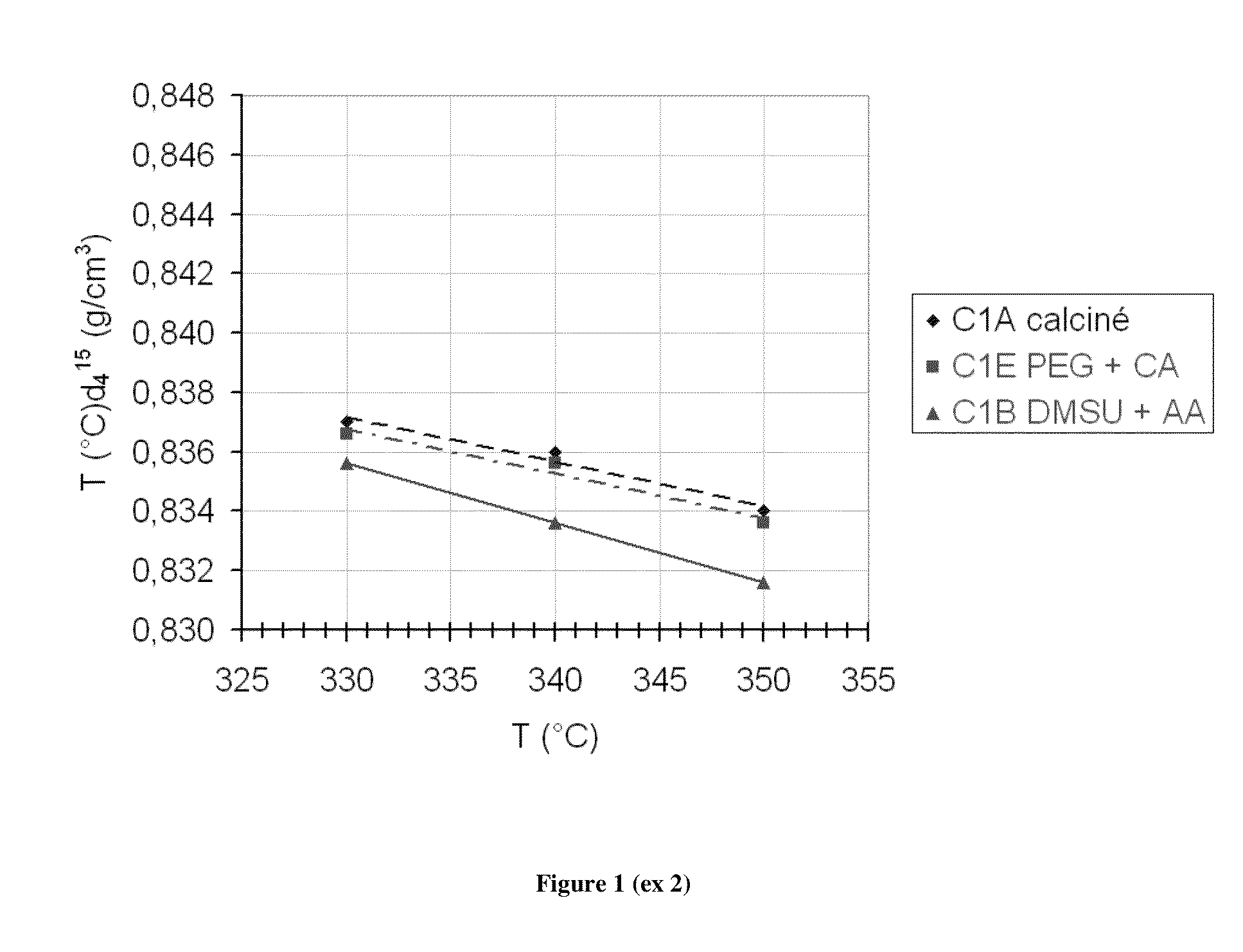

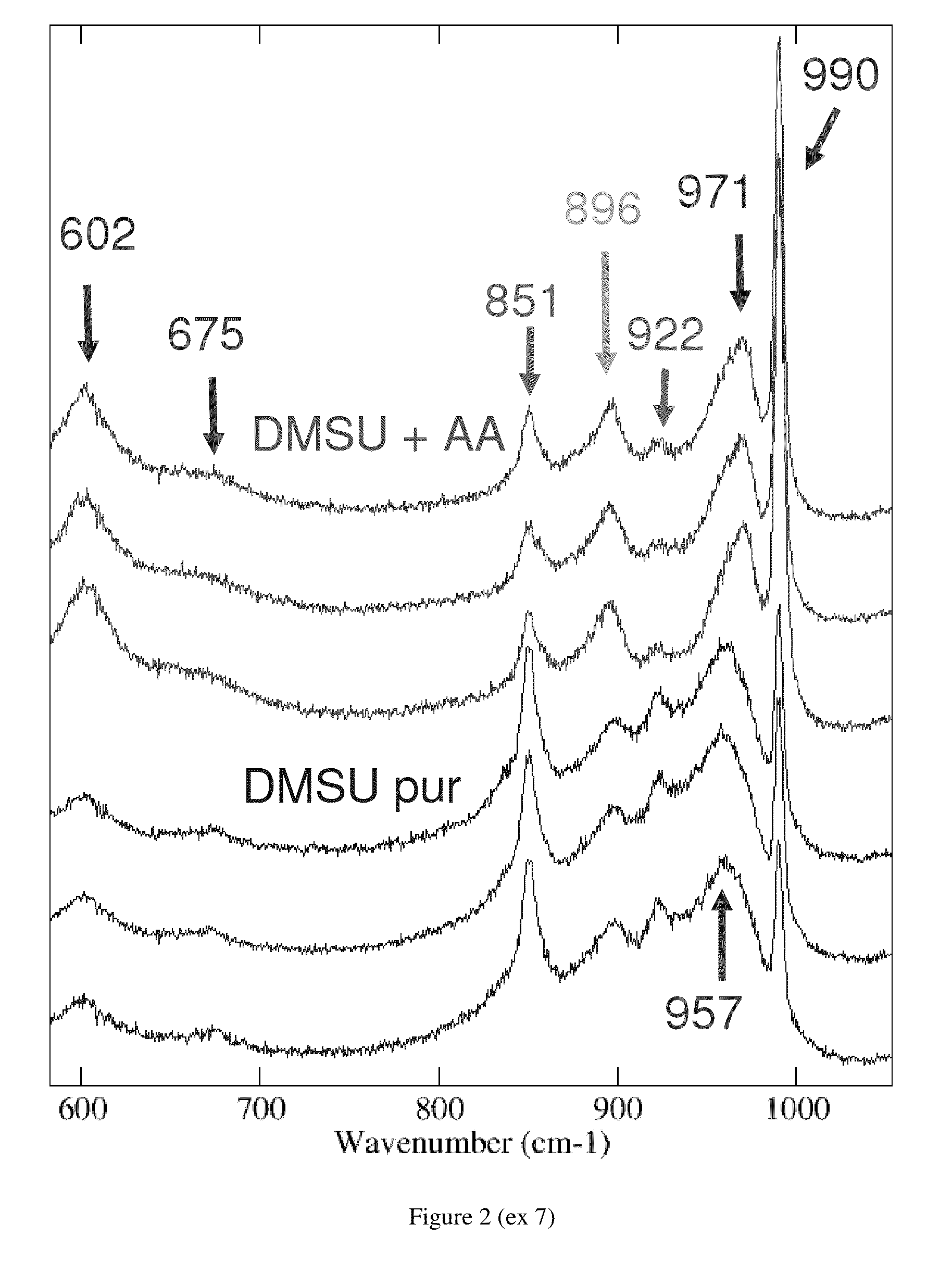

The invention relates to a catalyst usable in hydrotreatment processes, which comprises an alumina-based amorphous support, phosphorus, a C1-C4 dialkyl succinate, acetic acid and a hydro-dehydrogenizing function comprising at least one group VIII element and at least one group VIB element, preferably made up of cobalt and molybdenum, a catalyst whose Raman spectrum comprises the most intense bands characteristic of the Keggin heteropolyanions (974 and / or 990 cm−1), C1-C4 dialkyl succinate and acetic acid (896 cm−1). Preferably, the dialkyl succinate concerned is dimethyl succinate and its main band is at 853 cm−1.The invention also relates to the method of preparing said catalyst, wherein a catalytic precursor comprising the group VIB and group VIII elements, in particular the molybdenum-cobalt pair, and phosphorus, introduced by impregnation, then dried at a temperature below 180° C., is impregnated by the C1-C4 dialkyl succinate, the acetic acid and the phosphorus compound, if the latter has not been entirely introduced beforehand, then, after maturation, dried at a temperature below 180° C. prior to being optionally sulfurized.The invention also relates to the use of this catalyst in any hydrotreatment process.

Owner:TOTAL RAFFINAGE MARKETING +1

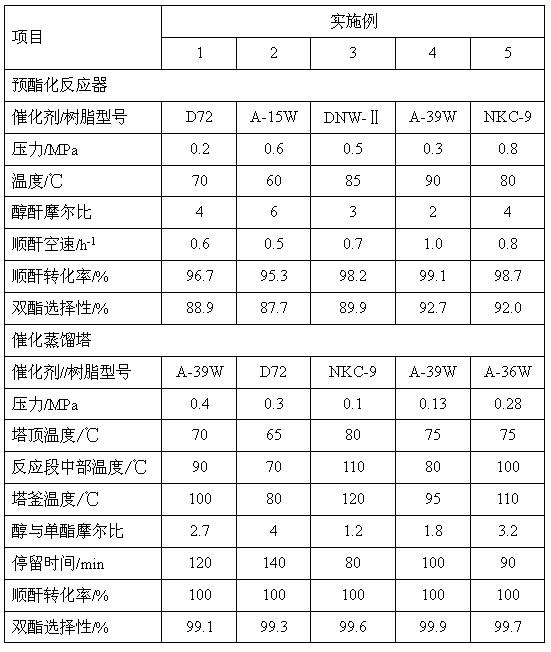

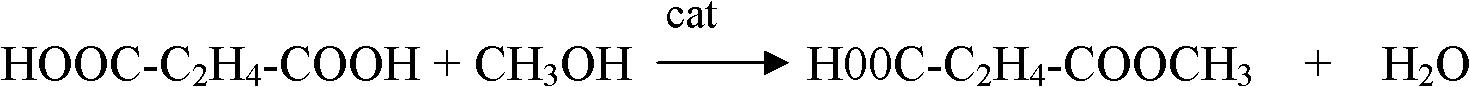

Method for preparing dimethyl succinate

ActiveCN102070448ASimple separation processImprove responseOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystSolid acid

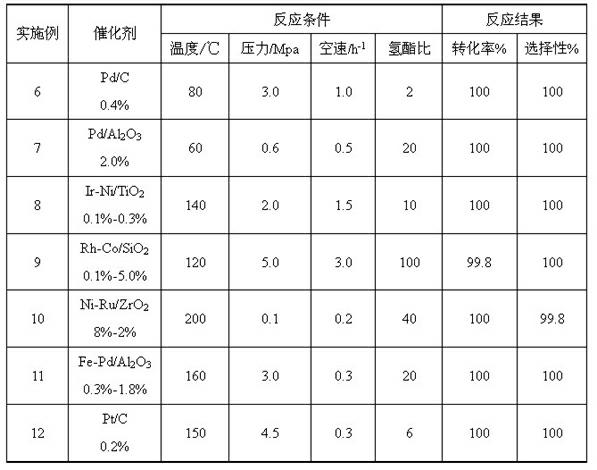

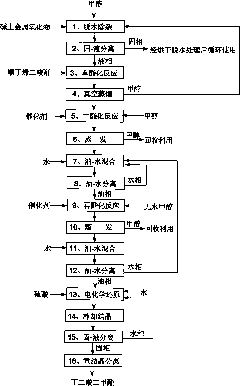

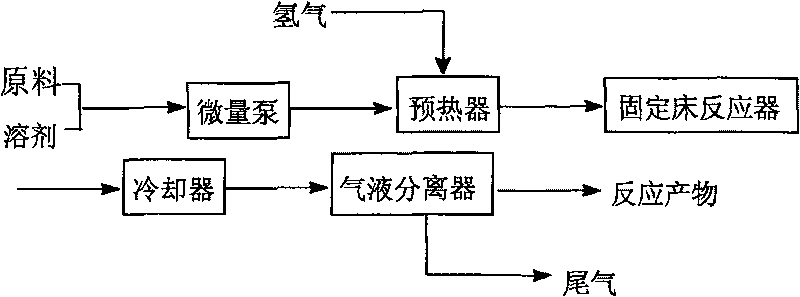

The invention discloses a method for preparing dimethyl succinate. The method comprises two reaction processes of esterification and hydrogenation and the reaction processes are as follows: (1) after pre-esterification reaction, maleic anhydride-methanol solution enters a catalytic distillation tower from the upper rectifying section of the tower, methanol enters the tower from the lower stripping section of the catalytic distillation tower, the reaction section is filled with solid acid catalyst, the two material flows perform countercurrent contact on the surface of the catalyst to perform esterification reaction and synthetize dimethyl maleate; and (2) dimethyl maleate and hydrogen are placed in a fixed bed reactor to perform hydrogenation reaction and generate the dimethyl succinate product in the presence of hydrogenation catalyst under a certain reaction condition. The method of the invention has the advantages of high raw material conversion rate and good product selectivity; and the process flow is simple, the energy consumption is low, no pollution can be caused and the scale production of dimethyl succinate can be realized.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

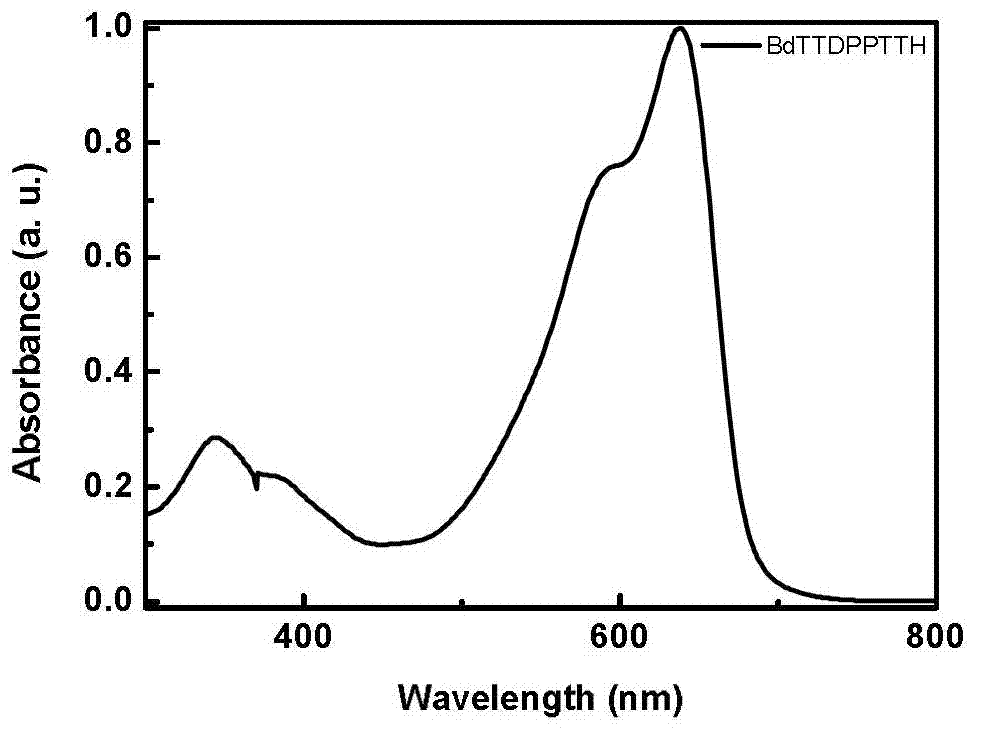

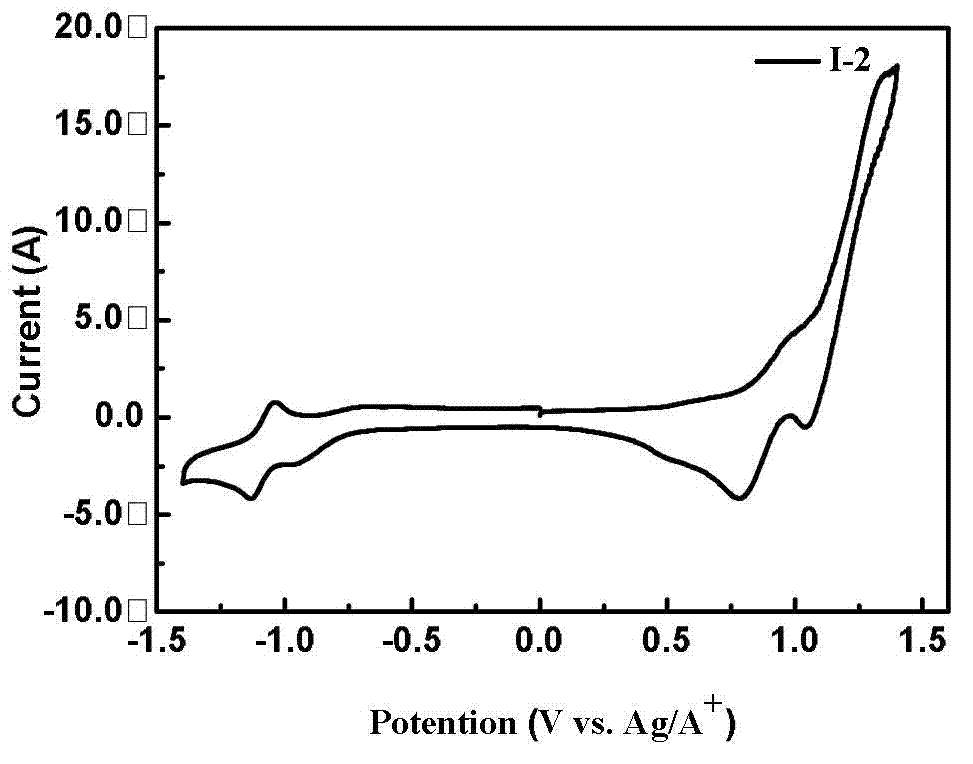

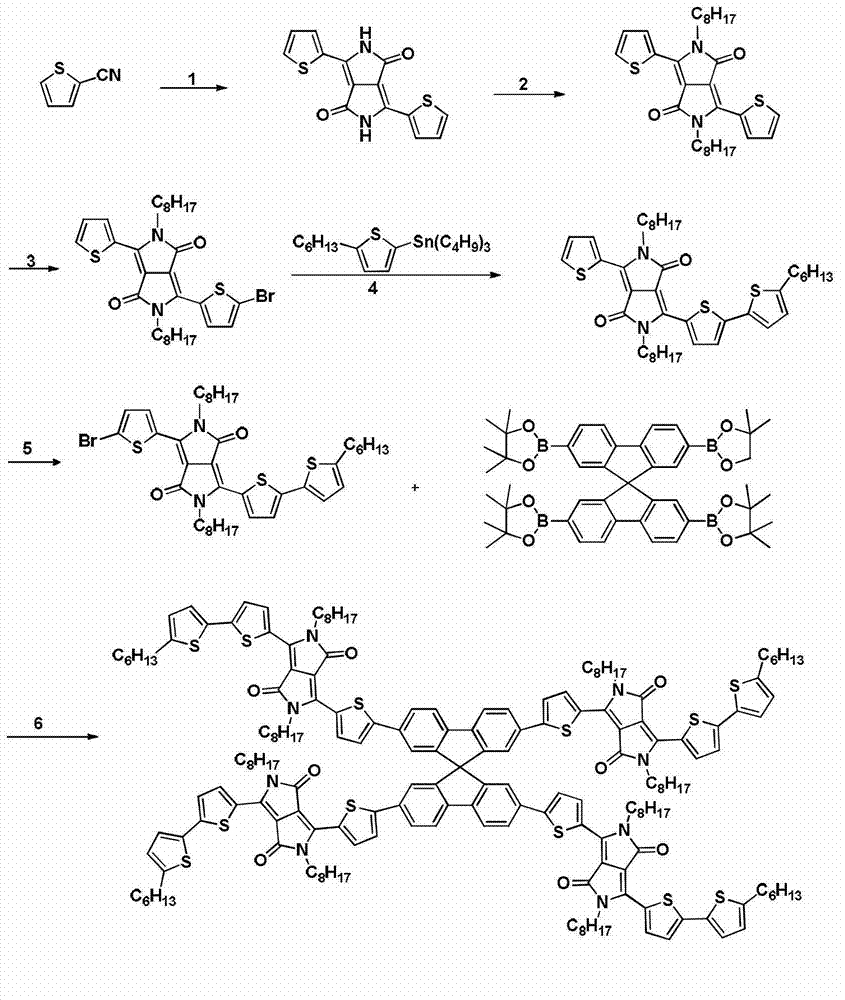

Diketopyrrolopyrrole derivative and preparation method and application thereof

InactiveCN103087083AGood absorbanceImprove solubilitySilicon organic compoundsSolid-state devicesKetoneCoupling reaction

The invention discloses a diketopyrrolopyrrole derivative. The structure of the diketopyrrolopyrrole derivative is as shown in a formula (I), wherein n=2 or 4, and R is selected from groups as shown in a formula (I-a), a formula (I-b) or a formula (I-c). The diketopyrrolopyrrole derivative disclosed by the invention achieves high absorbing capacity on visible light and can be applied to the field of organic solar energy as a micromolecular donator material. The invention also discloses a preparation method of the diketopyrrolopyrrole derivative. The diketopyrrolopyrrole derivative is obtained through a series of reaction, namely ring closing reaction, bromination reaction and coupling reaction, by taking 2-thiophenecarbonitrile and dimethyl succinate as initial raw materials.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

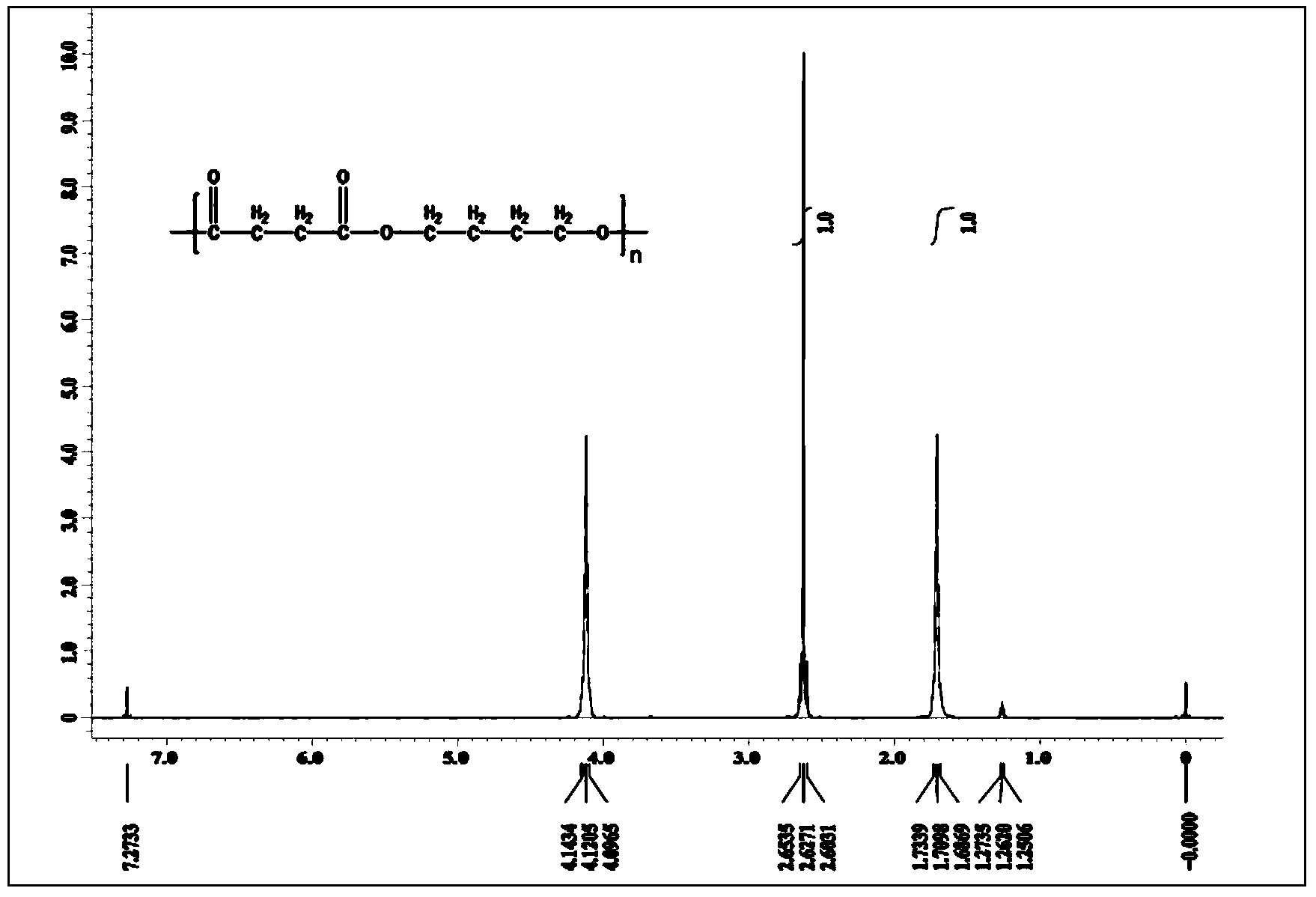

Preparation method of all-biological-base poly butylenes succinate (PBS)

The invention provides a preparation method of all-biological-base poly butylenes succinate (PBS). According to the preparation method, biological-base dimethyl succinate and 1,4-butanediol are used as polymerization monomers, an efficient composite catalyst system is adopted, and the all-biological-base PBS is prepared through an ester exchange and polycondensation two-stage polymerization process route. The biological-base PBS prepared by the method has the advantages of high molecular weight, good product color and luster, few by-products, high product yield and the like, and in addition, because chain extenders are not used, the application range of aliphatic polyester degradable plastics to the food package field can be further enlarged. In addition, compared with the existing method for preparing the PBS from petroleum bases as raw materials, the method provided by the invention also has the advantages that the production cost is low.

Owner:TANGSHAN XUYANG CHEM IND CO LTD

Method for preparing dimethyl succinate

ActiveCN101824627AThorough responseLow production costElectrolysis componentsOrganic compound preparationEvaporationCis-Butenedioic Acid

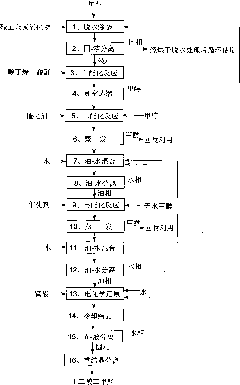

The invention relates to a method for preparing dimethyl succinate, which comprises the following steps that: (1) dehydration and decontamination: methanol and alkali-earth metal oxide are mixed, dehydrated and decontaminated; (2) separation of solid and liquid; (3) monoesterification reaction: maleic anhydride is added in the liquid-phase material which is obtained in the previous step; (4) vacuum distillation; (5) 2-esterification reaction; (6) evaporation; (7) mixing of oil and water; (8) separation of oil and water; (9) re-eesterification; (10) evaporation; (11) mixing of oil and water; (12)separation of oil and water; (13) electrochemical reduction: hydrogen is introduced to reduce dimethyl maleate to dimethyl succinate; (14) cooling and crystallization; (15) separation of solid and liquid: solid material enters the next step; (6) re-crystallization and separation: the product dimethyl succinate is obtained. The method is simple, and has reasonable process, low preparation cost, high product purity and good quality.

Owner:RUNTAI CHEM CO LTD

Preparation method of diethyl succinate

ActiveCN102863335AGood for separation and refinementSimple production processOrganic compound preparationCarboxylic acid esters preparationSolubilityReaction rate

The invention provides a preparation method of dimethyl succinate. The method comprises the steps of mixing maleic anhydride, an alcohol compound, carbon dioxide, hydrogen and a hydrogenation catalyst and conducting esterification hydrogenation reaction to obtain the dimethyl succinate. According to the method, the maleic anhydride, the alcohol compound and hydrogen serve as raw materials, the carbon dioxide serves as a solvent and an acid catalyst, under catalysis of the hydrogenation catalyst, the esterification hydrogenation reaction is conducted, and the dimethyl succinate is obtained. The carbon dioxide serves as the solvent of the esterification hydrogenation reaction and the acid catalyst, high catalytic activity is achieved, and the reaction rate is improved; the carbon dioxide and water generated in the reaction process can form acid, and an obtained product has certain solubility in the carbon dioxide, so that the reaction can be conducted in a positive direction, and the conversion rate and the production rate of the dimethyl succinate are improved. Experimental results show that the yield rate of the obtained dimethyl succinate exceeds 99%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

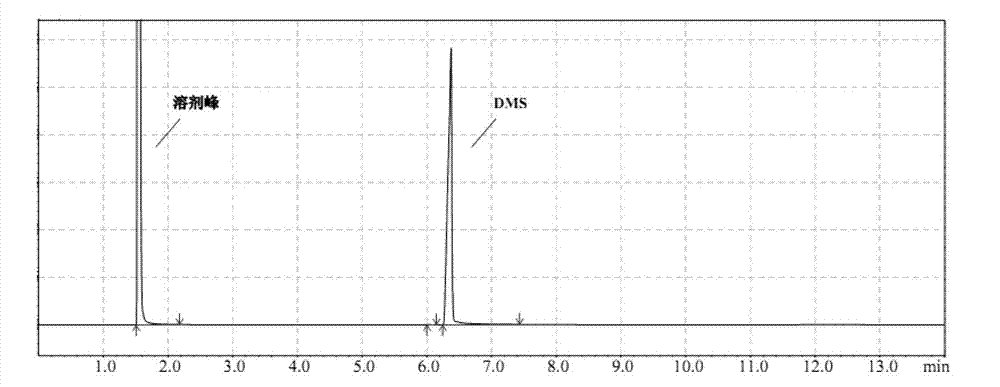

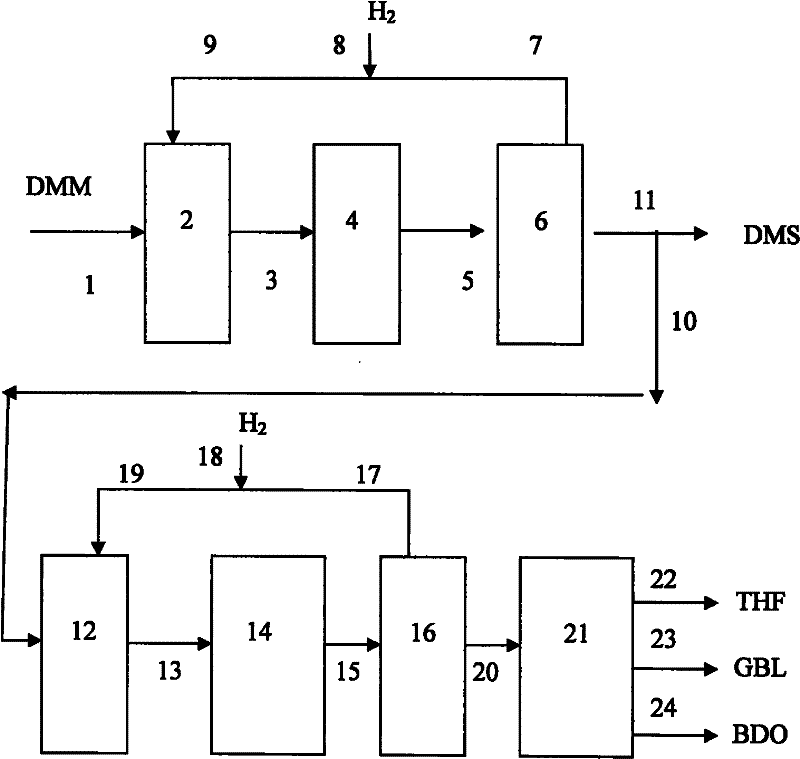

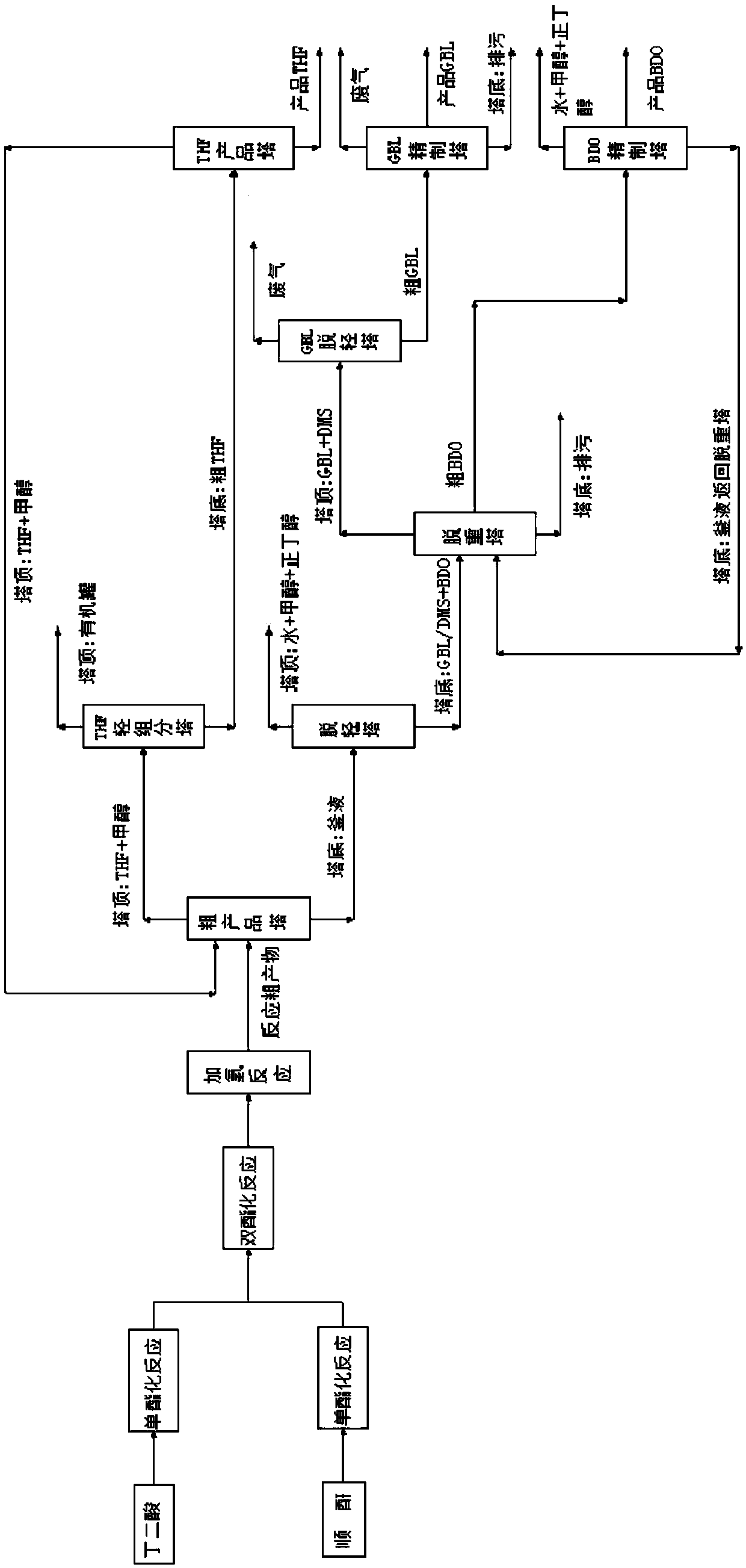

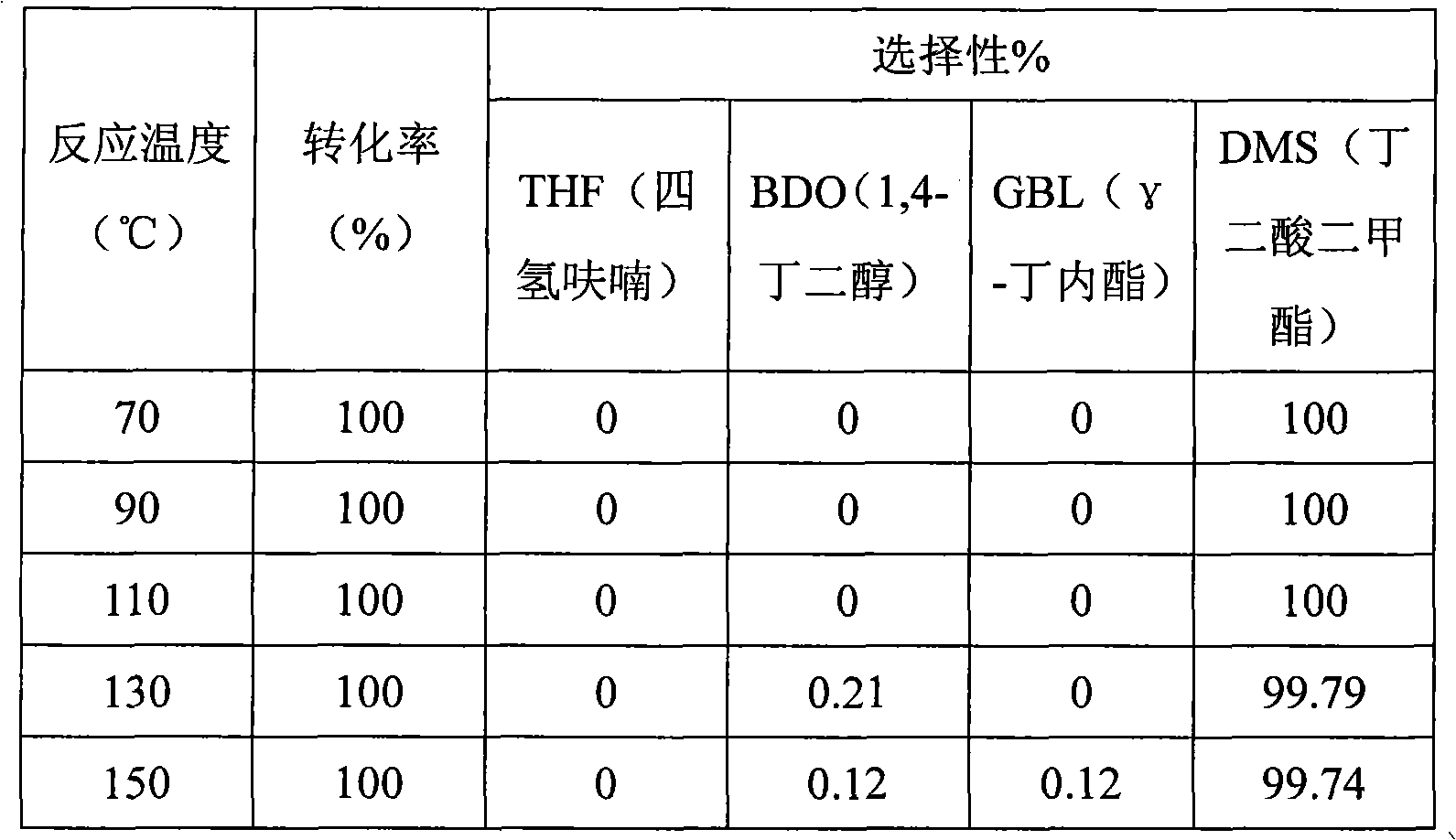

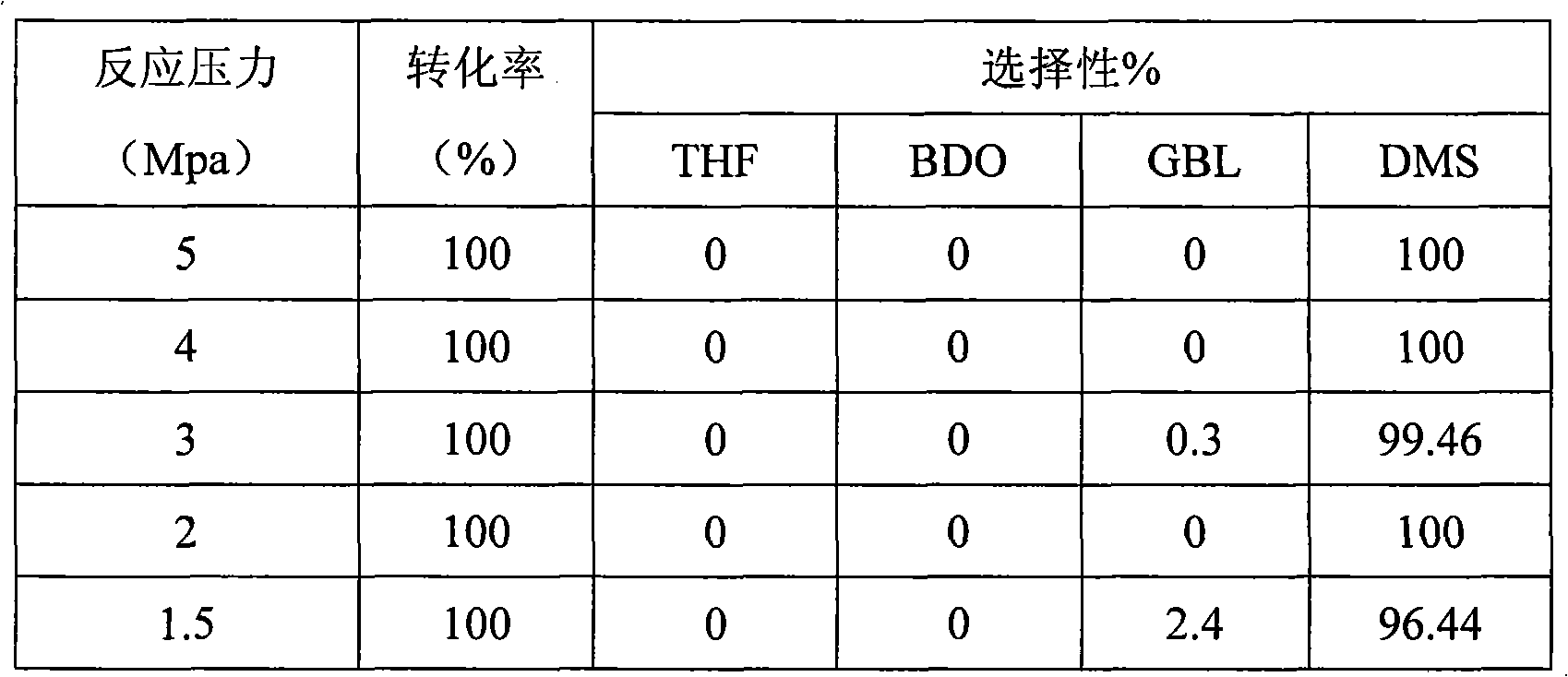

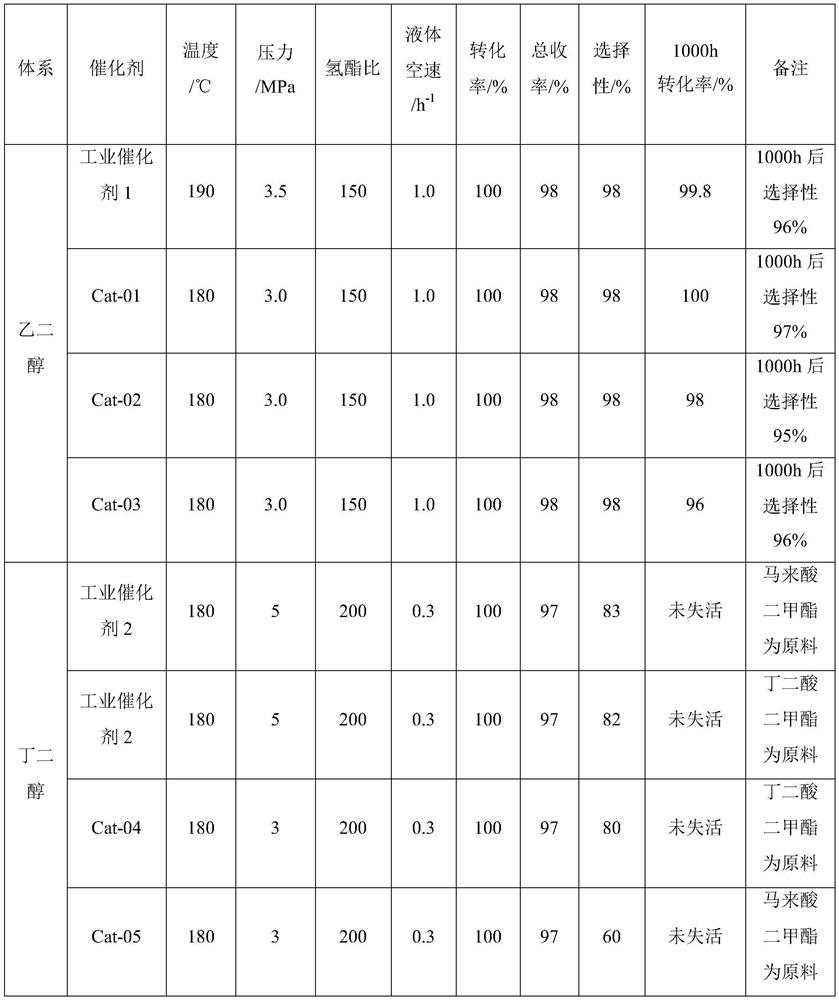

Method of simultaneously producing dimethyl succinate and 1,4-butyl glycol

ActiveCN102190582AFlexible productionOvercome defectsOrganic compound preparationCarboxylic acid esters preparationFuranGas phase

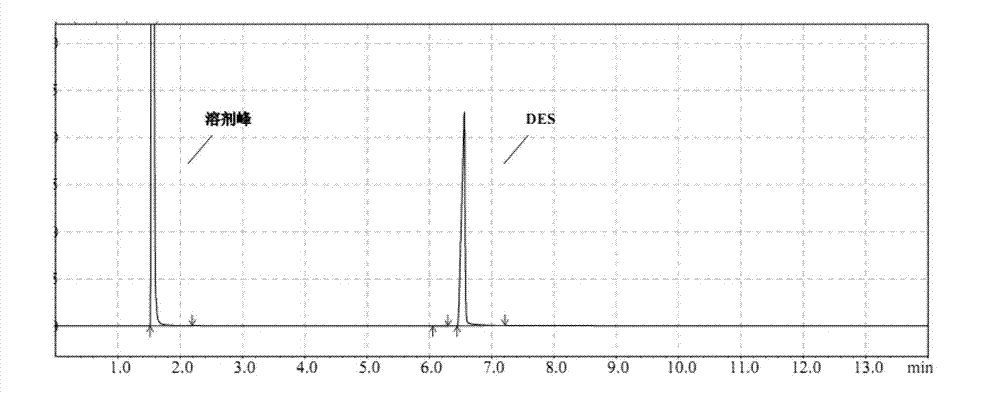

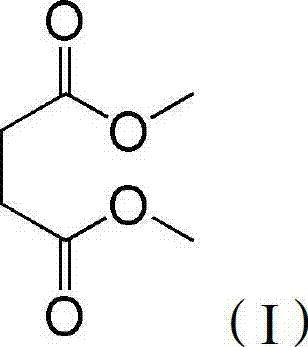

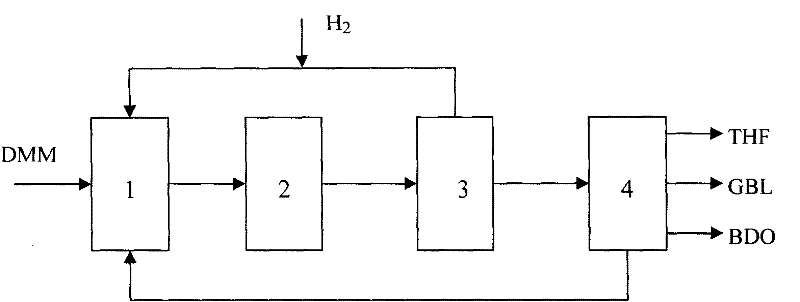

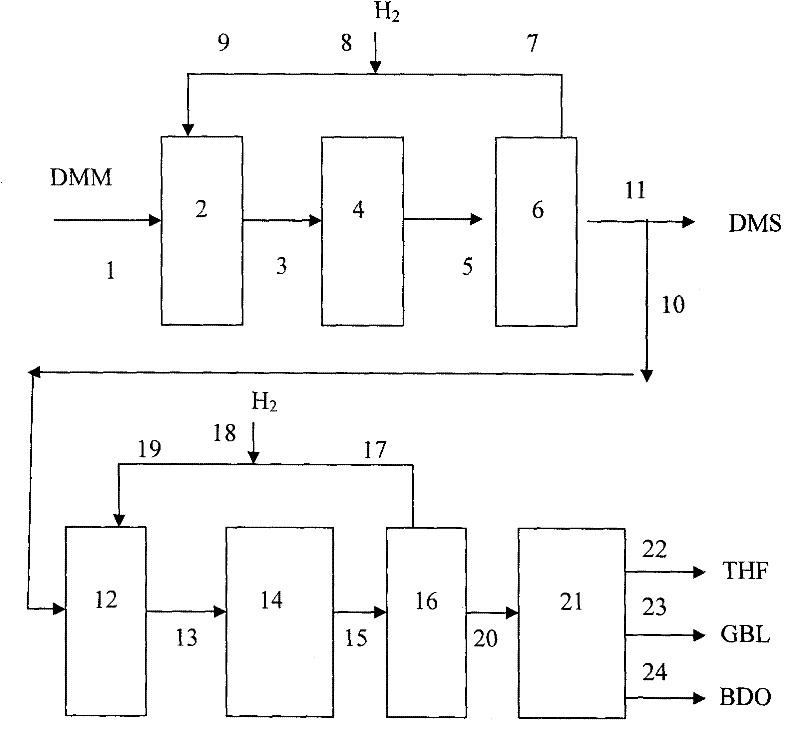

The invention relates to a method of simultaneously producing dimethyl succinate (DMS) and 1, 4-butyl glycol. The method can also be used to simultaneously produce at least one of Tetrahydro furan (THF) and gamma-irradiation butyl lactone (GBL). In the invention, dimethyl maleate (DMM) is used as raw materials and contacts with hydrogen under the condition of gas phase in a low pressure reaction district and a middle pressure reaction district respectively. A low-pressure reactor and a middle-pressure reactor are equipped with a catalyst. DMS products are produced in the low pressure reaction district and 1, 4-butyl glycol products are produced in the middle pressure reaction district. Simultaneously, at least one of the GBL and THF can be produced in the middle pressure reaction district. Purity of DMS can reach over 99.5% without refining through using a gas-liquid separator. In the invention, the method is used in mild condition; heavier component does not need to be circulated; operation is simple; transesterification type polymerization and other side reactions are greatly reduced in a system.

Owner:SHANGHAI HUAYI ENERGY CHEM

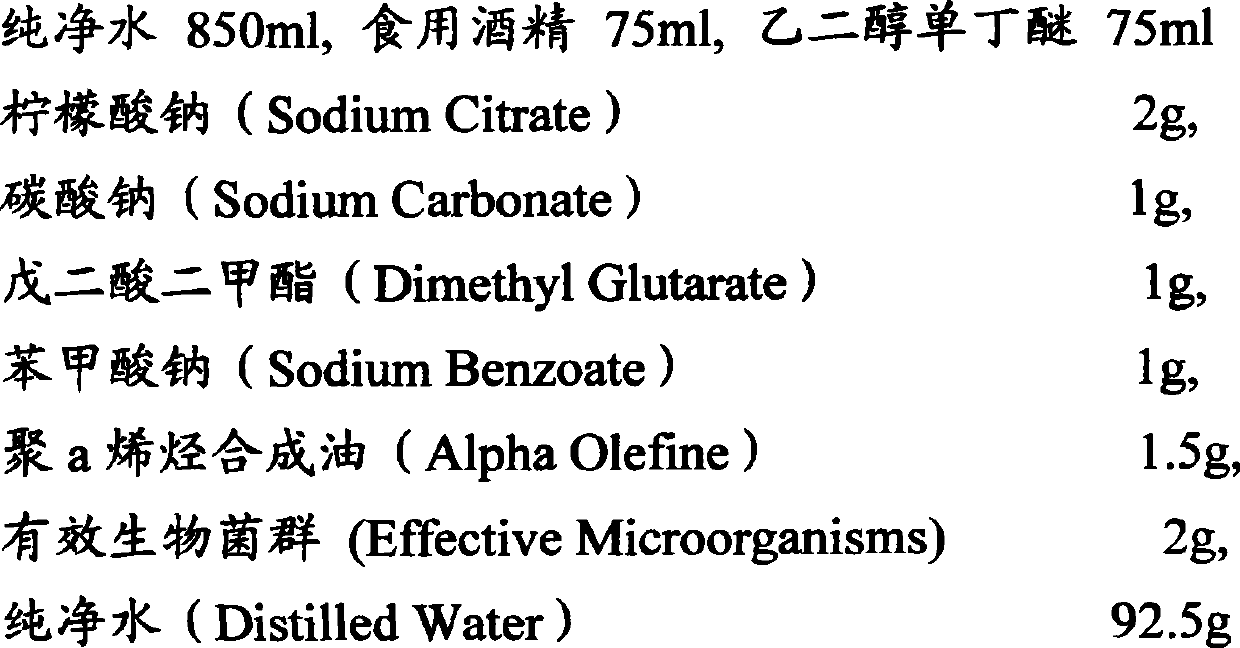

Touch screen washing agent

ActiveCN102533475AReduce volatilitySmall smellSurface-active non-soap compounds and soap mixture detergentsOrganic non-surface-active detergent compositionsEtherDiethylene glycol

The invention provides a touch screen washing agent and belongs to the field of electronic product washing agents. The touch screen washing agent in the prior art is poor in washing effect; and after being inhaled to a human body, the washing agent can be accumulated in the human body so as to harm the human body. The touch screen washing agent provided by the invention is obtained by successively adding raw materials in a reaction container and evenly mixing, and the raw materials comprise the following components by weight percent: 60%-80% of dimethyl succinate, 5%-12.5% of diethylene glycol mono-methyl ether, 5%-12.5% of diglycol mono-butyl ether and 10%-15% of ethanol. The washing agent provided by the invention is used for washing the touch screen of a mobile phone, has good dissolution property for adhesive residues, can wash adhesive residual substances and meet the washing requirement of the touch screen of the mobile phone, and washing capability is improved; the washing agent provided by the invention is used to wash the old polaroid on the touch screen of the mobile phone so that the washing qualified rate of the touch screen of the mobile phone is improved, thereby prolonging the service life of the mobile phone; and the washing agent provided by the invention has the advantages of low volatilization, small smell and low toxicity and is not accumulated in the humanbody, so as to reduce the harm to the human body.

Owner:东莞优诺电子焊接材料有限公司

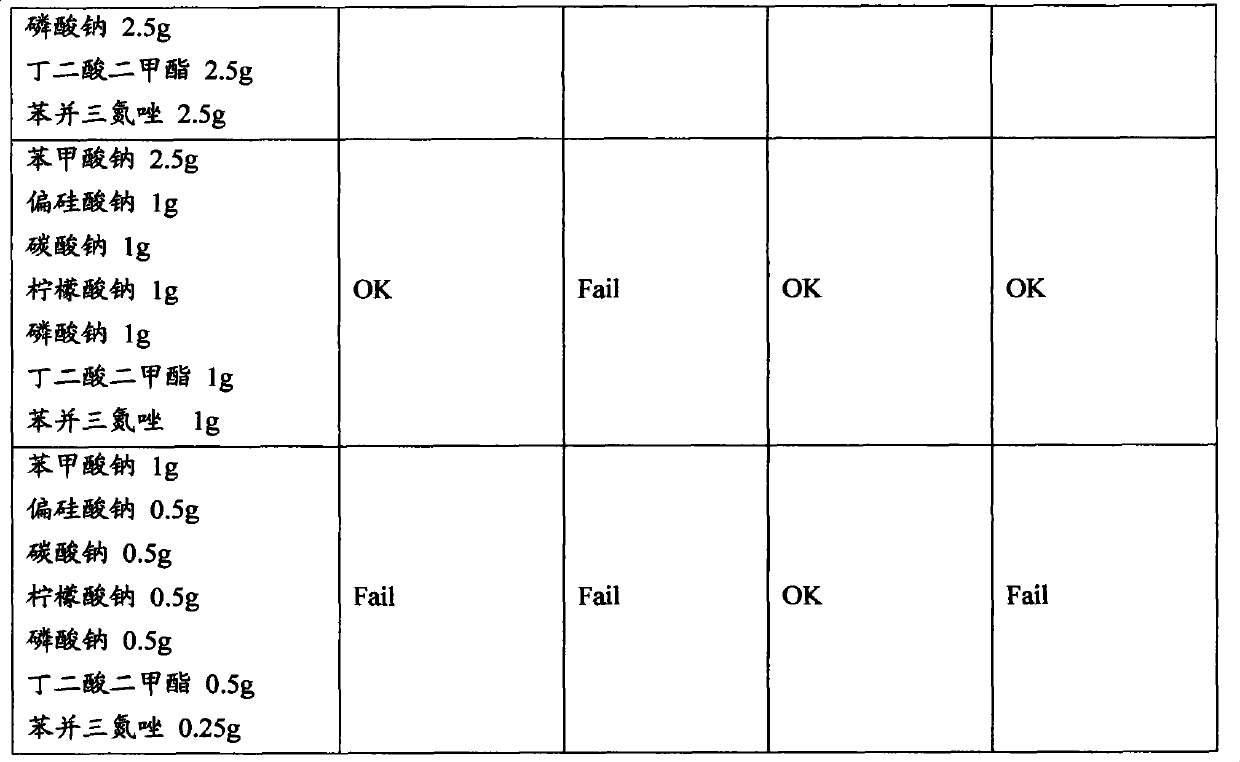

Cloth carpet deodorant and preparation method thereof

InactiveCN107711883AStrong decontaminationImprove antistatic performanceBiocideOther chemical processesAntioxidantSalicylic acid

The invention discloses a cloth carpet deodorant, and belongs to the technical field of deodorants, wherein the raw materials comprise, by weight, 25-30 parts of ethylene glycol, 5-6 parts of benzalkonium chloride, 2-4 parts of polysorbate, 3-5 parts of essential oil, 15-17 parts of a plant extraction liquid, 1-3 parts of orange peel tincture, 8-10 parts of nanometer titanium dioxide, 4-6 parts ofdiatomaceous earth, 1-2 parts of dimethyl succinate, 2-4 parts of boric acid, 1-2 parts of salicylic acid, 0.1-0.8 part of a bactericide, 0.5-1 part of an antioxidant, 0.5-1.5 parts of an antistaticagent, and 80-100 parts of water. The invention further discloses a preparation method of the cloth carpet deodorant. According to the present invention, the preparation method is simple, and the cloth carpet deodorant can effectively purify the air and remove odors, and has effects of sterilization and decontamination.

Owner:ANHUI ZHONGHONG TECH DEV CO LTD

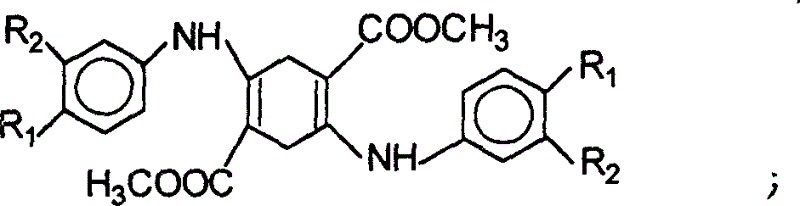

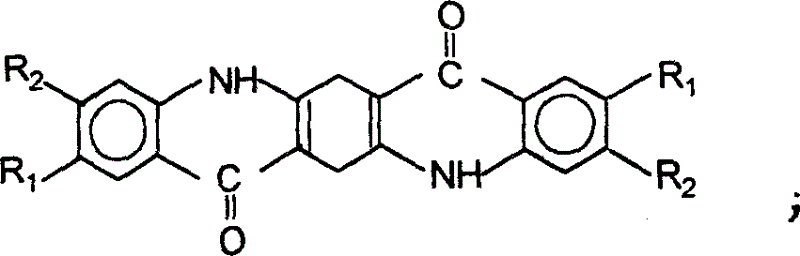

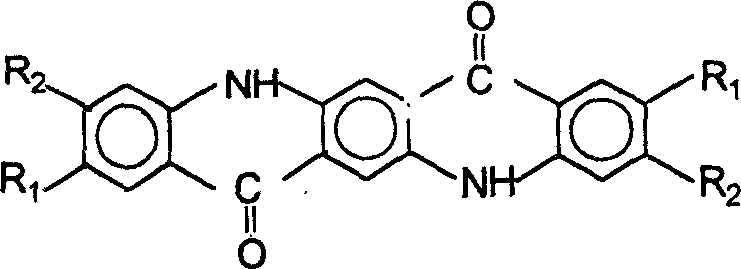

Process for preparation of quinacridone series pigments

InactiveCN1521218AAvoid generatingLow oxidation temperatureQuinacridonesReaction temperaturePhosphoric acid

The present invention discloses the preparation process of serial quinacridone dyes. The preparation process includes the first condensation of diacyl dimethyl succinate and aniline derivative in ethanol under the catalysis of hydrochloric acid to obtain 1, 4-(N-phenyl amino)-2, 5-dimethyl carboxylate; direct cyclization of 1, 4-(N-phenyl amino)-2, 5-dimethyl carboxylate under the action of phosphoric acid polymer to produce dihydroquinacridone; and final chemical oxidation or hydrogenating aromatization and cyclization under catalysis of Pt catalyst of dihydroquinacridone in the condition of being favorable to form aromatic nucleus to produce quinacridone. The process of the present invention has low reaction temperature and mild reaction condition, and the product has no deep colored impurity produced and no need of purification and crystal transformation in obtaining dye with required hue and crystal form.

Owner:余世春 +1

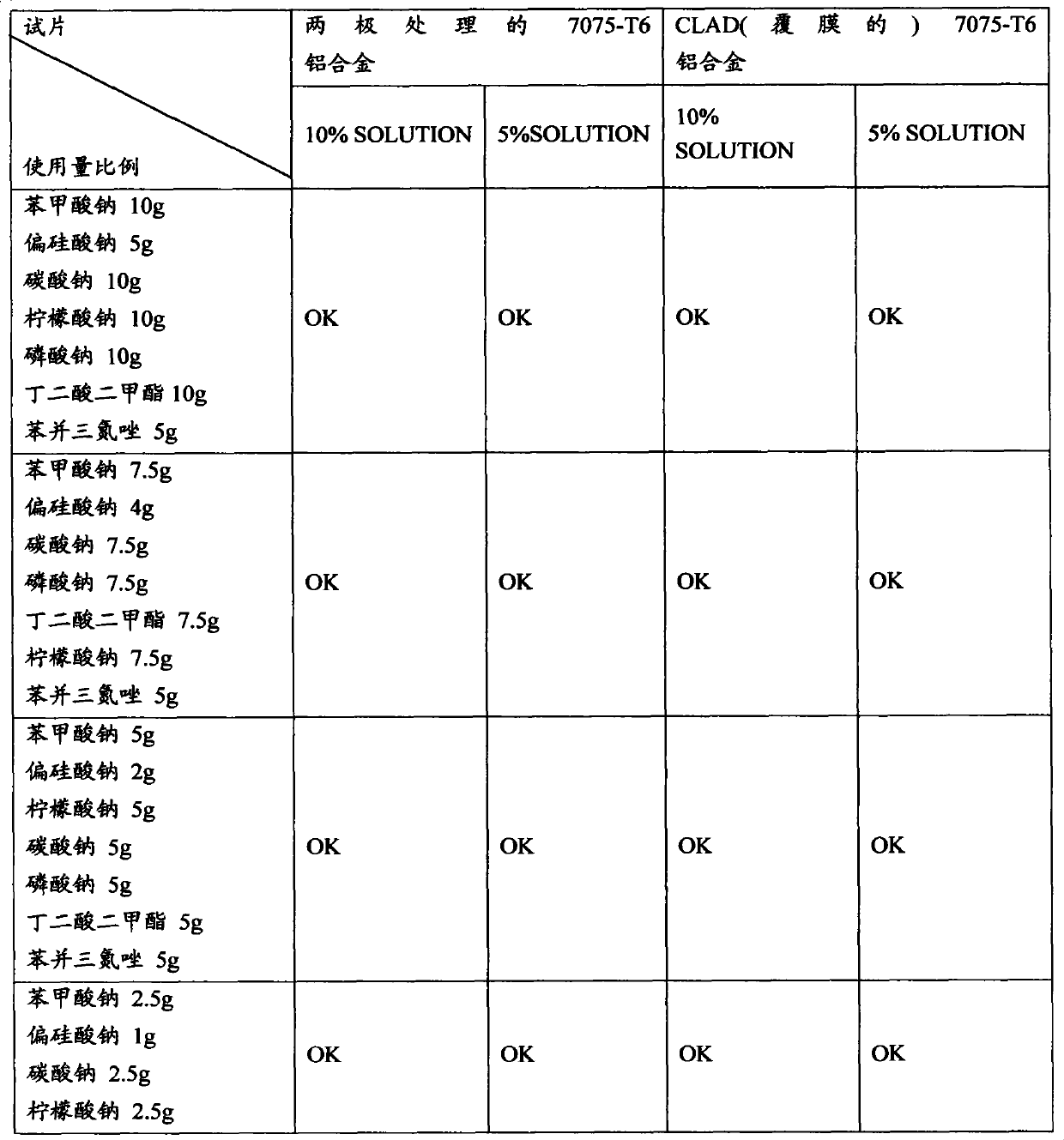

Special cleaning agent for airplane enclosure and preparation method thereof

ActiveCN102994271ANo pollution in the processRaise the ratioDetergent compounding agentsSodium metasilicateSodium phosphates

The invention discloses a special cleaning agent for an airplane enclosure, which comprises the following raw materials in percentage by mass: 0.2-0.5% of sodium benzoate, 0.2-0.5% of sodium metasilicate, 0.2-0.5% of sodium carbonate, 0.2-0.5% of sodium citrate, 0.2-0.5% of sodium phosphate, 0.2-0.5% of dimethyl succinate, 0.2-0.5% of benzotriazole, 7.5-15% of ethylene glycol butyl ether and 5-10% of polyethylene glycol. According to the invention, a polluted volatile solvent is not adopted in the whole formula, 1-H benzotriazole serves as a metal anti-corrosion agent, hydrocarbon solvents such as TEC, TC and the like or halogen solvents are not used, edible alcohol is used as a solvent, sodium benzoate is added to realize anti-corrosion performance, and polyethylene glycol is used as a surfactant. Therefore, the special cleaning agent disclosed by the invention has the advantages of simple proportioning, health and environmental protection, no volatile solvent, good anti-corrosion effect, friendliness to environment, no corrosion to the airplane enclosure and connecting pieces and no pollution to environment.

Owner:重庆芸中鹰航空科技有限公司

Load type polymeric acidic ionic liquid catalyst and preparation method and application thereof

ActiveCN105688993ALower synthesis costPrevent leakageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryIonic liquid

The invention relates to a load type polymeric acidic ionic liquid catalyst and a preparation method and application thereof, and belongs to the technical fields of catalysis, materials and chemical industry. The catalyst comprises granules which are dispersed on the surface of a porous carrier and contain ionic liquid, the loading capacity of the acidic ionic liquid of the catalyst ranges from 2% to 10%, and for the catalyst, the specific surface area measured through a specific surface area and micropore adsorption analysis meter ranges from 250 m<2> / g to 350 m<2> / g. The load type polymeric acidic ionic liquid catalyst and the preparation method and application thereof have the advantages that the loaded ionic liquid content of the catalyst is high, and the catalytic esterification effect is good; under a specific reaction device and reaction condition, the yield of catalytically synthesizing dimethyl succinate can reach 85%.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

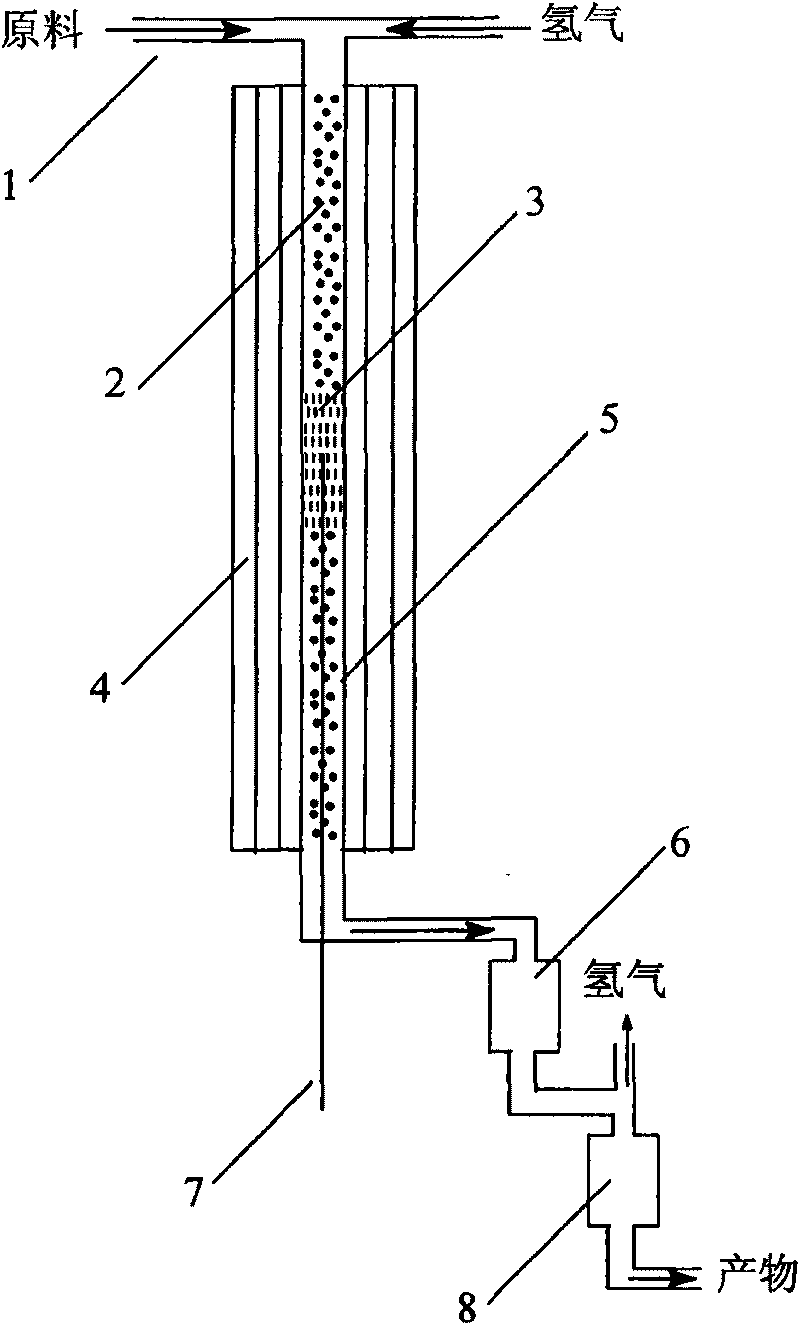

Method for preparing gamma-butyrolactone through catalytic hydrogenation of dimethyl succinate

InactiveCN101704805ARaise the pHHigh activityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFixed bedReaction temperature

The invention relates to a method for preparing gamma-butyrolactone through catalytic hydrogenation of dimethyl succinate, which belongs to the field of chemical technology. Gamma-butyrolactone is prepared by utilizing the catalytic hydrogenation of multicomponent metallic oxide catalyst through a fixed bed tubular reactor by adopting dimethyl succinate as raw material and carbinol as solvent. The multicomponent metallic oxide catalyst is prepared through a coprecipitation method, the major catalyst comprises 15 to 80 percent (Wt) of copper oxide and 10 to 50 percent (Wt) of zinc oxide, the catalyst accelerator comprises 0 to 10 percent (Wt) of one or a plurality of the oxides of calcium, barium, magnesium, manganese, nickel, molybdenum or cobalt, and a carrier comprises 5 to 30 percent (Wt) of one or a plurality of aluminium oxide, zirconium dioxide and silicon dioxide. When the reaction temperature is 200 to 300 DEG C, the reaction pressure is 2 to 4 MPa, the mol ratio of hydrogen to ester is 100 to 250, and the liquid hourly space velocity is 0.2 to 0.5 h per hour, the conversion rate of dimethyl succinate is larger than 95 percent, and the selectivity of gamma-butyrolactone is larger than 90 percent. The multicomponent metallic oxide catalyst has higher activity and is inexpensive, and both preparation and recovery of the catalyst can not pollute the environment.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Method for preparing dimethyl succinate

InactiveCN104878048AMeet operational requirementsReaction process greenOrganic compound preparationCarboxylic acid esters preparationChemical industryDisodium Succinate

The invention relates to a method for preparing dimethyl succinate. The method comprises the following steps: (1) preparing disodium succinate fermented liquid; (2) treating the disodium succinate fermented liquid; and (3) preparing dimethyl succinate by using a bipolar-membrane electrodialysis apparatus. The processes such as catalyst cleaning, regeneration, and the removal of a deactivated catalyst, and the like existing in the traditional preparation process are omitted; and the whole reaction process is green and clean, and completely conforms to the operating requirements of the modern chemical industry.

Owner:镇江博睿兴邦生物科技有限公司

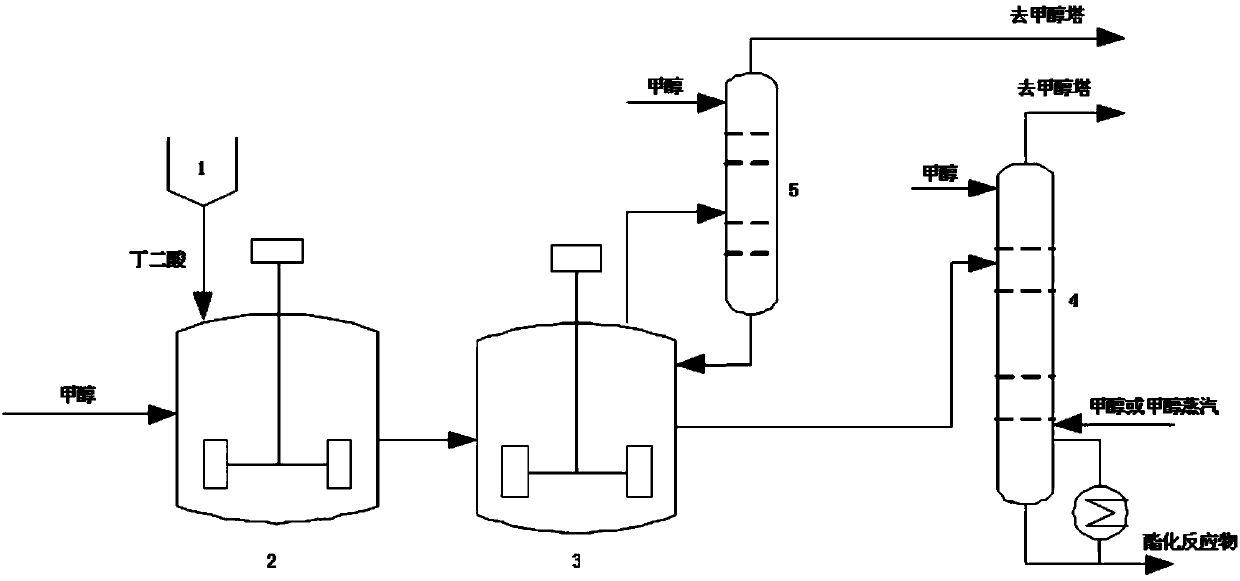

Continuous preparation method of 1,4-butanediol

ActiveCN111018669AAvoid mutual influence of co-monoesterificationAvoid interactionOrganic compound preparationCarboxylic acid esters preparationSuccinic acid monomethyl esterButanedioic acid

The invention discloses a continuous preparation method of 1,4-butanediol. The method comprises the following steps: carrying out a monoesterification reaction on bio-based succinic acid and methanolto obtain a succinic acid monoesterification liquid containing succinic acid monomethyl ester; mixing with monomethyl maleate to obtain a mixed esterification liquid; feeding into a double esterification reaction tower, and carrying out a double esterification reaction to generate a mixture of dimethyl succinate and dimethyl maleate; feeding the mixture into a hydrogenation reactor, and carrying out a hydrogenation reaction, wherein the the dimethyl maleate in the mixture is hydrogenated to generate dimethyl succinate; and performing a cascade reaction to convert into an intermediate product gamma-butyrolactone, and then generating 1,4-butanediol and tetrahydrofuran. According to the method, the bio-based succinic acid is adopted to partially replace monomethyl maleate to produce 1,4-butanediol, so that the consumption of petroleum chemicals is reduced, and the production cost of 1, 4-butanediol is reduced; and bio-based succinic acid and methanol are subjected to a monoesterificationreaction, and then mixing is performed with monomethyl maleate, so that the mutual influence caused by co-monoesterification of succinic acid and maleic anhydride is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

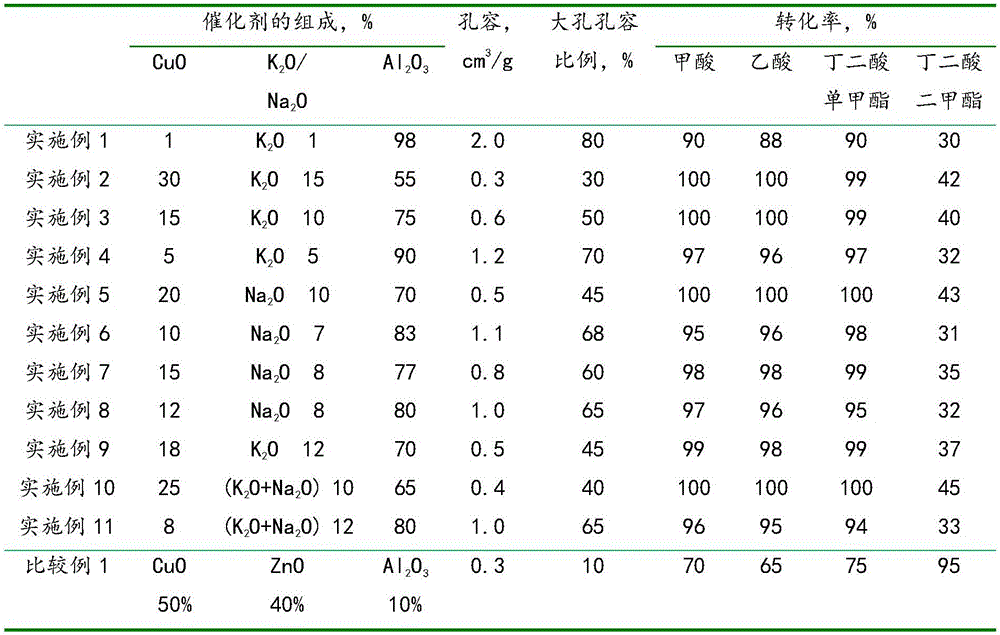

Pre-hydrogenation catalyst for preparing 1,4-butanediol, preparation method and application thereof

ActiveCN105797732ALarge hole volumeGreat ability to adsorb impuritiesOrganic compound preparationHeterogenous catalyst chemical elements1,4-ButanediolAcetic acid

The invention discloses a dimethyl succinate pre-hydrogenation catalyst for preparing 1,4-butanediol, a preparation method and application thereof. The catalyst provided by the invention can be used for effectively removing few amount of impurities, such as formic acid, acetic acid and dimethyl succinate existing in the process of preparing succinic acid in dimethyl succinate through a fermentation method and the catalyst poisoning and breaking can be prevented.

Owner:SINOPEC YANGZI PETROCHEM +1

Method for preparing poly(butylene succinate) through transesterification method

The invention relates to the field of high polymer material synthesis and discloses a method for preparing poly(butylene succinate) through a transesterification method. The method comprises the following steps: carrying out esterification reaction on dimethyl succinate, a dihydric alcohol monomer containing 1,4-butanediol and a composite catalyst in a nitrogen atmosphere, wherein the reaction temperature is 110-150 DEG C and the reaction time is 2-3 hours; carrying out condensation polymerization in a vacuum condition, wherein the vacuum degree is 10-300Pa of absolute pressure, the reaction temperature is 150-240 DEG C and the reaction time is 2-3 hours, thereby preparing the poly(butylene succinate). According to the method, on one hand, the problem of high corrosivity of a polymeric monomer in the prior art can be solved, and on the other hand, the problems of multiple byproduct micromolecules and relatively low yield in the prior art can be solved, so that the production cost of the poly(butylene succinate) can be effectively reduced.

Owner:NINGBO ZHETIE JIANGNING CHEM

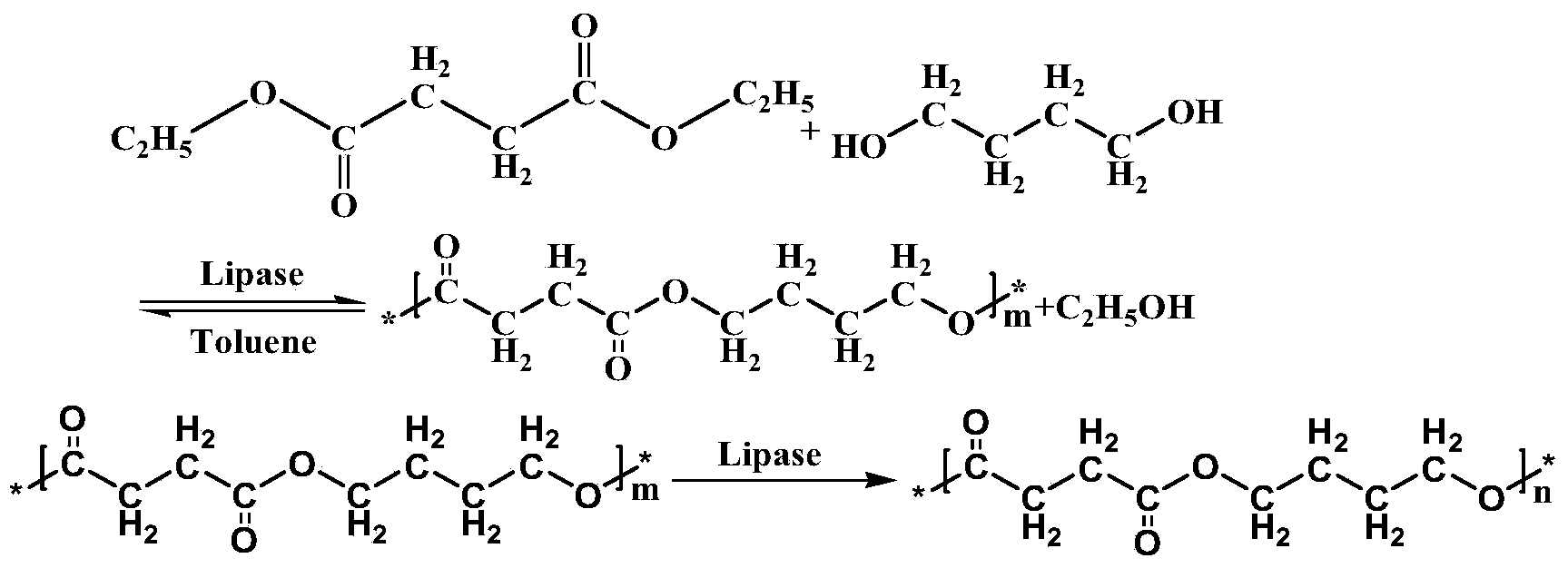

Preparation method of poly(butylene succinate)

The invention discloses a preparation method of poly(butylene succinate). The preparation method comprises the following steps: (1), under catalytic action of lipase, polymerizing an acyl donor and 1,4-butanediol through liquor to obtain a prepolymer, wherein the acryl donor is at least one of succinic acid, dimethyl succinate and diethyl succinate; (2), under the catalytic action of the lipase, polymerizing the prepolymer by virtue of a main body to obtain poly(butylene succinate). The invention provides the preparation method of poly(butylene succinate) with high molecular weight. Compared with the existing technology of synthesizing polyesters in an enzymatic manner, under the condition that material ingredients are the same, the method disclosed by the invention can be used for greatly reducing consumption of energy and dosage of the organic solvent in the processing process, and improving the molecular weight and material performance of a product. Moreover, the method can be used for overcoming a bottleneck of short-chain aliphatic monomer polymerization in an enzymatic manner, obtaining a high molecular product which can be put into practical application; meanwhile, the production cost is lowered by virtue of normal-pressure polymerization, and a basis is provided for industrially producing the polyesters by virtue of an enzyme process.

Owner:TSINGHUA UNIV

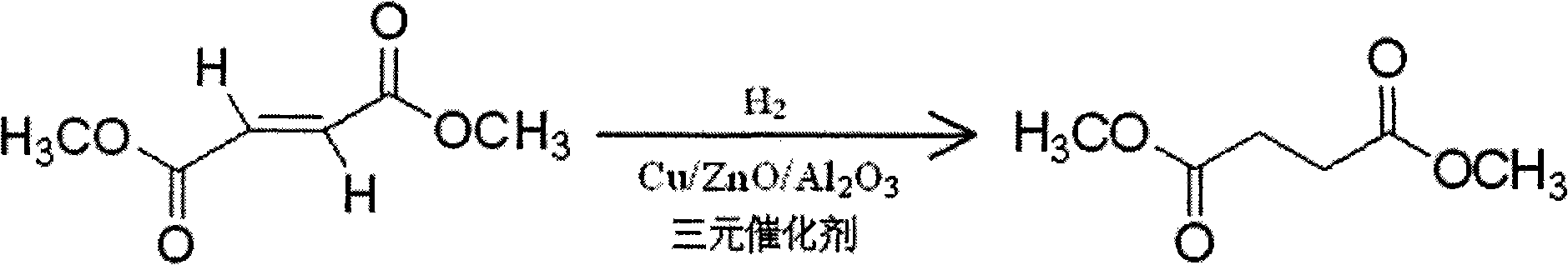

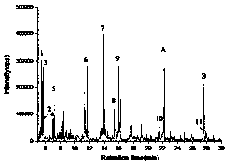

Catalyst for use in synthesis of dimethyl succinate and application thereof

InactiveCN101905160ALarge specific surface areaGood choiceOrganic compound preparationCarboxylic acid esters preparationChemical industryPore distribution

The invention relates to a catalyst for use in the synthesis of dimethyl succinate and application thereof, which belong to the field of chemical industry. The catalyst consists of copper, zinc oxide and alumina serving as active ingredients, and the application of the catalyst in synthesizing dimethyl succinate is also disclosed. Meanwhile, the invention also discloses a method for synthesizing the dimethyl succinate. In the method, the dimethyl succinate is prepared by using monomethyl maleinate as raw material and by hydrogenation in the presence of the catalyst of the invention. Compared with a copper-based catalyst prepared by using traditional methods, the catalyst of the invention has the advantages of neater pore distribution, larger specific surface area, and excellent hydrogenation activity and selectivity, and the target product has the advantages of specific selectivity and good thermal stability. By using the new catalyst, the synthesis method of the invention overcomes the problems of high pressure and high cost and the like of the prior art, and has the advantages of simple process and easily controlled conditions and the like. Therefore, the synthesis method has a good industrial application prospect.

Owner:SHANGHAI HUAYI ENERGY CHEM

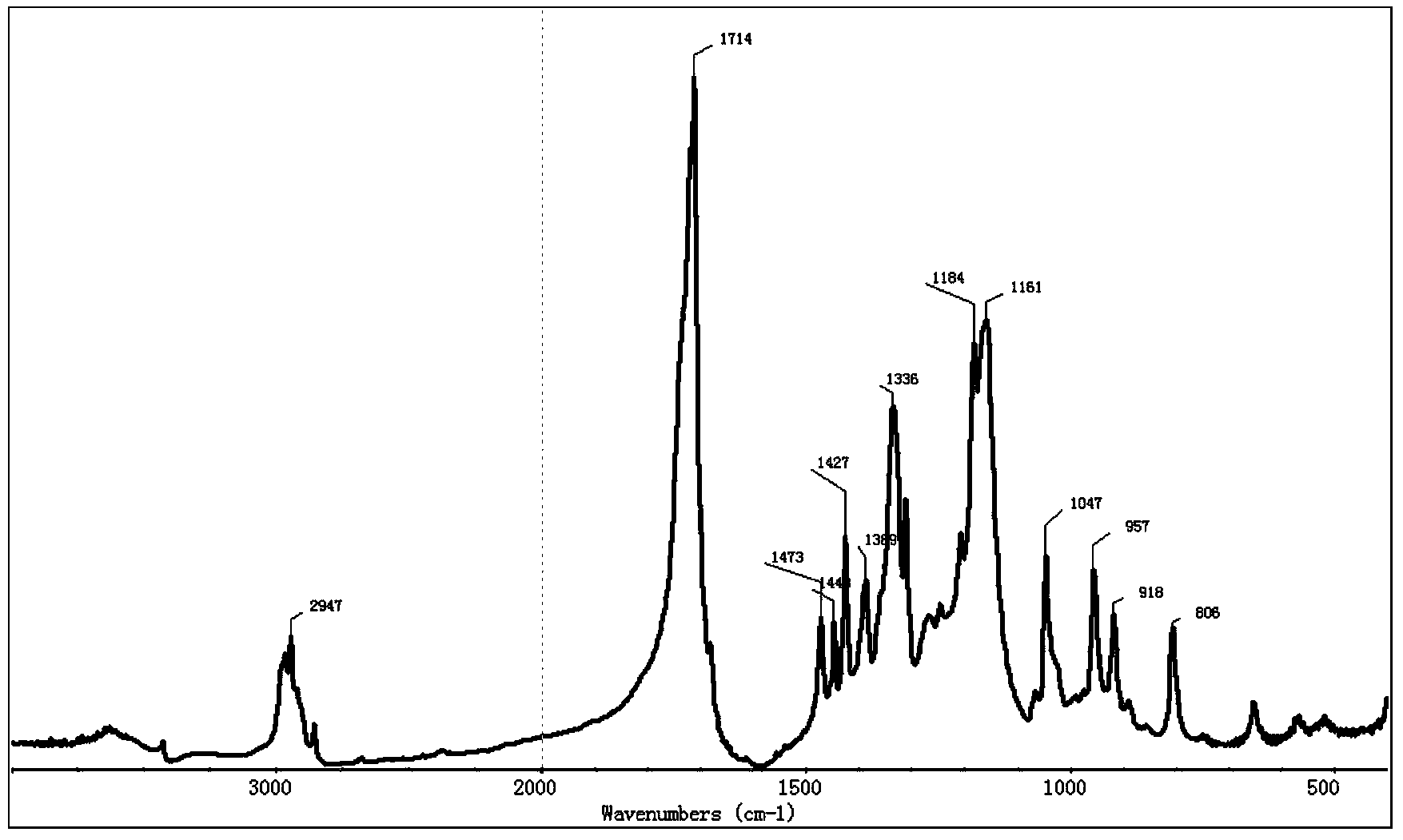

Catalyst that can be used in hydrotreatment, comprising metals of groups VIII and VIB, and preparation with acetic acid and dialkyl succinate C1-C4

ActiveUS9174202B2Improve catalytic performanceHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAcetic acidCobalt

A catalyst usable in hydrotreatment processes: an alumina-based amorphous support, phosphorus, a C1-C4 dialkyl succinate, acetic acid and a hydro-dehydrogenizing function of at least one group VIII element and at least one group VIB element, preferably made up of cobalt and molybdenum, a catalyst whose Raman spectrum comprises the most intense bands characteristic of the Keggin heteropolyanions (974 and / or 990 cm−1), C1-C4 dialkyl succinate and acetic acid (896 cm−1). Preferably, the dialkyl succinate concerned is dimethyl succinate and its main band is at 853 cm−1.

Owner:TOTAL RAFFINAGE MARKETING +1

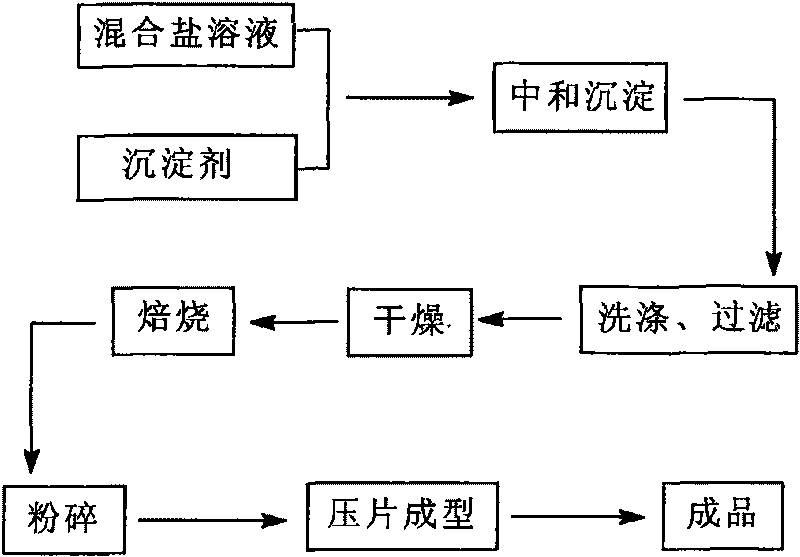

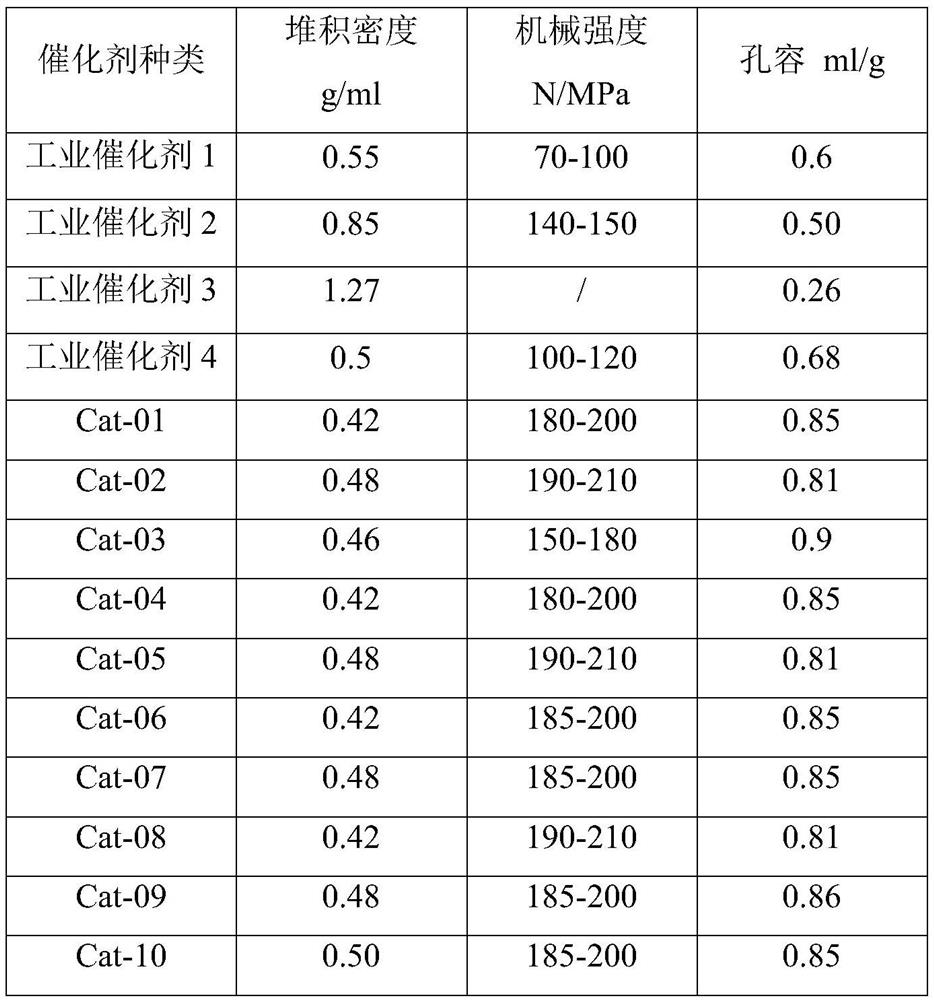

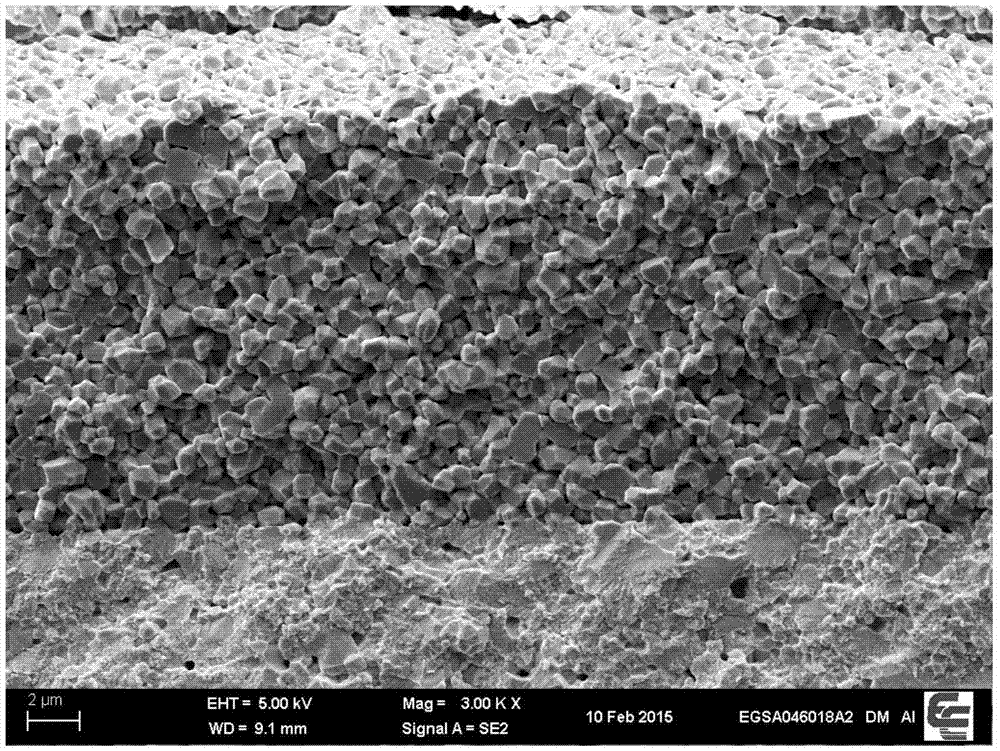

Preparation method of copper hydrogenation catalyst

PendingCN113649021AHigh porositySize porosityOrganic compound preparationHydroxy compound preparationPtru catalystWarm water

The invention relates to a preparation method of a copper hydrogenation catalyst, which comprises the following steps: adding a mixed salt solution of soluble copper salt and other metal soluble salts into an alkali solution to prepare corresponding hydroxide precipitate, filtering, washing with water, uniformly mixing with a sodium hydroxide solid phase, adding warm water and aluminum powder paste into the mixed material, and uniformly stirring, and maintaining for a certain time at a certain temperature, then transferring into a still kettle for treatment, then replacing sodium ions in the system through hydrothermal treatment, and finally drying and roasting to obtain the copper-based catalyst. The copper-based catalyst prepared by the method has the characteristics of small stacking density, large porosity, high activity and multiple catalytic functions, and is particularly suitable for and simultaneously used as a catalyst for preparing ethylene glycol by hydrogenation of dimethyl oxalate, preparing butanediol by hydrogenation of dimethyl maleate / dimethyl succinate, preparing 1, 4-cyclohexanedimethanol by hydrogenation of 1, 4-cyclohexanedicarboxylic acid dimethyl ester, preparing 2-methyl furan by hydrogenation of furfural / furfuryl alcohol, and the like.

Owner:濮阳圣恺环保新材料科技股份有限公司 +1

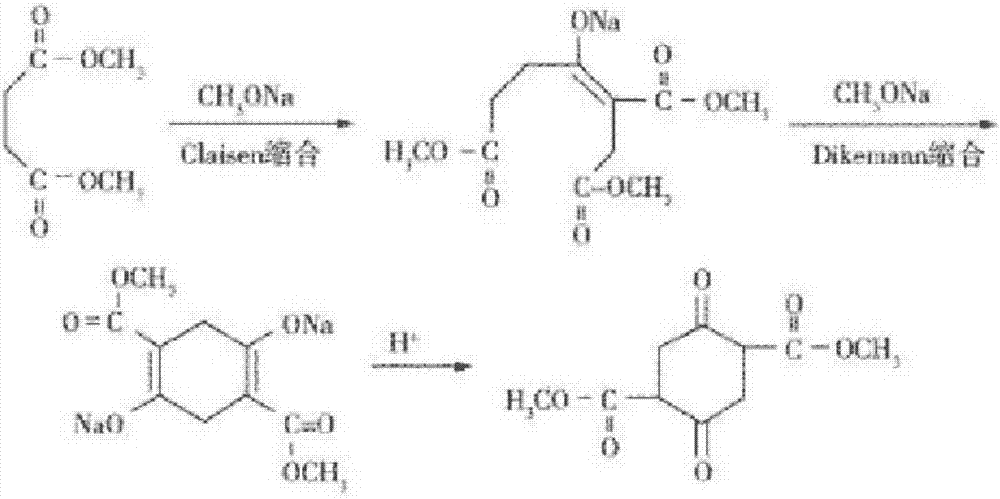

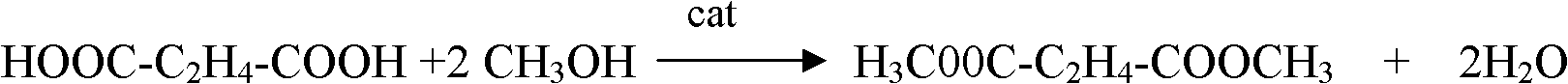

Method for continuous production of dimethyl succinylo succinate

InactiveCN106986771AOvercome the problem of large quality differencesShort reaction timeOrganic compound preparationCarboxylic acid esters preparationSodium methoxideClaisen condensation

The invention provides a method for continuous production of dimethyl succinylo succinate. The technical scheme employs continuous drip adding to carry out Claisen condensation reaction on dimethyl succinate and sodium methoxide and Dieckmann condensation reaction, and can realize continuous discharge, after a certain product is collected, and then dilute sulfuric acid acidification is carried out to obtain dimethyl succinylo succinate. The method provided by the invention is designed based on classical experimental principles, and the operation mode is improved to form a brand-new technological process. The technical scheme shortens the reaction time, also reduces energy consumption, significantly improves the production efficiency, and at the same time overcomes the problem of large quality difference between different batches in batch production. The method provided by the invention takes innovative technological improvement and achieves good technical effect, simultaneously has the characteristics of low cost and easy realization, thus having good popularization prospect.

Owner:淄博鸿润新材料有限公司

Alumina insulation slurry and preparing method thereof, and alumina insulation layer preparing method

InactiveCN105448383AAdjustable viscosityImprove liquidityMetallic oxidesCable/conductor manufactureInsulation layerSlurry

The invention relates to an alumina insulation slurry and a preparing method thereof. The alumina insulation slurry comprises, by mass percentage, 50-83% of alumina powder, 1-5% of inorganic additives, 12-25% of organic solvents, 2-10% of organic carrier, and 2-10% of organic promoter, wherein the inorganic additives include at least one selected from MgO, ZrO2, B2O3, TiO2, ZnO, BaO, CaO and SiO2, and the organic solvents include at least one selected from styrene, terpineol, butyl carbitol acetate, dibutyl phthalate, dimethyl succinate, dimethyl adipate, dioctyl phthalate, trichloroethylene, carbon tetrachloride, dimethyl phthalate, N,N-dimethylacetamide, propylene glycol monomethyl ether acetate and butyl acetate. The alumina insulation slurry is of high liquidity, and is applicable to printing.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

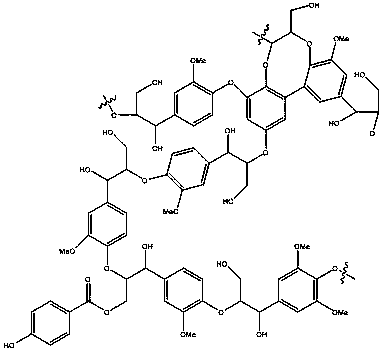

Method for preparing aromatic acid ester and aliphatic ester through directional catalytic oxidation of lignin

ActiveCN108863776ADifficult to handleEasy to cause pollutionOrganic compound preparationCarboxylic acid esters preparationDepolymerizationRare earth

Lignin is a unique reproducible aromatic compound source in the nature; the yield is huge, but the structure is complicated, so that the directional depolymerization is difficult; the utilization degree at present is not high. The method for preparing the aromatic compound through catalytic oxidation of lignin has the main step of dissolving the lignin into a sodium hydroxide water solution; the corrosion on equipment is serious; the waste liquid cannot be easily treated; the environment pollution can be easily caused. The invention provides a method of using the special structure and effect relationship of the rare-earth nanometer metal oxide, directly using agricultural stalks as raw materials under the relatively mild conditions, performing catalytic oxidization on the lignin by a one-pot method to obtain high-added-value products of benzenedicarboxylic acid dimethyl ester, dimethyl succinate and the like. After the separation, the benzenedicarboxylic acid dimethyl ester can be usedfor obtaining phthalic acid through hydrolysis reaction, and becomes a raw material for producing PBT and PET. The method has the advantages that the operation is performed in neutral environment such as organic alcohol; no corrosion is caused on the equipment; the equipment production cost is low. Solvents and catalysts can be recovered by a simple method and can be circularly utilized; the massdischarge into the environment is not needed; the green and environmental-friendly effects are achieved.

Owner:昌吉学院

Preparation method for dimethyl succinylo succinate (DMSS)

InactiveCN102584593ALow investment costThe main raw material is easy to getOrganic compound preparationCarboxylic acid esters preparationWater bathsHigh pressure

The invention discloses a preparation method for dimethyl succinylo succinate (DMSS). The method comprises the following steps of: a), esterifying dimethyl succinate; b), synthesizing DMSS, namely after reaction, cooling materials in a water bath to below 60 DEG C, adding methanol, stirring to pulpifying the materials, transferring into a special film pressure device into which high pressure can be introduced, and separating dimethyl succinate liquid out of dimethyl succinylo succinate sodium salt under pressure of 1.0 to 1.2 MPa to obtain a dimethyl succinylo succinate sodium salt solid filter cake; transferring the acidized materials into a vacuum filter and filtering, suction-filtering a mother solution, completely washing the filter cake by using hot water, and drying in a drying box at the temperature of between 90 and 100 DEG C for 18 hours to obtain DMSS. The preparation method is low in investment, main raw materials can be obtained easily, the preparation method is environment-friendly, and the recycling rate is high.

Owner:ZHEJIANG EUCHEM CHEM

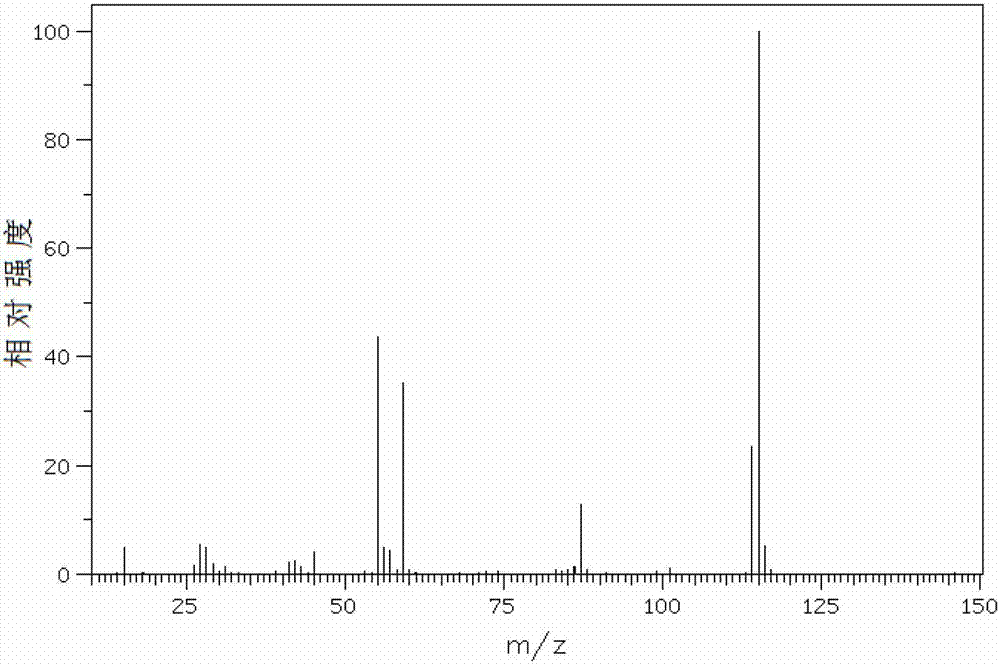

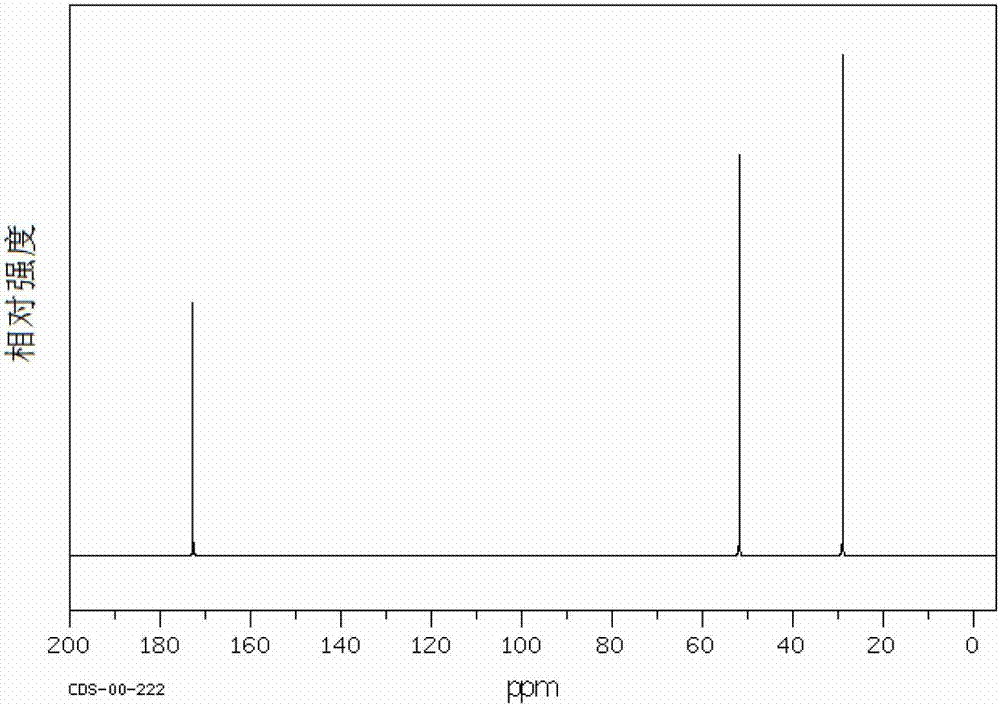

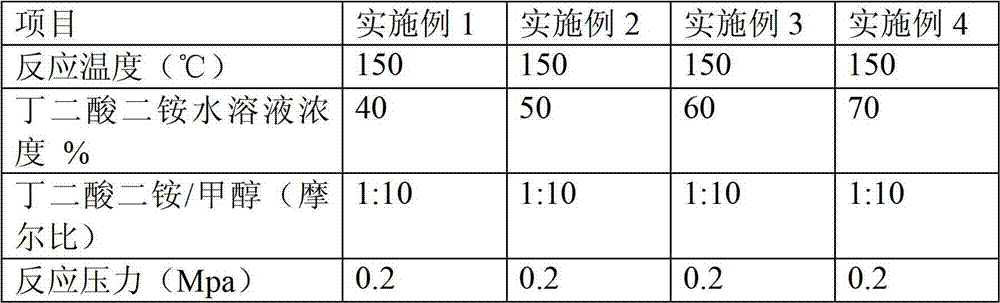

Method for preparing diester succinate by esterifying diammonium succinate

ActiveCN102731302AEasy to separateImprove responseOrganic compound preparationCarboxylic acid esters preparationSide reactionSuccinates

The invention discloses a method for preparing diester succinate by esterifying diammonium succinate, belonging to the field of chemical technology, and particularly discloses a method for preparing the diester succinate product with the purity of more than 99.8% by taking diammonium succinate as a raw material, contacting the raw material with an esterifying agent in a reactor filled with solid acid catalyst to generate dimethyl succinate crude product and finally refining. The method is simple, mild in technological conditions, reasonable in process flow, less in side reaction, high in product purity and good in quality.

Owner:TANGSHAN XUYANG CHEM IND CO LTD

Synthesis of crystalline polymers from cyclic diolides

ActiveUS20190211144A1Organic-compounds/hydrides/coordination-complexes catalystsChemical synthesisDispersity

Biodegradable polymers with advantageous physical and chemical properties are described, as well as methods for making such polymers. In one embodiment, a new chemical synthesis route to technologically important biodegradable poly(3-hydroxybutyrate) (P3HB) with high isotacticity and molecular weight required for a practical use is described. The new route can utilize racemic eight-membered cyclic diolide (rac-DL), meso-DL, or a rac-DL and meso-DL mixture, derived from bio-sourced dimethyl succinate, and enantiomeric (R,R)-DL and (S,S)-DL, optically resolved by metal-based catalysts. With a stereoselective racemic molecular catalyst, the ROP of rac-DL under ambient conditions produces rapidly P3HB with essentially perfect isotacticity ([mm]>99%), high crystallinity and melting temperature (Tm=171° C.), as well as high molecular weight and low dispersity (Mn=1.54×105 g / mol, Ð=1.01).

Owner:COLORADO STATE UNIVERSITY

Cast stone containing lubricating oil and preparation method thereof

InactiveCN108728223AImprove wear resistanceImprove corrosion resistanceLubricant compositionMethyl carbamatePolyvinyl alcohol

The invention provides a cast stone containing lubricating oil and a preparation method of the cast stone. The cast stone containing lubricating oil is prepared from the following ingredients: mineralbase oil, a cast stone, modified zirconite, dimethyl succinate, nonylphenol polyoxyethylene ether, polyvinyl alcohol, methyl carbamate, borate, triethylamine oleate, a friction additive and a surfactant. The prepared lubricating oil is excellent in abrasion resistance, rust resistance, heat stability, anti-foaming property, sealing adaptability and is higher in cleanliness, the requirement of high-strength mechanical equipment on the lubricating oil is met, the adhesive force of the lubricating oil is stronger, the oil is not easily lost rapidly, the preparation method is simple, the industrial production of the lubricating oil is convenient, the cost is low, the defect of poor oxidation stability of the traditional lubricating oil is overcome, and the stability is better.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

Method for preparing dimethyl succinate

ActiveCN102070448BSimple separation processImprove responseOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystSolid acid

The invention discloses a method for preparing dimethyl succinate. The method comprises two reaction processes of esterification and hydrogenation and the reaction processes are as follows: (1) after pre-esterification reaction, maleic anhydride-methanol solution enters a catalytic distillation tower from the upper rectifying section of the tower, methanol enters the tower from the lower stripping section of the catalytic distillation tower, the reaction section is filled with solid acid catalyst, the two material flows perform countercurrent contact on the surface of the catalyst to perform esterification reaction and synthetize dimethyl maleate; and (2) dimethyl maleate and hydrogen are placed in a fixed bed reactor to perform hydrogenation reaction and generate the dimethyl succinate product in the presence of hydrogenation catalyst under a certain reaction condition. The method of the invention has the advantages of high raw material conversion rate and good product selectivity; and the process flow is simple, the energy consumption is low, no pollution can be caused and the scale production of dimethyl succinate can be realized.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

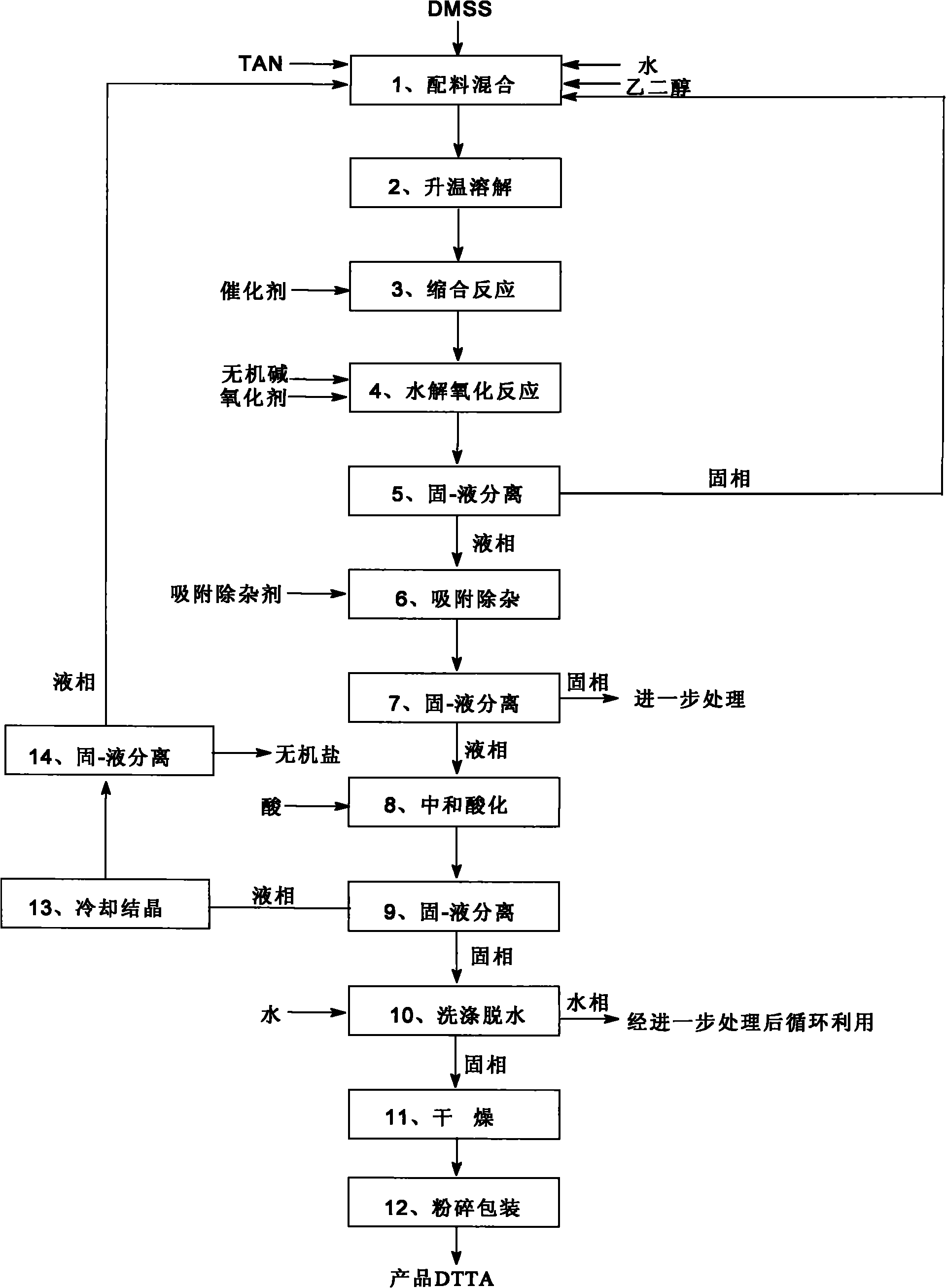

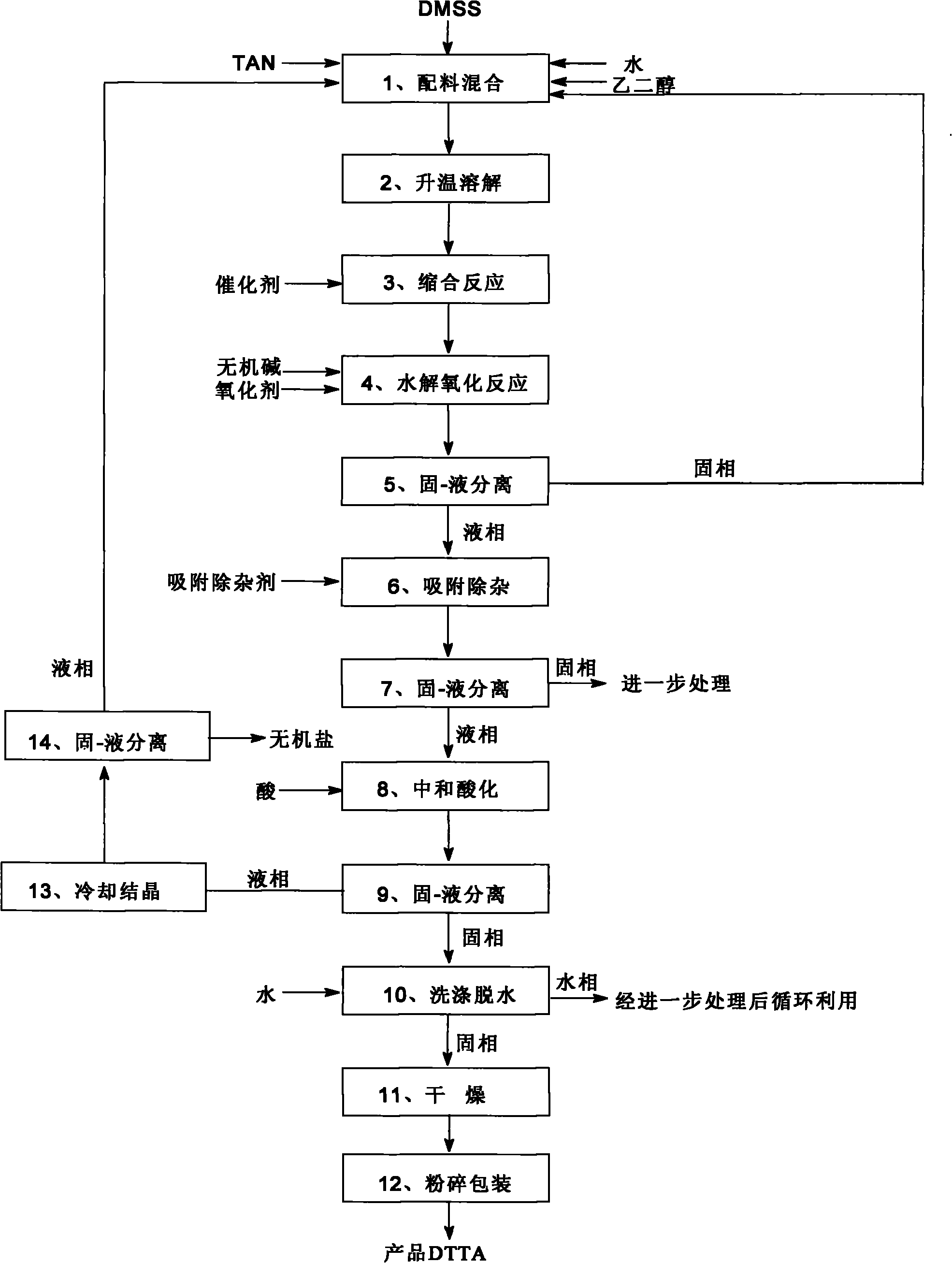

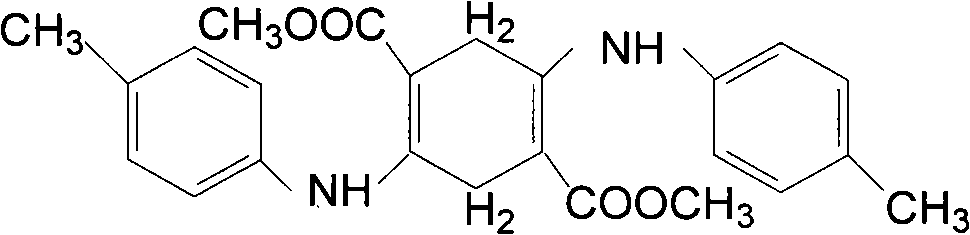

Method for preparing 2,5-diparamethylaniline terephthalic acid (DTTA)

InactiveCN101830820ALow purityImprove solubilityOrganic compound preparationAmino-carboxyl compound preparationHydrolysisImpurity

The invention relates to a method for preparing 2,5-diparamethylaniline terephthalic acid (DTTA) which is prepared by using dimethyl succinate succinyl (DMSS) and 4-toluidine as raw materials. The method comprises the steps of: 1, mixing materials; 2, raising the temperature for dissolving; 3, carrying out condensation; 4, carrying out hydrolysis oxidizing reaction; 5, carrying out solid-liquid separation; 6, absorbing and removing impurities; 7, carrying out solid-liquid separation; 8, neutralizing and acidizing; 10, washing and dehydrating; 11, drying; and 12, crushing and packaging. The product of the DTTA is obtained by the steps. The invention has the advantages of reasonable process, high purity of products, stable quality, high yield and safe and reliable reaction process.

Owner:淮安苏瑞精细化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com