Patents

Literature

437 results about "Catalyst poisoning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst poisoning refers to the partial or total deactivation of a catalyst by a chemical compound. An important historic example was the poisoning of catalytic converters by leaded fuel. Poisoning refers specifically to chemical deactivation, rather than other mechanism of catalyst degradation such as thermal decomposition or physical damage. Although usually undesirable, poisoning may be helpful when it results in improved catalyst selectivity (e.g. Lindlar's catalyst).

Composite photocatalyst prepared from stephanoporate mineral and method thereof

InactiveCN101322944ALow costReduce the risk of poisoningMolecular sieve catalystsWater/sewage treatment by irradiationPoisoning riskLight energy

The invention relates to the preparation of an inorganic functional material, in particular to a photochemical catalyst prepared by taking a porous mineral as a carrier for carrying an n-typed semiconductor with a large energy gap and a method thereof. The natural porous mineral and an artificial porous mineral are used for preparing the carrier to carry the n-typed semiconductor and a compound semiconductor with photochemical catalysis function; the catalyst prepared is applied to the degradation of organic pollutants by photochemical catalysis or to serving as the filling of paints which can reproduce after being poisoned. The carrier prepared by the invention has large specific surface area, strong adsorption capacity, good adhesive force and low environment cost, can remarkably improve the efficiency of the photochemical catalyst and lower the poisoning risk of the catalyst; the sol of the semiconductor or the compound semiconductor has a photoresponse range covering visible light area and ultraviolet light area, thus being capable of effectively utilizing the light energy and being beneficial to reduce the cost of the light sources; the sol-gel dipping method is adopted to realize loading, which has the advantages of mild condition, even distribution, simple technique and convenience for mass production.

Owner:JILIN UNIV

Electrolyte material for polymer electrolyte fuel cells, electrolyte membrane and membrane-electrode assembly

ActiveUS20060099476A1Increase temperatureOrganic chemistryIon-exchanger regenerationOxygenMembrane electrode assembly

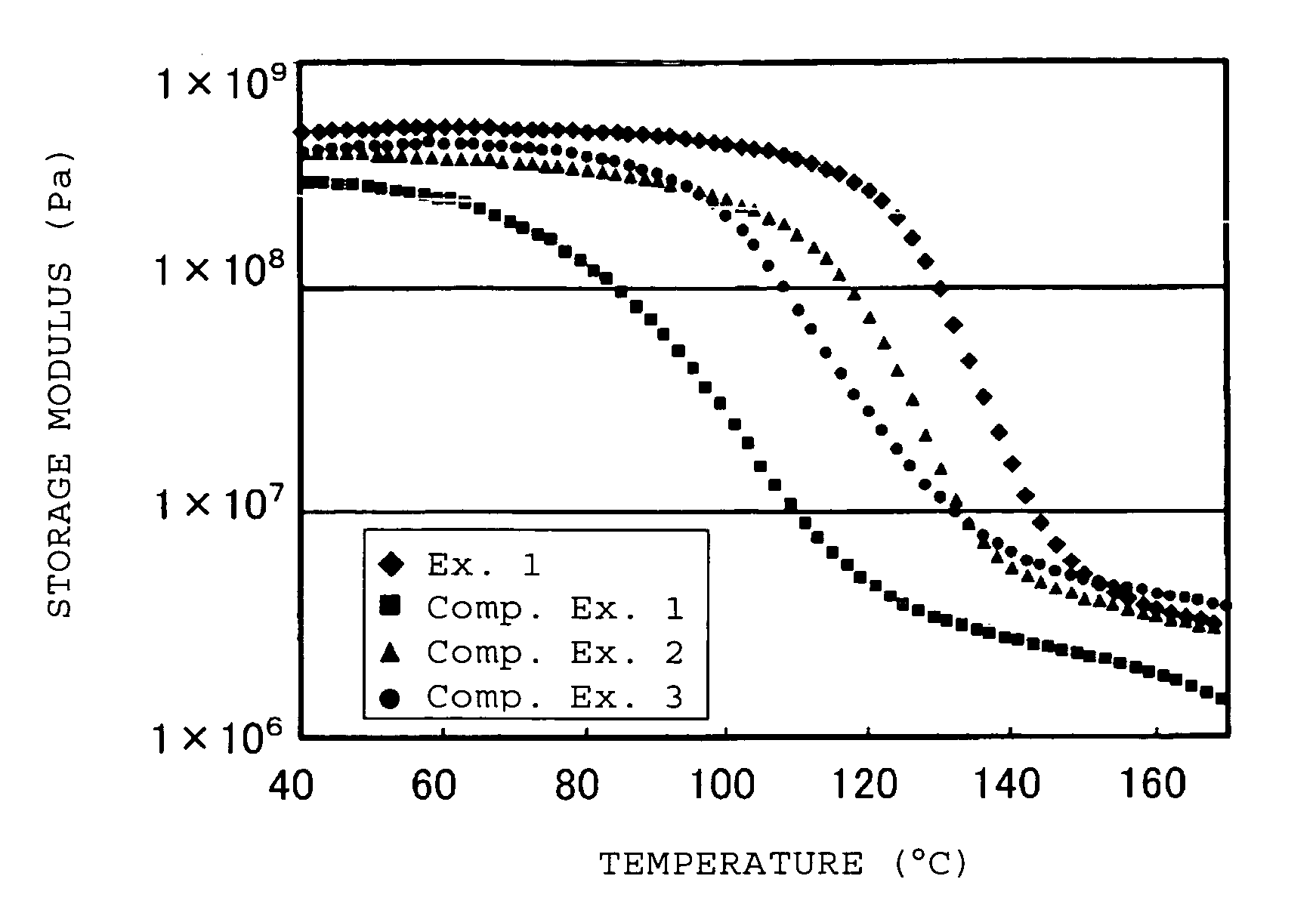

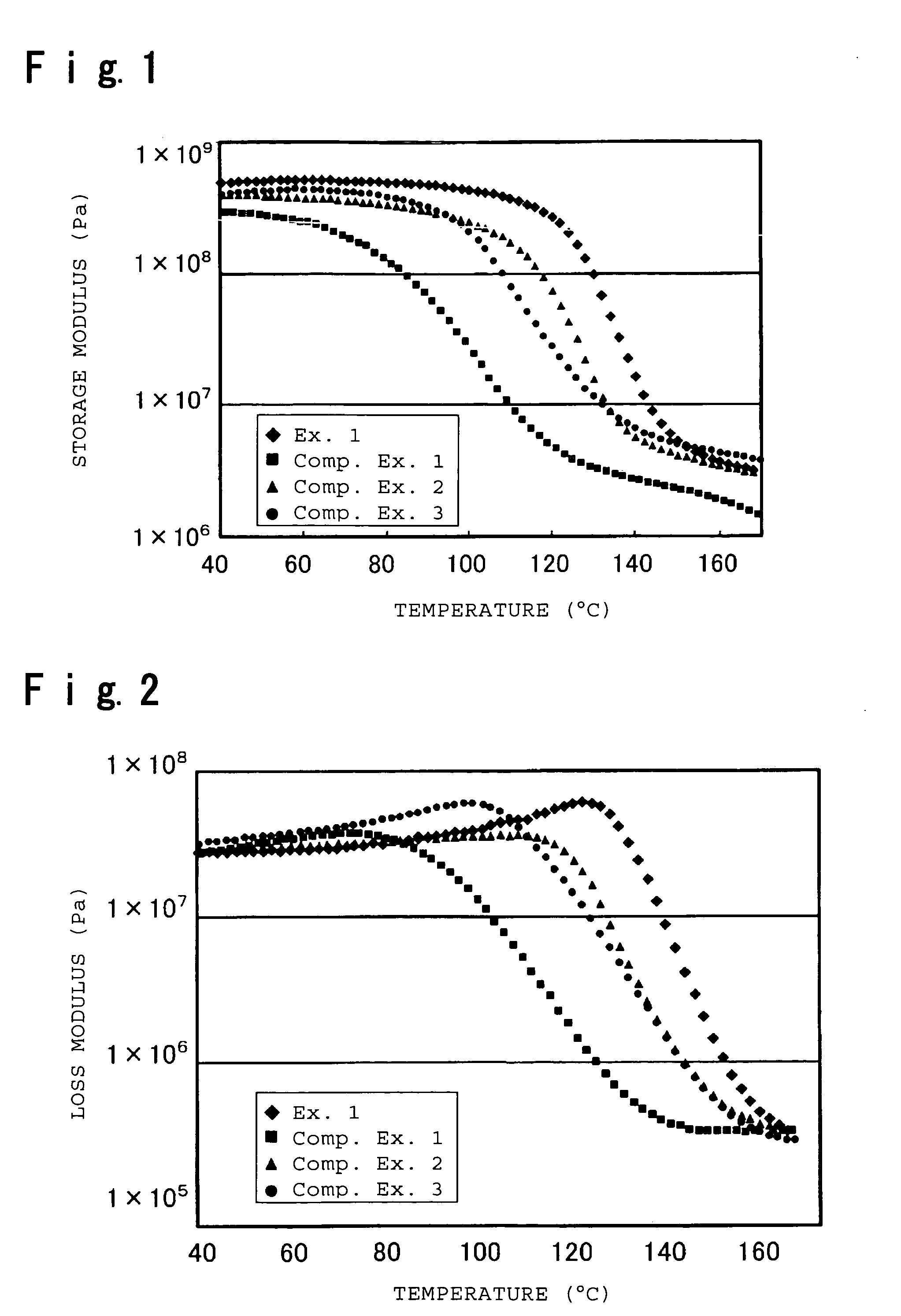

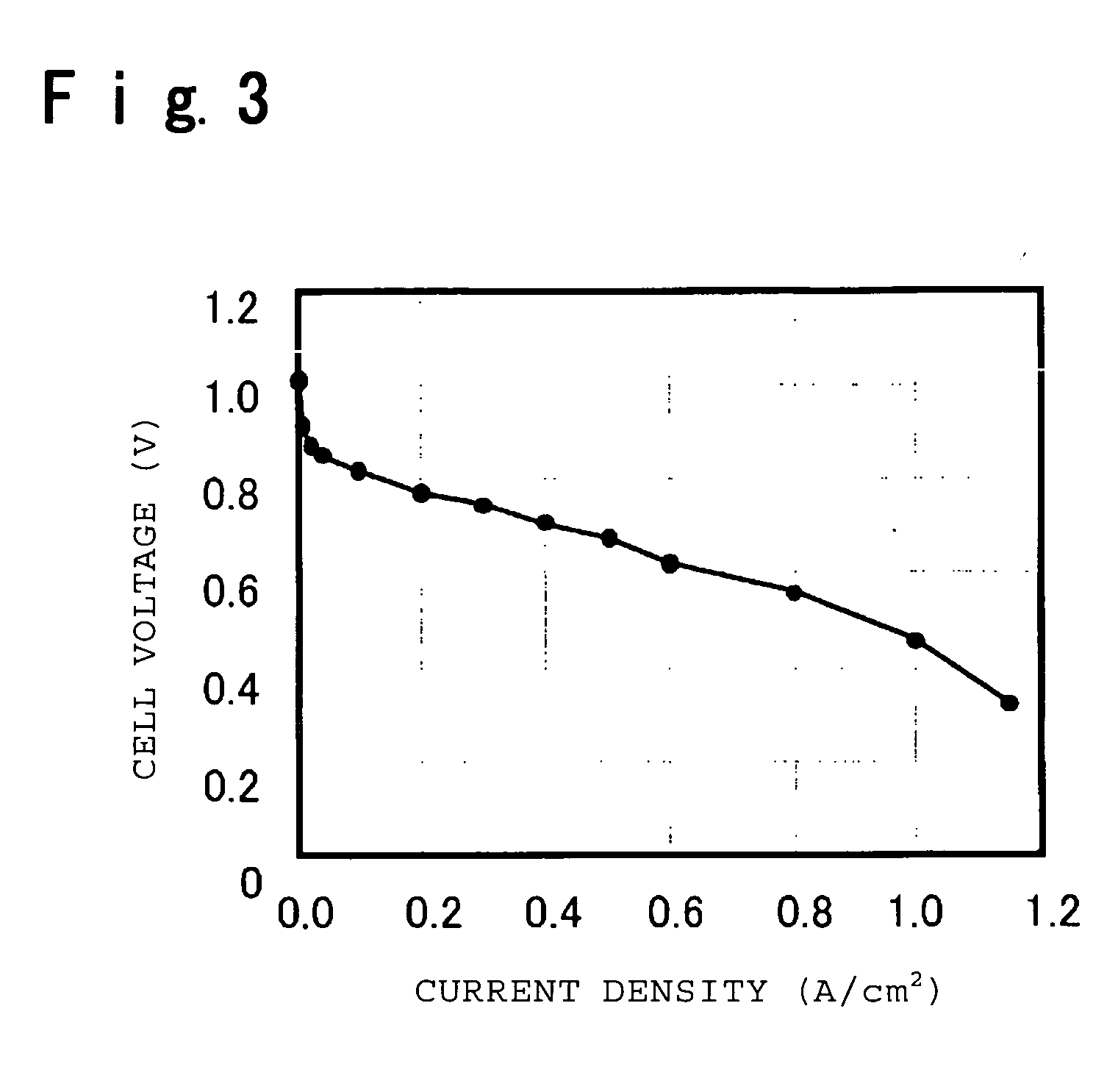

To present an electrolyte material having a high softening temperature, which is useful for obtaining a polymer electrolyte fuel cell which can be operated at a high temperature and whereby a high output power can be obtained with little catalyst poisoning. An electrolyte material for polymer electrolyte fuel cells, which is made of a polymer containing repeating units based on a fluoromonomer having a radical polymerization reactivity, wherein the repeating units contain a 5-membered ring (which may contain 1 or 2 oxygen atoms), of which at least one carbon atom is contained in the main chain of the polymer, and an ionic group such as a sulfonic acid group which is bonded to the 5-membered ring directly or via a perfluoroalkylene group having a linear or branched structure; and the polymer has a softening temperature of at least 120° C.

Owner:ASAHI GLASS CO LTD

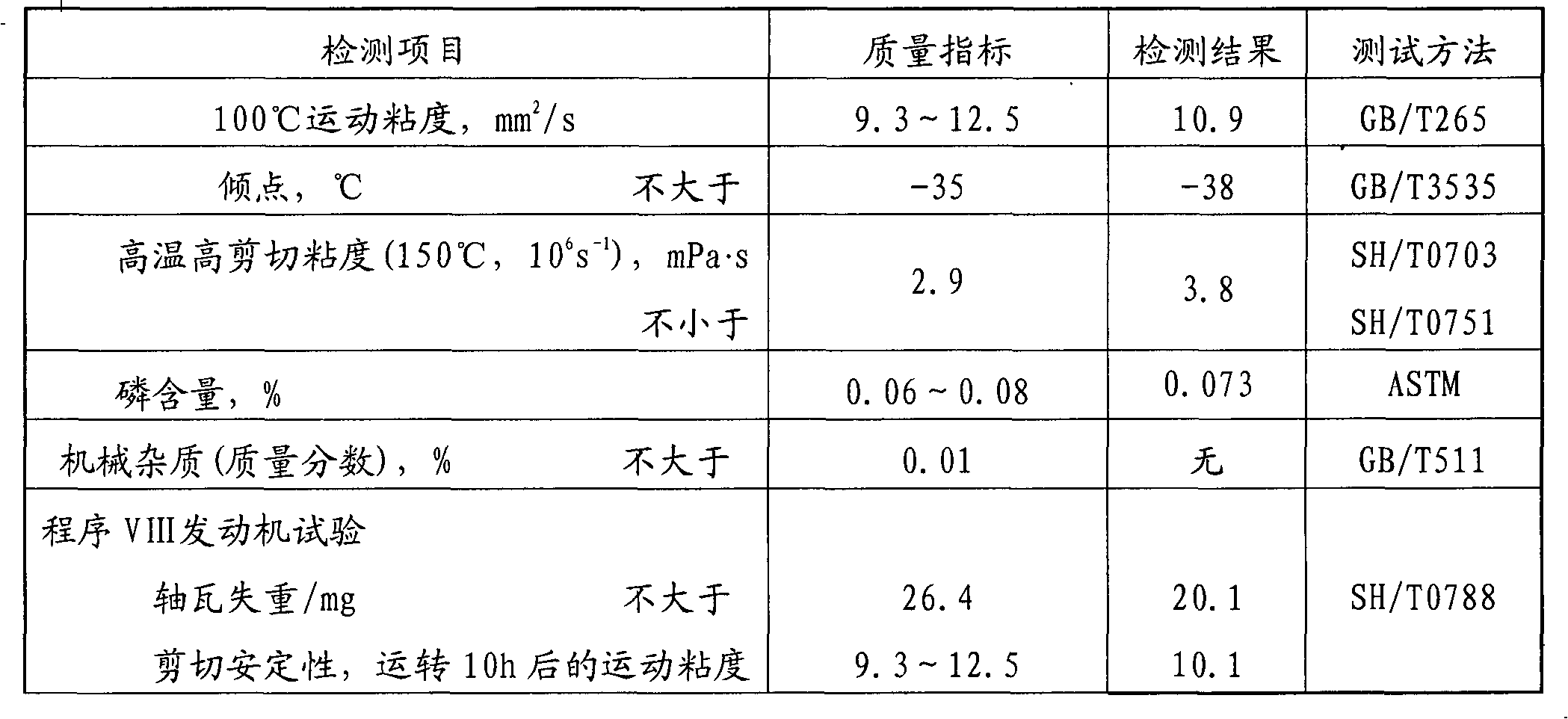

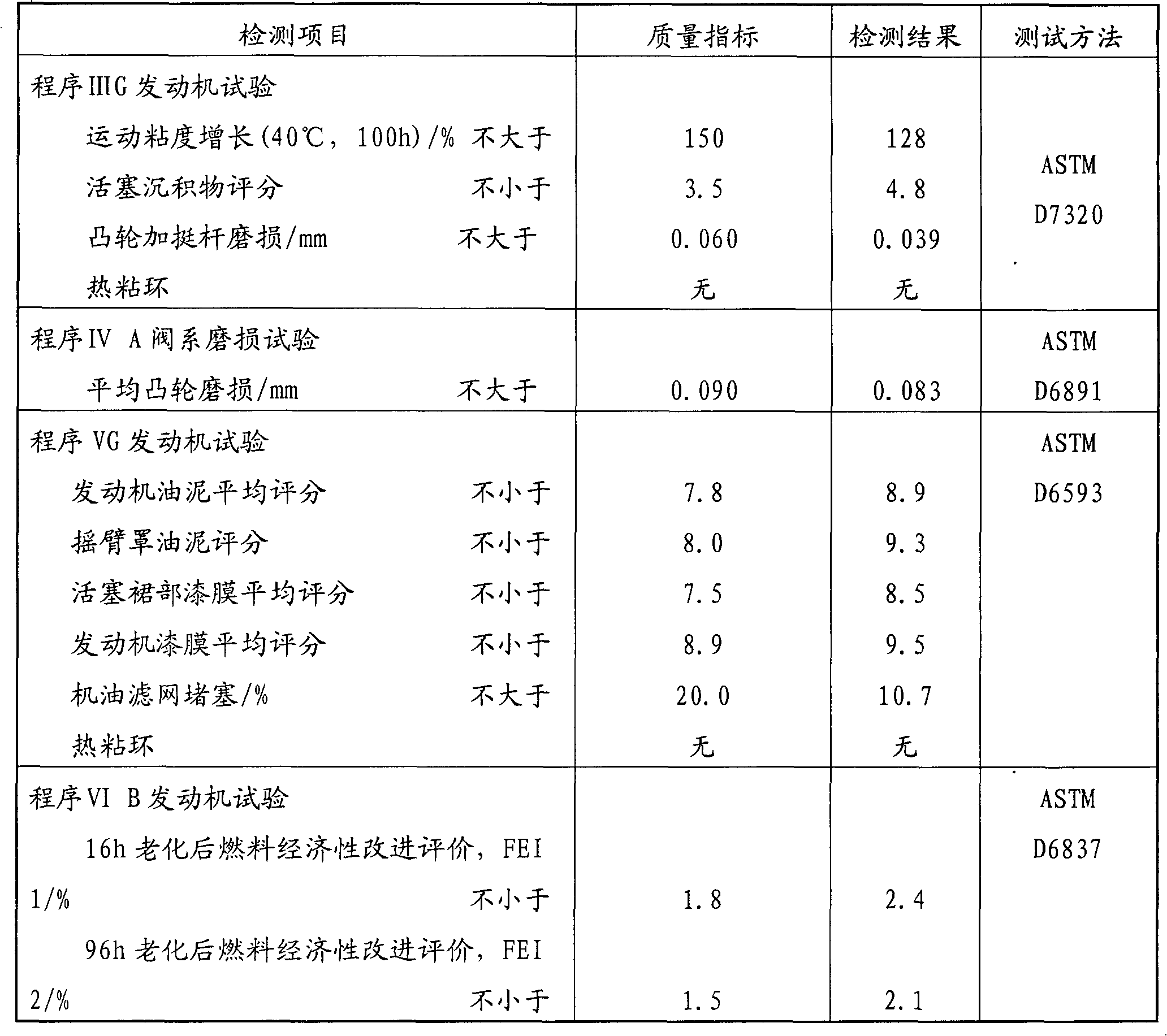

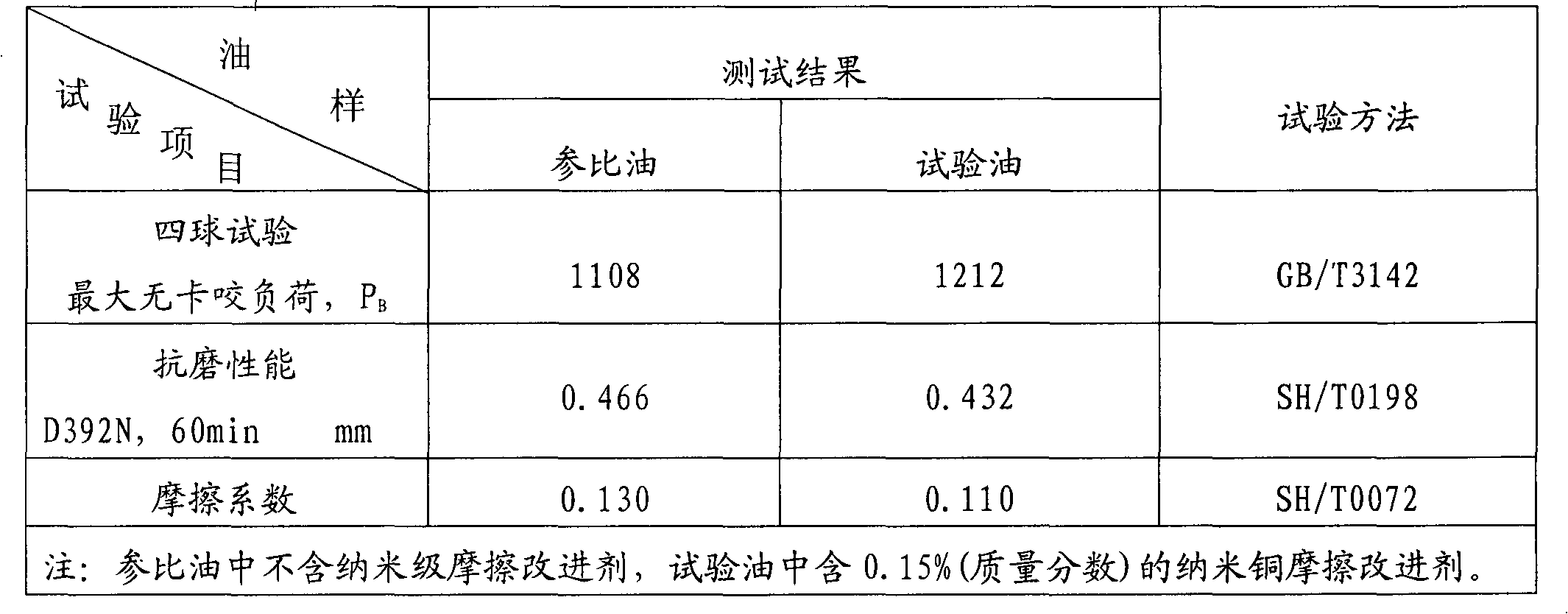

Energy-efficient long-life gasoline engine oil

InactiveCN101982534AReduce sulfur and phosphorus contentImprove carrying capacityLubricant compositionEcological environmentOil sludge

The invention discloses energy-efficient long-life gasoline engine oil prepared from the following components: synthetic base oil, a composite antioxygen, a metal cleaning agent, an ashless dispersant, a nano-level friction improver, a viscosity improver and a pour point reducer. The gasoline engine oil provided by the invention has the following advantages: requirements of API SM, ILSAC GF-4 and SAEJ300 are met and the service life is long; the complete synthetic base oil features low pour point, high viscosity index, good economy of fuel, degradability and reduced harm to the ecological environment; the phenol type antioxygen is combined with ZDDP, the anti-oxygen and antifriction properties are good and the catalyst poisoning in a tail gas processing unit is prevented; the acid neutralization capacity is good, the cleaning dispersibility is good and the oil sludge and carbon deposit are prevented from being generated; and the nano-level friction improver is added, the frictional factor is low, and the oil film features high carrying capacity and can automatically repair abraded surface and lengthen the service life of the engine.

Owner:GUANGDONG SANVO CHEM IND TECH

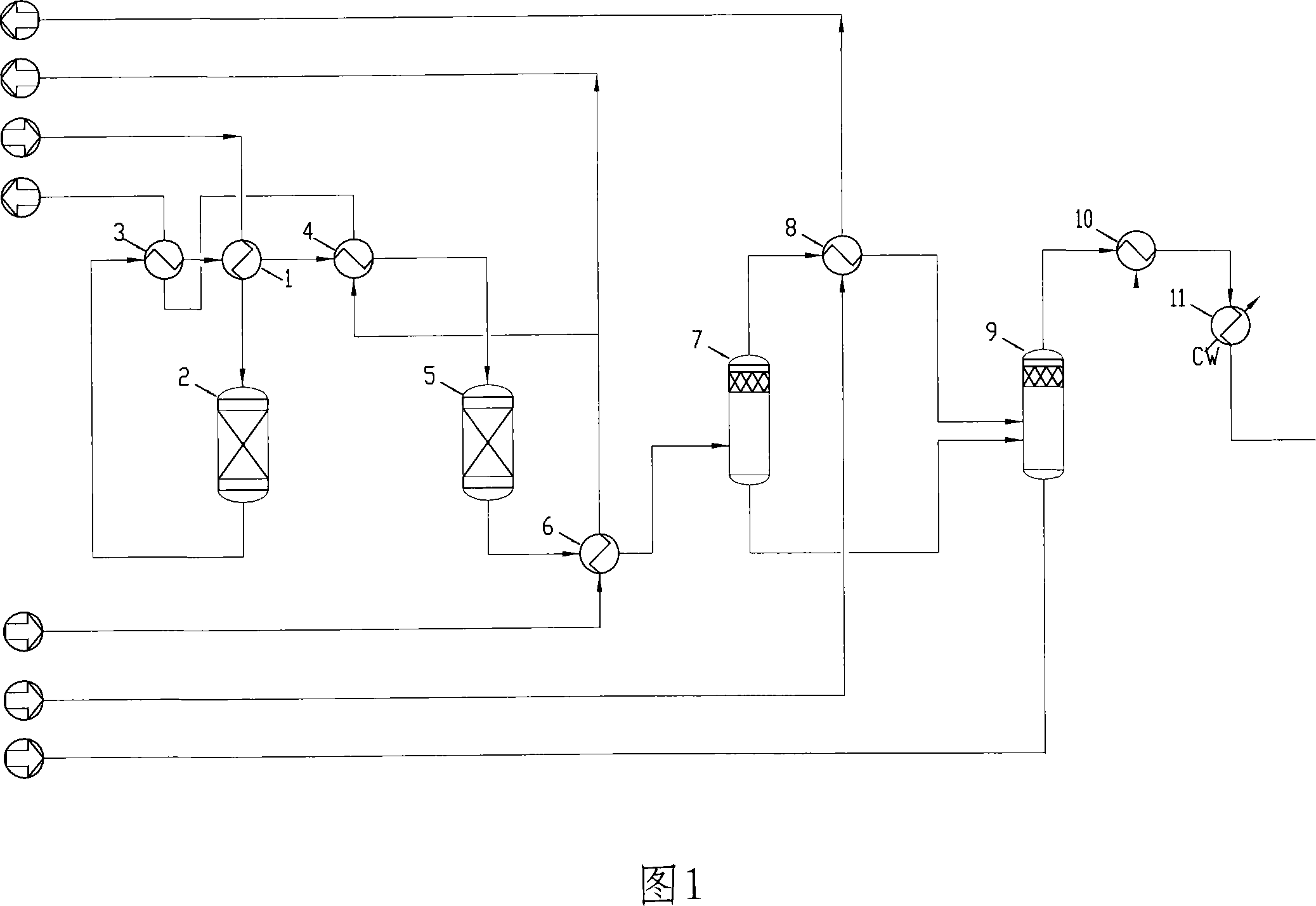

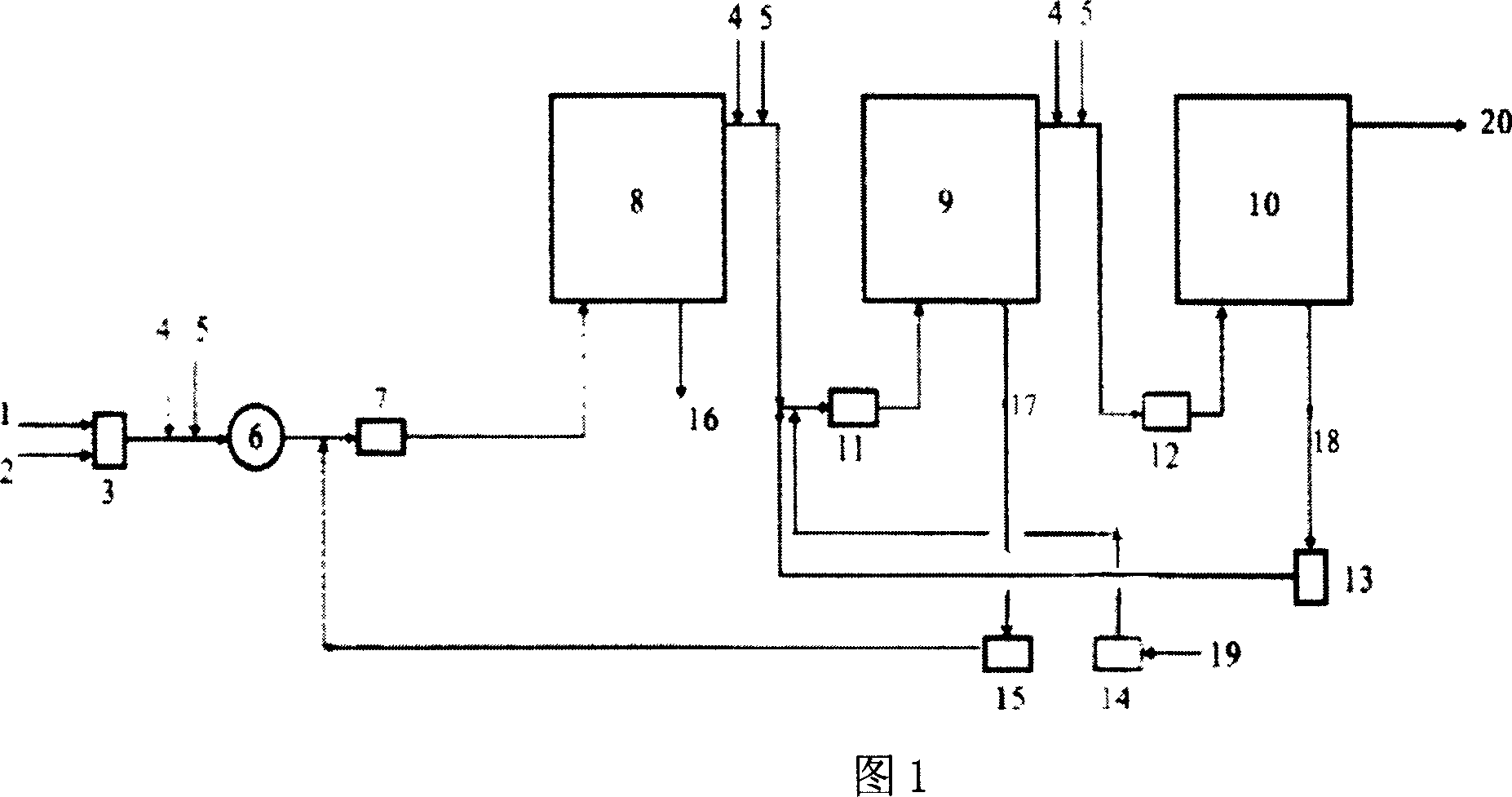

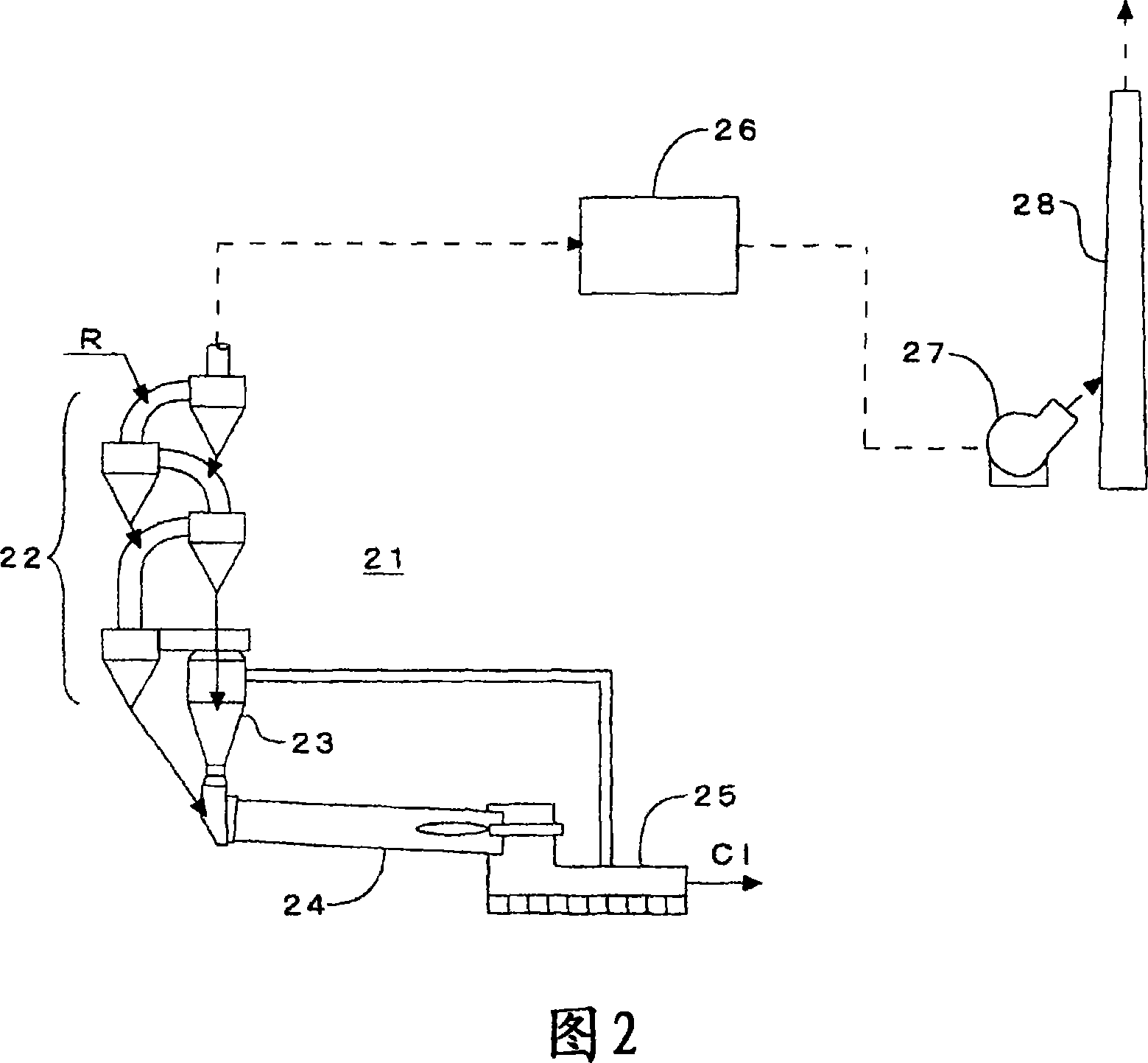

CO conversion technique matched to coal gasification

ActiveCN101050390AEasy to handleExtended service lifeCombustible gas catalytic treatmentEnergy inputPressure decreaseVapor–liquid separator

This invention discloses a process for converting CO in pulverized coal gasification. The process comprises: introducing crude synthesis gas from pulverized coal gasification into a gas-liquid separator, mixing the gas from separator top with outside middle-pressure overheated steam, middle-pressure steam and a small amount of condensate from steam stripping, introducing into a pre-conversion furnace, controlling the temperature increase, introducing the converted gas into 1# conversion furnace, performing in-depth CO conversion, introducing high-temperature shift gas into a middle-pressure waste boiler to generate4.0 MPa steam with the condensate produced in the process, introducing all middle-pressure steam into fresh converted gas for recycling, quenching with the condensate for humidification, converting in 2# conversion furnace, cooling he converted gas by a water preheater, introducing into 3# conversion furnace, recovering waste heat until the output gas is less than or equal to 40 deg.C, and introducing into the following procedures. The CO concentration is decreased from 60-65 mol. % to less than or equal to 0.4 mol. %. The pre-conversion furnace can prevent catalyst poisoning. The pressure decrease of the conversion system is reduced, thus can ensure the pressure at the inlet of the synthesis gas compressor.

Owner:SINOPEC NINGBO ENG +1

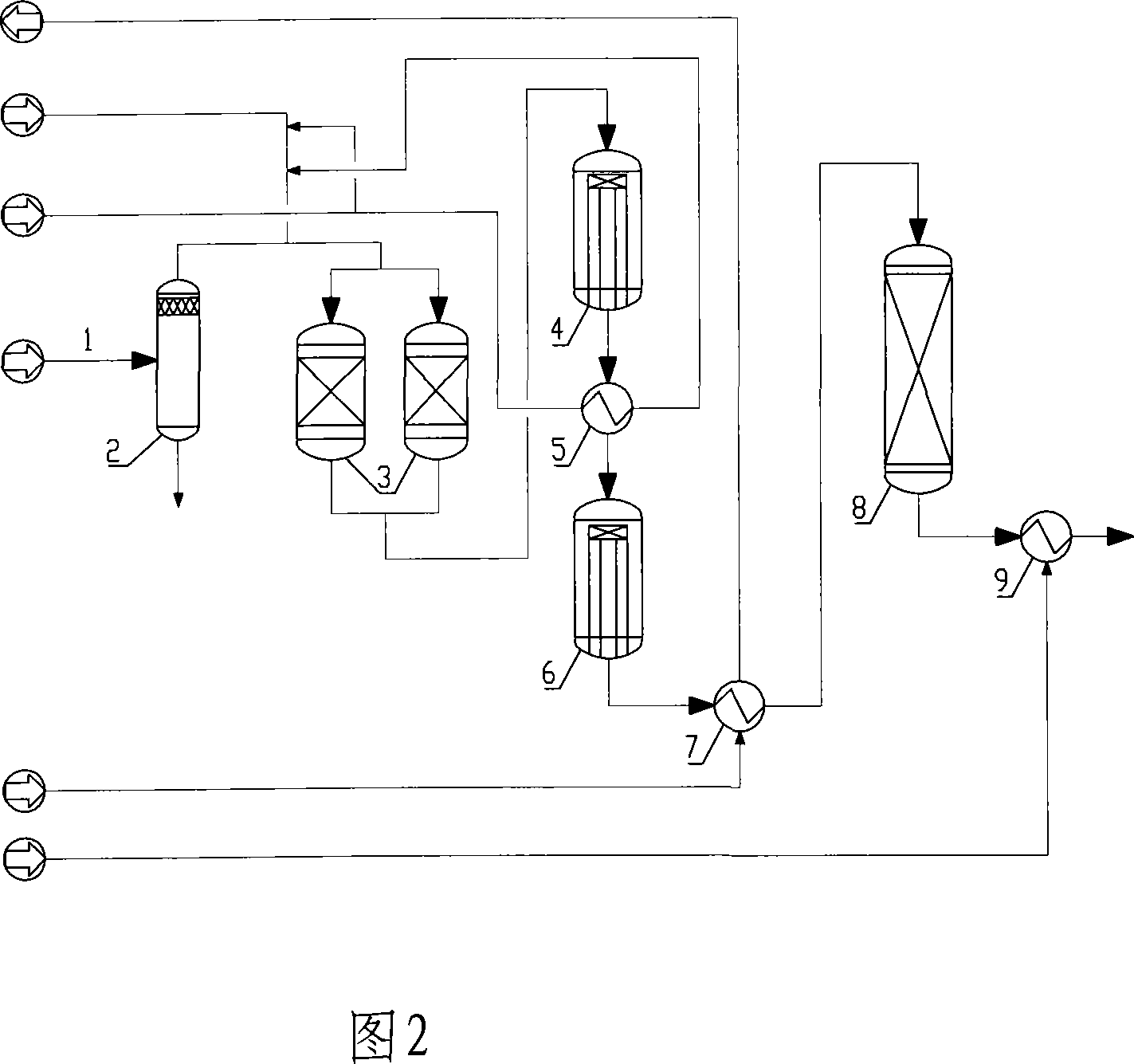

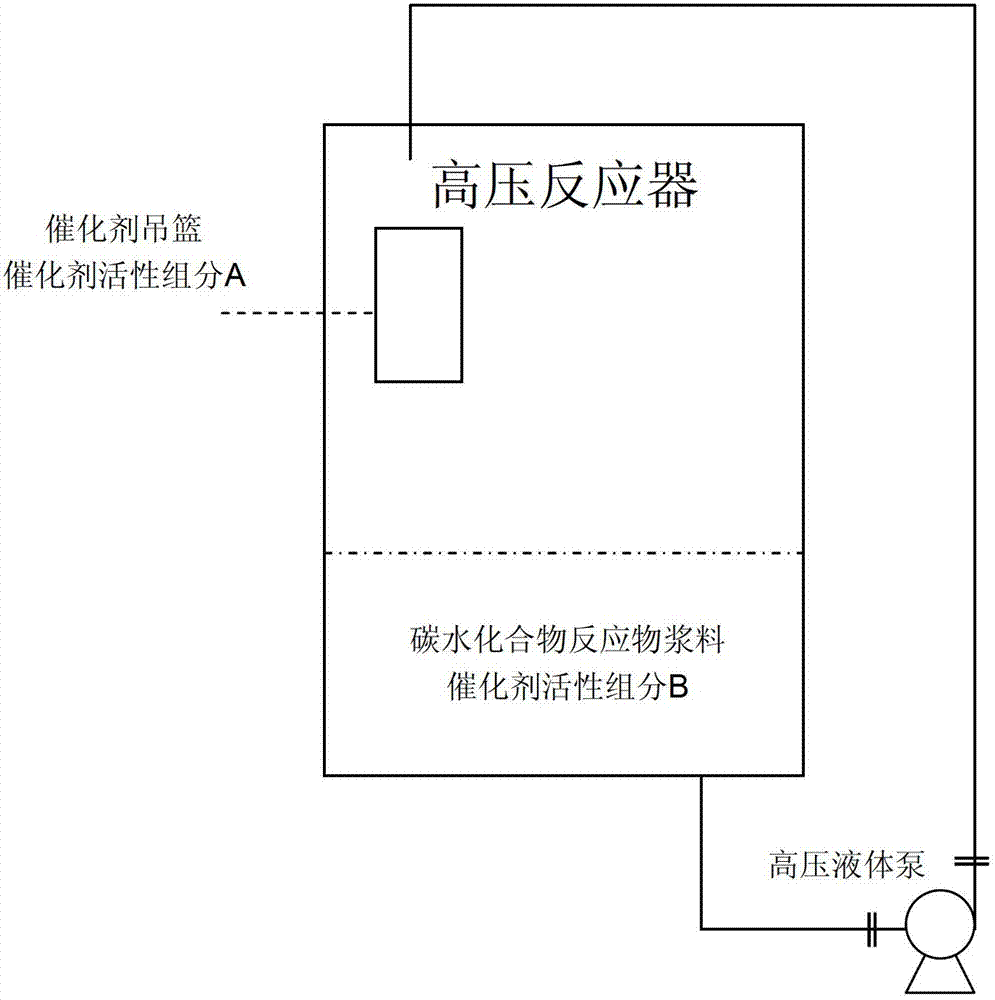

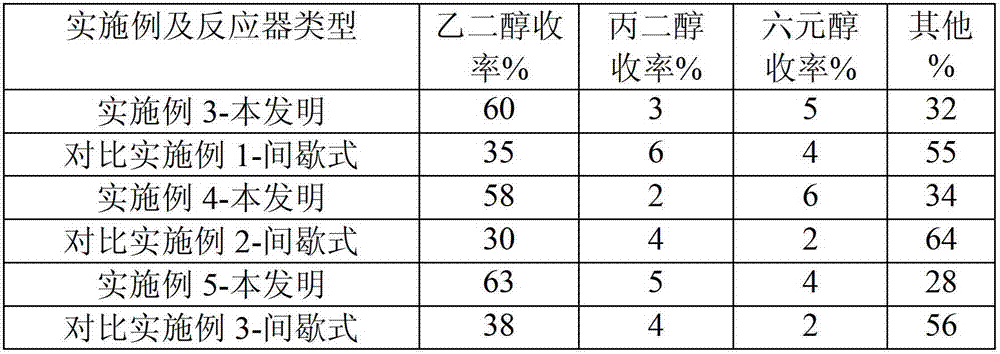

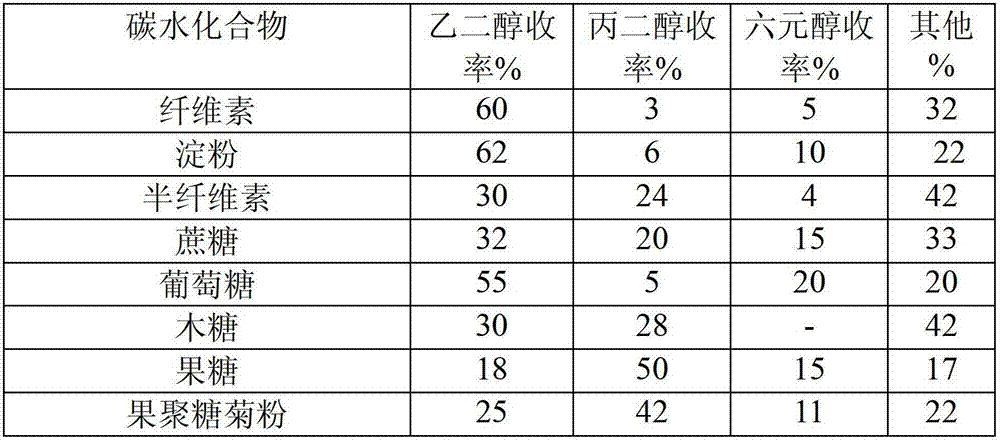

Method for preparing low carbon polyol by internal circulating catalysis and conversion of carbohydrate

ActiveCN102731258ASolve poisoningExtend your lifeOrganic compound preparationHydroxy compound preparationPolyolSlurry

The present invention relates to a reaction apparatus for preparing a low carbon polyol by catalysis and conversion of a carbohydrate, and a reaction process thereof. The reaction process adopts a high pressure reactor, wherein a catalyst filtering gondola is positioned inside the high pressure reactor, the position of the gondola is higher than the liquid level of the reactant inside the reactor, and the reaction is carried out under a high temperature hydrothermal condition. During the reaction, reactant slurry of the carbohydrate (comprising one or more than two materials selected from cellulose, hemicellulose, sucrose, glucose, fructose, xylose, soluble xylooligosaccharide and starch) flows from the bottom of the reactor, is driven to flow back to the reactor by a high pressure liquid pump, then is injected into the gondola to perform a catalytic reaction with the catalyst inside the gondola, and flows and accumulates on the bottom of the reactor, and the reaction is circulated. With the process, catalyst poisoning and deactivation can be effectively reduced, such that the reaction selectivity and the catalyst life can be improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

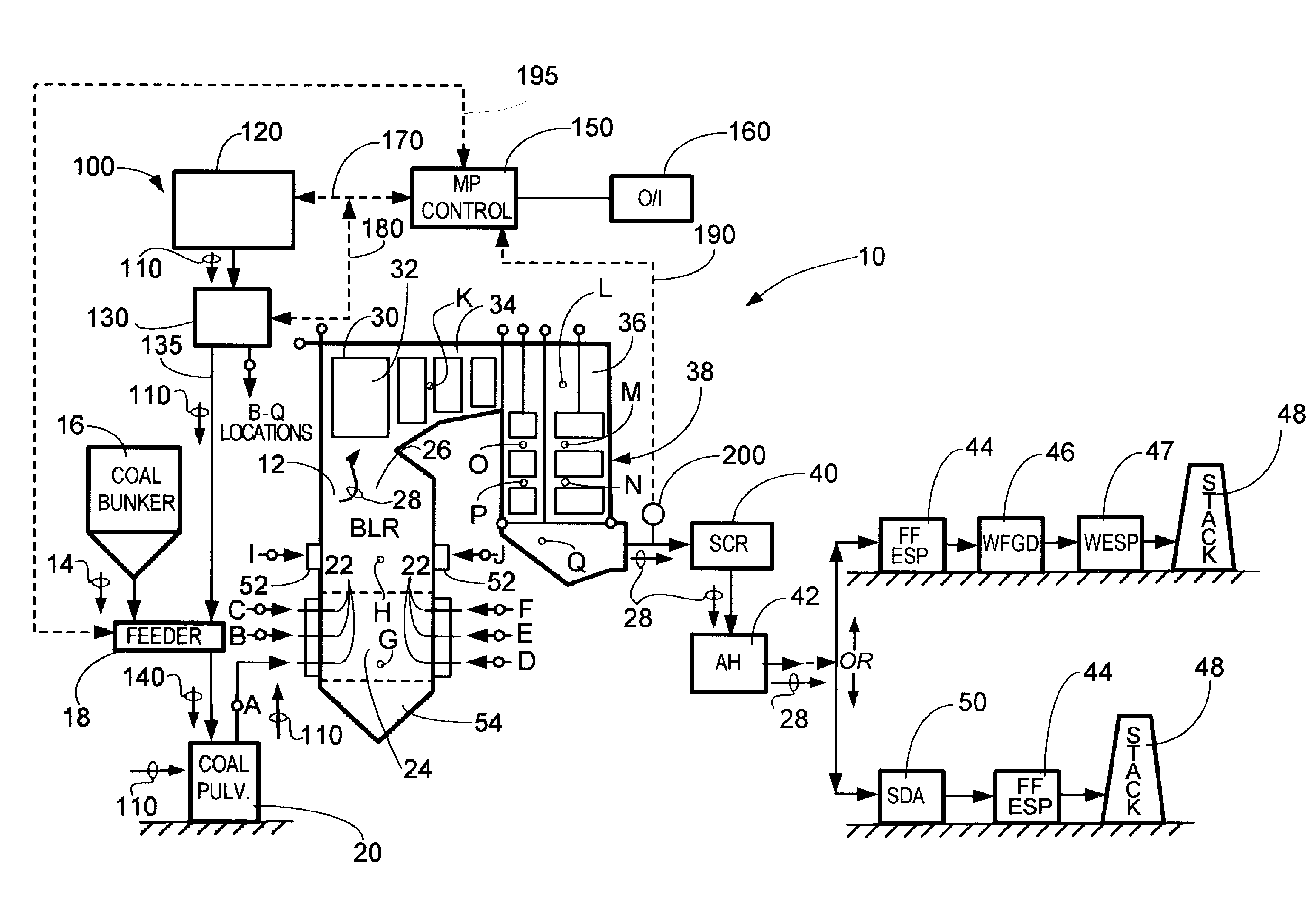

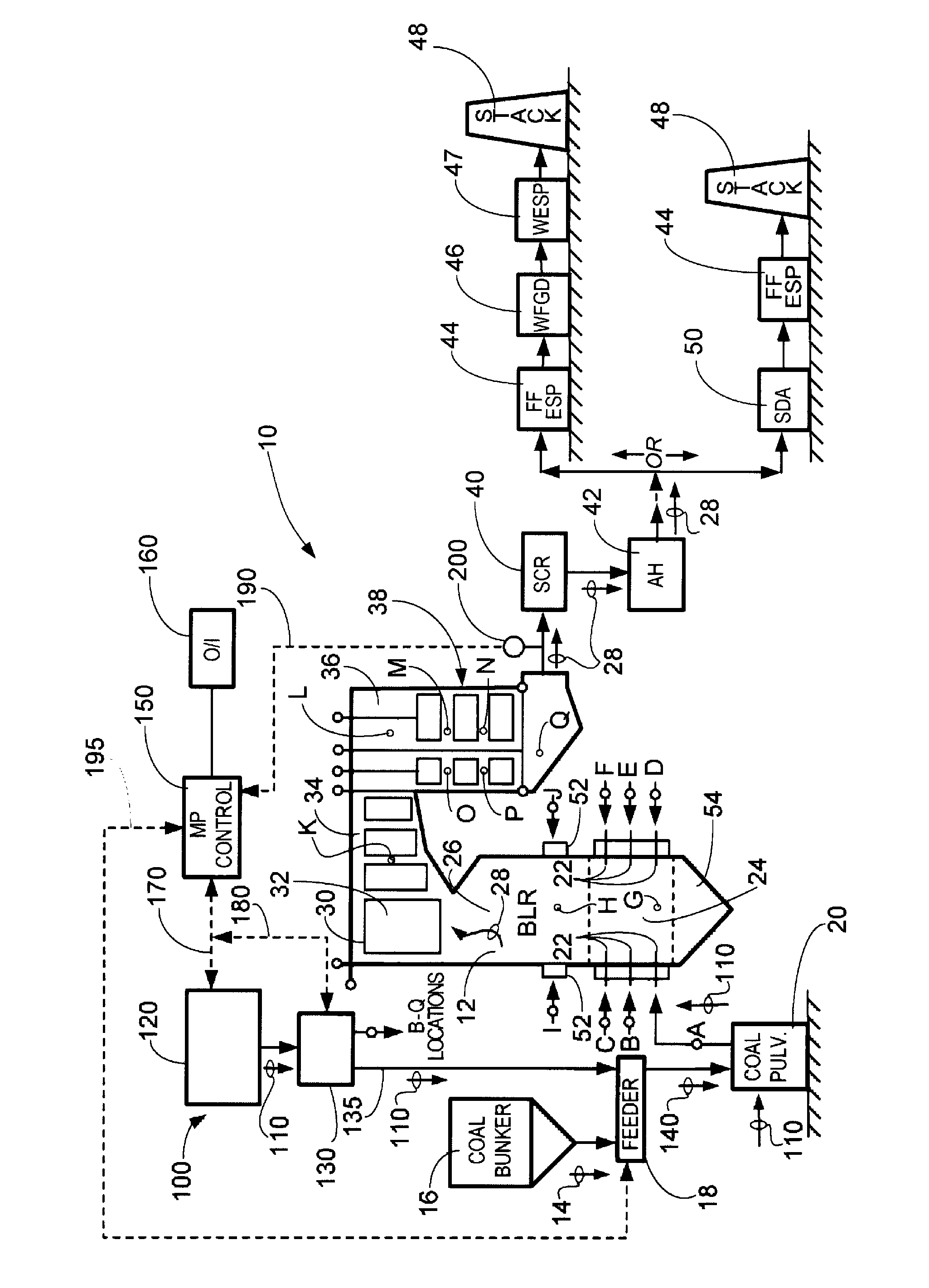

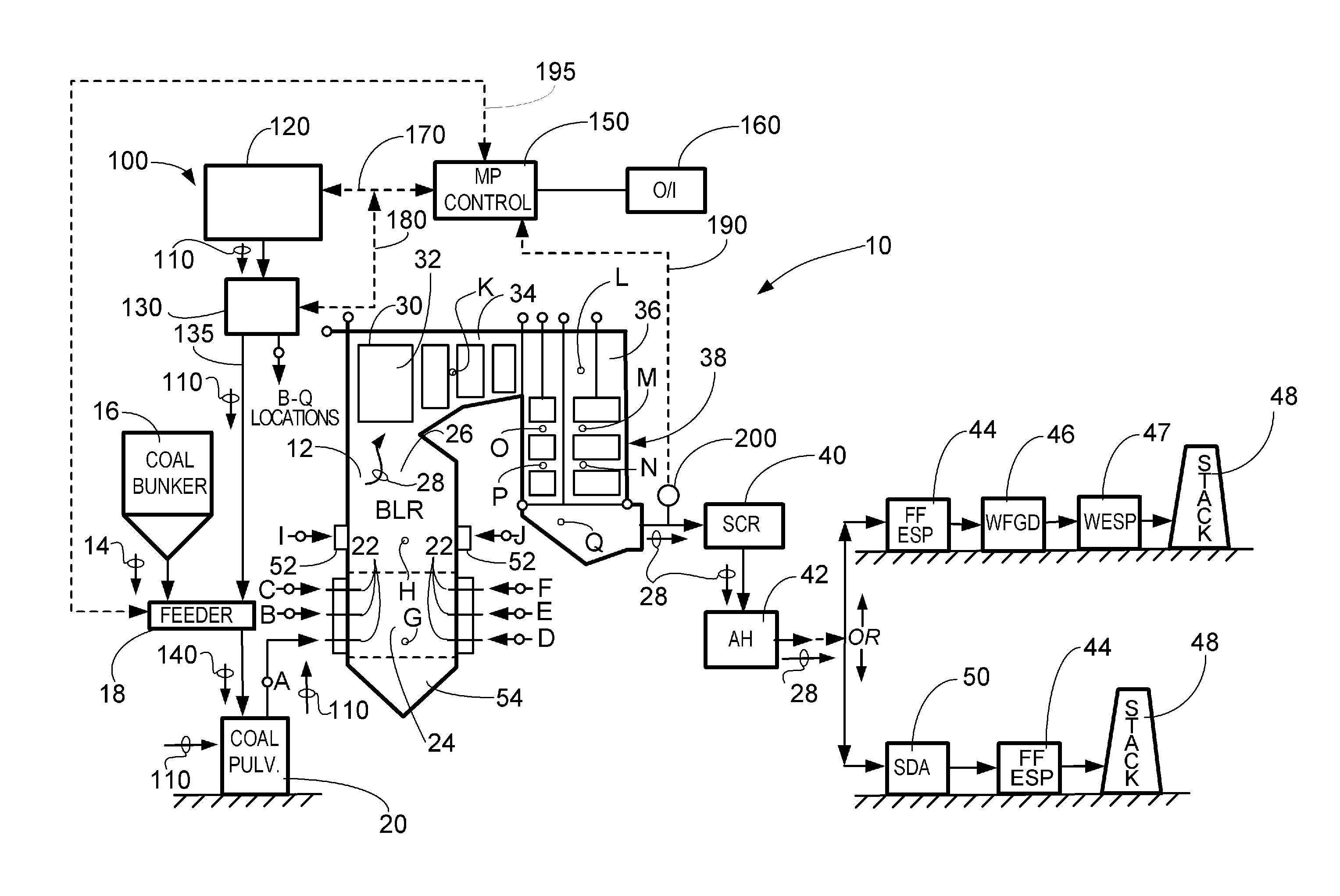

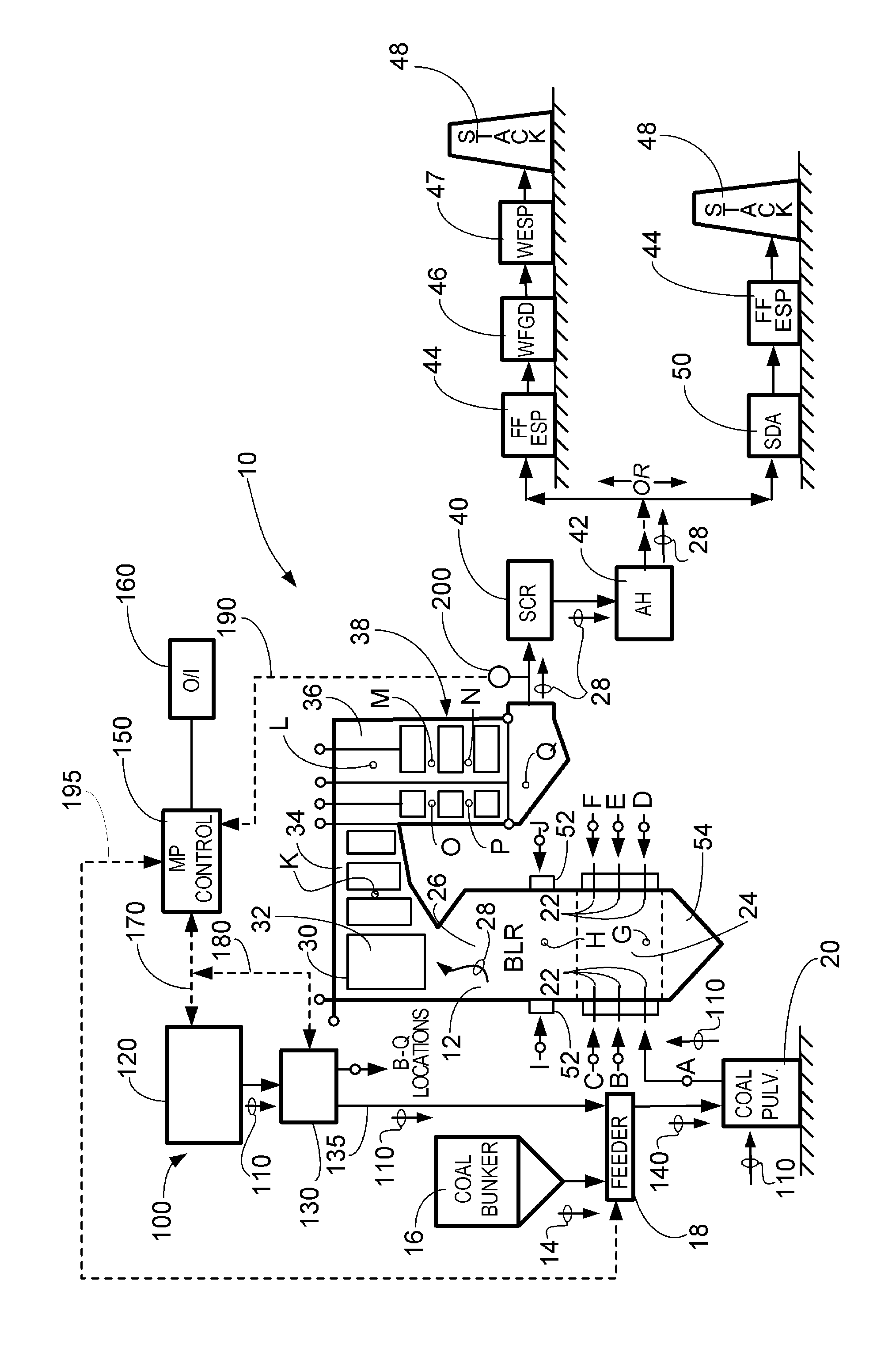

System and method for protection of SCR catalyst and control of multiple emissions

Owner:THE BABCOCK & WILCOX CO

Electric field purifying process of coal-tar oil

ActiveCN100999675AAvoid poisoningAvoid cloggingWorking-up tarRefining by electric/magnetic meansPtru catalystGasoline

The electric field coal tar purifying process includes the technological steps of preparing mixed oil, the first stage of electric purifying, the second stage of electric purifying, the third stage of electric purifying, draining waste water, etc. The experiments show that the coal tar purifying process of the present invention is superior to available coal tar purifying process, and has the advantages of simple technological process, low running cost, high purifying rate, etc. The present invention can reach coal tar purifying rate over 95 %, and the purified coal tar may be used in producing gasoline and diesel oil through hydromodification with no corrosion to the production apparatus, no catalyst poisoning, no blocking of the reactor bed layer and long production apparatus running period.

Owner:SHENMUFUYOU ENERGY TECH

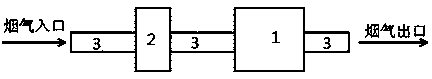

Method for inhibiting low-temperature denitration catalyst poisoning caused by SO2

ActiveCN104162349AInhibition of poisoningThe purpose of suppressing poisoningDispersed particle separationSalt depositCatalyst poisoning

The invention discloses a method for inhibiting low-temperature denitration catalyst poisoning caused by SO2. A NO oxidation device is arranged at a flue gas inlet of a selective catalytic reduction (SCR) denitration facility, 5-70% of NO in flue gas is oxidized into NO2 by the NO oxidation device, the flue gas containing NO2 is fed into the SCR denitration facility at a space velocity of 1000-200000h<-1> and the flue gas is subjected to denitration purification at a temperature of 50-300 DEG C. Through a reaction of NO2 obtained by oxidation of NO and an ammonium salt deposited on the surface of the low-temperature denitration catalyst, the method can effectively inhibit SO2-ammonia gas reaction-caused deposition of ammonium salts such as ammonium sulfate and ammonium sulfite on the surface of the low-temperature denitration catalyst thereby inhibiting SO2-caused low-temperature SCR denitration catalyst poisoning so that a service life of the low-temperature denitration catalyst is prolonged and a SCR denitration operation cost is reduced.

Owner:ZHEJIANG UNIV

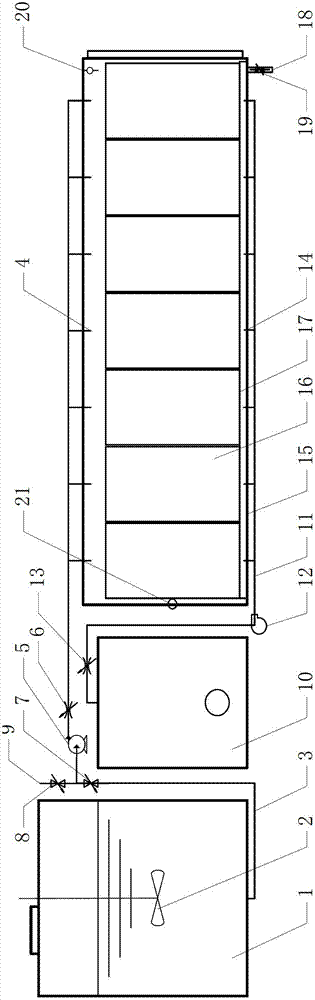

Movable cleaning and regenerating device and cleaning and regenerating method for SCR (selective catalytic reduction) denitration catalysts

InactiveCN102861621AAvoid long distance transportAvoid shipping damageCatalyst regeneration/reactivationEngineeringToxic material

Disclosed are a movable cleaning and regenerating device and a cleaning and regenerating method for SCR (selective catalytic reduction) denitration catalysts. The device comprises a soot blowing system, a cleaning and regenerating system and a drying and calcining system. The complete offline cleaning and regenerating system for the SCR catalysts is highly integrated to be mobile, can be transported to a user via railway or road traffic to clean the SCR catalysts according to the degree of catalyst poisoning, and the catalysts are regenerated by adding catalytic ingredients while sediments, pore blockage, alkali metal and other soluble toxic substances on surfaces of the catalysts are removed. The device and the method have the advantages that activity of the catalysts is improved, the service lives of the catalysts are prolonged, a full cleaning and regenerating process can be completed without long-distance transportation, the catalysts can be regenerated to the greatest extent, cleaning cycle of the catalysts is shortened, and cost is saved for the user of the SCR denitration catalysts.

Owner:XI AN JIAOTONG UNIV +1

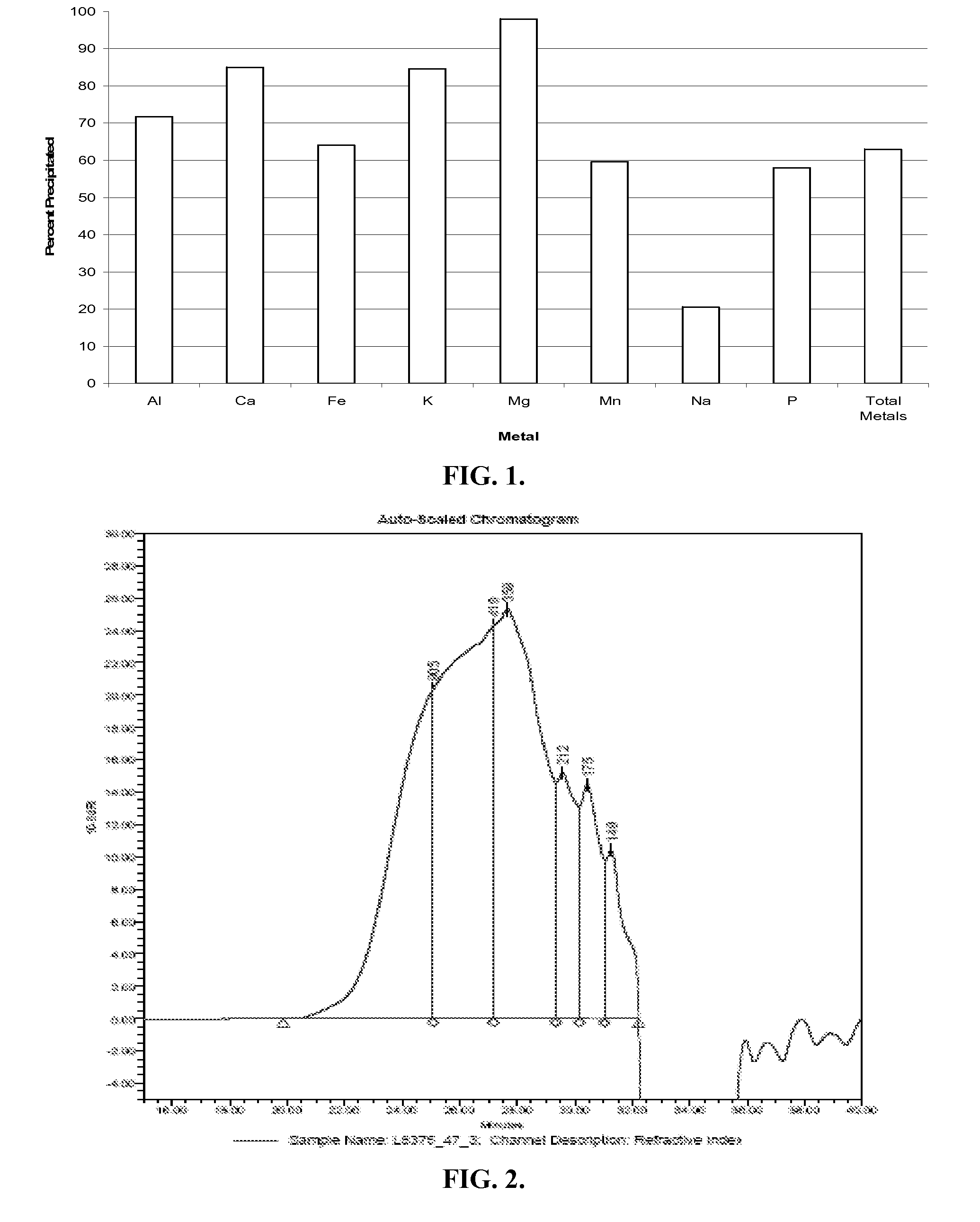

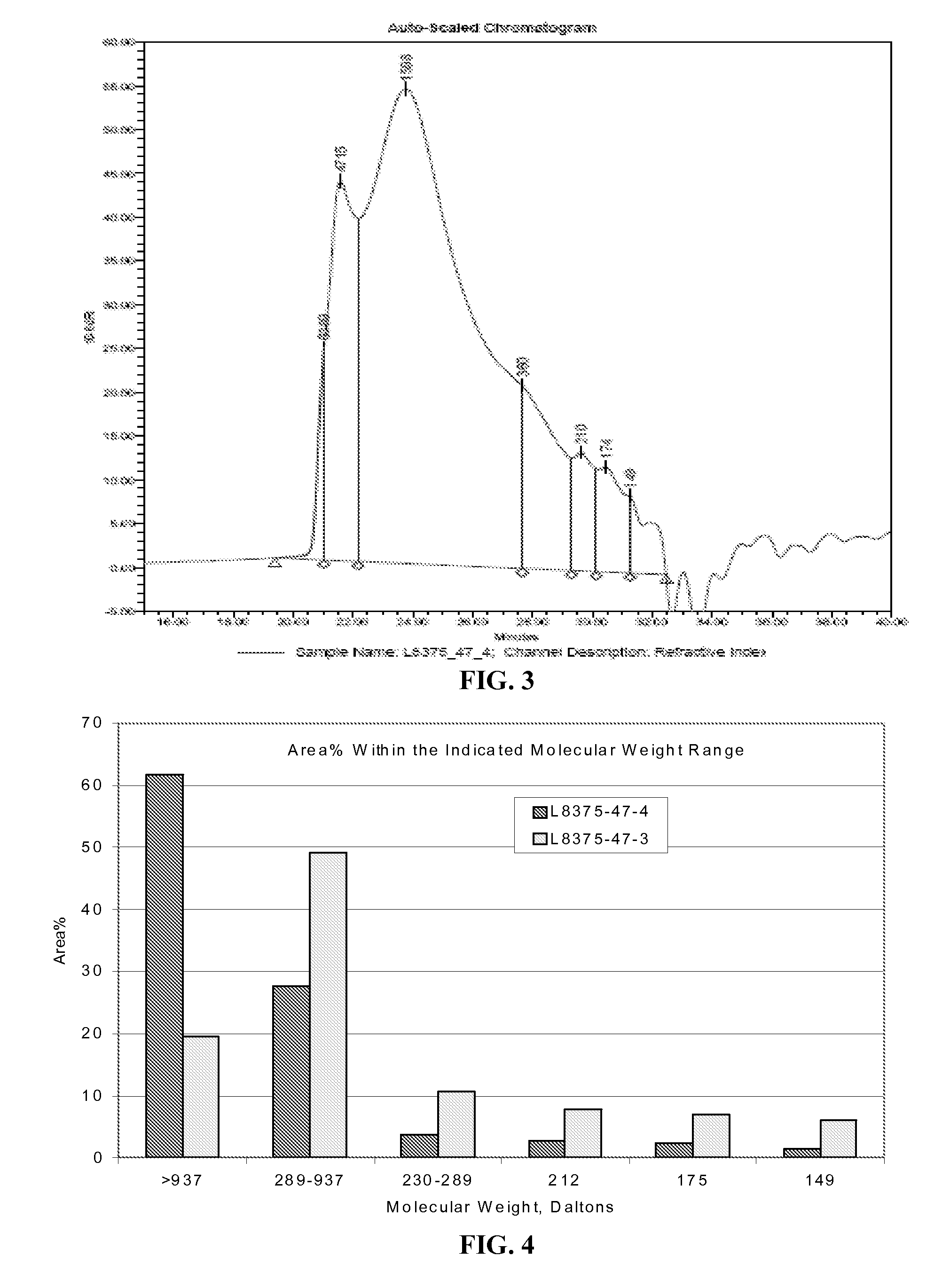

Metal impurity and high molecular weight components removal of biomass derived biocrude

This invention relates to a process for production of transportation fuels from biomass. More particularly, this invention relates to a process for using solvent to remove metal impurities and high molecular weight components from biomass derived biocrude to prevent potential catalyst poisoning and catalyst bed plugging in biocrude-to-transportation fuel upgrading process.

Owner:PHILLIPS 66 CO

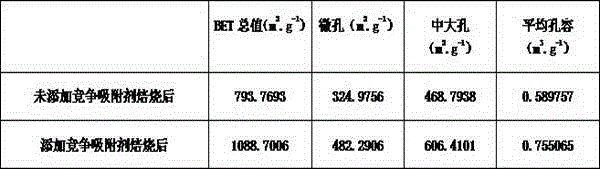

SCR method for removal of NOx by utilizing metal-organic frameworks as catalyst

The invention discloses an SCR (selective catalytic reduction) method for removal of NOx by utilizing metal-organic frameworks (MOFs) as the catalyst. The MOFs are used as the catalyst, and NH3 is utilized for removal of NOx with the SCR method, and catalytic denitration application with sulfur resistance is implemented with the flue gas conditional ranges of 400-1,000 ppm of NOx, 400-1,000 ppm of NH3, 3-5 percent of O2, 100-500 ppm of SO2, 10,000 h<-1>-40,000 h<-1> of air speed and 250-350 DEG C of temperature, and the denitration activity of the catalyst can reach more than 80%. Based on that the MOFs have the characteristics of large specific surface area, orderly dispersed metal active sites and three-dimensional transparent pore structure, catalyst poisoning and inactivation caused by deposition of sulfate in the reaction process can be effectively delayed, so that catalytic reduction of NOx can be efficiently and continuously realized.

Owner:DALIAN UNIV OF TECH

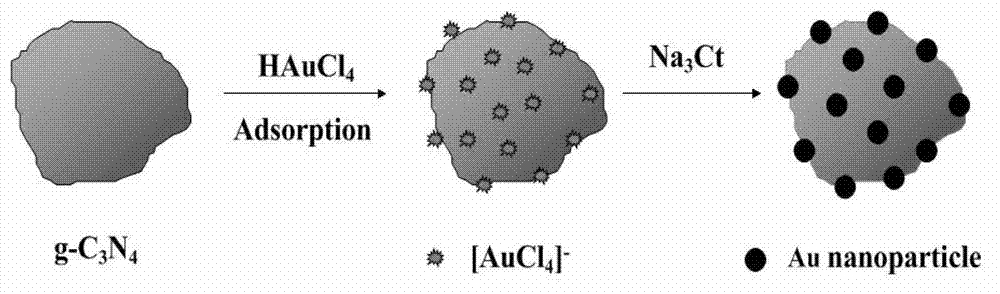

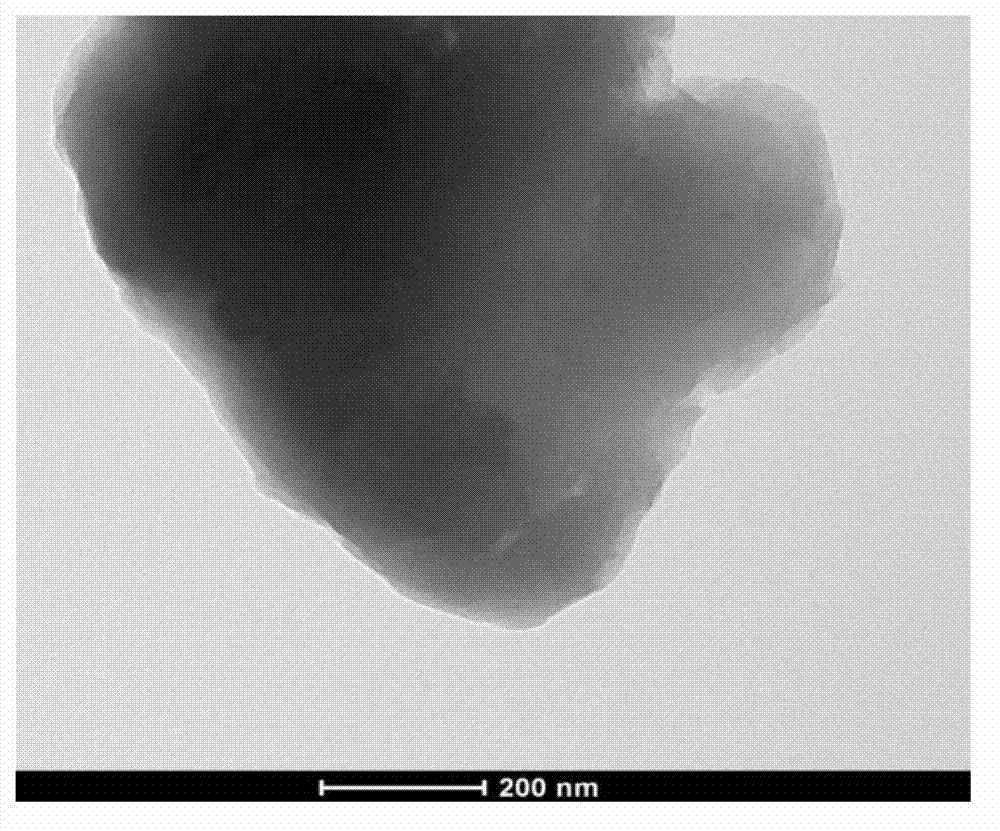

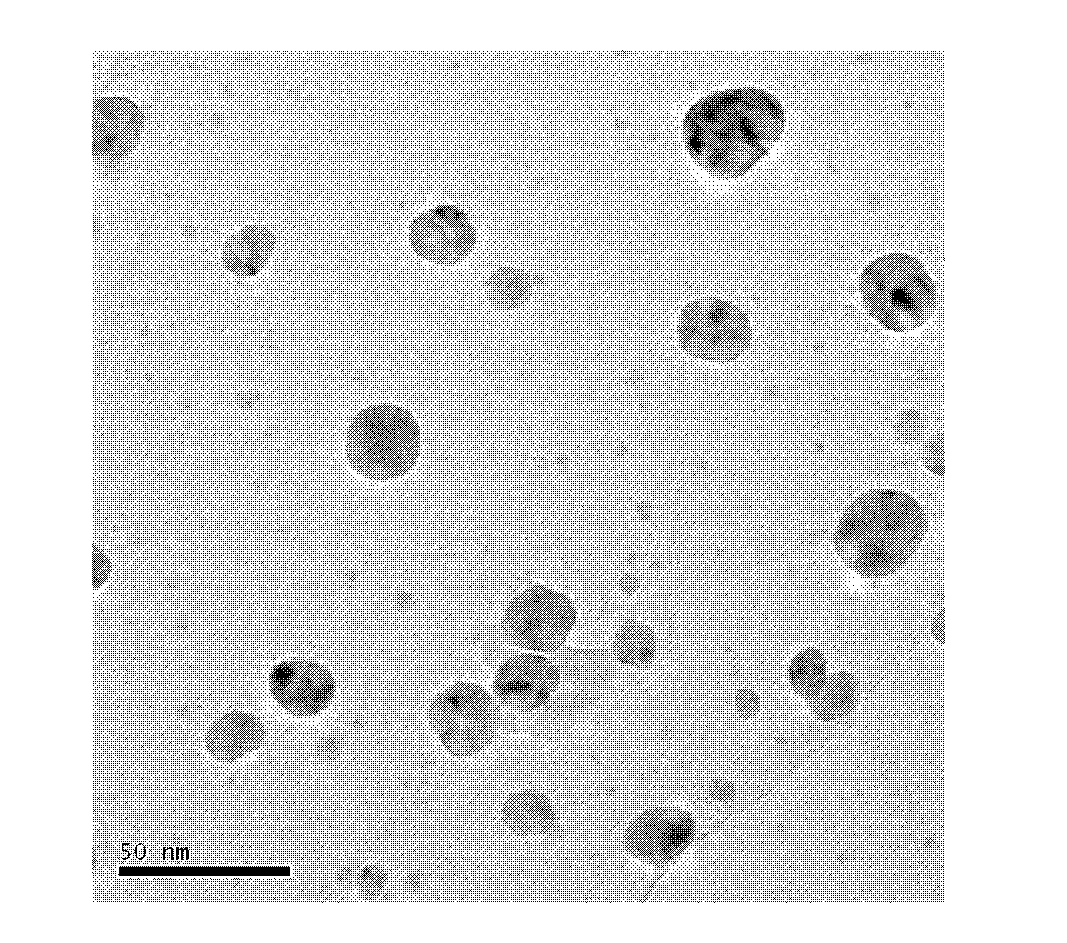

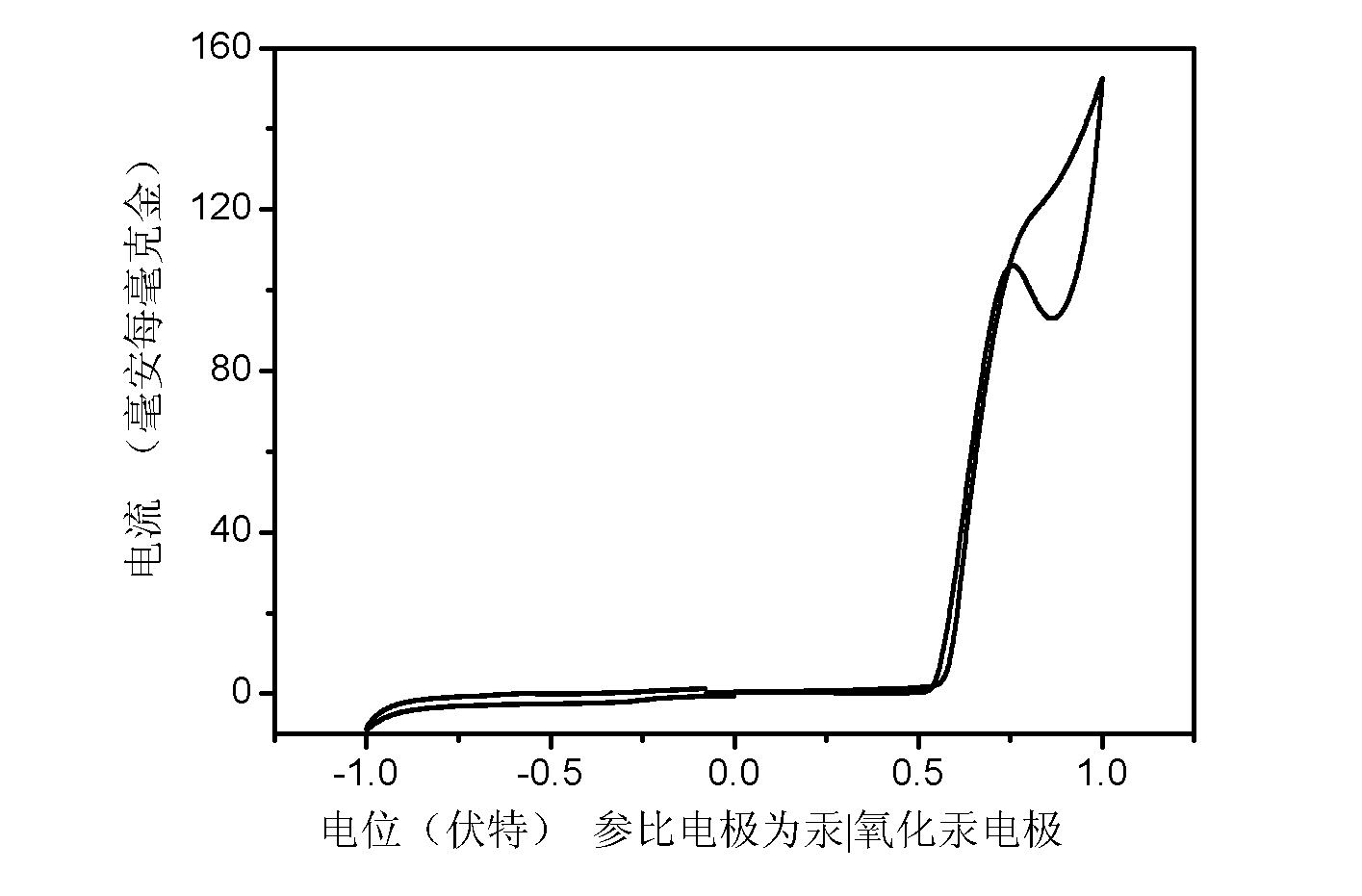

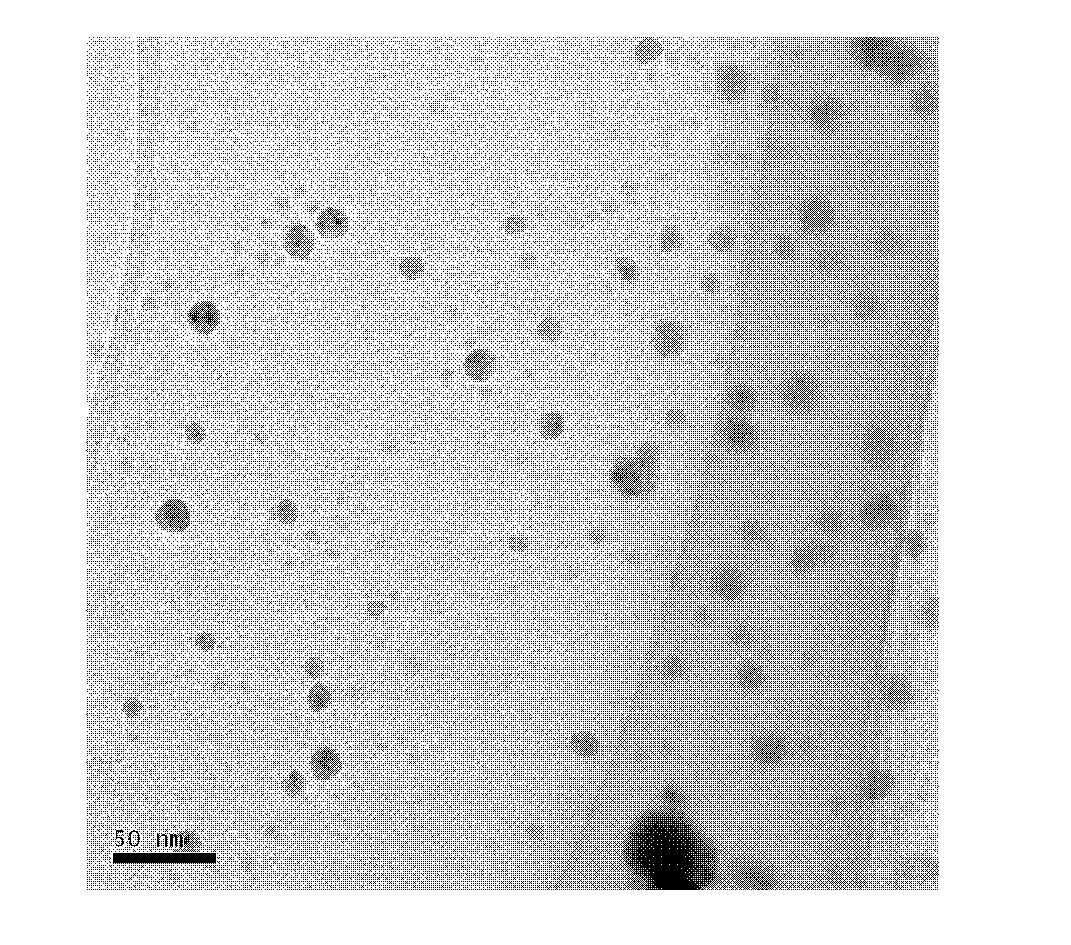

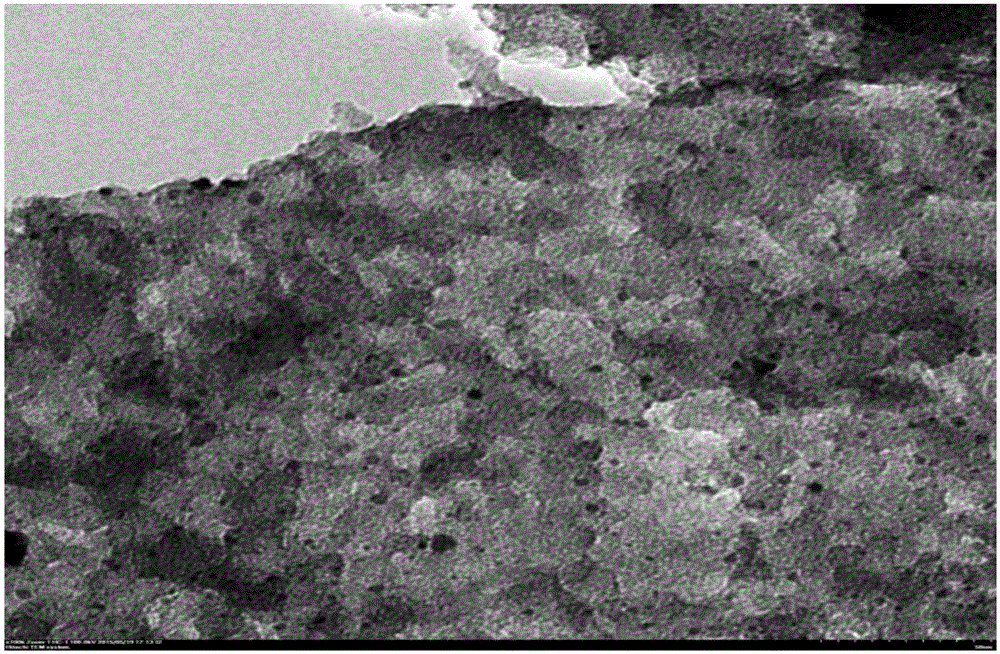

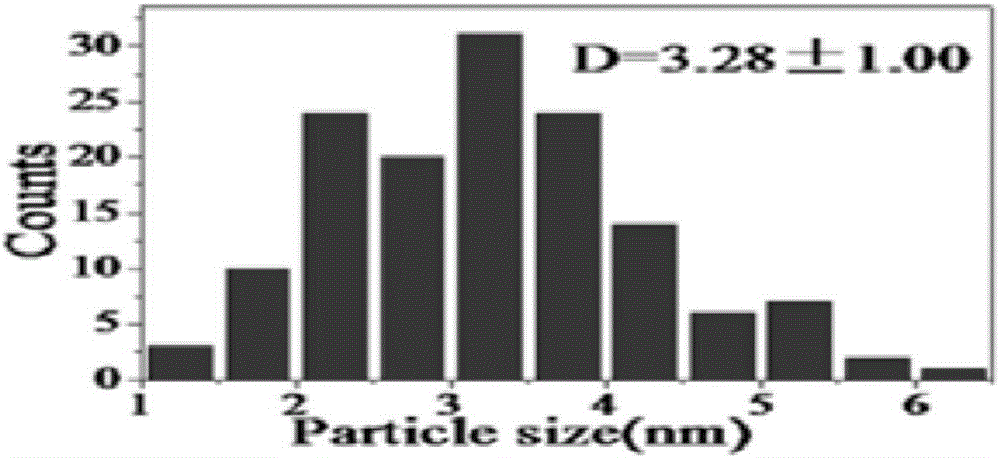

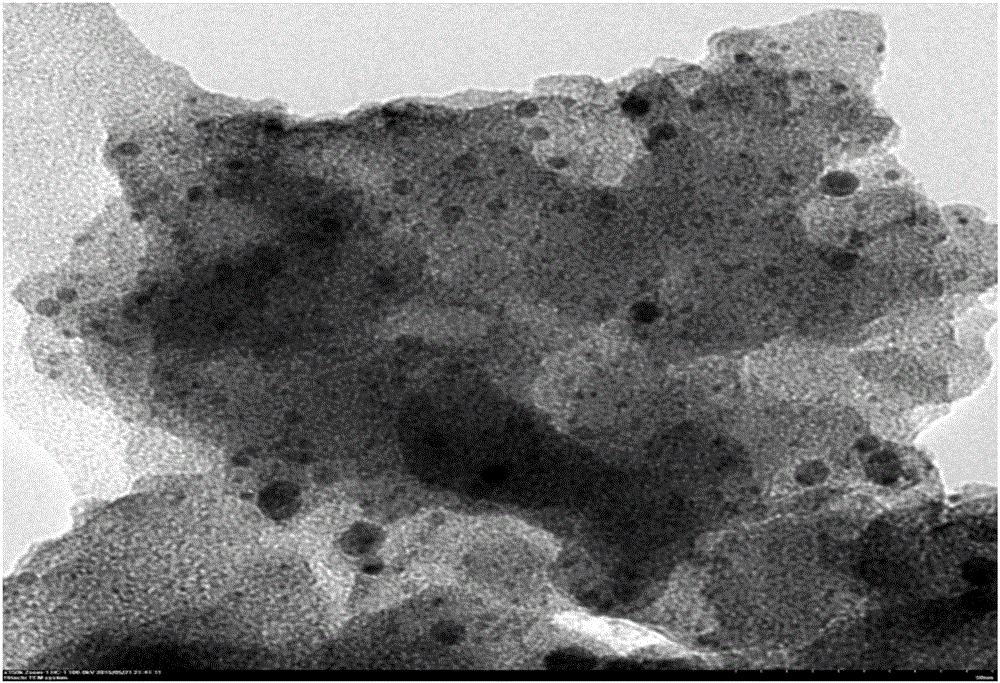

Method for preparing Au/g-C3N4 composite-type micro-nano material

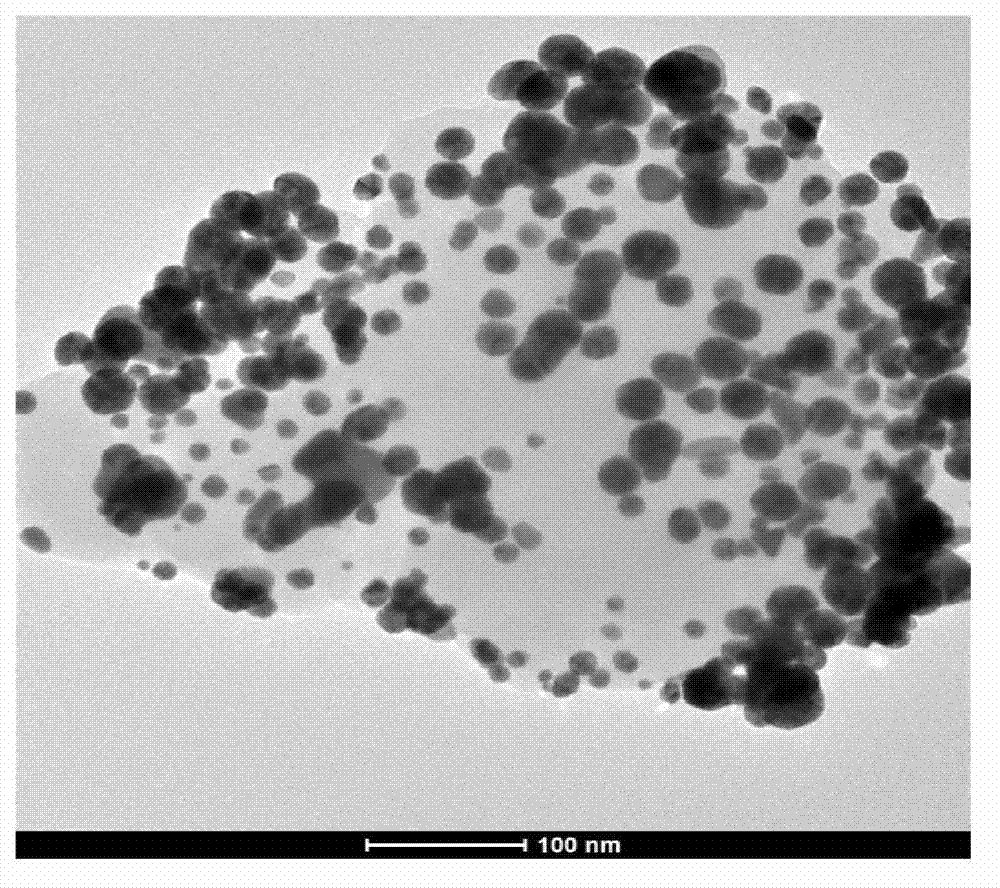

InactiveCN102895987AUniform particlesNo reunionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMicro nanoWater baths

The invention relates to a method for preparing Au / g-C3N4 composite-type micro-nano material. The method is realized by steps of adding g-C3N4 powder in 400-900nano in granularity to chloroauric acid solution, ultrasonically dispersing the g-C3N4 powder so as to prepare turbid liquid; heating the turbid liquid in water bath; then, adding sodium citrate to solution, stirring, washing, separating and drying a mixture so as to obtain Au / g-C3N4 composite-type micro-nano material; the Au / g-C3N4 composite-type micro-nano material has excellent photochemical catalysis effect to formic acid oxidation; and oxidation potential is negatively shifted by 800mV (close to the catalytic oxidation potential of Pt) without ctalyst poisoning phenomenon. According to the advantages of the invention, acquired composite material particles are even and not united; a preparation method is simple; and cost is relatively low.

Owner:CENT SOUTH UNIV

Catalyst deterioration detecting system and catalyst deterioration detecting method of internal combustion engine

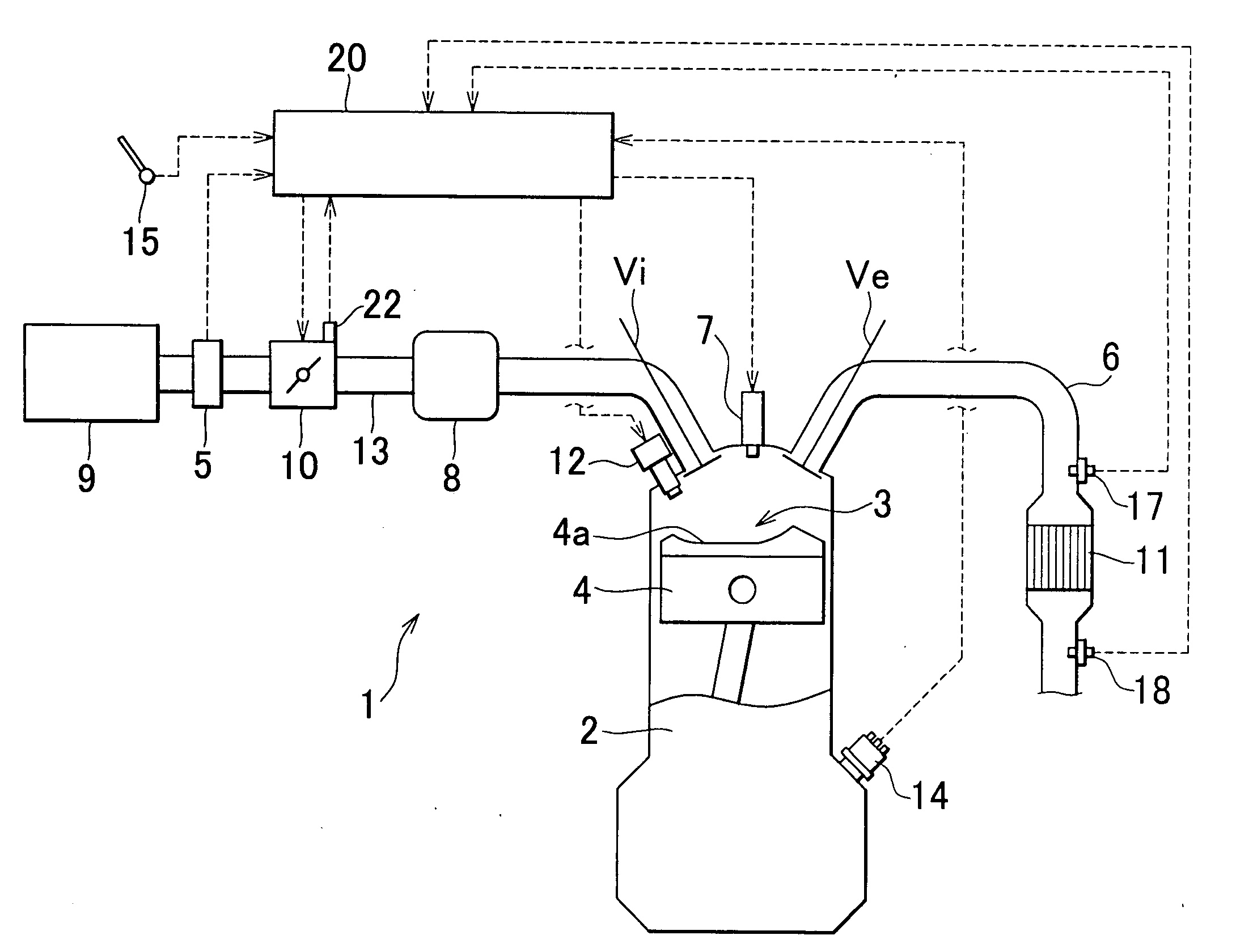

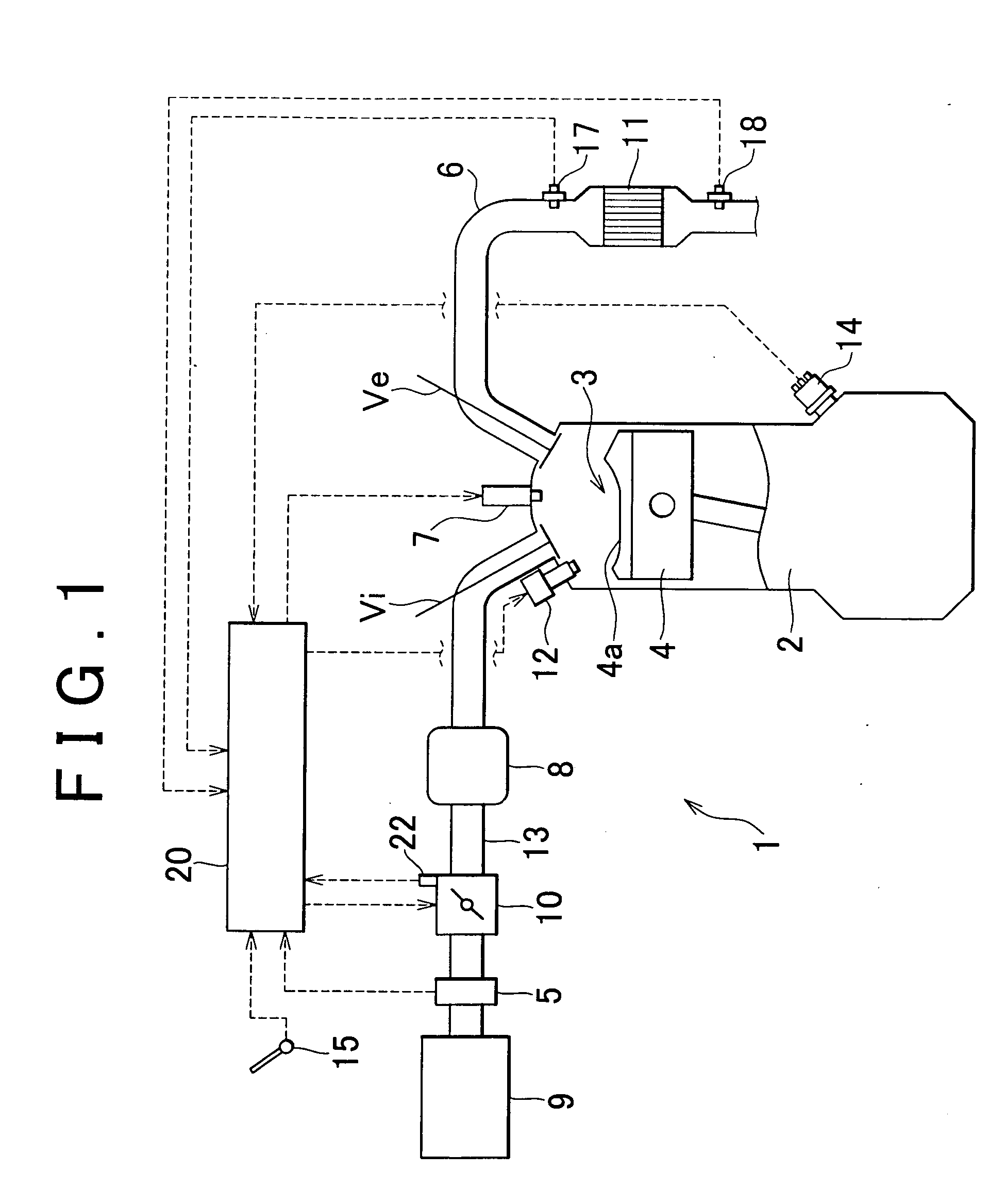

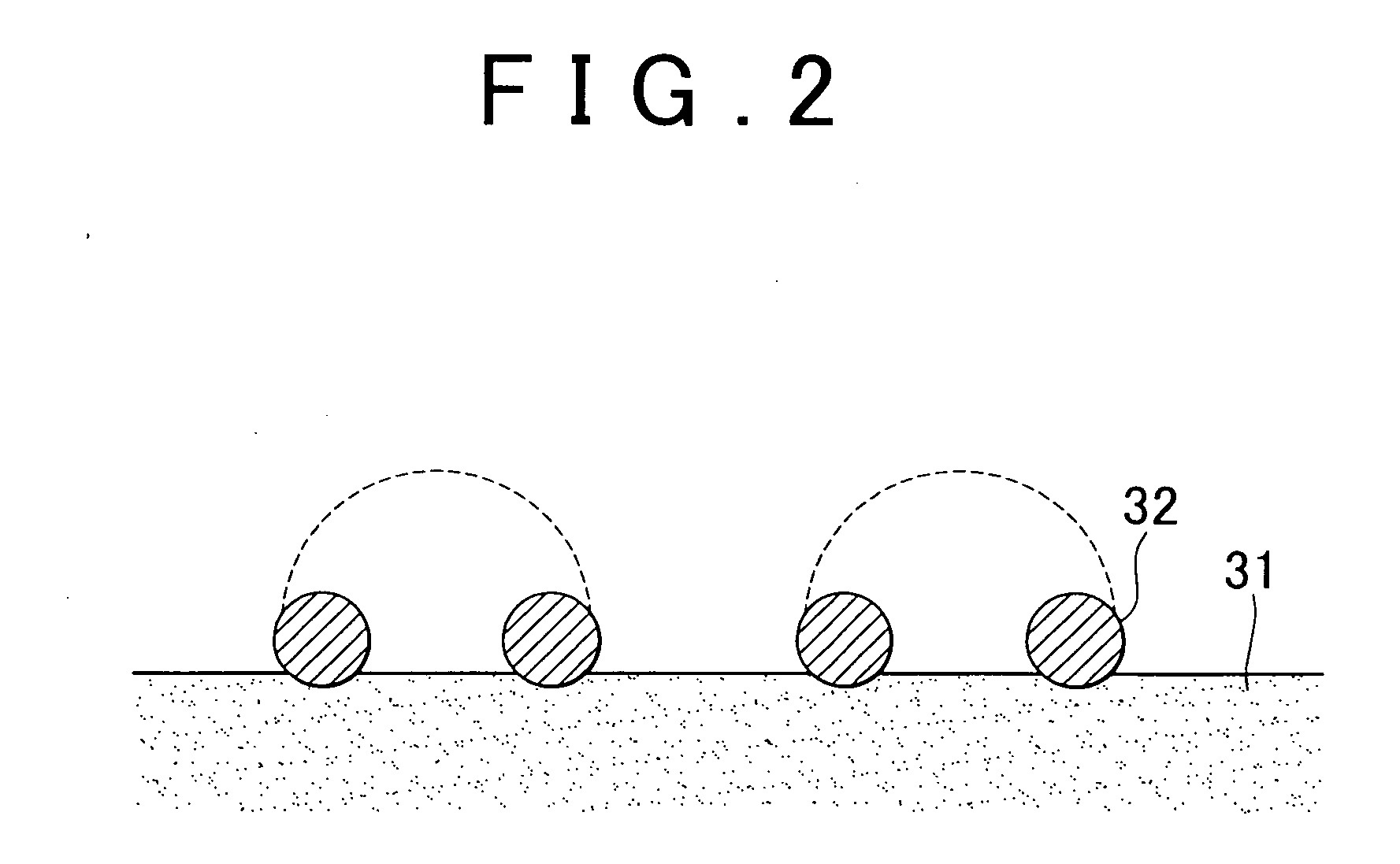

InactiveUS20080173008A1Good effectEasy to determineInternal combustion piston enginesExhaust apparatusEngineeringInternal combustion engine

A catalyst deterioration detecting system of an internal combustion engine includes a measuring unit that measures the oxygen storage capacity of a catalyst, a detector that detects or estimates the temperature of the catalyst, and a detector that detects poisoning of the catalyst based on the relationship between a change in the catalyst temperature and a change in the oxygen storage capacity corresponding to the change in the catalyst temperature. The change in the oxygen storage capacity corresponding to the change in the catalyst temperature varies depending on the presence or absence of poisoning of the catalyst. Thus, the catalyst deterioration detecting system is able to favorably detect poisoning of the catalyst by utilizing this relationship, and distinguish temporary deterioration due to catalyst poisoning from permanent deterioration. A method of detecting deterioration of the catalyst is also provided.

Owner:TOYOTA JIDOSHA KK

Regeneration method for arsenic poisoning selective catalytic reduction denitration catalyst

InactiveCN103894240AClean up thoroughlyGain resistance to arsenic poisoningCatalyst regeneration/reactivationBULK ACTIVE INGREDIENTArsenic poisoning

The invention discloses a regeneration method for an arsenic poisoning selective catalytic reduction denitration catalyst. The regeneration method comprises the following four steps of blowing ash, dipping, dipping, and drying and roasting. According to the regeneration method, an arsenic component which can cause SCR (Selective Catalytic Reduction) denitration catalyst poisoning can be effectively removed by using regenerated liquid and active ingredients can be supplemented; an SCR denitration catalyst obtains a certain arsenic poisoning resisting capability; meanwhile, a regeneration process is greatly simplified and the regeneration cost of the SCR denitration catalyst is reduced; with the adoption of the method, the regenerated denitration catalyst can be used for carrying out denitration activity detection and the denitration rate can be up to 80-88%.

Owner:河北宏庚环保设备有限公司

Lubricating oil composition

InactiveUS20070129263A1Reducing catalyst poisoningLiquid carbonaceous fuelsAdditivesChemical compositionAfter treatment

The present invention is directed to a lubricating oil composition comprising (a) a major amount of an oil of lubricating viscosity (b) one or more lithium-containing detergents (c) one or more detergents other than a lithium-containing detergent (d) one or more anti-oxidants (e) one or more dispersants and (f) one or more anti-wear agents, wherein the lubricating oil composition contains no more than 0.1 weight percent of lithium-containing detergents and no more than 0.12 weight percent phosphorus, and provided the lubricating oil composition does not contain a calcium-containing detergent. The present invention is also directed to a lubricating oil composition comprising (a) an oil of lubricating viscosity (b) a lithium-containing detergent (c) a detergent other than a lithium-containing detergent (d) an amine-containing anti-oxidant (e) an ethylene carbonate treated dispersant and (f) a phosphorus-containing anti-wear agent, wherein the lubricating oil composition contains no more than 0.1 weight percent of lithium and no more than 0.12 weight percent phosphorus, and provided the lubricating oil composition does not contain a calcium-containing detergent. The present invention is also directed to method for reducing catalyst poisoning in exhaust after treatment systems in internal combustion engines, which comprises operating the engine with the lubricating oil compositions of the present invention.

Owner:CHEVRON ORONITE CO LLC

Graphene-loaded double-metal nano particles for methanol and ethanol fuel cells, and preparation method for graphene-loaded double-metal nano particles

InactiveCN102489314AHigh catalytic activityLow costMaterial nanotechnologyCell electrodesCarbon monoxide poisonOrganocatalysis

The invention relates to graphene-loaded double-metal nano particles for methanol and ethanol fuel cells, and a preparation method for the graphene-loaded double-metal nano particles. The method comprises the following steps of: sequentially adding graphene oxide, polymeric dispersant, and anionic surfactant into a water-ethanol mixed solution, stirring, adding double-metal nano particles, and adding sodium borohydride to obtain black precipitate double-metal nano particle graphene; and performing centrifugal separation on precipitate by using a centrifugal machine, repeatedly washing by using secondary deionized water and ethanol to remove unreacted reactant, and then performing vacuum drying. According to the method, gold and silver which is low in price, and non-noble metal such as cobalt and nickel which is lower in price is used instead of noble metal such as platinum and ruthenium which is high in price, so cost is reduced. Methanol is catalyzed and ethanol is oxidized under thealkaline condition, so the condition that intermediate carbon monoxide poisons a catalyst under the acid condition so that the activity of the catalyst is reduced can be effectively overcome. The graphene-loaded double-metal nano particles can be directly used for methanol and ethanol fuel cells, formic acid fuel cells, and organic catalytic reaction.

Owner:TIANJIN UNIV

Acid pickling regenerating liquid for denitration catalyst and regenerating method

InactiveCN104289258AGood regeneration performanceImprove denitrification efficiencyDispersed particle separationCatalyst regeneration/reactivationFatty alcoholSURFACTANT BLEND

The invention provides an acid pickling regenerating liquid for a denitration catalyst and a regenerating method. The acid pickling regenerating liquid comprises 0.1-1.0% of a surfactant and the balance being an acid solution, wherein the surfactant comprises one or more of JFC type fatty alcohol-polyoxyethylene ether, JFC-1 type fatty alcohol-polyoxyethylene ether, and JFC-2 type fatty alcohol-polyoxyethylene ether. Compared with the prior art, the acid pickling regenerating liquid has good effect of regenerating the toxic denitration catalyst in metallic elements, and the regenerated denitration catalyst has high denitration efficiency. Experiment results prove that in the regenerated denitration catalyst, the content of the metallic elements causing the denitration catalyst to be toxic is effectively controlled, and the denitration efficiency of the denitration catalyst is above 90%.

Owner:TIANHE BAODING ENVIRONMENTAL ENG

System and method for protection of scr catalyst and control of multiple emissions

ActiveUS20100273643A1Prolong lifePhysical/chemical process catalystsDispersed particle separationPower stationFlue gas

The present invention relates generally to the field of emission control equipment for boilers, heaters, kilns, or other flue gas-, or combustion gas-, generating devices (e.g., those located at power plants, processing plants, etc.) and, in particular to a new and useful method and apparatus for preventing the poisoning and / or contamination of an SCR catalyst. In another embodiment, the method and apparatus of the present invention is designed to protect an SCR catalyst, while simultaneously providing emission control.

Owner:THE BABCOCK & WILCOX CO

Exhaust gas purification catalyst and method for production thereof

The invention realizes a catalyst which is hardly deteriorated even when volatile catalyst-poisoning compounds such as P and As are accumulated and which can reduce the rate of oxidation of SO2 to a level as low as a fraction of that of the catalyst in the prior art, and provides an exhaust gas purification catalyst which can maintain a high activity and a low rate of oxidation of SO2 for a long time even with any diversified coal, a method of producing the same, and an exhaust gas purification method using the same. Disclosed is an exhaust gas purification catalyst having a composition comprising oxides of titanium (Ti), molybdenum (Mo) and / or tungsten (W), vanadium (V) and bismuth (Bi), wherein the atomic ratio of Ti:(Mo and / or W):V is 75 to 98.9:1 to 0.1 to 10 and the atomic ratio of Bi / (Mo and / or W) is 0.1 to 0.8.

Owner:BABCOCK HITACHI KK

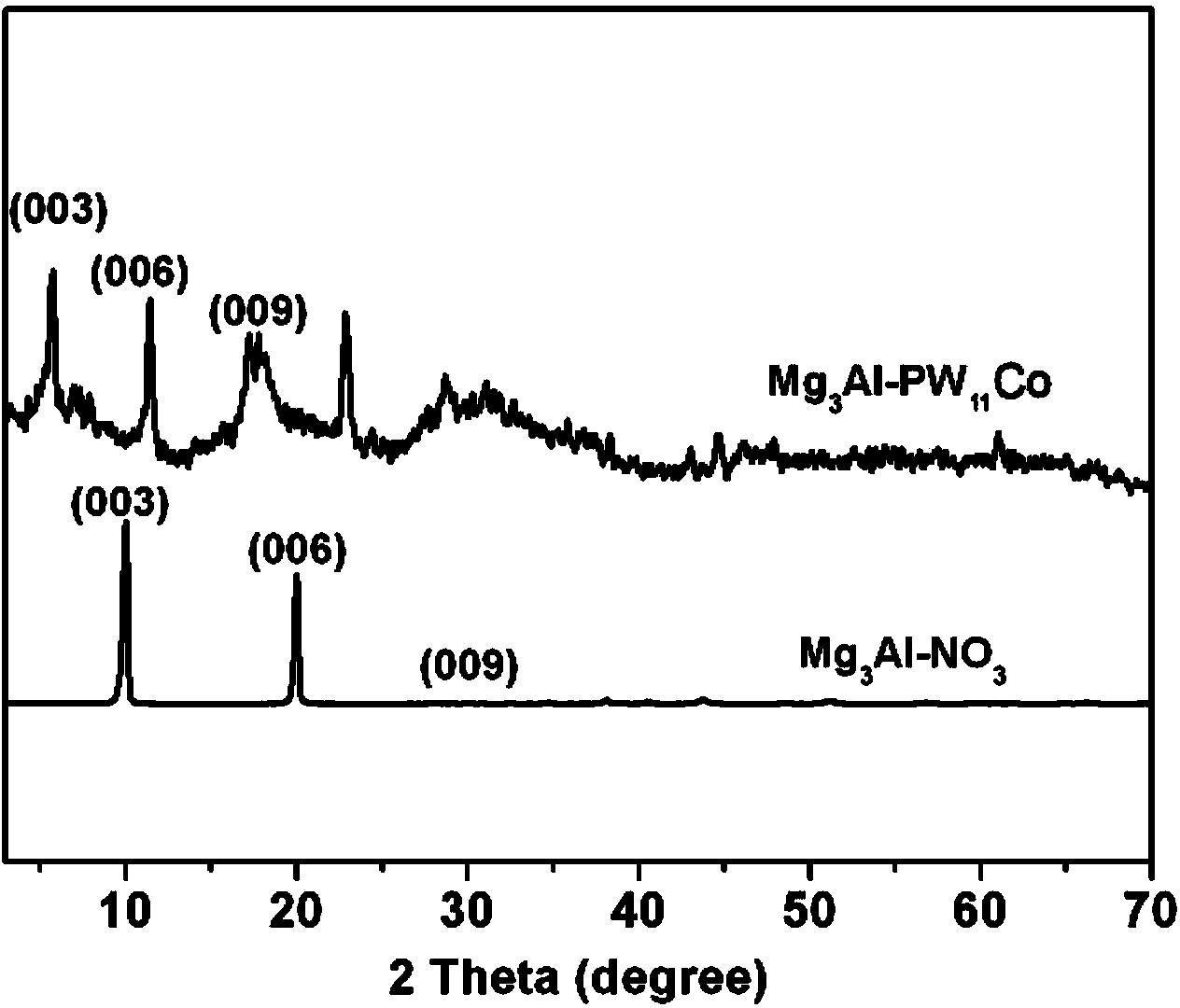

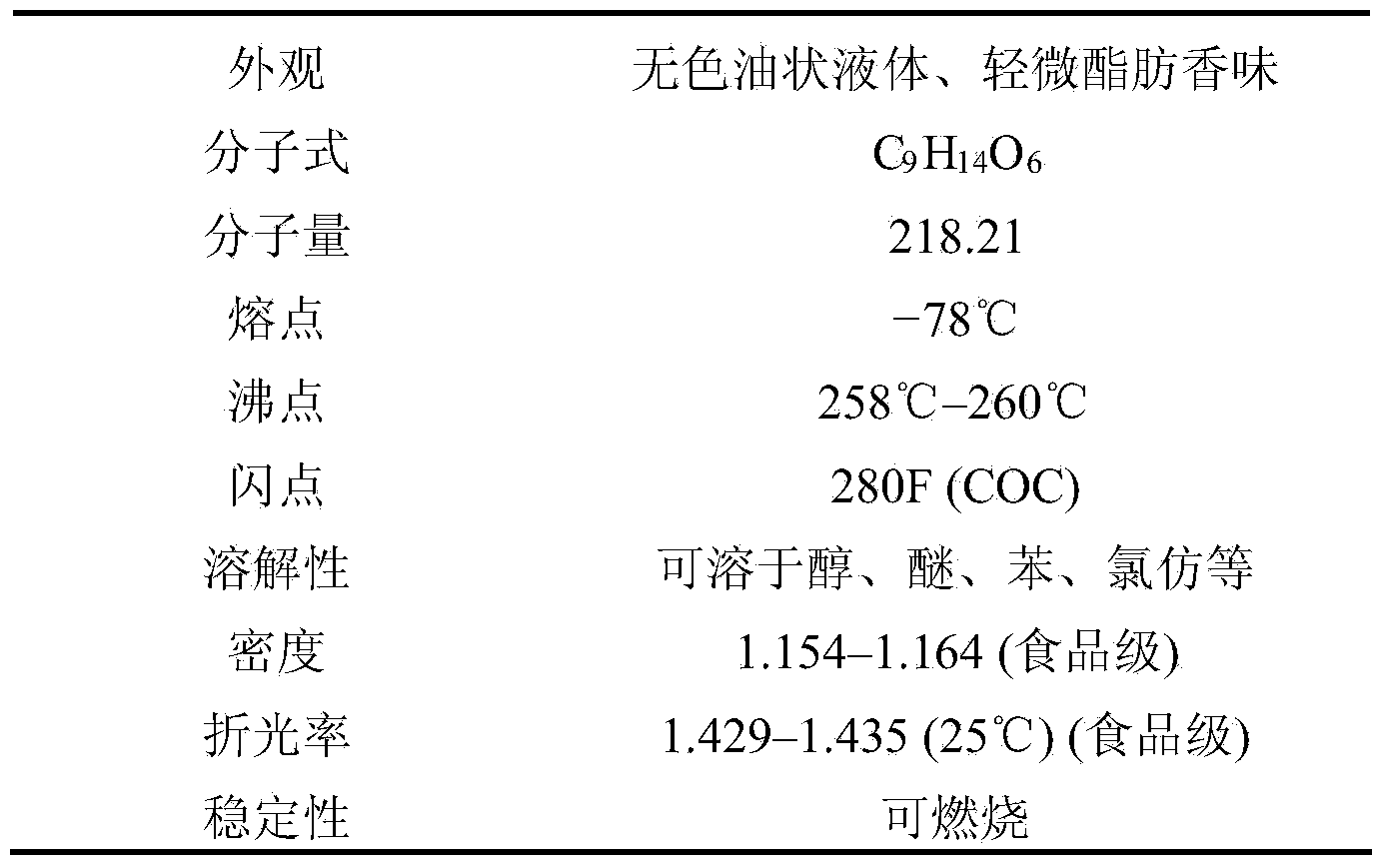

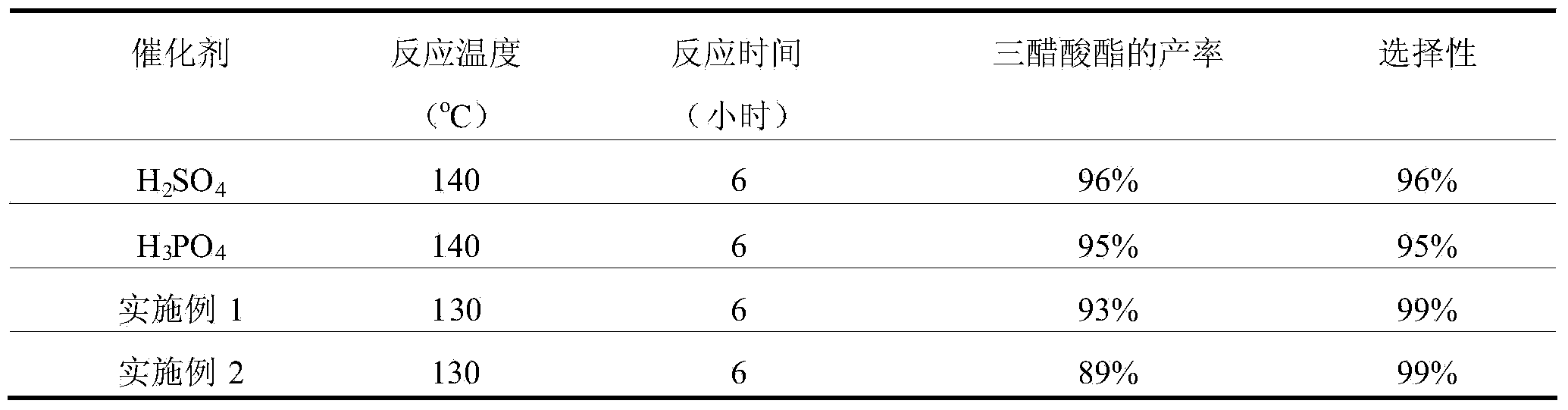

Application of polyacid intercalated hydrotalcite catalyst in preparing glyceryl triacetate

ActiveCN103706403ARealize green productionReduced activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureIon exchange

The invention discloses a polyacid intercalated hydrotalcite catalyst and application of the polyacid intercalated hydrotalcite catalyst to preparation of environment-friendly toxic-free glyceryl triacetate, which belong to the technical field of catalyst preparation. Polyacid is intercalated into hydrotalcite through an ion exchanging method and firstly used for producing the glyceryl triacetate. The prepared polyacid intercalated hydrotalcite catalyst has a supermolecular lamella structure and a nano-grade size; the glyceryl triacetate is prepared through the catalysis of the polyacid intercalated hydrotalcite catalyst. Compared with concentrate sulfuric acid and phosphoric acid, the polyacid intercalated hydrotalcite catalyst has the advantages that the high-efficient catalytic activity and catalytic selectivity can be maintained under the situation that the reaction temperature is lowered; the corrosion on equipment is small, and no waste liquid with high acidity is produced; easiness in recycling can be realized, the stability is good, and after the catalyst is continuously used for 3 months, the poisoning phenomenon of the catalyst does not occur and the activity of the catalyst is not obviously reduced.

Owner:BEIJING UNIV OF CHEM TECH +1

Metallic foam trap for poisons: aircraft ozone

InactiveUS20070154375A1Improve trapping efficiencyCombination devicesOrganic chemistryOil additiveAir purification

The present invention is directed to an improved apparatus and method of minimizing catalyst poisoning by inorganic deposits from lube oil additives and particulate matter, especially in aircraft. More specifically, the present invention is directed to an air purification system comprising an upstream metallic foam trap and downstream converter, wherein the trap physically blocks inorganic deposits and particulate matter from poisoning the downstream catalysts. The present invention is also directed to a metallic foam trap containing a coat comprising a first metallic thermal arc sprayed layer and optionally a second refractory metal oxide.

Owner:BASF CATALYSTS LLC

Urea supported carbon based denitration catalyst, preparation and application method thereof

InactiveCN101428237AReduce usageThe denitrification process is green and environmentally friendlyOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationIncipient wetness impregnationFixed bed

The invention discloses a urea-carried carbon-based denitrification catalyst, as well as a preparation method and an application method thereof. The components in weight percentages of the denitrification catalyst are as follows: 75% to 99.9% of activated carbon carrier and 0.1% to 25% of urea. The preparation method adopts the incipient wetness impregnation technique and comprises the following steps: impregnating activated carbon carrier in a urea aqueous solution, standing, and drying to obtain the catalyst. The obtained catalyst is loaded in a fixed bed reactor under such conditions that the reaction temperature is controlled in the range from 30 DEG C to 90 DEG C, the normal-pressure flue gas is introduced, and the air speed ranges from 2000 / h to 12000 / h. Under the catalytic action of the activated carbon-based carrier, the NOx in the flue gas reacts with the urea to generate N2, CO2 and H2O. The urea-carried carbon-based denitrification catalyst has the advantages of environmental protection, no secondary pollution, recovery of activated carbon carrier, repeated use of urea, no need of water, strong resistance to flue gas erosion, no risk of catalyst poisoning, high denitrification rate, wide denitrification concentration range, wide application range and good market potential.

Owner:EAST CHINA UNIV OF SCI & TECH

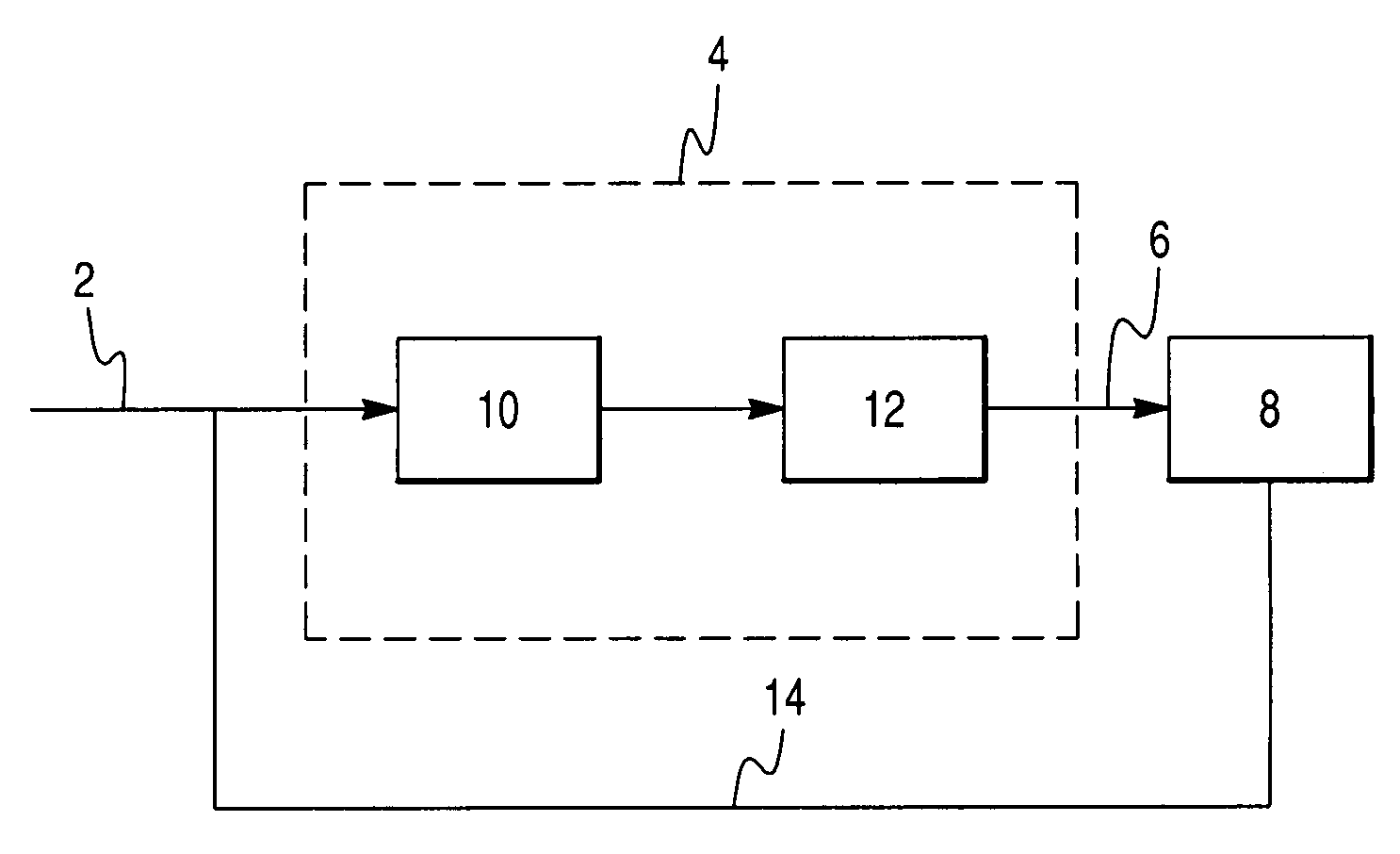

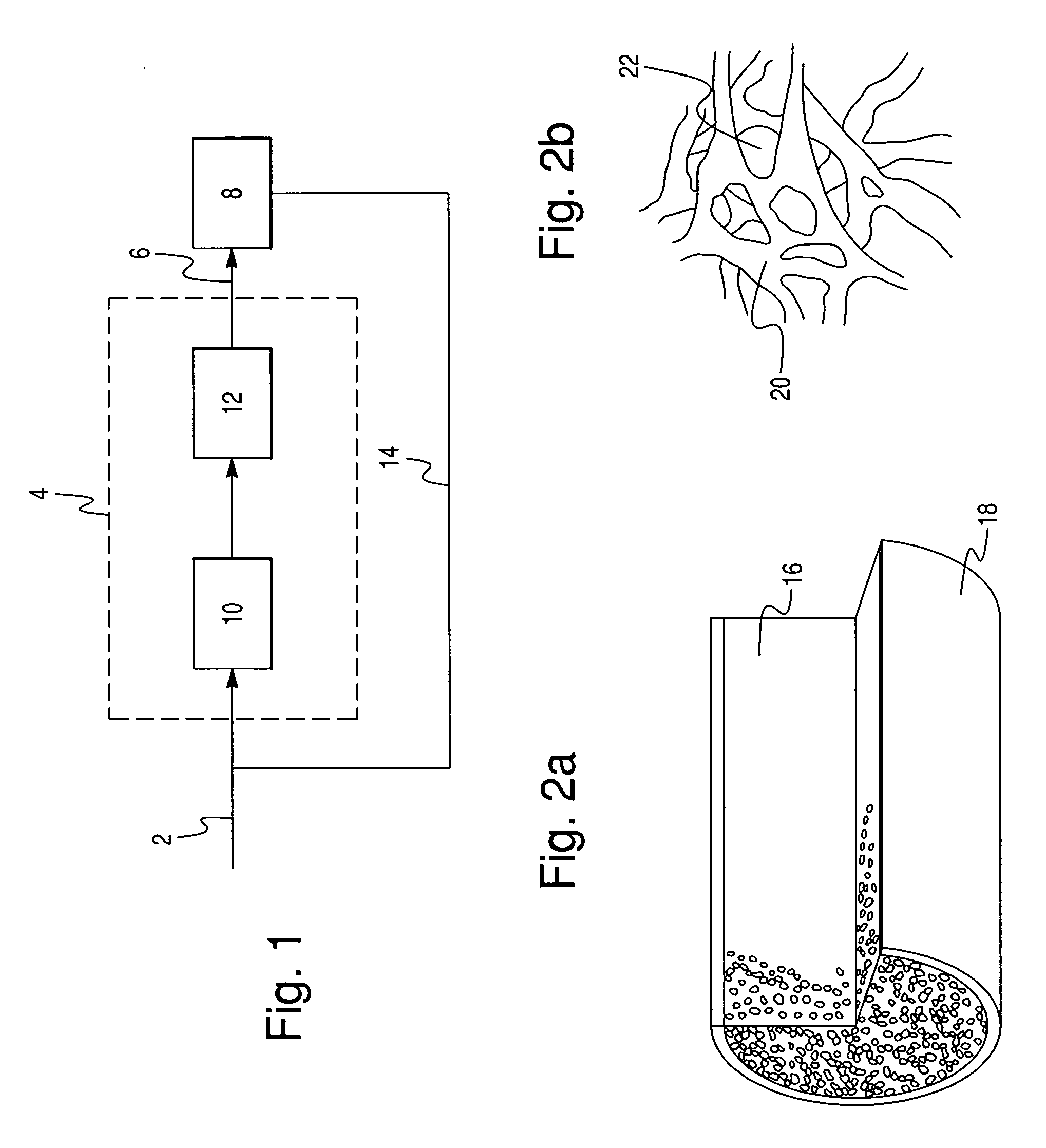

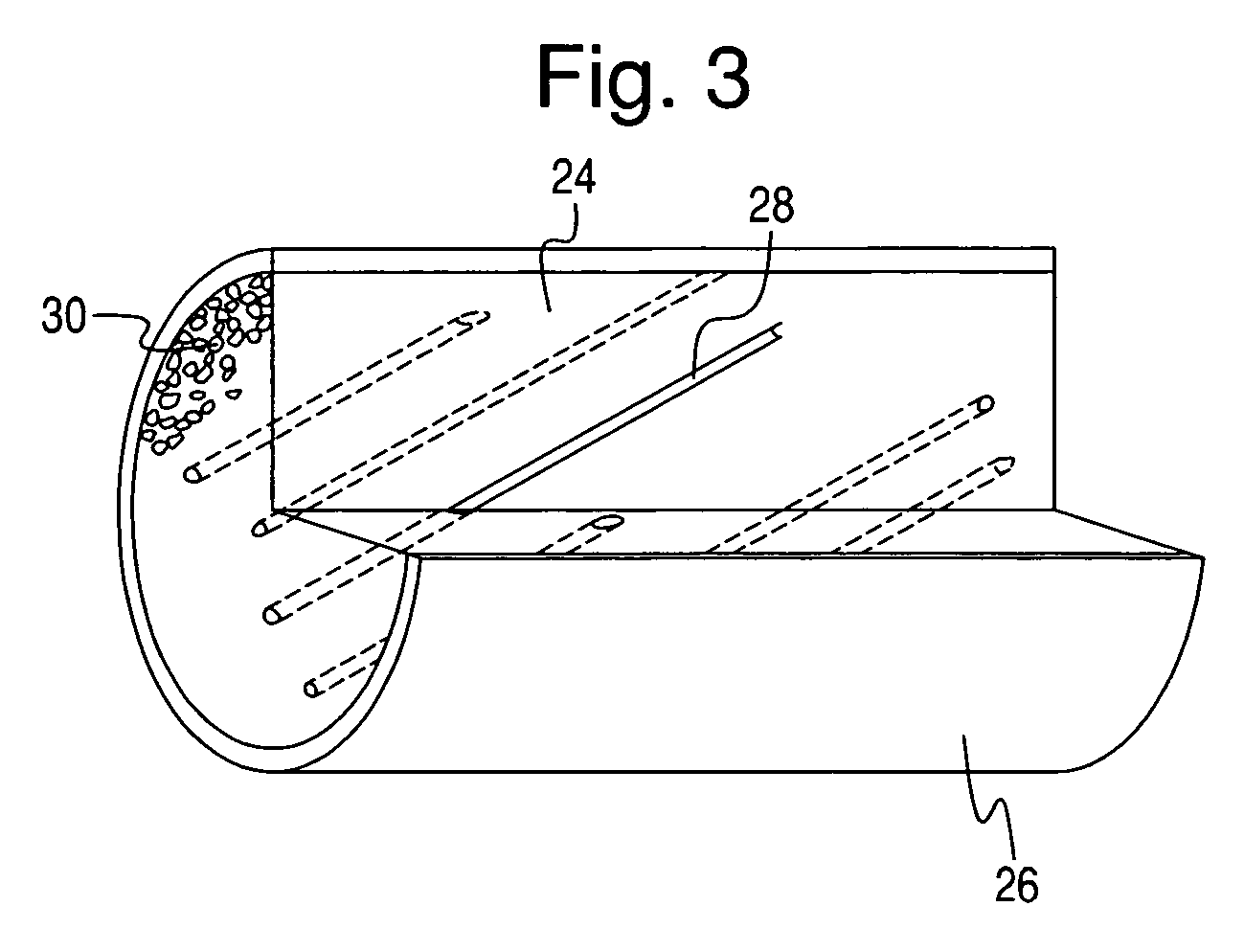

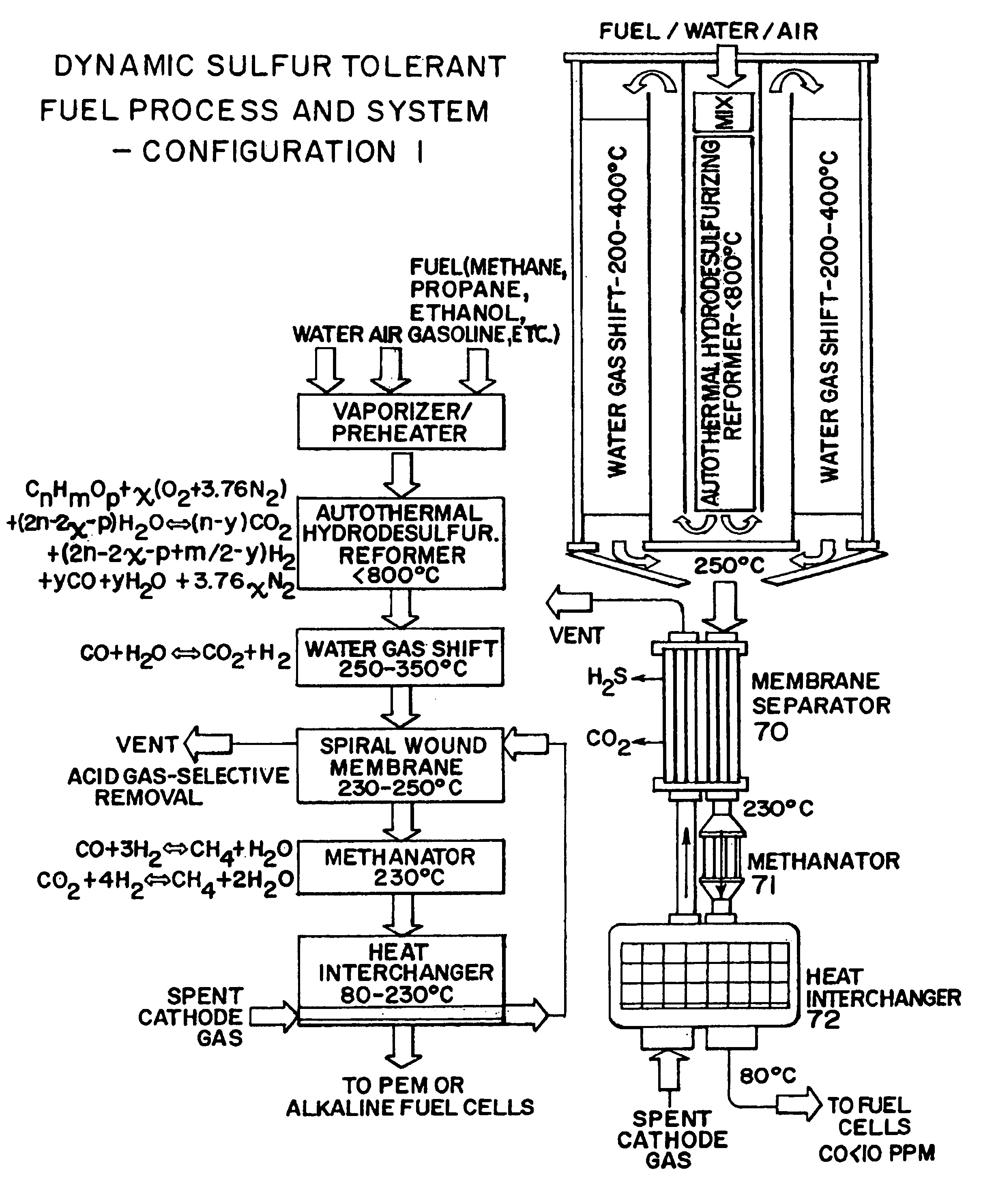

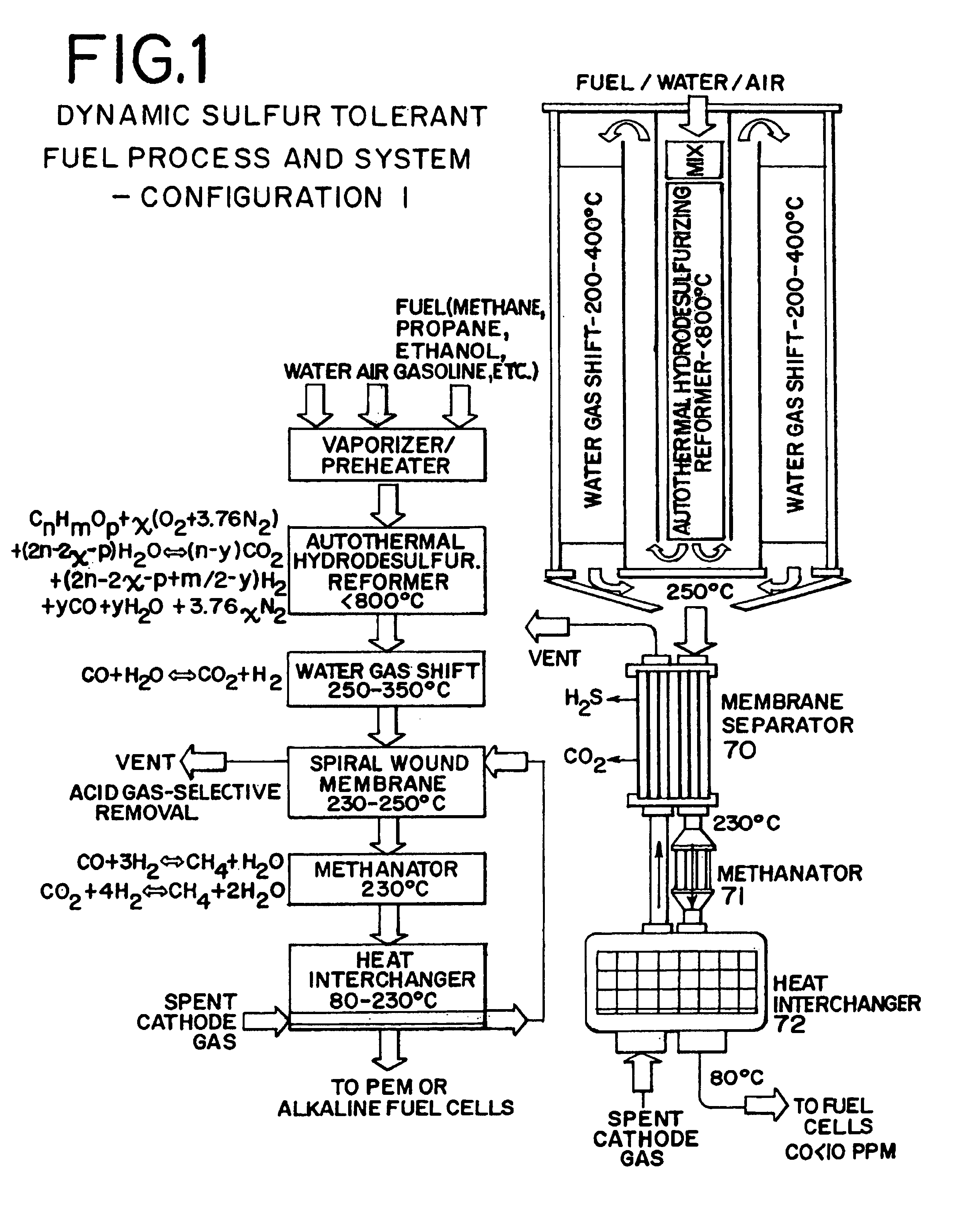

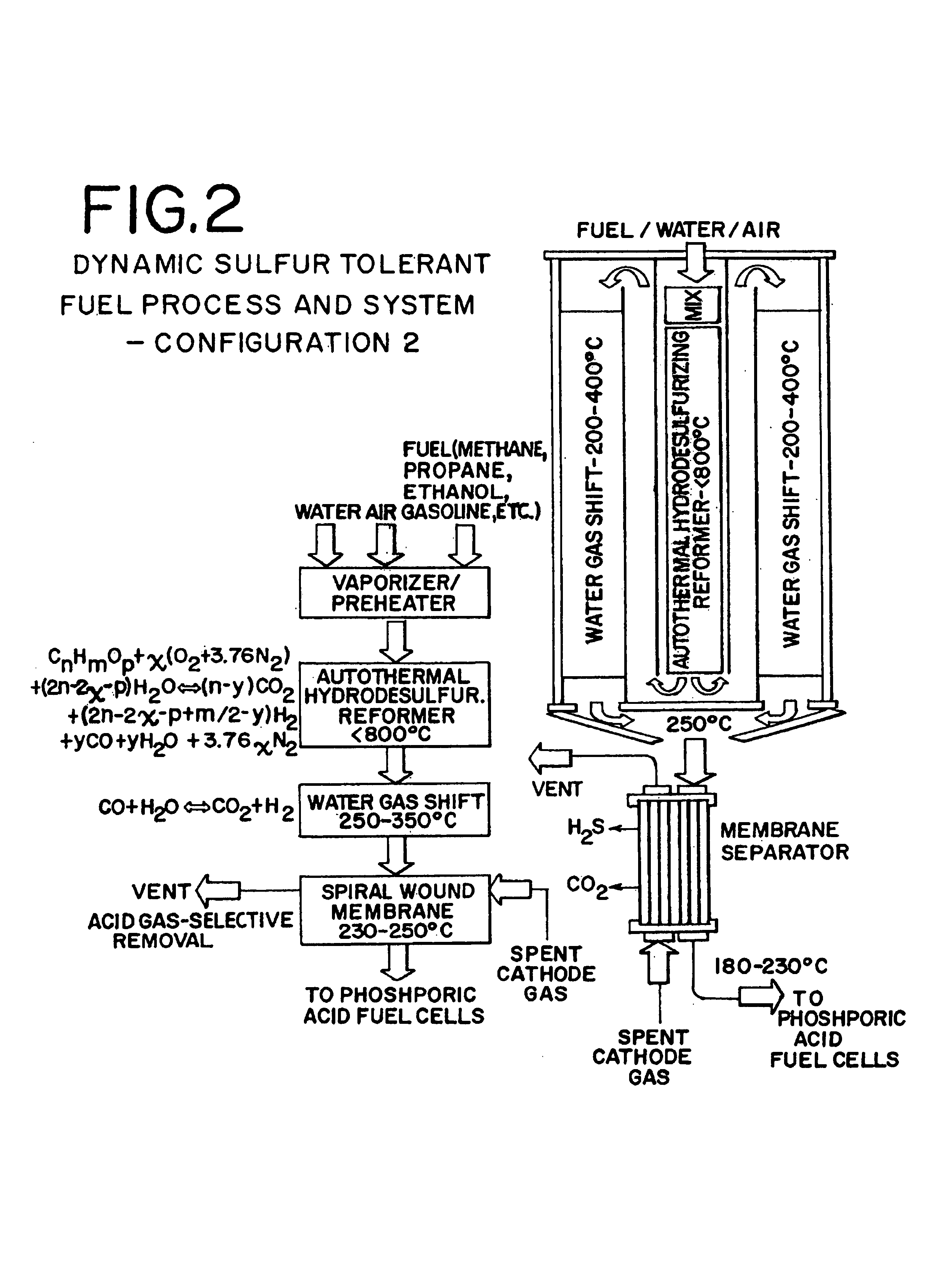

Dynamic sulfur tolerant process and system with inline acid gas-selective removal for generating hydrogen for fuel cells

InactiveUS6984372B2Economical and efficient and compactly configuredSimpler thermal managementFuel cell auxillariesHydrogen/synthetic gas productionChemical treatmentHydrogen

This invention relates to a sulfur tolerant, dynamic, compact, lightweight fuel process and system that is capable of converting sulfur bearing carbonaceous fuels to hydrogen rich gases suitable for fuel cells or chemical processing applications. The process and system is based on the AHR and WGS reactions, followed by cleanup of byproduct sulfur-containing gases and carbon oxides that would otherwise poison the fuel cell electrocatalyst. Advantageously, this is accomplished via an ASMS and a methanator or an AWMR. The process and system preferably uses a special sulfur tolerant catalysts and hardware designs that enable the conversion in an energy efficient manner while maintaining desirable performance characteristics such as rapid start-stop and fast response to load change capabilities.

Owner:H2FUEL

Catalyst for ethyne hydrochlorination for synthesis of chloroethylene and preparation method thereof

ActiveCN105521801AHigh activityLess side effectsPreparation by halogen halide additionMetal/metal-oxides/metal-hydroxide catalystsDispersitySorbent

The invention discloses a catalyst for ethyne hydrochlorination for synthesis of chloroethylene and a preparation method thereof. The catalyst of the invention is prepared by impregnation of an active carbon carrier, metallic compound active components and a hydroxyl-containing water-soluble carboxylic acid competitive adsorbent. The active components contain at least one component selected from chloride, nitrate, sulfate or phosphate of cobalt, copper, manganese, zinc, bismuth, barium and potassium. The competitive adsorbent contains citric acid, malic acid, salicylic acid, oxalic acid, tartaric acid and lactic acid. The prepared catalyst has characteristics of high activity, good selectivity, simple production method and low cost. By adding the hydroxyl-containing water-soluble carboxylic acid competitive adsorbent, the active components are greatly fixed to the carrier, and high temperature transfer of the active components is reduced; by roasting decomposition of the competitive adsorbent, rich pore structures are generated, and gas dispersion in the reaction process is improved; and dispersity of the active components is improved, catalyst poisoning is alleviated, and life of the catalyst is prolonged.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD

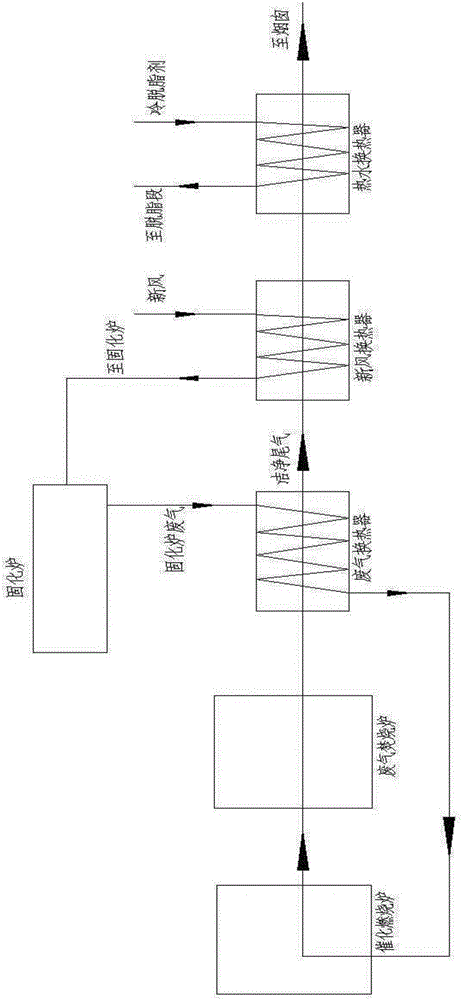

Technological method for color-coating line waste gas treatment

InactiveCN105091000AReduce dosageSolve the problem of inability to deal with exhaust gasPretreated surfacesCoatingsExhaust gas emissionsEnvironmental engineering

The invention discloses a technological method for color-coating line waste gas treatment. The technological method comprises the steps that waste gas generated in a color-coating line curing oven is preheated to be above the firing point of organic matter waste gas; preheated waste gas is subjected to catalytic combustion; and the waste gas after the catalytic combustion is further burnt at the temperature higher than the temperature of the catalytic combustion fully. The waste gas obtained through the high-temperature burning meets the exhaust gas emission requirement and waste heat can be recycled. According to the technological method, compared with traditional single catalytic combustion, the problems that catalytic combustion is incomplete due to a large amount of waste gas and the waste gas can not be treated after catalyzer poisoning are effectively solved by the combined technology of the catalyzing and the high-temperature burning; compared with a traditional high-temperature burning technology, the temperature of the waste gas is up to 500-550 DEG C due to catalytic burning of the combined technology of the catalyzing and the high-temperature burning; the natural gas amount consumed in the high-temperature burning is reduced by 30%-40% compared with the single high-temperature burning.

Owner:CHINA IRON & STEEL RES INST GRP +1

Cleaning catalyst for tail gas of automobile, and preparation method

ActiveCN1872409AImprove sulfur resistanceIncrease concentrationDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemistryAutomotive exhaust

A catalyst for cleaning the tail gas of car by decreasing the sulfide is composed of the carrier (67-95 Wt%) consisting of alumina and the oxide of the metal chosen from La, Ce, Pr, Nd, Zr, Mg, Cr, Mn, Fe, Co and Ni, and the active component consisting of the oxide of the metal chosen from Co, Mo, Ni, W, Zr, Ti, La, Ce, Pr and Nd and the oxide of noble metal chosen from Pt, Pd and Rh. Its preparing process is also disclosed.

Owner:CHINA PETROLEUM & CHEM CORP +1

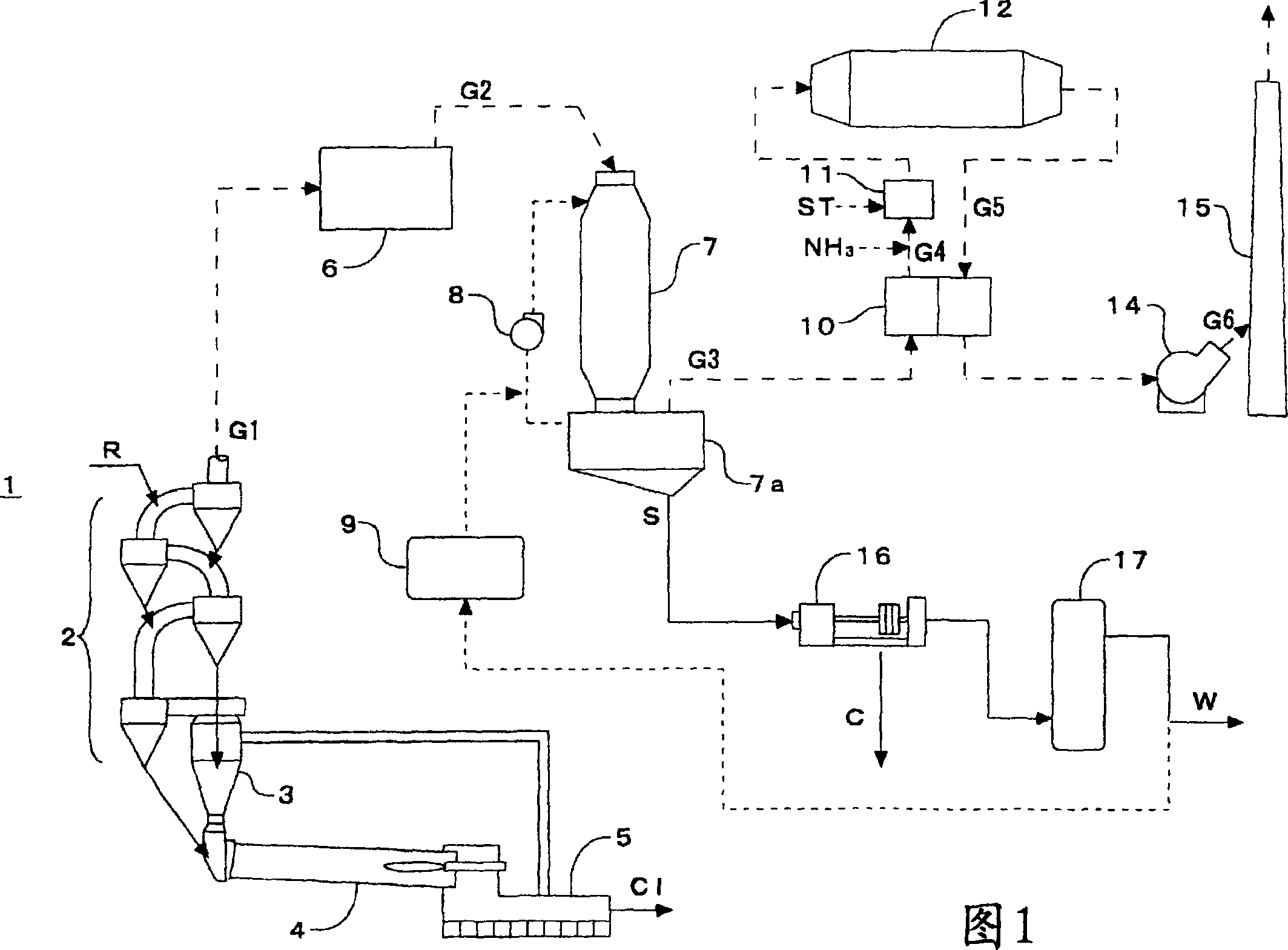

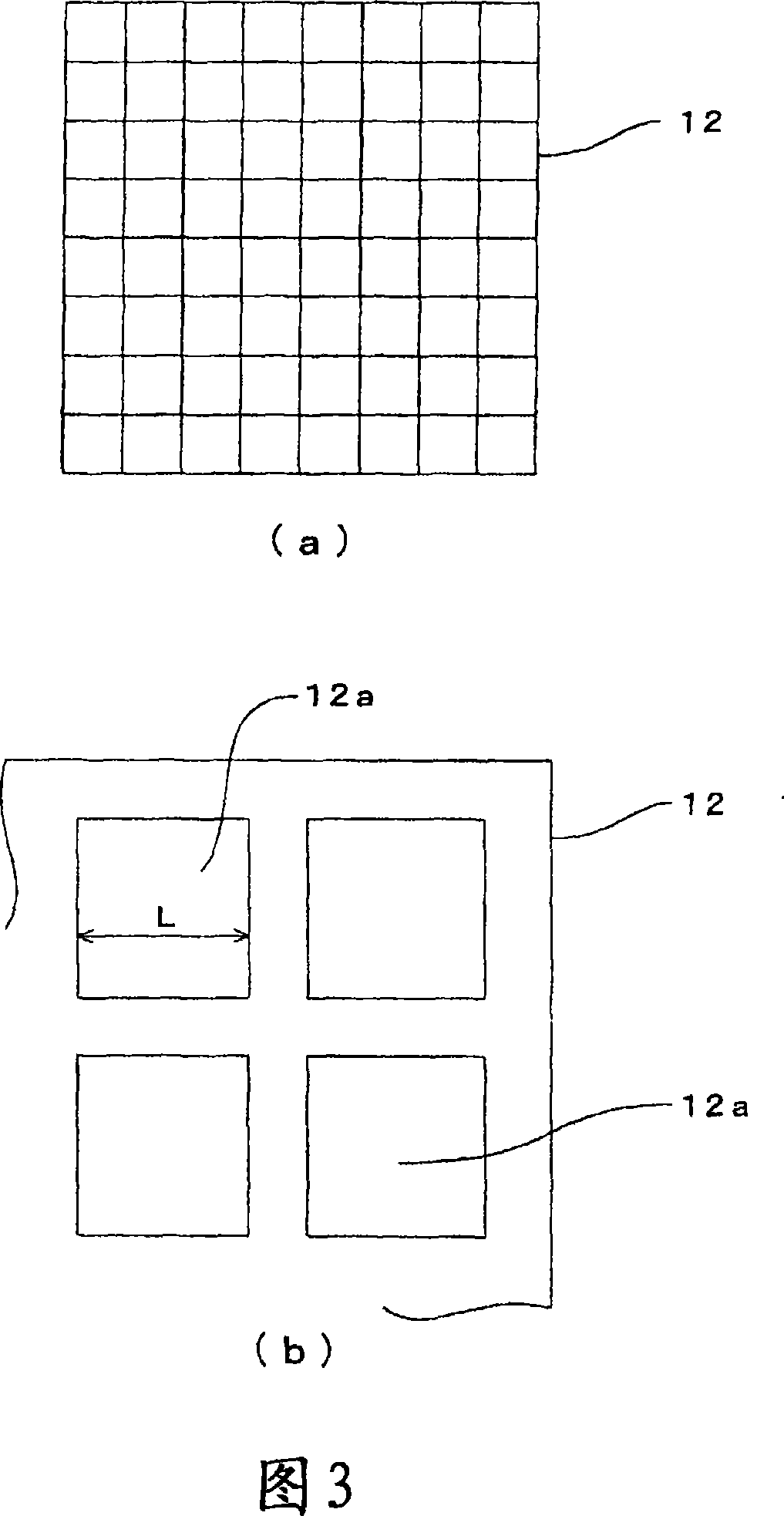

Device and method for processing cement kiln combustion exhaust gas

InactiveCN101098835AEfficient removalLow costRotary drum furnacesDispersed particle separationHazardous substanceDecomposition

To while keeping facility cost and operating cost low, efficiently remove from a cement kiln firing waste gas any hazardous substances, such as dust, NOx, residual organic pollutants, volatile organic compounds, CO and odorous substances. [MEANS FOR SOLVING PROBLEMS] There is provided firing waste gas treating apparatus (1) comprising dust collection unit (6) for collecting of dust from cement kiln firing waste gas (G1), wet dust collector (7) as a catalyst poisoned substance removing unit for removing of catalyst poisoned substances from firing waste gas (G2) having passed through the dust collection unit (6), preheating units (10,11) for preheating of firing waste gas (G3) having passed through the wet dust collector (7), and catalyst unit (12) for removing of NOx, residual organic pollutants, etc. from the preheated firing waste gas. A titanium / vanadium catalyst or the like as oxide catalyst is used in the upstream side of the catalyst unit (12), while a platinum catalyst or the like as noble metal catalyst is used in the downstream side thereof. The firing waste gas after removing of catalyst poisoned substances is heated to = 140 DEG C by means of the preheating units, thereby preventing any drop of the efficiency of denitration and volatile organic compound decomposition.

Owner:TAIHEIYO CEMENT CORP +1

Reactivation method of biotin-intermediate hydrogenation palladium-carbon catalyst

ActiveCN106732656AEfficient activationSolve poisoningCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsAlkaline waterHigh activation

The invention discloses a reactivation method of a biotin-intermediate hydrogenation palladium-carbon catalyst. The current biotin-intermediate hydrogenation palladium-carbon catalysts have the defects of deep poisoning and difficult treatment of poisoning impurities. The reactivation method comprises the following steps: firstly, washing an inactivated palladium-carbon catalyst with an alcohol, ketone or ester solvent, filtering, washing with pure water, performing oxidation treatment on the palladium-carbon catalyst with hydrogen peroxide, washing the palladium-carbon catalyst with alkaline water after oxidation treatment, then washing with pure water to neutral, filtering, adding a reducer for performing reduction after filtering, washing the palladium-carbon catalyst with pure water to neutral, filtering and drying to obtain the reactivated palladium-carbon catalyst. The reactivation method effectively activates deeply poisoned palladium-carbon catalysts, has high activation efficiency, restores the activity of the poisoned catalysts like a raw catalyst, can effectively solve the problem of catalyst poisoning when applied in production, realizes continuous application and reduces the production cost.

Owner:ZHEJIANG NHU CO LTD +1

Organic silicon hydrogen-containing tackifying crosslinking agent for addition type silicon rubber and preparation method thereof

InactiveCN108384014ASimple preparation processMild reaction conditionsCyclohexene oxideRefractive index

The invention belongs to the technical field of a tackifying crosslinking agent, and particularly relates to an organic silicon hydrogen-containing tackifying crosslinking agent for addition type silicon rubber and a preparation method thereof. The tackifying crosslinking agent is prepared by performing addition reaction on high-hydrogen-content silicon oil or D4H and vinyl cyclohexene oxide or allyl glycidyl ether and then adding inhibitors. The process is simple; the reaction conditions are mild; the therepeatability and the controllability are good; the impurities in the reaction process are few; organic solvents are not used; the environment is protected; no pollution is caused. The obtained tackifying crosslinking agent has the stable performance; the tackifying and crosslinking effects can be achieved at the same time. The compatibility with silicon rubber is good; no catalyst poisoning phenomenon exists; the bonding performance of the addition type silicon rubber with metal suchas copper foil can be obviously improved; in addition, the refractive index of the organic silicon hydrogen-containing tackifying crosslinking agent is adjustable and controllable in a range of 1.40to 1.55, so that the tackifying crosslinking agent is applicable to the silicon rubber with (high and low) different refractive indexes.

Owner:SOUTH CHINA UNIV OF TECH

Application of composite bed low-temperature selected catalytic reduction (SCR) denitrification catalyst

ActiveCN104741000AEasy to prepareLow costOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationFiberCatalytic oxidation

The invention relates to an application of a composite bed low-temperature selected catalytic reduction (SCR) denitrification catalyst. In the airflow direction of flue gas, a NO catalytic oxidation bed and a NOx catalytic reduction bed are sequentially arranged inside a fixed bed reactor; the NO catalytic oxidation bed adopts microporous activated carbon or a carbonaceous porous material of activated carbon fiber as a catalyst, and the NOx catalytic reduction bed adopts a urine-loaded carbonaceous porous material or a molecular sieve as a catalyst. Compared with the prior art, the denitrification catalyst disclosed by the invention has the characteristics of being ammonium-free, green and environment-friendly, free from secondary pollution, cheap and easily available in carbonaceous porous material and molecular sieve carriers, being reusable after recovering the loaded urine and the like; by virtue of a flue gas denitrification process, the loading amount of a reducer is greatly improved, the service life of the catalyst is prolonged, and the construction and operation costs of denitrification are greatly reduced; and the denitrification catalyst has significant advantages of being free from catalyst poisoning, high in denitrification efficiency, wide in denitrification concentration range and the like.

Owner:SHANGHAI HUAMING HI TECH GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com