Device and method for processing cement kiln combustion exhaust gas

A combustion waste gas and treatment device technology, which is applied in the field of cement kiln combustion waste gas treatment devices, can solve problems such as increased emissions of harmful substances, and achieve the effects of suppressing operating costs, equipment costs, and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] Preparation examples of noble metal-based catalysts are shown below. For example, salts of these noble metals or solutions thereof may be added to the aforementioned titanium / vanadium-based catalyst powder or slurry. Further, at least one noble metal selected from platinum, palladium, rhodium, and ruthenium and / or its compound component can be supported by impregnation, and it is preferable to support by impregnation.

[0070] In the noble metal-based catalyst, the noble metal and / or its compound component contains 0.001% by mass to 5% by mass, more preferably 0.05% by mass to 2.5% by mass of the metal relative to the carrier. If it is less than 0.001% by mass, the decomposition activity of volatile organic compounds will decrease, and if it exceeds 5% by mass, activity commensurate with addition cannot be obtained, so it is not preferable.

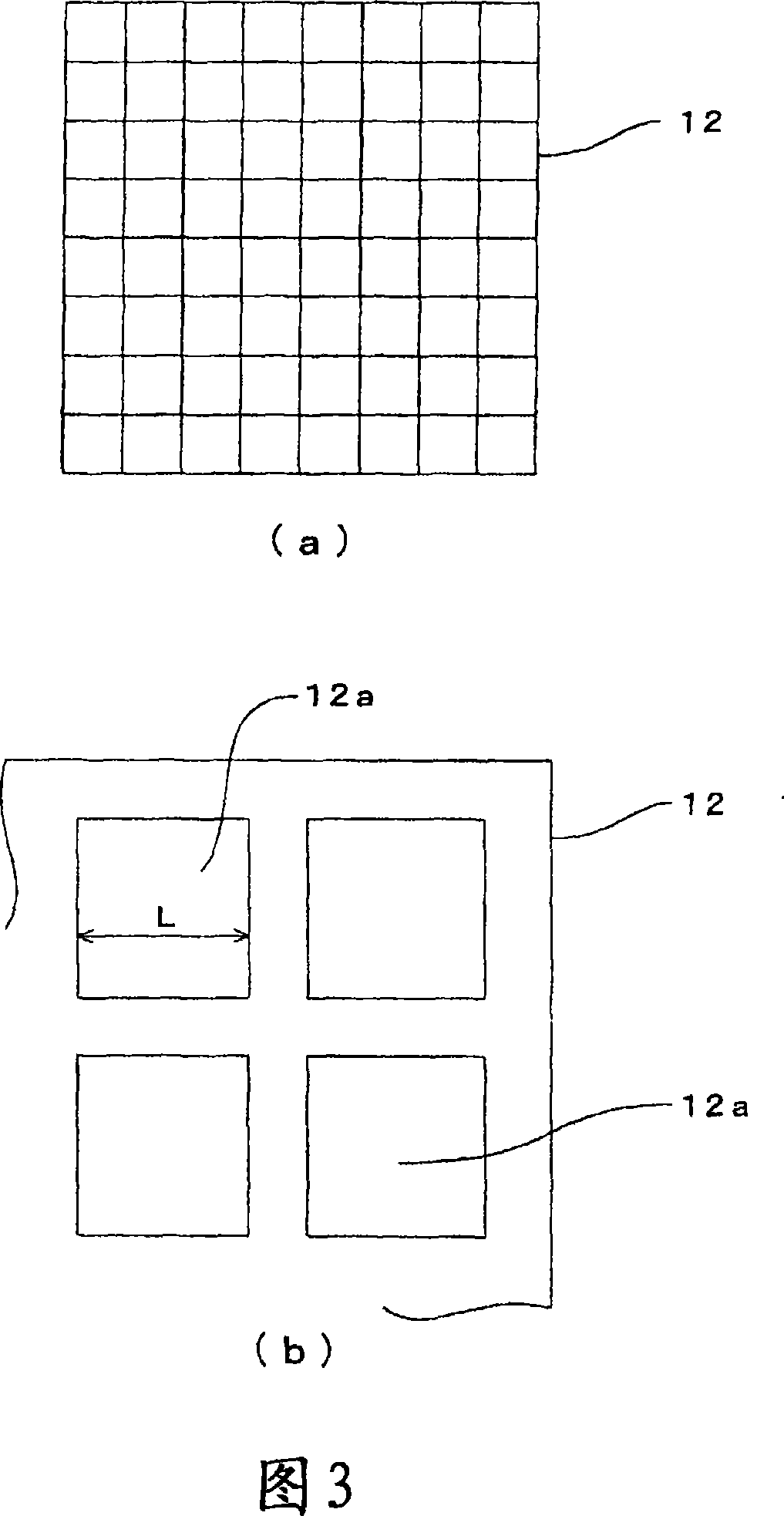

[0071]In addition, the above-mentioned oxide-based catalysts and noble metal-based catalysts used in the catalyst device 12 may ...

Embodiment 1

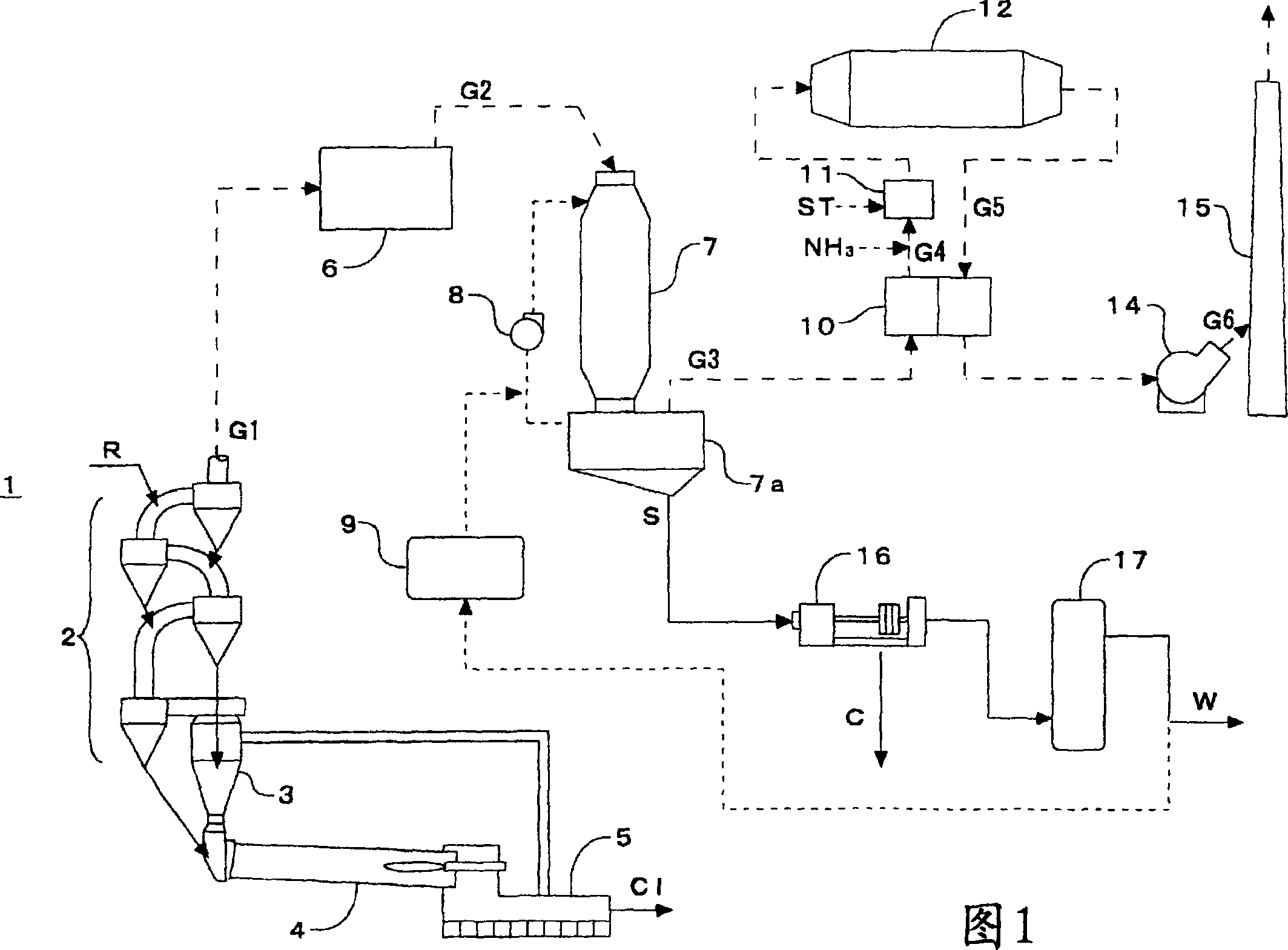

[0091] Next, as the first embodiment of the cement kiln combustion exhaust gas treatment device and treatment method related to the present invention, use the combustion exhaust gas treatment device with the structure shown in Fig. 1, and use titanium vanadium catalyst in the catalyst device 12. The substance removal rate is shown in Table 1. In this test, the combustion exhaust gas temperature at the inlet of the catalyst device 12 was set at 180°C, and the space velocity (SV value) was set at 5060h -1 , In addition, the harmful substance removal rate is calculated using the concentration of each harmful substance at the outlet of the electric precipitator 6 and the concentration of each harmful substance at the outlet of the catalyst device 12 . That is, the ratio of each harmful substance removed by the catalyst device 12 and the like at the outlet of the electrostatic precipitator 6 is shown.

[0092] 〔Table 1〕

[0093] harmful materials

[0094] As shown in T...

Embodiment 2

[0096] Next, as the second embodiment of the cement kiln combustion exhaust gas treatment device and treatment method related to the present invention, the combustion exhaust gas treatment device with the structure shown in Fig. 1 is used, and the catalyst device 12 is provided with a titanium vanadium catalyst ( Table 2 shows each harmful substance removal rate when a platinum catalyst (noble metal catalyst) is installed on the downstream side.

[0097] In this test, it was confirmed that the combustion exhaust gas temperature at the inlet of the catalyst device 12 was set at 180°C, 210°C, and 250°C. In addition, the space velocity (SV value) is 5,060h for the titanium vanadium catalyst -1 , platinum catalyst for 24,200h -1 . Reducing agent (NH 3 Gas) is sprayed on the upstream side of the catalyst device, and NOx and NH 3 The molar ratio is set to 1. Furthermore, the harmful substance removal rate is to use the concentration of each harmful substance at the outlet of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com