Patents

Literature

334results about "Synthetic fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electret filter media

InactiveUS6119691AReduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersMicrometerFilter media

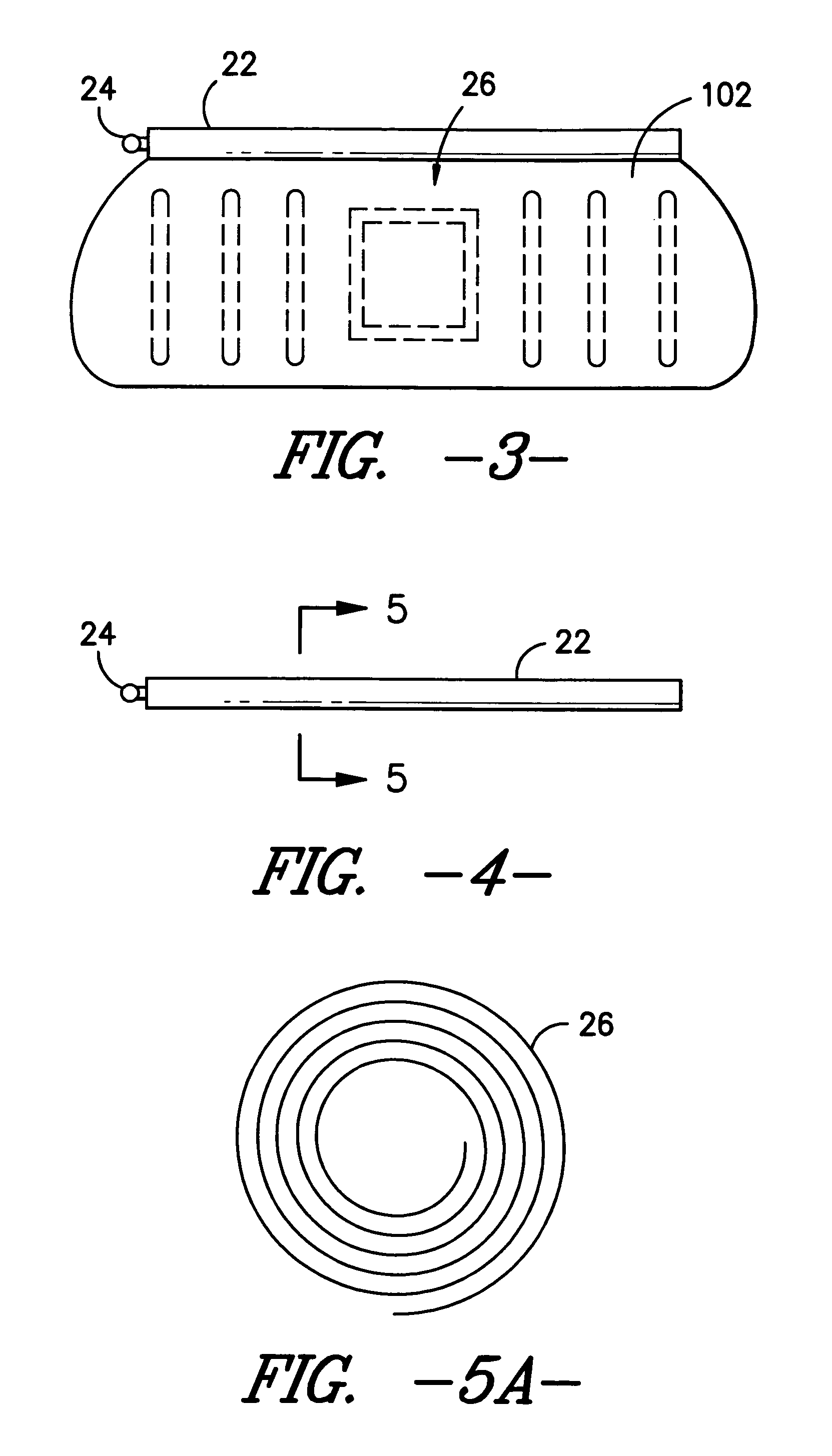

An electret filter media, and mask, that is made of a nonwoven web of thermoplastic microfibers. The thermoplastic microfibers are of substantially the same composition, are nonconductive, and have an effective fiber diameter less than about 15 micrometers. The nonwoven web also has sufficient unpolarized trapped charge to exhibit an initial filtration quality factor of at least 0.31 when measured under the DOP Penetration and Pressure Drop Test.

Owner:3M CO

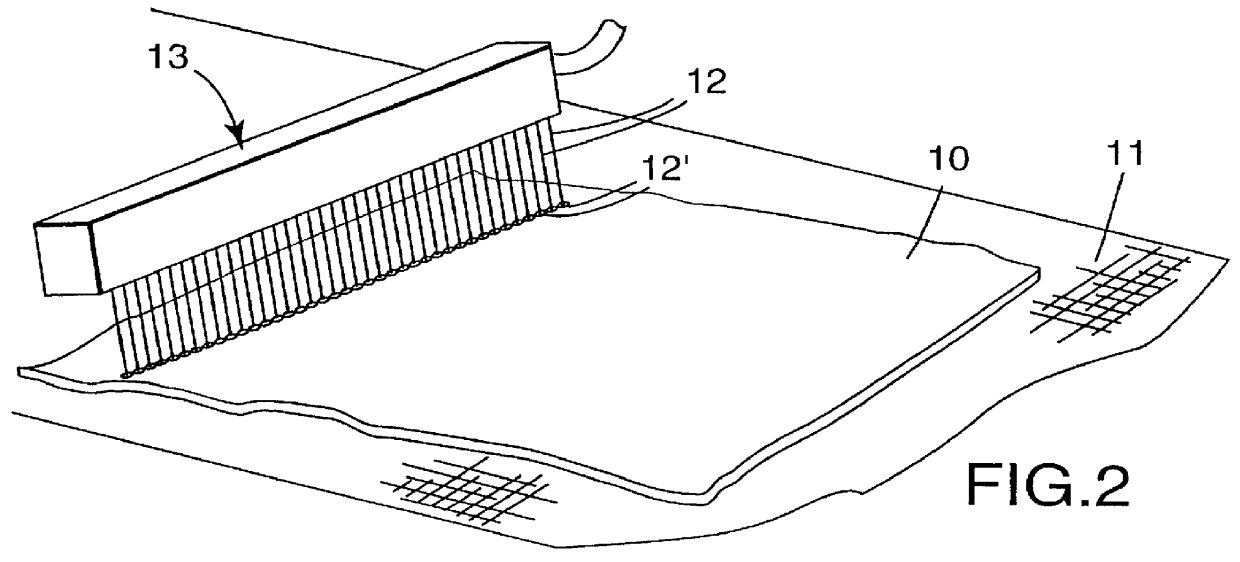

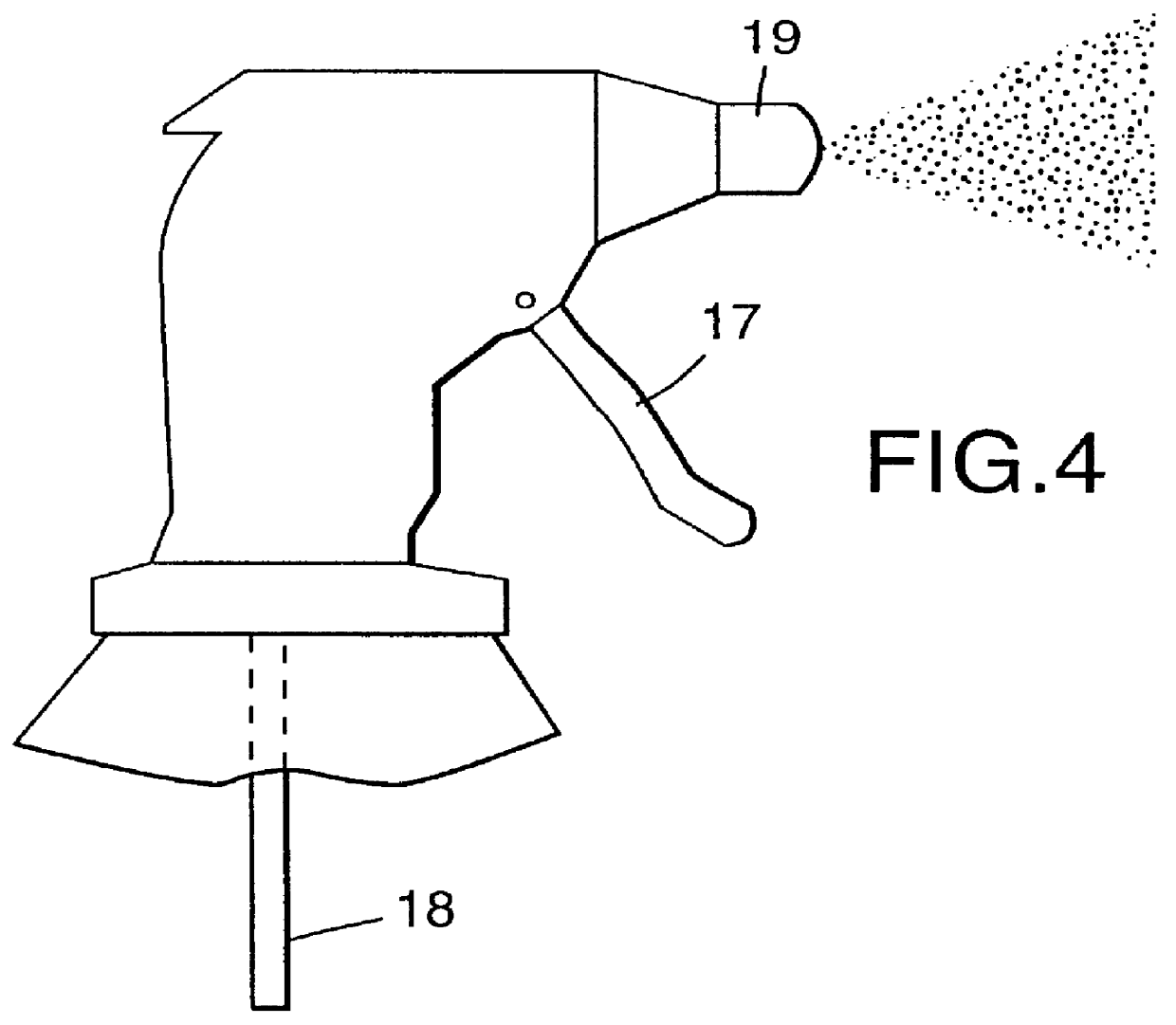

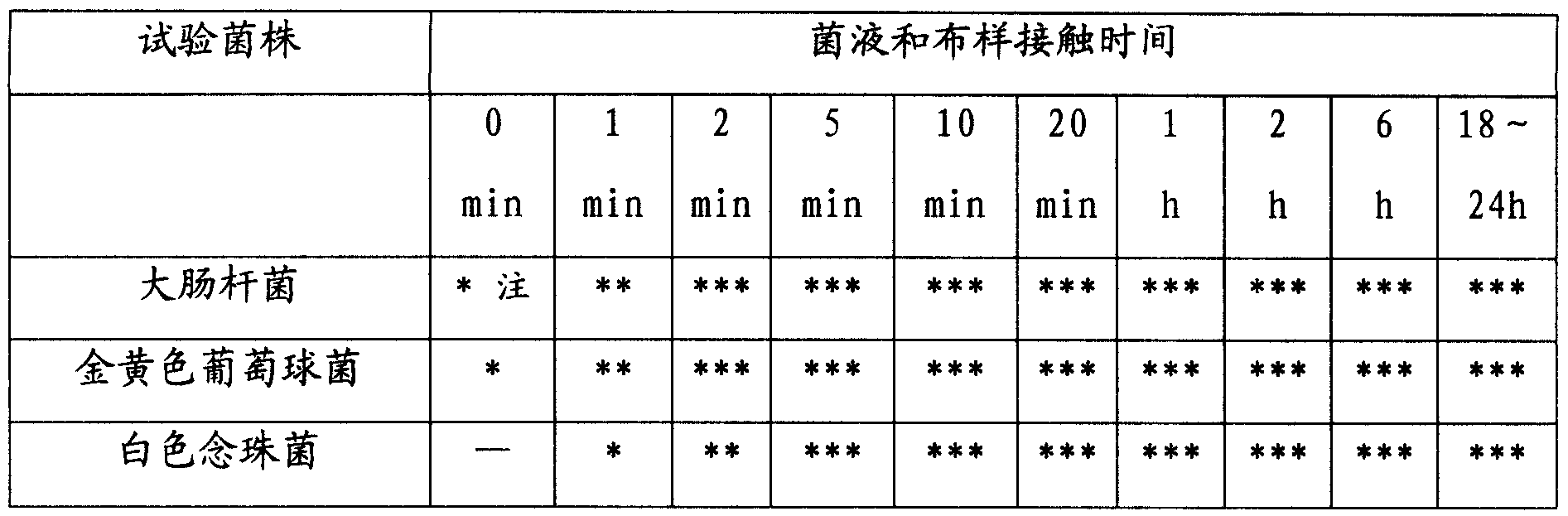

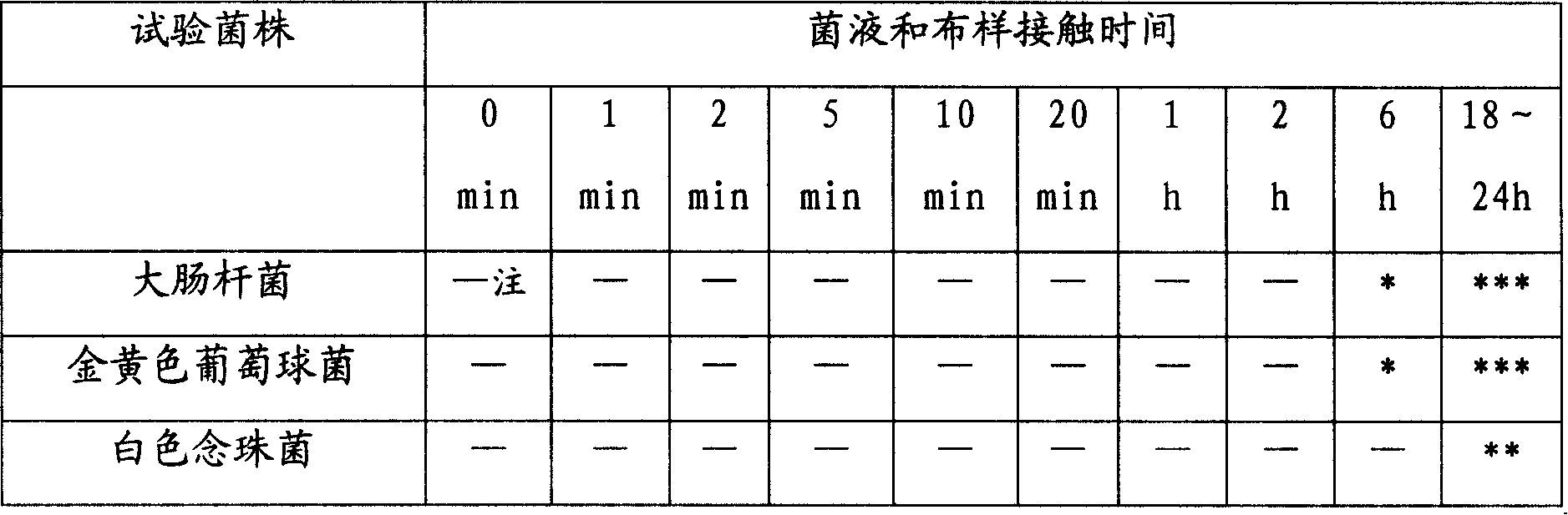

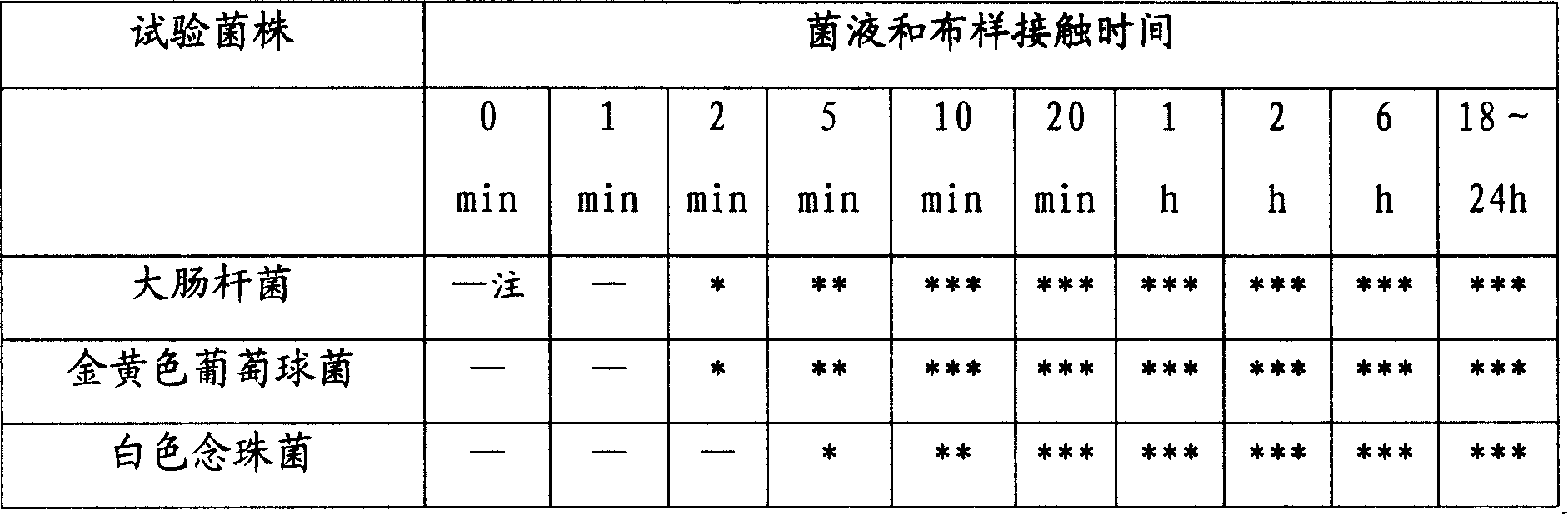

Inorganic/organic nano composite antibacterial agent and its fabric product application

The invention relates to an inorganic / organic nano-composite antibacterial and application of fiber product thereof. 0.01-20 proportions of inorganic antibacterial, 0.01-35 proportions of organic antibacterial, 0.0001-0.4 proportion of inorganic / organic antibacterial compatibility finishing agent, 0.05-40 proportions of macromolecule bond, 0.0001-0.4 proportion of stabilizer that prevents color change of the inorganic antibacterial, 0.1-30 proportions of high efficiency emulsifying agent and 100 proportions of distilled water are added in sequence by weight proportion, wetted, dispersed, ground, dispersed at high-speed, stirred, etc., so as to acquire the nano-composite antibacterial. The antibacterial can process the fiber product by a dip-dye method, a roll-dye method, a spray method, etc. Dresses, socks and socks, blankets, beddings, gowns, patient wears, masks, medicinal gauzes, air filtering nettings, etc., made from the inorganic / organic nano-composite antibacterial of the invention are characterized by high antibacterial efficiency, rapid antibacterial function, long lasting antibacterial performance, laundering durability, etc., and the inorganic / organic nano-composite antibacterial of the invention is applicable to life, medical care, etc., and has the functions of preventing the occurrence and transmission of diseases, protecting the health of people and improving life quality.

Owner:BEIJING CHAMGO NANO TECH

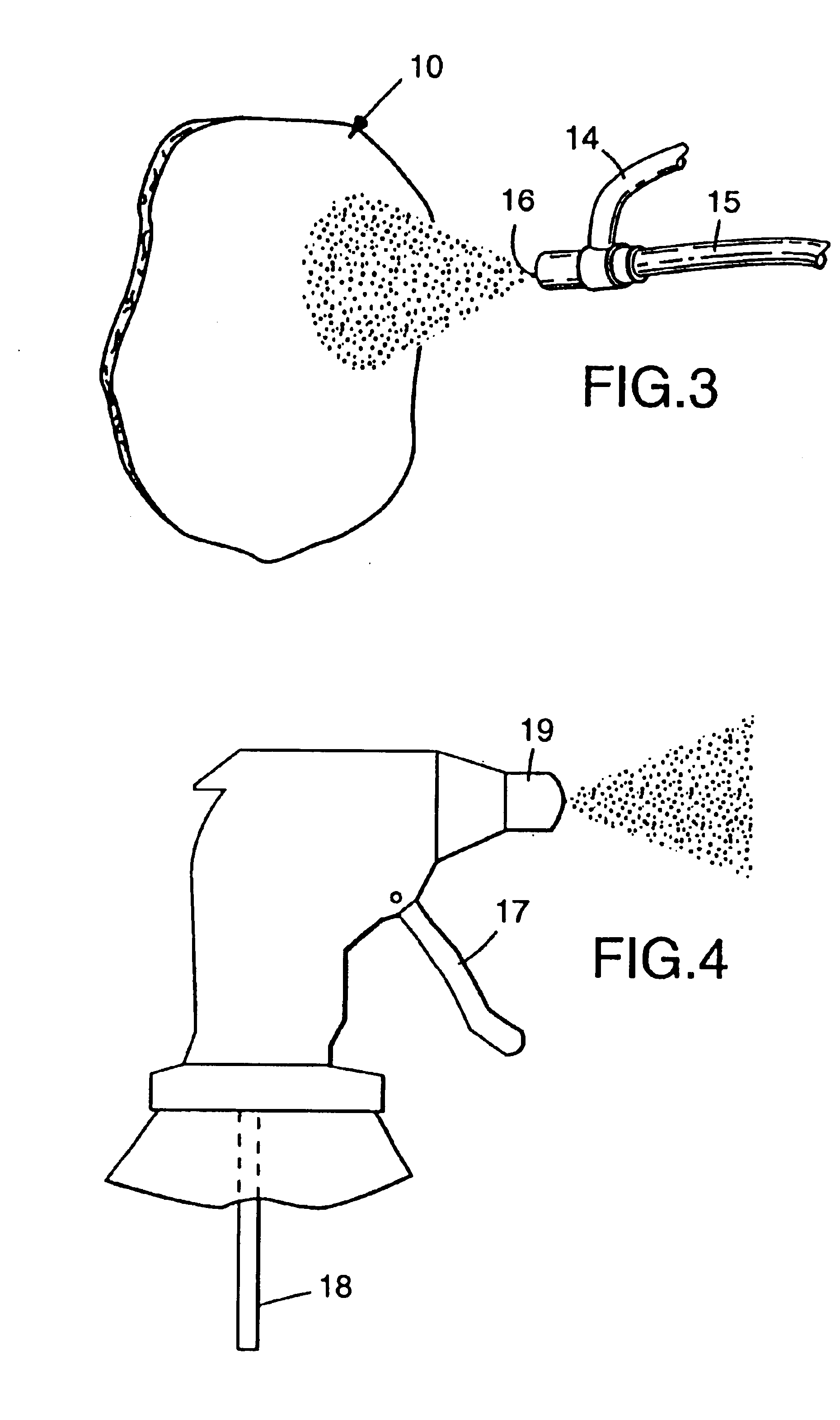

Electret filter media and filtering masks that contain electret filter media

InactiveUS6783574B1Reduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersFilter mediaRespiratory mask

Electret filter media comprising a nonwoven web of thermoplastic nonconductive microfibers having trapped charge, said charge provided by (1) subjecting the nonwoven web to a corona treatment, followed by (2) impingement of jets of water or a stream of water droplets on the web at a pressure sufficient to provide the web with filtration enhancing electret charge and (3) drying the web. This electret filter media may be used in a respiratory mask to provide extraordinarily good filtration properties.

Owner:3M CO

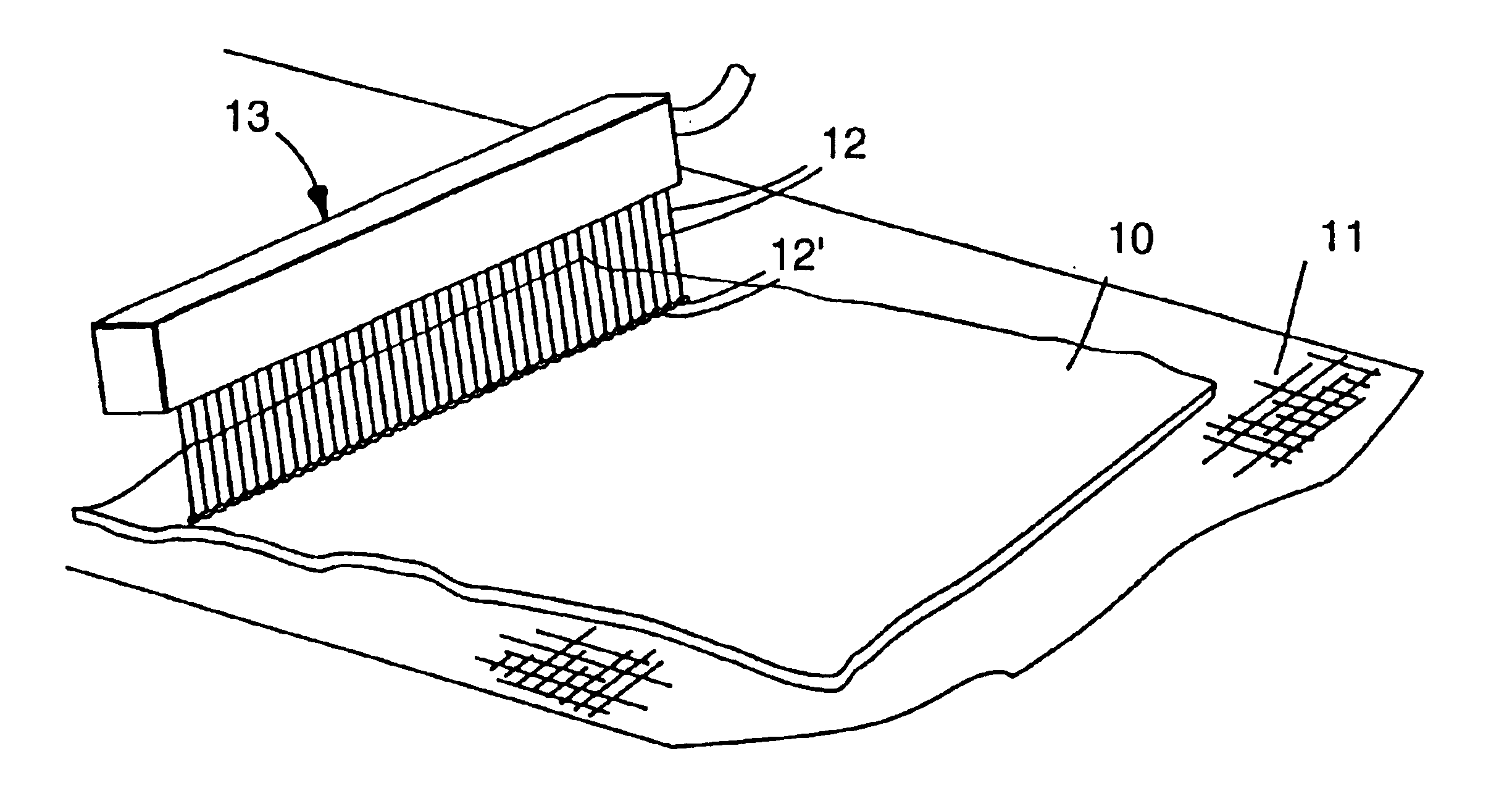

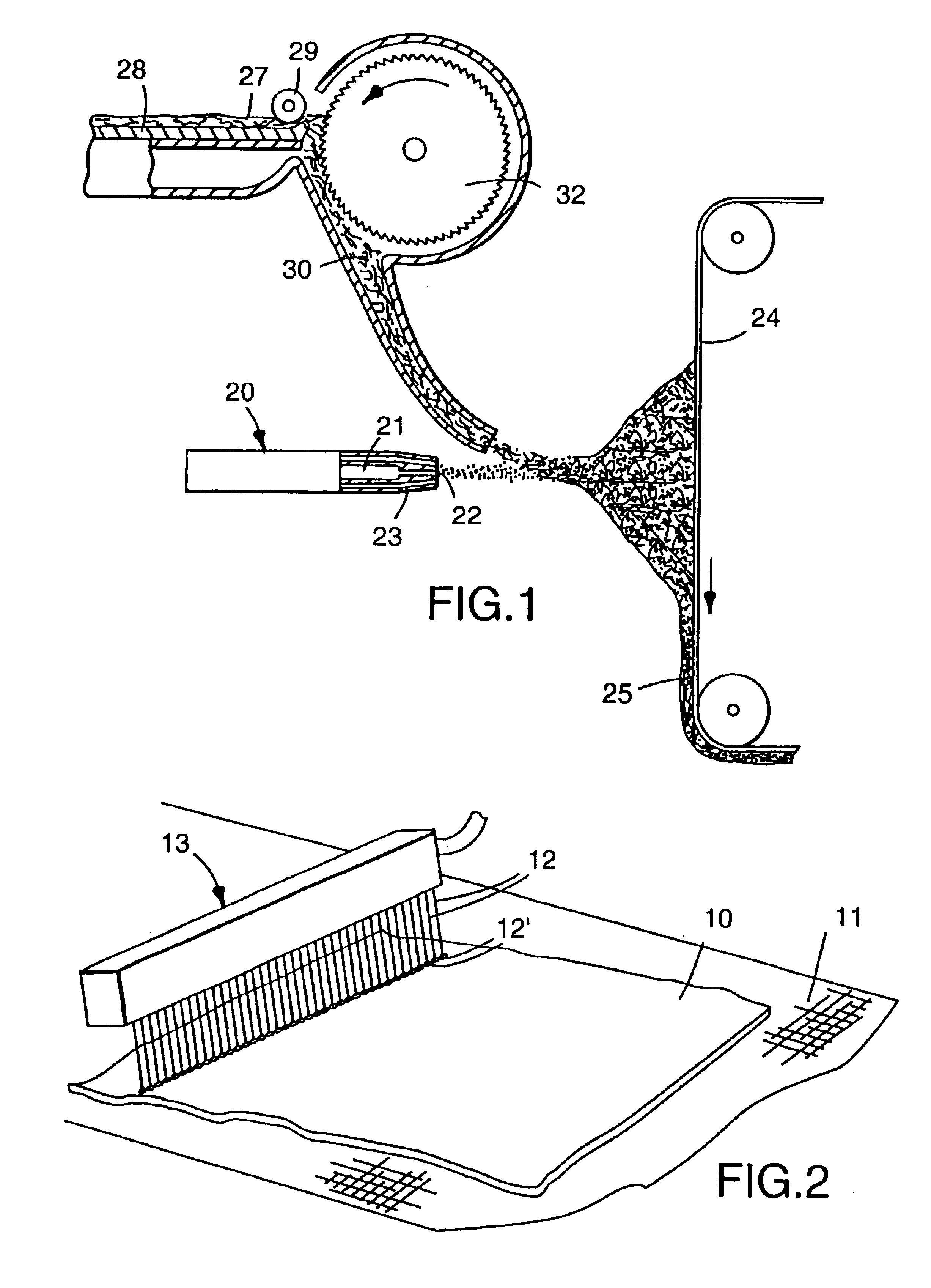

Wiper containing a controlled-release anti-microbial agent

InactiveUS6916480B2Controlled release rateGood flexibilityHeavy metal active ingredientsBiocideControlled releaseSimple Organic Compounds

A wiper having a controlled release anti-microbial agent therein for providing anti-microbial cleansing of surfaces is provided. The wiper is formed from an absorbent base web to which an anti-microbial formulation is adhered. The formulation includes an anti-microbial agent that is capable of being controllably released from the wiper. In some embodiments, a polymer mixture may be employed to control the rate of release of the anti-microbial agent. Various anti-microbial agents, such as metal ions and organic compounds may be employed.

Owner:KIMBERLY-CLARK WORLDWIDE INC

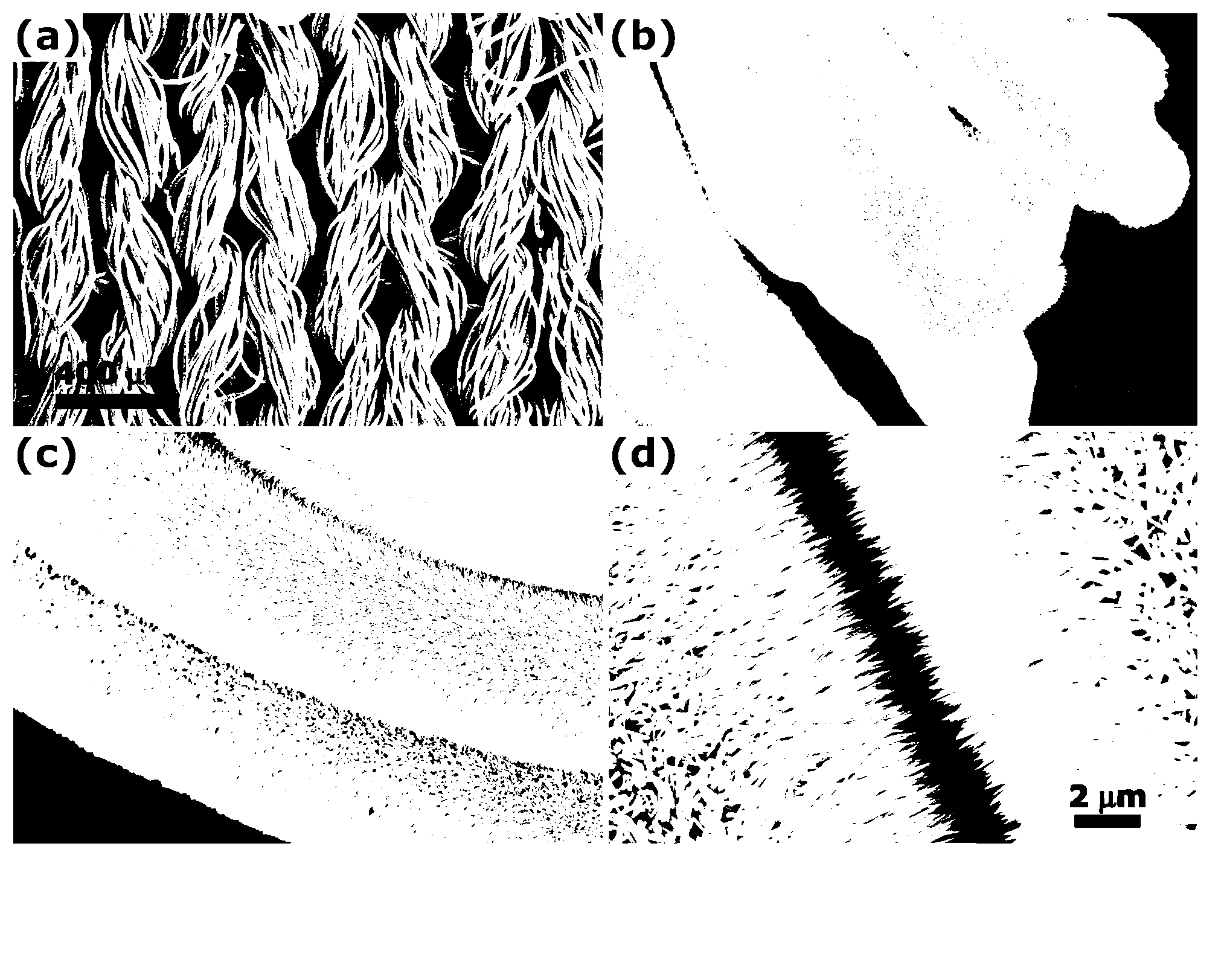

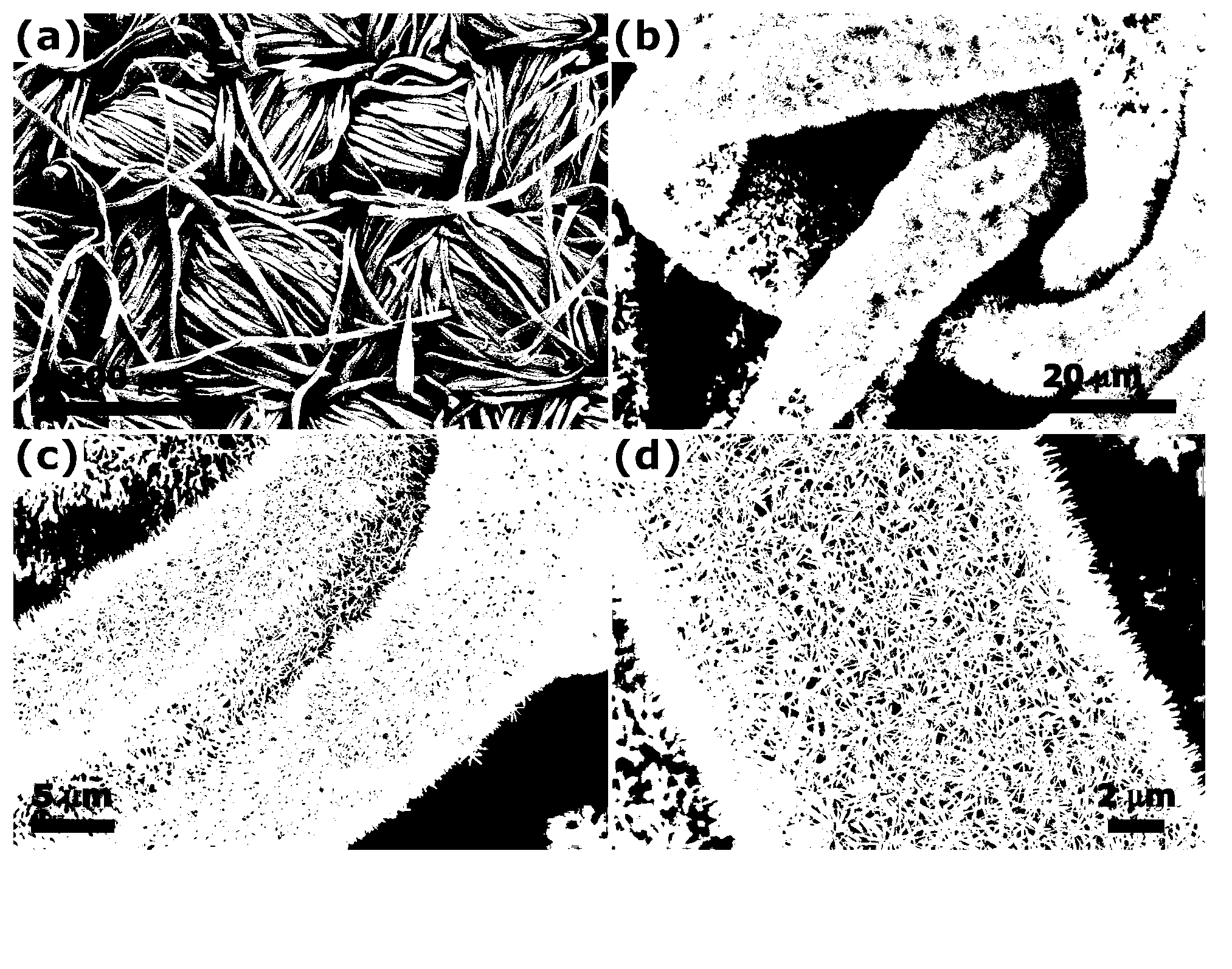

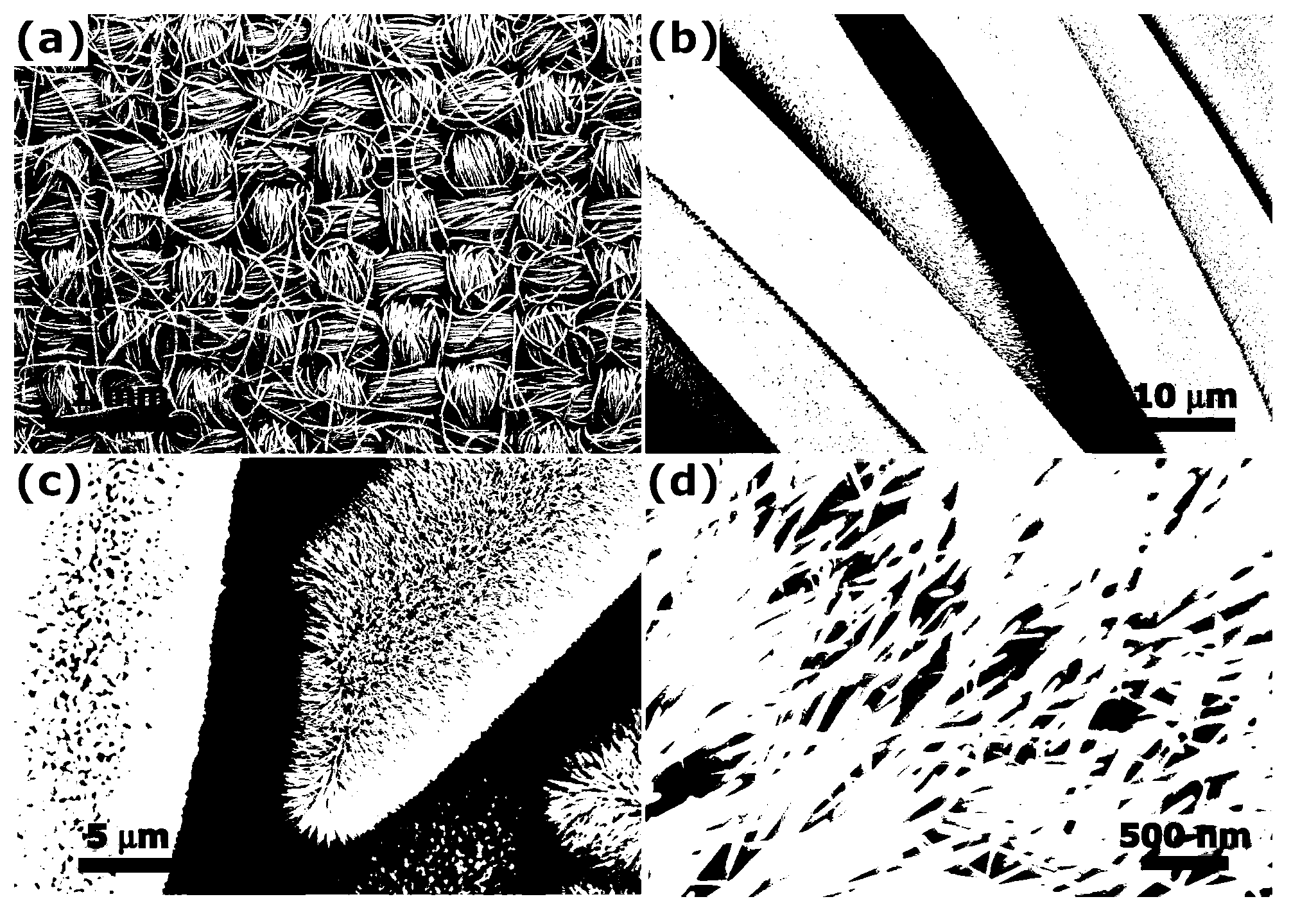

Nano-silver antibacterial fabric and preparation method thereof

InactiveCN103015166ASmall sizeImprove release efficiencyPhysical treatmentSynthetic fibresAir filtrationBio aerosol

The invention provides a nano-silver antibacterial fabric and a preparation method thereof. The nano-silver antibacterial fabric has the characteristics that a zinc oxide nano line grows on the fabric; and silver nano particles are deposited on the zinc oxide nano line. The zinc oxide nano line is synthesized by a solution chemical method; and the silver nano particles are deposited on the zinc oxide nano line by a simple 'immersion-illumination' method. The nano-silver antibacterial fabric prepared by the method has extremely obvious long-time antibacterial performance; the silver nano particles are small in size and cannot be accumulated; a synthesis process is environment-friendly; and the nano-silver antibacterial fabric can be recycled and reused. The nano-silver antibacterial fabric can be used for single-point water treatment to reduce microorganism content in water and can be suitable for medical surgical dressing and medical fabrics; and the nano-silver antibacterial fabric can be used as an antibacterial air filtration device for preventing bio-aerosol from being gathered on a ventilating, heating and air conditioning system.

Owner:BEIHANG UNIV

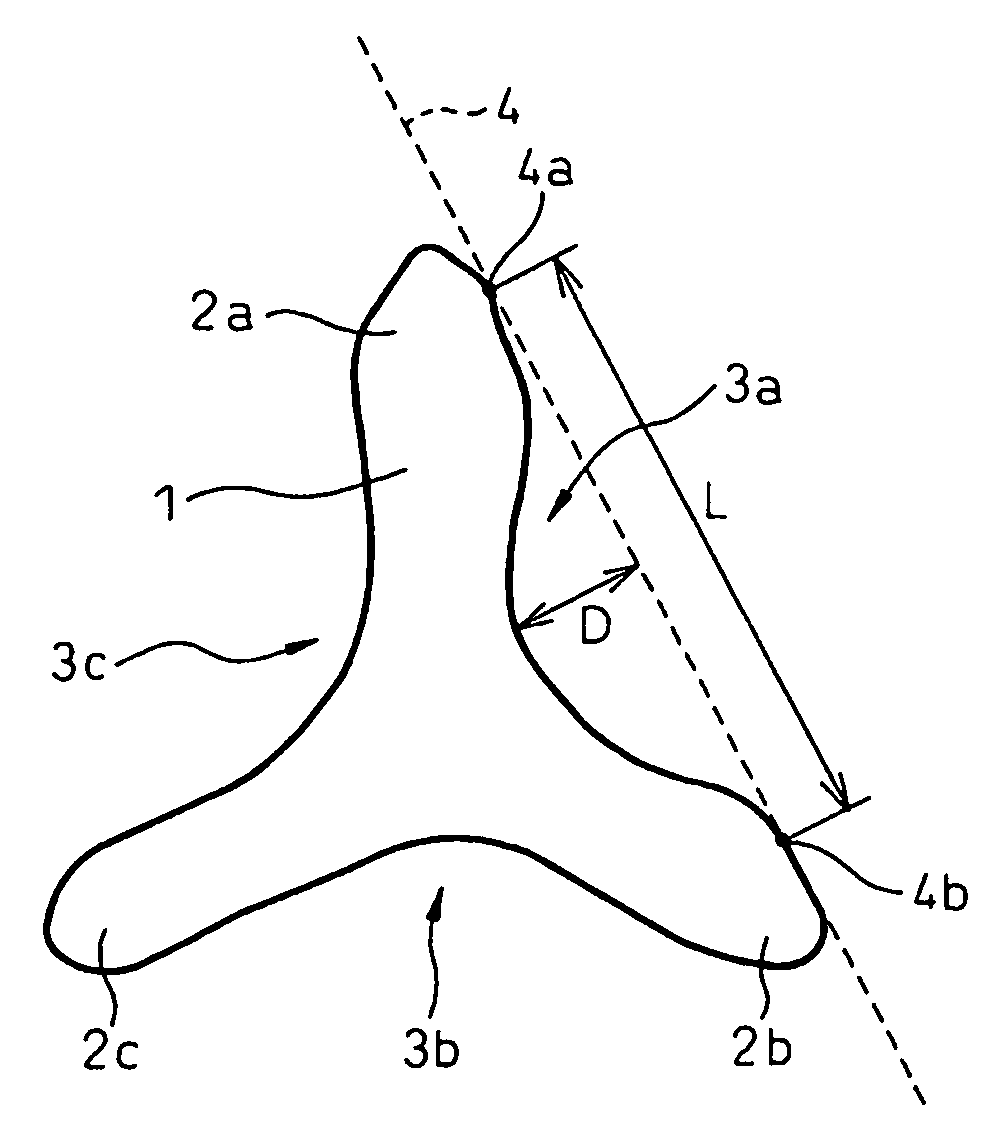

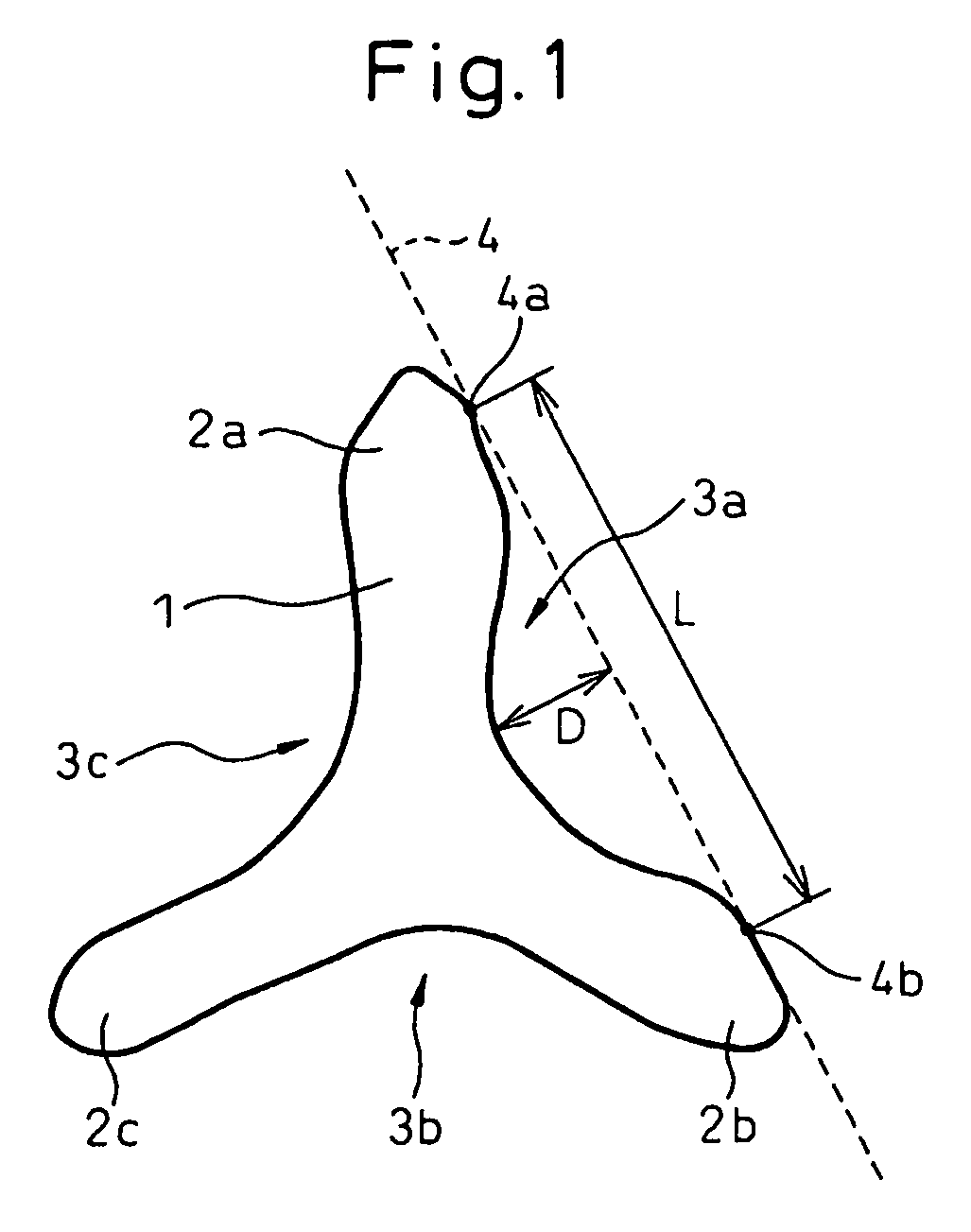

Synthetic staple fibers for an air-laid nonwoven fabric

InactiveUS7560159B2Few defectQuality improvementSynthetic fibresFilament/thread formingMetallurgyNonwoven fabric

Synthetic staple fibers having good air opening property and useful for producing an air-laid nonwoven fabric having excellent quality, have a fiber length of 0.1 to 45 mm and a cross-sectional profile having 1 to 30 concavities, in which cross-sectional profile the ratio D / L, of a largest depth D of each concavity to a largest width L of the opening of the concavity, is in the range of from 0.1 to 0.5.

Owner:TEJIN FIBERS LTD

Manufacturing process of antibacterial fiber

Tea polyphenol obtained by the extraction from tea has an antibacterial effect. In methods for producing an antibacterial fiber by fixing the tea polyphenol to fiber, the object of the present invention is to provide a process for manufacturing an antibacterial fiber capable of exerting an excellent antibacterial performance without the use of metal chelates potentially causing metal allergy and environmental problems. In order to achieve the above object, the present invention manufactures an antibacterial fiber by a process comprising the steps of contacting fiber with or immersing fiber in an aqueous solution in which a cationic surfactant with a quaternary ammonium salt group, a water-soluble protein, and an alkaline compound are dissolved; and separating said fiber from the aqueous solution, to immerse the fiber in another aqueous solution containing tea polyphenol.

Owner:SHOKUHIN SANGYO HIGH SEP

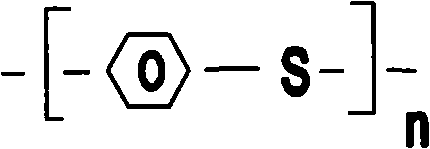

Multifunctional macromolecule filter material and preparation method thereof

InactiveCN101314091ALow costMoisture resistantSynthetic fibresFiltration separationGlass fiberPrice ratio

The invention relates to a multifunctional polymer filtering material which comprises 70 to 85 percent of glass fiber, the balance being one or a plurality of aramid, polytetrafluoroethylene (PTFE) fiber, polyphenylene sulfide fiber, poly (p-phenylene-benzobisoxazole) (PBO) fiber, p-aramid, ceramic fiber, stainless steel fiber and copper fiber. The invention also discloses a method for preparing the multifunctional polymer filtering material. The method comprises the following steps: mixing the 70 to 85 percent of glass fiber and at least one of aramid, polytetrafluoroethylene (PTFE) fiber, polyphenylene sulfide fiber, poly (p-phenylene-benzobisoxazole) (PBO) fiber, para-aramid, ceramic fiber, stainless steel fiber, copper fiber into a synthetic fabric; and puncturing and shaping the synthetic fabric and a base fabric to obtain a finished product. The filtrating material produced by the method has the advantages of low cost, water proofing, temperature resistance, corrosion resistance and high performance to price ratio.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Sun protective fabric

InactiveUS6025284AReduce ultraviolet radiation transmissionLow production costGarment special featuresSynthetic fibresWrinkle skinPolyester

Wrinkled fabrics comprising ultraviolet absorbers are disclosed which provide improvements in ultraviolet transmission, wearer comfort, and cost over those of the prior art. The preferred fabric is polyester and the preferred UV absorbers are chlorobenzotriazoles. The polyester is wrinkled permanently so as to provide an extra barrier to ultraviolet radiation from solely utilizing UV absorbers alone. This wrinkled product is also more comfortable to a wearer, particularly in warm weather or hotter climates. Other non-apparel uses are also contemplated including tents, awnings, and crowd covers. A method of making such a fabric is also disclosed comprising stuffing a jet dyeing machine with a more than normal load amount of fabric and eventually heat setting such resultant wrinkles into the finished product.

Owner:MILLIKEN & CO +1

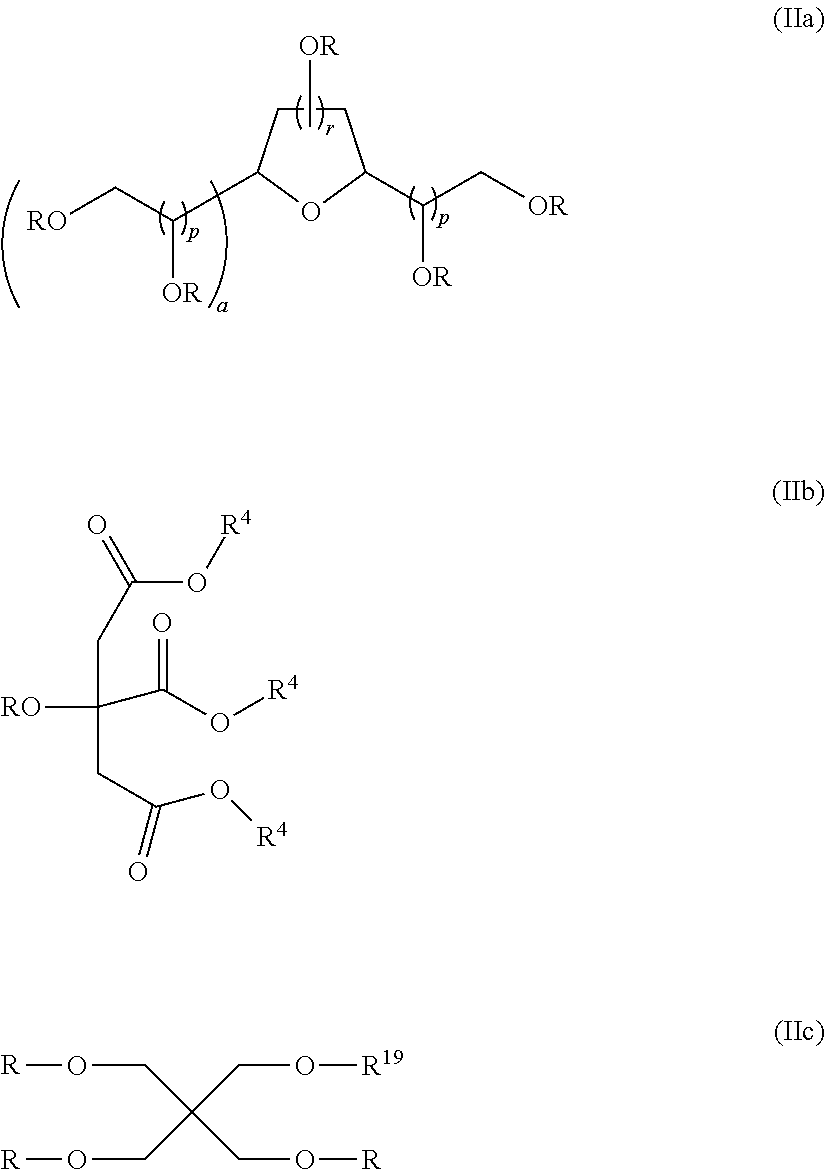

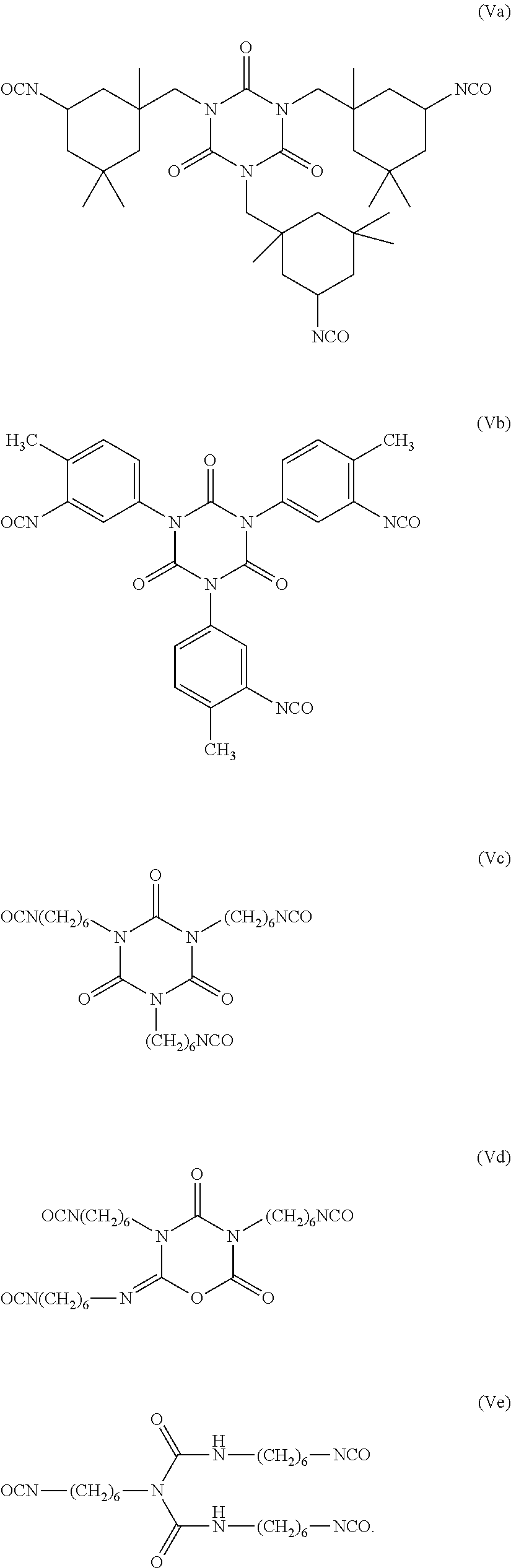

Non-fluorinated urethane based coatings

ActiveUS20160090508A1Imparting durable water repellencyIncreased durable water repellencyWater-repelling agents additionSynthetic fibresSaccharic acidPolymer science

The present invention is an aqueous composition comprising at least one hydrophobic compound having at least one linkage of Formula I:—NHC(O)—X— (I)wherein X is the residue of a cyclic or acyclic sugar alcohol which is substituted with at least one —R1; —C(O)R1; —(CH2CH2O)n(CH(CH3)CH2O)mR2; —(CH2CH2O)n(CH(CH3)CH2O)mC(O)R1; or mixtures thereof; where the cyclic or acyclic sugar alcohol is selected from a saccharide, reduced sugar, aminosaccharide, aldonic acid, or aldonic acid lactone; wherein each n is independently 0 to 20; each m is independently 0 to 20; m+n is greater than 0; each R1 is independently a linear or branched alkyl group having 5 to 29 carbons optionally comprising at least 1 unsaturated bond; each R2 is independently —H, a linear or branched alkyl group having 6 to 30 carbons optionally comprising at least 1 unsaturated bond, or mixtures thereof.

Owner:THE CHEMOURS CO FC LLC

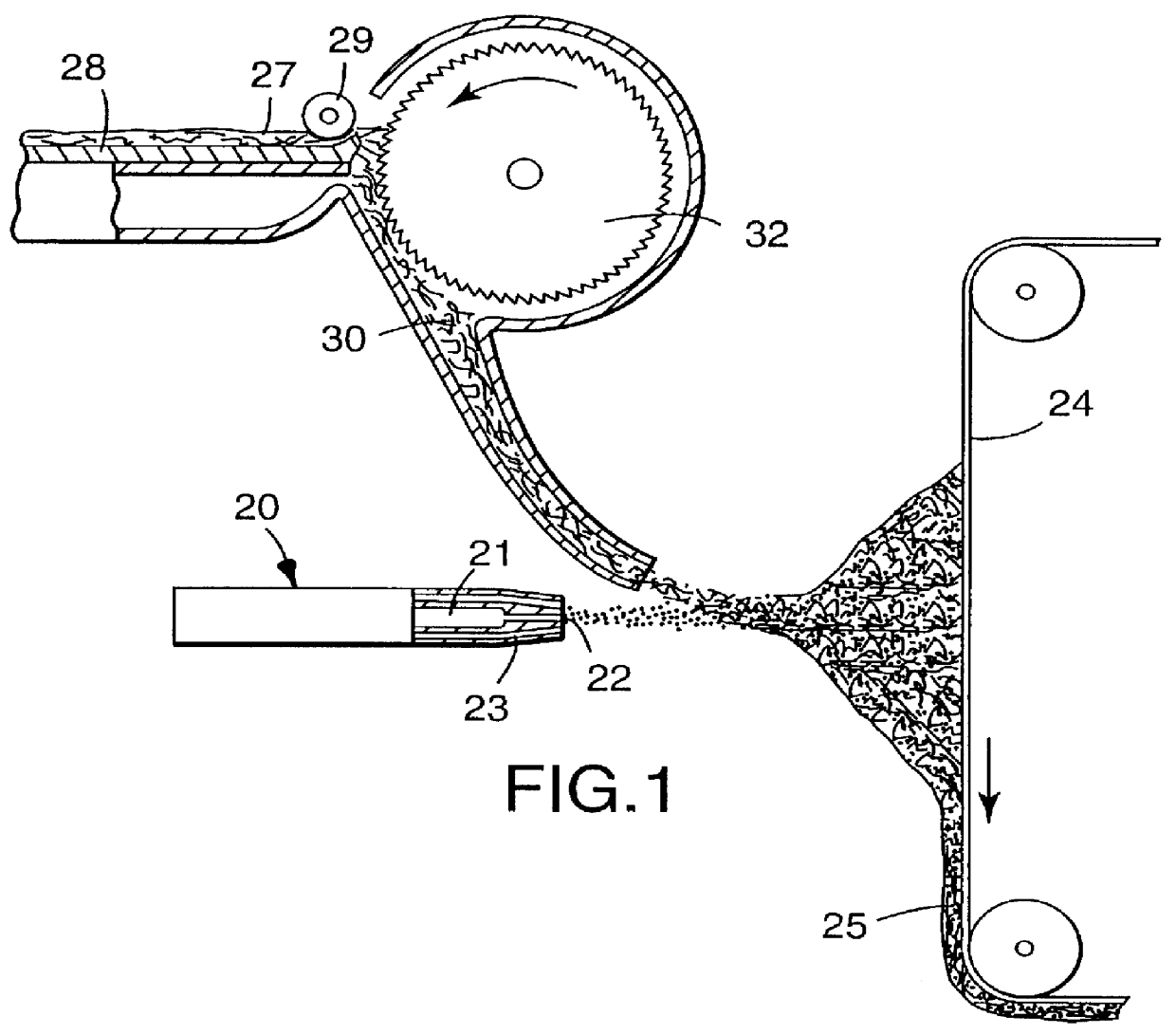

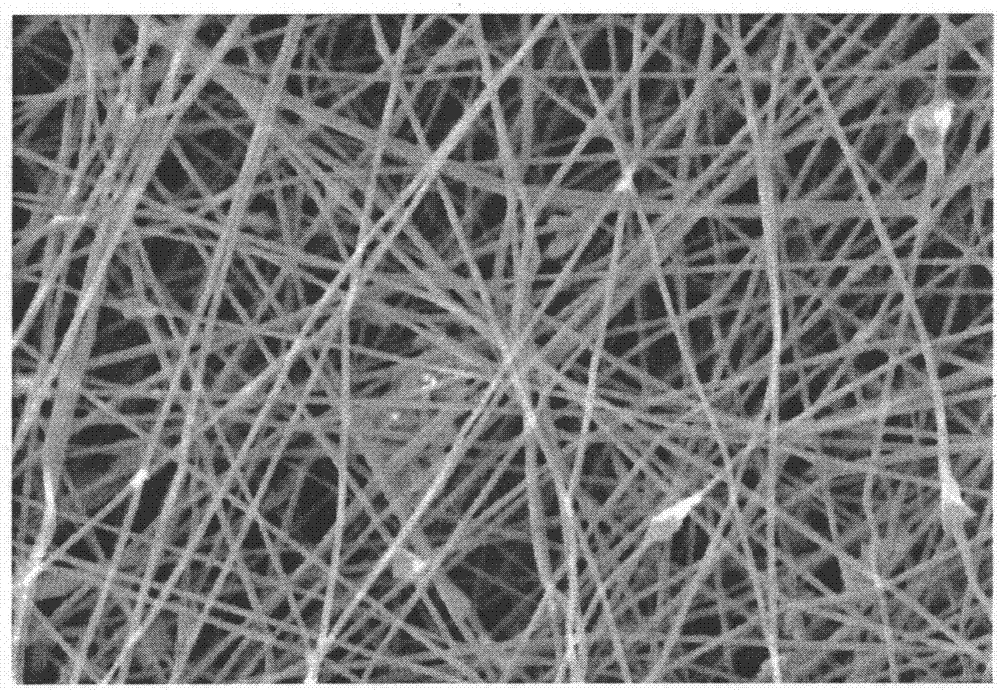

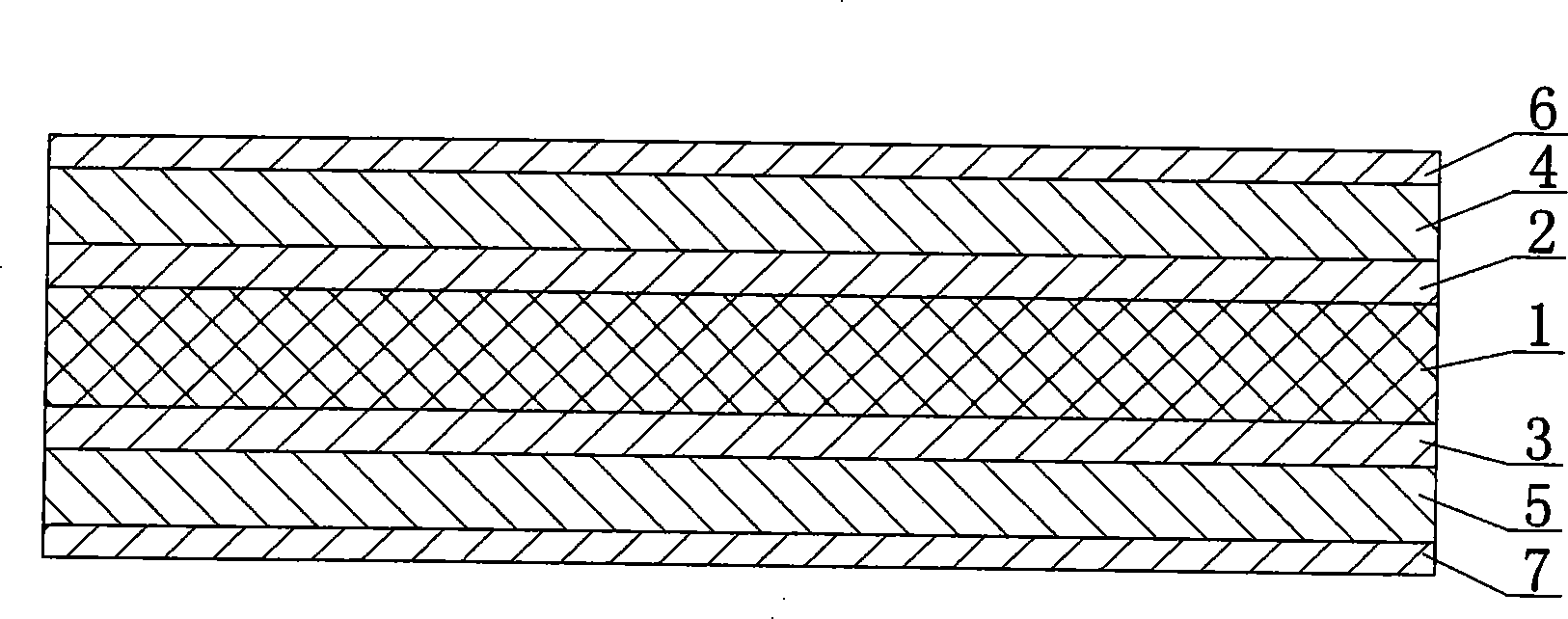

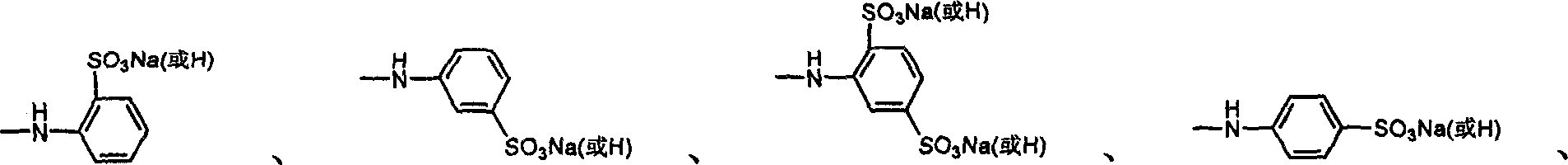

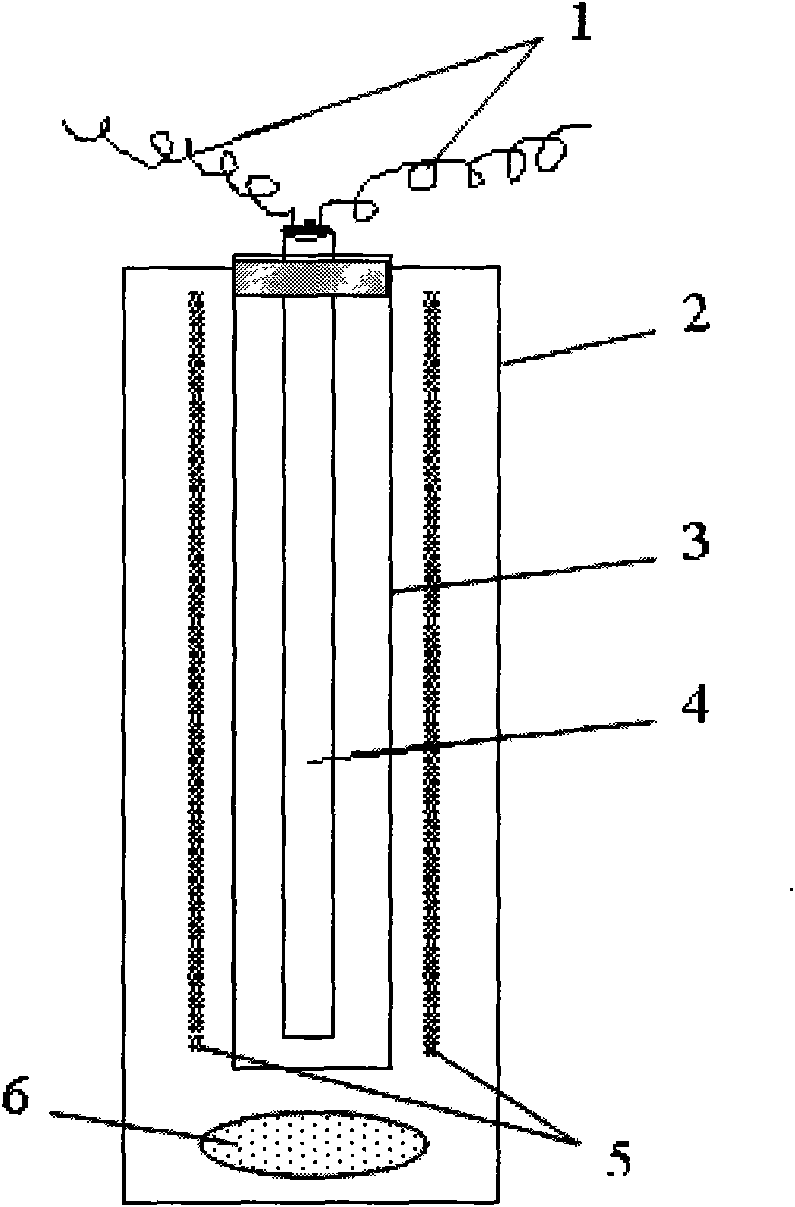

Multilayer electret nano-fiber filtering material and preparation method thereof

ActiveCN107441827AIncrease spinning speedSolve problems such as easy blockageSynthetic fibresElectro-spinningFiberSpinning

The invention relates to a multilayer electret nanofiber filtering material and a preparation method thereof. The invention adopted the technical scheme is as follows: through an electric-field stepped increasing / reducing technology, utilizing a combined needle head for electrostatic spinning to realize deposition of spinning polymer solution on a receiving substrate to obtain nanofiber, carrying out slight dissolving treatment on the surface of a nanofiber layer by a certain release rate by adopting a recovery solvent steam, wherein the nanofiber layer is uniformly filled with electret materials and the diameter of the nanofiber layer is distributed in a stepped-increasing or stepped-reducing manner along the direction vertical to the breadth. According to the multilayer electret nano-fiber filtering material, the electret charge stability is extremely high, the surface electrostatic potential is 250-7000V, simultaneously the filtering performance is excellent, the filtering efficiency for 0.03-10 microns particulates is more than 99.997%, the resistance pressure drop is less than or equal to 39Pa, the service life is long, and the development and application prospect in the aspect of filtering materials for air purifiers, window gauzes, masks and filtering papers and the like are wide.

Owner:DONGHUA UNIV

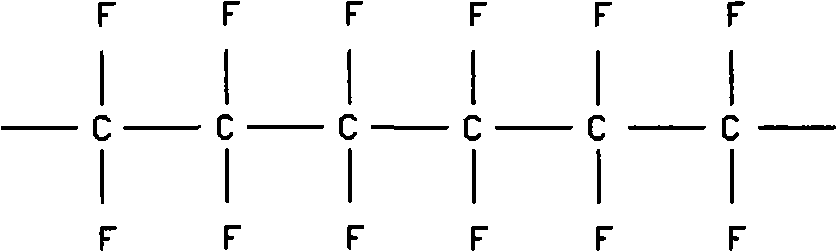

Method for preparing polytetrafluoroethylene spatial structure building film material

The invention relates to a producing method of a teflon spatial structure membrane comprising following steps: fiberglass cloth low temperature genapping treatment, fiberglass cloth bottom layer dipping treatment, structure layer dipping treatment, surface layer dipping treatment and sintering treatment. Low temperature high speed genapping, multitime coating low-temperature treatment, and once hyperthermia flash sintering effectively reduce tensile strength descending caused by high-sintering treatment. Since fiberglass cloth is used as backing material, dipping treatment is not needed to be performed on the fiberglass yarn, the procedure is simplified to facilitate the production thereof, and shortcomings in prior art are overcome which are modified fiberglass yarn weaving difficulty and intensity and plasticity descending caused by multitime sintering. The teflon spatial structure membrane produced by using the invented method has a bottom layer, a structure layer and a surface layer, is provided with high pulling-against intensity, high tearing-against intensity, anti-aging property, good flexibility, good light-admitting quality and a long service life, and can be used widely in air stations, gymnasiums, exhibition halls, large-scale factory buildings and factory building warehouses.

Owner:JIANGSU VEIK TECH & MATERIALS CO LTD

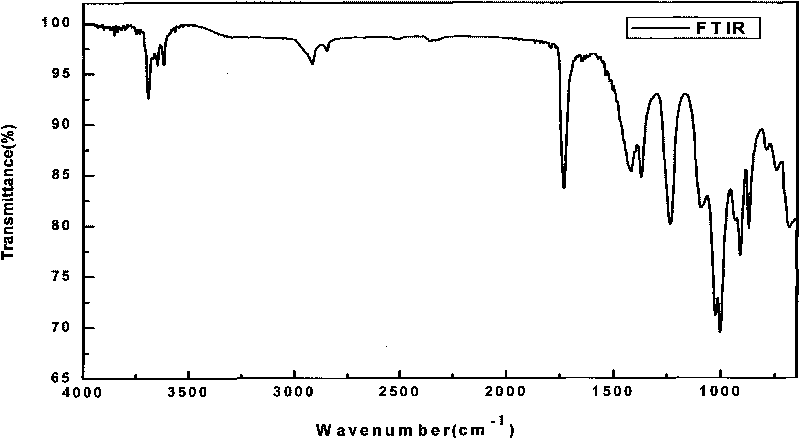

Temperature-sensitive hydrophilic cross-linking crystal type polyurethane coating agent, preparation method thereof and application thereof

InactiveCN101709197AGood waterproof and moisture permeabilityHigh precisionSynthetic fibresPolyurea/polyurethane coatingsPolyesterCross-link

The invention discloses a temperature-sensitive hydrophilic cross-linking crystal type polyurethane coating agent, a preparation method thereof and application thereof, and belongs to the technical field of textile chemical engineering. The preparation thereof comprises the following steps of: using a prepolymer method, taking 4,4'-diphenylmethane diisocyanate (pure MDI) as a hard segment, taking polyester polyol or polyether polyol as a soft segment, adding micromolecular diol chain-extension into the segments, and performing self-emulsification to obtain the polyurethane coating agent. After textile is coated by adopting a proper process, the capability of hydrostatic pressure and moisture permeability of the textile is greatly improved, and the moisture permeability of the textile represents higher response accuracy and sensitivity to environmental temperature changes. The response range of the moisture permeability of the finished coated textile to the environmental temperature changes is between about 17.0 and 28.0 DEG C so as to furthest meet the requirement of a human body on comfort.

Owner:广东广纺检测技术股份有限公司

Heat-resisting flame-retardant fiberglass product for industrial heat preservation and preparation method thereof

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Material having separating function

InactiveUS6844371B1Improve adsorption capacityDesired separation performanceCation exchanger materialsOther chemical processesPolymer scienceBackbone chain

An object of the present invention is to provide a separation functional material having more excellent adsorptive separation performance than previously. In order to attain this object, separation functional materials of the present invention are characterized in that they are formed by introducing a polymer side chain derived from a p-haloalkylstyrene onto the backbone of an organic polymer base and introducing a functional group onto the polymer side chain.

Owner:EBARA CORP

Fabrics, airbags and methods

InactiveUS7686331B2Large specific surface areaImprove the immunitySynthetic fibresProtective equipmentPuncture resistanceEngineering

This invention relates generally to abrasion resistant and / or puncture resistant fabrics, coated, layered and / or laminated inflatable fabrics, and methods. More particularly, it concerns airbag cushions to which films, fabrics, layers, and / or coatings have been applied and which exhibit enhanced abrasion resistance and / or puncture resistance. The inventive inflatable fabrics are especially suited for use in automotive restraint cushions that require abrasion resistance and / or puncture resistance (such as side curtain airbags).

Owner:MILLIKEN & CO

Durability natural object machining textile

The present invention discloses a durable textile processed with natural substances. The functional natural substances are attached on the fiber surface of the textile. The natural substances are firmly combined with the fibers of the textile and have good durability. The textile has properties, such as corrosion prevention, resistance to bacteria and health caring, and is an environment-friendly product.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

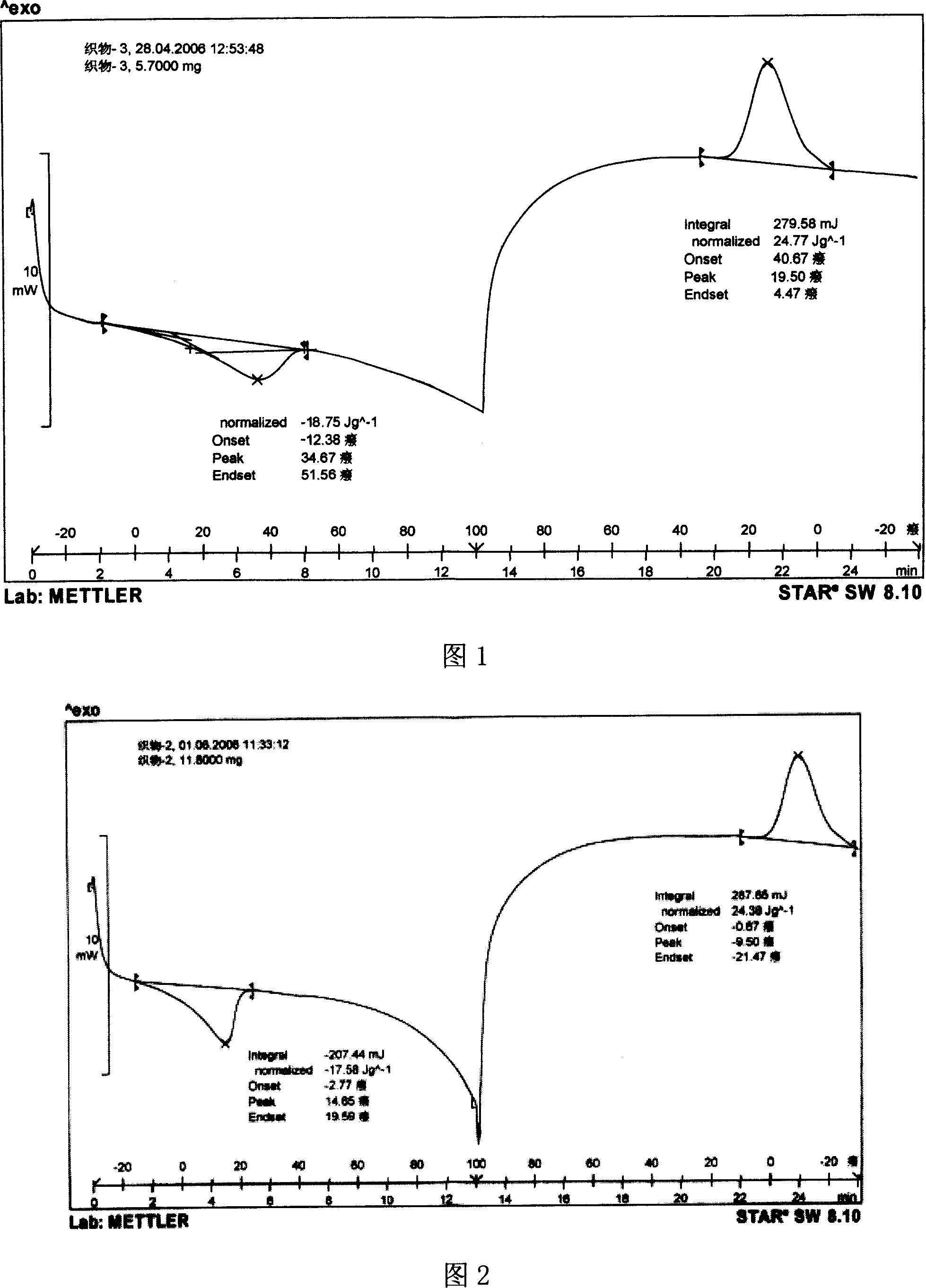

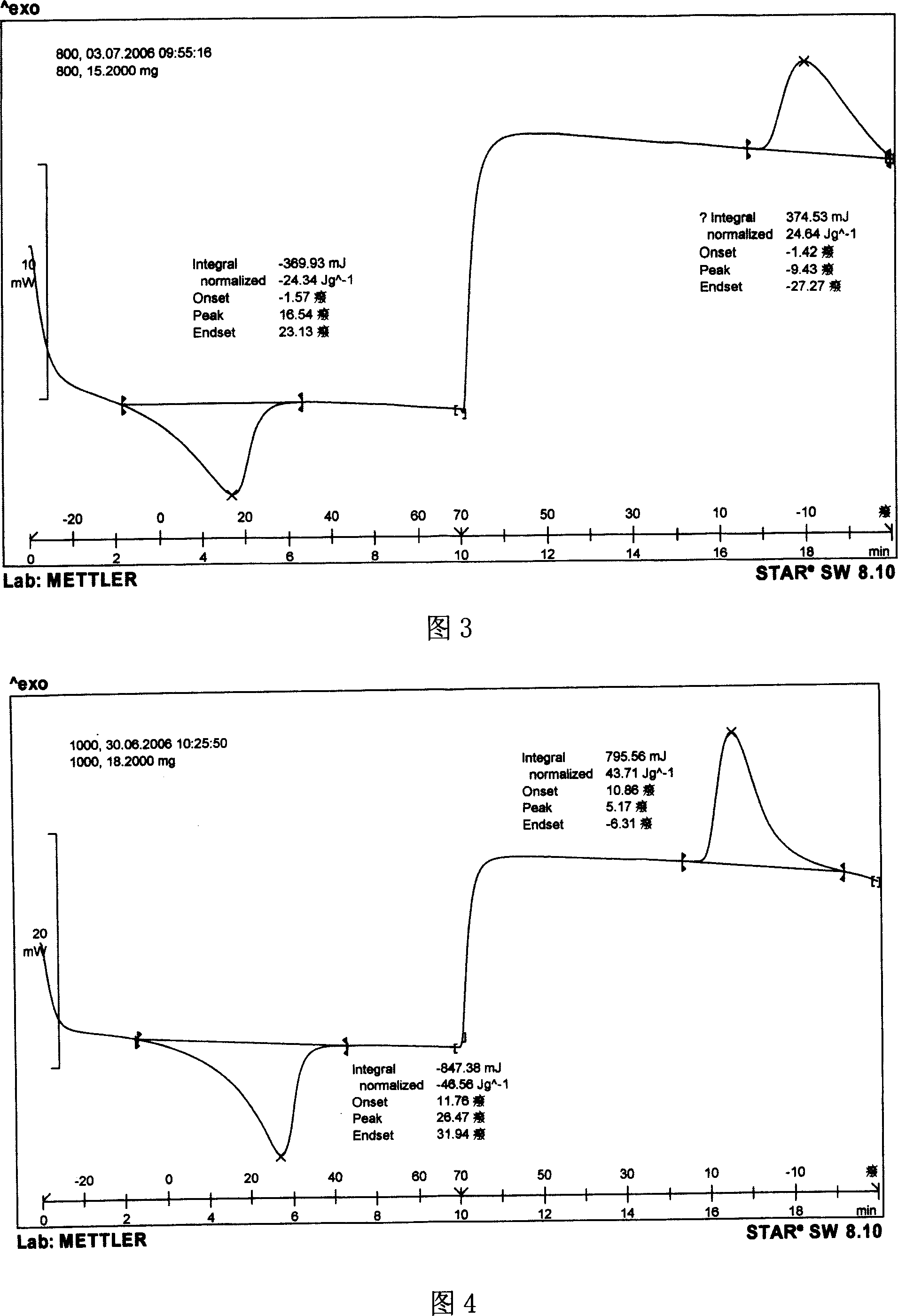

Bombax cotton phase-change material production method

InactiveCN1936169AIdeal thermostat functionImprove wrinkle resistanceSynthetic fibresHeat-exchange elementsPre treatmentPhase-change material

The invention discloses a manufacturing method for kapok phase-change material that includes the following steps: taking preprocess to 5-100% kapok fiber, 0-95% cellulose fiber, 0-90% other fiber through refining technology of cotton fabric, dipping into phase-change finishing agent for 1-5 hours, extruding the rest finishing agent, pre-drying for 3-10 minutes at 40-100 degree centigrade, baking for 1-5 minutes at 80-160 degree centigrade, taking soaping for 10-20 minutes at 60 degree centigrade, cleaning by water. The benefit effect of the invention is that it achieves optimal temperature adjusting function for kapok, saves refrigeration and heating energy, improves the anti crease and humidity transmission capability.

Owner:DONGHUA UNIV +1

Vinylon spinning oil

The invention discloses vinylon spinning oil composed of lauryl oleate, polyoxyethylene (3) cetyl sulfate, sperm oil hydrosulfate and polyethylene. The invention has reasonable formula, good use effect, and low production cost.

Owner:殷兰芳

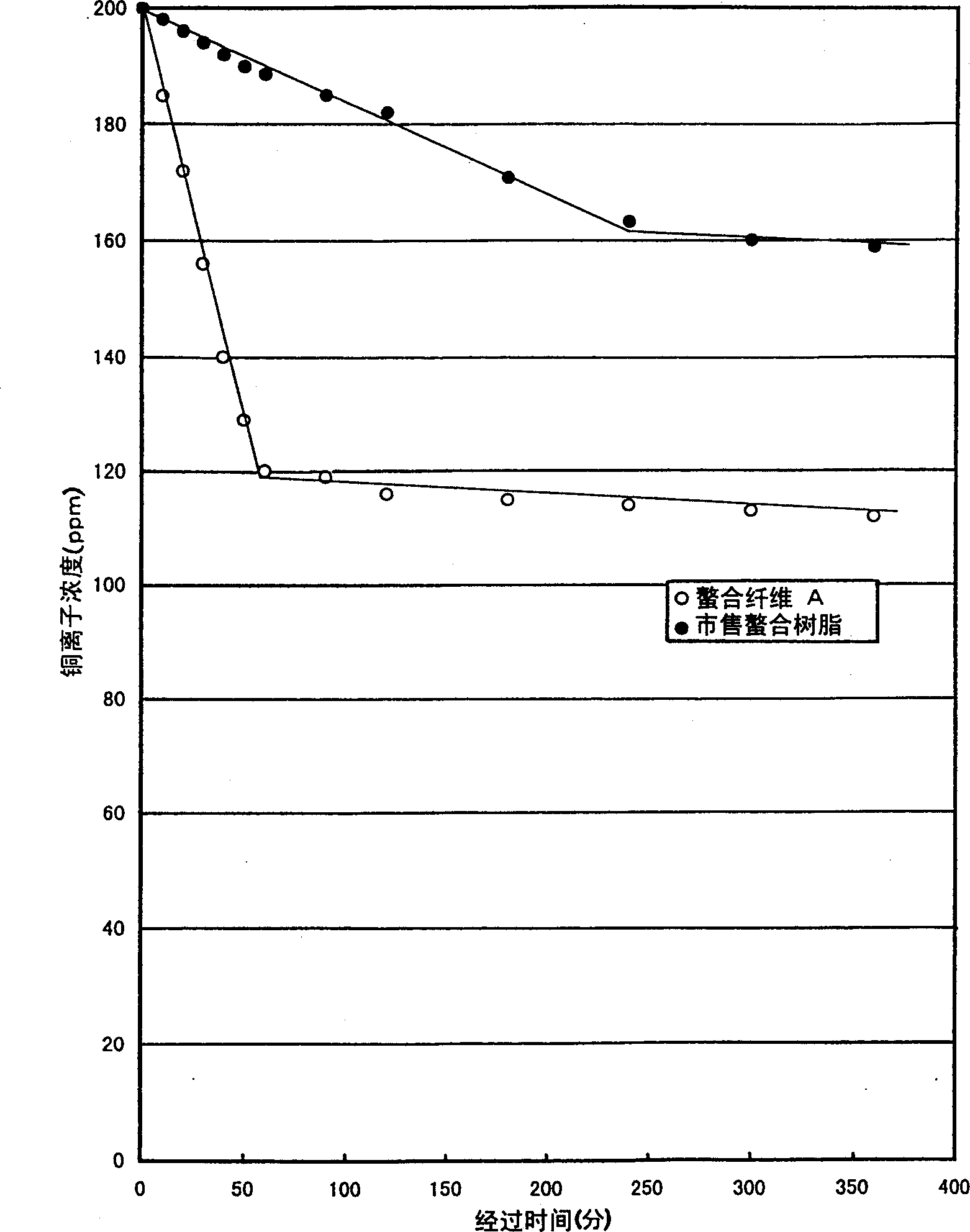

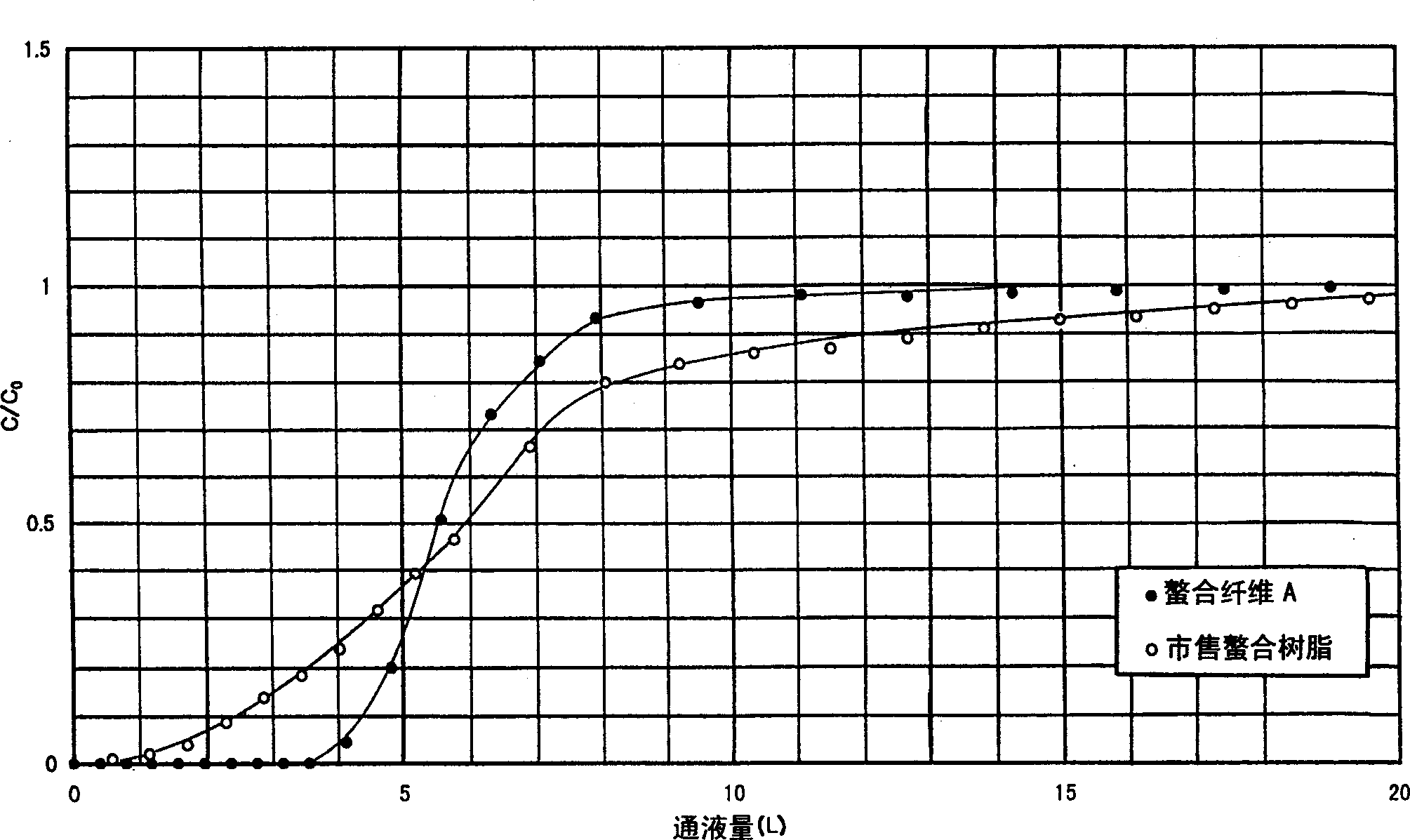

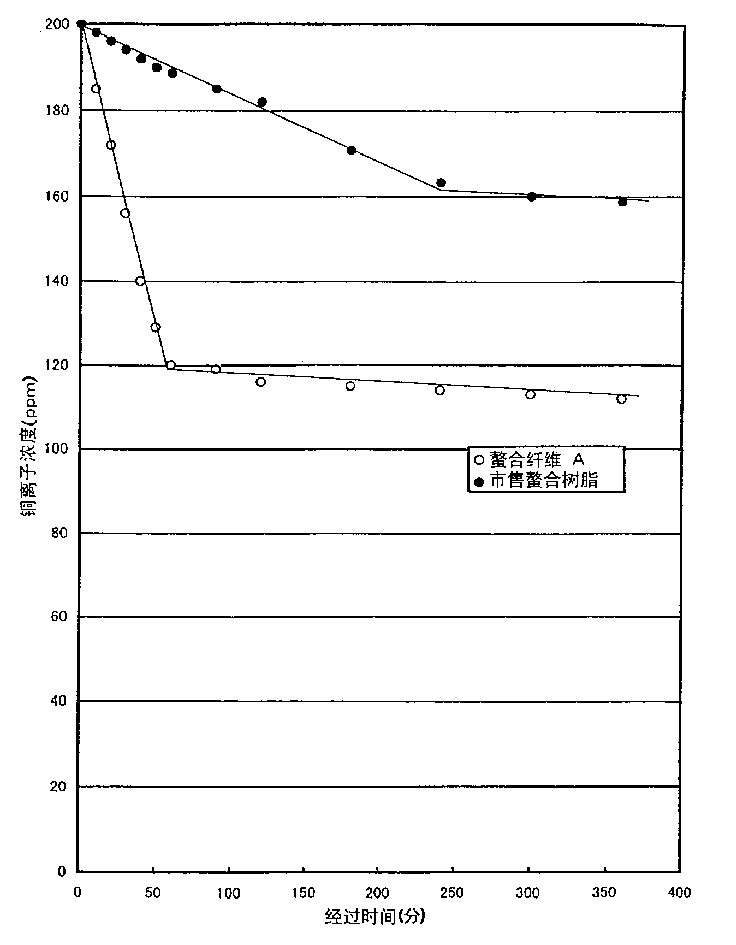

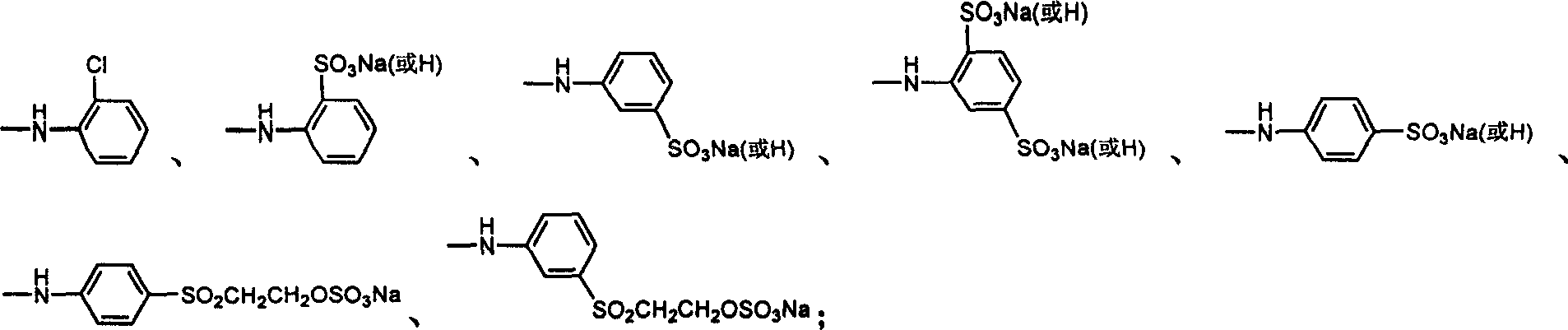

Metal chelate-forming fiber, process for producing the same, method of trapping metal ion with the fiber, and metal chelate fiber

InactiveCN1352713ASimple and Safe ManufacturingManufacture is simple and safe and efficientSynthetic fibresWater contaminantsThiocarboxylic acidPhosphoric acid

A fiber capable of forming a metal chelate and a process for producing the same are disclosed, wherein the fiber is characterized in that at least one metal chelate-forming compound selected from the group consisting of aminocarboxylic acid. aminocarboxylic acid, thiocarboxylic acid and phosphoric acid. which are reactive with a glycidyl group, is bonded to a molecule of a synthetic fiber through a crosslinkable compound having a reactive double bond and a glycidyl group in its molecule. The chelate-forming fiber is excellent in capturing harmful heavy metal ions and can be easily produced in a simple and safe way at a low cost.

Owner:CHUBU KIRESUTO +1

Method for improving ink-spraying printing image performance by using Gemini type compound

InactiveCN101117766AImproving image performance in inkjet printingImprove claritySynthetic fibresDyeing processTextile fiberGemini compound

The present invention relates to a method for improving image property of ink-jetting printing with Gemini compounds and belongs to the technical field of textile chemistry. The present invention is characterized in that the method comprises the following steps: removing the residues on the surface of the textile fiber and then treating with sodium carbonate and peregal O solutions; immersing or padding finishing with impregnating solutions of Gemini cationic compounds; and then baking and ink-jetting printing. The Gemini quaternary ammonium salt finishing technology can improve the ink-jetting printed image property of textiles and increase the definition as well as the color depth and the brightness. The finished textiles have excellent color fastness and feel good. Besides, the method has the advantages of low fiber damage, zero sewage discharge, energy saving and high production efficiency and is worth of vigorous popularization.

Owner:JIANGNAN UNIV

Method for improving ink-spraying printing image performance by using Gemini type compound

InactiveCN100500982CImproving image performance in inkjet printingImprove claritySynthetic fibresDyeing processTextile fiberGemini compound

The present invention relates to a method for improving image property of ink-jetting printing with Gemini compounds and belongs to the technical field of textile chemistry. The present invention is characterized in that the method comprises the following steps: removing the residues on the surface of the textile fiber and then treating with sodium carbonate and peregal O solutions; immersing or padding finishing with impregnating solutions of Gemini cationic compounds; and then baking and ink-jetting printing. The Gemini quaternary ammonium salt finishing technology can improve the ink-jetting printed image property of textiles and increase the definition as well as the color depth and the brightness. The finished textiles have excellent color fastness and feel good. Besides, the method has the advantages of low fiber damage, zero sewage discharge, energy saving and high production efficiency and is worth of vigorous popularization.

Owner:JIANGNAN UNIV

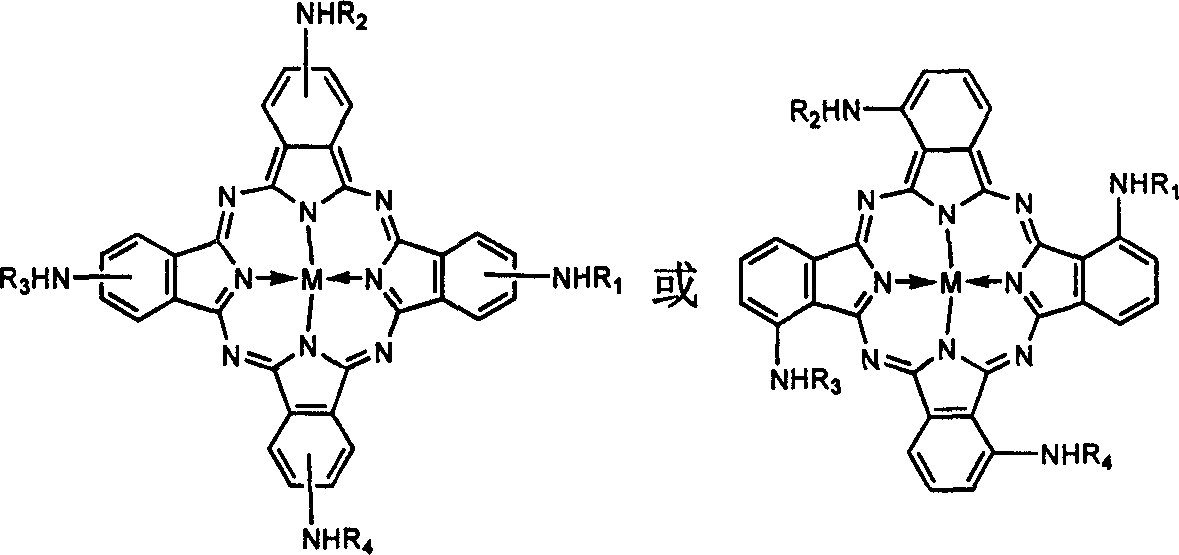

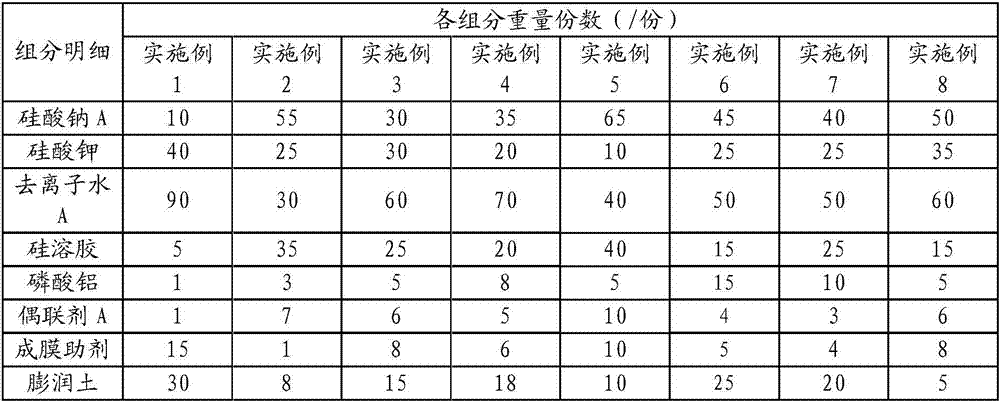

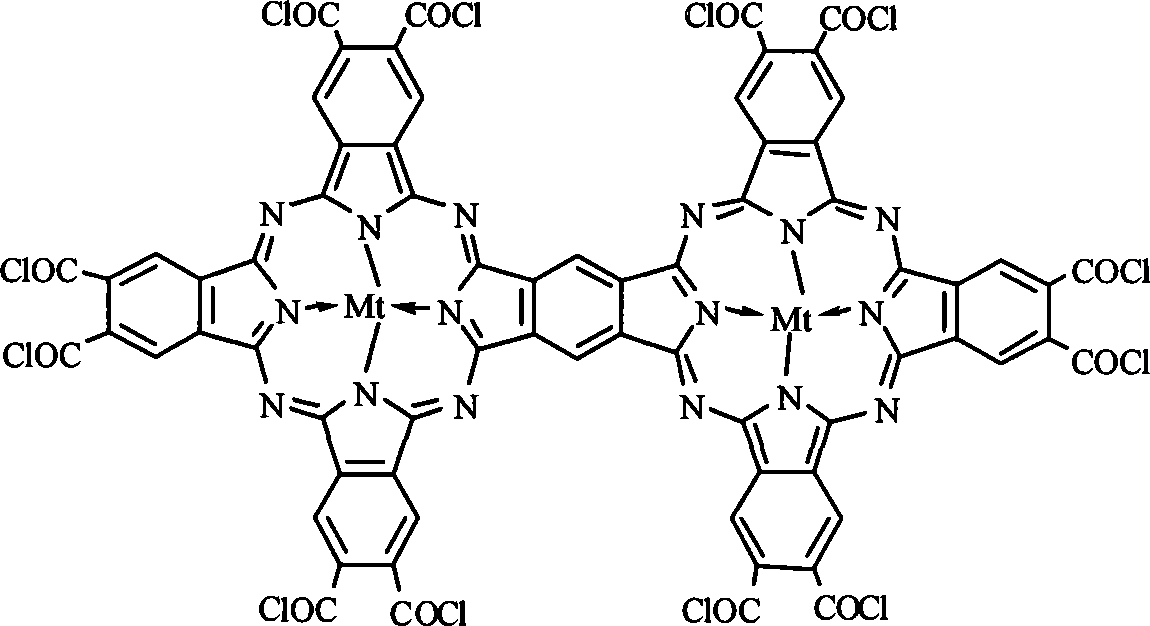

Metal phthalocyanine loaded fiber with catalytic activity and preparing method

InactiveCN1900411AAvoid gatheringGood selective adsorption functionSynthetic fibresCarbon fibresFiberTriazene

The present invention relates to a metal phthalocyanine fiber-supported metal phthalocyanine having catalytic activity and preparation method, said metal phthalocyanine with fiber or fabric through covalent bond conjoint mode combining to form supported fiber having catalytic activity. The used etal phthalocyanine is transition metal ion such as characterized in having the structure of formula 1, in which M is a Fe,Co,Cu,Mn,Rb,Al,Zn and Ni; R1,R2,R3,R4 each can be H, any of the five in formular (1), and others are all H, the construction of the radical R5 can be -NH2, -NHCOCH3, -NHSO3Na, and -NHSO3H. Said preparation method is selecting metal phthalocyanine as reactive group having triazine structure under pH 8- 11 reaction temperature 45 -95 degree centigrade condition, adding fiber or fabric to finite concentration reactivity metal phthalocyanine aqueous solution, continuously stirring, after reaction taking out fiber or fabric and respectively to make caustic washing and water washing, drying to obtain fiber-supported metal phthalocyanine or fabric. Said invention has simple equipment, easy to operate etc advantages.

Owner:ZHEJIANG SCI-TECH UNIV

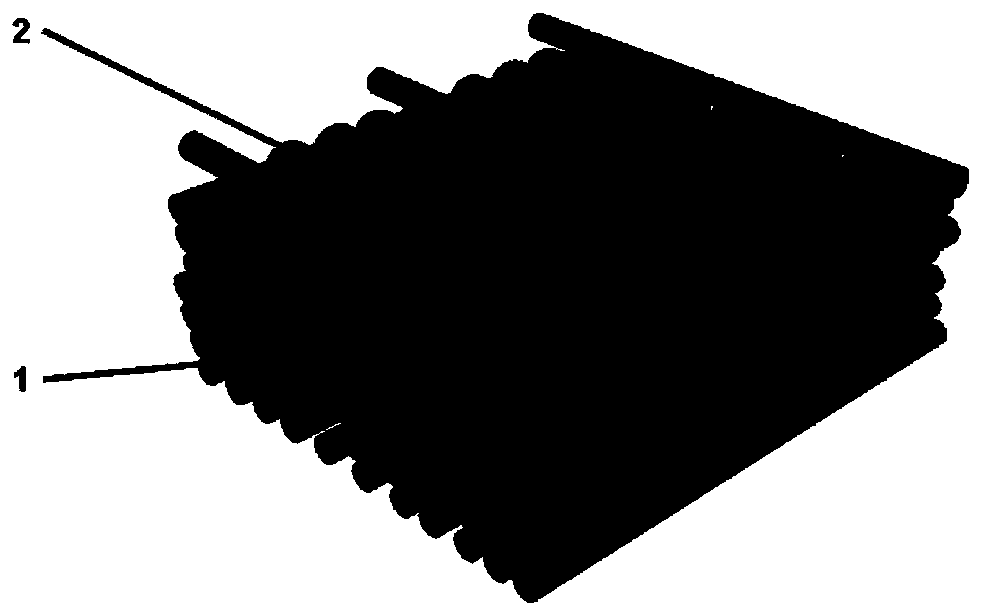

Radiation refrigeration composite-photon-structure thin membrane and preparation method thereof

ActiveCN110552199AStrong solar reflectionHigh infrared radiationSynthetic fibresAngle dependenceFiber

The invention discloses a radiation refrigeration composite-photon-structure thin membrane and a preparation method thereof. The thin membrane comprises a fiber layer and a microsphere layer from bottom to top. The thin membrane system has the advantages of high sunlight reflection, high infrared radiation, low angle dependence and the like, reflection to energy of sunlight wave bands (0.25-2.5 microns) reaches 97%, the average emissivity in atmospheric window wave bands (8-13 microns) reaches 0.96, the temperature can be reduced by 10 DEG C to the greatest extent under irradiation of 1,000 W / m<2> sunlight, the radiation refrigeration effect is excellent, and the thin membrane has good flexibility and high strength. A simple two-step method is adopted as the preparation method and comprises the steps that the fiber layer is obtained through electrostatic spinning, and the microsphere layer is obtained through deposition of silicon dioxide microsphere dispersion liquid. The thin membrane is simple in structure, efficient in performance, easy to prepare, low in cost, capable of meeting the demand of industrial large-scale production, and high in potential application value.

Owner:SHANGHAI JIAO TONG UNIV

Latex dispensing glove and preparation method thereof

ActiveCN103981723AResistant to chemically aggressive mediaOil resistantSynthetic fibresVegetal fibresFiberPolymer science

The invention relates to a latex dispensing glove and a preparation method thereof. The glove includes a glove liner and an outer glue dipping layer. The glove liner is knitted from nylon, terylene, cotton or rayon fiber through seamless knitting, the outer glue dipping layer is a latex outer glue dipping layer, and the surface of the outer glue dipping is distributed with friction substances made of a polymer material; and the latex outer glue dipping layer consists of the following components: oil and solvent resistant rubber or polymer alloy material or electrostatic material or high temperature resistant material, a curing agent and san accelerator. According to the invention, friction substances made of the polymer material on the glove surface isolate the contact between glove and a held object to give more secure and reliable protection on the hand, and also increase the frictional force between the glove and the held object, so that the glove is safe and convenient for application, and can be used for hand protection under different conditions.

Owner:ZHEJIANG KANG LONG DA SPECIAL PROTECTION TECH CO LTD

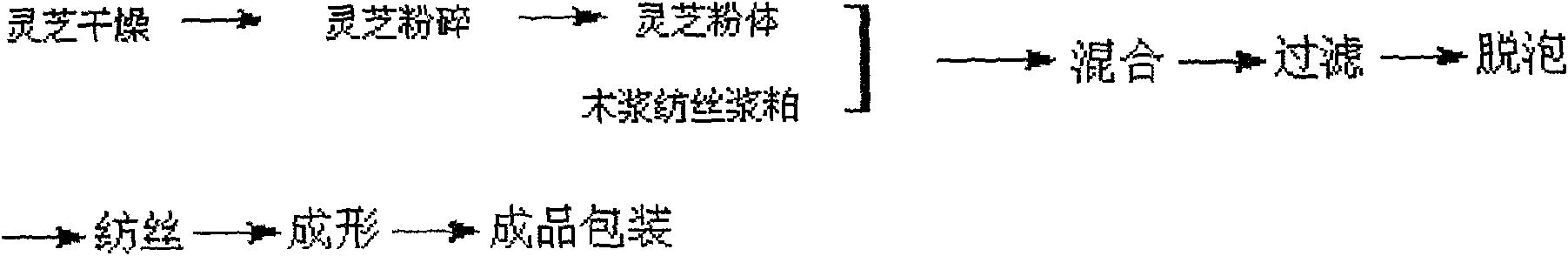

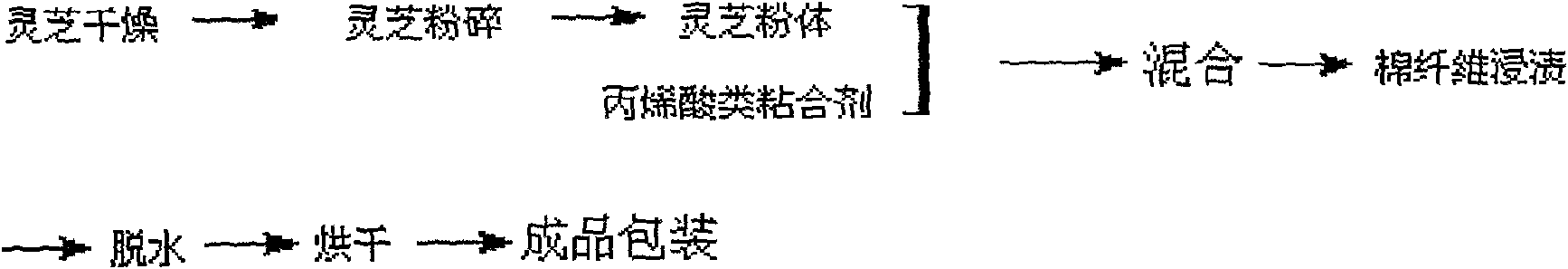

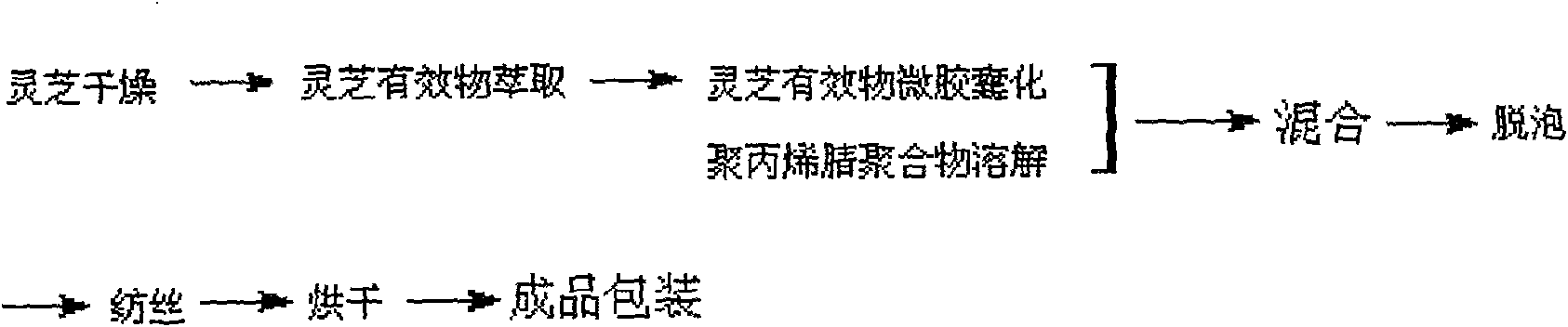

Ganoderma lucidum fibre with function of health care and preparation method thereof

InactiveCN101634055AImprove the immunityImprove immunityMonocomponent protein artificial filamentSynthetic fibresDiseaseNylon 66

The invention relates to ganoderma lucidum fibre with the function of health care and a preparation method thereof. The fibre contains traditional Chinese medicine ganoderma lucidum components; the preparation method comprises the following steps: adding the ganoderma lucidum components into regenerated cellulose fibre spinning liquid, regenerated protein fiber spinning liquid, terylene fibre spinning liquid, orlon fibre spinning liquid and nylon 6 or nylon 66 fibre spinning liquid and adopting conventional spinning to obtain the ganoderma lucidum fibre. The fibre can reinforce the resistance and immunity of an organism, eliminates in-vivo free radicals, resists radiation and has the effects of preventing and treating diseases, building the body, strengthening the body and prolonging the life; the invention has simple preparation method and is suitable for industrialized production.

Owner:陈对范 +1

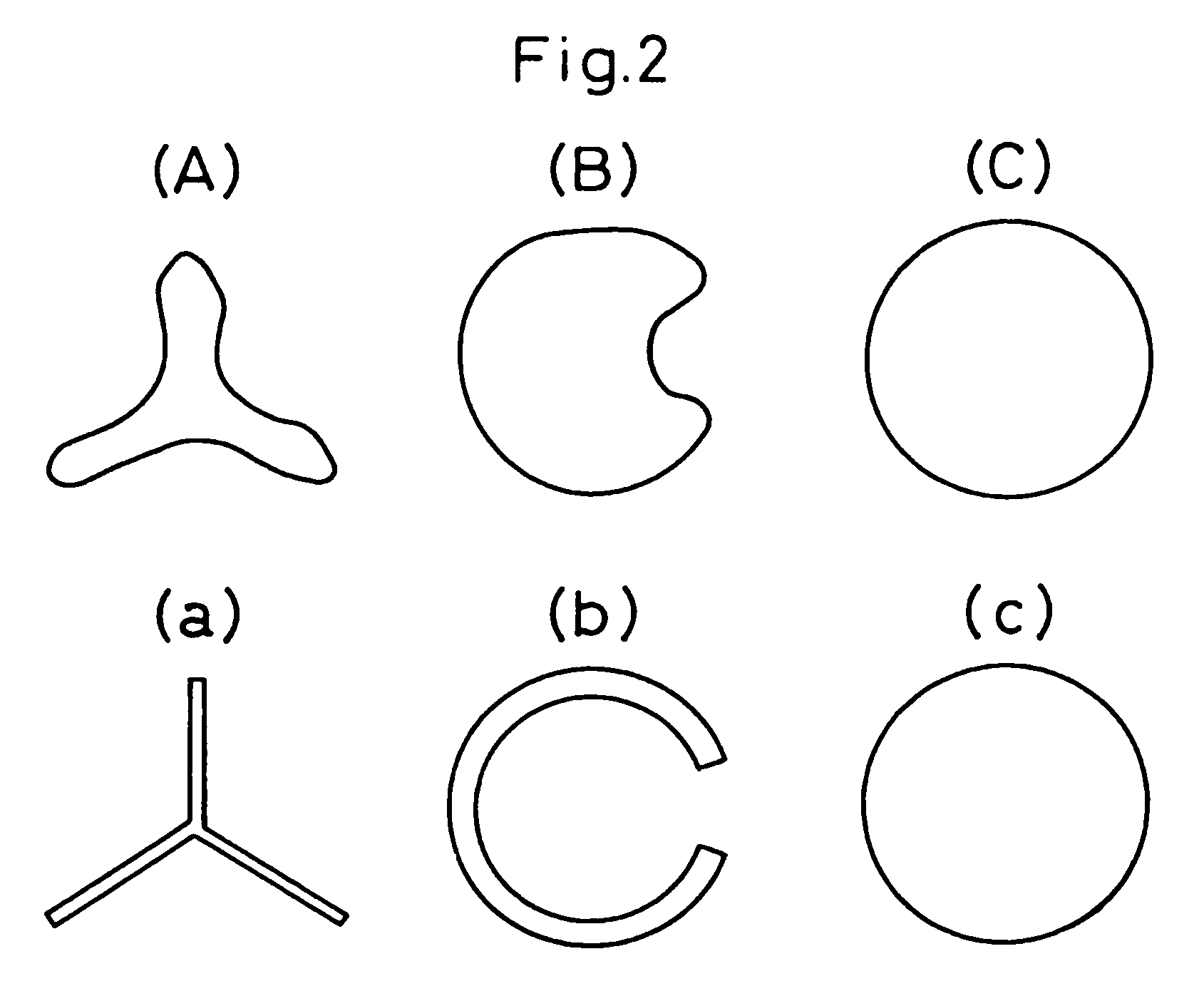

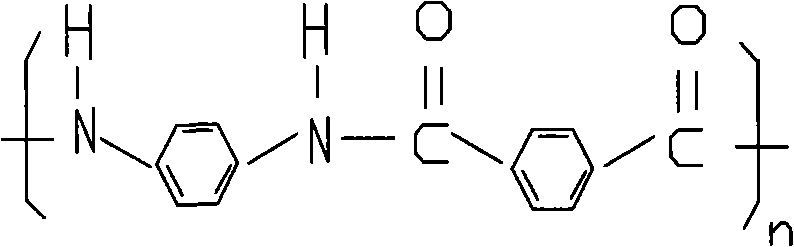

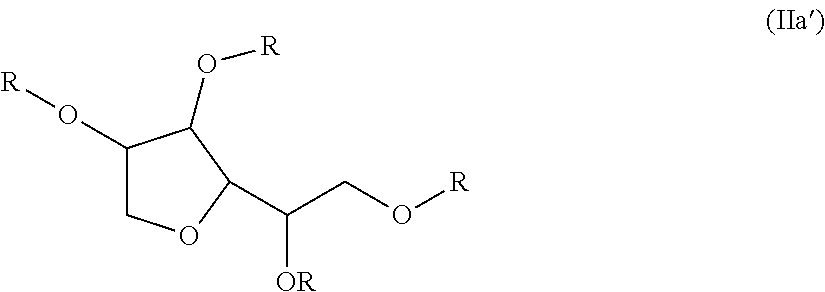

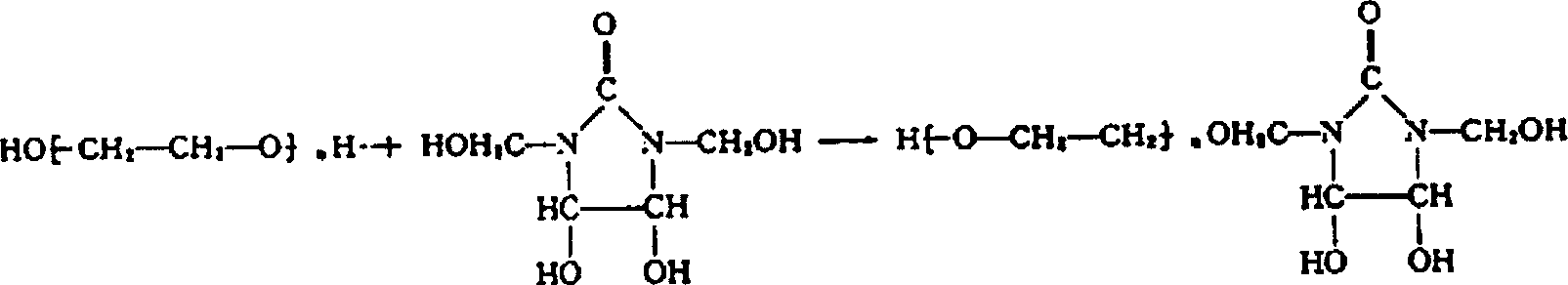

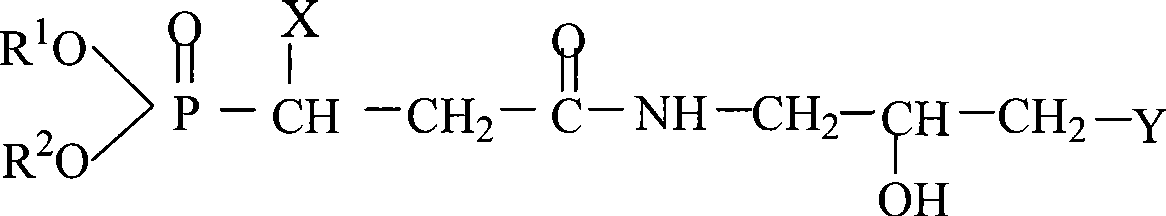

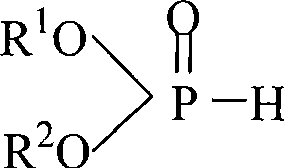

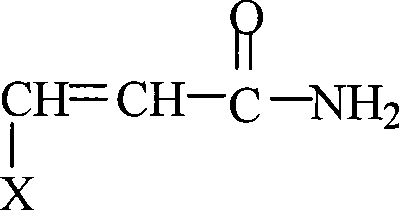

Non-formaldehyde flame retardant for viscose fiber

InactiveCN101498103AImprove flame retardant performanceIncreased durabilitySynthetic fibresGroup 5/15 element organic compoundsUreaAddition reaction

The invention discloses a formaldehyde-free flame retardant for viscose fibers, which is a phosphate esters flame retardant of synthesizing acid amide by carrying out Michael addition reaction of phosphite ester and acrylamide compounds, and carrying out the reaction of generated acid amide functional groups and epoxy compounds. The structural formula of the flame retardant is shown above. The flame retardant, together with a cross-linking agent, a penetrating agent, a catalyst and a urea, is prepared into a flame retardant finishing liquid in proportion with water for fire retardant treatment of viscose fibers. The viscose fiber fabric after treatment has the advantages of good flame retardant effect, high durability, good hand touch, little strength reduction, good whiteness and the like.

Owner:CHANGCHUN UNIV OF TECH

Treatment method of textile

InactiveCN101643998AReduce generationEmission reductionSynthetic fibresVegetal fibresChemical treatmentUltraviolet lights

The invention discloses a treatment method of textile, comprising the following steps: adopting nanometer powder as photocatalyst to prepare photocatalysis bath, adding in a batch or continuous reactive unit, introducing air or oxygen continuously under ultraviolet light with the wavelength of 200-400nm to pretreat textile green body through photocatalysis, and then performing conventional one bath process treatment under gentle condition to realize the desizing and bleaching pretreatment of textile. The invention adopts active substances such as strong oxidizing radicals and the like which are generated through the photocatalysis of nanometer material as the pretreating agent of sizing agent of textile and natural impurities so that the reaction can be performed at room temperature and normal pressure and the photocatalysis pretreating agent can be used repeatedly; in addition, by using wet chemical treatment under gentle condition, large dosage of chemicals in traditional pretreatment technology can be avoided. Therefore, the textile green body pretreatment technology provided by the invention can reduce the production and emission of pollutants and is characterized by simple device and technology, high efficiency, and energy-saving and emission reduction.

Owner:WUXI RUIDE TEXTILE FASHION DESIGN

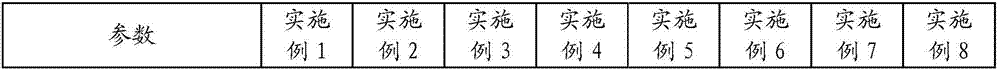

Powder removal prevention aerogel composite insulation felt and preparation method thereof

ActiveCN107140938AShorten the replacement periodImplement reflectionSynthetic fibresCarbon fibresFiberMaterials science

The invention belongs to the technical field of energy-saving and environment-friendly materials, and particularly relates to powder removal prevention aerogel composite insulation felt used for building and industrial energy saving and insulation. The insulation felt comprises an aerogel wet gel solution and a fiber framework material at a weight ratio of (2-30):1. A preparation method of the insulation felt comprises the steps of immersing the fiber framework material into the aerogel wet gel solution according to the aerogel wet gel solution and the fiber framework material at the weight ratio of (2-30):1 to achieve saturation adsorption of the aerogel wet gel solution by the fiber framework material, and then performing drying to obtain the insulation felt. The insulation felt overcomes the problems of high cost and easy powder removal of the existing insulation felt, and is better in performance and more environment-friendly.

Owner:天津朗华科技发展有限公司

Binuclear metal phthalolyanin carrier fiber material for eliminating formaldehyde and preparing method

InactiveCN101070680AStrong adsorption functionImprove adsorption capacitySynthetic fibresAnimal fibresTextile fiberOrganic solvent

A binuclear metal phthalocyanine load fibrous material eliminates the formaldehyde and the preparation method. It uses the acid radical chloro- binuclear metal phthalocyanine to respond in the organic solvent with the fibrous material, to obtain the binuclear metal phthalocyanine load fibrous material conjoint by covalent that can catalyze oxidation formaldehyde; Its preparation method is: Uses the acid radical chloro- binuclear metal phthalocyanine to dissolve in the right amount organic solvent, after treating the full dissolution, joins after the vacuum drying the textile fiber, the agitation and responded under certain temperature, then takes out the textile fiber with the distilled water cleaning, carries on processing with the alkaline solution, finally uses the distilled water to clean, drying then; The catalyzed oxidation formaldehyde's method is: According to the formaldehyde density's difference, the name takes the ration the binuclear metal phthalocyanine load fibrous material, lays aside it in contains in the formaldehyde environment, carries on the effective catalyzed oxidation to the formaldehyde; And in the formaldehyde catalyzed oxidation processing step, the use temperature range is: - 50degree C-50degree C; The use barometric pressure scope is: - 0.01-10 standard atmospheric pressure; It has good effect to eliminate the formaldehyde, and can duplicate uses, raised its use factor, the preparation equipment is simple, the craft was simple and easy to operate.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com