Binuclear metal phthalolyanin carrier fiber material for eliminating formaldehyde and preparing method

A dual-core metal and fiber material technology, applied in synthetic fiber, animal fiber, fiber treatment, etc., can solve the problems of non-renewable use, adsorption saturation, complicated manufacturing, etc., and achieve the effects of easy operation, faster speed, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

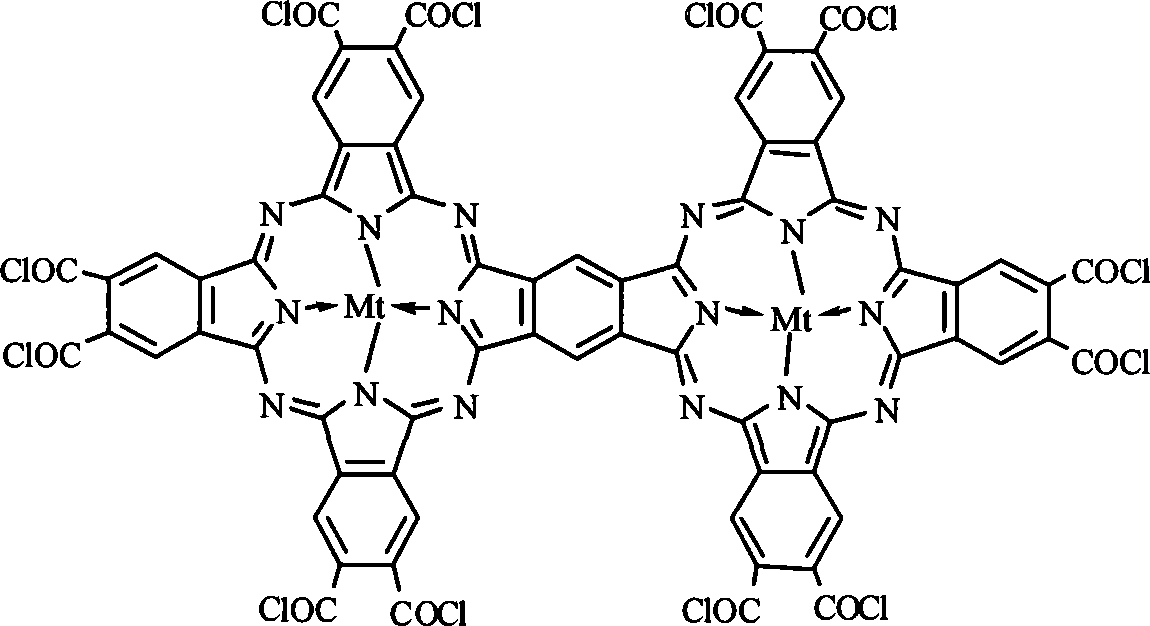

[0024] The preparation of the dual-nuclear metal phthalocyanine-loaded fiber material and its catalytic oxidation of formaldehyde are as follows: first, the dual-nuclear metal phthalocyanine-loaded fiber material is prepared by using an acid chloride-based binuclear metal phthalocyanine, and then the dual-nuclear metal phthalocyanine-loaded fiber material is placed in a formaldehyde-containing environment. Effective catalytic oxidation of formaldehyde in the environment.

[0025] A dual-nuclear metal phthalocyanine-loaded fiber material, which is prepared by reacting the acid chloride-based dual-nuclear metal phthalocyanine with the fiber material in an organic solvent to prepare a covalently bonded dual-nuclear metal phthalocyanine-loaded fiber material with catalytic oxidation of formaldehyde ,

[0026] The mass percentage of metal phthalocyanine in the dual-core metal phthalocyanine-loaded fiber is 0.1-10%.

[0027] A method for preparing a dual-nuclear metal phthalocyanin...

Embodiment 1

[0037] Dissolve 0.4g of dodecanoyl chloride-based cobalt phthalocyanine in 100ml of DMF solution. After fully dissolving, add 5g of vacuum-dried silk fiber, stir, and treat at 80°C for 8h. After taking it out, wash it with distilled water and wash it with 0.1mol.L -1 Treat the NaOH solution at 70°C for half an hour, take it out, wash it with distilled water, and dry it to get the binuclear cobalt phthalocyanine-loaded fiber material.

[0038] Weigh 0.1kg of dual-nuclear cobalt phthalocyanine-loaded fiber material, then place the fiber in 100 cubic meters of newly renovated bedrooms, and the formaldehyde concentration is 7.1mg / m 3 (5ppm), at regular intervals, the concentration of formaldehyde is detected to test the effect of its catalytic oxidation of formaldehyde.

Embodiment 2

[0040] Dissolve 0.4g of lauryl chloride iron phthalocyanine in 100ml of DMF solution. After fully dissolving, add 5g of vacuum-dried silk fiber, stir, and treat at 80°C for 8h. After taking it out, wash it with distilled water and wash it with 0.1mol.L -1 Treat the NaOH solution at 70°C for half an hour, take it out, wash it with distilled water, and dry it to get the binuclear cobalt phthalocyanine-loaded fiber material.

[0041] Weigh 0.1kg of dual-core iron phthalocyanine-loaded fiber material, and then place the fiber in 100 cubic meters of newly renovated bedrooms with a formaldehyde concentration of 7.1mg / m 3 (5ppm), at regular intervals, the concentration of formaldehyde is detected to test the effect of its catalytic oxidation of formaldehyde.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com