Composite air purifying preparation containing nanometer mineral substance and preparation method thereof

An air purifier and mineral technology, which is applied in the field of composite air purifier and its preparation, can solve the problems of low efficiency of air purifier, difficult powder application, large amount of waste water, etc., and achieves good overall mechanical strength and surface strength, The process is environmentally friendly and the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

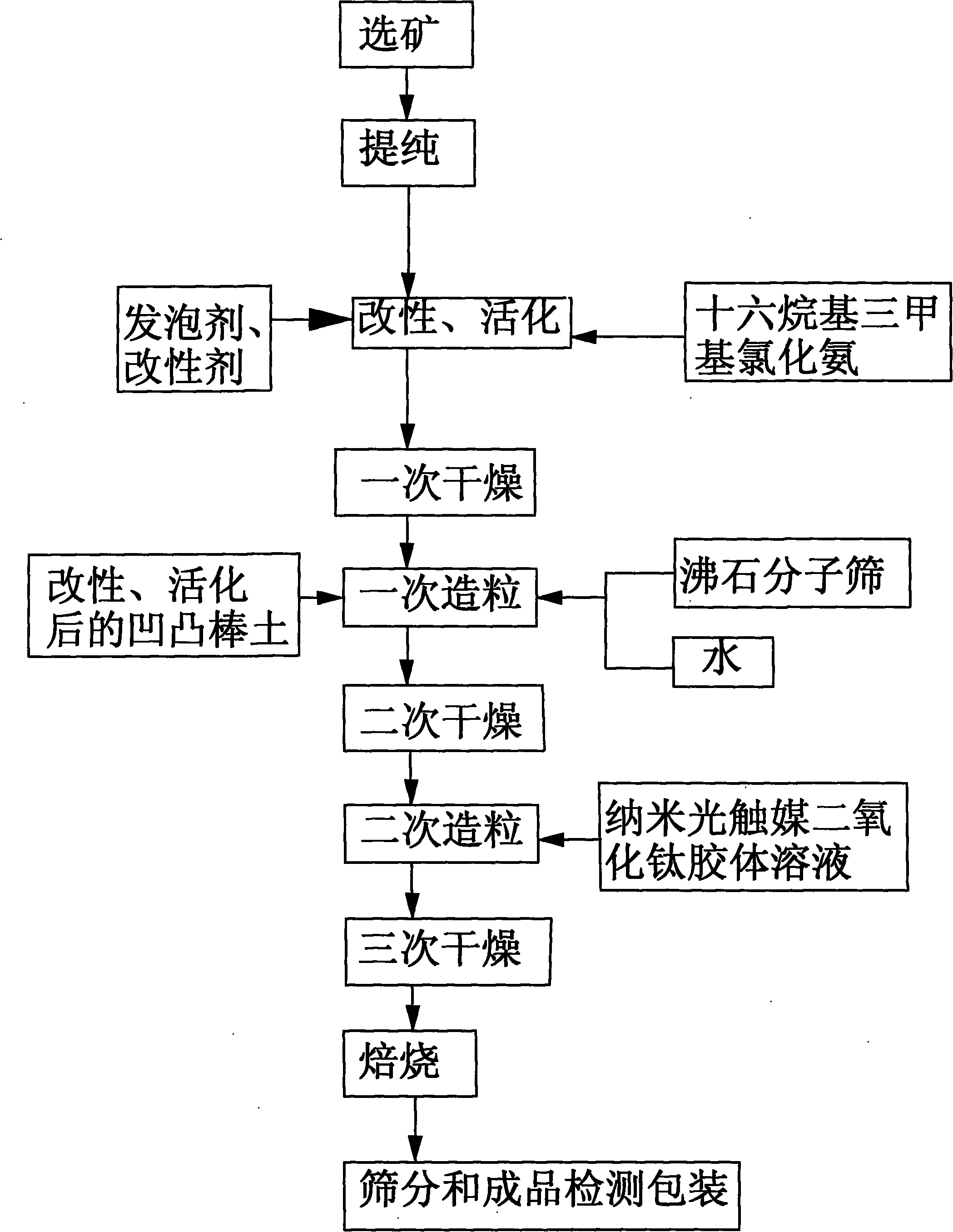

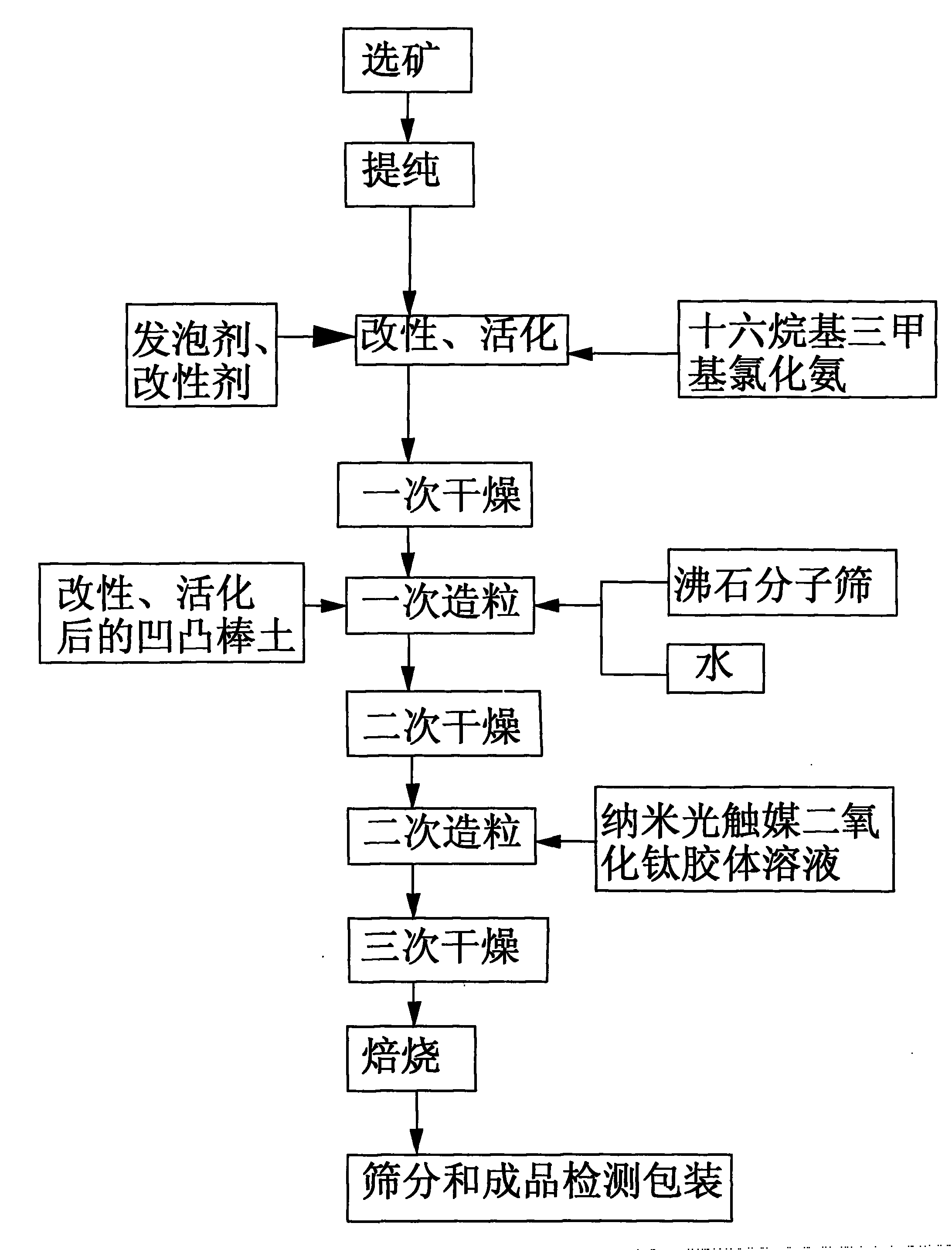

[0038] (1) mineral processing step: select attapulgite to have the pure natural mineral material concentrate with adsorption capacity, and the content is more than 60%;

[0039] (2) Purification step: the selected natural mineral material is purified, and attapulgite is pulverized to 325 orders;

[0040] (3) modification, activation step: by the appropriate proportioning of the weight of the natural mineral material after the proportioning after purification, wherein the weight percentage of the attapulgite after the proportioning is 77%, the weight percentage of the artificial zeolite molecular sieve is 20%, for the purified The attapulgite is added with a surfactant, and the weight percentage of the surfactant hexadecyltrimethylammonium chloride is 0.5%, and the temperature is controlled at 50° C. to activate and expand the pores; Sodium bisulfate and 1% aluminum sulfate are mixed and dissolved in an appropriate amount of water, and attapulgite is added to the kneader togeth...

Embodiment 2

[0050] In Example 2, the steps of beneficiation, purification, modification, activation, primary drying, primary granulation, secondary drying, secondary granulation, tertiary drying, roasting, sieving and finished product testing and packaging are the same as in Example 1, with different The percentage by weight is attapulgite 47%, artificial zeolite molecular sieve 50%, and the temperature is controlled at 80°C to activate and expand pores; wherein attapulgite, artificial zeolite molecular sieve, cetyltrimethylammonium chloride, sulfurous acid The sum of sodium hydrogen, aluminum sulfate and nano photocatalyst titanium dioxide powder is 100%.

Embodiment 3

[0052] In embodiment 3, the packing steps including ore dressing, purification, modification, activation, primary drying, primary granulation, secondary drying, secondary granulation, tertiary drying, roasting, sieving and finished product testing and packaging are the same as in Example 1, with different It is 58% by weight of attapulgite, 33% by weight of artificial zeolite molecular sieve, 2% by weight of surfactant hexadecyl trimethyl ammonium chloride, and 2.5% sulfurous acid Sodium hydrogen, 2.5% aluminum sulfate and 2% nano photocatalyst titanium dioxide powder material were weighed, and the temperature was controlled at 65°C for activation and hole expansion; wherein attapulgite, artificial zeolite molecular sieve, cetyl trimethyl chloride The sum of ammonia, sodium bisulfite, aluminum sulfate and nano photocatalyst titanium dioxide powder is 100%.

[0053] The air purifier prepared by the invention has a very strong selective adsorption capacity for organic pollutants...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com