Patents

Literature

1953 results about "Colloidal Solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A colloidal solution, sometimes known as a colloidal suspension, is a solution in which a material is evenly suspended in a liquid. In other words, a colloid is a microscopically small substance that is equally dispersed throughout another material.

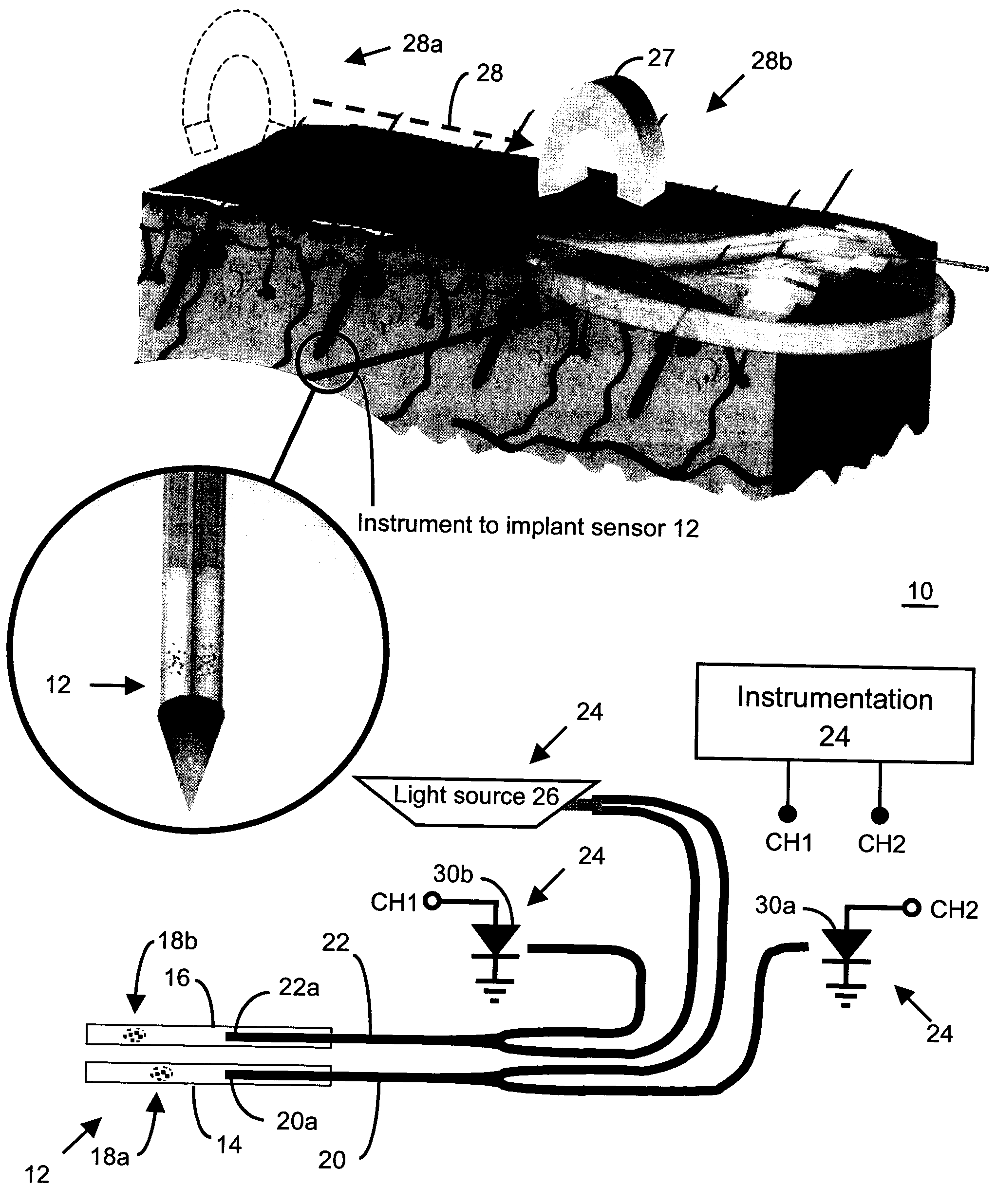

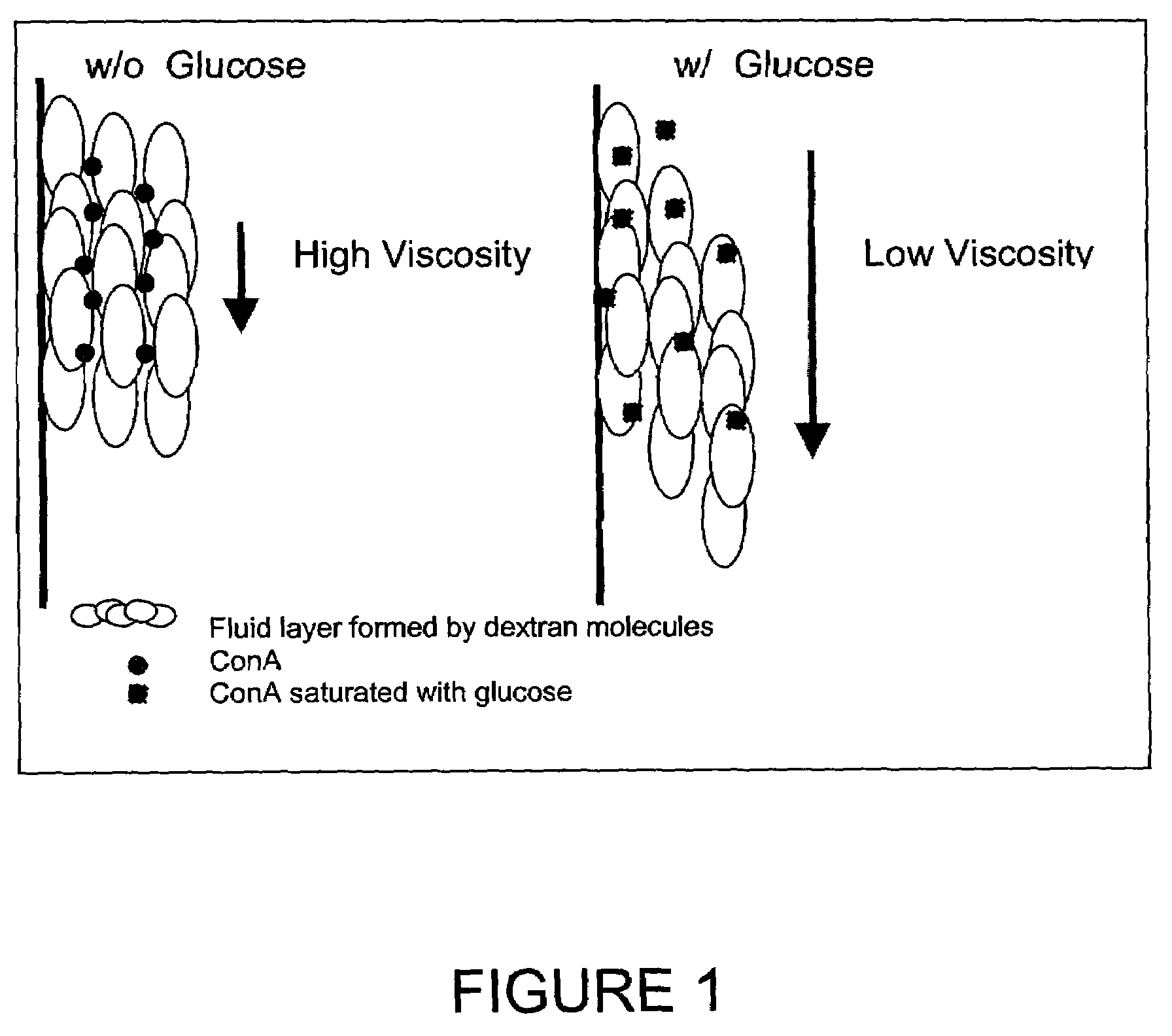

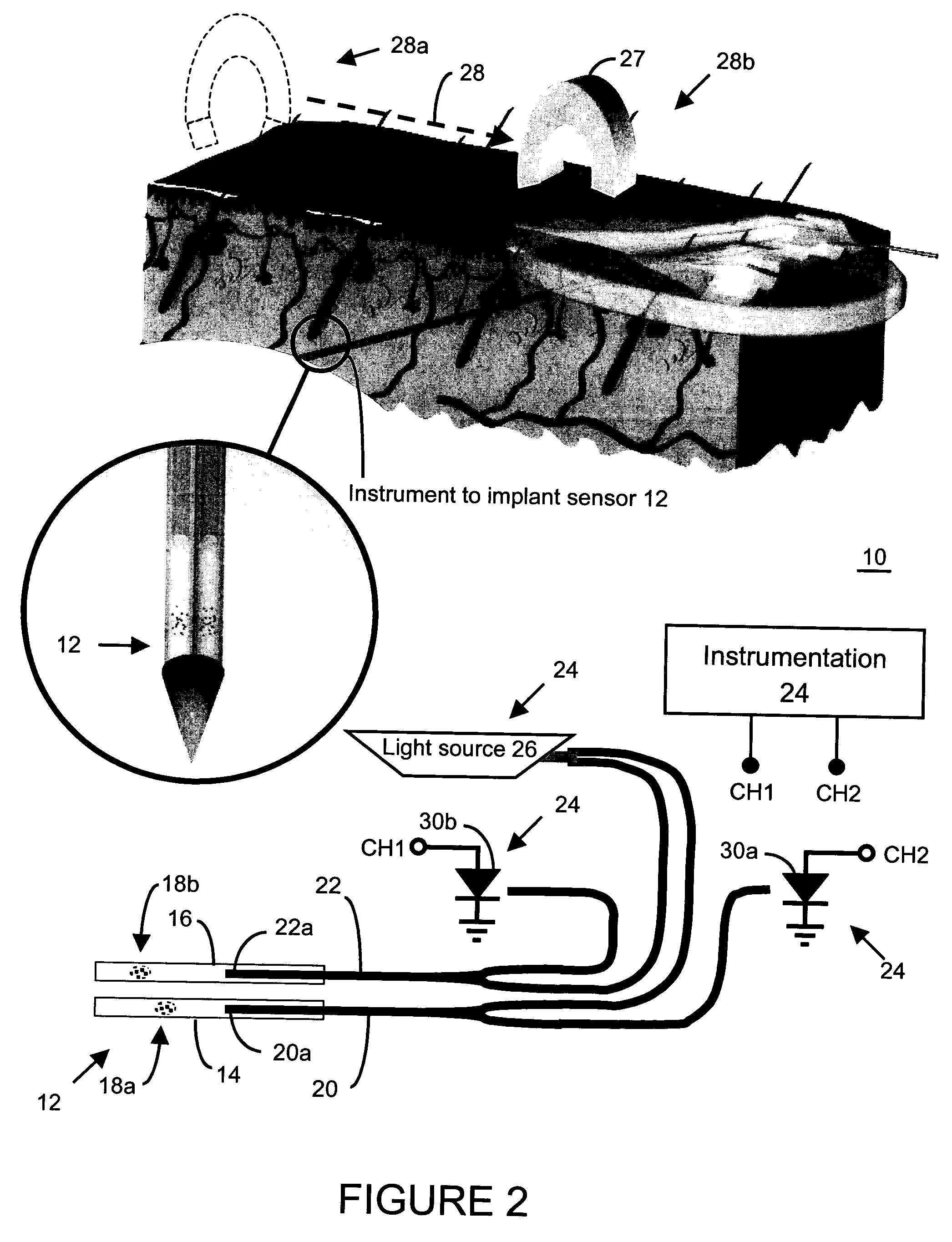

Method and apparatus for analyte sensing

InactiveUS7226414B2Reducing dispersion viscosityLow viscosityCatheterDiagnostic recording/measuringRare-earth elementEngineering

In one aspect, the present invention is directed to a glucose sensing device for implantation within subcutaneous tissue of an animal body. In one embodiment, the glucose sensing device includes a first chamber containing first magnetic particles and a hydrocolloid solution (for example, ConA-dextran hydrocolloid) wherein the first magnetic particles are dispersed in the hydrocolloid solution. In operation, glucose within the animal may enter and exit the first chamber and the hydrocolloid solution changes in response to the presence or concentration of glucose within the first chamber. The sensing device also includes a reference chamber containing second magnetic particles and a reference solution wherein the second magnetic particles are dispersed in the reference solution. The reference solution (for example, oil or alcohol compounds) includes a known or fixed viscosity. The reference solution may also be a hydrocolloid solution (for example, ConA-dextran hydrocolloid). The first and / or second magnetic particles may include amine-terminated particles, at least one rare earth element (for example, neodymium or samarium), and / or a ferromagnetic material.

Owner:BIOTEX

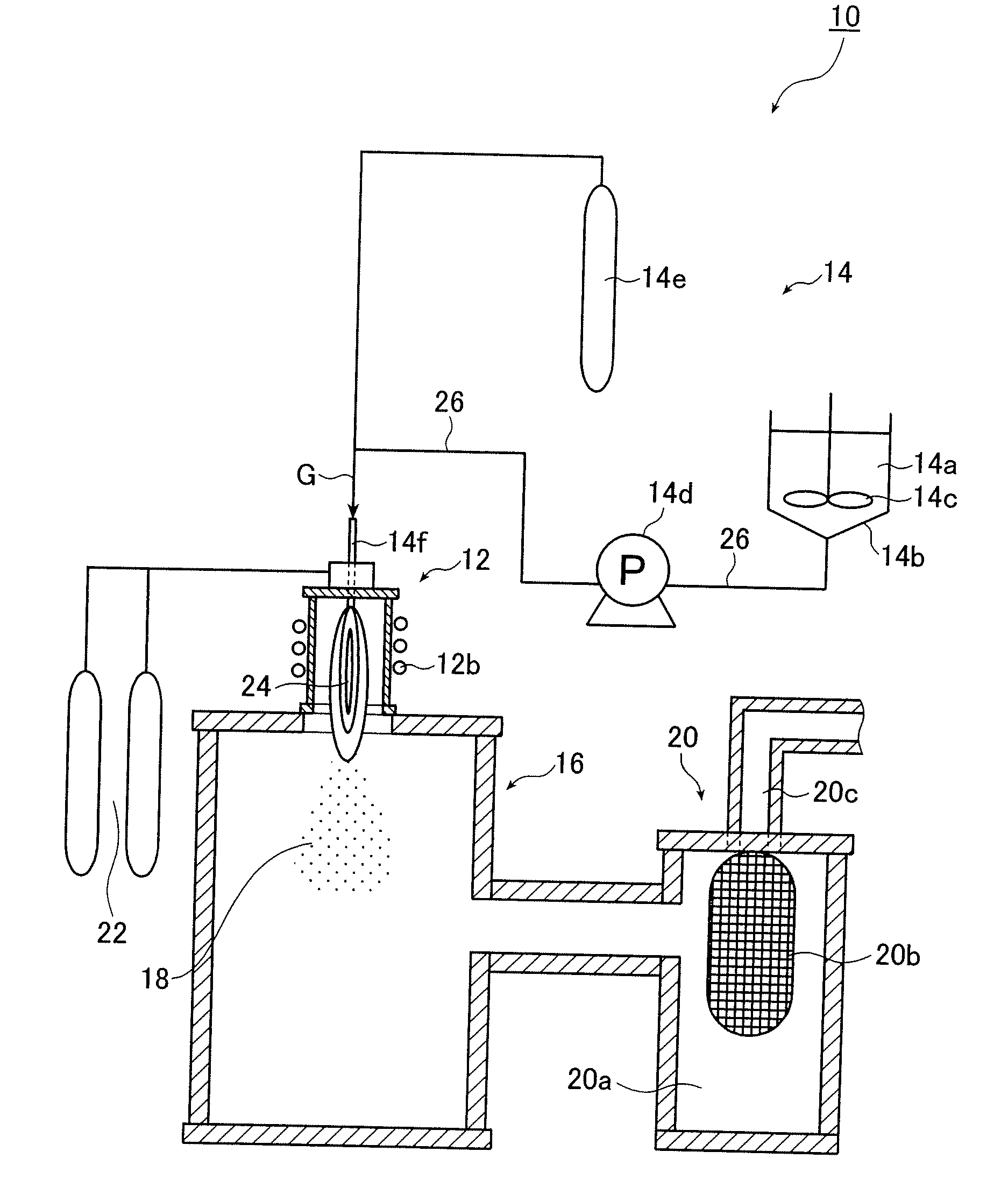

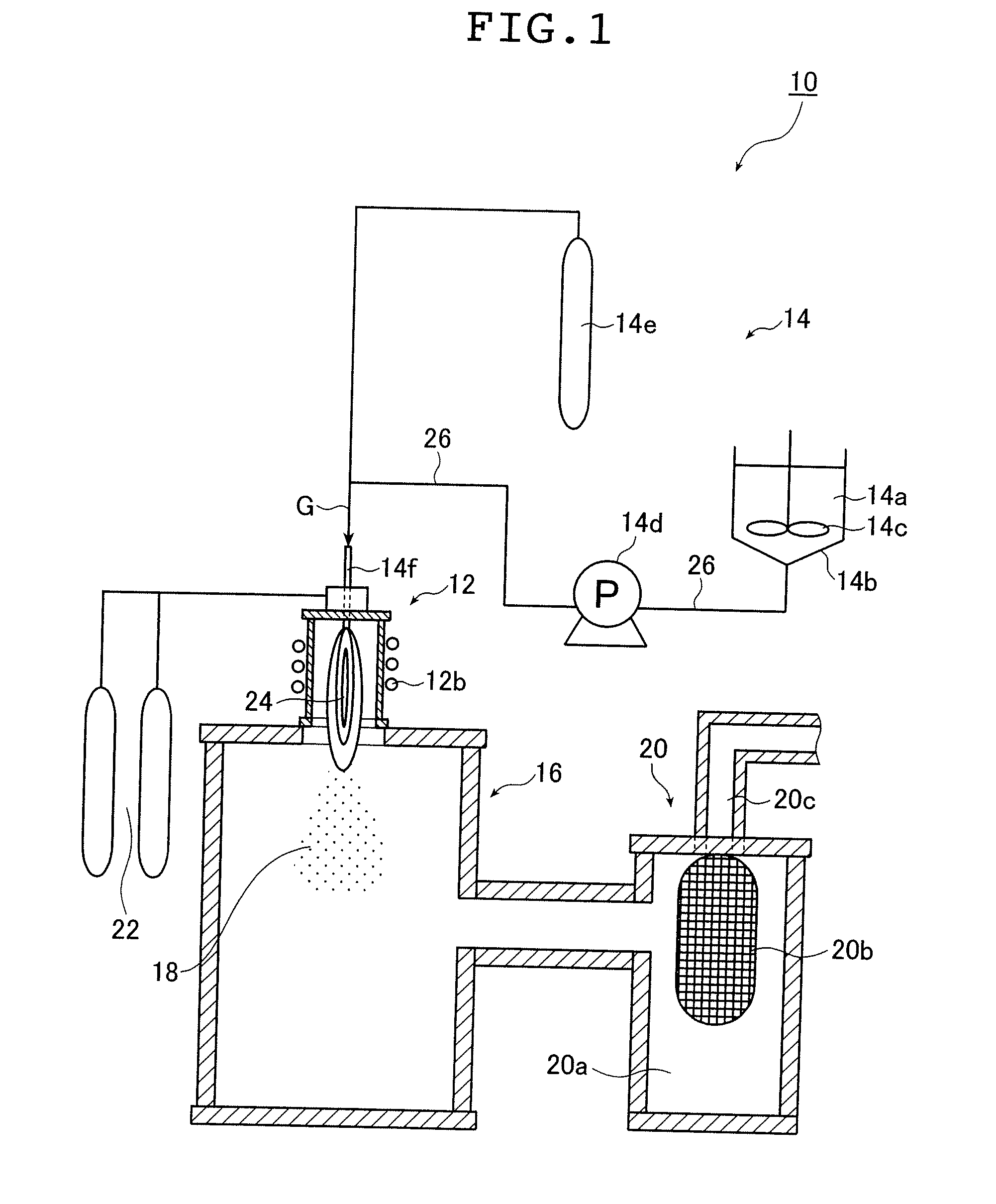

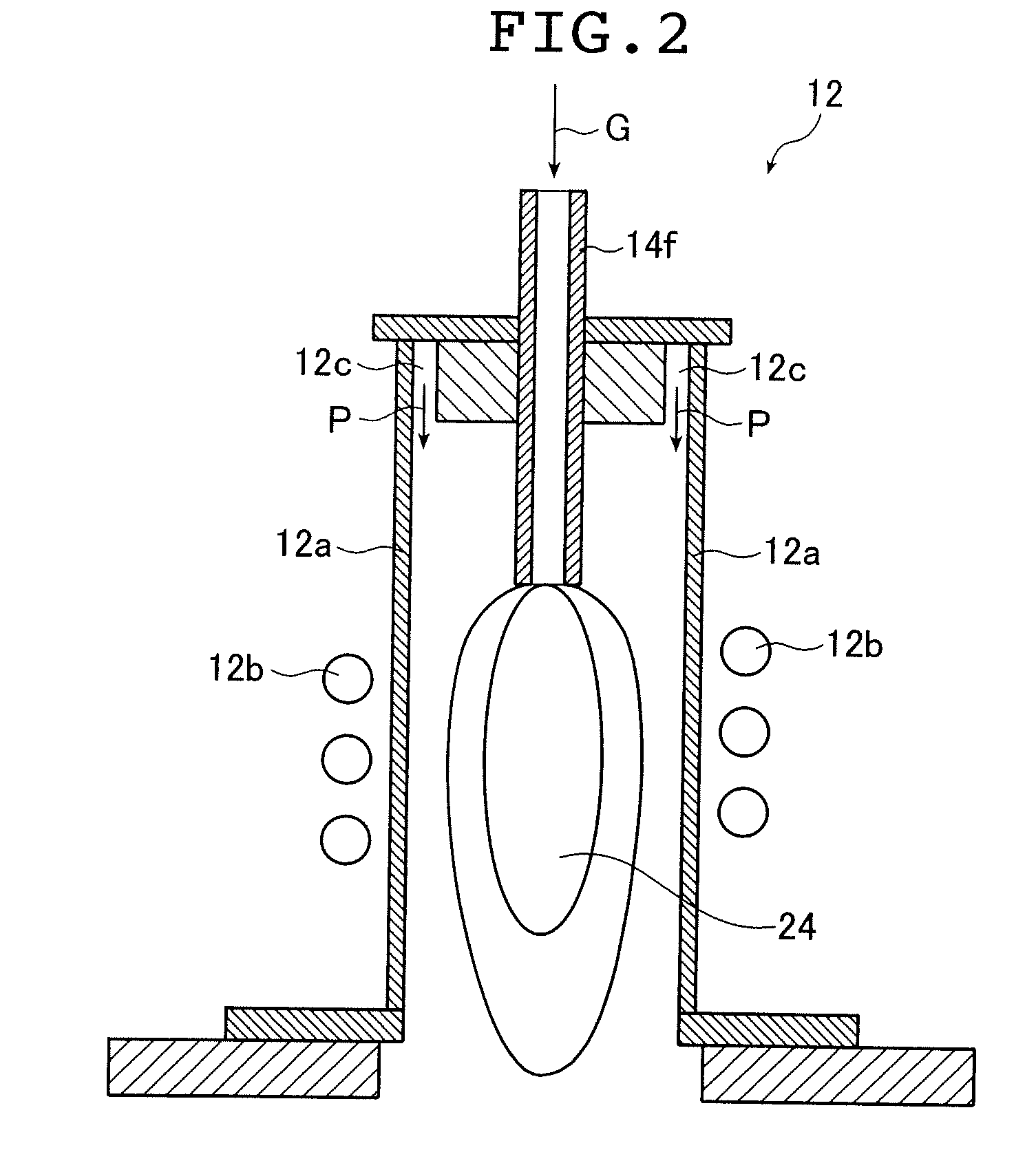

Process and Apparatus for Producing Fine Particles

ActiveUS20080006954A1Improve productivityFunction increaseAlkaline earth titanatesMaterial nanotechnologyGas phaseSlurry

A fine particle producing process introduces a material for producing fine particles into a thermal plasma flame to make a vapor-phase mixture and quenches the vapor-phase mixture to form the fine particles. In the process, the material for producing the fine particles is dispersed or dissolved in a dispersion medium or solvent, preferably containing a combustible material to prepare a dispersion such as a slurry, a colloidal solution or a dissolution solution, the dispersion is made into a form of droplets, or the material for producing the fine particles is dispersed with a carrier gas and a combustible material and the dispersion in a droplet form or the dispersed material is introduced into the thermal plasma flame. In the fine particle producing process and apparatus, a gas of an amount sufficient to quench the vapor-phase mixture is supplied toward a tail of the thermal plasma flame. In the process and apparatus, primary fine particles are introduced into a cyclone to be subjected to cooling and classification and secondary fine particles having a particle size of 100 nm or less which are left upon removal of coarse particles are recovered.

Owner:NISSHIN SEIFUN GRP INC +1

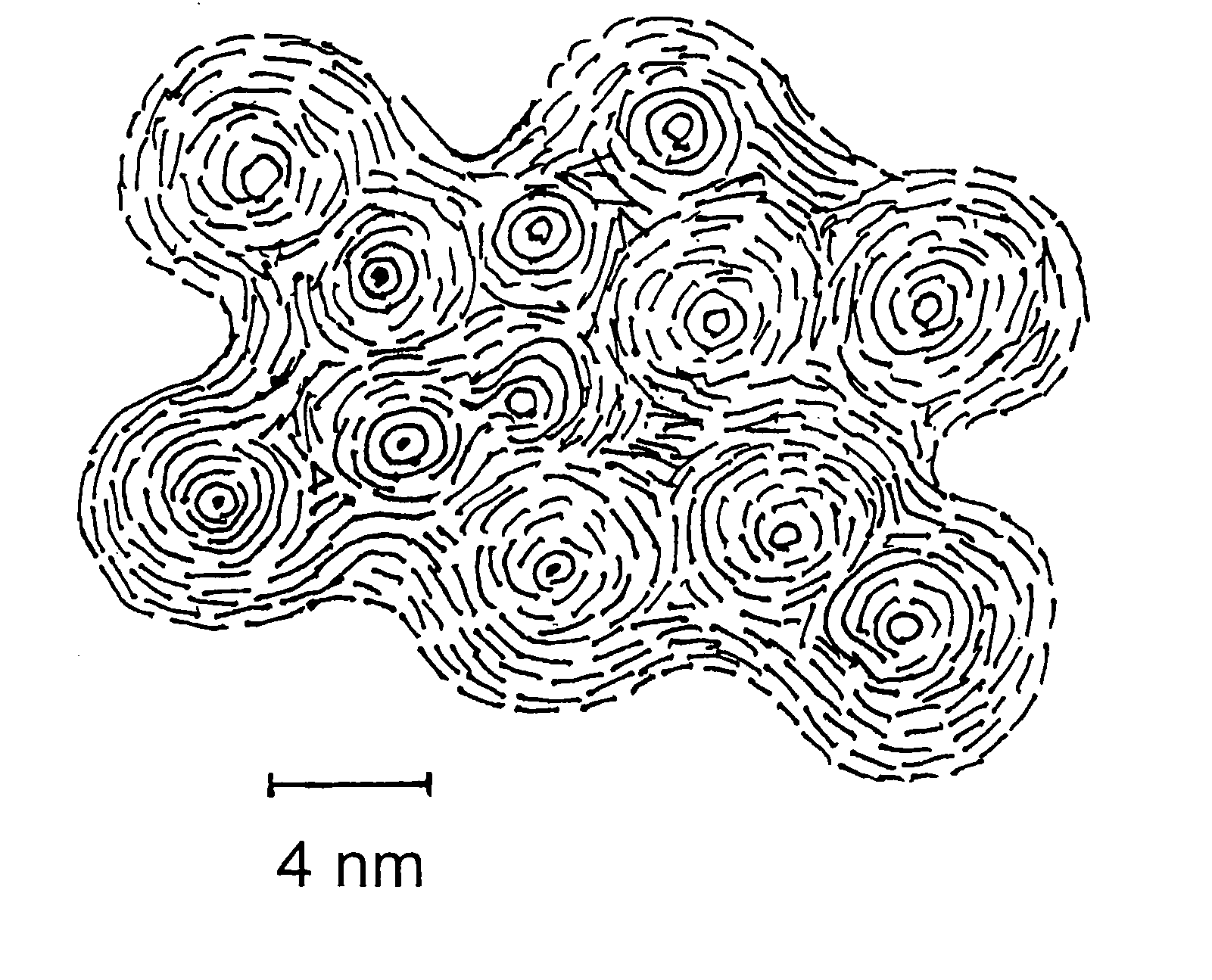

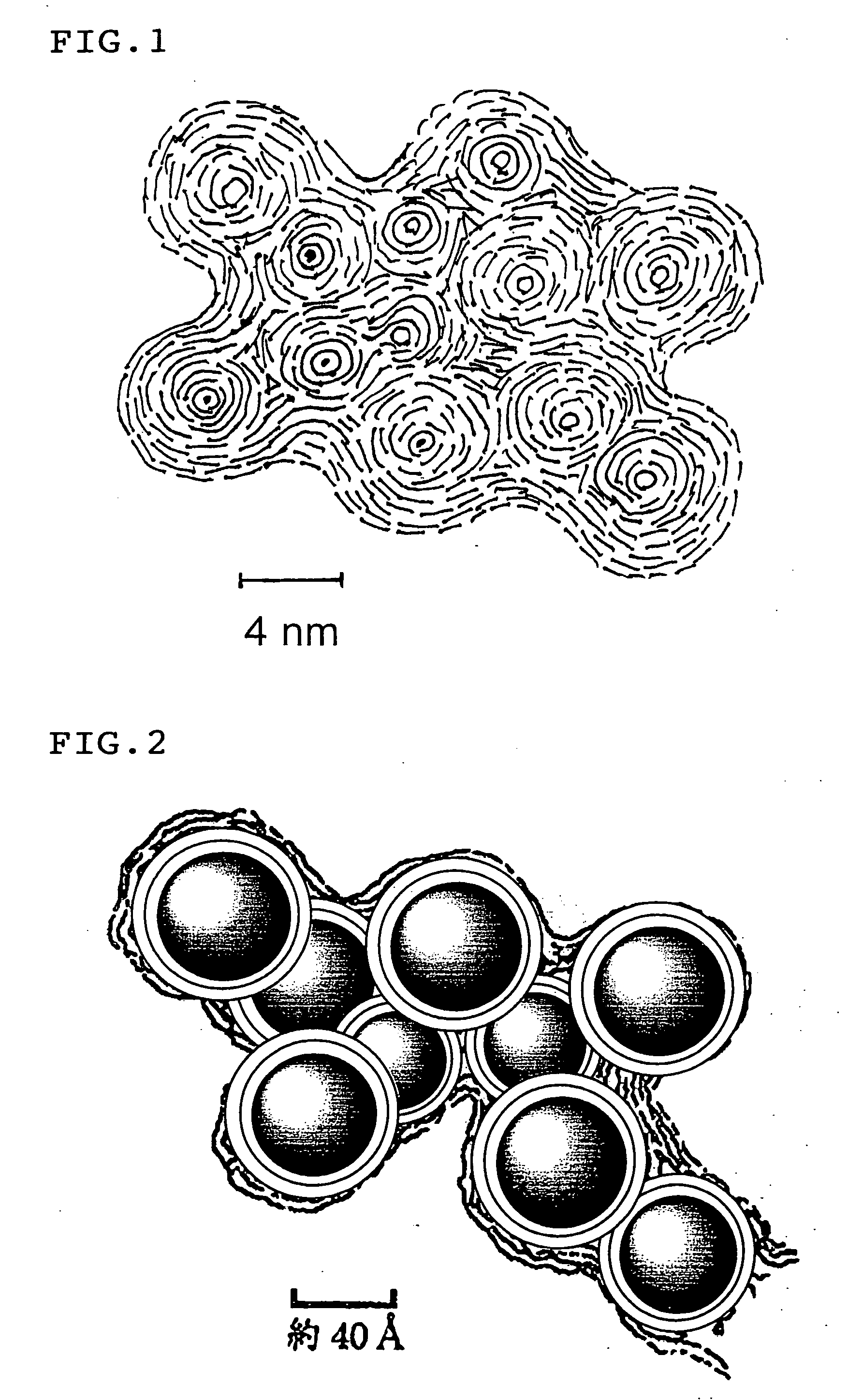

Ultra-dispersed nanocarbon and method for preparing the same

InactiveUS20050008560A1Avoid reorganizationMaterial nanotechnologyPigmenting treatmentDispersed mediaHigh energy

Ultradispersed ones of primary particles of nanometer-sized carbon are obtained by applying a wet-type milling method and / or a wet dispersion method to an aggregate structure of the primary particles to overcome van der Waals forces, by which forces the primary particles are held together to form the aggregate structure, whereby the ultradispersed primary particles are obtained in a colloidal dispersion on a large-scale basis at low cost without using any additive. In a method of manufacturing the ultradispersed primary particles, the wet-type milling method is carried out in a ball mill, preferably in combination with a high-energy ultrasonic-wave process carried out in a dispersing medium such as pure water, whereby a colloidal solution or slurry with a low-concentration of the primary particles ultradispersed in the dispersing medium is obtained.

Owner:FUTABA CORPORATION +2

Making colloidal ternary nanocrystals

InactiveUS20100289003A1Short radiative lifetimeFluorescence stabilizationPolycrystalline material growthFrom normal temperature solutionsNanocrystalSemiconductor

A method of making a colloidal solution of ternary semiconductor nanocrystals, includes providing binary semiconductor cores; forming first shells on the binary semiconductor cores containing one of the components of the binary semiconductor cores and another component which when combined with the binary semiconductor will form a ternary semiconductor, thereby providing core / shell nanocrystals; and annealing the core / shell nanocrystals to form ternary semiconductor nanocrystals containing a gradient in alloy composition.

Owner:EASTMAN KODAK CO

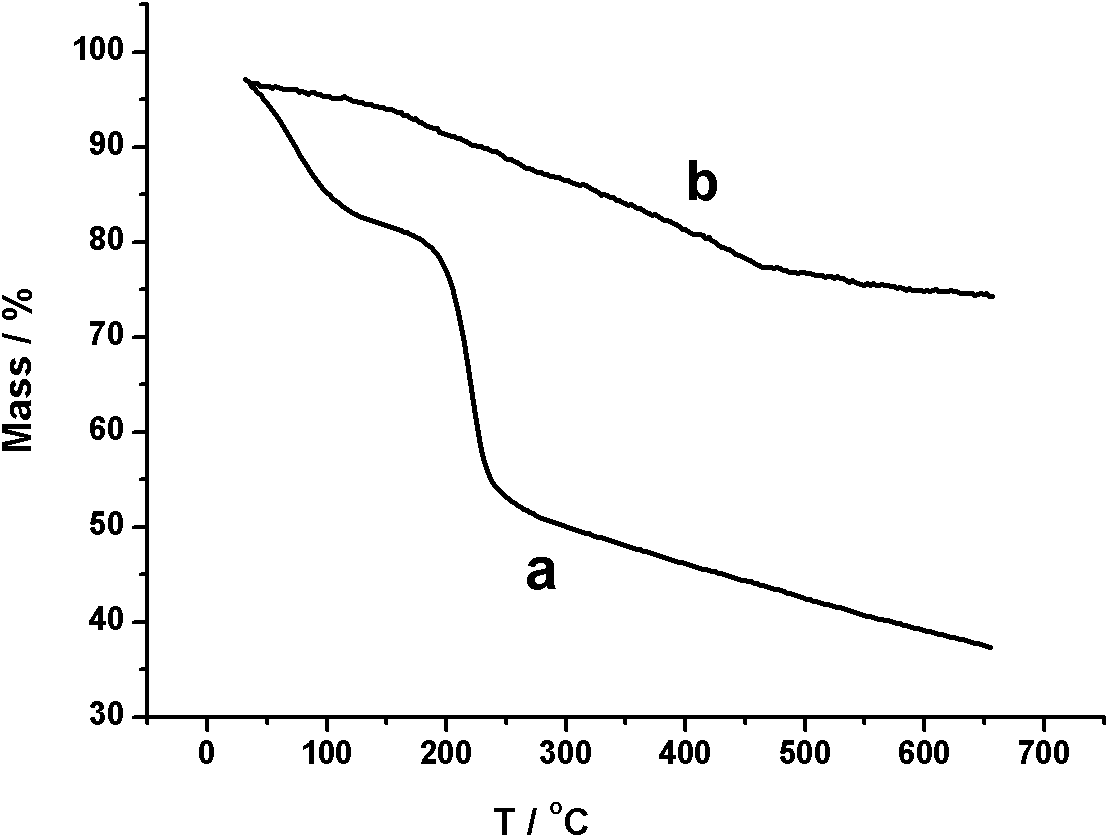

A kind of preparation method of graphene material

The invention discloses a preparation method of a graphene material. The preparation method comprises the following steps of: with graphite carbon as a raw material, adding potassium hypermanganate and concentrated sulfuric acid in batches in different stages to control an oxidation process of graphite; adjusting the pH value of the oxidized solution to obtain graphene oxide colloidal dispersing solutions (GOS) with different concentrations; dropwise adding the GOS on the surface of a carrier or spreading out the GOS on a non-intersolubility liquid / liquid interface and drawing into a grapheneoxide thin-film (GOF); carrying out high-speed centrifugation and drying treatment on the GOS to obtain graphene oxide solid powder (GOP); reducing the GOS by selecting an appropriate reducing agent,and centrifugally drying to obtain reduced graphene solid powder (GRP); dispersing a proper amount of GRP in an organic solvent to prepare a reduced graphene oxide colloidal dispersing solution (GRS); and dropwise adding the GRS on the surface of the carrier or spreading out on the non-intersolubility liquid / liquid interface and drawing into the reduced graphene thin-film (GRF). Various graphene materials prepared by the invention are easy to mutually transform; and the concentration of the colloidal solution and the thickness of the thin-film can be controlled in a certain range.

Owner:CENT SOUTH UNIV

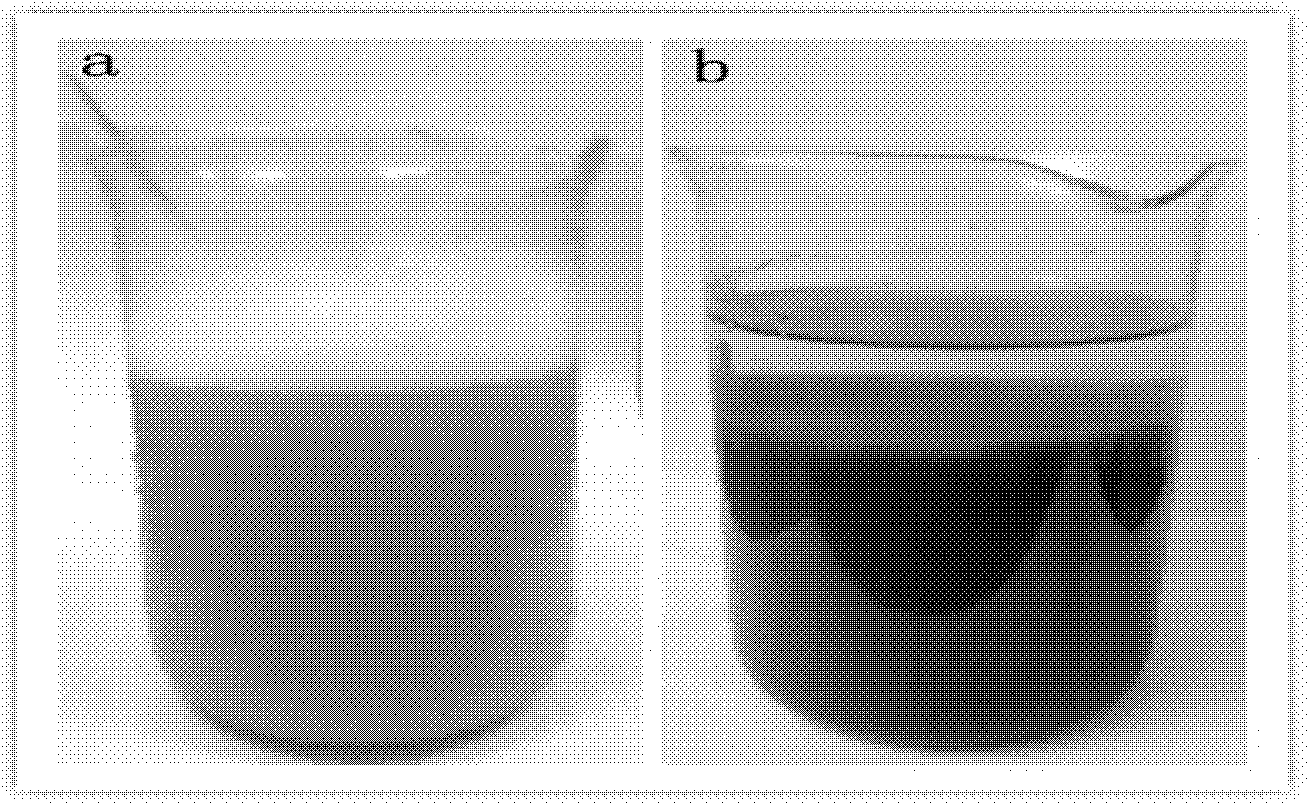

Preparation method of graphene solution phase

The invention relates to a preparation method of graphene solution phase. The method is characterized by comprising the following steps: (1) oxidizing graphite, (2) stripping mother liquid of the oxidized graphite, (3) reducing graphene oxide, wherein, polymer surface-active agent added into colloidal solution of graphene oxide is used as stabilizing agent and hydrazine hydrate is used as reducing agent. Compared with the prior art, the invention has the advantages that the obtained graphene has large area which can reach thousands or more square microns; the effective control of the sizes of graphene product can be realized only by selecting the size of the raw material of graphite, and the size of graphene can be effectively controlled between 20-200 microns; the concentration of the obtained graphene soliquid is high, which can be up to 5-10g / l, the stability of the graphene soliquid is good, and the graphene soliquid can not be subsided when being stewed for months; the method has the advantages of simple whole process, strong controllability and low price of adopted polymer surface active agent, thus being applicable to low-cost and large-scale production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

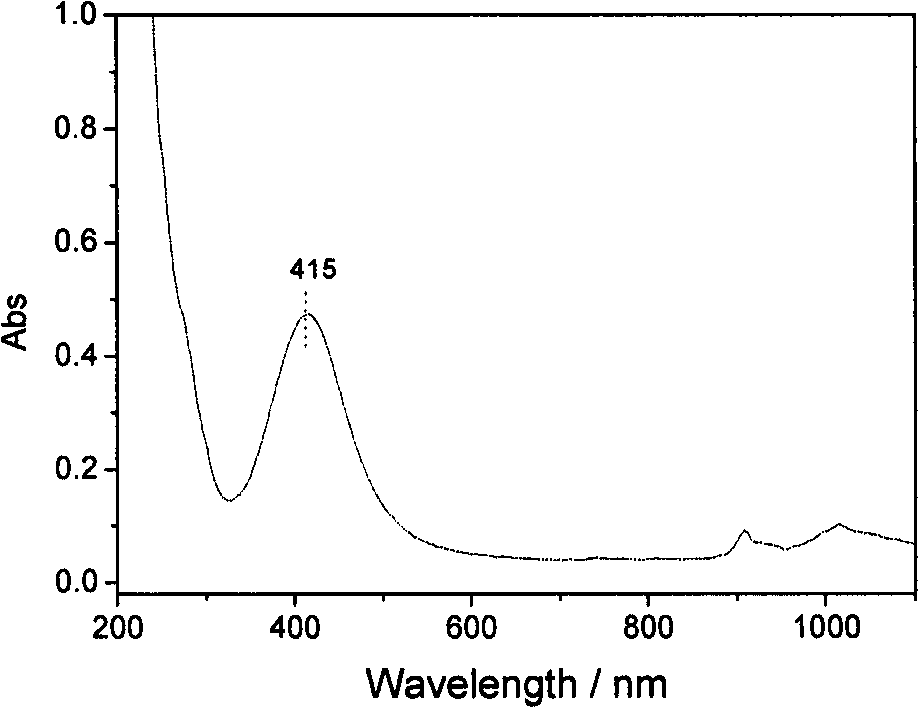

Metallic colloidal solution and inkjet-use metallic ink

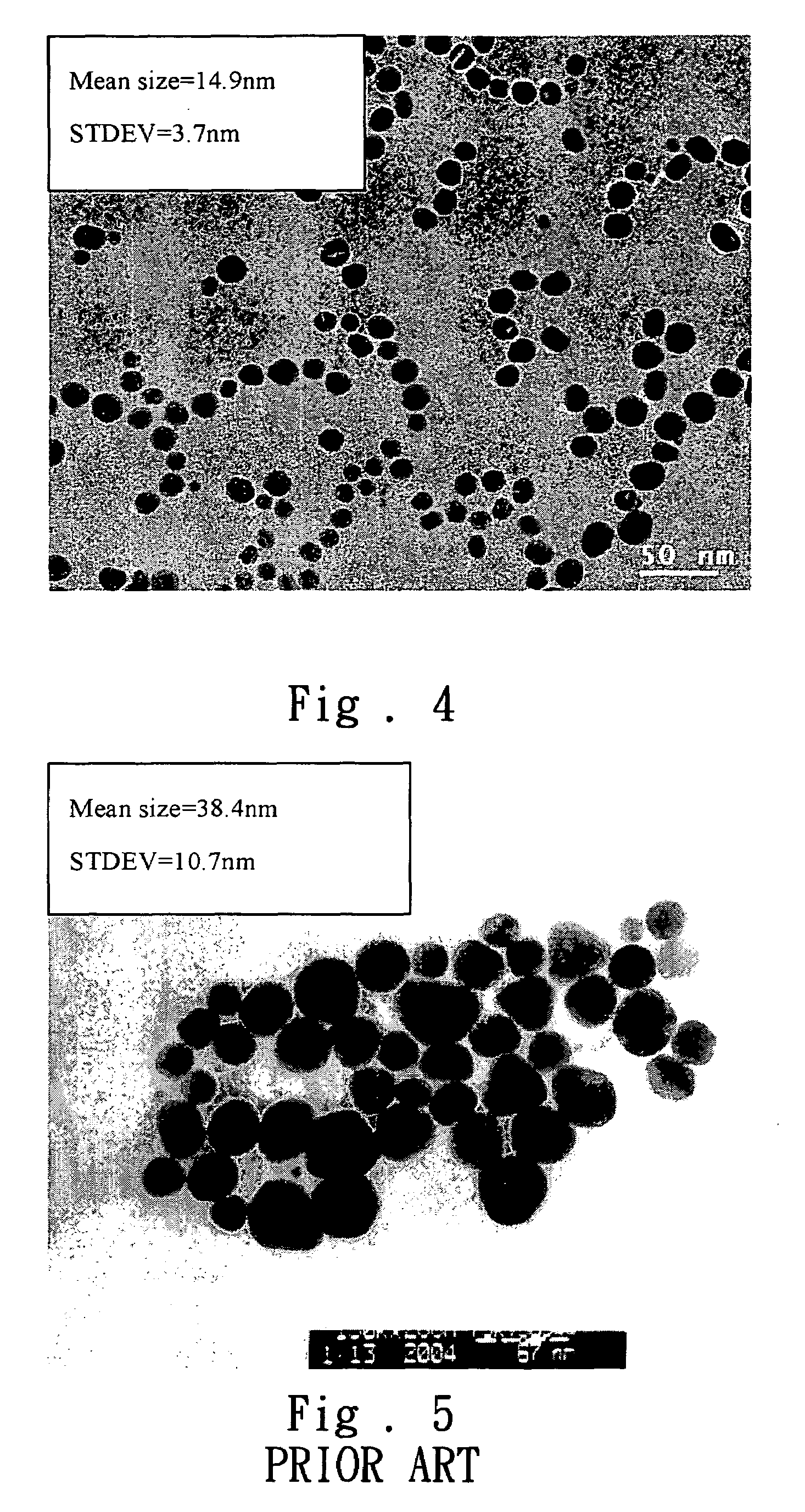

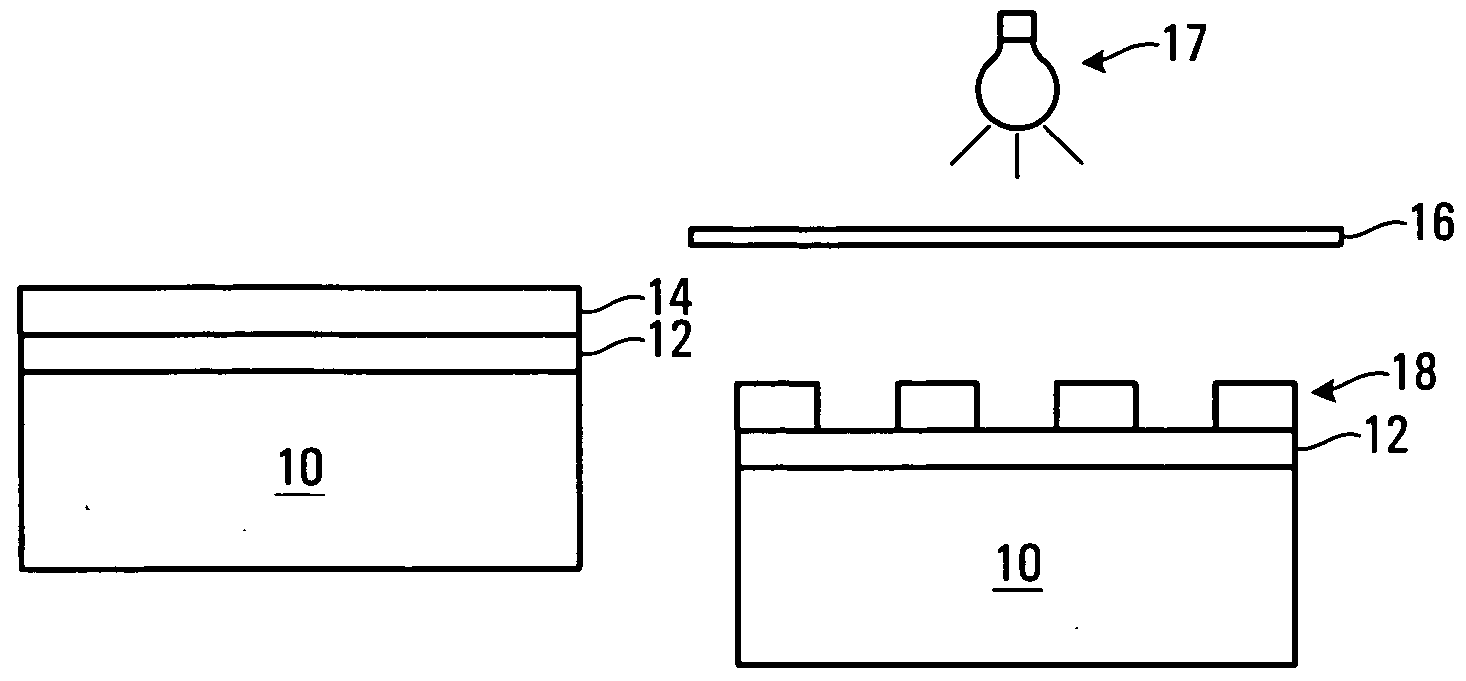

InactiveUS20050189520A1Easy to handleUniform particle sizeLiquid surface applicatorsConductive materialWater basedOrganic solvent

A metallic colloidal solution (a) includes a water-based dispersion medium that is easy in handling with regard to safety and environment and metallic particles having a uniform particle diameter and being excellent in properties such as conductivity and (b) has properties suitable for various printing methods and ink-applying methods. In addition, an inkjet-use metallic ink incorporating the metallic colloidal solution has properties suitable for the inkjet printing method. The metallic particles are deposited by reducing metallic ions in water and have a primary-particle diameter of at most 200 nm. The dispersion medium is made of a mixed solvent of water and a water-soluble organic solvent. The metallic particles are dispersed in the dispersion medium under the presence of a dispersant having a molecular weight of 200 to 30,000.

Owner:SUMITOMO ELECTRIC IND LTD

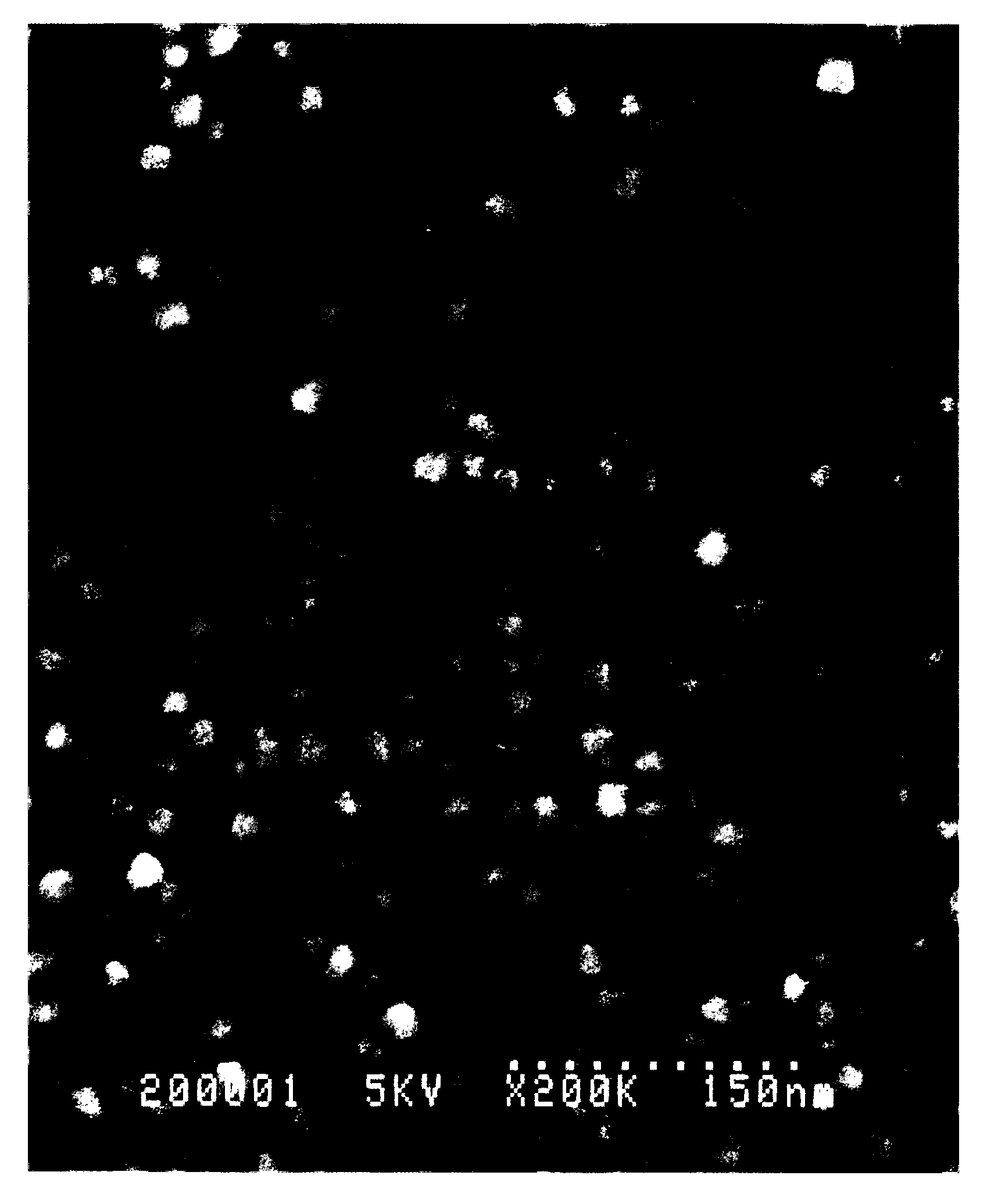

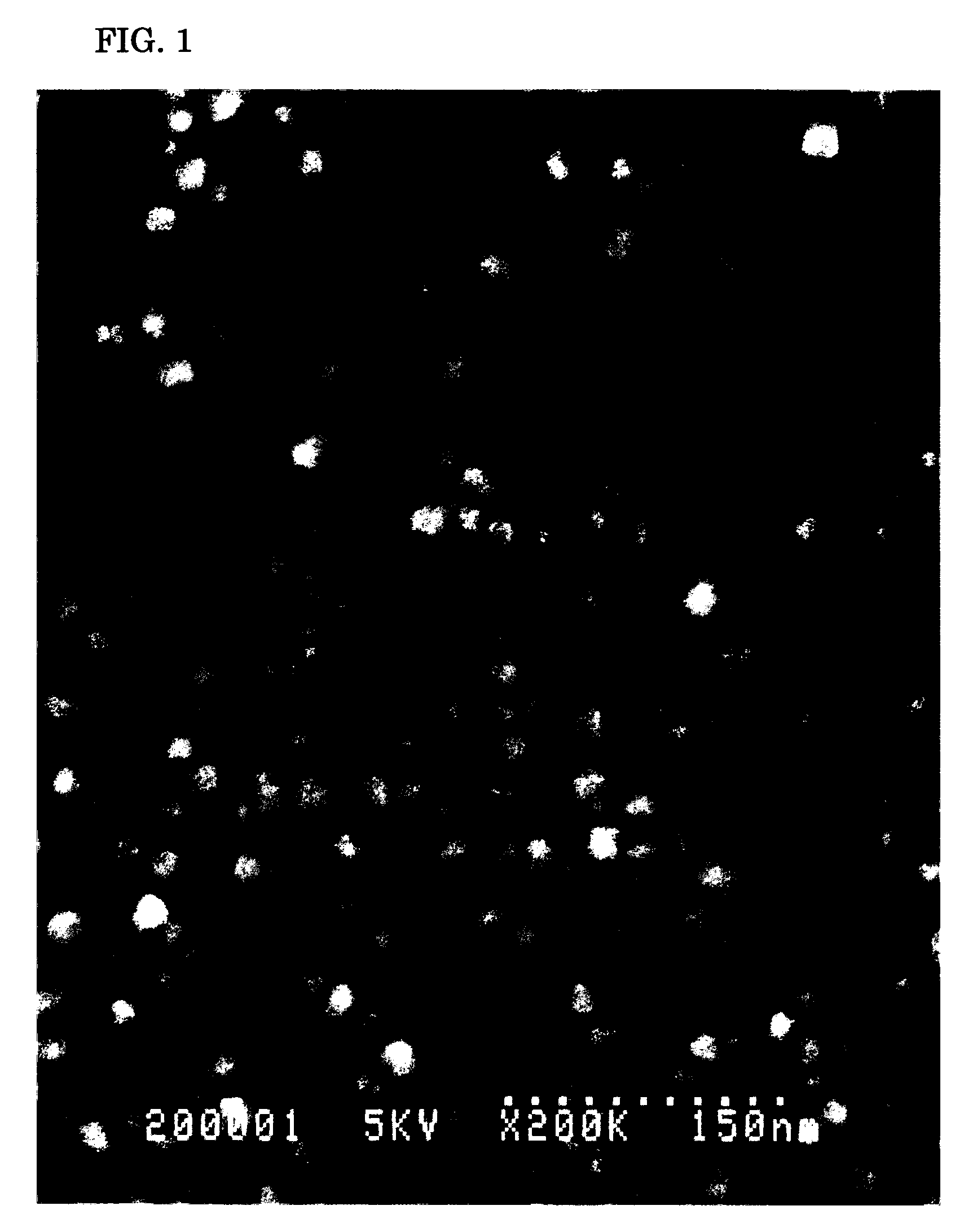

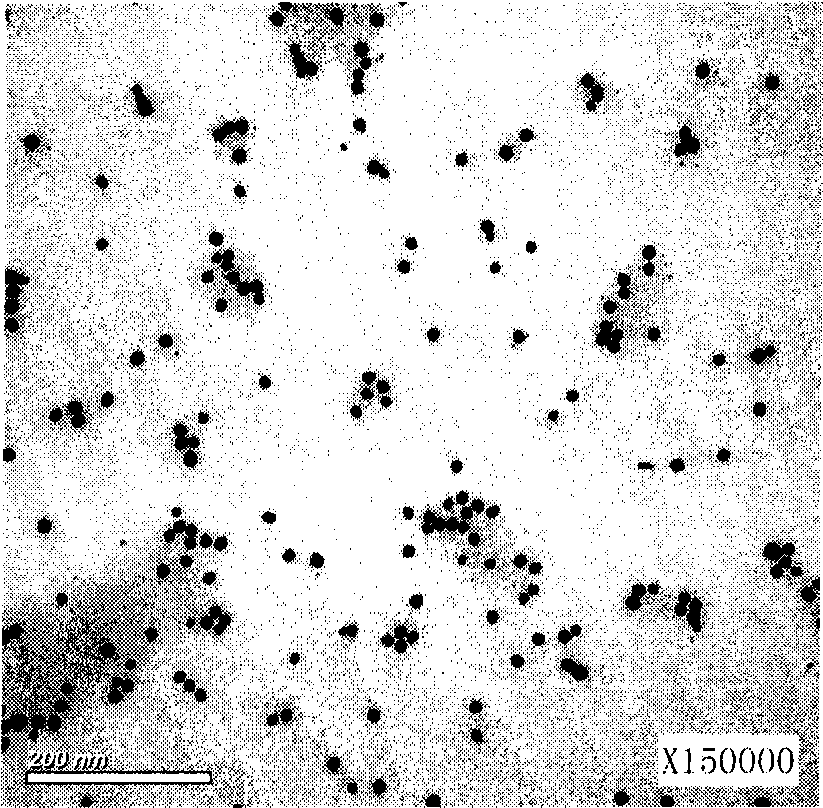

Colloidal nanosilver solution and method for making the same

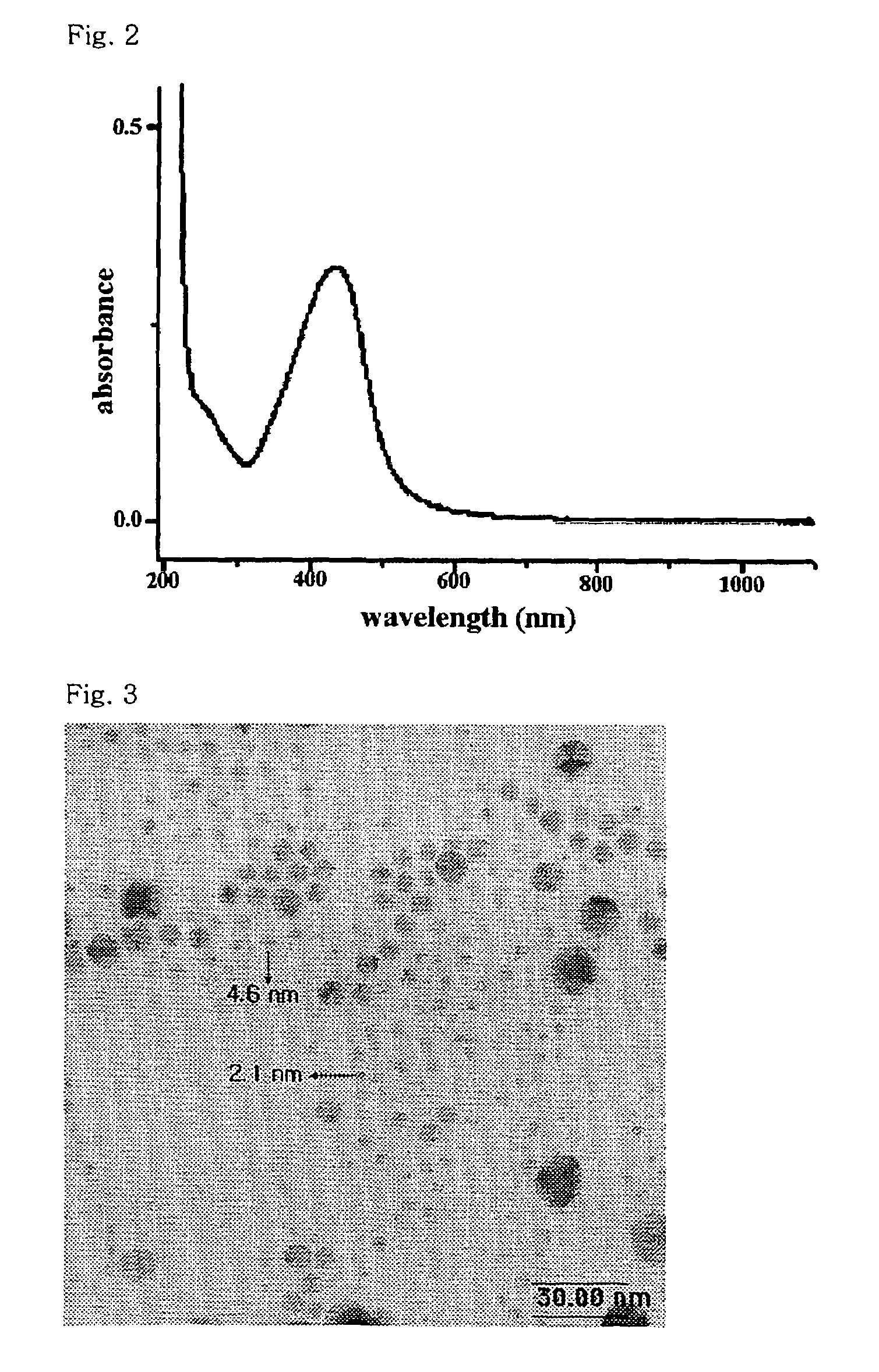

InactiveUS20030185889A1Suitable for useHigh concentrationPowder deliveryBiocideAlginic acidColloidal Solution

The present invention provides a colloidal nanosilver solution which contains nanosilver particles having diameters between 1 nm and 100 nm. The silver content in the colloidal solution is between 0.001% to 0.4% by weight. The colloidal nanosilver solution also contains a gelling agent which includes, but is not limited to, starch or its derivative, cellulose or its derivative, polymer or copolymer of acrylate or acrylate derivative, polyvinyl pyrrolidone, alginic acid, and xanthogenated gel. The present invention also provides a method for making the colloidal nanosilver solution. The colloidal nanosilver solution prepared by this method does not contain any toxic or impure substances.

Owner:CC TECH INVESTMENT

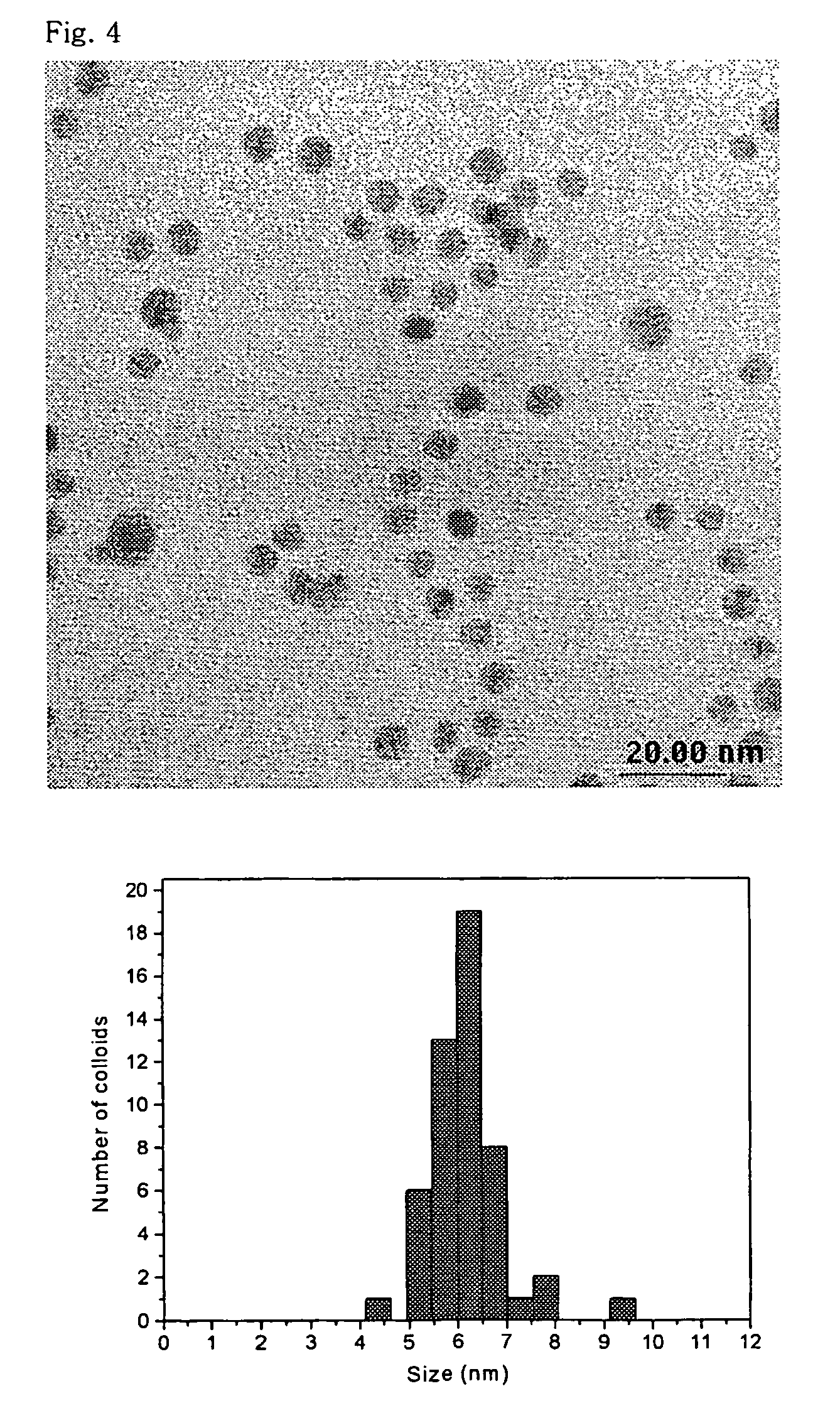

Colloid solution of metal nanoparticles, metal-polymer nanocomposites and methods for preparation thereof

InactiveUS7348365B2Easy to controlGood effectOther chemical processesTransportation and packagingStabilizer for polymersNanometre

A metal nanoparticle colloid solution, metal-polymer nanocomposites, and methods for preparing the same are provided. The metal nanoparticle colloid solution and the metal-polymer nanocomposites can be prepared with a variety of polymeric stabilizers and have uniform particle diameter and shape. The metal nanoparticle colloid solution and the metal-polymer nanocomposites have wide applications, for example, as an antibacterial agent, a sterilizer, a conductive adhesiv, conductive ink or an electromagnetic wave shielder for an image display.

Owner:POSTECH ACAD IND FOUND +1

Biodegradable non-reactive oil-well stimulation fluid and method of use

InactiveUS8778850B2Well remediationIncrease stimulationCleaning apparatusFluid removalParaffin waxSolvent

Formulation for a natural product as a replacement for the use of traditional acidic chemical stimulation methods for the emulsification, removal and release of paraffin and asphaltenes from low producing or pumped off wells and reservoirs with the use of traditional methodologies. Also a method of use of formulation for stimulating an oil well consisting of introducing into the wellbore a biodegradable, non-reactive fluid system containing a water-miscible fatty acid solvent, a solution of fatty acids, an amino alcohol, and at least one non-ionic surfactant. The fluid system may be further in the form of a nanoemulsion that is formed by combining a colloidal solution with one or more emulsifiers, an alcohol, and water. The fluid system may be used in well remediation and stimulation as well as additional, alternative applications such as the cleaning of surface and / or downhole equipment.

Owner:GREEN EARTH TECH

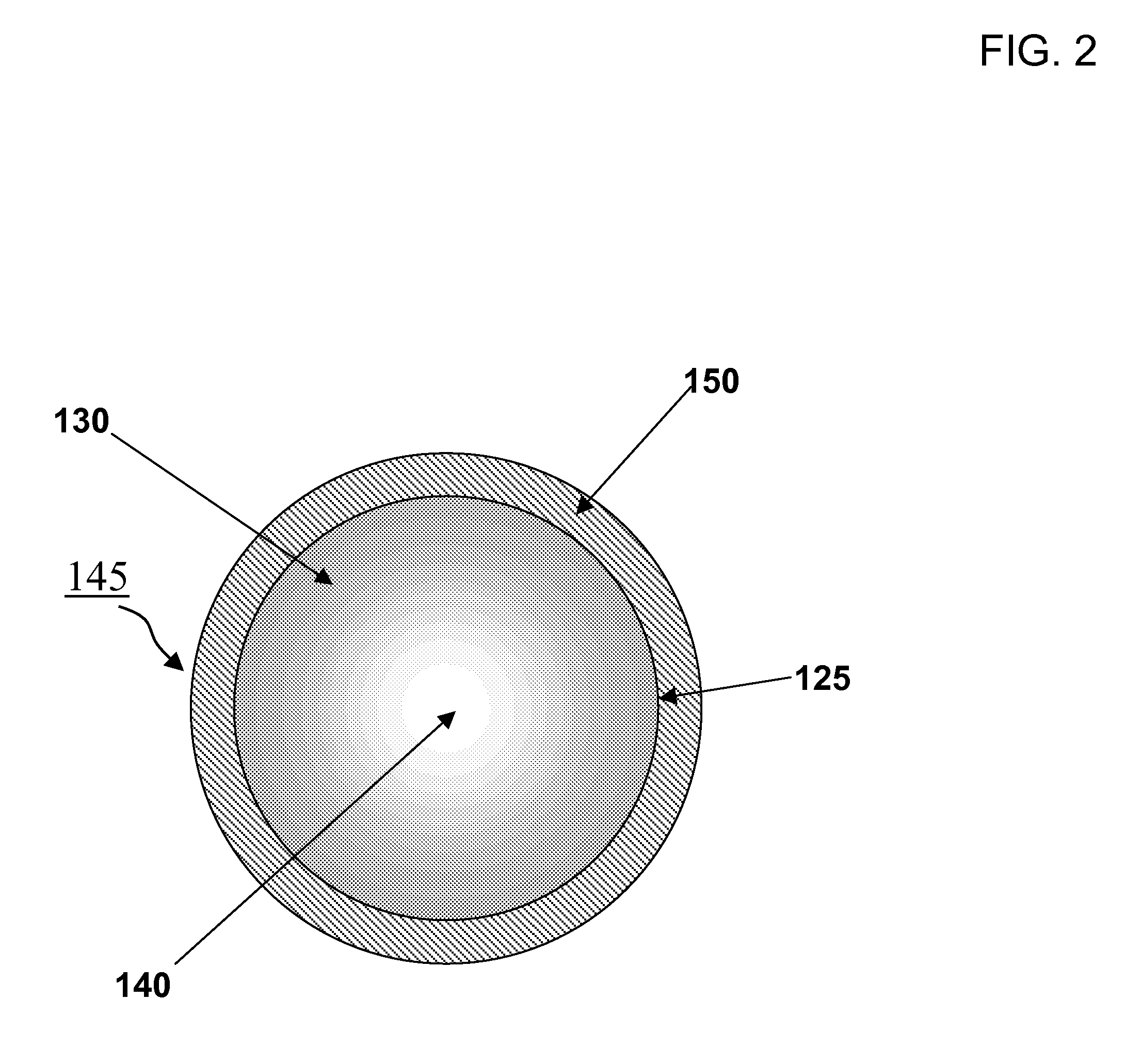

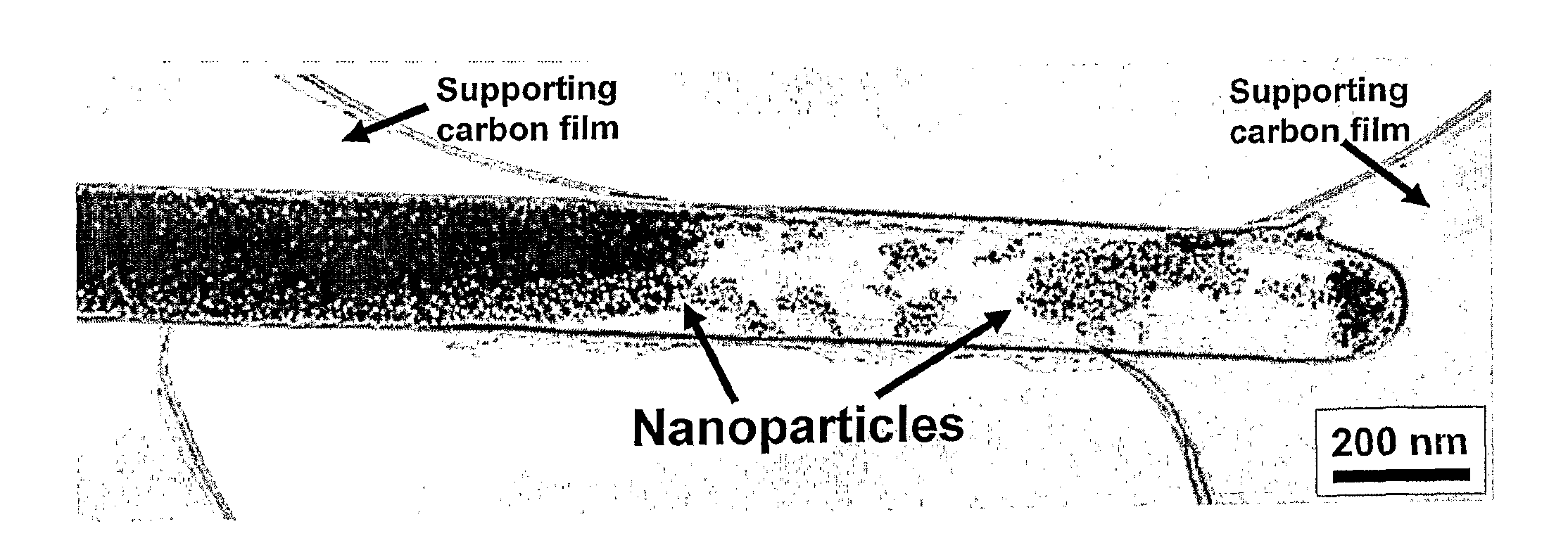

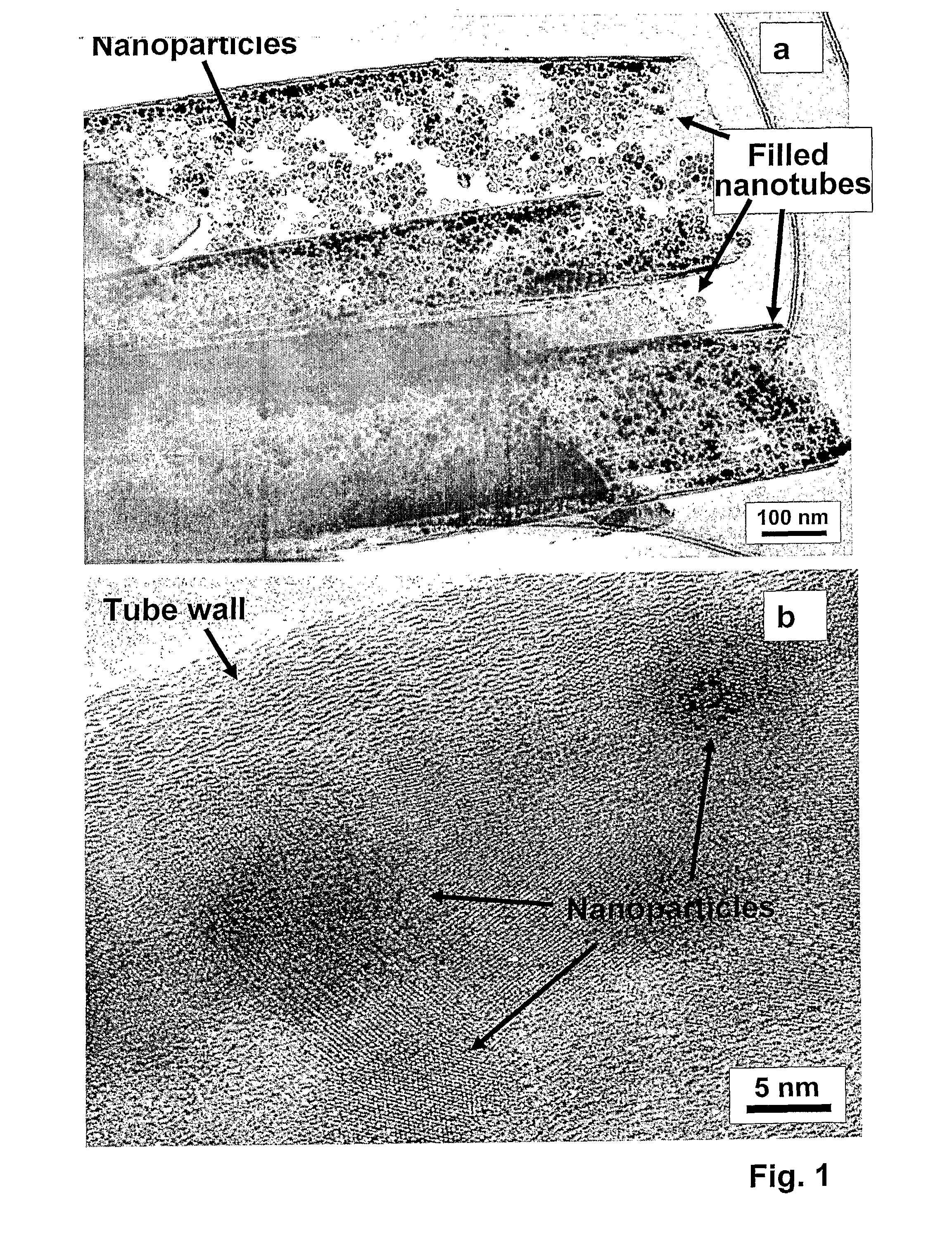

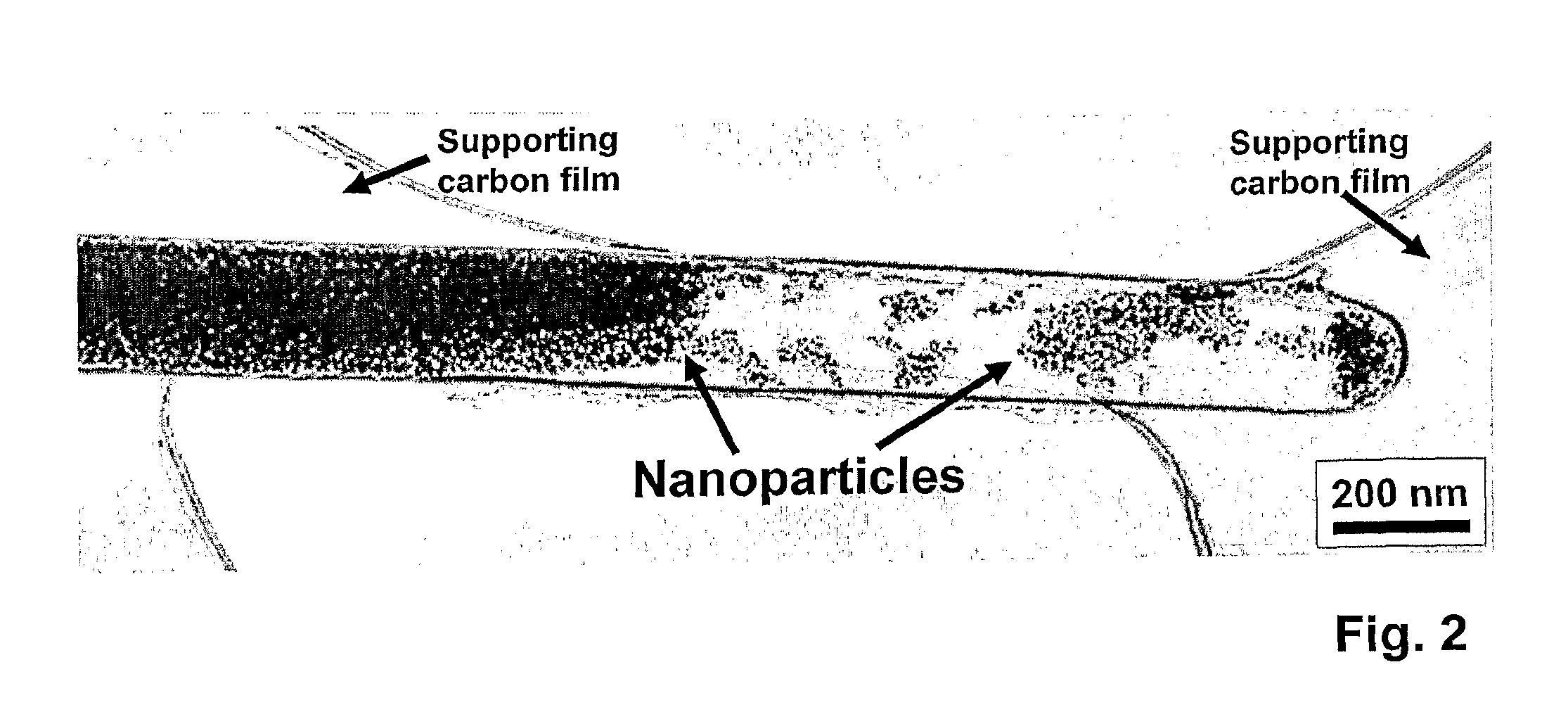

Functional nanoparticle filled carbon nanotubes and methods of their production

Carbon nanotubes filled with a suspension or colloidal solution of functional nanoparticles and methods for production of carbon nanotubes loaded with functional nanoparticles are provided.

Owner:DREXEL UNIV

Nano silicon dioxide emulsion, its preparation method and application

InactiveCN1536032AImprove hydrophilicityGood dispersionEmulsion paintsPigment treatment with non-polymer organic compoundsWater basedEmulsion

The present invention discloses a nano silicon dioxide emulsion, its preparation method and application. Said emulsion contains nano silicon dioxide, silane coupling agent, surfactant and water. The described nano silicon dioxide and the described silane coupling agent are combined into a hydrophobic particle, and the described hydrophobic particles are covered with surfactant, and dispersed in the water. Its preparation method includes the following steps: adding water-soluble alcohol into the colloid solution of silicon dioxide in the water, then adding silane coupling agent and adding surfactant and water; another preparation method includes the following steps: adding water-soluble alcohol or aqueous solution of described alcohol into nano silicon dioxide gel, then adding silane coupling agent, surfactant and water. Said emulsion can be directly added into the water-based paint, and can be used for modifying water-based paint and improving various properties of the water-based paint.

Owner:ZHEJIANG YUDA CHEM IND

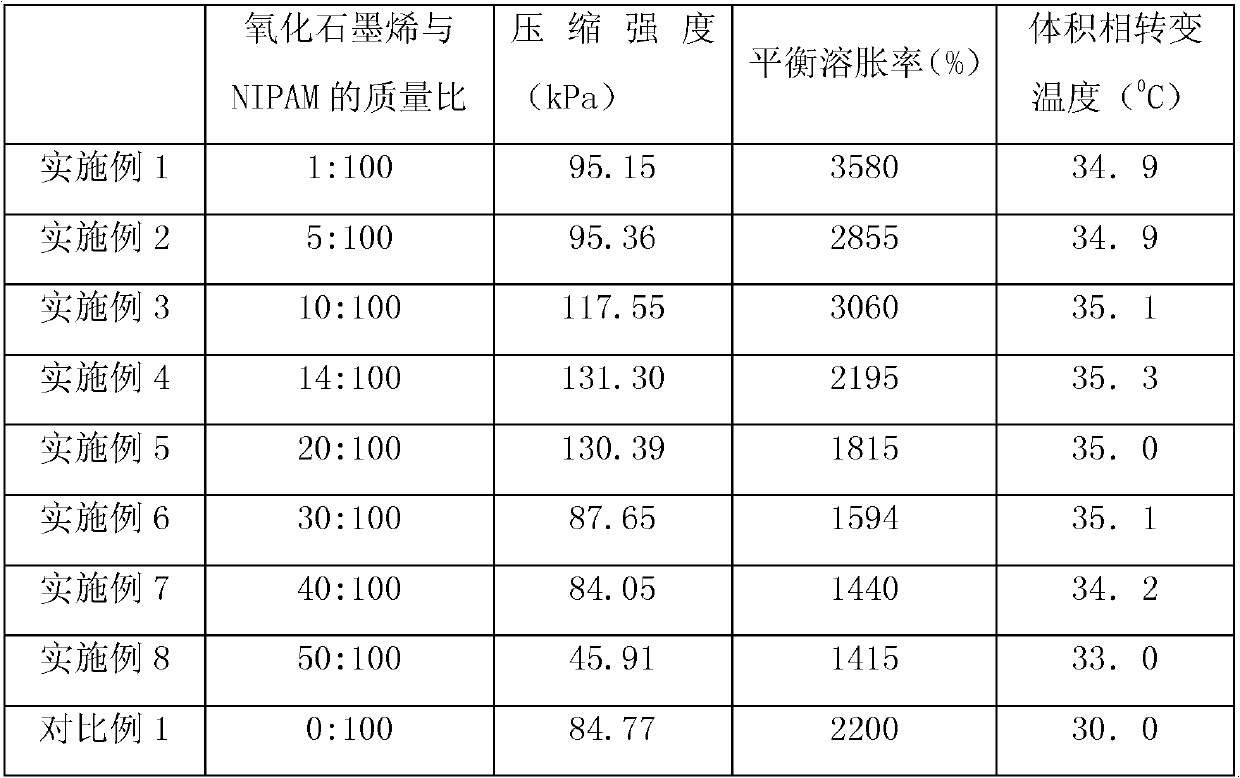

Preparation method of graphene oxide/poly(N-isopropylacrylamide) composite hydrogel

InactiveCN102580633AIncrease temperatureImprove mechanical propertiesColloidal chemistry detailsWater bathsCross-link

The invention discloses a preparation method of graphene oxide / poly(N-isopropylacrylamide) composite hydrogel. The preparation method comprises the steps of: firstly, placing the graphene oxide in water and ultrasonically dispersing the graphene oxide for 30-60 min to obtain a graphene oxide colloidal solution; then adding N-isopropylacrylamide, a cross-linking agent and an initiator 1 in the graphene oxide colloidal solution; stirring for dissolving so as to obtain a mixed solution; then inflating nitrogen in the mixed solution to deoxidize fully, then adding an initiator 2 in the deoxidized mixed solution, mixing uniformly and placing the mixture in a thermostatic water bath at 25+ / -1 DEG C so as to obtain the graphene oxide / poly(N-isopropylacrylamide) composite hydrogel. The graphene oxide / poly(N-isopropylacrylamide) composite hydrogel prepared by the method disclosed by the invention has the advantages of good temperature responsiveness and mechanical property and wide application prospect in the biomedical field (such as tissue engineering and drug controlled release).

Owner:QINGDAO UNIV

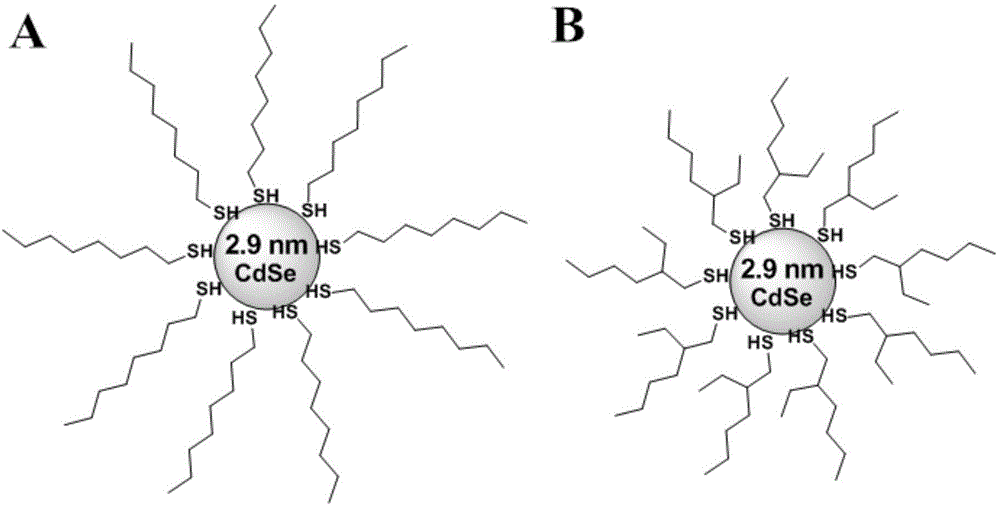

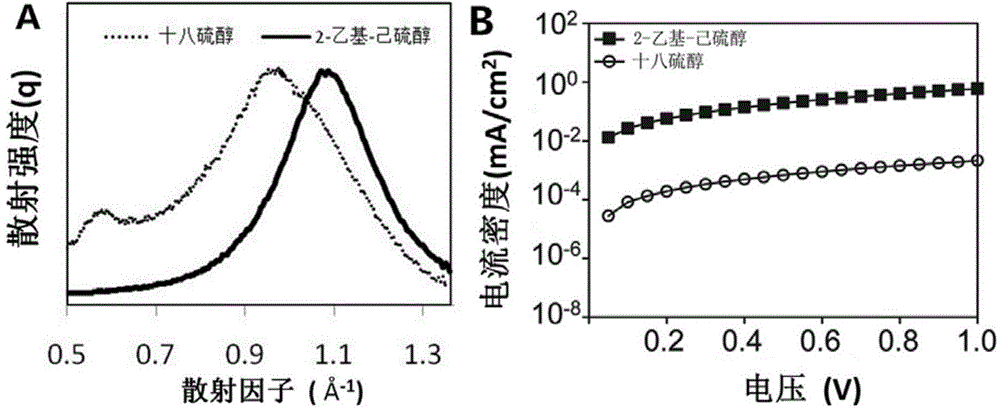

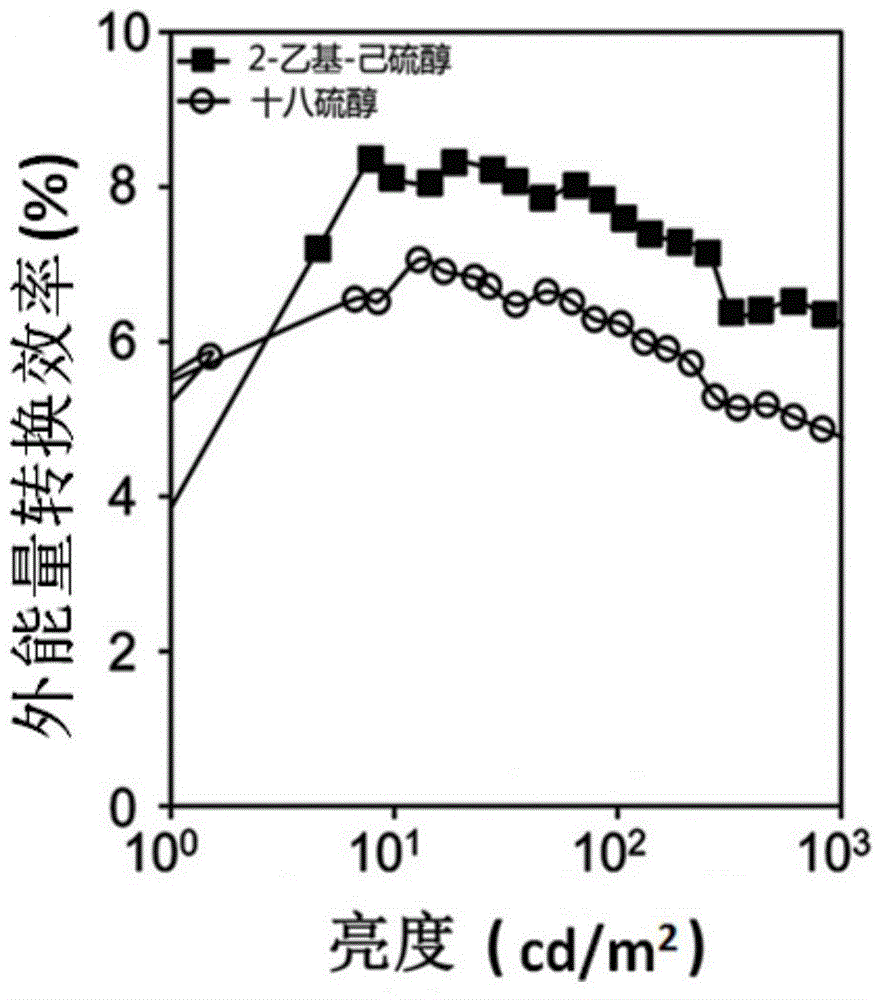

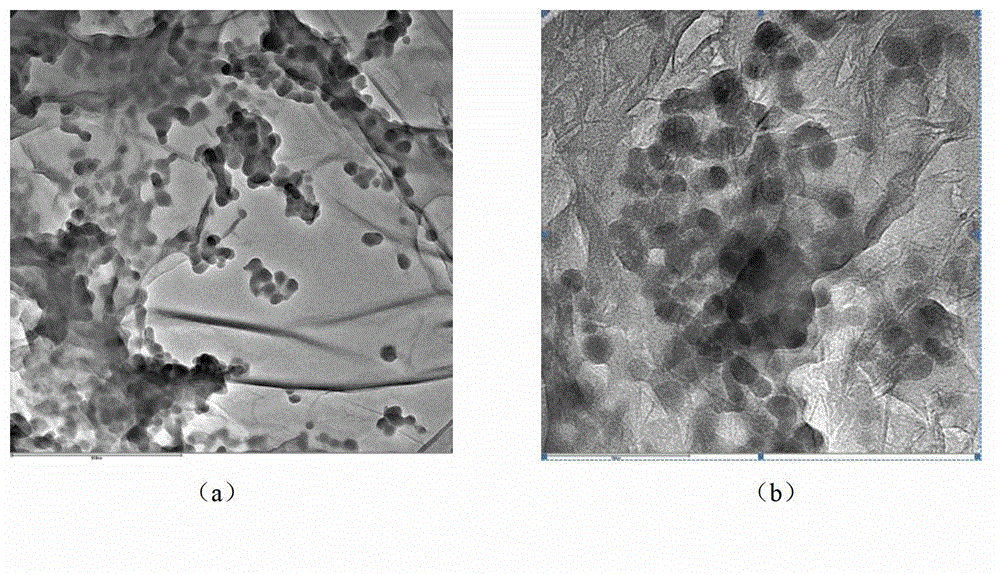

Nanocrystalline-ligand compound, preparation method of nanocrystalline-ligand compound, printing material and use of printing material

ActiveCN105985774APrevent coagulationImprove solubilityStampsDuplicating/marking methodsSolubilityChain structure

The invention provides a nano crystal-ligand complex, a preparation method thereof, a printing material and an application of the printing material. The nanocrystal-ligand complex includes nanoparticles and entropy ligands that form surface coordination with the nanoparticles; wherein, the entropy ligands have a branched chain structure, and the total number of main chain skeleton atoms and branch chain skeleton atoms is ≤ 30. In the above-mentioned nanocrystal-ligand complex, the entropy ligand used is different from the traditional linear ligand, which has a branched chain structure, and the total number of main chain skeleton atoms and branch chain skeleton atoms is ≤30. This entropy ligand can effectively inhibit the interaction between nanoparticles and nanoparticles in the solution, and because the C-Cσ bond on it can rotate freely, it can effectively increase the solubility of nanoparticles in the solvent, thereby effectively inhibiting the The coagulation and precipitation of nanoparticles in the solvent greatly improves the stability and processability of the nanoparticle colloidal solution, which is more suitable for application in printing materials.

Owner:NANJING TECH CORP LTD +1

Mesoporous graphite type carbon nitride/nitrogen doped graphene sol nanocomposite and method for preparing same

ActiveCN102974283ASimple processLow costMaterial nanotechnologyColloidal chemistry detailsNew energyNitrogen doped graphene

The invention belongs to the technical field of new energy materials and preparation thereof, and relates to a mesoporous graphite type carbon nitride / nitrogen doped graphene sol nanocomposite and a method for preparing the same. The method comprises the following steps that: graphene oxide and a surfactant are added into deionized water and are ultrasonically mixed uniformly to obtain a colloidal solution; mesoporous graphite type carbon nitride is added to be continuously and ultrasonically treated, and a nitrogen-containing compound is then added to be stirred at constant temperature to form a mixed solution; and hydrothermal reaction and natural cooling are then carried out, ammonia which is adsorbed to a material surface is removed through washing, and the material is dried. The yield of the prepared mesoporous graphite type carbon nitride / nitrogen doped graphene sol nanocomposite is high, and the mesoporous graphite type carbon nitride / nitrogen doped graphene sol nanocomposite has a wide application scope, can be applied to fuel cells, photodegradation reactors and the like. The method has the advantages of simplicity in technology, low cost, high yield, short period and environmental friendliness, and can be suitable for industrially producing the mesoporous graphite type carbon nitride / nitrogen doped graphene sol nanocomposite in a large scale.

Owner:TONGJI UNIV

Method for self-assembling photonic crystal

ActiveCN101338447AIncrease profitLarge deposition areaFrom gel stateColloidal chemistry detailsPhotonic crystalPhotonic-crystal fiber

A self-assembling photonic crystal method relates to a preparation method of photonic crystal. The invention solves the problems existing in the current method that the photo crystal with large area can not be prepared and the prepared photonic crystal can not be bent. The method comprises the procedures as follows: (1) the surface of a base plate is treated: (2) colloidal solution is prepared: and (3) the base plate is put into a vessel and the colloidal solution is added into the vessel; the colloidal solution volatilizes under the constant temperature of 20 DEG C to 70 DEG C; the photonic crystal is taken out until no substance volatilizes, and the photonic crystal is made. The self-assembling photonic crystal can make the single or double sides of the photonic crystal deposit on the base plate, thus making the photonic crystal deposit on the base plate to a maximum.

Owner:HARBIN INST OF TECH +1

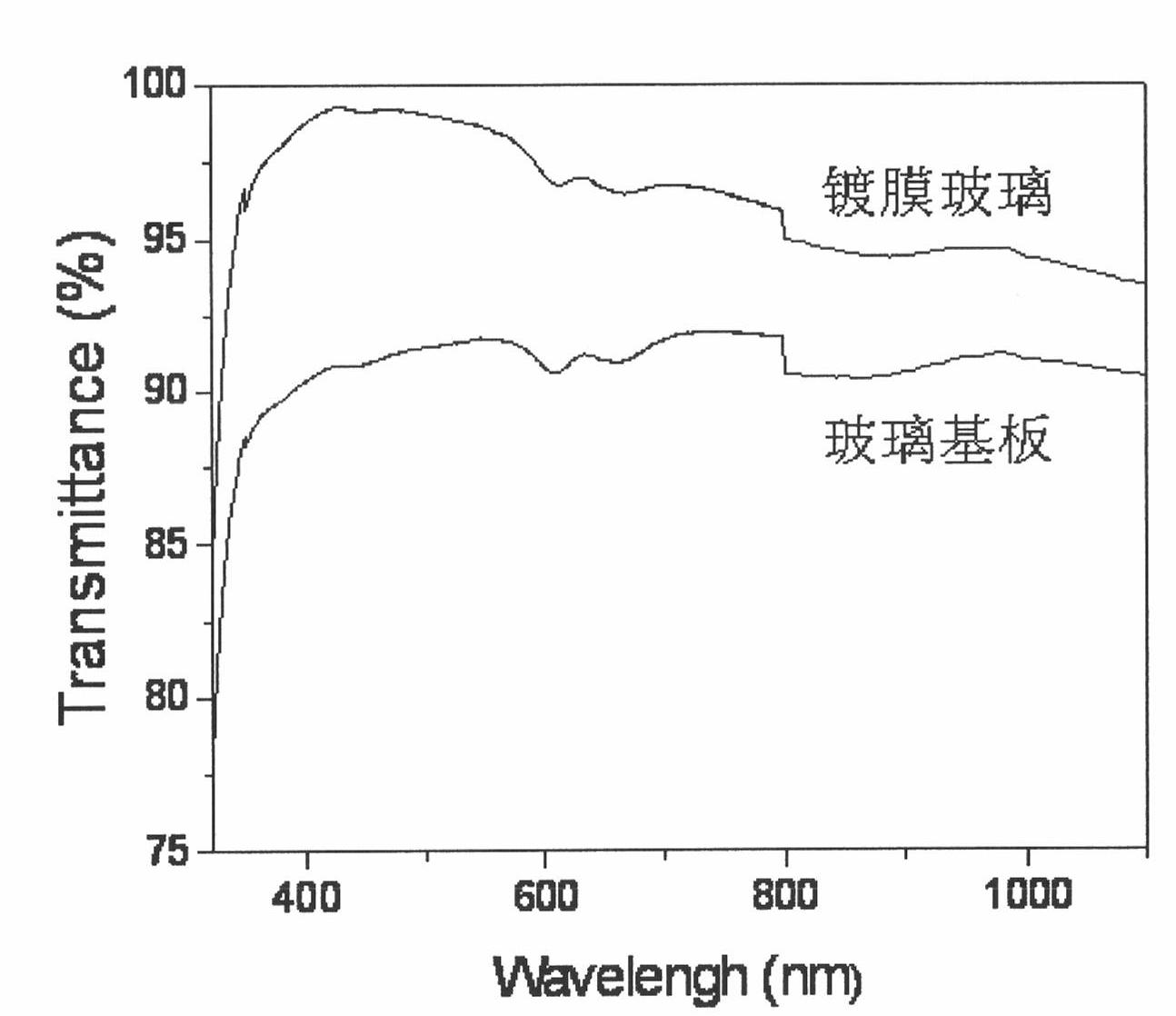

Preparation method of composite metal organic framework material colloidal solution and application thereof in optical coatings

InactiveCN102061112AImprove transmittanceImprove wear resistanceCoatingsOptical elementsWeather resistanceOptical coating

The invention discloses a preparation method of a composite metal organic framework material colloidal solution and application thereof in optical coatings. The composite material is formed by compounding silicon sol and a metal organic framework material colloidal solution, and then the composite material is coated on a substrate and cured at high temperature to obtain a film with an anti-reflection function. The film has high transmissivity, and the light transmissivity of the film is obviously improved within the sunlight spectrum, particularly in a visible light range, and moreover, the film has good wear resistance and weather resistance.

Owner:EAST CHINA NORMAL UNIV

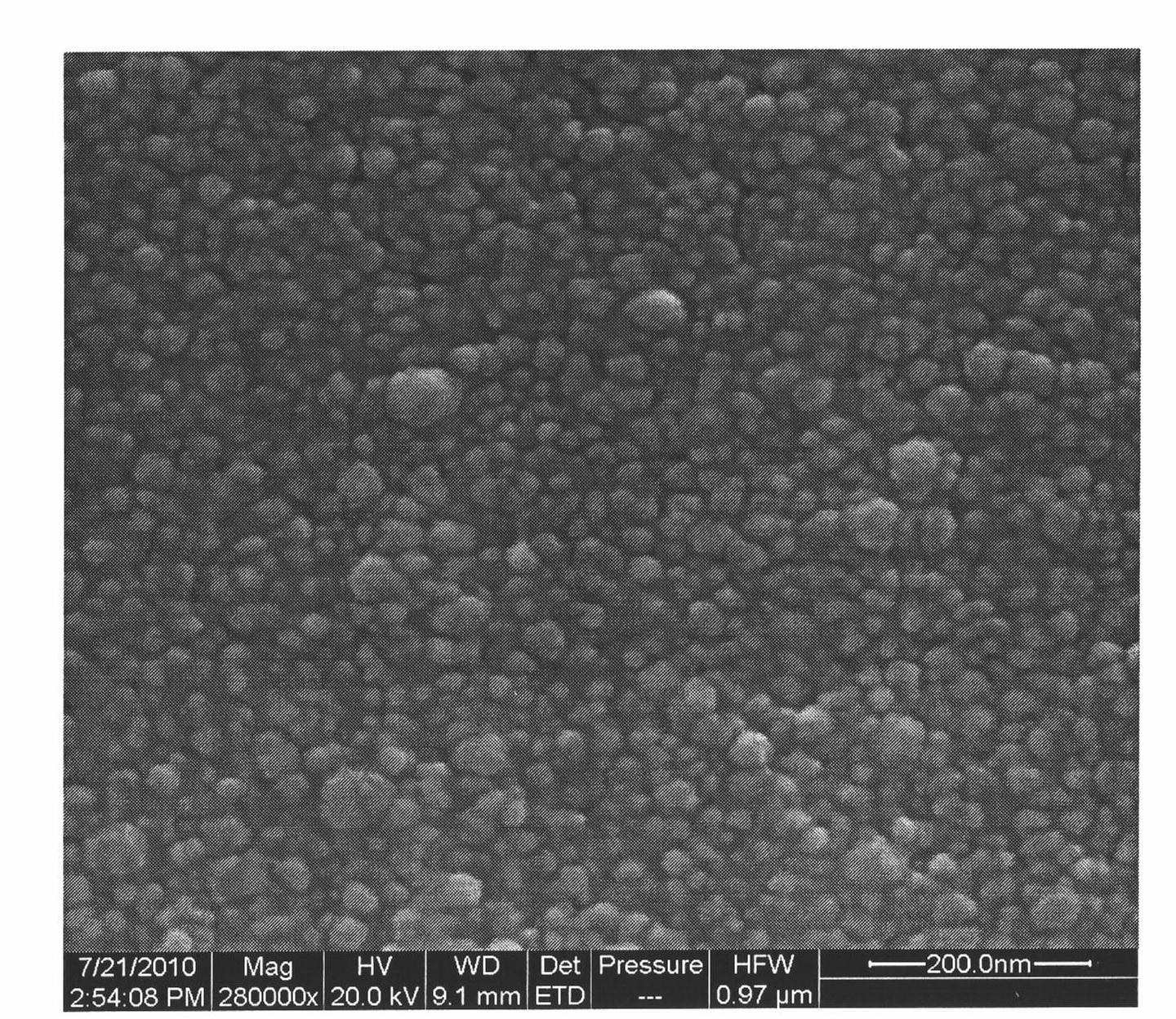

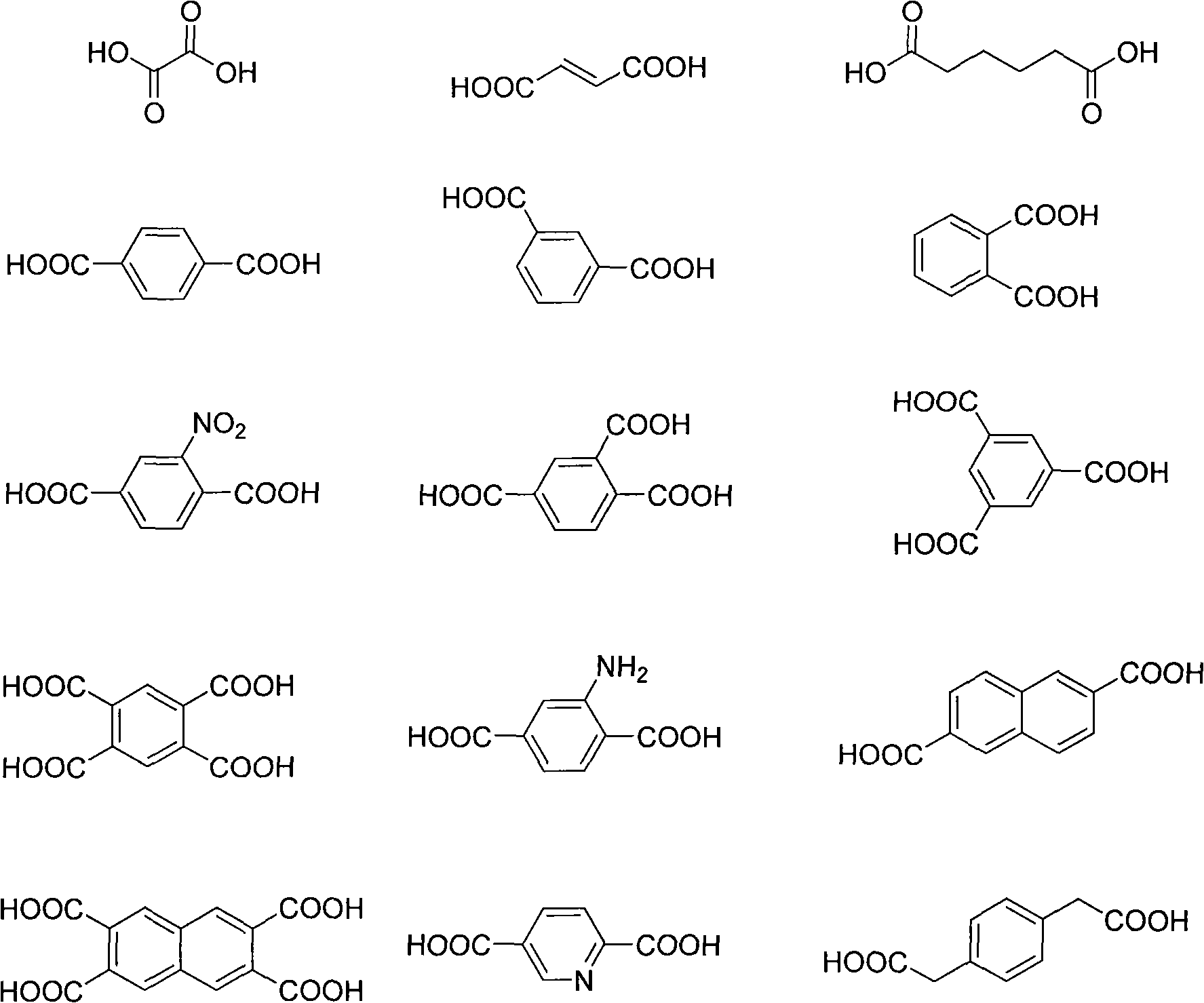

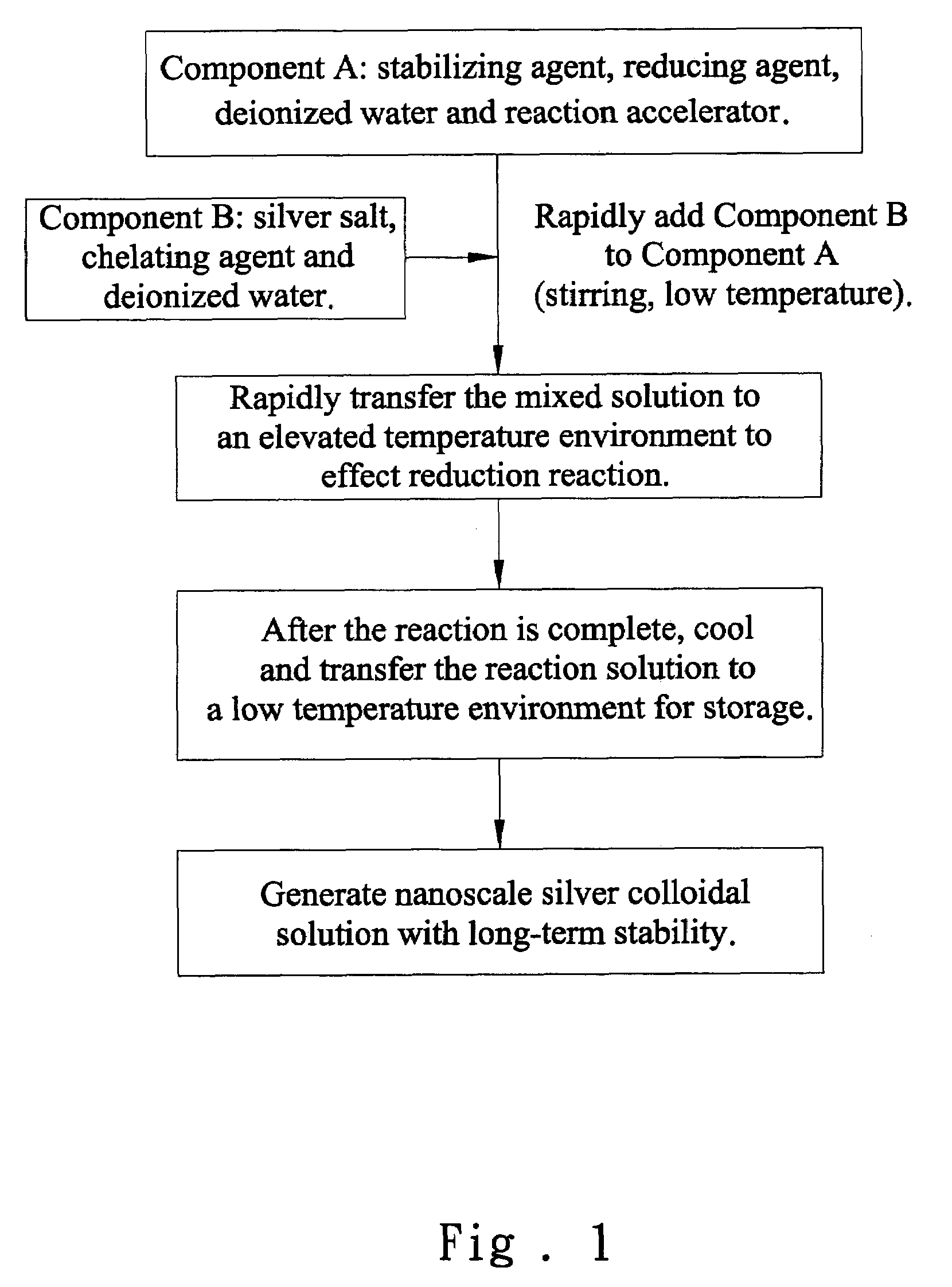

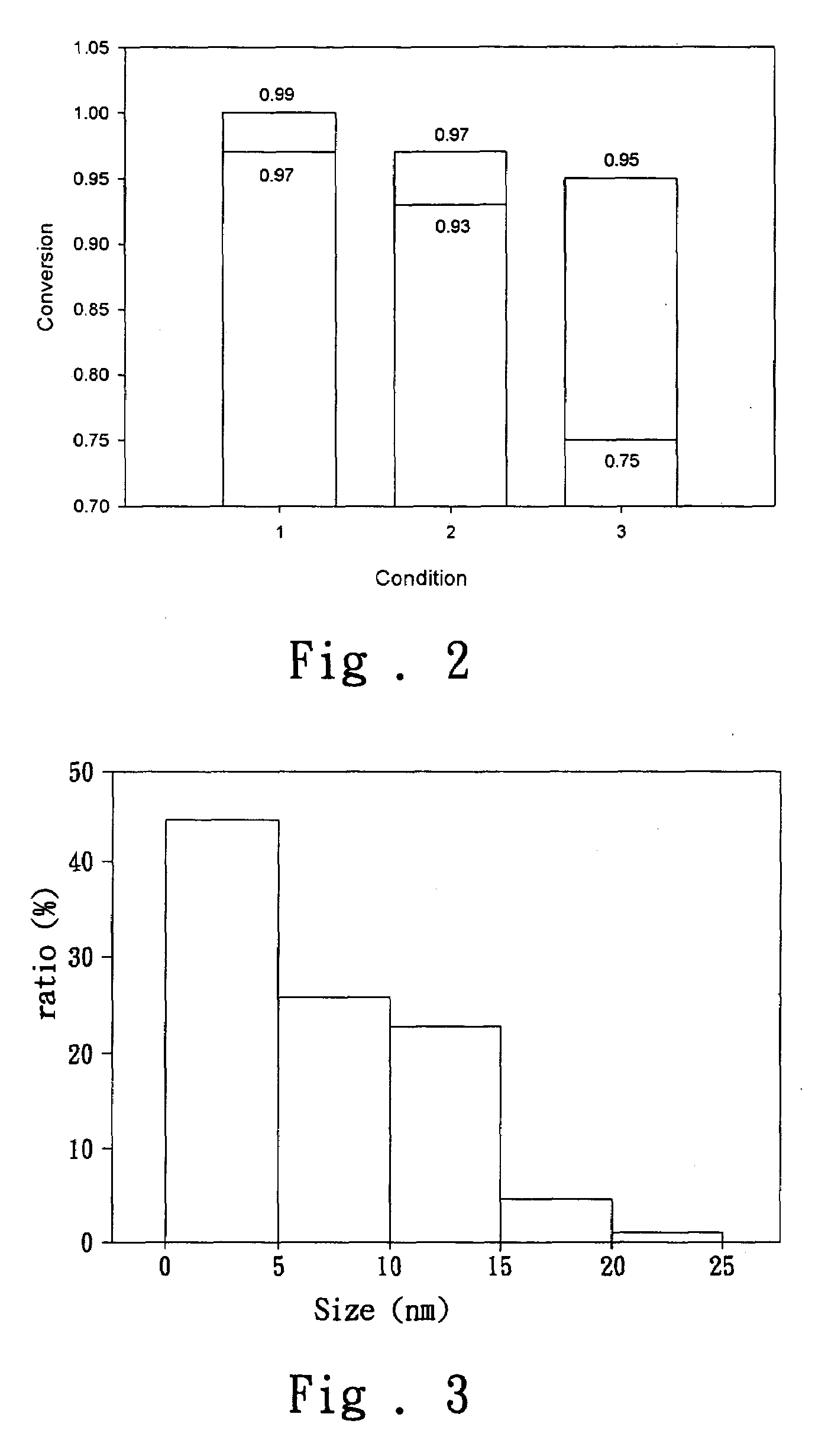

High-concentration nanoscale silver colloidal solution and preparing process thereof

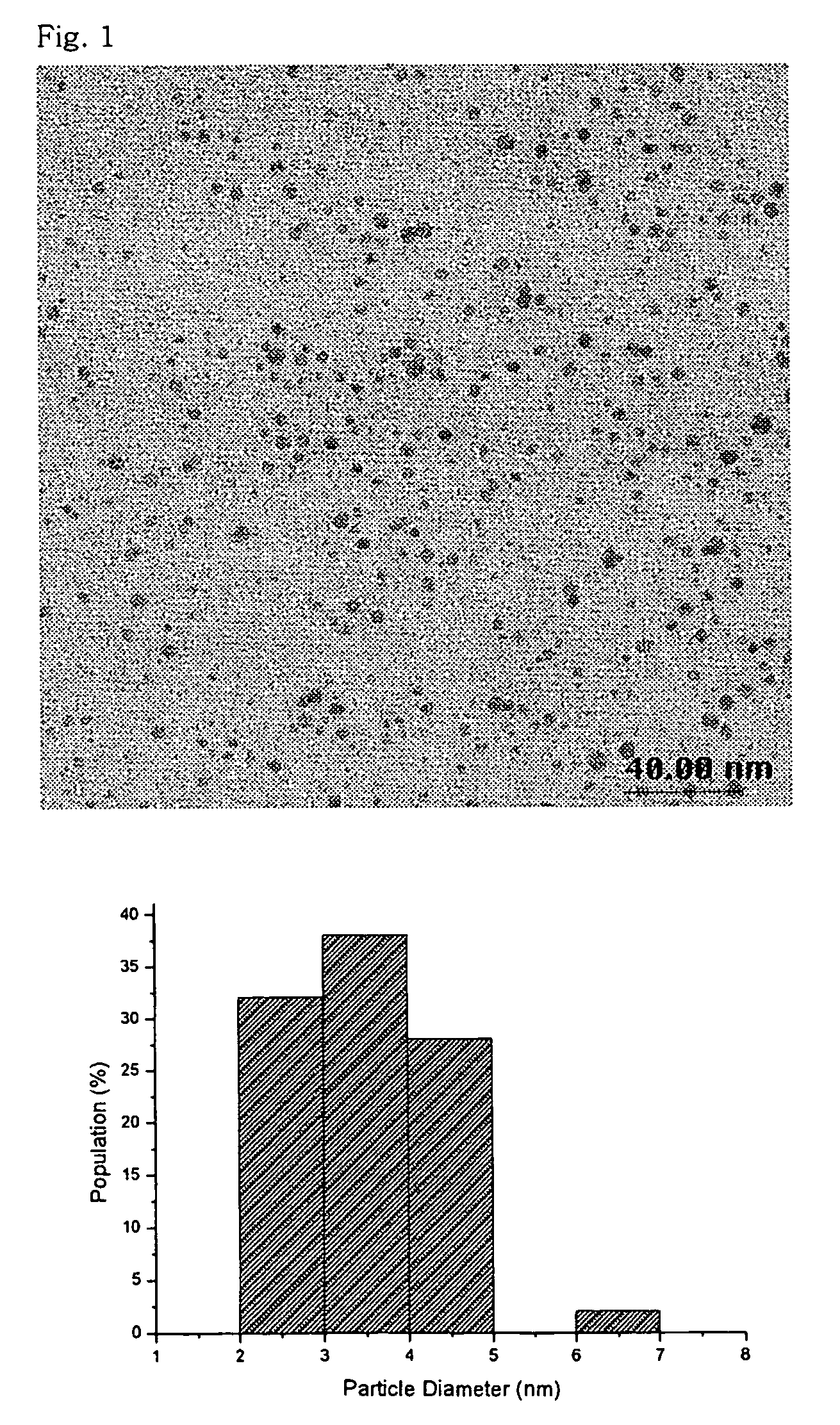

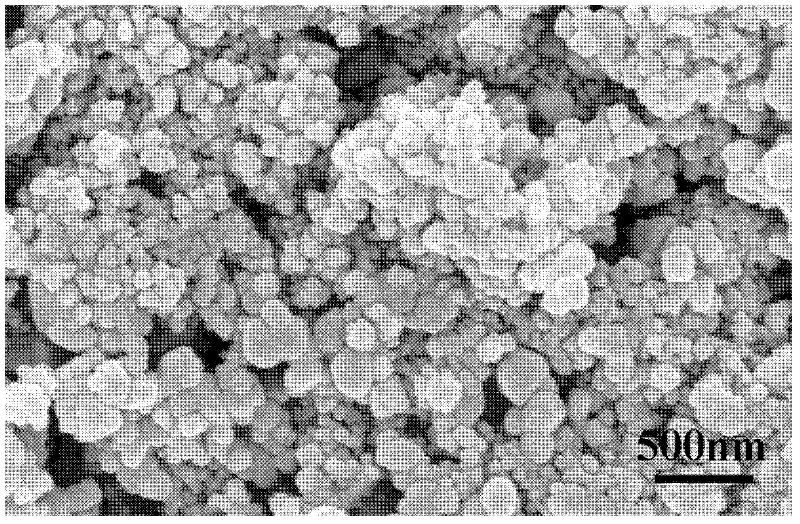

InactiveUS20080064767A1Good dispersionProvide energyMaterial nanotechnologyOther chemical processesHigh concentrationHigh density

The present invention relates to a high-concentration nanoscale silver colloidal solution and the preparing process thereof. The colloidal solution of the present invention comprises a high content of silver particles, i.e. approximately 1.5 wt %. The mean size of the nanoscale silver is less than 10 nm. In the preparing process, silver salt, ionic chelating agent, stabilizing agent, reducing agent, solvent and reaction accelerator are homogeneously mixed together. The increase of reaction temperature by external heat source accelerates completed reaction. By using the specified reaction accelerator and chelating agent and under the operating condition of the present invention, high-density silver colloidal solution is obtained while inhibiting particle aggregation. Therefore, the resulting nanoscale silver colloidal solution contains very small-sized particles and the stability thereof is satisfactory.

Owner:NATIONAL TSING HUA UNIVERSITY

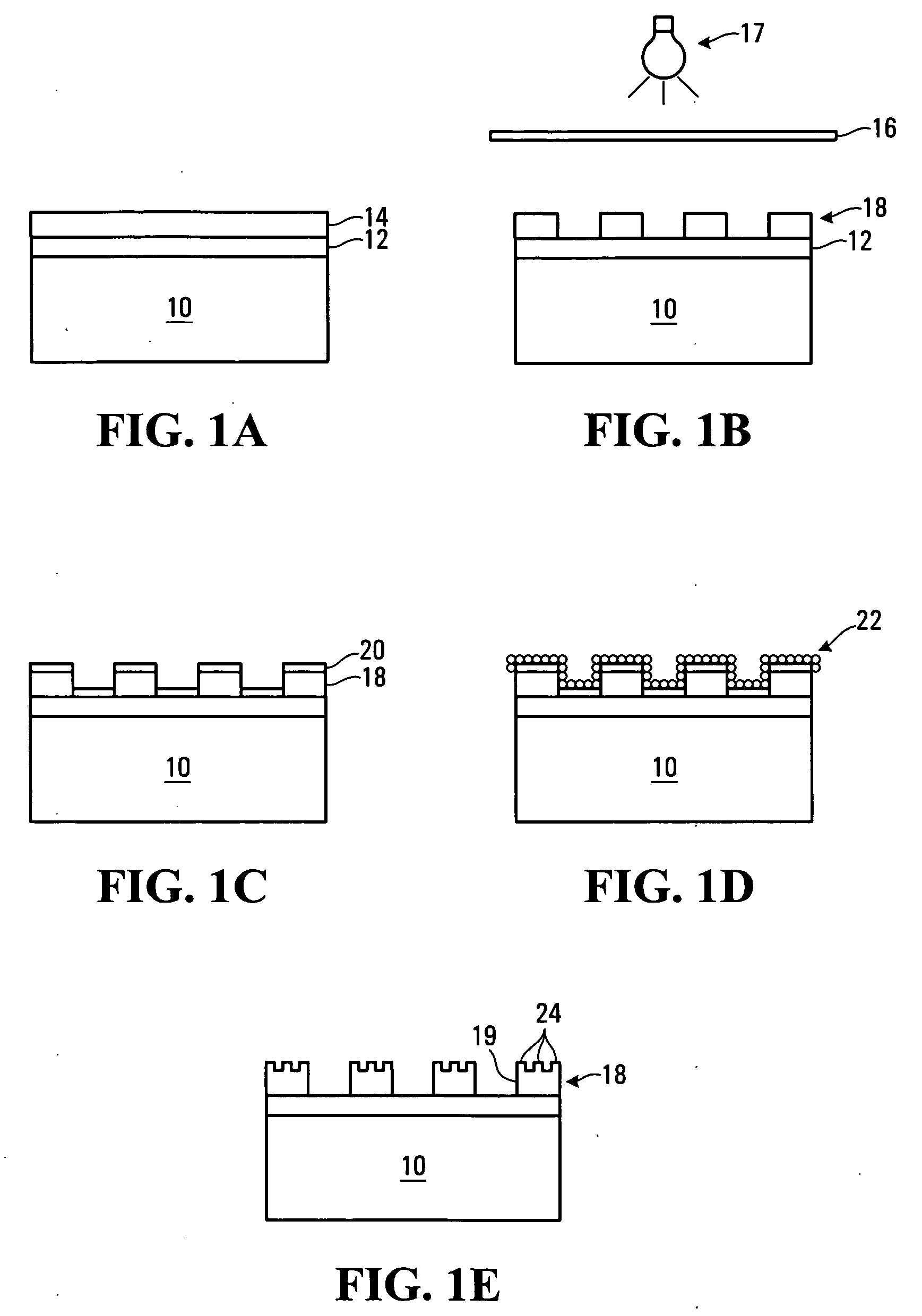

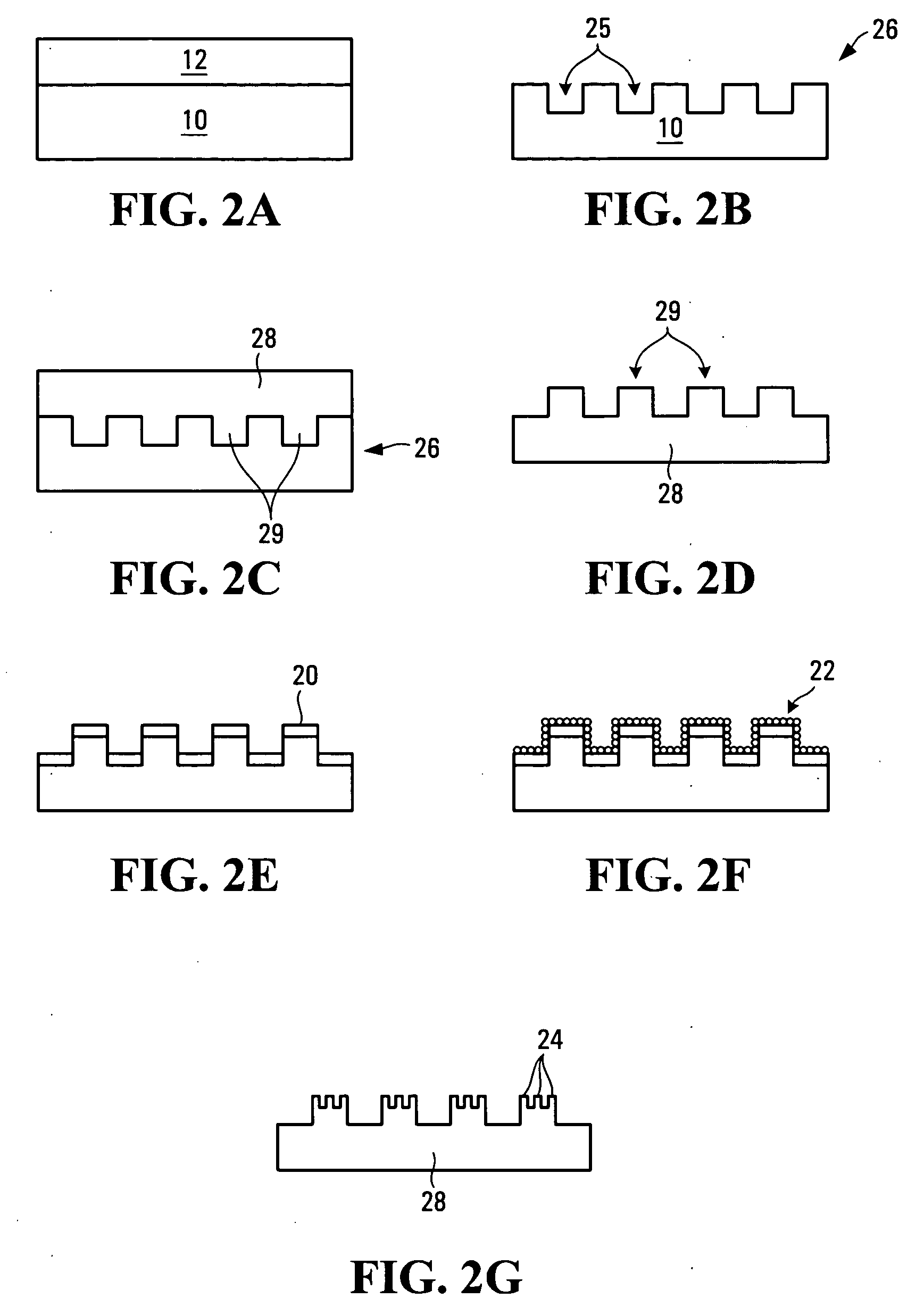

Method of forming branched structures

InactiveUS20060131265A1Decorative surface effectsSemiconductor/solid-state device manufacturingPolyelectrolyteColloidal particle

The present invention provides a method of forming a branched structure which comprises applying colloidal-sized particles over structures. The coated structures are then etched such that the structures are etched through the colloidal particles to form branched structures. The etch may be a reactive ion etch. The structures may be microstructures formed as high aspect ratio microstructures. The colloidal-sized particles may be applied as a colloidal solution and a polyelectrolyte (PE) layer may be applied to the microstructures prior to the colloidal solution to promote adsorption of the colloidal particles.

Owner:AGENCY FOR SCI TECH & RES

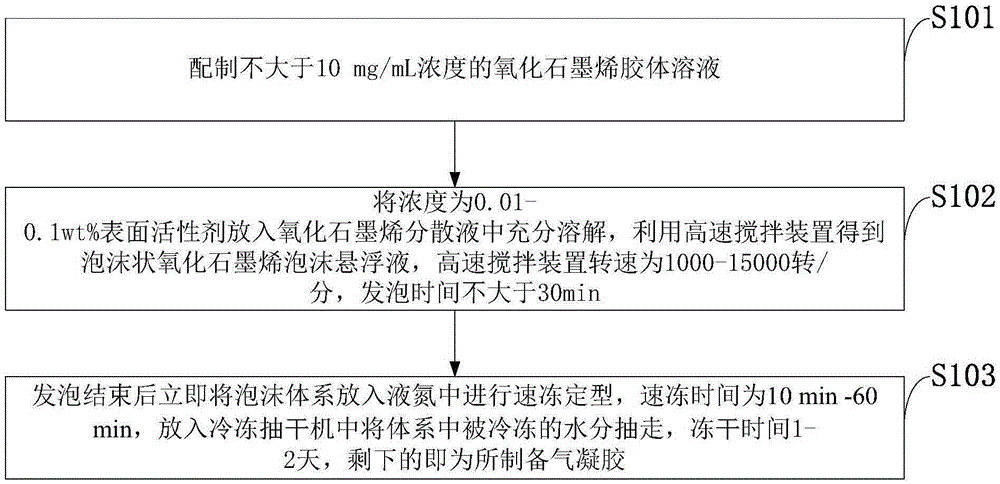

Spongy-like lightweight graphene aerogel preparation method

The present invention discloses a spongy-like lightweight graphene aerogel preparation method, which comprises: preparing a graphene oxide colloid solution with a concentration of not more than 10 mg / mL; adding a surfactant with a concentration of 0.01-0.1 wt% into the graphene oxide dispersion, and completely dissolving to obtain a foam-like graphene oxide foam suspension; and immediately placing the foam system into liquid nitrogen after completing the foaming, carrying out rapid freezing shaping, carrying out freeze drying, and removing the water to obtain the graphene aerogel material. According to the spongy-like lightweight graphene aerogel of the present invention, the solution system surface tension is reduced, and the dispersion property of the graphene oxide in the solvent is improved while the specific surface area of the aerogel material is further increased so as to improve the adsorption property on dyes, organic solvents and other substances; and the prepared spongy-like lightweight graphene aerogel material has characteristics of simple process, low cost, stable structure, excellent performance, and maximal maintaining of the excellent properties of the graphene material.

Owner:CAPITAL NORMAL UNIVERSITY

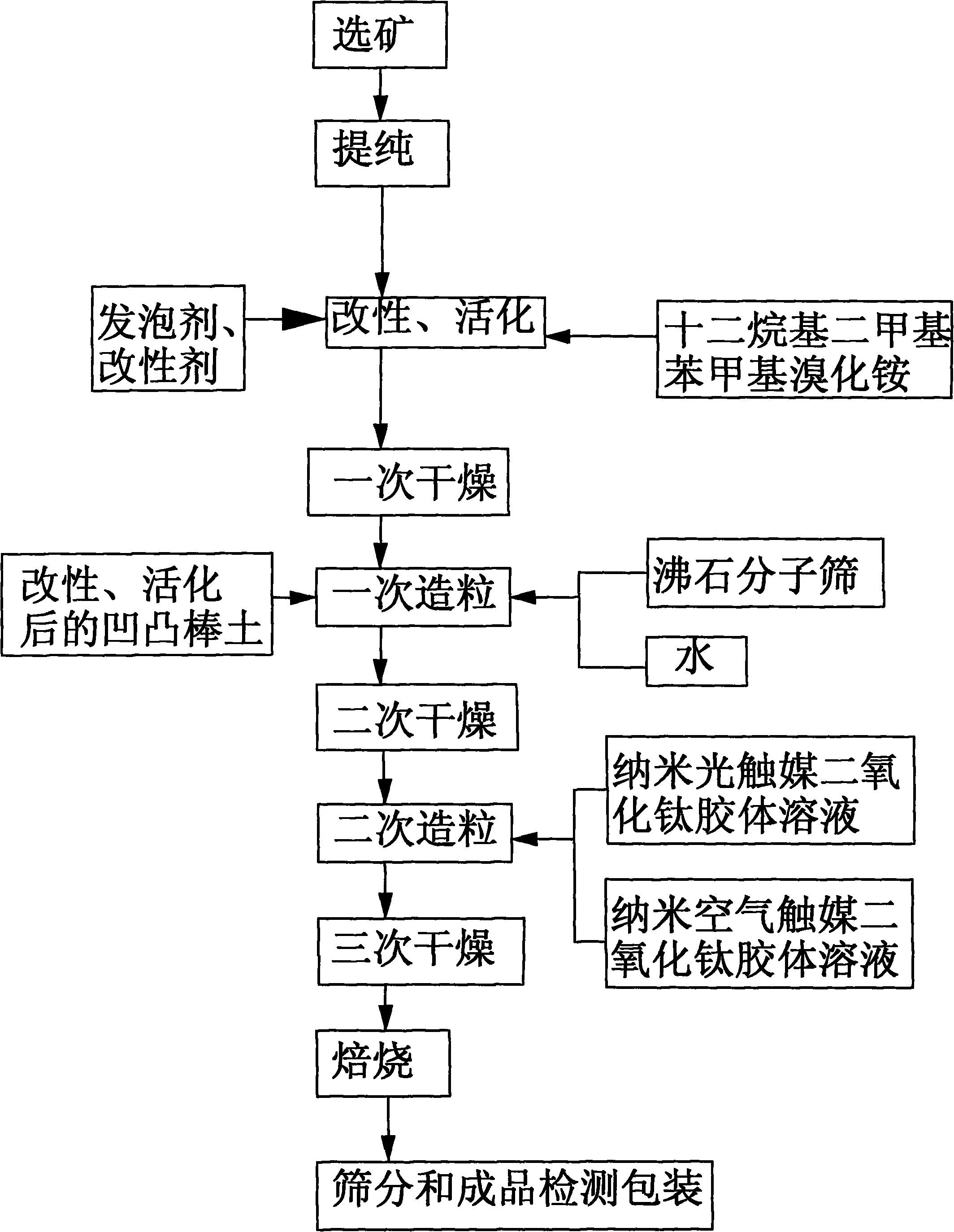

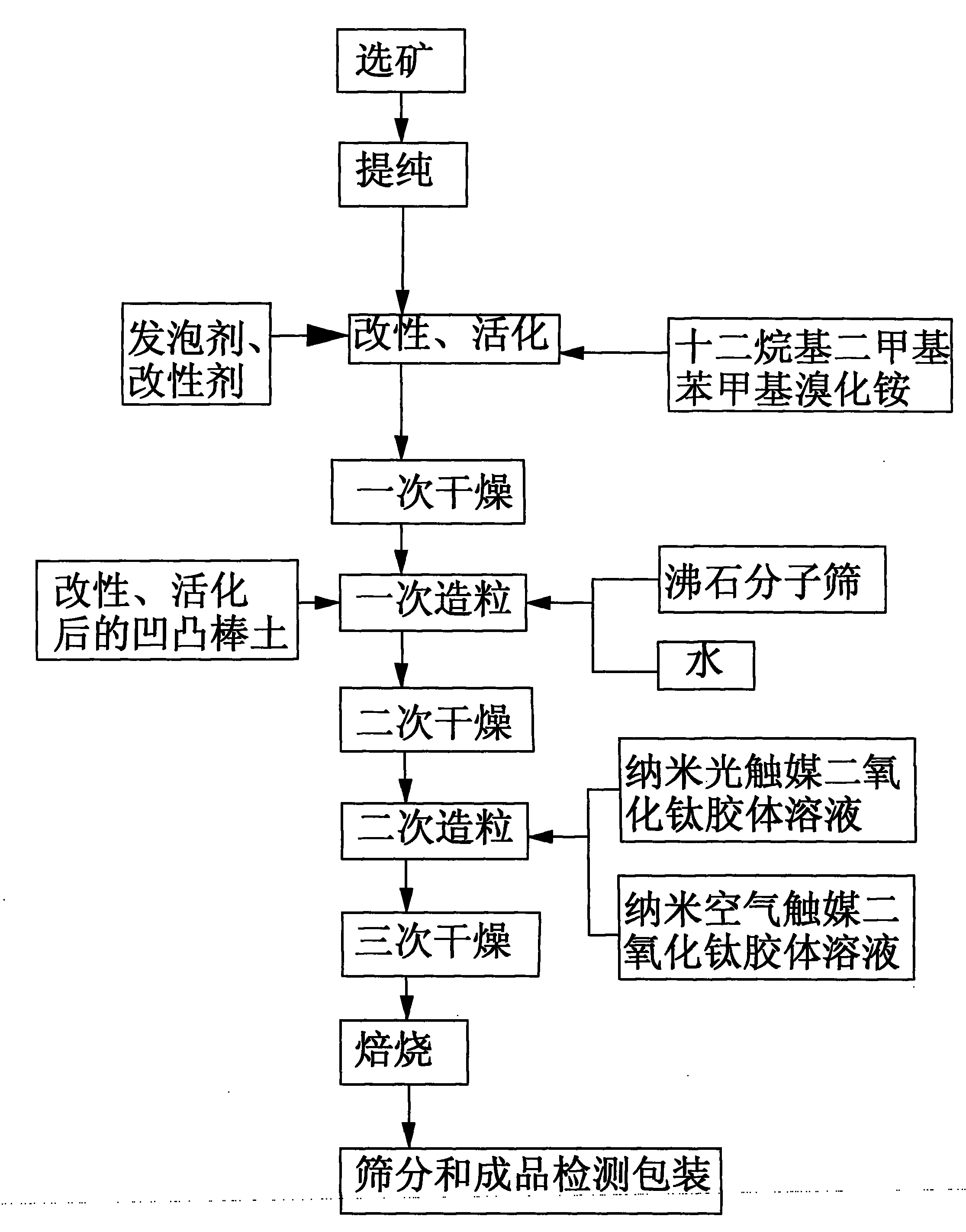

Composite air purificant containing nanometer mineral matters and preparation method thereof

ActiveCN101780288AWill not polluteProcess environmental protectionPhysical/chemical process catalystsDispersed particle separationSodium bicarbonateDecomposition

The invention provides a composite air purificant containing nanometer mineral matters, which contains 47wt% to 78wt% of attapulgite as a natural mineral, 20wt% to 50wt% of synthetic zeolite molecular sieve as a molecular sieve, 0.5wt% to 5wt% of sodium carbonate or sodium chloride or sodium fluoride or sodium hydrogensulfite as a modifier, 0.5wt% to 5wt% of ammonium bicarbonate or sodium bicarbonate or aluminum sulfate as a foaming agent, 0.5wt% to 2wt% of dodecyldimethylbenzylammonium chloride as a surface active agent, 0.2wt% to 2wt% of nanometer photocatalyst titanium dioxide colloidal solution as a photocatalyst and 0.1wt% to 1wt% of nanometer aircatalyst titanium dioxide colloidal solution as photochemical catalysts. The composite air purificant is prepared by first drying, first pelleting, second drying, second pelleting, third drying, baking and finish product detection and package. The invention has high alternative adsorbability and high decomposition efficiency for organic pollutants in the air.

Owner:宁波市沧海新材料开发有限公司

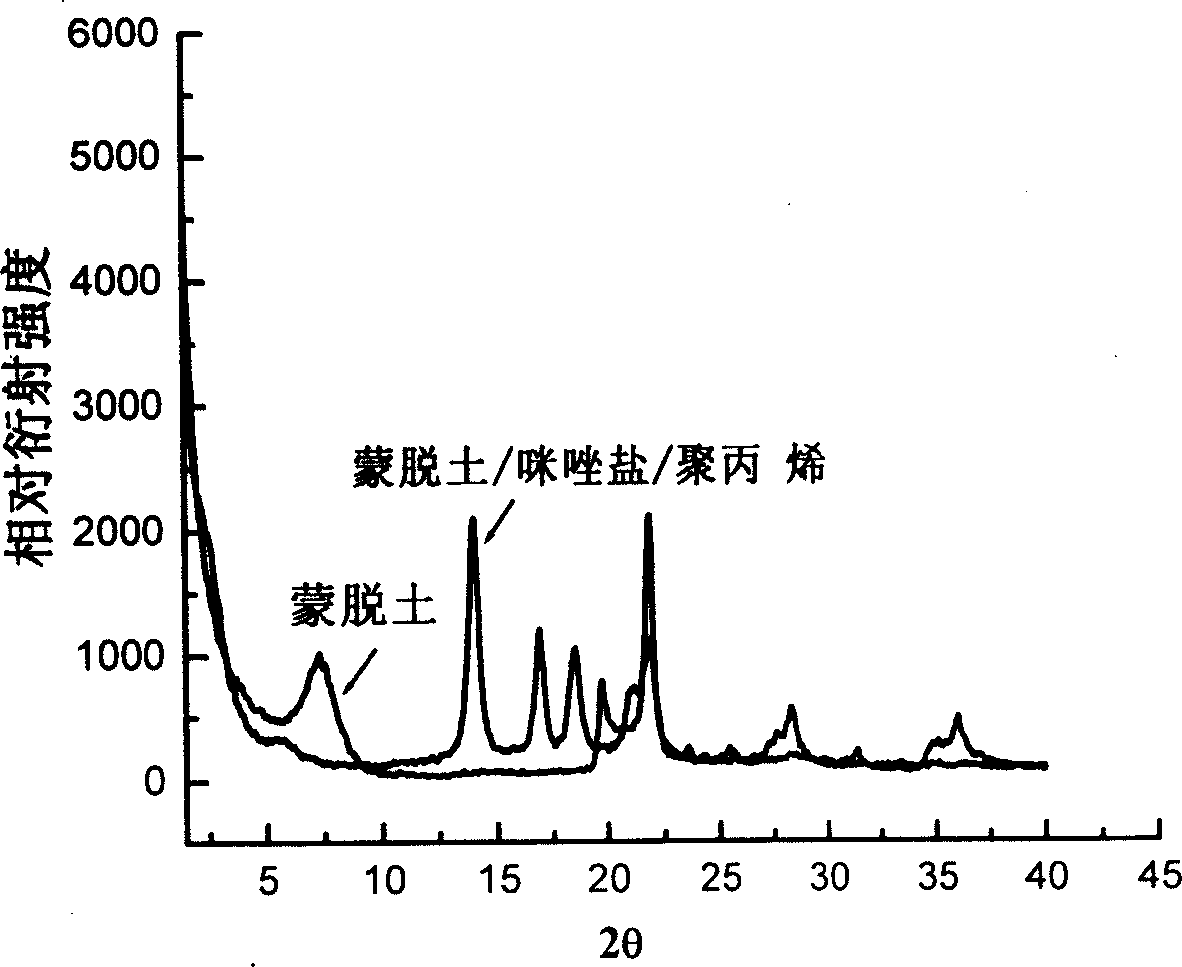

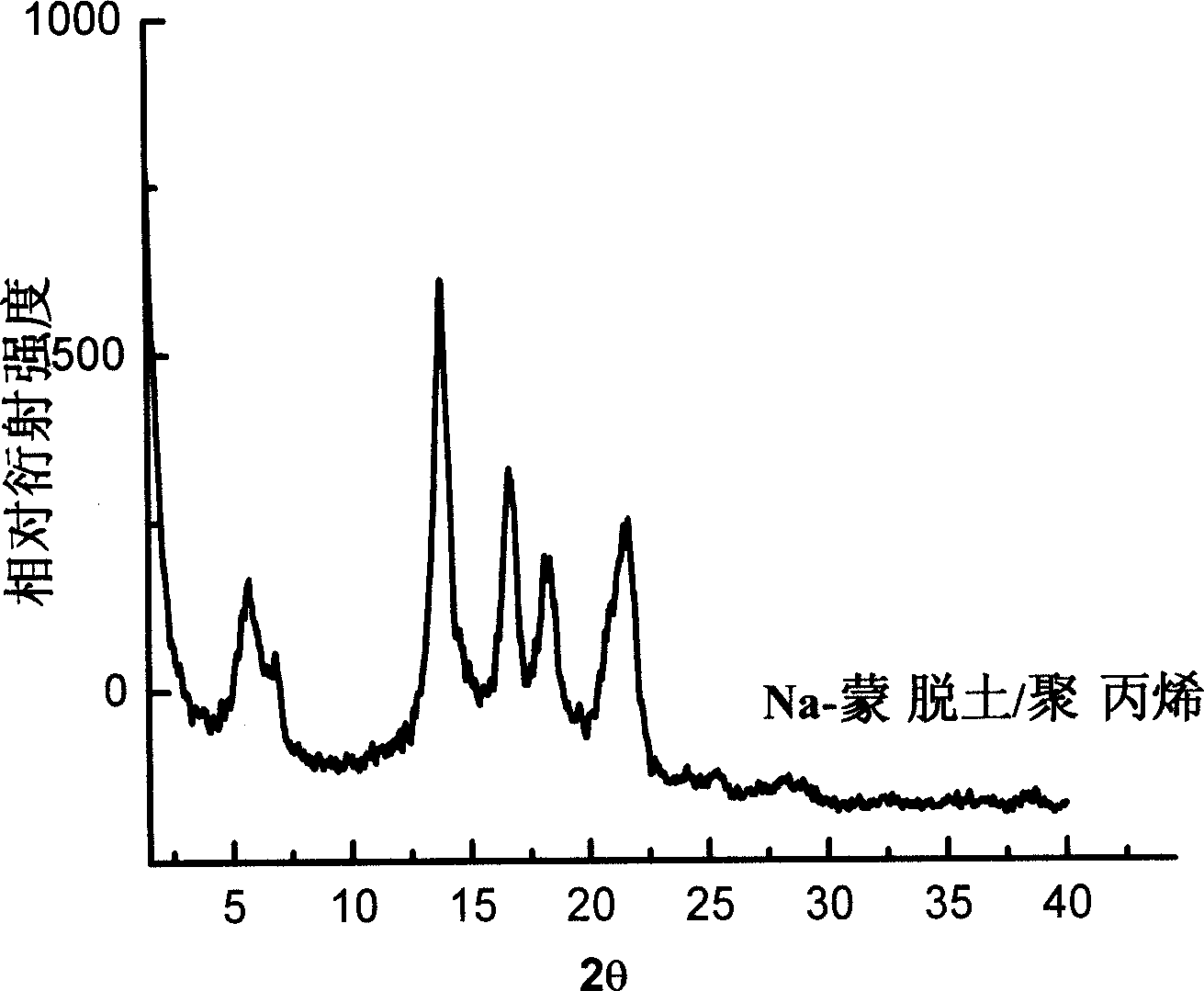

Method of preparing polymer/montmorillonid nano-composite material by montmorillonoid in-situ organization

A process for preparing composite polymer / montmorillonite nanoparticles by in-situ organizing of montmorillonite features that the imidazole-type or pyridine-type organic salt is used in non-water solvent to obtain organic modifier for organizing and dispersing the montmorillonite, resulting in the colloidal solution of its nanoparticles. The solvents with different properties and the organic salts with different molecular structures can be chosen for preparing the nanoparticles with relative performance. Its advantages are high thermal stability and high compatibility.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Prepn process of hollow silica ball

The preparation process of hollow silica ball includes the following steps: adding alcohol solvent into ammonia water solution of polymer electrolyte in 3-500 g / L concentration, dropping silicon source precursor solution of 1.1-4.4 mol / L concentration in the speed of 0.05-0.2 ml and silicon source precursor / ammonia water volume ratio of 1 / 15 to 2, reaction in a sealed container at 10-40 deg.c for 2-24 hr, and washing and drying the product, with the ammonia water having concentration of 10-25 wt% and the volume ratio between alcohol solvent and ammonia water being 3 to 25. The preparation process of the present invention is simple and suitable for industrial production, and has mild reaction condition, no environmental pollution and high yield, and the obtained hollow silica ball is loose, has inner diameter of 10-250 nm and water thickness of 10-40 nm, and may be used as medicine carrier and catalyst carrier.

Owner:UNIV OF SCI & TECH OF CHINA

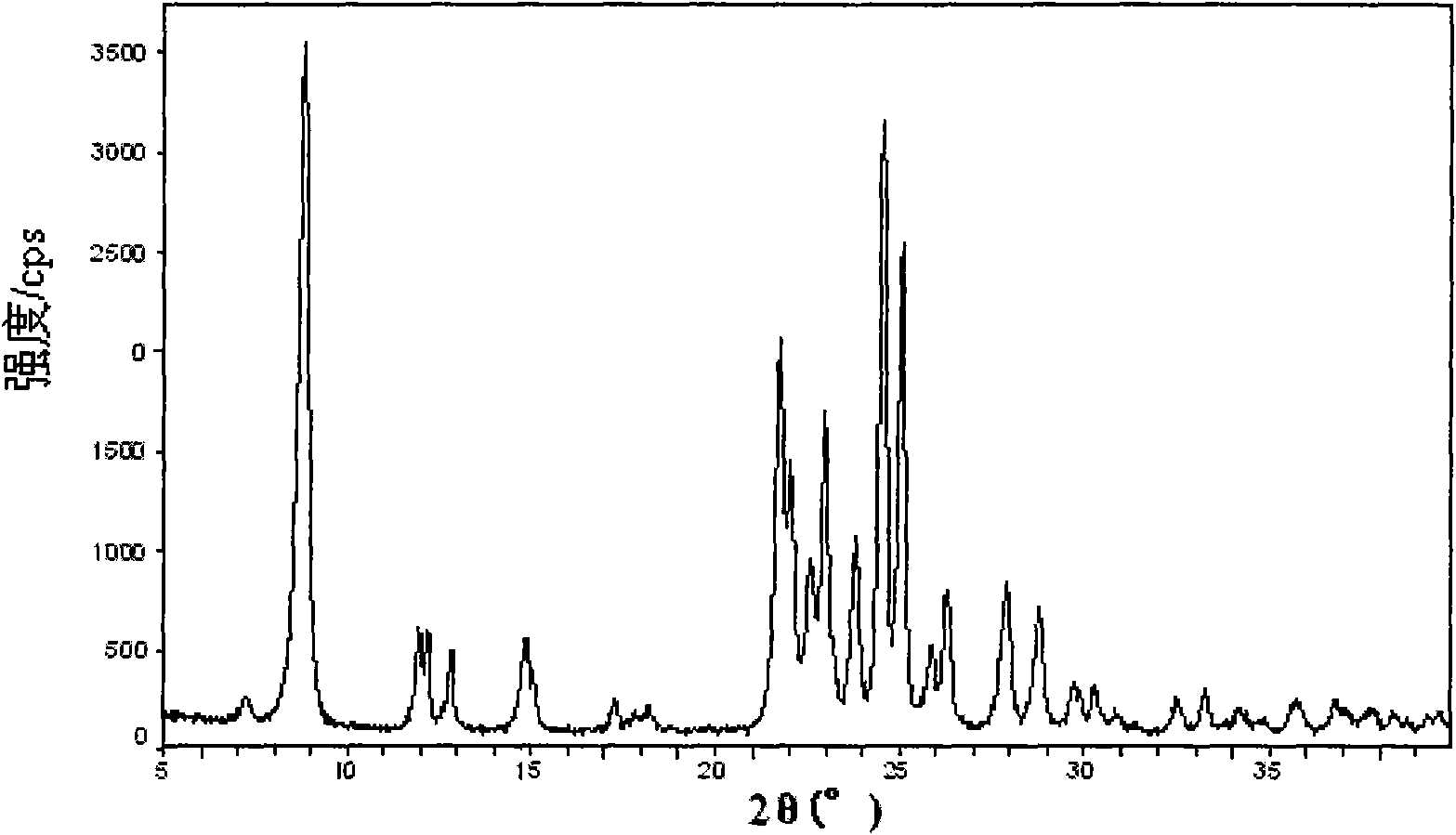

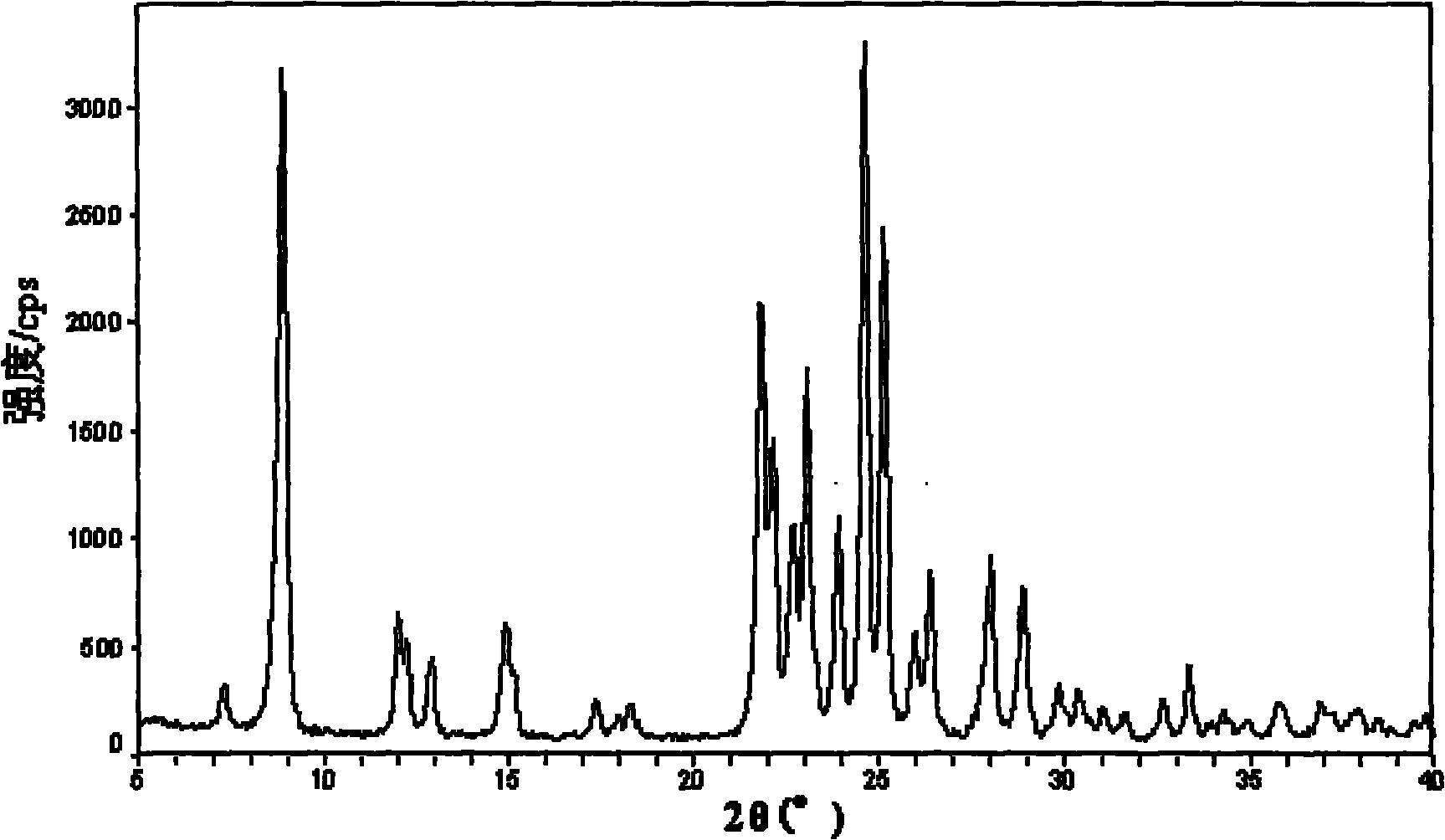

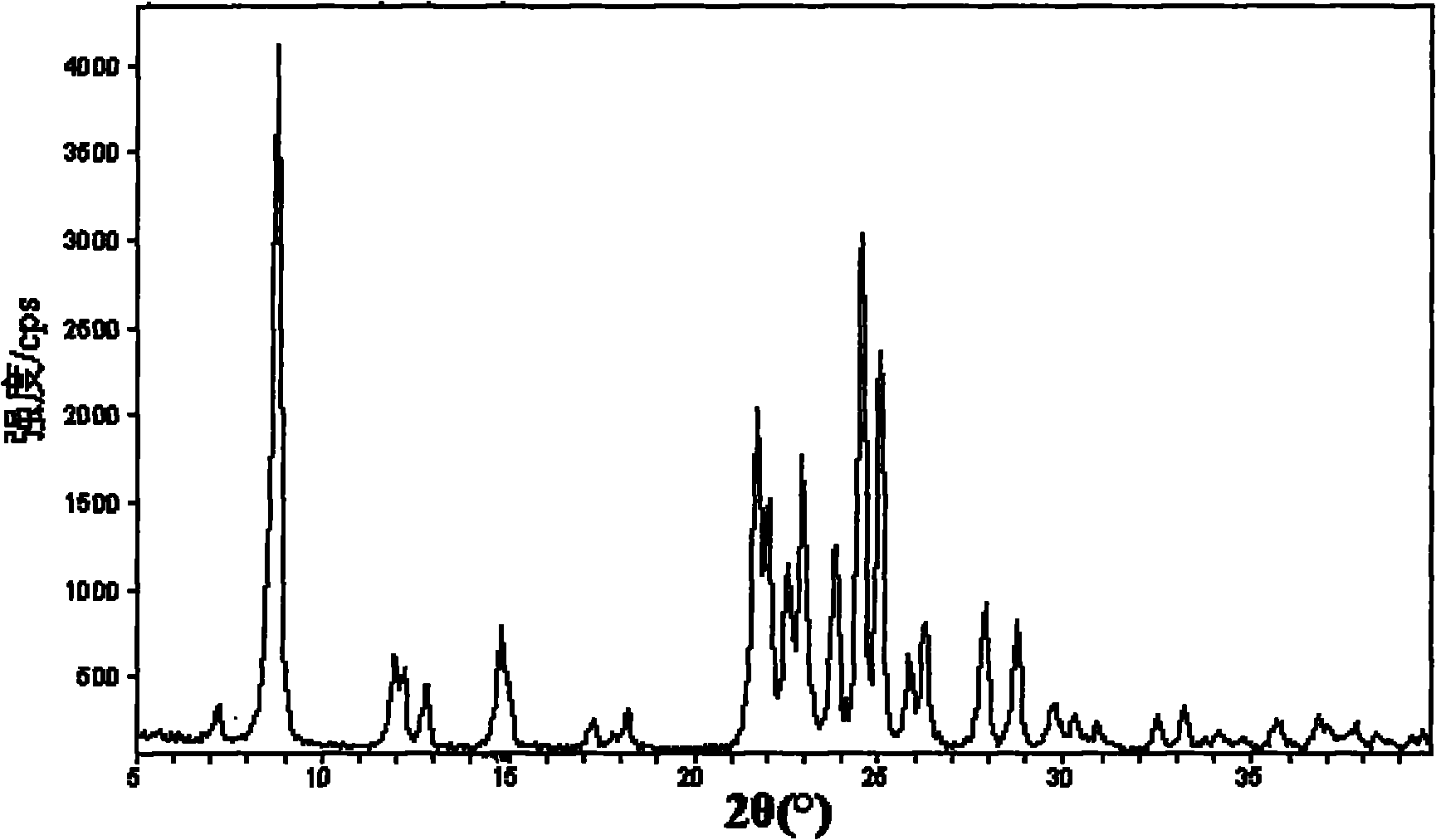

Method for preparing ZSM-35 molecular sieve

ActiveCN101928011AFerrierite aluminosilicate zeoliteHydrocarbon by isomerisationMolecular sieveImproved method

The invention provides an improved method for preparing a ZSM-35 molecular sieve. The method comprises the following steps of: uniformly mixing a silicon source, an aluminum source, an alkali source and water to obtain colloidal solution; ultrasonically vibrating and aging the colloidal solution; adding a template agent into the colloidal solution; and hydrothermally crystallizing the mixture to obtain the ZSM-35 molecular sieve. The method can remarkably shorten the crystallization time of the ZSM-35 molecular sieve and enhance the degree of crystallization of a synthetic product; and the generated molecular sieve has small crystal grains and uniform particles and can be taken as a catalyst in the process of isomerizing an n-butene framework into isobutene.

Owner:CHINA PETROLEUM & CHEM CORP

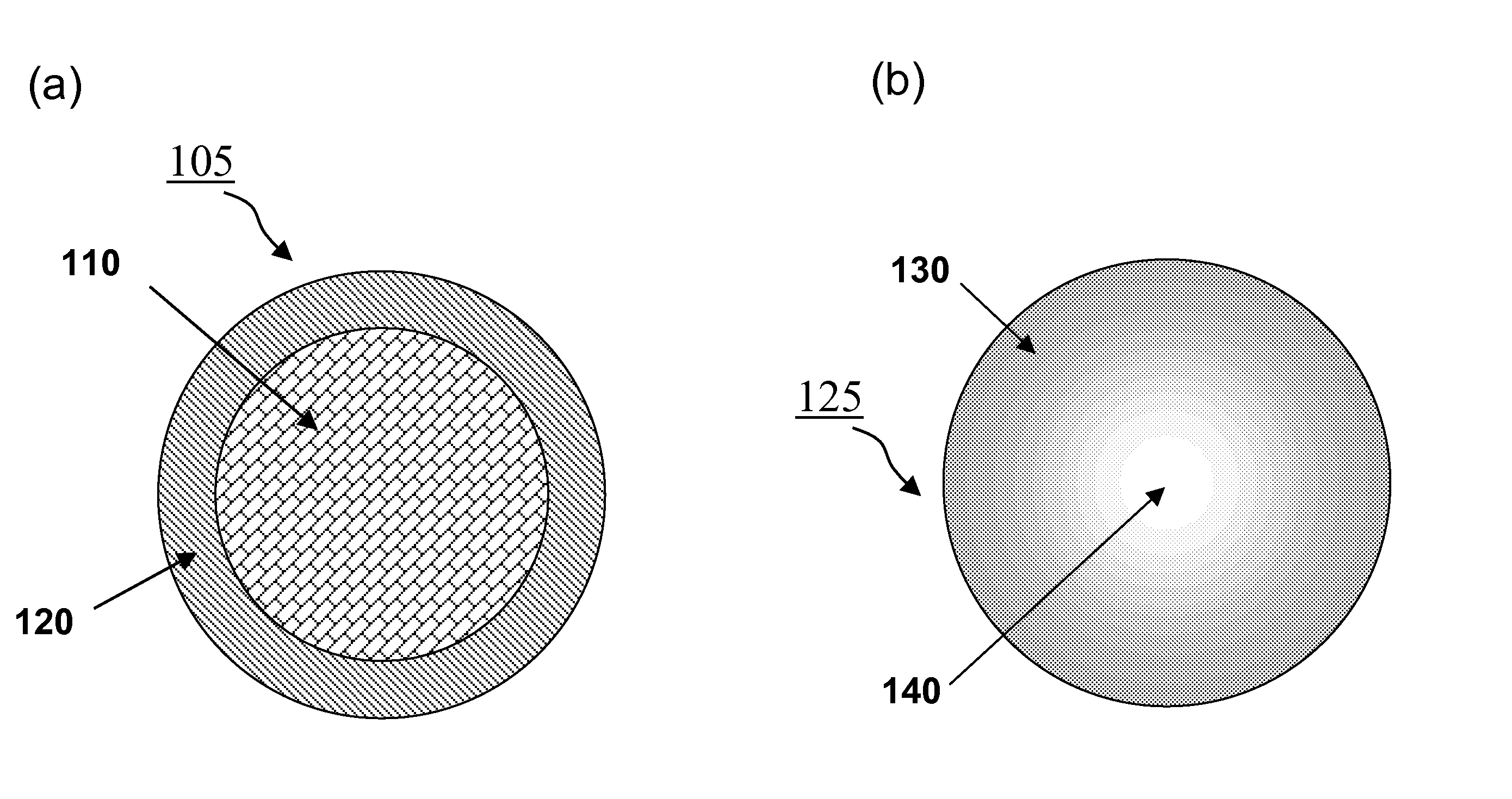

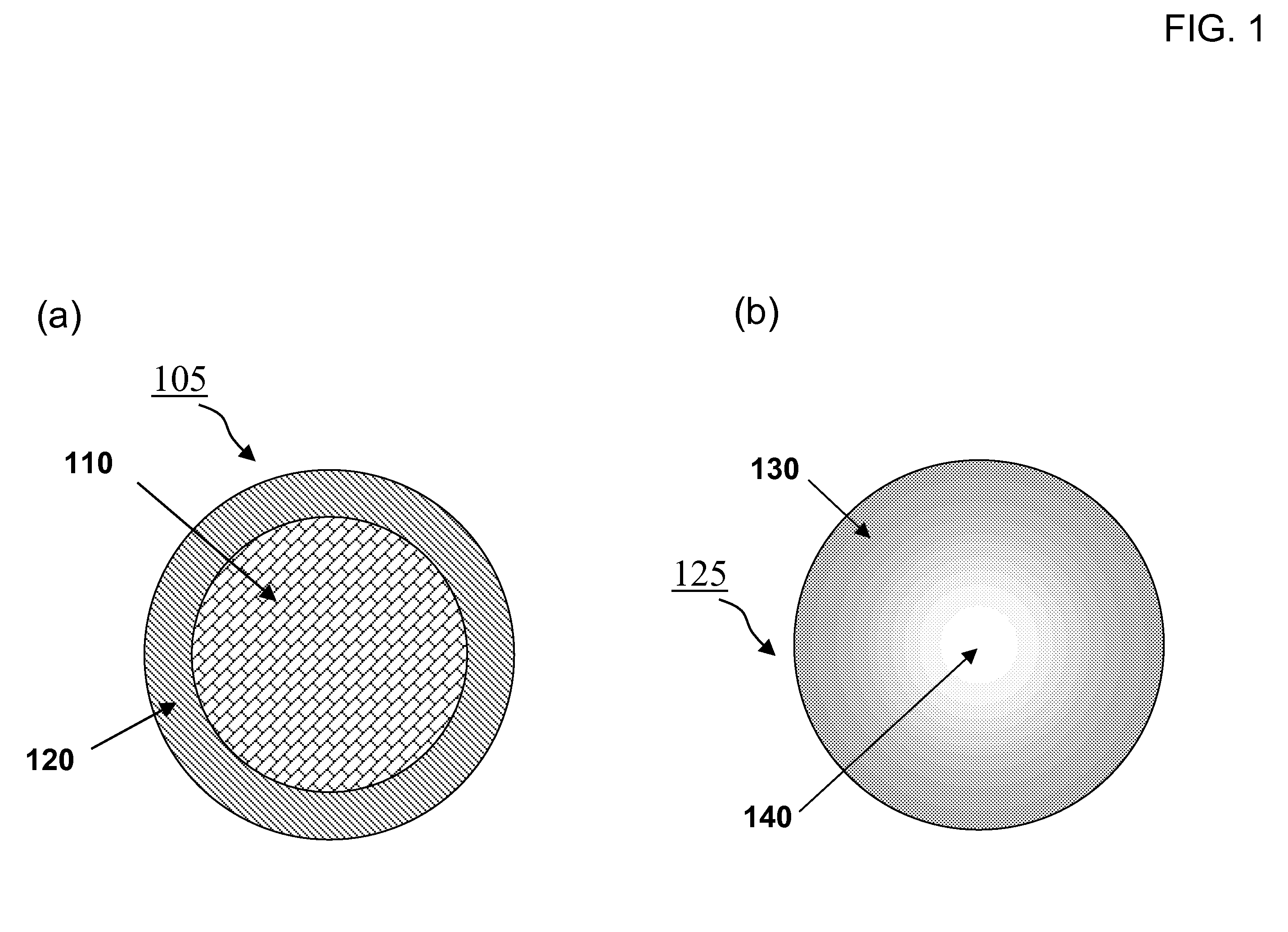

Halide-based scintillator nanomaterial

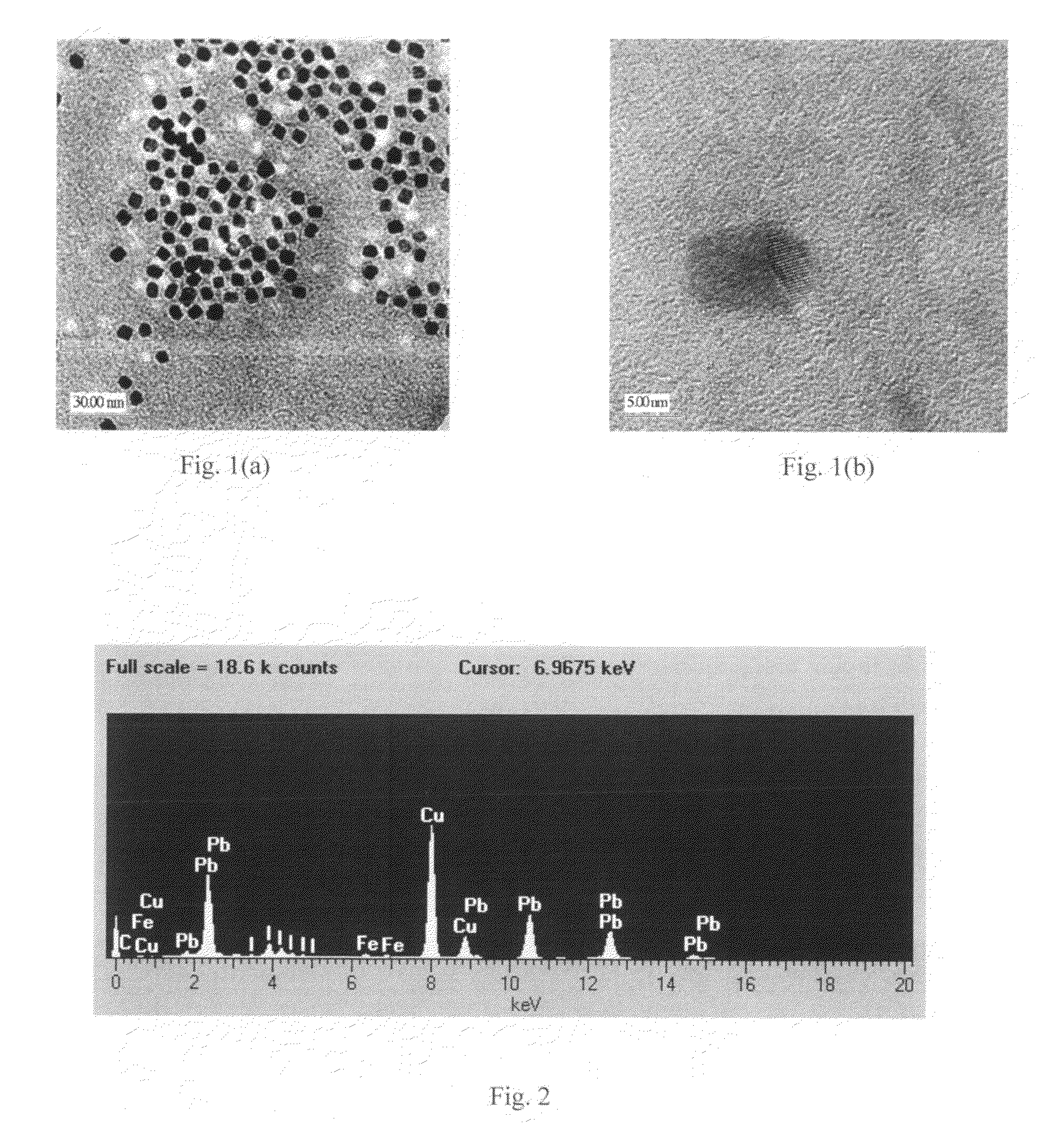

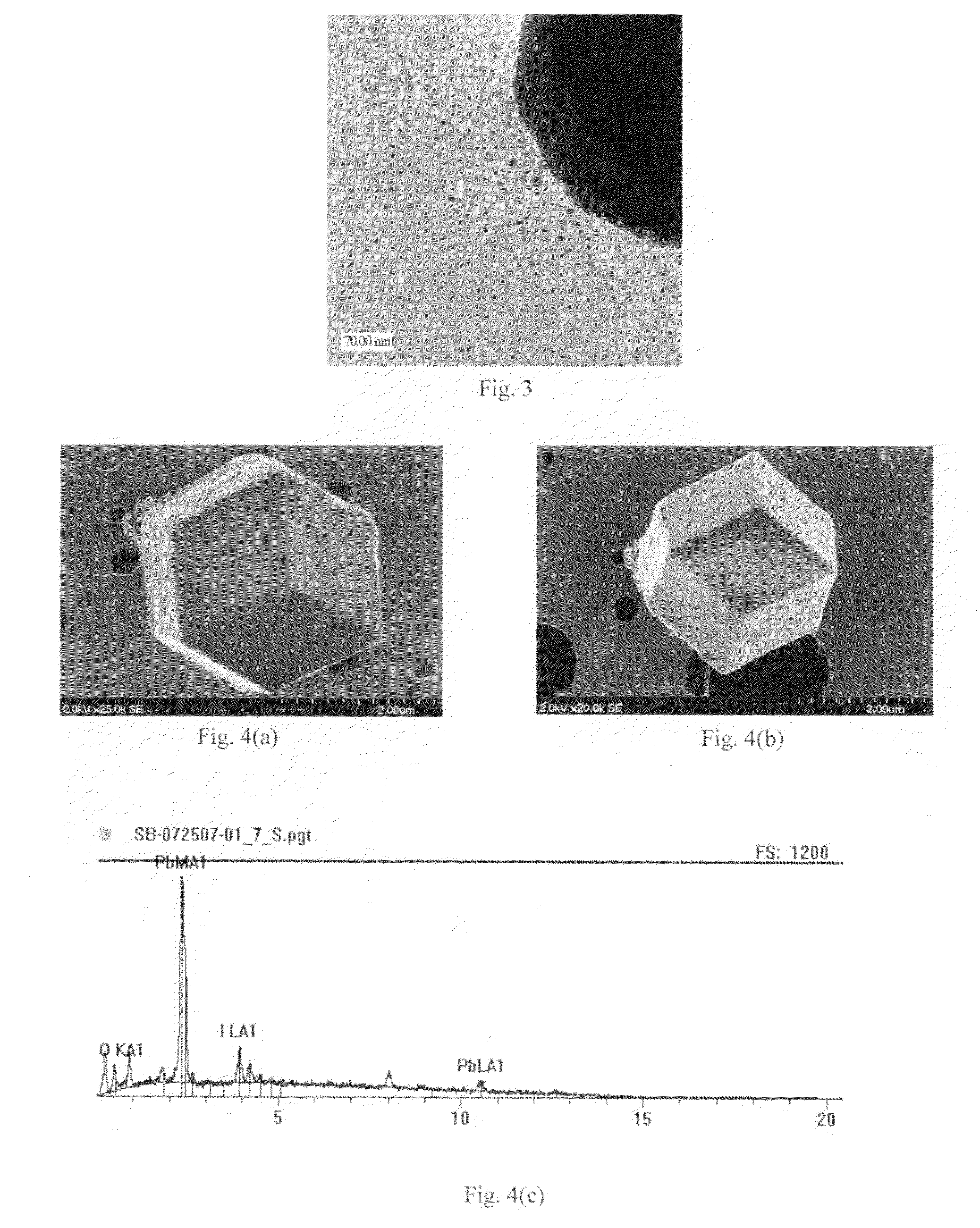

ActiveUS20100001209A1Improve signal-to-noise ratioReduced dosLuminescent dosimetersGlass/slag layered productsAlkaline earth metalGamma irradiation

Scintillator material comprising nanoparticles (nanocrystals) comprising lead (Pb), iodine (I), and optionally one or both of oxygen (O) and hydrogen (H) wherein the nanoparticles exhibit room-temperature scintillation under gamma irradiation. The scintillator nanoparticles can comprise Pb3O2I2. The scintillator nanoparticles can comprise PbIOH in generally equiatomic proportions or non-equiatomic variants thereof that exhibit scintillation under gamma irradiation. The scintillator nanoparticles have a particle dimension in the range of about 5 to about 100 nm. Microparticles (microcrystals) also are provided comprising lead (Pb), iodine (I), and optionally one or both of oxygen (O) and hydrogen (H) grown in a nanoparticle colloidal solution over time to a particle dimension greater than 0.1 μm, such as about 2 microns. A heterogeneous scintillator material is provided comprising core / shell nanoparticles having a highly hygroscopic or deliquescent halide-based core activated with trivalent Ln3+ or divalent Ln2+ lanthanide ions (Ln=La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu) and a stable non-hygroscopic shell thereon. The heterogeneous nanoparticles can comprise highly hygroscopic lanthanide halide (LaBr3, LuI3) cores protected with stable non-hygroscopic LaF3 shells. The heterogeneous nanoparticles can comprise deliquescent alkaline earth halide (SrI2, BaI2) cores protected with stable non-hygroscopic (SrF2, BaF2) shells.

Owner:STC UNM

Method for preparing loading type nano Pd/C catalyst from colloidal solution

InactiveCN1966144AAvoid organic pollutionReduce manufacturing costCatalyst carriersNanostructure manufacturePalladium catalystChemical reduction

The invention relates to a method for using colloid solution to prepare carrier nanometer Pd / C catalyst, wherein said method comprises that using chemical reduction to process palladium salt to prepare the nanometer palladium colloid solution with stable surface activity, then using some carrier to absorb it to obtain the palladium colloid, to obtain the nanometer palladium catalyst with different loaded amounts. The inventive catalyst can be used in hydrogenation.

Owner:DALIAN UNIV OF TECH

Formulation for spray-drying large porous particles

InactiveUS7279182B2Reduce and eliminate needEasy to preparePowder deliveryBiocidePrillVolumetric Mass Density

Particles having a tap density less than about 0.4 g / cm3 are formed by spray drying from a colloidal solution including a carboxylic acid or salt thereof, a phospholipid, a divalent salt and a solvent such as an aqueous-organic solvent. The colloidal solution can also include a therapeutic, prophylactic or diagnostic agent. Preferred carboxylic acids include at least two carboxyl groups. Preferred phospholipids include phosphatidylcholines, phosphatidylethanolamines, phosphatidylglycerols, phophstidylserines, phosphatidylinositols and combinations thereof. The particles are suitable for pulmonary delivery.

Owner:CIVITAS THERAPEUTICS

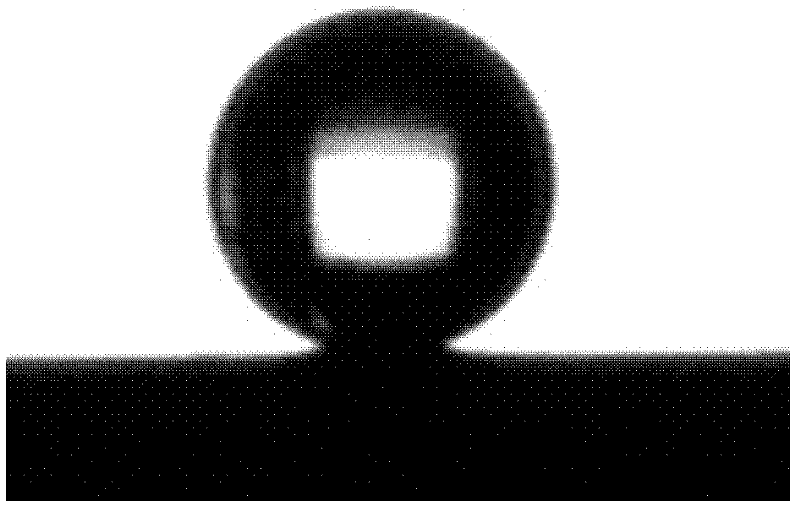

Method for preparing corrosion-resisting and self-cleaning coating

ActiveCN102390936ARealize self-cleaningImprove corrosion resistanceSolid/suspension decomposition chemical coatingCeramicNew materials

The invention discloses a method for preparing a coating having corrosion-resisting and self-cleaning functions, which belongs to the field of new materials. The method comprises the following steps: cleaning and drying the surface of a coated material; utilizing a sol thermo-curing method to prepare an oxide connecting layer on the surface of the coated material substrate; coating a prepared colloidal solution containing nanometer solid grains onto the oxide connecting layer; and after forming a film and curing, coating a material with low surface energy on the surface, thereby obtaining the surface having a self-cleaning function. The surface of a product obtained in the technique of the method is higher in hydrophobic property, is capable of achieving a self-cleaning effect and is ultrahigh in corrosion resistance. The method has the advantages that the demand on equipment is low; the method is free from being limited by the shape of the surface of the coated material; the material substrates, such as ceramics, glass, metal and the like, can be subjected to coating and film-forming treatment according to the method; industrialization is easily realized; and the product after being subjected to the coating and film-forming treatment can be applied to various severe corroding environments and has an ultrahigh application value.

Owner:TSINGHUA UNIV

Method for preparing spherical silver nano granule

The invention discloses a method for preparing spherical silver nanoparticles, which comprises the following steps: evenly mixing a silver nitrate clearing solution, a reducer clearing solution and a stabilizing agent clearing solution of anhydrous low mass molecule alcohols; stirring the mixture at a temperature of between 70 and 80 DEG C and refluxing the product to obtain a silver nanoparticle colloidal solution; and vaporizing or removing the low mass molecule alcohols, and drying the remaining substance to obtain the spherical silver nanoparticles with the particle size not more than 15 nanometers. A reaction system of the invention has simple process, saves raw materials, reduces links and improves preparation efficiency; in the reaction system, the anhydrous low mass molecule alcohols are taken as solvent to replace the prior water solution to prepare the anhydrous spherical silver nanoparticles; therefore, the invention discloses a method for preparing the anhydrous spherical silver nanoparticles with good dispersibility and stability, which has the advantages of simple process, few varieties of used raw materials and high preparation efficiency.

Owner:NINGBO UNIV

Slow release fertilizer applicable to water-fertilizer integration and preparation method thereof

ActiveCN103910586ATo achieve the purpose of slow release and controlled releaseSuitable for integrationFertilizer mixturesPolymer dissolutionOrganic solvent

Owner:广西田阳县创新农业综合开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com