Patents

Literature

4918results about "Solid/suspension decomposition chemical coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

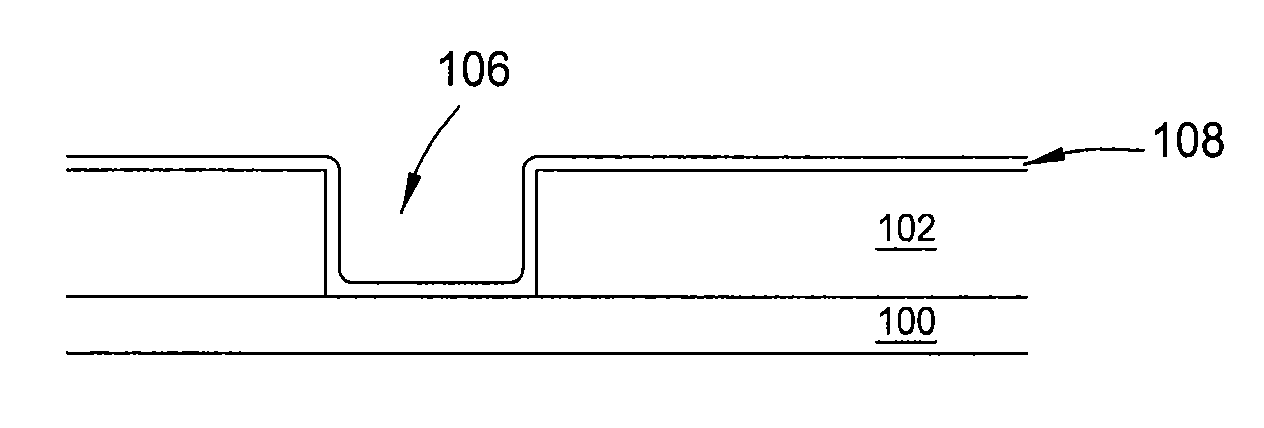

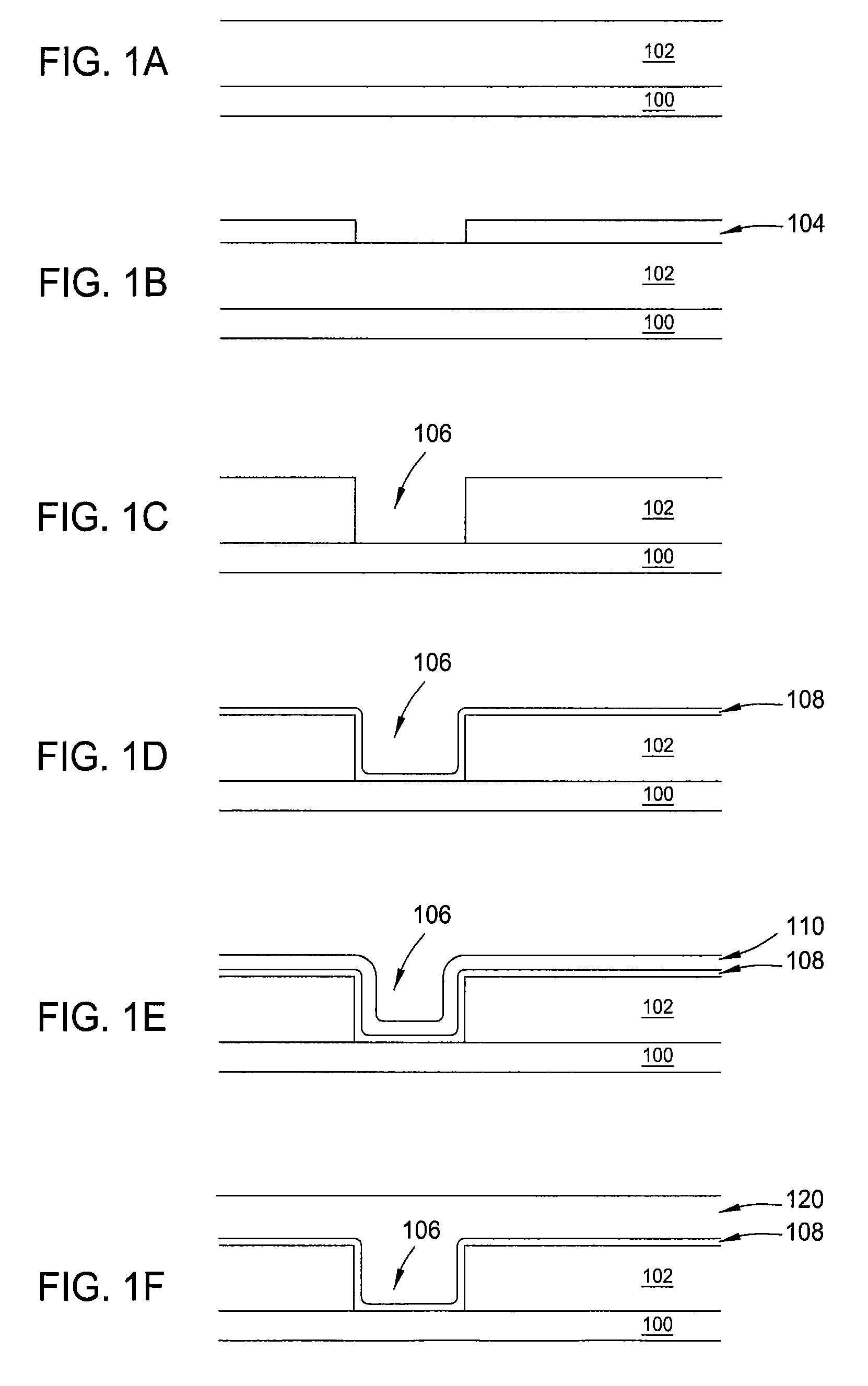

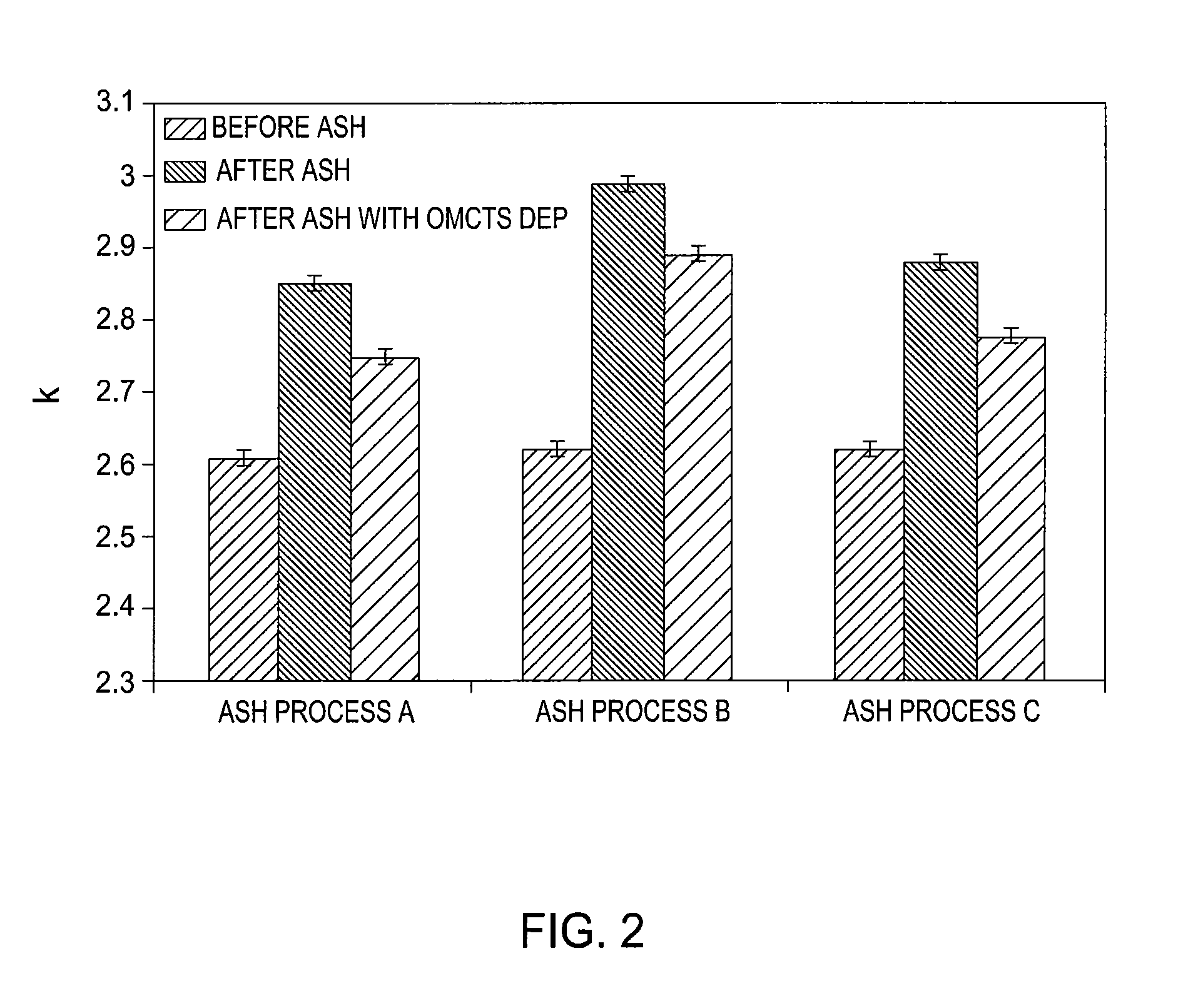

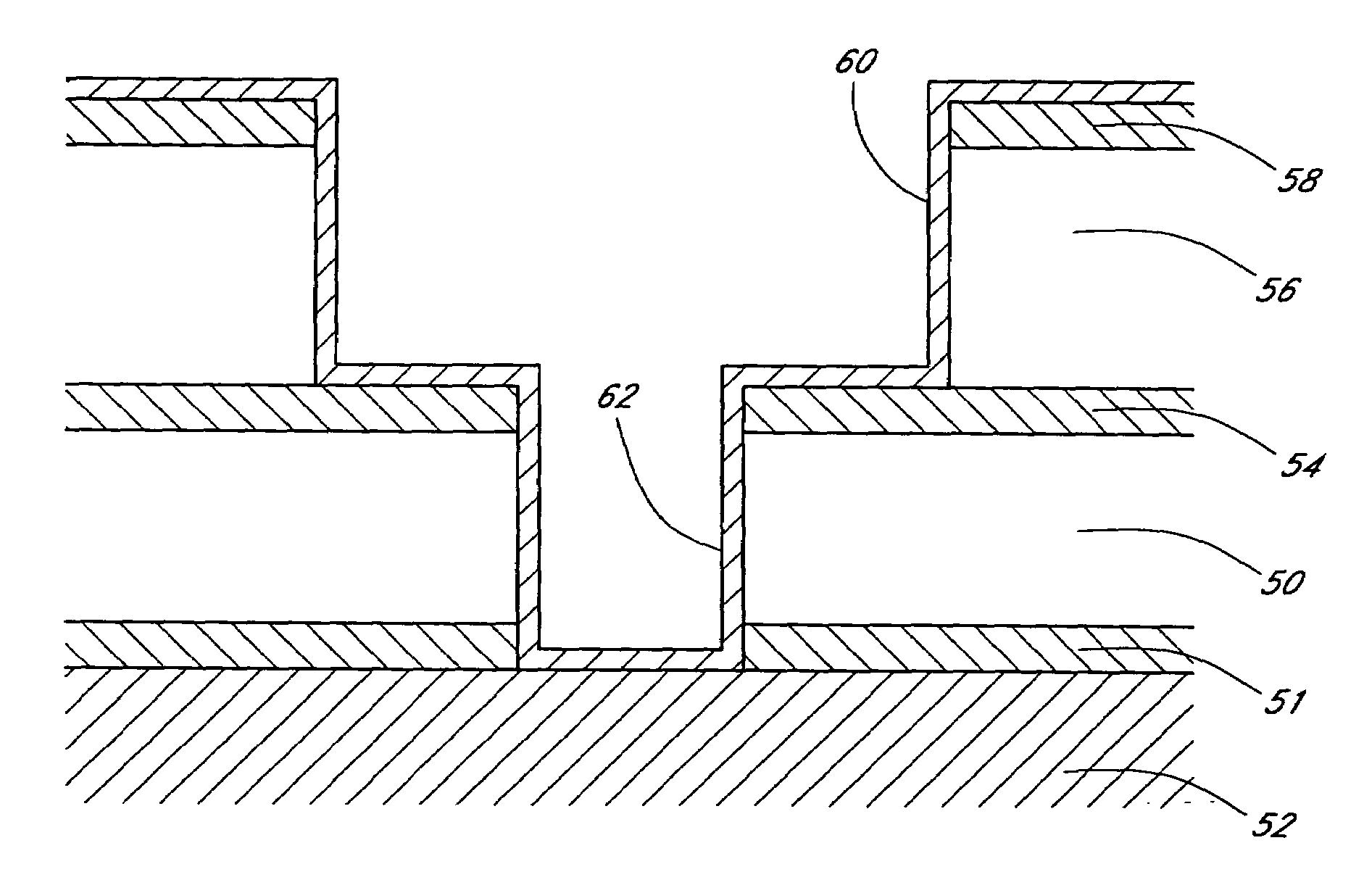

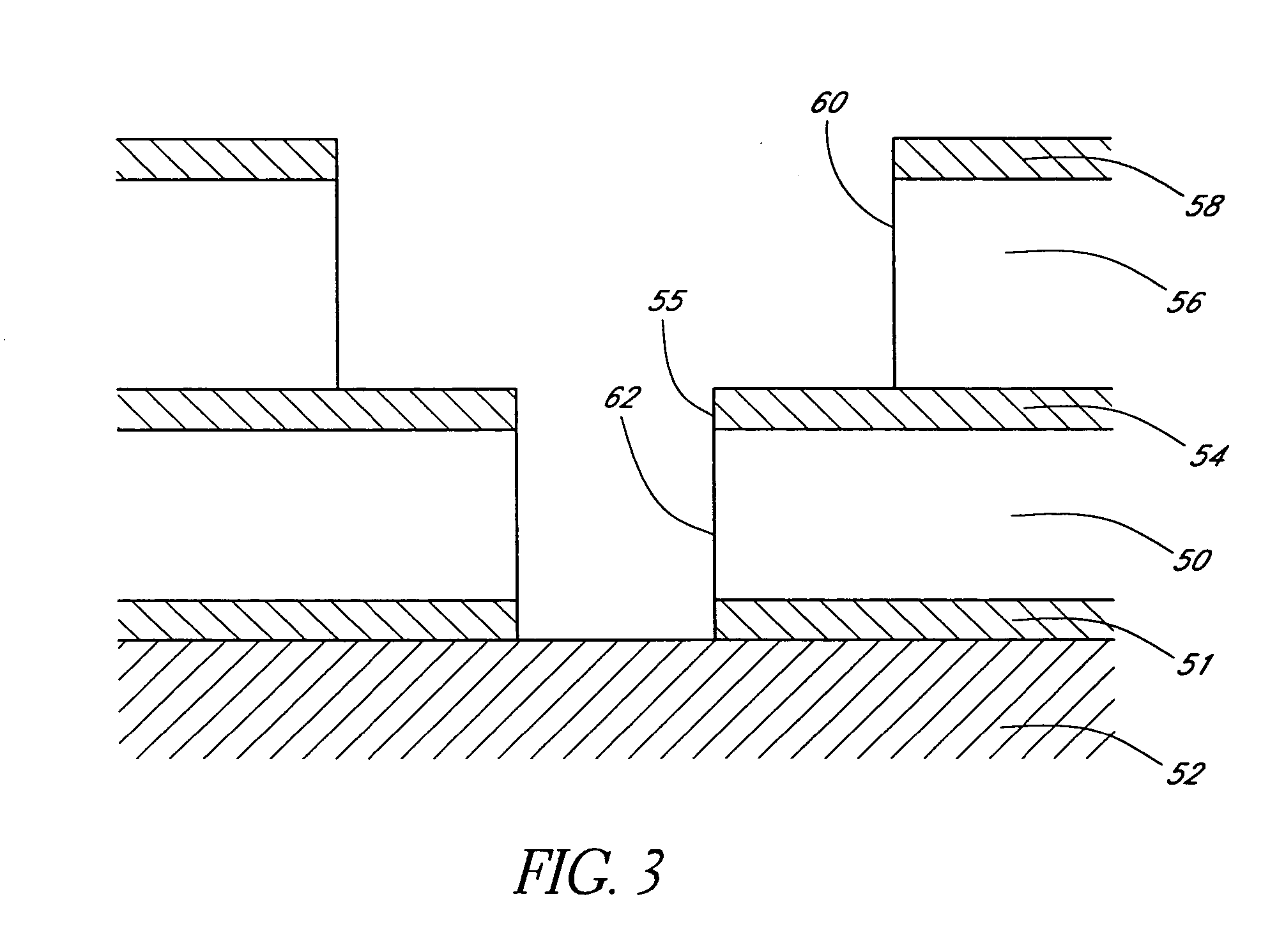

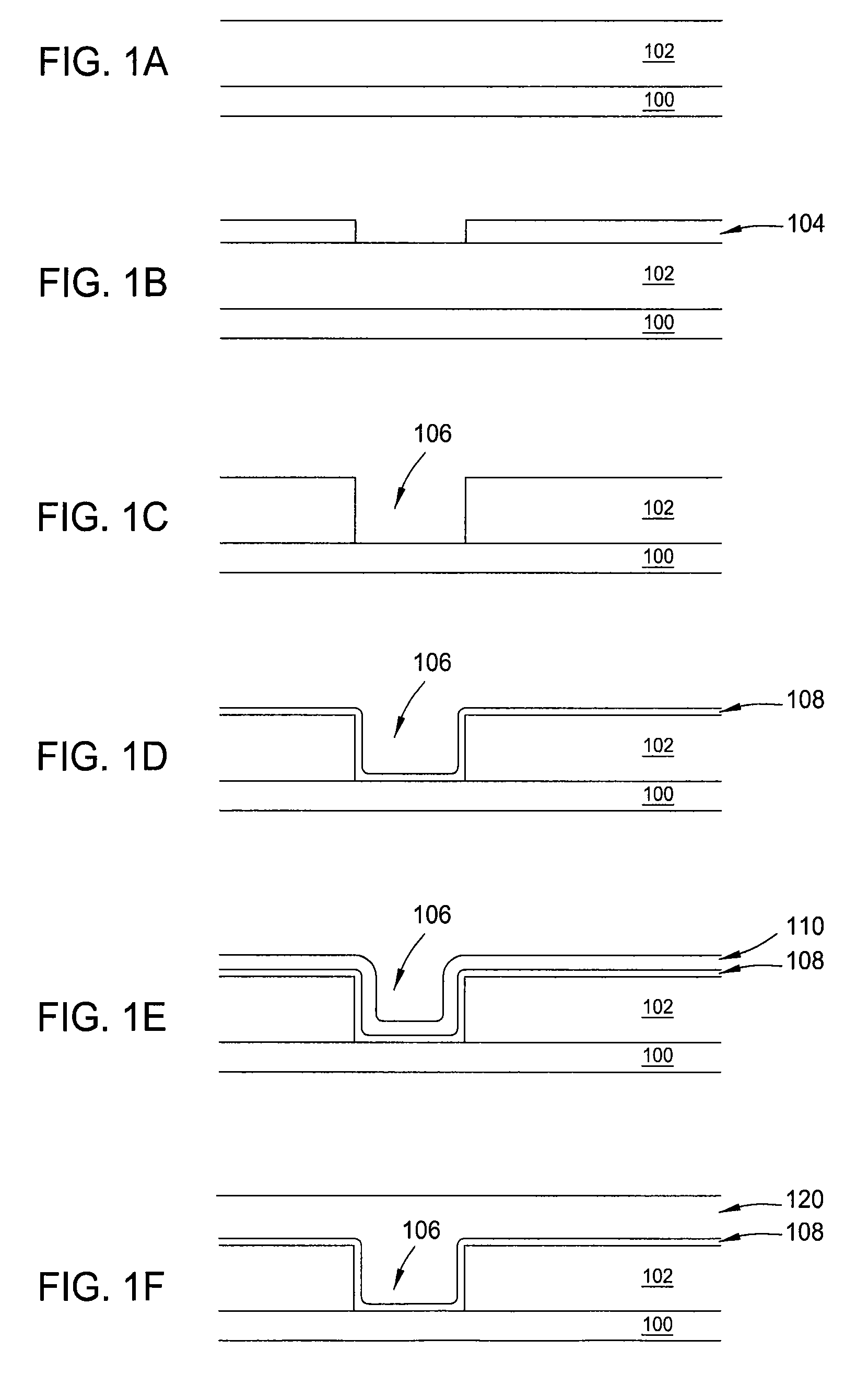

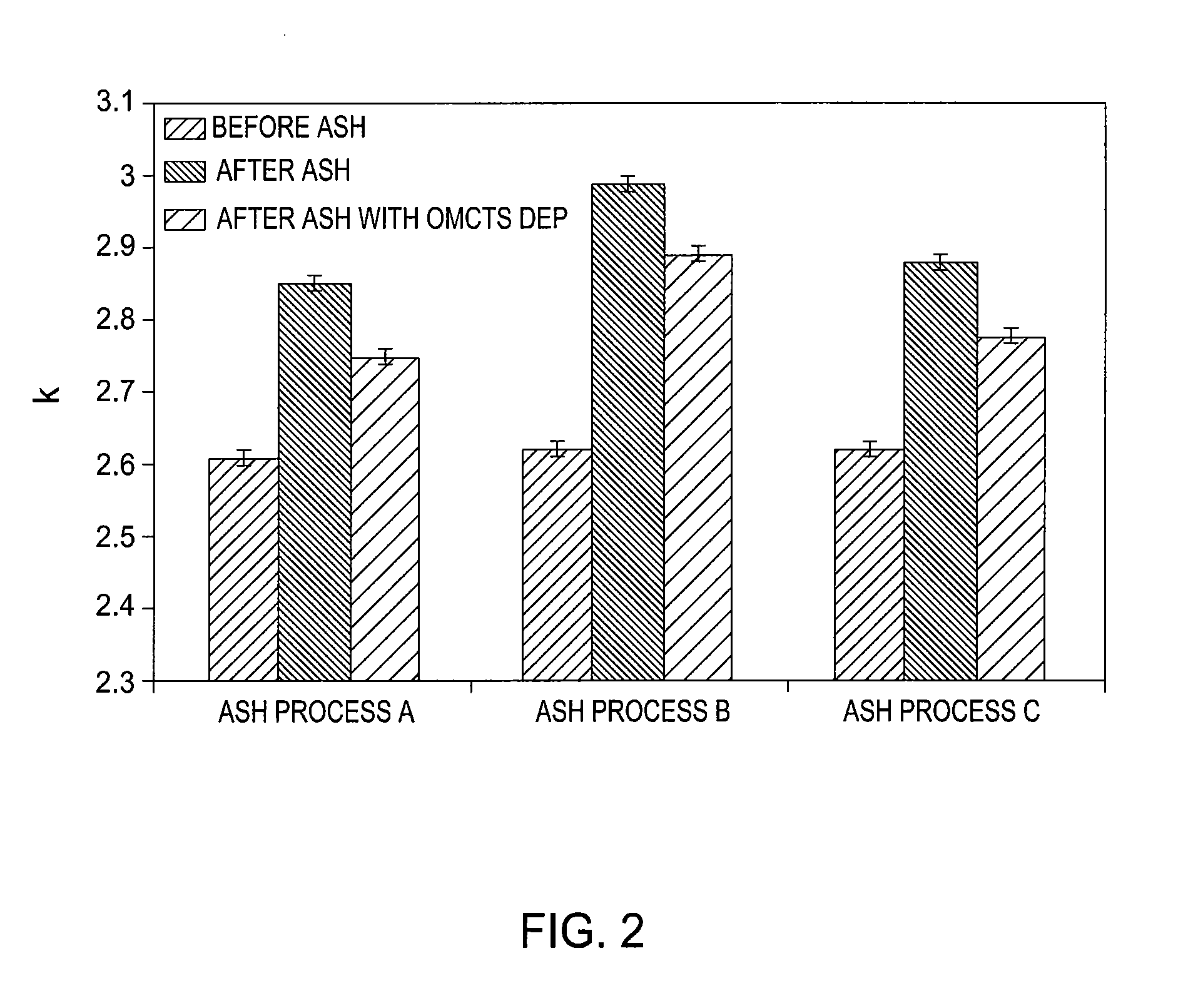

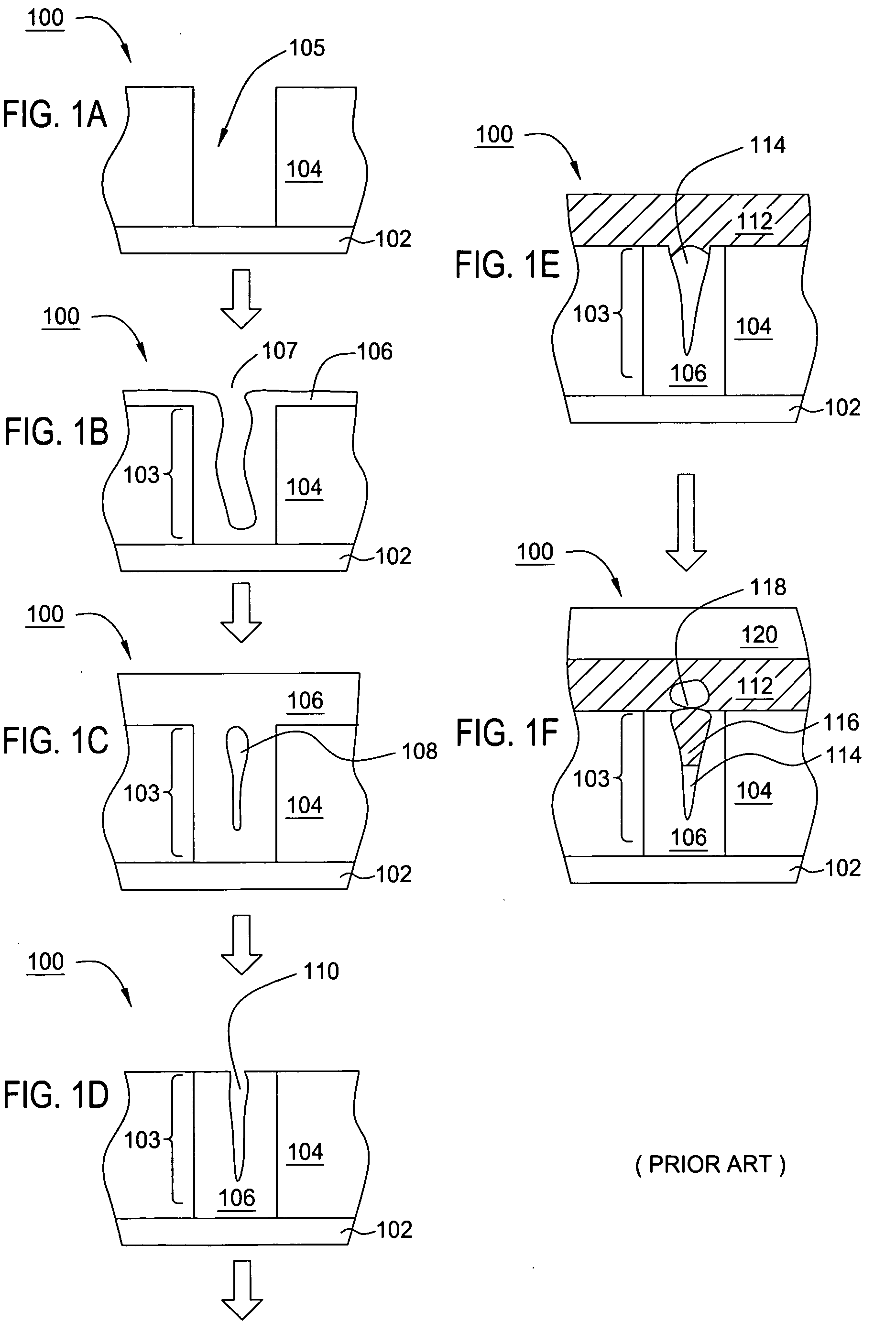

Method to minimize wet etch undercuts and provide pore sealing of extreme low k (k<2.5) dielectrics

ActiveUS8445075B2Constant ratePrevents undercuts and CD lossVacuum evaporation coatingPretreated surfacesNitrogenThin layer

Methods of processing films on substrates are provided. In one aspect, the methods comprise treating a patterned low dielectric constant film after a photoresist is removed from the film by depositing a thin layer comprising silicon, carbon, and optionally oxygen and / or nitrogen on the film. The thin layer provides a carbon-rich, hydrophobic surface for the patterned low dielectric constant film. The thin layer also protects the low dielectric constant film from subsequent wet cleaning processes and penetration by precursors for layers that are subsequently deposited on the low dielectric constant film.

Owner:APPLIED MATERIALS INC

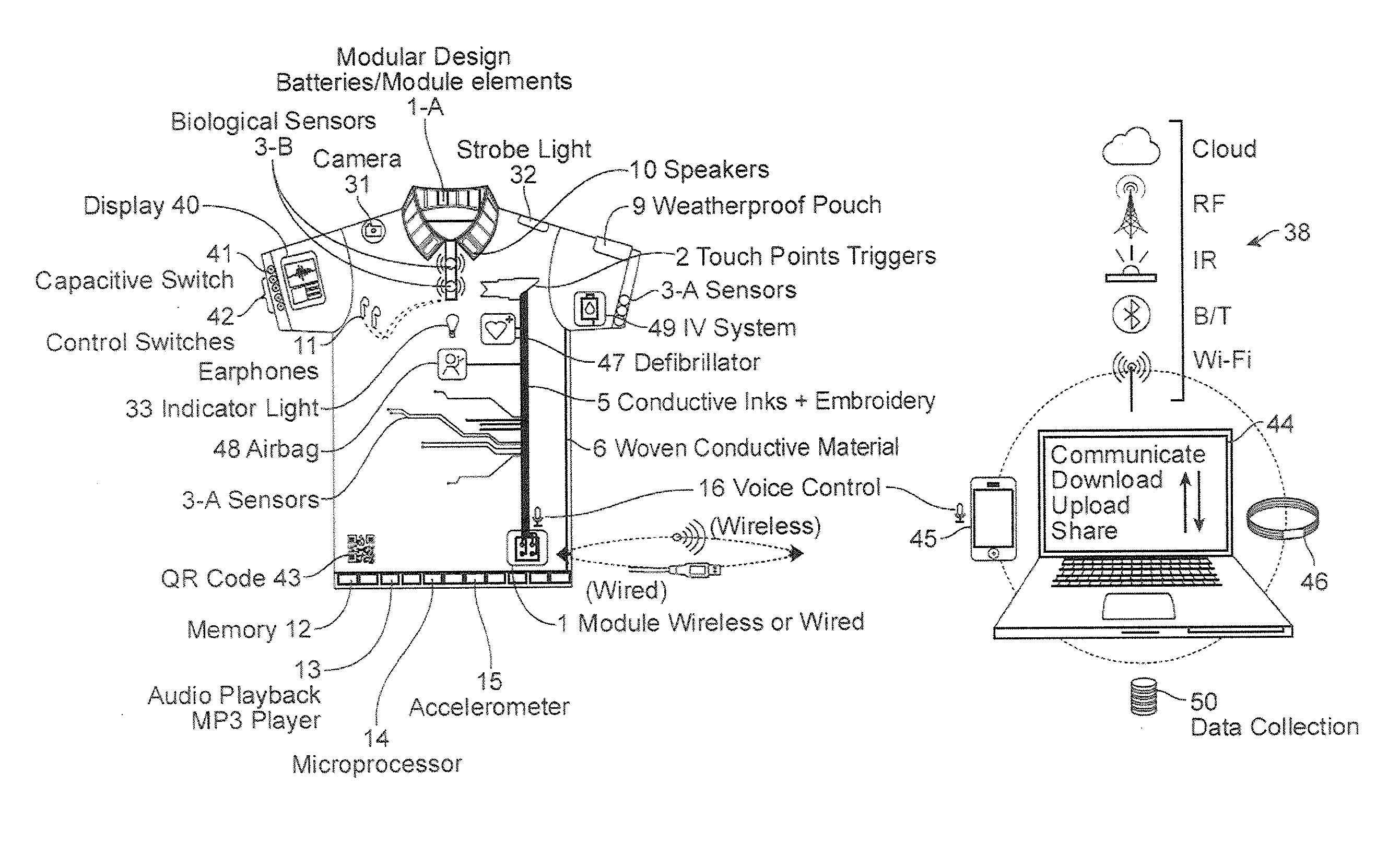

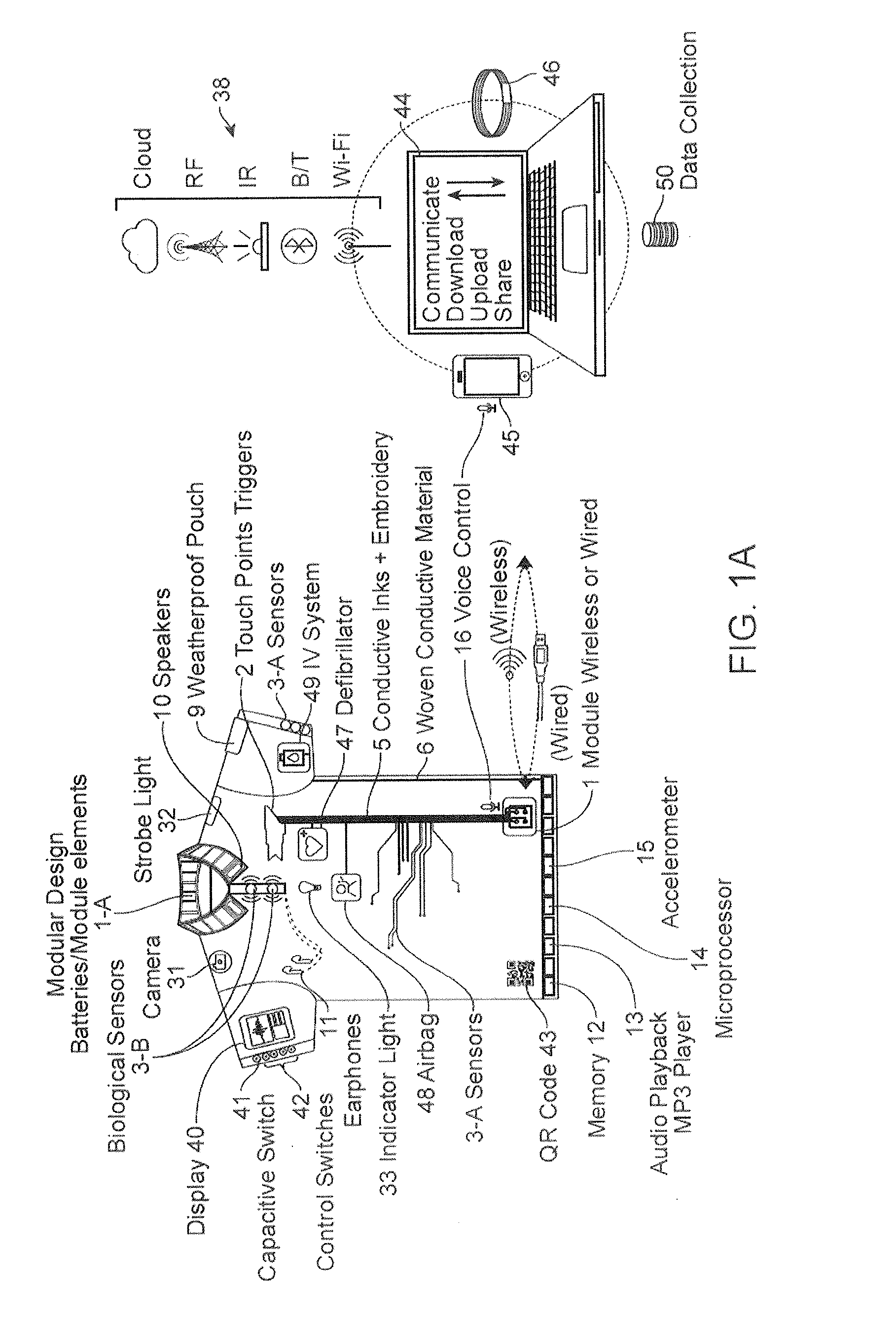

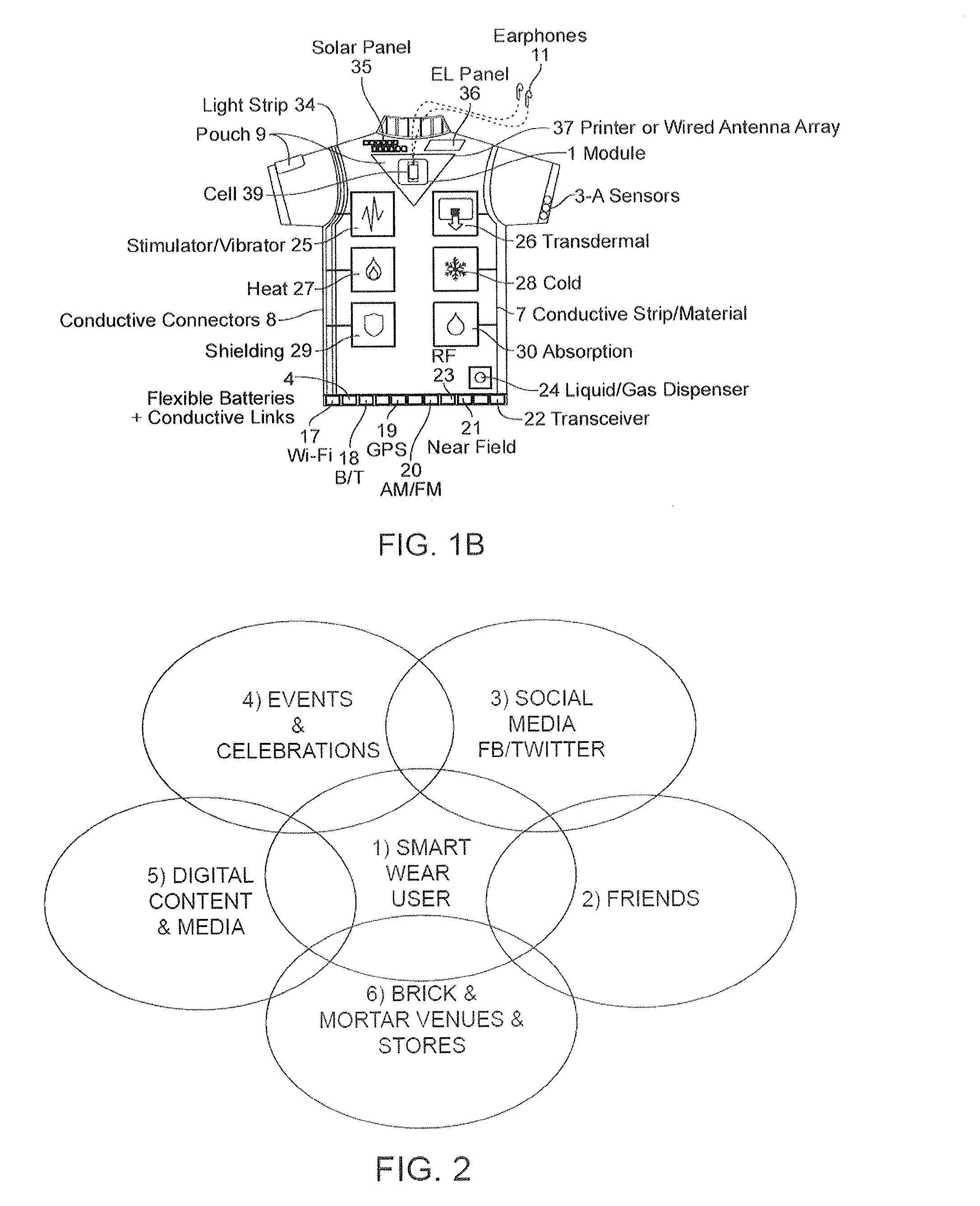

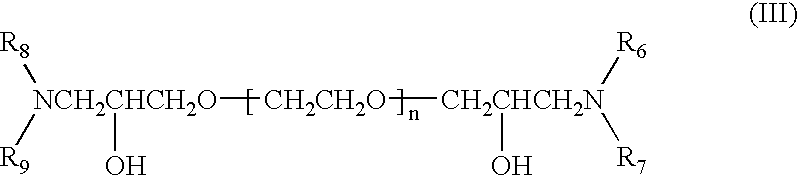

Methods of making garments having stretchable and conductive ink

InactiveUS20140318699A1Stable and continuous positioningRobust detectionPrinted circuit manufactureResistor manufactureAdhesiveSolvent

Methods of forming garments having one or more stretchable conductive ink patterns. Described herein are method of making garments (including compression garments) having one or more highly stretchable conductive ink pattern formed of a composite of an insulative adhesive, a conductive ink, and an intermediate gradient zone between the adhesive and conductive ink. The conductive ink typically includes between about 40-60% conductive particles, between about 30-50% binder; between about 3-7% solvent; and between about 3-7% thickener. The stretchable conductive ink patterns may be stretched more than twice their length without breaking or rupturing.

Owner:L I F E

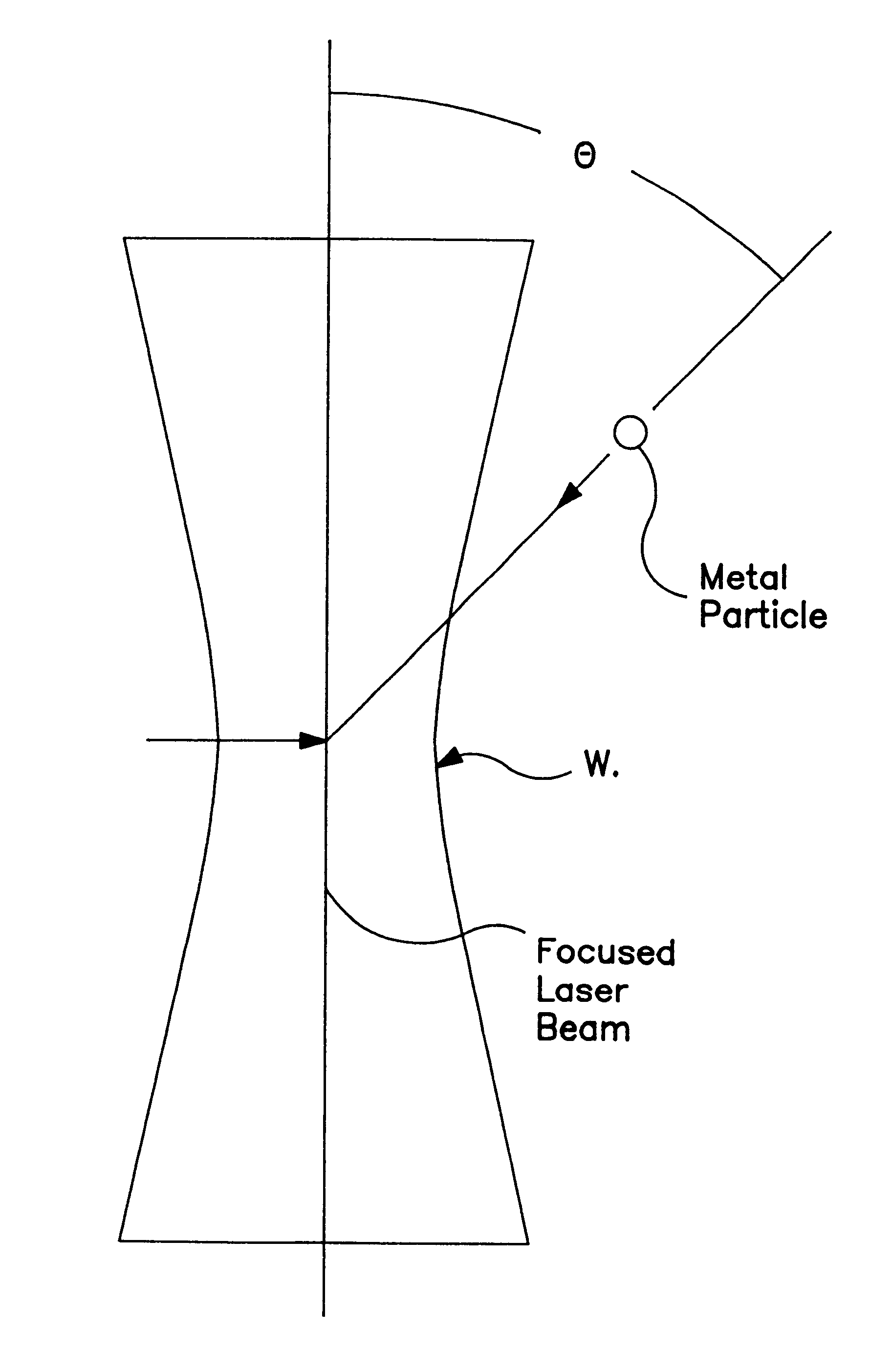

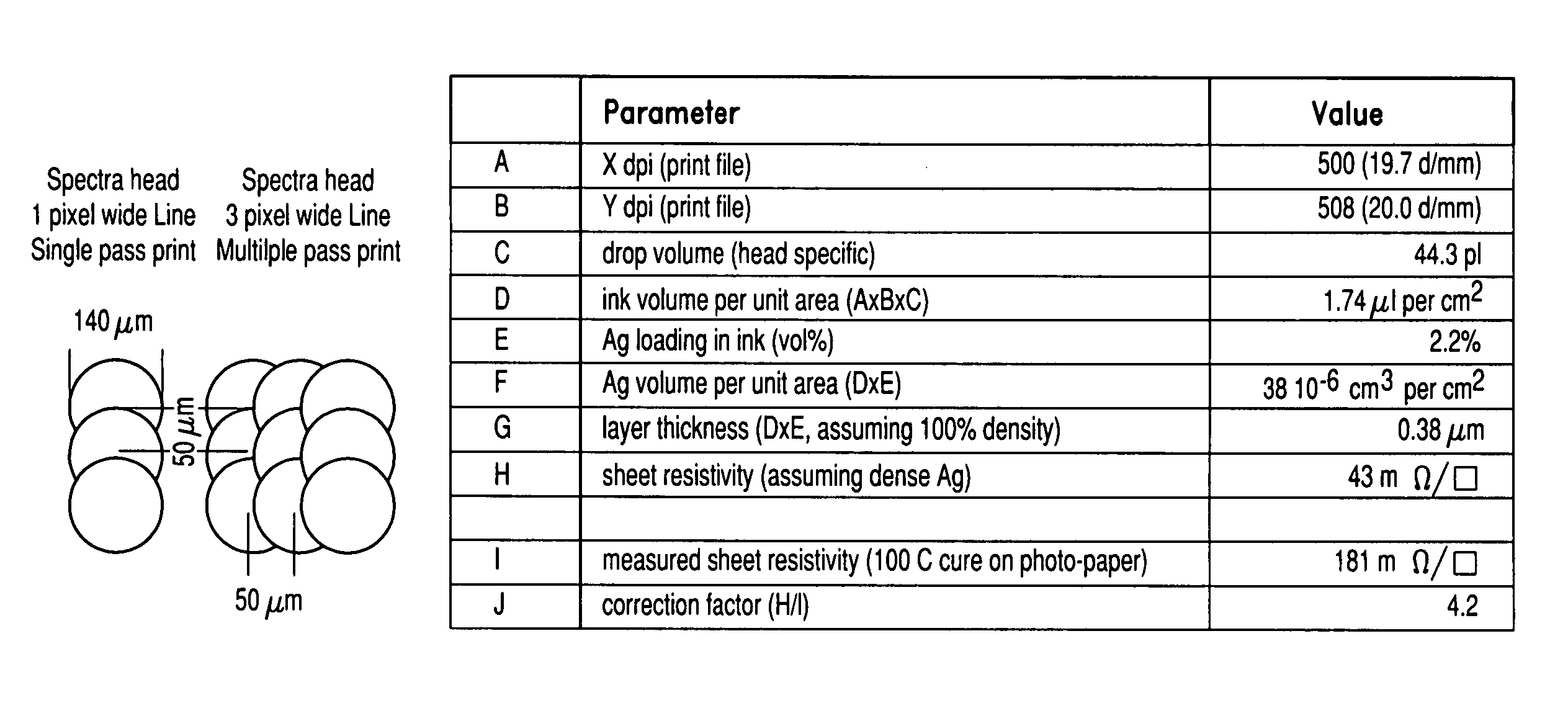

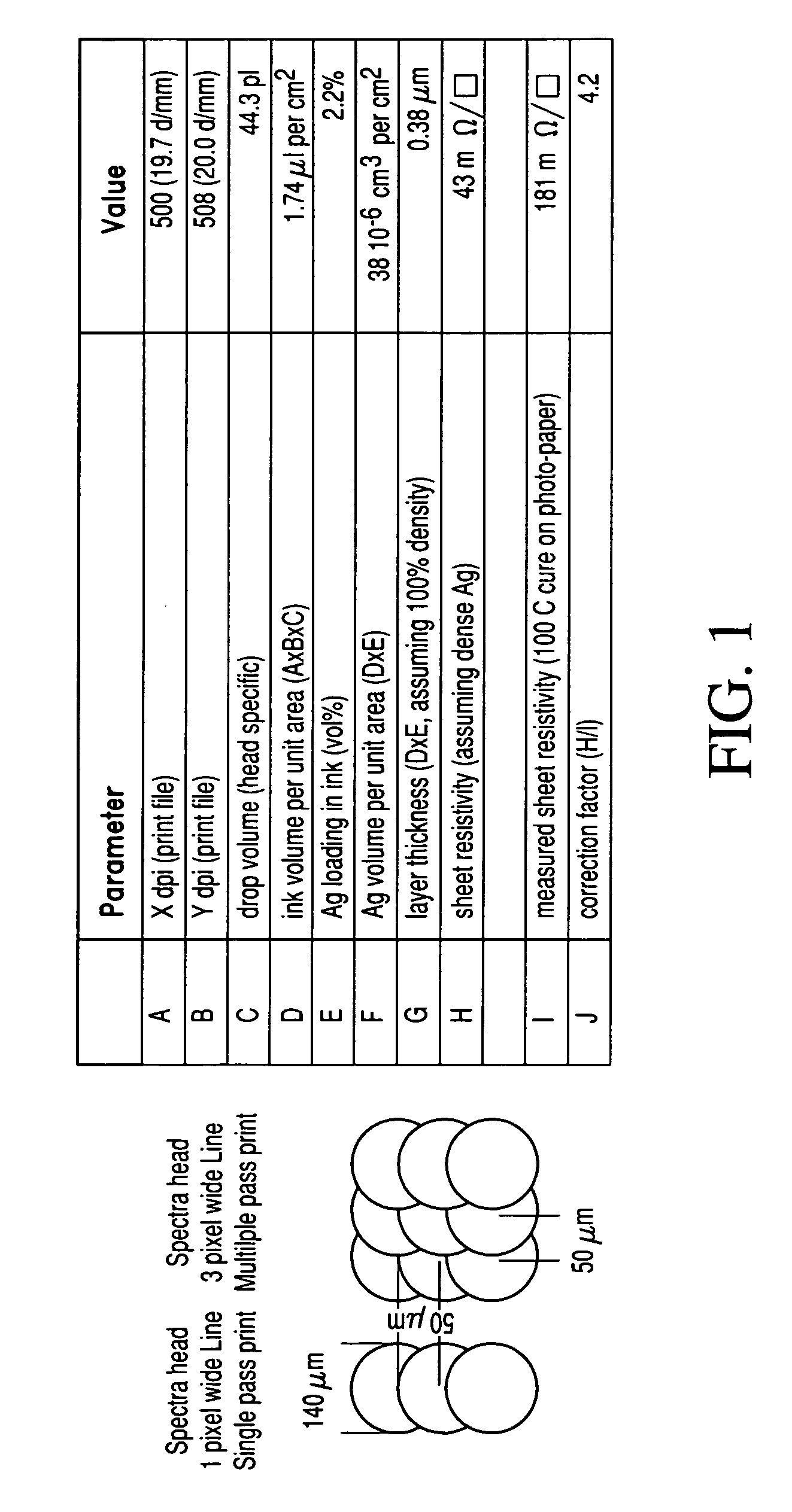

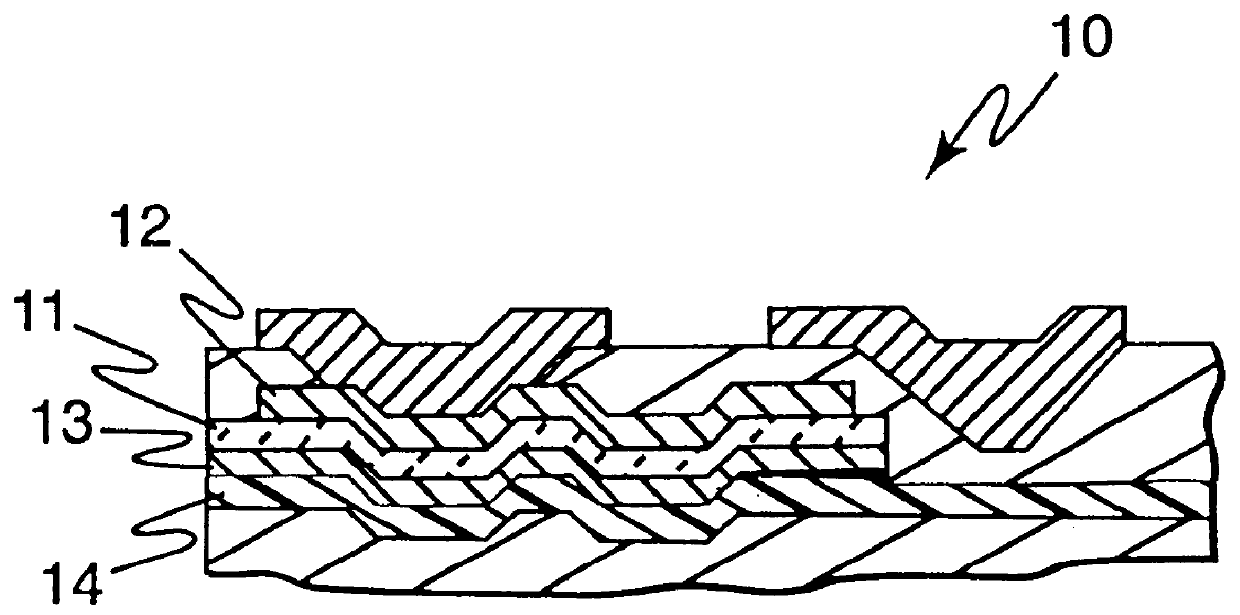

Precision spray processes for direct write electronic components

InactiveUS6251488B1Keep for a long timeIncrease probabilityMolten spray coatingVacuum evaporation coatingElectrical resistance and conductanceElectronic component

This invention combines the precision spray process with in-flight laser treatment in order to produce direct write electronic components. In addition to these components, the process can lay down lines of conductive, inductive, and resistive materials. This development has the potential to change the approach to electronics packaging. This process is revolutionary in that components can be directly produced on small structures, thus removing the need for printed circuit boards.

Owner:OPTOMEC DESIGN CO

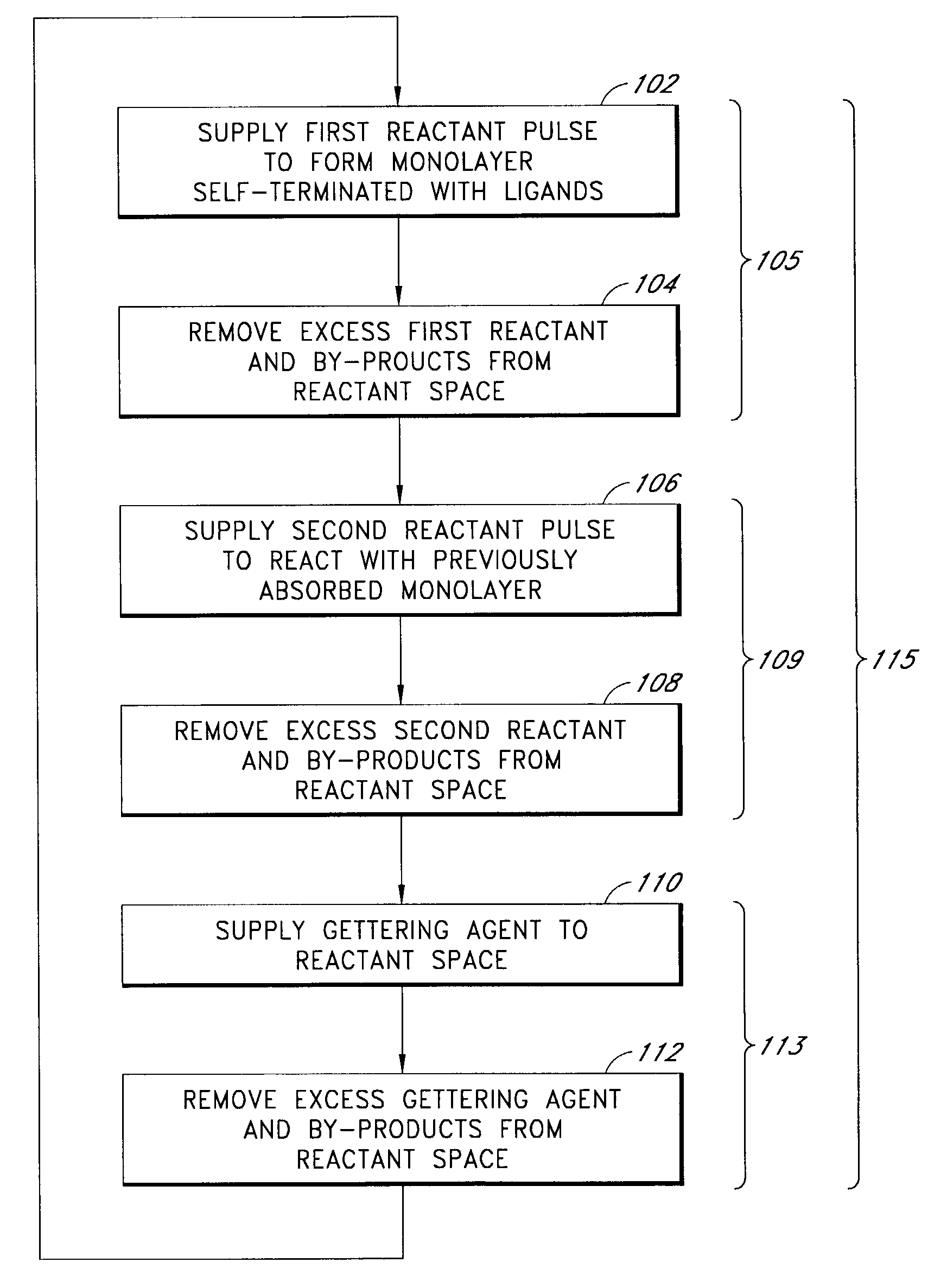

Metal nitride carbide deposition by ALD

InactiveUS7410666B2Material nanotechnologySemiconductor/solid-state device detailsHydrogen halideCorrosive chemical

Owner:ASM INTERNATIONAL

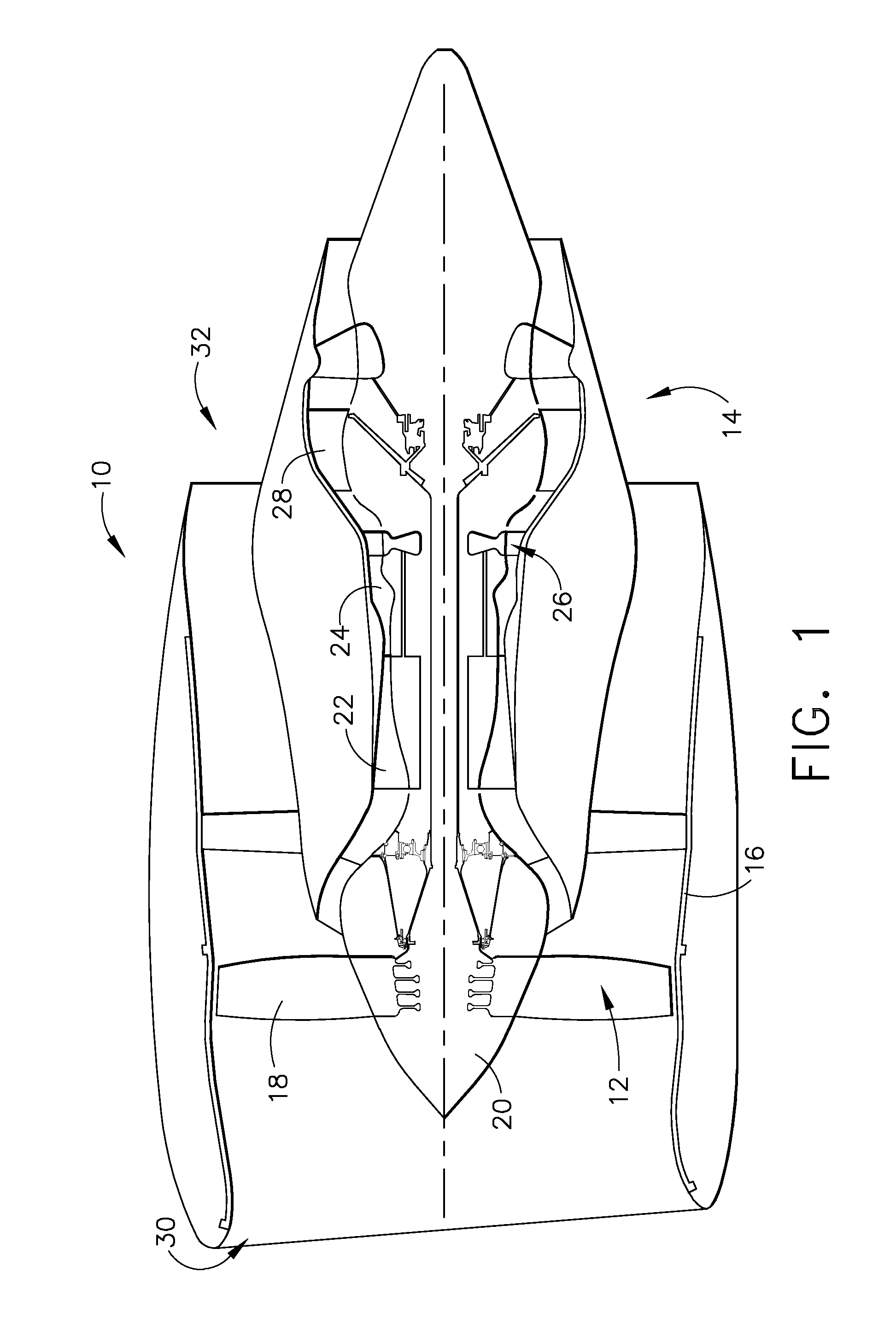

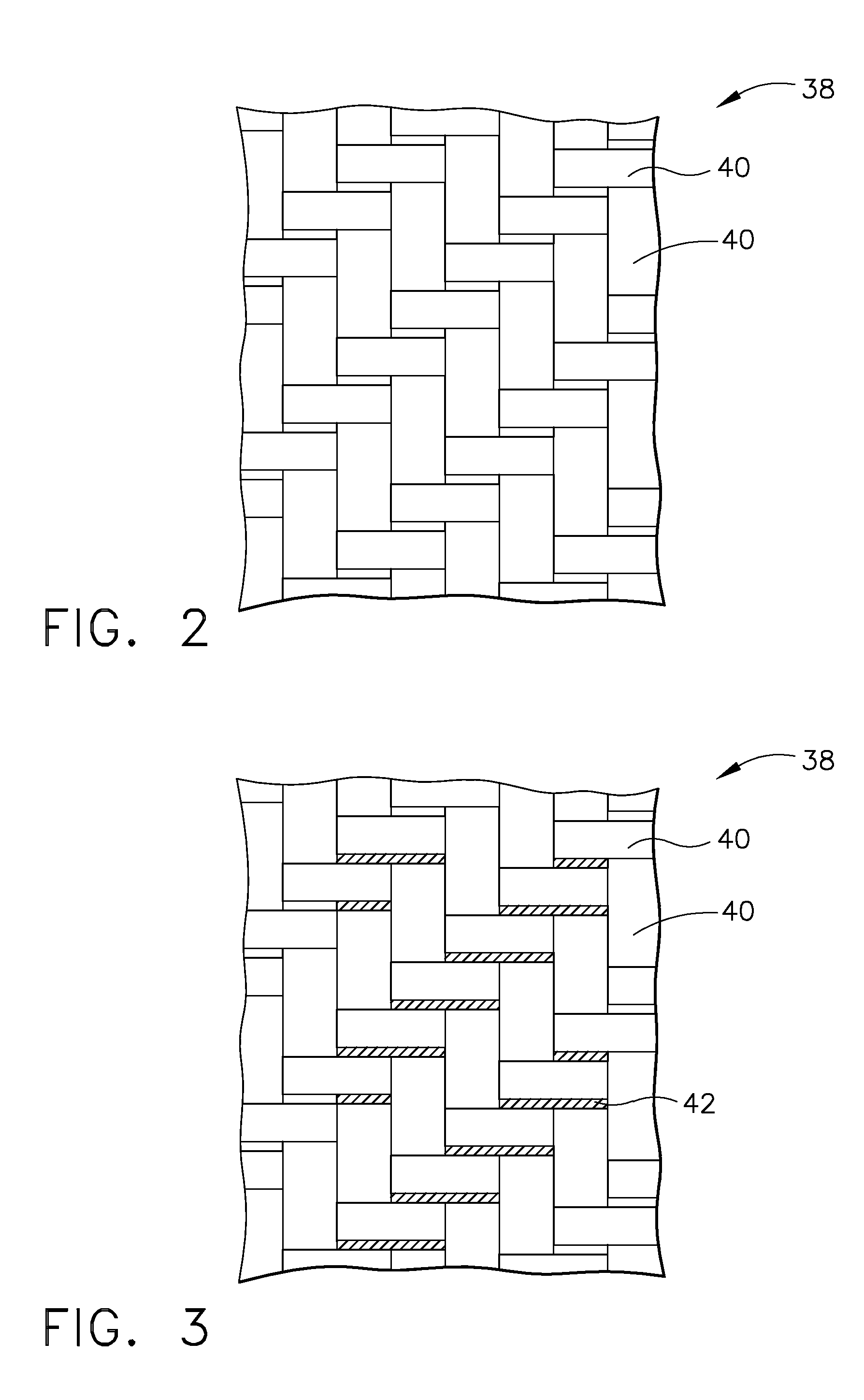

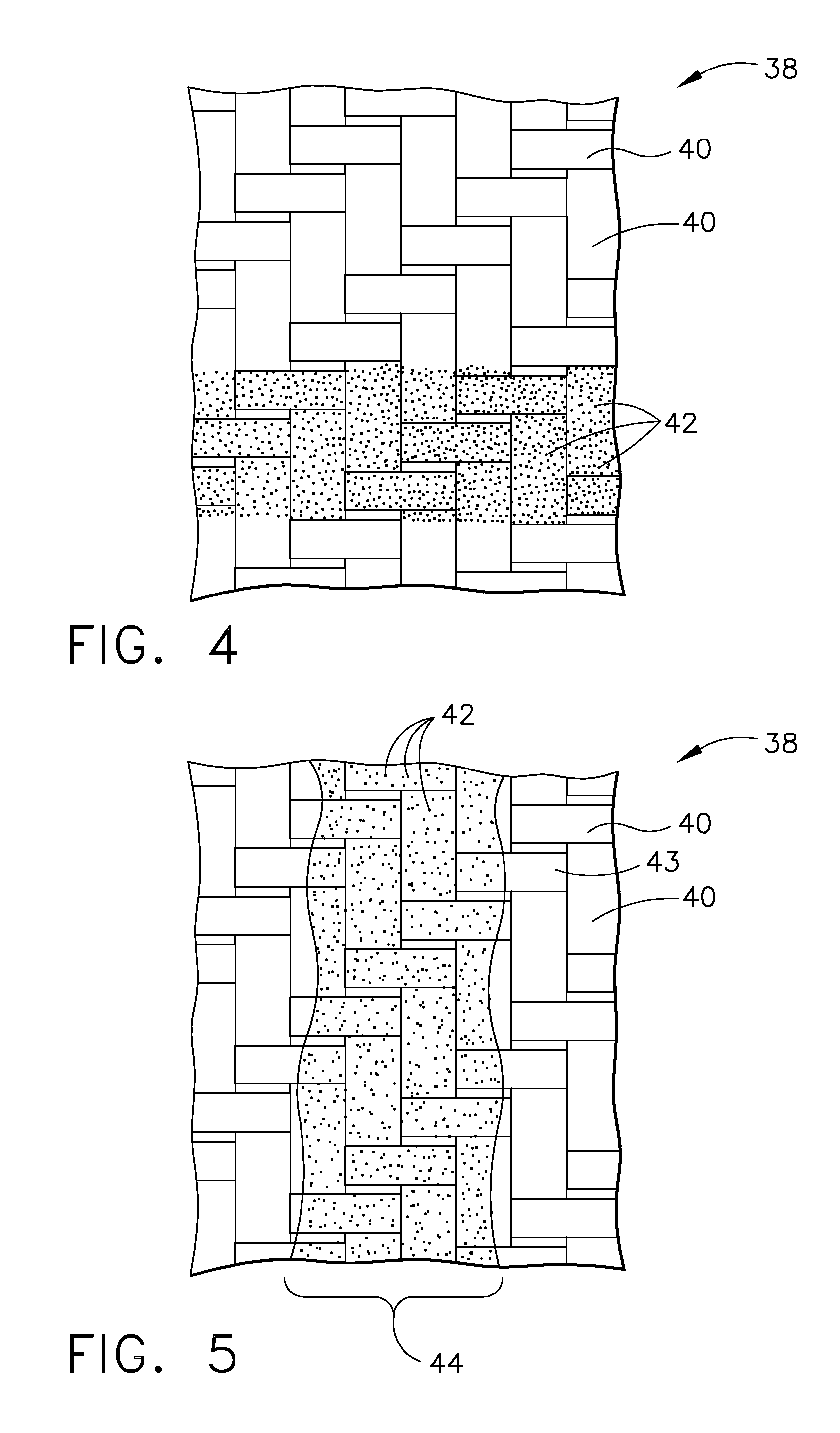

Methods of making articles having toughened and untoughened regions

ActiveUS20100148396A1Weight increaseHigh strengthPretreated surfacesLiquid/solution decomposition chemical coatingProviding materialFracture toughness

Methods of making an article having at least one toughened region and at least one untoughened region involving providing a material, applying a toughening agent to a portion of the material, shaping the material to produce a preform, applying an untoughened resin to the preform, and curing the preform having the applied untoughened resin to produce the at least one toughened region and the at least one untoughened region wherein the toughened region comprises a toughened resin having a fracture toughness of at least about 1.0 MPa-m1 / 2.

Owner:GENERAL ELECTRIC CO

Metal nitride deposition by ALD with reduction pulse

The present methods provide tools for growing conformal metal thin films, including metal nitride, metal carbide and metal nitride carbide thin films. In particular, methods are provided for growing such films from aggressive chemicals. The amount of corrosive chemical compounds, such as hydrogen halides, is reduced during the deposition of transition metal, transition metal carbide, transition metal nitride and transition metal nitride carbide thin films on various surfaces, such as metals and oxides. Getter compounds protect surfaces sensitive to hydrogen halides and ammonium halides, such as aluminum, copper, silicon oxide and the layers being deposited, against corrosion. Nanolaminate structures incorporating metallic thin films, and methods for forming the same, are also disclosed.

Owner:ASM INTERNATIONAL

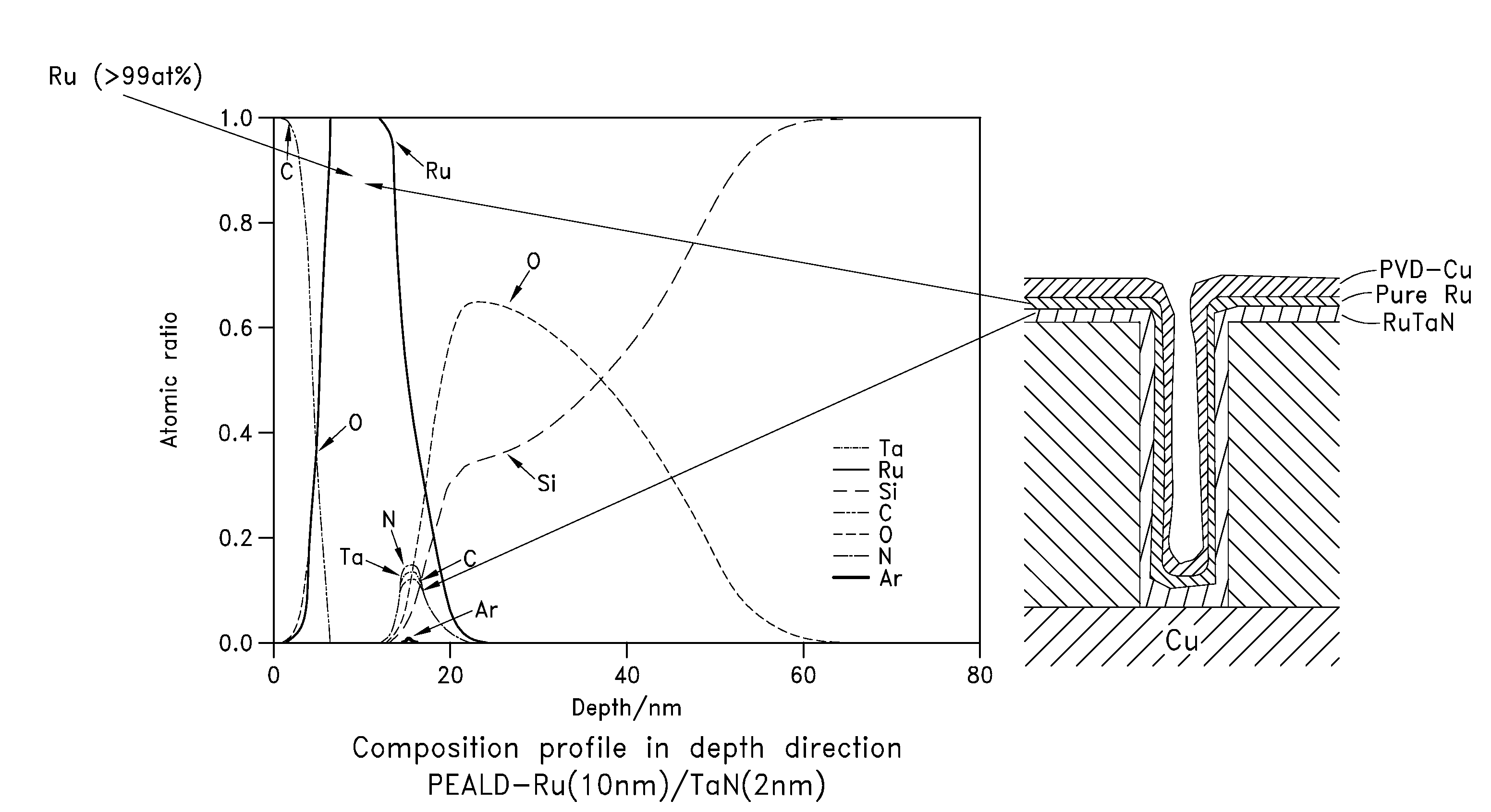

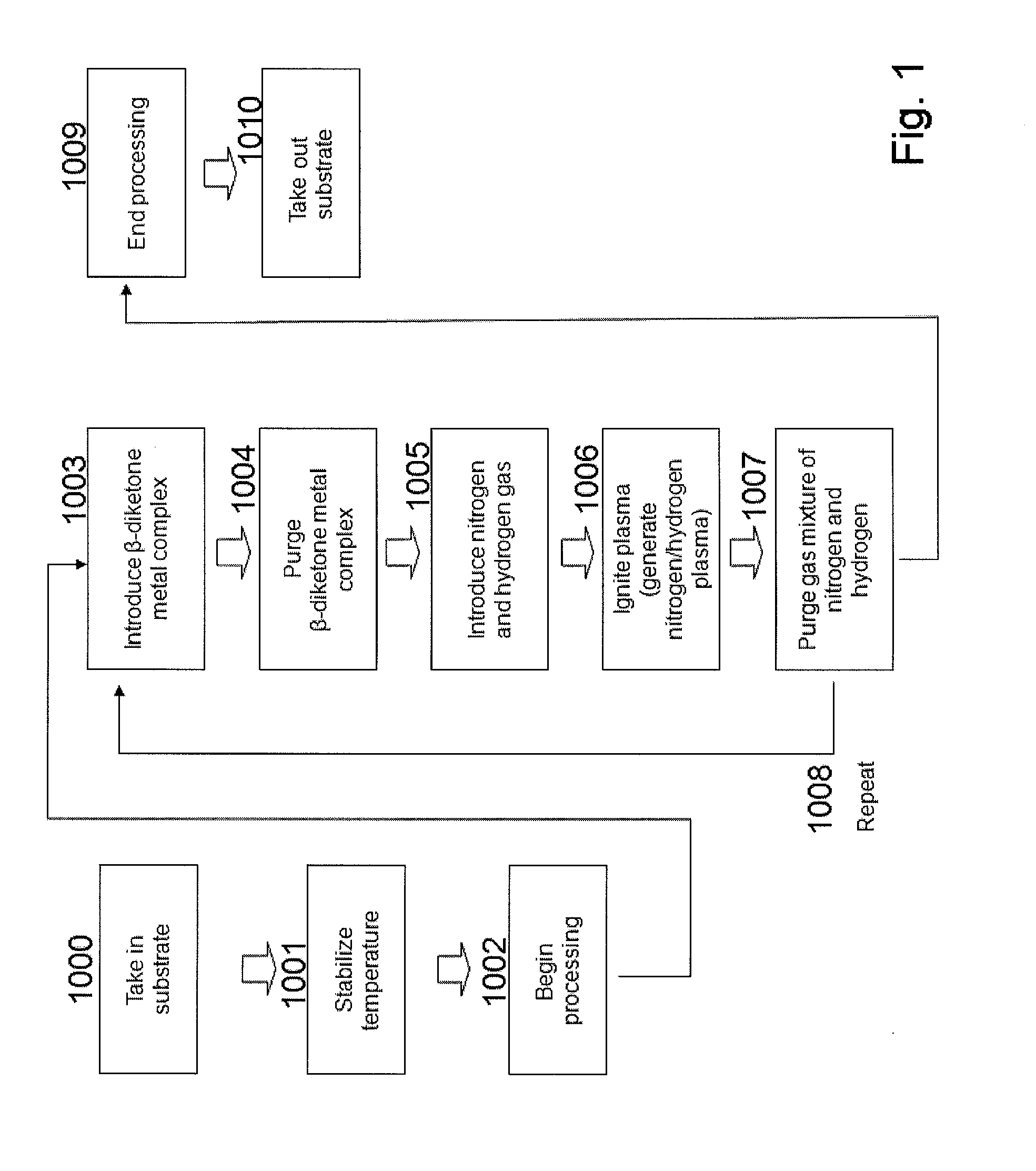

Method for forming metal film by ald using beta-diketone metal complex

ActiveUS20100092696A1Improve shielding effectRapid and reliable mannerVacuum evaporation coatingPretreated surfacesDiketoneHydrogen

A method of forming a single-metal film on a substrate by plasma ALD includes: contacting a surface of a substrate with a β-diketone metal complex in a gas phase; exposing molecule-attached surface to a nitrogen-hydrogen mixed plasma; and repeating the above steps, thereby accumulating atomic layers to form a single-metal film on the substrate.

Owner:ASM JAPAN

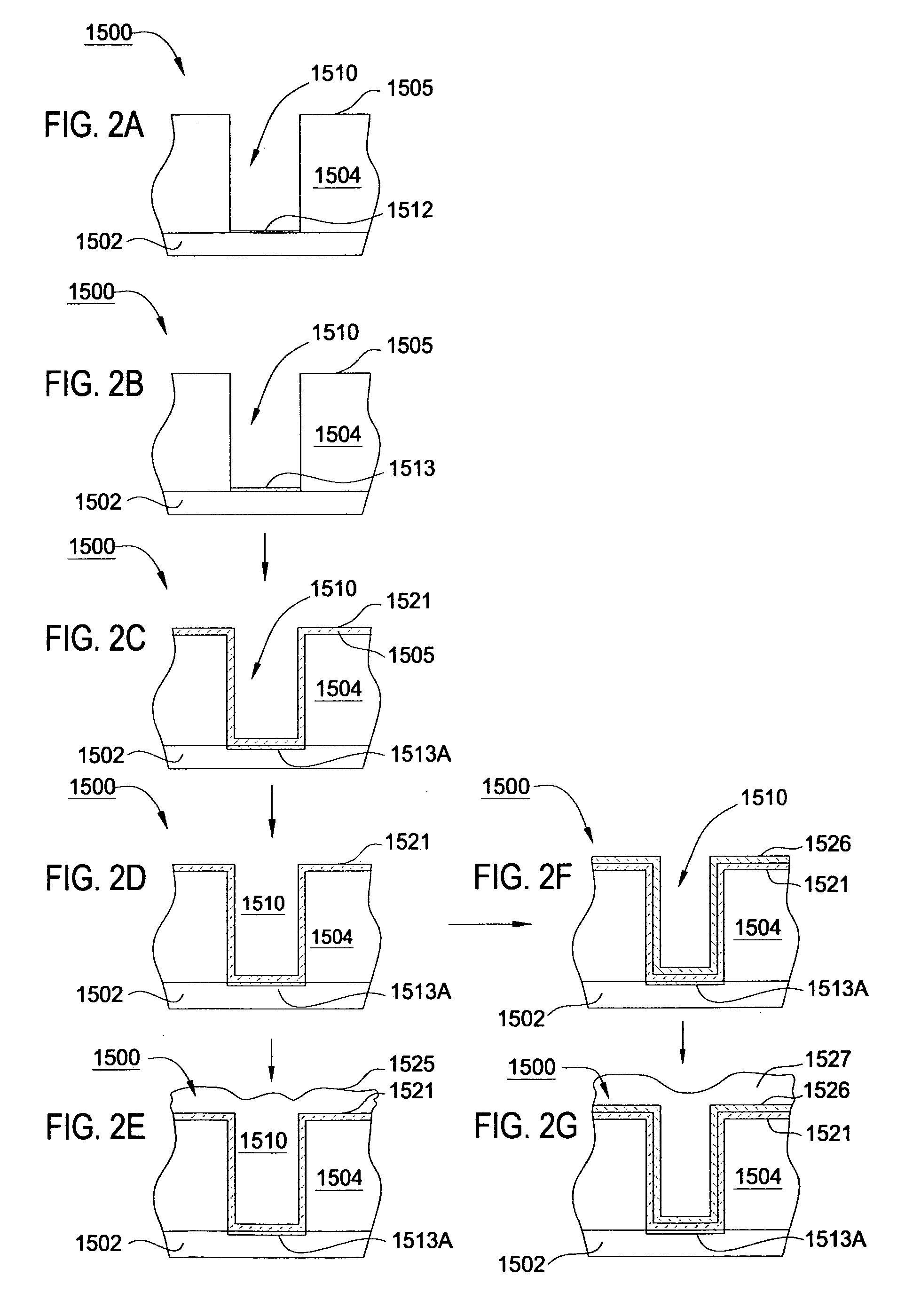

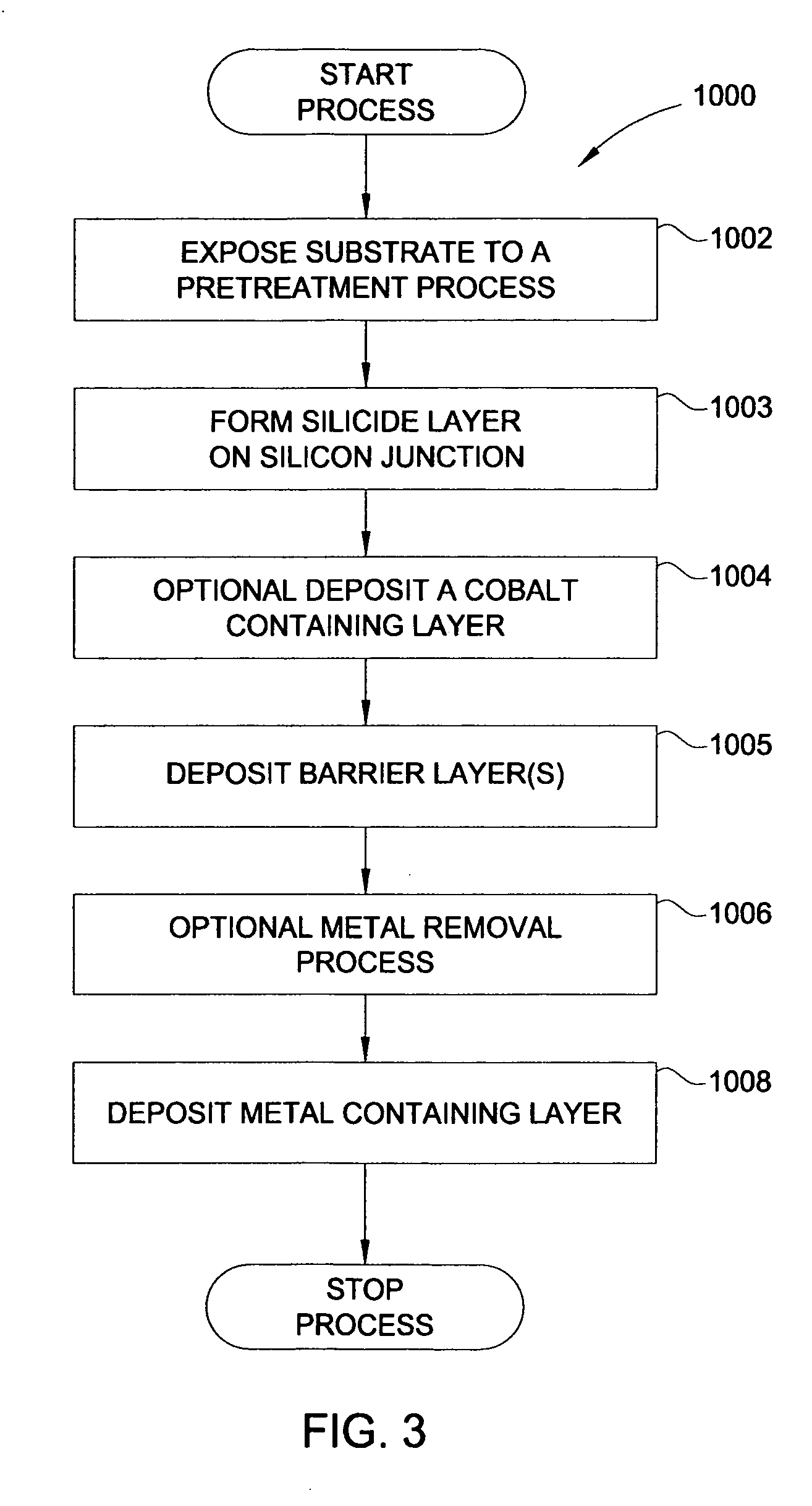

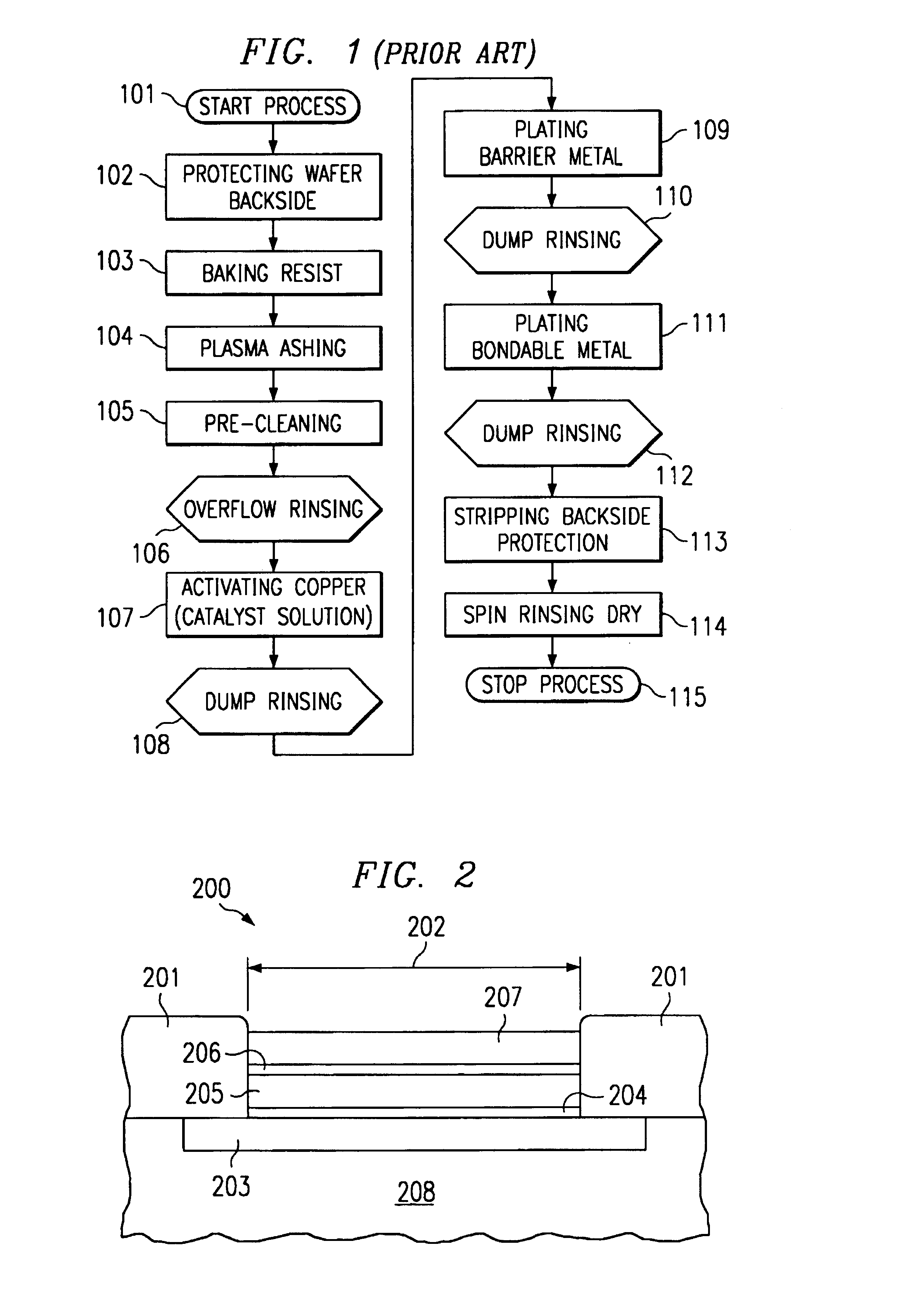

Contact metallization scheme using a barrier layer over a silicide layer

ActiveUS20060251800A1Material nanotechnologySemiconductor/solid-state device detailsDevice materialElectroless deposition

Embodiments of the invention generally provide methods of filling contact level features formed in a semiconductor device by depositing a barrier layer over the contact feature and then filing the layer using an PVD, CVD, ALD, electrochemical plating process (ECP) and / or electroless deposition processes. In one embodiment, the barrier layer has a catalytically active surface that will allow the electroless deposition of a metal on the barrier layer. In one aspect, the electrolessly deposited metal is copper or a copper alloy. In one aspect, the contact level feature is filled with a copper alloy by use of an electroless deposition process. In another aspect, a copper alloy is used to from a thin conductive copper layer that is used to subsequently fill features with a copper containing material by use of an ECP, PVD, CVD, and / or ALD deposition process. In one embodiment, a portion of the barrier layer is purposely allowed to react with traces of residual oxide at the silicon junction of the contact level feature to form a low resistance connection.

Owner:APPLIED MATERIALS INC

Method for applying an LbL coating onto a medical device

The present invention provides an improved LbL-coating process for modifying the surface of a medical device, preferably an ophthalmic device, more preferably a contact lens. An LbL coating on a contact lens, which is prepared according to the process of the invention, can have increased hydrophilicity characterized by an averaged contact angle of about 80 degree or less, preferably about 50 degrees or less, while maintaining the desired bulk properties such as oxygen permeability and ion permeability of lens material.

Owner:ALCON INC

Metal nanoparticle compositions

InactiveUS20060189113A1Low processing (curing)Improve mechanical propertiesMaterial nanotechnologyTransportation and packagingNanometreViscosity

Owner:CABOT CORP

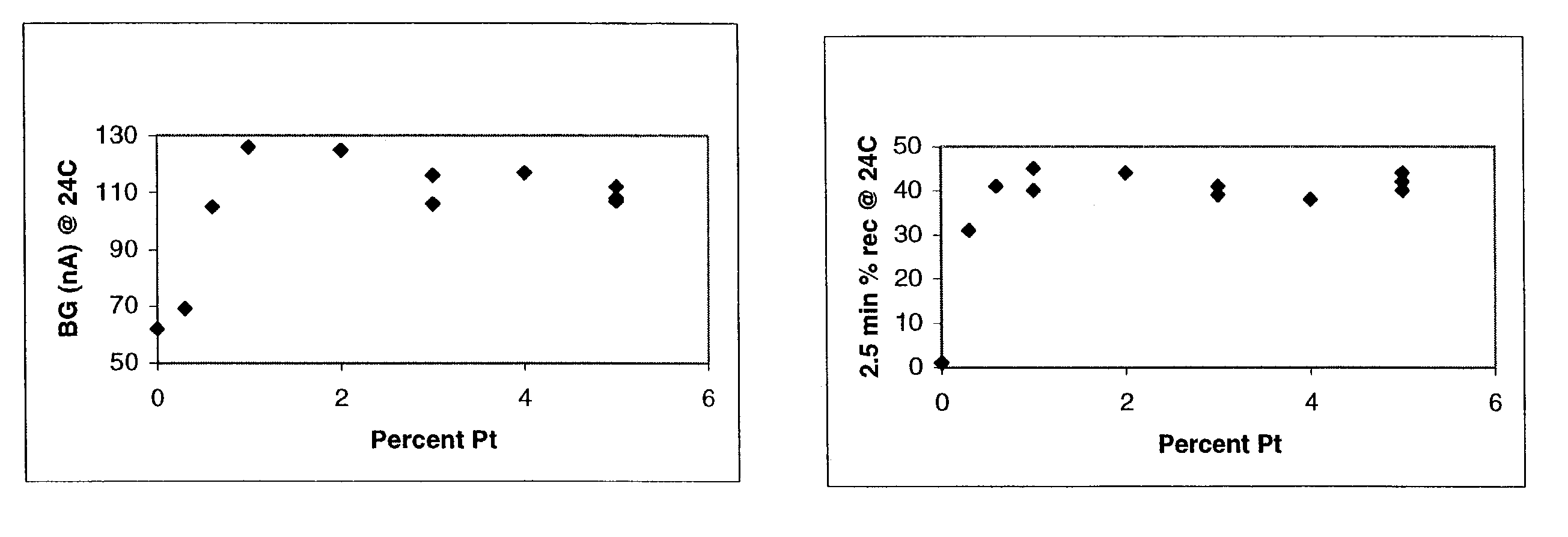

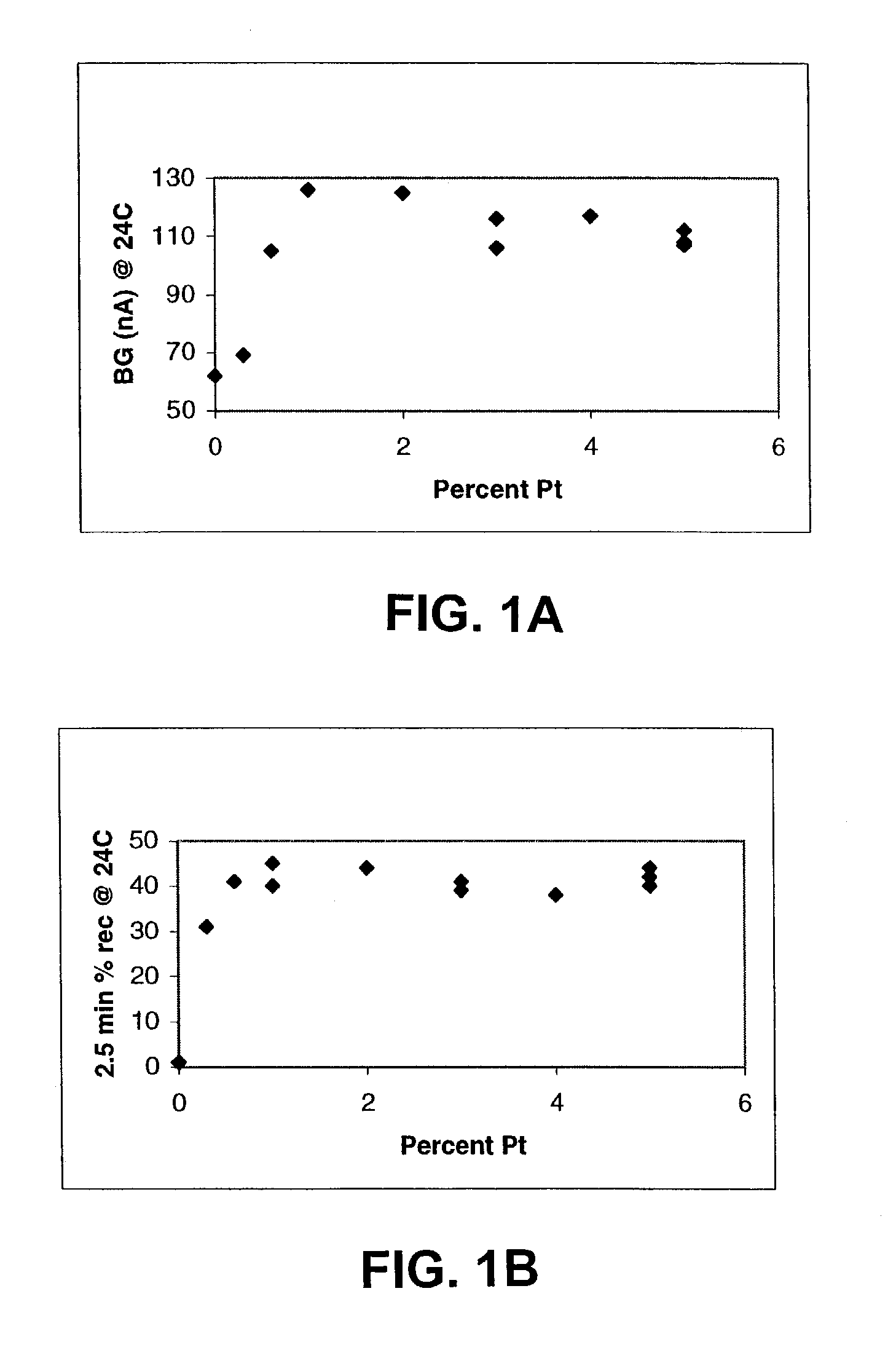

Highly catalytic screen-printing ink

ActiveUS7018568B2Easy to produceConductive layers on insulating-supportsConductive materialConductive polymerPrinting ink

The invention is directed to conductive polymer compositions, catalytic ink compositions (e.g., for use in screen-printing), electrodes produced by deposition of an ink composition, methods of making, and methods of using thereof. An exemplary ink material comprises platinum black and / or platinum-on-carbon as the catalyst, graphite as a conducting material, a polymer binding material, and an organic solvent. The polymer binding material is typically a copolymer of hydrophilic and hydrophobic monomers. The conductive polymer compositions of the present invention can be used, for example, to make electrochemical sensors. Such sensors can be used in a variety of analyte monitoring devices to monitor analyte amount or concentrations in subjects, for example, glucose monitoring devices to monitor glucose levels in subjects with diabetes.

Owner:LIFESCAN IP HLDG LLC +1

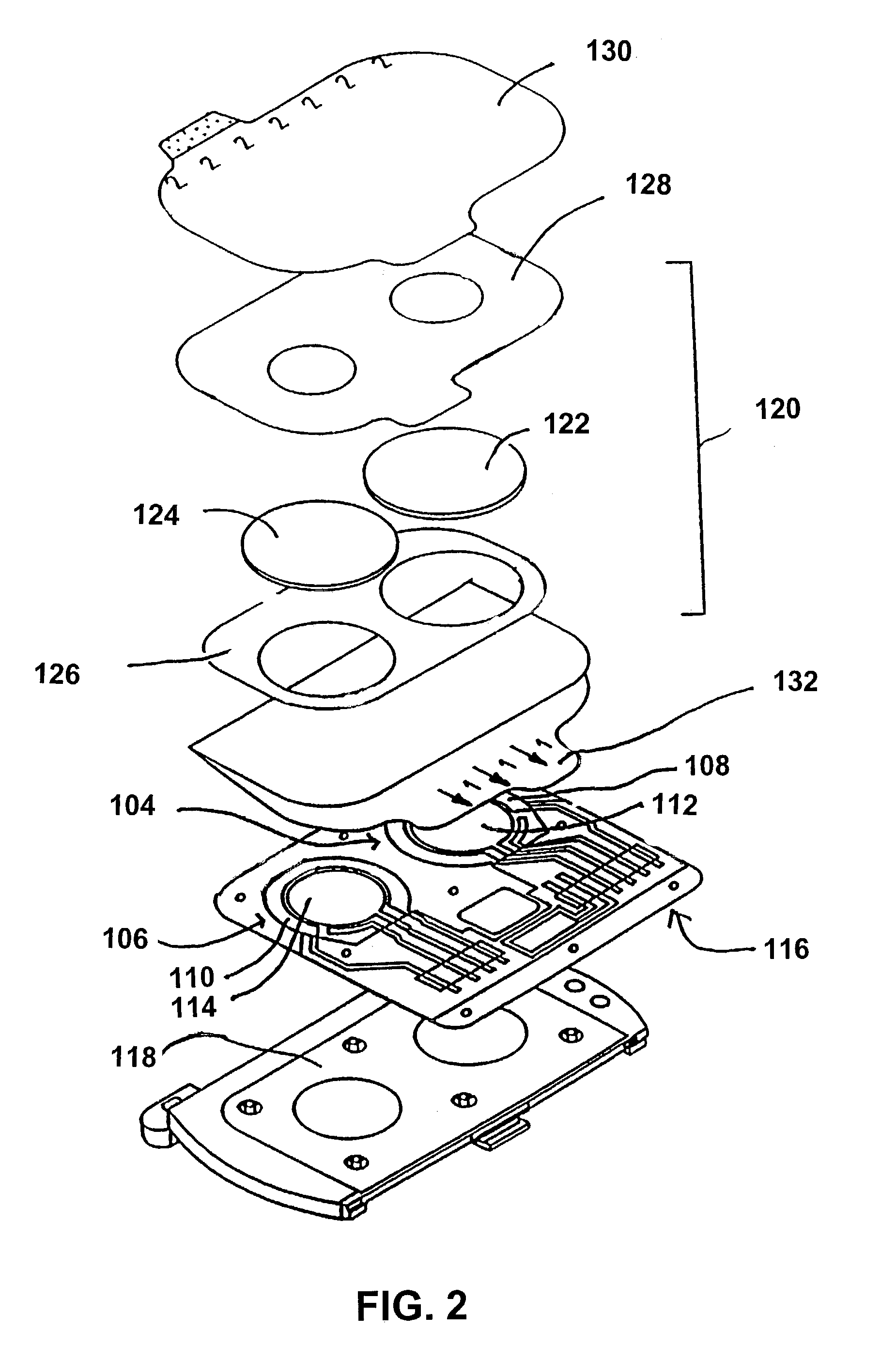

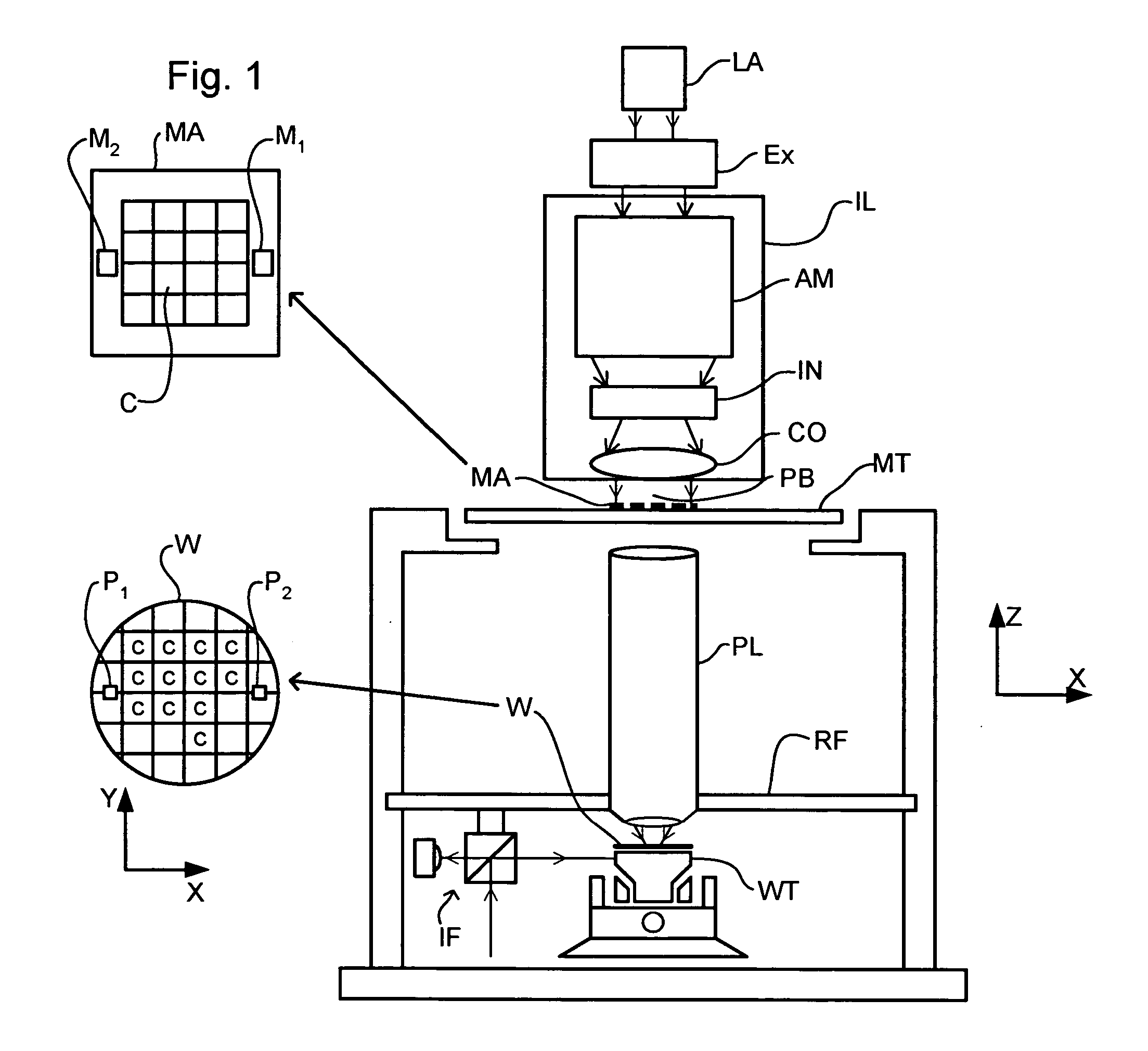

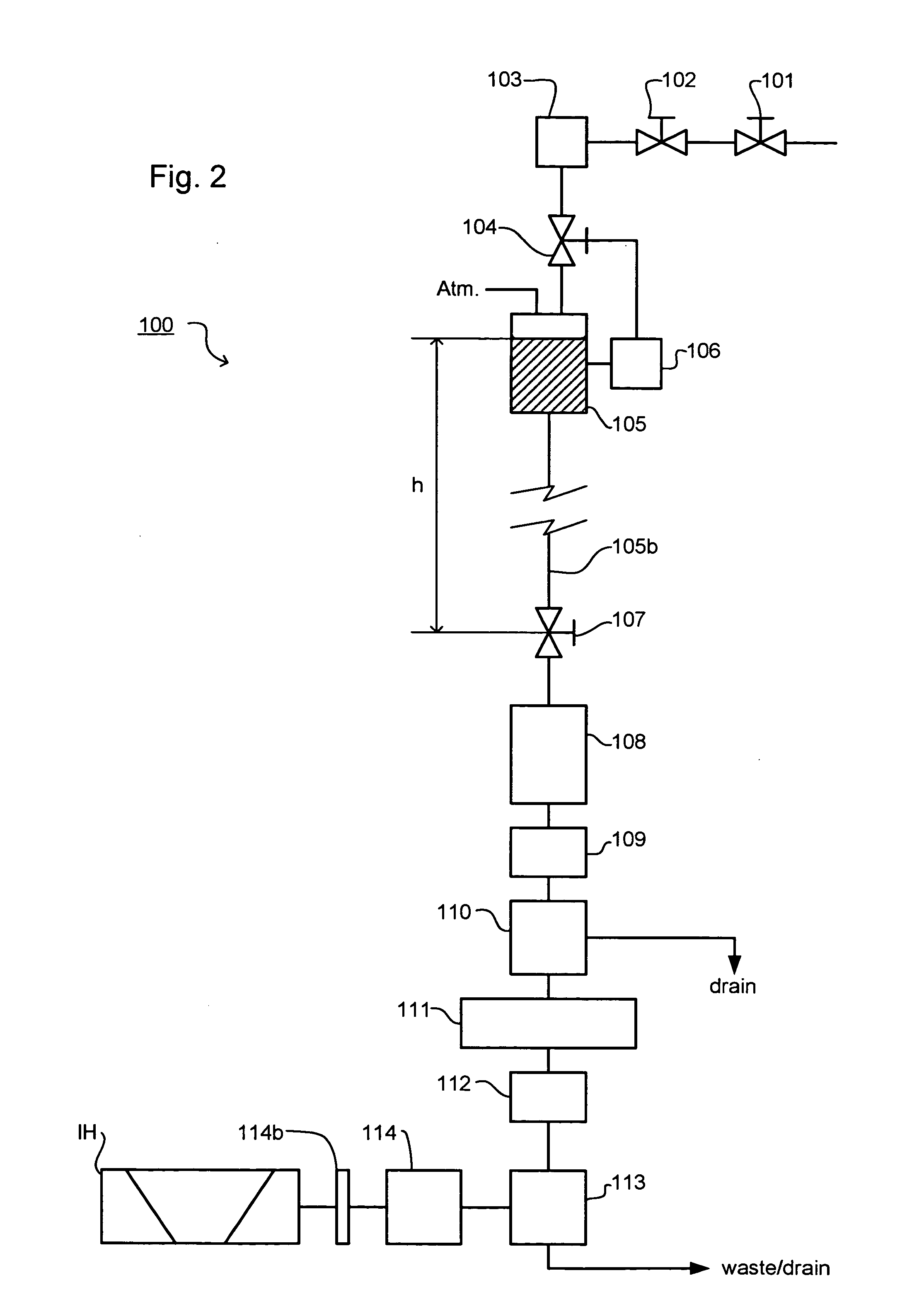

Lithographic apparatus and device manufacturing method

InactiveUS20050048220A1ConstantAvoid pollutionSemiconductor/solid-state device manufacturingPretreated surfacesEngineeringImmersion lithography

In an immersion lithography apparatus, the immersion liquid is supplied from a tank via a flow restrictor. The liquid held in the tank is maintained at a substantially constant height above the flow restrictor to ensure a constant flow of liquid.

Owner:ASML NETHERLANDS BV

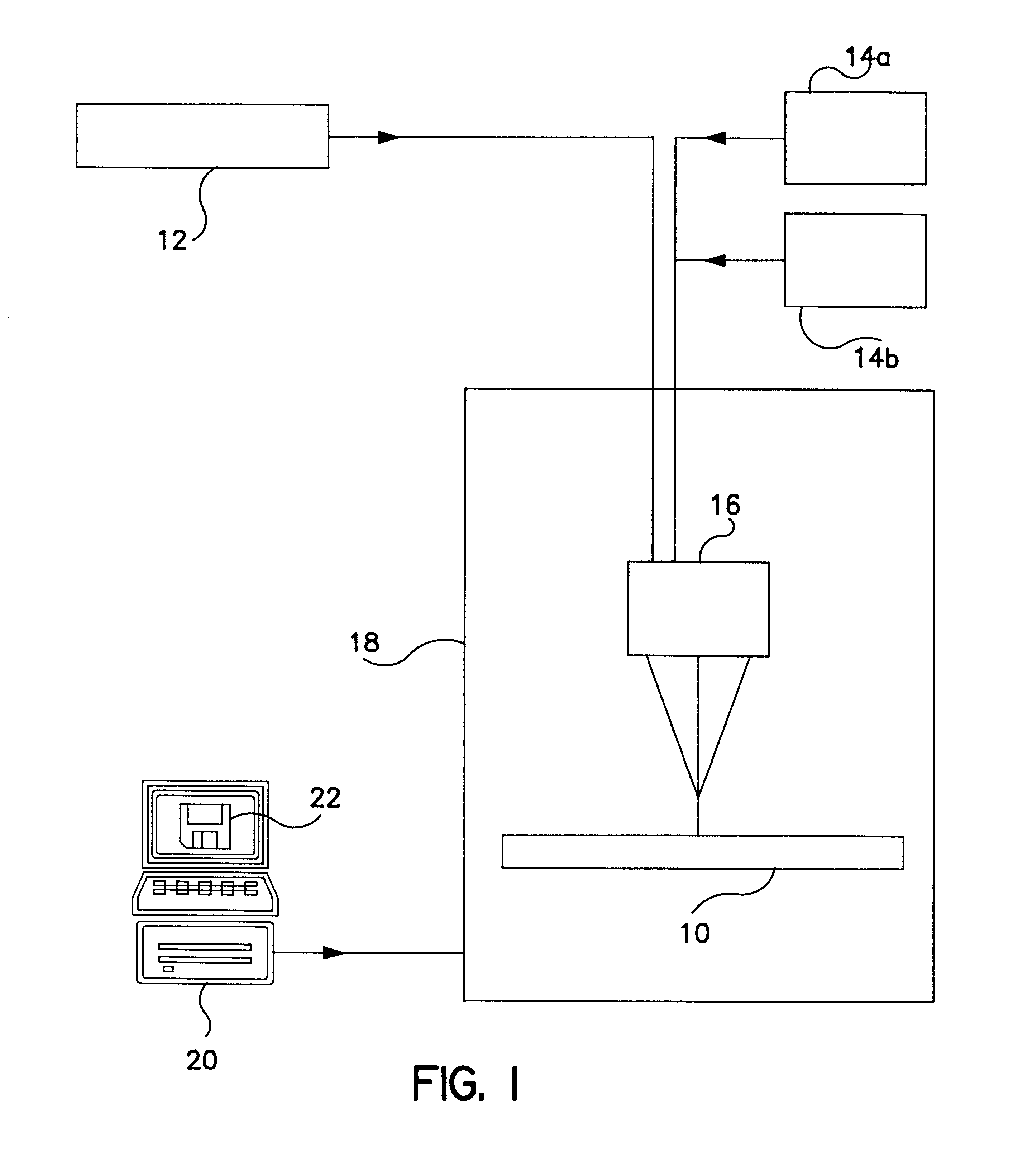

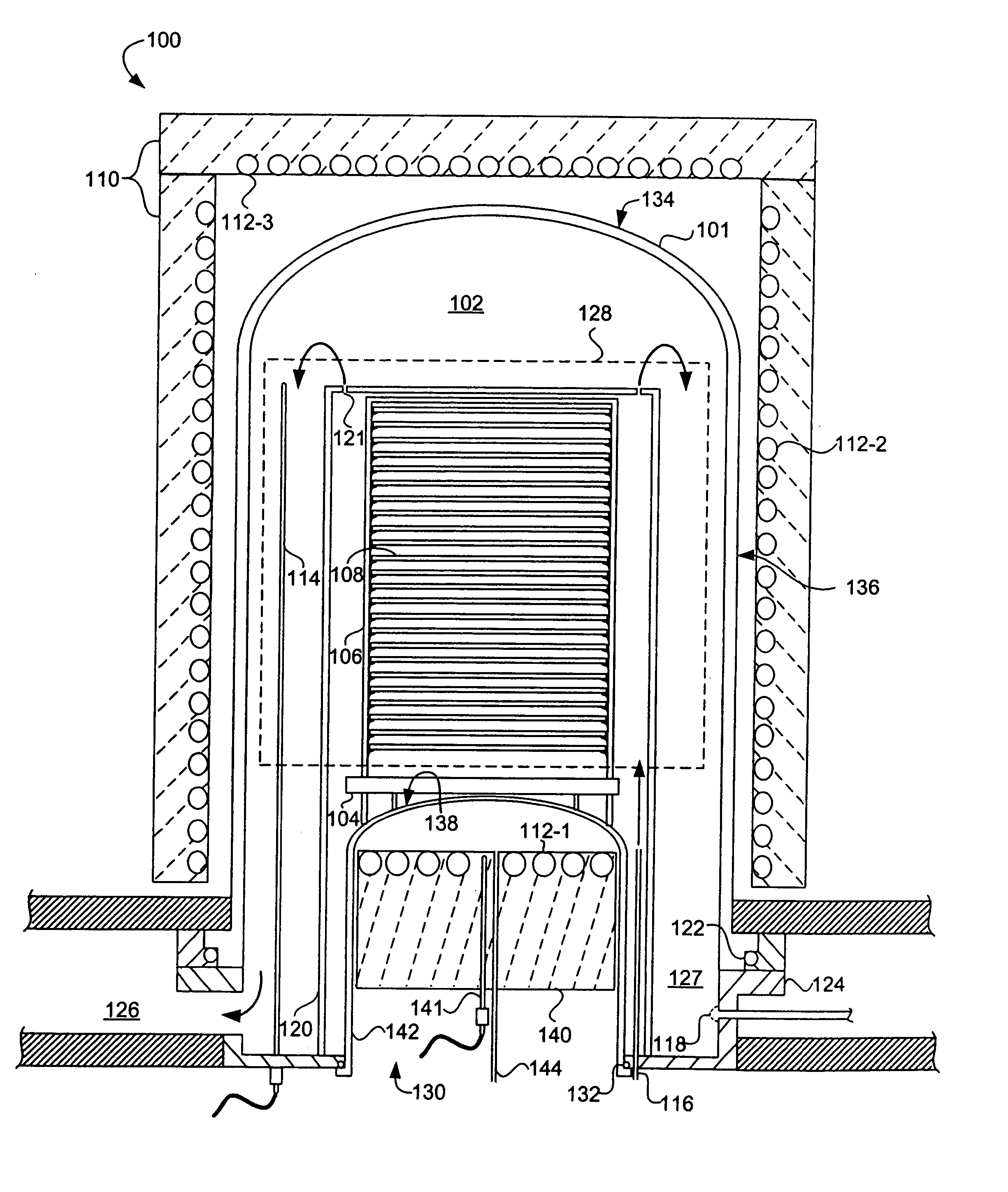

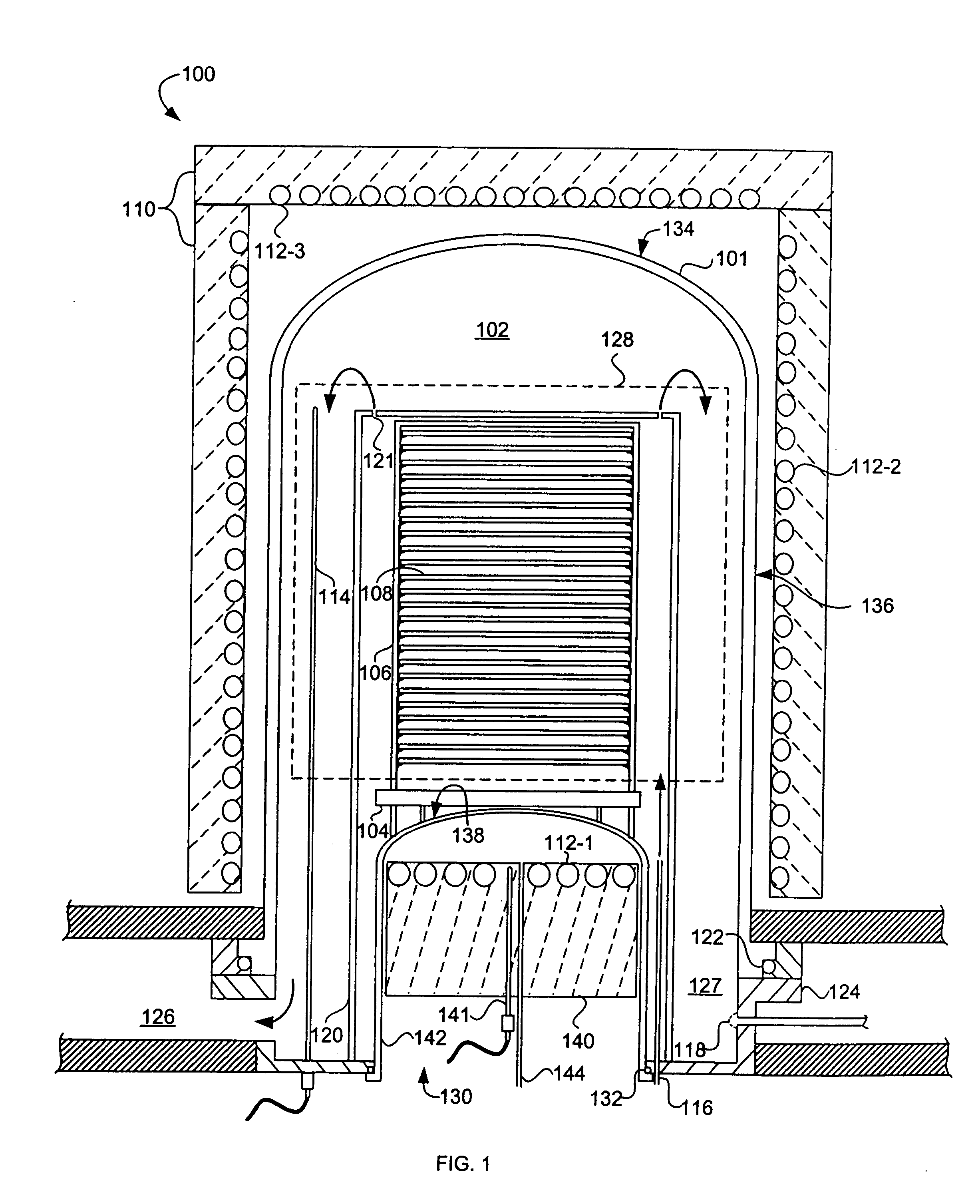

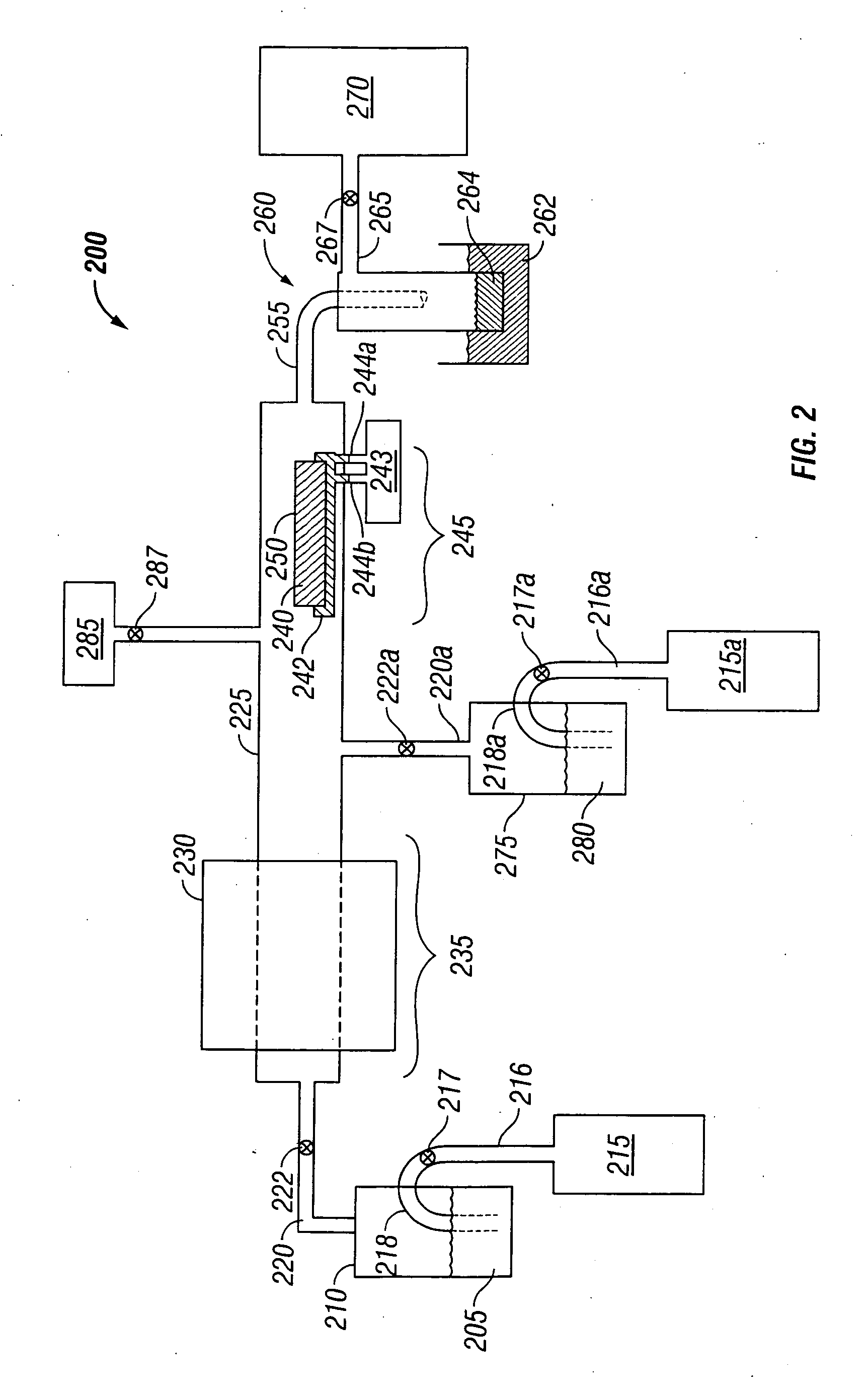

Thermal Processing System and Configurable Vertical Chamber

InactiveUS20070243317A1Semiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingEngineeringIsothermal process

An apparatus (100) and method are provided for thermally processing substrates (108) held in a carrier (106). The apparatus (100) includes a vessel (101) having a top (134), side (136) and bottom (138), and a heat source (110) with heating elements (112-1, 112-2, 112-3) proximal thereto. The vessel (101) is sized to enclose a volume substantially no larger than necessary to accommodate the carrier (106), and to provide an isothermal process zone (128) extending throughout. In one embodiment, the bottom wall (138) includes a movable pedestal (140) with a bottom heating element therein (112-1), and the pedestal can be lowered and raised to insert the carrier (106) into the vessel (101). The apparatus (100) can include a movable shield (146) that is inserted between the pedestal (140) and the carrier (106) to shield the substrates (108) from the heating element (112-1) and to maintain pedestal temperature. A magnetically coupled repositioning system (162) repositions the carrier (106) during processing of the substrates (108) without use of a movable feedthrough into the volume enclosed by the vessel (101), and without moving the bottom heating element (112-1) in the pedestal (140).

Owner:DU BOIS DALE R +4

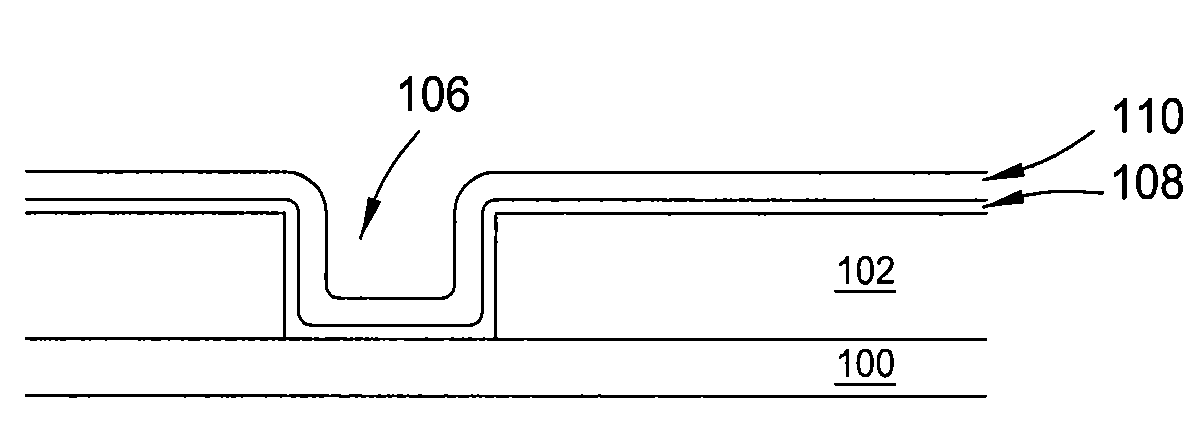

Method to minimize wet etch undercuts and provide pore sealing of extreme low k (k<2.5) dielectrics

ActiveUS20110092077A1Constant ratePrevents undercuts and CD lossVacuum evaporation coatingSemiconductor/solid-state device manufacturingThin layerNitrogen

Methods of processing films on substrates are provided. In one aspect, the methods comprise treating a patterned low dielectric constant film after a photoresist is removed form the film by depositing a thin layer comprising silicon, carbon, and optionally oxygen and / or nitrogen on the film. The thin layer provides a carbon-rich, hydrophobic surface for the patterned low dielectric constant film. The thin layer also protects the low dielectric constant film from subsequent wet cleaning processes and penetration by precursors for layers that are subsequently deposited on the low dielectric constant film.

Owner:APPLIED MATERIALS INC

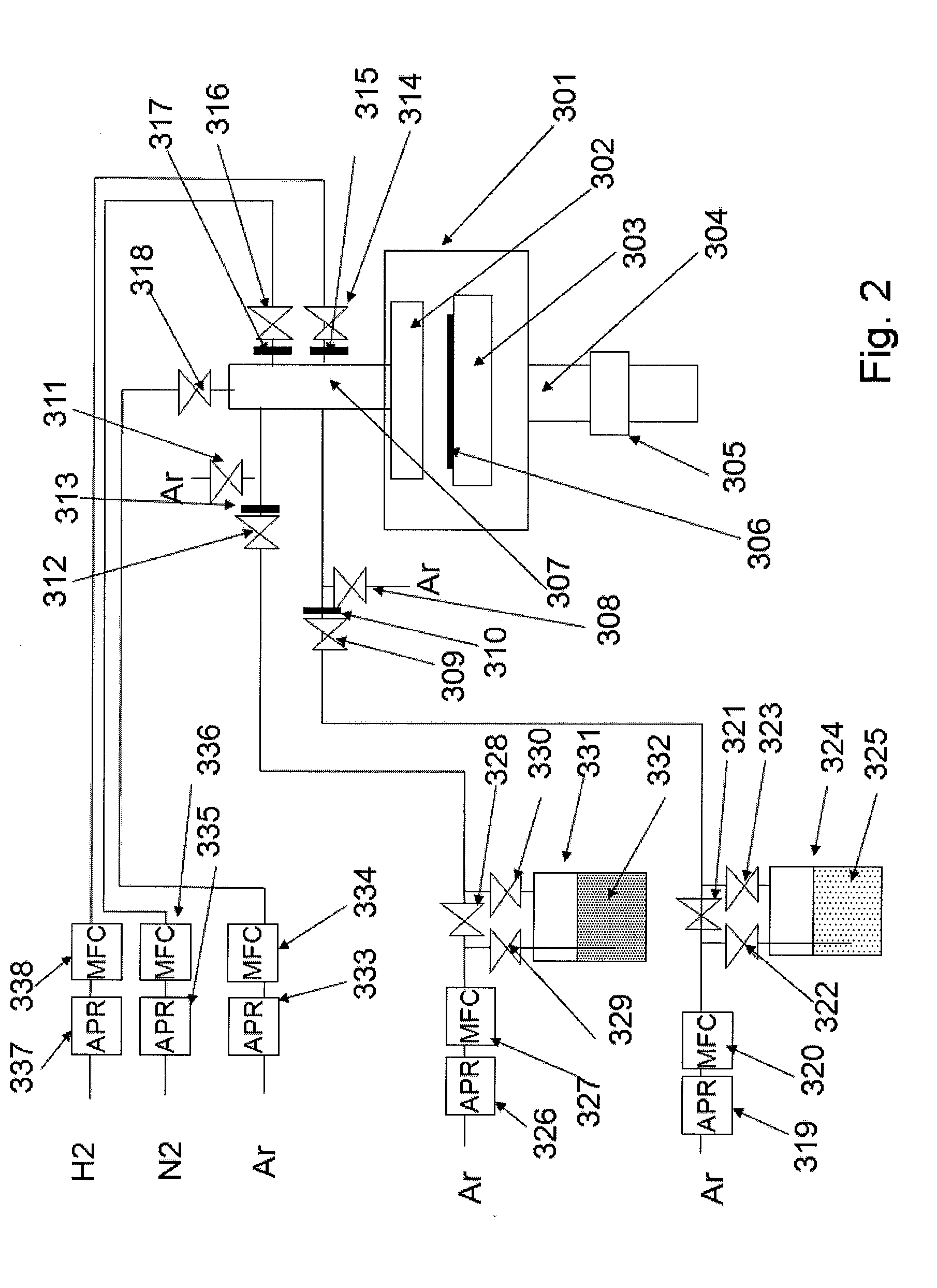

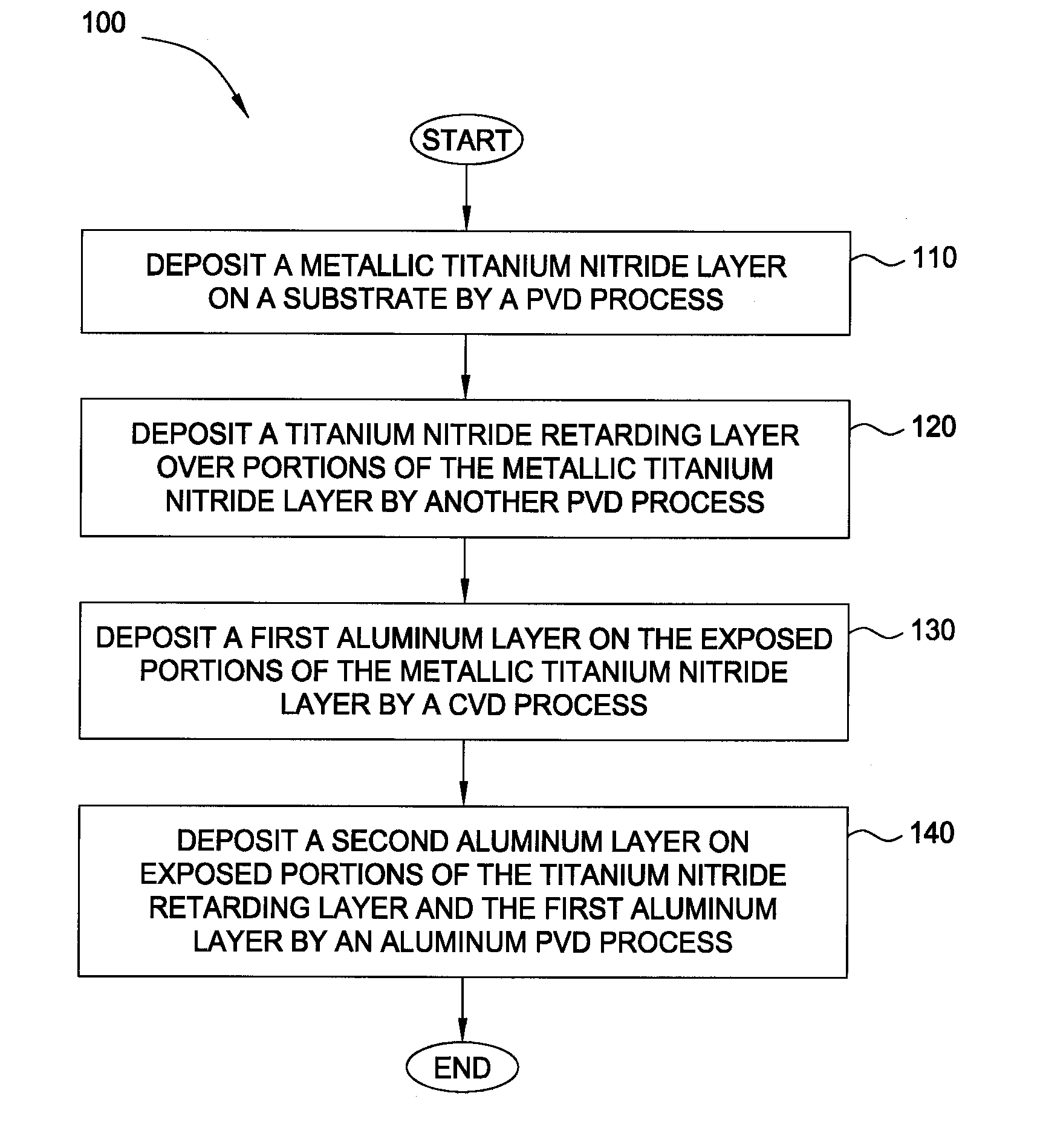

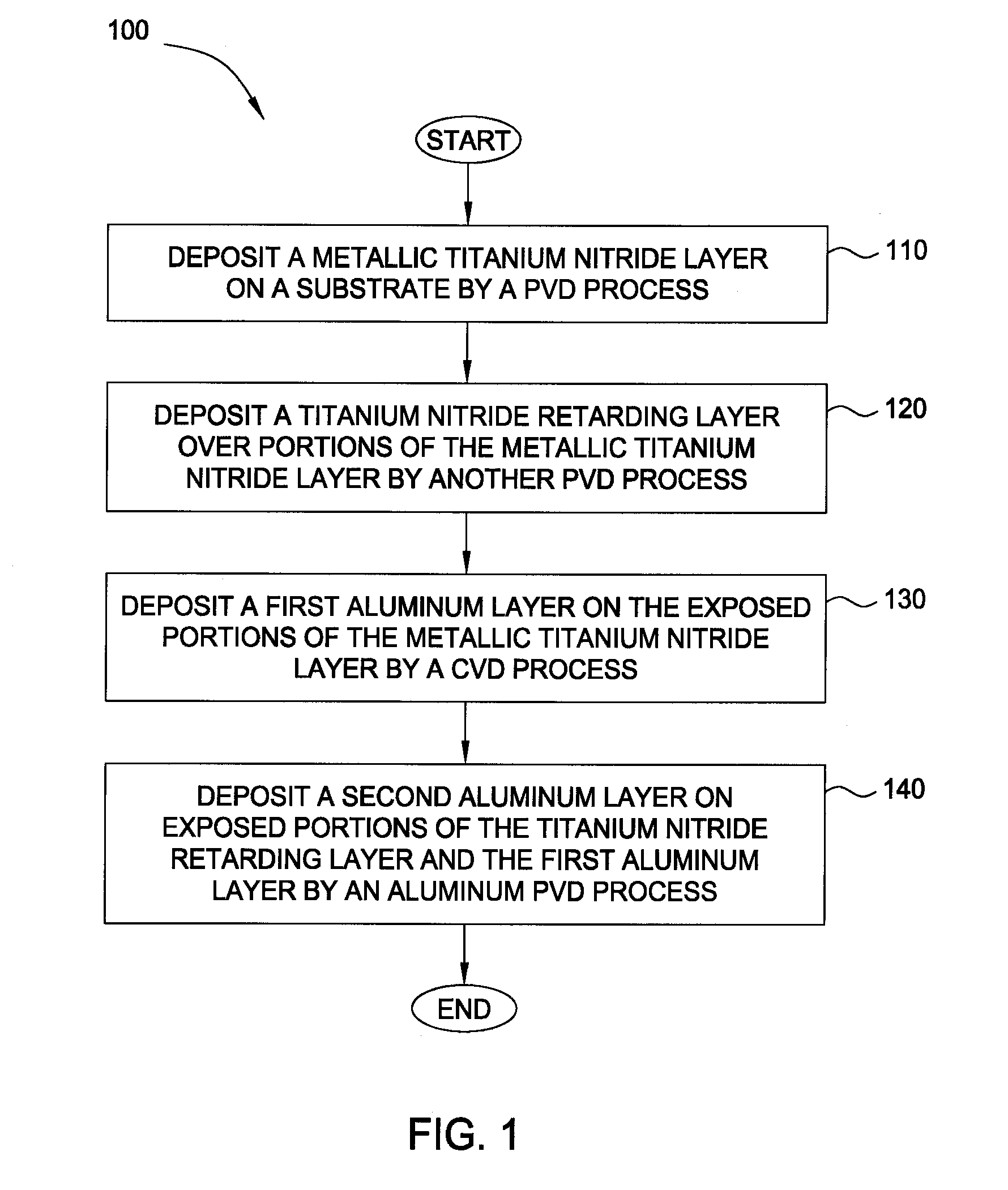

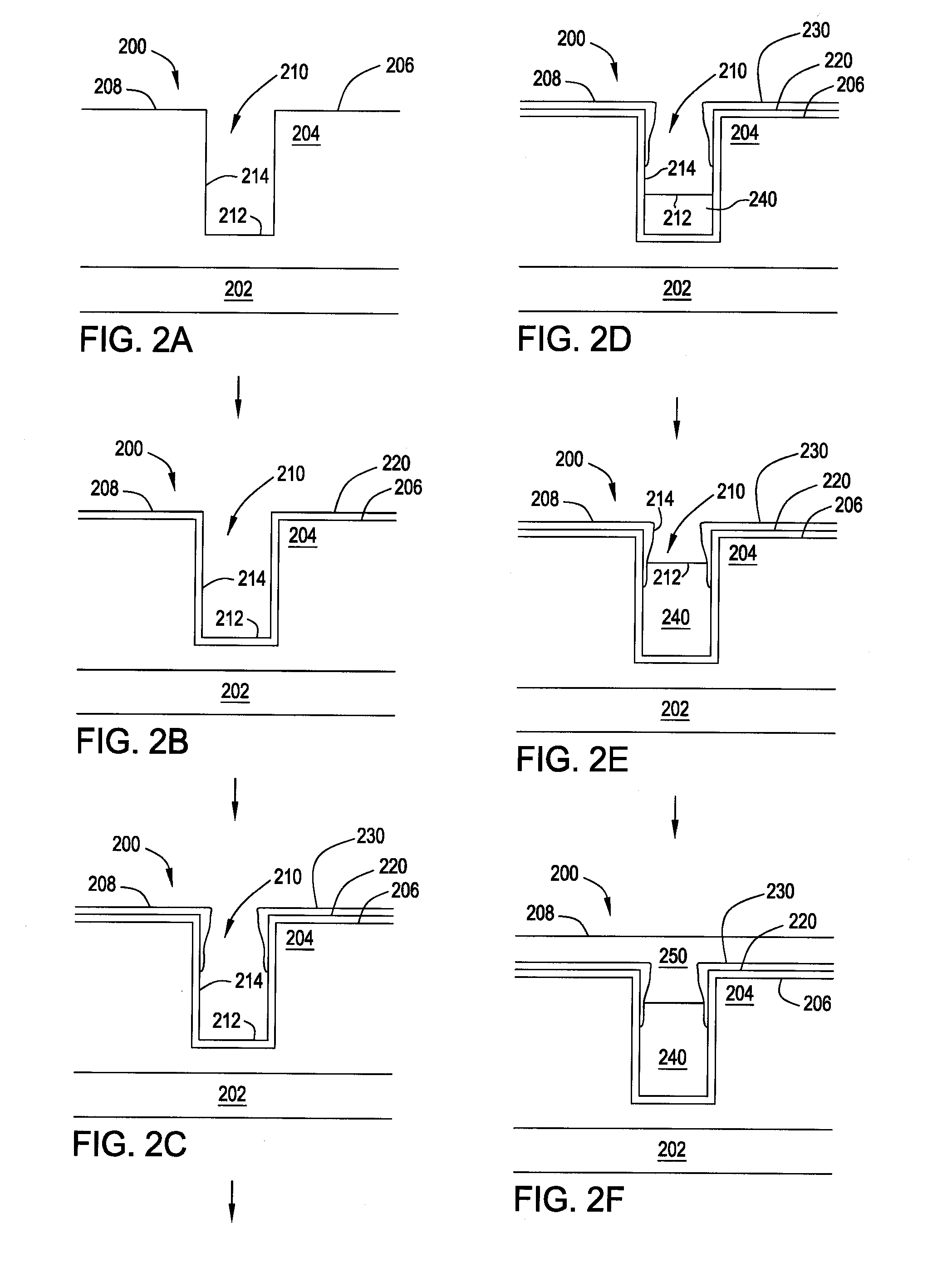

Deposition processes for titanium nitride barrier and aluminum

InactiveUS20090087585A1Increasing nitrogen gas flowDecrease DC powerSemiconductor/solid-state device detailsSolid-state devicesTitanium nitrideDeposition process

Embodiments described herein provide a method for forming two titanium nitride materials by different PVD processes, such that a metallic titanium nitride layer is initially formed by a PVD process in a metallic mode and a titanium nitride retarding layer is formed over a portion of the metallic titanium nitride layer by a PVD process in a poison mode. Subsequently, a first aluminum layer, such as an aluminum seed layer, may be selectively deposited on exposed portions of the metallic titanium nitride layer by a CVD process. Thereafter, a second aluminum layer, such as an aluminum bulk layer, may be deposited on exposed portions of the first aluminum layer and the titanium nitride retarding layer during an aluminum PVD process.

Owner:APPLIED MATERIALS INC

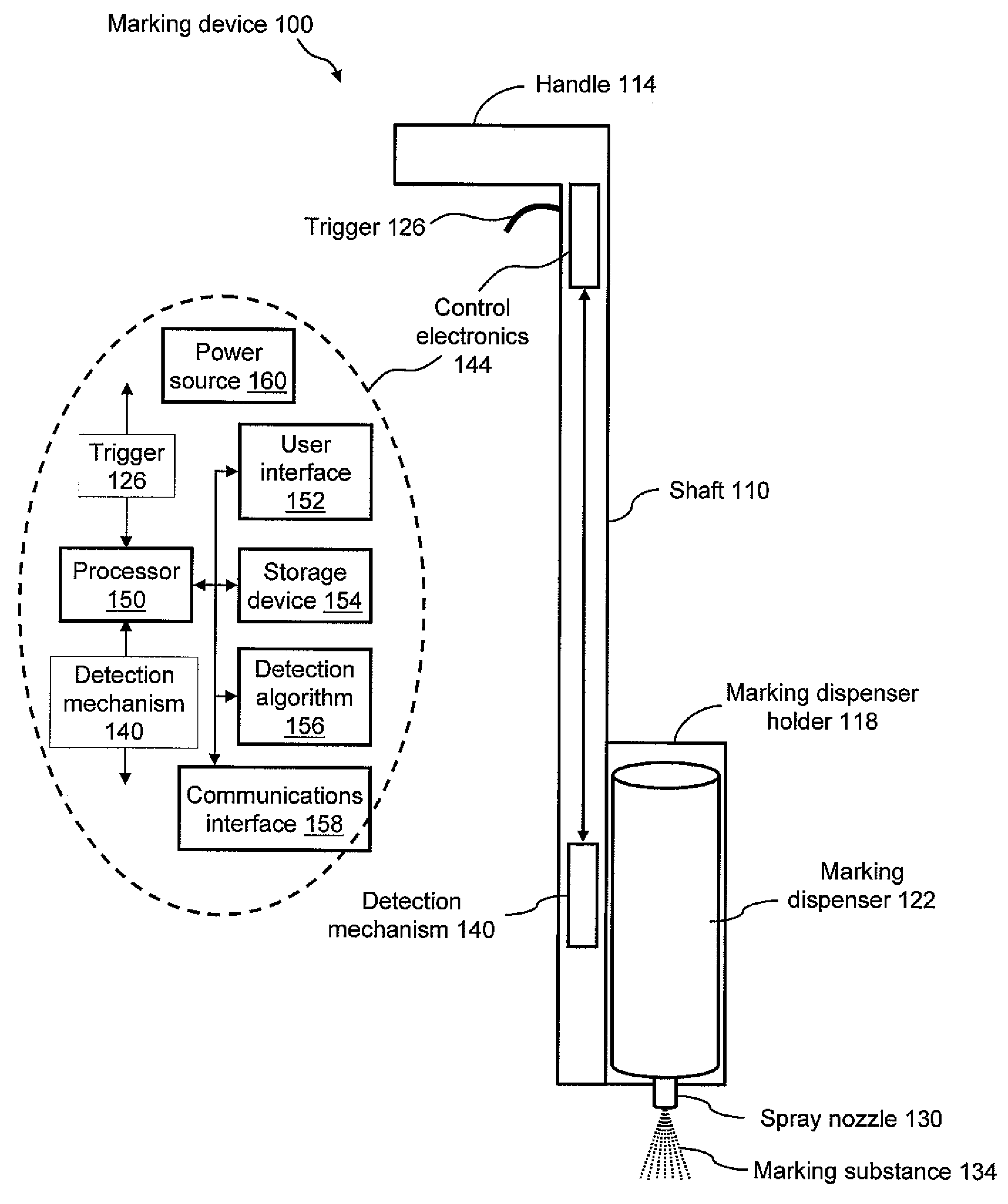

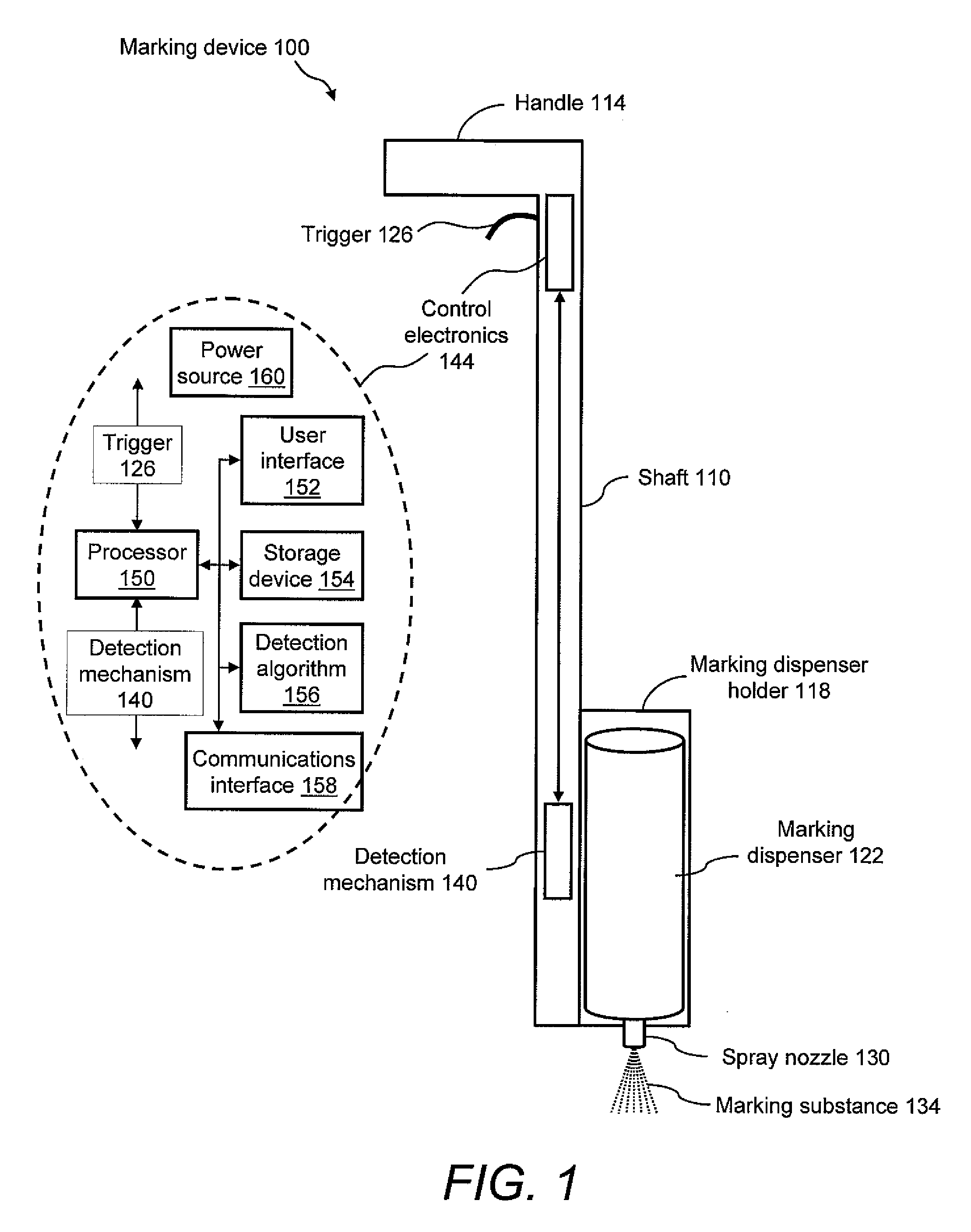

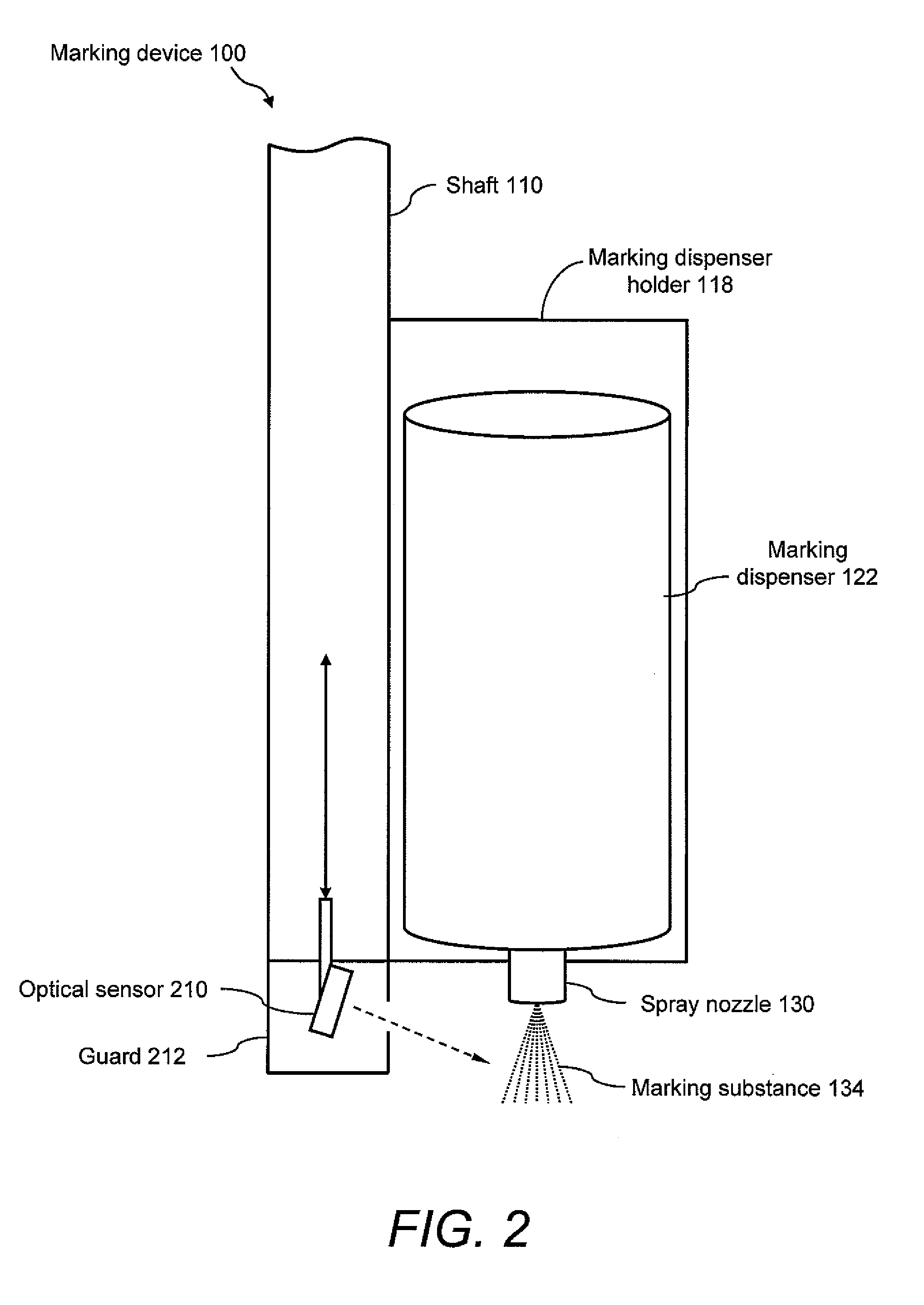

Marker detection mechanisms for use in marking devices and methods of using same

ActiveUS20100006667A1Watering devicesWeighing apparatus for materials with special property/formBiomedical engineering

Owner:CERTUSVIEW TECH LLC

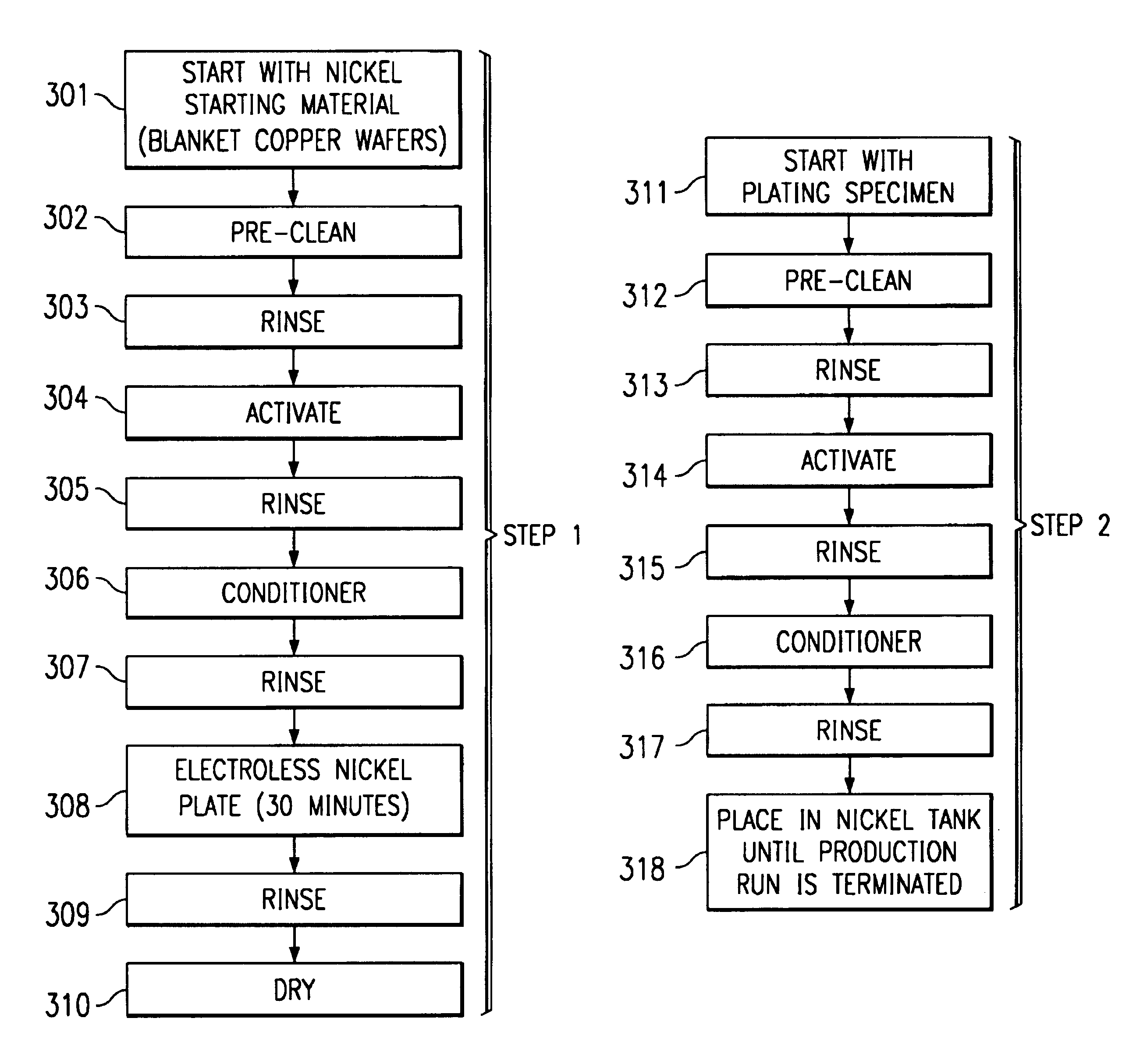

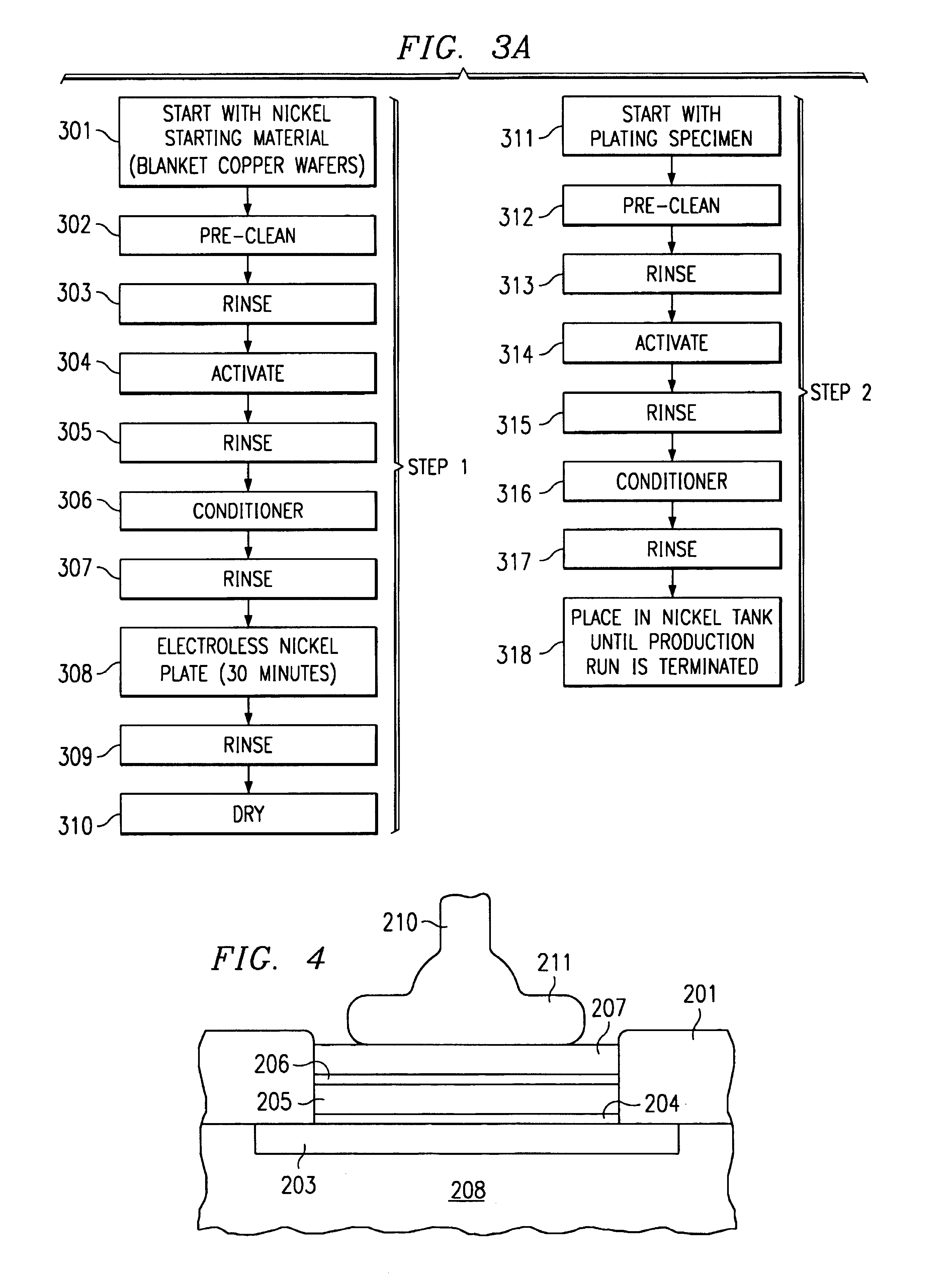

Method to achieve continuous hydrogen saturation in sparingly used electroless nickel plating process

InactiveUS6616967B1Maintain saturationSemiconductor/solid-state device detailsSolid-state devicesHydrogenCopper

An improved wire bonding process for copper-metallized integrated circuits is provided by a nickel layer that acts as a barrier against up-diffusing copper. In accordance with the present invention the nickel bath is placed and remains in hydrogen saturation by providing a piece of metal that remains in the nickel plating tank before and during the plating process.

Owner:TEXAS INSTR INC

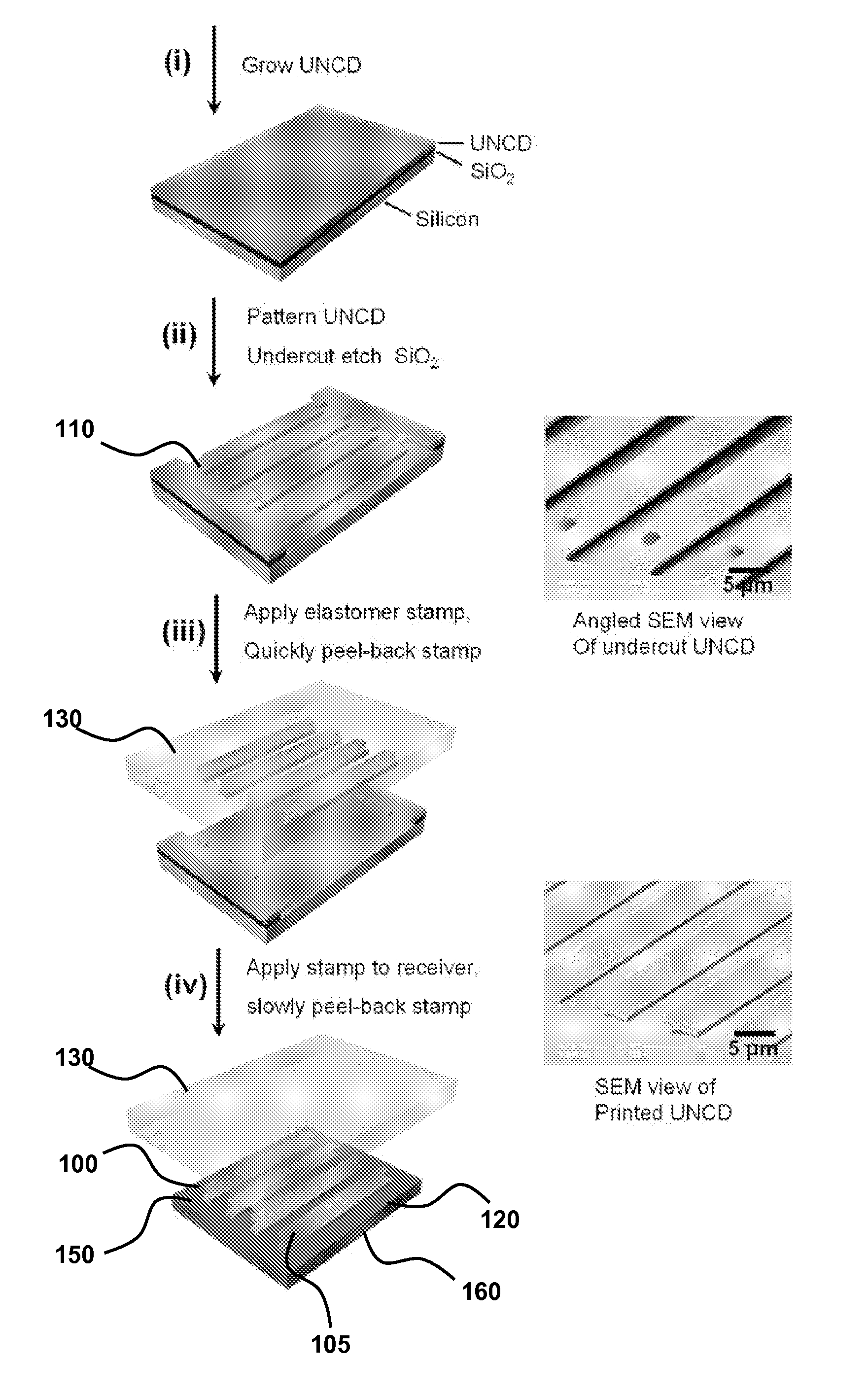

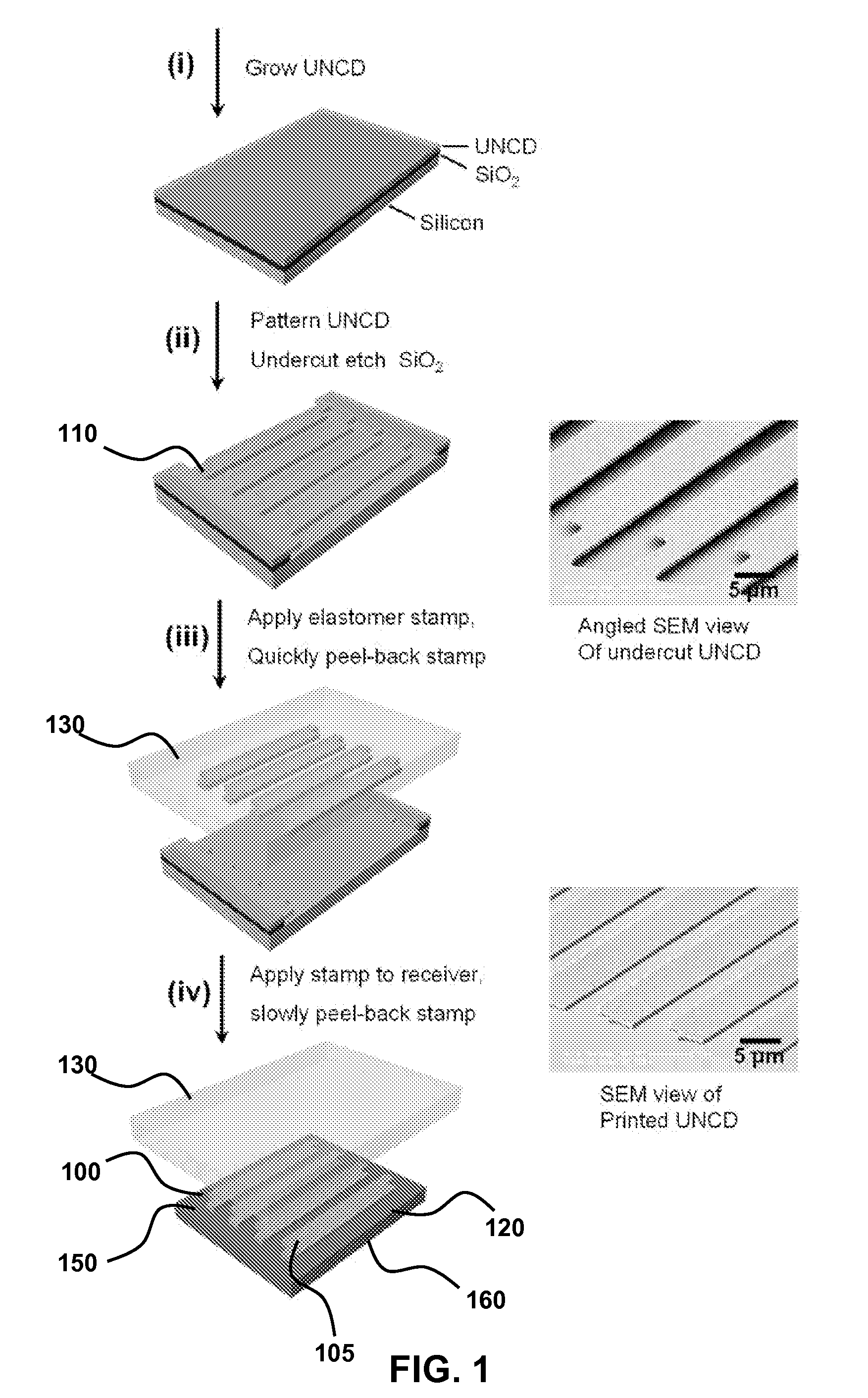

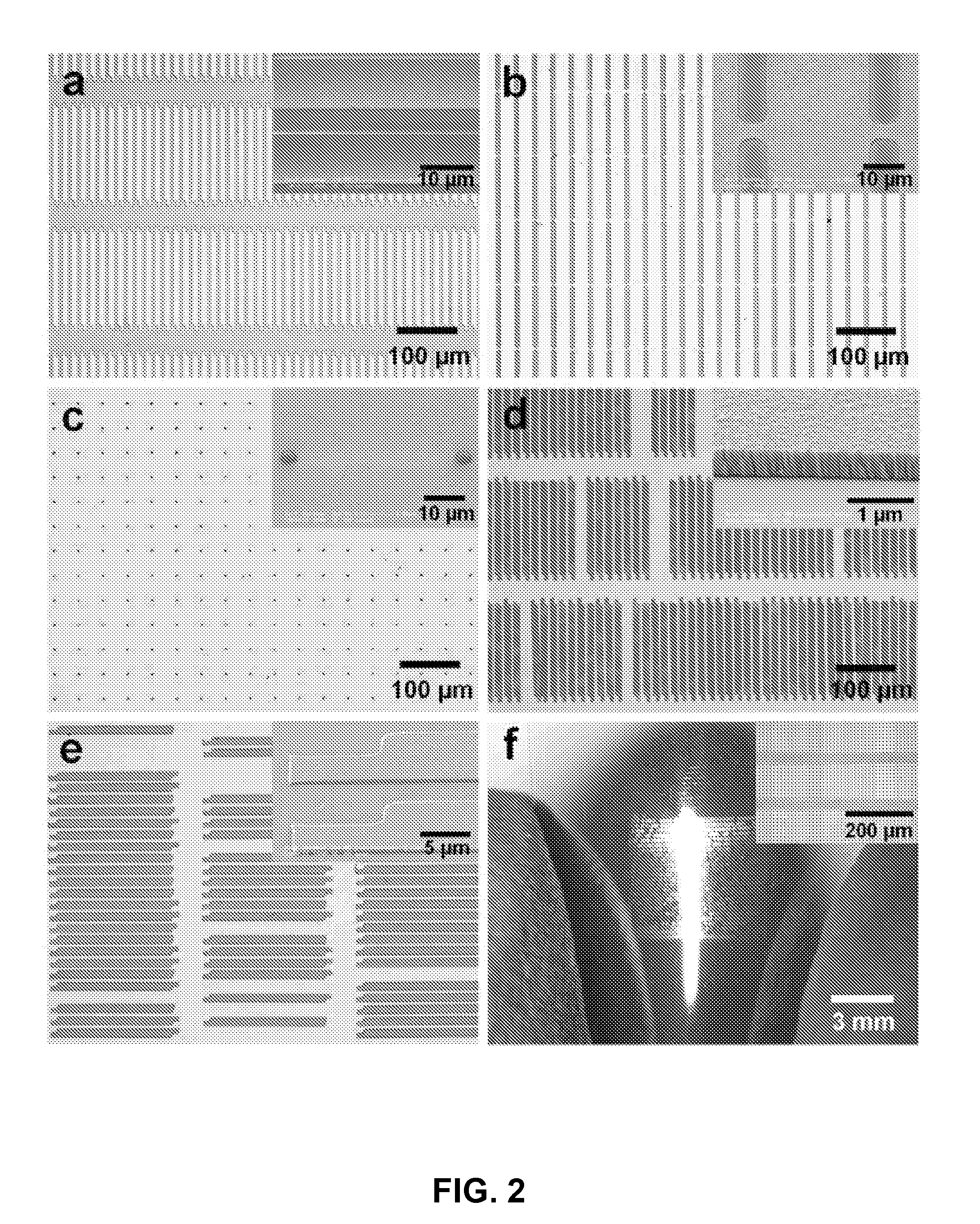

Printable, flexible and stretchable diamond for thermal management

InactiveUS8470701B2Reduce the amount requiredHeat dissipationSemiconductor/solid-state device detailsSolid-state devicesFlexible electronicsHeat sink

Owner:JOHN CRANE INC +2

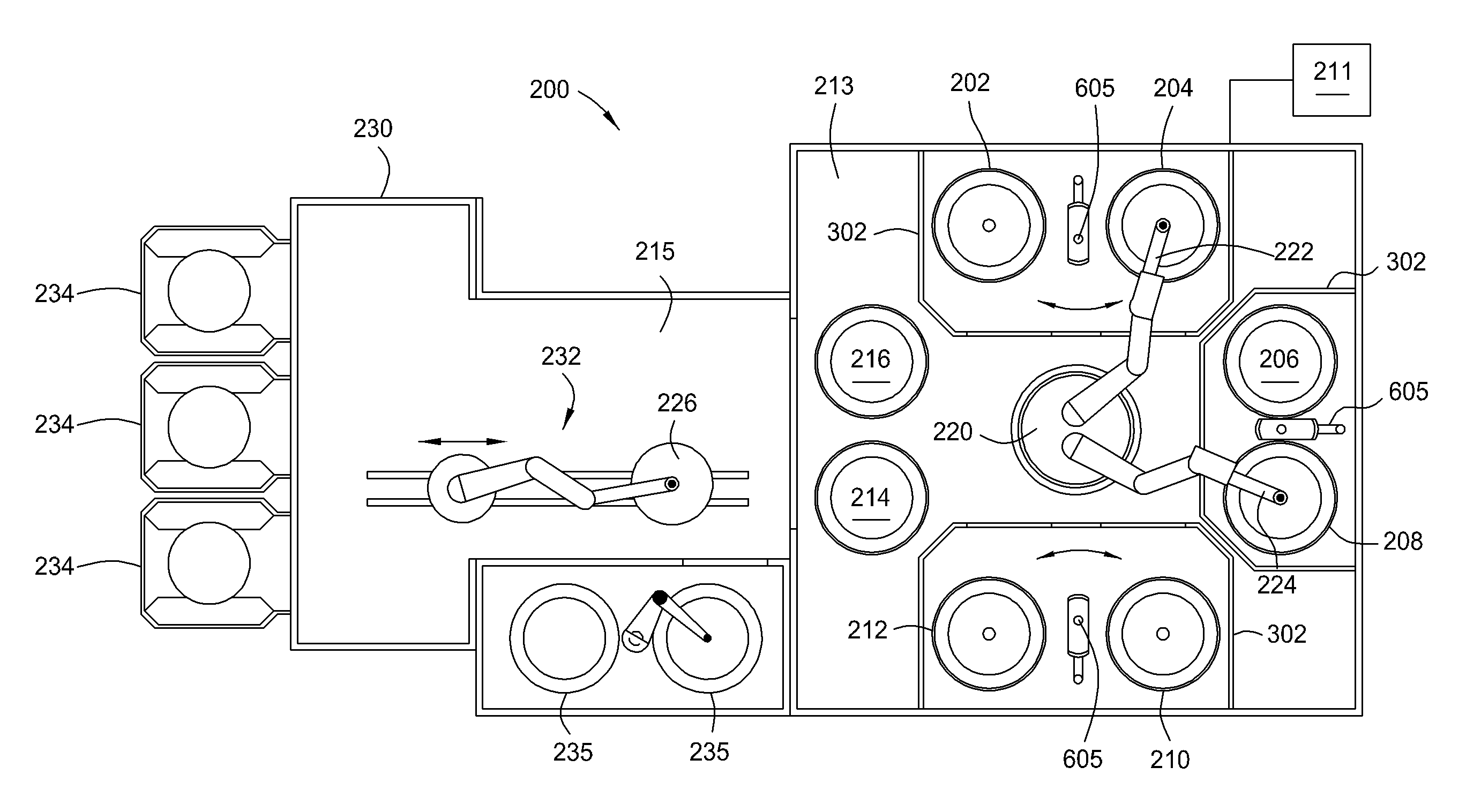

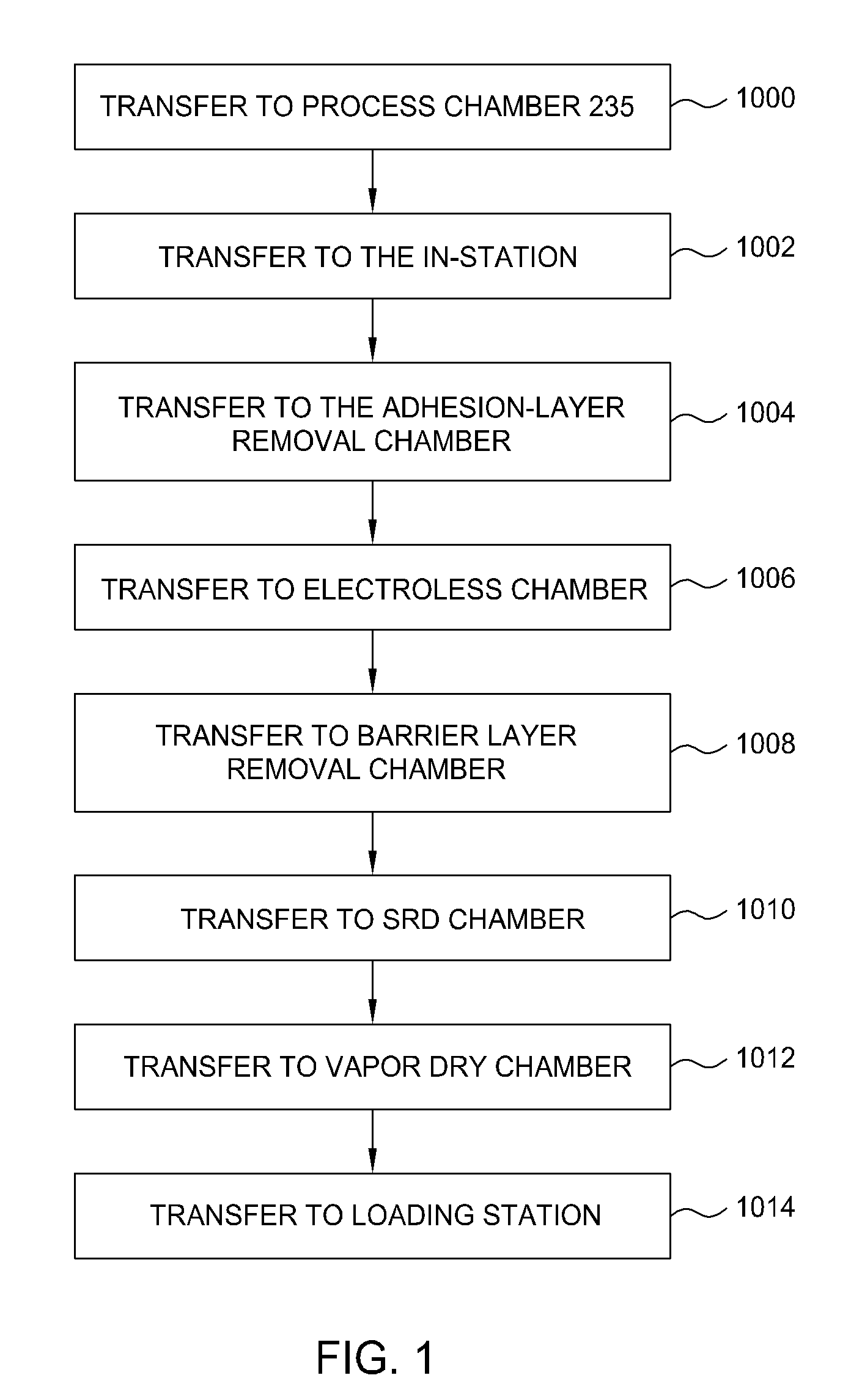

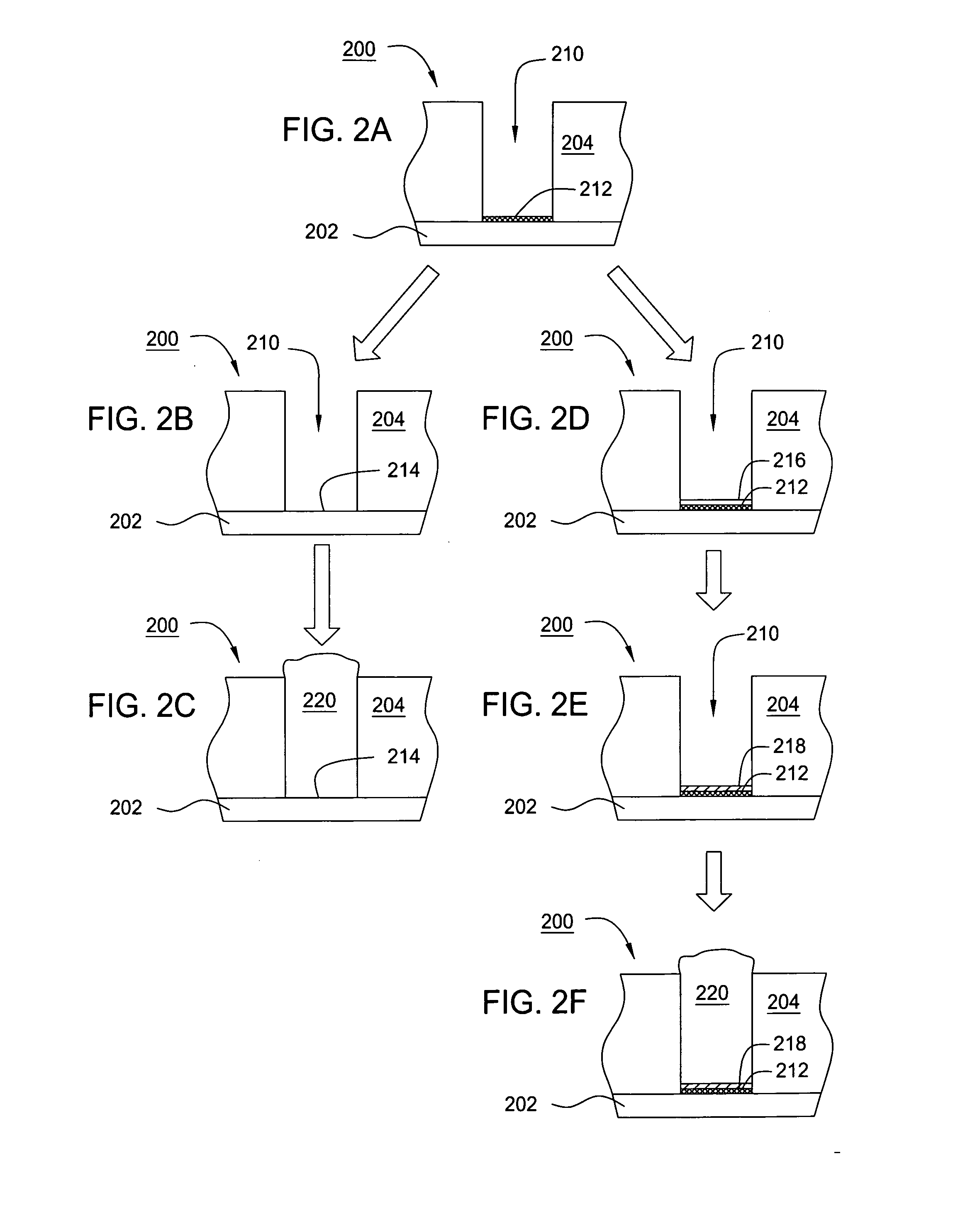

Method and apparatus for forming device features in an integrated electroless deposition system

InactiveUS20070071888A1Growth inhibitionPrinted circuit aspectsSemiconductor/solid-state device manufacturingMaterial removalEngineering

Embodiments of the invention generally provide a cluster tool that is configured to electrolessly fill features formed on a substrate. More particularly, embodiments of the invention are used to integrate the filling of an interconnect or contact level feature using an electroless fill process and material removal steps. A typical sequence for forming an interconnect includes depositing one or more non-conductive layers, etching at least one of the layer(s) to form one or more features therein, depositing a barrier layer in the feature(s) and depositing one or more conductive layers, such as copper, to fill the feature.

Owner:APPLIED MATERIALS INC

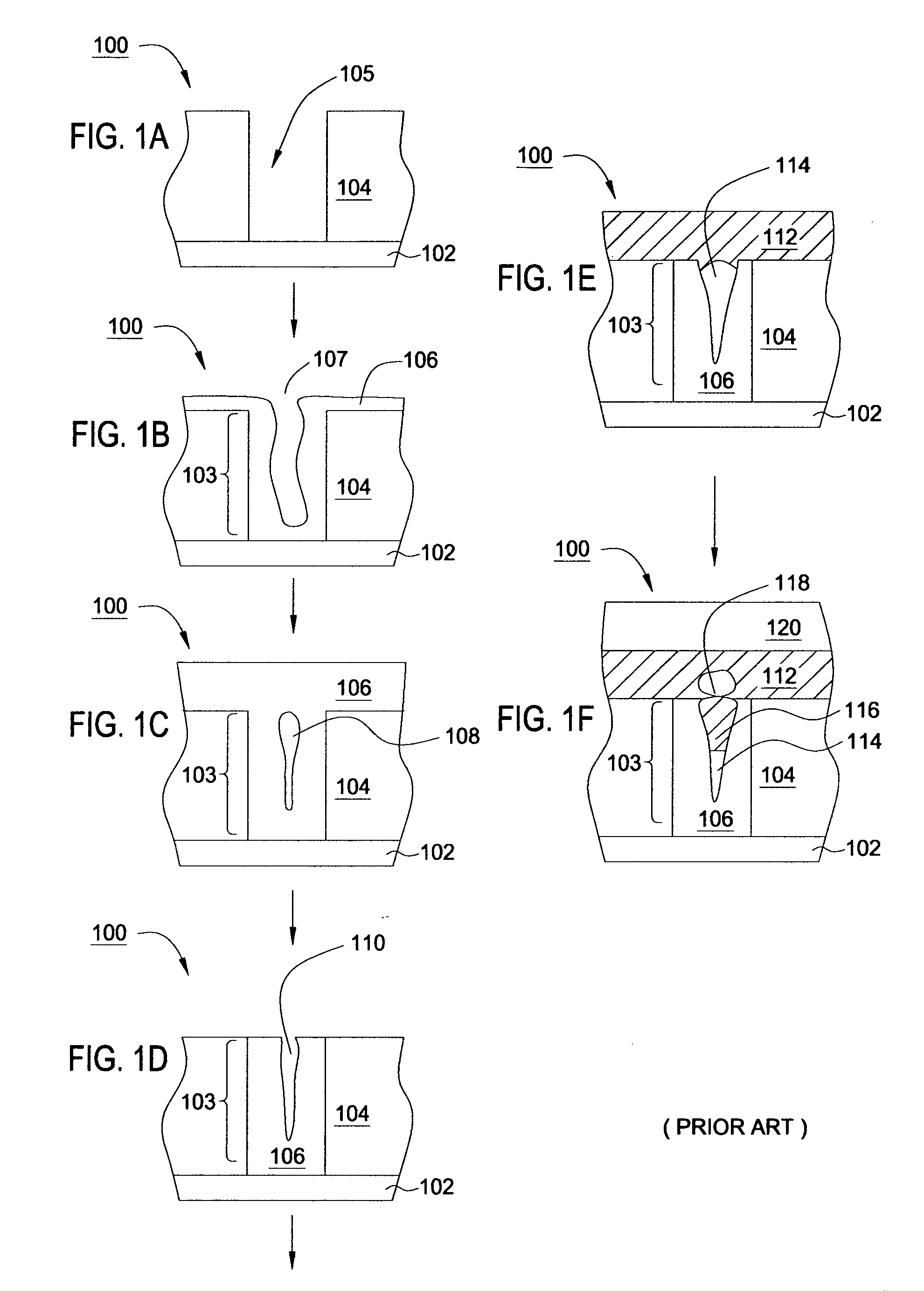

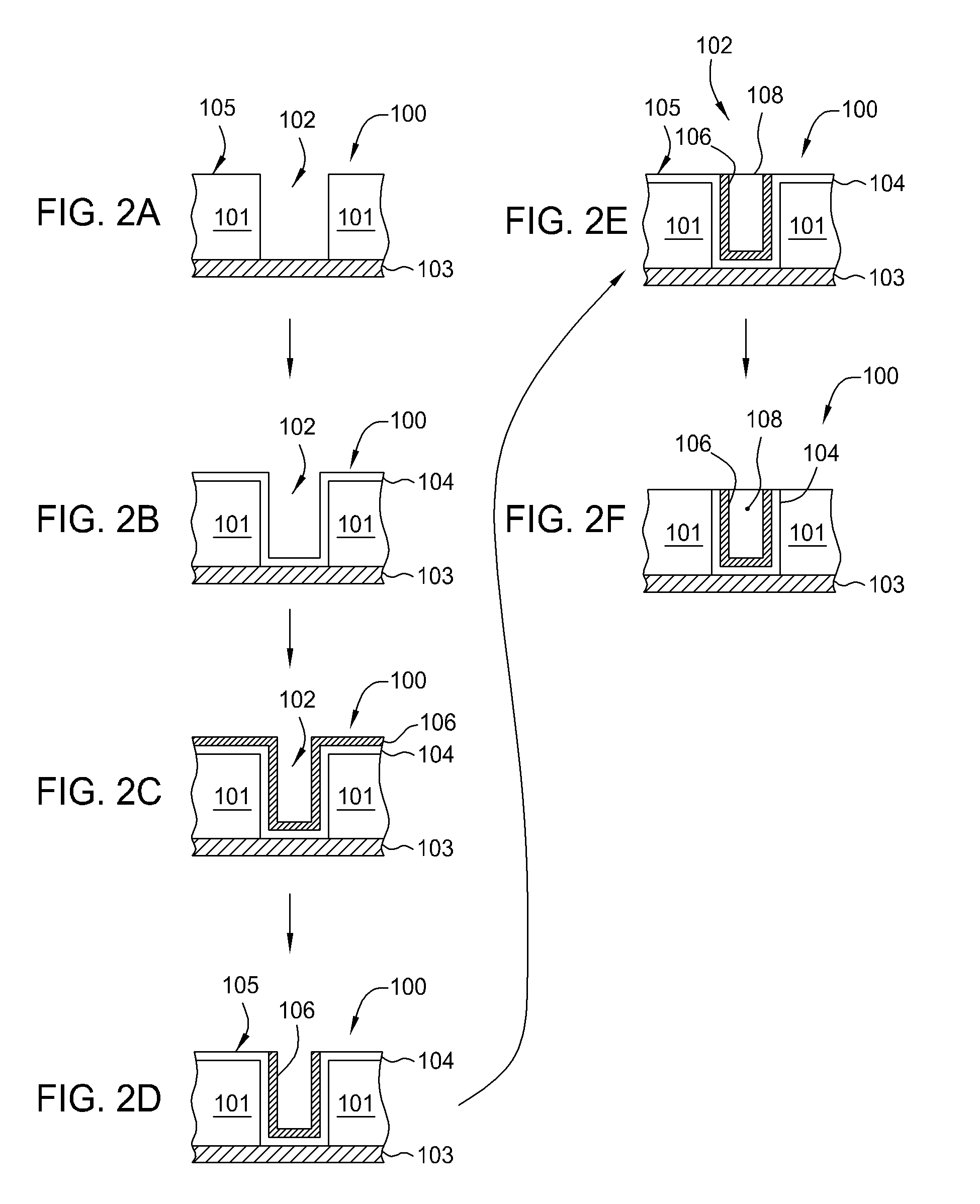

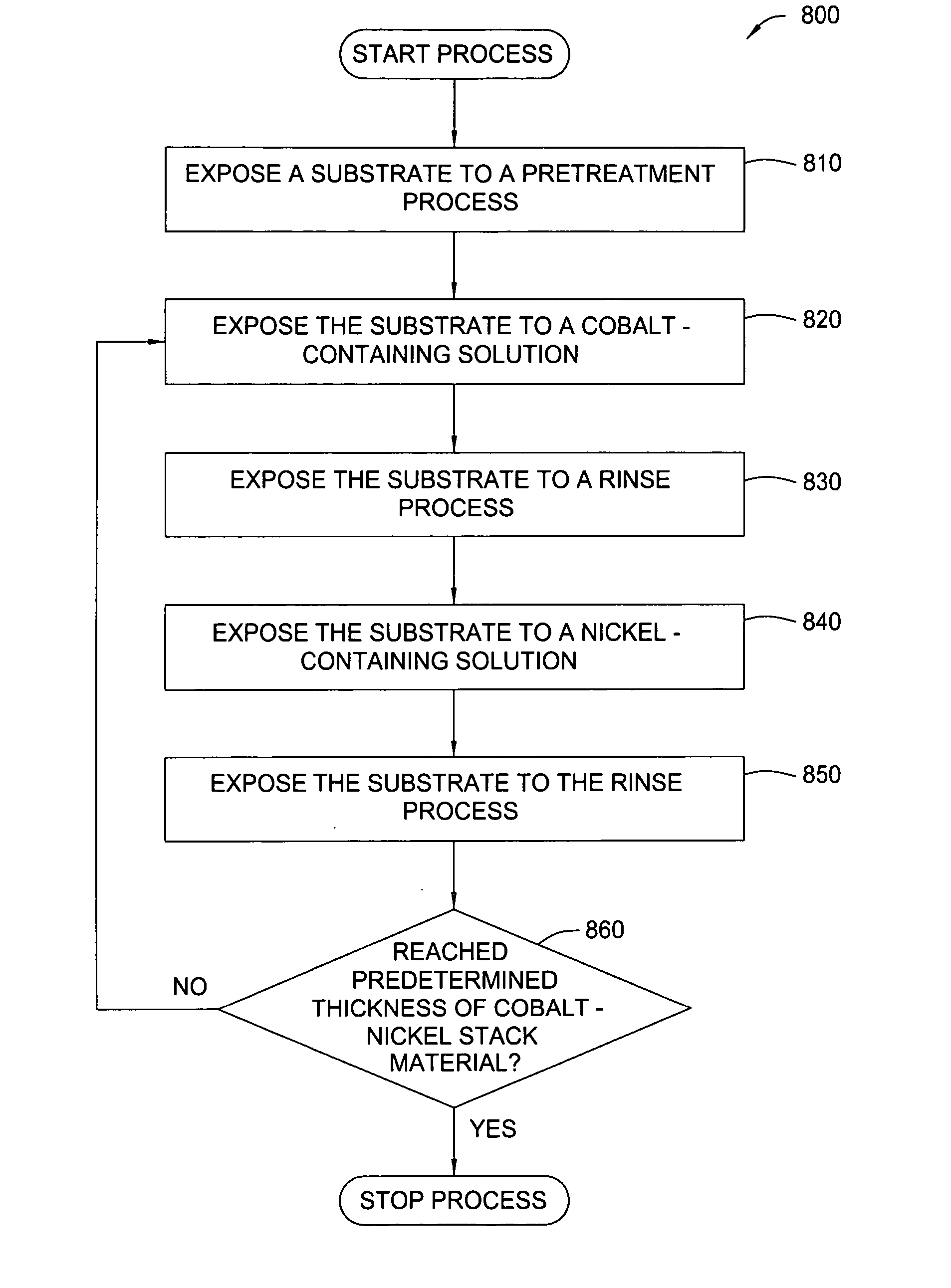

Electroless deposition process on a silicide contact

InactiveUS20060246217A1Material nanotechnologySemiconductor/solid-state device manufacturingSalicideElectroless deposition

Embodiments as described herein provide methods for depositing a material on a substrate during electroless deposition processes, as well as compositions of the electroless deposition solutions. In one embodiment, the substrate contains a contact aperture having an exposed silicon contact surface. In another embodiment, the substrate contains a contact aperture having an exposed silicide contact surface. The apertures are filled with a metal contact material by exposing the substrate to an electroless deposition process. The metal contact material may contain a cobalt material, a nickel material, or alloys thereof. Prior to filling the apertures, the substrate may be exposed to a variety of pretreatment processes, such as preclean processes and activations processes. A preclean process may remove organic residues, native oxides, and other contaminants during a wet clean process or a plasma etch process. Embodiments of the process also provide the deposition of additional layers, such as a capping layer.

Owner:APPLIED MATERIALS INC

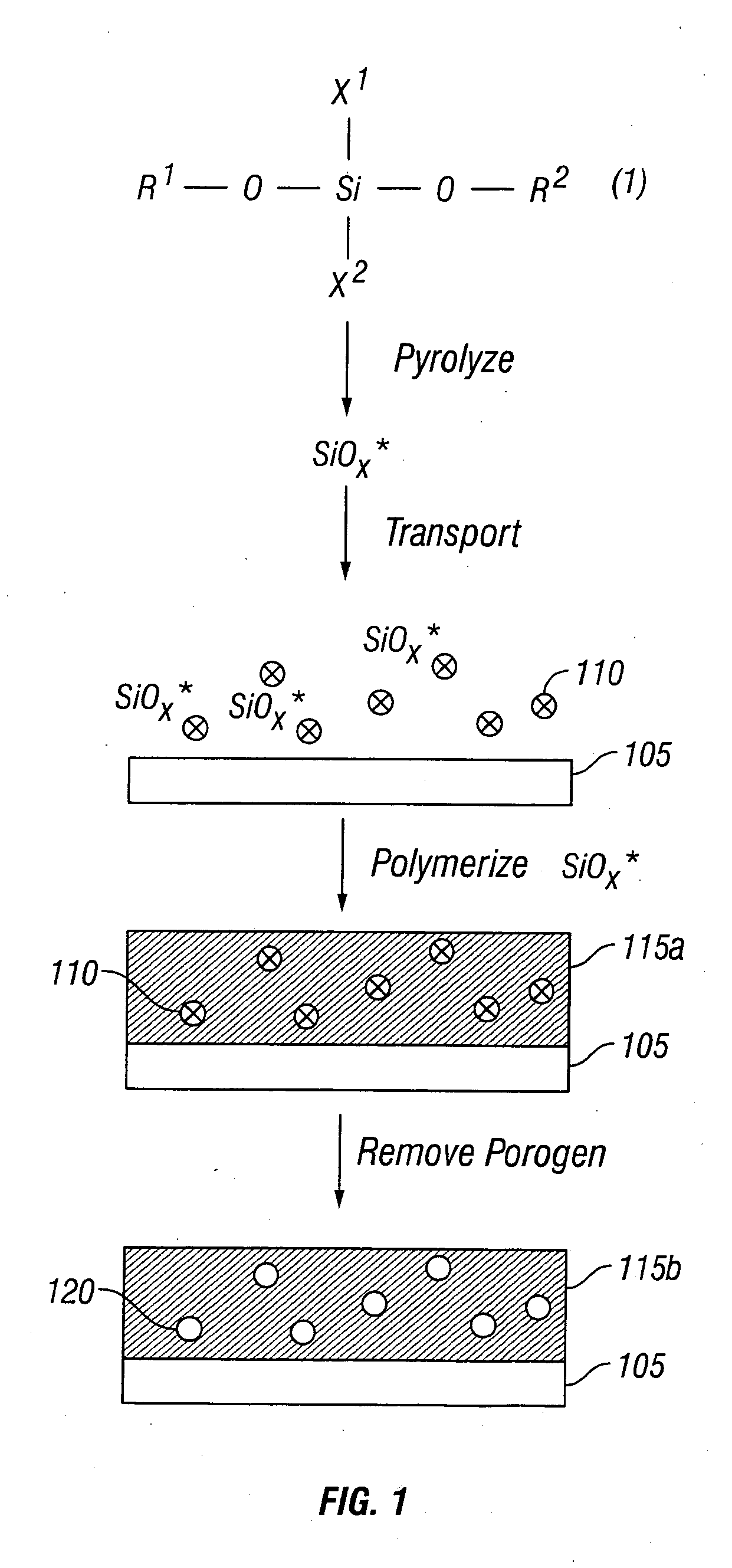

Apparatus, precursors and deposition methods for silicon-containing materials

A method for making a Si-containing material comprises transporting a pyrolyzed Si-precursor to a substrate and polymerizing the pyrolyzed Si-precursor on the substrate to form a Si-containing film. Polymerization of the pyrolyzed Si-precursor may be carried out in the presence of a porogen to thereby form a porogen-containing Si-containing film. The porogen may be removed from the porogen-containing Si-containing film to thereby form a porous Si-containing film. Preferred porous Si-containing films have low dielectric constants and thus are suitable for various low-k applications such as in microelectronics and microelectromechanical systems.

Owner:ASM JAPAN

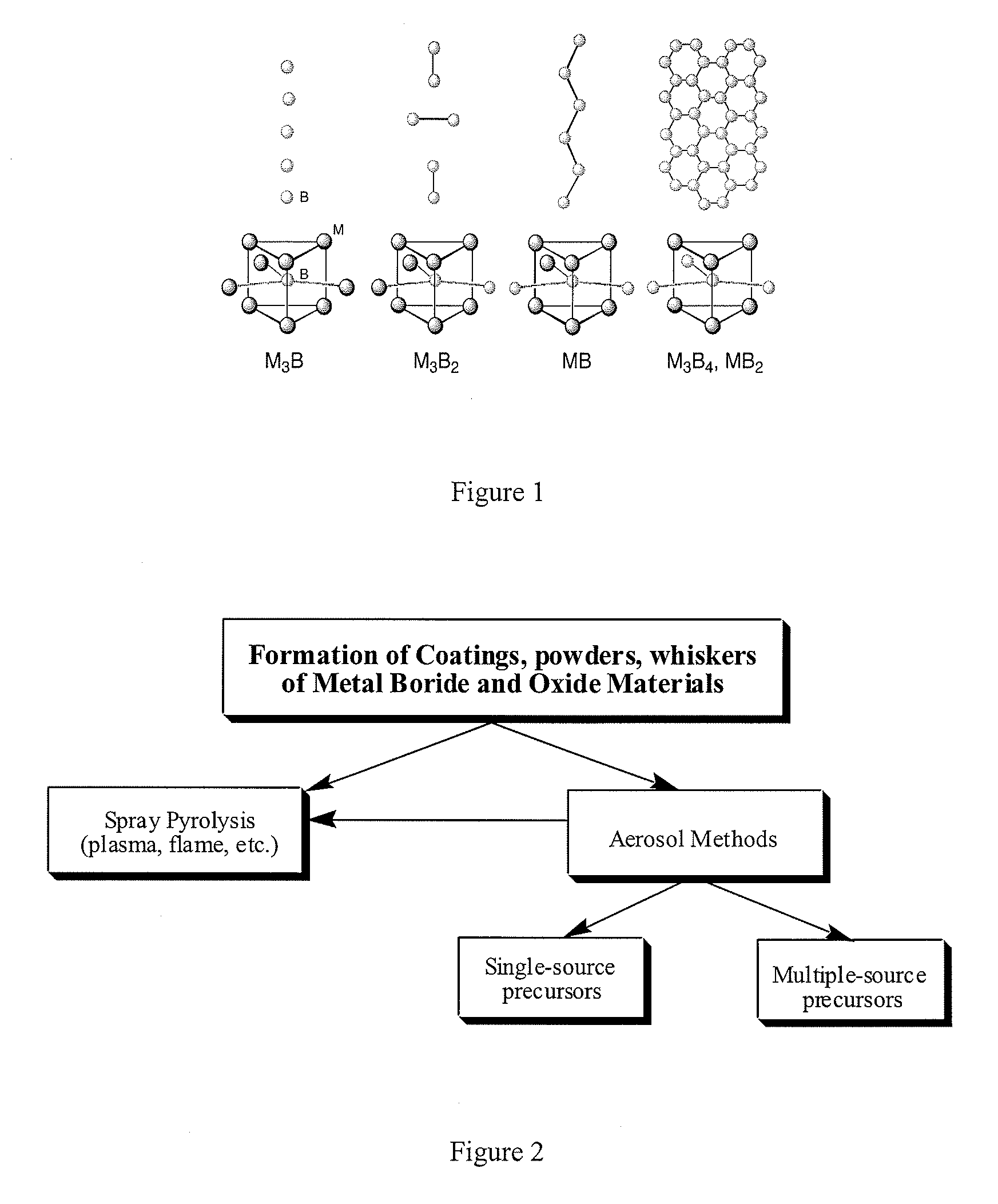

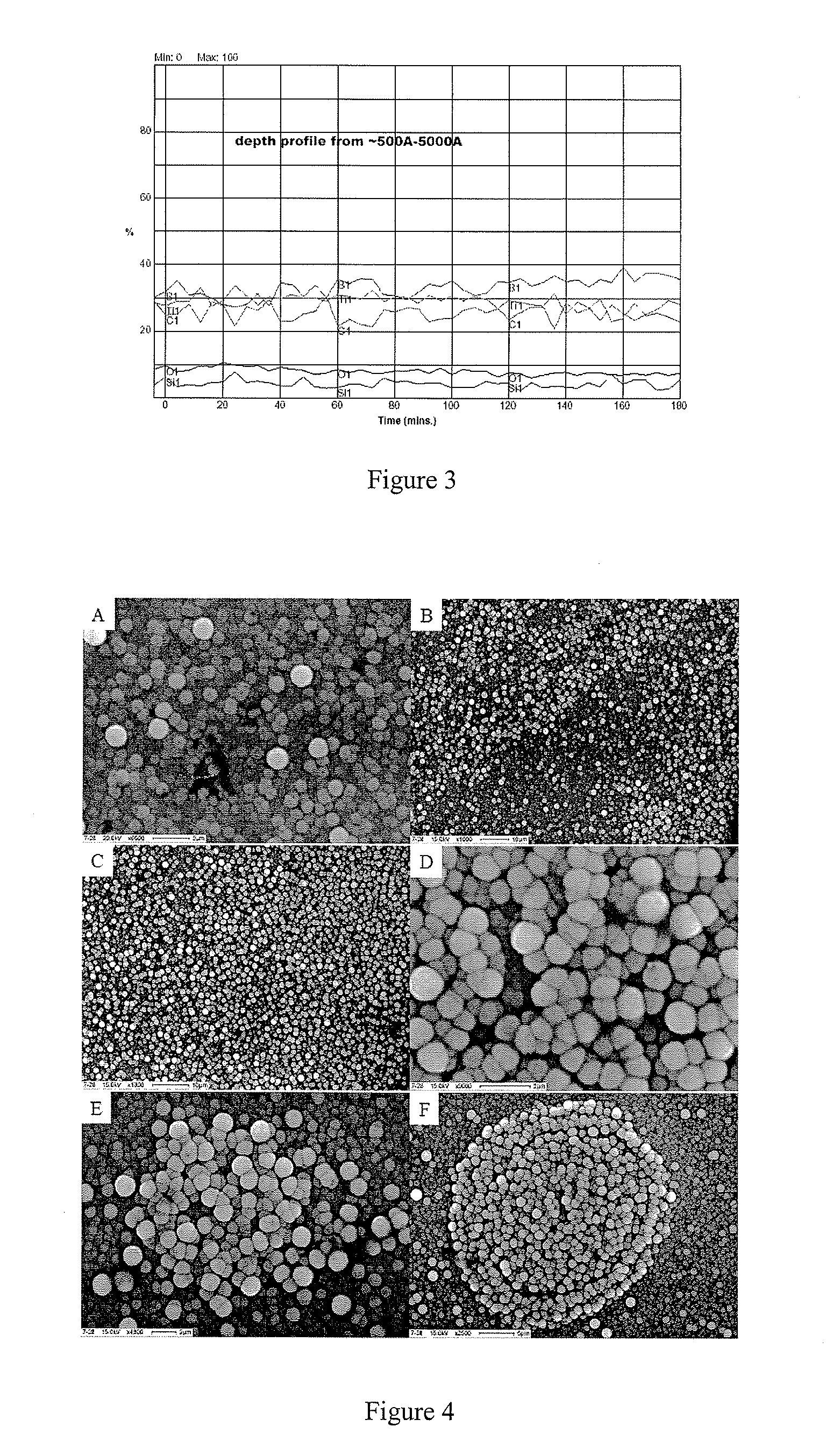

Systems and Methods of the Formation of Solid State Metal Boride and Oxide Coatings

InactiveUS20080003425A1Easy to implementMolten spray coatingLayered productsCelsius DegreeMicrometer

A system and method for the formation of novel small particles, thin films, and coatings of solid state metal boride material. The metal boride materials may be formed using aerosol methods and / or spray pyrolysis to form a generally uniform, thin film coating of boride compound spheres. Boride solutions or compounds are sprayed via a gas nebulizer in a reactor containing a substrate and heated to approximately 900° Celsius. The boride compounds form uniform, spherical particles of approximately one micrometer in diameter. The boride compounds are extremely strong, non-reactive, dense, and, when prepared as films or coating, adhere very well to substrates, such as metals.

Owner:SYRACUSE UNIVERSITY

Transparent Conductive Carbon Nanotube Film and a Method for Producing the Same

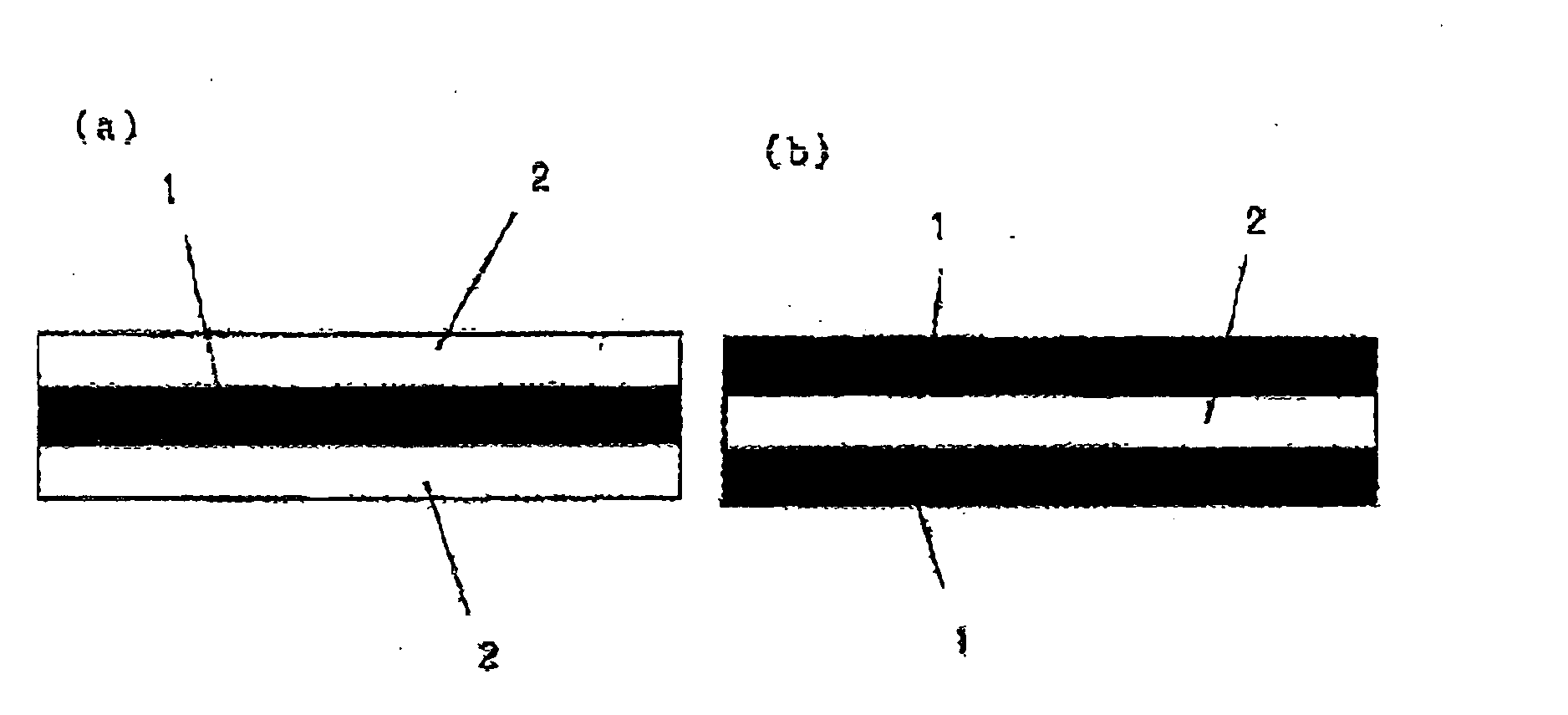

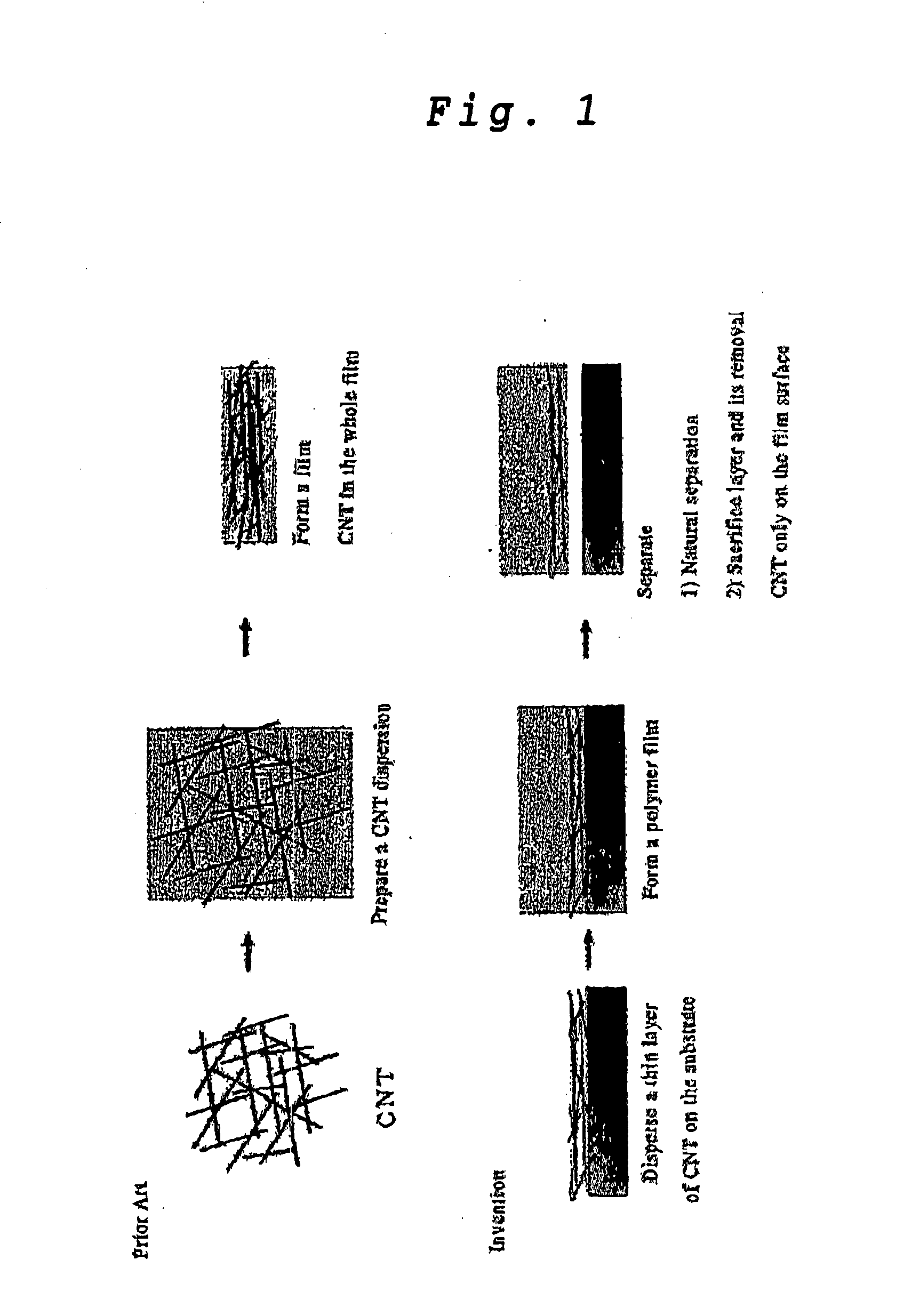

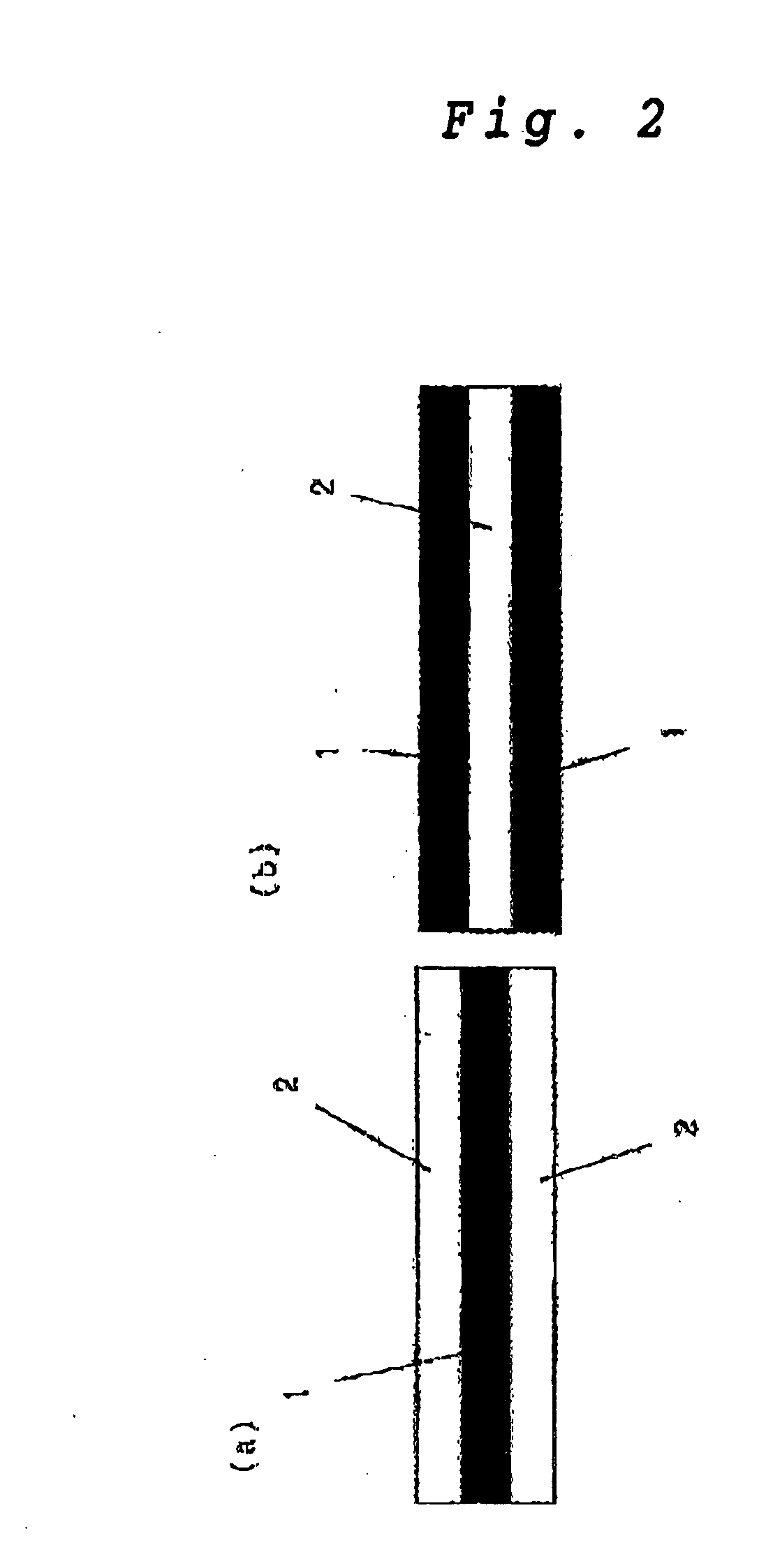

InactiveUS20070298253A1Conductive and soft and flexibleImprove conductivityMaterial nanotechnologyConductive layers on insulating-supportsCarbon nanotubeTransparent conducting film

A transparent conductive film wherein carbon nanotubes are discursively embedded in the surface portion of a resin film is produced by (A) dispersing carbon nanotubes on a substrate surface, (B) forming a transparent resin film over the substrate on which the carbon nanotubes are dispersed, and then (C) separating the thus-formed resin film. This is a novel technique for realizing a highly transparent conductive film which is flexible and highly conductive even when amount of carbon nanotubes used therefor is small.

Owner:NAT INST OF ADVANCED IND SCI & TECH

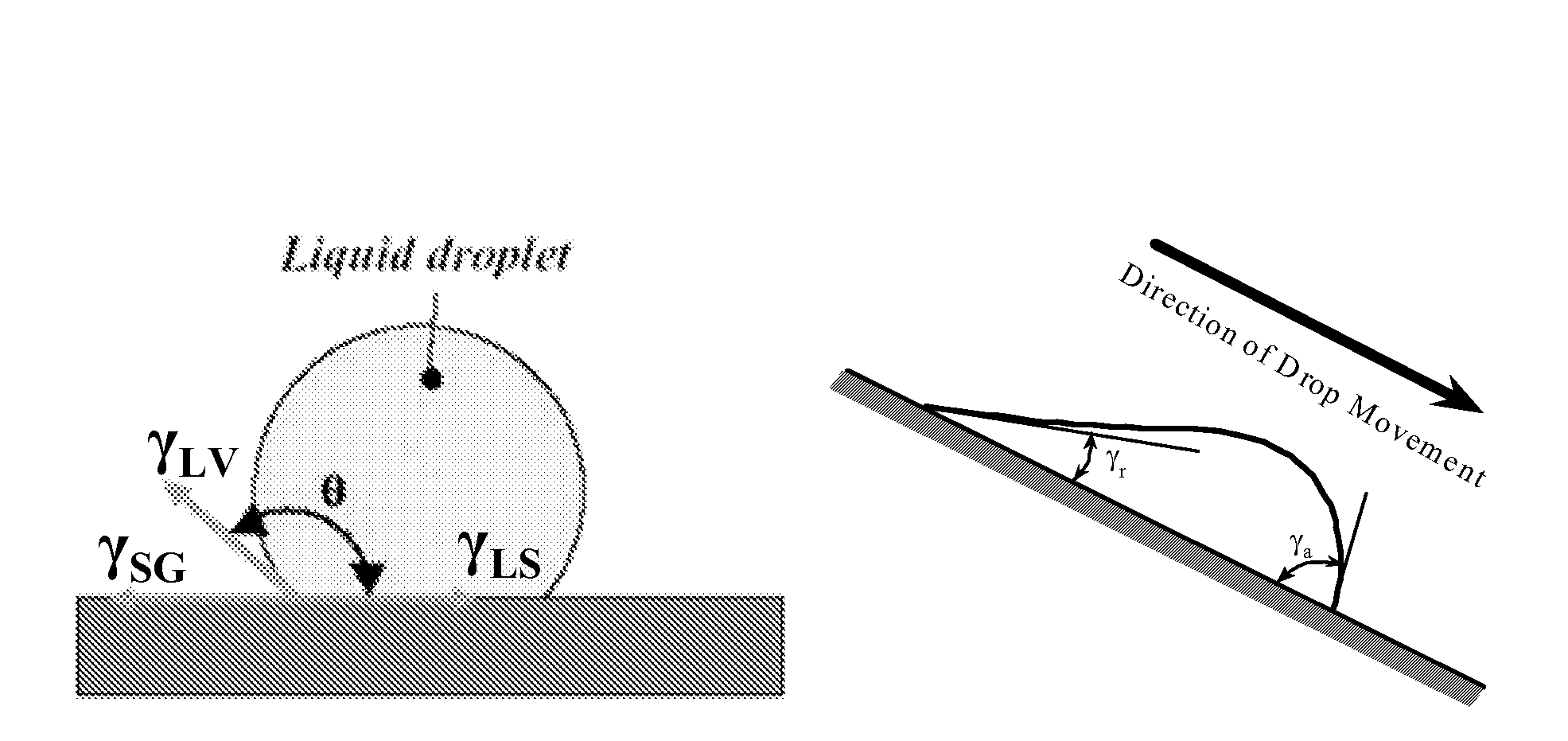

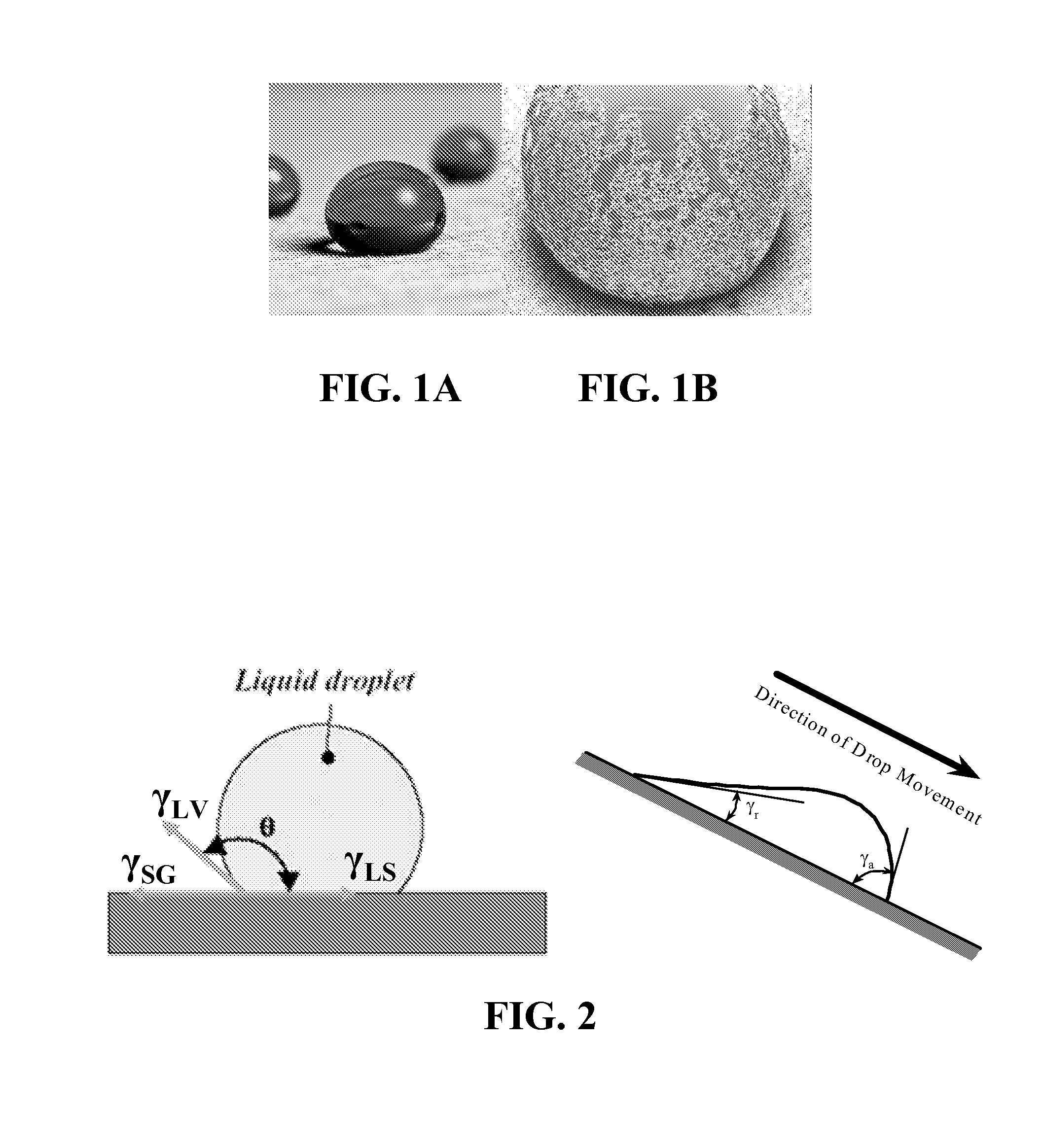

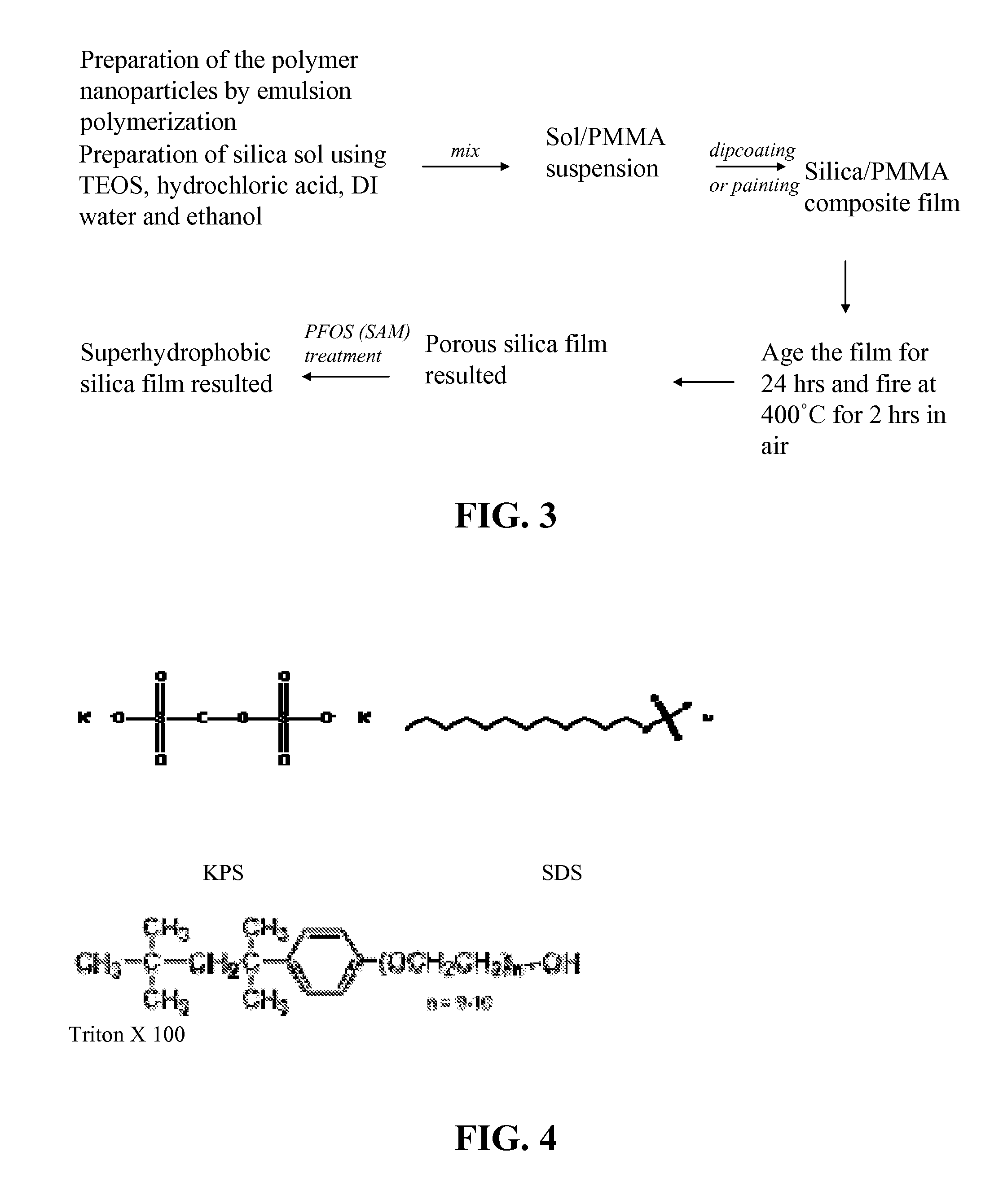

Superhydrophobic surface and method for forming same

InactiveUS20090011222A1Excellent superhydrophobicityIncrease contact angleLayered productsPretreated surfacesLotus effectHydrophobic surfaces

Owner:GEORGIA TECH RES CORP

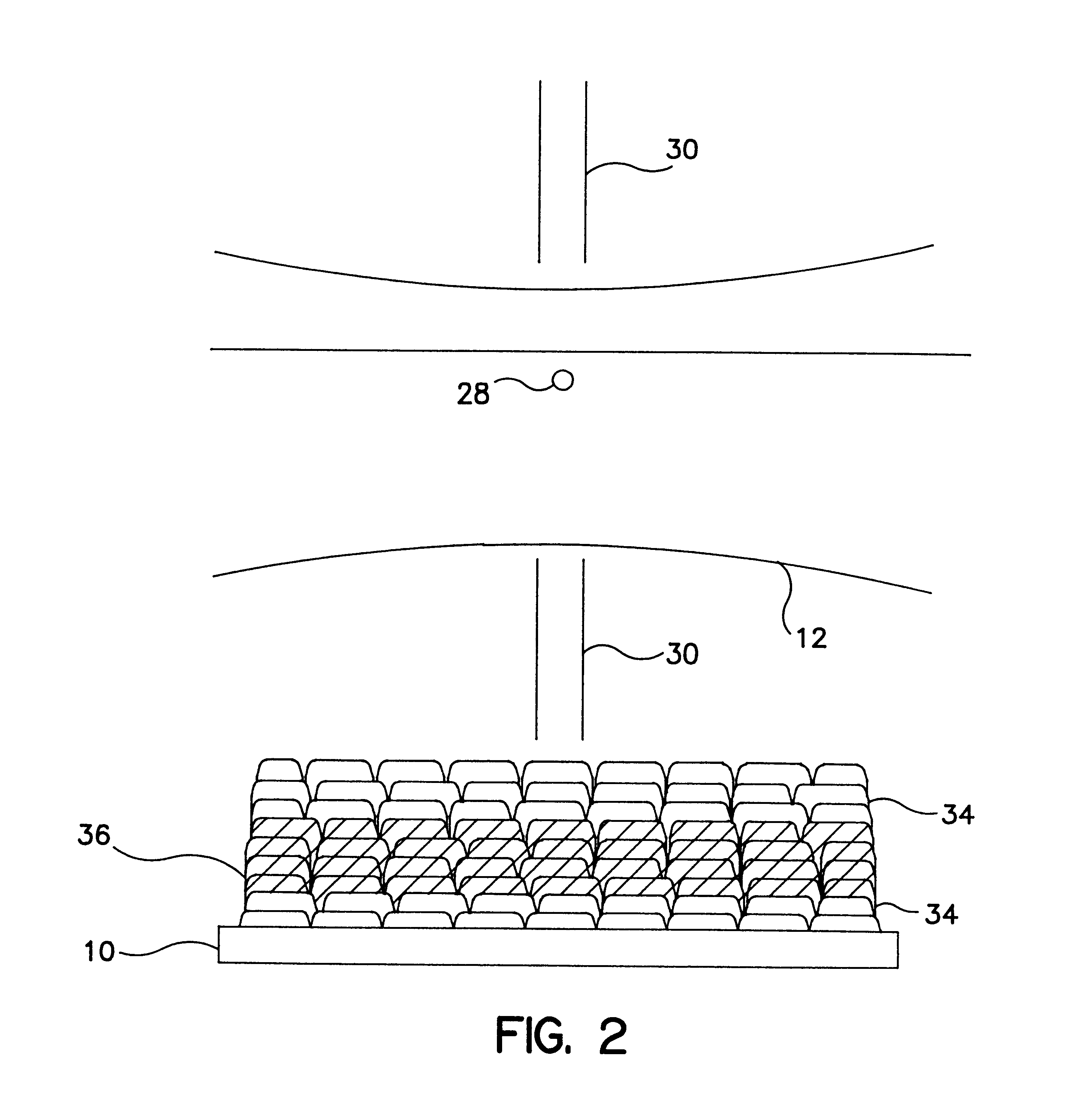

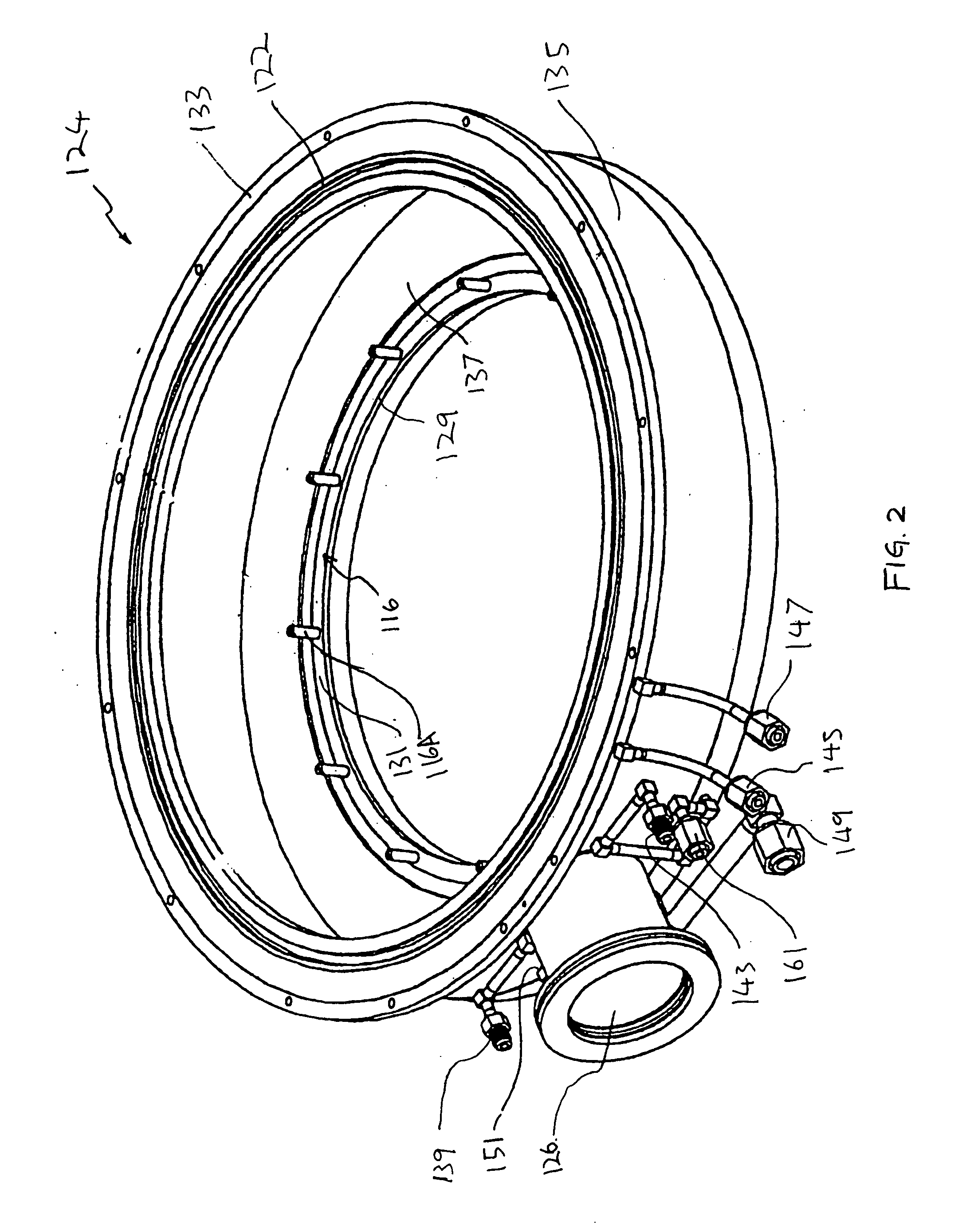

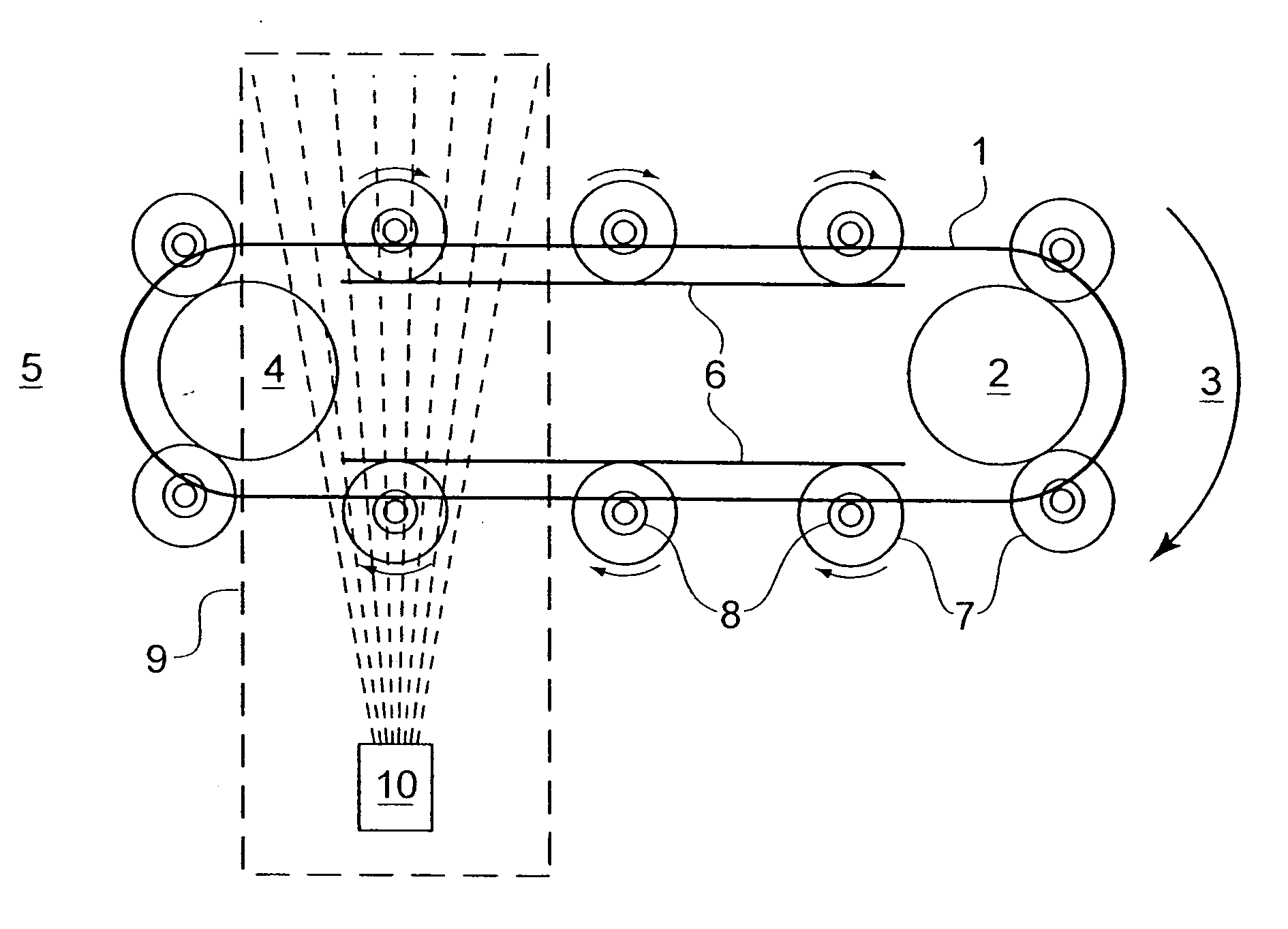

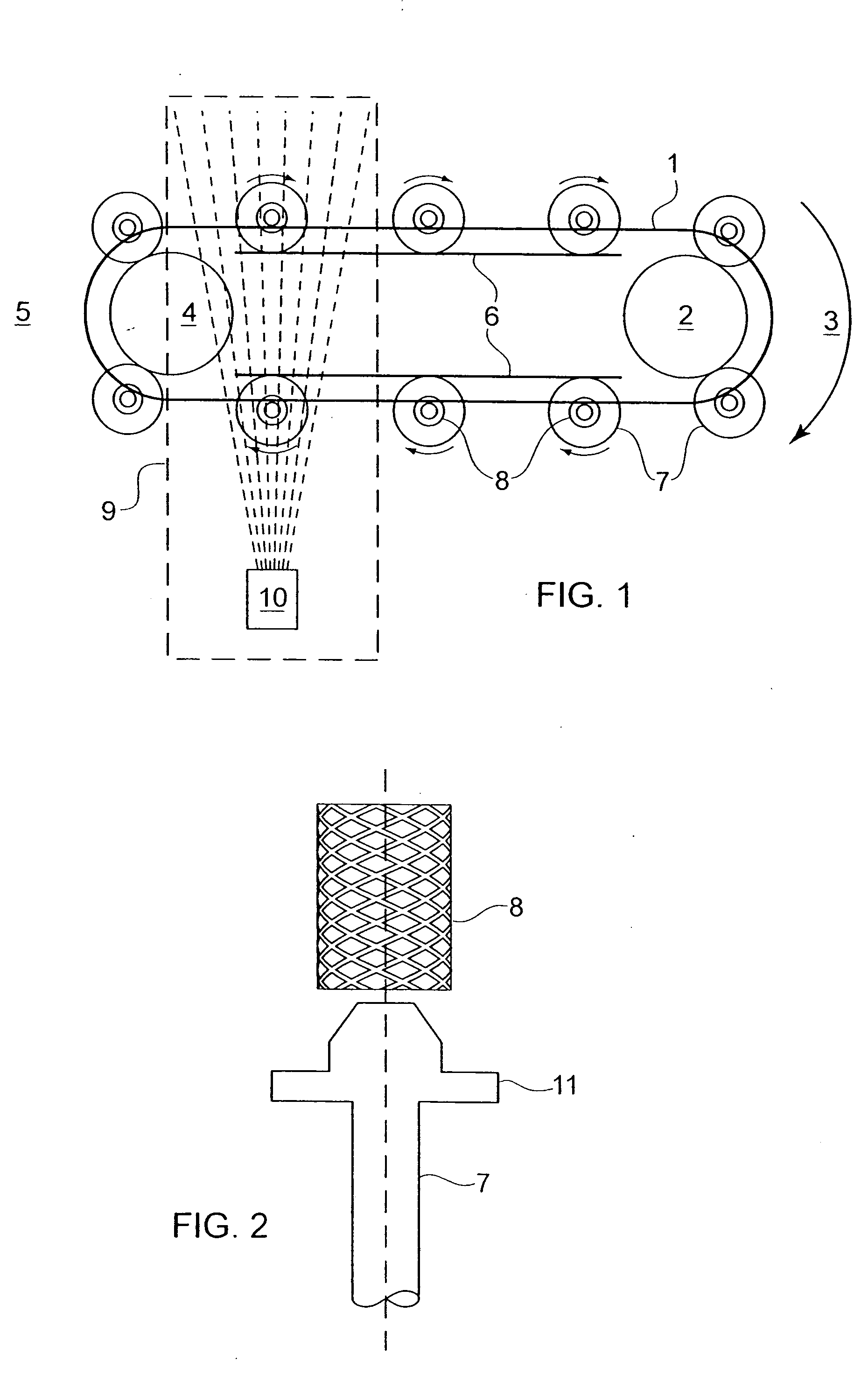

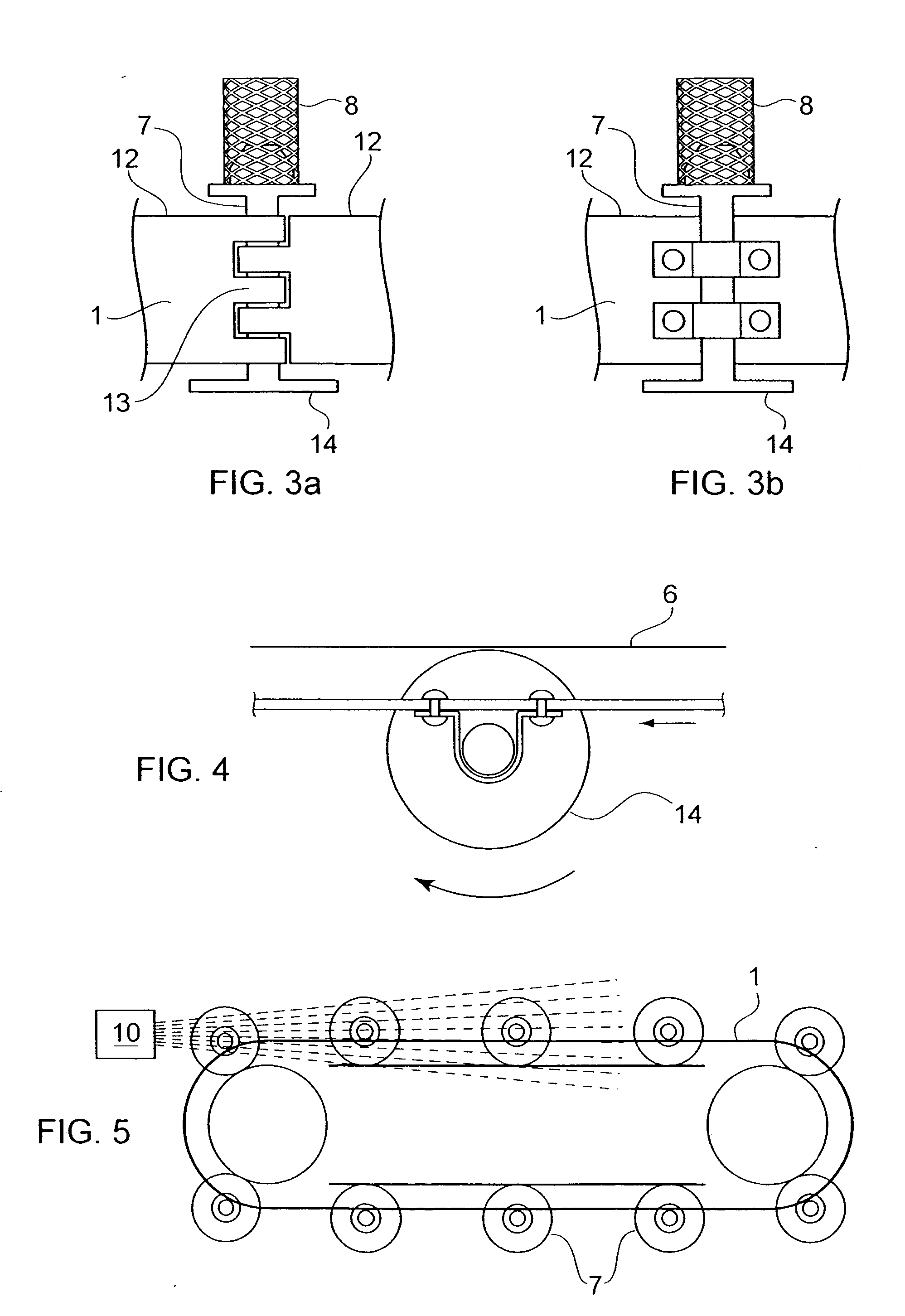

Method for coating multiple stents

ActiveUS20050079274A1Facilitate stent handlingLong exposureSpraying apparatusPretreated surfacesMedicineInsertion stent

An improved method for high-volume production of coated stents with highly uniform stent coatings using a roll coating technique is provided. In a first embodiment, uncoated stents are placed onto rotating stent holders with automated stent handling equipment. The holders are mounted on an endless conveyer belt which advances the stents toward a stent coater. As the stents advance through the coater, the holders rotate, thereby rolling the stents about their longitudinal axes as coating material is sprayed toward them, ensuring the stents are uniformly coated on their exterior and interior surfaces. After the conveyer turns to carry the coated stents back toward the loading area, the rotating stents pass again through the coating spray, downstream of the initial coating location, thereby increasing the efficient utilization of the coating material. The conveyer then advances the coated stents to an unloading area for removal before the holders return to the stent loading area to receive new stents.

Owner:BOSTON SCI SCIMED INC

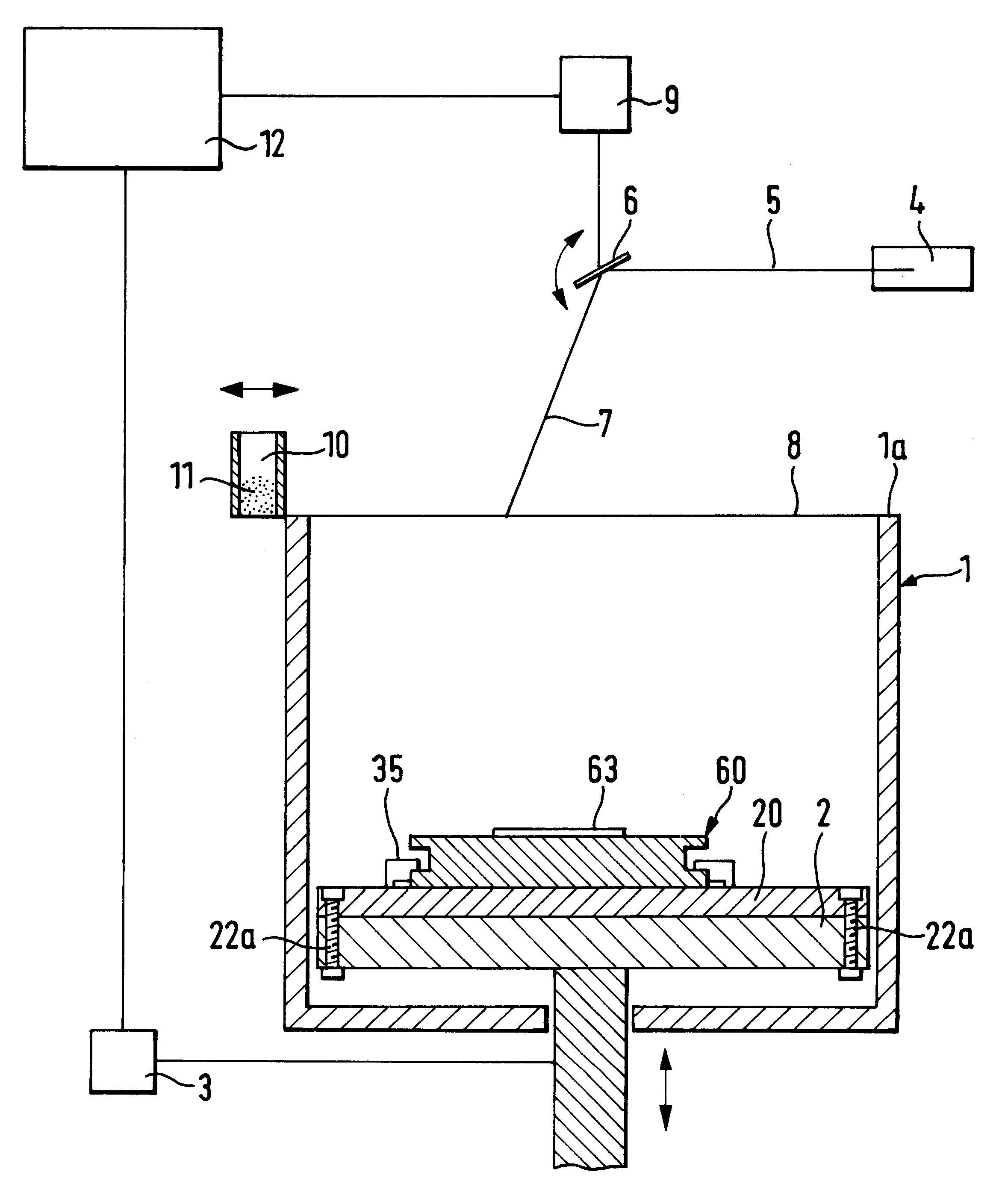

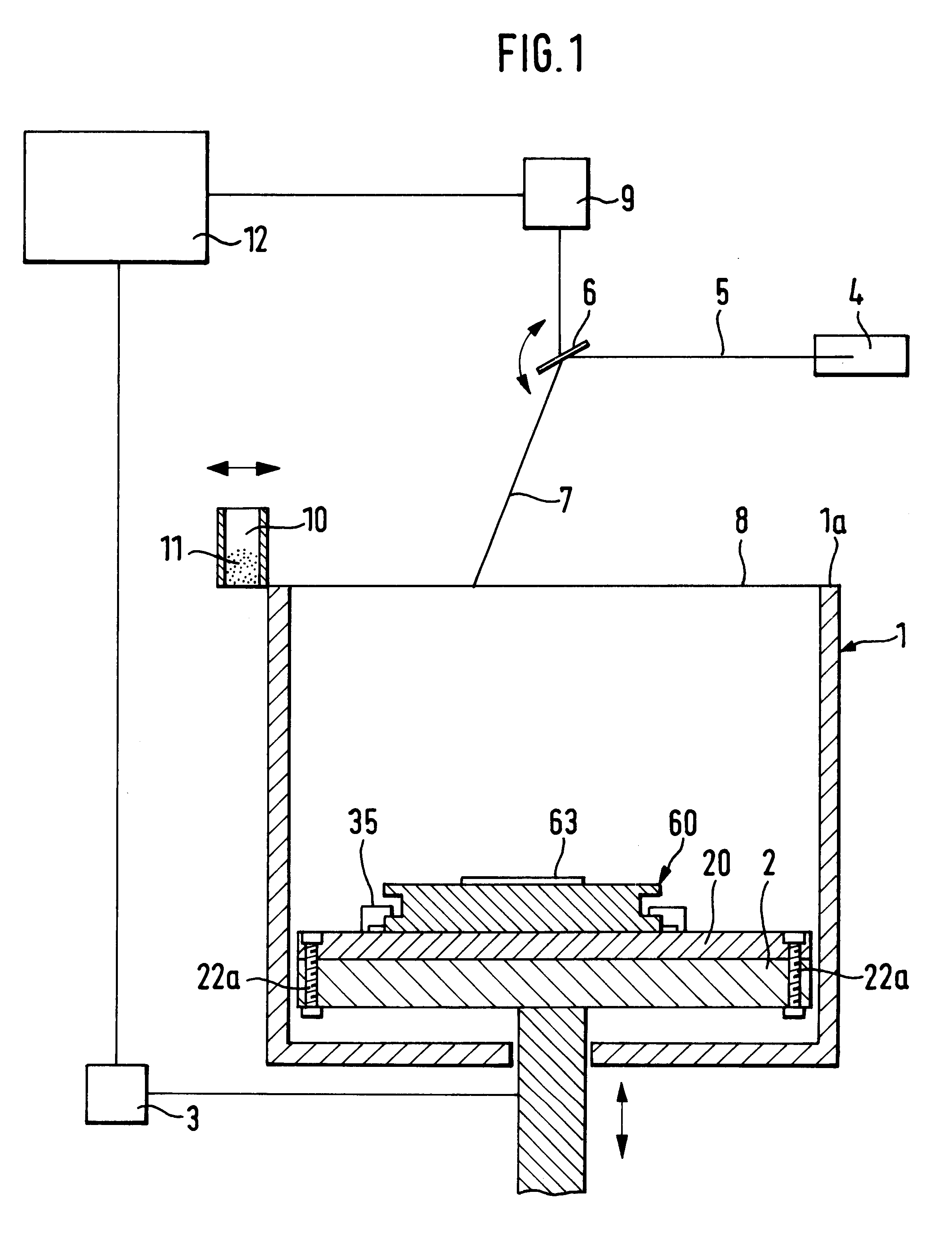

Method of calibrating an apparatus for producing a three-dimensional object, calibration apparatus and method and apparatus for producing a three-dimensional object

InactiveUS6483596B1Simple methodEnhanced radiationPretreated surfacesElectrical measurementsElectromagnetic radiationRapid prototyping

The invention refers to a method for calibrating the control of a radiation device producing electromagnetic radiation or particle radiation in a rapid prototyping system. The method comprises the steps of arranging a calibration plate at a defined position in the rapid prototyping system, the calibration plate having an upper side with a first region and a second region separate from the first region, the first region being provided with optically detectable reference marks and the second region having a medium which is sensitive to the radiation of the radiation device, producing a test pattern by exposing said medium to said radiation at predetermined desired positions defined by position coordinate data, digitizing the first region of the calibration plate with the reference marks thereon and the second region of the calibration plate having the test pattern, comparing the digitized reference marks and the digitized test pattern and calculating and providing correction data for the control of the radiation device on the basis of the comparison.

Owner:EOS ELECTRO OPTICAL SYST

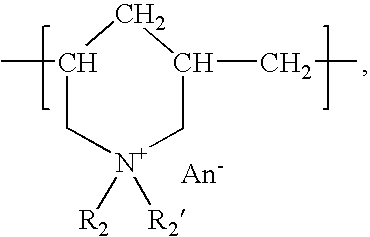

Leveler compounds

ActiveUS7128822B2No suppressed local platingOverplating is reduced or substantially eliminatedOrganic chemistrySpray nozzlesCopper platingMetal

Compounds that function to provide level or uniform metal deposits are provided. These compounds are particularly useful in providing level copper deposits. Copper plating baths and methods of copper plating using these compounds are also provided. These baths and methods are useful for providing a planarized layer of copper on a substrate having small apertures. The compositions and methods provide complete fill of small apertures with reduced void formation.

Owner:SHIPLEY CO LLC

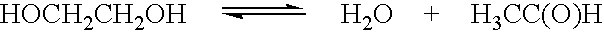

Copper plating bath and plating method for substrate using the copper plating bath

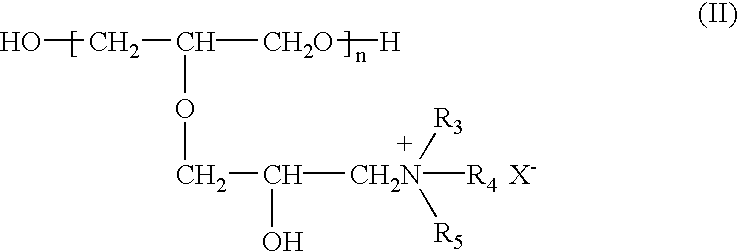

InactiveUS6800188B2Excellent characteristic and uniformityImprove reliabilityAnti-corrosive paintsLiquid/solution decomposition chemical coatingCopper platingGlycidyl ethers

A copper plating bath comprising a reaction condensate of an amine compound and glycidyl ether and / or a quaternary ammonium derivative of this reaction condensate, and a plating method using this copper plating bath are disclosed. A copper plating bath capable of providing highly reliable copper plating on a substrate such as a silicone wafer semiconductor substrate or printed board having minute circuit patterns and small holes such as blind via-holes, through-holes, and the like, and a method of copper plating using the copper plating bath can be provided.

Owner:EBARA-UDYLITE CO LTD

Method of depositing films by using carboxylate complexes

InactiveUS6010969AVacuum evaporation coatingPretreated surfacesSemiconductor structureCarboxylic salt

A method of forming a film on a substrate using chemical vapor deposition techniques and carboxylate complexes. The complexes and method are particularly suitable for the preparation of semiconductor structures.

Owner:MICRON TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com