Patents

Literature

665 results about "Wet cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet cleaning refers to methods of professional cleaning that, in contrast to traditional dry cleaning, avoids the use of chemical solvents, the most common of which is tetrachloroethylene (commonly called perchloroethylene or "perc"). Environmental groups and the United States Environmental Protection Agency have indicated that such alternative "wet cleaning" methods are better for the environment than perc, and proponents of wet cleaning state that these methods can be used without shrinking or otherwise damaging garments that typically require dry cleaning.

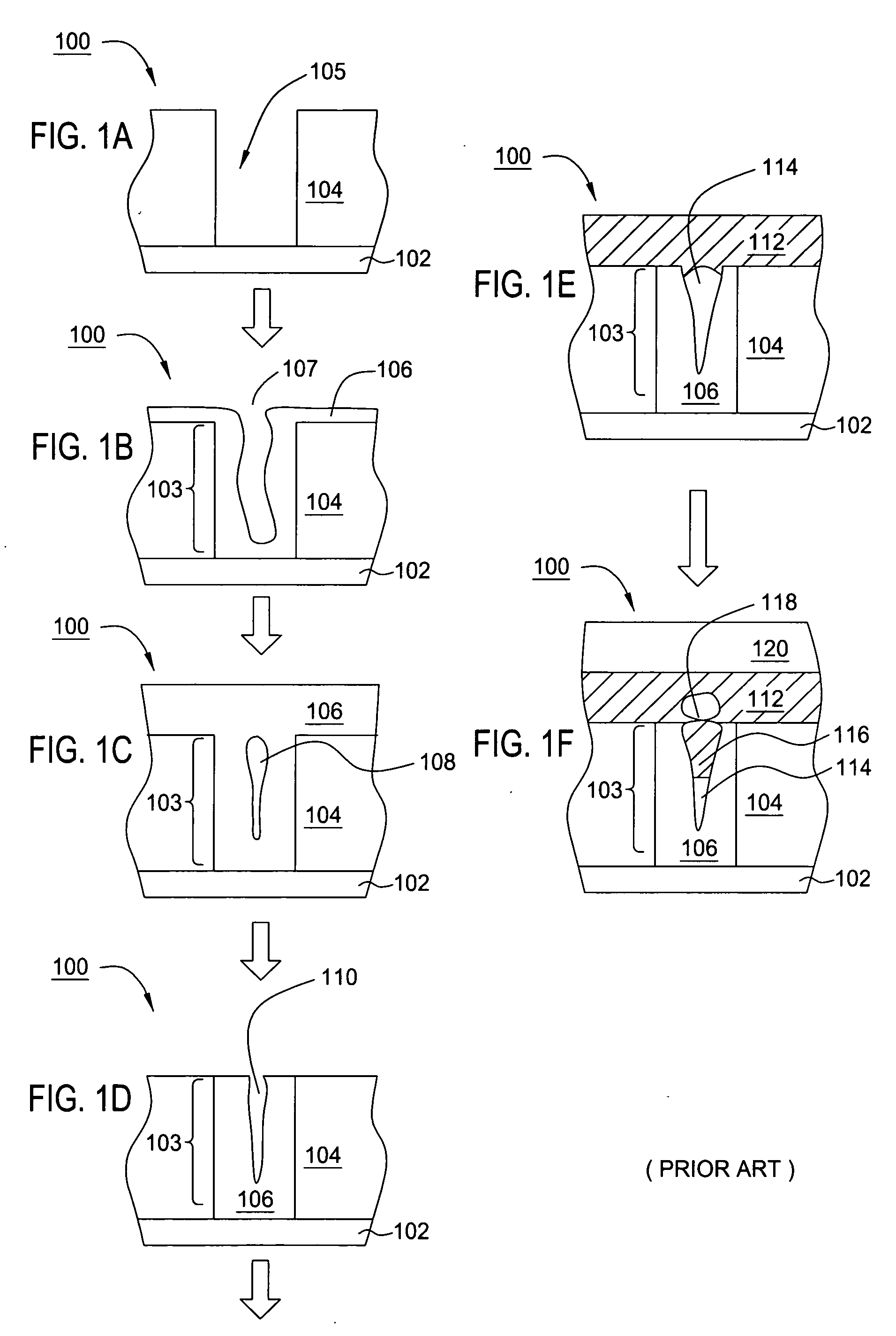

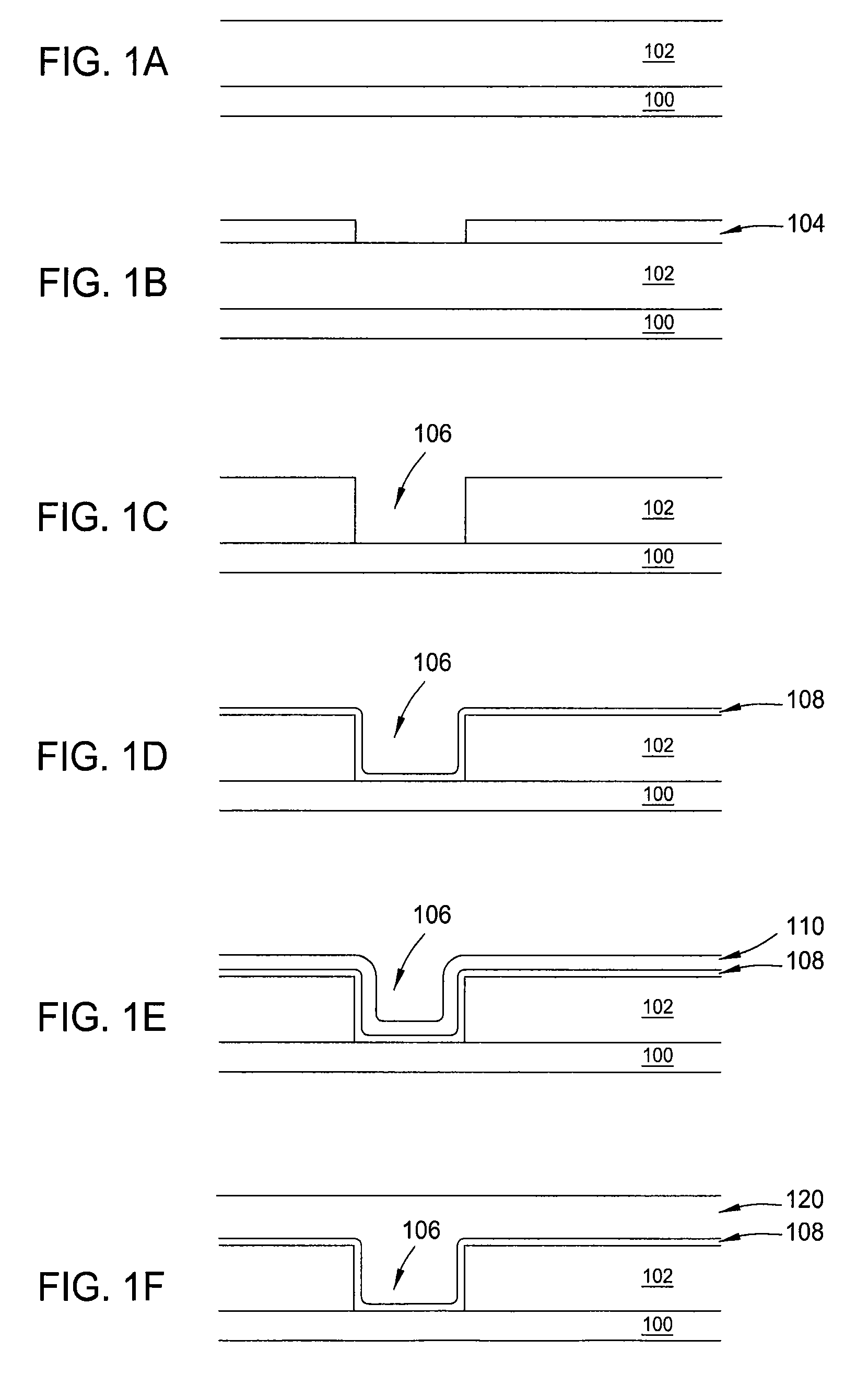

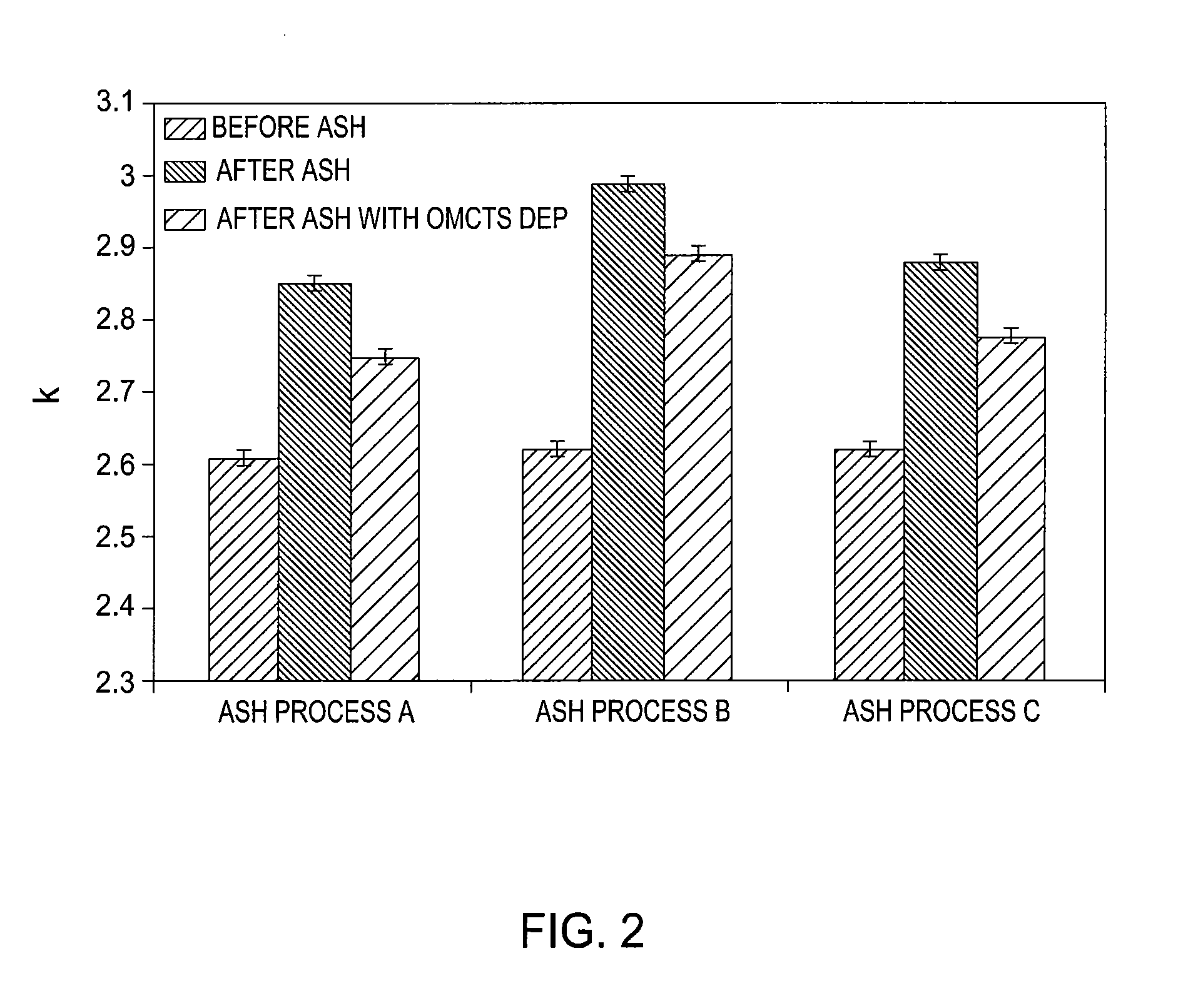

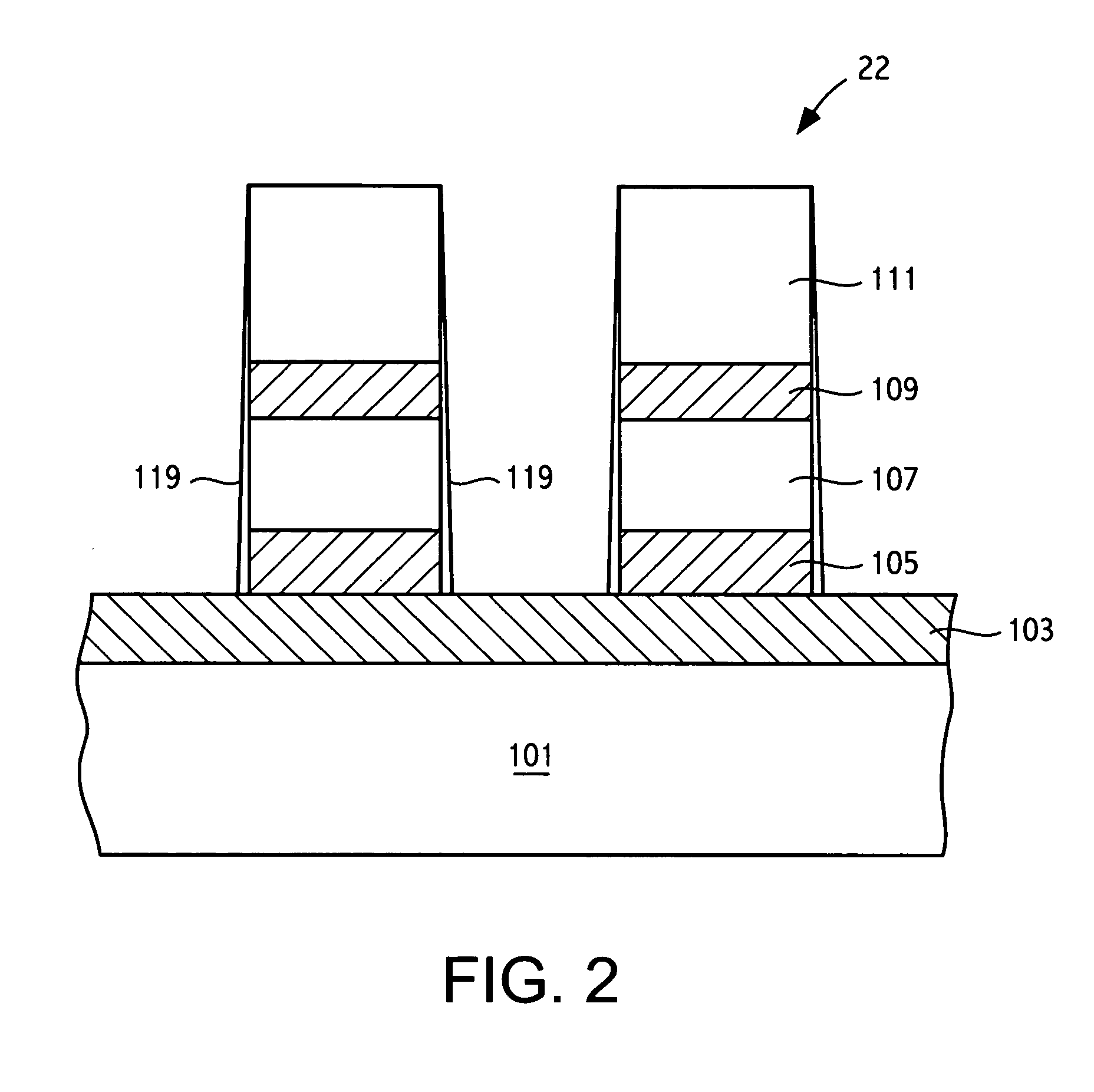

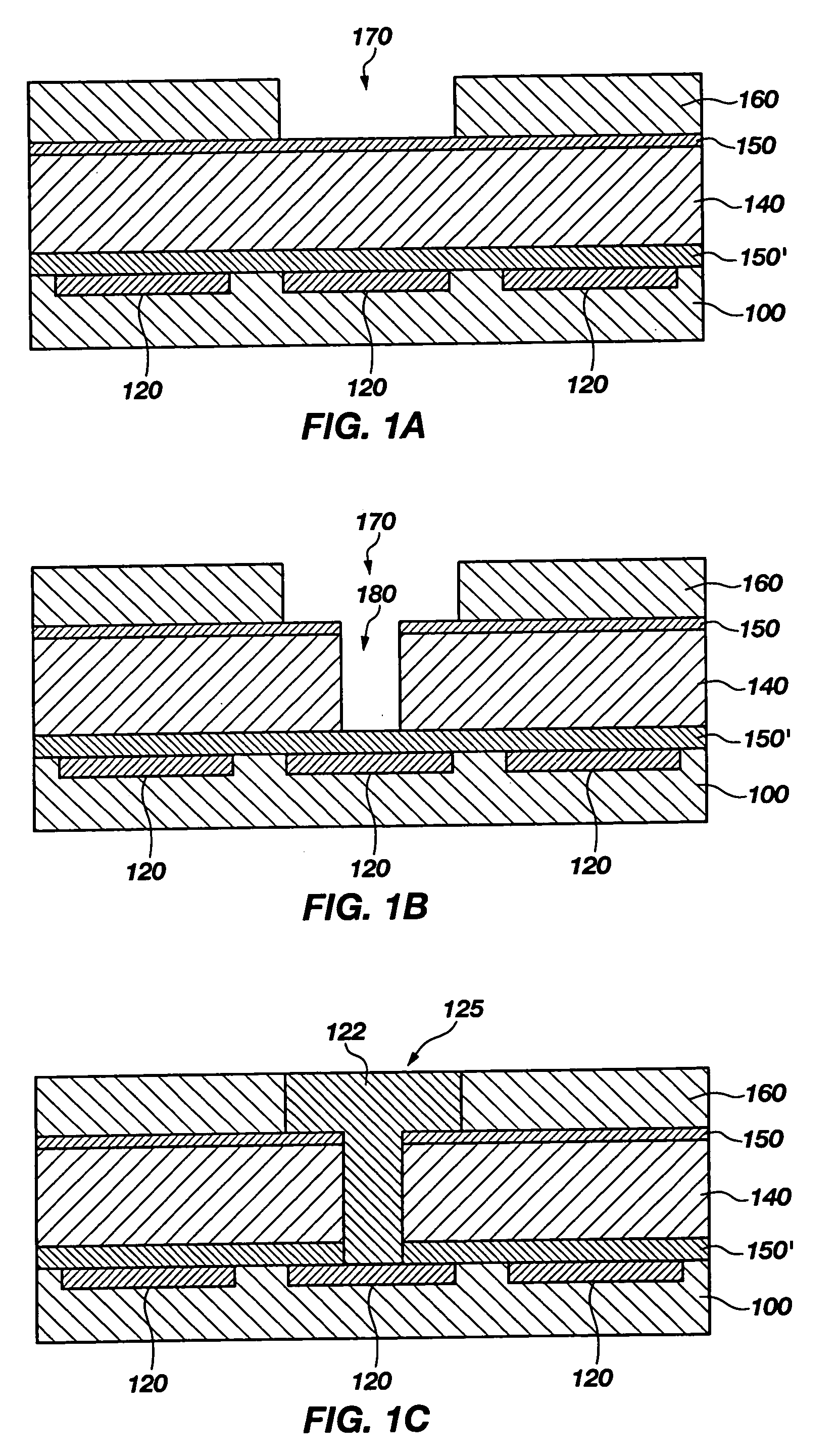

Method to minimize wet etch undercuts and provide pore sealing of extreme low k (k<2.5) dielectrics

ActiveUS8445075B2Constant ratePrevents undercuts and CD lossVacuum evaporation coatingPretreated surfacesNitrogenThin layer

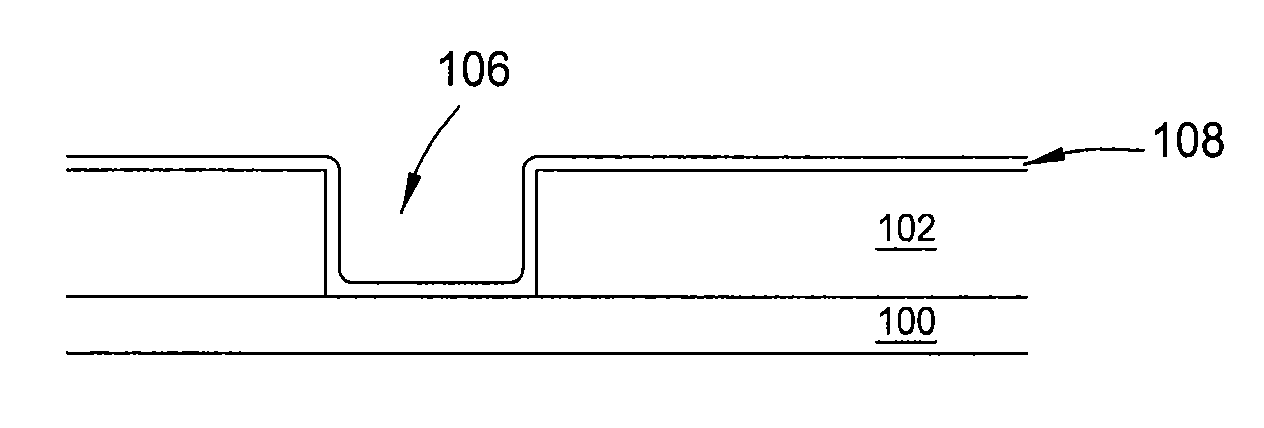

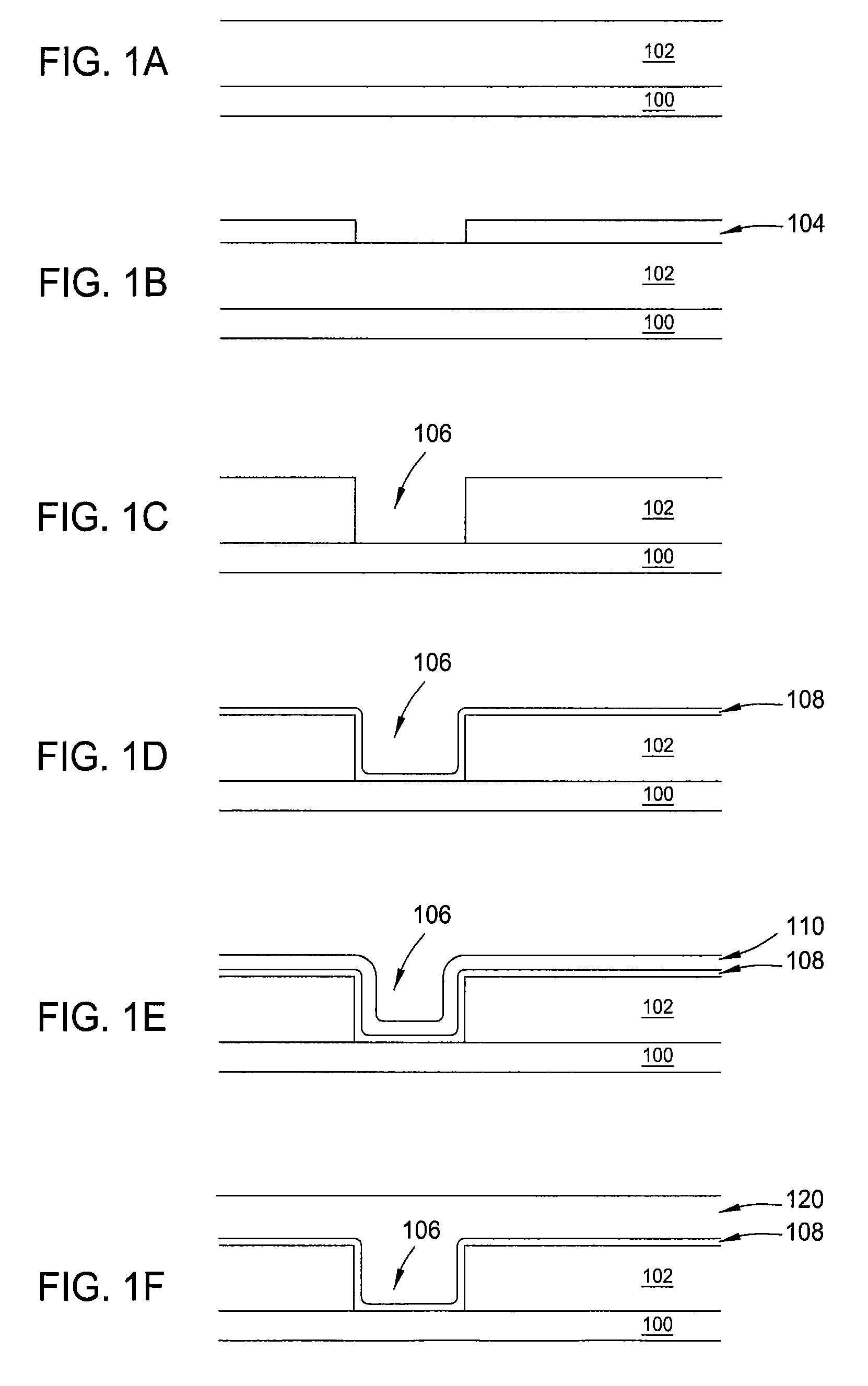

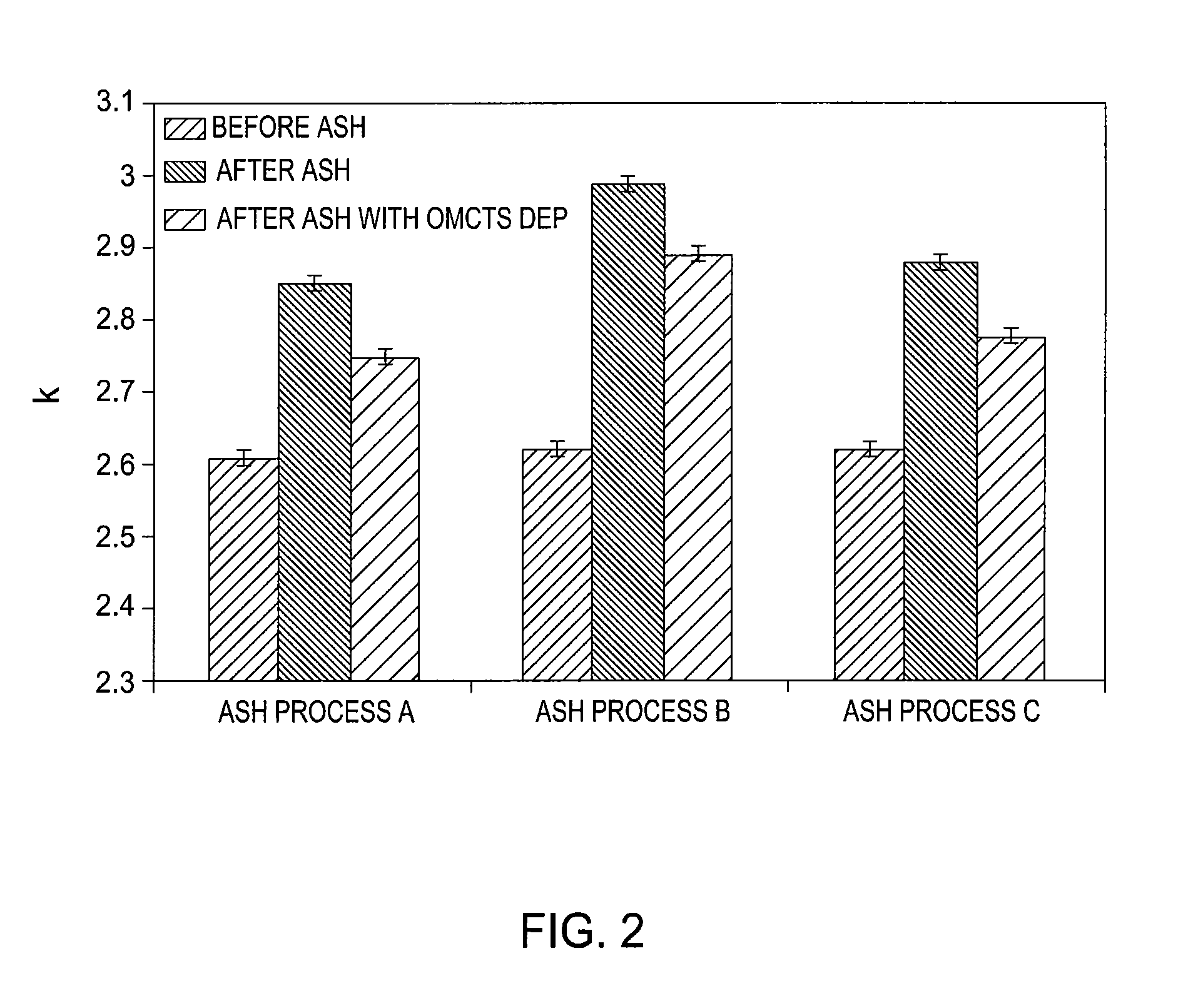

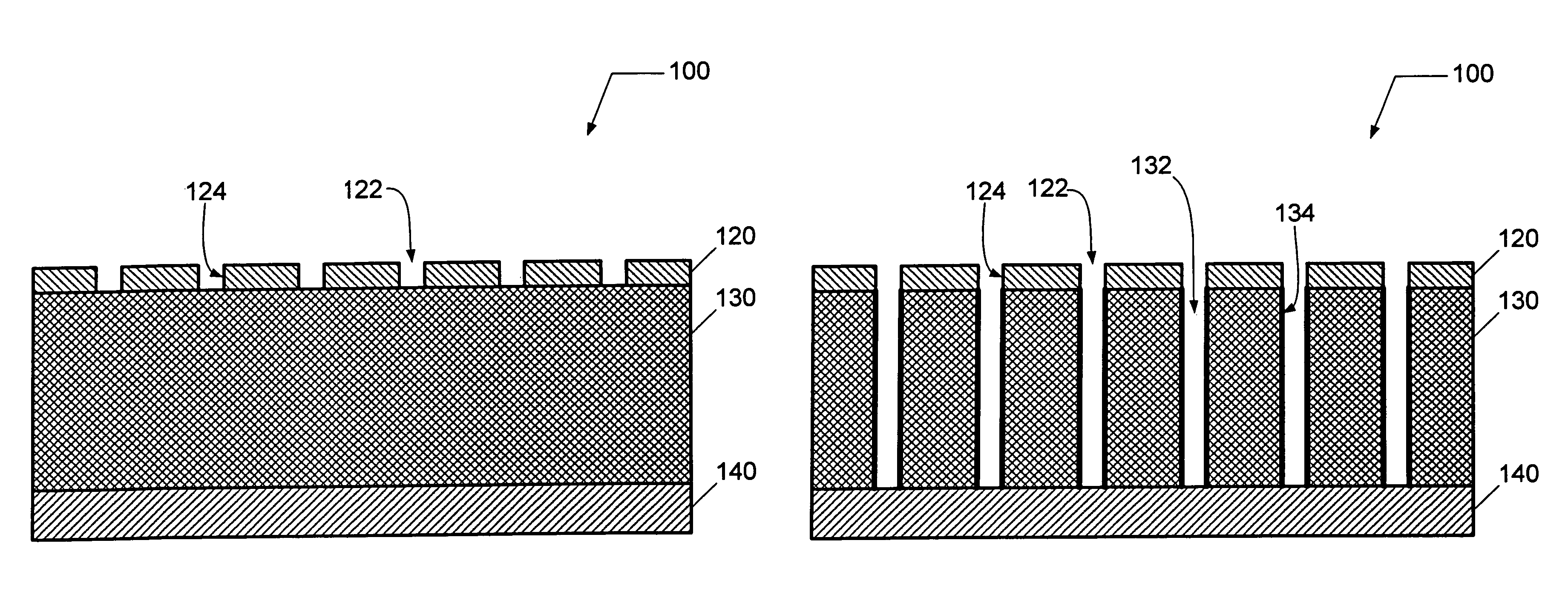

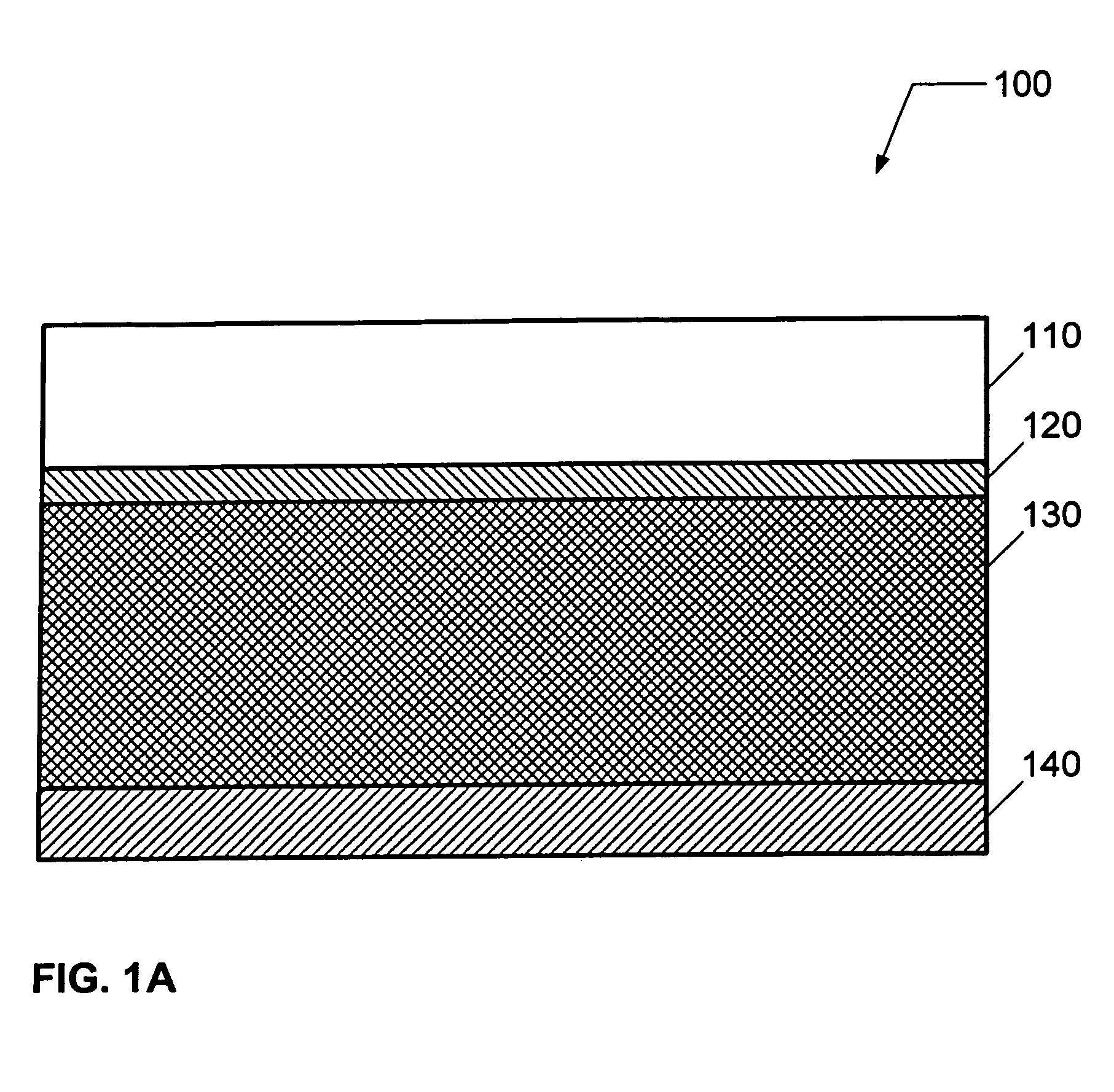

Methods of processing films on substrates are provided. In one aspect, the methods comprise treating a patterned low dielectric constant film after a photoresist is removed from the film by depositing a thin layer comprising silicon, carbon, and optionally oxygen and / or nitrogen on the film. The thin layer provides a carbon-rich, hydrophobic surface for the patterned low dielectric constant film. The thin layer also protects the low dielectric constant film from subsequent wet cleaning processes and penetration by precursors for layers that are subsequently deposited on the low dielectric constant film.

Owner:APPLIED MATERIALS INC

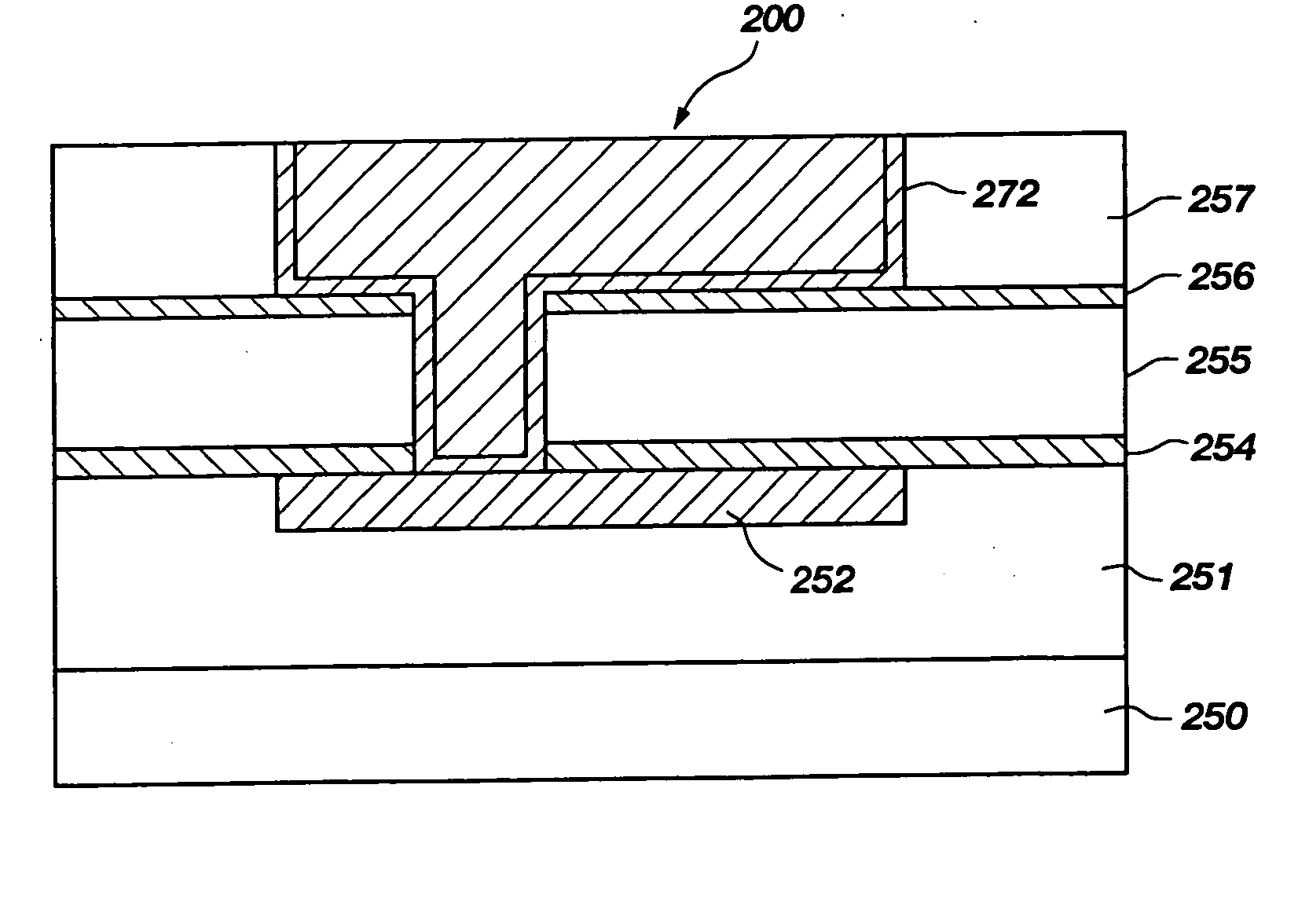

Electroless deposition process on a silicon contact

ActiveUS20060264043A1Material nanotechnologySemiconductor/solid-state device manufacturingSalicideAlloy

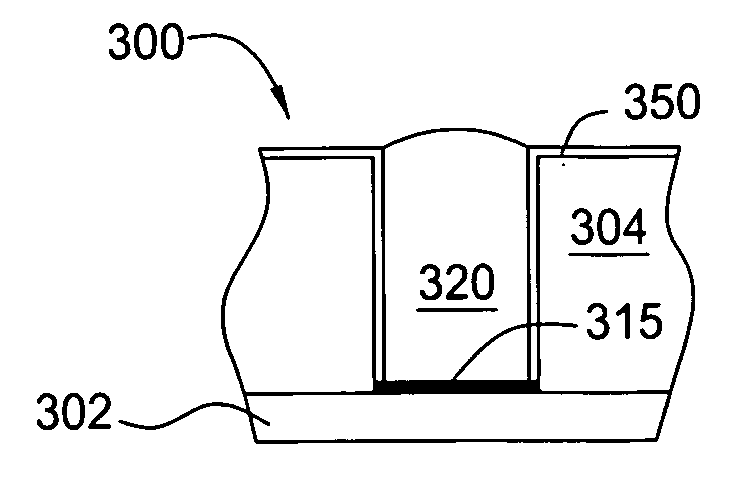

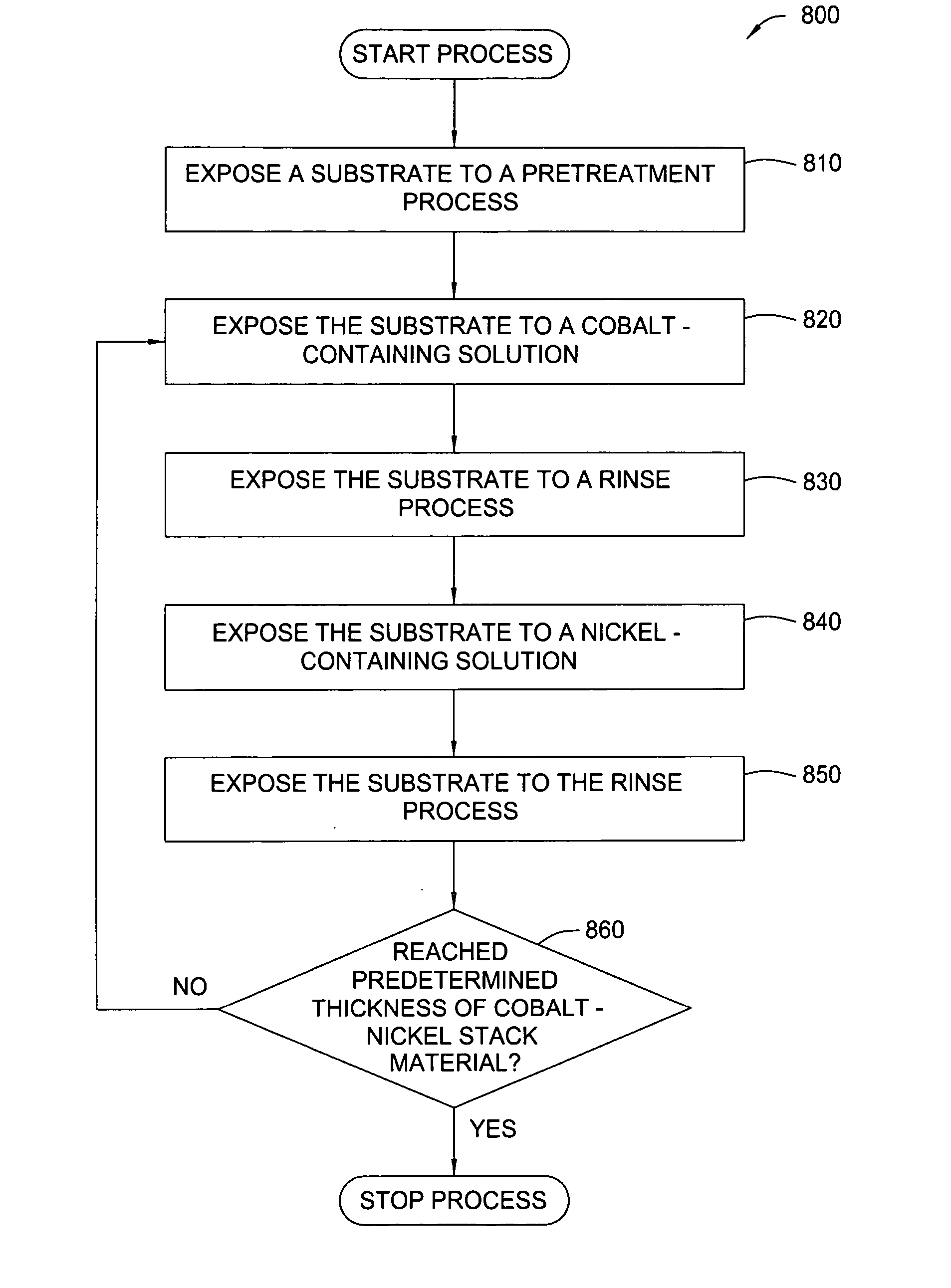

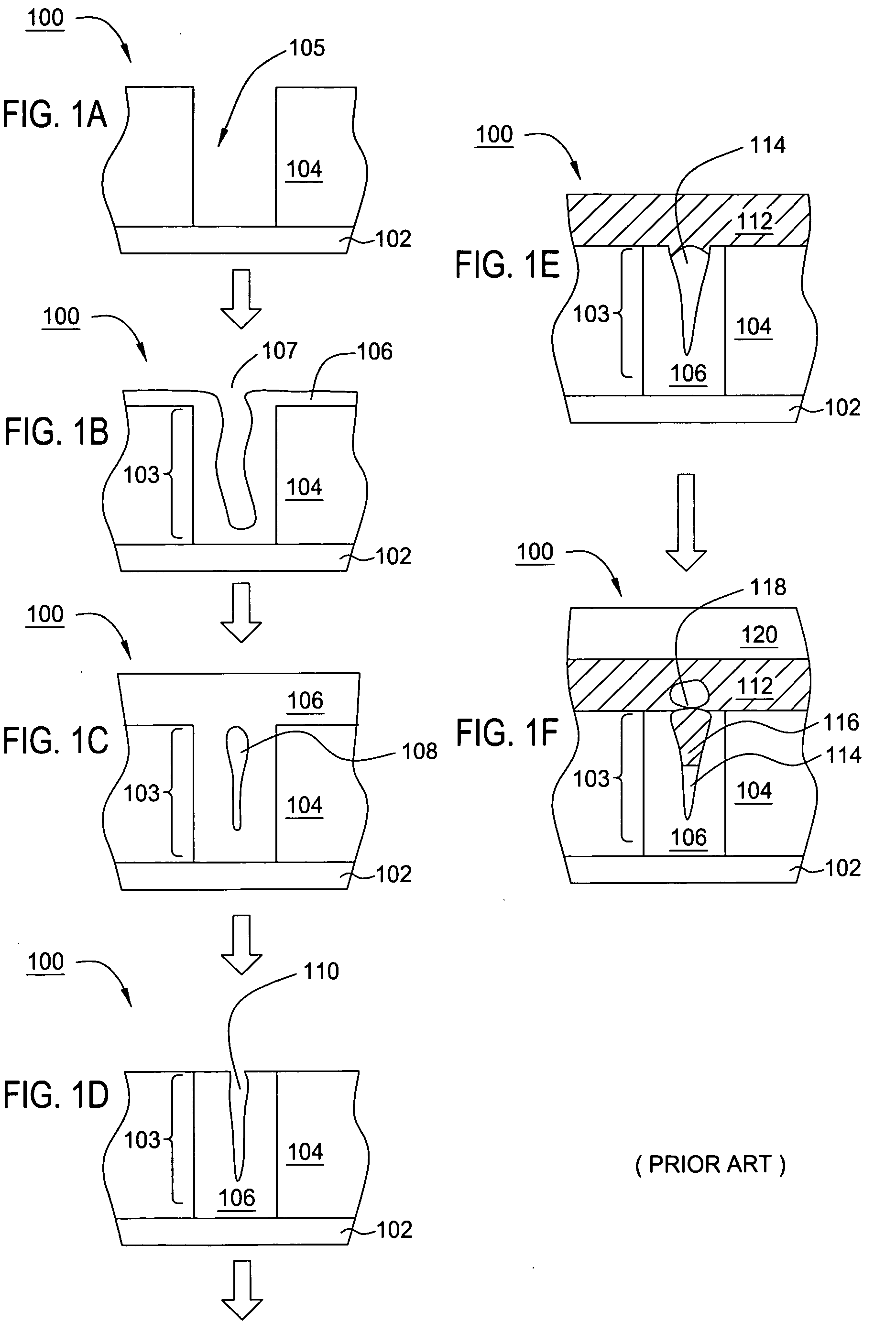

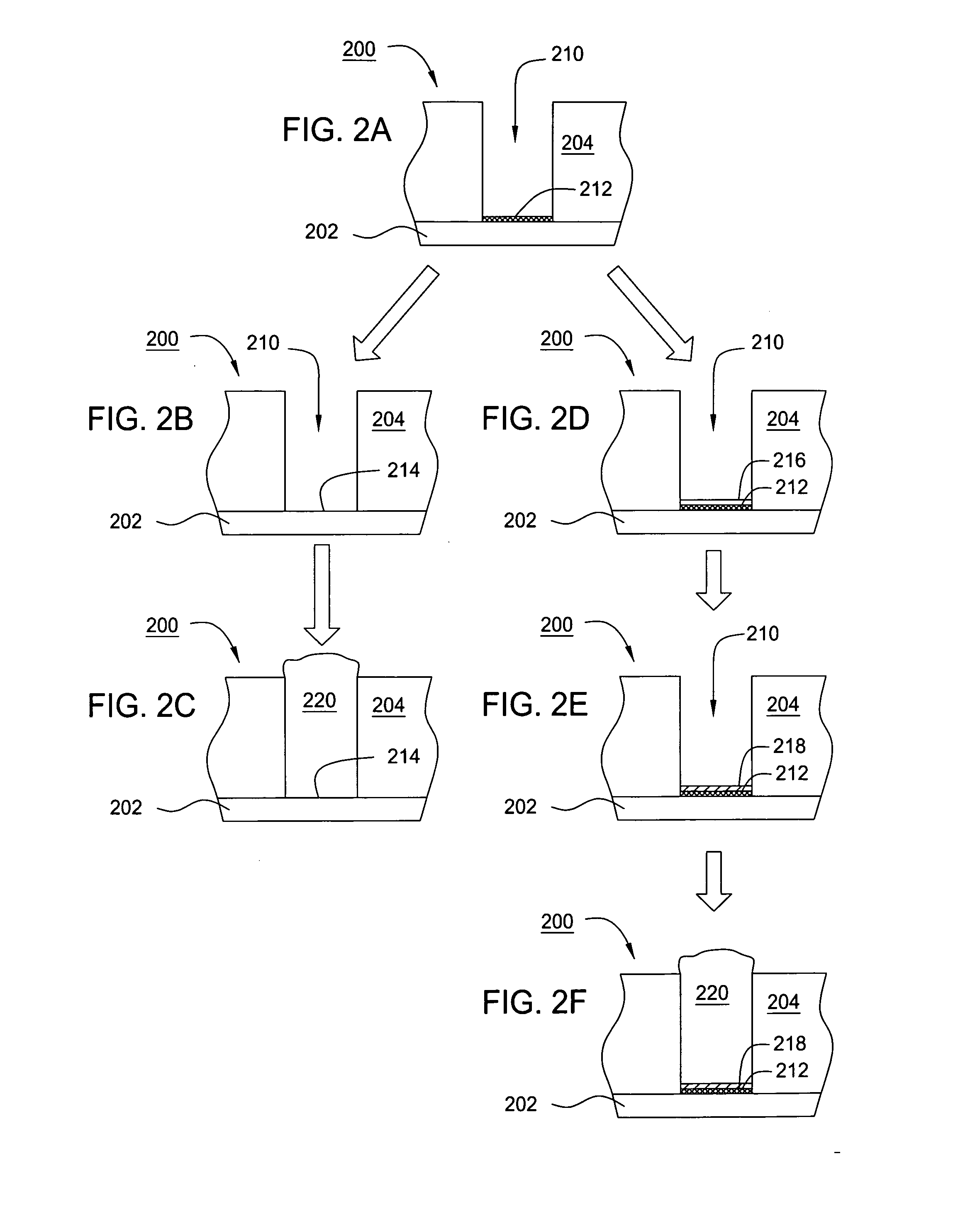

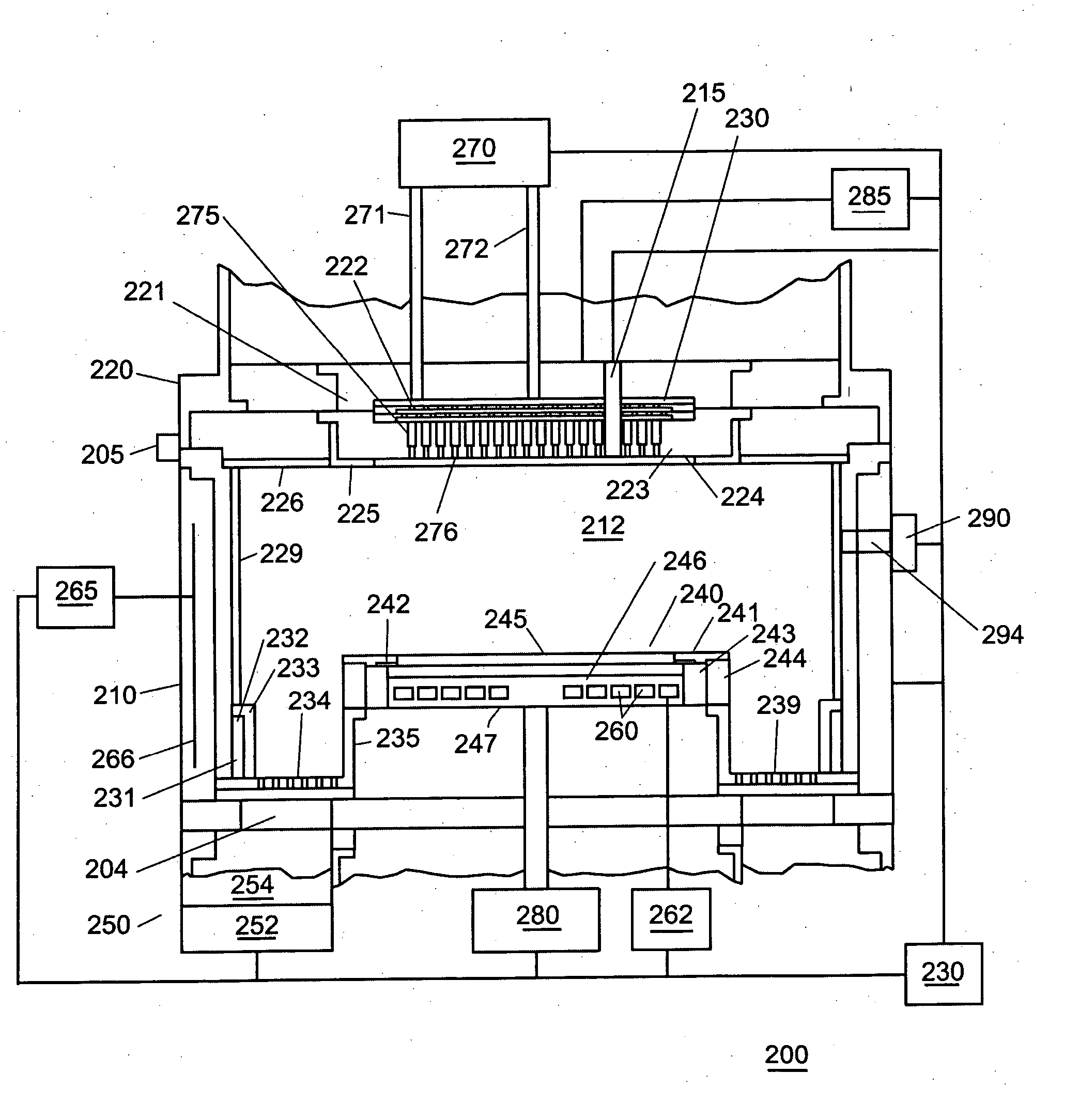

Embodiments as described herein provide methods for depositing a material on a substrate during electroless deposition processes, as well as compositions of the electroless deposition solutions. In one embodiment, the substrate contains a contact aperture having an exposed silicon contact surface. In another embodiment, the substrate contains a contact aperture having an exposed silicide contact surface. The apertures are filled with a metal contact material by exposing the substrate to an electroless deposition process. The metal contact material may contain a cobalt material, a nickel material, or alloys thereof. Prior to filling the apertures, the substrate may be exposed to a variety of pretreatment processes, such as preclean processes and activations processes. A preclean process may remove organic residues, native oxides, and other contaminants during a wet clean process or a plasma etch process. Embodiments of the process also provide the deposition of additional layers, such as a capping layer.

Owner:APPLIED MATERIALS INC

Method to minimize wet etch undercuts and provide pore sealing of extreme low k (k<2.5) dielectrics

ActiveUS20110092077A1Constant ratePrevents undercuts and CD lossVacuum evaporation coatingSemiconductor/solid-state device manufacturingThin layerNitrogen

Methods of processing films on substrates are provided. In one aspect, the methods comprise treating a patterned low dielectric constant film after a photoresist is removed form the film by depositing a thin layer comprising silicon, carbon, and optionally oxygen and / or nitrogen on the film. The thin layer provides a carbon-rich, hydrophobic surface for the patterned low dielectric constant film. The thin layer also protects the low dielectric constant film from subsequent wet cleaning processes and penetration by precursors for layers that are subsequently deposited on the low dielectric constant film.

Owner:APPLIED MATERIALS INC

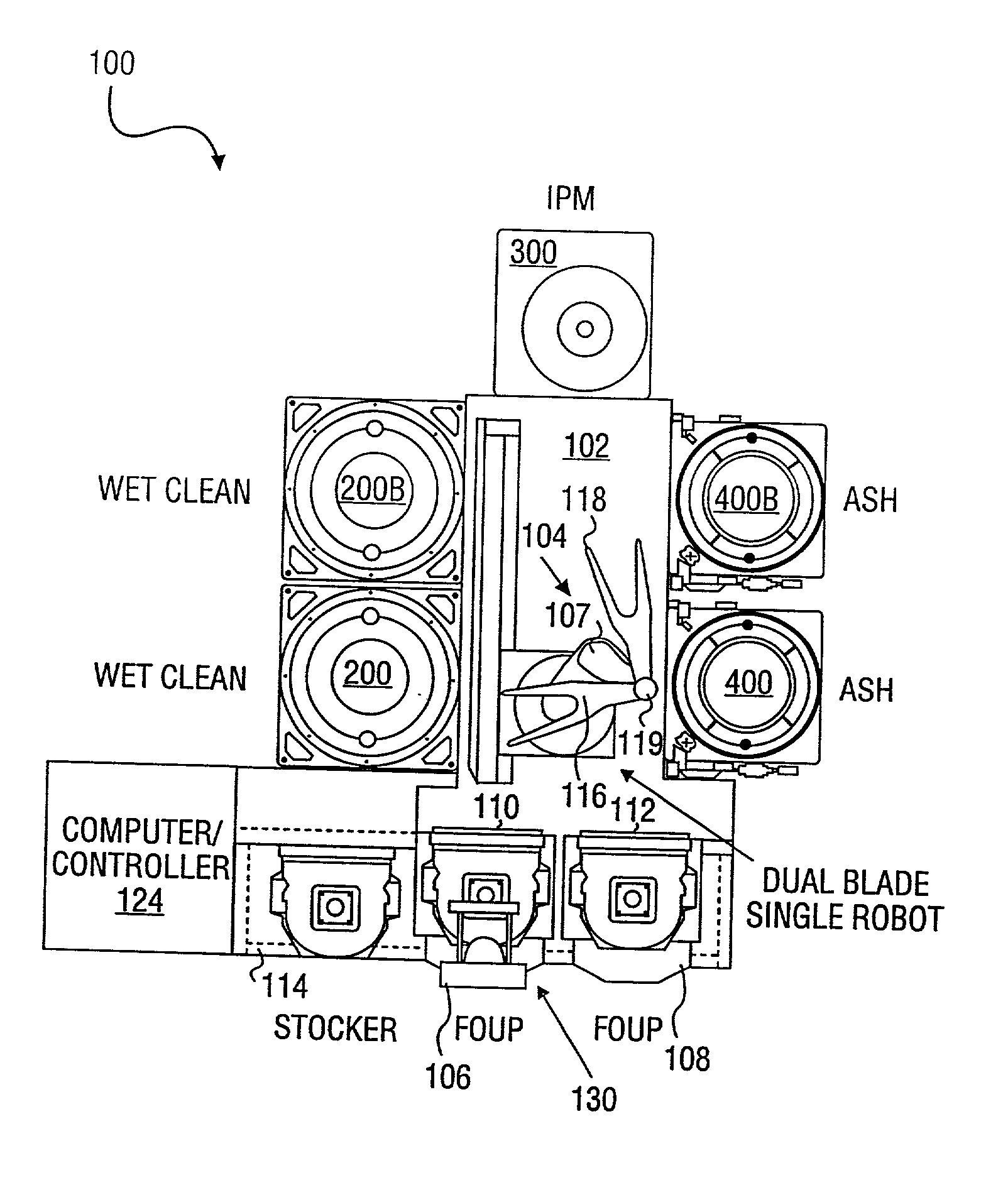

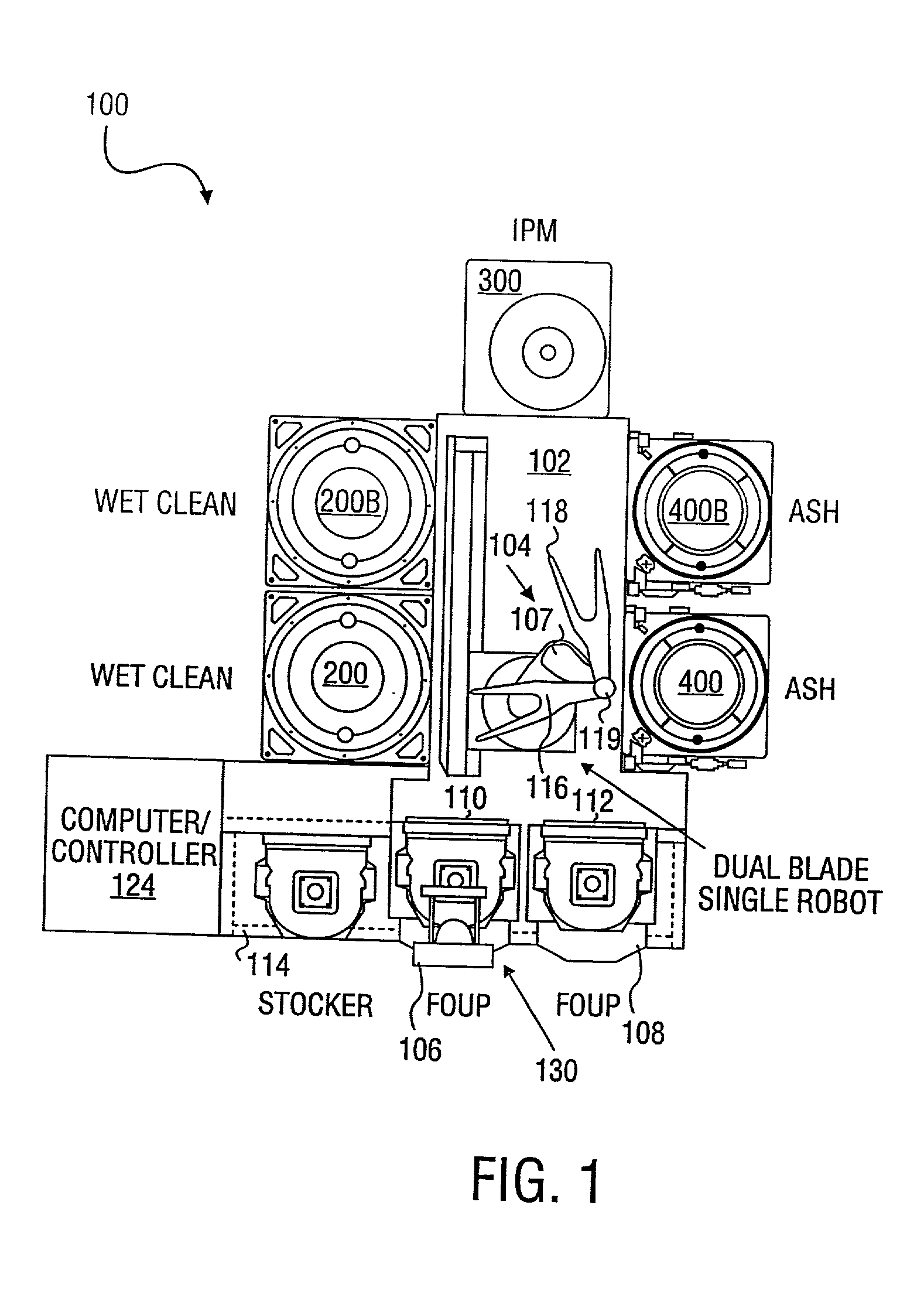

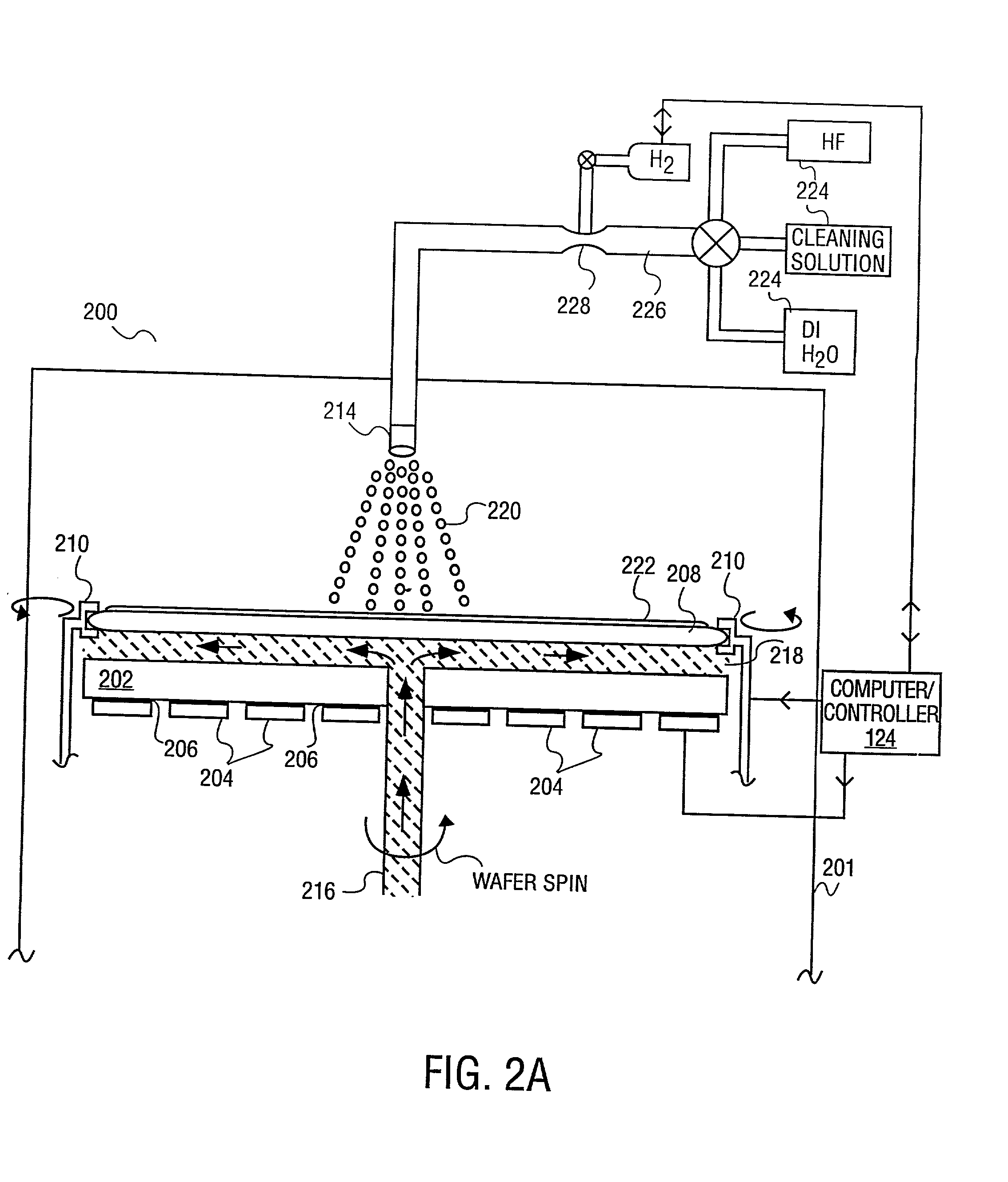

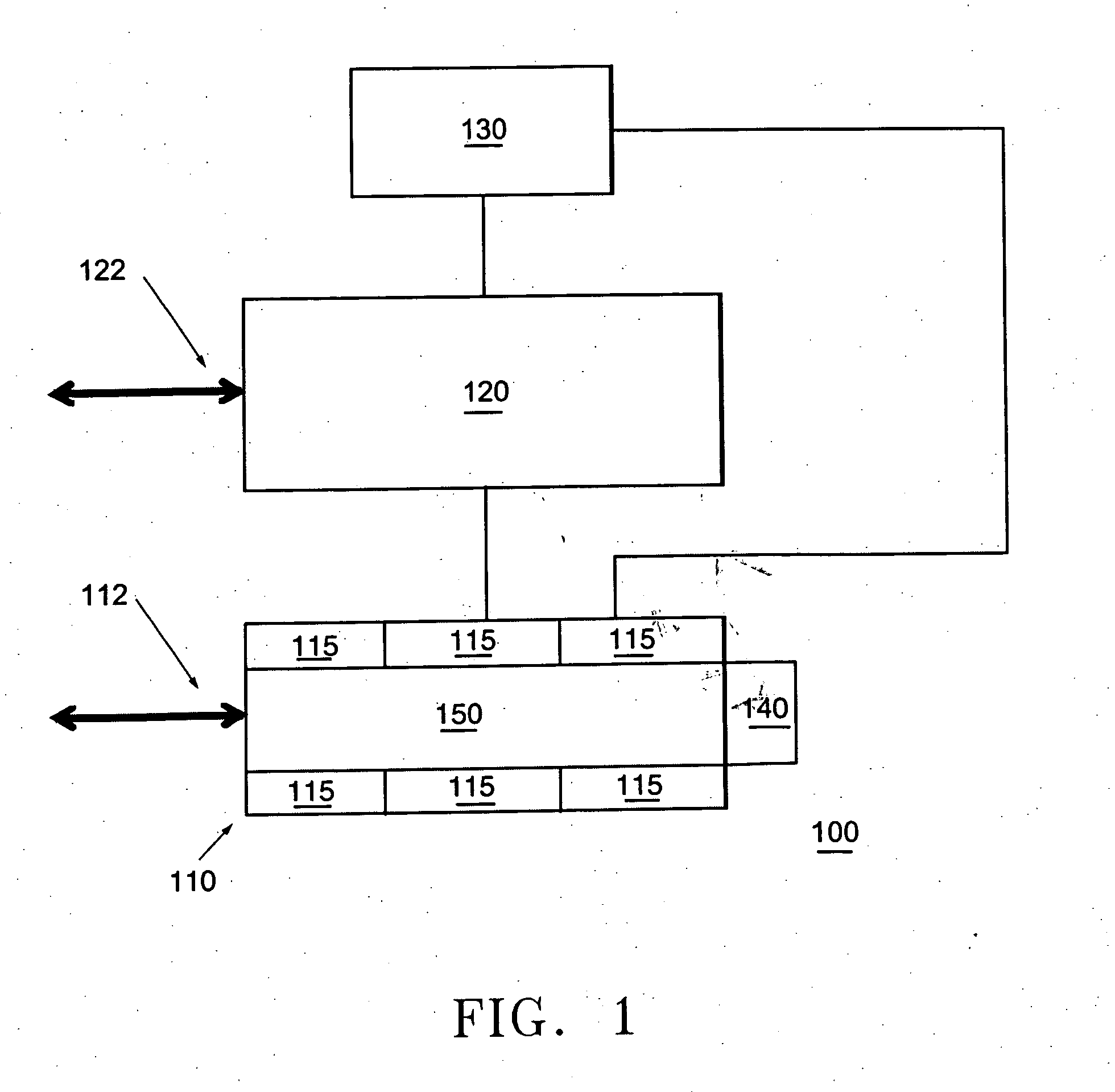

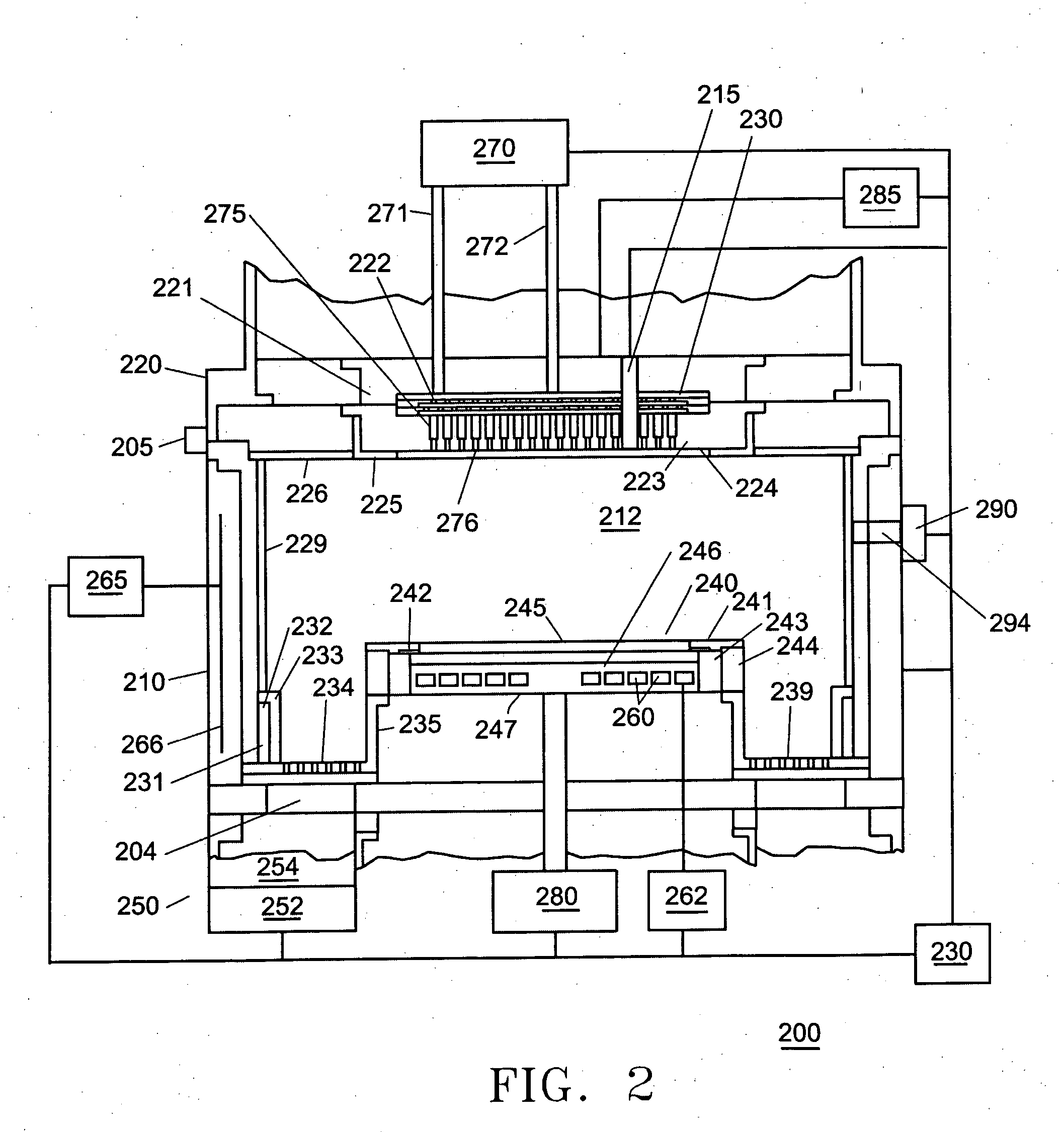

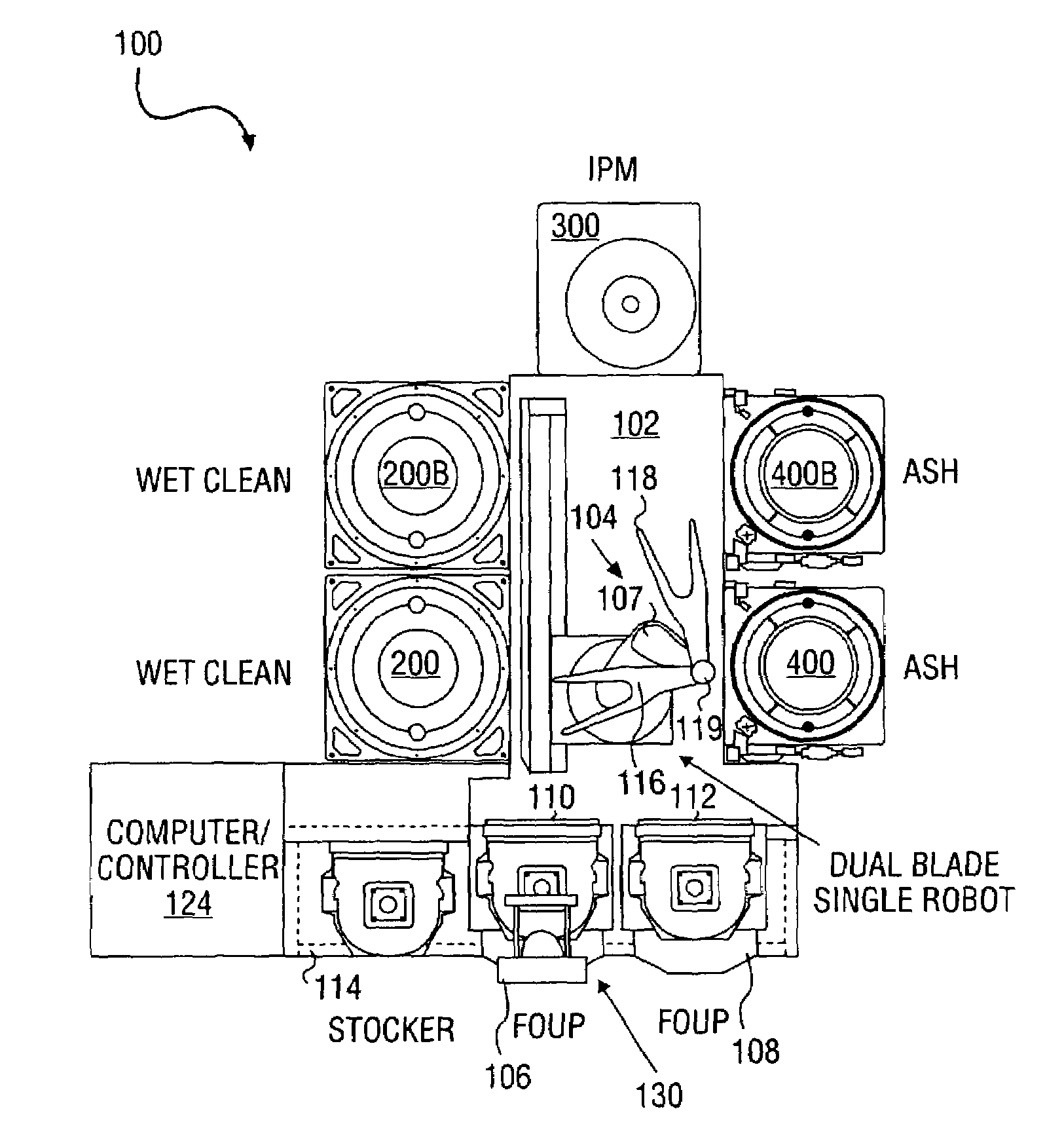

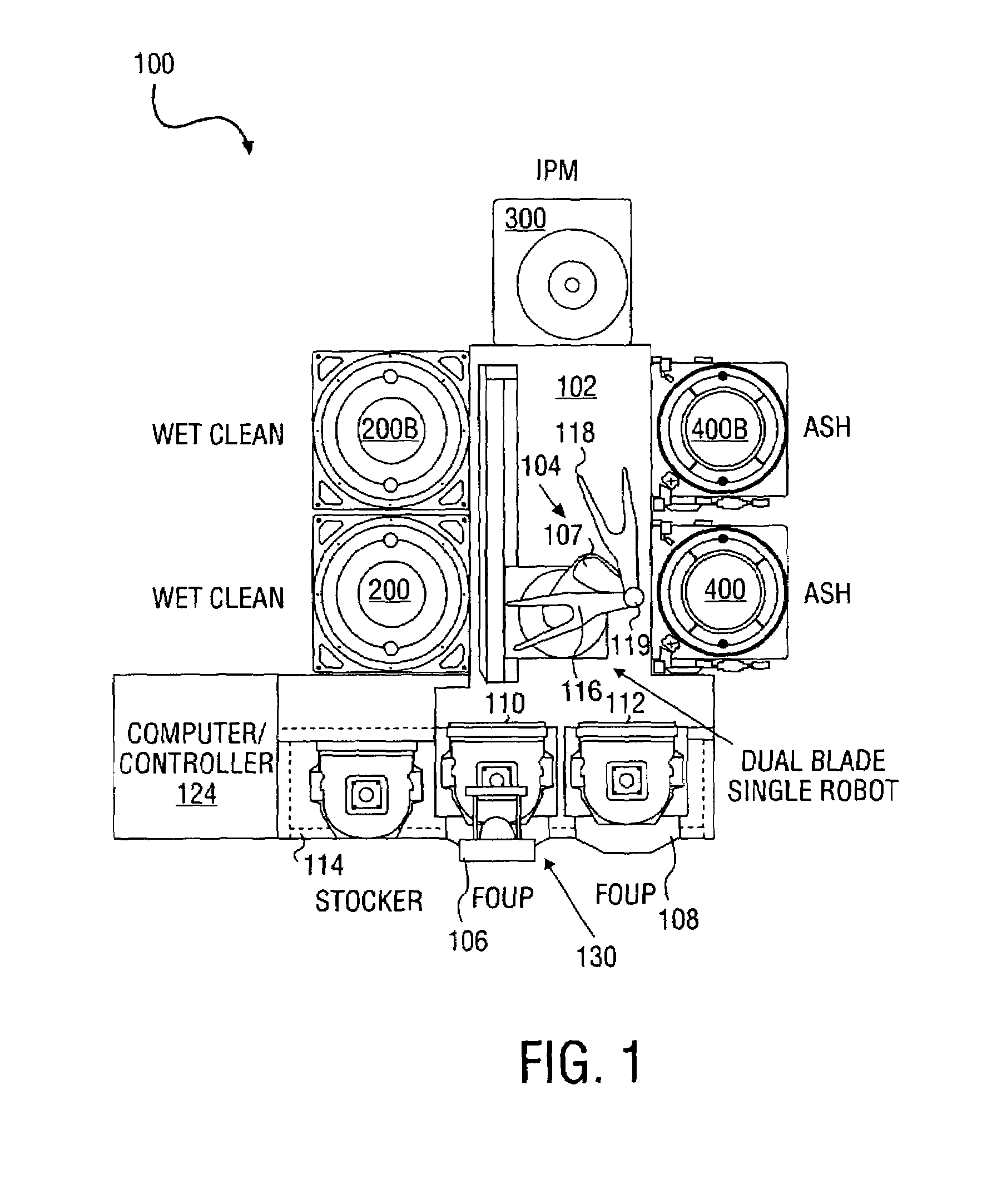

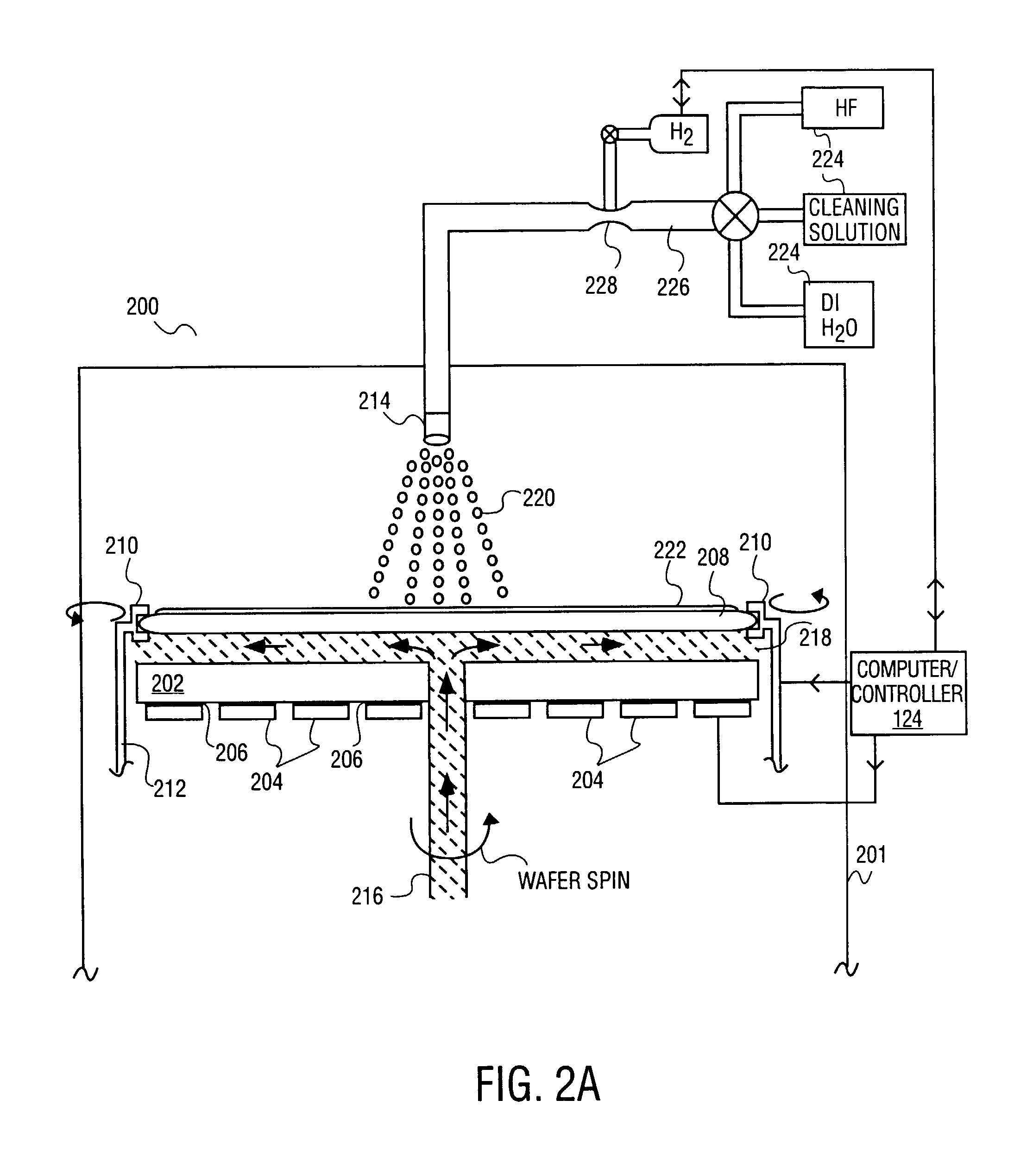

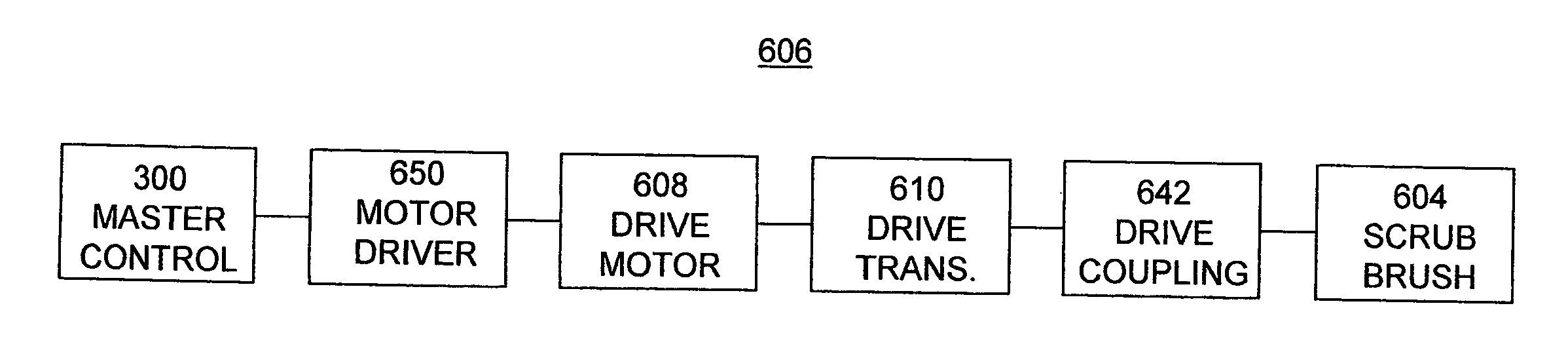

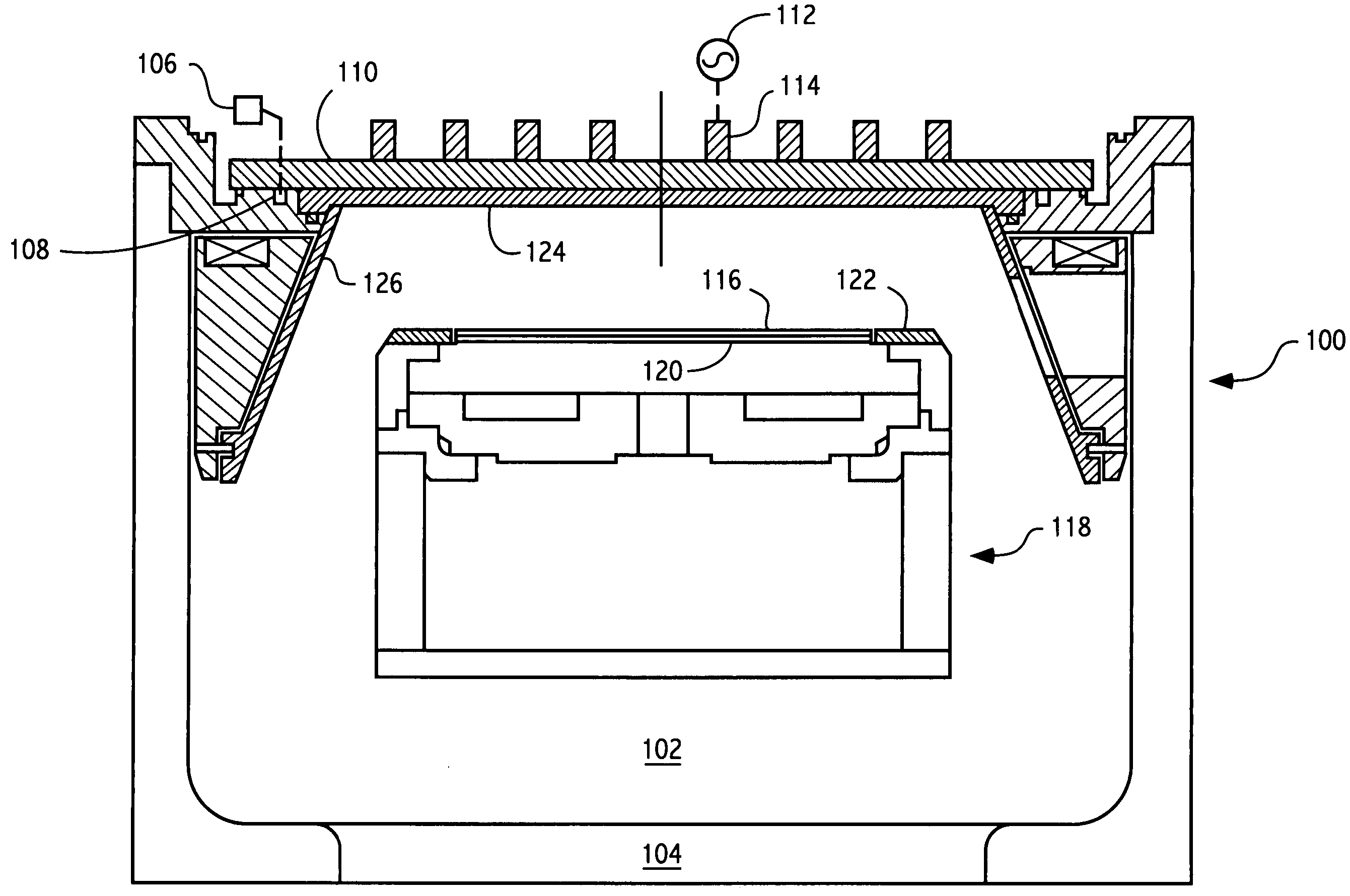

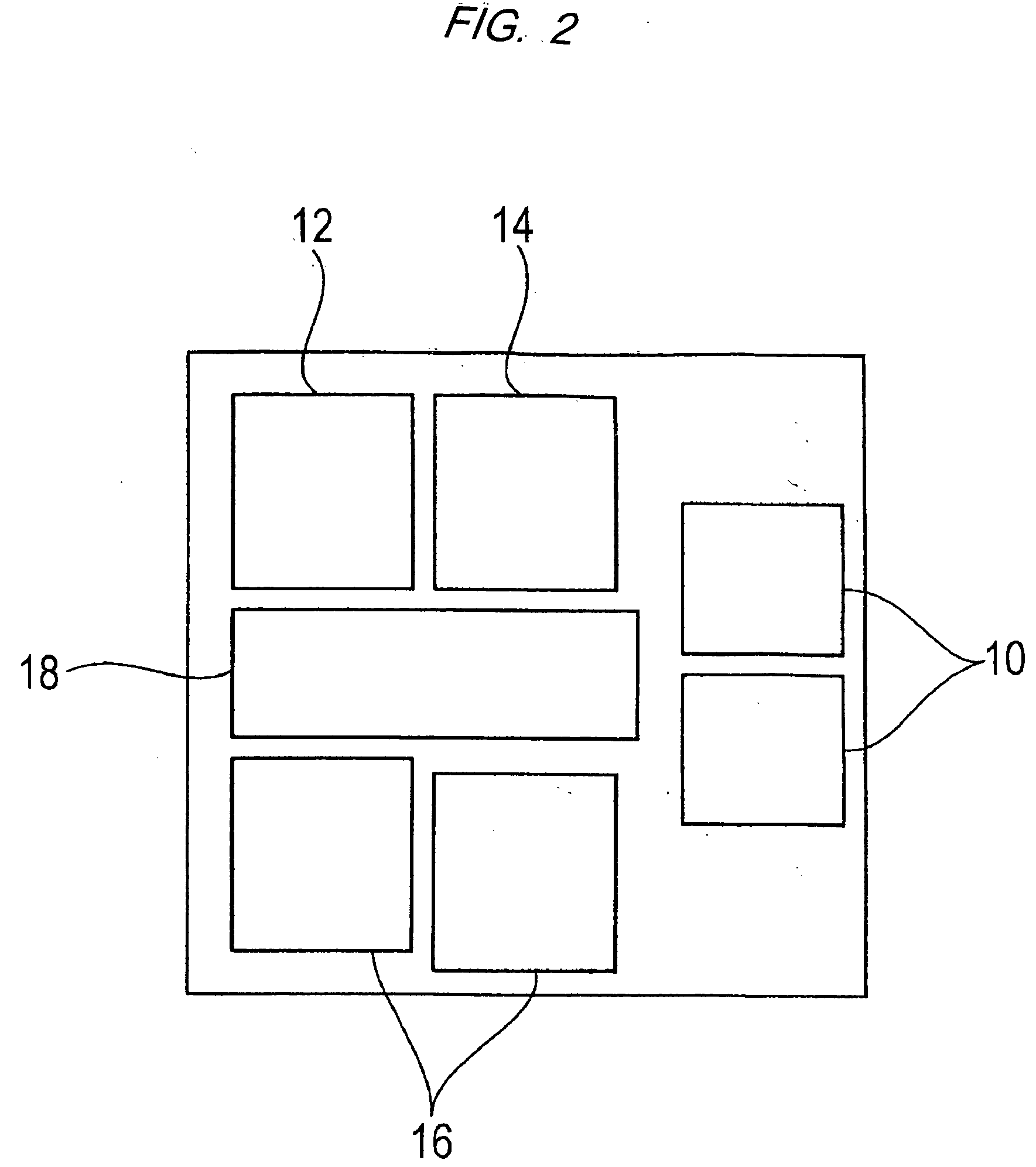

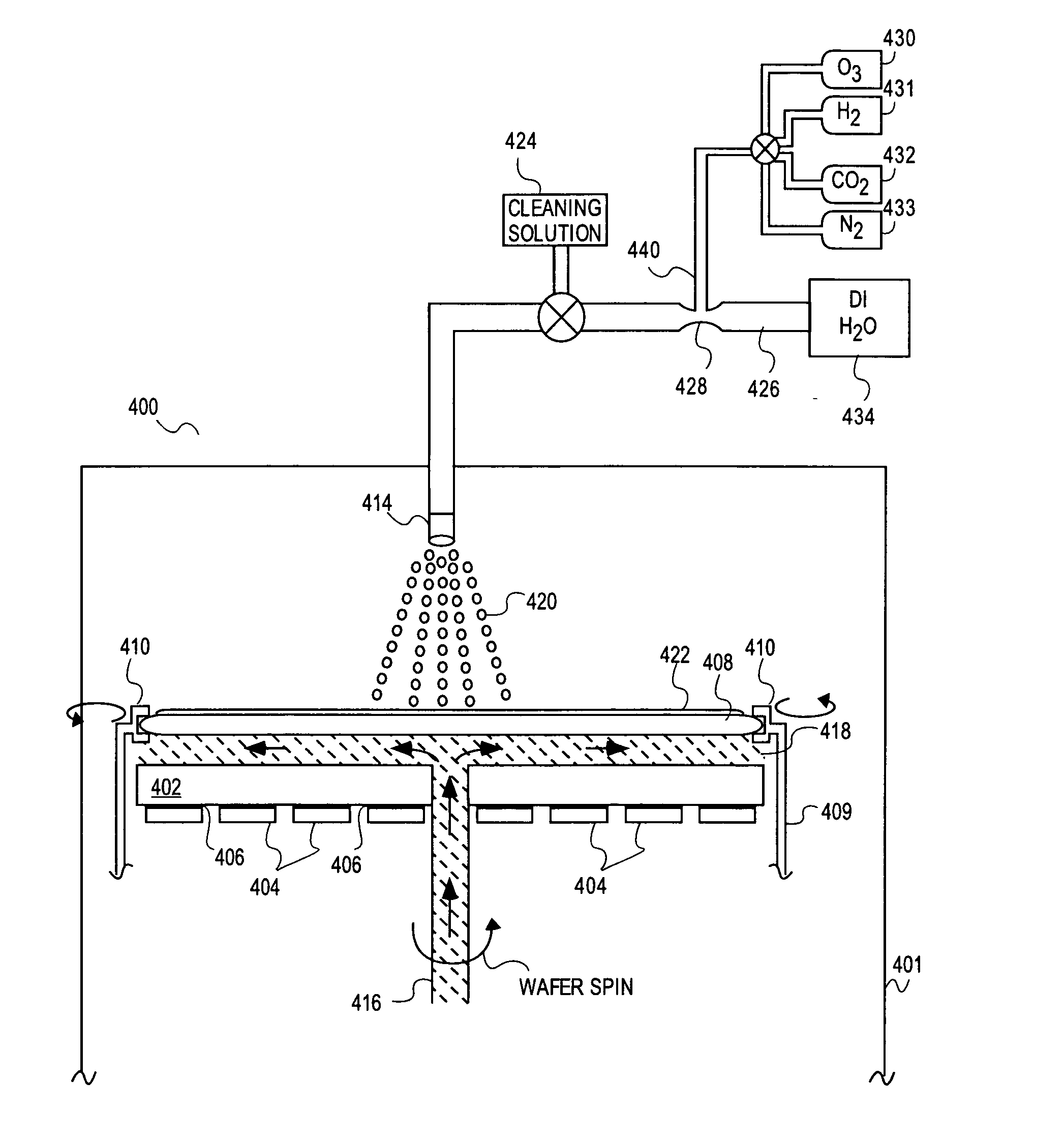

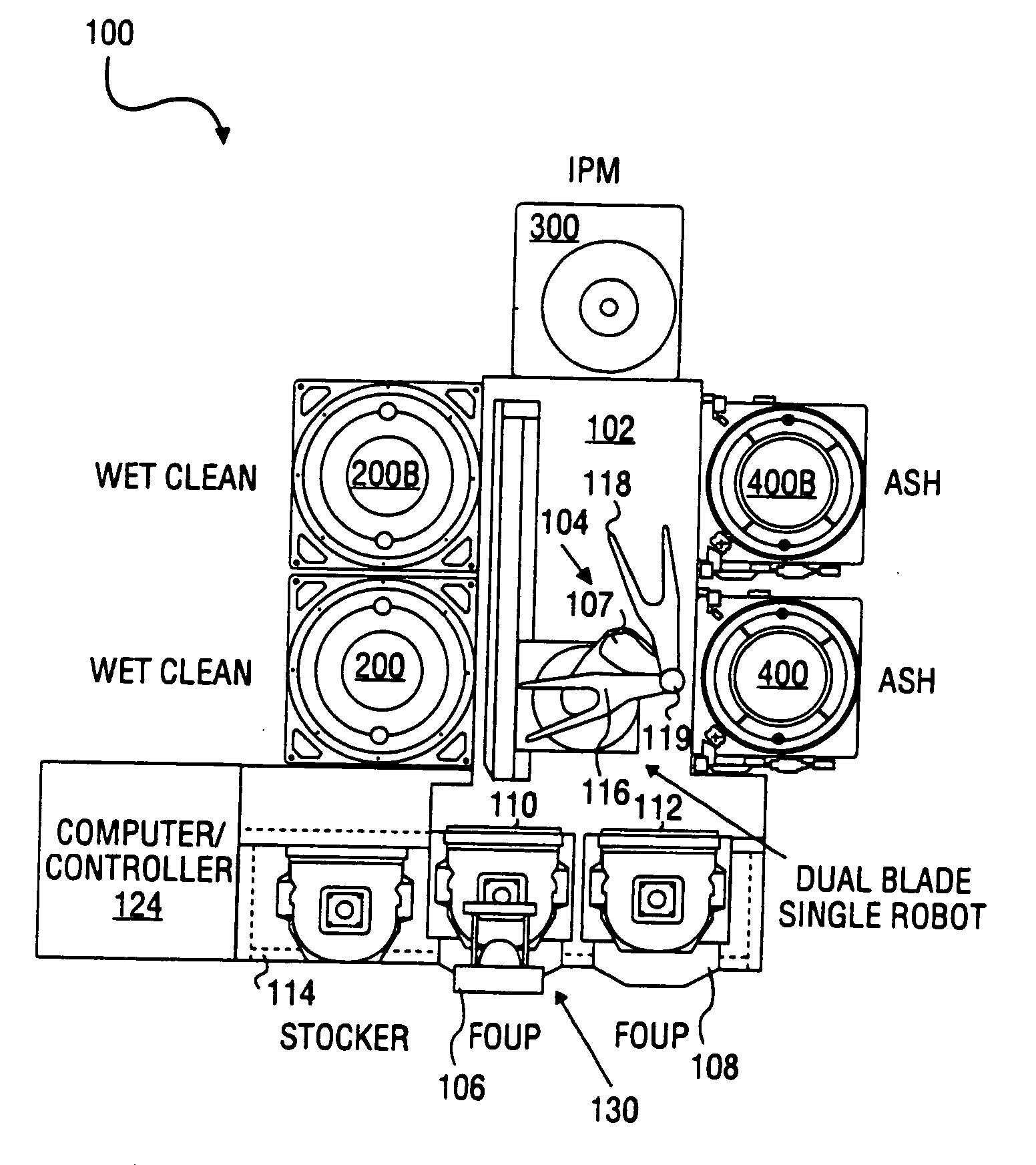

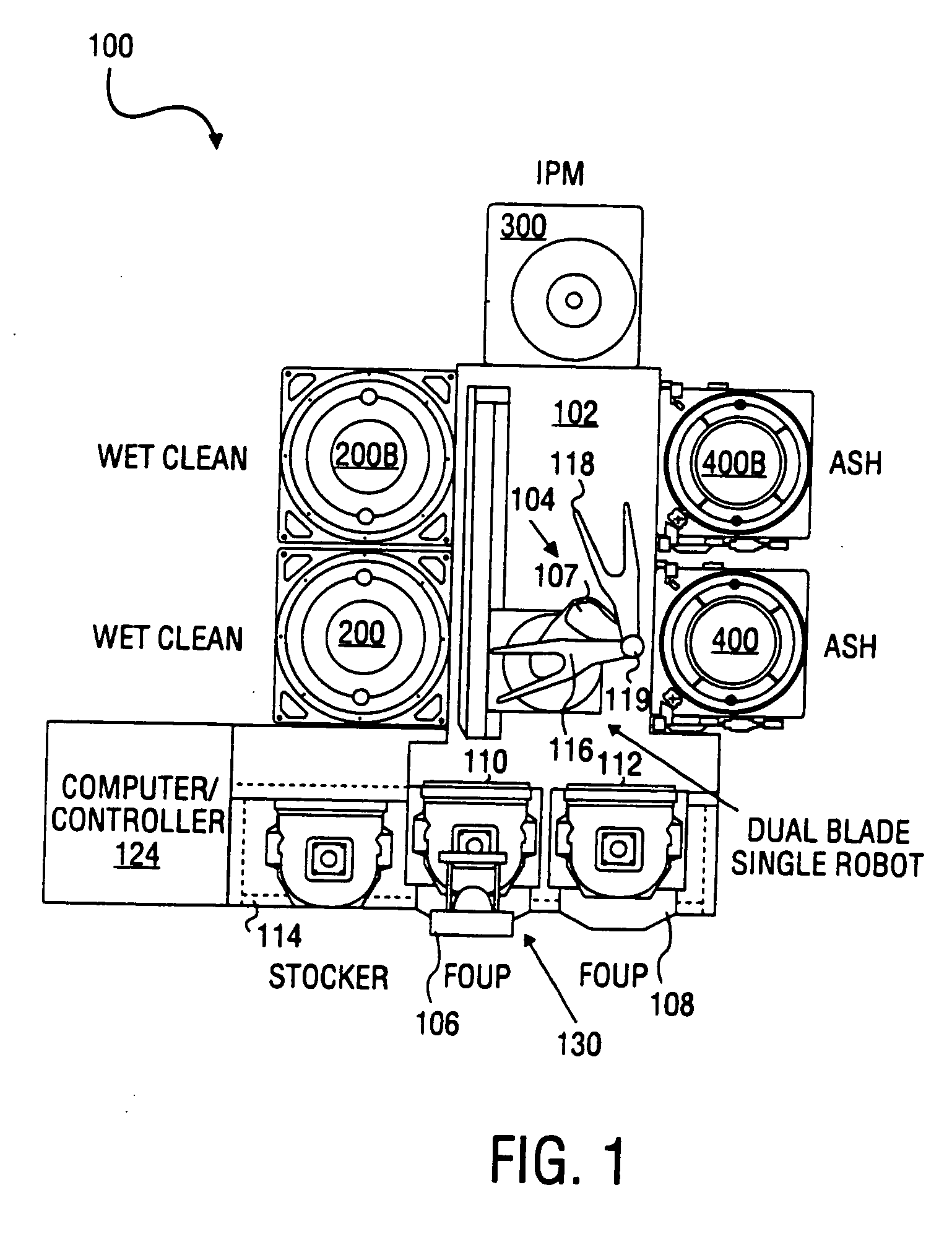

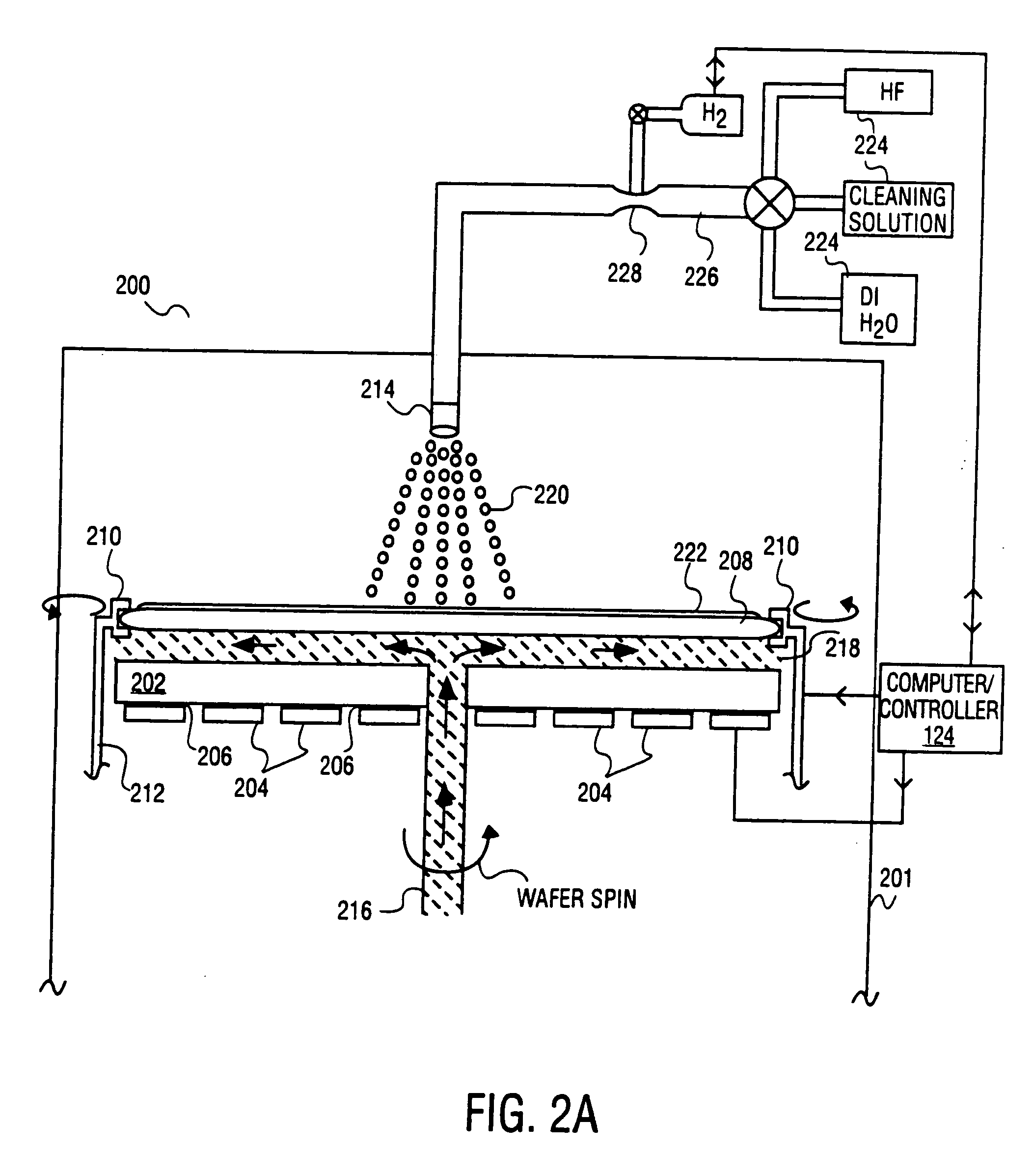

Method and apparatus for processing a wafer

InactiveUS20030045098A1Vacuum evaporation coatingPhotomechanical apparatusEngineeringMechanical engineering

A method of a single wafer wet / dry cleaning apparatus comprising: a transfer chamber having a wafer handler contained therein; a first single wafer wet cleaning chamber directly coupled to the transfer chamber; and a first single wafer ashing chamber directly coupled to the transfer chamber.

Owner:APPLIED MATERIALS INC

Electroless deposition process on a silicide contact

InactiveUS20060246217A1Material nanotechnologySemiconductor/solid-state device manufacturingSalicideElectroless deposition

Embodiments as described herein provide methods for depositing a material on a substrate during electroless deposition processes, as well as compositions of the electroless deposition solutions. In one embodiment, the substrate contains a contact aperture having an exposed silicon contact surface. In another embodiment, the substrate contains a contact aperture having an exposed silicide contact surface. The apertures are filled with a metal contact material by exposing the substrate to an electroless deposition process. The metal contact material may contain a cobalt material, a nickel material, or alloys thereof. Prior to filling the apertures, the substrate may be exposed to a variety of pretreatment processes, such as preclean processes and activations processes. A preclean process may remove organic residues, native oxides, and other contaminants during a wet clean process or a plasma etch process. Embodiments of the process also provide the deposition of additional layers, such as a capping layer.

Owner:APPLIED MATERIALS INC

Method for conditioning a process chamber

A method of conditioning a processing chamber for a production process includes performing a conditioning step at a conditioning process recipe substantially different than a process recipe of the production process, and performing a warm-up process at a warm-up process recipe substantially the same as the process recipe of the production process. The method can be performed after a wet-cleaning process has been performed. The conditioning procedure can allow the maintenance time to be decreased and can cause the etched features to be more accurate.

Owner:TOKYO ELECTRON LTD

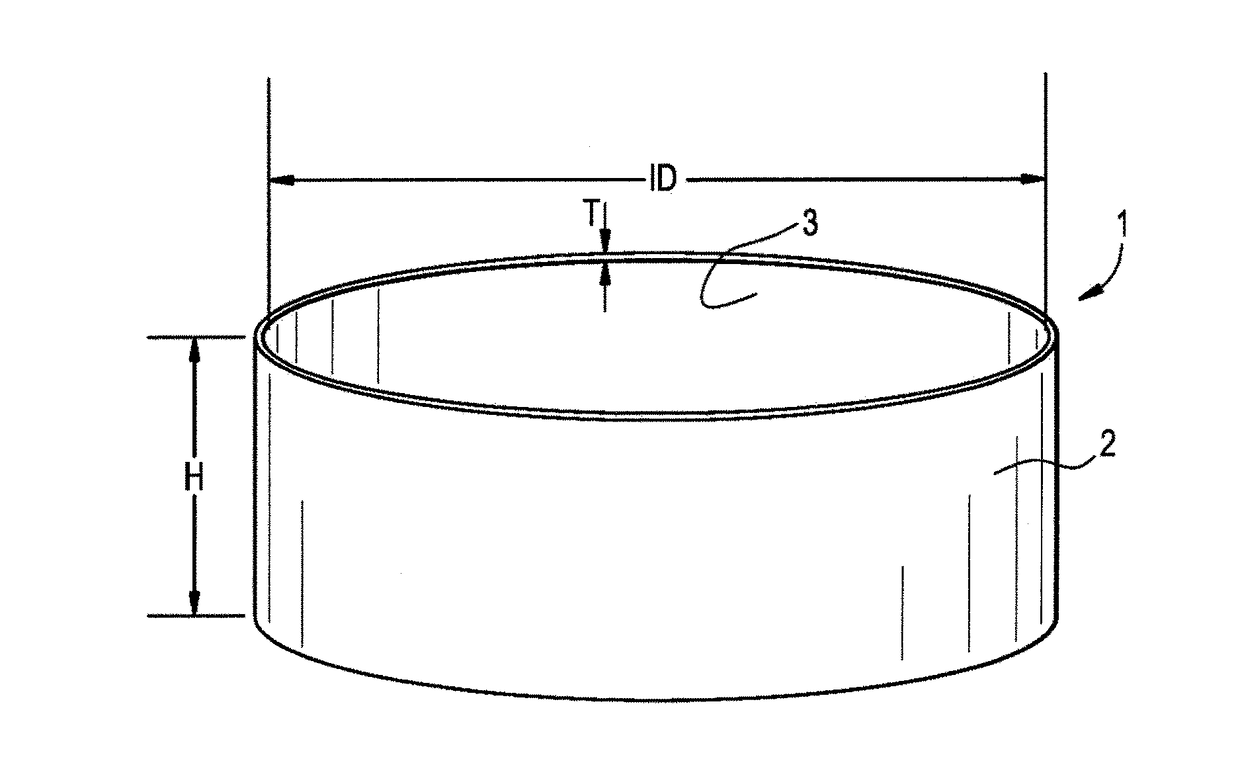

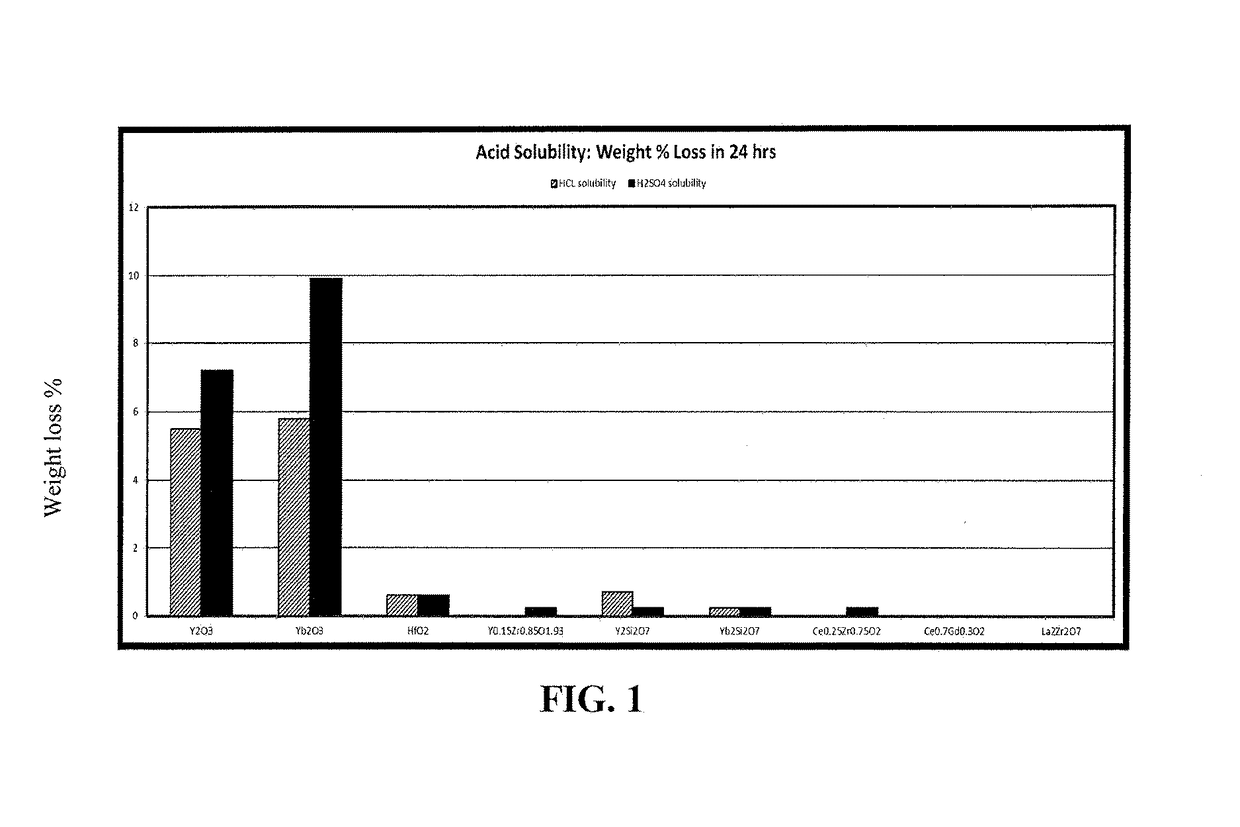

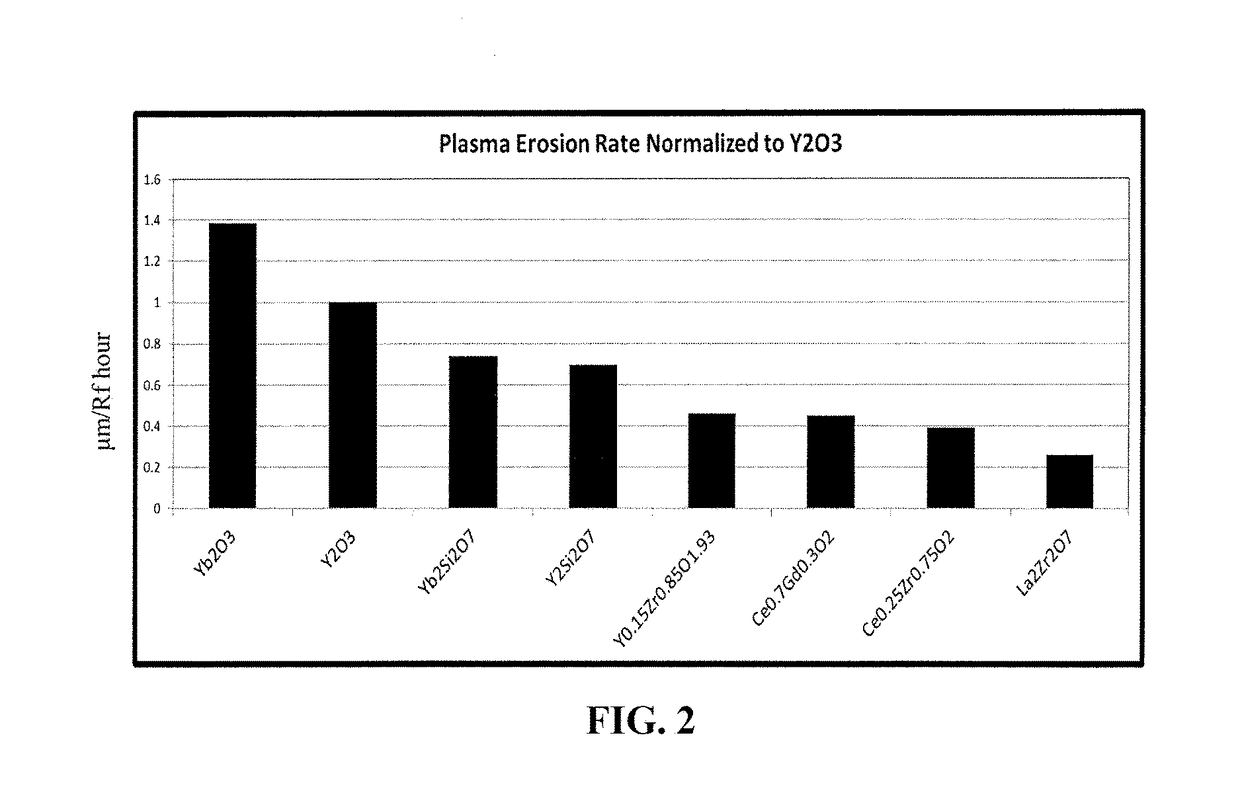

Coated semiconductor processing members having chlorine and fluorine plasma erosion resistance and complex oxide coatings therefor

ActiveUS20170301519A1High tensile bond strengthReduce pollutionMolten spray coatingElectric discharge tubesSolid solutionPlasma sprayed

A semiconductor processing member is provided, including a body and a plasma spray coating provided on the body. The coating is an ABO or ABCO complex oxide solid solution composition, where A, B and C are selected from the group consisting of La, Zr, Ce, Gd, Y, Yb and Si, and O is an oxide. The coating imparts both chlorine and fluorine plasma erosion resistance, reduces particle generation during plasma etching, and prevents spalling of the coating during wet cleaning of the semiconductor processing member.

Owner:FM INDS

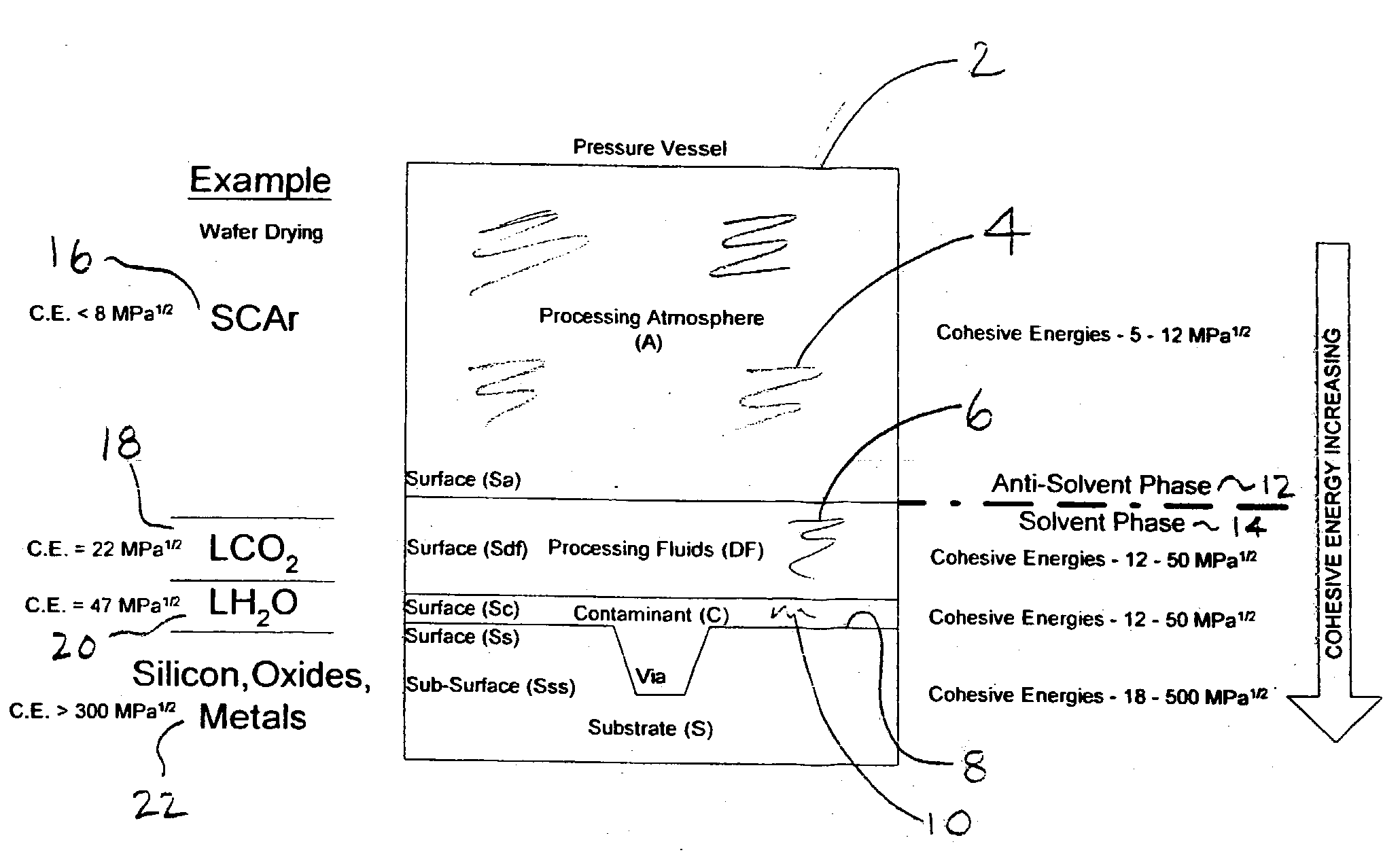

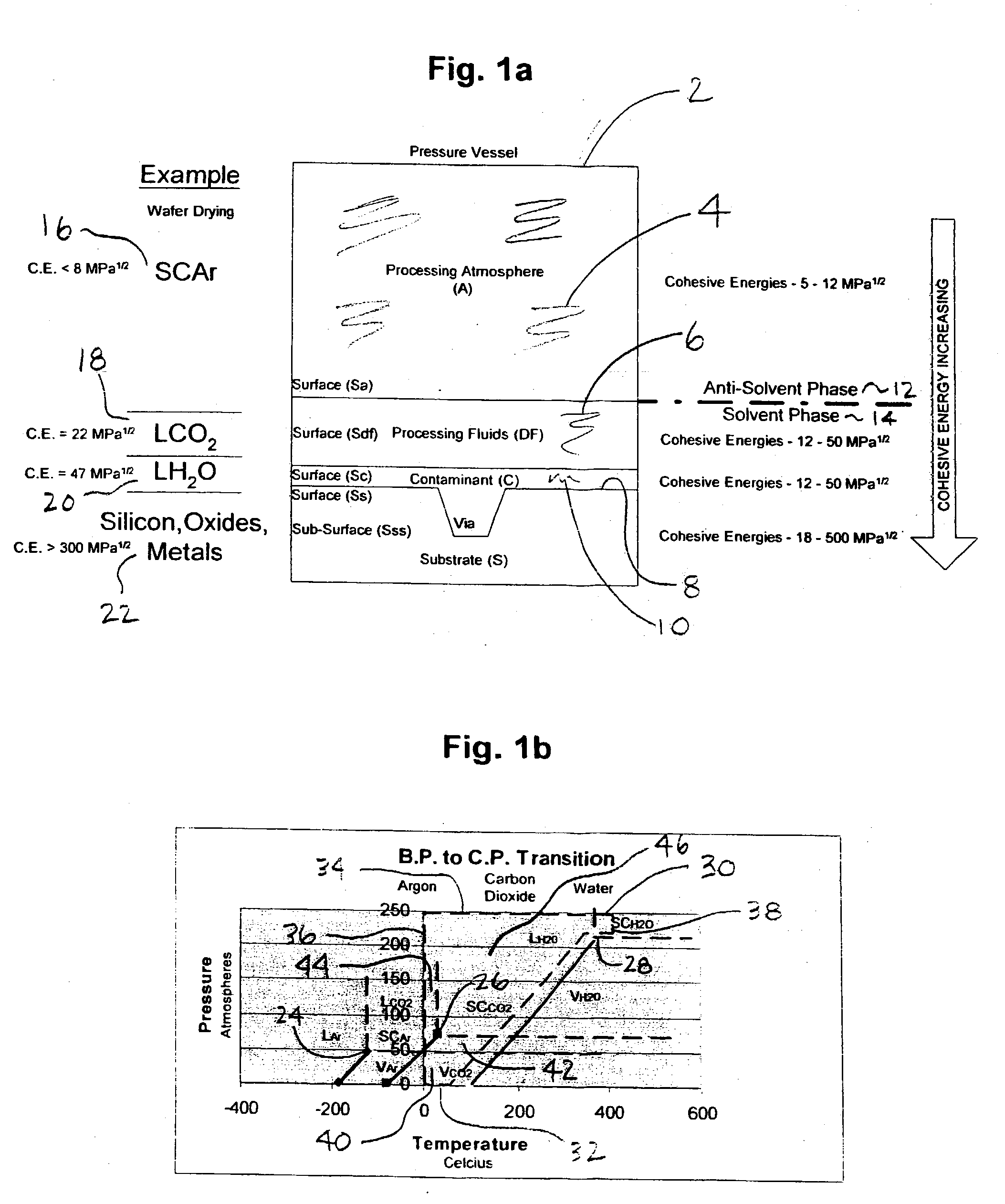

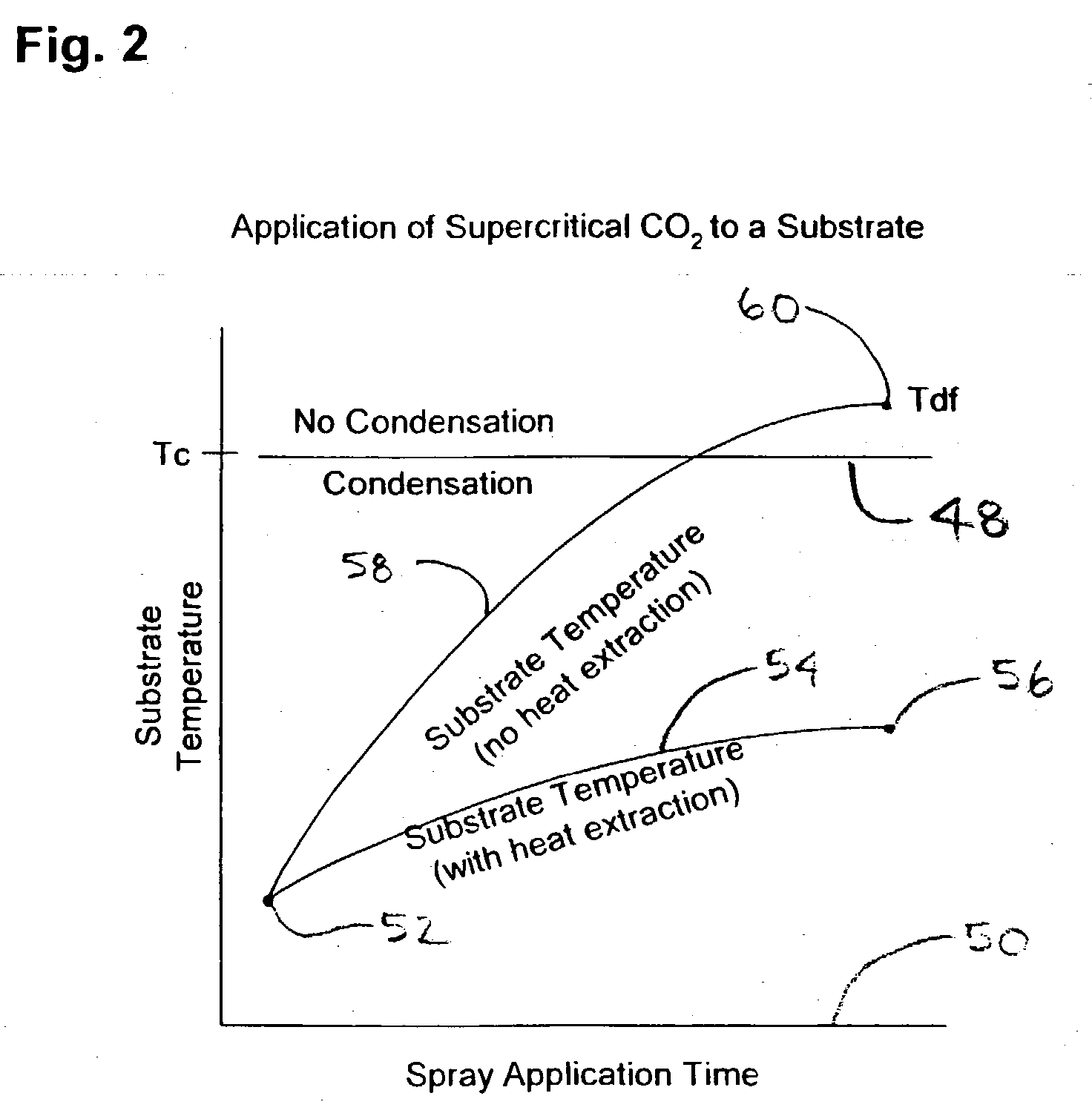

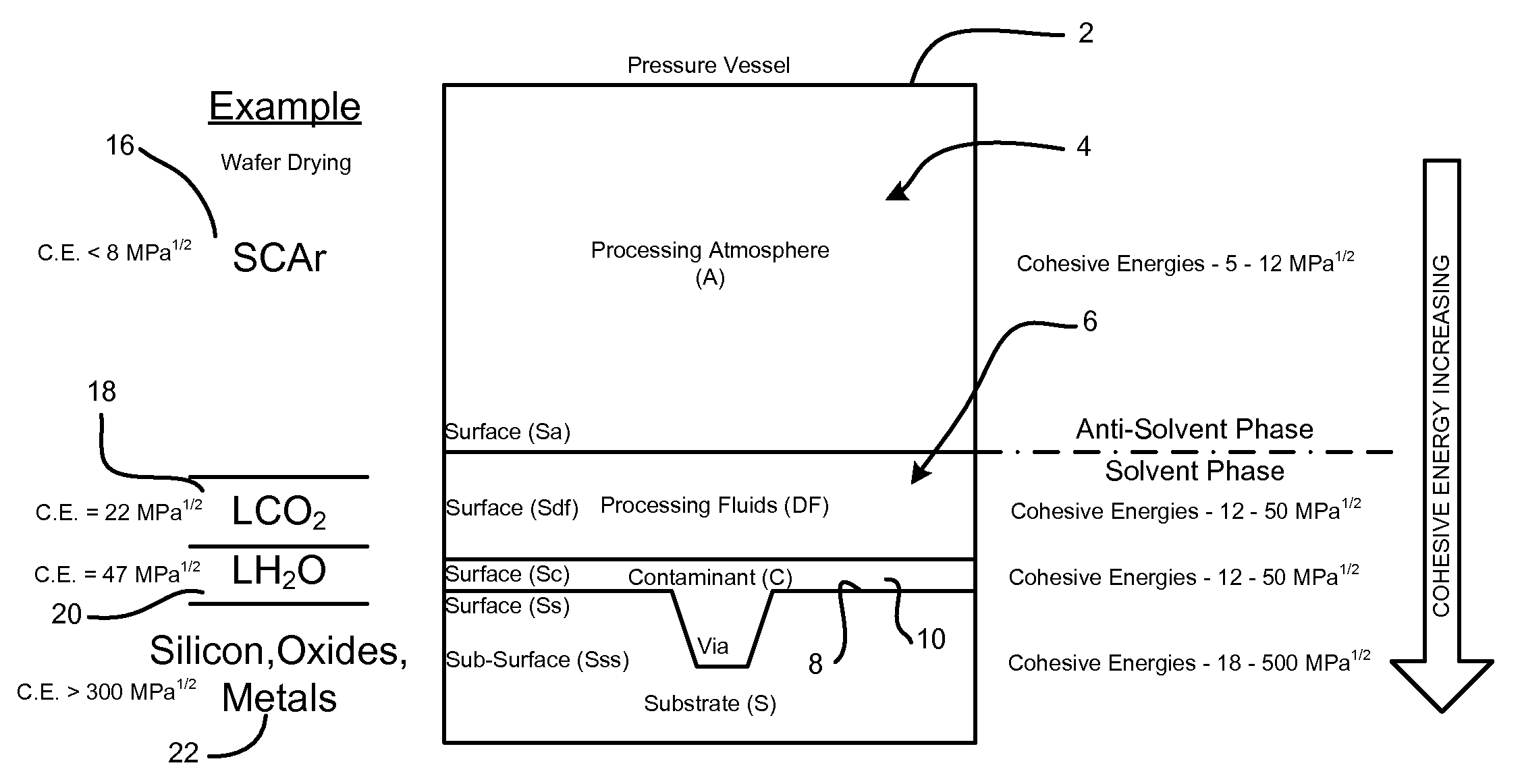

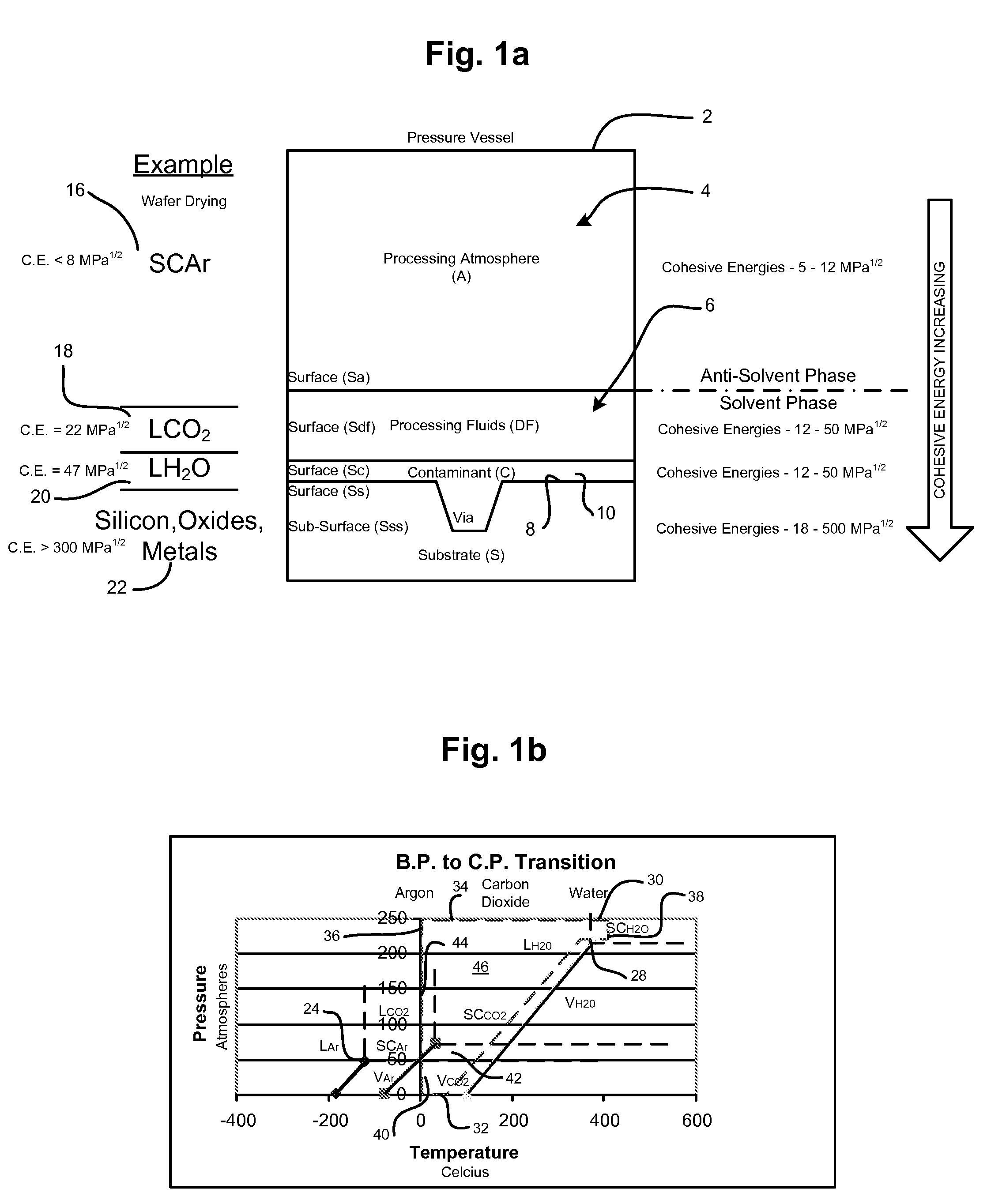

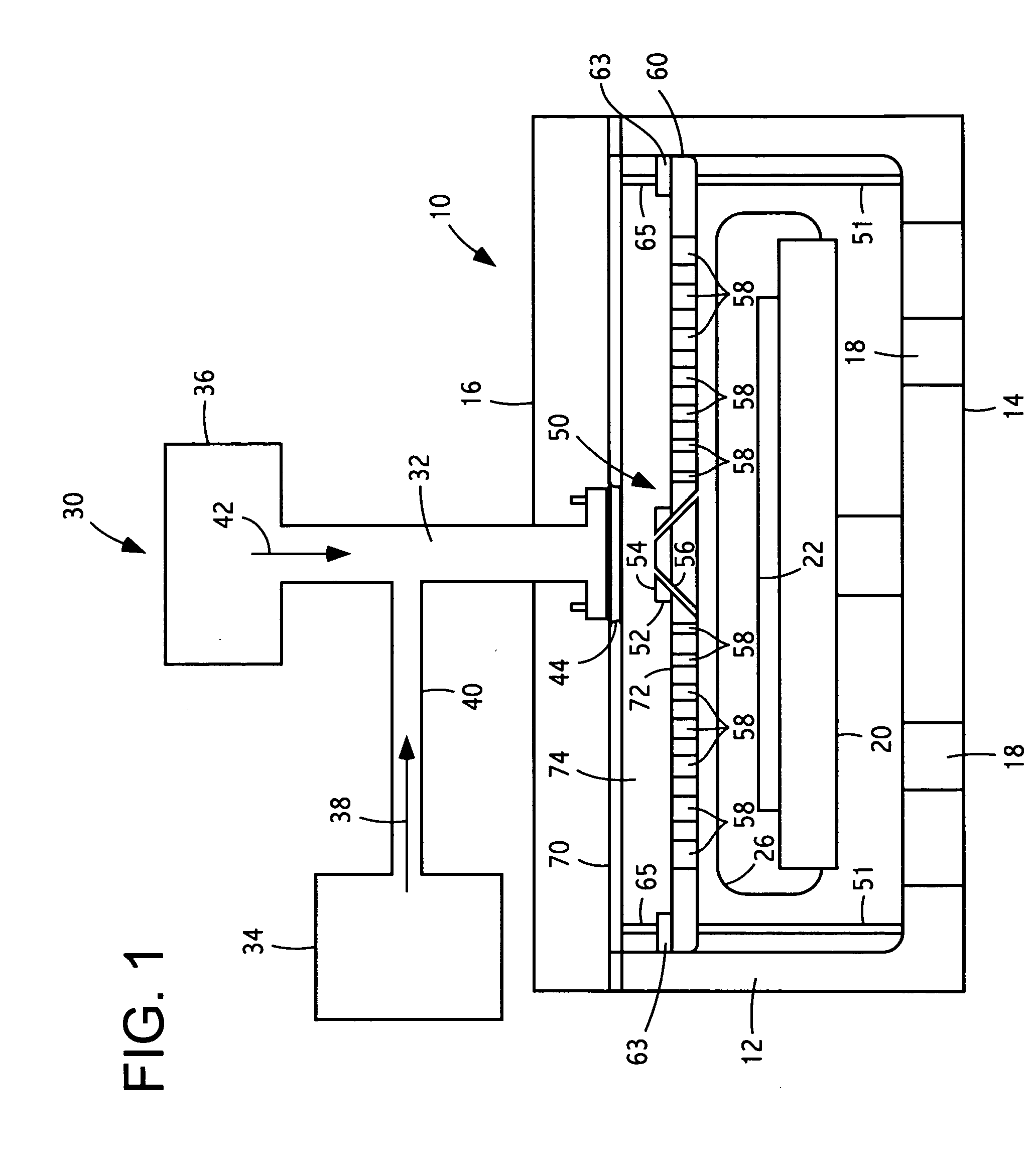

Precision surface treatments using dense fluids and a plasma

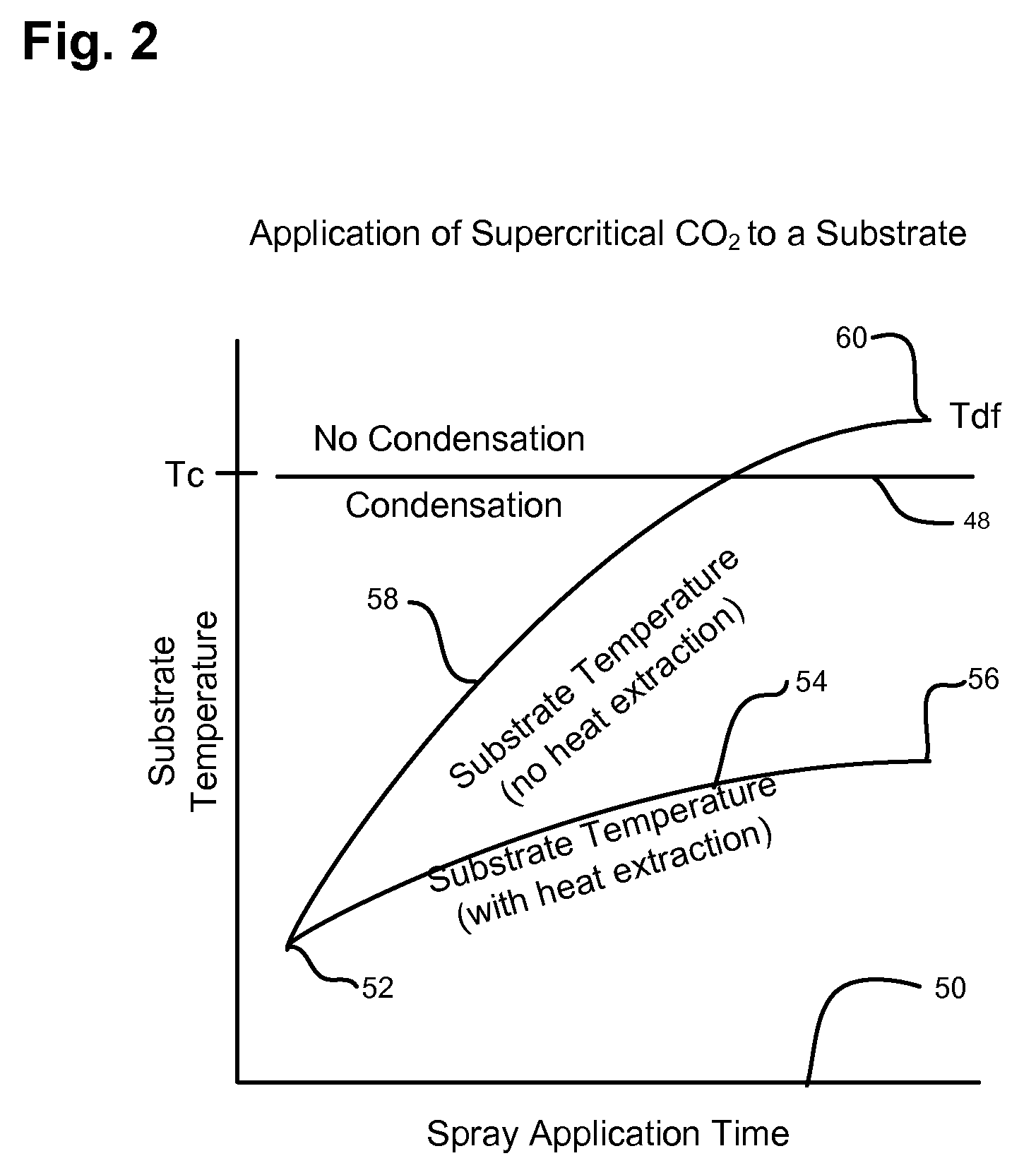

InactiveUS20040003828A1Reduce the temperatureEasy to separateElectric discharge tubesElectrostatic cleaningSolventSolid phases

The present invention is a method, process and apparatus for selective cleaning, drying, and modifying substrate surfaces and depositing thin films thereon using a dense phase gas solvent and admixtures within a first created supercritical fluid antisolvent. Dense fluids are used in combination with sub-atmospheric, atmospheric and super-atmospheric plasma adjuncts (cold and thermal plasmas) to enhance substrate surface cleaning, modification, precision drying and deposition processes herein. Moreover, conventional wet cleaning agents such as hydrofluoric acid and ammonium fluoride may be used with the present invention to perform substrate pre-treatments prior to precision drying and cleaning treatments described herein. Finally, dense fluid such as solid phase carbon dioxide and argon may be used as a follow-on treatment or in combination with plasmas to further treat a substrate surface.

Owner:JACKSON DAVID P

Method and apparatus for processing a wafer

InactiveUS7159599B2Semiconductor/solid-state device manufacturingCleaning using liquidsDirect couplingEngineering

A method of a single wafer wet / dry cleaning apparatus comprising:a transfer chamber having a wafer handler contained therein;a first single wafer wet cleaning chamber directly coupled to the transfer chamber; anda first single wafer ashing chamber directly coupled to the transfer chamber.

Owner:APPLIED MATERIALS INC

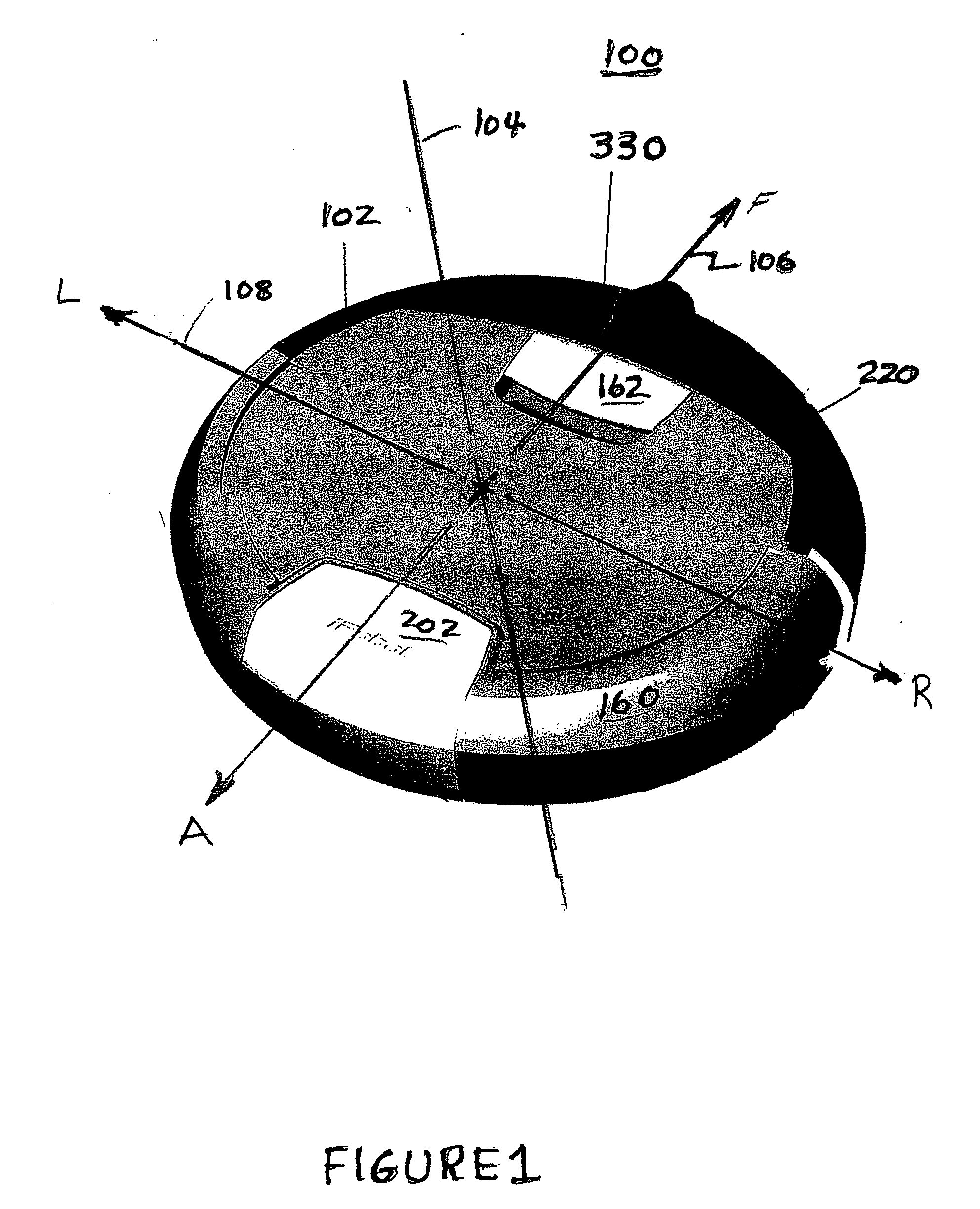

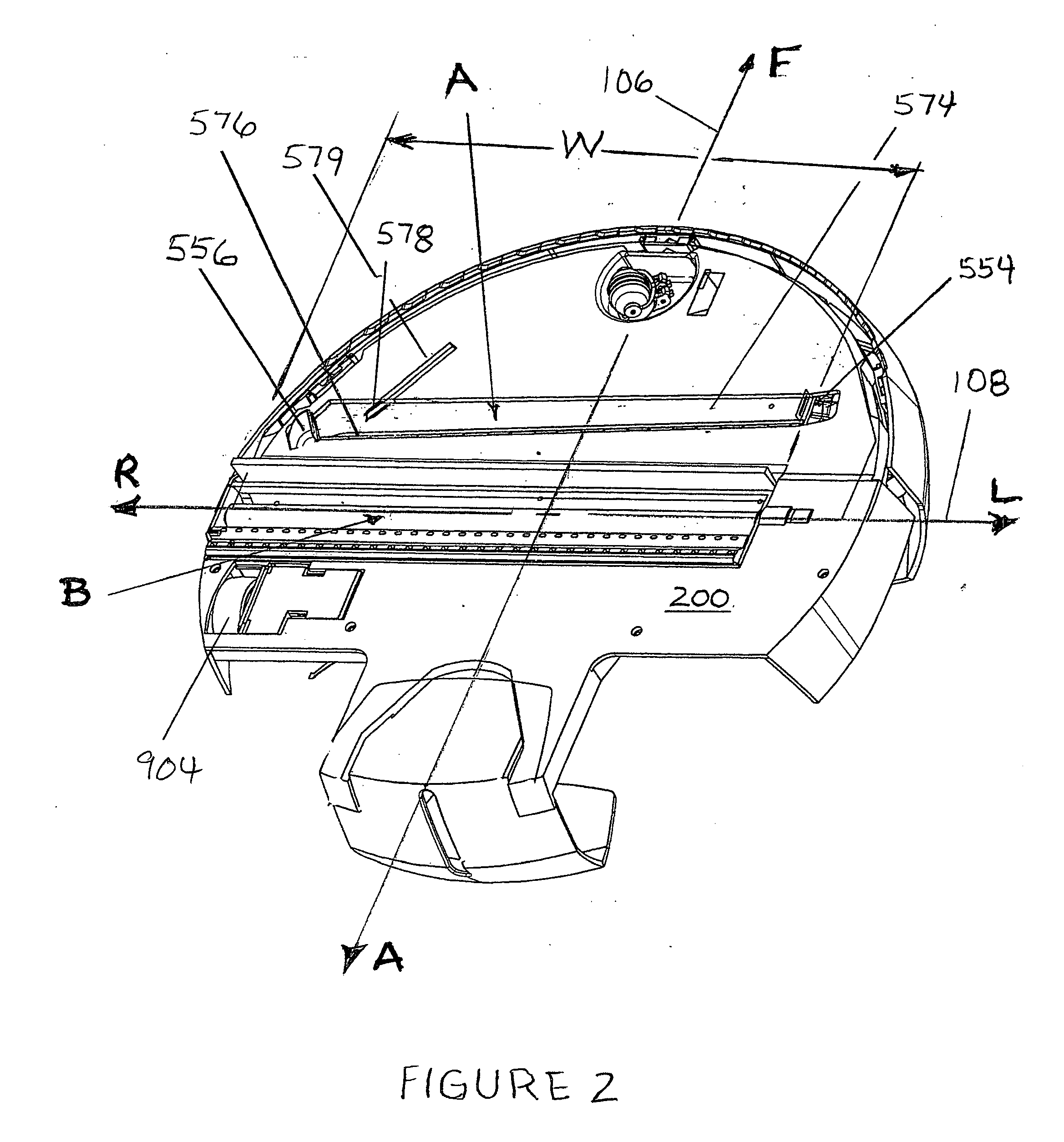

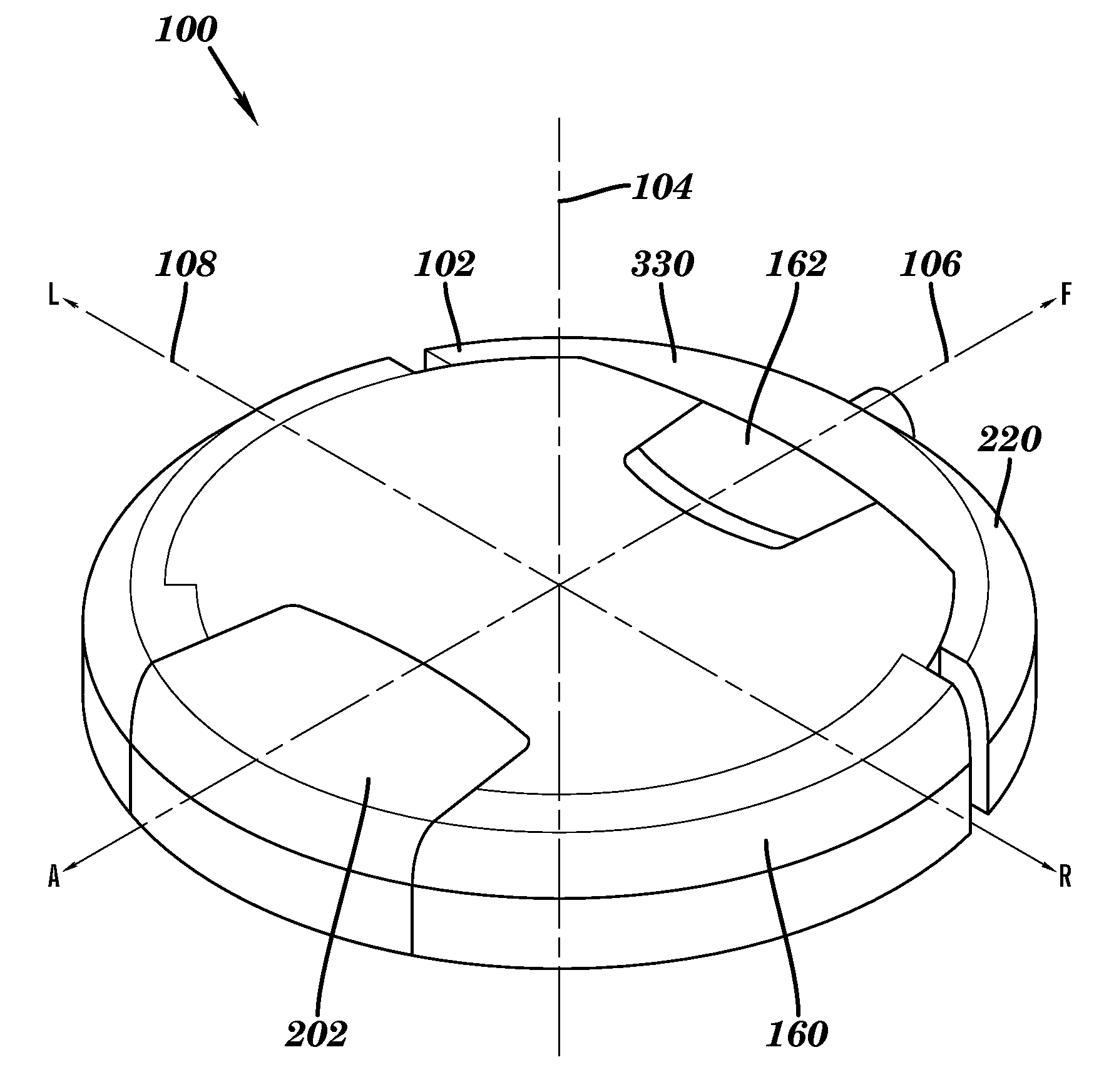

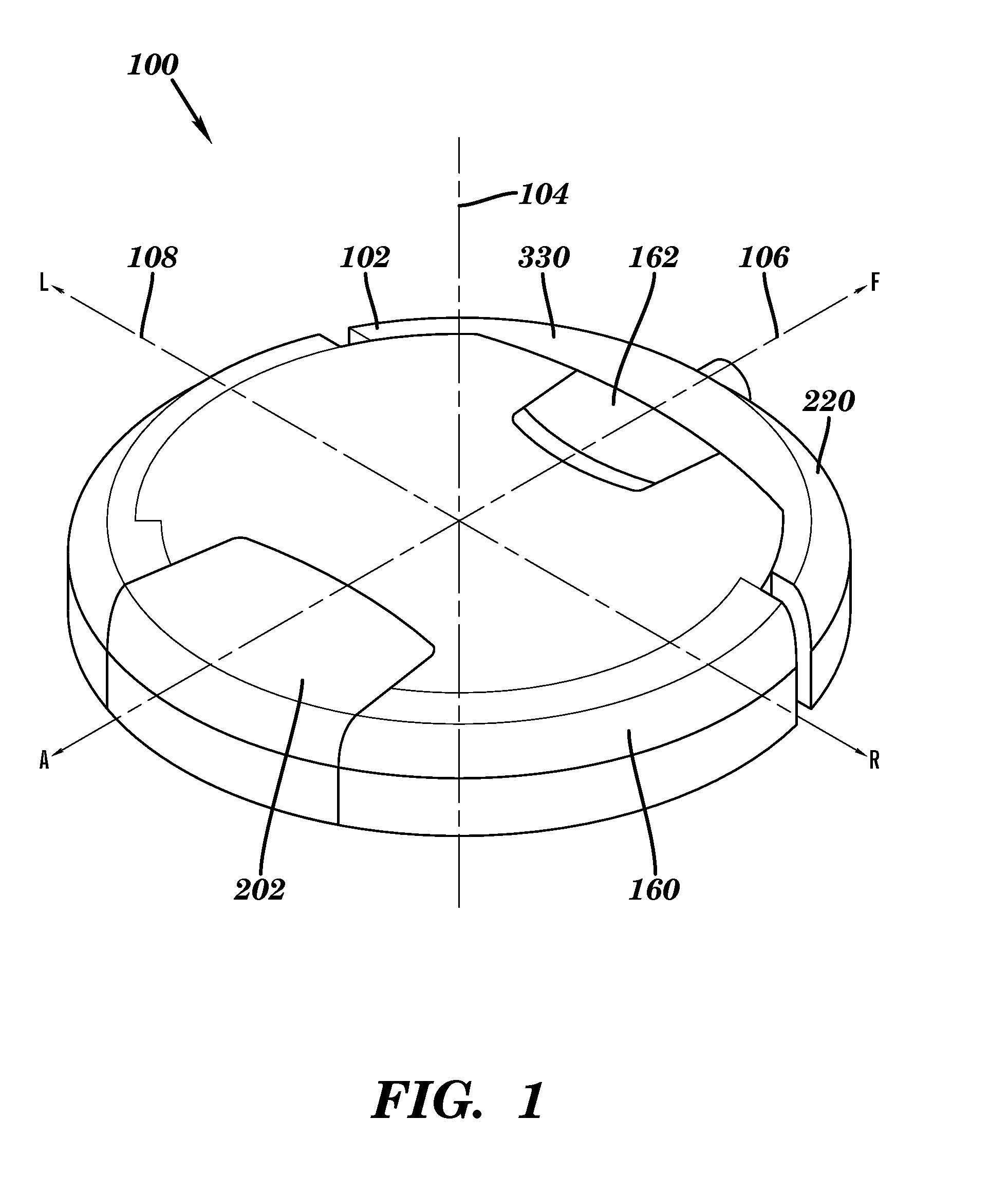

Autonomous surface cleaning robot for wet cleaning

InactiveUS20060184293A1Low costAffordable for home useCarpet cleanersFloor cleanersLiquid wasteSurface cleaning

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries cleaning elements arranged to spray a liquid cleaning fluid onto the cleaning surface across a cleaning width. The cleaning fluid mixes with contaminated on the floor, which become emulsified or otherwise mixed with the cleaning fluid. The robot further include cleaning elements configured to suction up waste materials and particularly the liquid waste material generated by the mixing of the cleaning fluid and contaminates.

Owner:IROBOT CORP

Method and apparatus for treating a substrate with dense fluid and plasma

ActiveUS20060278254A1High densityDivergent cohesion energyElectric discharge tubesElectric arc lampsSolid phasesWet cleaning

The present invention is a method, process and apparatus for selective cleaning, drying, and modifying substrate surfaces and depositing thin films thereon using a dense phase gas solvent and admixtures within a first created supercritical fluid anti-solvent. Dense fluids are used in combination with sub-atmospheric, atmospheric and super-atmospheric plasma adjuncts (cold and thermal plasmas) to enhance substrate surface cleaning, modification, precision drying and deposition processes herein. Moreover, conventional wet cleaning agents such as hydrofluoric acid and ammonium fluoride may be used with the present invention to perform substrate pre-treatments prior to precision drying and cleaning treatments described herein. Finally, dense fluid such as solid phase carbon dioxide and argon may be used as a follow-on treatment or in combination with plasmas to further treat a substrate surface.

Owner:HITACHI HIGH-TECH CORP

Methods for wet cleaning quartz surfaces of components for plasma processing chambers

InactiveUS20050274396A1Electric discharge tubesDecorative surface effectsOrganic solventSemiconductor

Methods for wet cleaning quartz surfaces of components for plasma processing chambers in which semiconductor substrates are processed, such as etch chambers and resist stripping chambers, include contacting the quartz surface with at least one organic solvent, a basic solution and different acid solutions, so as to remove organic and metallic contaminants from the quartz surface. The quartz surface is preferably contacted with one of the acid solutions at least two times.

Owner:LAM RES CORP

Cleaning method

InactiveUS6348157B1Strong resistanceSuppress formationSemiconductor/solid-state device manufacturingElectrostatic cleaningCleaning methodsChemical cleaning

A cleaning method capable of processing at room temperatures without conducting heating, uses little chemicals and water, and does not require special devices or materials. The chemical cleaning processes and rinse processes employ pure water or ultrapure water in a semiconductor wet cleaning process, rinse water or chemicals which suppresses formation of surface oxide films, removes particles and prevent their redeposition, and aids in the hydrogen termination of the silicon atoms. The cleaning method of the resent invention includes cleaning which is conducted using pure water containing ozone, cleaning conducted using a cleaning liquid containing HF, H2O, and surfactant, while applying vibration having a frequency of 500 kHz or more, cleaning conducted using pure water containing ozone, cleaning conducted using a cleaning liquid containing HF and H2O in order to remove oxide films, and cleaning which is conducted using pure water. After cleaning a material to be cleaned using chemicals, rinsing is conducted using pure water or ultrapure water containing hydrogen gas in an amount of 0.5 ppm or more and containing oxygen gas in an amount of 100 ppb or less.

Owner:OHMI TADAHIRO +1

Method of manufacturing semiconductor device

A chemical oxide film formed on a semiconductor substrate is formed by wet cleaning using a strongly acidic solution so that the adhesion of impurities to the chemical oxide film can be reduced between a wet cleaning process and an insulation film forming process. This makes it possible to prevent insulation degradation of a gate insulation film when the gate insulation film embracing the chemical oxide film is formed in the insulation film forming process in which low-temperature processing is conducted.

Owner:SPANSION LLC

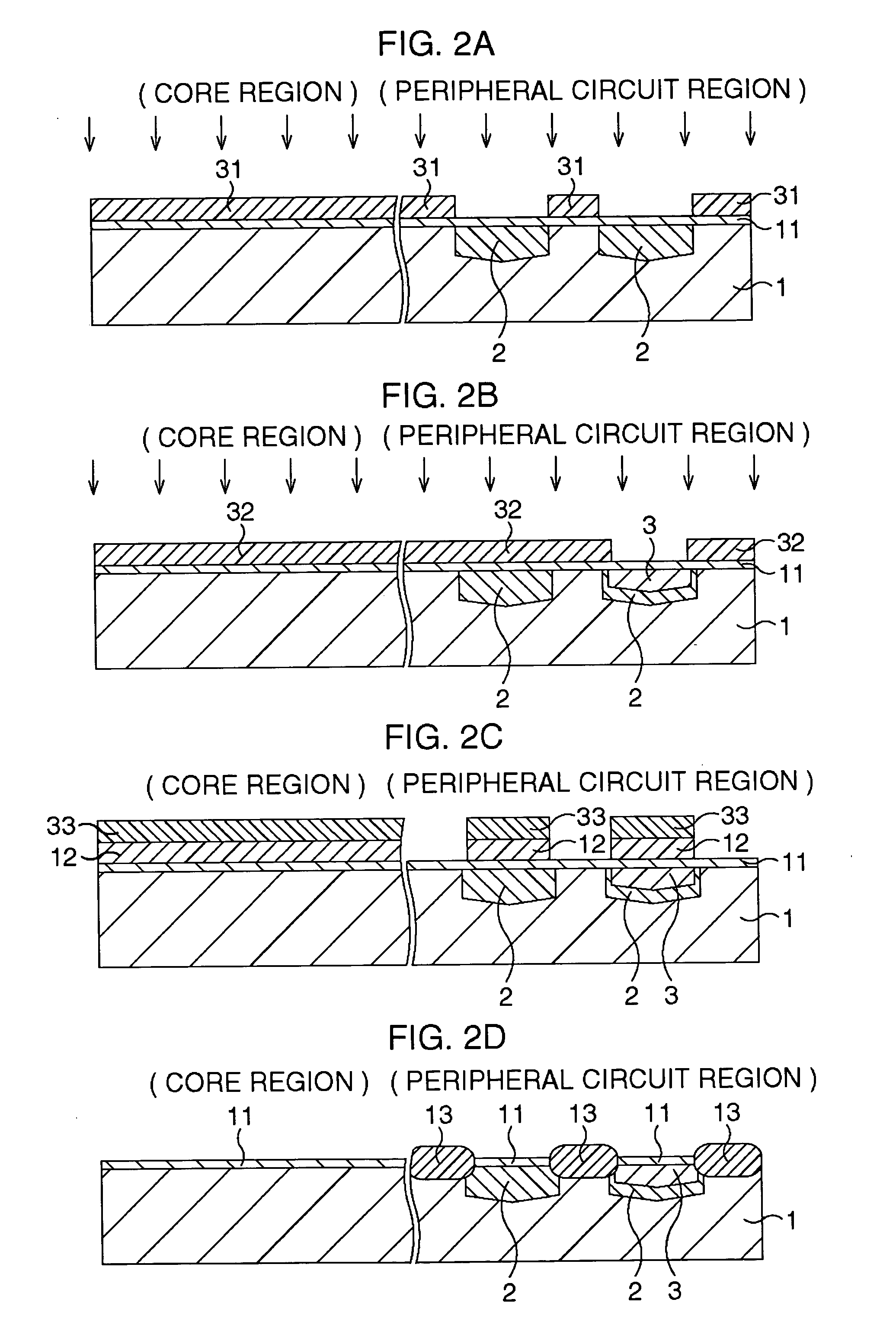

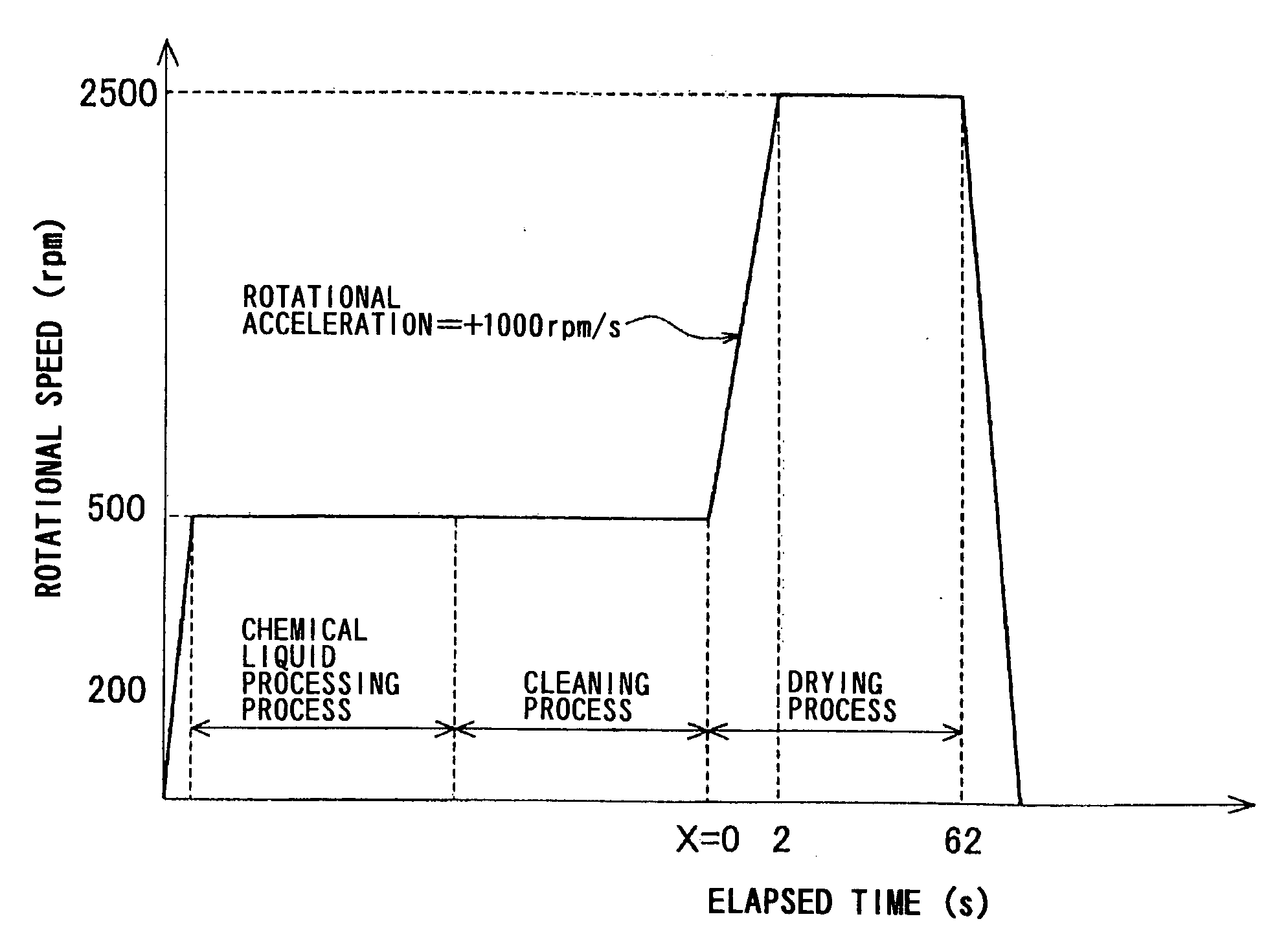

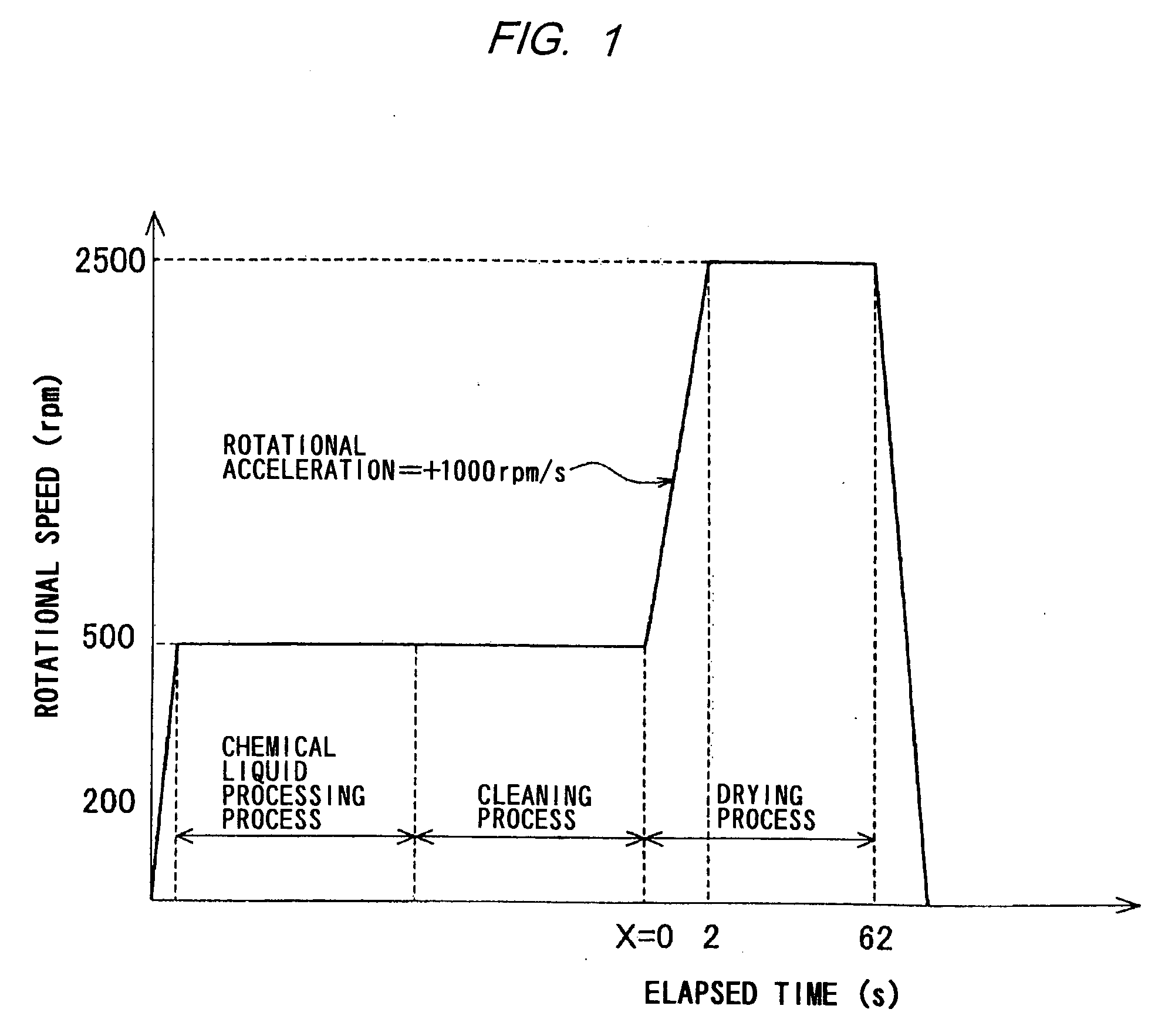

Substrate processing apparatus and substrate processing method

InactiveUS20050026455A1Suppress formationIncreased substrate speedSemiconductor/solid-state device manufacturingEngineeringWet cleaning

The present invention provides a substrate processing apparatus having a drying mechanism for removing water from the surface of a substrate which has been cleaned by a wet cleaning process, and a substrate processing apparatus and a substrate processing method which are capable of efficiently removing an unnecessary thin film deposited on or adhering to a bevel or edge portion of a substrate. The substrate processing apparatus of this invention has a substrate holder for holding a substrate, and a dry gas supply section for turning an atmosphere to which at least a portion of a surface of the substrate held by the substrate holder is exposed into a humidity-controlled dry gas atmosphere.

Owner:EBARA CORP

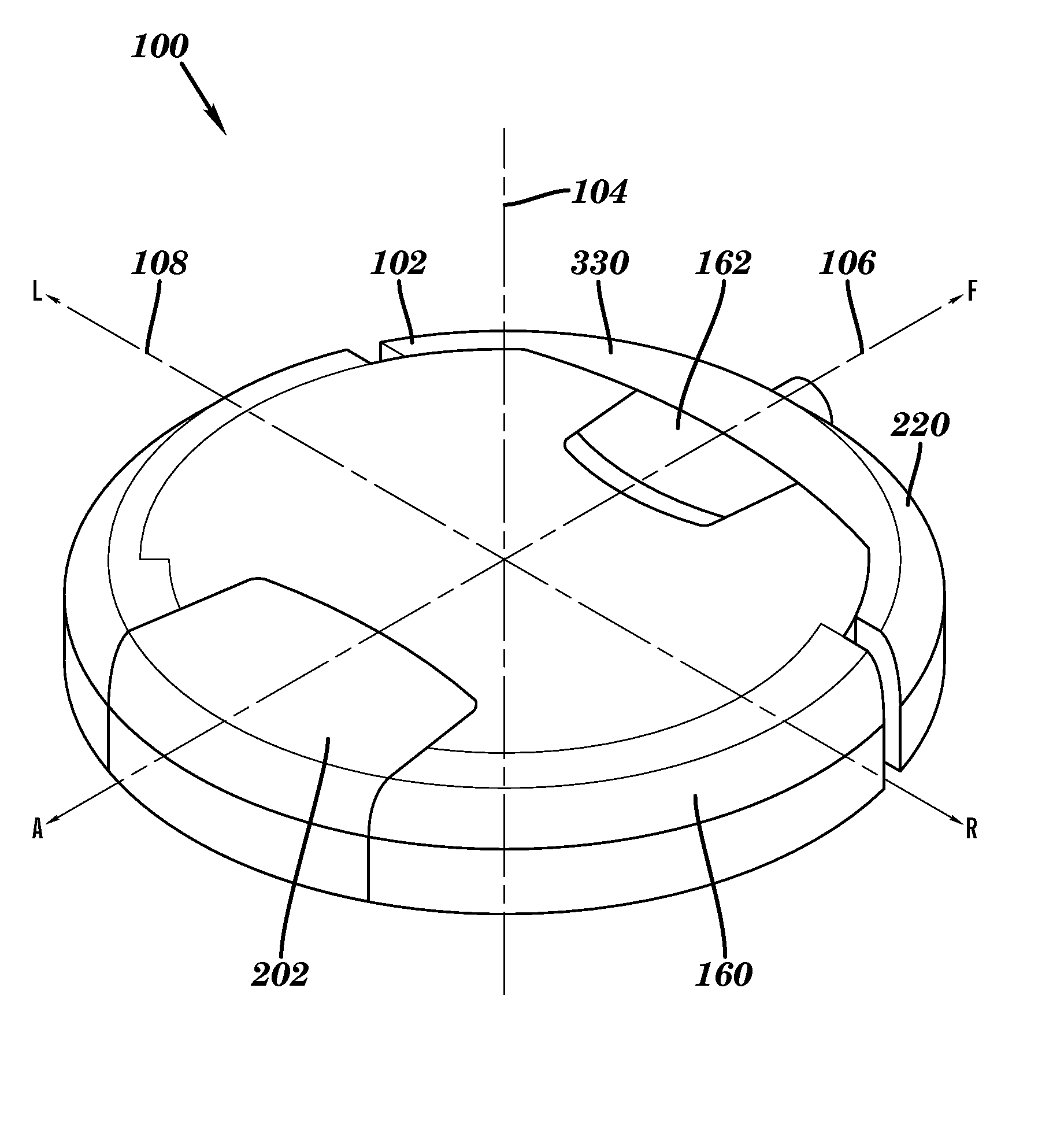

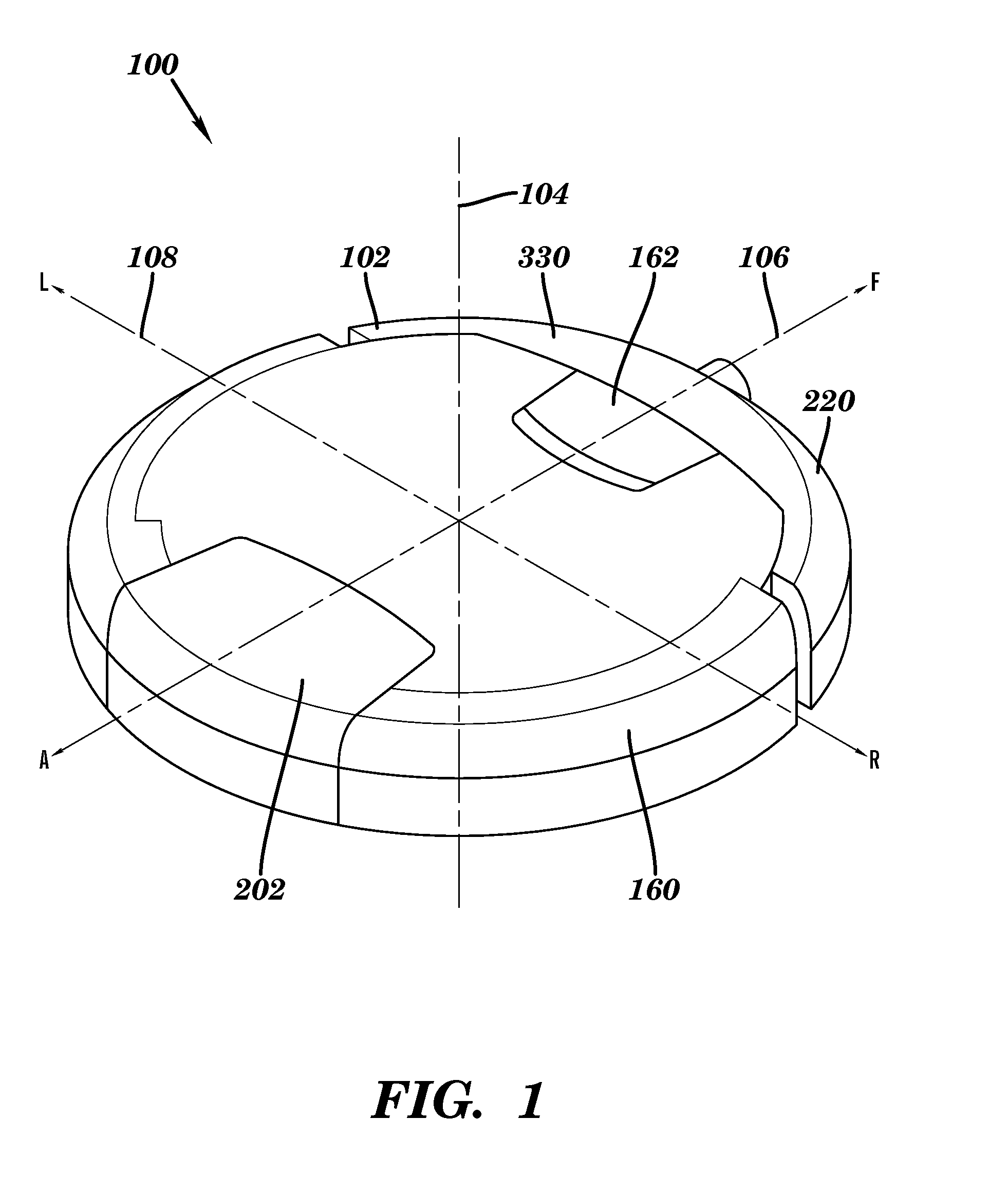

Autonomous surface cleaning robot for wet cleaning

ActiveUS8382906B2Low costWet cleaningAutomatic obstacle detectionLiquid processingParticulatesSurface cleaning

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries a first cleaning zone comprising cleaning elements arranged to suction loose particulates up from the cleaning surface and a second cleaning zone comprising cleaning elements arraigned to apply a cleaning fluid onto the surface and to thereafter collect the cleaning fluid up from the surface after it has been used to clean the surface. The robot chassis carries a supply of cleaning fluid and a waste container for storing waste materials collected up from the cleaning surface.

Owner:IROBOT CORP

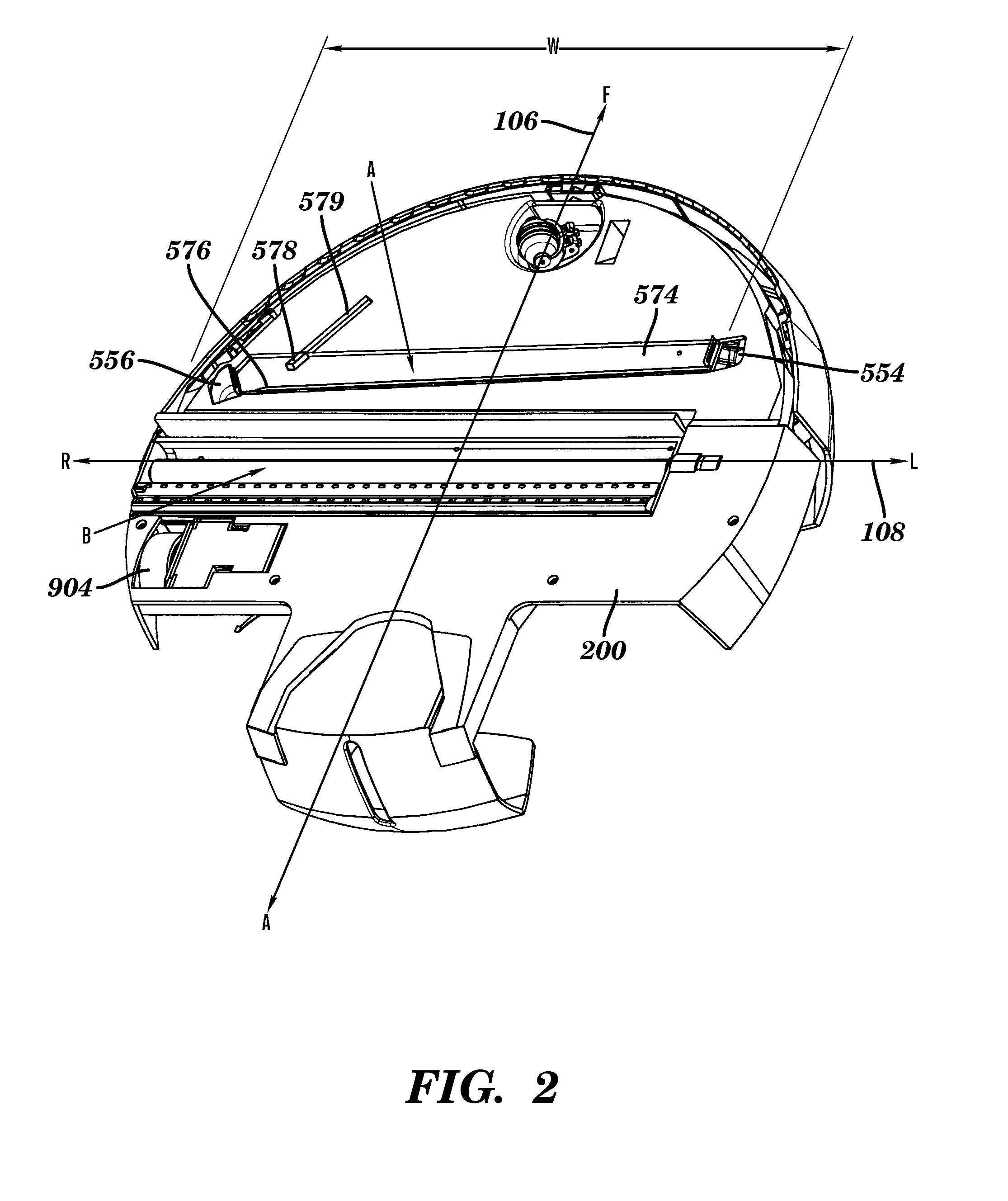

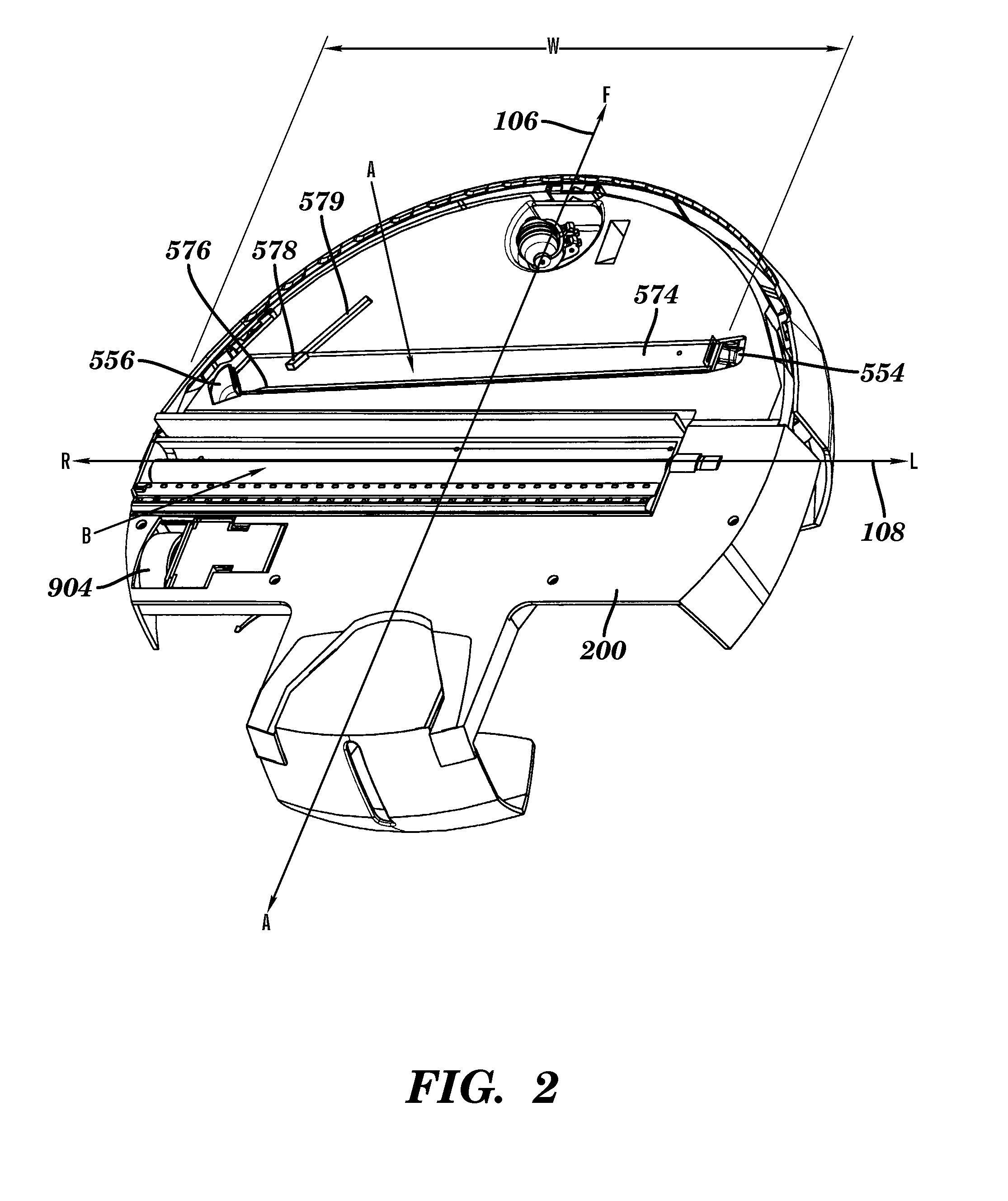

Autonomous surface cleaning robot for wet cleaning

ActiveUS20080127445A1Low costWet cleaningAutomatic obstacle detectionLiquid processingParticulatesControl system

Owner:IROBOT CORP

Apparatus and methods for mask cleaning

InactiveUS20070068558A1Semiconductor/solid-state device manufacturingOriginals for photomechanical treatmentParticulatesCompound (substance)

An integrated substrate cleaning processes capable of removing residues and particulates from the surface of a photomask is described. In one embodiment, an ozonated de-ionized water treatment is the first wet cleaning operation. In an embodiment of the present invention, the substrate cleaning process includes a wet cleaning operation employing an ammonium hydroxide-based chemical cleaning solution diluted with hydrogenated de-ionized water. In another embodiment of the present invention, the substrate cleaning process uses a plasma treatment prior to the first wet cleaning operation.

Owner:APPLIED MATERIALS INC

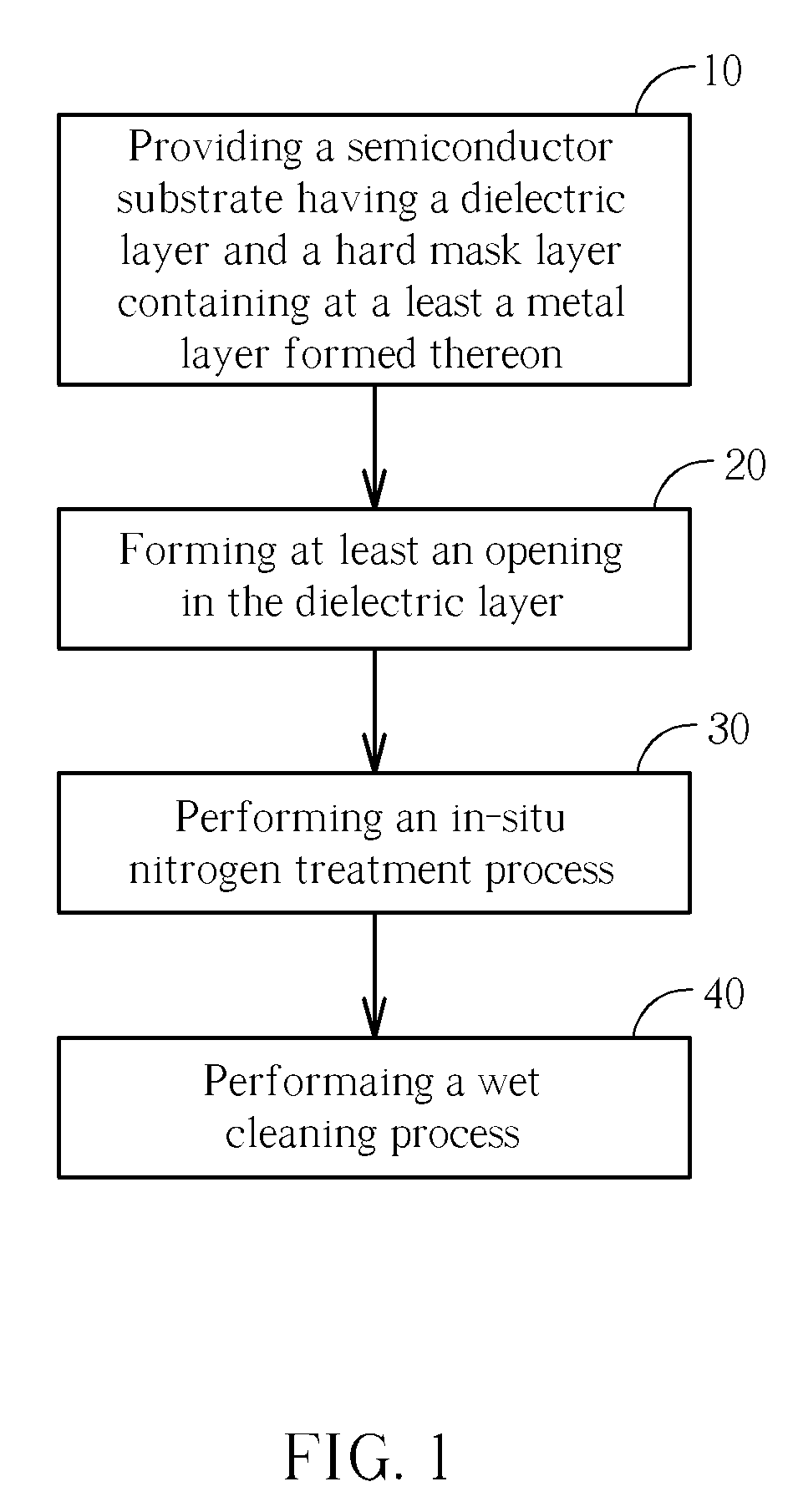

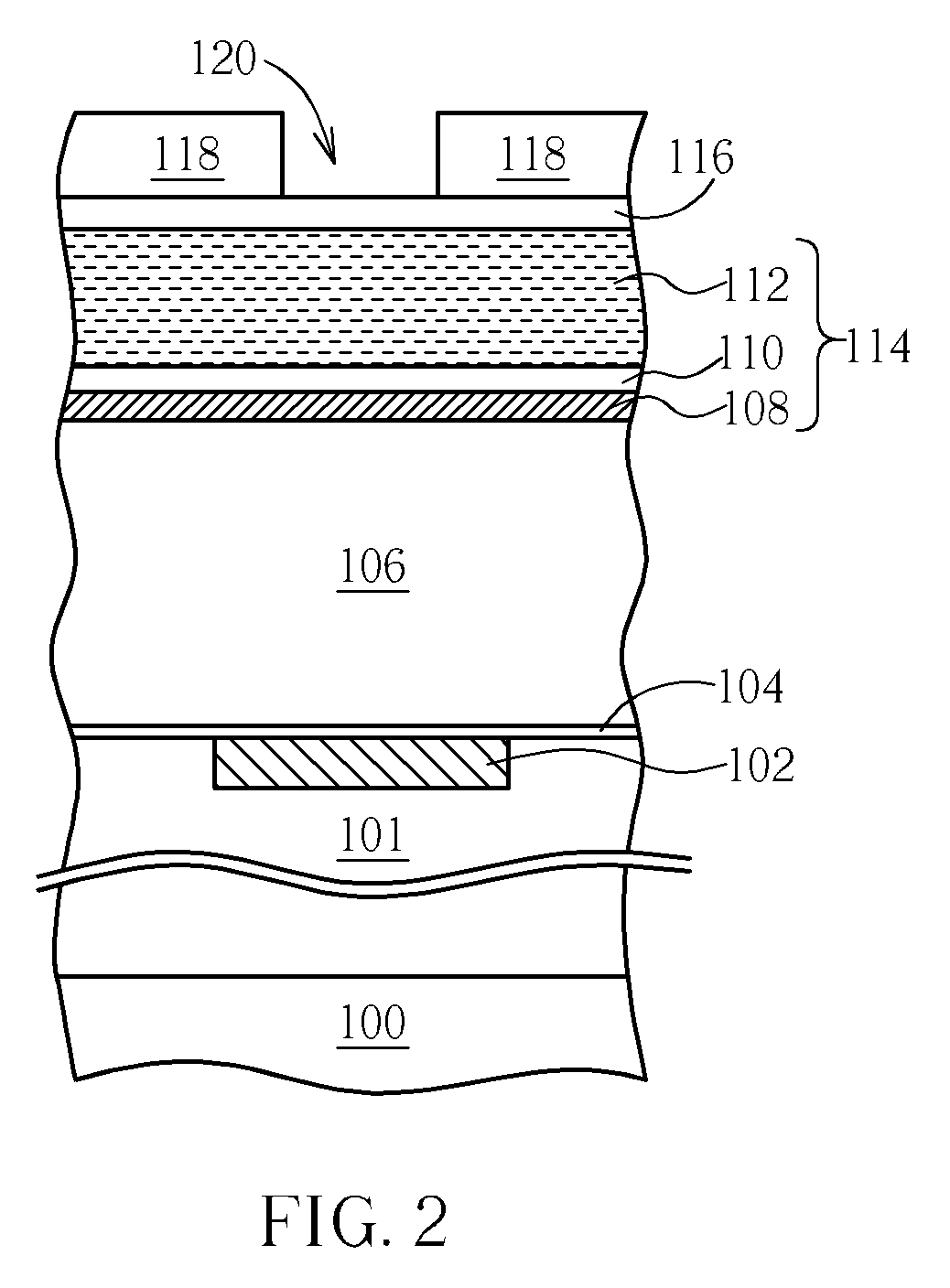

Cleaning method following opening etch

ActiveUS20090142931A1Improve cleaning efficiencyFabrication processDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingNitrogen

A cleaning method following an opening etching is provided. First, a semiconductor substrate having a dielectric layer is provided. The hard mask layer includes at least a metal layer. The opening etch is then carried out to form at least an opening in the dielectric layer. A nitrogen (N2) treatment process is performed to clean polymer residues having carbon-fluorine (C—F) bonds remained in the opening. Finally, a wet cleaning process is performed.

Owner:UNITED MICROELECTRONICS CORP

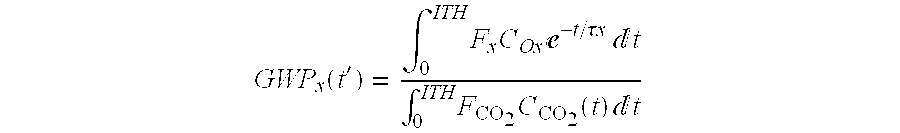

Use of fluorinated ketones as wet cleaning agents for vapor reactors and vapor reactor components

InactiveUS6394107B1Organic compound preparationDetergent mixture composition preparationHydrogen atomHydrogen

A method for cleaning a vapor reactor by applying a liquid cleaning agent comprising a fluorinated ketone having about 5 to about 10 carbon atoms and up to two hydrogen atoms is described. The fluorinated ketone has low global warming potential.

Owner:3M INNOVATIVE PROPERTIES CO

Method and apparatus for processing a wafer

InactiveUS20070093071A1Semiconductor/solid-state device manufacturingPhotomechanical coating apparatusEngineeringAshing

A method of a single wafer wet / dry cleaning apparatus comprising: a transfer chamber having a wafer handler contained therein; a first single wafer wet cleaning chamber directly coupled to the transfer chamber; and a first single wafer ashing chamber directly coupled to the transfer chamber.

Owner:VERHAVERBEKE STEVEN +3

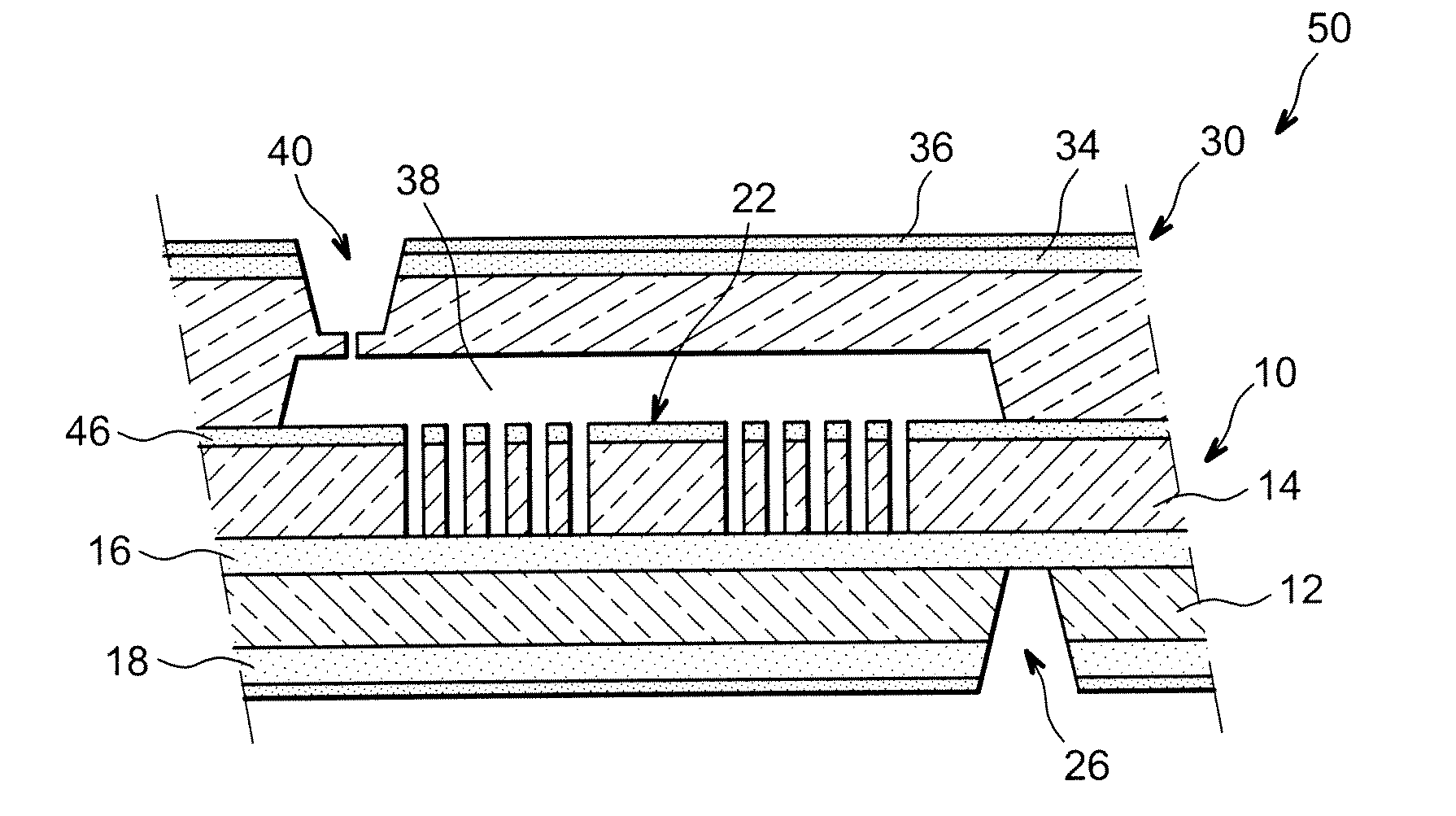

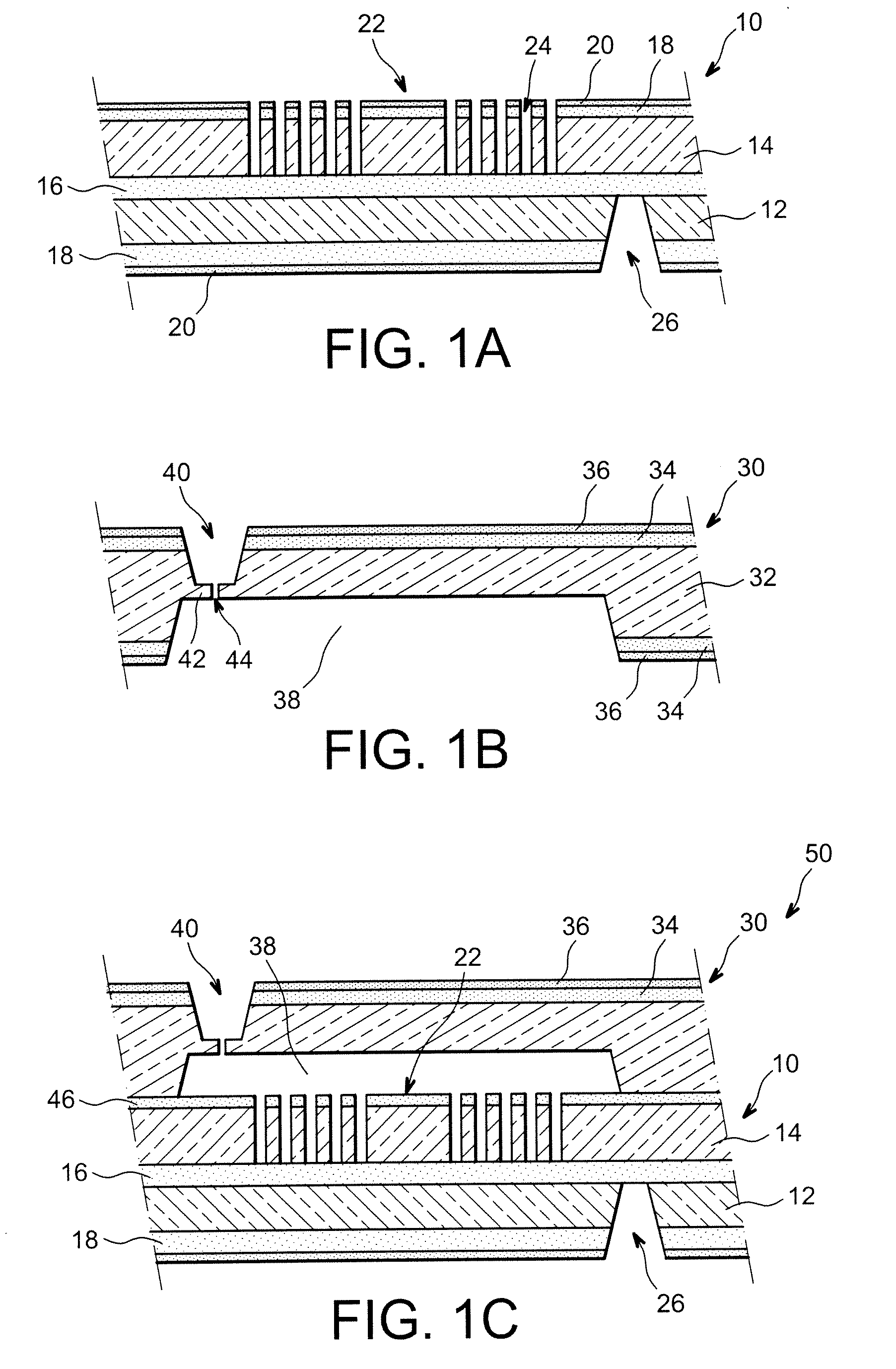

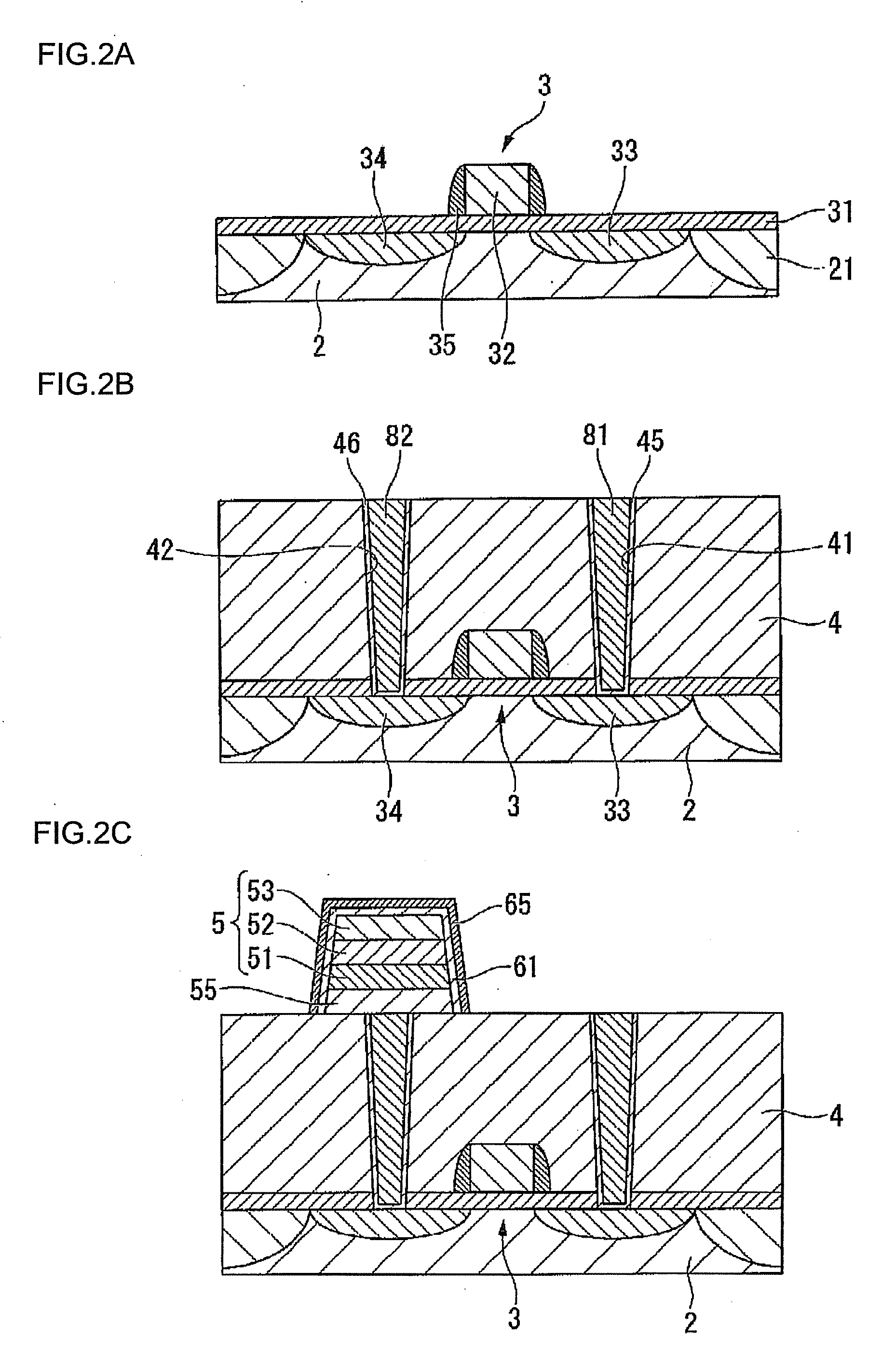

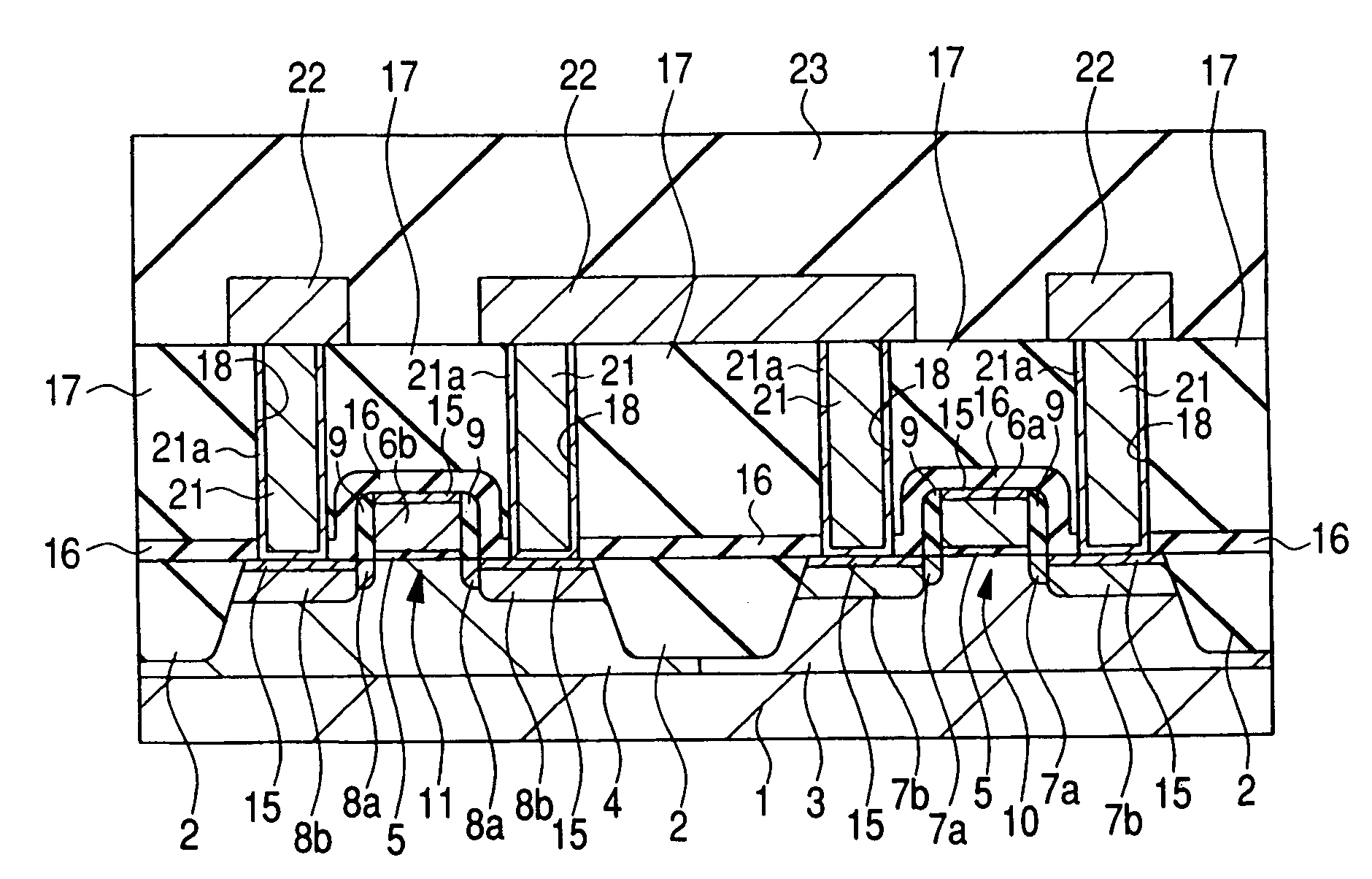

Encapsulation in a hermetic cavity of a microelectronic composite, particularly of a MEMS

InactiveUS20070218585A1Semiconductor/solid-state device manufacturingForming microstructural systemsEngineeringSilicon

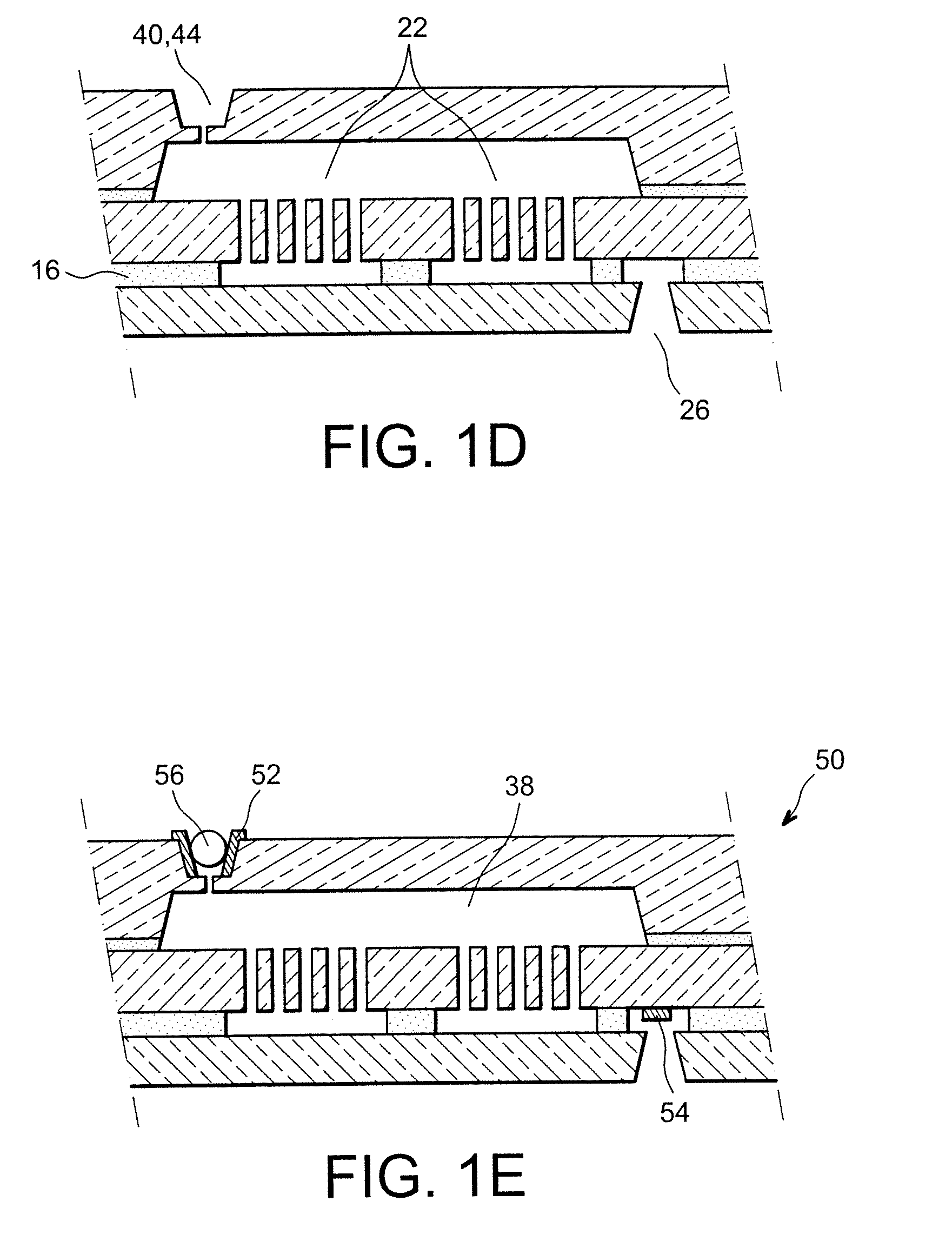

To produce a structure of a micro-electro-mechanical system (MEMS) in a hermetic cavity (38) of a microelectronic device (50), a prepared cover (30) and substrate (10) are bonded by means of silicon direct bonding (SDB). To optimise the preparation of surfaces by means of wet cleaning without impairing the properties of the MEMS (22), i.e. without causing adhesions, the MEMS structure (22) is not released during bonding, but attached to the base (12) by means of a sacrificial intermediate layer (16). Said layer is removed once bonding has been carried out by injecting HF vapour via a vent (40) opening into the cavity (38).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

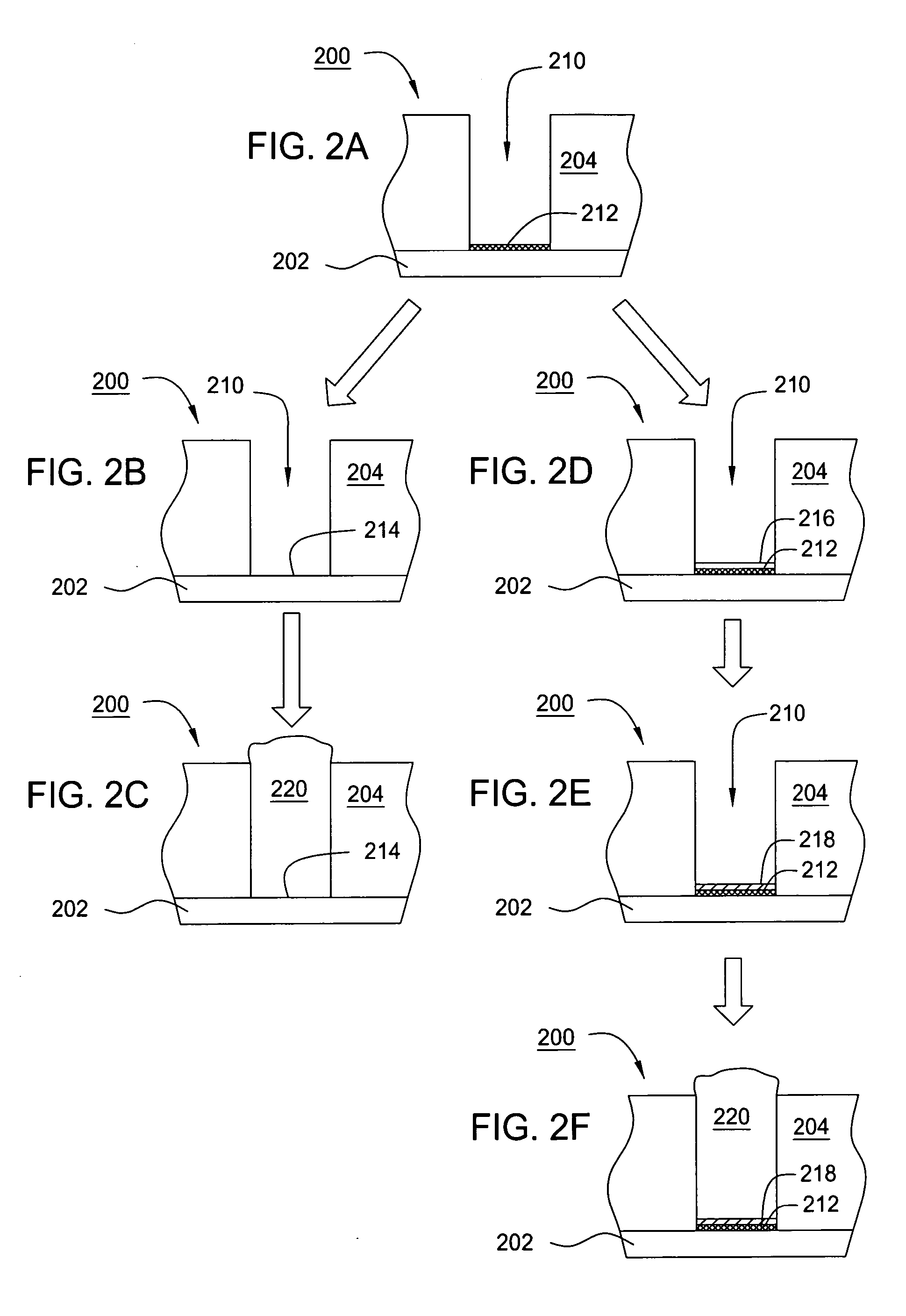

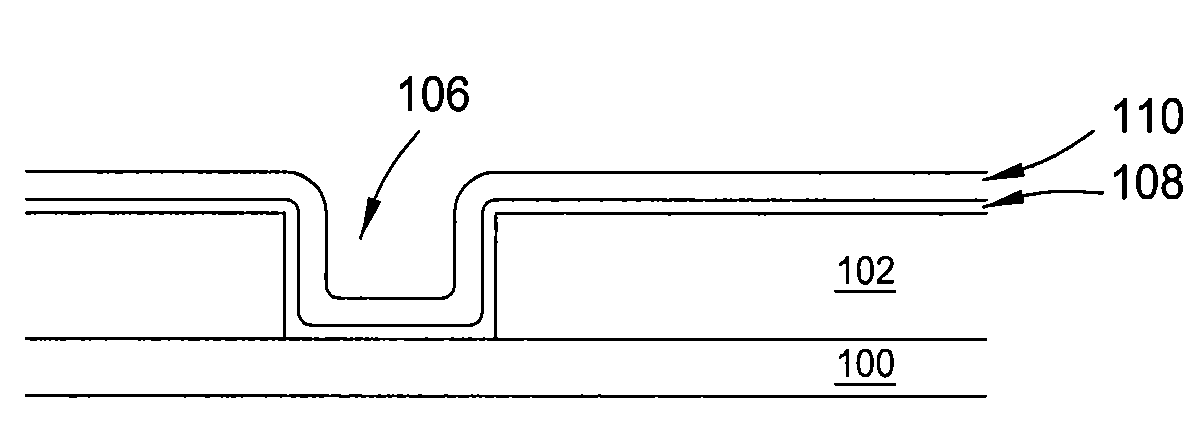

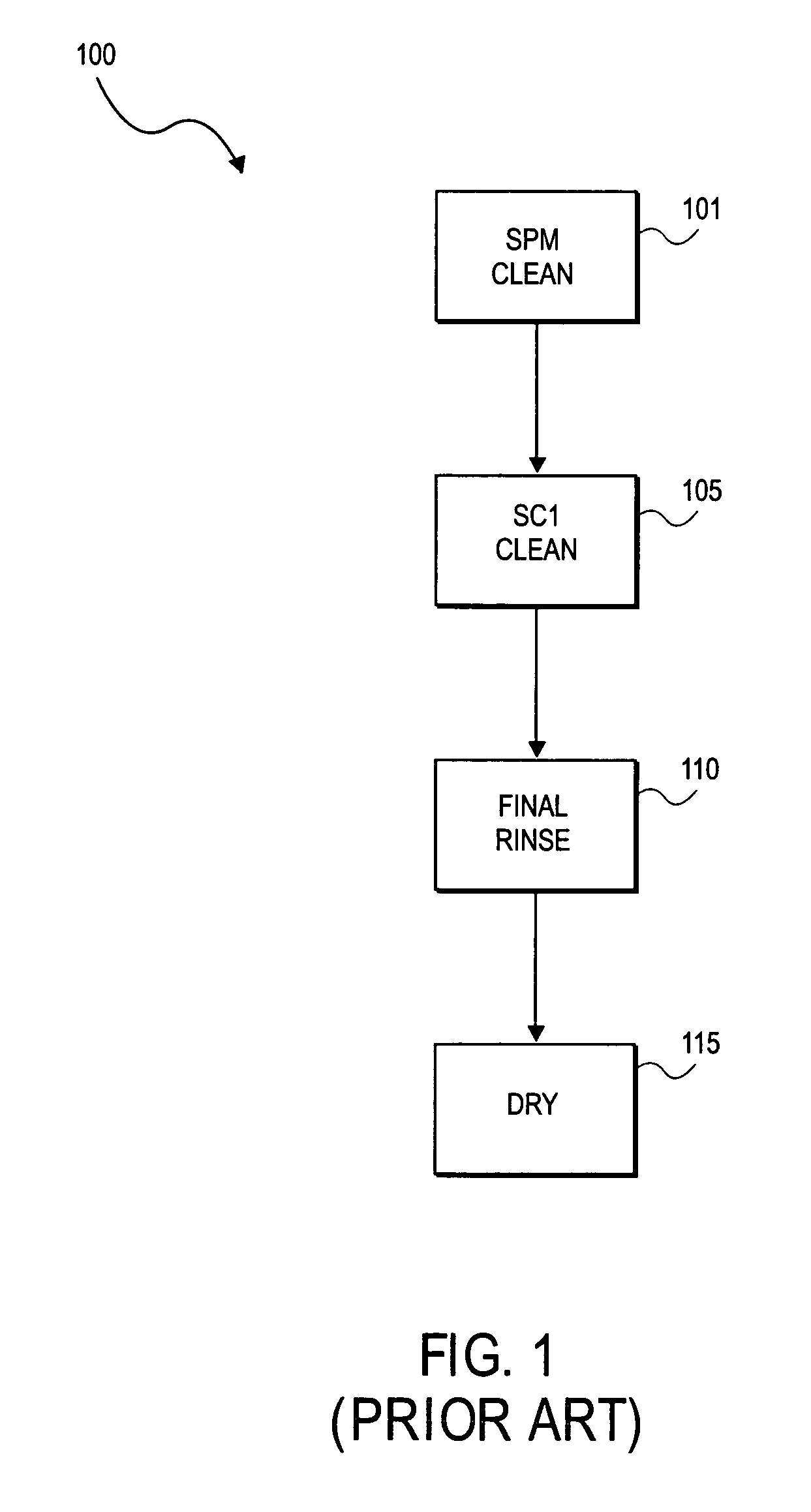

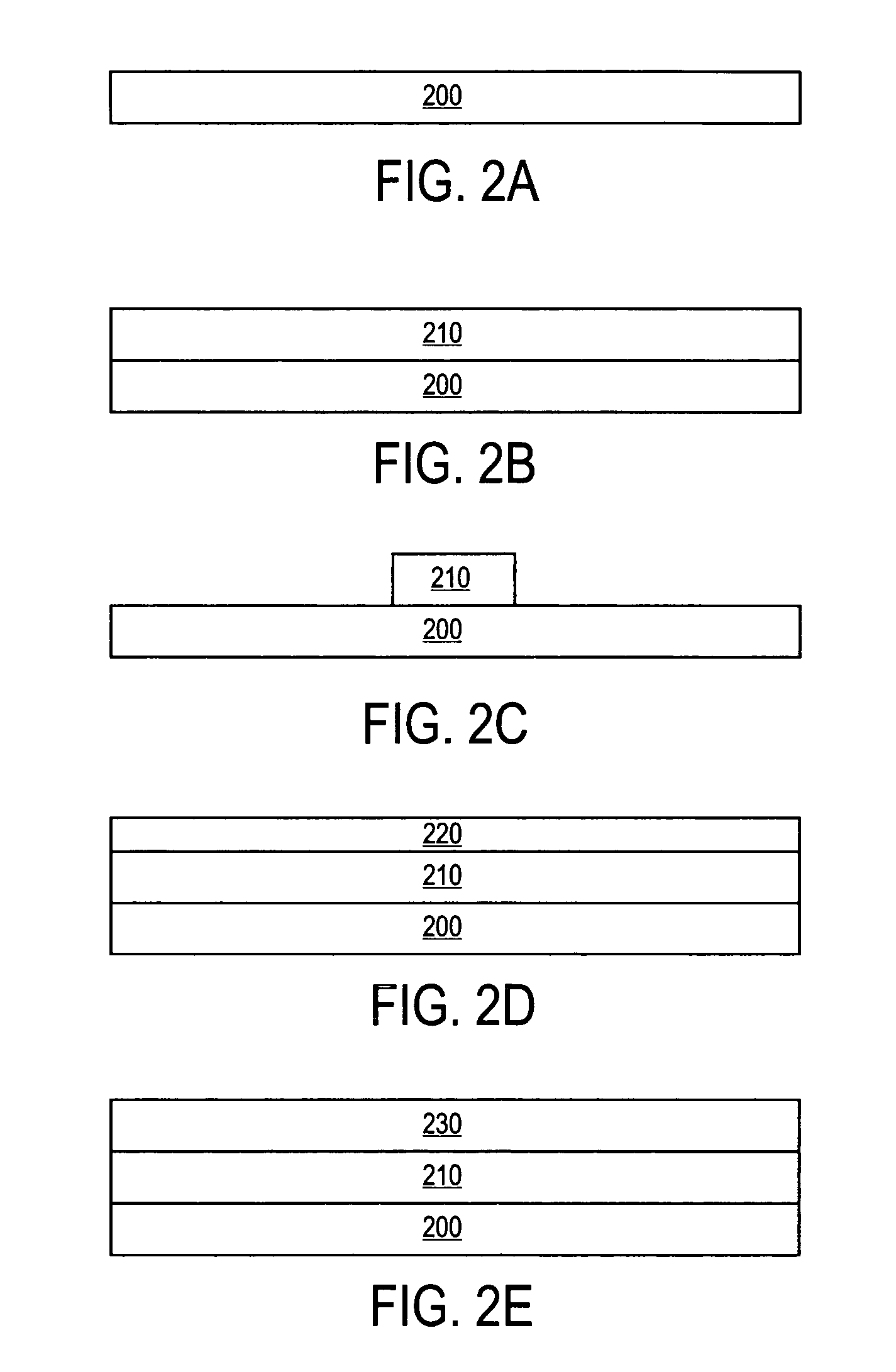

Wet clean method for semiconductor device fabrication processes

InactiveUS20100122711A1Detergent mixture composition preparationSemiconductor/solid-state device manufacturingCleaning methodsEngineering

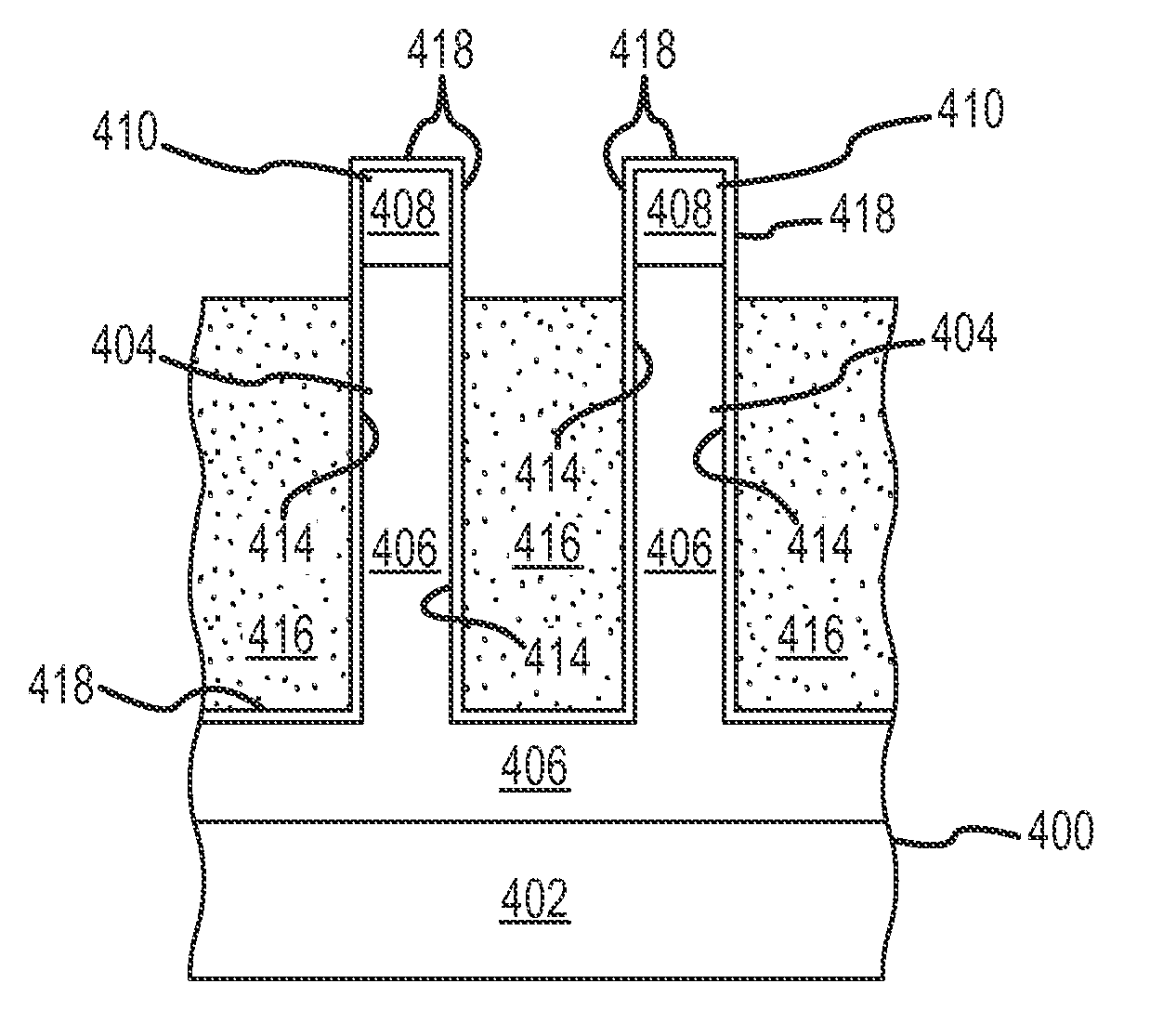

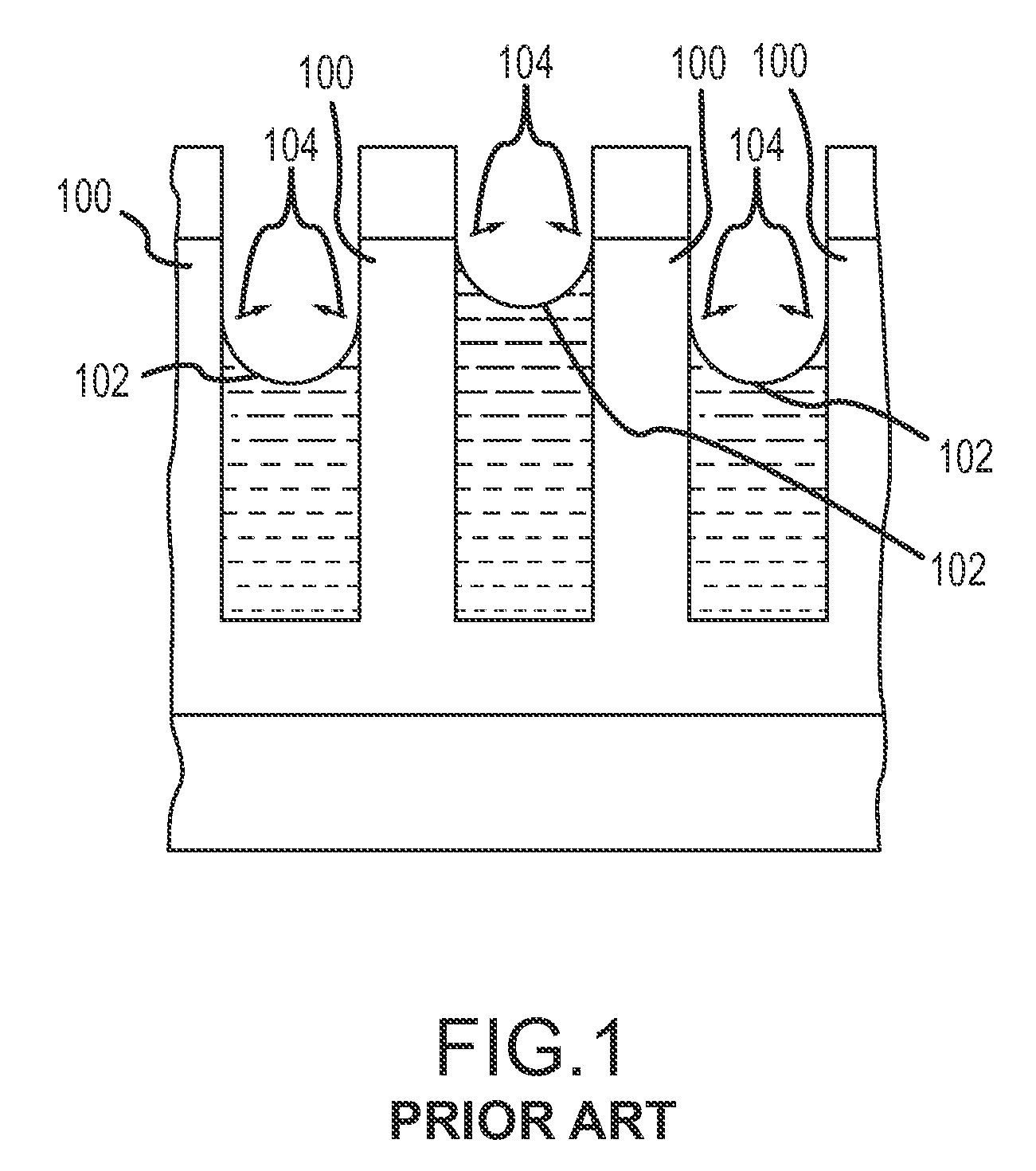

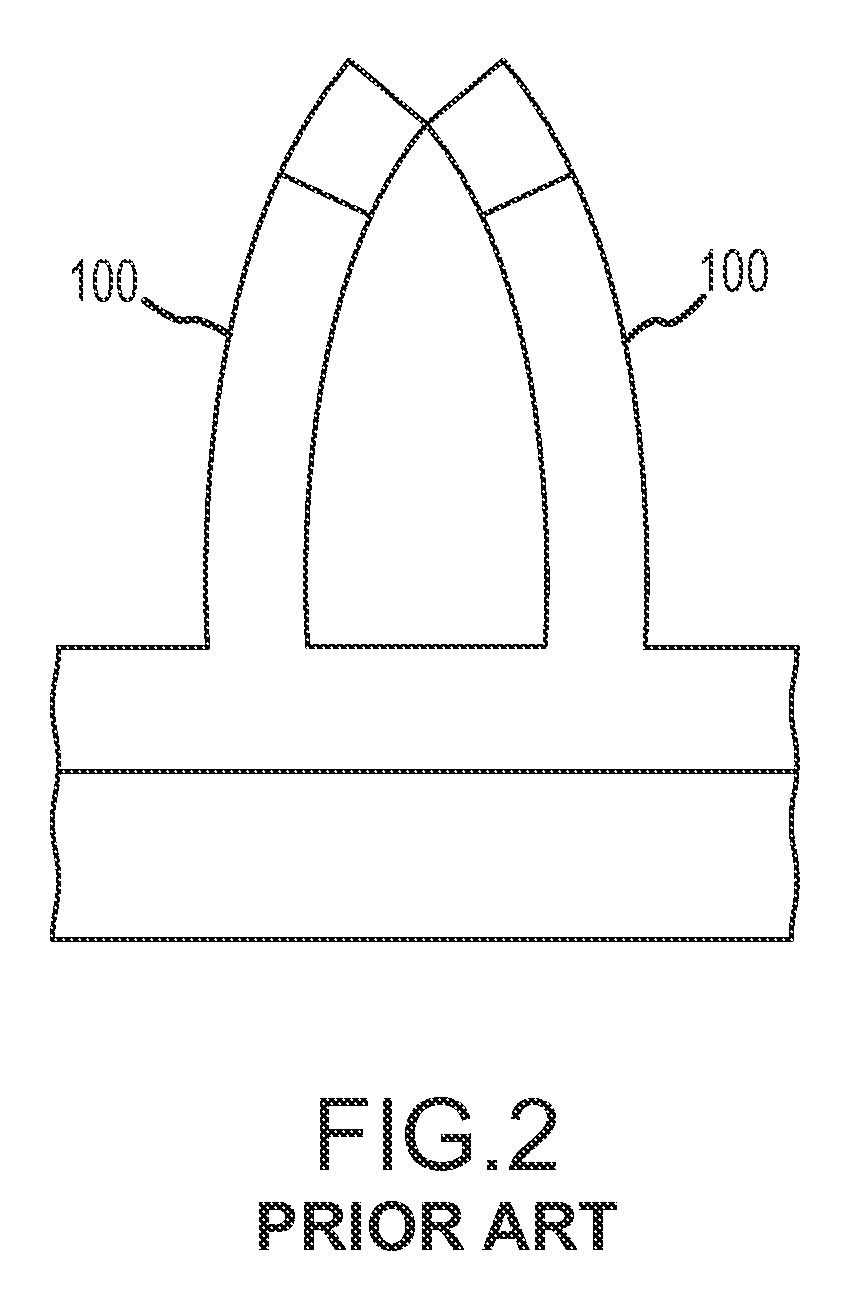

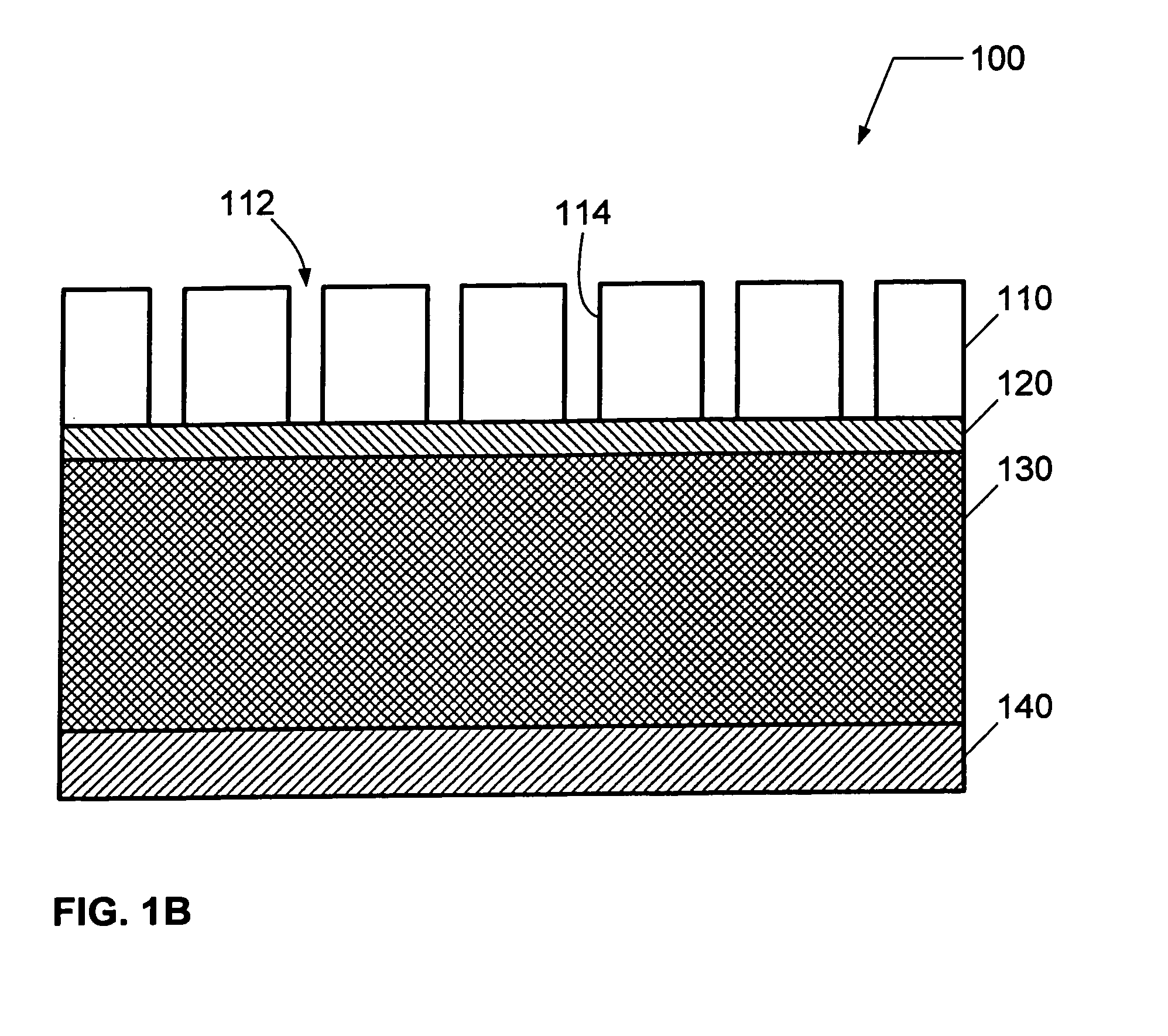

A wet clean method for semiconductor device fabrication begins by providing a semiconductor device structure having a substrate and features protruding from the substrate. The features are formed from a dielectric material, such as an ultra-low-k material. The method continues by cleaning the semiconductor device structure with an aqueous solution and, following the cleaning step, displacing the aqueous solution with a first solvent. Thereafter, the features are exposed to a second solvent that contains a hydrophobic treatment agent that reacts with sidewalls of the features to form a hydrophobic layer on the sidewalls.

Owner:ADVANCED MICRO DEVICES INC

Method for removing damaged dielectric material

InactiveUS7795148B2Decorative surface effectsSemiconductor/solid-state device manufacturingChemical treatmentSurface layer

A method for removing a damaged dielectric material following an etch process, an ashing process, or a wet cleaning process is described. A dry, non-plasma removal process is implemented to remove a thin layer of damaged material on a feature following formation of the feature. The dry, non-plasma removal process includes a chemical treatment of the damaged material, followed by a thermal treatment of the chemically treated surface layer. The two steps, chemical and thermal treatment, can be repeated.

Owner:TOKYO ELECTRON LTD

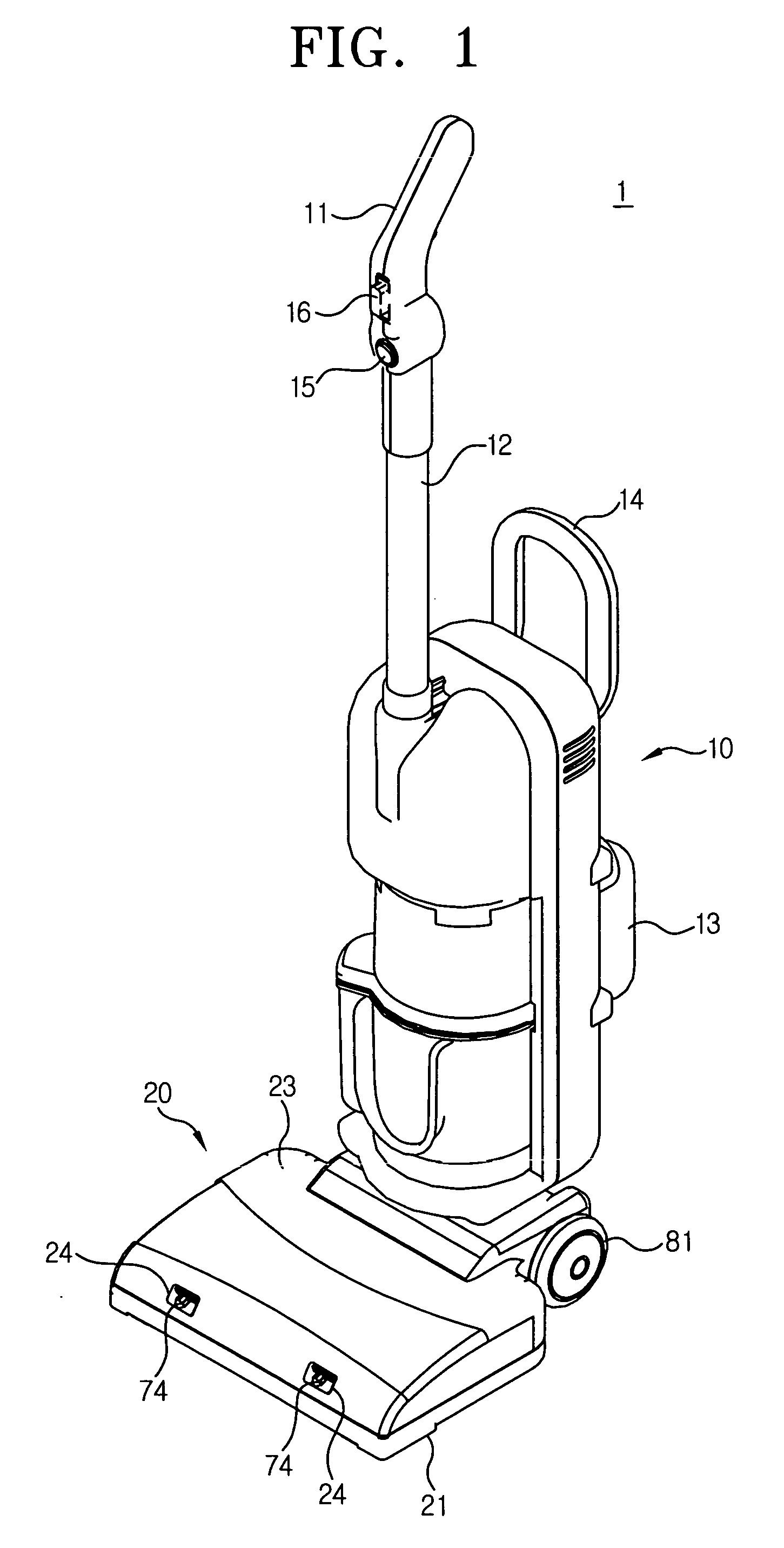

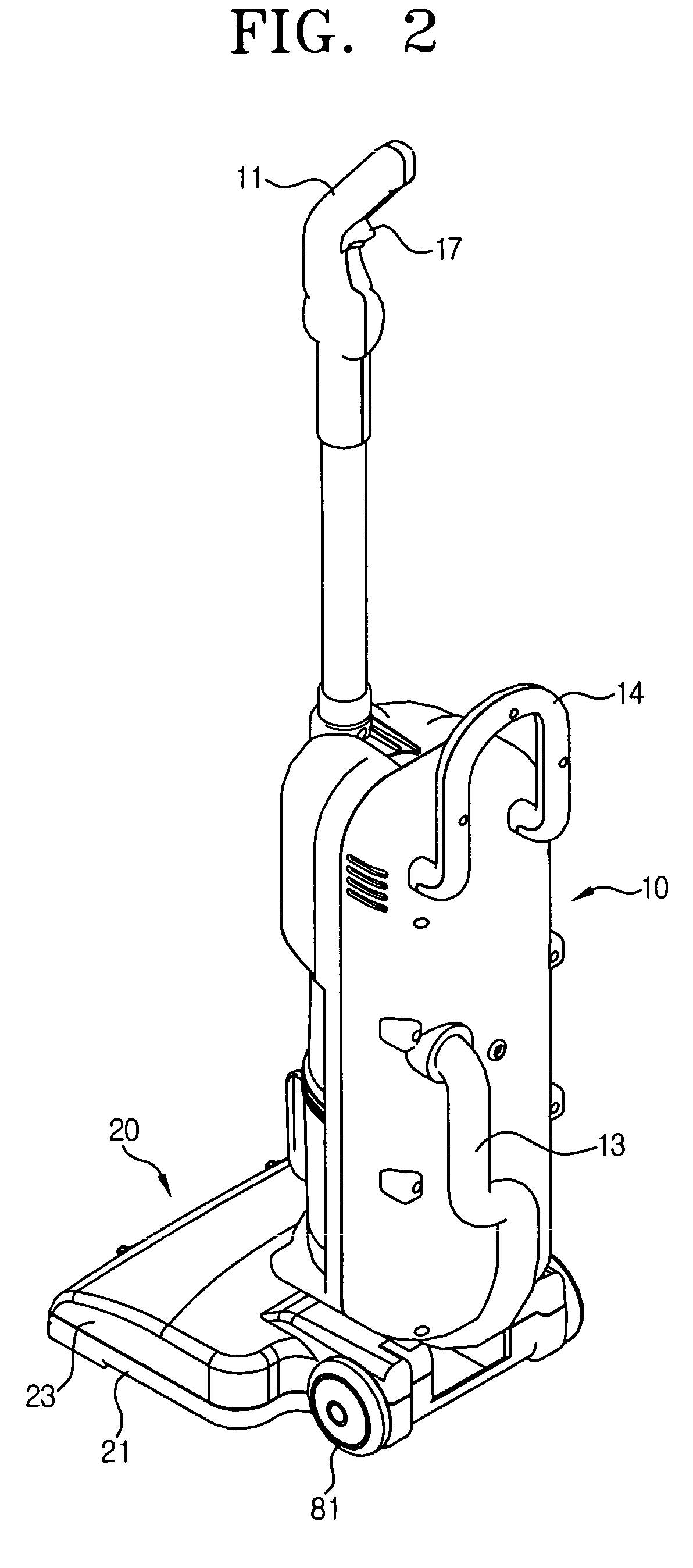

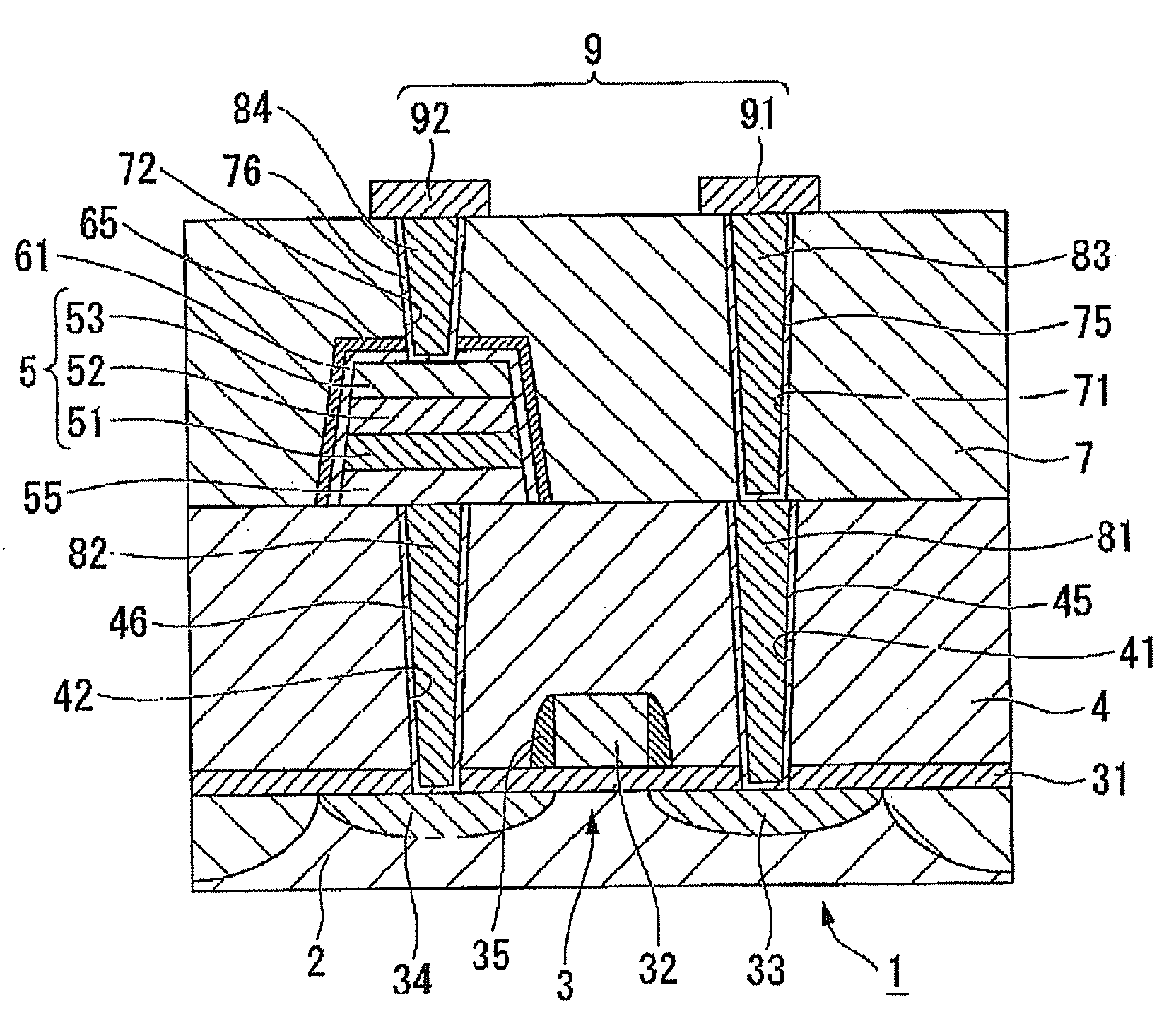

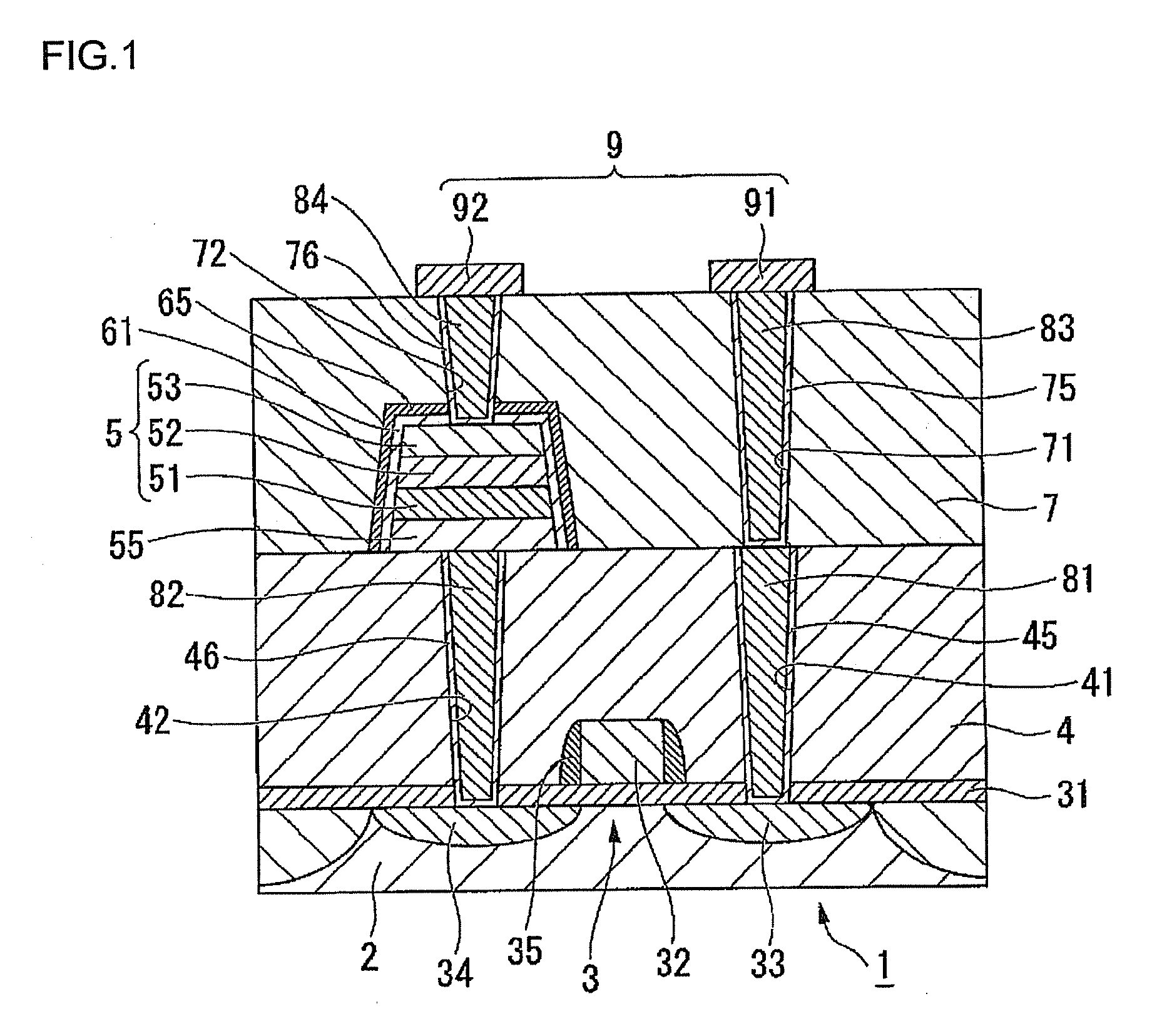

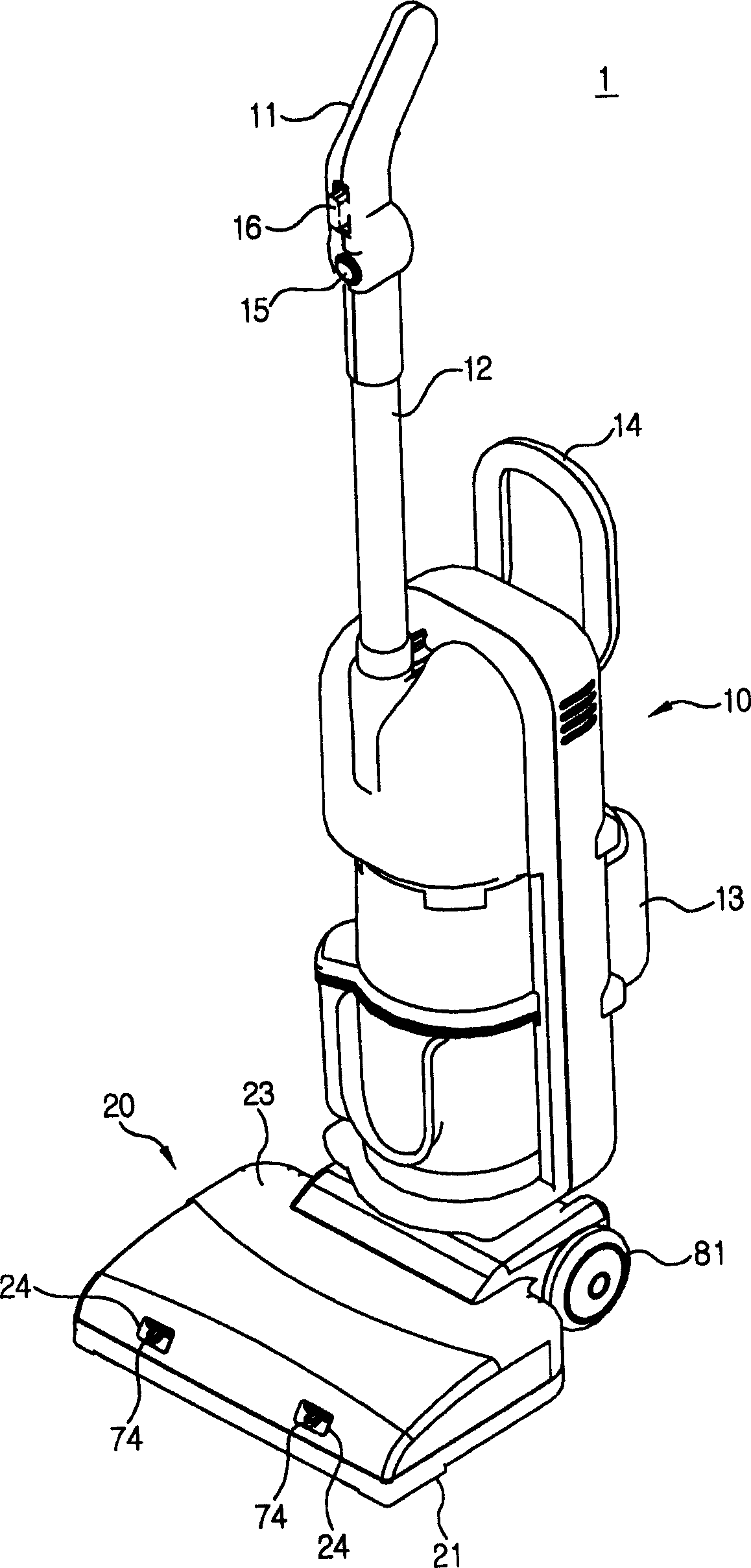

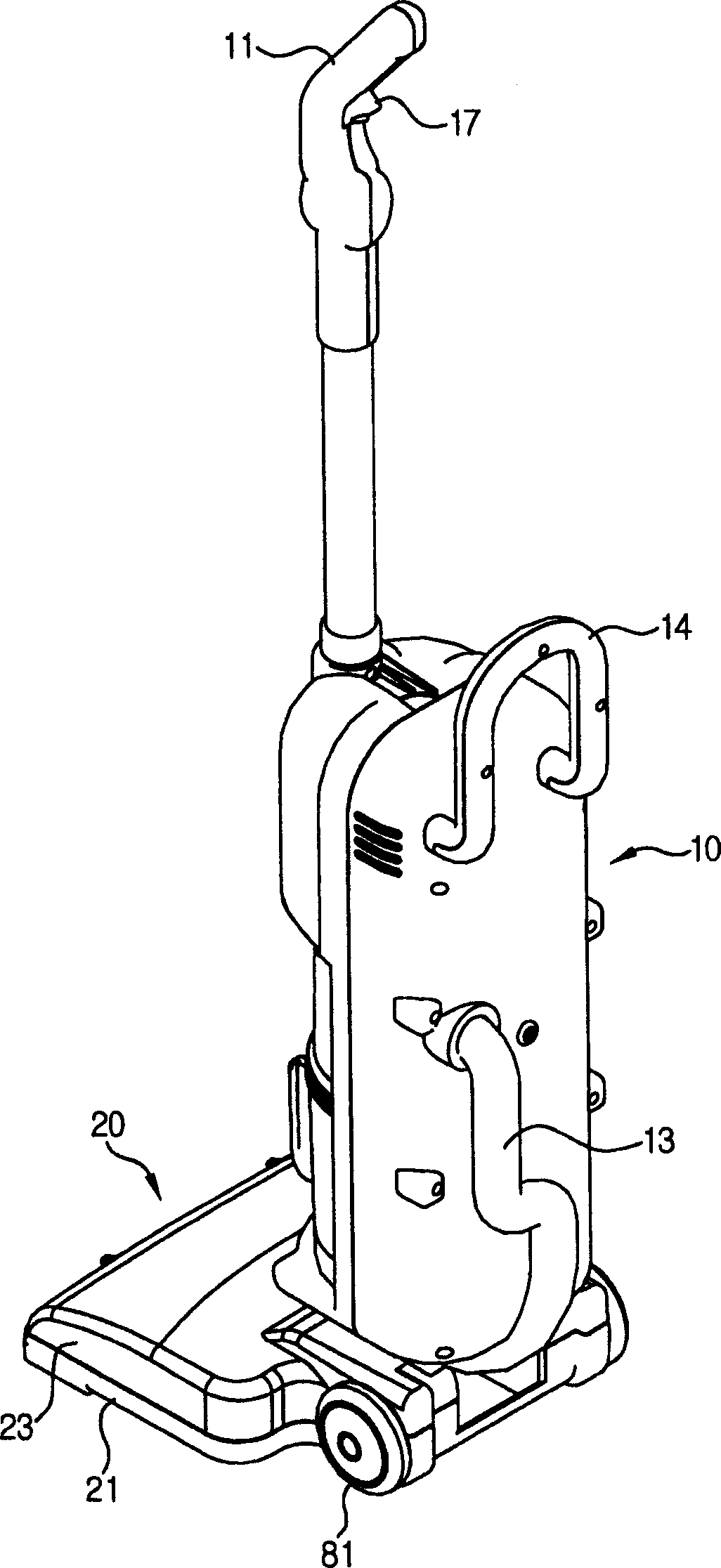

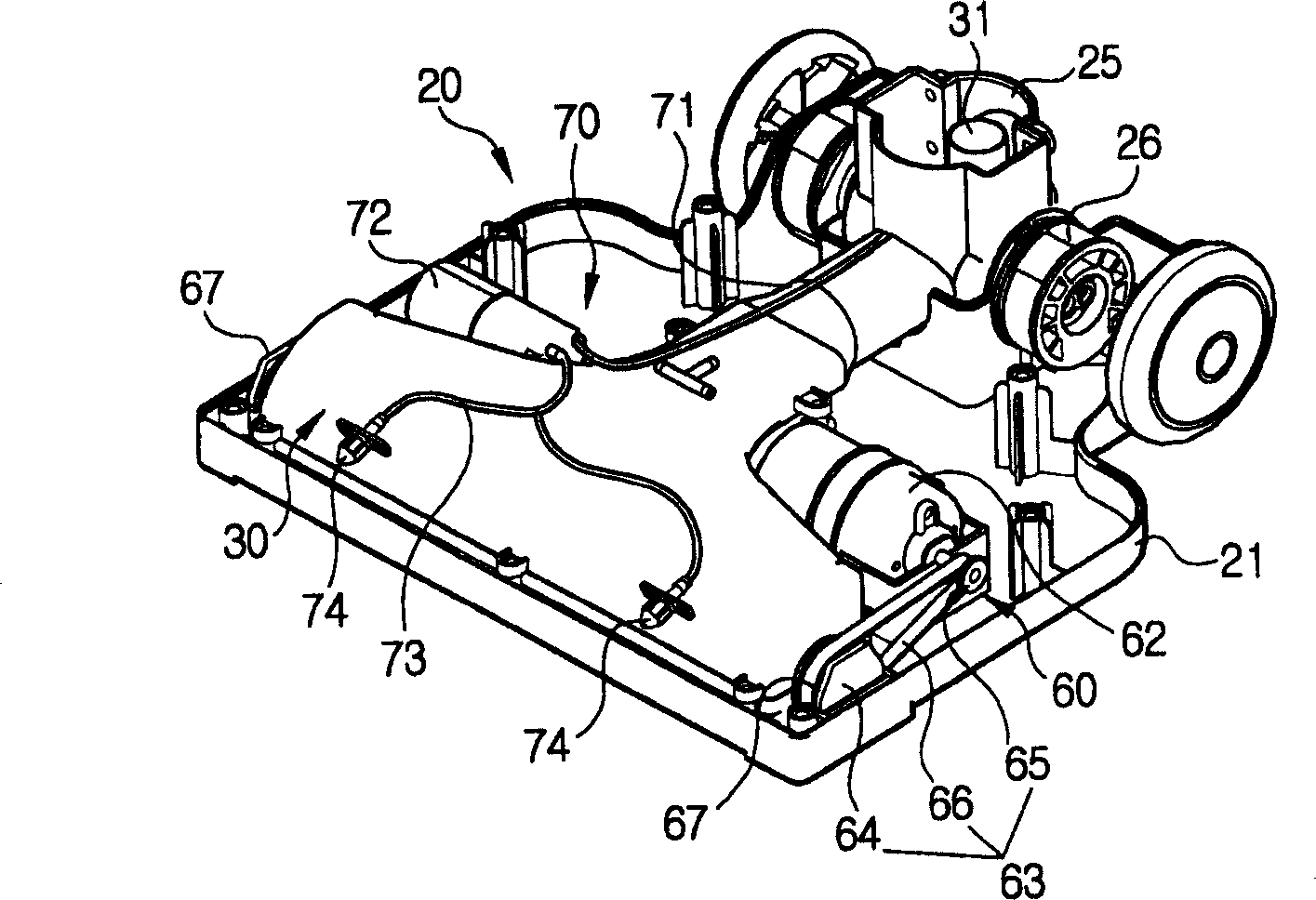

Vacuum cleaner having wet cleaning function

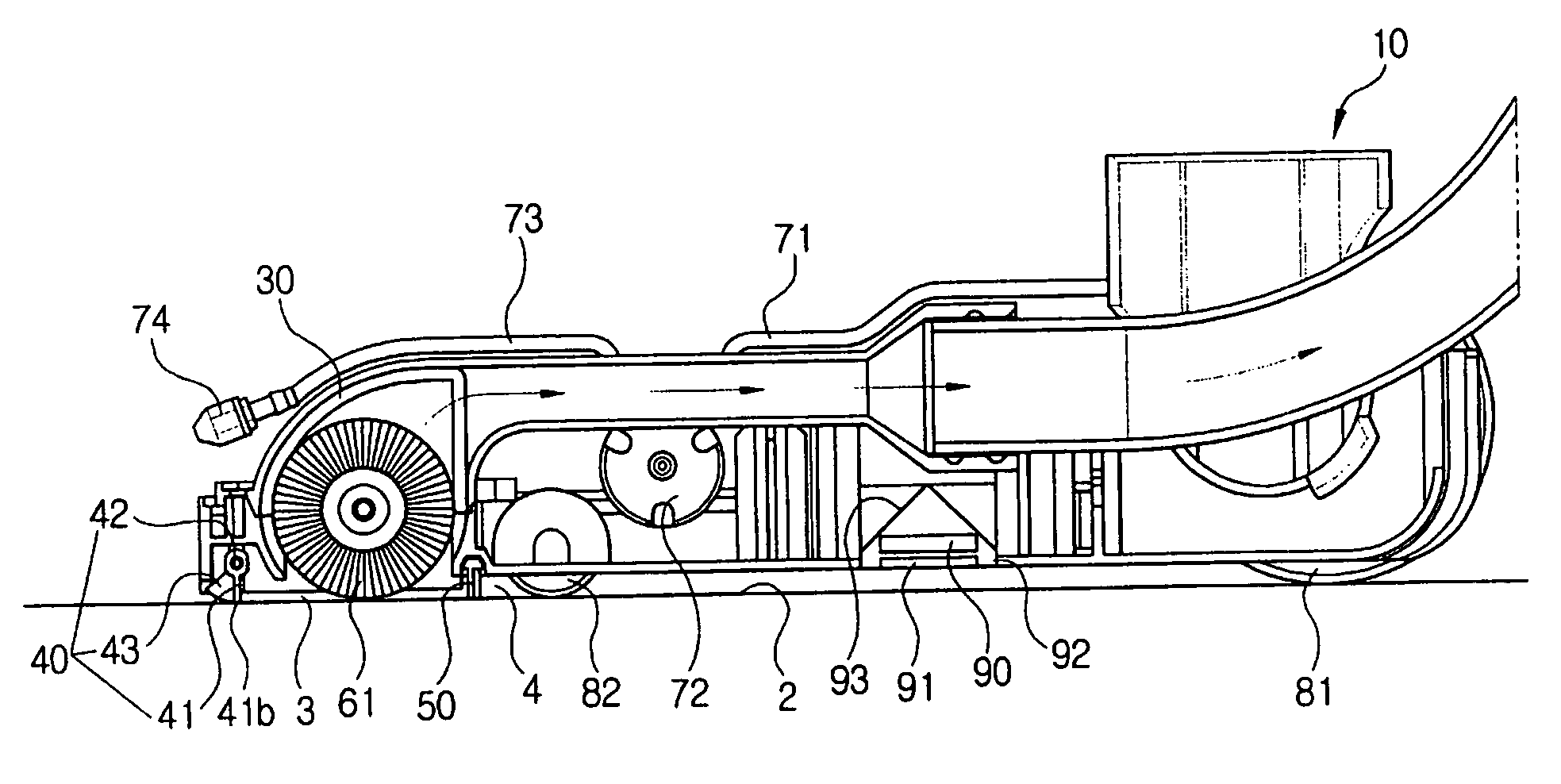

InactiveUS20060288517A1Simple structureReduce cleaningCarpet cleanersFloor cleanersEngineeringFriction force

A vacuum cleaner with a wet cleaning function comprises a main body, a brush assembly having a contaminant suction port facing a cleaning surface, a brush of the contaminant suction port to rotate in contact with the cleaning surface, and a water exhaust nozzle, the contaminants suction port is fluidly communicated with the main body, and a front and a rear block parts formed at a front and a rear of the brush on a bottom surface of the brush assembly to selectively open or block a contaminant suction path by a friction force against the cleaning surface.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

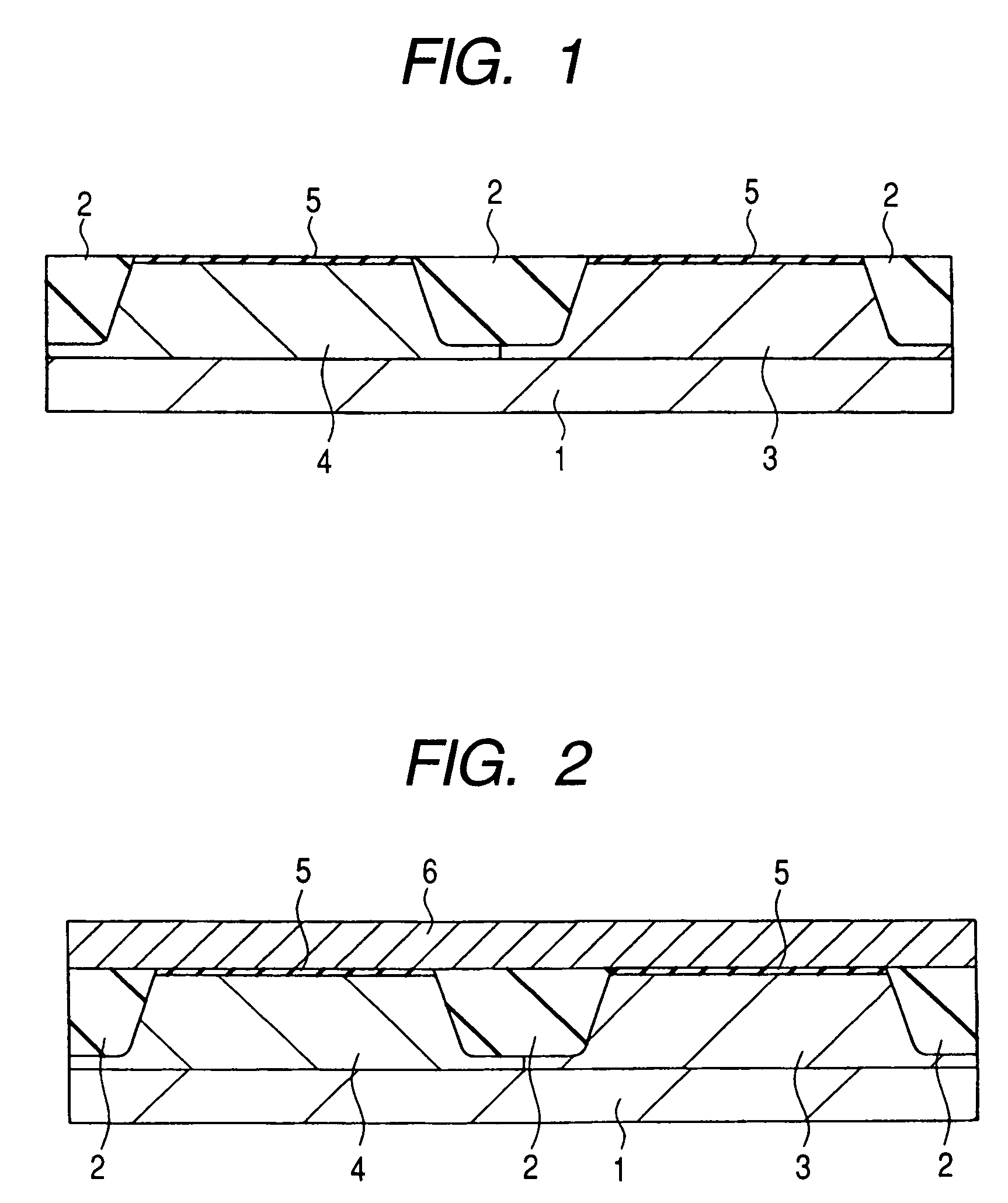

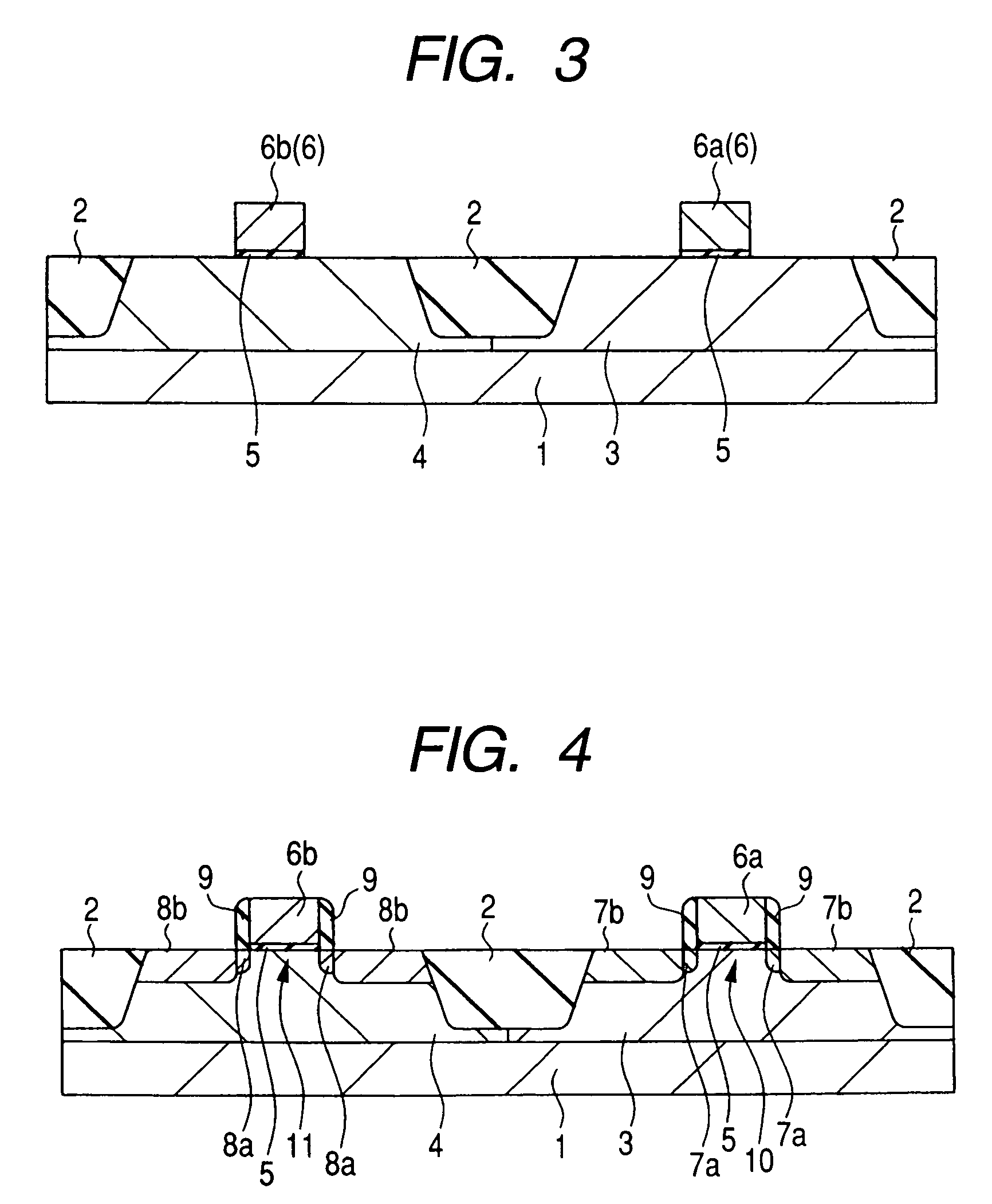

Method for manufacturing ferroelectric capacitor, and ferroelectric capacitor

InactiveUS20080290385A1Etch rate reductionImprove hysteresis characteristicsTransistorSolid-state devicesDielectricResist

A method for manufacturing a ferroelectric capacitor includes the steps of: forming a base dielectric film on a substrate, and forming a first plug conductive section in the base dielectric film at a predetermined position; forming, on the base dielectric film, a charge storage section formed from a lower electrode, a ferroelectric film and an upper electrode; forming a stopper film from an insulation material that covers the charge storage section; forming a hydrogen barrier film that covers the stopper film; forming an interlayer dielectric film on the base dielectric film including the hydrogen barrier film; forming, in the interlayer dielectric film, a first contact hole that exposes the first plug conductive section; forming a second contact hole that exposes the upper electrode of the charge storage section by successively etching the interlayer dielectric film, the hydrogen barrier film and the stopper film by using a resist pattern as a mask, and then removing the resist pattern by a wet cleaning treatment; forming an adhesion layer from a conductive material having hydrogen barrier property inside the second contact hole in a manner to cover an upper surface of the upper electrode; forming a second plug conductive section inside the first contact hole; and forming a third plug conductive section inside the second contact hole, wherein the stopper film is formed from a material having a lower etching rate for a cleaning liquid used for the wet cleaning treatment to remove the resist pattern than an etching rate of the hydrogen barrier film for the cleaning liquid.

Owner:SEIKO EPSON CORP

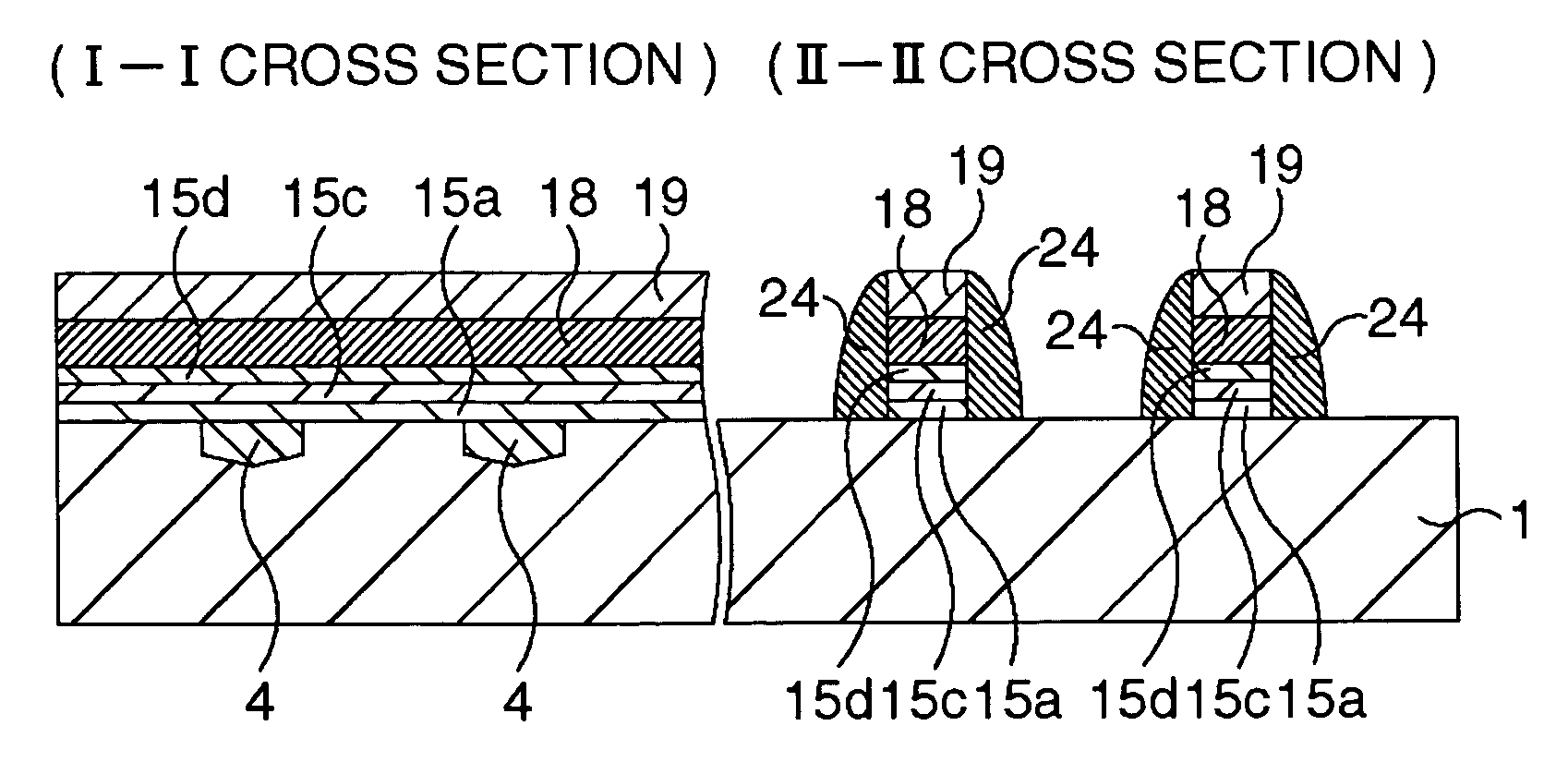

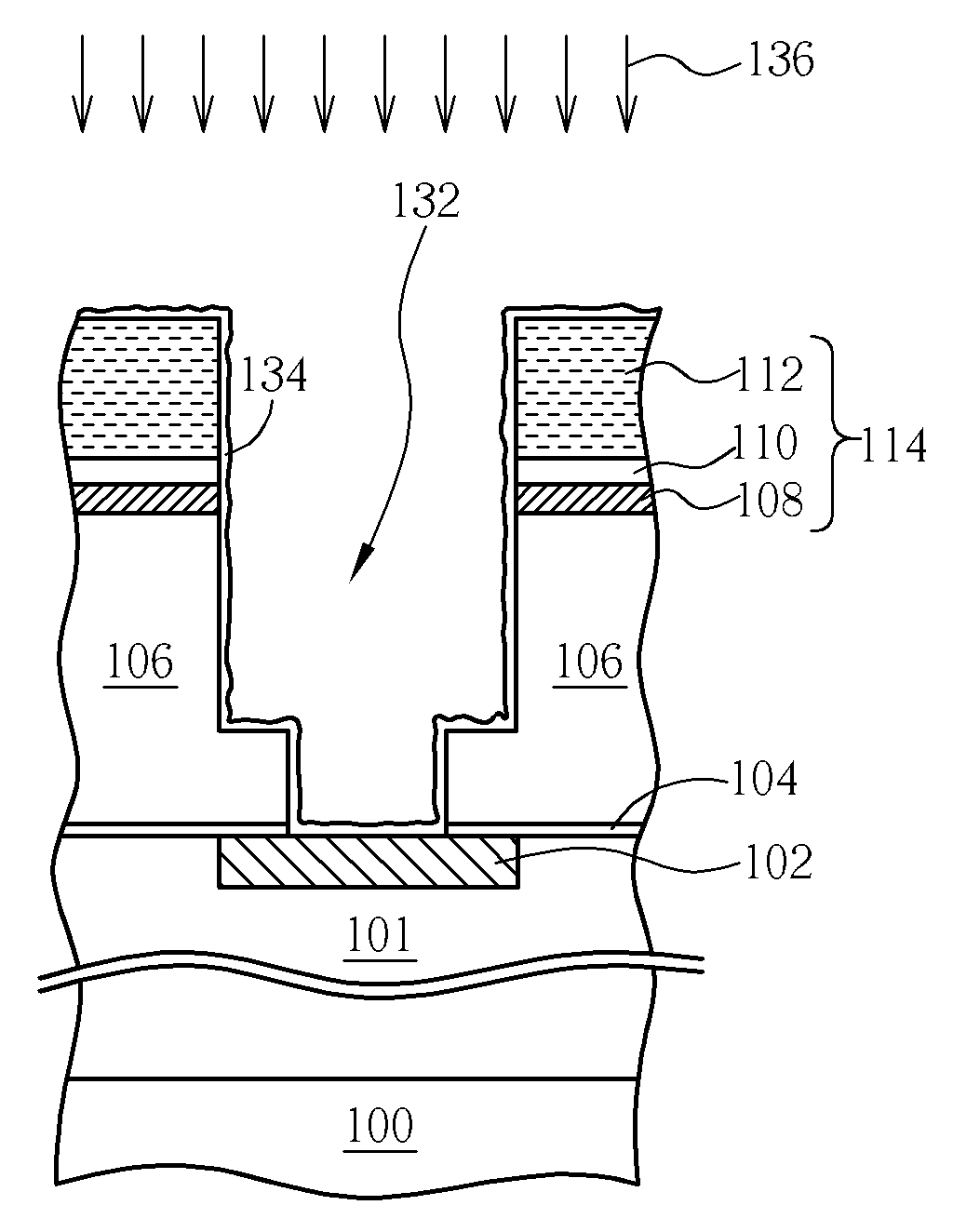

Manufacturing method of semiconductor device

ActiveUS7348230B2Increase currentIncrease resistanceTransistorSemiconductor/solid-state device detailsTitanium nitrideCobalt

A method of manufacture of a semiconductor device includes forming a gate insulating film and a gate electrode made of polycrystalline silicon over a semiconductor substrate; implanting ions into the semiconductor substrate to form a semiconductor region as a source or drain; forming a cobalt film and a titanium nitride film over the semiconductor substrate to cover the gate electrode; carrying out annealing to cause a reaction between Co and Si and the semiconductor region to form a CoSi layer; carrying out wet cleaning to remove the titanium nitride film and unreacted cobalt film to leave the CoSi layer over the gate electrode and semiconductor region; carrying out annealing to cause a reaction between the CoSi layer and the gate electrode and semiconductor region to form a CoSi2 layer; carrying out HPM cleaning; and forming over the semiconductor substrate a silicon nitride film by low-pressure CVD to cover the gate electrode.

Owner:RENESAS ELECTRONICS CORP

Methods for improving metal-to-metal contact in a via, devices made according to the methods, and systems including the same

ActiveUS20050170642A1Compromise reliabilityMinimize exposureSemiconductor/solid-state device manufacturingState of artProcess integration

In damascene process integration, a reducing plasma is applied after the etch stop or barrier layer is opened over a copper layer. Currently known methods for opening barrier layers suffer from the disadvantage that they cause at least some of the underlying copper to oxidize to copper oxide.. Because copper oxide is selectively removed by subsequent wet cleaning, voids can form where damaged copper (e.g., copper oxide) is removed, thus compromising the reliability of metal-to-metal contact in vias. The present invention advantageously overcomes this and other disadvantages of the prior art through the use of a hydrogen plasma following the barrier layer opening step, which repairs damaged copper (e.g., reduces copper oxide to copper), thus preventing and / or diminishing defects in metal-to-metal contacts in vias and concomitantly improving the reliability of the same.

Owner:MICRON TECH INC

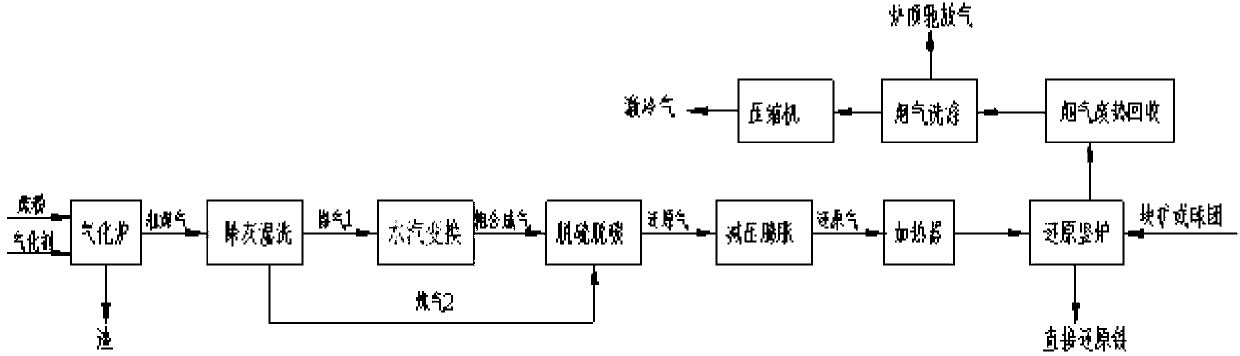

Method and system for pulverized coal gasification for gas generation and direct reduction metallurgy of gas-based shaft furnace

ActiveCN102994678AGet rid of dependenceOvercome limitationsShaft furnaceGas emission reductionWater vaporShaft furnace

The invention provides a method for pulverized coal gasification for gas generation and direct reduction metallurgy of a gas-based shaft furnace. According to the method, feed coal is ground and then enters a gasification furnace in a form of pulverized coal; the pulverized coal reacts with a gasification agent oxygen and water vapor to generate crude gas rich in CO and H2; the high-temperature raw gas generated by the gasification furnace is subjected to cooling and wet cleaning for dust removal to obtain crude synthesis gas mainly containing CO and H2; the crude synthesis gas is adjusted into a reducing agent for a gas-based shaft furnace through water vapor conversion and purification; and the reducing agent enters the shaft furnace and reacts with lump ores or pellets to generate reducing iron. Through the invention, the coal gasification is combined with a gas-based direct reduction shaft furnace technology, thus the limitation on total natural gas of a gas-based direct reducing method is overcome, and large-scale production is realized; and the method has the advantages of low energy consumption, little pollution and the like.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Vacuum cleaner with wet method cleaning function

InactiveCN1883354ASimple structureSave cleaning timeCarpet cleanersFloor cleanersEngineeringFriction force

A vacuum cleaner with a wet cleaning function comprises a main body, a brush assembly having a contaminant suction port facing a cleaning surface, a brush of the contaminant suction port to rotate in contact with the cleaning surface, and a water exhaust nozzle, the contaminants suction port is fluidly communicated with the main body, and a front and a rear block parts formed at a front and a rear of the brush on a bottom surface of the brush assembly to selectively open or block a contaminant suction path by a friction force against the cleaning surface.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com