Method and system for pulverized coal gasification for gas generation and direct reduction metallurgy of gas-based shaft furnace

A gas-based shaft furnace and coal gasification technology, applied in shaft furnaces, furnaces, furnace types, etc., can solve problems such as development restrictions, and achieve the effects of getting rid of dependence, low energy consumption, and reducing carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better illustrate the present invention, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

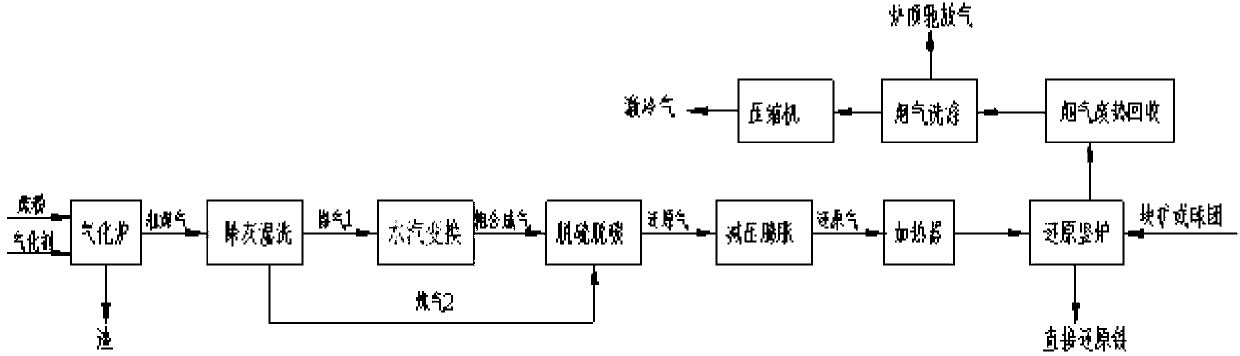

[0029] (1) The specific implementation method is as figure 1 As shown, the process flow includes:

[0030] 1. Raw coal is pulverized into pulverized coal and sent to the pulverized coal gasifier. Oxygen and water vapor are used as gasification agents. The design pressure of the pulverized coal gasifier is 0.2-4MPa;

[0031] 2. The temperature of the raw gas produced in the combustion chamber of the gasifier is reduced to 150-280°C after gas quenching and water quenching, and then after ash removal and wet cleaning, a large amount of dust and some impurities entrained in the crude gas are removed , get CO and H 2 Gases with main components, CO and H 2 The volume percentage of dry gas accounts for 80-94%;

[0032] 3. The crude g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com