Patents

Literature

2822 results about "Coal gasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal gasification is the process of producing syngas–a mixture consisting primarily of carbon monoxide (CO), hydrogen (H₂), carbon dioxide (CO₂), natural gas (CH₄) , and water vapour (H₂O)–from coal and water, air and/or oxygen.

Hydrogen production from carbonaceous material

InactiveUS6790430B1Avoid the needCalcium/strontium/barium carbonatesGas turbine plantsCalcinationExothermic reaction

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE +1

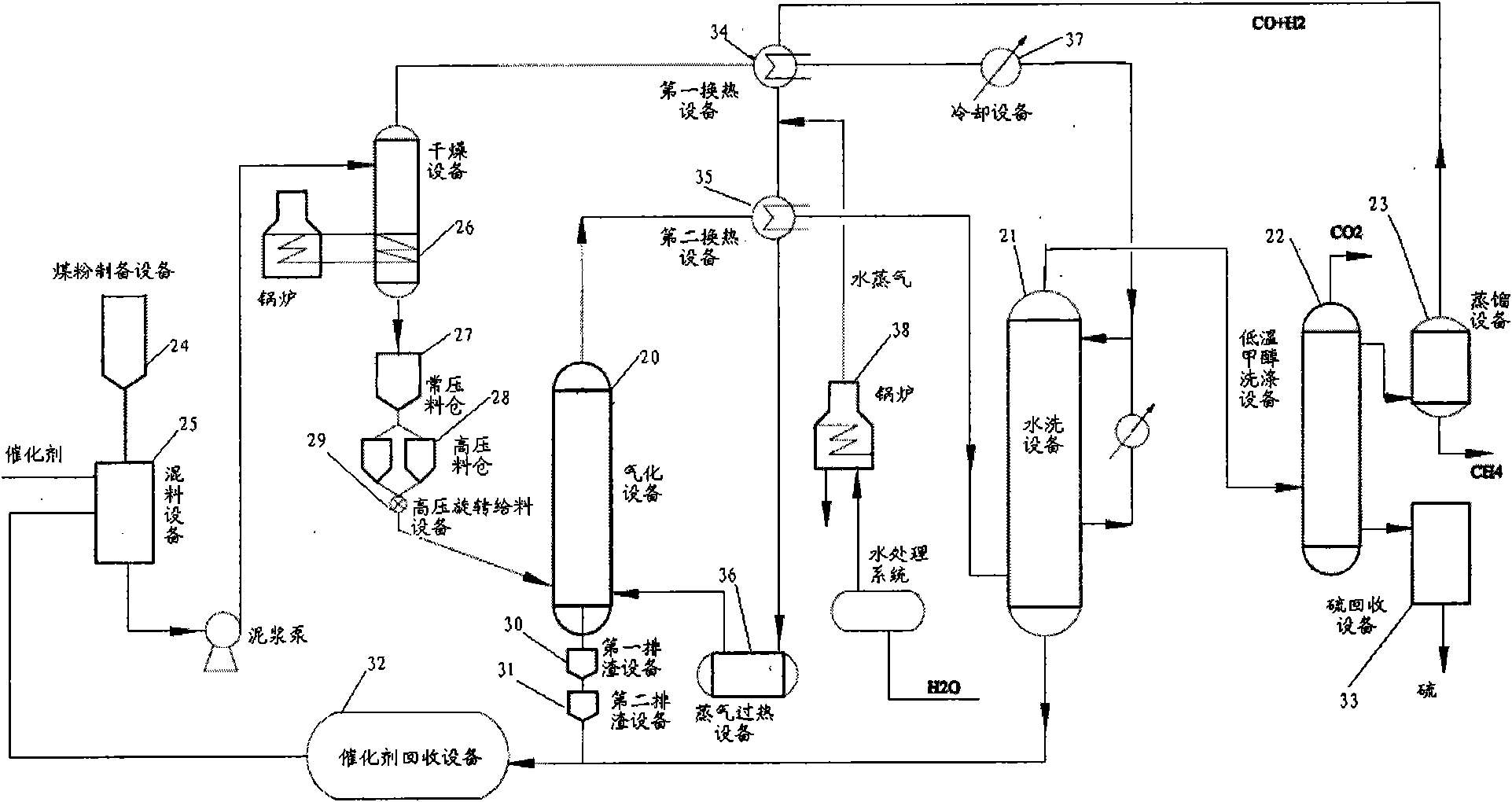

Steam Generating Slurry Gasifier for the Catalytic Gasification of a Carbonaceous Feedstock

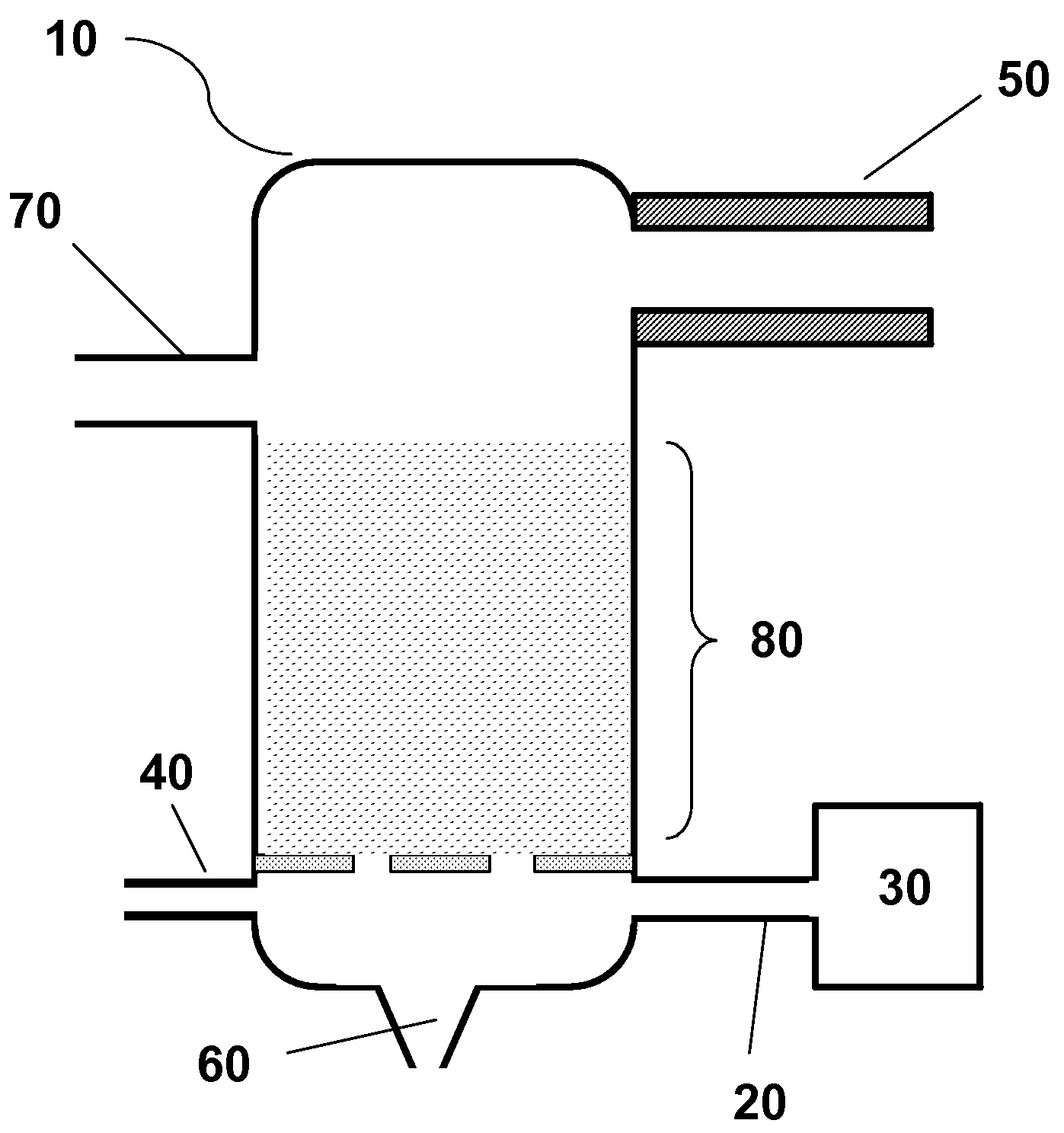

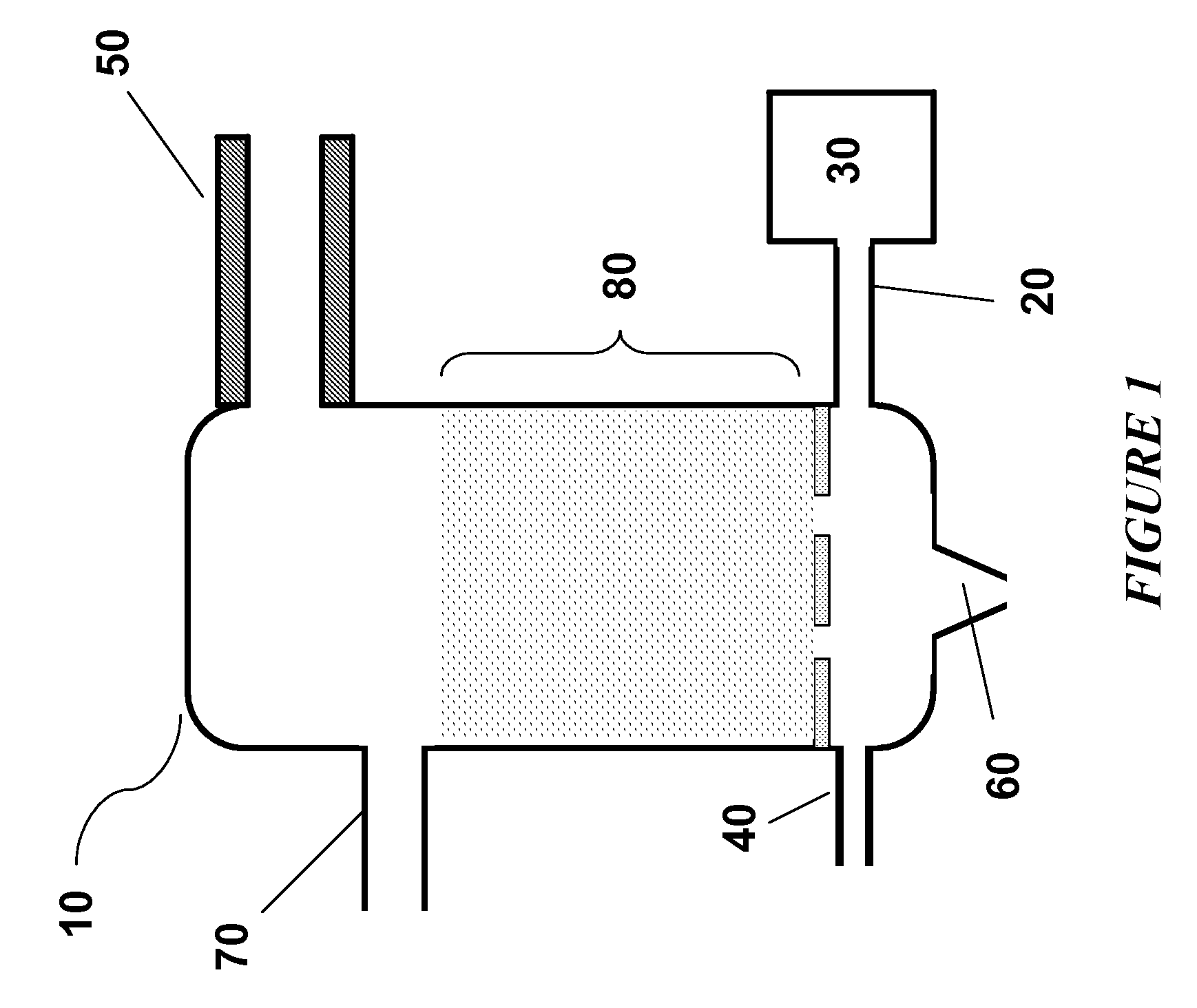

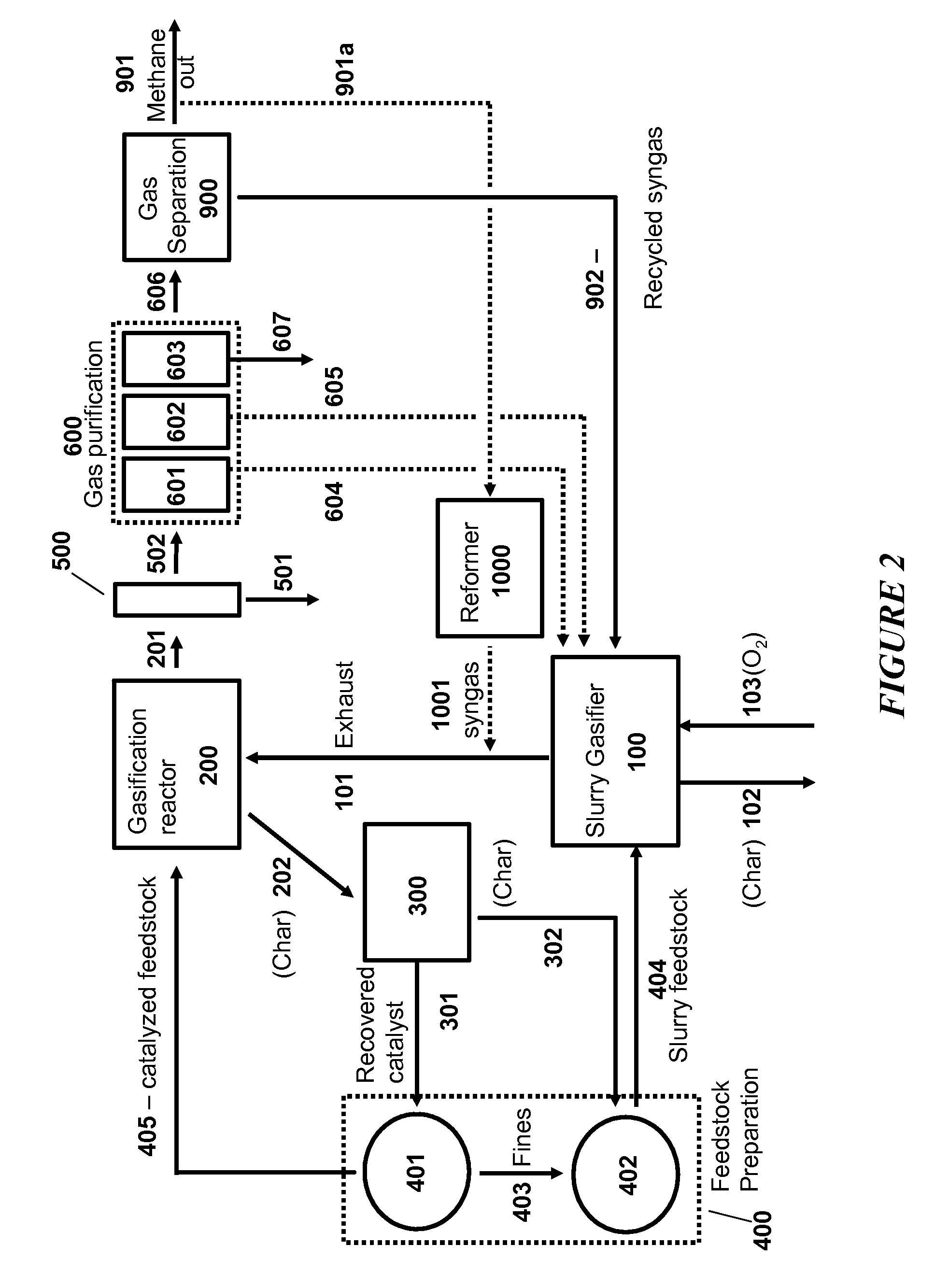

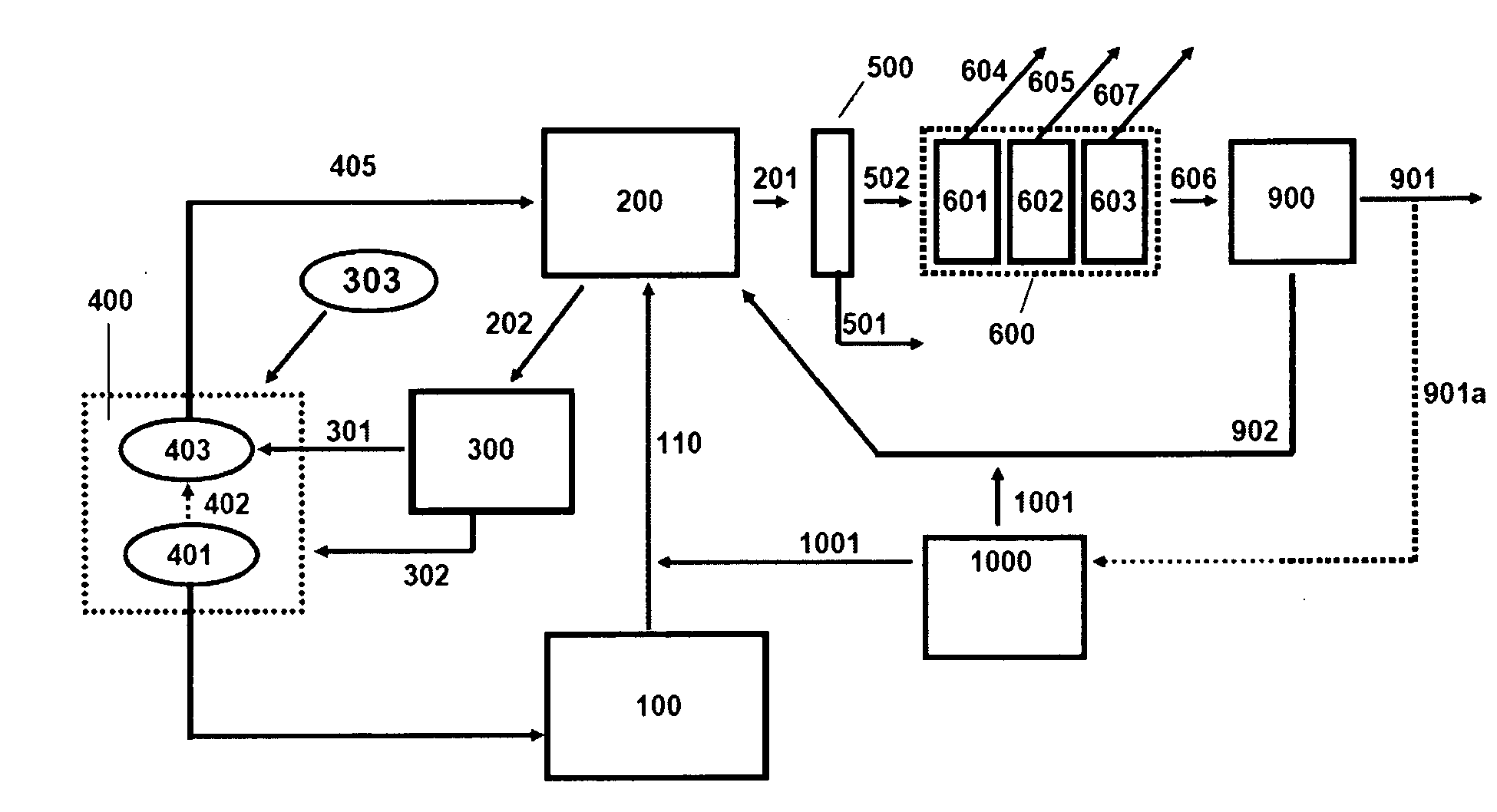

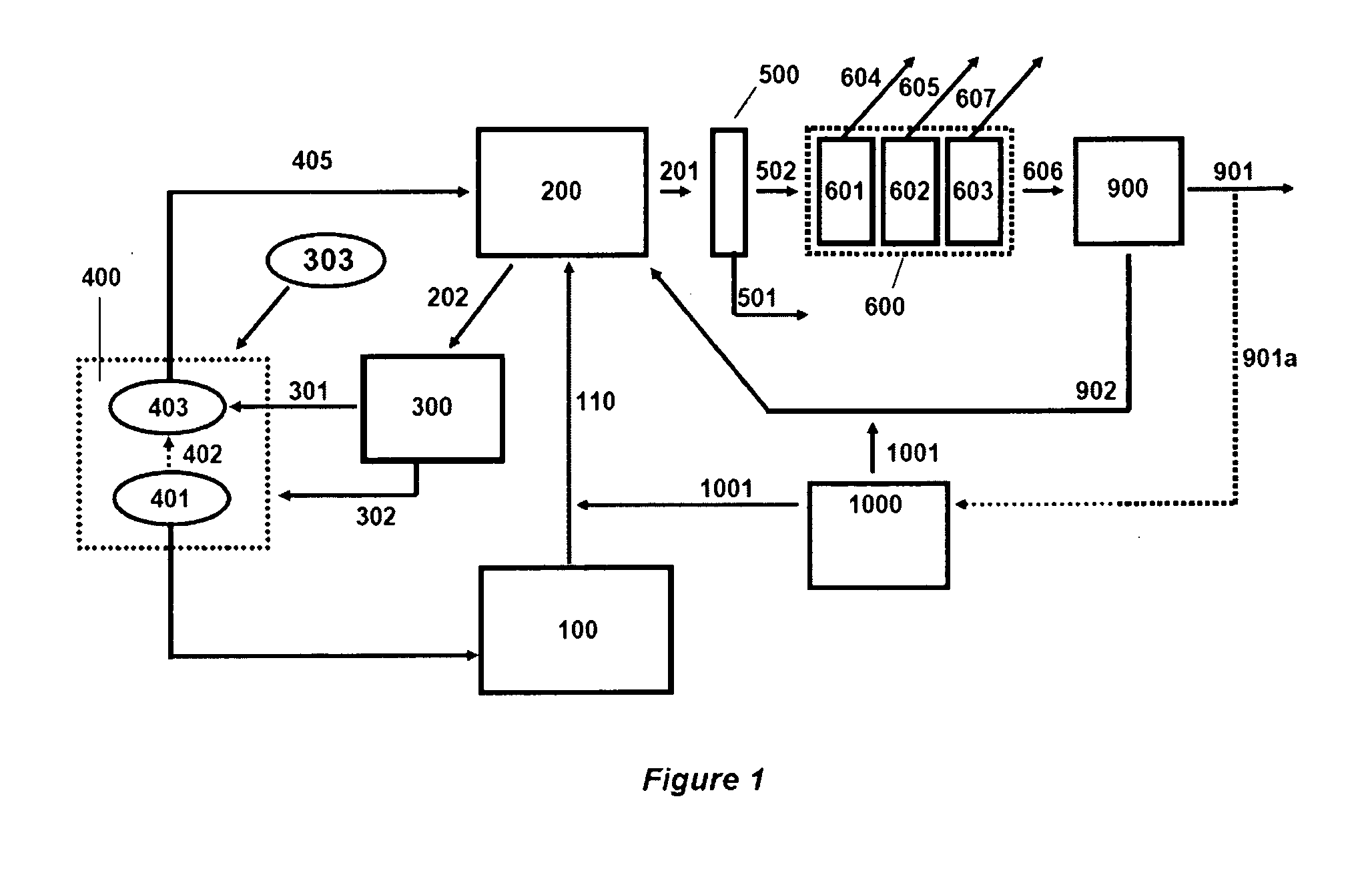

Steam generating gasification reactors for providing high-pressure and high-temperature steam for catalytic gasification of a carbonaceous feedstock can be based on oxygen blown gasification reactors adapted for processing a slurry feedstock comprising at least 40% water. The exhaust from the slurry gasifier comprises at least steam, carbon monoxide and hydrogen. The slurry composition and the oxygen to fuel ratio can be varied to control the ratio of carbonaceous gases in the generator exhaust. By directing substantially all of exhaust gases produced from the slurry gasification reactor through the catalytic gasifier and subsequent gas separation and sequestration processes, a greatly higher energy efficiency and decreased carbon footprint can be realized.

Owner:SURE CHAMPION INVESTMENT LTD

Co-Feed of Biomass as Source of Makeup Catalysts for Catalytic Coal Gasification

Continuous processes are provided for converting a carbonaceous feedstock comprising biomass containing alkali metal, non-biomass components, and at least one gasification catalyst including an alkali metal recovered from solid char, into a plurality of gaseous products including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons.

Owner:SURE CHAMPION INVESTMENT LTD

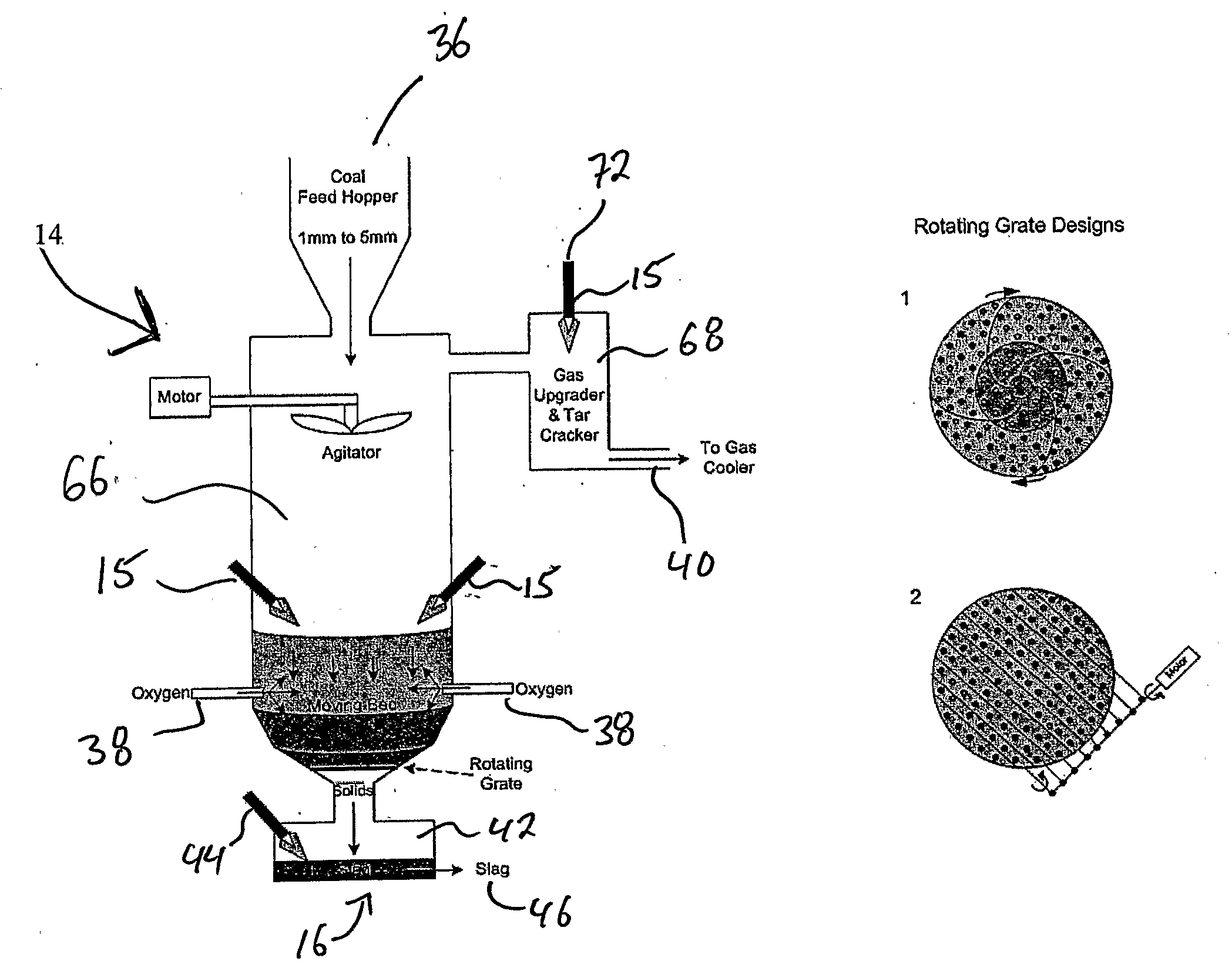

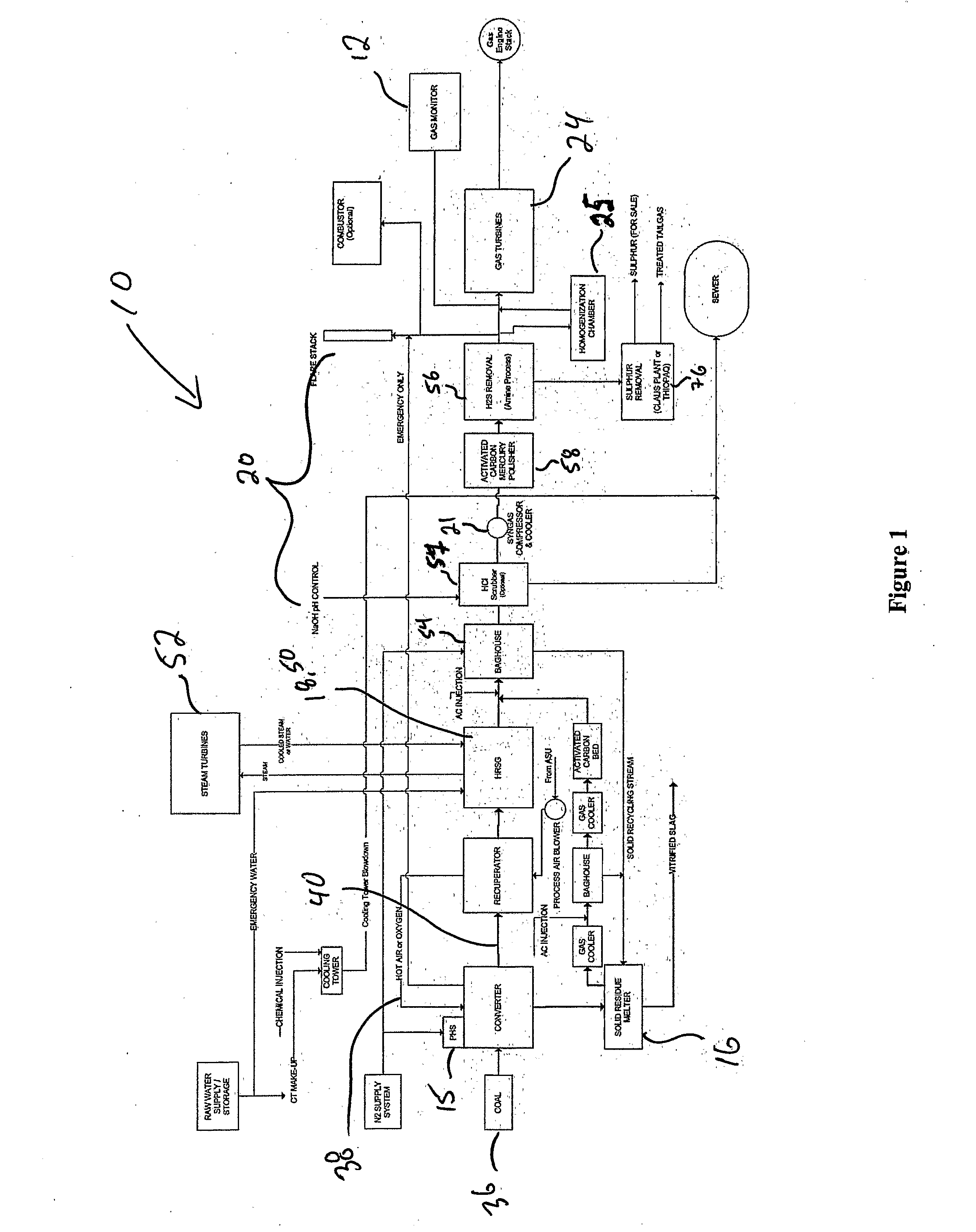

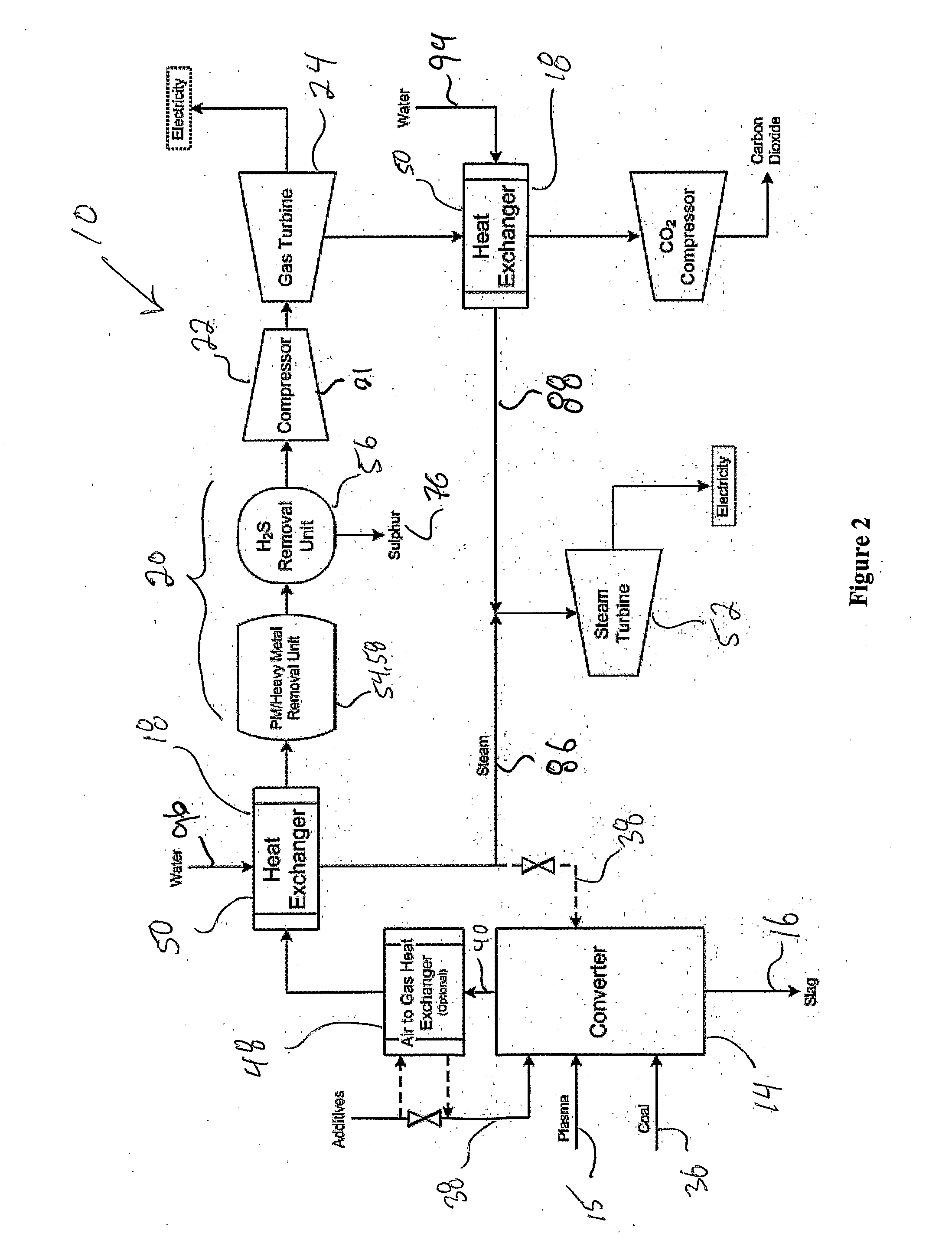

System for the Conversion of Coal to a Gas of Specified Composition

InactiveUS20080222956A1Energy inputCarburetting by solid carbonaceous material pyrolysisEnergeticsProduct gas

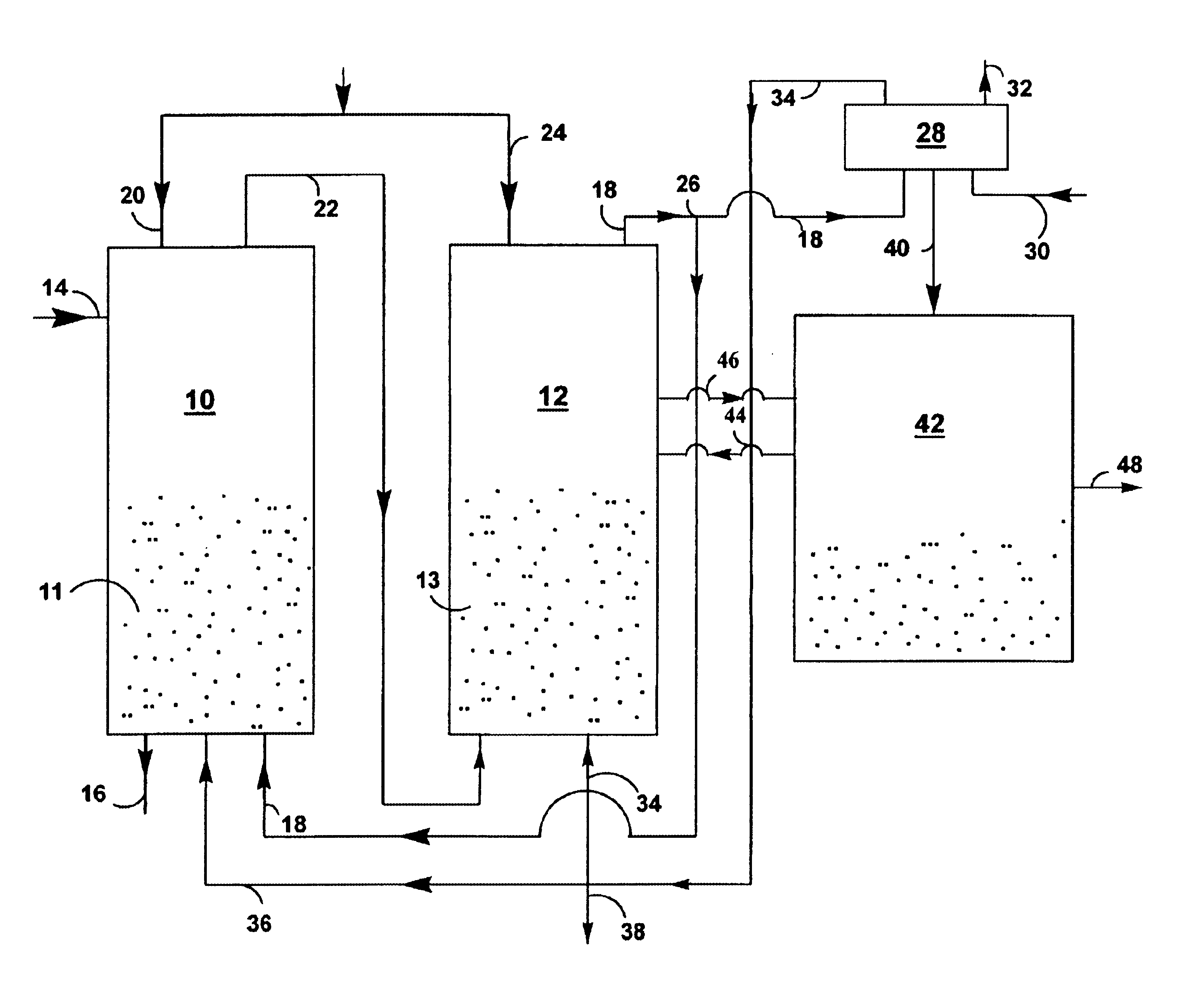

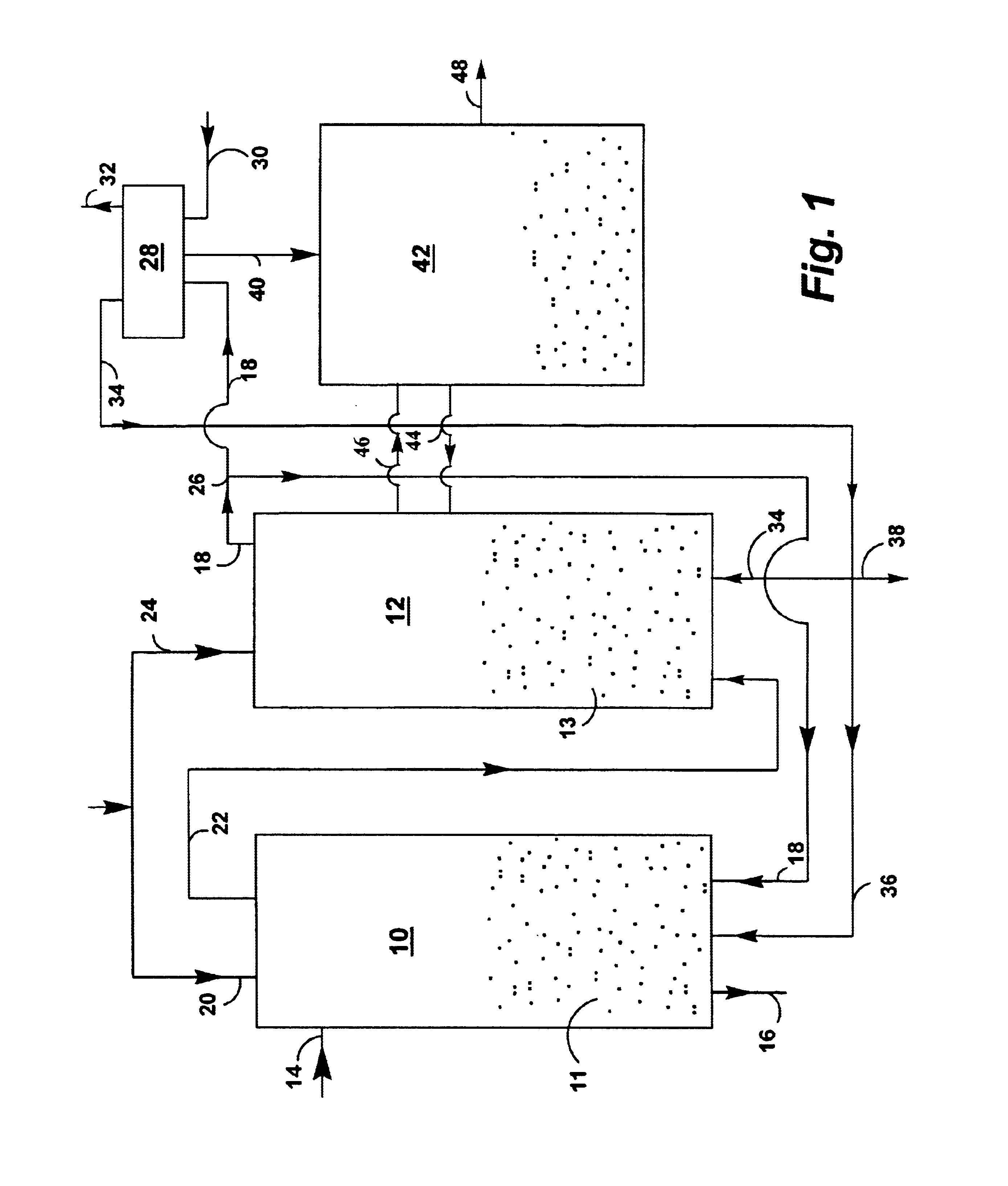

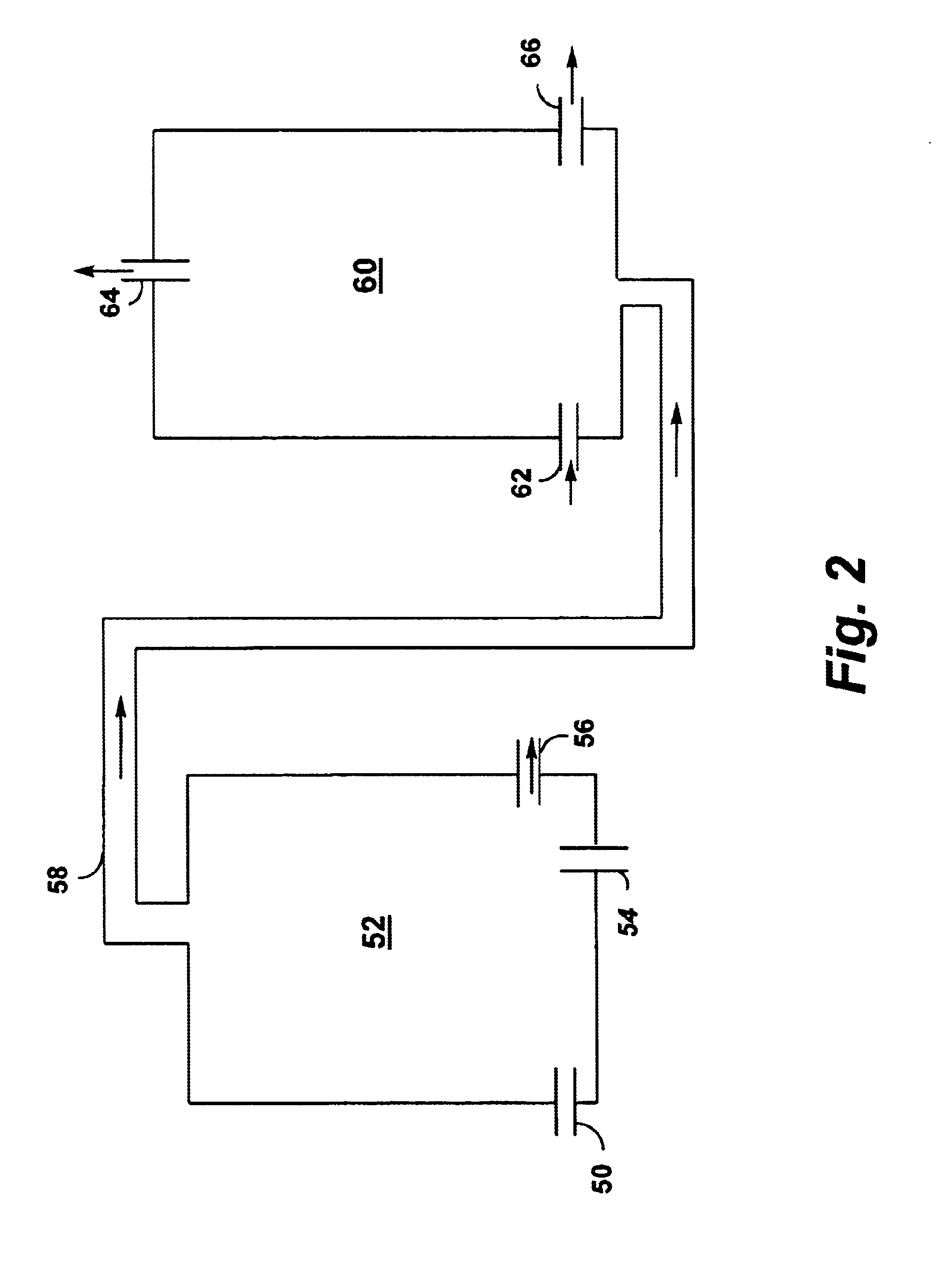

The present invention provides a coal gasification system with an integrated control subsystem. The system generally comprises, in various combinations, a gasification reactor vessel (or converter) having one or more processing zones and one or more plasma heat sources, a solid residue handling subsystem, a gas quality conditioning subsystem, as well as an integrated control subsystem for managing the overall energetics of the conversion of coal to energy and maintaining all aspects of the gasification processes at an optimal set point The gasification system may also optionally comprise a heat recovery subsystem and / or a product gas regulating subsystem.

Owner:PLASCO ENERGY GROUP INC

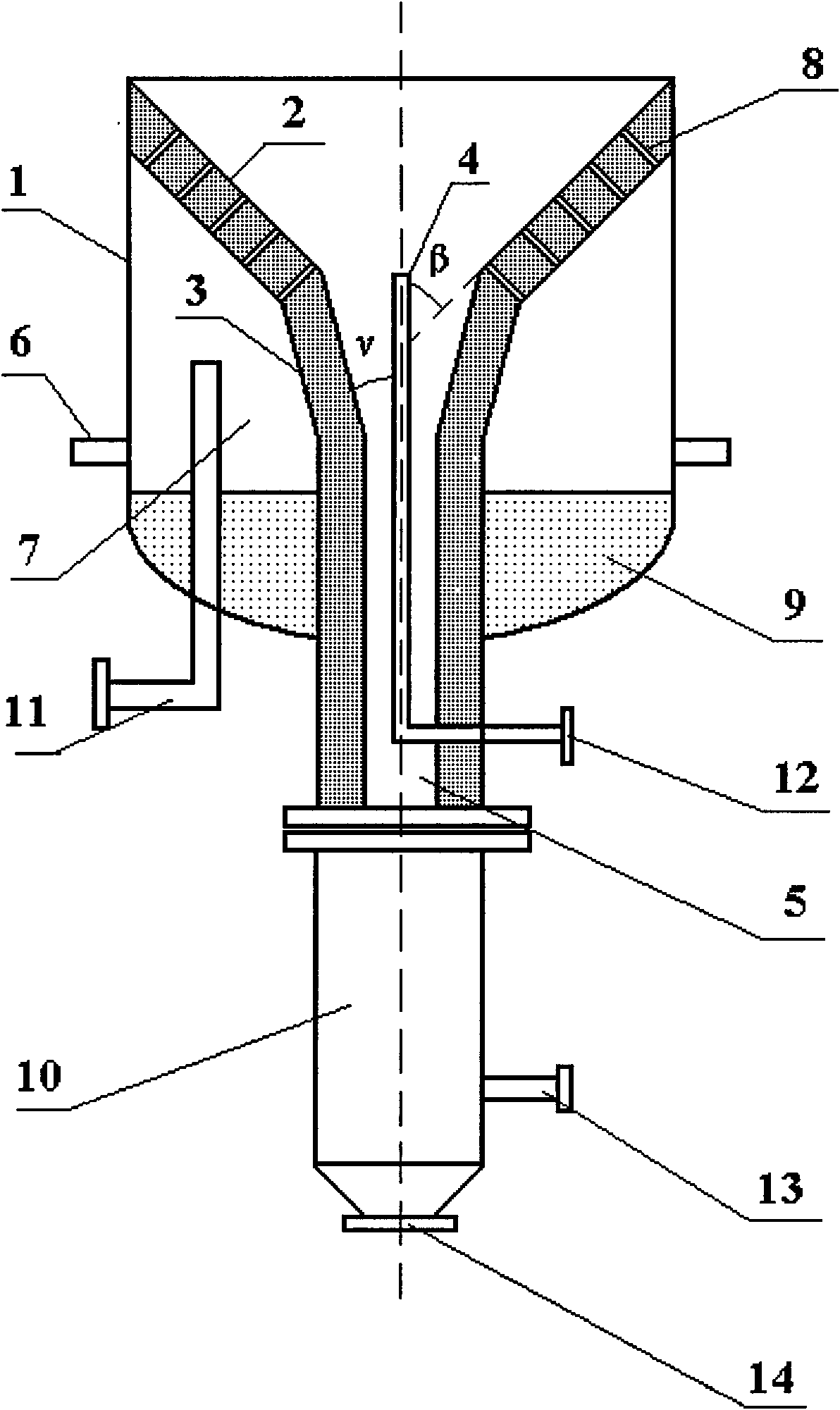

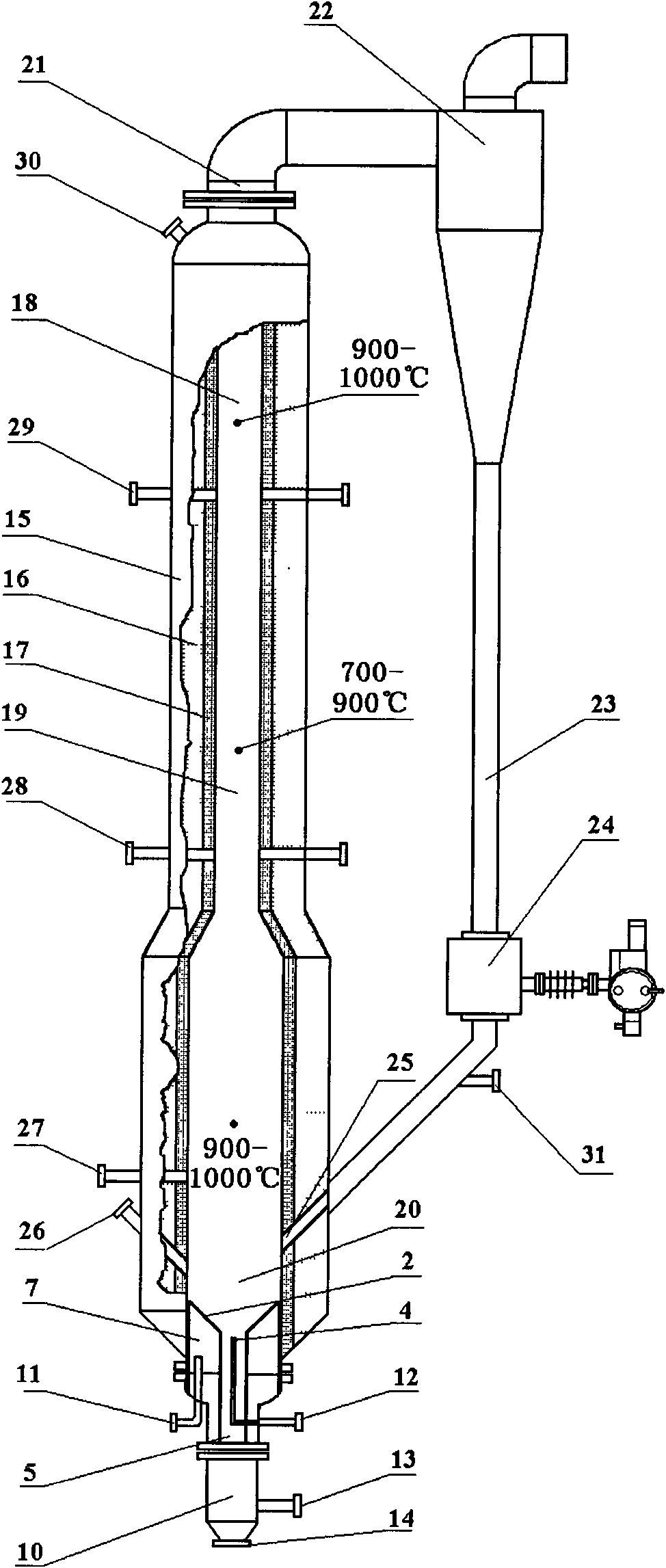

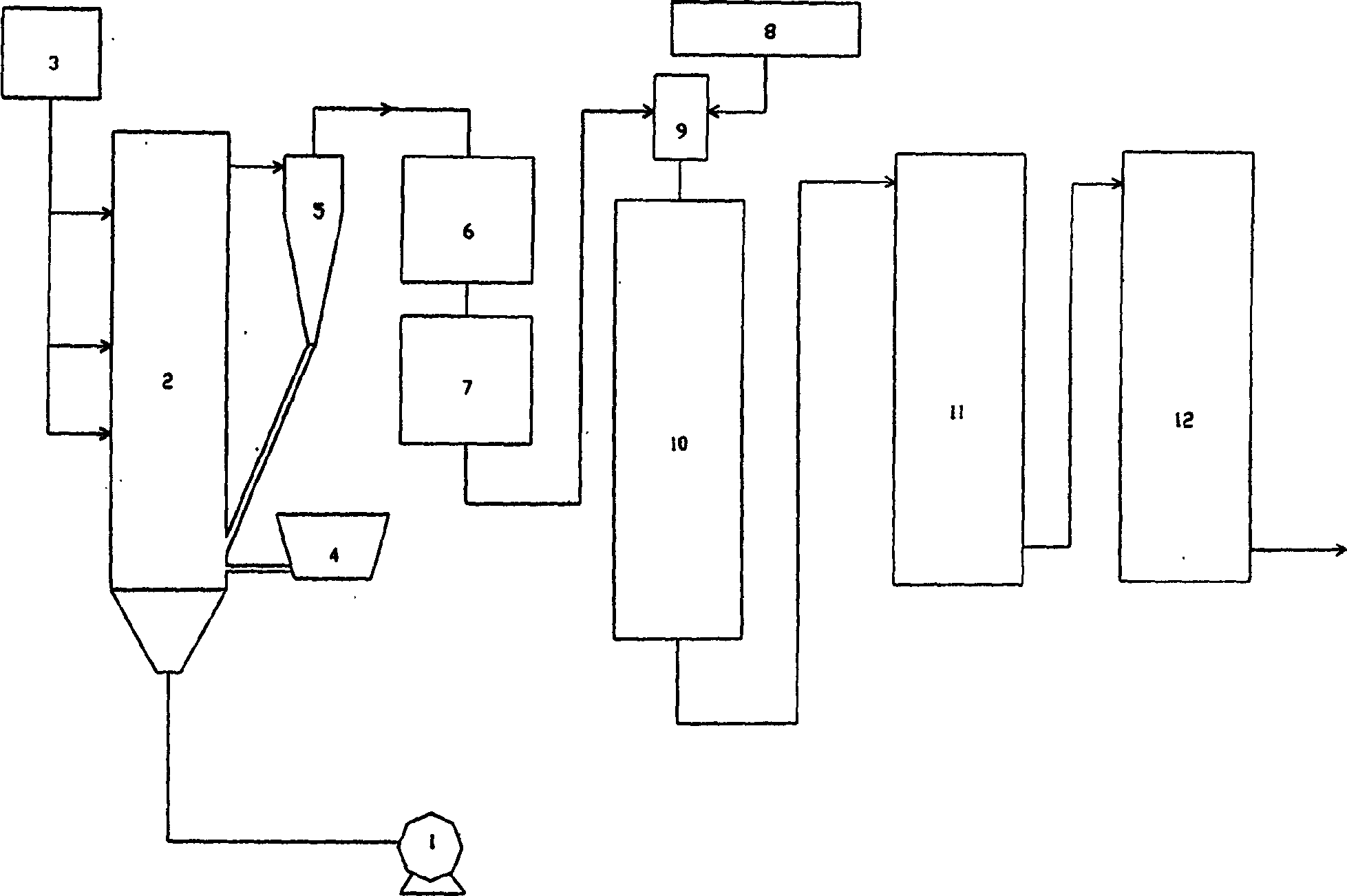

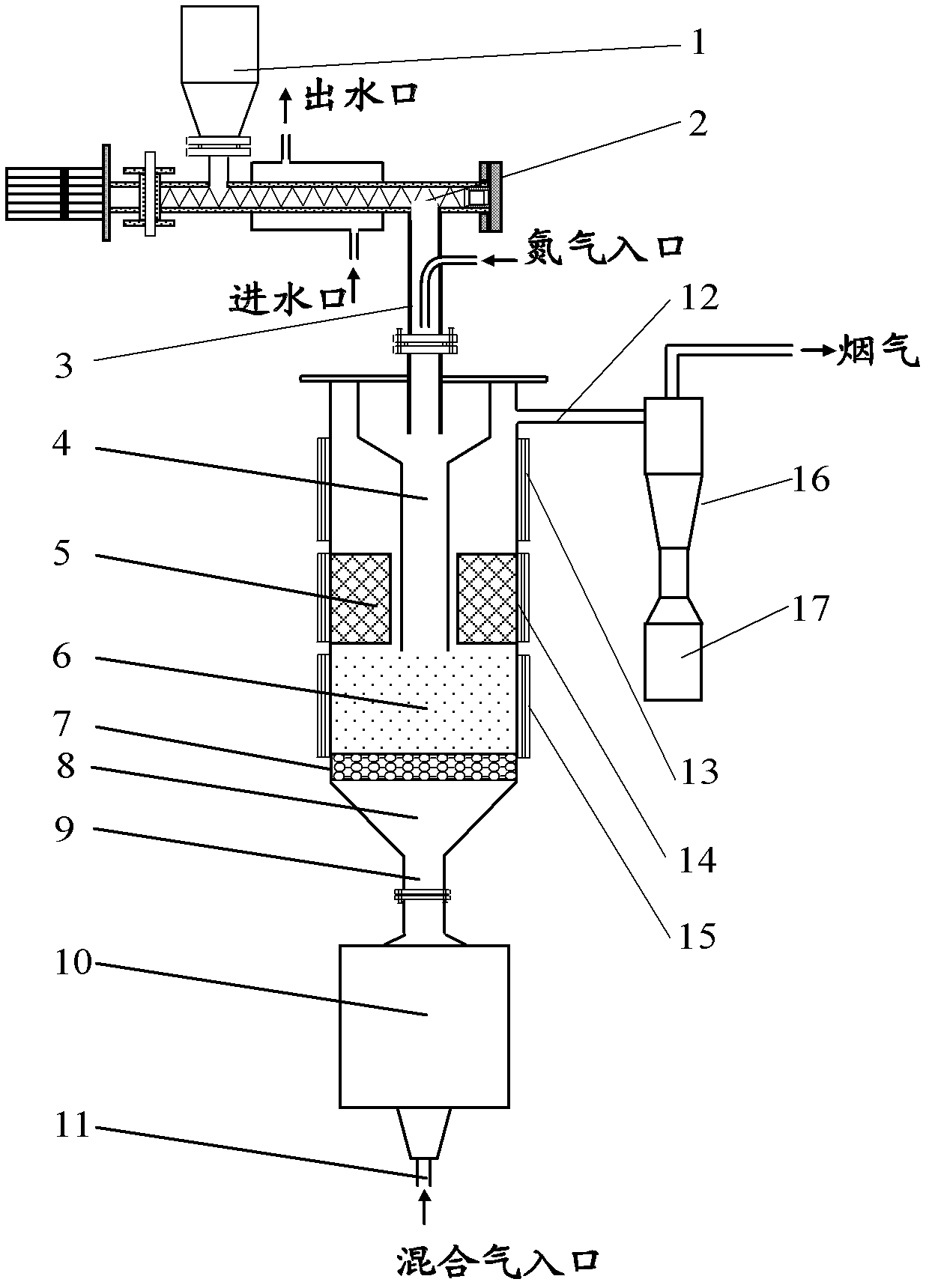

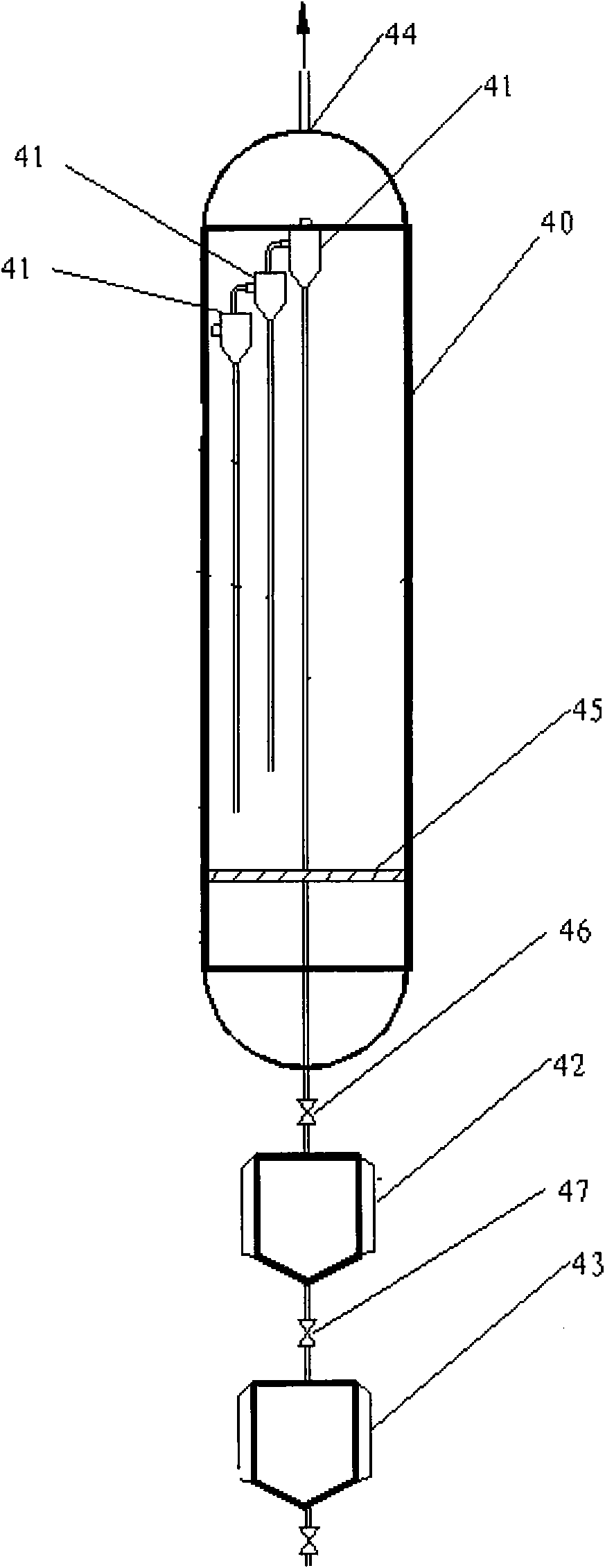

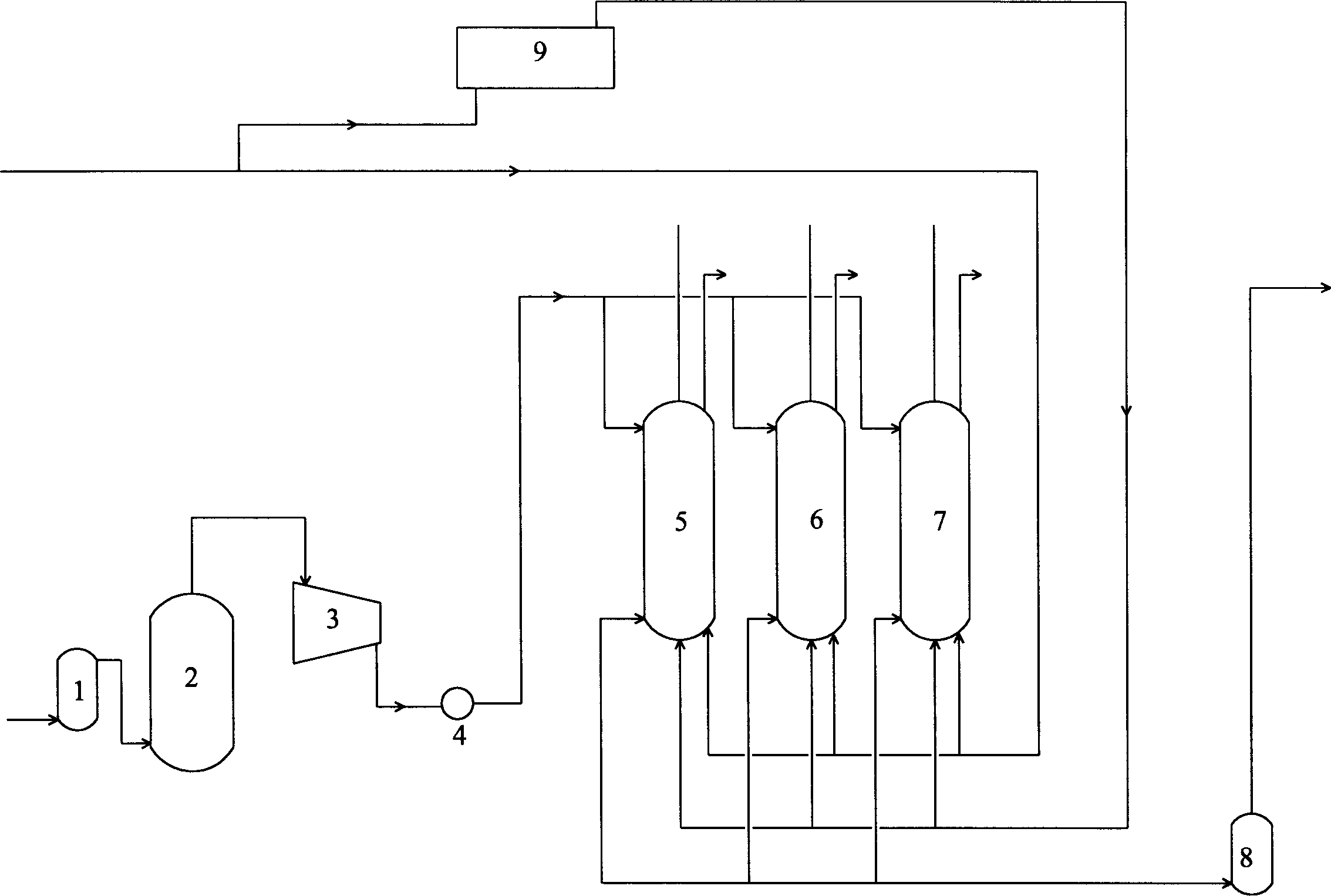

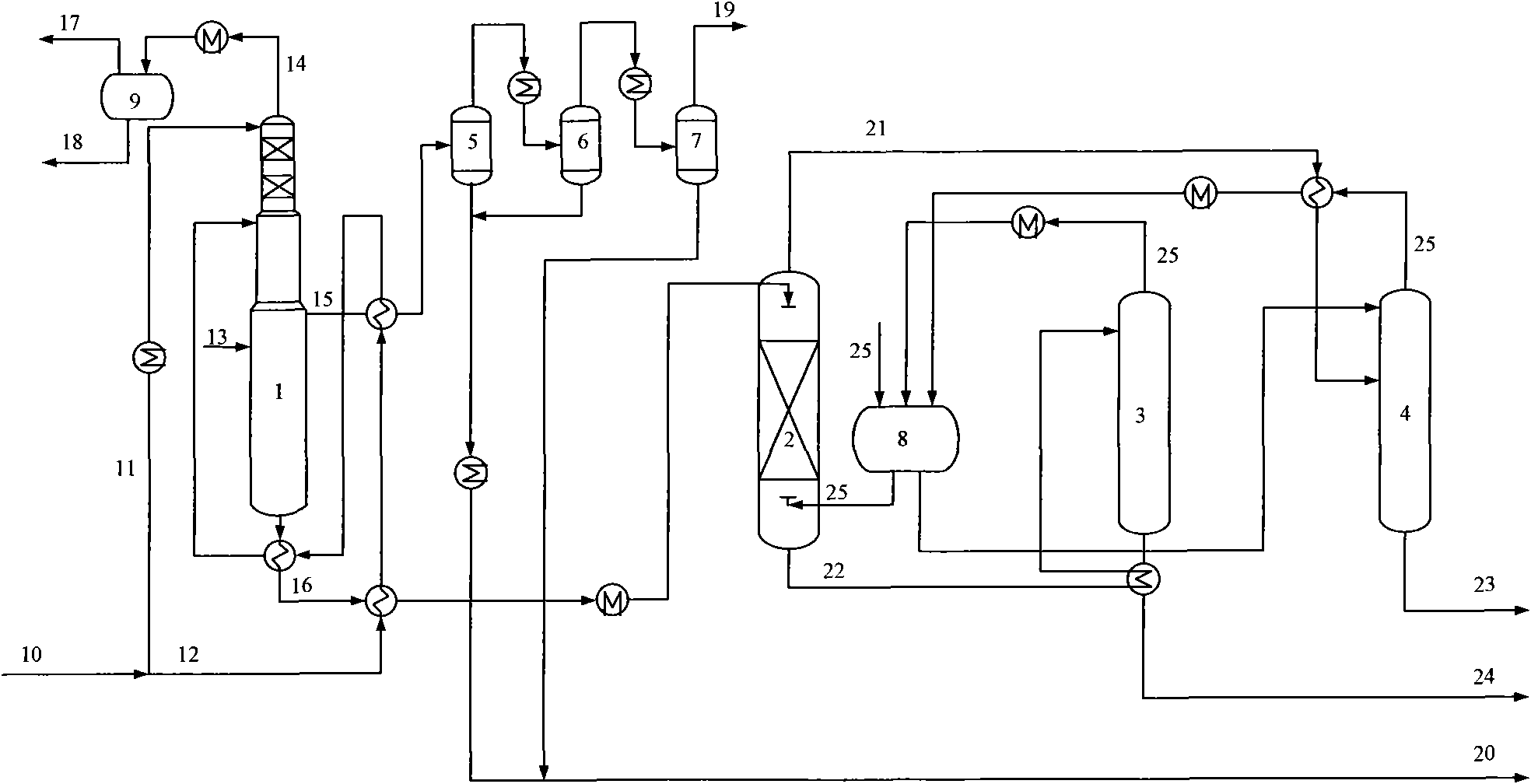

Method and device for gasifying multi-segment staged converted fluidized bed

ActiveCN101942344ALow ash carbon contentExtended stayEnergy inputCombined combustion mitigationFluidized bedProcess engineering

The invention relates to method and device for gasifying a multi-segment staged converted fluidized bed. The method comprises the following steps of: supplying coal; supplying gas; gasifying; slagging; and conveying fine powder. The device for gasifying the multi-grade staged converted fluidized bed comprises an agglomerating ash separating unit, a pyrolyzing and gasifying reactor of the multi-segment staged fluidized bed and a semicoke fine powder cyclic feeding unit. The invention has the advantages of high volume utilization rate of a gasifying oven, great handling capacity and high utilization rate of total carbon, is suitable for a coal staging and converting system and can be singly used for producing gas for mass coal-based methane synthesis and coal chemical industry.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

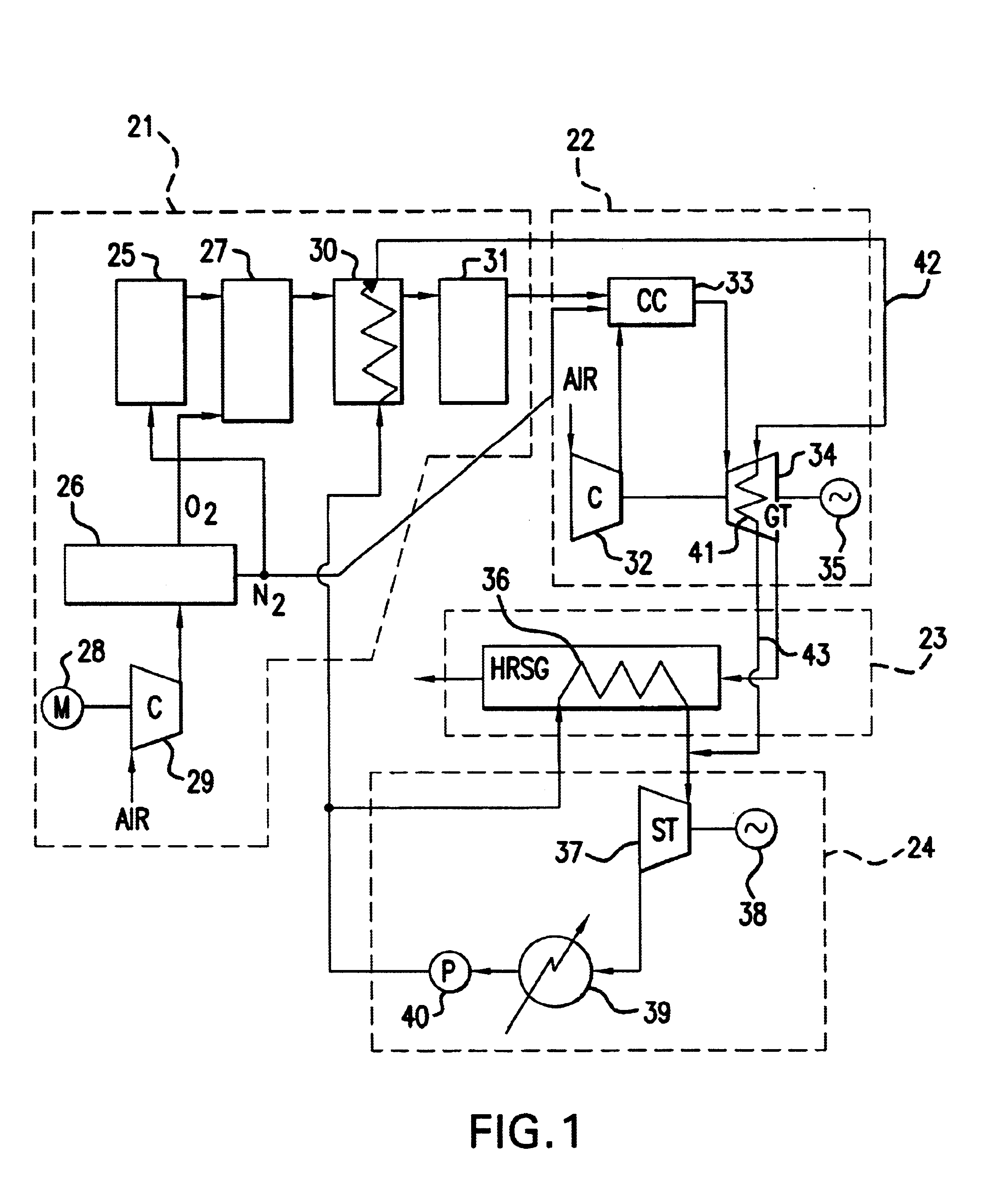

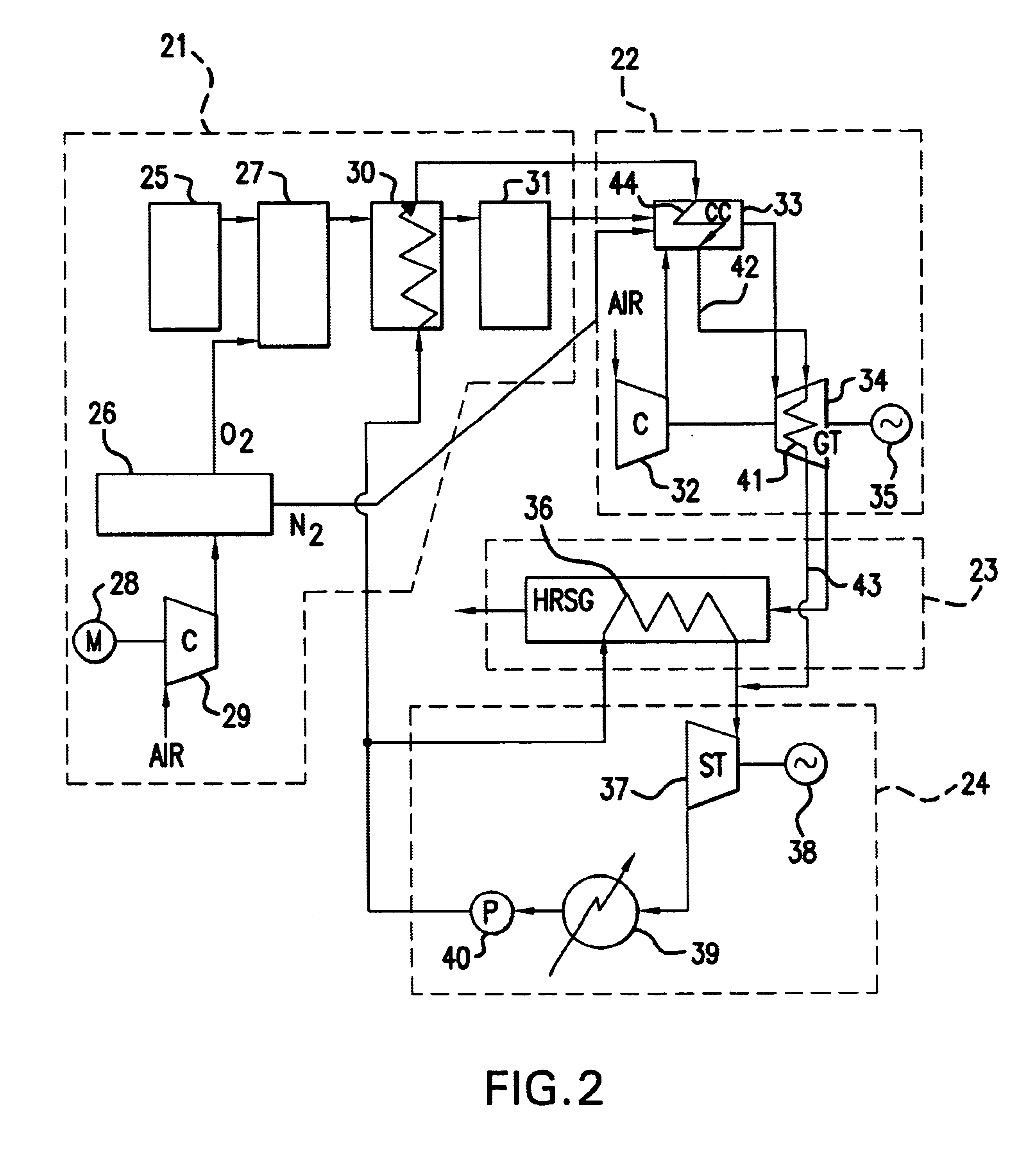

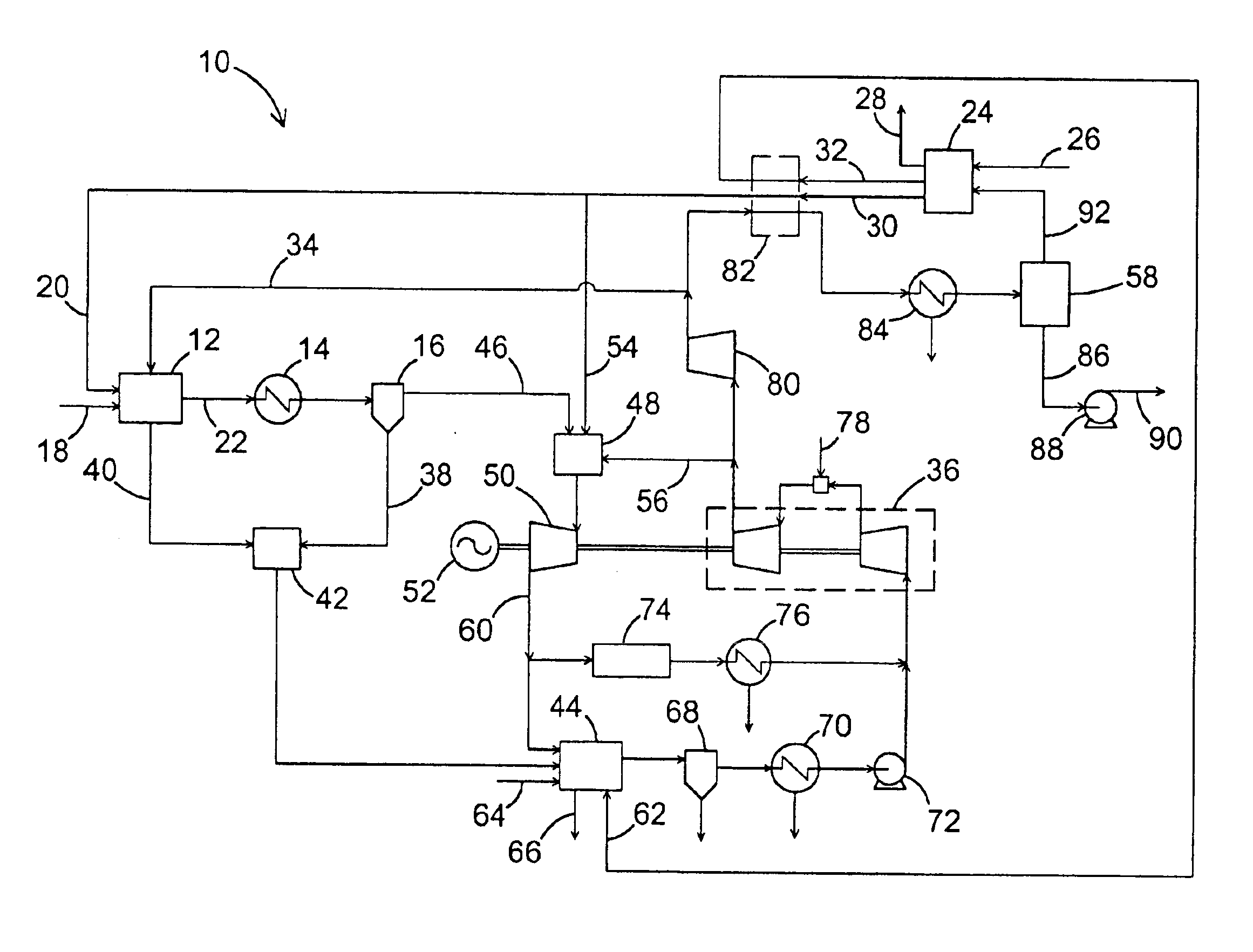

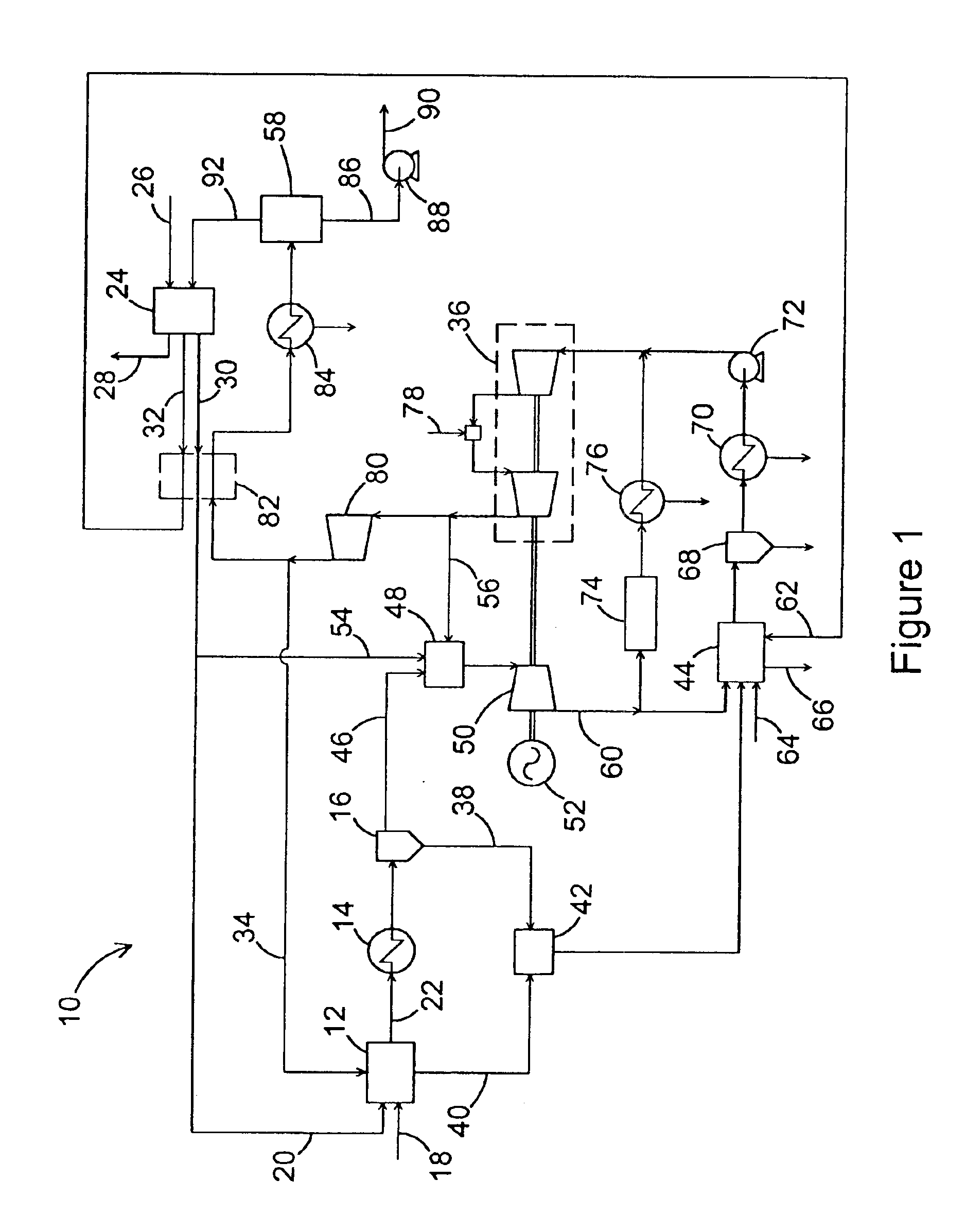

Integrated coal gasification combined cycle power generator

Embodiments of the invention provide an IGCC which achieves improved plant thermal efficiency by using a cooling steam supply system that cools the high-temperature sections of the gas turbine 34. Embodiments of the invention further provide and IGCC in which the cooling steam recovery system recovers steam after cooling the gas-turbine high-temperature section and makes practical re-use of the energy and substances within the system. Therefore, embodiments of the invention can reduce or eliminate the degradation of certain equipment by cooling the high-temperature sections. Methods are provided for increasing the thermal efficiency o an IGCC.

Owner:KK TOSHIBA

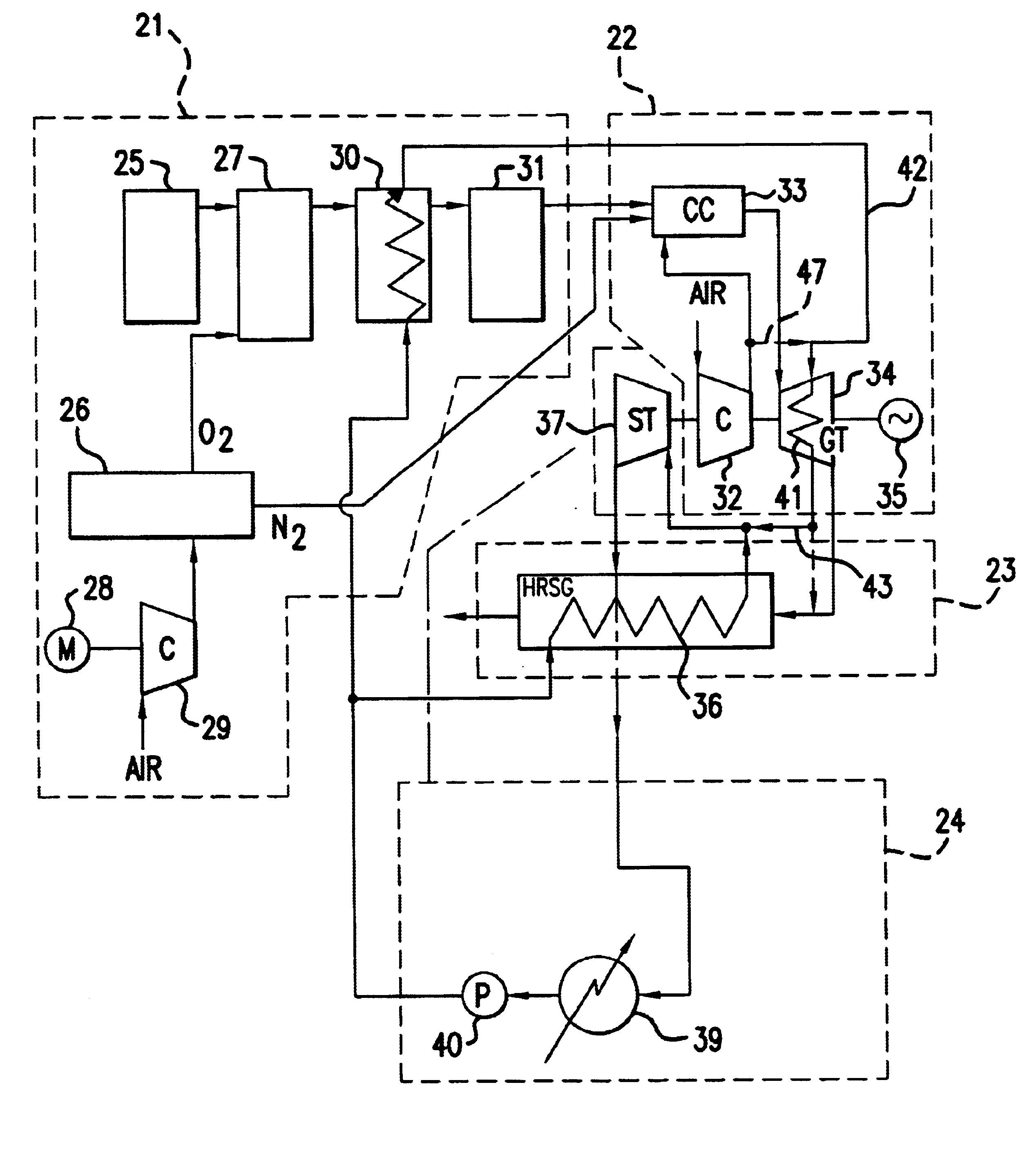

Advanced hybrid coal gasification cycle utilizing a recycled working fluid

InactiveUS6877322B2Generate efficientlyEliminate and reduce carbon dioxide emissionSolidificationLiquefactionSyngasCombustor

A power generating system having a hybrid gasification cycle, in which CO2 is recycled to a gasifier to be used as a gasification reactant and working fluid. The power generating system includes a source of fresh, pure oxygen, a gasifier, a particle separator arranged in flow connection with the gasifier, a syngas combustor, a gas turbine arranged in flow connection with the syngas combustor, a steam generator arranged in flow connection with the outlet of the gas turbine, and a gas compressor system which discharges a stream of compressed exhaust gas. A first portion of the stream of compressed exhaust gas is conducted to the gasifier to control the temperature in the gasifier, to provide CO2 and steam for gasification, and to decrease the demand for fresh, pure oxygen therein.

Owner:FOSTER WHEELER ENERGY CORP

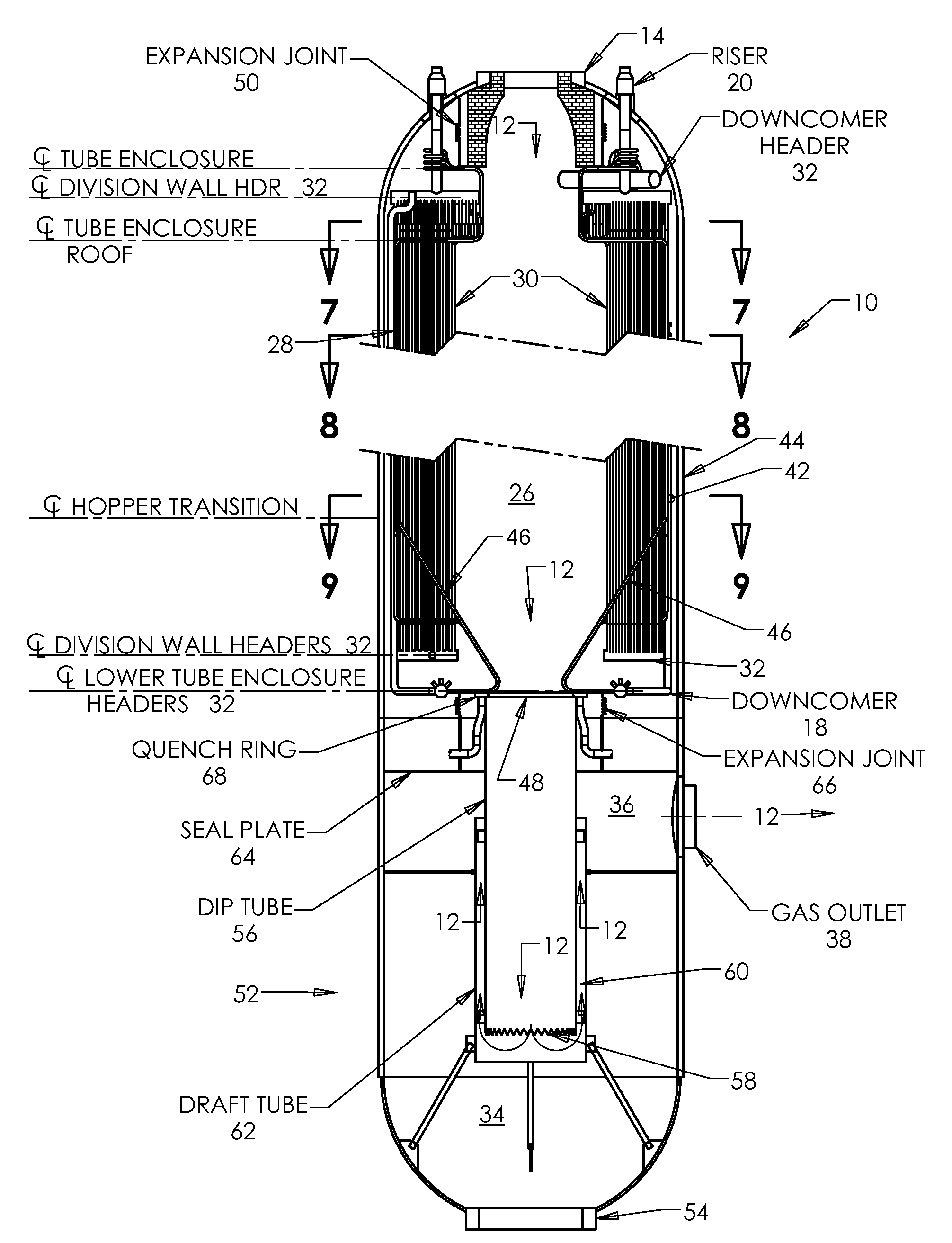

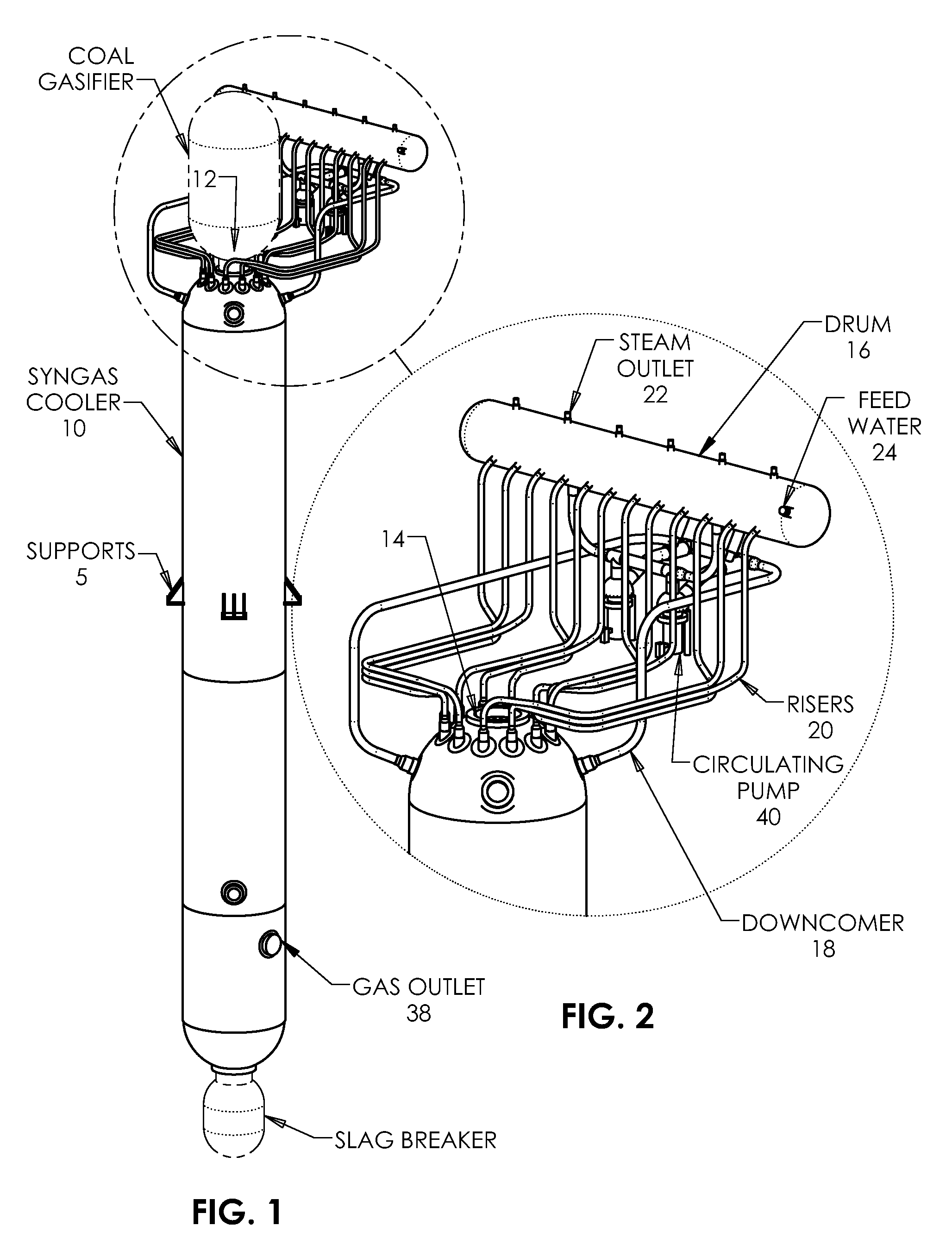

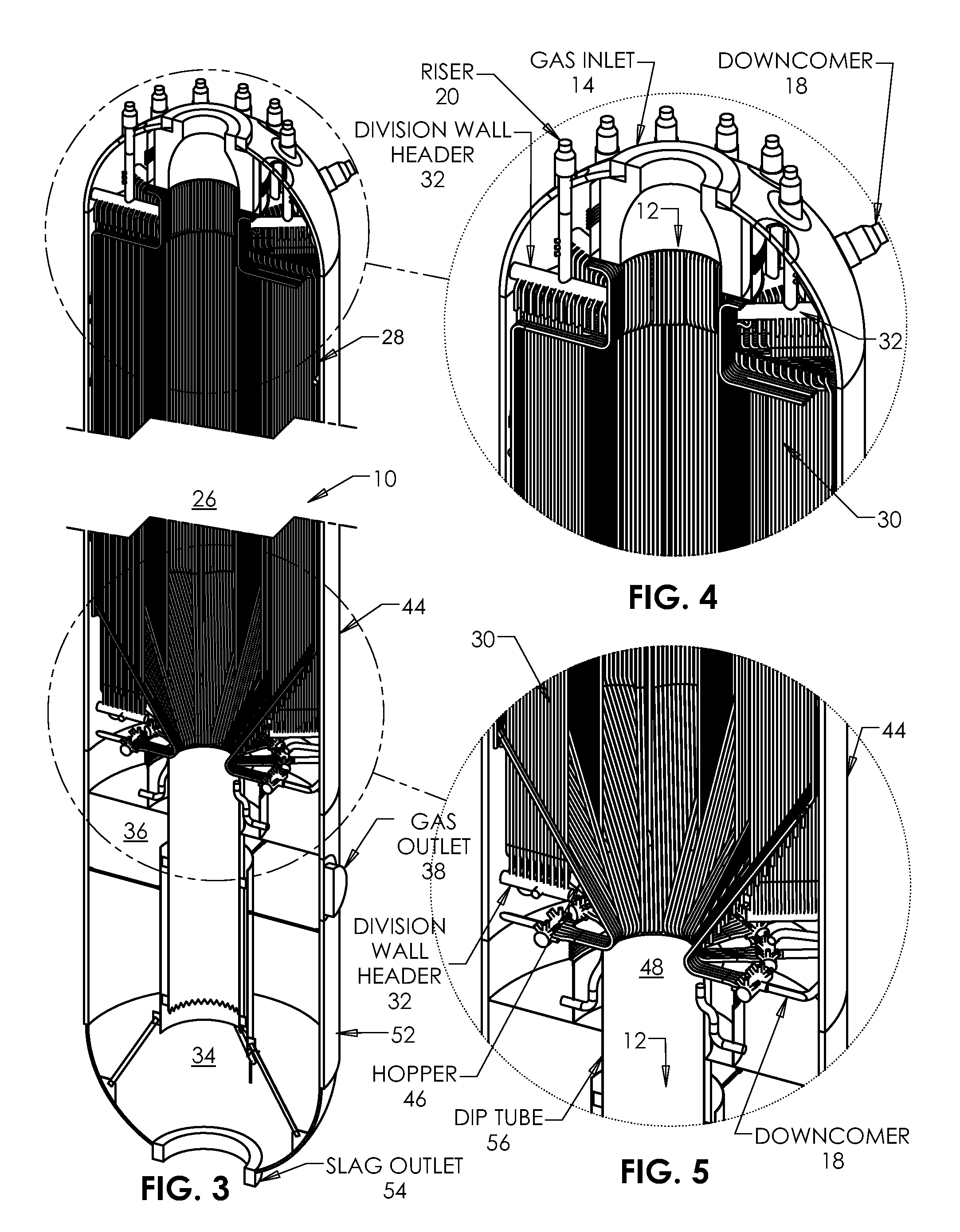

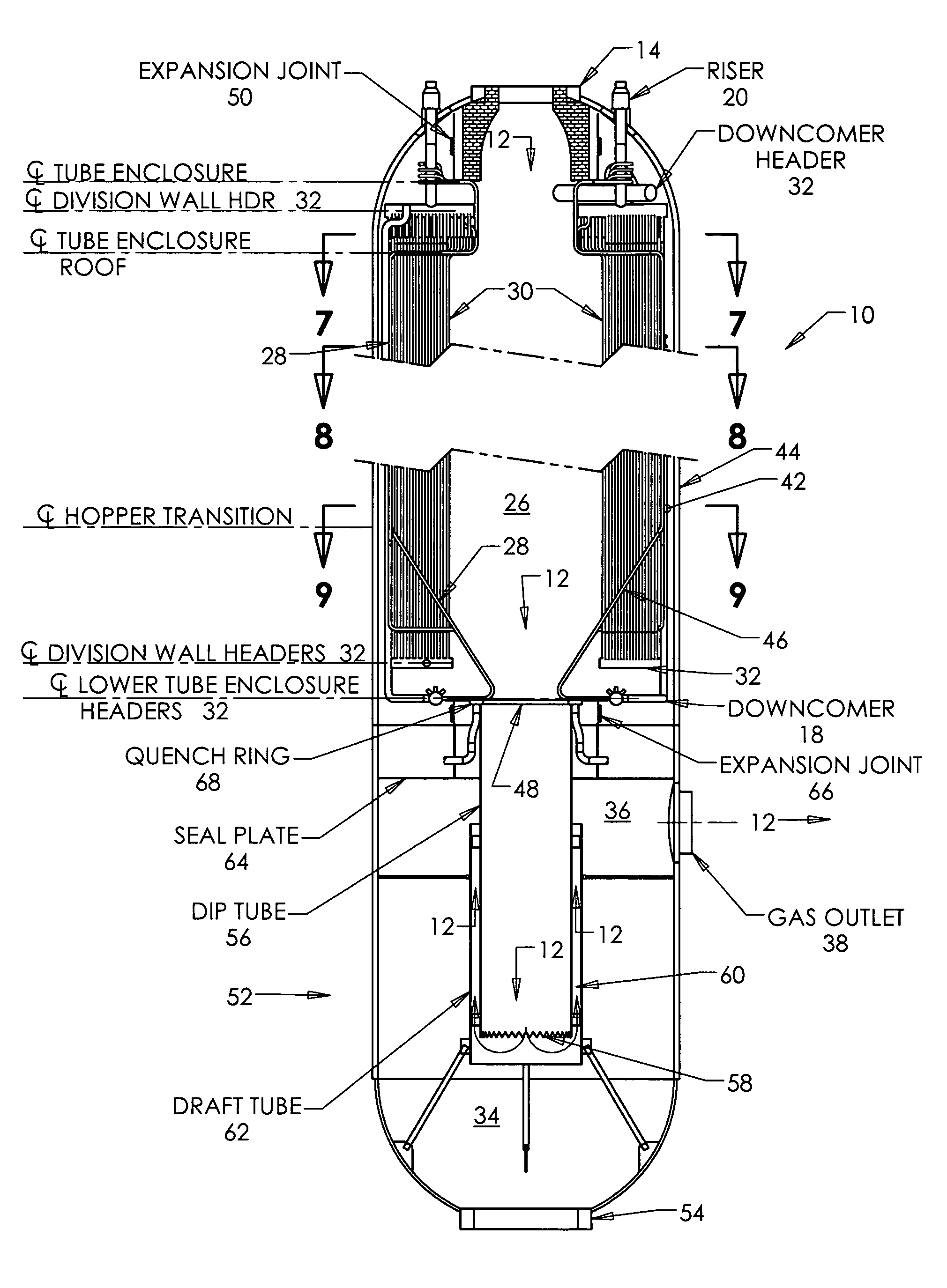

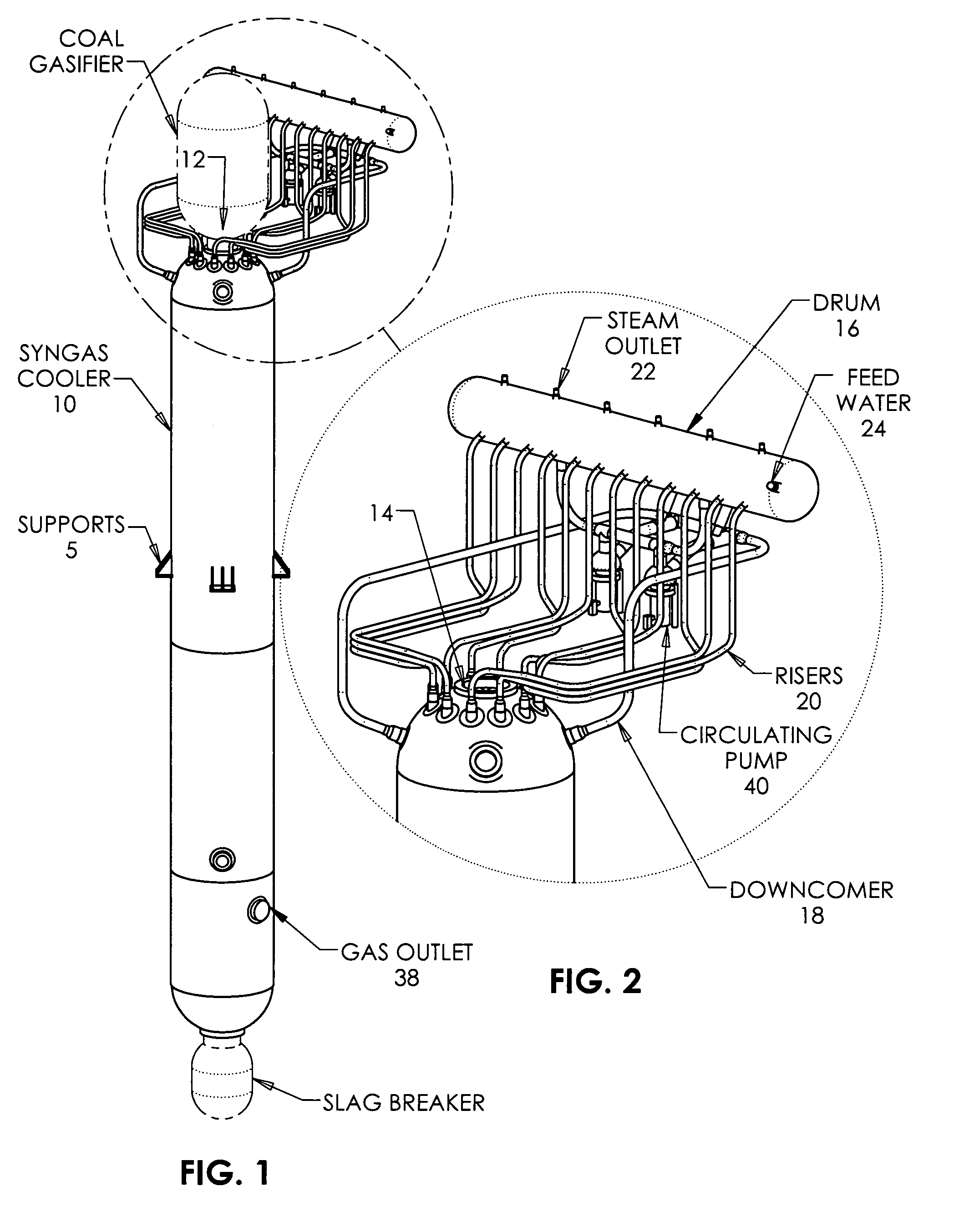

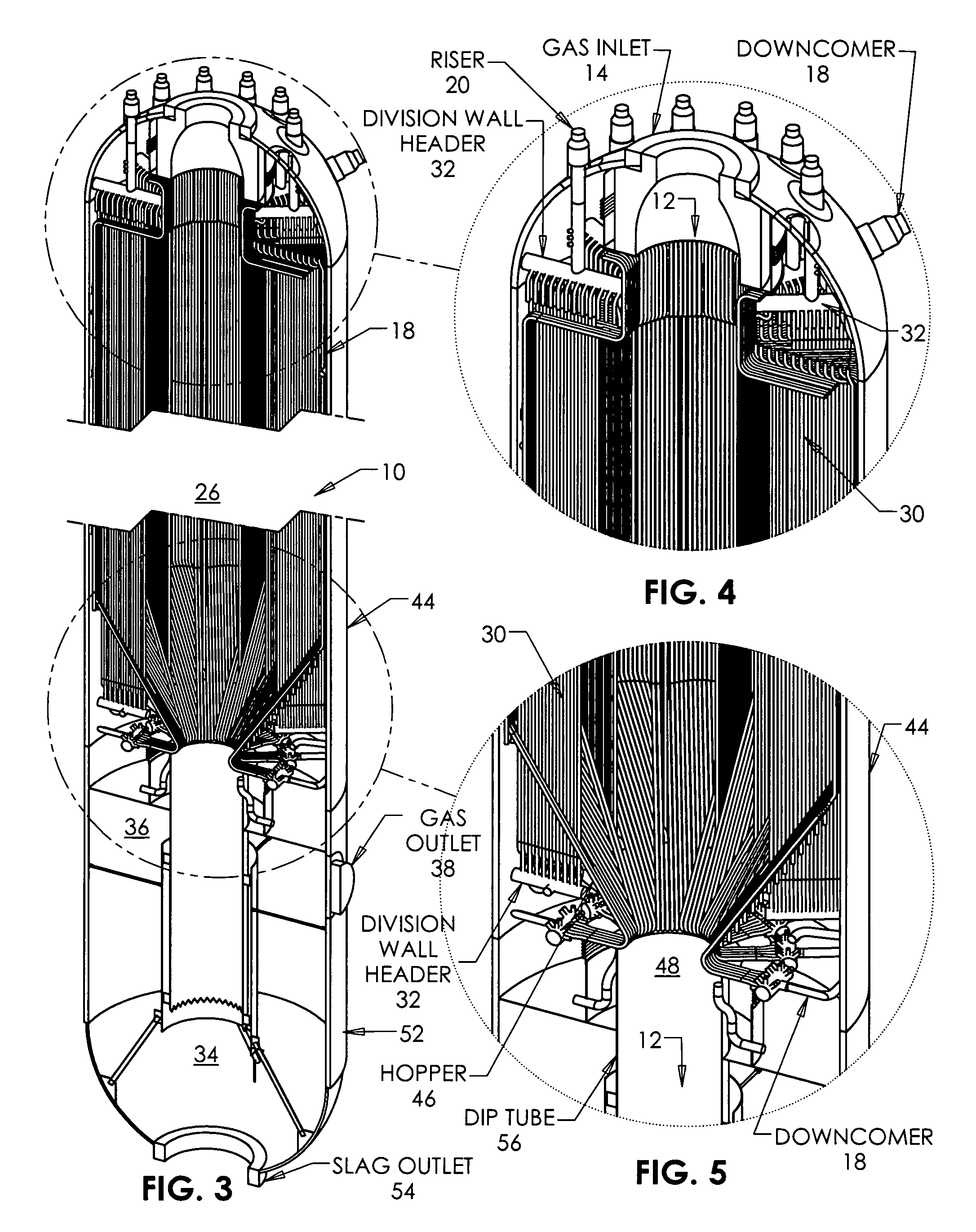

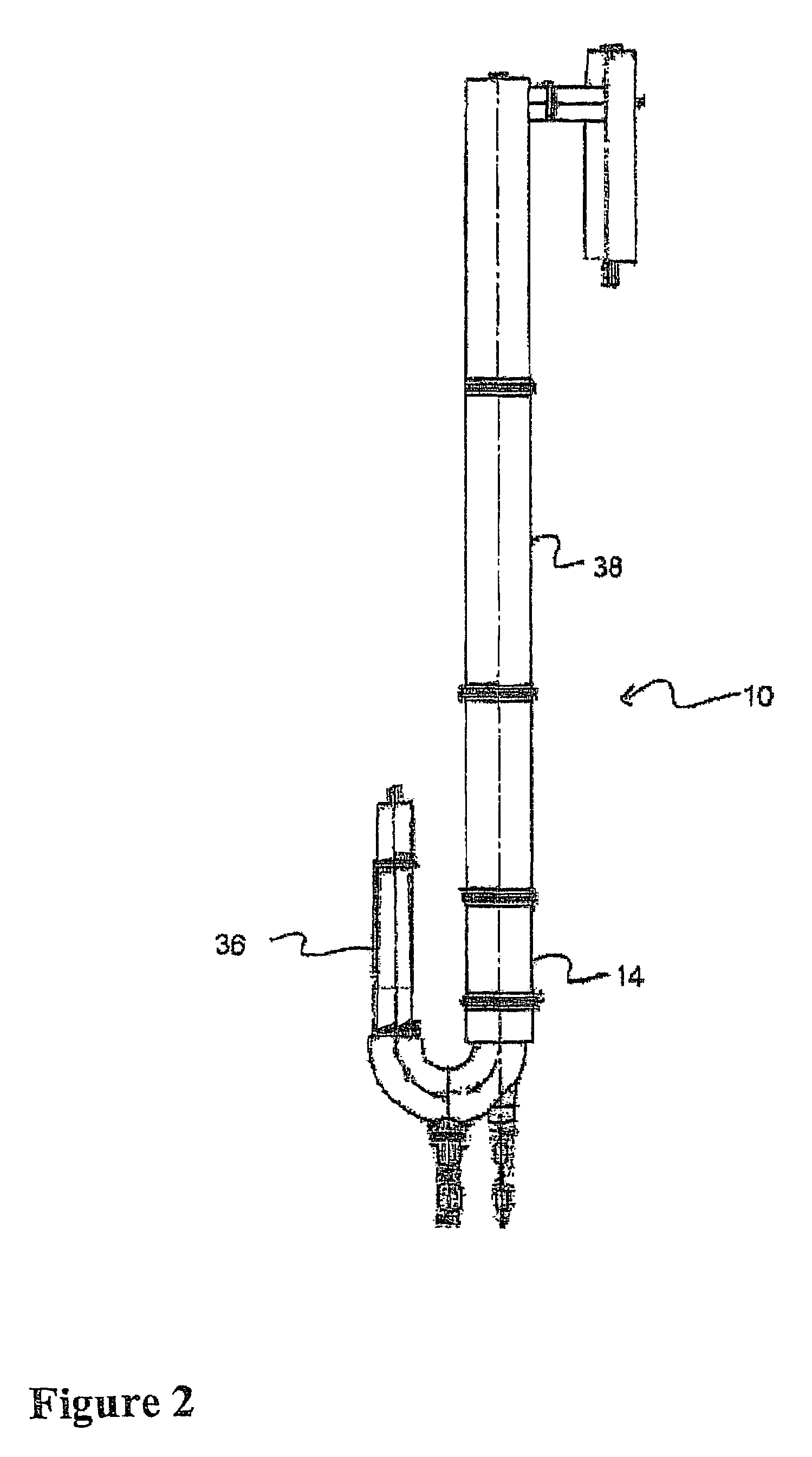

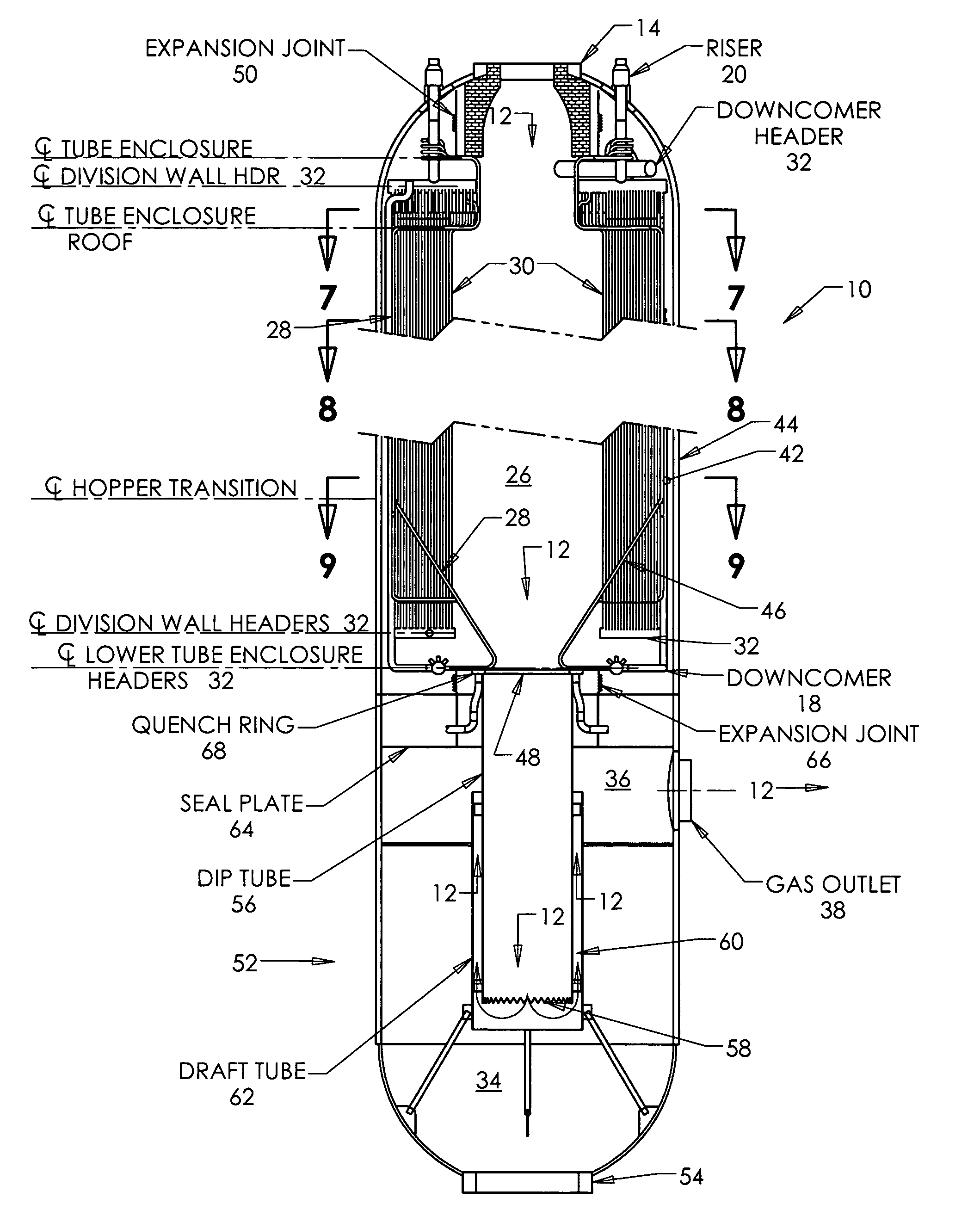

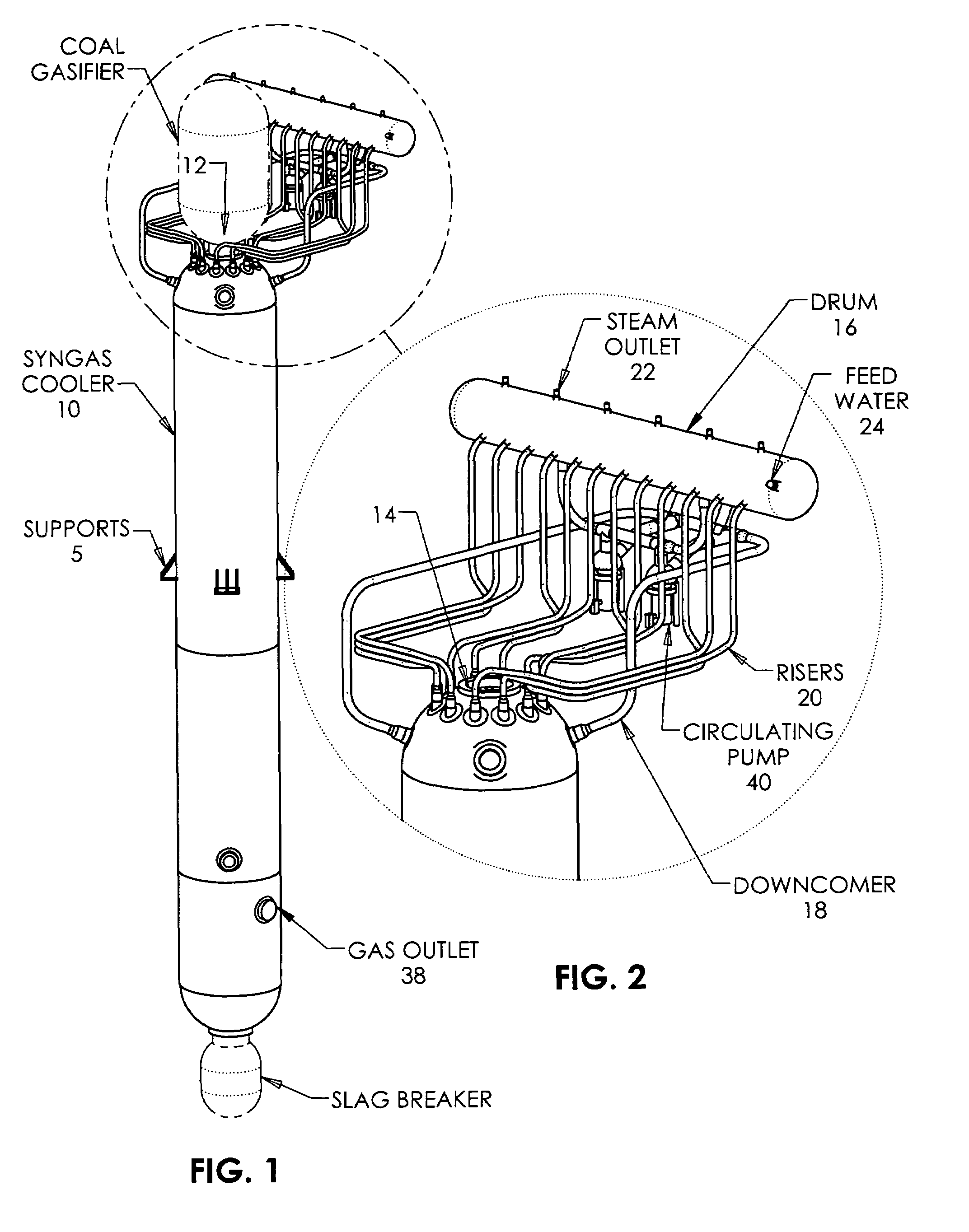

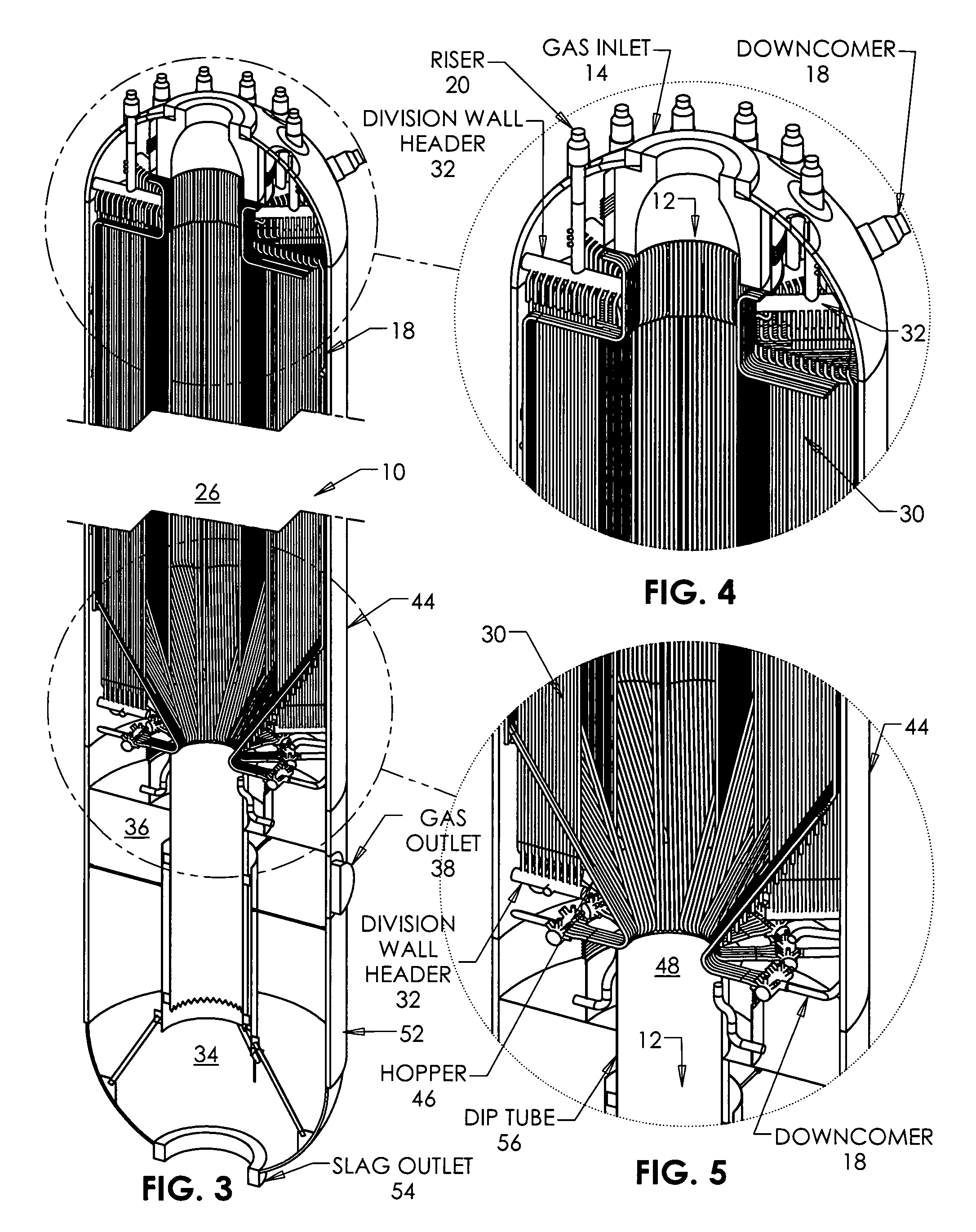

Radiant syngas cooler

A radiant syngas cooler used to contain and cool the synthesis gas produced by coal gasification processes employs radiant and convection surfaces in a specific arrangement to achieve a cost-effective, compact design.

Owner:THE BABCOCK & WILCOX CO

Method of producing fuel oil by coal tar hydrogenation modifying

ActiveCN1903994AReduce temperature riseReduce coking rateTreatment with hydrotreatment processesGasoline stabilisationLow nitrogenSulfur

The present invention relates to a method for producing fuel oil by utilizing coal tar. It is characterized by that said method includes the following steps: after the whole coal tar in which the moisture and ash are removed and diluting oil are mixed according to a certain mixing ratio, making the obtained mixture be successively passed through a shallow hydrogenation unit with hydrogenation protecting agent and prehydrogenation catalyst and a deep hydrogenation unit with main hydrogenation catalyst, then making the product obtained after deep hydrogenation undergo the processes of high-pressure separation, low-pressure separation and fractionation so as to obtain light-oil fraction, medium-oil fraction and tail-oil fraction, namely obtain low-sulfur low-nitrogen fuel oil and light oil product.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

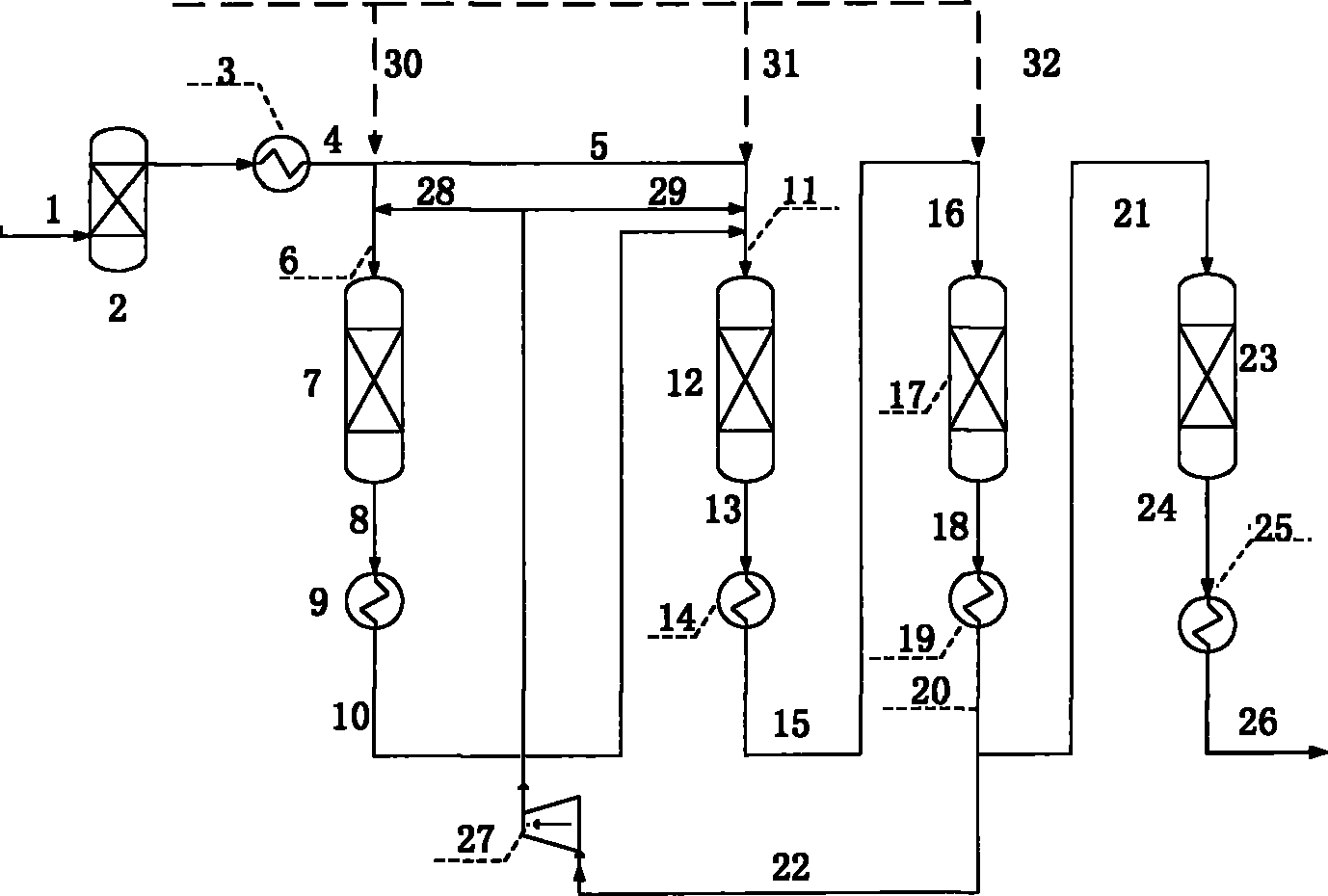

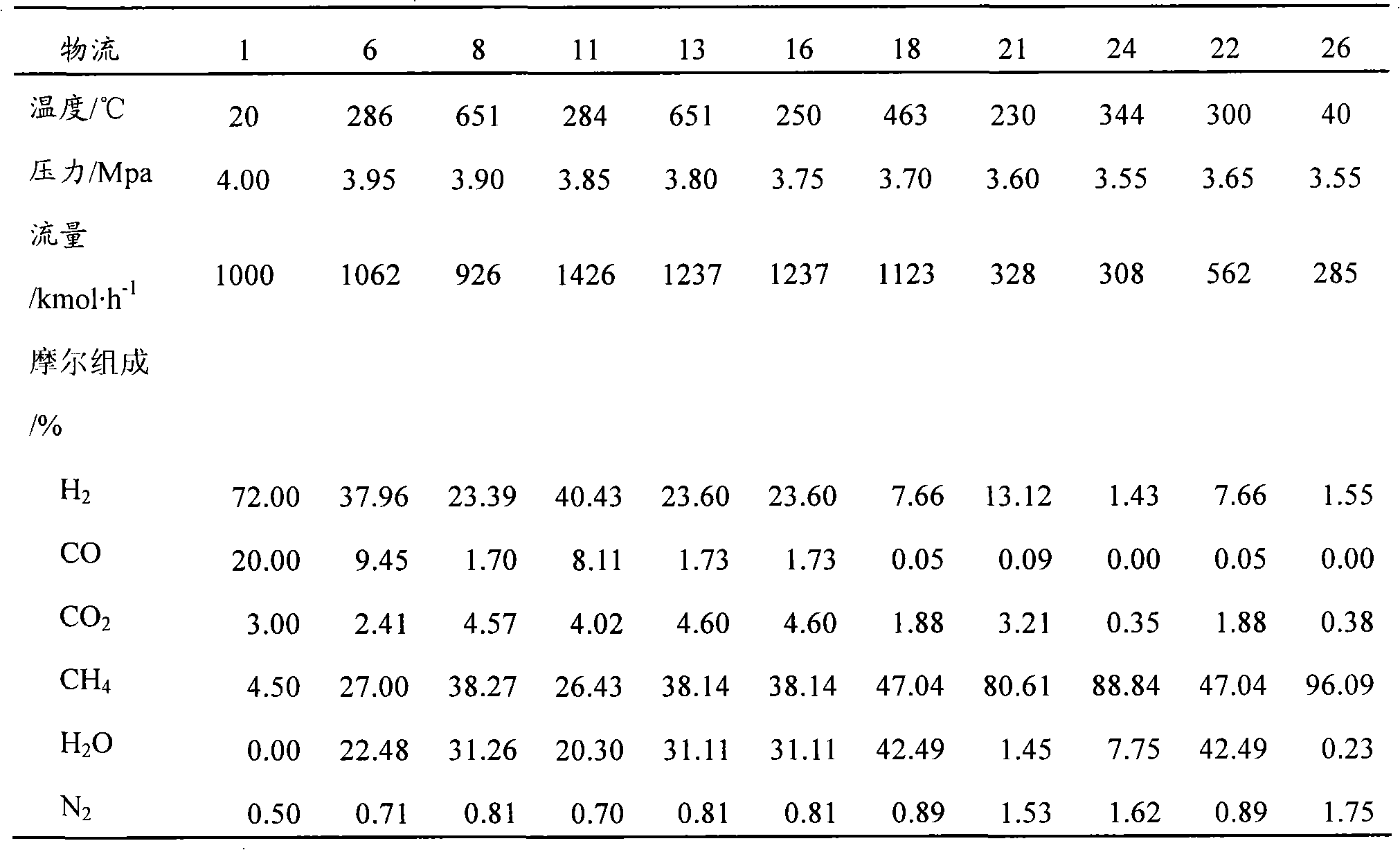

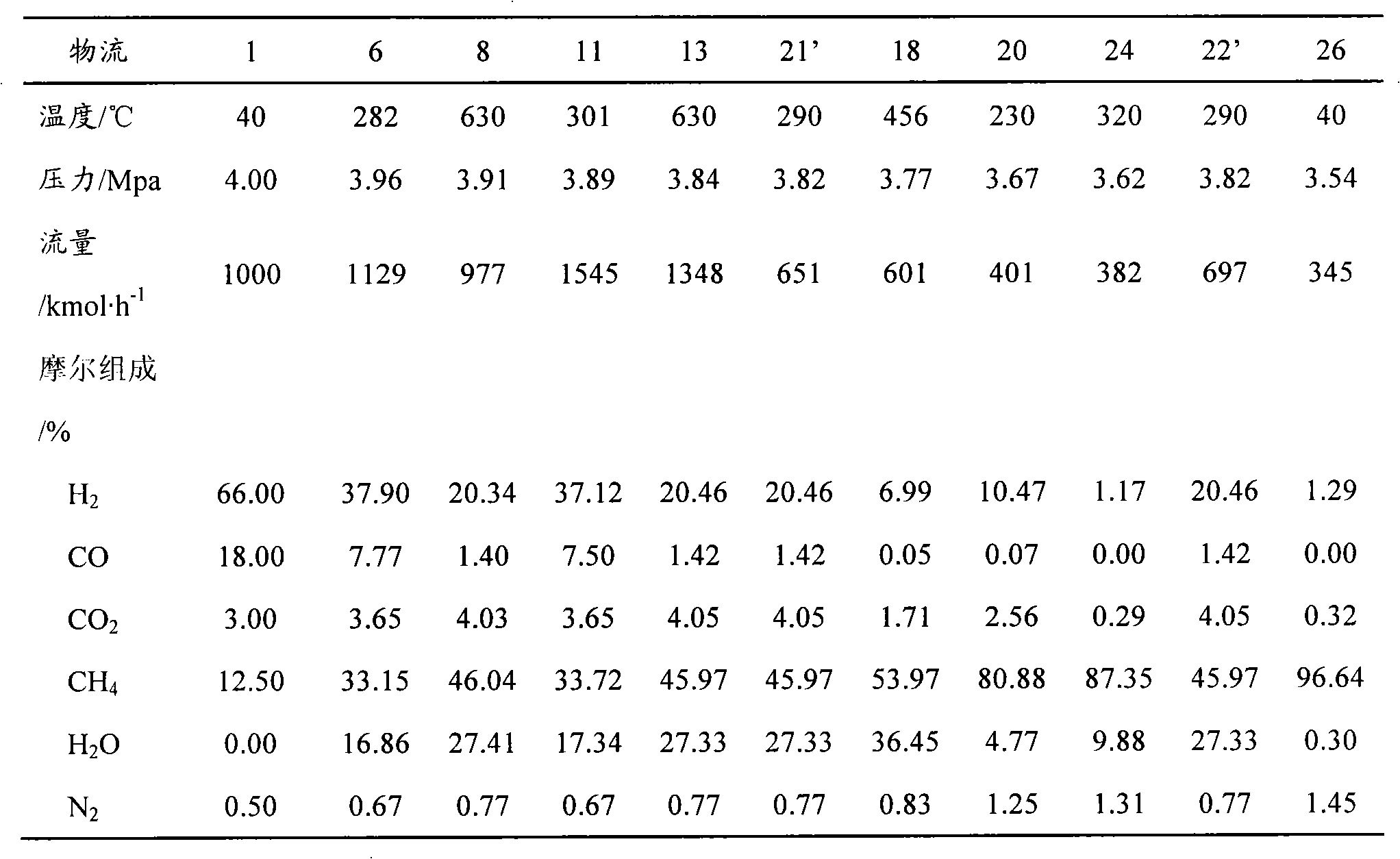

Method and device for producing synthetic natural gas, and natural gas product thereof

InactiveCN101812339AImprove utilization efficiencyControl reaction temperatureGaseous fuelsNatural productMethanation

The invention provides a method for producing synthetic natural gas and a device thereof. The continuous technological process of the invention is realized in a way that gasified product gas is used as the raw material for producing high methane gas containing more than 94 mol% of methane. The method can well adjust the methanation reaction temperature and avoid the problems of catalyst temperature-runaway sintering and the like due to improper material composition, excessive fluctuation or unexpected accident, thereby reducing the recycle gas amount and enhancing the energy comprehensive utilization efficiency.

Owner:DATANG INT CHEM TECH RESINST

Method for synthesizing dimethyl ether by adopting biomass indirect liquification one-step process

InactiveCN1477090ASelf-heating reactionOvercoming the deficiency of hydrogen contentEther preparationSyngasPetroleum

The present invention relates to a method for synthesizing dimethyl ether by high-effectively cleanly utilizing biomass. It utilizes the gasified gas produced by catalytic gasification of biomass air-water vapor, and makes the gasified gas undergo the process of methane reformation to prepare synthetic gas, and utilizes the synthetic gas to directly synthesize clean fuel dimethyl ether.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

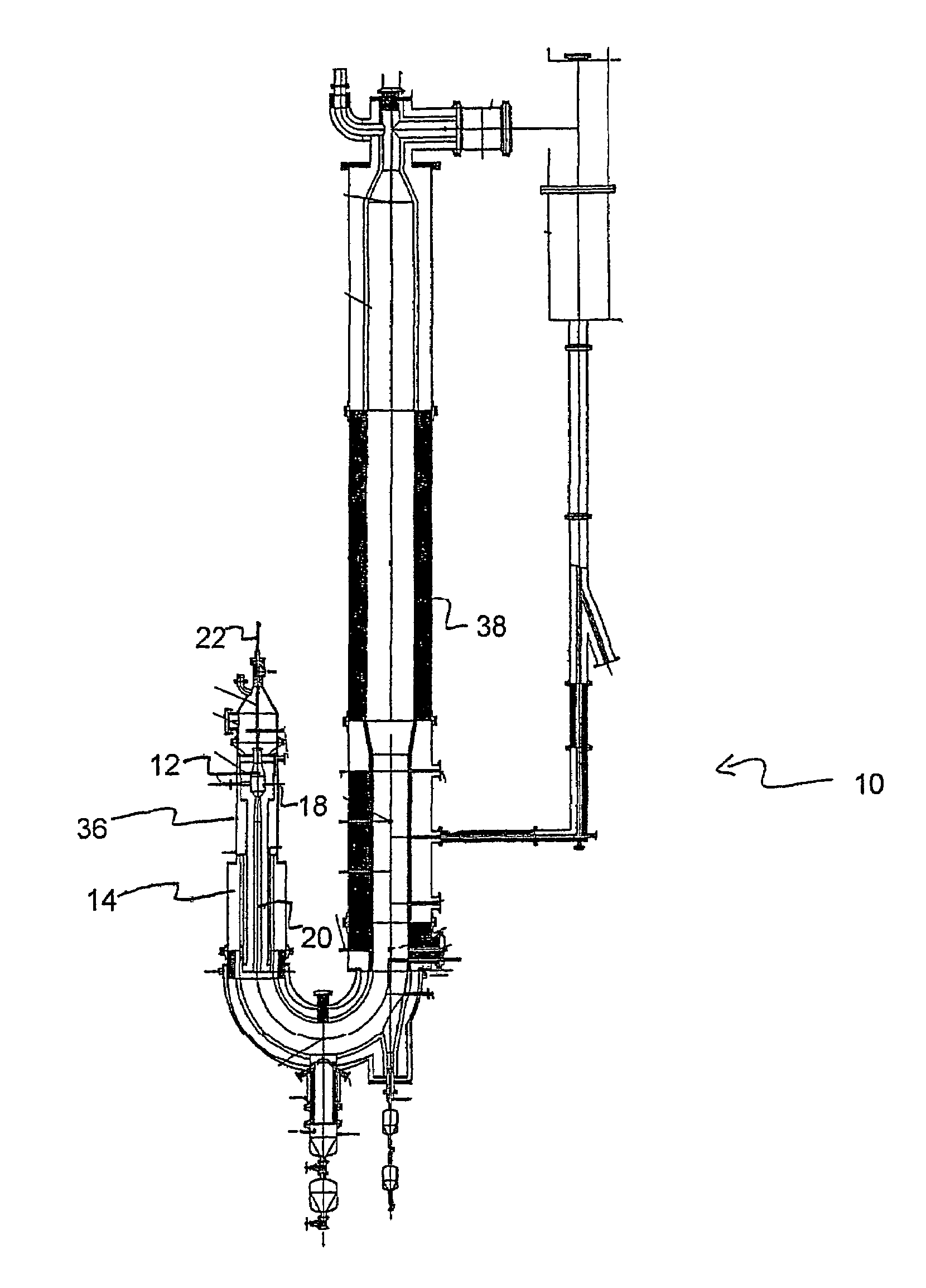

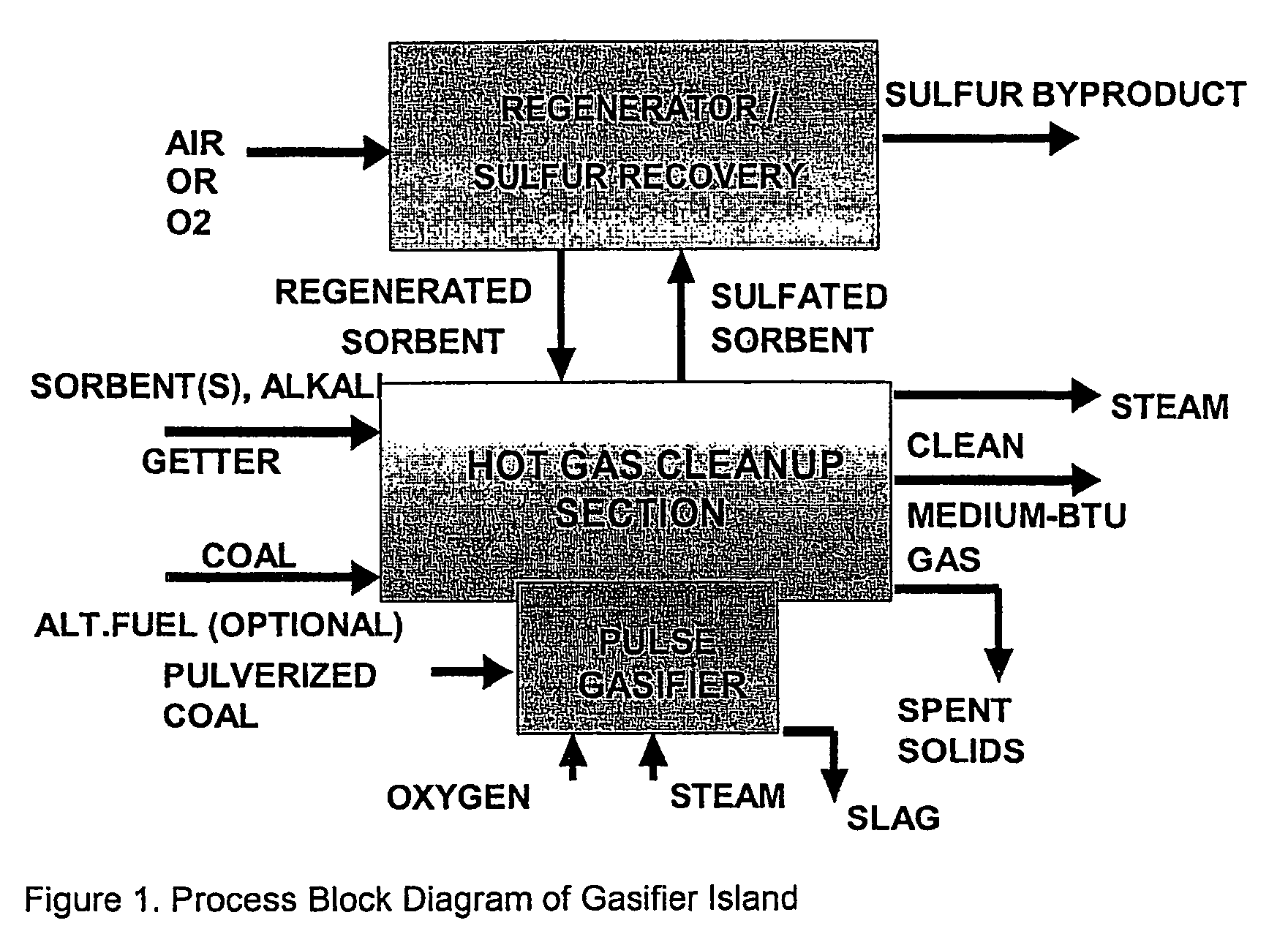

Pulse gasification and hot gas cleanup apparatus and process

InactiveUS6997118B2Easy to useConducive to agglomerationAuxillary pretreatmentGasifier mechanical detailsSteam reformingElectricity

A gasifier system and process comprises a pulse combustion device in communication with a fluid channel for producing a gas stream having heat or fuel value. The pulse combustion device is operated under sub-stoichiometric conditions such that combustion and steam reforming both occur in the fluid channel. The pulse combustion device also produces a pulsating combustion product stream and an acoustic pressure wave. The acoustic pressure wave serves to cause agglomeration of particles contained within the combustion stream for easy removal. In one embodiment, a sulfur capturing agent is injected into the fluid channel for not only removing sulfur from the combustion product stream but for also facilitating particle agglomeration. Ultimately, a gas stream containing hydrogen is produced that may be used in various processes, such as in the production of electricity.

Owner:MFG & TECH CONVERSION INT

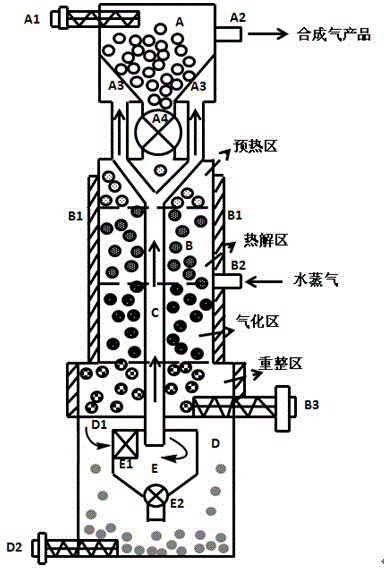

Method for preparing synthetic gas by three-phase type biomass pyrolysis-gasification-catalytic reforming

ActiveCN102424359AImprove conversion utilizationHigh yieldHydrogenWaste based fuelCatalytic reformingChemical industry

The invention belongs to the technical field of energy chemical industry. The process for preparing synthetic gas by biomass pyrolysis and gasification is divided into three steps of biomass low-temperature pyrolysis, coke or semi-coke high-temperature gasification and crude synthetic gas / tar catalytic reforming. The three reaction steps are successively and continuously carried out in three relatively independent spaces of an upper pyrolysis hearth, a lower gasification hearth and a catalyst bed inside the same gasification reaction device so as to finally obtain the high-quality synthetic gas. The method provided by the invention has high carbon conversion rate, produces no secondary pollution and is simple to realize. In addition, required biomass is rich in reserves and can be regenerated, thus realizing integrated sustainable utilization of resource, energy and environment.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL +1

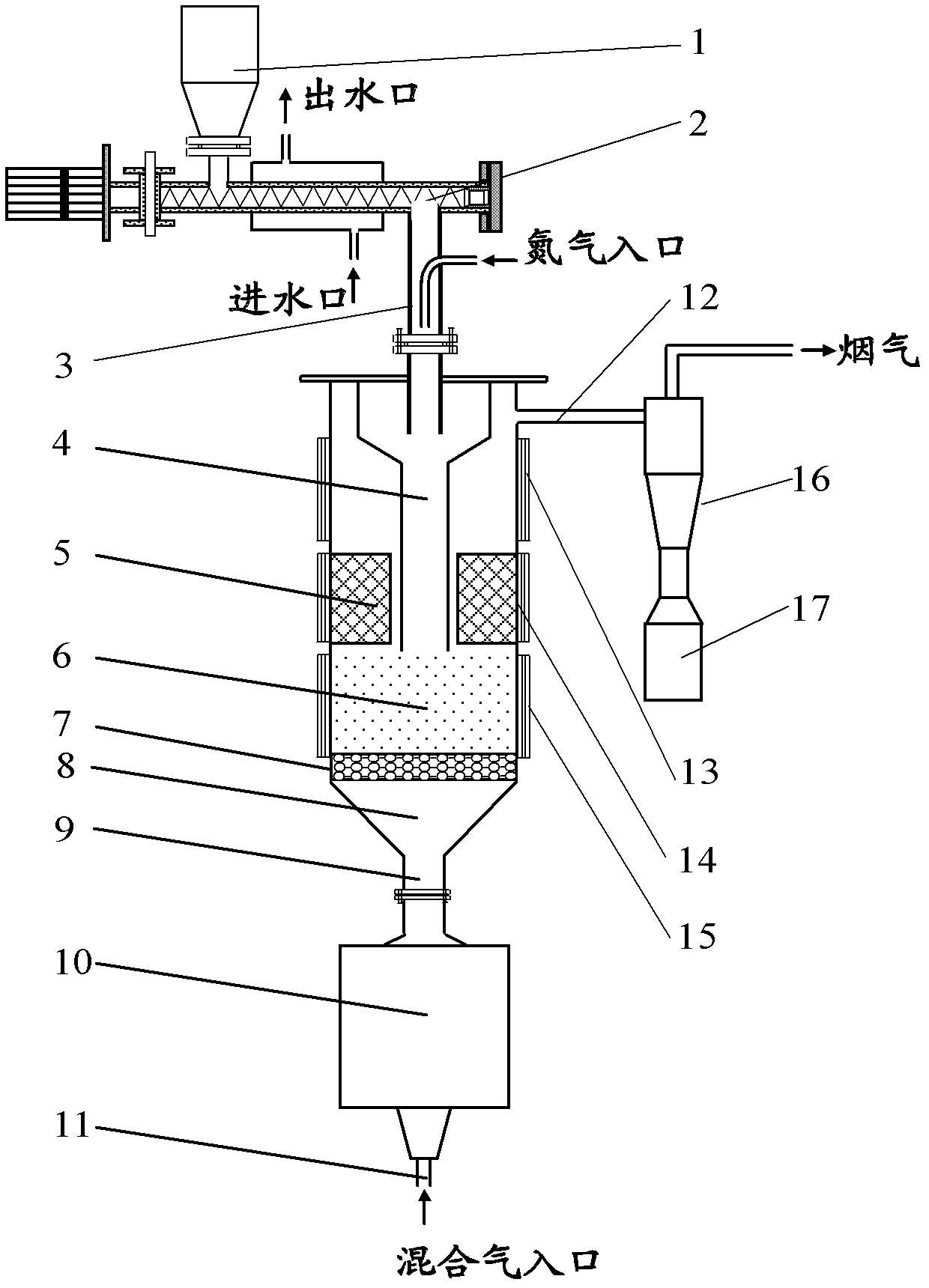

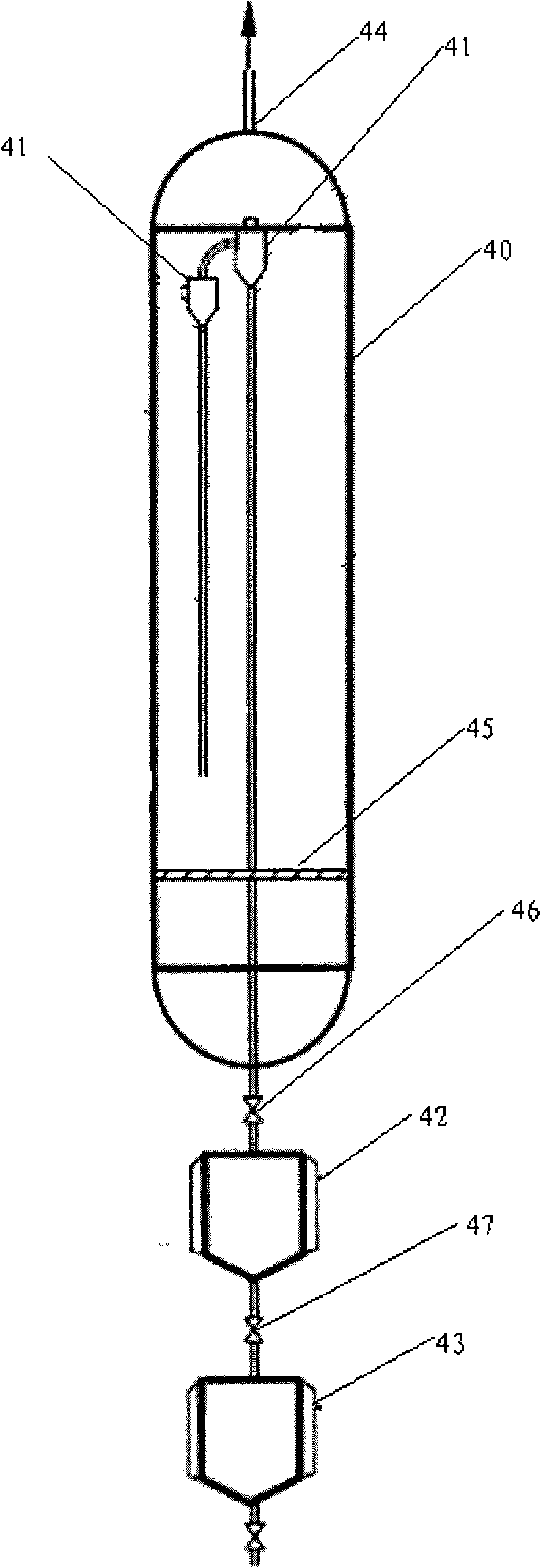

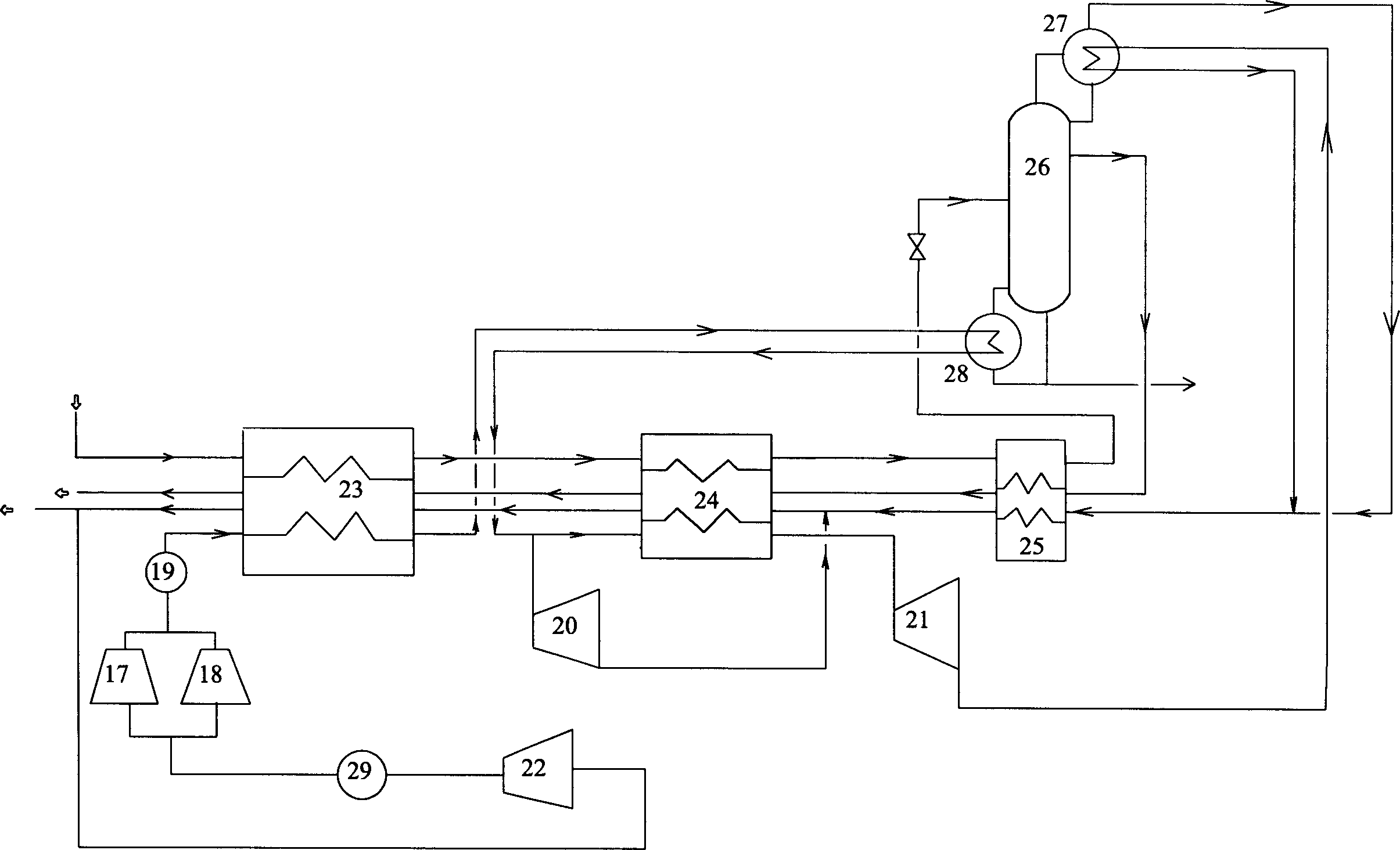

Method, system and equipment for catalytic coal gasification

ActiveCN101555420AContinuous slaggingCombined combustion mitigationGasification with fuel pre-distillationHydrogenProduct gas

The embodiment of the invention discloses a method for catalytic coal gasification. The method comprises the following steps: delivering pulverized coal to gasification equipment under high pressure of high-pressure rotating equipment, allowing a gasification reaction of the coal and a gasification agent in the presence of a catalyst in the gasification equipment, performing gas-solid separation on substances from the gasification reaction, delivering solid obtained from the gas-solid separation to first cinder discharge equipment, and delivering the solid from the first cinder discharge equipment to second cinder discharge equipment; and washing gases obtained from the gas-solid separation to obtain acidic water and purified gases, performing low temperature methanol washing on the purified gases to obtain a mixed gas of methane, hydrogen and carbon monoxide, distilling the mixed gas at low temperature to obtain the methane, delivering the acidic water to a catalyst recovery plant, and returning the recovered catalyst to mixing equipment. The embodiment of the invention further discloses a system and equipment for catalytic coal gasification. The method, the system and the equipment can help realize continuous cinder discharge under high pressure.

Owner:ENN SCI & TECH DEV

Radiant syngas cooler

A radiant syngas cooler used to contain and cool the synthesis gas produced by coal gasification processes employs radiant and convection surfaces in a specific arrangement to achieve a cost-effective, compact design.

Owner:THE BABCOCK & WILCOX CO

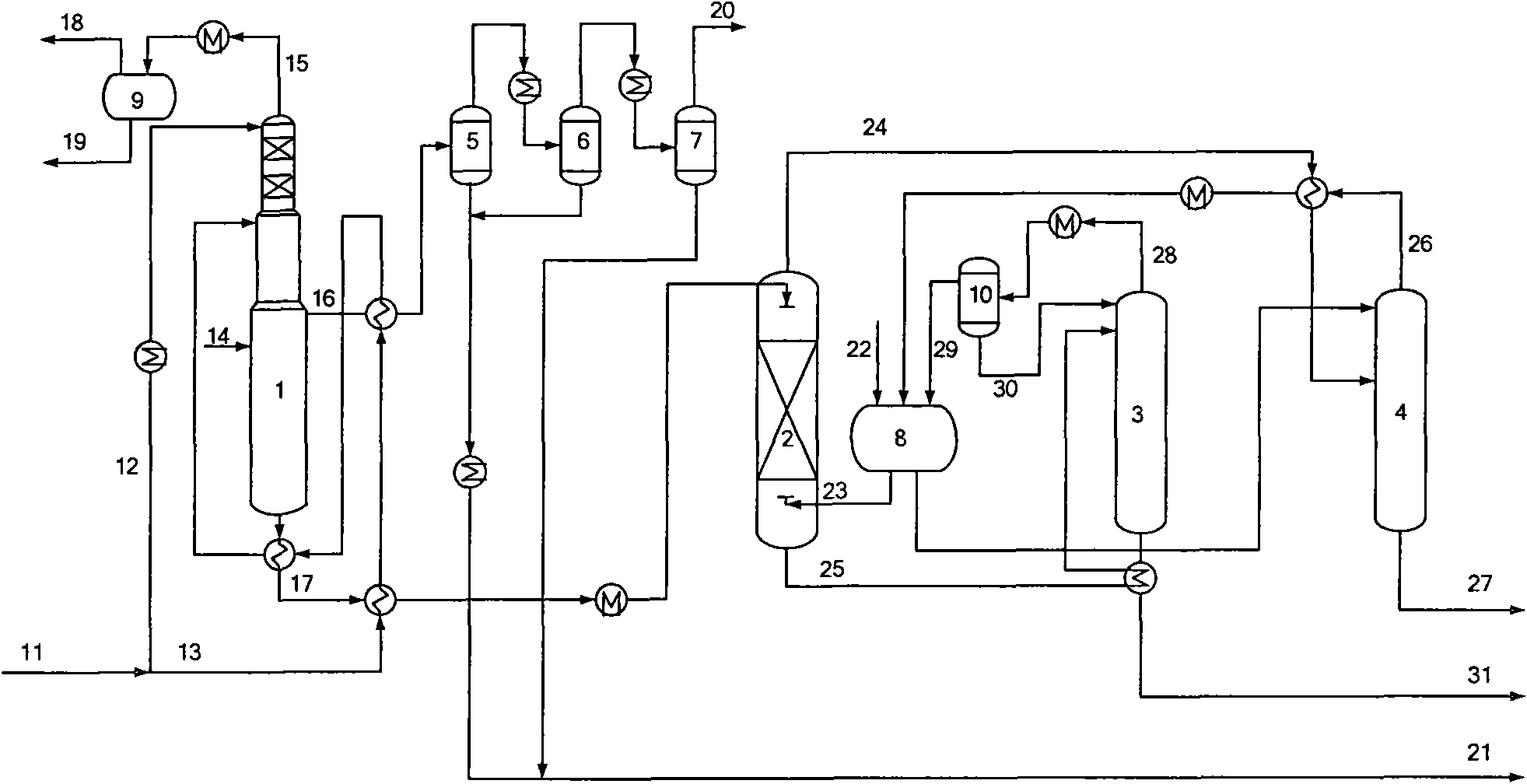

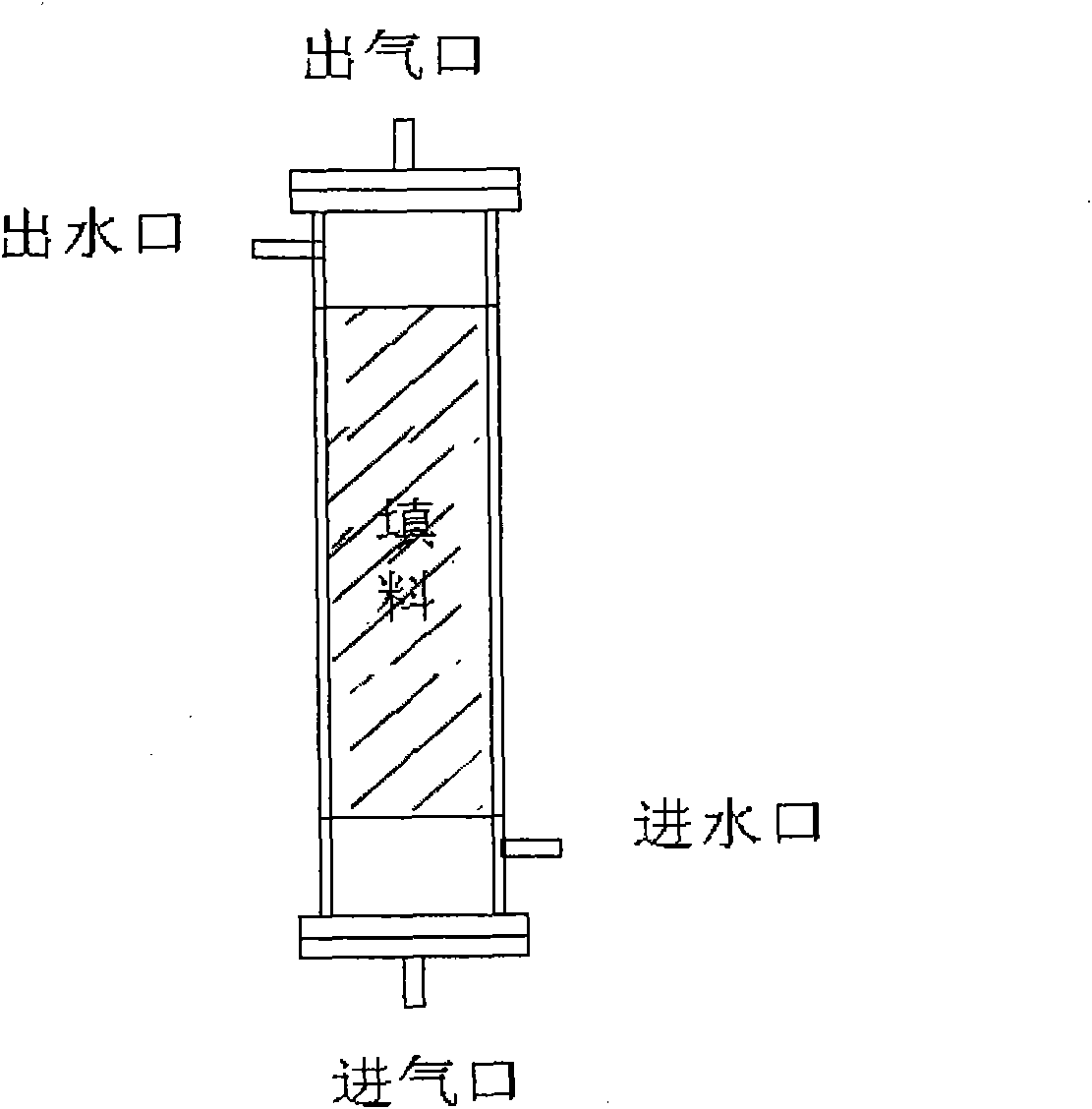

Method for treating coal gasification wastewater by single-tower pressurization stripping and device therefor

InactiveCN1884150AHigh removal rateReduce crystallizationFatty/oily/floating substances removal devicesMultistage water/sewage treatmentCoal gasification wastewaterOrganic solvent

The invention discloses a gasification wastewater disposing method and device through single-tower pressurizing stripping, which comprises the following steps: entering the extracted of acid gas or ammonia gas of cold and hot coal gasification wastewater from band lateral line in the stripping tower from top and upper top; blending gas; dividing phases; washing; separating light oil and acid gas; preparing liquid ammonia through two-grade concreting and refining; separating crude phenol and organic solvent from bottom of tower through inversed-extracting autoclave liquid and organic solvent; recycling organic solvent through stripping. The gasification disposing device contains oil acid gas / ammonia stripping tower, extracting tower, acid gas washing tower, solvent stripping tower, solvent recycling tower, oil-water separator, dephlegmator, pump and reservoir.

Owner:SOUTH CHINA UNIV OF TECH

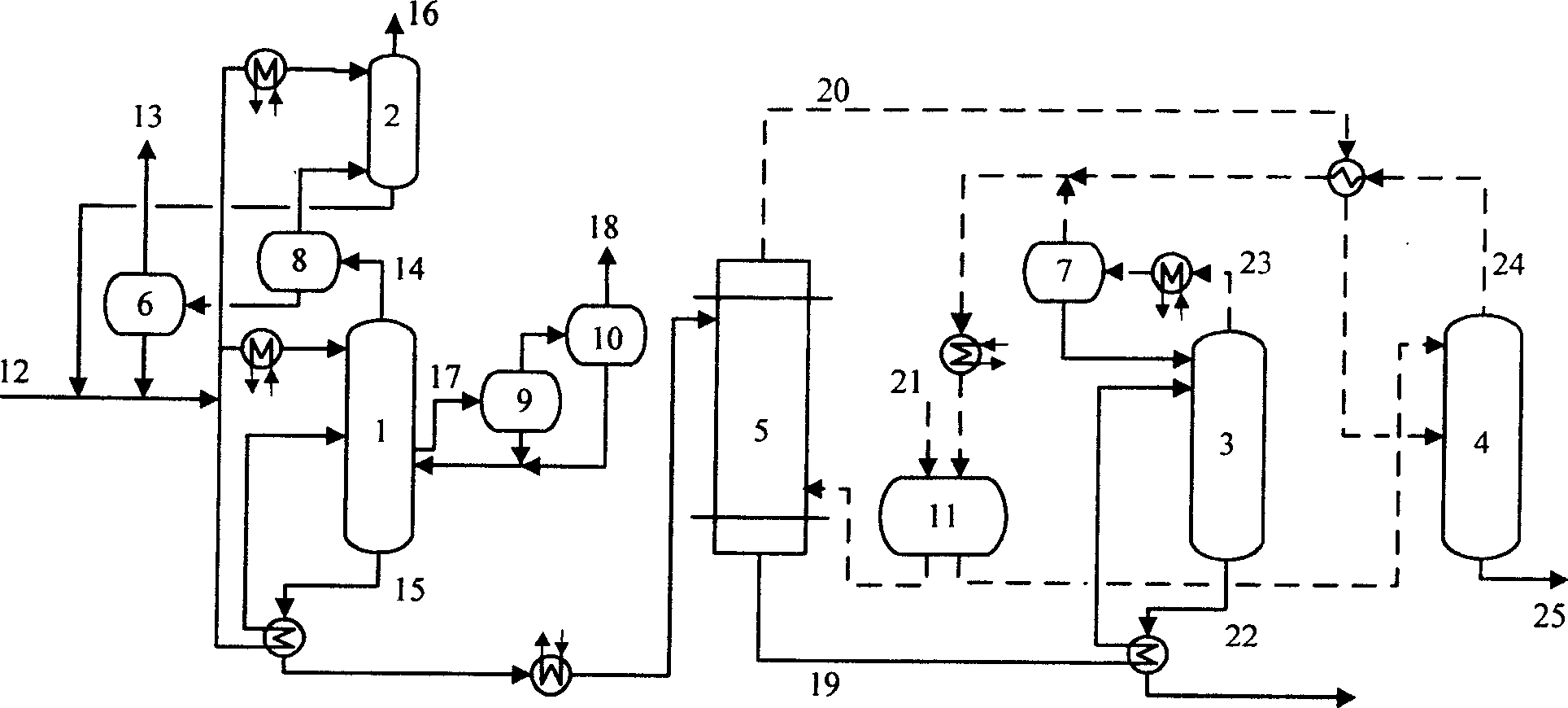

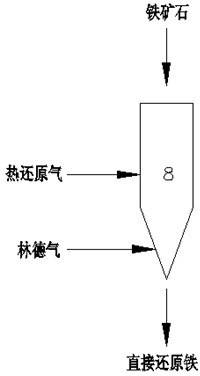

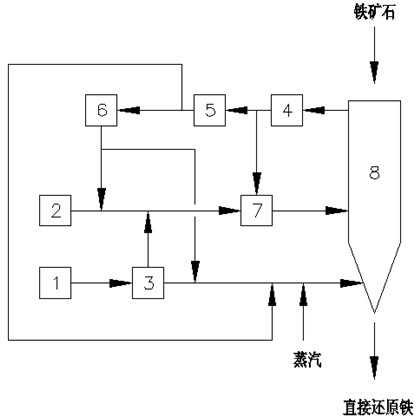

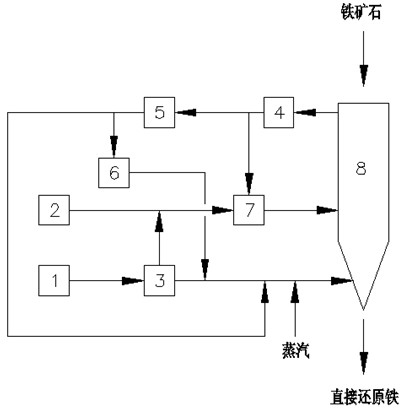

Method and device for producing direct reduced iron by using gas-based reduction shaft furnace

The invention discloses a method and device for producing direct reduced iron by using a gas-based reduction shaft furnace. Coal reducing gas and coke oven gas are mixed and supplied to a shaft furnace so as to produce direct reduced iron. The method comprises the following steps: separating the coke oven gas into hydrogen gas and linde gas, mixing the hydrogen gas with the coal reducing gas and using as reducing gas to reduce iron ores, and using the linde gas as cooling gas to cool direct reduced iron. The device for realizing the method comprises a shaft furnace, a coke oven gas source, a coal gasification device, a coke oven gas hydrogen-extracting device and a gas heating device. In the invention, coal gasification devices of different sizes can be flexibly used with a coke oven gas supply device, thereby reducing the size of the coal gasification device and effectively using the coke oven gas. Meanwhile, the invention cancels the minor cycle of a cooling section of a common shaft furnace, saves the equipment and investment, and brings the heat of direct reduced iron to a reducing section, thereby saving the heating load of the system reducing gas.

Owner:CISDI SHANGHAI ENG CO LTD +1

High-temperature gas composite oxide desulfurizer and production thereof

InactiveCN1712500AHigh mechanical strengthHigh wear resistanceGas purification by catalytic conversionActive componentFluidized bed

A high-temperature gas composite oxide desulfurizer and its production are disclosed. The desulfurizer consists of active component zinc oxide 33í½50% and multiple additives 31í½51% which comprises titanium dioxide, active stabilizer, surface modifier, strength reinforcer, regenerative improver and composite binder. The process is carried out by mixing active component with additives, grinding, kneading, forming, laying aside, drying, particle rectifying, calcining at 850í½1060íÒC in high-temperature furnace, and obtaining desulfurizer. It achieves better reactivity and efficiency, good abrasion resistance and regeneration. It can be used for fixed bed, fluidized bed and desulfurizing reactor of flowing bed.

Owner:CHINA COAL RES INST

Air-contained coal gas gasification and separation process and equipment

The present invention relates to an air-contained coal gas gasification and separation process, which is chiefly to passing over the air-contained coalbed gas to the middle of the fractionating tower after cooling, through the evaporation of the evaporator in the bottom of the fractionating tower and the condensation of the top condenser, gas fraction inside the inner of the tower, the sufficient quality and heat exchange of the liquid fraction. The high purity nitrogen gas is obtained in the top of the fractionating tower and the high purity liquid natural gas is obtained in the bottom of the fractionating tower, wherein one part of pure air is induced to the heat exchanger at the entrance between the top of the fractionating tower and the air-contained coalbed gas. The invention also provides an equipment of the separation process. The air-contained coal gas gasification and separation process and equipment are separation liquefaction process specially designed for the air-contained coalbed gas, which adopts the single stage rectifying still simpler than the doublestage rectifying, and has convenient operation, low cost and easy to popularize in large scale.

Owner:BEIJING ZHONGKE RUIAO ENERGY TECH CO LTD

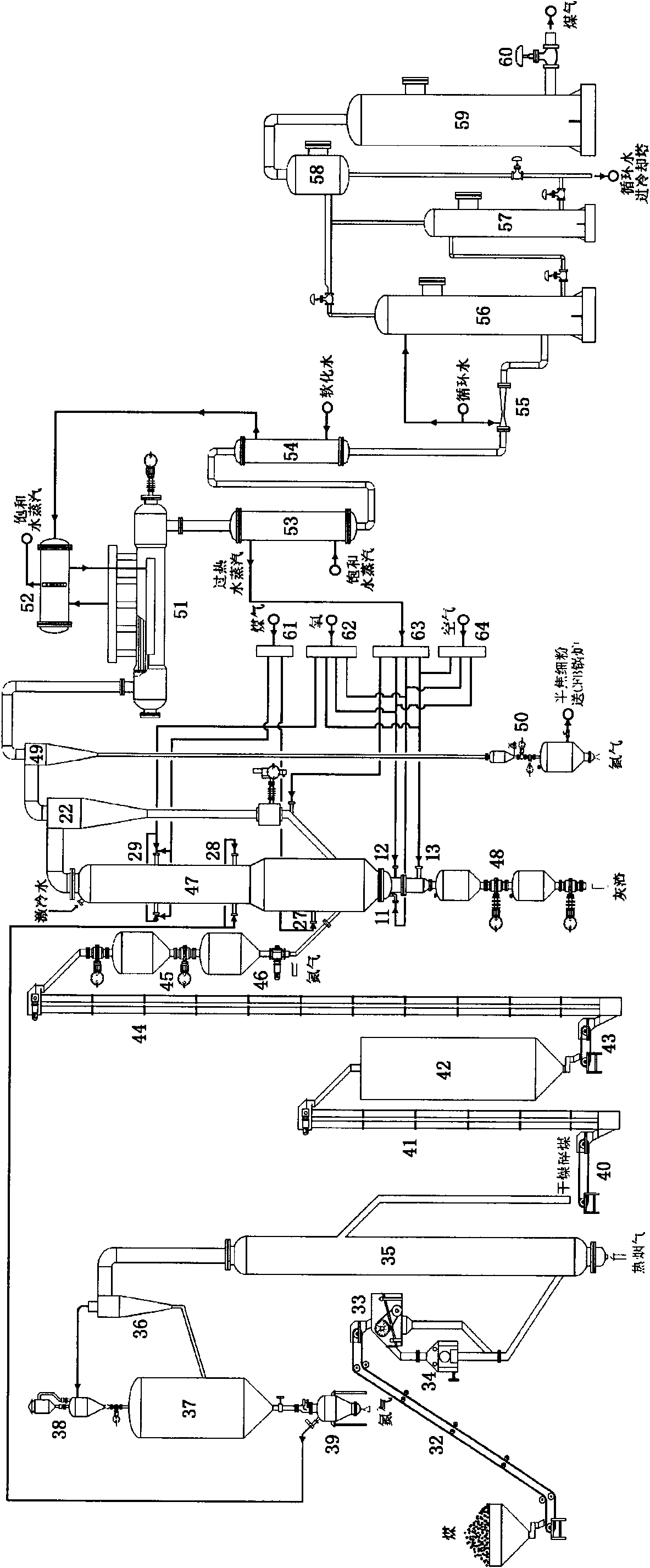

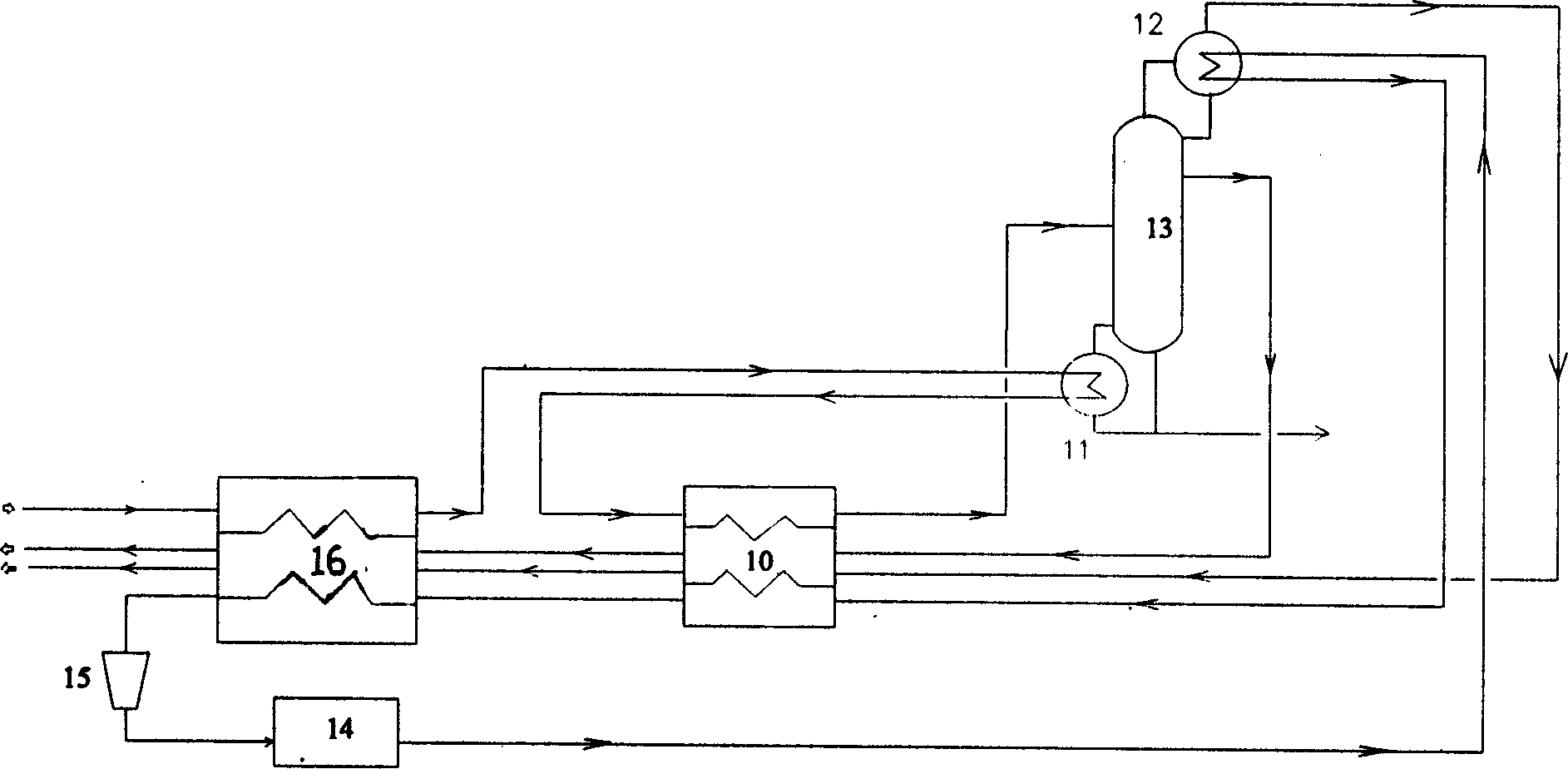

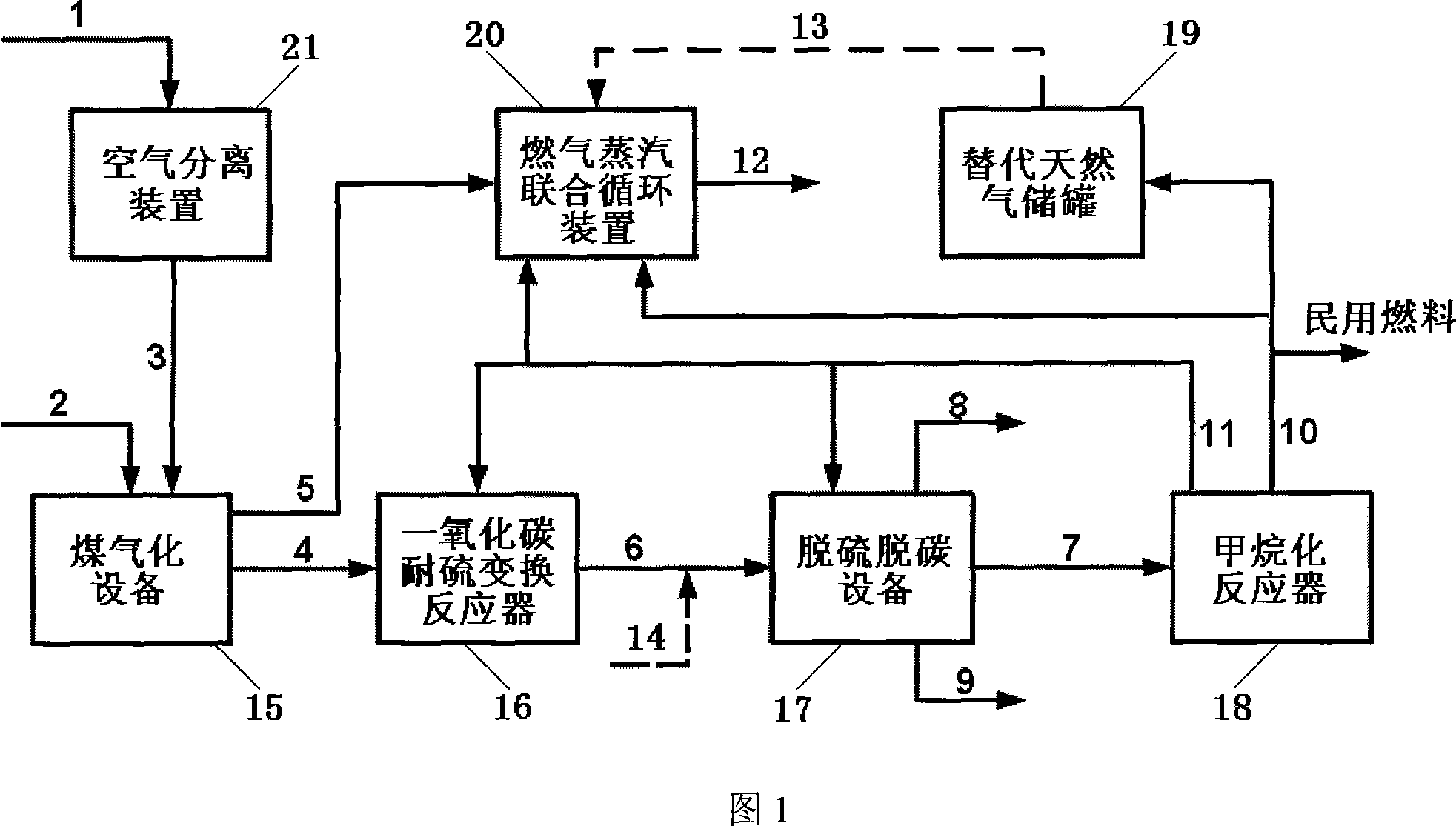

Combined system and process for producing electric-substituted natural gas based on coal gasification and methanation

ActiveCN101074397AEfficient and clean utilizationEfficient use ofCombustible gas chemical modificationCombustible gas purificationMethanationSlurry

An electric-substituting natural gas combined system and process based on coal gasification and methanation are disclosed. The process is carried out by delivering oxygen, powdered coal or water-gas slurry into gasified apparatus, recovering for crude gasified gas by wet heat, delivering into sulfur-resisting carbon monoxide carbon reactor, adjusting hydrogen-carbon ratio, entering into desulfurizing decarbonizer, recovering elementary sulfur while enriching carbon dioxide, delivering synthetic gas into methane reactor to generate substituted natural gas as domestic gas partially, entering into gas and steam combined circulator partially, and entering into substituted natural gas storage tank partially. It integrates coal gasified, methanation and gas steam combined circulation together, it's efficient and clean, has better utilizing rate, no CO2 discharge and need for changing gas turbine or load.

Owner:TSINGHUA UNIV

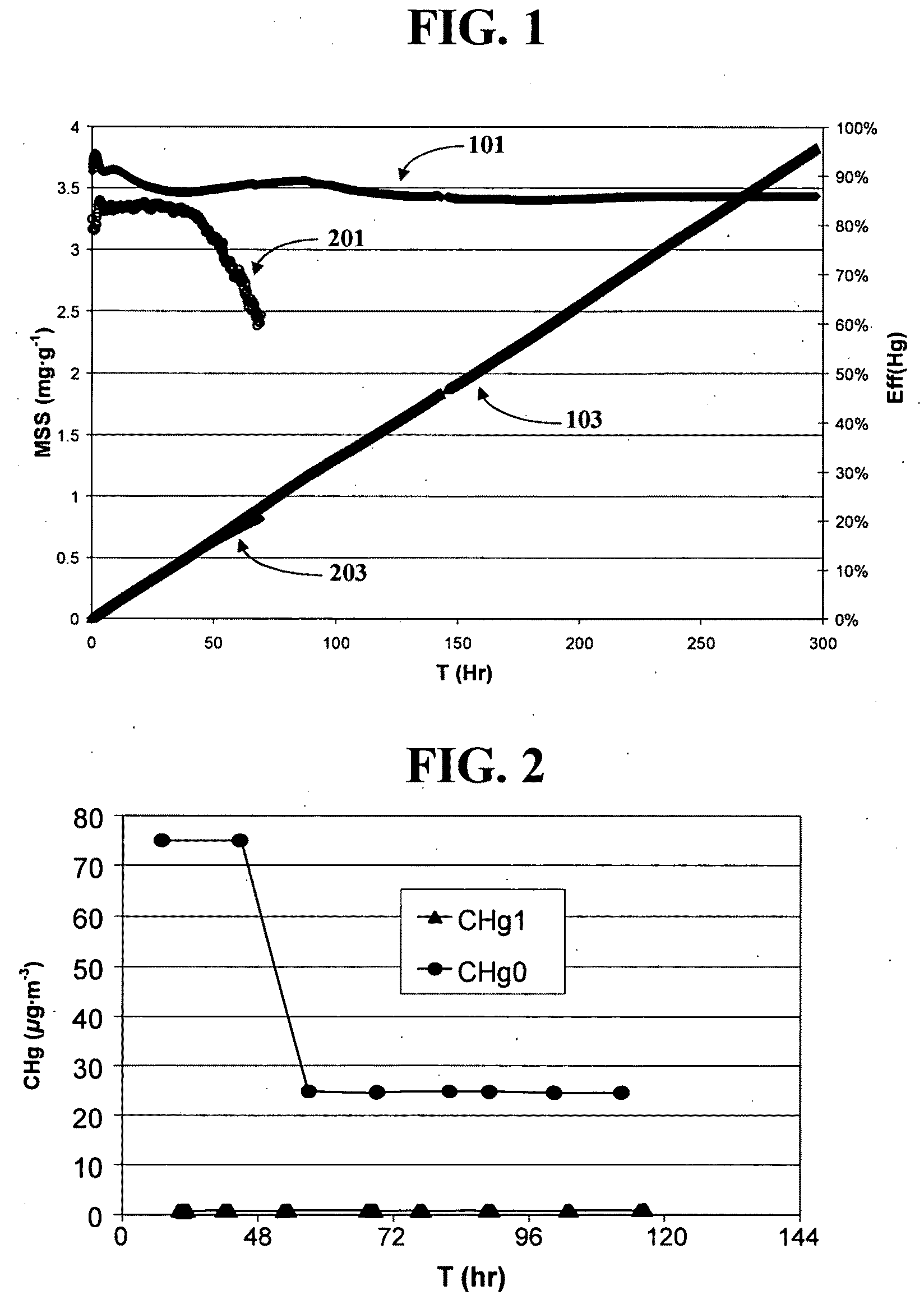

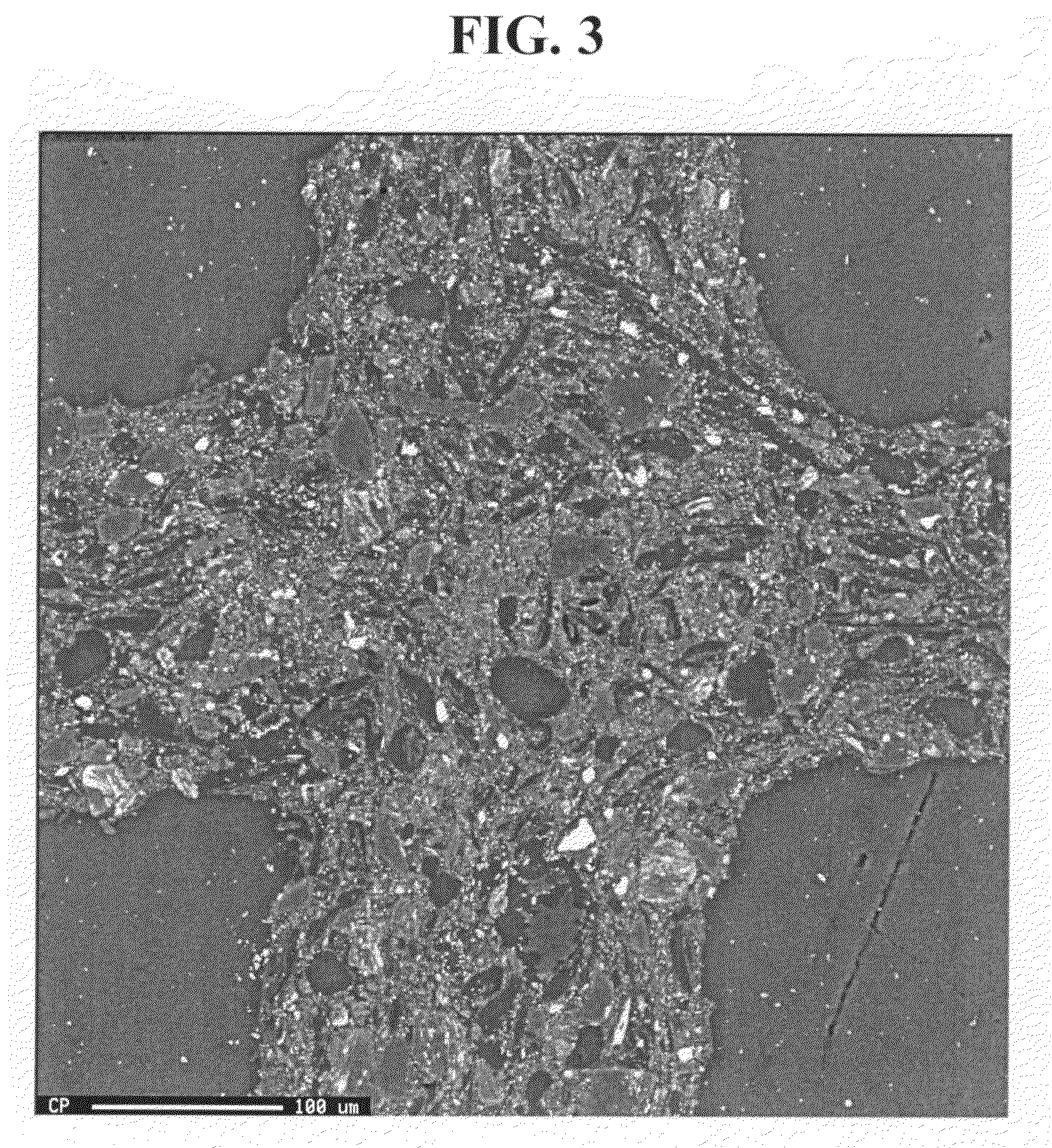

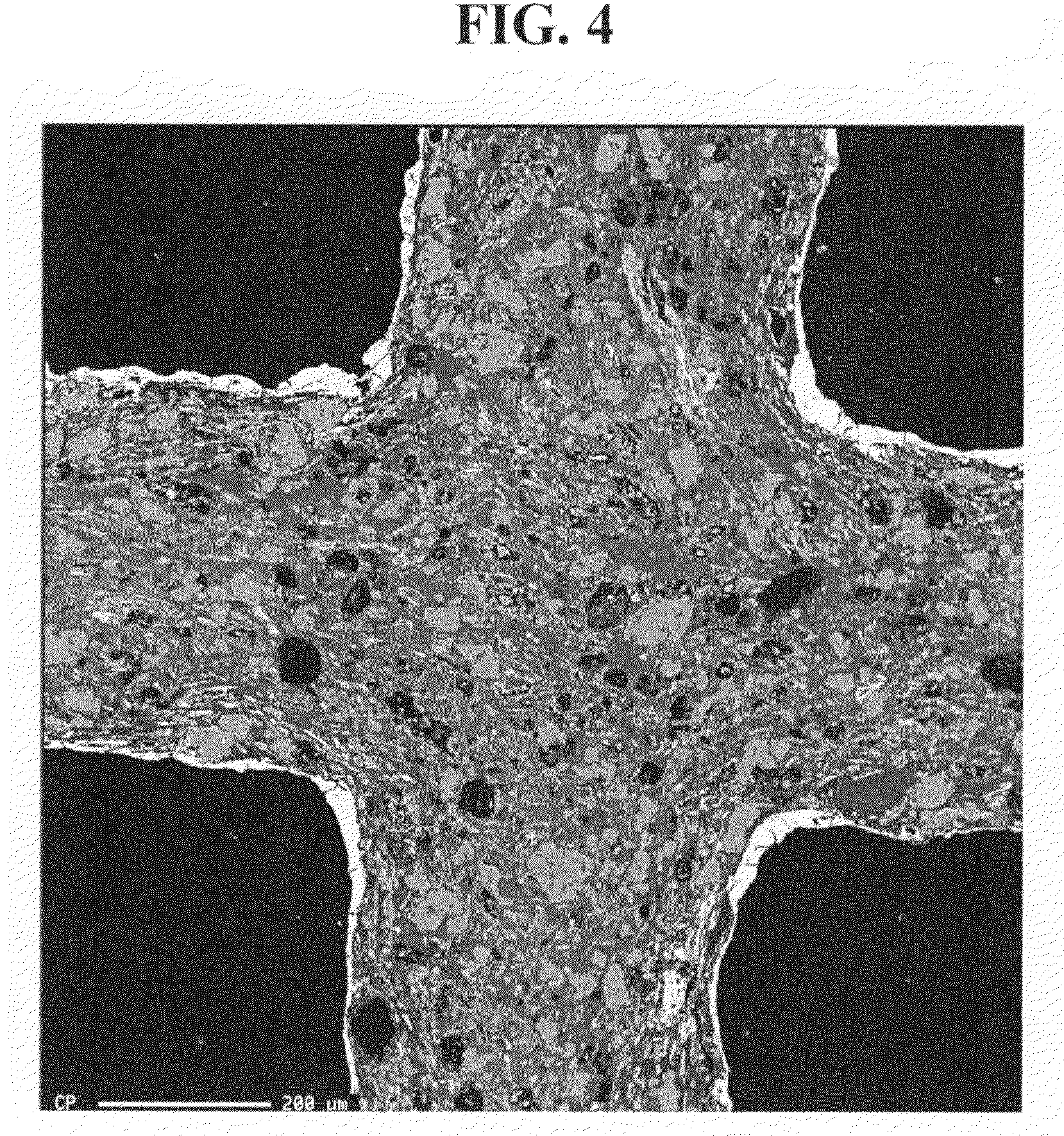

Sorbent comprising activated carbon, process for making same and use thereof

InactiveUS20090111690A1Large specific surface areaPromoting sorption of a toxic elementAdditive manufacturing apparatusOther chemical processesActivated carbonSyngas

A sorbent body adapted for abating toxic elements from a fluid stream, such as a carbon combustion flue gas stream or a syngas stream produced in coal gasification process, and process for making such sorbent. The sorbent body comprises an activated carbon matrix defining a plurality of pores, sulfur and an additive adapted for promoting the abatement of toxic elements from the fluid stream. At least one of the additive is formed into the sorbent body by in-situ forming such as in-situ extrusion. The sorbent is useful for abatement of, e.g., arsenic, cadmium, mercury and selenium from gas streams.

Owner:CORNING INC

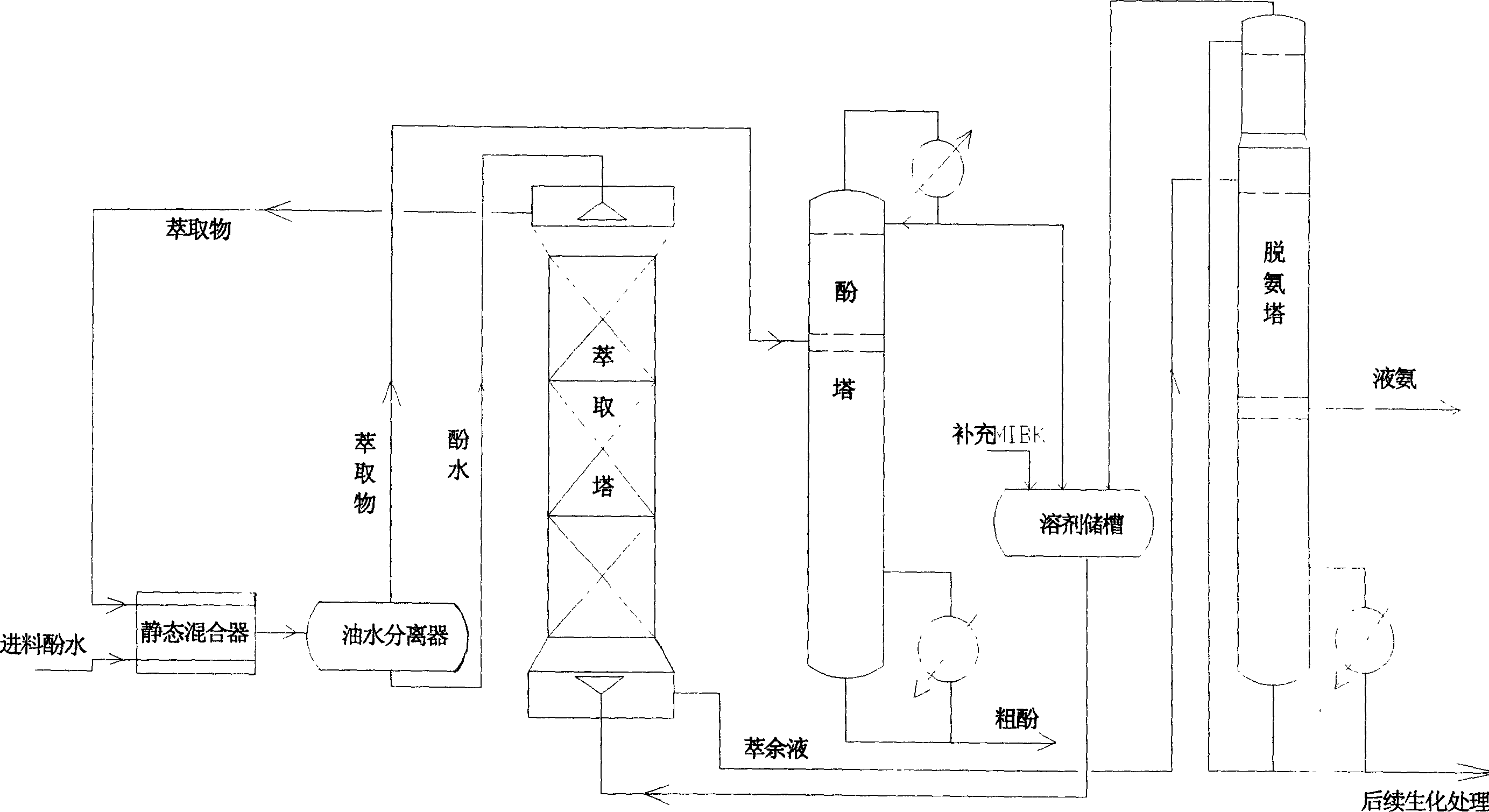

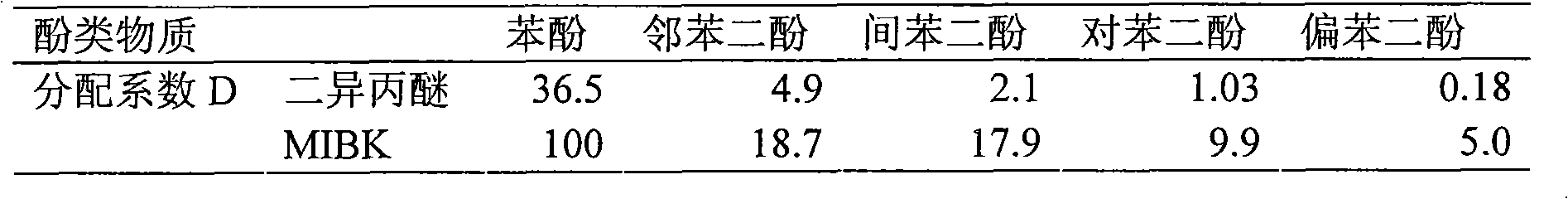

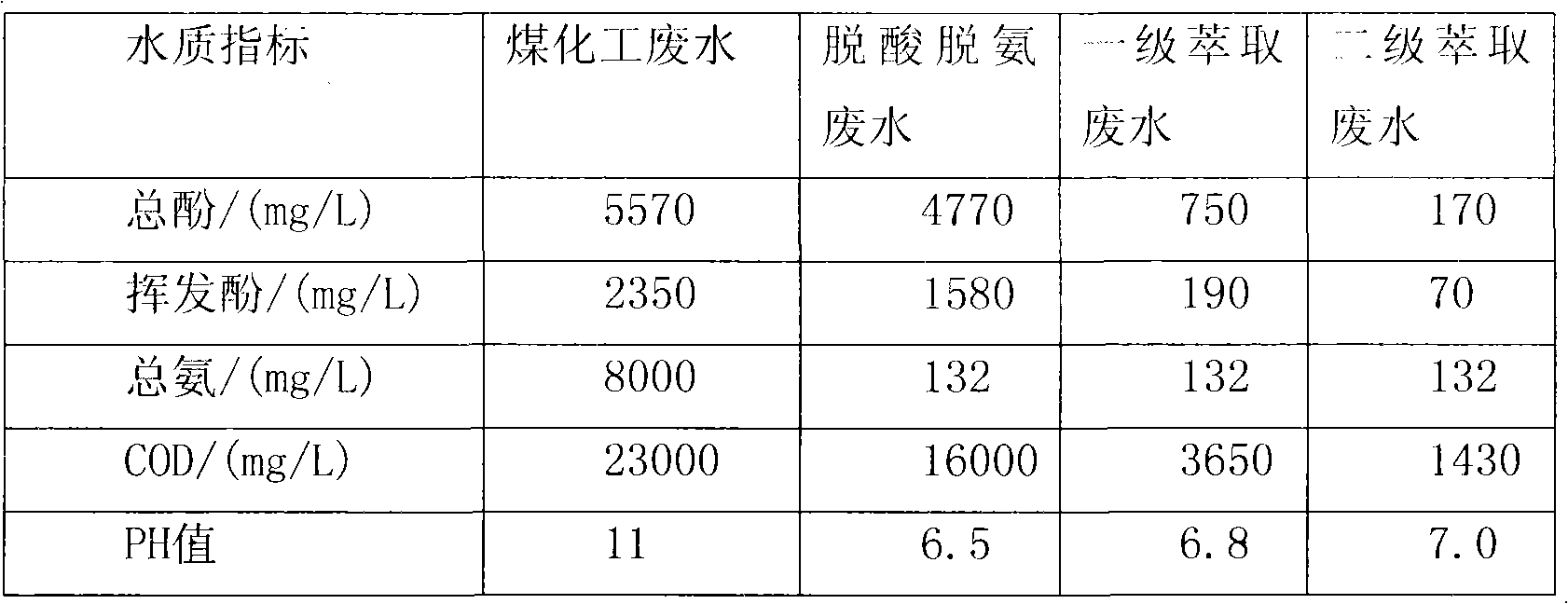

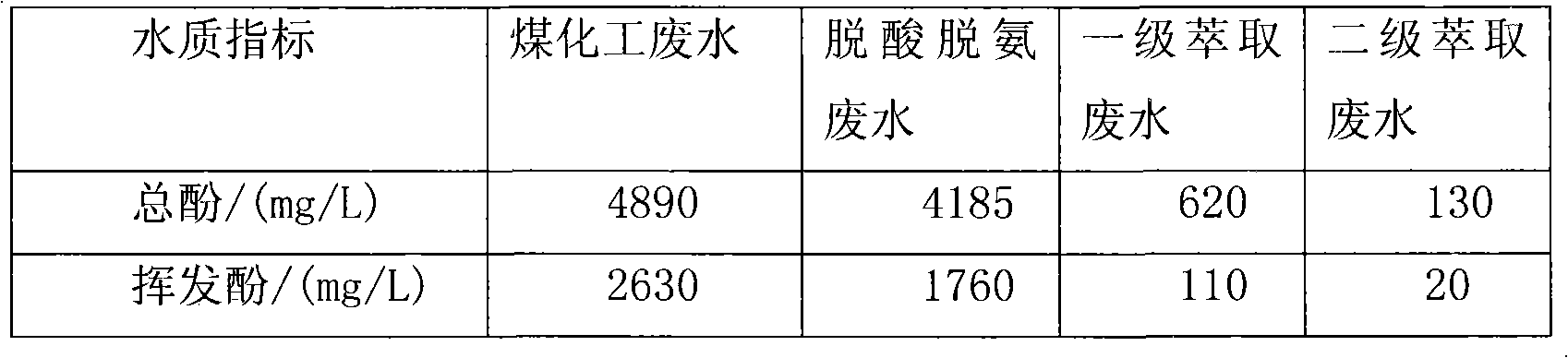

Treatment and reclaimation method of coal gasification wastewater contg. phenol

InactiveCN1834039AEfficient extractionHigh partition coefficientMultistage water/sewage treatmentWater/sewage treatment by extractionHigh concentrationCoal gasification wastewater

This invention relates to a method to dispose and recycle coal-gasification sewage containing high-concentration hydroxybenzenes, which includes following steps: a) acid removal; b) hydroxybenzene removal by extraction; c) regeneration of extraction solvent; d) ammonia recycling and rudimental extraction solvent recycling. The extraction solvent is isobutyl methyl ketone. After disposal with this method, more than 92% hydroxybenzenes and 99.5% ammonia can be recycled from the sewage. The extractant can be regenerated by distillation separation. The regenerated extractant is high purified and can meet the requirement of circulative extraction. Besides, while hydroxybenzenes, especially polyphenols are effectively recycled, CODCr of the sewage is also greatly lowered, which is benefic to sewage biochemical standardization.

Owner:SOUTH CHINA UNIV OF TECH

Method for treating coal gasification wastewater containing phenol and ammonia

InactiveCN101597124AEffective removal of fixed ammonia contentMeet the requirements of subsequent biochemical treatmentMultistage water/sewage treatmentWater/sewage treatment by degassingCoal gasification wastewaterHigh concentration

The invention relates to a method for treating coal gasification wastewater containing phenol and ammonia. The method comprises the following steps: single tower alkali injection and pressurization steam stripping removal of acidic gas and ammonia, three-level dephlegmation of lateral line tapped gas, extraction of phenol by diisopropyl ether and solvent recovery. The cold and hot coal gasification wastewater, according to a certain proportion, respectively enters a pressurization single tower from the upper part and middle upper part of a wastewater steam stripping tower, and acid gas is discharged from the tower top; the lateral line withdrawal mixed gas goes through three-level dephlegmation to obtain high-concentration ammonia, alkali is injected at the position below the lateral line to transform fixed ammonia into free ammonia which is to be removed; counter-current extraction is carried out on removed ammonia, residue of acid gas and diisopropyl ether to dephenolize; extraction solvent is recovered by a solvent recovery tower and a solvent steam stripping tower to obtain the byproduct, namely crude phenol. In the method of the invention, the process removing acid gas, free ammonia and fixed ammonia is carried out simultaneously on the coal gasification wastewater in the wastewater steam stripping single tower, as a result, high-concentration ammonia is obtained, the content of carbon dioxide, sulfureted hydrogen, free ammonia and fixed ammonia in tower kettle purified water is extremely low, encrustment is not prone to take place, and the purified coal gasification wastewater meets the requirement of follow-up biochemical treatment.

Owner:SOUTH CHINA UNIV OF TECH +2

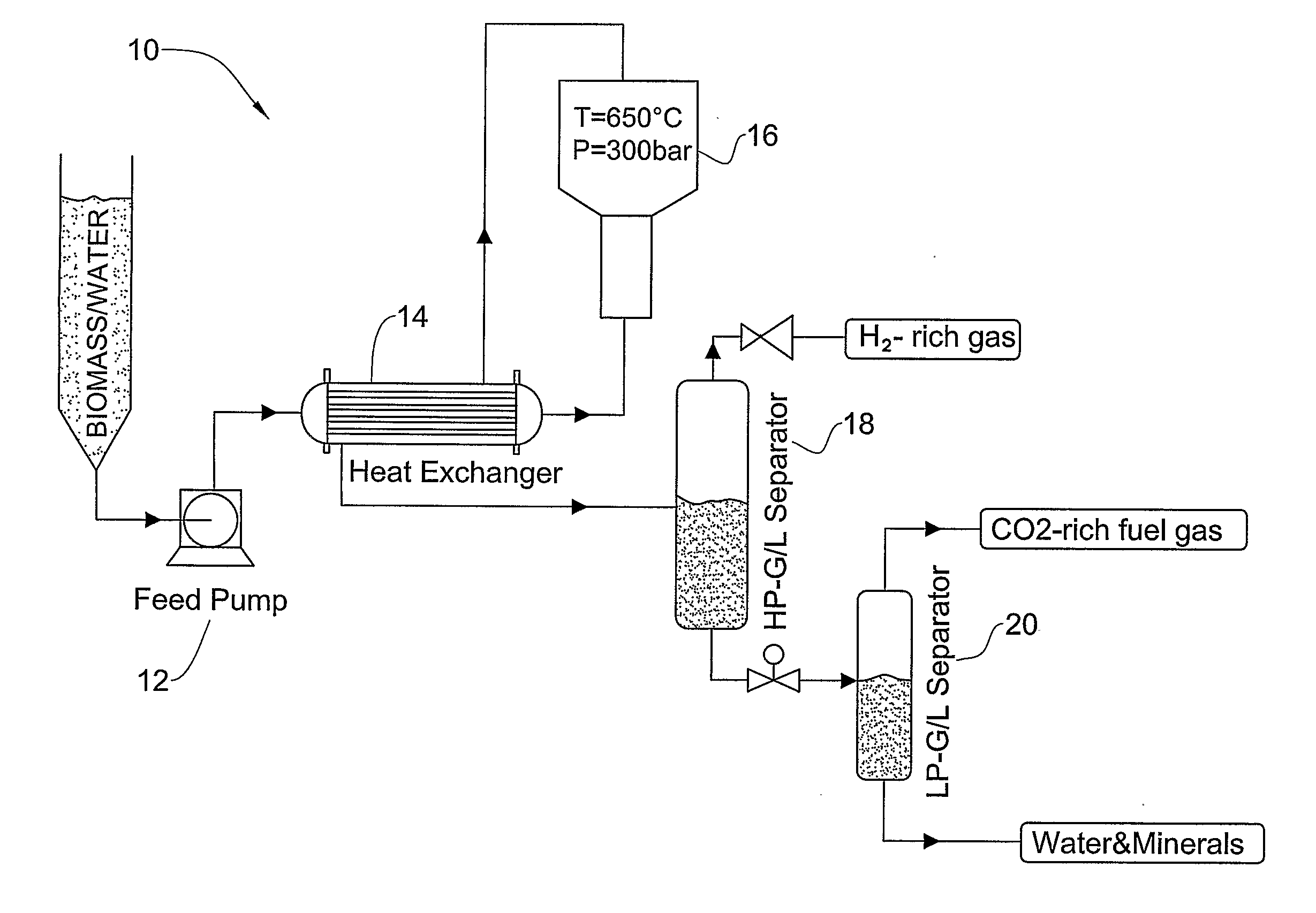

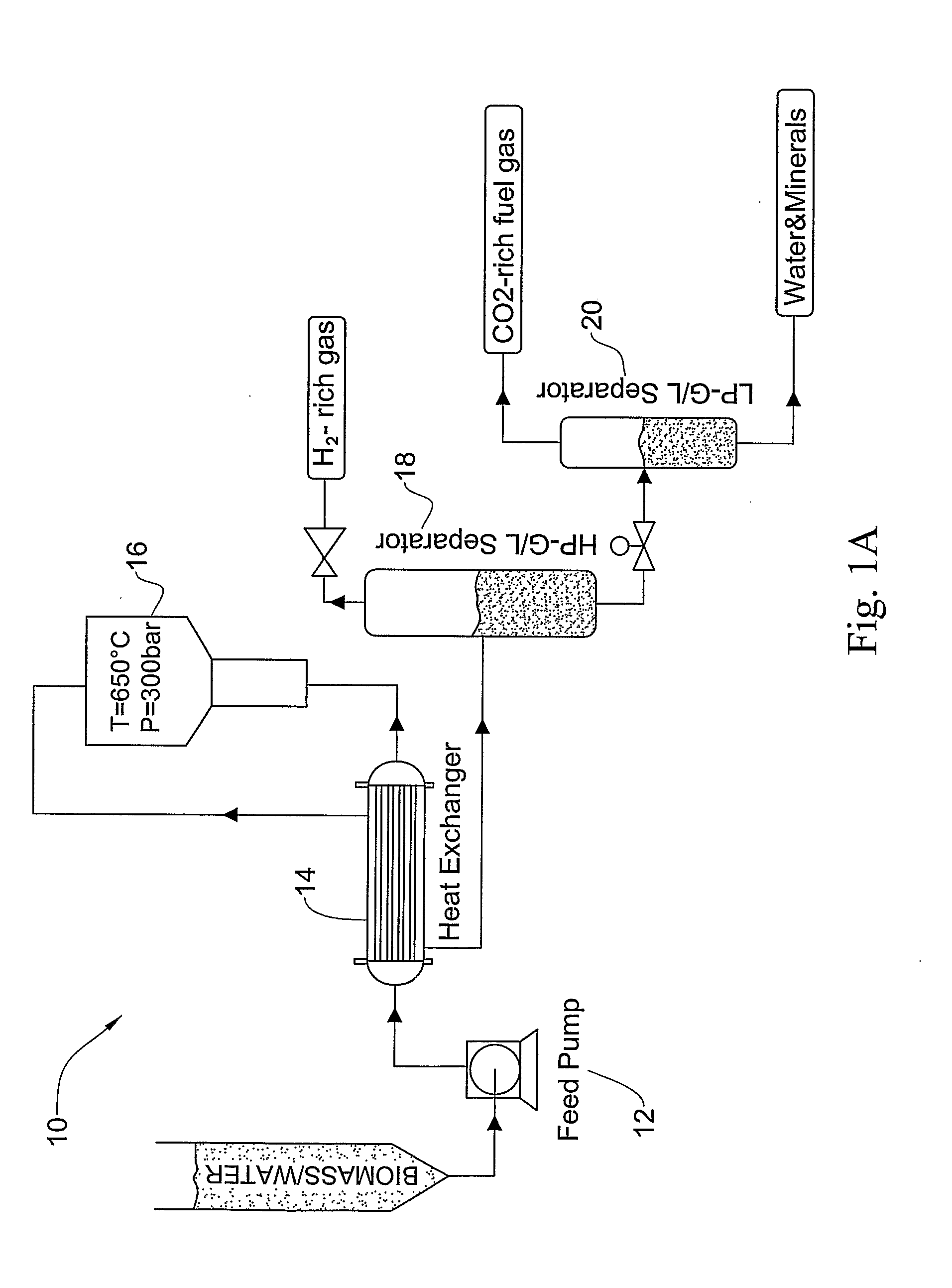

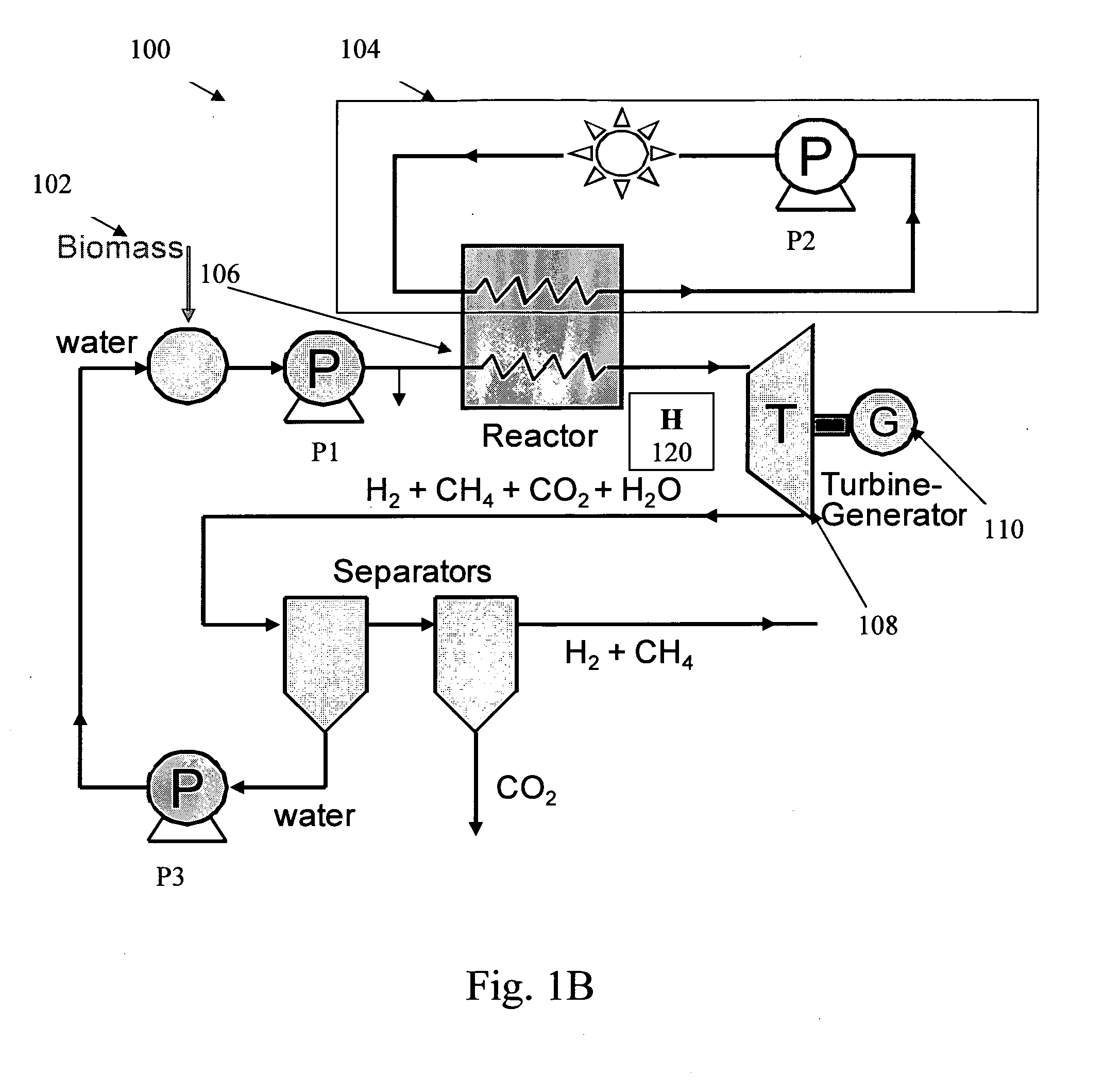

Catalytic gasification of organic matter in supercritical water

InactiveUS20120060418A1Reduce complexity and costReduce the temperatureWaste based fuelHydroxy compound preparationHigh pressureTemperature and pressure

A catalyst system including at least one metal and an oxide support, said oxide support including at least one of Al2O3, MnxOy, MgO, ZrO2, and La2O3, or any mixtures thereof; said catalyst being suitable for catalyzing at least one reaction under supercritical water conditions is disclosed. Additionally, a system for producing a high-pressure product gas under super-critical water conditions is provided. The system includes a pressure reactor accommodating a feed mixture of water and organic matter; a solar radiation concentrating system heating the pressure reactor and elevating the temperature and the pressure of the mixture to about the water critical temperature point and pressure point or higher. The reactor is configured and operable to enable a supercritical water process of the mixture to occur therein for conversion of the organic matter and producing a high-pressure product fuel gas.

Owner:RAMOT AT TEL AVIV UNIV LTD +2

Method for treating gasified waste water containing high-concentration phenol and ammonia

InactiveCN101665309AEasy extractionImprove extraction efficiencyOrganic chemistryOrganic compound preparationHigh concentrationThree level

Owner:SOUTH CHINA UNIV OF TECH +1

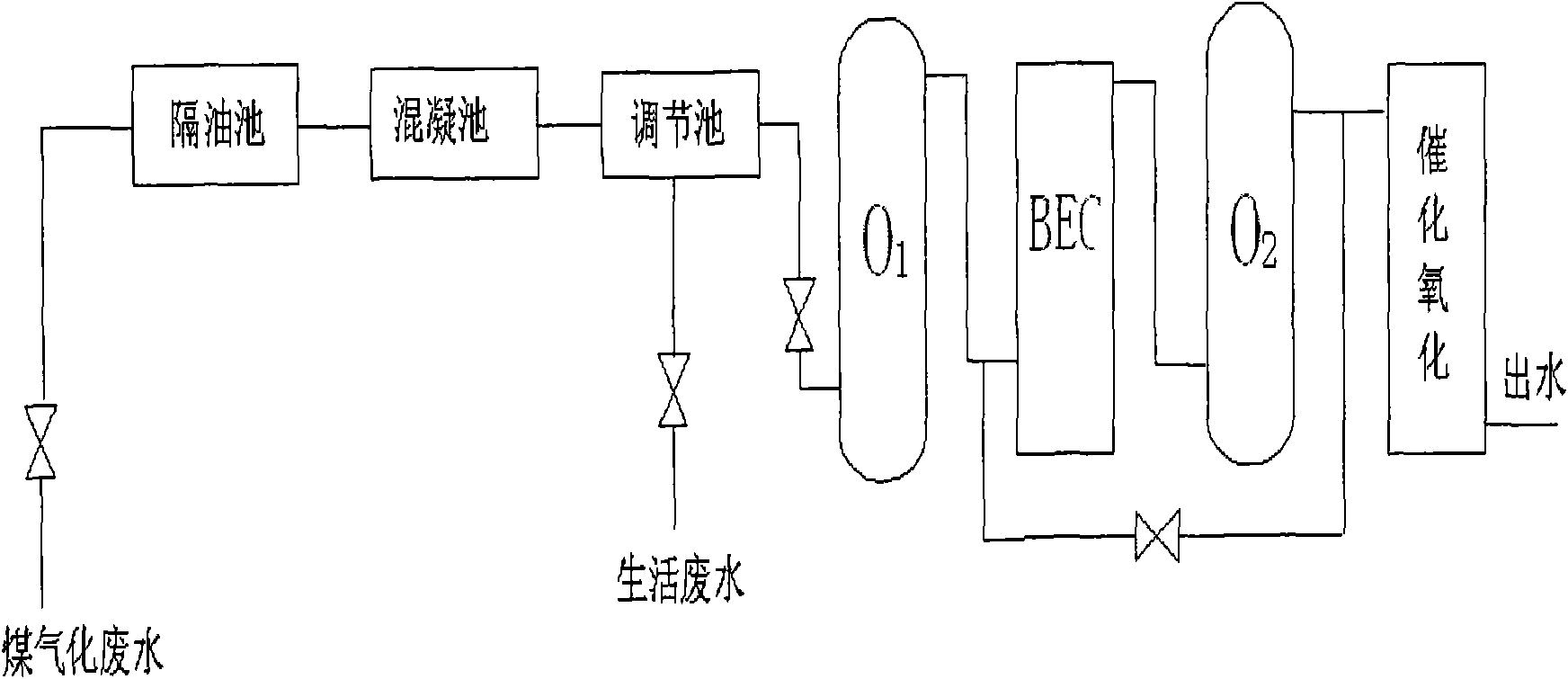

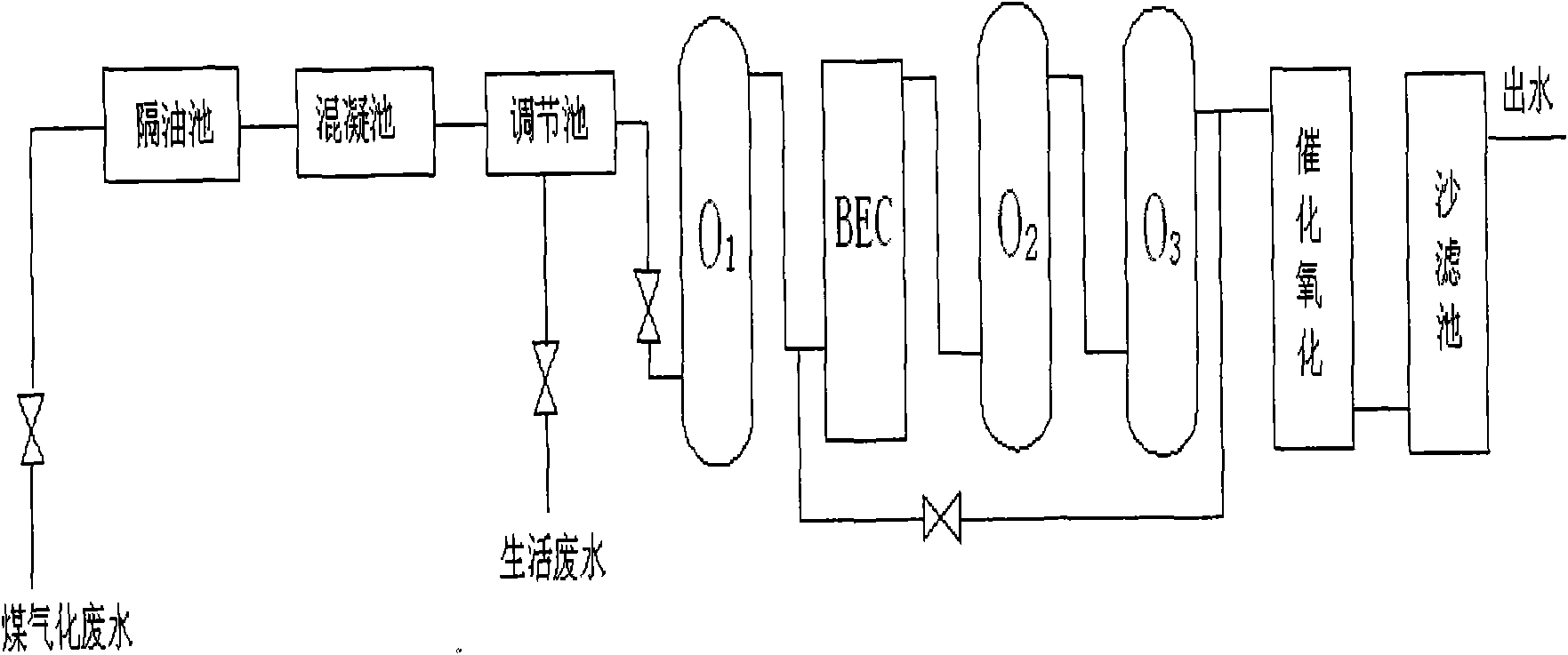

Method for processing coal gasification wastewater

ActiveCN101654316APromote degradationImprove nitrogen removal efficiencyWaste water treatment from gaseous effluentsMultistage water/sewage treatmentCoal gasification wastewaterCatalytic oxidation

The invention discloses a method for processing coal gasification wastewater. The method sequentially comprises the following steps: a. carrying out preprocessing on the coal gasification wastewater in a preprocessing step comprising oil removal processing, coagulation processing and optional adjustment processing; then b. leading the preprocessed coal gasification wastewater to sequentially flowthrough a first-class bio-contact oxidation reactor, a biological electrochemical reactor, a second-class bio-contact oxidation reactor and an optional third-class or multi-class bio-contact reactor to carry out biological processing; and c. leading the biologically processed coal gasification wastewater to carry out catalytic oxidation processing in a catalytic oxidation reactor.

Owner:ENN ENVIROTECH CO LTD

Pretreatment method of coal tar

ActiveCN101012385ARetain light and heavy componentsIncrease profitWorking-up tarPretreatment methodPre treatment

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Method for preparing synthetic gas through microwave pyrolysis and gasification of biomass

ActiveCN105524662ARelaxed size requirementsReduce preprocessing power consumptionCombustible gas chemical modificationFixed-bed gasificationHigh carbonLiquid fuel

The invention discloses a method for preparing synthetic gas through microwave pyrolysis and gasification of biomass. The method comprises the following steps: a biomass raw material sent to a bunker and a catalyst are introduced into a microwave pyrolysis reactor, and passes through a preheating zone, a pyrolysis zone, a gasification zone and a reforming zone in order for reactions of dehydration, cracking, gasification and reforming, the reformed product is performed with gas-solid separation, gas and a few of carried tar and coke are subjected to a cracking reaction in a gas lifting pipe again, synthetic gas is released from an outlet, and the coke and ash obtained by gas-solid separation can be discharged from a reactor. The method has the advantages of high biomass gasification rate and high carbon conversion rate, the obtained synthetic gas product has high quality, can satisfy synthesis requirement of a liquid fuel, and has good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

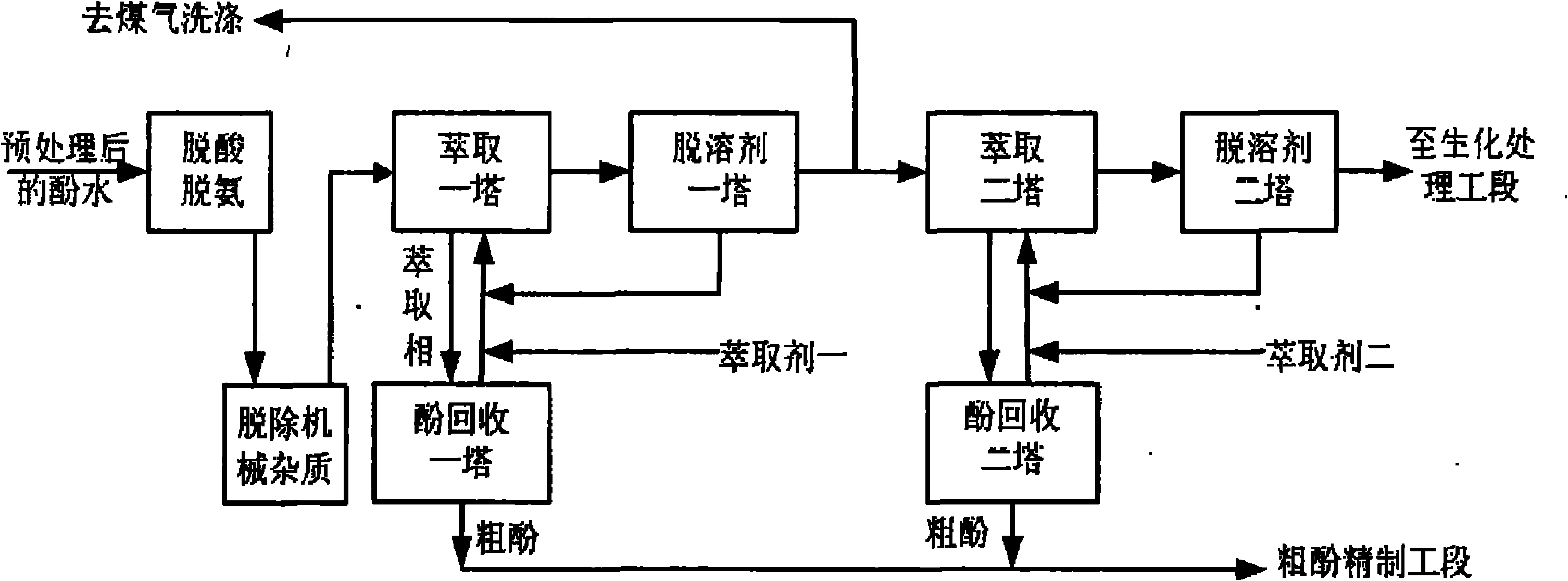

Method for extracting and dephenolizing coal chemical industry wastewater

ActiveCN101913718AReduce dosageImprove removal efficiencyMultistage water/sewage treatmentWater/sewage treatment by extractionHigh concentrationChemical industry

The invention discloses a method for extracting and dephenolizing coal chemical industry wastewater. Two different solvents are used as extracting agents, and serially-connected double-tower two-stage extracting dephenolization is adopted. The method comprises the following steps of: after carrying out gravity settling oil removal pretreatment on high-concentration phenol-contained wastewater produced in the coal chemical industry process and deacidifying, deaminizing and removing mechanical impurities, carrying out first-stage extracting dephenolization with the first solvent as the extracting agent; and carrying out second-stage extracting dephenolization with the second solvent as the extracting agent and conveying dephenolized water into a biochemical treatment working section. The wastewater subjected to first-stage dephenolization has the total phenol content of 400-1,000mg / l and the COD (Chemical Oxygen Demand) of 2,000-5,000mg / l; the wastewater subjected to second-stage dephenolization has the total phenol content of smaller than 300mg / l and the COD of smaller than 2,000mg / l; and the total phenol removal rate is larger than 90 percent, and the polyphenol removal rate is larger than 70 percent. The invention can meet the requirement of water quality of biochemical treatment, has the advantages of high phenol removal rate, less solvent dosage and low energy consumption and is particularly suitable for treating the wastewater which has high polyphenol content and is produced in the coal gasification, coking and chemical industry synthesis process.

Owner:哈尔滨瑞格能源环境技术发展有限责任公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com