Patents

Literature

426results about How to "Control reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

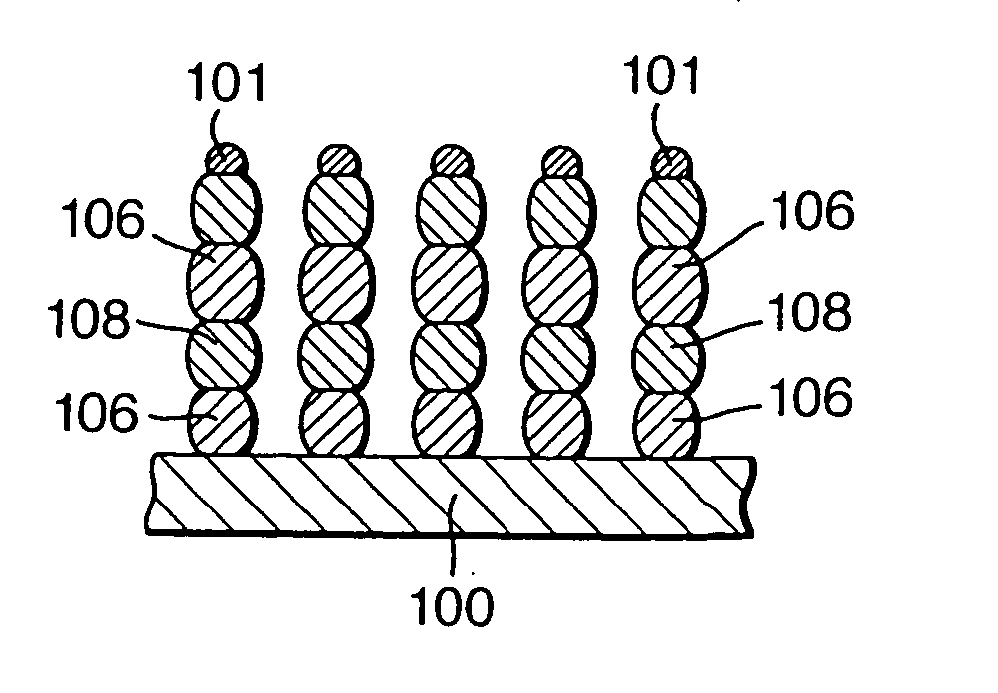

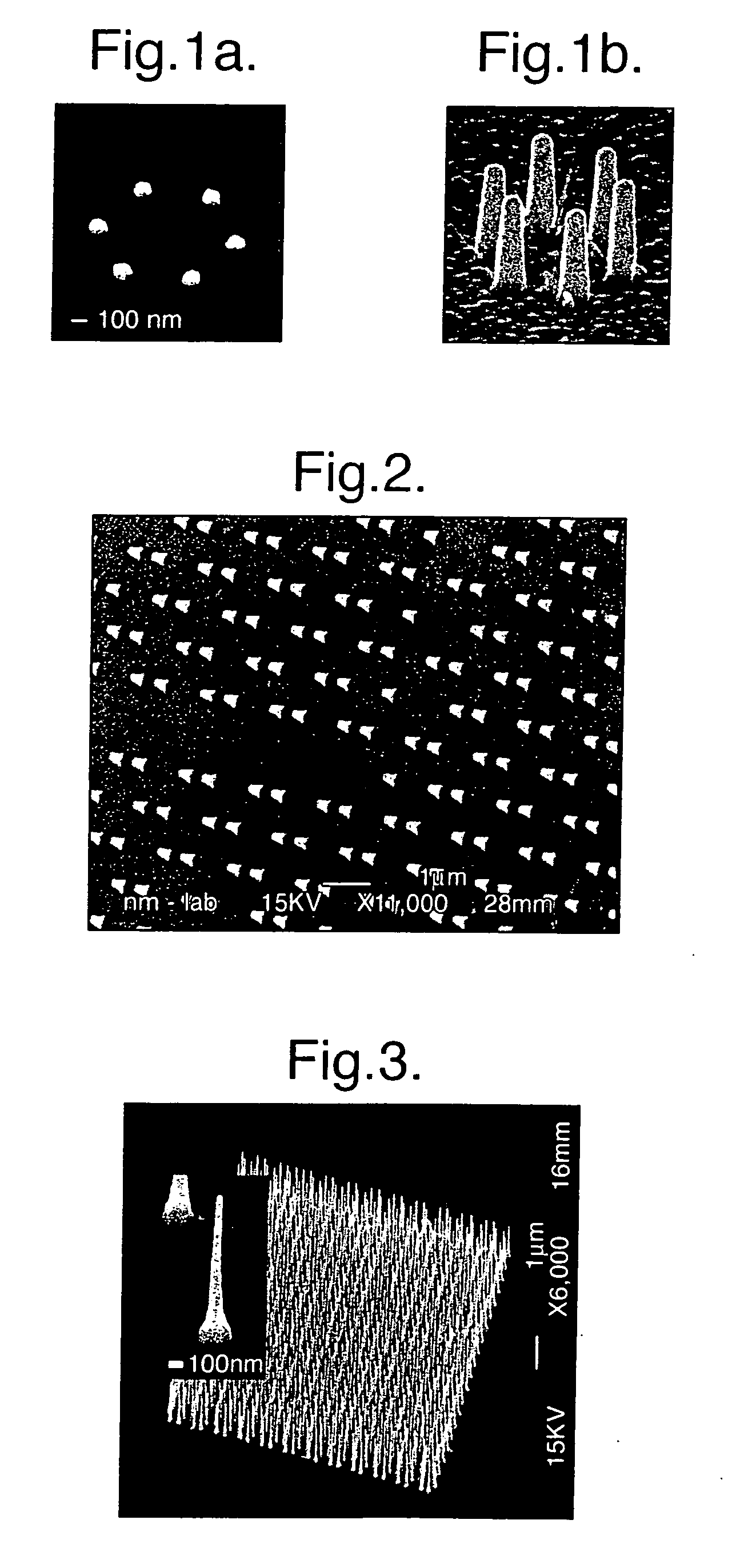

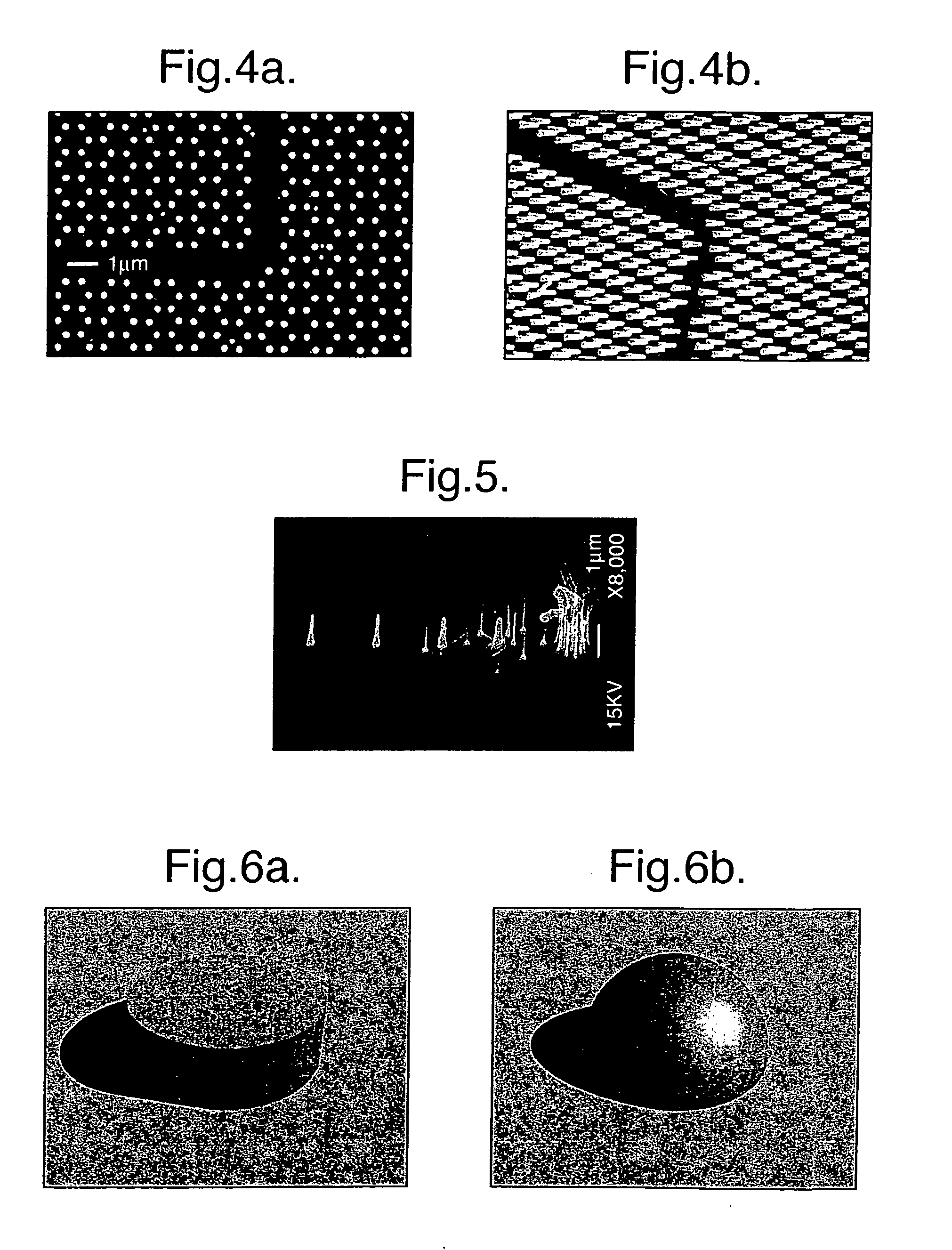

Precisely positioned nanowhiskers and nanowhisker arrays and method for preparing them

InactiveUS20050011431A1Increase forceImprove stabilityMaterial nanotechnologyPolycrystalline material growthPhotonic bandgapAdemetionine

A nanoengineered structure comprising an array of more than about 1000 nanowhiskers on a substrate in a predetermined spatial configuration, for use for example as a photonic band gap array, wherein each nanowhisker is sited within a distance from a predetermined site not greater than about 20% of its distance from its nearest neighbour. To produce the array, an array of masses of a catalytic material are positioned on the surface, heat is applied and materials in gaseous form are introduced such as to create a catalytic seed particle from each mass, and to grow, from the catalytic seed particle, epitaxially, a nanowhisker of a predetermined material, and wherein each mass upon melting, retains approximately the same interface with the substrate surface such that forces causing the mass to migrate across said surface are less than a holding force across a wetted interface on the substrate surface.

Owner:QUNANO

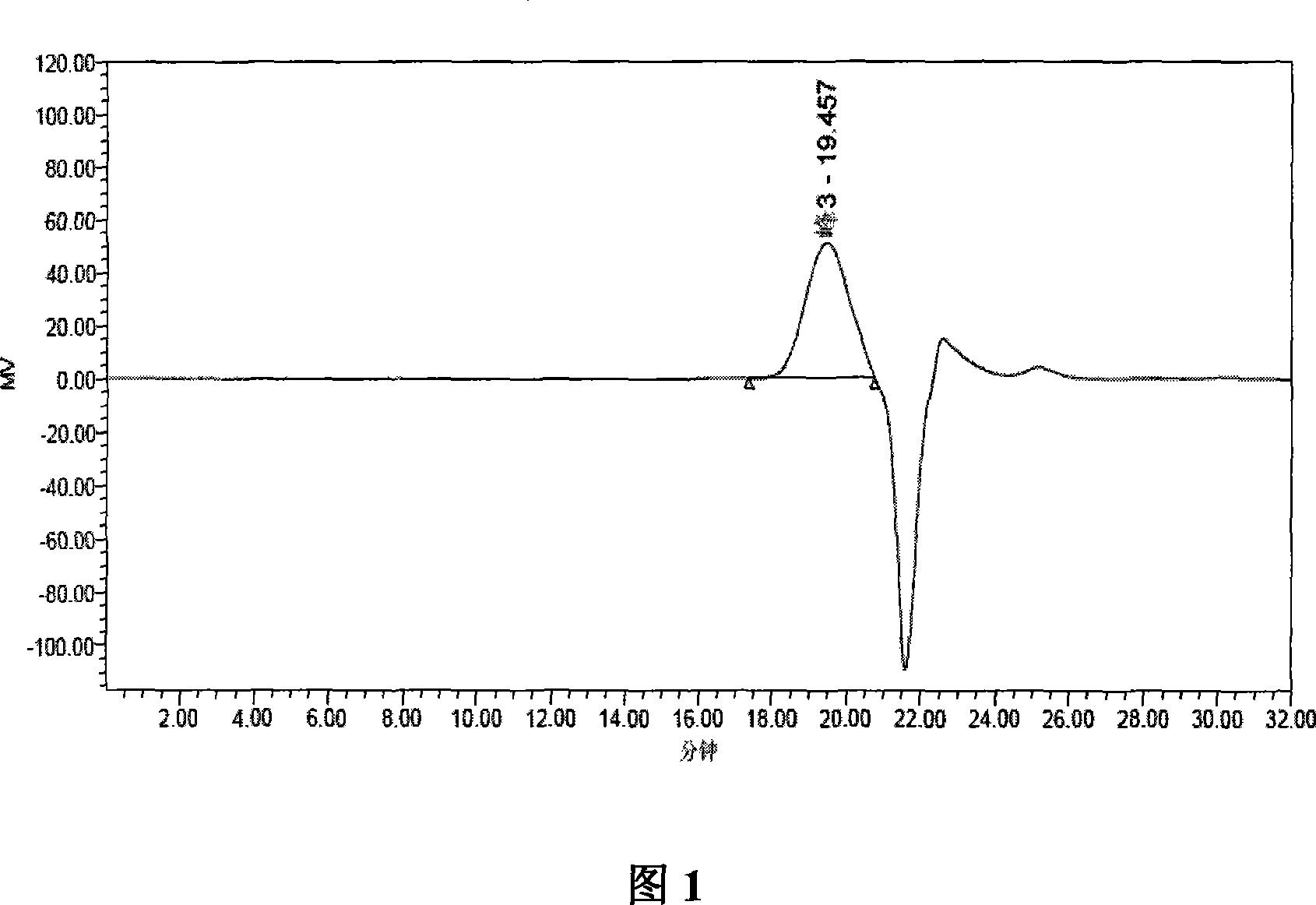

Preparation method of graft copolymerization carboxylate high-performance dehydragent

InactiveCN101041570ANo pollution in the processLow conversion rate of esterificationNitrogen gasAqueous solution

The invention discloses a preparing method of graft copolymerization carboxylate high-performance dehydragent belonging to dehydragent domain, which comprises the following steps: choosing methoxy carbowax with molecular weight distributing between 1000-2000 and acroleic acid or methacrylic acid as main raw material; adopting total acid method esterified priority method; preparing intermediate (big monomer) with polymerization activity; adding third monomer into polymerization reaction; adjusting polymerization activity of copolymerization system; proceeding technique route synthesis of main chain polymerization in the water solution. The getting big monomer possesses merits of high conversion rate, short reacting time, simple process flow and strong controlling property.

Owner:BEIJING UNIV OF TECH

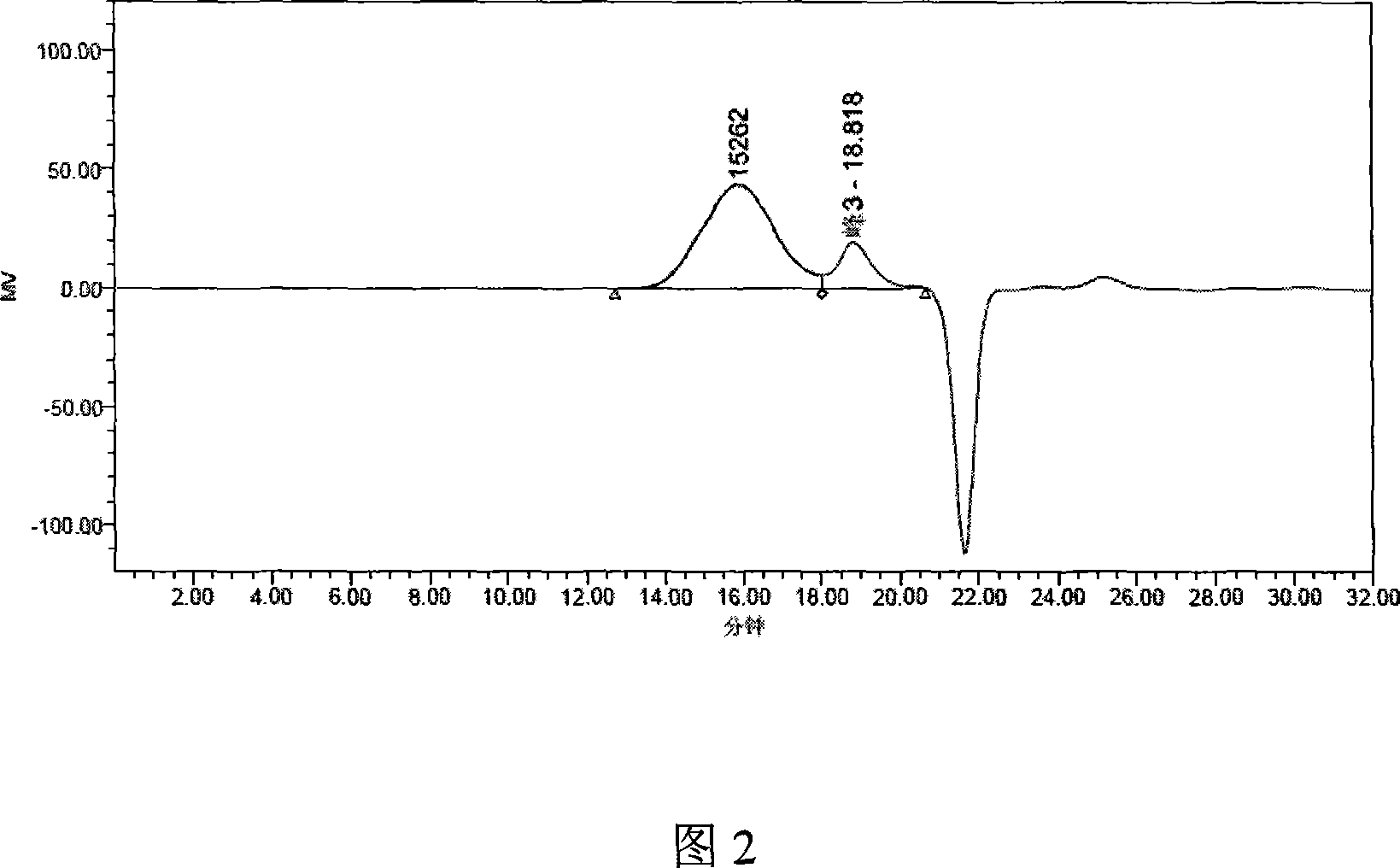

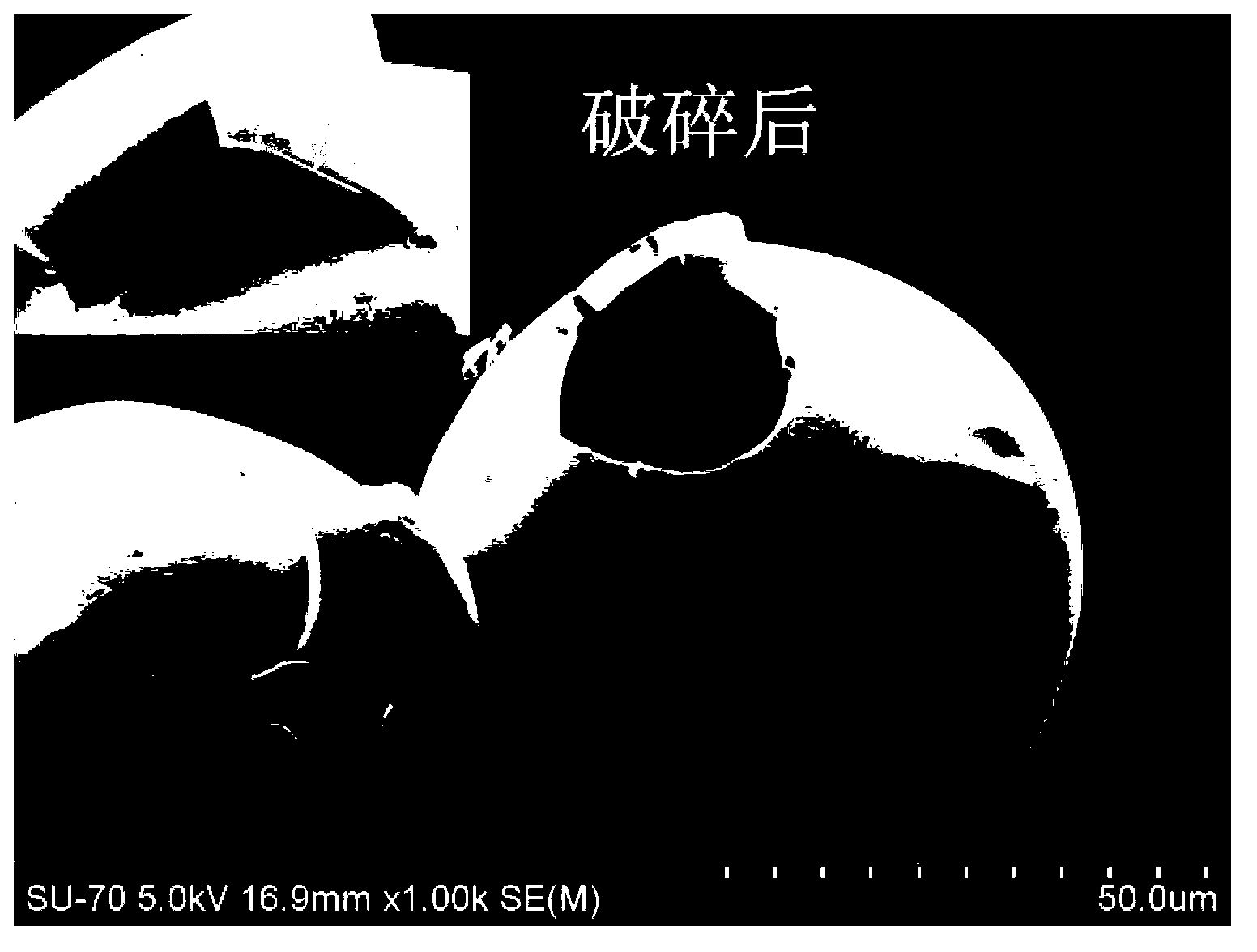

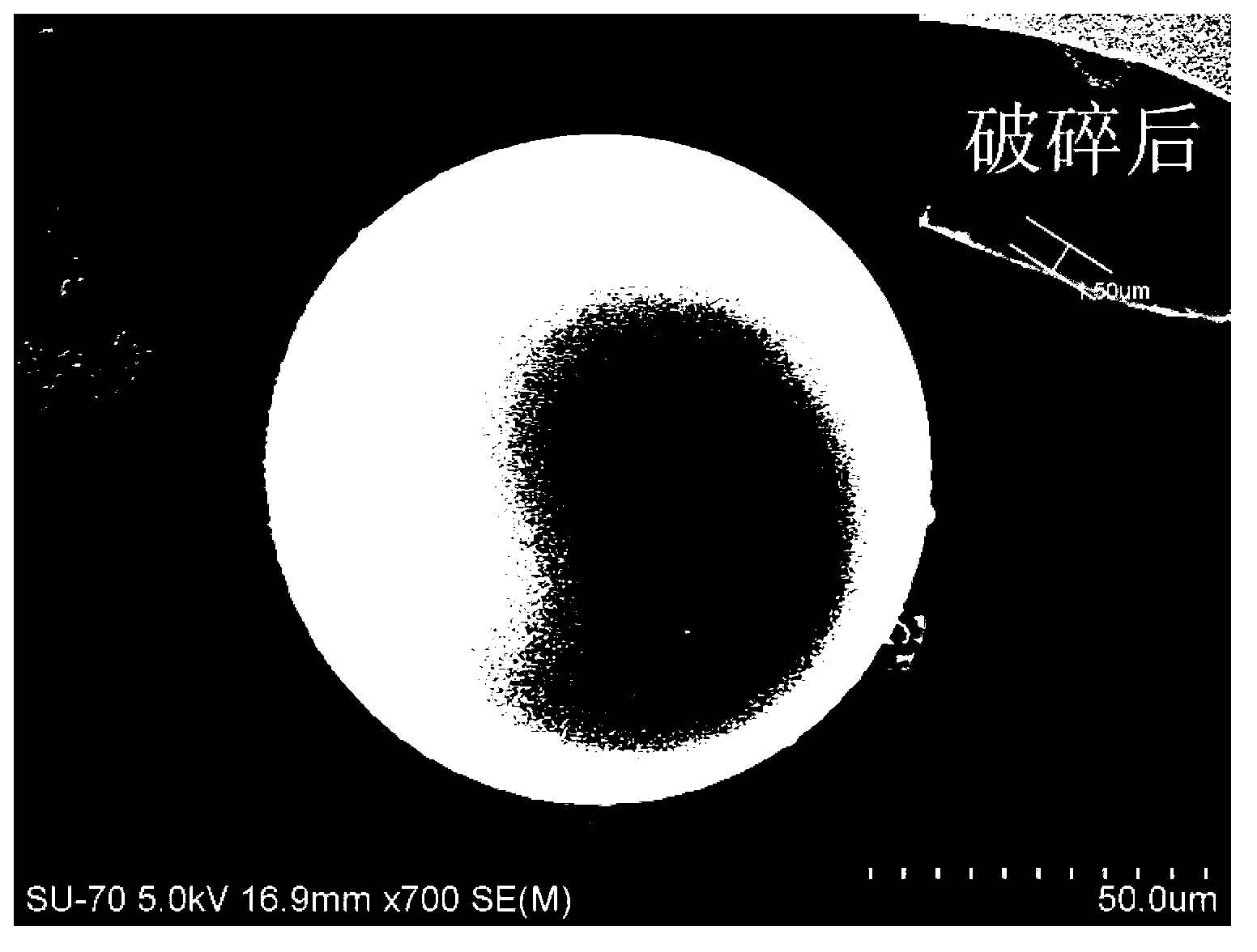

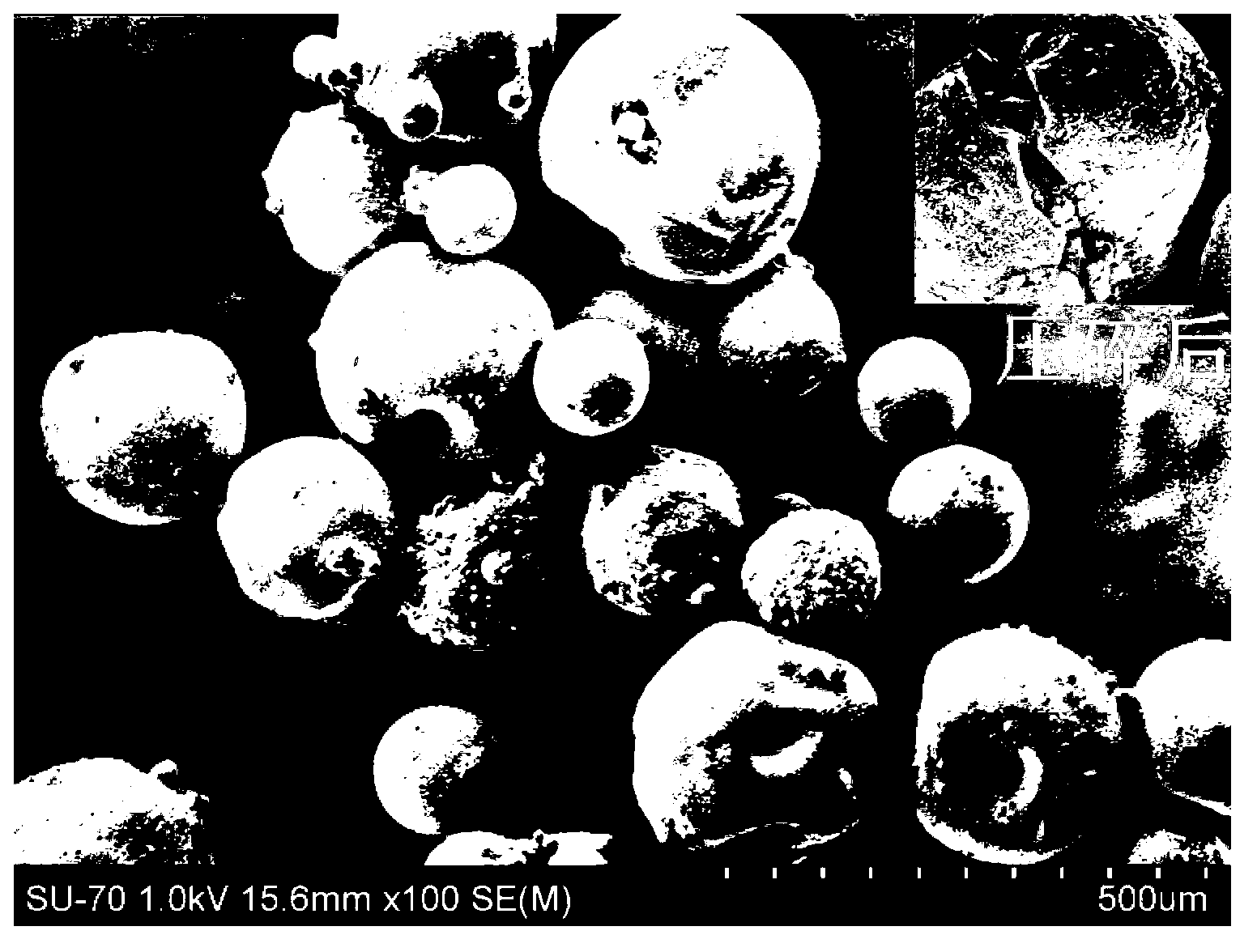

Epoxy microcapsule and preparation method thereof

InactiveCN103304775AParameter controlControl reaction temperatureMicroballoon preparationMicrocapsule preparationEpoxySelf-healing material

The invention is applicable to the field of microcapsule preparation and self-repairing materials, and provides an epoxy resin microcapsule. The epoxy resin microcapsule comprises a capsule core and a capsule wall, wherein the capsule core consists of epoxy resin or a mixture containing the epoxy resin; and the capsule wall is obtained through a reaction between partial epoxy resin in the capsule core and a curing agent. The invention also provides a preparation method of the epoxy resin microcapsule. The preparation method of the epoxy resin microcapsule provided by the invention has a simple process.

Owner:SHENZHEN UNIV

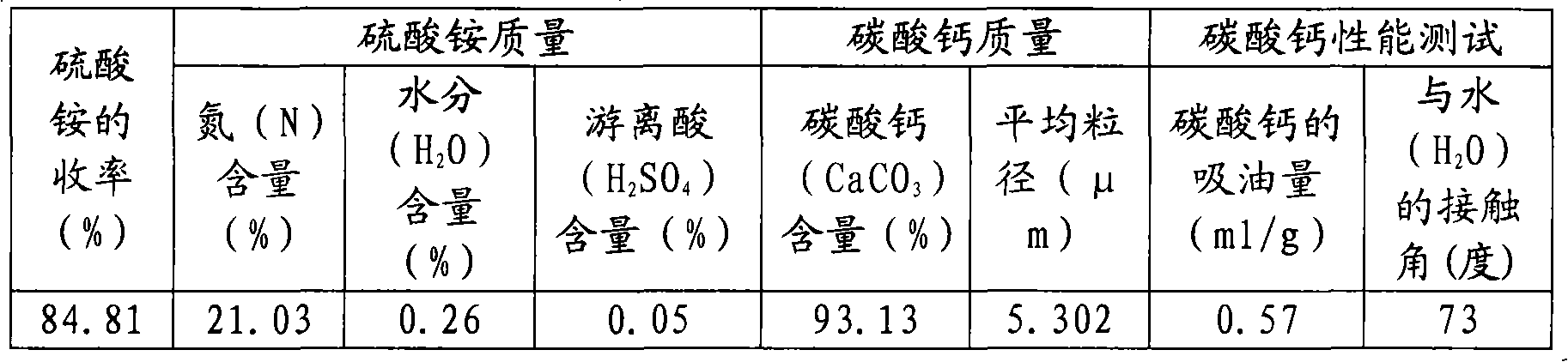

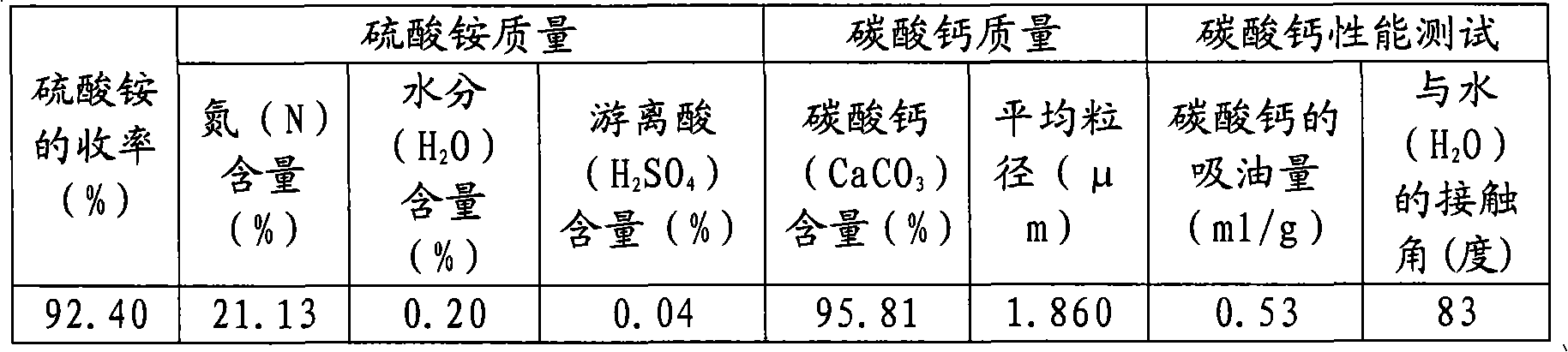

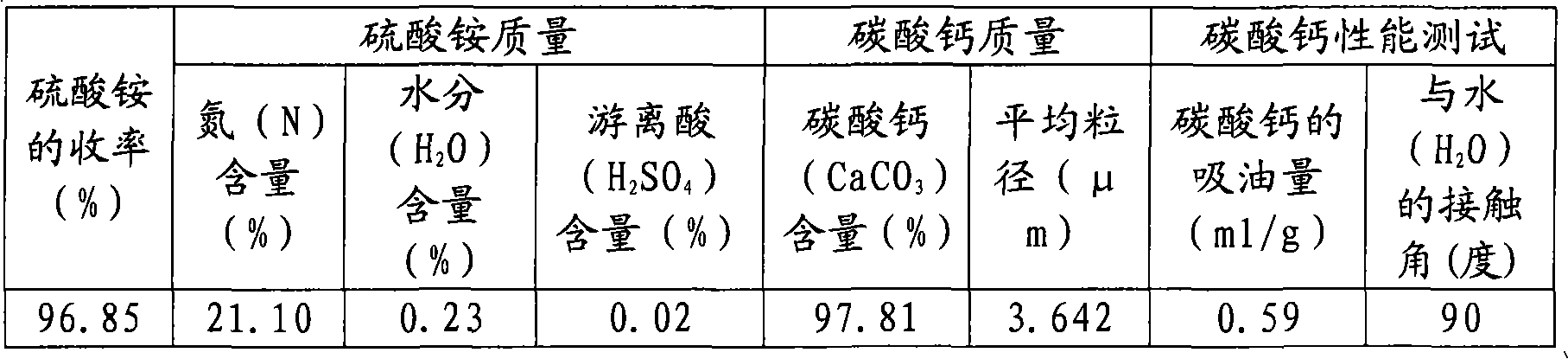

Method for joint production of ammonium sulphate and calcium carbonate with phosphogypsum

InactiveCN101492178AReduce contentIncrease contact areaCalcium/strontium/barium carbonatesAmmonia compoundsReaction temperaturePhosphogypsum

The invention discloses a method for co-producing ammonia sulfate and calcium carbonate by ardealite. The method comprises that: the ardealite serous liquid is taken and added into a reaction kettle; a stirrer is started, and the reaction kettle is heated up to the temperature of between 30 and 60 DEG C; an additive and (NH4)2CO3 are added into the reaction kettle, the reaction temperature is controlled to be between 30 and 60 DEG C, and the reaction time is between 0.5 and 2 hours; after the reaction, the heating device and the stirrer are closed, the mixture in the reaction kettle is cooled down to the normal temperature and filtered, the pH value of the filtrate is adjusted to be between 5.5 and 6.0, and the filtrate is condensed, crystallized and dried to obtain the ammonia sulfate product; the filter residue is added with water to obtain solid pulp of which the content of CaCO3 is between 30 and 60 percent, and the solid pulp is placed into a reactor; and the stirrer is started, and solid pulp is heated up to the temperature of between 70 and 90 DEG C and mixed with a surface modifier, the reaction temperature is maintained for 0.5 to 1 hour, the heating device is closed, the mixture is continuously stirred, cooled down to the temperature of between 30 and 50 DEG C and filtered, and the filter residue is dried to obtain the modified CaCO3. The method has the advantages of preparing the ammonia sulfate and the calcium carbonate at the same time and improving the utility value of the calcium carbonate, along with simple process, high recovery rate and low production cost.

Owner:WENGFU (GRP) CO LTD

High-temperature-resistance pork paste essence and preparation method thereof

The invention discloses a high-temperature-resistance pork paste essence. The pork paste essence comprises the following components in parts by weight: 90-98 parts of thermal reaction pork paste and 2-10 parts of pork flavoring base, wherein, the thermal reaction pork paste is prepared from the following raw materials according to a certain mass ratio: a pork thermal reactant, edible salt, white granulated sugar, sodium glutamate, disodium 5'-ribonucleotide, disodium succinate, corn starch, hydroxypropyl distarch phosphate, beta-cyclodextrine and glycerin monostearate; and the pork thermal reactant is prepared from the following raw materials according to a certain mass ratio: a pork zymolyte, a yeast extract, glucose, xylose, dark soy sauce, animal fat, sodium glutamate, amino acid, ginger powder, cinnamon powder and water. After high-temperature treatment, the pork paste essence disclosed by the invention still has the characteristics of rich and durable flavor and strong high temperature resistance. Meanwhile, the invention further discloses a preparation method of the high-temperature-resistance pork paste essence.

Owner:广东江大和风香精香料有限公司

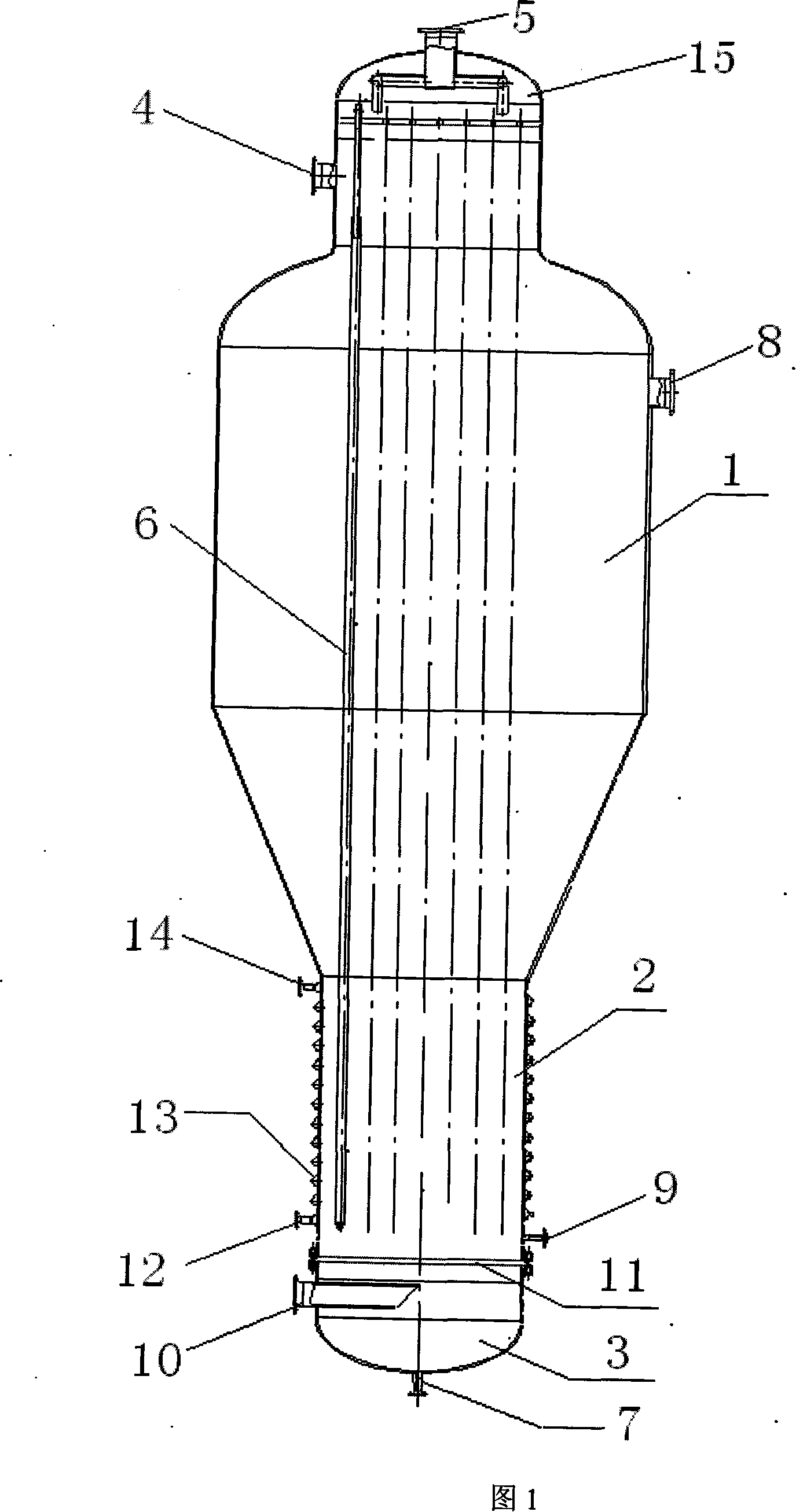

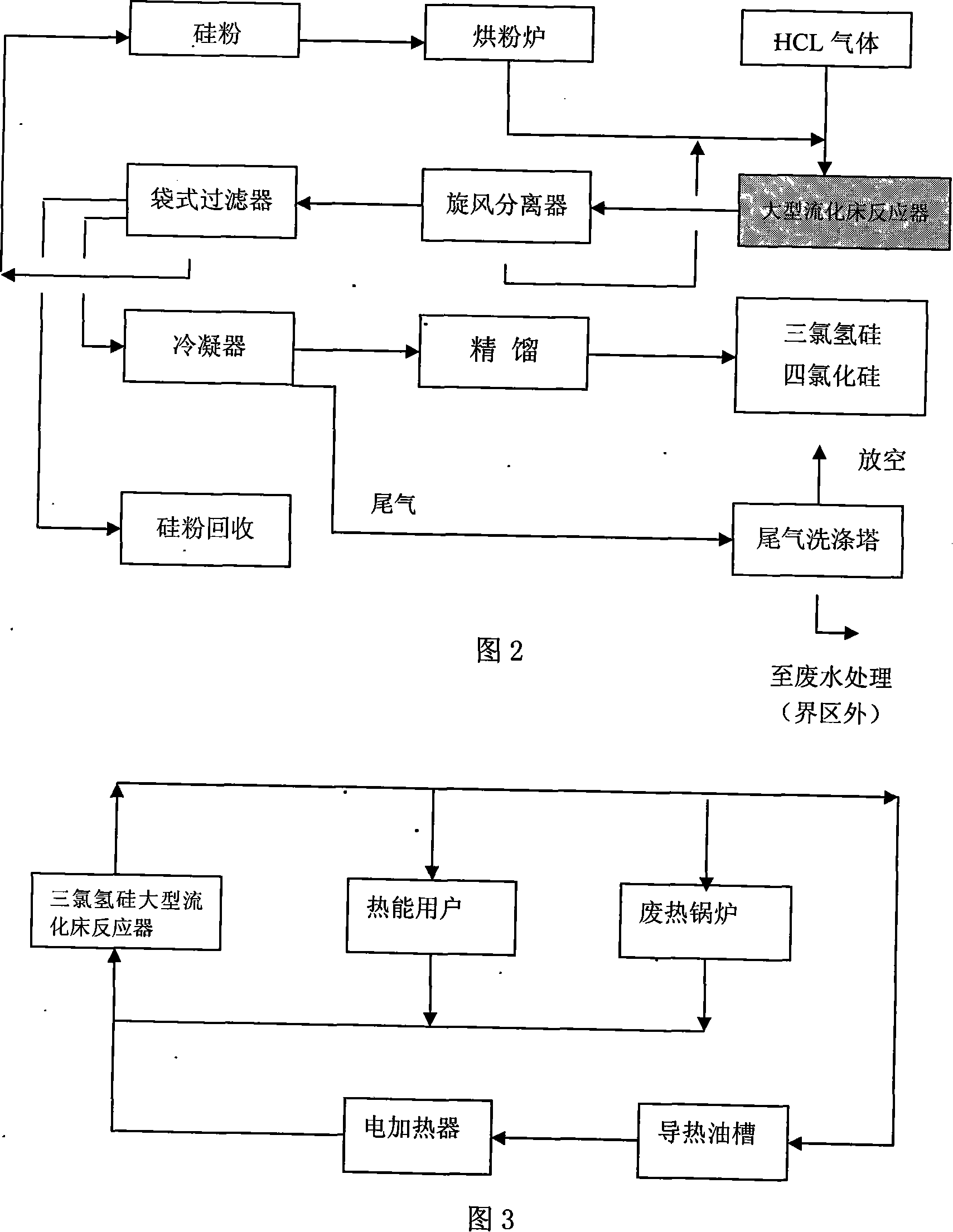

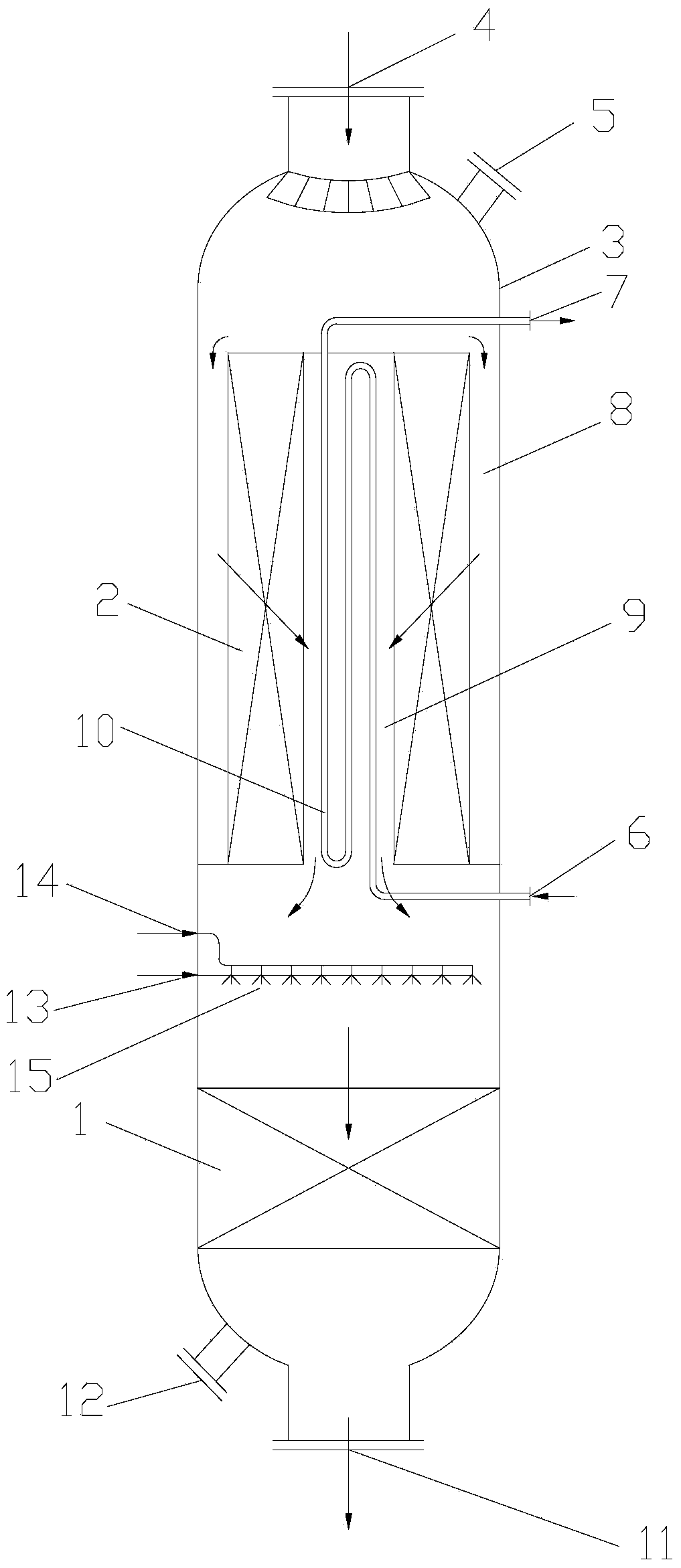

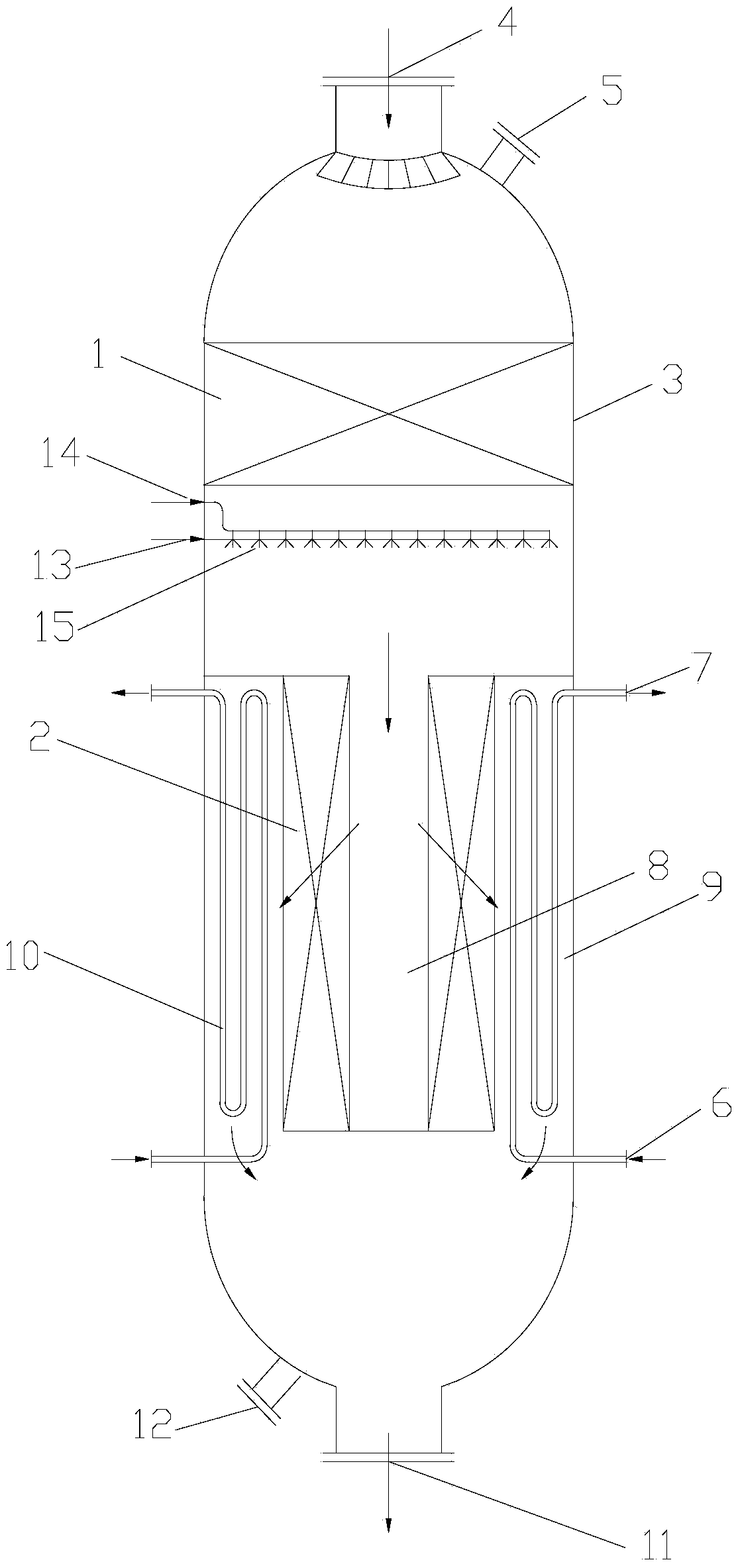

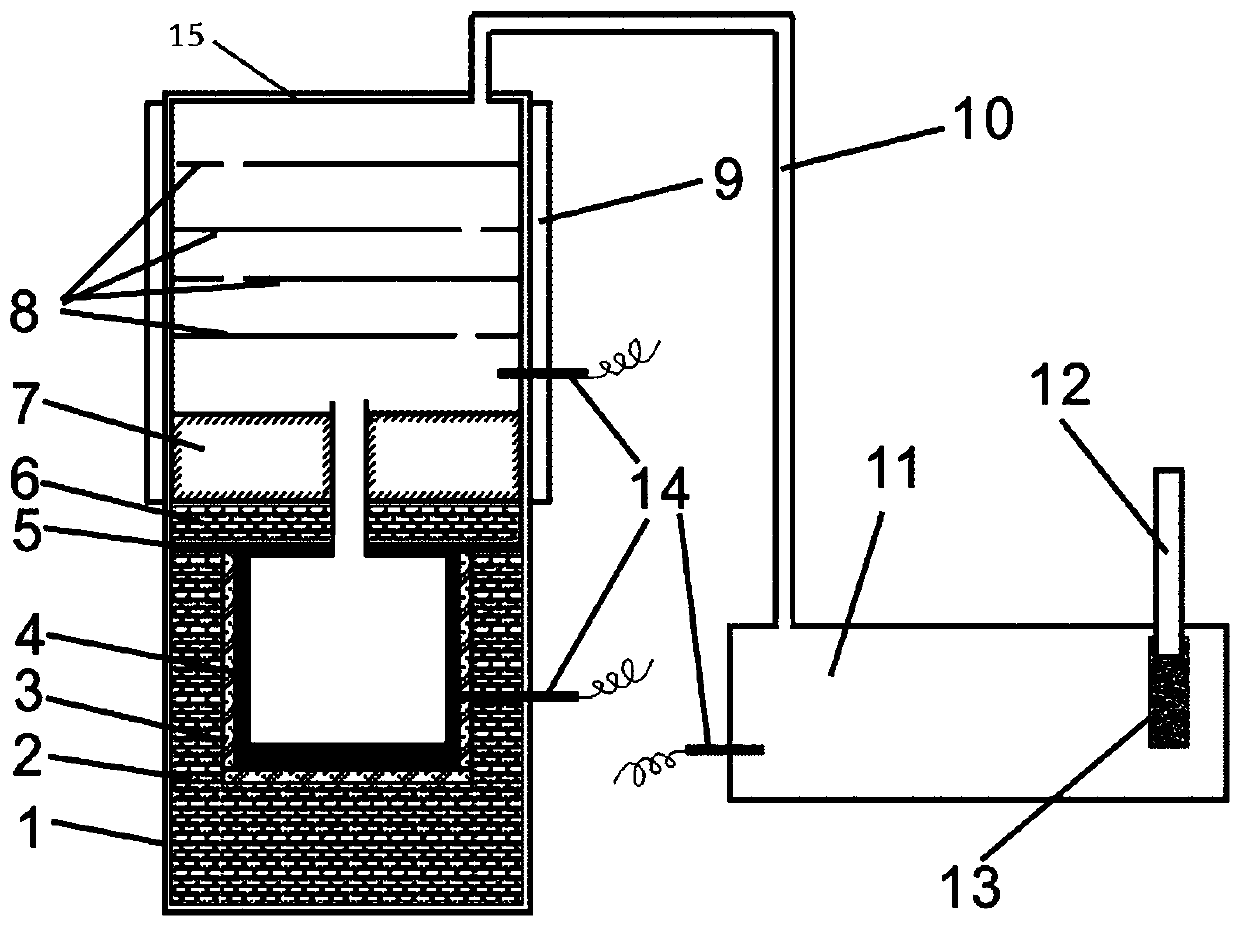

Large-scale fluidized bed reactor used for trichlorosilane production

InactiveCN101125654ASimple structureIncrease the diameterChemical/physical processesHalogenated silanesFluidized bedReaction temperature

The invention discloses a large trichlorosilane fluidized bed reactor, comprising a lower reaction section and an upper extension section; the lower part of the reaction section is provided with a silicon powder inlet, and the lower part of a reactor is provided with an overhaul cap which is provided with a hydrogen chloride inlet and a discharge mouth; the extension section has a synthesized gas outlet, and a hydrogen chloride gas distributor is arranged between the overhaul cap and the reaction section; a heat transfer oil finger-shaped tube is arranged in the reaction section and the extension section and extends from the extension section till the bottom of the reaction section; the top of the extension section is provided with a finger-shaped overhaul flange with a finger-shaped tubular heat transfer oil inlet, and the extension section is provided with a finger-shaped tubular heat transfer oil outlet; the outside of the reaction section is provided with a reactor half-pipe jacket, and both ends of the half-pipe jacket of the reactor are provided with a coiled-pipe heat transfer oil inlet and a coiled-pipe heat transfer oil outlet. The heat transfer oil is adopted to heat the reactor during the temperature rising period and transfer the reaction heat during the reaction, and the reaction temperature can be controlled by regulating the quantity of the heat transfer oil, thus acquiring the stable product yielding.

Owner:ZHEJIANG KAIHUA SYNTHETIC MATERIAL +1

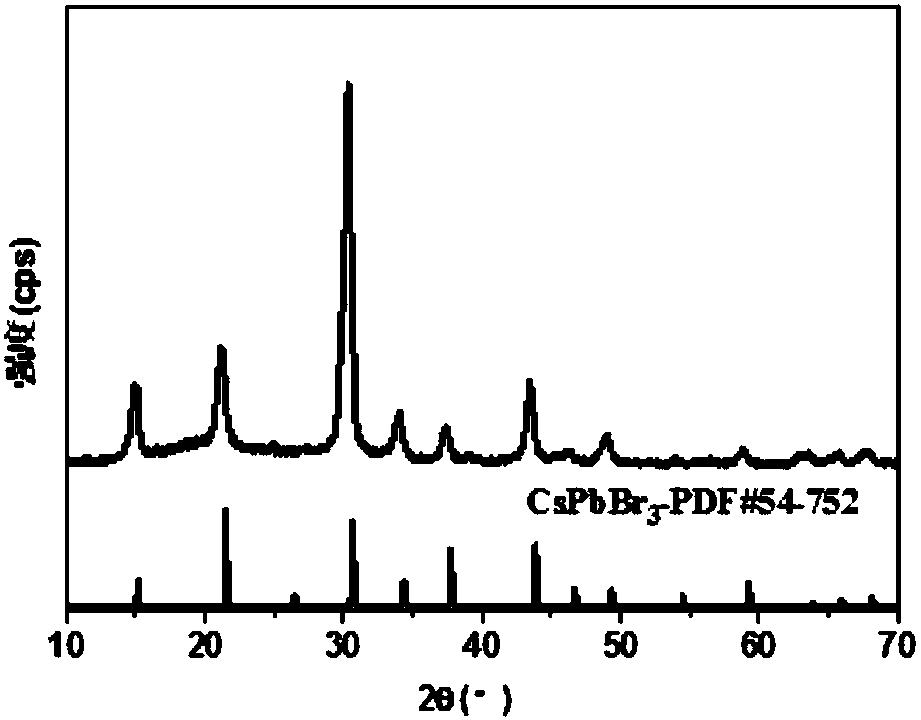

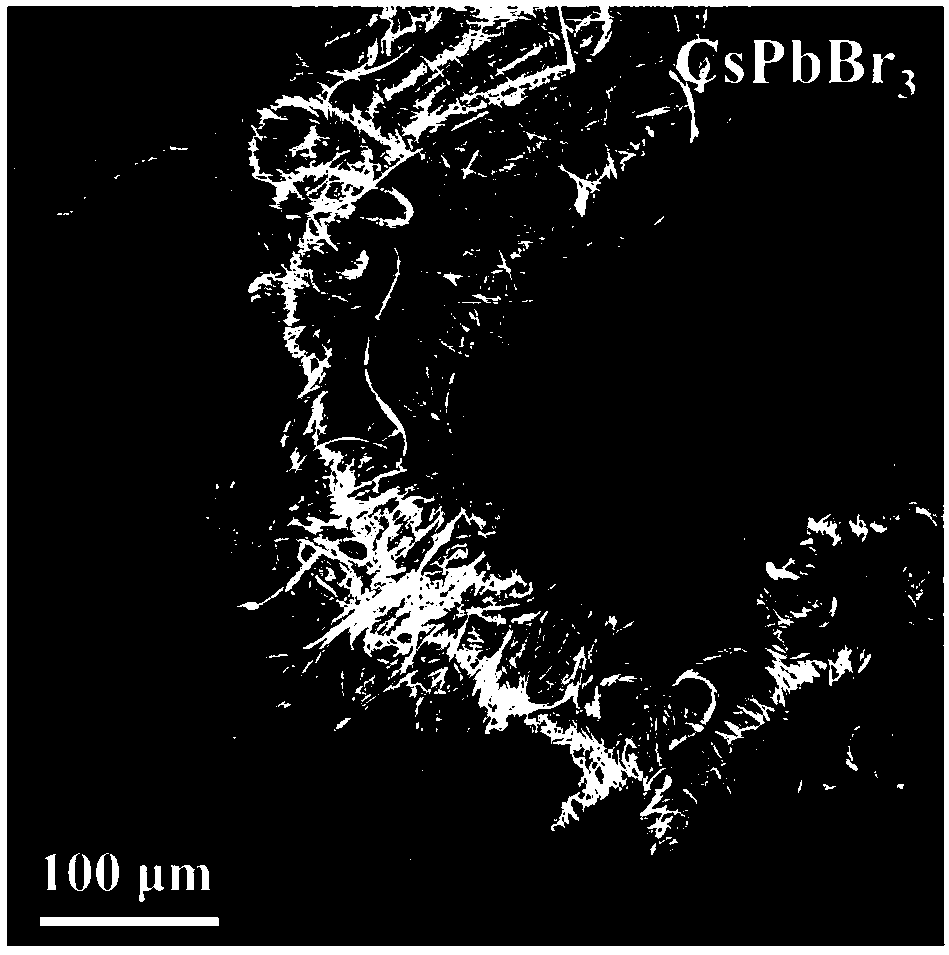

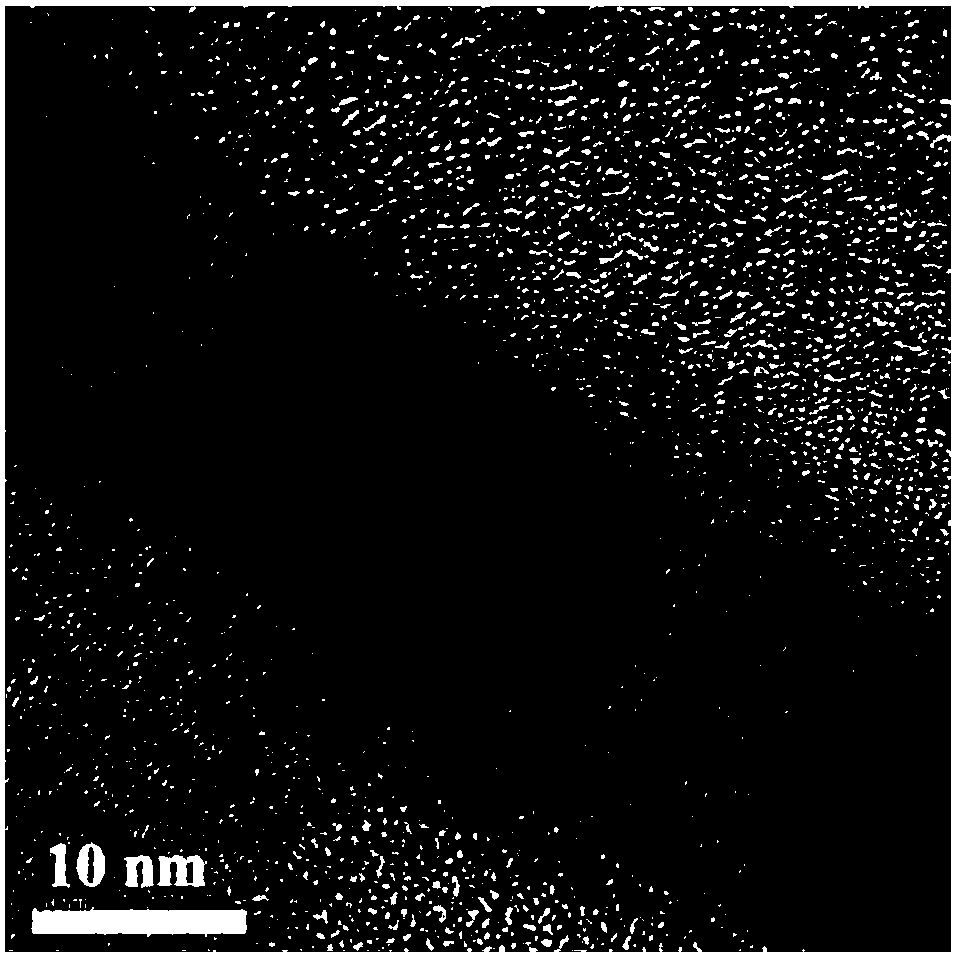

Method for synthesizing inorganic perovskite nanowires

ActiveCN108502918ALow reaction temperatureHigh yieldLuminescent compositionsLead compoundsDrawing ratioIon exchange

The invention discloses a method for synthesizing inorganic perovskite nanowires. According to the method, a CsPbBr3 nanowire which has a length of several millimeters, a diameter of only about 10 nmand an ultrahigh draw ratio is prepared at a low temperature by utilizing a solvothermal method and an anion exchange method, and nanowires CsPbI3 and CsPbCl3 are obtained by virtue of a simple anionexchange process. The method has a great effect of promoting industrial large-scale preparation of inorganic perovskite nanowires and is expected to further realize application in various aspects suchas photoelectric detection, laser and solar cells and the like. The method disclosed by the invention is simple, controllable, high in yield, uniform in morphology, low in reaction temperature and suitable for large-scale production.

Owner:HEBEI UNIV OF TECH

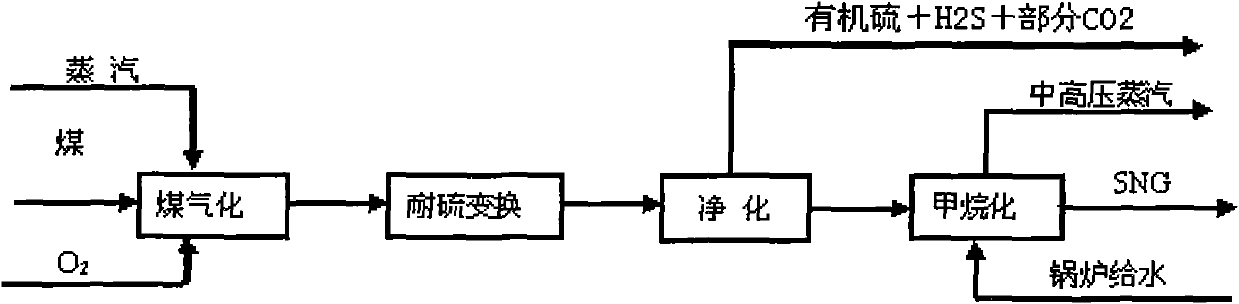

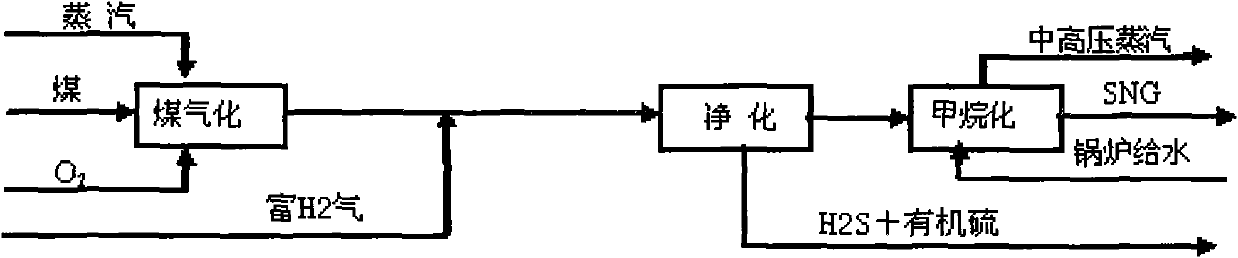

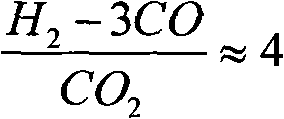

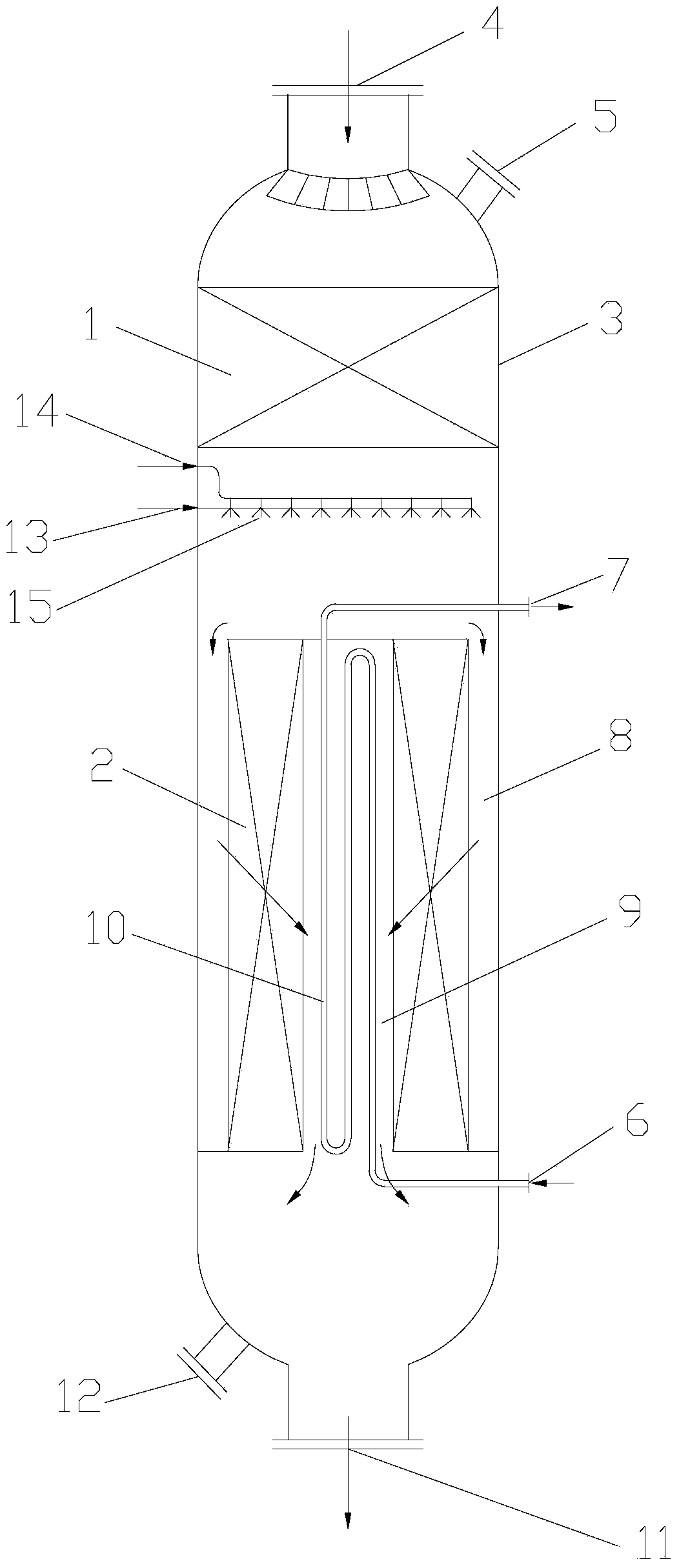

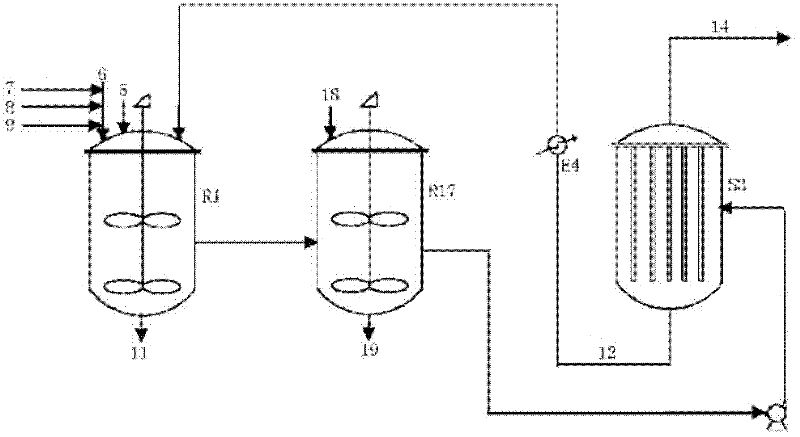

Method for producing synthetic natural gas SNG from coal and processing installation thereof

InactiveCN101775319AControl reaction temperatureAvoid overall overheatingGaseous fuelsMethanationSulfur

The invention relates to a method for producing synthetic natural gas SNG from coal and a processing installation thereof. The method includes the following steps that: coal is gasified and goes through sulfur-tolerant shift, the proportion between CO, CO2 and H2 in the gas is regulated, organic sulfur is converted into inorganic sulfur, the gas is then purified to remove the sulfur and part of the CO2 in the gas, and after the components of the gas meet the following formula: the ratio of(H2-3CO)to CO2 is about 4, the gas is sent into a methanation reactor, so that the H2, the CO and the CO2are methanated to synthesize the SNG (synthetic natural gas). The installation consists of a coal gasification process, a sulfur-tolerant shift process, a purification process and a methanation process, in particular, the methanation reactor in the methanation process adopts a water-cooled tube array structure, which can quickly take away reaction heat, so that the overheat of catalyst can be prevented, the high-pressure steam in the removed heat by-product serves as power for equipment such as a compressor and a pump, consequently, the reaction heat is rationally utilized, and the produced synthetic natural gas can be directly used as fuel for urban residents or further processed into SNG and LNG. Compared with the prior reactor methanation process, the method has the advantages of shortprocess, investment saving and high heat energy utilization rate.

Owner:SHANXI KELING ENVIRONMENT ENG DESIGN TECH

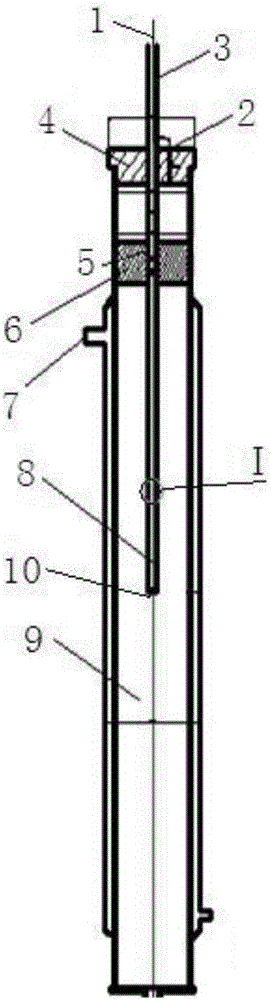

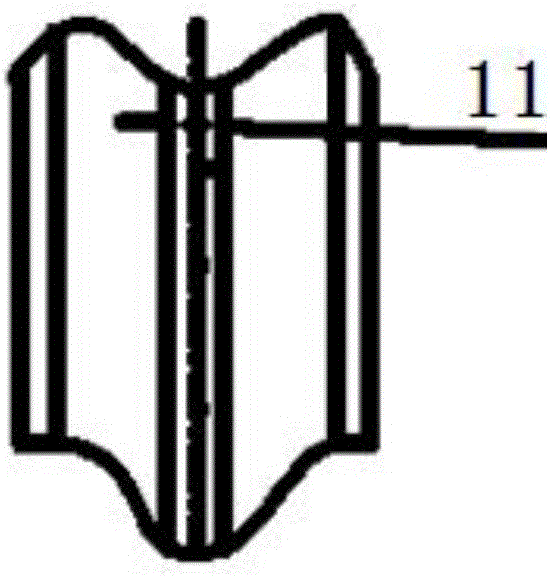

Axial and radial combined type fixed bed catalytic reactor for olefince oxidative dehydrogenation

ActiveCN103657536AControl reaction temperatureControl inlet temperatureHydrocarbonsChemical/physical processesDehydrogenationFixed bed

The invention relates to an axial and radial combined type fixed bed catalytic reactor for olefince oxidative dehydrogenation. The axial and radial combined type fixed bed catalytic reactor comprises a reactor shell, wherein a raw material gas inlet is formed in the top of the reactor shell; a product gas outlet is formed in the bottom of the reactor shell; at least one axial reaction section, a radial reaction section and an inter-section chilling section are arranged in the reactor shell; the inter-section chilling section is positioned between each axial reaction section and the radial reaction section. Compared with the prior art, the axial and radial combined type fixed bed catalytic reactor disclosed by the invention can easily realize enlargement, effectively control the reaction temperature and reduce pressure drop of a bed layer, so that the utilization rate of obtained energy is high, and the productivity is high; meanwhile, the difficulty in designing and operating an original heat exchanger can be effectively reduced; the utilization efficiency of reaction heat is improved.

Owner:WISON ENG

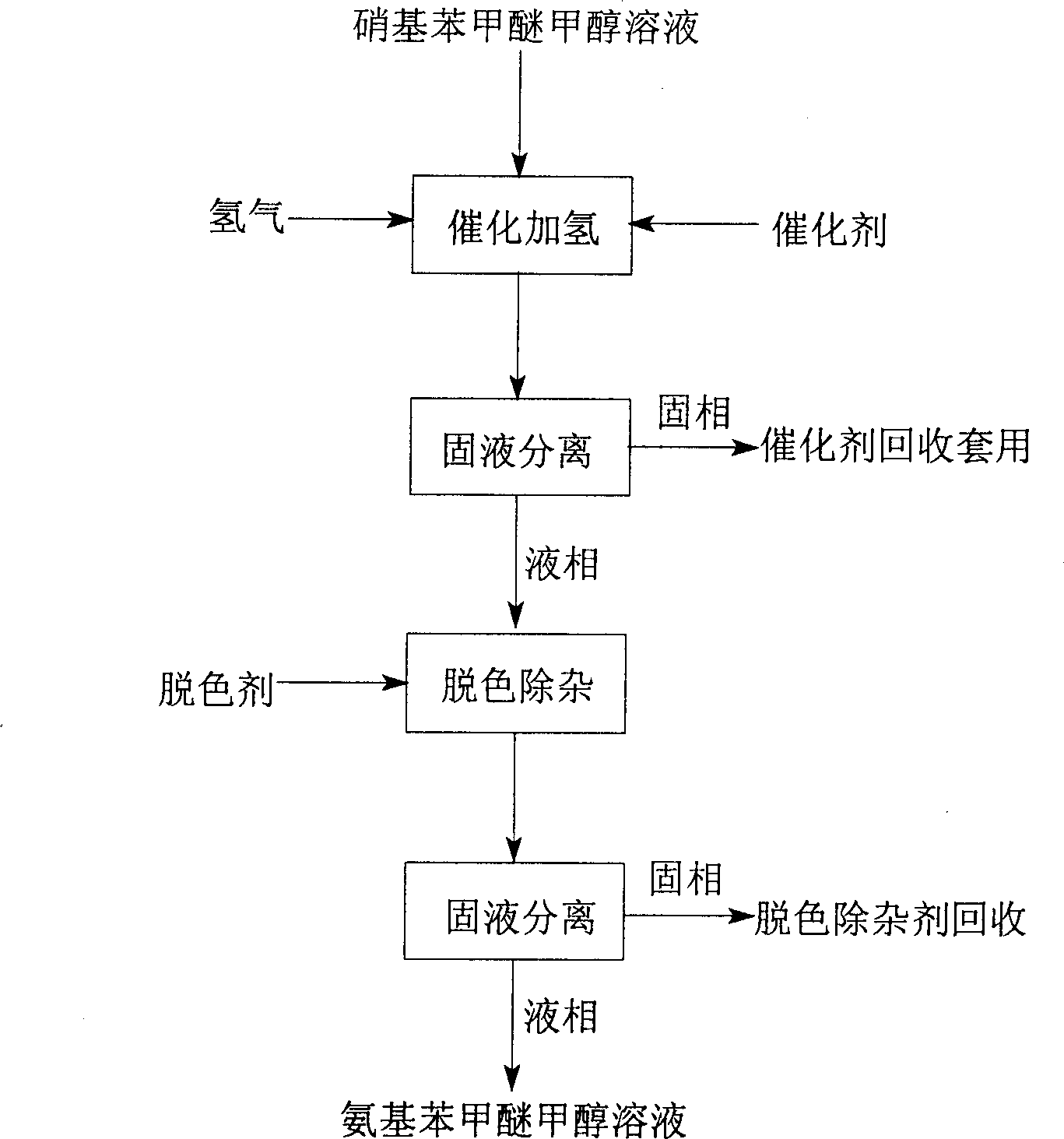

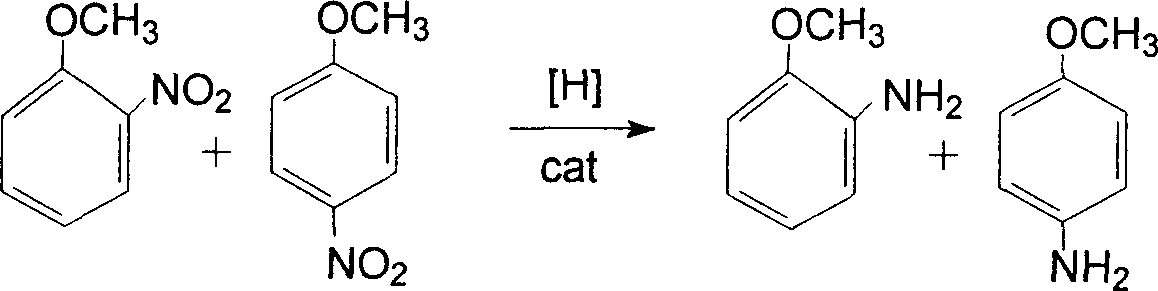

Tech. of preparing amino benz methyl-phenoxide by nitro methyl-phenoxide mixture catalyzing hydrogenation

InactiveCN1861570AImprove dispersionImprove recycling efficiencyOrganic compound preparationAmino-hyroxy compound preparationSolventImpurity

A process for preparing amino phenylmether from nitro phenylmether mixture by catalytic hydrogenating includes such steps as catalytic hydroreducing reaction between methanol, nitro phenylmether mixture and catalyst, recovering catalyst, decoloring, removing impurities, filtering to obtain liquid phase (the solution of amino phenylmether, methanol and water), separation and refining.

Owner:CHANGZHOU JIASEN CHEM +1

Modified polyether amine epoxy curing agent and preparation method thereof

The invention discloses a modified polyether amine epoxy curing agent. The modified polyether amine epoxy curing agent comprises the following raw materials in parts by weight: 45-60 parts of amine-terminated polyether (D-230), 2-5 parts of N-aminoethylpiperazine (N-AEP), 4-10 parts of benzyl alcohol, 3-8 parts of an accelerant (DMP (Dimethyl Phthalate)-30), 20-30 parts of nonyl phenol or tert-butyl phenol and 6-10 parts of epoxy resin (E-51). The modified polyether amine epoxy curing agent is scientific and reasonable in raw material component ratio; the modified polyether amine epoxy curing agent is low in viscosity, high in hardness and good in glossiness; the adhesive force, the solvent property, the low-temperature resistance and high wet resistance can be remarkably improved; the temperature and time of reaction in the preparation process can be effectively controlled; the cost is lowered; therefore, the modified polyether amine epoxy curing agent has a broad market application prospect.

Owner:宋良俊

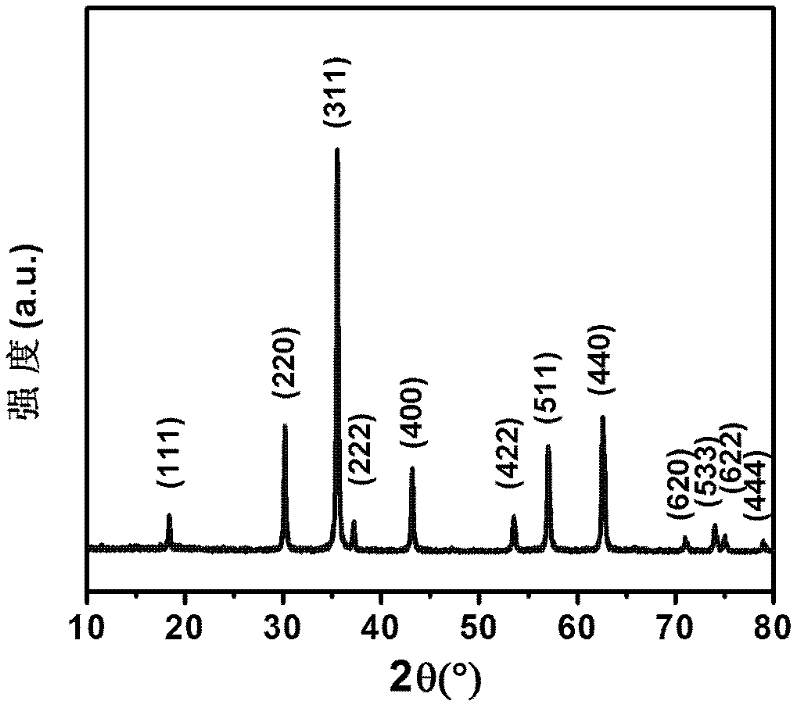

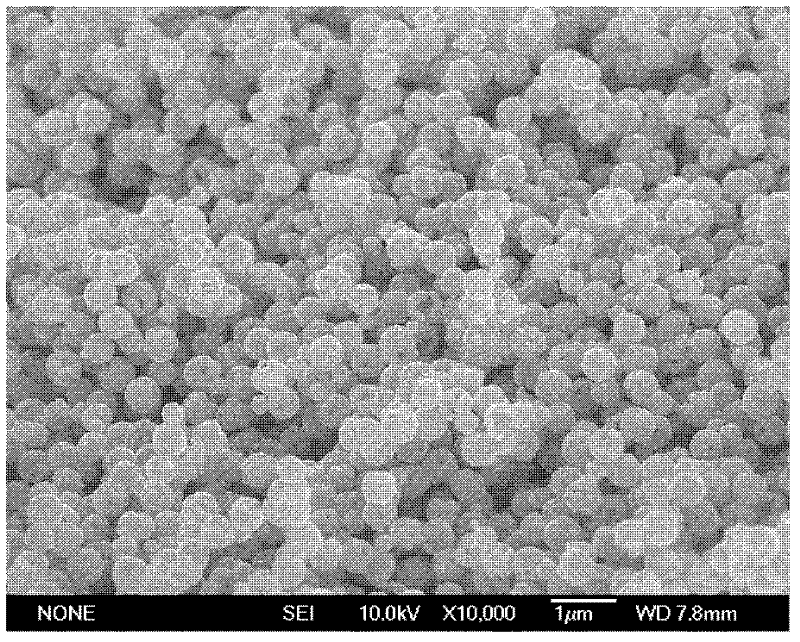

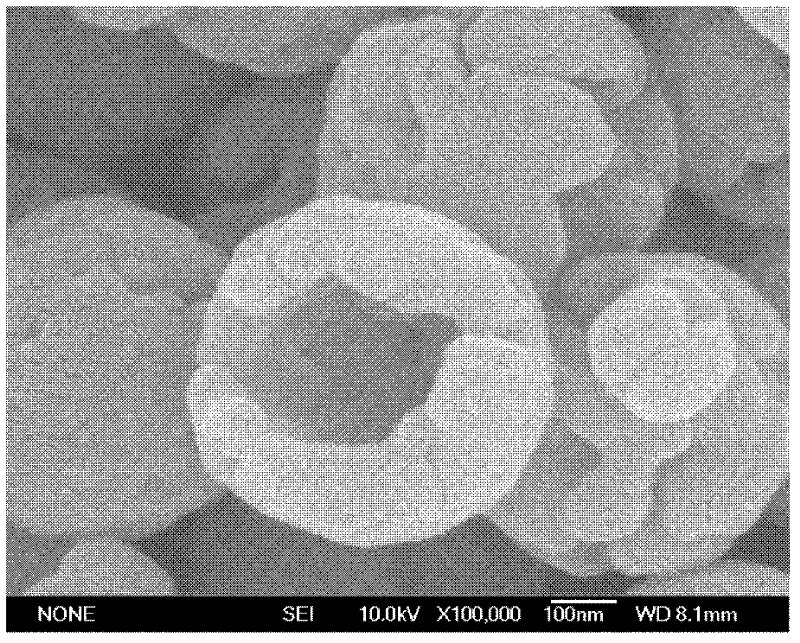

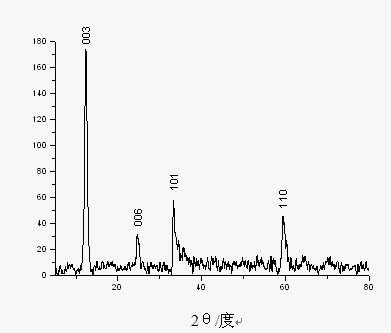

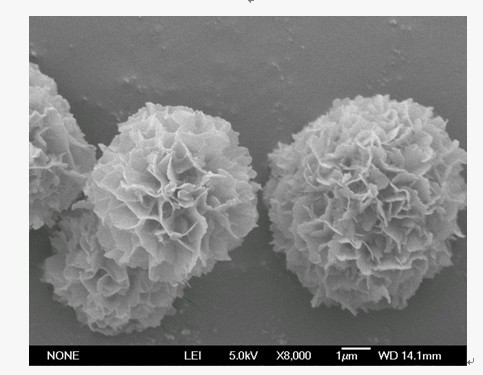

Spherical ferrate having hollow structure and preparation method thereof

InactiveCN102531066APromote formationHigh viscosityNanotechnologyIron compoundsPhysical chemistryNanocrystal

The invention discloses spherical ferrate having a hollow structure and a preparation method thereof. The ferrate MFe2O4 is of a hollow-structured spherical particle formed by self-assembling of nanocrystals having a particle size of 10-50nm, wherein M is Co, Ni or Zn, the diameter of the particle is 0.1-1mu m, and the thickness of a shell layer is 30-200nm. The spherical ferrate can be used as a negative electrode material of a lithium ion battery.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

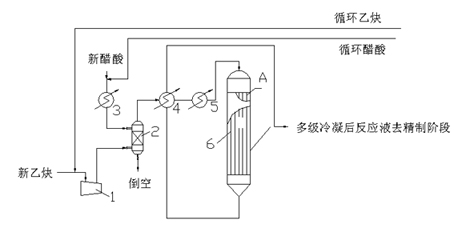

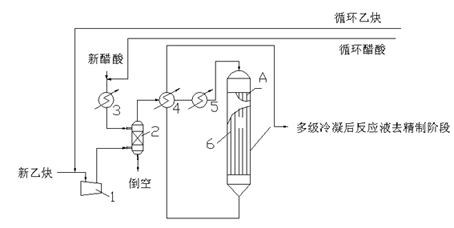

Novel method for synthetizing vinyl acetate by calcium carbide acetylene method

InactiveCN101928217AReduce generationGuaranteed circulation volumeOrganic compound preparationCarboxylic acid esters preparationFixed bedCarvacryl acetate

The invention relates to a novel method for synthetizing vinyl acetate by a calcium carbide acetylene method, which is characterized in that synthetic reaction is carried out on acetylene gas produced by adopting calcium carbide and acetic acid in a tube array type fixed bed reactor. The novel method is realized by utilizing a fixed bed technology in a process for synthetizing the vinyl acetate by the calcium carbide acetylene method, and especially, acetic acid simultaneously enters a gas-liquid mixed evaporator under the action of the acetylene gas after being preheated by changing an acetic acid feed mode into a gas-liquid mixed feed mode, and then enters the reactor through a second preheater and a third preheater, and the gas mixture passes through an inert heat transfer filler and then passes though a corresponding catalyst to be synthetized into the vinyl acetate. By adopting the mode, the novel method can reduce reaction byproducts and has the advantages of easy separation, raw material use ration improvement, production cost reduction, conversion rate improvement, small investment, high product purity, high quality and low impurity content.

Owner:国能英力特能源化工集团股份有限公司

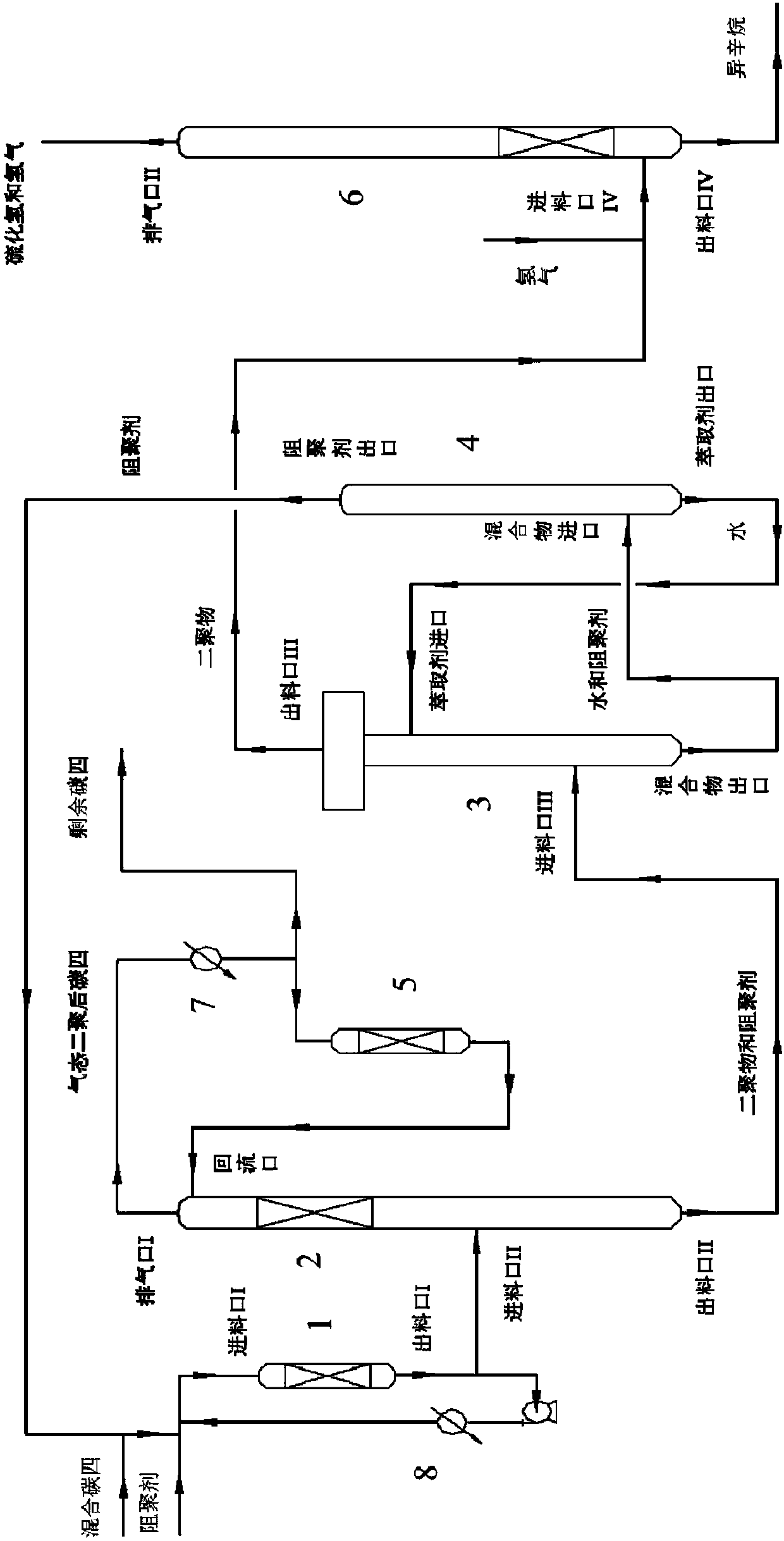

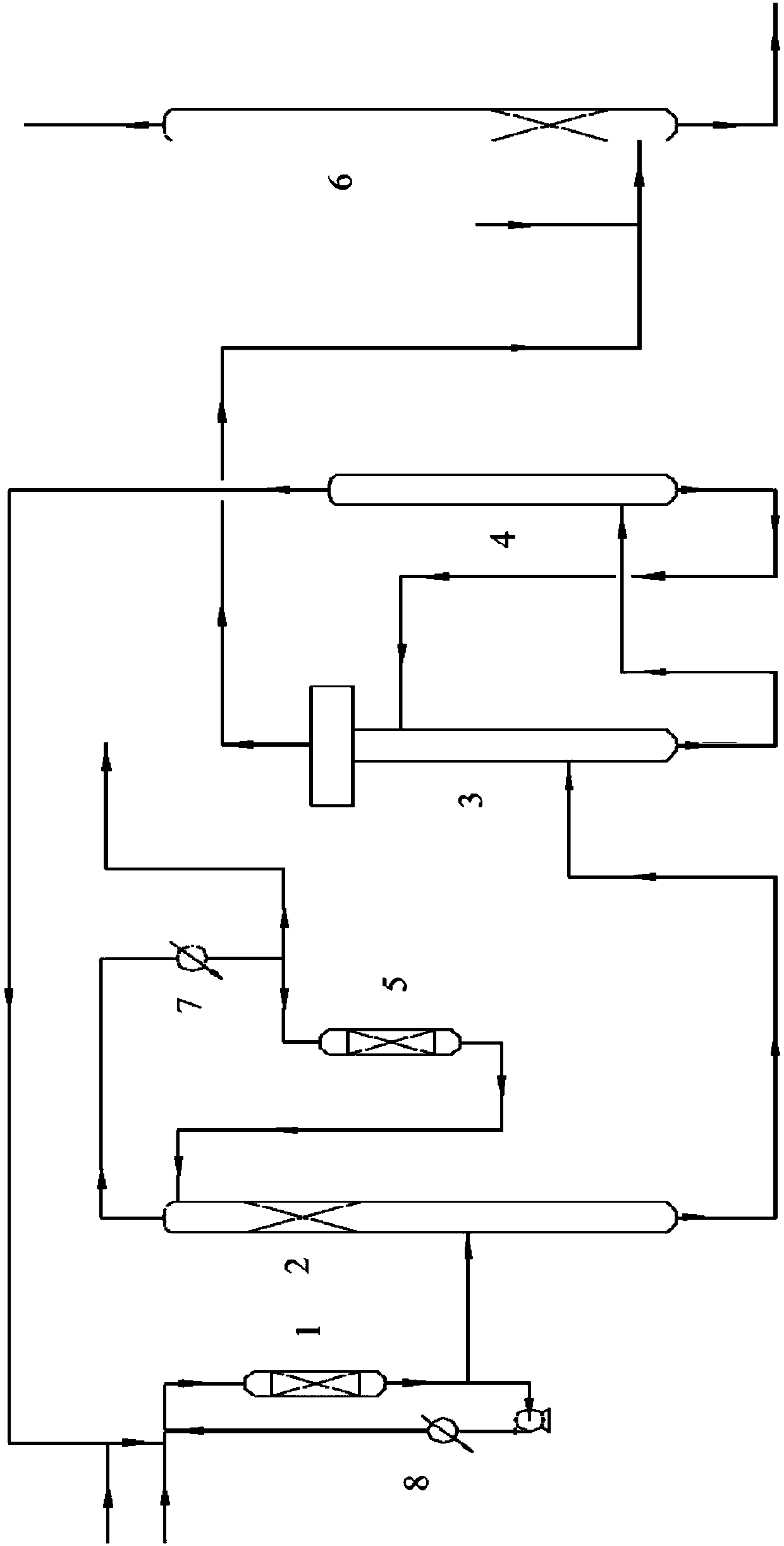

Apparatus and method to produce isooctane by indirect alkylation technique

PendingCN107827694ATemperature controlImprove conversion rateHydrocarbon by hydrogenationChemical industryAlkyl transferHydrogen

The invention discloses an apparatus and method to produce isooctane by an indirect alkylation technique. The apparatus comprises fixed-bed reactor I, a catalytic distilling column, an extracting column and a recycling column which are connected in sequence. The method comprises: allowing mixed C4 and a polymerization inhibitor to react in reactor I, feeding part of the product into the catalyticdistilling column, and removing reaction heat from the other part by a heat exchanger before returning; after catalytic distillation, feeding the overhead product into fixed-bed reactor II, reflowingafter reacting, and feeding the bottom product into the extracting column; after extracting, feeding overhead biopolymer into a desulfurizing column, and feeding the bottom product into the recyclingcolumn; after recycling, returning an extracting agent into the extracting column and the polymerization inhibitor to the reactor I; subjecting the biopolymer and hydrogen to hydrodesulfurization in the desulfurizing column to obtain isooctane that may act as a gasoline blend component. Existing MTBE (methyl tert-butyl ether) production equipment is modified into isooctane production equipment; the produced isooctane may act as an ethanol-gasoline blend component; byproducts of the isooctane may also act as other materials for reuse.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

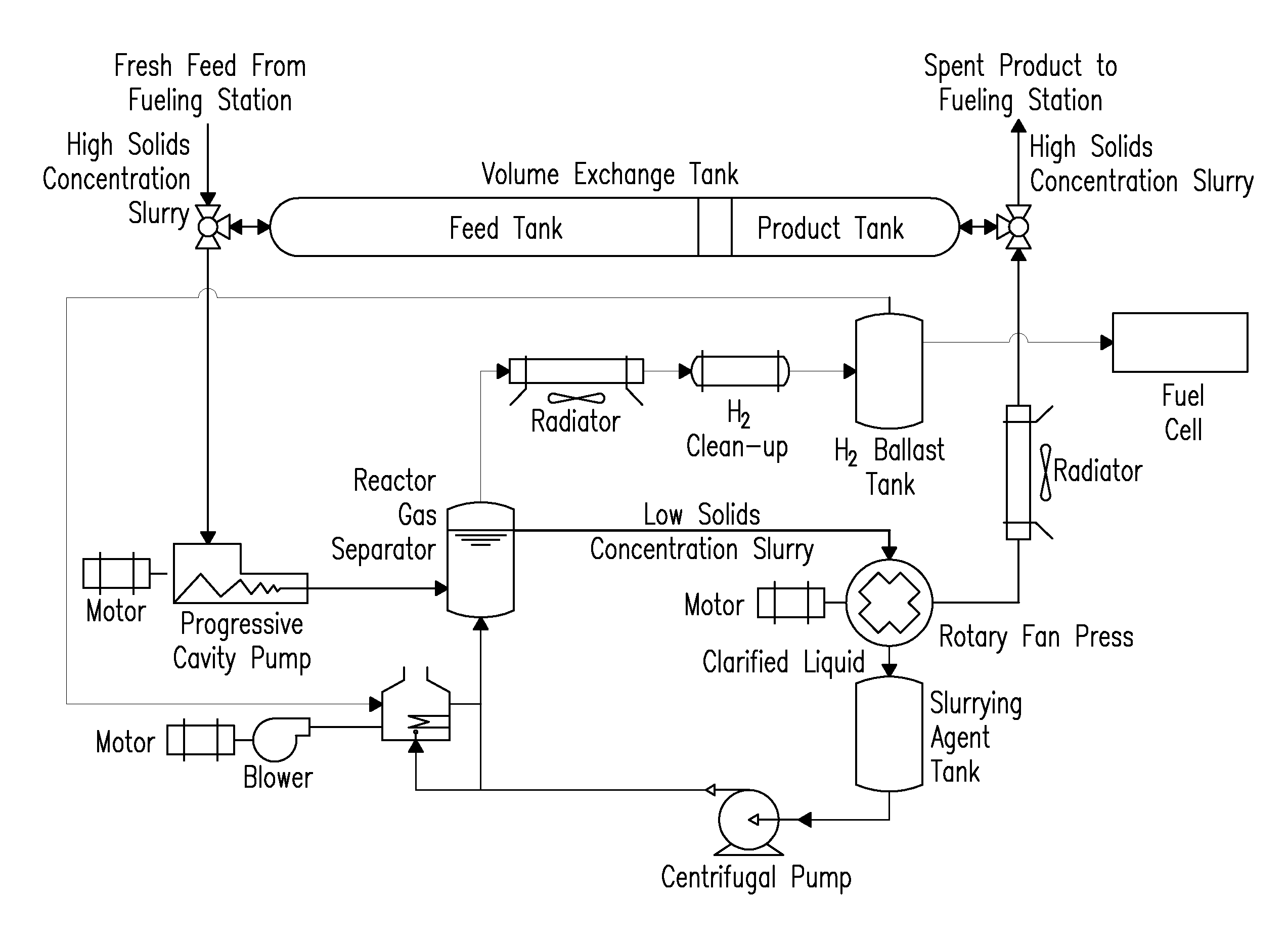

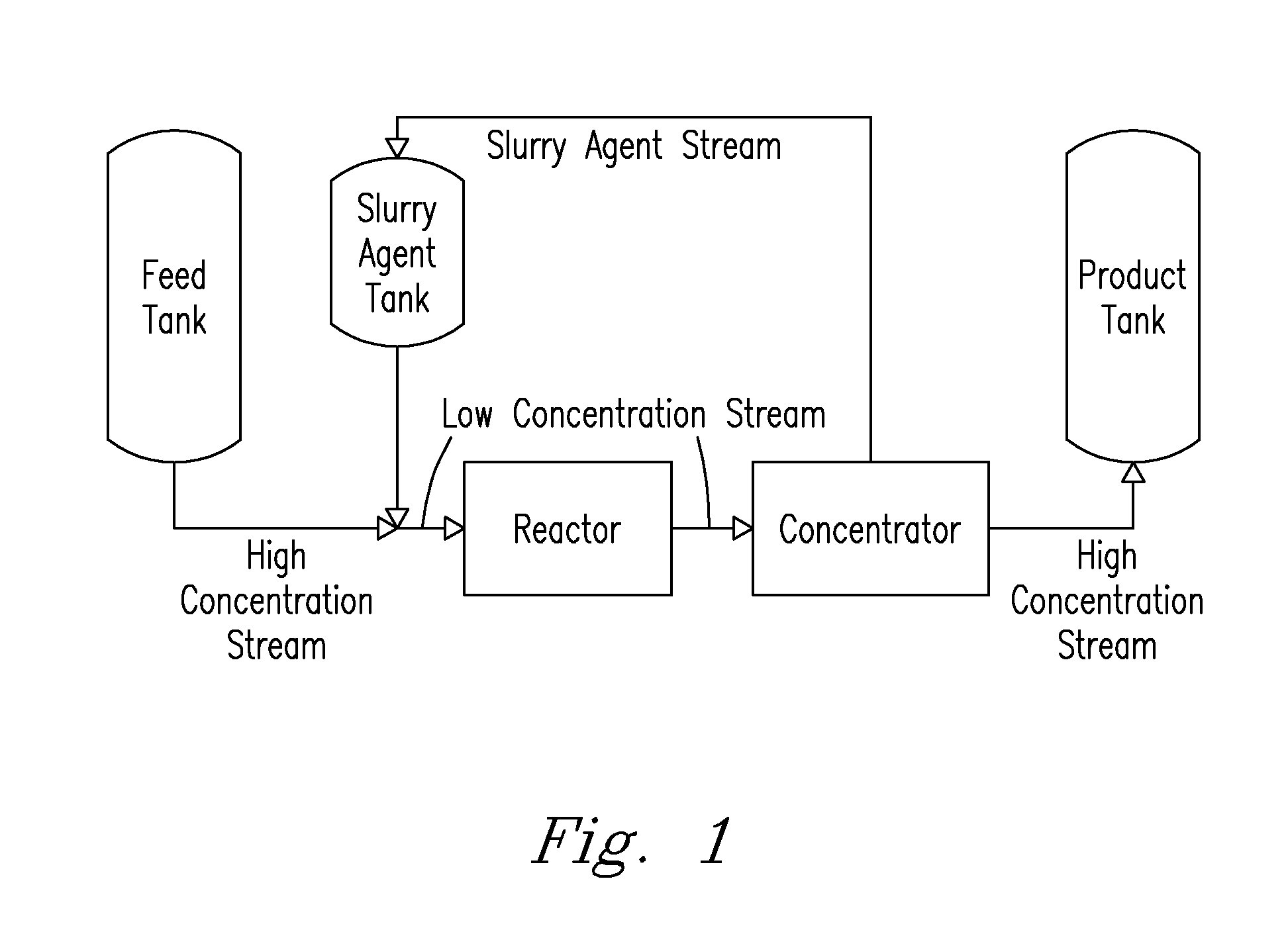

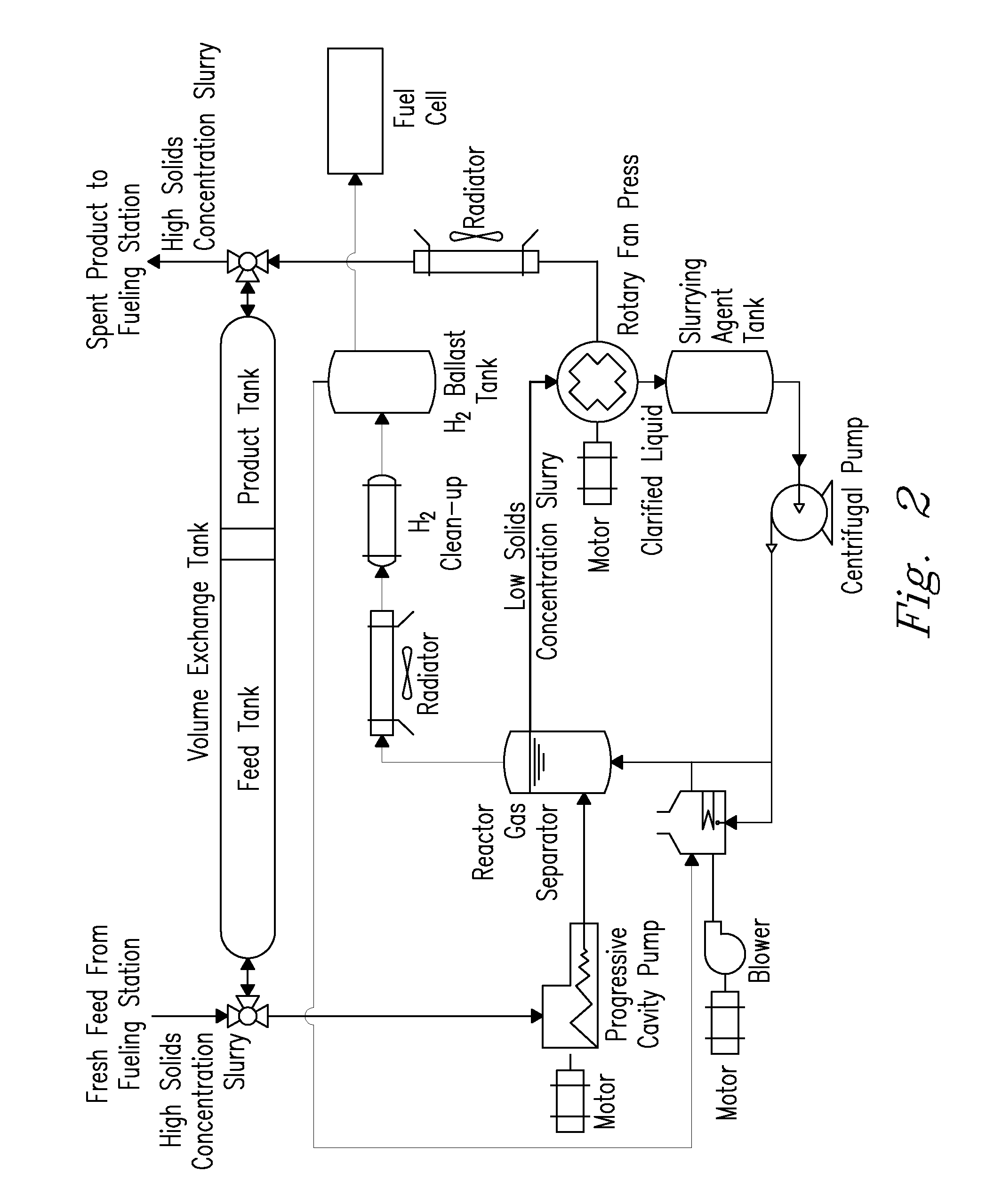

Combined on-board hydride slurry storage and reactor system and process for hydrogen-powered vehicles and devices

InactiveUS20120174984A1Reduce storage spaceEasy to optimizeHydrogenReactant parameters controlReactor systemSlurry reactor

An on-board hydride storage system and process are described. The system includes a slurry storage system that includes a slurry reactor and a variable concentration slurry. In one preferred configuration, the storage system stores a slurry containing a hydride storage material in a carrier fluid at a first concentration of hydride solids. The slurry reactor receives the slurry containing a second concentration of the hydride storage material and releases hydrogen as a fuel to hydrogen-power devices and vehicles.

Owner:BATTELLE MEMORIAL INST

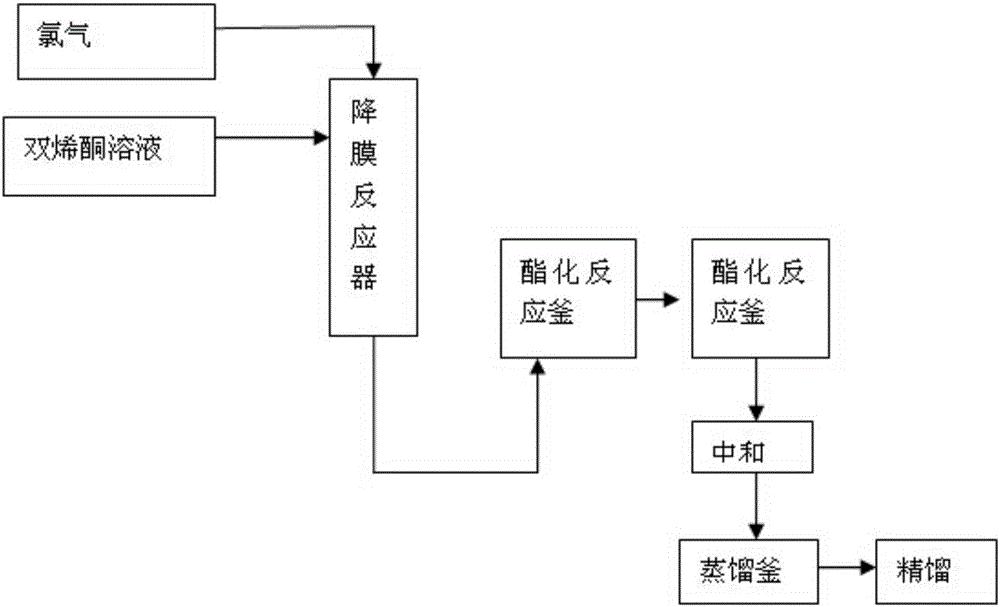

Method for continuously synthesizing ethyl 4-chloroacetoacetates

ActiveCN105693509AReduce volumeIncrease the effective cooling areaPreparation from carboxylic acid halidesCarboxylic acid halides preparationSolventEthyl Chloride

The invention relates to a method for continuously synthesizing ethyl 4-chloroacetoacetates. The method comprises the following steps: pumping a cooled diketene solution into a falling film reactor through a metering pump, and enabling the cooled diketene solution to uniformly form a film through a distributor, and flow into the reactor from a tower top; meanwhile, controlling the flow of chlorine gas through a gas flow meter; introducing the chlorine gas into the reactor through a gas distributor; carrying out a reaction on the diketene and the chlorine gas on the surface of the falling film reactor; after the reaction is finished, enabling reaction liquid to flow out from a tower bottom and enter an esterification reaction kettle; pumping in different alcohols and overflowing into a next esterification reaction kettle to continually react; absorbing hydrogen chloride gas, which is generated in a reaction process, with water; after the reaction is finished, washing with water and neutralizing to remove the residual hydrogen chloride; distilling an organic phase to recycle a solvent and excessive alcohol raw materials to obtain a crude product; rectifying the crude product to obtain an ethyl 4-chloroacetoacetates product. With the adoption of the method, reaction time can be shortened, energy consumption is reduced, polychlorides are controlled, reaction selectivity is improved, rectification is relatively easy, and yield and purity of the product are improved.

Owner:山东德澳精细化学品有限公司

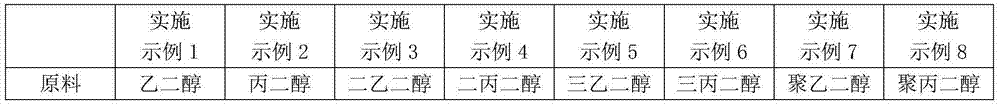

Method for preparing dihydric alcohol mono-t-butyl ether

InactiveCN104262117AControl timeControl reaction temperatureEther preparation by compound additionAlkyl transferAlcohol

The invention provides a method for preparing dihydric alcohol mono-t-butyl ether. The method comprises the following steps: carrying out an alkylation reaction on dihydric alcohol, liquefied petroleum gas and acid catalyst at 40-100 DEG C and 0.5-5.0MPa to obtain the dihydric alcohol mono-t-butyl ether. The method has the beneficial effects that the liquefied petroleum gas containing isobutene is used as a reaction raw material and matched with dihydric alcohol and acid catalyst, and the contact time and reaction temperature of reaction materials are controlled, thus a high-selectivity dihydric alcohol mono-t-butyl ether crude product can be obtained.

Owner:ZHUHAI FEIYANG NOVEL MATERIALS +1

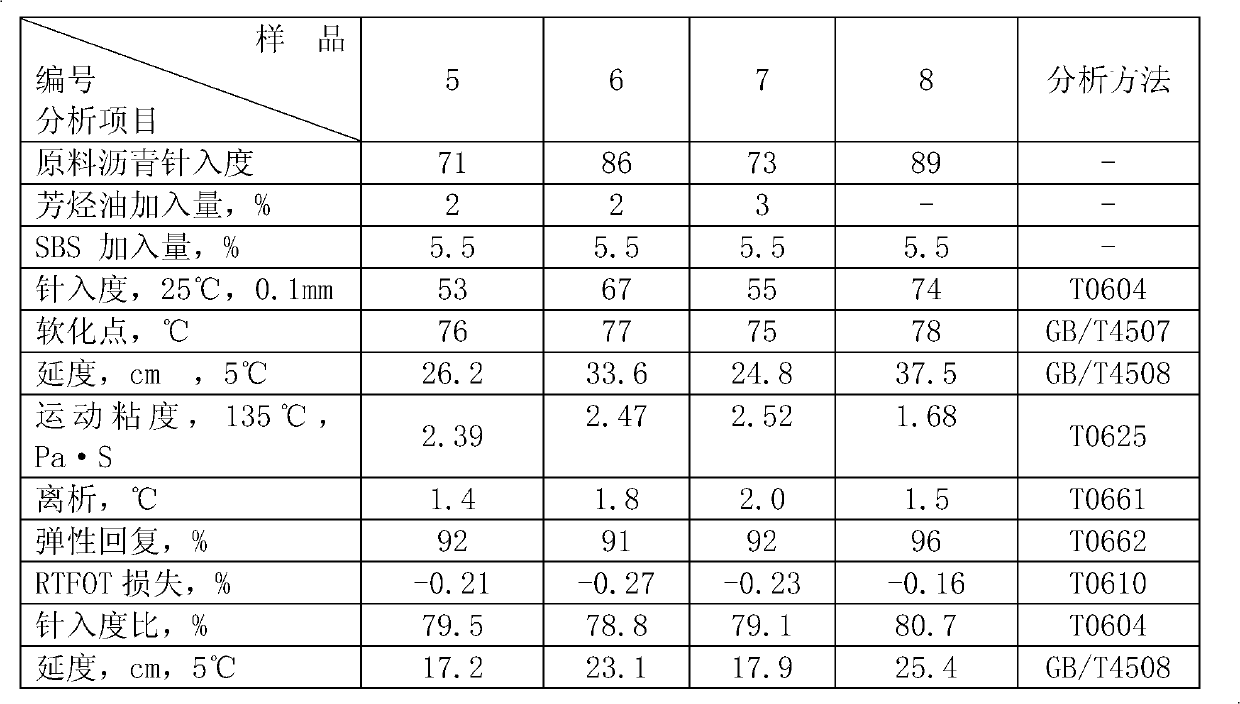

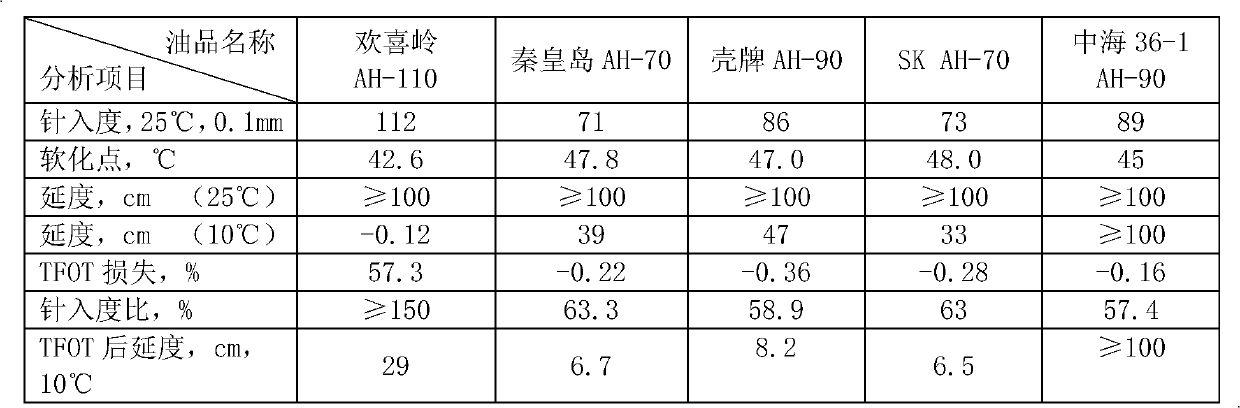

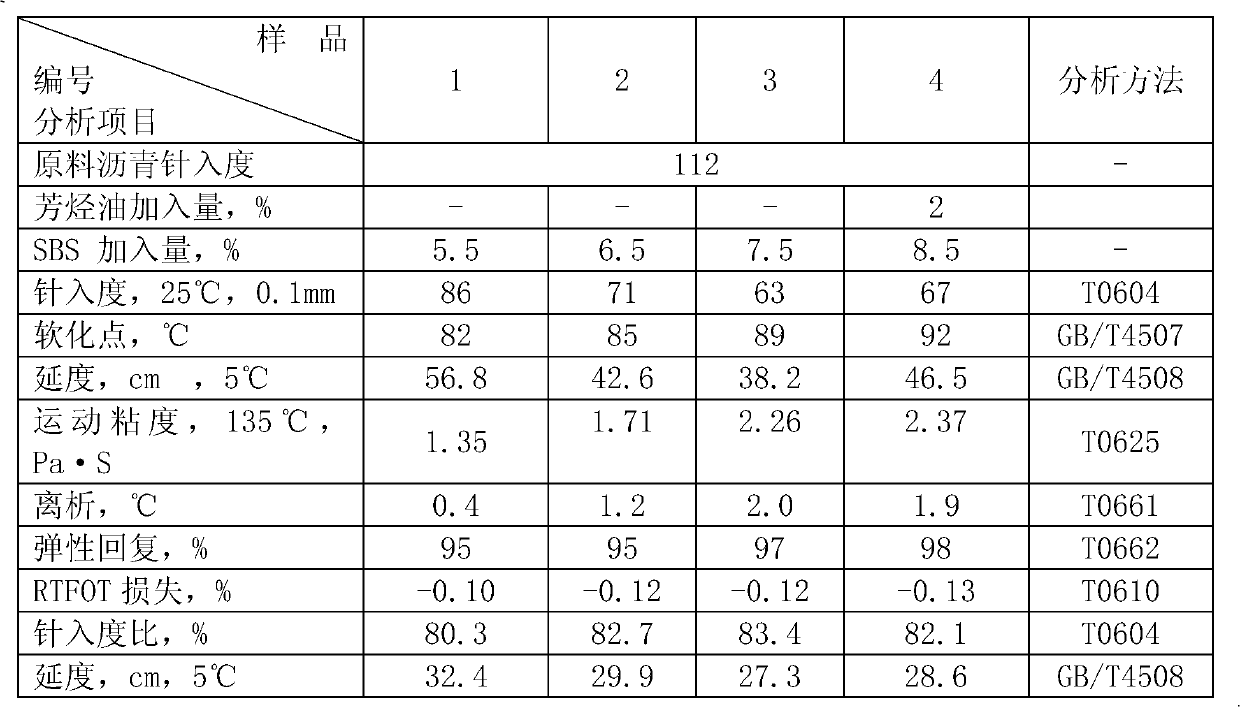

Stabilizer for SBS (styrene butadiene styrene) modified asphalt and preparation method thereof

ActiveCN103374229AEasy to addGood operating environmentBuilding insulationsButadiene-styrene rubberStabilizing Agents

The invention relates to a stabilizer for SBS (styrene butadiene styrene) modified asphalt and a preparation method thereof. The stabilizer comprises the following components in parts by weight: 6-30 parts of sulfur, 6-15 parts of phenyl olefin polymers, 30-40 parts of aromatic hydrocarbon thick oil and 10-40 parts of dispersed carrier substances. The preparation method comprises the following steps of: adding the components into an internal mixer at 180 DEG C, carrying out blending and internal mixing, and carrying out extruding, pelleting and cooling. The stabilizer is used for producing high-proportion SBS modified asphalt and high-viscosity asphalt and has the advantages that an isolation test result is lower than 2.5 DEG C, the softening point can reach 70-90 DEG C, and technical requirements in industry specifications of ministry of communications, namely 'Standard Specification for Construction and Acceptance of Highway Asphalt Pavements' (JTG F40-2004) are met.

Owner:PETROCHINA CO LTD

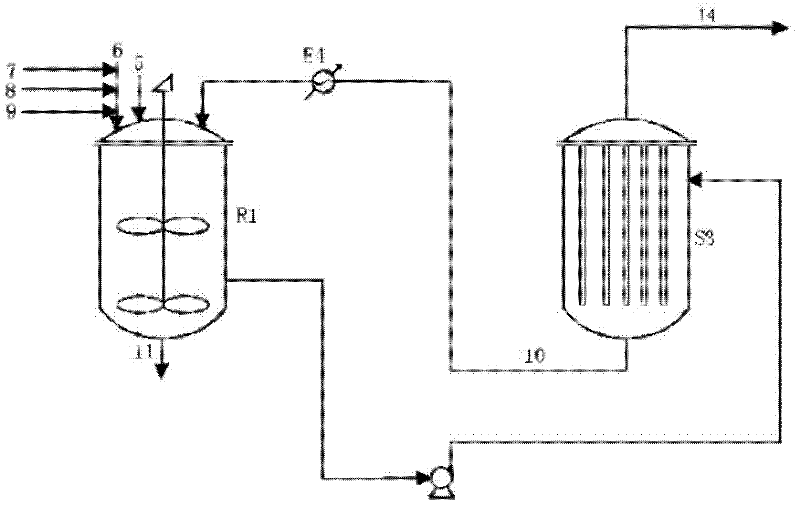

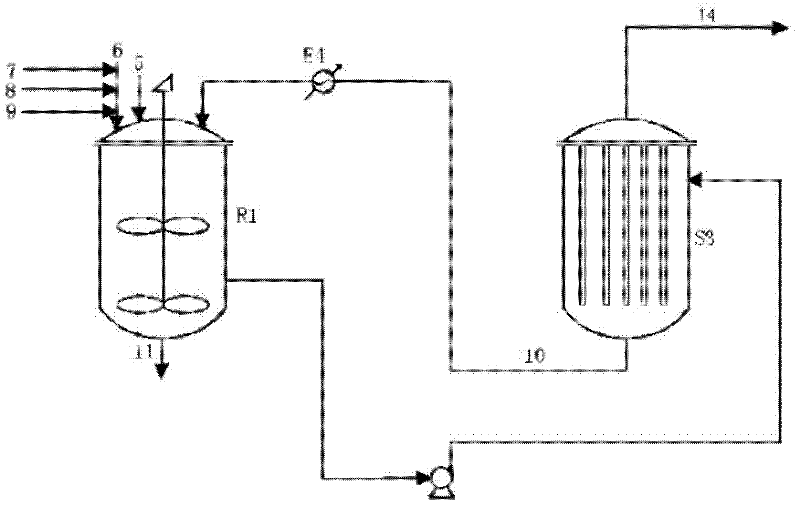

Method for preparing cyclohexanone oxime by ammoximation of cyclohexanone

InactiveCN102584624ASimple designIncrease production capacityOximes preparationMolecular sieveState of art

The invention provides a method for preparing cyclohexanone oxime by ammoximation of cyclohexanone. According to the method, 5.0-100 mu m of titanium silicalite molecular sieve is used as a catalyst, the reaction temperature is controlled by using an external circulation heating mode, and a reaction product and the titanium silicalite molecular sieve are separated in an external circulating filter. Compared with the prior art, the method has the advantages that the device investment is low, the separation problem between the catalyst and the reaction product can be better solved, the utilization rates of a molecular sieve and a reaction device can be improved, the reaction effect is better under the condition that the concentration of the catalyst is the same, the control is more stable, the overhauling of the device is easier, and the effective utilization rate of hydrogen peroxide can reach 90% or so.

Owner:湖南兴鹏化工科技有限公司

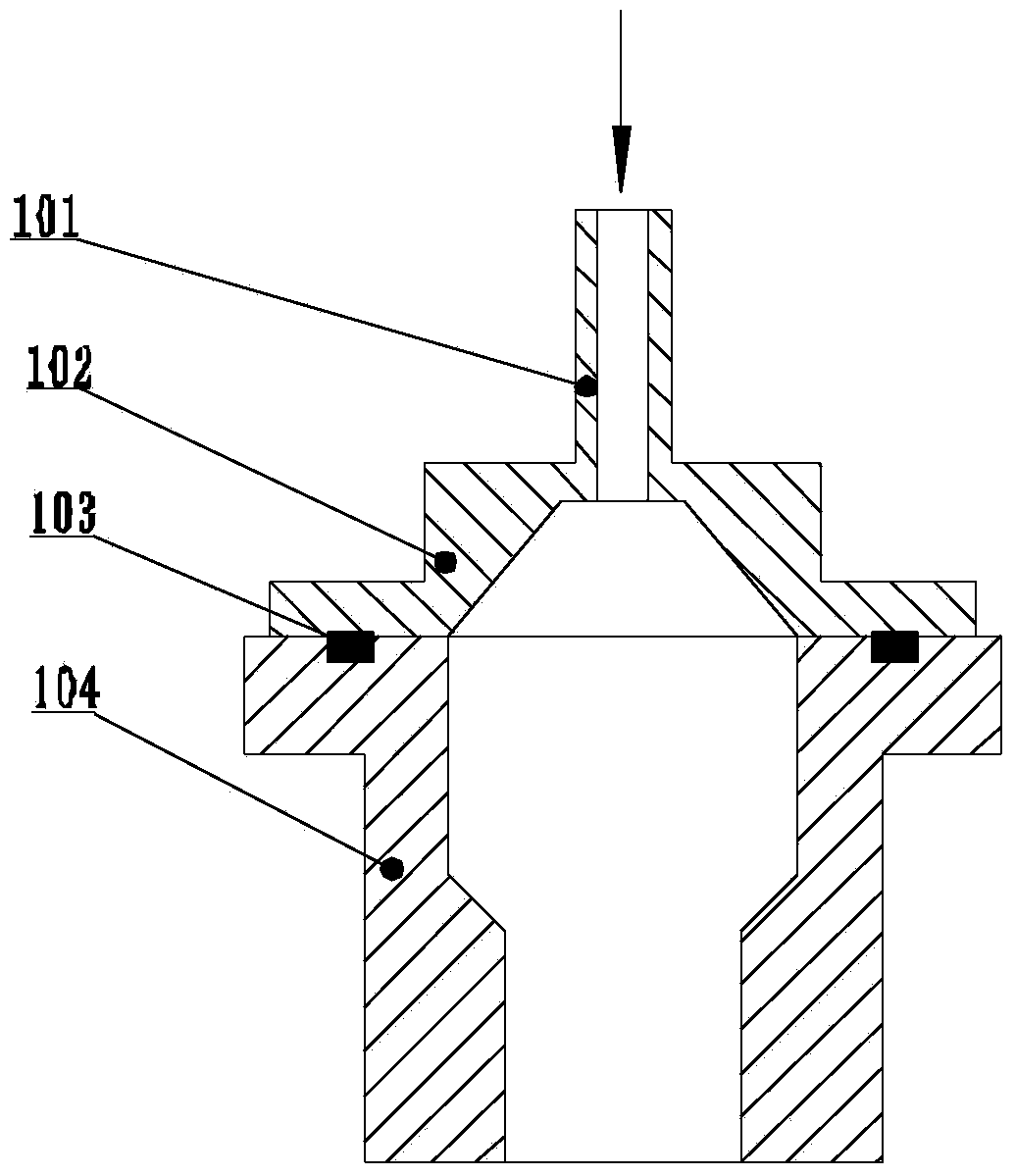

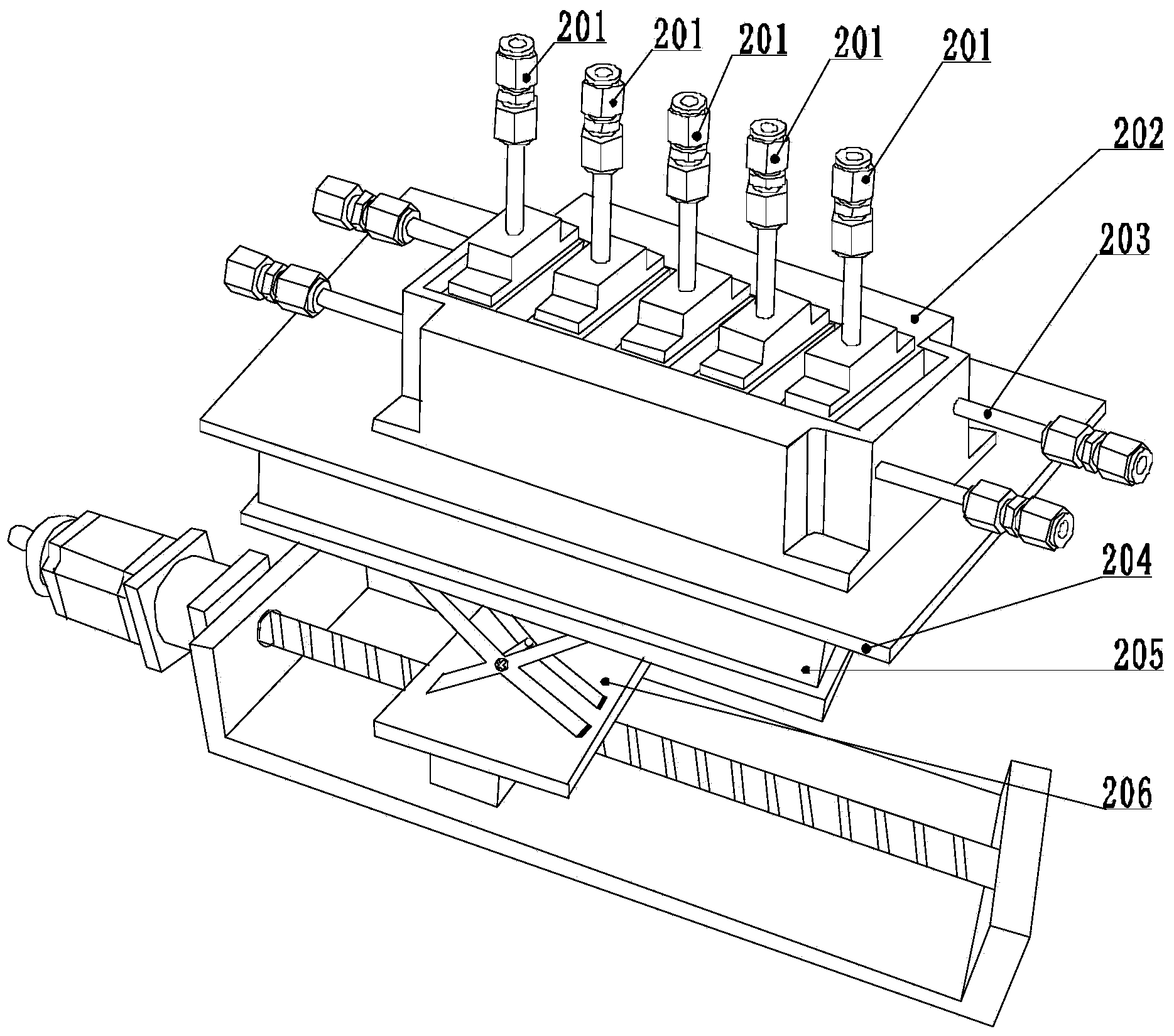

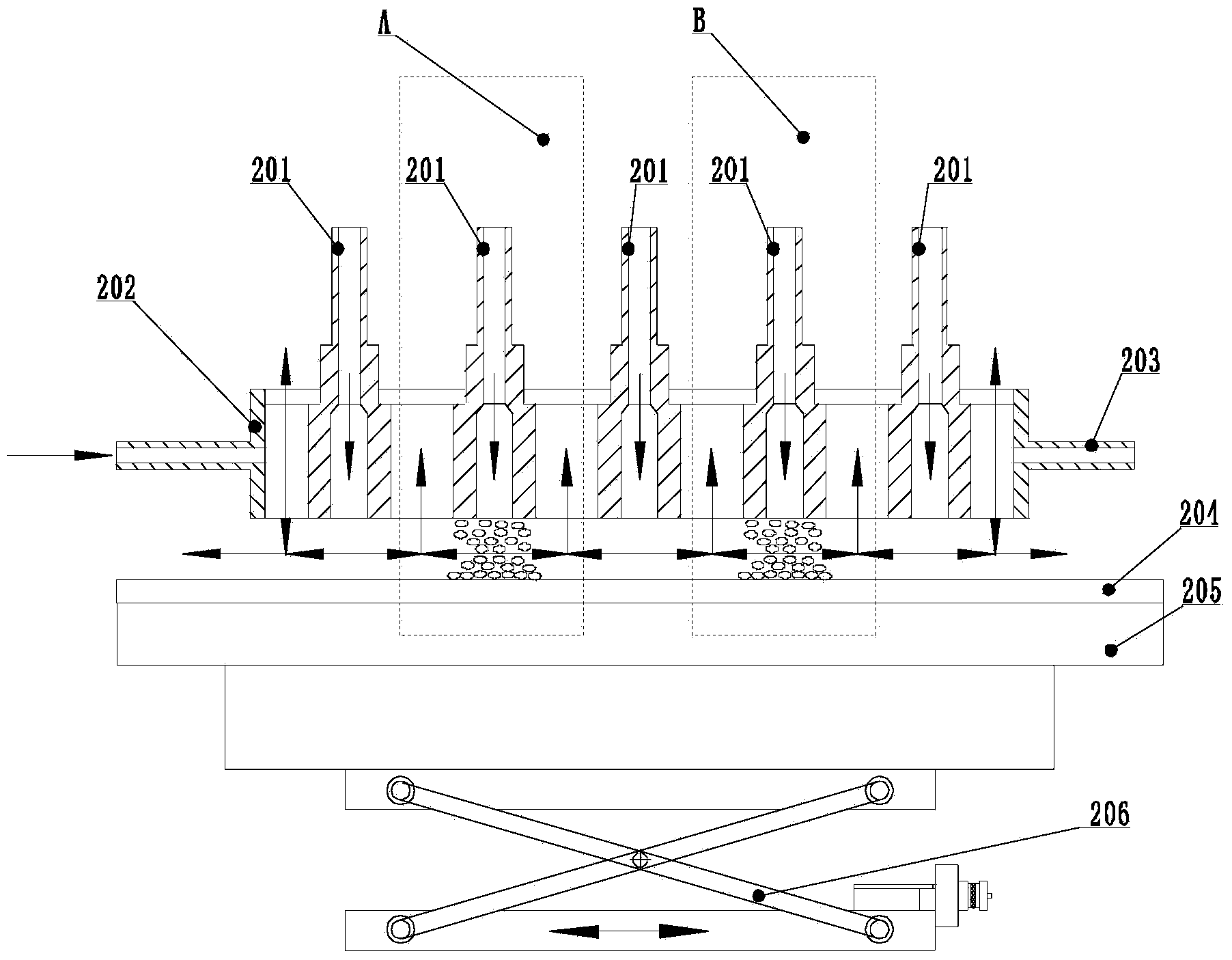

Detachable nozzle and device for manufacturing atomic layer deposited film

ActiveCN103628045AFlexible parameter adjustmentFlexible combinationChemical vapor deposition coatingEngineeringAtomic layer deposition

The invention discloses a detachable nozzle and device for manufacturing an atomic layer deposited film. The nozzle for manufacturing the atomic layer deposited film comprises an air inlet pipeline, an air inlet and an air outlet, wherein the air inlet, as well as the air outlet, has a cavity therein, the cavity is formed inside the air outlet and is divided into an upper half part and a lower half part between which a funneled structure is arranged; the air inlet pipeline is fixedly connected with the air inlet; the air inlet and the air outlet is in demountable sealing connection. The device used for manufacturing the atomic layer deposited film comprises nozzles, a cavity support frame, a substrate carrying table and a motion platform, wherein a strip-shaped hollow part is formed in the middle of the cavity support frame, the detachable nozzles can be sequentially arranged in the hollow part; the substrate carrying table is arranged below a cavity support frame and is driven by the motion platform. The nozzle and the device are suitable for deposition reaction of different atomic layers, can be used for quickly and effectively manufacturing the atomic layer deposited layers through a gas separation atomic layers deposition method.

Owner:HUAZHONG UNIV OF SCI & TECH

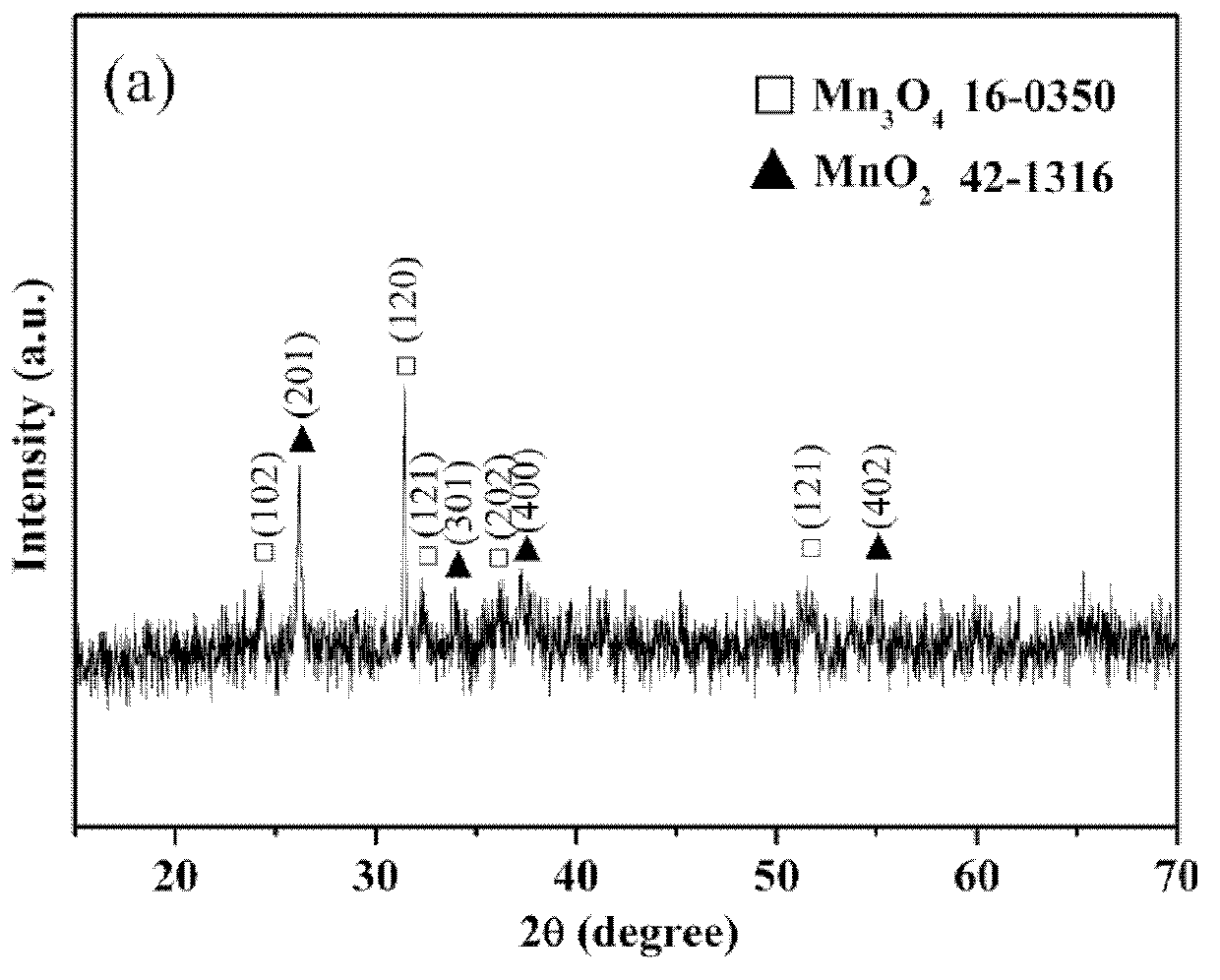

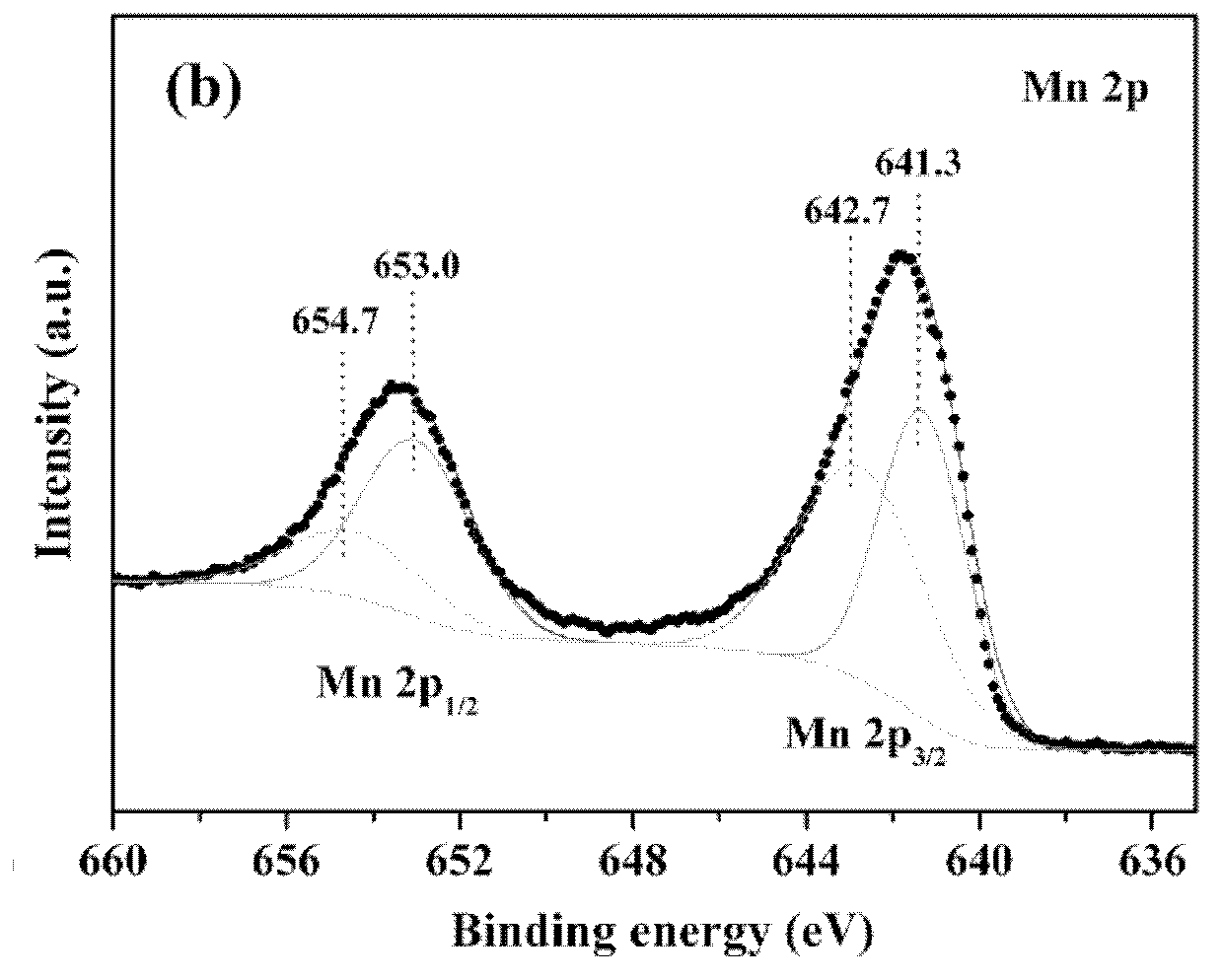

Mn3O4-MnO2 nano rod composite oxide as well as preparation method and application of Mn3O4-MnO2 nano rod composite oxide

ActiveCN104209119AControl reaction temperatureNo pollution in the processMaterial nanotechnologyManganese oxides/hydroxidesCatalytic oxidationPollution

The invention provides a Mn3O4-MnO2 nano rod composite oxide as well as a preparation method and application of Mn3O4-MnO2 nano rod composite oxide. The preparation method comprises the following steps: adding potassium permanganate, glucose and sodium chloride into de-ionized water, wherein the ratio of substance amounts is 1 to (0.1-0.3) to (0-0.4) and the concentration of potassium permanganate in the de-ionized water is 12mol / L-18mol / L; agitating uniformly and sealing; carrying out heating reaction a temperature of 110-125 DEG C for 6-24 hours; and washing a product obtained by the reaction with distilled water, carrying out centrifugal separation, and drying in vacuum to obtain the Mn3O4-MnO2 nano rod composite oxide. The prepared product is of a rod-shaped structure and has the length of 5-50 microns and the diameter of 30-120nm. The prepared Mn3O4-MnO2 nano rod composite oxide has an important effect in the aspect of catalytic oxidation. Compared with the prior art, the process is very simple and controllable and multi-step operation is not needed; any surfactant, any template agent and any acid-base reagent are not introduced, so that no pollution and no emission are caused; and synthesis conditions are very moderate and the production cost is low.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Preparation method of flower-like alpha-nickel hydroxide

The invention discloses a preparation method of flower-like alpha-Ni(OH)2. The preparation method comprises the following steps of: adding a nickel salt and urotropine into de-ionized water, stirring and dissolving, wherein the amount ratio of the nickel to the urotropine is 1:1-1:2, and the concentration of the nickel salt in the solution is 0.1-1 mol / L; taking 5 mL of mixed solution; adding 10-35 mL of lower alcohol into the mixed solution; adding the obtained solution into de-ionized water until the volume is 40 mL; transferring to 50 mL polytetrafluoroethylene-lined high pressure reaction kettle; reacting at 160 DEG C for 2 hours; cooling; filtering; washing with the de-ionized water and absolute ethyl alcohol for many times to filter a product respectively; an holding in a vacuum drying box of 60 DEG C for drying to prepare the flower-like alpha-Ni(OH)2. According to the preparation method, the urotropine is used as a precipitator, the ethanol is used as a solvent, and the finally purer flower-like alpha-Ni(OH)2 is prepared.

Owner:NANJING UNIV OF TECH

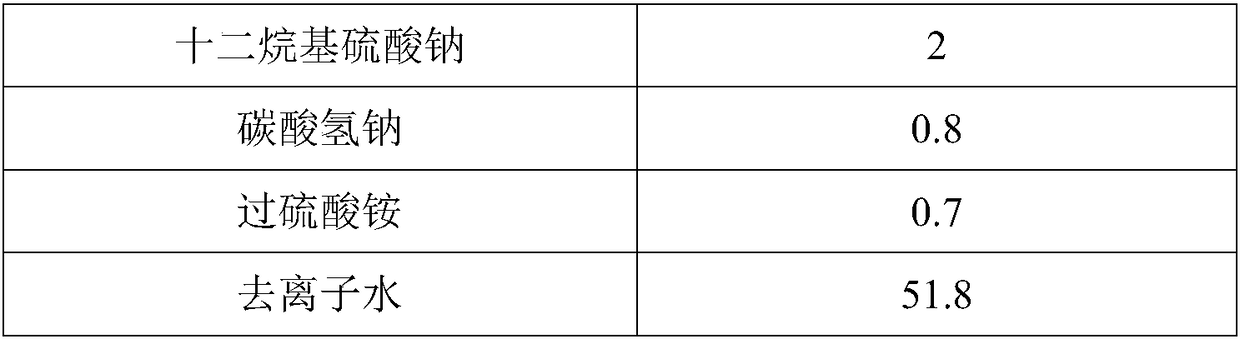

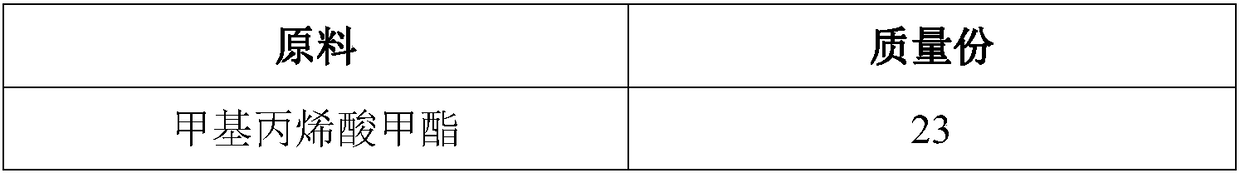

Emulsion with core-shell structure and environment-friendly interior wall coating containing emulsion

InactiveCN108484834AGood low temperature film formingImprove stain resistanceAntifouling/underwater paintsPaints with biocidesLatex particleDefoaming Agents

The invention discloses an emulsion with a core-shell structure and an environment-friendly interior wall coating containing the emulsion. The emulsion with the core-shell structure is obtained by semi-continuous polymerization of methyl methacrylate, styrene, butyl acrylate and methacrylic acid, wherein the environment-friendly interior wall coating consists of the emulsion with the core-shell structure, titanium white powder, a filler, a dispersing agent, a wetting agent, a defoaming agent, a thickening agent, a bactericide, a mildew inhibitor, a pH regulator and water. The latex particles in the emulsion with the core-shell structure provided by the invention have a soft-shell hard-core structure, wherein soft shells can ensure that the prepared coating product also has excellent low-temperature film forming property without the addition of a film-forming auxiliary agent, and hard cores can ensure that the prepared coating product has high hardness after film formation of the coating product, does not turn soft or sticky at a high temperature, and still has the basic properties of excellent stain resistance, washing resistance and the like. The environment-friendly interior wallcoating provided by the invention does not contain volatile organic compounds (VOC), is safe and environmentally friendly, and has high hardness and excellent stain resistance and washing resistanceafter the film formation.

Owner:NIPPON PAINT GUANGZHOU

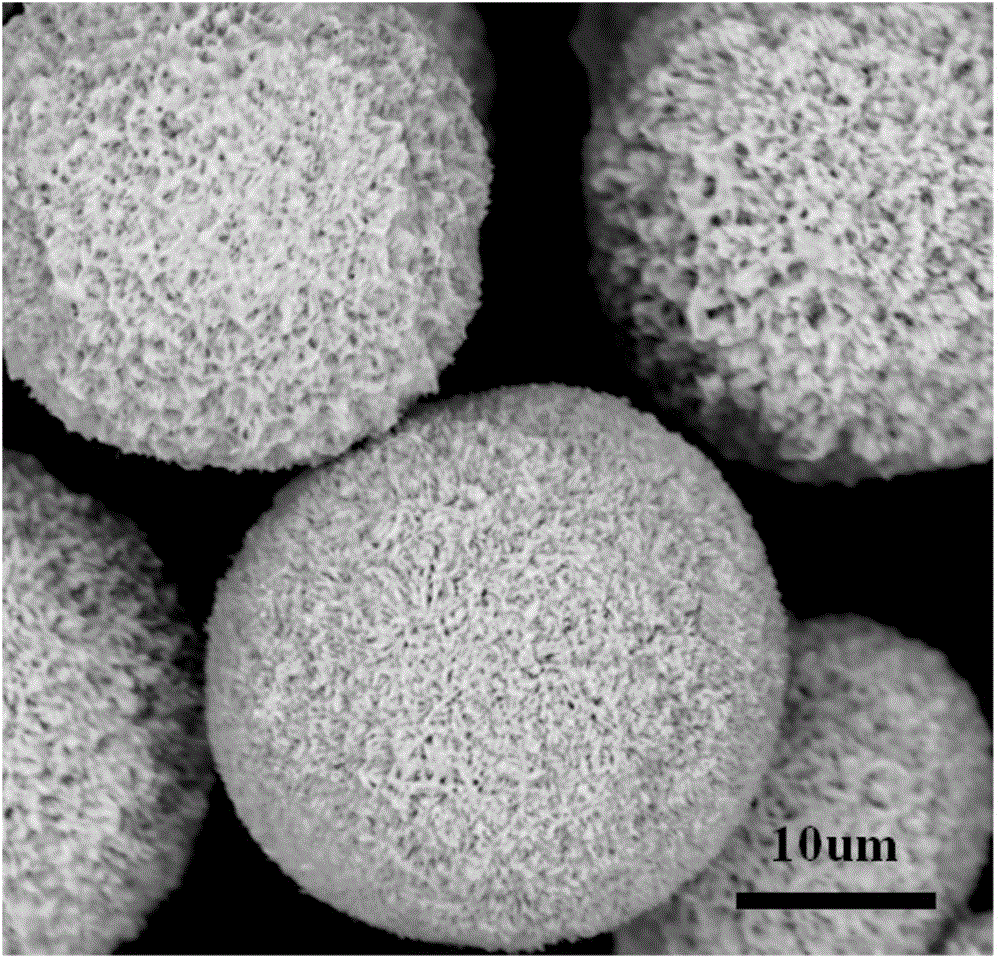

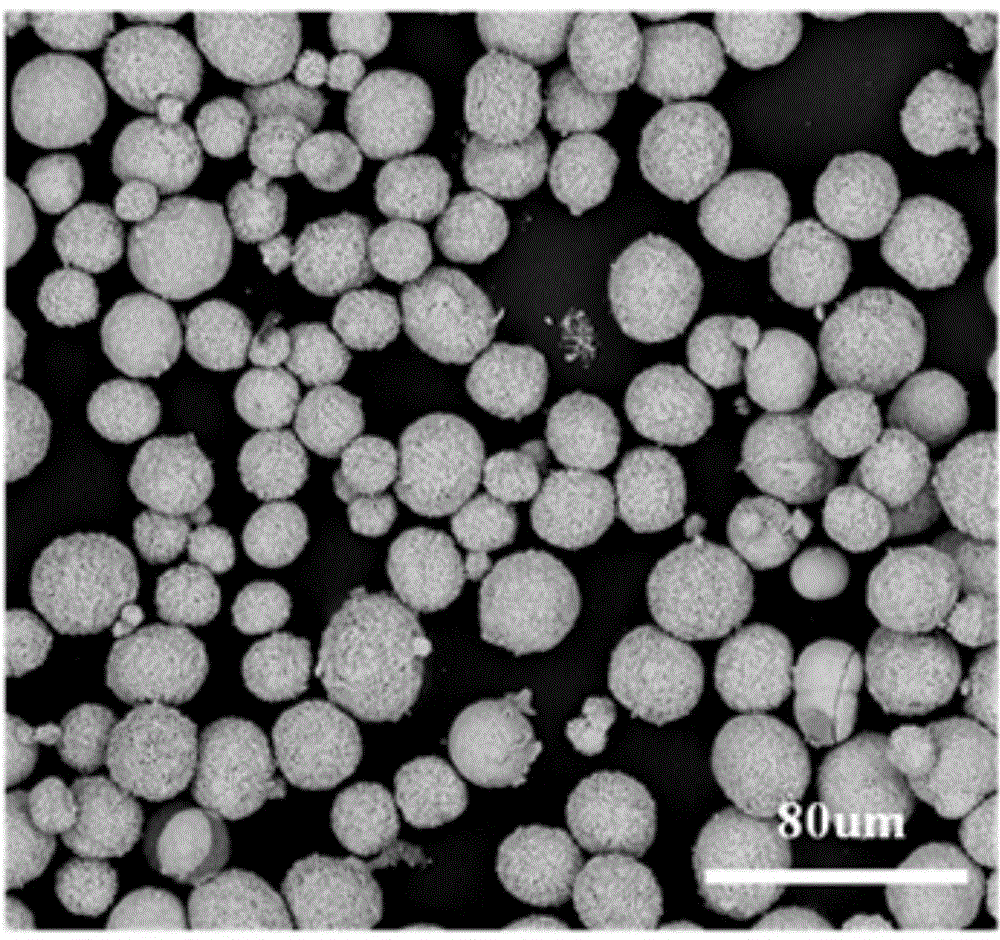

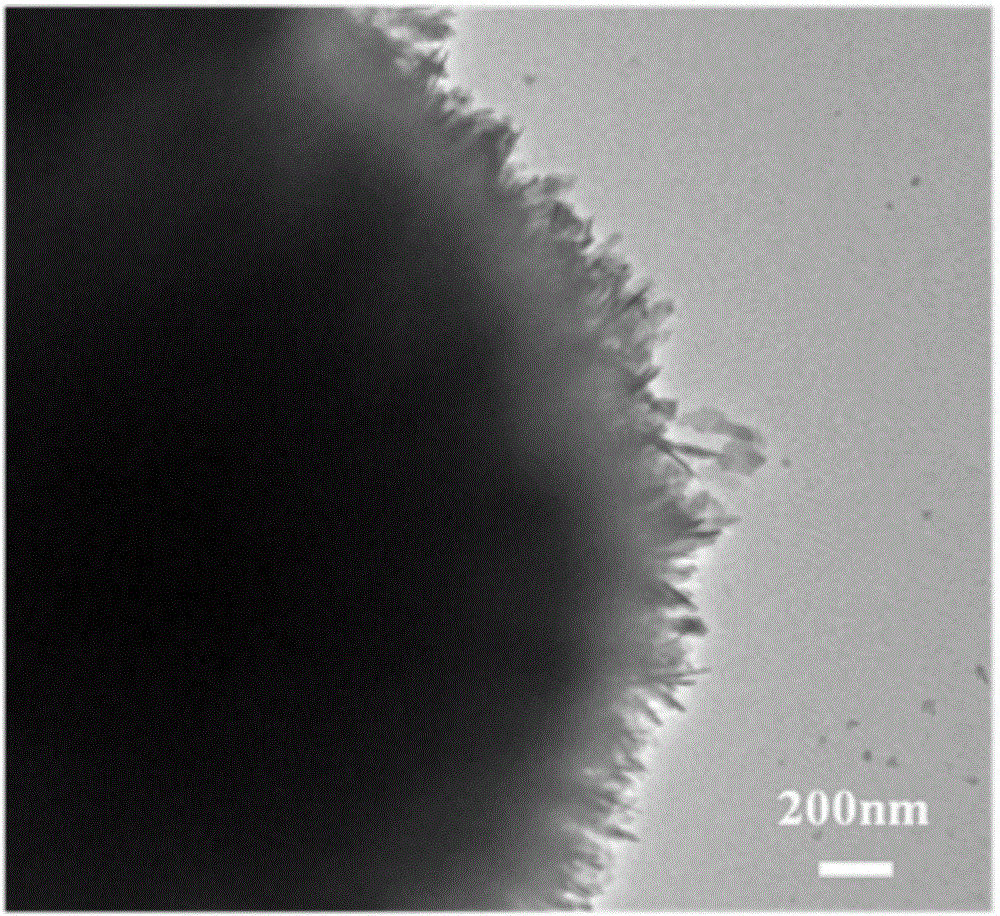

Method for preparing alkali type copper molybdate microsphere having surface nano-whisker structure

InactiveCN104692462ALarge specific surface areaIncrease contact areaMaterial nanotechnologyMolybdeum compoundsMolybdateMicrosphere

The invention relates to a method for preparing an alkali type copper molybdate microsphere having a surface nano-whisker structure. The method comprises the following steps of: (1), dropwise adding copper salt solution into molybdate solution, wherein the mol ratio of copper salt to molybdate is 1:1; (2), adjusting the pH of a mixed system obtained in the step (1) to 6, transferring the mixed system into a reaction kettle, stirring magnetically and ultrasonically so that the mixed system is uniformly dispersed, and keeping the temperature at 50-110 DEG C for 1-12h; and (3), cooling to room temperature by the end of the reaction, and centrifuging, washing, drying and collecting a sample so as to obtain the alkali type copper molybdate microsphere having the surface nano-whisker structure. Compared with the prior art, the method disclosed by the invention is simple in process, universal in preparation condition, steady in product morphology, high in purity and simple in product treatment, and is applied to medium-scale industrial production.

Owner:TONGJI UNIV

Small intermittent reducing distillation device

PendingCN107723472AFull condensate recoveryHigh yieldProcess efficiency improvementReaction layerDistillation

The invention relates to a small intermittent reducing distillation device. The small intermittent reducing distillation device is mainly used for laboratory investigation or preparation of small-batch volatile metal and oxide and comprises a reducing distillation furnace, wherein an opening is formed in the top of the reducing distillation furnace, a matched furnace lid is arranged at the opening, a gas outlet is formed in the furnace lid, inside of the reducing distillation furnace body is arranged in a layered manner and specially comprises a reduction reaction layer at the lower part, a sedimentation layer between the reduction reaction layer and the gas outlet and an accommodating layer between the reduction reaction layer and the sedimentation layer; the device further comprises a condensation chamber; the reducing distillation furnace is communicated with the condensation chamber through the gas outlet in the furnace lid. According to the device, gas is blocked by sedimentationpartitions, gaseous substances in a product are condensed sufficiently, the product that is not condensed sufficiently in the sedimentation layer is cooled again in the condensation chamber, dust is collected by a bag at an outlet of the condensation chamber, and the product is prevented from entering an induced draft fan. The product yield of the reducing distillation device is high, and the device is simple in structure and easy to manufacture, mount and maintain.

Owner:HUNAN UNIV OF TECH

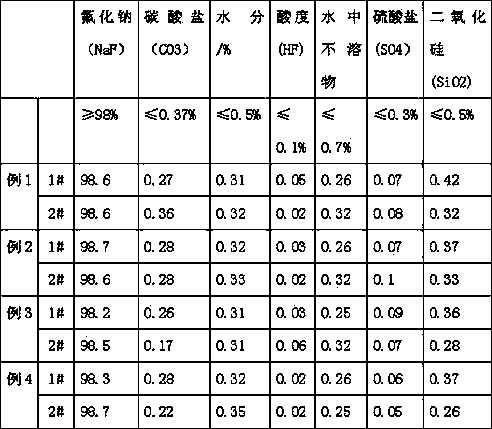

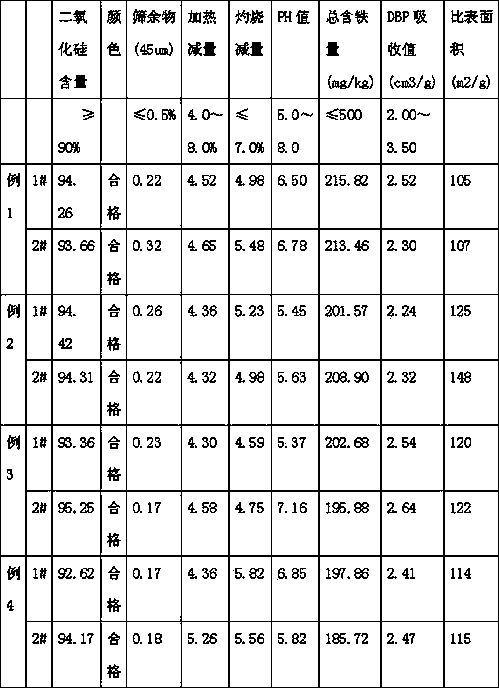

Novel production technology for producing sodium fluoride and white carbon black in co-production mode by using fluorosilicic acid

ActiveCN104030297ALow raw material costImprove business efficiencySilicaAlkali metal fluoridesSodium carbonateSodium fluoride

The invention provides a novel production technology for producing sodium fluoride and white carbon black in a co-production mode by using fluorosilicic acid. The fluorosilicic acid, water glass (sodium silicate) and sodium carbonate are used as main raw materials to produce high-purity silicon dioxide and sodium fluoride in the co-production mode, waste sodium fluoride mother liquor for producing the sodium fluoride is repeatedly used, waste water processing pressure of white carbon black enterprises and sodium fluoride enterprises is greatly relieved, cost of the raw materials of the sodium fluoride and the white carbon black is greatly reduced, and the revenue of the odium fluoride enterprises and the white carbon black enterprises is greatly improved.

Owner:JIANGXI QUCHENG CHEM

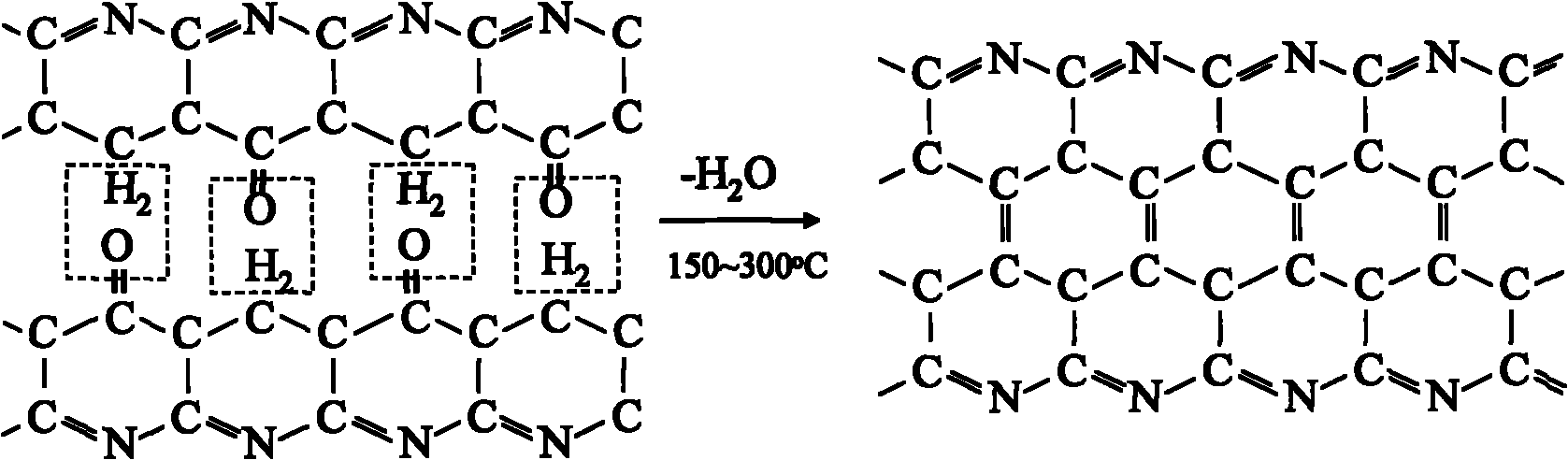

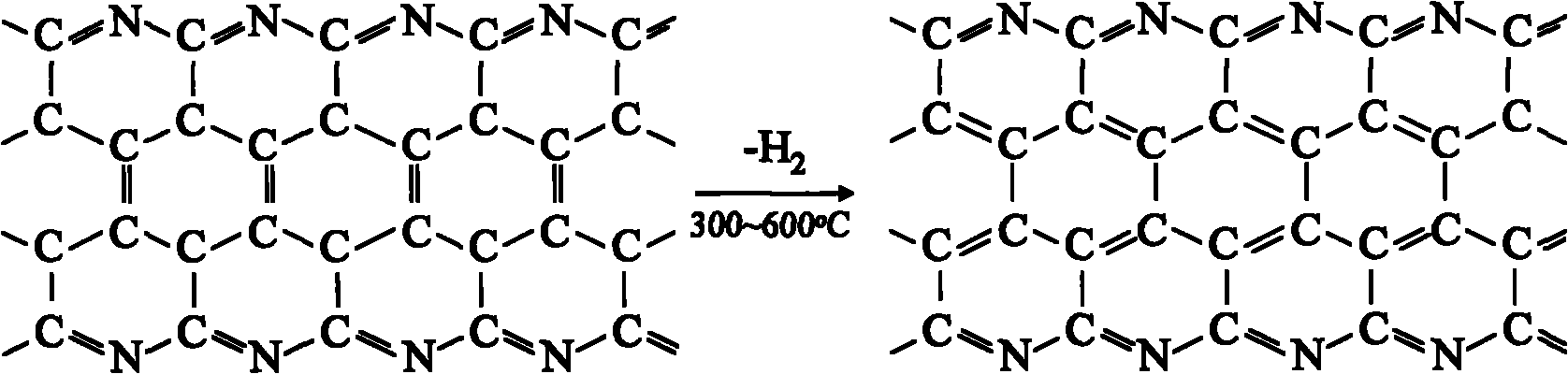

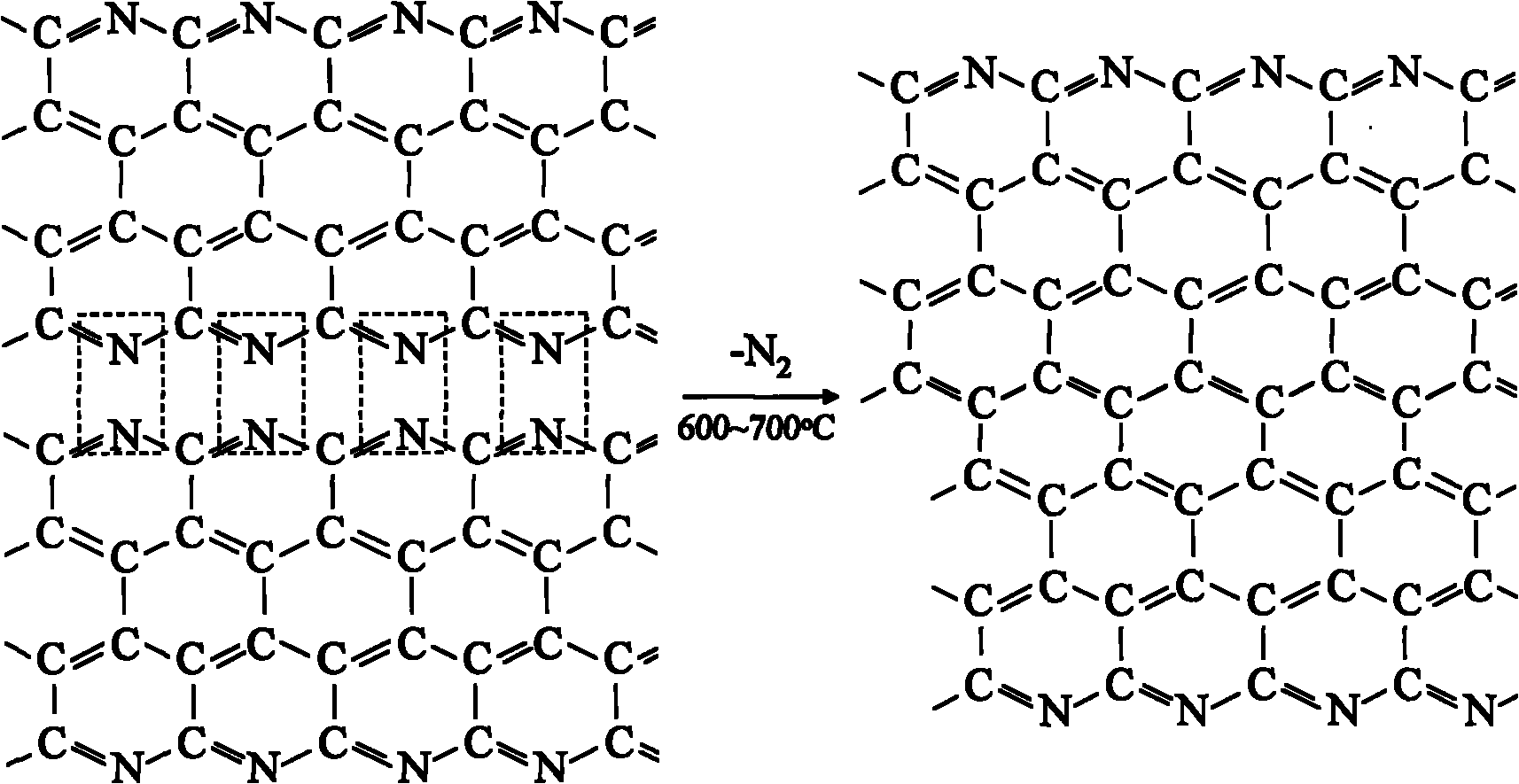

Method for preparing conducting film LiFePO4 cladding material containing nitrogen

InactiveCN101924204AImplementation of the problem of non-uniform growth rateEliminate the problem of non-uniform growth rateCell electrodesPhosphorus compoundsCarbon filmReaction temperature

The invention relates to a preparation method of a lithium ion battery anode material, aiming to provide a method for preparing a conducting film LiFePO4 cladding material containing nitrogen. The method comprises the following steps of: ball milling and mixing FePO4.4H2O, LiOH.H2O and a polyacrylonitrile emulsion, blending into a paste and putting the paste into a quartz reactor; regulating and controlling the microwave output power and controlling the reaction temperature to be at 150 DEG C; raising the microwave output power in an oxygen atmosphere and heating up to 300 DEG C from 150 DEG C; switching to a highly pure nitrogen atmosphere, raising the microwave output power and heating up to 600 DEG C from 300 DEG C; and continuously raising the microwave output power under the highly pure nitrogen atmosphere and annealing at 700-800 DEG C for denitrifying. Nitrogen atoms remain on the conducting carbon film formed by the invention, and lone pair electrons of the nitrogen atoms can effectively improve the conductivity of the carbon film so as to improve electrochemical and dynamic properties of the anode, reduce the electrode polarization and improve the velocity volume of the lithium cell, thus the invention can be applied to power cells of electric vehicles.

Owner:ZHEJIANG UNIV

Synthetic method of imidacloprid

The invention provides a synthetic method of imidacloprid, which comprises the synthetic steps of (1) sequentially adding an amine substance, 2-chlorine-5-chlorine picoline and a solvent into a reactor, conducting heating reflux for 2h, cooling, obtaining a catalyst solution, (2) sequentially adding a solvent, 2-nitryl imidogen imidazolidine and 1 / 5 alkali metal hydroxide into the catalyst solution, stirring, heating to 45 DEG C for heat preservation; (3) dropwise adding a solvent solution of 2-chlorine-5-chlorine picoline into reaction liquid for 30min each time and for four times totally after the heat preservation is over, adding 1 / 5 alkali metal hydroxide into the reaction liquid after dropwise adding the solvent solution each time, conducting heat preservation reaction for 1-2h after finishing the adding, and (4) conducting water washing for three times after the reaction is over, distilling the solvent out, crystallizing at 5 DEG C below zero, conducting suction filtration, drying, and obtaining a crude product of imidacloprid. According to the synthetic method, the reaction time is short; by-products are few; the purity of the crude product of imidacloprid reaches 98%; and a yield reaches 95.3%.

Owner:SHANDONG UNITED PESTICIDE IND CO LTD

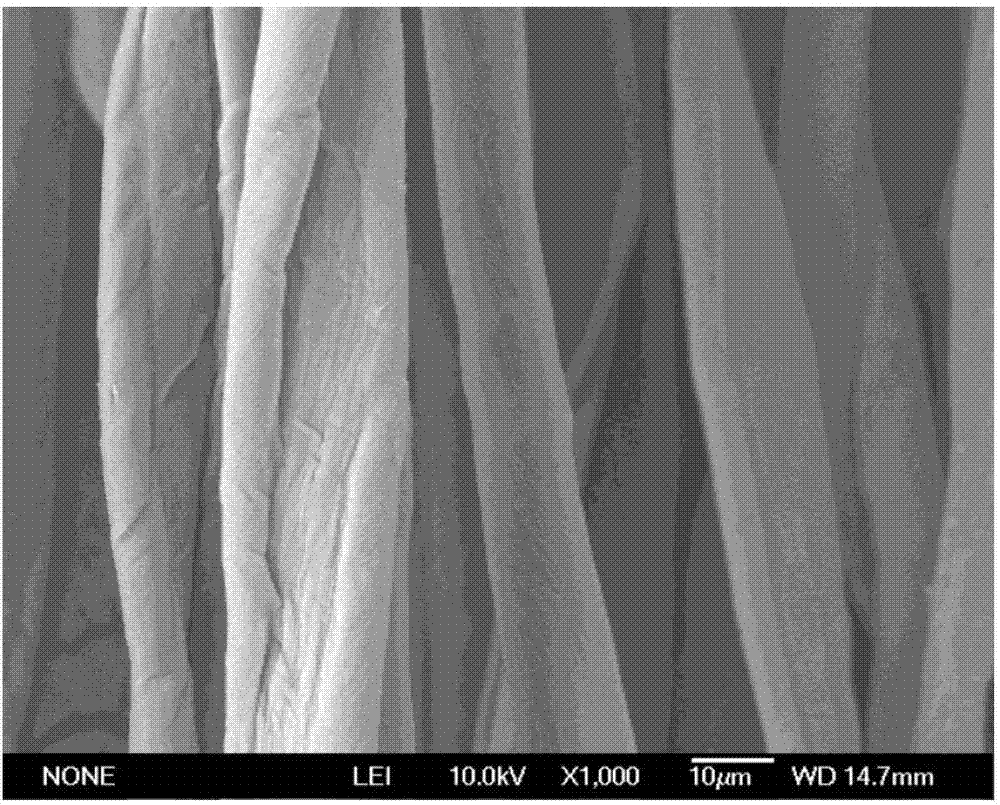

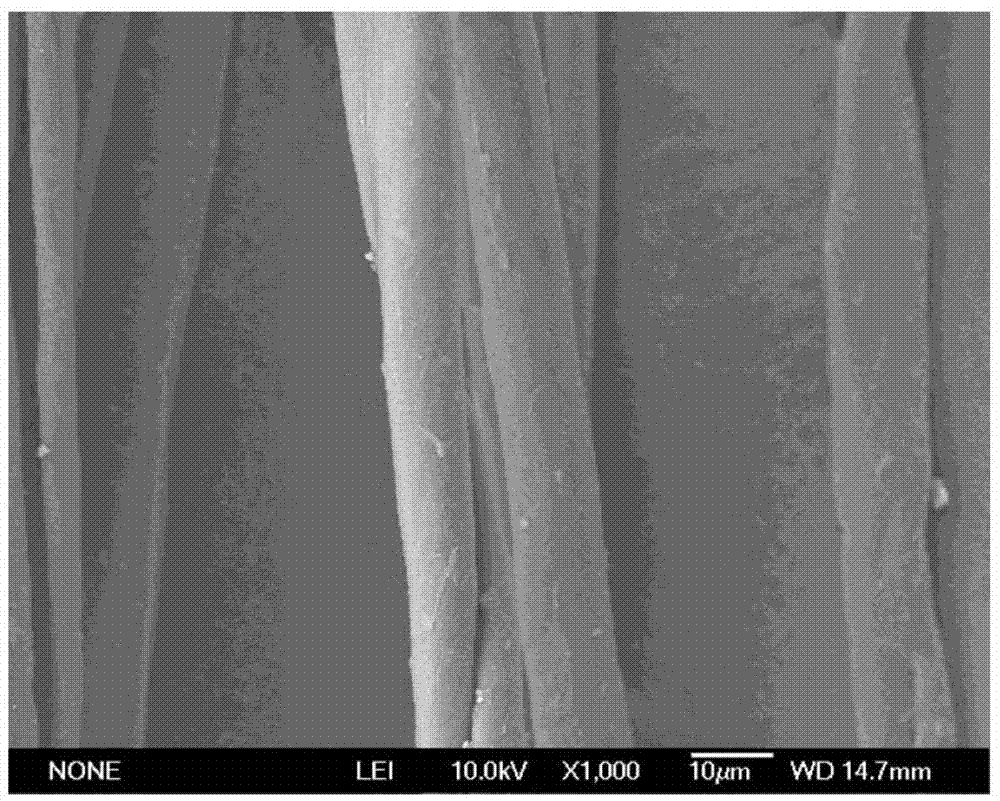

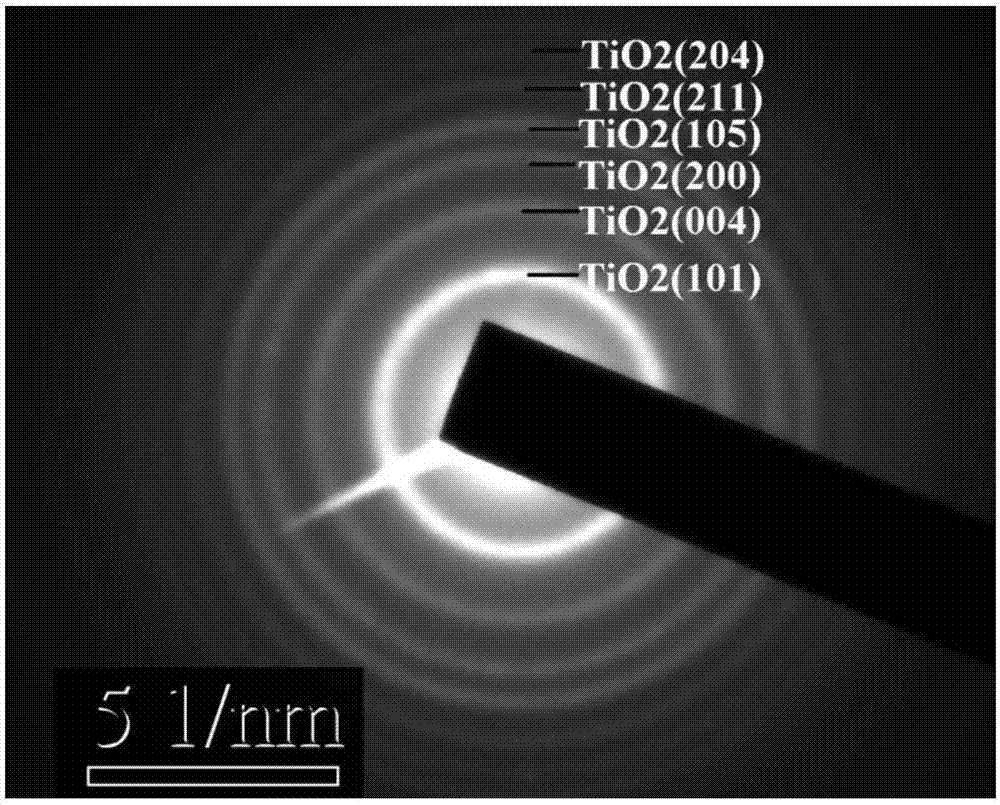

Nanometer titanium dioxide cotton fiber modifying method with improved dyeing property and attachment firmness

InactiveCN102899884AAdd depthImprove uneven coverageUltrasonic/sonic fibre treatmentVegetal fibresFiberPre treatment

The invention discloses a nanometer titanium dioxide cotton fiber modifying method with improved dyeing property and attachment firmness. The nanometer titanium dioxide cotton fiber modifying method comprises the following specific steps of: firstly, carrying out pretreatment on cotton fibers; secondly, configuring a modifying solution and carrying out modifying treatment on the cotton fibers by adopting a hydro-thermal method; and thirdly, carrying out post treatment on the modified cotton fibers. According to the nanometer titanium dioxide cotton fiber modifying method disclosed by the invention, the problems of poor dyeing properties of the nanometer titanium dioxide coated cotton fibers and low attachment firmness of nanometer titanium dioxide and cotton fibers are solved and the cotton fibers are endowed with the performances of ultraviolet resistance and bacteria resistance.

Owner:HOSA IND FUJIAN

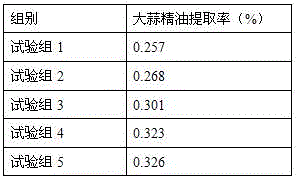

Separation and purification method of garlic essential oil

ActiveCN106367208AHigh extraction rateHigh active ingredientEssential-oils/perfumesPurification methodsDistillation

The invention relates to an essential oil extraction method, and particularly discloses a separation and purification method of garlic essential oil. The method comprises the steps of garlic cleaning and pulping, enzymolysis, ultrasonic extraction, extraction, centrifugation and distillation and purification. By conducting enzymolysis and extracting effective components in filter residues through an extracting agent, the extraction rate of the garlic essential oil and the effective components of the final garlic essential oil are increased. The separation and purification method of the garlic essential oil is mild in operating condition, low in cost and suitable for industrial production.

Owner:江苏黎明食品集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com