Apparatus and method to produce isooctane by indirect alkylation technique

An alkylation and isooctane technology, applied in chemical instruments and methods, chemical industry, organic chemistry, etc., can solve the problems of unacceptable additions, high value-added products that can no longer be used, and industrial chain interruptions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

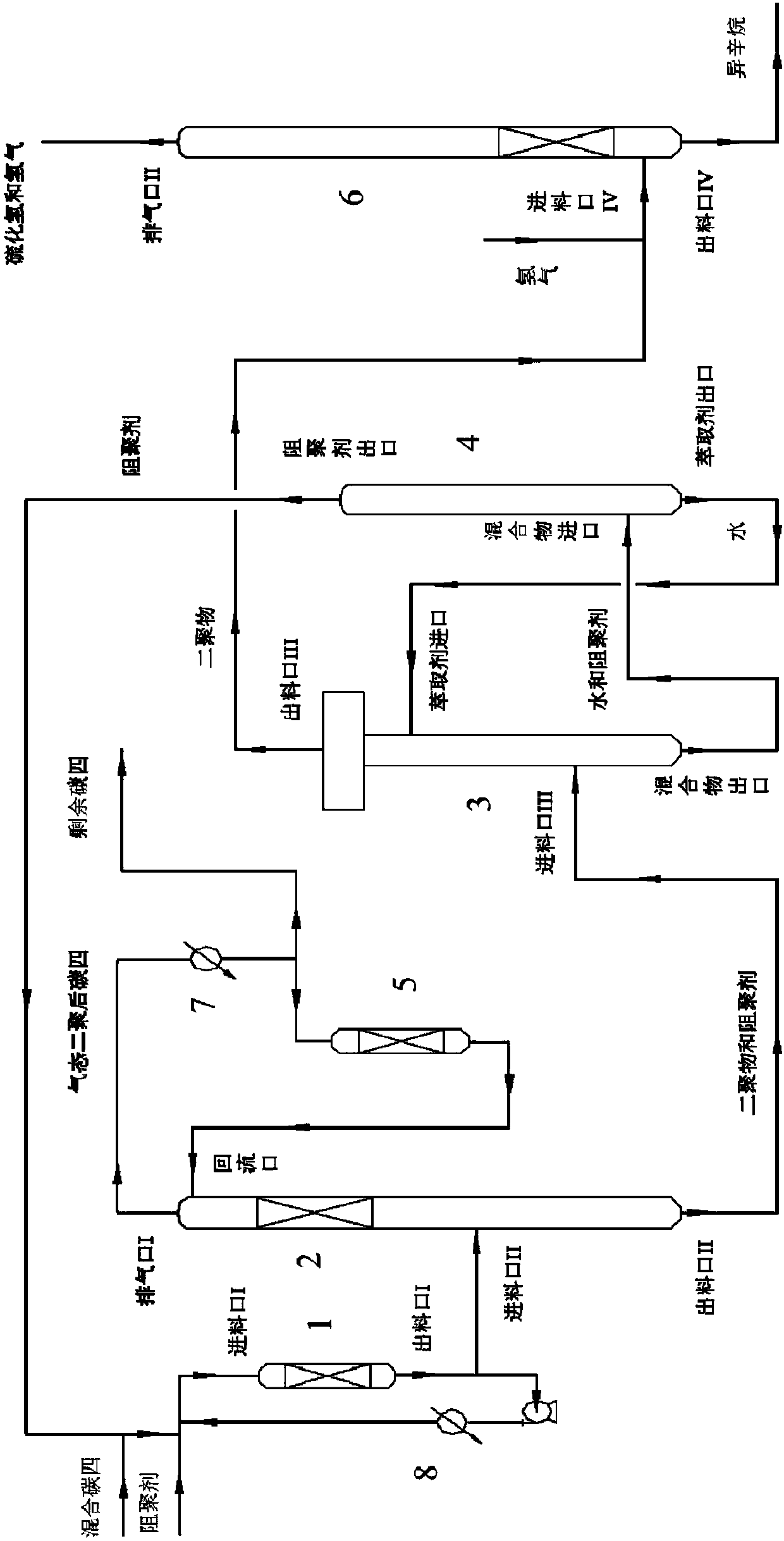

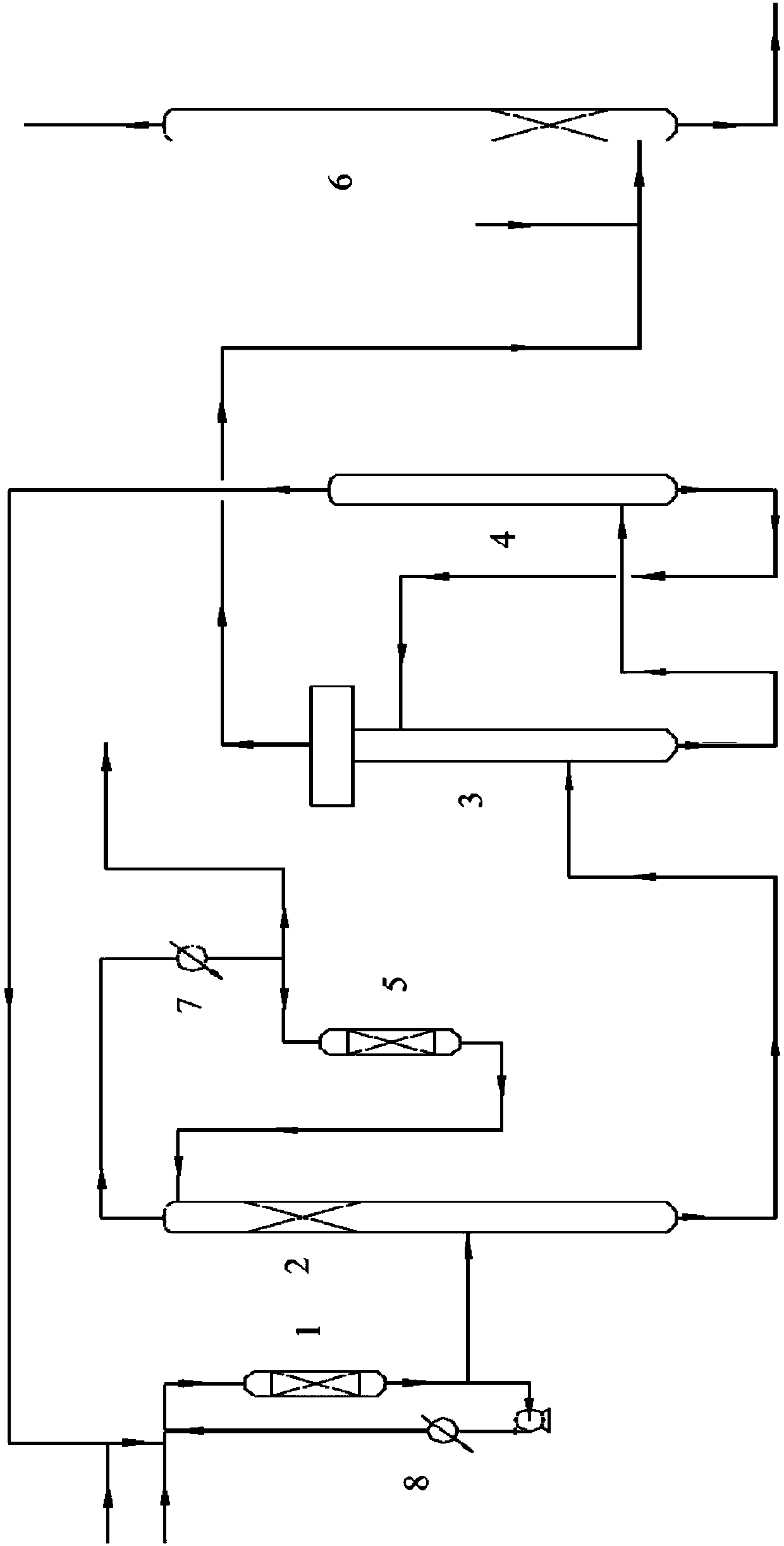

[0077] A method for producing isooctane by indirect alkylation technology, specifically comprising the following steps:

[0078] (1) Dimerization reaction: mixed carbon four and polymerization inhibitor pass into the fixed bed reactor 1 through the feed port 1, and the catalytic effect of the polymerization inhibitor and the mixed carbon four in the fixed bed reactor 1 is catalyst A The dimerization reaction is carried out under the lower pressure to obtain the reaction product; a part of the reaction product flows through the discharge port I, the pump and the heat exchanger in turn, and then returns to the feed port I for circulation. The reaction product removes the reaction heat through the heat exchanger and then returns to fix bed reactor I, thereby effectively controlling the temperature of the fixed-bed reactor I; another part of the reaction product flows through the discharge port I and the feed port II into the catalytic distillation tower in turn;

[0079] The comp...

Embodiment 2

[0097] A method for producing isooctane by indirect alkylation technology, specifically comprising the following steps:

[0098] (1) Dimerization reaction: mixed carbon four and polymerization inhibitor pass into the fixed bed reactor 1 through the feed port 1, and the catalytic effect of the polymerization inhibitor and the mixed carbon four in the fixed bed reactor 1 is catalyst A The dimerization reaction is carried out under the lower pressure to obtain the reaction product; a part of the reaction product flows through the discharge port I, the pump and the heat exchanger in turn, and then returns to the feed port I for circulation. The reaction product removes the reaction heat through the heat exchanger and then returns to fix bed reactor I, thereby effectively controlling the temperature of the fixed-bed reactor I; another part of the reaction product flows through the discharge port I and the feed port II into the catalytic distillation tower in turn;

[0099] The comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com