Patents

Literature

1905results about How to "Cost reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Floorboards, flooring systems and methods for manufacturing and installation thereof

ActiveUS20040139678A1Increase wear resistanceCost reductionStrutsWallsMechanical engineeringFloating floor

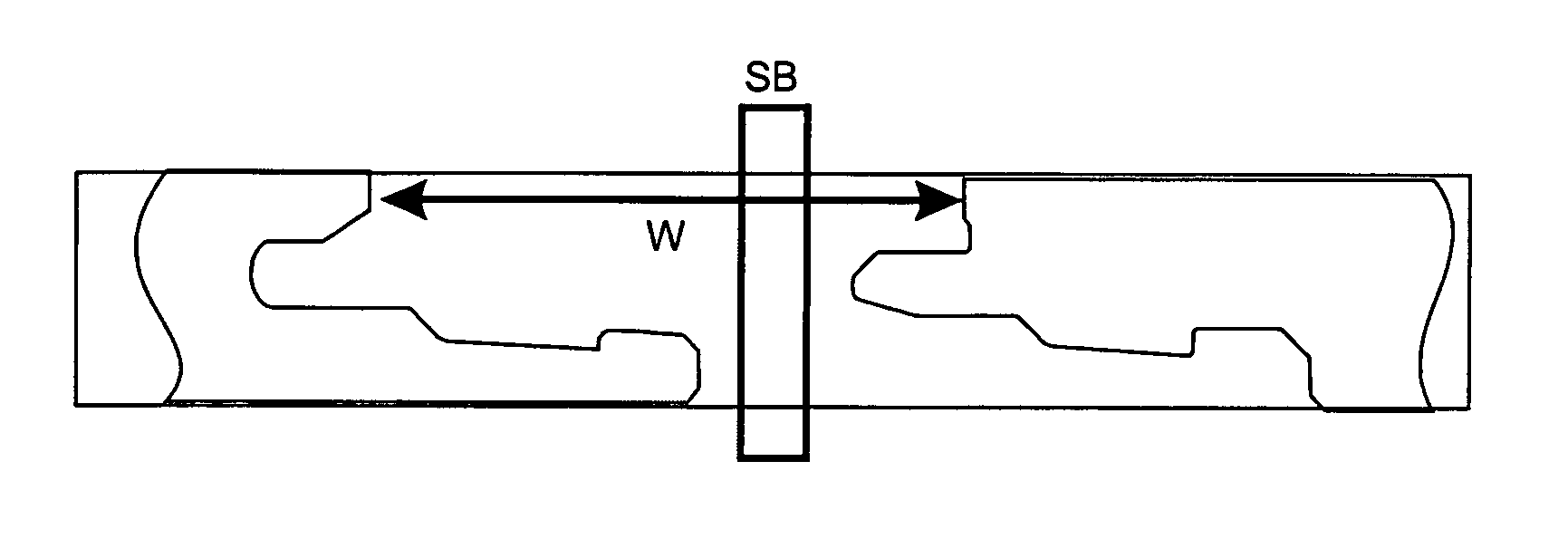

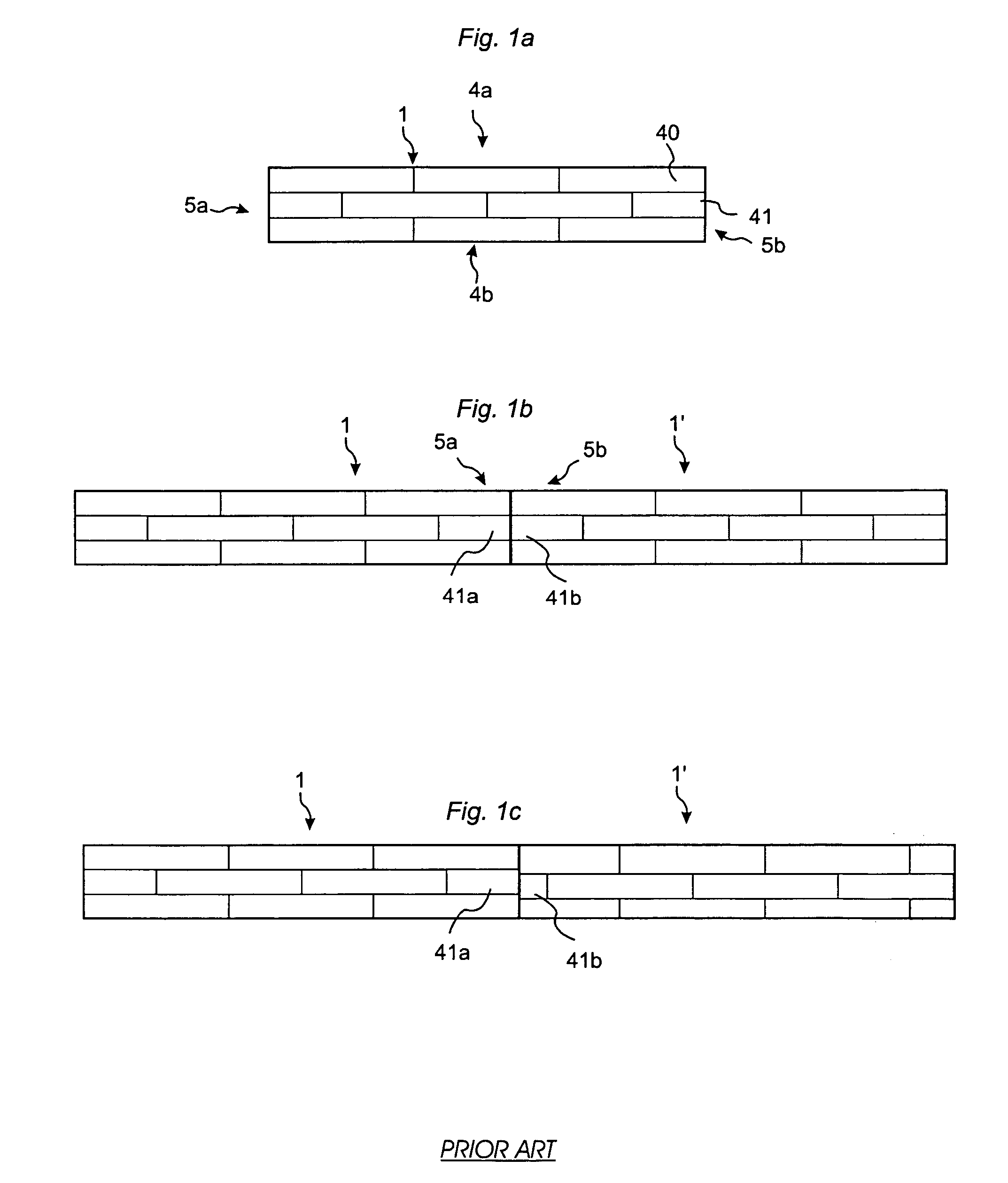

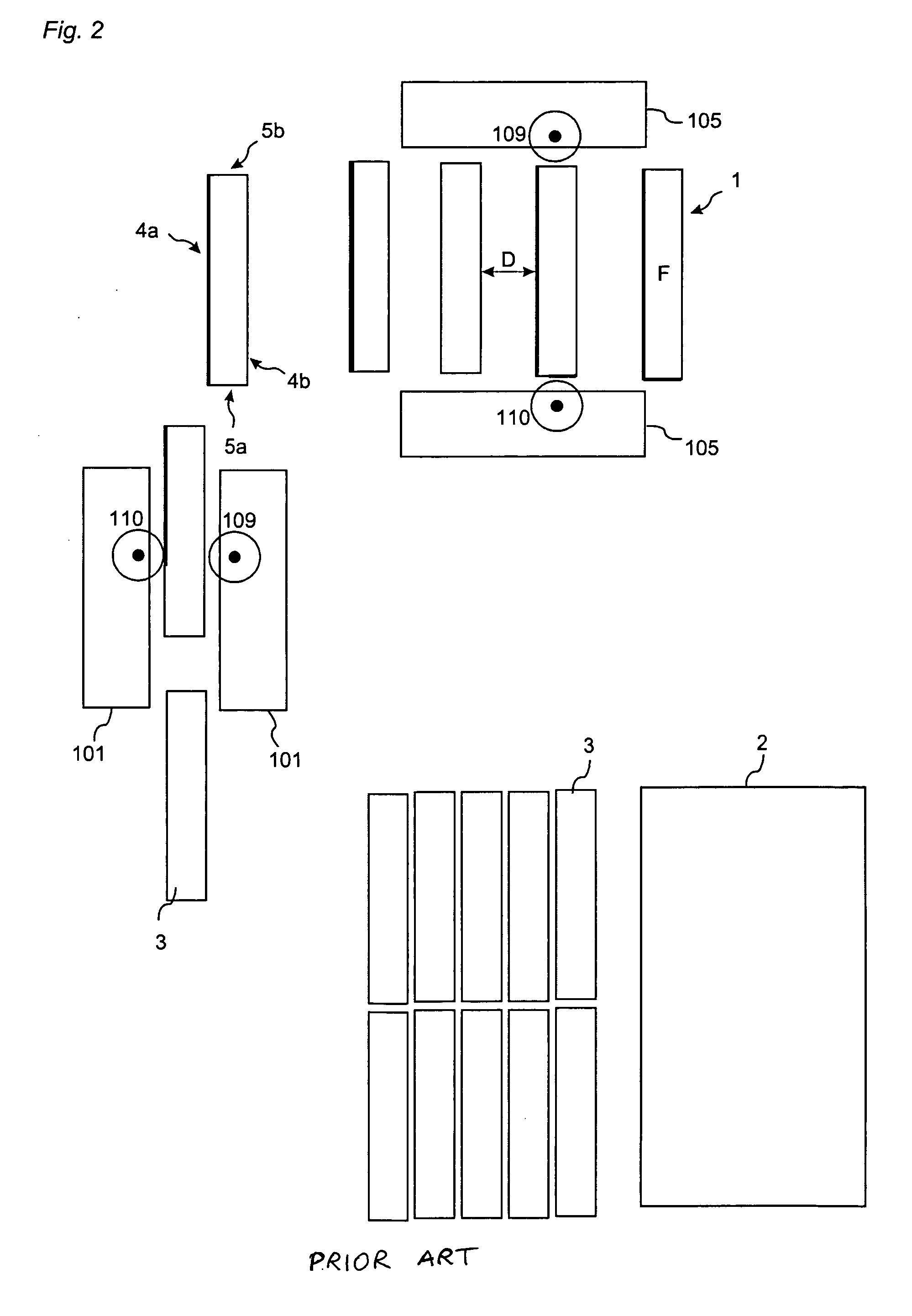

Floorboards with a format corresponding to a traditional parquet block for laying of mechanically joined floating flooring. Rectangular floorboards include a surface layer and a core with two long sides and two short sides, for making a floating flooring, which floorboards are mechanically lockable and which along their four sides have pairs of opposing connectors for locking similar, adjoining floorboards to each other both vertically and horizontally wherein the long sides have a length not exceeding 80 cm and the short sides have a width not exceeding 10 cm.

Owner:VÄLINGE INNOVATION AB

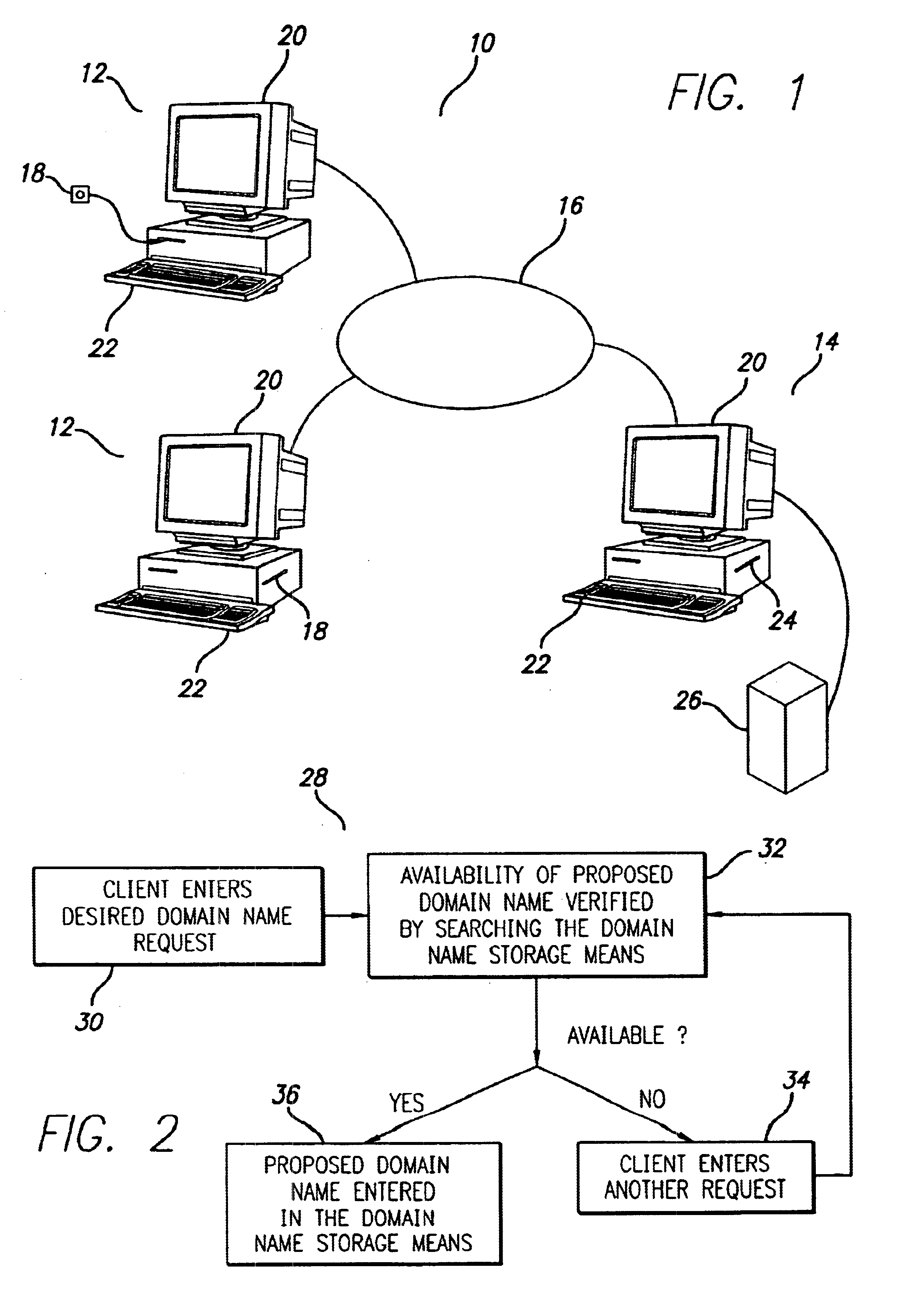

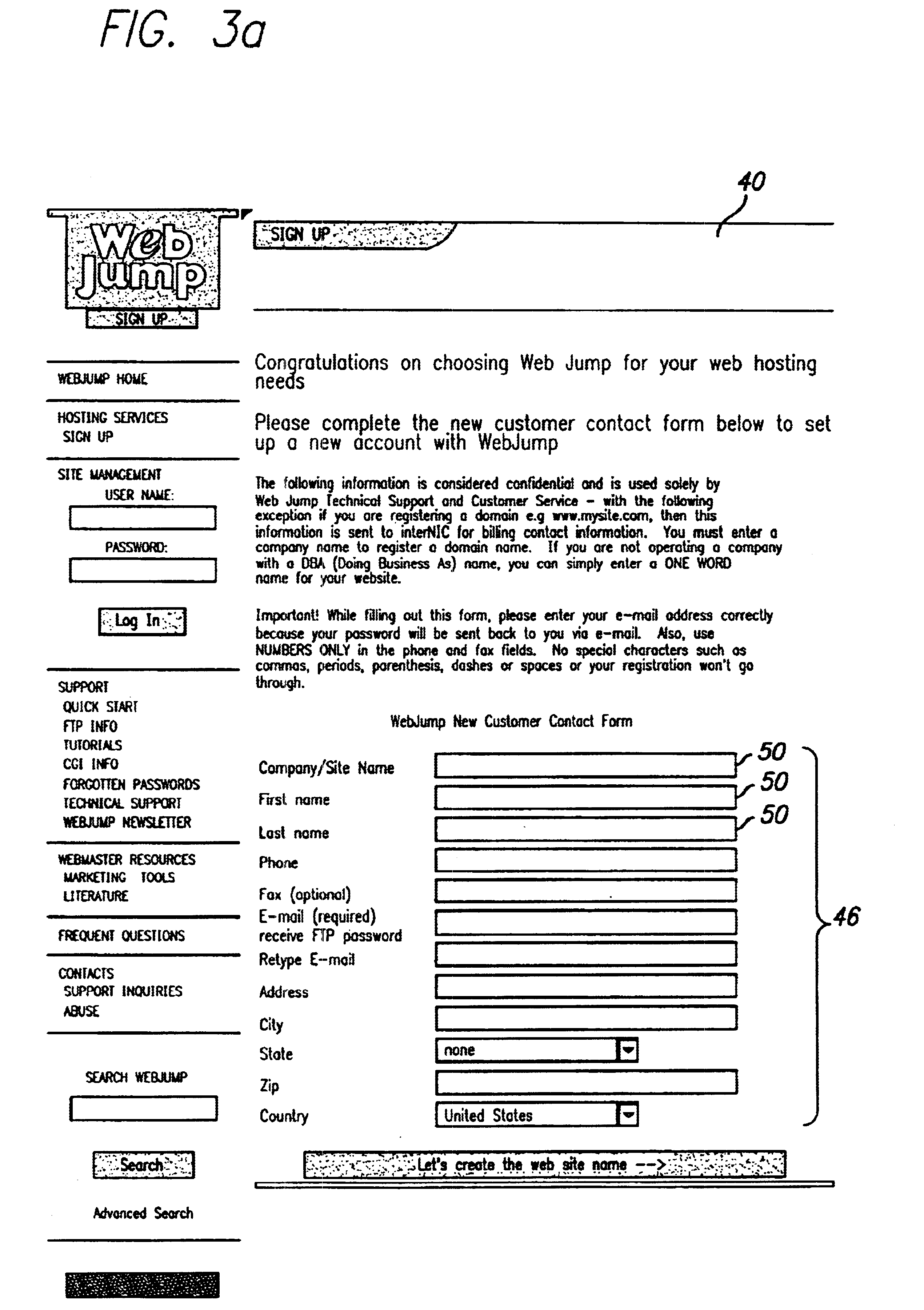

System apparatus and method for hosting and assigning domain names on a wide area network

InactiveUS6687746B1Eliminate costCost reductionData processing applicationsDigital data processing detailsManagement systemData mining

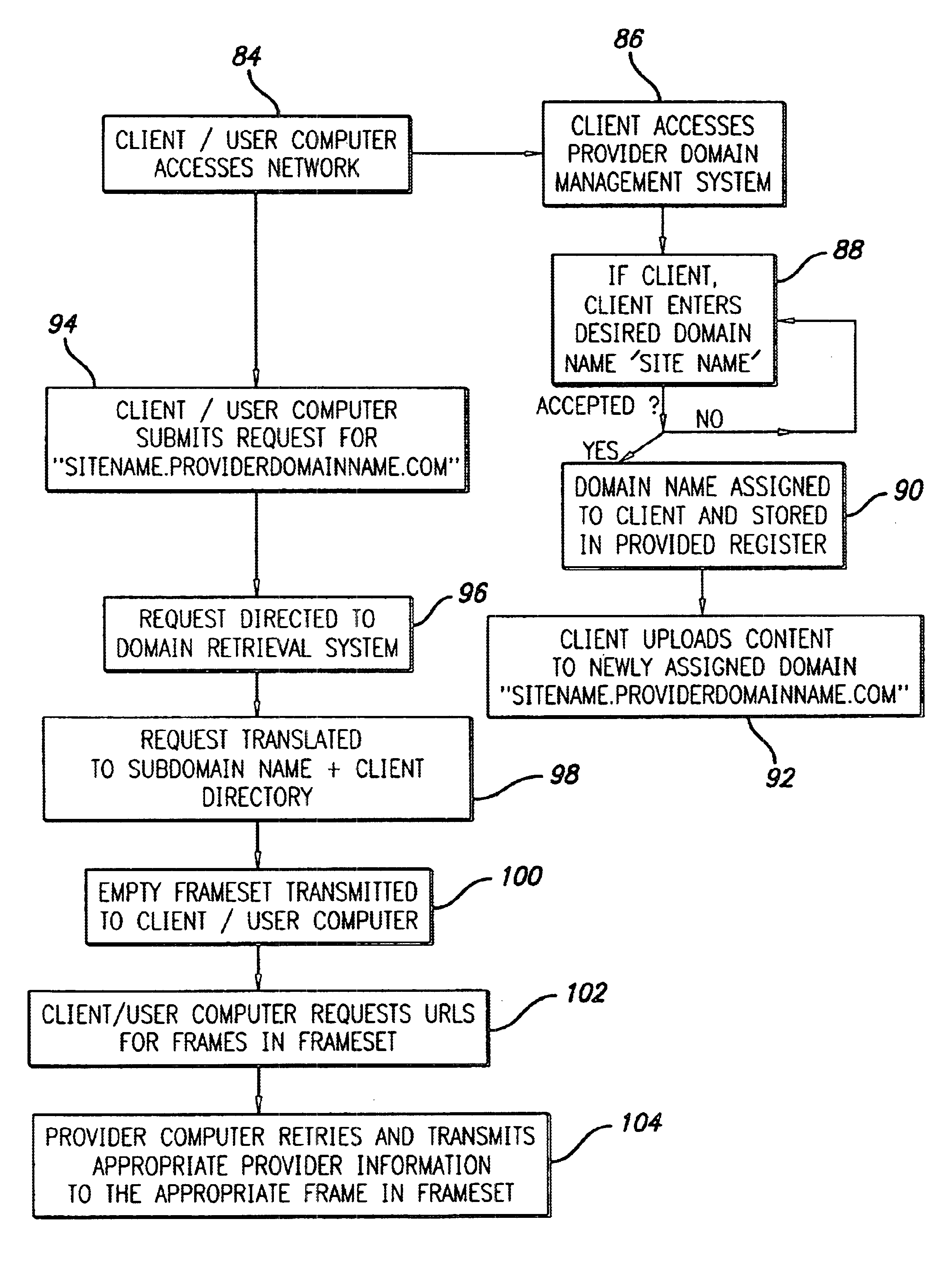

Embodiments of the instant invention are directed to a domain management system, apparatus and method for hosting and assigning domain names. Embodiments of the domain management system comprise a name assignment system and a hosting system, wherein the hosting system comprises a domain retrieval system and a data storage apparatus. The name assignment system verifies availability and assigns domain names to requesting clients. The name assignment system comprises an input component, a confirmation mechanism and a name storage means. Preferred embodiments of the domain retrieval system comprise a scheduler, a parsing member having a plurality of redirectors and a plurality of servers. The domain retrieval system locates the domain referenced by the domain name by parsing header information and utilizing a wildcard DNS. Once the domain is located, the domain retrieval system forwards the domain to the user computer.

Owner:FAR NORTH PATENTS LLC

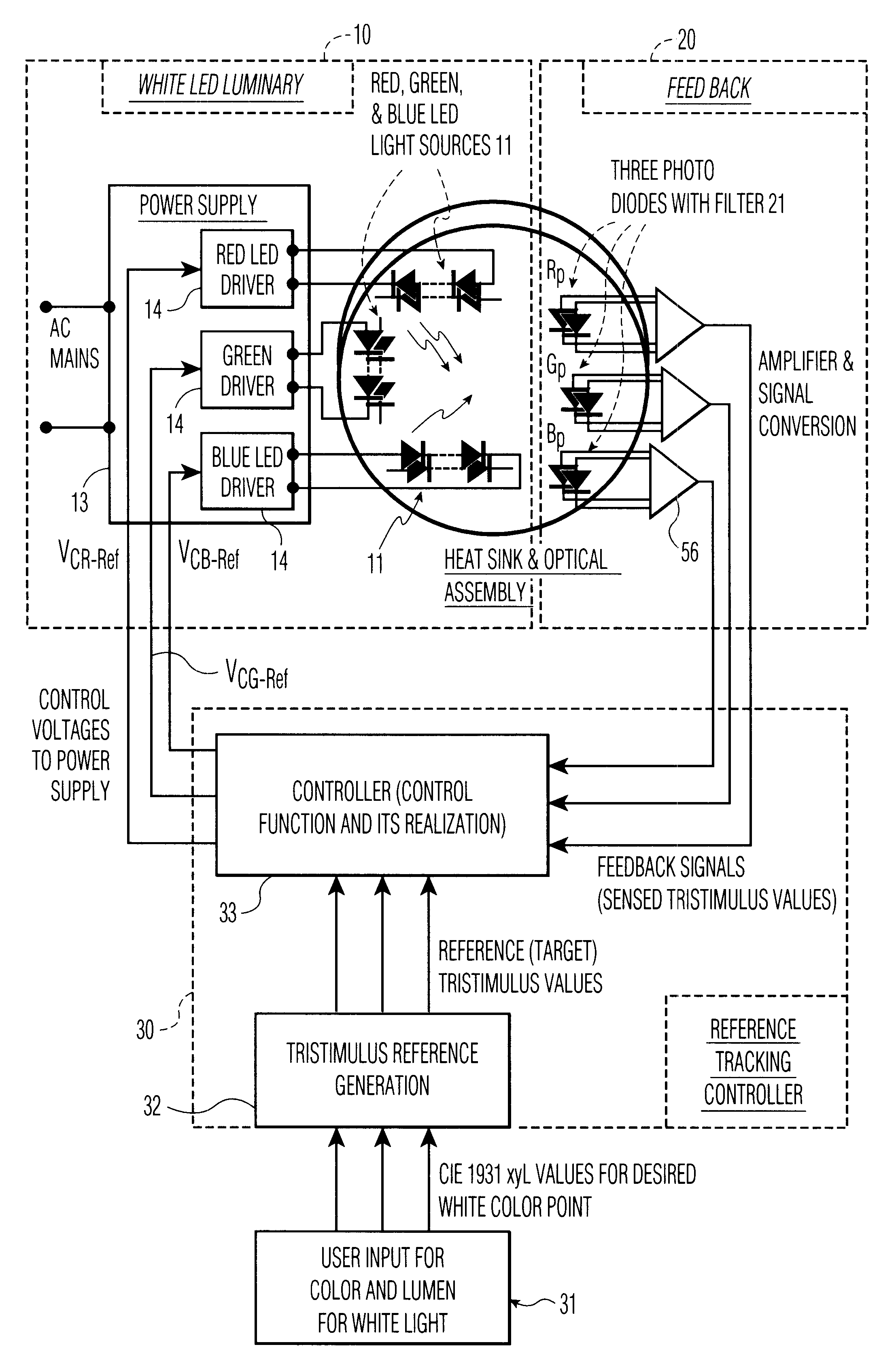

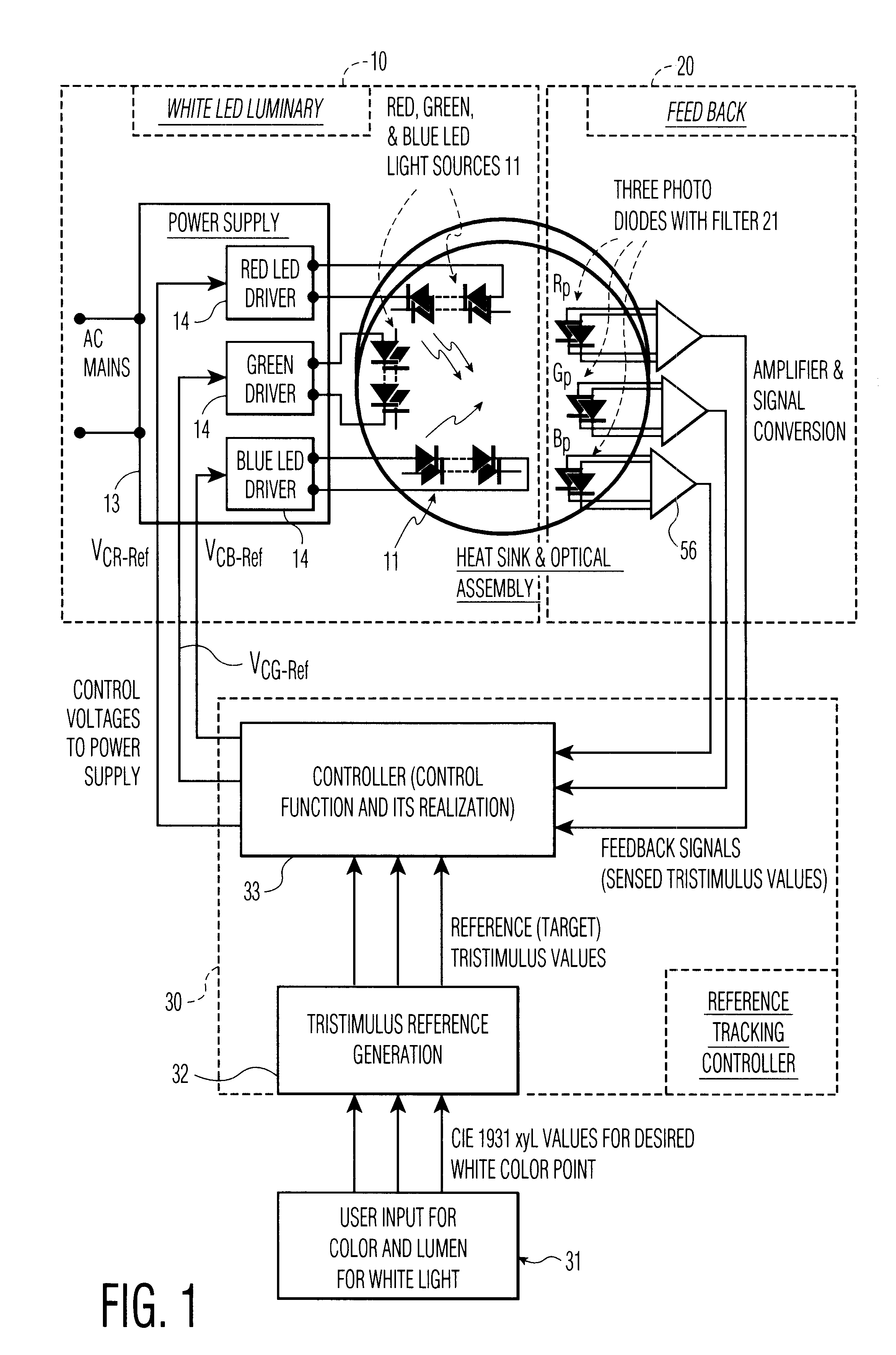

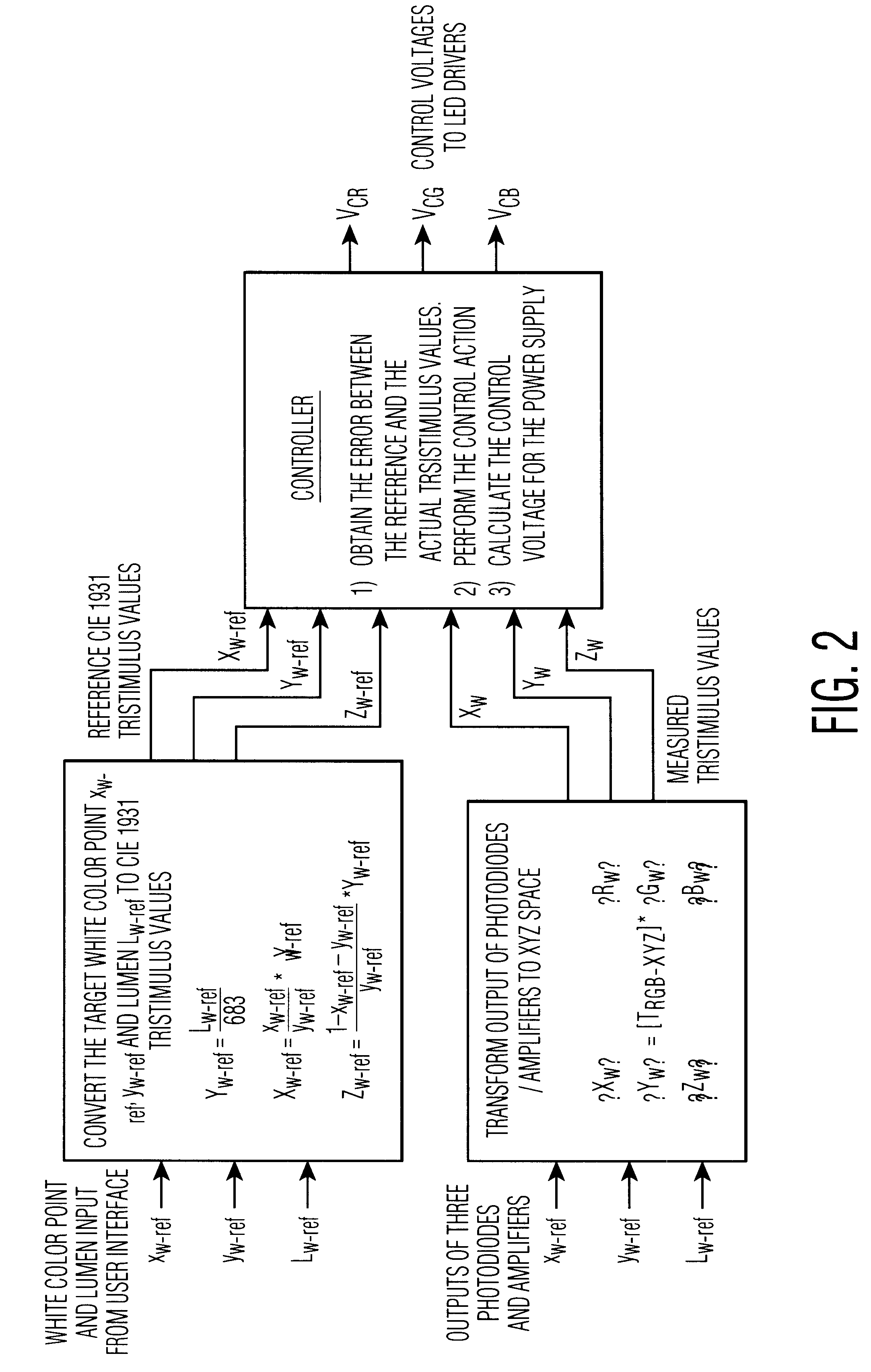

Controlling method and system for RGB based LED luminary

InactiveUS6507159B2Cost reductionHigh rippleStatic indicating devicesElectroluminescent light sourcesEngineeringForward current

A method and a system for controlling a RBG based LED luminary which tracks the tristimulus values of both feedback and reference whereby the forward currents driving the LED luminary are adjusted in accordance with the errors between the feed tristimulus values and the reference tristimulus values until the errors are zero.

Owner:SIGNIFY HLDG BV

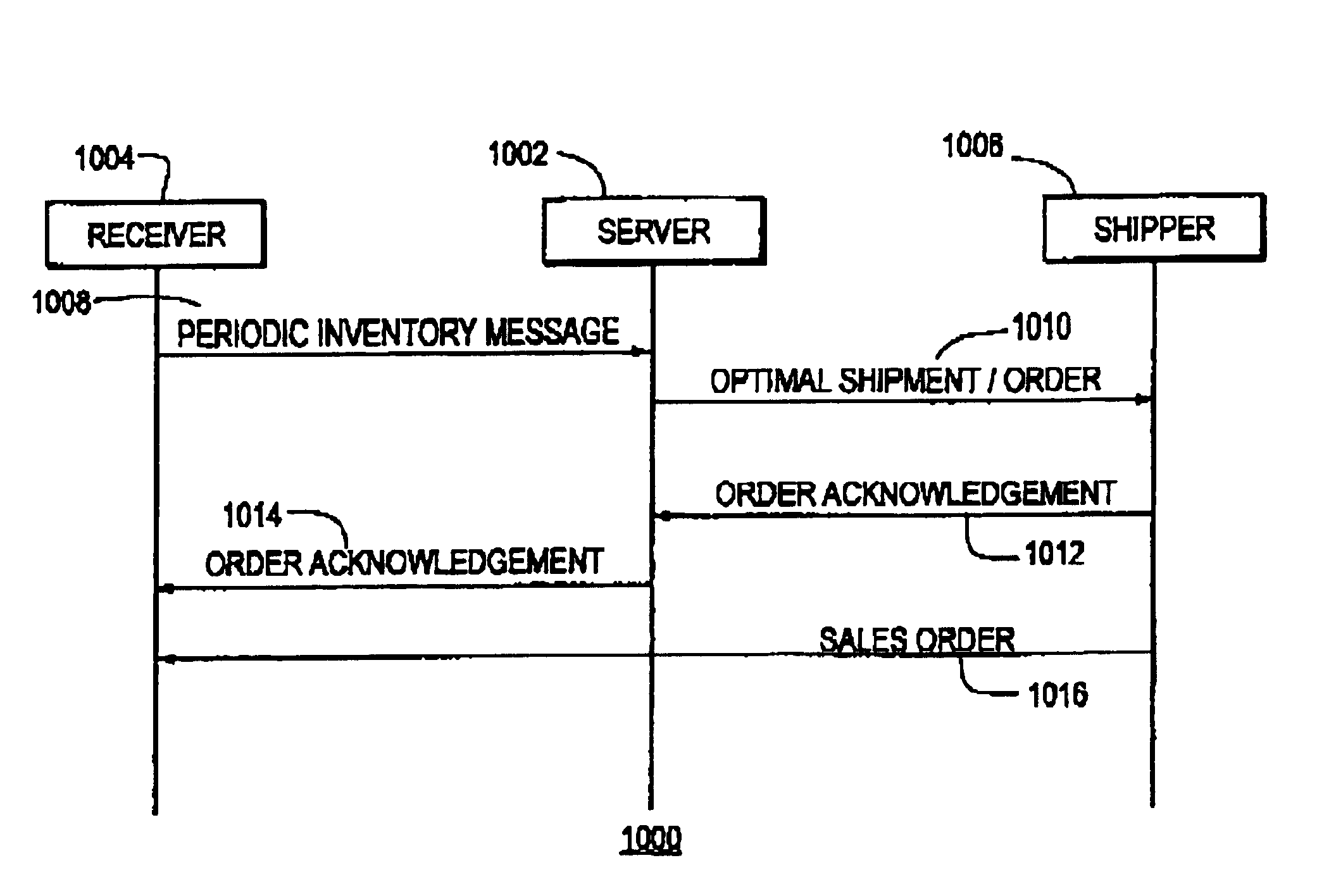

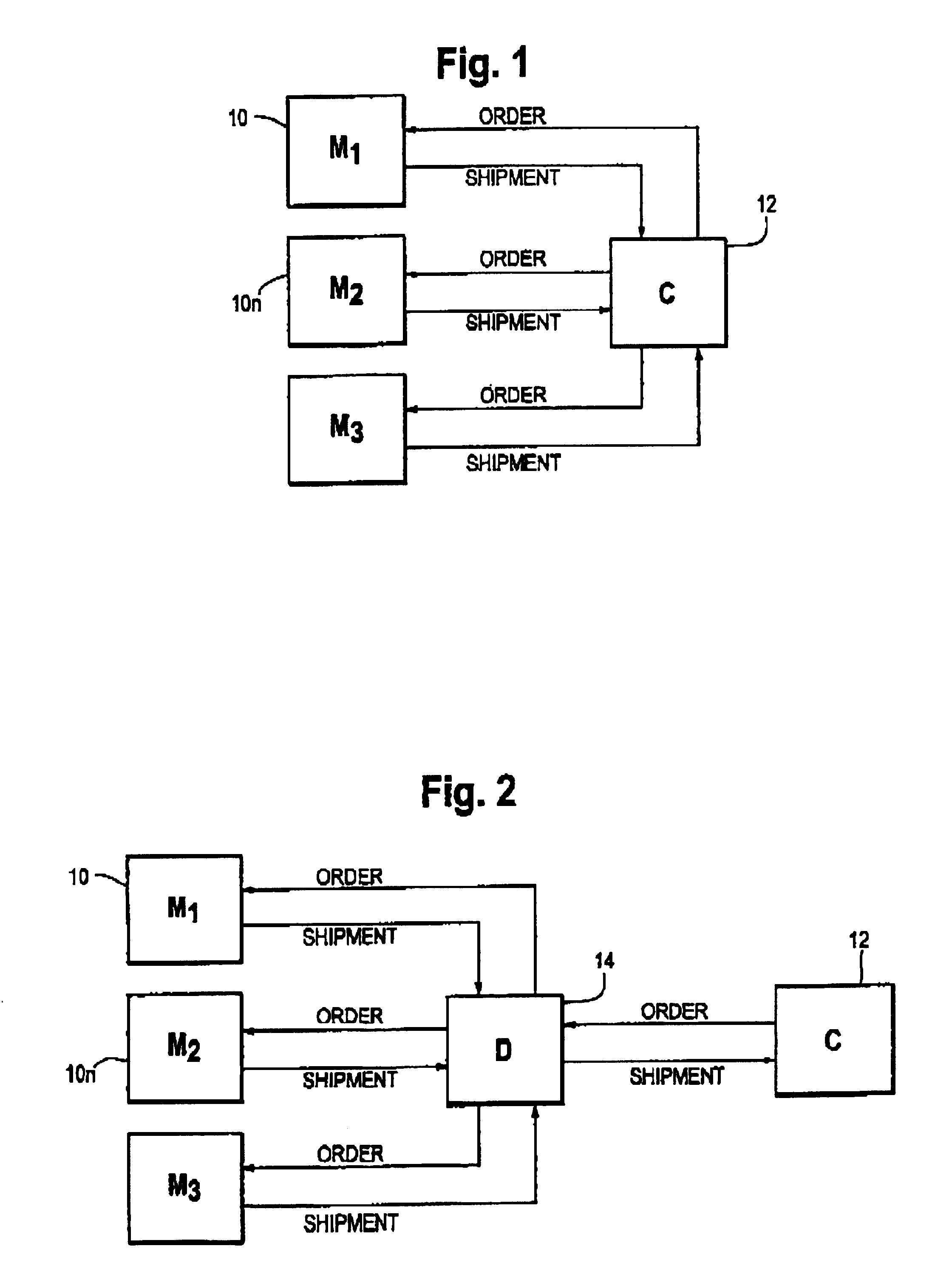

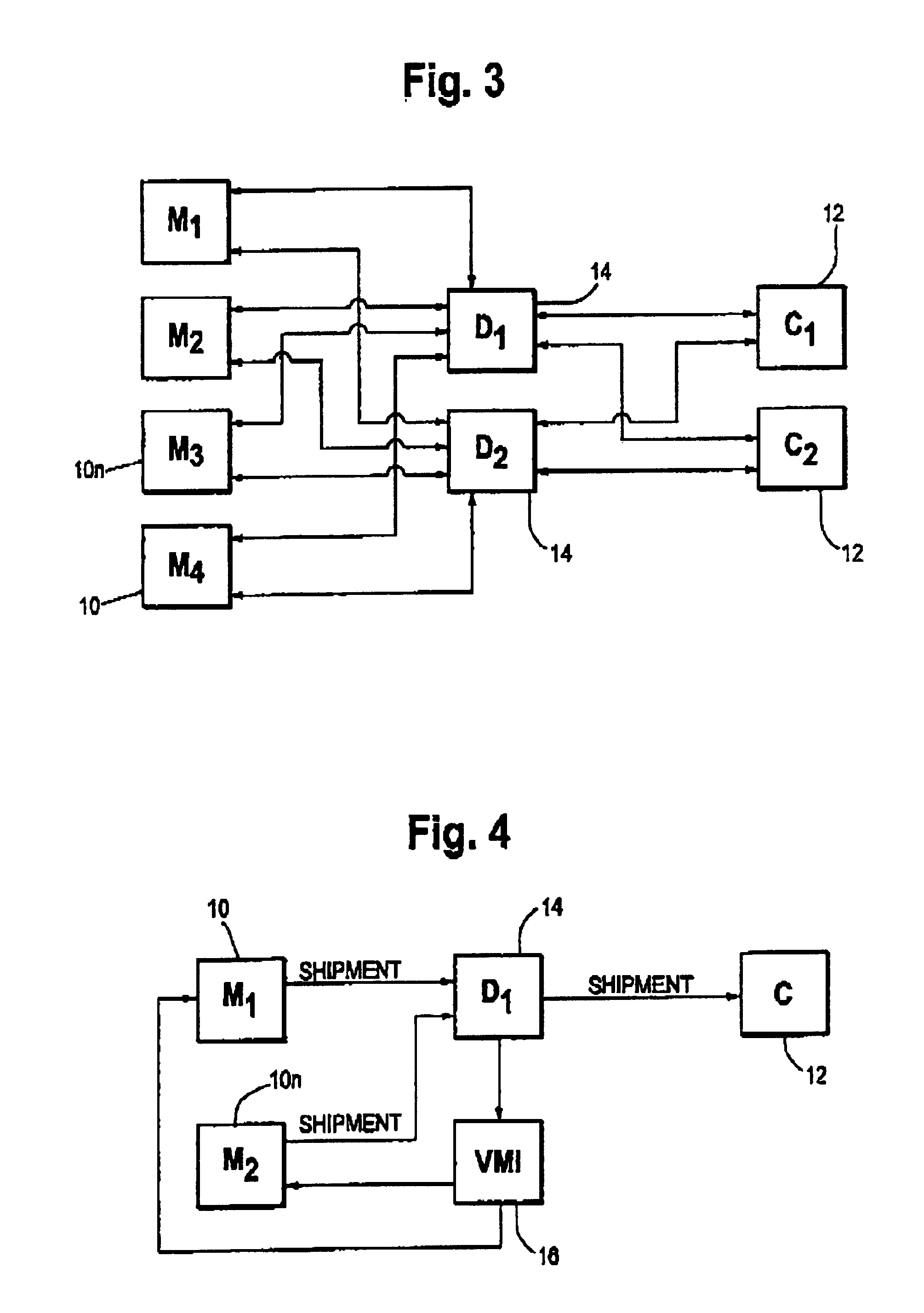

Transport vehicle capacity maximization logistics system and method of same

InactiveUS6937992B1Cost reductionReduce logistics costsAnimal feeding devicesForecastingAutomotive engineeringLogistics management

Owner:ARROWSTREAM

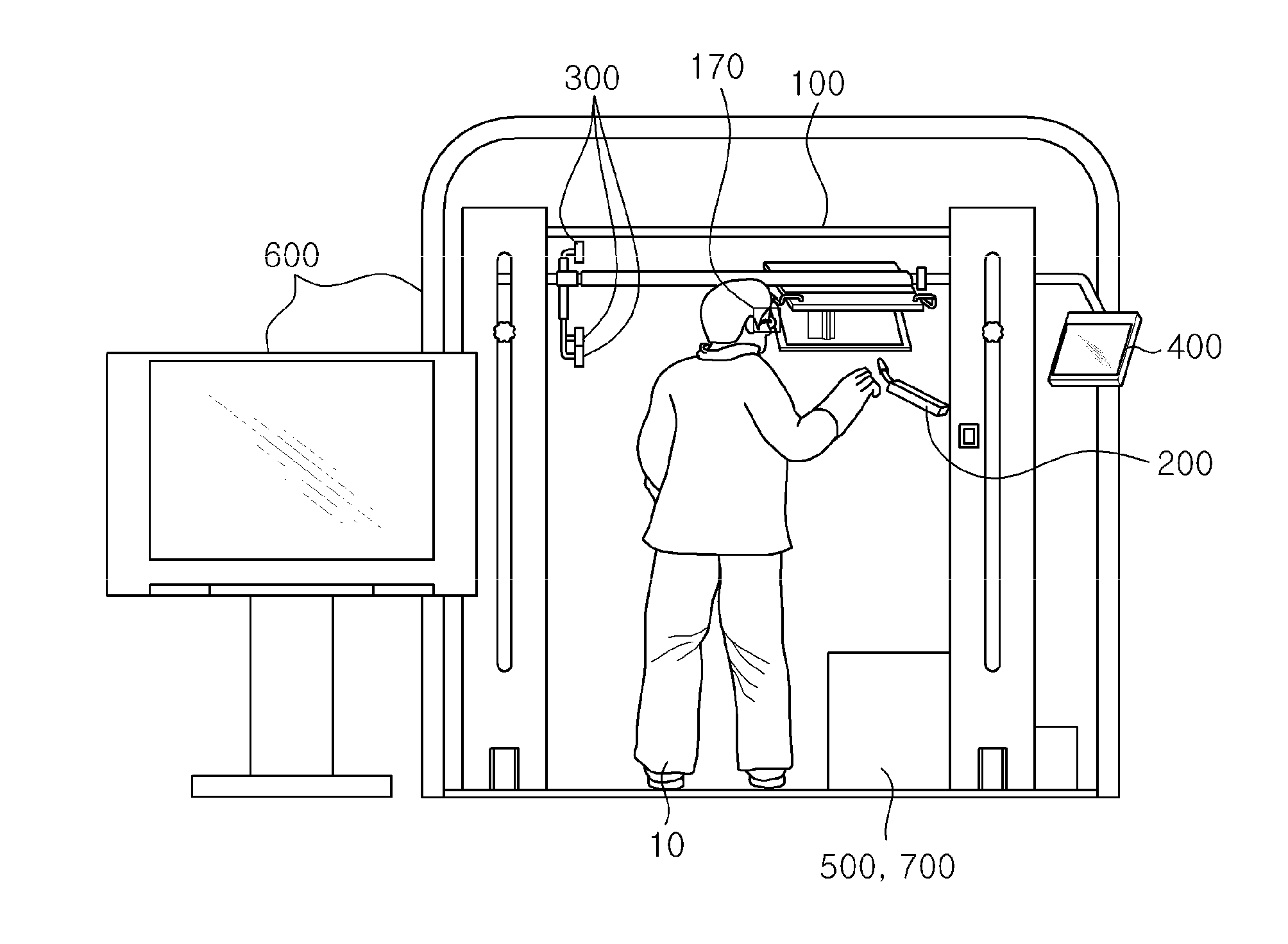

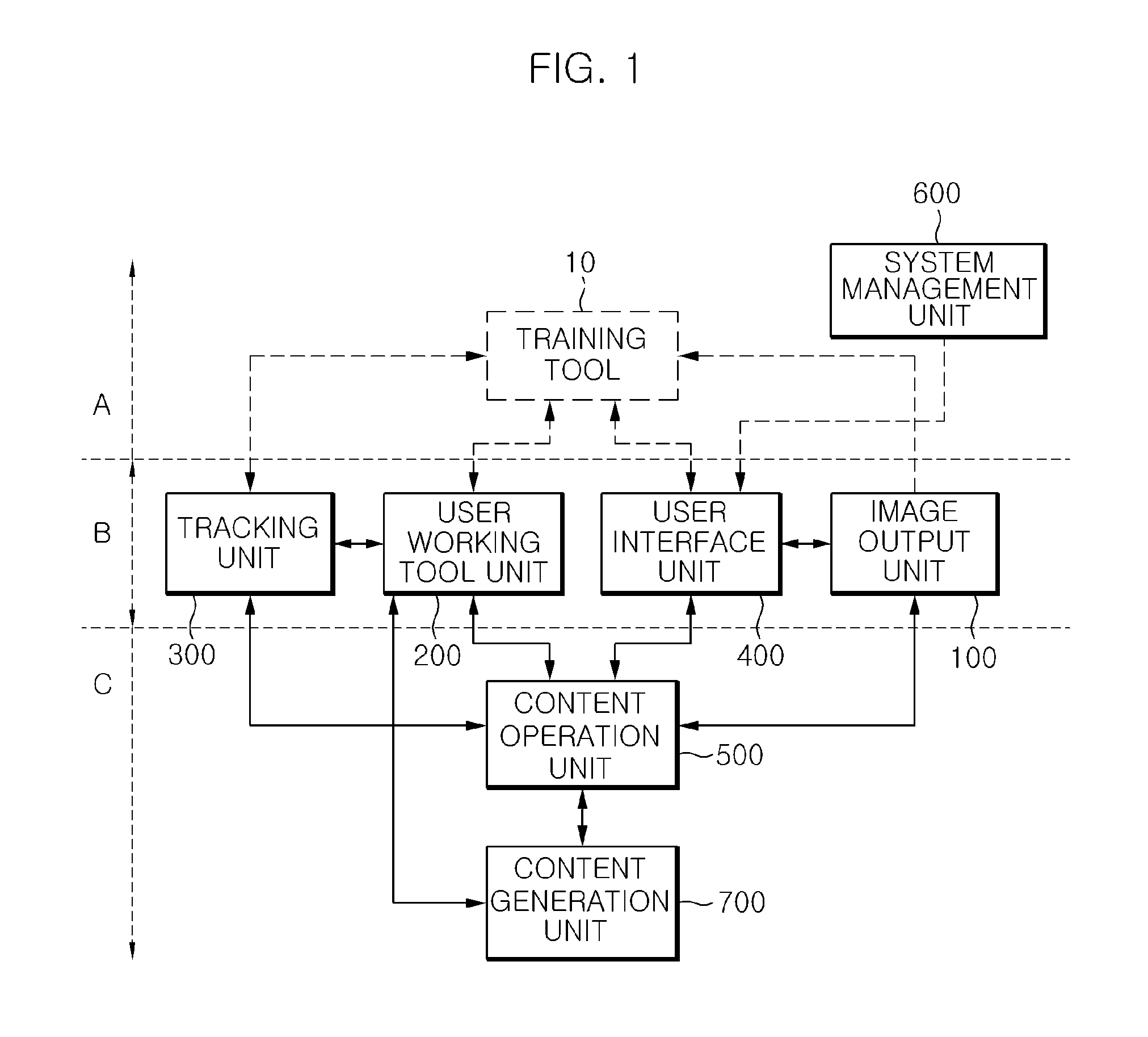

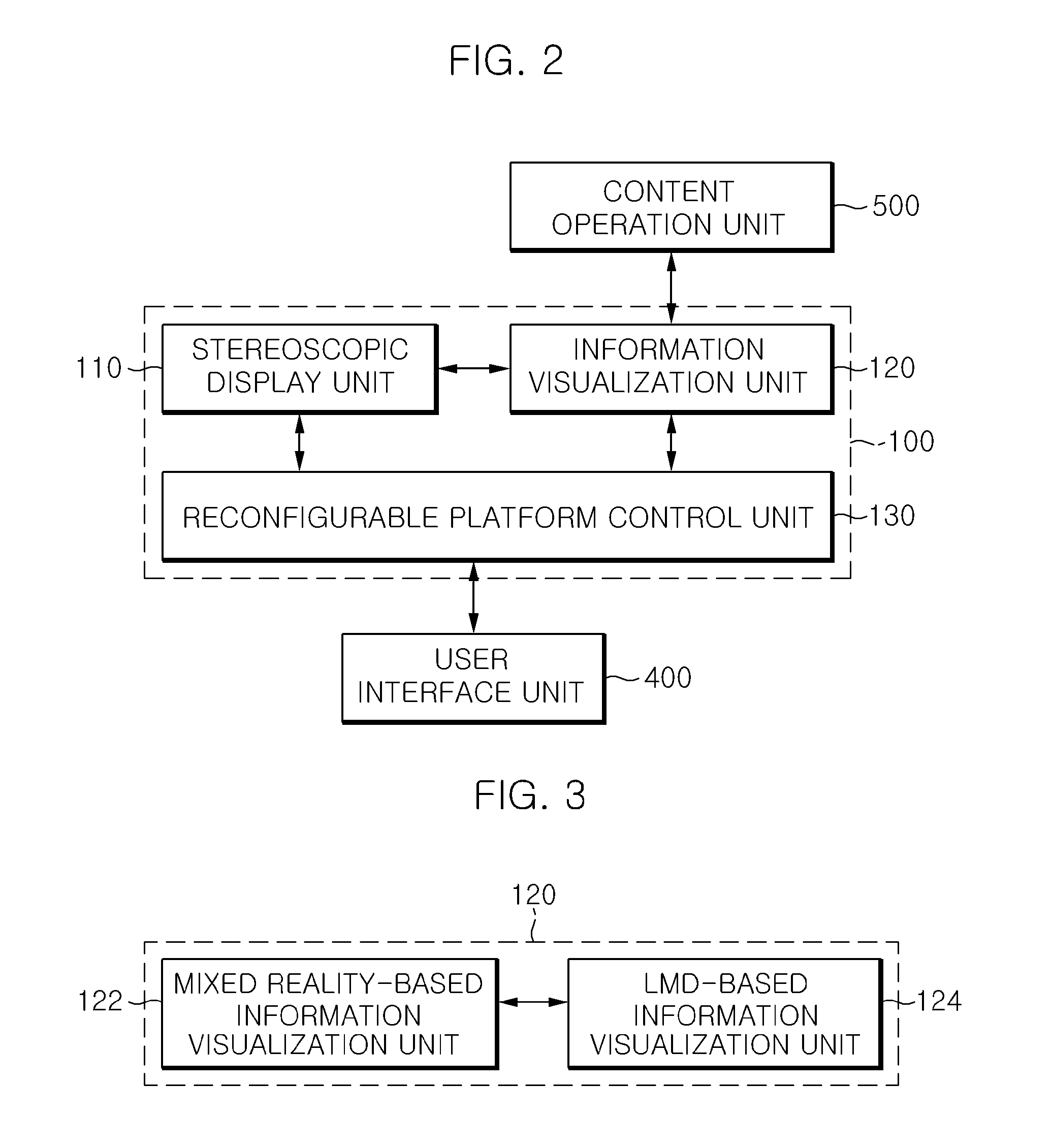

Reconfigurable platform management apparatus for virtual reality-based training simulator

InactiveUS20120122062A1Cost reductionReduce riskEducational modelsSimulatorsDriving simulatorTraining simulation

Disclosed herein is a reconfigurable platform management apparatus for a virtual reality-based training simulator, which enables a device platform to be reconfigured to suit various work environments and to fulfill various work scenario requirements of users. The reconfigurable platform management apparatus for a virtual reality-based training simulator includes an image output unit for outputting a stereoscopic image of mixed reality content that is used for work training of a user. A user working tool unit generates virtual sensation feedback corresponding to sensation feedback generated based on a user's motion to the outputted stereoscopic image when working with an actual working tool. A tracking unit transmits a sensing signal obtained by sensing a user's motion working tool unit to the image output unit and the user working tool unit.

Owner:ELECTRONICS & TELECOMM RES INST

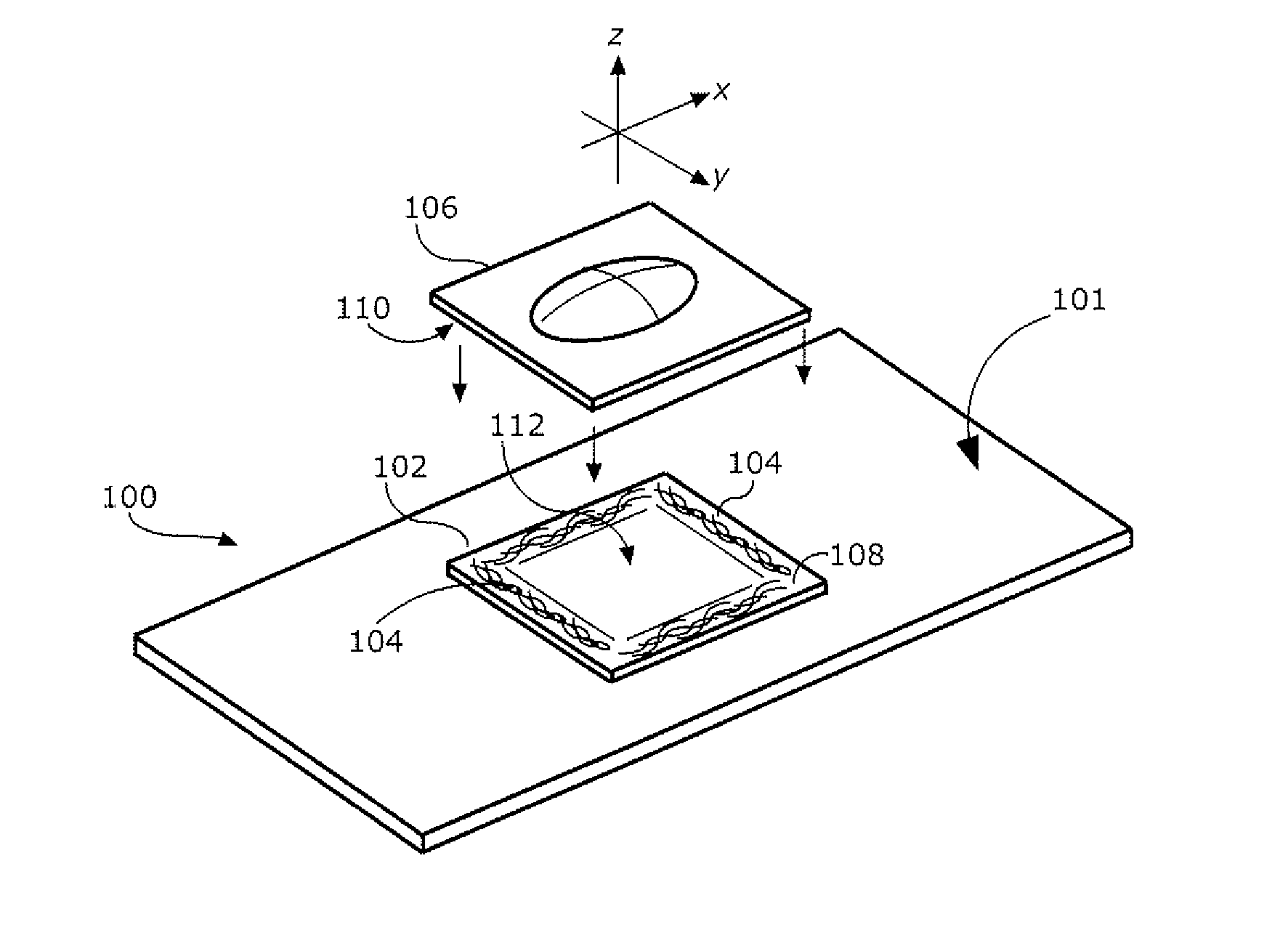

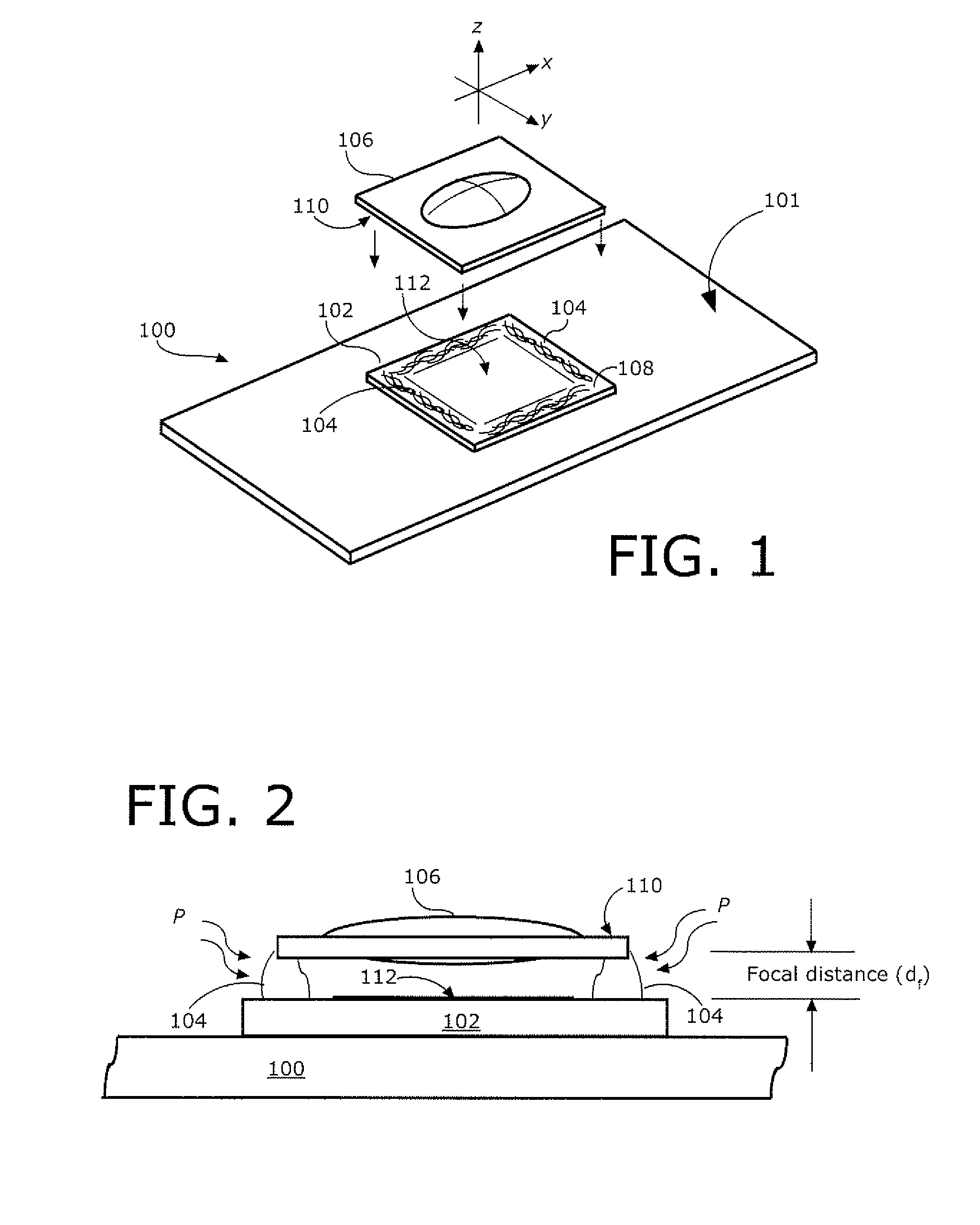

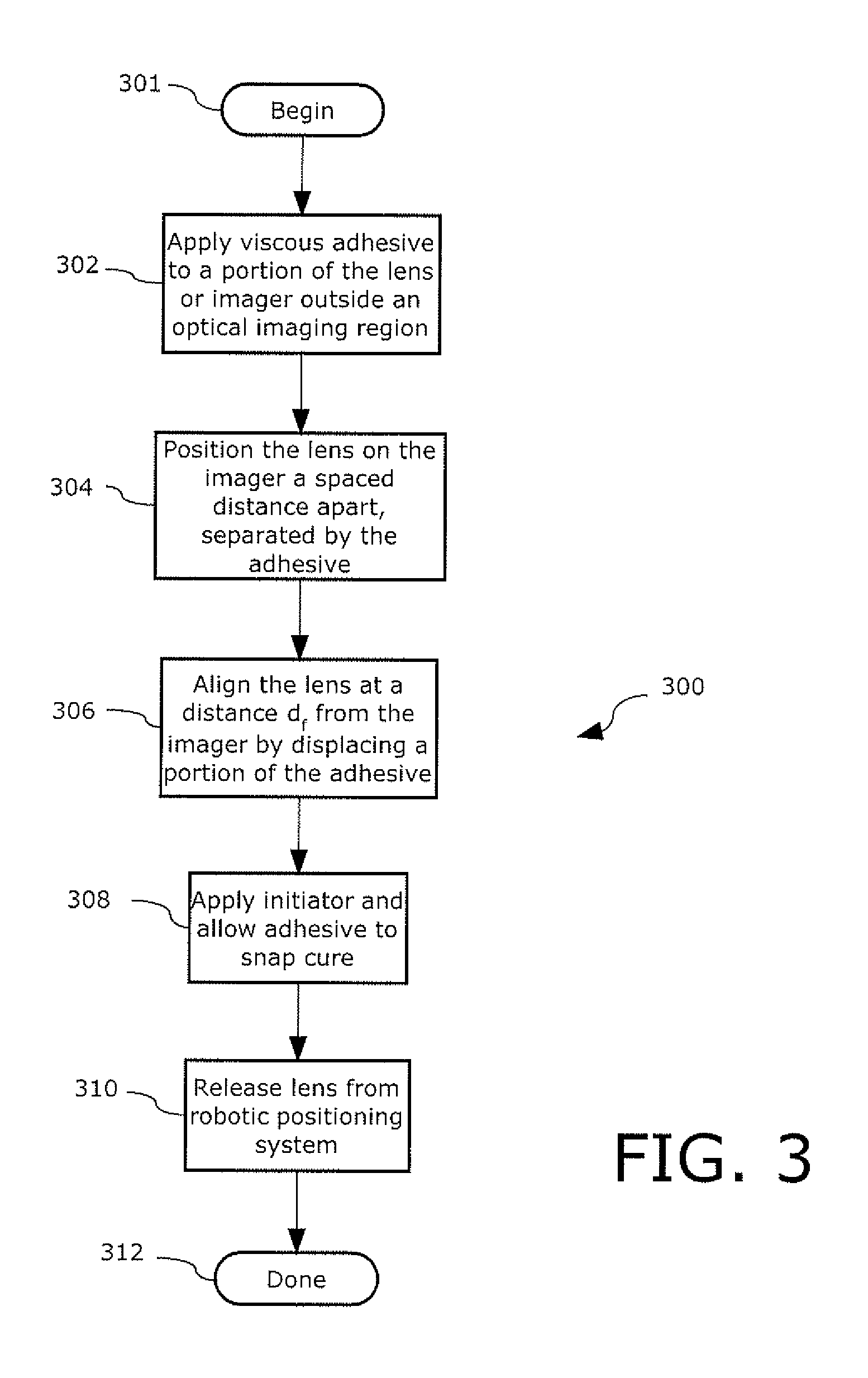

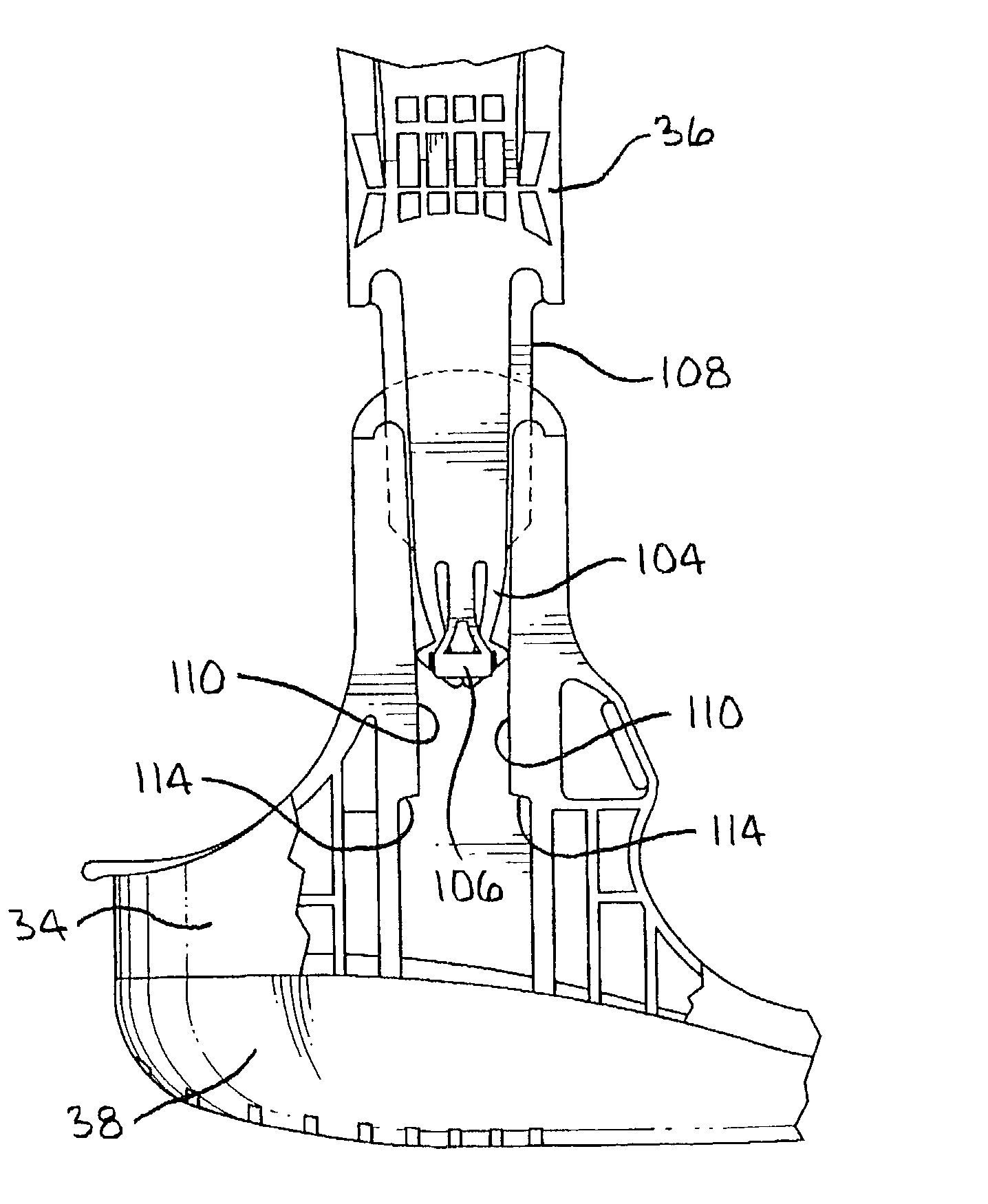

Positioning wafer lenses on electronic imagers

ActiveUS20100103308A1Cost reductionLow production costTelevision system detailsSolid-state devicesOptical pathEngineering

A low cost manufacturing method (300) and assembly (100) for positioning a lens (106) relative to an electronic imager (102). A viscous adhesive (104) is applied to the lens (106) or the electronic imager (102) outside of the optical path. The lens (106) is disposed on the electronic imager (102) exclusively with the adhesive (104) disposed between them.

Owner:JABIL CIRCIUT

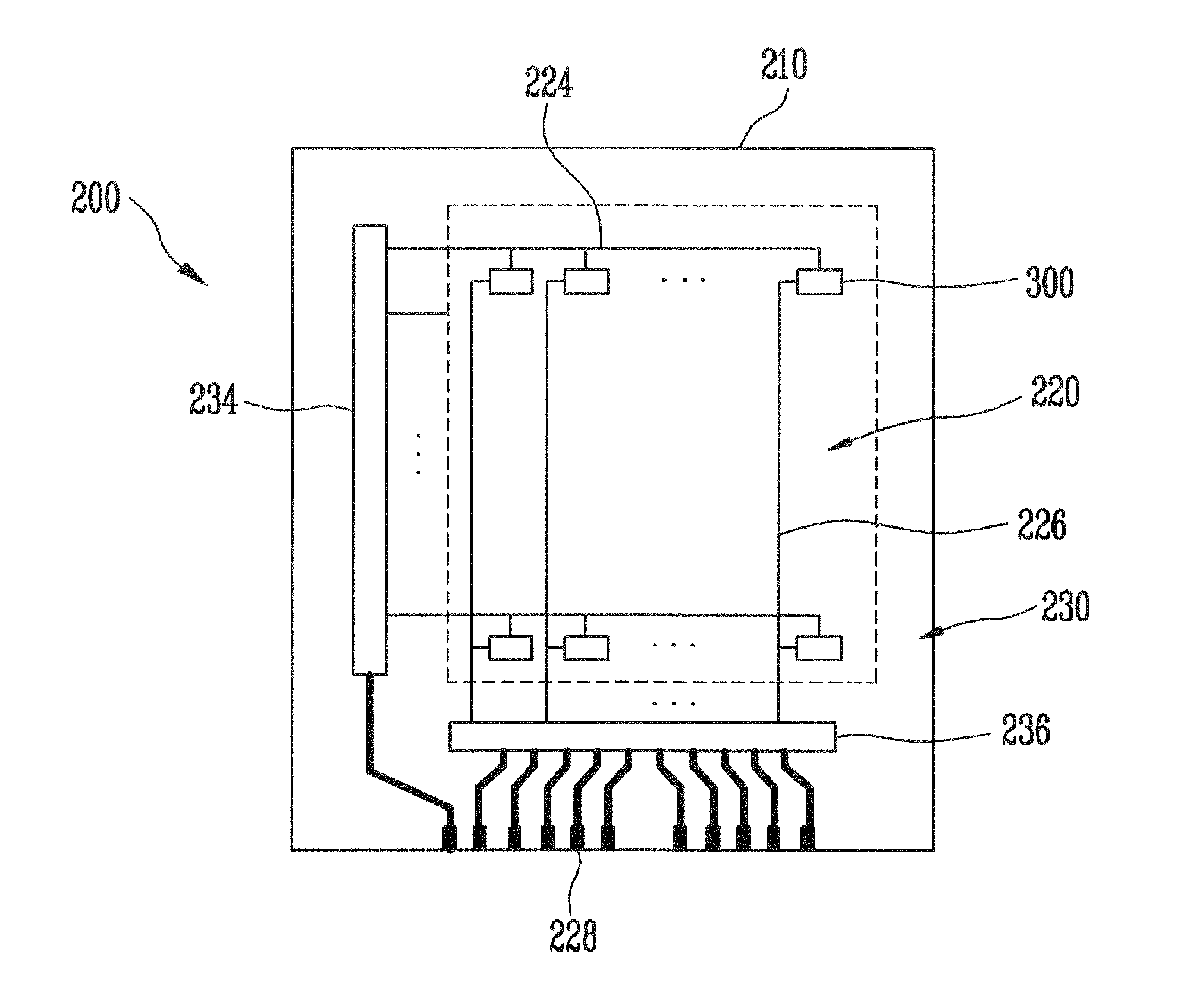

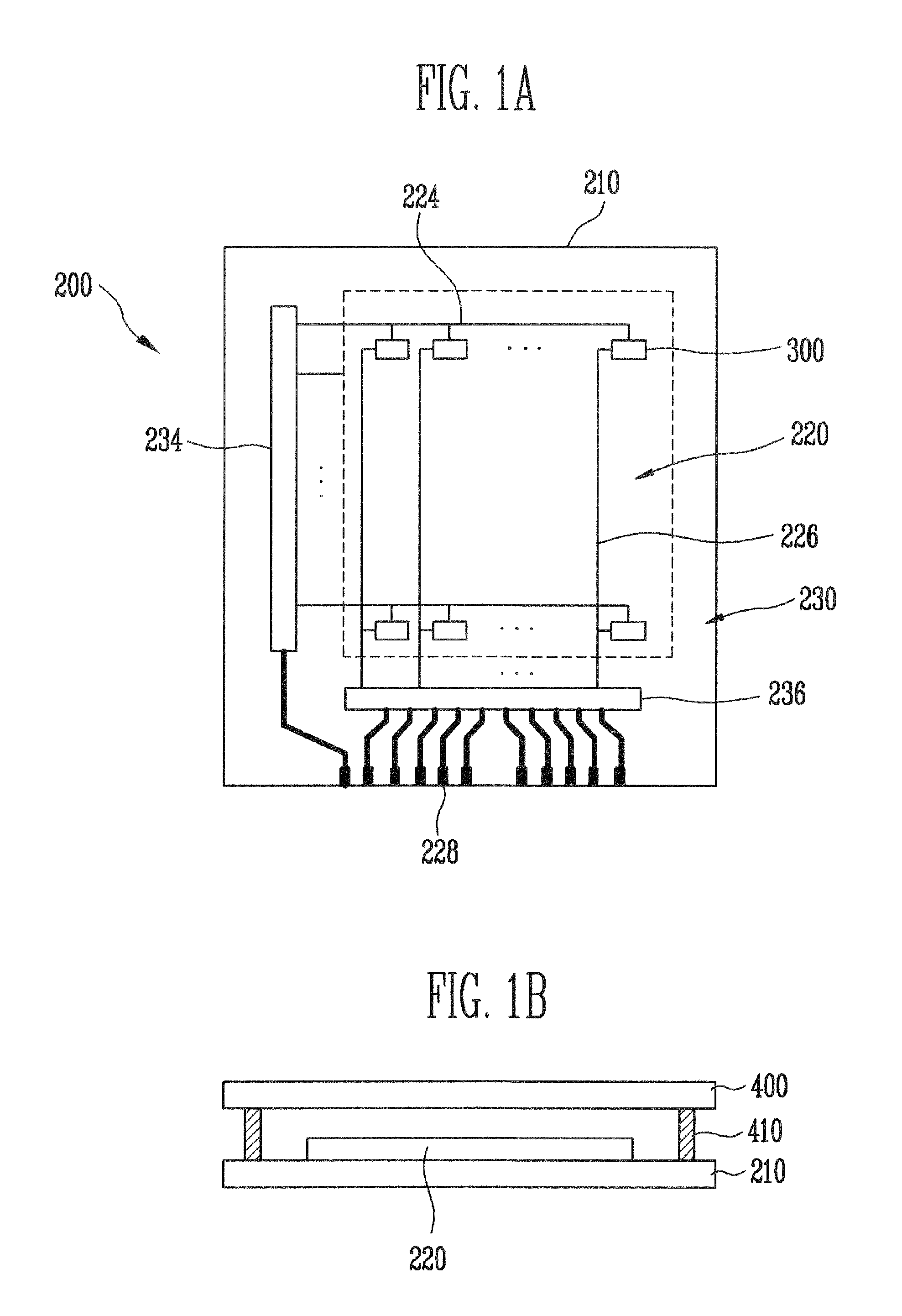

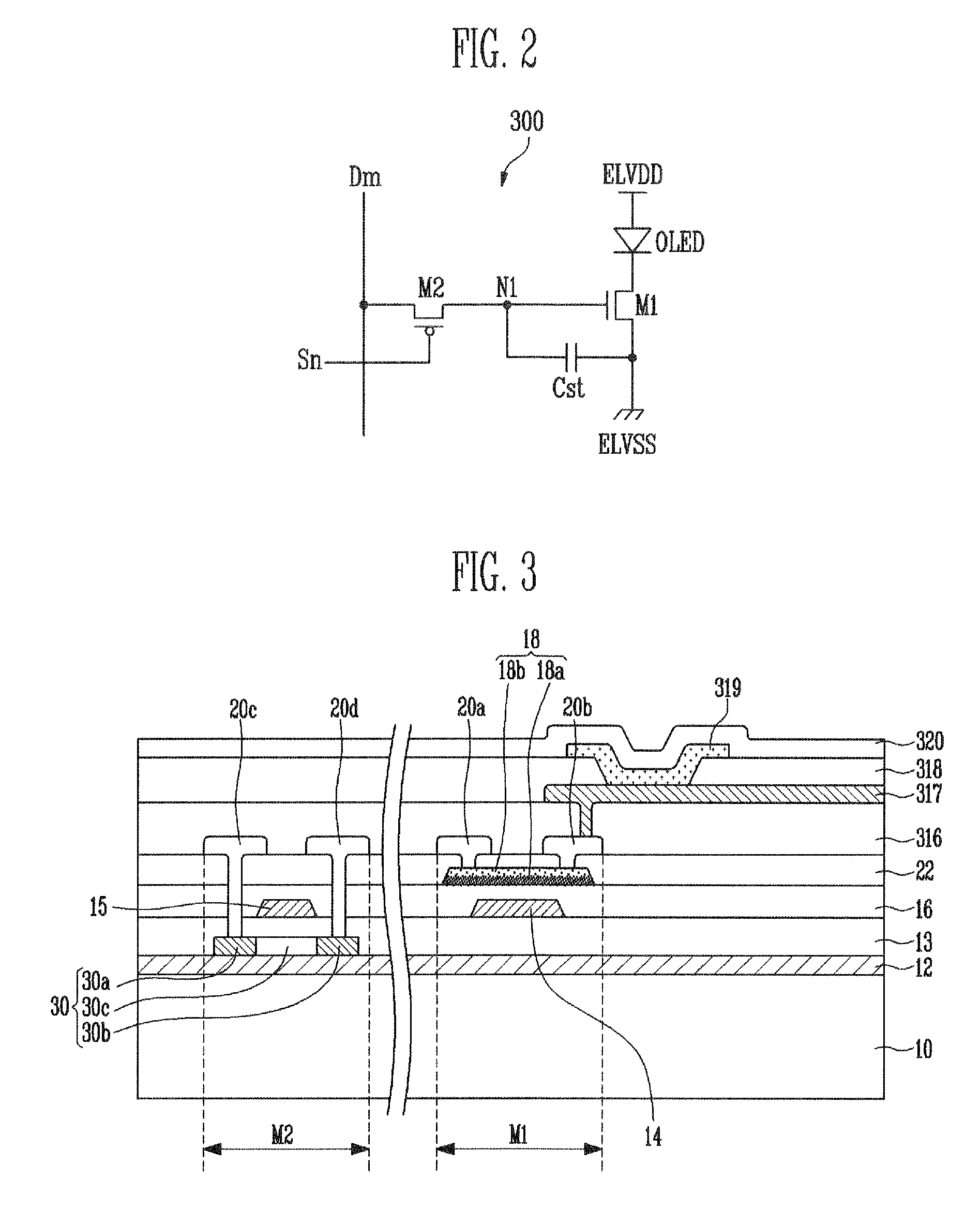

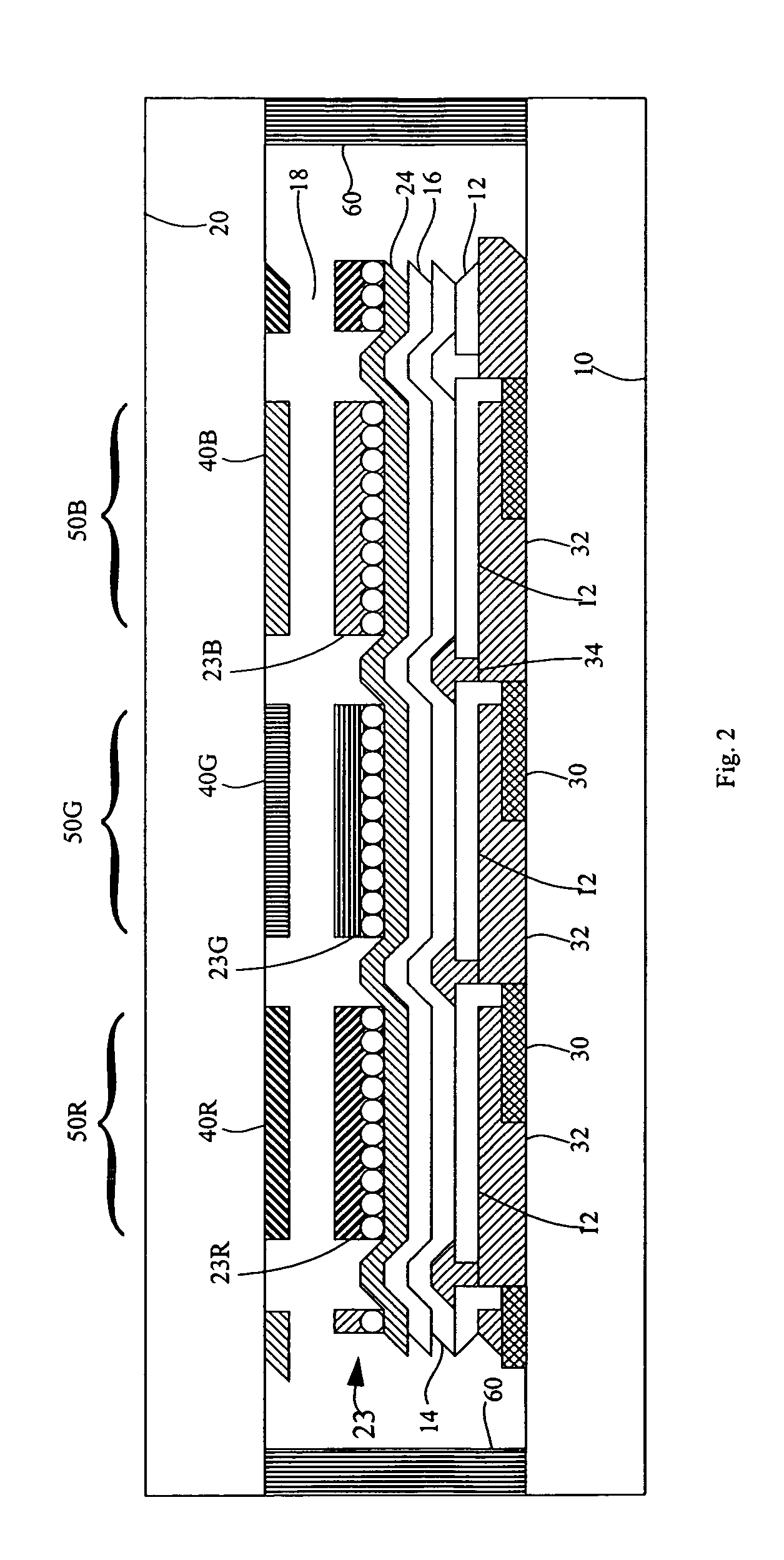

Organic light emitting display device

InactiveUS20100182223A1Improve performance and productivityCost reductionStatic indicating devicesSolid-state devicesOxide semiconductorPolycrystalline silicon

An organic light emitting display device that includes a plurality of signal lines and a plurality of scan lines, a plurality of pixels arranged at intersections of ones of the plurality of signal lines and ones of the plurality of scan lines, a scan driver to supply scan signals to the plurality of scan lines, the scan driver including a first plurality of thin film transistors and a data driver to supply data signals to the plurality of signal lines, the data driver including a second plurality of thin film transistors, wherein each of said plurality of pixels includes a first thin film transistor, a second thin film transistor and an organic light emitting diode, the first transistor being connected to the organic light emitting diode, the first transistor having an active layer made out of an oxide semiconductor, the second transistor, the first plurality of thin film transistors and the second plurality of thin film transistors each having an active layer made out of poly-silicon.

Owner:SAMSUNG DISPLAY CO LTD

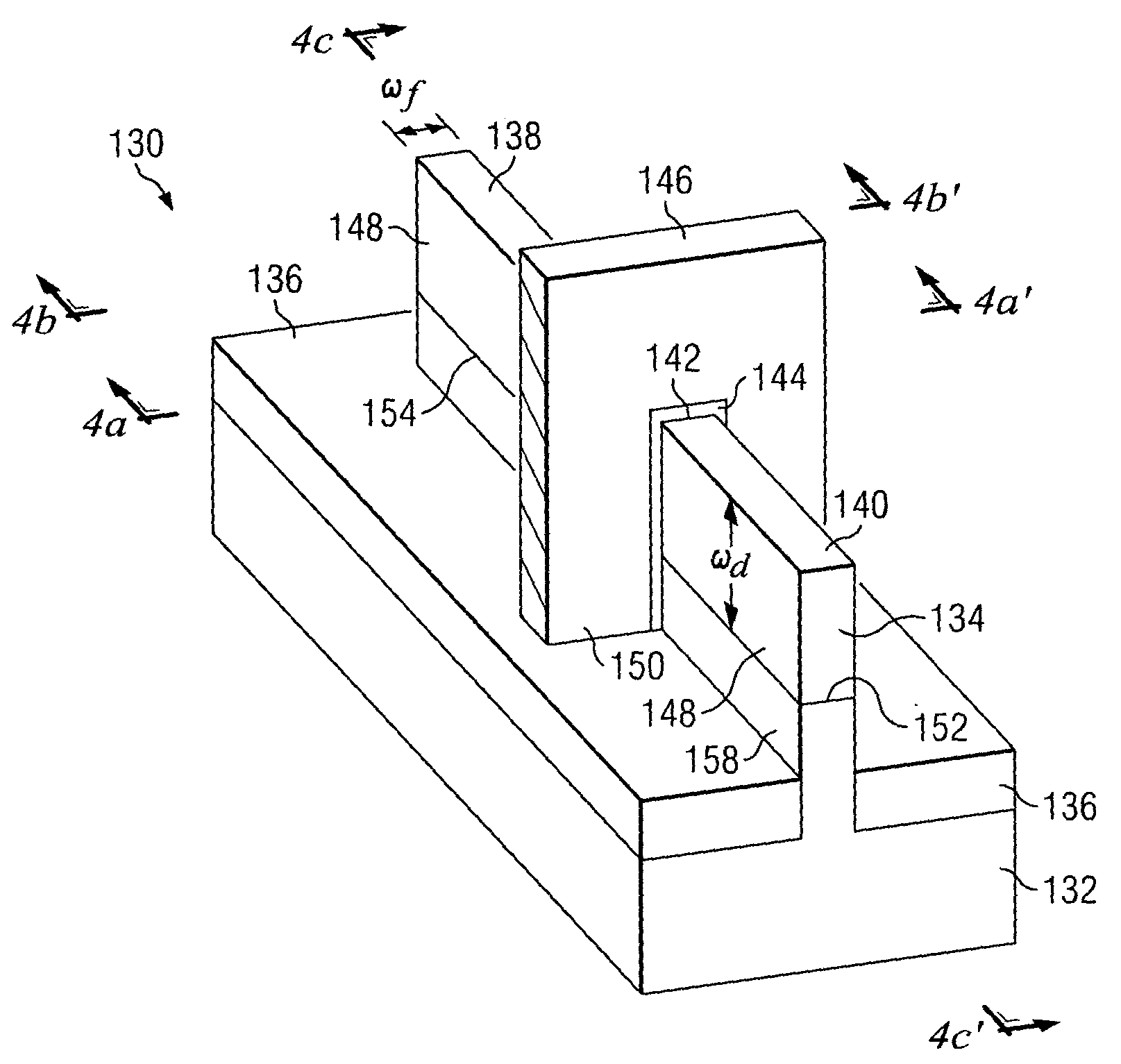

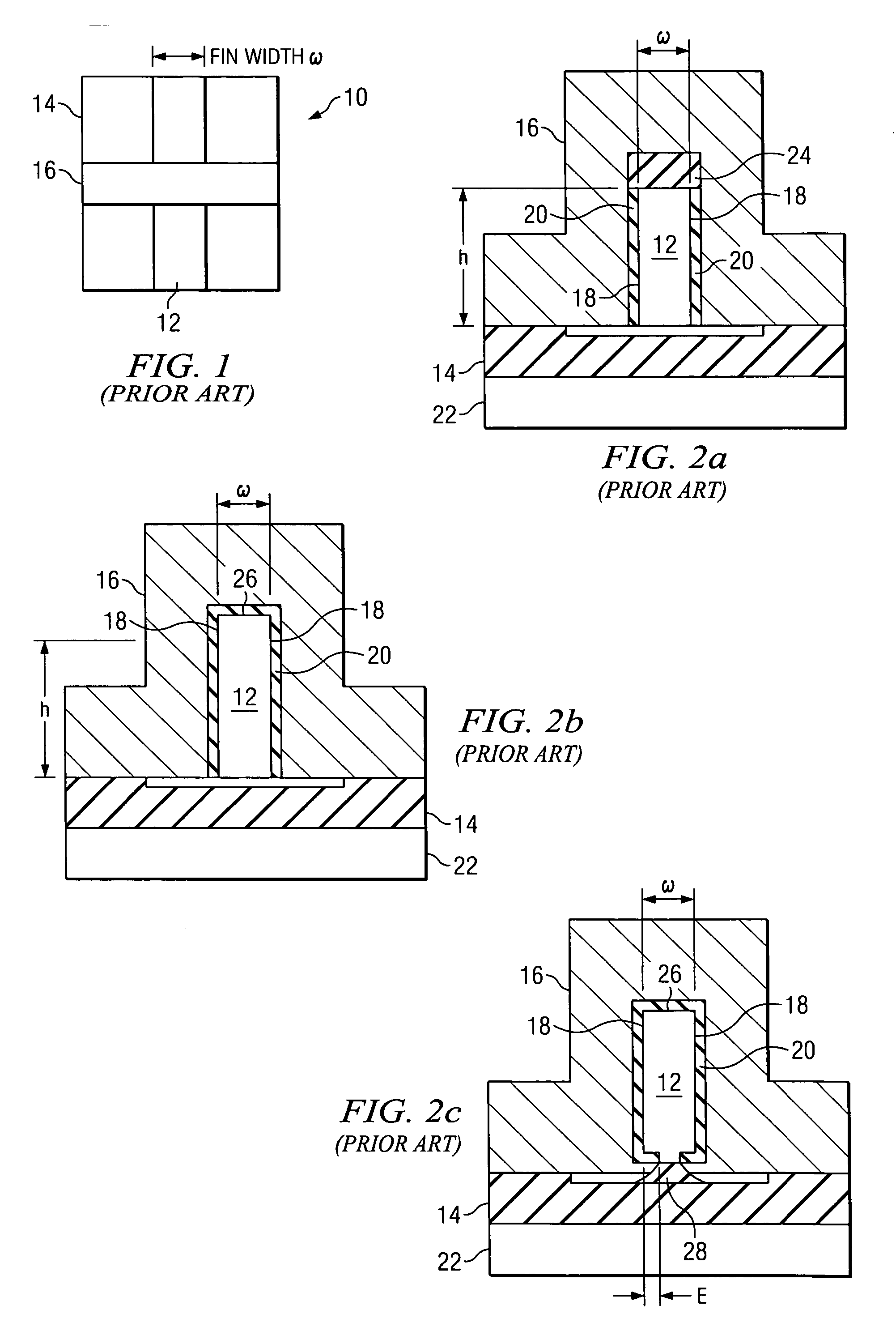

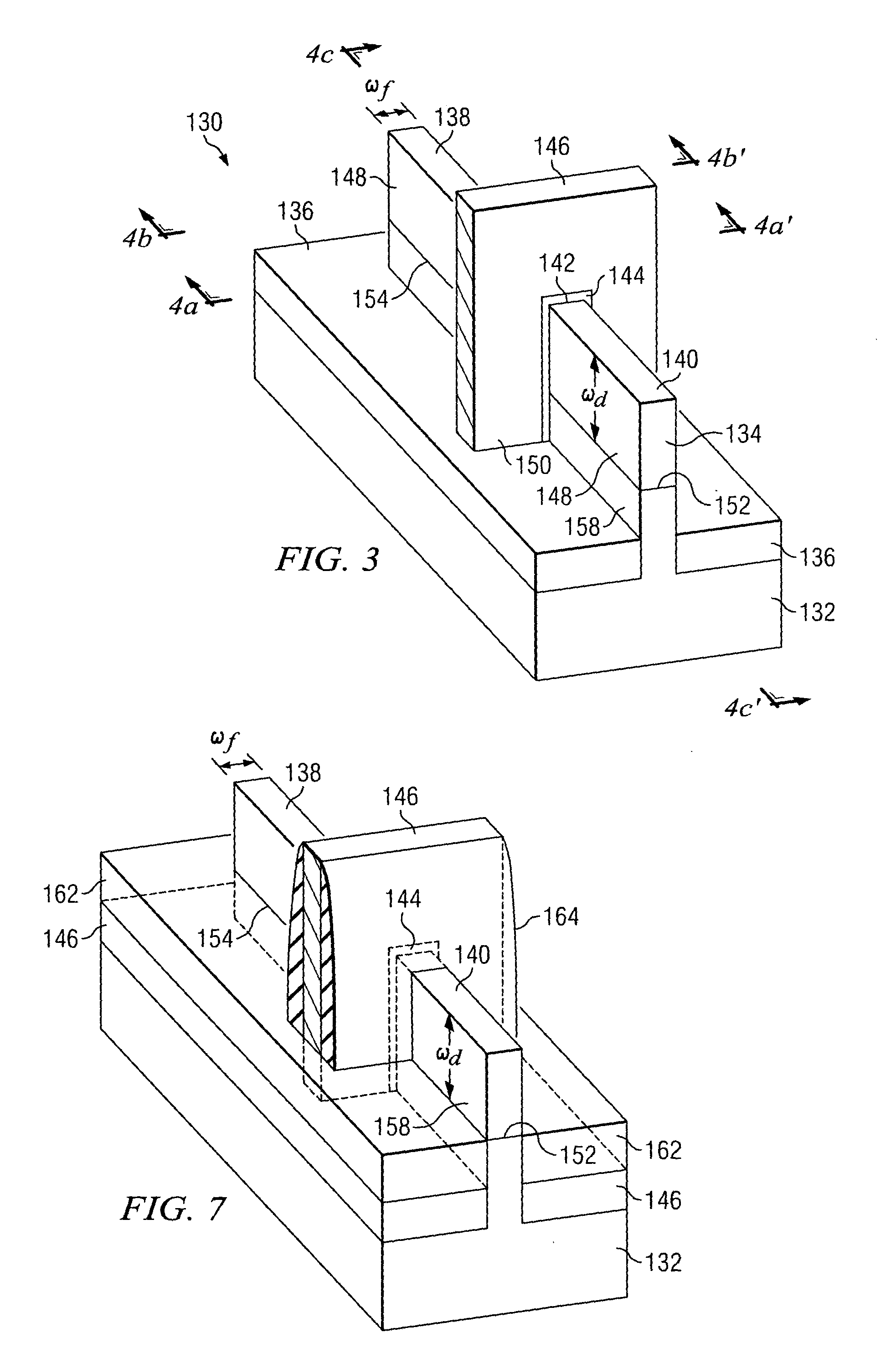

Multiple-gate transistors formed on bulk substrates

In one aspect, the present invention teaches a multiple-gate transistor 130 that includes a semiconductor fin 134 formed in a portion of a bulk semiconductor substrate 132. A gate dielectric 144 overlies a portion of the semiconductor fin 134 and a gate electrode 146 overlies the gate dielectric 144. A source region 138 and a drain region 140 are formed in the semiconductor fin 134 oppositely adjacent the gate electrode 144. In the preferred embodiment, the bottom surface 150 of the gate electrode 146 is lower than either the source-substrate junction 154 or the drain-substrate junction 152.

Owner:TAIWAN SEMICON MFG CO LTD

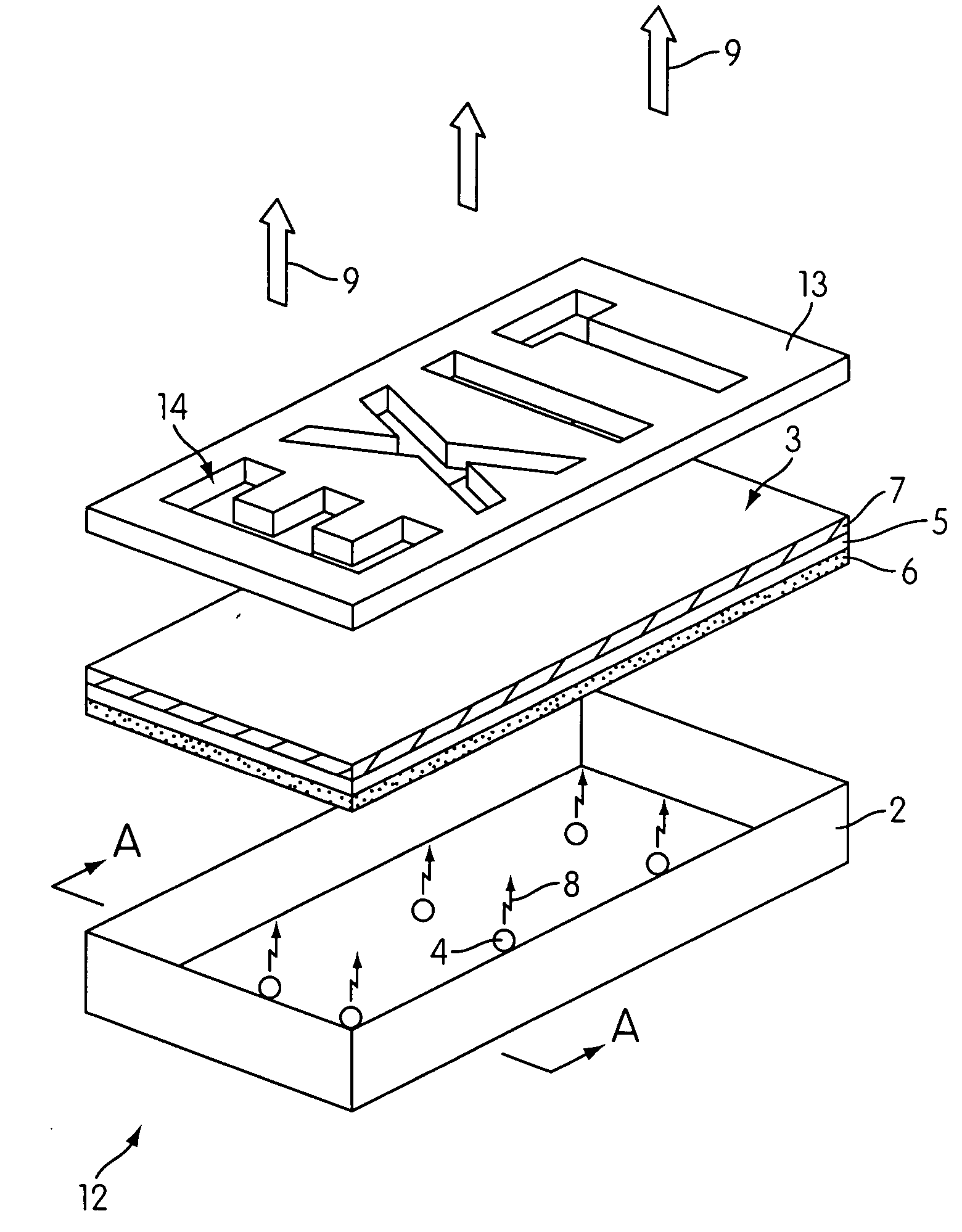

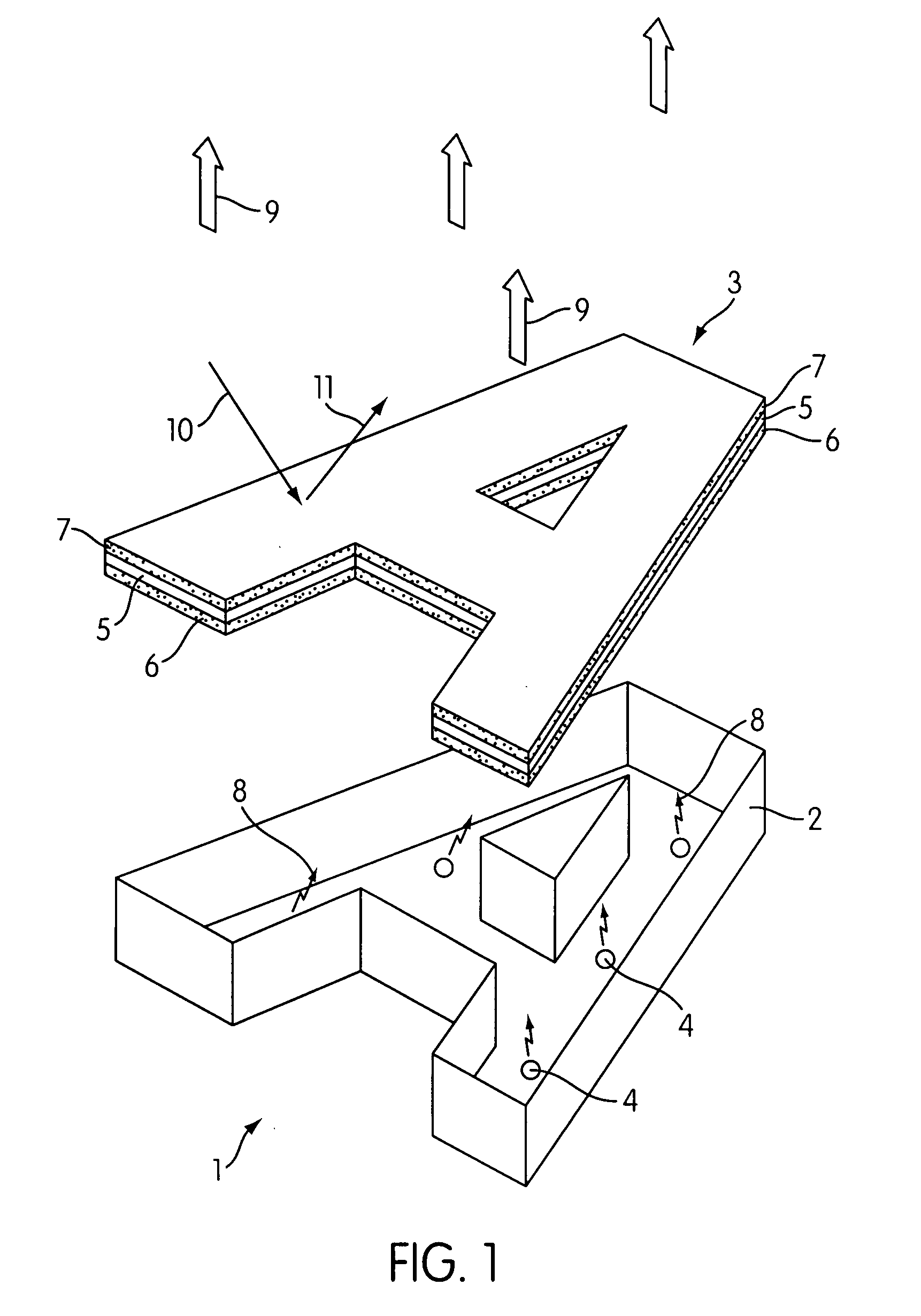

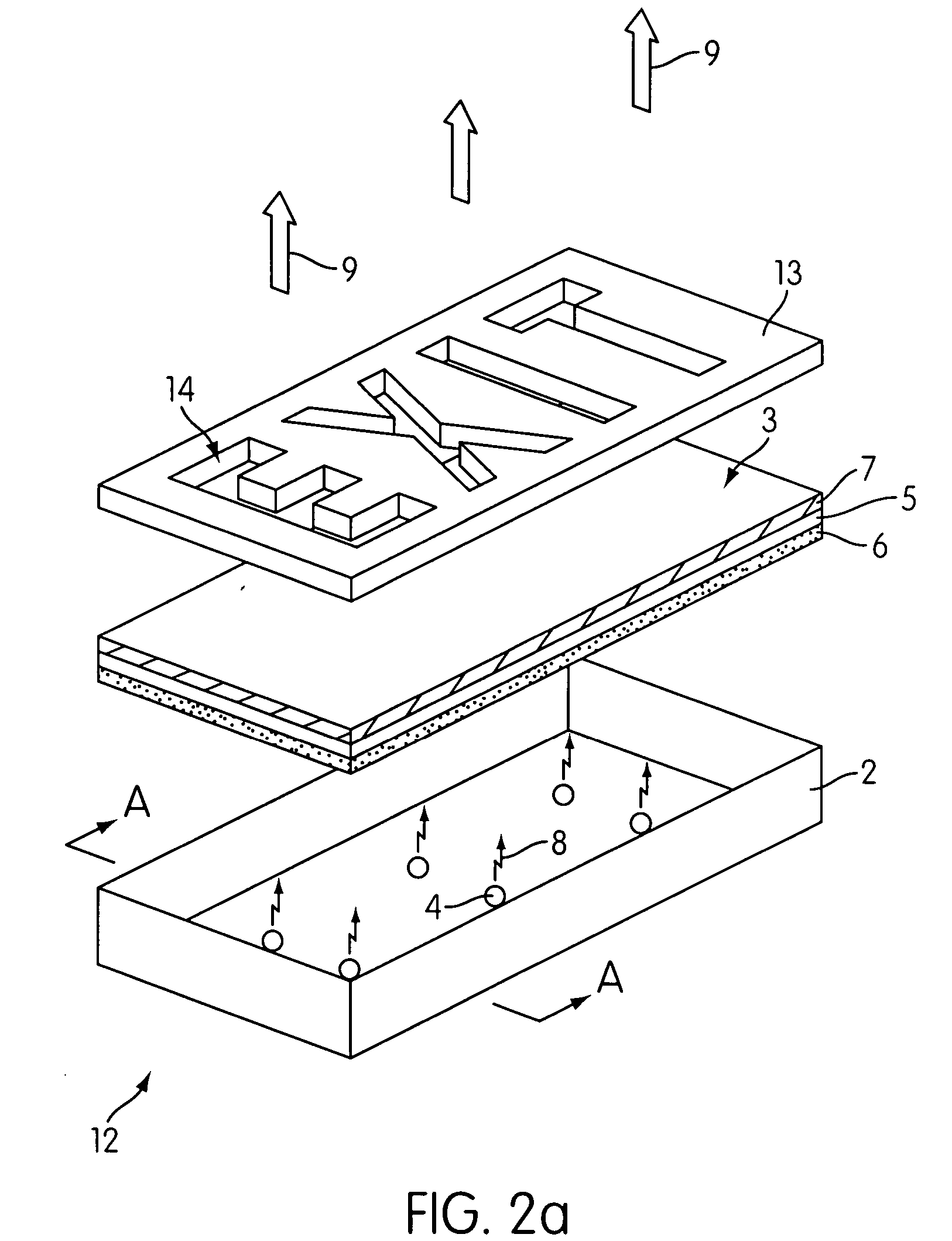

Light emitting sign and display surface therefor

InactiveUS20070240346A1Cost reductionWell light uniformityIlluminated signsSpectral modifiersPhysicsLight filter

A light emitting sign comprising a light emitting display surface including at least one phosphor, and at least one radiation source configured to irradiate the display surface with excitation energy such that the phosphor emits light of a selected color. The sign further comprises a filter which is substantially transparent to light emitted by the display surface, filtering other colors of light. The display surface may be configured into a shape of a character, a symbol, or a device. Alternatively, a mask having at least one window substantially transparent to the emitted light and / or at least one light blocking region may be provided in which the window and / or light blocking region define a character, a symbol, or a device.

Owner:INTEMATIX

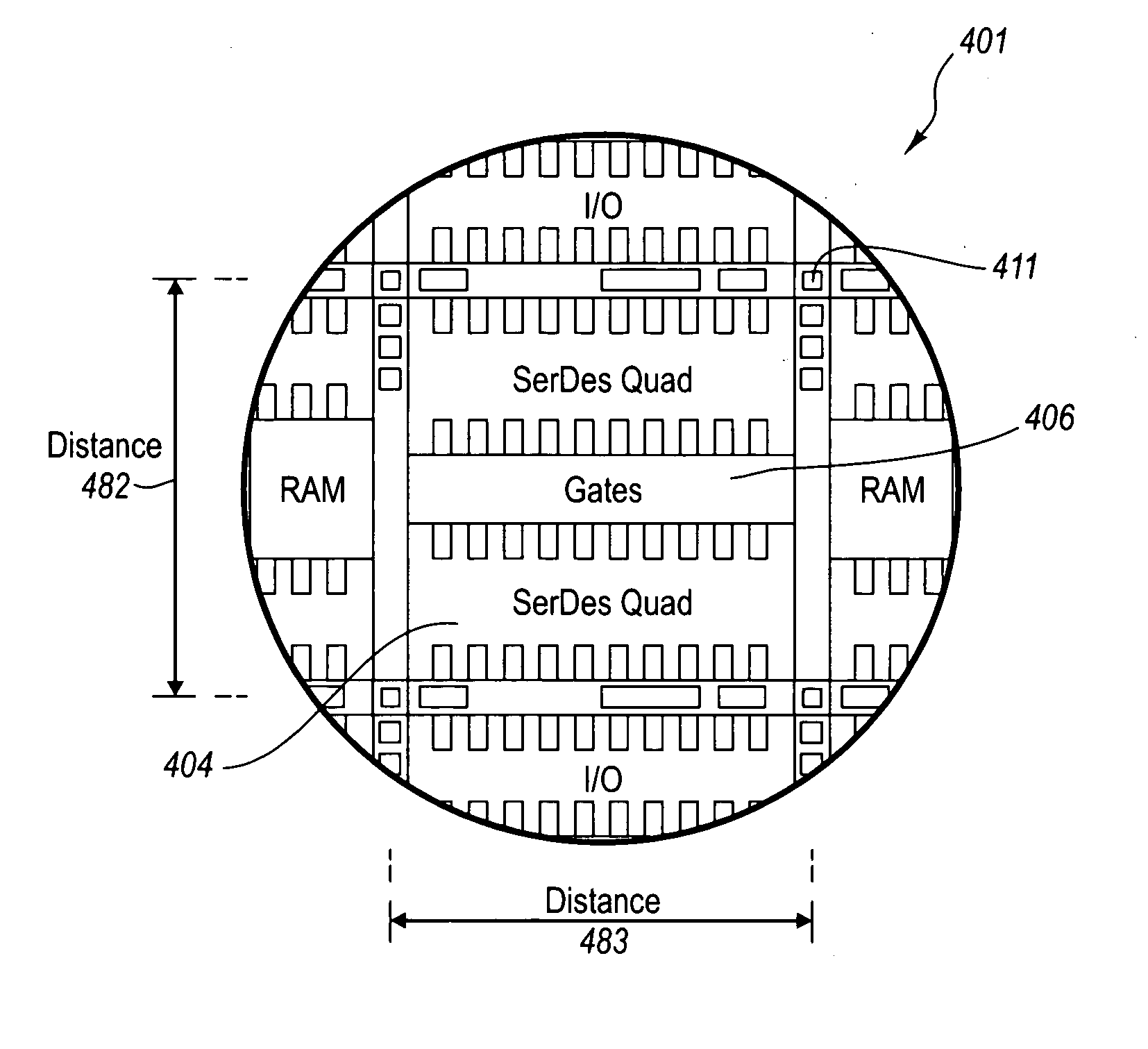

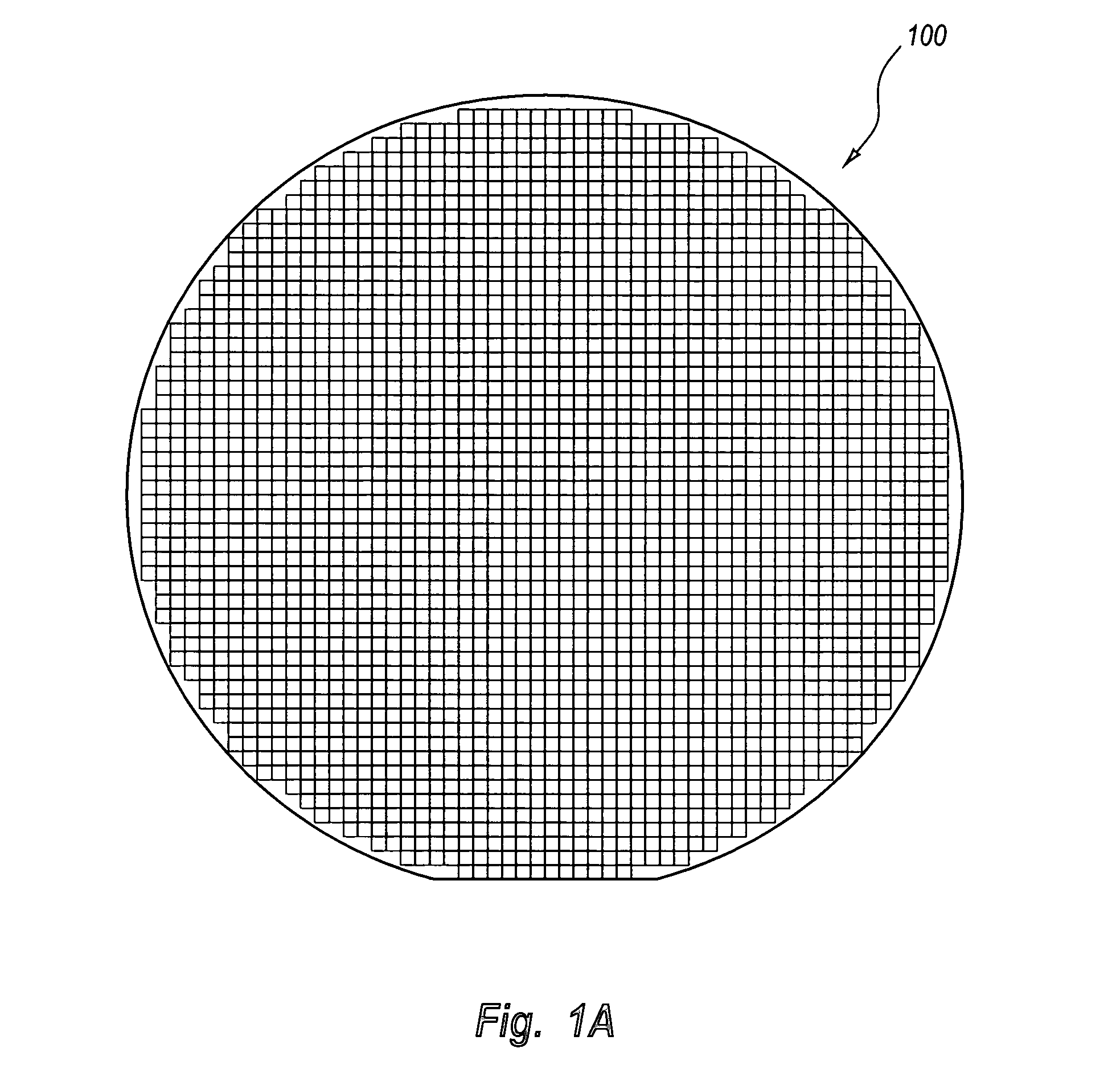

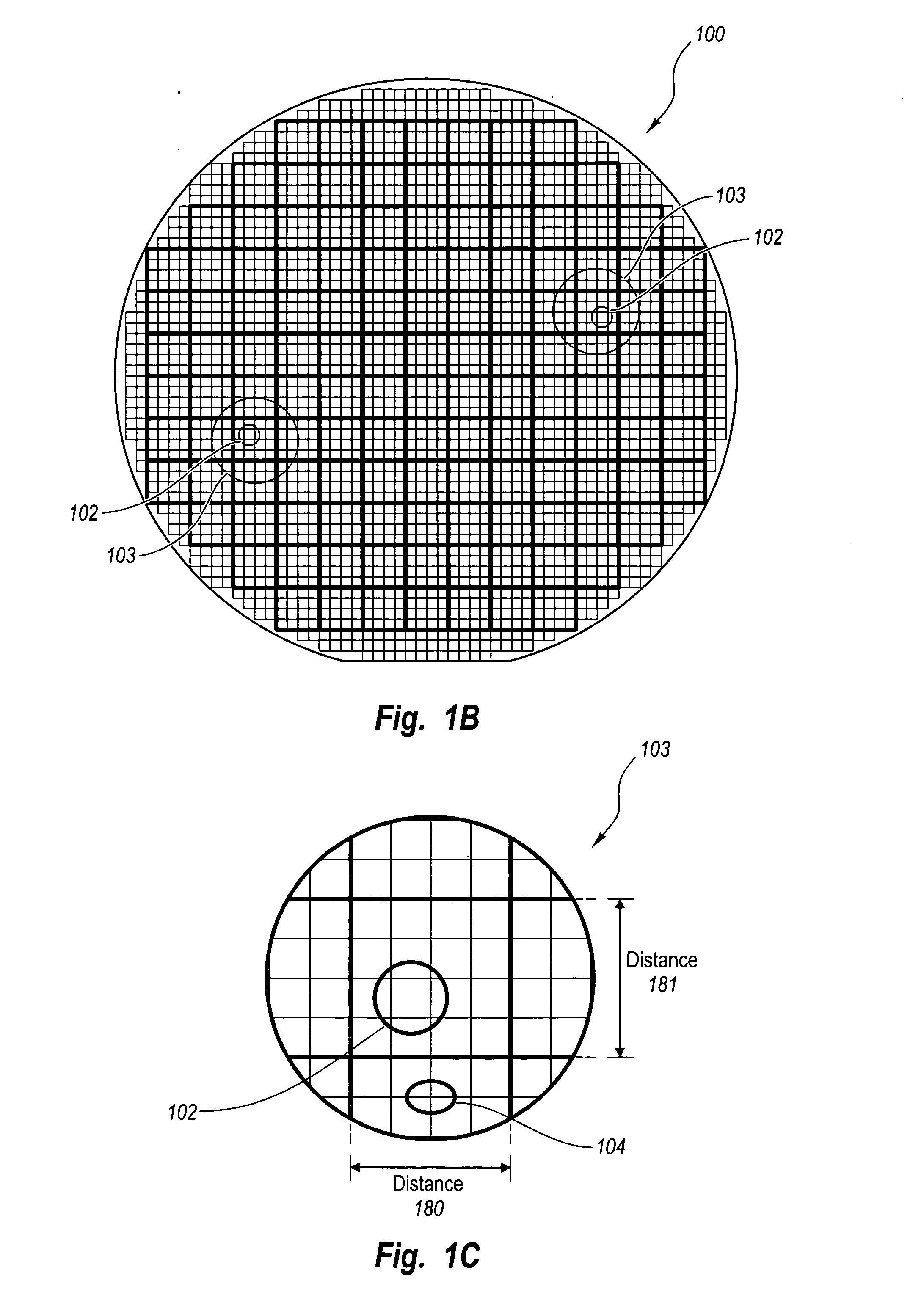

Structured ASIC device with configurable die size and selectable embedded functions

ActiveUS20050273749A1Reduce number of baseCost reductionSemiconductor/solid-state device detailsSolid-state devicesEmbedded systemChip size

One embodiment of the present invention provides for a master or universal base and base tooling which addresses the general purpose Structured ASIC requirements. Another embodiment of the present invention provides for a common set of base tooling from which the master / universal base is created as well as additional custom bases with customized selection and quantity of embedded Platform ASIC functions. Embodiments can utilize conventional Structured ASIC architecture and processing and are compatible with traditional probing and packaging.

Owner:SEMICON COMPONENTS IND LLC

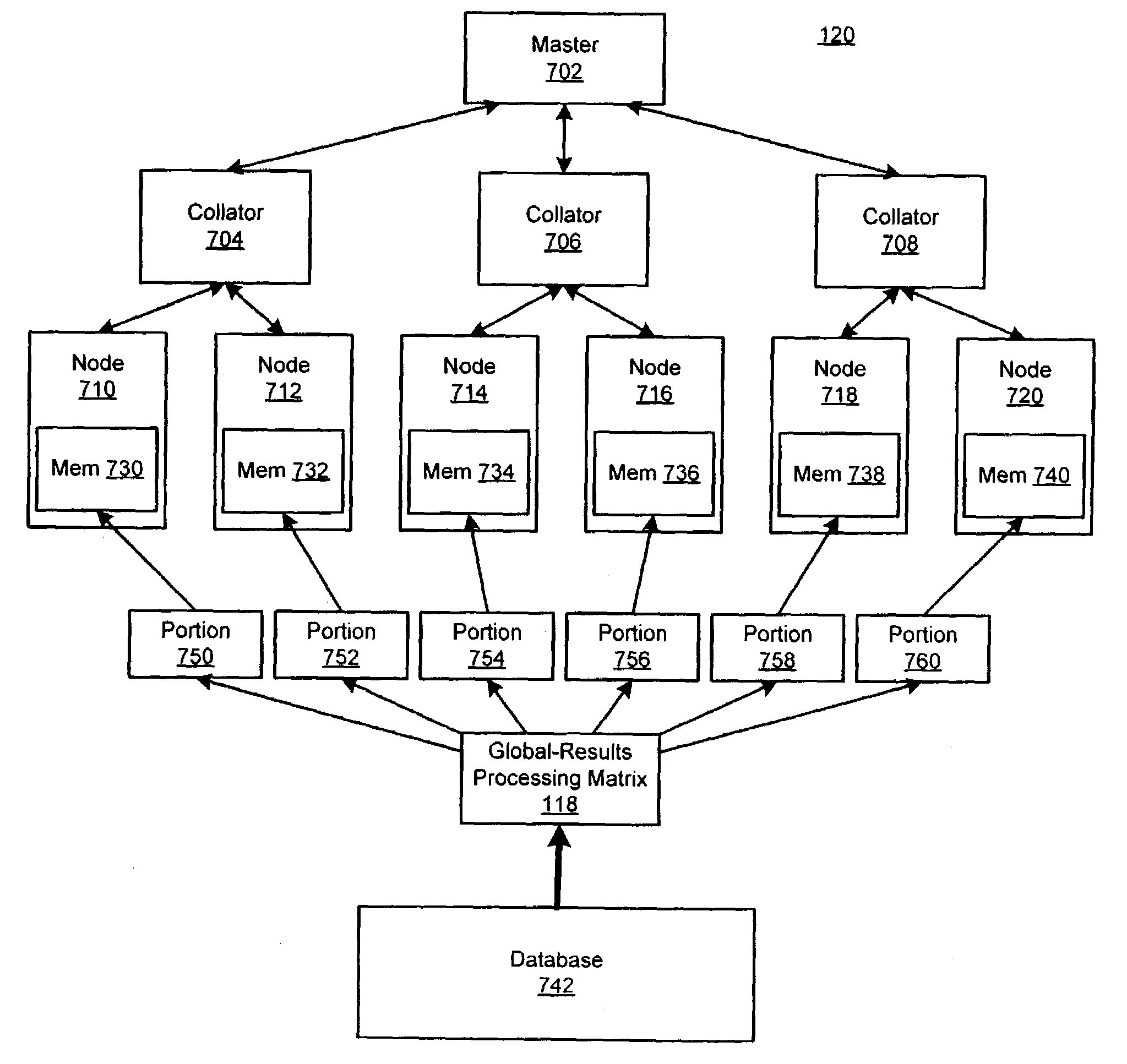

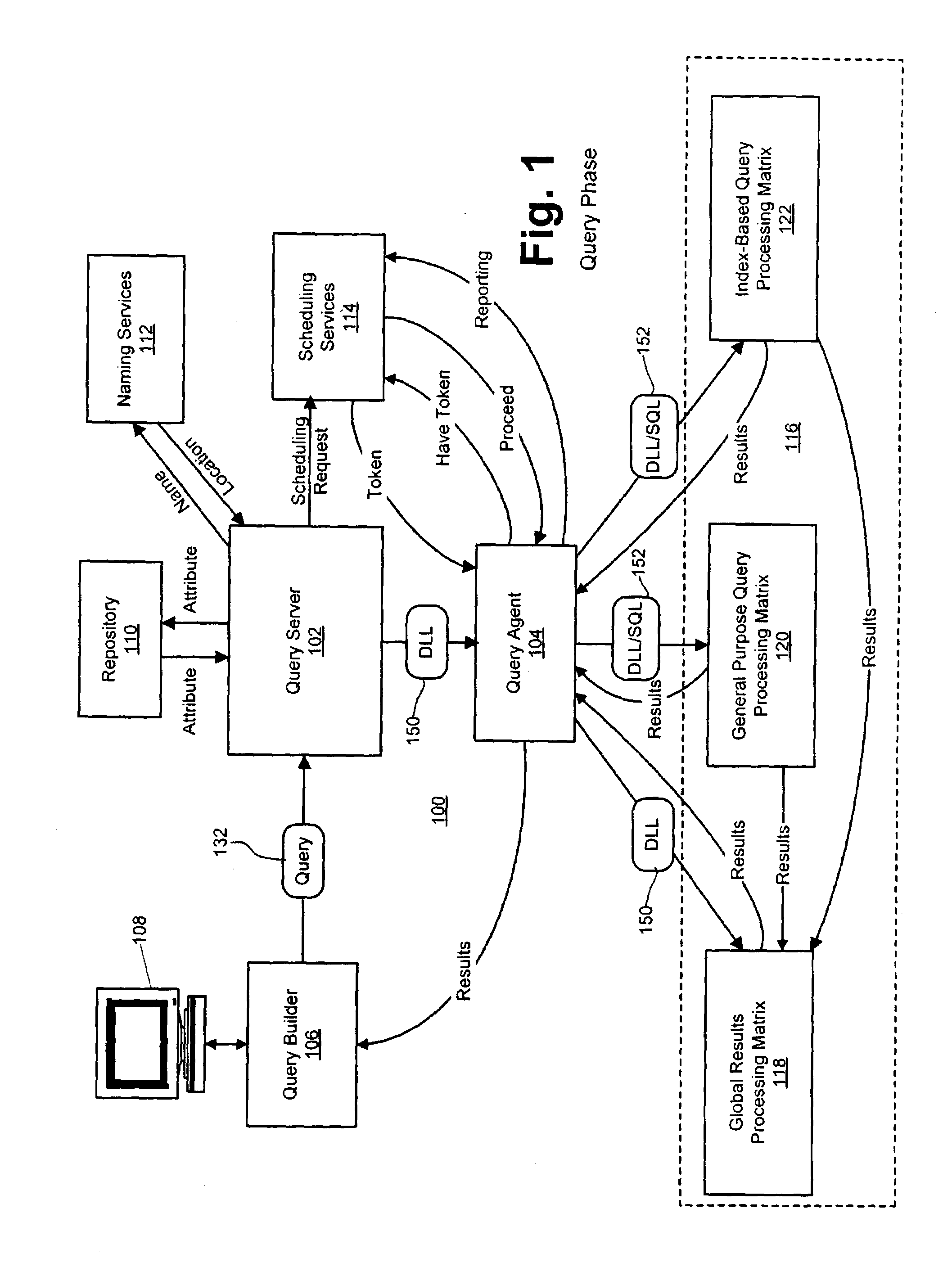

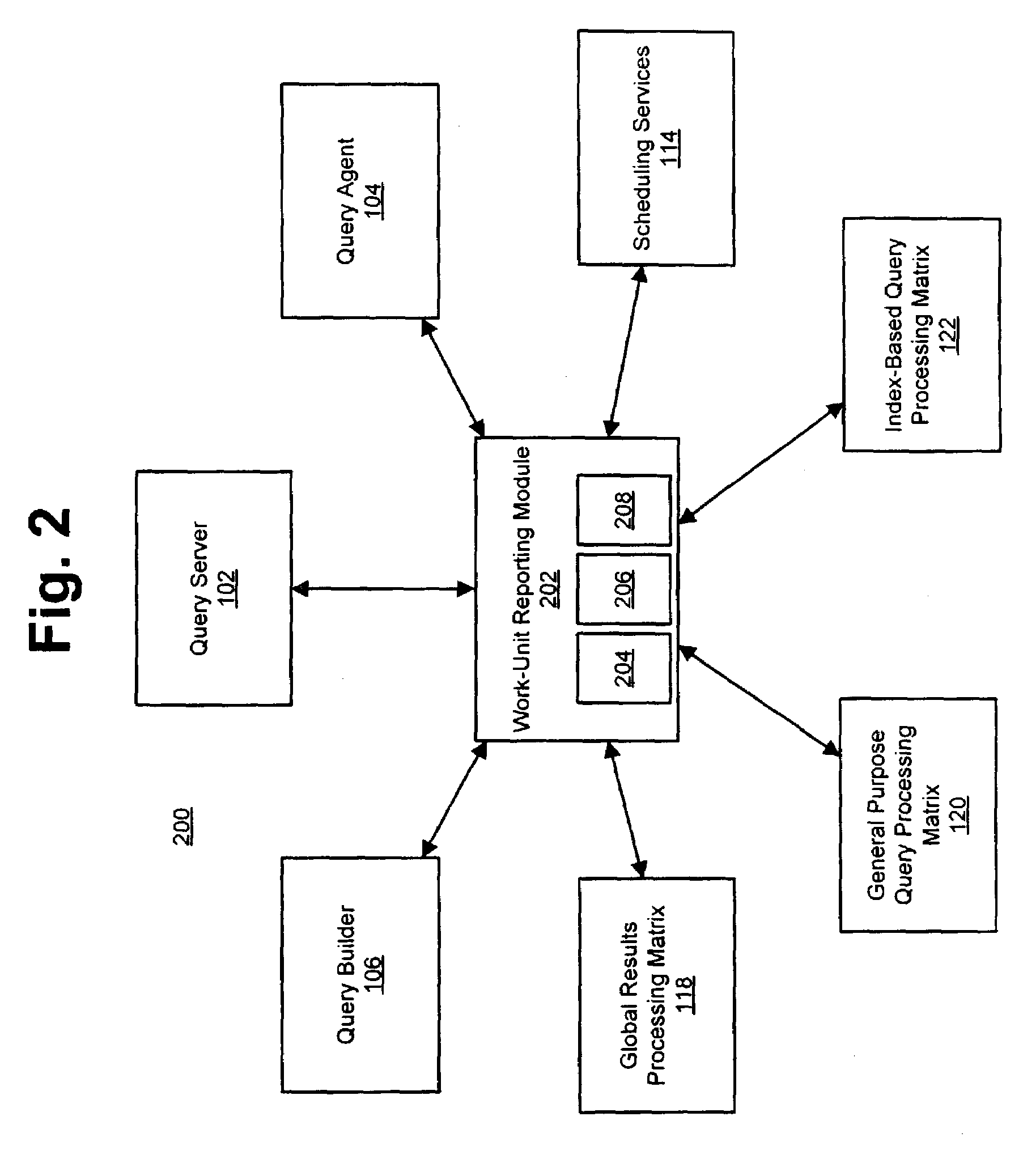

System and method for configuring a parallel-processing database system

ActiveUS7240059B2Transparent operationCost reductionDigital data information retrievalDigital data processing detailsExecutableSoftware

A system and method for configuring a plurality of processing nodes into a parallel-processing database system are described herein. Each of a plurality of processing nodes connected by a network receive software and one or more configuration files related to the intended function of the processing node. The software may include homogeneous agent software, one or more library dynamic-link libraries (DLL), and the like. The configuration file is used to configure the homogeneous agent to operate as the intended node in a global-results processing matrix, a general-purpose query processing matrix, or a index-base query processing matrix. Another node or nodes may be configured to convert query-based programming code to intermediary source code in a common programming language and then compile the intermediary source code into a dynamic link library (DLL) or other type of executable. The DLL is then distributed among the processing nodes of the processing matrix, whereupon various subsets of the processing nodes execute related portions of the DLL substantially in parallel to generate query results.

Owner:LEXISNEXIS RISK DATA MANAGEMENT

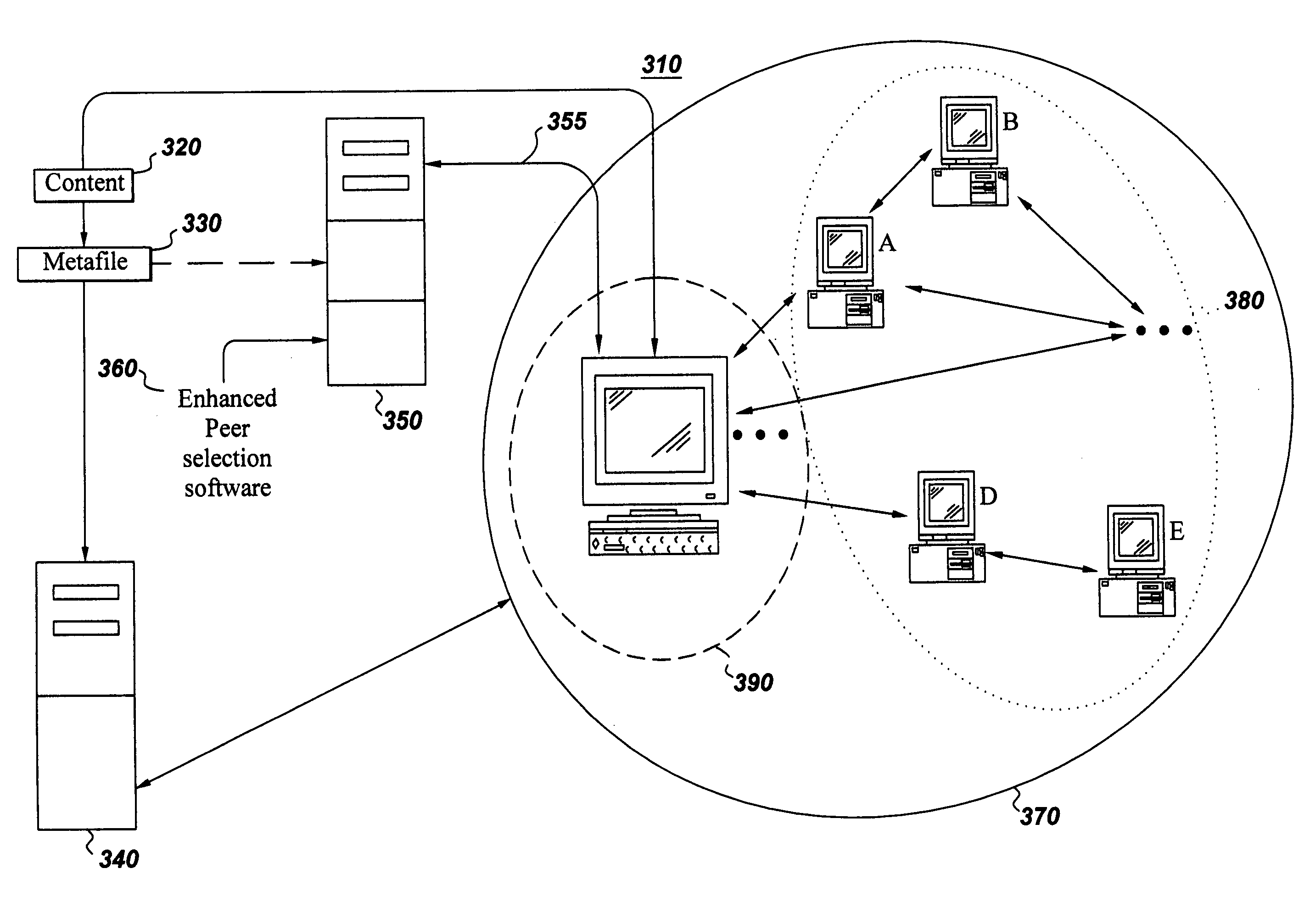

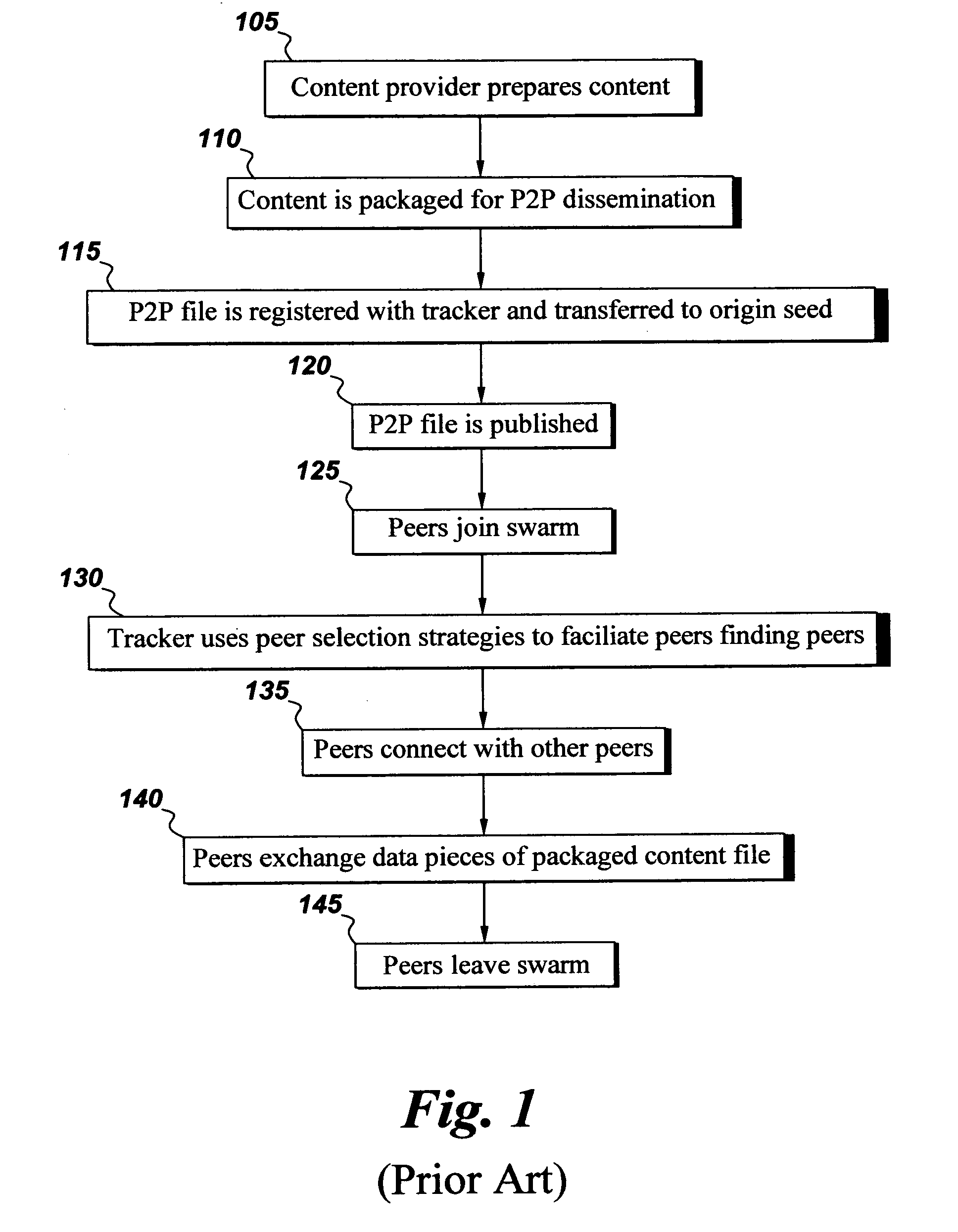

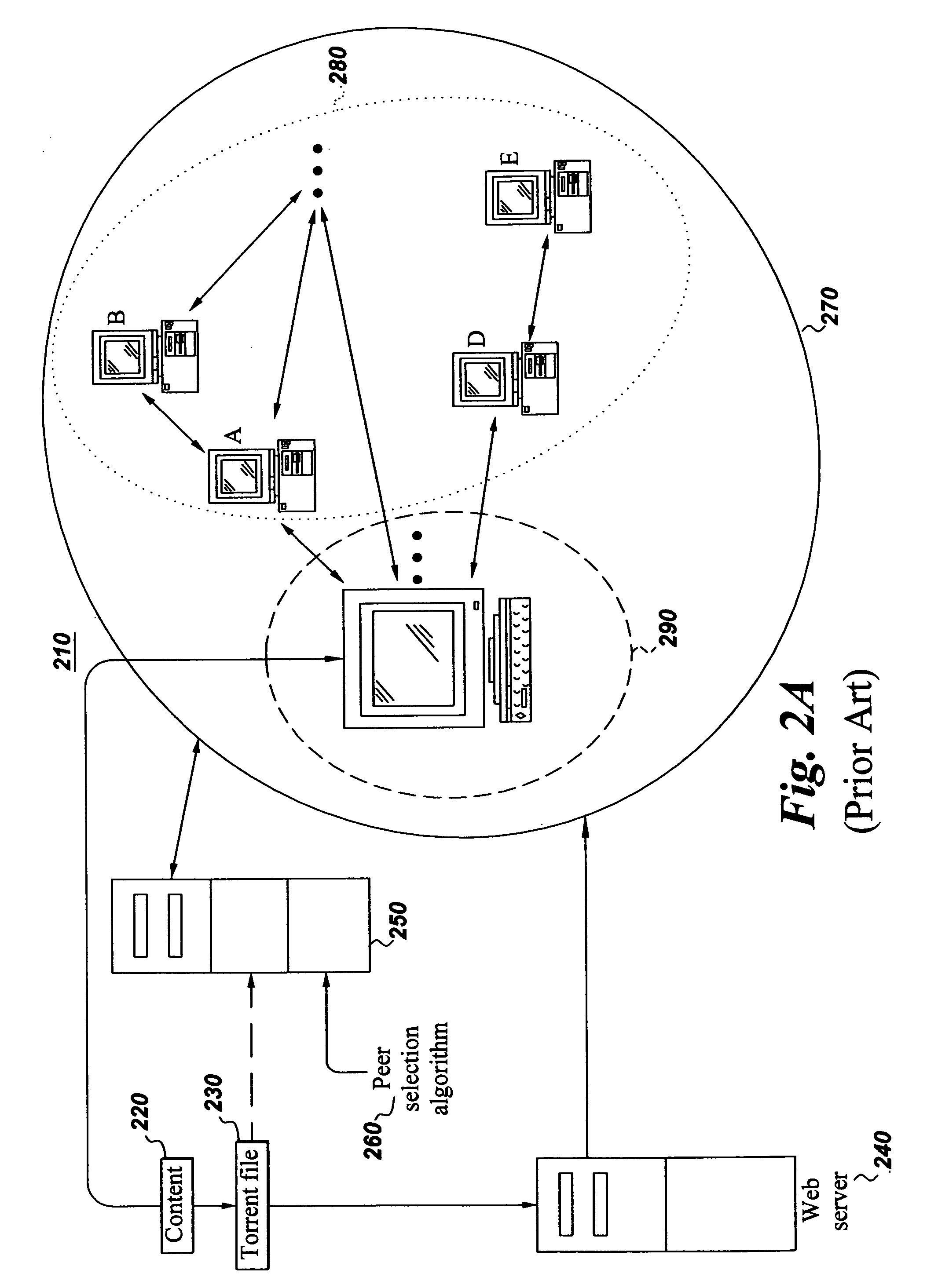

Accelerating peer-to-peer content distribution

InactiveUS20090100128A1Cost reductionCost and efficiency issueMultiple digital computer combinationsTransmissionContent distributionSelection algorithm

The acceleration of peer-to-peer downloads of content files using auxiliary resources in combination with peer-to-peer content distribution. A further feature relates to the use of enhanced message scheme for communications between the tracker and peers. One embodiment is a swarm having at least one seed capable of at least initially storing the content files with at least one tracker maintaining a list of peers wherein the tracker uses at least one peer selection algorithm to generate a selective peer-list and provides a selective peer-list to the peers.

Owner:NBCUNIVERSAL

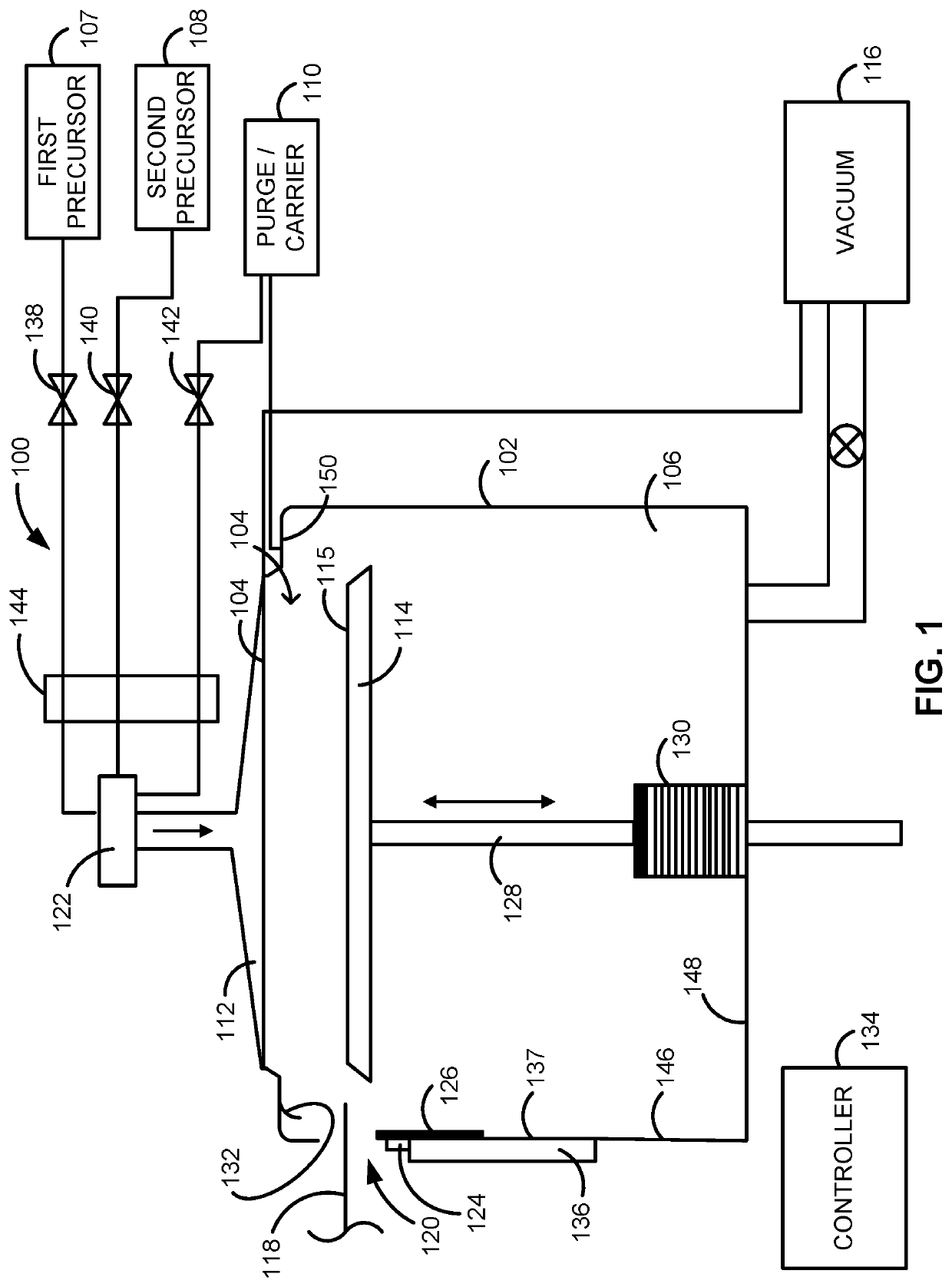

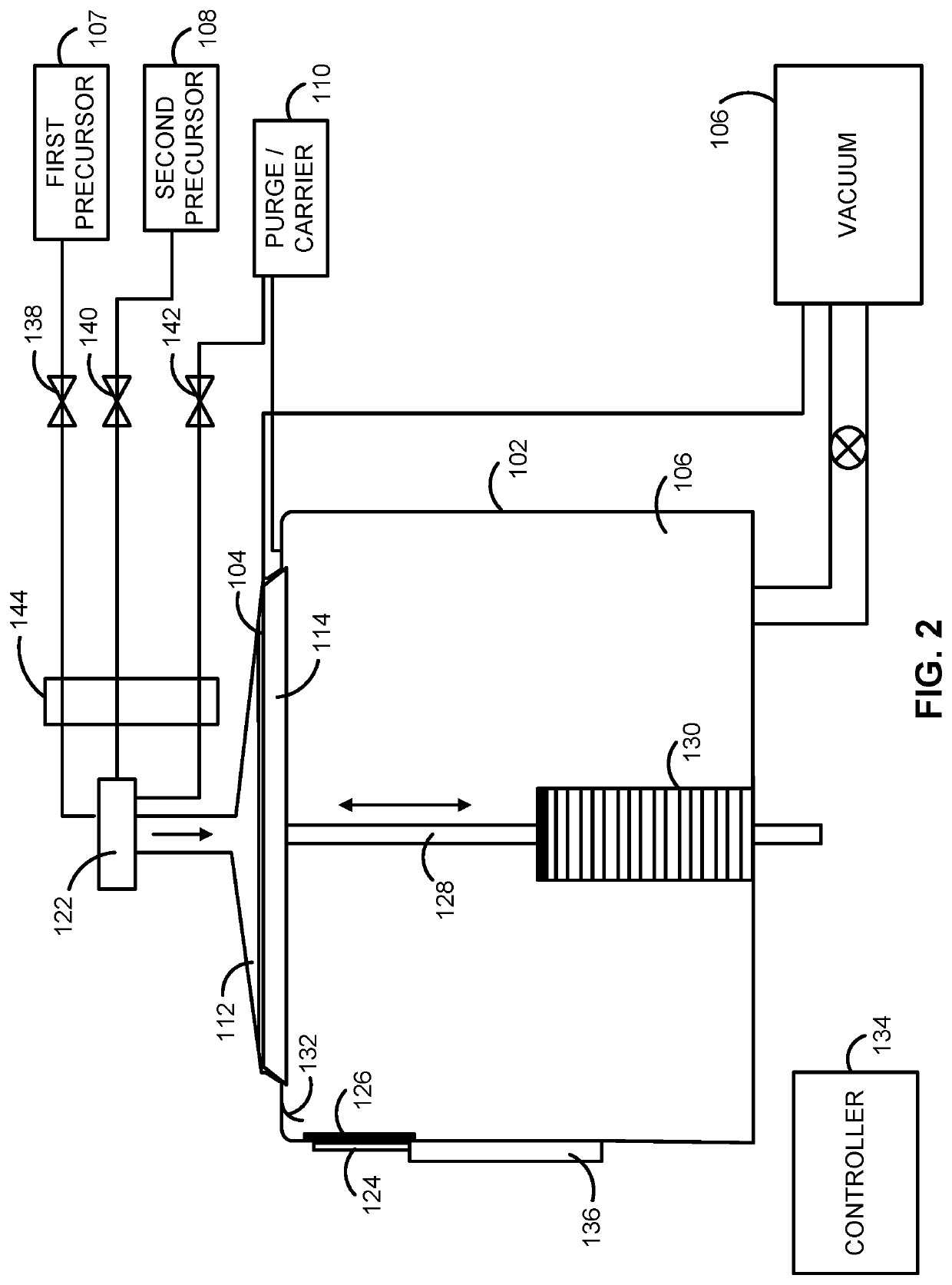

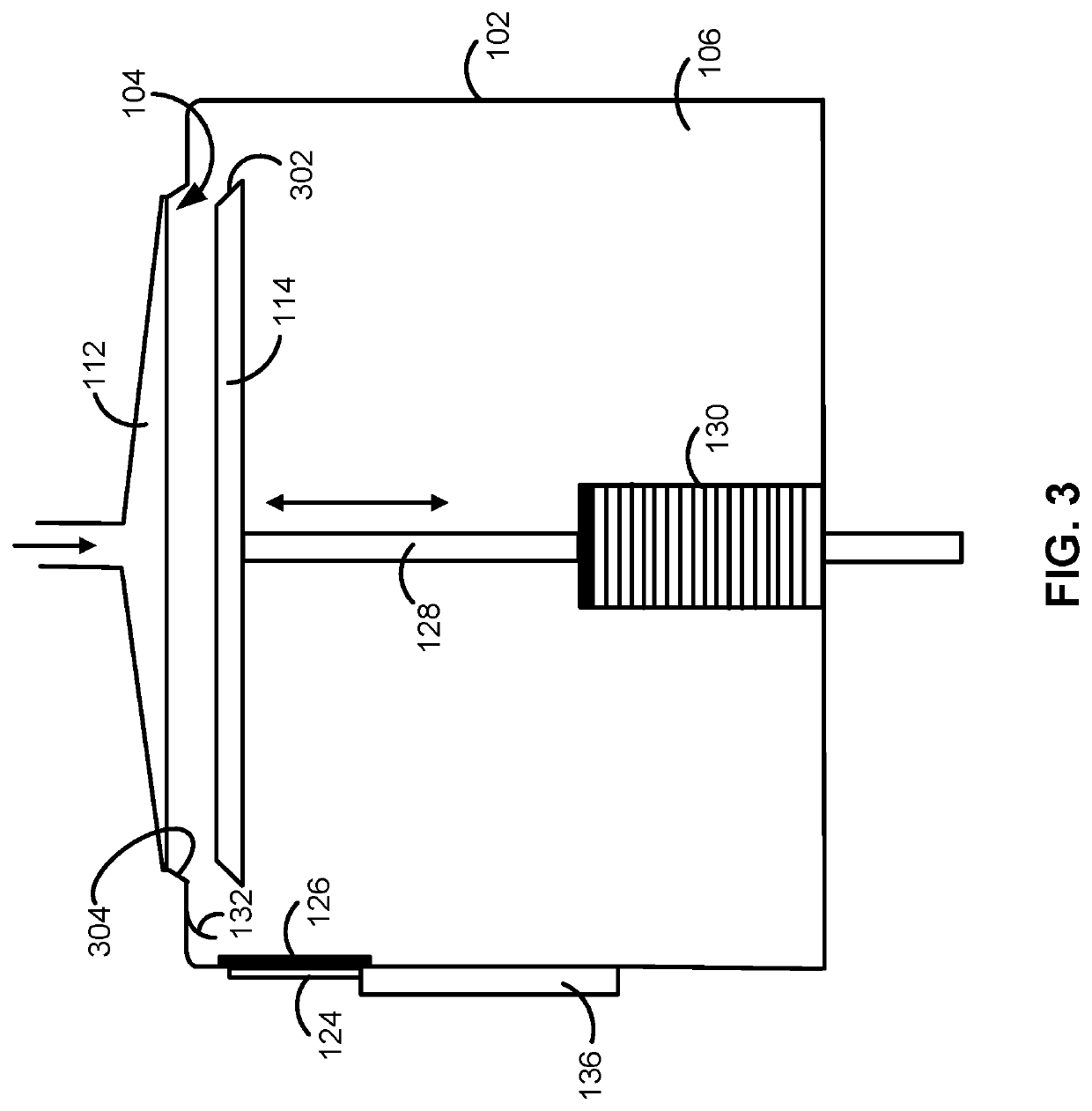

Gas-phase chemical reactor and method of using same

ActiveUS20190376180A1Less wastefulCost reductionElectric discharge tubesChemical vapor deposition coatingRadiochemistryResidence time

A gas-phase chemical reactor, a system including the reactor, and methods of using the reactor and system are disclosed. An exemplary reactor includes a reaction chamber and is configured to provide a precursor within the reaction chamber for a soak period—e.g., a period wherein a supply of the precursor to the reaction chamber is ceased and before purging of the reaction chamber begins. This allows relatively high residence times, relatively high partial pressures of the precursor(s) and / or a relatively high absolute pressure to be obtained within the reaction chamber during substrate processing.

Owner:ASM IP HLDG BV

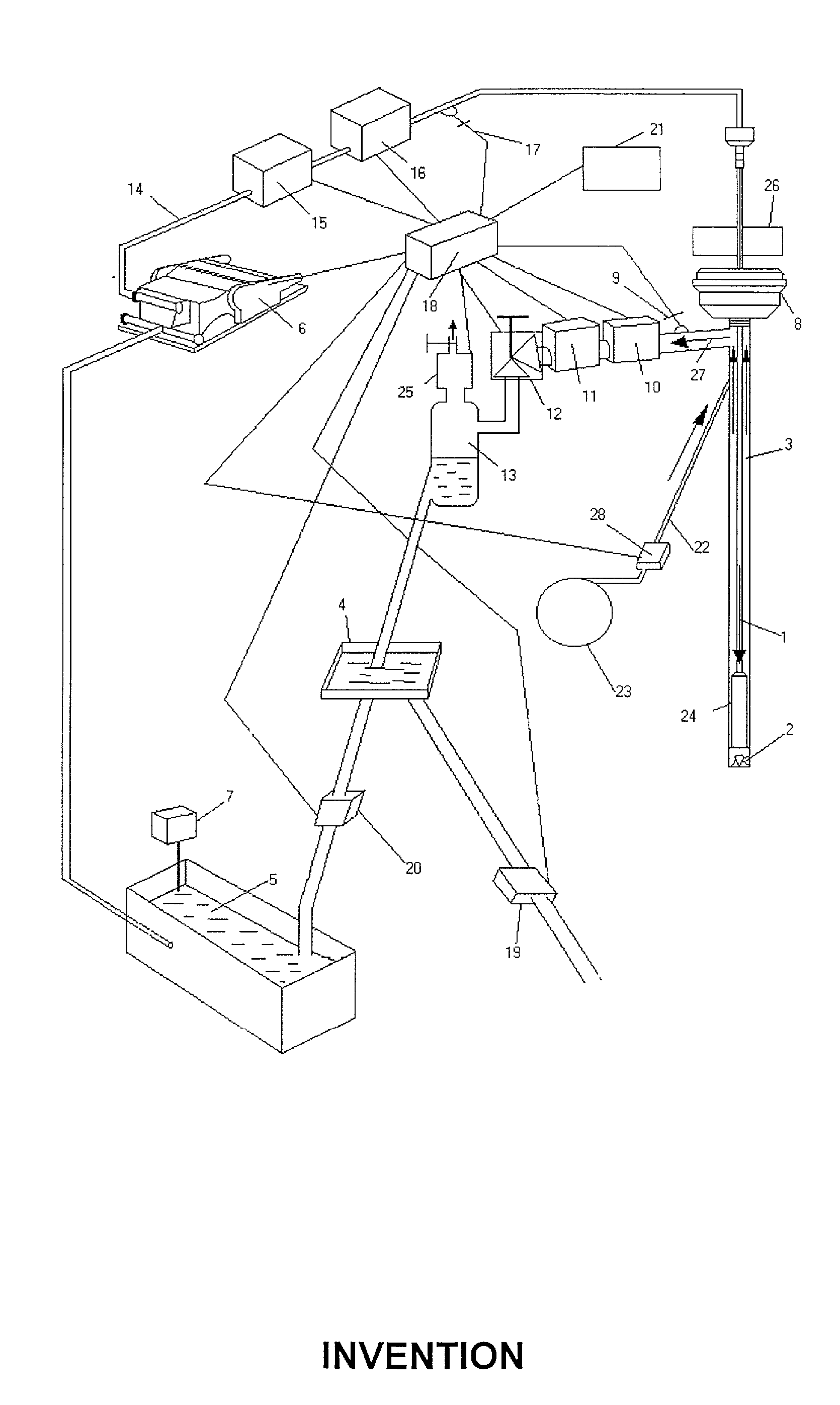

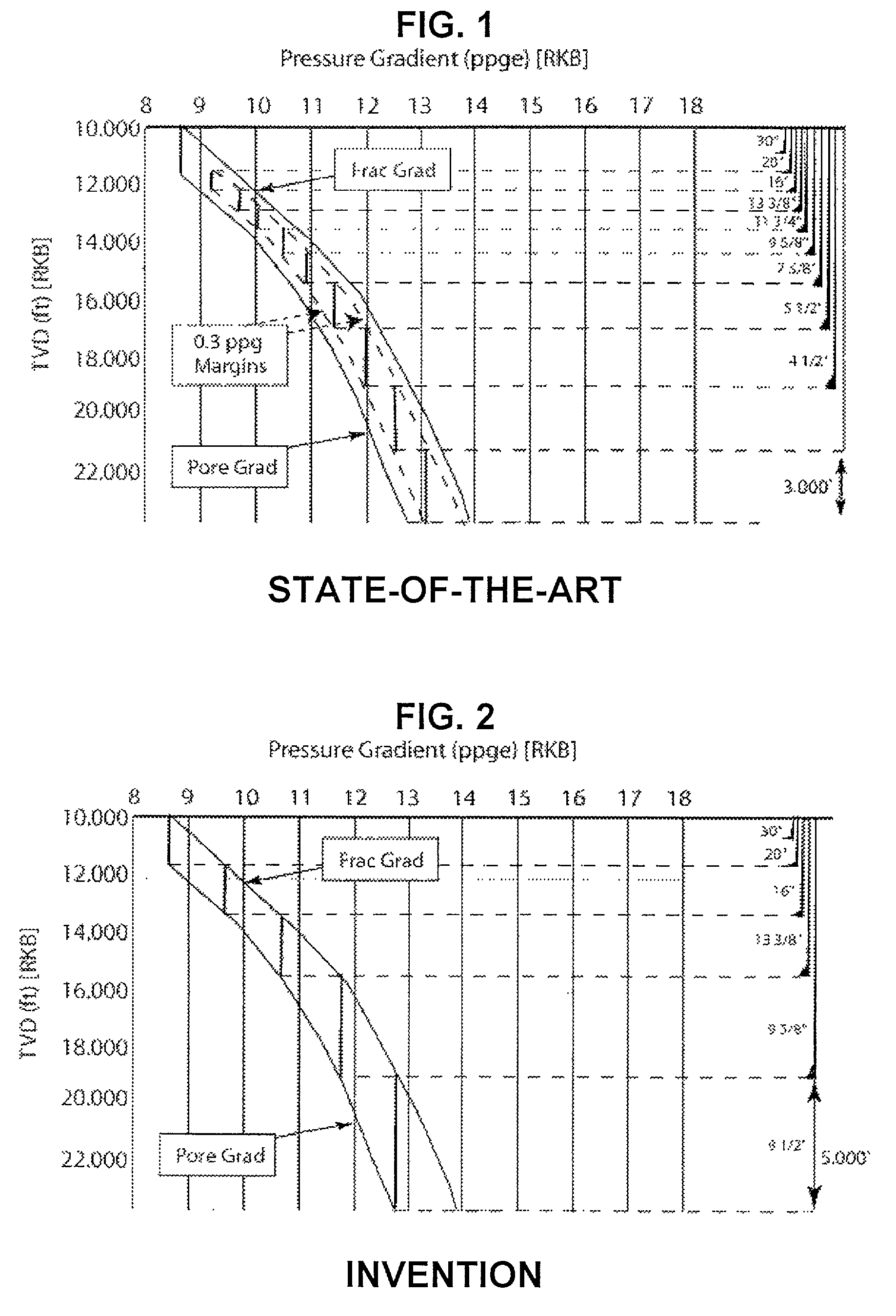

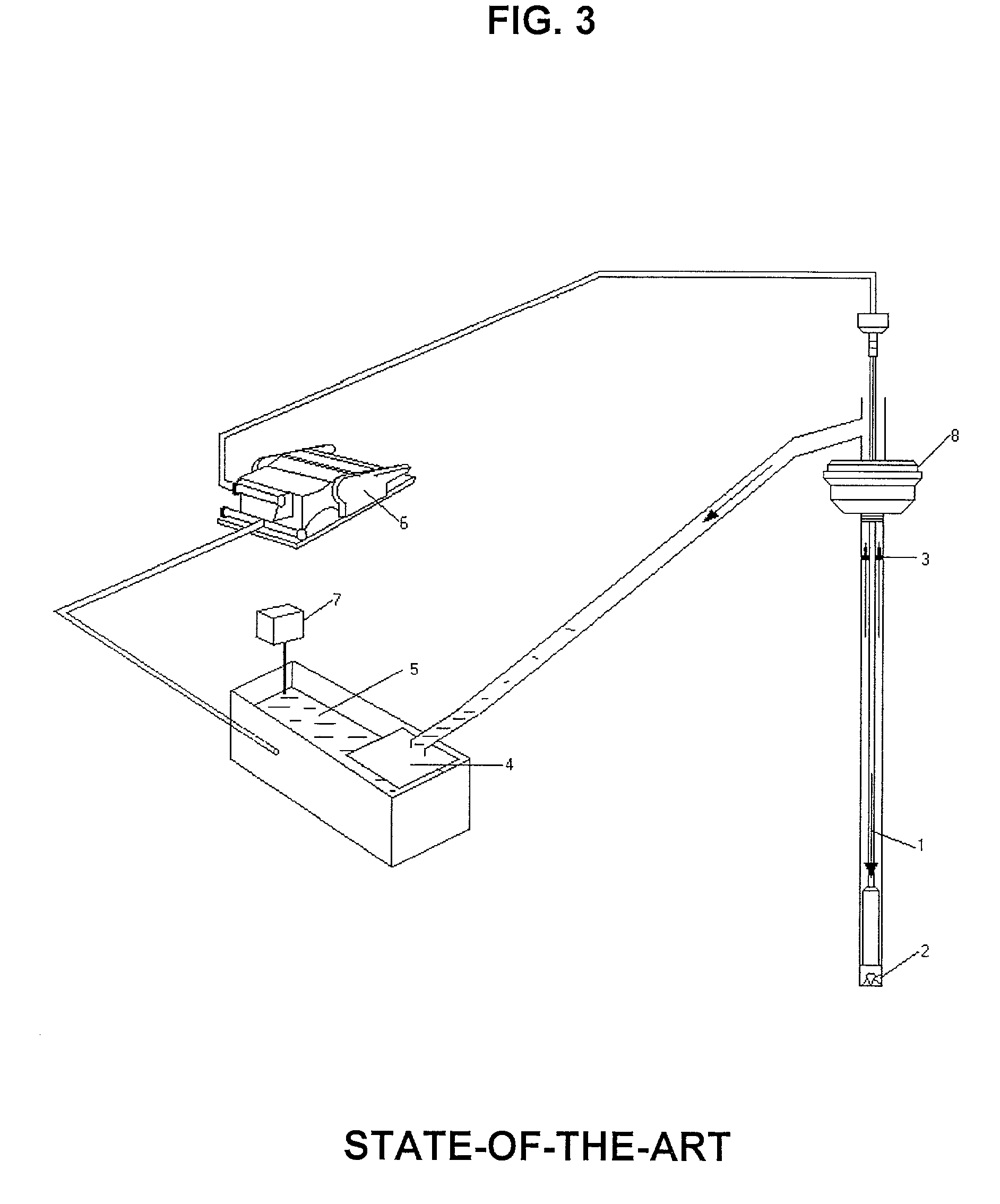

Drilling system and method

InactiveUS20020112888A1Cost reductionEliminate timeConstructionsFlushingDrilling systemCourse of action

A closed-loop drilling system and method of drilling oil, gas, or geothermal wells is described, whereby through the control of the flow rates in and out of the wellbore, and by adjusting the pressure inside the wellbore by a pressure / flow control device installed on the return line, surface pressure being increased or decreased as required, this in turn decreasing or increasing downhole pressure, occurrence of kicks and fluid losses may be greatly minimized and quickly controlled. Through the method of the invention the elimination of the kick tolerance and tripping margin on the design of the well is made possible, since the pore and fracture pressure will be determined in real-time while drilling the well, and, therefore, nearly no safety margin is necessary when designing the well, reducing significantly the number of casing strings necessary. The inventive method can be called intelligent safe drilling since the response to influx or fluid loss is nearly immediate and so smoothly done that the drilling can go on without any break in the normal course of action. The new method is applicable to the whole wellbore from the first casing string with a BOP connection, and it can be implemented and adopted to any rig or drilling installation that uses the conventional method with very few exceptions and limitations. The new method is applicable to all types of wells, onshore, offshore, deepwater and ultra-deepwater, with huge safety improvement in difficult drilling scenarios.

Owner:IMPACT ENG SOLUTIONS +2

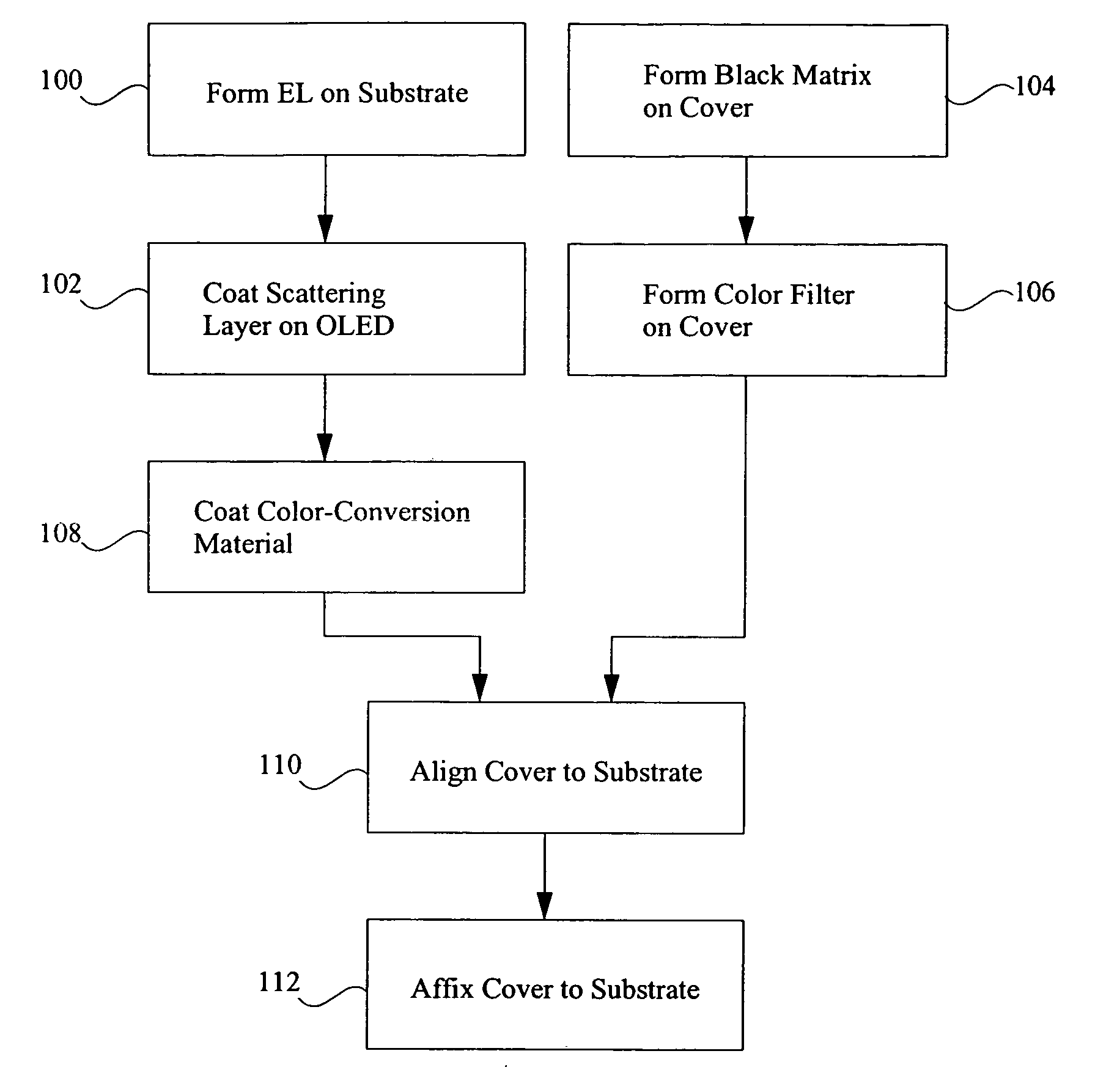

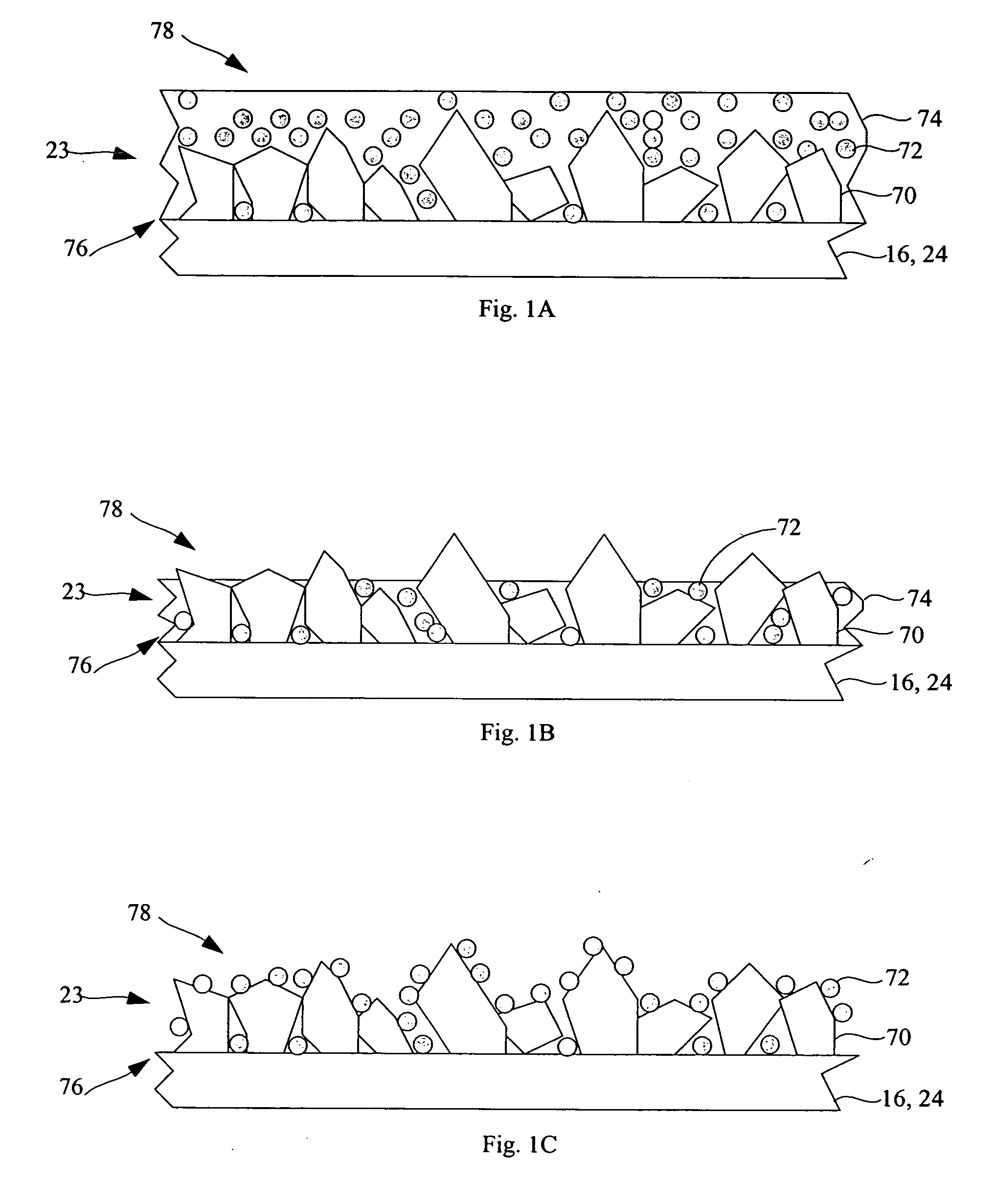

Light-scattering color-conversion material layer

InactiveUS20070201056A1Cost reductionImprove performanceMaterial nanotechnologyDigitally marking record carriersPhysicsOptical coupling

A light-scattering color-conversion material layer having two sides, comprising first light-scattering particles intermixed with second different color-conversion material particles, wherein the concentration of the light scattering particles is greater towards a first side of the layer relative to the concentration of light-scattering particles towards the opposite side of the layer, and / or wherein the concentration of the color-conversion material particles is less towards the first side of the layer relative to the concentration of color-conversion material particles towards the opposite side of the layer. A method of making such a light-scattering color-conversion material layer is also described, and light emitting devices comprising one or more EL elements formed on a substrate and such a light-scattering color-conversion material layer optically coupled with the EL element.

Owner:EASTMAN KODAK CO

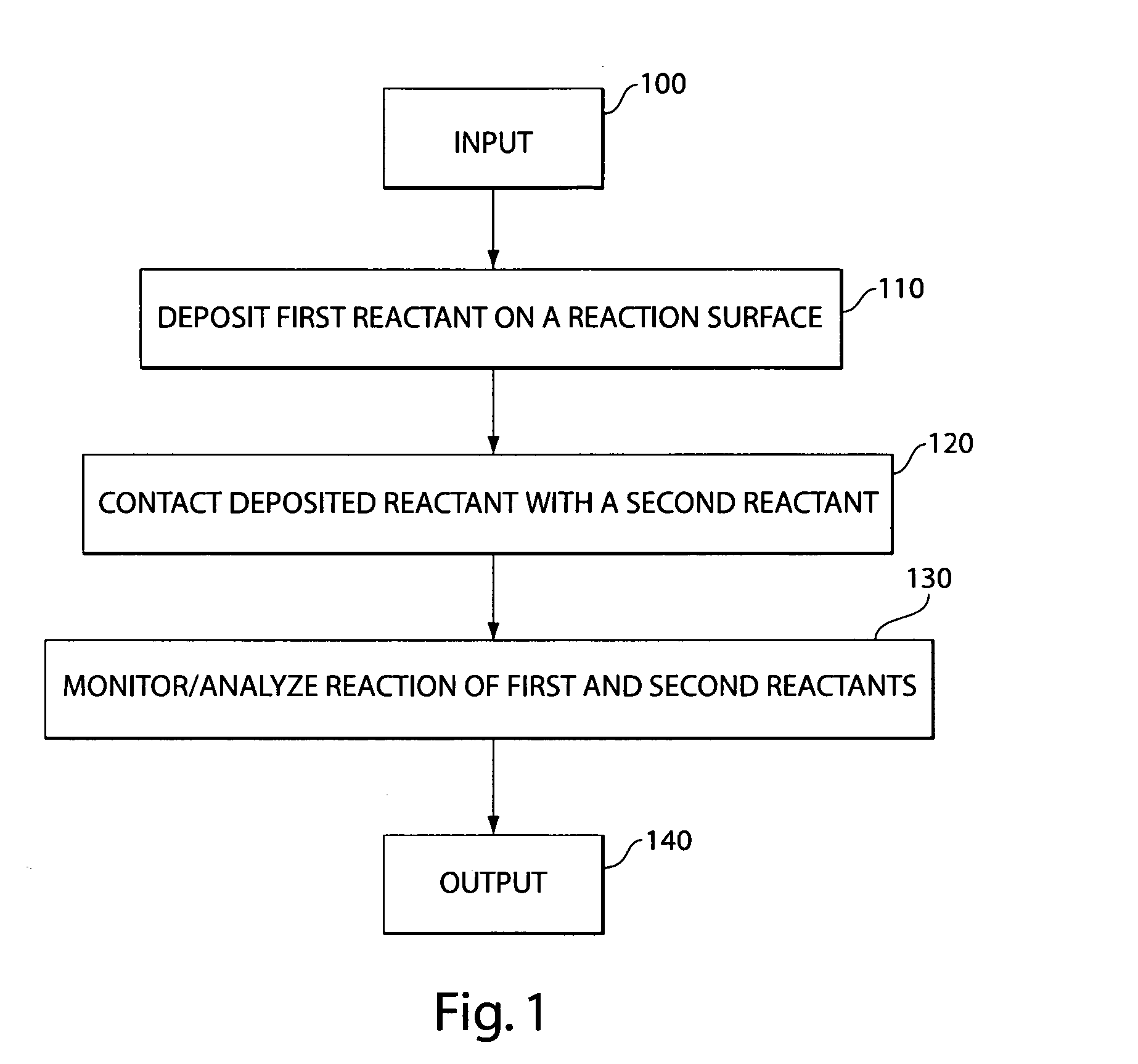

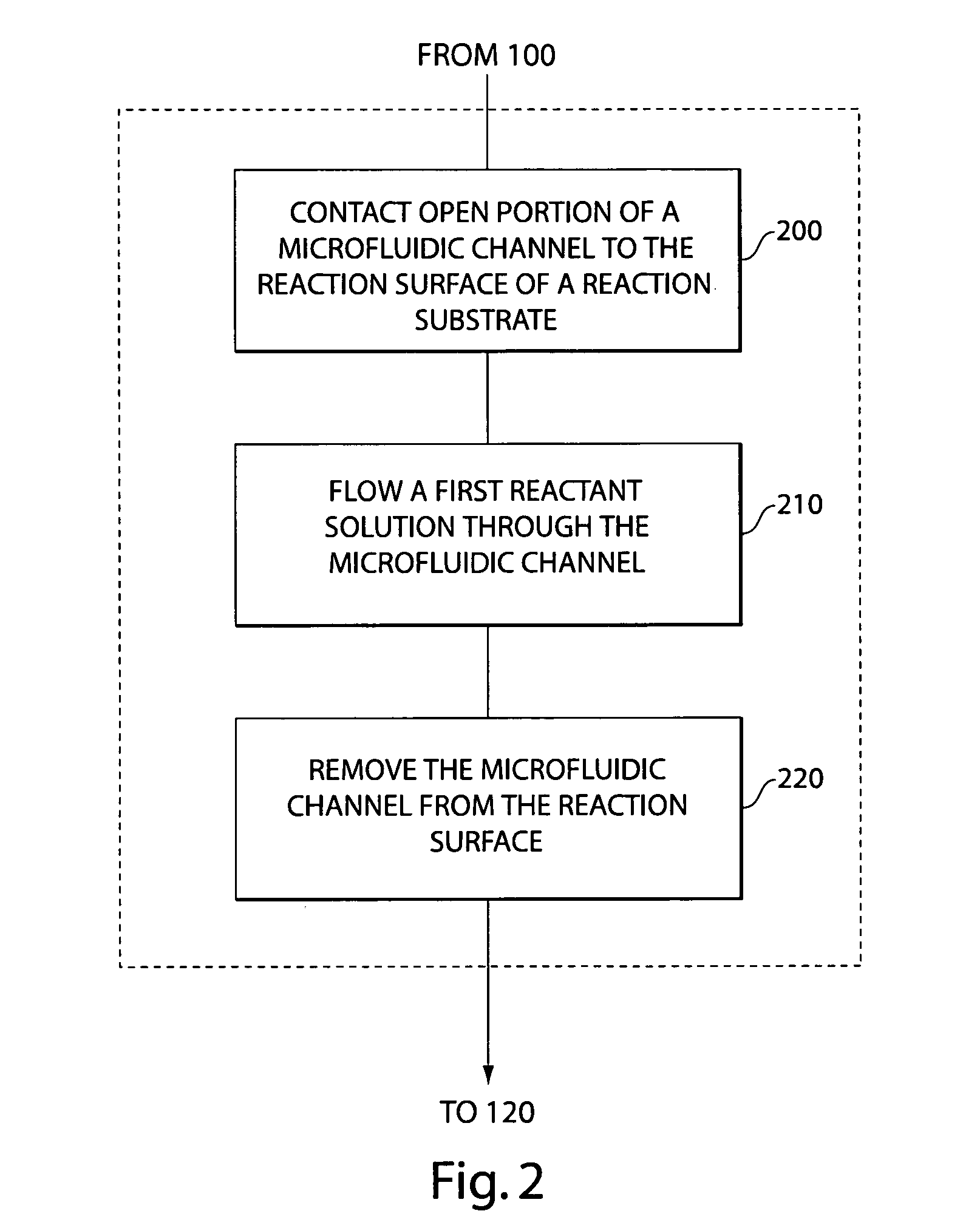

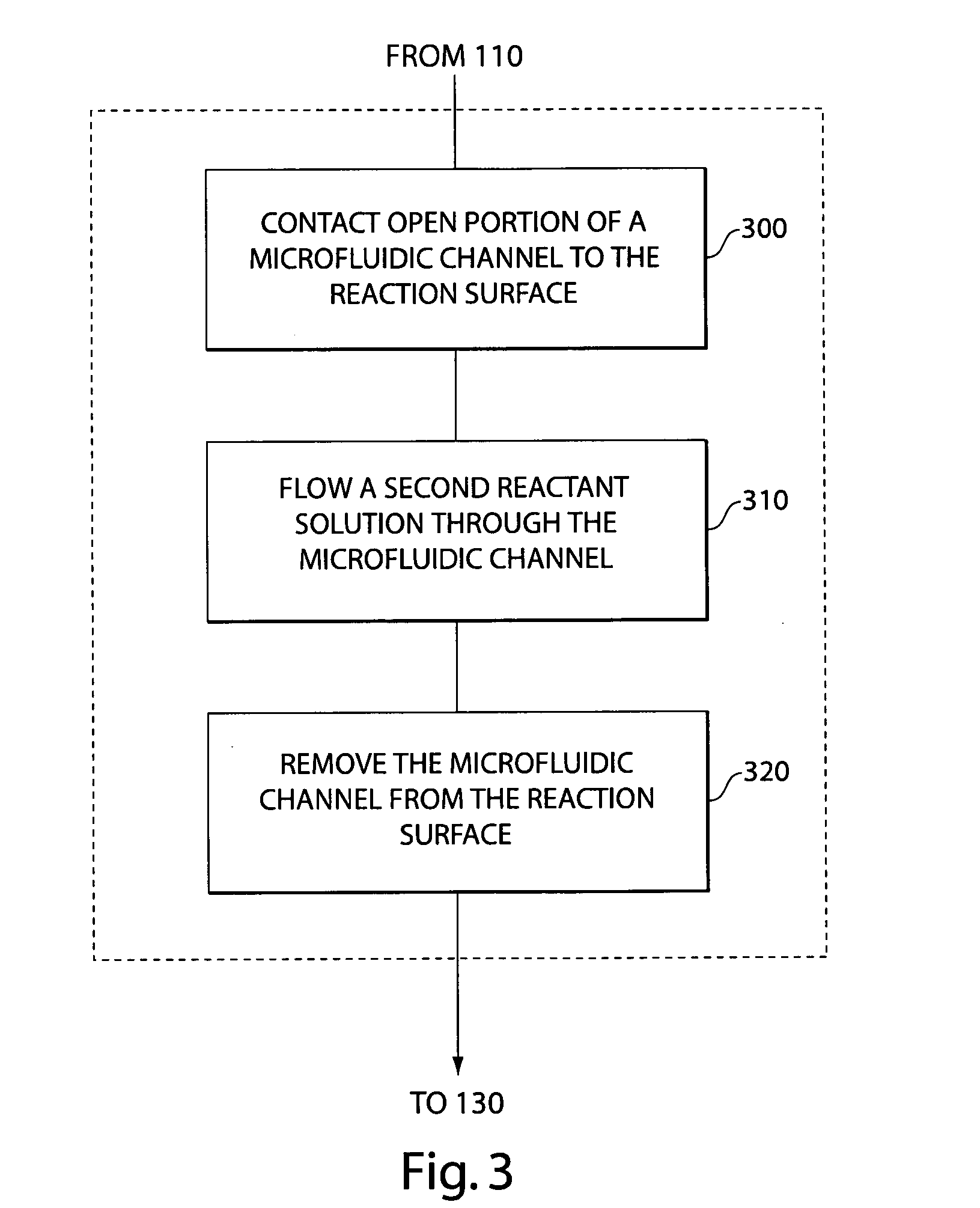

High-density reaction chambers and methods of use

InactiveUS20050277125A1Cost reductionIncrease speedBioreactor/fermenter combinationsSequential/parallel process reactionsEngineeringBiomedical engineering

Owner:MASSACHUSETTS INST OF TECH

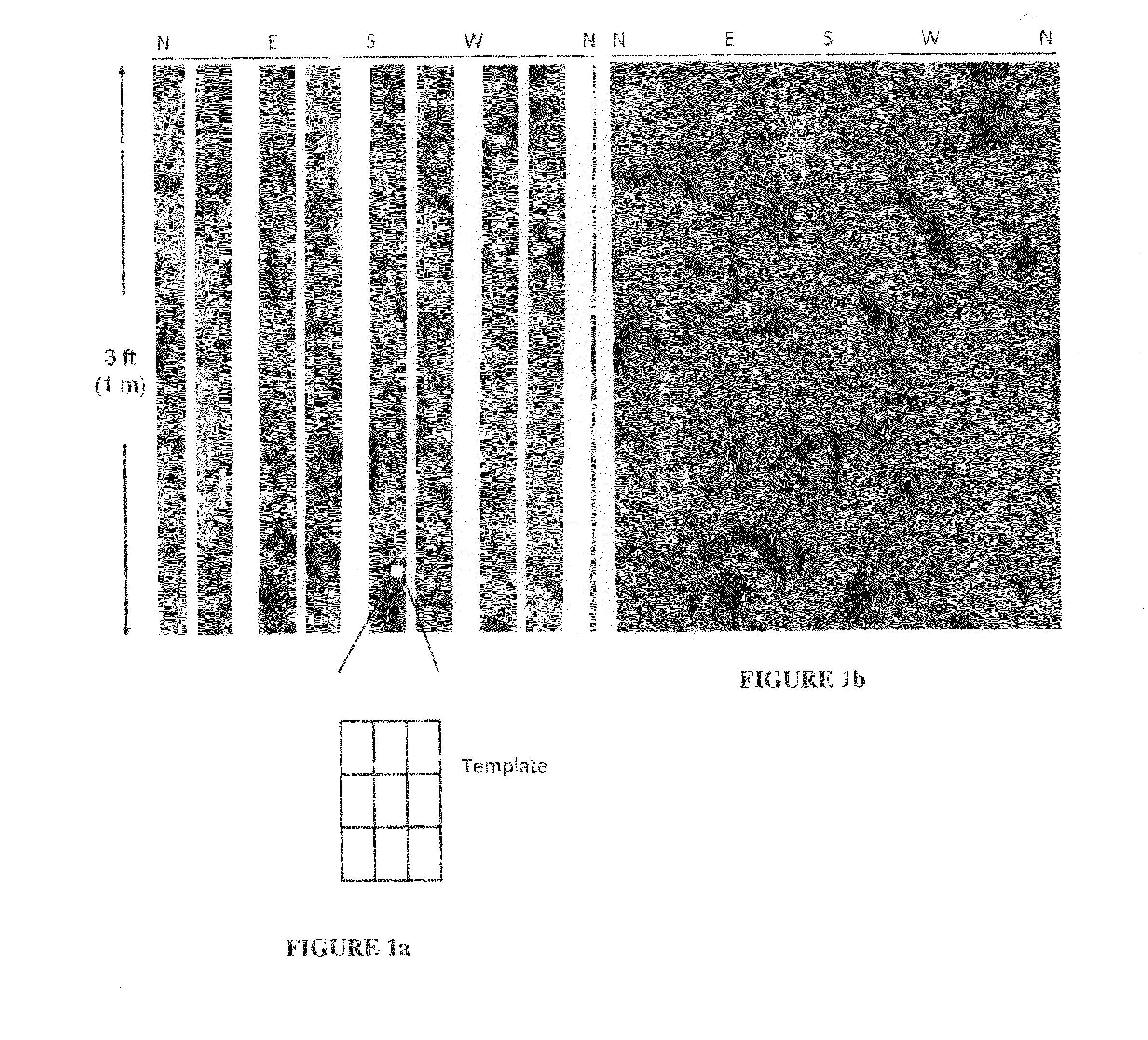

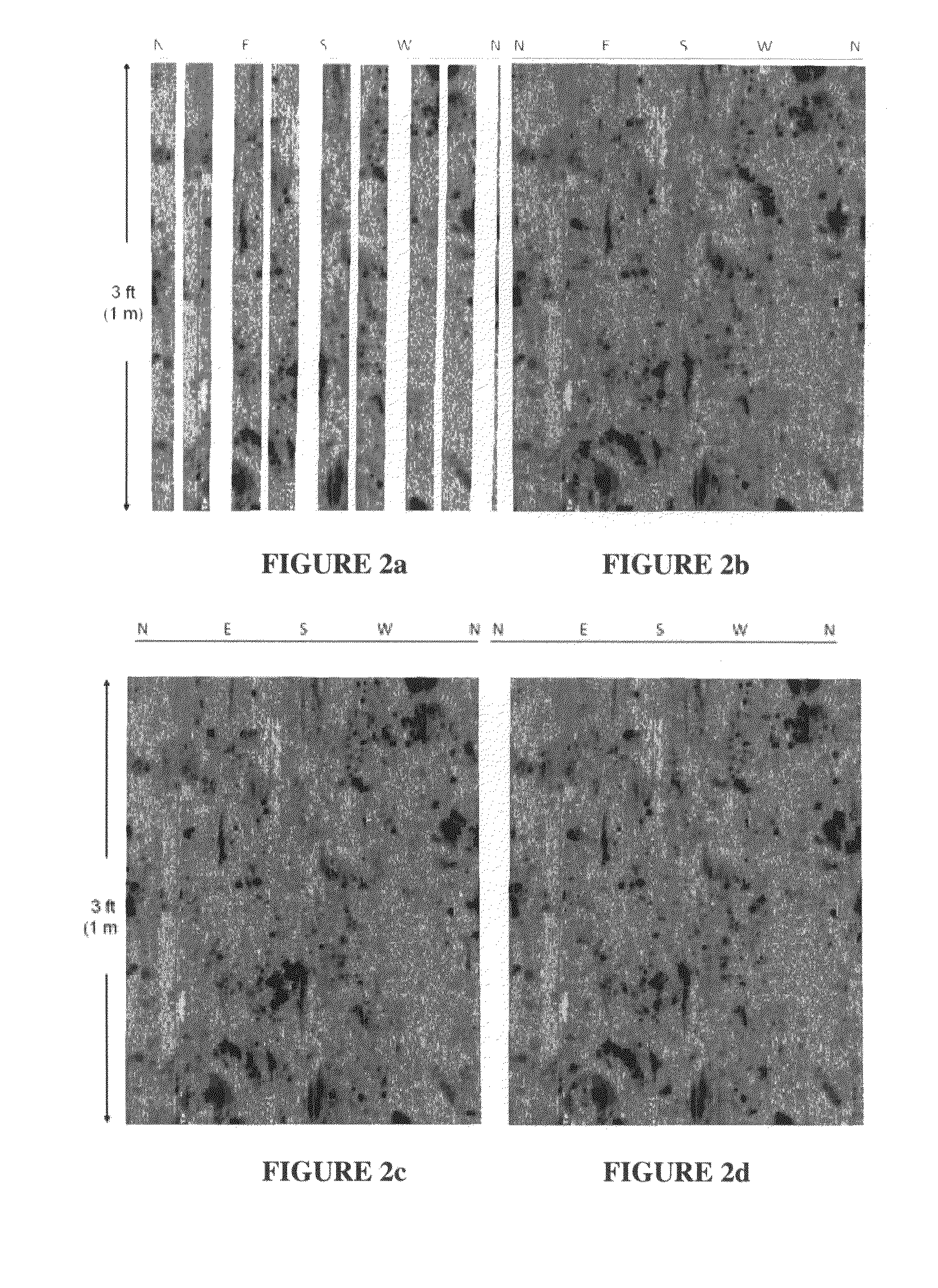

Method to generate numerical pseudocores using borehole images, digital rock samples, and multi-point statistics

ActiveUS20090259446A1Cost reductionImprove shape reproductionSurveyComputation using non-denominational number representationNumeric ValueData processing

Methods and systems for creating a numerical pseudocore model, comprising: a) obtaining logging data from a reservoir having depth-defined intervals of the reservoir, and processing the logging data into interpretable borehole image data having unidentified borehole image data; b) examining one of the interpretable borehole image data, other processed logging data or both to generate the unidentified borehole image data, processing the generated unidentified borehole image data into the interpretable borehole image data to generate warped fullbore image data; c) collecting one of a core from the reservoir, the logging data or both and generating a digital core data from one of the collected core, the logging data or both such that generated digital core data represents features of one or more depth-defined interval of the reservoir; and d) processing generated digital core data, interpretable borehole image data or the logging data to generate realizations of the numerical pseudocore model.

Owner:SCHLUMBERGER TECH CORP

Method of promoting employee wellness and health insurance strategy for same

In an effort to reduce employer health insurance related costs, a state-governed fully-insured supplemental health insurance policy is provided for a group of employees. At least one benefit under the supplemental health insurance policy is conditional on the employee voluntarily participating in a wellness program. The wellness program could include wellness categories such as a tobacco free category, normal blood pressure category, regular exercise category and even a non-overweight category. In addition, the wellness program could condition coverage, or subsidize deductibles for, certain illnesses on employee submission to screening tests on a prescribed basis for the identified illness, such as cancer screening for early detection of cancer. Partial premium payments on behalf of the employee for a core health insurance policy could also be a reward for participation in a wellness program. The voluntary wellness program can also include a variety of other aspects including wellness education, disease inoculation, and injury prevention. The invention provides an incentive for employees to make healthier lifestyle choices.

Owner:SHORT DOUGLAS J

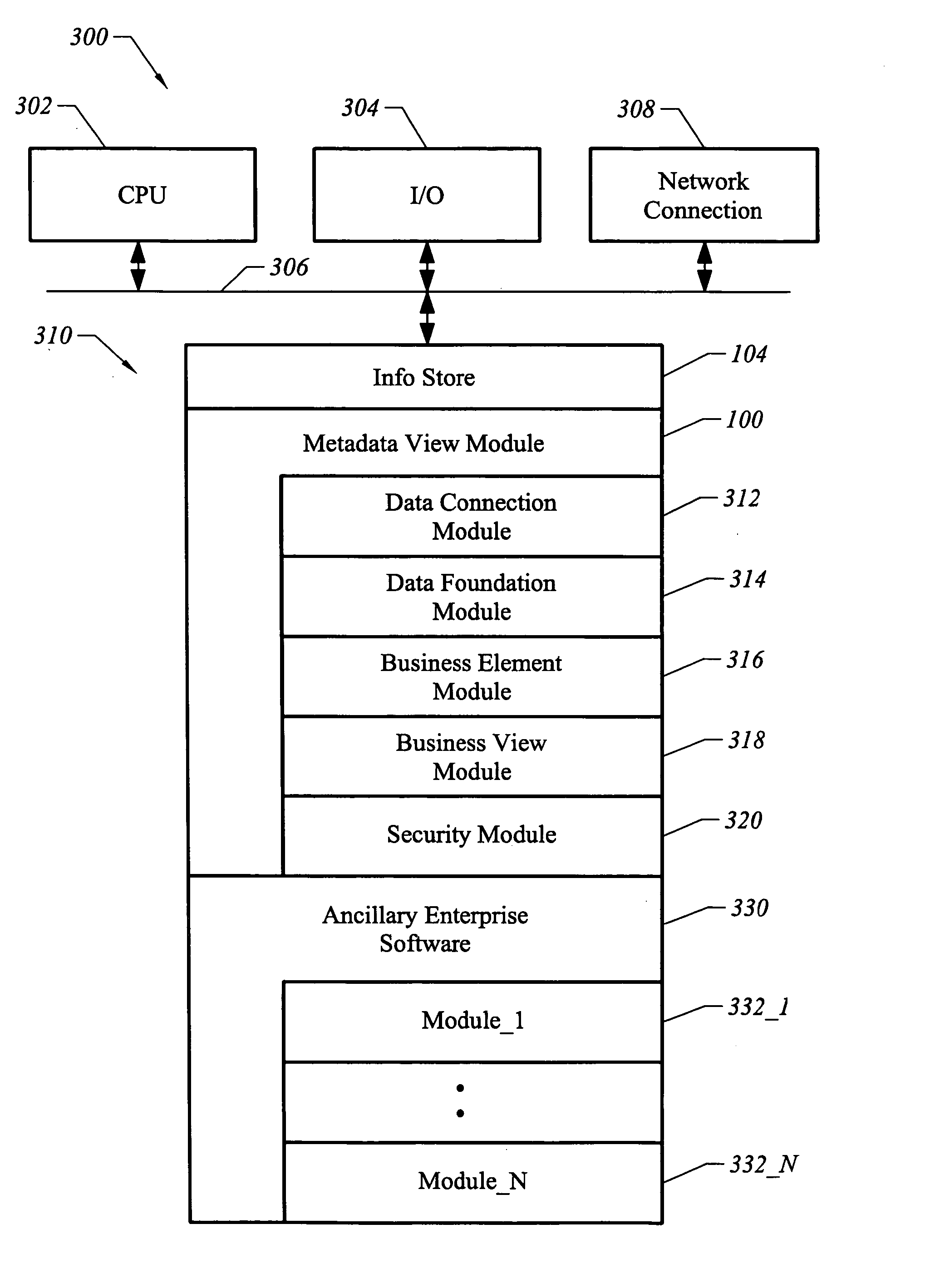

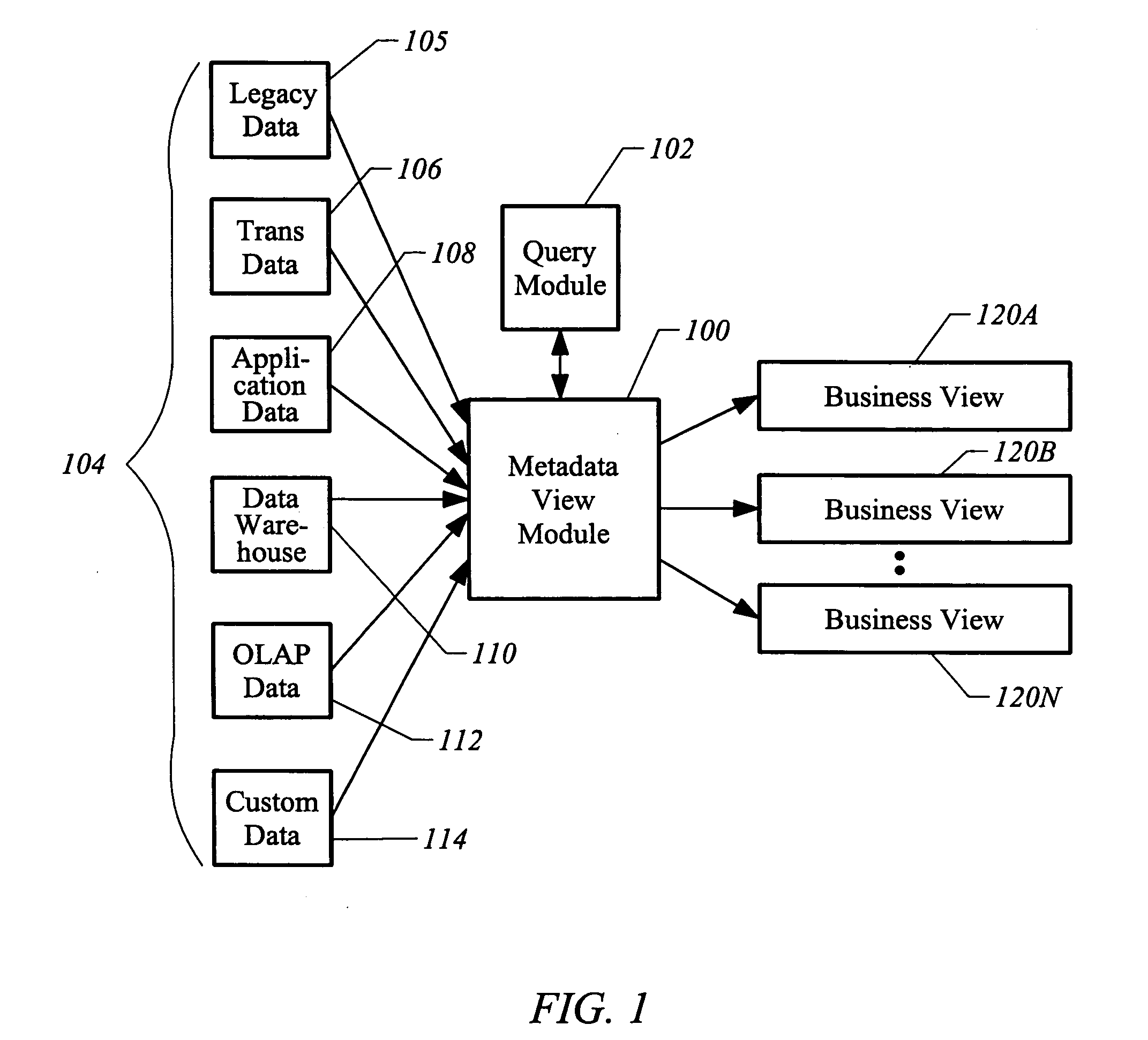

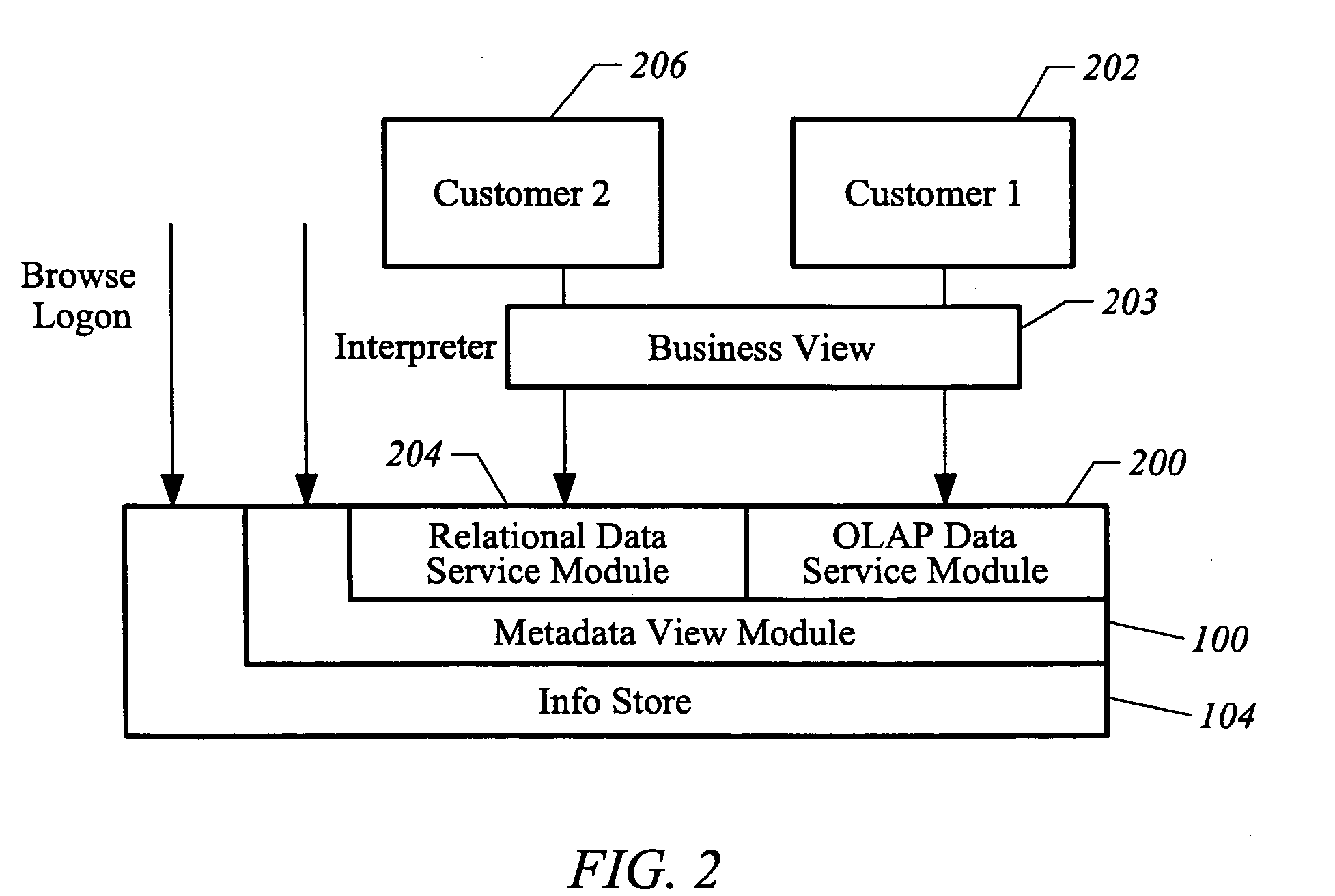

Apparatus and method for accessing diverse native data sources through a metadata interface

InactiveUS20050033726A1Cost reductionImprove profitabilityDatabase management systemsDigital data processing detailsMetadataDatabase

A computer readable medium storing executable instructions includes a metadata view module. The metadata view module has a data foundation module to facilitate data abstraction of enterprise data, where the enterprise data is stored in diverse native formats. A business element module facilitates the logical grouping of the enterprise data to form business elements and a business view module facilitates the logical grouping of business elements.

Owner:BUSINESS OBJECTS SOFTWARE

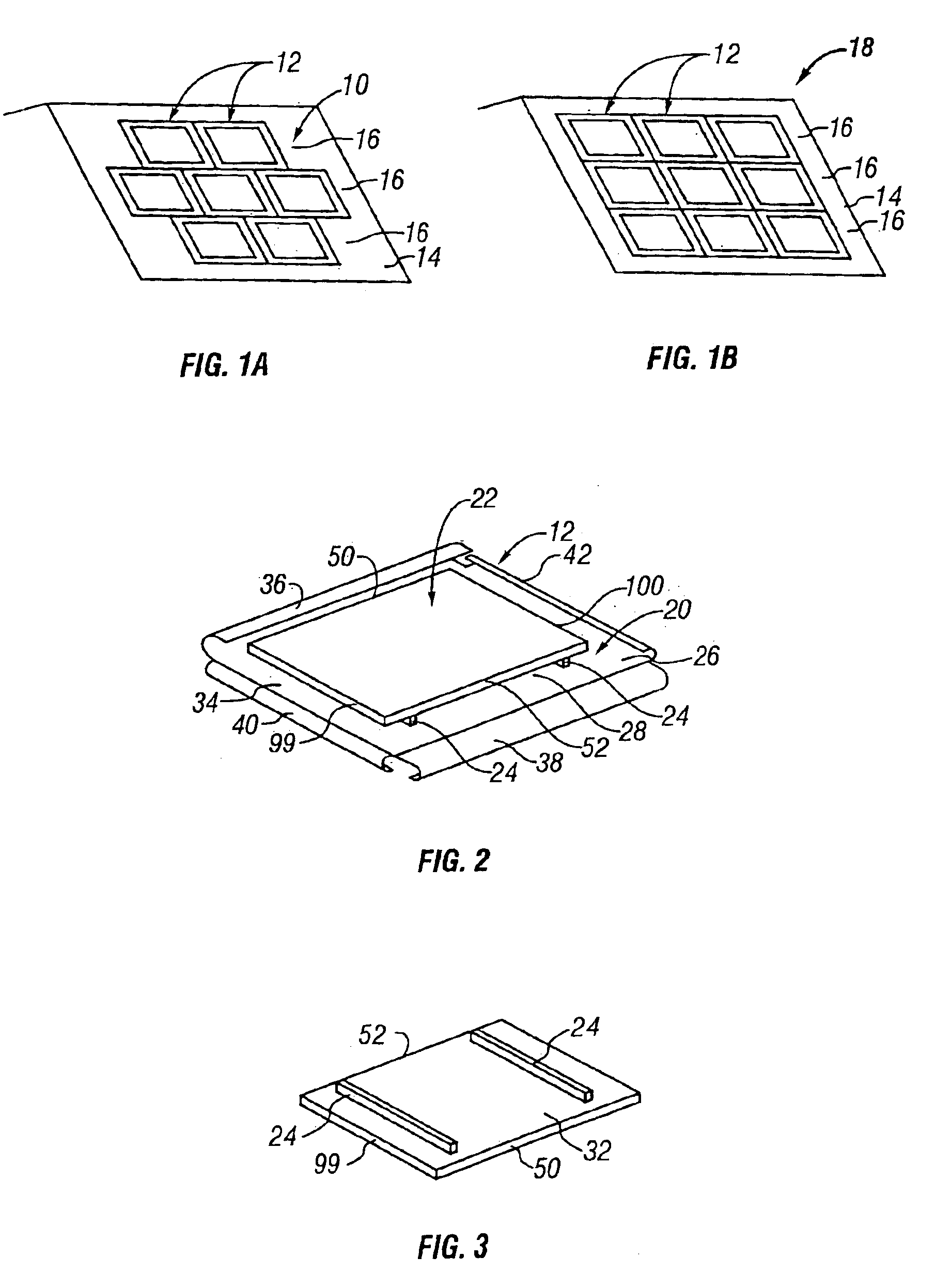

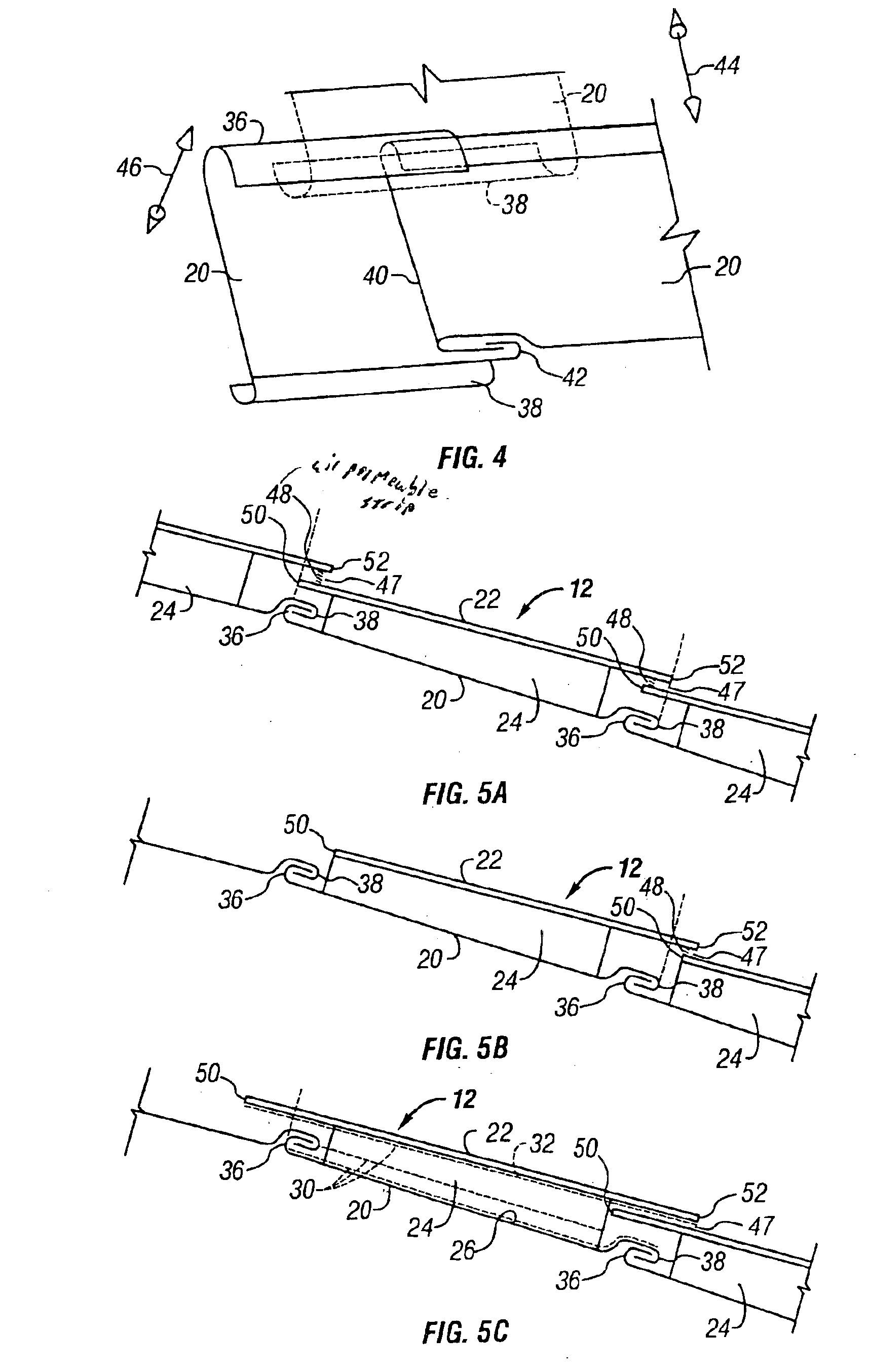

Shingle system and method

InactiveUS6883290B2Increase efficiencyCost reductionPhotovoltaic supportsSolar heating energyMechanical engineeringComputer module

A barrier, such as a PV module, is secured to a base by a support to create a shingle assembly with a venting region defined between the barrier and base for temperature regulation. The bottom edges of the barriers of one row may overlap the top edges of the barriers of another row. The shingle assemblies may be mounted by first mounting the bases to an inclined surface; the barriers may be then secured to the bases using the supports to create rows of shingle assemblies defining venting regions between the barriers and the bases for temperature regulation.

Owner:SUNPOWER CORPORATION

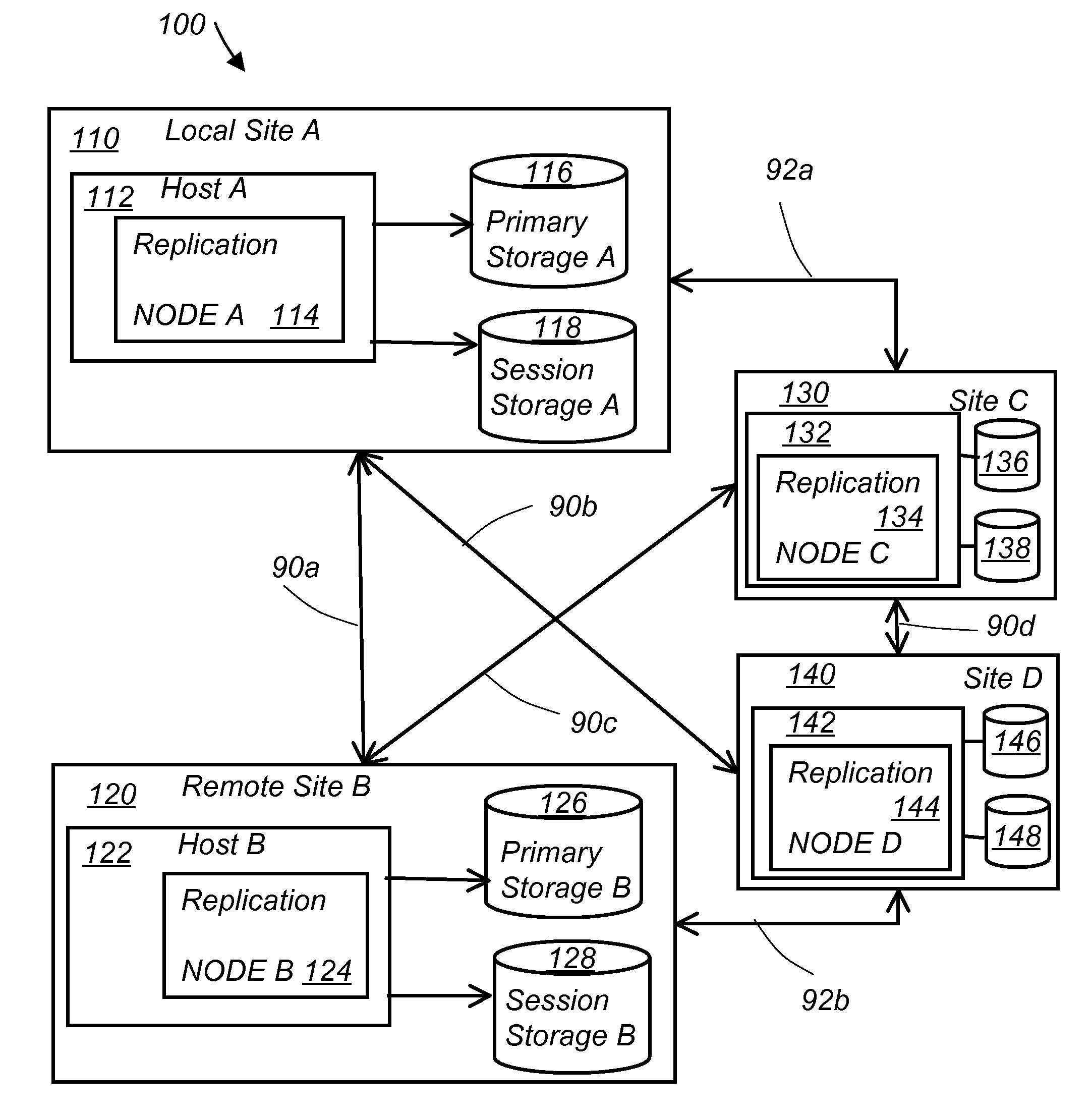

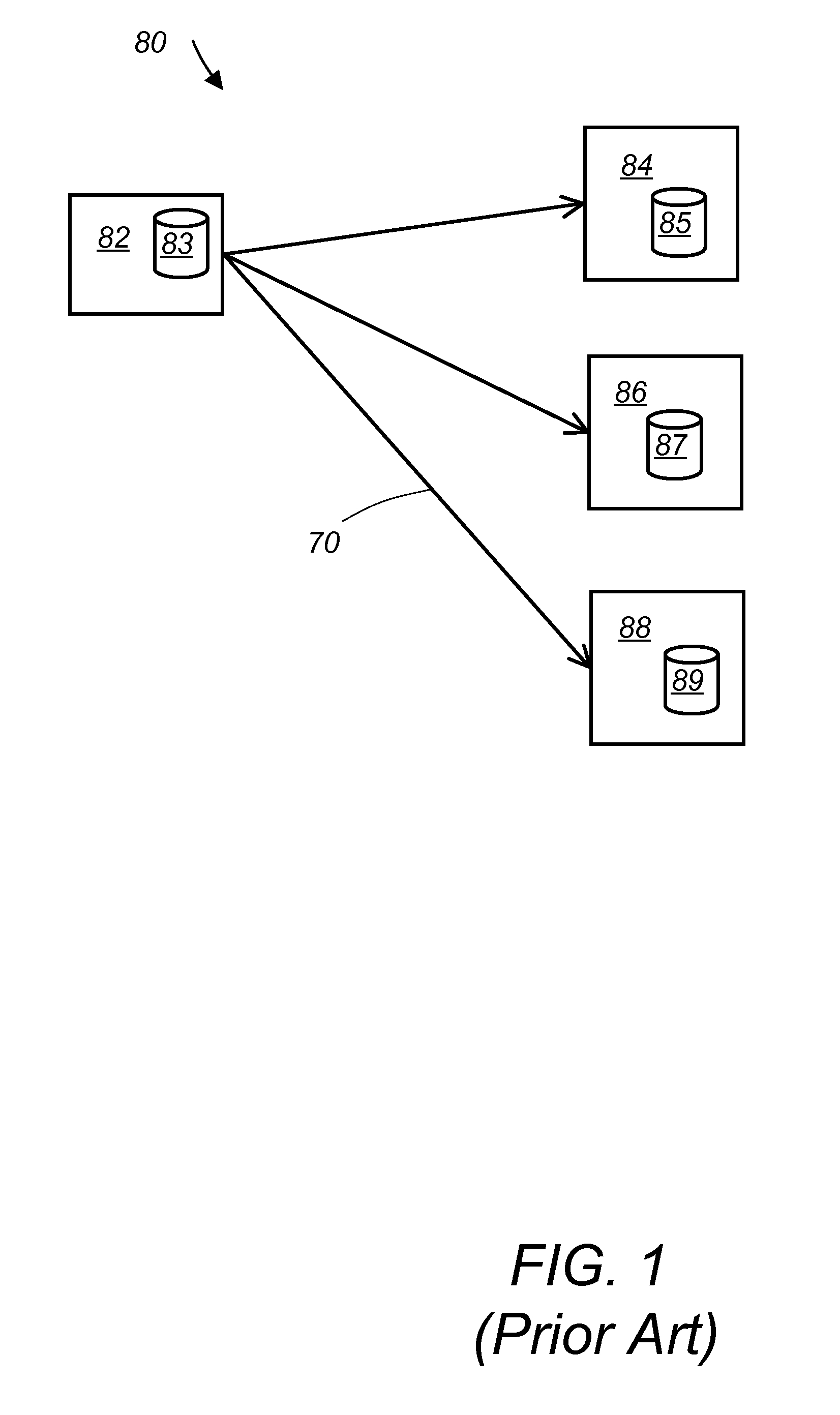

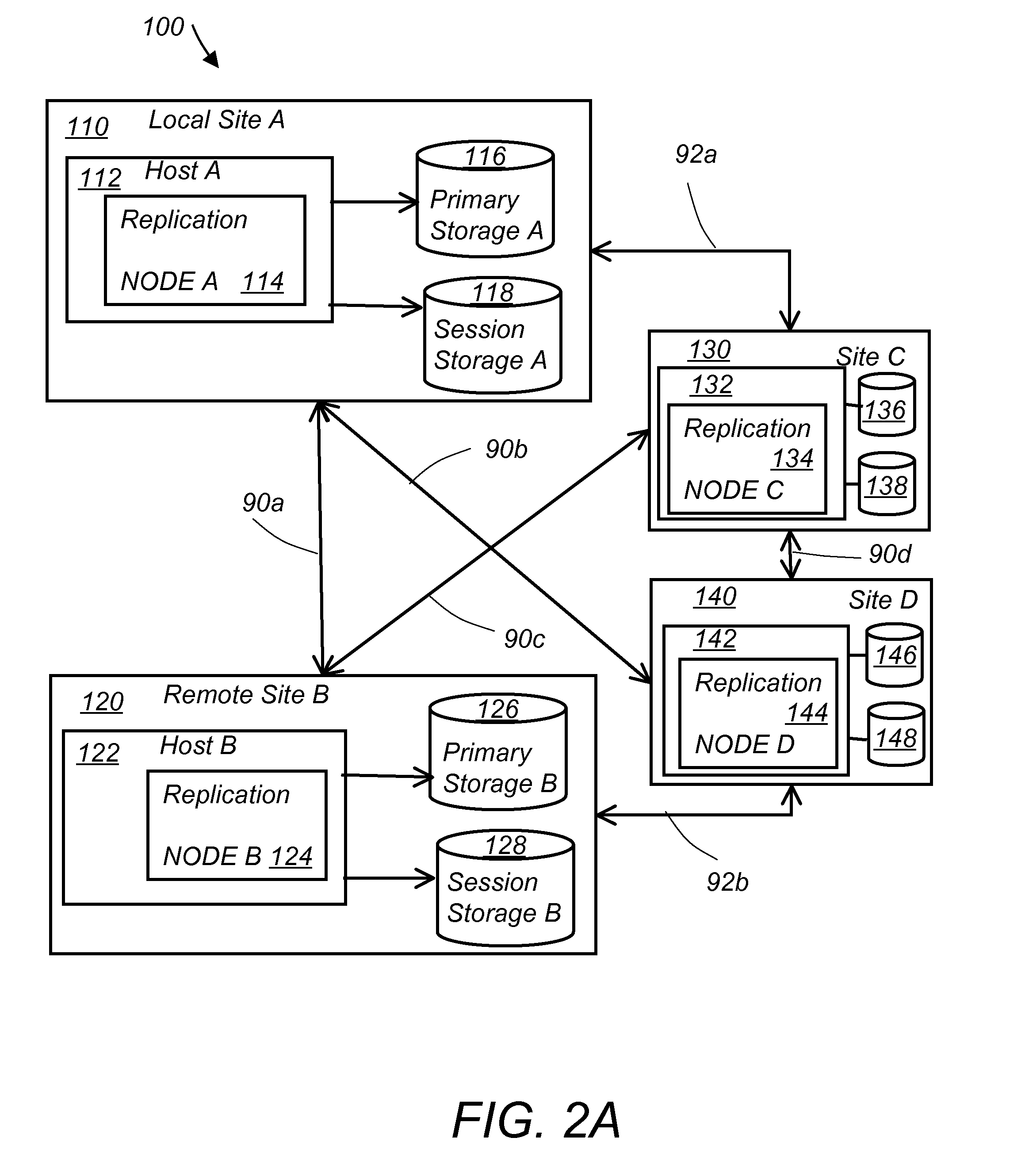

System and method for remote asynchronous data replication

ActiveUS20090030986A1Cost reductionWithout increase bandwidth requirementError detection/correctionMultiple digital computer combinationsClient-sideDistributed computing

An asynchronous peer-to-peer data replication method implemented within a replication cluster comprising at least one master node and at least a first client node includes entering an update in a data volume of the master node and storing the update in a master node storage. Next, updating a first active session in a master log and then sending a first message from the master node to the first client node. The first message comprises a first message content and first “piggybacked” data indicating that the first active session in the master log was updated. Next, receiving the first message by the first client node, registering that the first active session in the master log was updated and signaling internally that the first active session in the master log was updated. Next, sending an update request from the first client node to the master node, processing the update request by the master node and sending the update to the first client node. Finally, receiving the update by the first client node and updating the first active session in a first client log.

Owner:EMC IP HLDG CO LLC

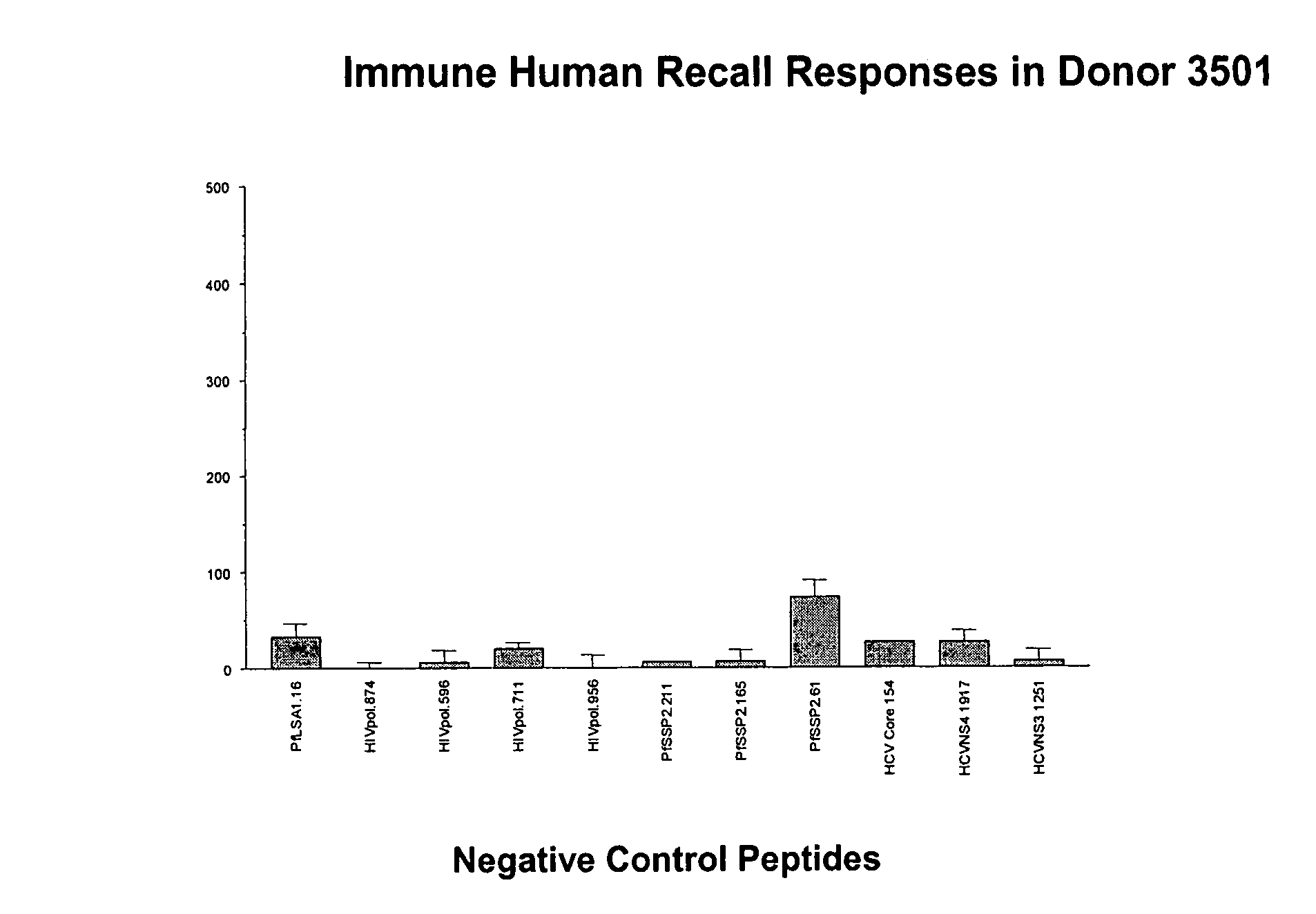

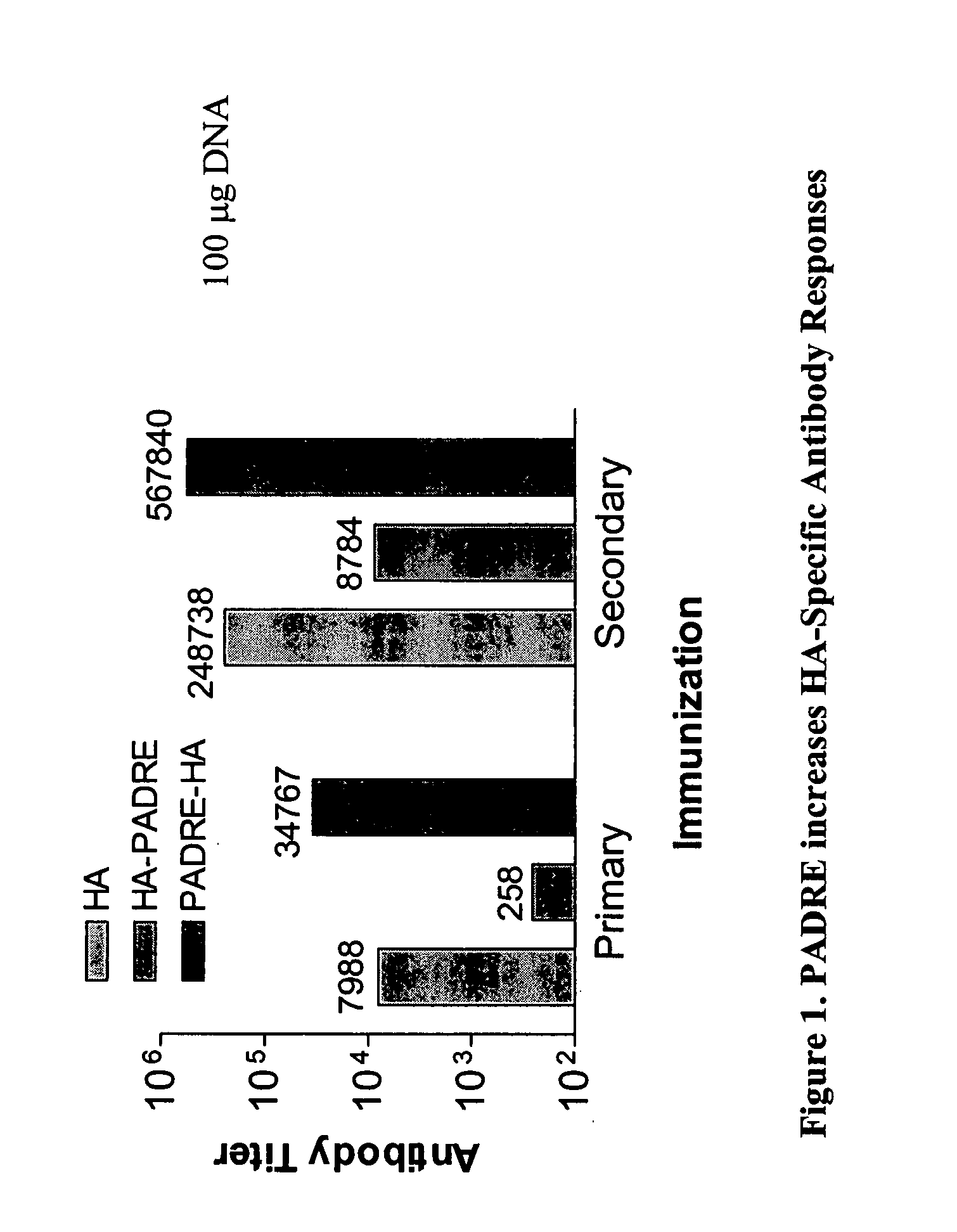

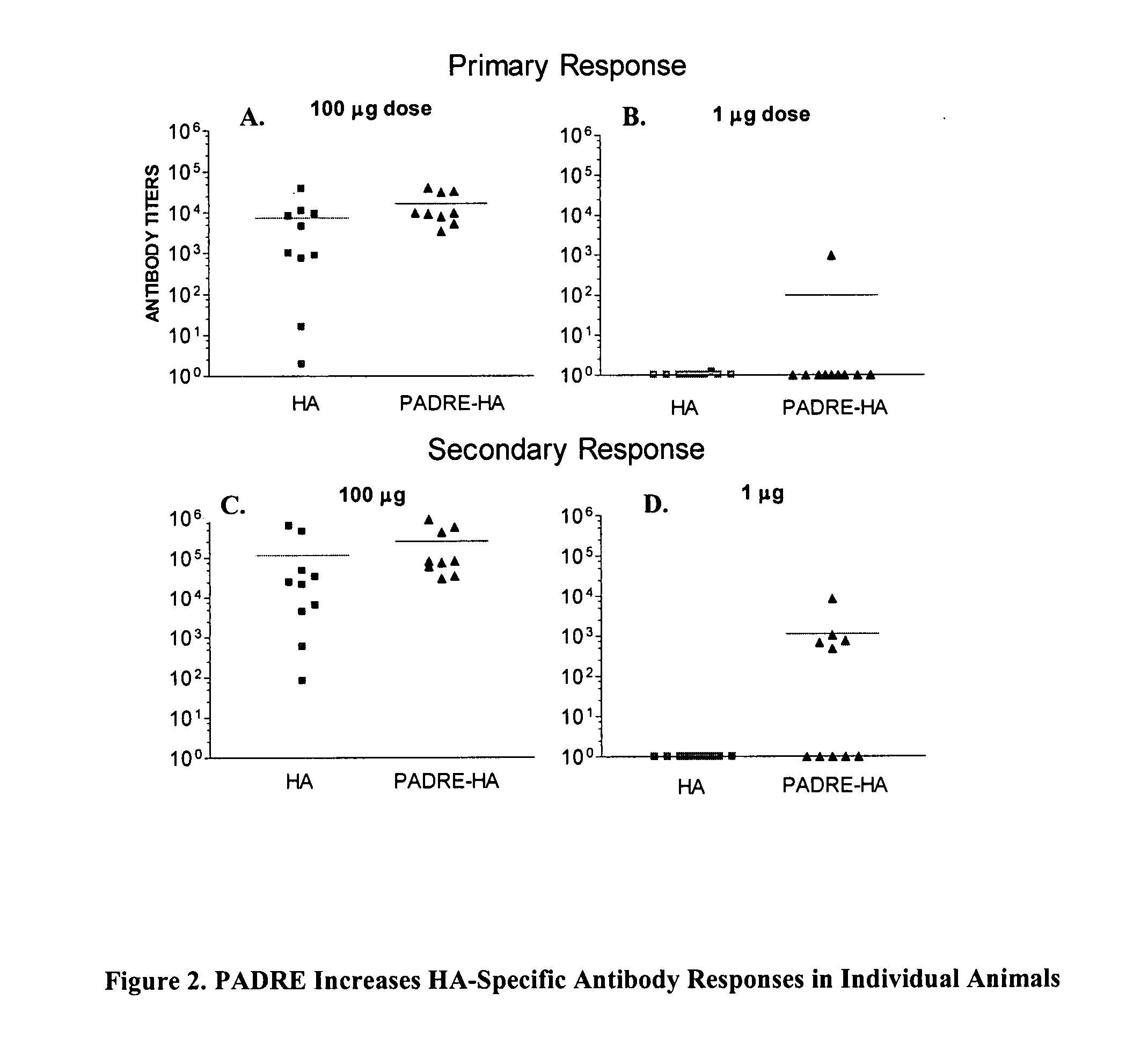

Inducing immune responses to influenza virus using polypeptide and nucleic acid compositions

ActiveUS20080032921A1Cost reductionImproving immunogenicityVirusesPeptide/protein ingredientsNucleotideImmunology

Owner:EPIMMUNE

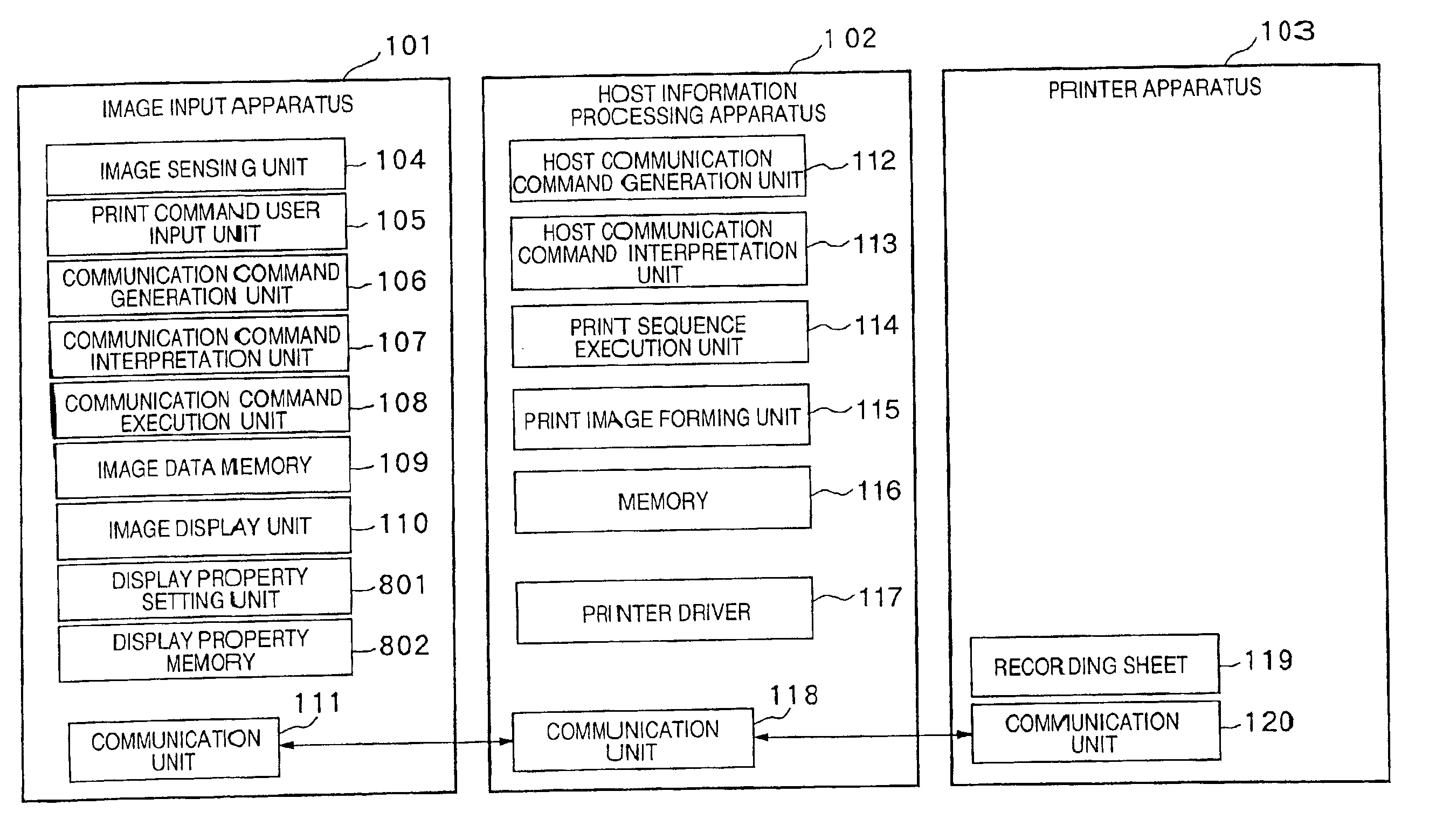

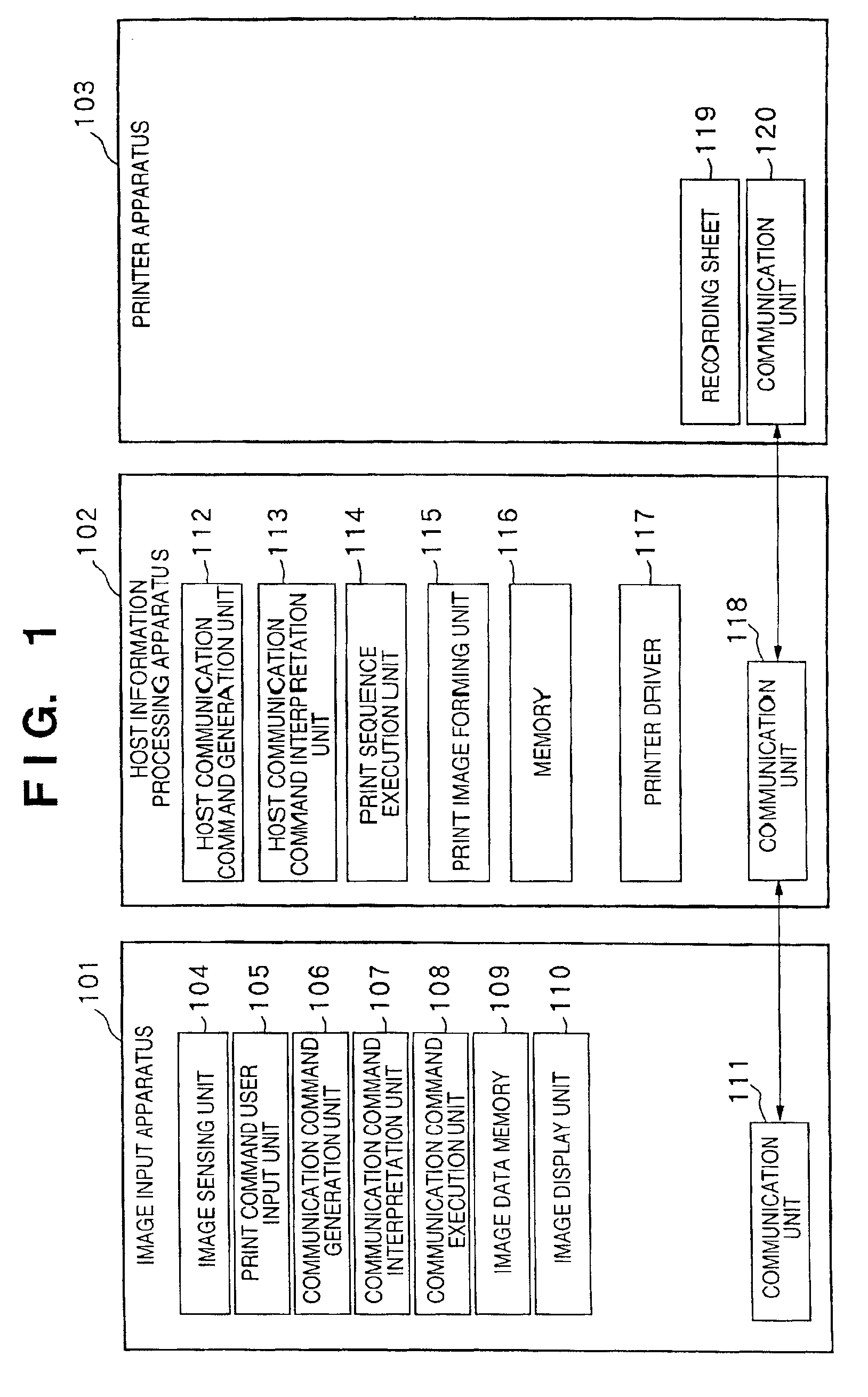

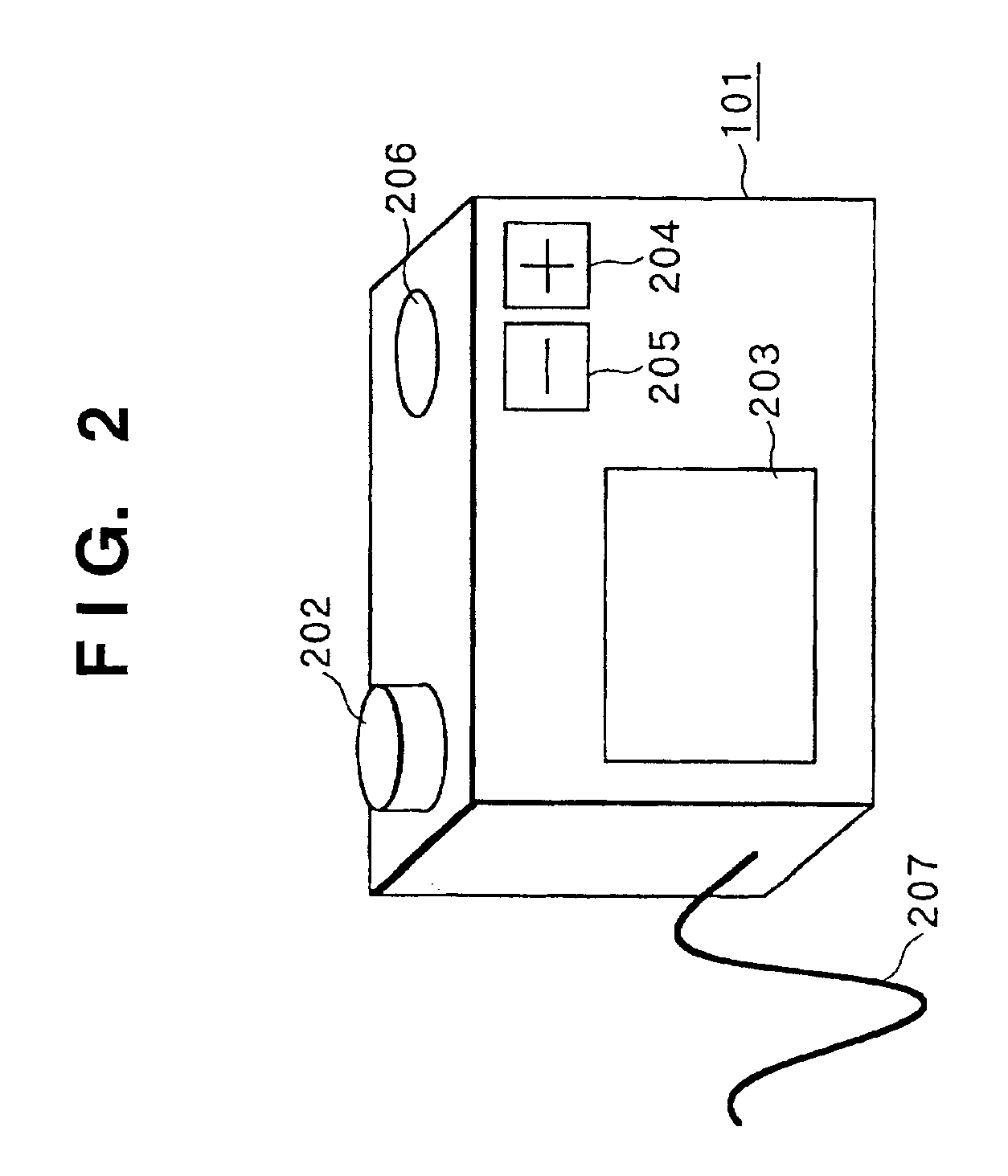

Image inputting apparatus and its control method, information processing apparatus and method, and print system

InactiveUS6867882B1Easily printCost reductionTelevision system detailsDigitally marking record carriersInput deviceImage processing

In a print system which has a digital still camera, computer, and printer, it is difficult for a user who is not accustomed to the computer to operate the computer. A direct printer is expensive since the printer itself requires a controller, a digital signal processor for image processes, a module for communicating with the image inputting apparatus, and the like. To combat this problem, an image inputting apparatus transmits a print execution instruction and an image to be printed to an information processing apparatus upon inputting a print request of a sensed image or an image stored in a memory. Upon receiving the print execution instruction and the image to be printed, the information processing apparatus issues a print request of the received image to a connected printer apparatus, and transmits the received image.

Owner:CANON KK

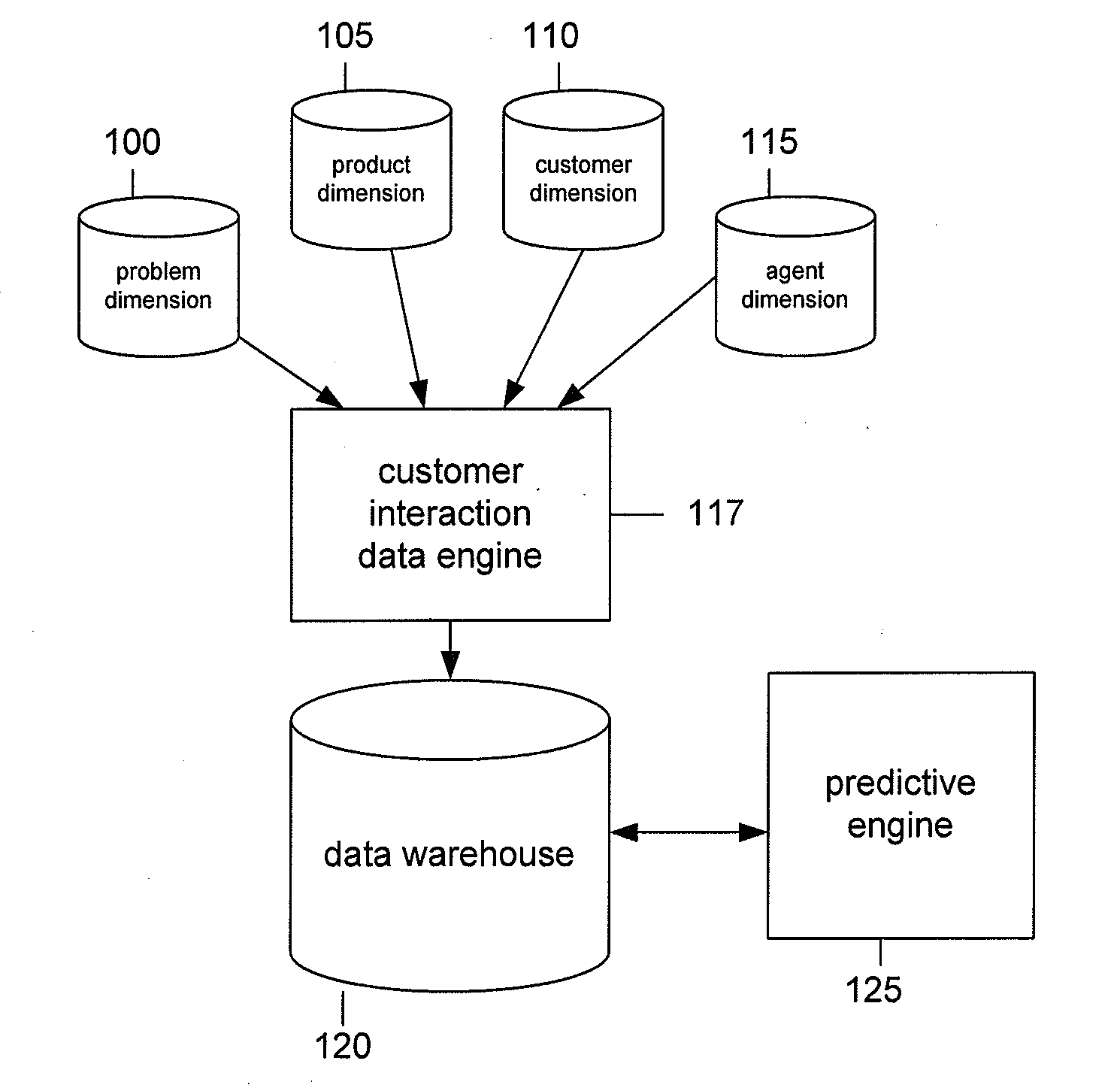

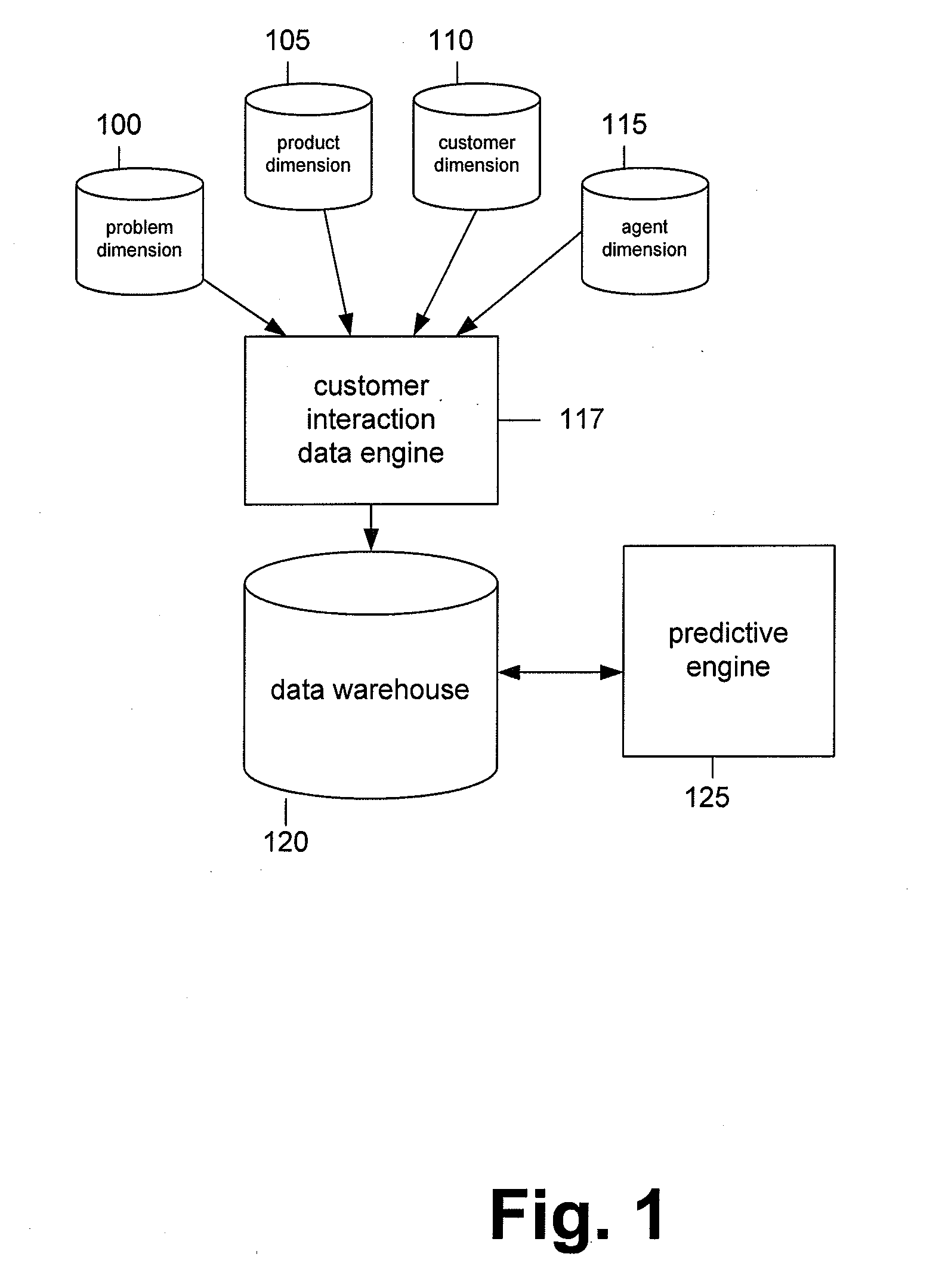

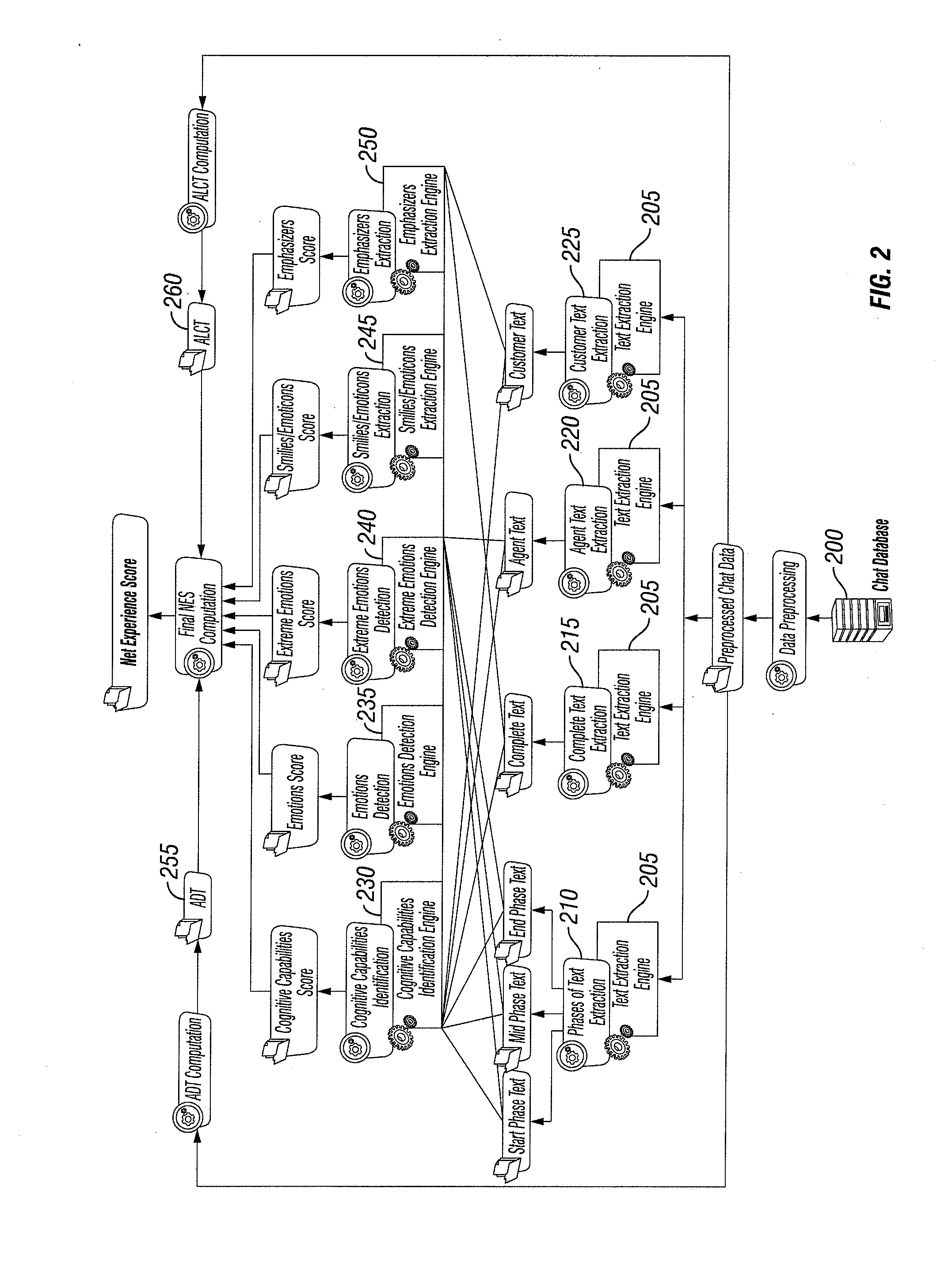

Apparatus and method for predicting customer behavior

ActiveUS20090222313A1Enhanced customer experienceCost reductionFuzzy logic based systemsKnowledge representationData conversionAnalysis data

A predictive model generator that enhances customer experience, reduces the cost of servicing a customer, and prevents customer attrition by predicting the appropriate interaction channel through analysis of different types of data and filtering of irrelevant data. The model includes a customer interaction data engine for transforming data into a proper format for storage, data warehouse for receiving data from a variety of sources, and a predictive engine for analyzing the data and building models.

Owner:24 7 AI INC

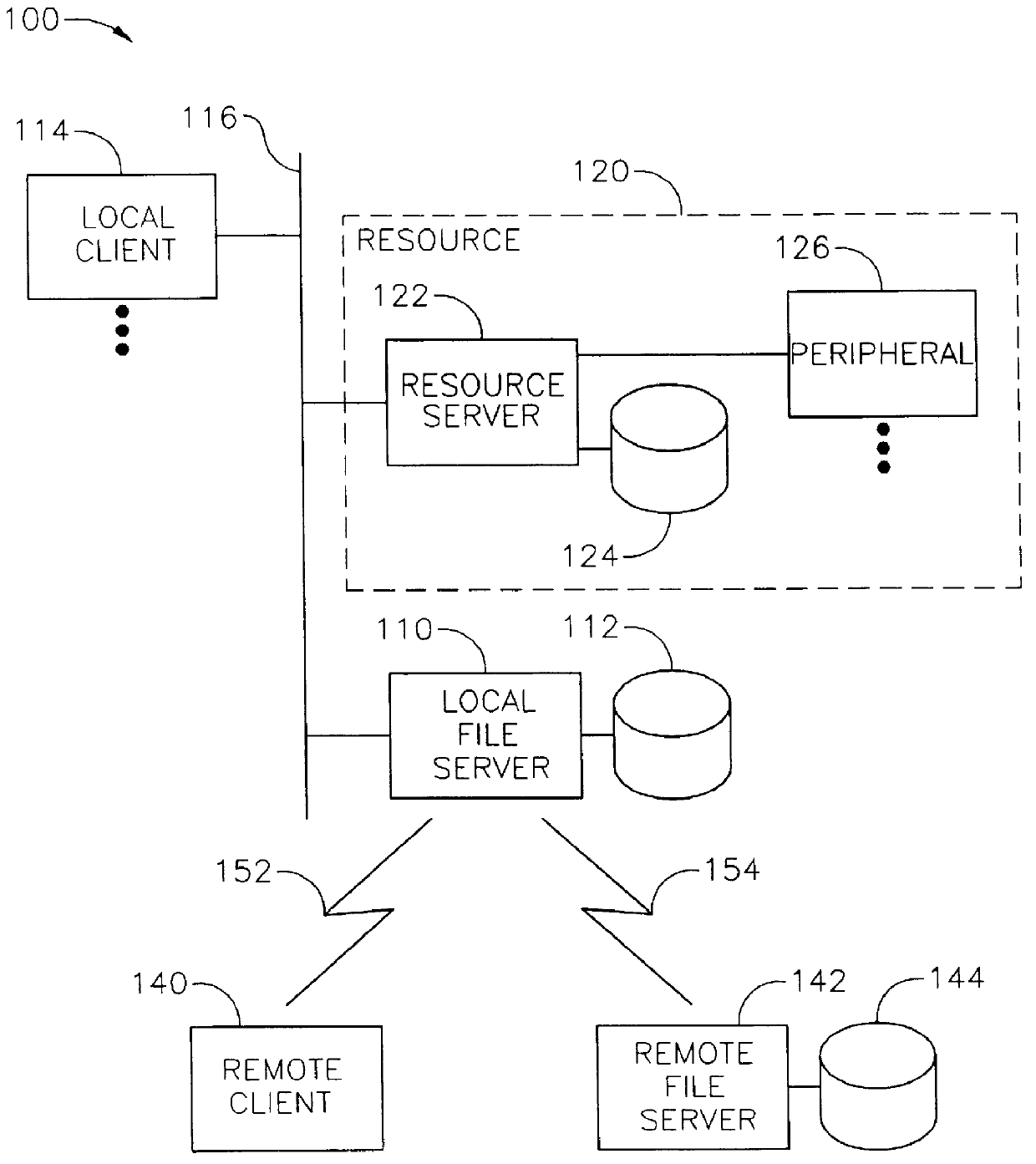

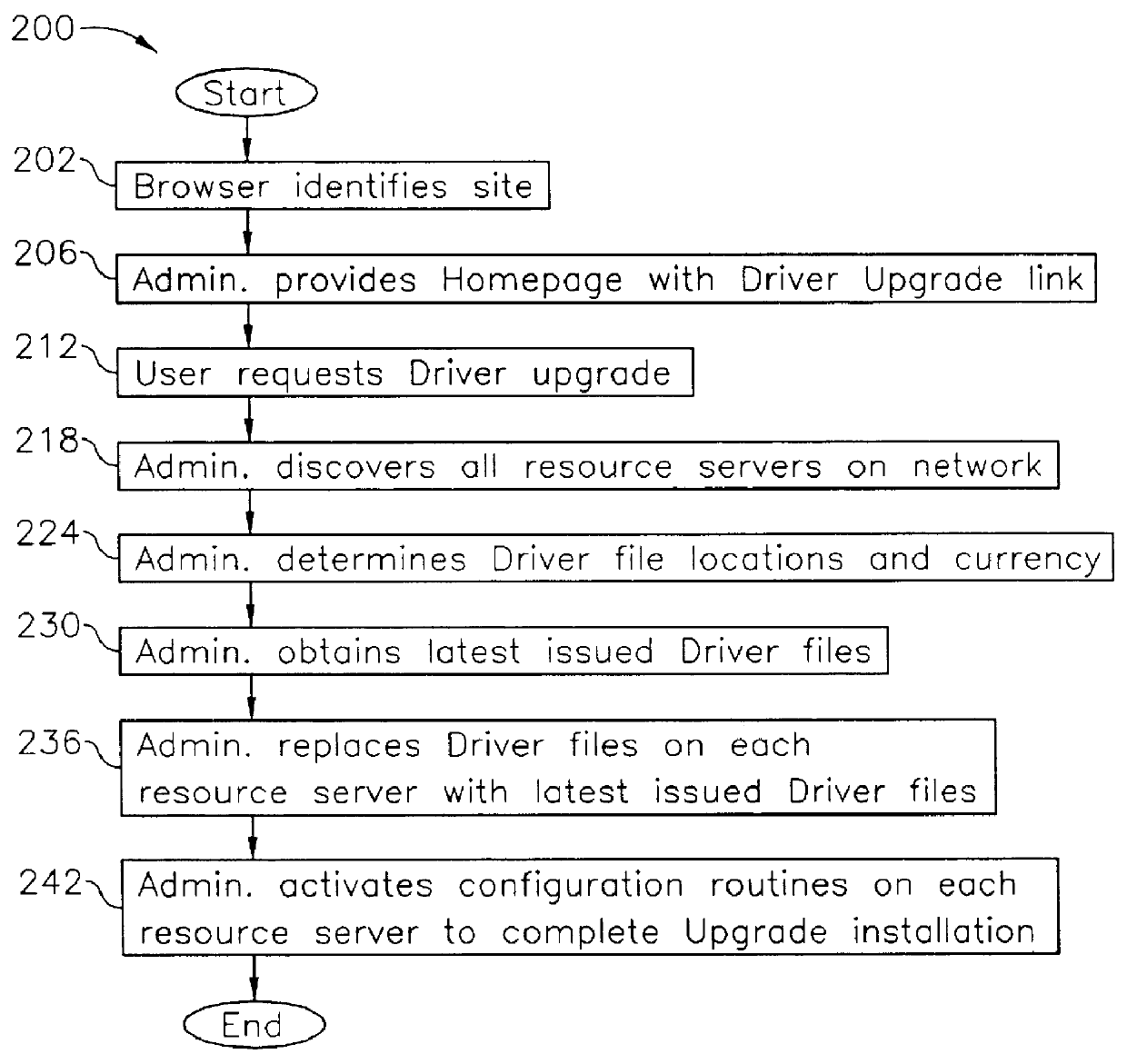

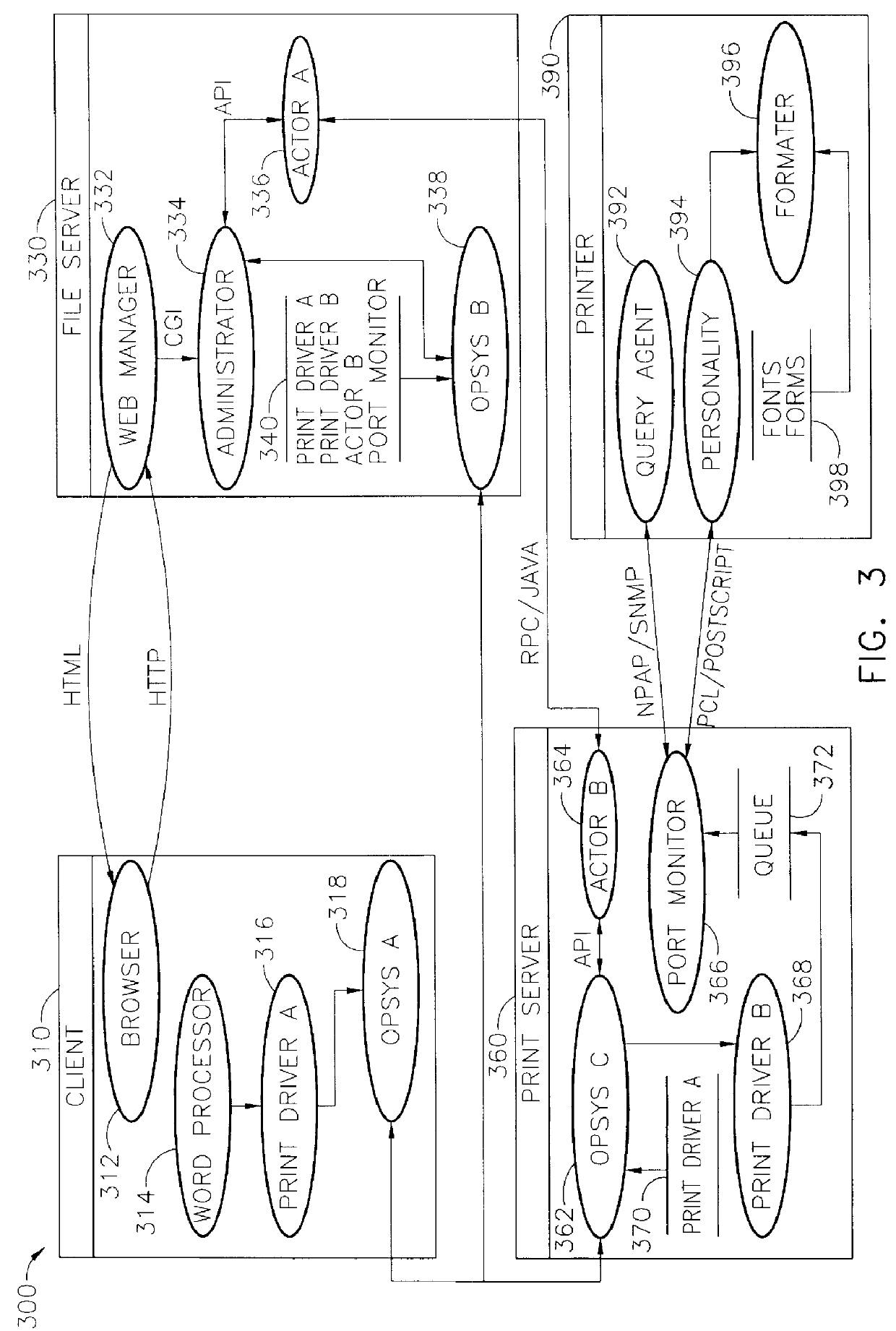

Server system and method of updating server software

InactiveUS6125372ACost reductionSave resource costData processing applicationsDigital data information retrievalClient-sidePeripheral

A system with resource server updating provides upgraded system operation by installing replacement files on the resource when needed and without manual intervention. The system in an exemplary embodiment includes client workstations, a file server, and several resource servers coupled to a network for data communication. Several printers, scanners, and other peripherals are coupled to each resource server. In response to a hypertext page provided by the file server to a workstation, a user initiates file version checking and file replacements on all resource servers on the network. Replacement files exist on the file server or are obtained from a remote file server, as needed.

Owner:HEWLETT PACKARD CO

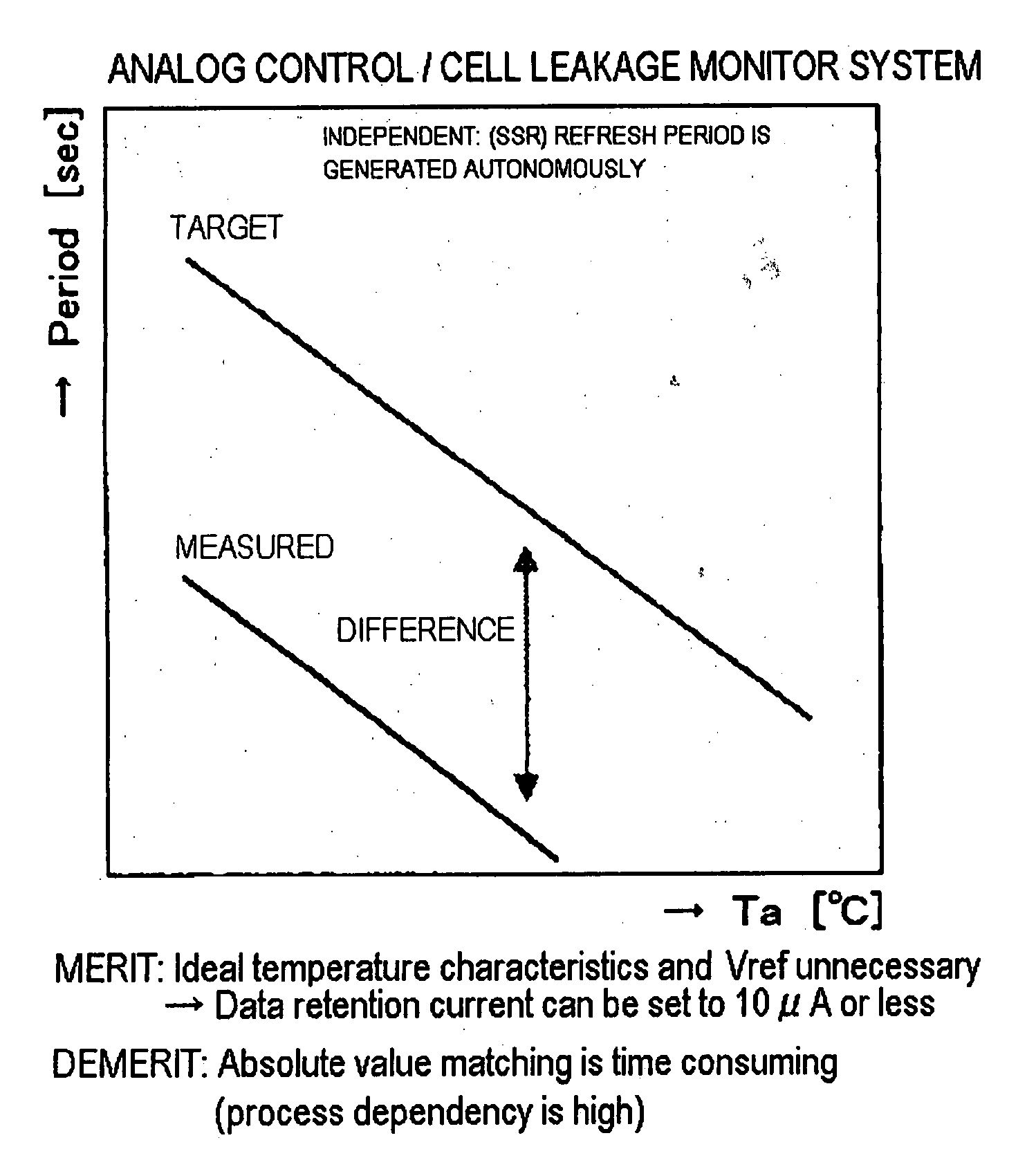

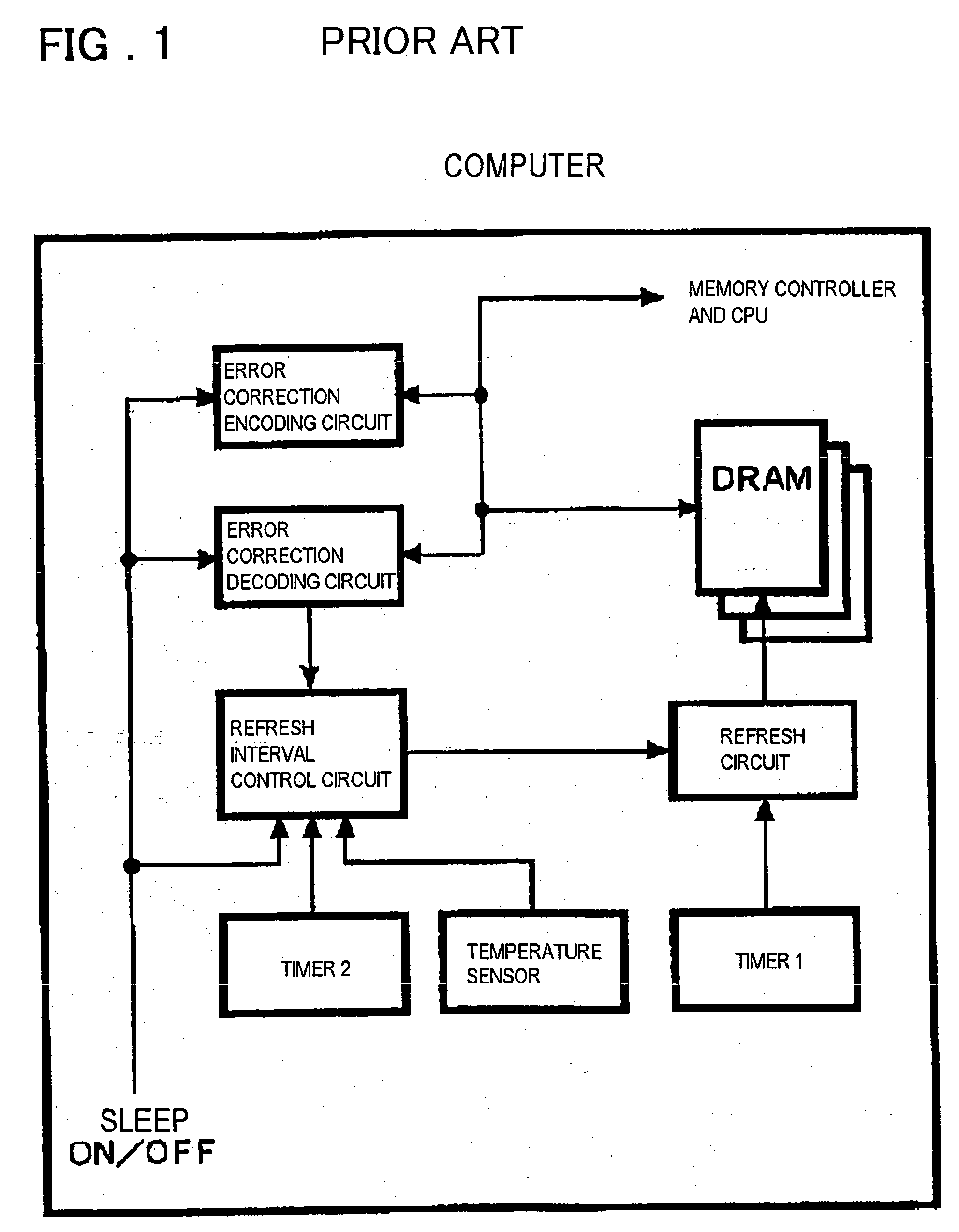

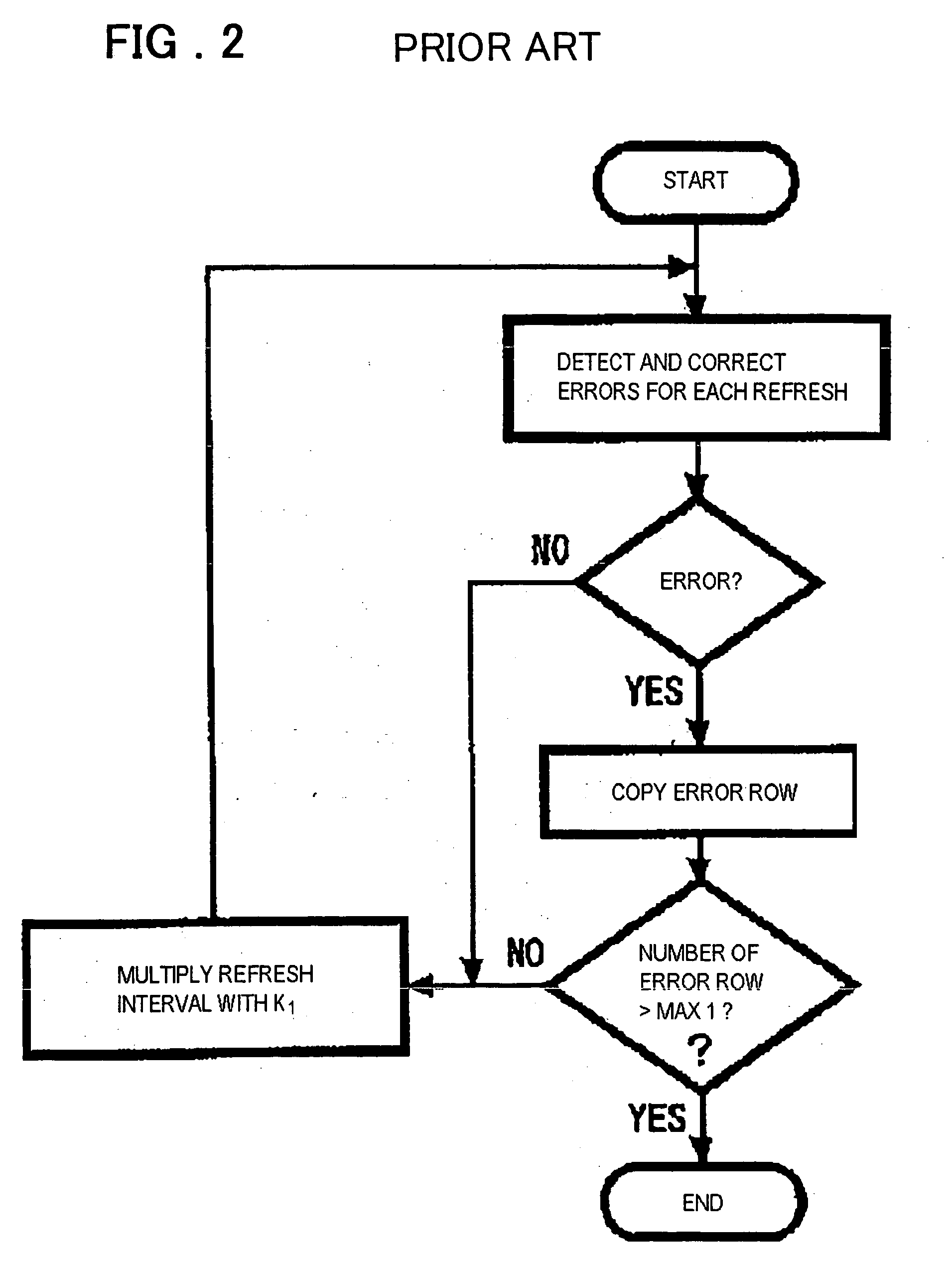

Semiconductor memory device and refresh period controlling method

InactiveUS20050281112A1Improved temperature compensationCost reductionError detection/correctionCode conversionError ratioRate measurement

Disclosed is a memory device including an error rate measurement circuit and a control circuit. The error rate measurement circuit, carrying a BIST circuit, reads out and writes data for an area for monitor bits every refresh period to detect an error rate (error count) with the refresh period. The control circuit performs control for elongating and shortening the refresh period so that a desired error rate will be achieved. The BIST circuit issues an internal command and an internal address and drives the DRAM from inside. The BIST circuit writes and reads out desired data, compares the monitor bits to expected values (error decision) and counts the errors.

Owner:PS4 LUXCO SARL

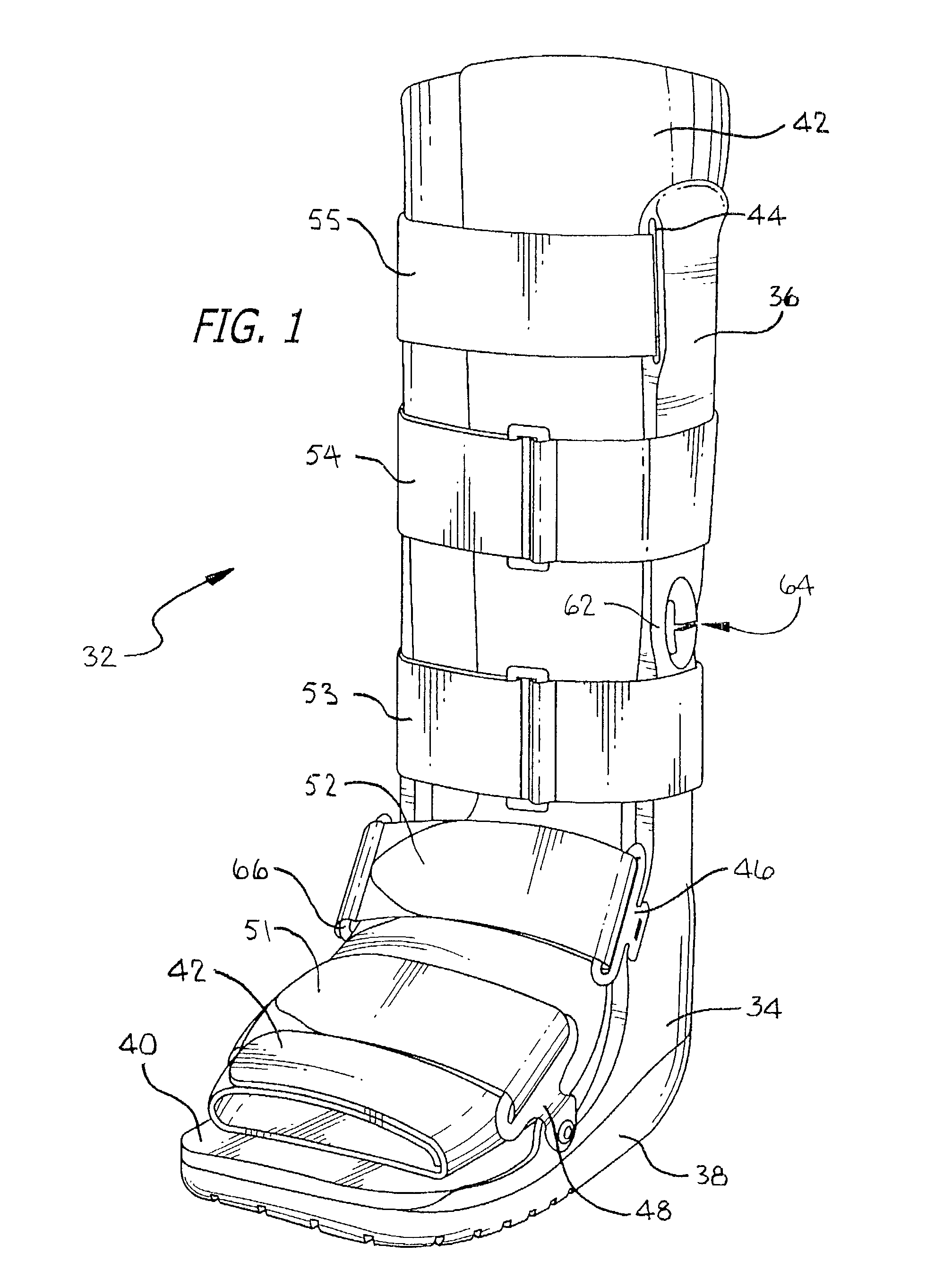

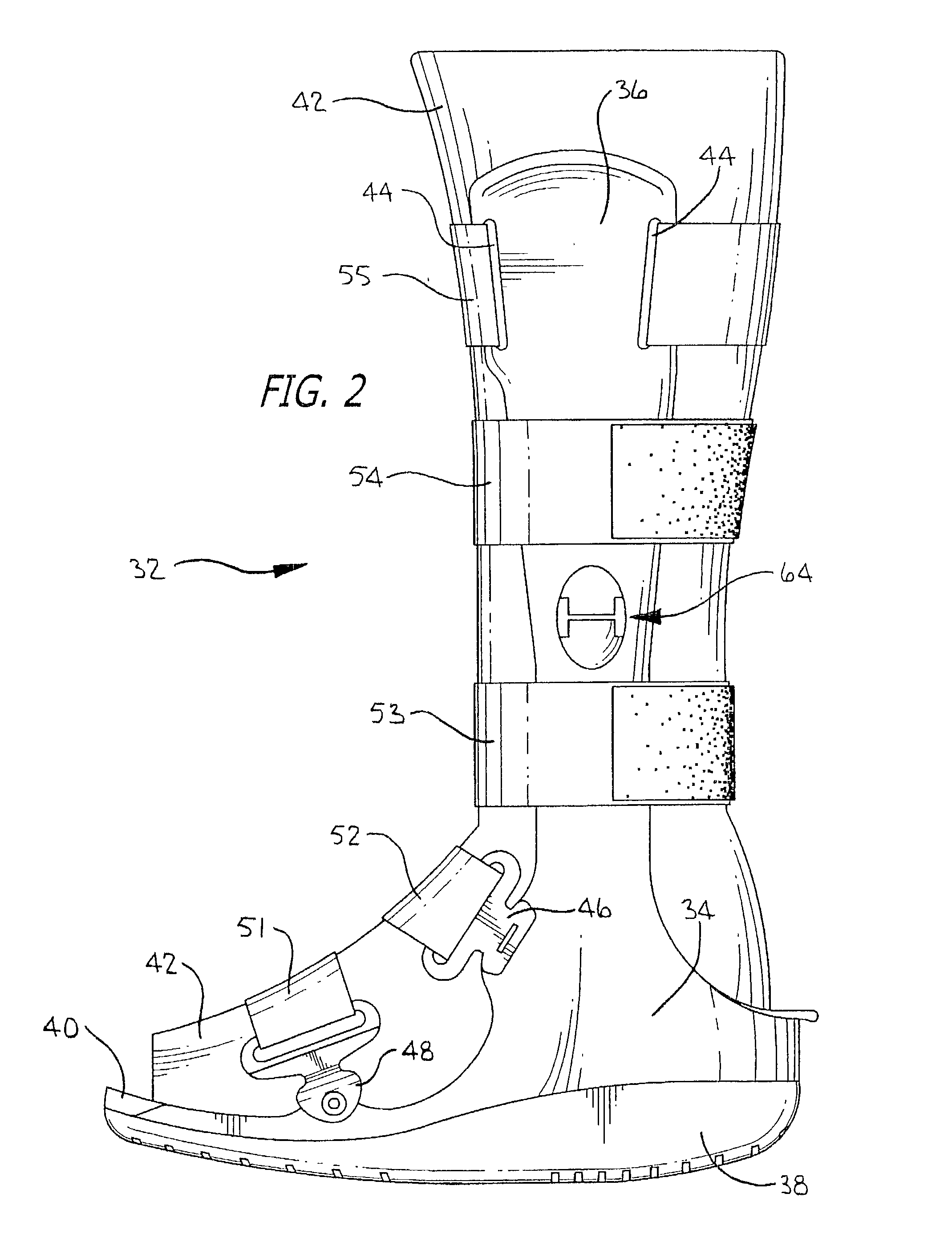

Versatile orthopaedic leg mounted walkers

ActiveUS7303538B2Cost reductionIncreased surface contact and grip actionWalking aidsNon-surgical orthopedic devicesPlastic surgeryMechanical engineering

A versatile orthopedic walker includes a high strength engineered plastic base with spaced upper and lower surfaces and upwardly extending slotted strut supports. The base may be laterally and vertically cored, and an outer sole is provided which extends upward over the core openings, with the upper edges of the outsole being ridged to fit into a peripheral groove in the base to provide a smooth exterior surface. Struts of different lengths are provided, and all of the struts have identical arrangements for interlocking with the base. All of the struts may be provided with a three pronged construction to triply lock the struts into the base. The struts may have areas of reduced cross-section providing pivot points or areas of flexibility to accommodate different size patients, and limiting stops may be provided to assure adequate orthopedic support. Fully integrally molded pivoting D-rings may hold walker straps in place.

Owner:OSSUR HF

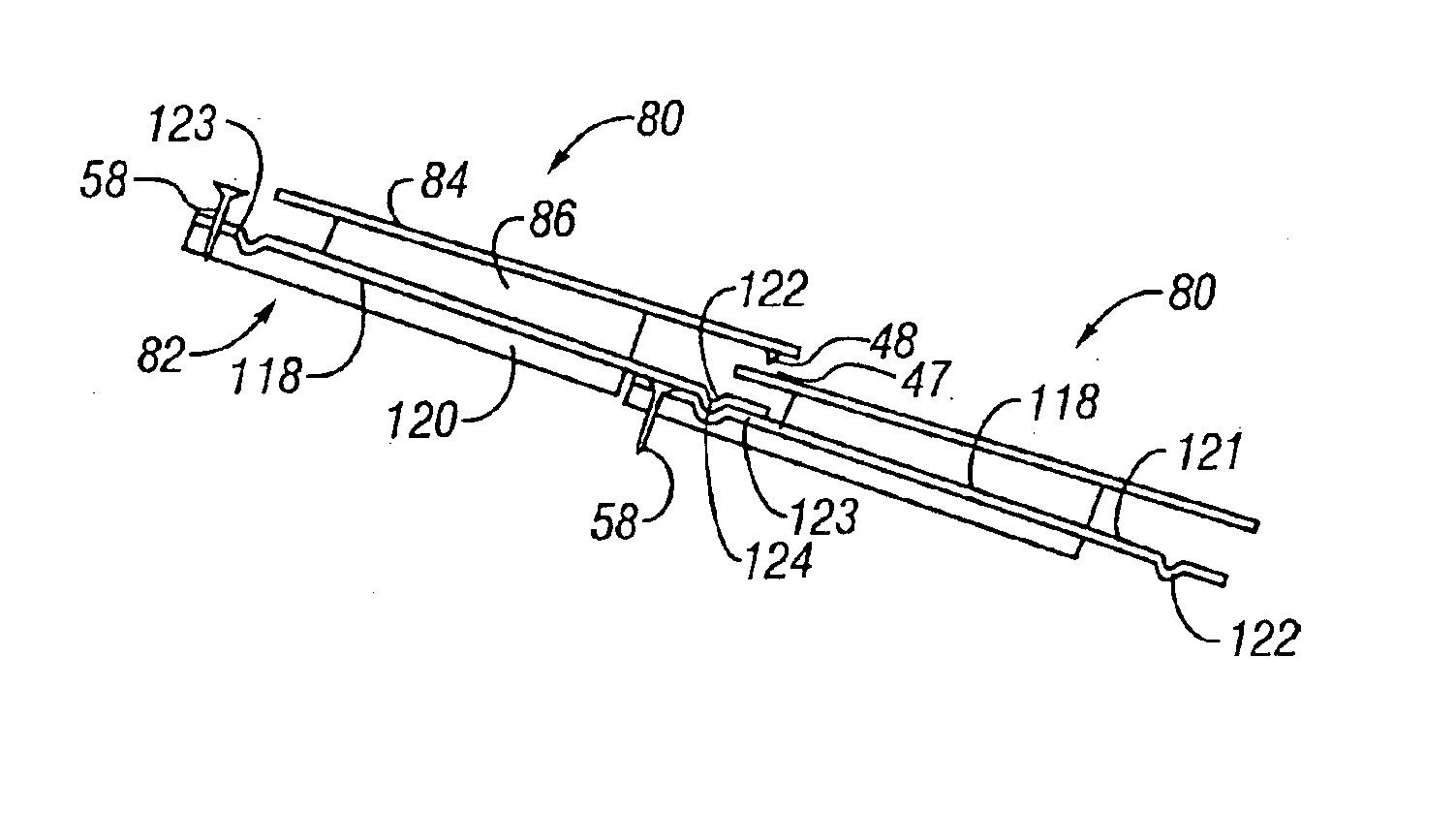

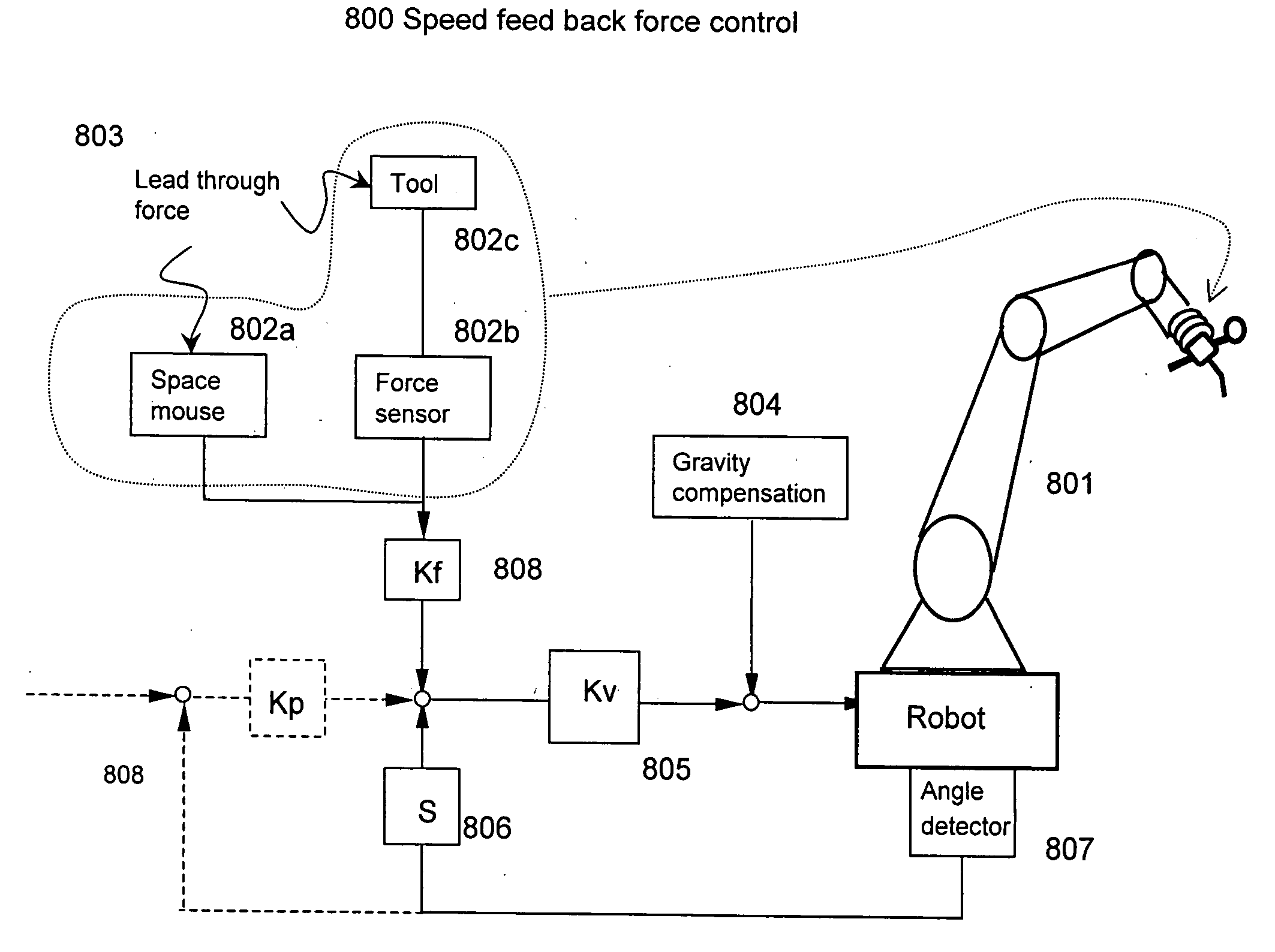

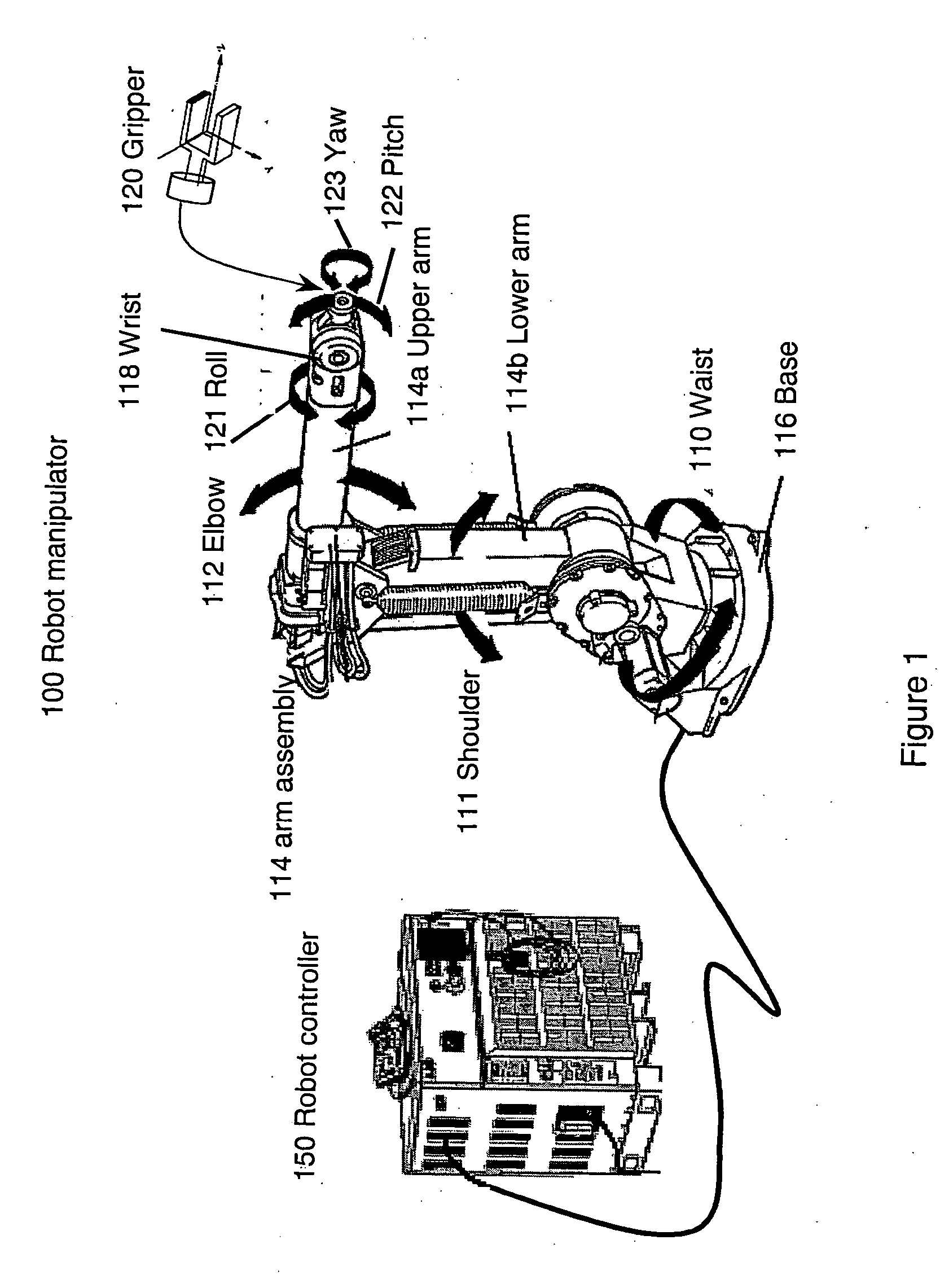

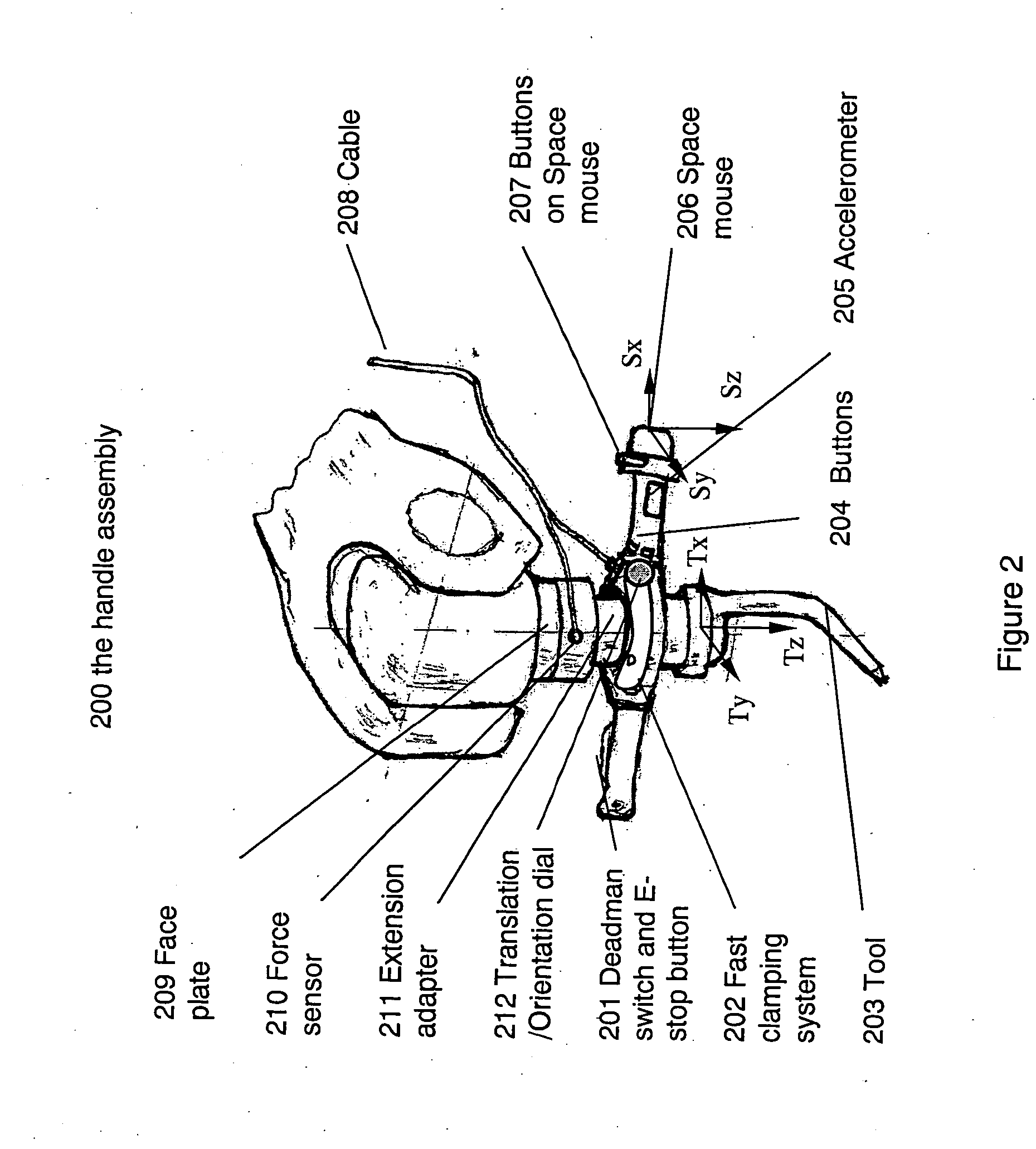

Accelerometer to monitor movement of a tool assembly attached to a robot end effector

InactiveUS20060178775A1Cost reductionProgramme controlProgramme-controlled manipulatorRobot end effectorMetallic Lead

An accelerometer is mounted on a robot to monitor movement of a tool assembly attached to the robot end effector for safety monitoring purposes. The accelerometer provides an output signal to the robot controller which the controller uses to monitor the robot movement and stop that movement when a predetermined values of acceleration, speed and distance are detected during lead-through teaching of the robot. A handle can be attached to the robot end effector and the accelerometer can be mounted on the handle.

Owner:ABB RES LTD

Method and apparatus for temperature, conductance and/or impedance testing in remote application of battery monitoring systems

InactiveUS20070046261A1Improved installation maintenance reliabilityCost reductionBatteries circuit arrangementsElectrical testingPeripheralEngineering

An apparatus and method of monitoring at least one battery, includes measuring an analog signal related to the at least one battery, converting the analog signal to a digital signal and communicating the digital signal in a wireless manner to an external device, in which the measuring, converting, and communicating are performed by an arrangement that is embedded in or attached to the at least one battery.

Owner:ENERSAFE

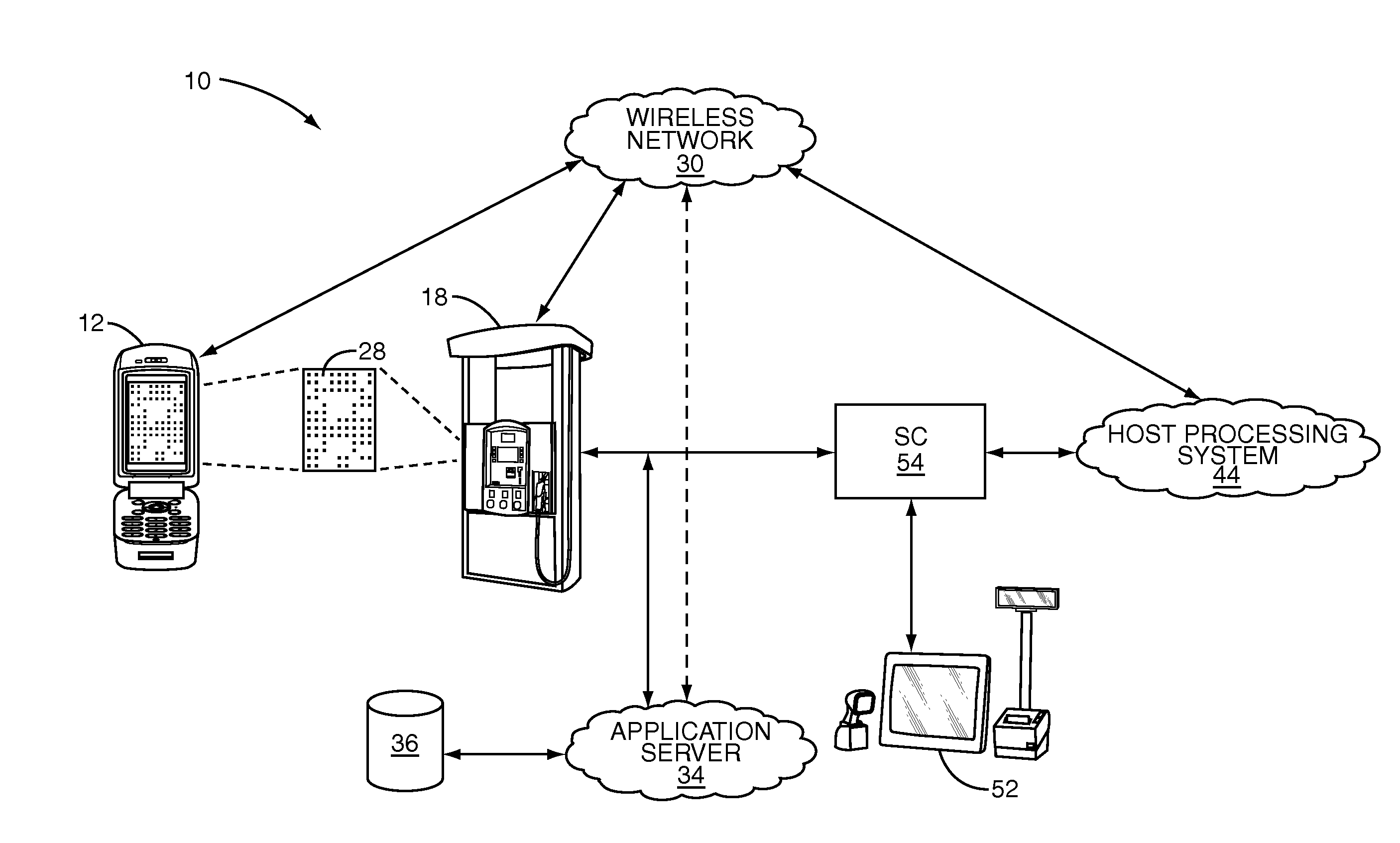

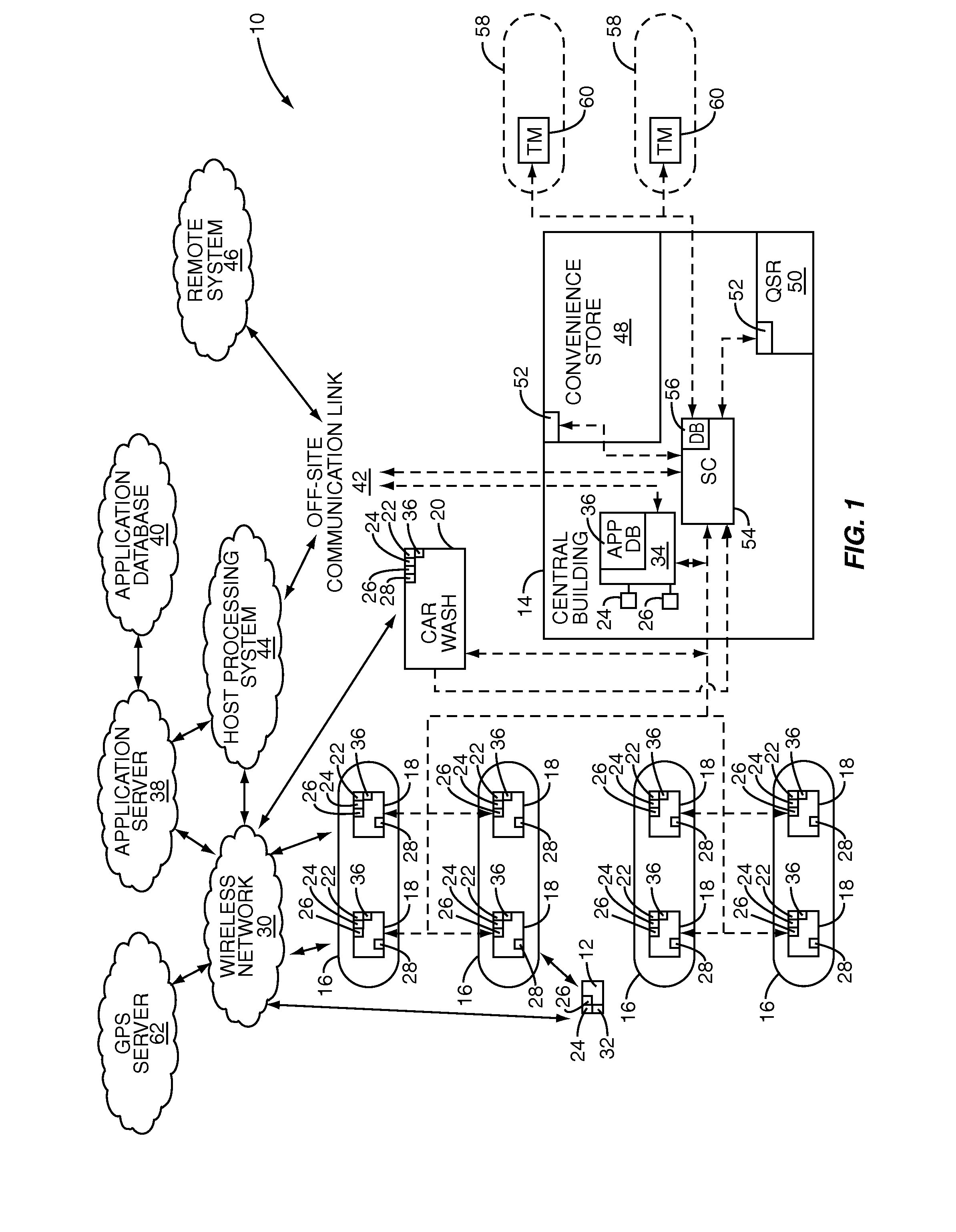

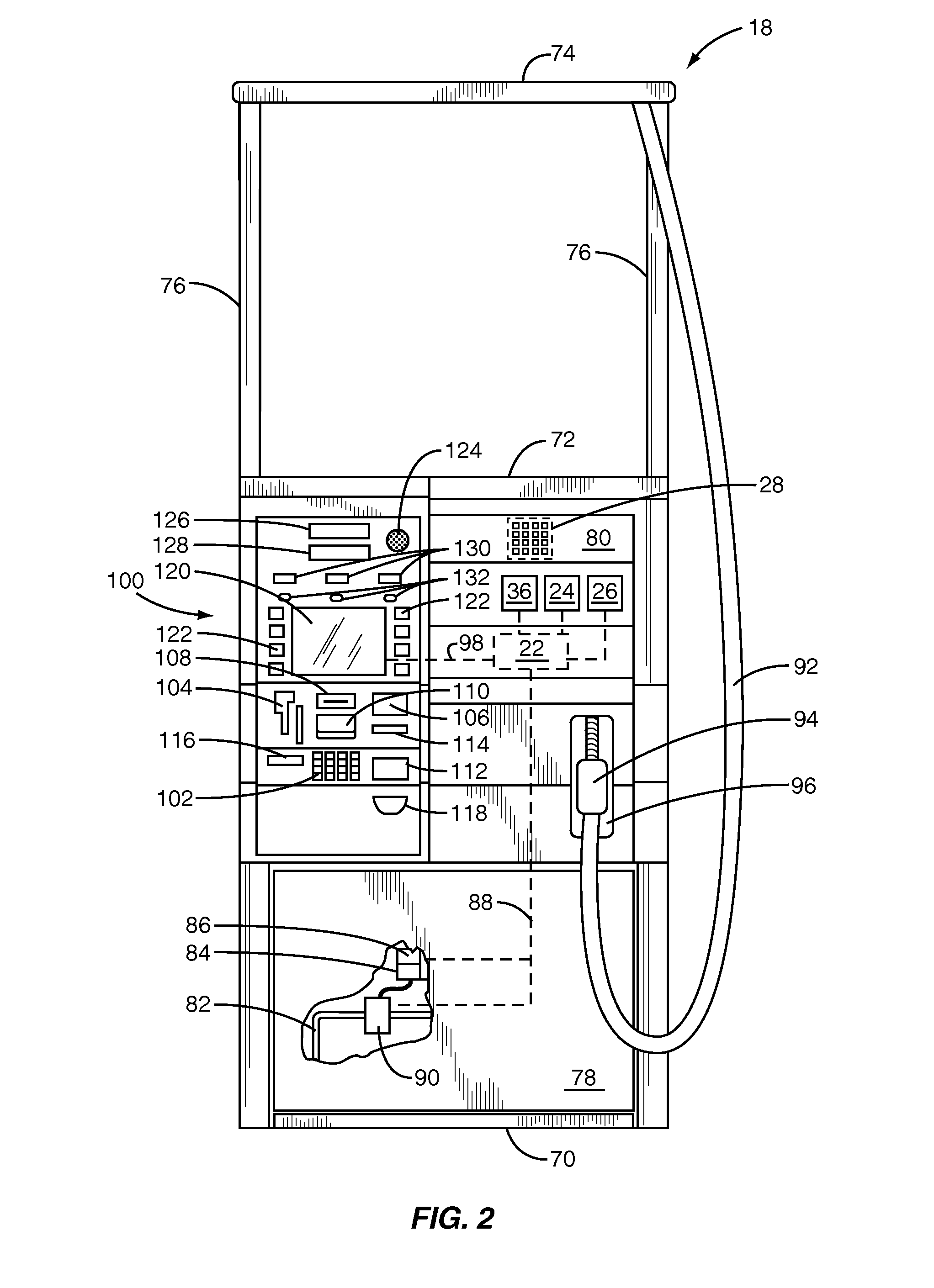

System and method for providing receipts, advertising, promotion, loyalty programs, and contests to a consumer via an application-specific user interface on a personal communication device

ActiveUS20080308628A1Cost reductionLow costLiquid transferring devicesApparatus for dispensing fluids/granular materialsProgram planningLoyalty program

Systems and methods for performing a consumer advertising transaction at a retail device are disclosed. According to one system and method, an identifier associated with the retail device is provided to a personal communication device. An application-specific user interface specific to the retail device is associated based on the identifier. A selection is received for the consumer advertising transaction made by a consumer interacting with the application-specific user interface executing on the personal communication device. The consumer advertising transaction is performed based on the received selection for the consumer advertising transaction made by the consumer interacting with the application-specific user interface.

Owner:GILBARCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com