Patents

Literature

871 results about "Surface pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term surface pressure has two distinct definitions, depending on the context.

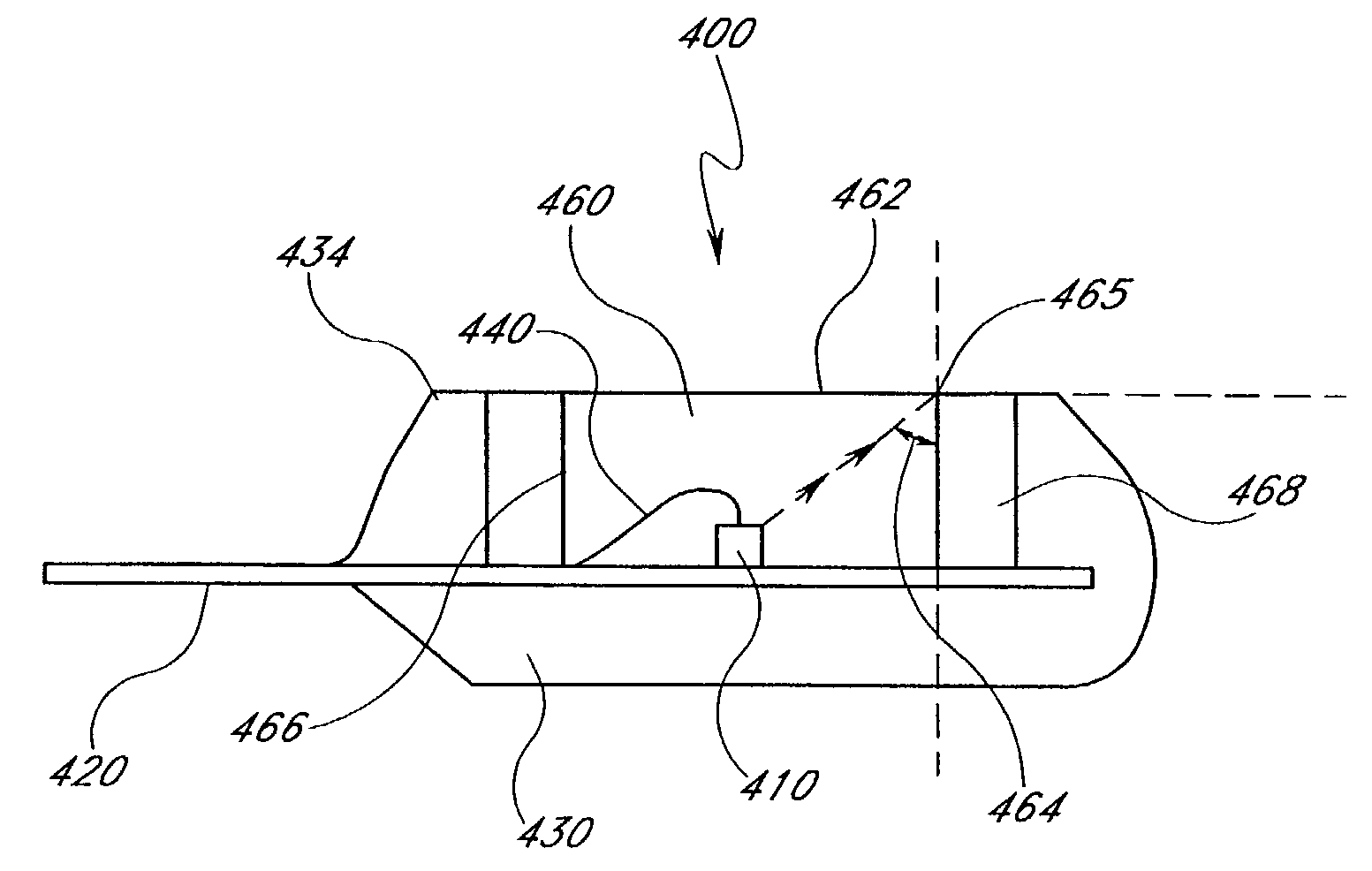

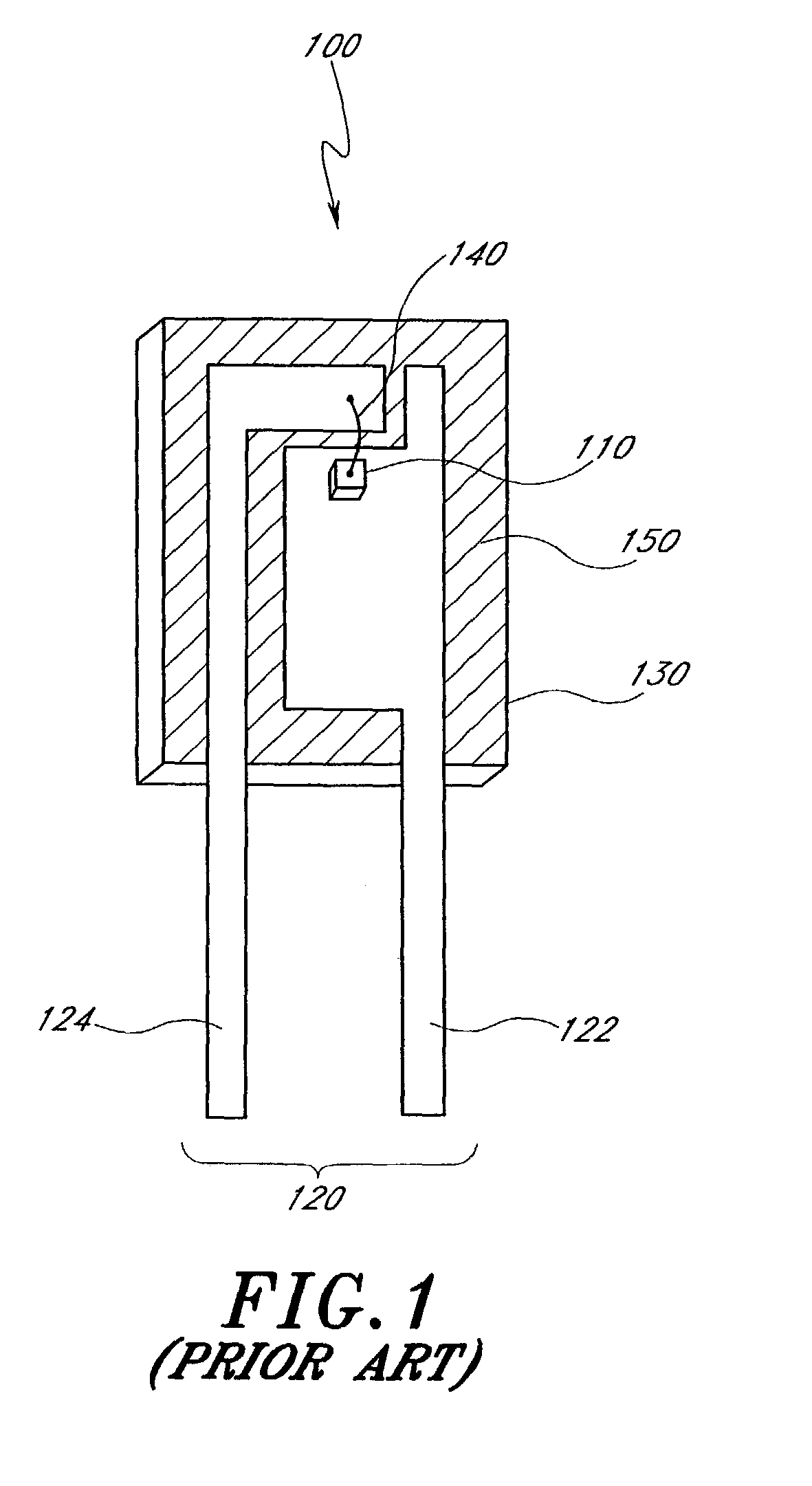

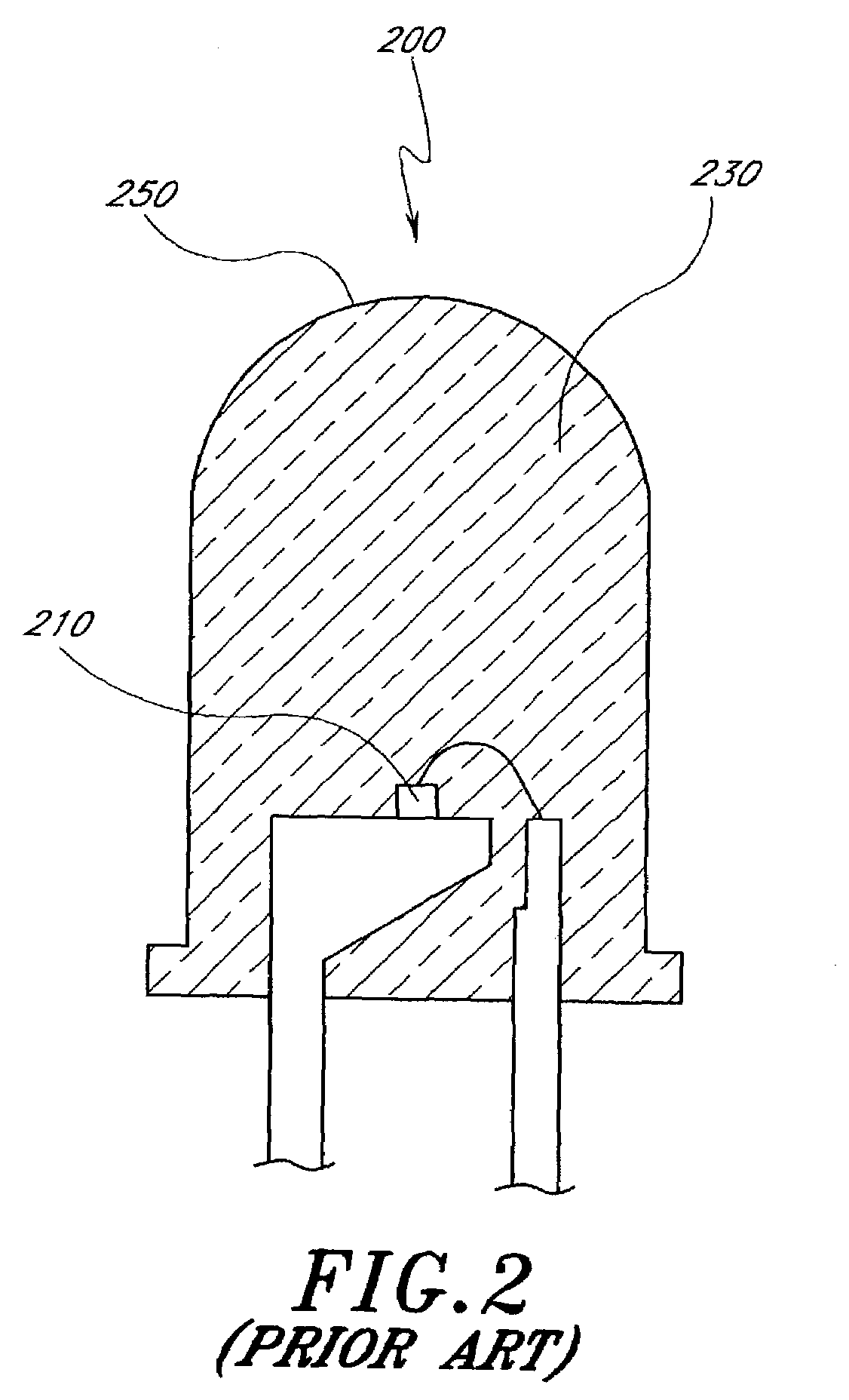

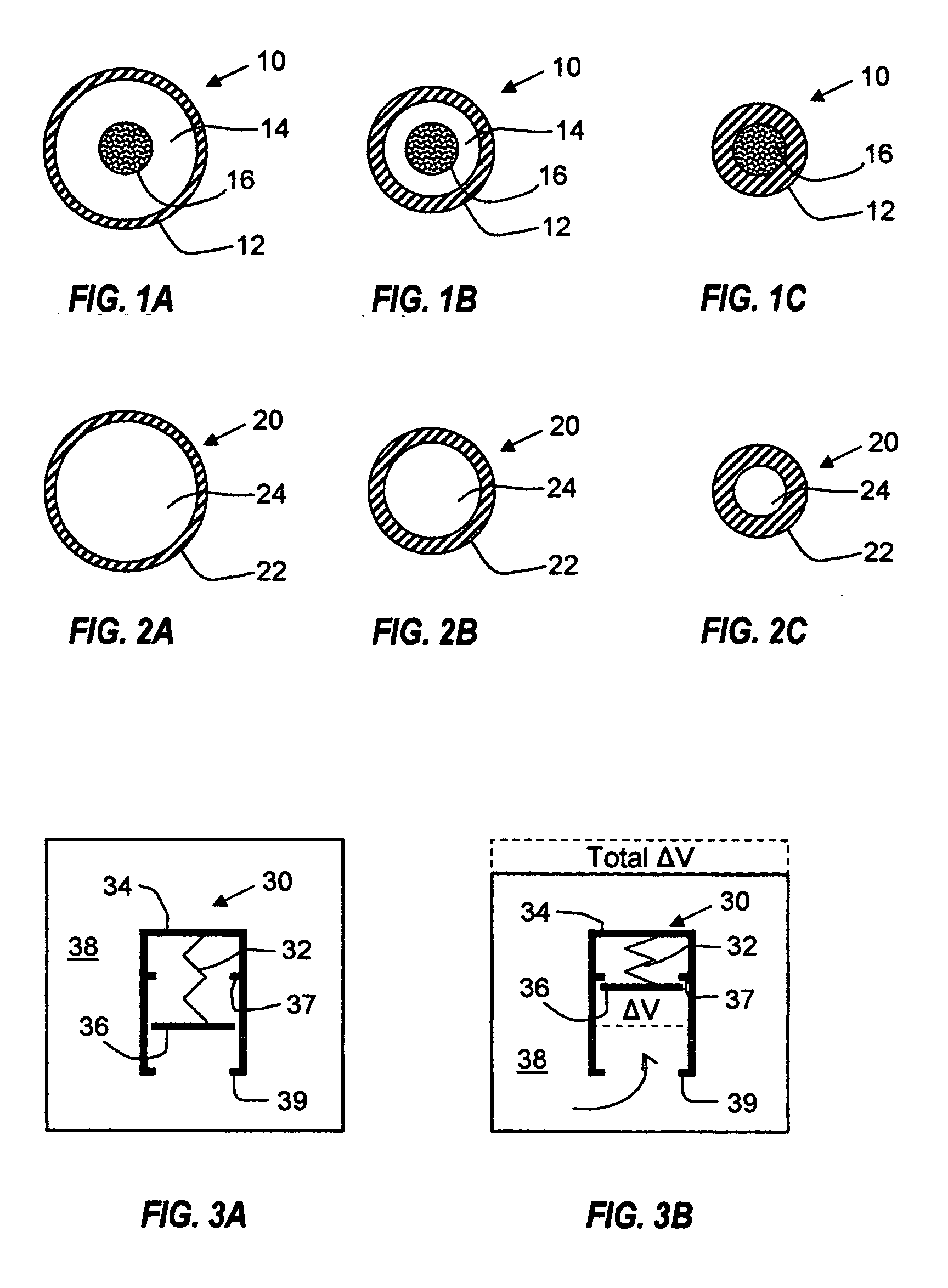

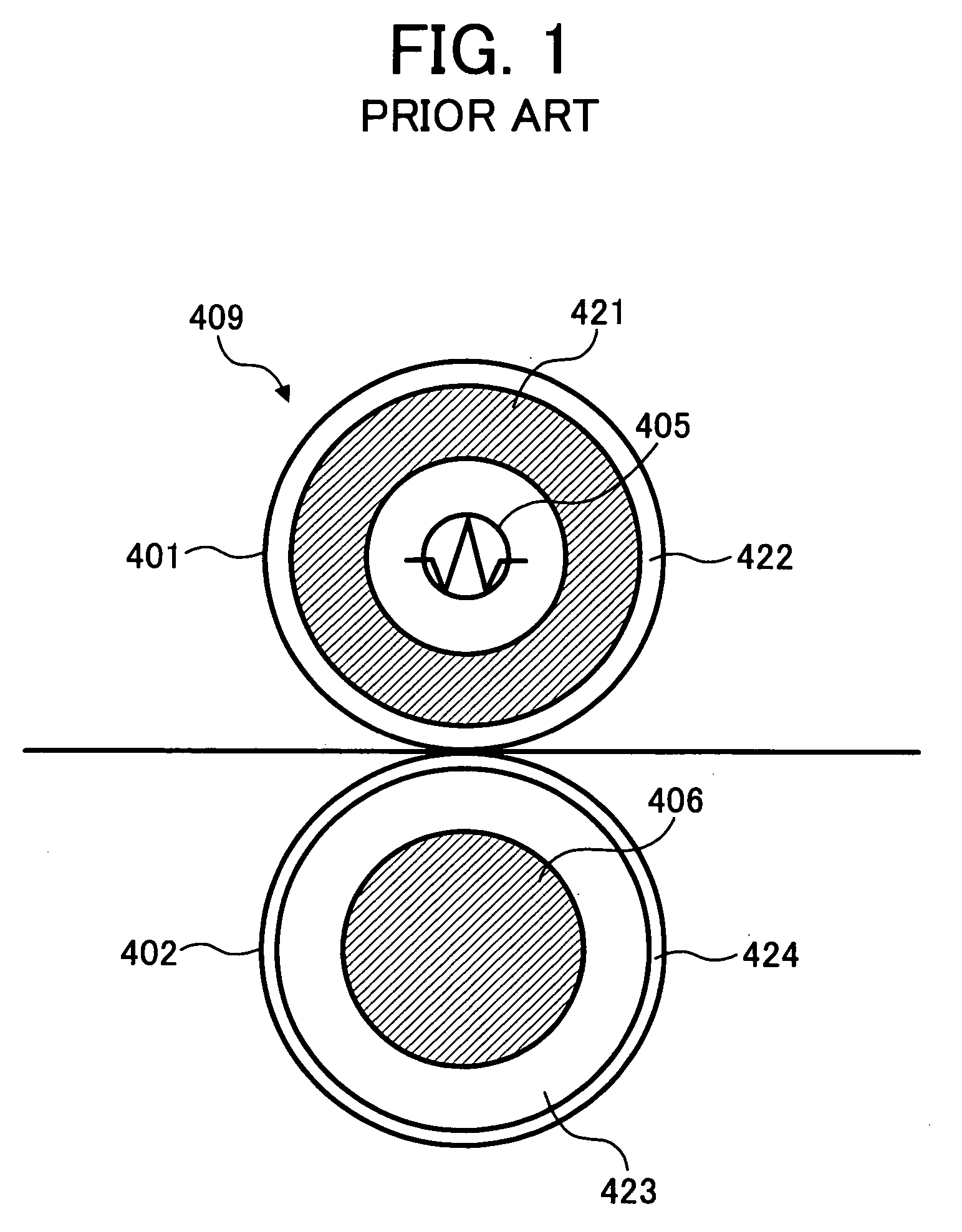

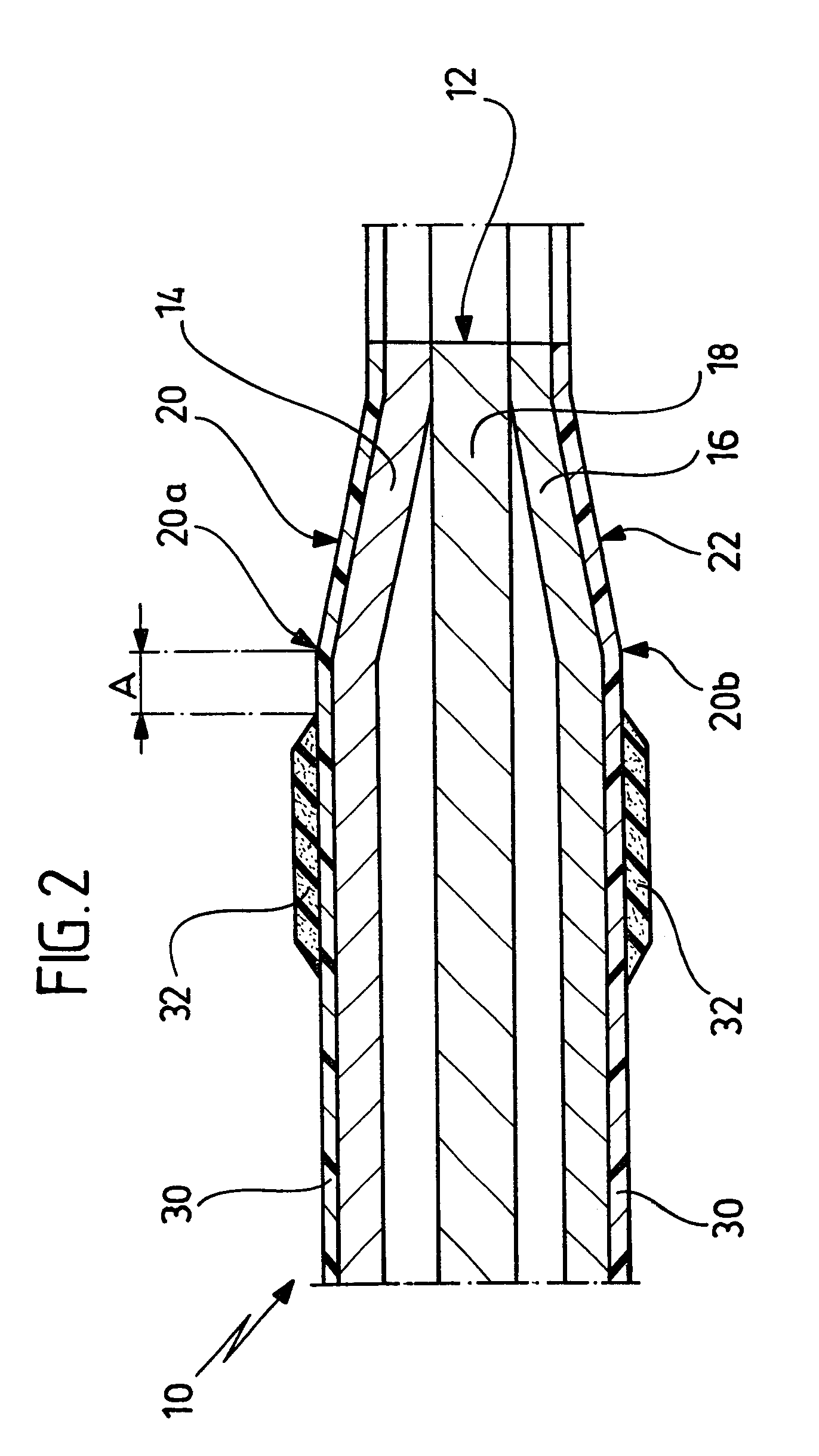

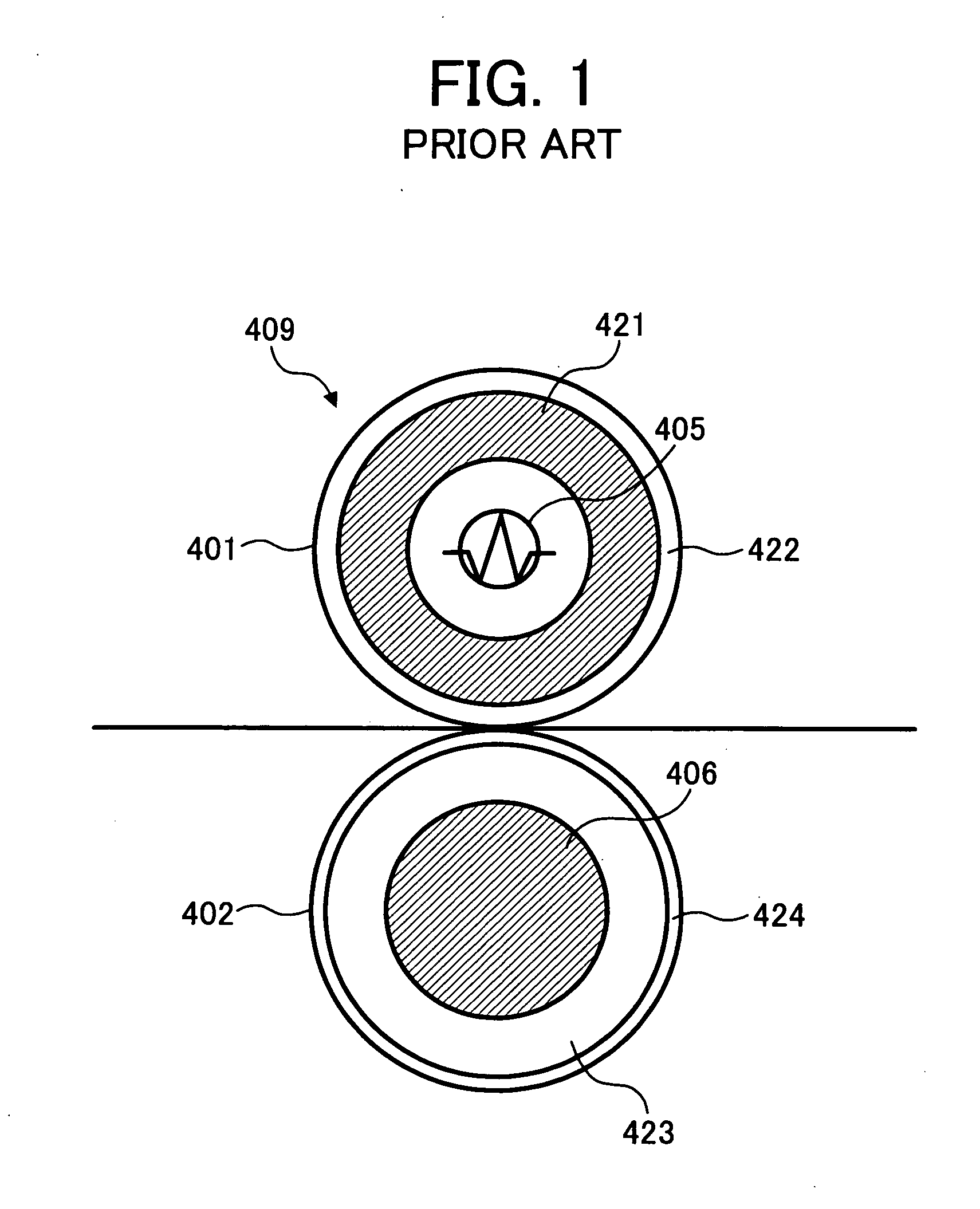

Optoelectronic element with a non-protruding lens

InactiveUS7067893B2Improve component performanceReduce reflectionSolid-state devicesDiagnostic recording/measuringCamera lensReduced size

An optoelectronic component has a lens that is formed in the surface of an encapsulant surrounding a semiconductor diode element. With respect to emitters, the lens reduces internal reflection and reduces dispersion to increase overall efficiency. With respect to detectors, the lens focuses photons on the active area of the detector, increasing detector sensitivity, which allows a detector having a reduced size and reduced cost for a given application. The lens portion of the encapsulant is generally nonprotruding from the surrounding portions of the encapsulant reducing contact surface pressure caused by the optoelectronic component. This non-protruding lens is particularly useful in pulse oximetry sensor applications. The lens is advantageously formed with a contoured-tip ejector pin incorporated into the encapsulant transfer mold, and the lens shape facilitates mold release.

Owner:JPMORGAN CHASE BANK NA

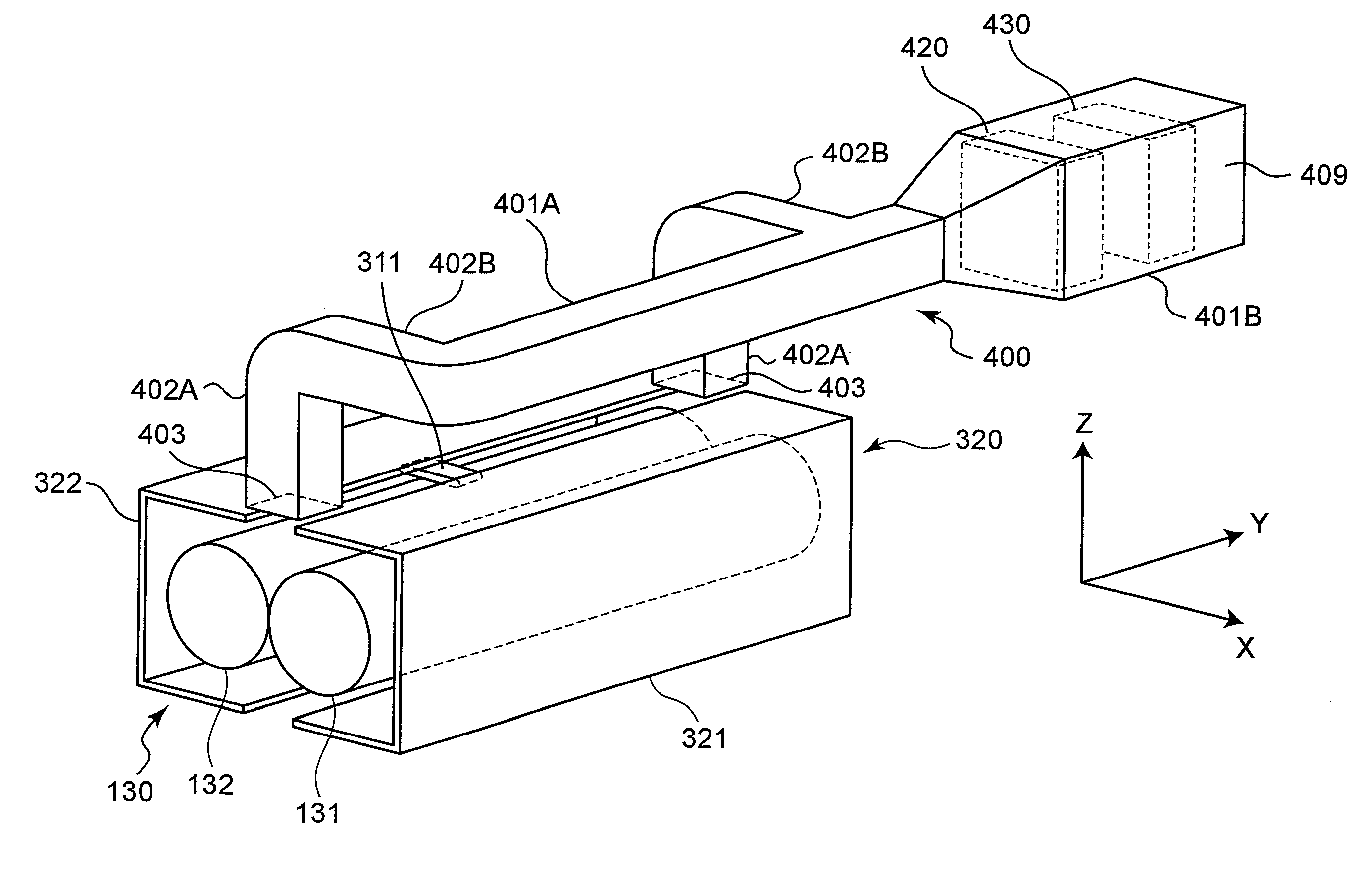

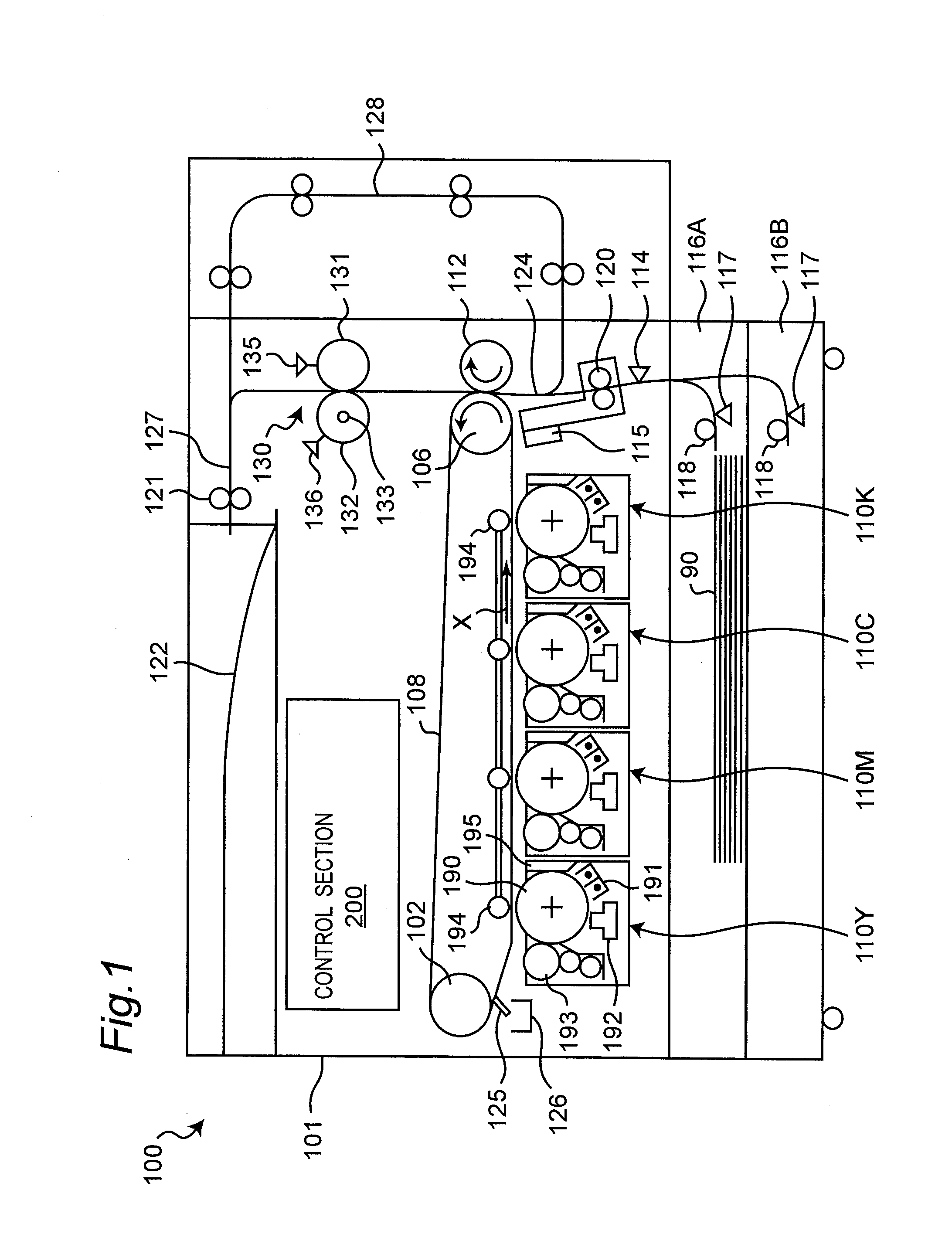

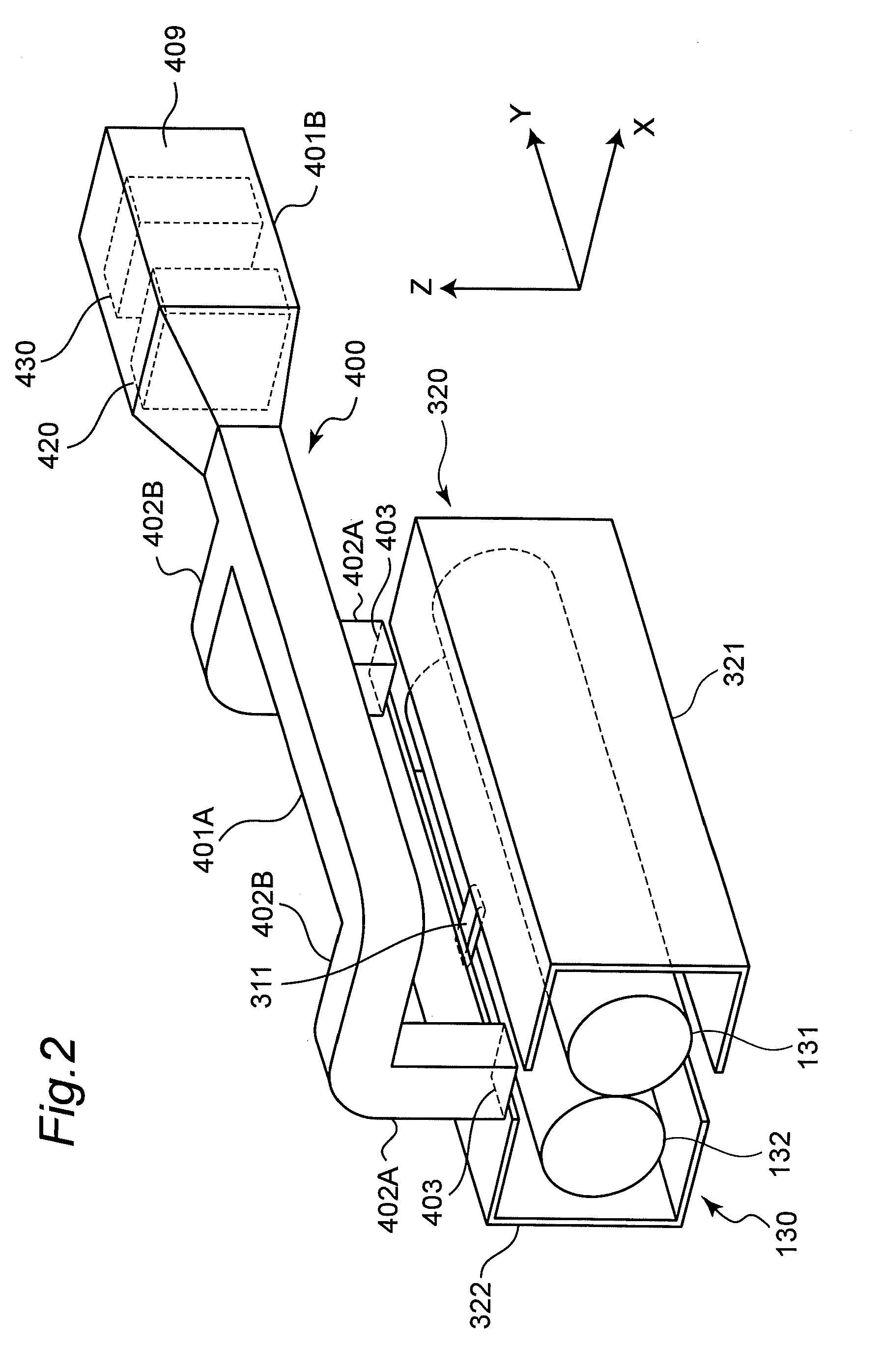

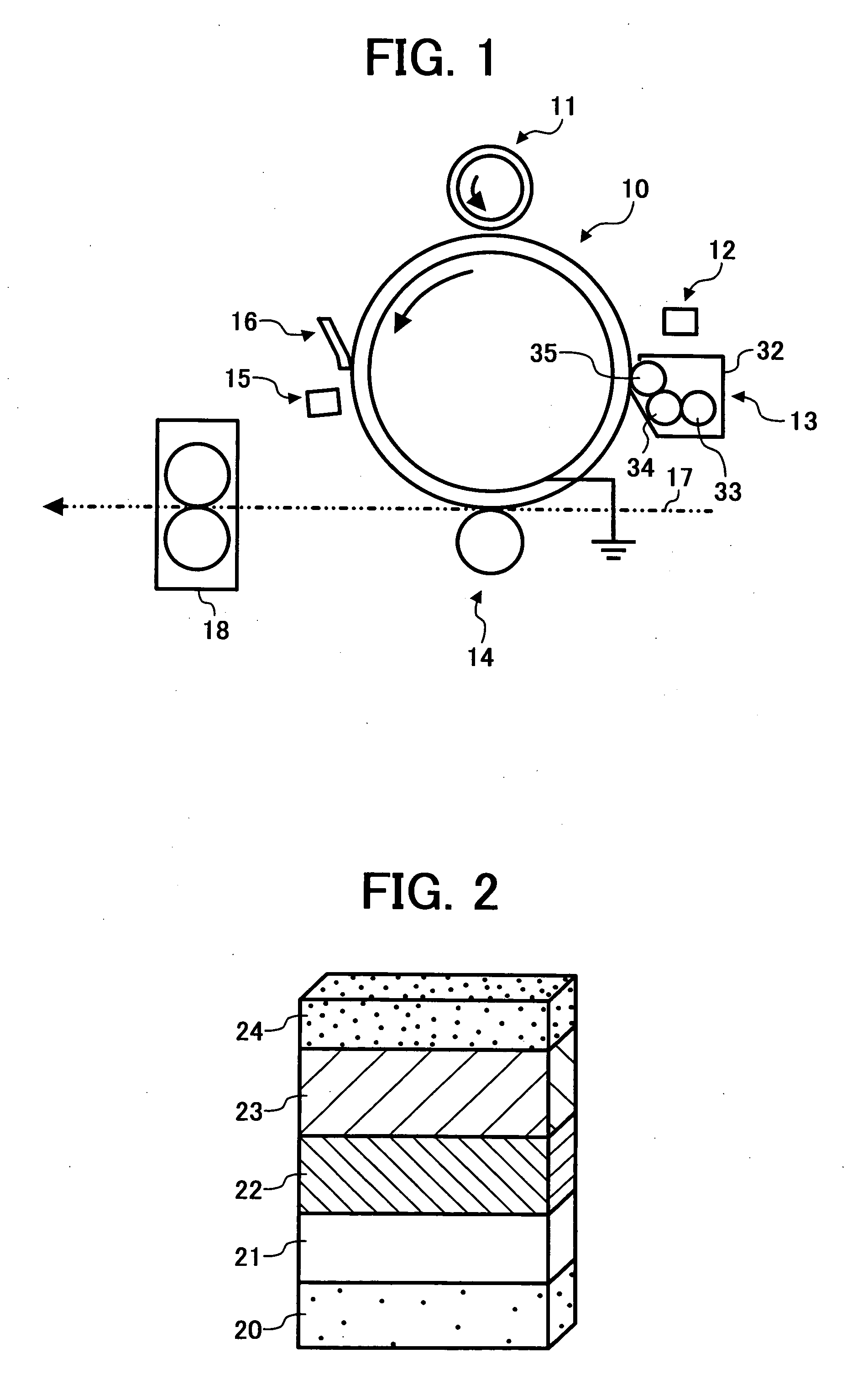

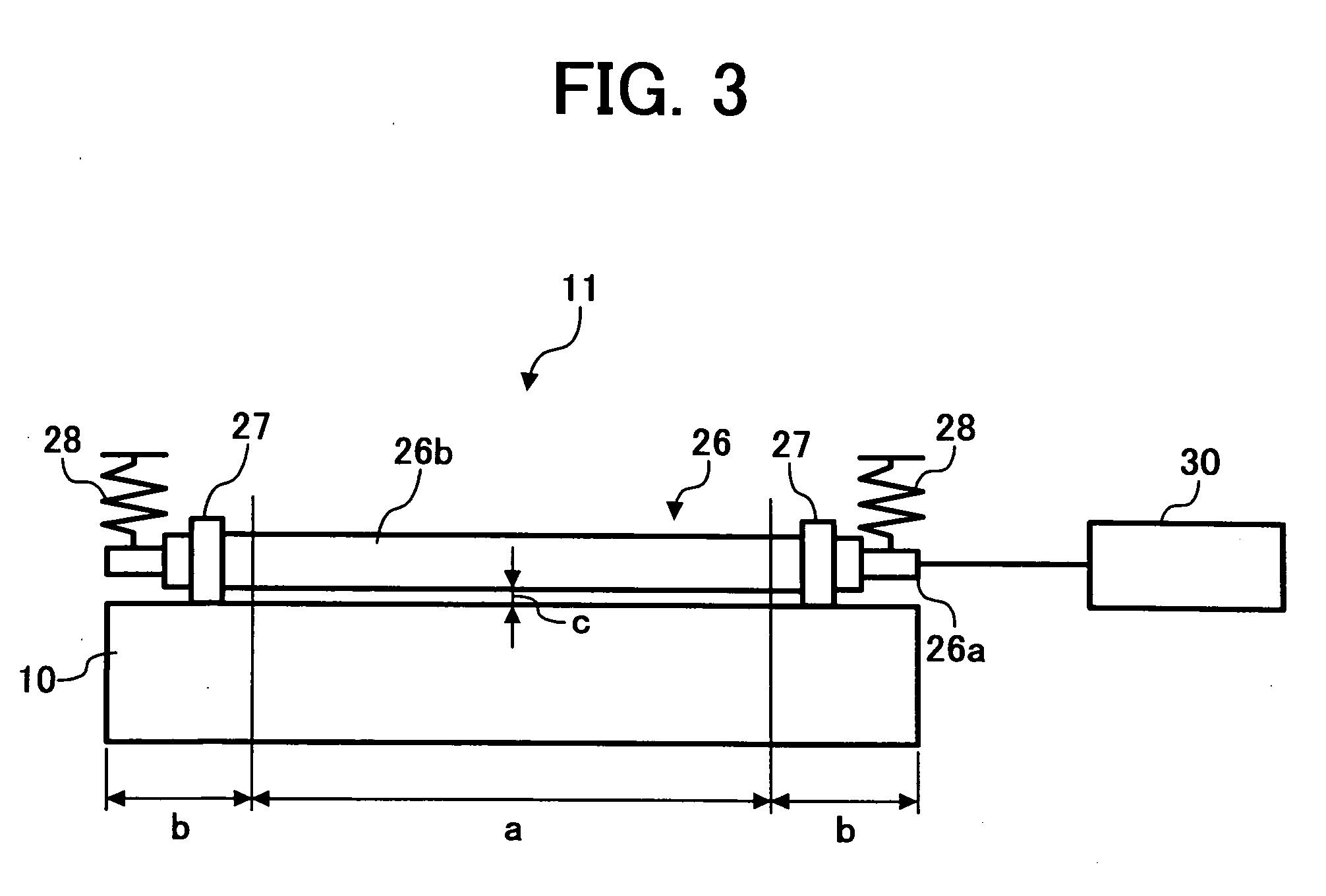

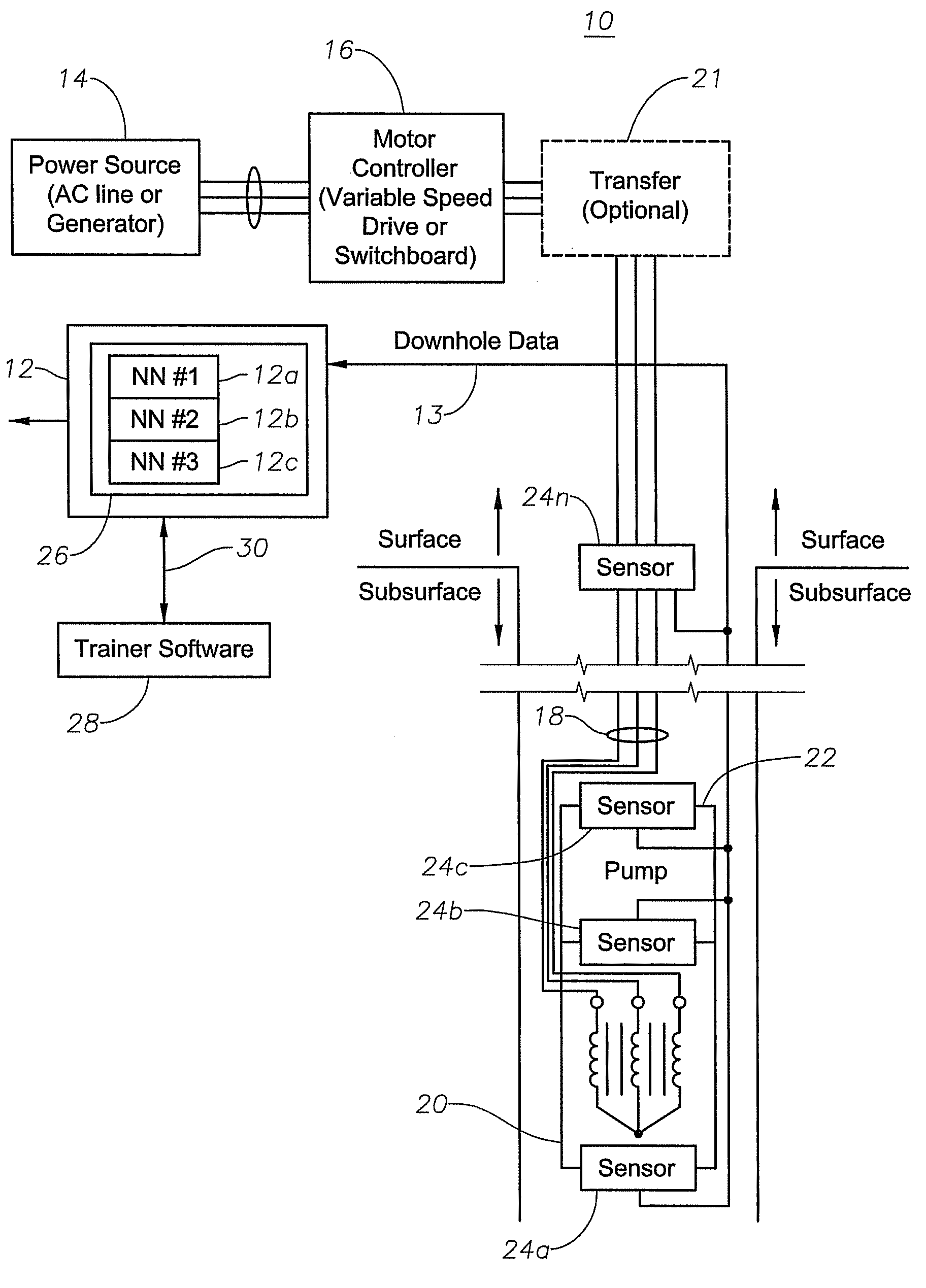

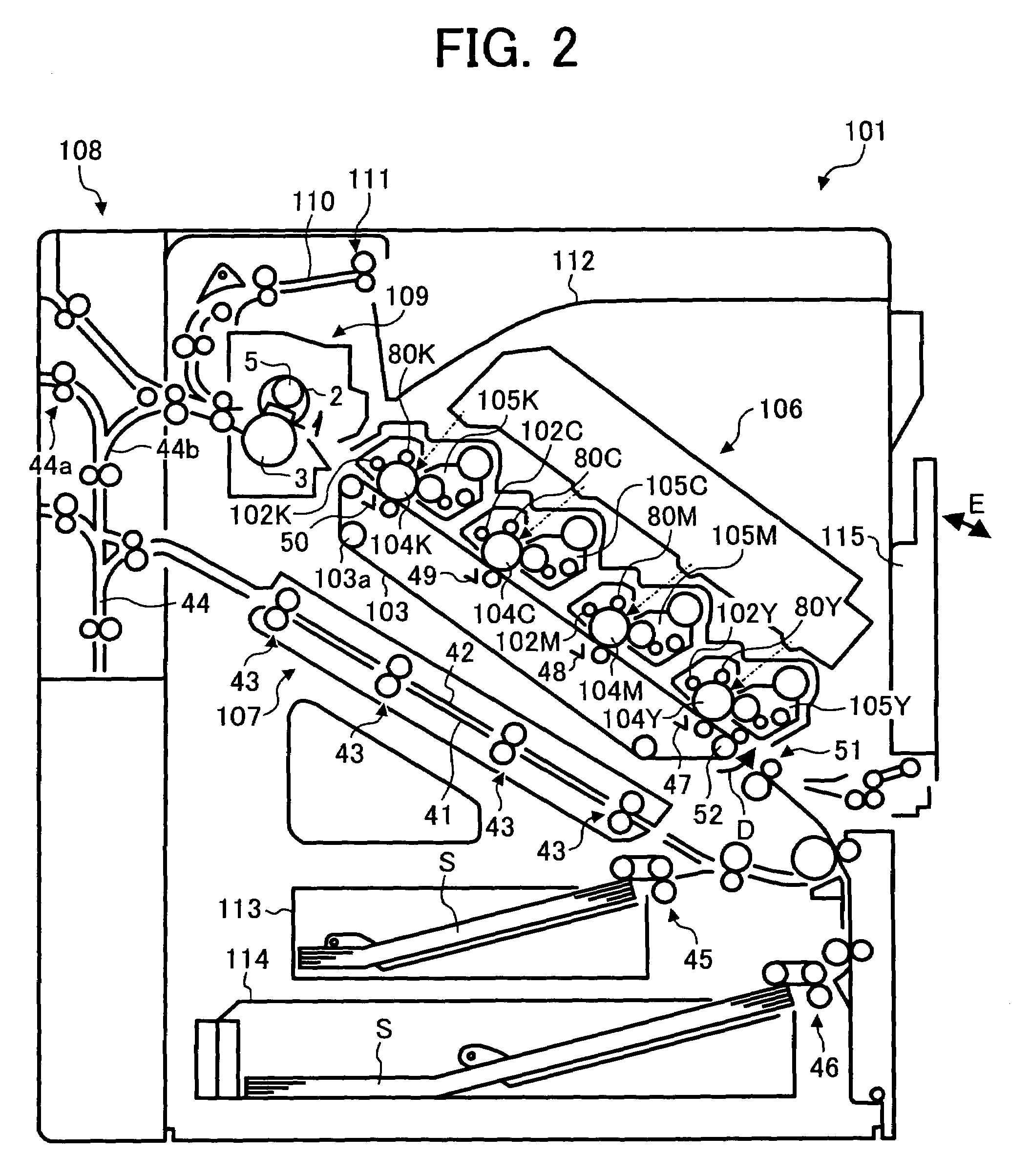

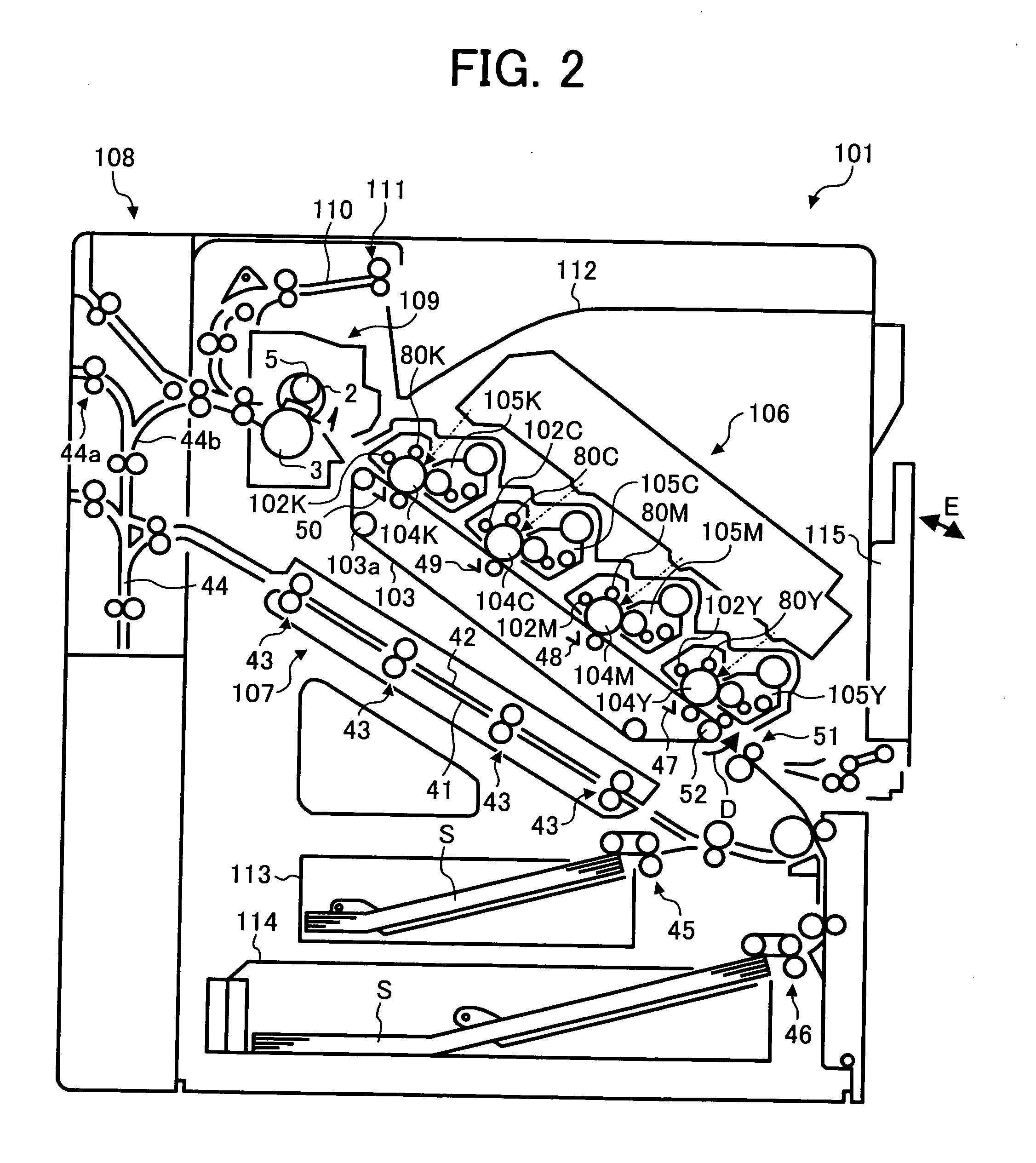

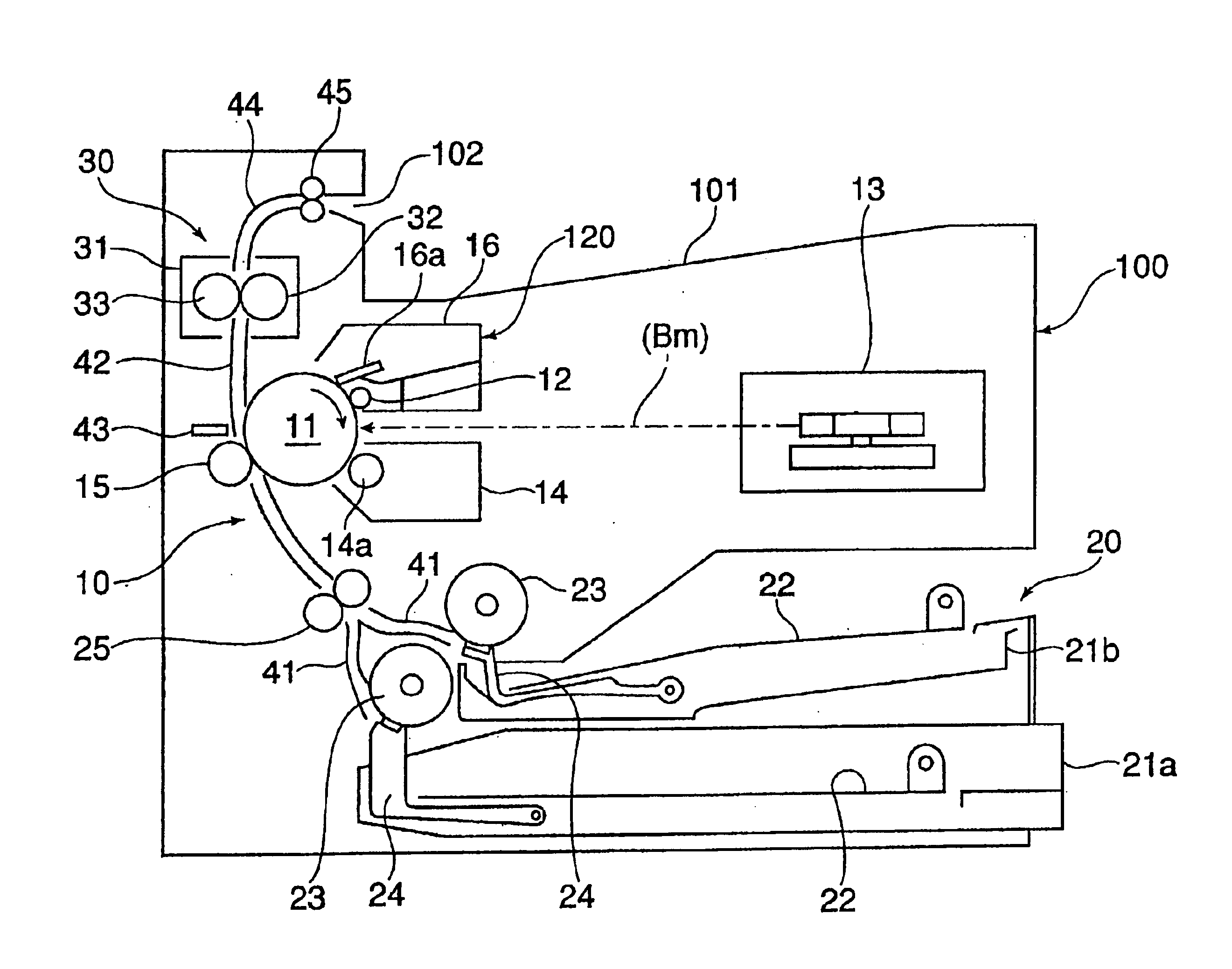

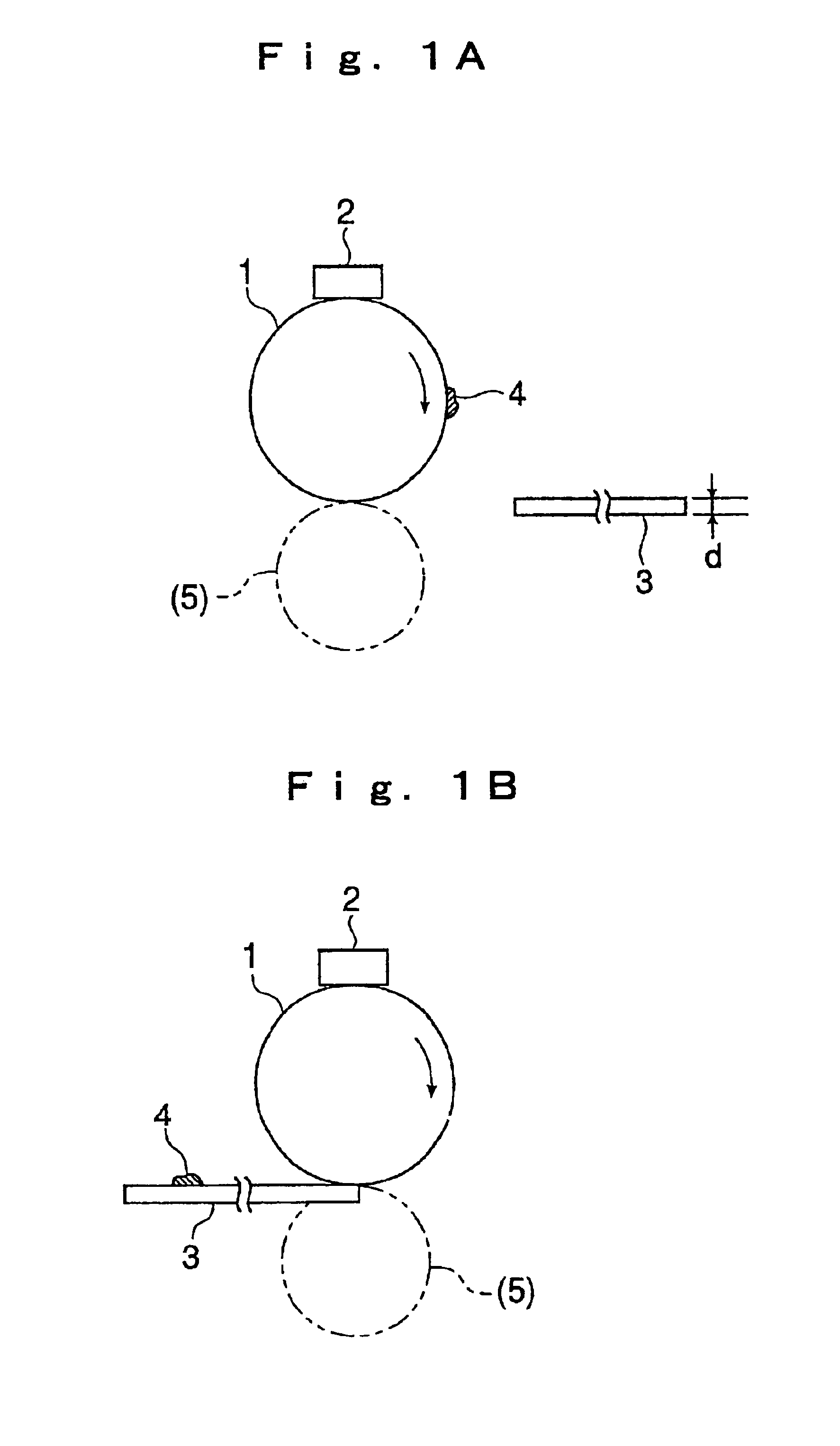

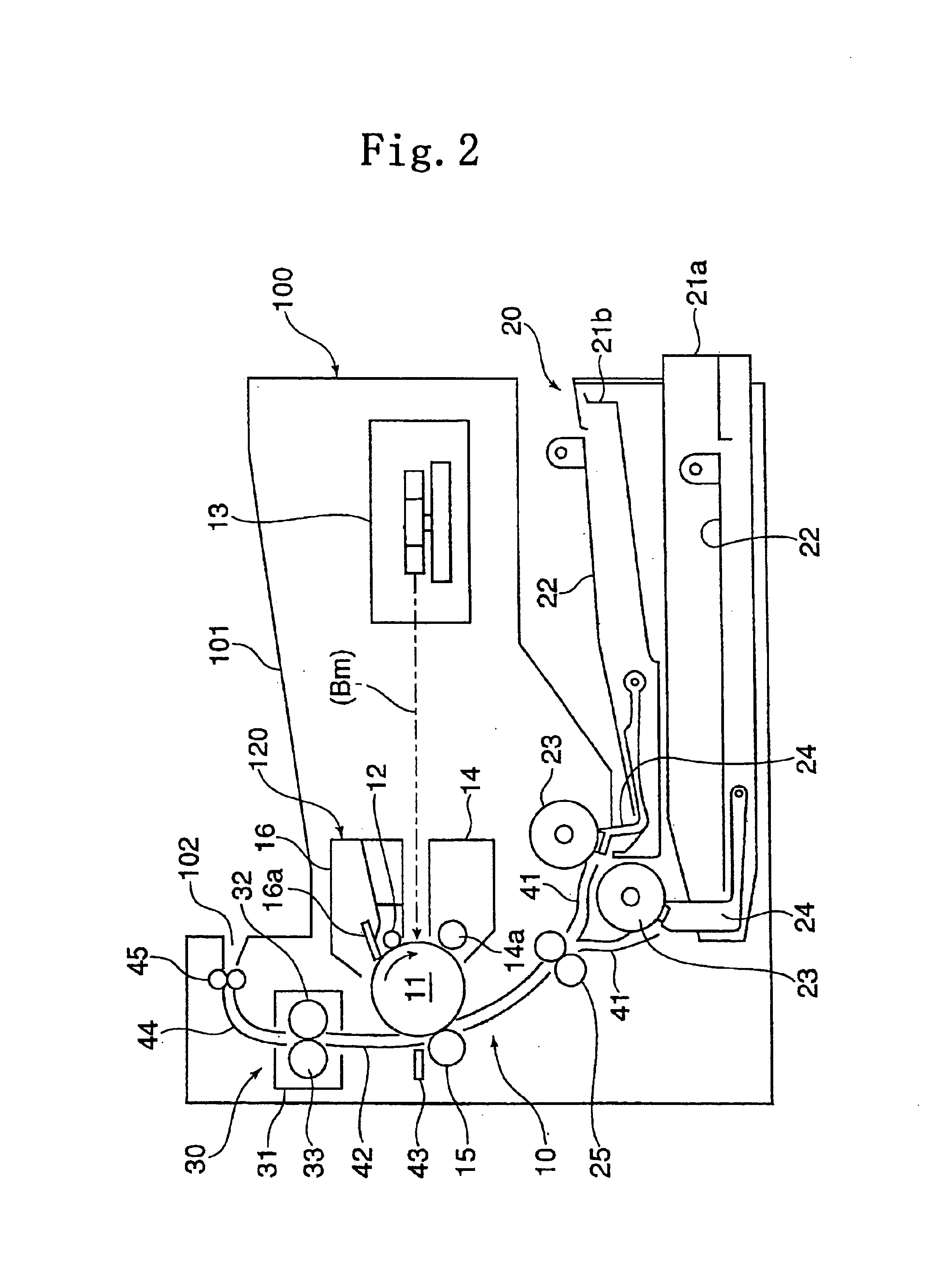

Image forming apparatus

An image forming apparatus includes a fixing member having a cylindrical or annular shape for fixing an image onto a sheet which is in pressure contact with an outer surface thereof; and a heating source for heating the fixing member to a fixing temperature. A duct is provided in a position facing the fixing member with respect to a width direction perpendicular to a circumferential direction of the fixing member and which has an inlet for taking in fine particles generated from the fixing member. A filter member is provided inside the duct and which can trap the fine particles which flow through the duct. An exhaust fan is provided in the duct upstream or downstream from the filter member for generating an air flow going from the inlet to an outlet of the duct. A control section controls the operation of the exhaust fan according to initial burst conditions under which the fine particles are emitted from the fixing member.

Owner:KONICA MINOLTA BUSINESS TECH INC

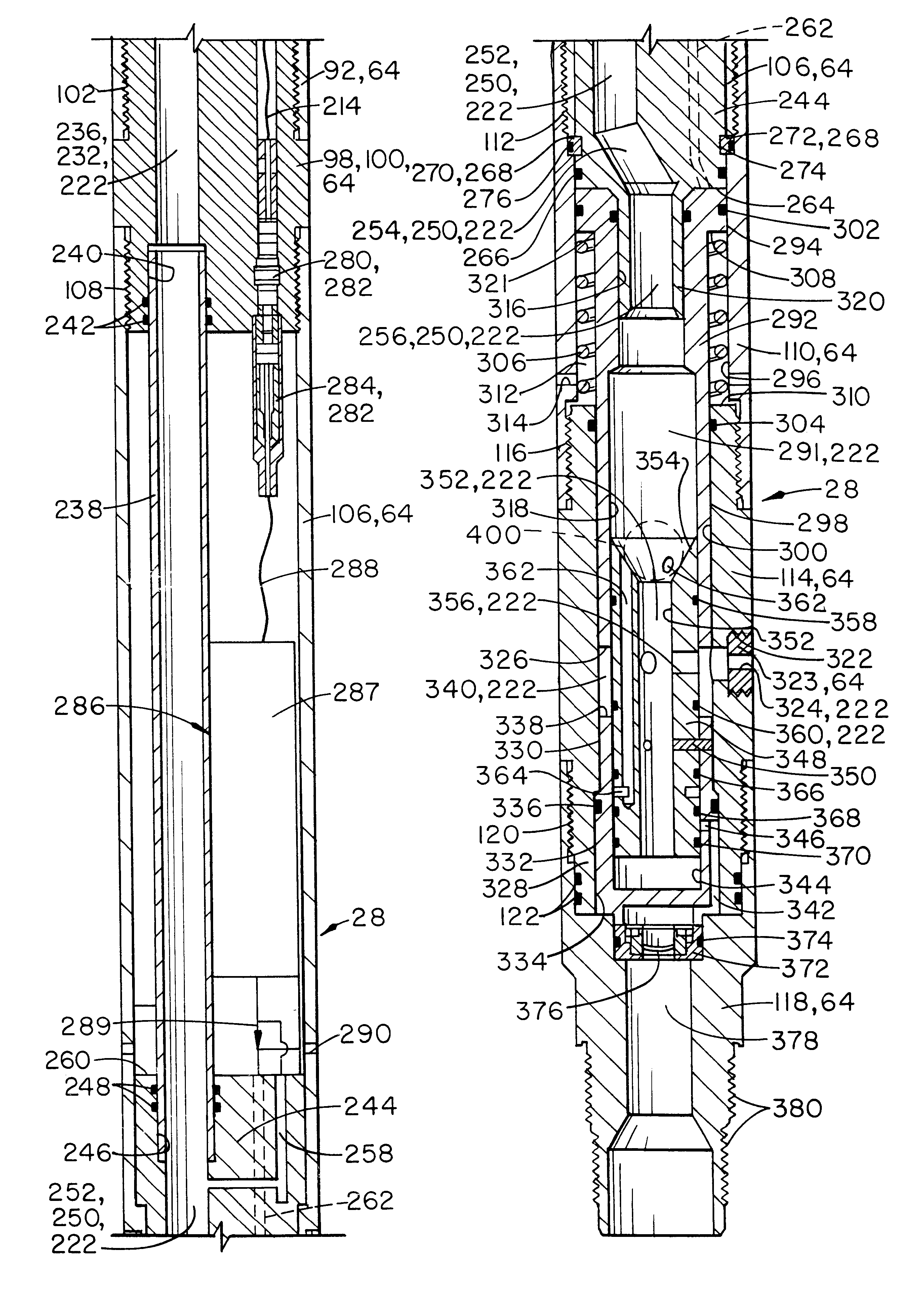

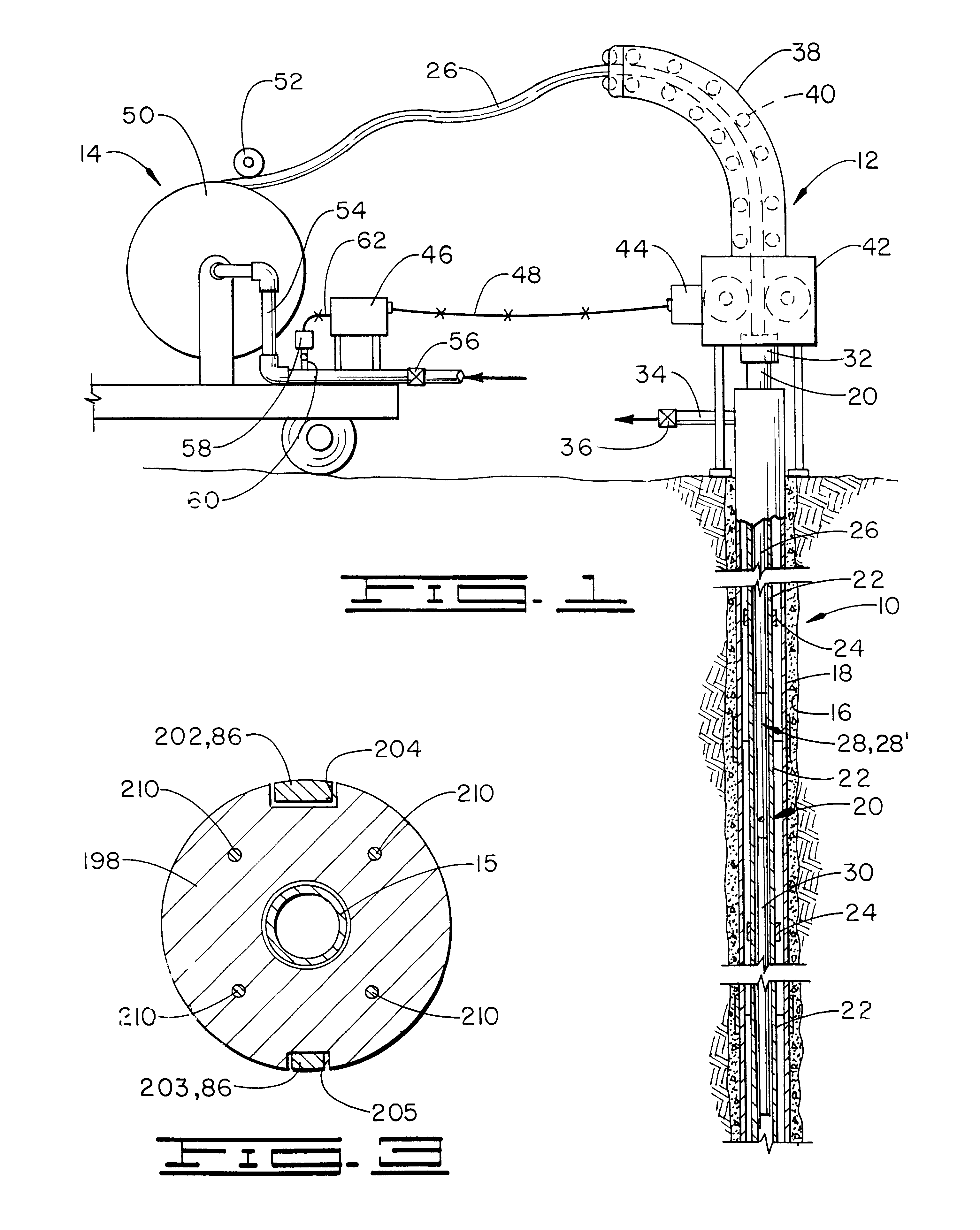

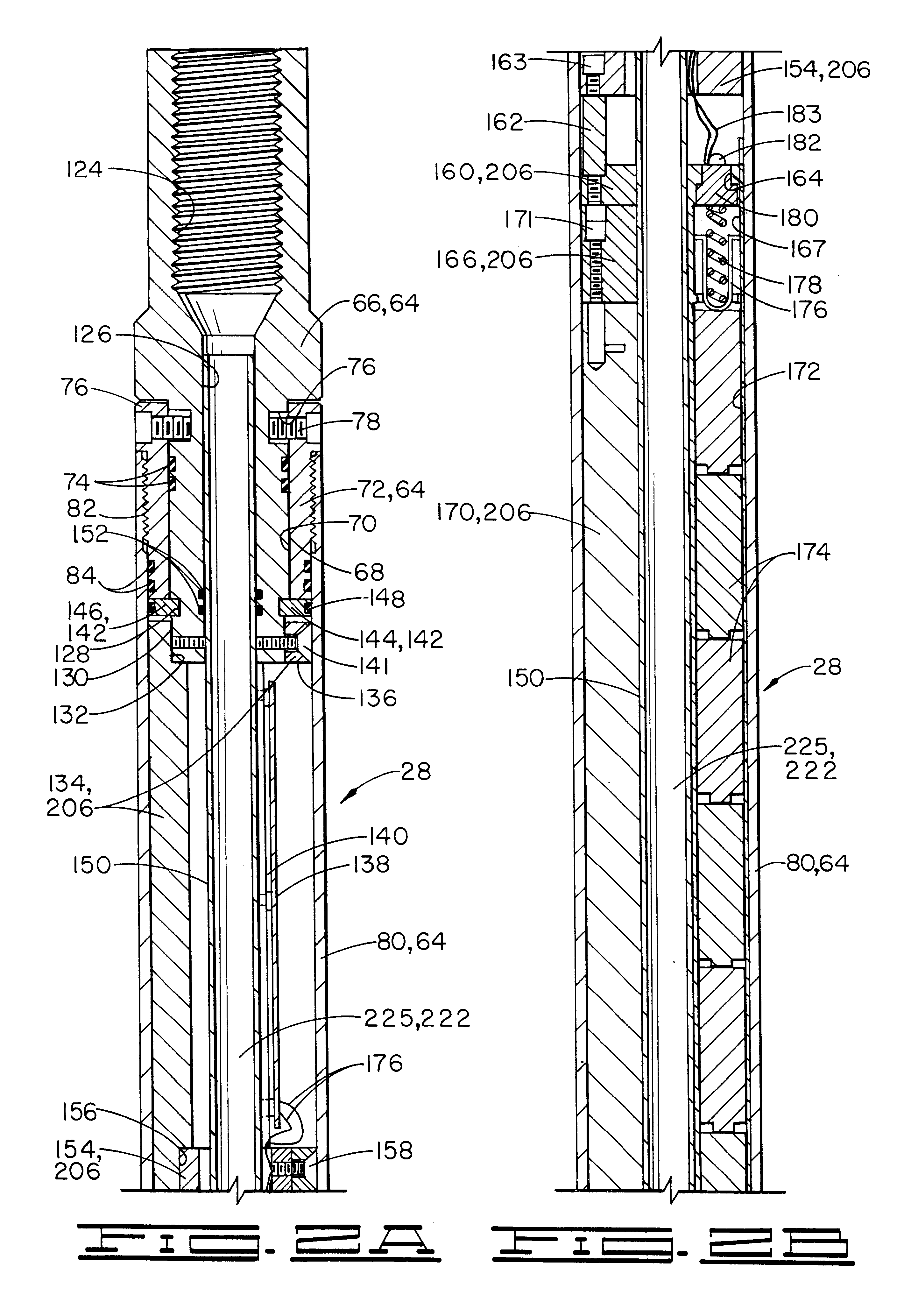

Wireless coiled tubing joint locator

A wireless coiled tubing joint locator for locating joints or collars in a production tubing string. An electromagnetic coil assembly or giant magnetoresistive digital field sensor senses the increased mass of a pipe joint, and provides a signal to an electric circuit which generates a signal received by a pilot solenoid valve. The solenoid valve momentarily opens a pilot passageway which activates a piston to close a circulation port in the joint locator, resulting in an increase in a surface pressure reading observable by the operator. In one embodiment, a rupture disk is provided so that pressure cannot be applied to any downhole tool below the joint locator prematurely. A seat sleeve prevents premature communication of fluid to the rupture disk but can be opened by dropping a ball into the joint locator. A second embodiment may be used for either logging or washing operations or both. The electronic circuit can provide a selected one of a plurality of time delays. A fixed test period in the circuit delays activation of the time delay so that the joint locator may be tested before it is run into the well. The electric circuit and power supply are provided in a removable case.

Owner:HALLIBURTON ENERGY SERVICES INC

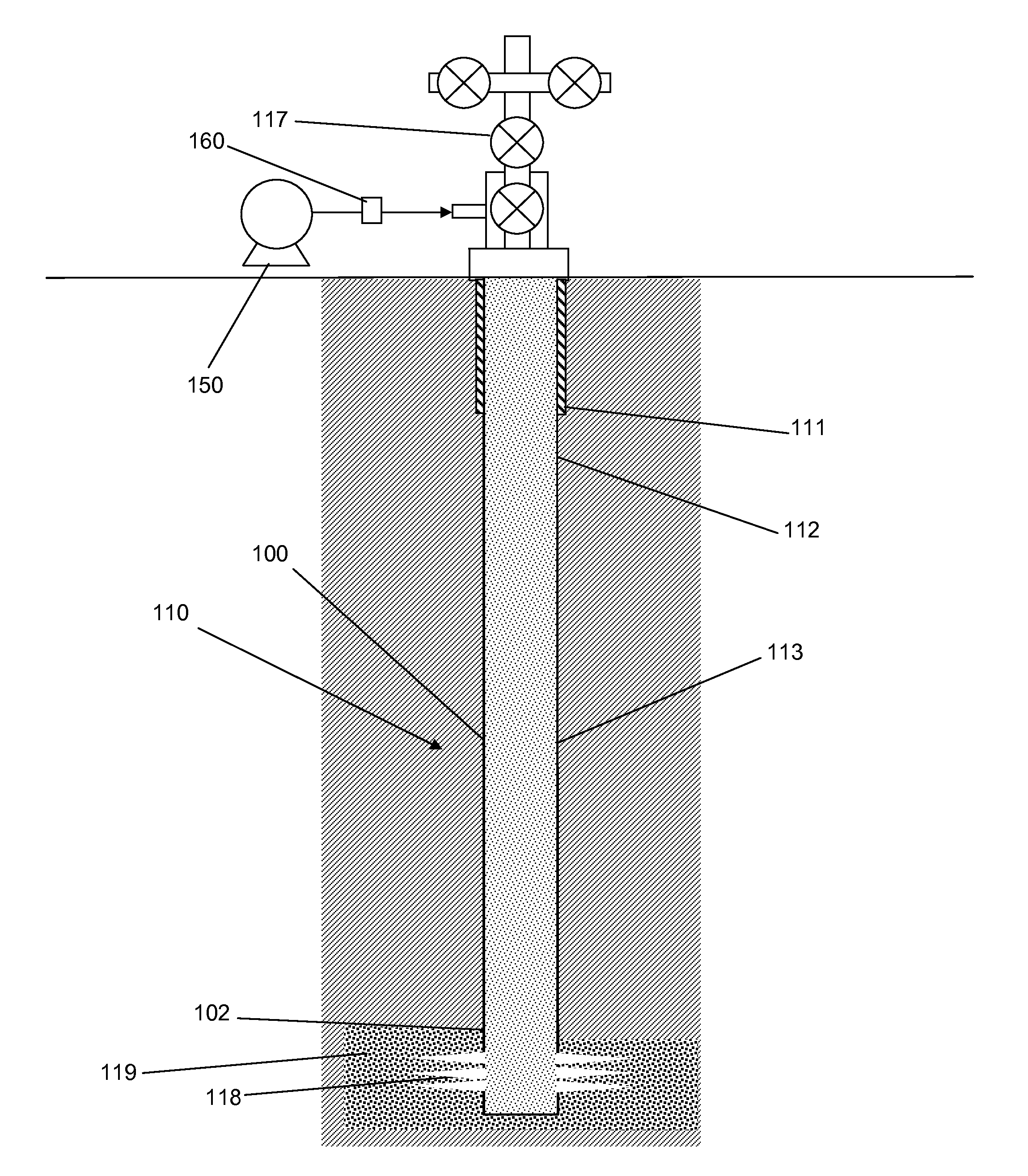

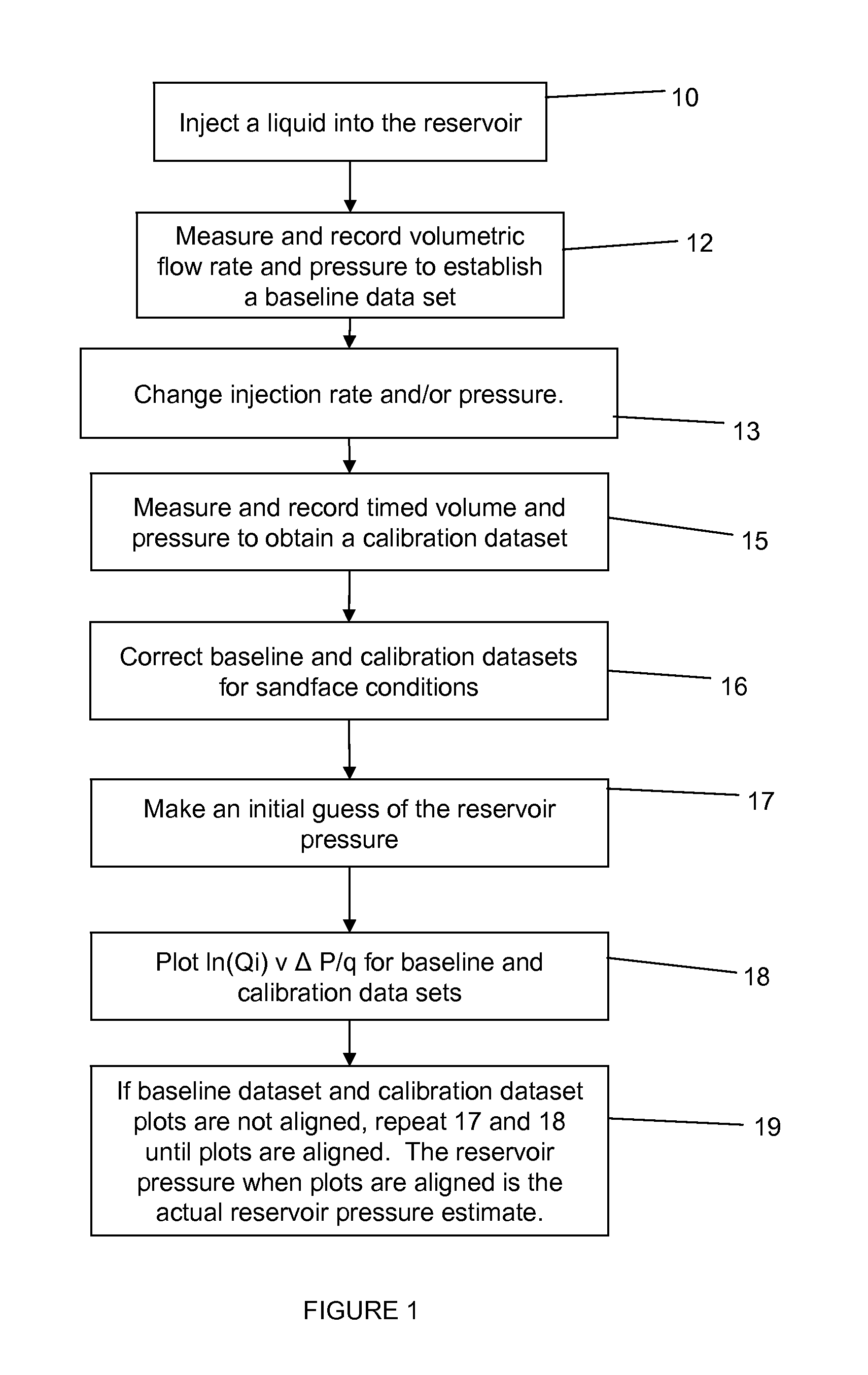

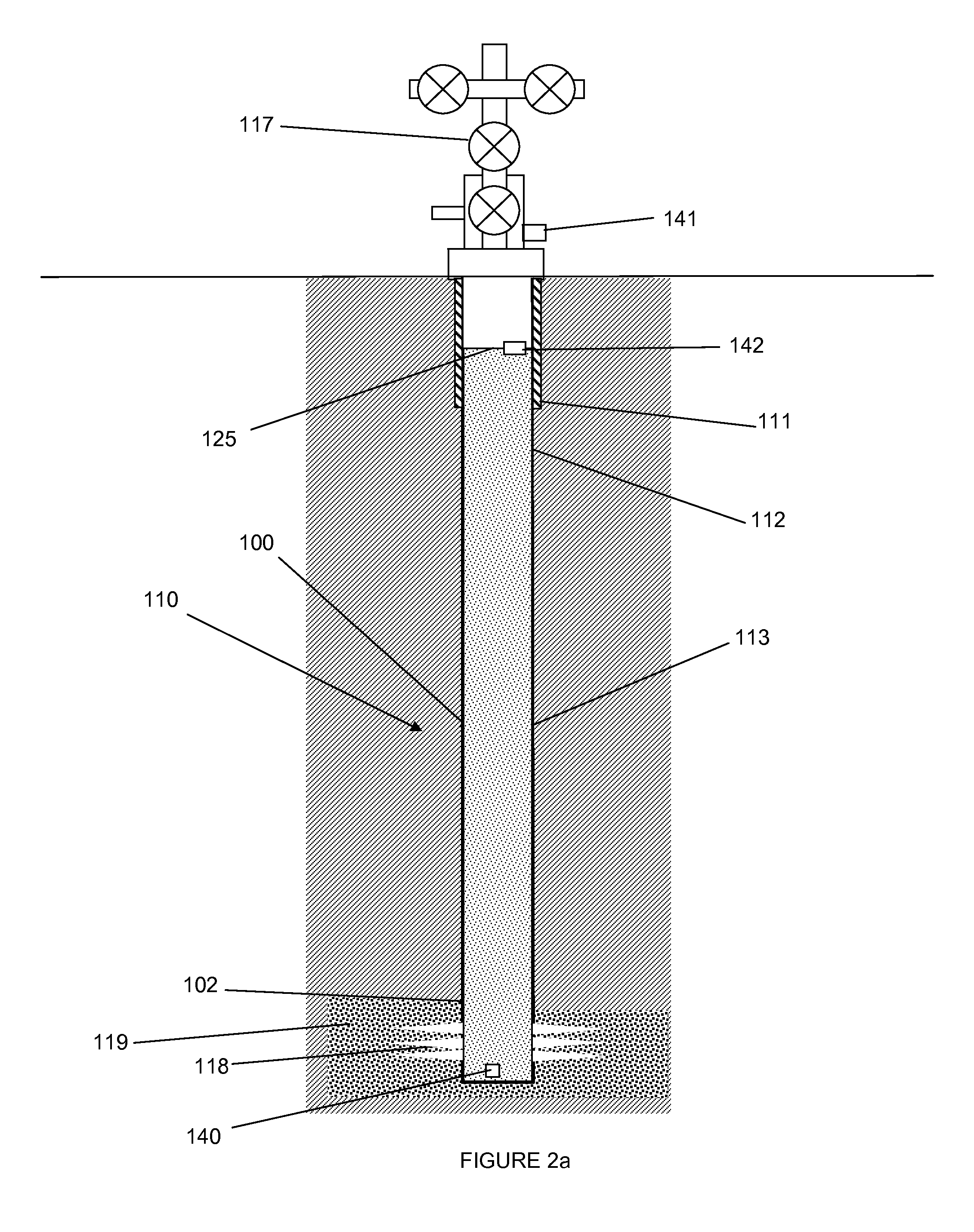

Method of determining reservoir pressure

ActiveUS20120158310A1Reduce penetrationElectric/magnetic detection for well-loggingSurveyBaseline dataInjection pressure

A new approach is disclosed for measuring the pressure of tight gas reservoirs, using information obtain from continuous injection prior to hydraulic fracture stimulation. The technique can be obtained utilizing either bottom-hole or surface pressure gauges and properly instrumented surface injection pumps. The analysis is completed by plotting injection and rate data in a specialized form from terms arranged in Darcy's radial flow equation to obtain a curve or trend. The key component to proper application of this technique is to obtain both baseline and one or more calibration data sets. These calibration data sets are obtained by either increasing or decreasing the injection pressure and / or rate from the baseline data. Initial reservoir pressure is assumed, but the calibration data indicates if the guess was too high or low. Accurate estimates of reservoir pressure may be obtained in a few iterations.

Owner:BP CORP NORTH AMERICA INC

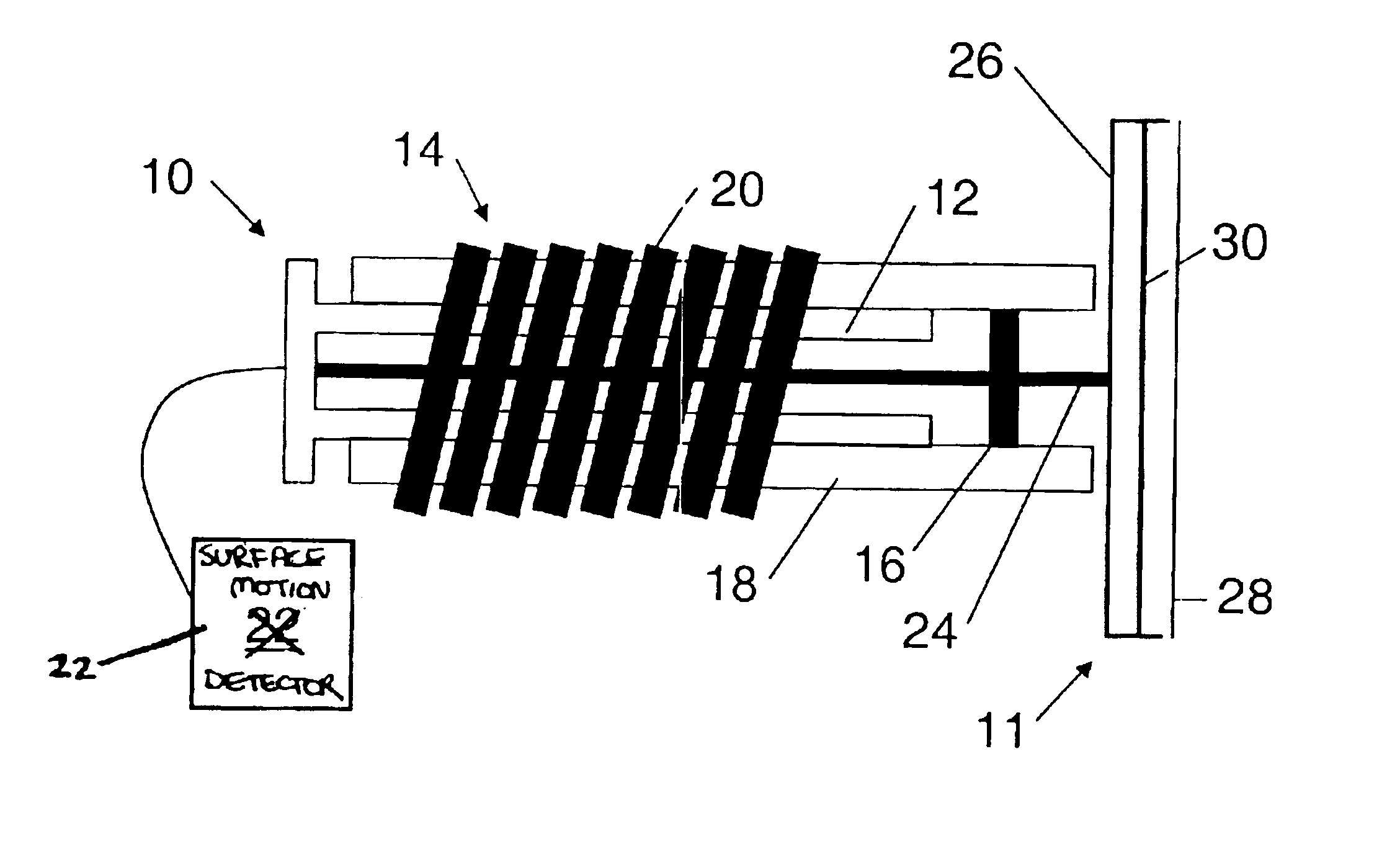

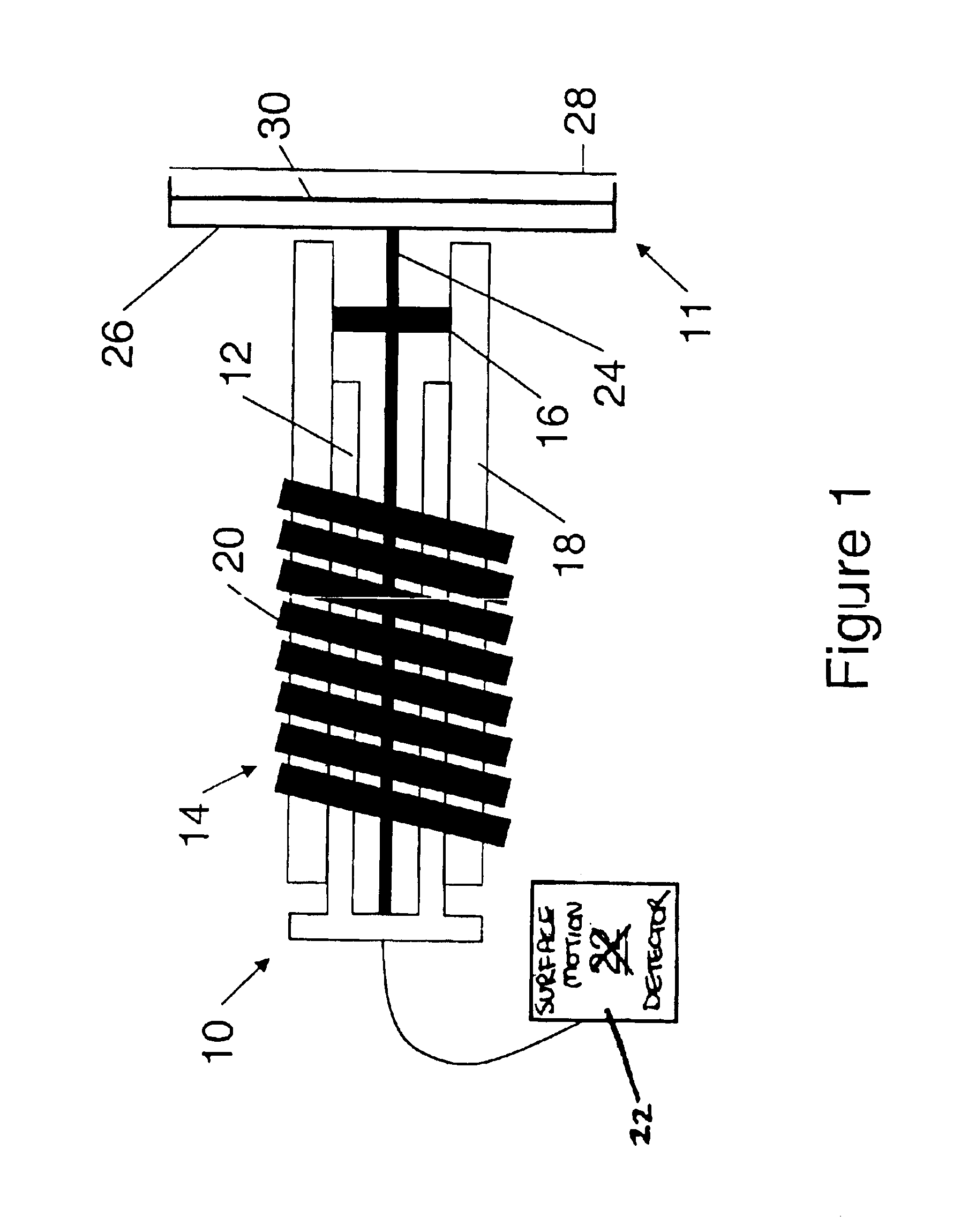

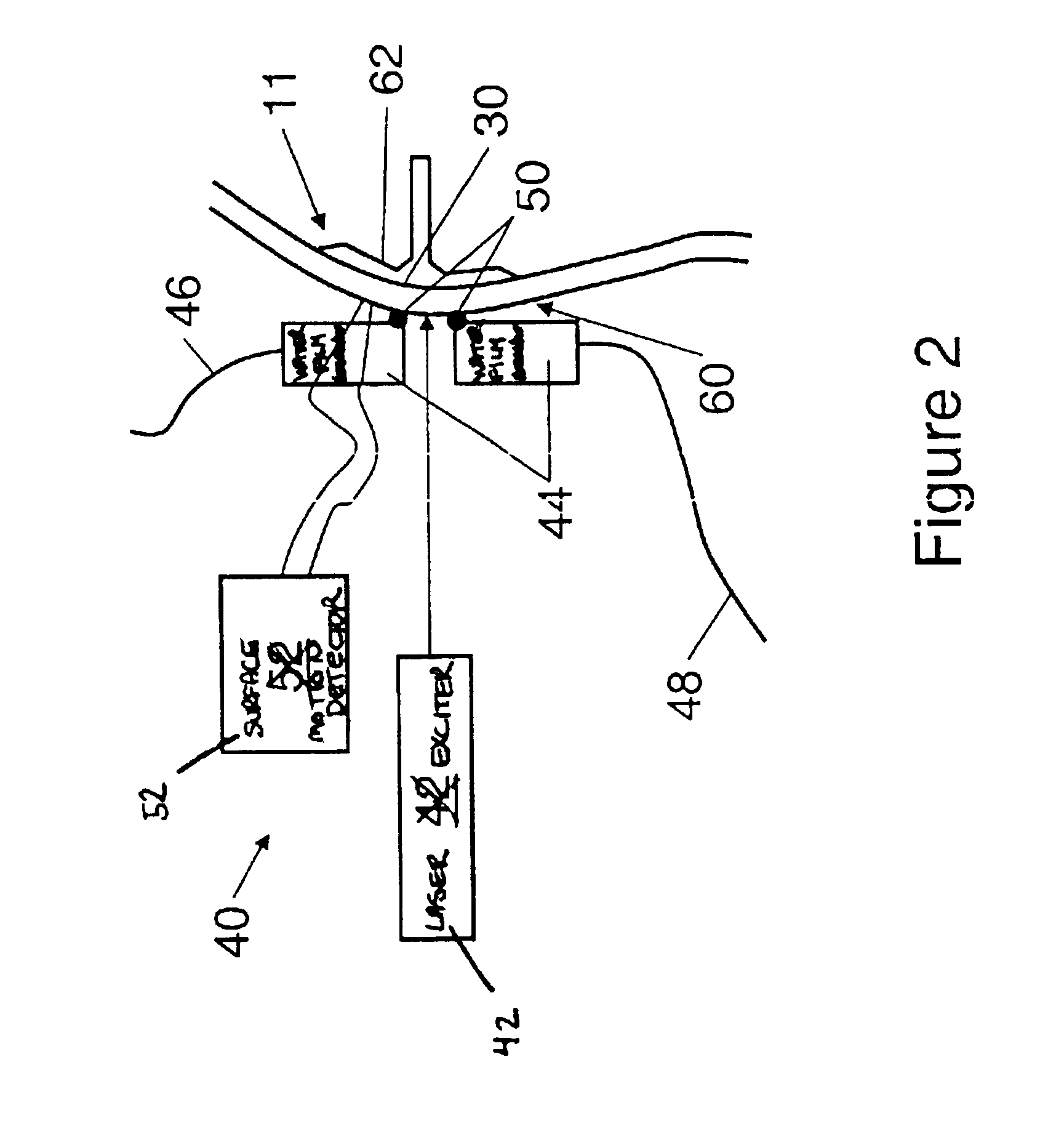

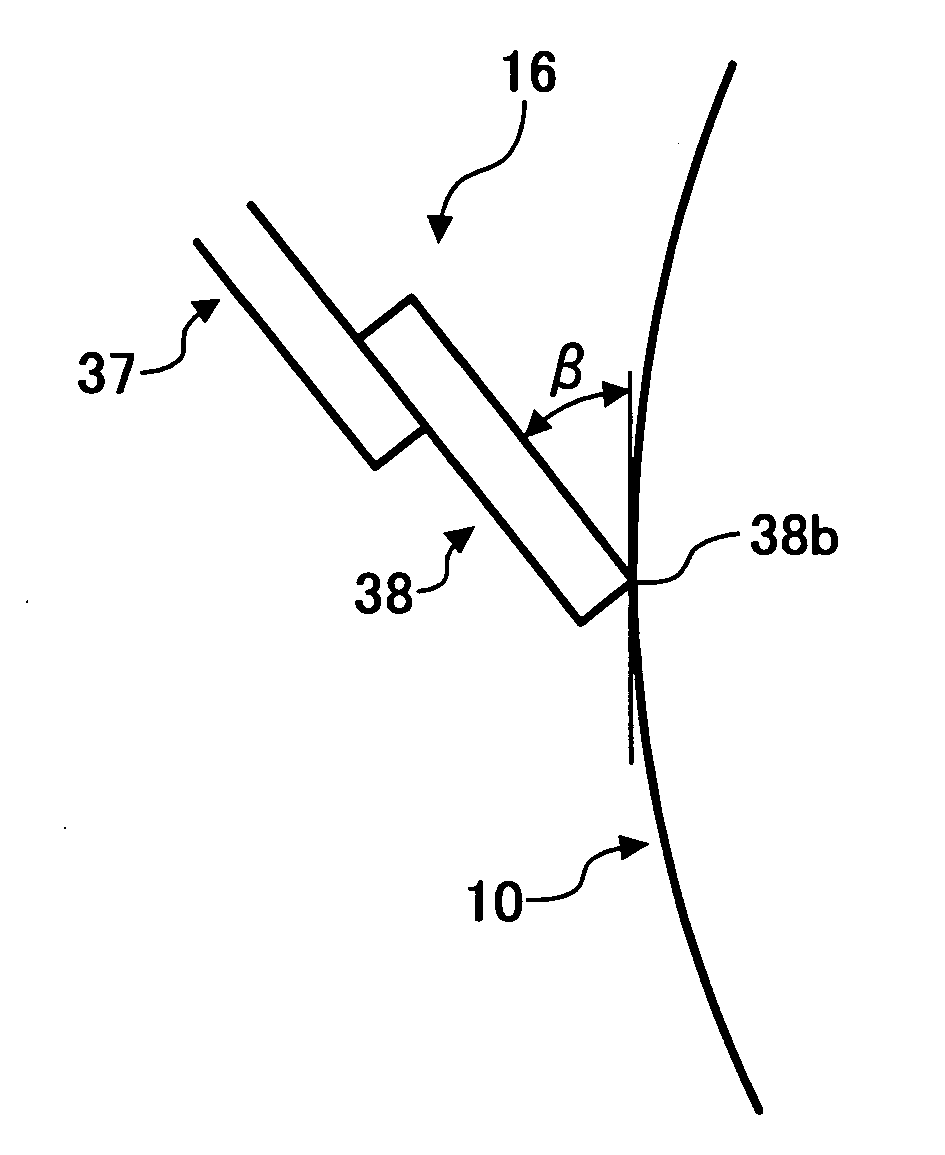

Bond strength measurement system using shock loads

InactiveUS6848321B2Rapid pressure applicationFlow propertiesMaterial strength using tensile/compressive forcesNon destructiveMotion detector

A system and method for non-destructively testing the strength of bonded joints, particularly a bonded joint between two composite components, is provided. The method generally includes activating a source of rapid surface pressure application against a bonded assembly containing the bonded joint to create a shock load. The resulting shock load first generates compression and then tension within the bonded joint, along with surface motions proximate the bonded assembly, and a surface motion detector measures the surface motions to determine the minimum strength of the bonded joint. Accordingly, the surface motions are correlated to the strength of the bonded joint. Further, the magnitude of the impact may be adjusted to vary the amount of tension within the bonded joint to correspond with various load conditions.

Owner:THE BOEING CO

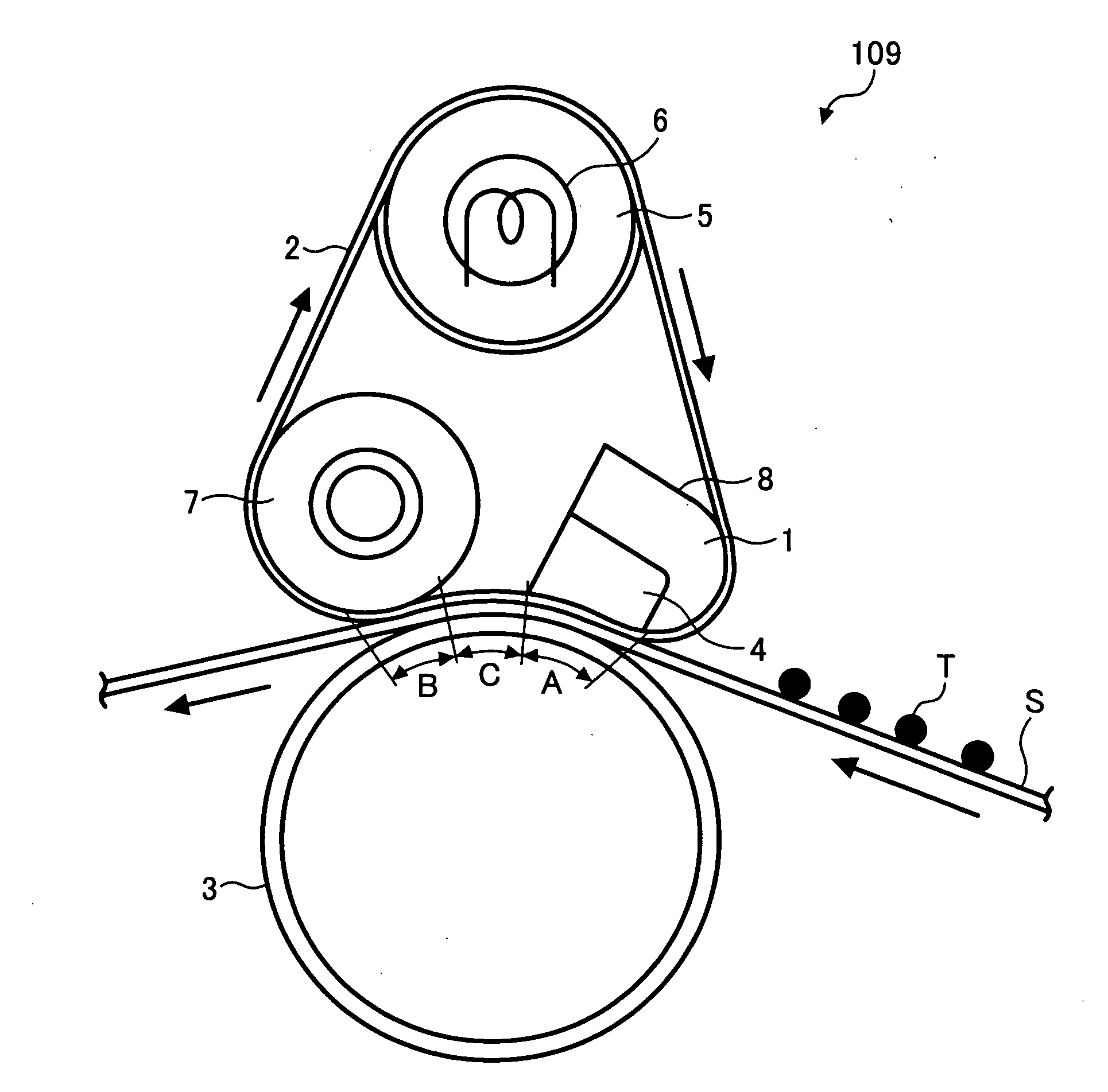

Cleaning device, process cartridge, and image forming apparatus

A cleaning device cleans off a toner from a surface of a member rotating in a first direction. The cleaning device includes a blade made of an elastic material including a tip portion with a slanting portion that is pressed against the surface in a second direction counter to the first direction. A supporter supports the blade. An angle between the slanting portion and a longitudinal direction of the blade is obtuse. The slanting portion is pressed against the surface at a surface pressure of 2.0 MPa or more.

Owner:RICOH KK

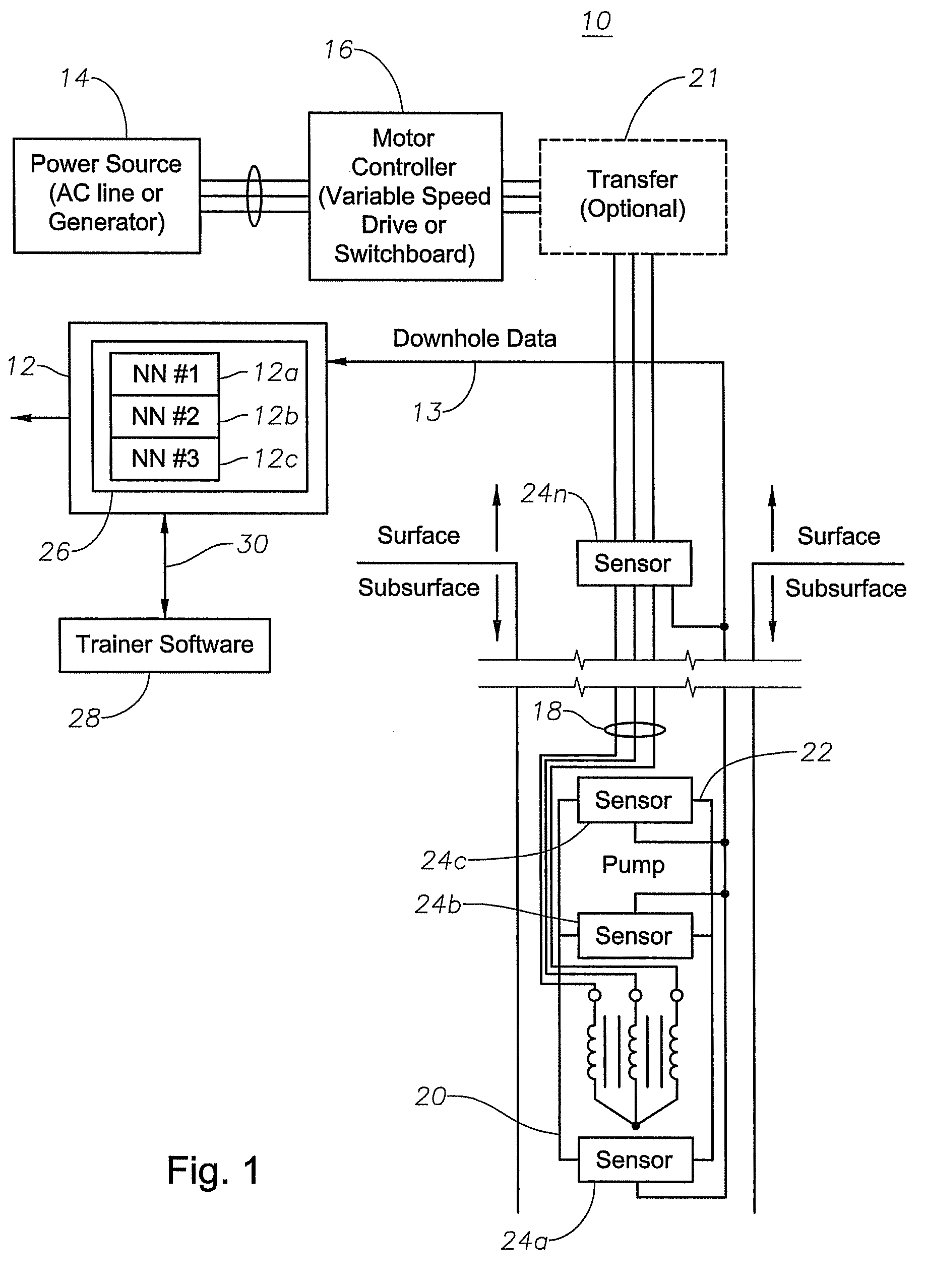

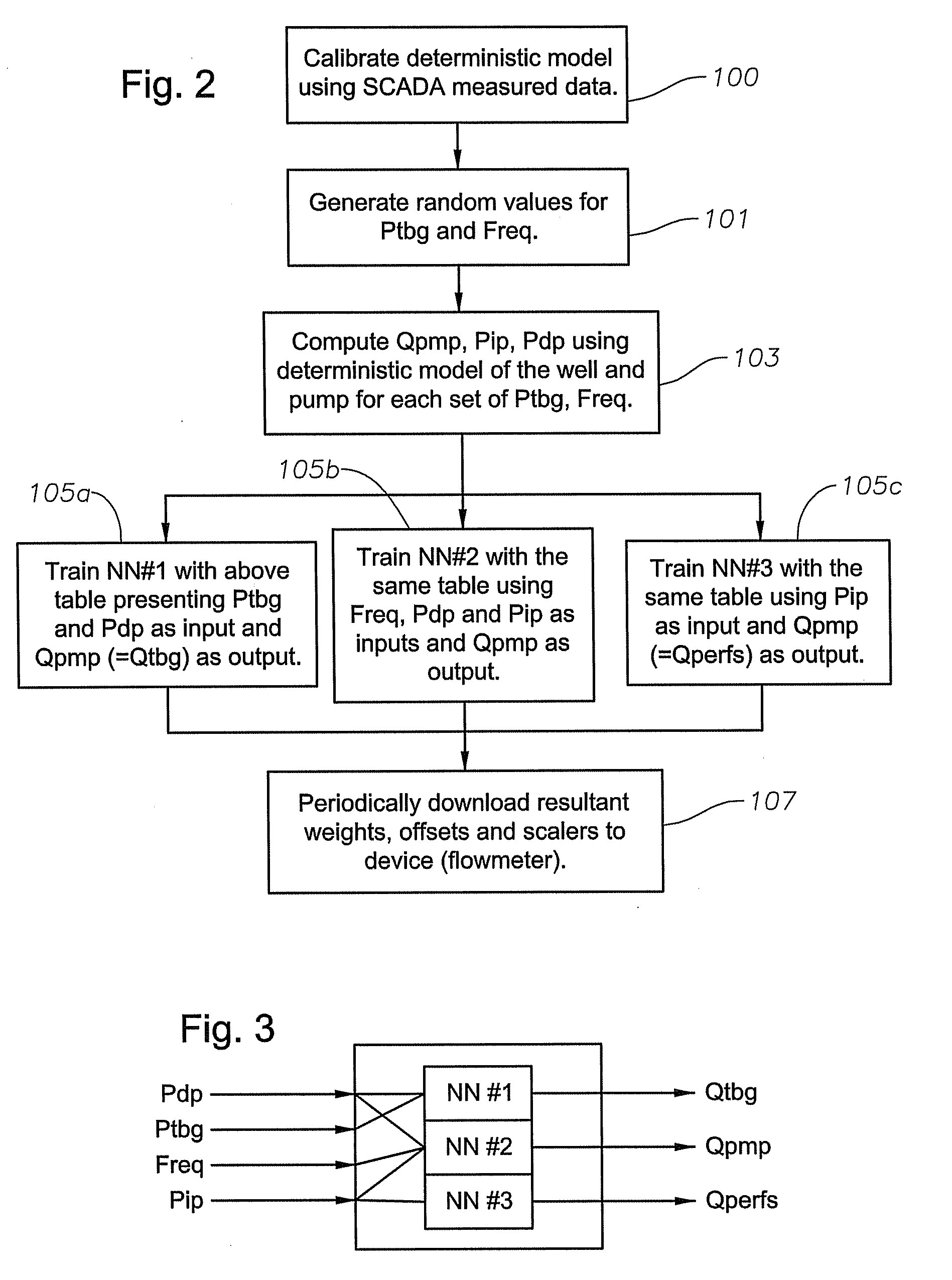

Multiphase flow meter for electrical submersible pumps using artificial neural networks

A multiphase flow meter used in conjunction with an electrical submersible pump system in a well bore includes sensors to determine and transmit well bore pressure measurements, including tubing and down hole pressure measurements. The multiphase flow meter also includes at least one artificial neural network device to be used for outputting flow characteristics of the well bore. The artificial neural network device is trained to output tubing and downhole flow characteristics responsive to multiphase-flow pressure gradient calculations and pump and reservoir models, combined with standard down-hole pressure, tubing surface pressure readings, and the frequency applied to the electrical submersible pump motor.

Owner:BAKER HUGHES INC

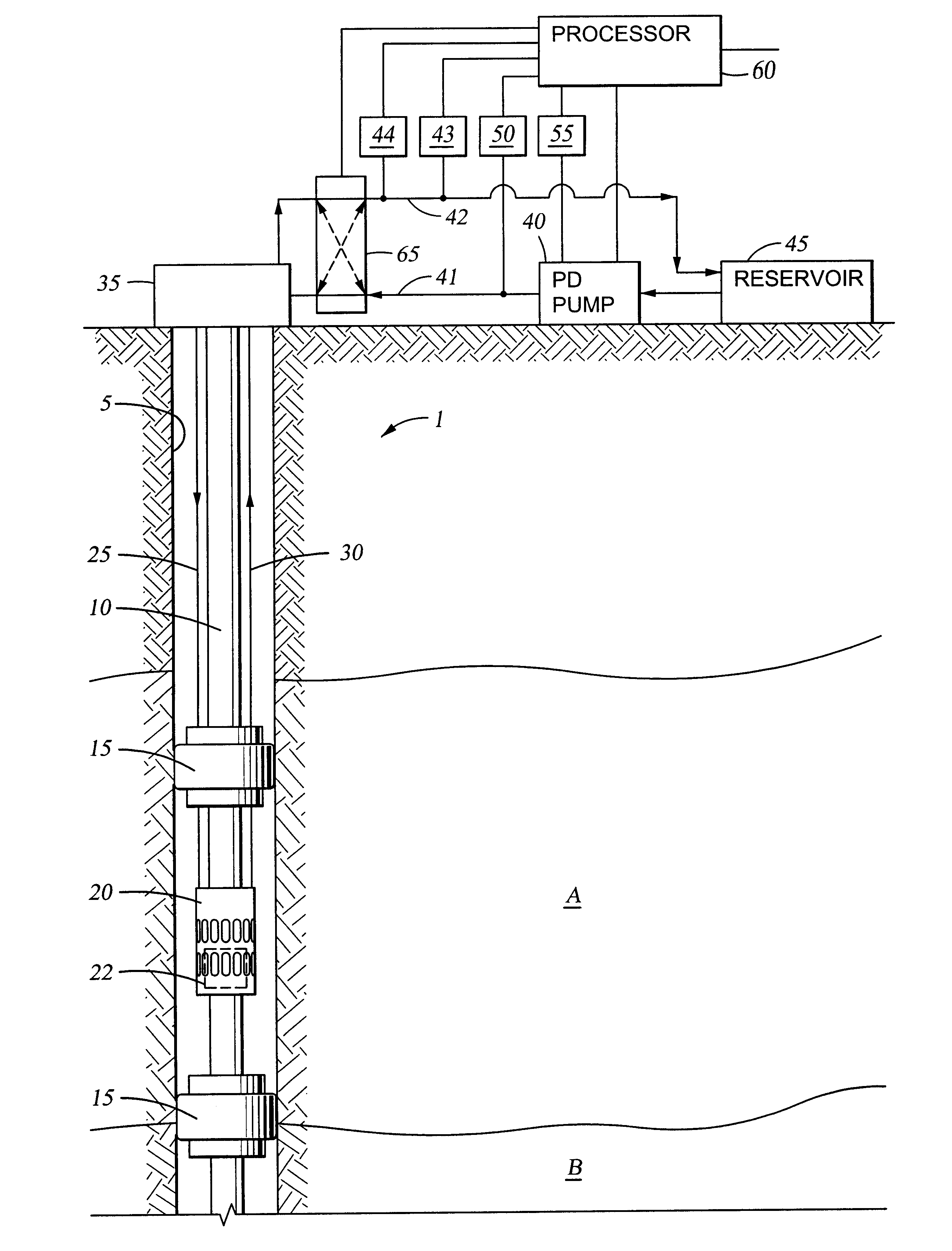

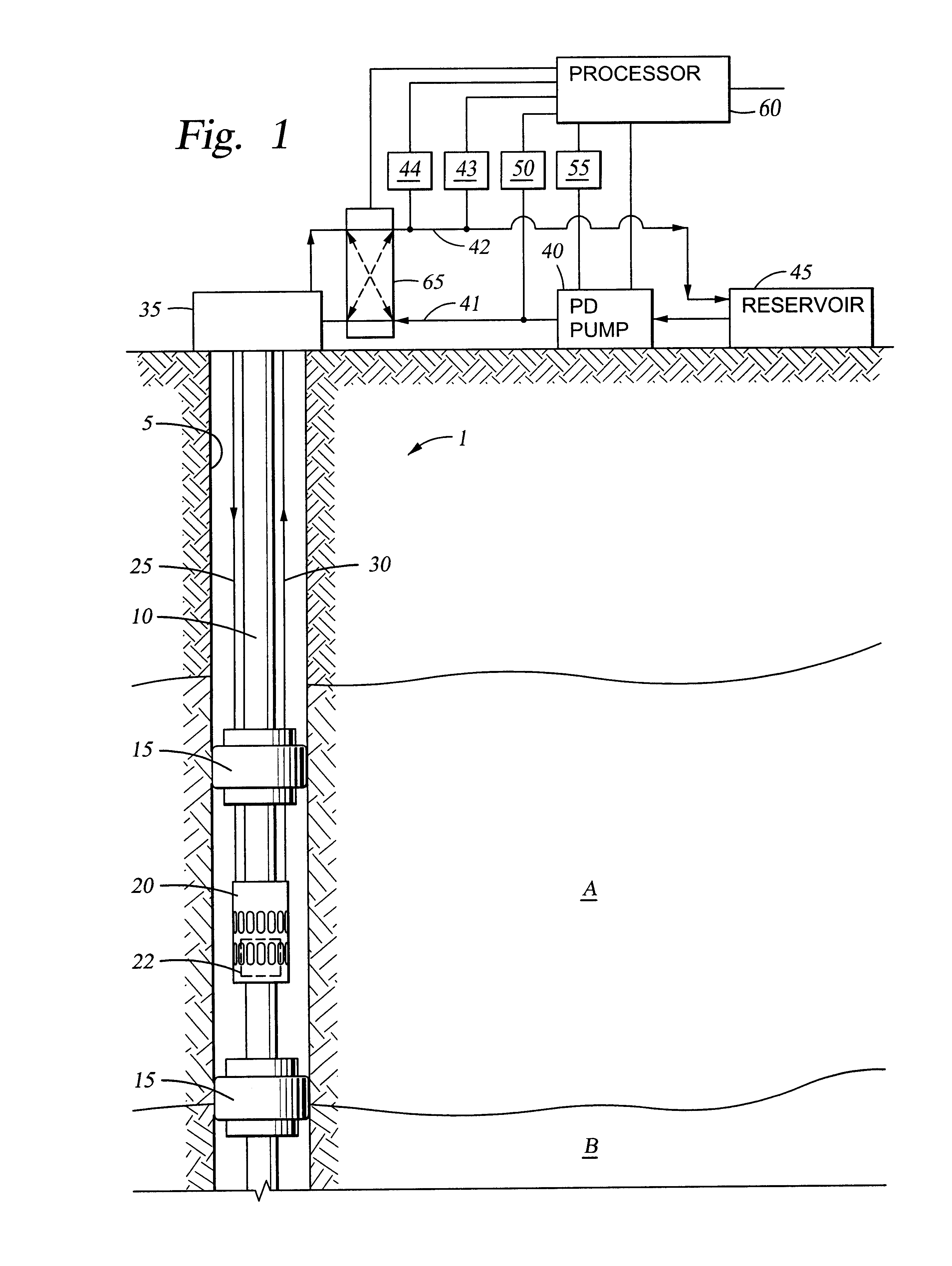

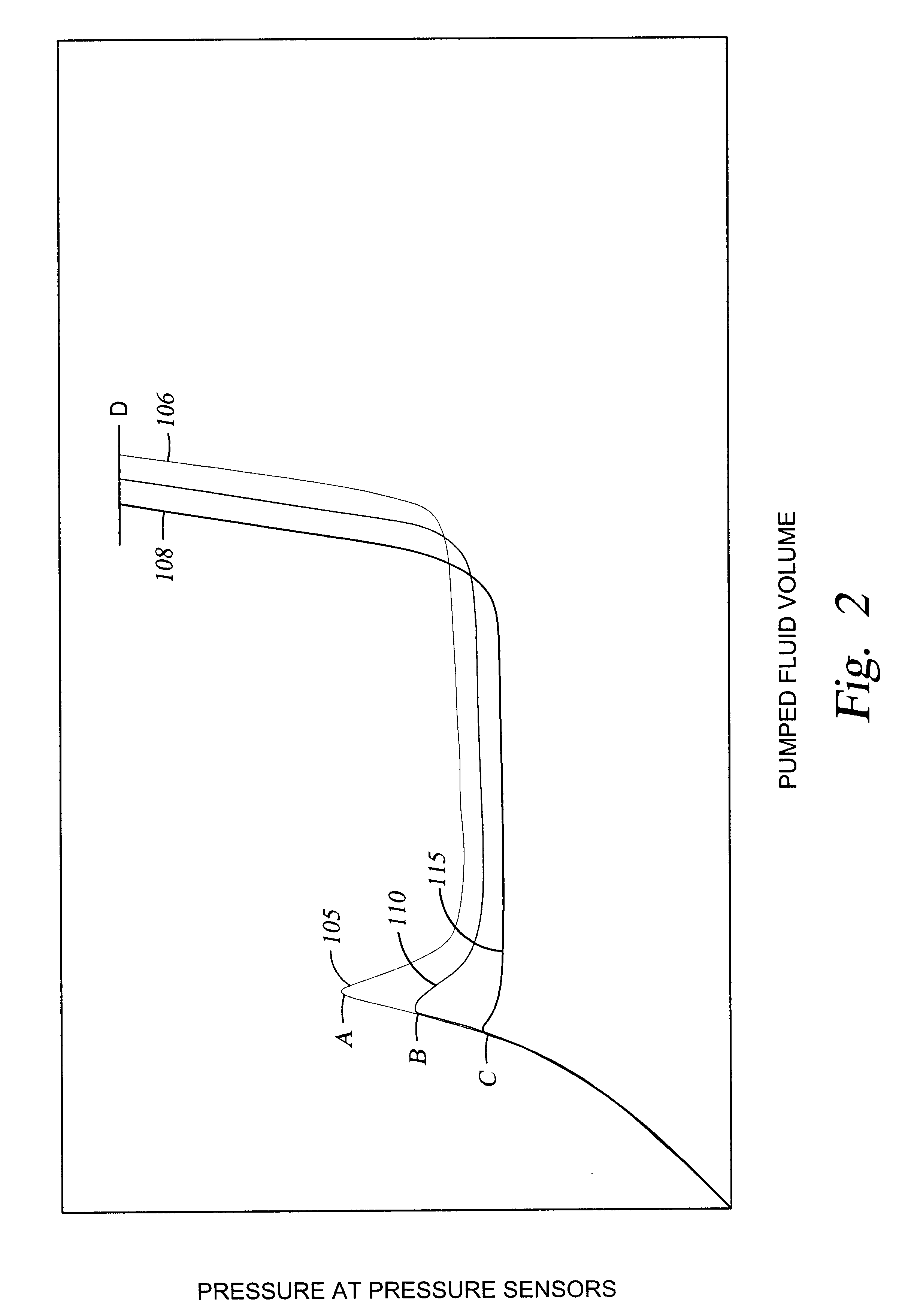

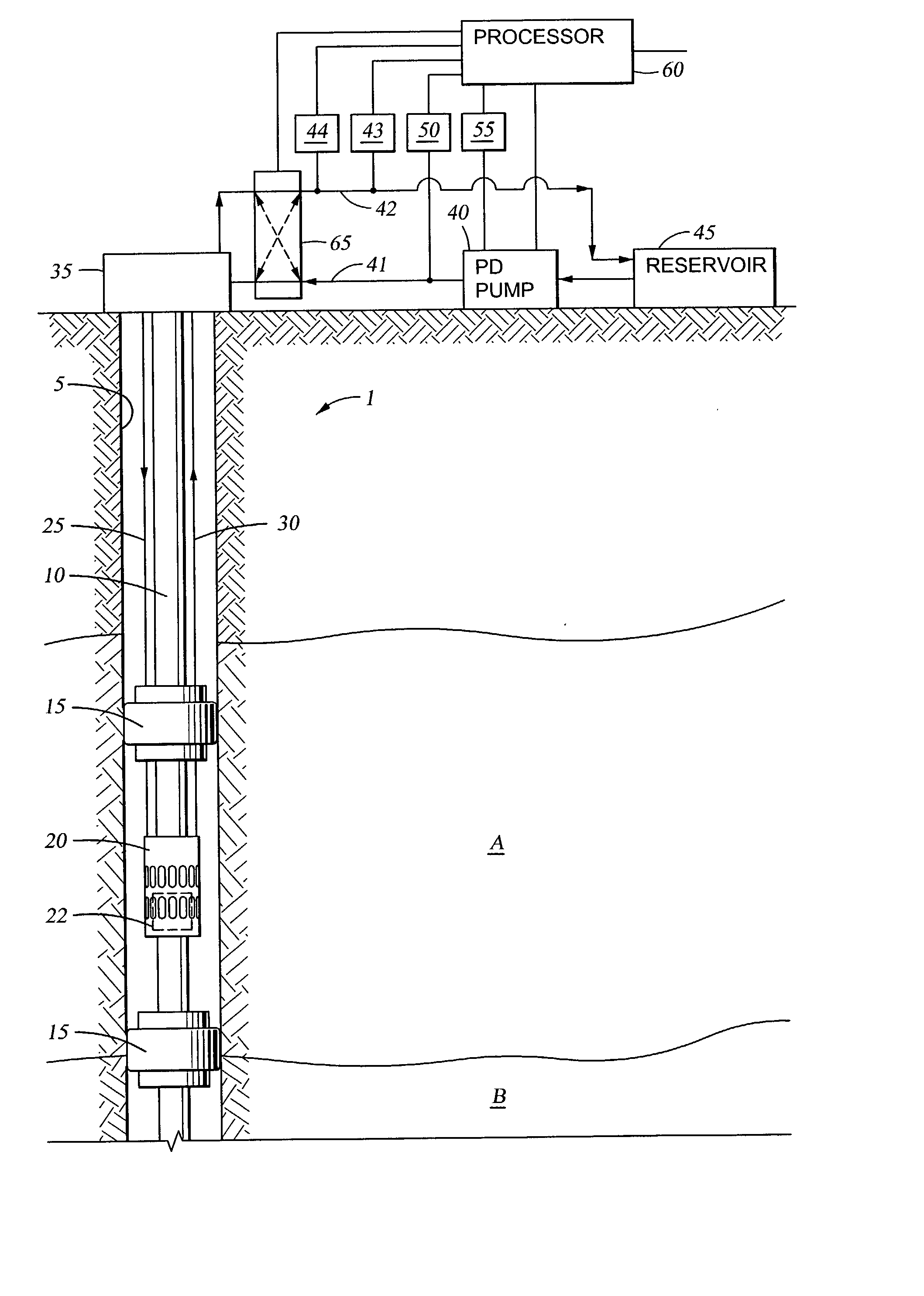

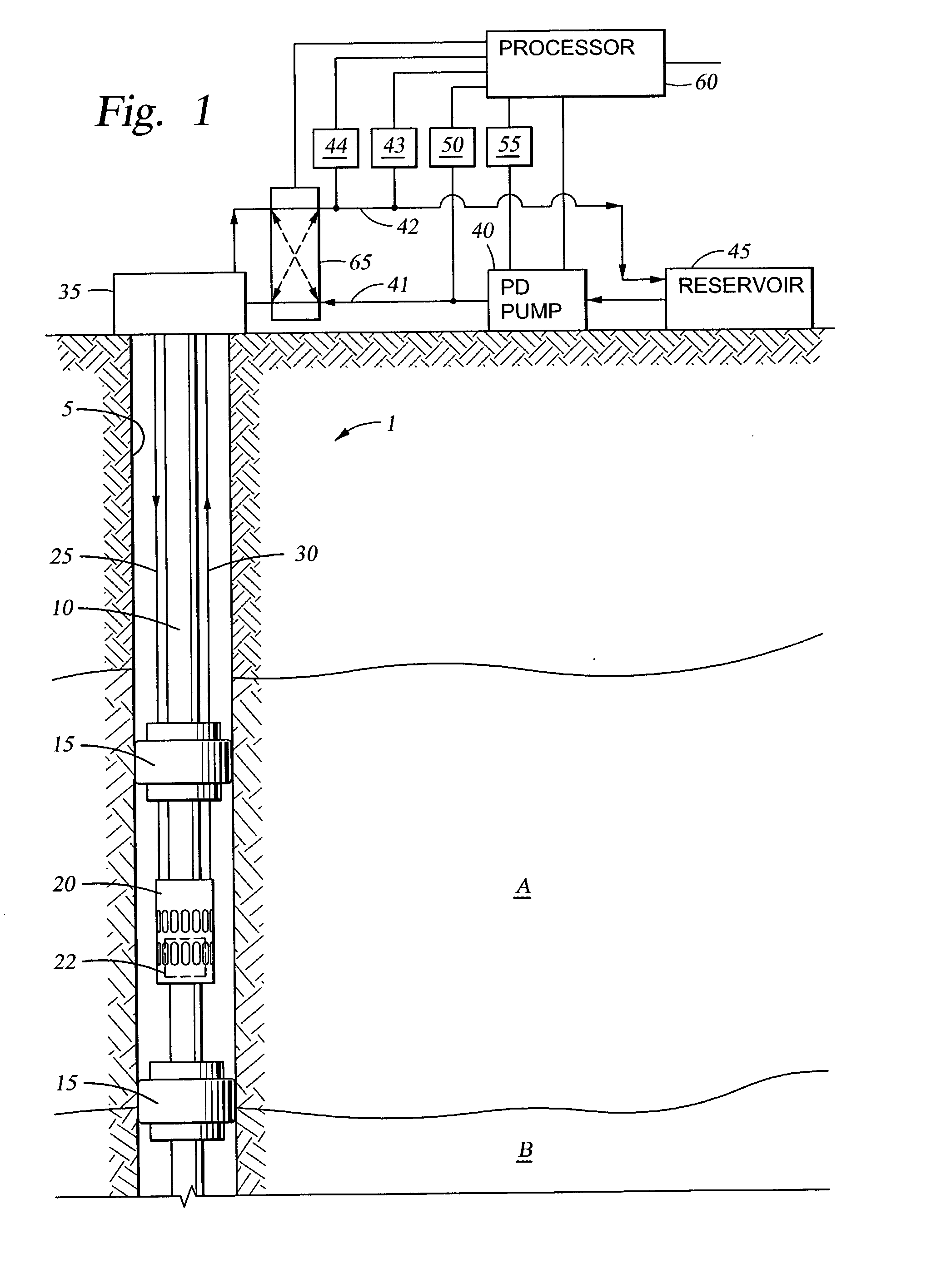

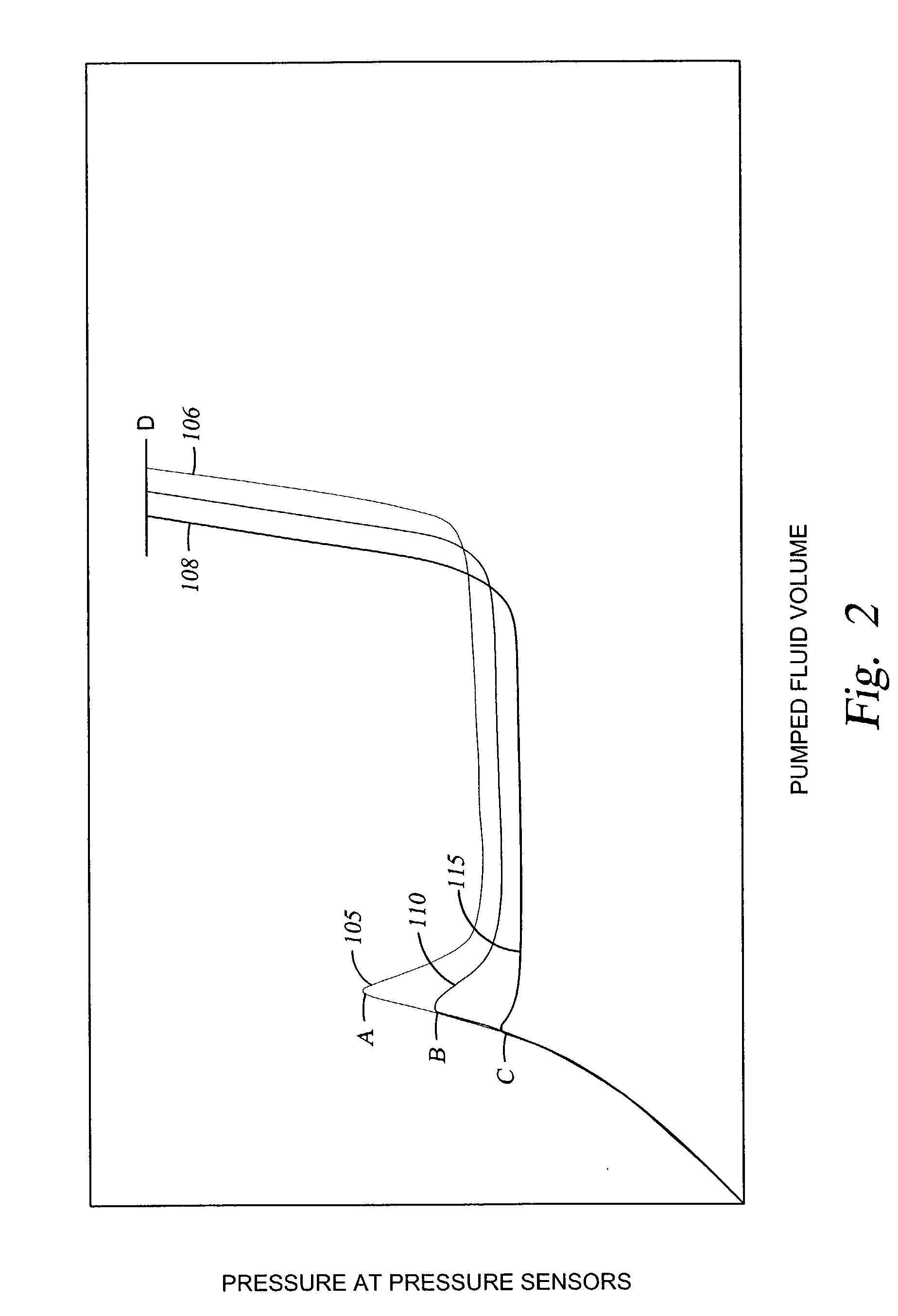

Method and system for controlling a downhole flow control device using derived feedback control

A system and methods for proportionally controlling hydraulically actuated downhole flow control devices using derived feedback control. The system comprises a downhole flow control device with a moveable element in a stationary housing. The moveable element is actuated by a balanced hydraulic piston. Hydraulic lines are fed to either side of the piston to effect actuation in either direction. A processor controlled, surface mounted hydraulic system supplies fluid to the piston. A pressure sensor measures supply pressure to the piston and a cycle counter indicates pump cycles and both sensors generate outputs to the processor. The downhole moveable element is cycled between end stops until successive moveable element breakout pressures are within a predetermined value as measured by the surface pressure sensor. A relationship is then derived between moveable element movement and pumped fluid volume and the relationship is used to move the moveable element to a predetermined position to control flow.

Owner:BAKER HUGHES HLDG LLC

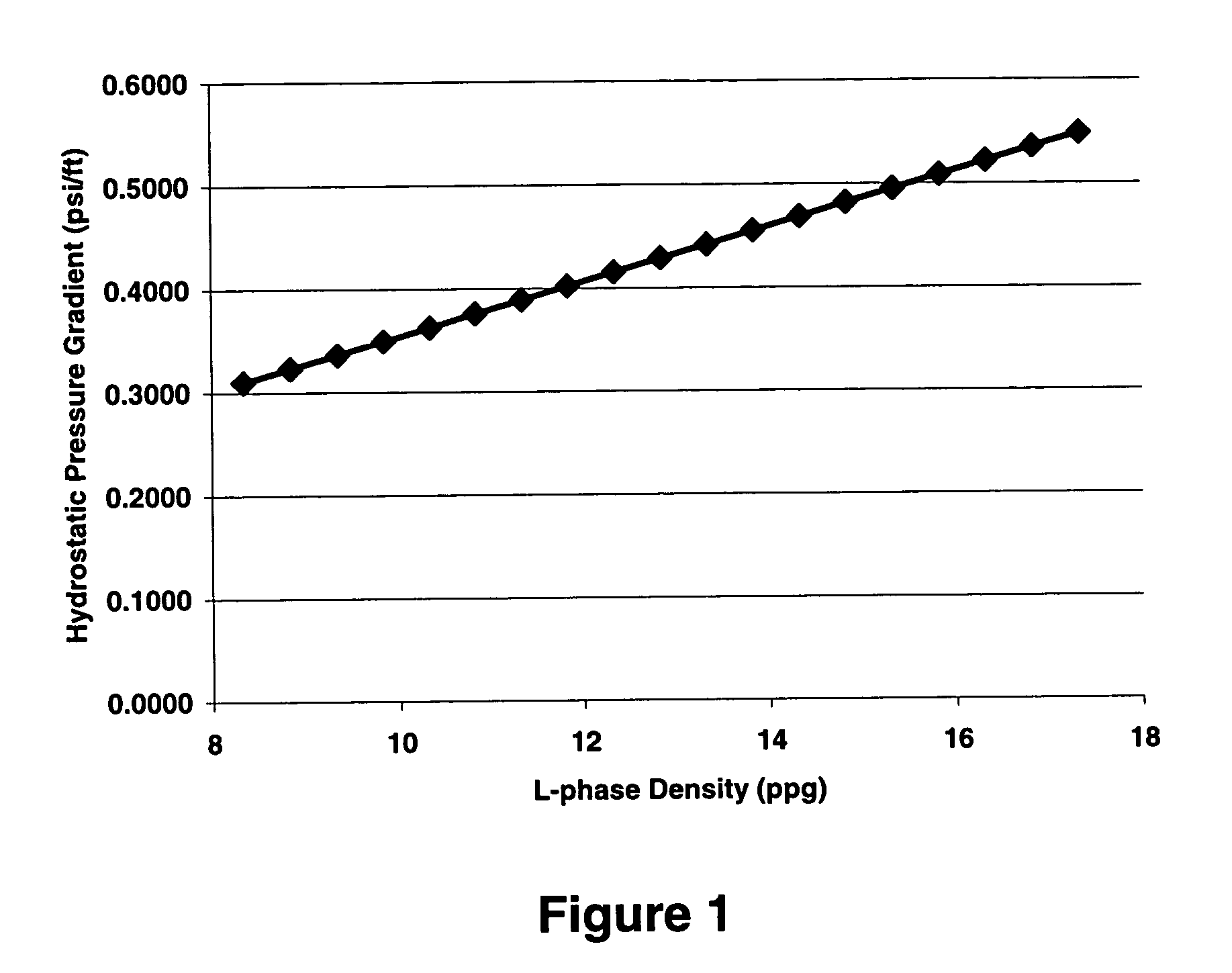

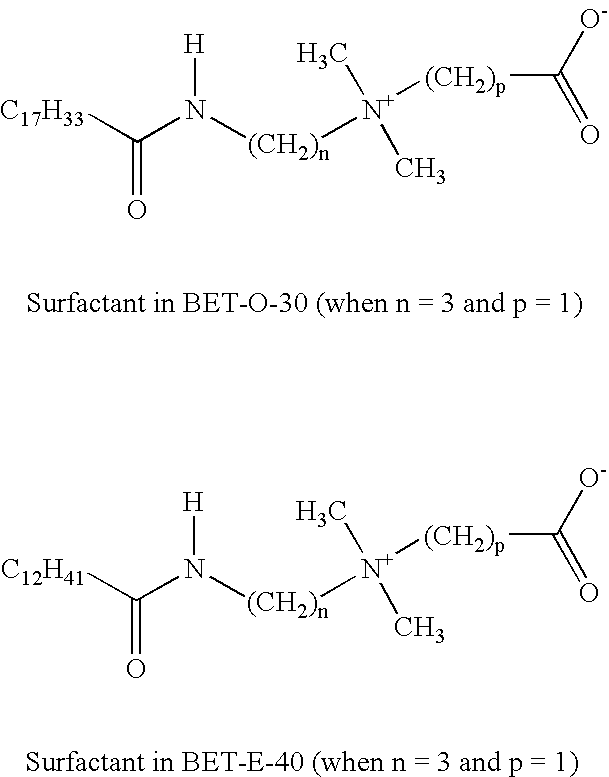

Controlled variable density fluid for wellbore operations

Fluid systems may contain elements to provide changes in bulk fluid density in response to various environmental conditions. One environmental driver to the variable density is pressure; other environmental drivers include, but are not limited to, temperature or changes in chemistry. The variable density of the fluid is beneficial for controlling sub-surface pressures within desirable pore pressure and fracture gradient envelopes. The variability of fluid density permits construction and operation of a wellbore with much longer hole sections than when using conventional single gradient fluids.

Owner:BAKER HUGHES INC

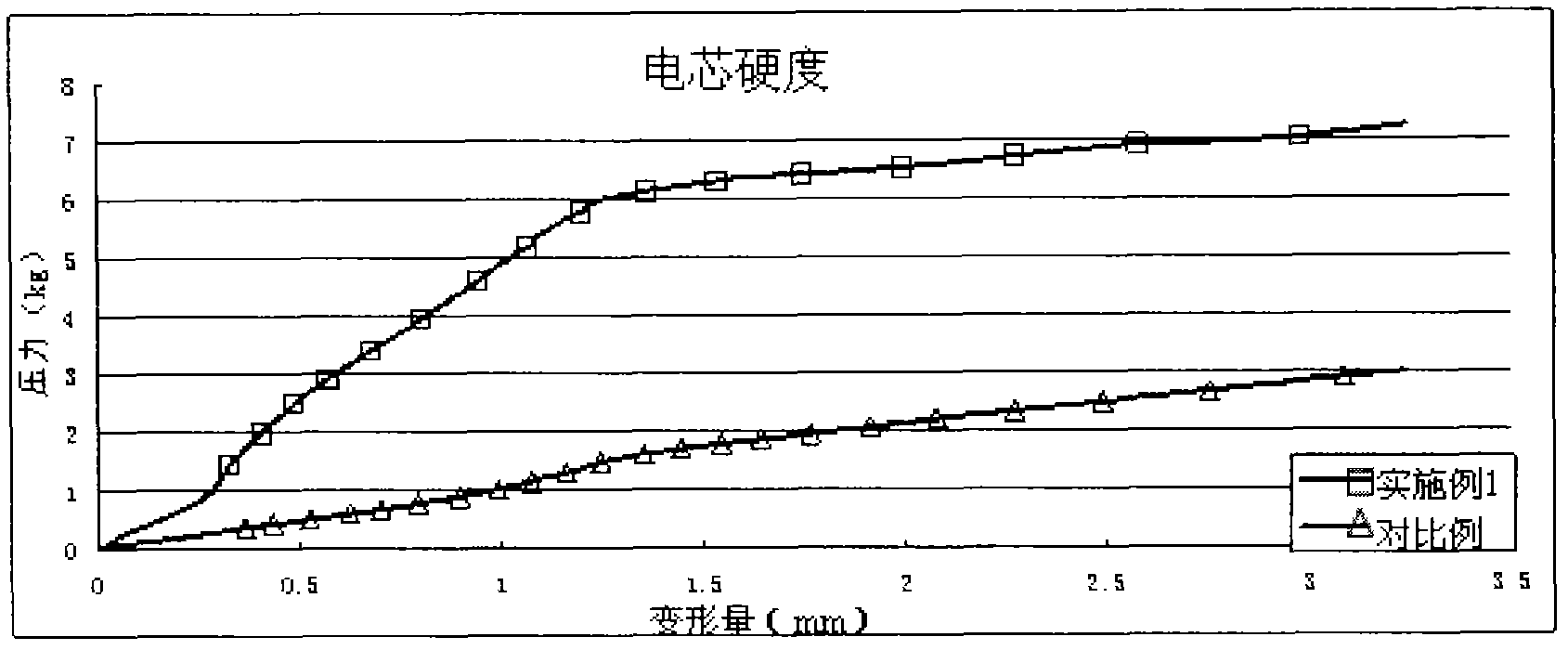

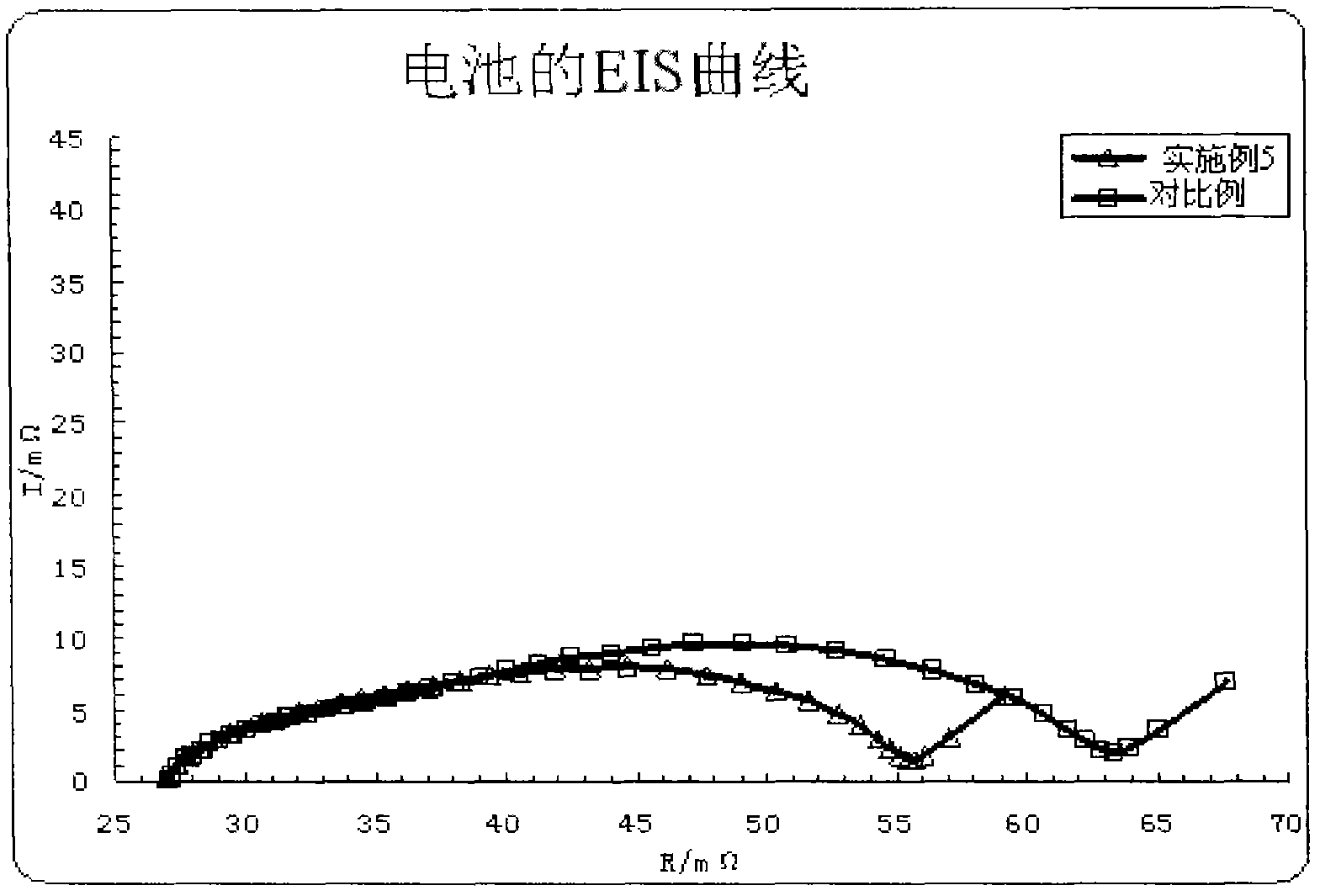

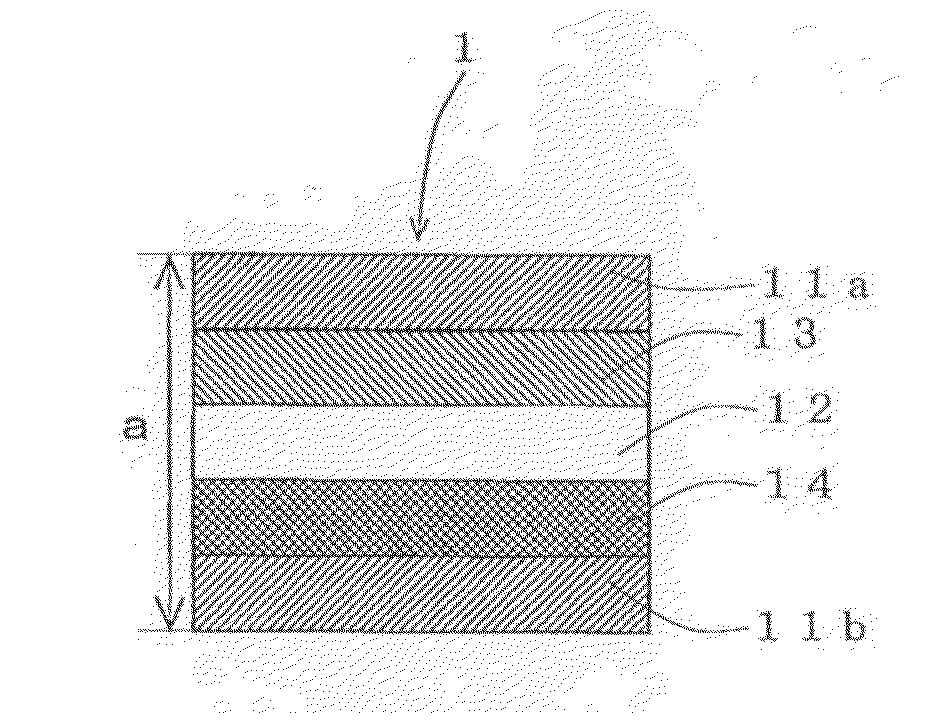

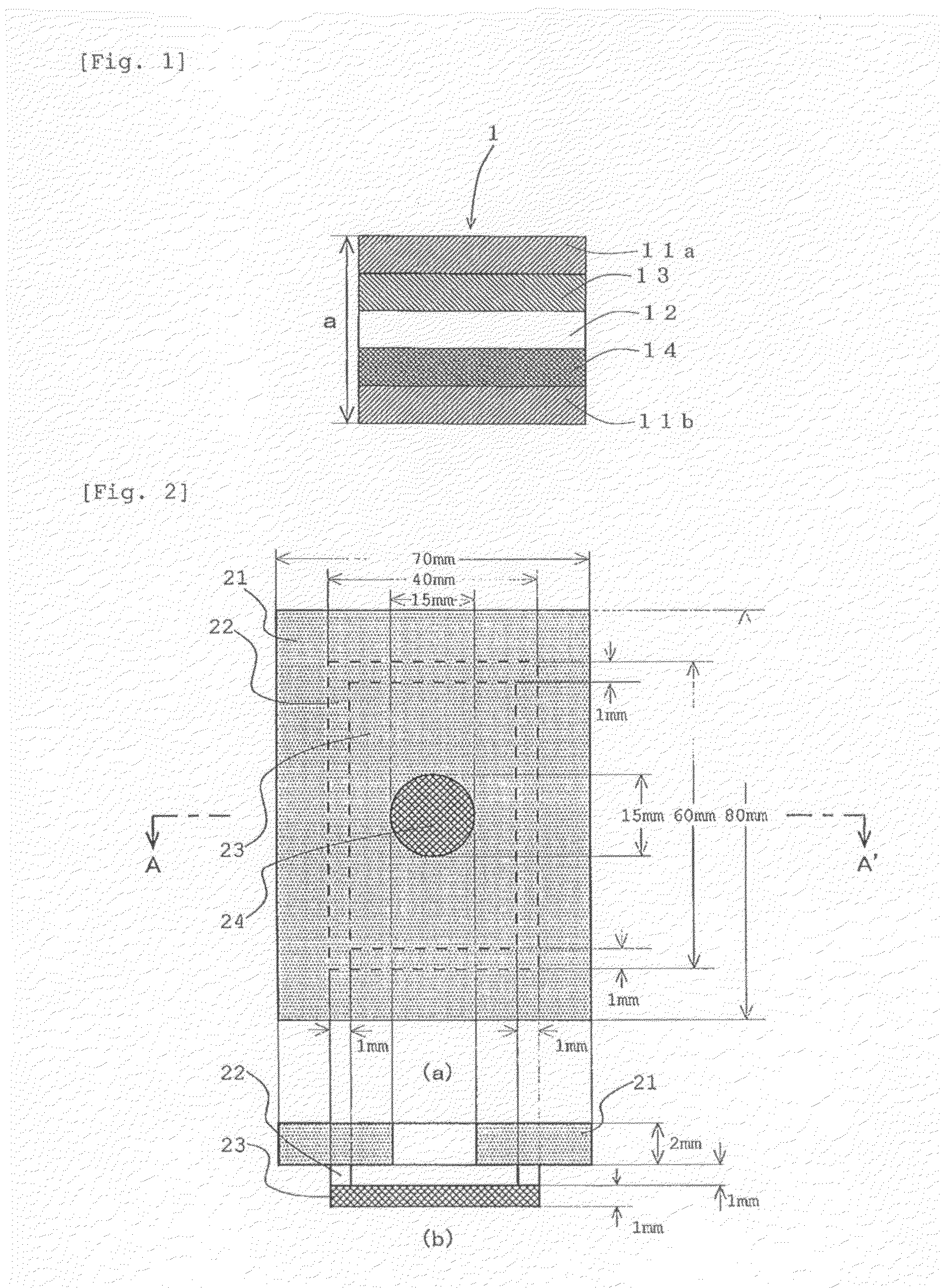

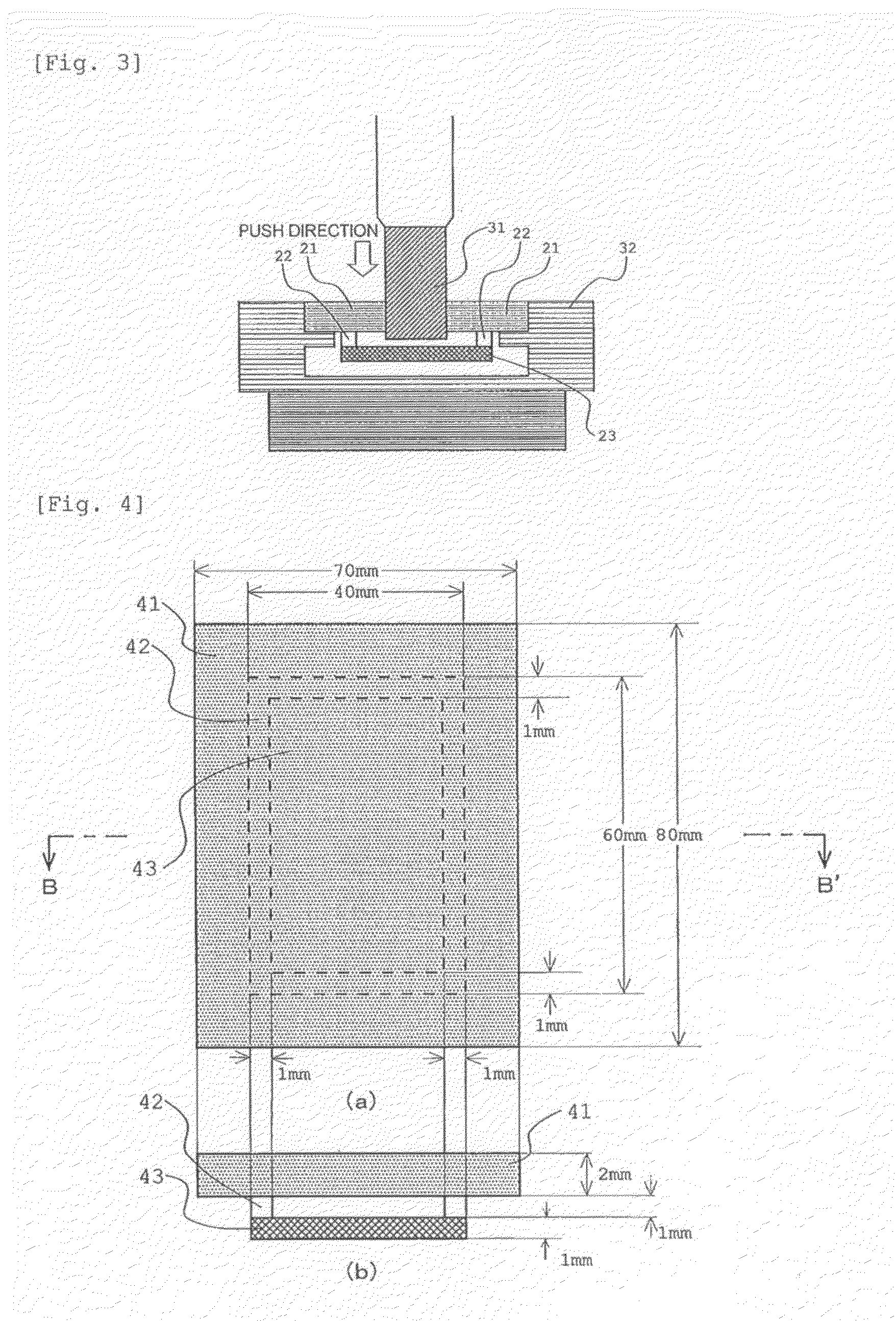

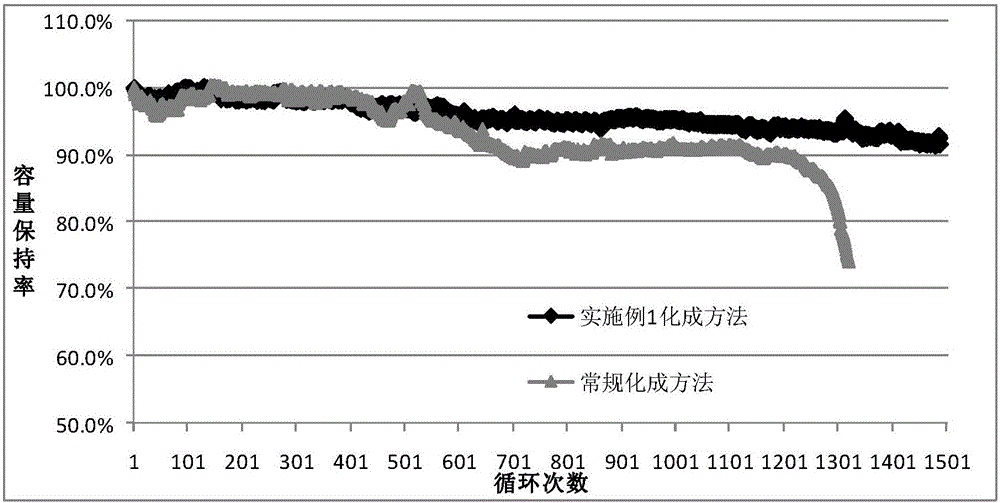

Method for improving hardness of lithium ion cell

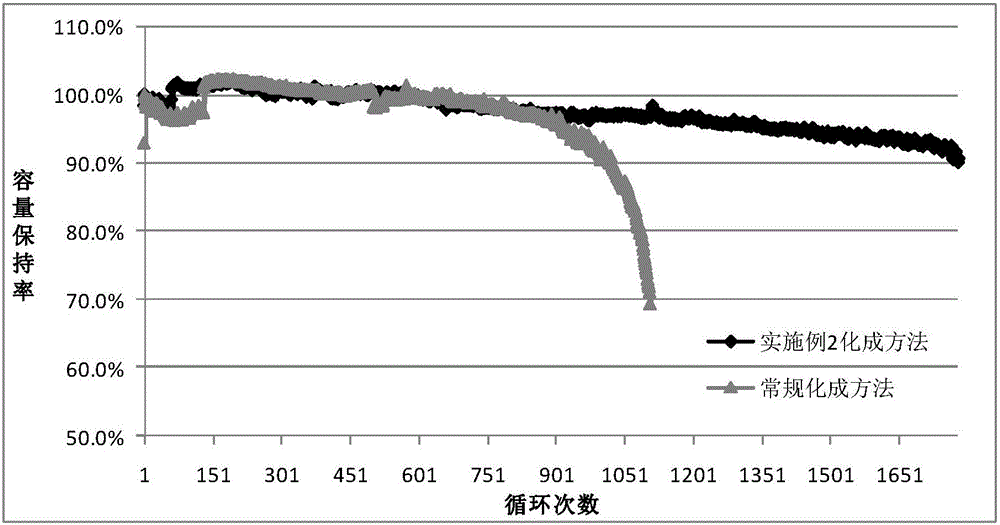

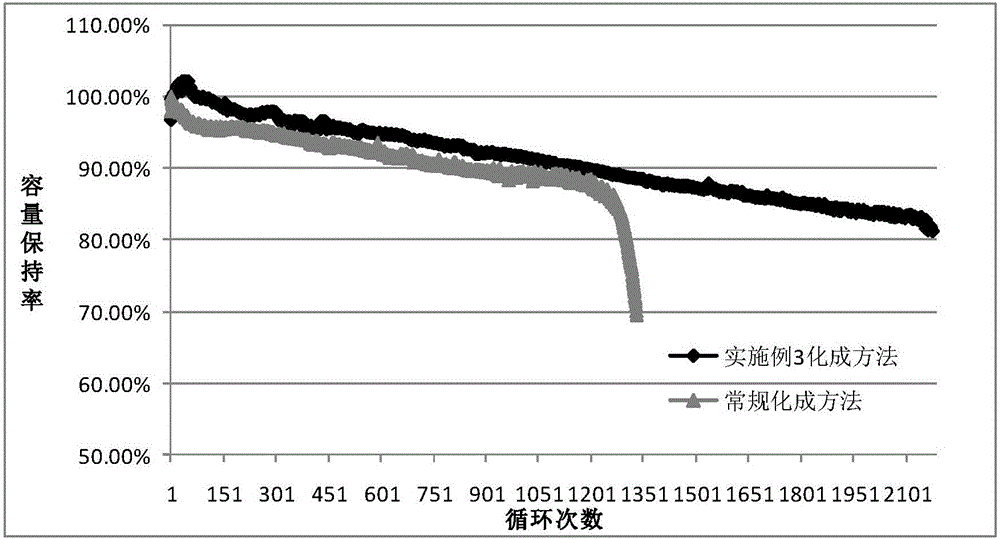

ActiveCN102593520AFast charge and dischargeIncrease the speed of formationFinal product manufactureElectrolyte accumulators manufactureCooking & bakingLithium

The invention belonging to the technical field of lithium ion cells, and particularly relates to a method for improving hardness of a lithium ion cell by rapid formation. In the method, by adjusting the pre-baking time and temperature and the formation temperature of an electric core as well as the surface pressure on an electric core main body, the purpose of reducing the electric core polarization is achieved, high-current rapid formation is further realized, and finally the formation stopping potential is adjusted, so as to prepare the lithium ion cell with higher hardness. As compared with the prior art, the method has the following advantages: the high-temperature cramping and baking reshaping after formation is cancelled, so that the prepared electric core is higher in capacity; the electric core bears constant (or variable) pressure during the charge and discharge processes, thus the polarization in the charge and discharge processes is lower, and the capacity consistency of the prepared electric core is better; and because different temperatures and an SOC (state of charge) stopping manner are adopted for formation, the prepared electric core not only has excellent performance, but also has higher hardness.

Owner:NINGDE AMPEREX TECH +1

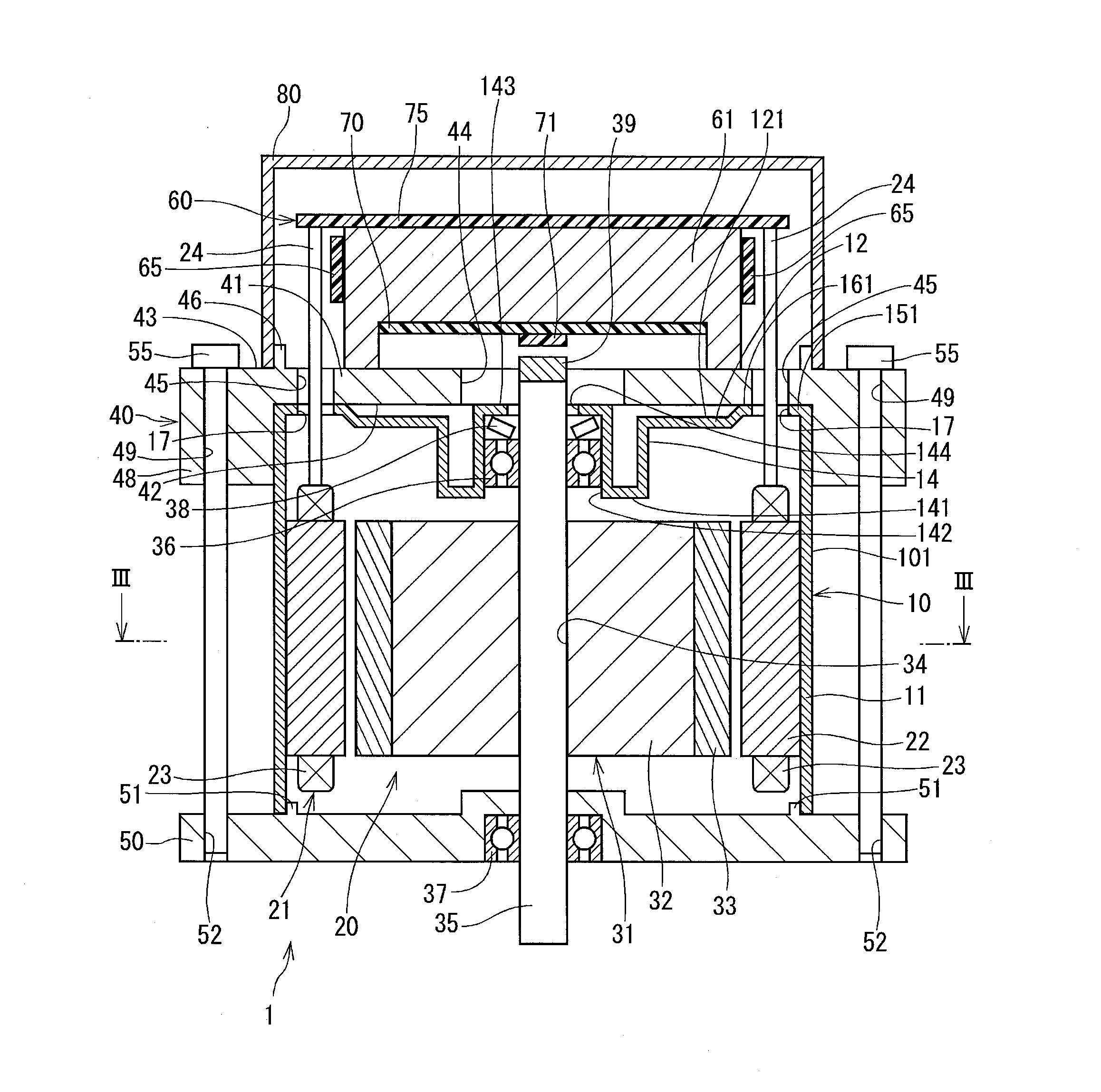

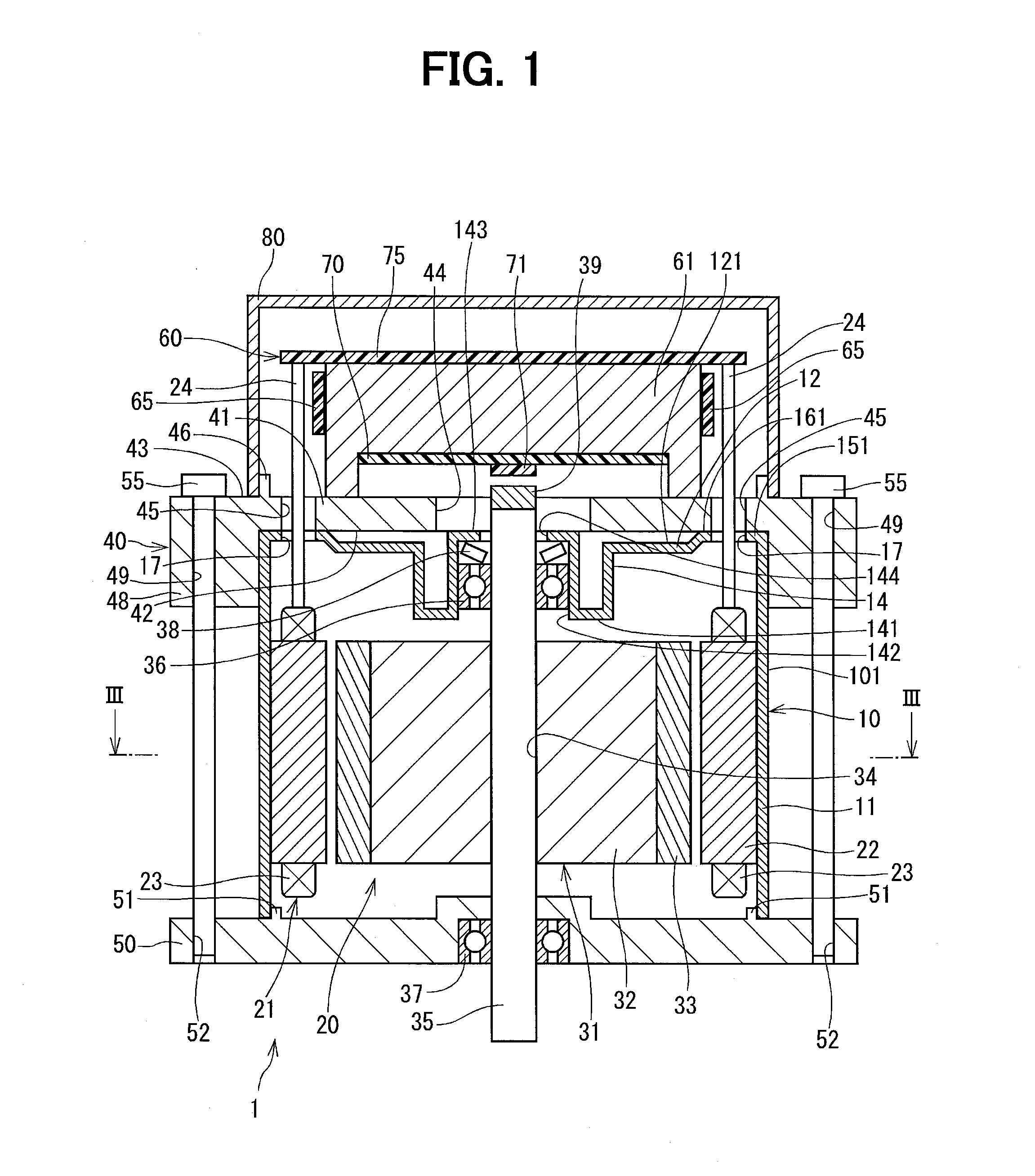

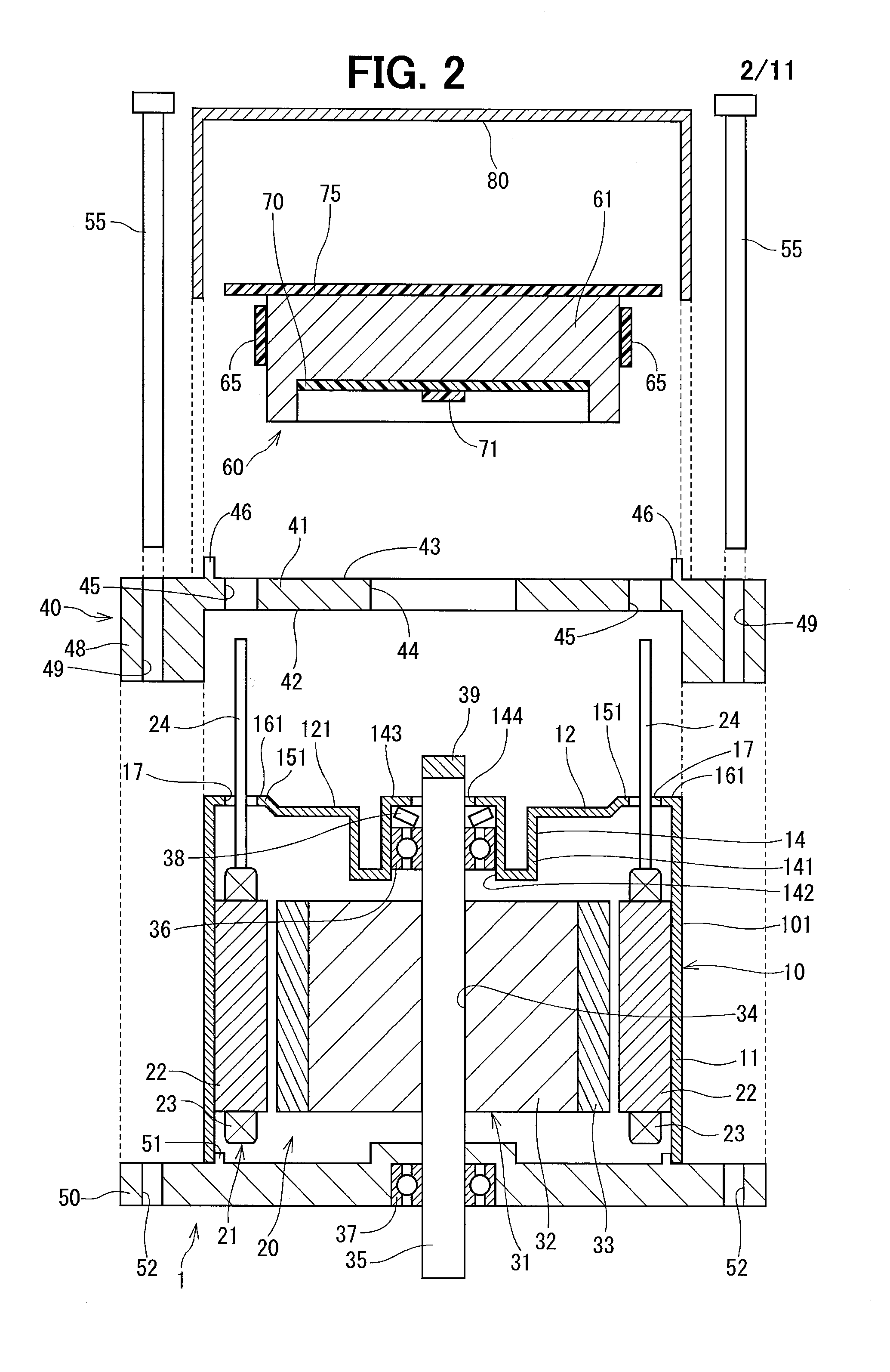

Driving device

ActiveUS20140339966A1Reduce vibrationSufficient surface pressureSynchronous generatorsAssociation with control/drive circuitsEngineeringMotor control

A motor casing of a driving device has a cylindrical wall portion, a bottom wall portion and a bearing holding portion formed in the bottom wall portion. An electric motor has a stator, a shaft and a rotor. A motor control unit controls operation of the electric motor. A first frame, to which the motor control unit is fixed, is provided between the motor control unit and the bottom wall portion of the motor casing. A first contacting portion is formed in the bottom wall portion and projected toward the first frame. The first contacting portion is in contact with the first frame at a front-side surface of the first contacting portion. A contacting surface area between the motor casing and the first frame is limitedly reduced, to thereby reduce noise caused by vibration. In addition, since a sufficient surface pressure can be obtained, strength of the driving device in its axial direction is increased.

Owner:DENSO CORP

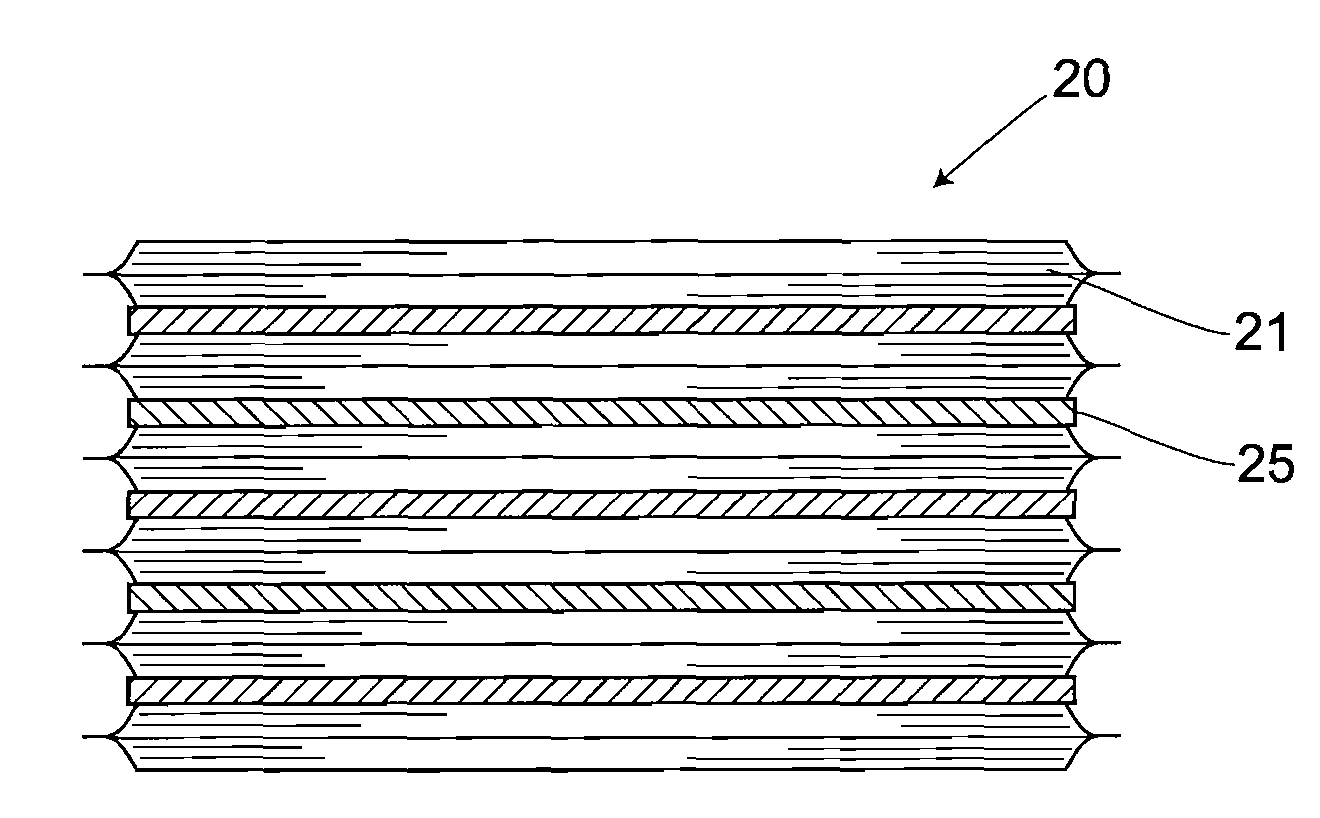

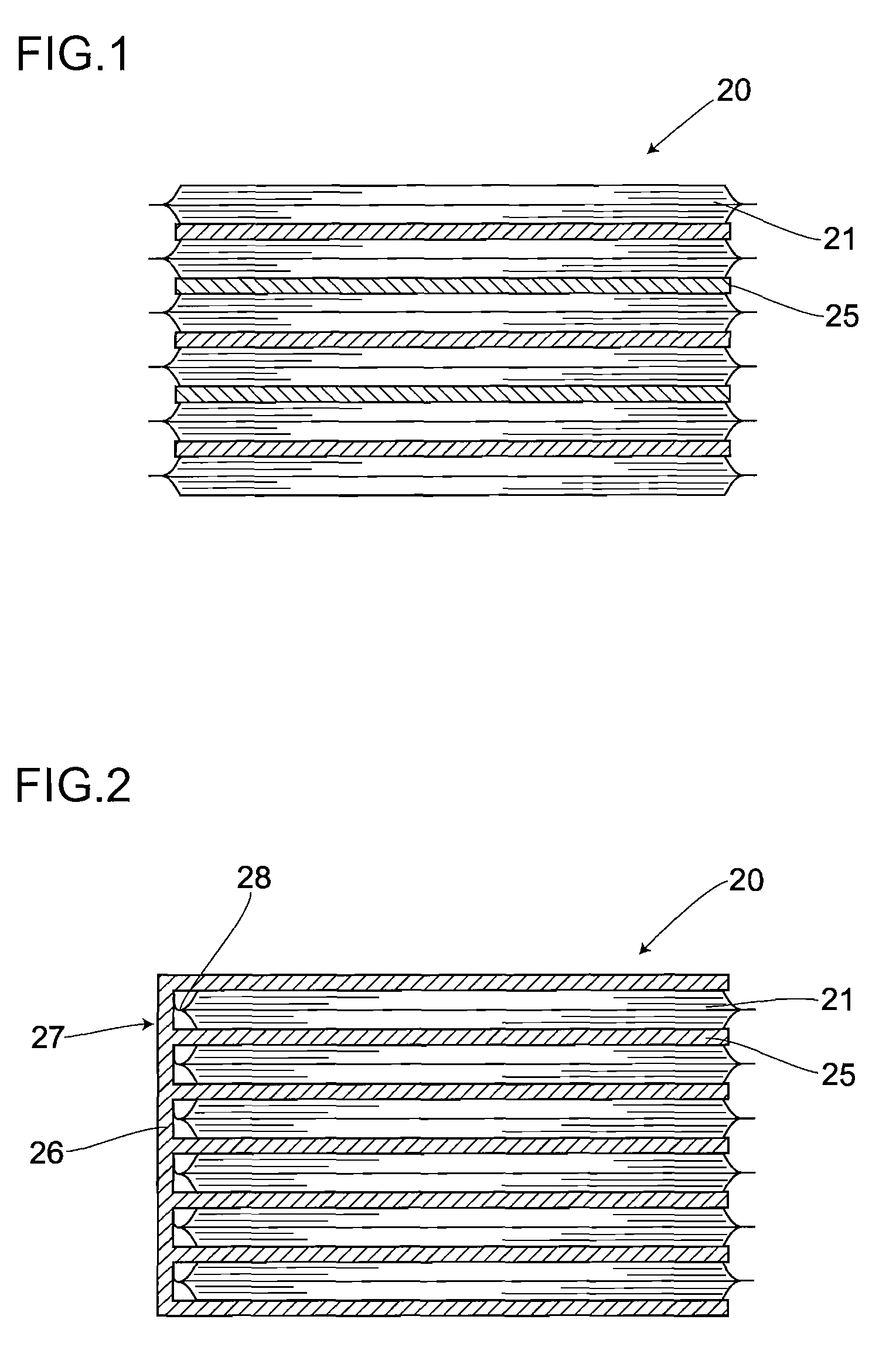

Double-coated pressure-sensitive adhesive tape

InactiveUS20110300361A1Small thicknessExcel in removabilitySynthetic resin layered productsEster polymer adhesivesSurface pressureTotal thickness

Disclosed is a double-coated pressure-sensitive adhesive tape which has a small total thickness, includes a foam layer, and excels in removability. The double-coated pressure-sensitive adhesive tape has a total thickness of 500 μm or less and includes a foam layer; a reinforcing layer; and two surface pressure-sensitive adhesive layers, in which at least one of the two surface pressure-sensitive adhesive layers is formed from a pressure-sensitive adhesive composition containing an acrylic polymer, a tackifier resin, and a crosslinking agent, the acrylic polymer including, as an essential monomer component, an alkyl(meth)acrylate whose alkyl moiety being a linear or branched-chain alkyl group having 4 to 9 carbon atoms.

Owner:NITTO DENKO CORP

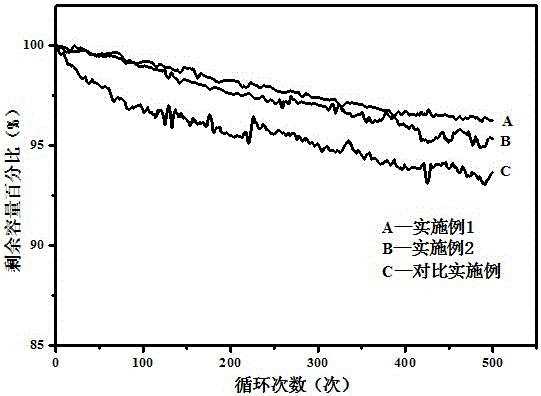

Formation method of softly-packed lithium ion battery

InactiveCN106684426AQuality improvementDense massFinal product manufactureSecondary cells manufactureSurface pressureEngineering

The invention relates to a formation method of a softly-packed lithium ion battery. The method comprises: using a 0.01-0.05 C current to perform low-current pre-charging to a softly-packed lithium ion battery till the cut-off voltage reaches 3.0 V; using a 0.1-1.0 C current to perform constant-current charging till the cut-off voltage reaches 3.6 V; and using a 0.5-3.0 C current to perform constant-current charging till the cut-off voltage reaches 4.2 V and the cut-off current reaches 0.01-1.0 C. In the formation process, the surface pressure of two sides of the softly-packed lithium ion battery is kept no less than 0.4 MPa, and the temperature of the softly-packed lithium ion battery is kept no more than 80 DEG C. In the formation process, pressure is applied to two sides of the battery, so that the positive and negative electrodes fully contact the separator film, the surface states of electrode pieces are balanced, and surface SEI films are uniformly formed. The formed softly-packed lithium ion battery has stable impact SEI films, is uniform in quality, less in defects, high in battery liquid retention and excellent in cycle performance and safety performance.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

Hydraulic fracturing method

The invention relates to a method of fracturing a subterranean formation at reduced surface pressure including injecting into a wellbore an energized fracturing fluid based on a liquid medium having a density higher than 1.2 g / cm3.

Owner:SCHLUMBERGER TECH CORP

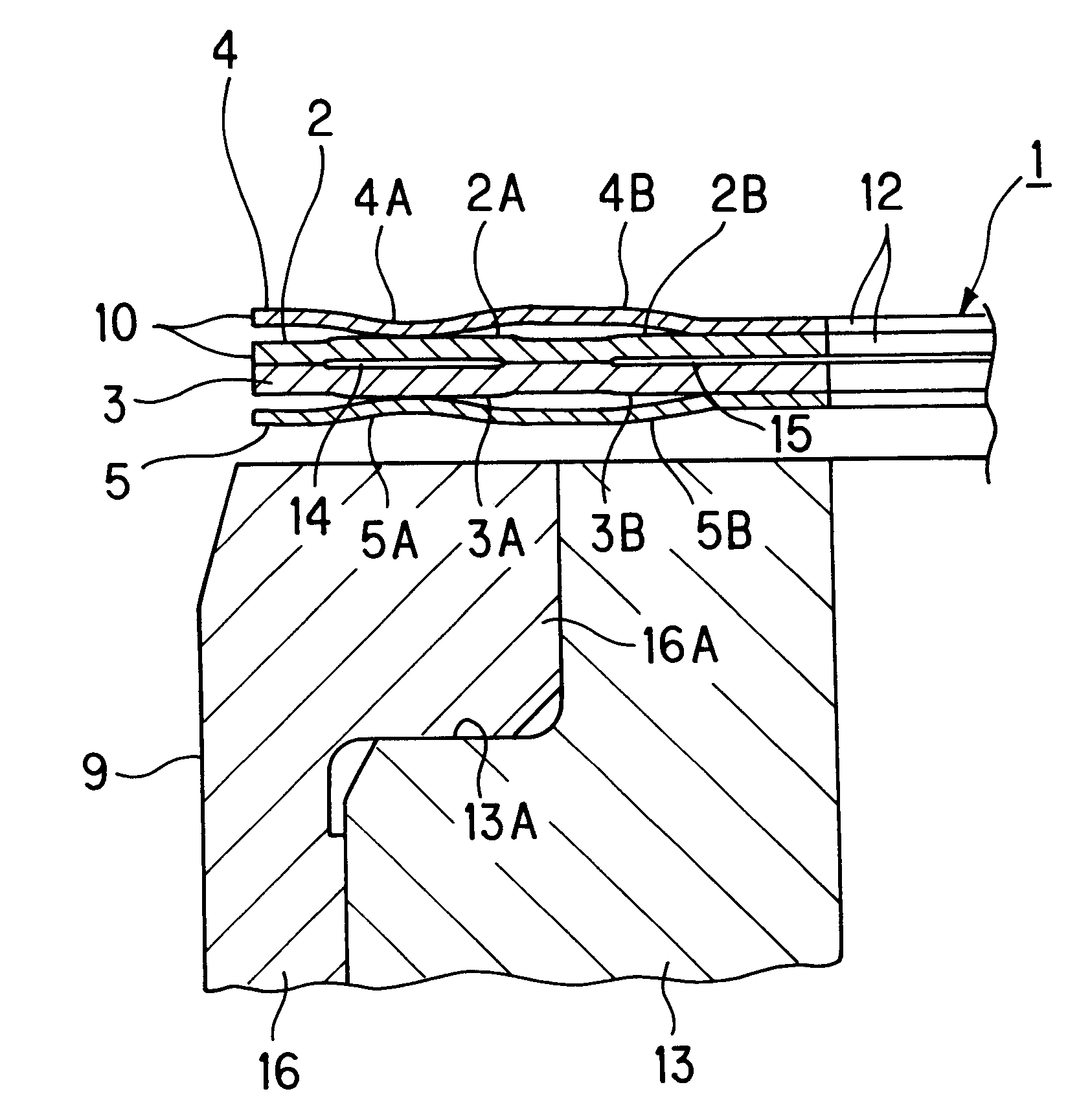

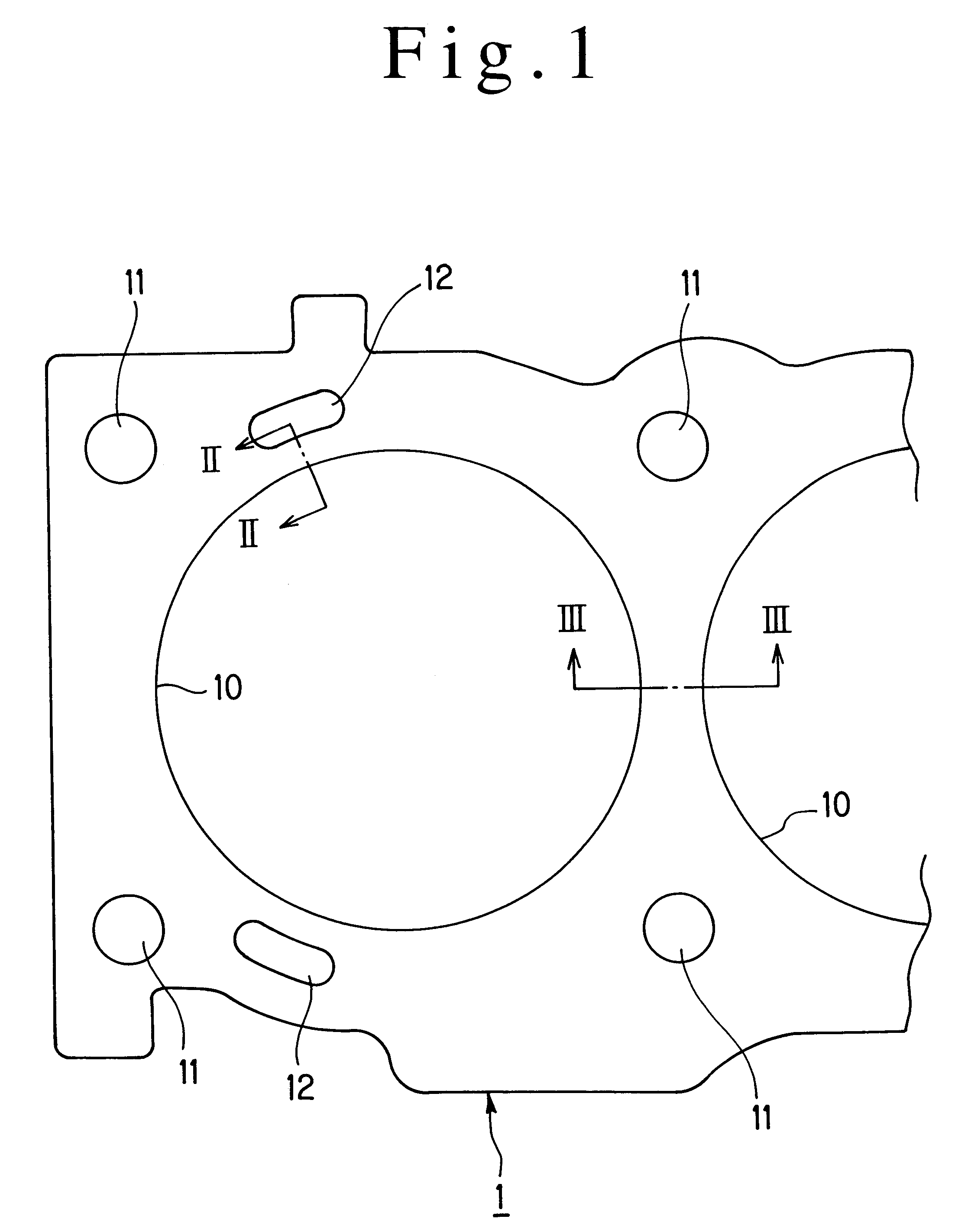

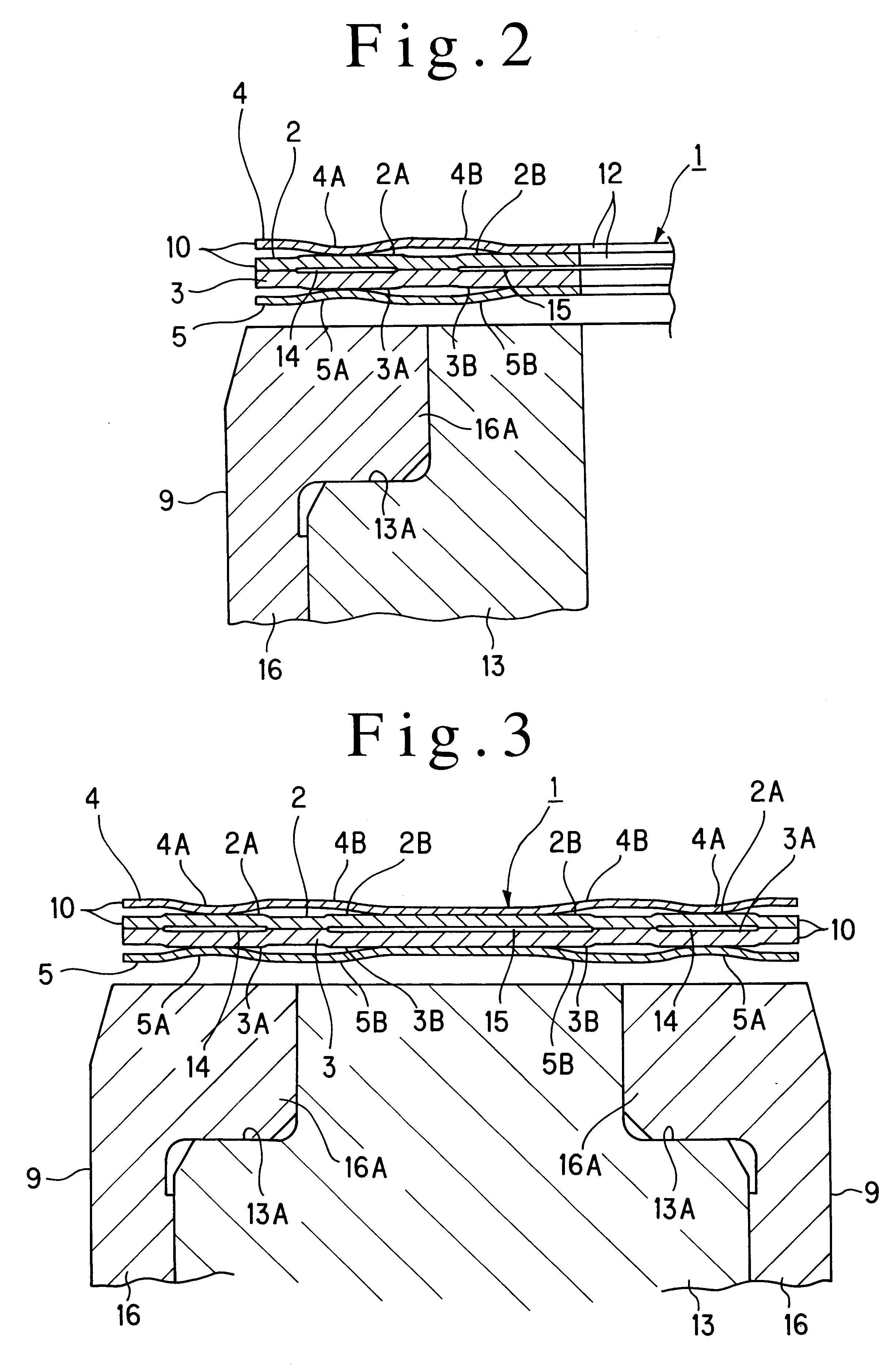

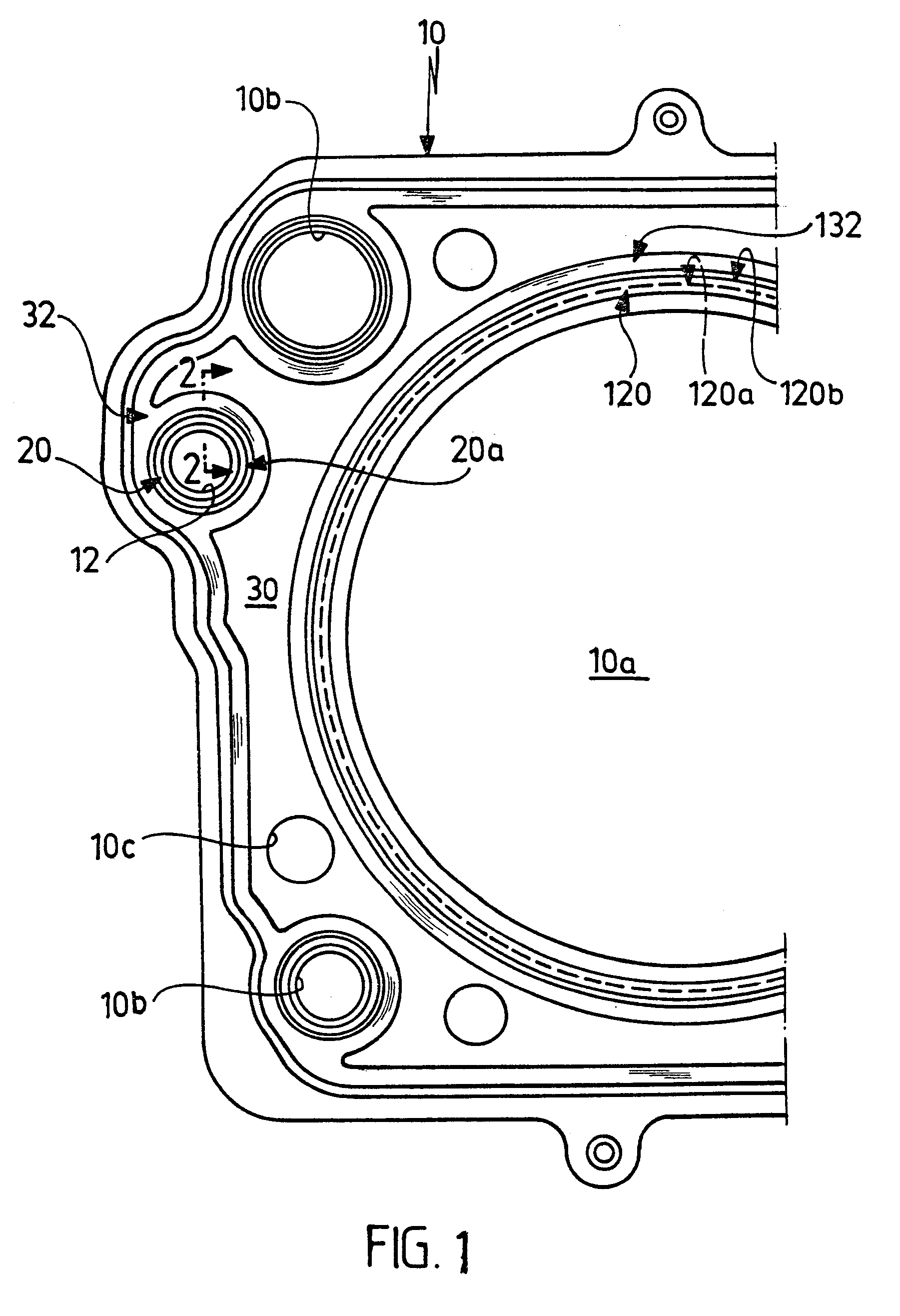

Cylinder head gasket

InactiveUS6328314B1Increases magnitudeEngine sealsSealing arrangements for enginesCylinder headEngineering

A cylinder head gasket includes a pair of first and second gasket substrates. The gasket substrates are each formed with a first and a second projection which project in opposite directions, with a clearance therebetween. According to a first aspect of the invention, each projection undergoes a plastic deformation toward the clearance defined between them when the gasket substrates are held sandwiched between a cylinder head and a cylinder block, each projection undergoing a magnitude of plastic deformation which is greater or lesser in accordance with the magnitude of a surface pressure therebetween. According to a second aspect of the invention, each projection is formed with a radially central part which projects toward the radially central part of the other projection and which is in close contact with each other continuously in the circumferential direction.

Owner:TAIHO INDUSTRIES CO LTD +1

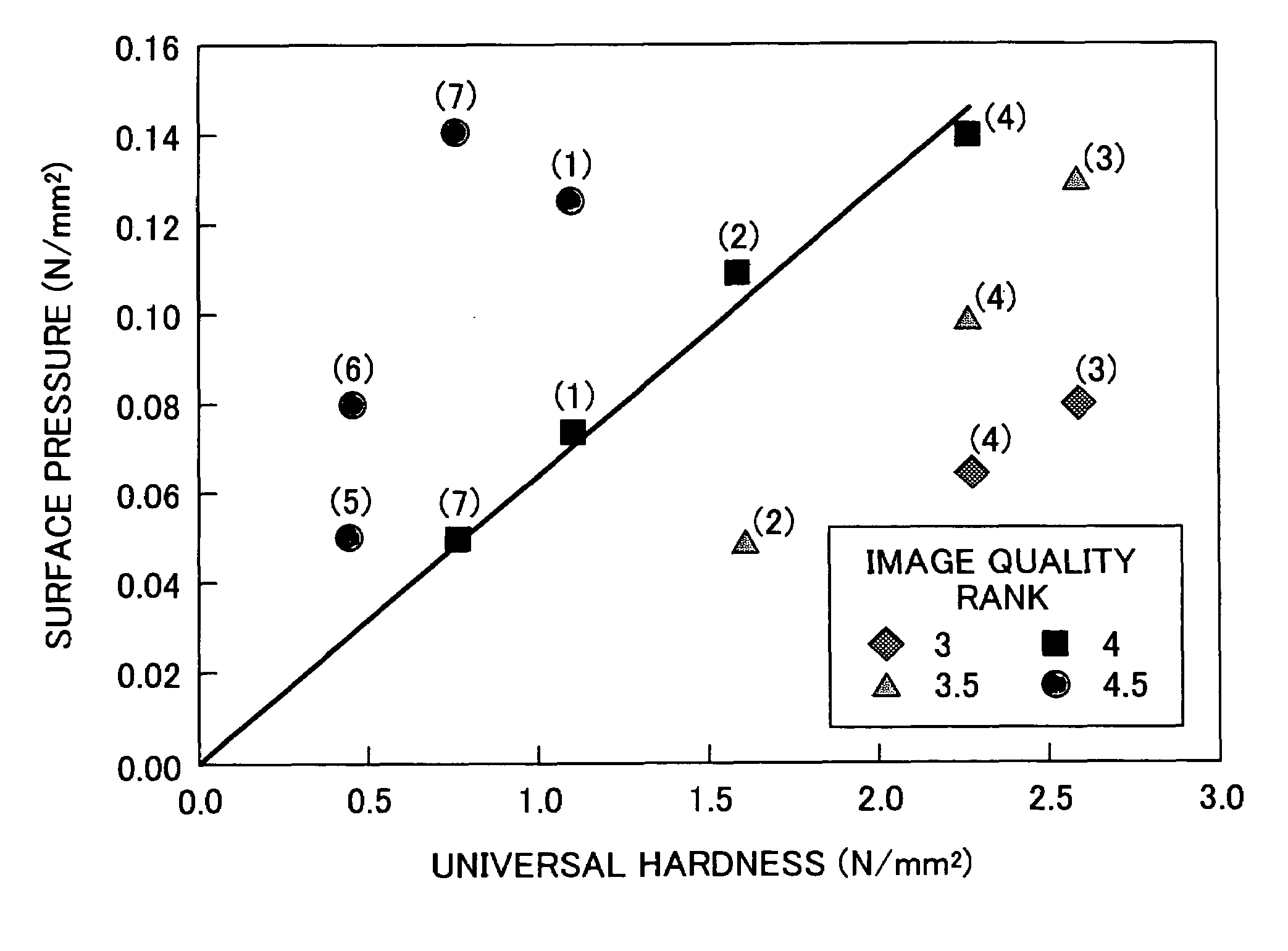

Image forming method and apparatus for fixing an image

An image forming apparatus, includes an image forming mechanism configured to form an image, and a fixing unit configured to fix a toner image formed on a recording medium. The fixing unit includes a fixing device having a first endless moving member configured to rotate, and a second endless moving member configured to rotate to form a nip area together with the first endless moving member to fix, at the nip area, a toner image disposed on the recording medium onto the recording medium with heat and pressure, the second endless moving member including a surface layer having a universal hardness HU and a maximum nip surface pressure P each within a predetermined range.

Owner:RICOH KK

Method and system for controlling a downhole flow control device using derived feedback control

A system and methods for proportionally controlling hydraulically actuated downhole flow control devices using derived feedback control. The system comprises a downhole flow control device with a moveable element in a stationary housing. The moveable element is actuated by a balanced hydraulic piston. Hydraulic lines are fed to either side of the piston to effect actuation in either direction. A processor controlled, surface mounted hydraulic system supplies fluid to the piston. A pressure sensor measures supply pressure to the piston and a cycle counter indicates pump cycles and both sensors generate outputs to the processor. The downhole moveable element is cycled between end stops until successive moveable element breakout pressures are within a predetermined value as measured by the surface pressure sensor. A relationship is then derived between moveable element movement and pumped fluid volume and the relationship is used to move the moveable element to a predetermined position to control flow.

Owner:BAKER HUGHES INC

High-wearing high-rigidity reinforced nylon 66 complexes and method for making same

ActiveCN101182388ALow surface energy activitySpherulite refinementStatic friction coefficientGlass fiber

The invention relates to a highly wear-resistant and high-rigidity reinforced nylon 66 compound. The invention is characterized in that the compound consists of materials of the following weight portions: 66 portions to 100 portions of nylon, 0.1 portions to 15 portions of nucleater, 5 portions to 30 portions of wear-resistant agent, 0.5 portion to 3 portions of heat stabilizer and processing aid, and 15 portions to 105 portions of glass fiber. The invention has the advantage that each index all reaches or surpasses the scheduled requirements; the bending modulus of the material reach above 11000MPa; the hardness reaches to 135 N / mm2. Under the condition of no lubrication, surface pressure of 1.5 kg / m2, speed of 29 m / min and a temperature of 23 DEG C, the maximum static friction coefficient is 0.11; the maximum dynamic friction coefficient is 0.07. Under the condition of no lubrication, surface pressure of 100kg / cm<2> and speed of 23m / min, the PV value reaches above 2270kg / cm<2> question mark m / min.

Owner:SHANGHAI KINGFA SCI & TECH +1

Method for quickly generating lamination flexible package lithium ion battery

ActiveCN106099202ADischarge fullyRestructuring and StabilityFinal product manufactureSecondary cells charging/dischargingSurface reactionPole piece

The invention belongs to the technical field of lithium ion batteries and particularly relates to a method for quickly generating a lamination flexible package lithium ion battery. The method comprises a stage of forming a solid electrolyte phase interface film and a stage of discharging formation gas. The main theoretical foundation is that the solid electrolyte phase interface film is mainly formed at the initial stage of formation charging, accompanied with the discharging of the formation gas. The formation of an SEI film is subjected to the influences of current density and temperature and the like. Under a small current density, first organic lithium salt is formed on the surface of a cathode and then inorganic lithium salt is formed, so that the formed SEI film is denser, and ingredients are more stable. At this stage, a high-pressure pressurization formation mode is adopted, the reaction activity can be increased, the reaction is accelerated, battery surface pressure is increased, the ionic migration distance can be shortened, and formation efficiency and pole piece surface reaction consistency are improved. Compared with a conventional formation process, according to the method, the formation time is shortened, the formed SEI film is denser and more stable, and the method can be widely applied to industrial production.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

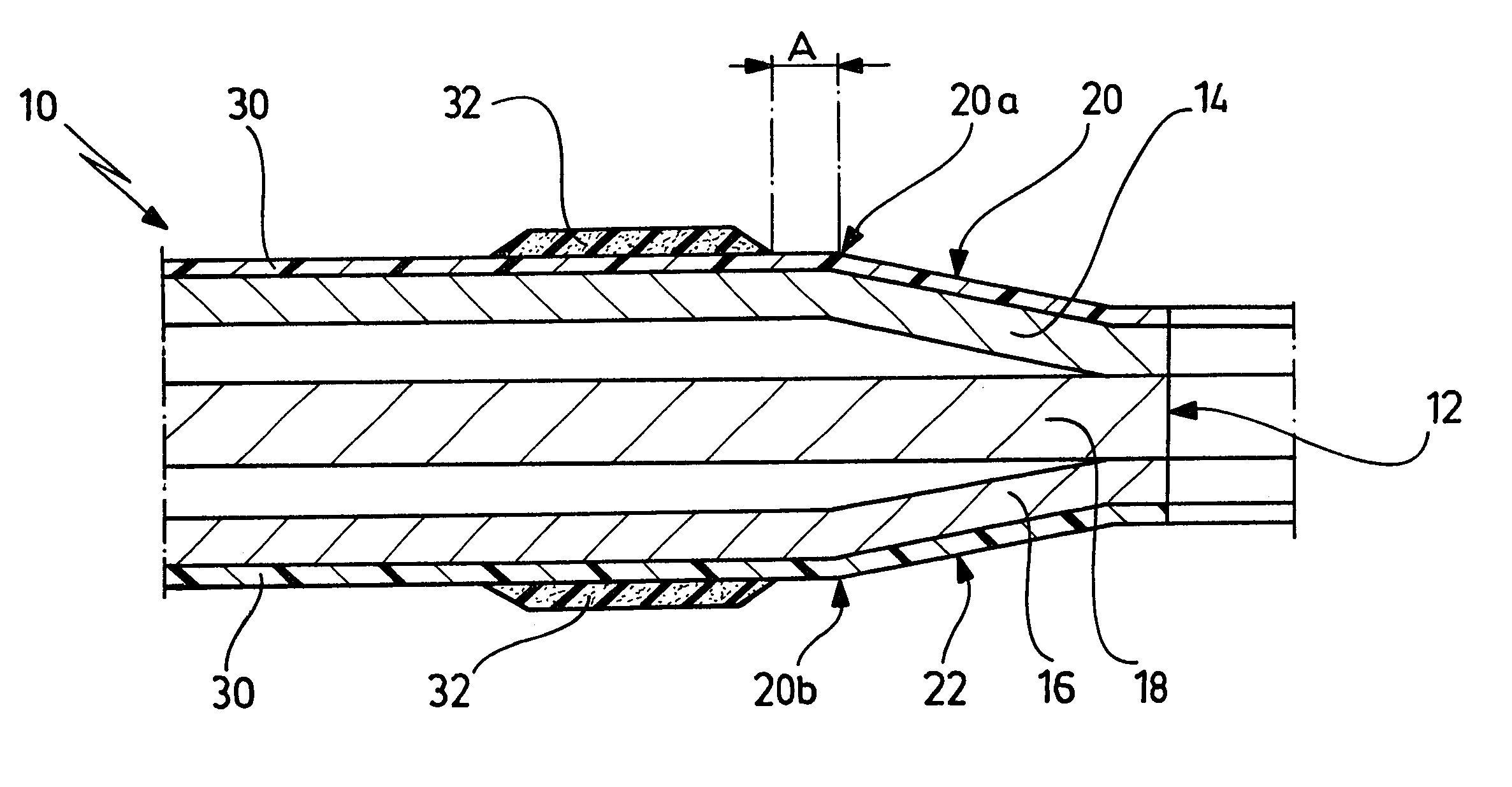

Cylinder head gasket

InactiveUS6349945B1Increase surface pressureImprove plasticityEngine sealsSealing arrangements for enginesPlastic materialsEngineering

Cylinder head gasket comprising a gasket plate which has at least one metal layer with elastic properties and in which a through opening is formed which is surrounded by a bead-like embossment formed in this metal layer, wherein the bead-like embossment forms an approximately linear, self-contained sealing zone with increased sealing surface pressure when the gasket is fitted and the metal layer is provided with a first coating consisting of a plastic material which has elastic properties on its side forming this sealing zone at least in the area of this sealing zone as well as to both sides of the latter; to improve the sealing capacity of the cylinder head gasket around the said through opening, the metal layer is coated on its side provided with the first coating with a sealing bead closed upon itself, likewise surrounding the through opening and consisting of a plastic material, this bead being arranged on the side of the sealing zone facing away from the through opening as well as at a radial distance from the sealing zone in relation to the through opening, wherein the ridge of the sealing bead is at a greater distance from the metal layer supporting it than the upper side of the first coating.

Owner:ELRINGKLINGER AG

Grain storage quantity detection method for horizontal warehouse and shallow silo

InactiveCN102706417ALow costReduce workloadWeighing apparatus for materials with special property/formGrain storageSurface pressure

The invention relates to a grain storage quantity detection method for horizontal warehouses and shallow silos. The grain storage quantity detection method comprises the following steps of: firstly selecting specific pressure sensors to lay a grain warehouse pressure sensor detection network; distributing the pressure sensors along the side wall of the grain warehouse in the mode that all the pressure sensors are evenly-spaced laid at d meter distance from the side wall; and determining whether a grain warehouse is calibrated or not so as to obtain a calibration parameter and a grain warehouse weight prediction model, spreading the top surface of a grain pile in the grain warehouse after the grain warehouse is fully filled with the grain, detecting the average output valve of the pressure sensor at the bottom of the grain warehouse, and detecting the grain storage quantity of the grain warehouse according to an actually-tested bottom surface area of the grain warehouse, a bottom surface area of the calibrated grain warehouse and calibrated parameters by using a model so as to obtain an estimated value of the weight of the grain warehouse. According to the grain storage quantity detection method provided by the invention, the pressure sensors are required to be arranged on the bottom surface of the grain warehouse, and a compensating item of a side grain warehouse friction action is added into a bottom surface pressure estimating model in order to avoid using the side pressure sensor and accurately obtain the estimated value of the pressure of the bottom surface of the grain warehouse, so that the quantity of the sensors is obviously reduced, and the device detection cost and the installation and maintenance cost are reduced.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

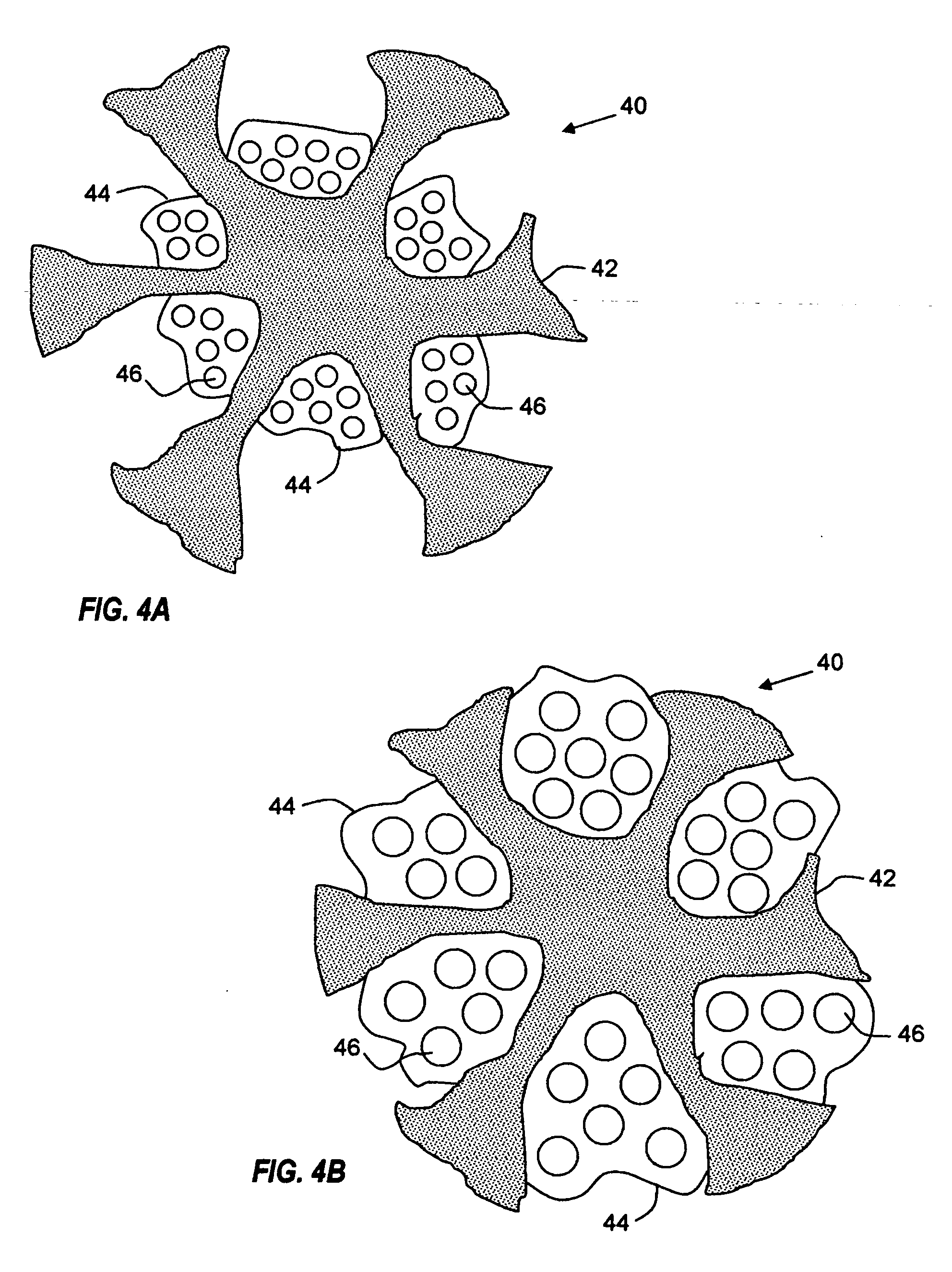

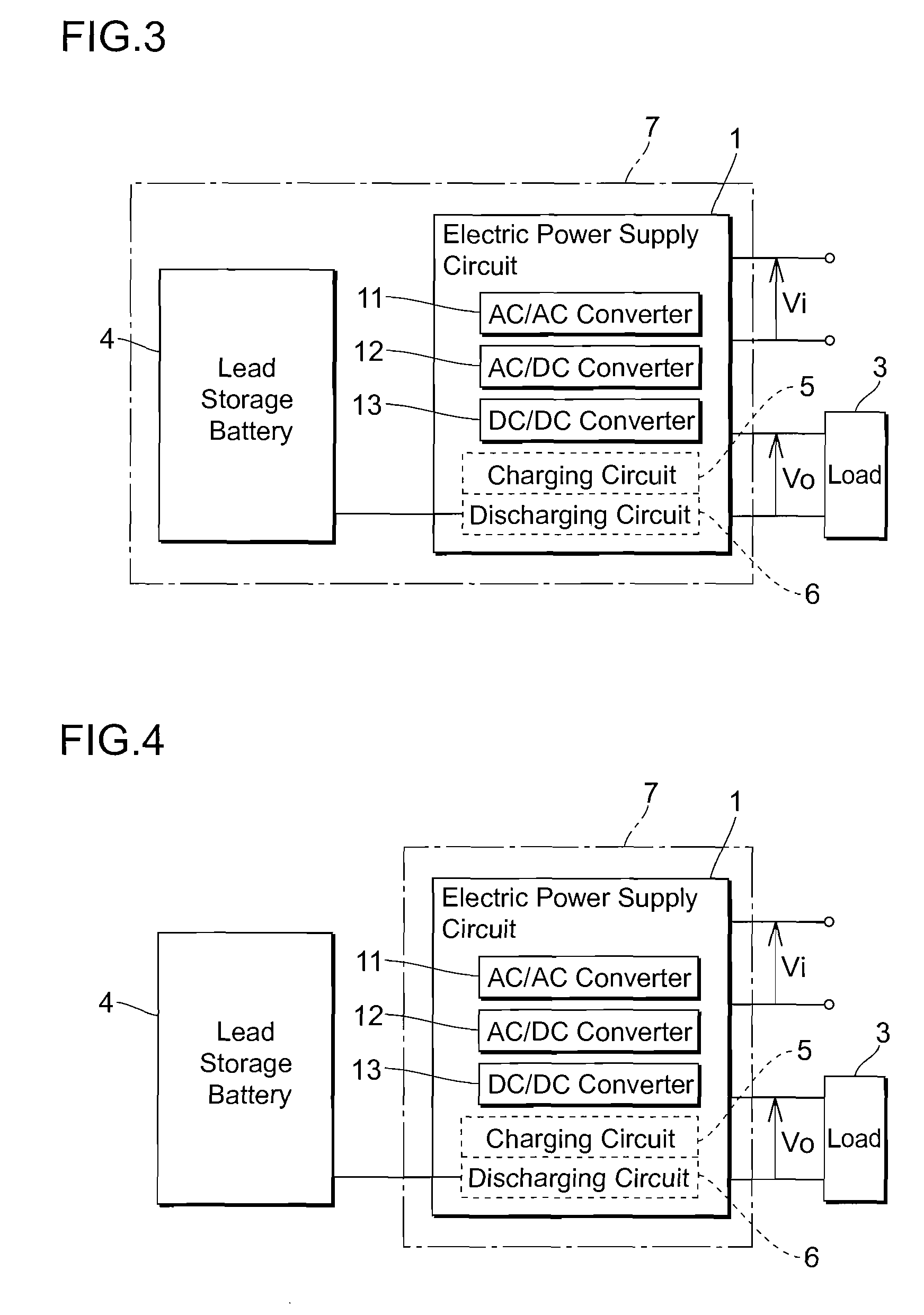

Battery pack

InactiveUS20080299452A1Dissipate quicklyExtend your lifeBattery isolationSecondary cellsElectricitySurface pressure

The battery pack is made up by stacking vertically a plurality of electrically-series-connected flat-plate-like battery cells so as to attain a given voltage and a given capacity. Interlayer members are interposed between each battery cell stacked. The interlayer member functions as a surface pressure distributing member to thereby equalize surface pressures of the battery cells building up the battery pack, thus permitting the whole of the battery pack to lengthen in life span. Further, by employing, as the interlayer members, heat insulating members with heat insulating efficiency or heat dissipating members with excellent thermal conductivity, the battery cell located in a central position of the battery pack is prevented from shortening partially in life span, thus permitting the whole of the battery pack to lengthen in life span.

Owner:TDK LAMBDA CORP

Image forming method and apparatus for fixing an image

An image forming apparatus, includes an image forming mechanism configured to form an image, and a fixing unit configured to fix a toner image formed on a recording medium. The fixing unit includes a fixing device having a first endless moving member configured to rotate, and a second endless moving member configured to rotate to form a nip area together with the first endless moving member to fix, at the nip area, a toner image disposed on the recording medium onto the recording medium with heat and pressure, the second endless moving member including a surface layer having a universal hardness HU and a maximum nip surface pressure P each within a predetermined range.

Owner:RICOH KK

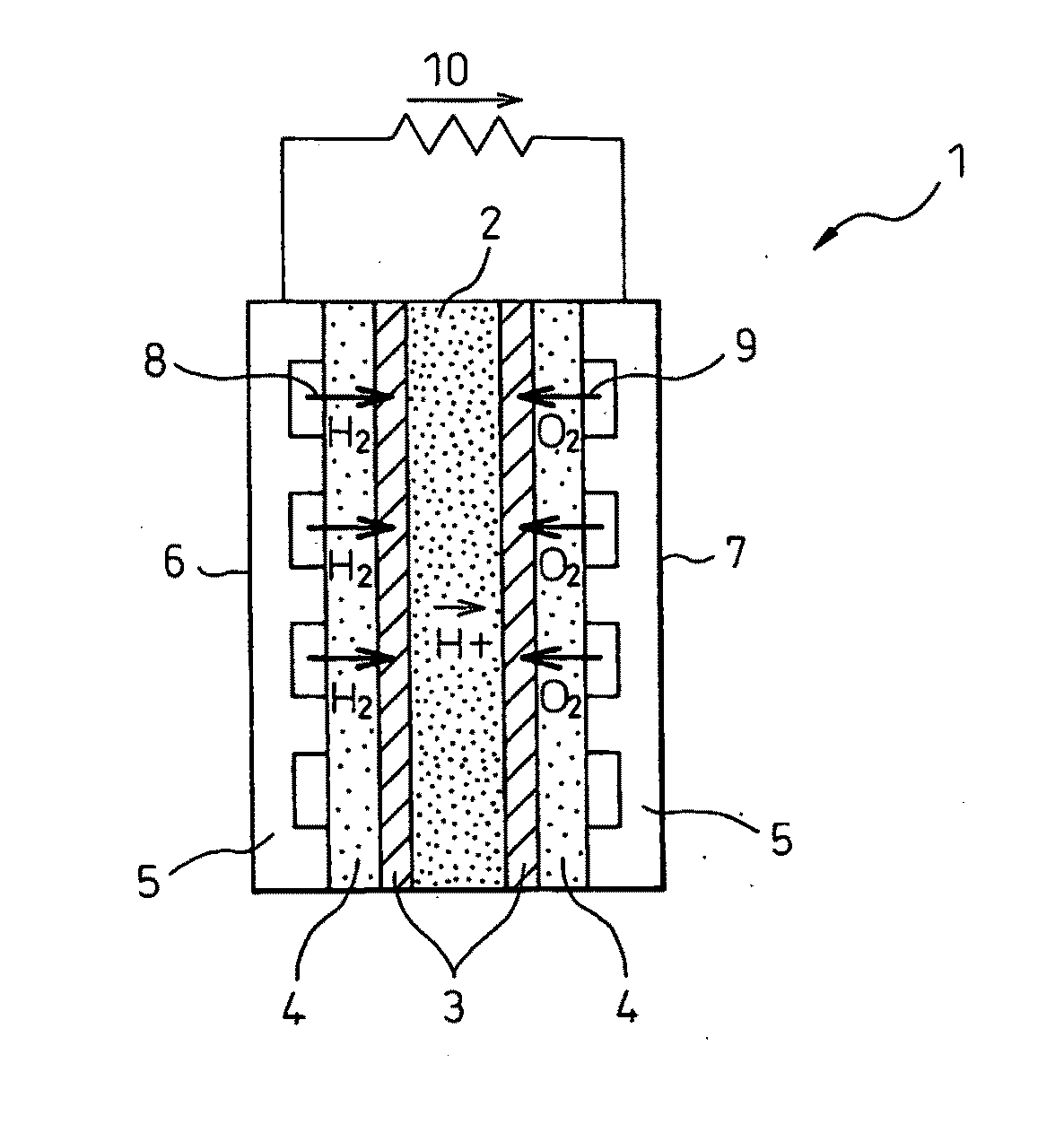

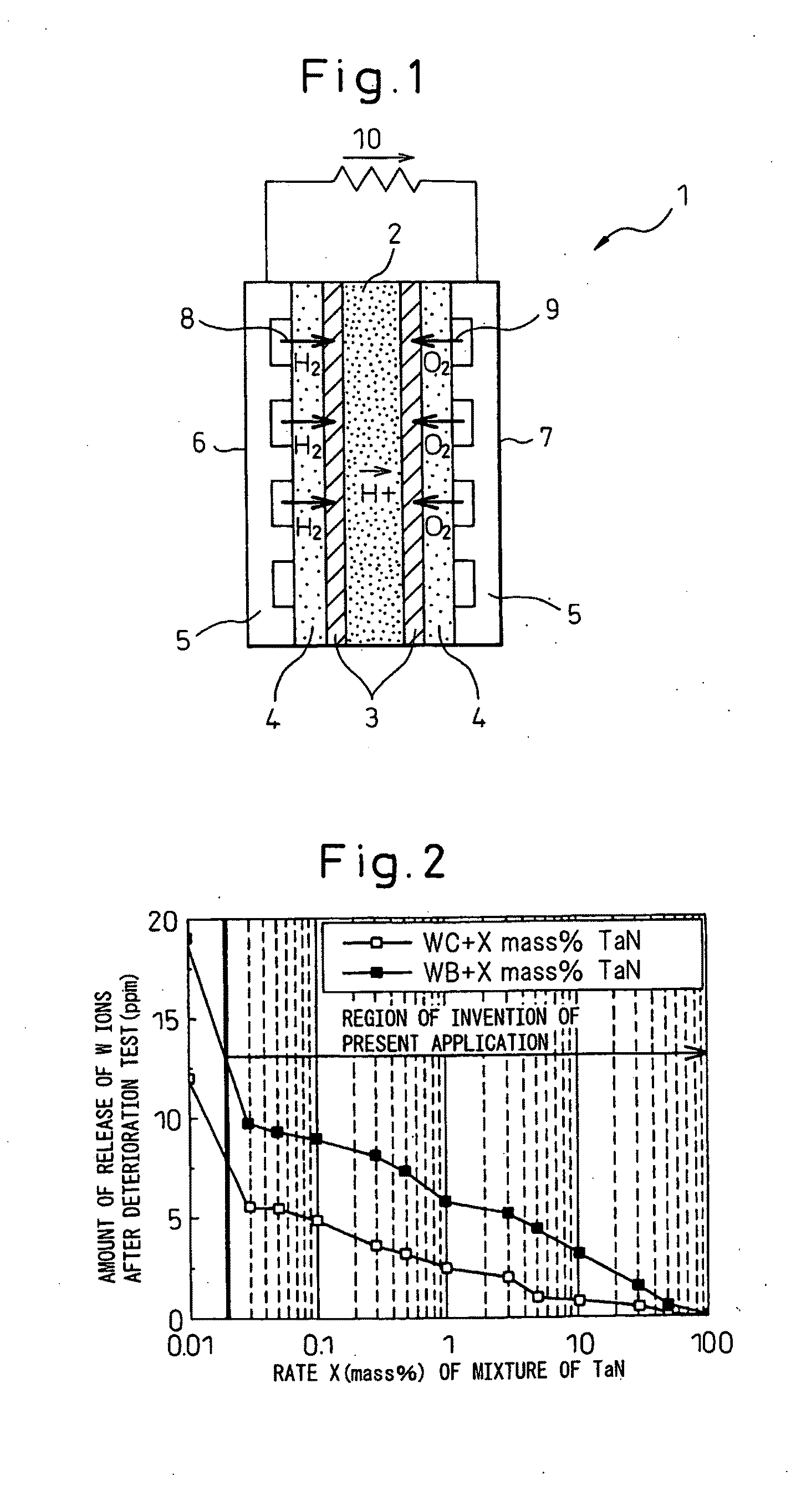

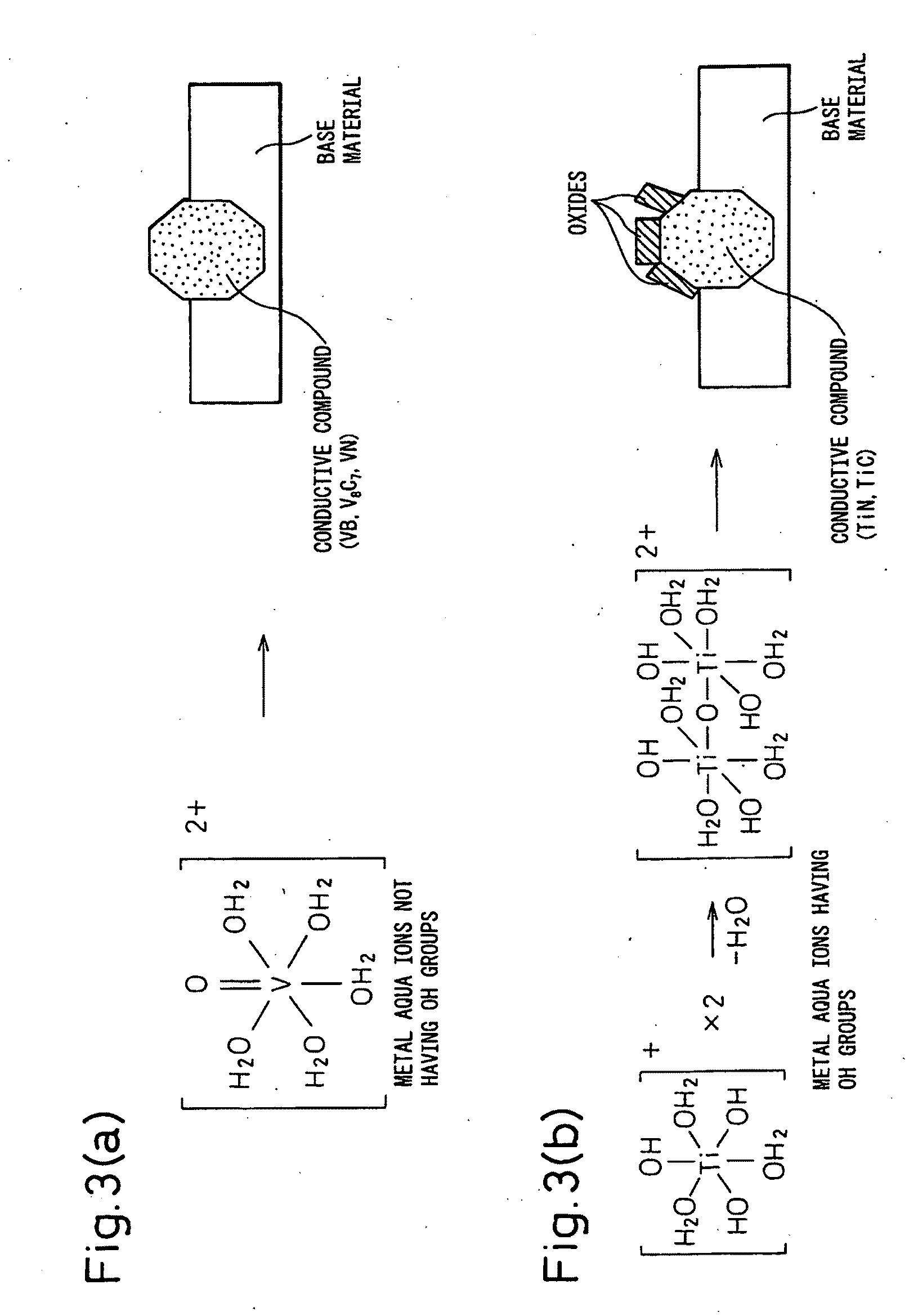

Stainless Steel, Titanium, or Titanium Alloy Solid Polymer Fuel Cell Separator and Its Method of Produciton and Method of Evaluation of Warp and Twist of Separator

ActiveUS20090226785A1Little dropLow costTransportation and packagingFinal product manufactureTitanium alloyContact resistance

The present invention releases a method of producing a metal separator for a solid polymer fuel cell by stainless steel, titanium, or titanium alloy during which securing lower cost and mass producibility by using a material having a high workability to form a complicated shape by a high productivity, then using an inexpensive blast process to drive a conductive substance into the surface of the metal separator member, that is, provides a stainless steel, titanium, or titanium alloy solid polymer fuel cell separator comprised of stainless steel, titanium, or titanium alloy in the surface of which a low ion release conductive substance is buried, having an arithmetic mean roughness (Ra) of the separator surface of 0.5 to 5.0 μm, having a 10-point mean roughness (Rz) of 3 to 20 μm, having an average spacing of surface relief shapes (Sm) of 300 μm or less, having values of a warp rate and twist rate of a separator of 0.1 or less, and having a contact resistance value with respect to carbon paper of 15 mΩcm2 or less at a surface pressure of 1 MPa.

Owner:SINTOKOGIO LTD

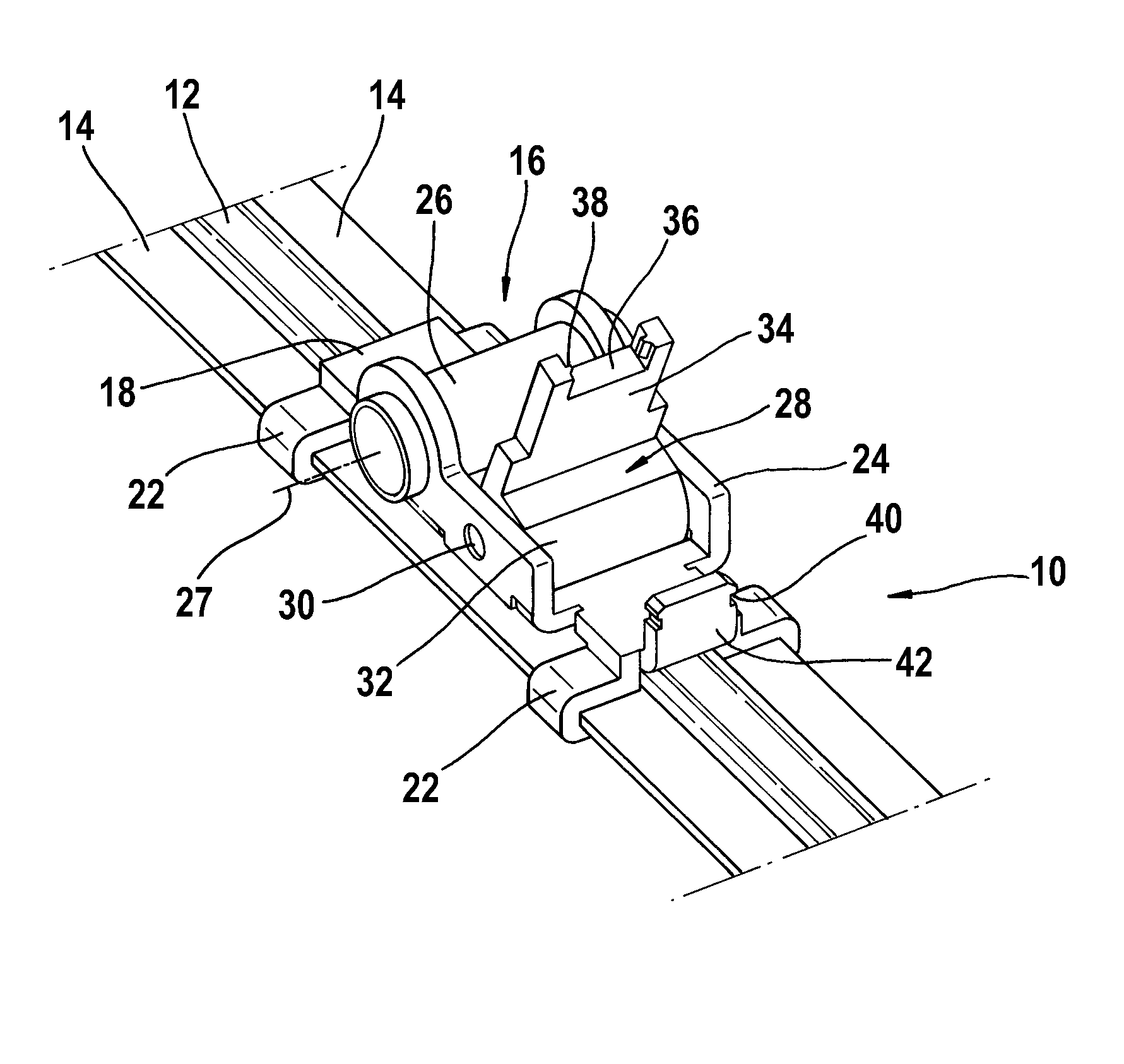

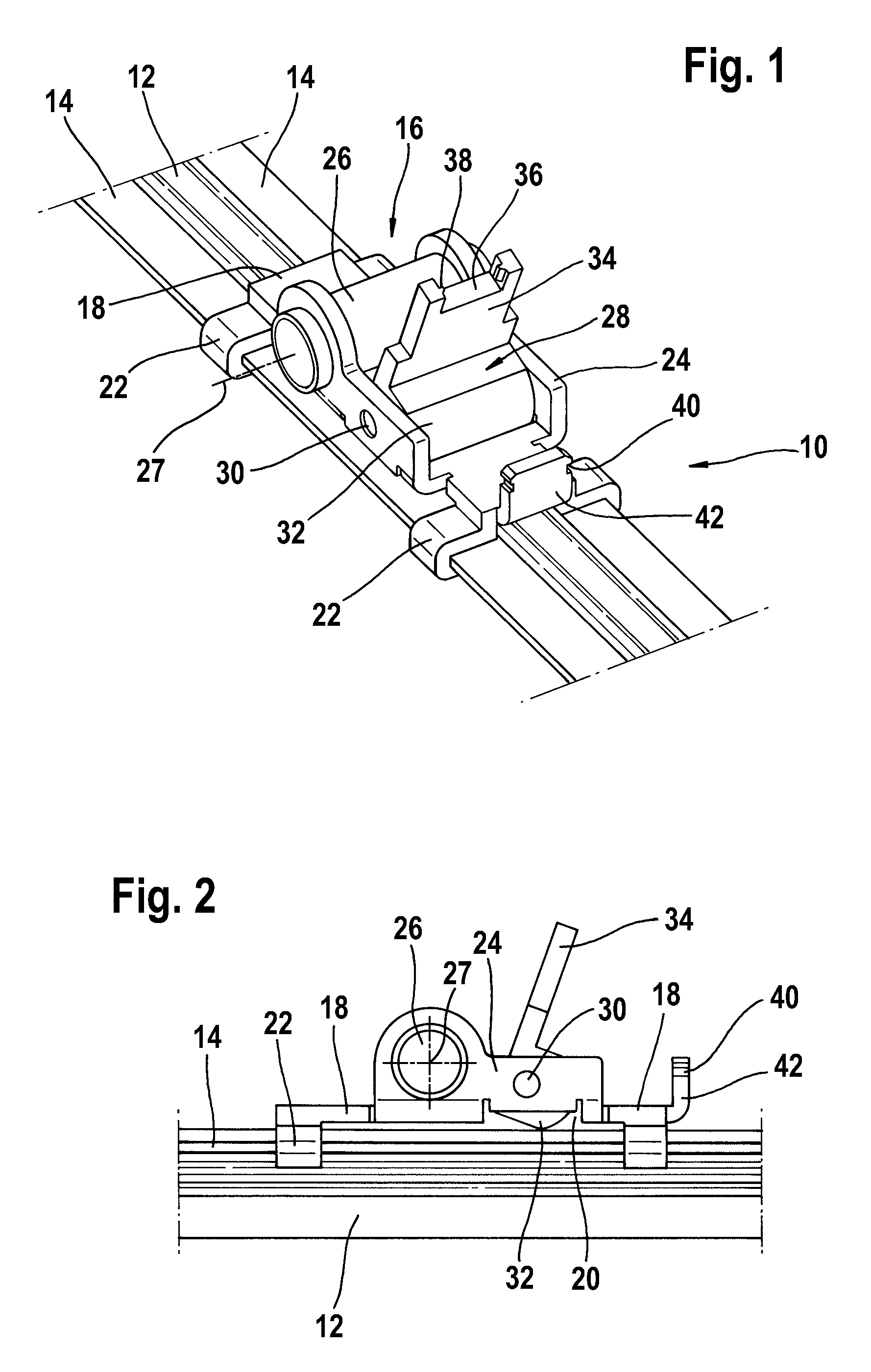

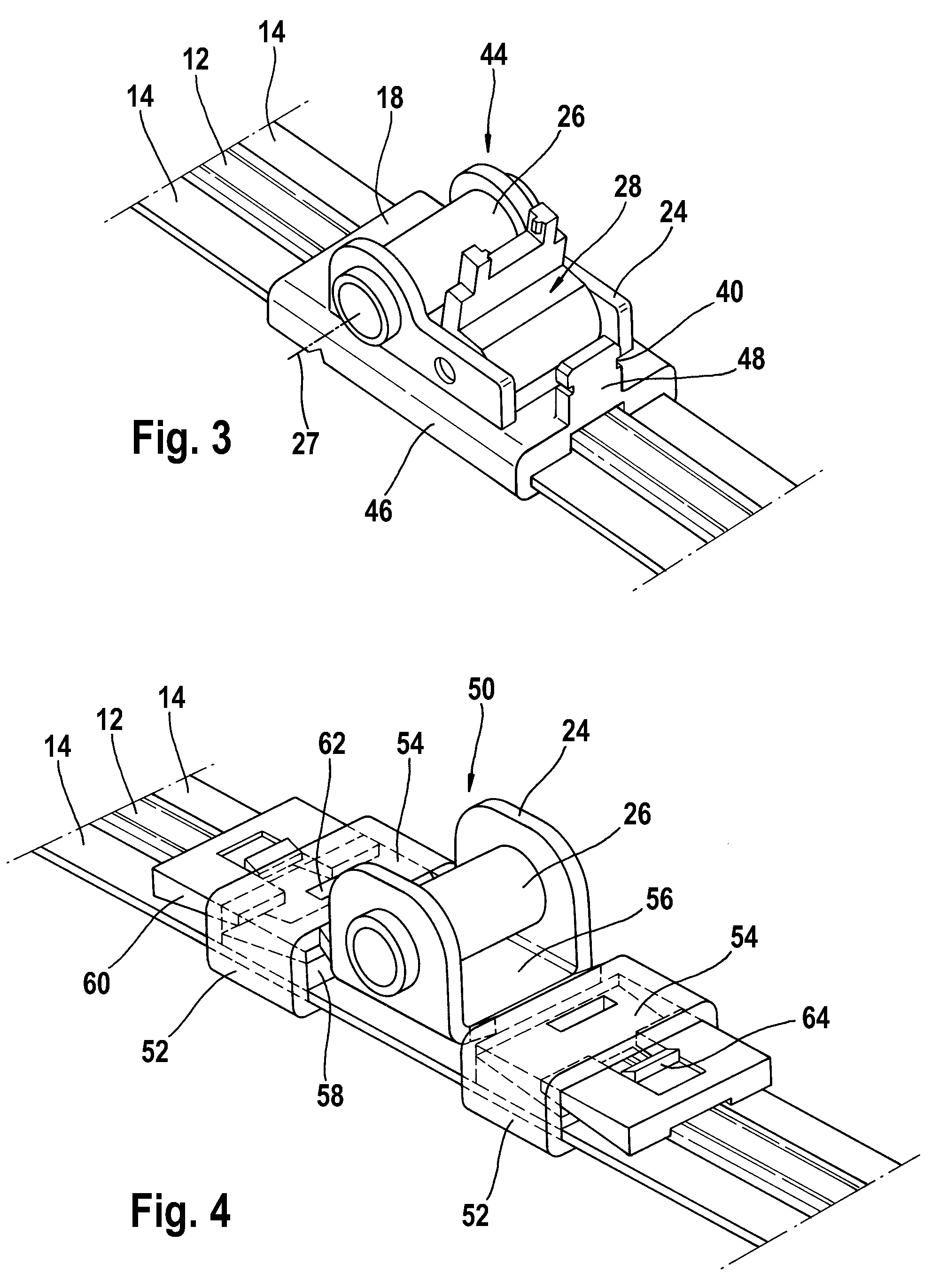

Connection element

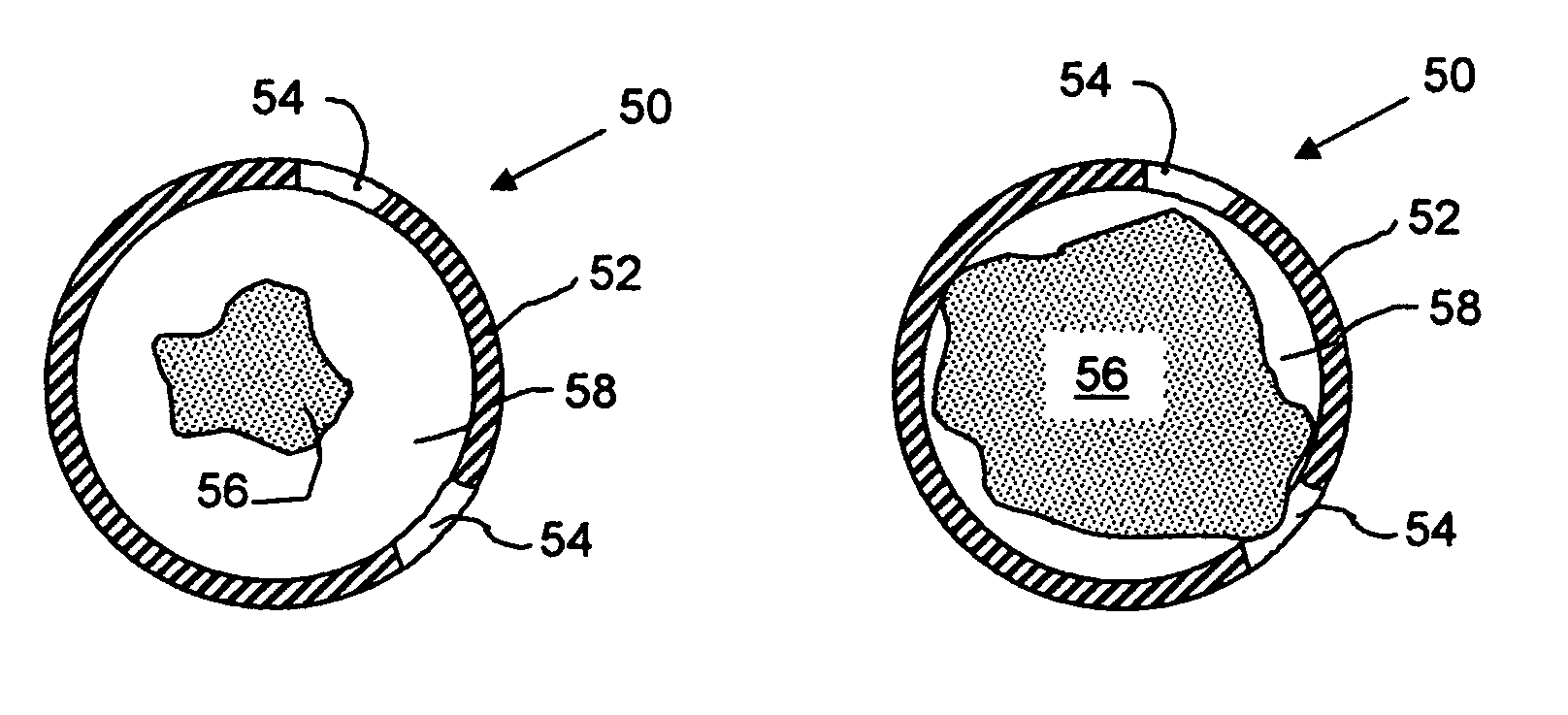

InactiveUS8191201B2Increase surface pressureDamage of the wiper rubberWindow cleanersVehicle cleaningSurface pressureEngineering

The invention is based on a connection element (16, 44, 50, 66, 74, 80) for connecting a wiper blade (10), which has at least one spring rail (14) as a supporting element, to a wiper arm in an articulated manner, with the connection element (16, 44, 50, 66, 74, 80) having claws (22, 46, 52) which are integrally formed on the side of a base part (18) and, in the mounted state, surround and retain the spring rail (14) by the base part (18) being supported on a part of a wiper rubber (12) which is arranged between the spring rail (14) and the base part (18, 56, 68, 70). The invention proposes that the connection element (16, 44, 50, 66, 74, 80) has means (28, 58, 60, 68, 72, 76, 78, 82, 84) with which the surface pressure between the base part (18, 56, 68, 70) and the wiper rubber (12) is locally increased.

Owner:ROBERT BOSCH GMBH

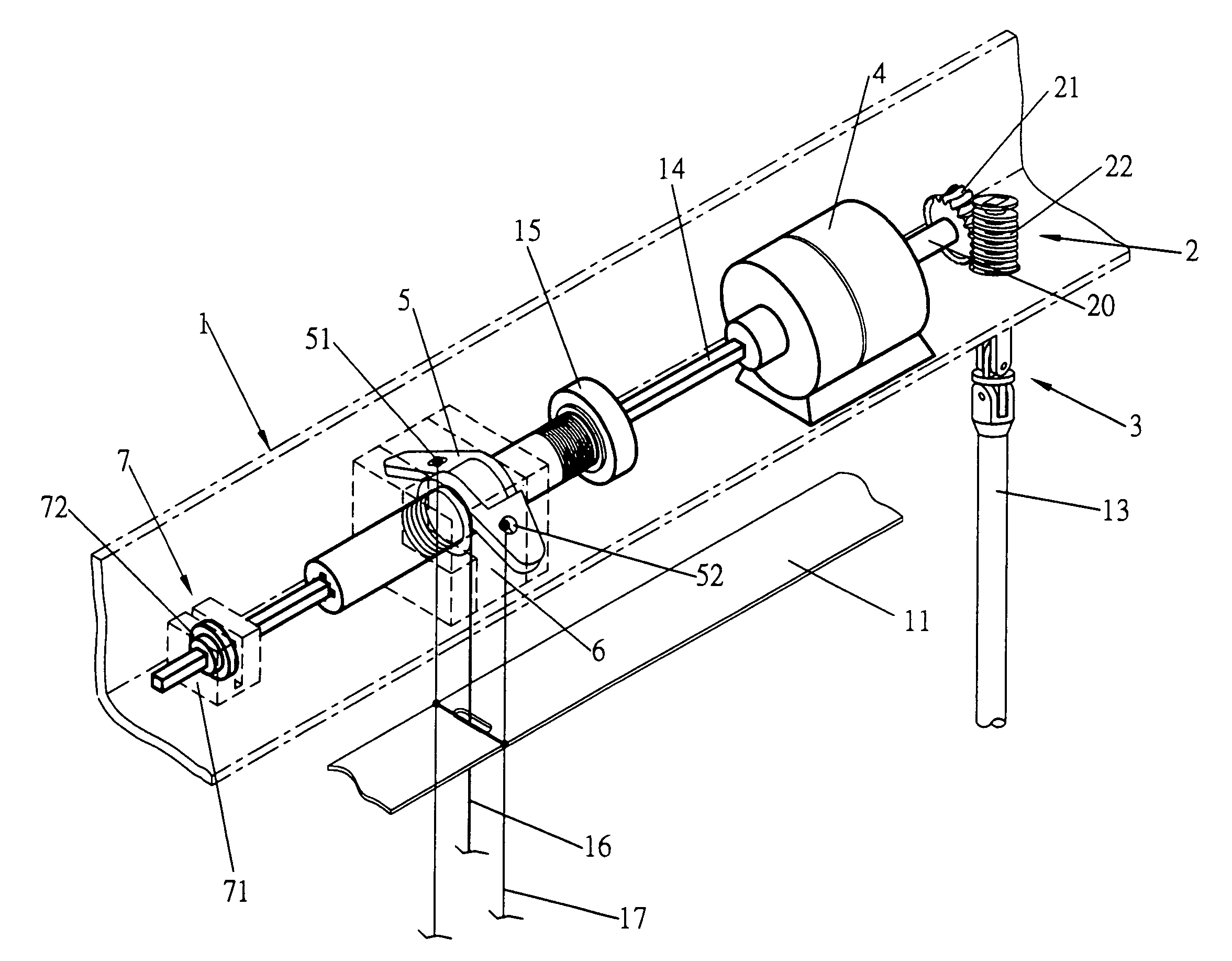

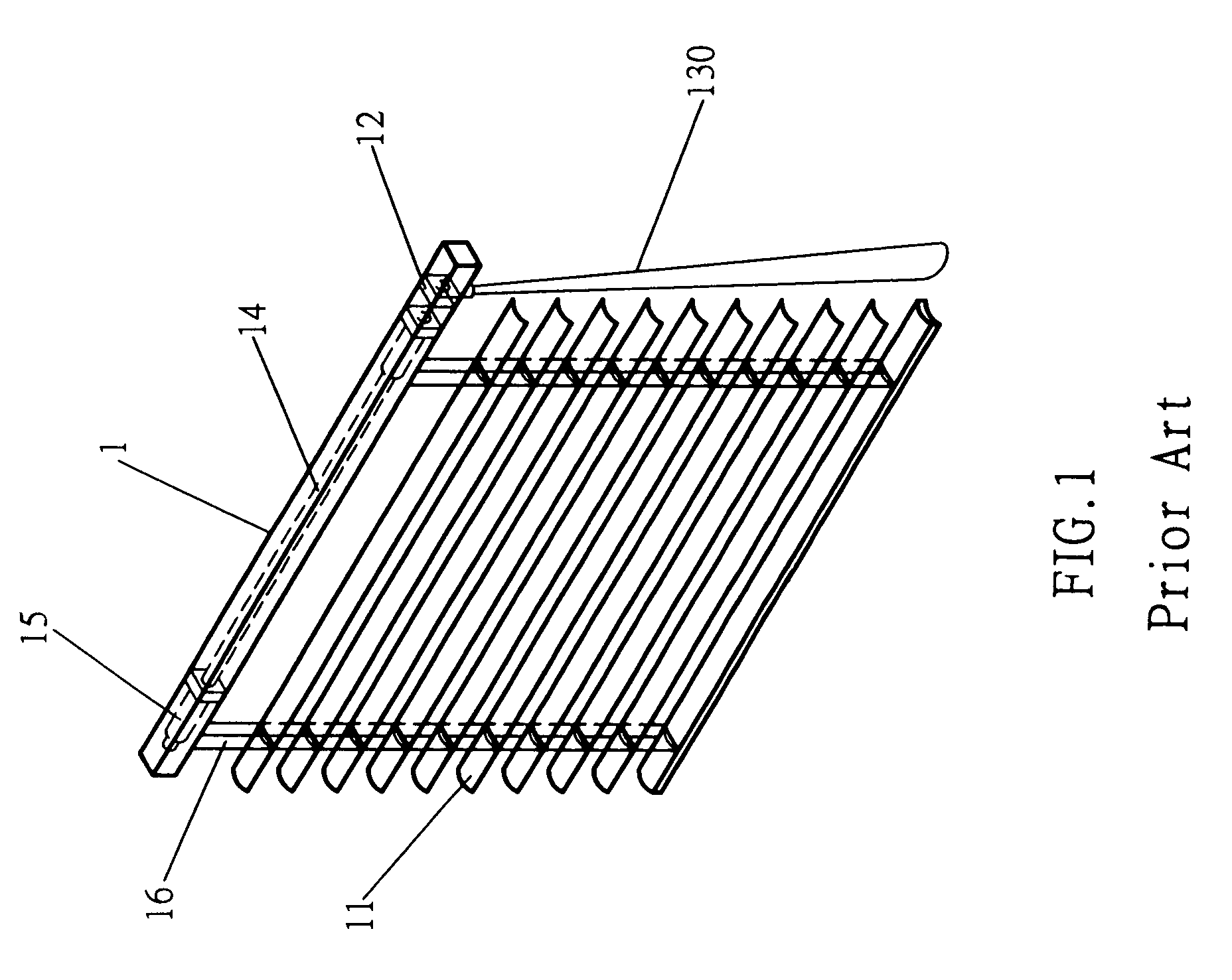

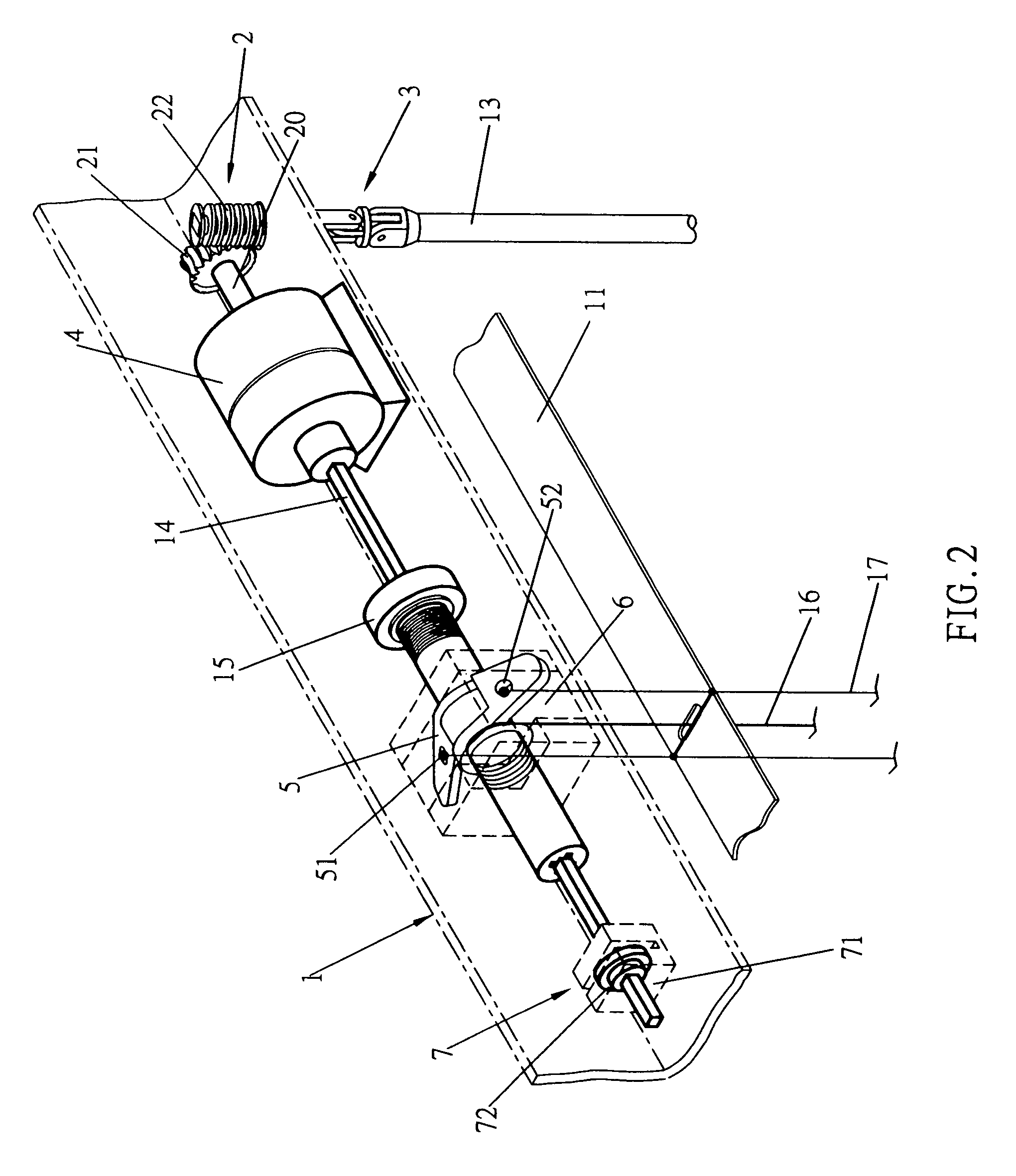

Curtain blind take-up drive mechanism with non-slip effect

InactiveUS6910516B2Avoid dangerSimple and easy and facilitating changeLight protection screensCouplingDrive shaft

A curtain blind take-up drive mechanism with non-slip effect having a freehand turn operation. The non-slip effect is configured to prevent slats of the blind from slipping down, and further includes coupling a power end of a drive shaft to a reel. The drive shaft connects to a worm gear via a transmission amplifier. The worm gear is actuated through reciprocally engaging with a worm driven via a flexible shaft coupling and through operation of a slat tilt rod. Reciprocal teeth meshing and teeth surface pressure between the worm gear and the worm achieves a high slip-rate, and thereby inhibits reverse transmission, thus accomplishing a reverse direction stoppage effect, and further producing a large frictional force and forming a surface-pressure slip effect thereof. The transmission amplifier allows the drive shaft to achieve a high rotational speed, thereby facilitating freehand operation for taking-up and letting-down of the slats.

Owner:HUANG SHIEN TE

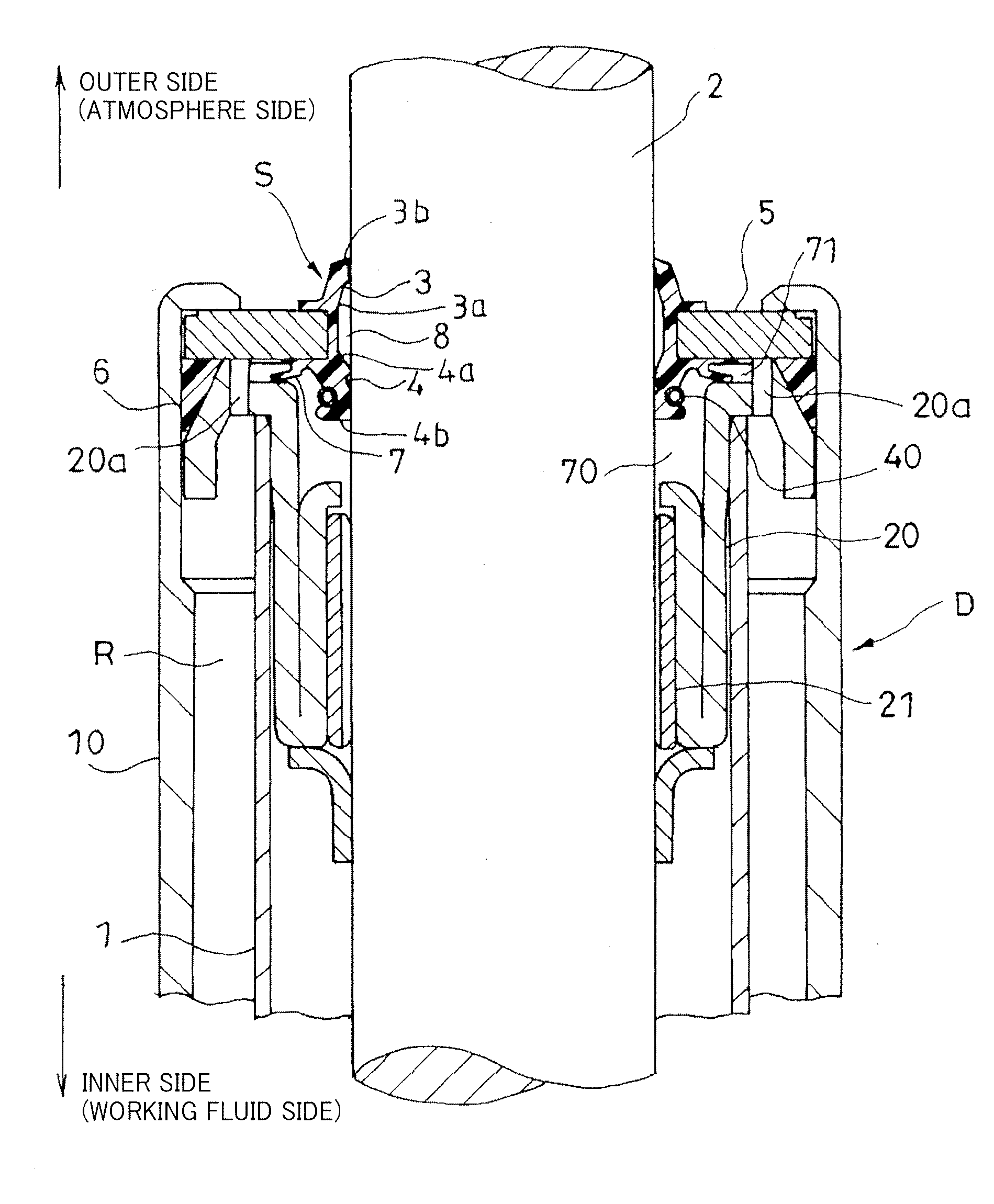

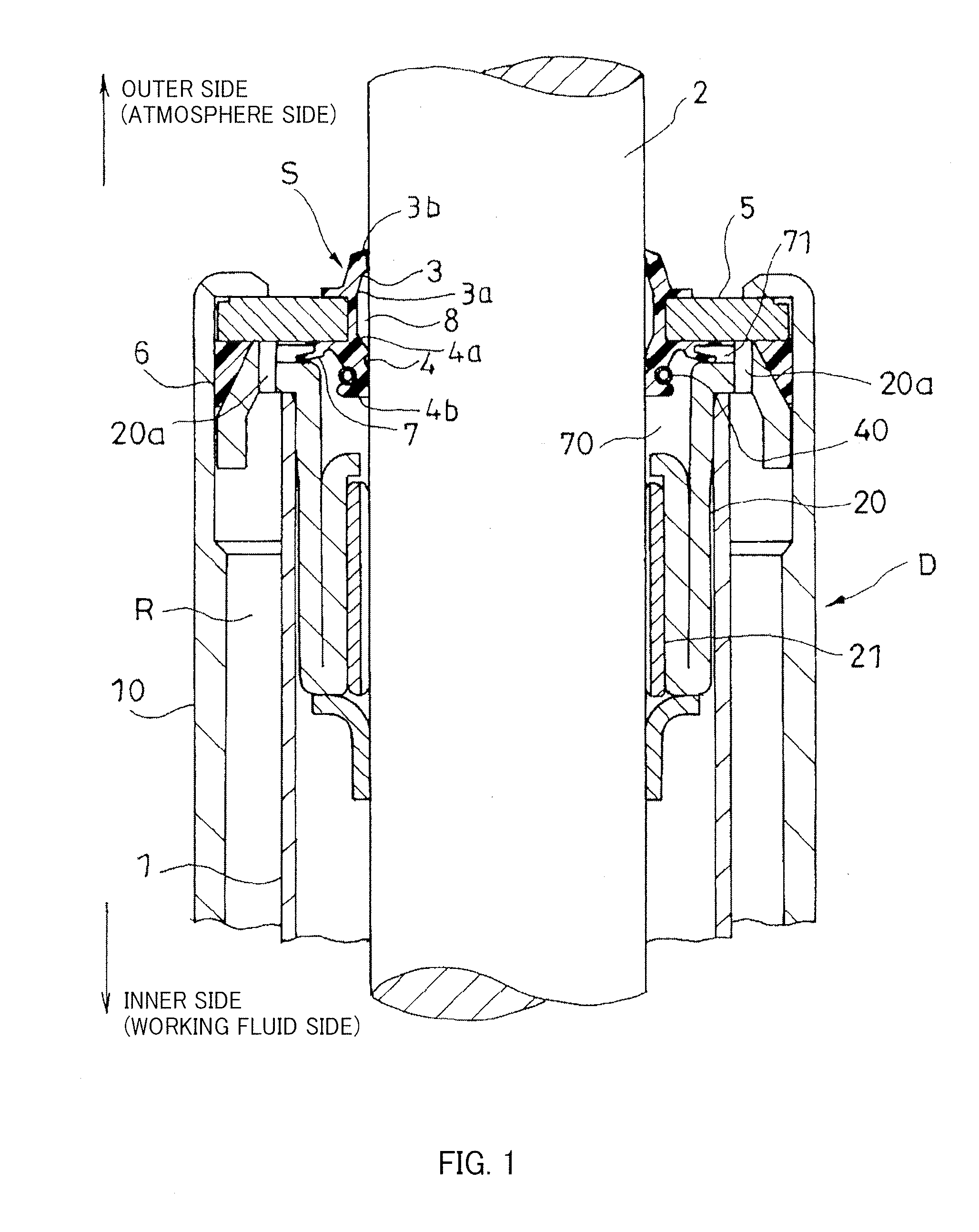

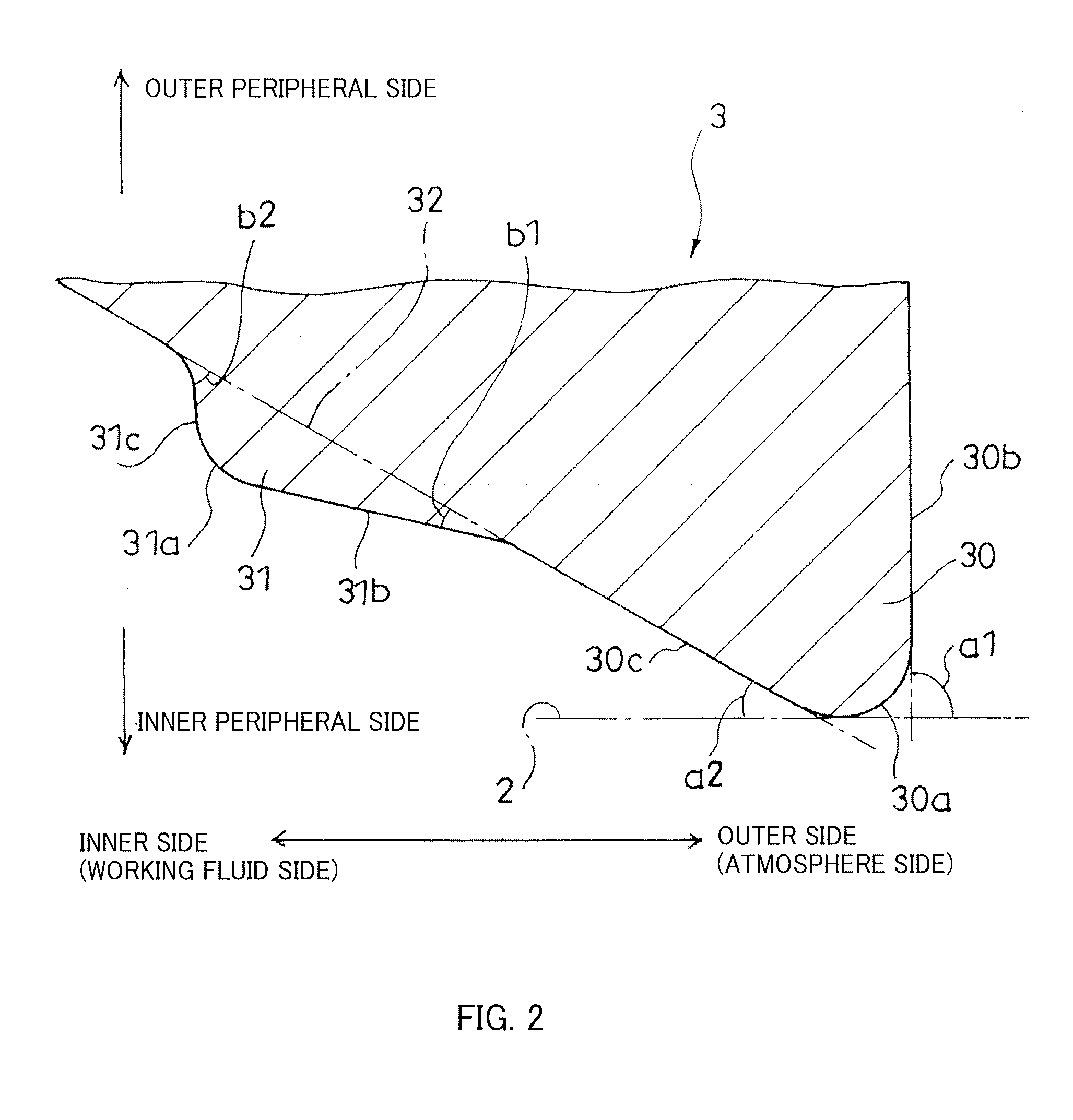

Sealing device and shock absorber with the sealing device

A sealing device adapted to seal an outer periphery of a shaft member inserted into a tubular member includes a dust seal lip arranged on an outer side of the tubular member and an oil seal lip arranged on an inner side of the tubular member to form a space for accumulating working fluid between the oil seal lip and the dust seal lip. The dust seal lip includes a main lip portion and an auxiliary lip portion formed to be closer to the oil seal lip than the main lip portion. A maximum value of a surface pressure gradient absolute value of the inner side in the auxiliary lip portion is set to be larger than that of a surface pressure gradient absolute value of the outer side in the auxiliary lip portion.

Owner:KYB CORP

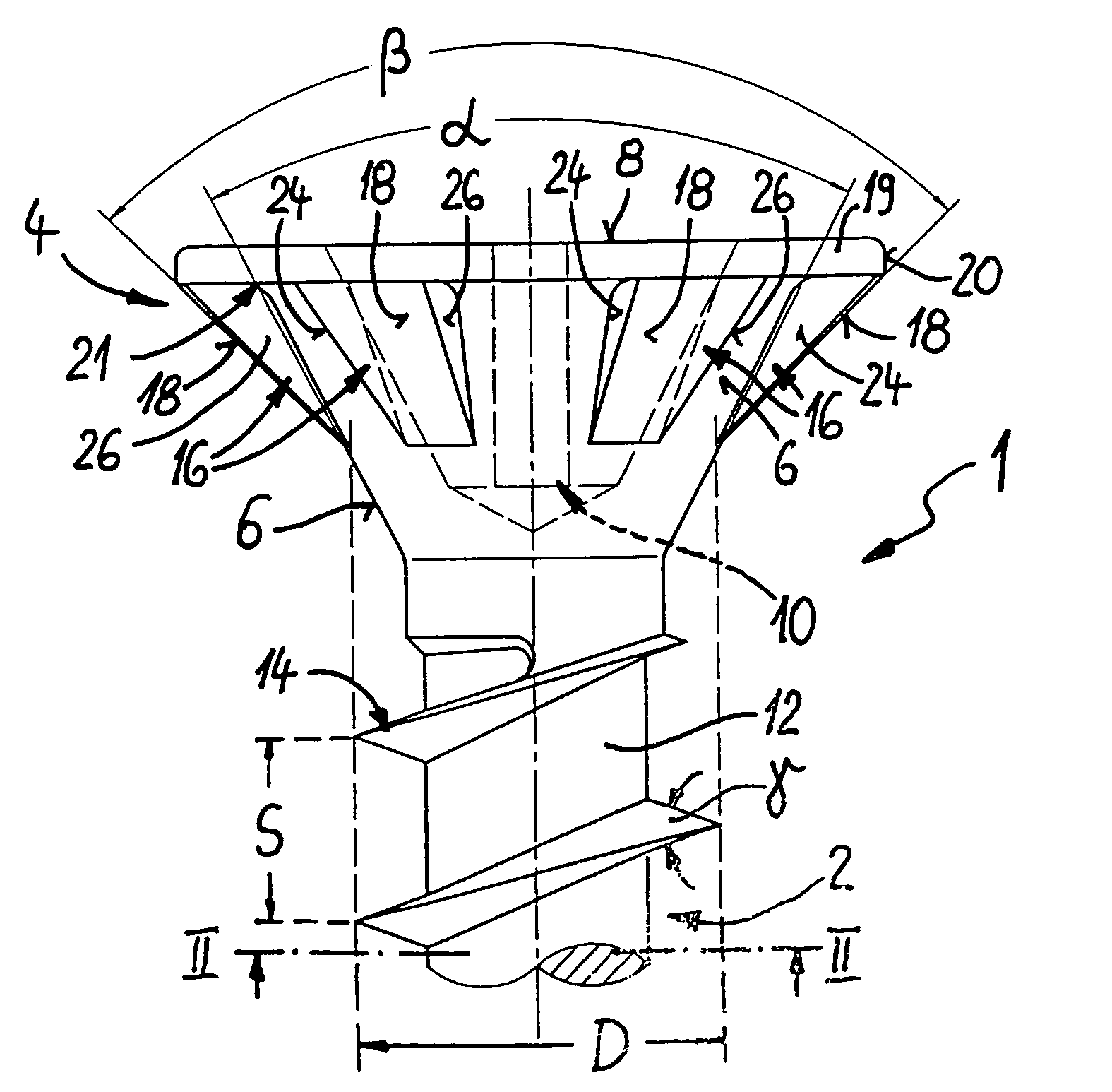

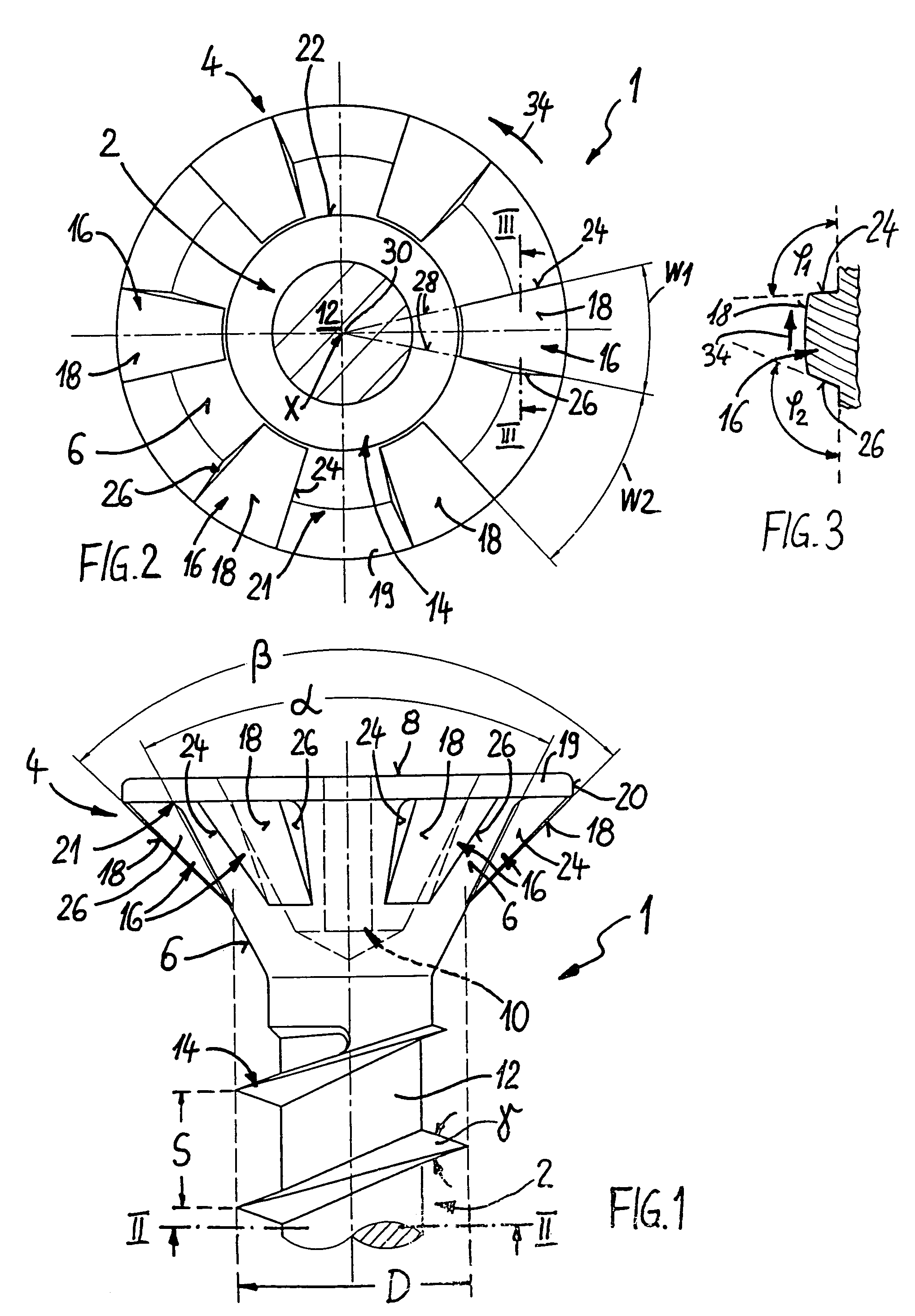

Countersunk screw

Owner:SPAX INT

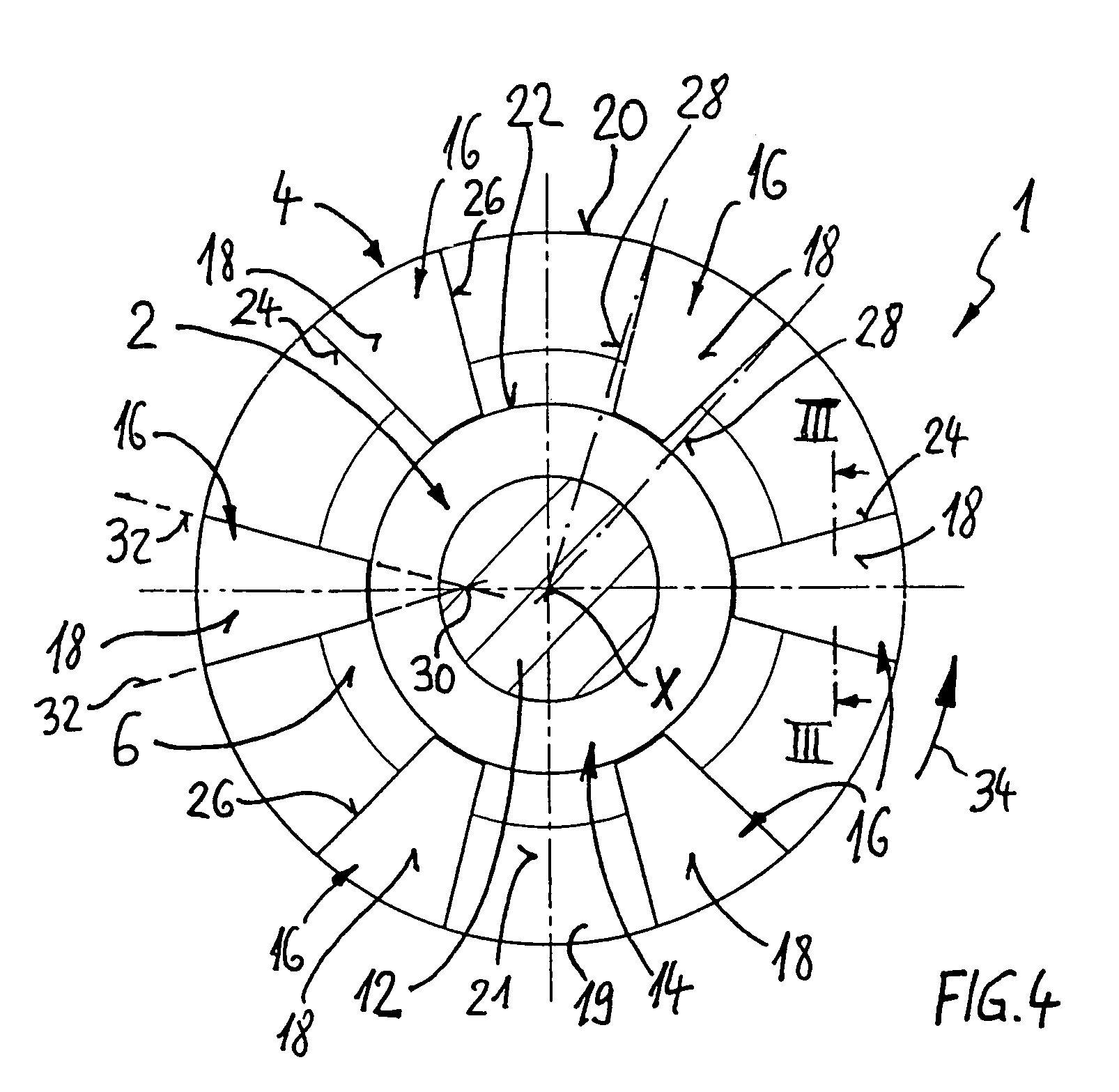

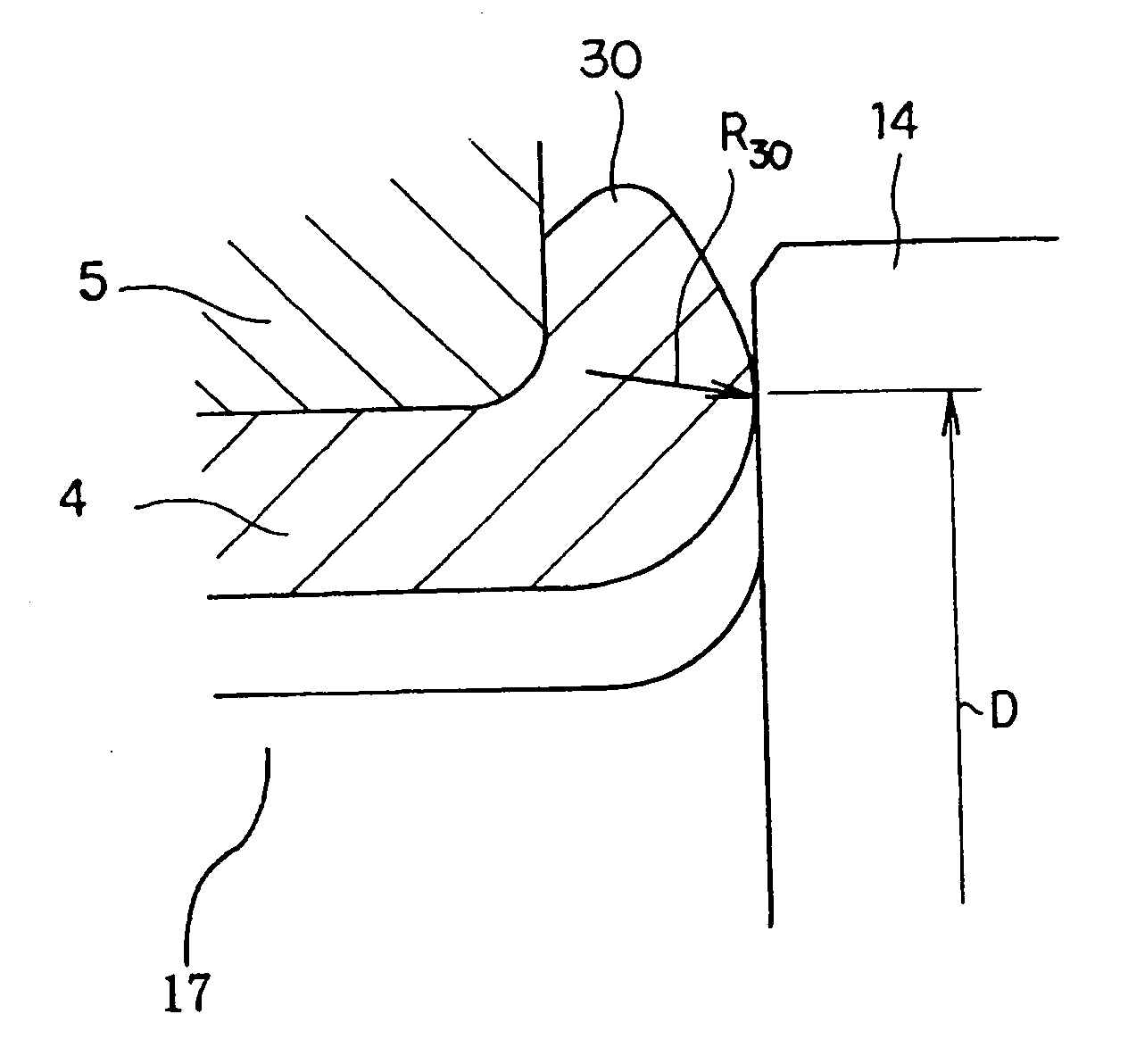

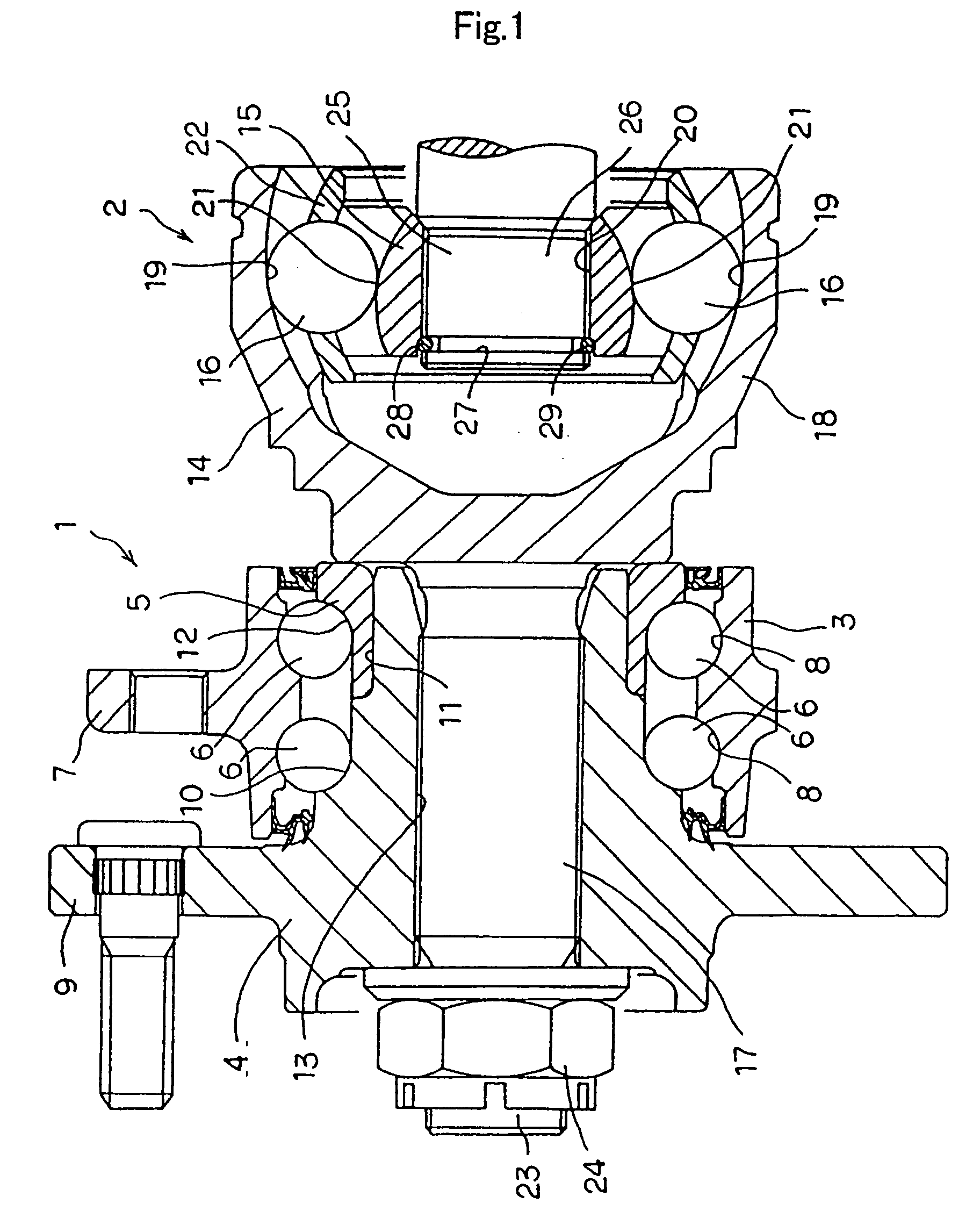

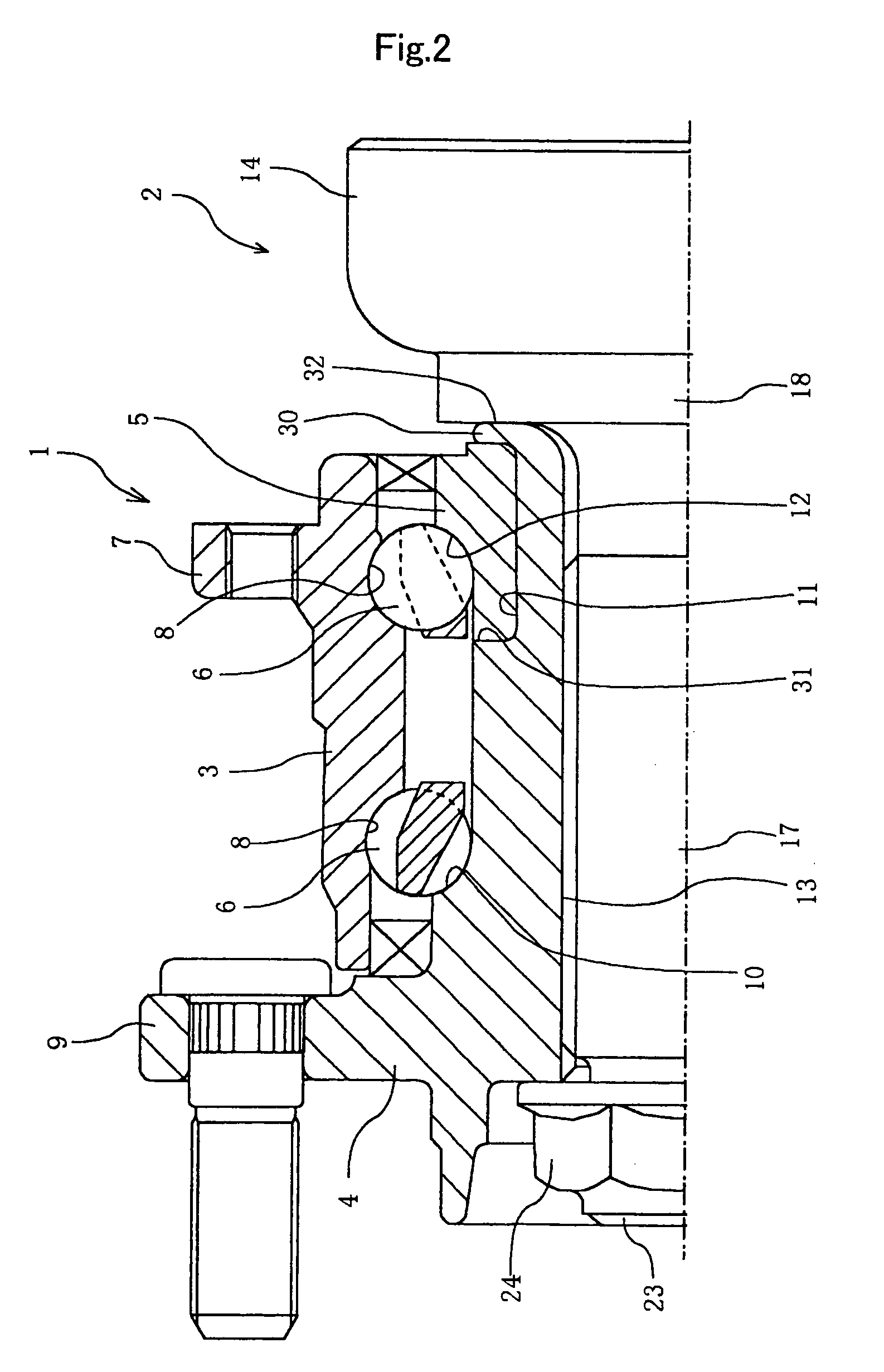

Bearing unit for wheel drive

An inner race 5 is retained by a crimped portion 30, so that a pre-load is applied to rolling elements 6. A bearing unit for wheel support 1 is connected to a constant velocity joint 2 through tightening of a nut 24. By regulating the tightening force of the nut 24, at the area of contact between the inside end of the crimped portion 30 and the outside end of the outer ring of the constant velocity joint 14, the load per unit length is controlled up to 125 N / mm, or the surface pressure is controlled up to 1.5x10<8 >Pa. Consequently, a bearing unit for wheel support is realized at a low cost with the pre-load securely applied, preventing unpleasant noise from occurring during operation, and preventing play due to plastic deformation.

Owner:NSK LTD

Cleaning sheet, cleaning method, and image forming apparatus

InactiveUS6845225B2Easy to disassembleFixed imageElectrographic process apparatusImage formationEngineering

Provided is a cleaning sheet adapted to clean a surface of a heating roll in a fixing device, which causes a recording sheet bearing a toner image formed of a magnetic toner containing a magnetic material to pass through the fixing device under a state in which the recording sheet is in press contact with the surface of the heating roll having arranged thereon a contact component in contact with the surface of the heating roll and heated to a fixing temperature to rotate, to perform fixing of the toner image, including a synthetic resin sheet with a thickness of 100 μm or more, which is made of a thermoplastic resin with a melting point higher than the fixing temperature and Rockwell hardness of M60 or more or thermosetting resin with Rockwell hardness of M60 or more.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com