Patents

Literature

92results about How to "Improve component performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

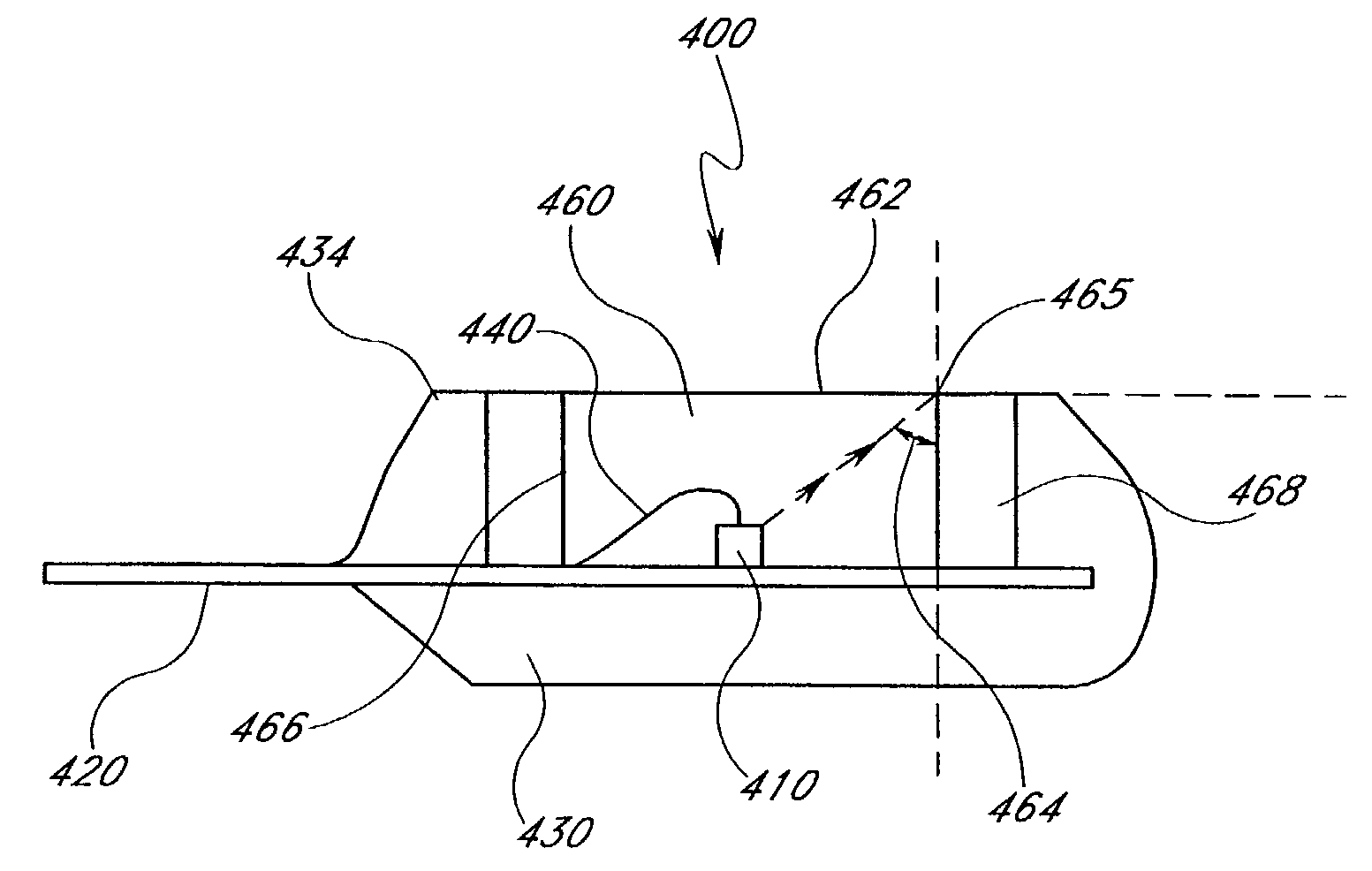

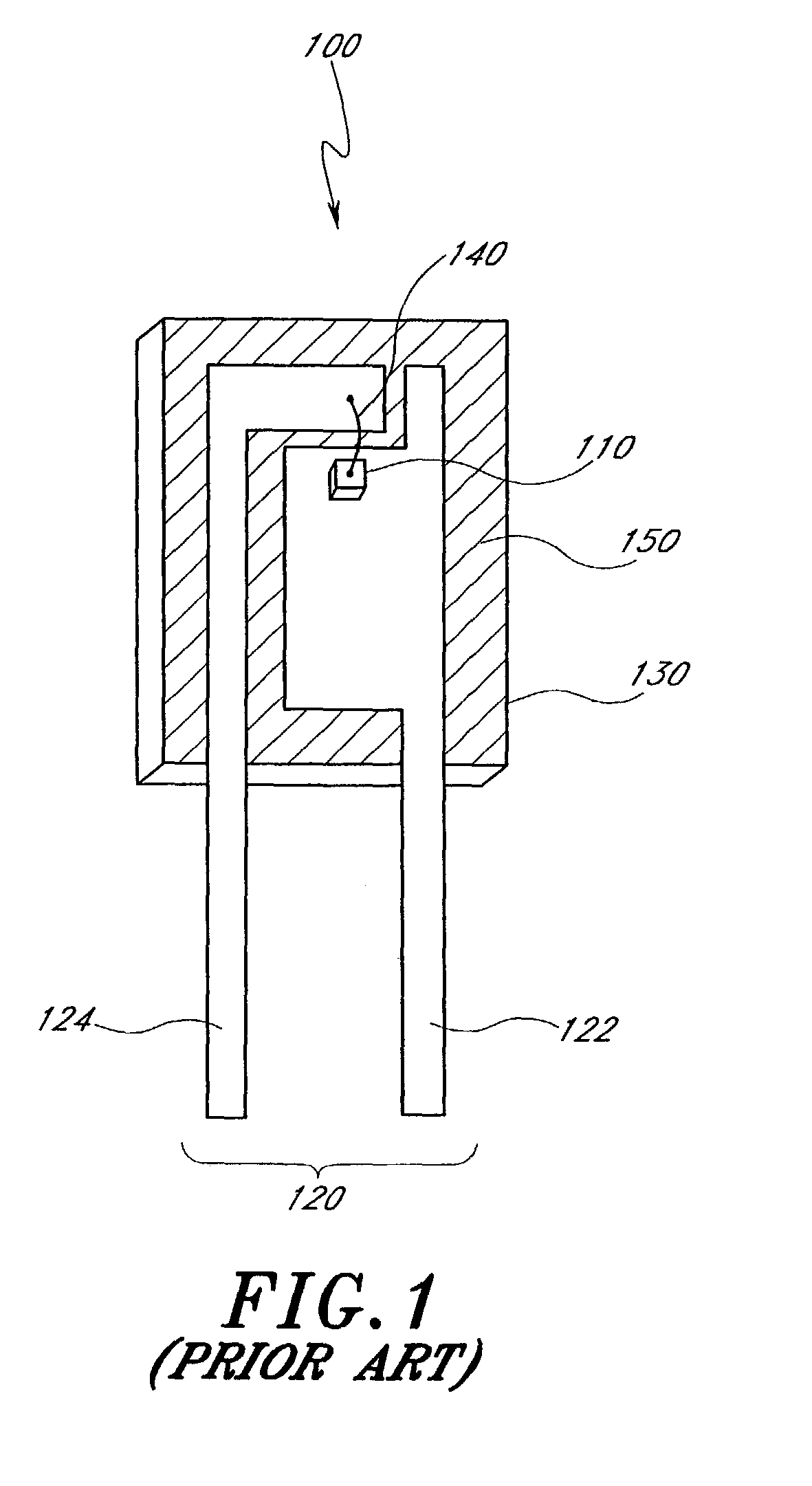

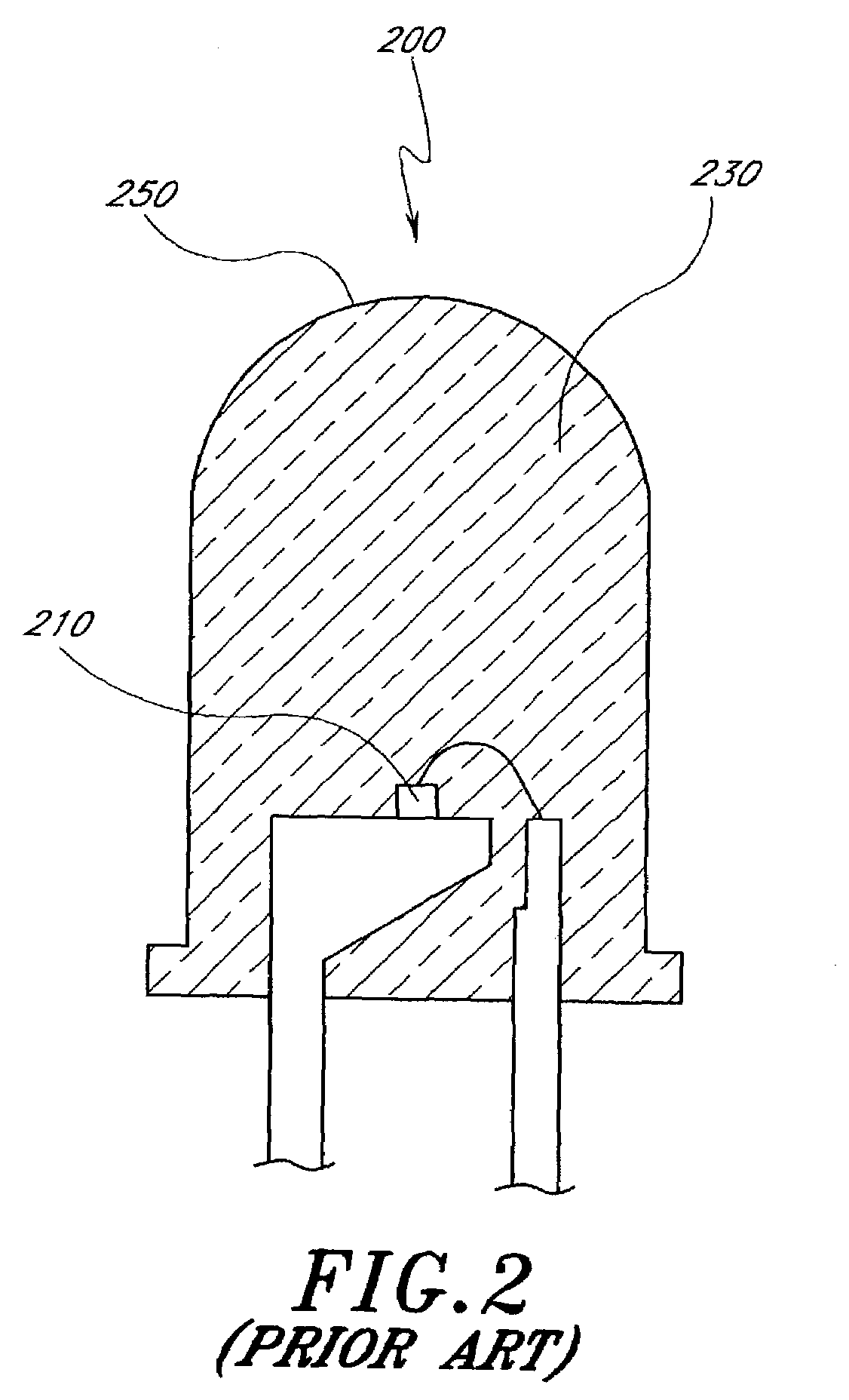

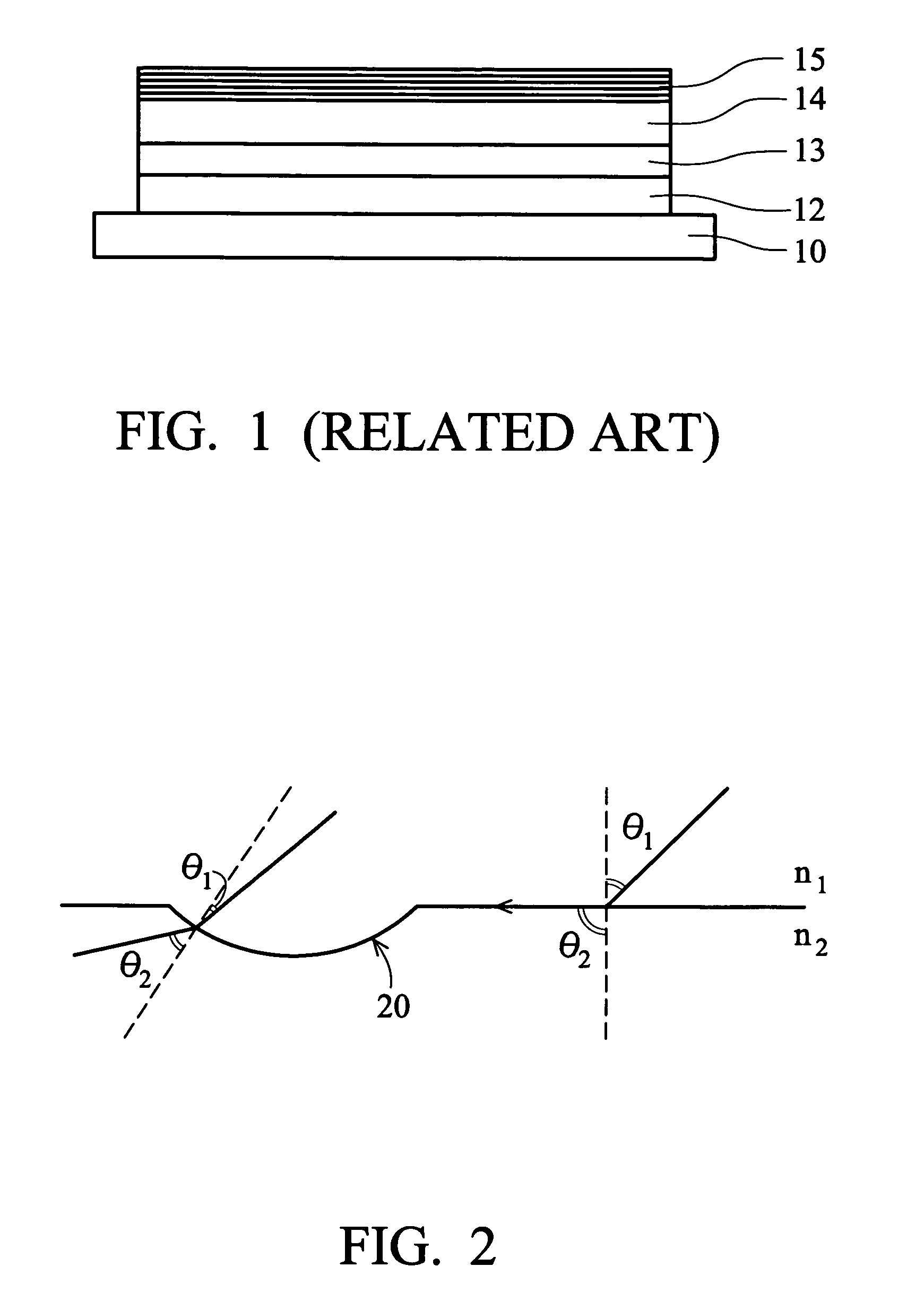

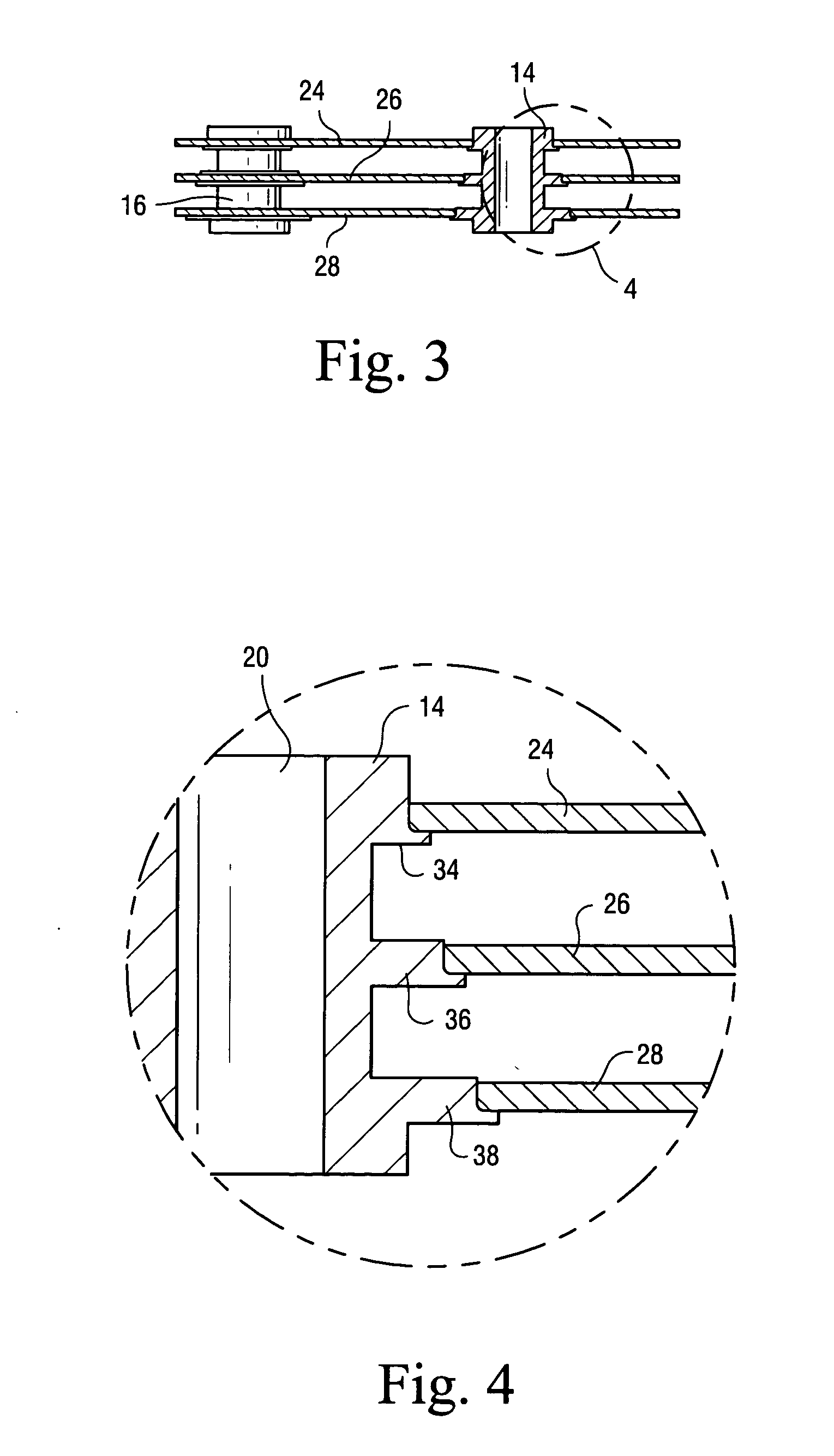

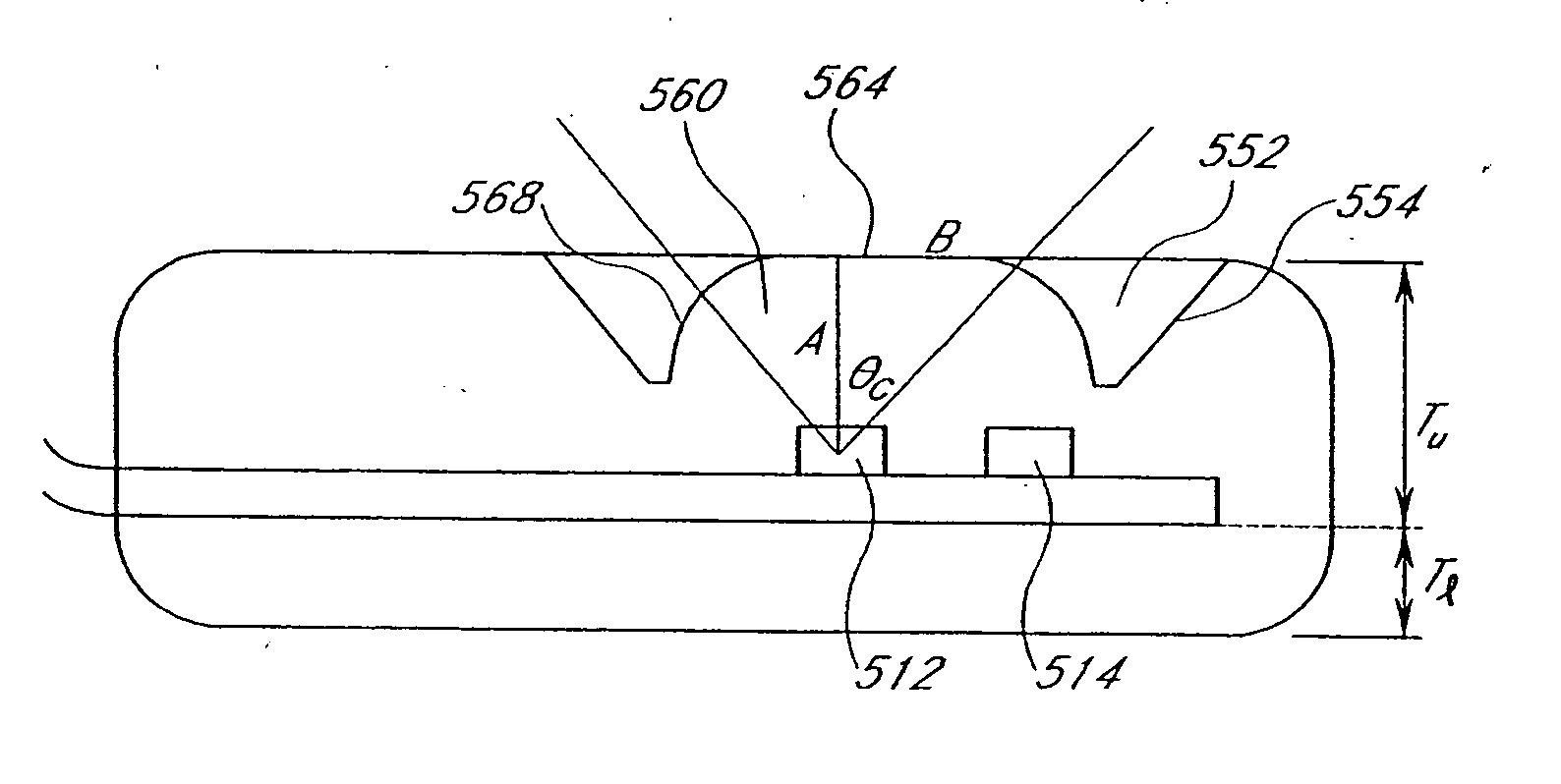

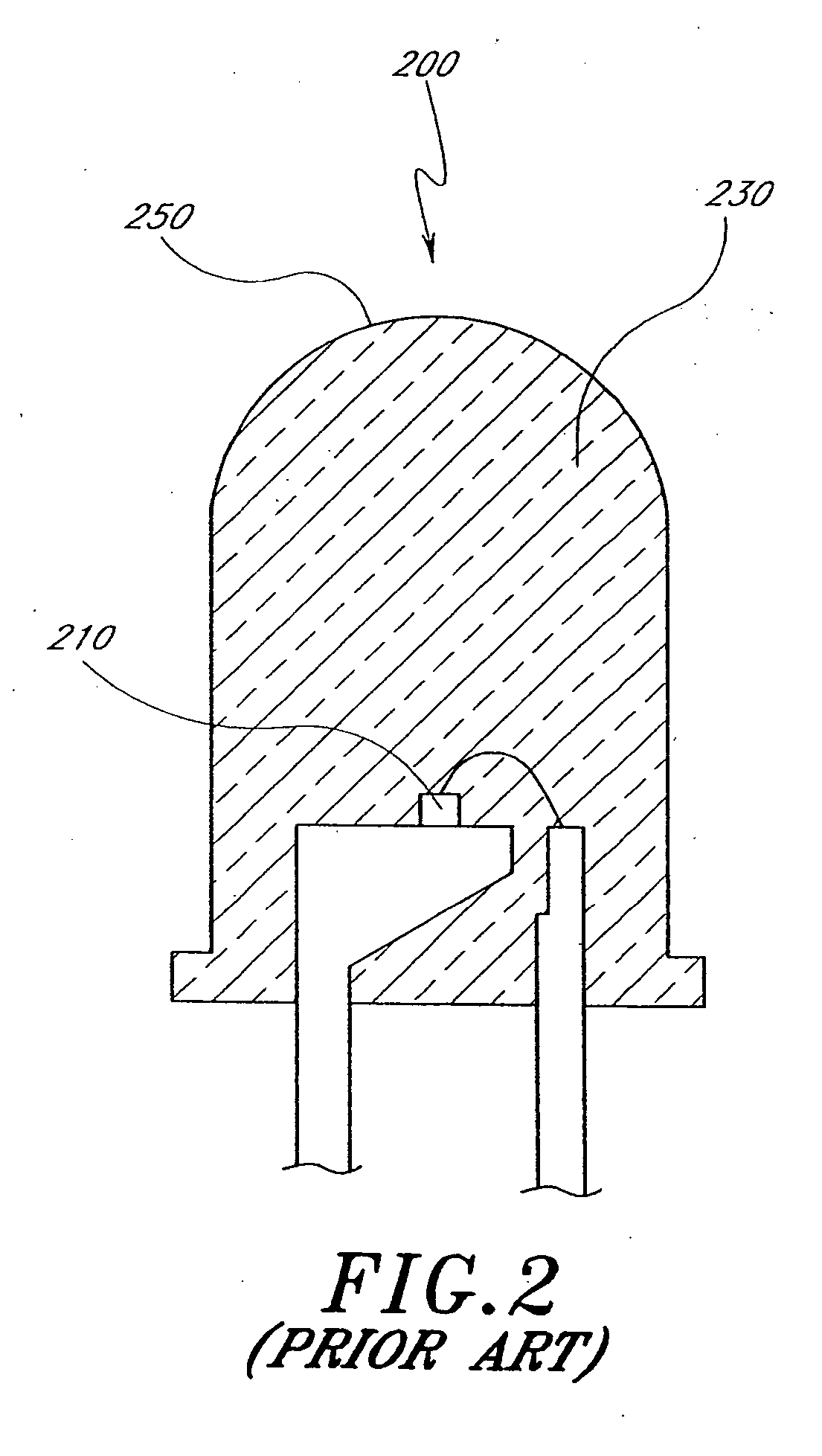

Optoelectronic element with a non-protruding lens

InactiveUS7067893B2Improve component performanceReduce reflectionSolid-state devicesDiagnostic recording/measuringCamera lensReduced size

An optoelectronic component has a lens that is formed in the surface of an encapsulant surrounding a semiconductor diode element. With respect to emitters, the lens reduces internal reflection and reduces dispersion to increase overall efficiency. With respect to detectors, the lens focuses photons on the active area of the detector, increasing detector sensitivity, which allows a detector having a reduced size and reduced cost for a given application. The lens portion of the encapsulant is generally nonprotruding from the surrounding portions of the encapsulant reducing contact surface pressure caused by the optoelectronic component. This non-protruding lens is particularly useful in pulse oximetry sensor applications. The lens is advantageously formed with a contoured-tip ejector pin incorporated into the encapsulant transfer mold, and the lens shape facilitates mold release.

Owner:JPMORGAN CHASE BANK NA

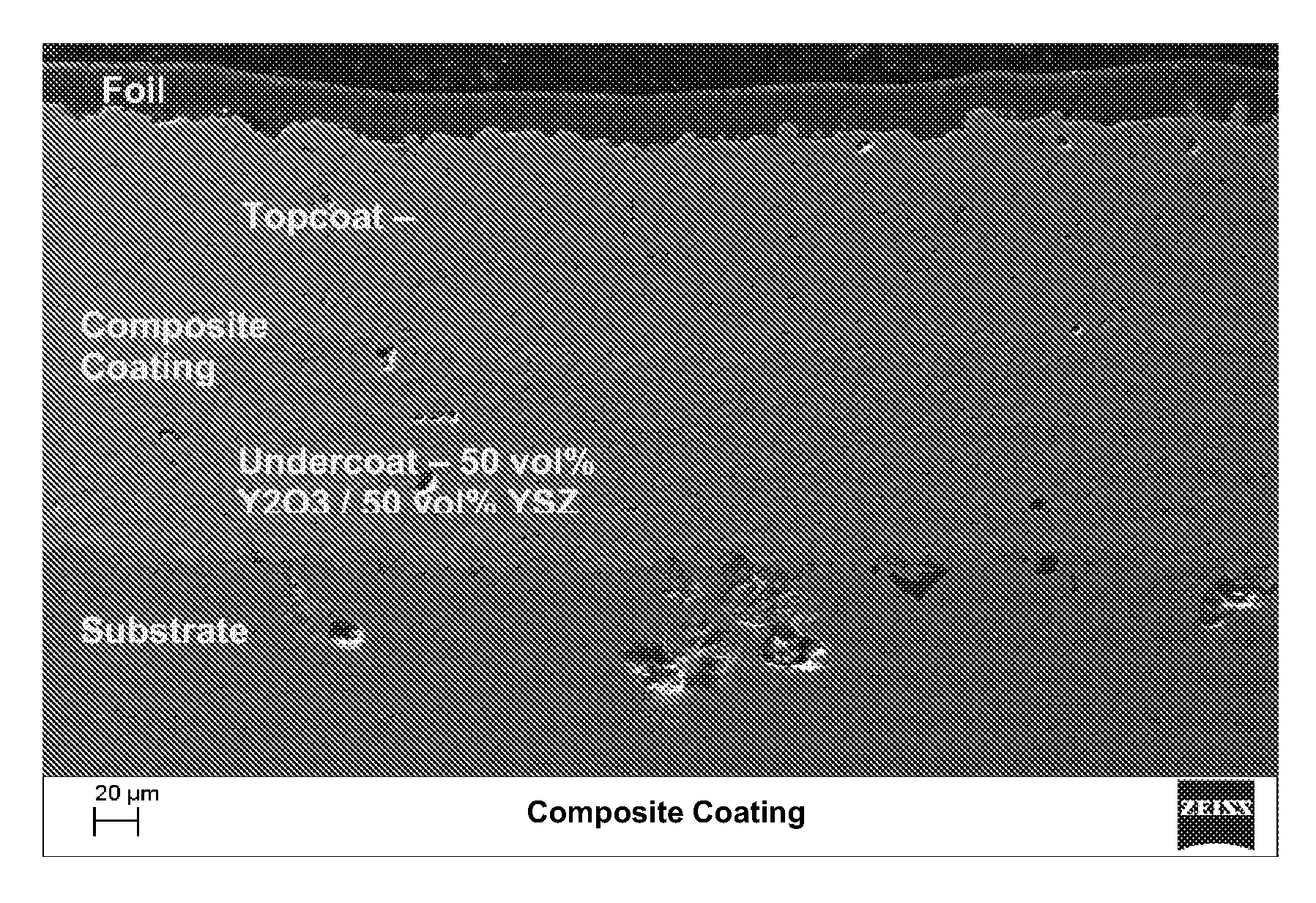

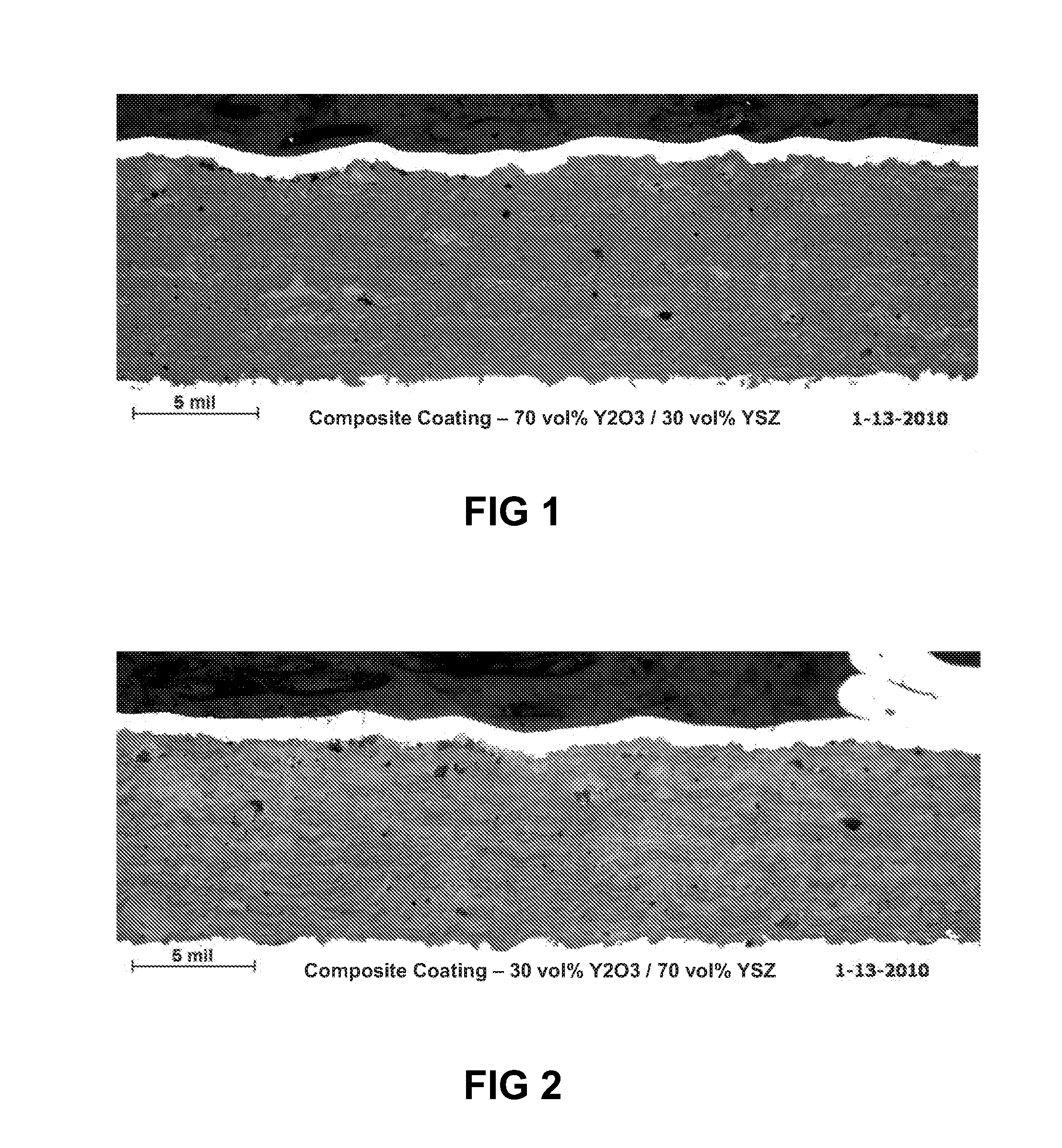

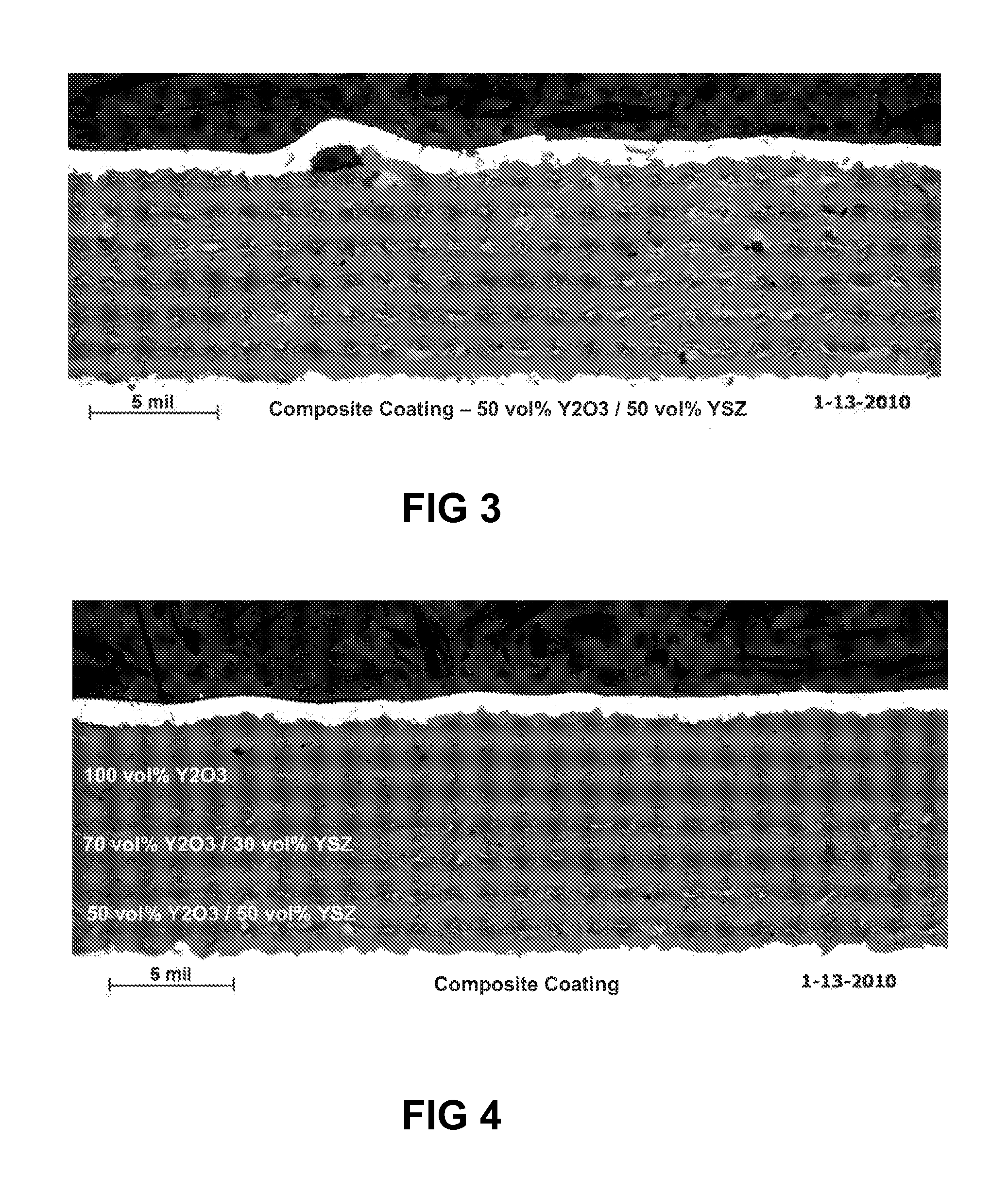

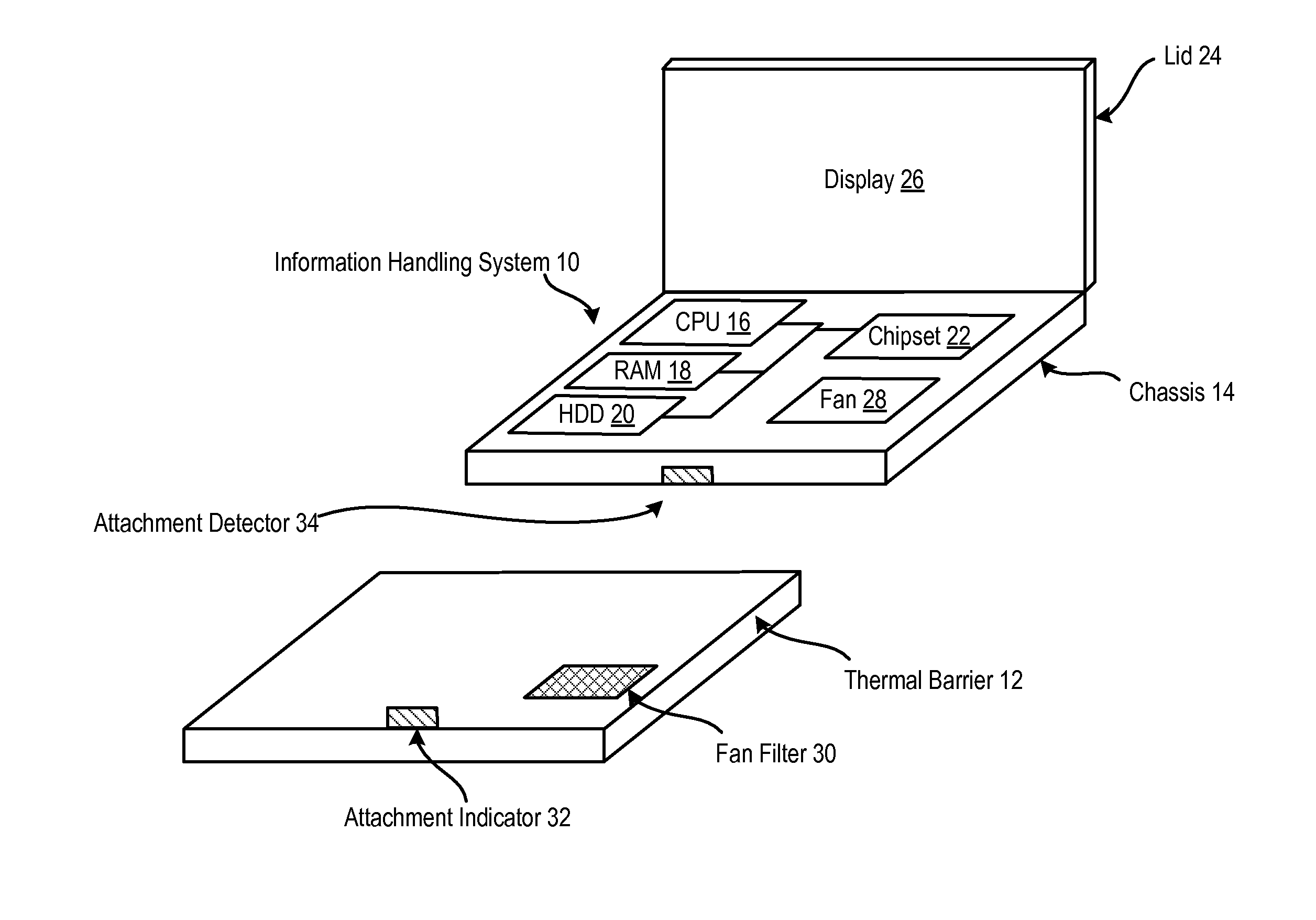

Thermal spray composite coatings for semiconductor applications

InactiveUS20120196139A1Improved erosion and corrosion resistantLower Level RequirementsLiquid surface applicatorsMolten spray coatingThermal sprayingCeramic composite

This invention relates to thermal spray composite coatings on a metal or non-metal substrate. The thermal spray composite coatings comprise (i) a ceramic composite coating undercoat layer having at least two ceramic material phases randomly and uniformly dispersed and / or spatially oriented throughout the ceramic composite coating, and (ii) a ceramic coating topcoat layer applied to the undercoat layer. At least a first ceramic material phase is present in the undercoat layer in an amount sufficient to provide corrosion resistance to the ceramic composite coating, and at least a second ceramic material phase is present in the undercoat layer in an amount sufficient to provide plasma erosion resistance to the ceramic composite coating. This invention also relates to methods of protecting metal and non-metal substrates by applying the thermal spray coatings. The composite coatings provide erosion and corrosion resistance at processing temperatures higher than conventional processing temperatures used in the semiconductor etch industry, e.g., greater than 100° C. The coatings are useful, for example, in the protection of semiconductor manufacturing equipment, e.g., integrated circuit, light emitting diode, display, and photovoltaic, internal chamber components, and electrostatic chuck manufacture.

Owner:PRAXAIR ST TECH INC

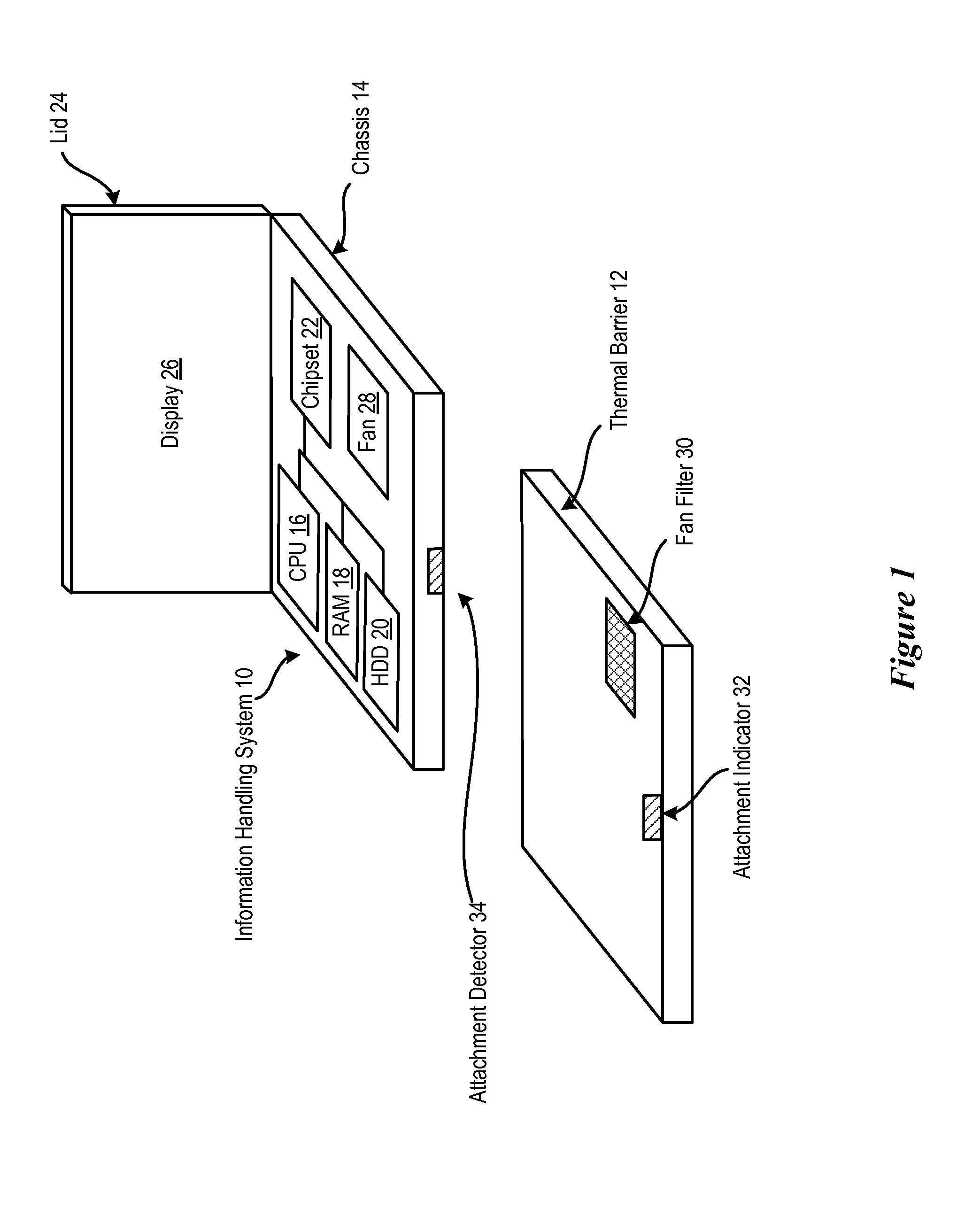

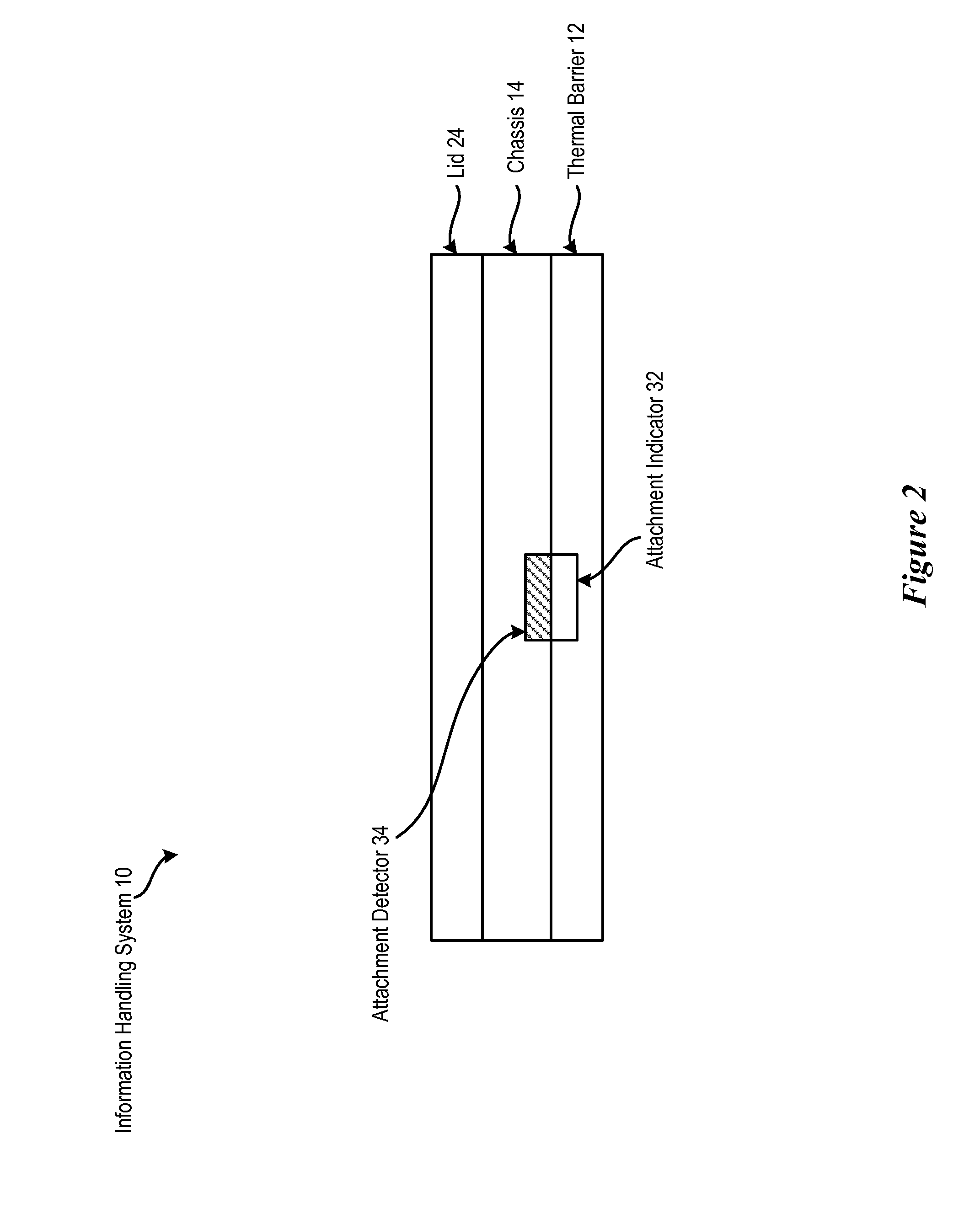

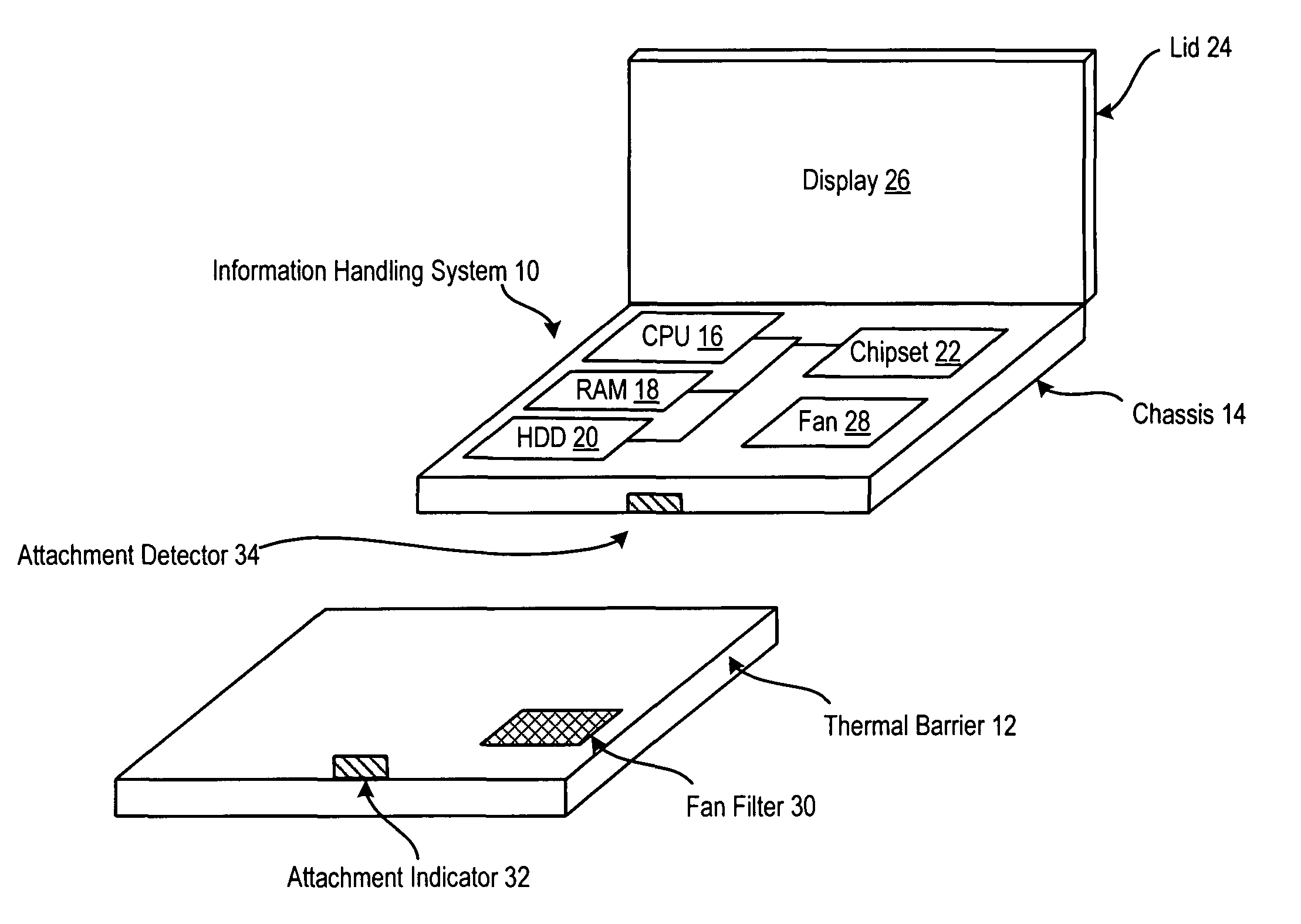

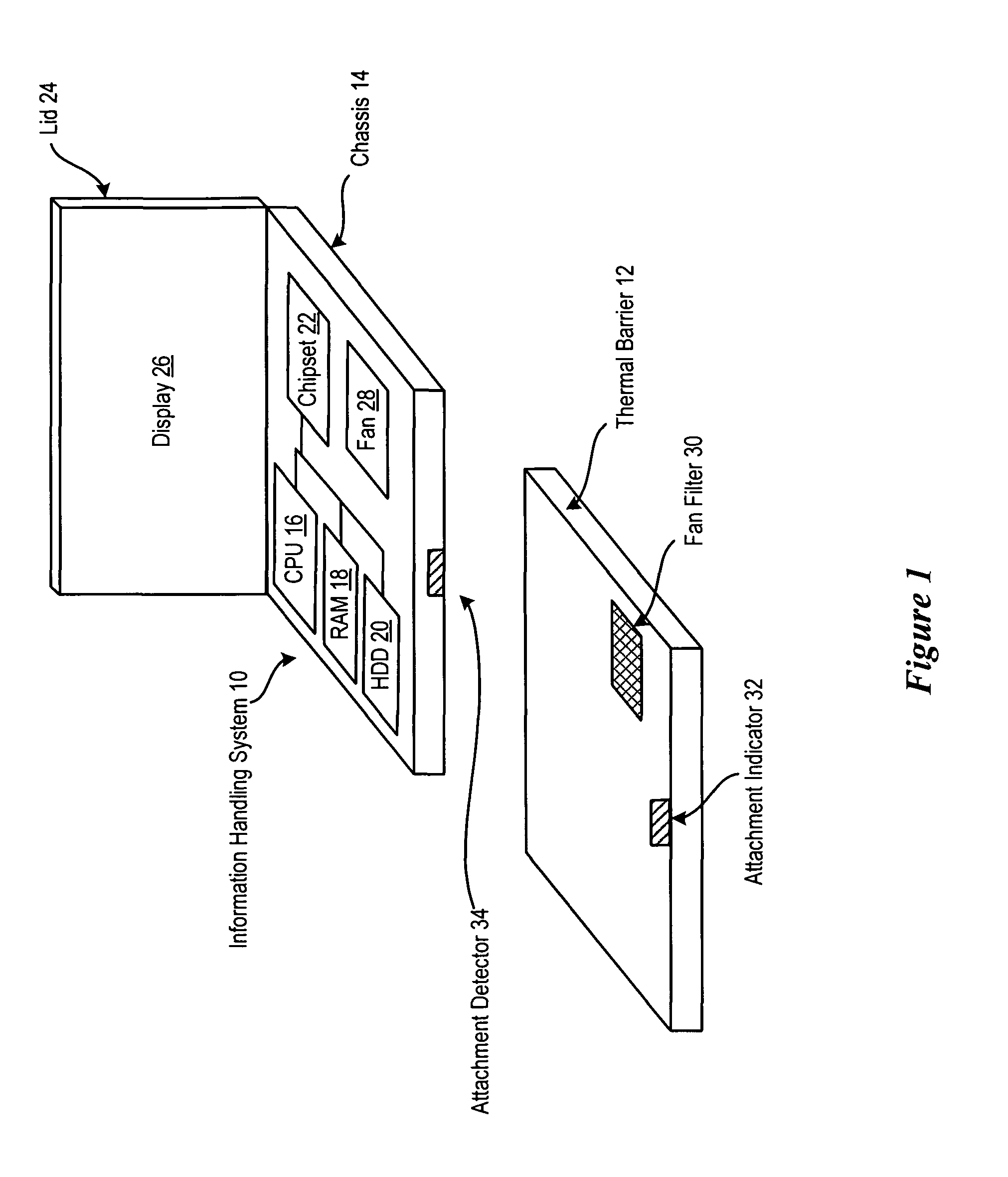

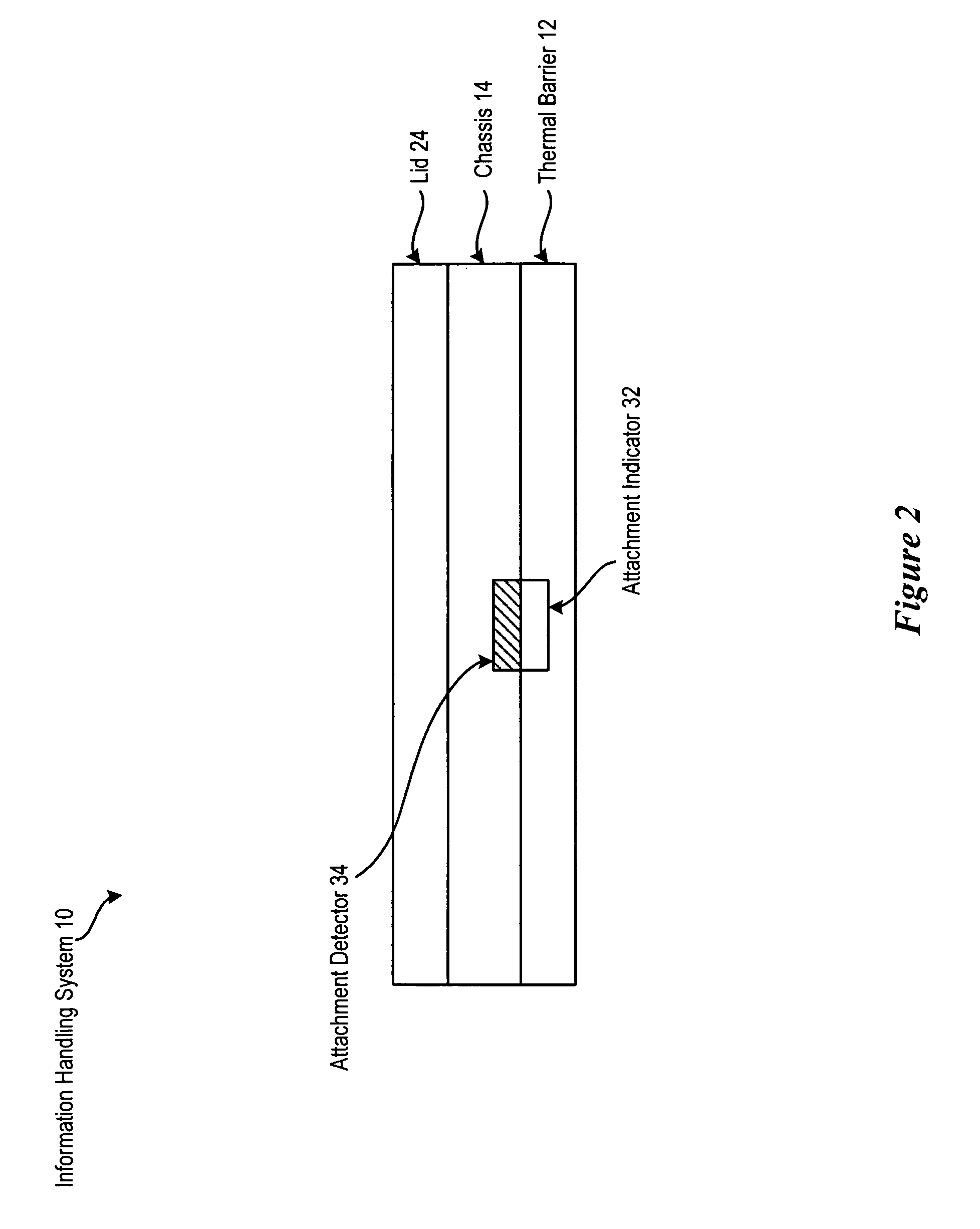

System and Method for Portable Information Handling System Parallel-Wall Thermal Shield

ActiveUS20090323275A1Reduce disadvantagesReduce problemsEnergy efficient ICTDigital data processing detailsThermal energyEngineering

An information handling system's thermal management is selectively altered by coupling a thermal barrier to the bottom surface of the information handling system chassis so that an air channel insulates against the passage of thermal energy from the bottom surface. A vent opening in a side of the thermal barrier allows airflow through the air channel to a vent opening of the information handling system. The airflow through the air channel cools the base of the thermal barrier so that an end user will experience reduced thermal energy if the information handling system rests on the end user, such as in the end user's lap.

Owner:DELL PROD LP

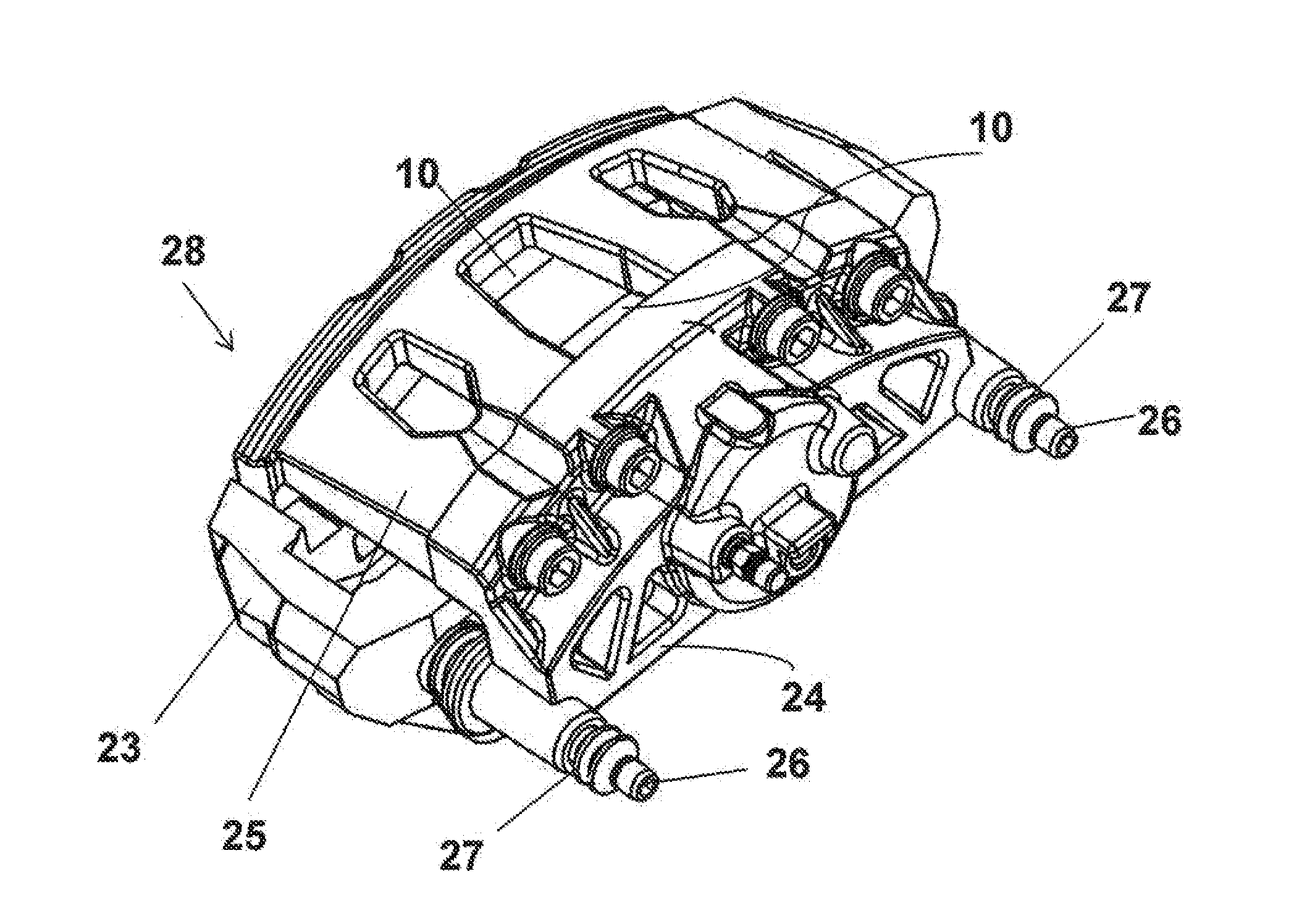

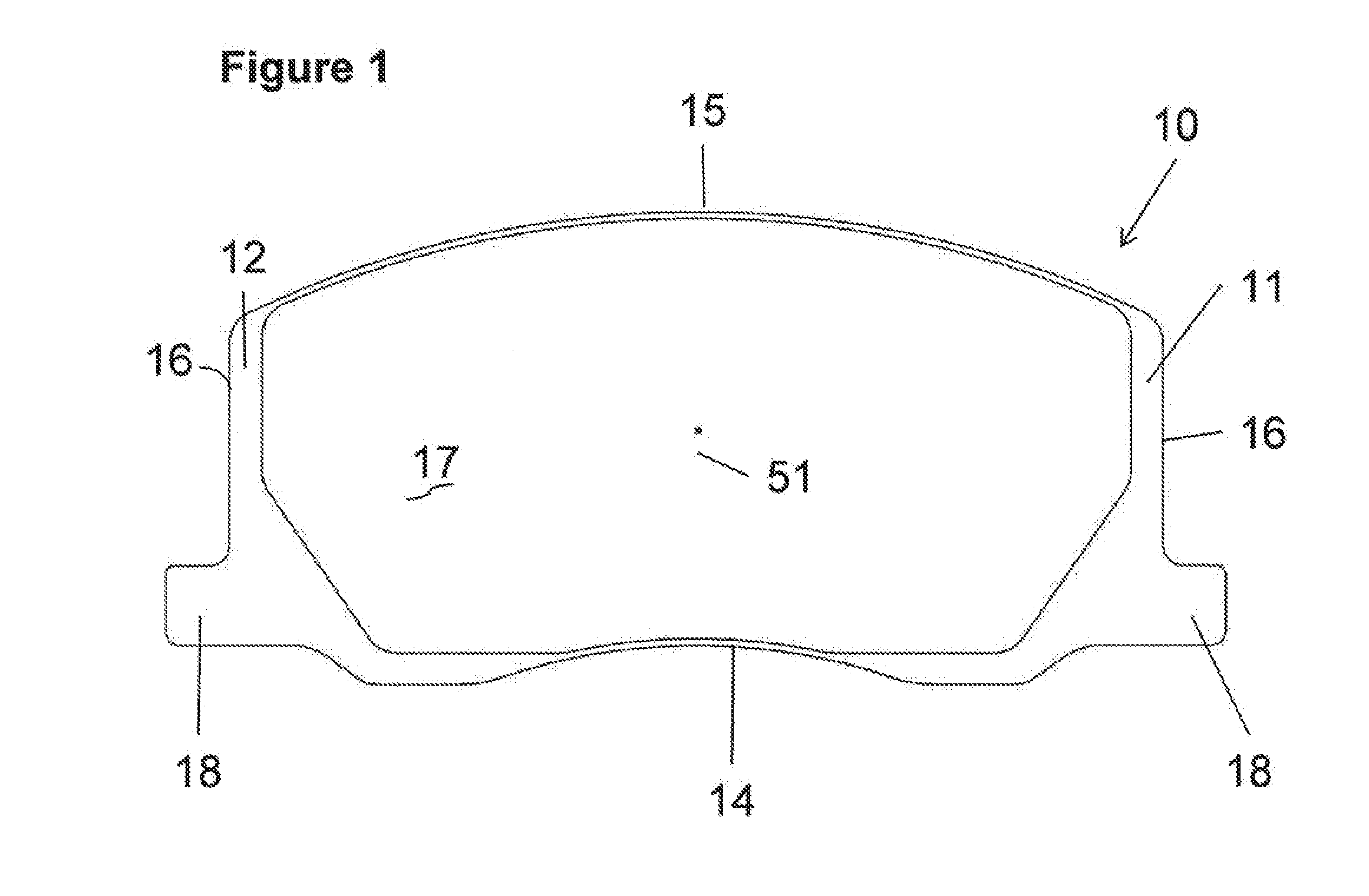

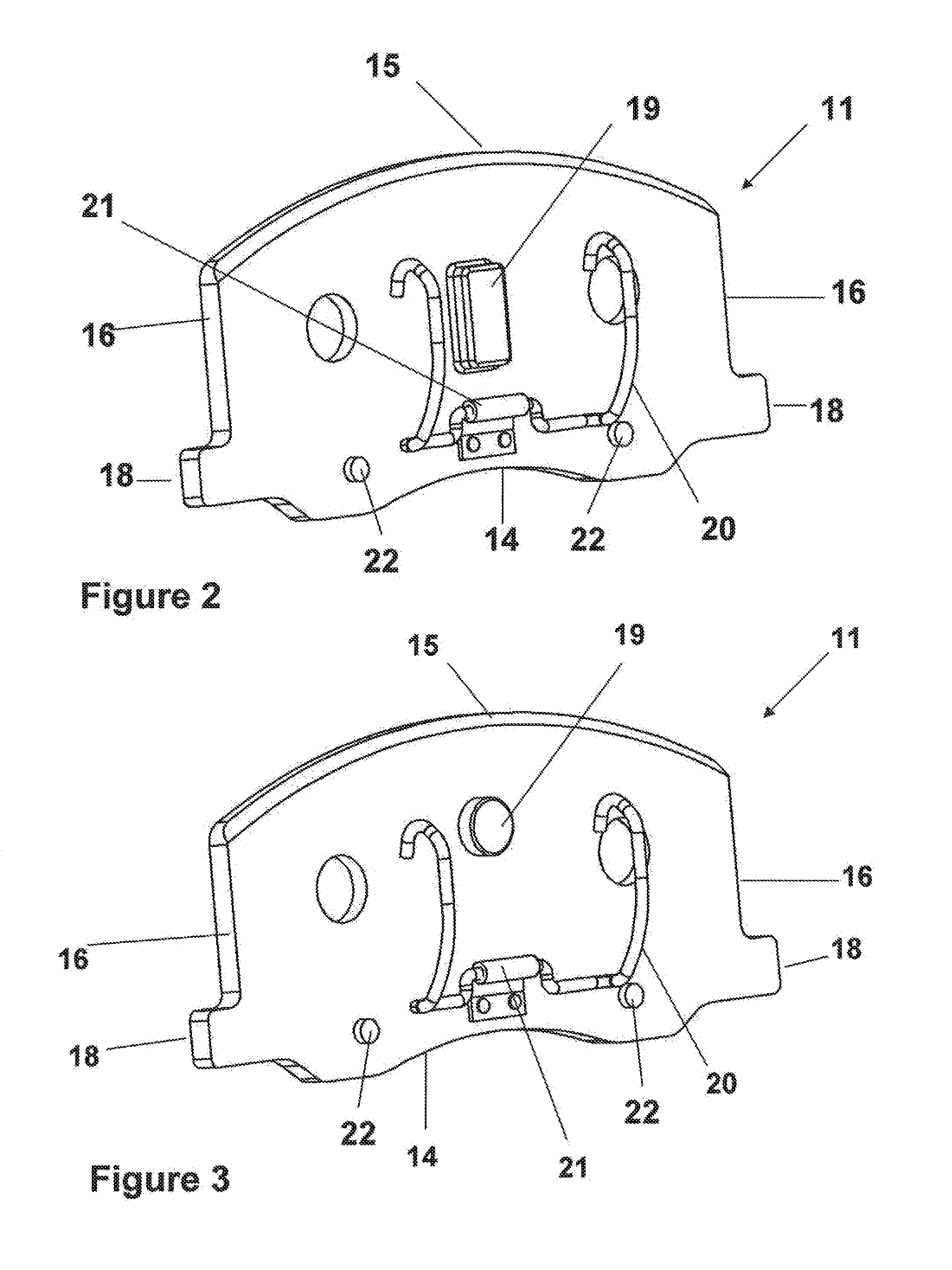

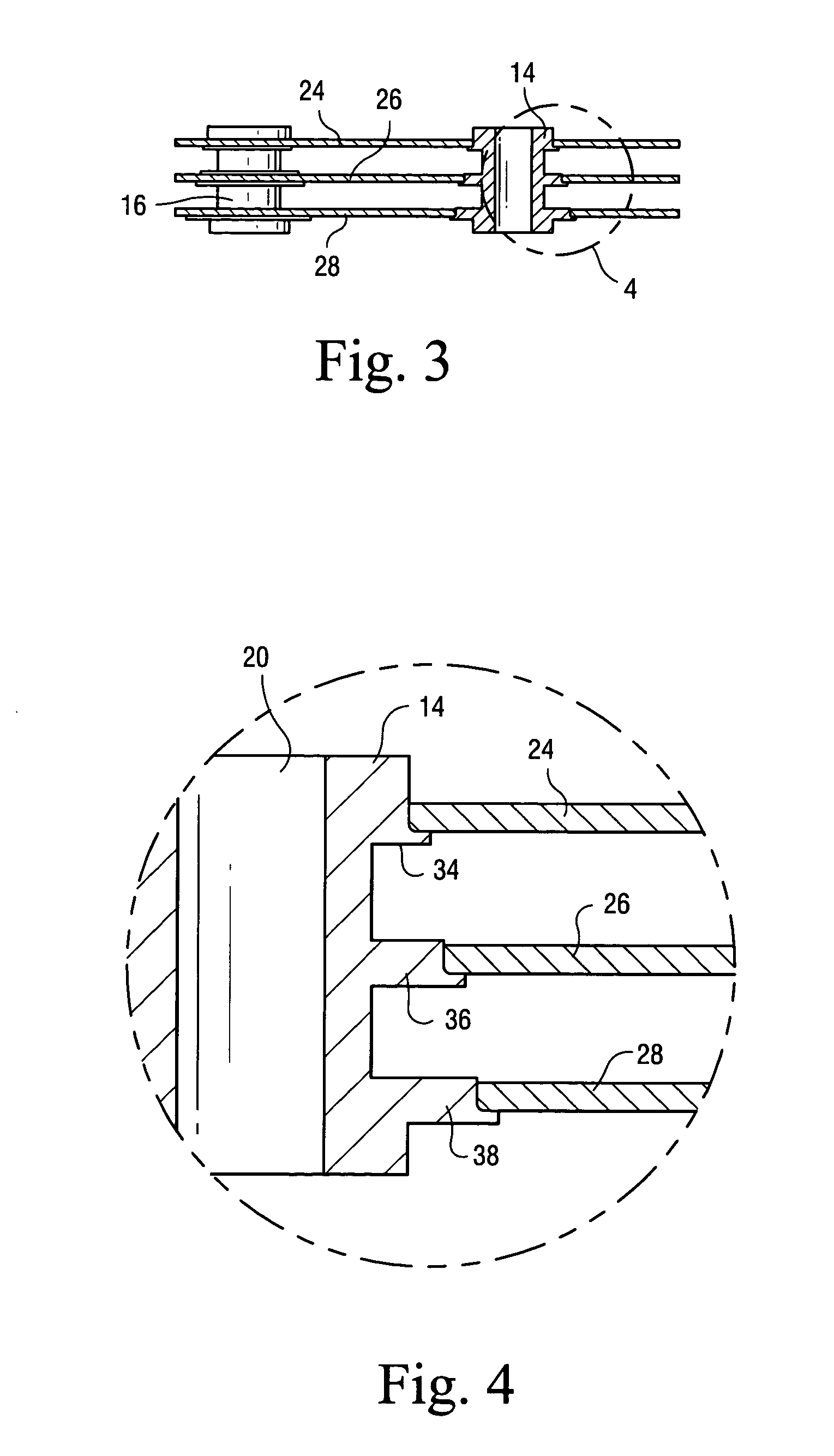

Caliper assembly for disc brake system

InactiveUS20120085597A1Improve NVH performanceImprove component performanceMechanically actuated brakesSlack adjustersEngineeringCalipers

A caliper assembly comprising: a brake pad comprising a carrier plate having two opposing faces and a top edge a bottom edge and two opposing side edges, wherein on one face is friction material and on the opposing face is a projection adapted to seat in a matched hole or recess in a caliper body, the two opposing side edges each having an ear which is adapted to seat in pad locator indentations in a support structure; a support structure comprising a recess for housing at least one brake pad and at least two pad locator indentations adapted for receiving the ears located on the two opposing sides of the brake pad and at least two caliper body locator indentations for seating two ears defined by the caliper body; and a caliper body having a hole or recess adapted for seating the projection on the opposing face of the brake pad and having two ears on each opposing side which are adapted to seat in the caliper body locator indentations of the support structure; wherein the ears of the brake pad are seated in the pad locator indentations of the support structure, the projection on the opposing face of the brake pad is seated in the hole or recess located in the caliper body, and a clip which engages the opposing face of the brake pad and the caliper body and holds the brake pad in position with respect to the caliper body and the ears of the caliper body are seated in the caliper body locator indentations in the support structure.

Owner:AKEBONO BRAKE

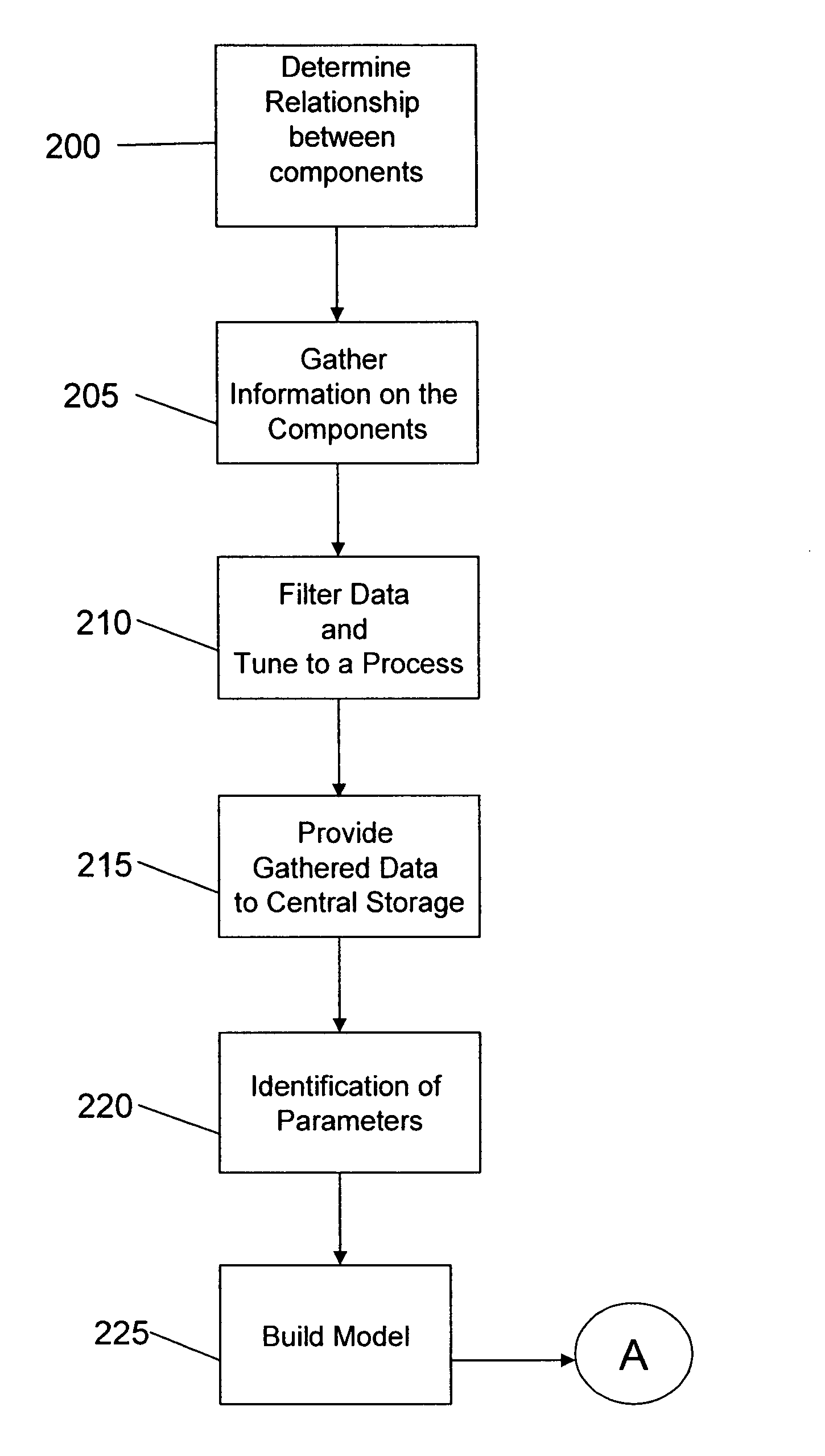

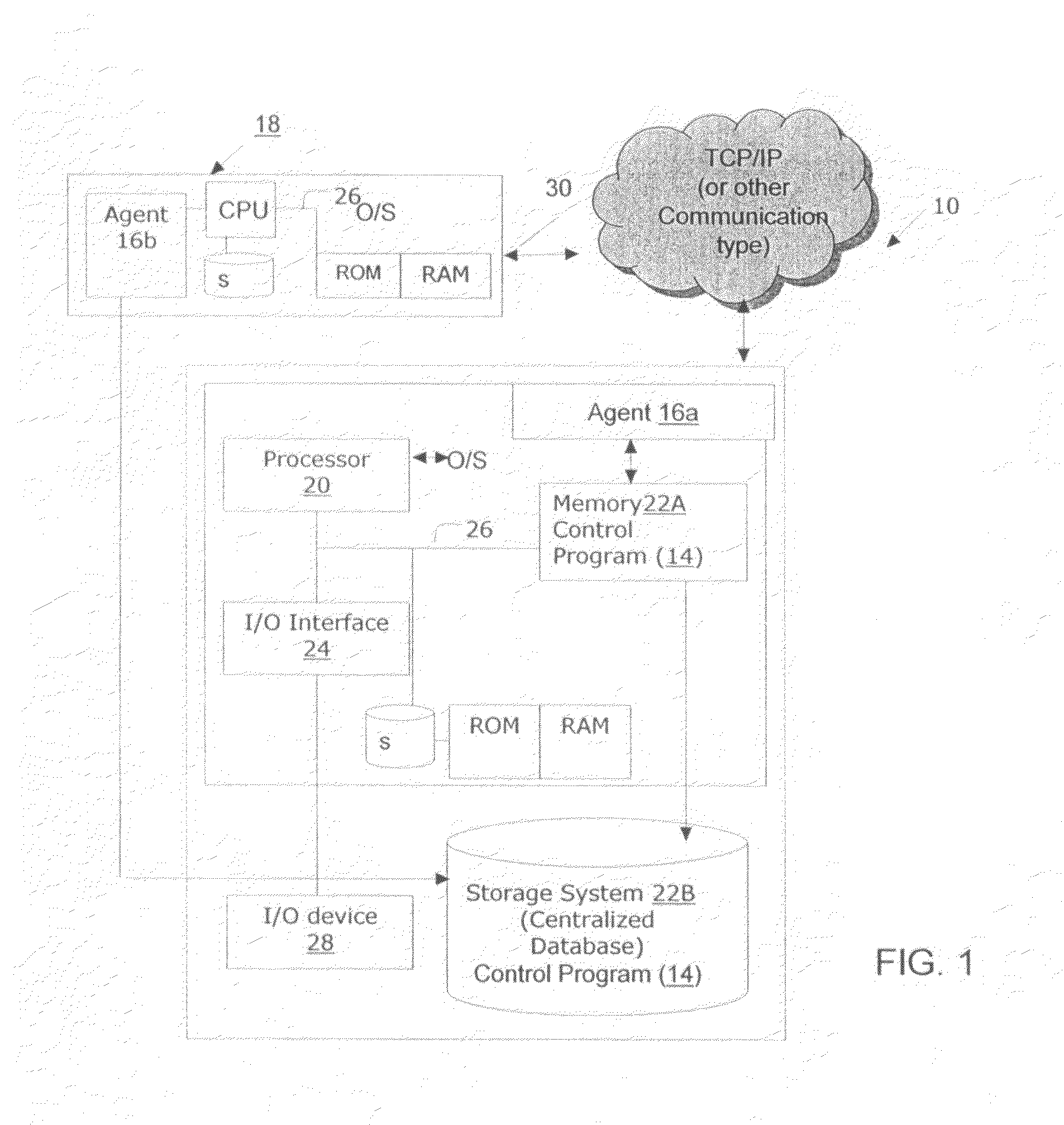

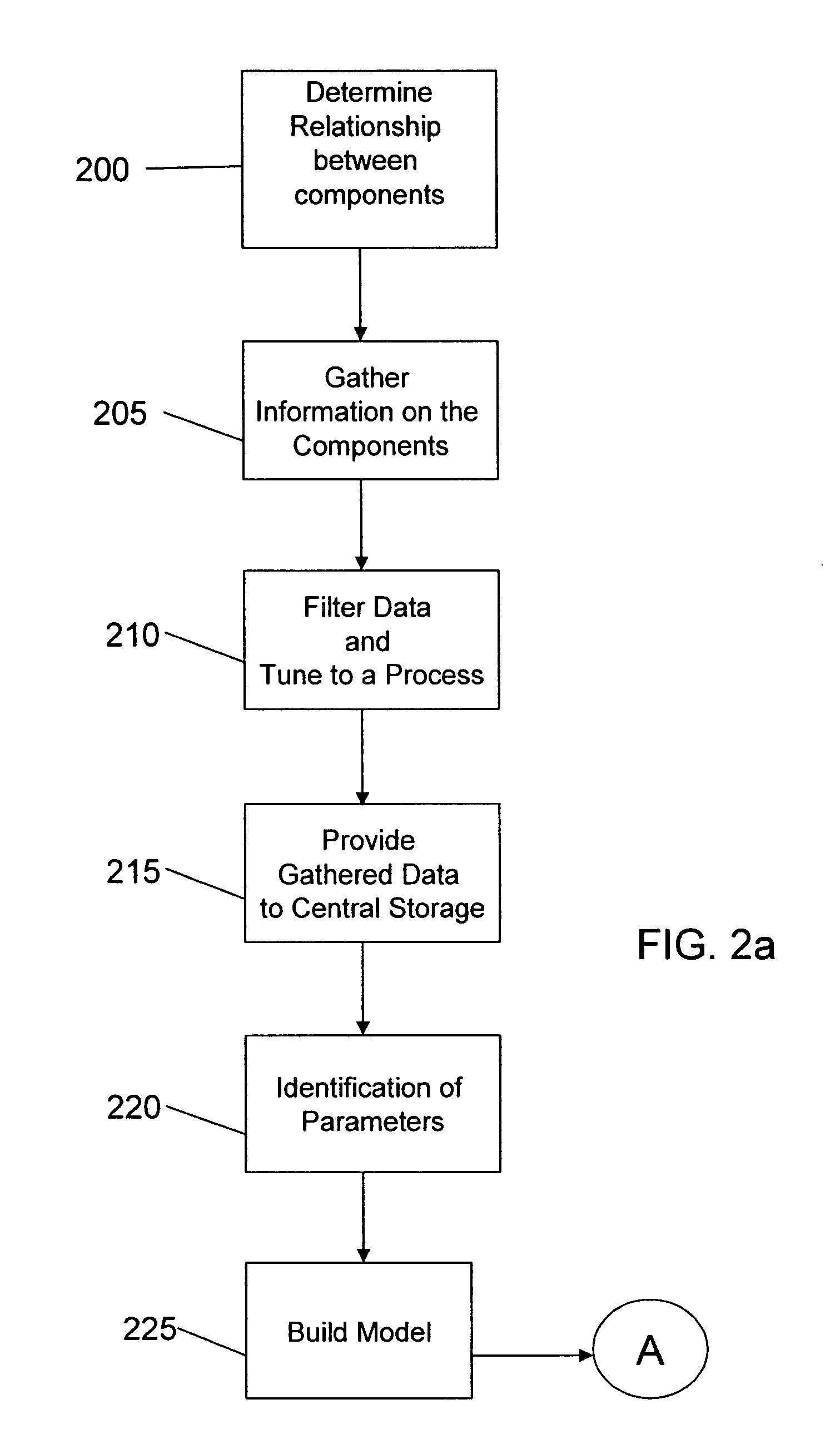

Real-time performance modeling of application in distributed environment and method of use

InactiveUS20090006069A1Improve component performanceImprove performanceError detection/correctionSpecific program execution arrangementsCurrent loadDistributed Computing Environment

A system and method of managing computing systems and, more particularly, to a system and method for modeling applications in a network. The method includes determining dependency of components in a shared distributed computing environment and measuring consumption of the dependent components. The method further includes building a model to compare component behavior with a current load of the dependent components to optimize component performance or to find a deviation and hence a “troubled spot”. The system includes a local agent configured to perform the method and to provide data to a centralized storage.

Owner:IBM CORP

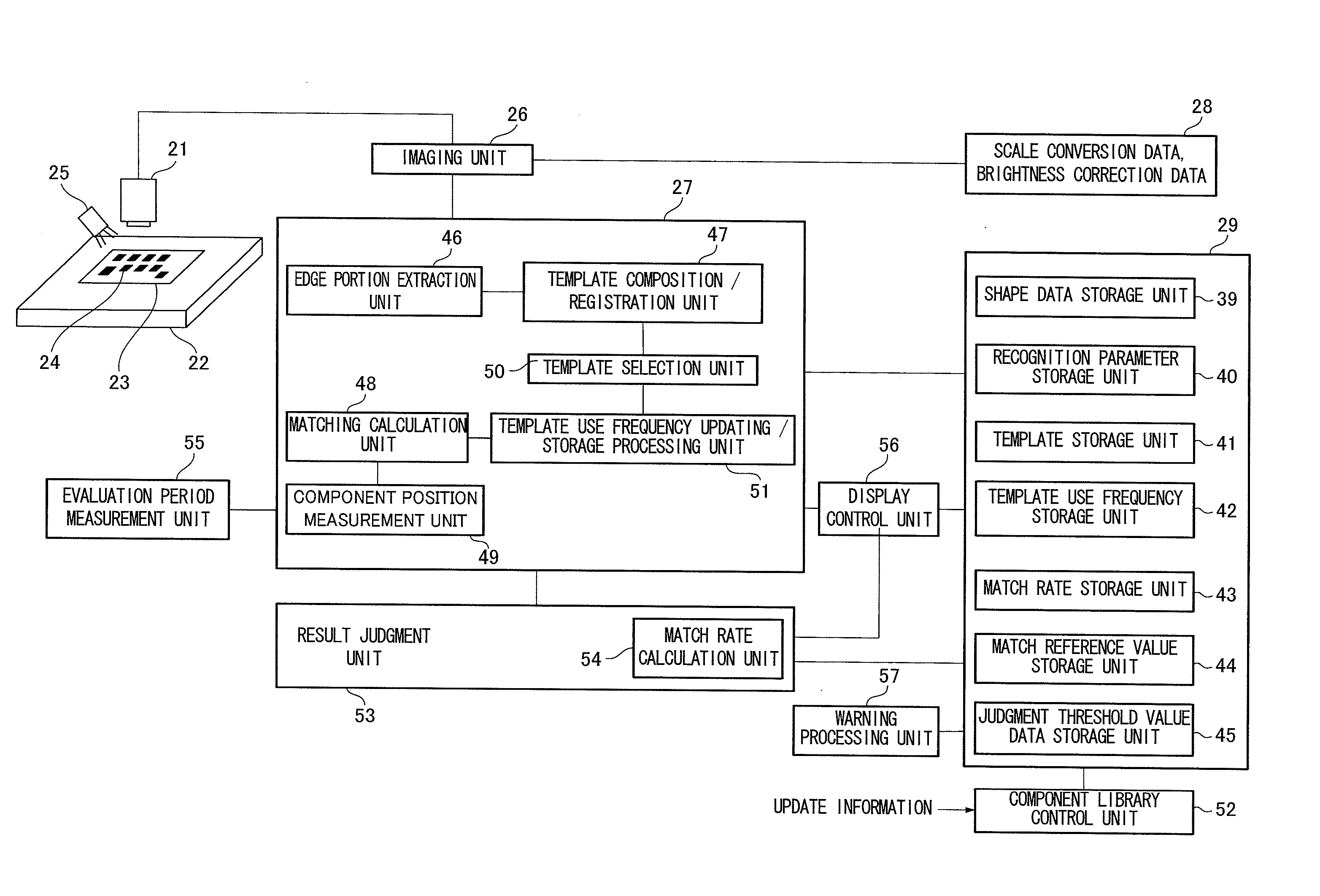

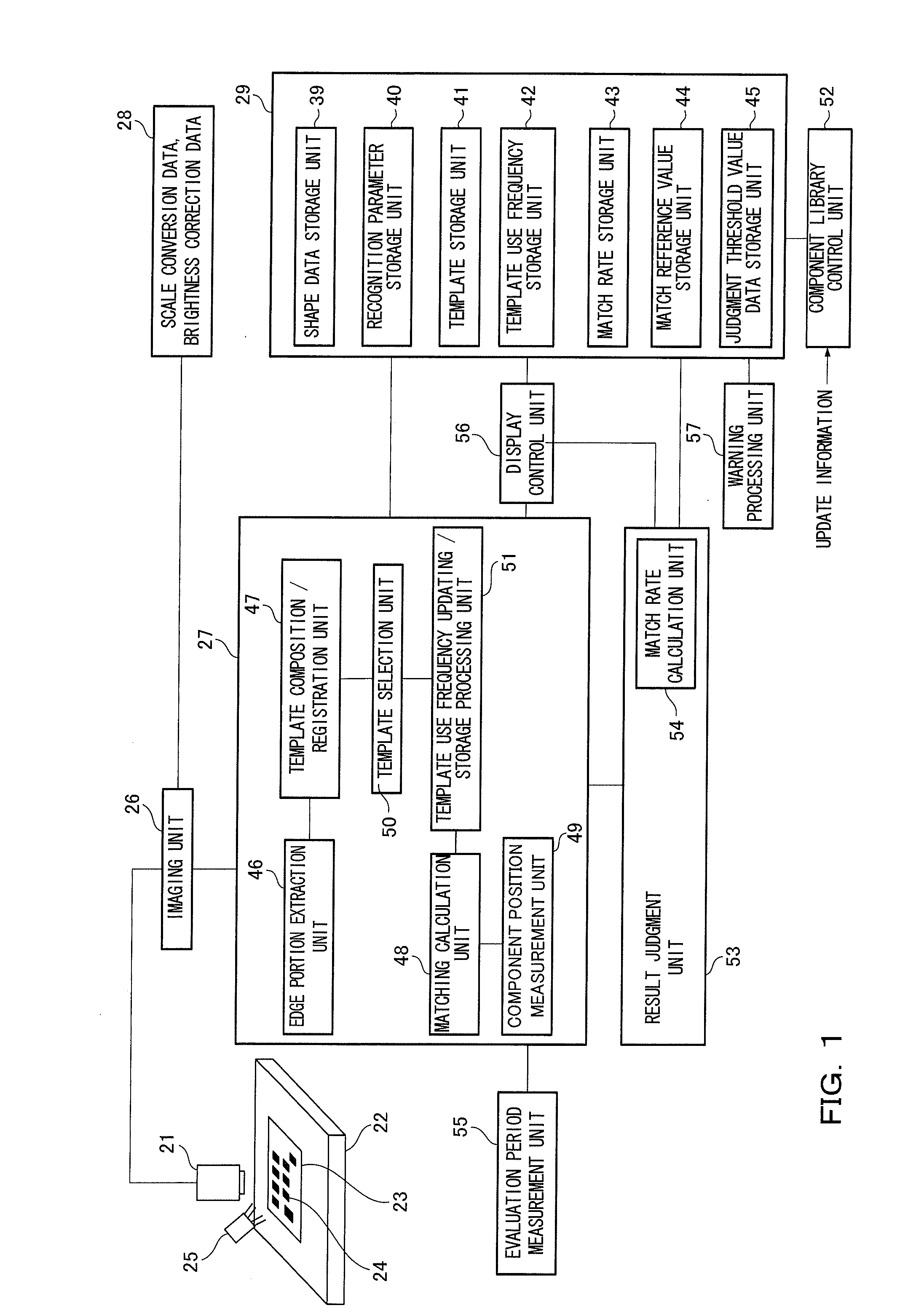

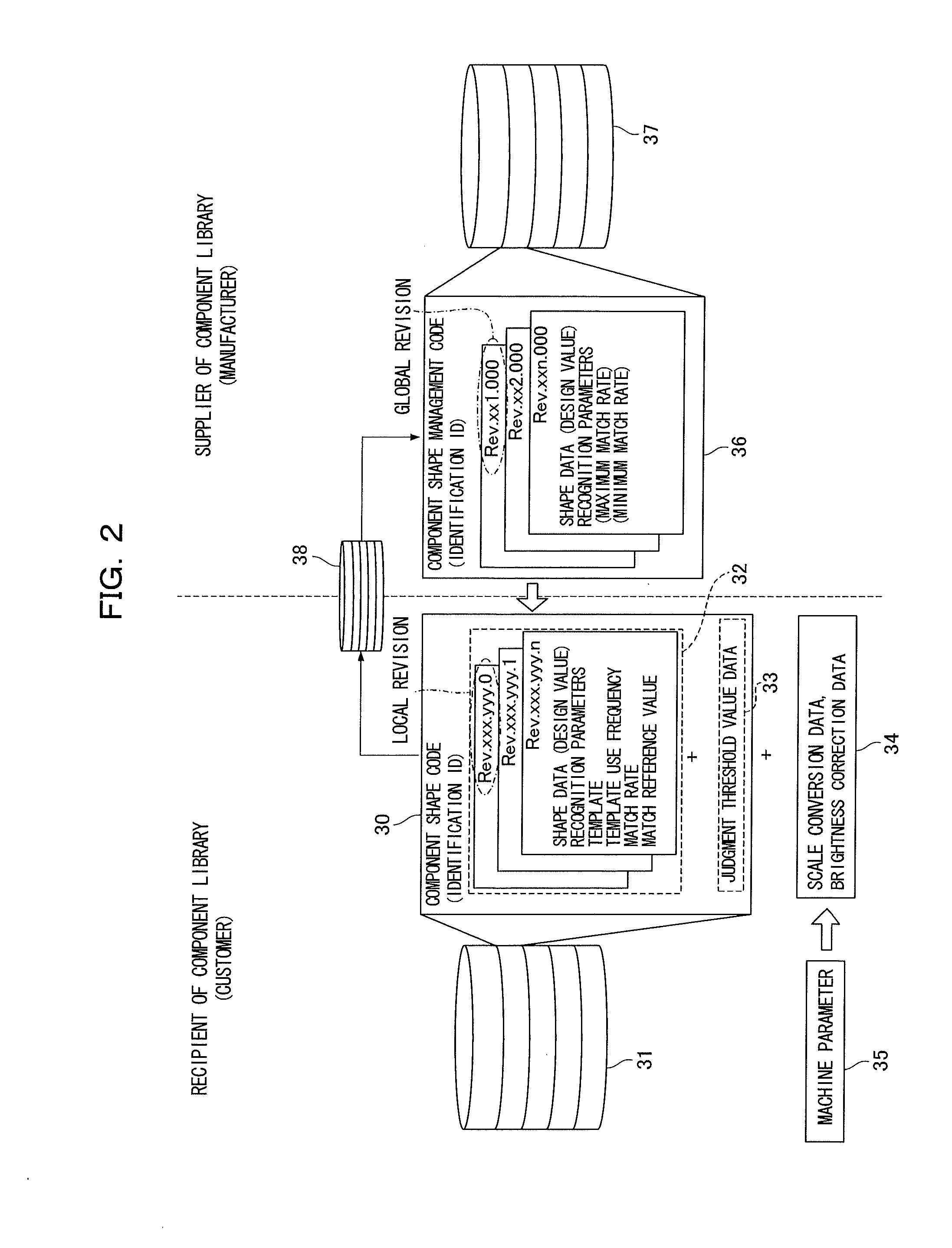

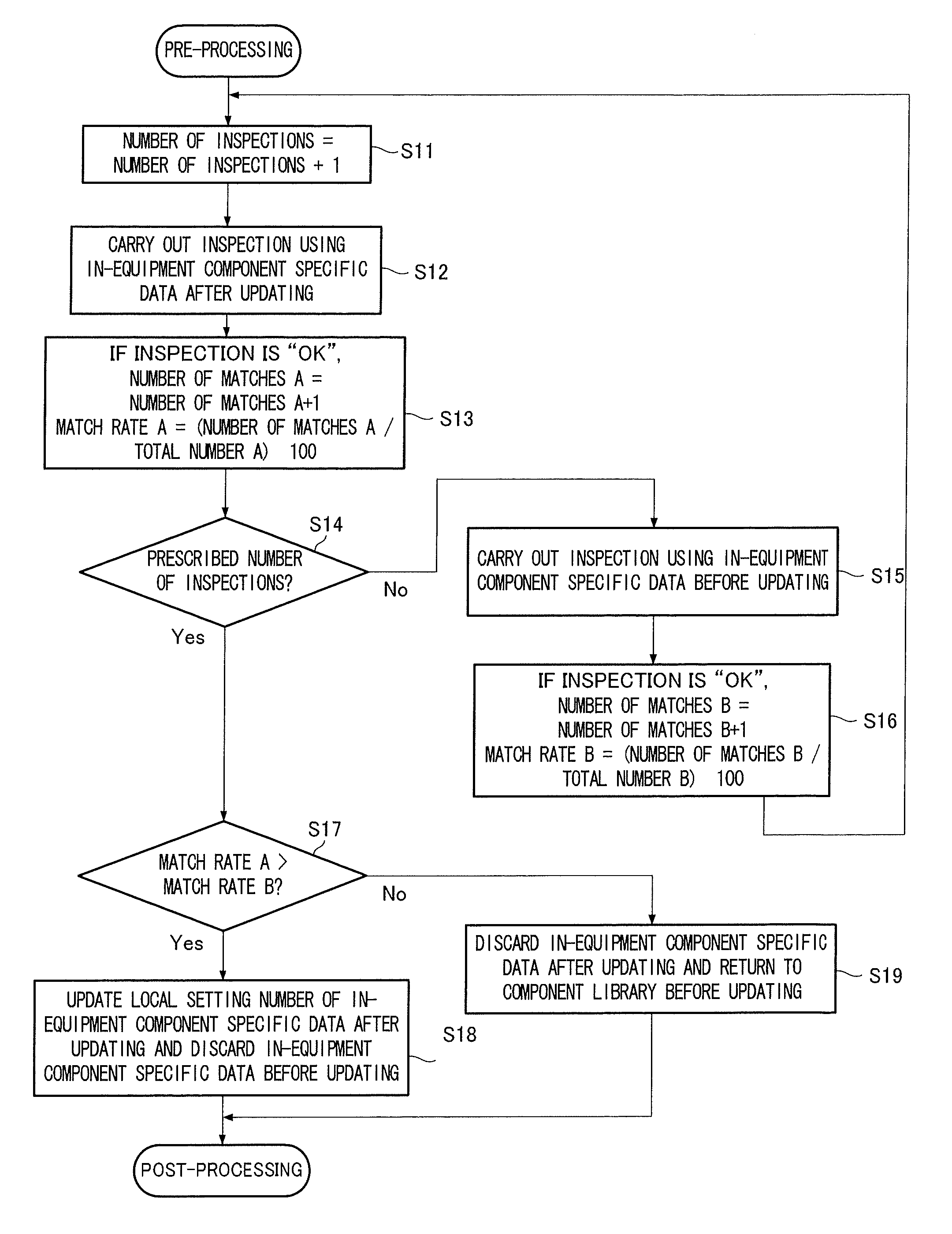

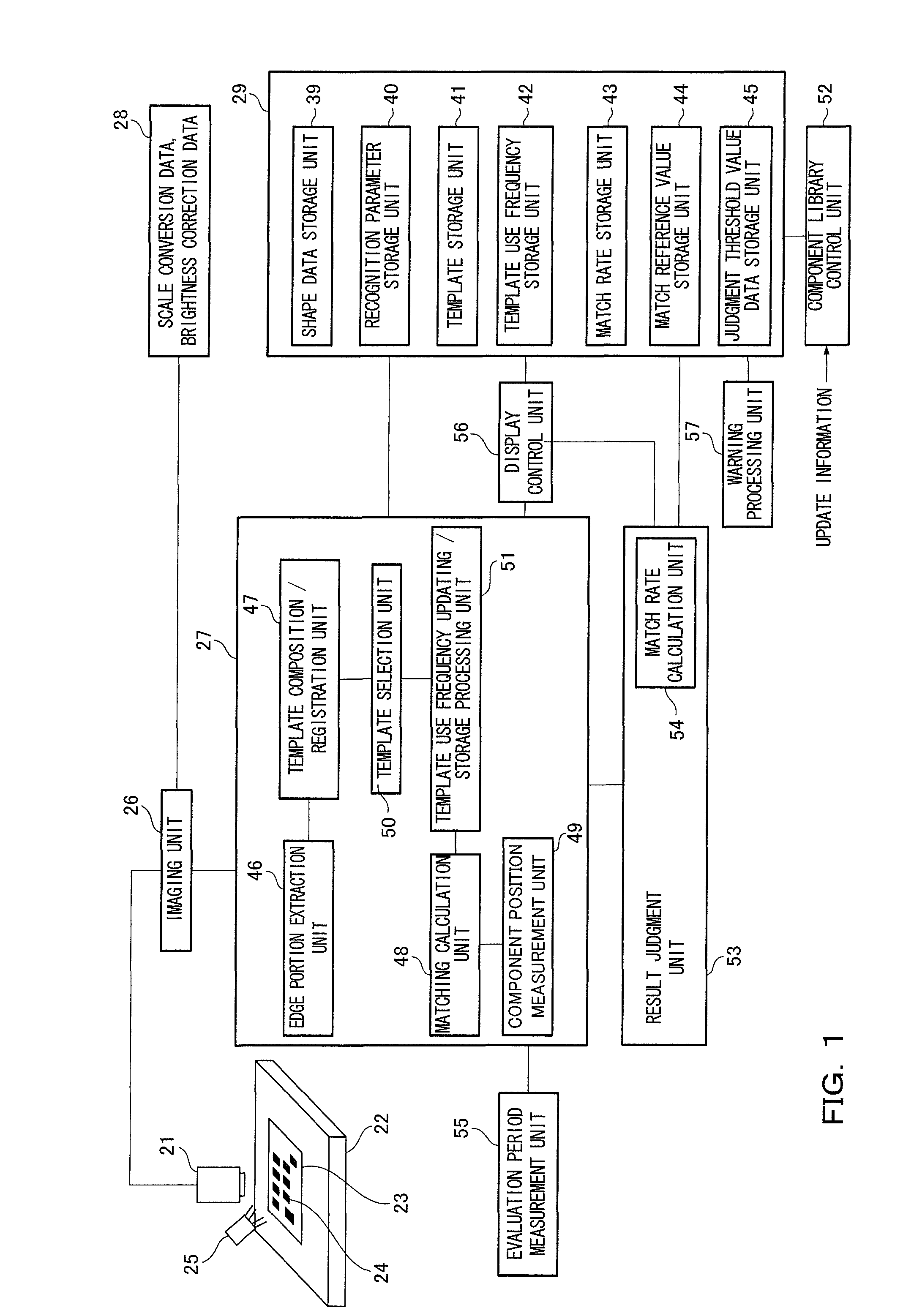

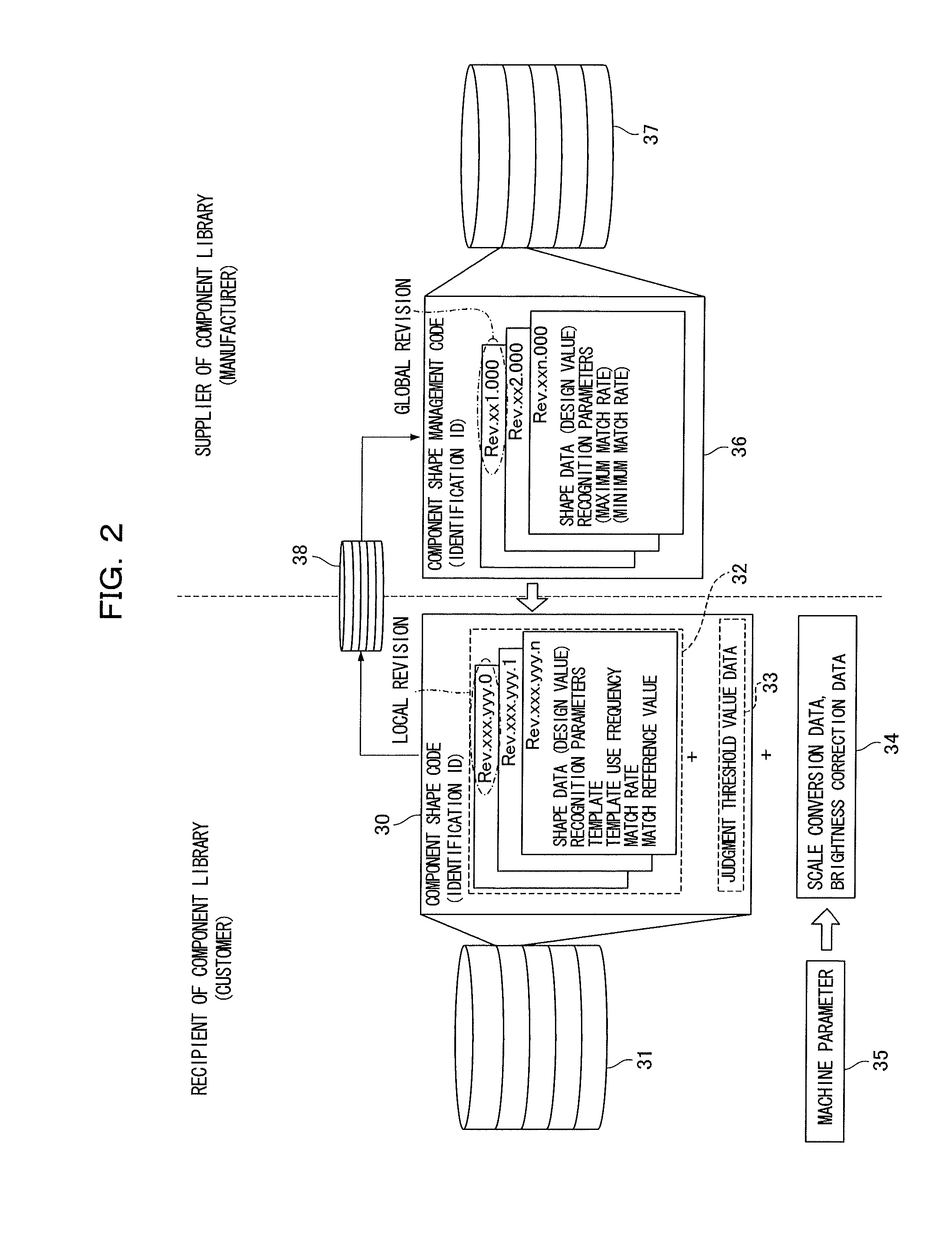

Mounted component inspection apparatus, component mounting machine comprising the mounted component inspection apparatus, and mounted component inspection method

InactiveUS20100189340A1Improve component performanceRapid introductionAutomatic control devicesAssembly machinesProcessing elementMatch rate

A mounted component inspection apparatus according to the present invention includes: a component library holding inspection information; an inspection processing unit for inspecting a component under inspection using the component library; a match rate acquisition unit for acquiring a match rate indicating the degree to which the inspection information is suitable for the inspection by the inspection processing unit, on the basis of the result of the inspection by the inspection processing unit; and a judgment unit for selecting the inspection information having a higher match rate, of the inspection information before updating and the inspection information after updating. The component library can hold the inspection information before and after updating, and the inspection processing unit carries out the inspection using the inspection information before and after updating held in the component library.

Owner:PANASONIC CORP

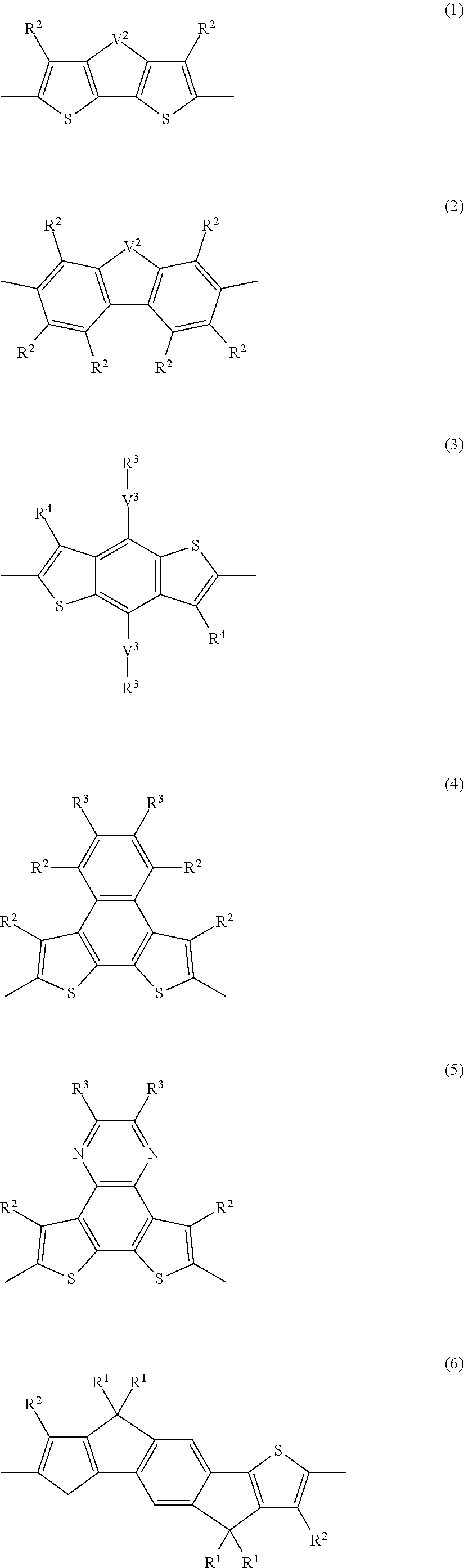

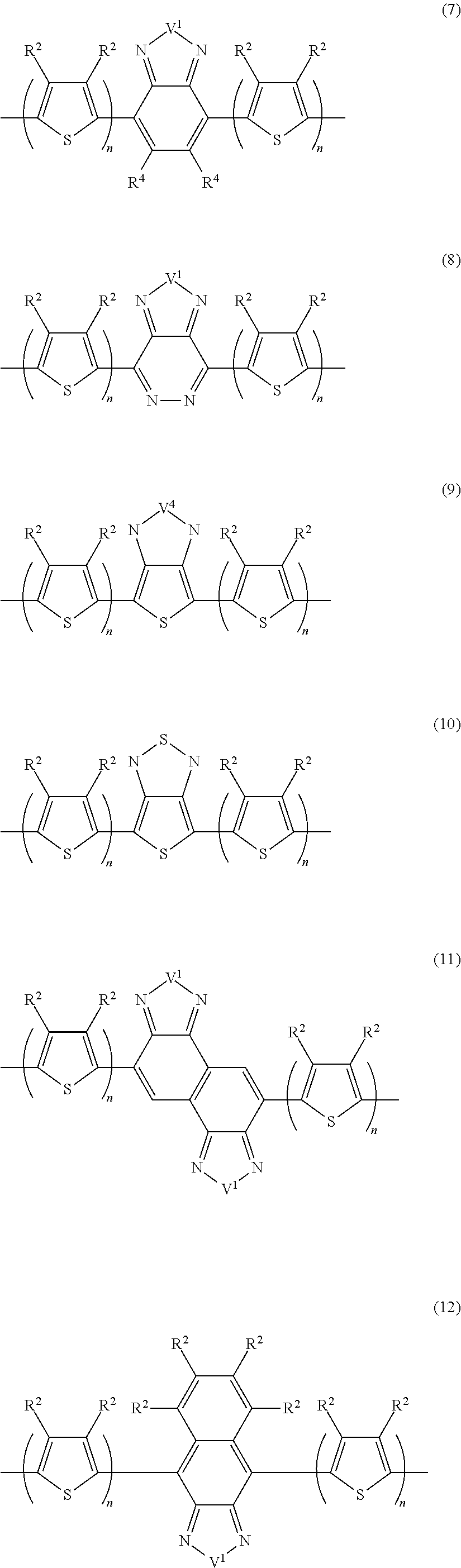

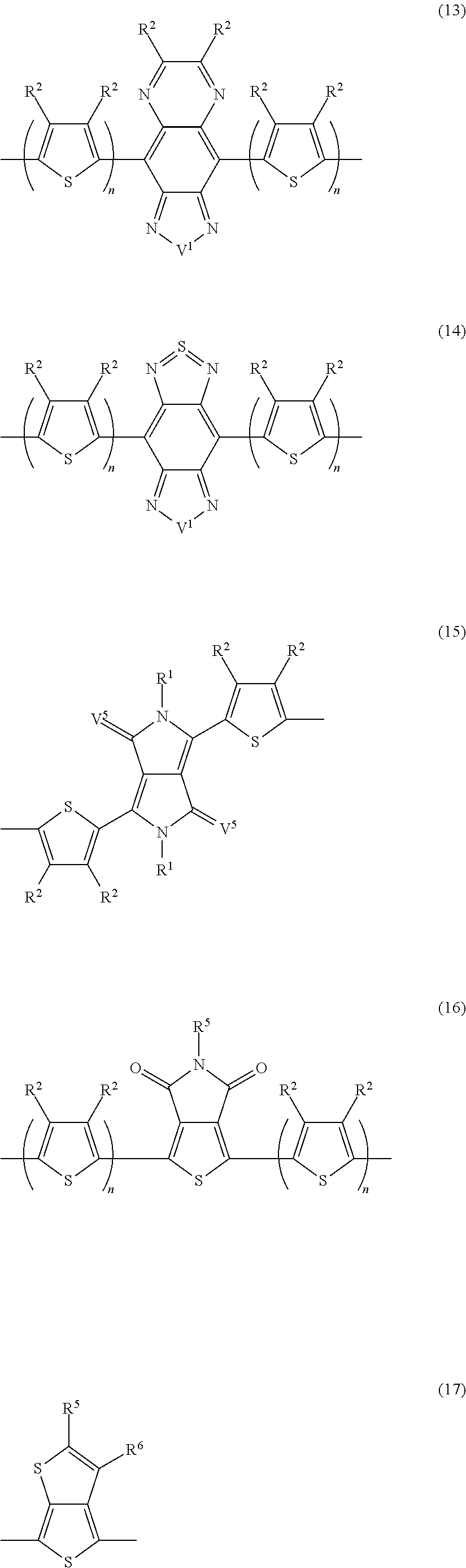

Block copolymer and photoelectric conversion element

InactiveUS20140166942A1Increase valueReduce resistanceNon-metal conductorsConductive materialChemical structurePolymer science

Provide are: a conjugated block copolymer capable of increasing the amount of optical absorption by a photoelectric conversion active layer and controlling the morphology thereof and capable of achieving excellent photoelectric conversion efficiency; and a photoelectric conversion element comprising a composition including an electron accepting material and this kind of conjugated block polymer. A π-electron conjugated block copolymer comprising: a polymer block (A) which involving a monomer unit having at least one heteroaryl skeleton selected from the group consisting of a fused π-conjugated skeleton, a fluorene, a carbazole, a dibenzosilole and a dibenzogermole containing at least one thiophene ring in a part of a chemical structure thereof; and a polymer block (B) involving a monomer unit of a thiophene-2,5-diyl group having a substituent at least at a 3-position thereof.

Owner:KURARAY CO LTD

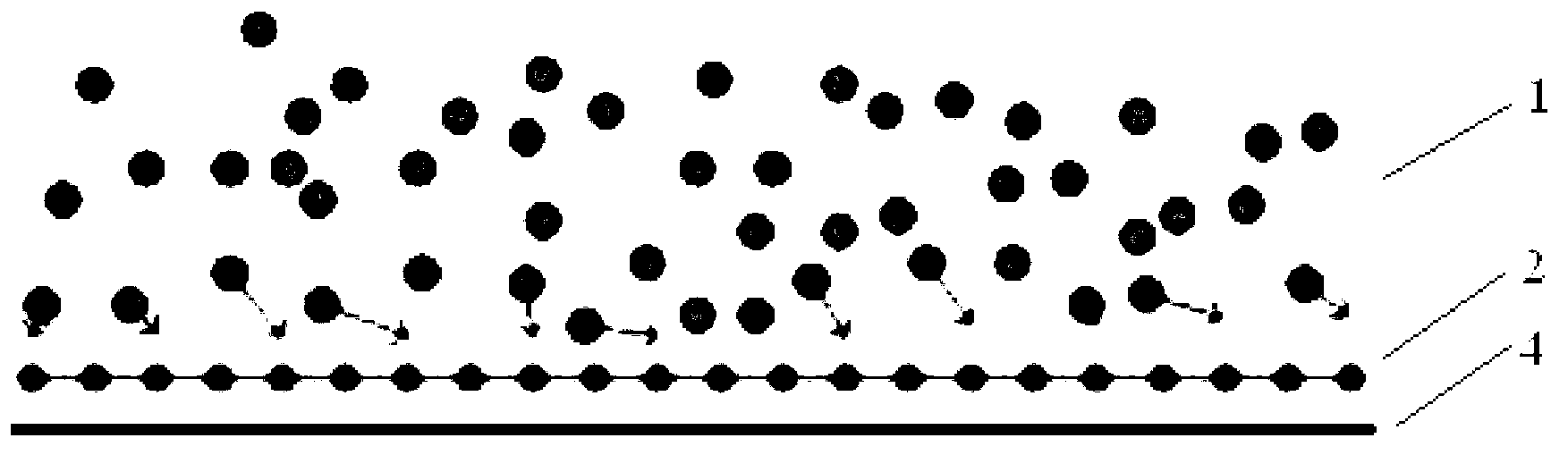

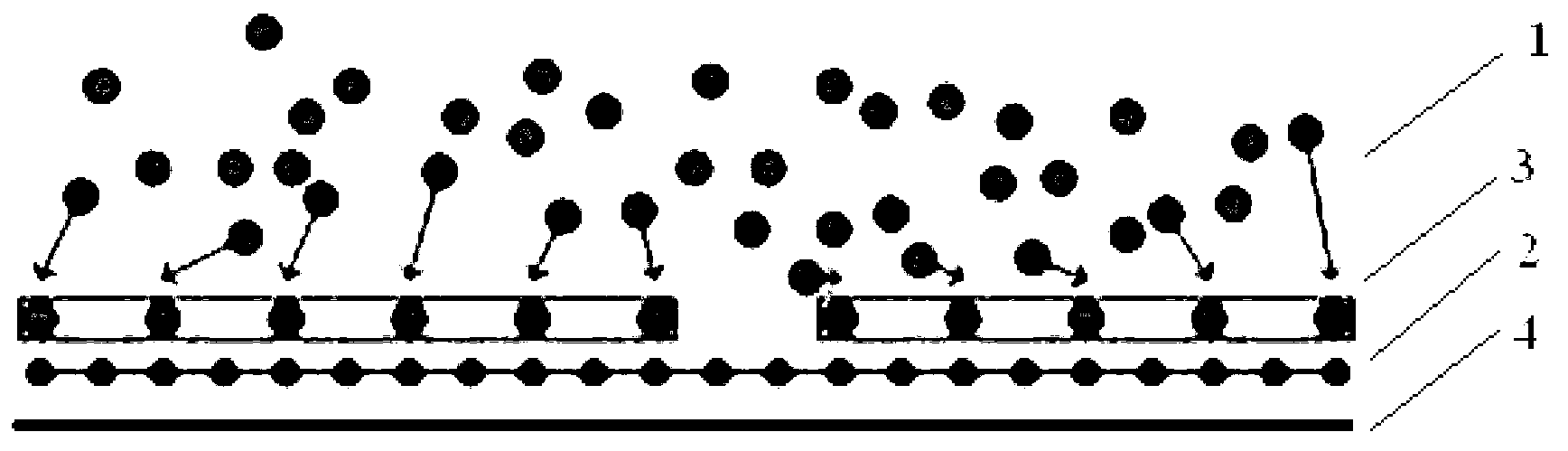

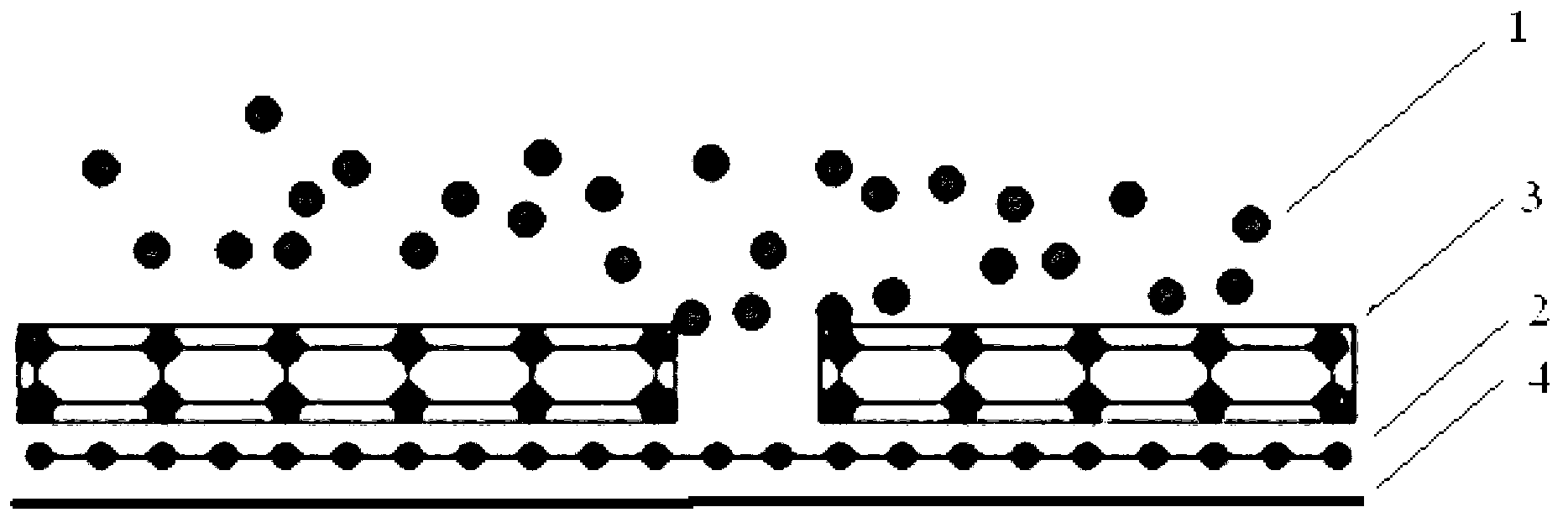

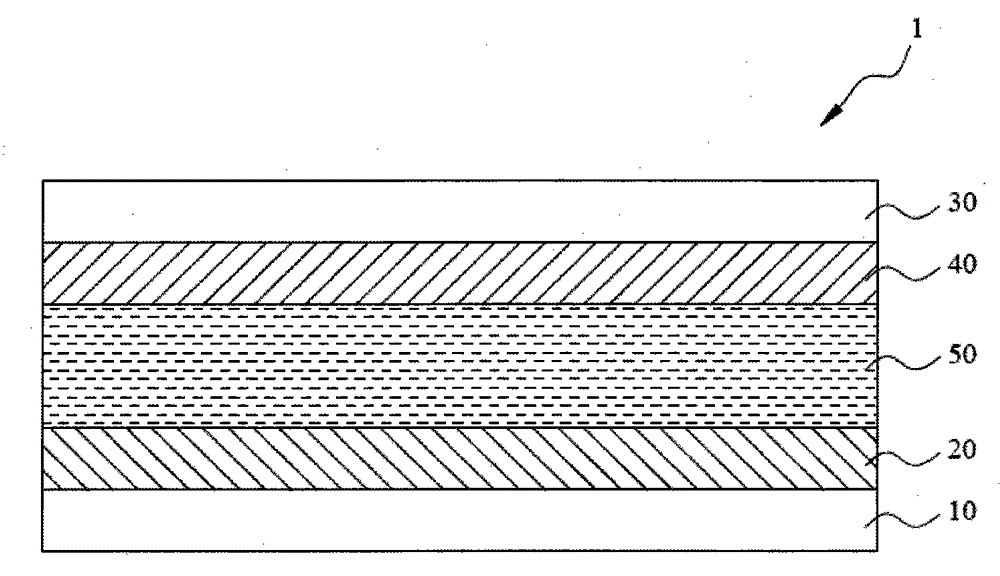

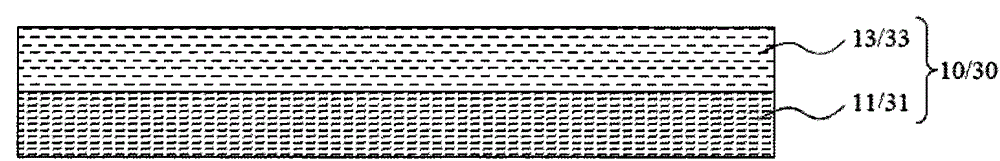

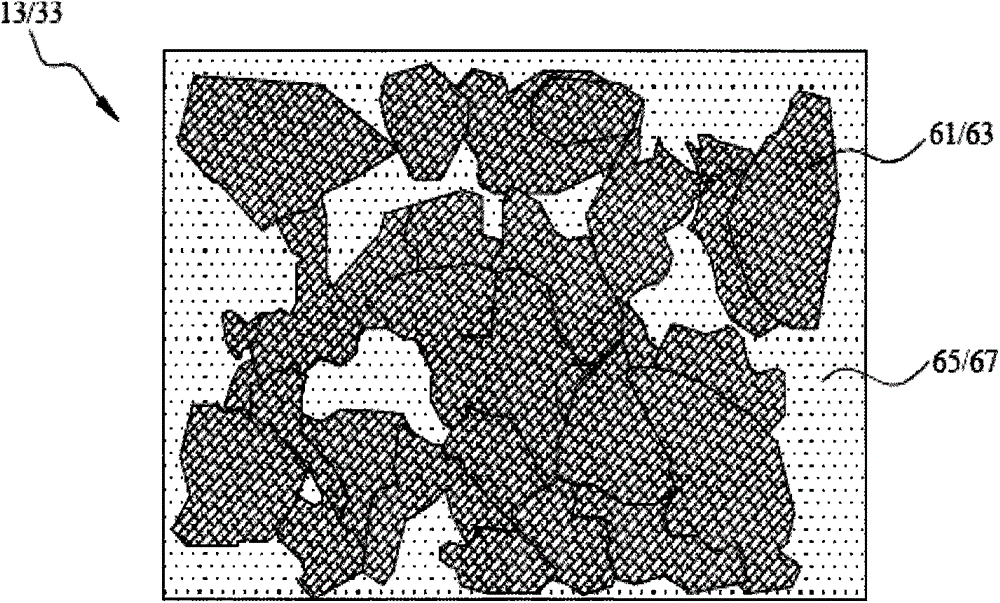

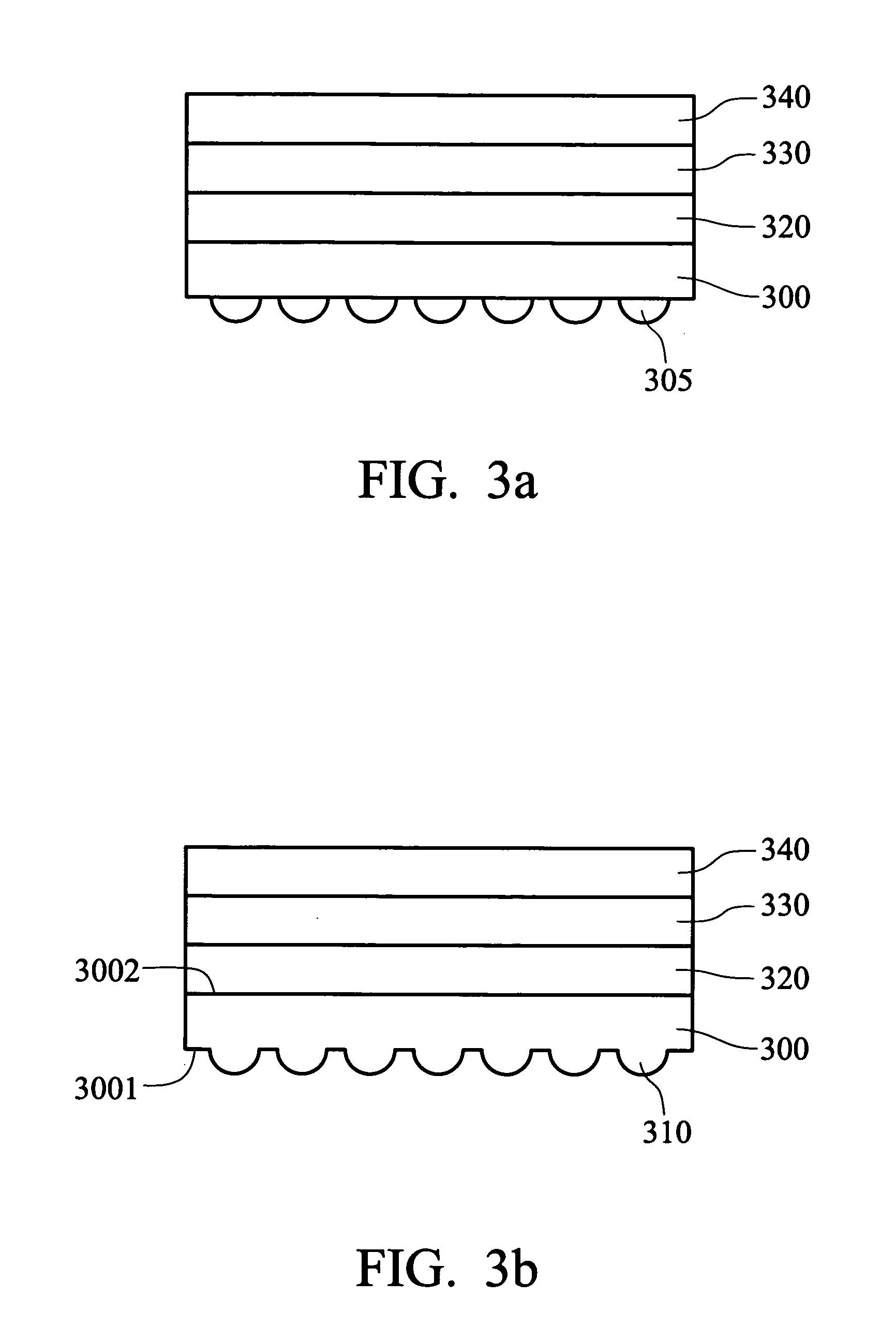

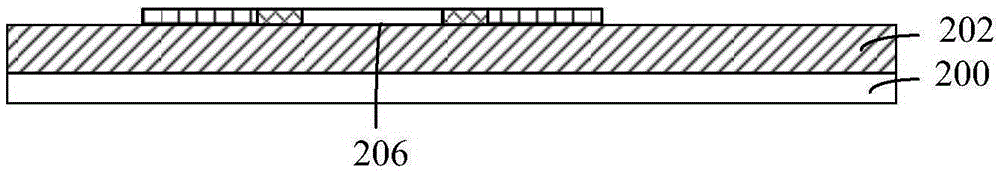

Polycrystalline silicon film, preparation method thereof, array substrate and display device

ActiveCN102856173ALarge grainUniform grain sizeSolid-state devicesSemiconductor/solid-state device manufacturingCharge carrierDisplay device

The invention discloses a polycrystalline silicon film and a preparation method thereof, an array substrate and a display device, belonging to the technical field of semiconductors. The preparation method of the polycrystalline silicon film comprises the following steps of: (1) forming a graphene layer and a noncrystalline silicon layer which are adjacent; and (2) enabling noncrystalline silicon to crystallize and form polycrystalline silicon and obtaining the polycrystalline silicon film. The polycrystalline silicon in the polycrystalline silicon film has the advantages of no pollution and low defect density, the crystal grain size of the polycrystalline silicon is uniform in size, the arrangement is ordered, the crystal grain is larger, and further the surface flatness is better. The speed rate of current carriers in the polycrystalline silicon film prepared by the method is increased, and the element performance of a polycrystalline silicon film transistor is improved.

Owner:BOE TECH GRP CO LTD

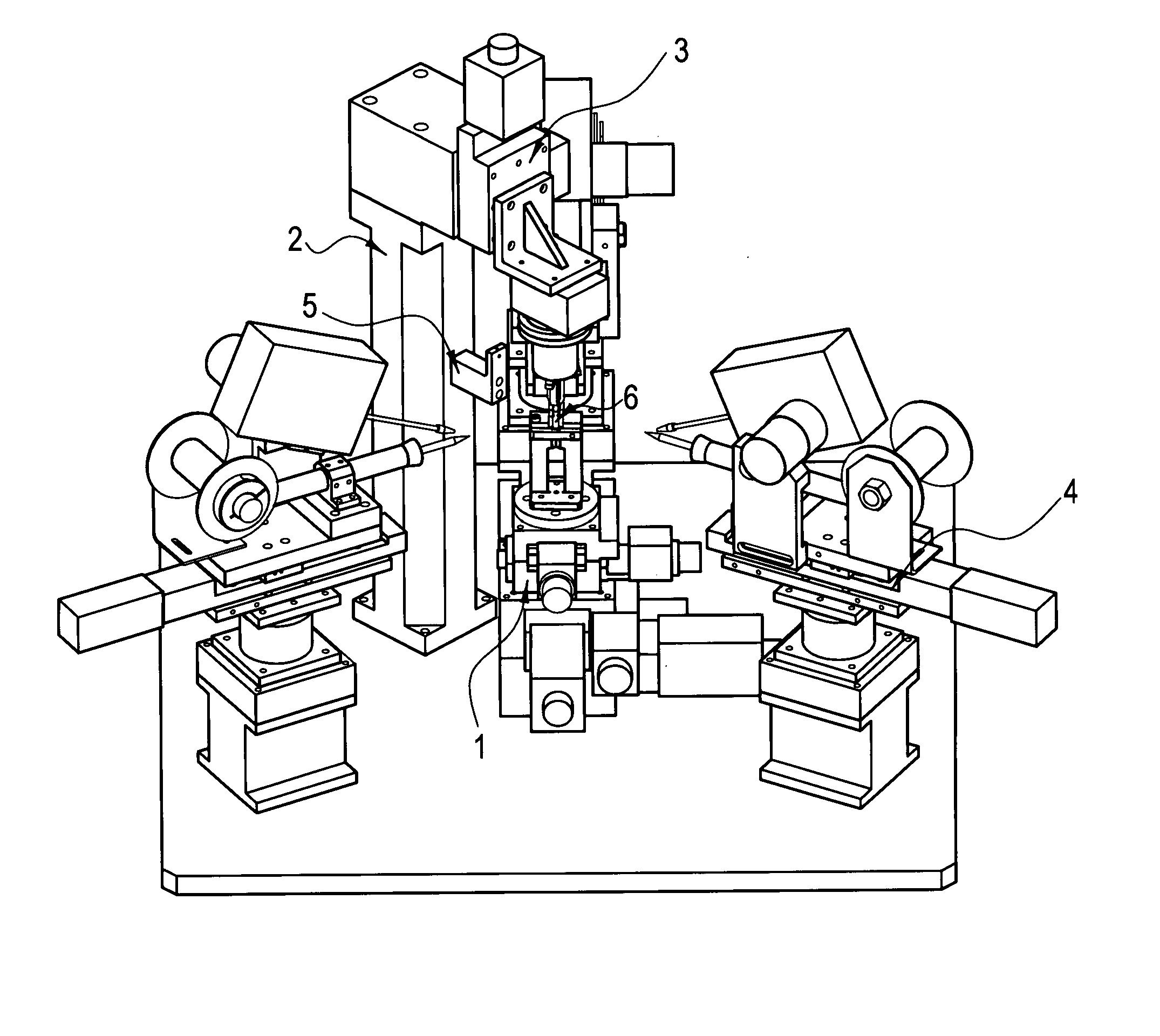

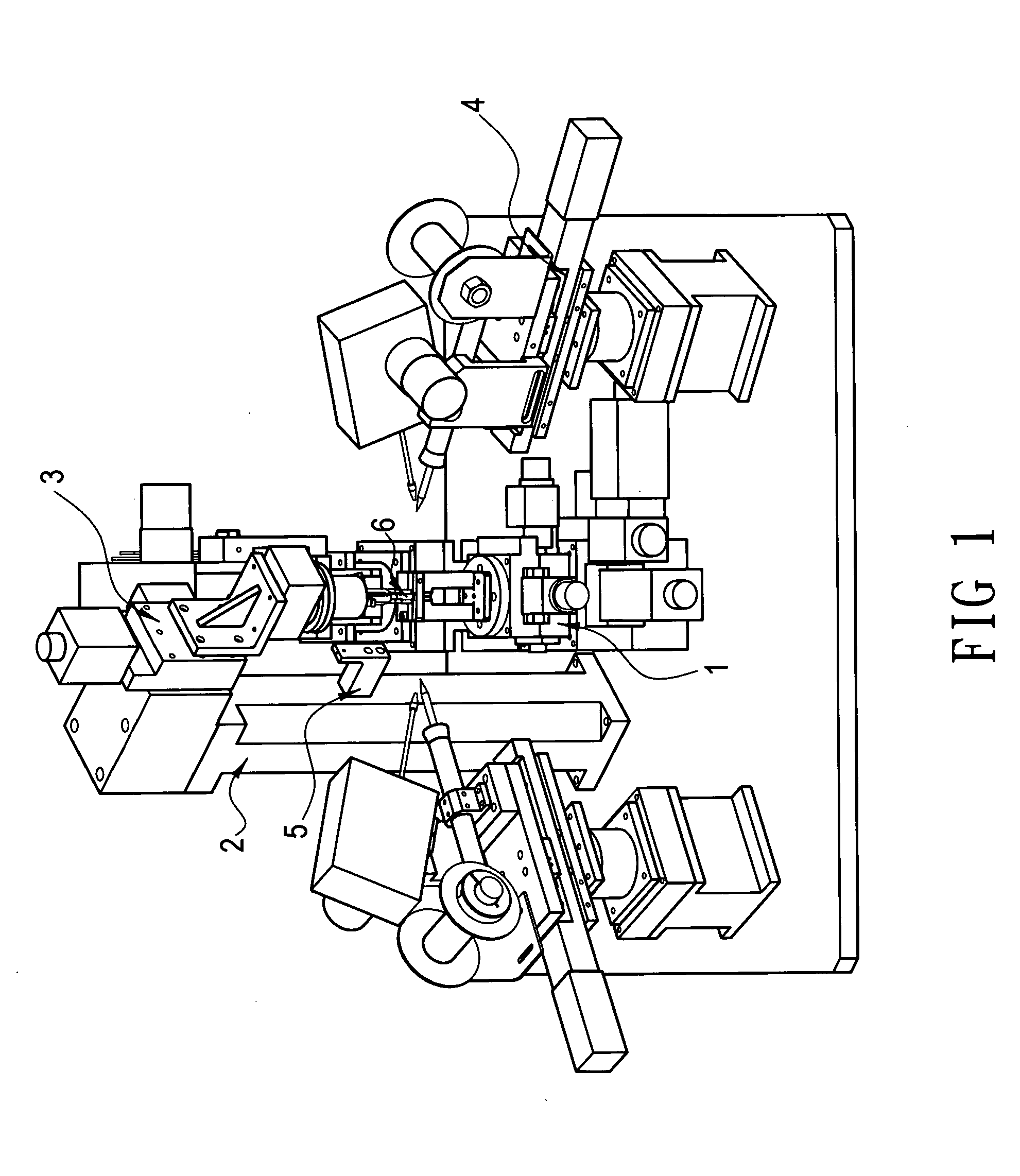

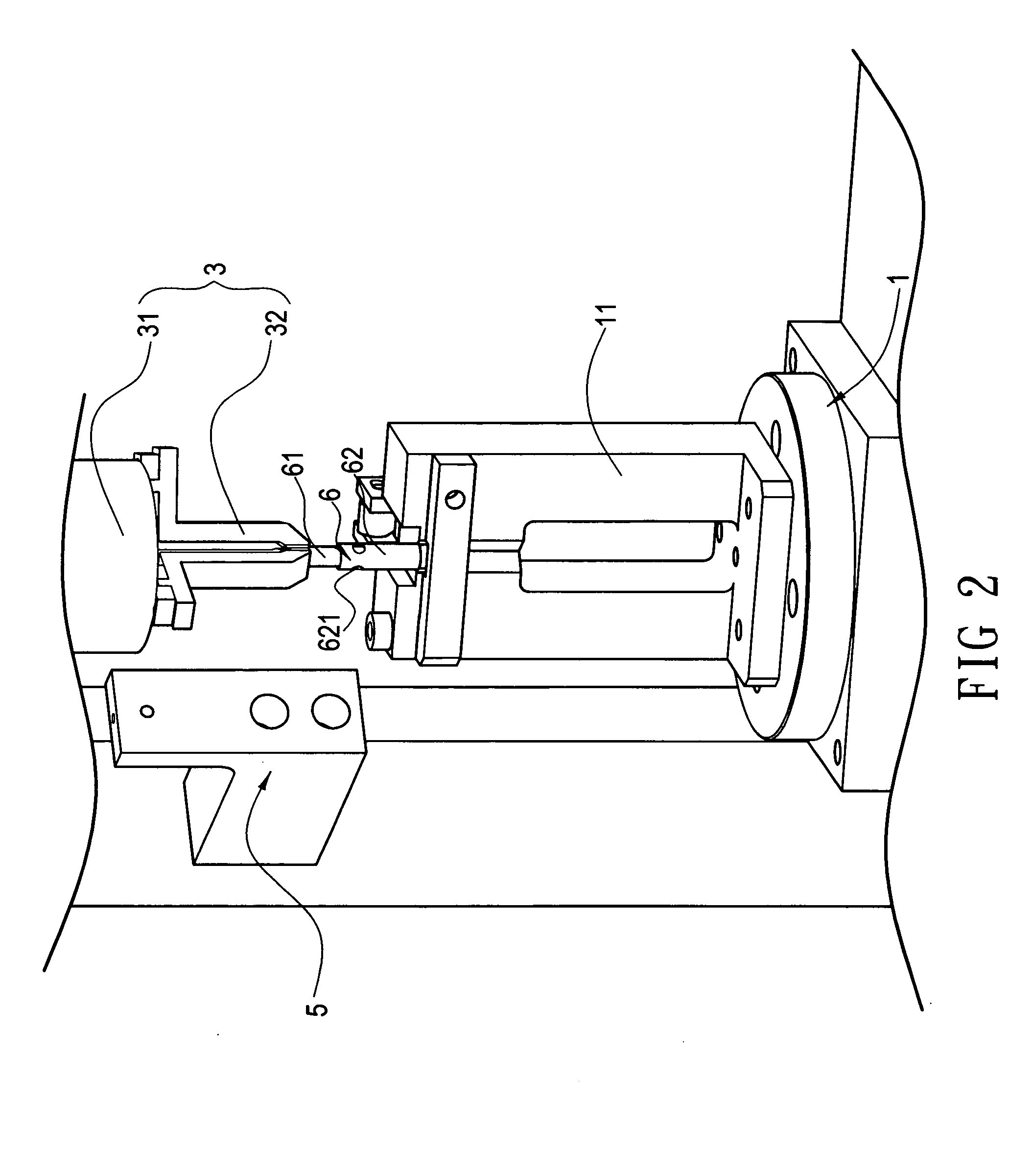

Automated packaging apparatus and method of optical elements

InactiveUS20050139638A1Efficient solutionMinimize thermal strainWelding/cutting auxillary devicesAuxillary welding devicesEngineering

Owner:IND TECH RES INST

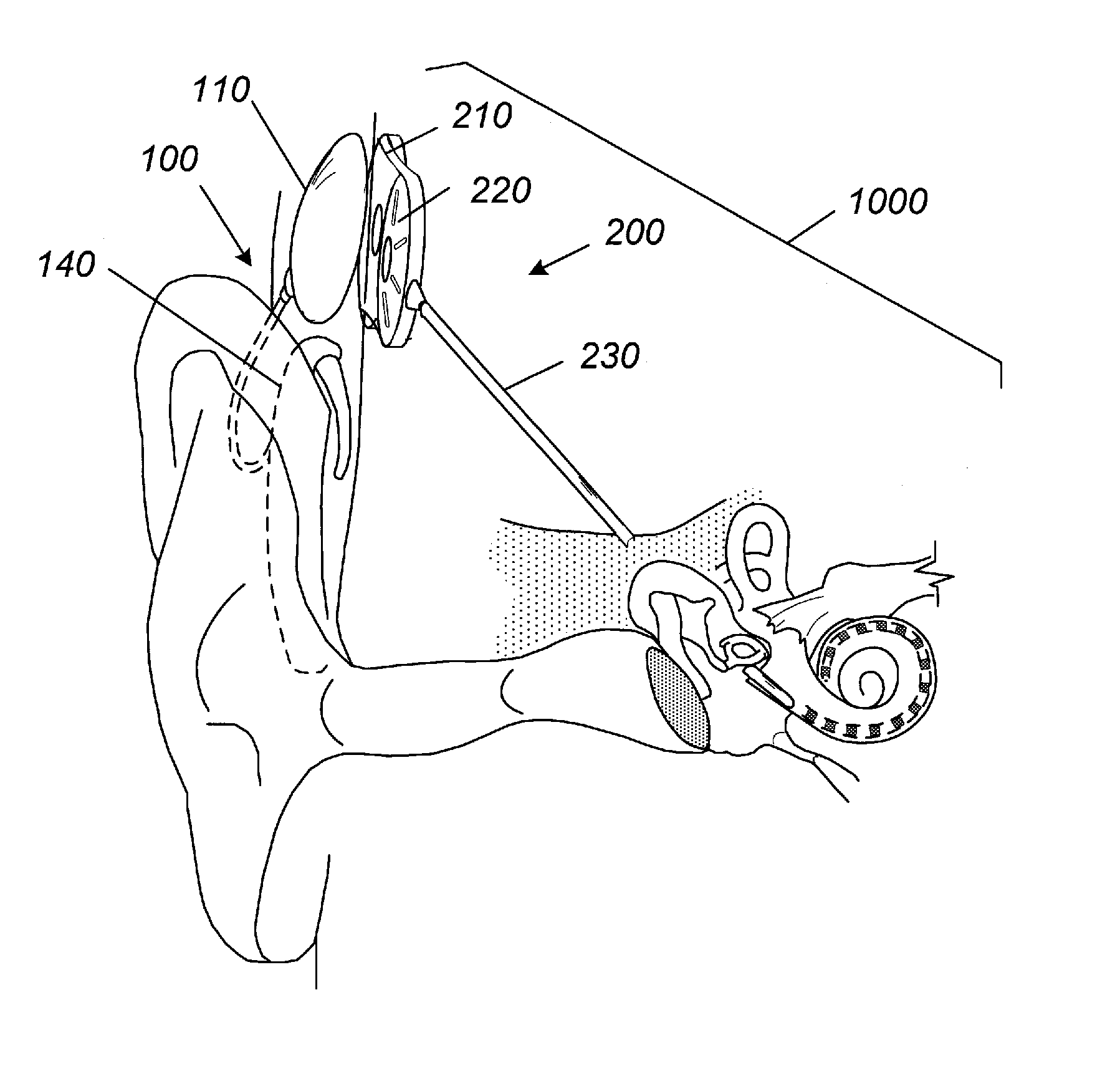

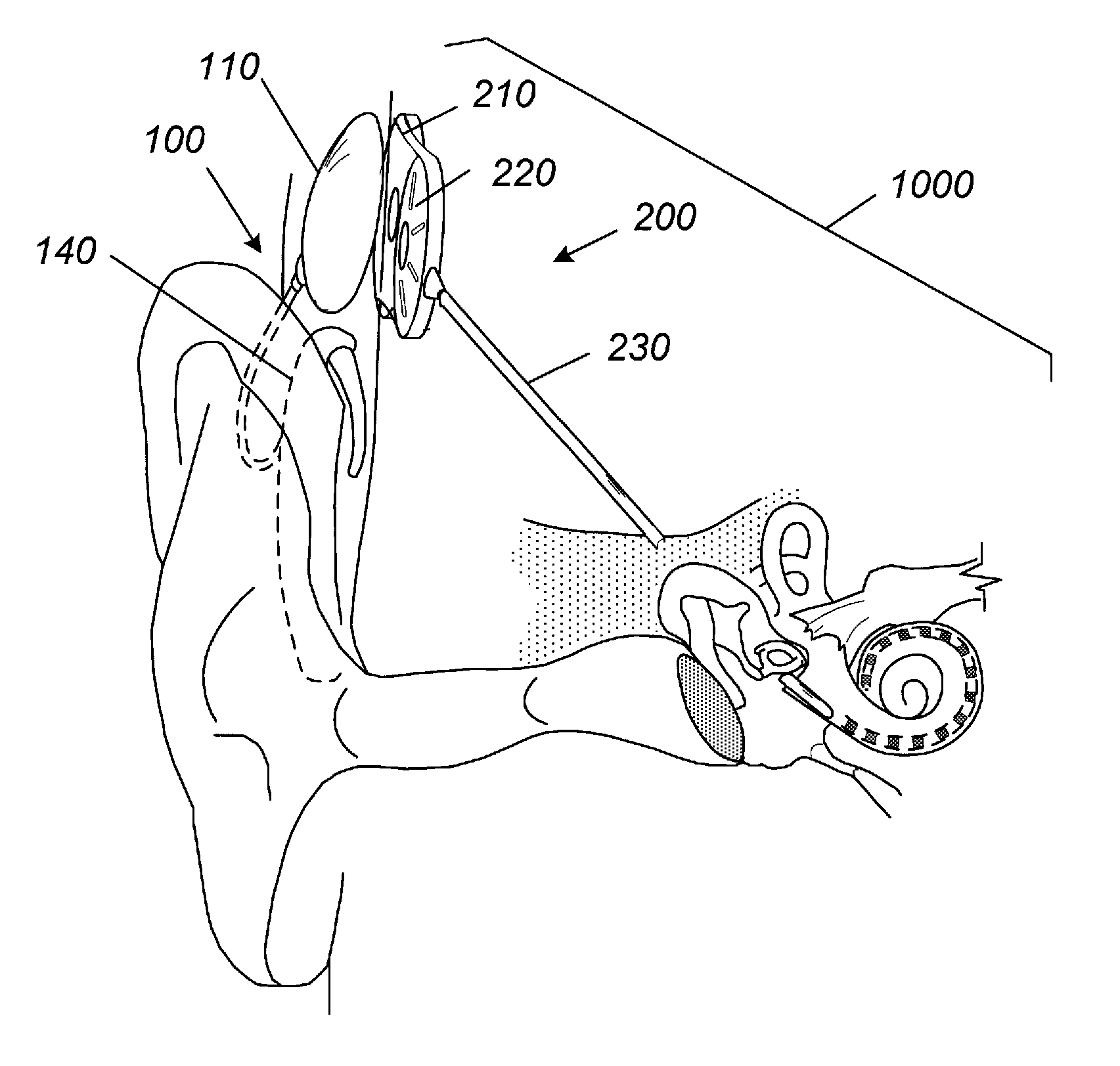

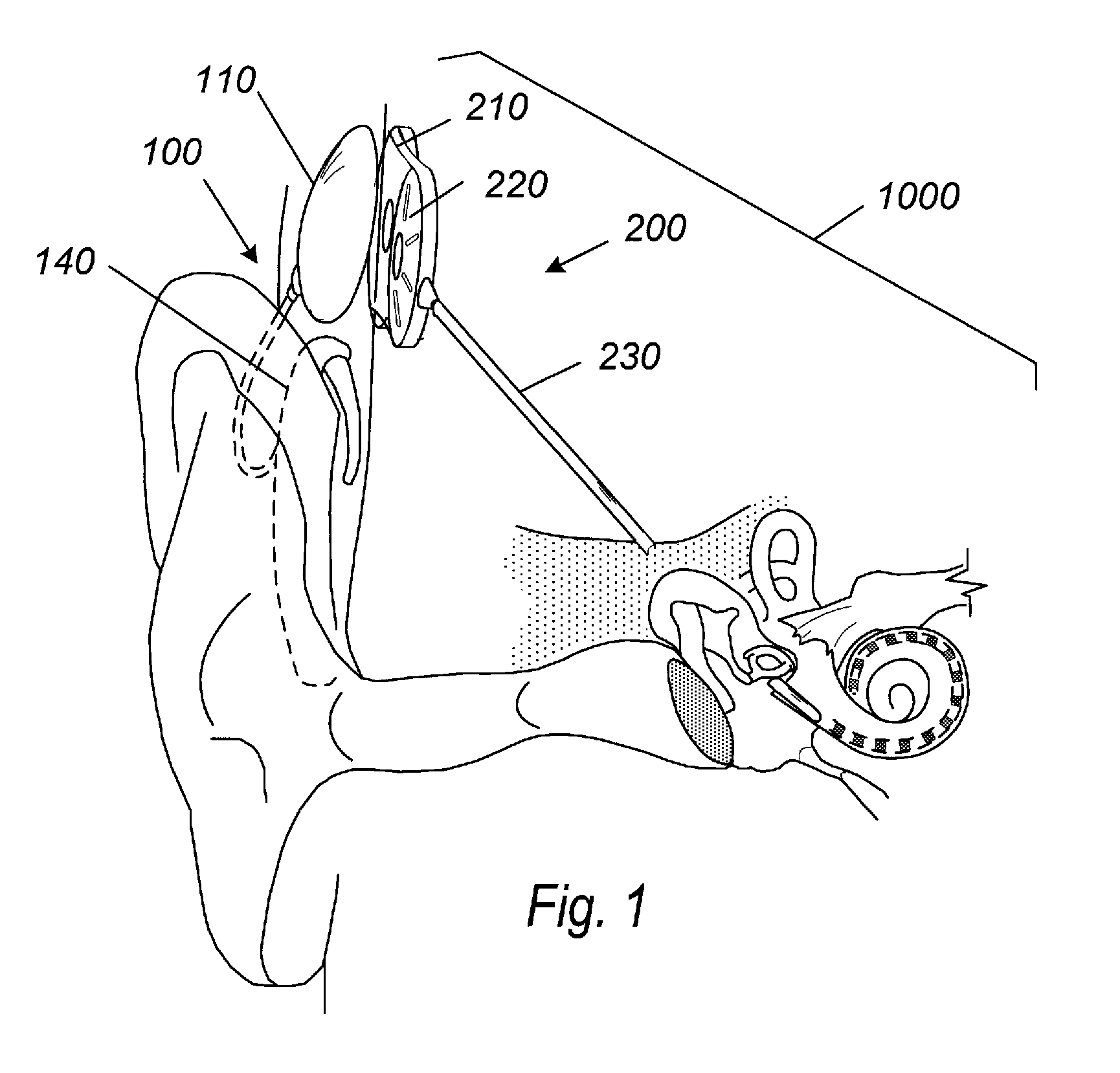

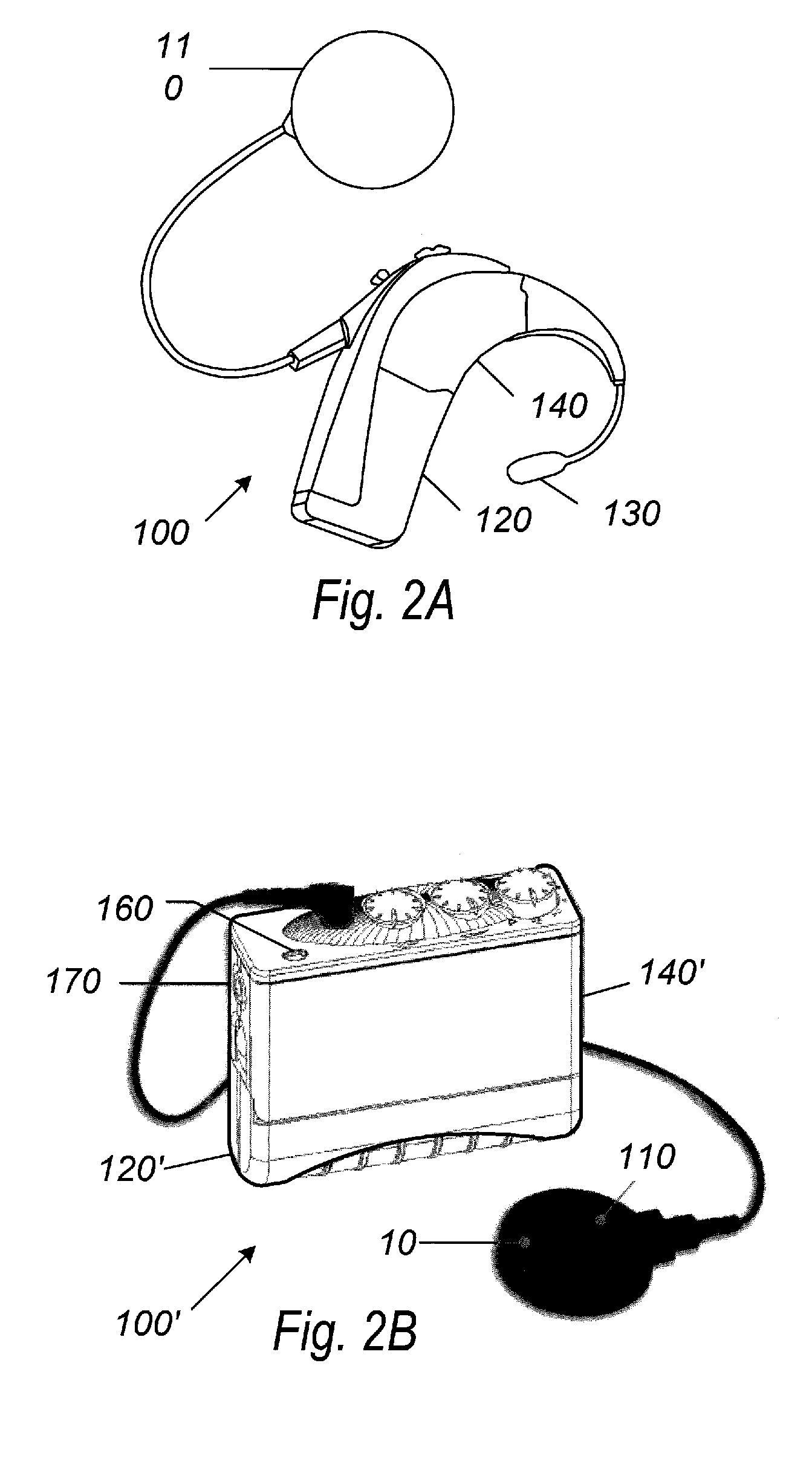

Waterproof acoustic element enclosures and apparatus including the same

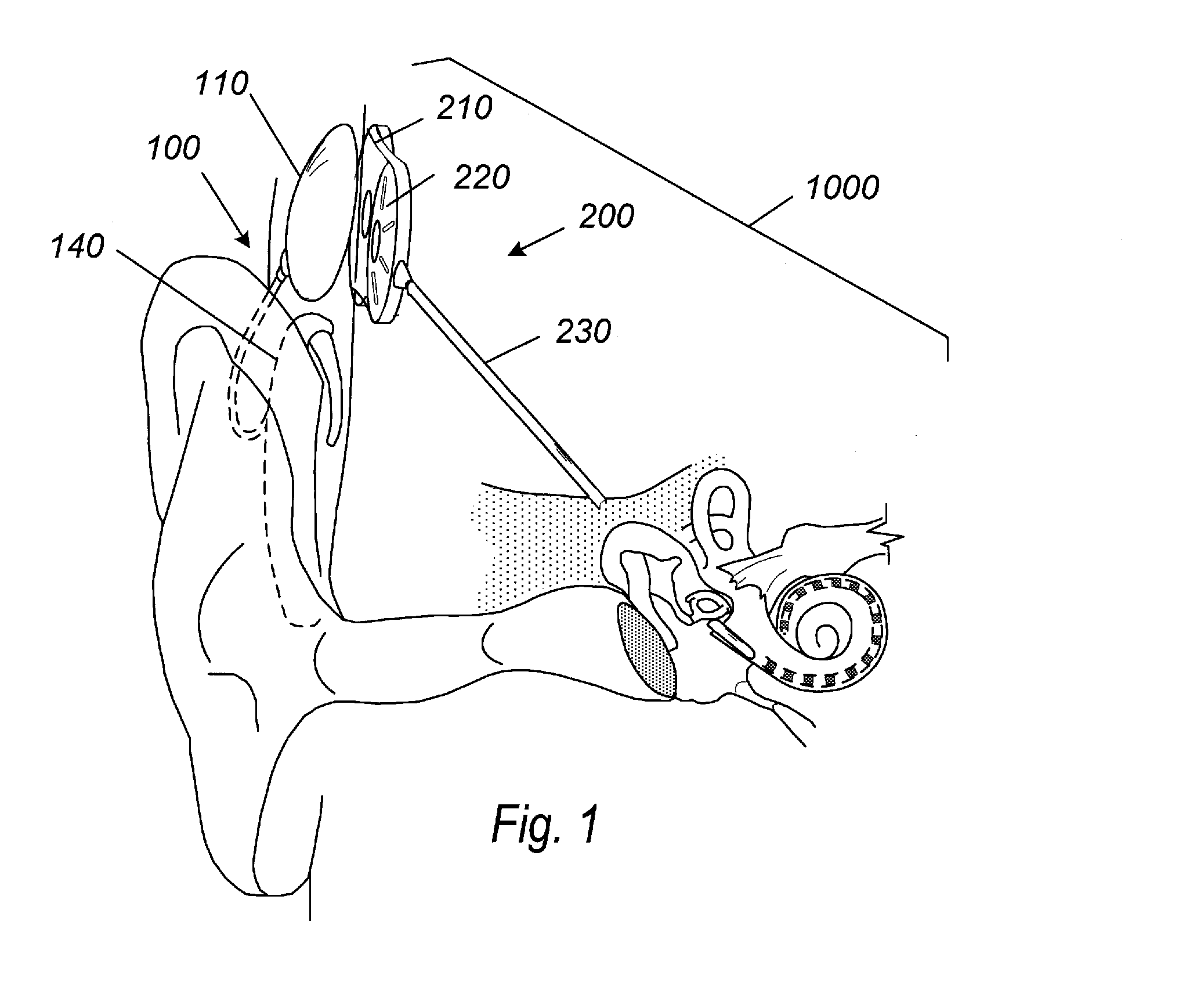

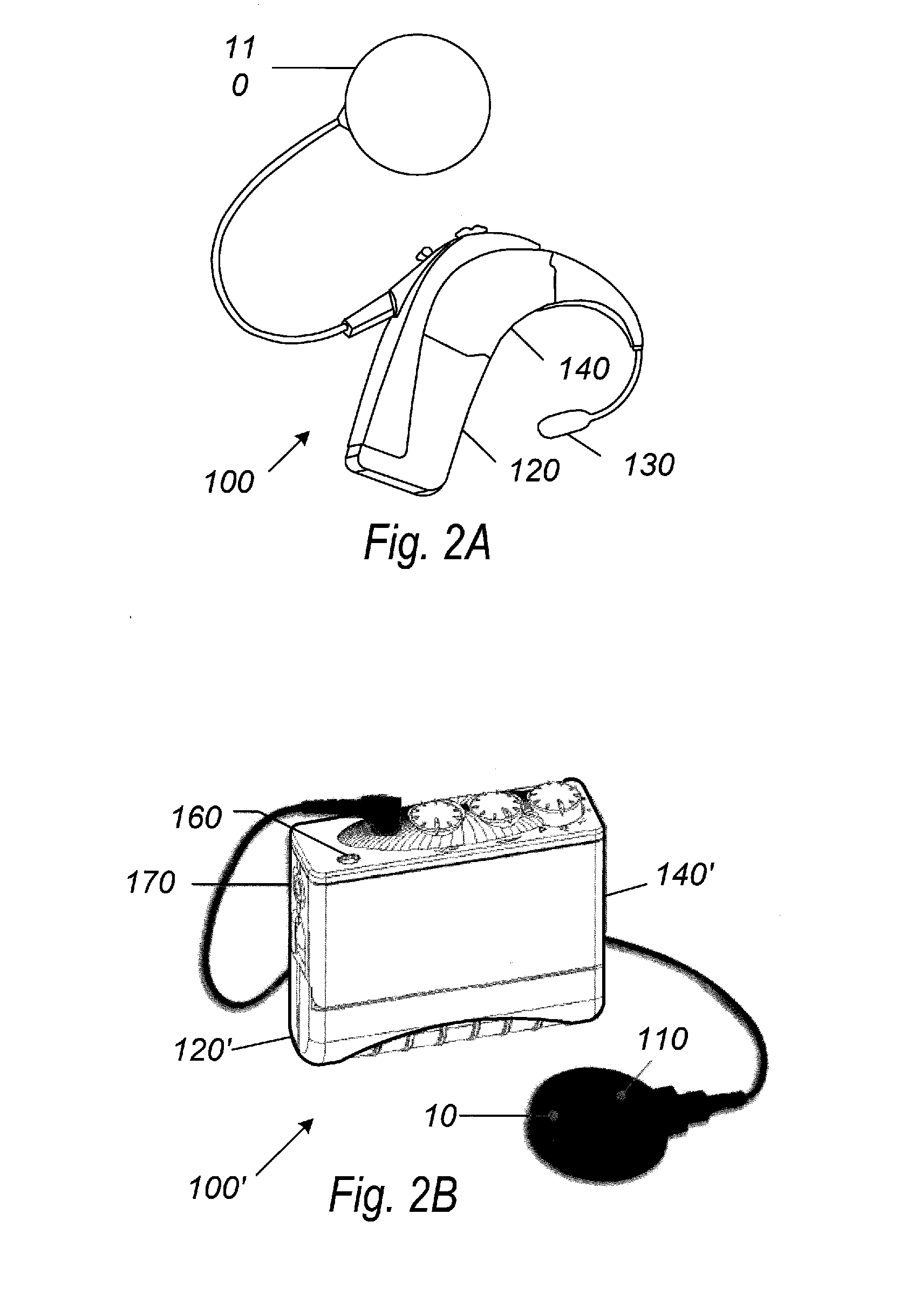

ActiveUS20130010992A1Minimize performance variationOptimize acoustic element performanceHead electrodesImplantable hearing aidsTectorial membraneEngineering

A waterproof enclosure for a cochlear implant system or other hearing assistance device includes an outer housing, an inner support in the interior of the outer housing, an acoustic element supported by the inner support, and water-impermeable polymeric protective membrane sealing the interior of the outer housing against water ingress. A hearing device such as a cochlear implant sound processor, a headpiece, an earhook, or a hearing aid comprises an outer housing, an inner support in the interior of the outer housing, a microphone supported by the inner support, and a water- impermeable polymeric protective membrane sealing the interior of the outer housing against water ingress. A method for waterproofing an acoustic element comprises molding an outer support having a water-impermeable polymeric protective membrane; inserting an acoustic element into an inner support; anchoring the acoustic element to the inner support; inserting the inner support into the outer support; and anchoring the inner support to the outer support.

Owner:ADVANCED BIONICS AG

Graphene-containing electrochemical device

InactiveCN104577129AImprove component performanceImprove conductivityHybrid capacitor electrodesElectrode carriers/collectorsMetal foilElectrochemistry

A graphene-containing electrochemical device includes cathode / anode current collectors, cathode / anode active layers and a separator. The cathode / anode active layers are formed on the cathode / anode current collectors, and include a metal foil substrate and a graphene conductive layer. The graphene conductive layer includes several first graphene sheets and the polymer binder used to bind the first graphene sheets. The cathode / anode active layers include several second graphene sheets and cathode / anode active particles. The second graphene sheets and the cathode / anode active particles are bound by the polymer binder and further adhered to the graphene conductive layer. The second graphene sheets are blended among the cathode / anode active particles. The graphene conductive layer is employed to increase the compatibility between the cathode / anode active material and the metal foil substrate, and to reduce the junction resistance, thereby forming an integrated conductive network and improving the performance of the elements in the device.

Owner:ENERAGE INC

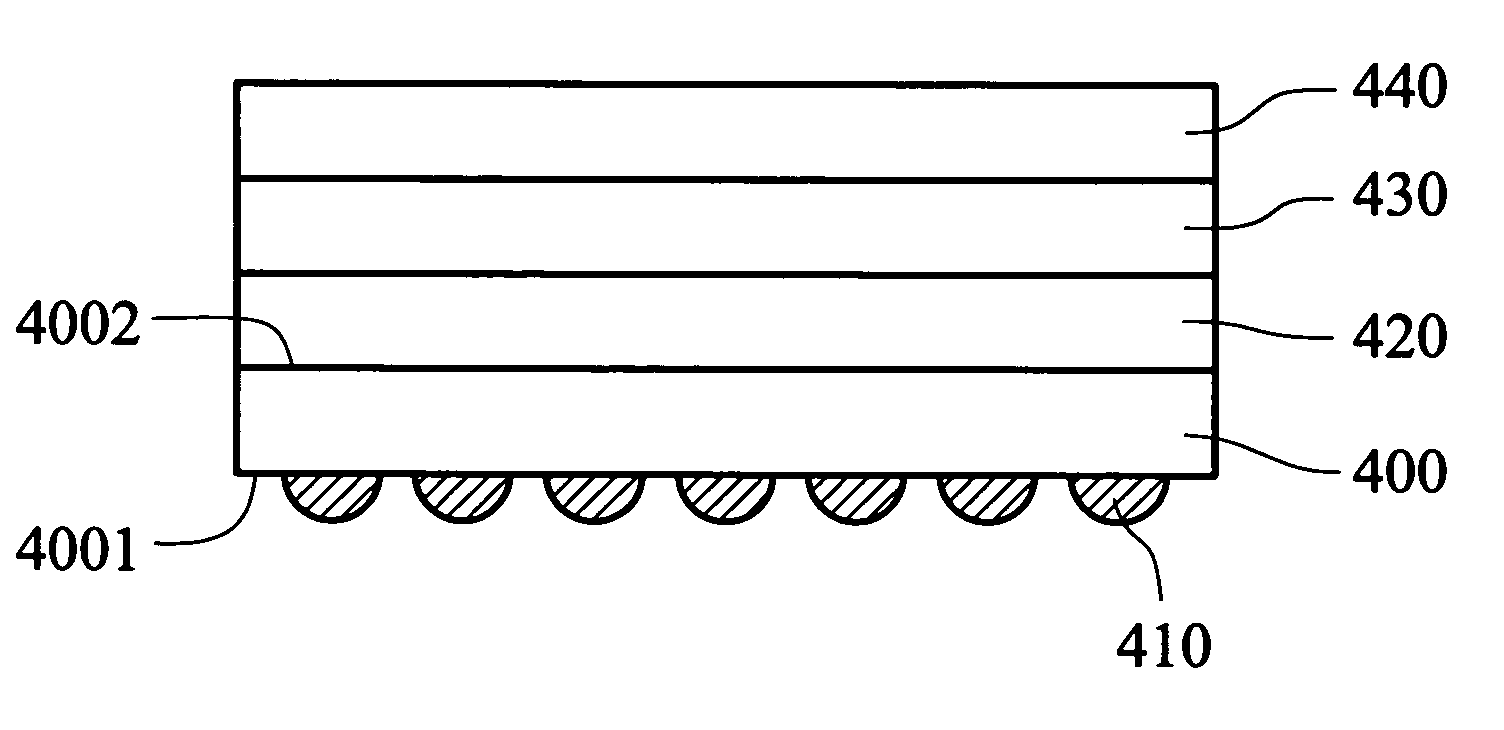

Organic light-emitting diode and method of fabricating the same

ActiveUS7205714B2Reduce reflectionImprove component performanceDischarge tube luminescnet screensElectroluminescent light sourcesLight-emitting diodeOLED

An organic light-emitting diode and method of fabricating the same. The organic light-emitting diode includes a substrate having a plurality of protrusions on a first plane thereof, a first electrode installed on a second plane of the substrate, wherein the second plane is opposed to the first plane, an organic light-emitting layer installed on the first electrode, and a second electrode installed on the organic light-emitting layer.

Owner:XIAMEN TIANMA DISPLAY TECH CO LTD

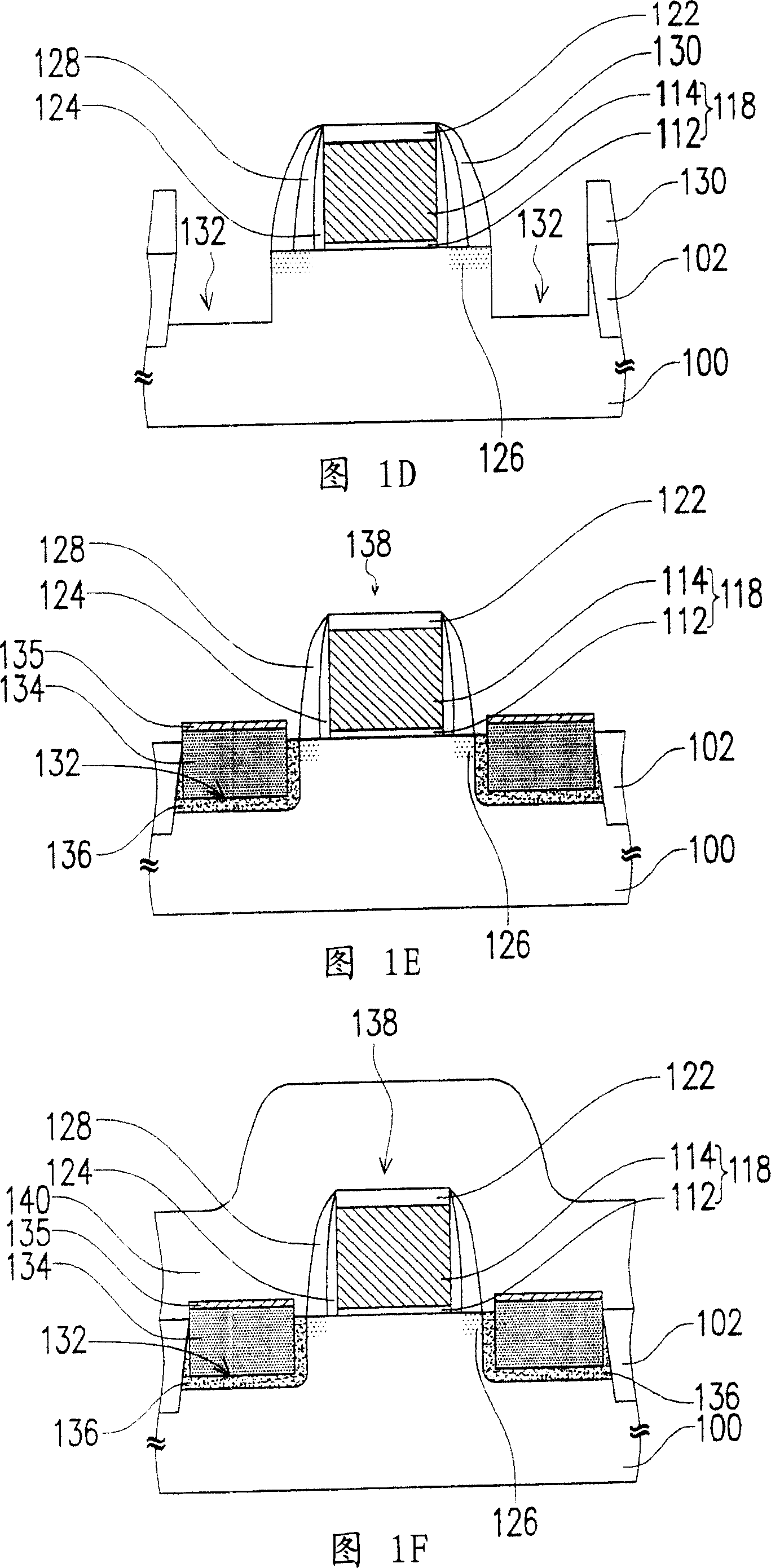

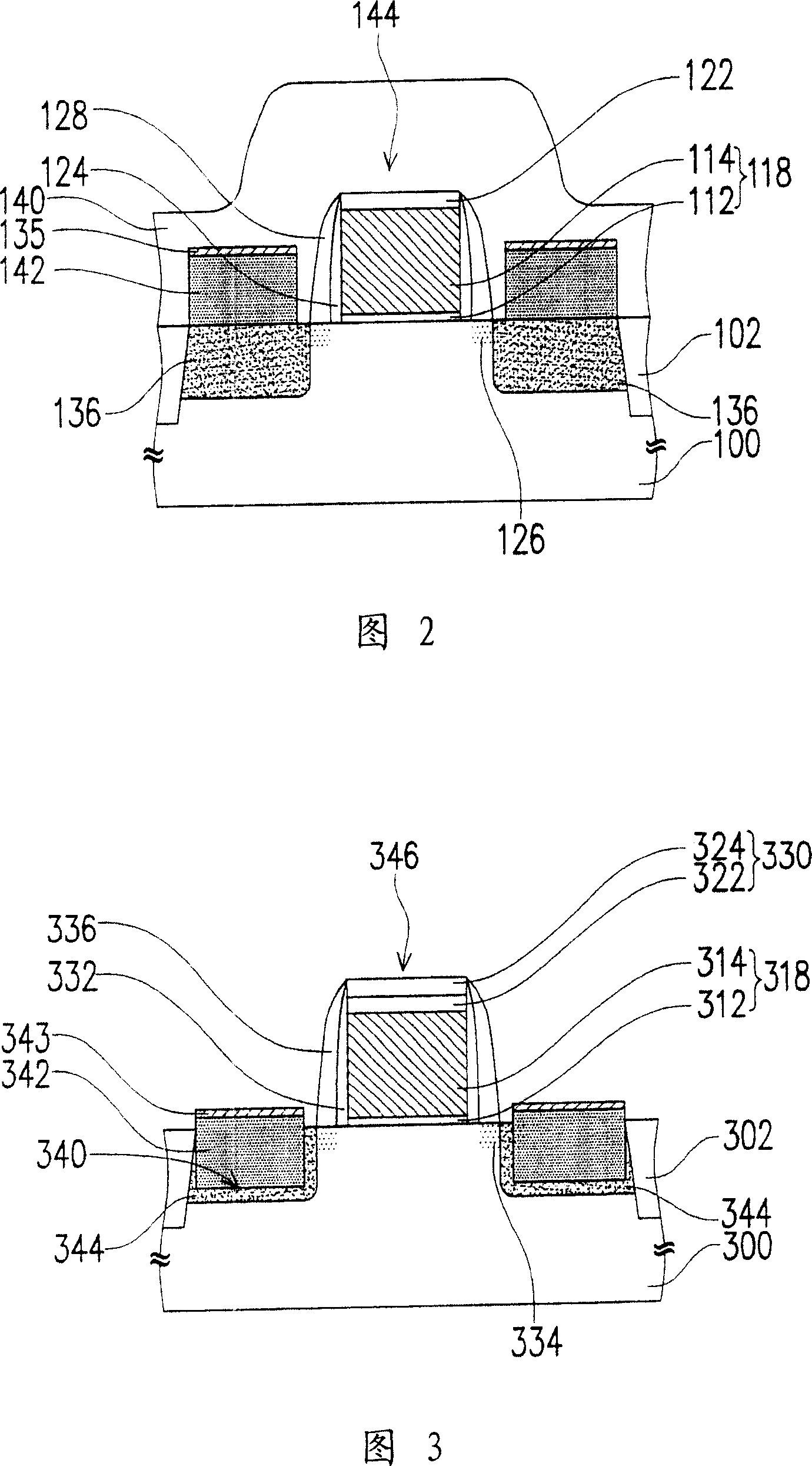

Metal-isolator-metal transformer and its manufacturing method

ActiveCN101047059AImprove coupling coefficientImprove component performanceTransformers/inductances coils/windings/connectionsFixed transformers or mutual inductancesTransformerMetal

The present invention relates to a method for manufacturing transformer of metal-insulant-metal. It is applicable to simultaneously form-metal-insulant-metal capacitor and transformer. Said manufacture method includes the following steps: firstly providing a base plate on which a dielectric layer is formed, then forming a patterned first metal layer of metal-insulant-metal capacitor on said base plate, simultaneously forming first metal coil of transformer, then forming an insulating layer for covering base plate, first metal layer and first metal coil, then forming patterned second metal layer or metal-insulant-metal capacitor on the insulating layer, at same time forming second metal coil of transformer.

Owner:UNITED MICROELECTRONICS CORP

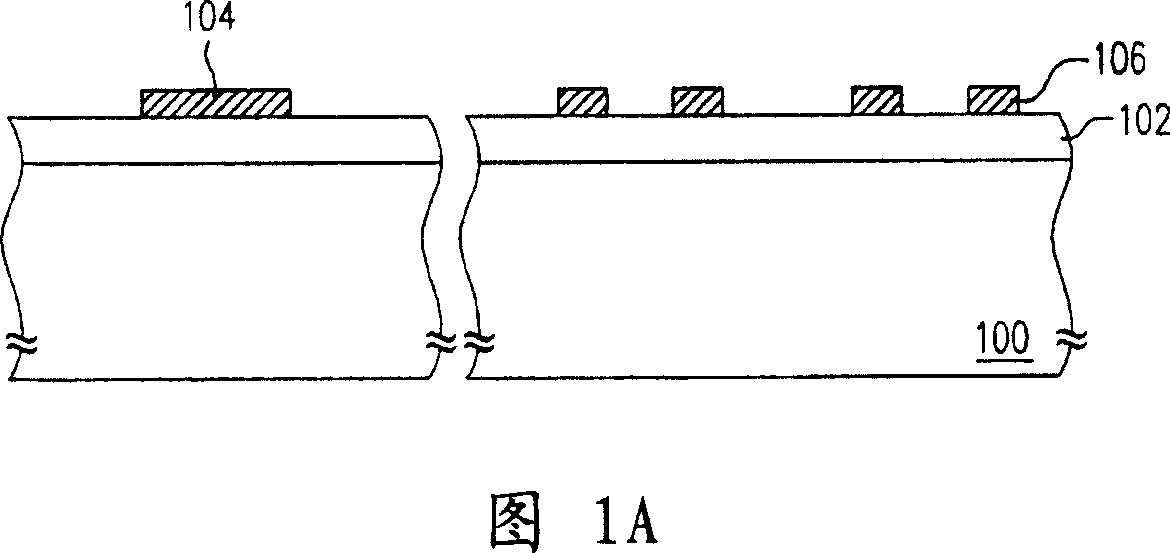

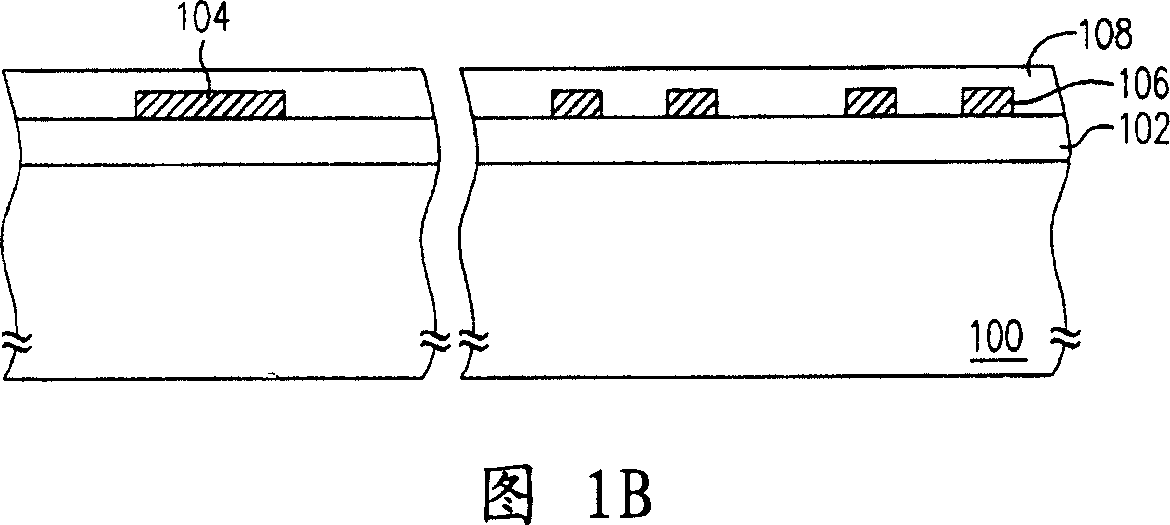

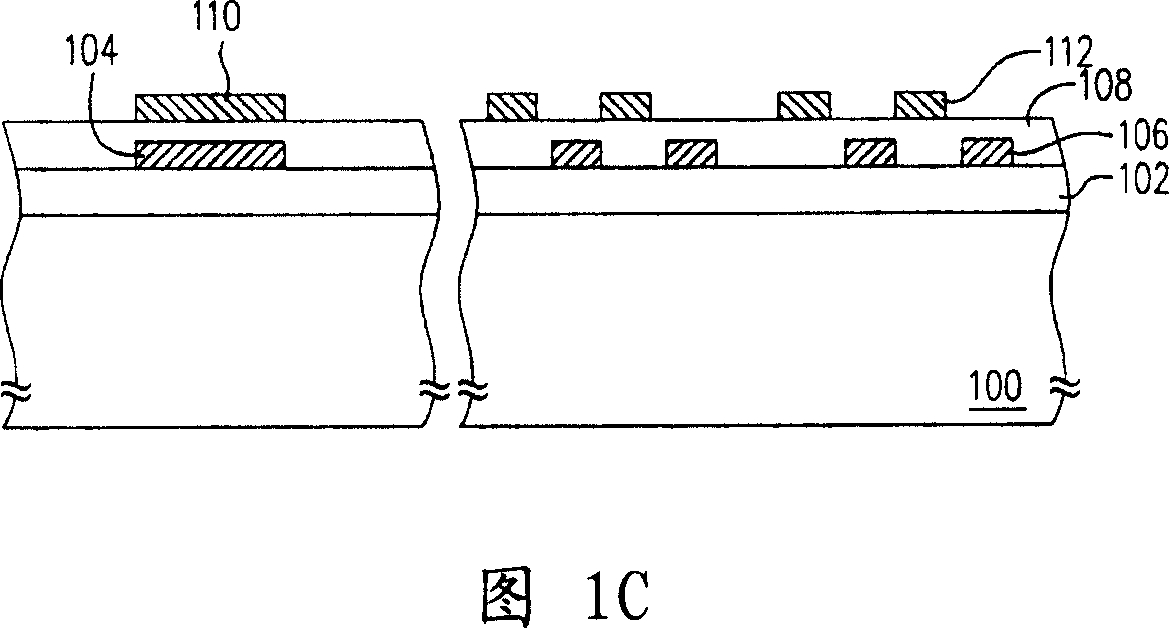

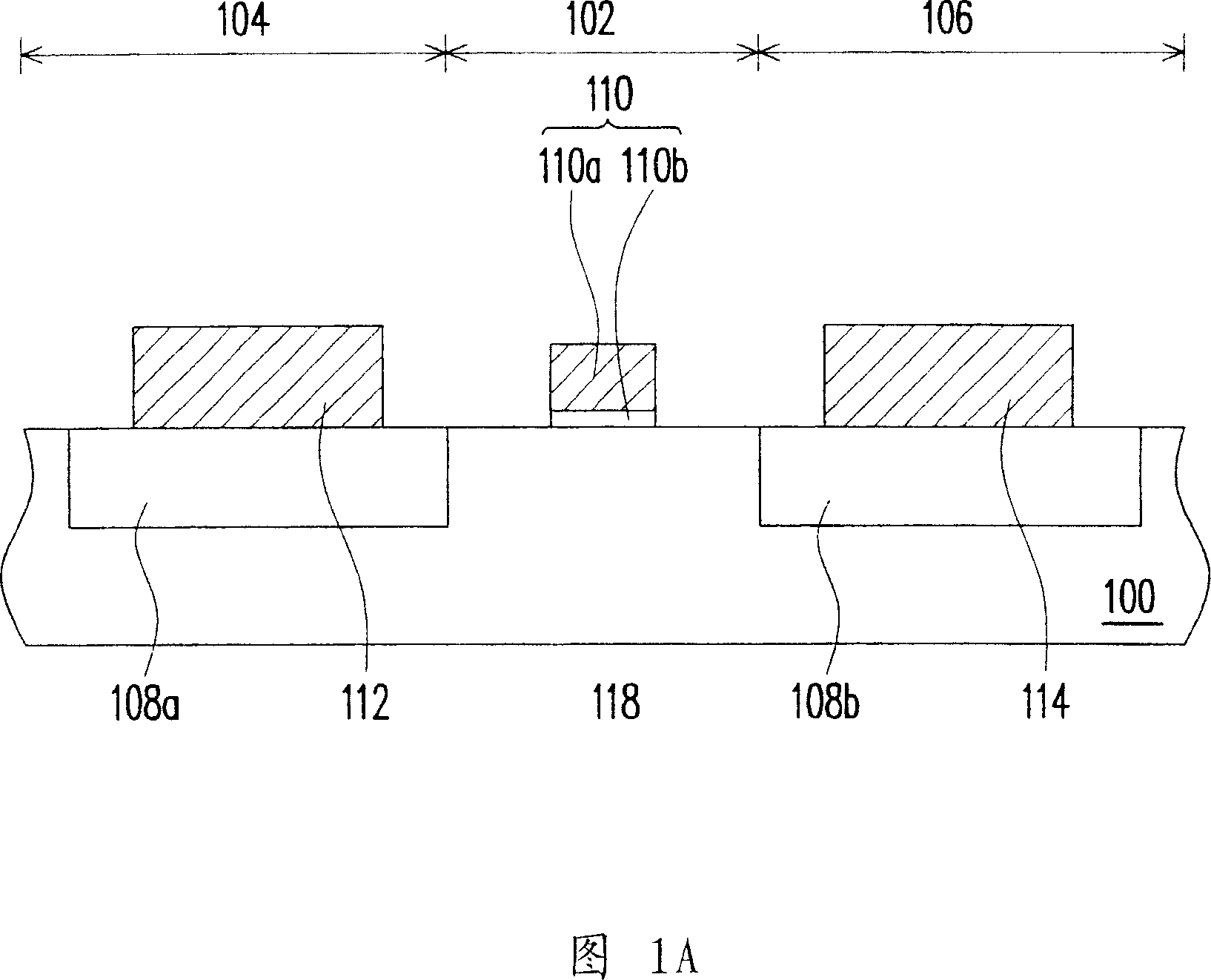

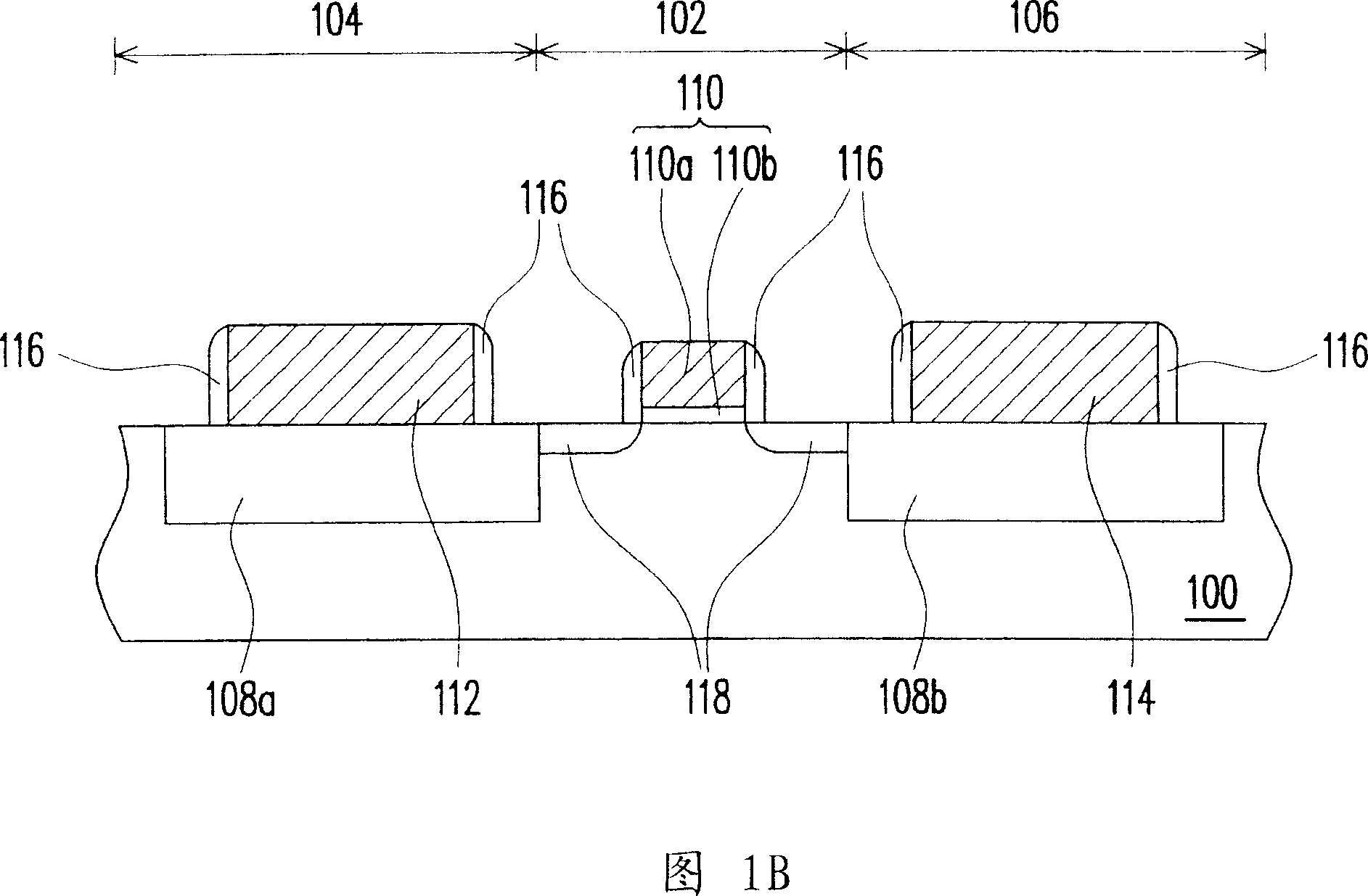

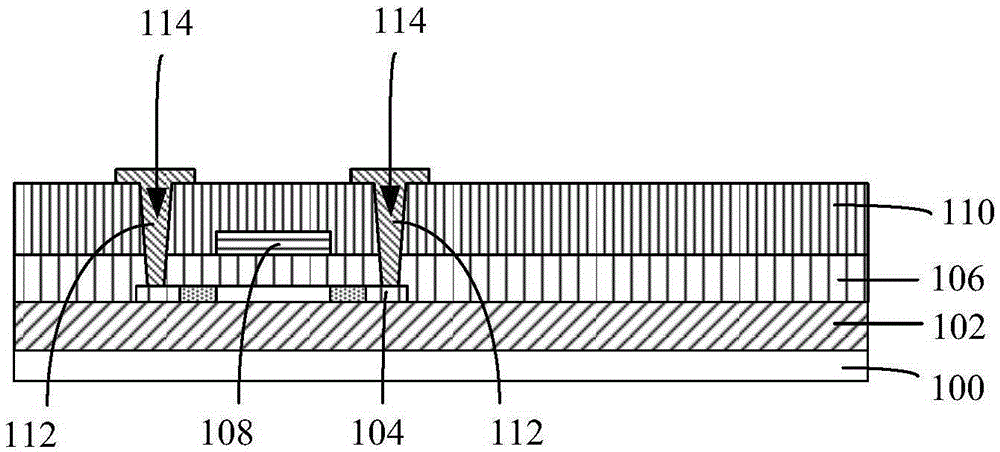

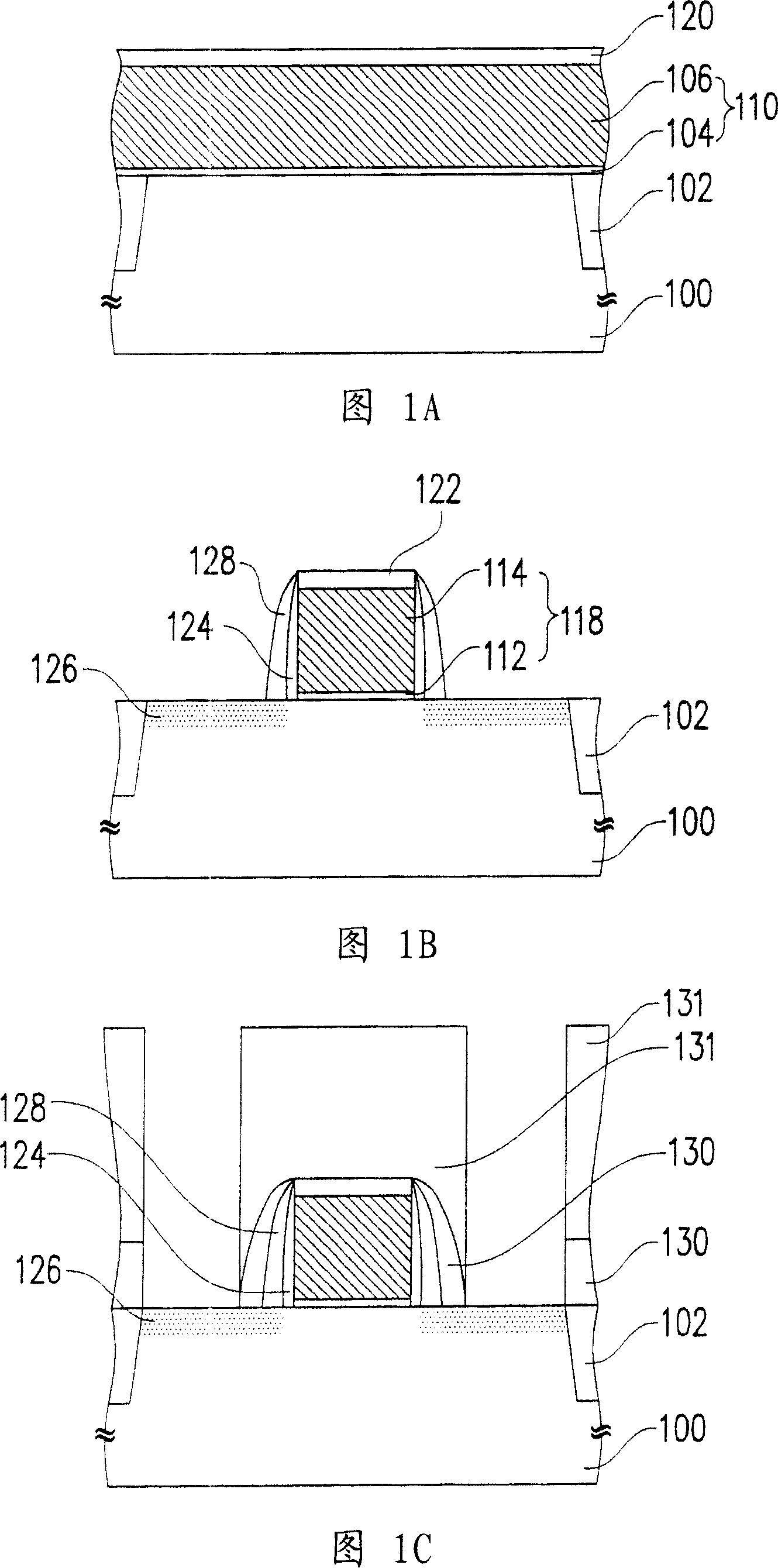

Semiconductor component and its making method

ActiveCN101118873AImprove accuracyImprove component performanceSolid-state devicesSemiconductor/solid-state device manufacturingMetal silicideConductive materials

The present invention relates to a method for manufacturing semiconductor component. The method includes the step as follows: first providing a substrate which consists of a transistor area containing grid structure, a capacitor area containing an electrode 1 and a resistor area containing a resistor 2. Wherein, both the capacitor area and the resistor area comprise separating structure; then, forming in order a source electrode or drain electrode area amid a spacer 1 and both ends of the grid; afterwards, constituting a dielectric layer and a conductive material layer 1 above the substrate; and then patterning conductor layer 1 so as to form an electrode 3 of the capacitor area and a conductor layer of the resistor area; forming a spacer 2; removing uncovered dielectric layer; after that, conducting the technique of autoregistration type metal silicide and forming a layer of metal silicide with the aim to cover surface of the component.

Owner:UNITED MICROELECTRONICS CORP

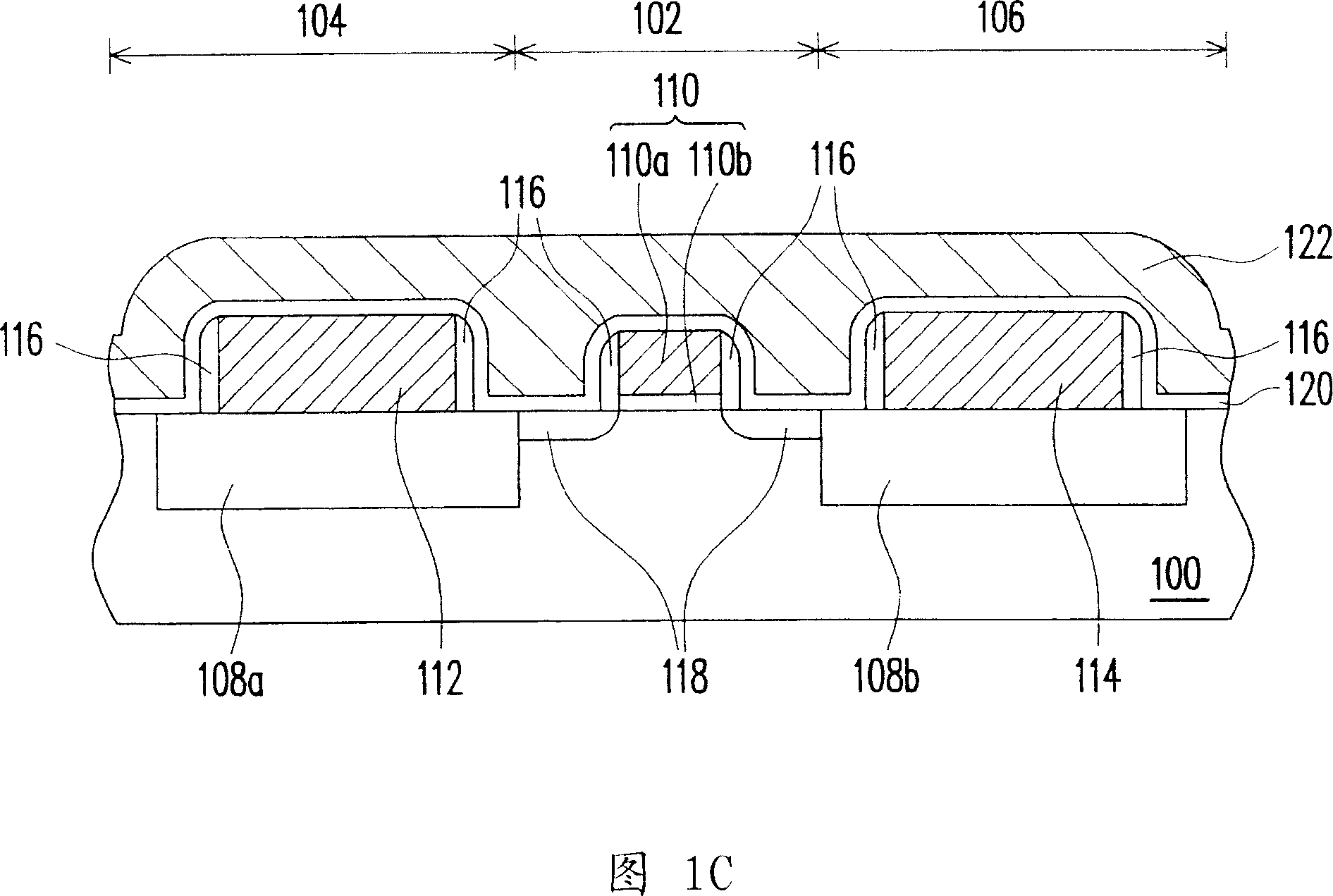

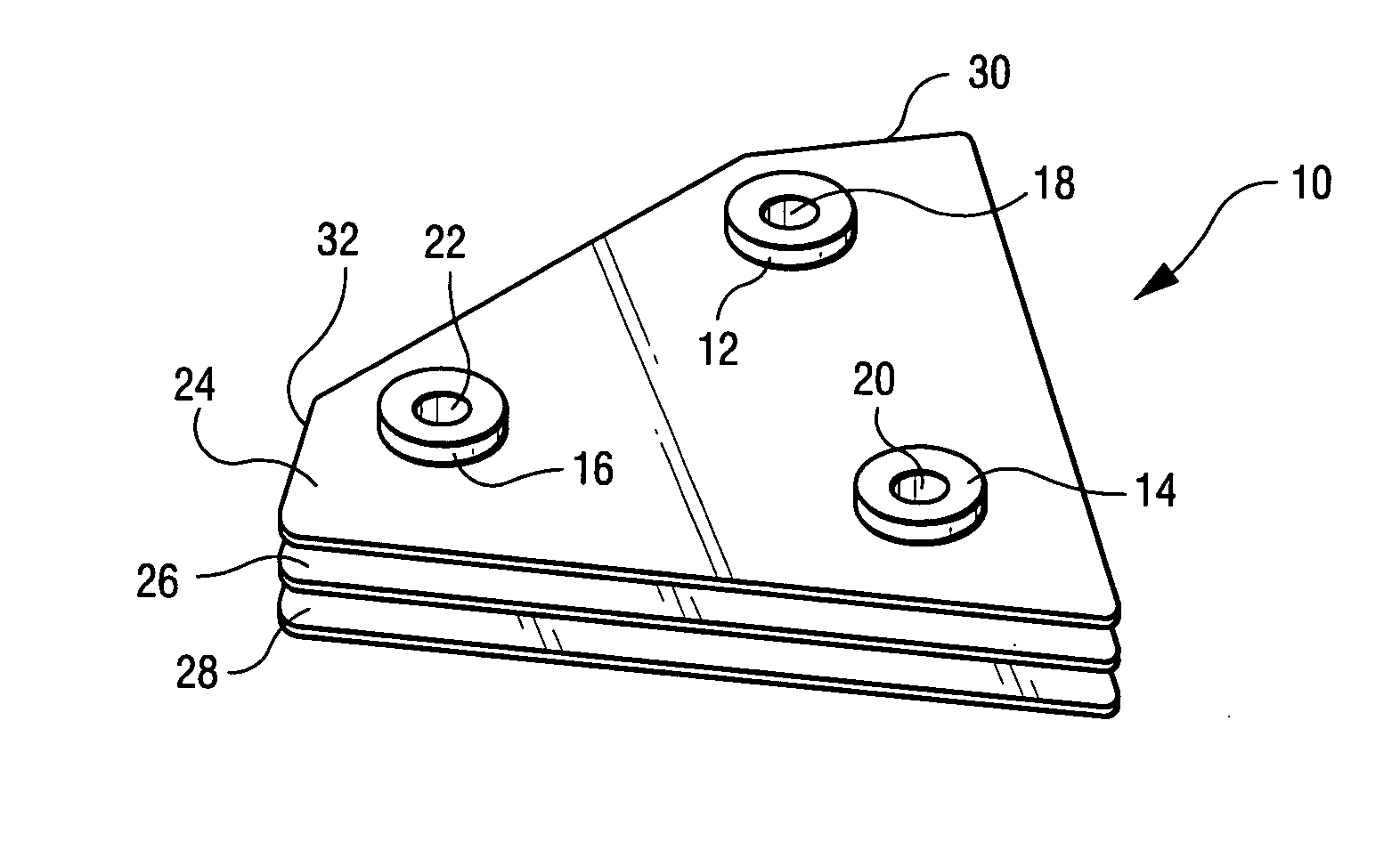

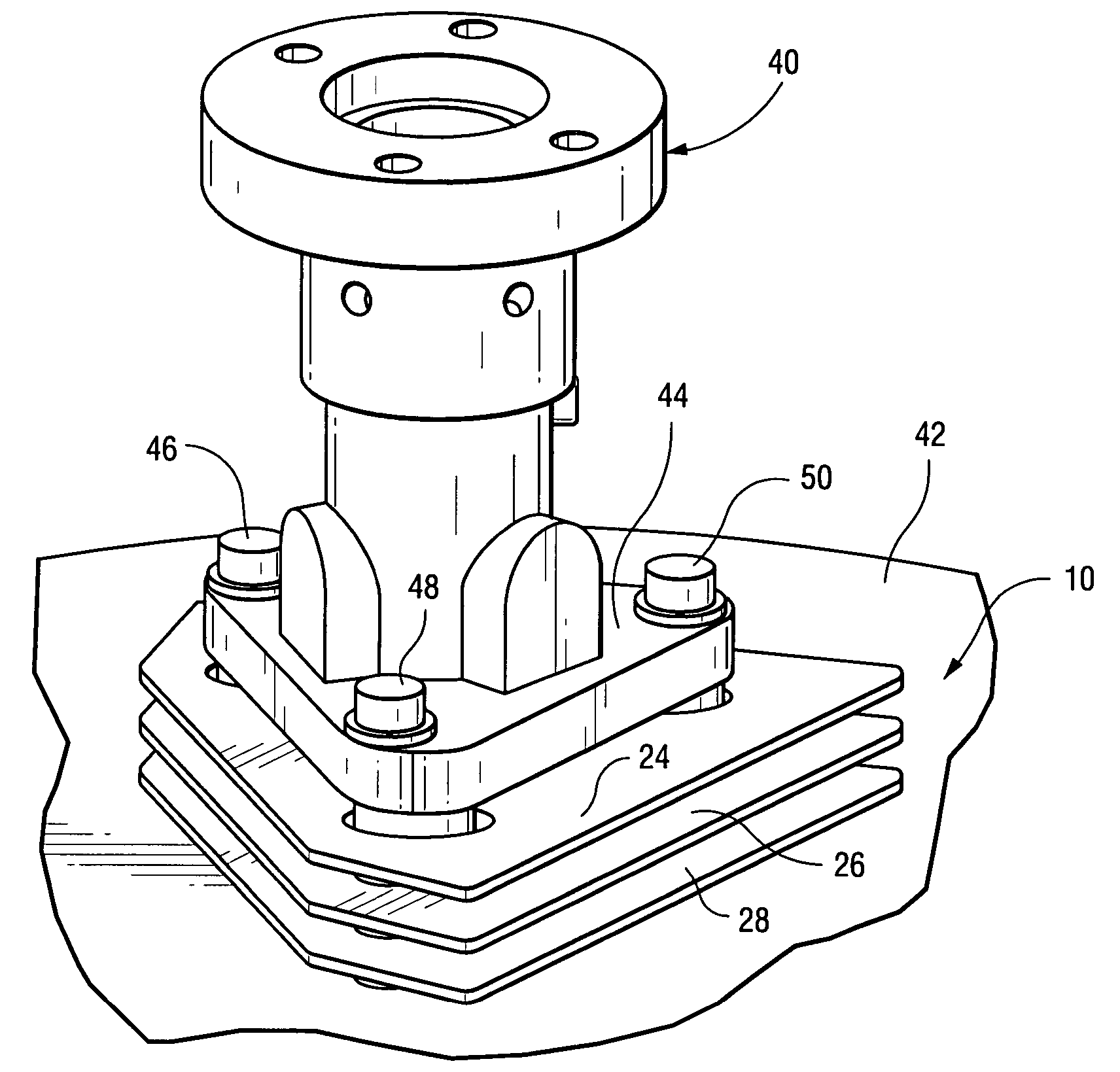

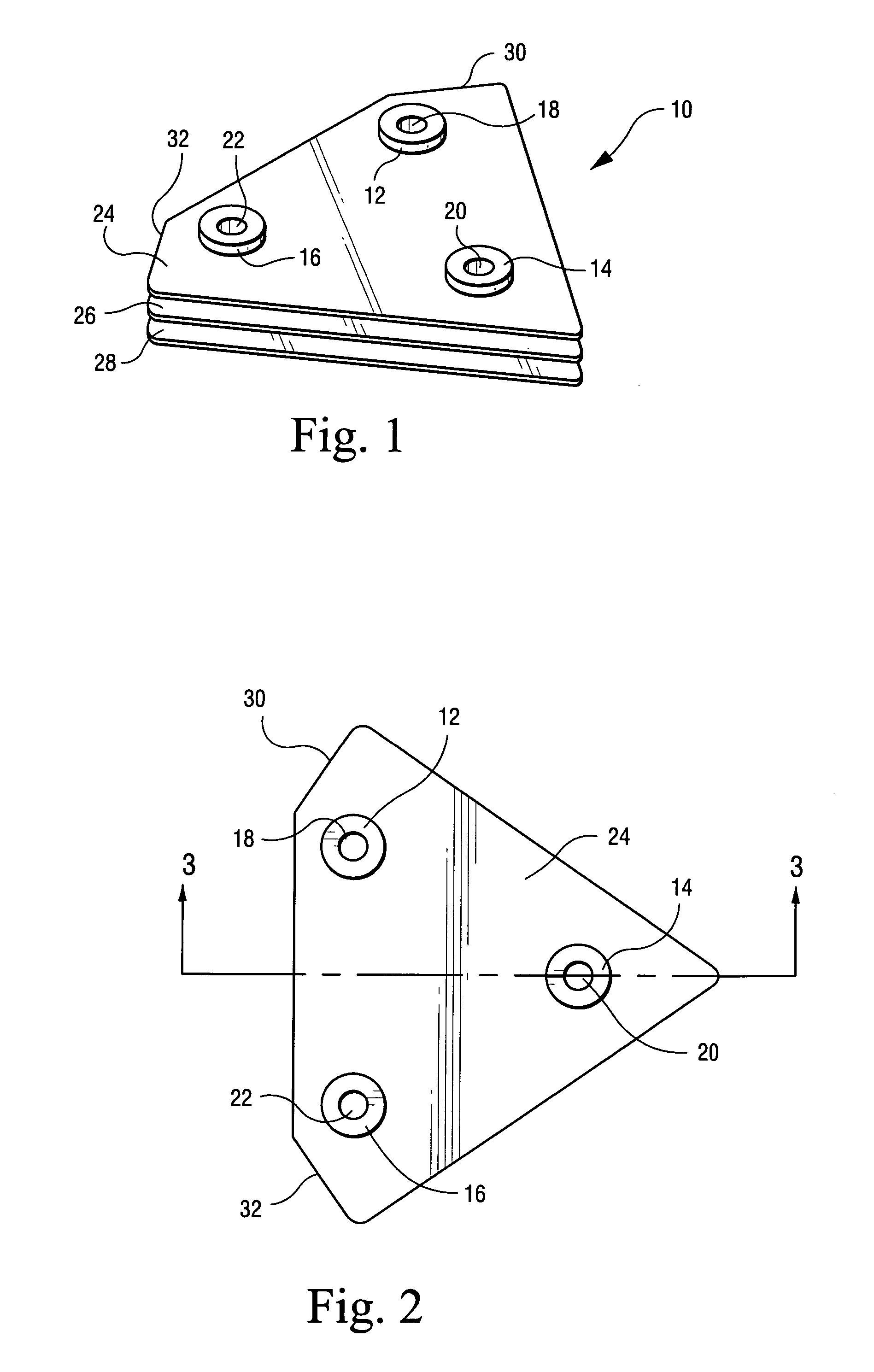

Thermal isolation device for liquid fuel components

InactiveUS20050022530A1Increase thermal resistanceReduce heat transferContinuous combustion chamberGas turbine plantsThermal isolationCombustor

A thermal isolation device for a gas turbine combustor assembly includes a plurality of substantially flat plates secured in spaced relationship by a plurality of columns, at least one column incorporating a bolt hole for use in securing the device between a pair of combustor components.

Owner:GENERAL ELECTRIC CO

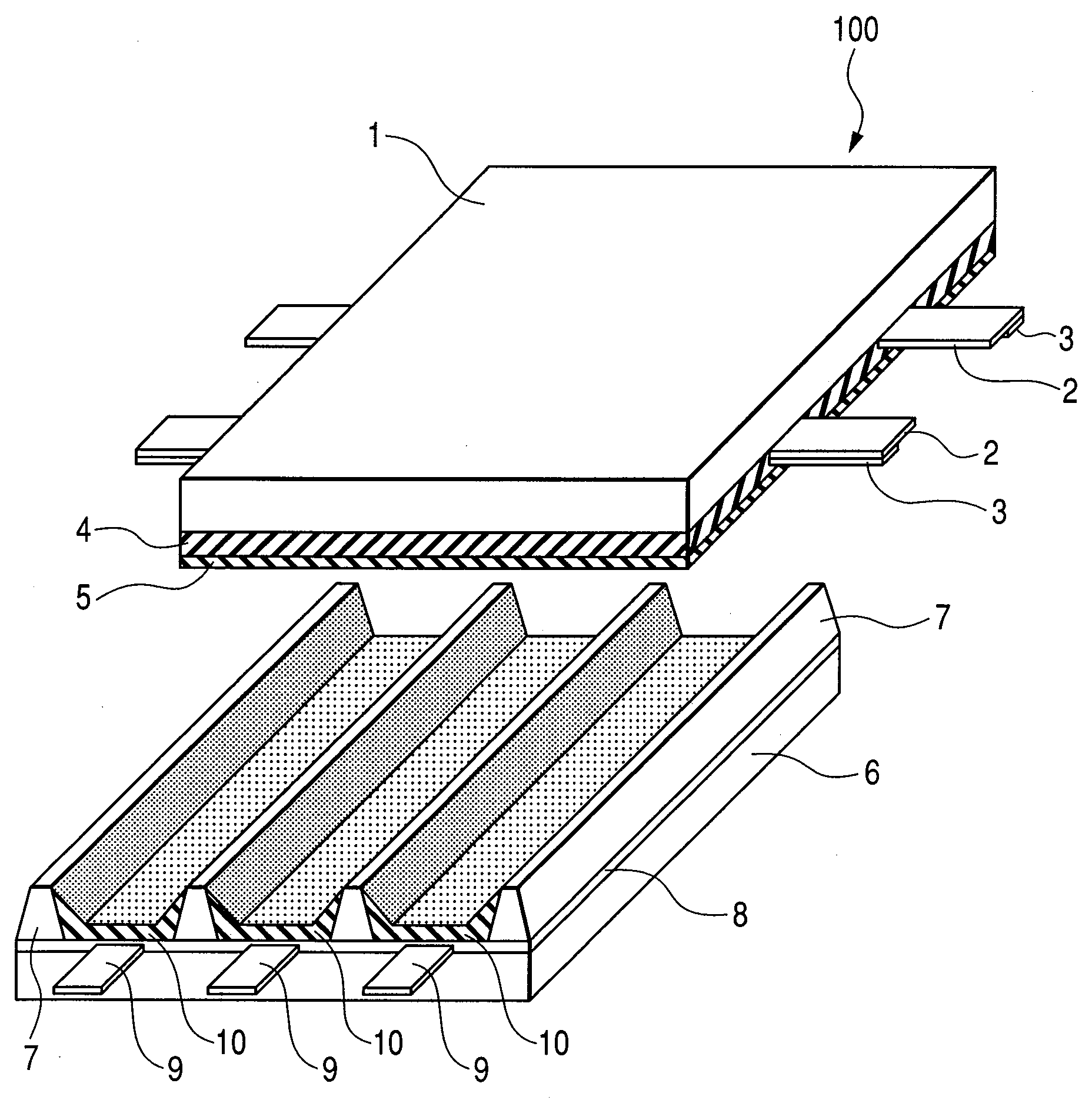

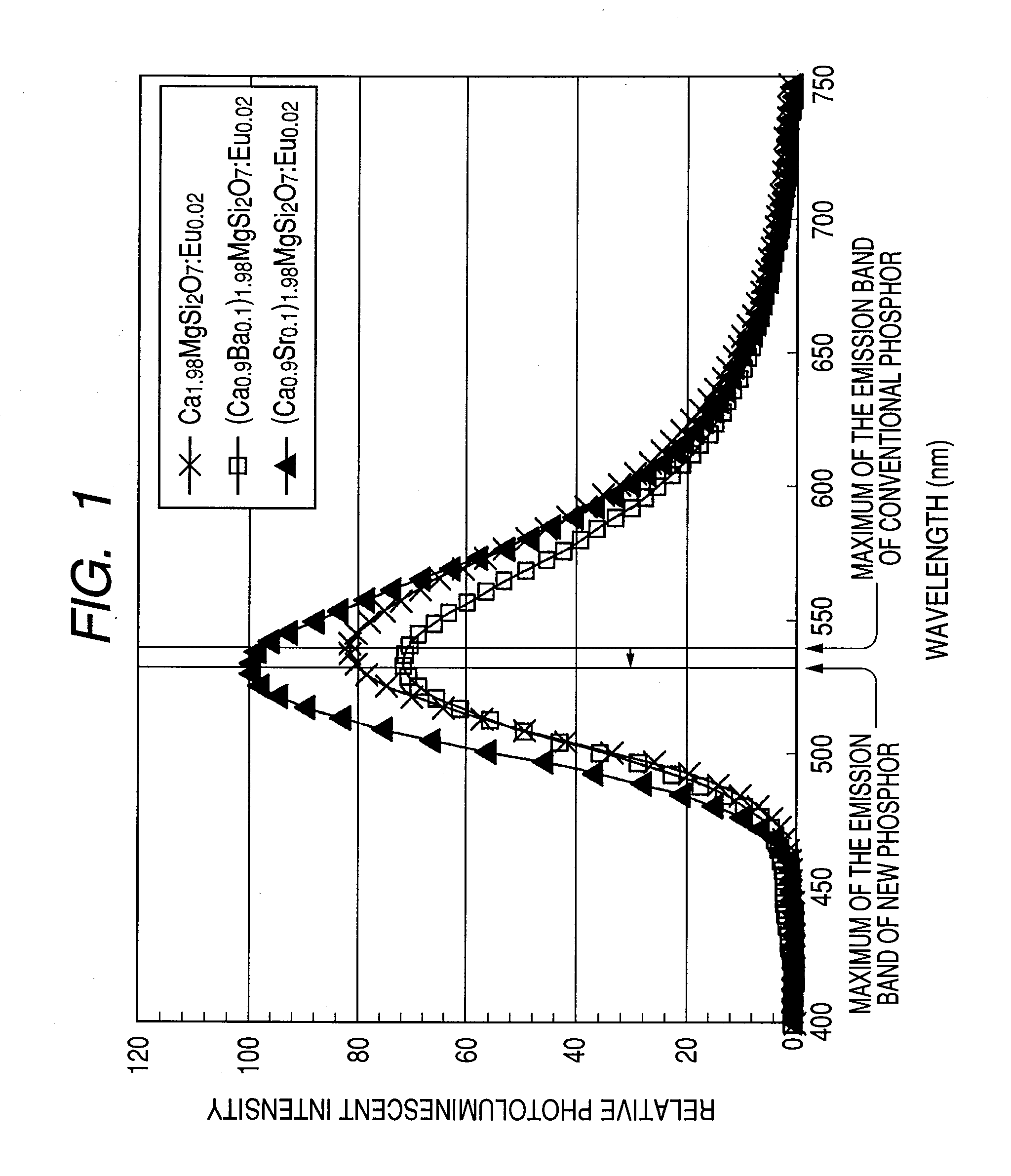

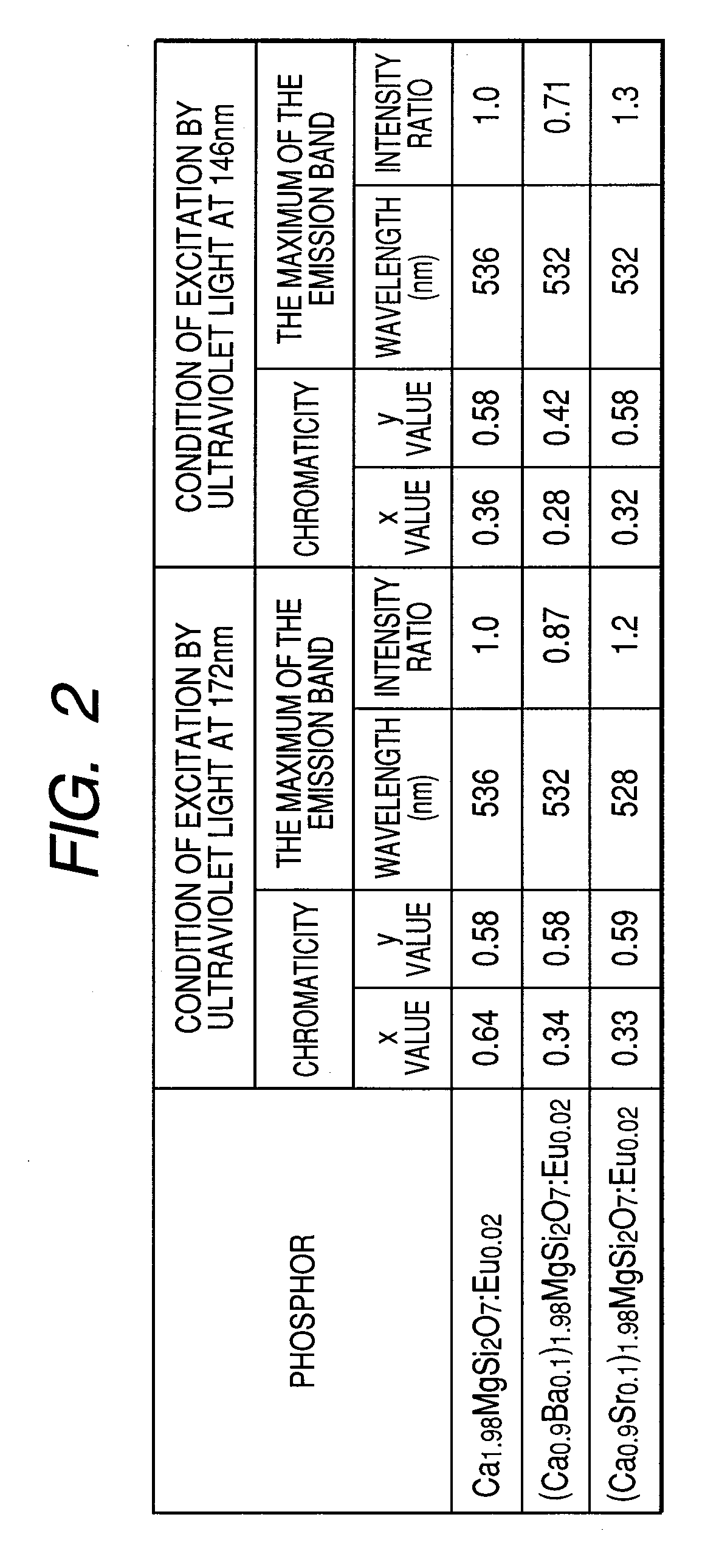

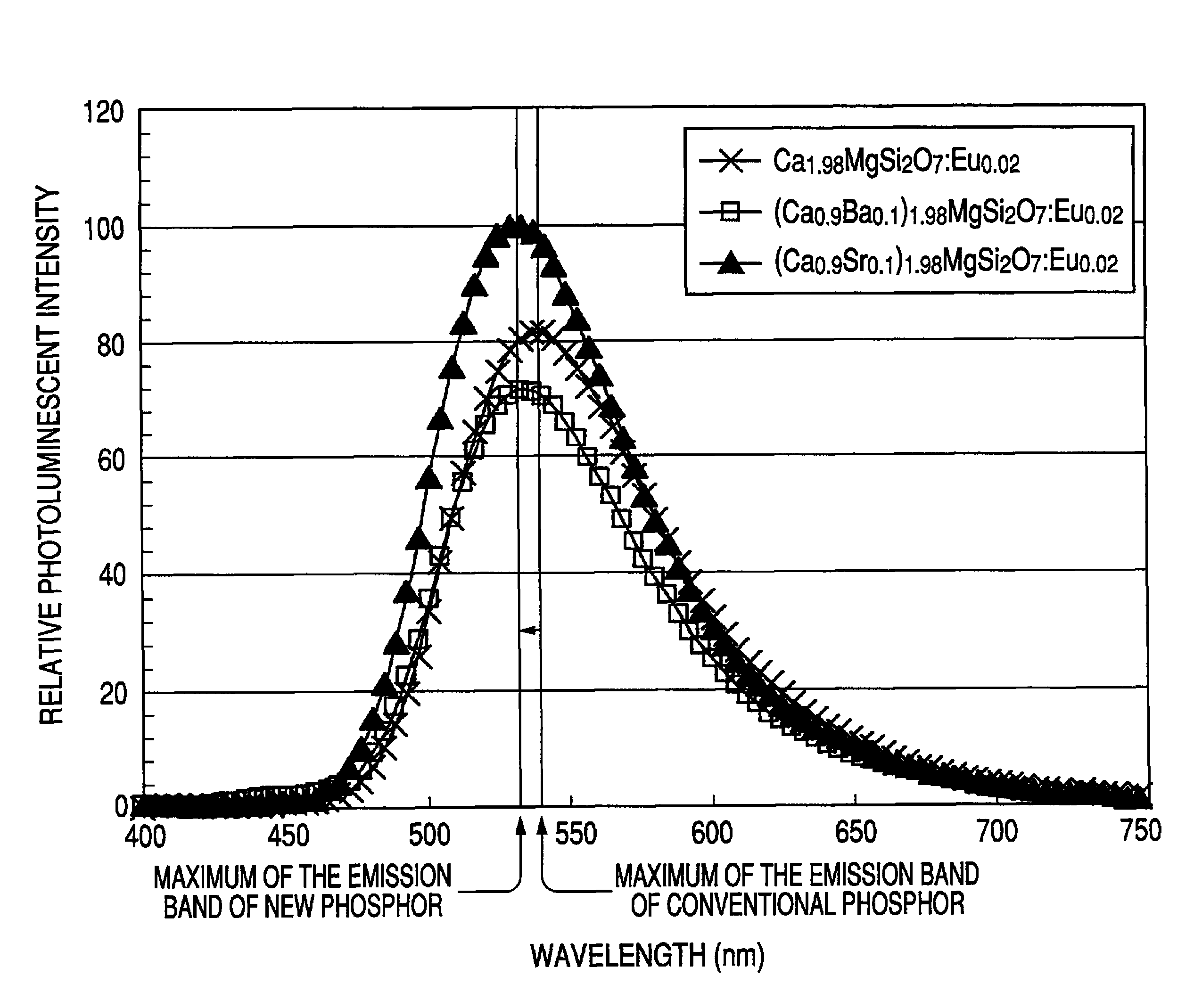

Plasma display device

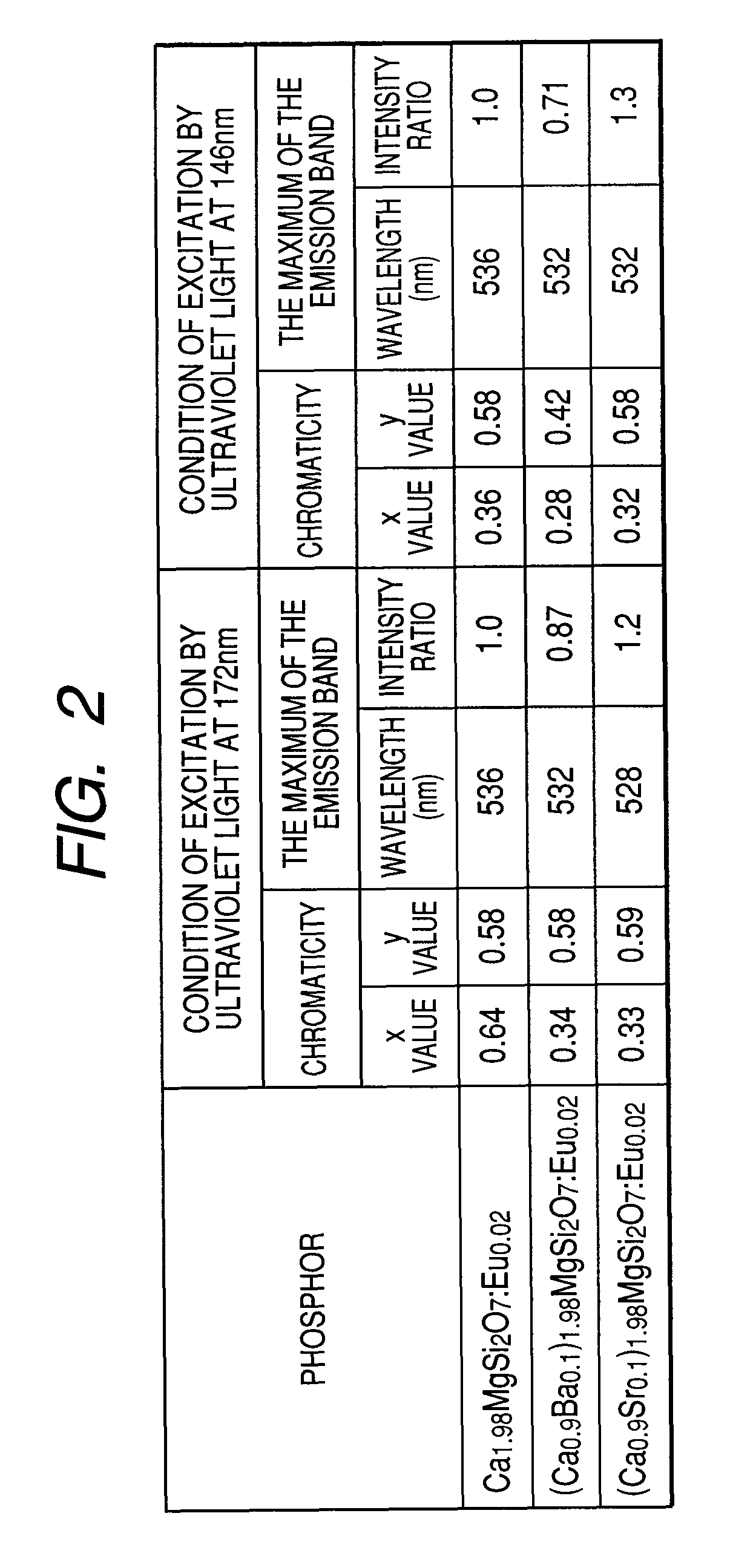

InactiveUS20090058255A1Excellent decay characteristicShorter decayAddress electrodesSustain/scan electrodesPhosphatePhosphor

Using Eu2+ as the luminescence center for a green-emitting phosphor, a plasma display panel and a PDP device using it are configured by using an Eu2+-activated silicate green-emitting phosphate (Ca1-xM1x)2-e.M2.Si2O7:Eue with improved decay characteristics. In the formula, M1 is at least one element selected from the group containing Sr and Ba; M2 is at least one element selected from the group containing Mg and Zn; and x indicates the mole fraction of the component M1 and e indicates the mole fraction of Eu respectively satisfy the following conditions: 0<x<1 and 0.001≦e≦0.2.

Owner:MAXELL HLDG LTD

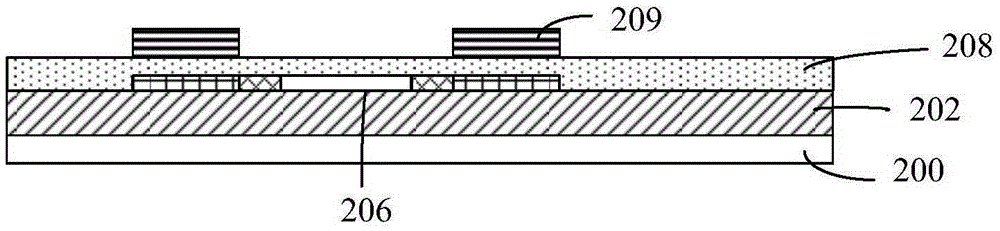

Low temperature polycrystalline silicon thin film transistor and manufacturing method therefor

InactiveCN105321825AImprove component performanceProtect from being etchedTransistorSemiconductor/solid-state device manufacturingOptoelectronicsContact resistance

The invention relates to a low temperature polycrystalline silicon thin film transistor and a manufacturing method therefor. A conductive buffer cushion is arranged in a source electrode region and a drain electrode region for preventing the polycrystalline silicon in a contact hole from being etched; and the electrical conductivity among the polycrystalline silicon layer, the source electrode and the drain electrode is improved so as to reduce contact resistance and improve the assembly performance of the polycrystalline silicon thin film transistor.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

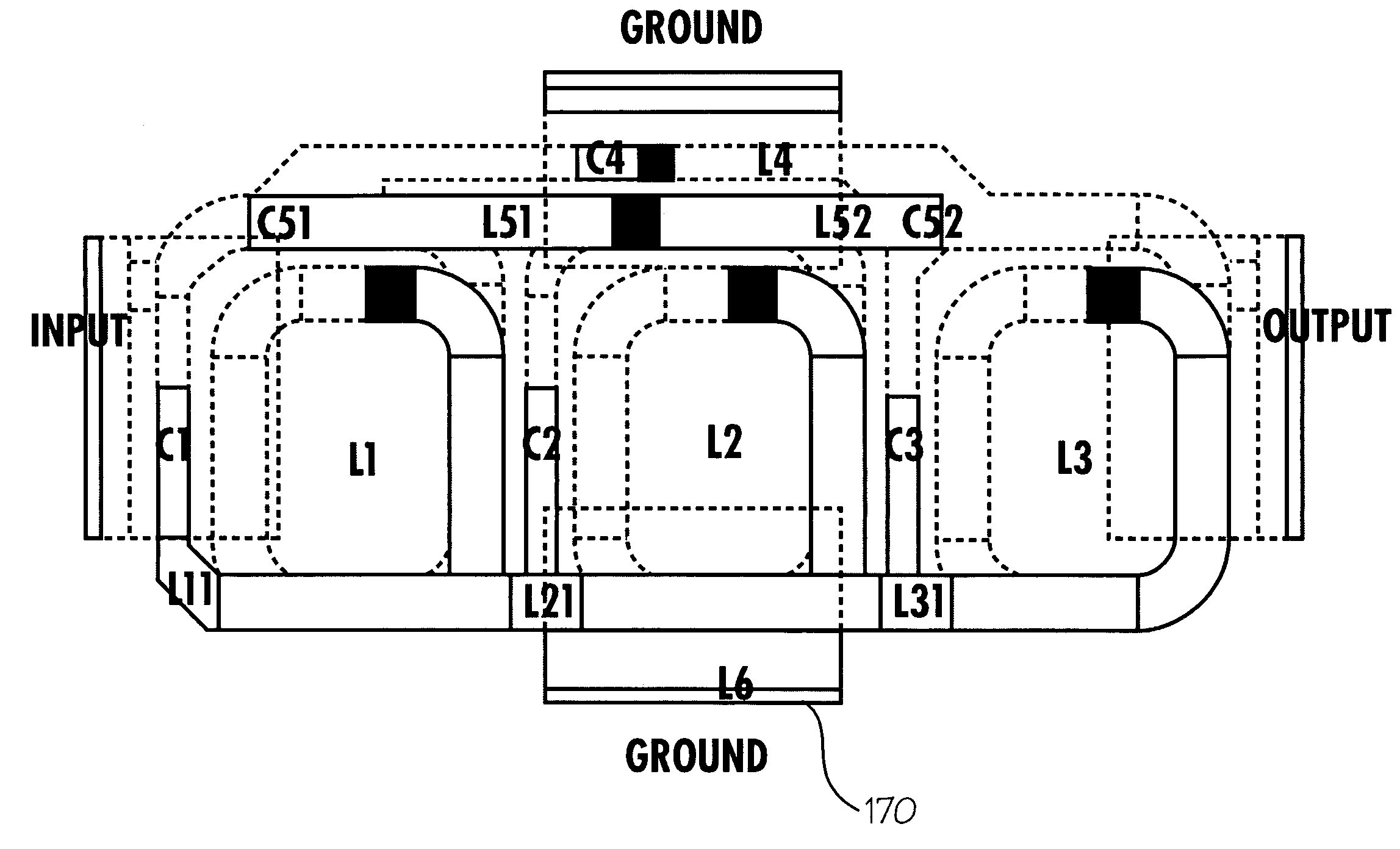

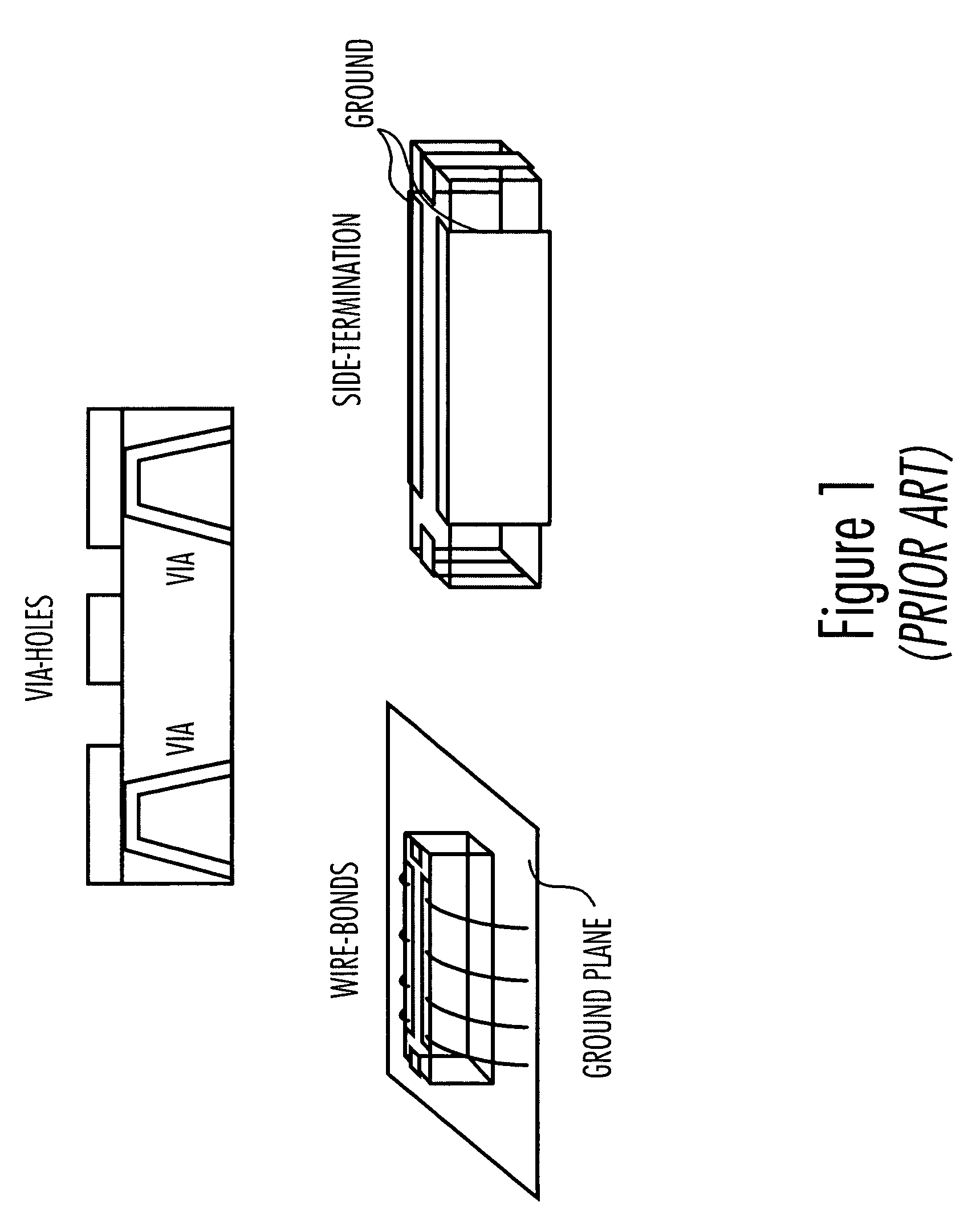

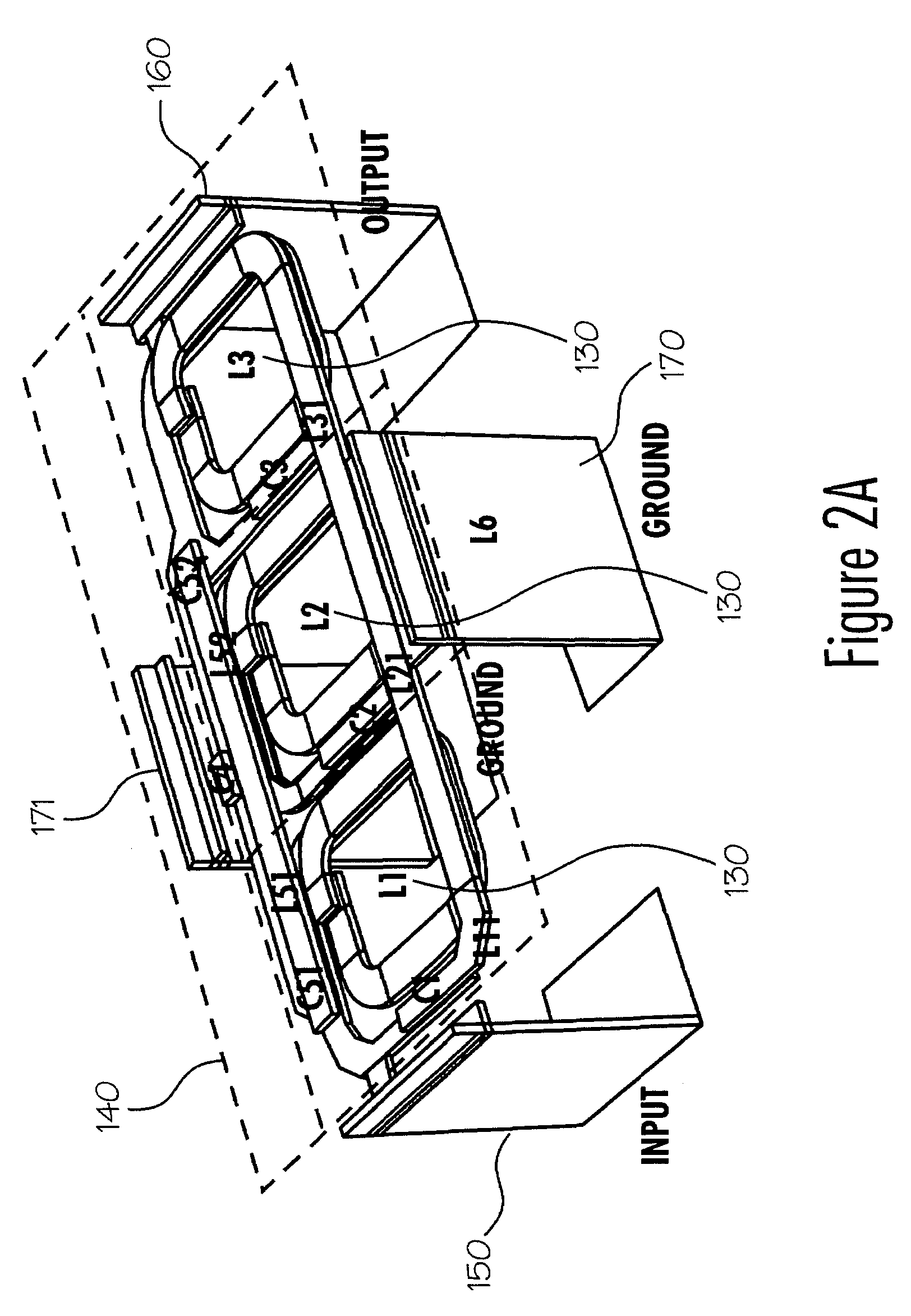

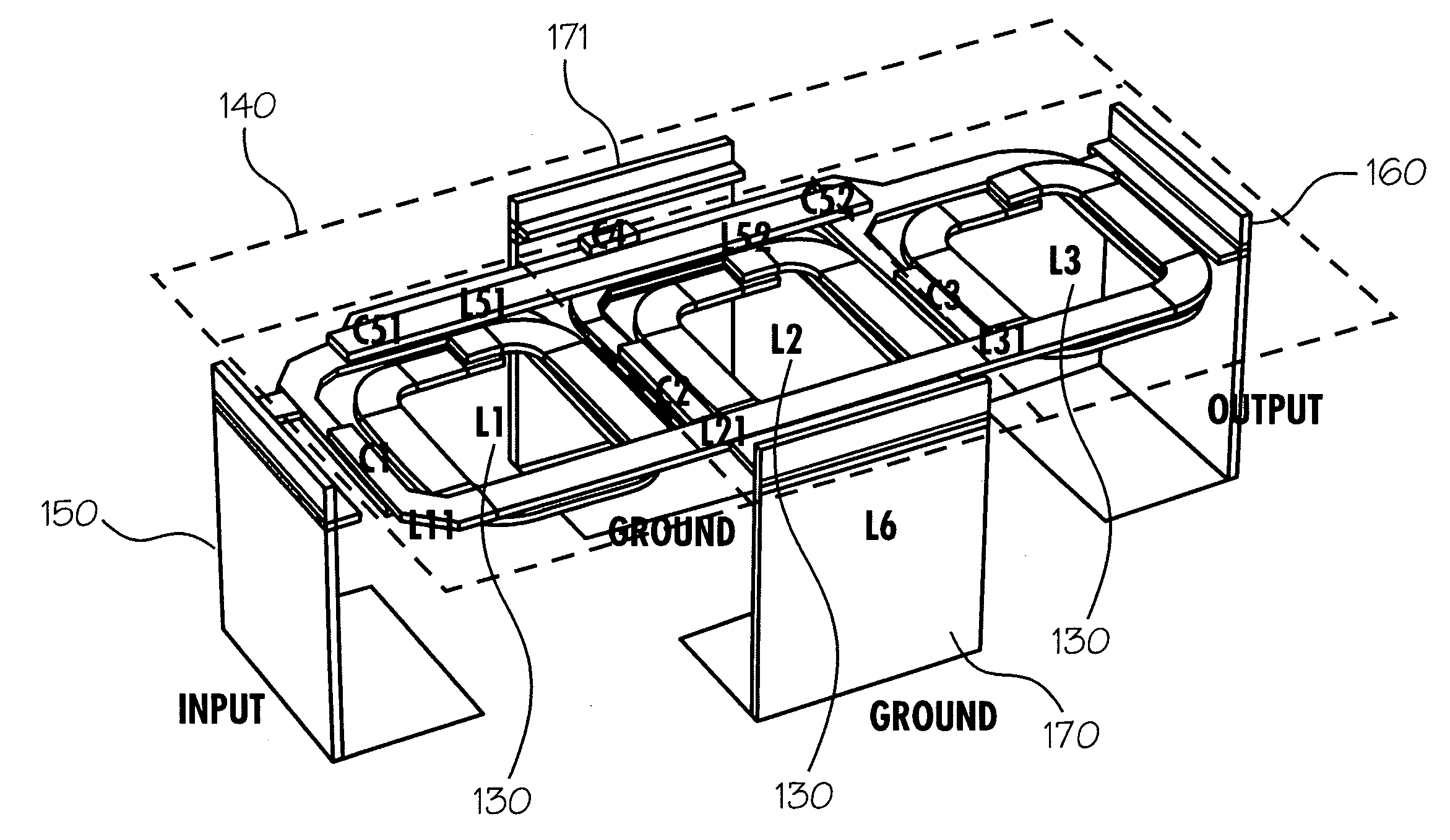

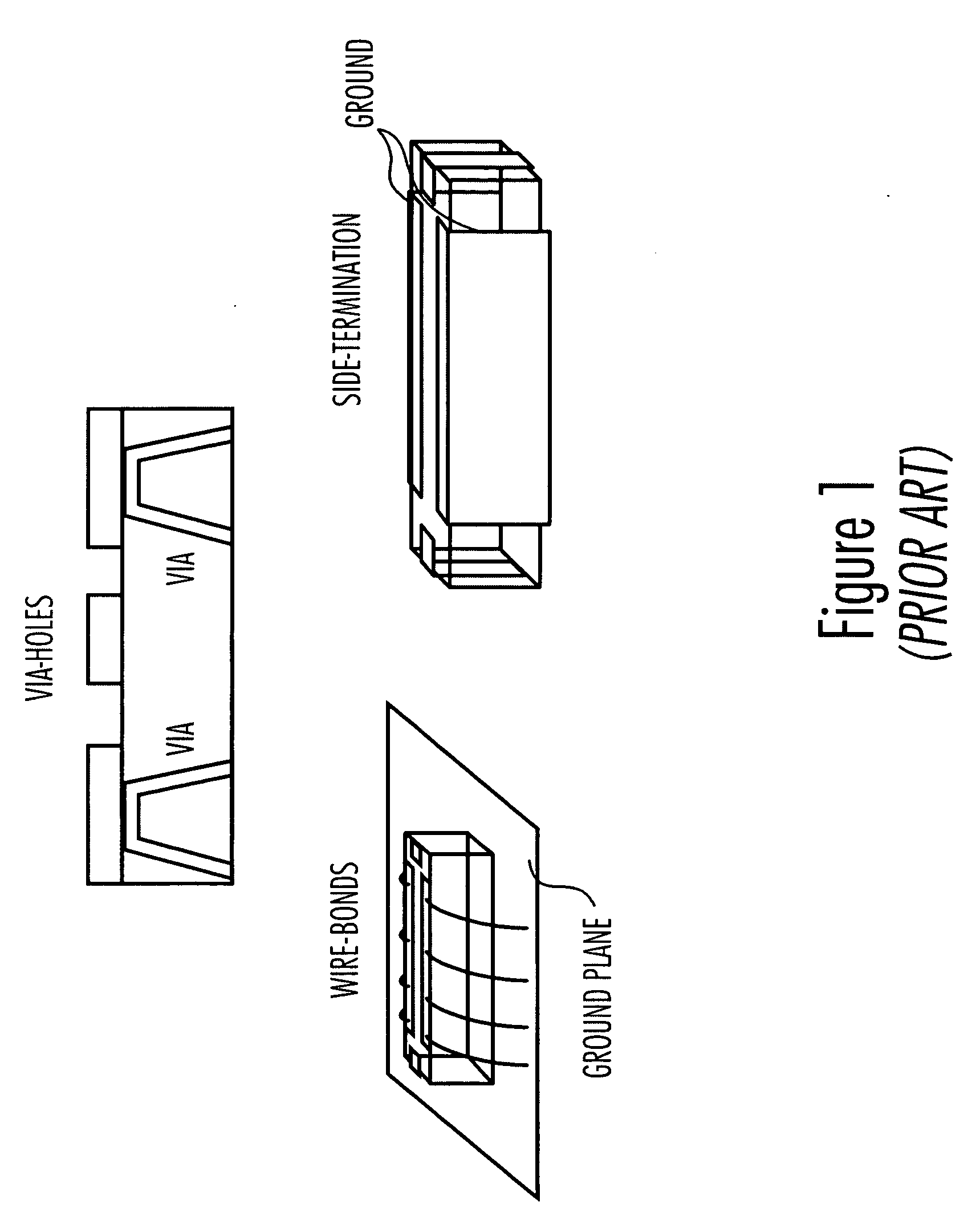

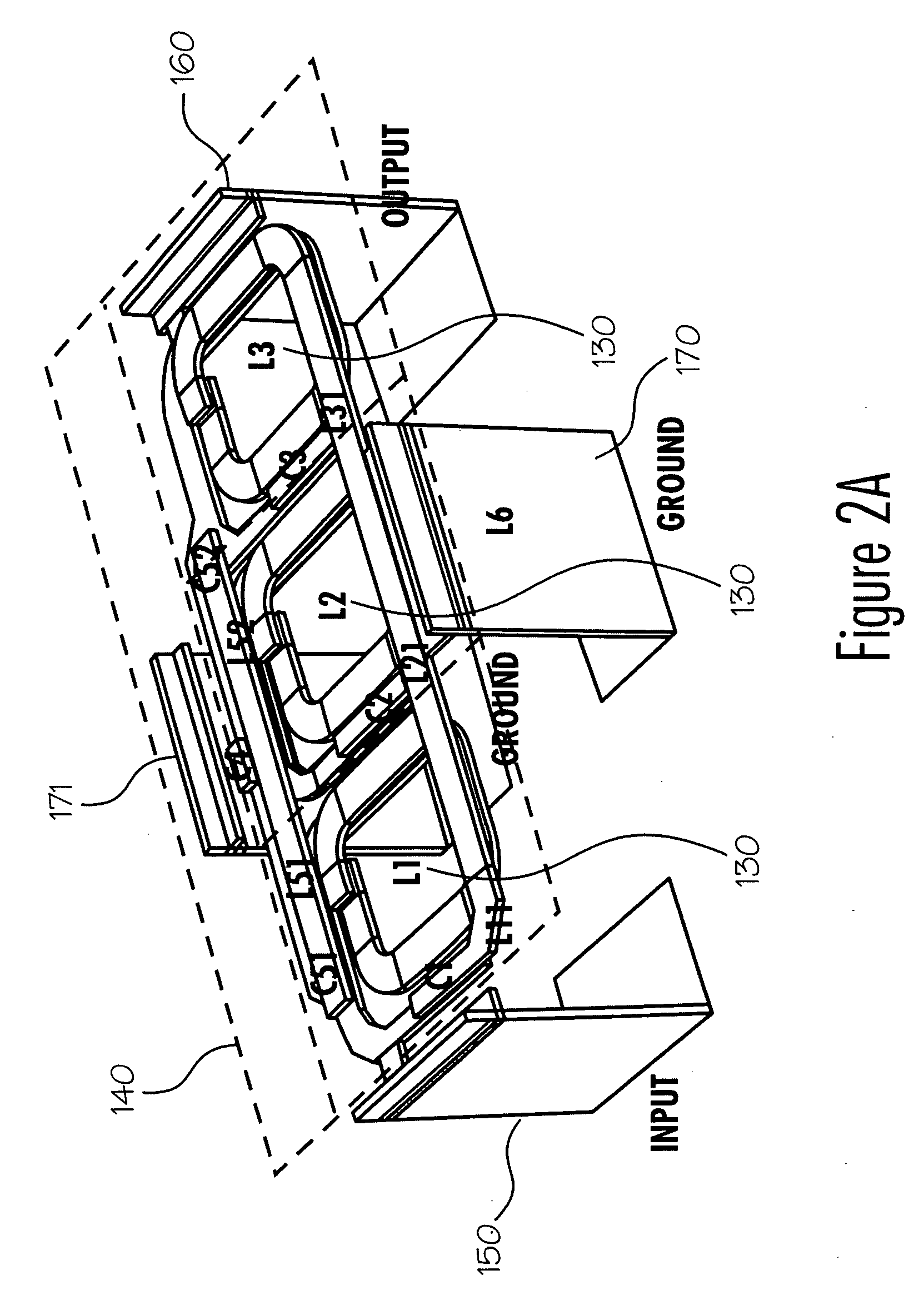

Grounding strategy for filter on planar substrate

ActiveUS7532092B2Reduces feedback effectReduce impactMultiple-port networksWaveguidesPlanar substrateEngineering

Owner:TDK CORPARATION

Method of providing an optoelectronic element with a non-protruding lens

InactiveUS20070007612A1Improve component performanceReduce reflectionSemiconductor/solid-state device detailsSolid-state devicesReduced sizePulse oximetry

An optoelectronic component has a lens that is formed in the surface of an encapsulant surrounding a semiconductor diode element. With respect to emitters, the lens reduces internal reflection and reduces dispersion to increase overall efficiency. With respect to detectors, the lens focuses photons on the active area of the detector, increasing detector sensitivity, which allows a detector having a reduced size and reduced cost for a given application. The lens portion of the encapsulant is generally non-protruding from the surrounding portions of the encapsulant reducing contact surface pressure caused by the optoelectronic component. This non-protruding lens is particularly useful in pulse oximetry sensor applications. The lens is advantageously formed with a contoured-tip ejector pin incorporated into the encapsulant transfer mold, and the lens shape facilitates mold release.

Owner:JPMORGAN CHASE BANK NA

System and method for managing portable information handling system cooling

ActiveUS7809478B2Reduce disadvantagesReduce problemsShow cabinetsSampled-variable control systemsThermal energyElectrical battery

Owner:DELL PROD LP

Metal-oxide-semiconductor transistor and method of manufacturing the same

ActiveCN101131935AReduce etch rateAvoid damageSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorMetal

The invention discloses a manufacturing method of metal oxide semiconductor transistors. This method includes following steps. It first provides a basement. Then, the material layer with the gate structure is formed on the basement. Later, the carbon-containing precursor gas and the reaction gas are pumped to form the carbon-containing mask material layer on the material layer with gate structure. Then, both carbon-containing mask material layer and the gate structure material layer are graphically modeled to form carbon-containing hard mask layer and gate structure. After that, the clearance wall is formed on the side wall of the gate structure and carbon-containing hard mask layer. Subsequently, the protective layer is formed on the basement. Then, some protective layer is removed to expose part of the surface of the substrate. Then, doping epitaxial layer is formed on the exposed surface of the basement formed.

Owner:UNITED MICROELECTRONICS CORP

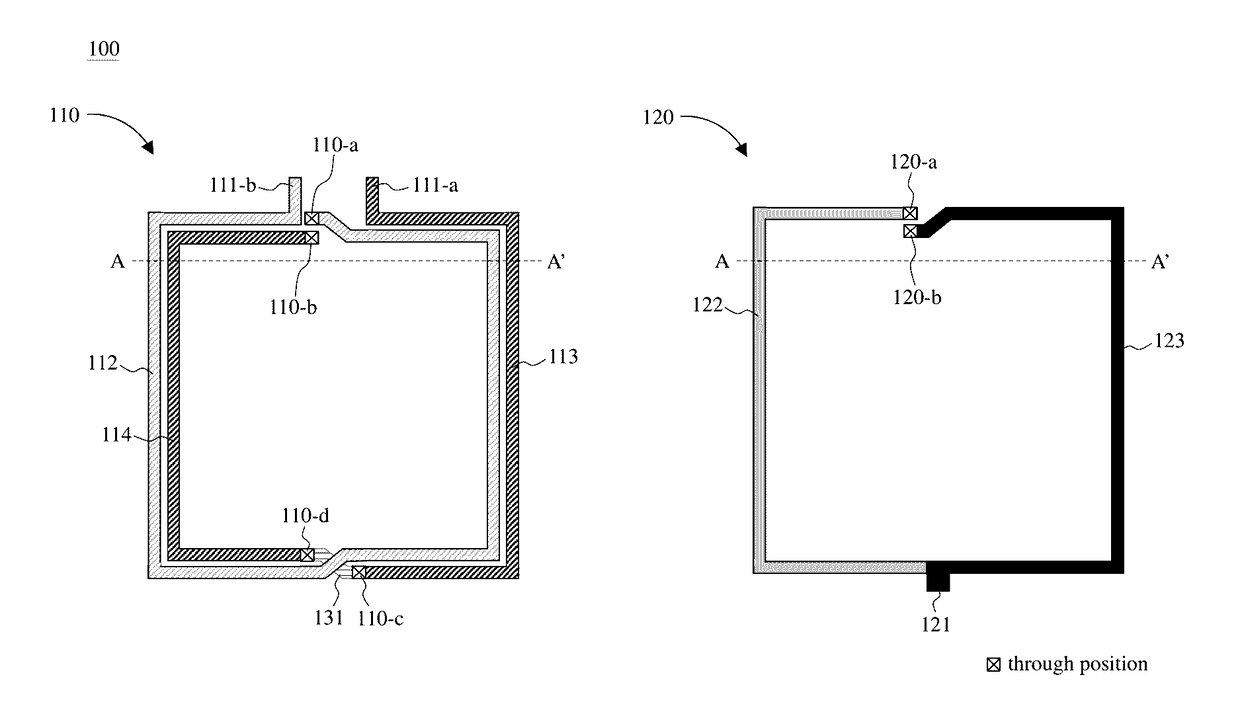

Waterproof acoustic element enclosures and apparatus including the same

ActiveUS8873783B2Minimize performance variationImprove component performanceHead electrodesImplantable hearing aidsTectorial membraneEngineering

A waterproof enclosure for a cochlear implant system or other hearing assistance device includes an outer housing, an inner support in the interior of the outer housing, an acoustic element supported by the inner support, and water-impermeable polymeric protective membrane sealing the interior of the outer housing against water ingress. A hearing device such as a cochlear implant sound processor, a headpiece, an earhook, or a hearing aid comprises an outer housing, an inner support in the interior of the outer housing, a microphone supported by the inner support, and a water-impermeable polymeric protective membrane sealing the interior of the outer housing against water ingress. A method for waterproofing an acoustic element comprises molding an outer support having a water-impermeable polymeric protective membrane; inserting an acoustic element into an inner support; anchoring the acoustic element to the inner support; inserting the inner support into the outer support; and anchoring the inner support to the outer support.

Owner:ADVANCED BIONICS AG

Thermal isolation device for liquid fuel components

InactiveUS7114321B2Increase thermal resistanceImprove component performanceContinuous combustion chamberGas turbine plantsThermal isolationCombustor

A thermal isolation device for a gas turbine combustor assembly includes a plurality of substantially flat plates secured in spaced relationship by a plurality of columns, at least one column incorporating a bolt hole for use in securing the device between a pair of combustor components.

Owner:GENERAL ELECTRIC CO

Mounted component inspection apparatus, component mounting machine comprising the mounted component inspection apparatus, and mounted component inspection method

InactiveUS8406503B2Improve component performanceRapid introductionMaterial analysis by optical meansCharacter and pattern recognitionMatch rateReliability engineering

A mounted component inspection apparatus according to the present invention includes: a component library holding inspection information; an inspection processing unit for inspecting a component under inspection using the component library; a match rate acquisition unit for acquiring a match rate indicating the degree to which the inspection information is suitable for the inspection by the inspection processing unit, on the basis of the result of the inspection by the inspection processing unit; and a judgment unit for selecting the inspection information having a higher match rate, of the inspection information before updating and the inspection information after updating. The component library can hold the inspection information before and after updating, and the inspection processing unit carries out the inspection using the inspection information before and after updating held in the component library.

Owner:PANASONIC CORP

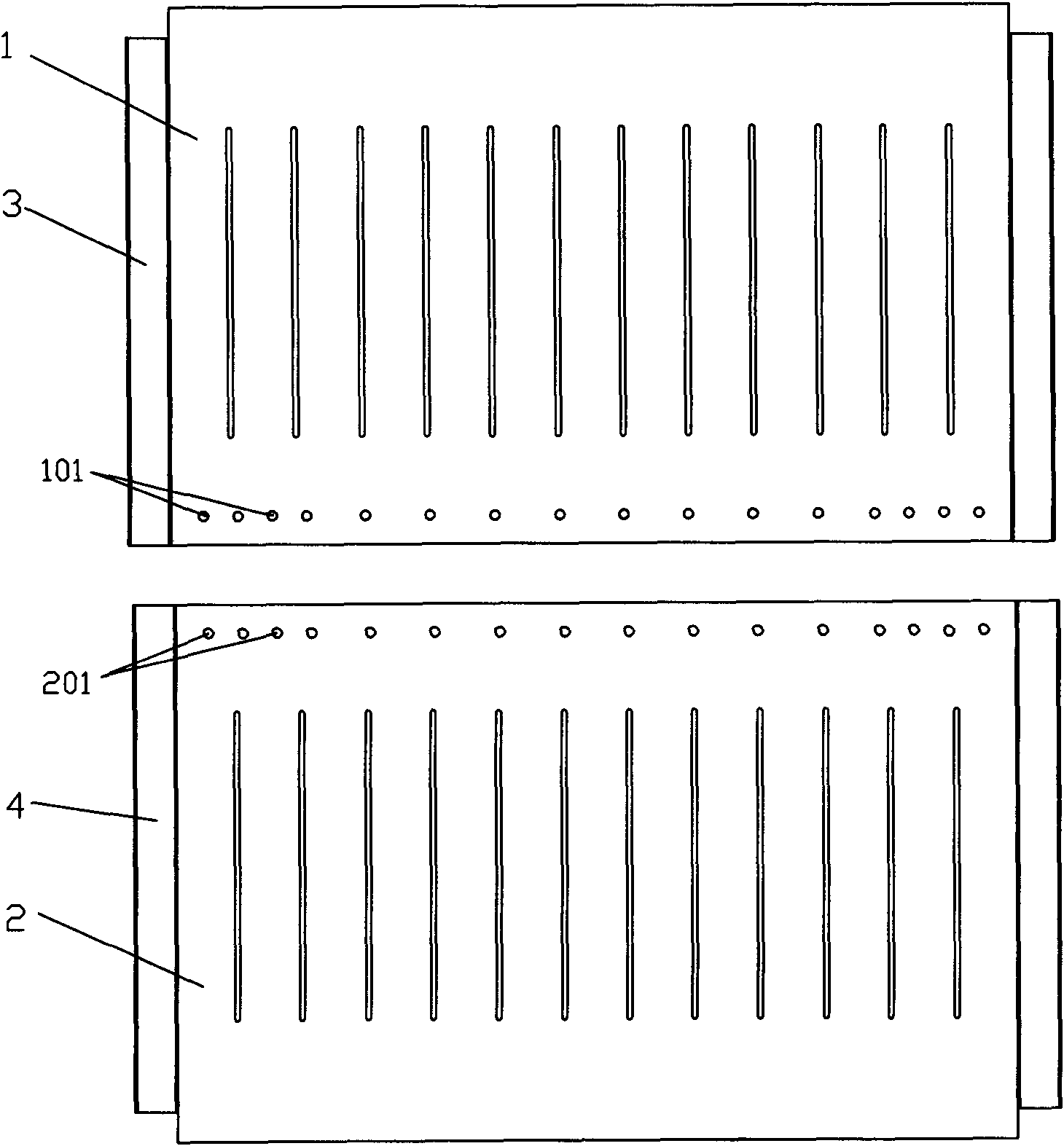

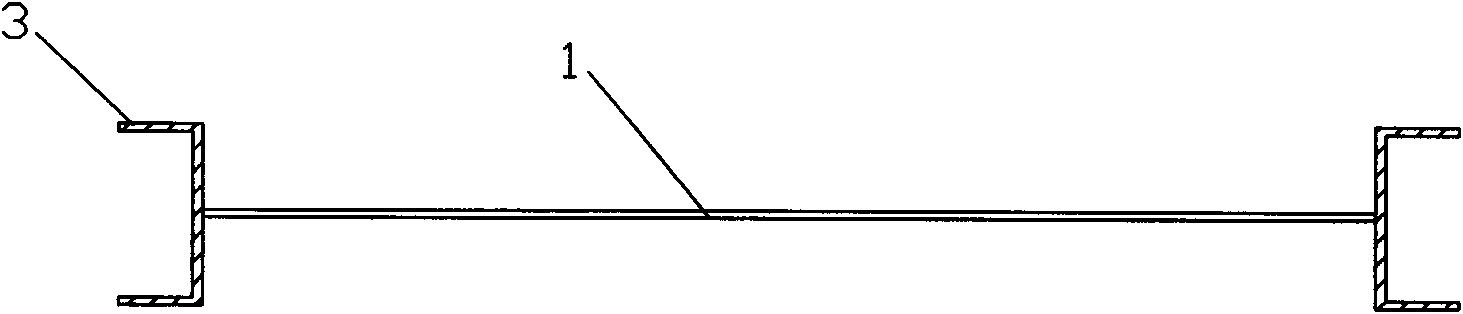

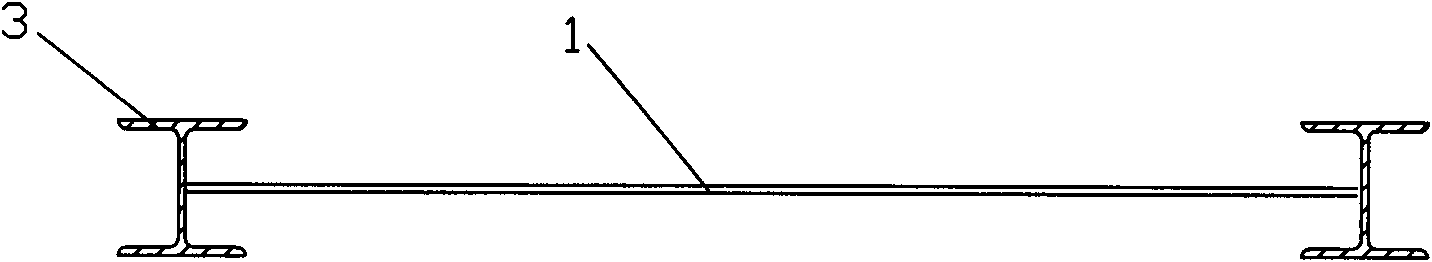

Middle-bolted slit steel plate shear wall and processing and manufacturing method thereof

ActiveCN101967862APrevent buckling deformationBuckling prevention or delayWallsSheet steelInstability

The invention discloses a middle-bolted slit steel plate shear wall and a processing and manufacturing method thereof. The slit steel plate shear wall comprises two vertical slit steel plates and two T-shaped splints, wherein the longitudinal edge of each vertical slit steel plate is provided with a profile steel stiffener; the two vertical slit steel plates are arranged one above the other; a gap for adjusting a vertical installation error is formed between the two vertical slit steel plates; and two T-shaped splints are connected with the two vertical slit steel plates which are arranged one above the other through bolts. A high-intensity bolt connection position of a slit steel plate wall is moved to a middle region in which overturning moment is reduced greatly and the slit steel plate wall is connected with upper and lower frame steel girders by welding, so that the problem of bolt slippage of the slit steel plate wall is solved to a great extent and the increase of a large number of construction expenses for preventing the bolt slippage is avoided. Due to the overcoming or delaying of the bolt slippage, great noise caused by slippage is avoided and the problem of corner instability of the slit steel plate shear wall caused by the slippage is avoided or relieved. Simultaneously, the T-shaped splints form stronger traverse stiffeners in the middle of the slit steel plate wall, so that anti-seismic performance is enhanced remarkably.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Grounding strategy for filter on planar substrate

ActiveUS20070290771A1Reduces feedback effectReduce the impactMultiple-port networksWaveguidesPlanar substrateElectronic component

Owner:TDK CORPARATION

Plasma display with a novel green-silicate phosphor

InactiveUS7786659B2Improve performanceComfortably appreciateAddress electrodesSustain/scan electrodesPhosphatePhosphor

Using Eu2+ as the luminescence center for a green-emitting phosphor, a plasma display panel and a PDP device using it are configured by using an Eu2+-activated silicate green-emitting phosphate (Ca1-xM1x)2-e.M2.Si2O7:Eue with improved decay characteristics. In the formula, M1 is at least one element selected from the group containing Sr and Ba; M2 is at least one element selected from the group containing Mg and Zn; and x indicates the mole fraction of the component M1 and e indicates the mole fraction of Eu respectively satisfy the following conditions: 0<x<1 and 0.001≦e≦0.2.

Owner:MAXELL HLDG LTD

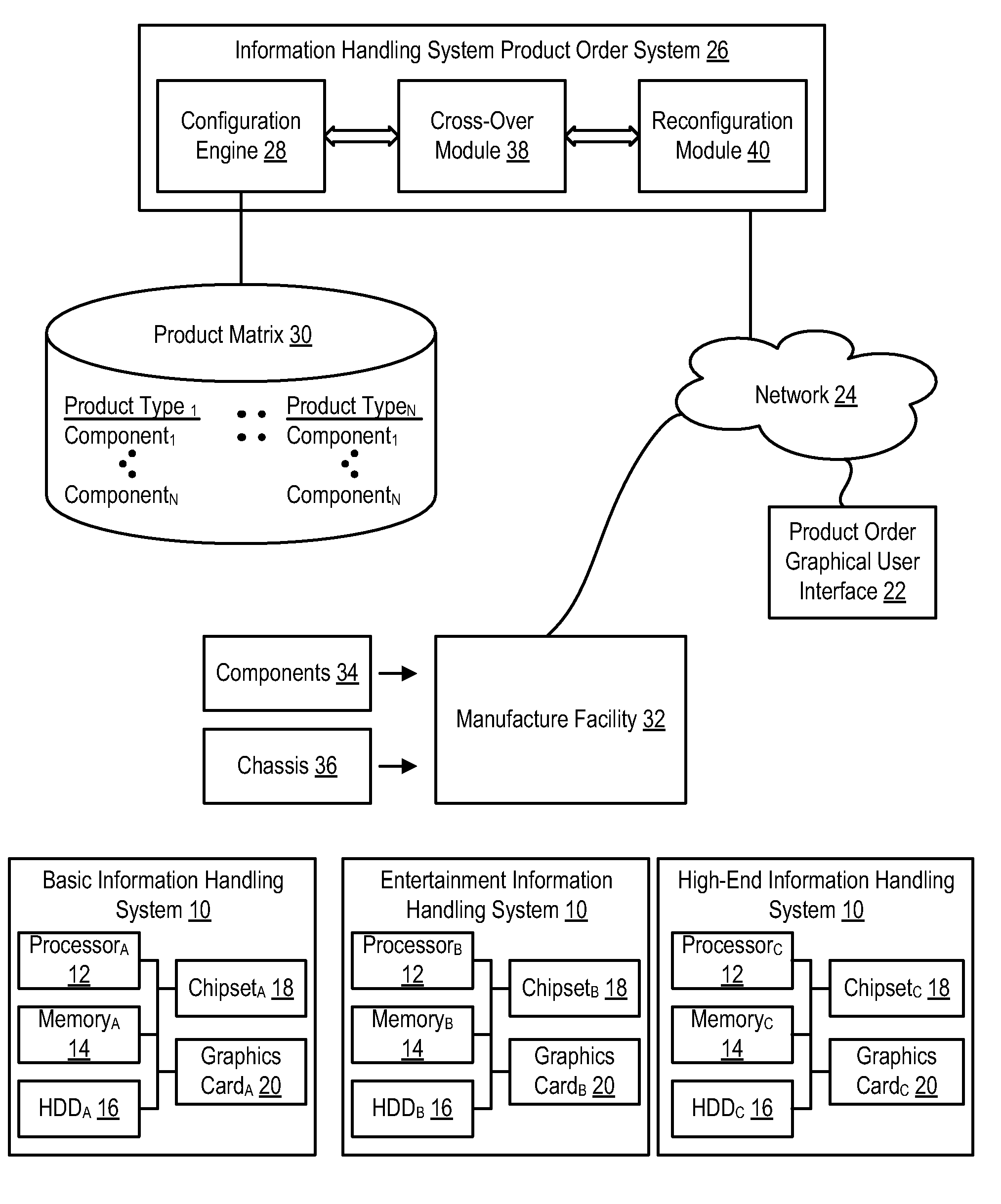

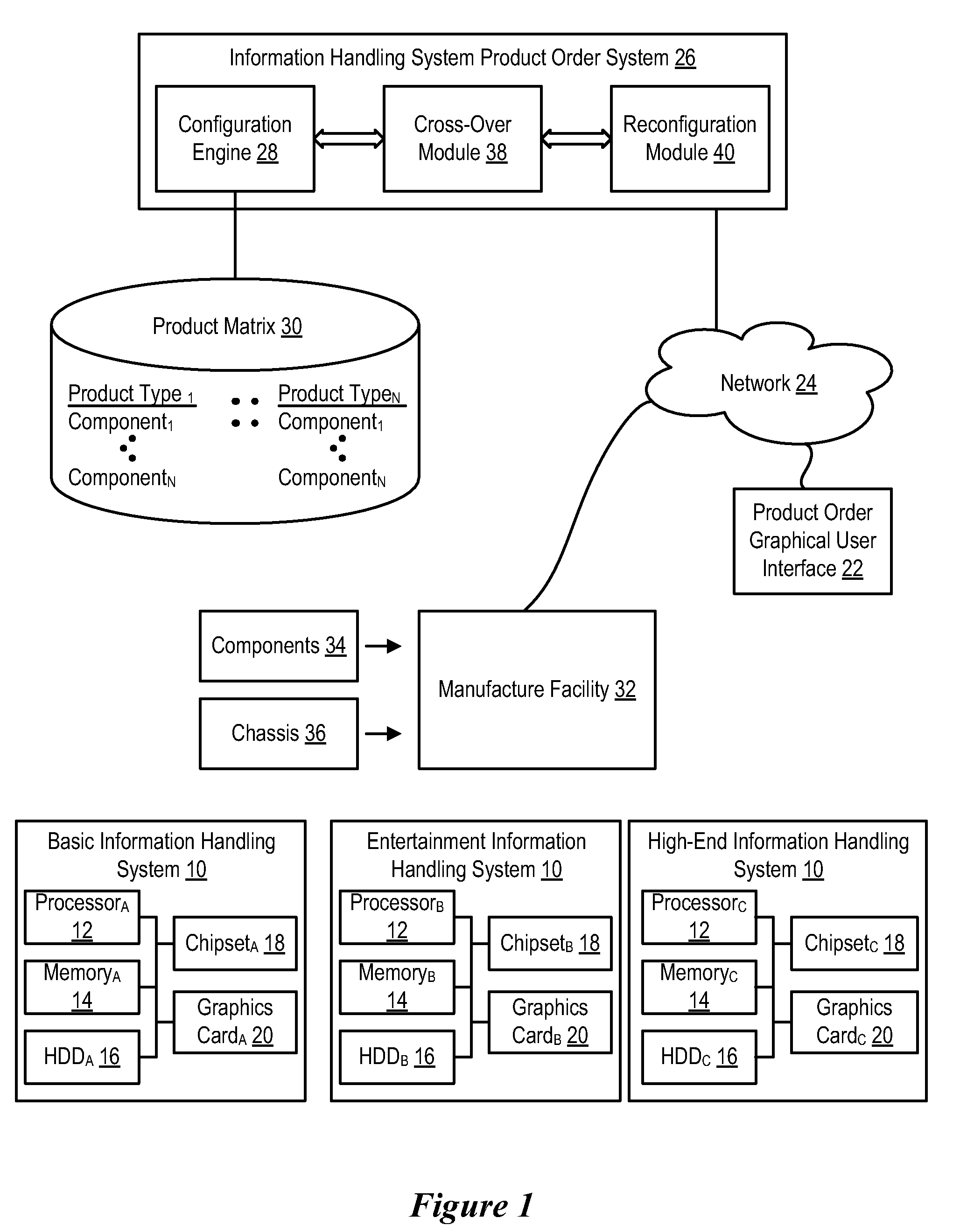

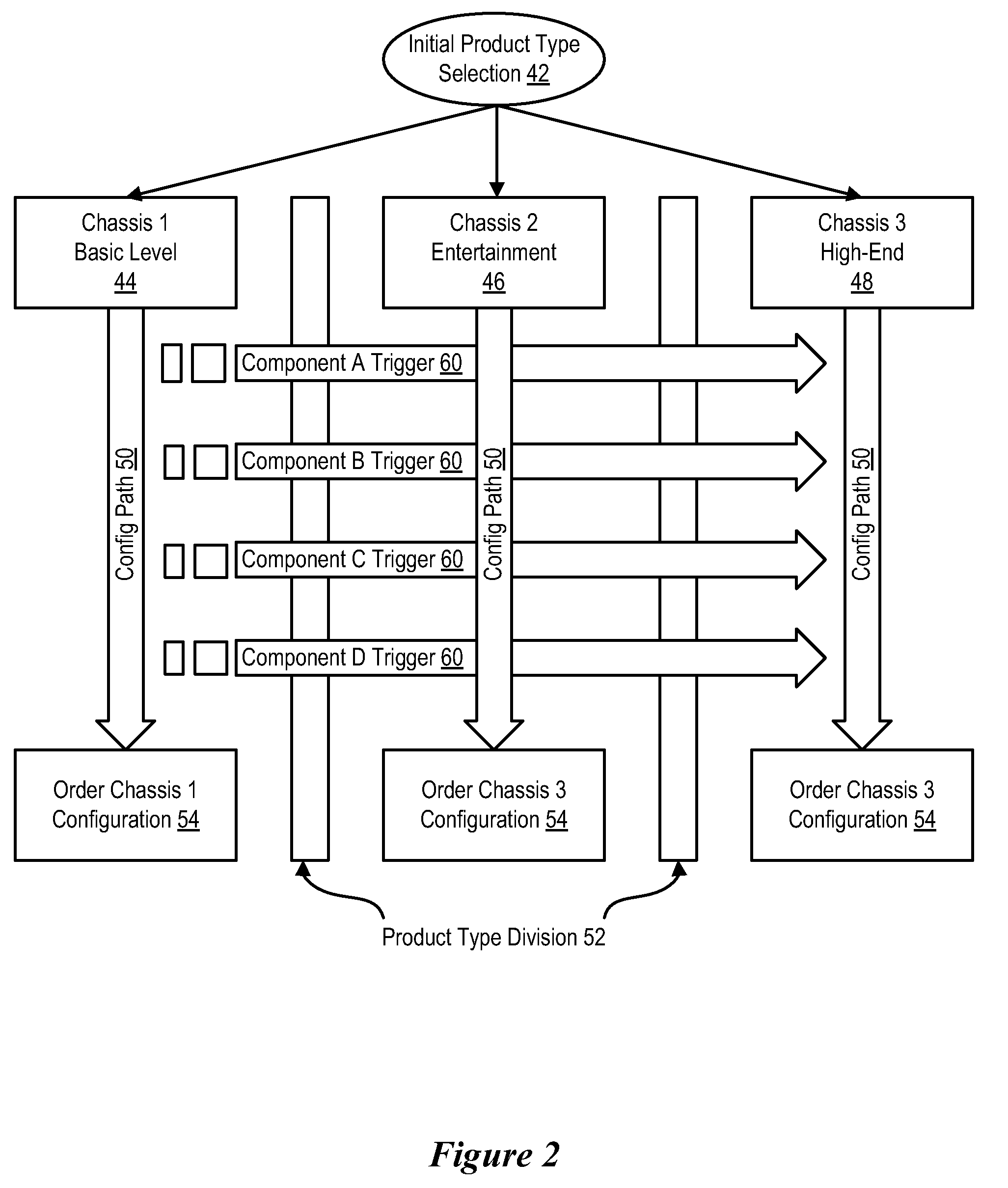

System and Method for Configuring a Configurable Product

ActiveUS20080208702A1Increase the number ofReduce confusionResourcesCommerceProduct typeConfiguration selection

Product configuration selections automatically cross-over between plural product types based upon end user component selections. If end user component selections initiate a cross-over trigger, the end user is presented with an option to cross over from an initially-selected product type to a product type associated with the cross-over trigger. Upon selection of the cross-over product type, the product configuration is automatically reconfigured to update components selected by the end user for the initially-selected product type to components associated with the cross-over product type.

Owner:DELL PROD LP

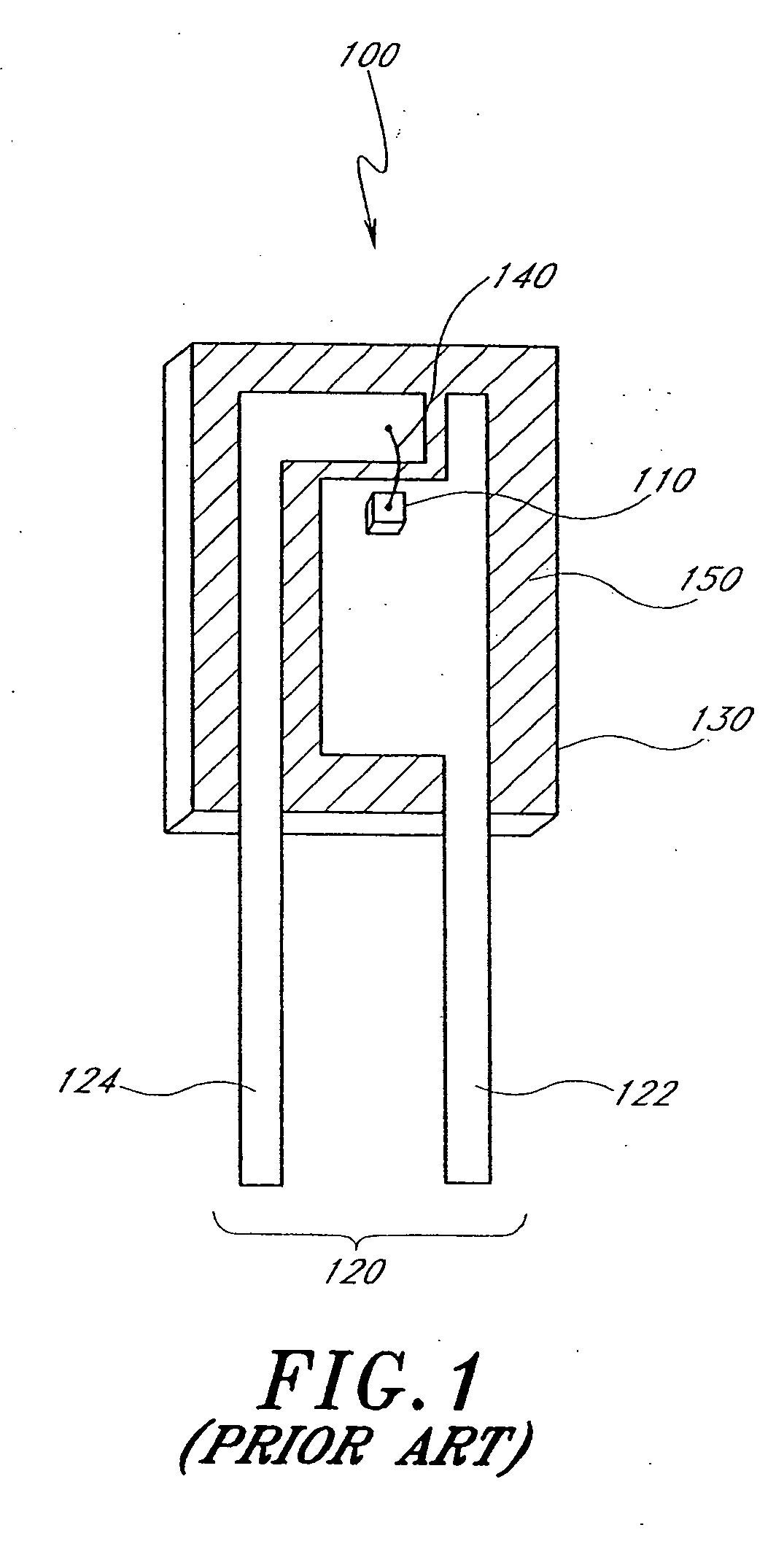

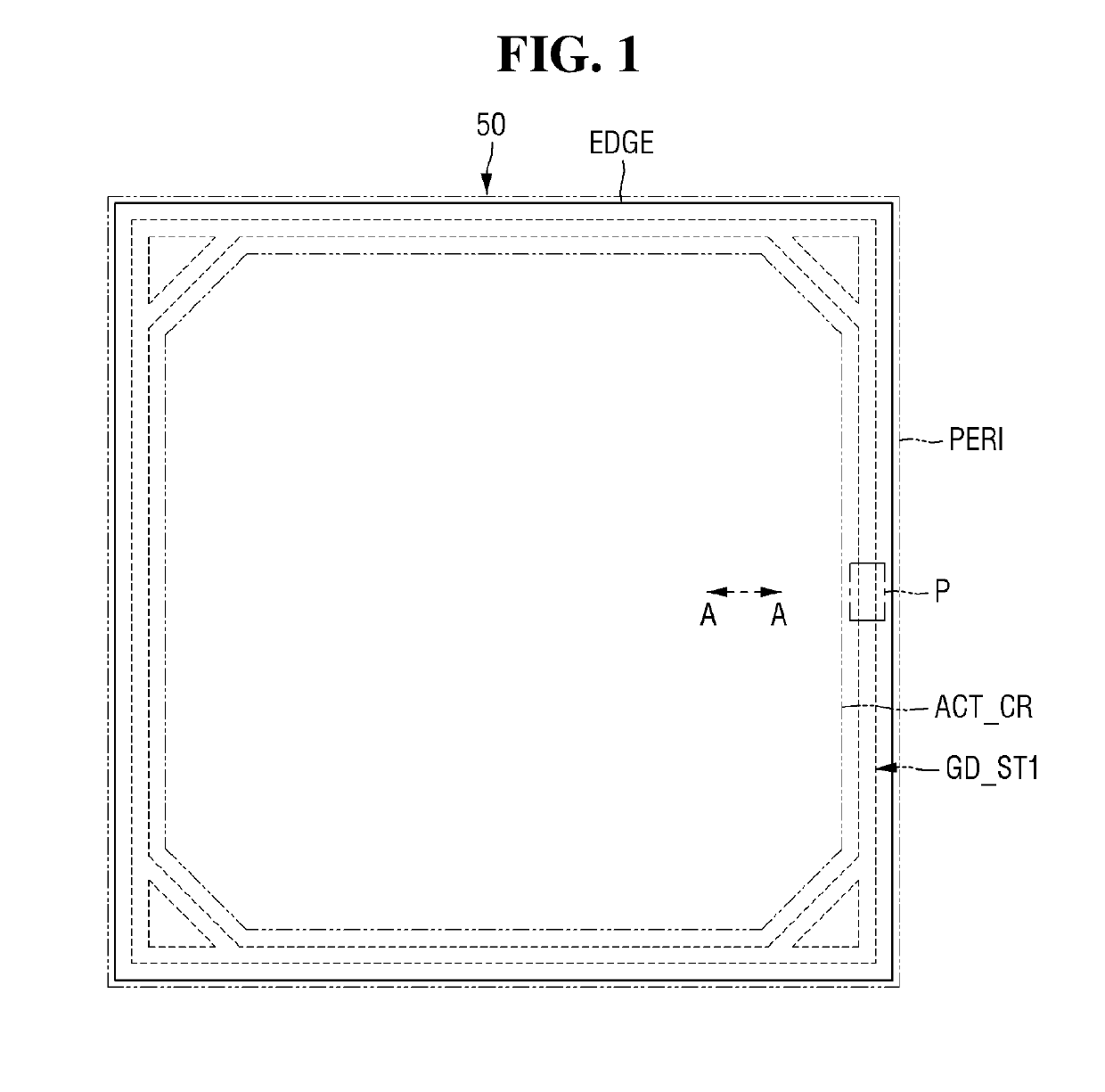

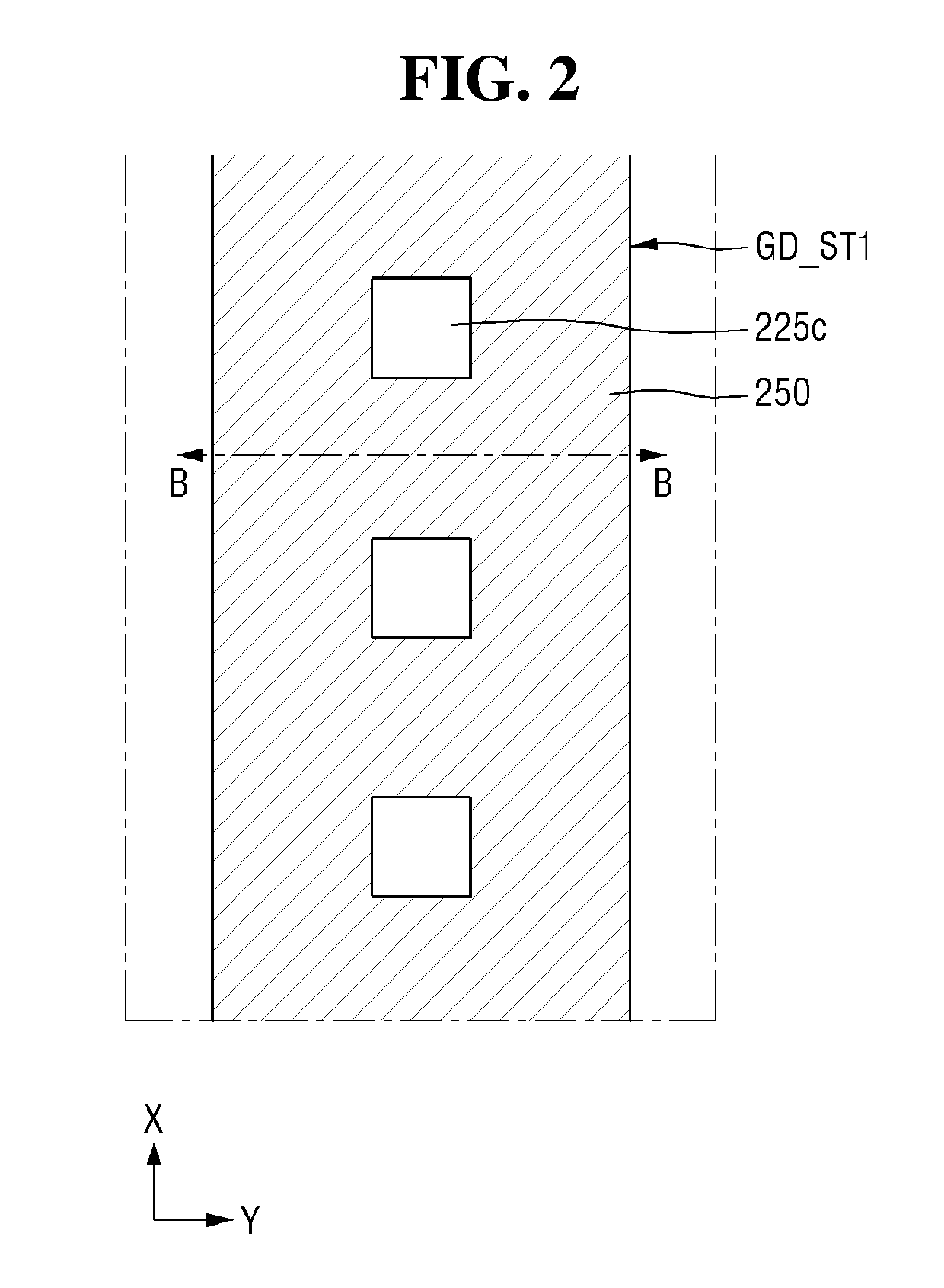

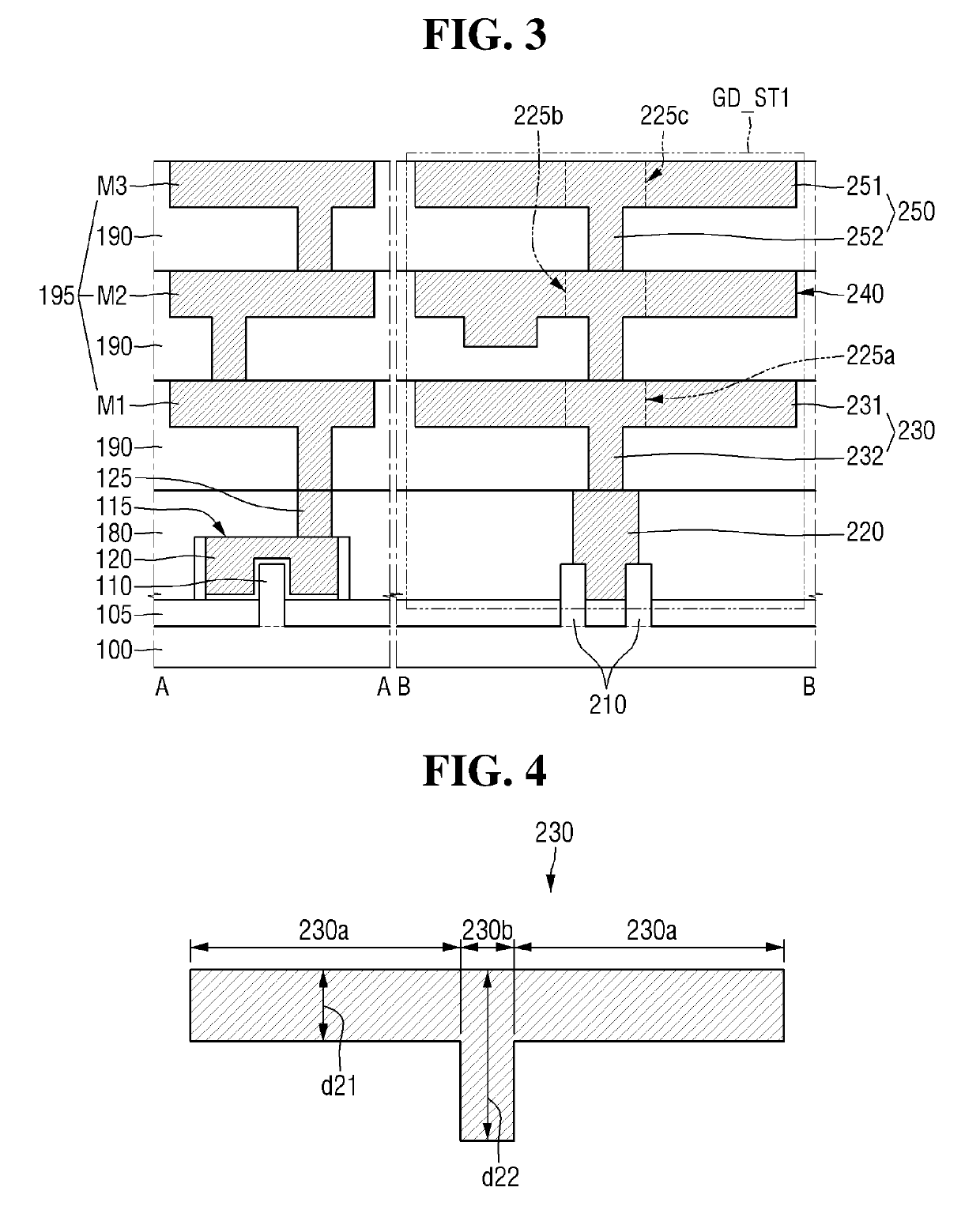

Semiconductor device

ActiveUS20190157150A1Improve component reliabilityImprove component performanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialBoundary region

A semiconductor device, comprising: a substrate which includes an active circuit region, and a boundary region surrounding the active circuit region, the boundary region including an edge portion of the substrate; a first lower conductive pattern disposed on the substrate of the boundary region; and a first upper conductive pattern connected to the first lower conductive pattern over the first lower conductive pattern, wherein the first upper conductive pattern includes a first portion having a first thickness, a second portion having a second thickness greater than the first thickness, and a third portion having a third thickness greater than the second thickness, and the third portion of the first upper conductive pattern is connected to the first lower conductive pattern, is provided.

Owner:SAMSUNG ELECTRONICS CO LTD

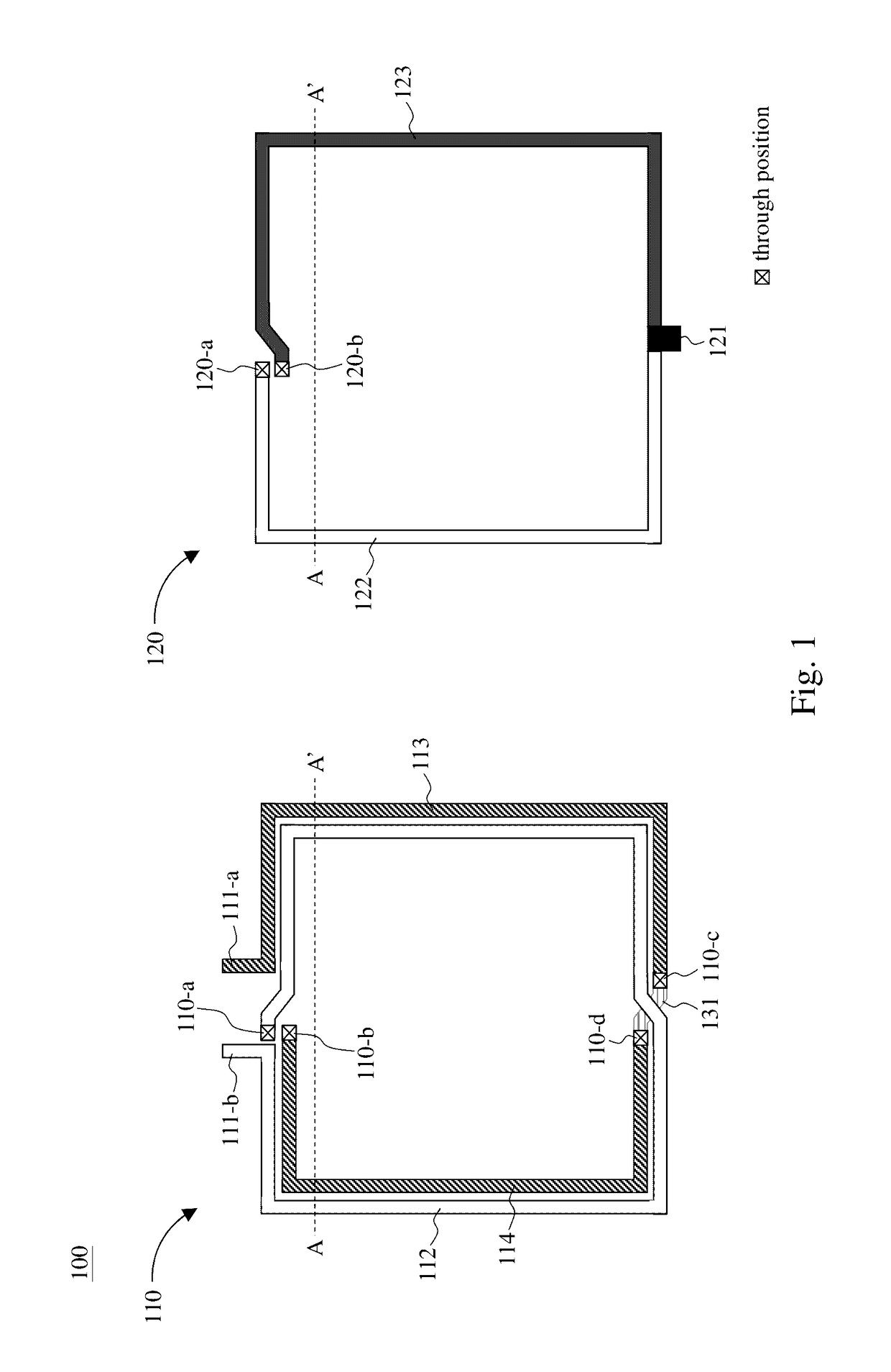

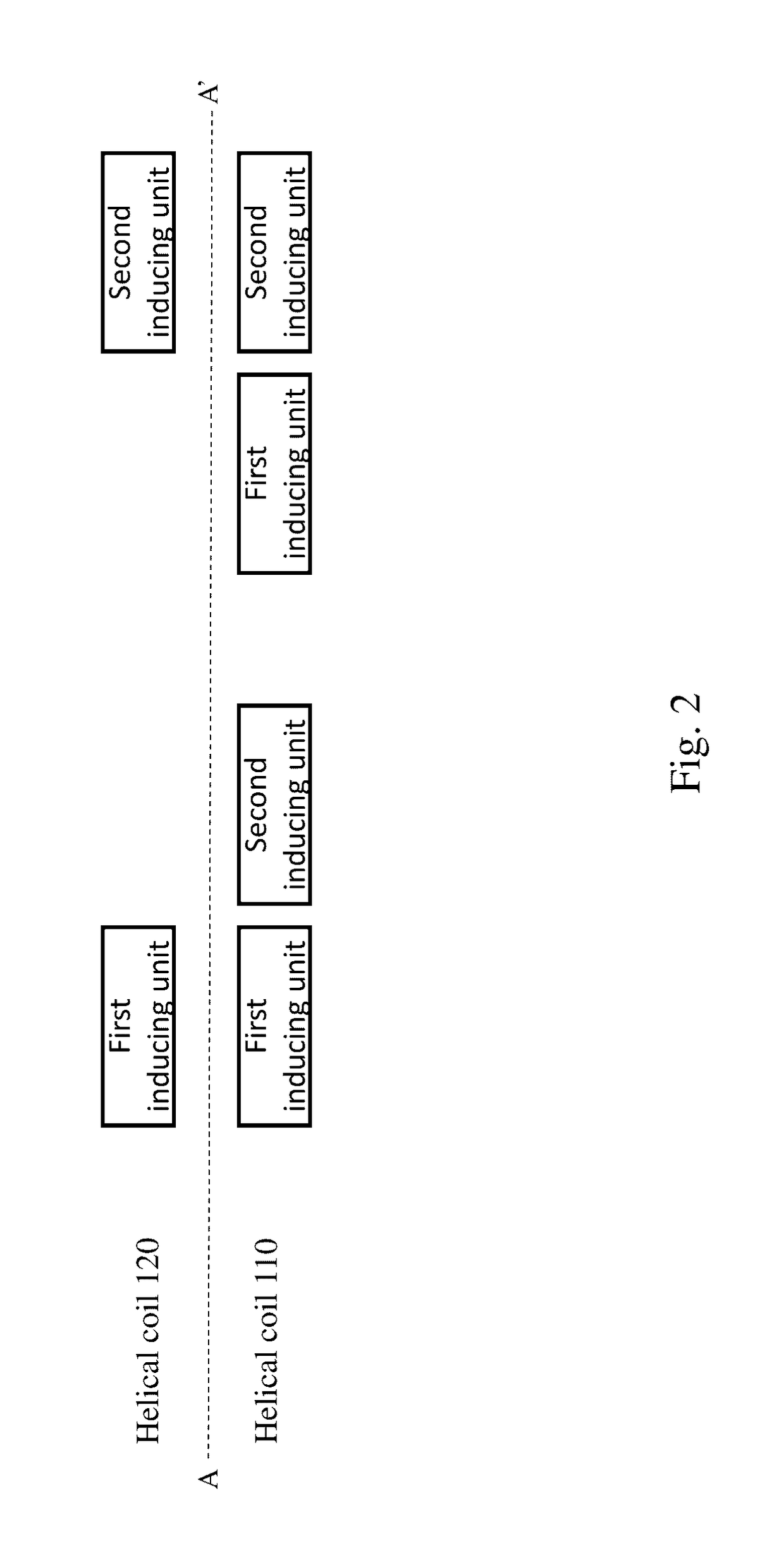

Helical Stacked Integrated Inductor and Transformer

ActiveUS20170162318A1Reduce winding complexityReduce component areaSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsTransformerHelical coil

A helical stacked integrated inductor formed by a first inducing unit and a second inducing unit includes a first helical coil and a second helical coil. The first helical coil is substantially located at a first plane and includes a first outer turn and a first inner turn. The first inner turn is surrounded by the first outer turn. The first helical coil forms a part of the first inducing unit and a part of the second inducing unit. The second helical coil is substantially located at a second plane different from the first plane and overlaps the first helical coil. The second helical coil forms a part of the first inducing unit and a part of the second inducing unit. The first helical coil and the second helical coil are stacked in a staggered arrangement.

Owner:REALTEK SEMICON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com