Middle-bolted slit steel plate shear wall and processing and manufacturing method thereof

A steel plate shear wall and seam technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of high-strength bolts, slippage, etc., achieve simple and feasible hoisting and installation, and overcome the problems of slippage and bolt slippage. relieving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

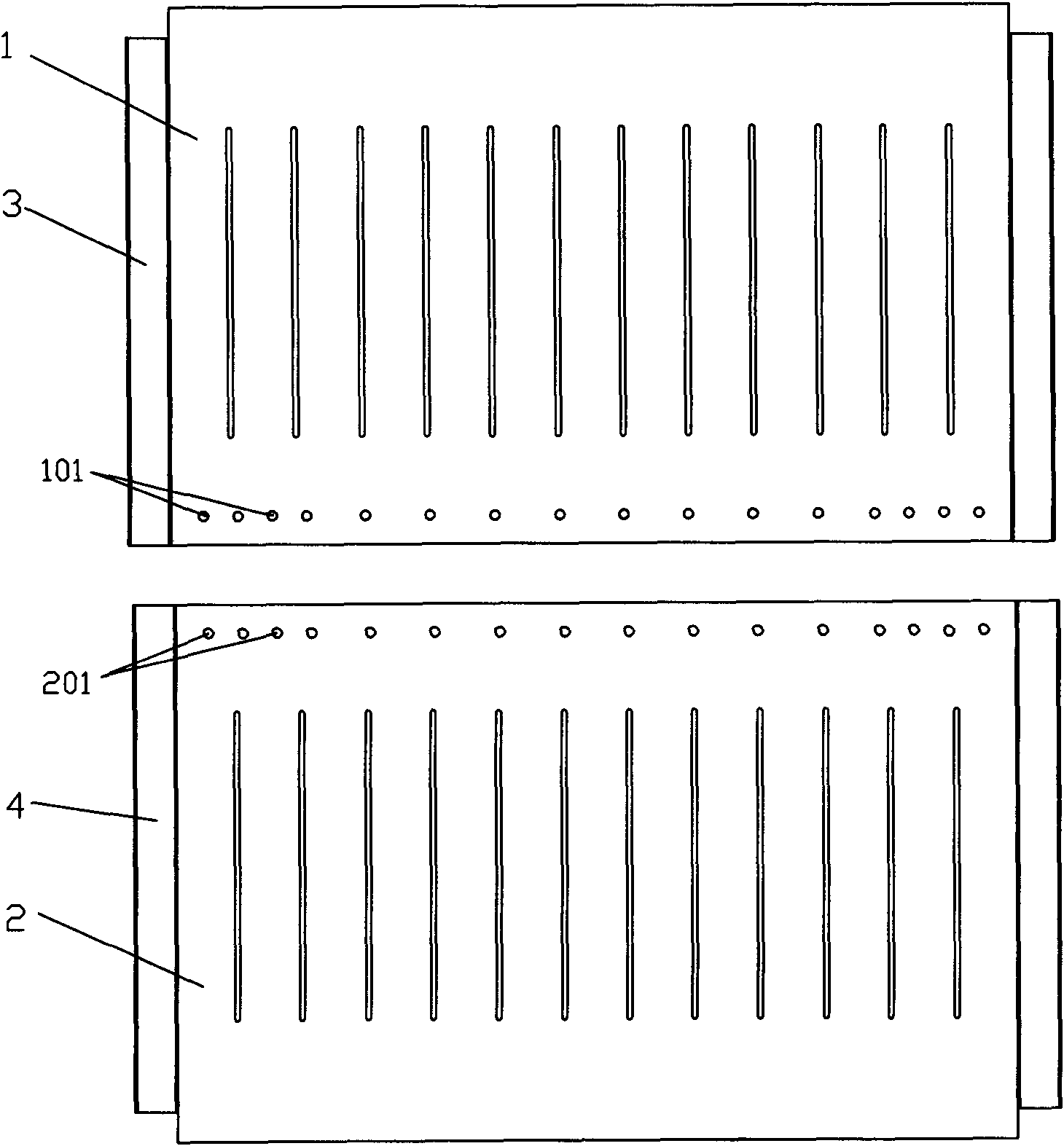

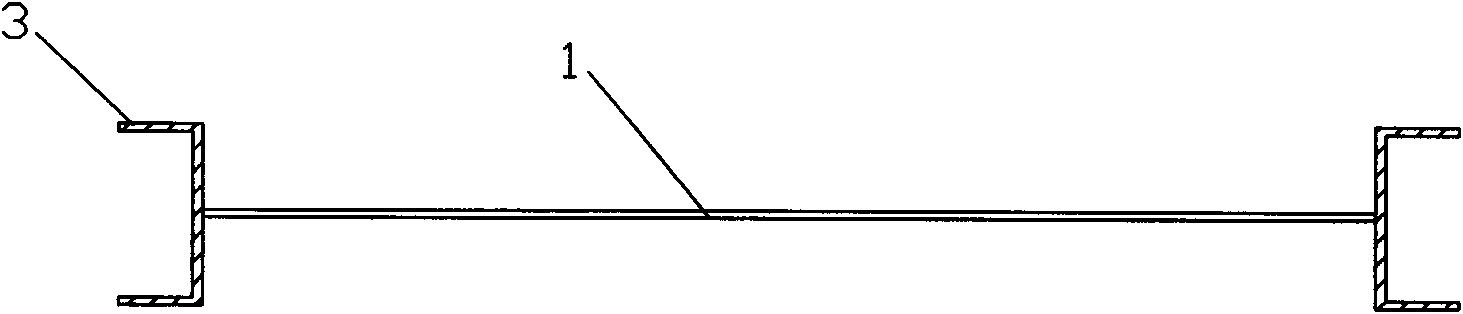

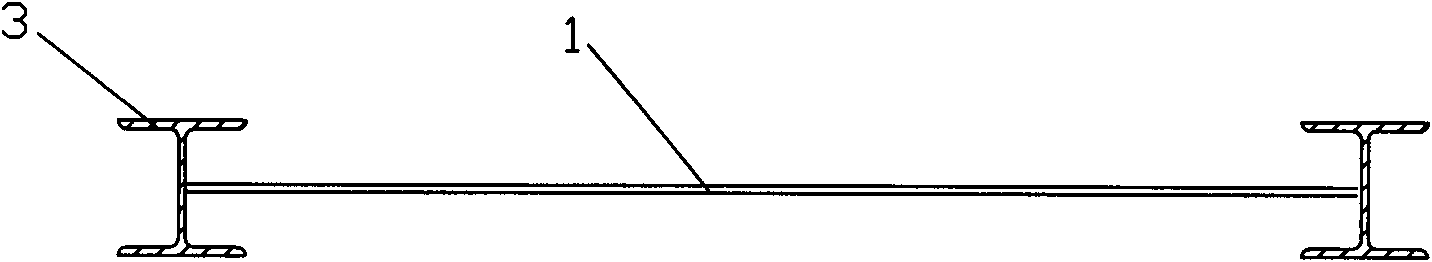

[0038] see Figure 1 ~ Figure 4b, the middle bolted steel plate shear wall with seams of the present invention, its upper and lower ends are respectively connected with the upper and lower frame beams 9, 9'; Stiffeners 3 and 4 are provided on the edge, and two steel plates 1 and 2 with vertical seams are arranged up and down, leaving a gap between them to adjust the vertical installation error; the upper and lower two steel plates with vertical seams 1 and 2 are at the close end along the length direction Bolt holes 101, 201 are provided; the two splints 5, 6 are also provided with two rows of connecting holes 501, 601 corresponding to the bolt holes 101, 201 of the two steel plates 1, 2 with vertical seams along the length direction, respectively through high-strength friction type bolts 7 Interpose and connect two steel plates with vertical seams 1, 2 arranged up and down; add webs 502, 602 along the length direction of the outer side midline of the splints 5, 6, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com