Bridge pier bent cap lower supporting system and construction method thereof

A support system and construction method technology, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of being unable to bear the joint action of dead load and traffic live load, insufficient bearing capacity, self-heavy structure, etc., to facilitate standardized prefabrication and Rapid construction with assembly, improved bearing capacity, and the effect of less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

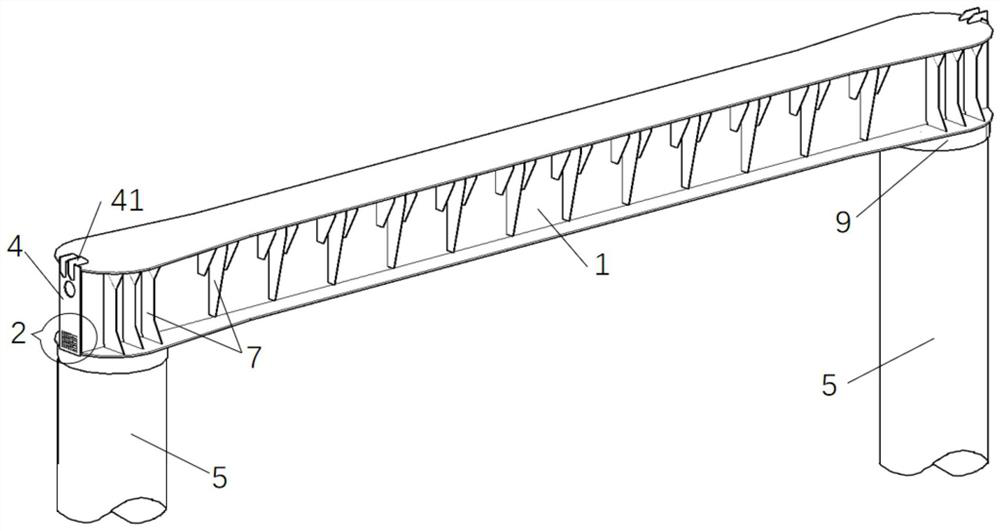

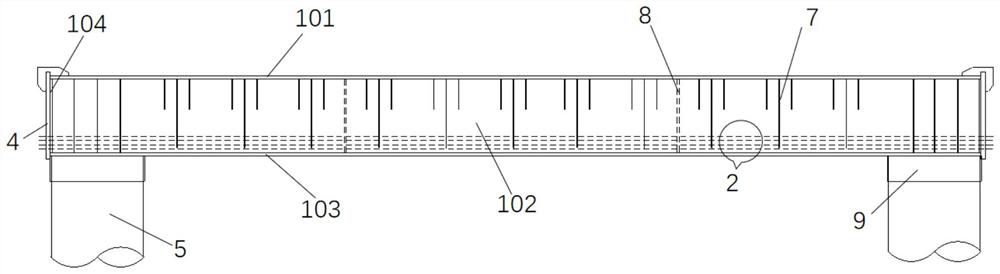

[0072] This embodiment provides a support system for the lower part of a bridge pier cover beam, see Figure 1-13 , including a bridge pier 5 and a cover beam, the cover beam includes a steel bar-shaped closed box 1, the closed box 1 is provided with a number of prestressed steel bundles 2 in the longitudinal direction, and the closed box 1 is filled with Concrete 3, the bottom surface of the closed box 1 is connected to the top of the bridge pier 5.

[0073] The steel box in this embodiment refers to the closed box body 1 . The lower support system of the bridge pier cover beam refers to the joint structure of the bridge pier 5, the cover beam and the connection structure between them.

[0074] For the cover beam described in this scheme, the strip-shaped closed box 1 is designed according to the shape and size required for the force safety of the cover beam, and the closed box 1 is used as the support template for the subsequent concrete 3 pouring and prestress tensioning, ...

Embodiment 2

[0095]The present embodiment provides a construction method for the lower support system of a bridge pier cover beam as described in Embodiment 1, comprising the following steps:

[0096] S1. Install the outer ring steel sleeve 901 and the inner ring steel sleeve 902 on the top surface of the bridge pier 5, and then pour the first concrete body; then hoist the closed box 1 so that the connecting lugs 906 on the bottom surface are inserted into the inner ring steel in the corresponding limiting groove 909 inside the sleeve 902, so that the first concrete body supports the closed box 1;

[0097] S2, pour concrete 3 into the closed box 1 through the pouring hole 105;

[0098] S3, pouring the second concrete body 911, the construction is completed;

[0099] Wherein, before the step S1, it also includes the construction of the limiting groove 909 on the top of the pier and the welding of the connecting lugs 906 on the bottom surface of the closed box 1; before the step S2, it also...

Embodiment 3

[0102] The present embodiment provides a construction method for the lower support system of a bridge pier cover beam as described in Embodiment 1, comprising the following steps:

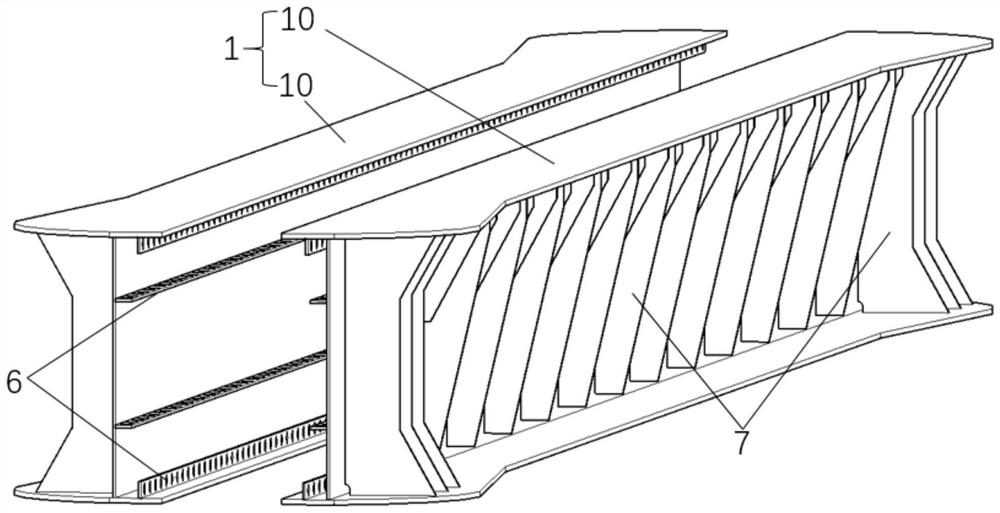

[0103] S01. Weld the vertically arranged shear nails 910 and the vertically arranged connecting lugs 906 with holes on the bottom surface of the lower flange plate 103 of the two I-beam girders 10 at the positions corresponding to the transverse middle of the bridge pier 5; on the bridge pier 5 Install the outer ring steel sleeve 901 and the inner ring steel sleeve 902 on the top surface, and then pour the first concrete body;

[0104] Before step S01, the double I-beam 10 can be prefabricated in the factory, the upper flange plate 101, the lower flange plate 103 and the web 102 are welded to form two pieces of the I-beam 10 member, and the box is welded at the corresponding position at the same time. The inner stiffener 6 and the box outer stiffener 7; each piece of I-beam 10 is divided into sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com