Patents

Literature

266results about How to "Improve structural durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

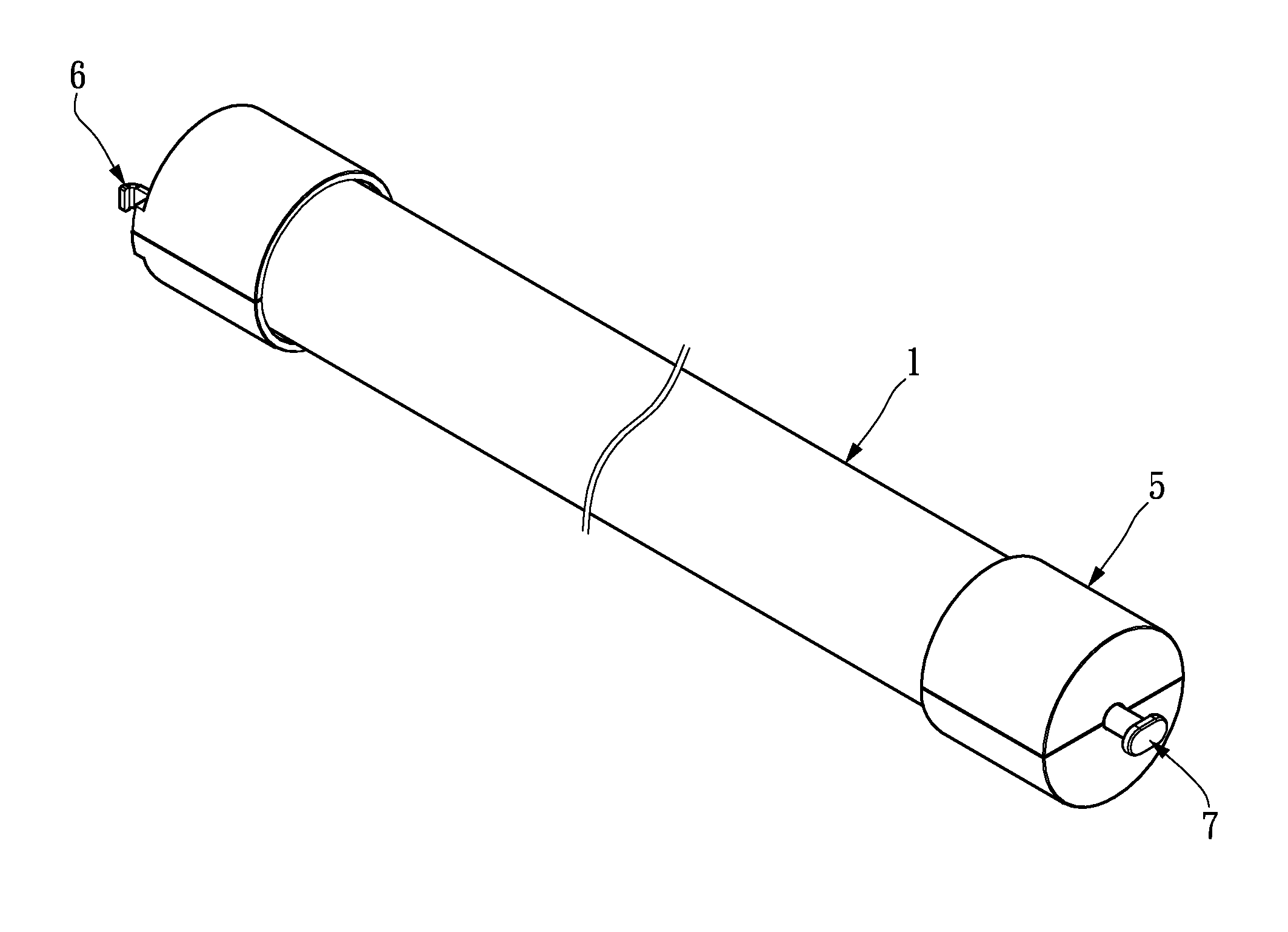

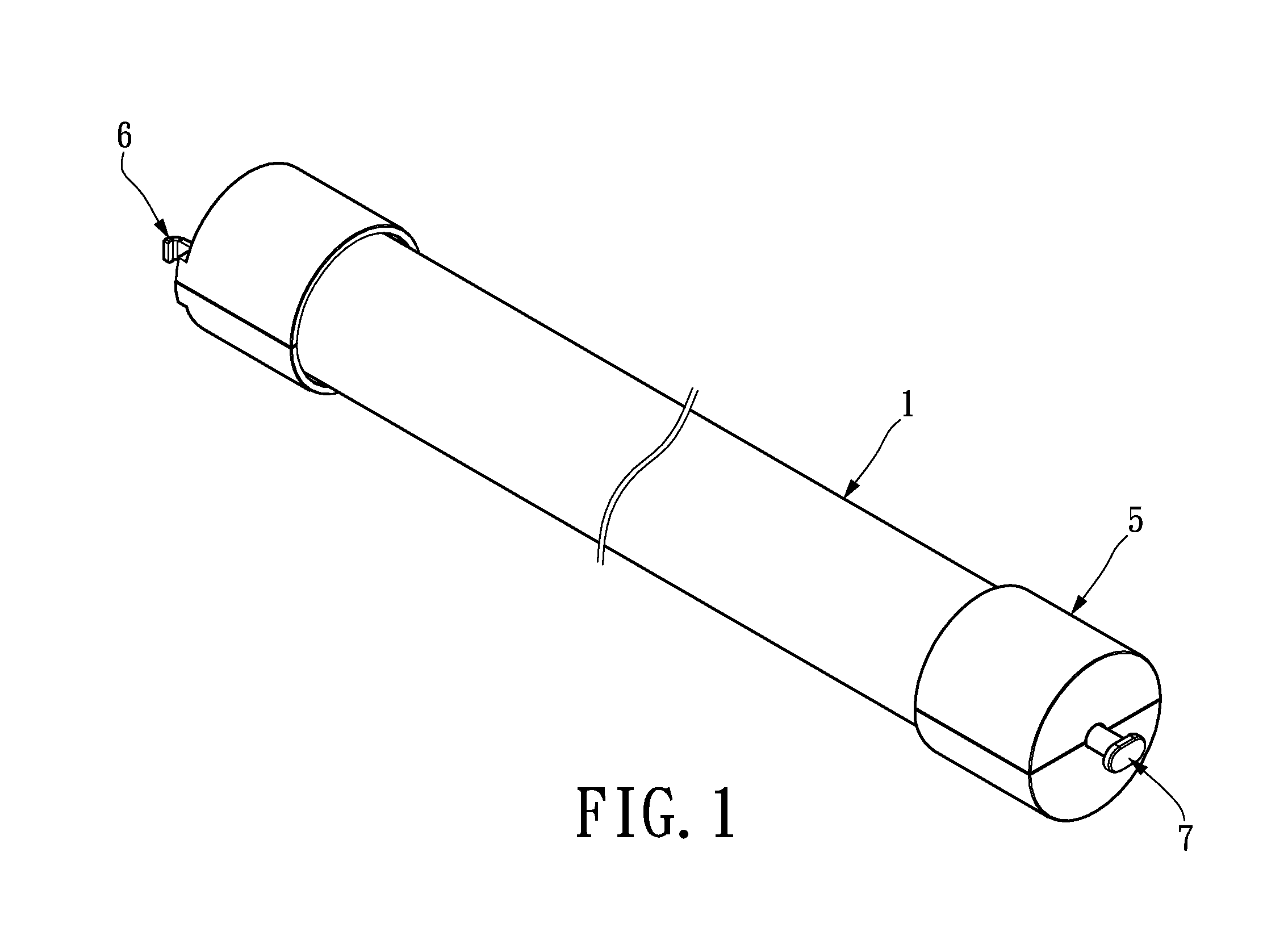

LED tube light

InactiveUS20130170196A1Improve structural durabilityReduce breakage ratePoint-like light sourceLighting support devicesEngineeringLED lamp

An LED tube light includes a glass tube, a base, a light emitting unit, and two lateral cover assemblies. The base has a length larger than the length of the glass tube, wherein two opposite end portions of the base are arranged out of a region defined by orthographically projecting from the glass tube to the base. The light emitting unit is fixed on the base and is used for emitting light, passing through the glass tube to illuminate. The two lateral cover assemblies are respectively covered around the two end portions of the glass tube, wherein the two lateral cover assemblies are respectively installed on the two end portions of the base for maintaining the relative position between the cover assemblies and the base.

Owner:LITE ON TECH CORP

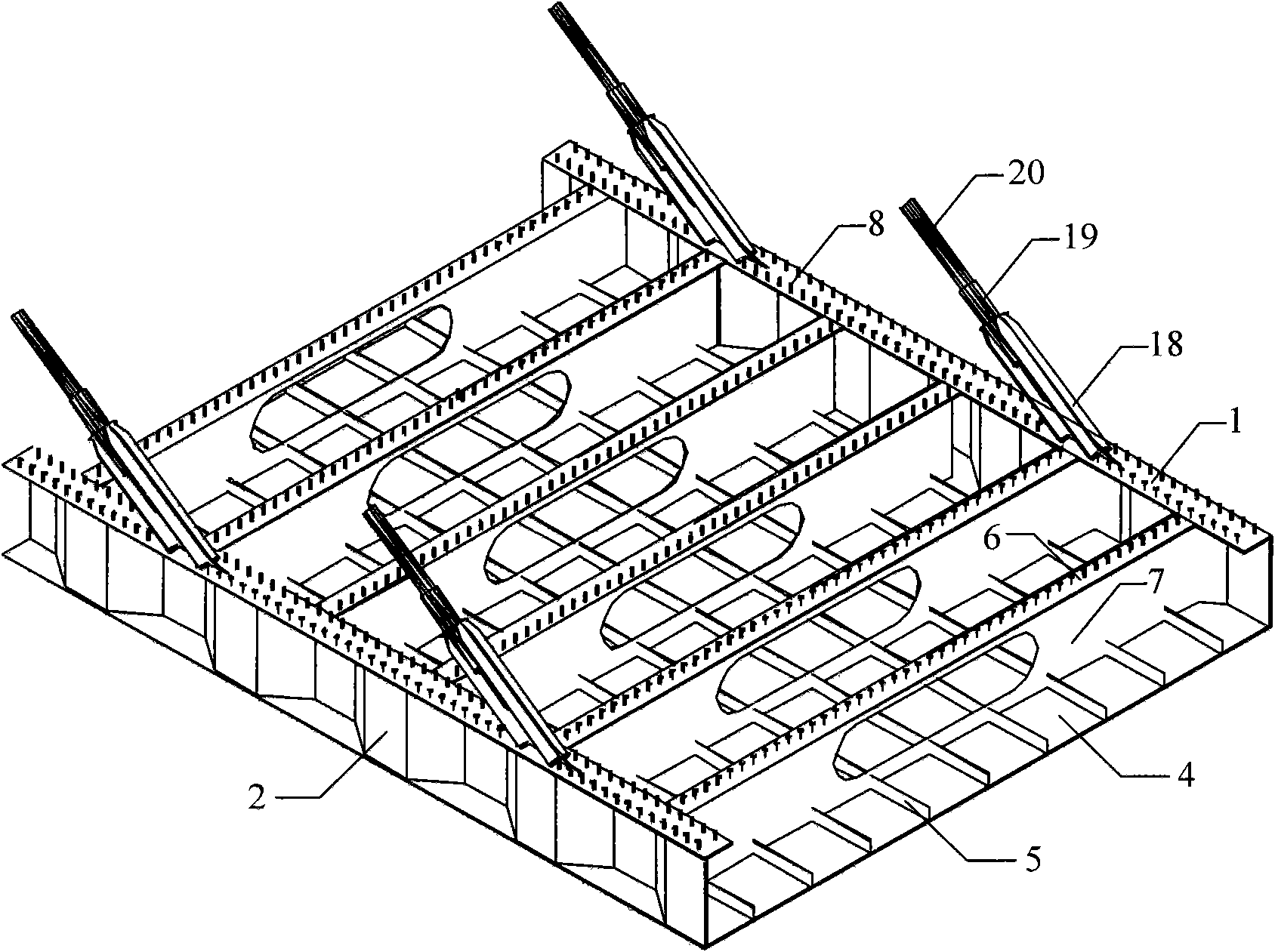

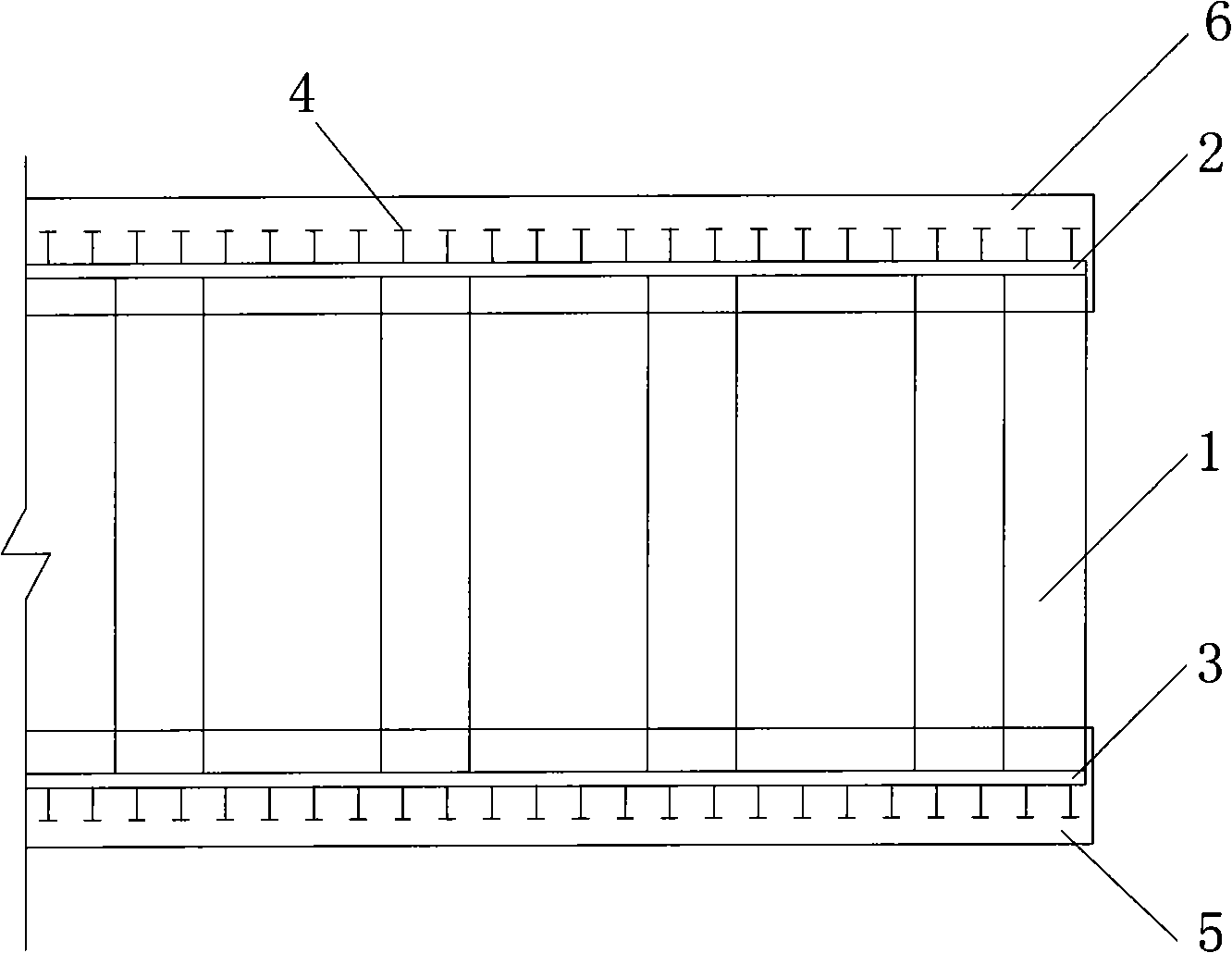

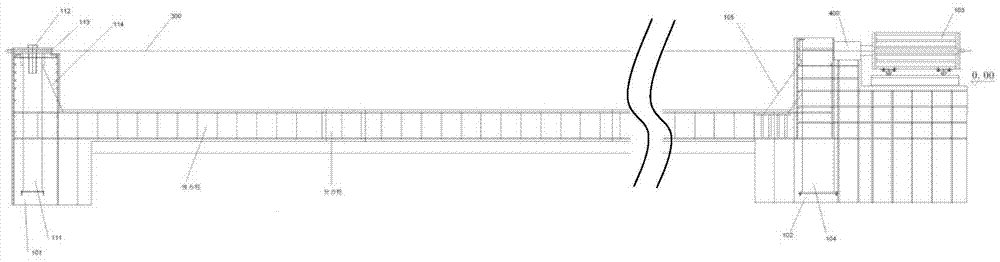

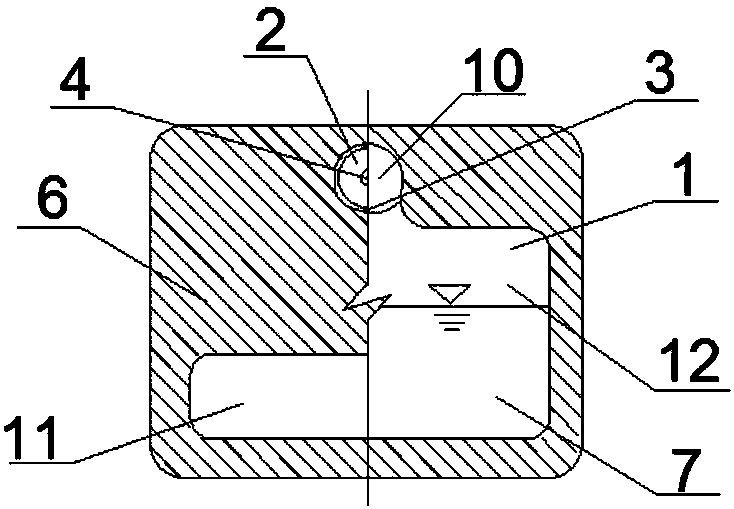

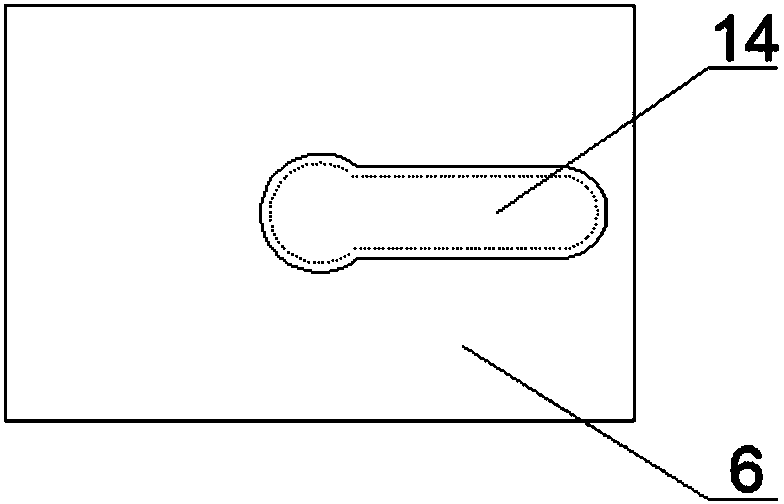

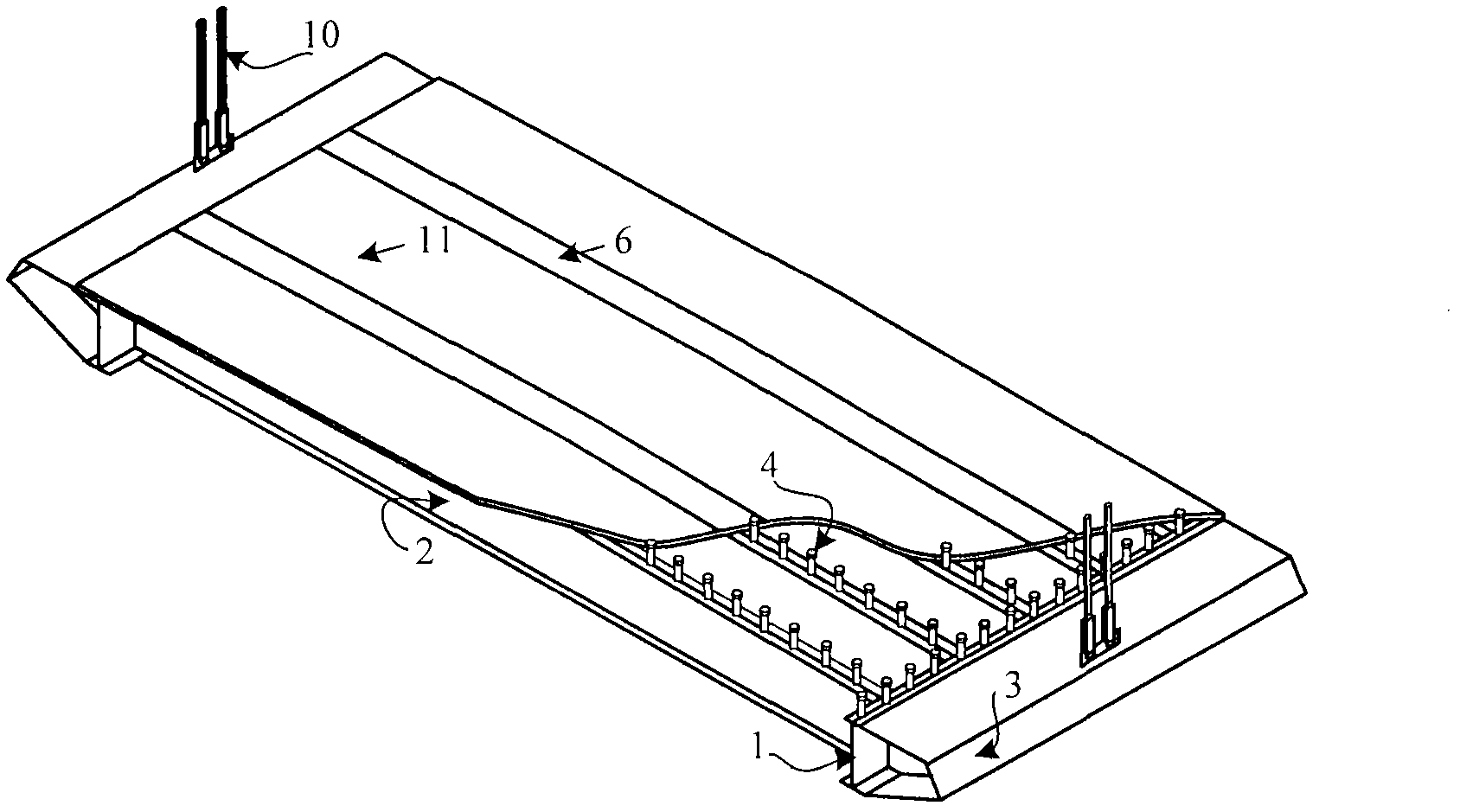

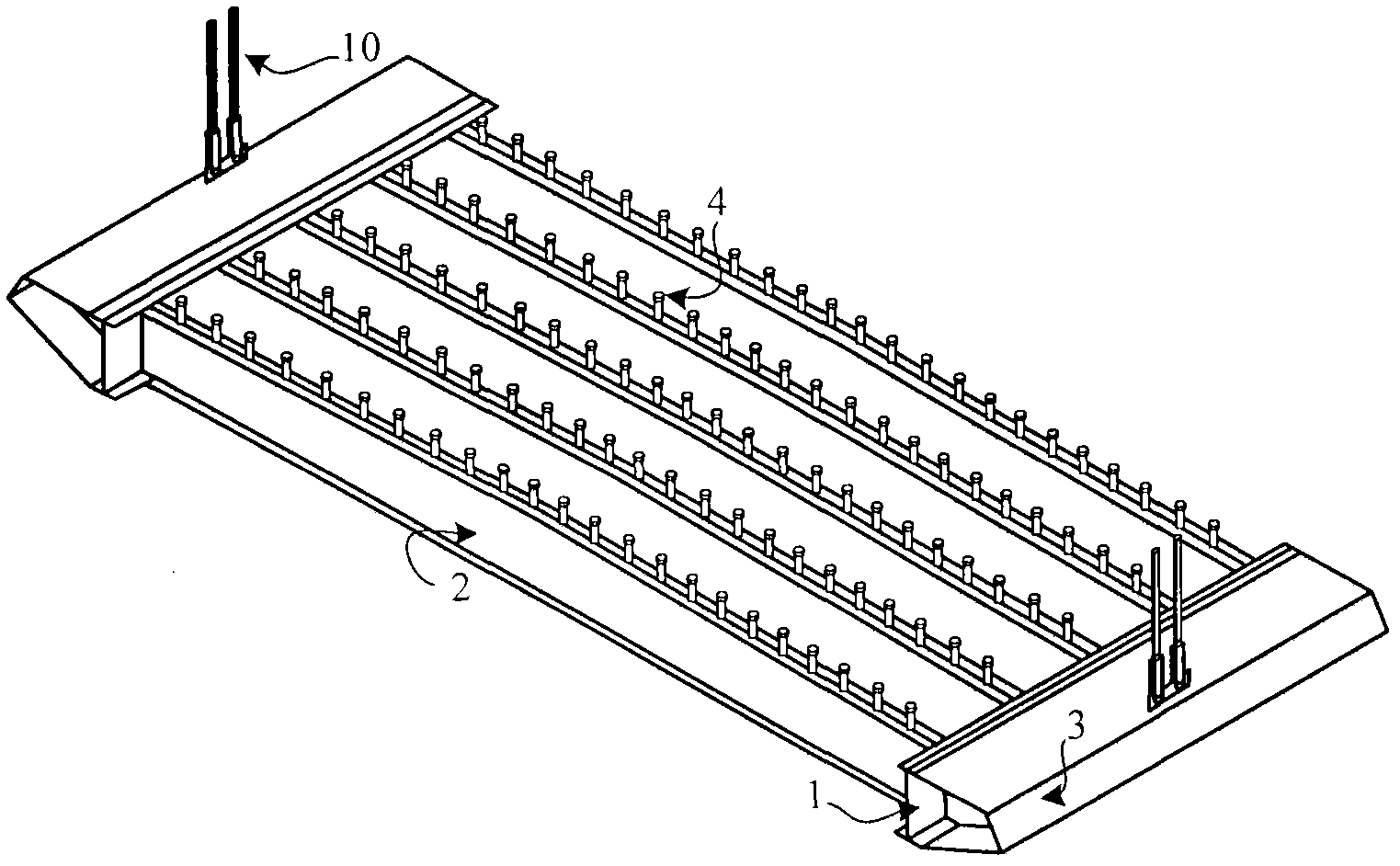

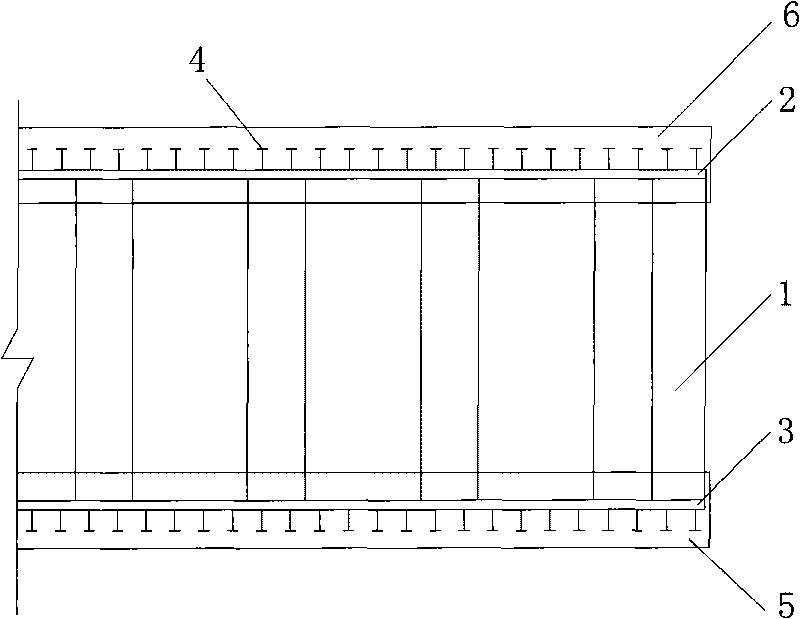

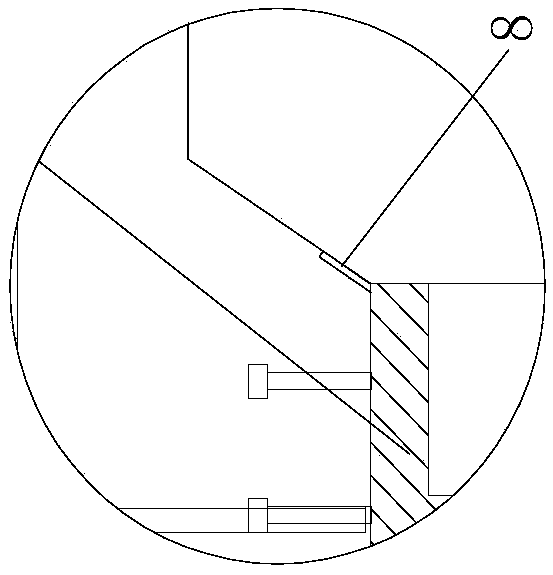

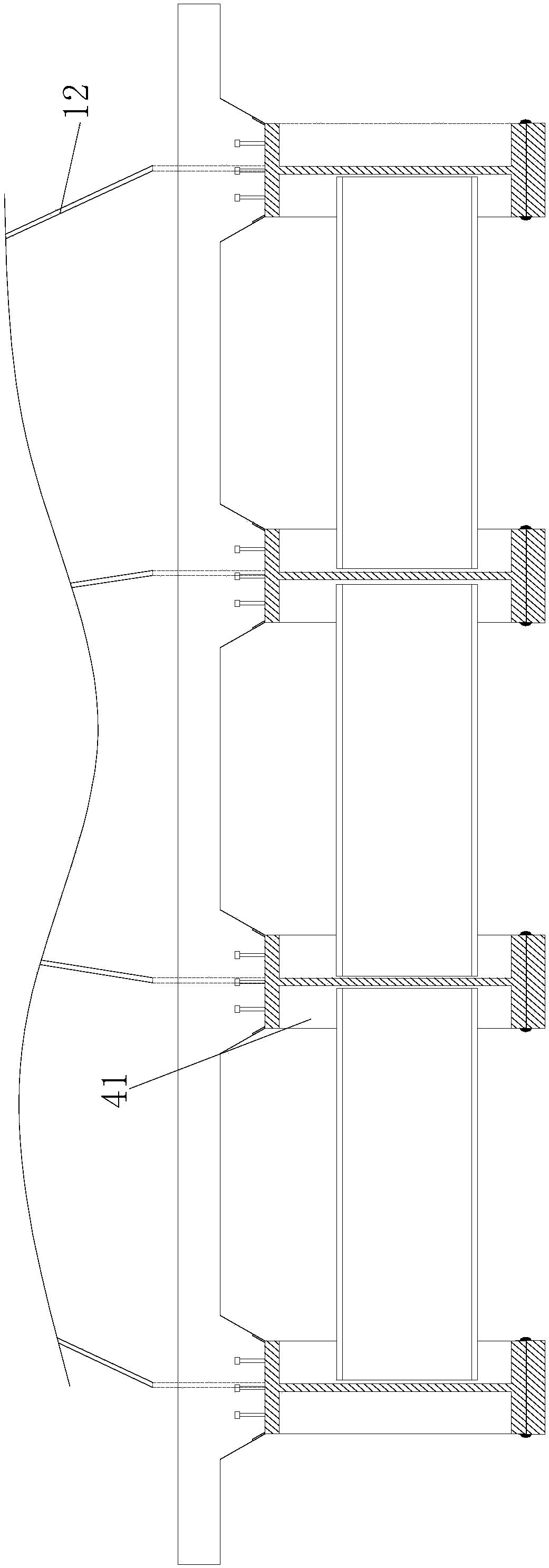

Corrugated steel webplate combined box girder floor system for cable-stayed bridge and construction method thereof

InactiveCN101864729AAvoid on-site molding processReduce wet work workloadCable-stayed bridgeBridge structural detailsCrack resistanceEngineering

The invention relates to a corrugated steel webplate combined box girder floor system for a cable-stayed bridge and a construction method thereof, and belongs to the technical field of bridge structures. The corrugated steel webplate combined box girder floor system comprises a precast concrete plank and a cast-in-place concrete seam, wherein the precast concrete plank is positioned on a steel box girder and is integrated with the steel box girder into a whole; the steel box girder is formed by welding a top flange steel plate, a corrugated steel webplate and a steel plate at the bottom of the box girder; a box girder baseplate stiffening rib and a diaphragm plate are welded in the steel box girder; the diaphragm plate comprises a top flange steel plate of the diaphragm plate and a steel webplate of the diaphragm plate; a toggle pin connecting piece is welded on the top flange steel plate and the top flange steel plate of the diaphragm plate; and a steel anchor pulling plate and a steel sleeve are welded on the top flange steel plate. The corrugated steel webplate combined box girder floor system simplifies the manufacturing process for the precast concrete plank, gives full play to the superior mechanical property of the corrugated steel webplate and the release action of the corrugated steel webplate on the creep effect of concrete shrinkage, improves the bearing capacity, stiffness and crack resistance of the structure, and improves the durability of the structure.

Owner:TSINGHUA UNIV

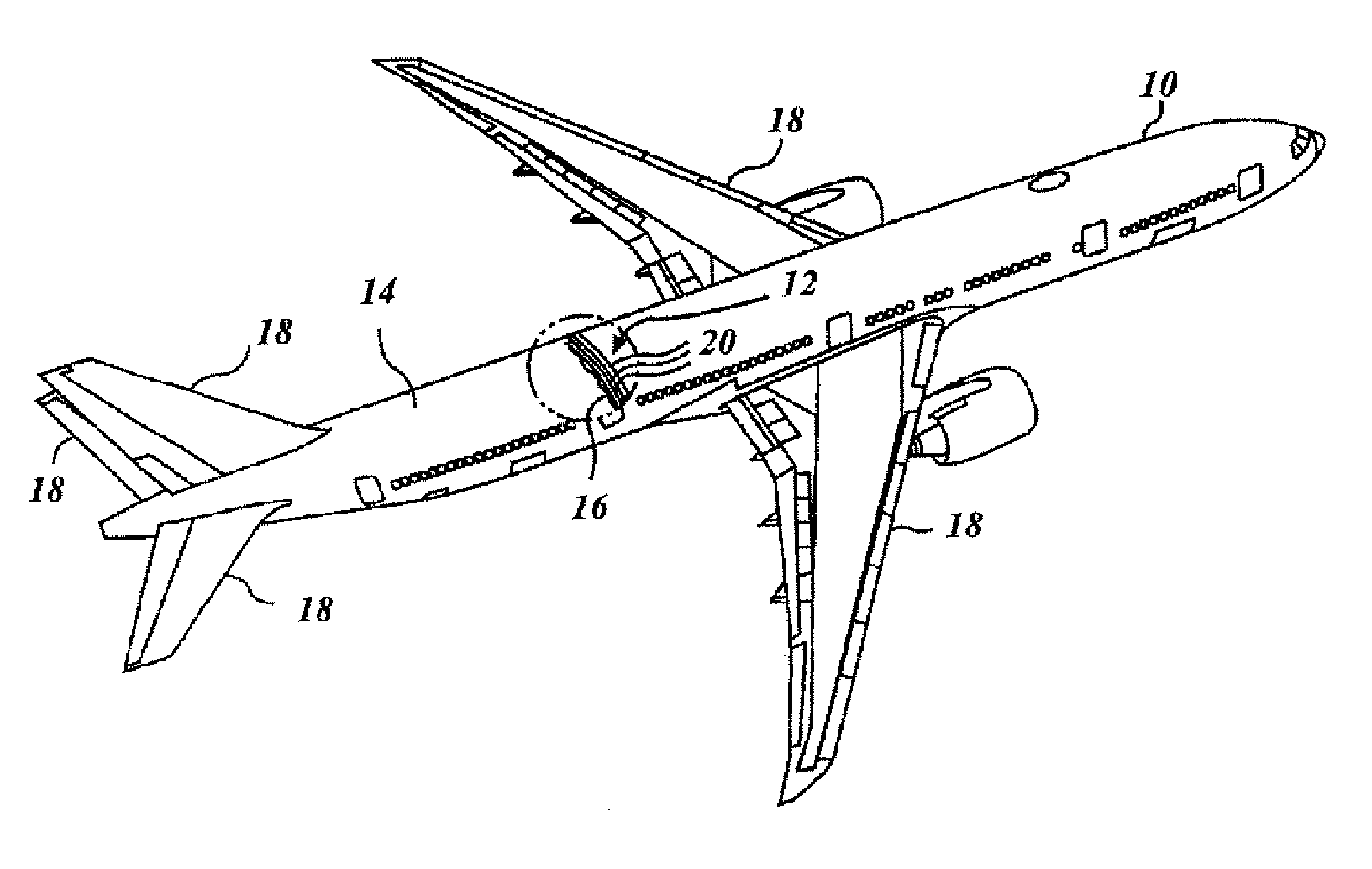

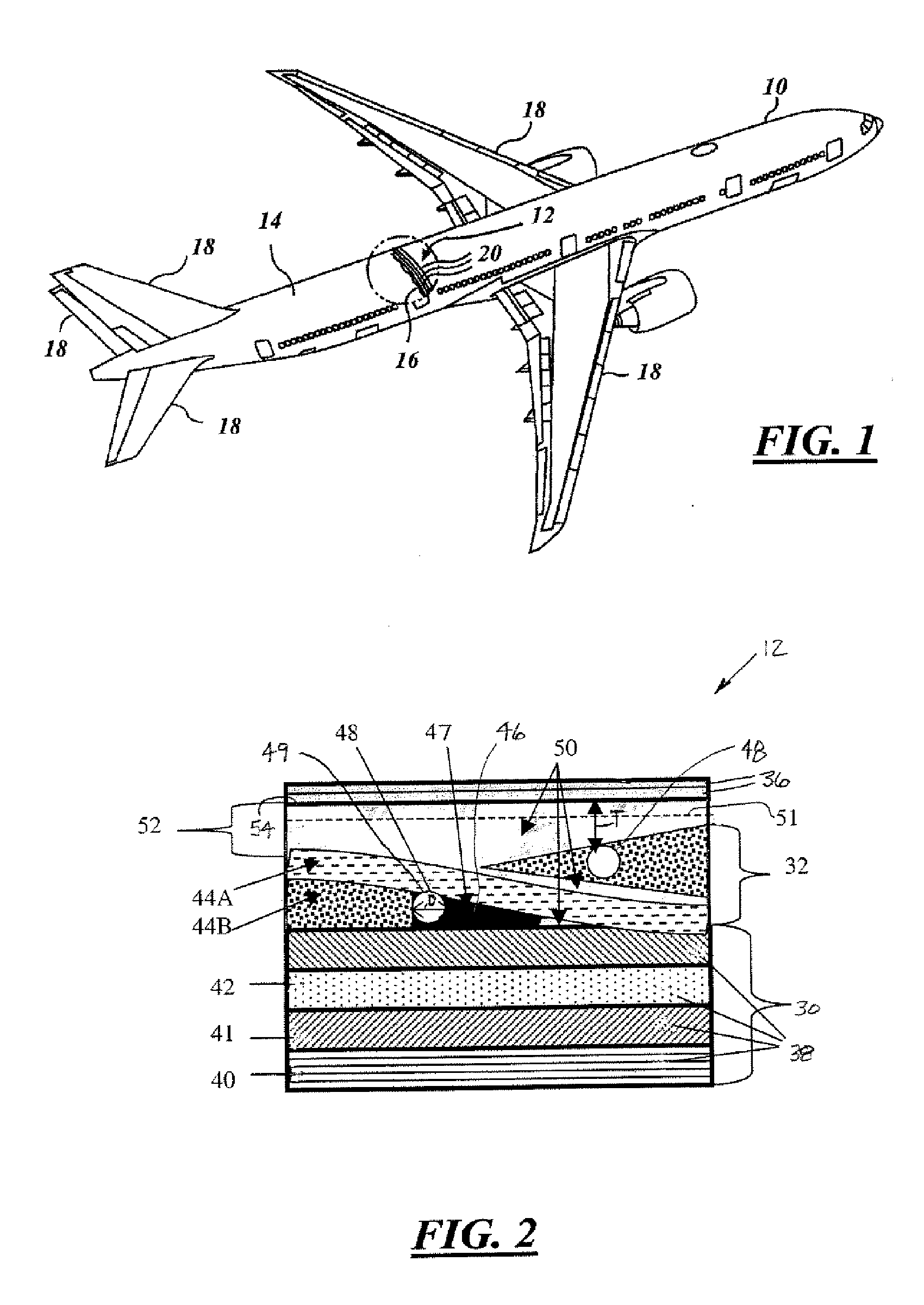

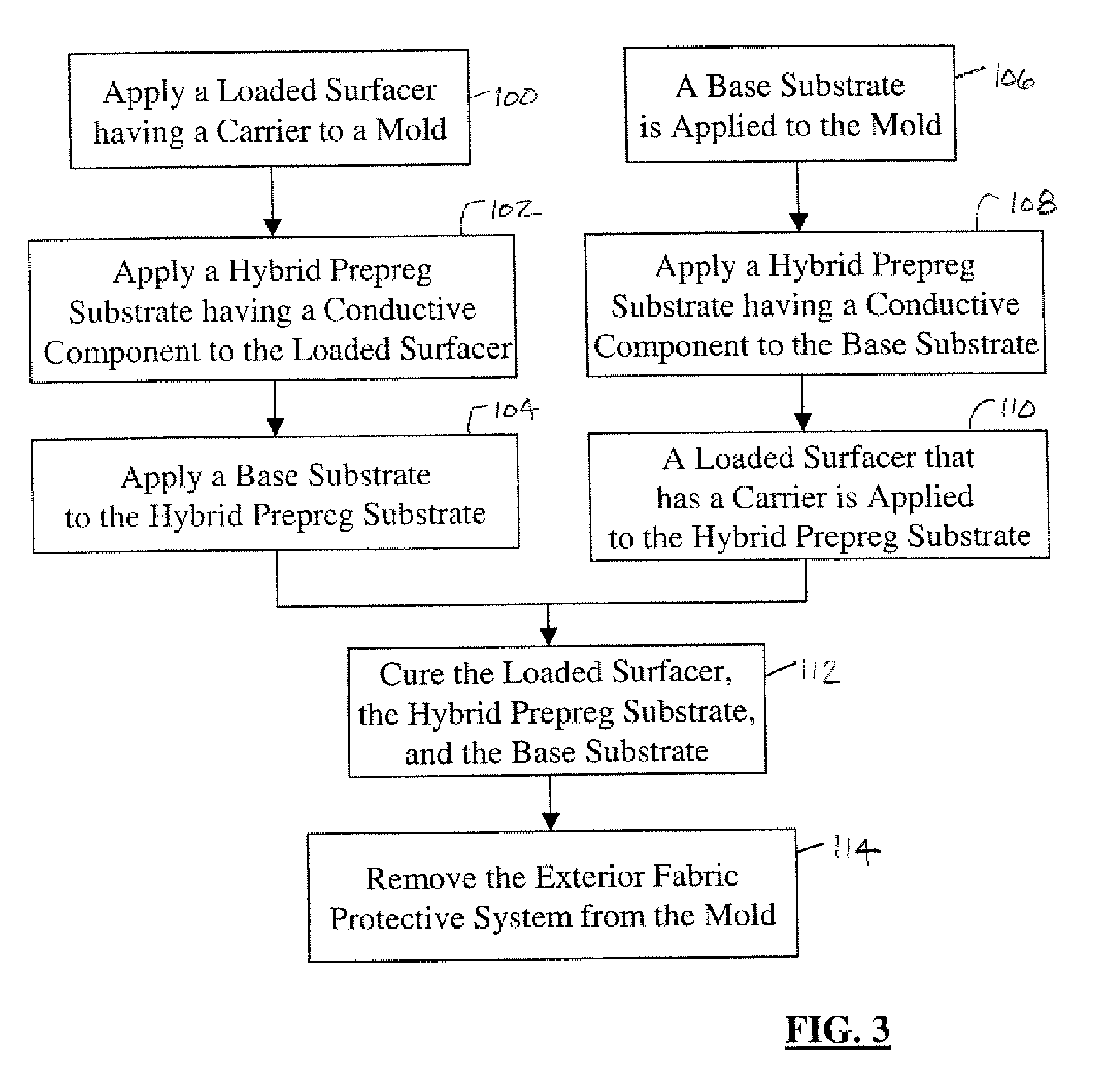

Environmentally stable hybrid fabric system for exterior protection of an aircraft

ActiveUS20070093163A1Reduce processing costsImprove structural durabilityVehicle componentsThin material handlingCarbon fibersEngineering

A method of forming an exterior surface protective structure (12) for an aircraft (10) includes uniting a loaded surfacer (52) having a carrier (51) to a hybrid prepreg substrate (32). The prepreg substrate (32) includes a carbon fabric (44) with an integral conductive component (48) having conductivity with in a metal conductivity range and is united to a base substrate (30). The loaded surfacer (52) and the prepreg substrate (32) are cured, which includes interfacially adhering matter between the loaded surfacer (52) and the prepreg substrate (32). A protective fabric system (12) for an exterior (14) of an aircraft (10) includes the base substrate (30). The hybrid prepreg substrate (32) is coupled to the base substrate (30). The loaded surfacer (52) with the carrier (51) is interfacially adhered to the prepreg substrate (32).

Owner:THE BOEING CO

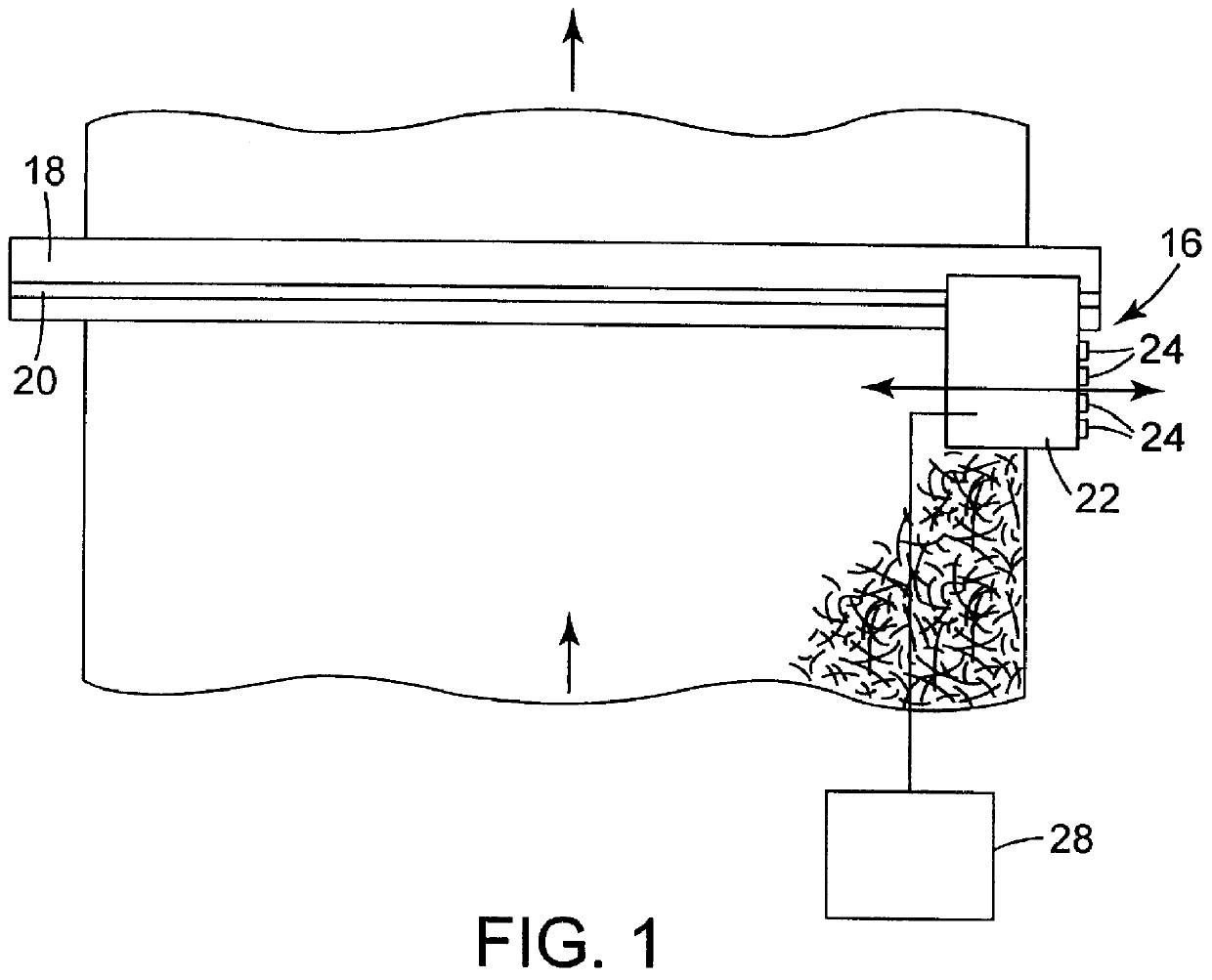

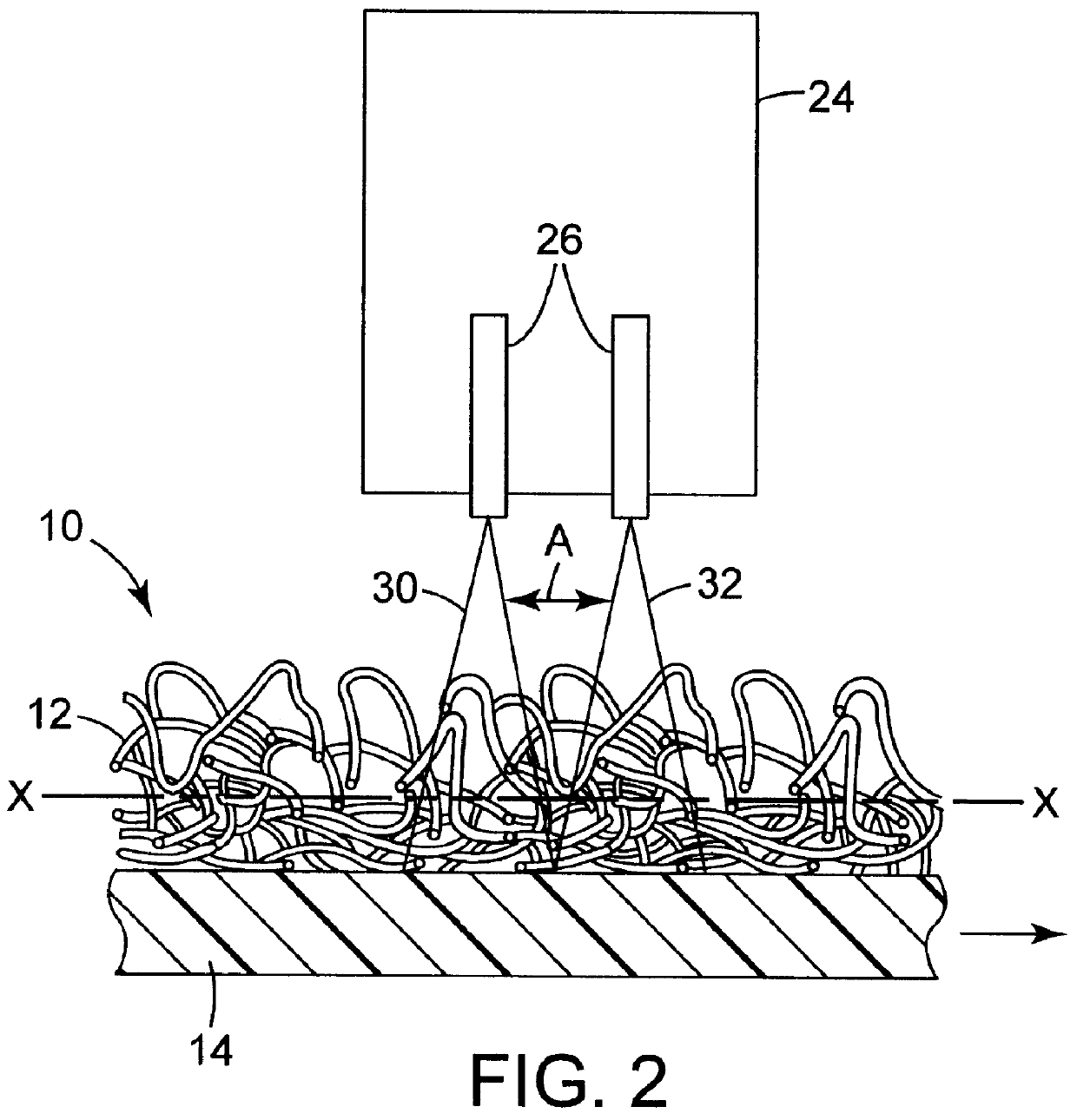

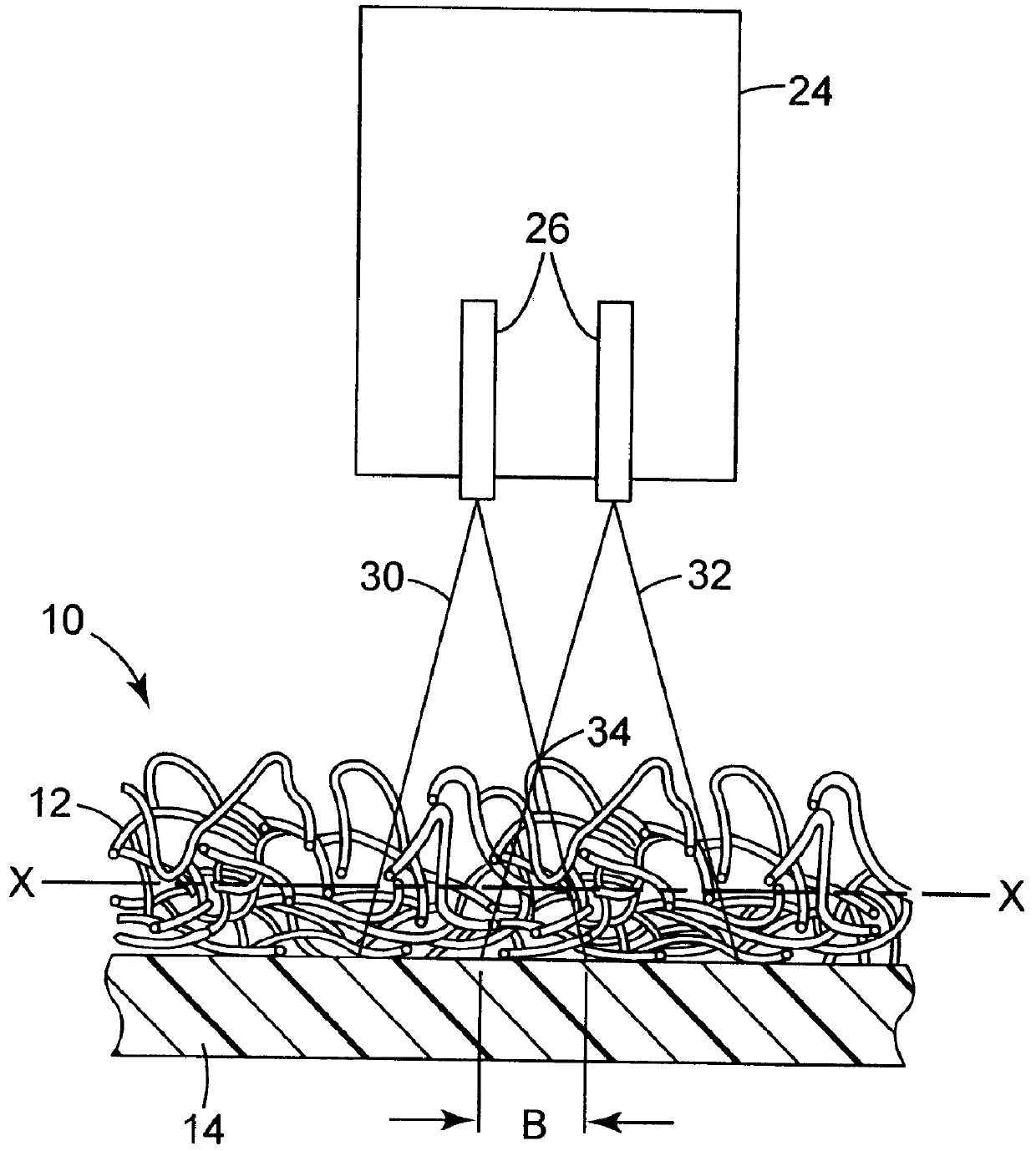

Method of continuous tone imaging to provide an imaged high loft mat product

InactiveUS6013347AImprove structural durabilityReliable imagingLayered productsBaby linensOpen structureEngineering

A method for continuous tone imaging on a mat product having a web material with a three dimensional open structure provides a mat product with a sufficiently clear image. Moreover, it is a specific aspect of the present method to provide a clear image on such a three dimensional structure without negatively affecting the characteristics of the web material having the three dimensional structure. More specifically, the present invention is directed to a method for imaging a flexible high loft matting material which can be used in providing a floor covering mat product. The present invention is also directed to the imaged mat product produced in accordance with this method.

Owner:3M INNOVATIVE PROPERTIES CO

Corrugated steel ventral shield preflex composite beam and construction method thereof

InactiveCN101550675AImproved prestress lossReduce steel consumptionBridge erection/assemblyBridge materialsRebarBridge engineering

The invention relates to a bridge composite beam structure, in particular to a corrugated steel ventral shield preflex composite beam and a construction method thereof. The corrugated steel ventral shield preflex composite beam consists of an I-shaped girder provided with a corrugated steel ventral shield, and reinforced concrete boards coated outside the margin plates of the upper and the lower wings of the I-shaped girder. The corrugated steel ventral shield preflex composite beam can be applied to urban interchange engineering and high-speed railway bridge engineering. As the rigidity of the longitudinal bridge direction of the corrugated steel ventral shield is very small, which can not absorb preflex force when preflexing the girder, the loss of prestress of the structure under shrinkage and creep effects can be reduced; the excellent shear resistance bearing capacity of the corrugated steel ventral shield avoids cracks of the ventral shield, and the durableness of the structure is good; moreover, the invention also provides the construction method of the corrugated steel ventral shield preflex composite beam.

Owner:SOUTHEAST UNIV

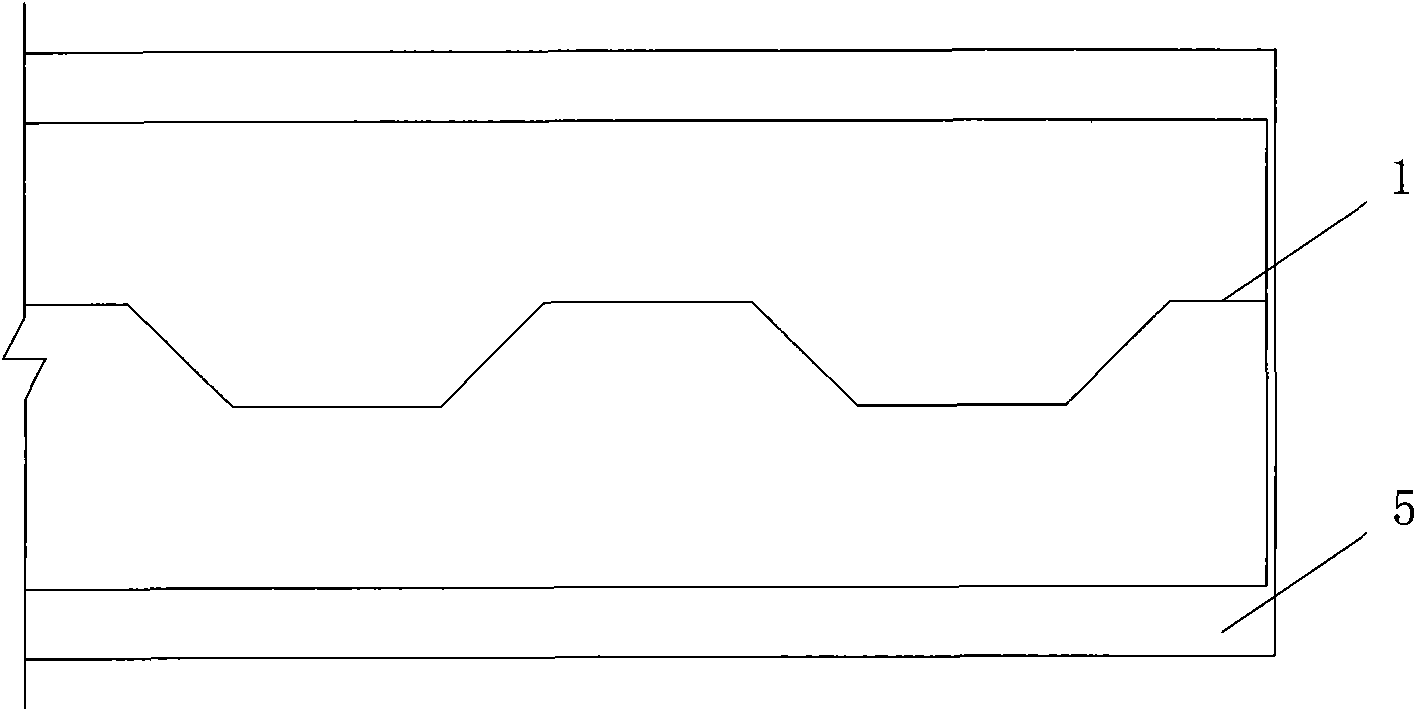

High-strength reinforced and functionally-graded concrete beam

The invention relates to a structure of a building member and a material, particularly relates to a high-strength reinforced and functionally-graded concrete beam and belongs to the technical field of building materials. The high-strength reinforced and functionally-graded concrete beam is mainly characterized in that common concrete and a high-toughness fiber-enhanced cement-based composite material are combined in a layering manner; the common concrete is adopted for the pressed area of the concrete beam; the high-toughness fiber-enhanced cement-based composite material is cast in a pulled area in the whole longitudinal-length range of the beam or the specific beam section; and interface-area treatment is adopted for a combined area of the common concrete and the high-toughness fiber-enhanced cement-based composite material. The high-strength reinforced and functionally-graded concrete beam has the advantages that uniform transition of the material system on performance is realized, discontinuous weak areas on the interface are eliminated, the bearing capability of the structure is effectively improved and the completeness and the stability of the whole structure are ensured.

Owner:YANGZHOU UNIV

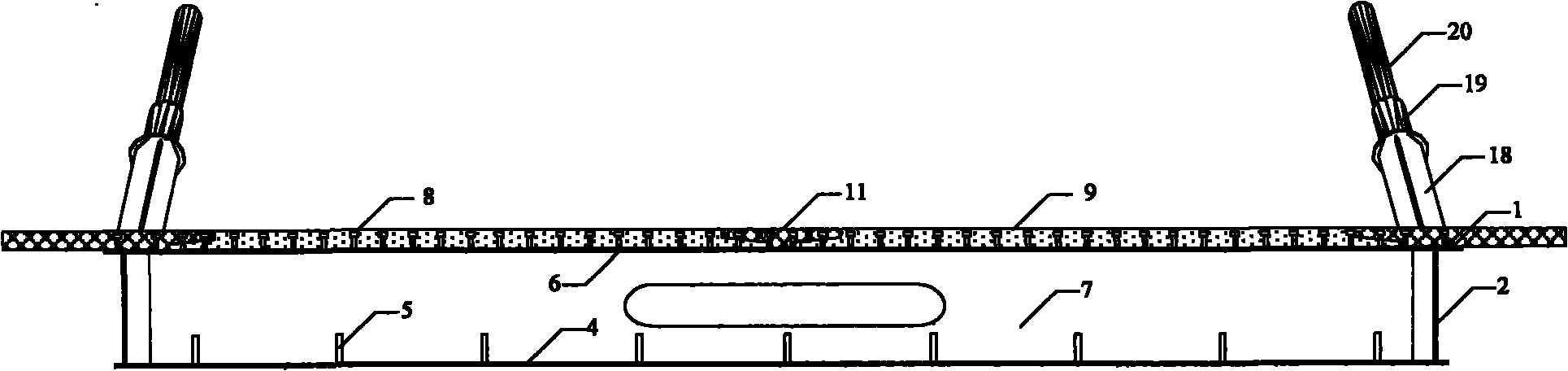

Two-way pre-tensioned prestressed concrete track plate and production method thereof

ActiveCN104264533AIncreased durabilitySolve crackingBallastwayCeramic shaping apparatusPre stressRebar

The invention provides a production method of a matrix pit type two-way pre-tensioned prestressed concrete track plate. The pre-tensioned process is different from a traditional pre-tensioned method that prestressed reinforcements are required to be exposed in air to generate rust; fixed-length reinforcements are adopted, and are additionally provided with anchor plates at the ends, so that the prestressed reinforcements can be closed through a seal anchoring mode, and the structural durability of the track plate is improved. The track plate adopts a matrix pit type tensioned pit structure. The invention discloses key equipment for production, technical parameters of key technological tools and structural principles or technical requirements of the key equipment.

Owner:CHINA RAILWAY 23RD BUREAU GRP RAILTRANSIT ENG CO LTD +3

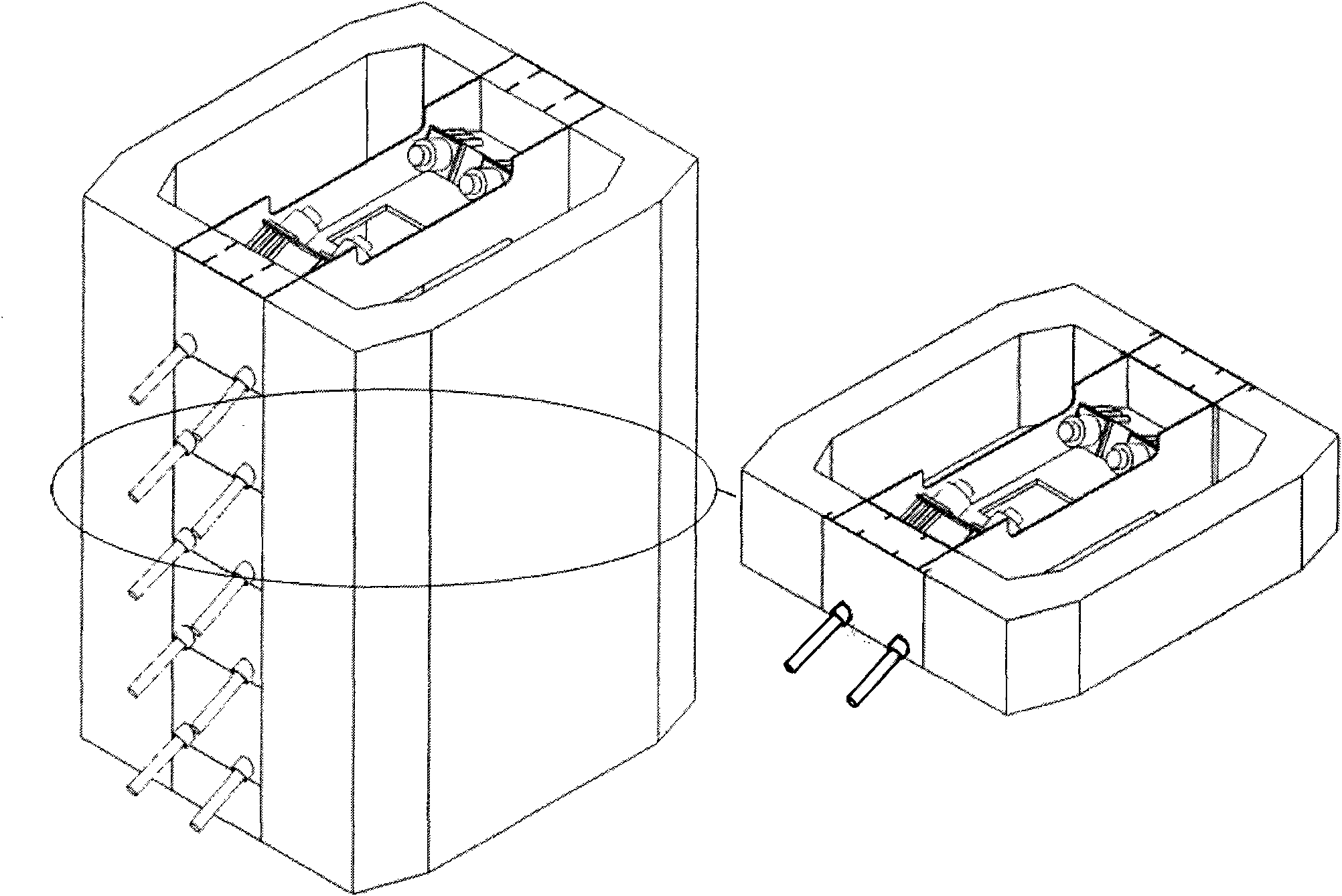

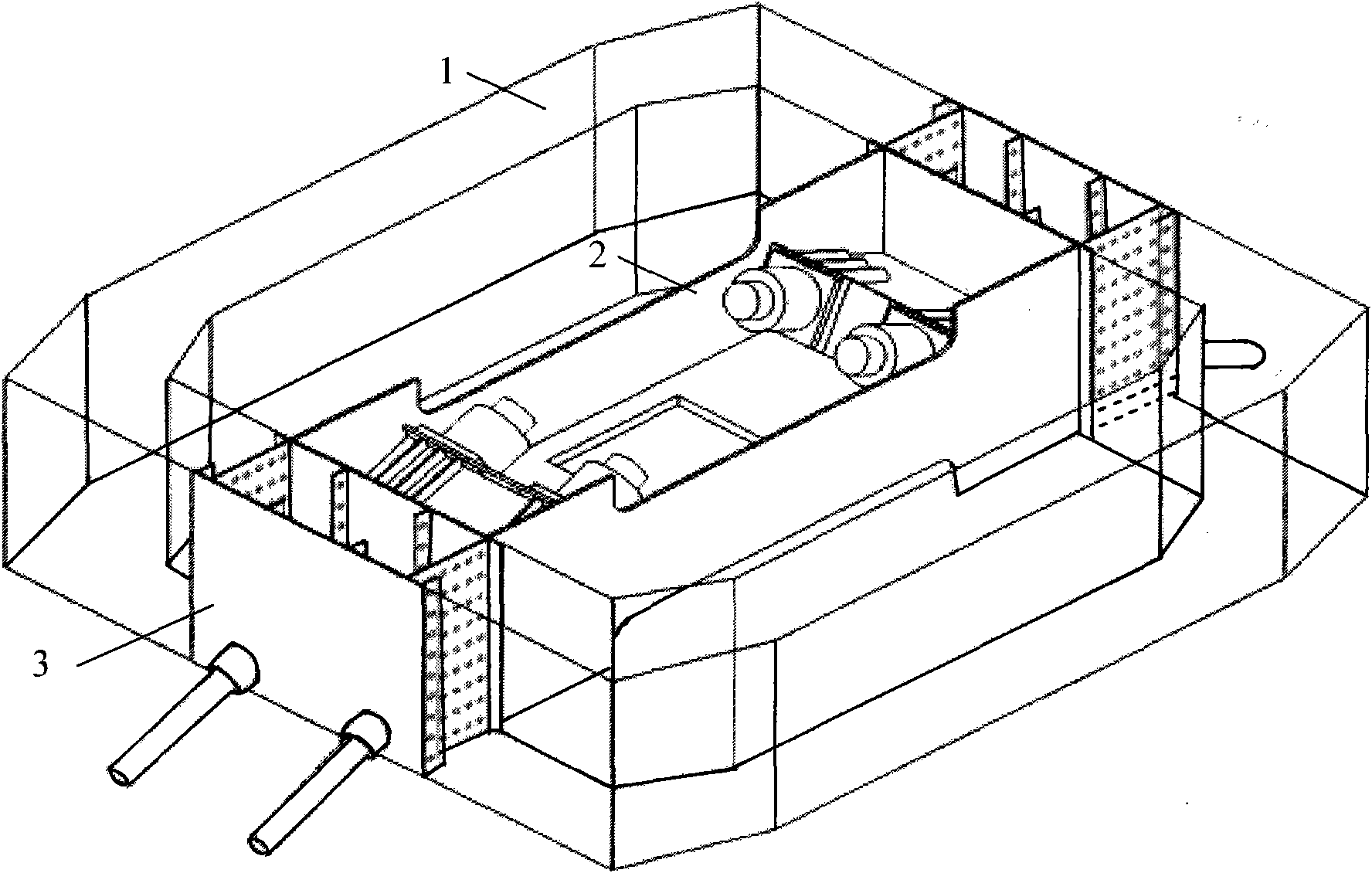

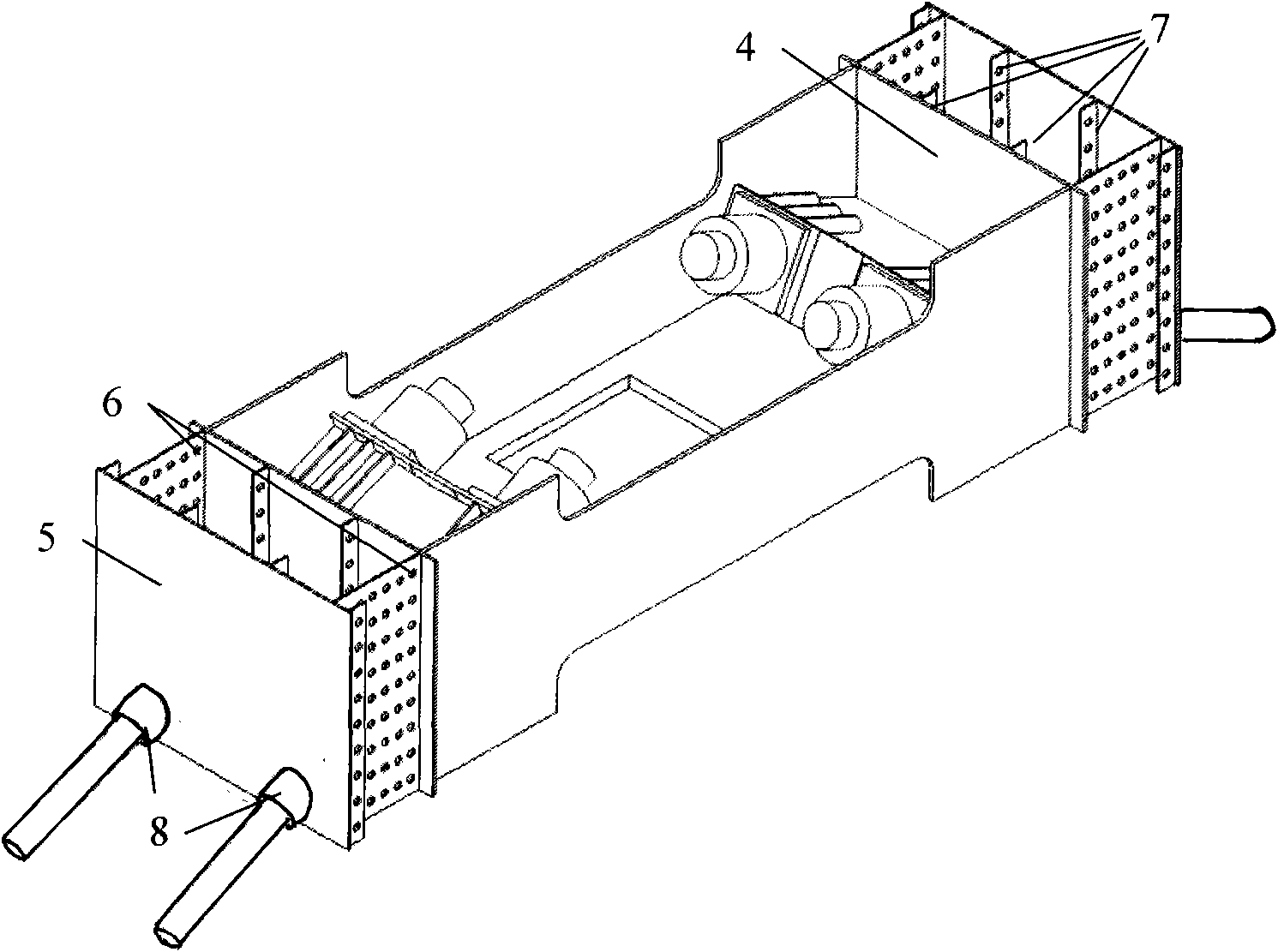

Composite anchoring structure on guyed tower end of cable-stayed bridge

The invention relates to a composite anchoring structure on the guyed tower end of a cable-stayed bridge. A plurality of steel anchor boxes with end box chambers are overlapped, and cast concrete with reinforcing bars penetrating through pinholes is arranged on the end box chambers. The box chambers are arranged on both ends of a steel anchor box and share the same end plate, a faceplate is arranged correspondingly opposite to the end plate, the end plate and the faceplate are connected by lateral plates on both sides to form a box chamber structure, the lateral plates are provided with a plurality of pinholes, and through holes are arranged on the lower part of the faceplate so that guyed sleeves can penetrate through. The invention accelerates the construction speed of a bridge tower, is convenient to manufacture, and has favorable durability.

Owner:TONGJI UNIV

Use of plastic film and plastic board as construction member, mechanical device protection layer, and reinforced layer

InactiveCN1963057AExtend your lifeIncreased durabilityCovering/liningsBuilding repairsAdhesiveMechanical equipment

The invention is an application of plastic film and plastic sheeting as building components, mechanical equipment protection layer and reinforcement layer, and it involves applications of plastic thin films, plastic complex film or plastic plate. The invention is aimed at the resolution of the durability of construction, the quality problems of concrete element cracking and the plaster cracking, the corrosion problems of mechanical equipment and the problem of concrete components is bad flexible. The invention daubs the adhesive or the polymer prepared of adhesive and inorganic powders or cement to the outer surface of buildings, then bonds the plastic thin films, plastic complex film or plastic plate on the outer surface of buildings or mechanical devices which is daubed with adhesive or polymer. The advantages of the invention are: it resolves the durability of construction and mechanical equipment effectively, increases the flexibility of concrete components and improve the performance of concrete structures; it is low cost, durable, easy operation, no complicated equipment needed, it bonds directly using adhesive or prepares polymer on site according adding other filler into adhesive and stirring.

Owner:吴淑环

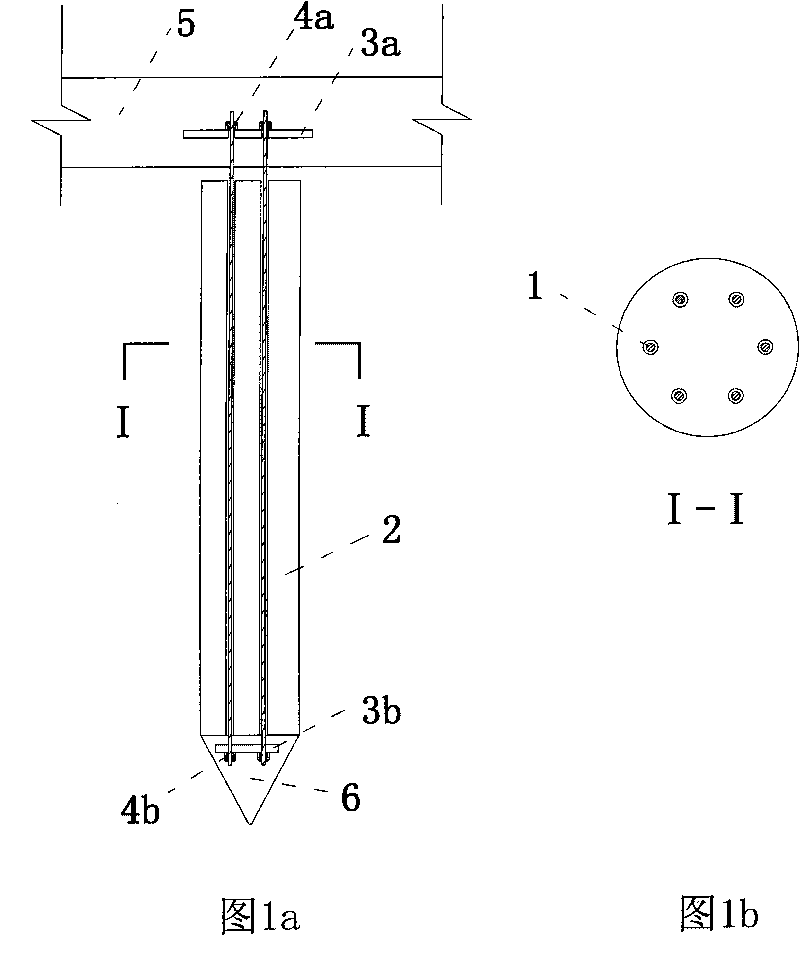

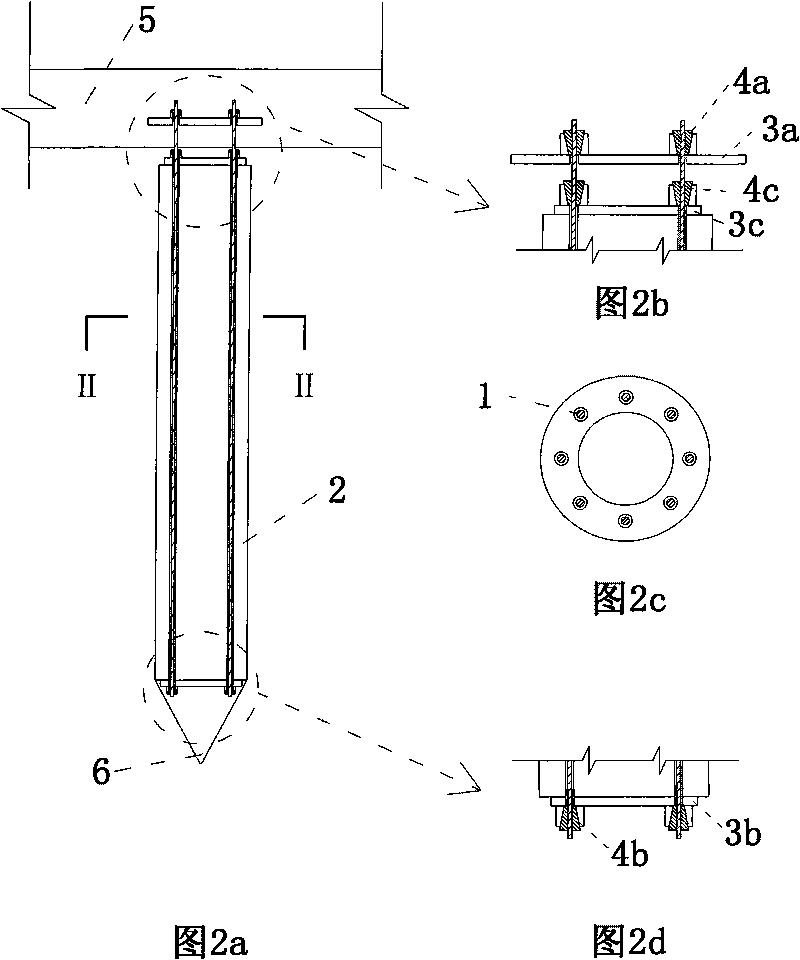

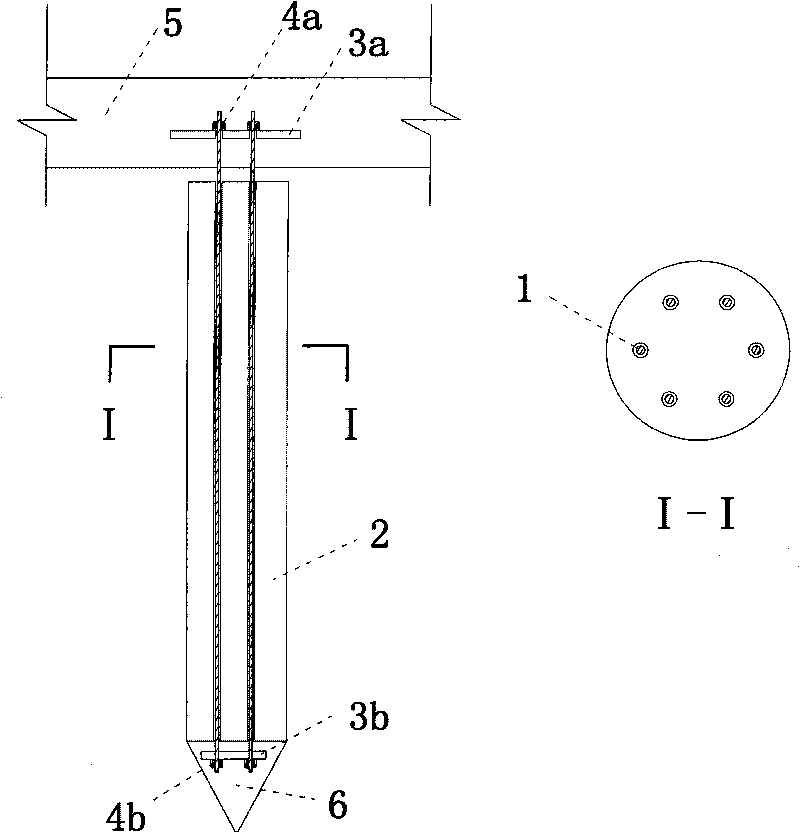

Fiber reinforced concrete uplift pile

InactiveCN101761089AInhibition of upward movementNo tensile cracksBulkheads/pilesPre stressFiber-reinforced concrete

The invention relates to a fiber reinforced concrete uplift pile which comprises a concrete pile body. A pile head is arranged at one end part of the concrete pile body; a FRP fiber reinforcement externally sleeved by a sleeve is arranged in the concrete pile body, one end thereof extends into the pile head, and the other end thereof reversely extends out of the concrete pile body; a second supporting plate is arranged in the pile head; one end of the FRP fiber reinforcement positioned in the pile head is fixed on a second supporting plate by a second anchorage device; a first supporting plate is sleeved at the other end of the FRP fiber reinforcement, and the other end of the FRP fiber reinforcement is fixed on the first supporting plate by a first anchorage device. Prestressing force is not applied to the FRP fiber reinforcement, the sleeve is enwrapped on the periphery of the FRP fiber reinforcement and is not bonded with concrete; and relative slide can be generated between the sleeve and the concrete. The lower end of the FRP fiber reinforcement is tensioned by the supporting plates at the bottom part of the pile and the anchorage devices, and the upper end of the RP fiber reinforcement is fixed in a bearing platform by the supporting plates in the bearing platform and the anchorage devices; and the bearing platform is completely separated with the concrete of the pile body.

Owner:NANCHANG CONSTR ENG GROUP

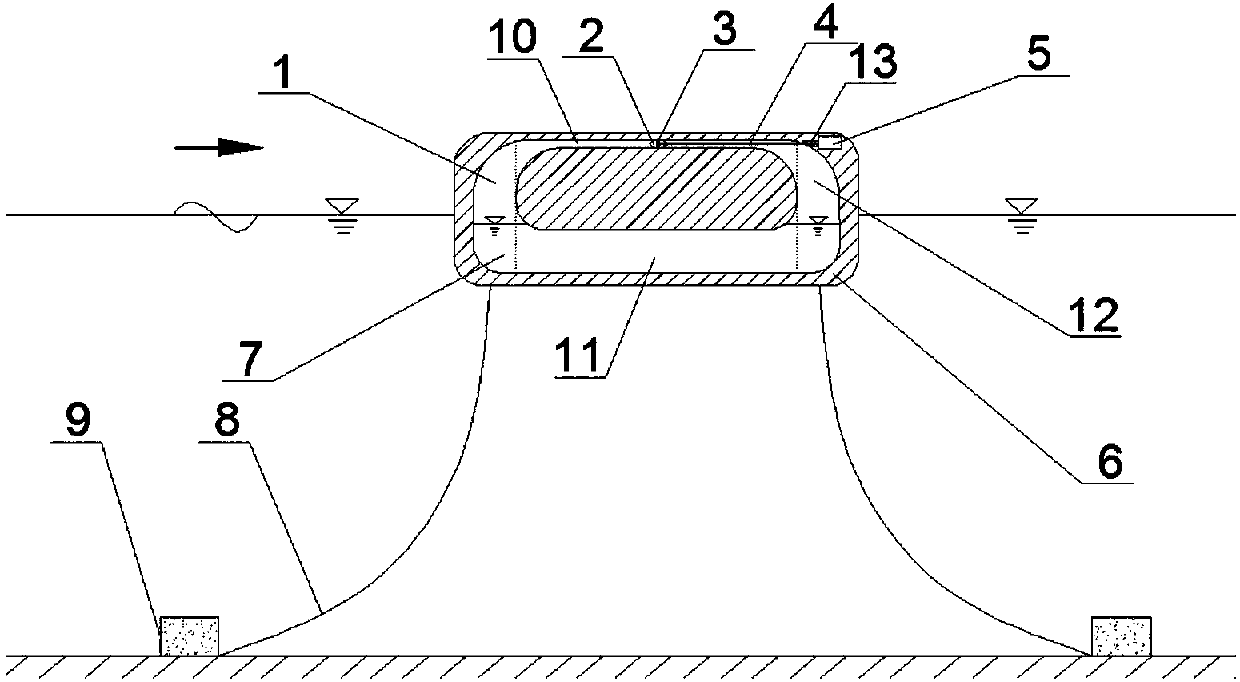

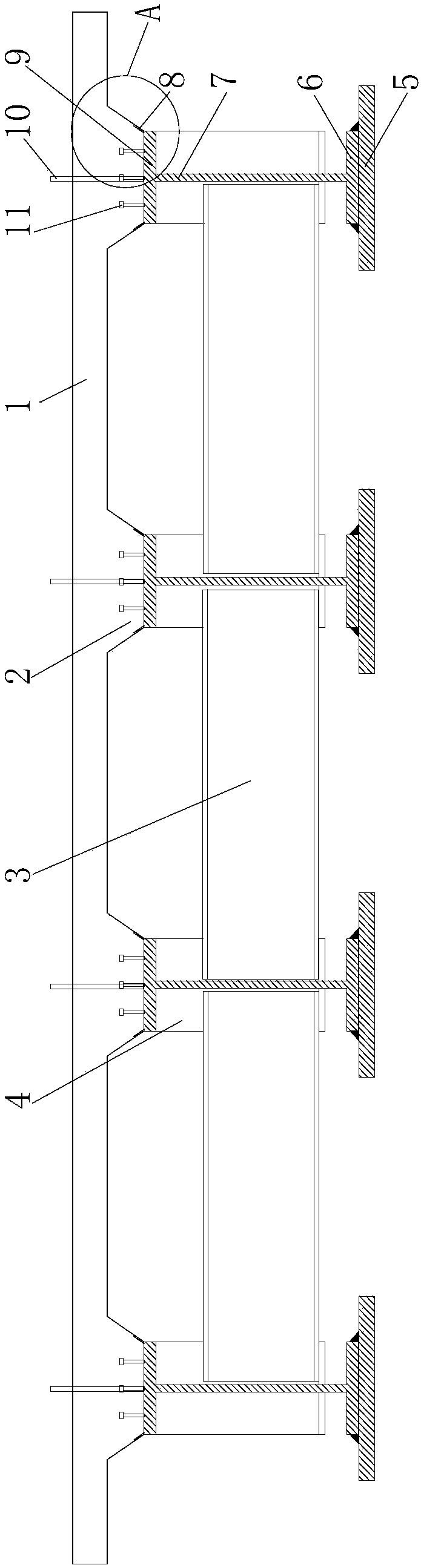

Floating breakwater capable of giving consideration to inner oscillation water column wave energy conversion function and method

The invention discloses a floating breakwater and a method capable of giving consideration to an inner oscillation water column wave energy conversion function. In the floating breakwater capable of giving consideration to the inner oscillation water column wave energy conversion function, the exterior of a floating body is anchored into a seabed through an anchor rope connection sinking block; anoverhauling channel is arranged at the upper part of the floating body; and wave energy conversion related configurations are arranged in the floating body, and comprise an air chamber, an air turbine, a turbine bracket, a linkage shaft, a generator, a cushion layer and an air chamber inner water body. A realization method of the floating breakwater capable of giving consideration to the inner oscillation water column wave energy conversion function comprises the steps of a breakwater arrangement process, a process of the floating body eliminating the wave effect, a wave energy conversion output process and an overhauling process. On the basis of maintaining traditional wave retaining and eliminating functions of the floating breakwater, the wave energy conversion function is realized byusing the oscillation design of water in an air chamber, and the power output in the wave energy conversion process is continuous, so that the reliability is good; the stress design of the breakwateris reasonable, and the durability is excellent; and meanwhile, the construction cost is low, and the engineering production advantages are obvious.

Owner:ZHEJIANG UNIV

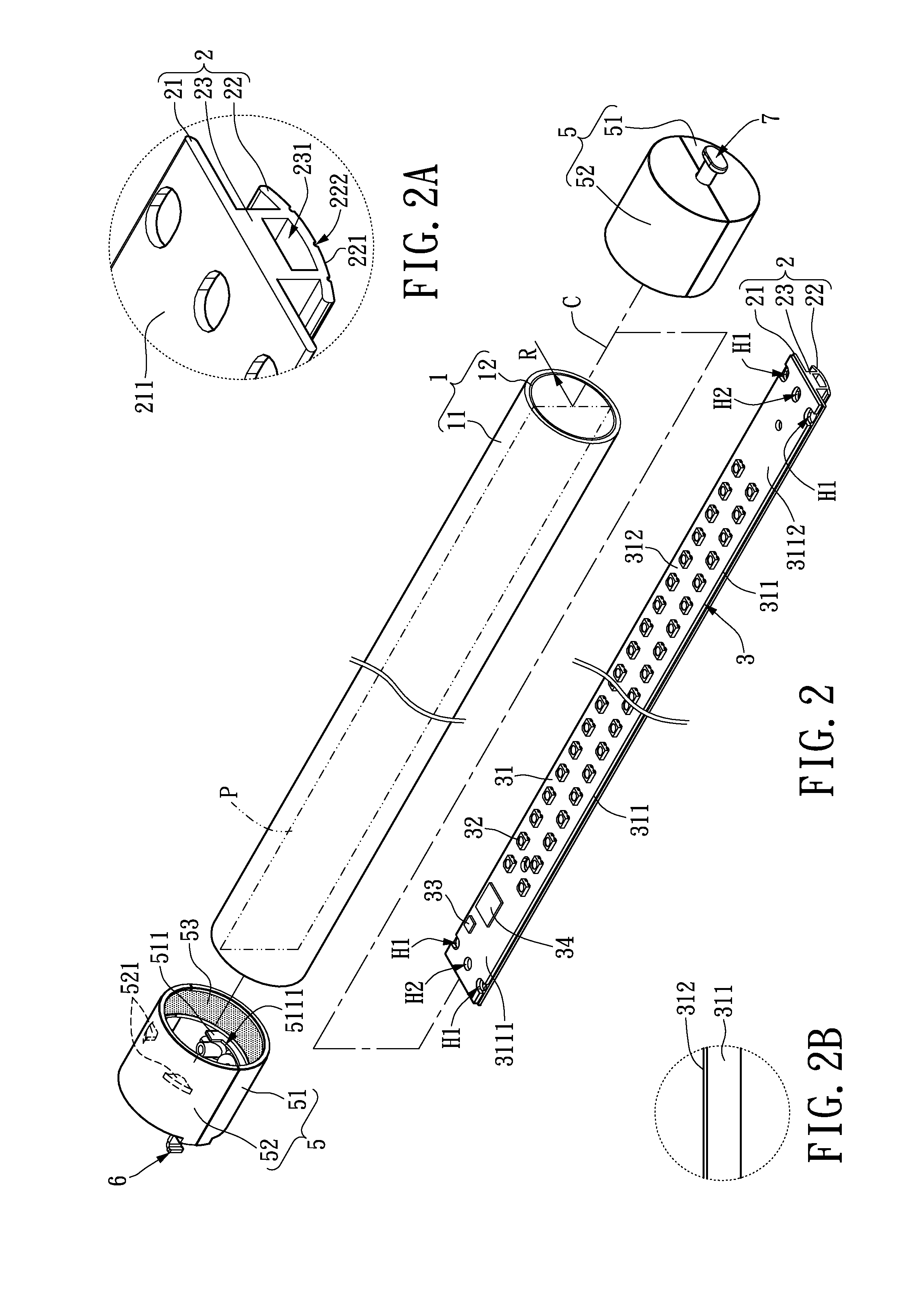

Locally uncombined suspension bridge steel-concrete combined bridge deck system and construction method of combined bridge deck system

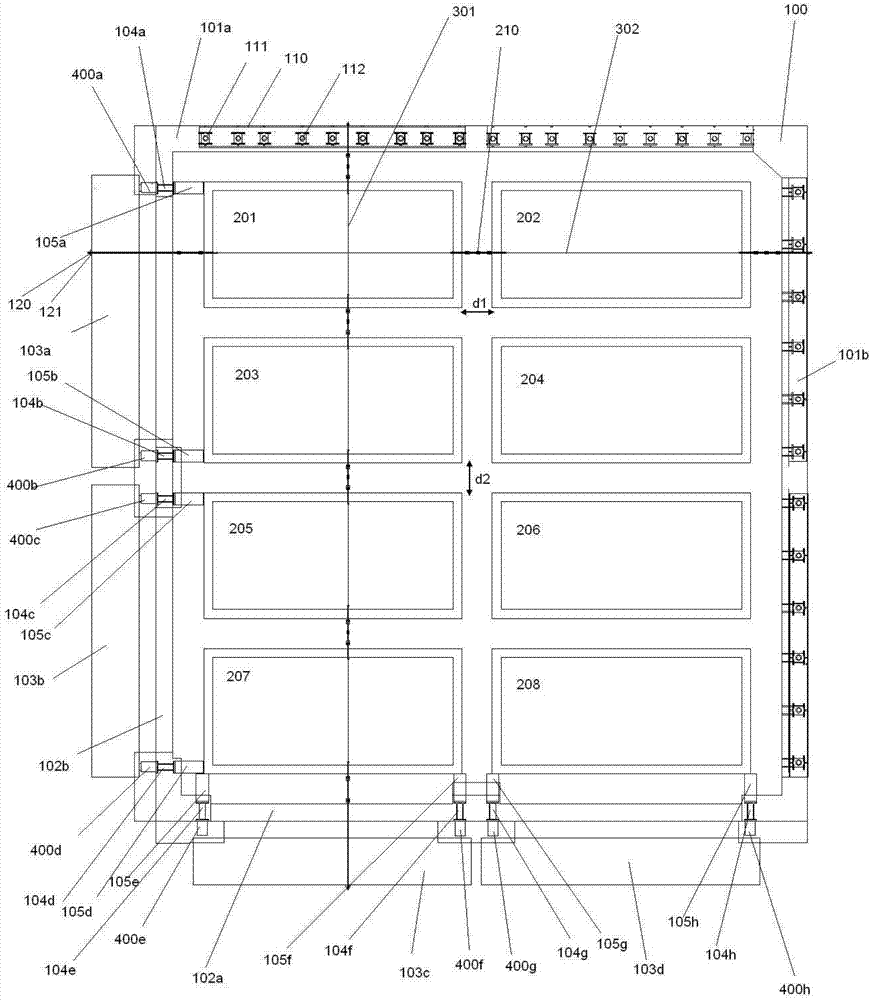

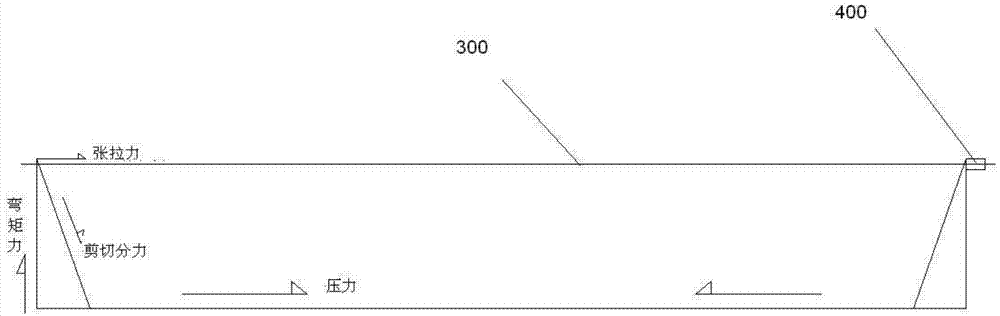

ActiveCN102146658AReduce stress concentrationReduced risk of crackingSuspension bridgeBridge structural detailsCrack resistanceBridge deck

The invention discloses a locally uncombined suspension bridge steel-concrete combined bridge deck system and a construction method of the combined bridge deck system, and belongs to the technical field of bridge structures. The bridge deck system consists of concrete slabs, longitudinal steel beams, cross steel beams, air nozzles and toggle pin connectors; and a suspension bridge section steel-concrete combined bridge deck system is prefabricated in a factory. The prefabricated concrete slabs and section steel main beams form a whole through concrete wet joints and the toggle pin connectors. The prefabricated concrete slabs and cast-in-place concrete joints are only connected with the cross steel beams to form a whole through the toggle pin connectors, the longitudinal steel beams are not provided with the toggle pin connectors, and meanwhile, the toggle pin connectors are not arranged in a certain area of the ends of the cross steel beams at hoisting points. The problems of cracking, complex structures of toothed grooves at the slab ends of the prefabricated concrete slabs and the like due to the factors of temperature, contraction, creep and the like of the concrete slabs of the traditional suspension bridge combined bridge deck system are solved by adopting a locally uncombined technology on the premise of keeping the consumption of steel, the manufacturing process of the prefabricated slabs is simplified, the bearing capacity, the rigidity and the cracking resistance of the structure are improved, and the durability of the structure is improved.

Owner:TSINGHUA UNIV

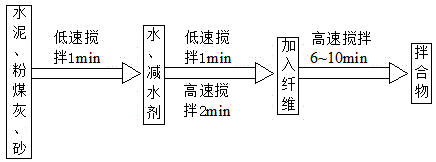

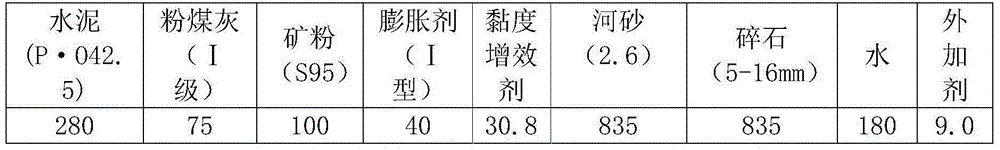

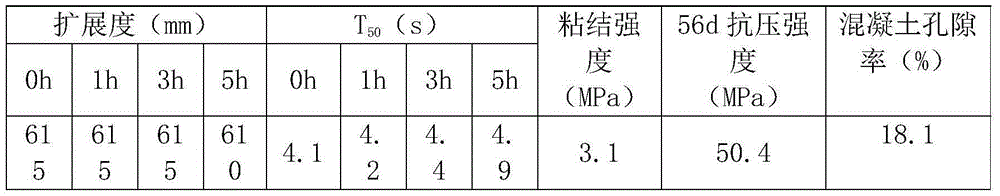

Self-compacting mass concrete construction method

InactiveCN106836808AImprove viscoplasticityImprove pumpabilityFoundation engineeringBuilding material handlingSilica fumeCoal

The invention discloses a self-compacting mass concrete construction method. The self-compaction mass concrete constructing method includes the steps of preparing self-compacting concrete, transporting the self-compacting concrete, pouring the self-compacting concrete, conducting curing and temperature control on the self-compacting concrete, and the like. The self-compacting concrete is composed of cement, aggregate, coal ash, additives, silica fume and a compound type WK expansion fiber anti-crack agent. According to the self-compacting mass concrete construction method, proportioning of the self-compacting concrete and the construction process are improved, so that it is guaranteed that the concrete has high fluidity, high anti-separating performance, high gap passing capacity and high filling ability simultaneously, and the mechanical property and durability of a structure are improved.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU +1

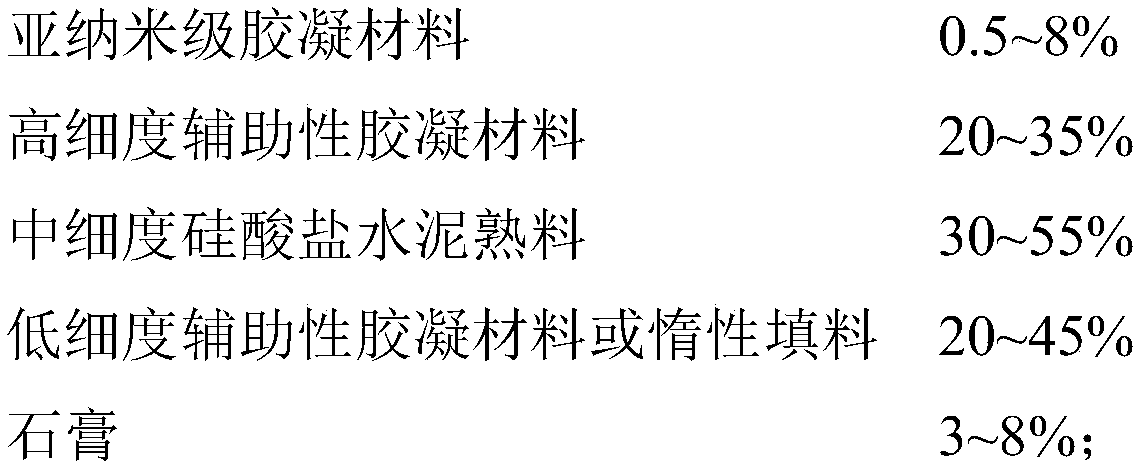

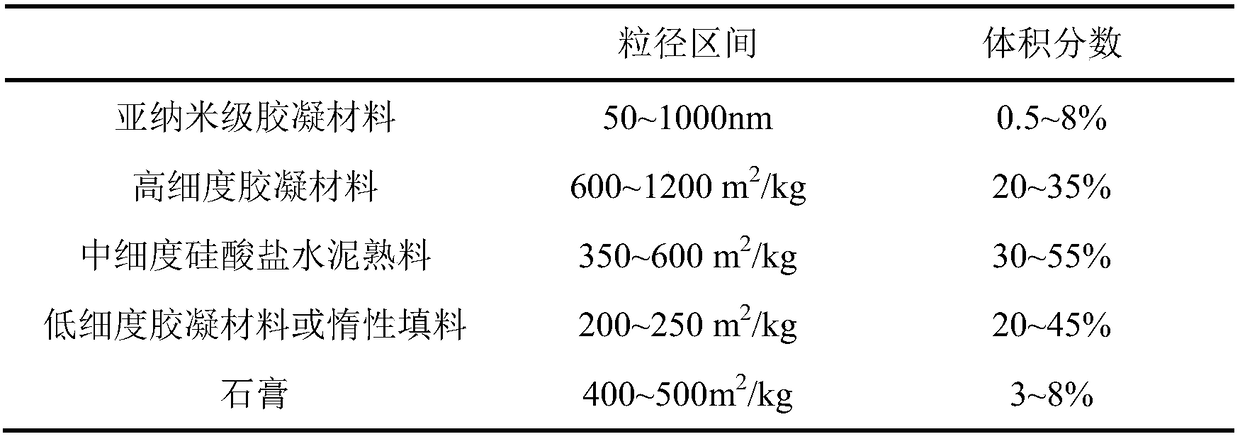

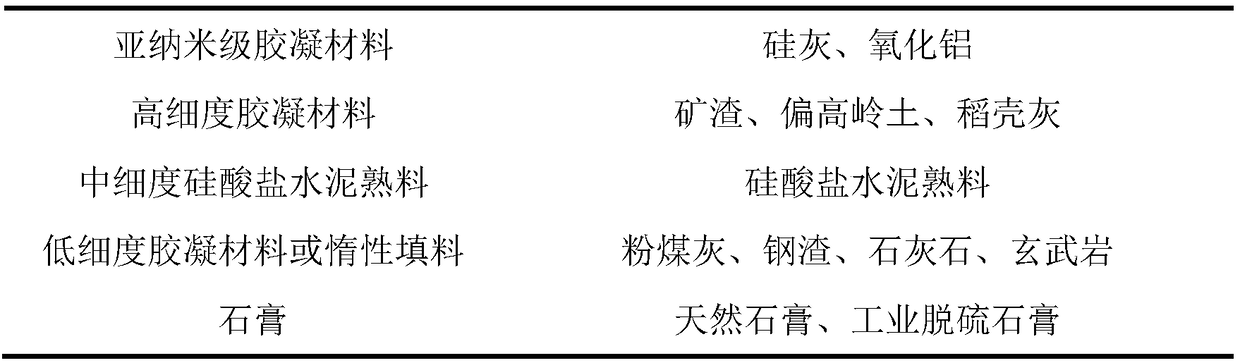

High-anticorrosion composite Portland cement and production method thereof

InactiveCN109020270AHigh strengthHigh resistance to sulfate attackCement productionSeawaterMaterials science

The invention belongs to the technical field of Portland cements, and discloses a high-anticorrosion composite Portland cement and a production method thereof. The high-anticorrosion composite Portland cement is mainly comprises, by volume, 0.5-8% of a sub-nanometer cementing material, 20-35% of a high-fineness auxiliary cementing materials, 30-55% of a medium-fineness Portland cement clinker, 20-45% of a low-fineness auxiliary cementing material or an inert filler and 3-8% of gypsum. The composite Portland cement has a good compressive strength and a high corrosion resistance, for example, the 28 d compressive strength is 45-65 MPa, the sulfate corrosion resisting coefficient is 1.1-1.3, the seawater erosion resisting coefficient is 1.2-1.4, and the chloride ion diffusion coefficient is 0.4 * 10<-12> to 0.8 * 10<-12> m<2> / s. The composite Portland cement is applied to fields with high requirements of the corrosion resistance.

Owner:SOUTH CHINA UNIV OF TECH

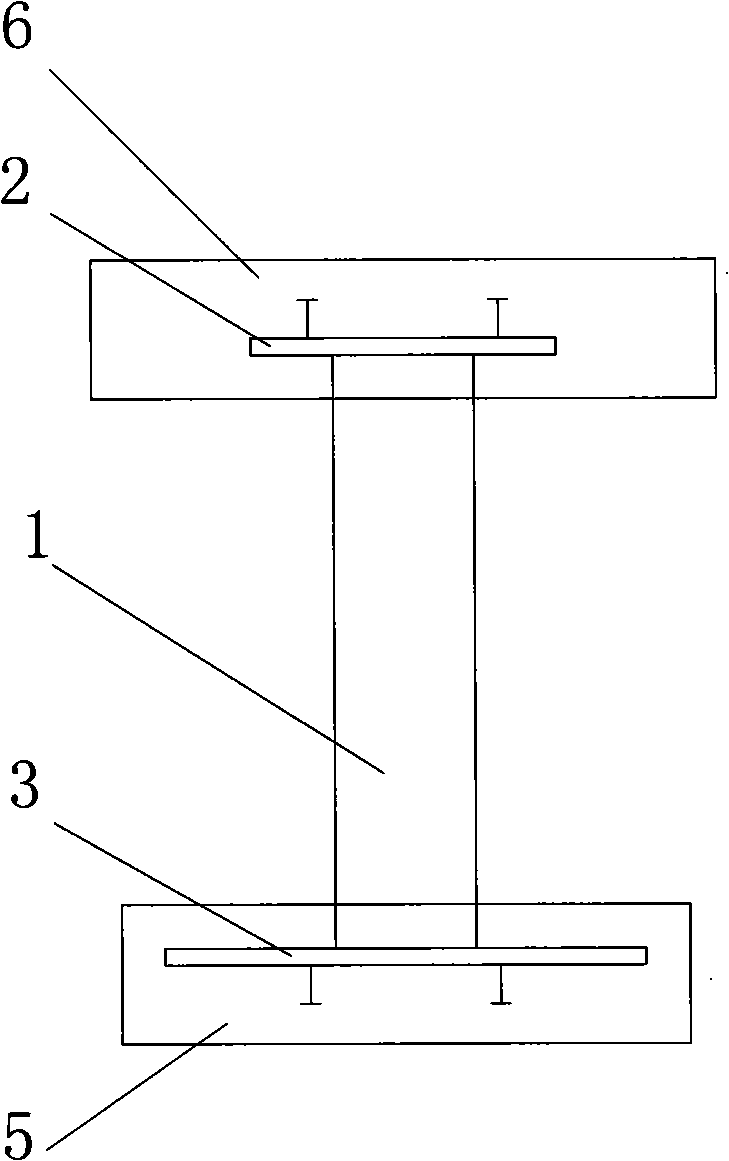

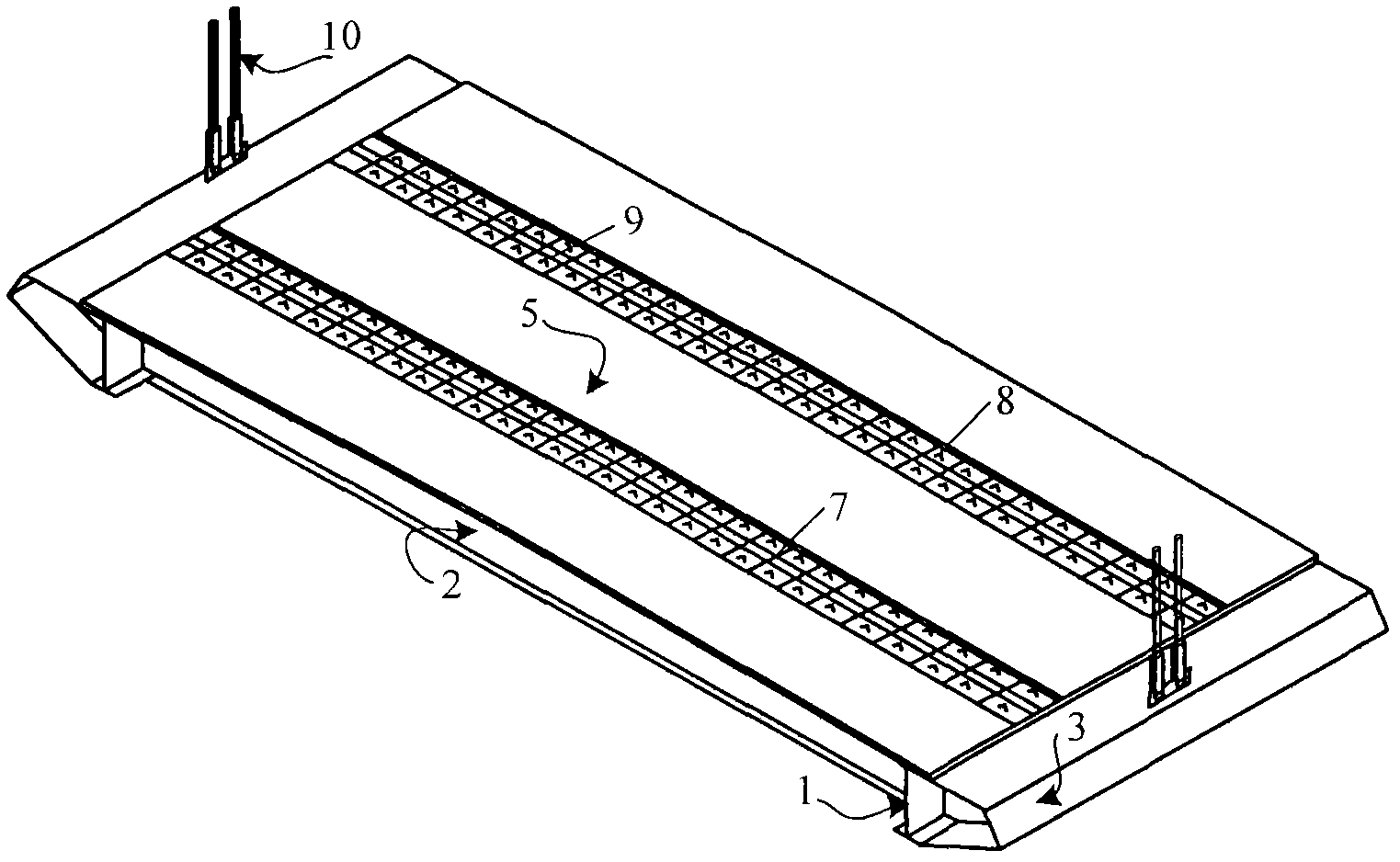

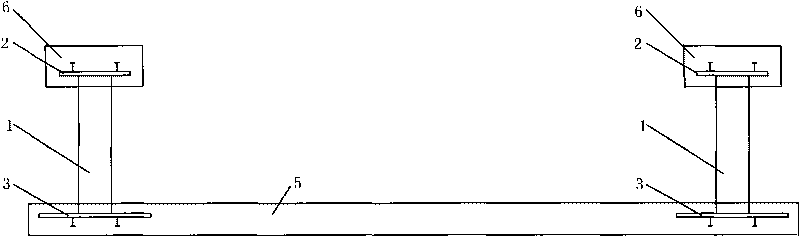

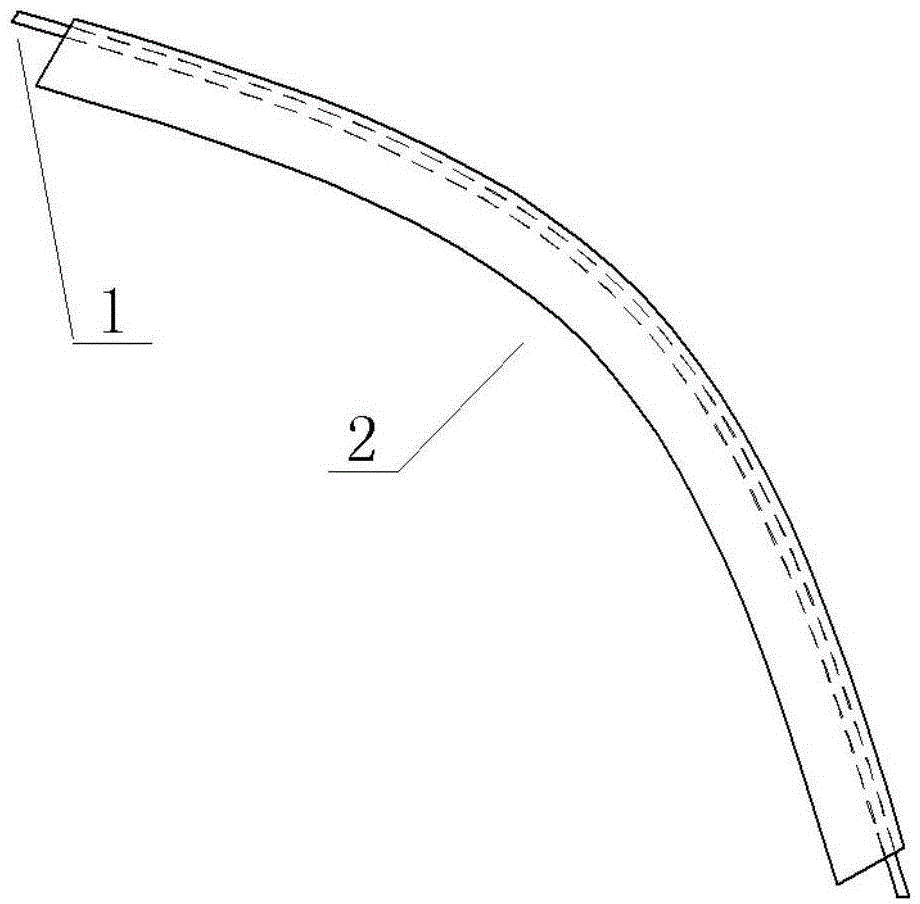

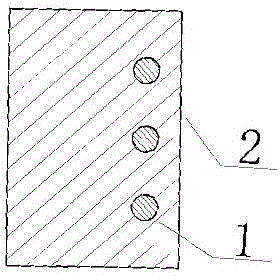

Corrugated steel web pre-flex assembled groove shape beam and manufacturing method thereof

InactiveCN101691737AEasy to manufactureIncreased complexityBridge erection/assemblyBridge materialsStress conditionsSheet steel

The invention discloses a corrugated steel web pre-flex assembled groove shape beam and a manufacturing method thereof. The assembled groove shape beam comprises a corrugated steel webs (1) located at two sides of the assembled groove shape beam, primary concrete bad plate (5) cast at the periphery of a lower flange steel plate (3), and a secondary concrete cast at the periphery of an upper flange steel plate (2) or connected with the upper flange steel plate (2) by a shear connecting piece (4), the upper parts of the corrugated steel webs (1) are connected with the upper flange steel plate (2), the lower parts of the corrugated steel webs (1) are connected with the lower flange steel plate (3), and the formed cross section is a groove shape structural beam. The assembled groove shape beam solves the problems of the complex stress condition of plate-beam joint position of common prestress concrete groove shape beam, the easy cracking of concrete, the complex structure of reinforcing bars of the plate-beam joint position and high construction difficulty, high requirements for construction technology and condition, the large occupied area of on-site casting construction, the long construction period, etc.

Owner:SOUTHEAST UNIV

Novel FRP (fiber reinforced plastic)-steel tube-epoxy resin-sea sand concrete compression member

The invention belongs to the field of engineering structures, and particularly relates to a novel FRP (fiber reinforced plastic)-steel tube-epoxy resin-sea sand concrete compression member. The member is characterized in that an epoxy resin layer is coated on the inner surface of a steel tube, and the steel tube is internally filled with sea sand concrete; an FRP material layer is overwrapped on the outer surface of the steel tube; because the FRP material layer is overwrapped outside the steel tube, and the steel tube is prevented from being in direct contact with the external environment, so that the durability of the steel tube is improved obviously; meanwhile the epoxy resin layer is coated on the inner surface of the steel tube, so that the sea sand concrete and the steel tube are isolated, and the corrosion effect of chloride ions in sea sand on the steel tube is avoided; and the potential safety hazards of the sea sand concrete are reduced, and the application of the sea sand concrete is promoted. The member is applied to high-corrosion coastal and offshore areas and the like, bears the load mainly focused on axle load, and has favorable economical and environmental benefits.

Owner:TSINGHUA UNIV

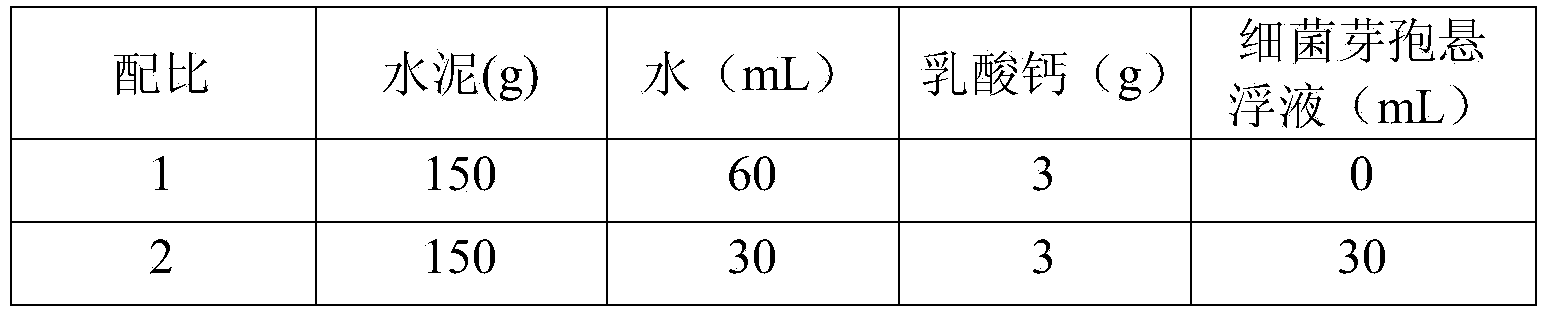

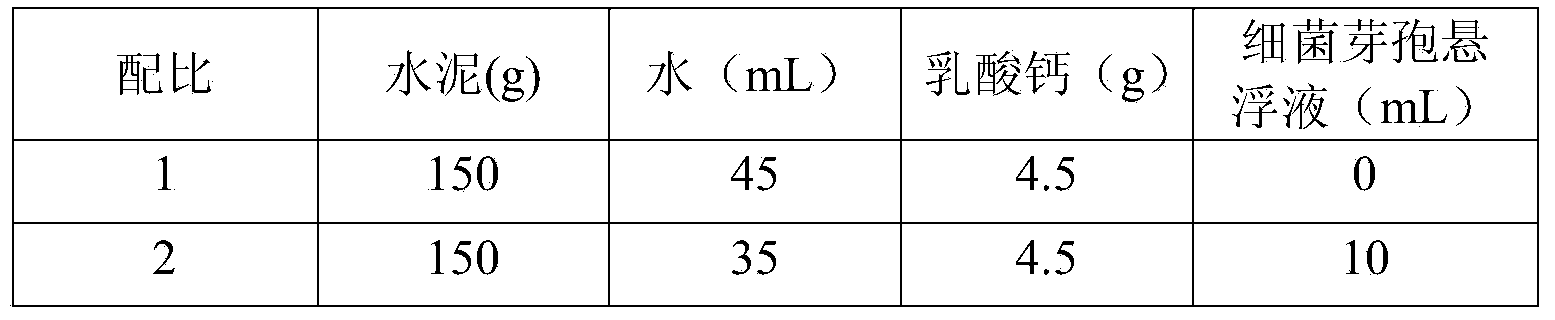

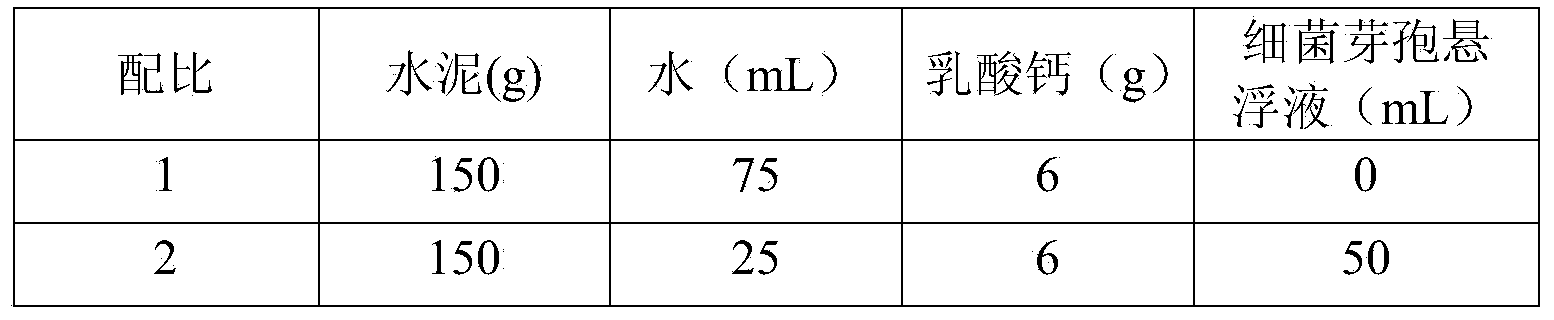

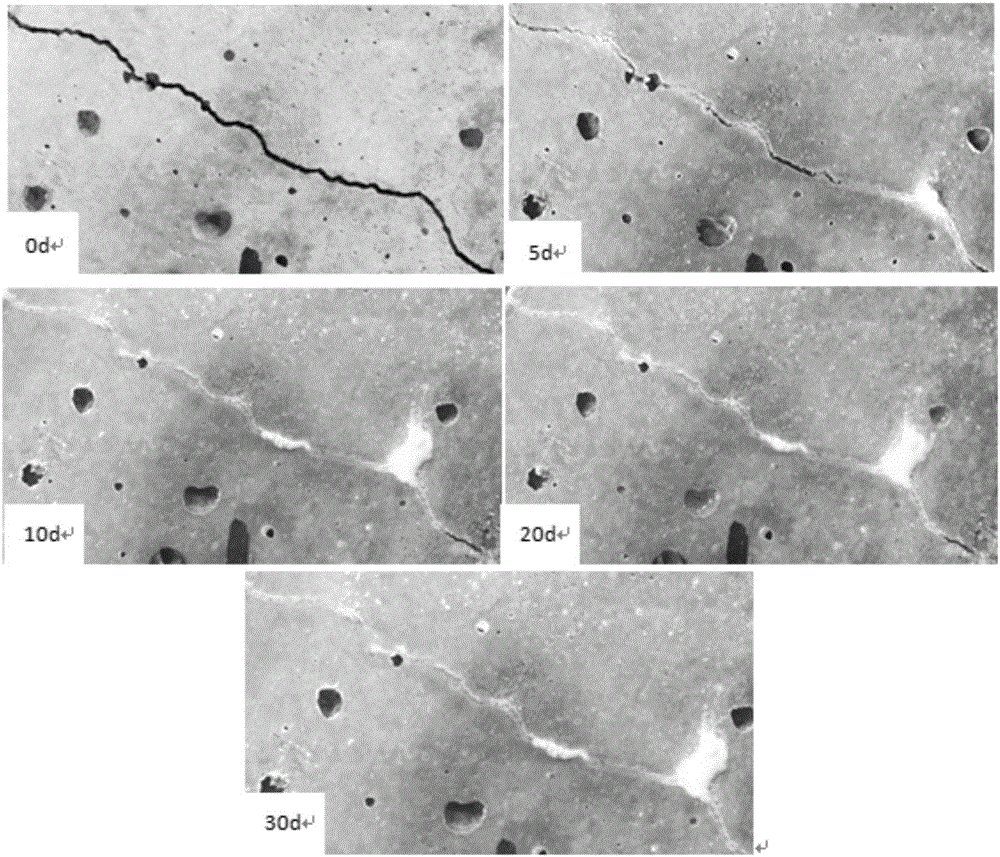

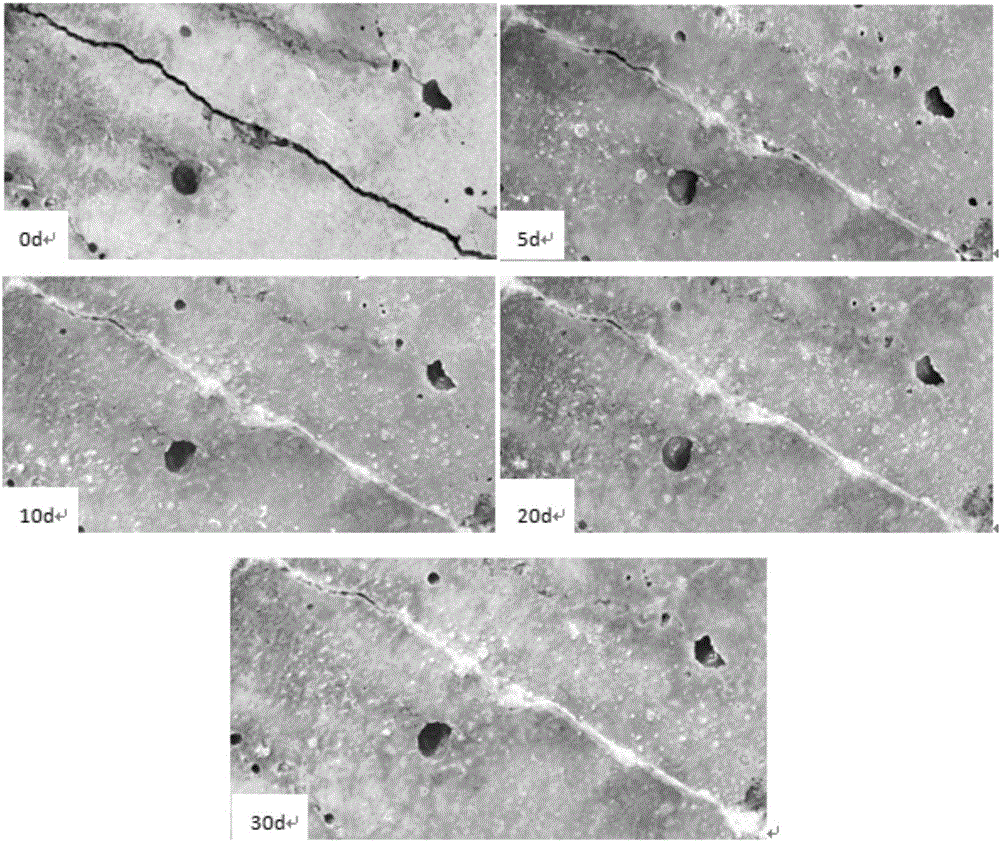

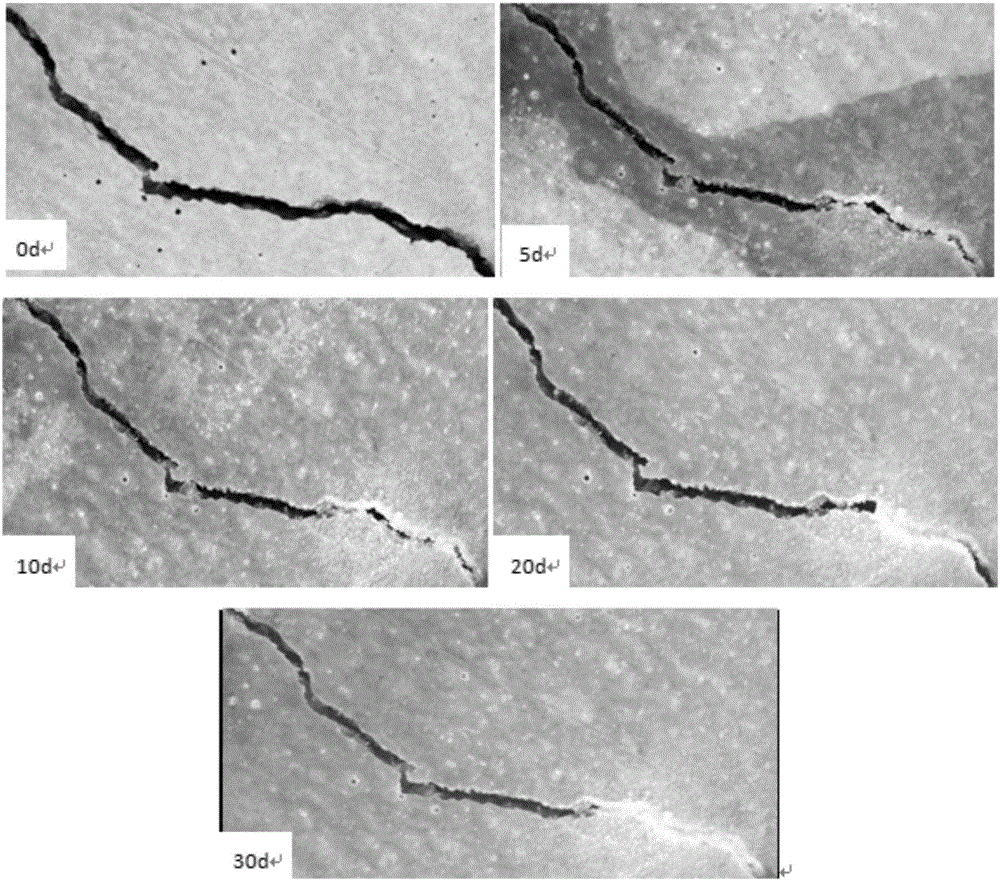

Self-healing cement-based material containing bacterial spores and preparation method thereof

The invention relates to a self-healing cement-based material containing bacterial spores and a preparation method thereof. The self-healing cement-based material consists of cement, water, calcium lactate and bacterial spores, wherein the mass ratio of the water to cement is 0.3-0.5, the mass of calcium lactate accounts for 1%- 5% of the mass of cement, 10<6>-10<9> spores are added into 1cm<3> of cement-based material. The preparation method comprises the steps of: inoculating alkali-resistant Bacillus, culturing to obtain strain solution having a high spore forming rate, heating the strain solution in a 80 DEG C water bath for 20min, centrifugally cleaning to obtain a spore suspension; weighing the required cement, proportionally weighing and adding calcium lactate, stirring until calcium lactate is evenly distributed in the cement; mixing the spores suspension which is used for replacing a part of mixing water with the rest water evenly in a shaking manner and pouring into the cement and calcium lactate, and stirring evenly, and pouring into a mold for forming.

Owner:SOUTHEAST UNIV

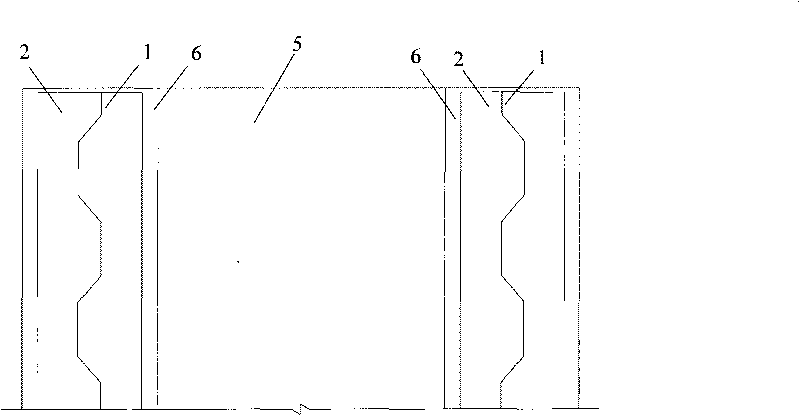

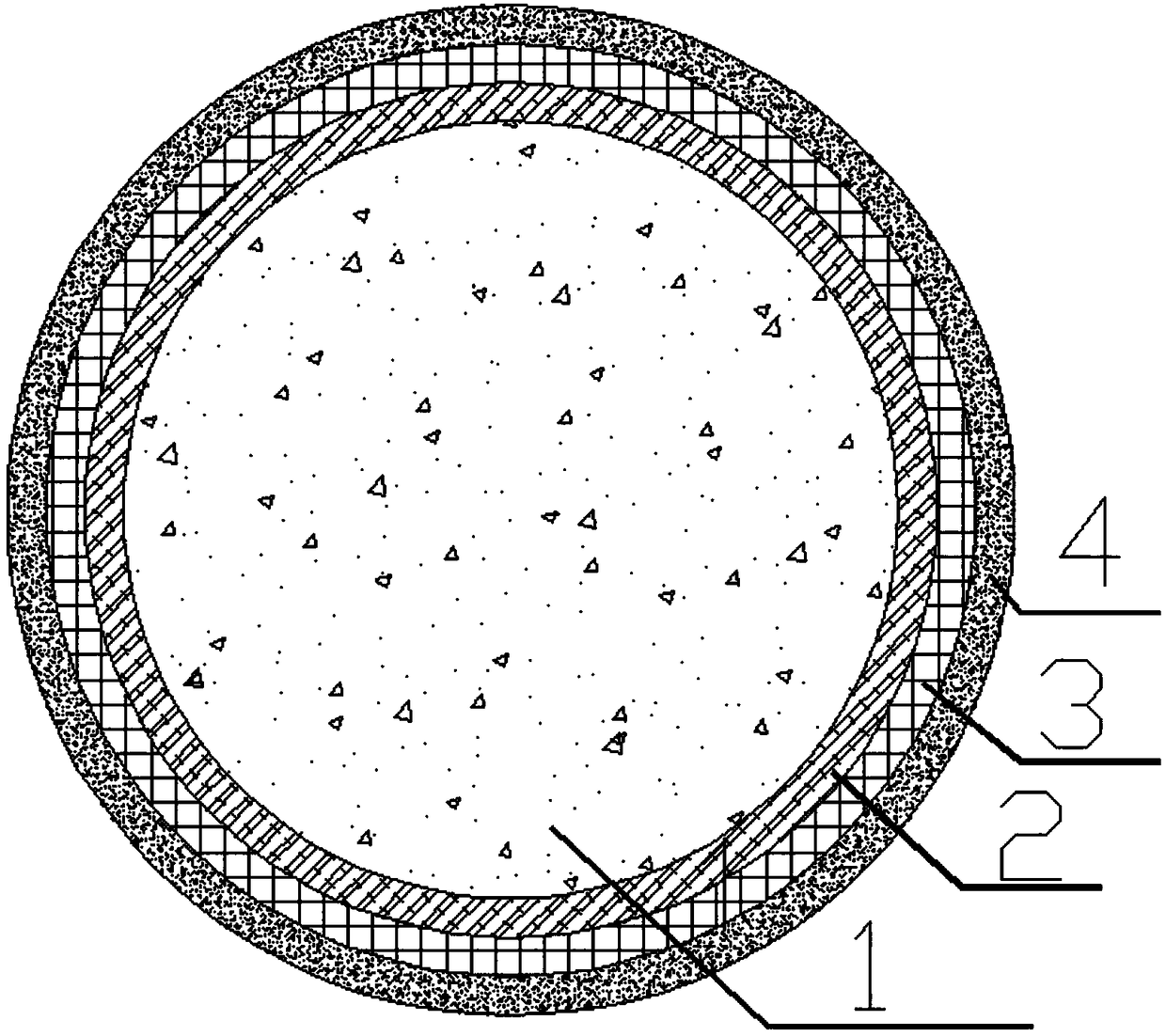

Composite rubber particle pad for shock absorbing and noise reduction of track and manufacturing method and application of composite rubber particle pad

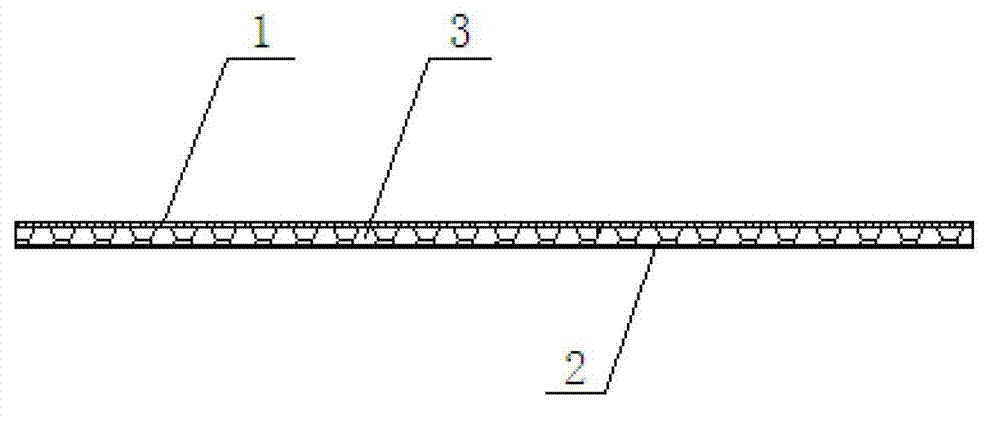

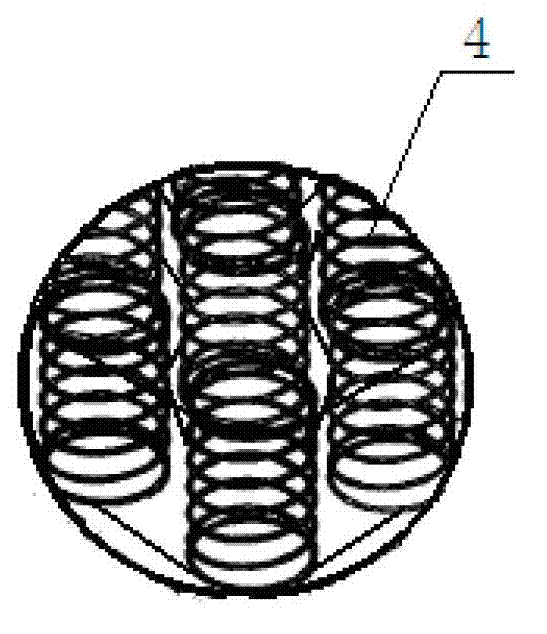

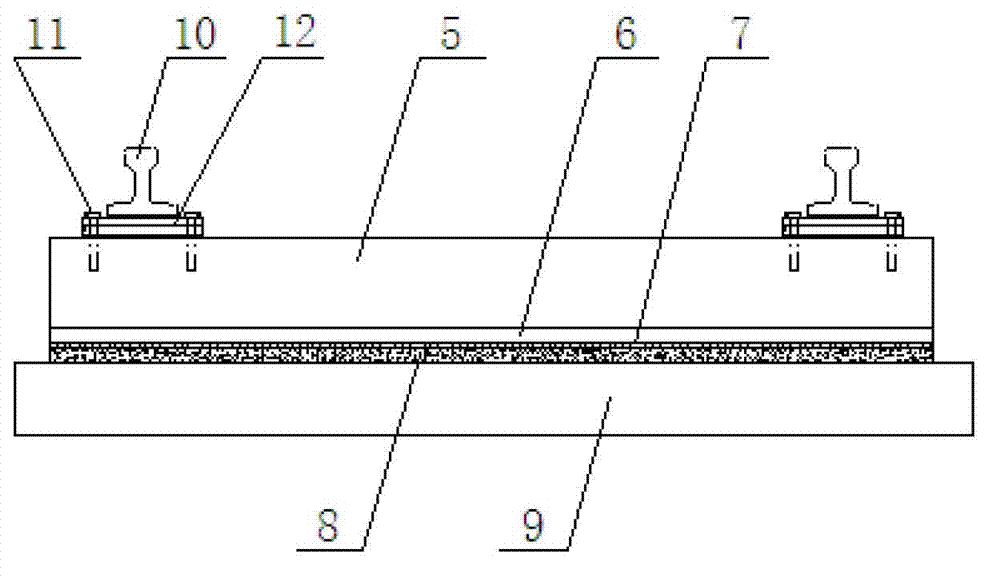

ActiveCN102926296ALow costEasy to manufactureBallastwayLaminationMaterials preparationPolymer science

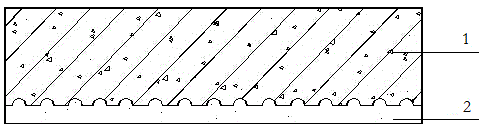

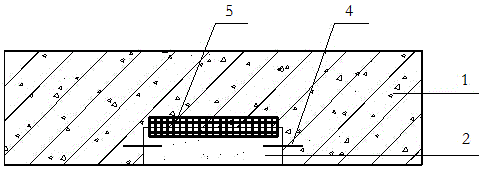

The invention relates to a composite rubber particle pad for shock absorbing and noise reduction of a track. The composite rubber particle pad comprises a surface non-woven fabric layer 1, a bottom face non-woven fabric layer 2 and a composite rubber particle layer 3. The composite rubber particle layer 3 comprises a mixture which is composed of two parts of rubber particles which are produced by crushing of waste automobile tires and one part of a polyurethane adhesion agent, diameters of rubber particles are no more than 3mm, and the thickness of the composite rubber particle pad is within a range of 6mm-8mm. The invention also discloses a method for producing the composite rubber particle pad. The method comprises the steps of material preparation, material feeding, material sealing and the like. The invention further discloses a plate type ballastless track structure in which the composite rubber particle pad is arranged. The structure comprises a steel rail assembly, a track plate 5, a quick-setting motor layer 6, the composite rubber particle pad 7, a cement asphalt (CA) motor layer 8 and a base 9. The composite rubber particle pad has the advantages of being low in cost, convenient to manufacture and good in structure durability, and the manufacturing method has the advantages of being simple in process and capable of achieving quick production.

Owner:CHINA RAILWAY 23RD BUREAU GRP RAILTRANSIT ENG CO LTD

A viscosity modifying material specially used for self-compacting concrete for CRTSIII type plates

A preparing method of a viscosity modifying material specially used for self-compacting concrete for CRTSIII type plates is disclosed. The viscosity modifying material is prepared by fully mixing fumed silica, calcium carbonate, low-viscosity hydroxyethyl cellulose, high-viscosity hydroxyethyl cellulose, a thixotropy modifier and water-soluble polymer rubber powder. The viscosity modifying material comprises 45-55% by mass of the fumed silica, 43-55% by mass of nanometer calcium carbonate, 0-0.5% by mass of the low-viscosity hydroxyethyl cellulose, 0-0.5% by mass of the high-viscosity hydroxyethyl cellulose, 0-2% by mass of the thixotropy modifier and 2-4% by mass of the water-soluble polymer rubber powder.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD +1

Liquid waterborne waterproof agent and preparation method thereof

The invention relates to a building material and particularly relates to a liquid waterborne waterproof agent and a preparation method thereof. The liquid waterborne waterproof agent disclosed by the invention contains aluminum silicate, an expanding agent, aluminum sulfate, sodium hydroxide and water. The liquid waterborne waterproof agent disclosed by the invention has the advantages of no organic solvent, no toxicity, no pollution to the environment, favorable flame-retardant performance, compact crystallization, water resistance, hydrophobility and aging resistance, capabilities of greatly improving the durability of a concrete structure and improving the compression strength and low cost; and the liquid waterborne waterproof agent is more ideal waterborne waterproof coating.

Owner:李鹏涛

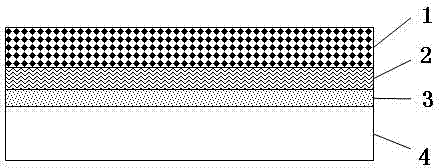

A non-earthing composite structure for a waterproof pavement layer of a top plate for a road tunnel

InactiveCN104264561AImprove waterproof performanceImprove impact performanceIn situ pavingsEpoxyMaterials science

The invention relates to a non-earthing composite structure for a waterproof pavement layer of a top plate for a road tunnel. The structure comprises the following structural layers from top to bottom: a rubber pitch protective layer, a waterproof layer, an epoxy resin priming coat and a cement concrete top plate. The invention provides a composite structure for a waterproof pavement layer of a top plate capable of efficiently resisting drying and watering cycle and impact load of the surface load. The composite structure for a waterproof pavement layer of a top plate has superior waterproof performance and capacity of resisting the impact load, greatly improves the integrity and effectiveness of the waterproof system of the road tunnel, enhances the structural durability and satisfies the waterproof requirement of the top plate of the road tunnel.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

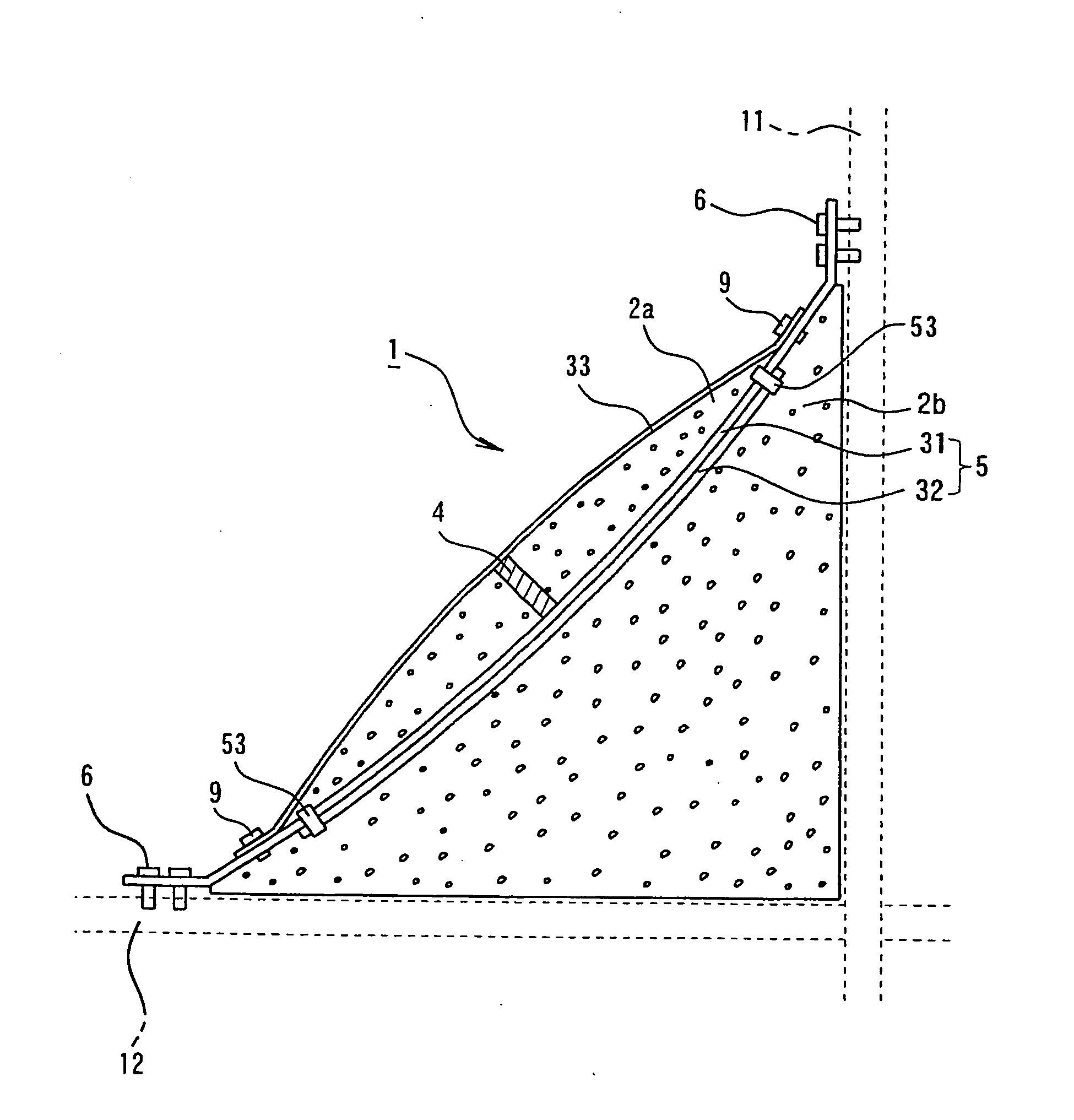

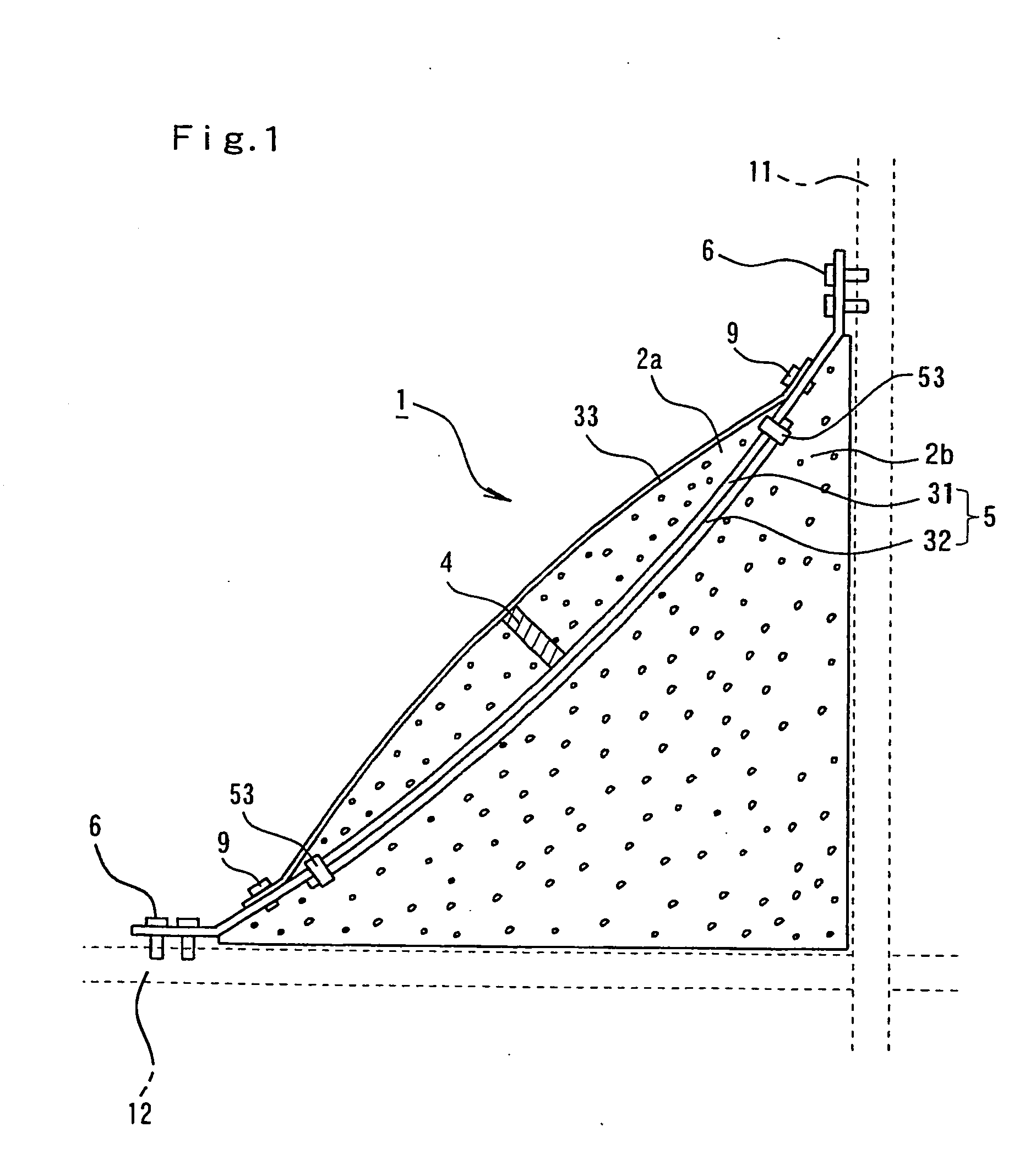

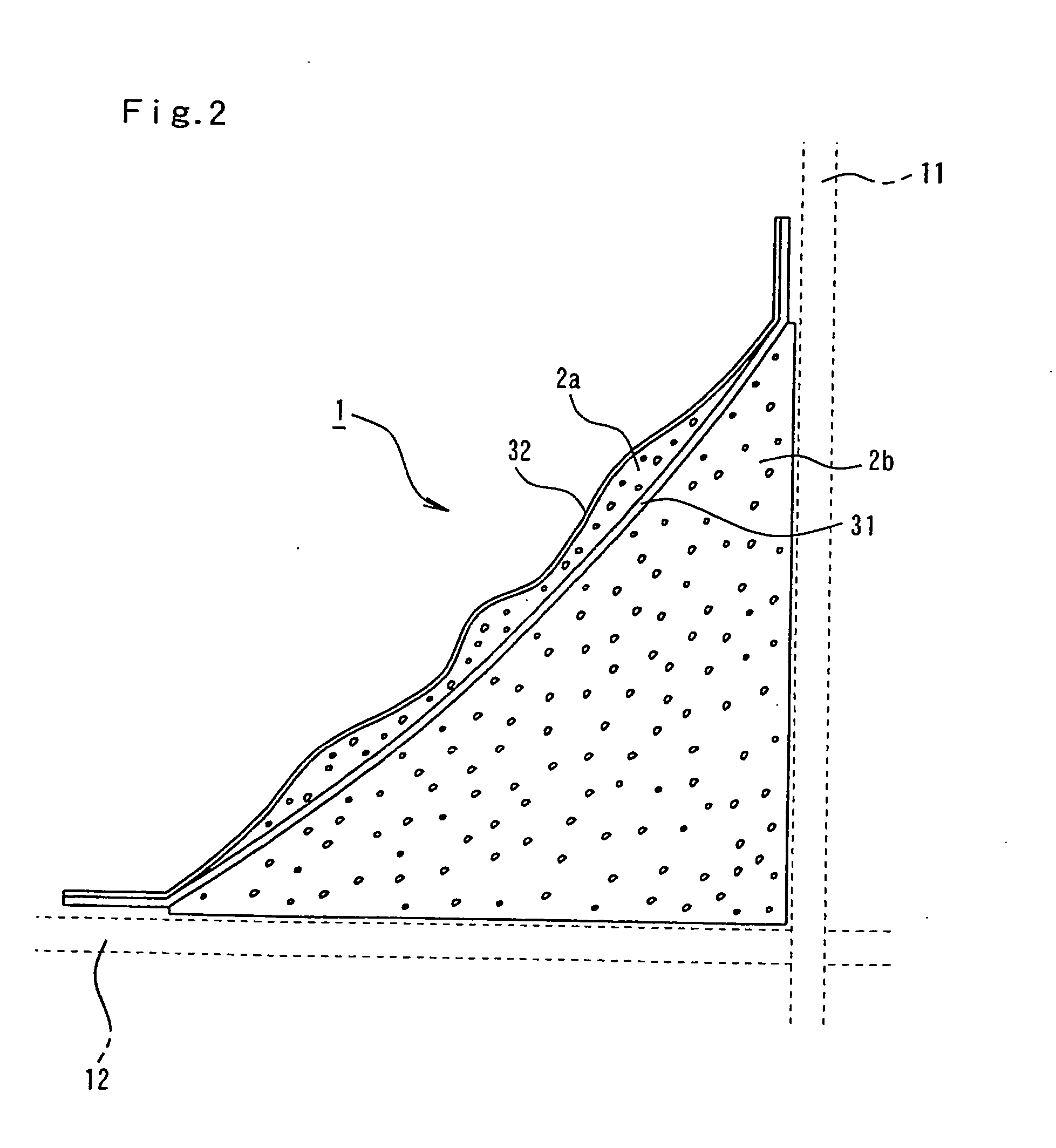

Reinforcing structure for building and reinforcing member for the structure

InactiveUS20060137292A1Excellent energy damping effectGood energyLeaf springsHigh internal friction springsSynthetic resinShock absorber

A reinforcing structure for a building and a reinforcing member used for the structure, where the structure has excellent anti-vibration characteristics and quake resistance. The reinforcing structure and member for a building are capable of reducing the deformation of structural members of the building caused by vibration and removing the deformation so that the original form is restored. A reinforcing member (1) is provided and fixed at a corner portion where structural members (11, 12) of a building intersect. The reinforcing member (1) is formed such that a first spring member (third leaf 33) and a second spring member (layered leaf (5)) are combined, and a damper (4) and a synthetic resin foam body (2a) are arranged in a space between the first and second spring members. A synthetic resin foam body (2b) is filled in a space surrounded by the structural members (11, 12) and the reinforcing member (1).

Owner:NAKAMURA BUSSAN

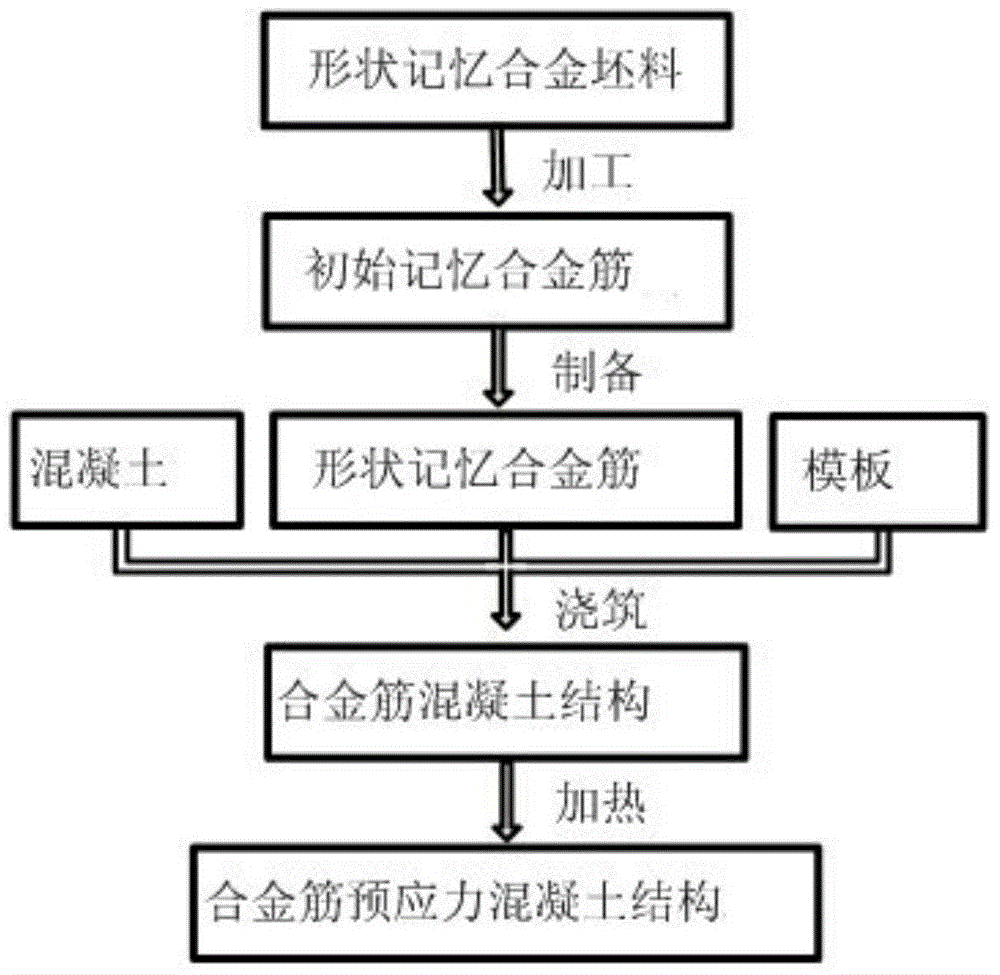

Prestressed concrete constructing process for curved shape memory alloy tendon

InactiveCN104806022ALow investment costReduce lossesCeramic shaping apparatusBuilding material handlingMemory effectCrack resistance

The invention discloses a prestressed concrete constructing process for a curved shape memory alloy tendon. The constructing process specifically comprises the following steps: a plurality of curved shape memory alloy tendons are embedded into a template along the length direction of the concrete, and two ends of each tendon are allowed to respectively penetrate through and extend out of the template; the concrete is poured in the template and integrally formed along with the curved shape memory alloy tendons; after the concrete strength reaches above 75%, the shape memory alloy tendons are in batches or gradually heated by adopting an electrothermal method, after the shape memory alloy tendons are gradually heated to appointed temperature, the shape memory alloy tendons generate the one-way shape memory effect, so that the lengths of the shape memory alloy tendons trend to be reduced to a primary memory alloy tendon shape, and the concrete generates a certain constraining force so as to generate the prestress. According to the constructing process, the crack resistance, rigidity, durability and application scope of a prestressed structure is improved, and thus the purpose of applying the prestress to the concrete can be achieved, the constructing process is simple, convenient to operate, and safe and reliable in effect.

Owner:XUZHOU UNIV OF TECH

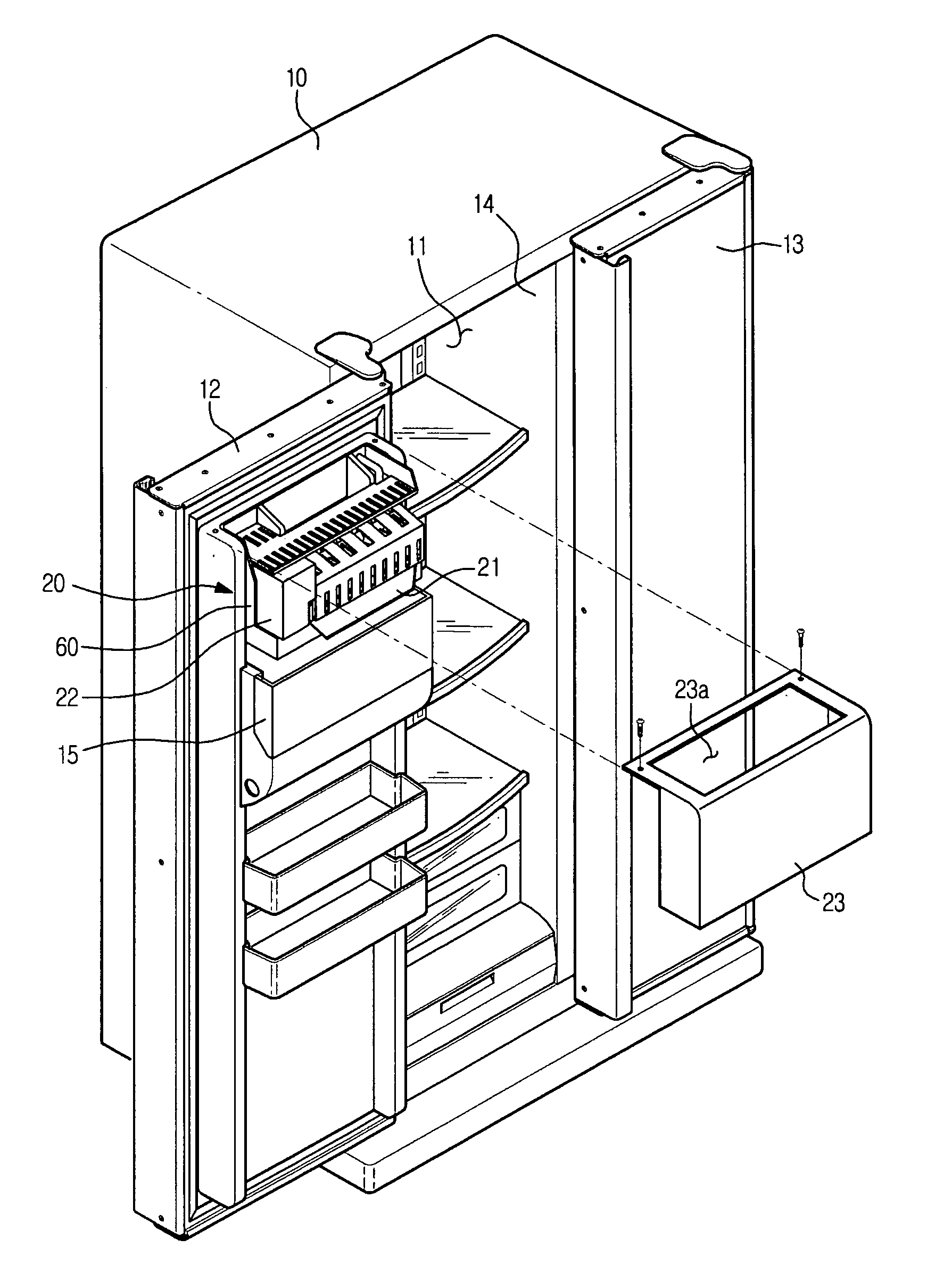

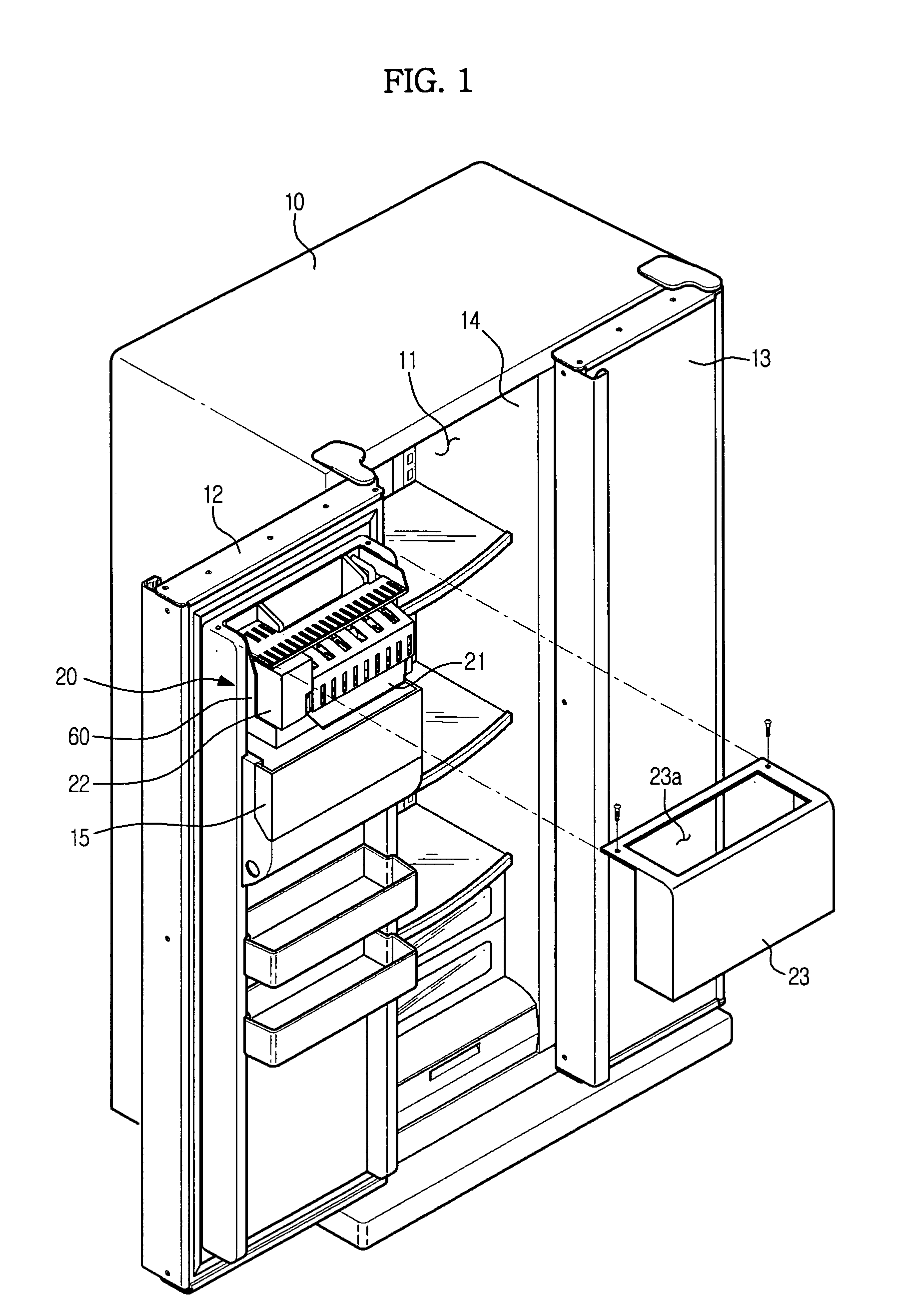

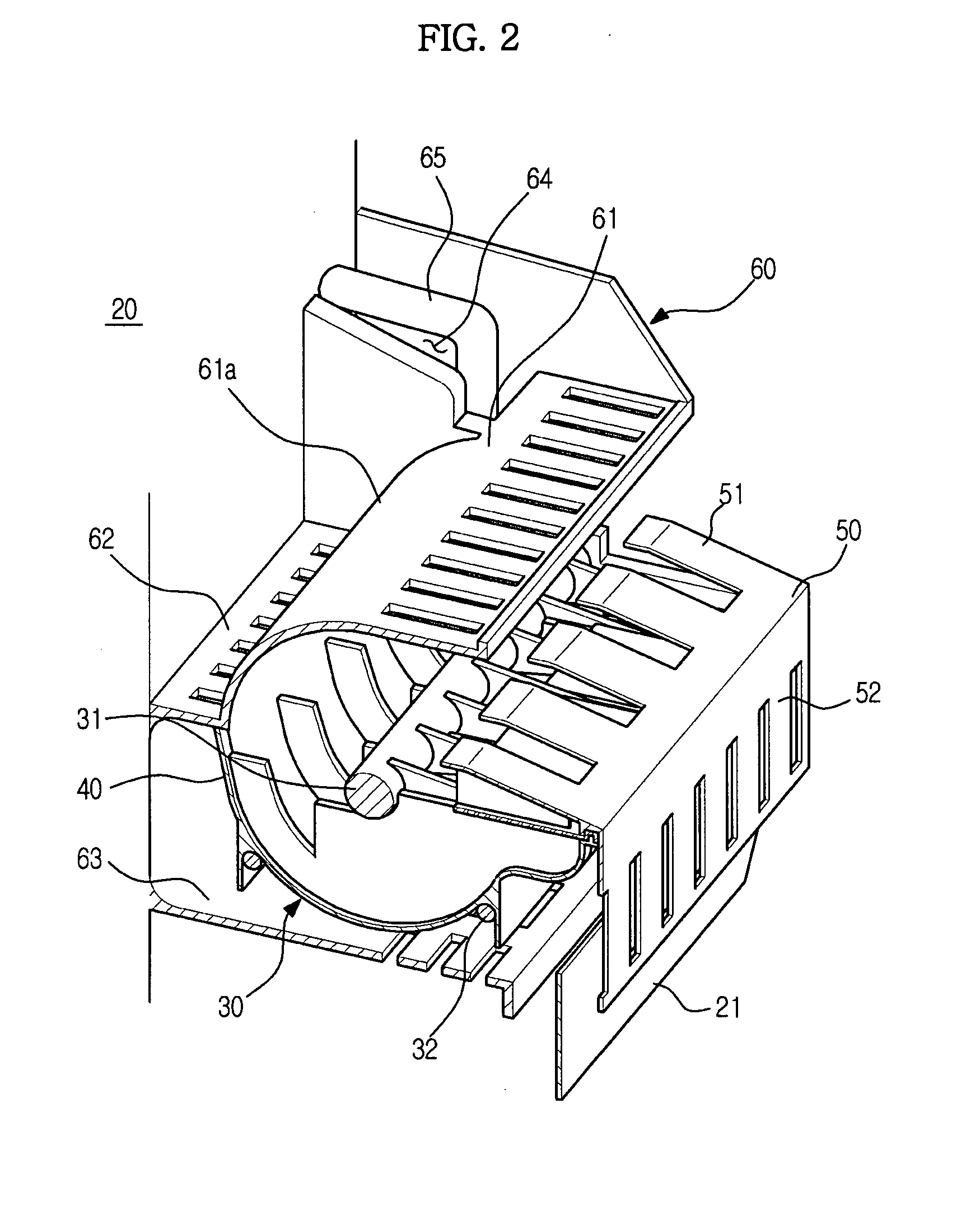

Ice making apparatus and refrigerator having the same

ActiveUS20080295537A1Improve structural durabilityLighting and heating apparatusIce productionMarine engineeringRefrigerated temperature

Owner:SAMSUNG ELECTRONICS CO LTD

Steel wire mesh fiber cloth reinforced pier column structure externally covered with concrete with ultra-high-performance

InactiveCN108342995AImprove tensile propertiesImproved brittle failure modeBuilding repairsBridge erection/assemblyEnvironment effectFiber-reinforced composite

The invention belongs to the technical field of civil engineering, and particularly relates to a steel wire mesh fiber cloth reinforced pier column structure externally covered with concrete with ultra-high-performance. The steel wire mesh fiber cloth reinforced pier column structure externally covered with concrete with ultra-high-performance comprises a reinforced pier column body, a FRP cloth,a steel wire mesh layer and an ultra-high performance concrete layer, wherein the FRP cloth, the steel wire mesh layer and the ultra-high performance concrete layer are arranged on the outer surface of the reinforcement pier column body from the inside out. The steel wire mesh fiber cloth reinforced pier column structure integrates the advantages of high tensile strength of fiber reinforced composite materials, can improve the brittle failure mode of FRP, and overcomes the disadvantages of slowing FRP aging and adhesive property of FRP binder prone to being affected by severe environment, thereinforced structure has the advantages of high yield load, large capacity reserve, good ductility, superior anti-seismic performance, improved durability of the structure and the like; and the steelwire mesh fiber cloth reinforced pier column structure is convenient and fast in construction, reinforcement effect is steady and obvious, and the interference of environmental factors is small.

Owner:HUBEI ENG UNIV

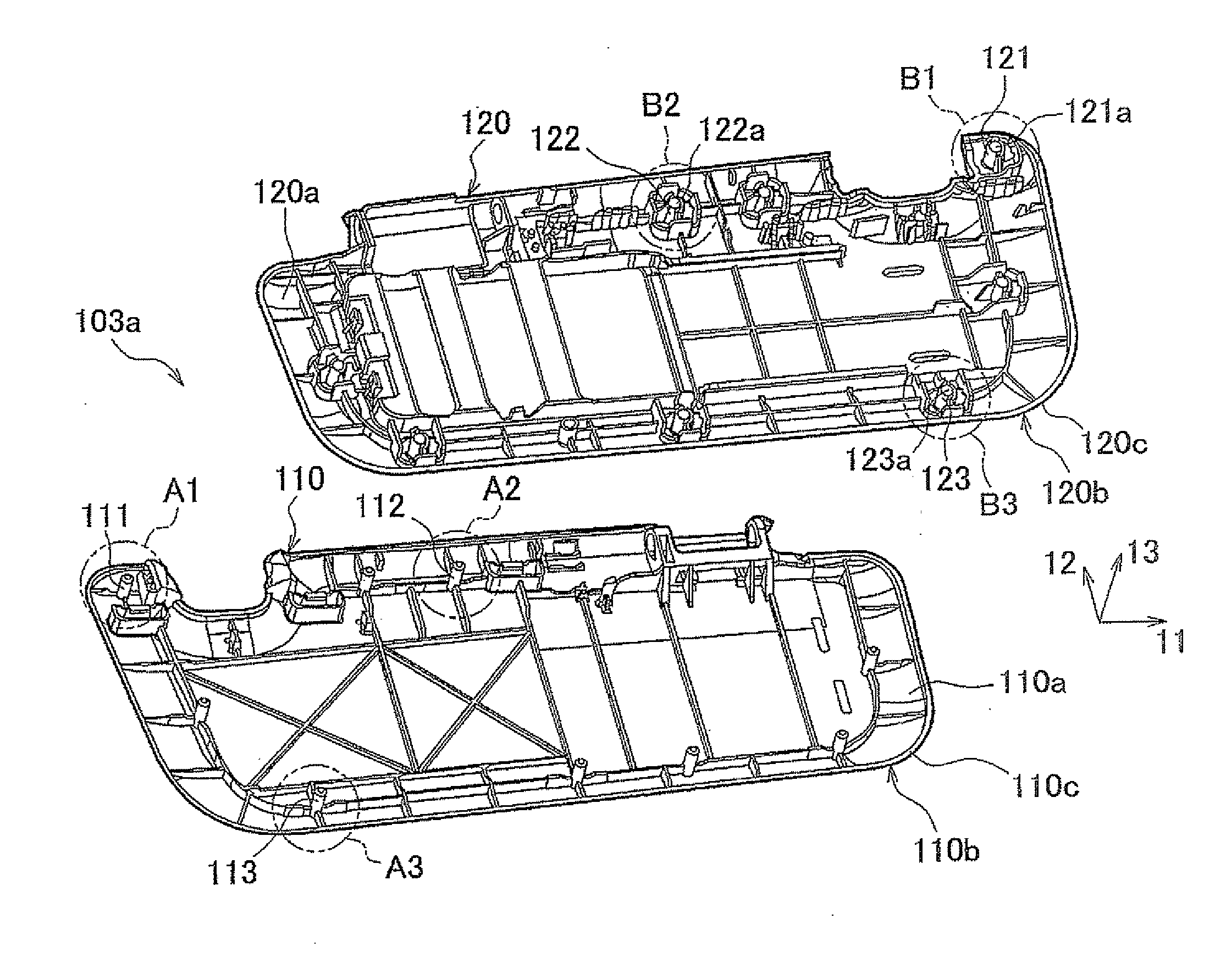

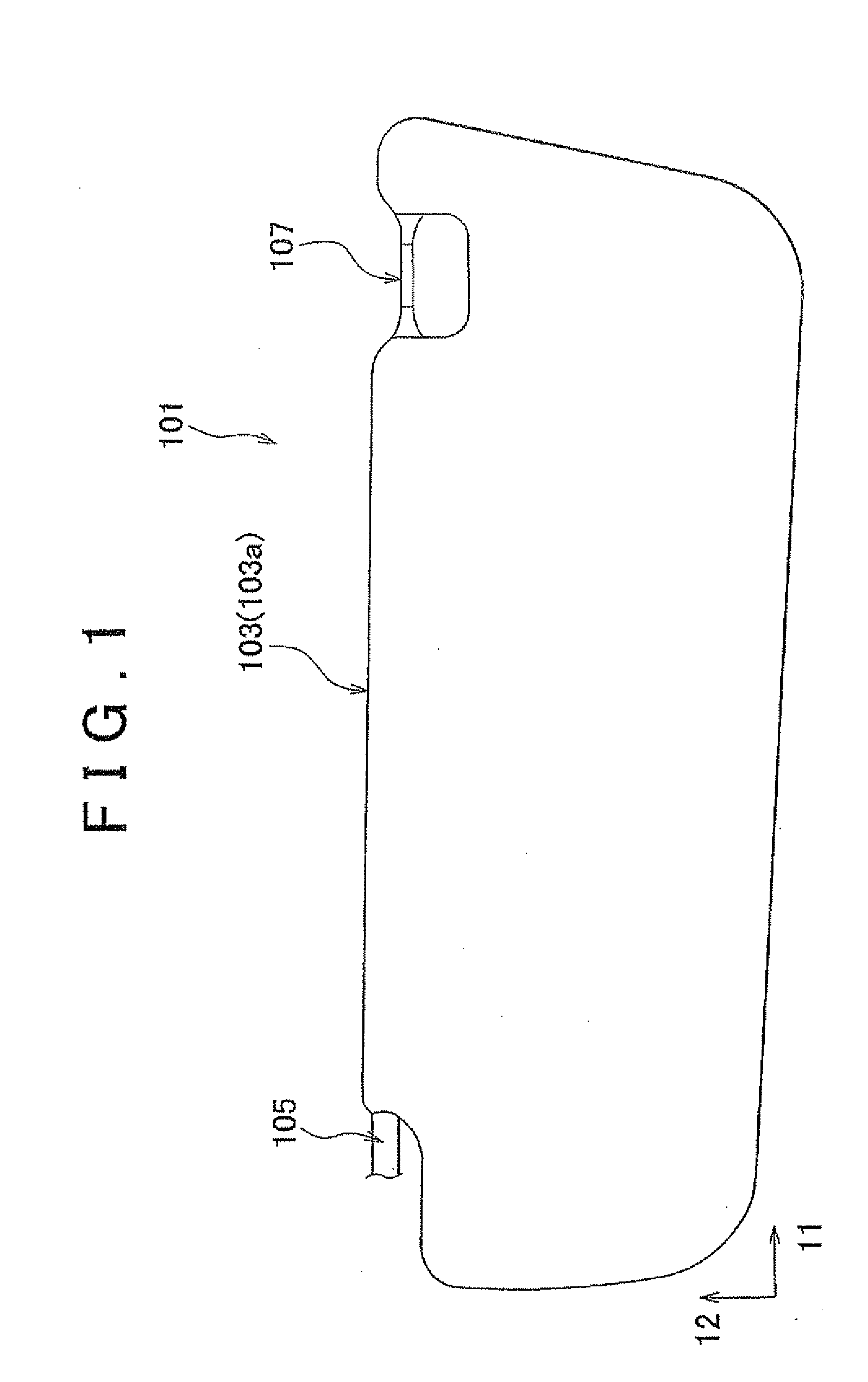

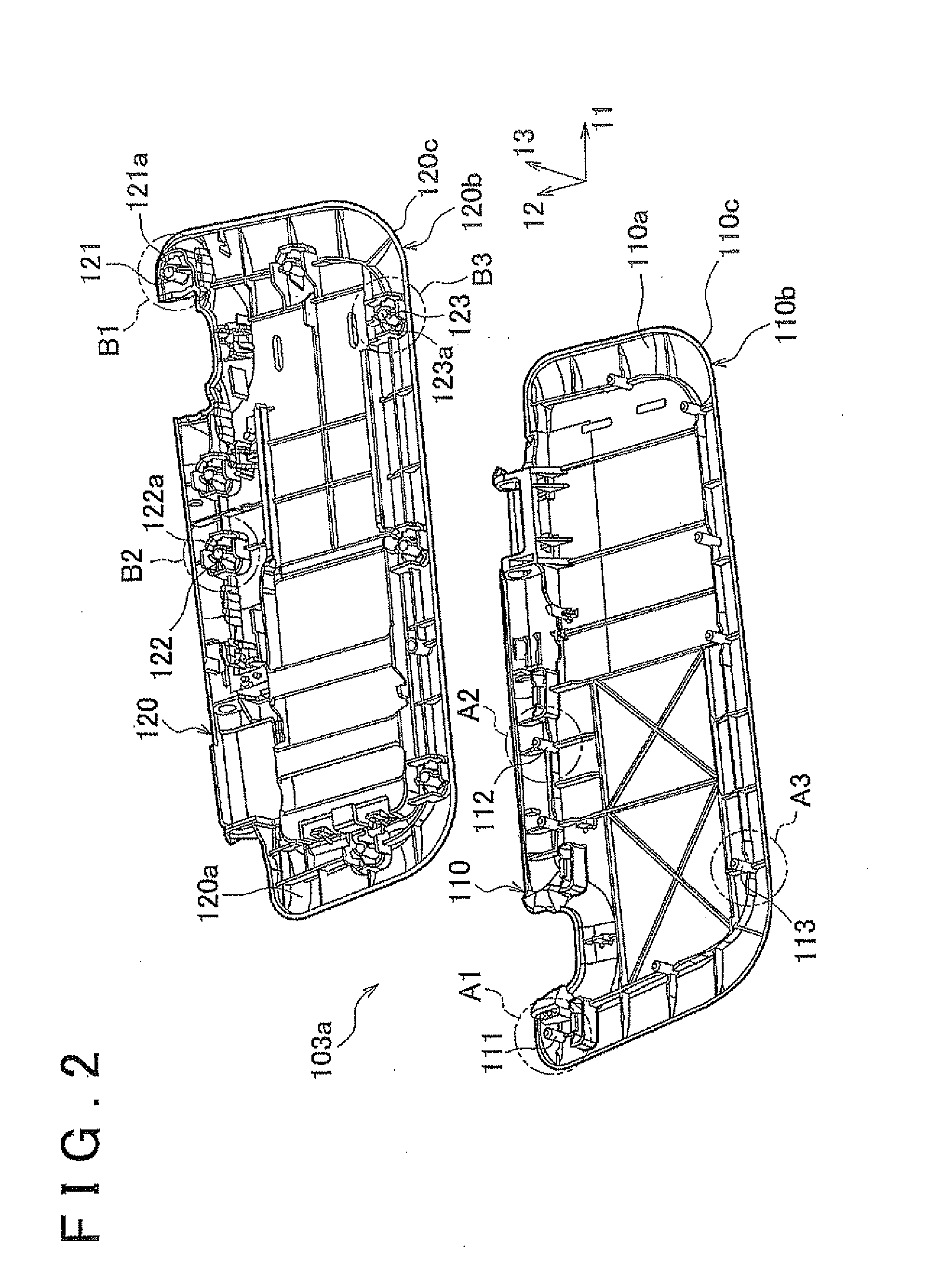

Sunvisor for vehicle

ActiveUS20120119537A1Improve structural durabilityIncreased durabilityAntiglare equipmentVehicle sealing arrangementsMechanical engineeringEngineering

A sun visor for a vehicle has a sun visor body including a first shell and a second shell. The first shell includes a pin, and the second shell includes a boss having an insert hole. Further, a first reinforcing portion that extends in a given direction from at least one of the pin and the boss and a second reinforcing portion that extends in a direction intersecting with the direction of extension of the first reinforcing portion are provided.

Owner:KYOWA SANGYO

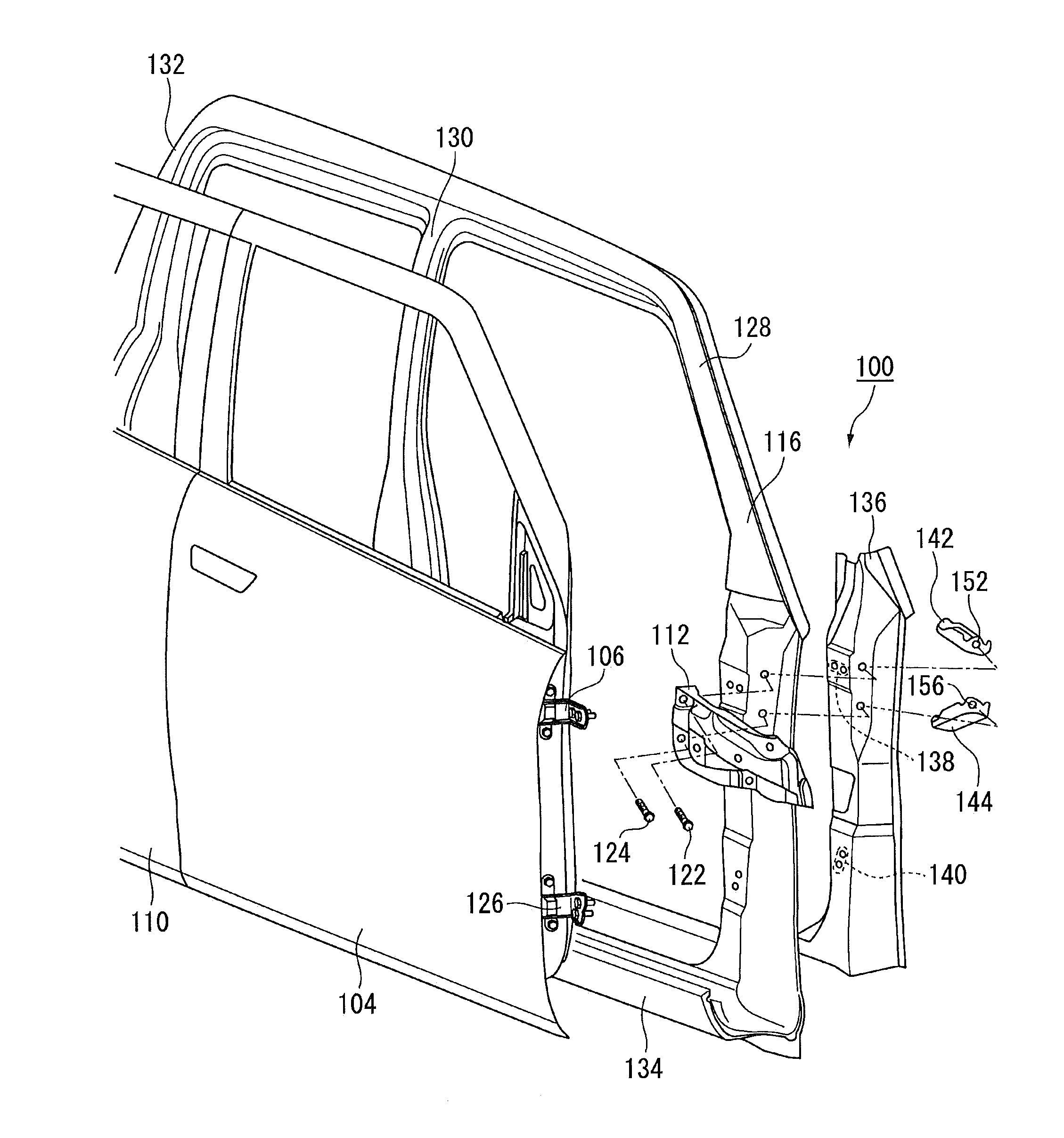

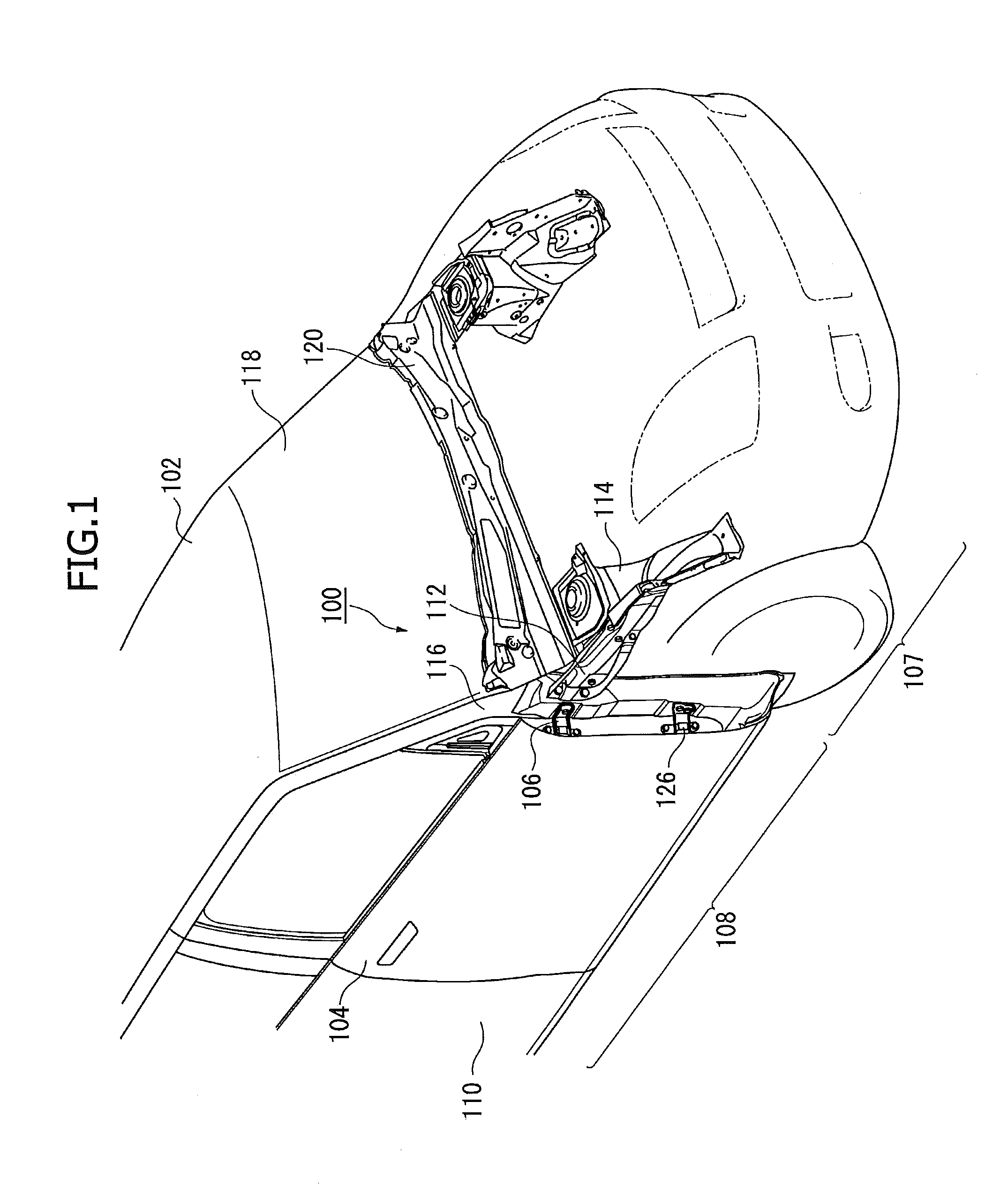

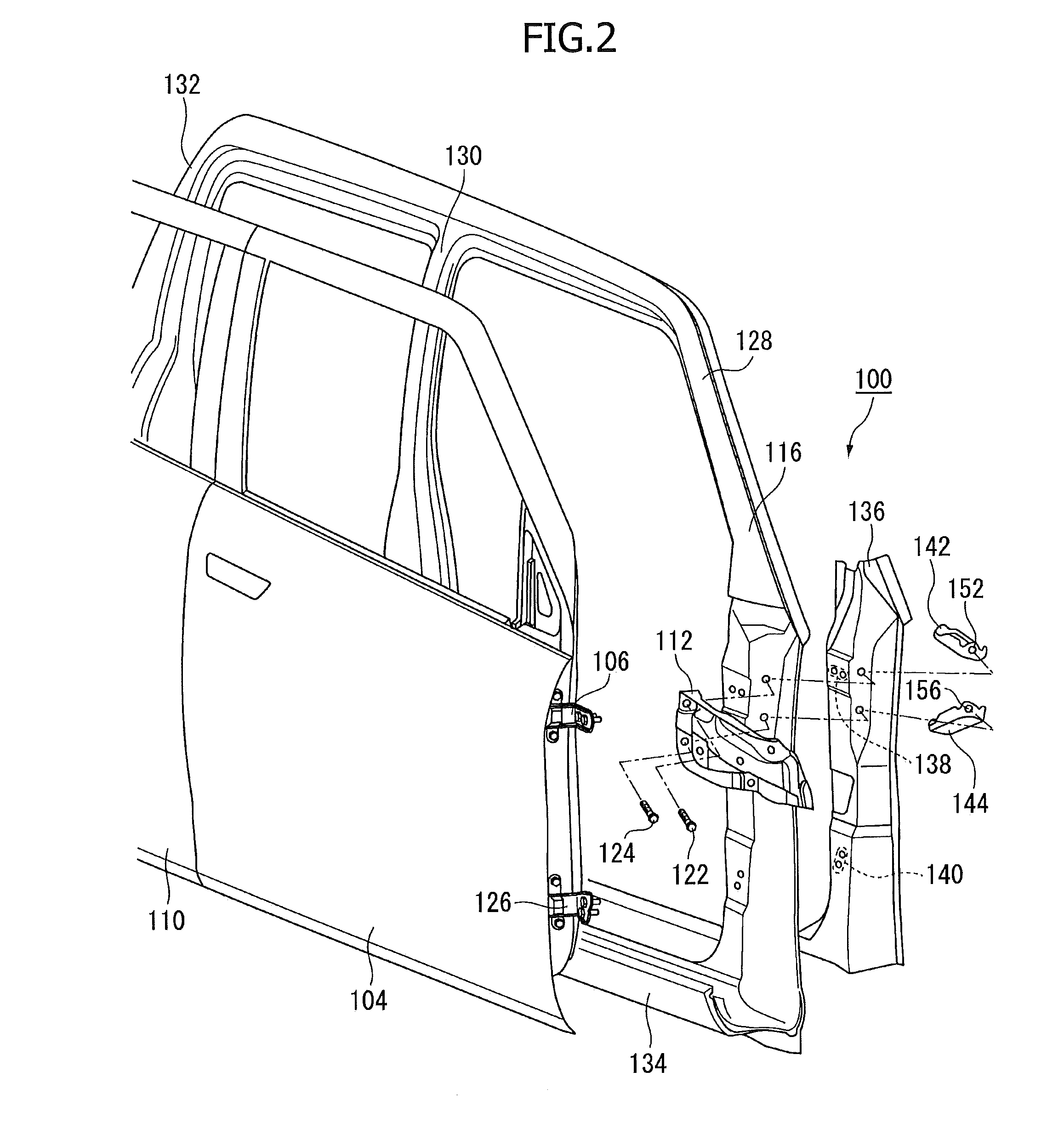

Vehicle body reinforcing structure

InactiveUS8205925B2Improve structural durabilityImprove rigidityVehicle seatsUnderstructuresEngineeringMechanical engineering

Owner:SUZUKI MOTOR CORP

Surface pre-coating method for crack self-repairing of cement-based material

ActiveCN106699004ASave on crack detection and manpower repair costsImprove structural durabilityBuilding repairsNutrientCalcium carbonate

The invention discloses a surface pre-coating method for crack self-repairing of a cement-based material. The method comprises the following steps: (1) preparing bacteria liquid from nutrient immobilized bacillus mucilaginosus powder; (2) adding a hydrophilic thickening agent into the bacteria liquid to obtain repairing liquid; (3) preparing weak-acid pretreatment liquid; and before spraying the repairing liquid, spraying the weak-acid pretreatment liquid to the surface of the cement-based material; and (4) after spraying the weak-acid pretreatment liquid to the surface of the cement-based material for 10min, spraying the repairing liquid. The repairing test result indicates that calcium carbonate can be precipitated at the crack of the cement-based material within 7d; and after 30d of continuous repairing, microcracks with average crack width below 0.4mm can be completely repaired.

Owner:SOUTHEAST UNIV

Whole-span prefabricated H-steel-concrete composite beam bridge and construction method

InactiveCN108342973AImprove integritySolve fatigueBridge structural detailsBridge erection/assemblyWelding residual stressBridge deck

The invention discloses a whole-span prefabricated H-steel-concrete composite beam bridge and a construction method. The whole-span prefabricated H-steel-concrete composite beam bridge comprises an H-steel combination and a concrete bridge plate which is poured on the H-steel combination; the H-steel combination comprises H-steels placed in parallel in the bridge width direction; and the whole-span length is the length direction of the H-steels. The whole-span prefabricated H-steel-concrete composite beam bridge has the advantages that the construction of a bridge deck slab is simple and the hoisting weight of the bridge deck slab is light; during making, factory machining and manufacturing procedure does not exist and the later mounting and erecting difficulty is reduced; and meanwhile, as the H-steels can avoid adverse effects such as welding residual stress, more stable mechanical property, better bearing capacity and better durability are obtained; and the making cost can be greatly reduced. Compared with the steel plate girder in the prior art, the whole-span prefabricated H-steel-concrete composite beam bridge has the advantages that the welding or bolting process can be eliminated; construction processes uneasy to control, such as prestressed structure steel strand tensioning and grouting, hollow slab girder hinge joint connection and so on do not exist; the quality of aprofiled-steel composite beam can be effectively guaranteed; and requirements on equipment and technical skills of workers can be reduced.

Owner:CHONGQING JIAOTONG UNIVERSITY

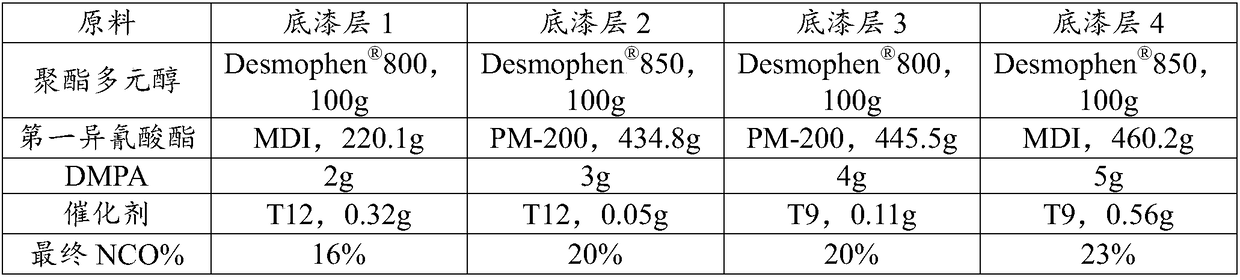

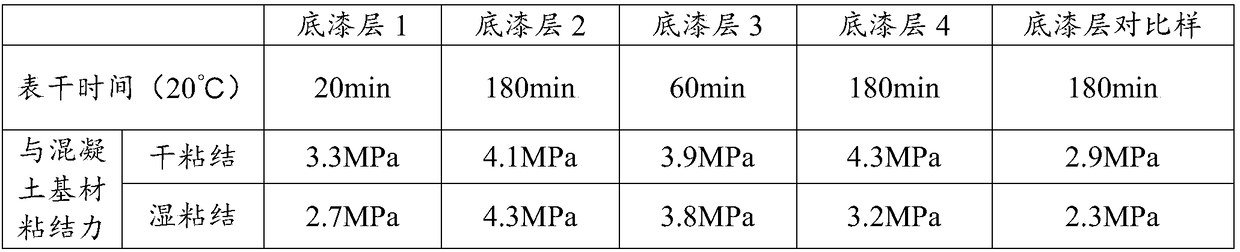

Preparation method of protection and repair system for surface of concrete base

ActiveCN108316667AImprove integrityGood flexibilityBuilding repairsPolyurea/polyurethane coatingsPolyesterPolyol

The invention provides a preparation method of a protection and repair system for the surface of a concrete base, convenient construction is achieved, and a systematic concrete protection and repair system with high adhesive force and durability is provided. The preparation method comprises the steps that the protection and repair system comprises a primer layer, polyurethane mortar layer and a polyurethane weather-proof finish paint layer, wherein the primer layer, the polyurethane mortar layer and the polyurethane weather-proof finish paint layer cover the surface of the concrete base from inside to outside, and the primer layer is obtained by solidifying monoisocyanate-terminated polyurethane prepolymers and a catalyst; the preparation method of the primer layer comprises the steps thatpolyester polyols and first isocyanates are subjected to a thermostatic reaction for 2-3h, a first part of dihydromethyl propionic acid is added to continue the thermostatic reaction for 1.5-2.5h, when the content of isocyanato reaches 16%-23%, cooling is carried out, the catalyst is added, and discharging can be carried out after stirring for 15-20 minutes and standing; and the polyester polyolsare linear or branched polyester polyols, and the mass ratio of the first isocyanate to the polyester polyols is (2.2-4.6) : 1.

Owner:江苏丰彩建材(集团)有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com