Patents

Literature

3130 results about "Box girder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A box or tubular girder is a girder that forms an enclosed tube with multiple walls, rather than an I or H-beam. Originally constructed of riveted wrought iron, they are now found in rolled or welded steel, aluminium extrusions or prestressed concrete.

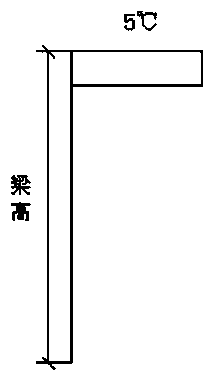

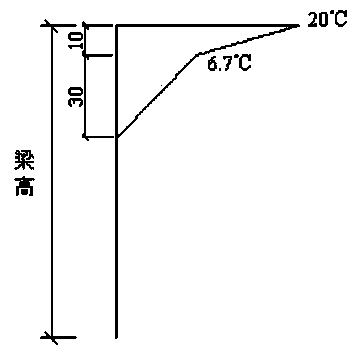

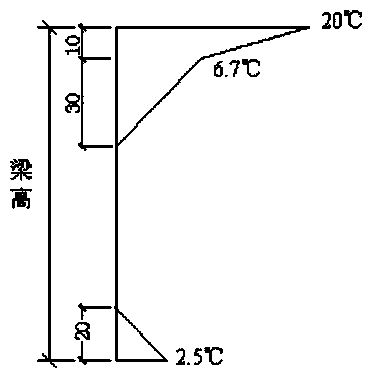

Finite element analysis method for temperature action on prestressed reinforced concrete continuous rigid frame bridge

ActiveCN104166792AAccelerated settlementEfficient solutionSpecial data processing applicationsStructural deformationElement analysis

The invention provides a finite element analysis method for the temperature action on a prestressed reinforced concrete continuous rigid frame bridge. The finite element analysis method is used for analyzing and calculating the stress and displacement distribution in the construction and finished bridge stage under different temperature gradient models, and provides references for designing and optimizing the prestressed reinforced concrete continuous rigid frame bridge. Through calculational analysis based on finite elements and the structural mechanics, the forward-calculation method is adopted for structural distortion and stress analysis according to the actual construction loading sequence of the bridge structure, so that the complex mechanics problem of box girder temperature self-stress, temperature secondary internal force in a prestressed reinforced concrete statically indeterminate structure and secondary stress of the temperature secondary internal force is solved easily, conveniently and efficiently, and the finite element analysis method has important practical value.

Owner:江苏中国科学院能源动力研究中心 +1

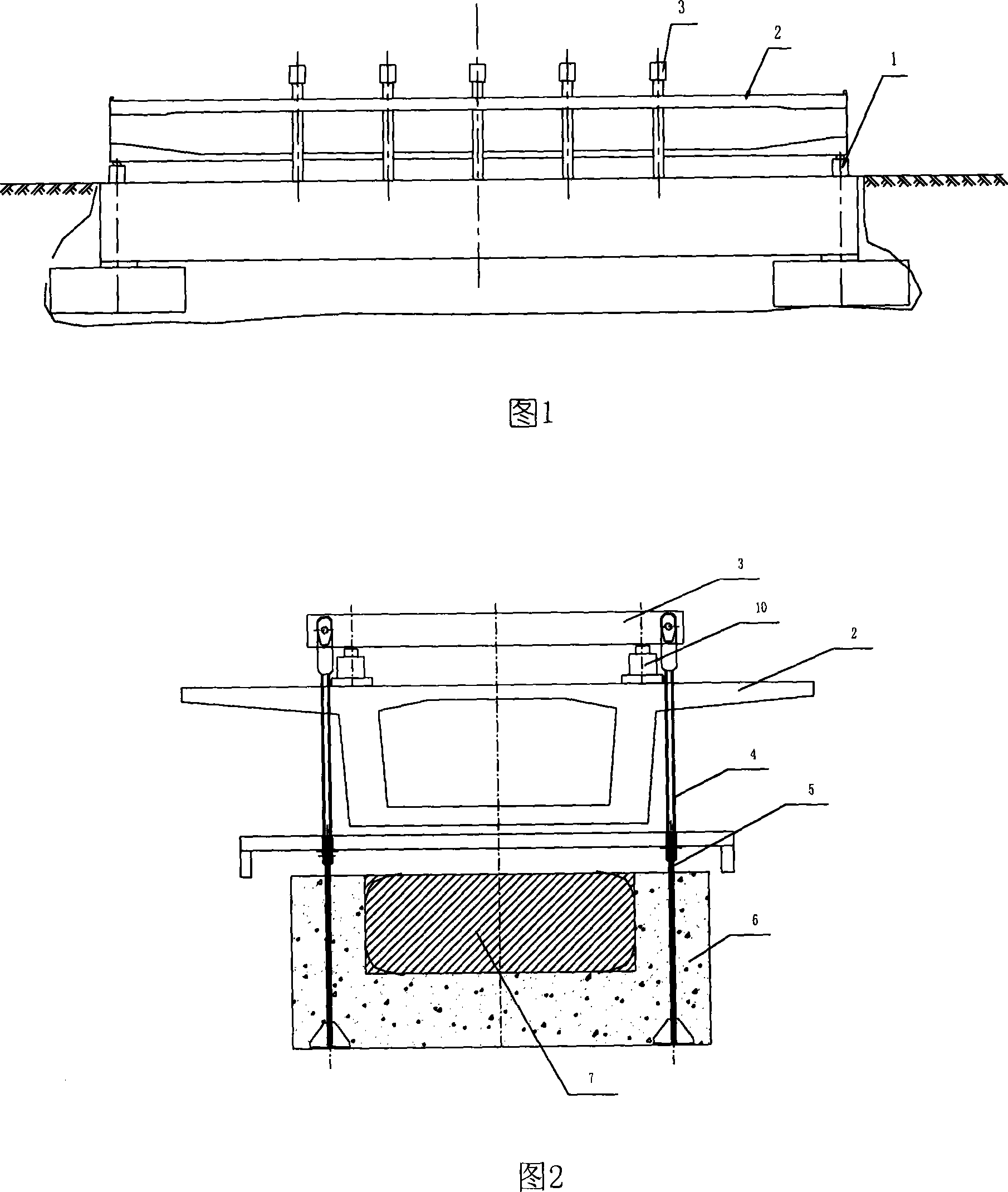

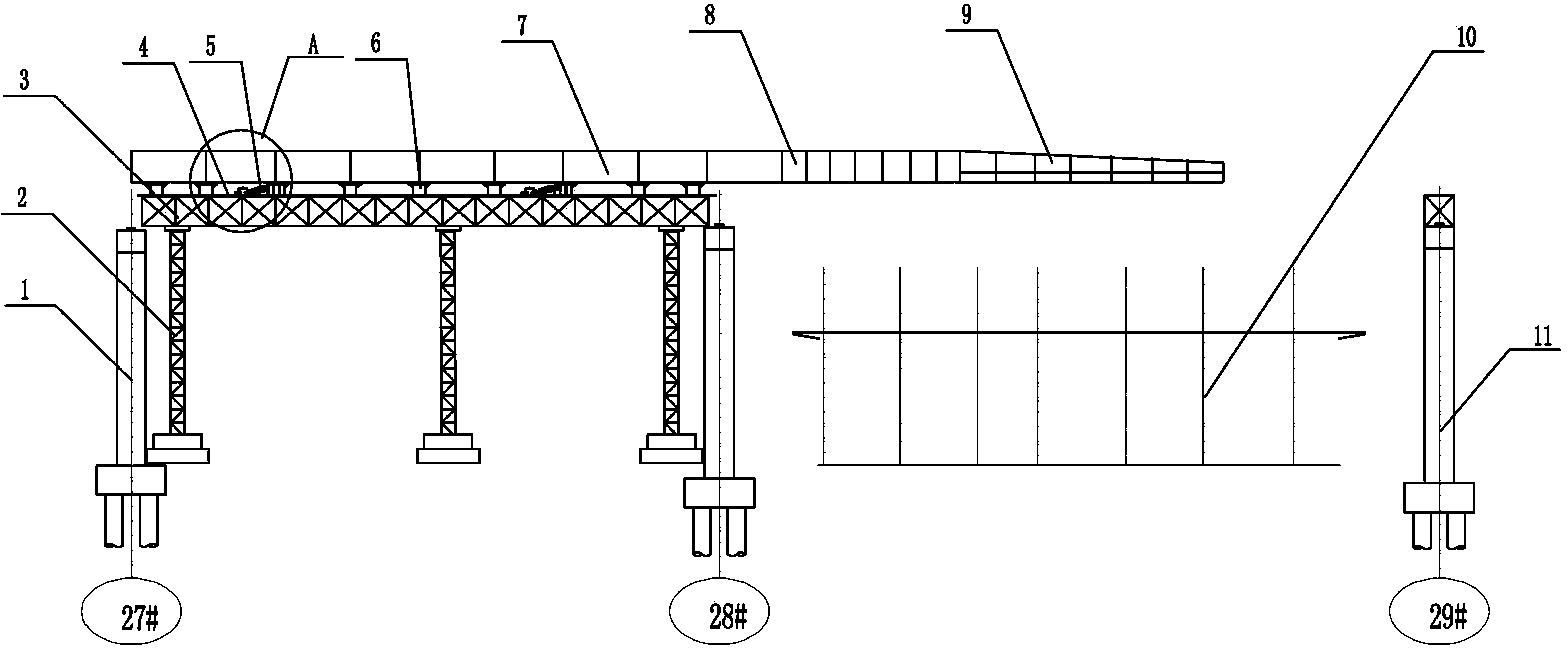

Receding construction method of cradle of continuous girder bridge made of prestressing concrete

The invention relates to a receding construction method of a cradle of a continuous girder bridge made of prestressing concrete, which is characterized in that the bridge surface of a bridge prefabricated by concrete is provided with a track and a door-shaped truss traveling device, and the width of a ceiling girder inside the door-shaped truss traveling device is wider than that of the bridge surface by 90cm-110cm; a front bottom cross beam and a rear bottom cross beam must extend to the outer side of an external mold by 45cm-55cm to form a main cradle truss, and an overhanging auxiliary door frame is additionally arranged outside the main cradle truss, after the construction of a closure segment of the bridge prefabricated by concrete is finished, and precise rolling deformed steel bars with the diameter of 32 outside a box girder positioned on the overhanging auxiliary door frame are connected with the rear bottom cross beam to disassemble a rear hanging strip; a bottom mold frame is separated from a beam body by utilizing a manual spiral type jack to loose the precise rolling deformed steel bars positioned on the door frame and the front bottom cross beam; a leading chain or a hoist are utilized to drive the main cradle truss so that the cradle recedes in a slideway to a first cast-in-situ segment; and a bottom mold and the external mold are fallen by the leading chain or the hoist to disassemble the main truss.

Owner:NO 1 ENG CO LTD OF CR11BG +1

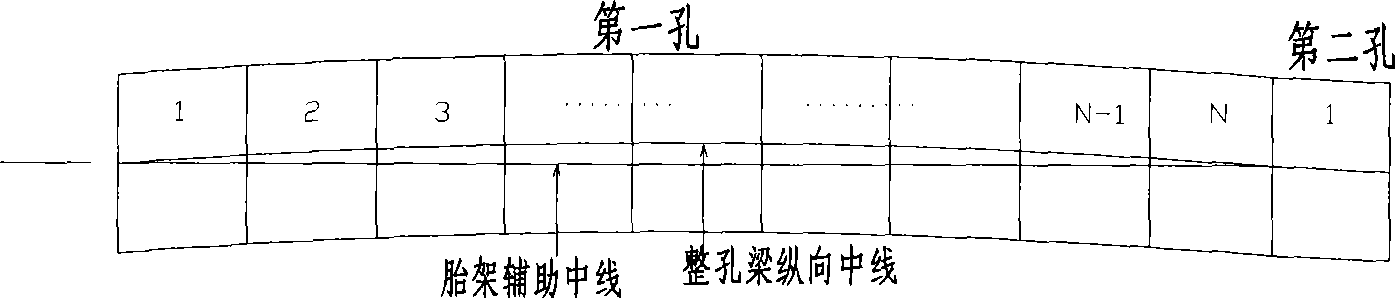

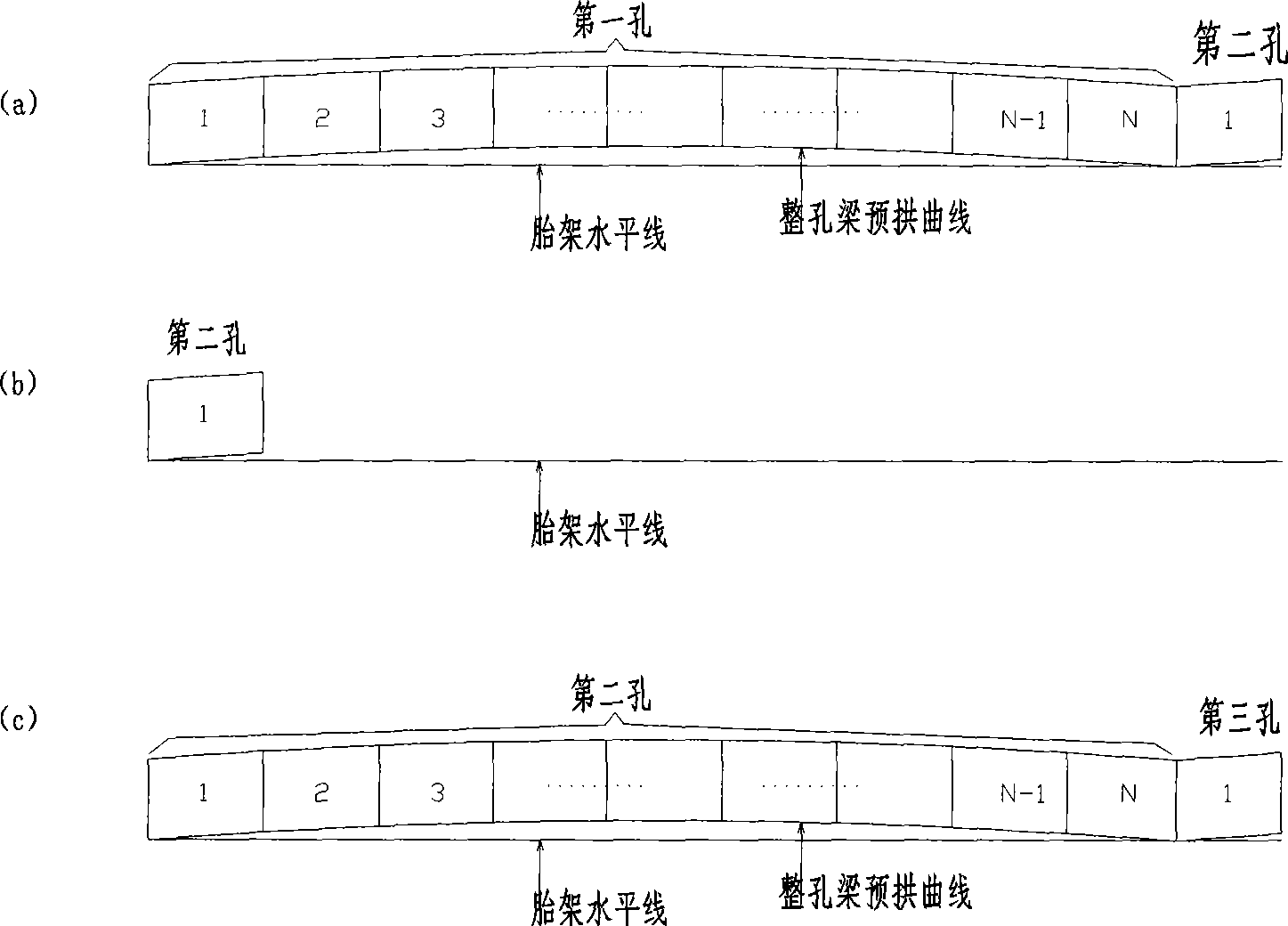

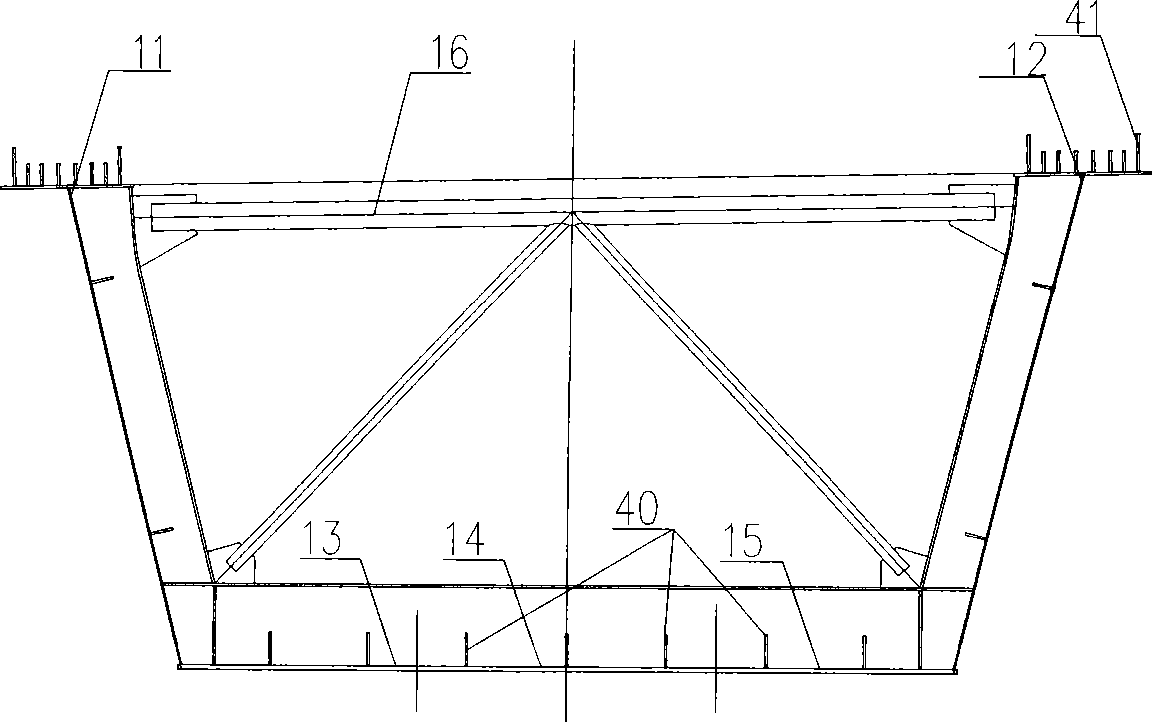

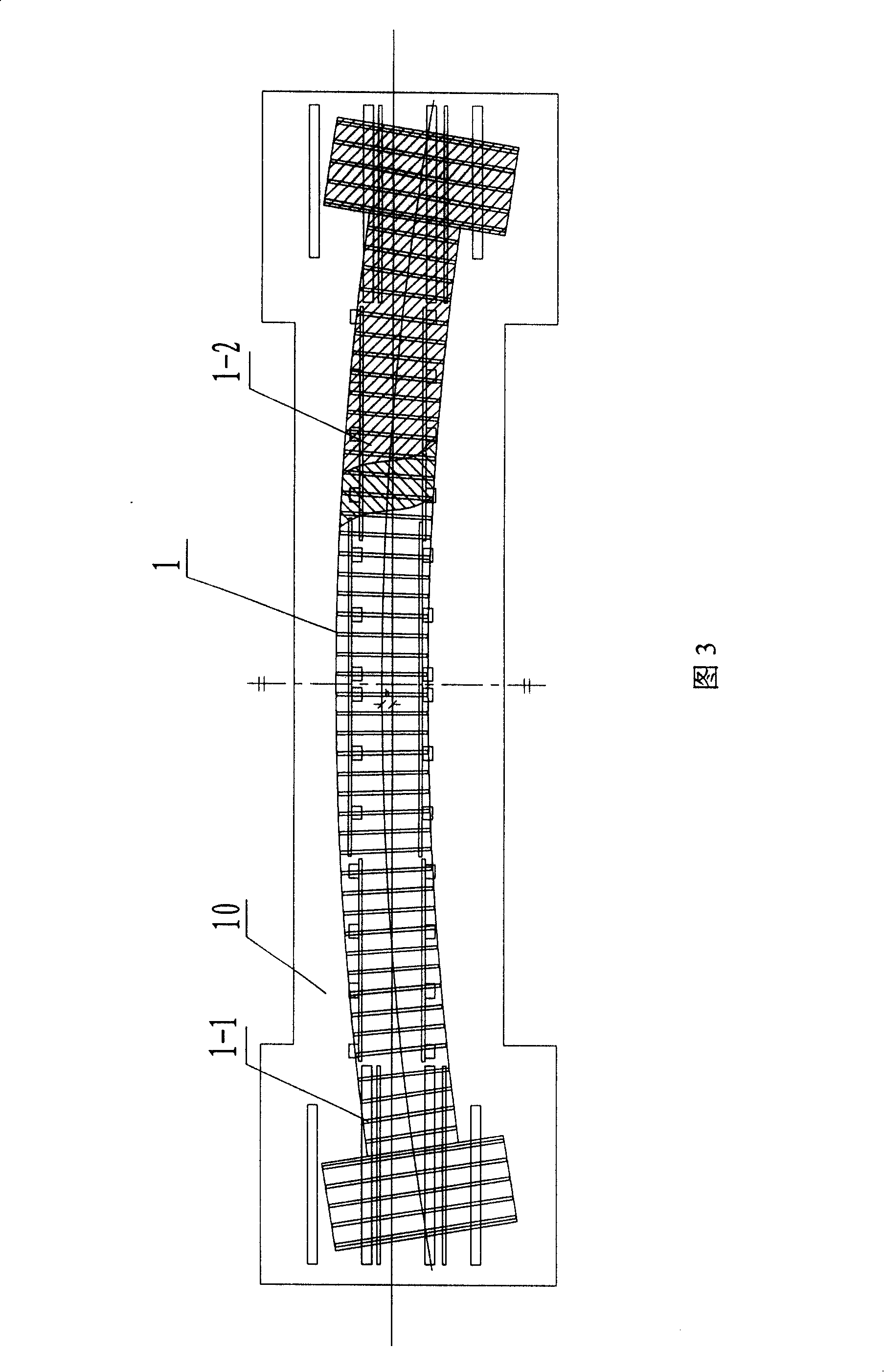

Segment-assembling simply supported box girder movable falsework construction method

The invention discloses a segment assembled simple box girder movable trestle construction method. The required construction simple box girder has single hole or multiple holes, and is assembled by a plurality of longitudinal (i.e. along bridge direction) segment box grinders; the method comprises the following steps: prefabricating all the segment box girders for assembling the simple box girder in concentration; assembling and erecting the first hole grinder, which comprises the steps of: assembling and erecting the trestle (i.e. assembling platform), hanging the segments on to the assembling platform according to the assembling sequence and adjusting the arch degree, line style and position accurately, constructing the segments on the assembling platform by segment assembling construction technology until complete the whole hole grinder construction, and dismounting the trestle and moving to the next hole grinder; and performing the subsequent hole grinders in order according to the construction steps of the first hole grinder. the invention achieves the advantages of simple steps, low construction difficulty, short construction cycle and low onetime fund investment; can solves the practical problems existing in the segment assembling construction process of current large-span bridge fabrication machine.

Owner:CHINA RAILWAY FIRST GRP CO LTD

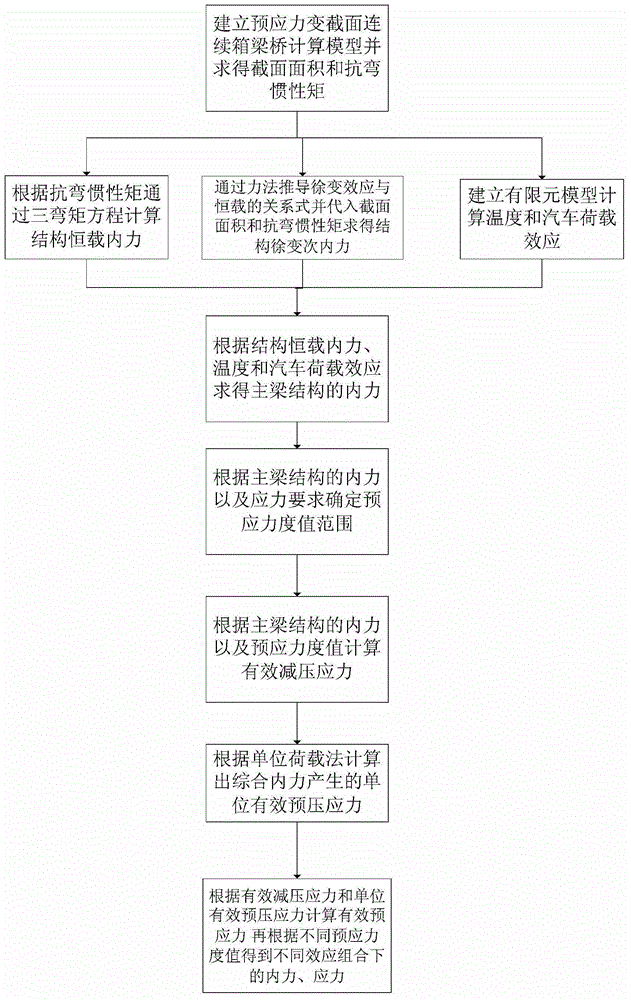

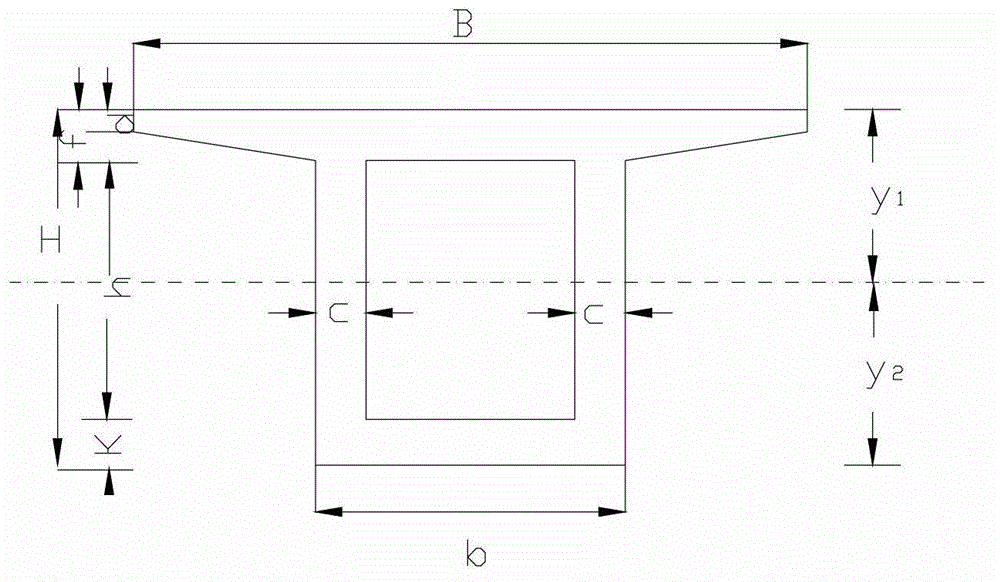

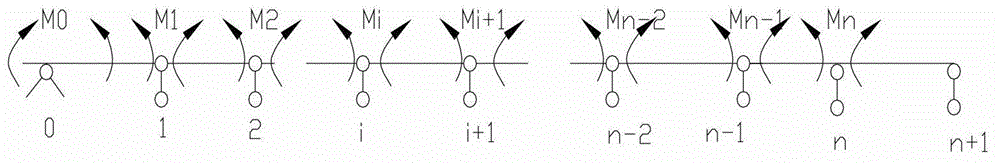

Design method for longitudinal pre-stressing tendons of variable-cross-section pre-stressed concrete continuous bridge

InactiveCN103065035ADevelop longitudinal prestressDevelopment of Analytical Computational MethodsSpecial data processing applicationsBridge materialsStress ratioPre stressing

The invention discloses a design method for longitudinal pre-stressing tendons of a variable-cross-section pre-stressed concrete continuous bridge. The optimization design method for the longitudinal pre-stressing tendons of the pre-stressed concrete continuous bridge is built based on the design principle of the pre-stressed degree and through combining an analytic method with a finite element method and compressively considering dead load and live load action effects. A three moment equation of the variable-cross-section pre-stressed concrete continuous box girder bridge is established to solve the internal force of the structure under the action of the self weight on the basis of the average bending moment method. A calculation formula of pre-stressed effective pre-pressure is built through a load equal effect method and a unit load method; a creep effect calculation formula is built through a force method; the temperature effect and the automobile load effect are calculated through the finite element method; and a variable-cross-section statically indeterminate structure pre-stressing tendon reinforcement calculation formula is obtained through combination of the stress ratio with the definition of the competitive pre-stressed degree.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

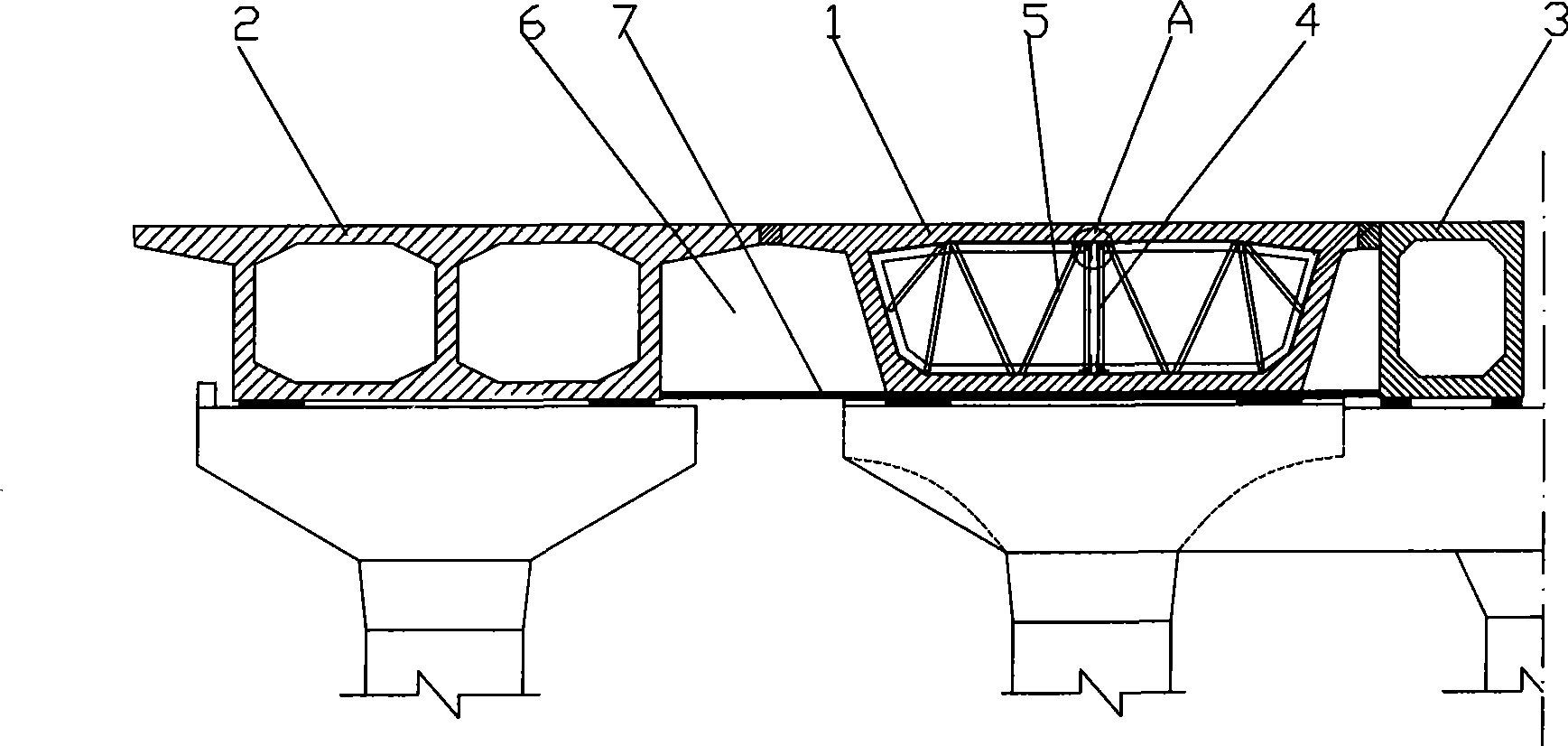

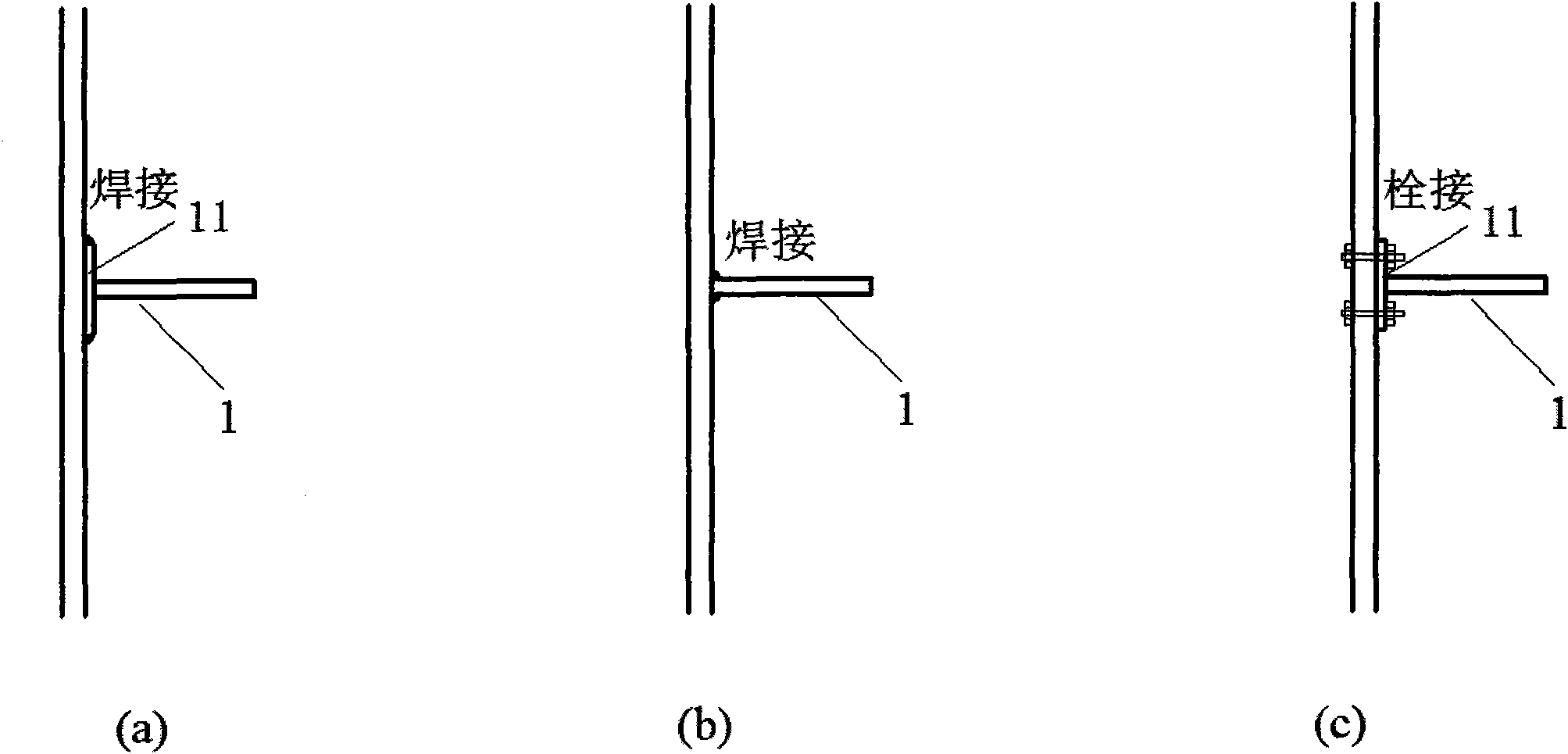

Concrete box girder bridge widening and reinforced structure and construction method thereof

InactiveCN101424075AImprove the state of stressClear forceBridge erection/assemblyBridge strengtheningSocial benefitsReinforced concrete

The invention discloses a widening and reinforcing structure for a concrete box girder bridge and a method for constructing the same. The widening and reinforcing structure comprises a new box girder I and a new box girder II which are parallel with the original box girder bridge and are positioned at two sides of the original box girder bridge; and the box girder of the new box girder I and the box girder of the new box girder II are in rigid connection with box girder flanges of the original box girder bridge. The new box girders share part of the load of the original box girder so that the internal force and the deformation (or the stress of a control point) of a controlled cross section of the original box girder bridge are reduced by about 20 percent; and the generation and the development of cracks on a crest slab, a bottom plate and a web plate of the original box girder bridge can be effectively inhibited. The widening and reinforcing structure is simple, has slight damage to the original box girder bridge, and does not increase obvious structure deadweight substantially. The method for widening and reinforcing constructions is simple and convenient; the reinforced concrete box girder bridge has a reliable structure; the construction period is relatively short; the impact on the road traffic is relatively small; and the damage to the natural environment and the bad social impact caused by the demolition of an old bridge are avoided, thus the method has good comprehensive technical, economic and social benefits.

Owner:CHONGQING JIAOTONG UNIVERSITY

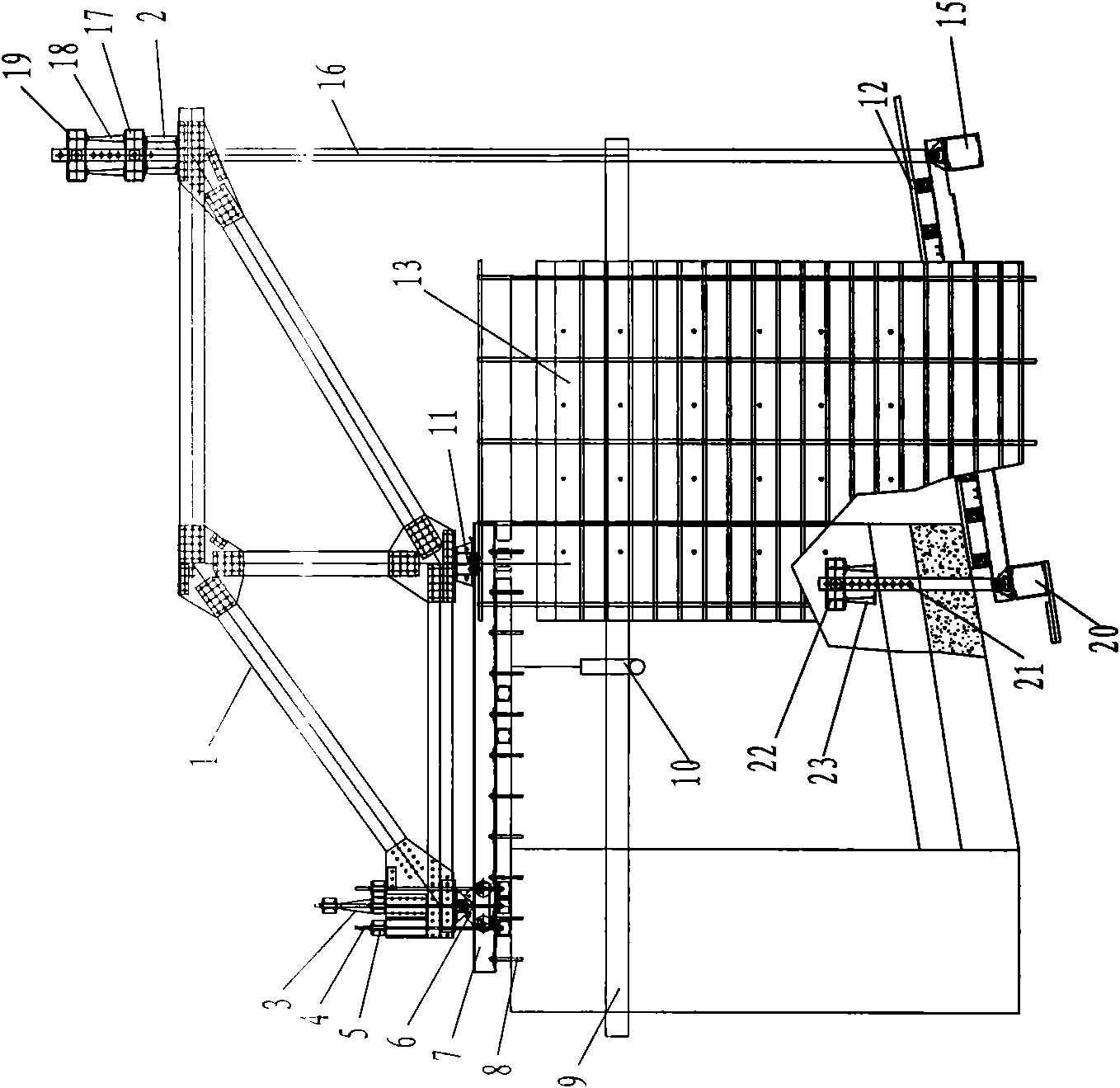

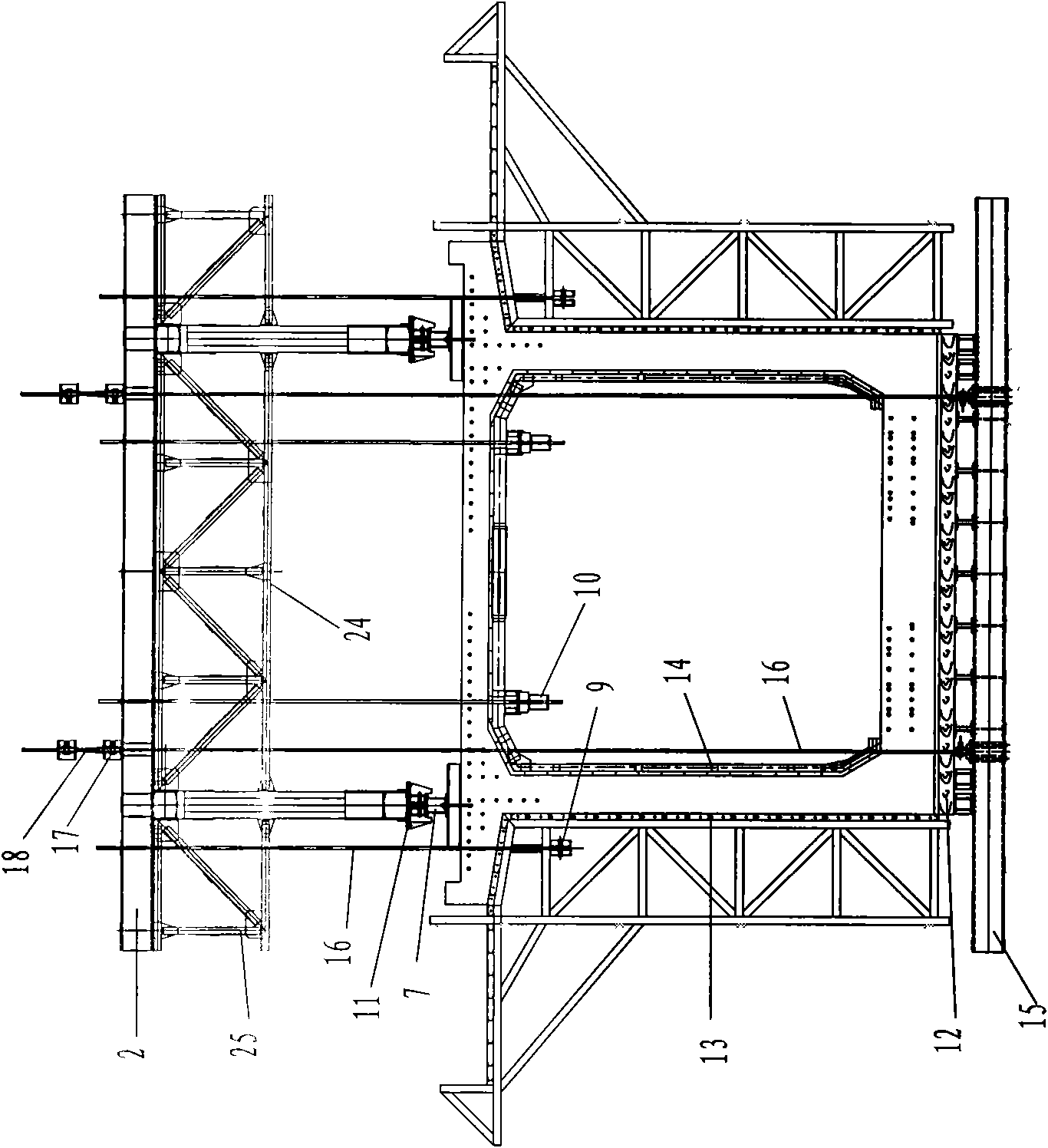

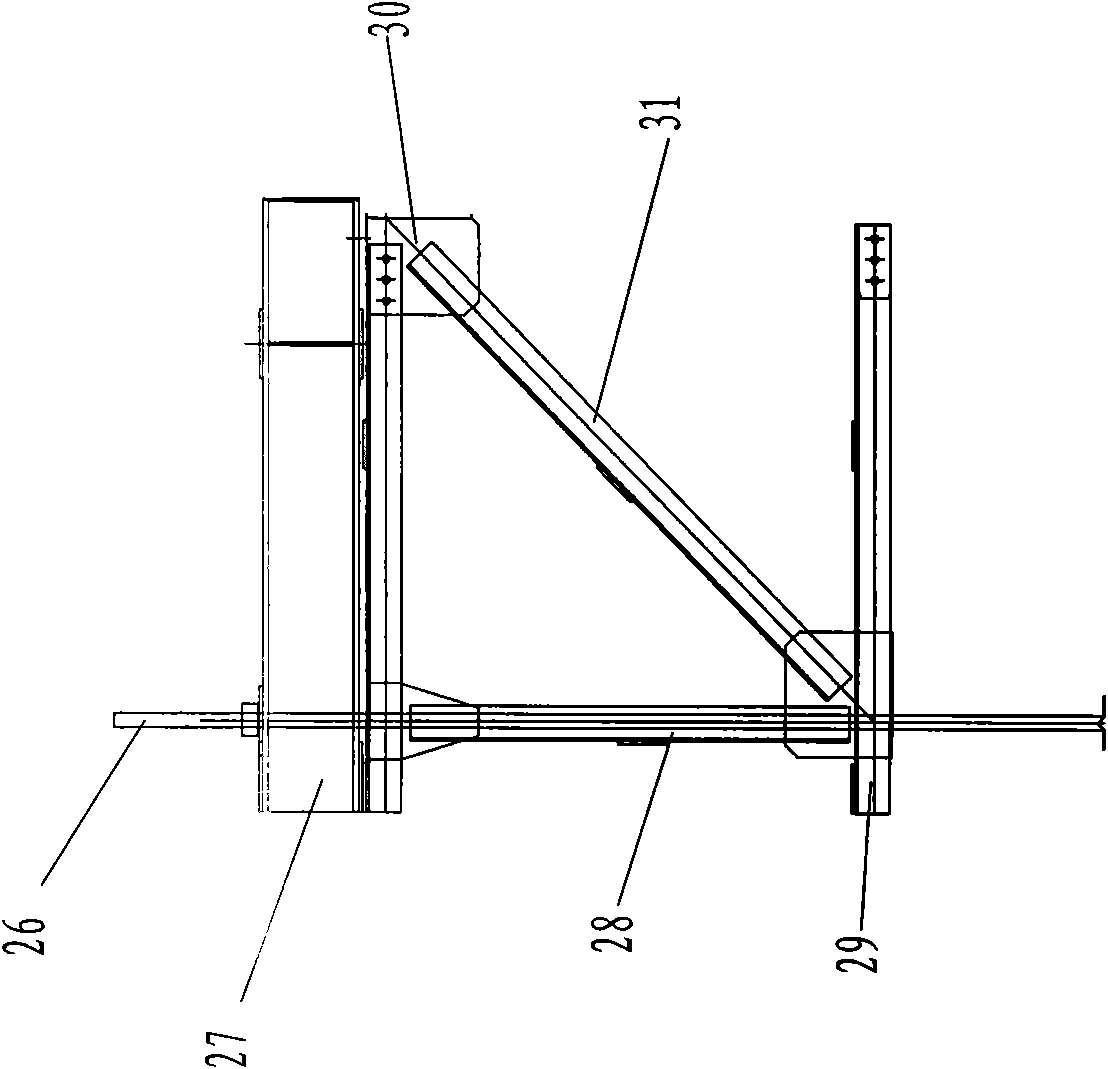

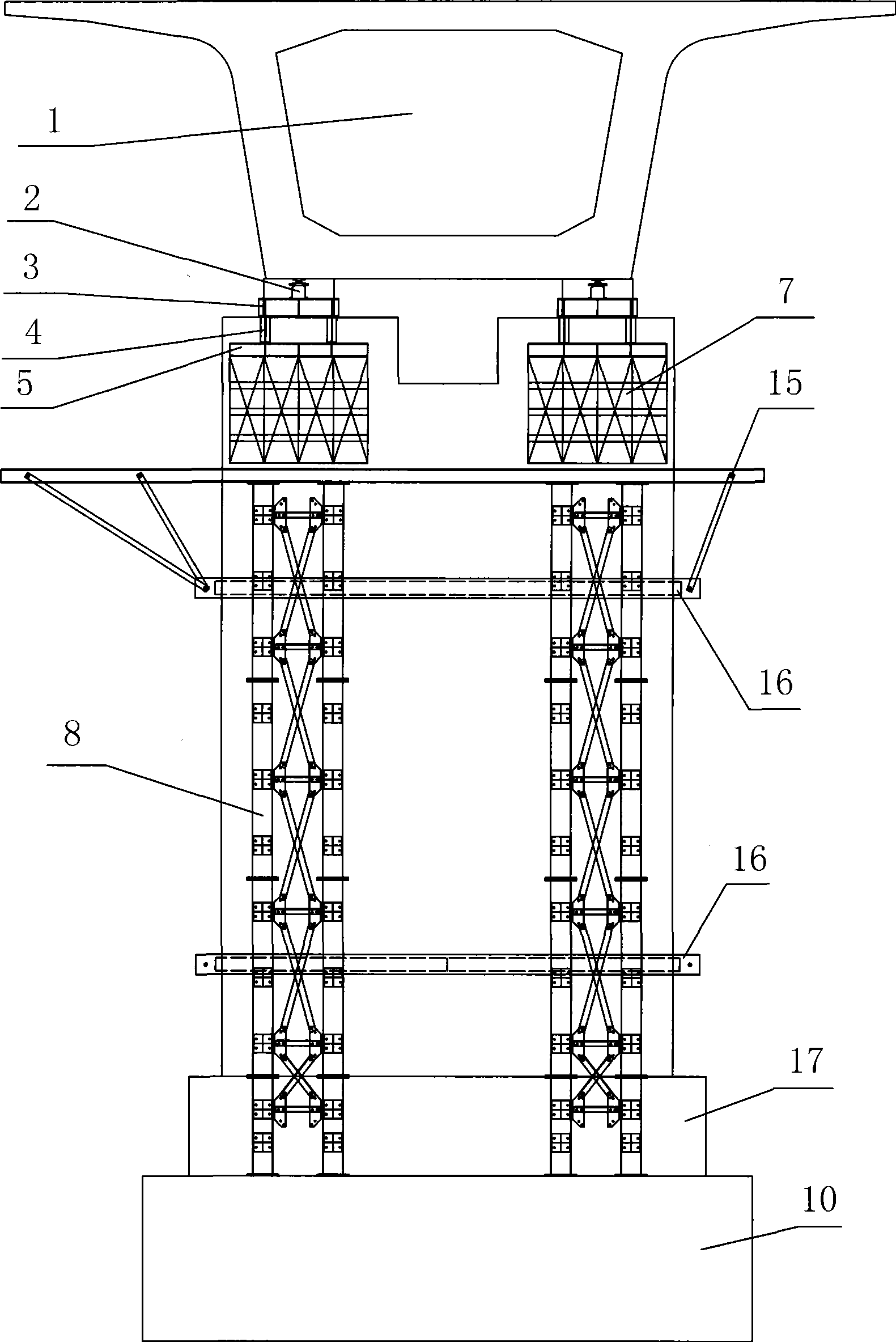

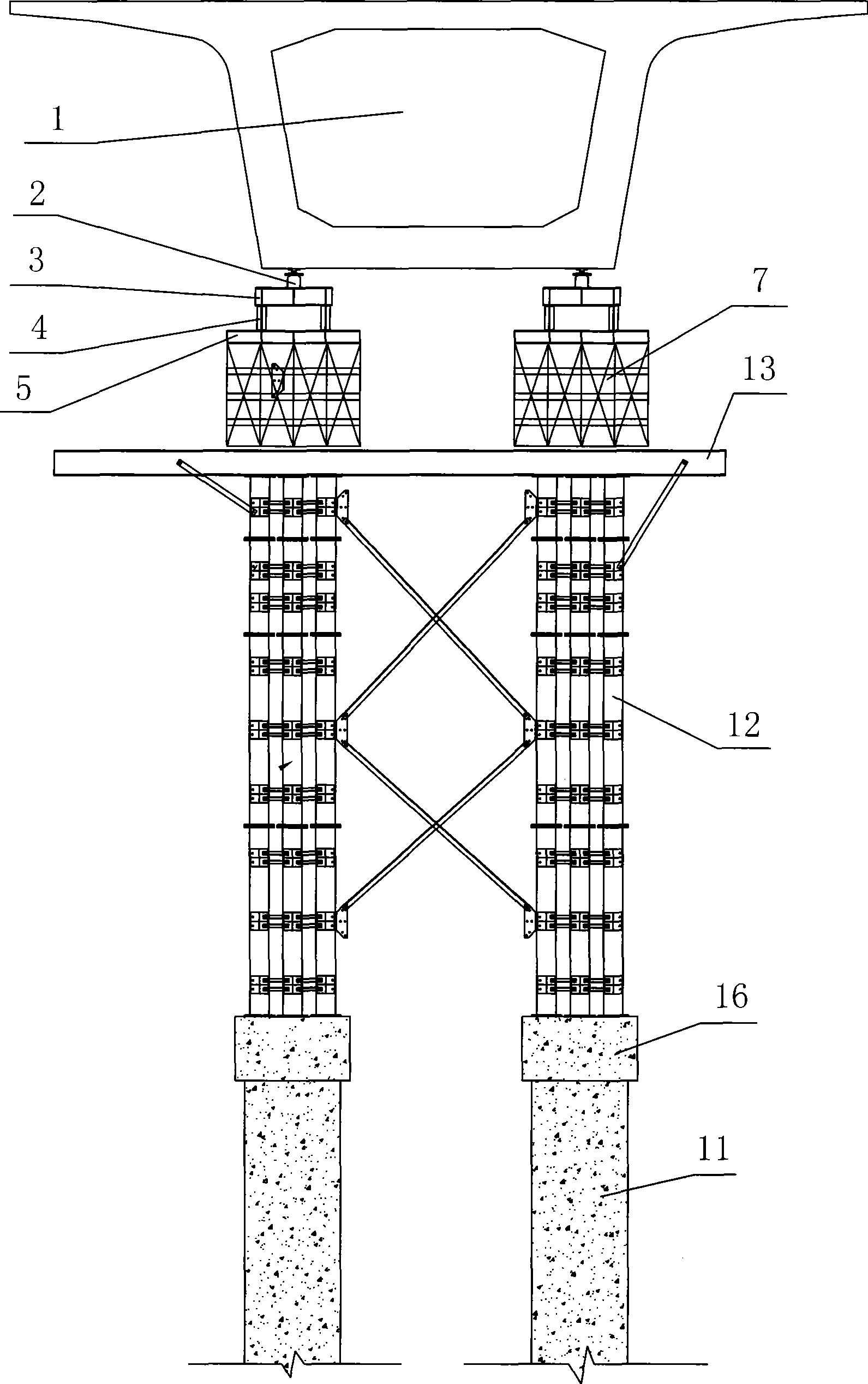

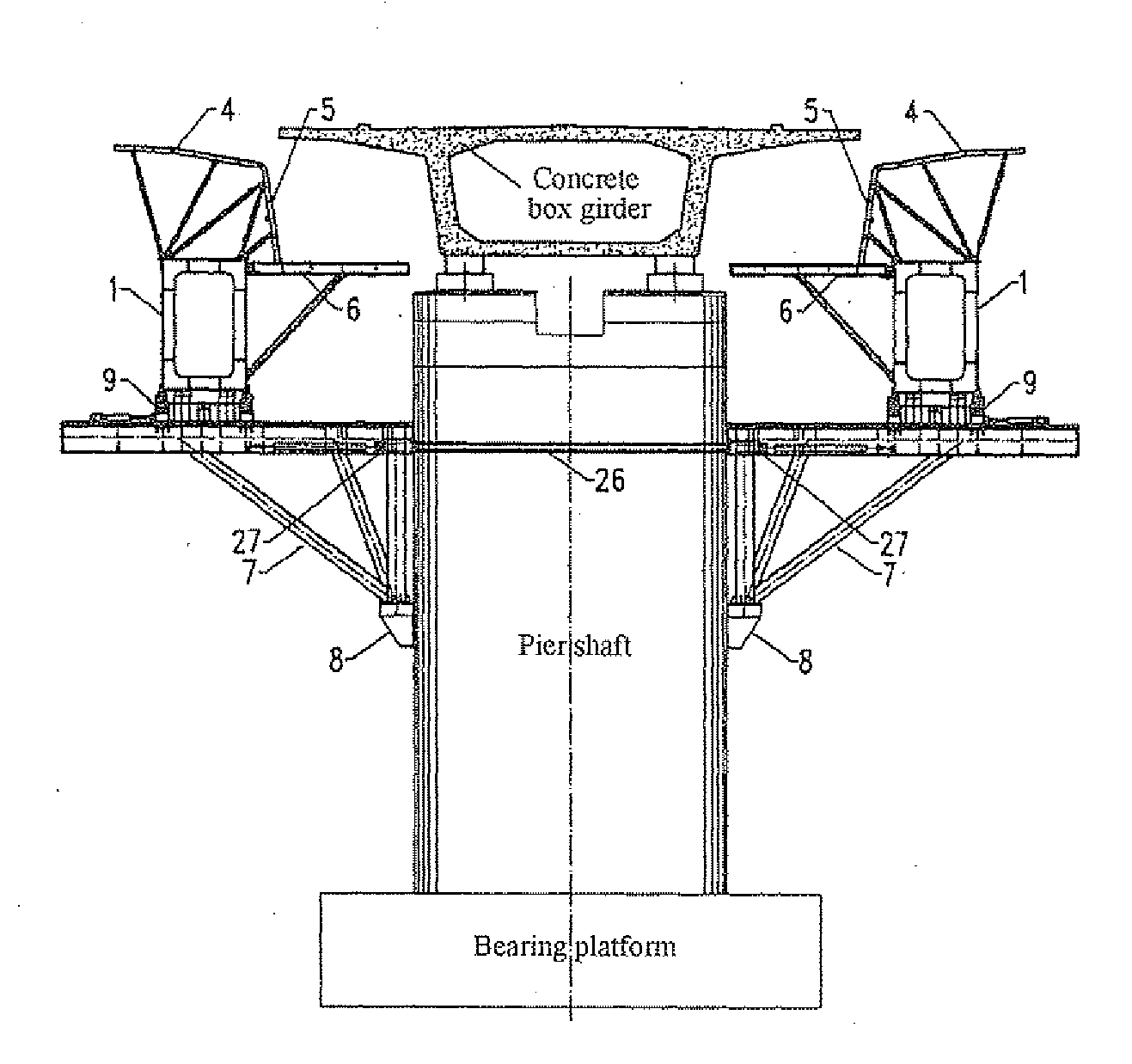

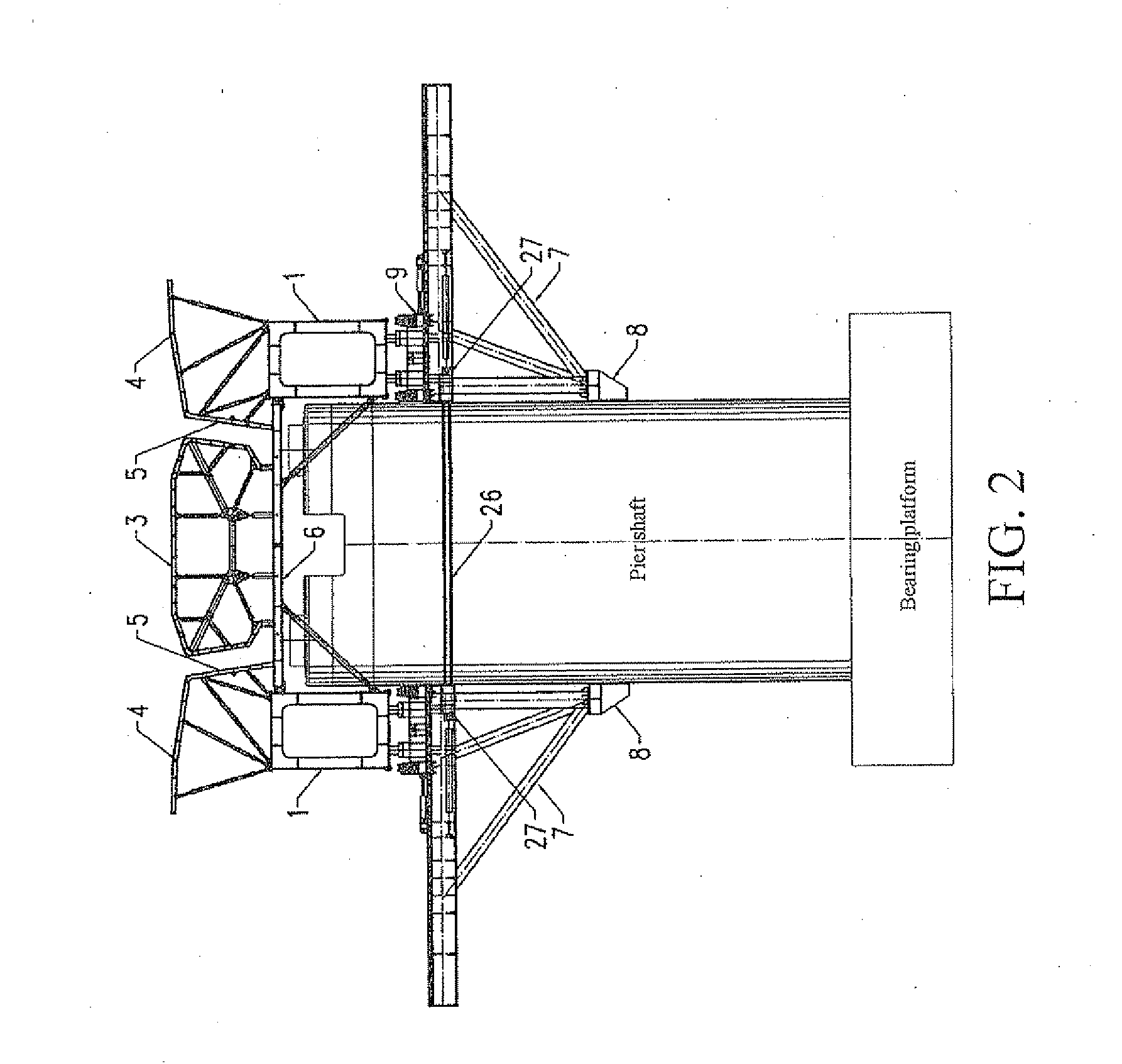

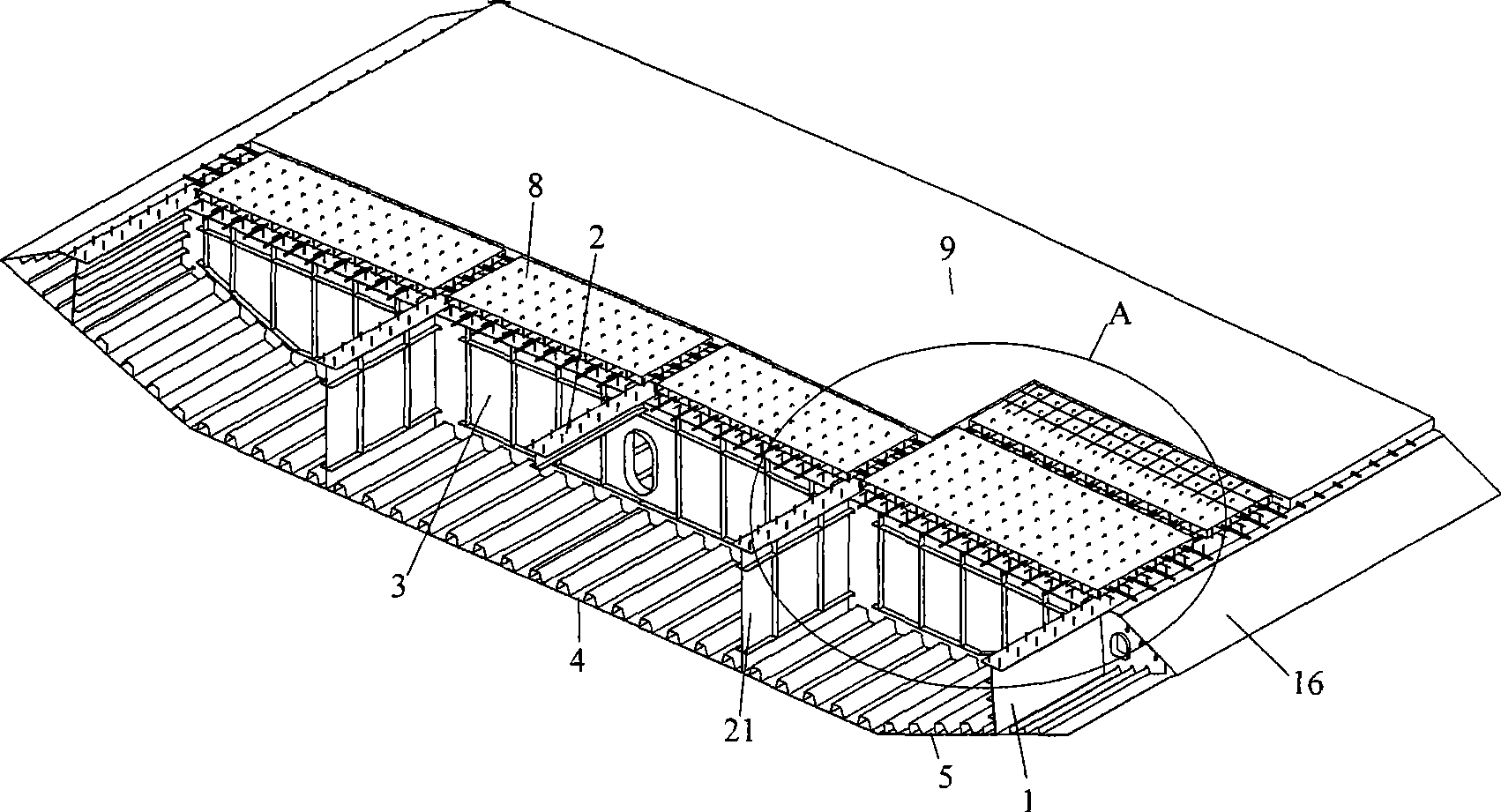

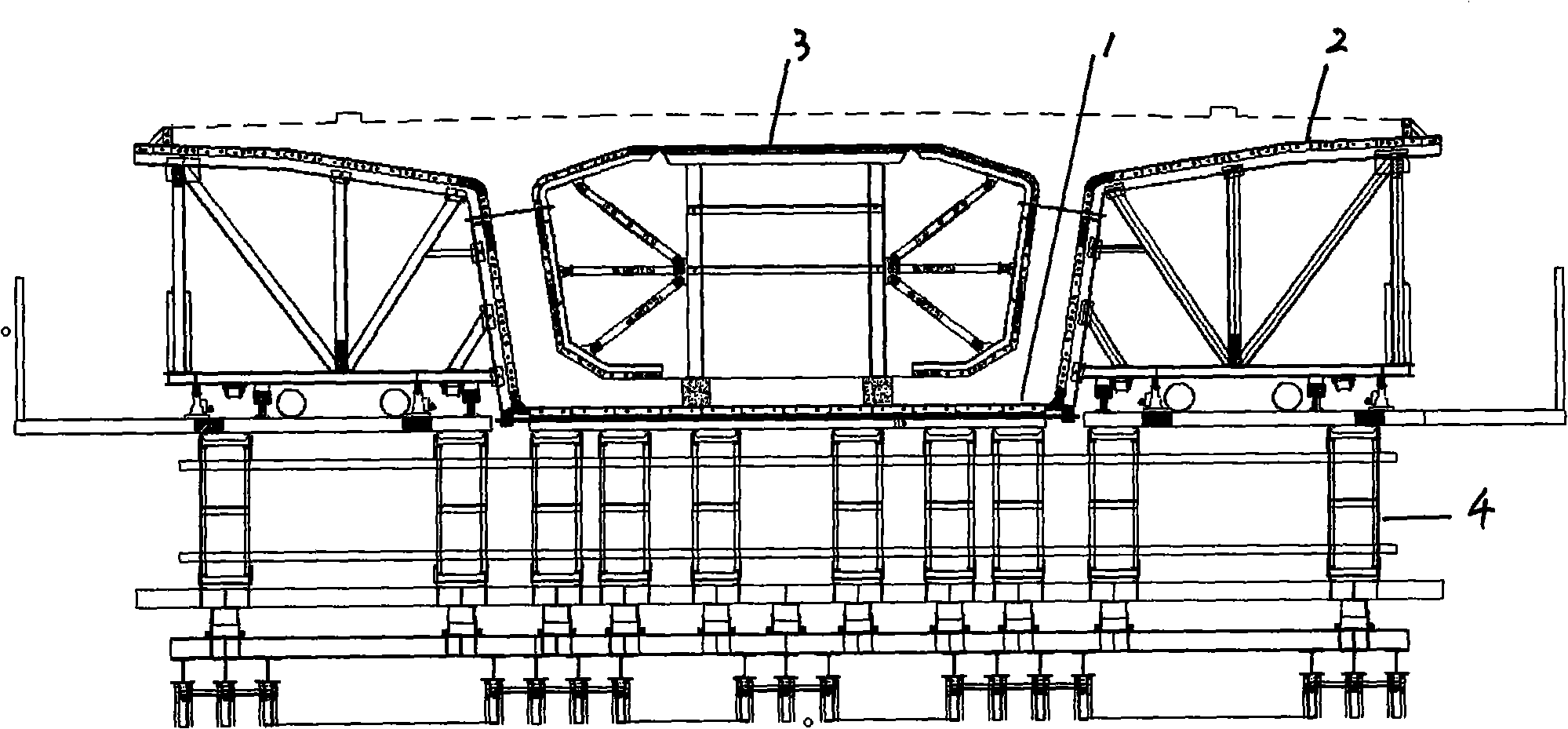

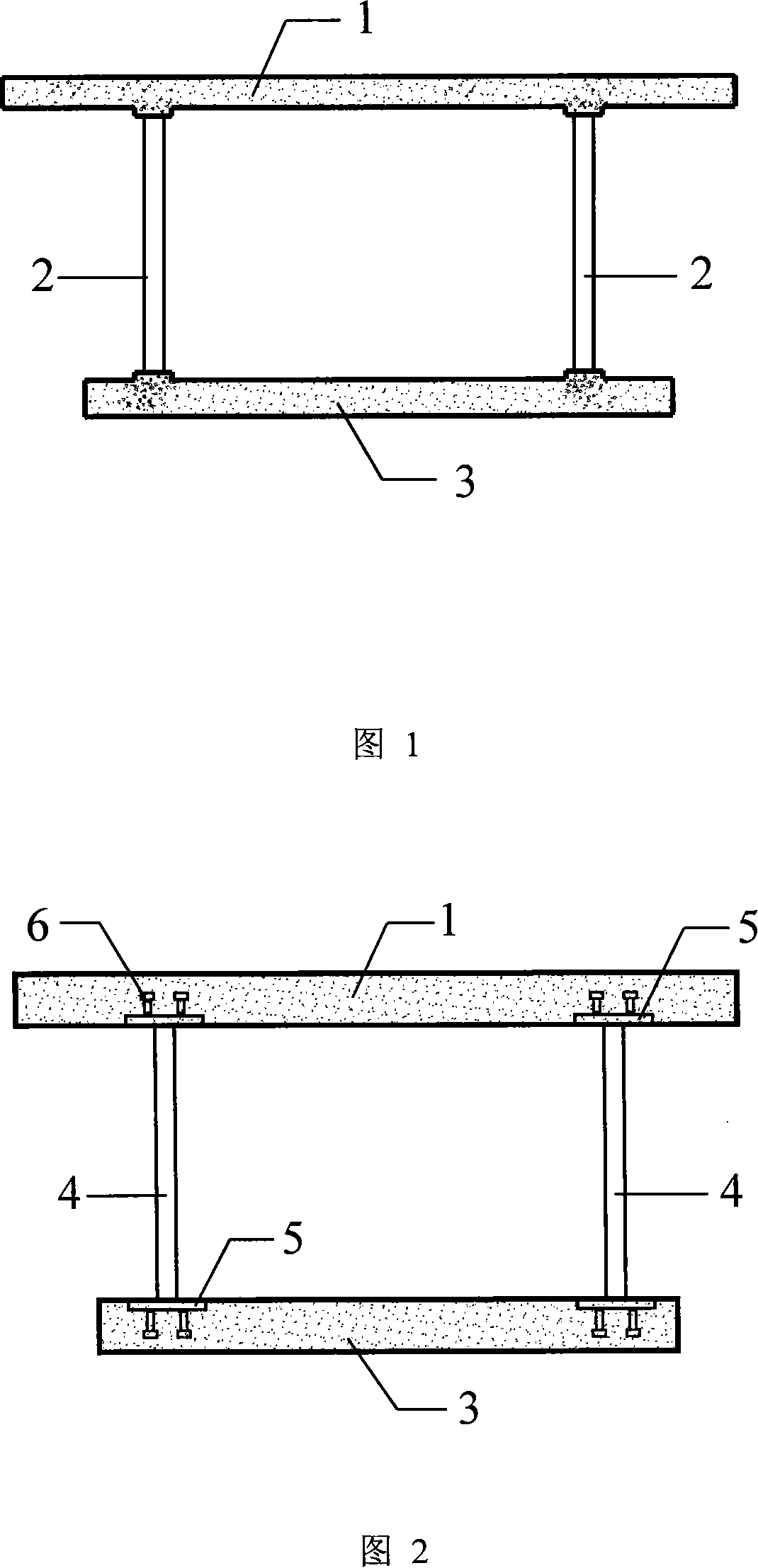

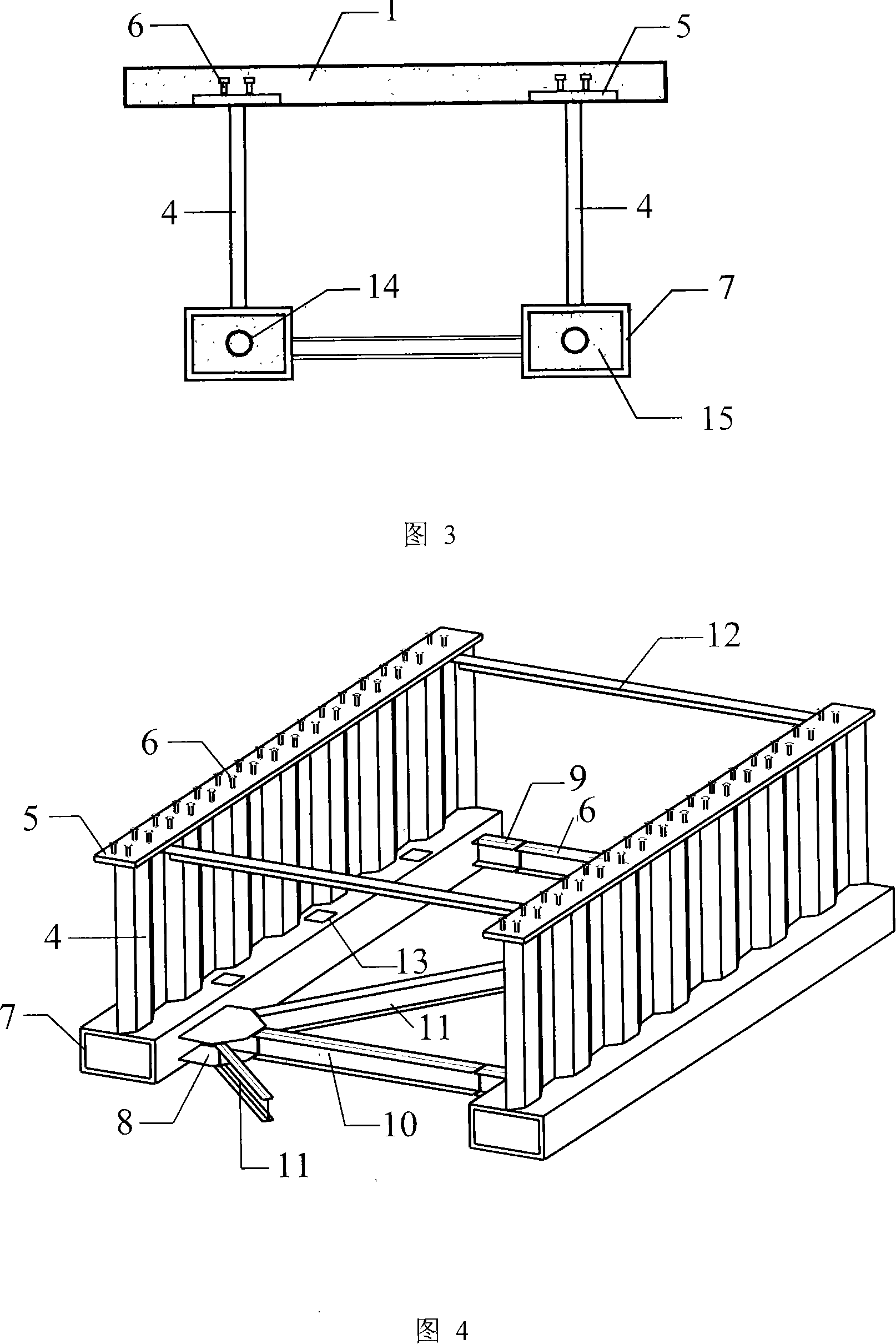

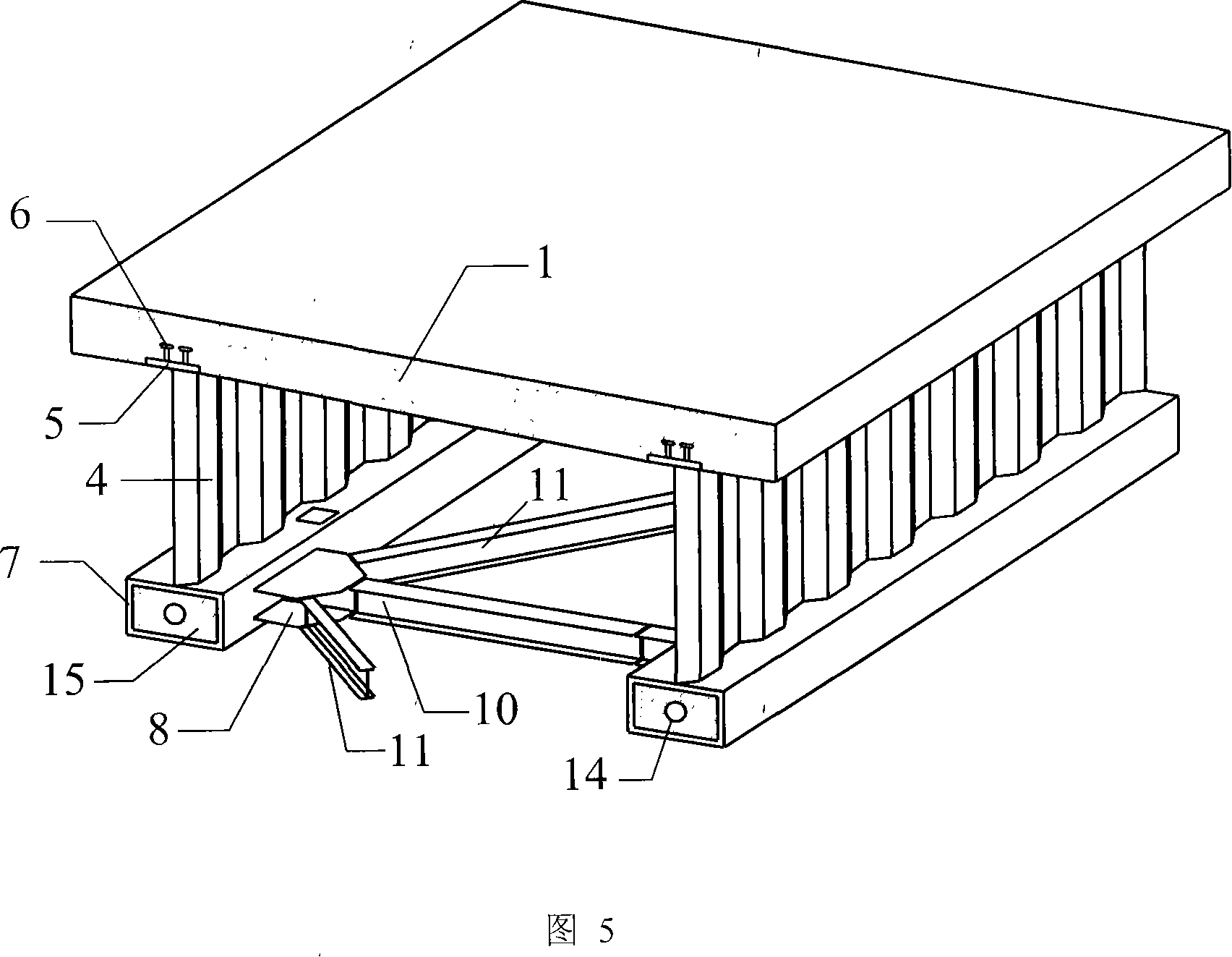

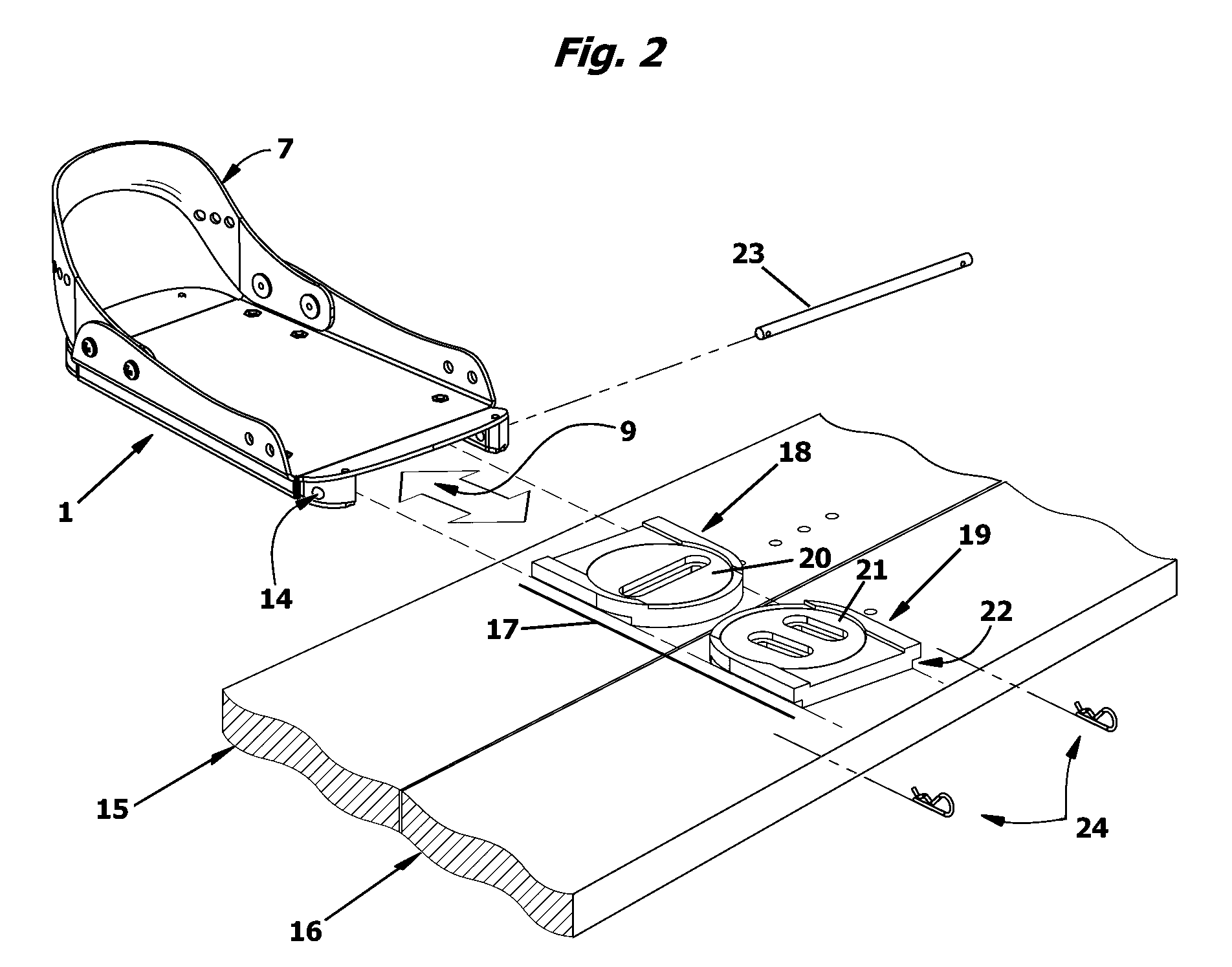

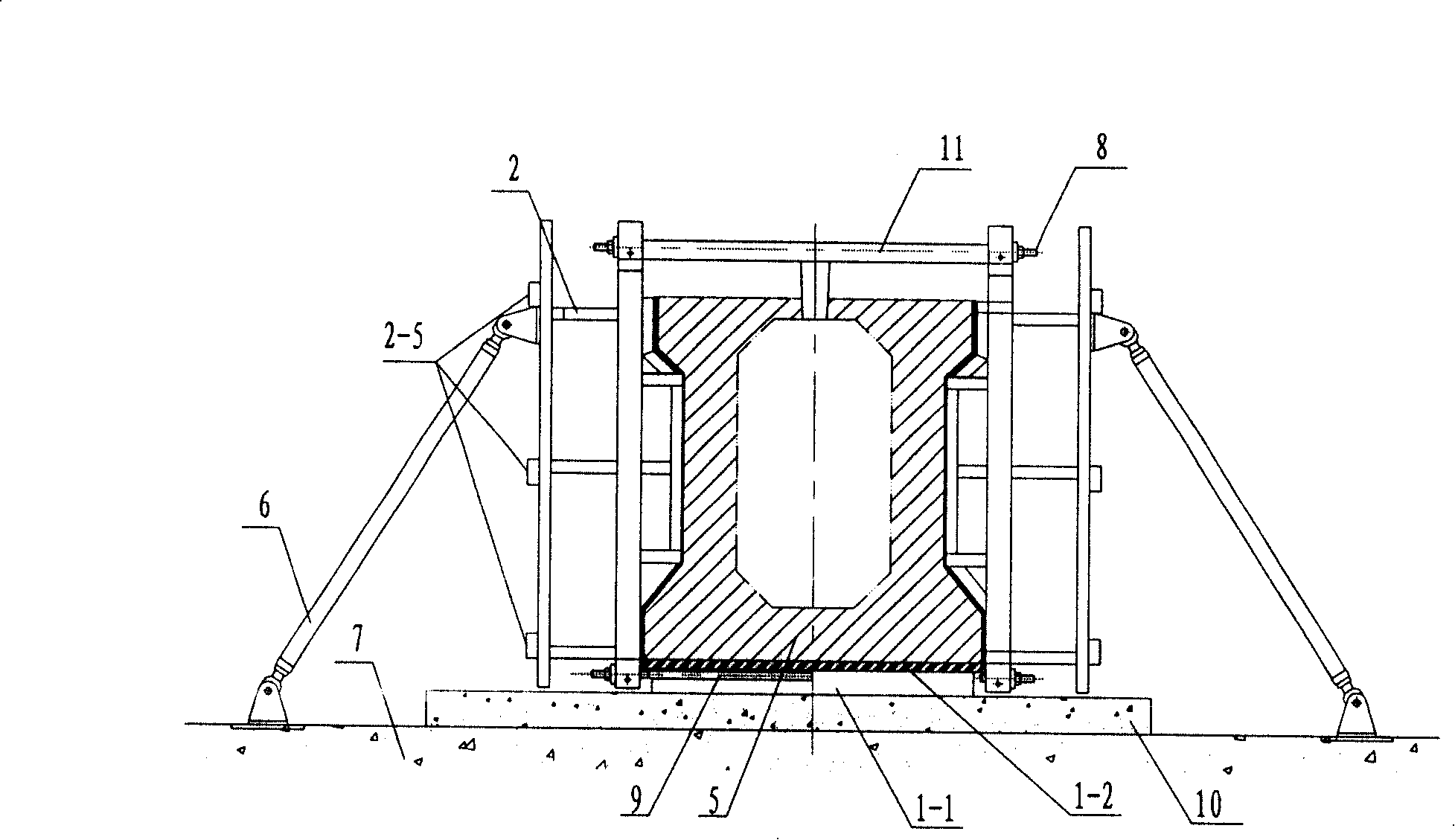

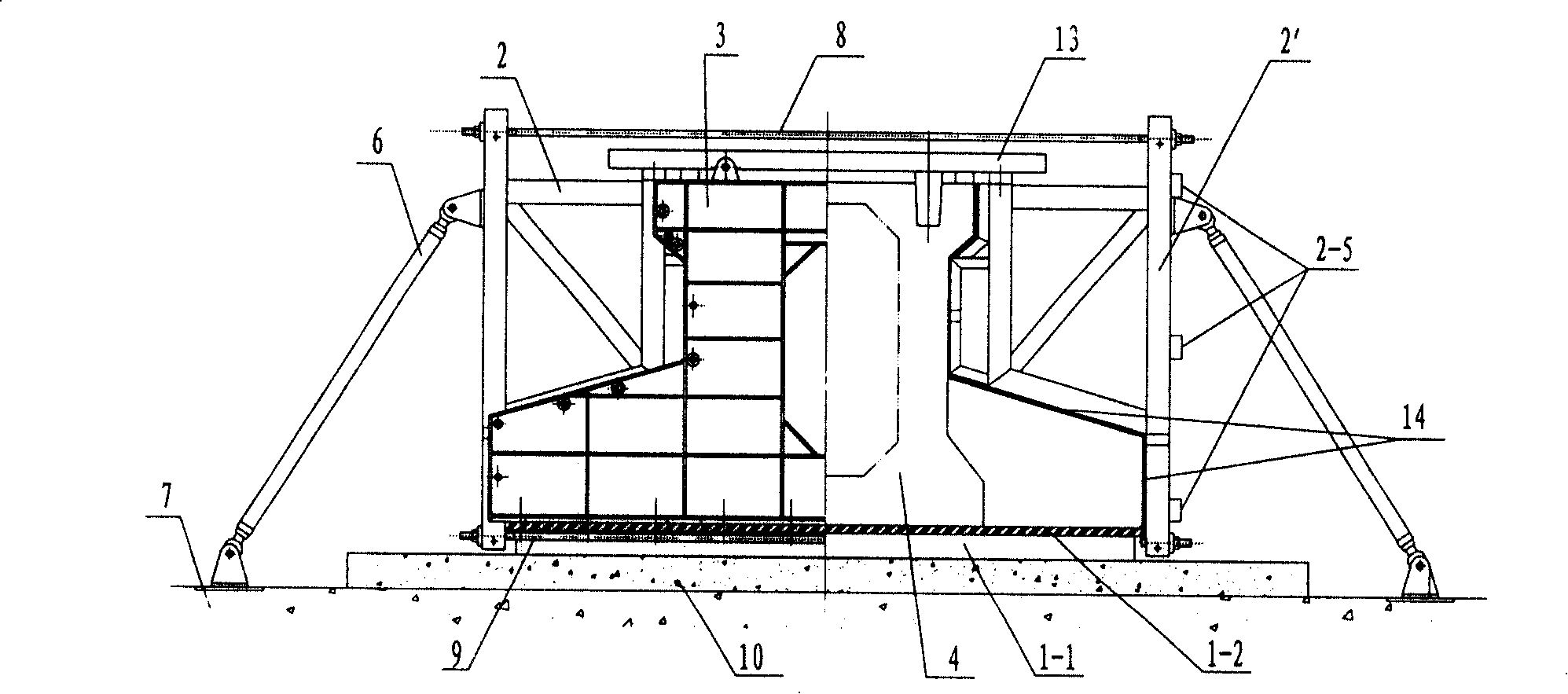

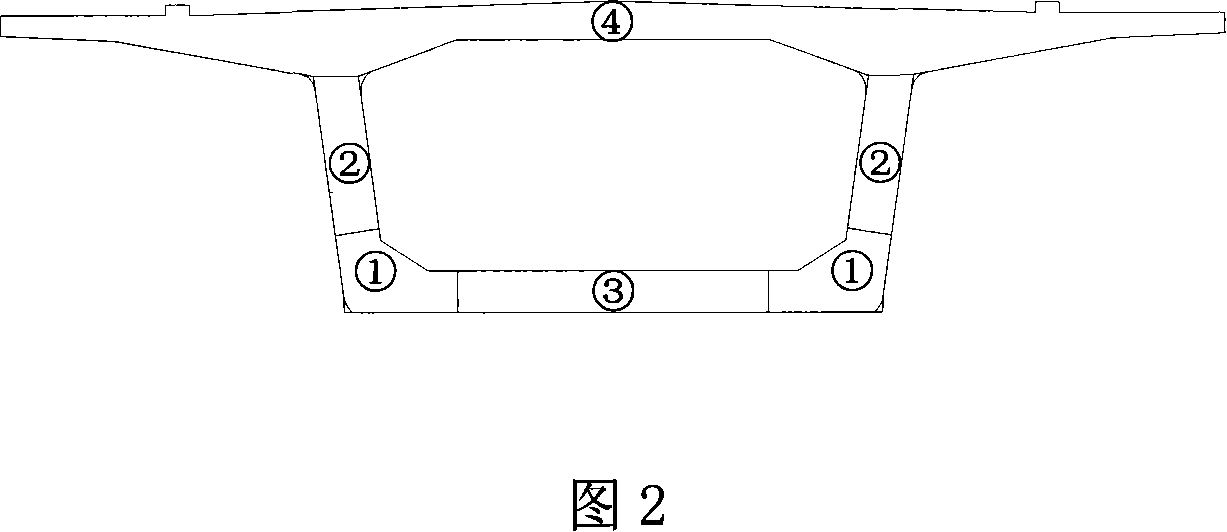

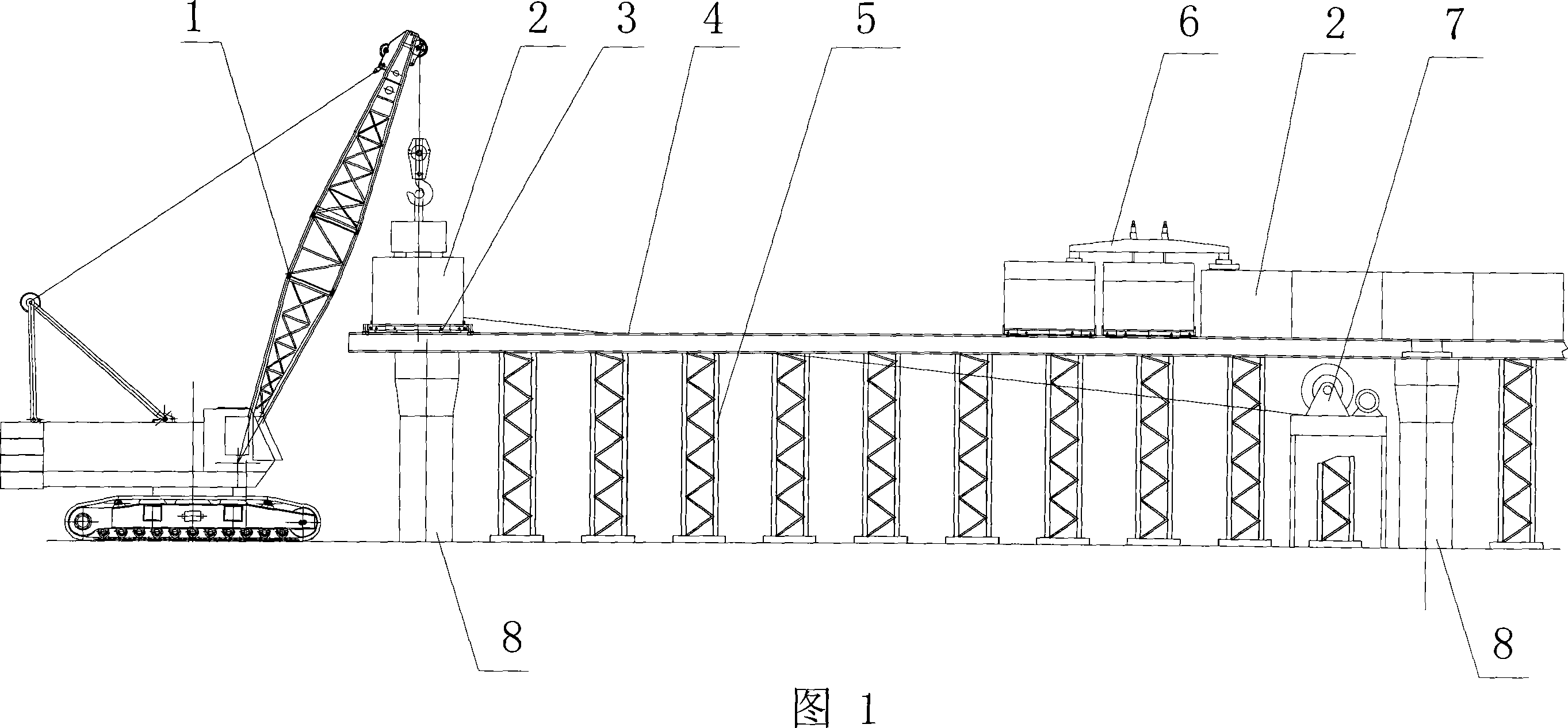

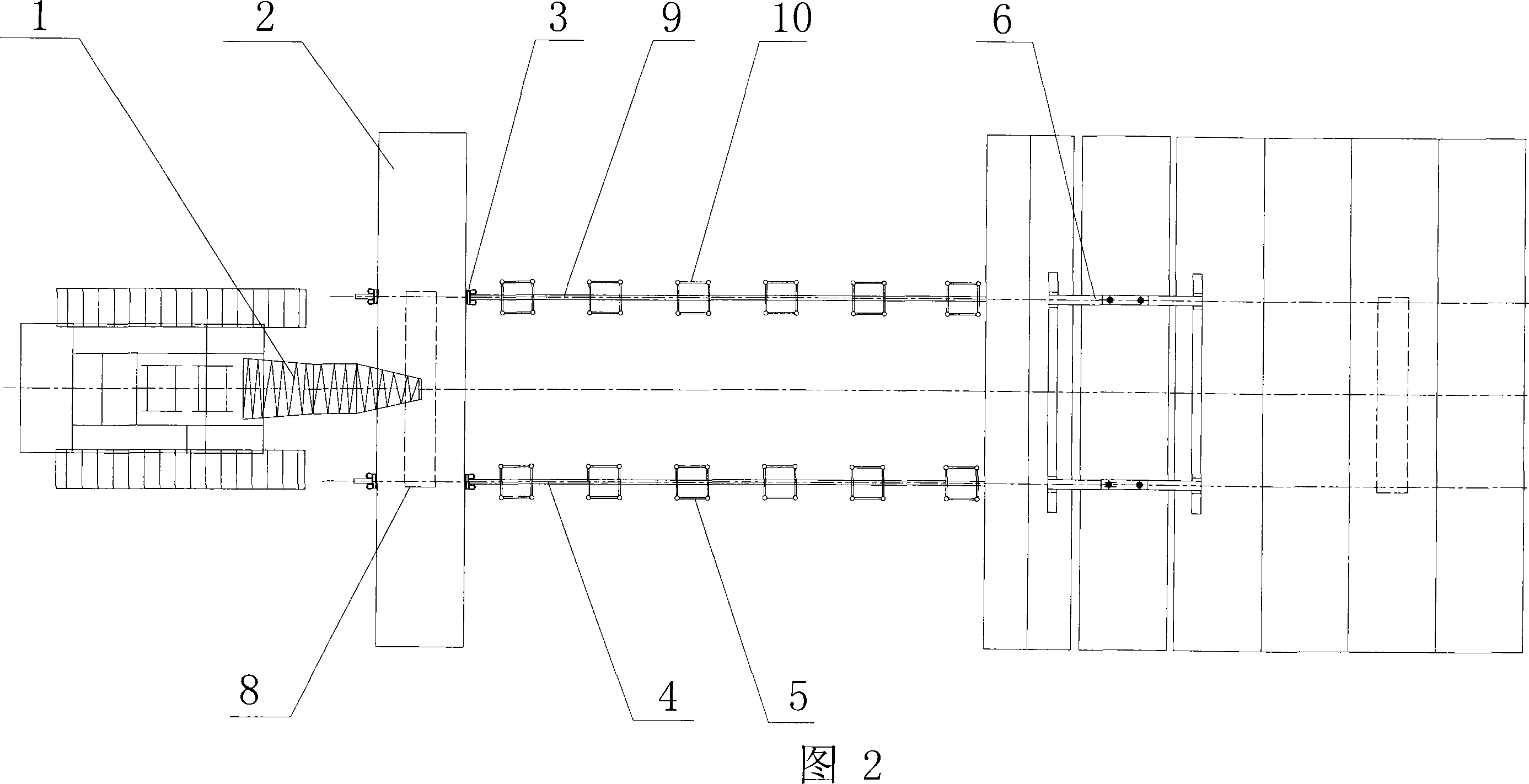

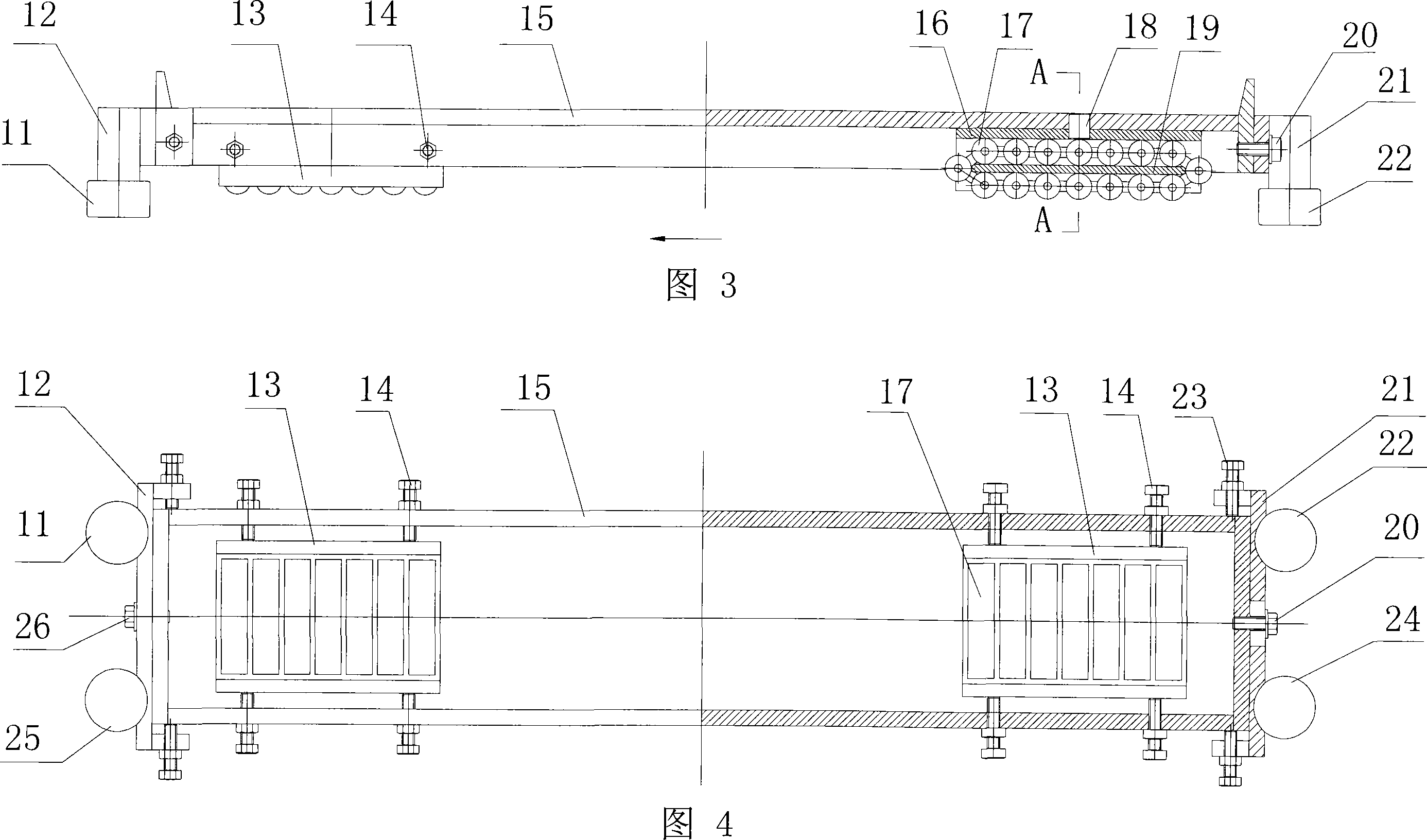

Upper-bearing typed movable formwork

ActiveUS20110133052A1Large dead weightIncreased footprintMouldsForms/shuttering/falseworksEngineeringBridge engineering

An upper-bearing typed movable formwork used for cast-in-situ of concrete box girder in bridge engineering, comprising left and right legs (7) which are respectively fixed on a pier, left and right longitudinal / transverse sliding mechanisms (9), bearing devices and a template system. The left and right longitudinal / transverse sliding mechanisms (9) are respectively arranged on the left and right legs (7) and can move horizontally along the left and right legs (7), the bearing devices are respectively fixed on the left and right longitudinal / transverse sliding mechanisms (9), the template system comprises a bottom formwork (6), an internal formwork (3), a left formwork and a right formwork, the bottom formwork (6) is formed by screw connection of a left bottom formwork and a right bottom formwork (6a,6b) which are symmetrical about the axis line of the concrete box girder, two ends of the bottom formwork are respectively fixed on two opposite internal side surfaces of the left main beam and the right main beam (1). The movable formwork also comprises a plurality of adjustable supporting rods (14) used for supporting the template system.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

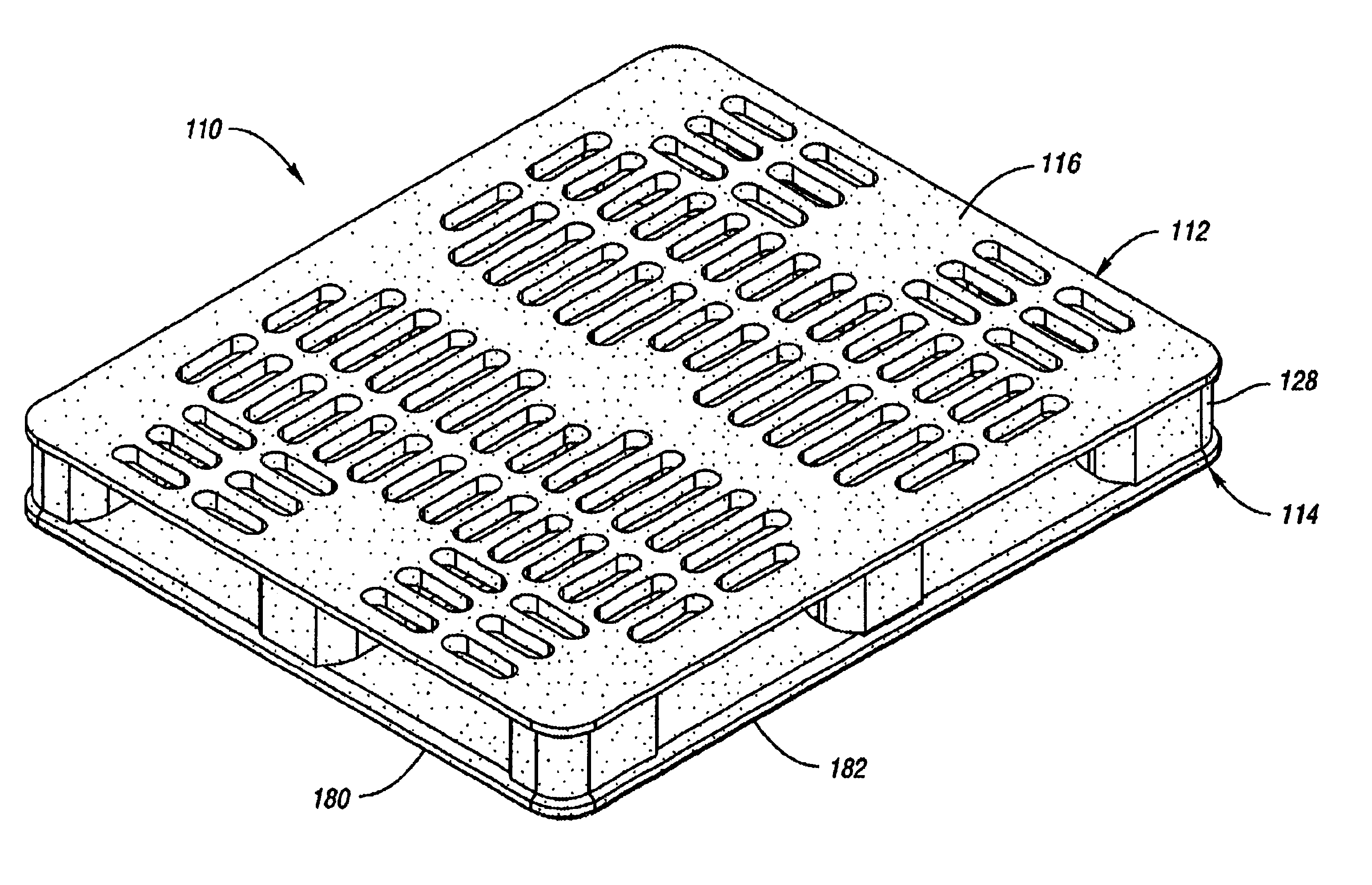

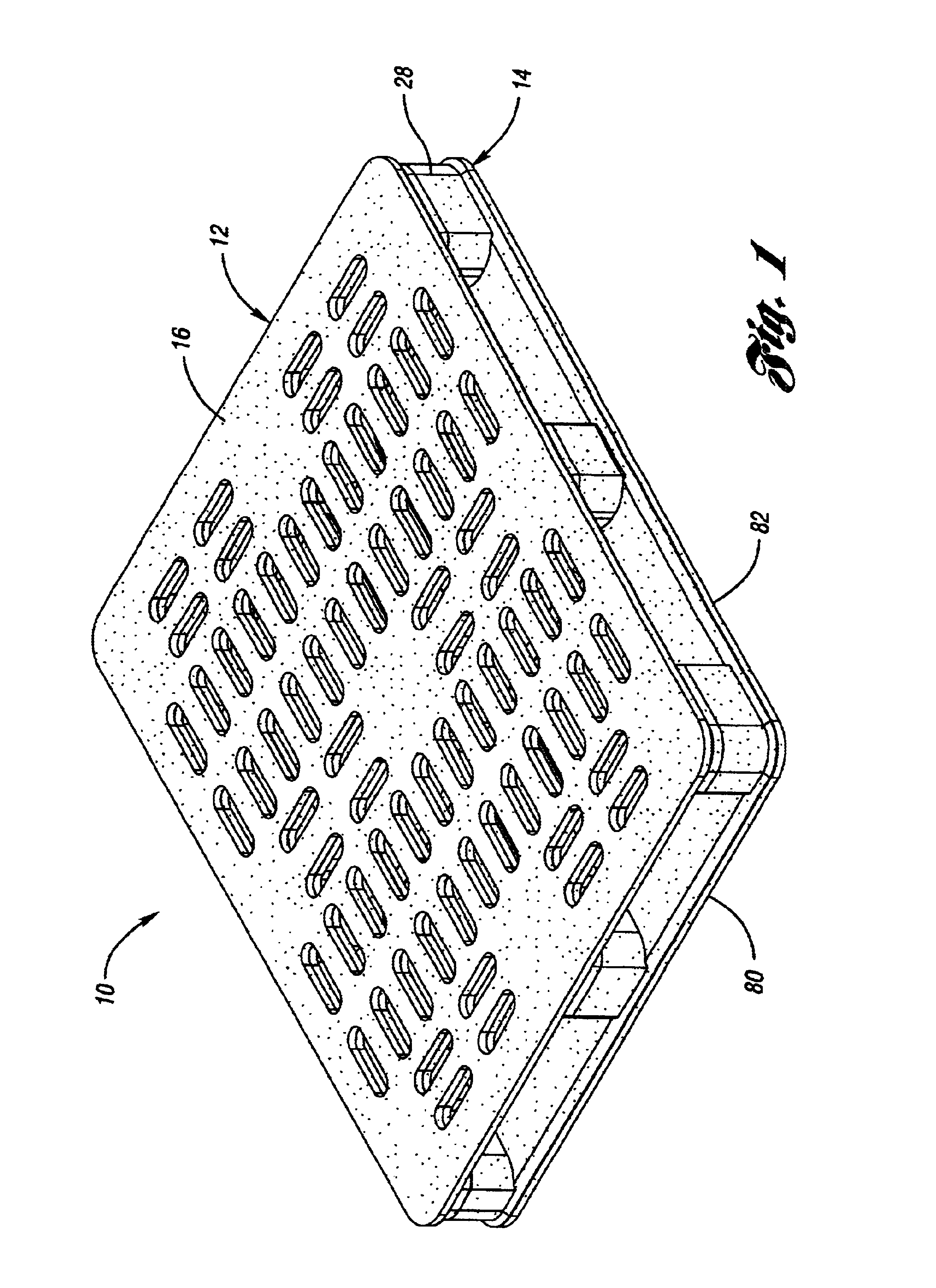

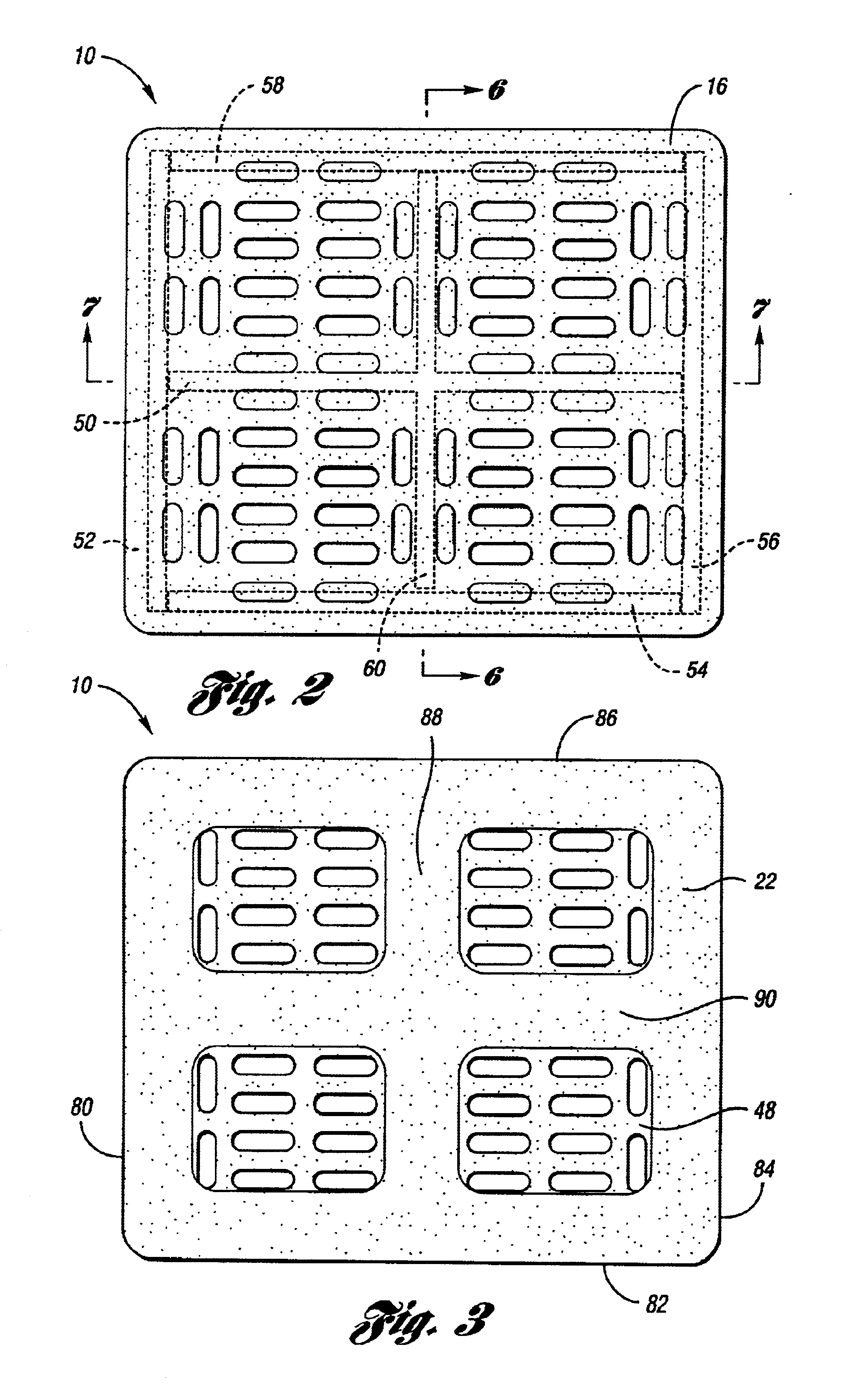

Reinforced pallet

InactiveUS6955128B2Improved strength and load supporting propertyGuaranteed effective sizeOther manufacturing equipments/toolsRigid containersSurface mountingEngineering

A reinforced pallet assembly having a first pallet deck and a second pallet deck. Each of the decks has an outer member and an intermediate member, each outer member and intermediate member having a one of a pair of mating cross-rib surfaces which are mounted together to define box-beam sections within each pallet deck. Also included is an elongate reinforcement member which is disposed between the outer member and the intermediate member of the second pallet deck for providing stiffness thereto. Further included is a plurality of columns which extend between the intermediate members.

Owner:REHRIG PACIFIC CO INC

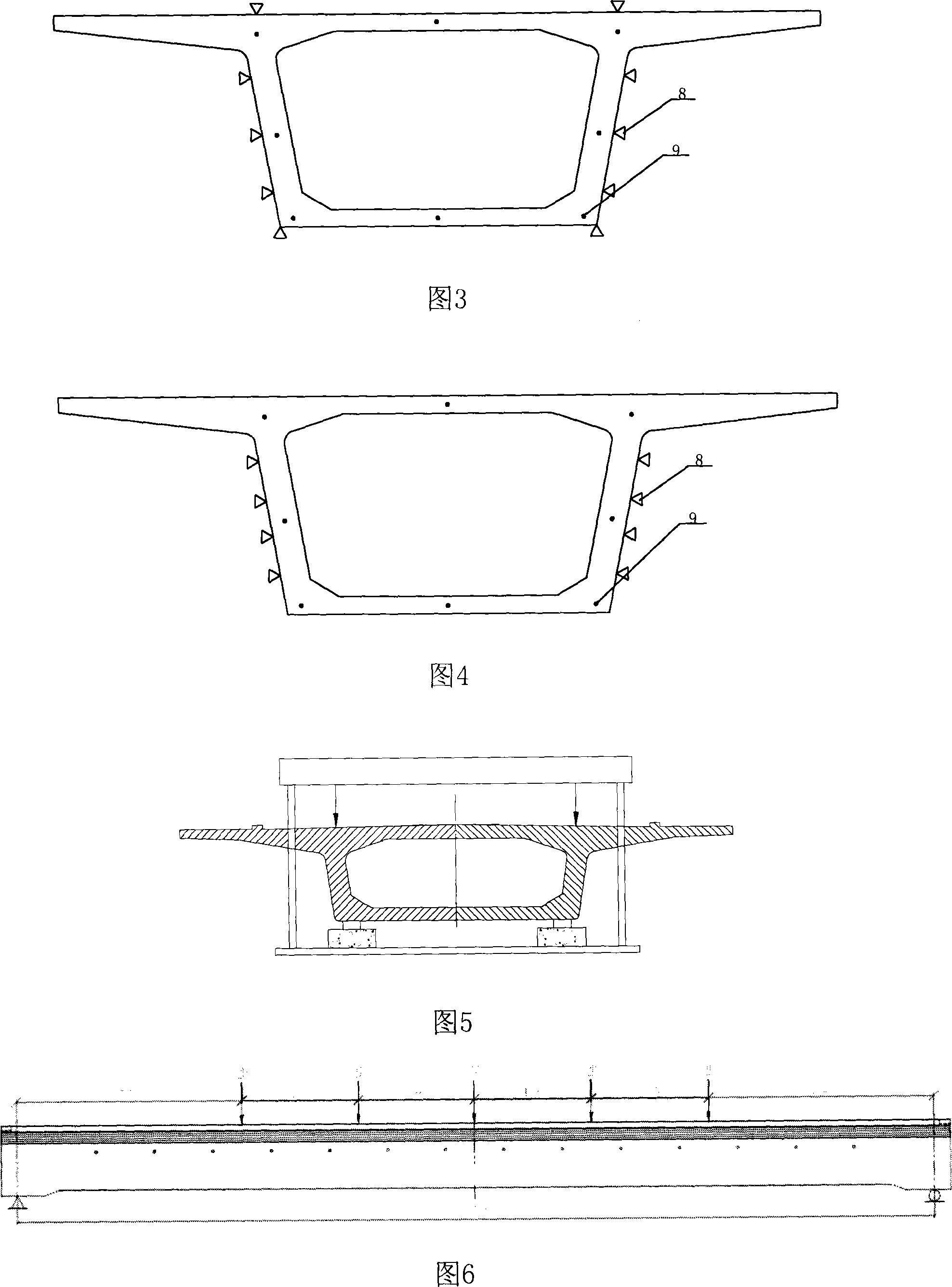

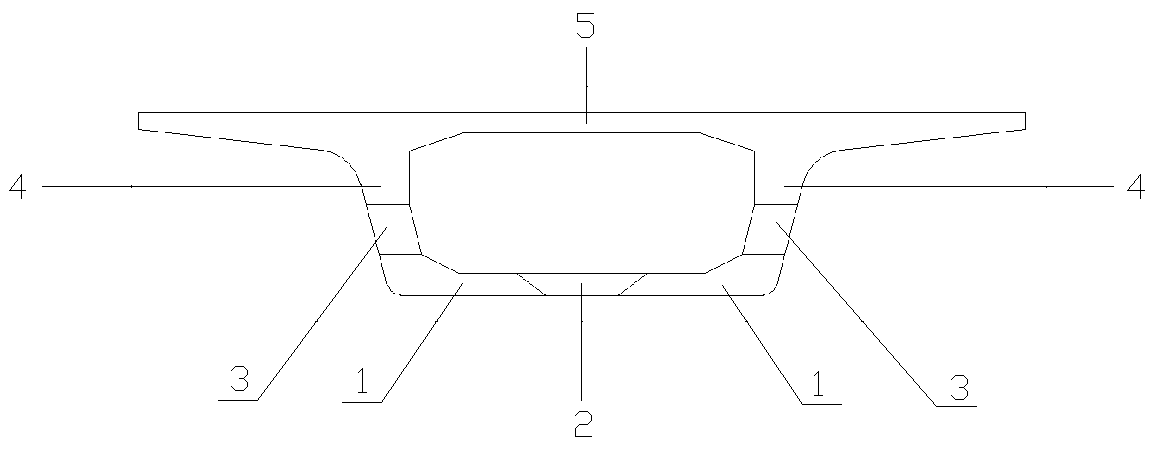

Streamline steel-concrete folding case beam

InactiveCN101413247AIncreased torsional stiffnessImprove wind resistanceBridge materialsBridge engineeringCable stayed

The invention discloses a streamlined steel-concrete superimposed box girder, which relates to the technical field of bridge engineering and is used for a long-span bridge girder. Two sides of the superimposed box girder are provided with tuyere structures, and a bridge panel adopts a superimposed structure consisting of prefabricated concrete slabs and a post-poured concrete layer. When the box girder is in use, the superimposed box girder is a streamlined single-box single-chamber or single-box multi-chamber cross section; the tuyere structures are polygonal open thin-walled structures; and longitudinal-transverse prestress is applied in the superimposed bridge panel. The box girder effectively improves the torsional rigidity and wind-resistant stability of the section of the girder, remarkably improves the integrity and durability of the bridge panel, and expands the application of superimposed girders in cable-stayed bridges and other long-span bridges.

Owner:CCCC HIGHWAY CONSULTANTS

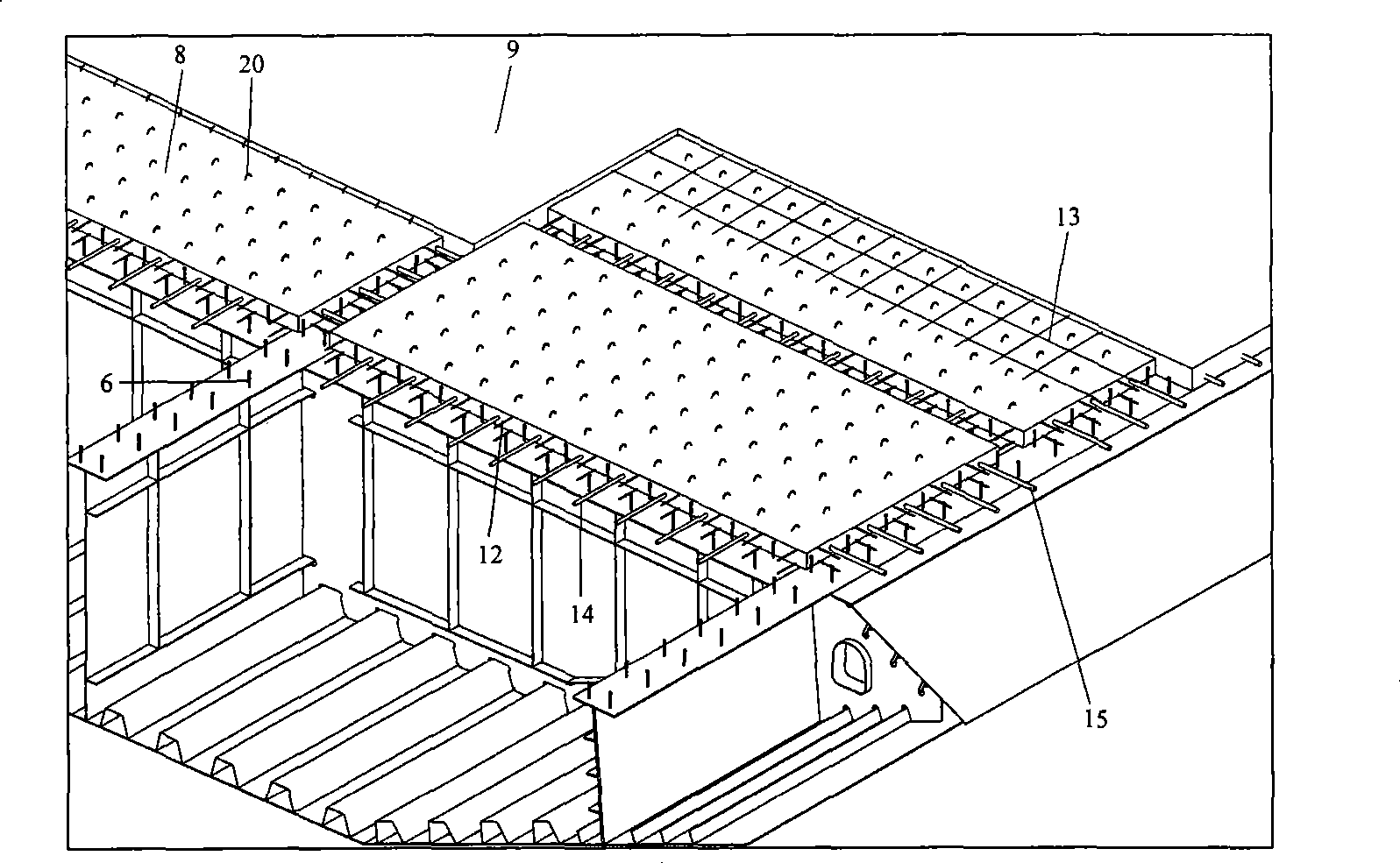

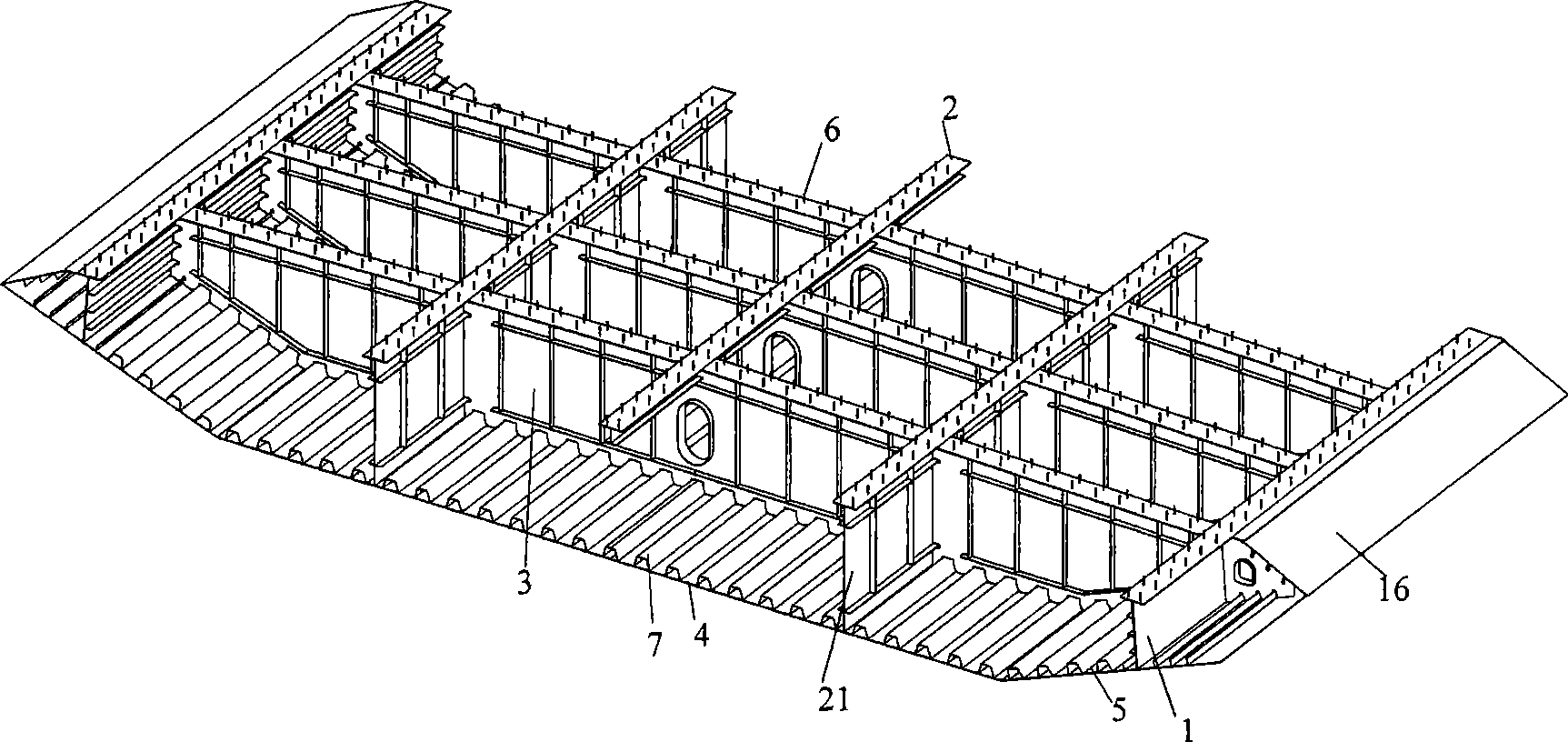

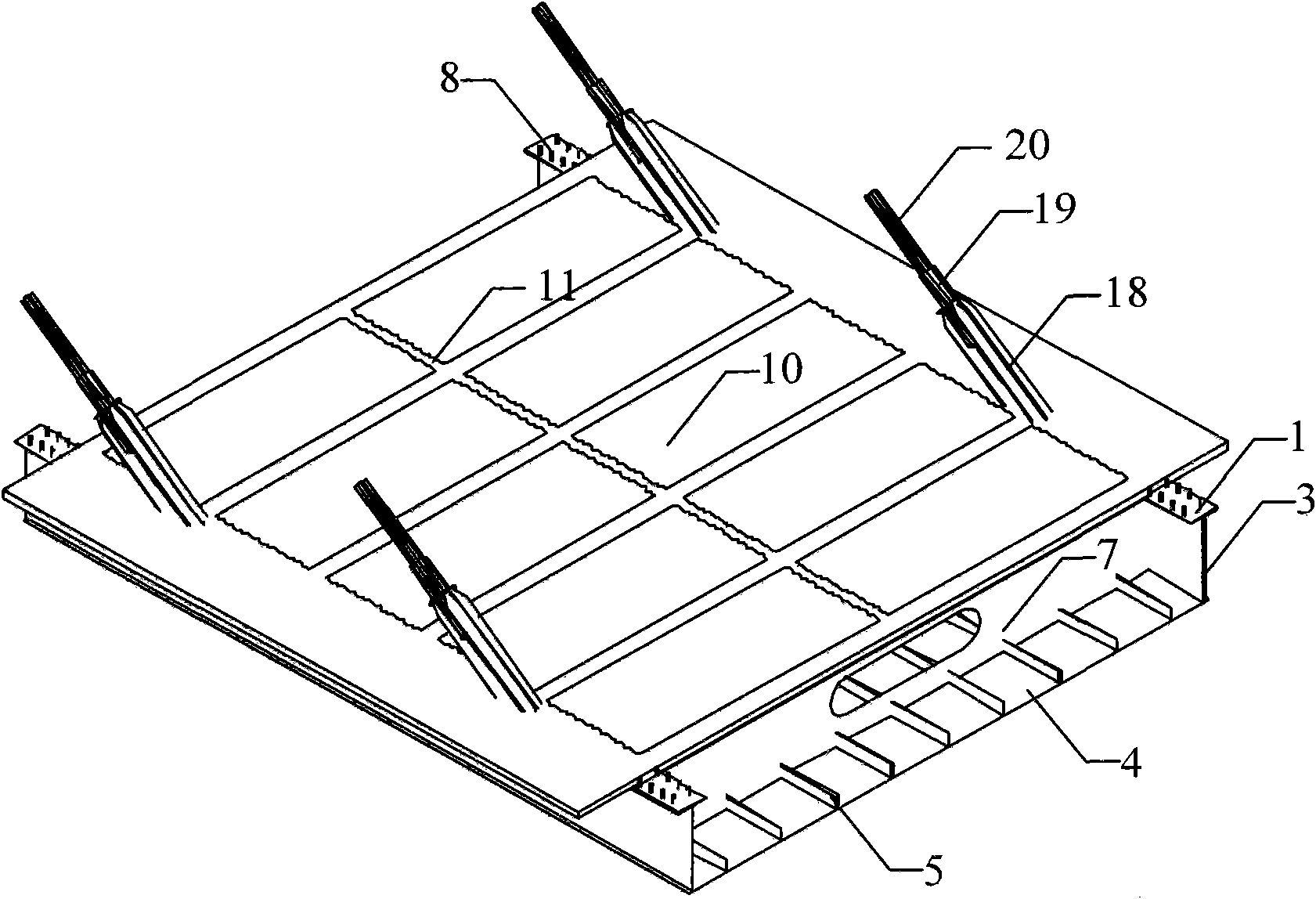

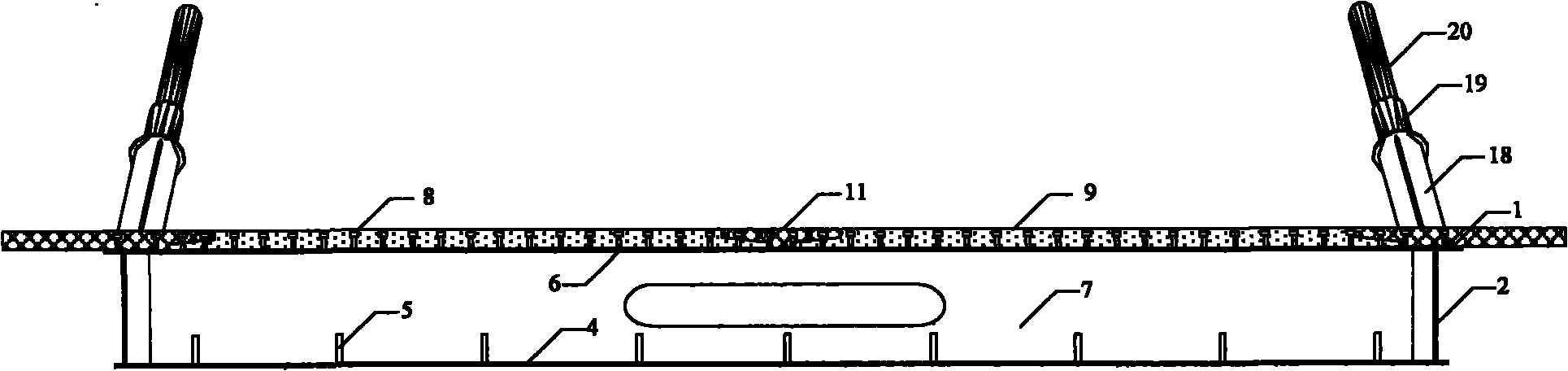

Corrugated steel webplate combined box girder floor system for cable-stayed bridge and construction method thereof

InactiveCN101864729AAvoid on-site molding processReduce wet work workloadCable-stayed bridgeBridge structural detailsCrack resistanceEngineering

The invention relates to a corrugated steel webplate combined box girder floor system for a cable-stayed bridge and a construction method thereof, and belongs to the technical field of bridge structures. The corrugated steel webplate combined box girder floor system comprises a precast concrete plank and a cast-in-place concrete seam, wherein the precast concrete plank is positioned on a steel box girder and is integrated with the steel box girder into a whole; the steel box girder is formed by welding a top flange steel plate, a corrugated steel webplate and a steel plate at the bottom of the box girder; a box girder baseplate stiffening rib and a diaphragm plate are welded in the steel box girder; the diaphragm plate comprises a top flange steel plate of the diaphragm plate and a steel webplate of the diaphragm plate; a toggle pin connecting piece is welded on the top flange steel plate and the top flange steel plate of the diaphragm plate; and a steel anchor pulling plate and a steel sleeve are welded on the top flange steel plate. The corrugated steel webplate combined box girder floor system simplifies the manufacturing process for the precast concrete plank, gives full play to the superior mechanical property of the corrugated steel webplate and the release action of the corrugated steel webplate on the creep effect of concrete shrinkage, improves the bearing capacity, stiffness and crack resistance of the structure, and improves the durability of the structure.

Owner:TSINGHUA UNIV

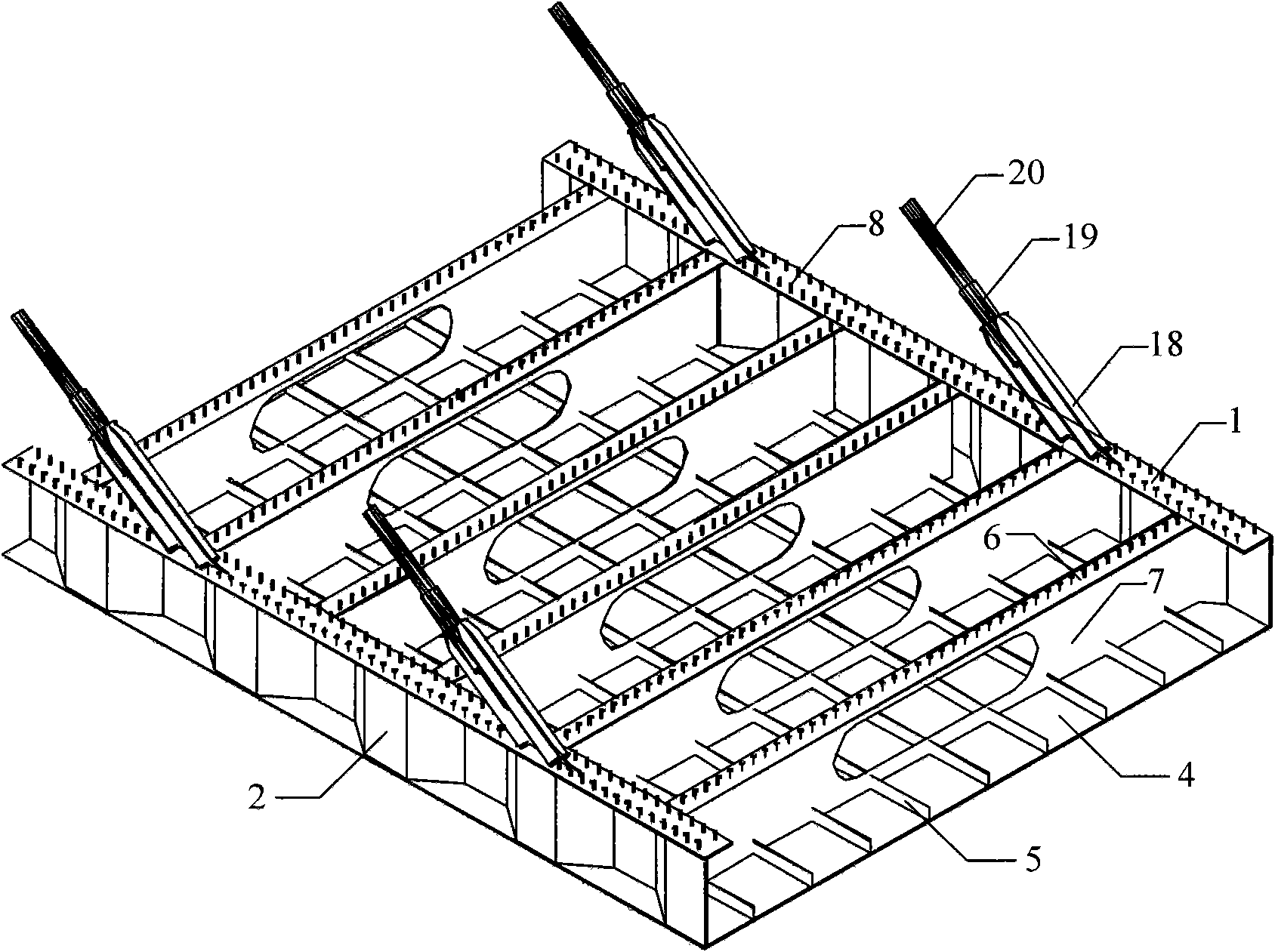

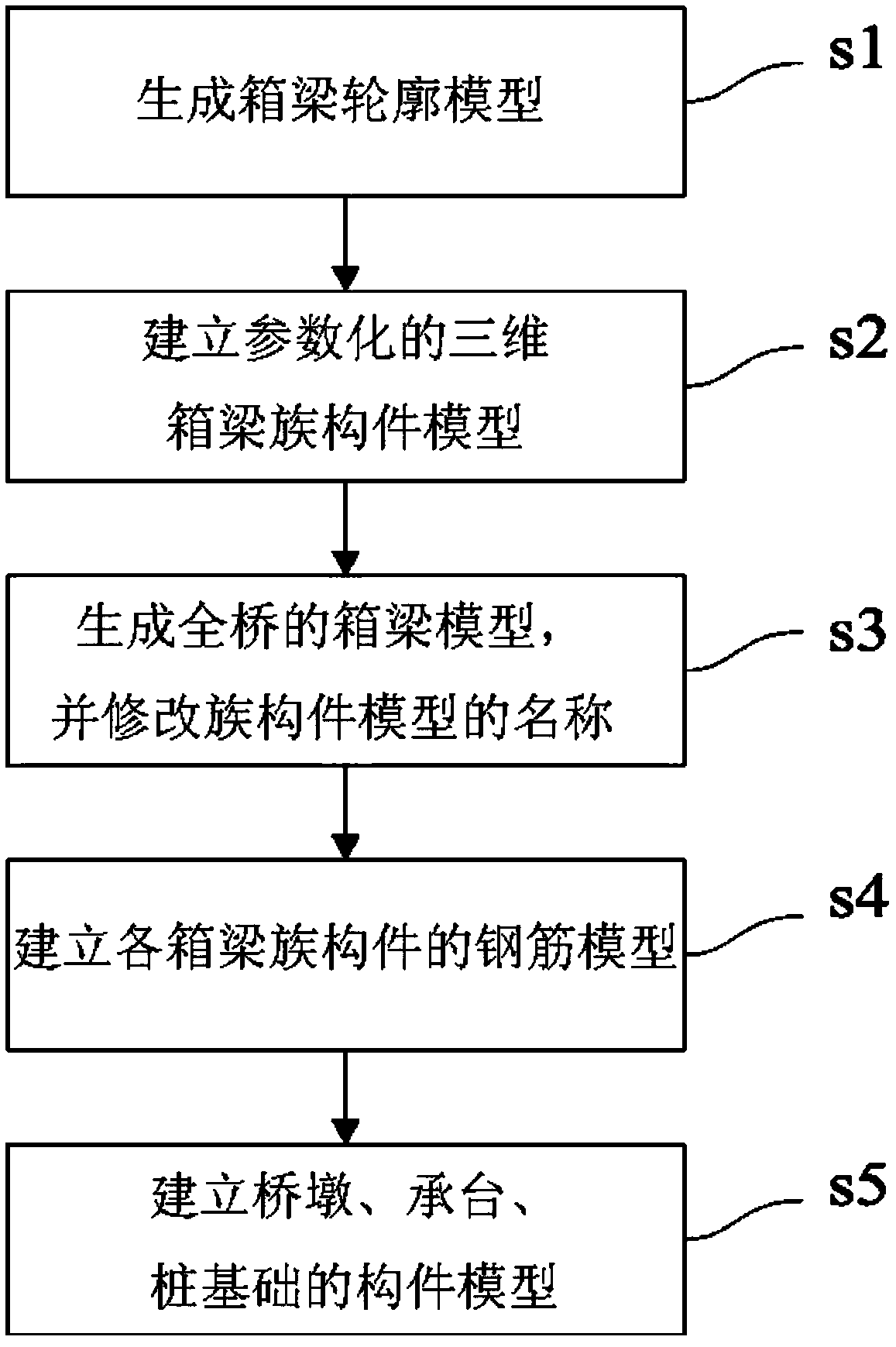

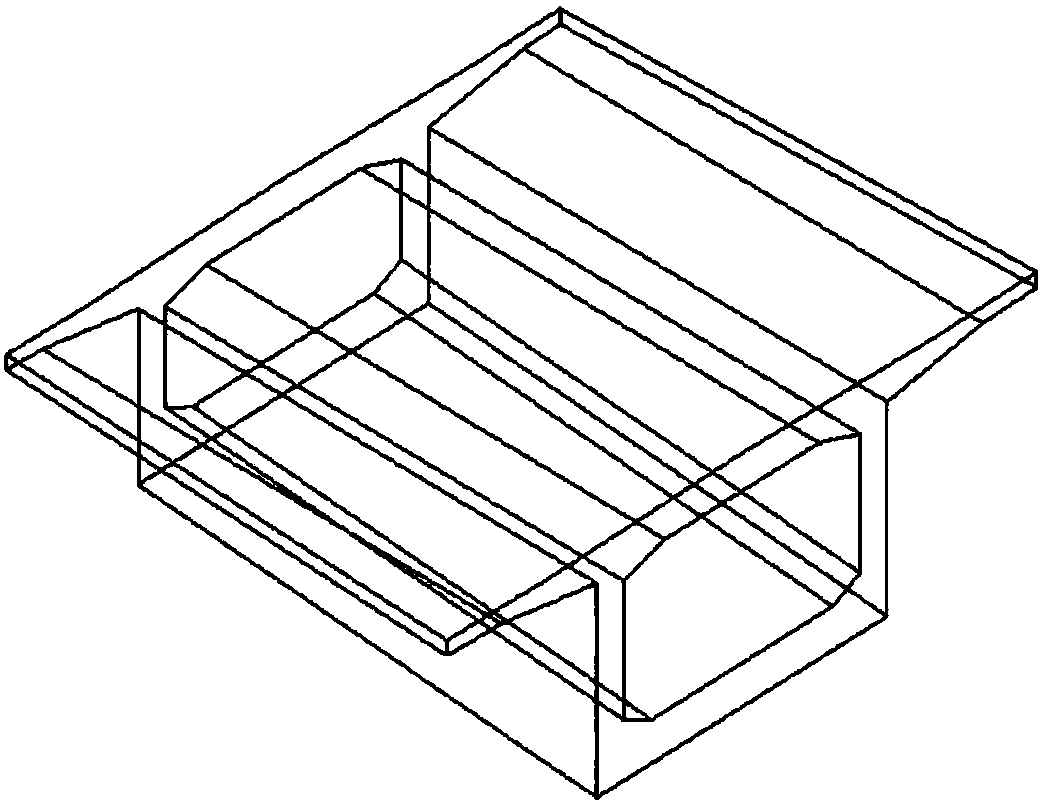

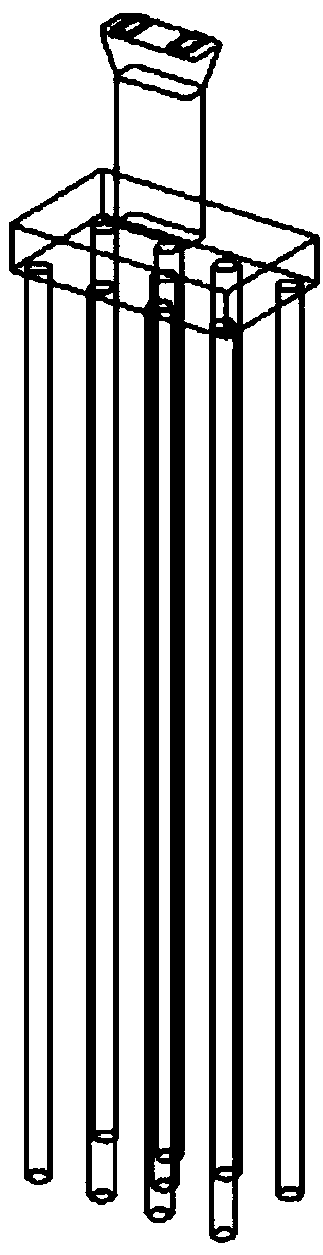

Revit platform based continuous-girder-bridge parametric modeling method

ActiveCN107609321AGood foundation of data platformImage data processingSpecial data processing applicationsData platformRebar

The invention relates to a Revit platform based continuous-girder-bridge parametric modeling method. The method includes: 1), leading in numerical values of coordinate points of box-girder sections ofa continuous girder bridge to generate a box-girder contour model; 2), adding datum lines, size markers and parameter constraints of the box-girder sections and establishing parametric three-dimensional box-girder component models; 3), according to instance data of a box girder, generating box-girder instance models of the entire bridge according to the parametric three-dimensional box-girder component models established in the step 2), and modifying names of the instance models of box-girder components according to actual needs; 4), establishing rebar models of the box-girder components; 5),establishing component models of bridge piers, bearing platforms and pile foundations. Automatic generation of statistic of work amount and drawings is achieved, and a good data platform foundation is provided for operation and maintenance of later bridge BIM (building information modeling); problems that two-dimensional drawings are repeated in data input, non-universal in data, dispersing in spatial relation, non-parametric, informative linkage forbidden in parameter design and the like are solved.

Owner:RAILWAY NO 10 ENG GRP CO LTD

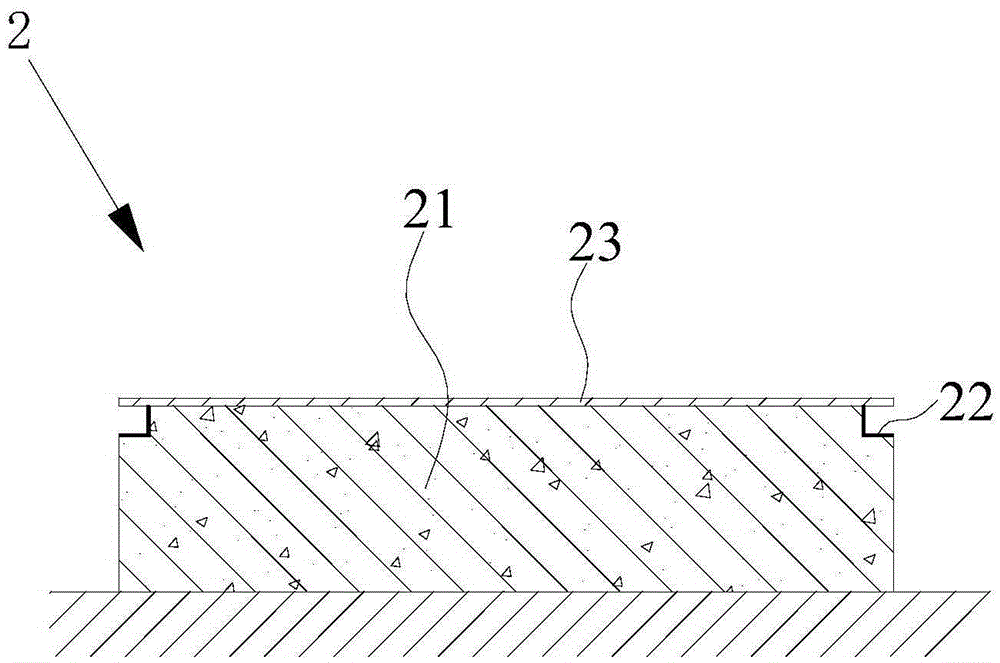

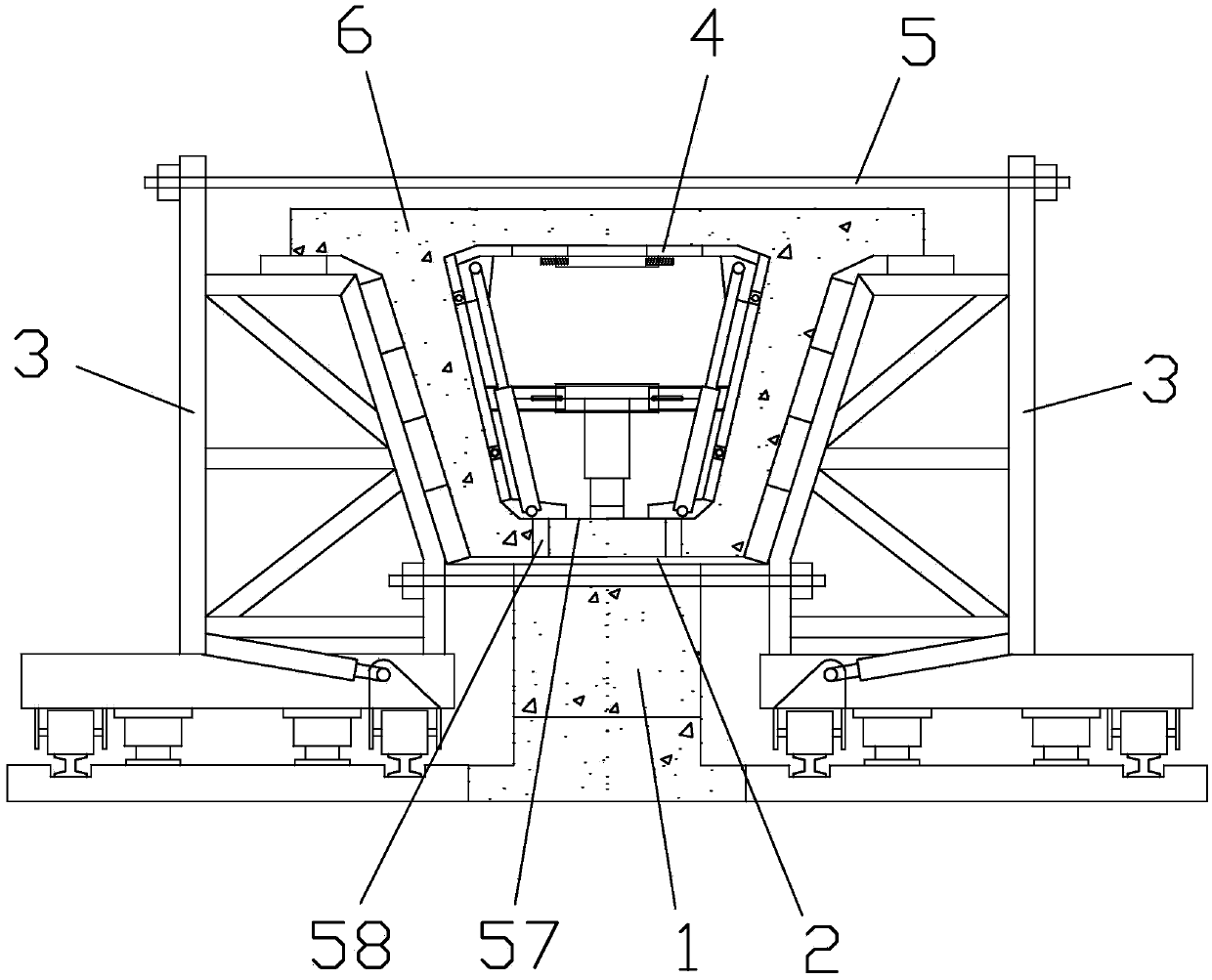

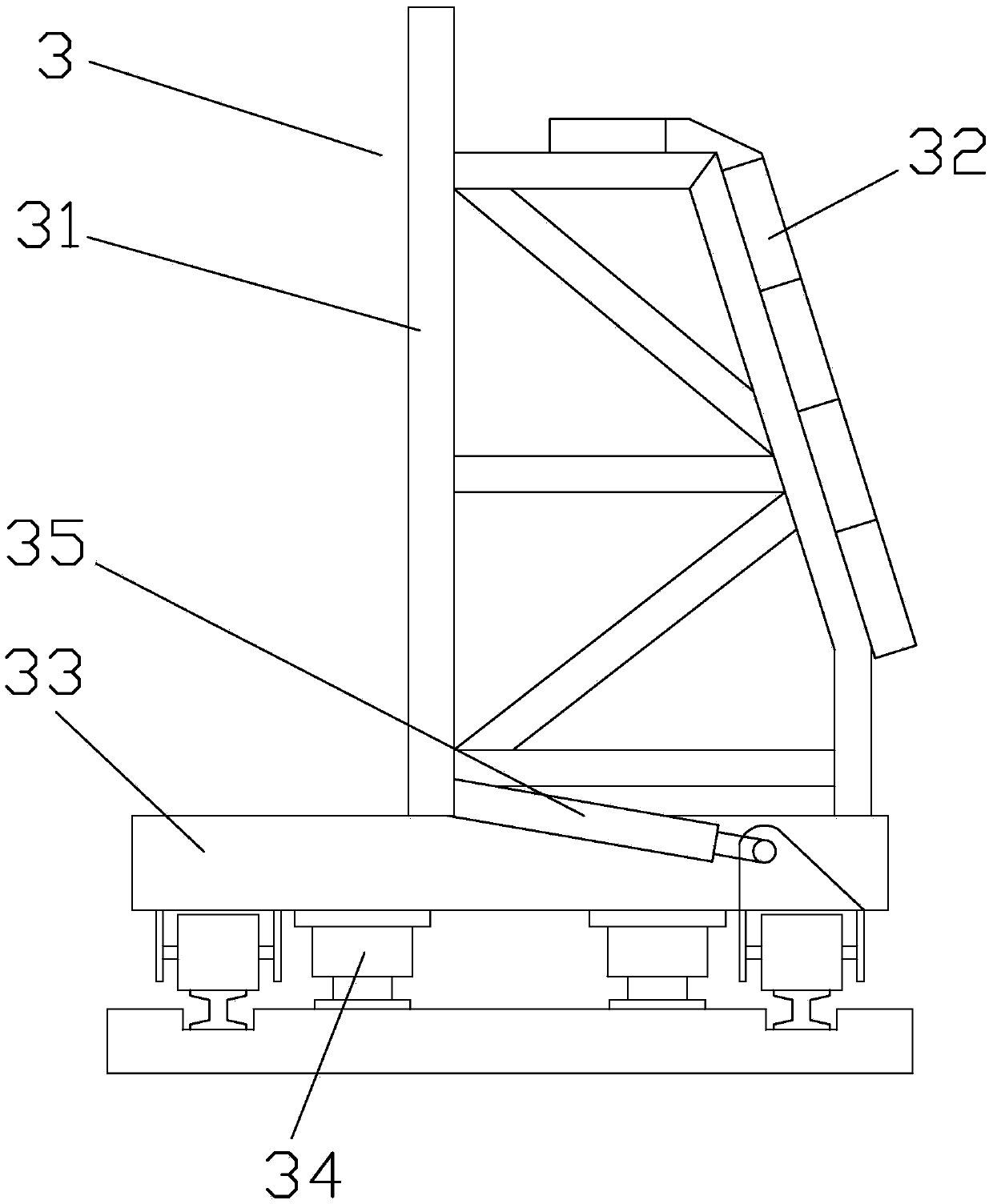

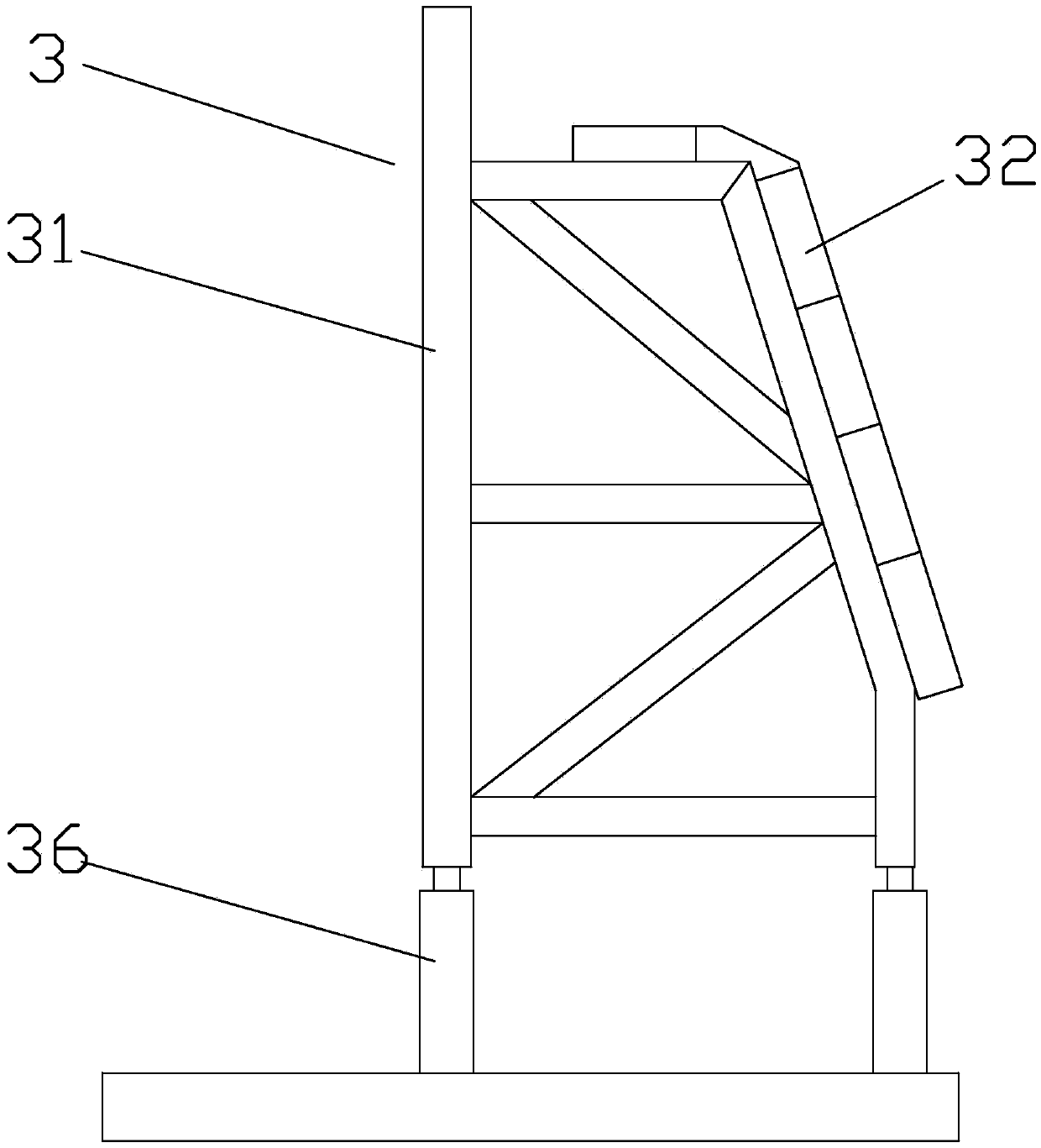

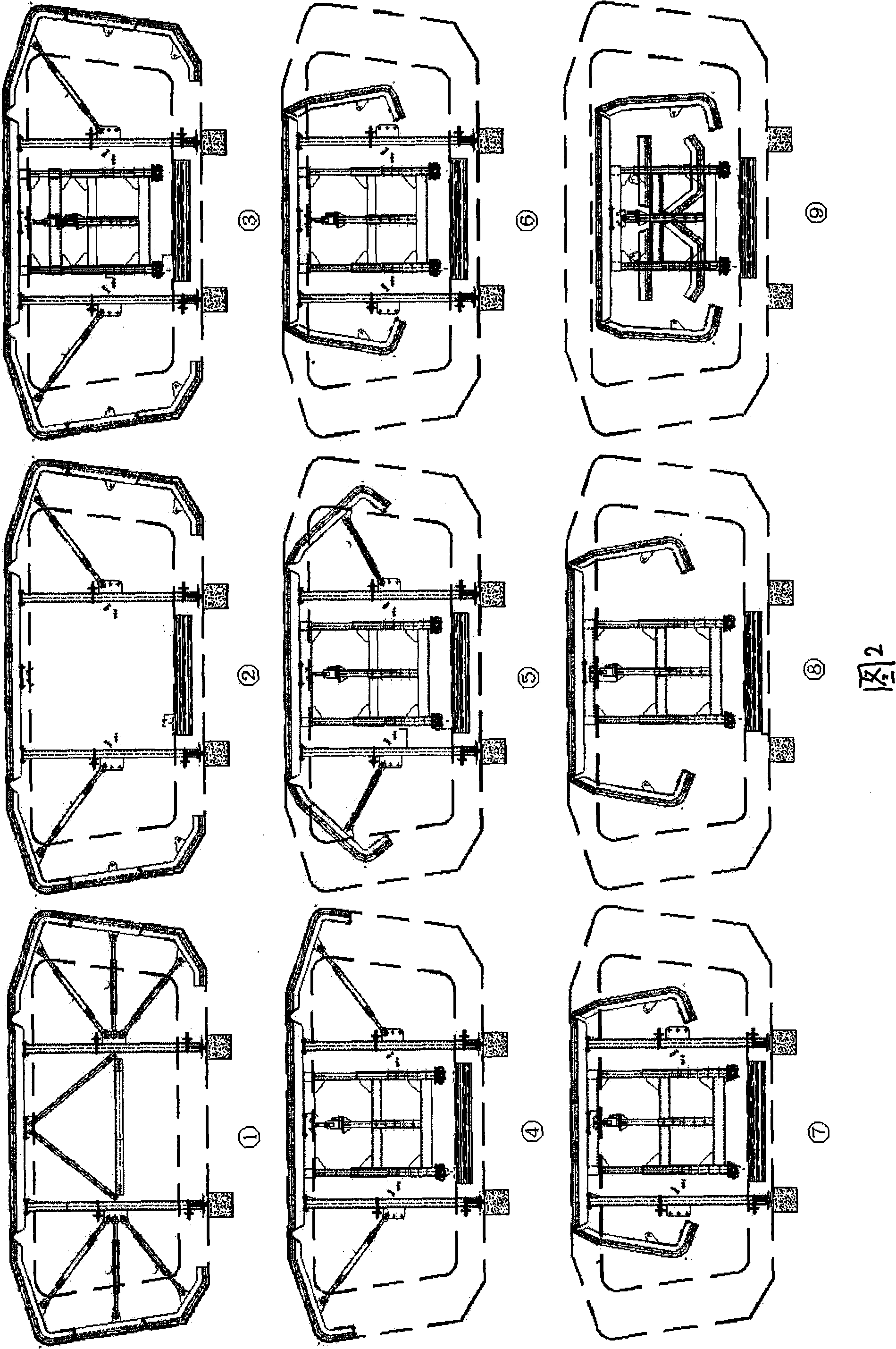

Manufacturing method of small prefabricated box girder

ActiveCN105365042AQuick releaseFast mold closingDischarging arrangementMouldsHydraulic actionEngineering

The invention discloses a manufacturing method of a small prefabricated box girder. The manufacturing method includes the following steps that firstly, a pedestal is prefabricated; secondly, mold plates are installed, wherein the mold plates are installed in the following sequence of bottom mold installation, side mold installation, inner mold installation, end mold installation and flange plate installation on side molds; thirdly, concrete is poured and cured; fourthly, demolding is conducted, wherein demolding includes detaching of end molds at the two ends of a girder body, inner mold demolding and side mold demolding; and fifthly, the girder body is cured. According to the manufacturing method, fully-hydraulic actions are achieved through the outer mold plates, the use effect is improved greatly, and labor intensity is lowered; and semi-automation is achieved through an inner mold, quick demolding and mold combination of the mold plates are facilitated, the operation intensity of workers in small space in the girder body is lowered, and the potential safety hazards of working under the high temperature are reduced. The mold plates are firm and general in structure, quick and convenient to use and advanced in design manufacturing and construction process idea.

Owner:FOSHAN HIGHWAY&BRIDGE CONSTR PREFAB CO LTD

Long continuous structural steel box beam or combination box beam construction method

InactiveCN101368373AReduce welding workloadSatisfy \"Light Large Span\"Bridge erection/assemblyBridge materialsButt weldingEngineering

The invention discloses a long continuous steel box girder or combined box girder construction method, including the following steps: 1, segment division and plate unit division; 2, butt welding the fulcrum segmental box girders and standard segmental box girders at a prefabrication plant, namely, pre-splicing the segmental box girders of a full span box girder and the first box girder segment of the adjacent span box girder through long line method on a segmental box girder molding bed on which plane curves and pre-camber are arranged; marking the box girder segments, taking away the segmental box girders of the full span box girder, leaving the first box girder segment of the adjacent span box girder, and continuing to splice and weld the segmental box girders of the rest full span box girders; 3, generally assembling the full span box girders in the prefabrication plant. The invention adopts full span prefabrication and arrangement to construct a long continuous steel box girder or combined box girder, thus greatly reducing welding work load at the site. The invention ensures that the adjacent spans close smoothly after the steel girders are arranged and meets the requirements of light large span, precast assembly and quick construction.

Owner:CHINA MAJOR BRIDGE ENG

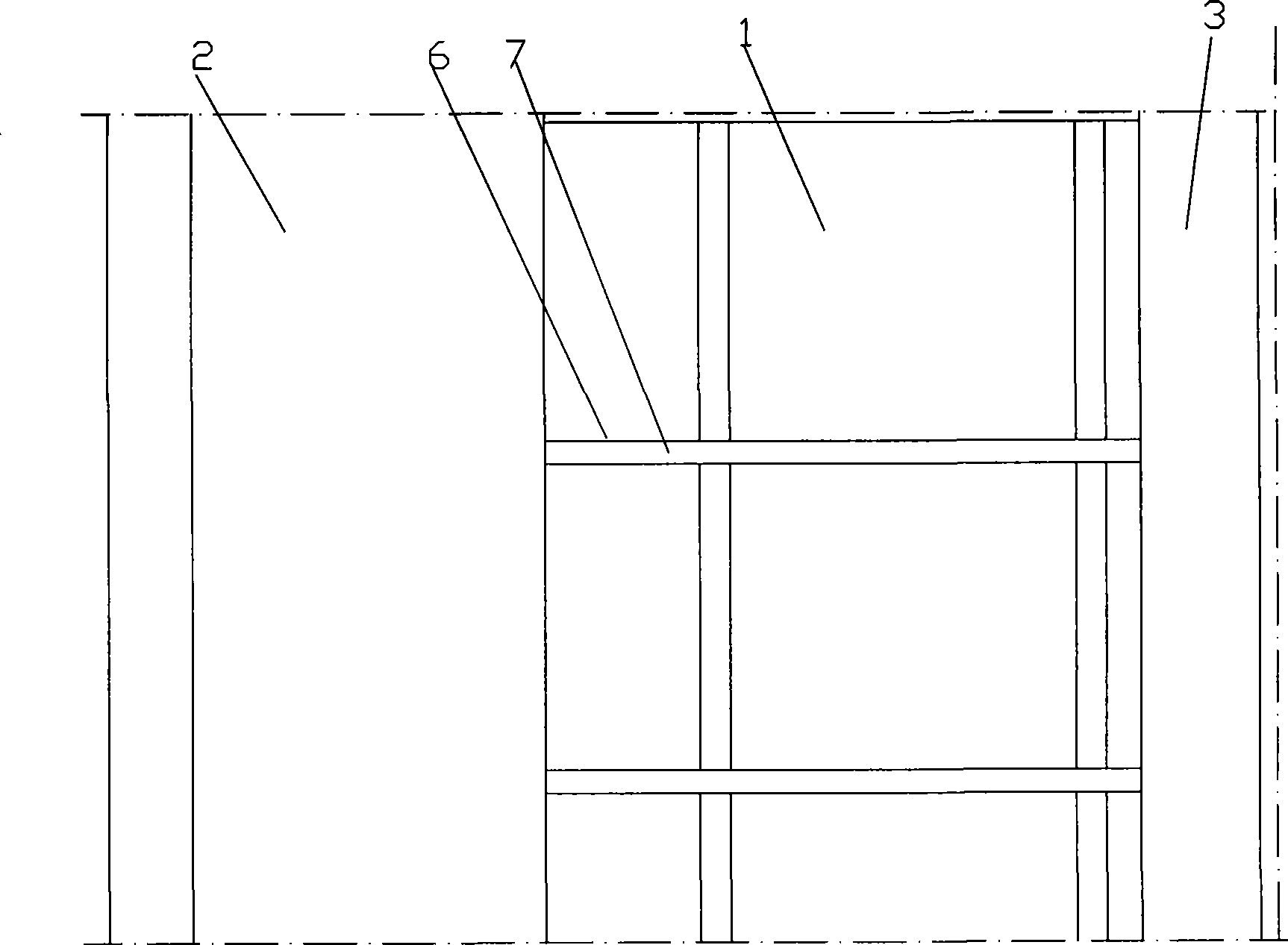

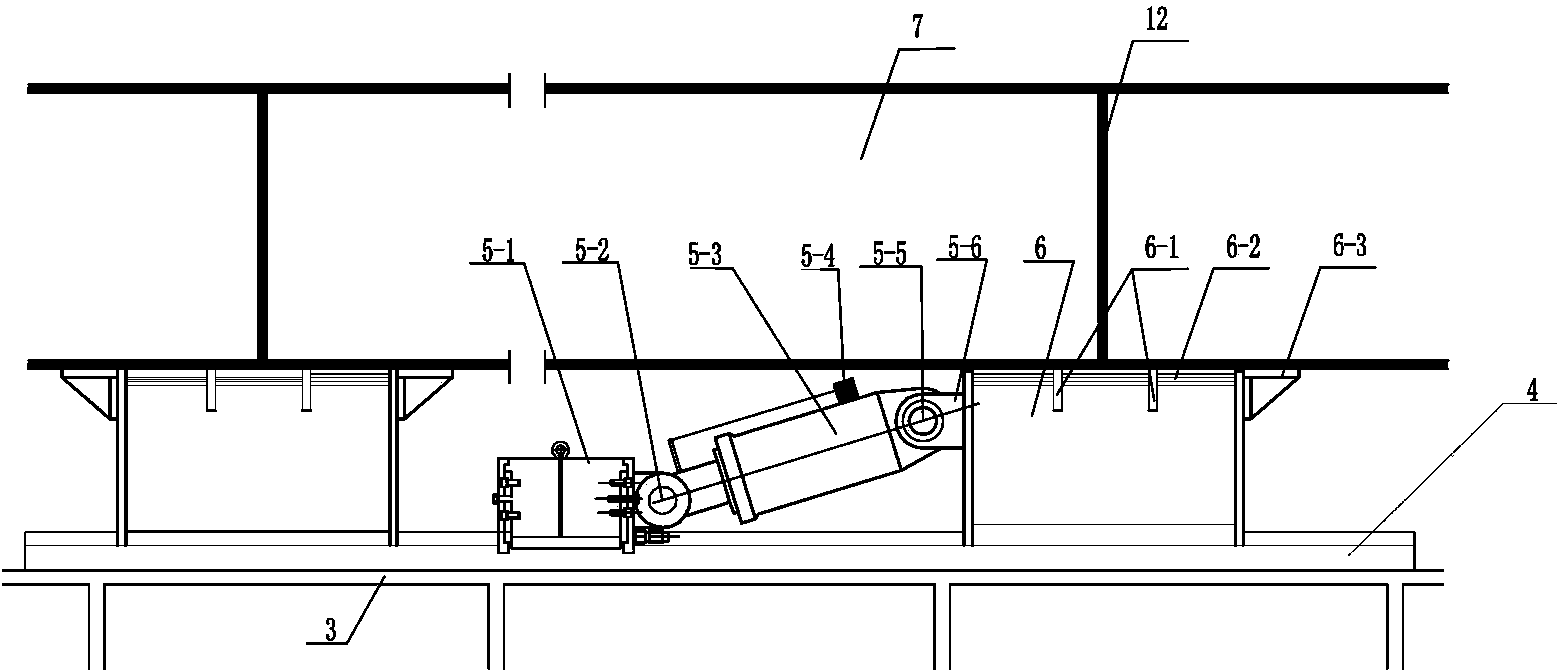

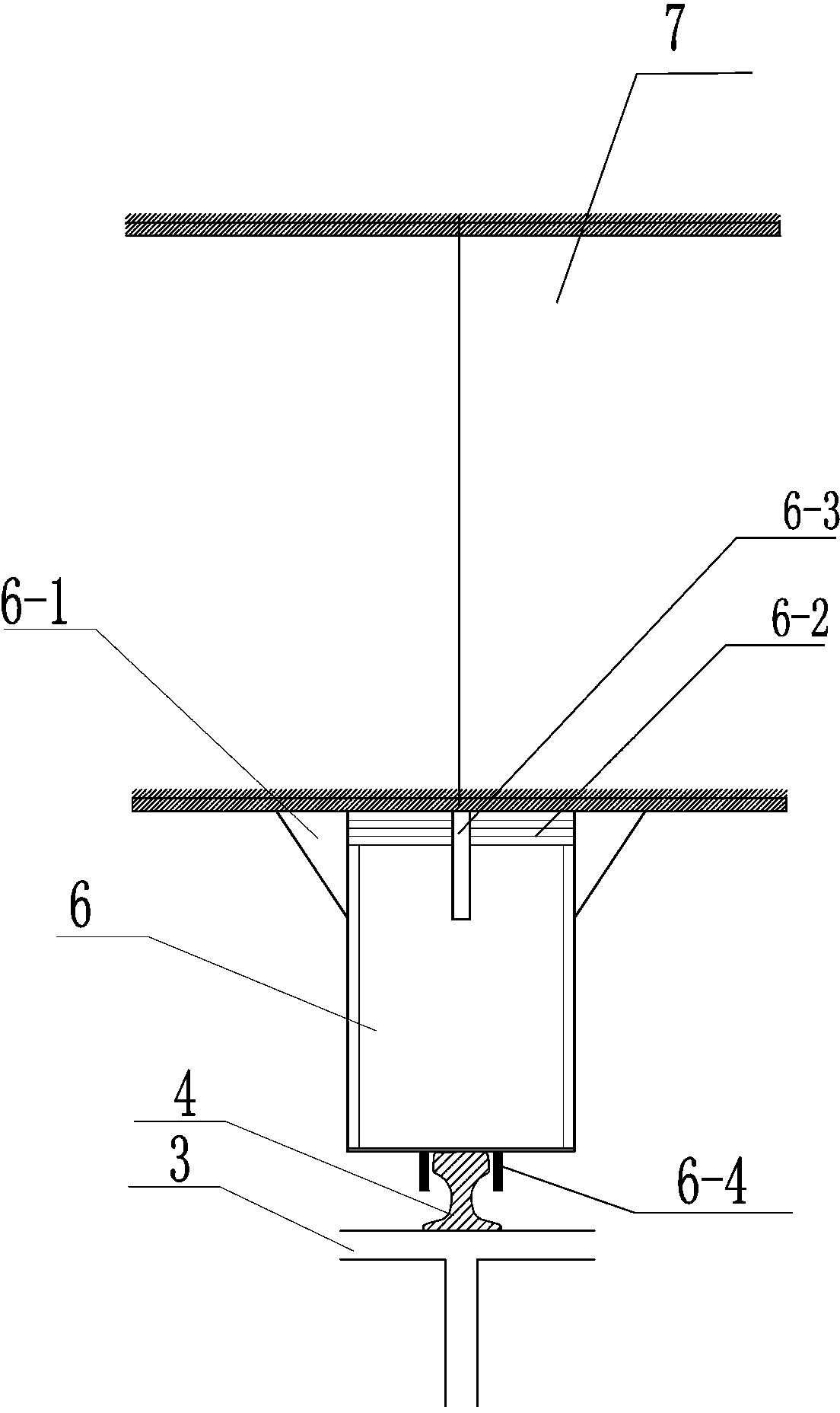

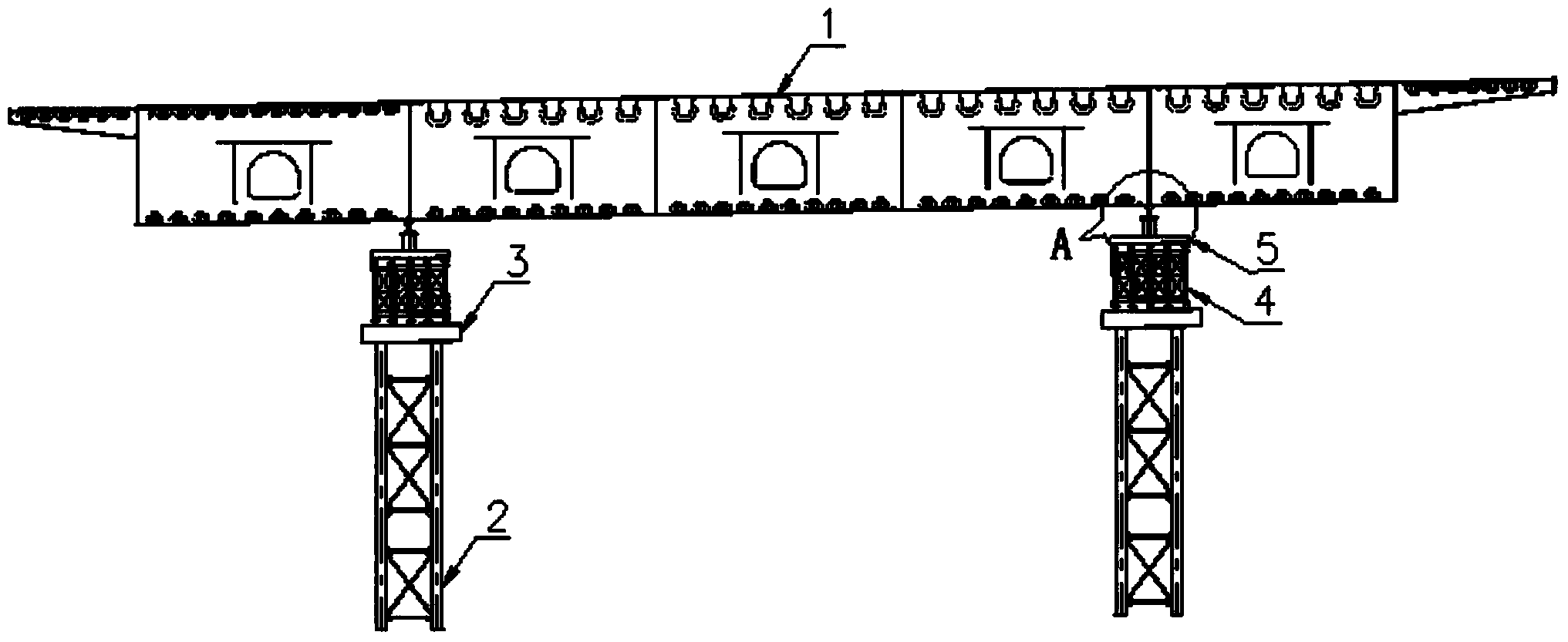

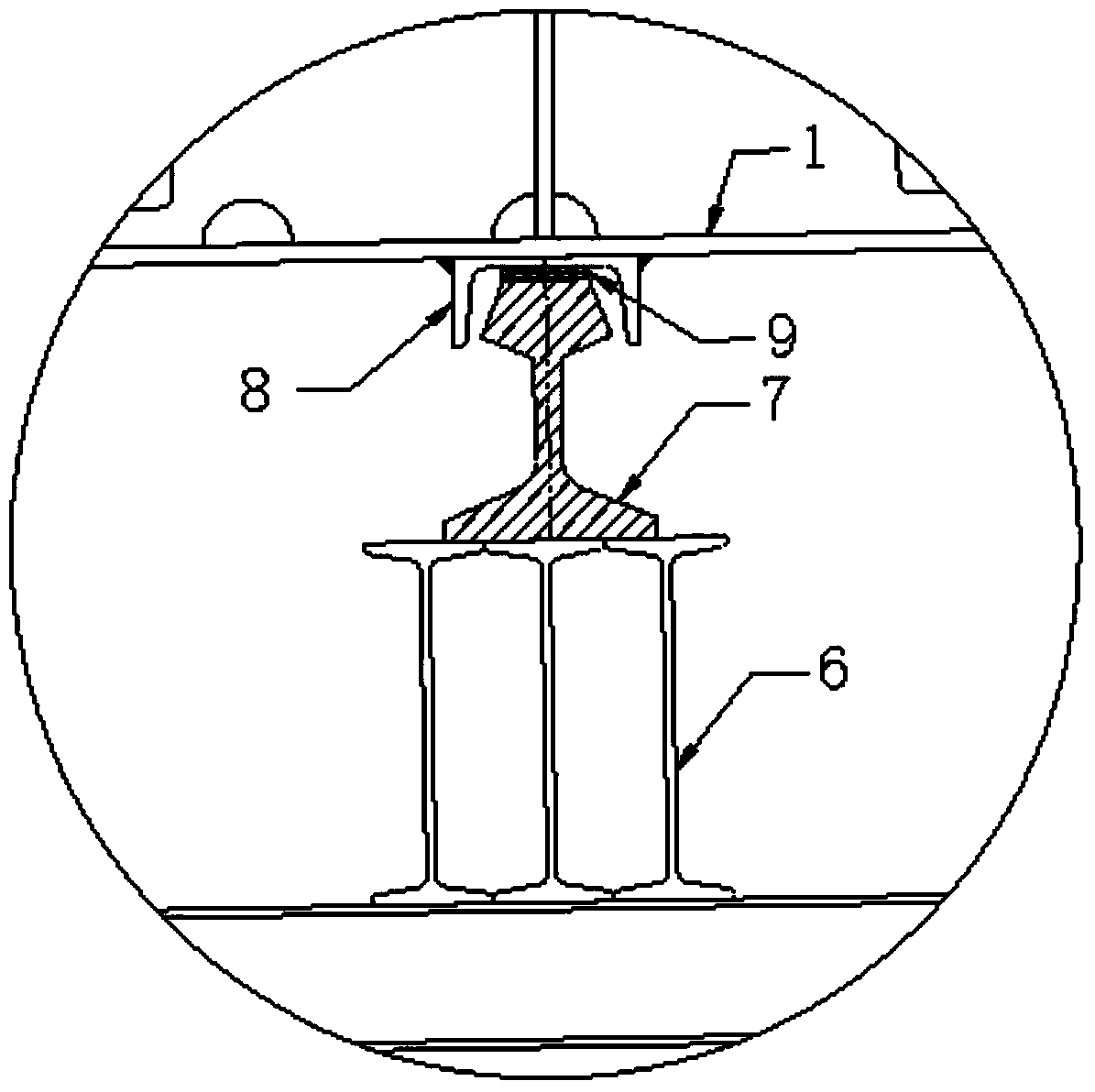

Cast-in-situ beam-making construction method of assembled support

ActiveCN101333801AMeet load requirementsEasy to installFoundation engineeringBridge erection/assemblyButtressSupporting system

Disclosed is a construction method of producing a beam in situ by pouring an assembly-style bracket, which is characterized in that a foundation is treated by cement compaction piles into a composite foundation; that buttresses in a support system adopt Bailey cranes and vertical load-bearing beams adopt military beams; that a box beam formwork is formed by combining such three major parts as a bottom mold, an external mold and an internal mold; wherein the bottom mold is formed by matching large pieces of flat steel templates; the external mold adopts a light welded steel structure, the internal mold adopts a screw mechanical contraction steel structure and is formed by matching the segments, and both the external mold and the internal mold can slip along a railway which is disposed on the military beam. The construction method has advantages that: 1. the load-bearing capacity of the composite foundation can reach up to 239KPa so as to meet the load-bearing requirement of the middle buttress; 2. the assembly-style bracket only costs about 3.7 million, the components thereof are standing parts so that installation is convenient. In addition, the moving of the external mold is beyond the restriction of box beam ages, as long as the intensity is satisfied, the external mold can be drilled with holes. The assembly-style bracket can be used as construction equipment such as a gantry, an erecting crane and a makeshift bridge after construction and can be reused repeatedly.

Owner:CHINA RAILWAY 20 BUREAU GRP +8

Lower edge open truss style corrugated steel web combination beam

InactiveCN101139812AImprove crack resistanceIncreased durabilityLoad-supporting elementsBridge materialsFalseworkCrack resistance

A truss-type corrugated steel web composite beam with an open bottom chord belongs to a bridge support member. The bottom chord opened and truss-type corrugated steel web composite beam comprises an upper wing edge concrete slab, a corrugated steel web and a bottom chord opened truss-type rectanglar steel tube concrete member. Compared with steel truss-type web composite corss section, the invention adopts the corrugated steel web with rather high shear strength to replace a steel web member, so as to guarantee quite high shear bearing capacity. The opened truss-type bottom chord is composed of two parallel-arranged rectanglar steel tubes arranged in parallel and internally cast concrete, as well as horizontal braces and batter braces between the rectanglar steel tubes. Moreover, the bottom chord adopts the steel tube concrete member to overcome the problem of rather high work volume that, in traditional composite cross section of corrugated steel web box beams and steel truss-type webs, such execution measures as scaffolding, formwork-support, concrete casting and etc. should be taken for lower wing edge concrete slabs. Meanwhie, the invention can effectively improve structure crack resistance, avoid crackage exposure and etc, and considerably increase structure durability. The bottom chord is a brace-connected open-type structure with advantages of simple structure and fast, smooth and convenient execution.

Owner:TSINGHUA UNIV

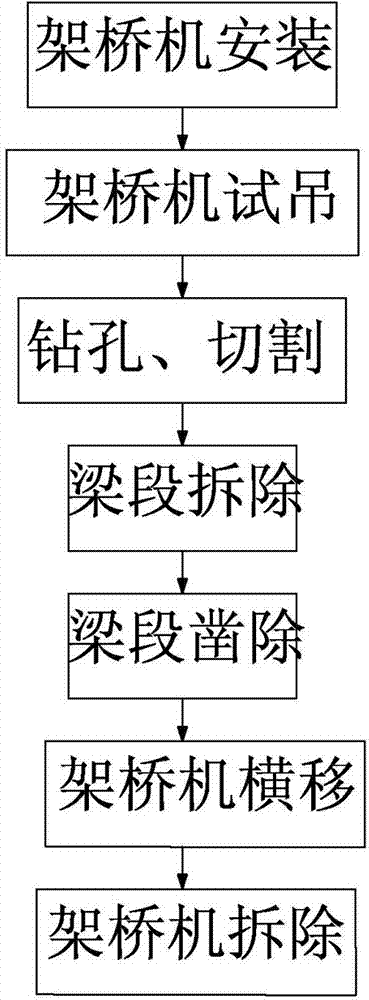

Construction process for using bridge girder erection machine to remove T-shaped cantilever continuous rigid frame box girders

InactiveCN103243663ALow costGuaranteed normal shippingBuilding repairsArchitectural engineeringBridge deck

The invention discloses a construction process for using bridge girder erection machines to remove T-shaped cantilever continuous rigid frame box girders. The process is characterized by including the steps of A, mounting the bridge girder erection machines; B, performing trial hanging by the bridge girder erection machine; C, drilling and cutting; D, removing girder sections; E, chiseling girder sections; F, transversely moving the bridge girder erection machine; and G, removing the bridge girder erection machines; wherein the removing equipment includes two 50m-span bridge girder erection machines, and girder turning is achieved by modifying hanging hooks of the bridge girder erection machines; the bridge girder erection machines are heightened by adding Berea groups and pouring concrete strip foundation below support legs of the bridge girder erection machines to realize that the removed girders are delivered out between two main trusses of the bridge girder erection machines through a bridge face. All girder section removing includes girder section prehanging, girder section cutting, girder section turning, girder section transferring, and girder section chiseling. The construction process is low in used equipment, short in construction period, and small in influence on the society, box girders are removed safely while cost is saved a lot and normal operation of channels or passages below a bridge is unaffected, and safe and environment-friendly T-shaped cantilever continuous rigid frame box girder removing is achieved.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

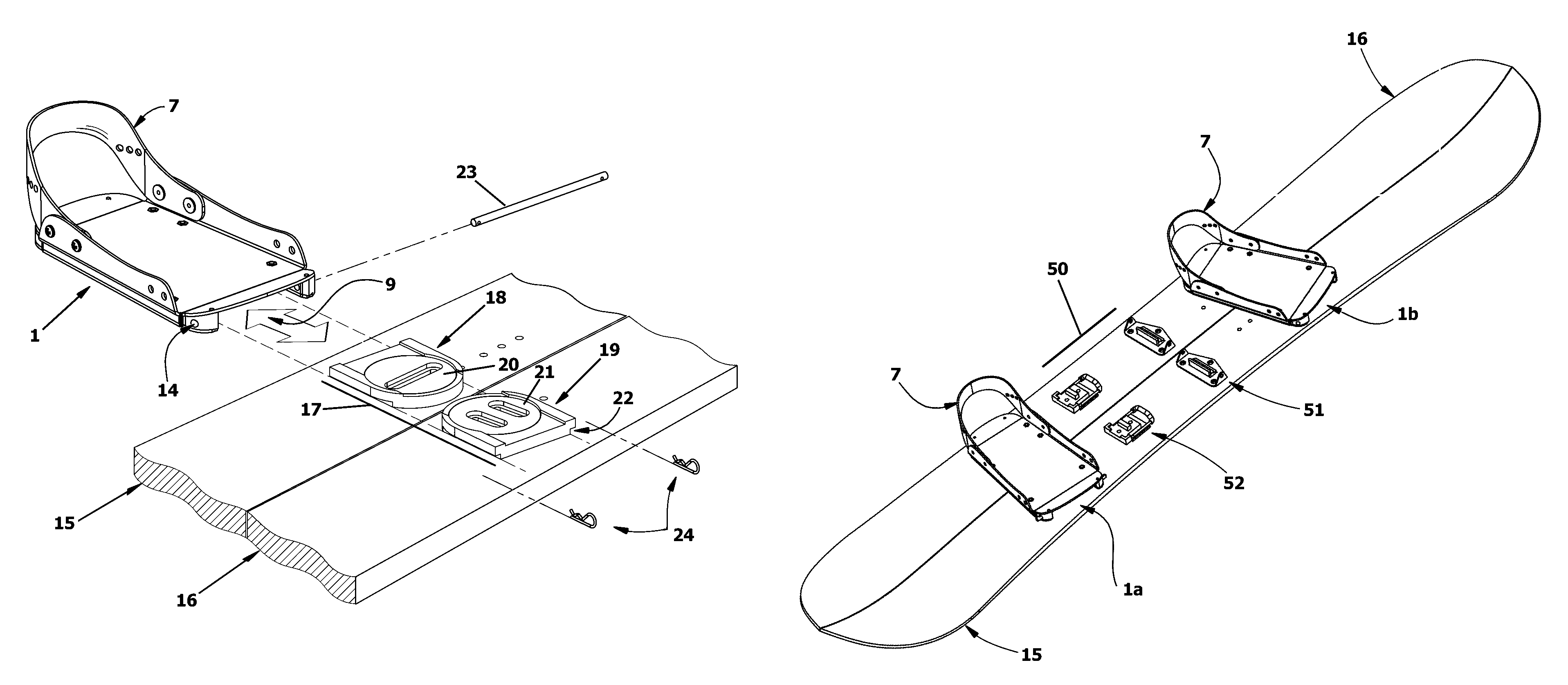

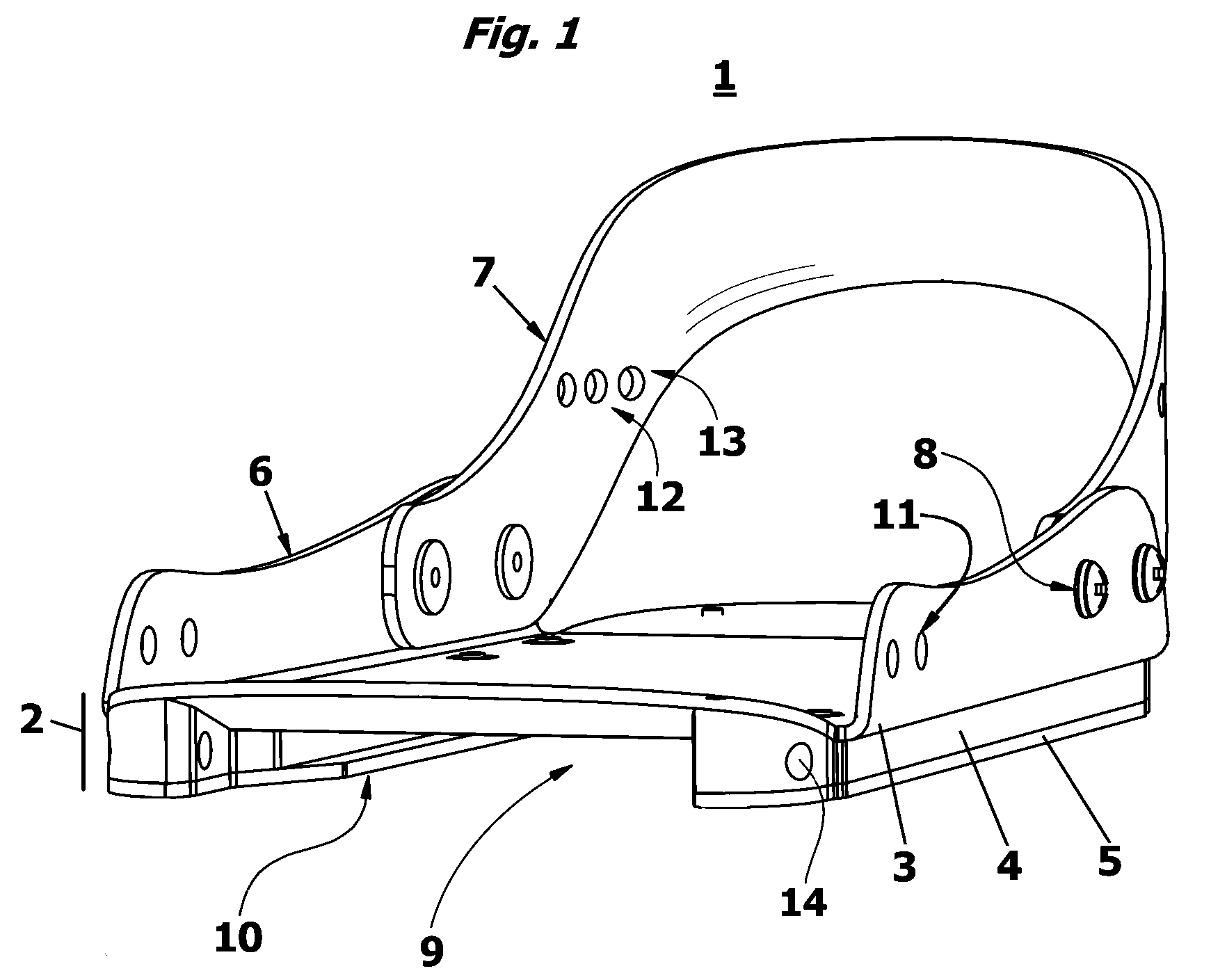

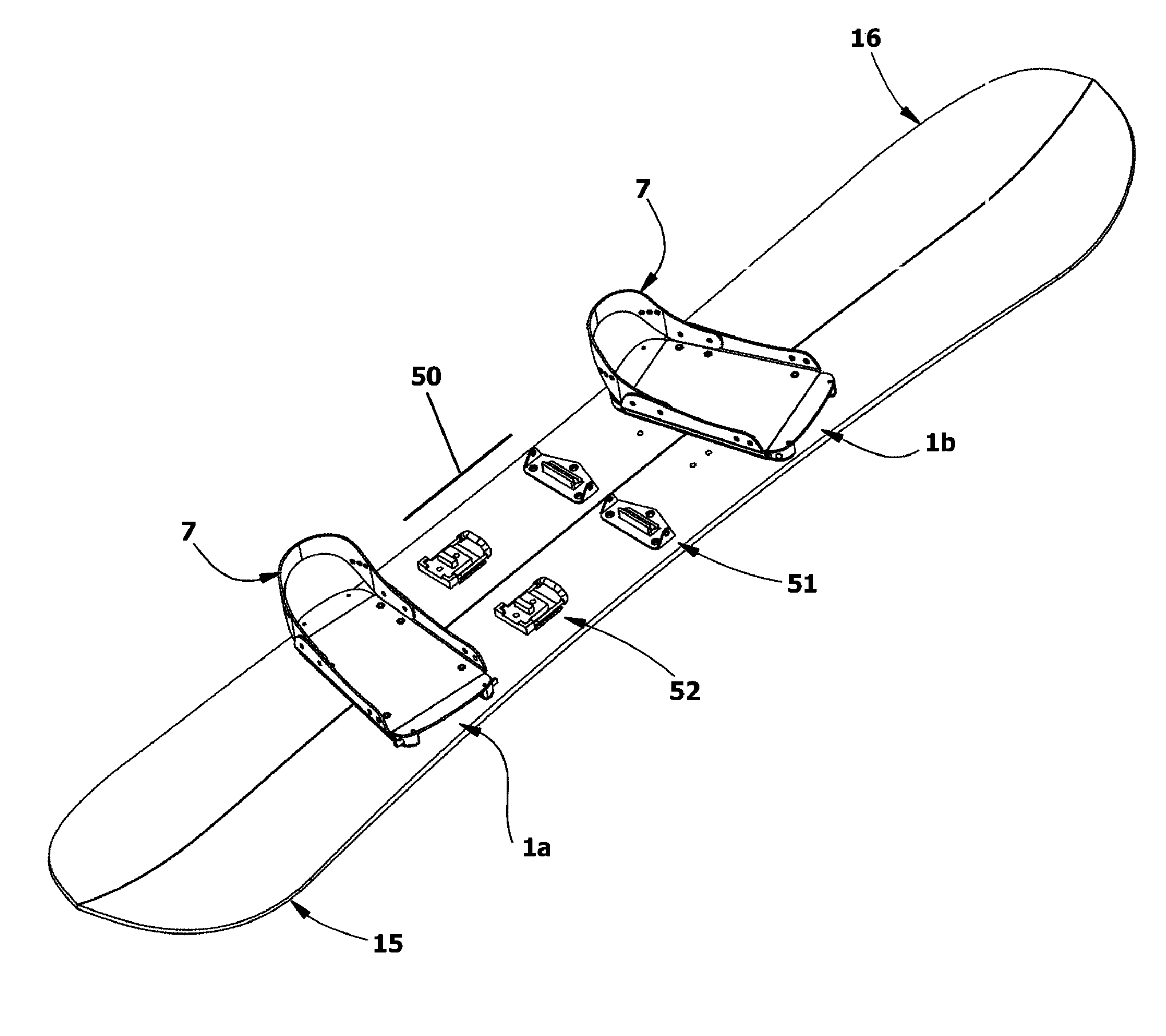

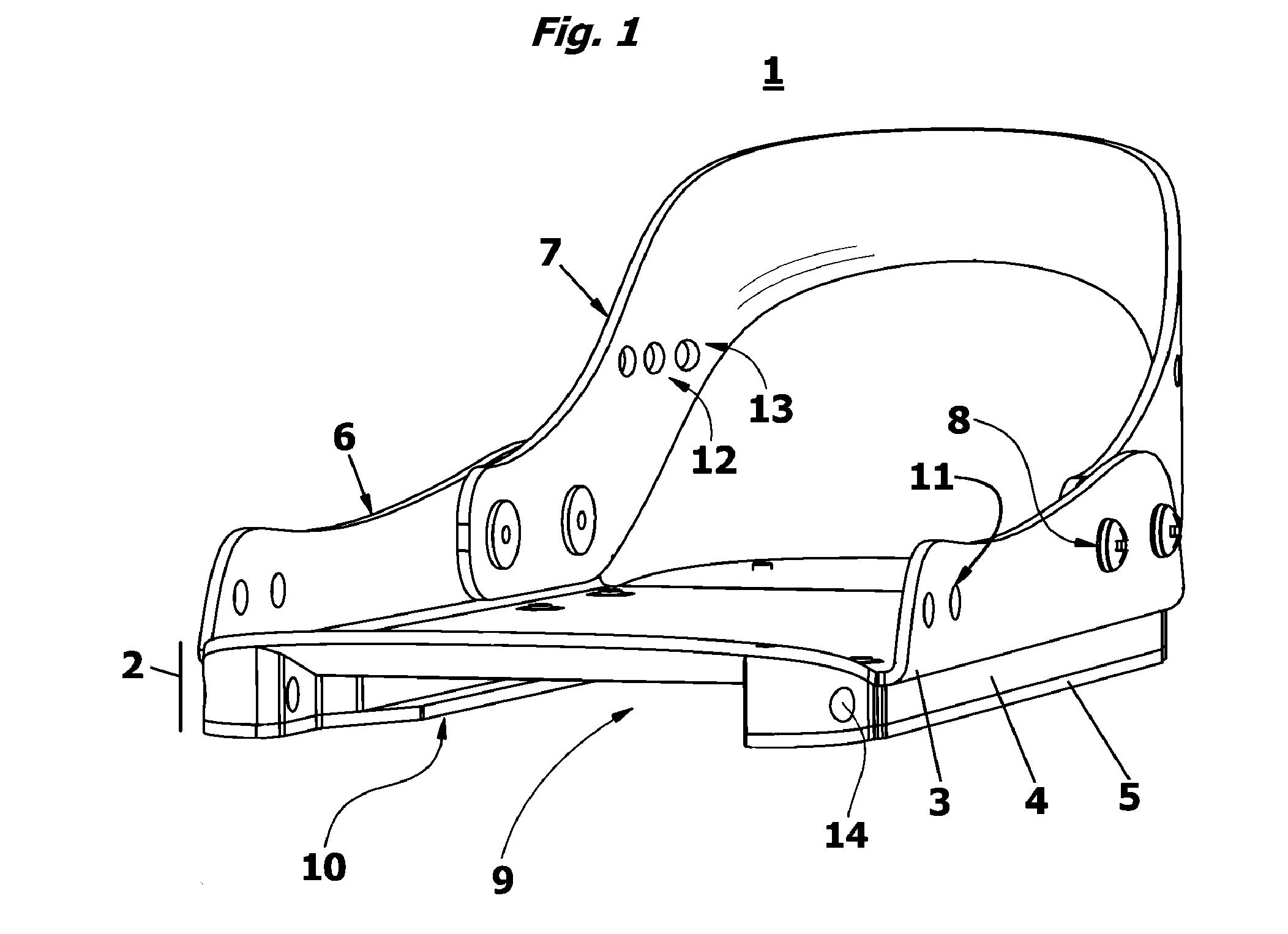

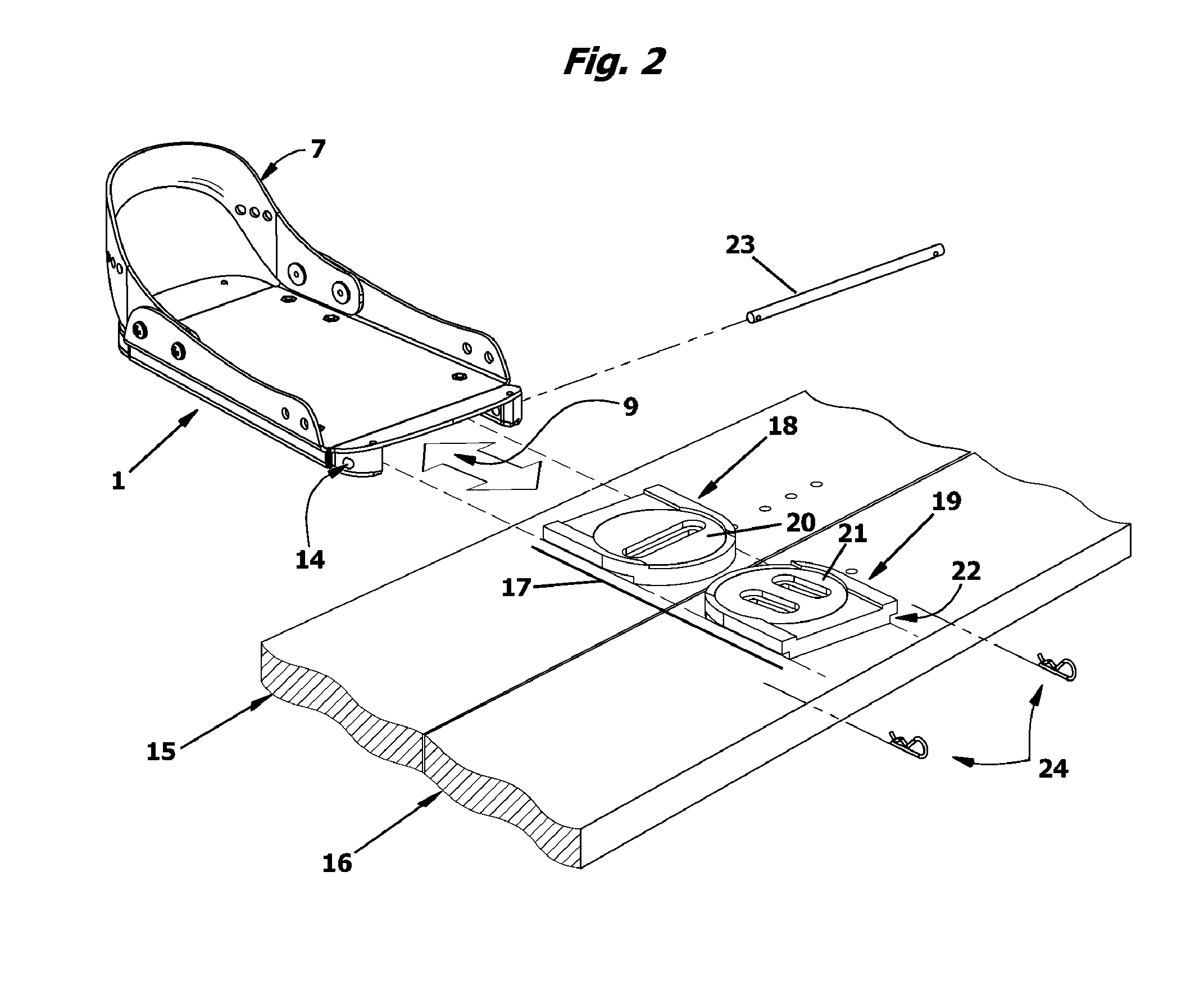

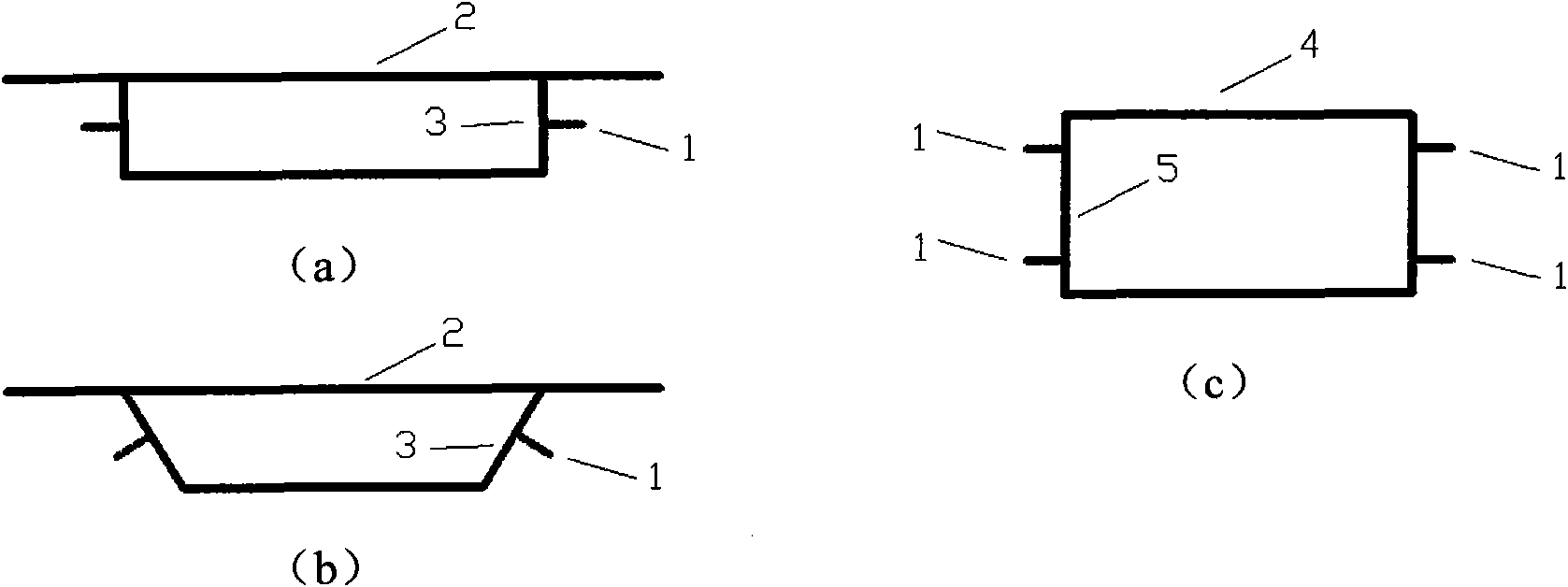

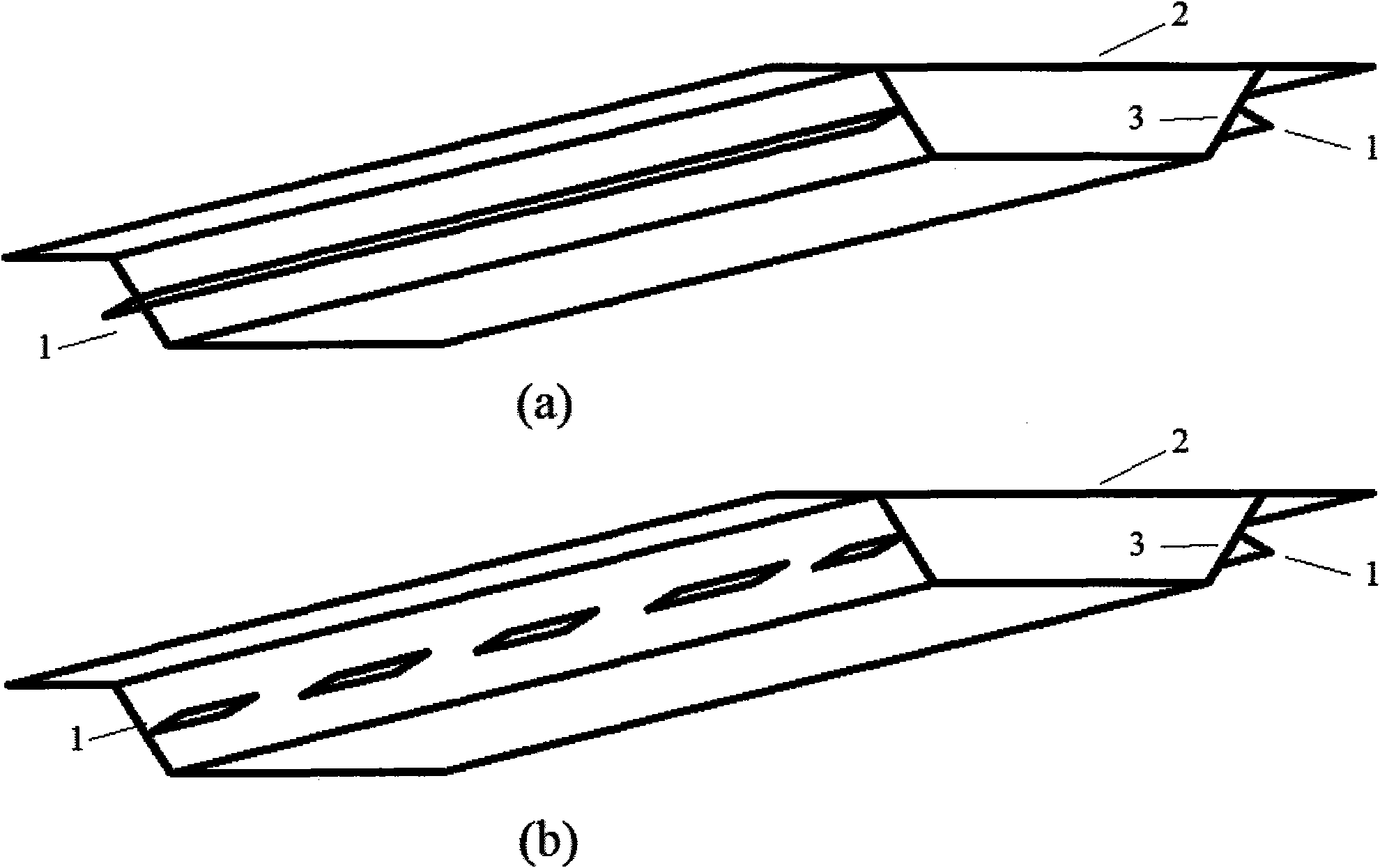

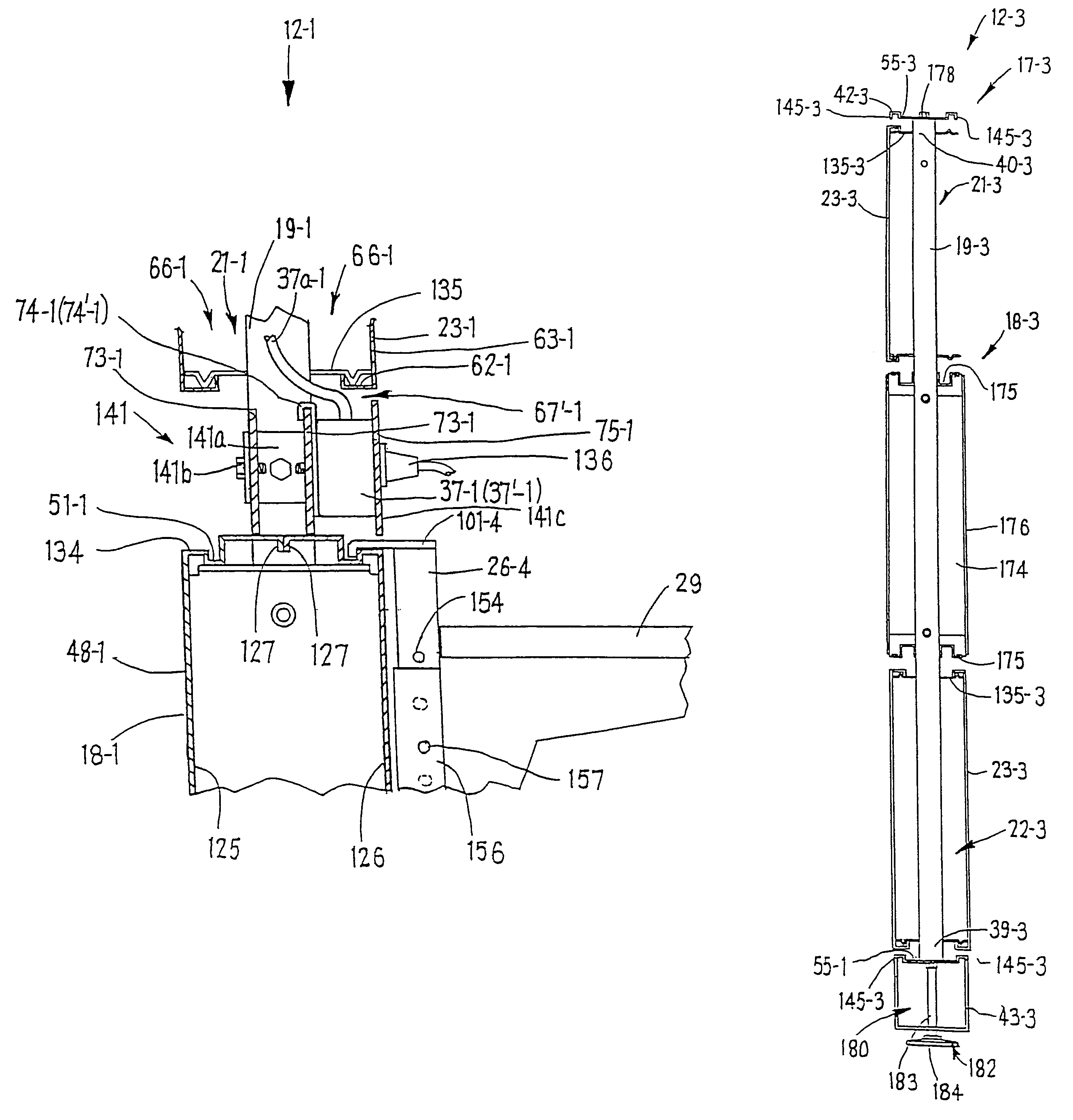

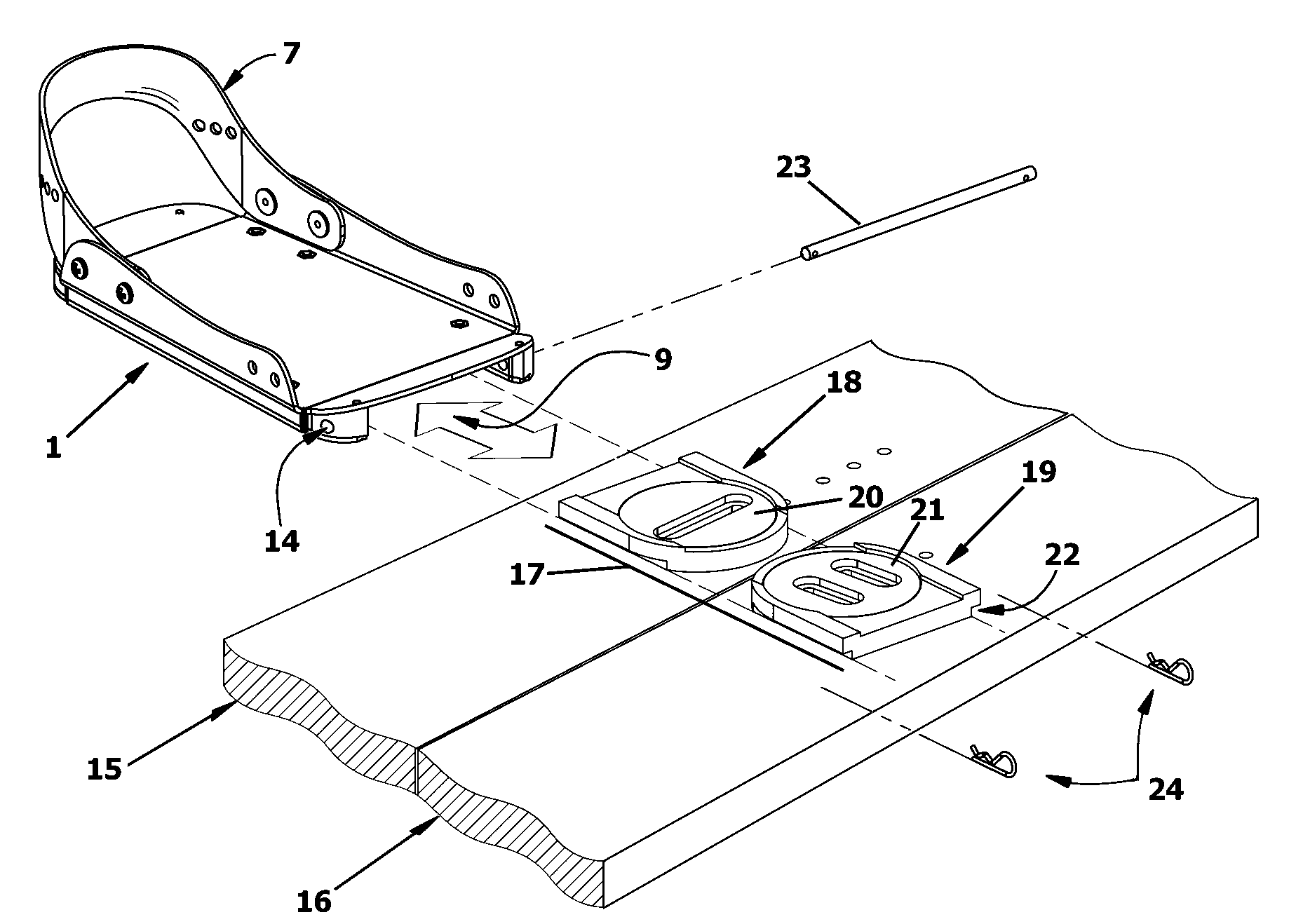

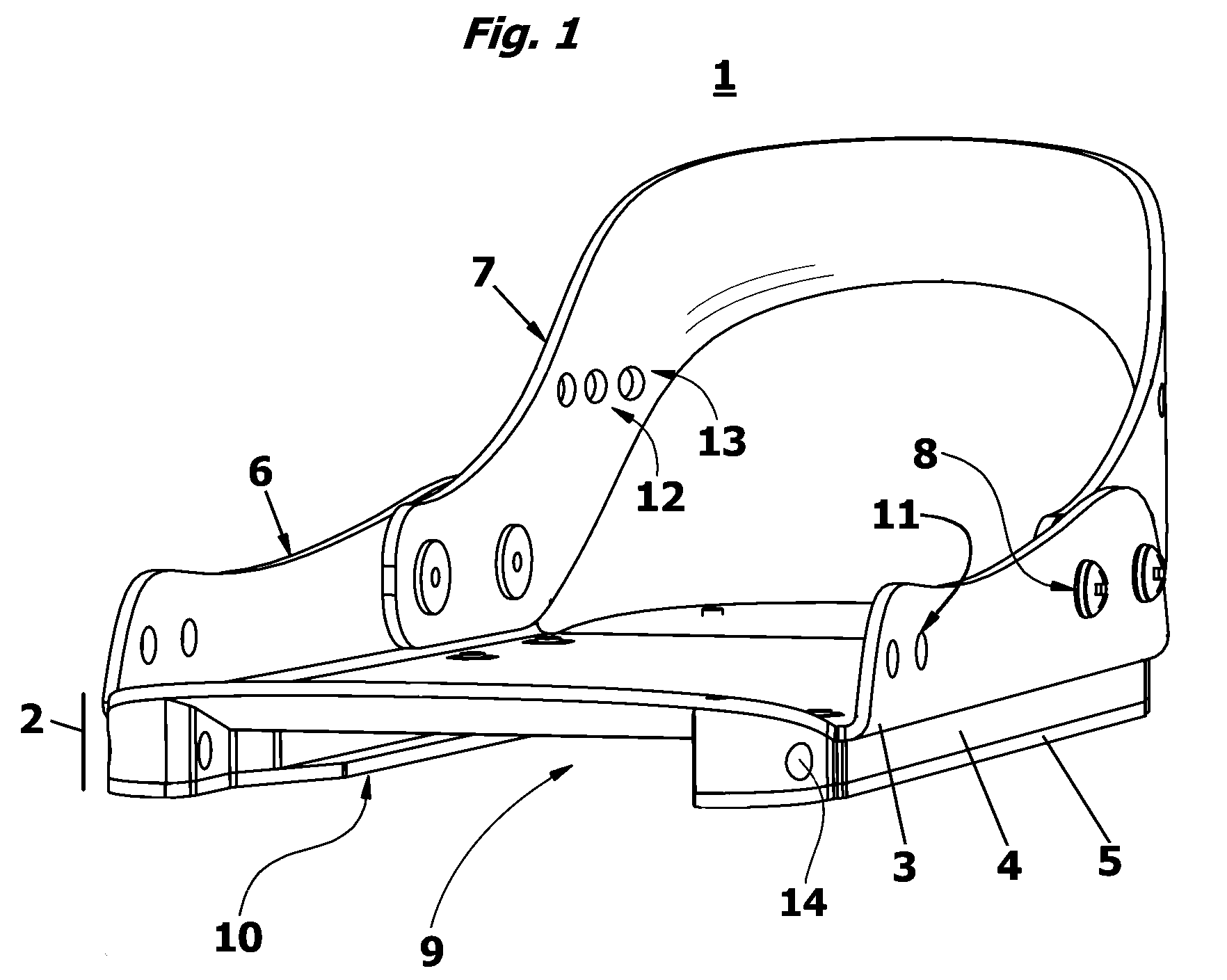

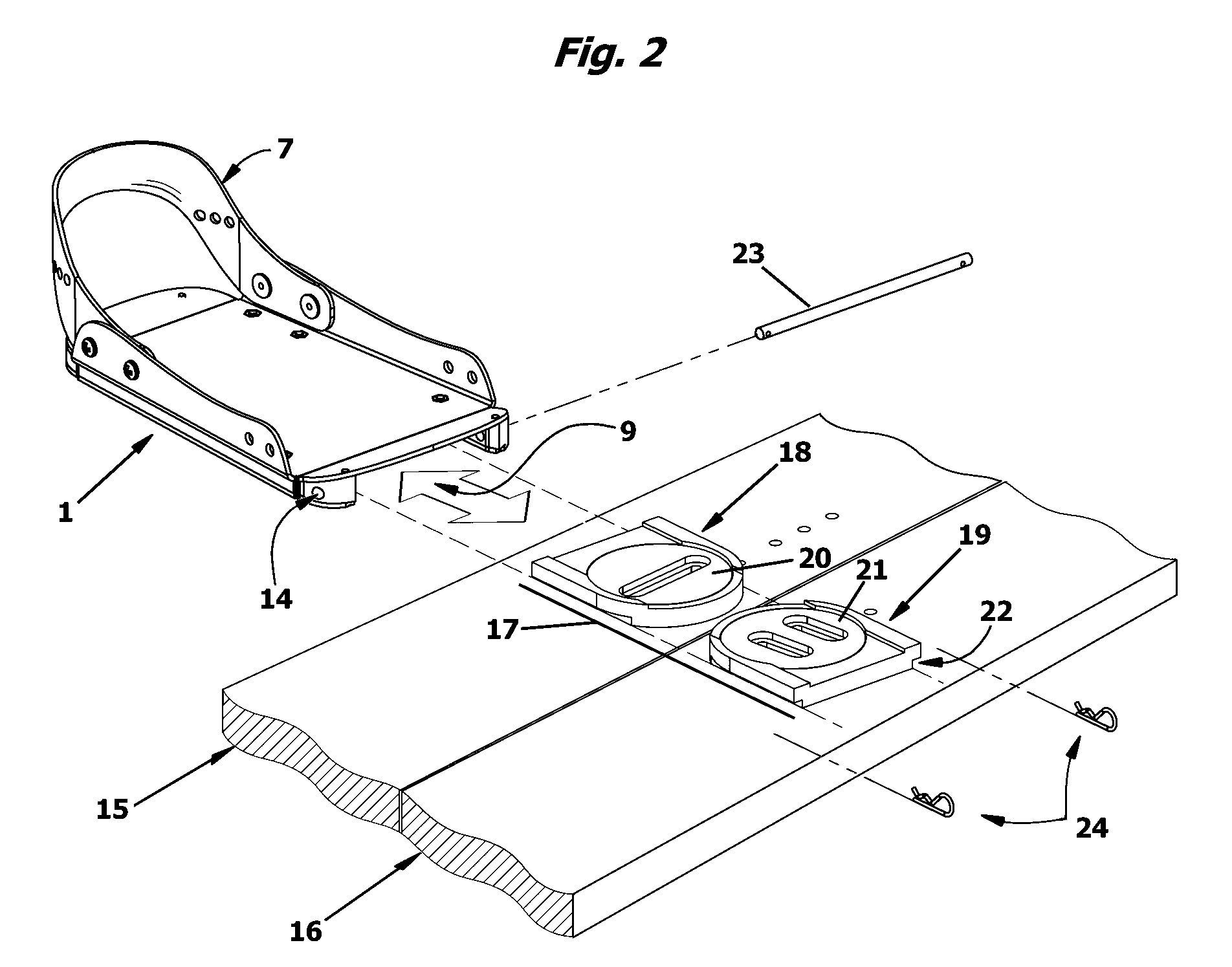

Splitboard bindings

ActiveUS8226109B2Improved boot bindingReduced torsional stiffnessCarriage/perambulator accessoriesSki bindingsEngineeringRigid structure

Splitboard boot bindings for backcountry splitboarding. Each of a pair of soft-boot bindings is provided with an integral boot binding lower that conjoins the two halves of a splitboard without the additional weight or height of an adaptor mounting plate, upper binding baseplate or “tray”, and extra fasteners of the prior art. The boot binding lower is formed as a modified sandwich box girder or modified monolithic box girder and provides improved torsional stiffness for splitboard riding. When subjected to a torque applied by the rider, the bottom mediolateral flanges of the box girders are configured to contactingly engage the top face of the splitboard, thereby dynamically coupling the rider's boot sole and the board via a single rigid structure. In a preferred embodiment, the web or “spacer” members are characterized by an aspect ratio or contour height that is varied from heel to toe.

Owner:SPARK R&D IP HLDG LLC

32m/900t prestressed concrete pretension box beam static loading test method

ActiveCN101101249AVerify crack resistanceAuthentication strengthFoundation testingMaterial strength using tensile/compressive forcesTest beamPre stress

The invention discloses a test procedure of 32m / 900t pre stress pre open box girder concrete box, it includes building testing counter, laying test beam body, fixing balance weight and setting test equipment, and doing load test of three circulation by ordering step by step, and dong crack test for the 32m / 900t pre open box girder effectively, splitting test and breaking test, dong experiment for the design of 32m pre open box girder, construct artwork, workmanship and the anti split and intensive properties of box girder.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Splitboard Bindings

ActiveUS20120256395A1Easy to repositionImprove performanceSki bindingsSnowboard bindingsClassical mechanicsEngineering

Splitboard boot bindings for backcountry splitboarding. Each of a pair of soft-boot bindings is provided with an integral boot binding lower that conjoins the two halves of a splitboard without the additional weight or height of an adaptor mounting plate, upper binding baseplate or “tray”, and extra fasteners of the prior art. The boot binding lower is formed as a box girder and provides improved torsional stiffness for splitboard riding. When subjected to a torque applied by the rider, the bottom mediolateral edges of the box girders are configured to contactingly engage the top face of the splitboard, thereby dynamically coupling the rider's boot sole and the board via a single rigid structure. In a preferred embodiment, the web or “spacer” members of the box girder are characterized by an aspect ratio or contour height that is varied from heel to toe.

Owner:SPARK R&D IP HLDG LLC

Wind fin plate for improving pneumatic performance of bridge

InactiveCN101892625AImprove flutter stabilityRaise flutter safety reservesBridge structural detailsShock proofingAccessory structureEngineering

The invention discloses a wind fin plate for improving the pneumatic performance of a bridge. The wind fin plate is arranged on an accessory structure of a main structure at a certain included angle; the wind fin plate can be designed in an equal section along the extending direction of the main structure or is divided into a plurality of sections to be arranged on the main structure at intervals; the main structure can be a girder of the bridge and the accessory structure can be a web plate of the bridge, wherein the girder of the bridge is a steel box girder or concrete box girder, and the web plate is a straight web plate or an inclined web plate; and the main structure also can be a bridge tower and the accessory structure also can be a tower column wall plate. The wind fin plate can greatly improve the pneumatic performance of the bridge, improve flutter stability and galloping stability, and effectively reduce or inhibit vortex-induced vibration so as to improve the wind resistance of the bridge; and the wind fin plate can be widely applied to members such as girders and bridge towers of bridges.

Owner:TONGJI UNIV

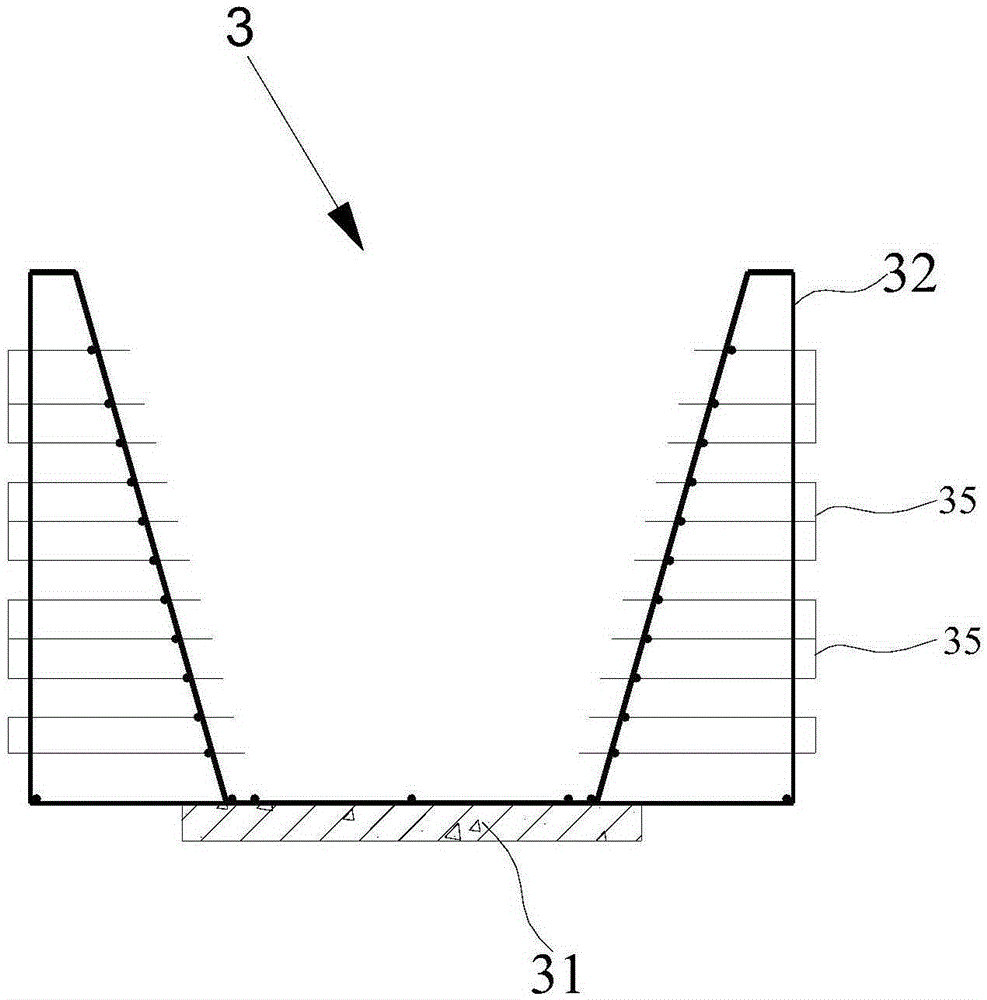

Curvature radius adjustable prefabricated box-beam mold and construction method thereof

ActiveCN101181796ASmooth and beautiful surfaceReduce manufacturing costMould separation apparatusMouldsEngineeringPeriod length

The invention discloses a prefabricated box girder mold with adjustable curvature radius and an installation and construction method of the mold. The invention adopts the concept of replacing the curved line with a folded line of a fixed length, and accurately sets out the bottom mold, so that the side mold is designed by It is composed of several fixed-length fixed sections. An elastic change section is set between the fixed-length fixed sections, and an adjustment link rod is set between the fixed-length fixed sections to realize the function of adjusting the curvature of the fixed-length broken line. At the same time, the adjustment insert section is embedded in the side mold The adjustment of inner and outer arc length changes can not only meet the needs of fixed section and variable curvature prefabricated building components, but also meet the production or construction needs of continuous variable section and variable curvature prefabricated building components. The prefabricated box girder mold with adjustable curvature radius of the present invention can not only meet the overall needs and accuracy requirements of the design curvature change, but also has a smooth and beautiful surface, with as few or no traces of template joints as possible.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

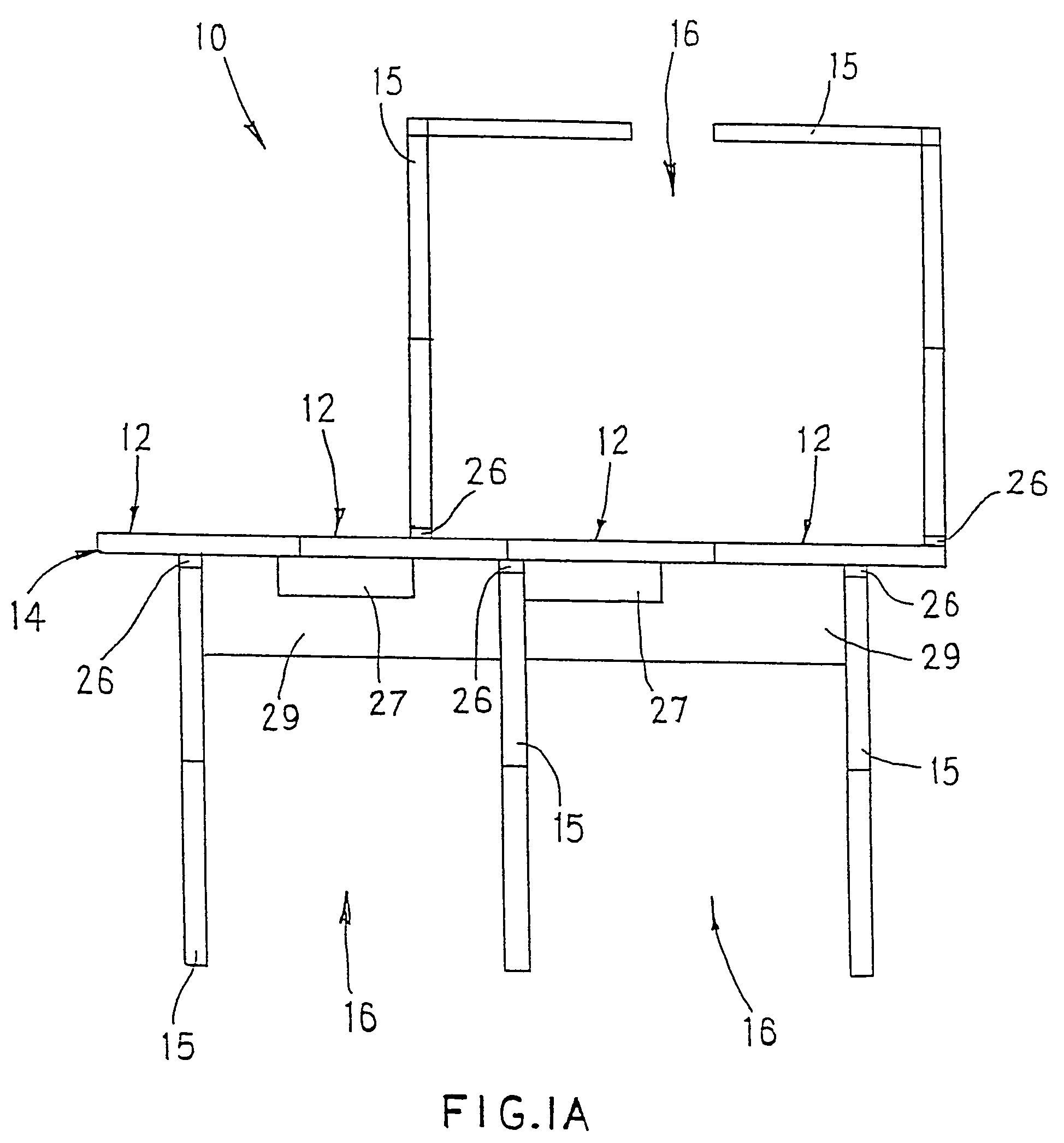

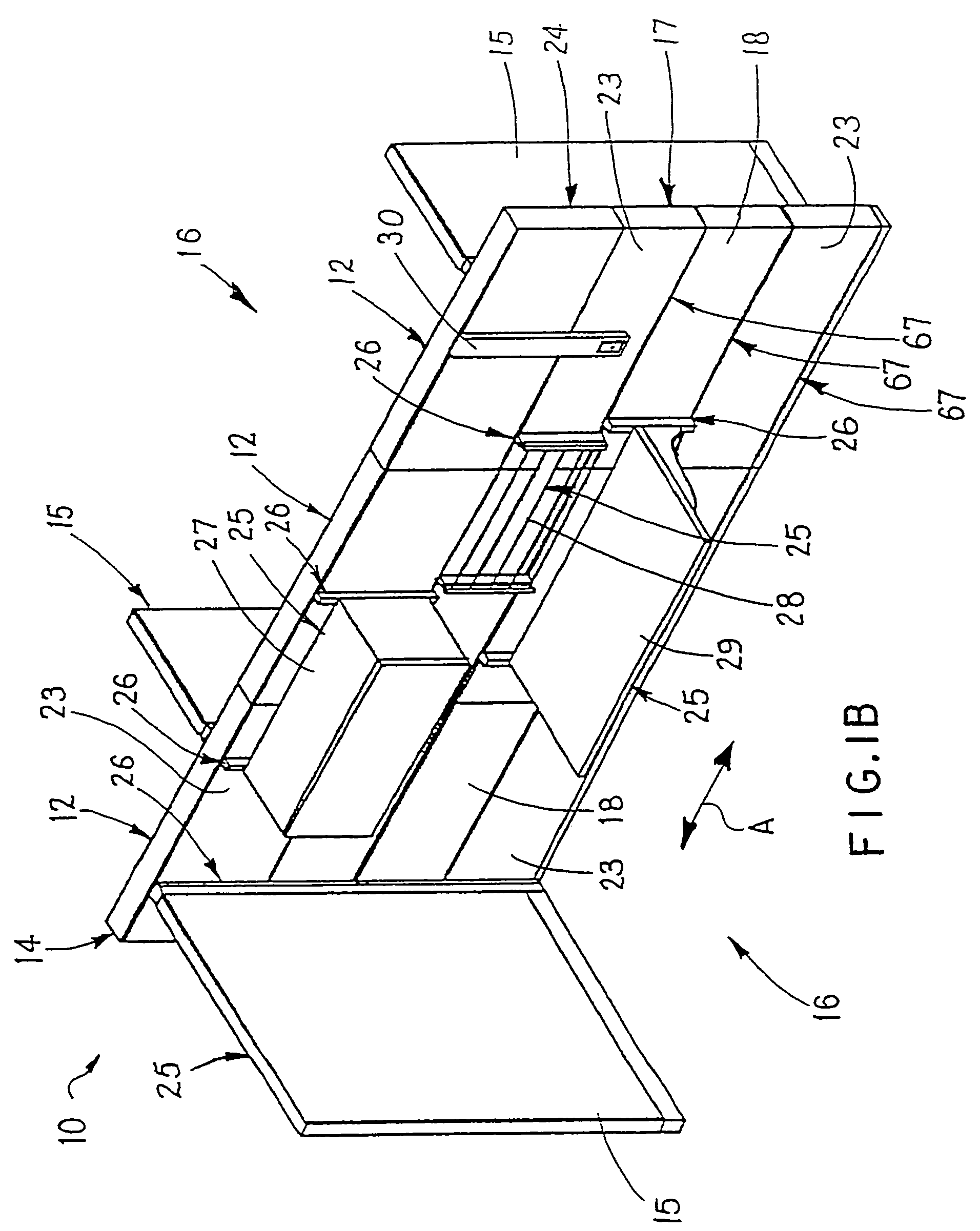

Panel arrangement

InactiveUS7055287B2Improve carrying capacityEasy to handleCarriage/perambulator accessoriesSledgesBox girderAdjacent channel

This invention relates to a space-dividing wall panel system having a plurality of base panels which are serially connectable one with the other to define a vertically enlarged wall supported on a floor. Each base panel is defined by at least one horizontal box-beam rigidly connected to a pair of laterally spaced apart vertical uprights which are connected at the opposite ends of the box-beam and have a reduced thickness compared thereto. With this clearance between the faces of the box-beam and the uprights, the box-beam, cross rails at the ends of the uprights as well as additional extension panels are formed with longitudinally extending channels which are positioned free of interference with the vertical uprights and aligned with serially-adjacent channels of serially-adjacent wall panels. The channels provide a continuous linear track on the opposite sides of the upright which permit the connection of mounting hooks of furniture components and permit continuous, uninterrupted sliding or adjustment of the furniture components along the entire length of the aligned channels.

Owner:PNC BANK NAT ASSOC AS ADMINISTATIVE AGENT

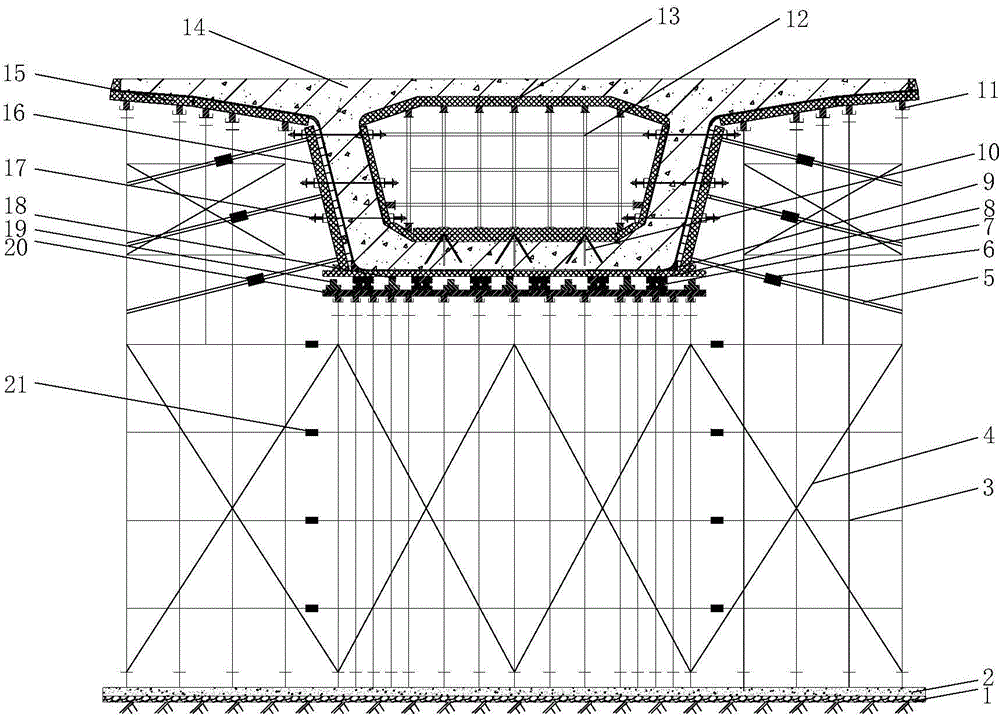

Mold supporting structure for variable cross-section cast-in-place box girder at section combining horizontal and longitudinal curves, and construction method of the mold supporting structure

ActiveCN104963290ARealize three-way stereo controlMonitor stress changesBridge erection/assemblyFalseworkBox girder

The invention relates to a mold supporting structure for a variable cross-section cast-in-place box girder at a section combining horizontal and longitudinal curves. The mold supporting structure mainly comprises an all-round scaffold, adjustable inclined supports, synchronous hydraulic jacks, composite moulds and adjustable supporting bases, wherein the all-round scaffold is formed by the overlapping connection of scaffold sets; the synchronous hydraulic jacks and the adjustable supporting bases are uniformly arranged at the joints of longitudinal supporting beams and transverse supporting beams at the top; the synchronous hydraulic jacks and the adjustable supporting bases are used as an upper part supporting body system, and a bottom mold is mounted on the top surface; the mounting angle of each lateral mold is adjusted through the adjustable inclined supports, and the lateral molds are fixedly connected with the bottom mold and an inner mold; custom-made steel templates are arranged at chamfers and circular-arc parts of the variable cross-section cast-in-place box girder; a core mold of the variable cross-section cast-in-place box girder is supported by an internal scaffold, and is fixed to the lateral molds through opposite-pull screw rods. Through the adoption of the mold supporting structure disclosed by the invention, the three-dimensional control for the moulds of the cast-in-place box girder at the section combining horizontal and longitudinal curves is realized, and besides, the uniform stress for the scaffold during concrete pouring can be guaranteed. The invention further provides a construction method of the mold supporting structure for the variable cross-section cast-in-place box girder at the section combining horizontal and longitudinal curves.

Owner:CITIC GUOAN CONSTR GRP CO LTD

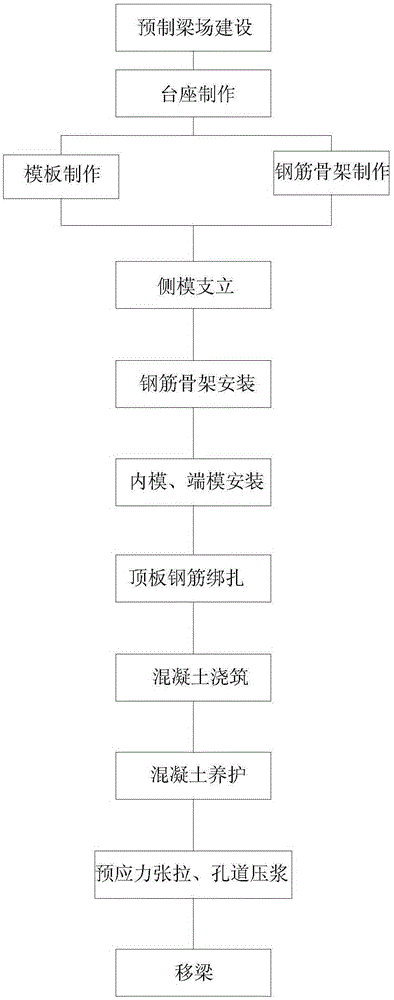

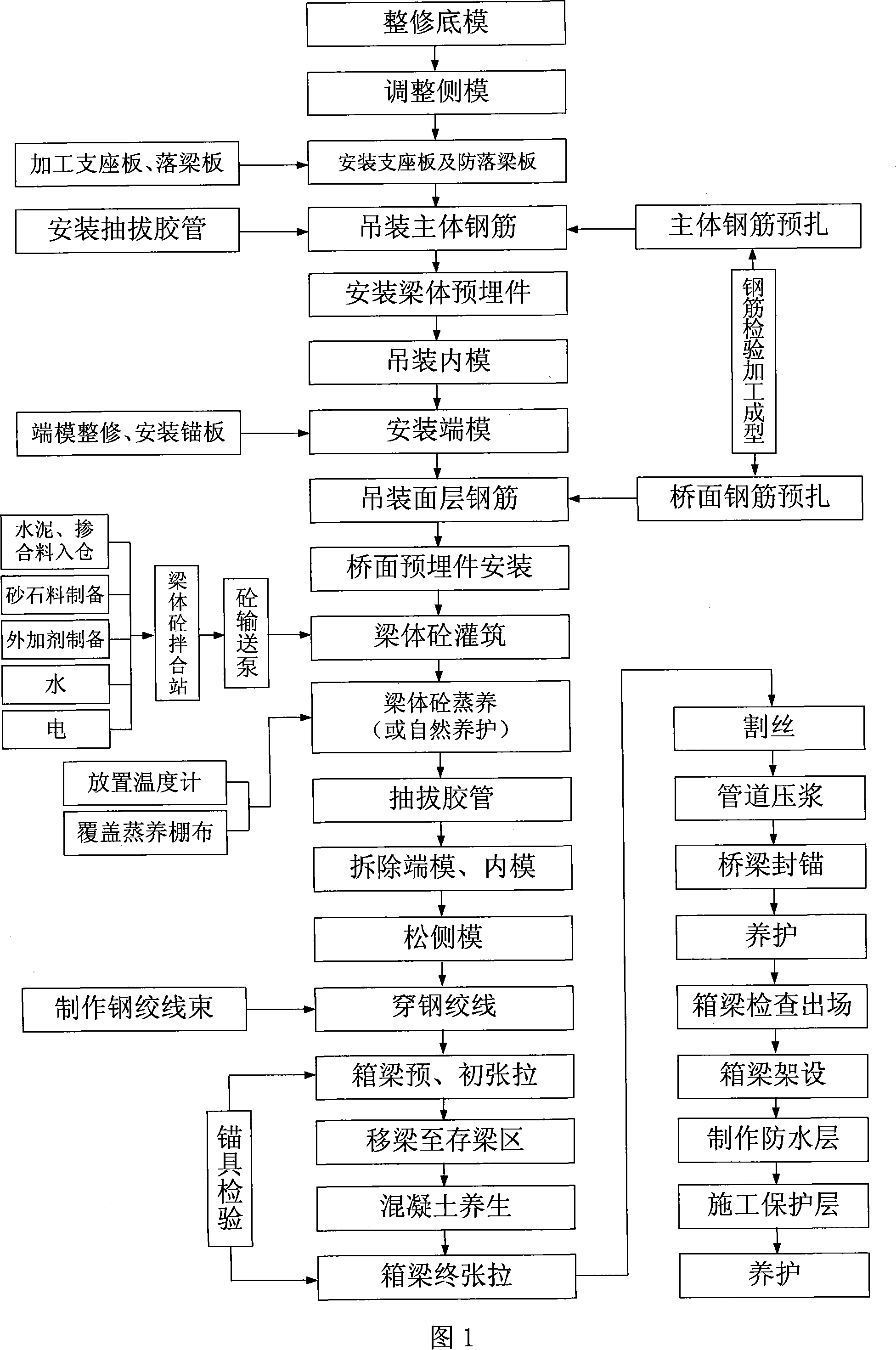

Post-tensioned method prestressed concrete box beam whole opening prefabricated construction method

ActiveCN101125441AGood pre-tied qualityAccurate pre-binding positionMouldsCeramic shaping plantsPre stressEngineering

The present invention discloses a monolithic prefabricated construction method of post-tensioned prestressed concrete box grider, which mainly comprises the following steps: moulding board, reinforcing steel bar and embedded part installation, grider concrete packing, grider concrete steaming or natural maintenance, moulding removal, tension, and postorder construction, etc, wherein, the reinforcing steel bar adopts the technologies of centralized prewing, and overall hoisting, and the tension step adopts three tension techniques of pretension, first tension and final tension; the internal die adopts a hydraulic internal die system, and the grider concrete packing step adopts the construction proposal of concrete centralized mixing, and pipeline pumping pouring, which adopts a decentralized and continuous process, and pours gradually from two ends to the middle so as to realize one-though moulding. The construction method of the present invention is suitable for monolithic prefabricated construction of prestressed concrete box grider with 32m / 900t big span and large tonnage in the special railway line for passenger transport.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

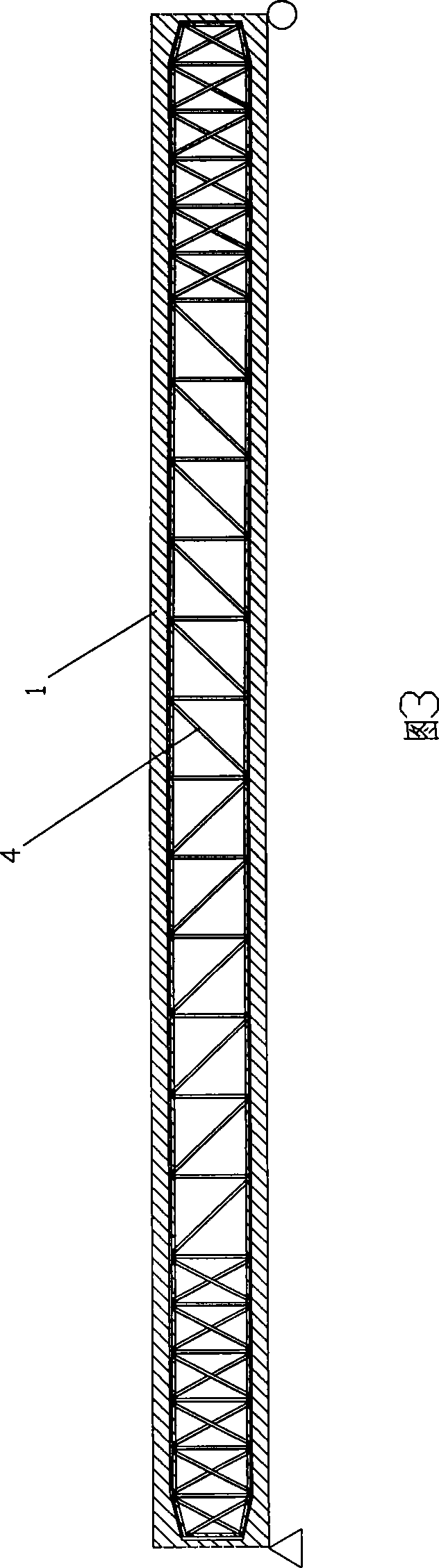

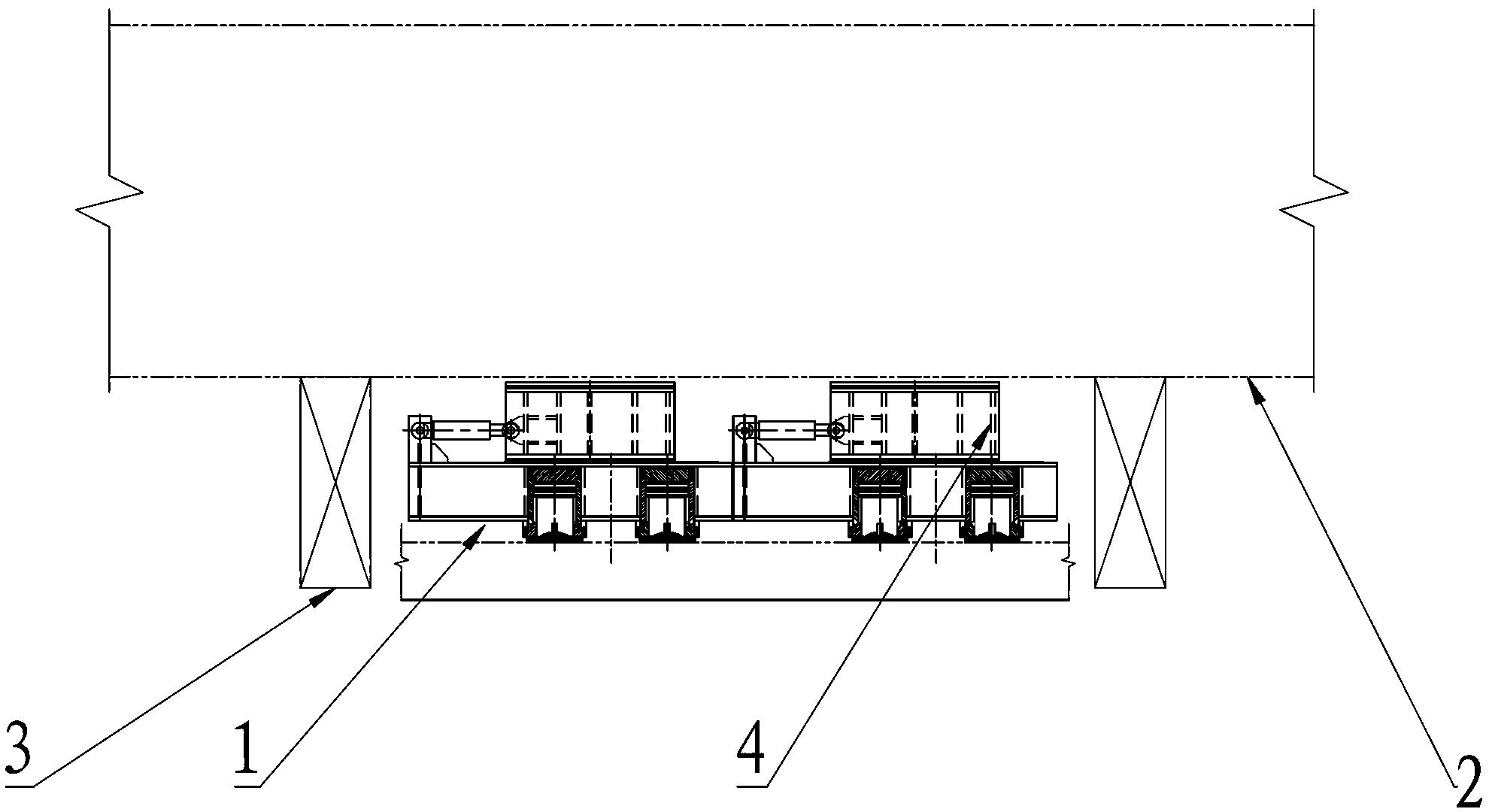

Variable cross-section cantilever bridge box girder self-locking synchronization pushing system and construction method

ActiveCN103541308AShorten the lengthGuaranteed lateral stabilityBridge erection/assemblyBridge typeTrackway

The invention relates to a variable cross-section cantilever bridge box girder self-locking synchronization pushing system and a construction method. The variable cross-section cantilever bridge box girder self-locking synchronization pushing system comprises a pushing sliding bridge box girder welding assembling platform system, sliding tracks, a group of sliding shoes and a group of self-locking synchronization pushing devices, wherein the group of sliding shoes and the group of self-locking synchronization pushing devices are installed on the sliding tracks, and pushing is automatically controlled. The variable cross-section cantilever bridge box girder self-locking synchronization pushing system is characterized in that every self-locking synchronization pushing device comprises a hydraulic pushing oil cylinder and a self-locking pushing rail clamping device, adjusting pad blocks for adjusting bridge type camber are arranged on the upper portions of the sliding shoes, and thrust plates and side limiting plates, which are used for preventing the sliding shoes from jumping during pushing, are respectively arranged in front of and on the sides of the sliding shoes. Track limiting plates for limiting sliding shoe offset are arranged on two sides of the parts on the lower portions of the sliding shoes contacted with the tracks, a bridge box girder is placed on the upper portions of the sliding shoes, and a bridge box girder transition section and a guide beam are arranged at the front end of the first section of bridge box girder. By adopting the variable cross-section cantilever bridge box girder self-locking synchronization pushing system construction method, the problem of difficulty in bridge erection in complex environments of crossing railways and the like is effectively solved, and the variable cross-section cantilever bridge box girder self-locking synchronization pushing system is safe, reliable and high in efficiency.

Owner:EAST STEEL STRUCTURE BRIDGE

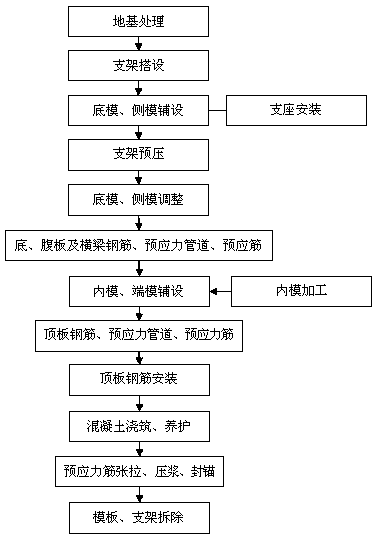

Cast-in-place prestressed concrete continuous box girder one-time pouring and forming construction method

InactiveCN108951425AEliminates transverse cracking problemsShorten the construction periodBridge erection/assemblyPre stressProject management

The invention discloses a cast-in-place prestressed concrete continuous box girder one-time pouring and forming construction method. The method includes the steps of foundation treatment, support erection, bottom mold and side mold laying, support pre-pressing, bottom mold and side mold adjustment, arrangement of bottom boards, webs and crossbeam reinforcing steel bars, prestressed pipelines and prestressed ribs, inner mold and end mold laying, arrangement of top board reinforcing steel bars, prestressed pipelines and prestressed ribs, top board reinforcing steel bar installation, concrete pouring and curing, prestressed rib tensioning, mud jacking and sealing anchorage, and formwork and support detachment. The problems of construction joints generated by a traditional construction processand transverse cracks of the jointing positions of flange plates and the webs can be solved, and the integral rigidity of a girder body is enhanced; the construction period of a continuous box girder is shortened, and the schedule of construction is quickened; and the use rate of a box girder formwork and steel pipe support transfer materials is increased, work efficiency is improved, treatmentof the construction joints is cancelled, erection and detachment work of supports in a box is reduced, working procedures are effectively switched, and expenditure of project management cost is reduced.

Owner:NINGBO CONSTR GRP

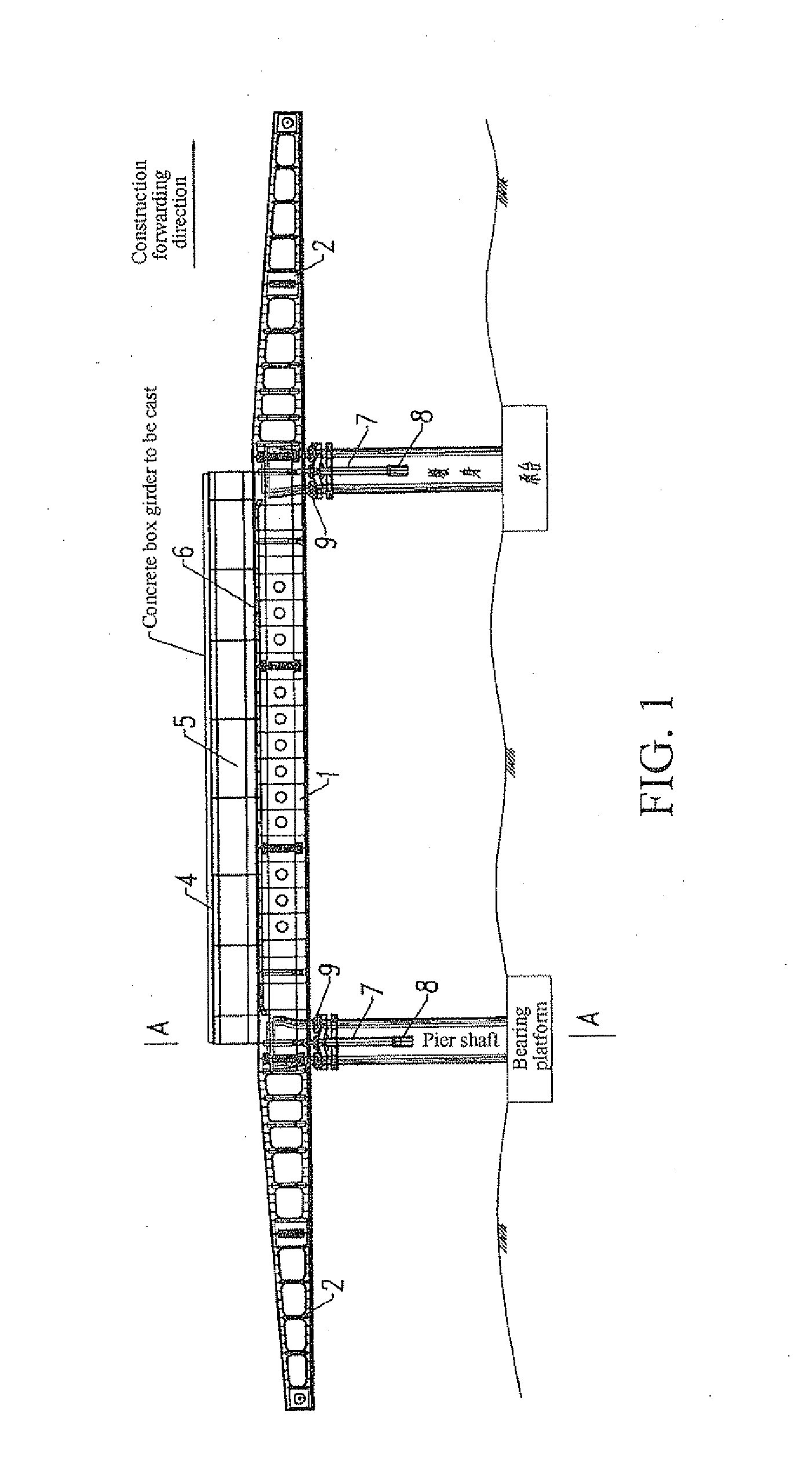

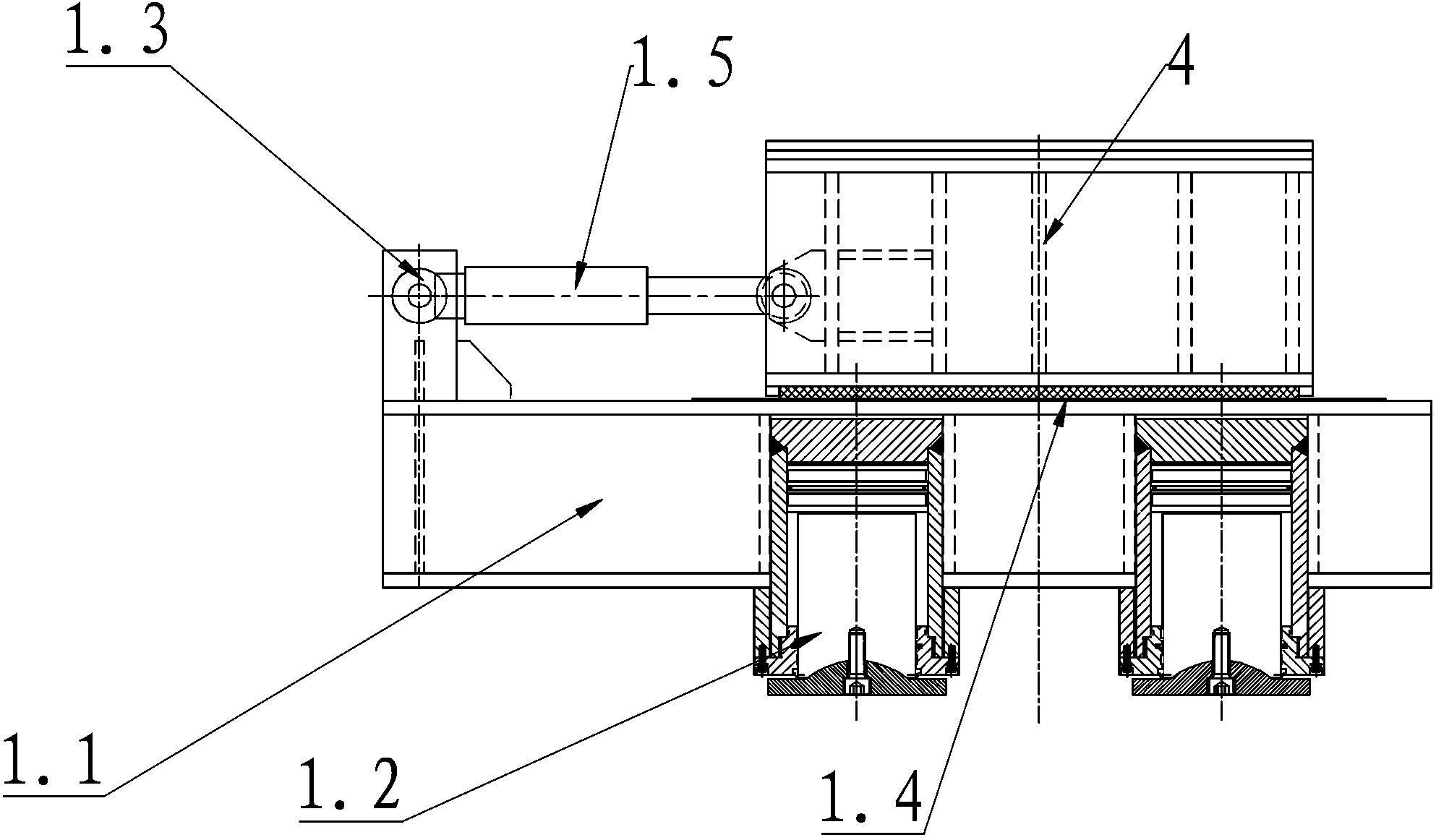

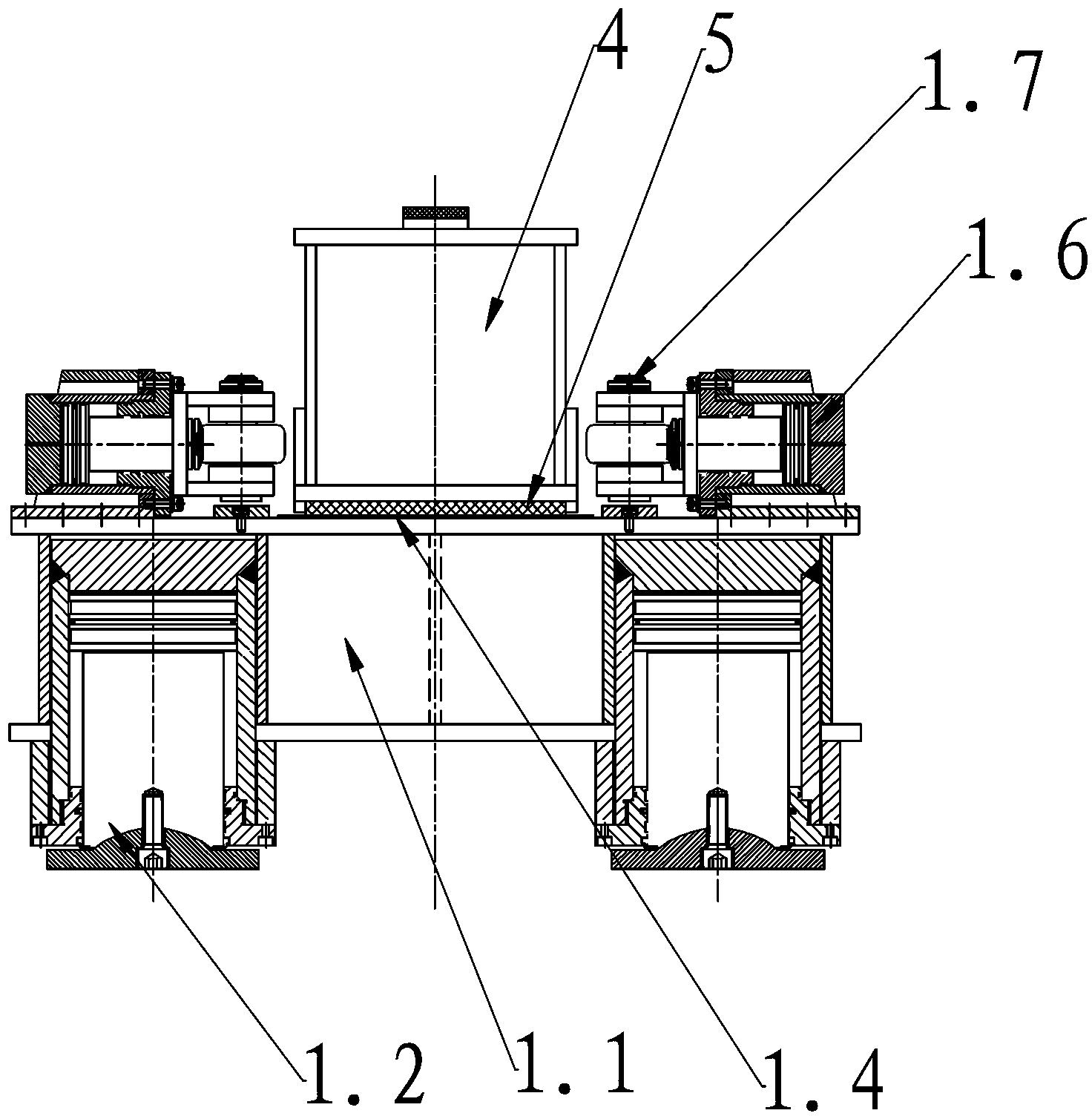

Walk-type continuous pushing system and construction method

InactiveCN103266566ARealize walking continuous pushingHigh speedBridge erection/assemblyBox girderWork time

The invention discloses a walk-type continuous pushing system and a construction method. The walk-type continuous pushing system comprises at least two sets of pushing equipment arranged along the same direction. The two sets of the pushing equipment are arranged between temporary piles used for temporarily supporting a to-be-mounted box girder. Each set of the pushing equipment comprises a supporting platform which is supported by vertical jacking oil cylinders arranged on the lower end face of the supporting platform. The upper end faces of the supporting platforms are connected with load bearing beams in a sliding mode. Horizontal pushing devices are arranged on the supporting platforms and the output ends of the horizontal pushing devices are connected with the load bearing beams. Through continuous working of the pushing equipment, lost work time of original vertical jacking oil cylinder return strokes and horizontal pushing oil cylinder return strokes is utilized to increase pushing speed and efficiency, so that walk-type continuous pushing of to-be-mounted bridges can be realized.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +1

Splitboard bindings

ActiveUS20090250906A1Easy to repositionImprove performanceCarriage/perambulator accessoriesSki bindingsEngineeringBox girder

Improved splitboard boot bindings for backcountry splitboarding are disclosed. Each of a pair of soft-boot bindings is provided with an integral boot binding lower that conjoins the two halves of a splitboard without the additional weight or height of an adaptor mounting plate, upper binding baseplate or “tray”, and extra fasteners of the prior art. The boot binding lower is formed as a modified sandwich box girder or modified monolithic box girder and provides improved torsional stiffness for splitboard riding. When subjected to a torque applied by the rider, the bottom mediolateral flanges of the box girders are configured to contactingly engage the top face of the splitboard, thereby dynamically coupling the rider's boot sole and the board via a single rigid structure. In a preferred embodiment, the web or “spacer” members are characterized by an aspect ratio or contour height that is varied from heel to toe.

Owner:SPARK R&D IP HLDG LLC

Steel box girder scattered-splicing sliding device and installation method

InactiveCN103669216AOvercoming many difficulties brought about by constructionAdaptableBridge erection/assemblyLarge sizeBox girder

The invention discloses a steel box girder scattered-splicing sliding device and an installation method and relates to the technical field of continuous steel box girder bridge construction. The steel box girder scattered-splicing sliding device and the installation method are high in adaptability, safe and reliable in construction and capable of saving large-size devices and improving the work efficiency. The device comprises a steel tube support (2), a bearing connecting beam (3) arranged at the top of the steel tube support and a sliding rail structure installed on the bearing connecting beam (3). The steel box girder scattered-splicing sliding installation method comprises the following steps that the support is erected, the sliding rail structure is installed, steel box girders are hoisted and welded in a spliced mode section by section in the hoisting position and slide to a designed position, the axes of the sectioned box girders are designed, elevation is adjusted, girth welding is conducted, and the girders are detached. The steel box girder scattered-splicing sliding device is high in adaptability, safe and reliable. The sparse sliding support is erected so that influence on the ground by construction can be reduced, foundation treatment and support usage can be reduced, the large-size devices can be omitted, the two sides of the hoisted position can be constructed at the same time, and the work efficiency of large-size hoisting devices can be improved.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Method for mounting trestle bridge segment box girder

InactiveCN101158145AIncrease lateral stiffnessImprove lateral stabilityBridge erection/assemblyStructural engineeringRoad traffic

The invention relates to an installation method of a viaduct segment box girder, which is characterized in that a mobile crane is adopted, the box girder segment of a front span is vertically lifted in the front of a front bridge pier; a vertically moving cart and a hoister are adopted and move vertically; and a horizontal moving device is adopted to conduct horizontal contraposition adjustment. The invention occupies relatively little traffic rode space and basically does not occupy the space in the two sides of the viaduct.

Owner:CHINA FIRST METALLURGICAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com