Cast-in-place prestressed concrete continuous box girder one-time pouring and forming construction method

A concrete and prestressed technology, which is applied in the field of cast-in-place prestressed concrete continuous box girder one-time pouring and forming construction, can solve the problems of large safety hazards in the construction process, high cost of building platforms, and low construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

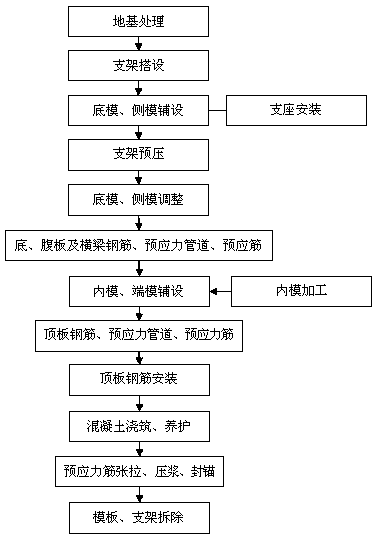

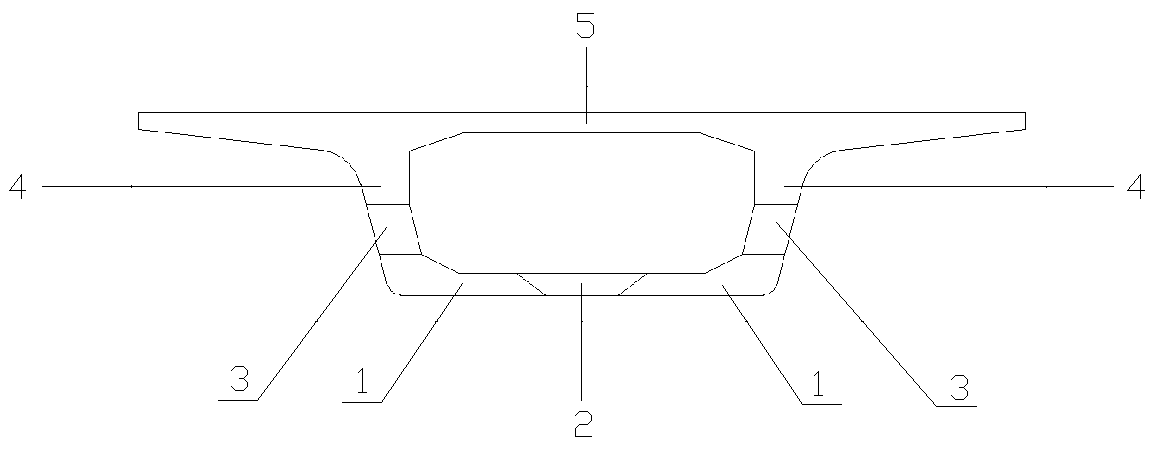

[0073] like Figure 1-2 As shown, the cast-in-situ prestressed concrete continuous box girder of the present invention is one-time pouring and forming construction method, comprising foundation treatment, bracket erection, base form, side form laying, support preloading, base form, side form adjustment, bottom, web plate And beam reinforcement, prestressed pipes, prestressed tendons, inner formwork, end formwork laying, roof reinforcement, prestressed pipes, prestressed tendons, roof reinforcement installation, concrete pouring, maintenance, prestressed tendon tensioning, grouting, anchor sealing , template, support removal, specifically include the following steps:

[0074] 1) Foundation treatment

[0075] For the support foundation, select an area with relatively flat terrain and landform conditions. If the bearing capacity of the foundation within the scope of the support foundation cannot meet the requirements of the design plan, foundation treatment must be carried out s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com