Patents

Literature

88 results about "Support removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

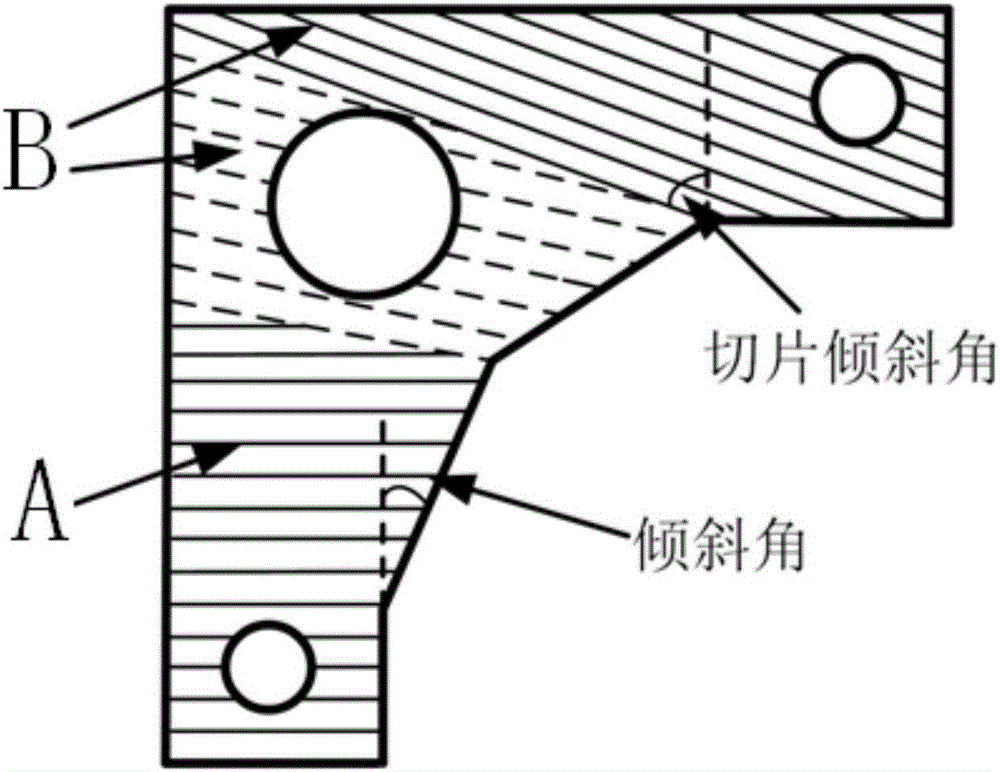

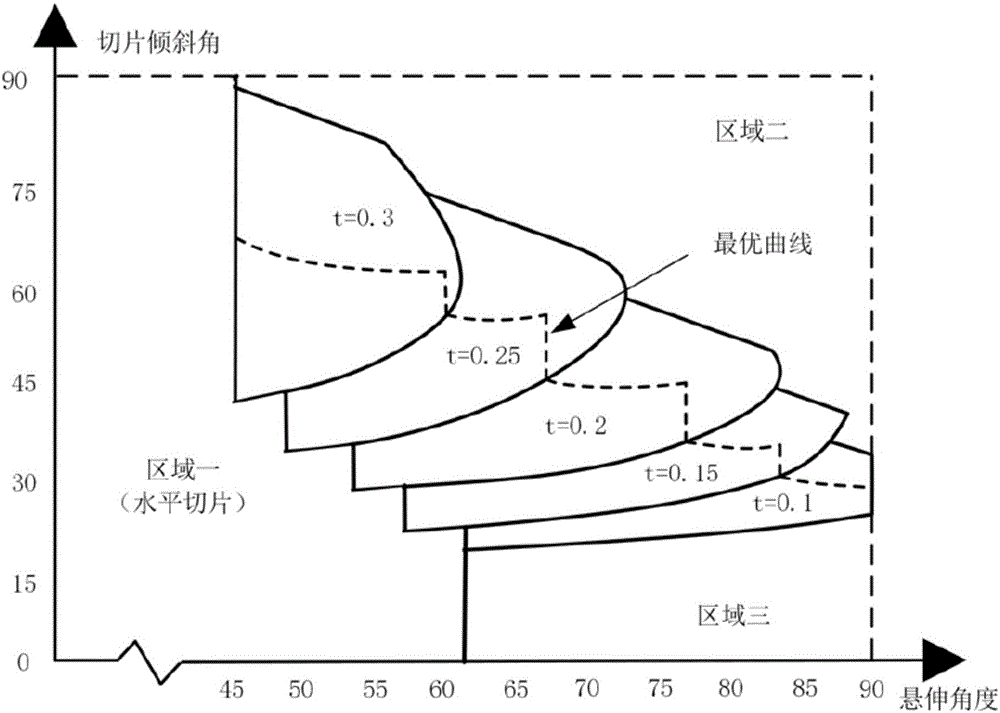

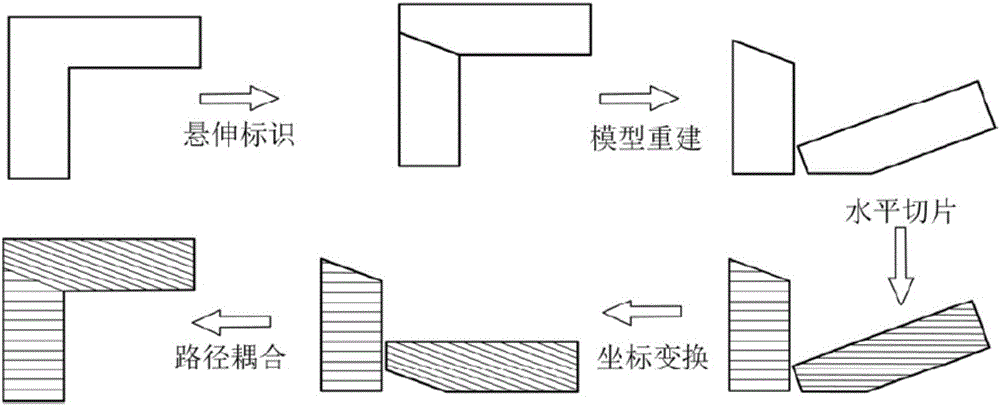

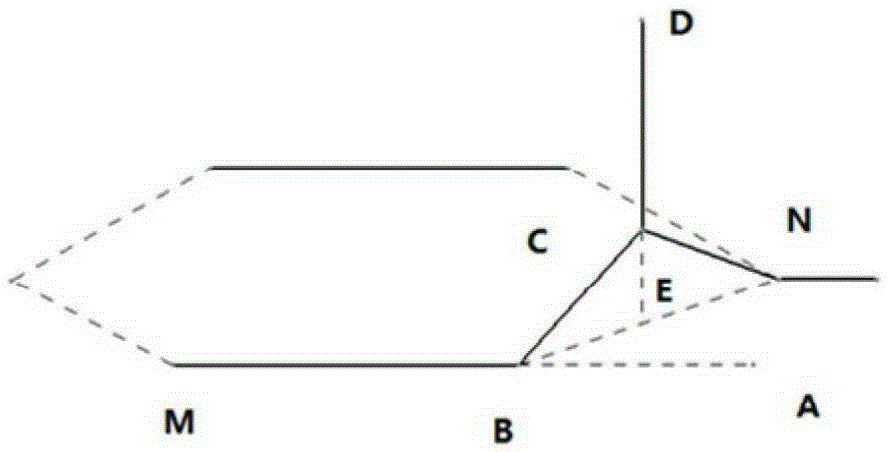

Non-support three-dimensional printing method based on inclined layering

ActiveCN105904729ASave printing raw materialsImprove printing efficiencyAdditive manufacturing apparatusSupport removalCoupling

The invention discloses a non-support three-dimensional printing method based on inclined layering. The method comprises five steps of model surface overhanging area identification, model reestablishment, horizontal slicing, motion code coordinate transformation, and path coupling; a path includes two parts: a horizontal layered path and an inclined layered path. A path track inclined relative to a horizontal plane is formed at an overhanging part; when the region is printed, a new layer of material can be guaranteed to be not only suffered from gravity but also is suffered from an adhesive force in a deposition process due to the presence of a formed printing layer on an upper layer. An additional supporting material is omitted, a printing raw material is saved, the printing efficiency is improved, and a process of subsequent support removal is omitted. The inclined layered three-dimensional printing path provided by the invention has a common code format, can be directly applied in commercial and open-source desktop type three-dimensional printers, has extensive application prospects, and can be extended to the three-dimensional printing technology in biology, chemical engineering, macromolecule and food industries.

Owner:ZHEJIANG UNIV

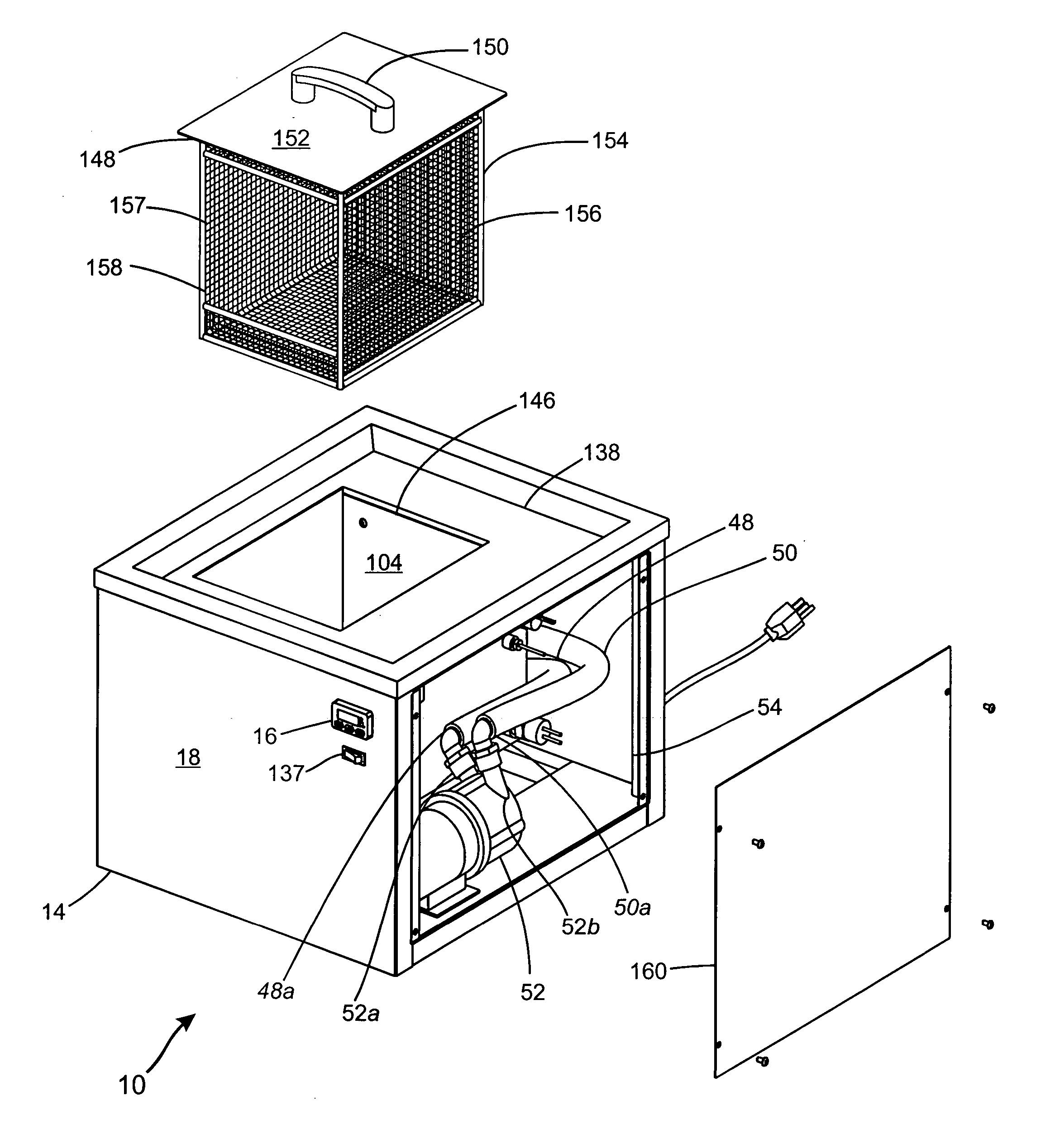

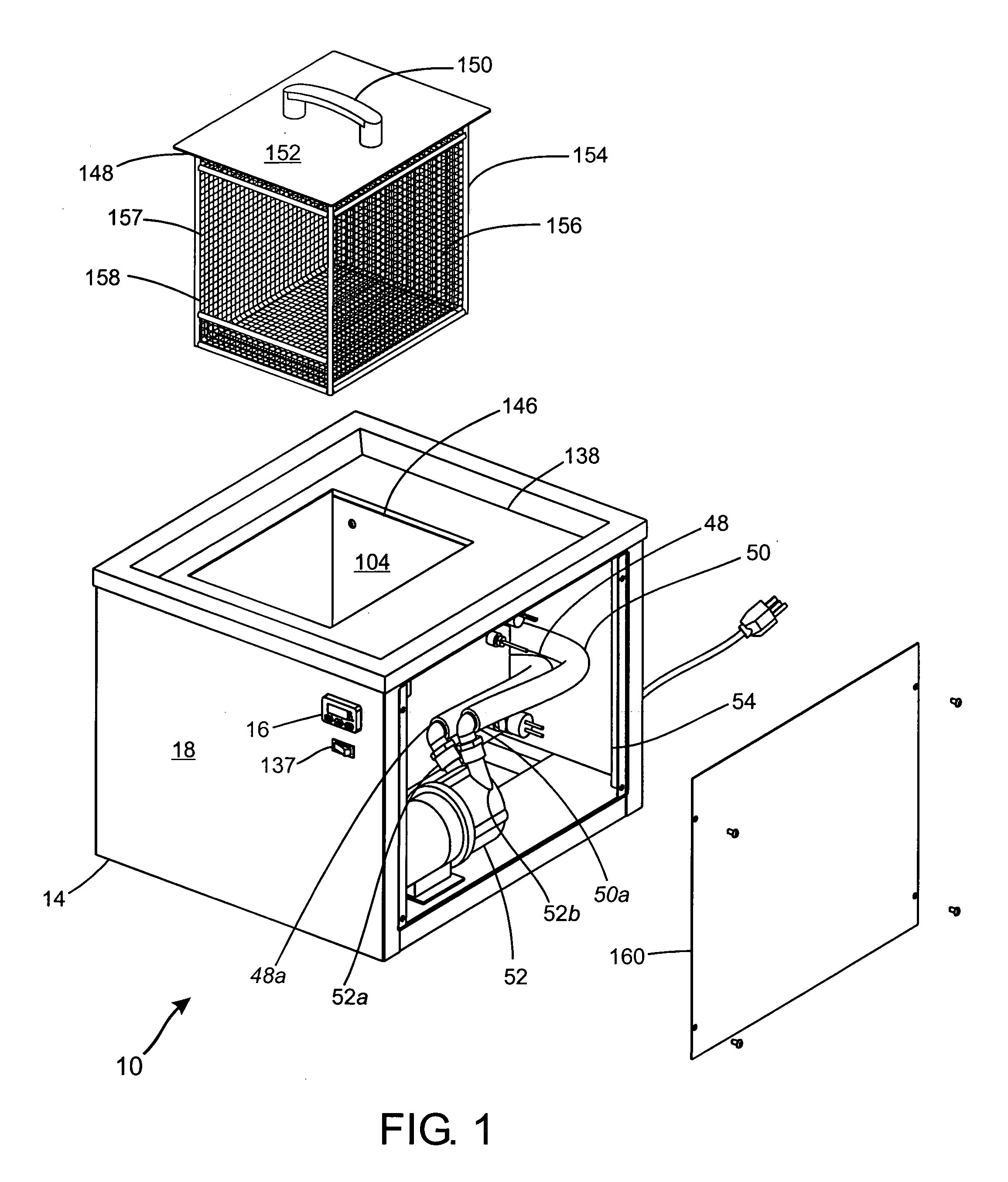

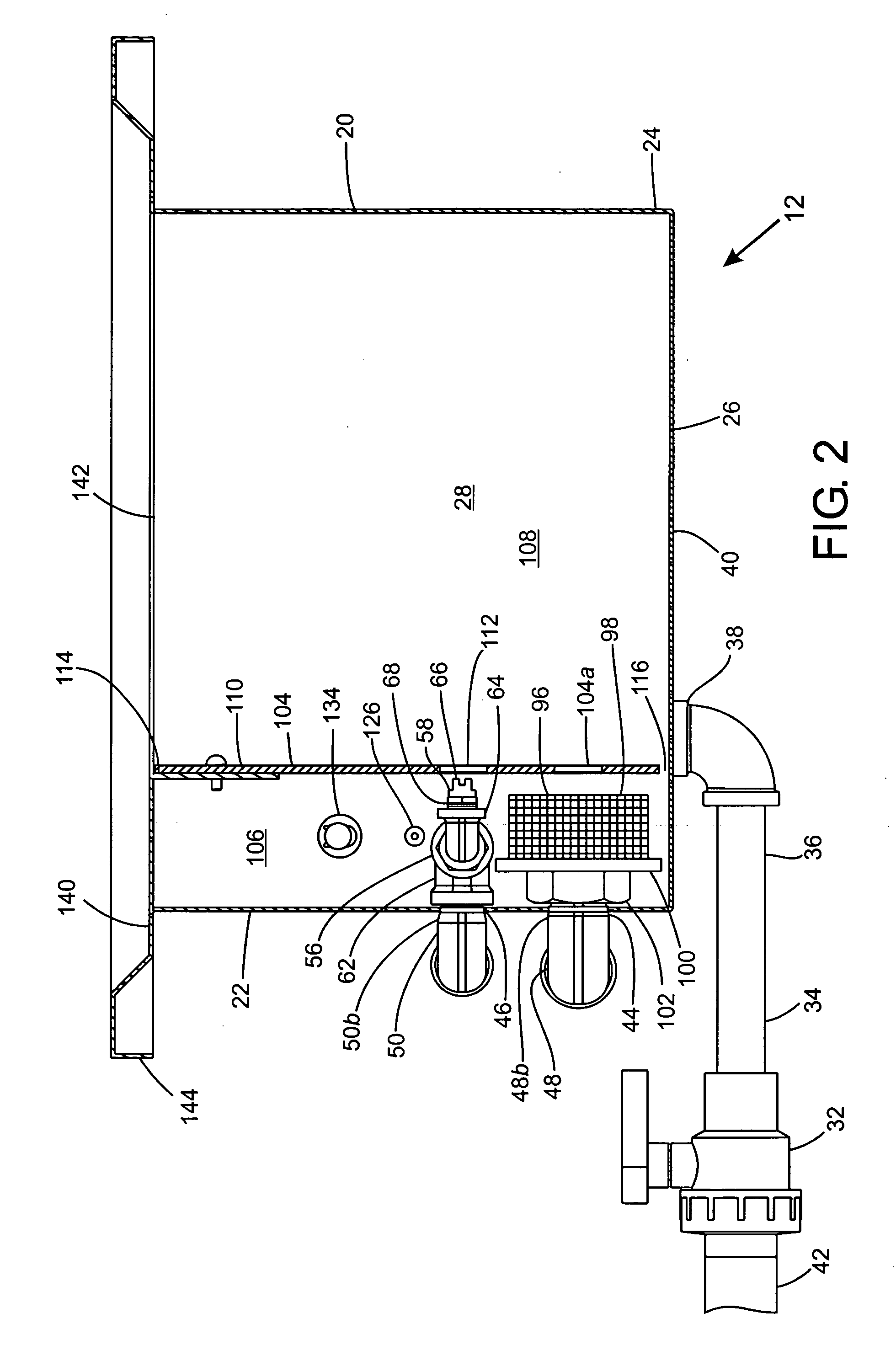

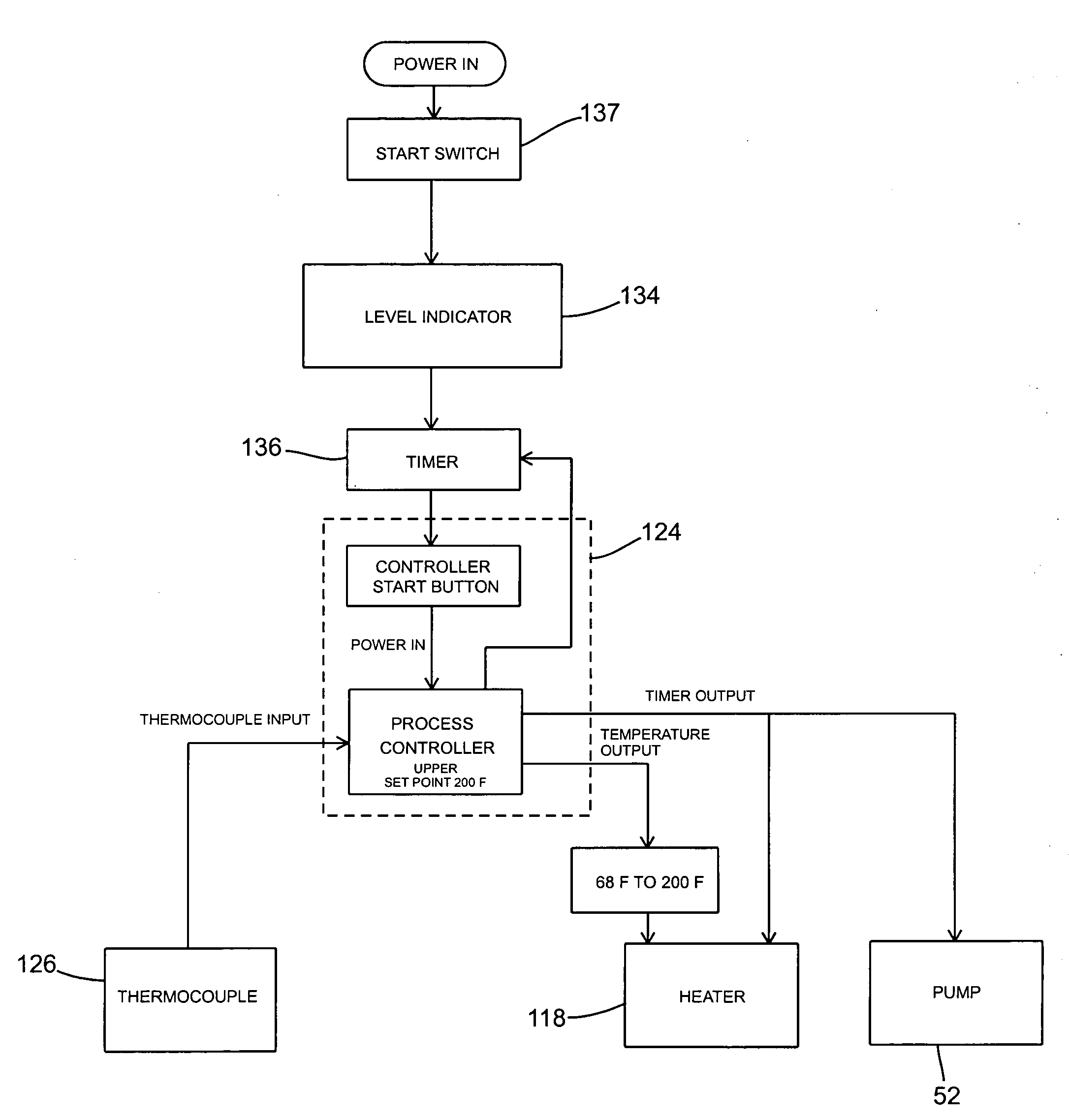

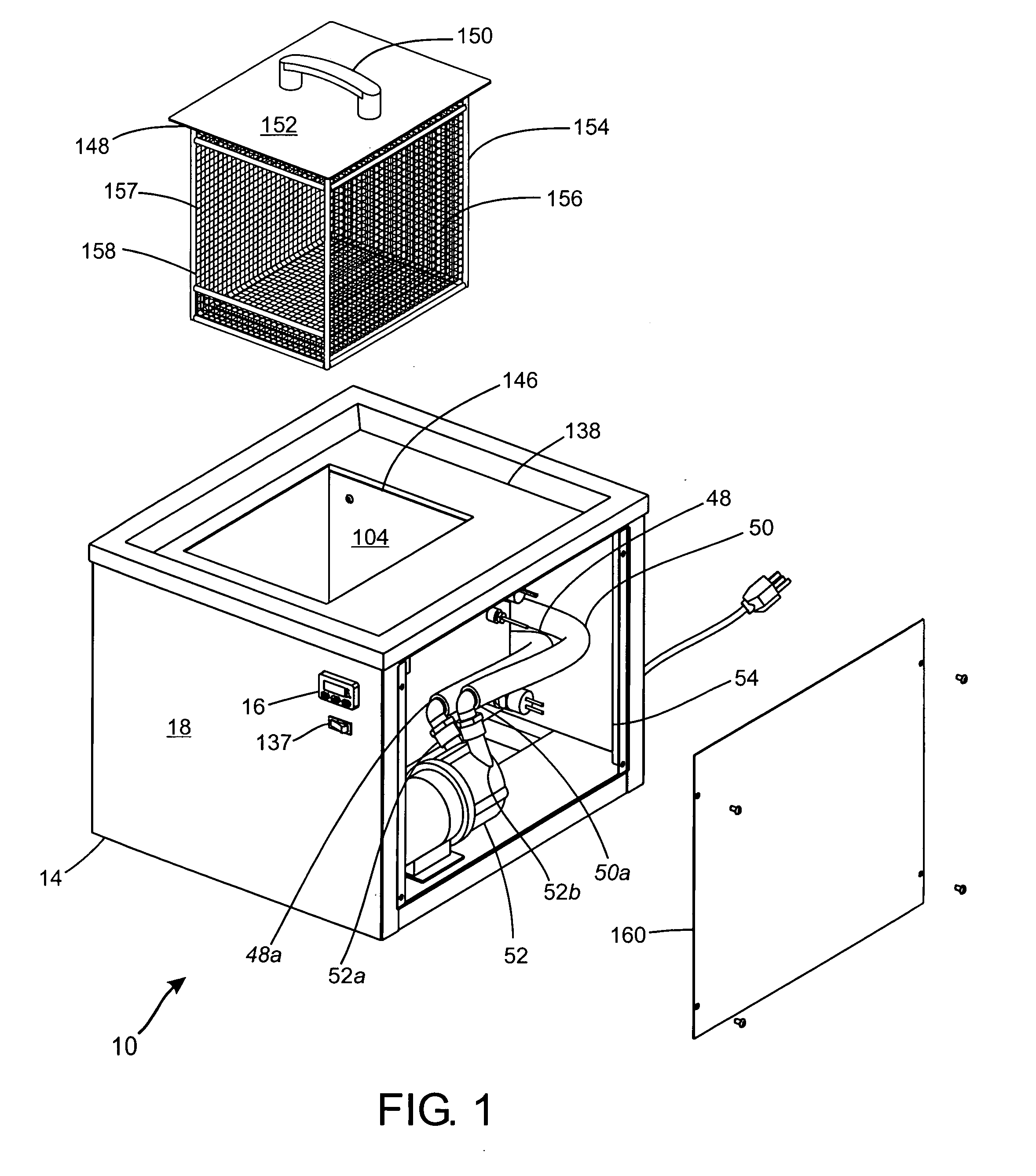

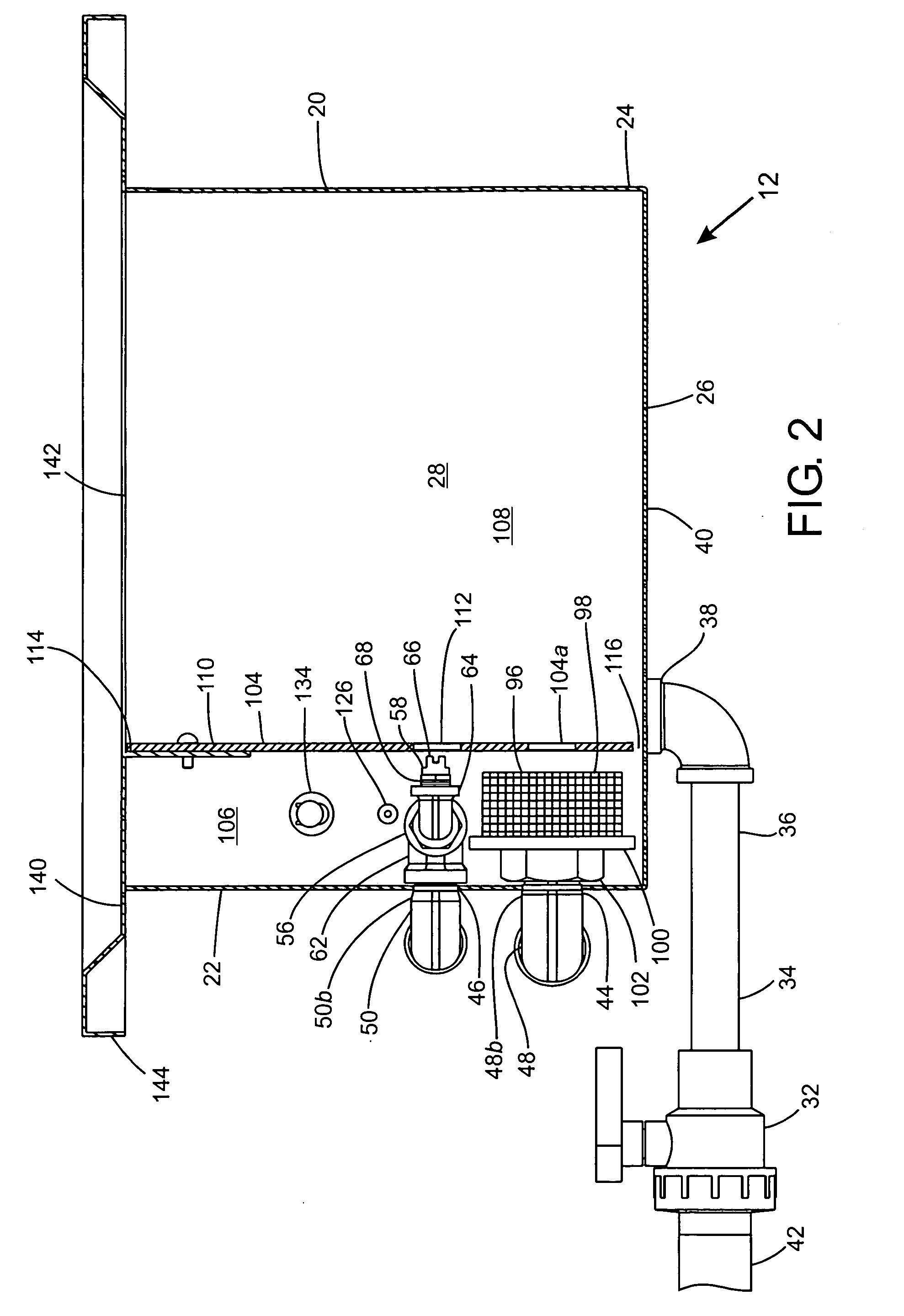

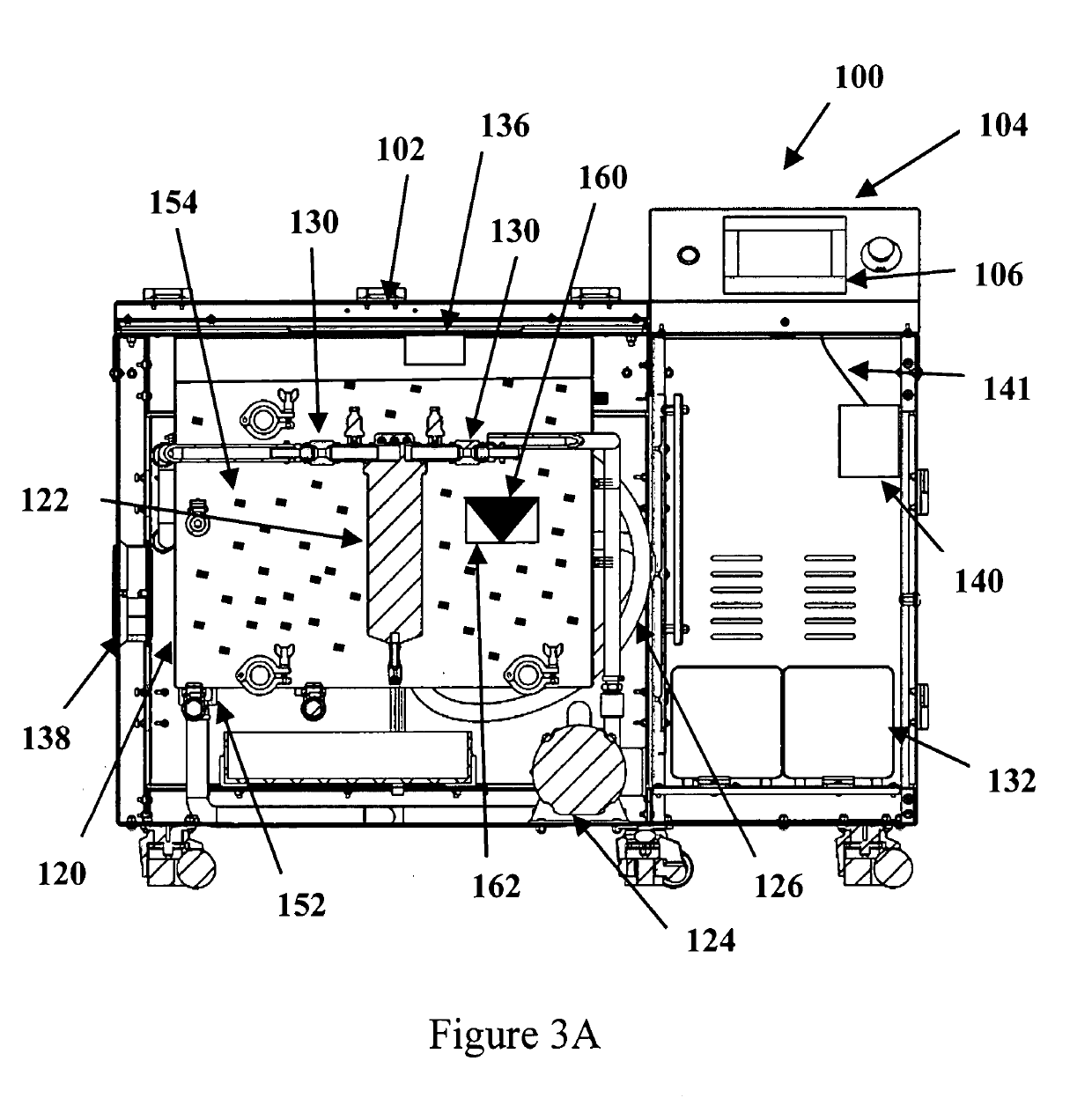

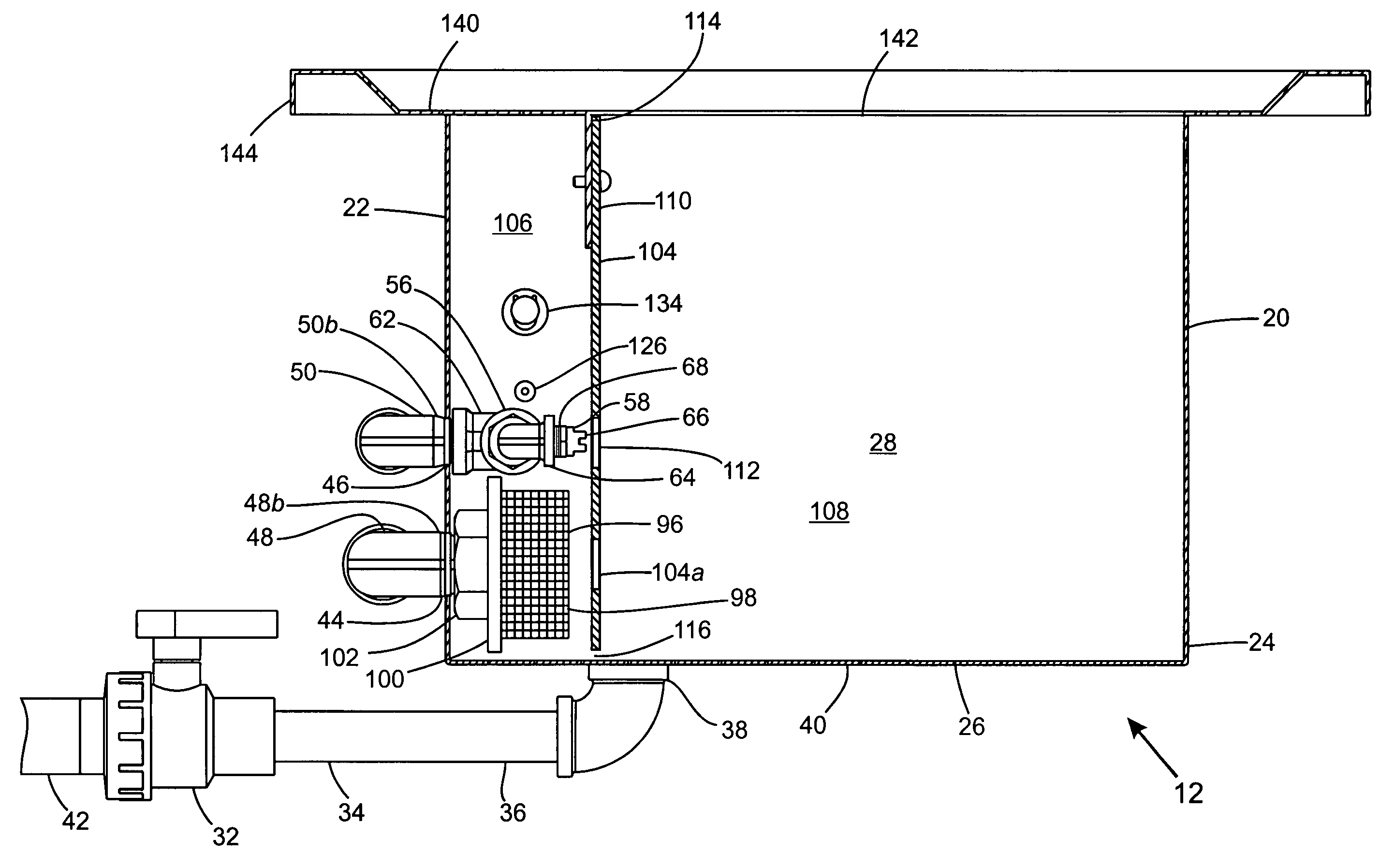

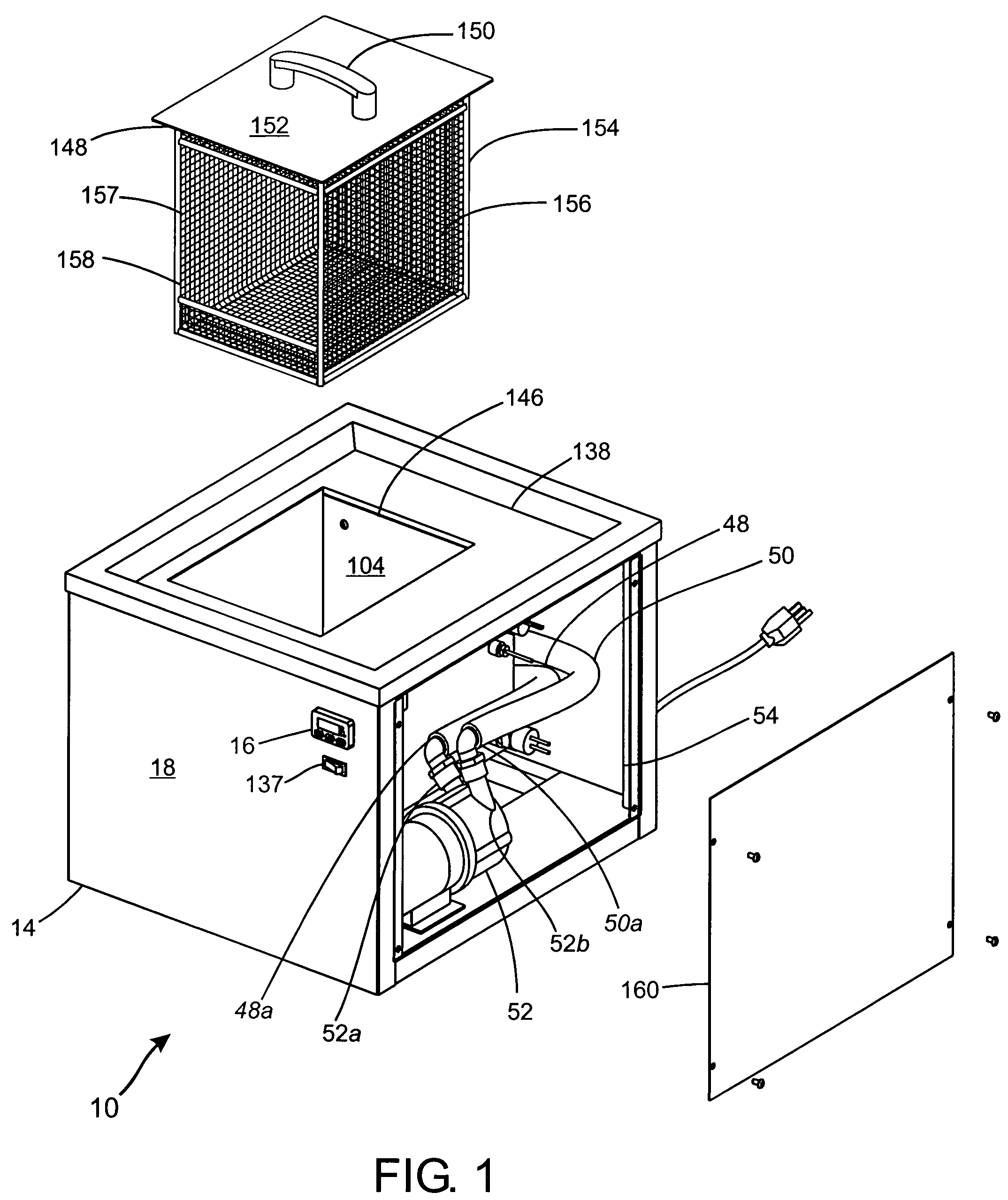

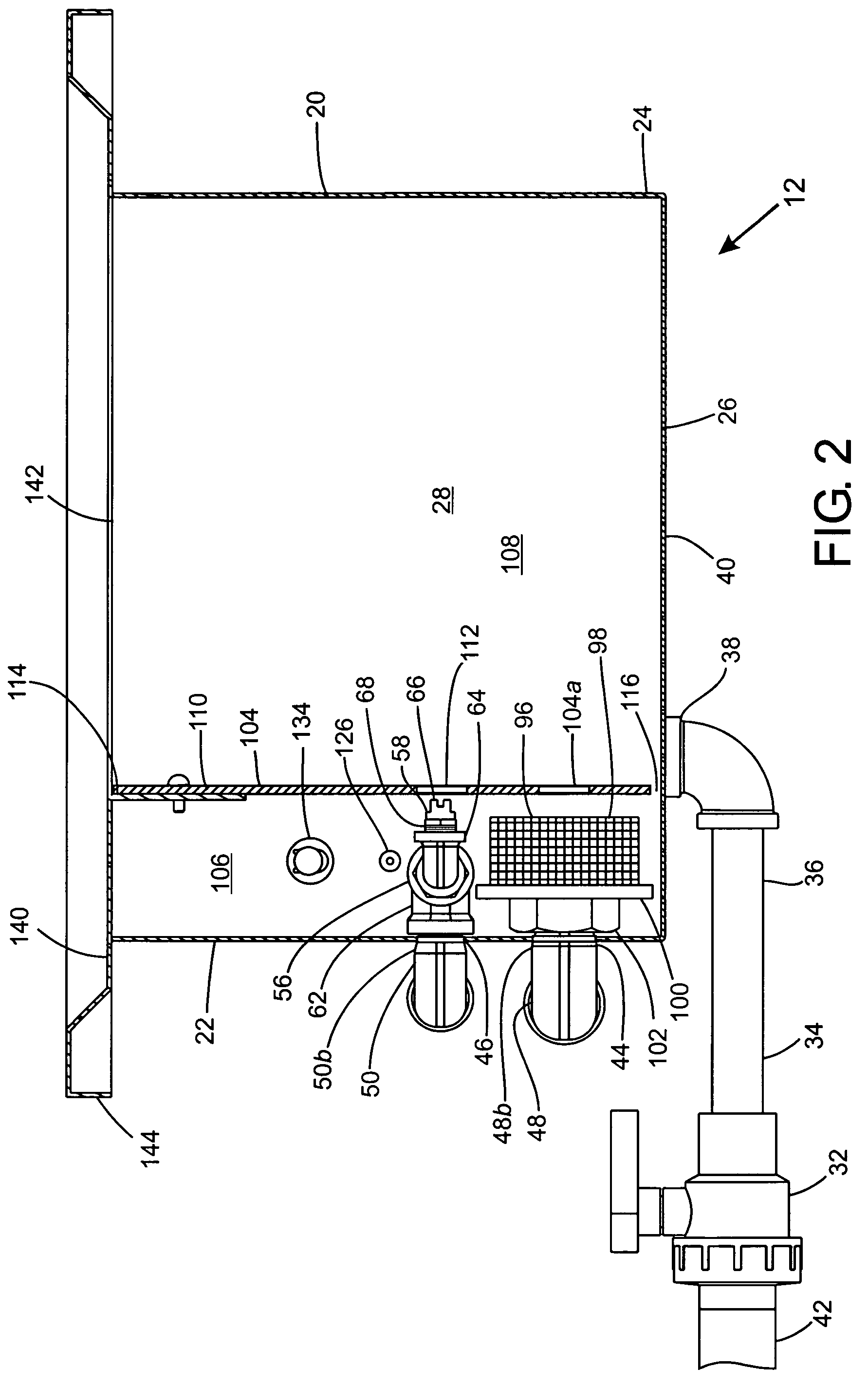

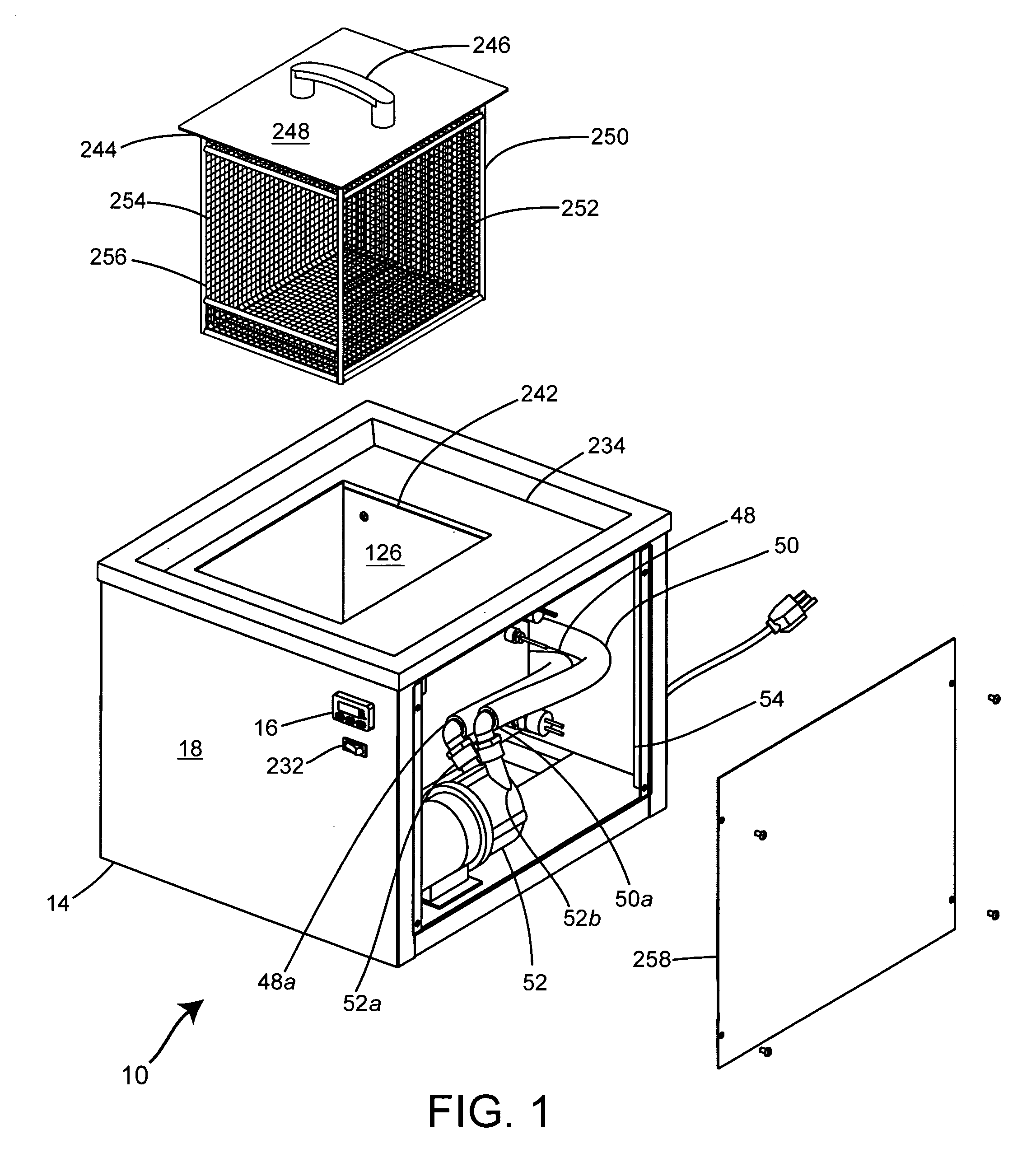

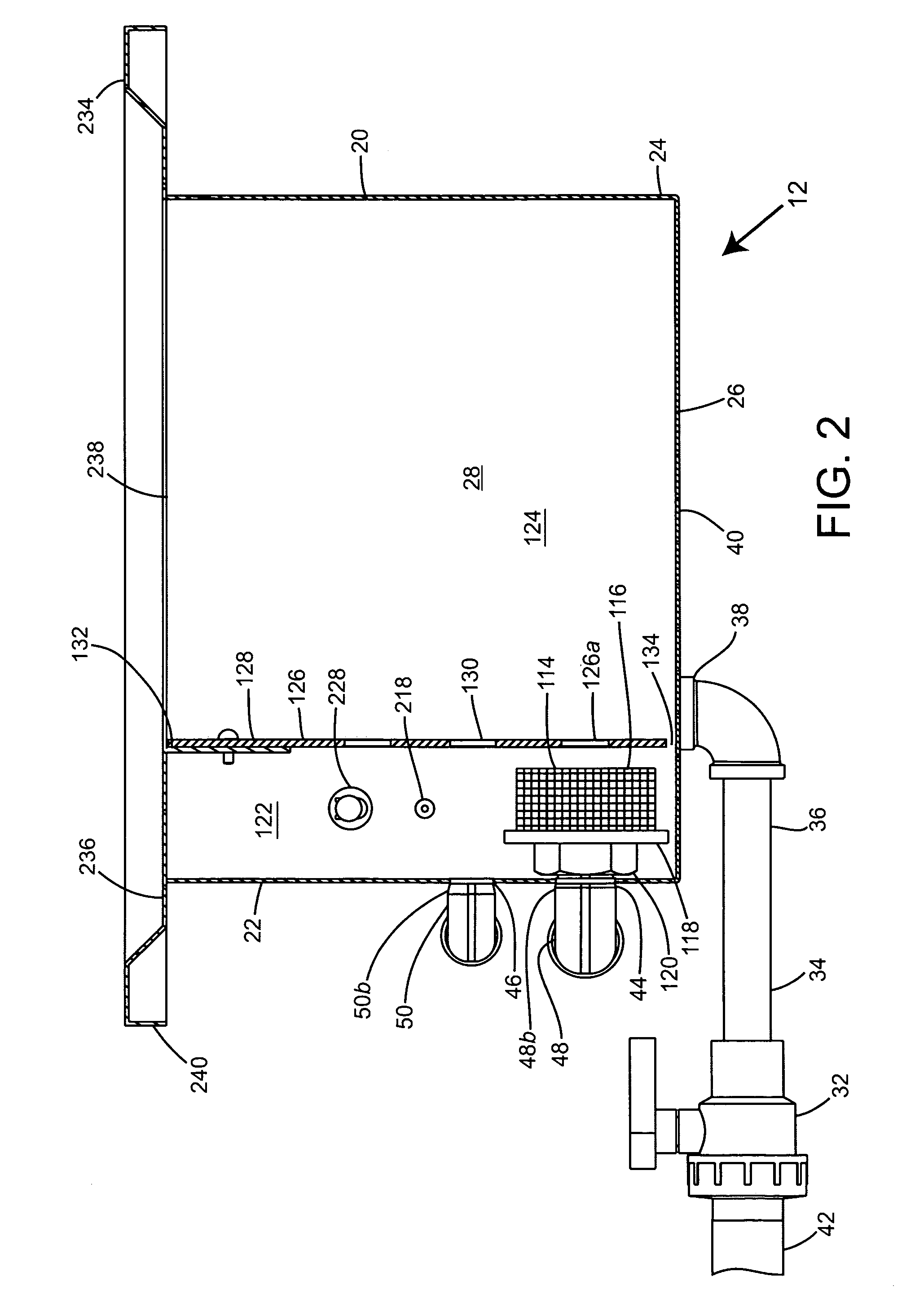

Apparatus and method of removing water soluble support material from a rapid prototype part

ActiveUS20050103360A1Low costEasy to useAdditive manufacturing apparatusHollow article cleaningSupport removalPotassium hydroxide

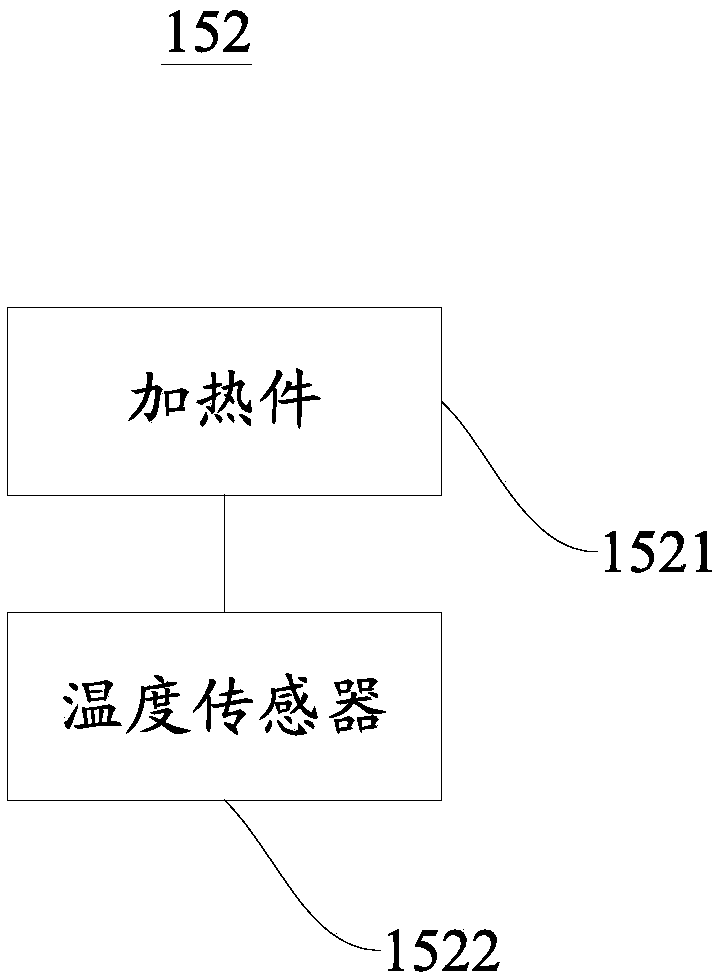

The support removal apparatus comprising in combination a retention tank having a manifold assembly comprising a plurality of nozzle heads in hydraulic communication with the discharge side of a pump, collectively configured for agitating an aqueous cleaning solution comprised of sodium or potassium hydroxide, sodium or potassium carbonate, and water; a heating element mounted within the retention tank for heating the aqueous cleaning solution to a predetermined temperature set point; a basket strainer mounted within the retention tank in hydraulic communication with the intake side of the pump to mitigate passage of small rapid prototype parts and residual support material therethrough and into the pump and manifold assembly; a work surface mounted atop the retention tank and having a movable lid fitted with a basket for containing small rapid prototype parts; a thermocouple for maintaining the temperature within a tolerable range for optimum removal of support material; a level indicator to ensure adequate solution level in the retention tank for operability of the pump and heating element; a cabinet having interface controller mounted on an exterior panel thereof for setting timer and heat functions; and a microprocessor having capabilities for making minute adjustments to the heating element via feedback from the thermocouple and controlling operation of the pump and heating element for a pre-set time interval.

Owner:TAFOYA DAVID JONATHAN

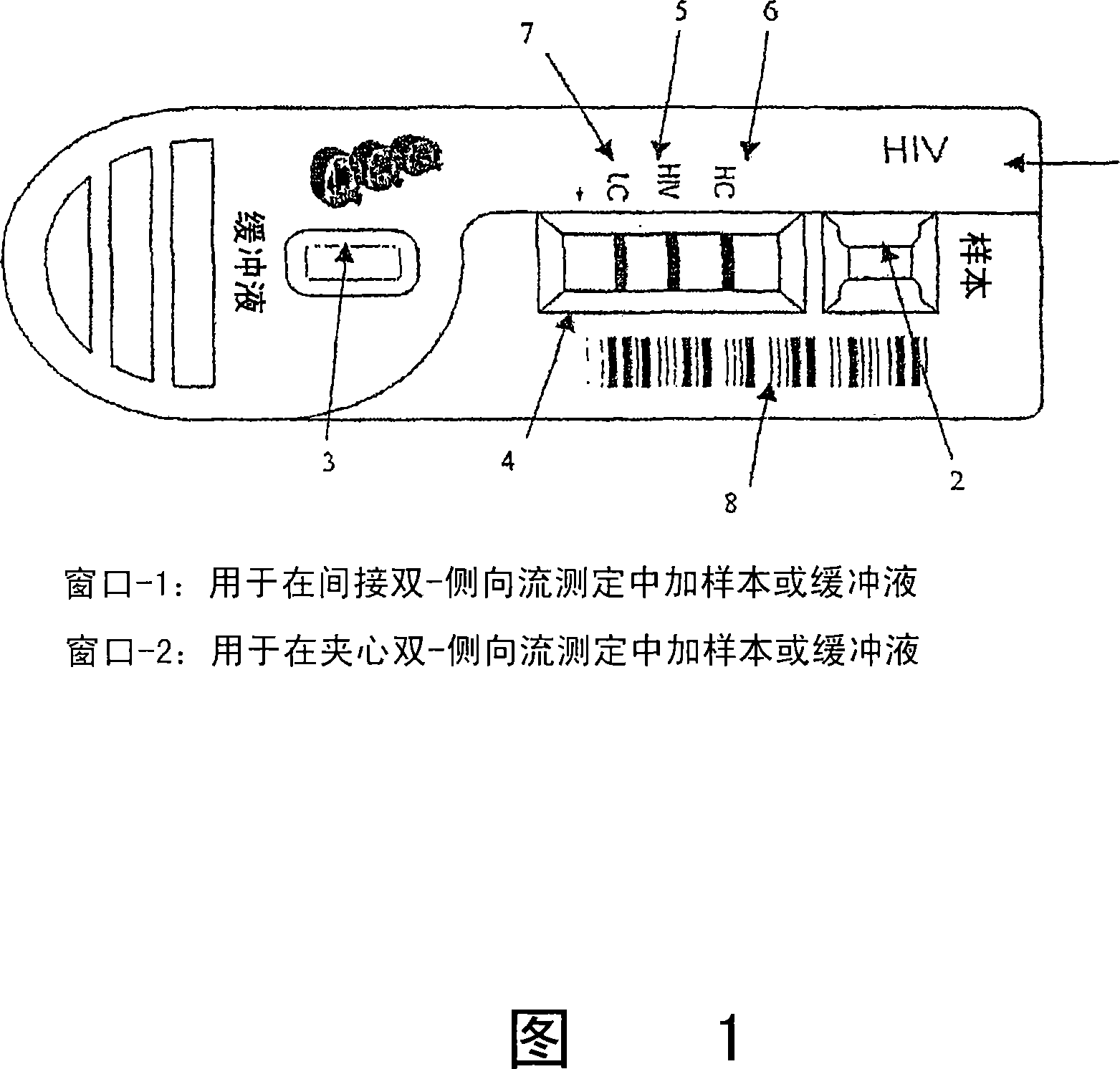

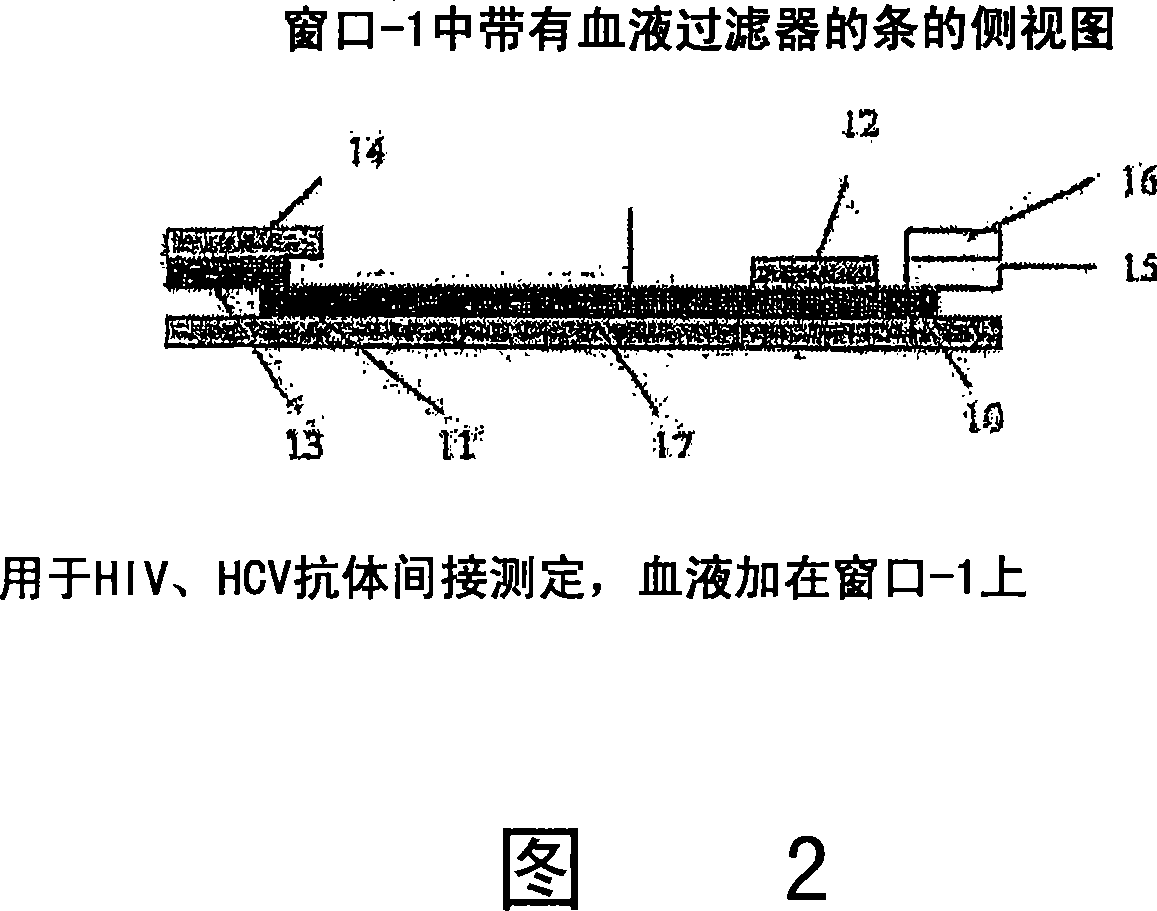

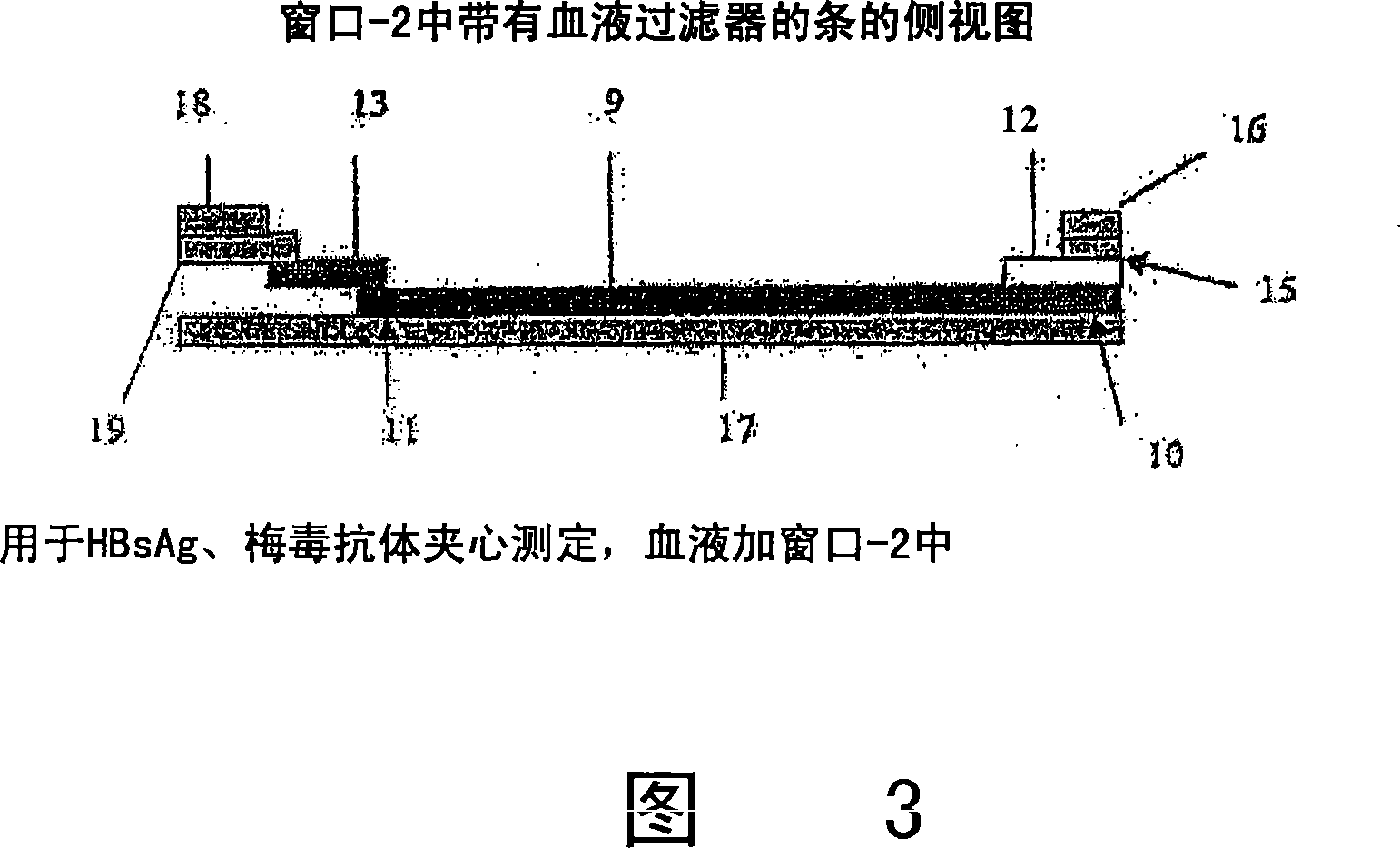

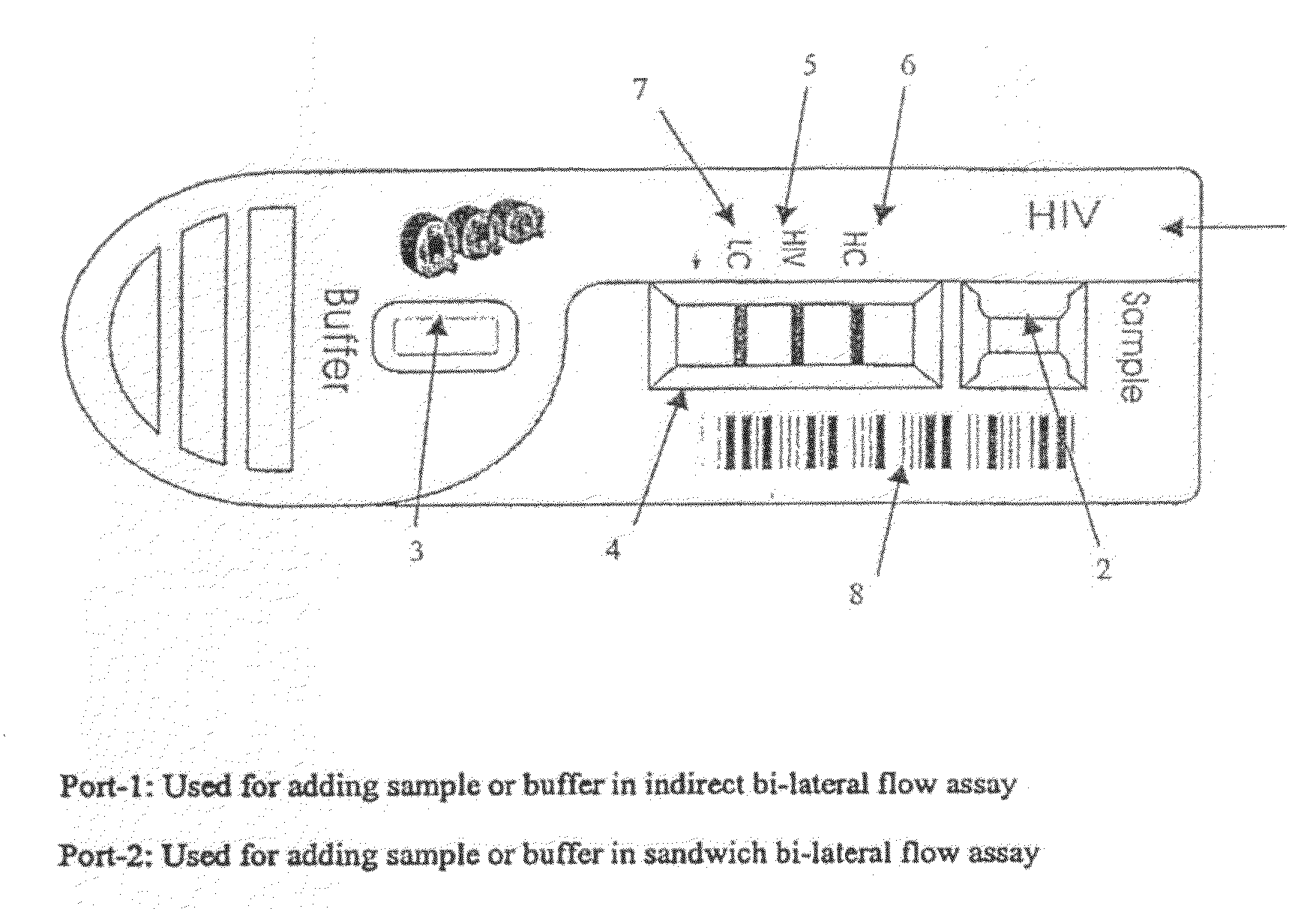

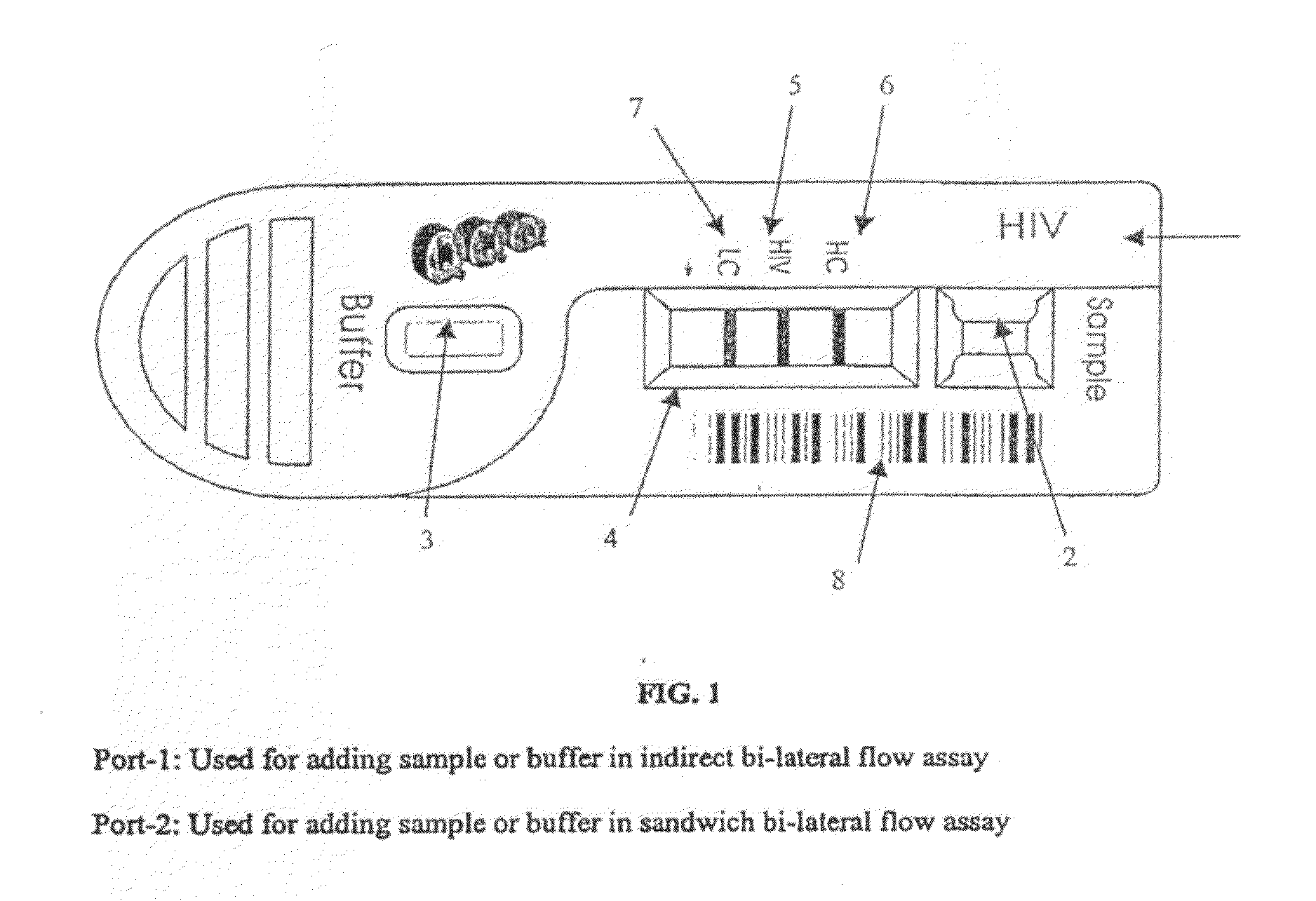

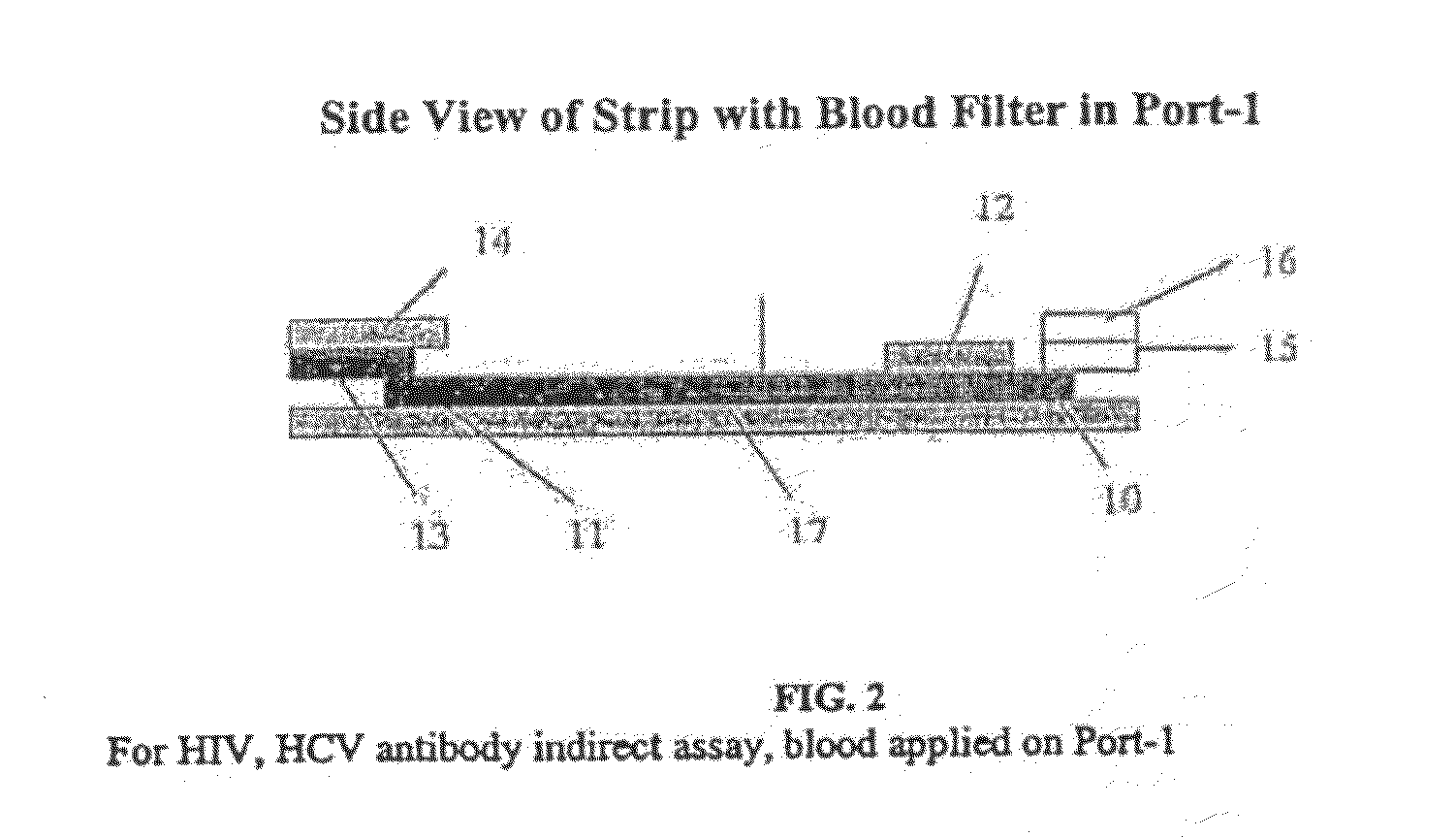

Quantitative lateral flow system and assay

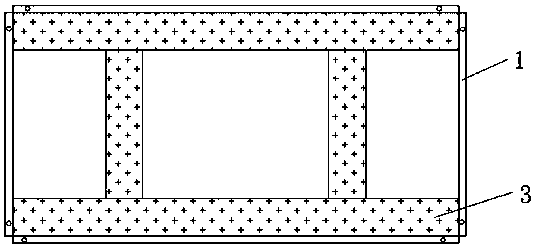

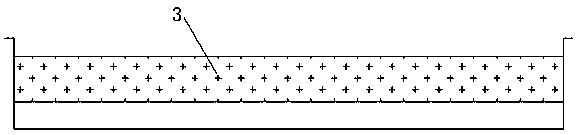

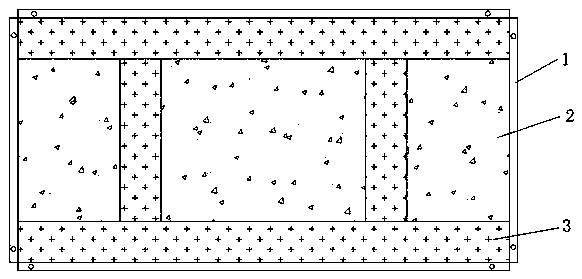

The present invention relates to a lateral flow assay and system, including a test strip, for detection and quantification of analytes in samples, such as samples containing cells and fluid, where the assay is volume independent, and the sample size is less than about 100 l, where the test strip includes a first membrane such as a sample filter, that is in capillary contact with an optional second membrane, such as a fluid collector, the second membrane, if present is in capillary contact with an optional third membrane, such as a conjugate pad containing a mobilizable detectable agent, or with a fourth membrane, which is a chromatographic strip, which optionally contains a mobilizable detectable agent, all such membranes being in fluid contact with a fifth membrane, such as a buffer pad, a sixth membrane, such as an absorbent pad, optionally a seventh membrane, which is also an absorbent pad, a capture band for capturing the analyte and at least one control band, or alternatively, the chromatographic strip contains the mobilizable detectable agent in place of a conjugate pad, where the test strip is configured to support removal of red blood cells from the sample and to allow uni-directional or bi-directional fluid flow of fluid from the sample filter to the capture band to be retained therein and detected thereon.The present invention relates to a lateral flow assay and system, including a test strip, for detection and quantification of analytes in samples, where the assay is volume independent, and the sample size is less than about 100 l, where the test strip includes a first membrane (12, 18) that is in capillary contact with an optional second membrane, the second membrane (9), if present is in capillary contact with an optional third membrane (13), containing a mobilizable detectable agent, or with a fourth membrane (9), all such membranes being in fluid contact with a fifth membrane (14), a sixth membrane (15).

Owner:RELIA BIOTECH SHENZHEN LTD

Method for rapidly removing 3D printing support

ActiveCN106738874ADoes not affect surface qualityReduce dosageAdditive manufacturing apparatus3D object support structuresSupport removalEngineering

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Quantitative lateral flow system and assay

InactiveUS20100099112A1Effective dissolutionImprove filtering effectBioreactor/fermenter combinationsBiological substance pretreatmentsSupport removalAnalyte

The present invention relates to a lateral flow assay and system, including a test strip, for detection and quantification of analytes in samples, such as samples containing cells and fluid, where the assay is volume independent, and the sample size is less than about 100 μl, where the test strip includes a first membrane such as a sample filter, that is in capillary contact with an optional second membrane, such as a fluid collector, the second membrane, if present is in capillary contact with an optional third membrane, such as a conjugate pad containing a mobilizable detectable agent, or with a fourth membrane, which is a chromatographic strip, which optionally contains a mobilizable detectable agent, all such membranes being in fluid contact with a fifth membrane, such as a buffer pad, a sixth membrane, such as an absorbent pad, optionally a seventh membrane, which is also an absorbent pad, a capture band for capturing the analyte and at least one control band, or alternatively, the chromatographic strip contains the mobilizable detectable agent in place of a conjugate pad, where the test strip is configured to support removal of red blood cells from the sample and to allow uni-directional or bi-directional fluid flow of fluid from the sample filter to the capture band to be retained therein and detected thereon.

Owner:RELIA DIAGNOSTIC SYST

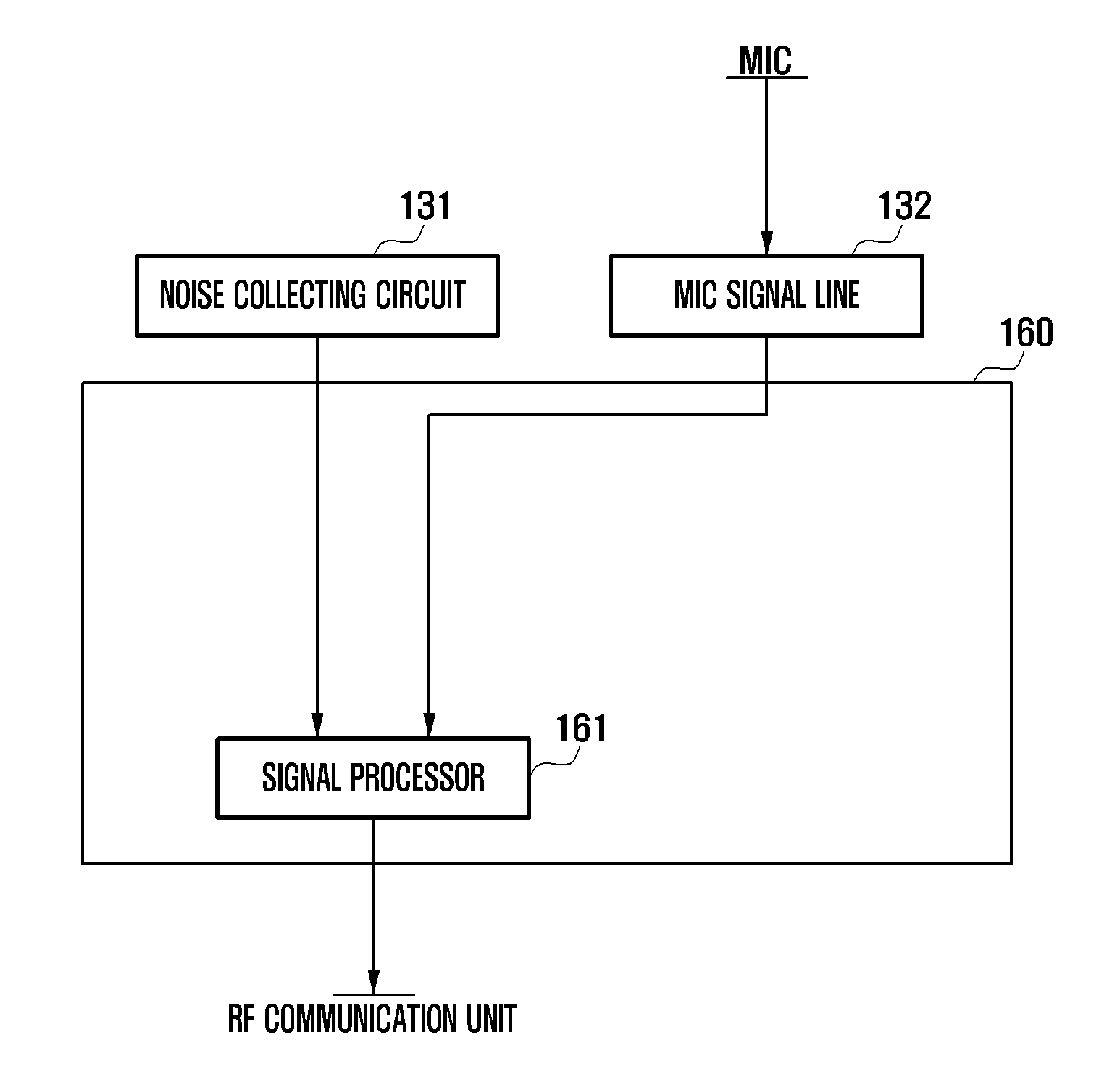

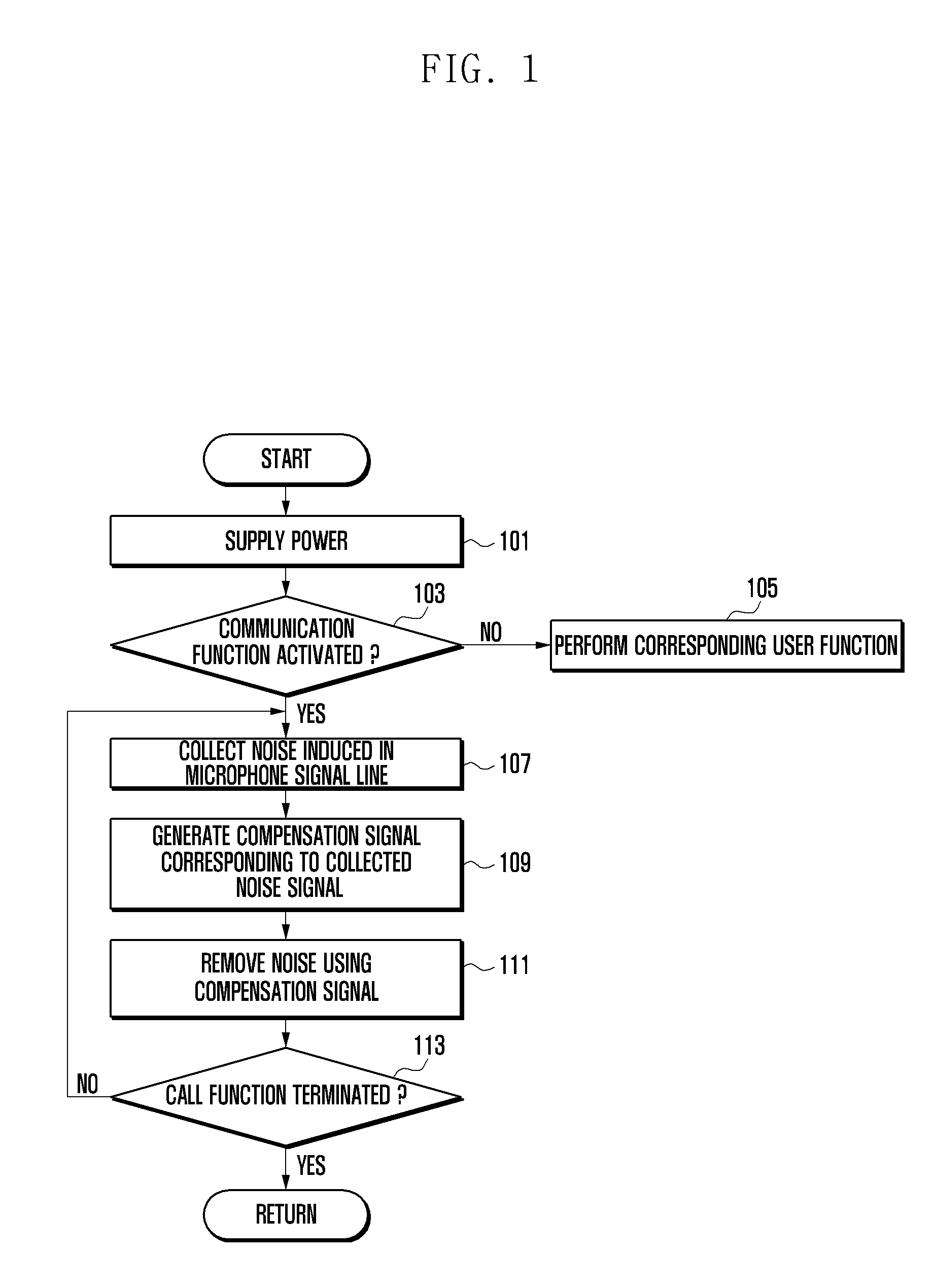

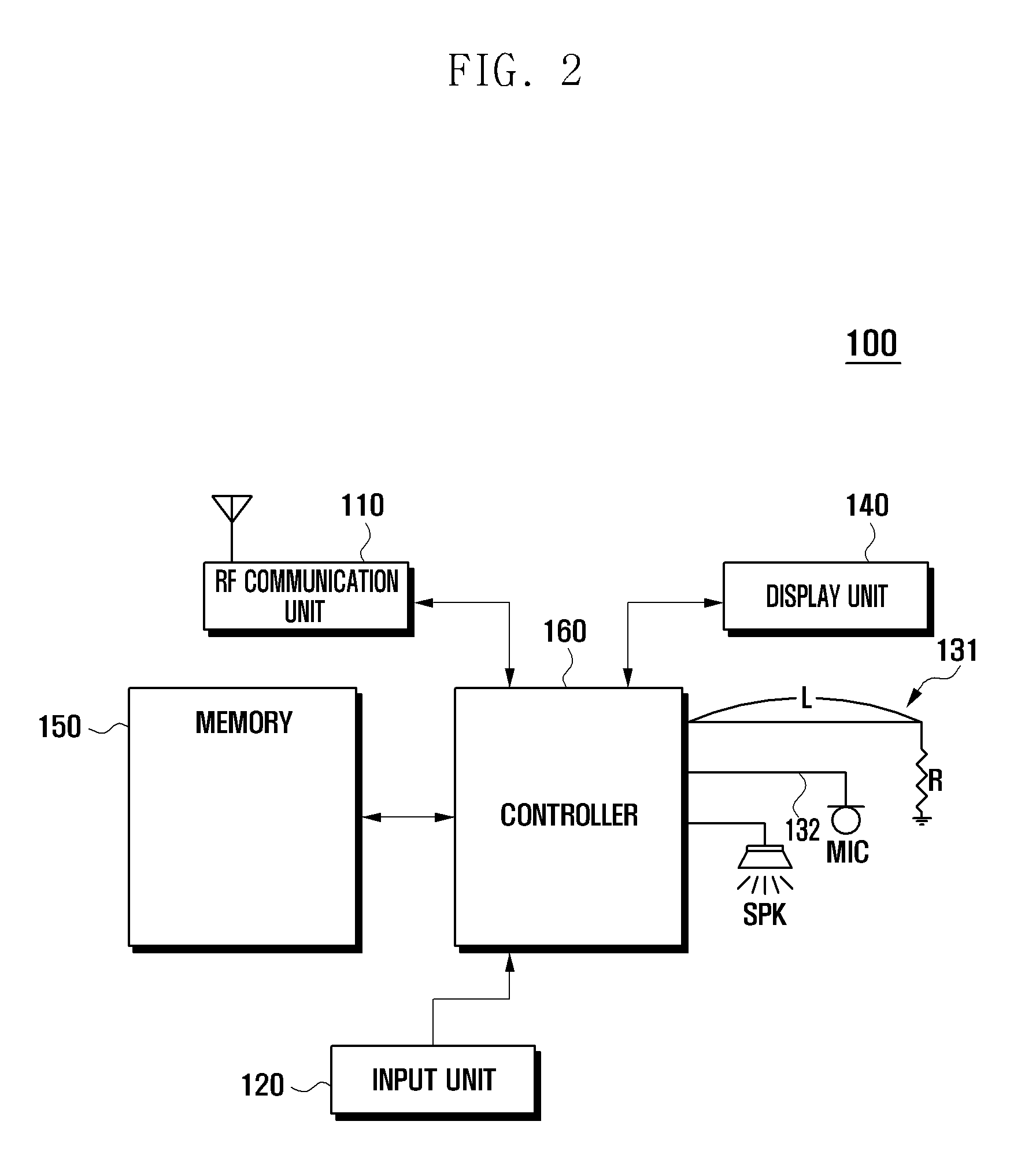

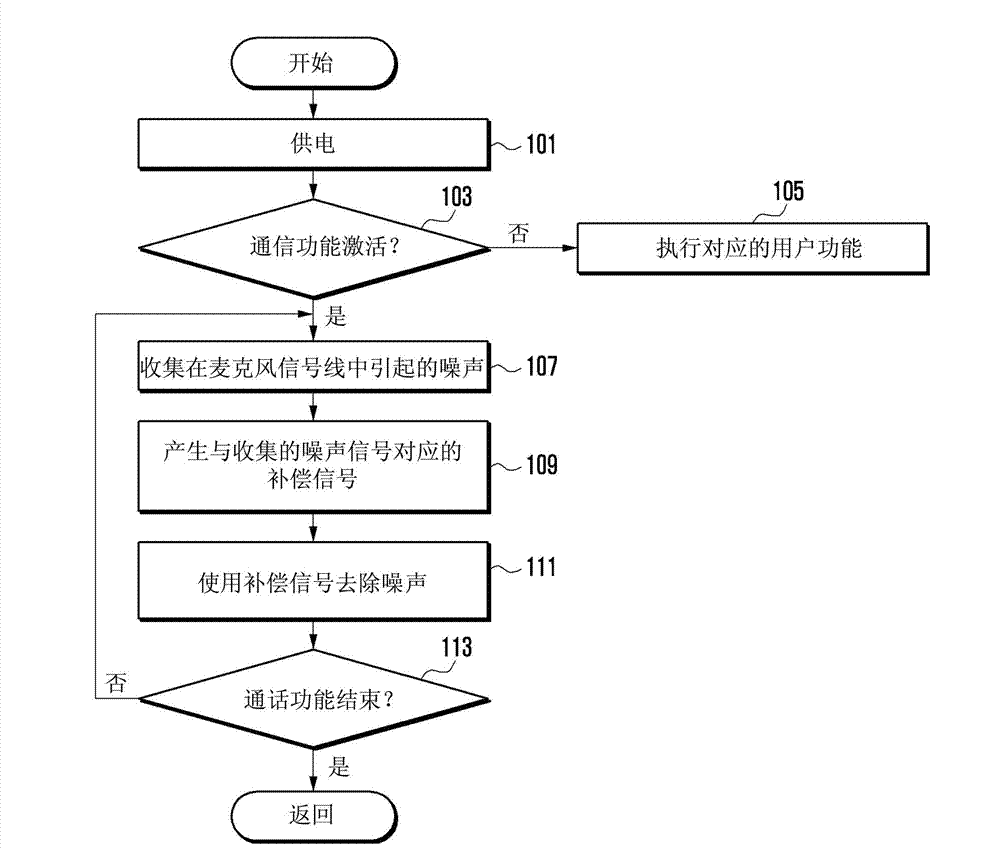

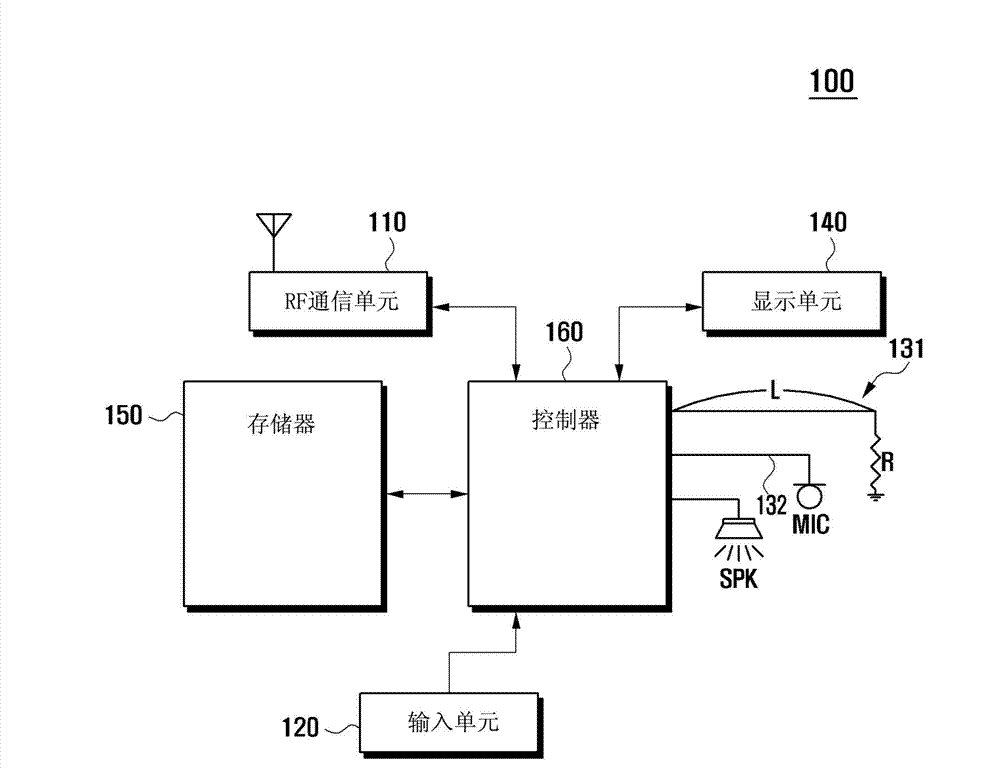

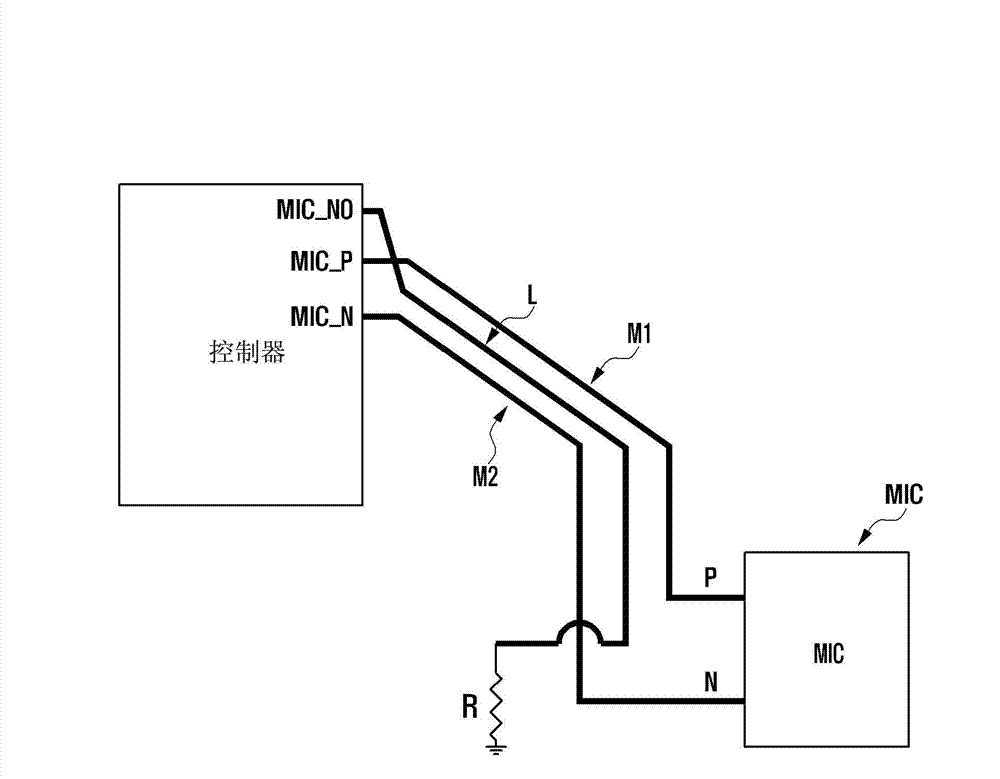

Method of removing microphone noise and portable terminal supporting the same

InactiveUS20130051574A1Cancel noiseImprove call qualityEar treatmentMicrophone structural associationSupport removalEngineering

A method of removing a microphone noise and a portable terminal supporting the same are provided. The portable terminal supporting removal of a microphone noise includes a microphone for collecting an audio signal, a controller for processing the audio signal collected by the microphone, a microphone signal line for transferring a microphone signal collected by the microphone to the controller, and a noise collecting circuit disposed at a neighboring region of the microphone signal line for collecting and providing a noise signal similar to a noise induced in the microphone signal line to the controller, wherein the controller controls such that the noise induced in the microphone signal line is removed based on the noise signal collected by the noise collecting circuit.

Owner:SAMSUNG ELECTRONICS CO LTD

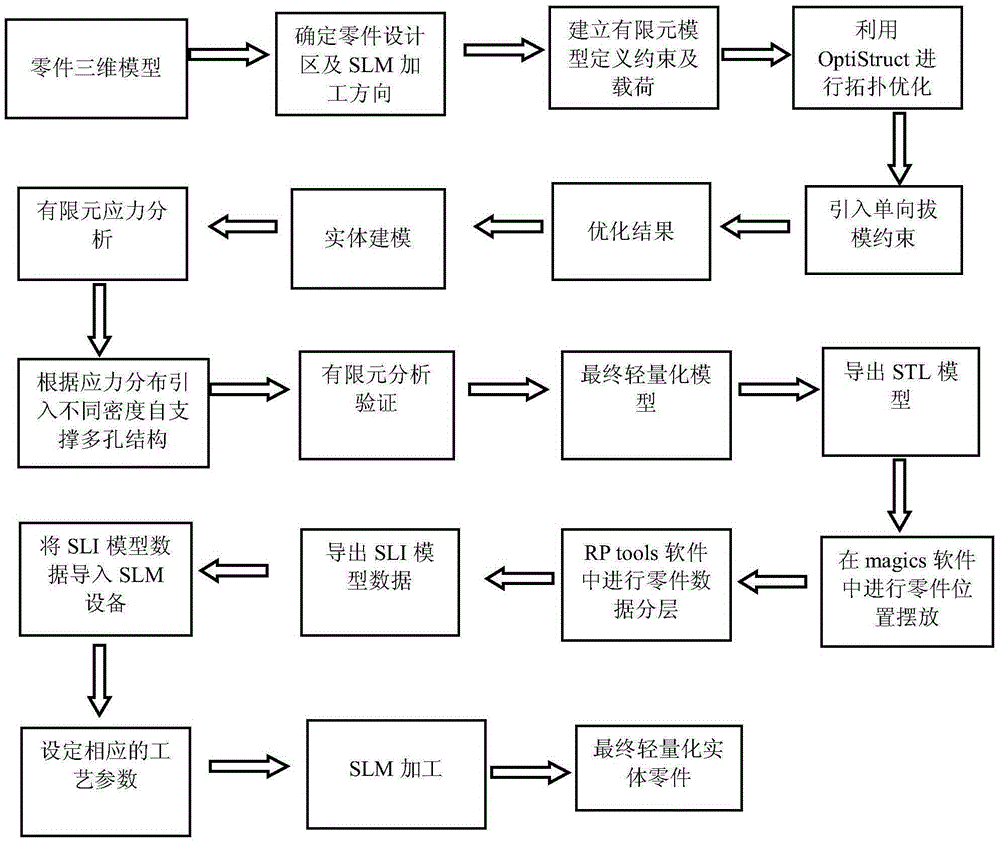

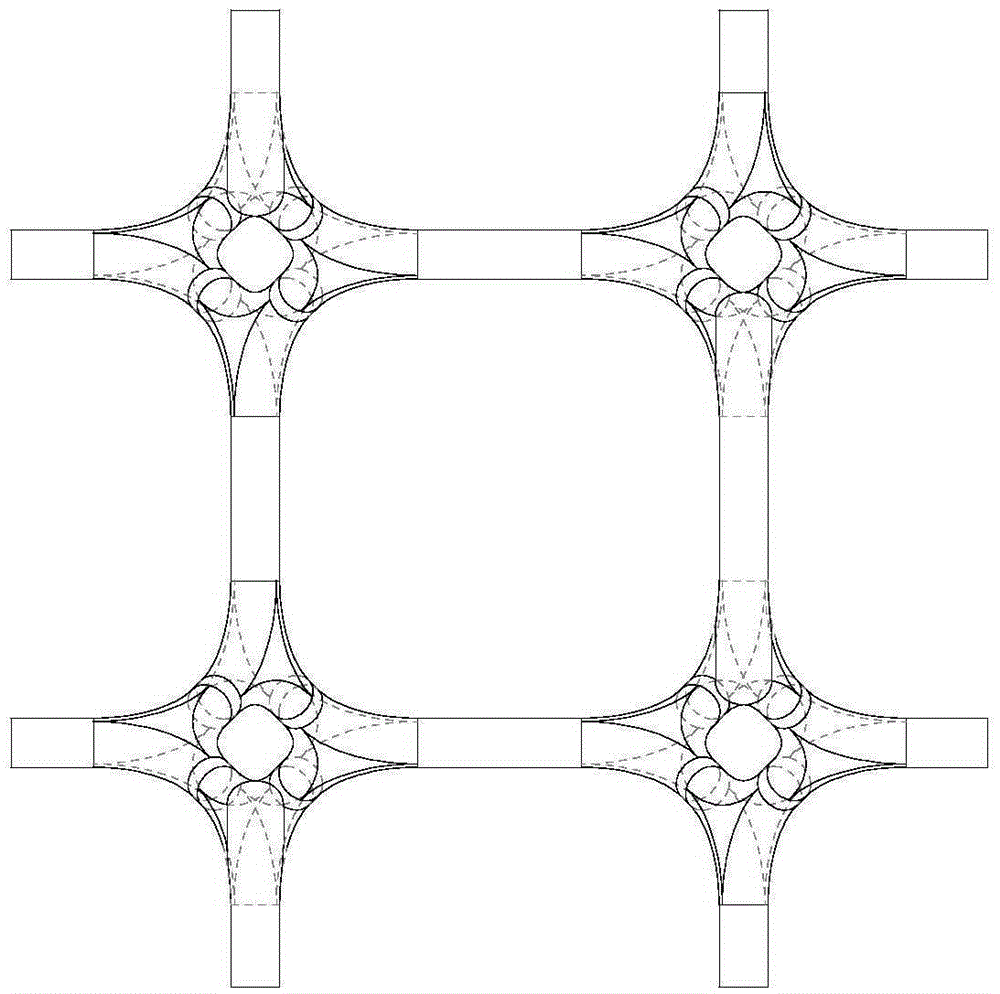

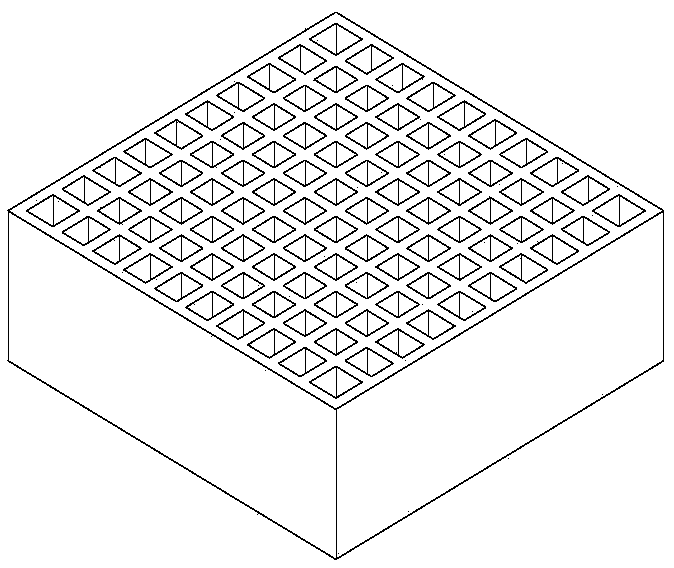

SLM (Selective Laser Melting) process based part lightweight design processing method

ActiveCN105373645AAchieve lightweight designRealize the designSpecial data processing applications3D modellingSelective laser meltingStress distribution

The invention discloses an SLM process based part lightweight design processing method. The method comprises the following steps: establishing a finite element model through a three-dimensional digital model of a part, and defining load and boundary conditions; establishing a part topological optimization model and setting a topological optimization unidirectional withdrawal constraint; performing part topological optimization to generate an initial lightweight model, performing mechanical performance analysis on the initial lightweight model, arranging self-supported porous structures with different densities according to stress distribution of the initial lightweight model, and generating a final lightweight model; and processing a final lightweight entity part through an SLM forming technology by utilizing the generated final lightweight model. The unidirectional withdrawal constraint is set in a specified direction during the topological optimization process, and the part topological optimization is finished, so that the part lightweight design is realized; a withdrawal constraint based topological optimization result is suitable for an SLM process, so that a supporting structure does not need to be added, a complicated support removal process is not required, and the design process is simplified; and the self-supported porous structures with different densities are introduced, so that the weight of the structure is further reduced.

Owner:SUZHOU XIDIMO THREE DIMENSIONAL PRINTING TECH CO LTD +2

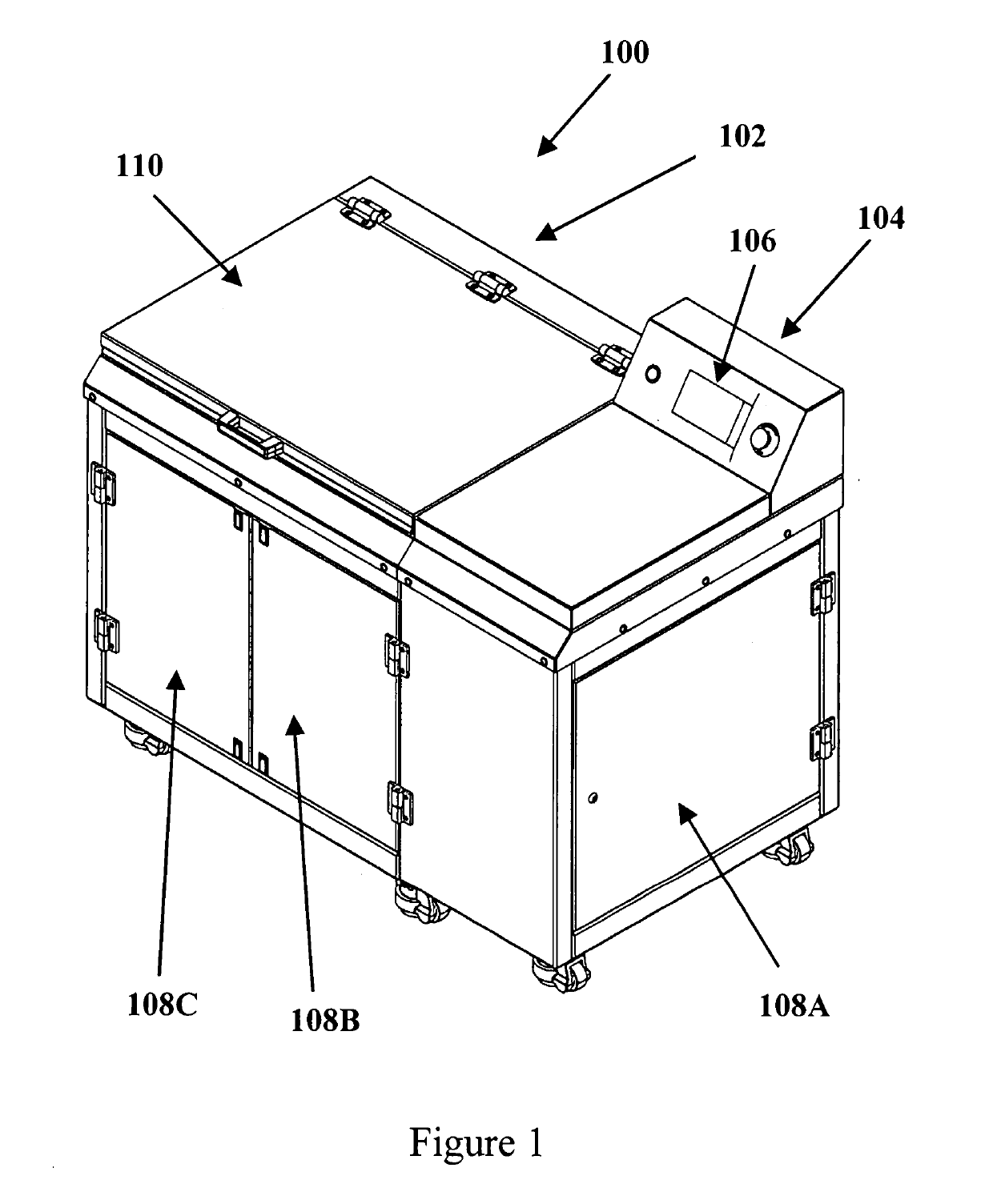

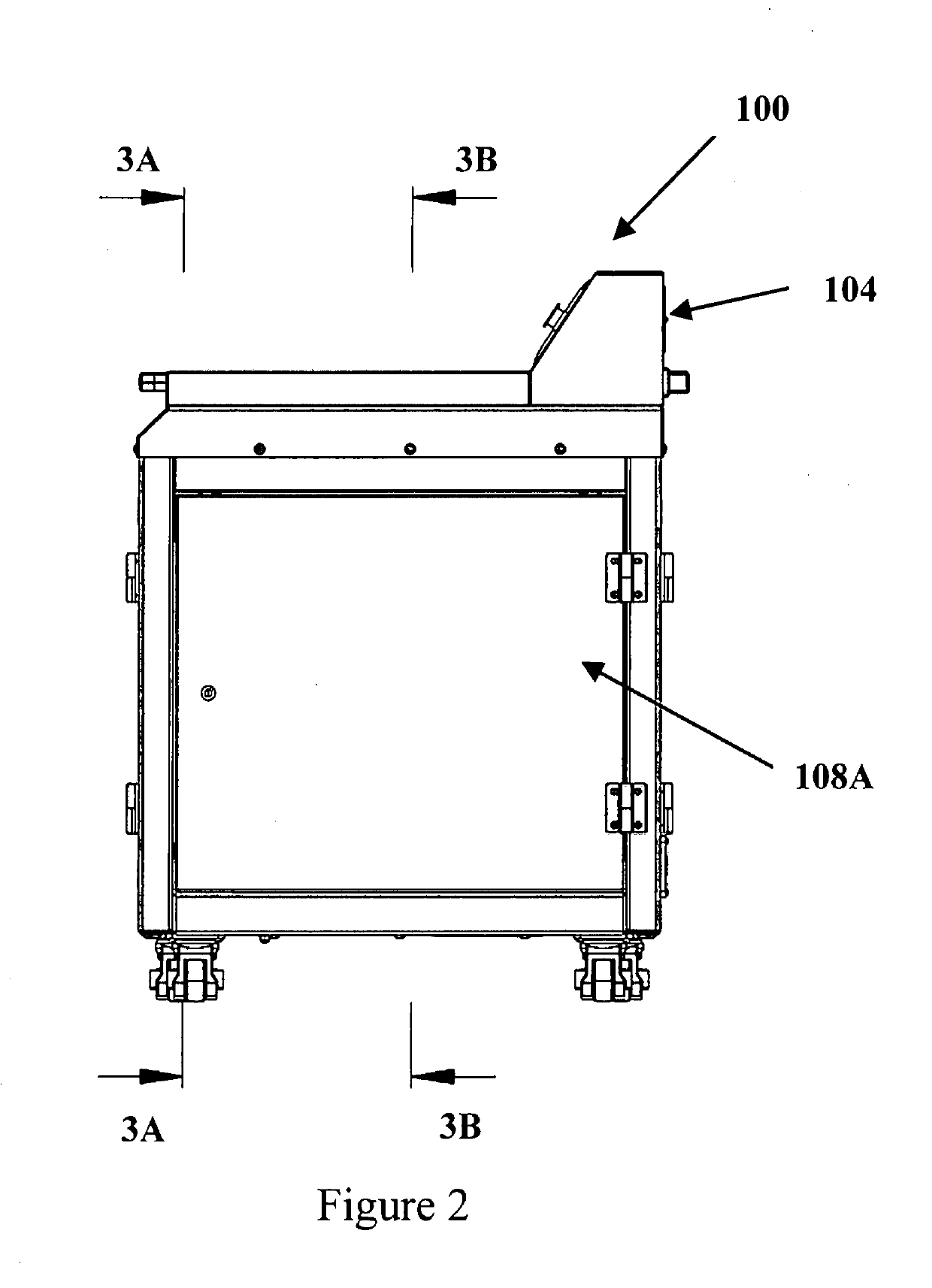

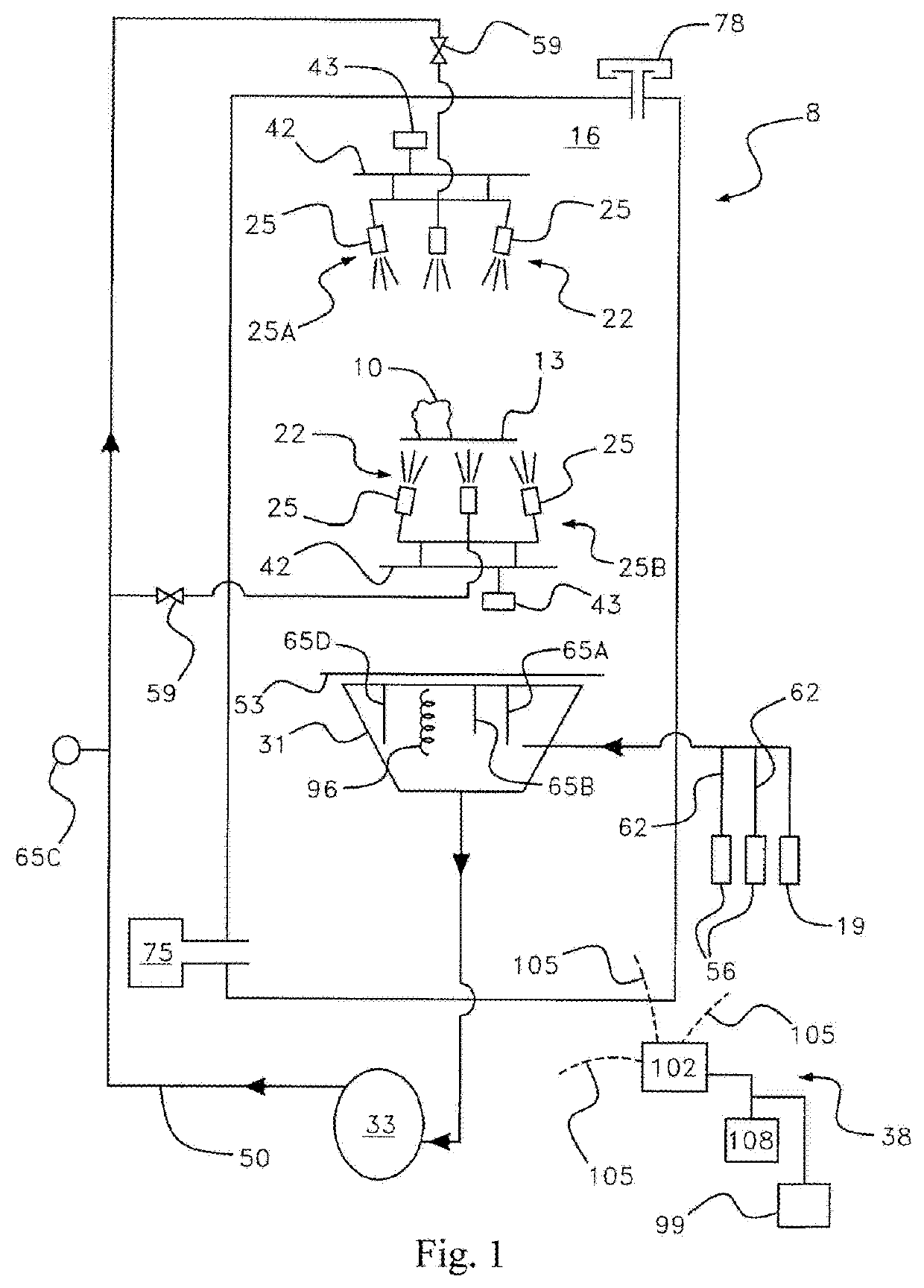

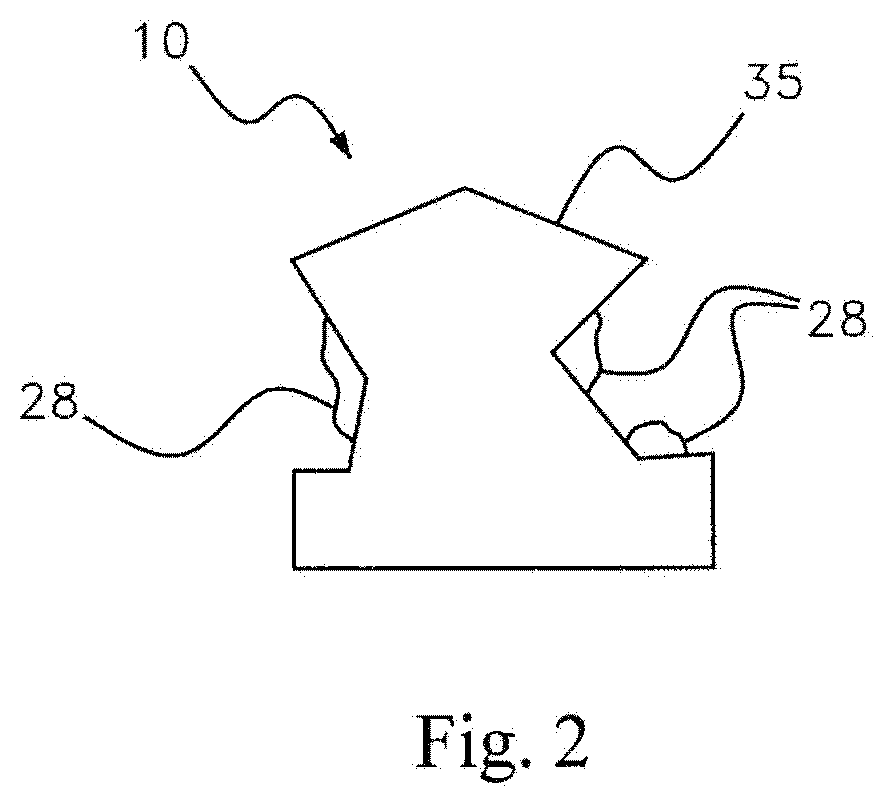

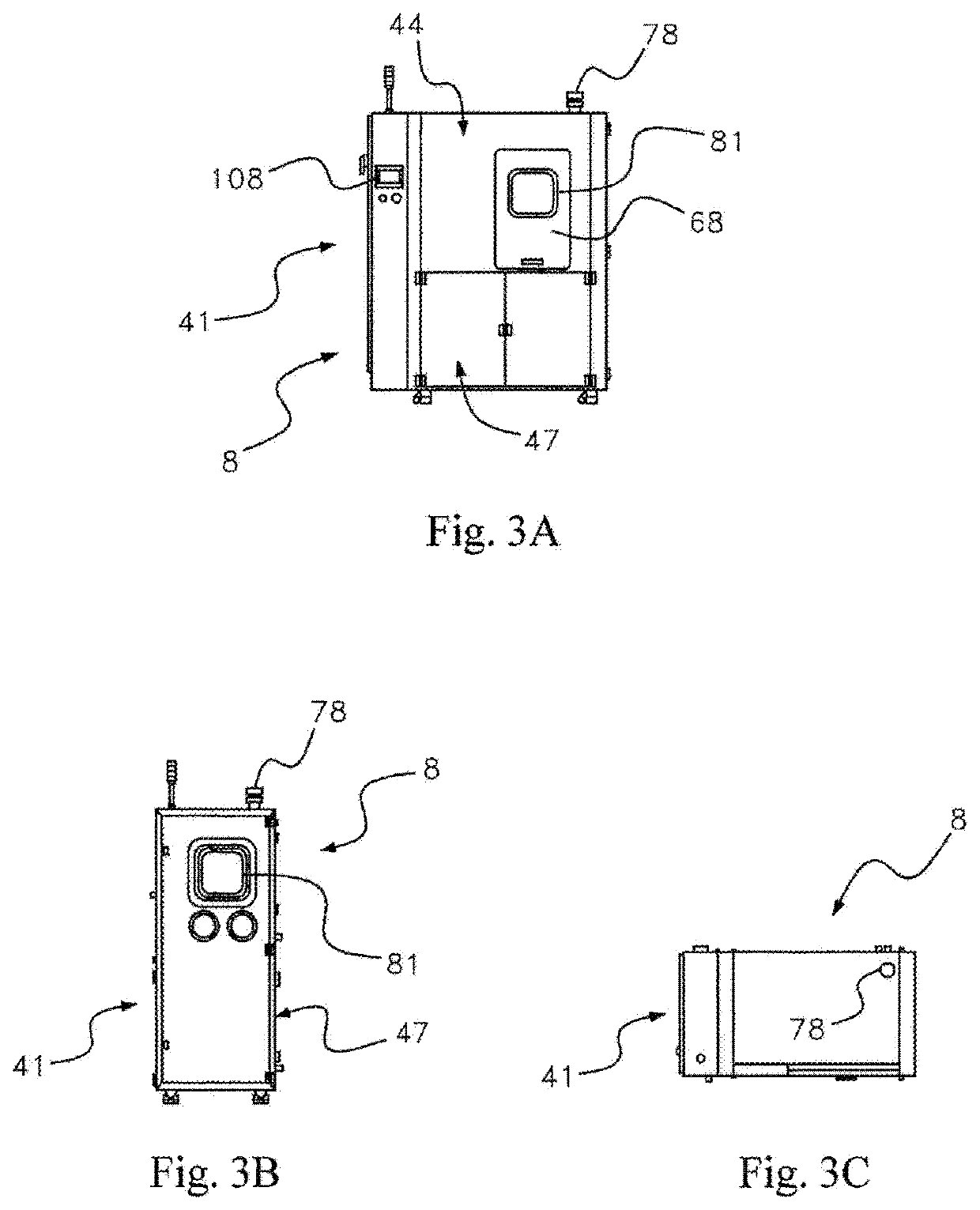

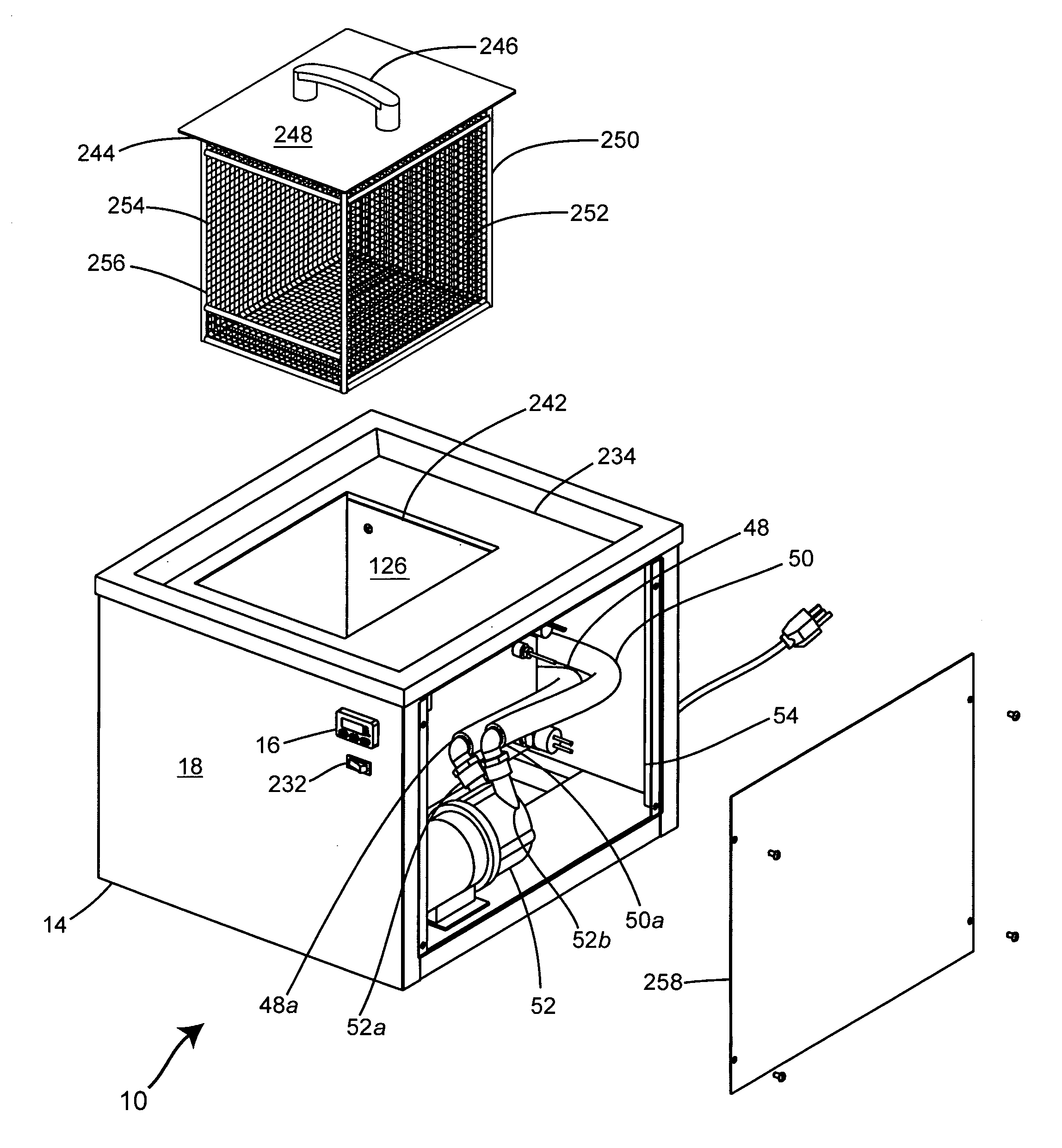

Apparatus for removing water-soluble support material from one or more rapid prototype parts

ActiveUS20090211616A1Low costEasy to useAdditive manufacturing apparatusElectrostatic cleaningSupport removalSpray nozzle

The support removal apparatus comprising in combination a retention tank having a manifold assembly comprising a plurality of nozzle heads, articulating arms or a combination of both in hydraulic communication with the discharge side of a pump, collectively configured for agitating an aqueous cleaning solution; a heating element mounted within the retention tank for heating the aqueous cleaning solution to a predetermined temperature set point; a basket strainer mounted within the retention tank in hydraulic communication with the intake side of the pump to mitigate passage of small rapid prototype parts and residual support material therethrough and into the pump and manifold assembly; a thermocouple for maintaining the temperature within a tolerable range for optimum removal of support material; a level indicator to ensure adequate solution level in the retention tank for operability of the pump and heating element; a cabinet having an interface controller mounted on an exterior panel thereof for setting timer and heat functions; and a microprocessor having capabilities for making minute adjustments to the heating element via feedback from the thermocouple and controlling operation of the pump and heating element for a pre-set time interval.

Owner:TAFOYA DAVID JONATHAN

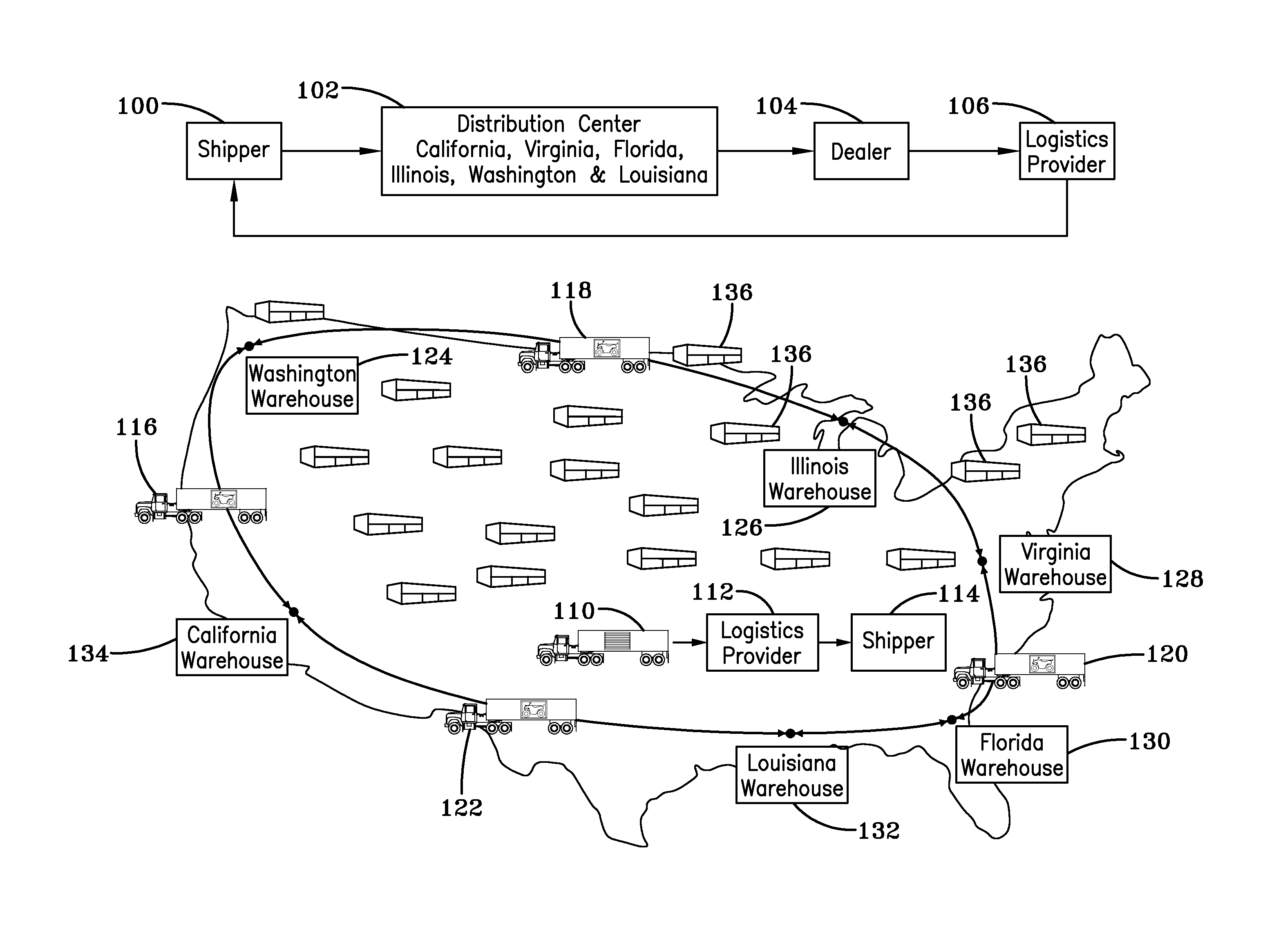

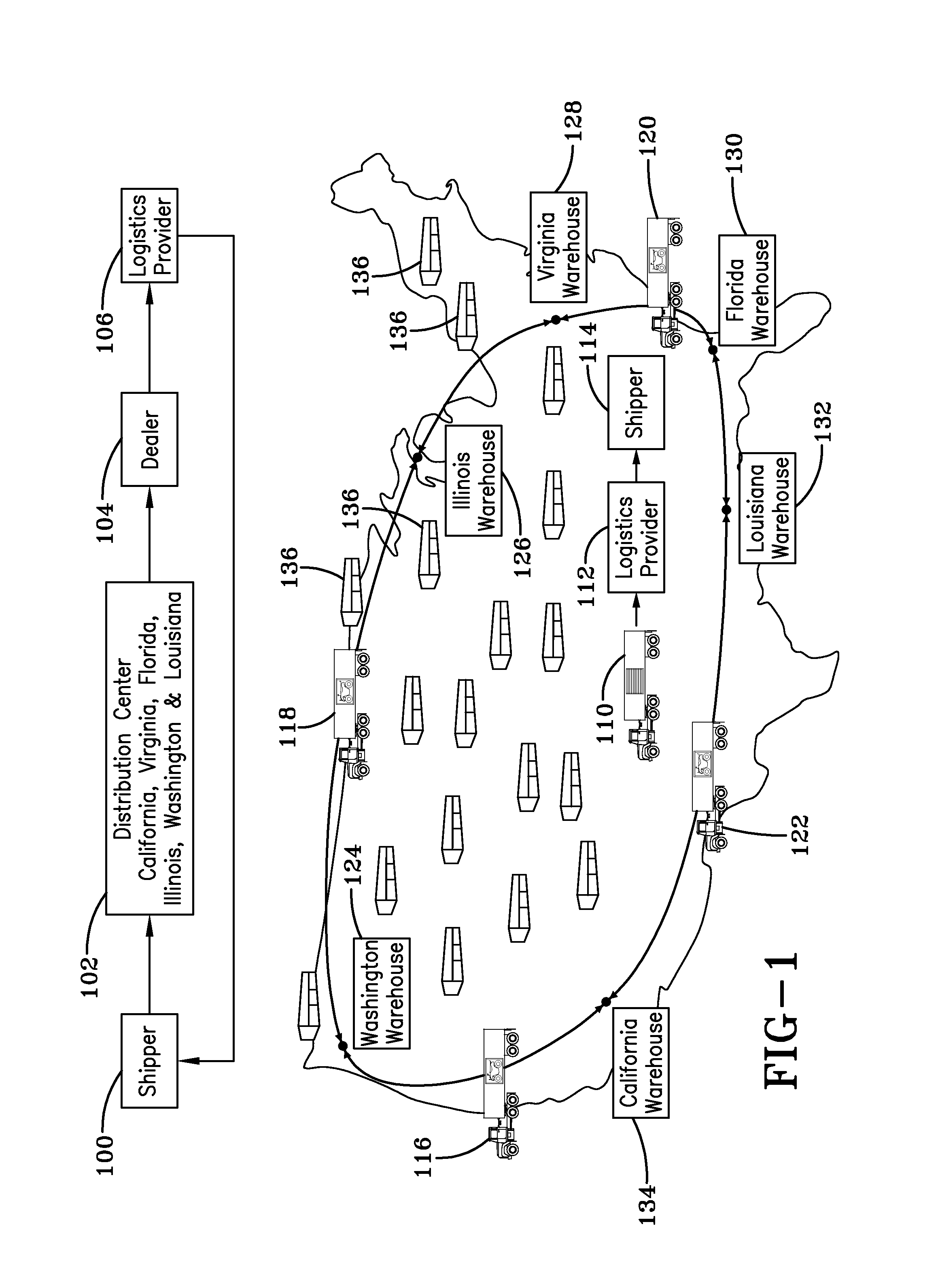

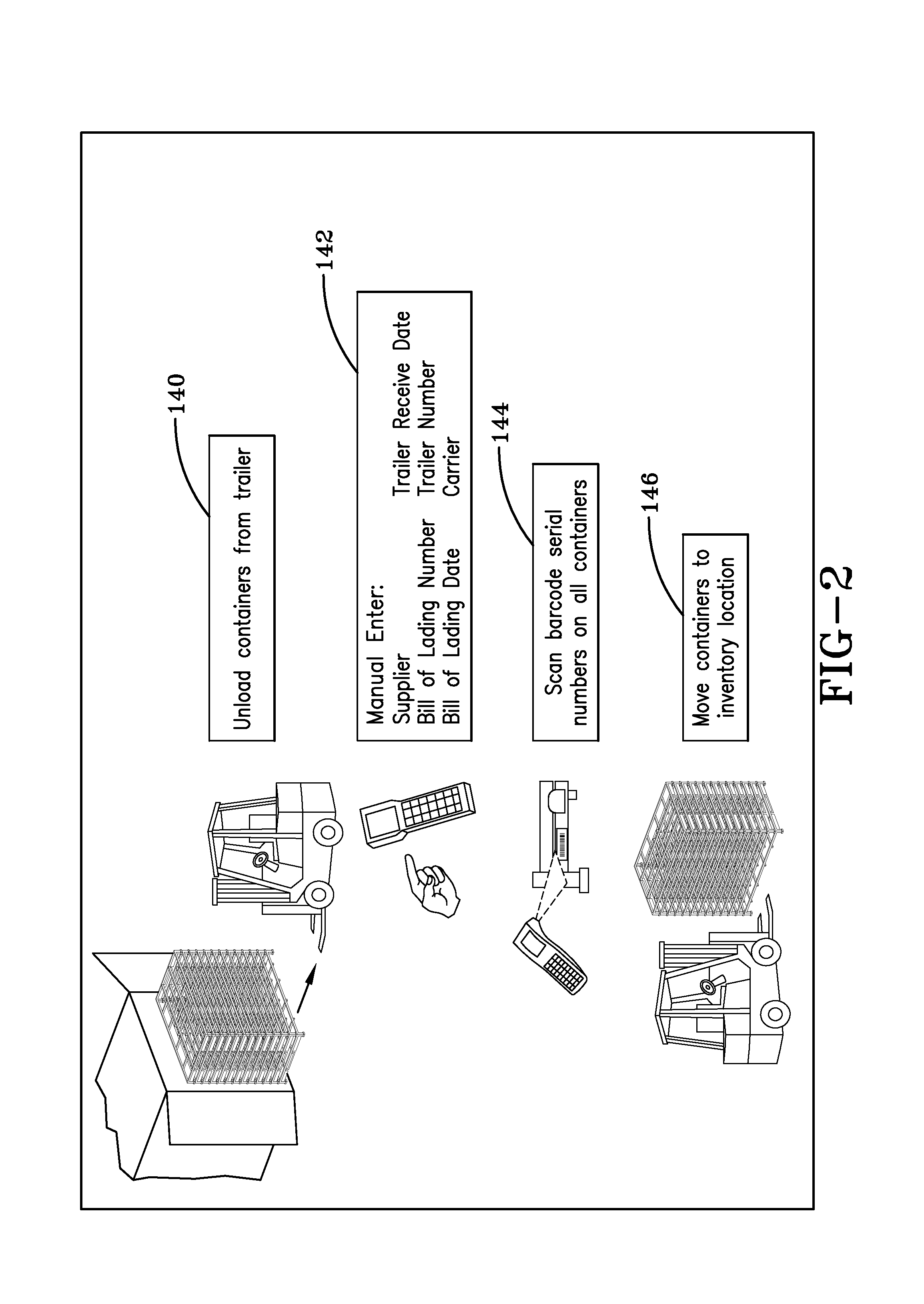

Returnable container management and repair system and method

A computerized system and method for managing a returnable container inventory and repairs of the returnable containers. The computerized system and method has features and functionality for tracking and managing repairs of special returnable containers that comprise multiple parts. The computerized system and method supports tracking of containers through a distribution network and management of data related to repairs performed on returnable containers as well as the spare parts that are used to repair the containers. Special handling features support removal of the containers from the distribution network for a variety of reasons. Report features allow a shipper to determine the status of containers throughout the distribution network, to view data related to the container and spare parts inventory, and to manage the container inventory using data collection and analysis features.

Owner:HONDA MOTOR CO LTD +1

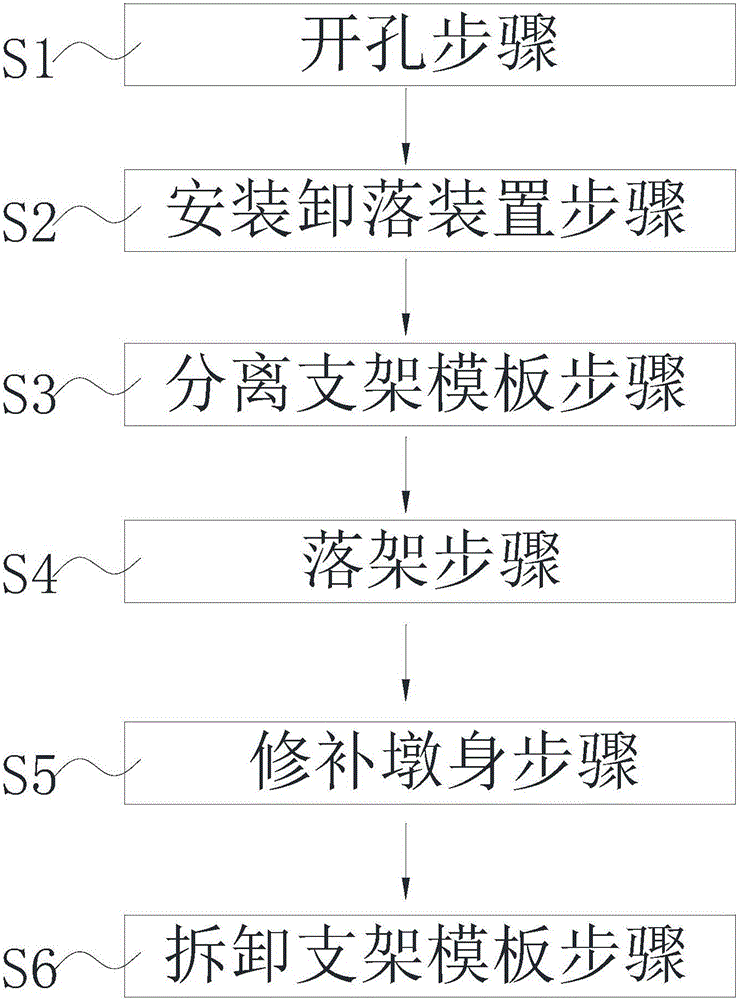

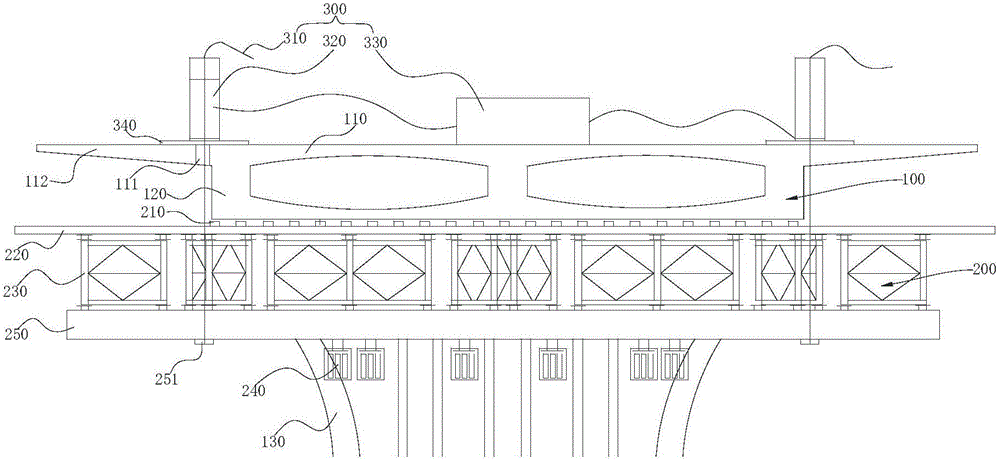

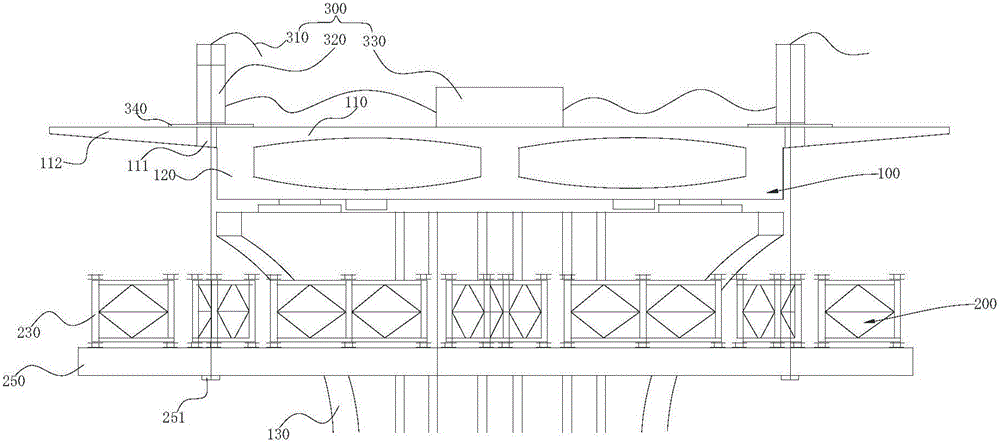

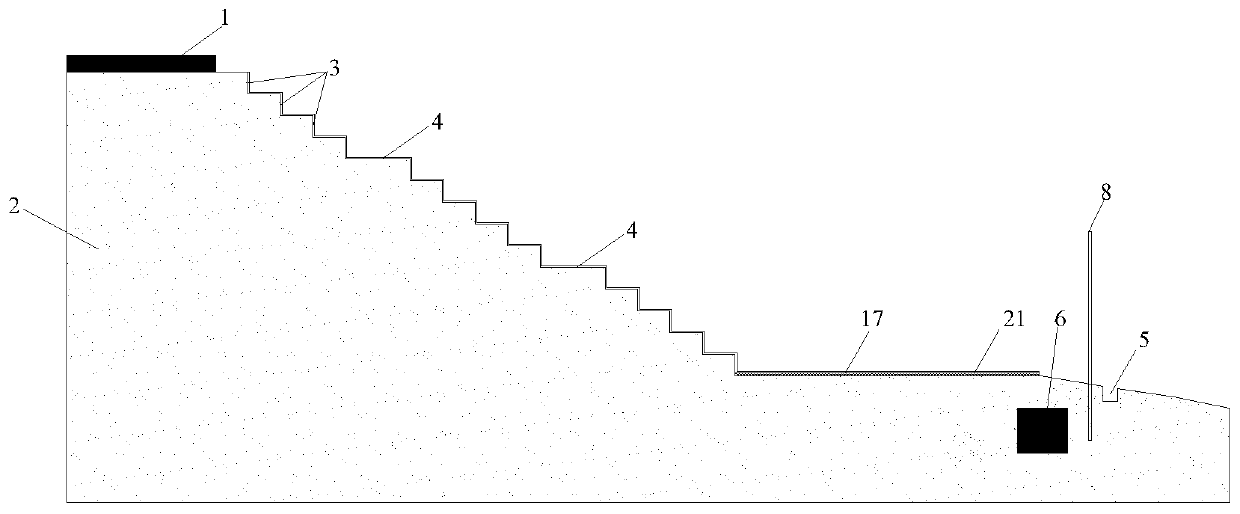

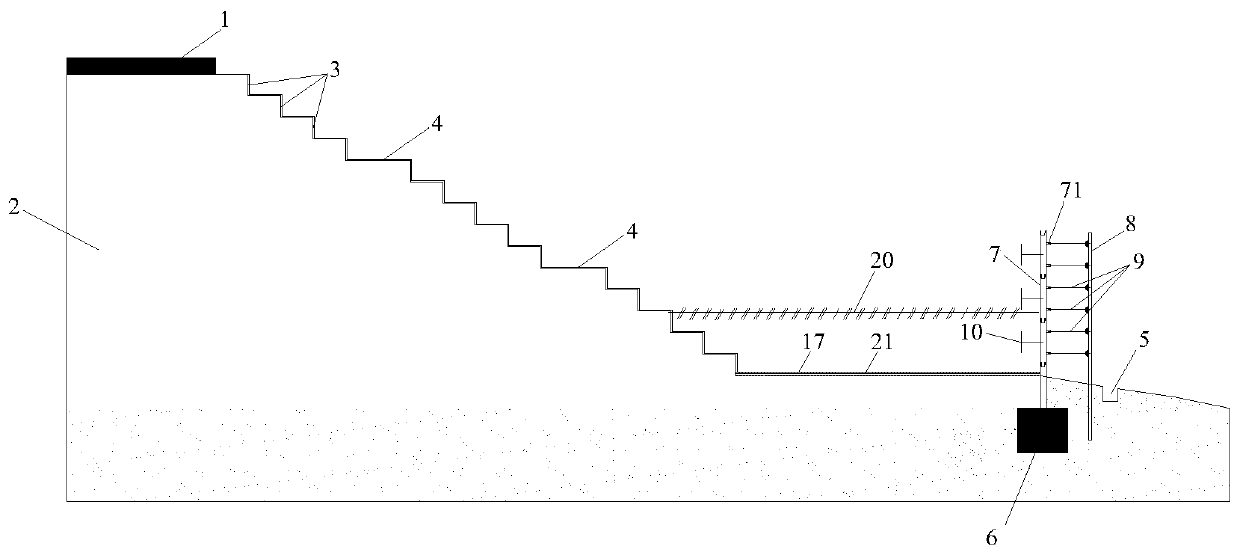

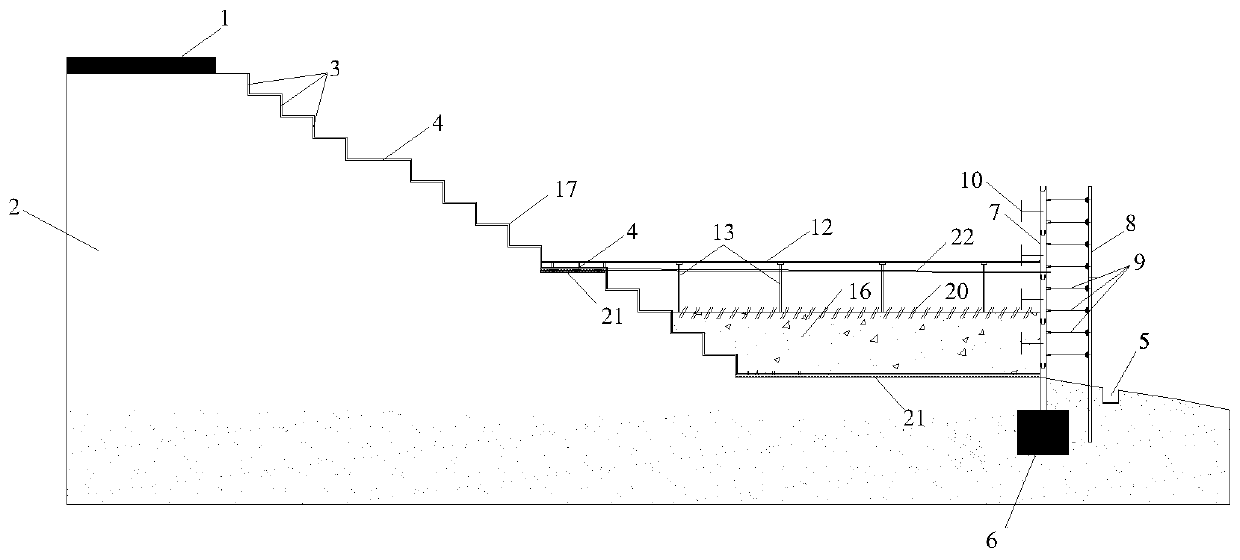

Construction method for overall support removal

ActiveCN106012852AEasy transitionSmall footprintBridge erection/assemblySupport removalSmall footprint

The invention provides a construction method for overall support removal and relates to the field of bridges. A cast-in-place box beam comprises a beam surface, a beam bottom and a pier body. A support formwork comprises sand boxes, a distributive beam, bailey beams and brackets. The construction method for overall support removal includes the steps that holes are formed, specifically, the through holes are formed in the beam surface; removal equipment is mounted, specifically, the removal equipment comprises hanging belts, collecting and releasing mechanisms and a control mechanism, the collecting and releasing mechanisms are mounted on the beam surface and close to the through holes, and the hanging belts penetrate through the through holes to hang a main cross beam; the support formwork is separated, specifically, the sand boxes and the brackets are removed, and the hanging belts hang the support formwork to suspend the support formwork; and the support formwork is dismounted, specifically, the collecting and releasing mechanisms continuously retract to release the hanging belts, and the support formwork is dismounted after slowly falling to an operation height. The removal equipment provided by the invention is simple, easy to transfer and small in occupied space, greatly reduces land, can be used at narrow construction sites or bridges on cliffs, and is wide in application area.

Owner:江苏燕宁工程科技集团有限公司

Self-Modifying Agitation Process And Apparatus For Support Removal In Additive Manufacturing And 3D Printed Material

ActiveUS20190270248A1Damage limitationEnhance support removalShaking/oscillating/vibrating mixersTransportation and packagingSupport removalSonification

A process for support material removal for 3D printed parts wherein the part is placed in a media filled tank and support removal is optimized in a multi-parameter system through an artificial intelligence process which may include, but is not limited to, the use of historical data, parametric testing data, normal support removal data, and outputs from other support removal AI models to generate optimally efficient use of each parameter in terms of pulse repetition interval (PRI) and cycle time as defined by pulse width (PW). The input parameters may include heat, circulation, ultrasound and chemical reaction, which are used in sequence and / or in parallel, to optimize efficiency of support removal. Sequentially and / or in parallel, heat, pump circulation and ultrasound may vary in application or intensity. Selection of means of agitation depends on monitored feedback from the support removal tank and application of a statistically dynamic rule based system (SDRBS).

Owner:POSTPROCESS TECH INC

Foam light soil high-filled subgrade broadening construction method

ActiveCN110042716AReduce vertical additional stressReduce the impact of settlementRoadwaysExcavationsSupport removalPre stress

The invention relates to a foam light soil high-filled subgrade broadening construction method. The foam light soil high-filled subgrade broadening construction method is characterized in that firstly, slope cutting is carried out on an original old subgrade into a stair type, a concrete baffle is arranged on the periphery of the broadening side of the subgrade and used as a foam light soil pouring template, a steel bar net is horizontally arranged at the position of a large platform and is connected with the baffle, a pre-stressed anchor rod is additionally arranged to be anchored on the baffle, pouring construction of foam light soil is carried out in layering, partition and segmentation modes, and finally, the baffle is removed and hanging soil engineering bags are mounted. The construction method comprises the steps of original subgrade construction, baffle mounting, foam light soil pouring, steel bar net and drainage pipe mounting, anchor cable construction, foam light soil pouring, steel support removal and hanging soil engineering bag mounting. According to the foam light soil high-filled subgrade broadening construction method, the baffle and embedded structural steel are arranged on the broadening side of high fill in an erection mode to form a stable supporting structure, the stability of the baffle can be effectively improved, the structural steel can be recycled andreused after construction, and material breakage and construction cost are reduced.

Owner:杭州悦为科技有限公司

Apparatus and method of removing water soluble support material from a rapid prototype part

ActiveUS7546841B2Low costEasy to useAdditive manufacturing apparatusHollow article cleaningSupport removalPotassium hydroxide

The support removal apparatus comprising in combination a retention tank having a manifold assembly comprising a plurality of nozzle heads in hydraulic communication with the discharge side of a pump, collectively configured for agitating an aqueous cleaning solution comprised of sodium or potassium hydroxide, sodium or potassium carbonate, and water; a heating element mounted within the retention tank for heating the aqueous cleaning solution to a predetermined temperature set point; a basket strainer mounted within the retention tank in hydraulic communication with the intake side of the pump to mitigate passage of small rapid prototype parts and residual support material therethrough and into the pump and manifold assembly; a work surface mounted atop the retention tank and having a movable lid fitted with a basket for containing small rapid prototype parts; a thermocouple for maintaining the temperature within a tolerable range for optimum removal of support material; a level indicator to ensure adequate solution level in the retention tank for operability of the pump and heating element; a cabinet having interface controller mounted on an exterior panel thereof for setting timer and heat functions; and a microprocessor having capabilities for making minute adjustments to the heating element via feedback from the thermocouple and controlling operation of the pump and heating element for a pre-set time interval.

Owner:TAFOYA DAVID JONATHAN

Method of removing microphone noise and portable terminal supporting the same

InactiveCN102956235AMicrophone structural associationSpeech analysisSupport removalMicrophone signal

A method of removing a microphone noise and a portable terminal supporting the same are provided. The portable terminal supporting removal of a microphone noise includes a microphone for collecting an audio signal, a controller for processing the audio signal collected by the microphone, a microphone signal line for transferring a microphone signal collected by the microphone to the controller, and a noise collecting circuit disposed at a neighboring region of the microphone signal line for collecting and providing a noise signal similar to a noise induced in the microphone signal line to the controller, wherein the controller controls such that the noise induced in the microphone signal line is removed based on the noise signal collected by the noise collecting circuit.

Owner:SAMSUNG ELECTRONICS CO LTD

Construction technology with alternative cutting removal and segmental re-jacking of double-side-wall temporary supports in shallow-buried silty-fine sand layer

InactiveCN110847915AEnsure construction safetyImprove construction progressUnderground chambersTunnel liningSupport removalArchitectural engineering

The invention relates to a construction technology with alterative cutting removal and segmental re-jacking of double-side-wall temporary supports in a shallow-buried silty-fine sand layer, and belongs to the technical field of rail traffic construction technologies. The construction technology includes the steps of carrying out zonal, regional, sectional and segmental construction on a double-side-wall pilot tunnel 6 and a double-side-wall pilot tunnel 9 with an alternative bay method, removing the temporary supports, chiseling away primary support concrete, and then cutting away grid arch trusses. The support removal length and part are adjusted and controlled with an alternative cutting and re-jacking method, rapid re-supporting is achieved, the temporary supports are partially removedand timely bear stress by re-jacking instead of being removed at the same time, and it is guaranteed that the temporary supports are in a stress state all the time in the construction process. According to the construction technology with alterative cutting removal and segmental re-jacking of the double-side-wall temporary supports in the shallow-buried silty-fine sand layer, the temporary supports are removed from inside to outside part by part in each segment of 6-8 m with the alternative bay method, the construction safety can be guaranteed, and multiple working faces can be constructed atthe same time to accelerate the construction progress.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +2

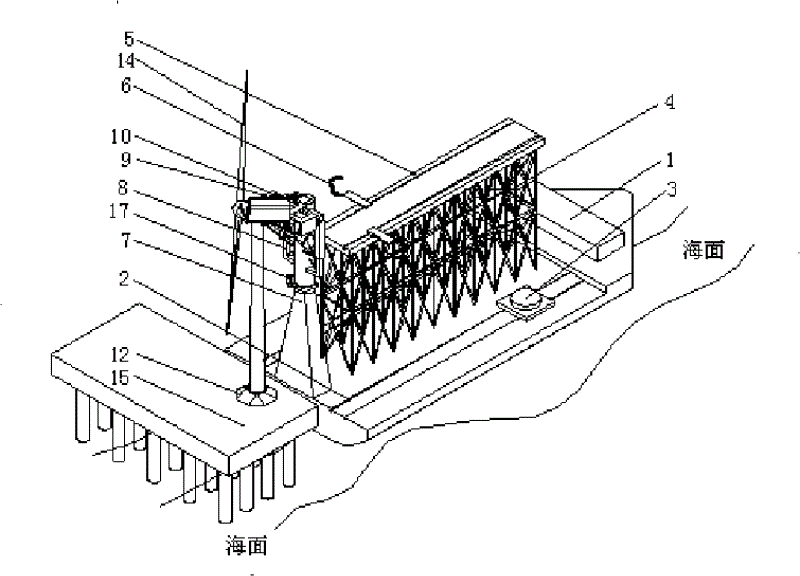

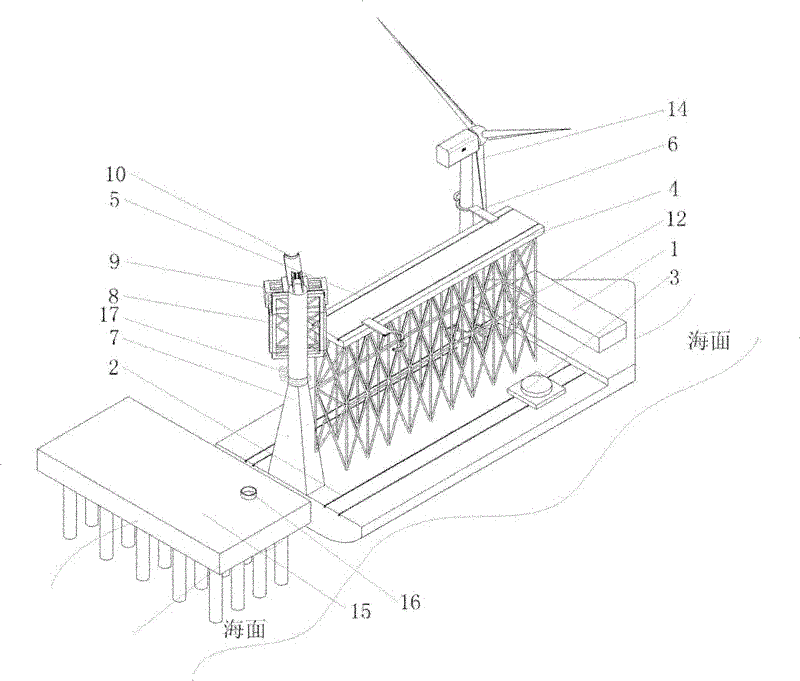

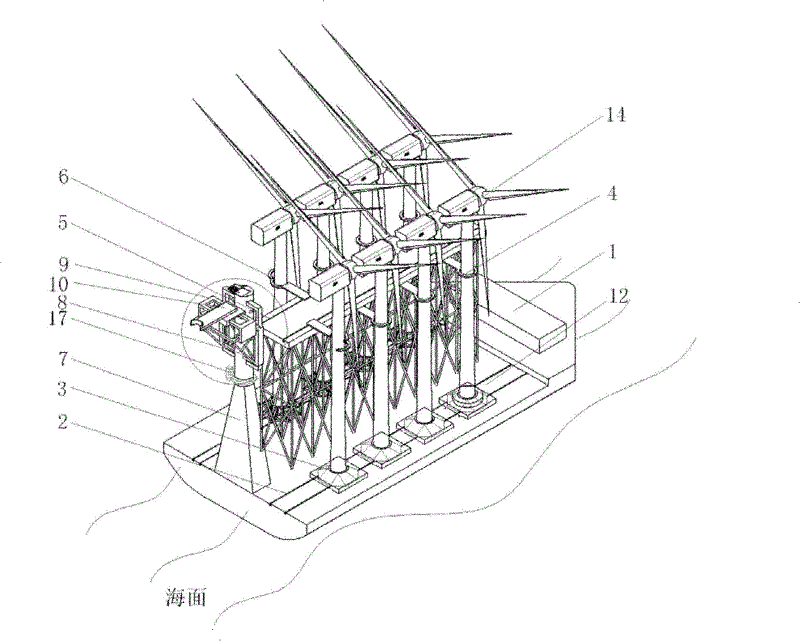

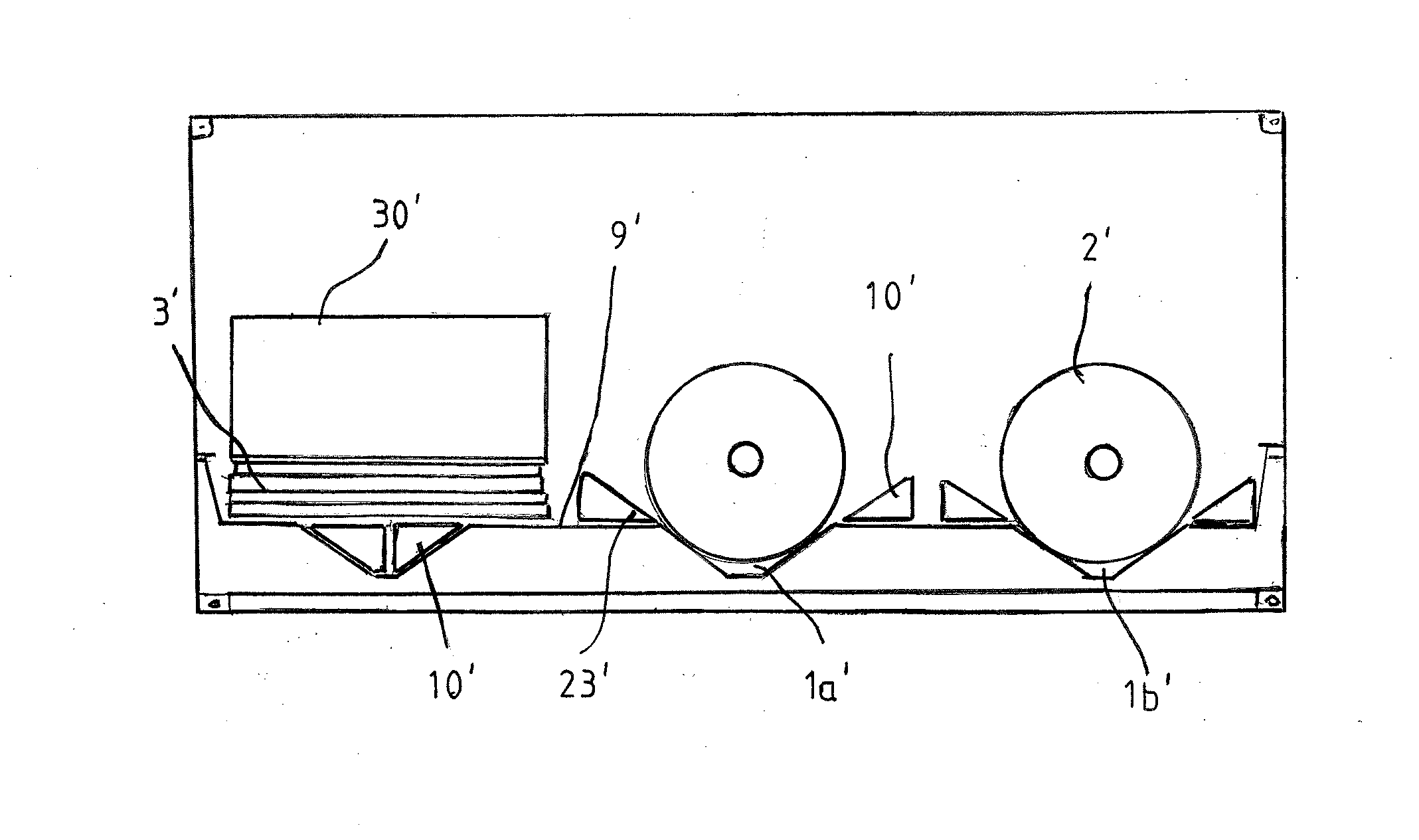

Ship for transporting wind turbines and transporting method for wind turbines

InactiveCN102616338AShorten the timeImprove offshore installation efficiencyCargo handling apparatusPassenger handling apparatusSupport removalMedial axis

The invention relates to a ship for transporting wind turbines, and a transporting method for the wind turbines. According to the invention, a deck is arranged on the upper surface of the ship body; the ship comprises a support framework fixed on a longitudinal medial axis and provided with a top plane, two guide rails parallel to the longitudinal medial axis and respectively positioned on two sides of the support framework, two second guide rails parallel to the longitudinal medial axis and respectively positioned on the two sides of the top plane of the support framework, a move support block arranged on the first guide rails, used for supporting the wind turbines and driving the wind turbines to move along the first guide rails, support removal brackets arranged on the second guide rails, connected with stepped drums of the wind turbines, and capable of synchronously moving with the corresponding removal support blocks along the second guide rails, an upper part suspension bracket connected with the bottoms of the wind turbines and fixed with the corresponding removal support blocks, and hoisting device arranged at one end of the support framework, fixed on the longitudinal medial axis and used for hoisting and moving the wind turbines to the removal support blocks or a marine foundation. The invention can improve the marine mounting efficiency of the wind turbines, and gets small influences from sea conditions.

Owner:SINOVEL WIND GRP

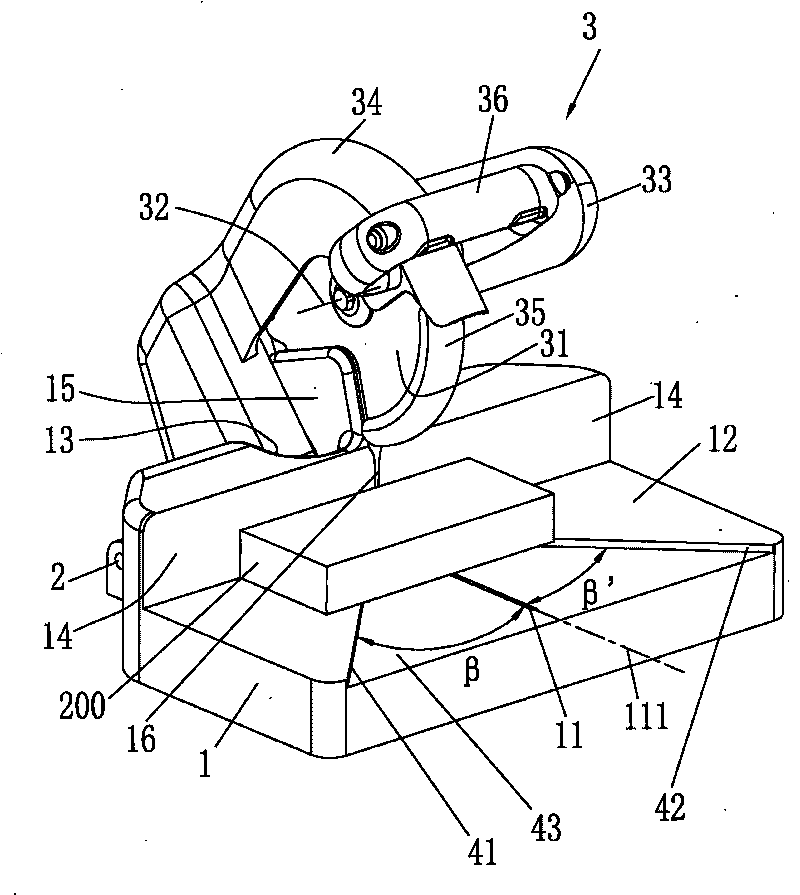

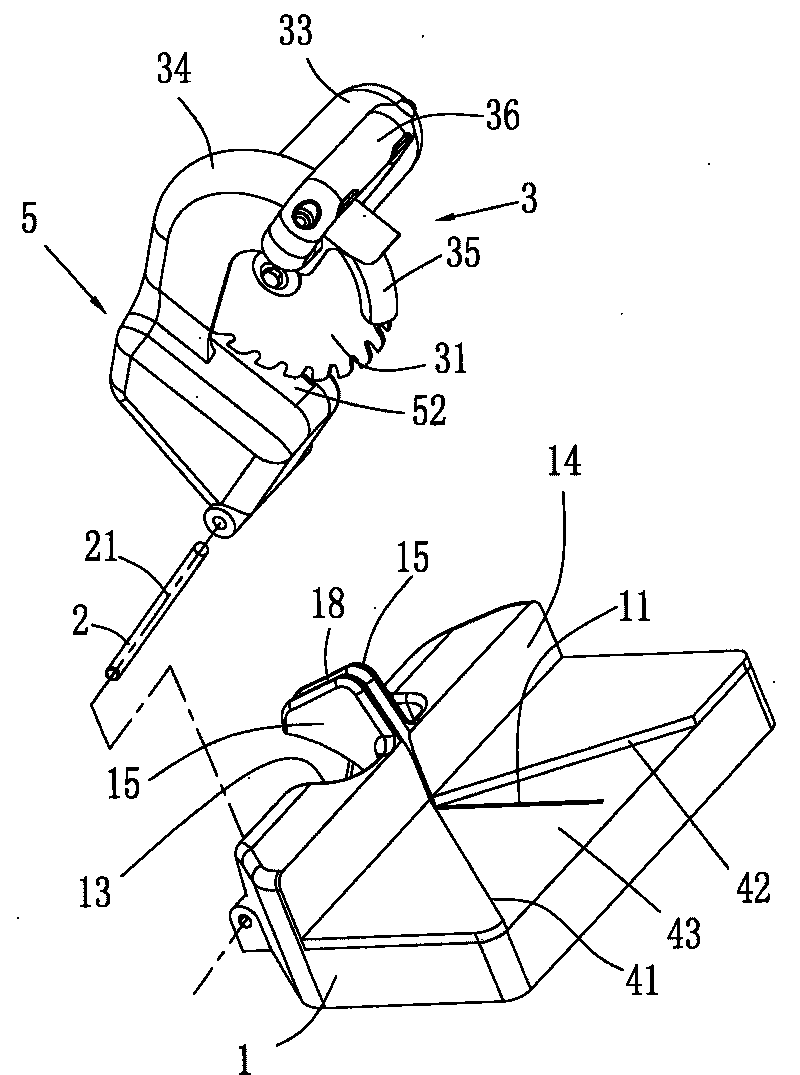

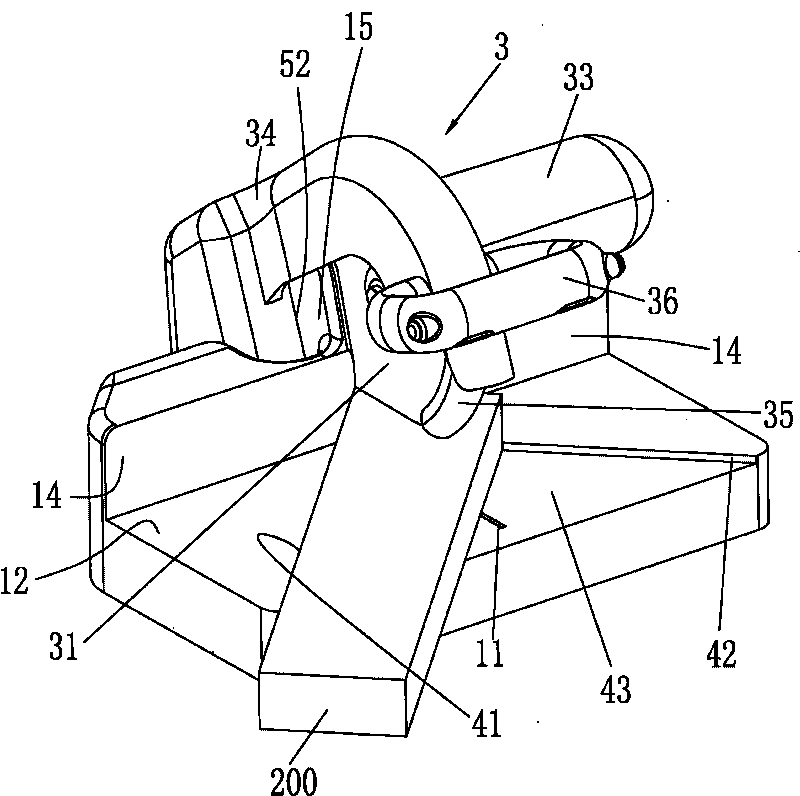

Cutter

ActiveCN101758291ASimple structureReduce manufacturing costMetal sawing devicesMetal sawing accessoriesSupport removalElectric machinery

The invention discloses a cutter, which comprises a worktable and a sawing mechanism that is pivoted with the worktable, wherein the sawing mechanism comprises a motor, a saw bit and a fixing shield; the motor is positioned above the worktable; the saw bit is driven by the rotation of the motor; the fixing shield is used for at least wrapping part of the saw bit. A first support area or a second support area is matched and connected with the worktable, therefore, 90-degree vertical cutting or left and right chamfering is realized only by placing the work piece in the first support area or the second support area without changing or adjusting any structure. Therefore, the whole structure of the cutter is greatly simplified, the production cost is lowered, and the operation is easy and convenient.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

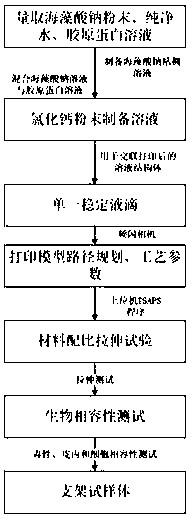

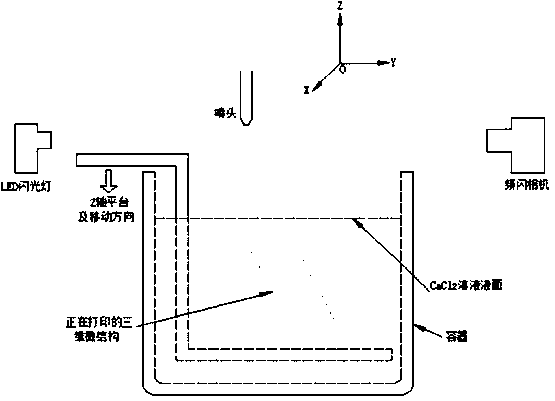

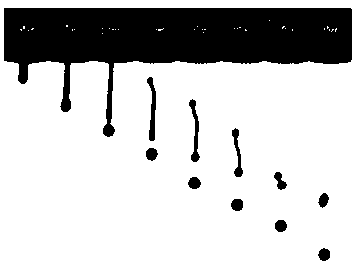

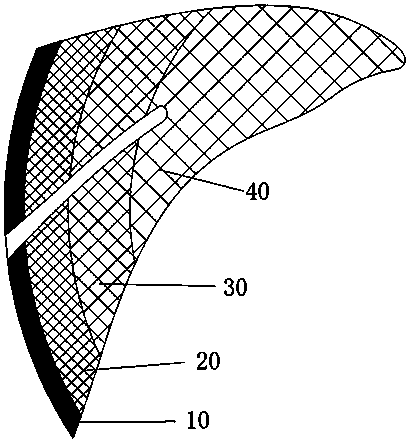

3D (Three-dimensional) printing method based on micro-droplet inkjet gelation vascular stent

InactiveCN109774119AEasy to operateSimple processAdditive manufacturing apparatus3D object support structuresProcessing InstructionHigh rate

The invention discloses a 3D (Three-dimensional) printing method based on a micro-droplet inkjet gelation vascular stent. The 3D printing method based on the micro-droplet inkjet gelation vascular stent comprises the following steps of: firstly preparing printing materials, wherein biological materials used are mixed liquid of a sodium alginate viscous solution and a collagen solution and a calcium chloride solution required for gelation; secondly, forming single and stable liquid droplets, then digitally producing the path, finally printing, and controlling the technological parameters of theprinting process. The 3D printing method based on the micro-droplet inkjet gelation vascular stent is simple in operation; and an inkjet type 3D printer is adopted according to the 3D printing method, has simple and standard processing instructions, and can be used for manufacturing a microstructure for cell vascularization. The method has simple process, high rate of finished products, controllable internal structure, low cost, safety and reliability, saves consumables, has no need of support, and omits the subsequent support removal process.

Owner:HANGZHOU DIANZI UNIV

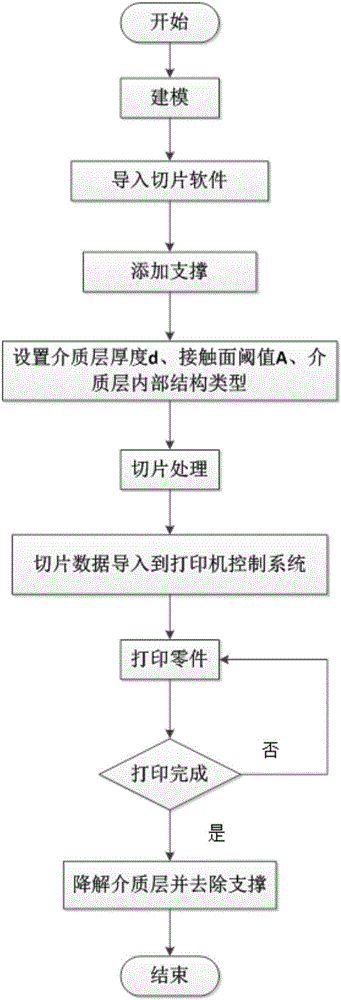

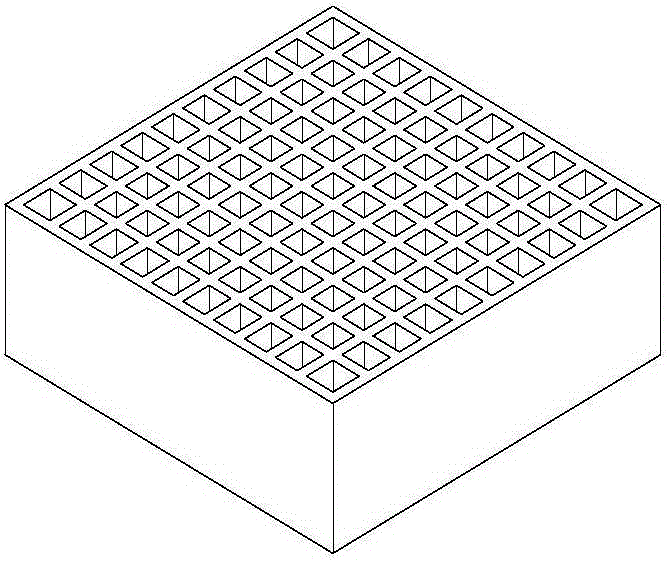

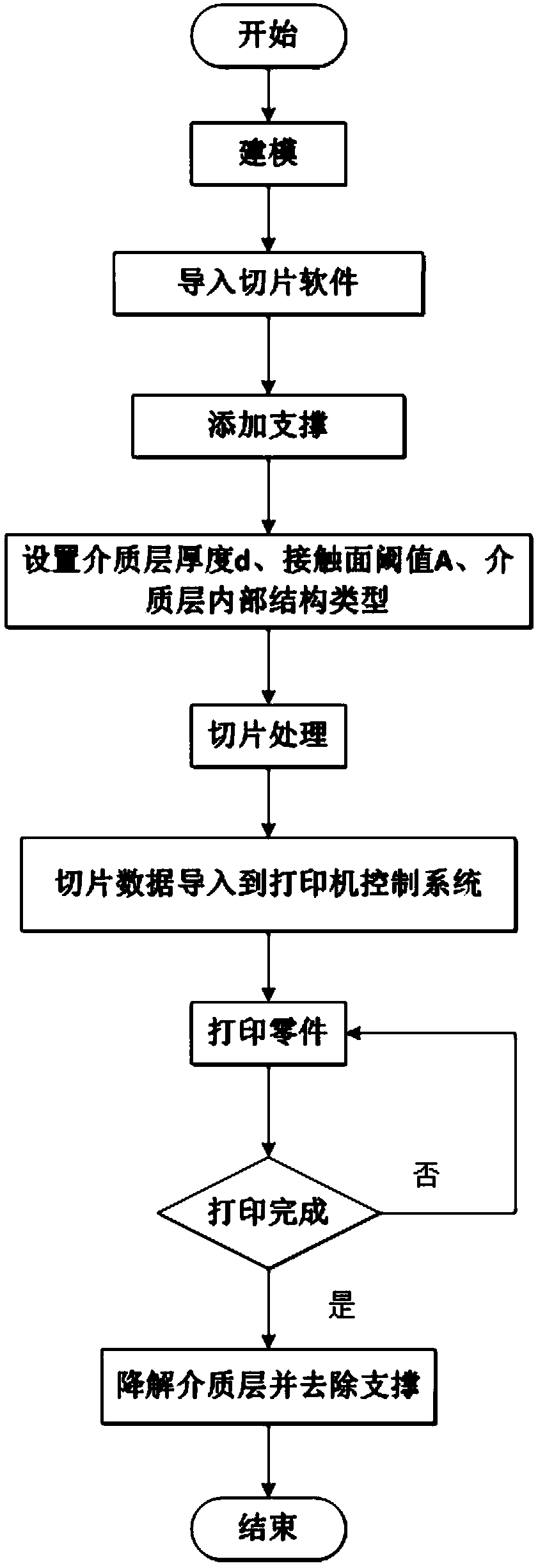

Method for quickly removing 3D printing support

InactiveCN109049724AViscosity disappears or decreasesEasy to separateAdditive manufacturing apparatus3D object support structuresSupport removalEngineering

The invention discloses a method for quickly removing 3D printing support. An adhesive medium material is printed between the supporting structure, the printing part, and the substrate respectively. The adhesive medium material is a resin-based hot melt adhesive. The method for quickly removing 3D printing support is suitable for 3D printing technologies such as FDM, 3DP and the like which need tobe supported is efficient and quick in support removal, does not affect the surface of the part, low in material cost, no other processing is required, and can be used after printing by performing simple processing.

Owner:SUZHOU CLOUDMPLANT MEDICAL TECH CO LTD

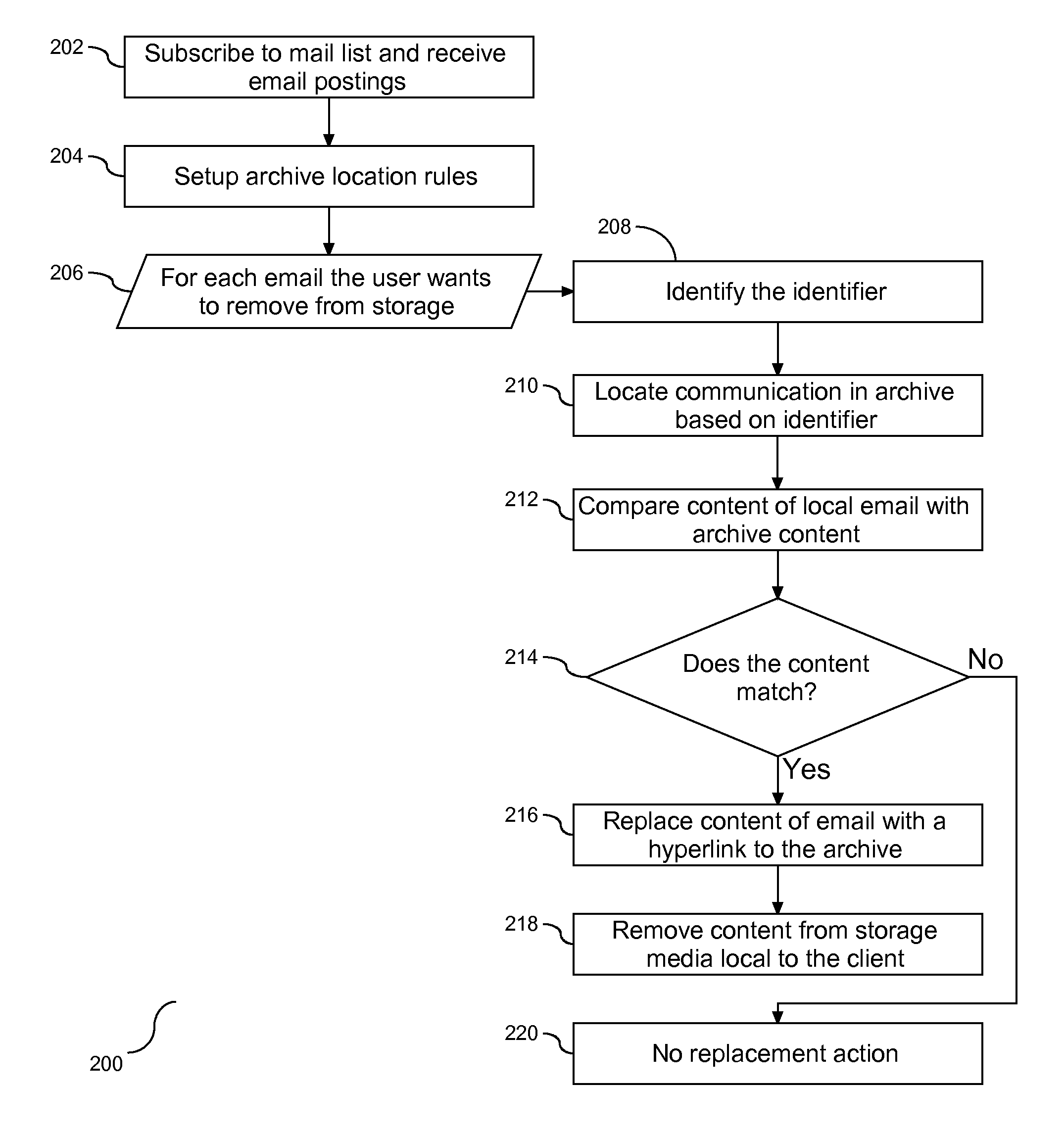

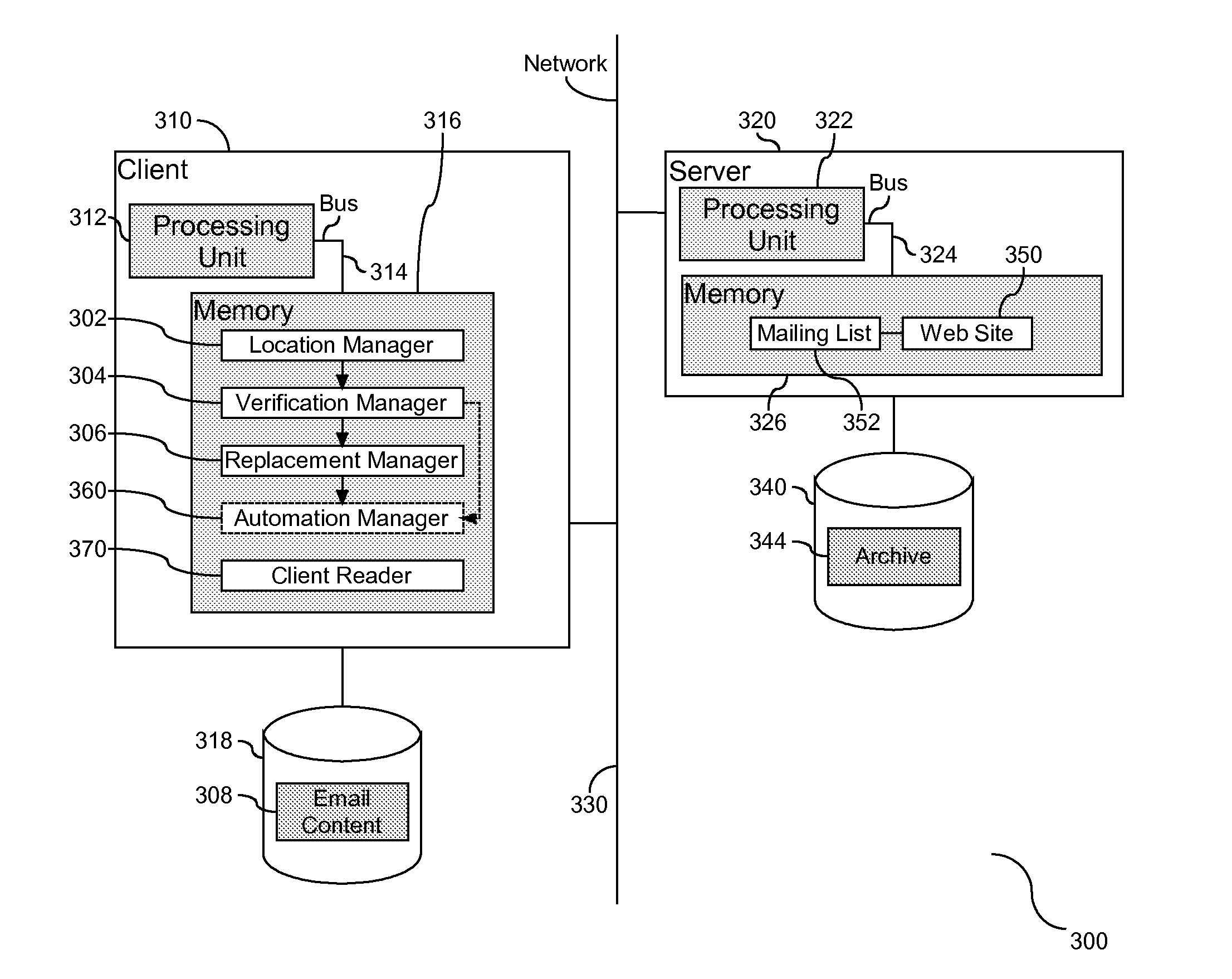

Method and system for management of electronic mail communication

Owner:INT BUSINESS MASCH CORP

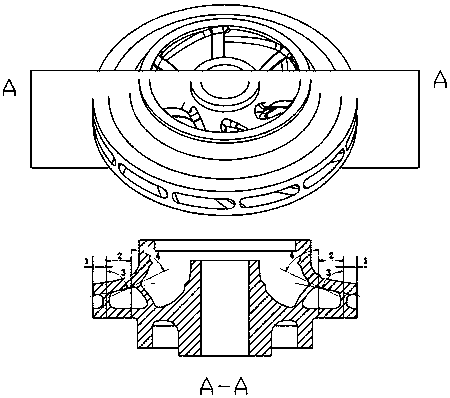

Gradient-type supporting method for selective laser melting forming of three-dimensional flow shrouded impeller

InactiveCN108374802AShorten the manufacturing cycleReduce support strengthPump componentsPumpsImpellerSelective laser melting

The invention provides a gradient-type supporting method for selective laser melting forming of a three-dimensional flow shrouded impeller. In the process of selective laser melting forming of the three-dimensional flow shrouded impeller, supporting structures of different strength are designed according to the distance from the forming part of the impeller to the opening part of the impeller andthe magnitude of an overhanging angle. Aiming at the structural characteristics of the three-dimensional flow shrouded impeller, a gradient-type supporting structure is designed according to the length from different parts of an inner cavity of the impeller to the opening part of the impeller and the overhanging angle. Under the condition that deformation in the process of selective laser meltingforming of the impeller is effectively controlled, the supporting strength is locally reduced, the supporting forming time is shortened, the difficulty of supporting removal is reduced, the workload is reduced, and the overall manufacturing cycle of the impeller is shortened.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

One-time forming construction process of embedded distribution box

InactiveCN110630021AReduce labor costsReduce material costsBuilding material handlingCable installation apparatusSupport removalPolystyrene

The invention provides a one-time forming construction process of an embedded distribution box. The one-time forming construction process comprises the concrete steps of (1) sealing line pipe holes inthe upper side and the lower side of the embedded distribution box with plastic caps; (2) constructing a support frame by means of wooden block assembly inside the embedded distribution box; (3) filling the remaining space inside the embedded distribution box except the support frame with filler; (4) cutting a polystyrene board according to the inner diameter of a box body of the embedded distribution box, and embedding the polystyrene board into the box body; (5) welding locating bars on the back of the box body of the embedded distribution box; (6) marking the elevation of the box body andthe axis position of the embedded distribution box on shear wall reinforcement at the embedded position, and welding additional bars around the box body of the embedded distribution box; and (7) carrying out mold sealing, concrete pouring, mold removal, polystyrene board removal, filler cleaning, wooden block support removal, installation of a cover plate and finished product protection operationin sequence. The one-time forming construction process has the advantages of reducing the manufacturing and installation and removal of a one-time box formwork and achieving the purposes of shorteningthe construction time, improving the construction efficiency and reducing the construction cost.

Owner:江苏永联精筑建设集团有限公司

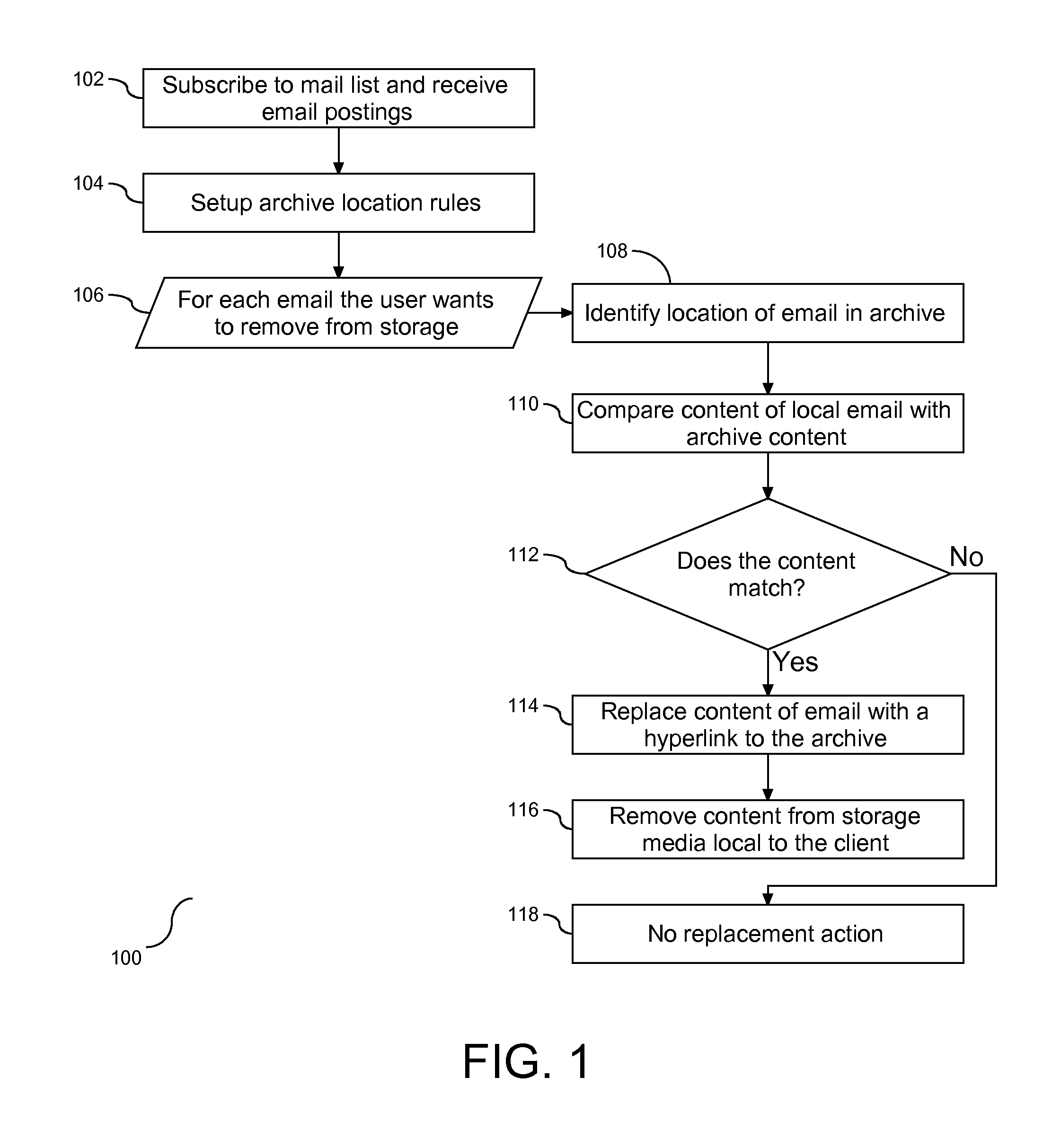

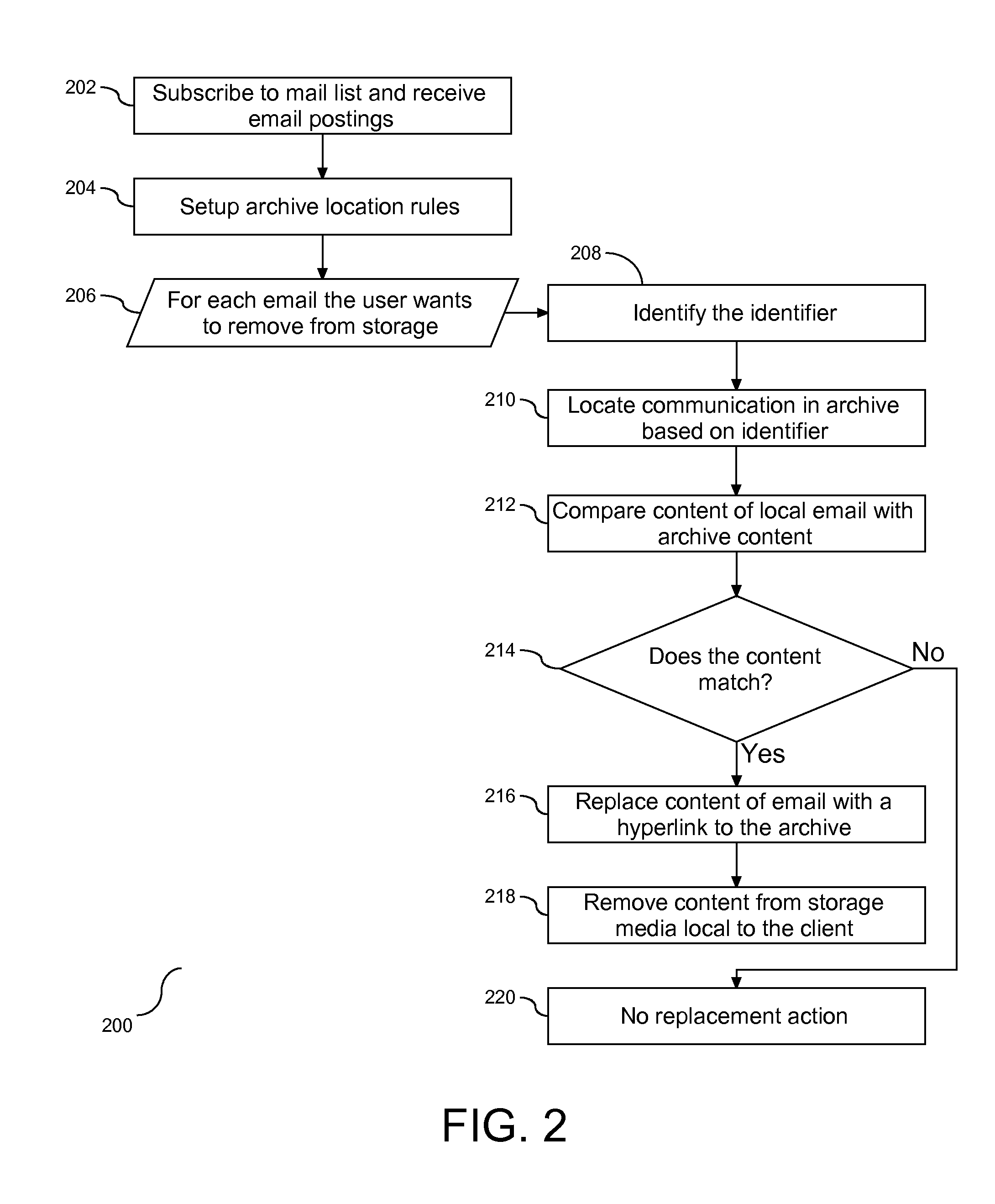

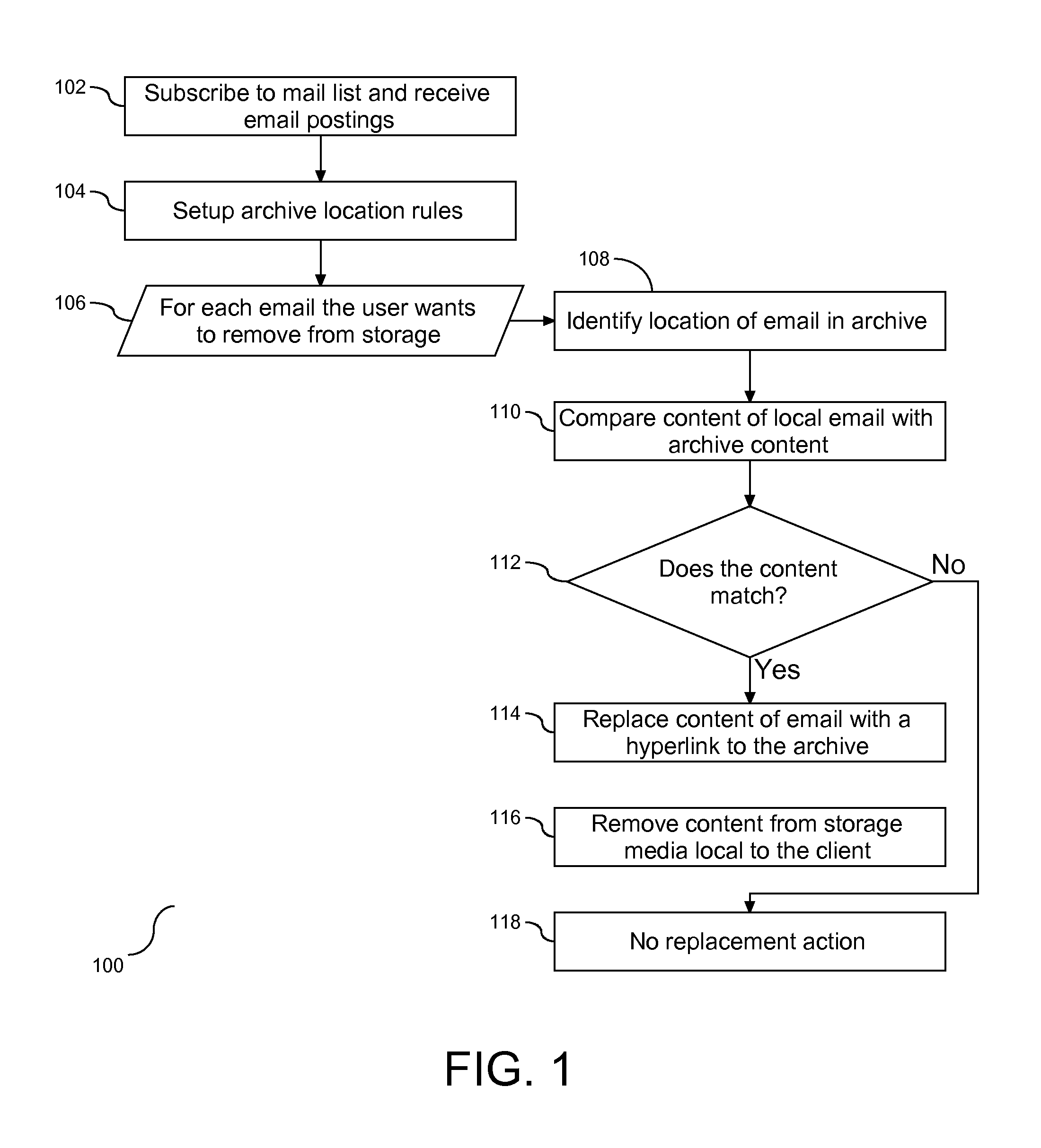

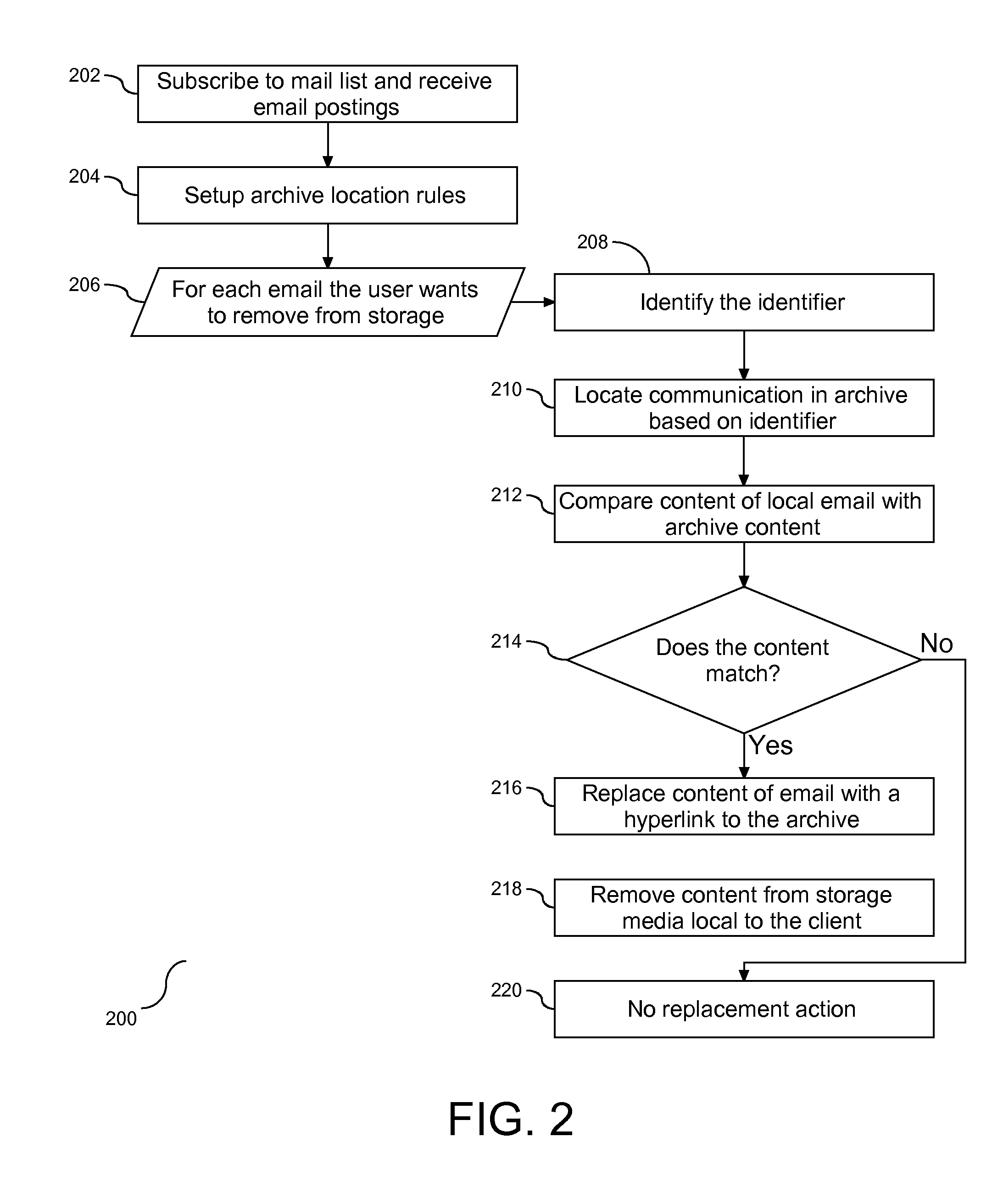

Method and System for Management of Electronic Mail Communication

InactiveUS20110264991A1Multiple digital computer combinationsOffice automationHyperlinkSupport removal

A method, system, and article for management of email communication content across a computer system network. An archive of email communications is retained on storage media in communication with the network. In addition, email communication is retained on storage media in communication with a client machine in the network. To mitigate duplication of email communications, duplicate communications are replaced with a hyperlink to the archive communication. This replacement supports removal of the duplicate communication from the storage media in communication with the client machine.

Owner:IBM CORP

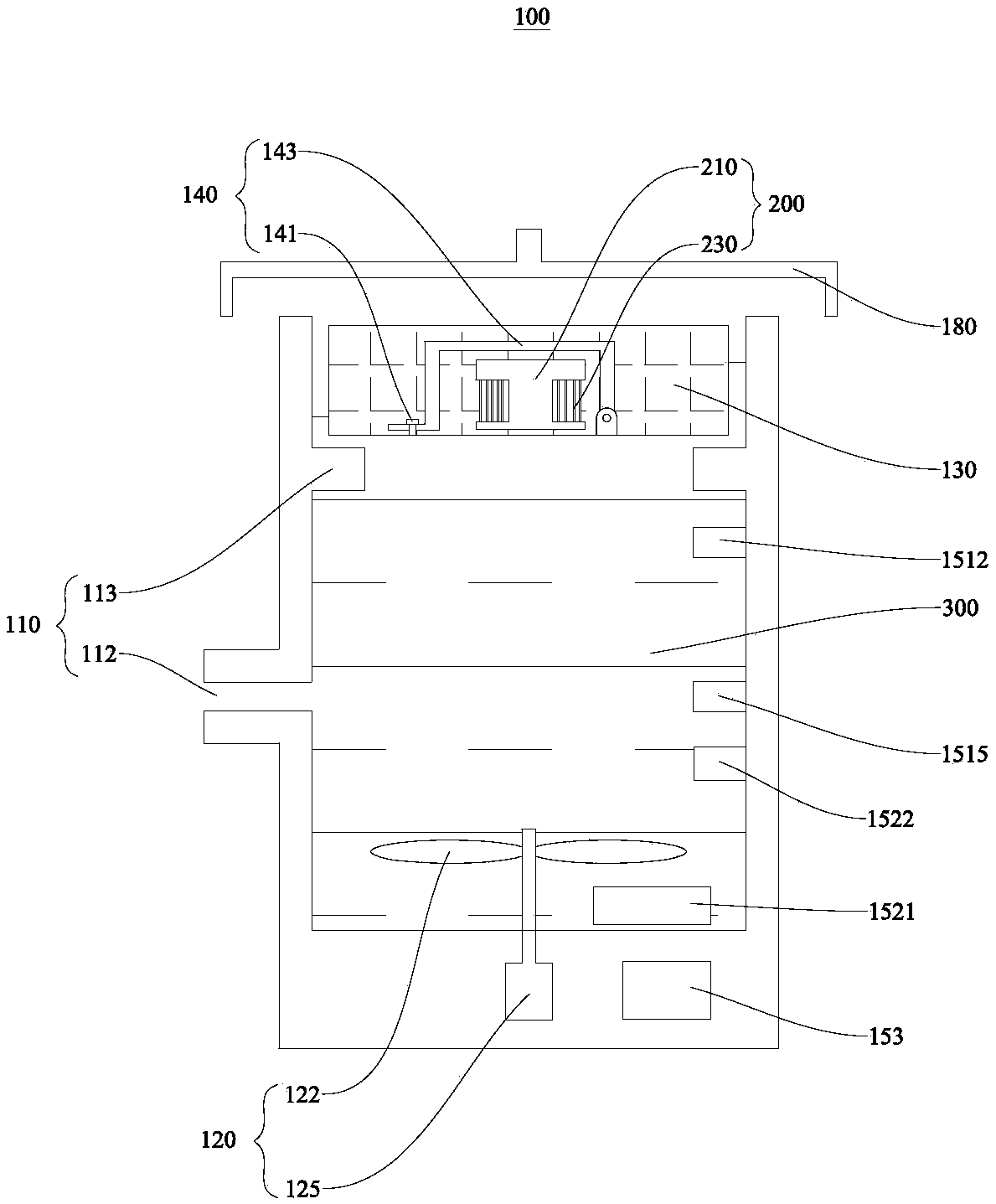

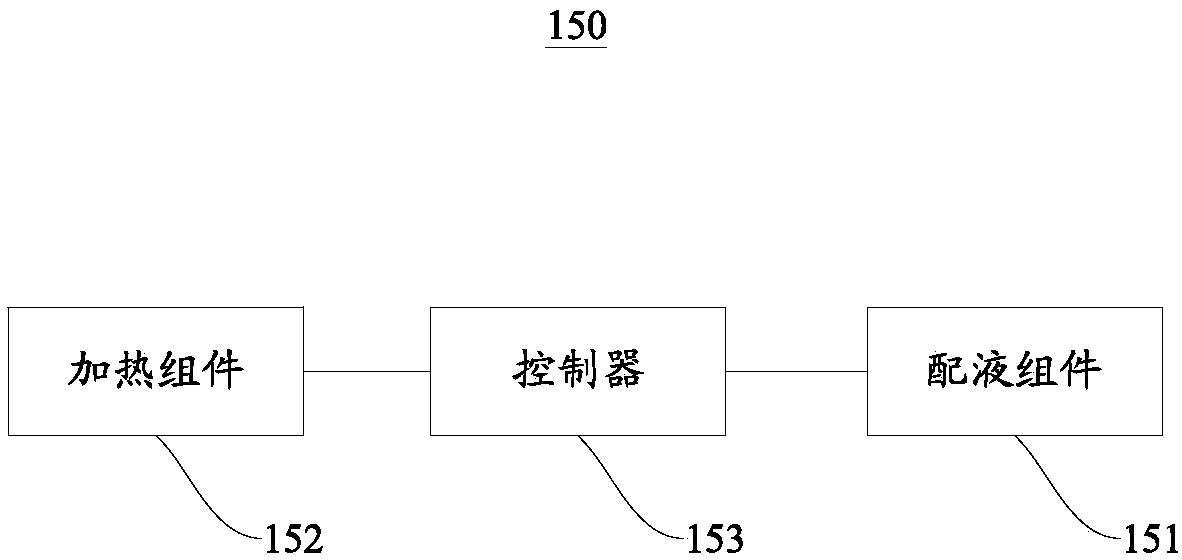

Support removal device and method as well as model printer

InactiveCN108162406AImprove removal efficiencyAdditive manufacturing apparatus3D object support structuresImpellerSupport removal

The invention discloses a support removal device and method as well as a model printer and relates to the field of model printers. The support removal device is applied to removing a supporting pieceof a printing model in a dissolved solution and comprises a support removal groove, a stirrer and a model bracket; the model bracket is a hollow structure; the stirrer comprises a stirring drive pieceand a stirring impeller which are mutually connected; the stirring drive piece is installed in the support removal groove; the model bracket is installed in the support removal groove; the support removal groove is used for receiving the dissolved solution; the model bracket is used for bearing the printing model and enabling the printing model to be soaked into the dissolved solution; and the stirring impeller is used for stirring the dissolved solution. The support removal device has the beneficial effects that the removal efficiency is high, and the supporting piece can be separated from the interior of the printing model.

Owner:广州形优科技有限公司

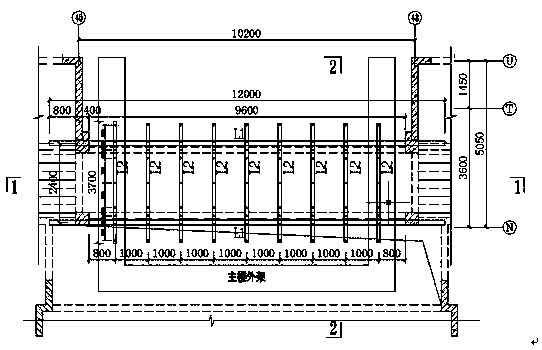

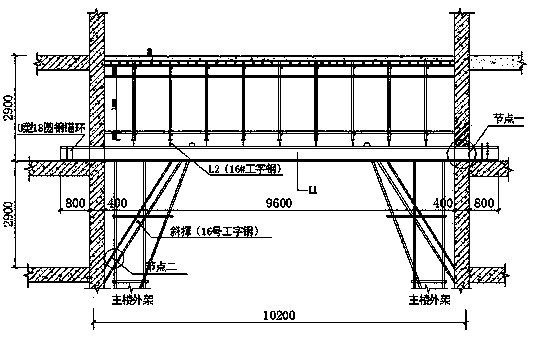

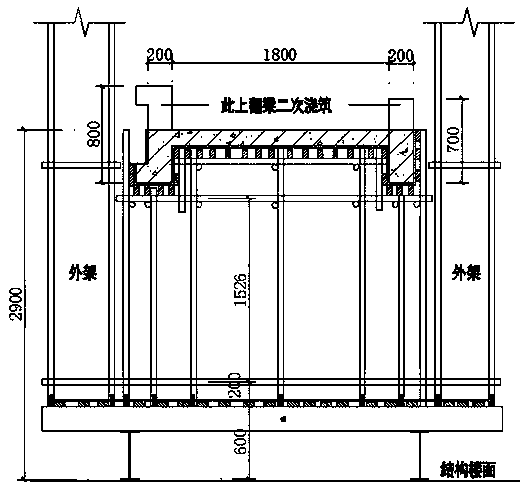

High-rise residential long-span interval corridor high-altitude formwork steel platform construction method

ActiveCN110512719AEasy to install and removeQuick installation and removalForms/shuttering/falseworksSupport removalLong span

The invention relates to a high-rise residential long-span interval corridor high-altitude formwork steel platform construction method. The construction method includes the following steps: step 1: asteel platform is deep designed and processed; step 2: hoisting and anchoring of a section steel main beam are conducted; step 3: installation of a section steel secondary beam is conducted; step 4: inclined support setting of the section steel main beam is conducted; step 5: plane protection setting is conducted; step 6: external protection frame erection is conducted; step 7: formwork support frame erection is conducted; step 8: beam and slab formwork installation is conducted; step 9: beam and slab reinforcement binding is conducted; step 10: concrete pouring is conducted; step 11: formworkremoval is conducted; step 12: corridor decoration construction is conducted; step 13: peripheral support removal is conducted; and step 14: steel beam removal is conducted. According to the technical scheme, a large-span steel beam is used as a main force-bearing component of a supporting platform, and a certain number of transverse connection steel secondary beams are set among steel beams to form a complete and reliable structural construction formwork steel platform.

Owner:NANJING CONSTR ENG GRP

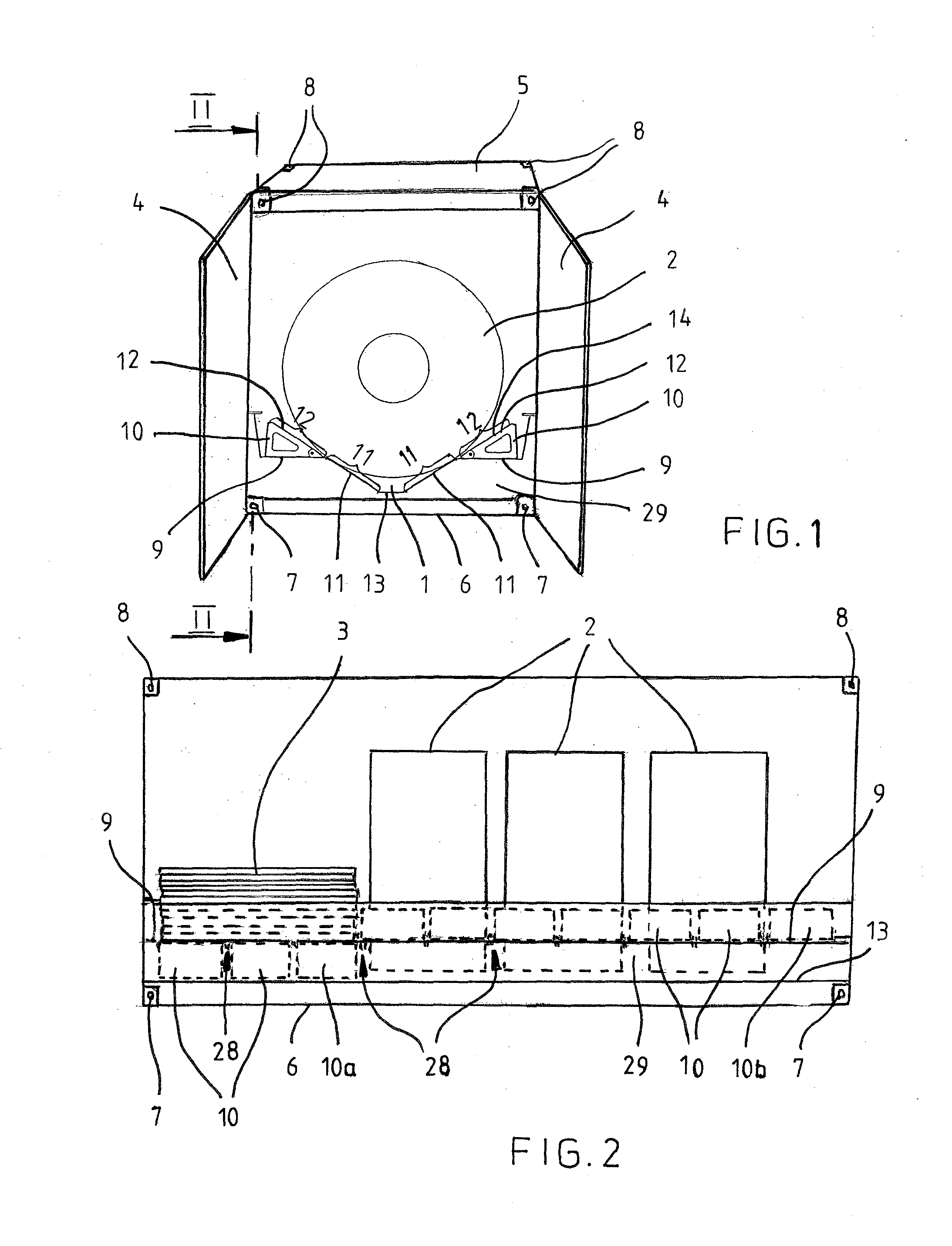

Container

ActiveUS20140027321A1Easy to modifyImprove sturdinessContainers for annular articlesLarge containersSupport removalBraced frame

A container includes a chute for supporting reels, the chute including a bottom, a lower wall zone, an upper wall zone, and a support frame for supporting the chute. The container has a horizontal support plane on both sides of the chute, the upper wall zone being formed by a first support surface of a wedge-like support member placed onto the support plane, a second support surface of the support member resting against the support plane when the support member is in a first use position; a pivot mechanism allowing the support member to be turned in relation to the support frame so that the first support surface sets against the lower wall zone of the chute and the second support surface sets onto the same height level as the support plane for forming a uniform loading plane and for placing the support member to a second use position.

Owner:OY LANGH SHIP AB

Closed removing method for basement enclosure supporting body

InactiveCN104250971AHarm controlReduce the impactArtificial islandsExcavationsBasementSupport removal

The invention relates to basement construction, in particular to a closed removing method for a basement enclosure supporting body. The closed removing method for the basement enclosure supporting body comprises the following steps: 1) after the construction of a concrete support lower part basement structure and the change of supports are completed, manually removing concrete non-main supports at positions intersected with the outer wall of a basement; 2) continuously conducting the construction of the basement structure, wherein concrete pouring and tamping spaces and overlapping reinforcements need to be reserved at corresponding positions for slab construction at an early stage for part of vertical structures such as concrete columns and concrete walls below the supports, and then structure supplementation is made after indoor demolition of the supports and debris removal are completed, i.e., deep design of reservation of construction joints needs to be conducted in advance; 3) after the construction of the basement structure is completed, removing concrete supports in a closed manner in the basement; 4) transporting waste reinforcements, debris and soil outside by using constructed basement lanes. closed removing method for the basement enclosure supporting body has the advantages that the protective shed does not need to be erected in large area, work such as the removal of the supports and the cleaning of wastes is simultaneously conducted with the construction of the upper structure, the construction period of a main line of a project is not occupied, the influence of support removal on the key line of structural construction is reduced, and the overall construction progress is accelerated.

Owner:CHINA MCC20 GRP CORP

A quick way to remove 3D printing supports

ActiveCN106738874BDoes not affect surface qualityReduce dosageAdditive manufacturing apparatus3D object support structuresSupport removalEngineering

The invention discloses a method for rapidly removing a 3D printing support. According to the main achieving manner of the method, a medium material printing head is used for printing a layer of easily degradable material before and after support printing, the support and a component are isolated through the medium material, the component and a substrate are isolated through the medium material, and the substrate and the support are isolated through the medium material. After component printing is over, a model is taken down, the medium layer is degraded, the medium material at the above part is dissolved, and the support structure naturally disengages from the surface of the component. The method is applicable to FDM, 3DP and other 3D printing technologies in which supports need to be added, support removal is fast and efficient, the component surface quality is not affected, the material cost is low, and a forming system is simple in structure.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method And Apparatus For Support Removal Using Directed Atomized And Semi-Atomized Fluid

ActiveUS20210008808A1Additive manufacturing apparatusIncreasing energy efficiencyInterior spaceSupport removal

Owner:POSTPROCESS TECH INC

Apparatus for removing water-soluble support material from one or more rapid prototype parts

ActiveUS8147620B2Low costEasy to useAdditive manufacturing apparatusElectrostatic cleaningSupport removalOperability

The support removal apparatus comprising in combination a retention tank having a manifold assembly comprising a plurality of nozzle heads, articulating arms or a combination of both in hydraulic communication with the discharge side of a pump, collectively configured for agitating an aqueous cleaning solution; a heating element mounted within the retention tank for heating the aqueous cleaning solution to a predetermined temperature set point; a basket strainer mounted within the retention tank in hydraulic communication with the intake side of the pump to mitigate passage of small rapid prototype parts and residual support material therethrough and into the pump and manifold assembly; a thermocouple for maintaining the temperature within a tolerable range for optimum removal of support material; a level indicator to ensure adequate solution level in the retention tank for operability of the pump and heating element; a cabinet having an interface controller mounted on an exterior panel thereof for setting timer and heat functions; and a microprocessor having capabilities for making minute adjustments to the heating element via feedback from the thermocouple and controlling operation of the pump and heating element for a pre-set time interval.

Owner:TAFOYA DAVID JONATHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com