Patents

Literature

87results about How to "Does not affect surface quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

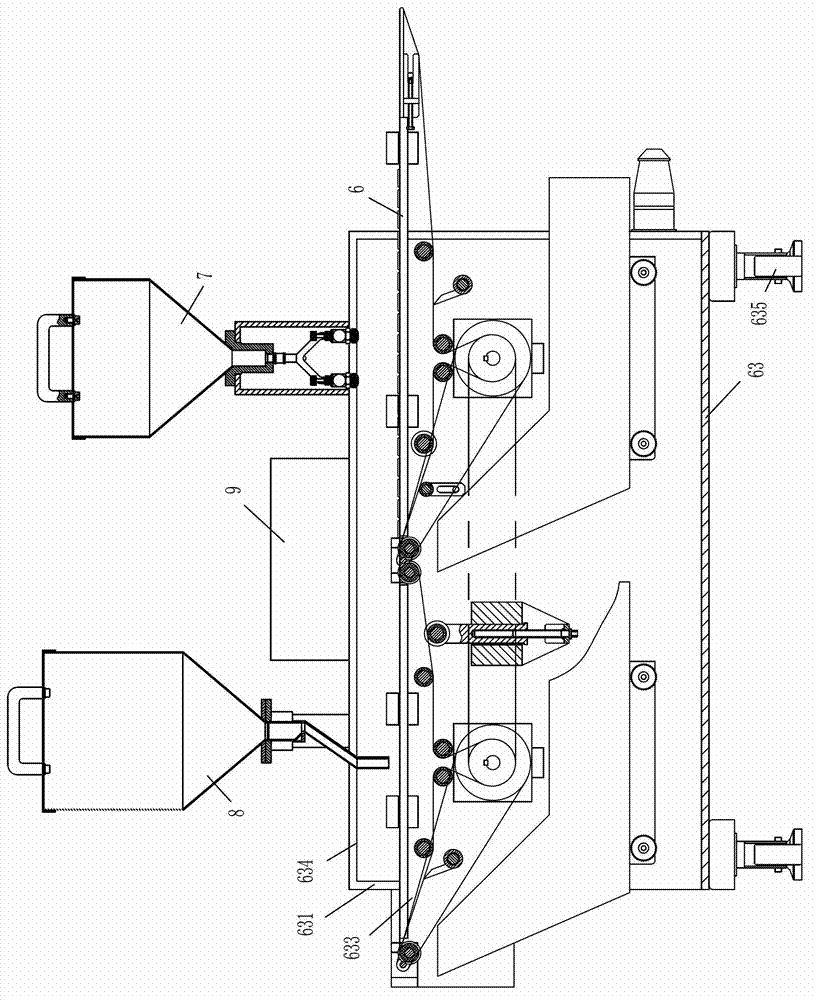

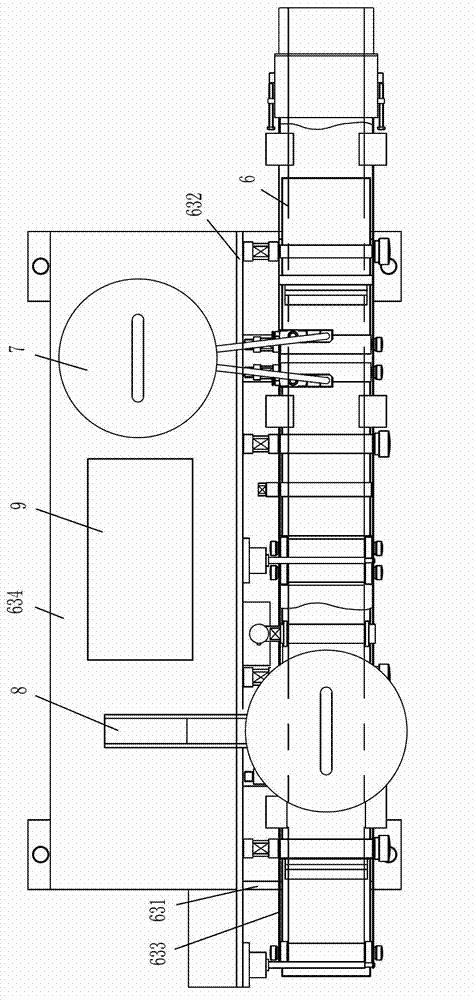

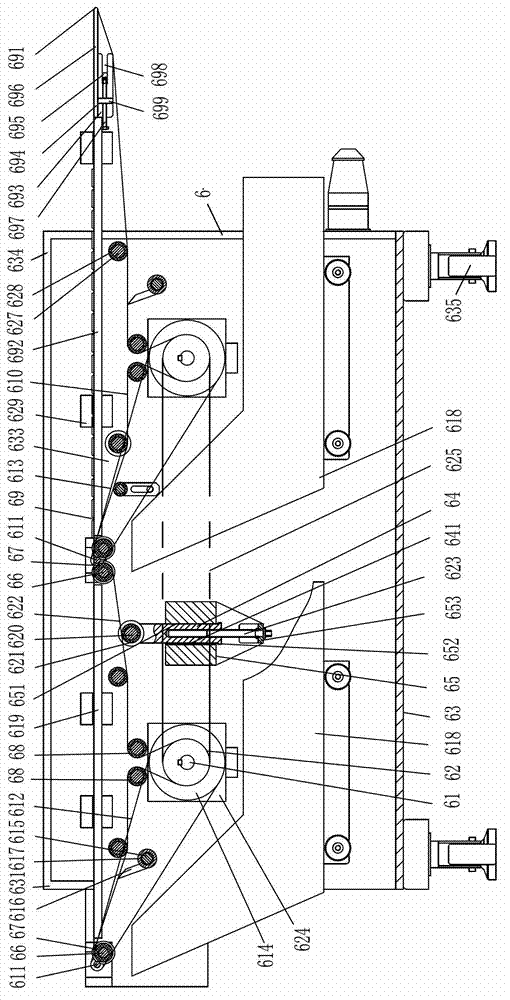

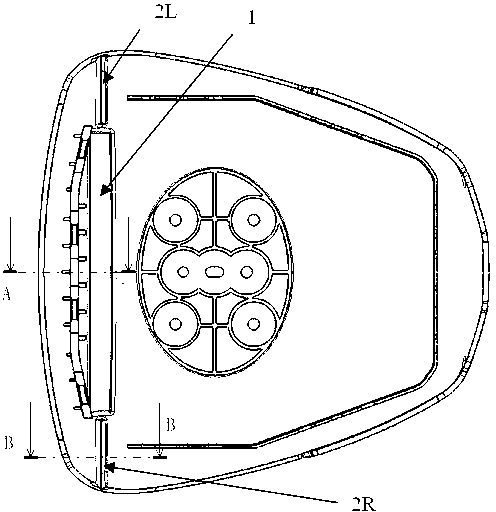

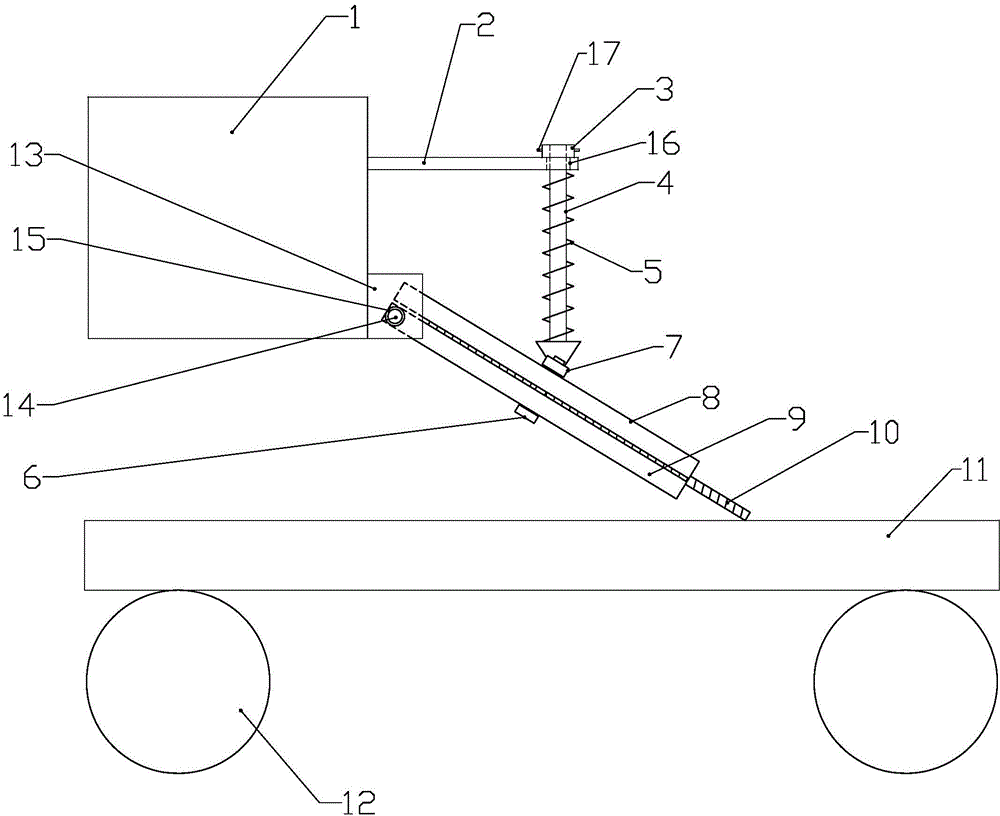

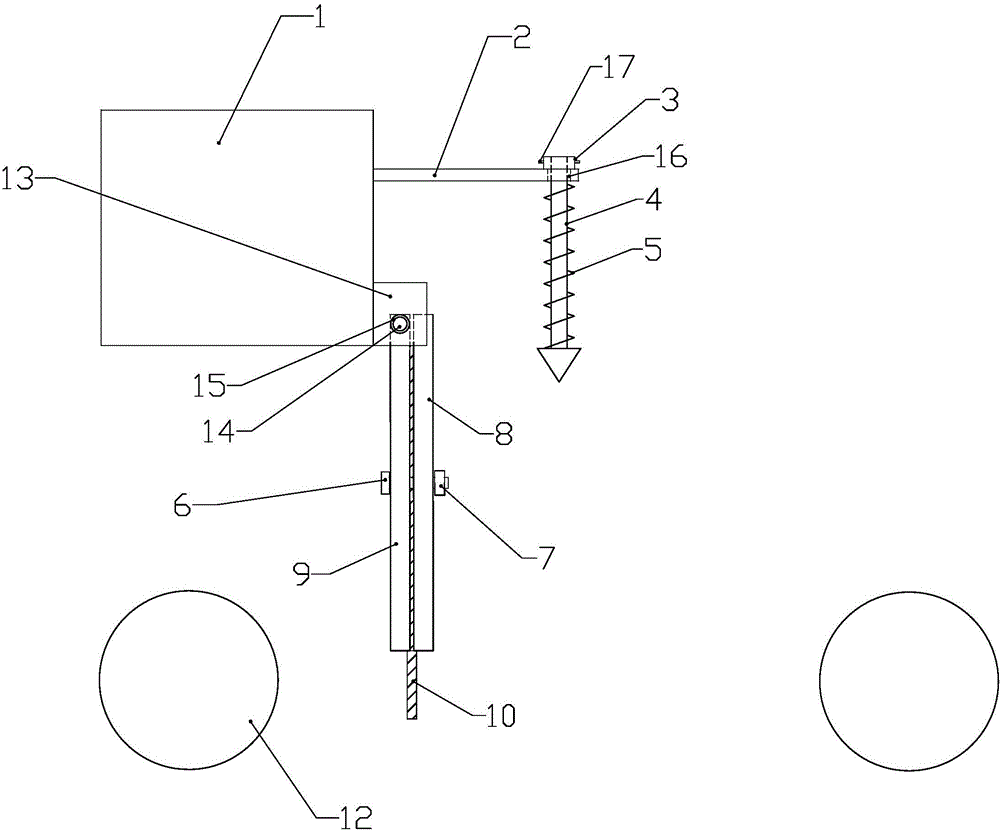

Oil-spraying sesame-scattering machine

InactiveCN103109885ADoes not affect surface qualityImprove surface qualityDough processingPhysicsEngineering

The invention relates to the field of food making equipment, and aims at providing an oil-spraying sesame-scattering machine. The oil-spraying sesame-scattering machine comprises a cake conveying device, an oil-spraying device and a sesame-scattering device, wherein the cake conveying device comprises a machine seat, a front conveyer belt mechanism, a rear conveyer belt mechanism, two transmission assemblies and a driving mechanism; the machine seat is provided with a fixed plate fixedly connected with an end plate, and two vertical plates; the front conveyer belt mechanism and the rear conveyer belt mechanism are connected with the vertical plates; and one transmission assembly is connected with the front conveyer belt mechanism in a transmission way, and the other transmission assembly is connected with the rear conveyer belt mechanism in the transmission way. The oil-spraying sesame-scattering machine provided by the invention ensures that oil (or pulp) and sesame can not be adhered to a conveyer belt after being mixed and can not influence the cake surface quality.

Owner:FUYANG HESHAN FOOD MACHINERY

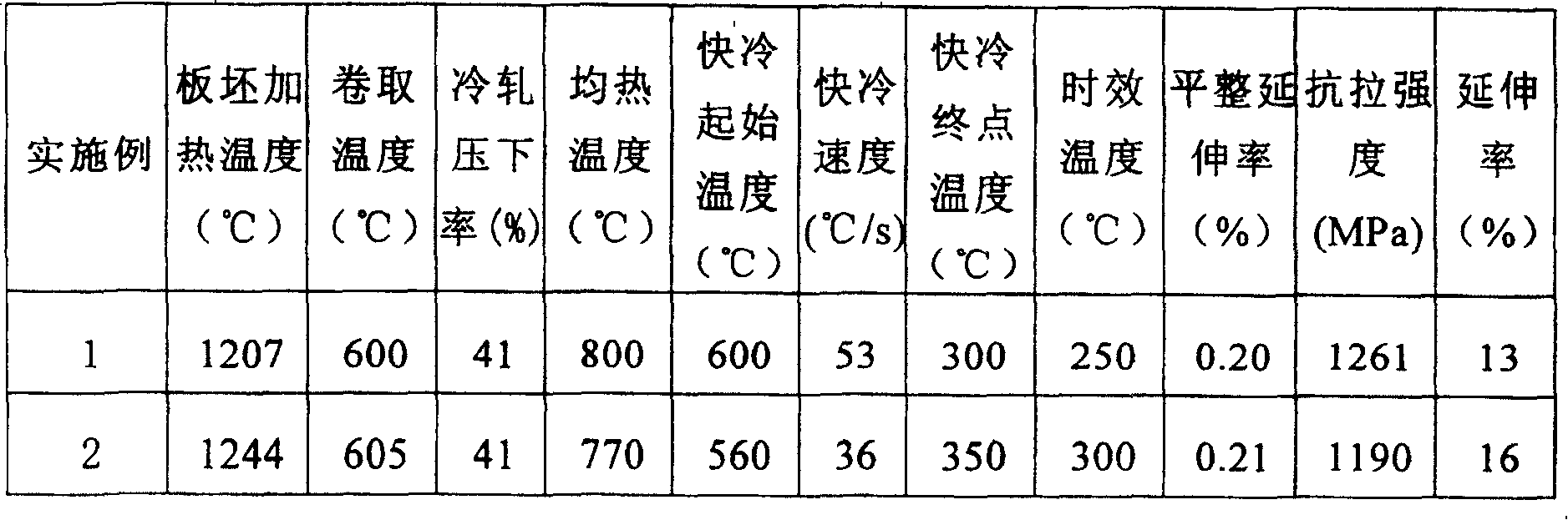

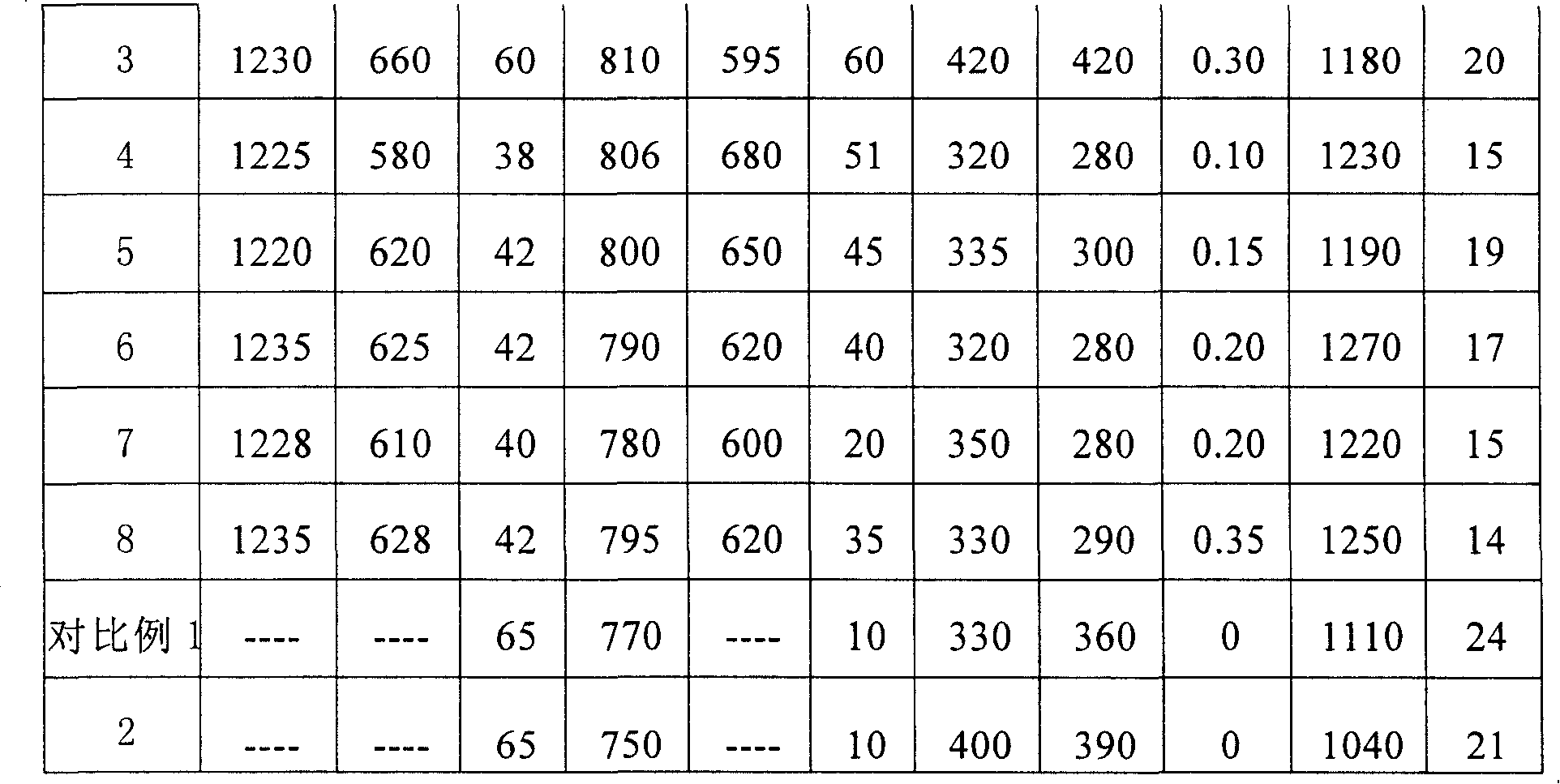

Ultra-high strength strip steel and its production process

ActiveCN1888117ADoes not affect surface qualityReduce manufacturing costFurnace typesMetal rolling arrangementsChemical compositionStrip steel

The ultra-high strength strip steel consists of C 0.10-0.20 wt%, Si<0.6 wt%, Mn not more than 2.6 wt%, Al 0.020-0.080 wt%, Cr 0.35-0.90 wt%, Nb 0.015-0.050 wt%, Ti 0.015-0.050 wt%, and B 0.0005-0.0030 wt%, except Fe and inevitable impurities. Its production process includes the following steps: smelting and casting; hot rolling, acid pickling and cold rolling; continuous annealing and complex roller cooling and gas jetting cooling or high speed gas jetting cooling; and flattening and trimming. It has simplified production process and low production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

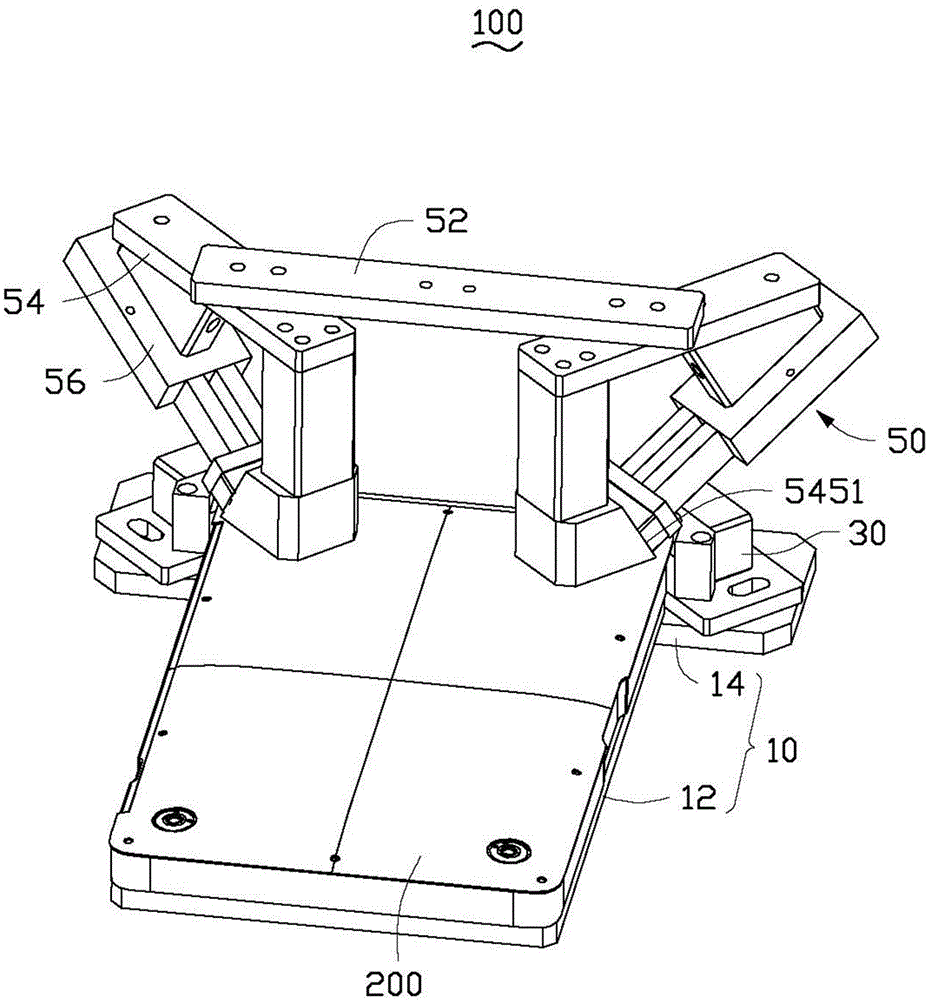

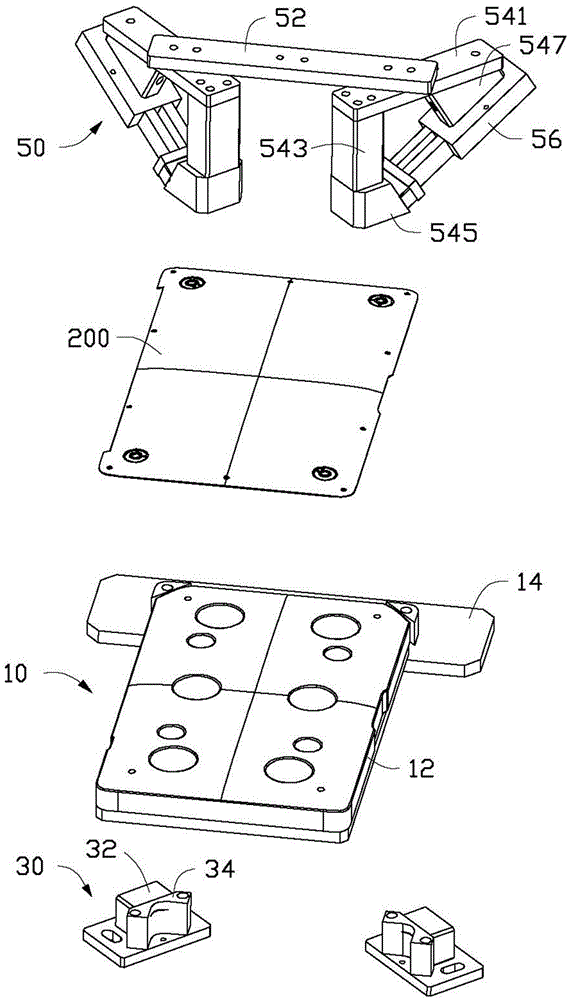

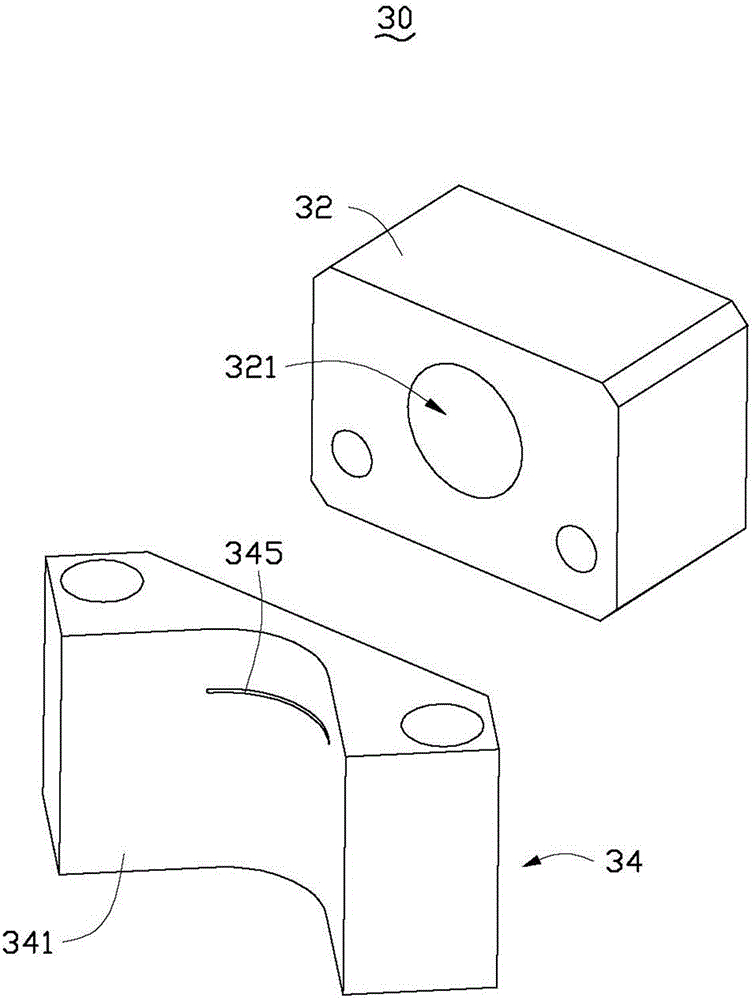

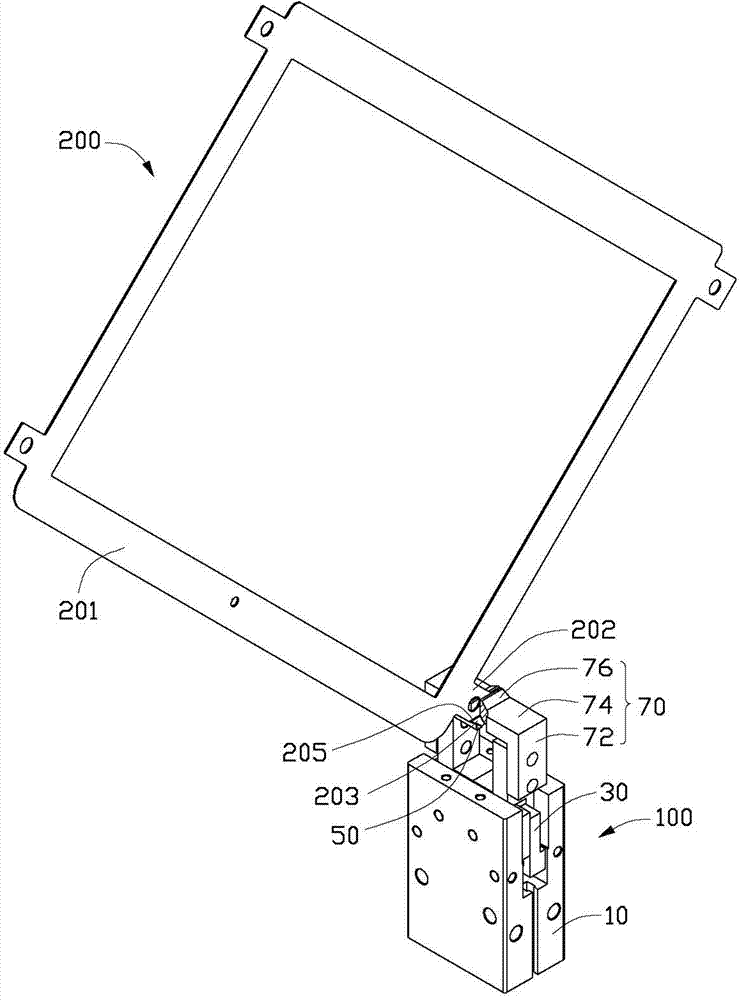

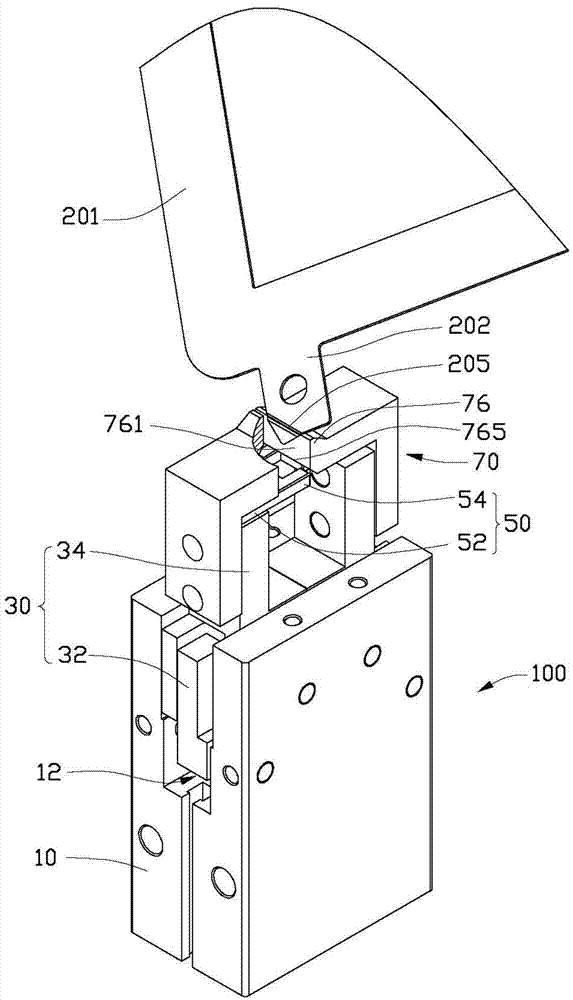

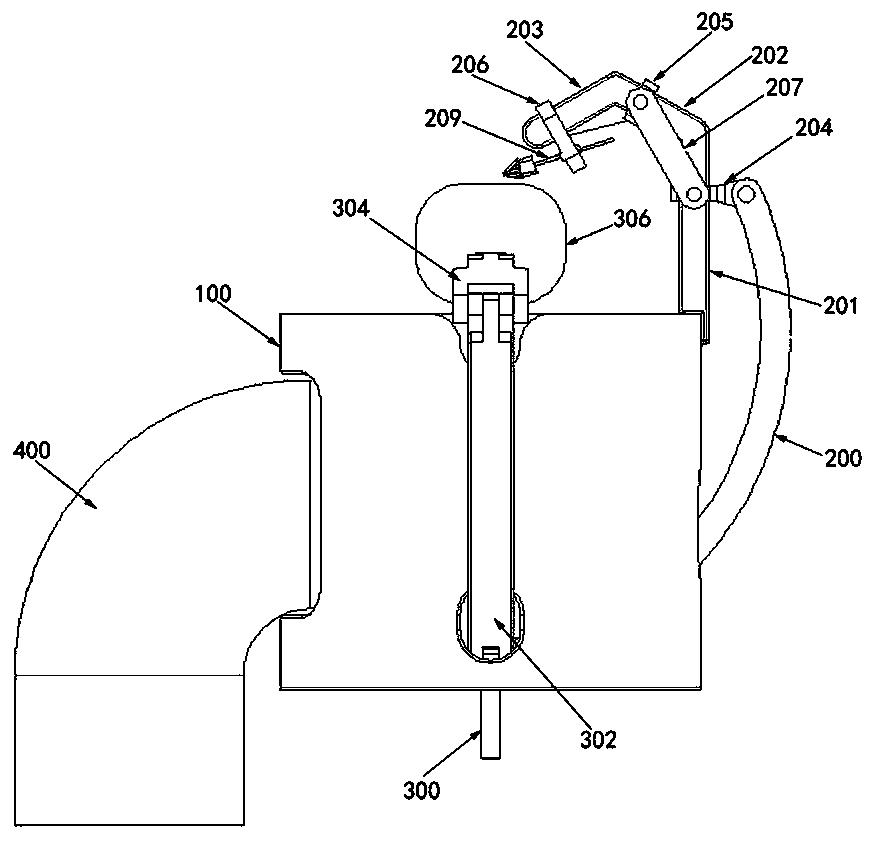

Film tearing mechanism

ActiveCN104553249ADoes not affect surface qualityImprove work efficiencyLamination ancillary operationsLaminationTectorial membraneHigh pressure

A film-removing mechanism configured to cooperate with a mechanical arm to remove a protecting film from a workpiece can include a base, a blowing member coupled to the base, and a holding assembly positioned adjacent to the blowing member. The base can be configured to support the workpiece. The blowing member defining an air outlet can be configured to communicate with an external air resource. The holding assembly can include a supporting member positioned adjacent to the base and a driving member coupled to the supporting member. The supporting member can correspond to the air outlet and the driving member can be configured to connect to the external mechanical arm.

Owner:FU DING ELECTRONICSAL TECH JIASHAN +2

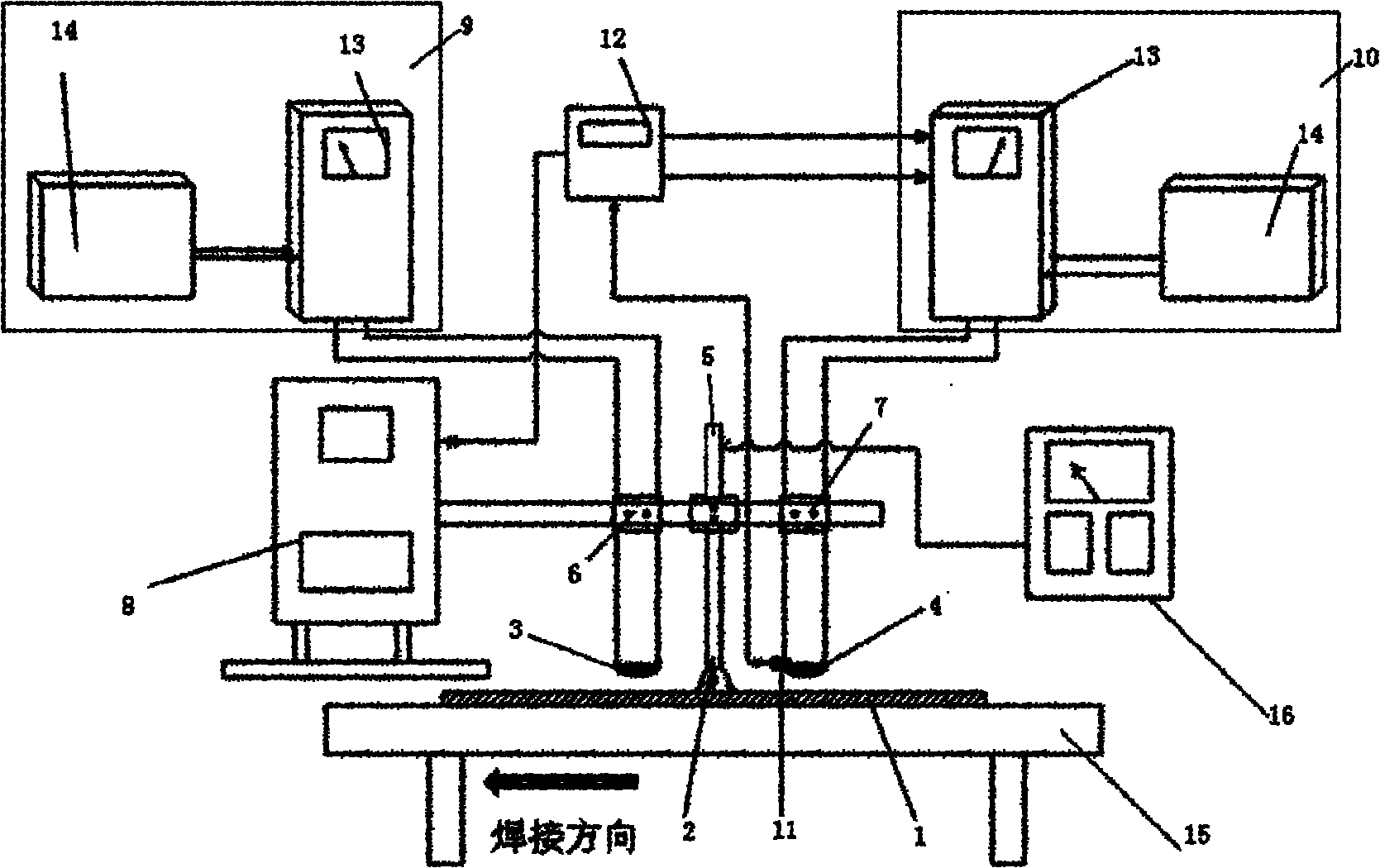

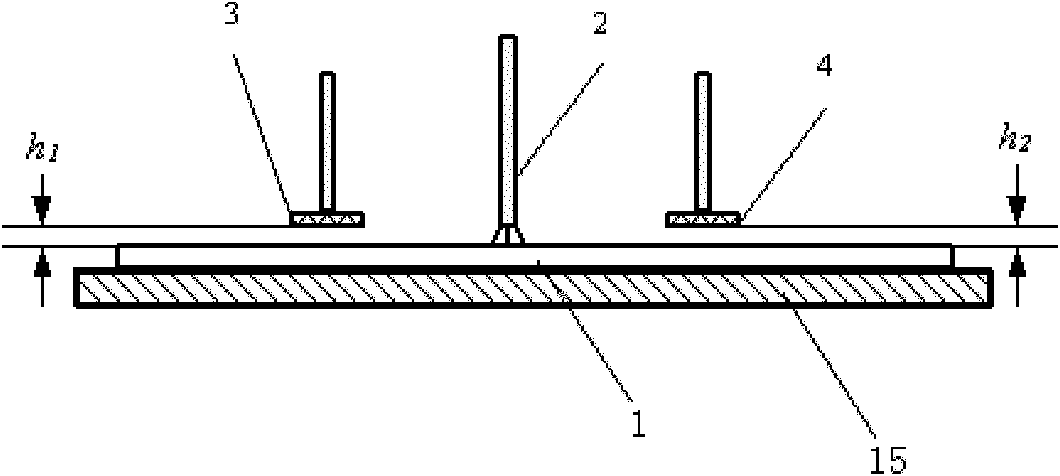

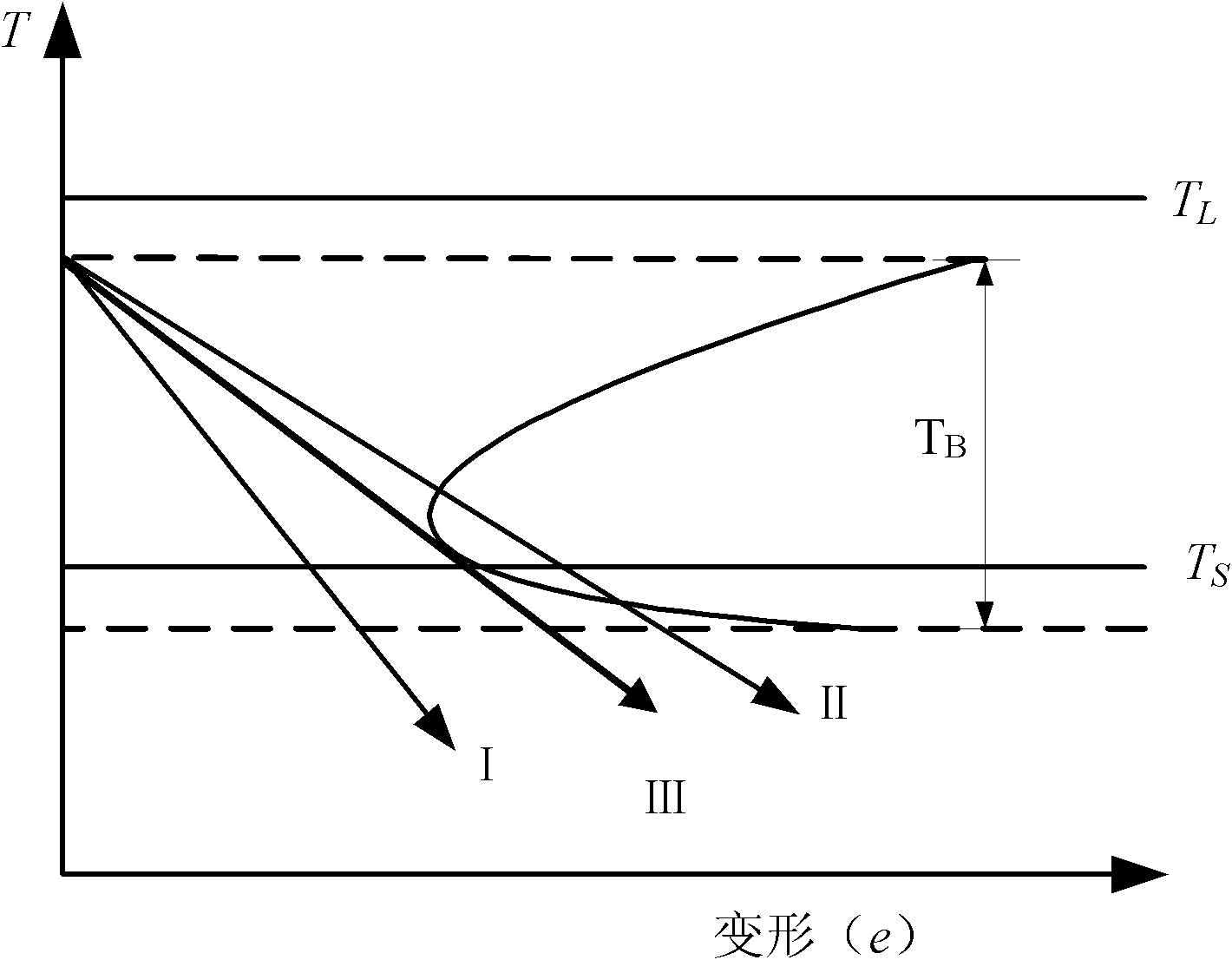

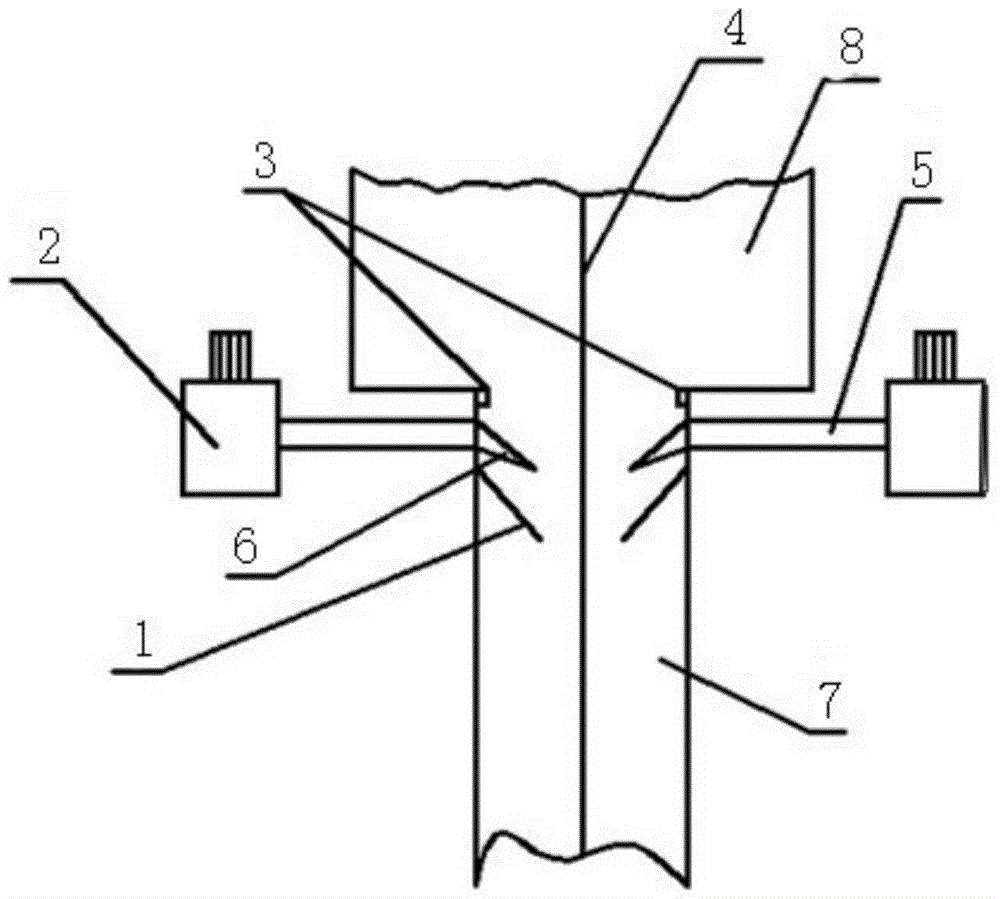

Method and device for controlling welding hot cracking during welding by performing electromagnetic induction heating

The invention relates to a method and device for controlling welding hot cracking during welding by performing electromagnetic induction heating. A preheating coil for preheating a workpiece to be welded is arranged in front of a welding gun; an after heating coil for heating a quickly-cooled welding seam for realizing slow cooling is arranged behind the welding gun; and the center of the after heating coil is positioned between positions which are in the center of a welding pool for the workpiece to be welded and are L1 and L2 distances away from corresponding positions of the upper limit temperature T1 and lower limit temperature T2 of the brittleness temperature rang TB of a welding material. In the invention, preheating before welding and slow cooling after welding are realized, so that the strain rate of the welding seam in the brittleness temperature rang is reduced, and welding hot cracking is controlled effectively on the aspects of metallurgy and mechanics; and moreover, the device has a simple structure, high production efficiency and low cost, is easy to realize, and contributes to energy saving and environmental protection.

Owner:CRRC QINGDAO SIFANG CO LTD

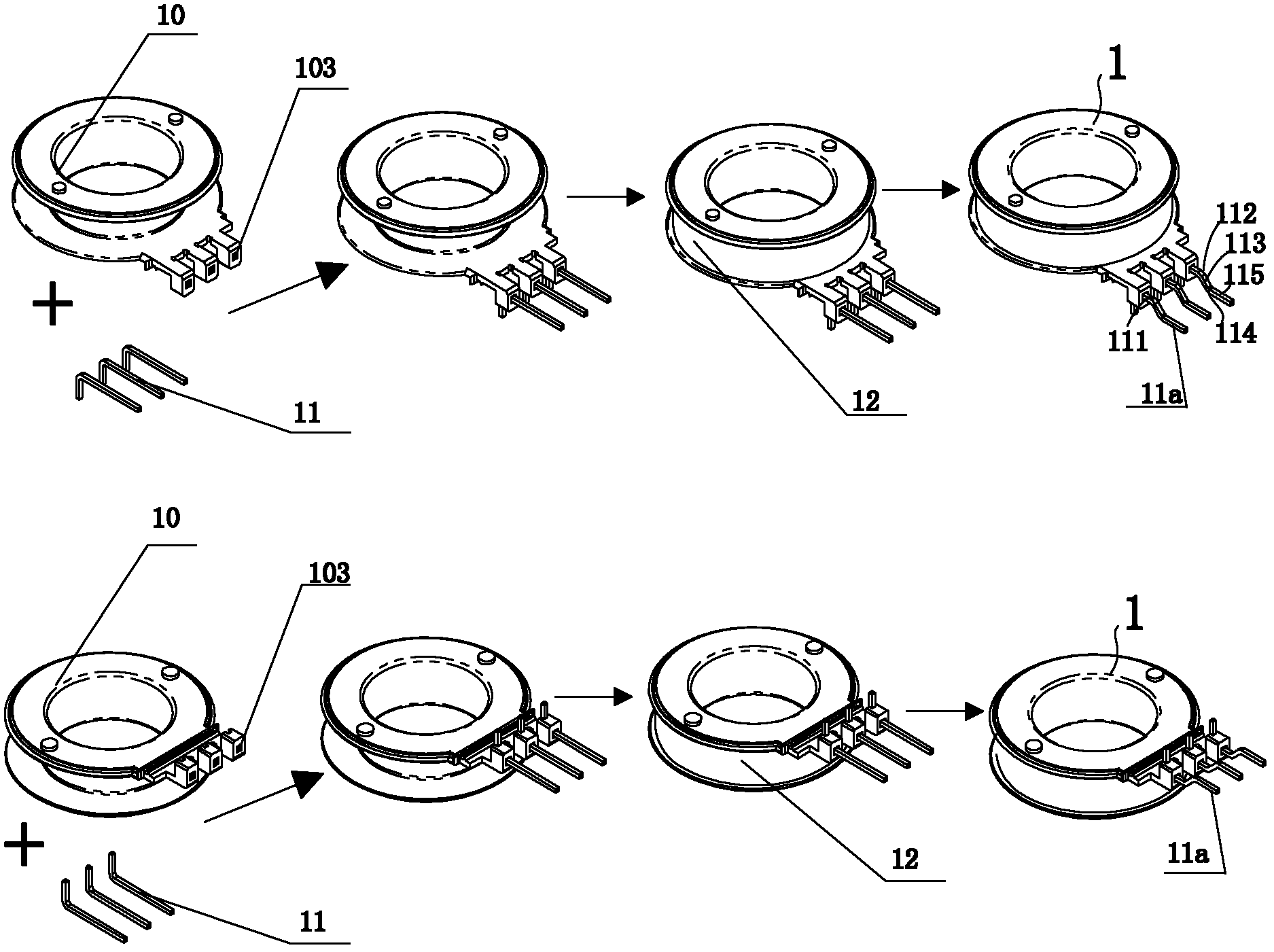

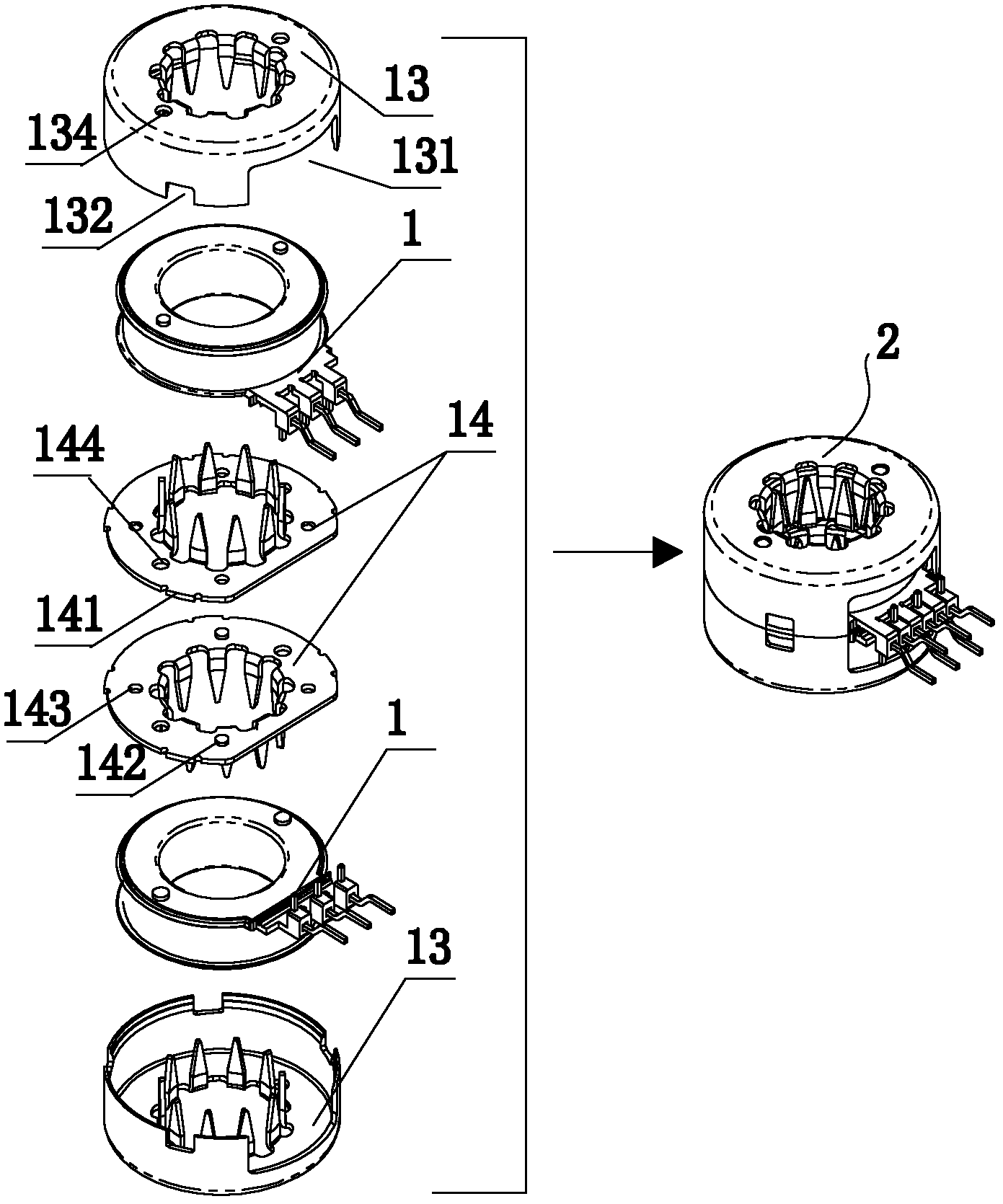

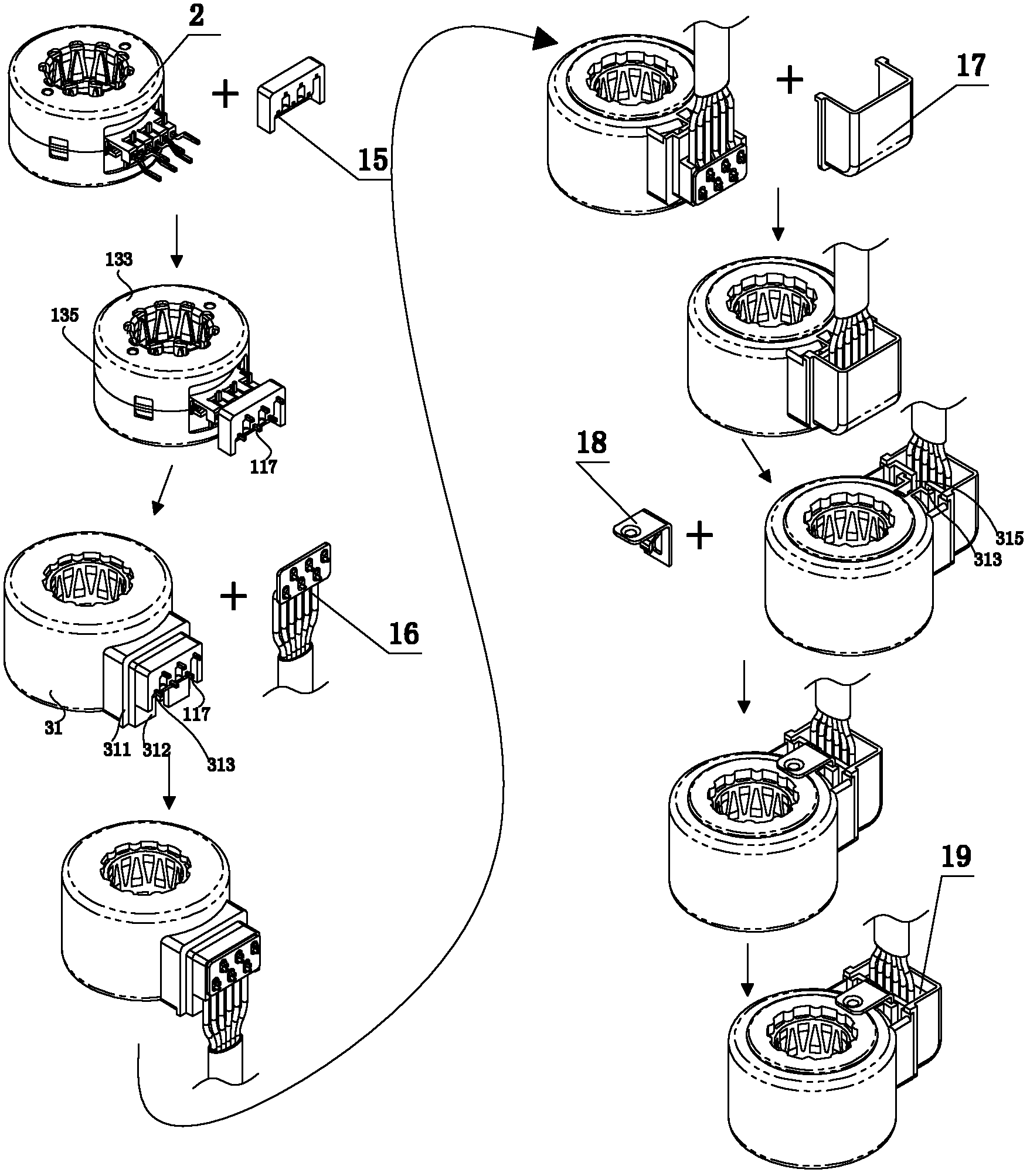

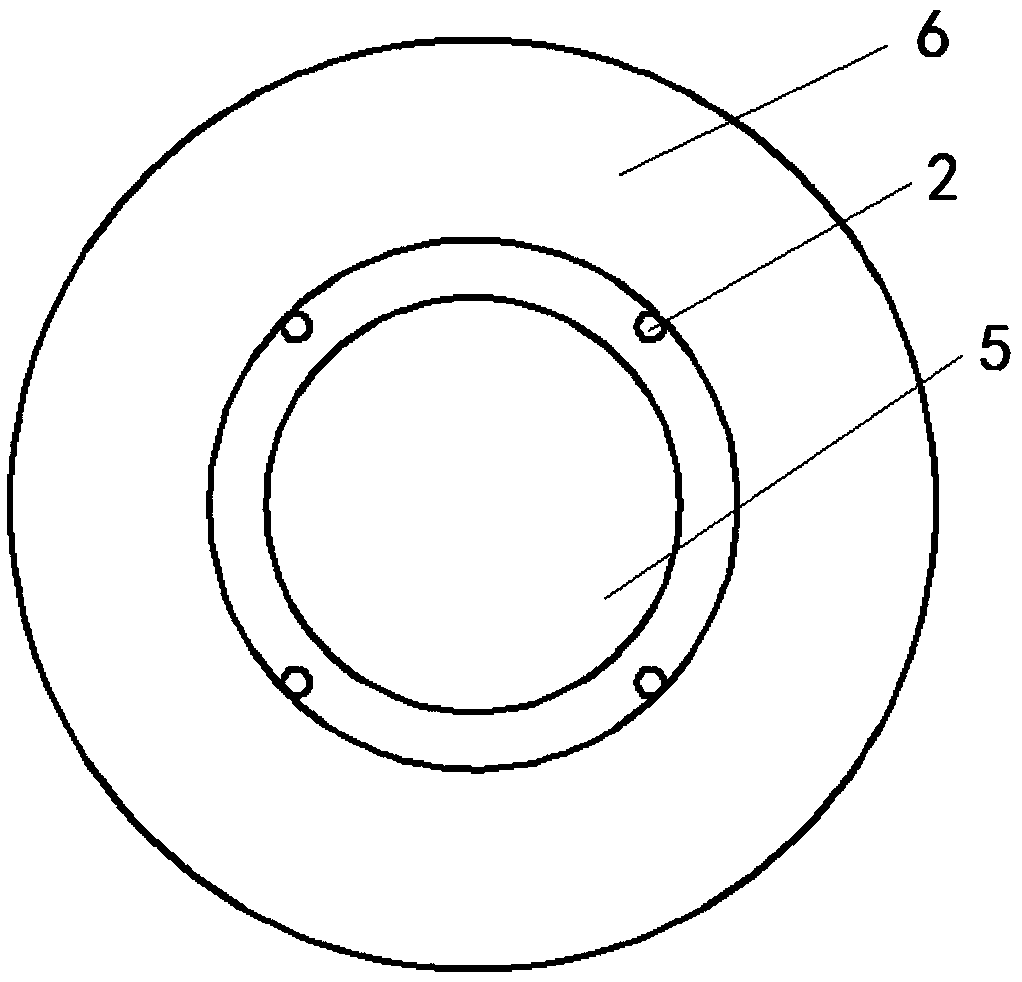

Coil part and manufacturing method therefor

ActiveCN102916514ADoes not affect surface qualityEasy loading and unloadingManufacturing dynamo-electric machinesEfficient regulation technologiesEngineeringElectrical and Electronics engineering

The invention discloses a coil part, which comprises a stator component, wherein the stator component comprises stator shells, electromagnetic polar plates and stator windings, and each stator winding is provided with three contact pins. The coil part also comprises contact pin protection elements, wherein a contact pin holes correspondingly matched with the stator component are arranged on each contact pin protection element, the contact pin on the stator component is inserted into the contact pin hole of the contact pin protection element and exposed out of the outer surface of the contact pin protection element, the contact pin protection element and the stator component are assembled together and then are subjected to injection molding to form a coil injection molding piece, an injection molding layer of the coil injection molding piece is coated with an insulated separation bars of the contact pin protection elements and is not coated on the end part of the contact pin, which stretches out of the contact pin protection element or the outer surface of the contact pin protection element, which is back to the stator component. Based on the coil part, the invention also provides a manufacturing method for the coil part.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

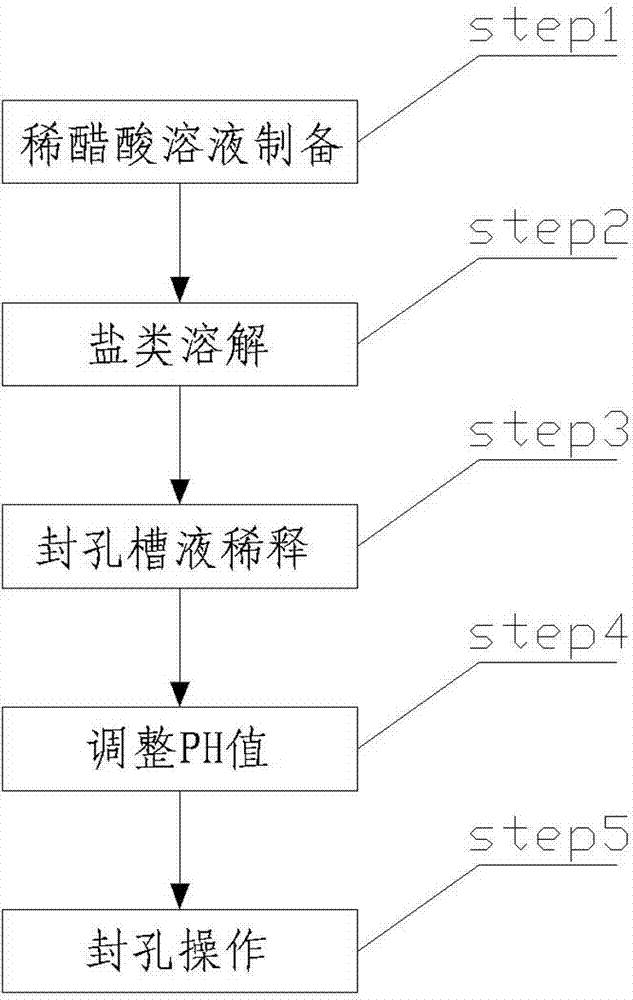

Novel hole sealing tank liquid for aluminum alloy oxidation section and sealing method by using the same

InactiveCN102817059ADoes not affect surface qualityTo achieve the effect of green surfaceSurface reaction electrolytic coatingAcetic acidActive agent

he invention provides a novel hole sealing tank liquid for an aluminum alloy oxidation section. The tank liquid is characterized by containing trivalent chromium ions with concentration of 0.05-0.5g / L and nickel ions with concentration of 0.5-5g / L. Preferably, the novel hole sealing tank liquid contains acetic acid, a surfactant and a dispersing agent, and has a pH value between 5 and 7 and concentration of the trivalent chromium ions of 0.1g / L. The novel hole sealing tank liquid for the aluminum alloy oxidation section provided by the invention utilizes a principle that trivalent chromium ions are greener than the nickel ions; and when transparent oxide film pores absorb a small amount of chromium ions, the film pores show a particularly green color, so as to realize a surface greening effect without influencing the surface quality. The invention also provides a sealing method based on the novel hole sealing tank liquid.

Owner:佛山金兰铝厂有限公司

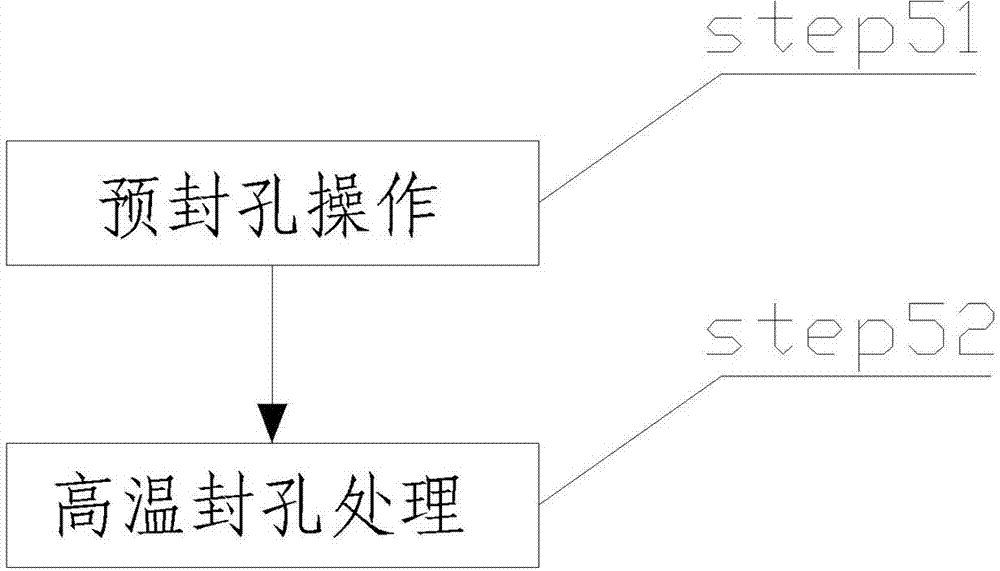

High-hardness roller processing method

ActiveCN101417342AImprove toughnessReduce heat transferAutomatic control devicesFeeding apparatusEngineeringHardness

The invention discloses a processing method of high-hardness rolls, comprising the following steps: (1) the roll with the hardness of 86HSD to 99HSD is placed on a lathe, a CBN polycrystalline blade is used as a lathe tool for carrying out rough machining to the roll at the cutting speed of 50 to 90m / min, the feed amount is 0.7 to 1.2mm / r, and the cutting depth is 0.5 to 1.5mm; (2) the CBN polycrystalline blade is used as the lathe tool for carrying out semifinishing machining to the roll at the cutting speed of 100 to 180m / min, the feed amount is 0.35 to 0.5mm / r, and the cutting depth is 0.2 to 0.5mm; and (3) the CBN polycrystalline blade is used as the lathe tool for carrying out finishing machining to the roll at the cutting speed of 200 to 250m / min, the feed amount is 0.15 to 0.3mm / r, and the cutting depth is 0.1 to 0.5mm. The method has short processing time, high efficiency and low cost.

Owner:BAOSTEEL ROLL SCI & TECH

Colorimetric ware and preparation method thereof

ActiveCN101042333AQuality improvementImprove adhesionMaterial analysis by optical meansComposite material

This invention relates to one analysis comparison hardware and its process method improvement, which is characterized by the following: the glass slice is added with melt agent; finely processing the glass slices into adhesive surface to keep natural absorptive property and then processing melt adhesive operation under lower comparison glass soften temperature.

Owner:YIXING JINGKE OPTICAL INSTR

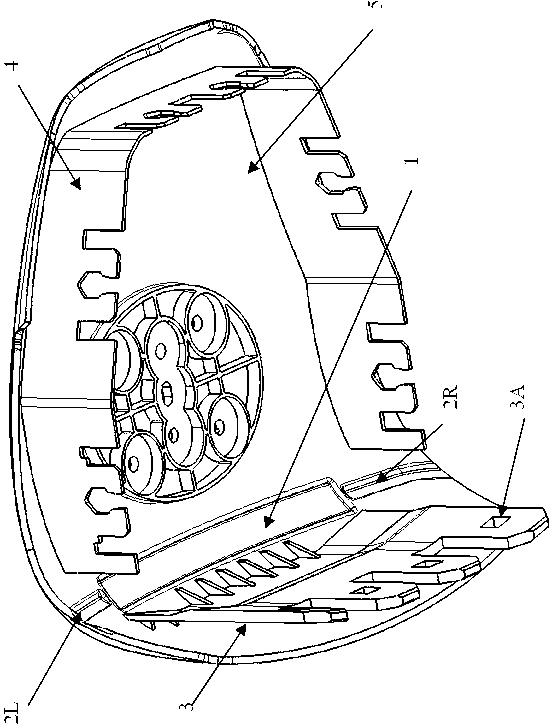

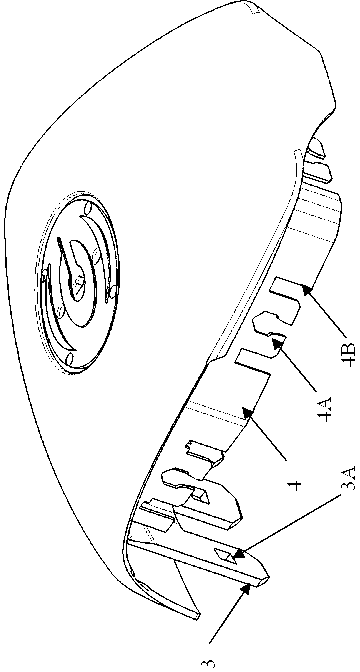

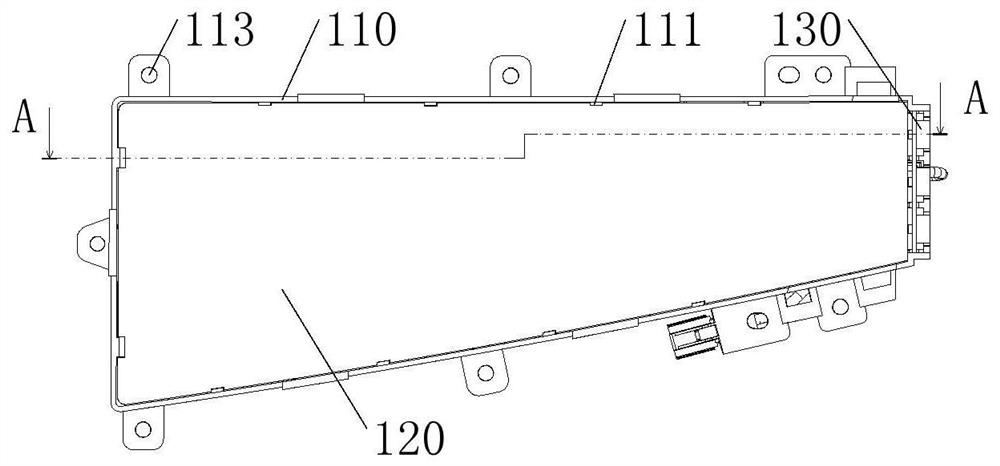

Trim cover of supplementary restraint system and installed on car steering wheel

ActiveCN103121430AChange the way it unfoldsDoes not affect surface qualityPedestrian/occupant safety arrangementSteering wheelEngineering

A trim cover of a supplementary restraint system and installed on a car steering wheel comprises a trim cover body, wherein a square wide groove is formed in the middle position of the rear part of the trim cover body to form a reduction structure, two short reduction lines are arranged on two sides of the square wide groove, and a hammer-shaped groove is formed in the periphery of the trim cover body. According to the trim cover of the supplementary restraint system and installed on the car steering wheel, a traditional unfolding method of the supplementary restraint system is changed. A tearing line design is not adopted on the trim cover, the reduction structure of the square wide groove is formed in the rear part of the trim cover and as a flipping rotary shaft, material which the square wide groove is made of is pretty thin, and the square wide groove plays a role as the rotary shaft in a flipping process. Due to the adoption of the flipping structure, the periphery of the trim cover and a shell body of the supplementary restraint system are clamped through the hammer-shaped groove and a hammer-shaped head, the traditional unfolding method of the supplementary restraint system is changed, and the supplementary restraint system is easy to open. Meanwhile, due to the fact that the two short reduction lines arranged on the two sides of the wide groove are located behind the trim cover, surface quality of the trim cover is not affected even if injection molding shrinkage marks exist.

Owner:JINZHOU JINHENG AUTOMOTIVE SAFETY SYST

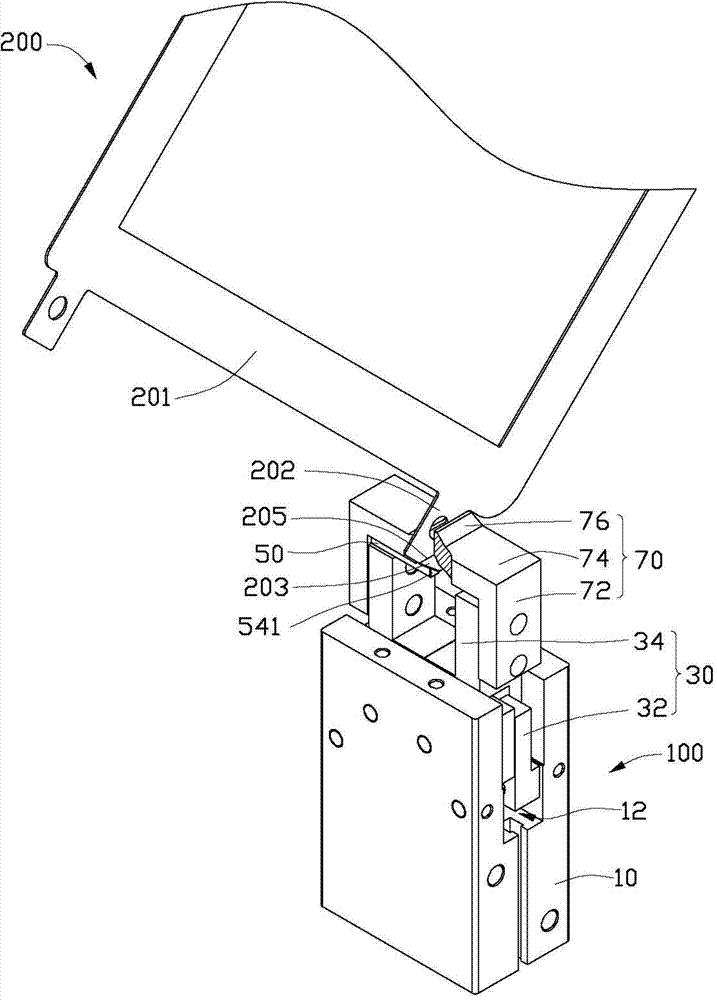

Film-stripping method and film-stripping mechanism therewith

InactiveCN104512089AImprove work efficiencyDoes not affect surface qualityLamination ancillary operationsLaminationEngineeringTectorial membrane

A peeling mechanism configured to cooperate with a mechanical arm to remove a protecting film from a workpiece can include a driver, two clamping members coupled to the driver and spaced from each other, and two cutting members respectively coupled to the clamping members oppositely to each other. Each cutting member can include a protruding end extending towards the other cutting member. The protruding end protrudes out of the clamping member. The driver can be configured to move the two clamping members towards each other.

Owner:FU DING ELECTRONICSAL TECH JIASHAN +2

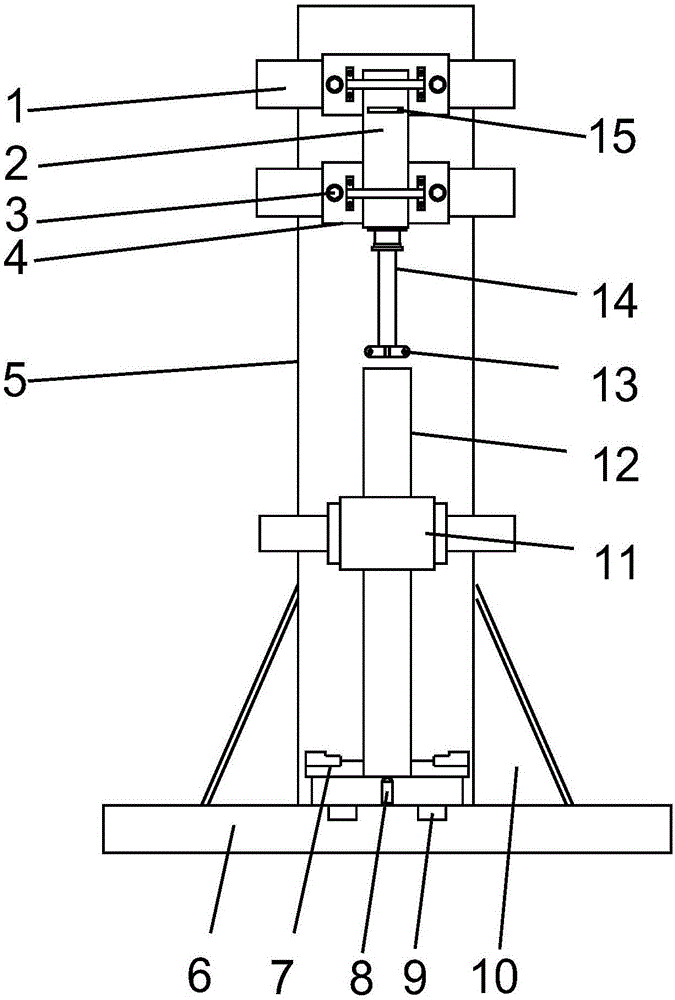

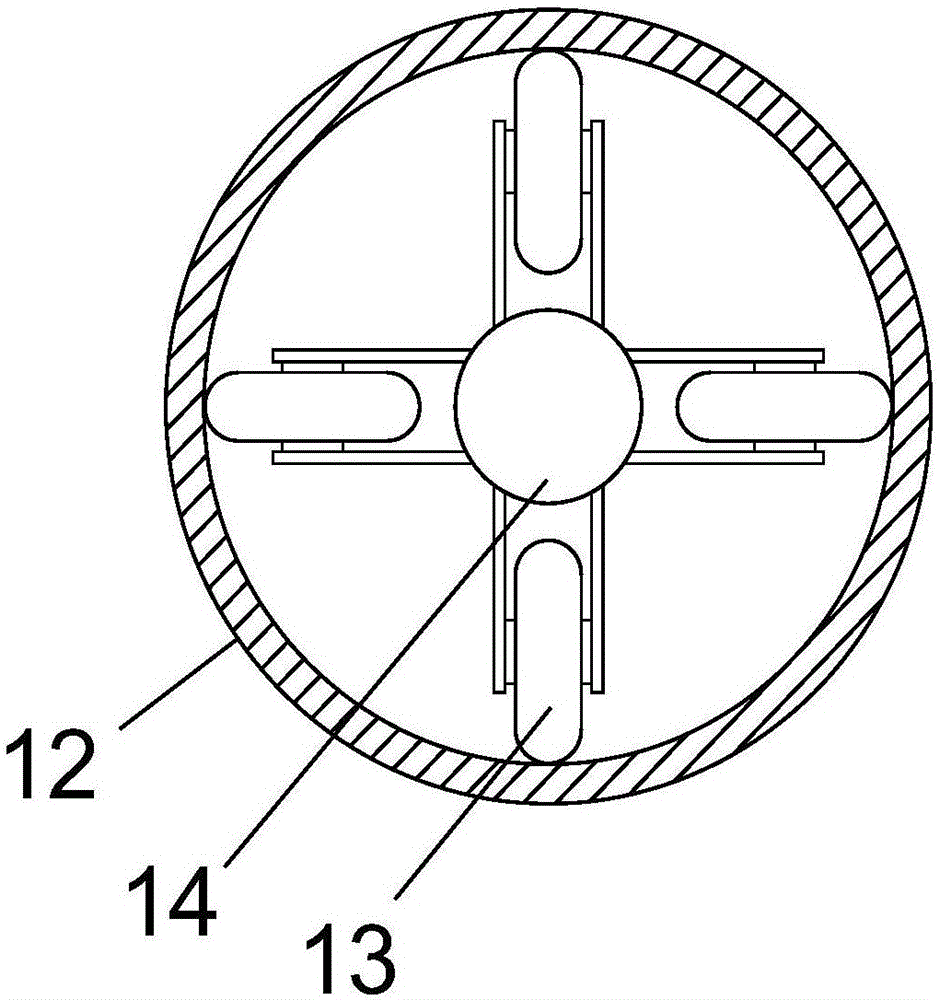

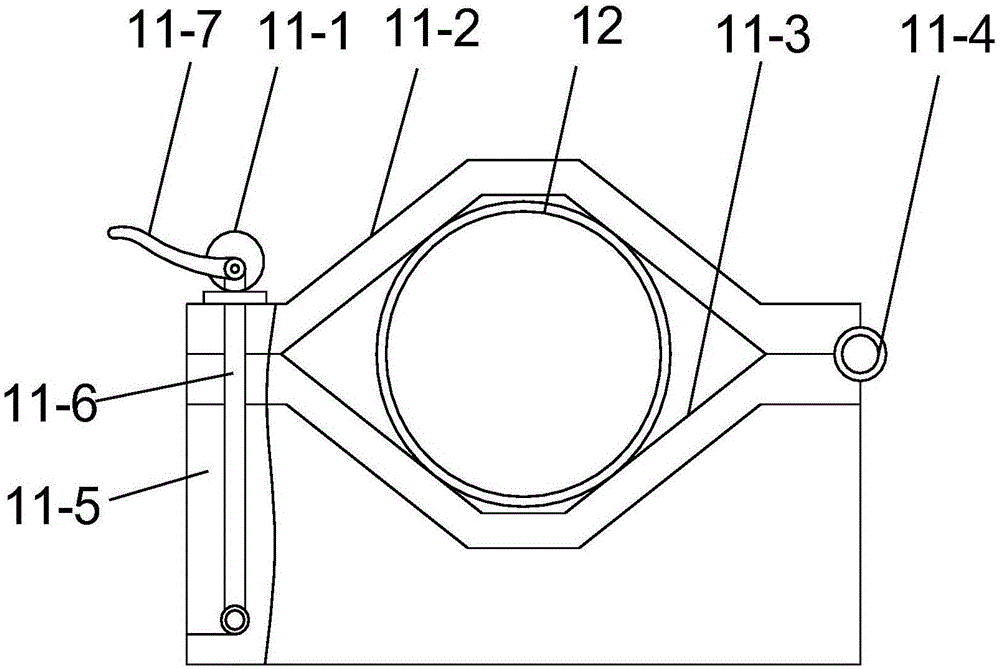

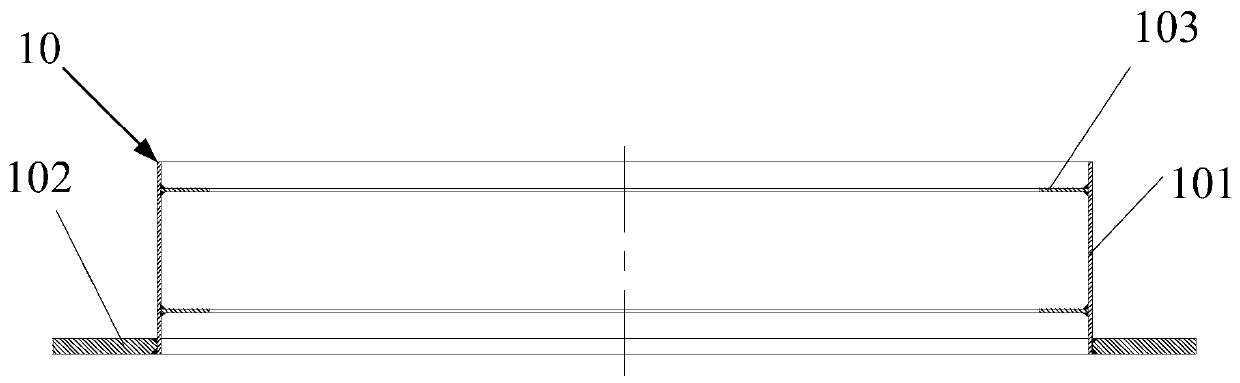

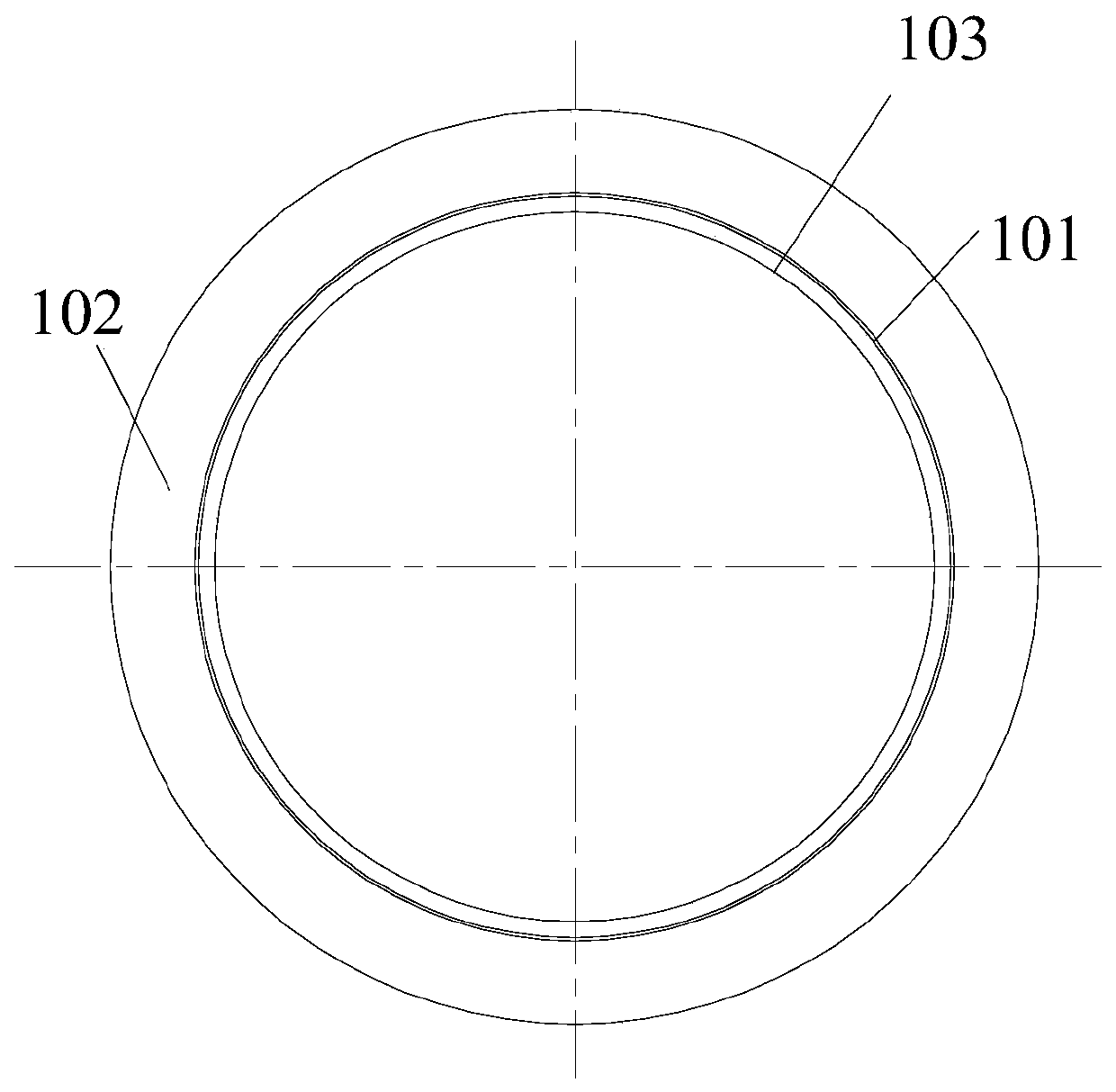

Vertical steel pipe self-centering straightening equipment

InactiveCN106670268AReduce frictionBe at easeMetal-working feeding devicesPositioning devicesSteel tubePiston rod

The invention discloses vertical steel pipe self-centering straightening equipment. The vertical steel pipe self-centering straightening equipment comprises a machine frame, a machine seat, an oil cylinder and straightening rollers; the machine frame is fixed to the machine seat; a three-claw clamping disc is welded and fixed to a welding block which is positioned on the machine seat; the oil cylinder is vertically downward and is fixedly mounted on a sliding seat; the sliding seat is arranged on a transverse guide rail which is positioned on the machine frame in a sliding manner; the straightening rollers are mounted on a connecting shaft; the connecting shaft is welded and fixed to a piston rod of the oil cylinder; at least four straightening rollers are uniformly arranged in the circumferential direction of the connecting shaft; the maximum distance between opposite two straightening rollers is equal to the inside diameter of a steel pipe. According to the vertical steel pipe self-centering straightening equipment, the friction between each straightening roller and the inner wall of the steel pipe is small, and the outer wall of the steel pipe cannot be worn, so that the surface quality of the outer wall of the steel pipe cannot be influenced; during a straightening process, the steel pipe is fixed; the problem of twisting or rotating is avoided; therefore, other negative effects cannot be produced.

Owner:合肥九州龙腾科技成果转化有限公司

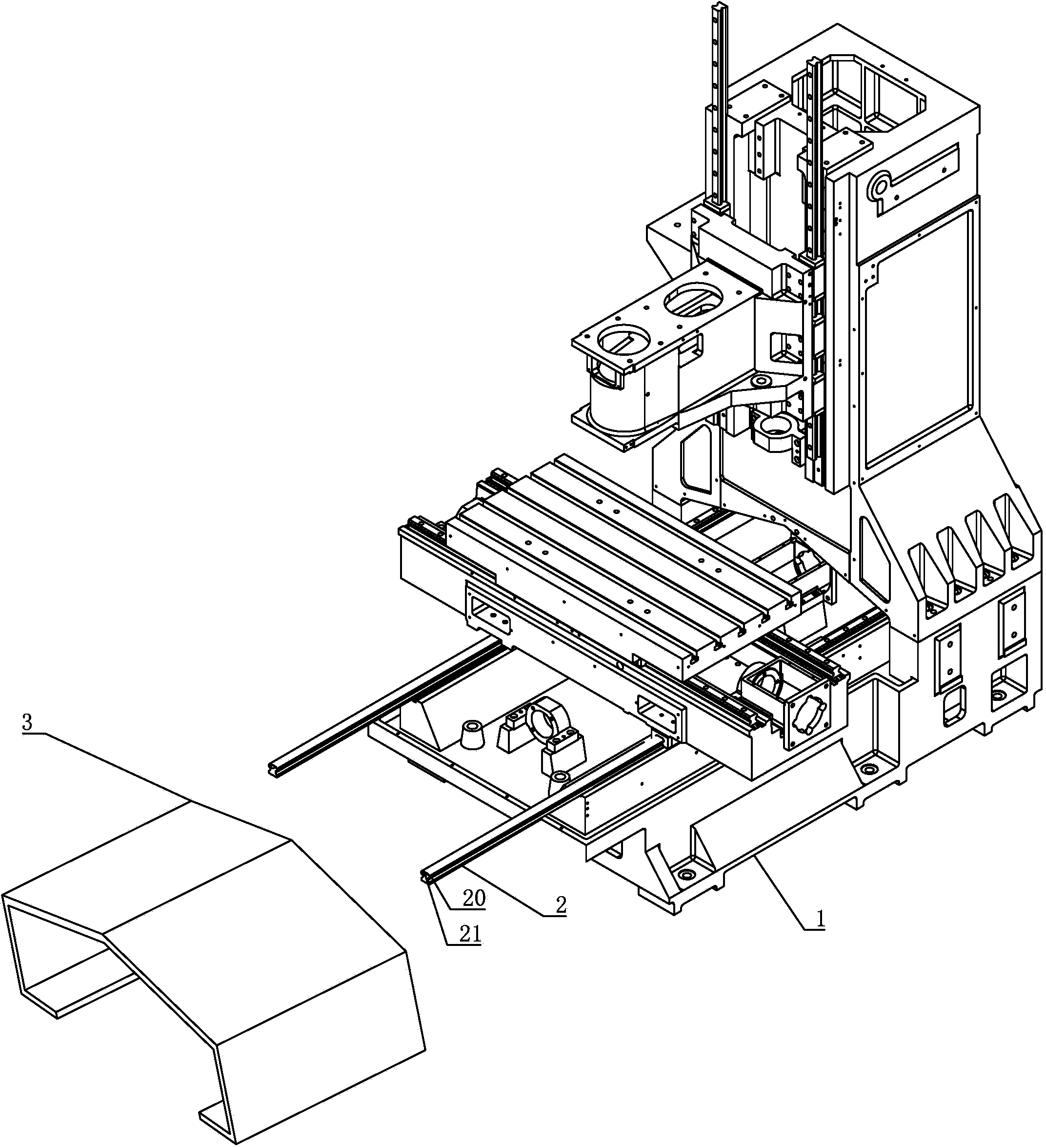

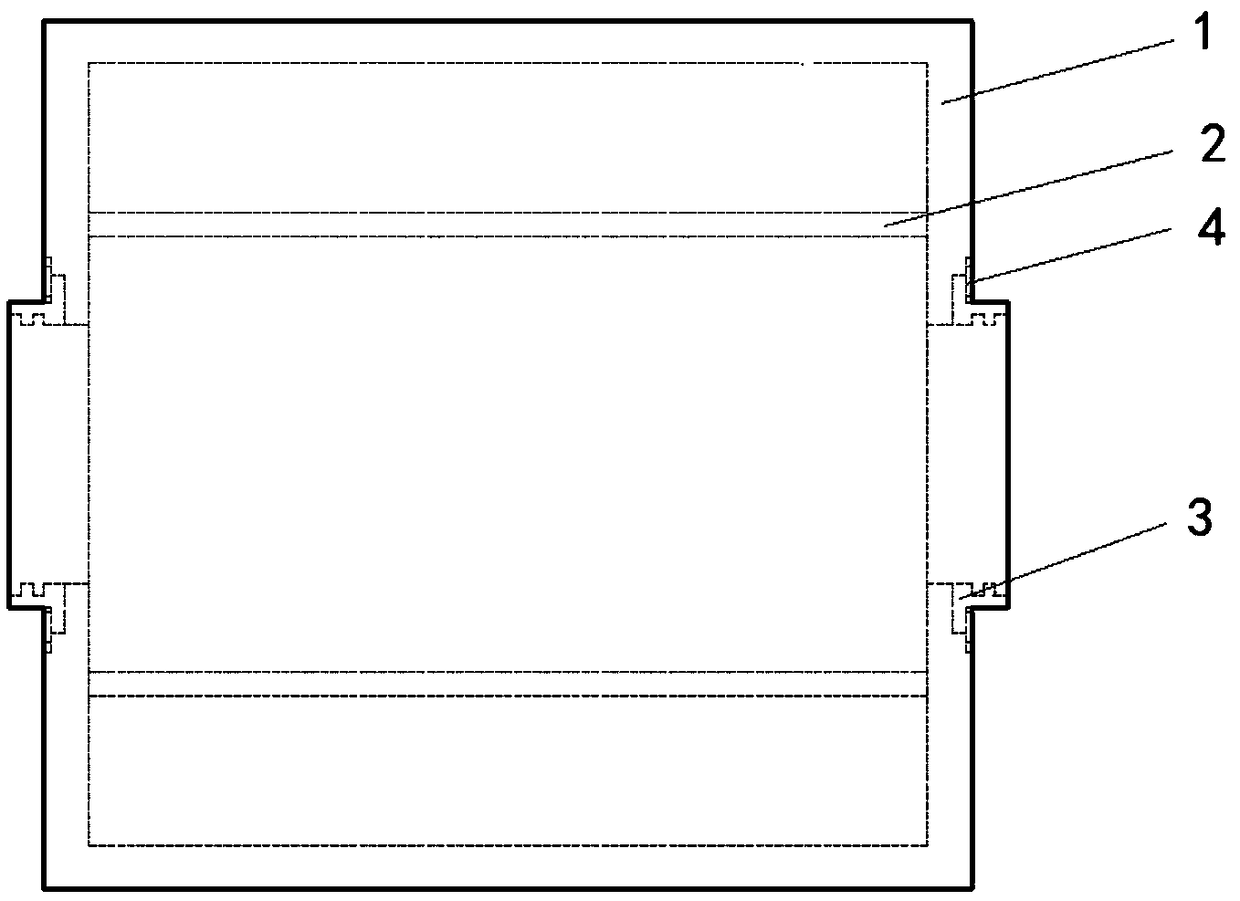

Protection device of track of machine tool

ActiveCN103659450ADoes not affect surface qualityLifespan will not be affectedMaintainance and safety accessoriesEngineeringIdler-wheel

The invention discloses a protection device of a track of a machine tool. The protection device comprises a guide rail stretching out of a base of the machine tool. A protection cover is installed on the portion, stretching out of the base, of the guide rail and comprises a hollow cover body. The cover body comprises five sliding covers, wherein the five sliding covers are overlapped, can slide relative to one another, and are connected through connecting rods. A supporting frame is connected to the sliding cover of the innermost layer, and more than three idler wheels capable of rolling on the guide rail are connected to the supporting frame. The sliding covers of the protection cover can be pulled to make the idler wheels slide on the guide rail; because the guide rail stretches out of the base of the machine tool, the sliding covers will not be affected when sliding on the guide rail and can very smoothly move without shaking, and neither the surface quality of the guide rail nor the service life of the guide rail will be affected.

Owner:JIANGMEN AOSILONG MACHINERY

Method for solving spray head blocking based on FDM technology

InactiveCN106633728ALow viscositySolve the clogging phenomenonAdditive manufacturing apparatusFiberEngineering

The invention discloses a method for solving spray head blocking based on an FDM technology. By adding a material component with a shear thinning characteristic and compatible with a base material during preparation of a printing material, when the equipment spray head bears a shear acting force due to the conical structure or the existence of impurity particles in a 3D printing process, the viscosity of the printing material is reduced, the fluidity is improved, and the phenomenon of printing spray head blocking is effectively solved; and after being extruded out of the spray head, the printing material does not bear the shear action, the viscosity quickly recovers to an initial state, and thus the surface quality of the printed product is not influenced in a solidification process. By adopting the method disclosed by the invention, a high-content reinforcing fiber material also can be added into the printing material, the strength of the printed product is improved, and the application field of the printed product is expanded. Moreover, the method disclosed by the invention also has the advantages of simple production technology, easiness in operation, convenience for industrial production and the like.

Owner:SHANDONG NON METALLIC MATERIAL RES INST

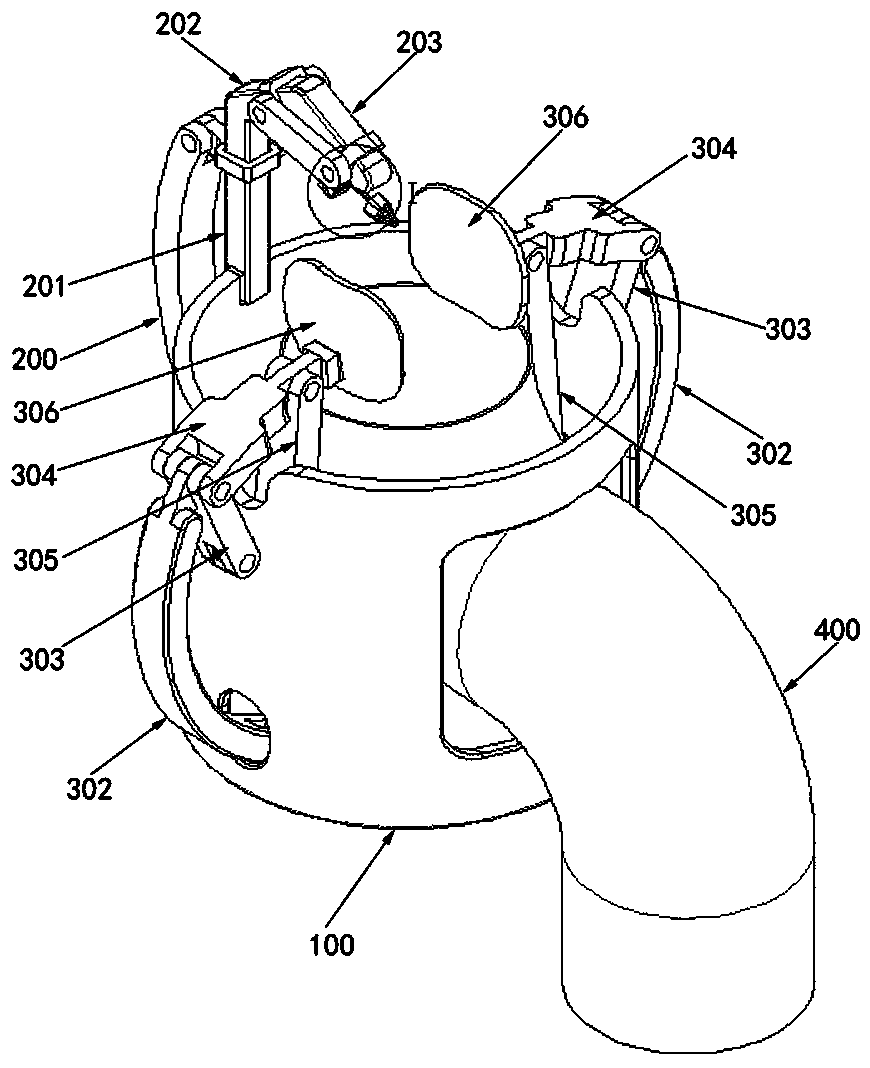

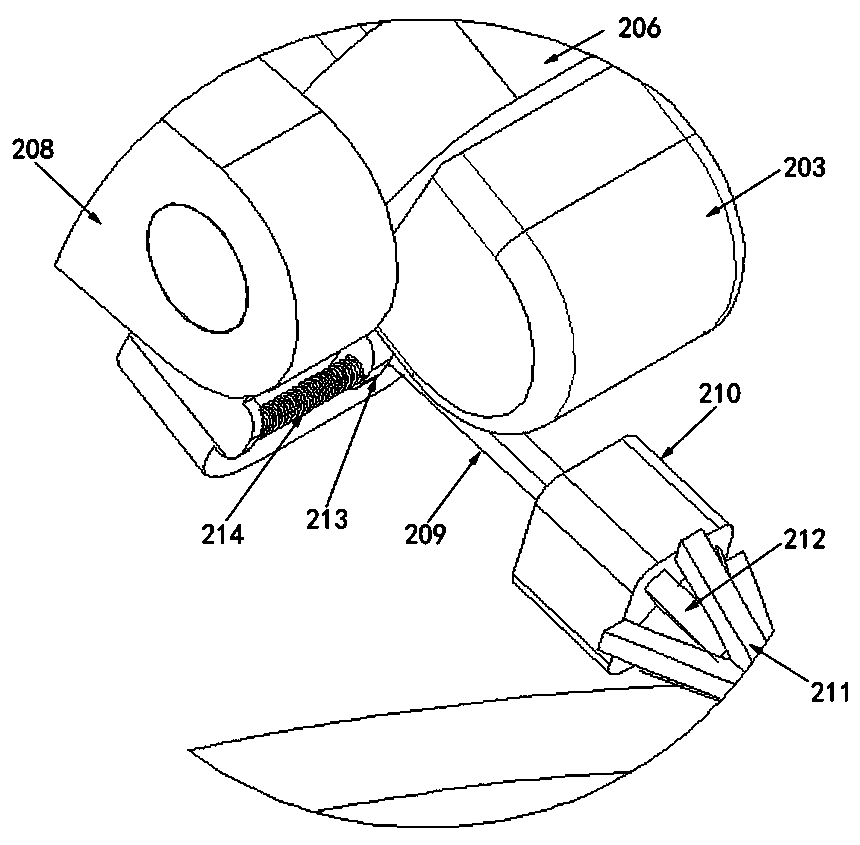

Apple picker capable of cutting fruit stems short

ActiveCN110383988AAvoid situations that damage the surface of other applesReduce follow-upPicking devicesEngineeringDrive motor

The invention relates to the field of fruit picking tools, and particularly relates to an apple picker capable of cutting fruit stems short. The apple picker comprises a rack cylinder, a cutting mechanism and a puller mechanism, wherein the puller mechanism comprises an air cylinder with a cylinder body fixed at the bottom of the rack cylinder; a piston rod of the air cylinder penetrates the bottom of the rack cylinder from the bottom up, and a control lever is horizontally fixed at the end part of the piston rod; two holders are fixed at the end part of a third transmission rod located abovethe rack cylinder, and are opposite, and a cambered surface structure fit with the middle of an apple is arranged in each holder; the cutting mechanism comprises a guiding pillar fixed on the cylinderbody of the rack cylinder; an outer cutting tool comprises an outer blade which has a cambered surface facing a driving motor and is of a branch structure, an inner cutting tool comprises an inner blade of a branch structure, the middle of the inner blade is rotationally matched with a positioning shaft, and the cutting edge position of the branch part of the outer blade is opposite to that of the branch part of the inner blade. While the fruit stems of the apples are cut to complete picking, the fruit stems are lower than the surfaces of the apples, the subsequent operation of fruit growersis reduced, the workload of the fruit growers is reduced, and the situation that the surfaces of other apples are damaged by the apple stems when the apples are in transportation is avoided.

Owner:ZHONGBEI UNIV

Ultra-high strength strip steel and its production process

ActiveCN100392135CDoes not affect surface qualityReduce manufacturing costFurnace typesMetal rolling arrangementsChemical compositionStrip steel

The ultra-high strength strip steel consists of C 0.10-0.20 wt%, Si<0.6 wt%, Mn not more than 2.6 wt%, Al 0.020-0.080 wt%, Cr 0.35-0.90 wt%, Nb 0.015-0.050 wt%, Ti 0.015-0.050 wt%, and B 0.0005-0.0030 wt%, except Fe and inevitable impurities. Its production process includes the following steps: smelting and casting; hot rolling, acid pickling and cold rolling; continuous annealing and complex roller cooling and gas jetting cooling or high speed gas jetting cooling; and flattening and trimming. It has simplified production process and low production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Anti-HIC (hydrogen induce crackle) hot rolled steel plate and magnesium processing smelting method thereof

The invention discloses an anti-HIC (hydrogen induce crackle) hot rolled steel plate and a magnesium processing smelting method thereof. The hot rolled steel plate prepared by adopting the magnesium processing and smelting method comprises the following chemical components in percentage by weight: 0.06wt%-0.20wt% of C, 0.10 wt%-0.50 wt% of Si, 0.4 wt%-1.6 wt% of Mn, not greater than 0.25 wt% of P, not greater than 0.010wt% of S, not greater than 0.06 wt% of Nb, not greater than 0.15 wt% of V, 0.0001 wt%-0.020 wt% of Mg and Ti, less than 0.010 wt% of Als, and the balance of Fe and inevitable impurities. The anti-HIC hot rolled steel plate can inhibit production of banded structures in a steel plate, and can improve performance of the steel plate.

Owner:LAIWU IRON & STEEL GRP

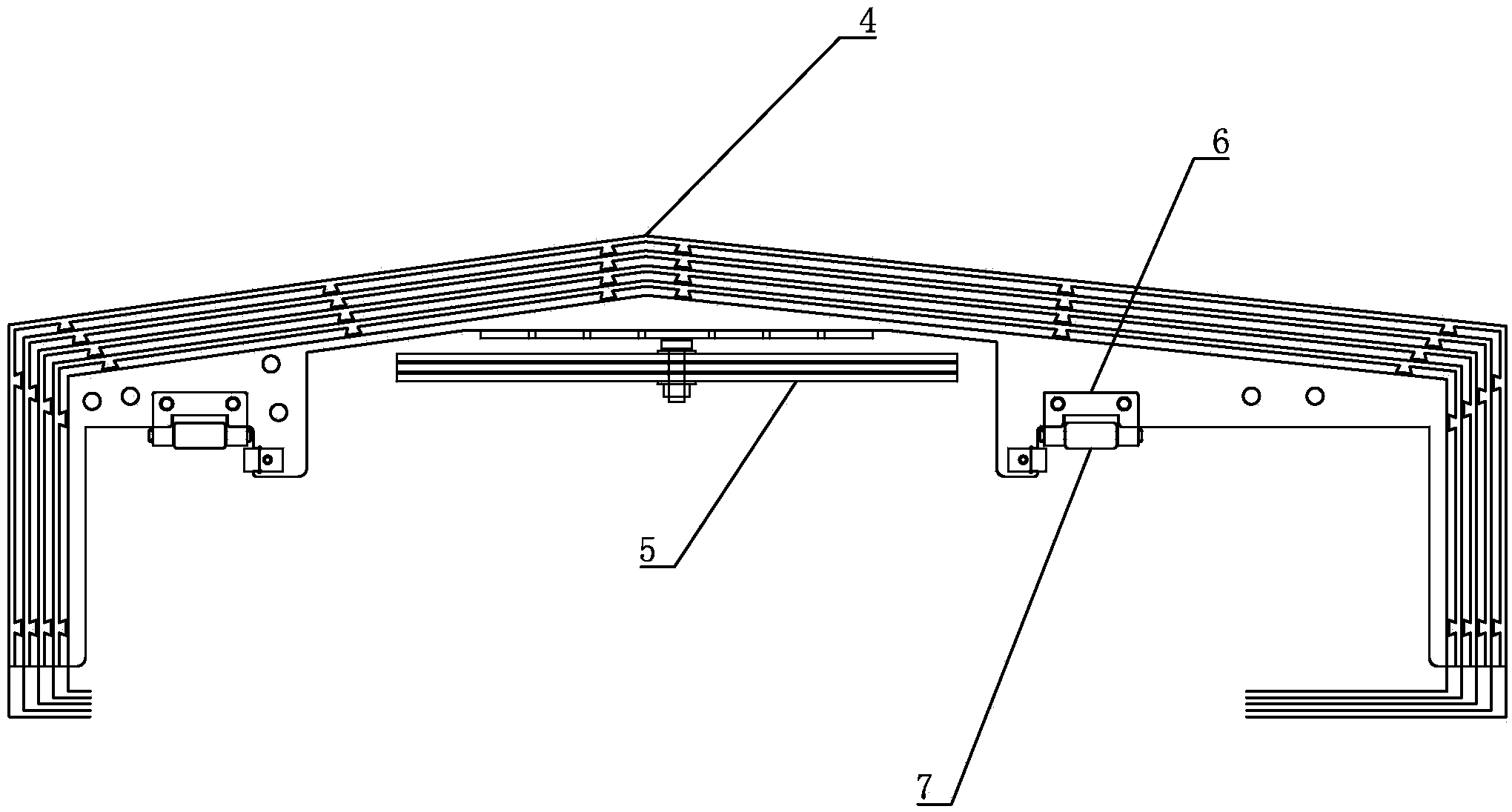

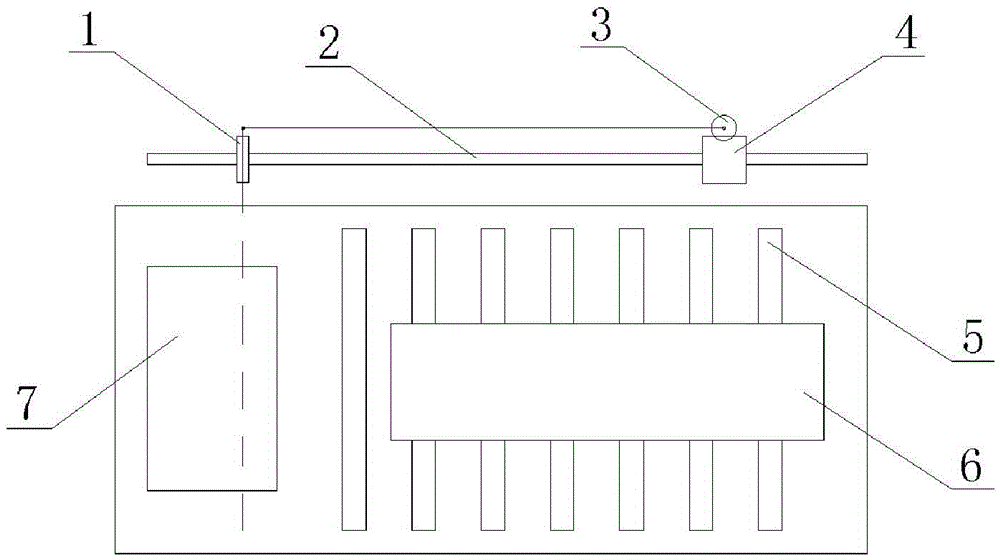

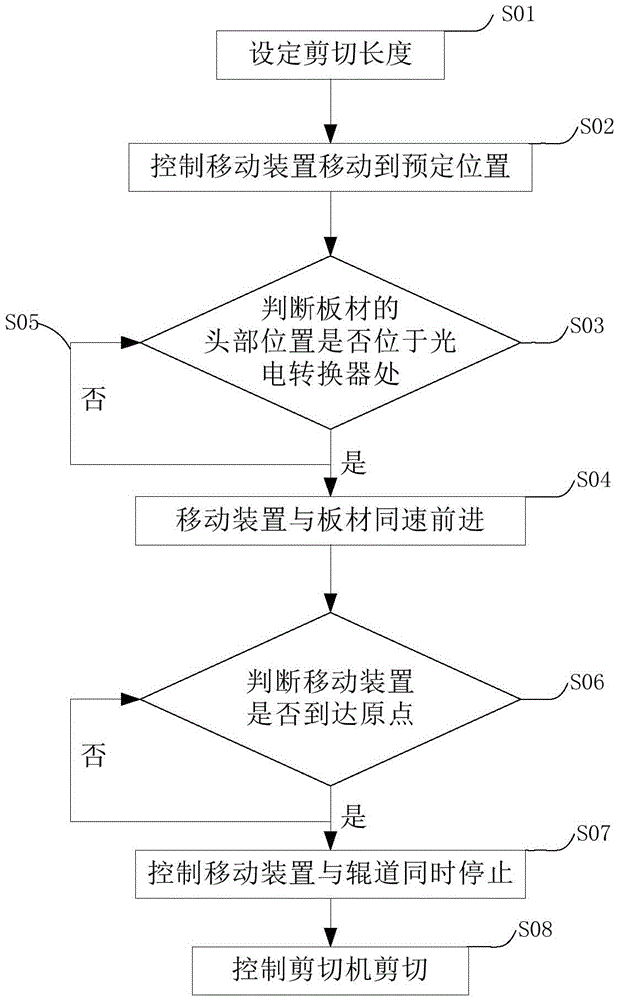

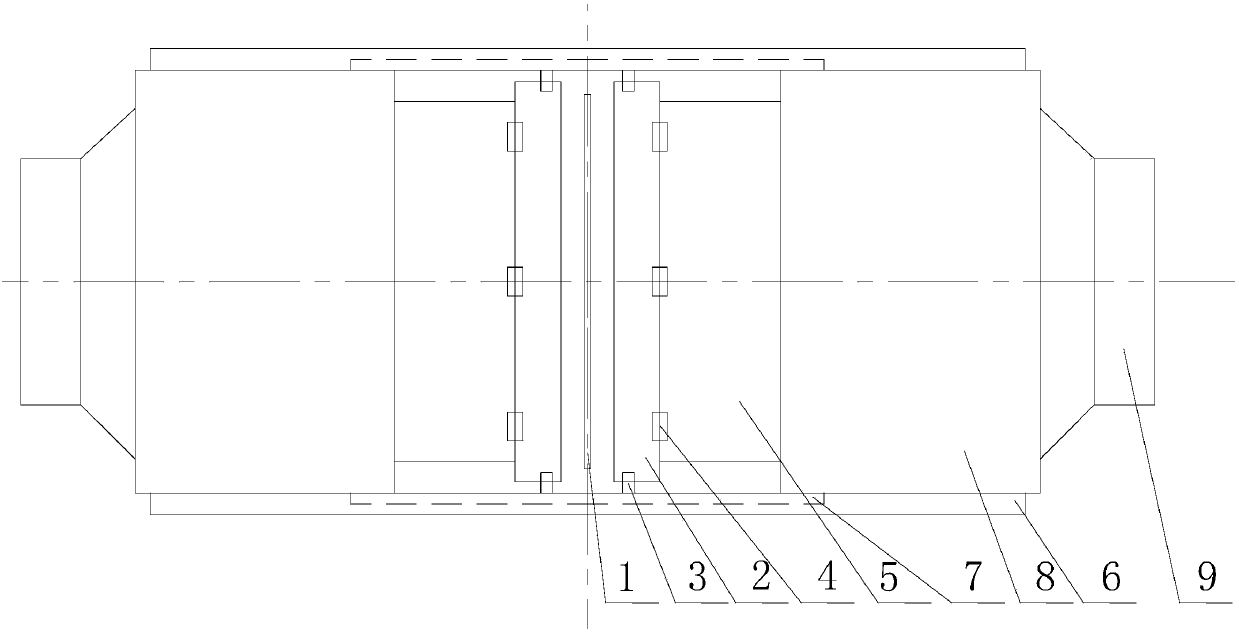

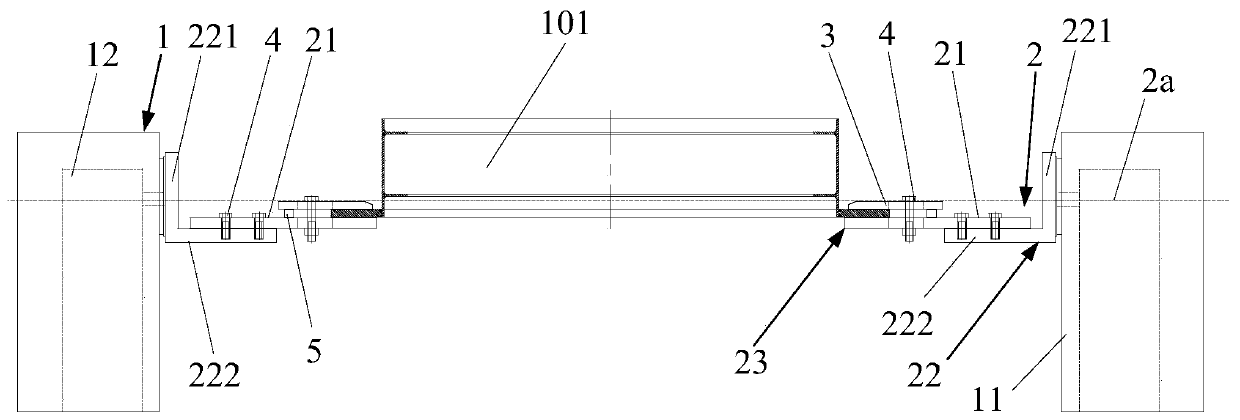

Plate cut-to-length system and method

ActiveCN105414653AFor precise cuttingDoes not affect surface qualityShearing machine accessoriesTransducerMechanical engineering

The invention provides a plate cut-to-length system. The plate cut-to-length system comprises a photoelectric transducer (1) located on one side of a shearing machine (7) and a guide rail (2) arranged on one side of a roller bed (5) in parallel. A moving device (4) is arranged on the guide rail (2) and provided with a displacement sensor (3), and the zero position of the displacement sensor (3) is identical with the position of the photoelectric transducer (1). Meanwhile, the invention further provides a plate cut-to-length method. By means of the plate cut-to-length system, a plate can be precisely cut, the plate cut-to-length system does not make contact with the plate in use, and therefore marks on the surface of the plate are avoided, and the surface quality of the plate cannot be affected.

Owner:LAIWU IRON & STEEL GRP

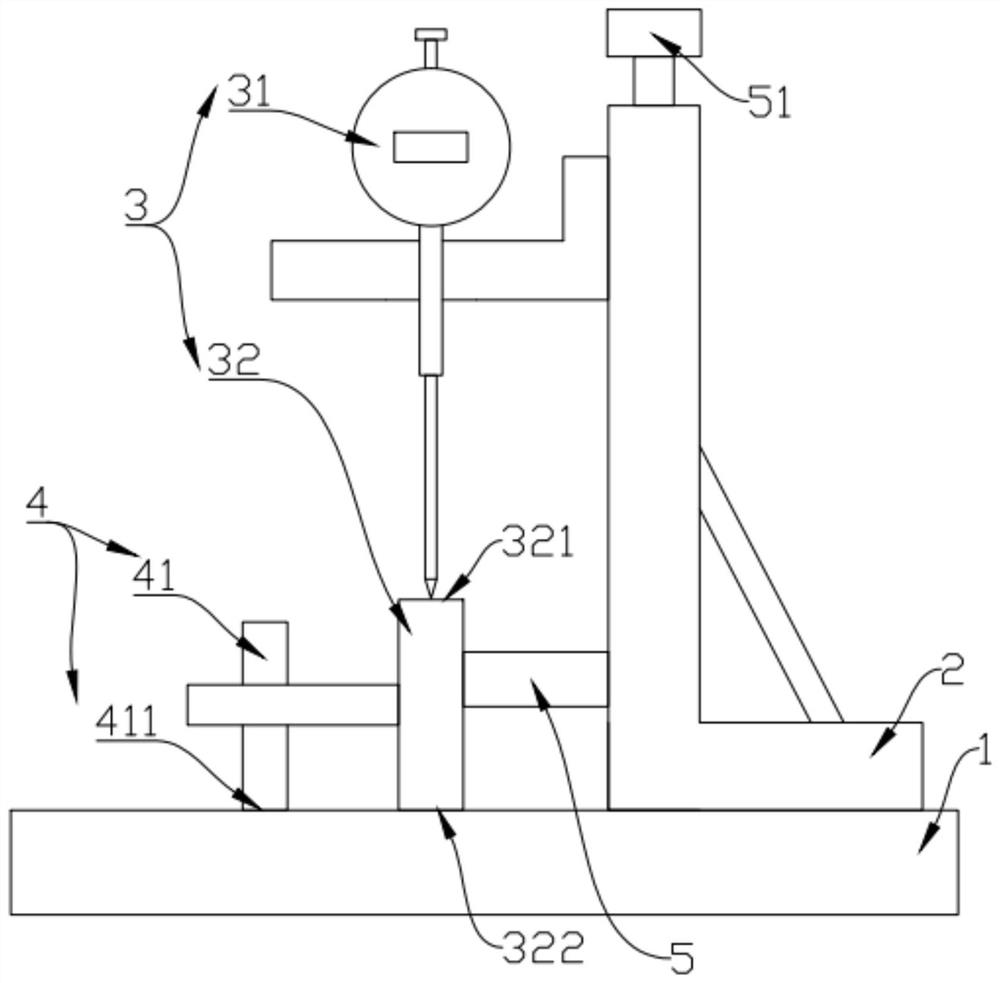

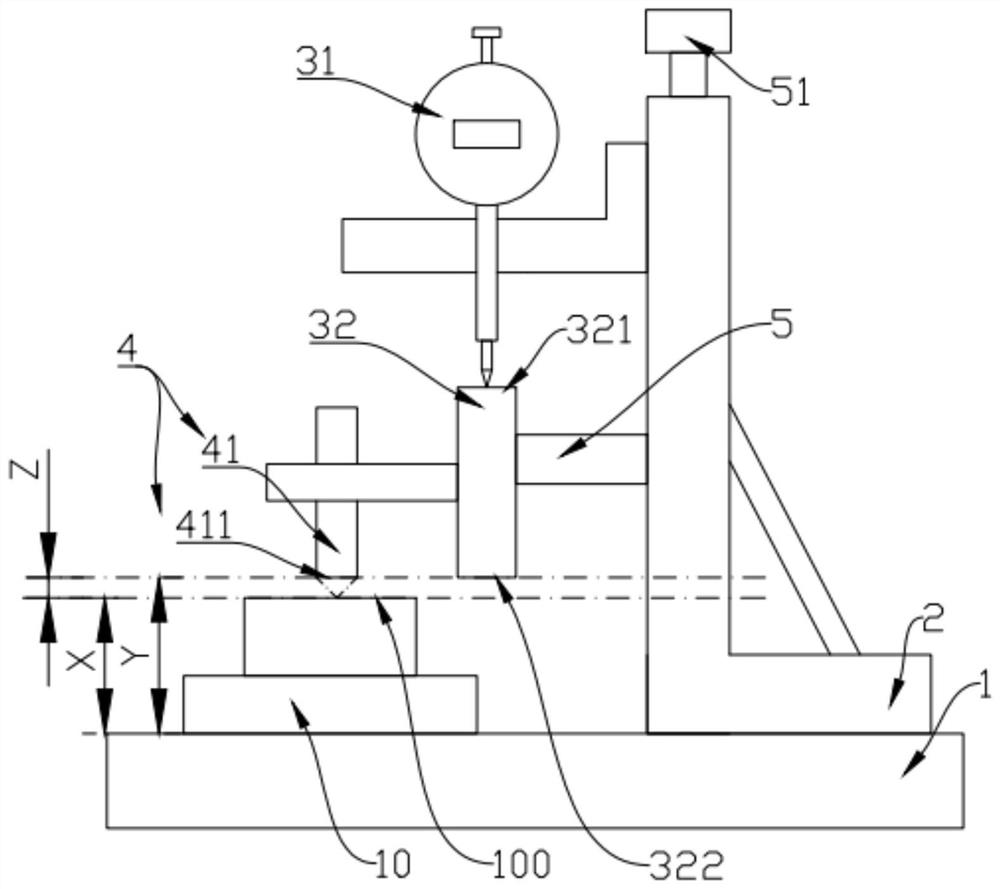

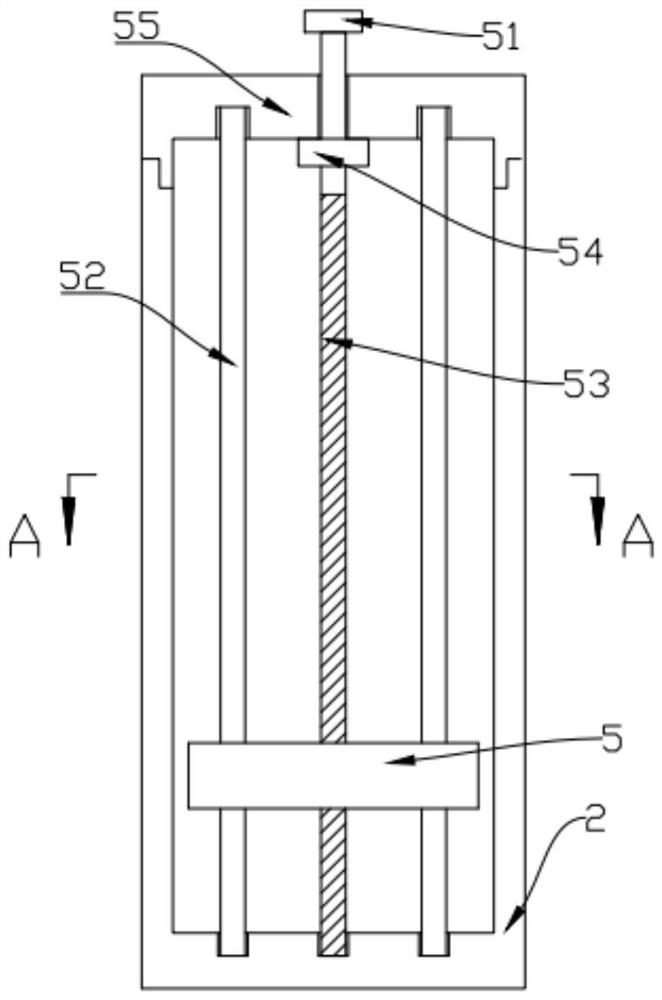

Non-contact precision measuring instrument

ActiveCN112504069AEasy to operateHigh precisionNuclear energy generationUsing optical meansMeasuring instrumentEngineering

The invention discloses a non-contact precision measuring instrument, which comprises a measuring platform used for placing a to-be-measured piece and a measuring tool, wherein the measuring tool comprises an upright post arranged on the measuring platform, and a coarse measuring tool and a fine measuring tool which are connected in series on the upright post, and the size of the to-be-measured piece is the reading difference of the coarse measuring tool and the fine measuring tool; the coarse measuring tool comprises a lifting block and a dial indicator arranged at the upper part of the lifting block, and when the bottom surface of the lifting block is arranged on the measuring platform, a dial indicator thimble is contacted with the top surface of the lifting block and displays that thereading is zero; and the fine measuring tool comprises a non-contact measuring tool fixed with the lifting block, and the measuring zero point position of the non-contact measuring tool is matched with the bottom surface position of the lifting block. The non-contact precision measuring instrument is simple to operate, wide-range, high-precision and non-contact measurement can be realized, and thesurface quality of a product is not influenced on the premise of ensuring the measurement precision.

Owner:HEFEI I TEK OPTOELECTRONICS CO LTD

Tool and method for clamping guide pipes by using hydraulic rubber bags

InactiveCN108942728AAvoid pipe end eccentricity problemsSmall deviceWork holdersEngineeringStable fixation

The invention provides a tool and a method for clamping guide pipes by using hydraulic rubber bags. The tool comprises a box provided with the rubber bags inside, and positioning rings; the positioning rings capable of being disassembled and replaced are arranged in guide pipe ports on the front and back sides of the box; the hollow rubber bags are fixed in the box; and the rubber bags are connected with an external hydraulic pump. The hydraulic pump is opened; when hydraulic oil is injected in the rubber bags by hydraulic pipelines, the rubber bags are inflated to enlarge to finally wrap thesurfaces of the guide pipes and to generate pressure; and when the ends of the guide pipes are machined, the guide pipes generate relative motion tendency under the effect of external force, so that the extrusion of the rubber bags to the guide pipes is converted to friction force for stable fixation of the guide pipes.

Owner:XIAN AIRCRAFT IND GROUP

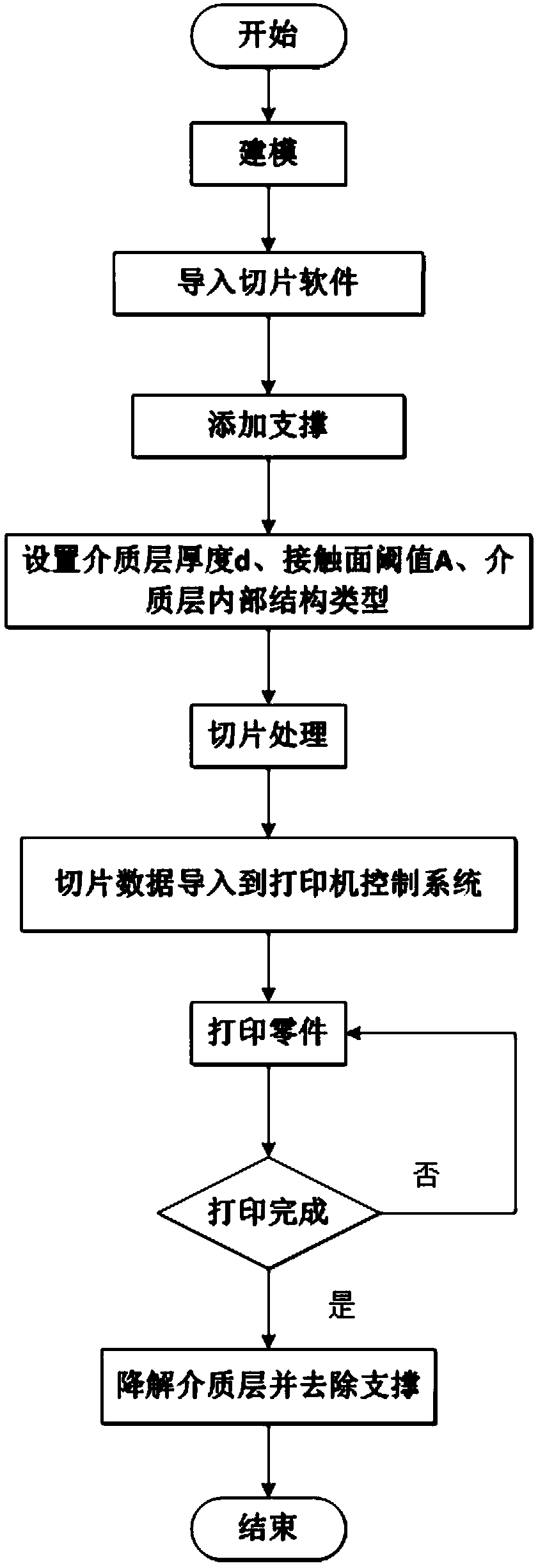

A quick way to remove 3D printing supports

ActiveCN106738874BDoes not affect surface qualityReduce dosageAdditive manufacturing apparatus3D object support structuresSupport removalEngineering

The invention discloses a method for rapidly removing a 3D printing support. According to the main achieving manner of the method, a medium material printing head is used for printing a layer of easily degradable material before and after support printing, the support and a component are isolated through the medium material, the component and a substrate are isolated through the medium material, and the substrate and the support are isolated through the medium material. After component printing is over, a model is taken down, the medium layer is degraded, the medium material at the above part is dissolved, and the support structure naturally disengages from the surface of the component. The method is applicable to FDM, 3DP and other 3D printing technologies in which supports need to be added, support removal is fast and efficient, the component surface quality is not affected, the material cost is low, and a forming system is simple in structure.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Gas sealing device and method for soaking zone of continuous annealing furnace

ActiveCN104673989AReduce flow rateDoes not affect surface qualityFurnace typesHeat treatment furnacesEngineeringContinuous annealing

The invention provides a gas sealing device and a gas sealing method for a soaking zone of a continuous annealing furnace. The gas sealing device comprises two baffles which are symmetrically arranged on an inner wall at an outlet of the soaking zone of the continuous annealing furnace, wherein the two baffles are downwardly inclined and are arranged inside the soaking zone to be V-shaped; an air supply opening is formed in the inner wall above the top of each baffle; the inner side of each air supply opening is connected with a nozzle, and the outer side of each air supply opening is connected with one end of an air supply pipe; the other end of each air supply pipe is connected with a fan; an infrared thermometer is arranged on the inner wall above each nozzle. According to the gas sealing device and the gas sealing method for the soaking zone of the continuous annealing furnace, rising of the hot air of the soaking zone can be effectively prevented, the alloying process of a galvanized steel strip is not affected, and the surface quality of the galvanized steel strip is improved.

Owner:武汉钢铁有限公司

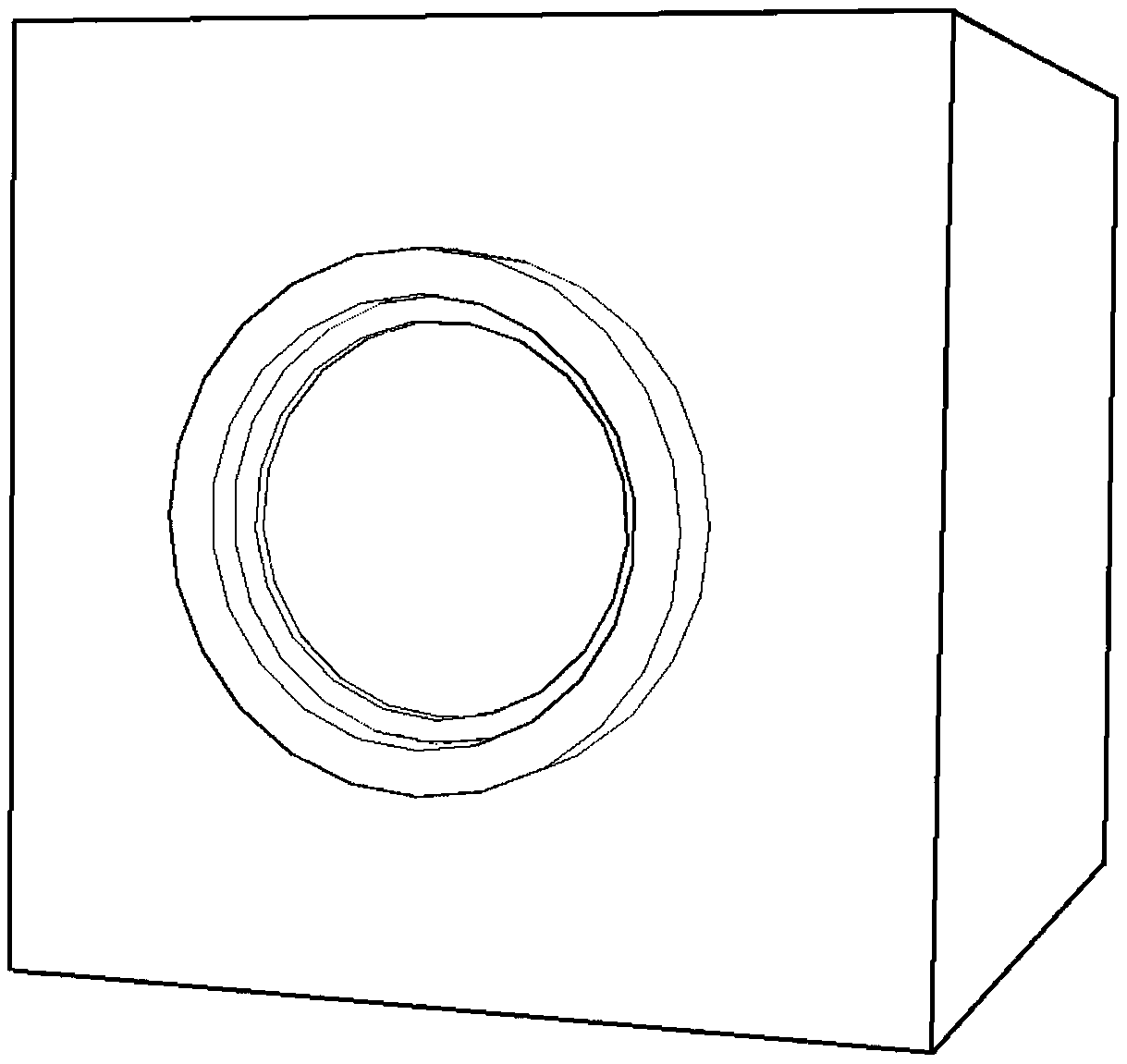

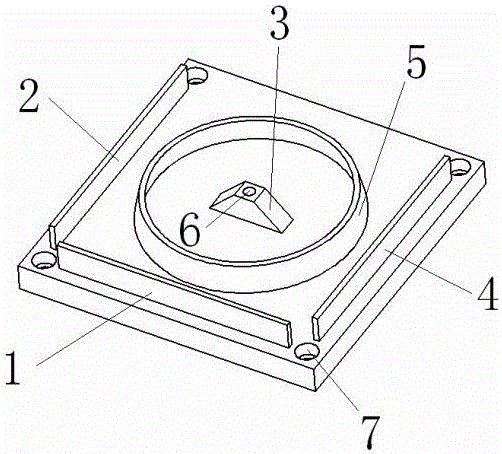

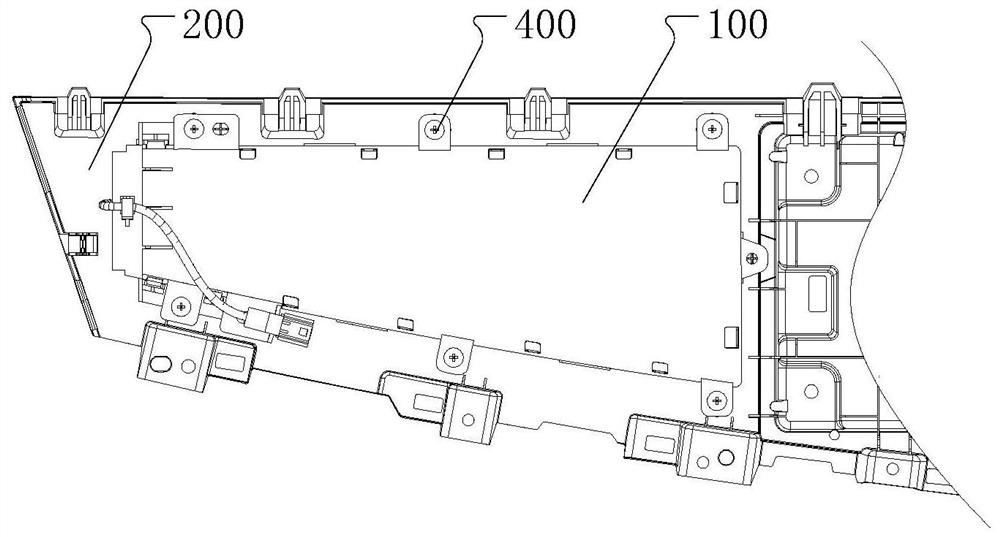

Trial cutting device for analysis of workpiece surface quality problems and analysis method

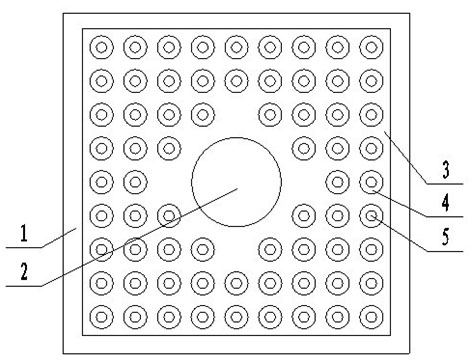

ActiveCN105710723APrecise positioningRapid positioningMeasurement/indication equipmentsMulti axisAnalysis method

The invention relates to the field of machining, in particular to a trial cutting device for the analysis of workpiece surface quality problems and an analysis method. The trial cutting device comprises a base, wherein the base is rectangular, and an X-axis test component, a Y-axis test component, a Z-axis test component, an A-axis test component, a B-axis-C-axis test component and an origin hole are arranged on the base; the X-axis test component, the Y-axis test component and the A-axis test component are all parallel with the edges of the base; the X-axis test component is arranged on the edge of the base, and the Y-axis test component and the A-axis test component are separately arranged on the edges, adjacent to the X-axis test component, of the base; the Z-axis test component is a bulge with a trapezoidal longitudinal section and is arranged in the middle of the base; the origin hole is formed in the middle of the top plane of the Z-axis test component; and the B-axis-C-axis test component is a ring and is arranged between the Z-axis test component and the X-axis test component and between the Y-axis test component and the A-axis test component. Through the independent processing of coordinates, workpiece surface quality problems caused by complicated multi-axis simultaneous processing are solved, and the accurate and rapid positioning of failure reasons is realized.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

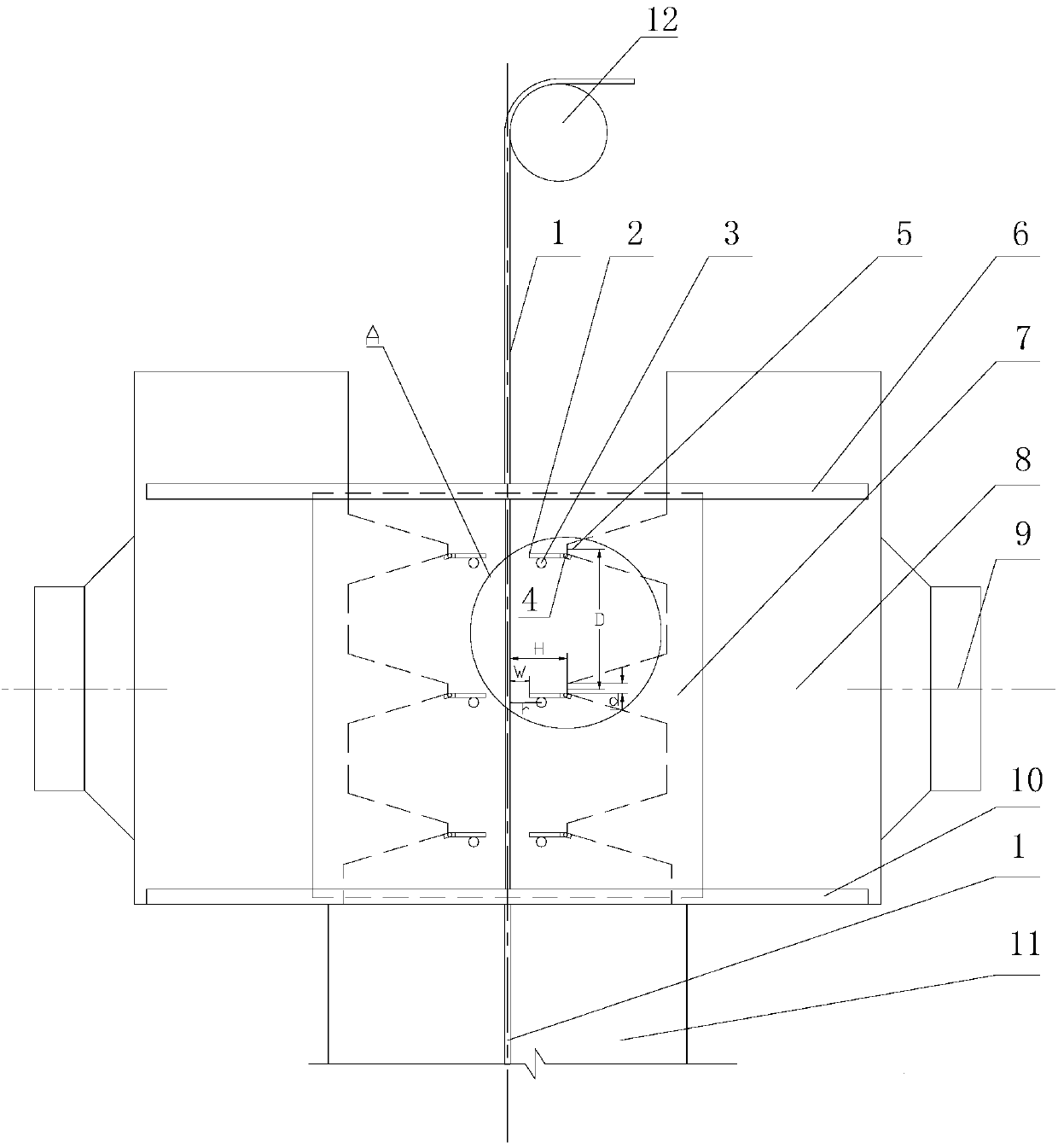

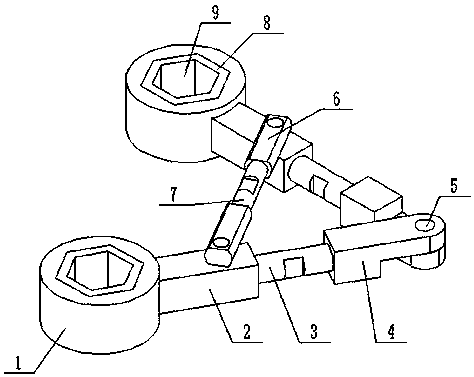

Wall-adhered jet seal pressure stabilizing device in galvanized strip steel alloying process and application method thereof

ActiveCN107604297ASimple and reliable structural designContinuous efficient operationHot-dipping/immersion processesStrip steelConductor Coil

The invention relates to a wall-adhered jet seal pressure stabilizing device in a galvanized strip steel alloying process and an application method thereof. The device mainly consists of an air box, anozzle, a movable side plate, a flow stop plate, a support column, an upper slide way and a lower slide way; when the movable side plate is located in a closed state, the support column fixedly connected to the movable side plate horizontally supports the flow stop plate; at this time, the distance W from the end part of the flow stop plate to galvanized strip steel is 30-60 mm, so that the winding and sucking effect on the lower side of free jet is reduced; when the movable side plate is opened by moving to two ends of the upper slide way and the lower slide way, the flow stop plate is rolled over under the effect of gravity to locate in a vertical state; and at this time, the distance from the plane of the flow stop plate to the galvanized strip steel is equal to the distance from the nozzle to the galvanized strip steel. The device can effectively stop hot air currents of an insulation section of the galvanized strip steel from upwards ascending, and meets the insulation requirements of the insulation section of the galvanized strip steel on the basis of not influencing the surface quality of hot galvanized strip steel.

Owner:WUHAN UNIV OF SCI & TECH

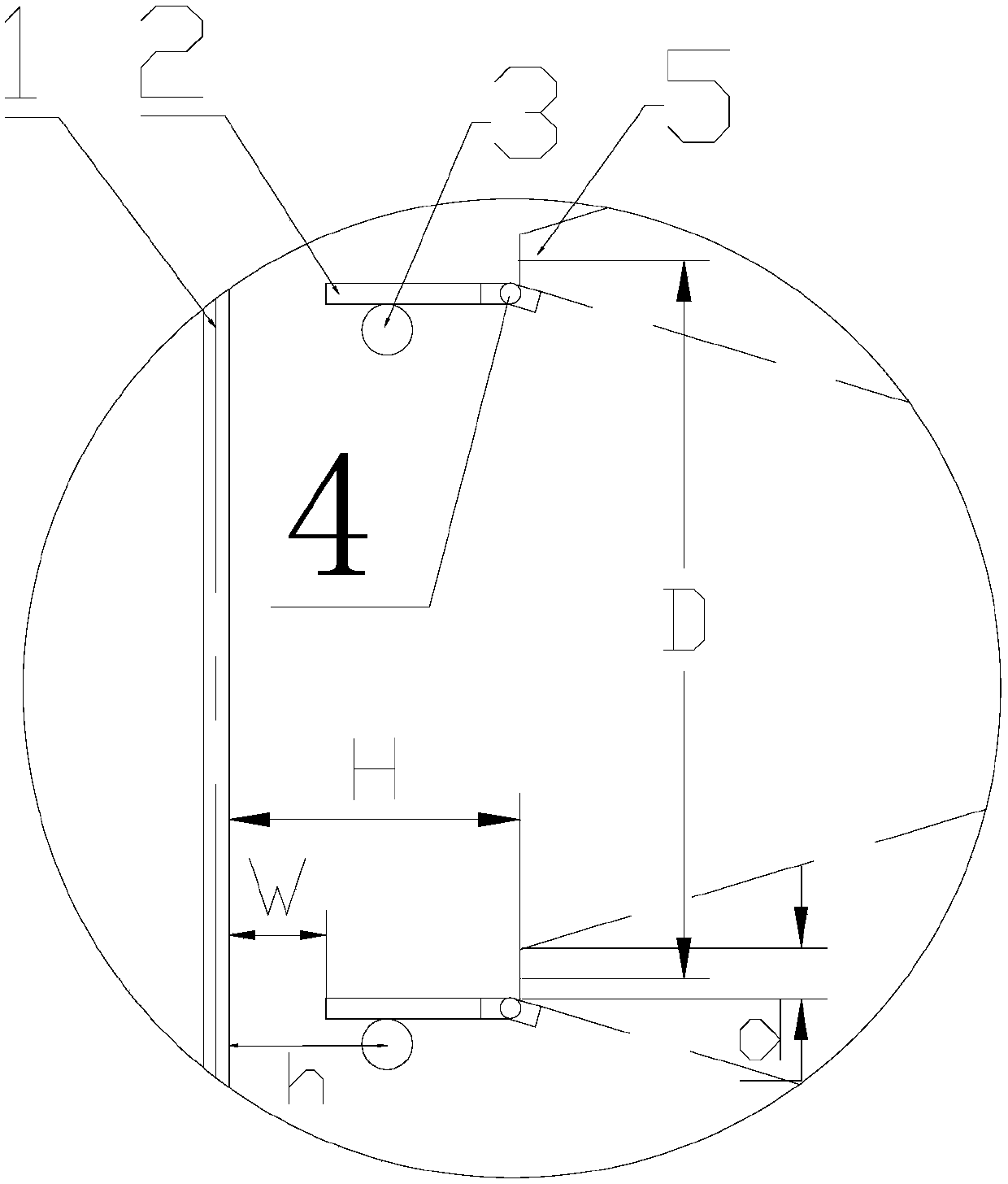

Micro-angle-adjustable anti-rotation tool

The invention discloses a micro-angle-adjustable anti-rotation tool, and belongs to the field of equipment tools. The micro-angle-adjustable anti-rotation tool comprises two locating blocks and a locating handle, wherein the two locating blocks are provided with limiting holes; the limiting holes are used for limiting nuts or bolts to be disassembled from rotating; the two locating blocks are provided with a connection handle respectively; the other ends of the two connection handles are provided with a lockable telescopic rod respectively; the other ends of the two telescopic rods are provided with a connector respectively; the other ends of the two connectors are hinged through a rotating shaft; the two connection handles are also provided with one mounting hole respectively; the locating handle consists of two segments of locating joints and one screw rod; the screw rod is arranged between the two segments of locating joints; the screw rod is in threaded connection with the two locating joints; the other ends of the two locating joints are respectively provided with a connection hole matched with the mounting holes in the two connection handles.

Owner:潍坊威广机器人科技有限公司

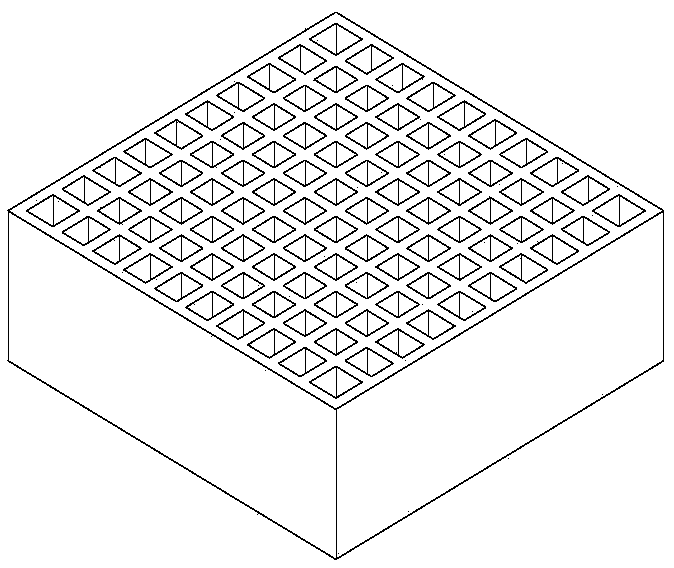

Anti-adhesion punch for powder molding

The invention discloses an anti-adhesion punch for powder molding, which is characterized in that small air vents are distributed on the punch perpendicularly and evenly, a ventilating pipe is arranged at each of the air vents in a matching mode, and ventilating pipes are directly connected with a peripheral equipment air compressor through an air separating joint. When the anti-adhesion punch for powder molding works, air films can be prevented from being formed between the punch and powder, the adhesion of the punch to the powder is effectively prevented, and the quality of punch stamping powder molding product surface is not affected simultaneously.

Owner:HEBEI HUIYUAN BUILDING MATERIAL

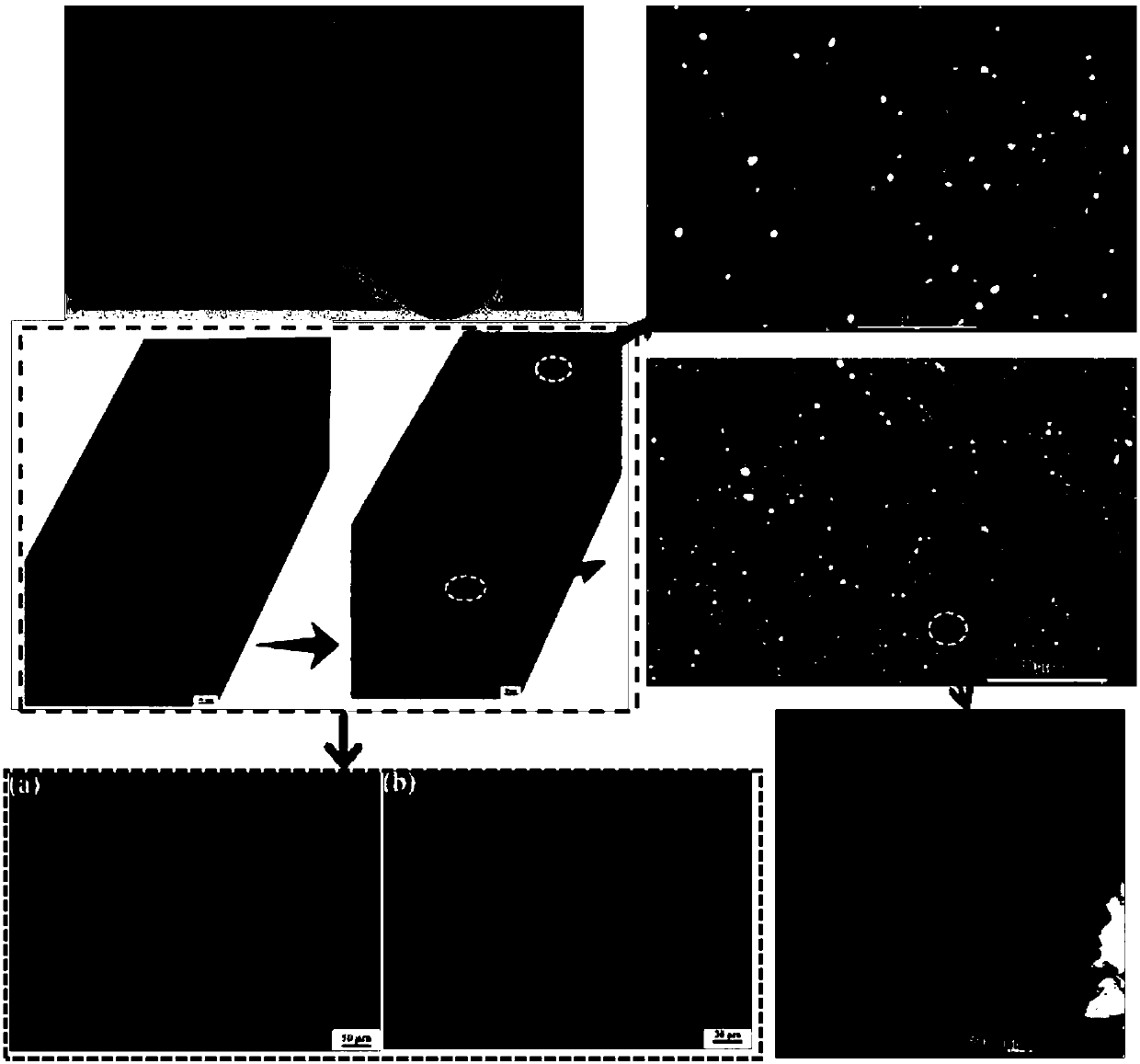

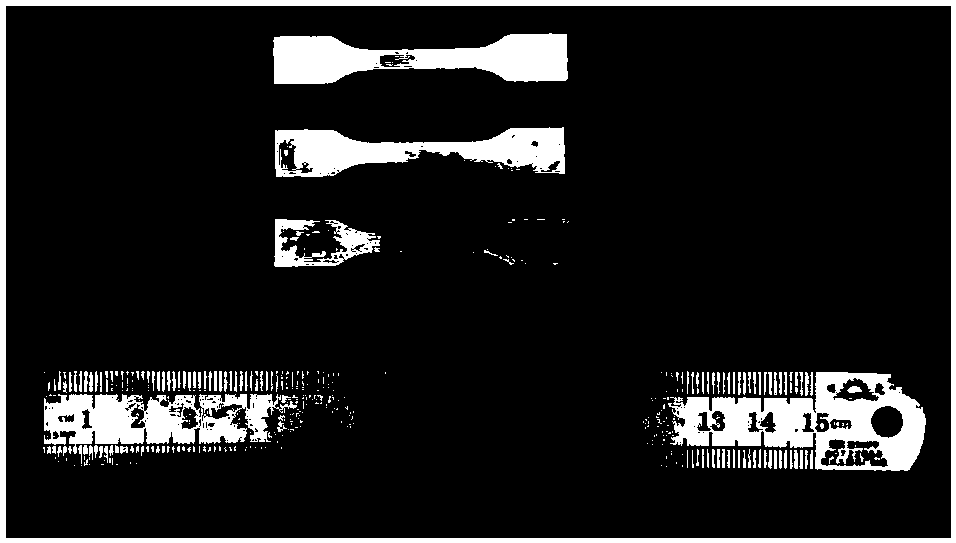

Short-flow rolling preparation process of high-strength and high-plasticity AlN/AZ91D magnesium base composite material plate

ActiveCN107747071AQuality improvementHigh quality and high performanceMagnesium matrix compositeIngot

The invention relates to a short-flow rolling preparation process of a high-strength and high-plasticity AlN / AZ91D magnesium base composite material plate; solid solution and water quenching processesof a cast ingot before rolling are formulated; subsequent rolling and annealing processes are optimized; and a set of cold rolling process for preparing a high-strength and high-plasticity magnesiumbase composite material rolled plate is provided. The cold rolling process is high in reduction in pass, few in annealing times among passes and short in annealing time, and can realize industrial short-flow preparation. In particular, through the patent technology, namely the optimal ratio of solid solution process parameters to water quenching process parameters to rolling process parameters toannealing process parameters, the edge cracking problem in the cold rolling process is solved when the high-strength and high-plasticity cold-rolled plate is obtained, and finally, the high-quality and high-performance magnesium alloy composite material cold-rolled plate can be obtained with high efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

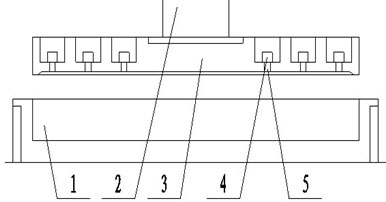

Welding tool and welding method of connecting plate

ActiveCN110434543ASave materialSmall machining allowanceWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingFlange

The invention discloses a welding tool and a welding method of a connecting plate, and belongs to the field of machining. When the connecting plate is welded, an annular cylinder, an annular flange plate and an annular rib plate are generally spot-welded and assembled, then the annular flange plate is placed on the supporting surfaces of two supporting structures, the annular flange plate is pressed by a pressing plate, the plate surface of the annular flange plate is clamped by the pressing plate and the supporting surface of the supporting structure of the welding tool, so that the positionof the annular flange plate is well fixed, the deformation generated in the welding process is small, therefore, the machining allowance reserved on the surface of the annular flange plate can be reduced, the material required for manufacturing the annular flange plate is reduced due to the reduction of the machining allowance, the machining allowance required for machining is also reduced, and the economic cost and the time cost for manufacturing the connecting plate are reduced. According to the two driving structures arranged at an interval in the welding tool, adjusting and overturning theposition of the connecting plate is convenient, so that the welding efficiency of the connecting plate is improved, and the time cost required by manufacturing the connecting plate is further reduced.

Owner:WUHAN MARINE MACHINERY PLANT

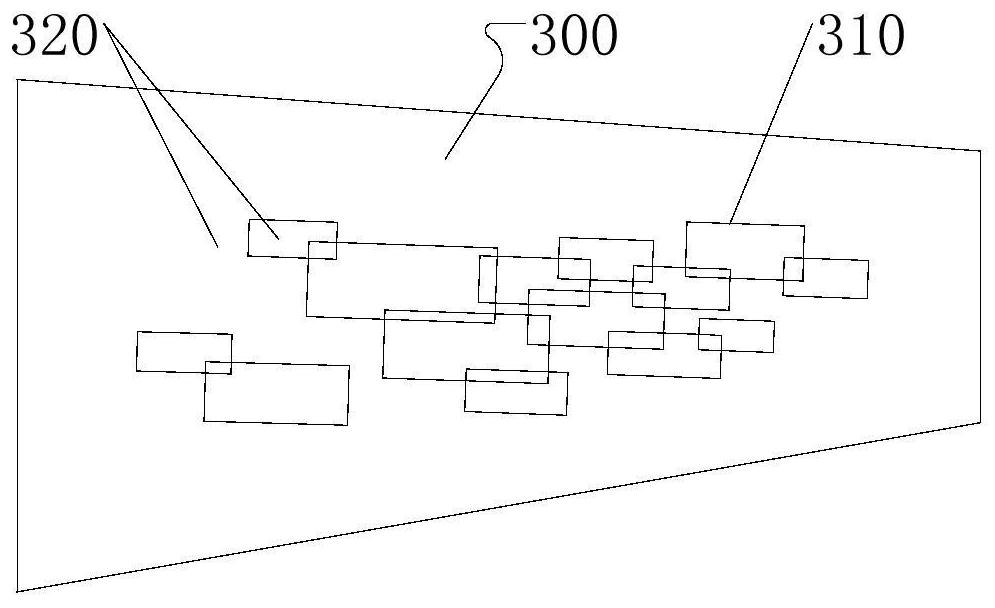

Pattern atmosphere lamp and method for manufacturing pattern atmosphere lamp

ActiveCN108081537BPlay the role of light transmissionImprove surface qualityOptical articlesDomestic articlesEngineeringMaterials science

The invention provides a patterned atmosphere lamp and a patterned atmosphere lamp manufacturing method, and relates to the technical field of automotive trims. The patterned atmosphere lamp comprisesan atmosphere lamp body and a mounting panel, a membrane capable of generating patterned light transmission is arranged on the mounting panel and positioned on the surface of the mounting panel or inside the mounting panel, and the membrane and the mounting panel are integrated. The atmosphere lamp body is fixedly mounted on the mounting panel and corresponds to the membrane. The patterned atmosphere lamp manufacturing method includes the steps of membrane printing, membrane blister forming, membrane punching, embedding of the membrane into an injection mold, injection molding of the mountingpanel and patterned atmosphere lamp assembly. The invention aims to provide the patterned atmosphere lamp and the patterned atmosphere lamp manufacturing method to relieve the problems of high production difficulty, low efficiency and high cost caused by high processing requirements of a light-transmitting plate in a patterned atmosphere lamp, and easiness in scratch and abrasion and the like caused by low surface hardness of the light-transmitting plate in the prior art.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

Scale removing brush

InactiveCN104014598AExtended service lifeDoes not affect surface qualityWork treatment devicesGrinding machinesEngineeringImpurity

The invention discloses a scale removing brush and belongs to auxiliary scale removing equipment. The scale removing brush structurally comprises a brush body and a spring pressing rod. The brush body is arranged on the outer side wall of a scale removing box. The brush body comprises a first steel plate, a second steel plate and steel wire ropes. The first steel plate and the second steel plate are connected through steel plate clamping bolts and steel plate clamping nuts. A plurality of steel wire ropes are arranged between the first steel plate and the second steel plate side by side. The steel wire ropes are clamped and fixed through the first steel plate and the second steel plate. The front ends of the steel wire ropes respectively extend out of the first steel plate and the second steel plate. The rear side of the first steel plate or the second steel plate is provided with a rotating shaft. The two sides of the rotating shaft are respectively connected with a brush body supporting part. The spring pressing rod is connected with the scale removing box through a spring support. A spring is arranged on the spring pressing rod located at the lower end of the spring support. The scale removing brush has the advantages of being capable of completely removing scale impurities which are attached to the surfaces of billets and can not be removed; moreover, the surface quality of products is not influenced, the service life of scale removing equipment is prolonged, and the production cost and the maintenance workload are reduced.

Owner:JIGANG GRP

Tritium-contaminated optical film non-destructive removal method based on inert ion beam etching

ActiveCN110013999AEfficient removalDoes not affect subsequent useCleaning processes and apparatusAcid etchingNon destructive

The invention belongs to the technical field of optical element manufacturing, and particularly relates to a tritium-contaminated optical film non-destructive removal method based on inert ion beam etching. In order to overcome the shortcoming that acid etching is used in the prior art to remove tritium-contaminated optical films, the method in the technical scheme comprises the steps that the thickness of optical films made according to the technology the same as that of the optical elements to be subjected film removing is firstly measured; then the etching rate of ion beams on the optical films on the element surfaces is calibrated; and finally inert ion beams with the energy being 100 eV to 1500 eV, the beam current being 100 mA to 500 mA and the ion beam incident angle being -90 degrees to 90 degrees are adopted to accurately etch and remove the tritium-contaminated optical films on the element surfaces. By means of the method, the shortcoming existing in an existing acid etchingtechnology for removing the tritium-contaminated optical films can be effectively overcome, and meanwhile, it is ensured that the surface quality, the optical performance and the laser damage resistance of an optical substrate are not affected.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com