Patents

Literature

1560 results about "Acid etching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

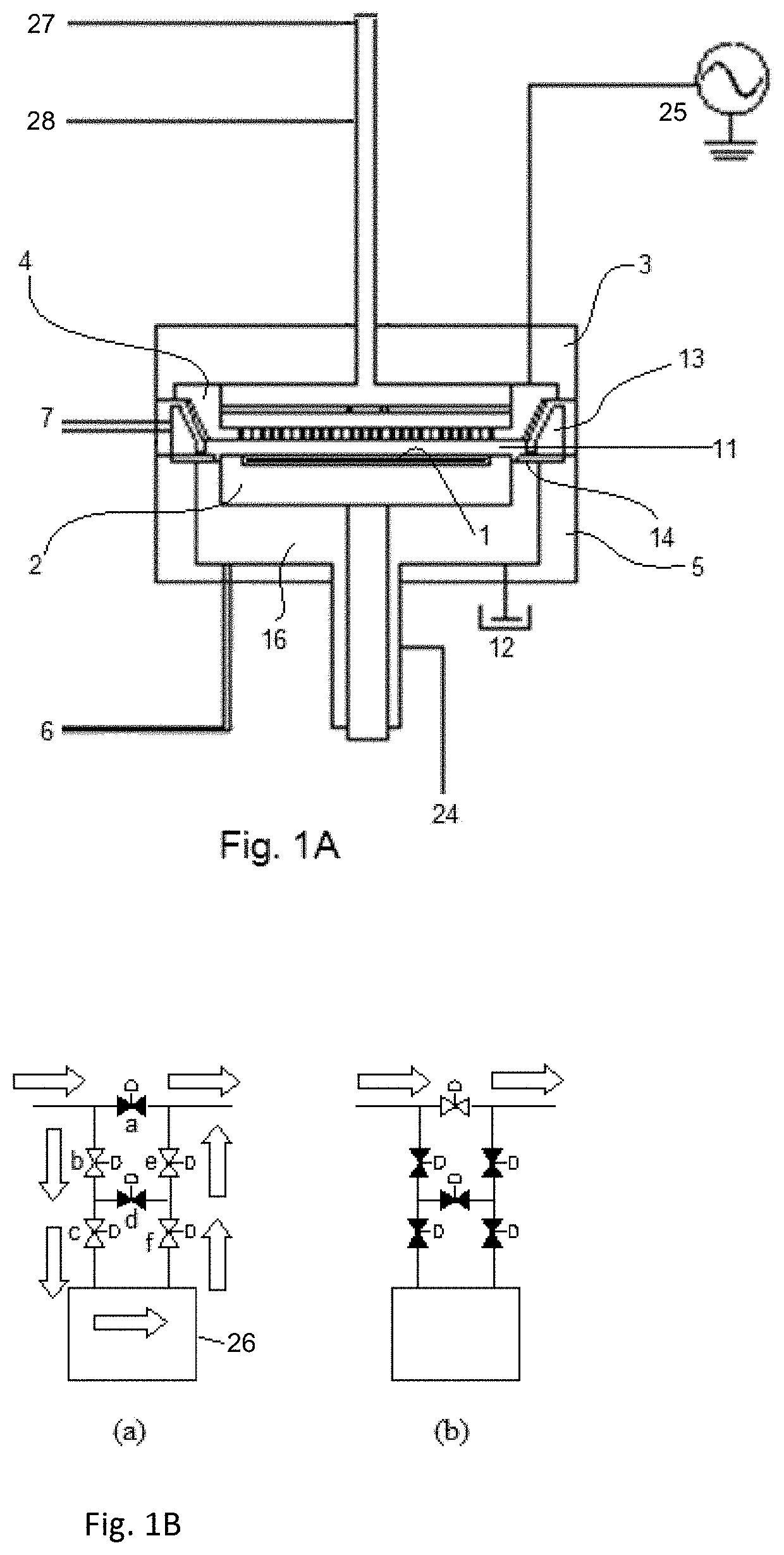

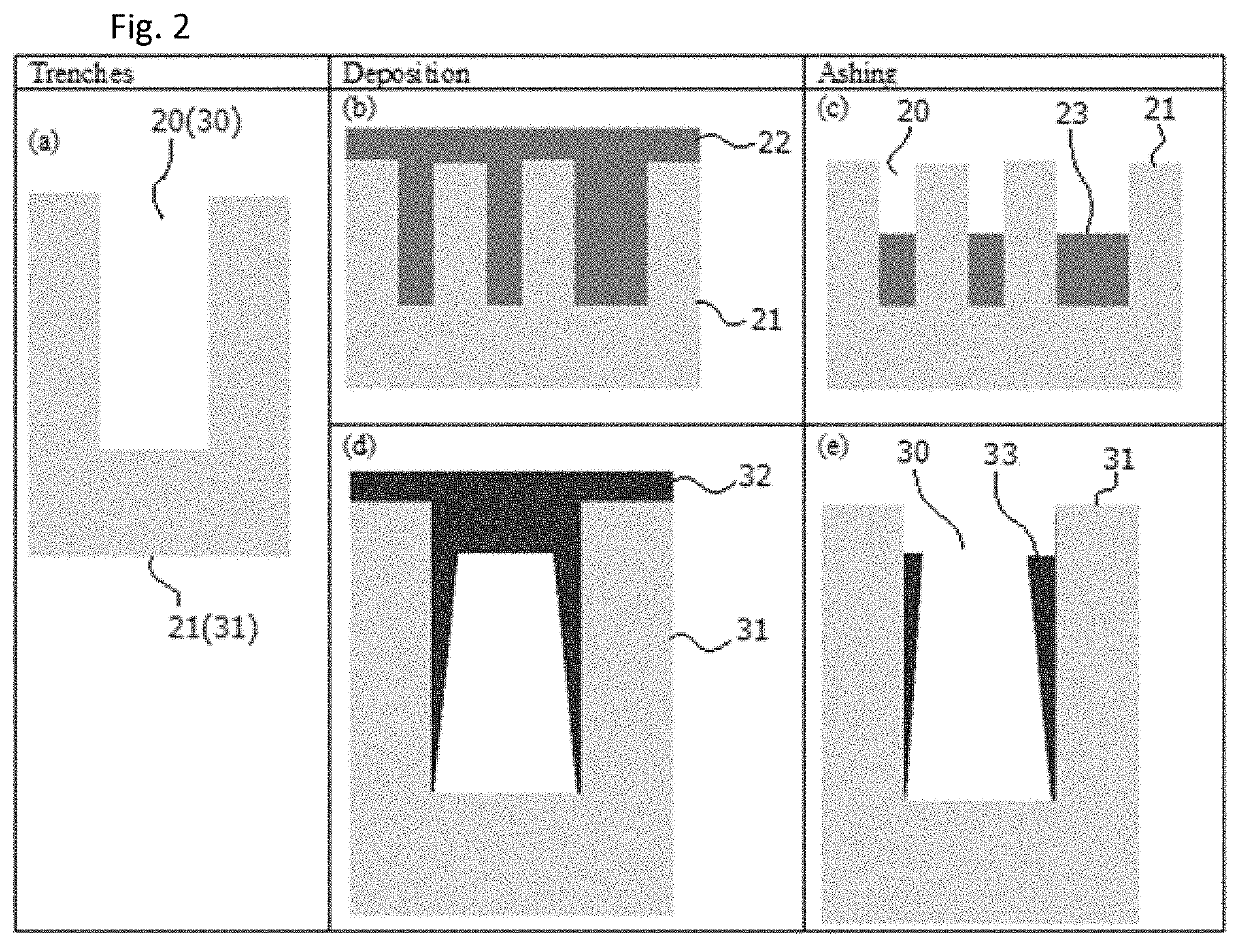

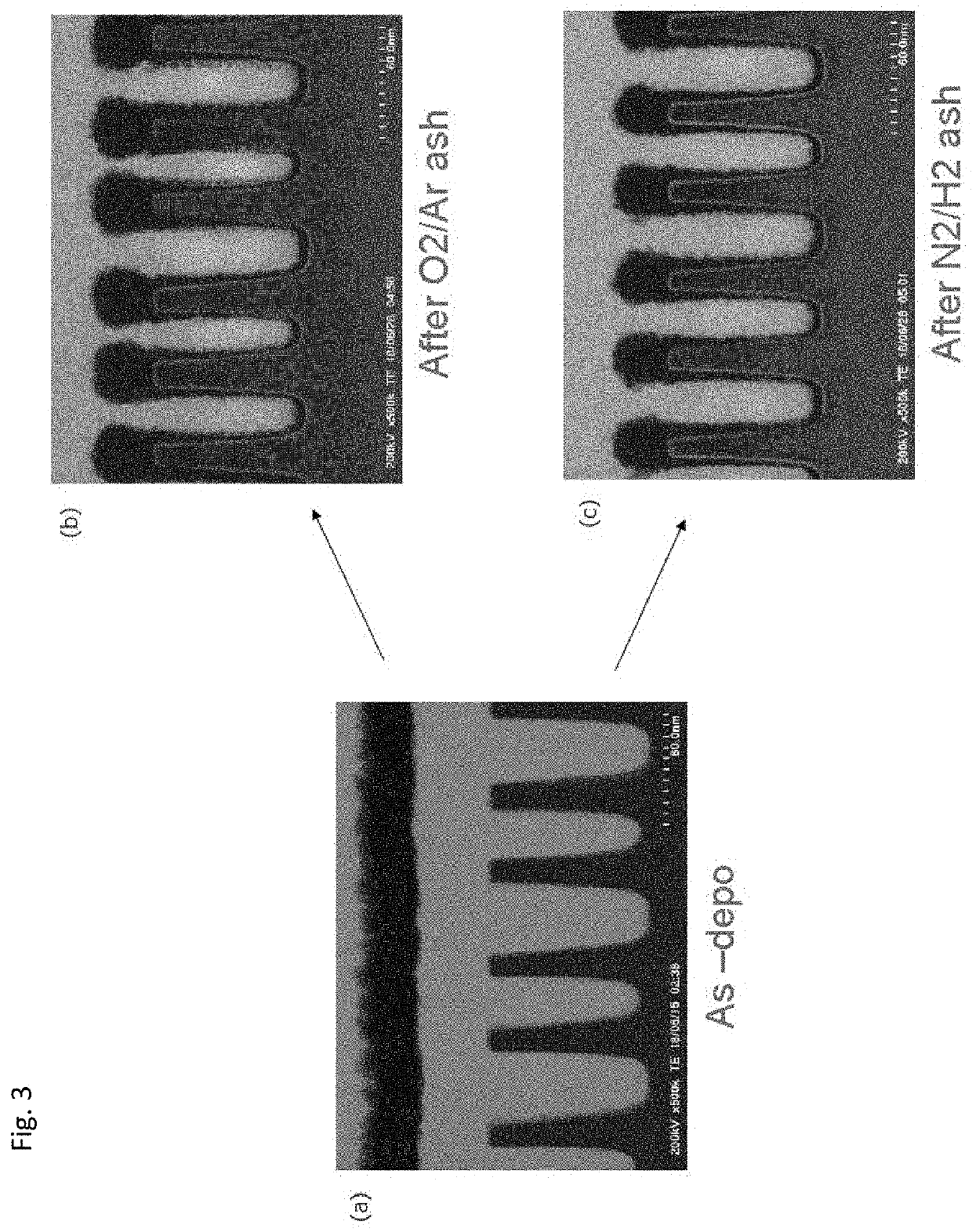

Method of forming topology-controlled amorphous carbon polymer film

ActiveUS20210020431A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingAcid etchingPolymer science

A method of forming a topology-controlled layer on a patterned recess of a substrate, includes: (i) depositing a Si-free C-containing film having filling capability on the patterned recess of the substrate by pulse plasma-assisted deposition to fill the recess in a bottom-up manner or bottomless manner; and (ii) subjecting the bottom-up or bottomless film filled in the recess to plasma aching to remove a top portion of the filled film in a manner leaving primarily or substantially only a bottom portion of the filled film or primarily or substantially only a sidewall portion of the filled film.

Owner:ASM IP HLDG BV

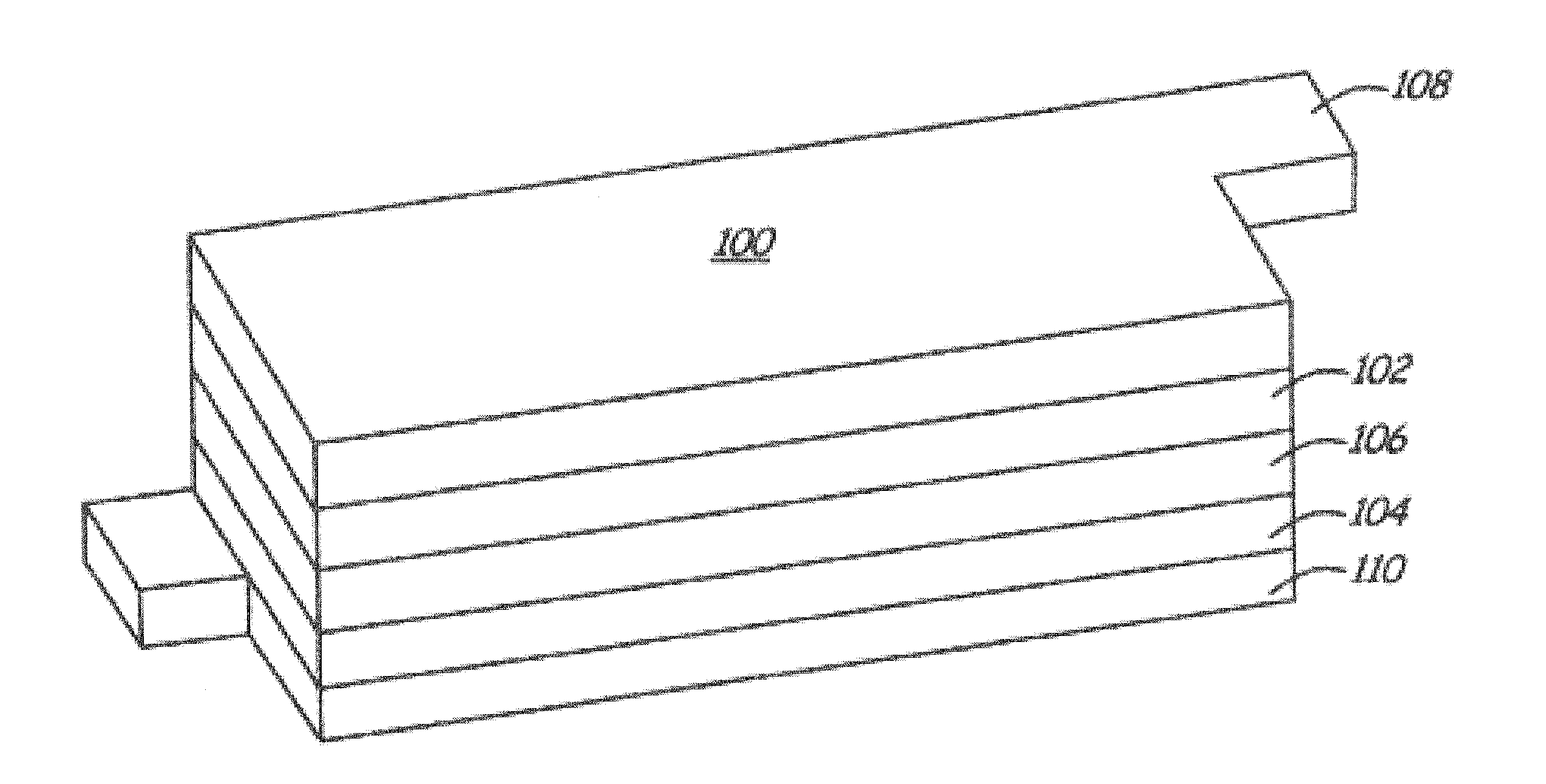

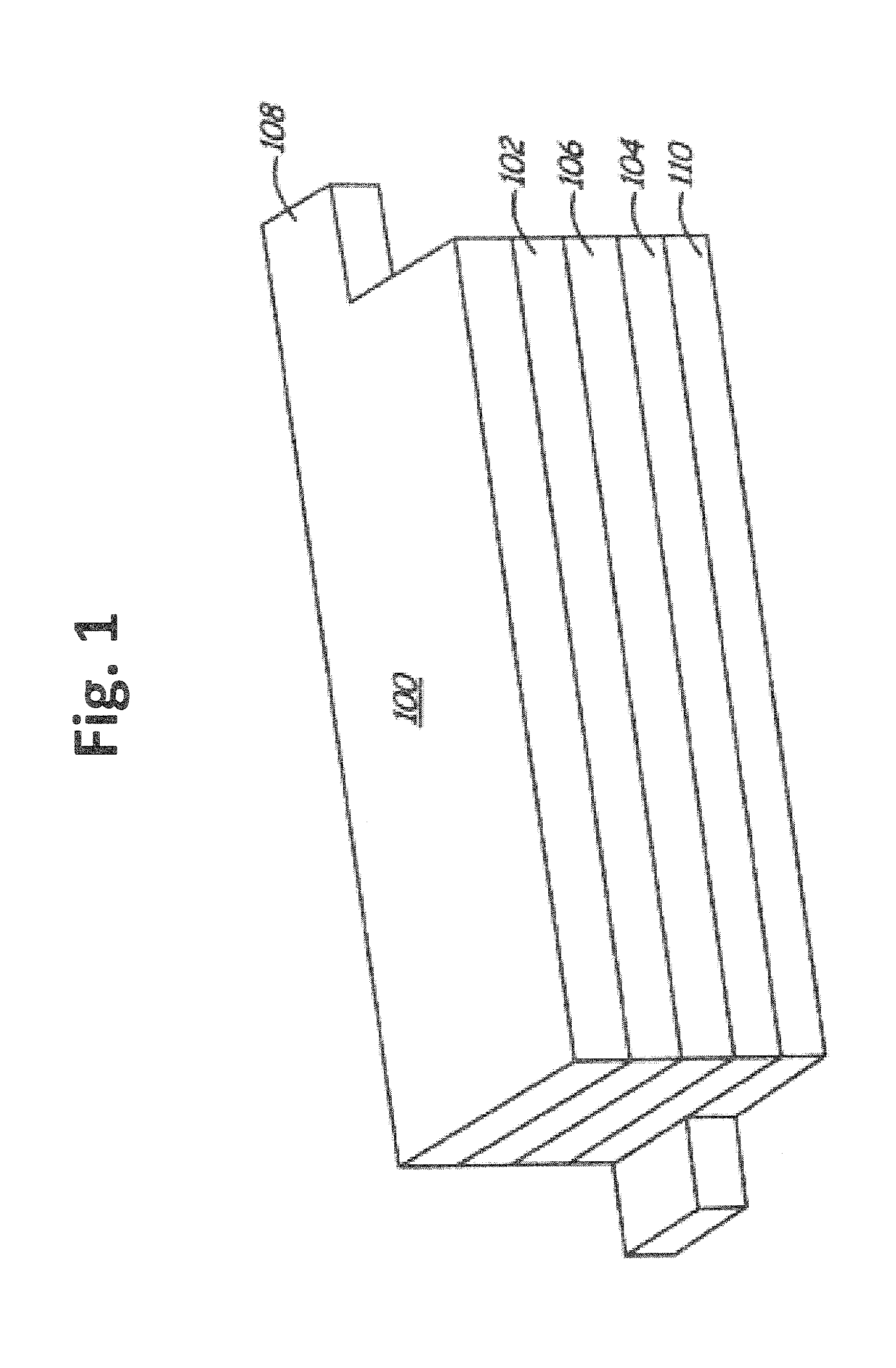

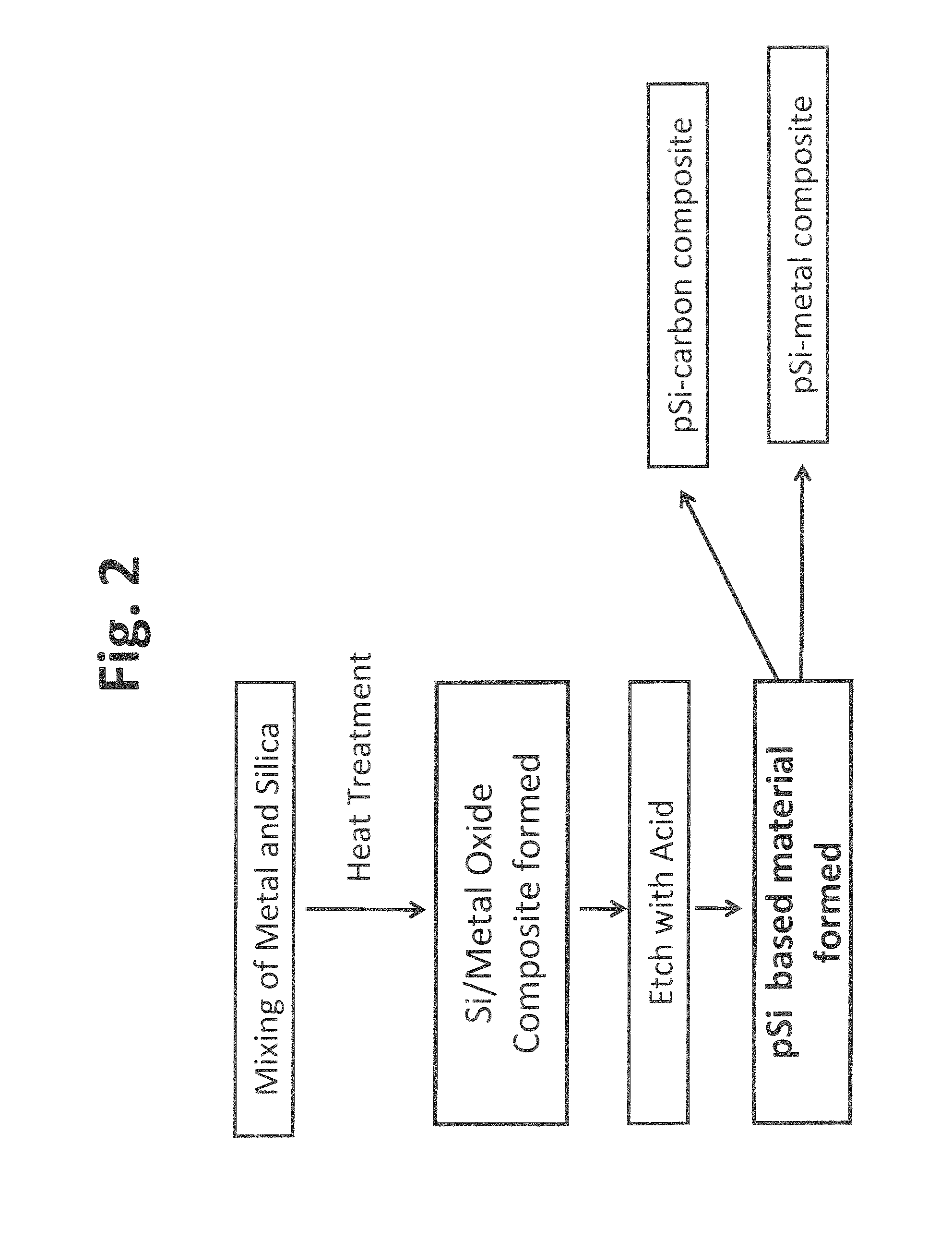

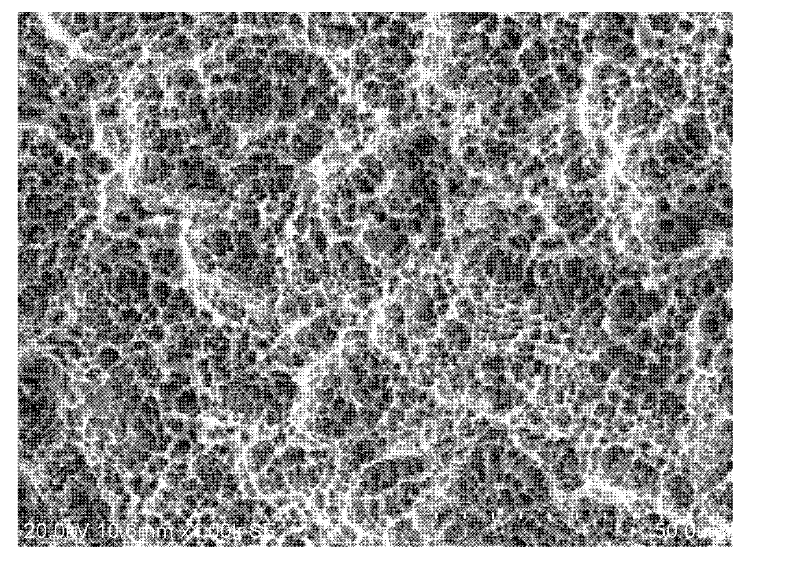

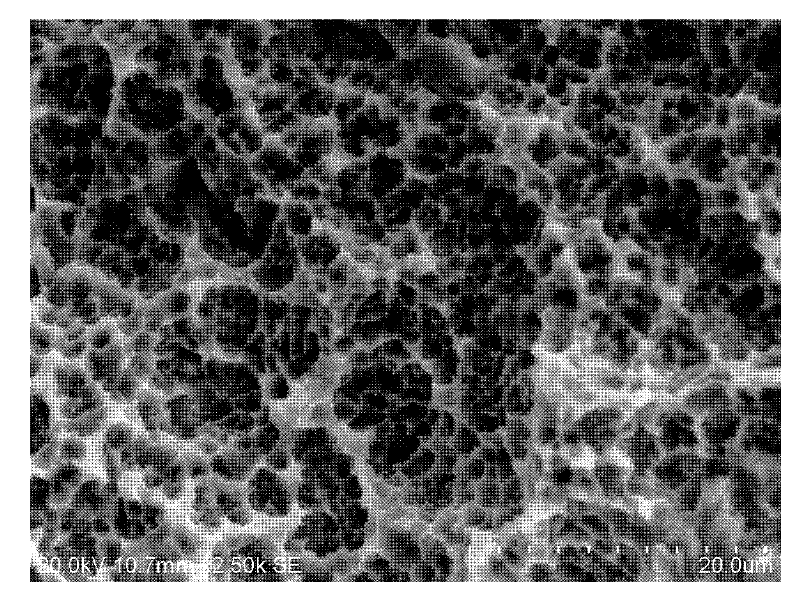

Porous silicon based anode material formed using metal reduction

A porous silicon based material comprising porous crystalline elemental silicon formed by reducing silicon dioxide with a reducing metal in a heating process followed by acid etching is used to construct negative electrode used in lithium ion batteries. Gradual temperature heating ramp(s) with optional temperature steps can be used to perform the heating process. The porous silicon formed has a high surface area from about 10 m2 / g to about 200 m2 / g and is substantially free of carbon. The negative electrode formed can have a discharge specific capacity of at least 1800 mAh / g at rate of C / 3 discharged from 1.5V to 0.005V against lithium with in some embodiments loading levels ranging from about 1.4 mg / cm2 to about 3.5 mg / cm2. In some embodiments, the porous silicon can be coated with a carbon coating or blended with carbon nanofibers or other conductive carbon material.

Owner:IONBLOX INC

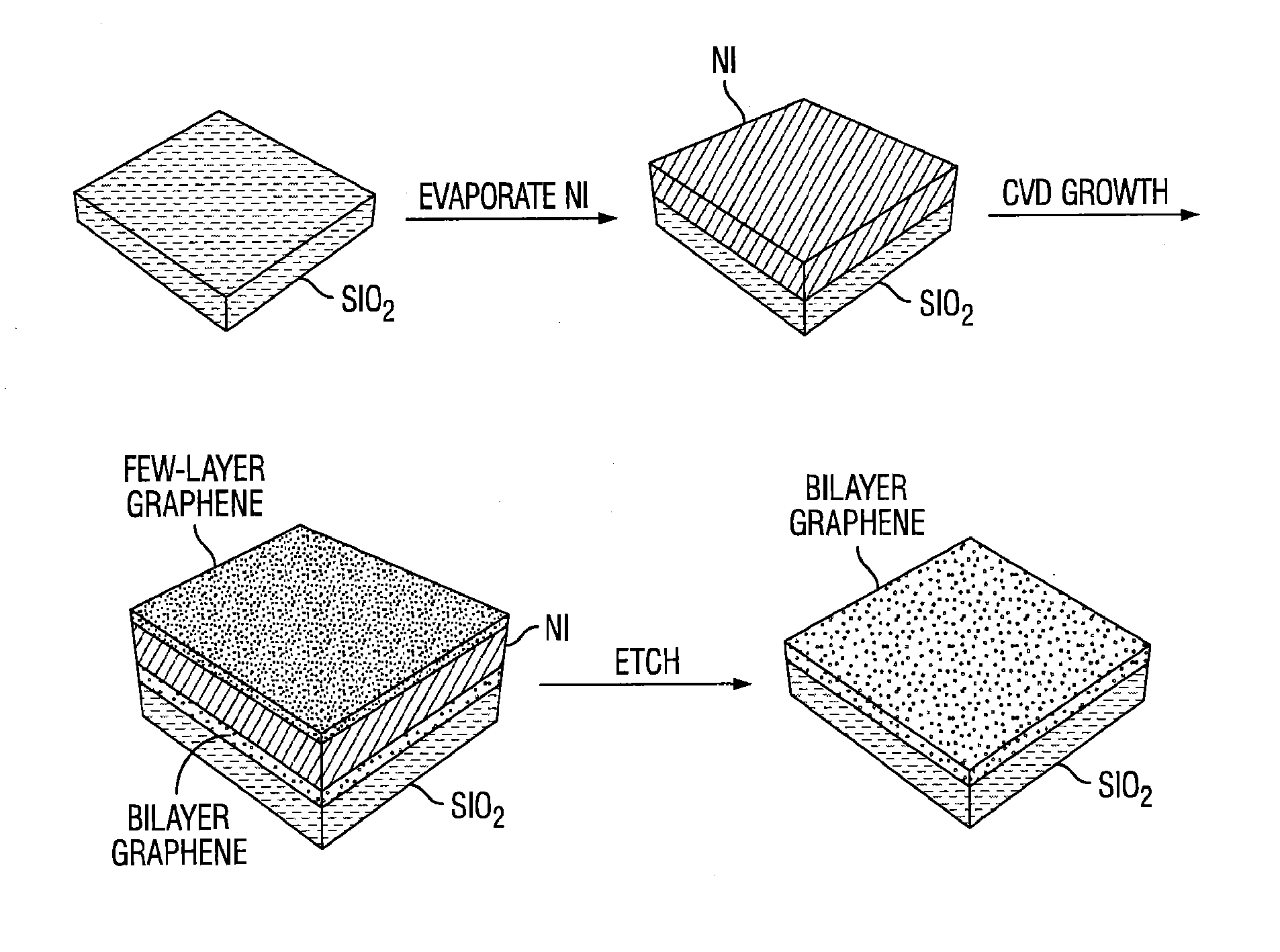

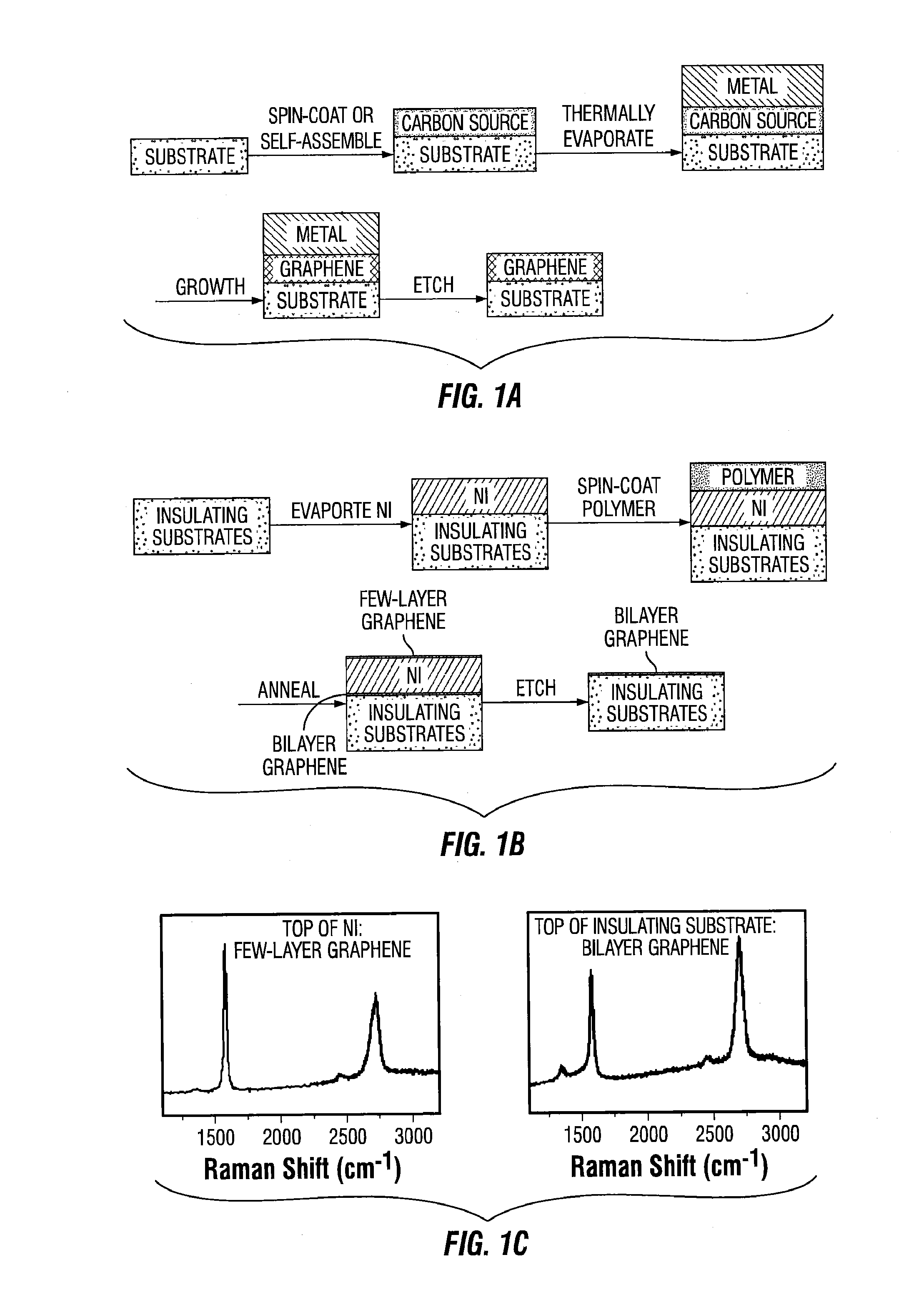

Direct growth of graphene films on non-catalyst surfaces

The present invention provides methods of forming graphene films on various non-catalyst surfaces by applying a carbon source and a catalyst to the surface and initiating graphene film formation. In some embodiments, graphene film formation may be initiated by induction heating. In some embodiments, the carbon source is applied to the non-catalyst surface before the catalyst is applied to the surface. In other embodiments, the catalyst is applied to the non-catalyst surface before the carbon source is applied to the surface. In further embodiments, the catalyst and the carbon source are applied to the non-catalyst surface at the same time. Further embodiments of the present invention may also include a step of separating the catalyst from the formed graphene film, such as by acid etching.

Owner:RICE UNIV

Methods for forming vias in glass substrates

ActiveUS20150060402A1Increase the diameterPaper/cardboard articlesDecorative surface effectsAcid etchingOptoelectronics

Methods for forming vias in glass substrates by laser drilling and acid etching are disclosed. In one embodiment, a method forming a via in a glass substrate includes laser drilling the via through at least a portion of a thickness of the glass substrate from an incident surface of the glass substrate. The method further includes etching the glass substrate for an etching duration to increase a diameter of an incident opening of the via and applying ultrasonic energy to the glass substrate during at least a portion of the etching duration. The applied ultrasonic energy has a frequency between 40 kHz and 192 kHz.

Owner:CORNING INC

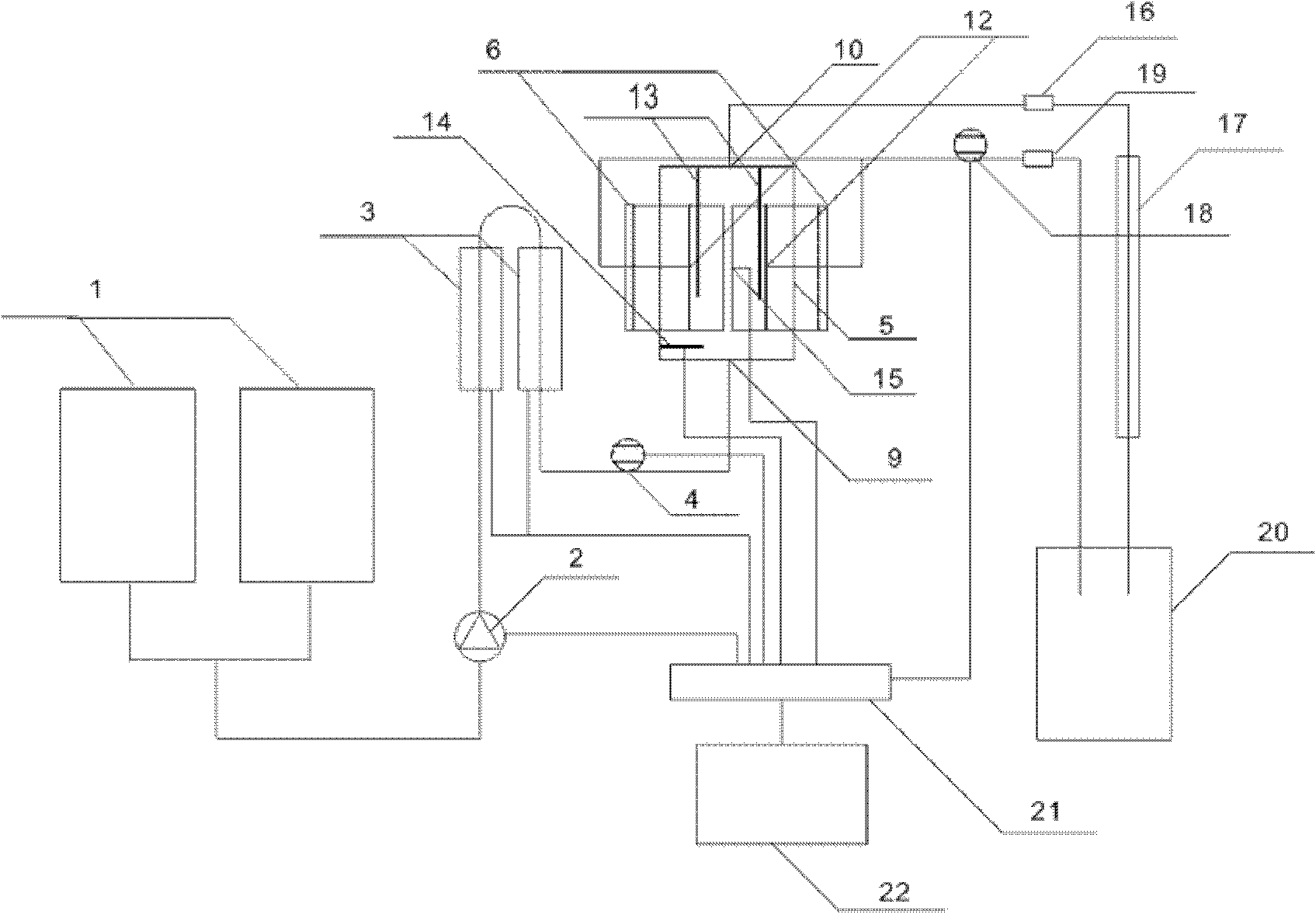

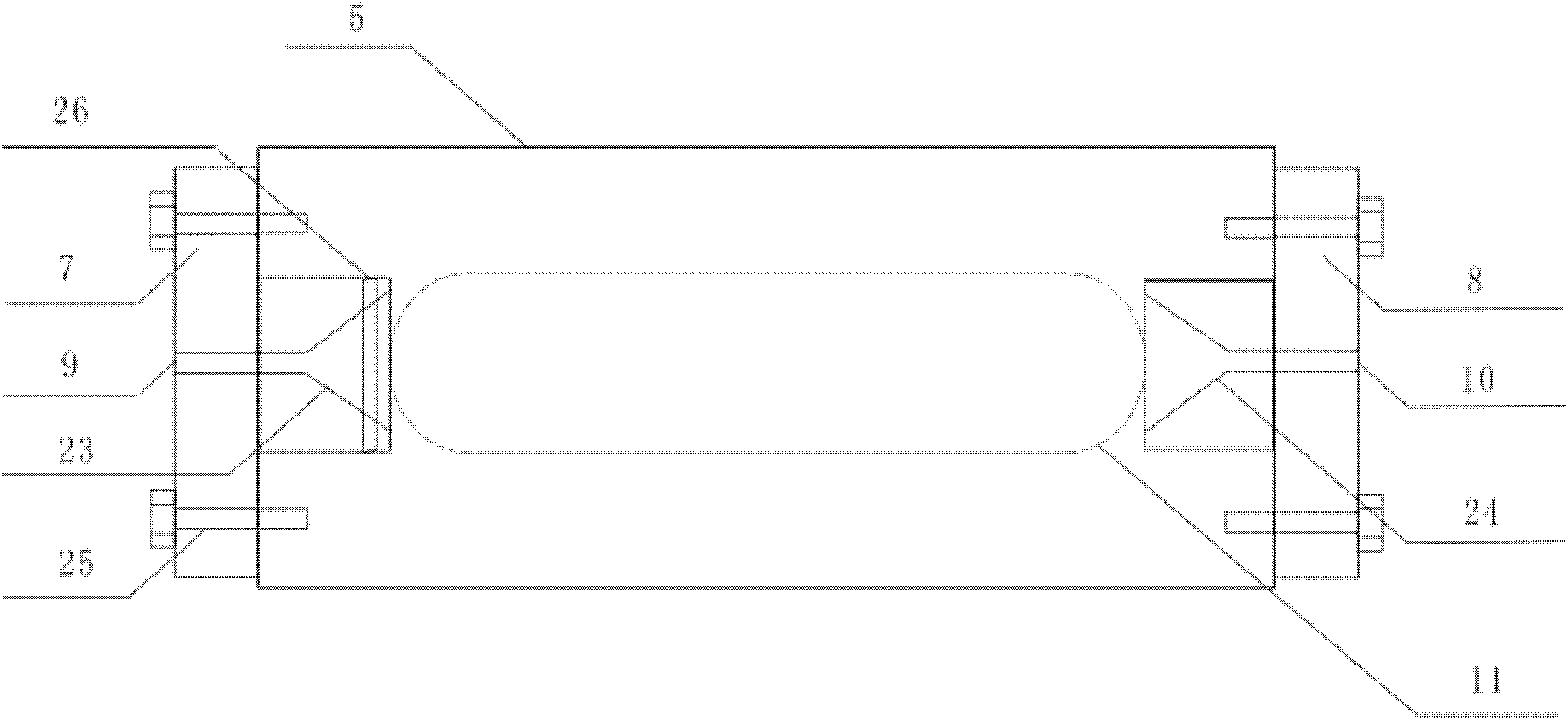

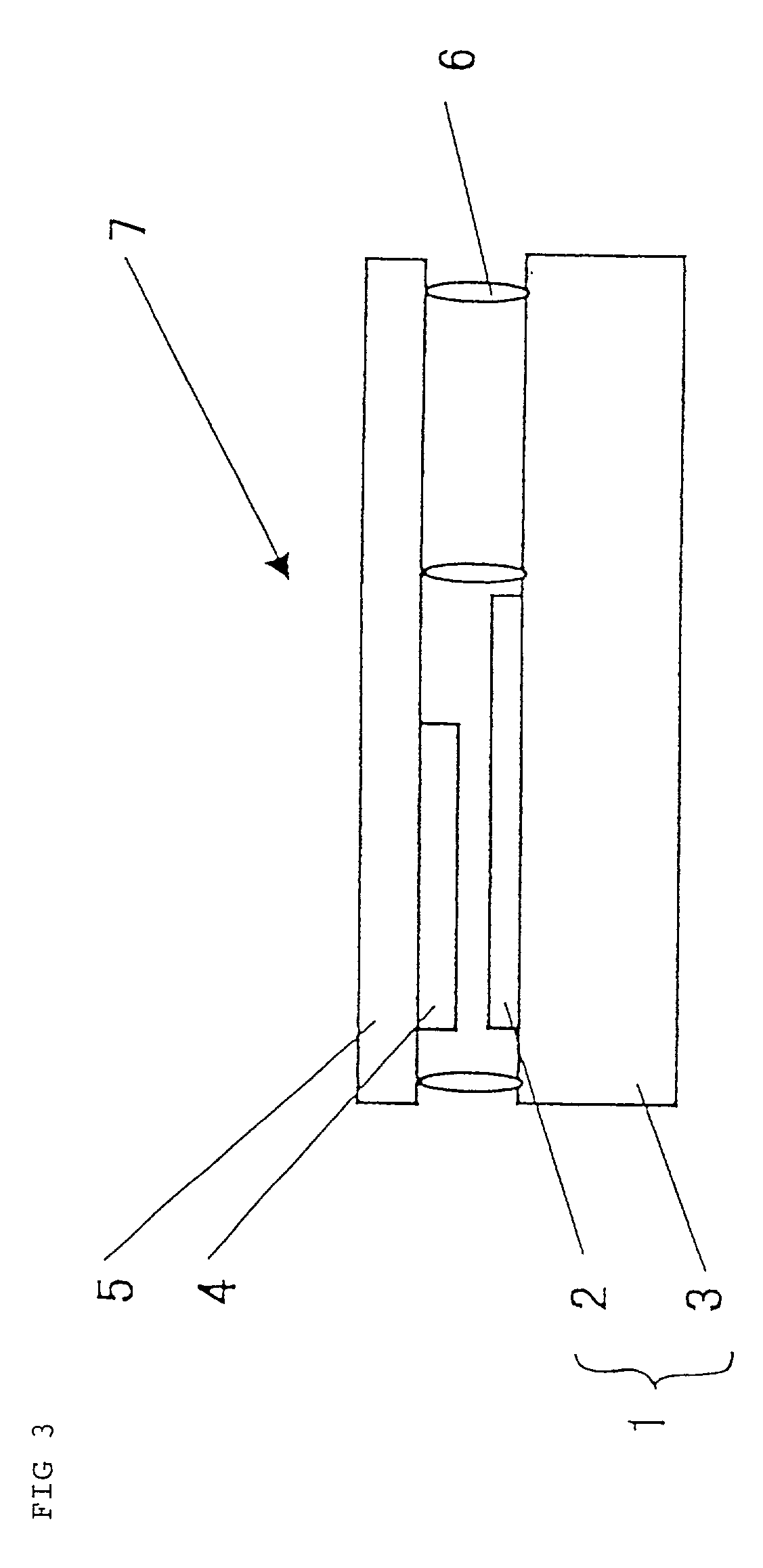

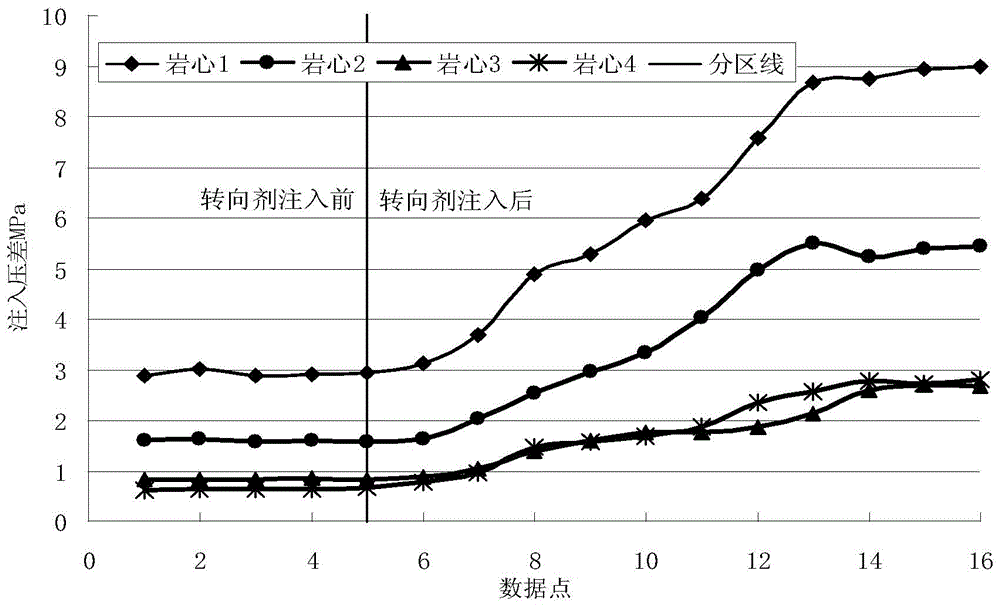

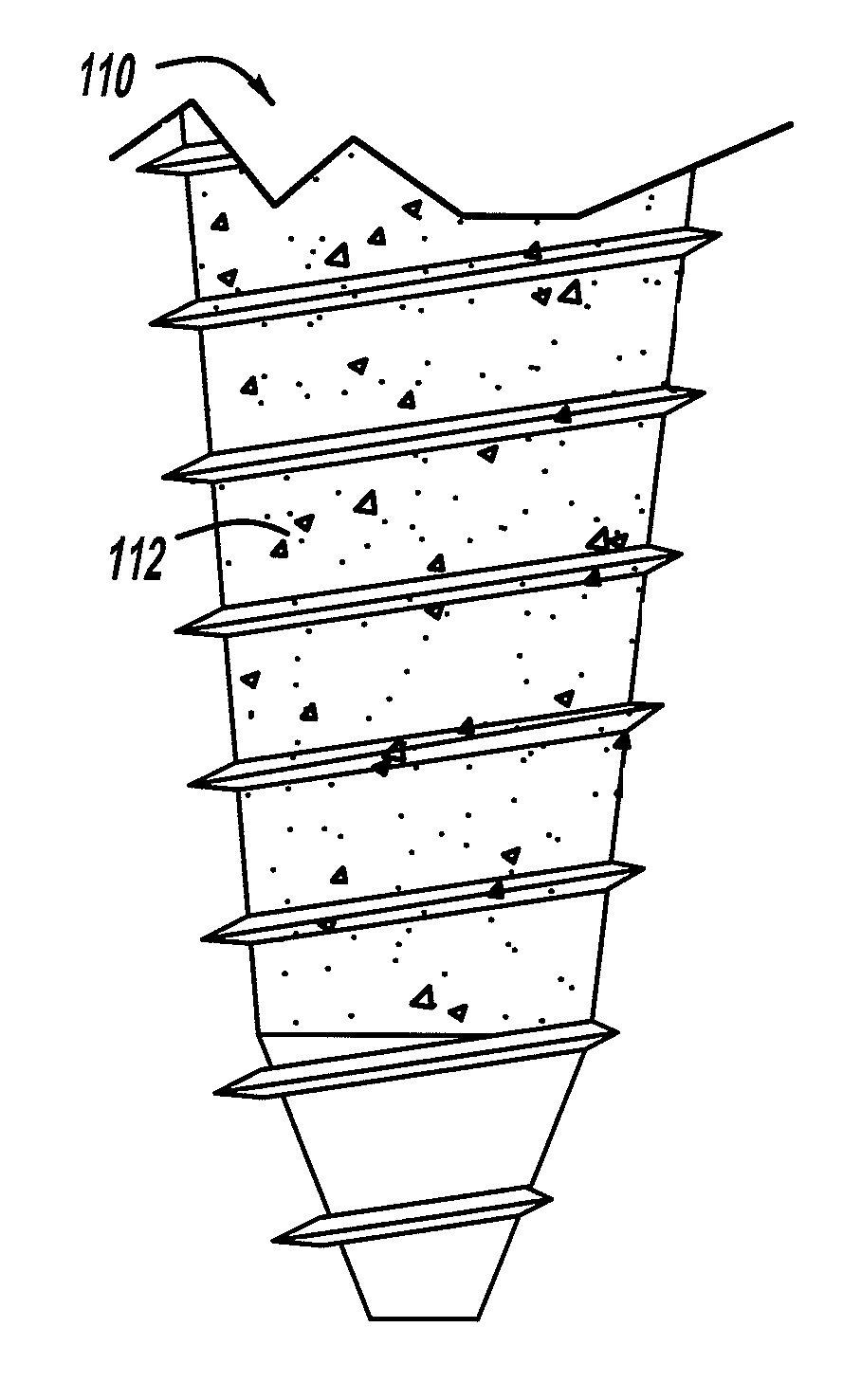

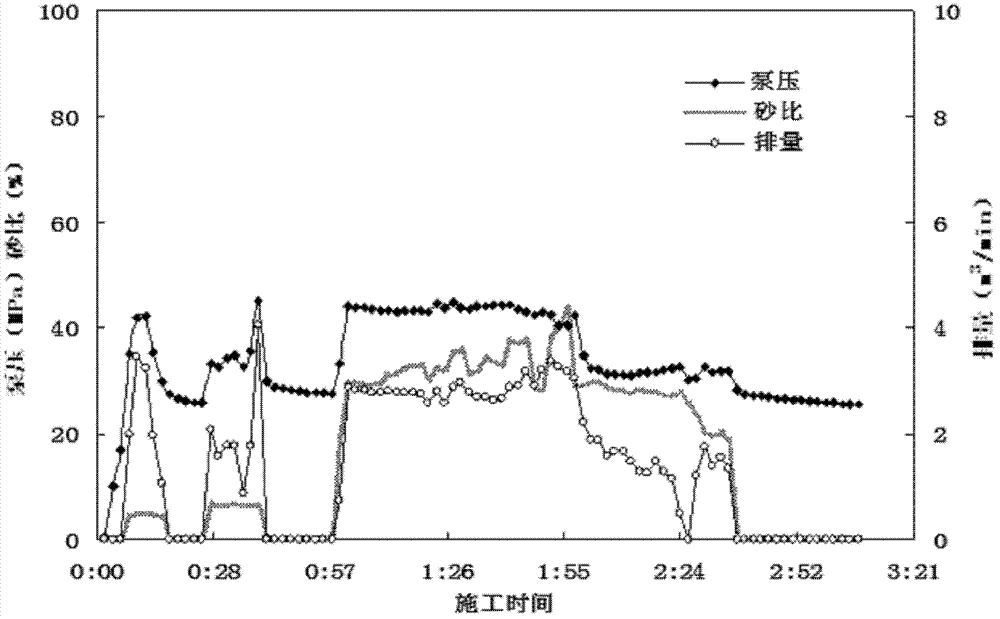

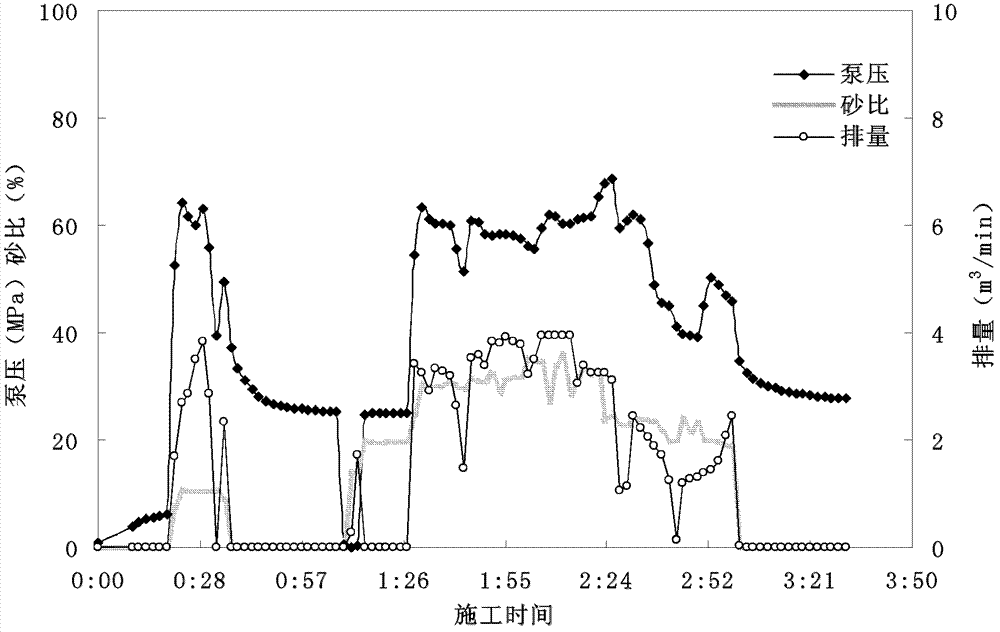

Test device and method for simulating acid etching crack flow guide capability

InactiveCN101864949AMonitor pressure in real timeMonitor temperature in real timeFluid removalAcid etchingWater storage tank

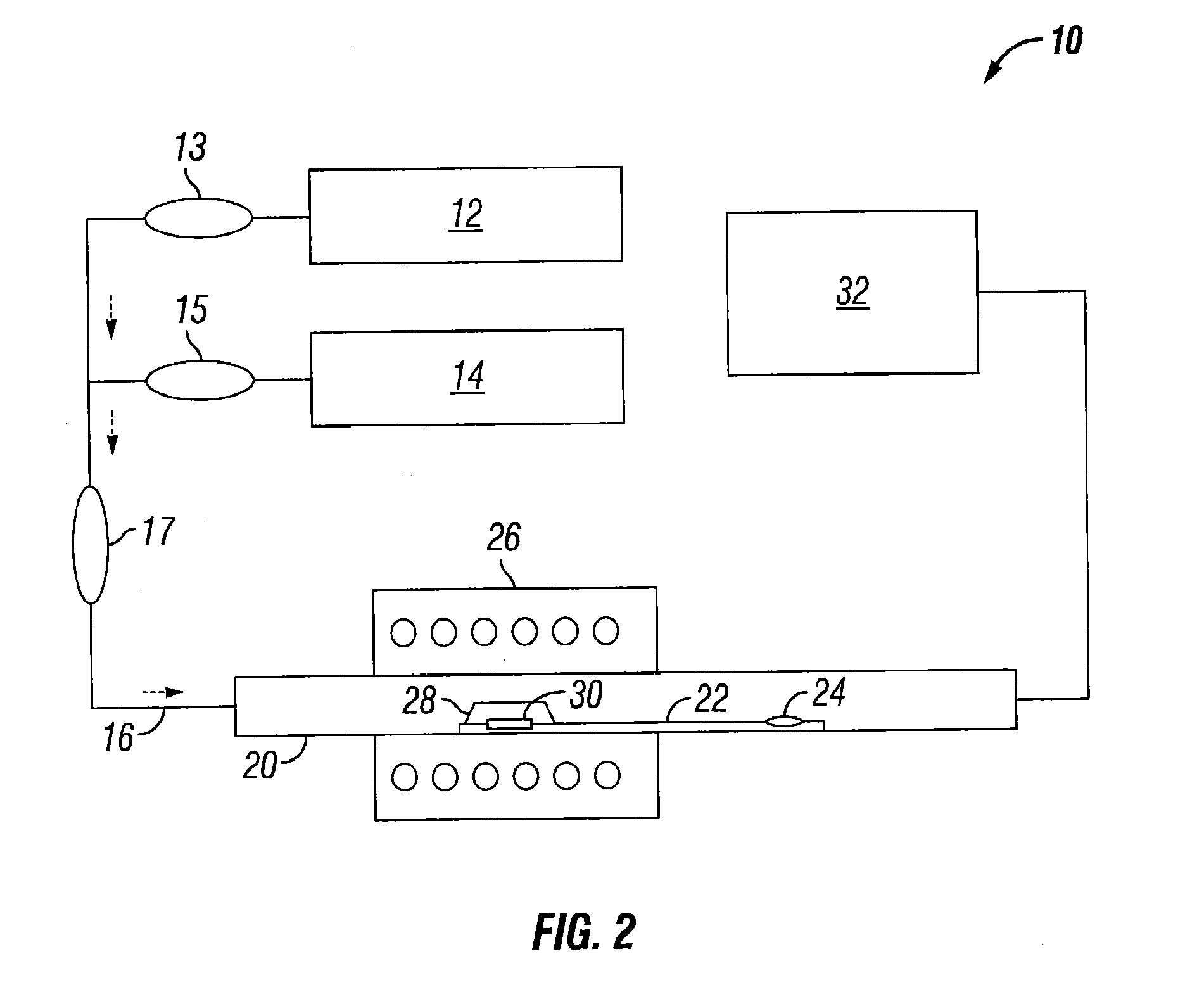

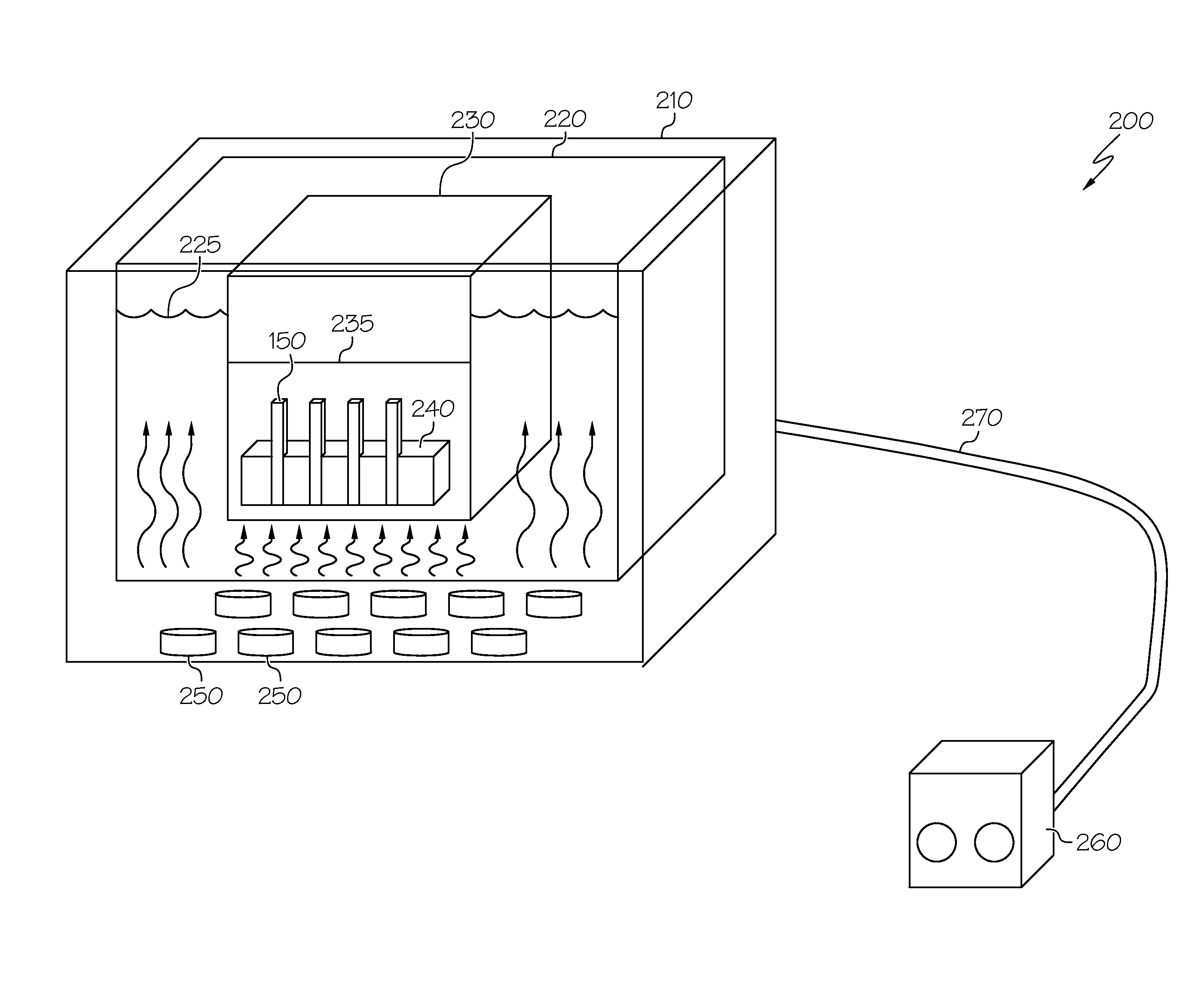

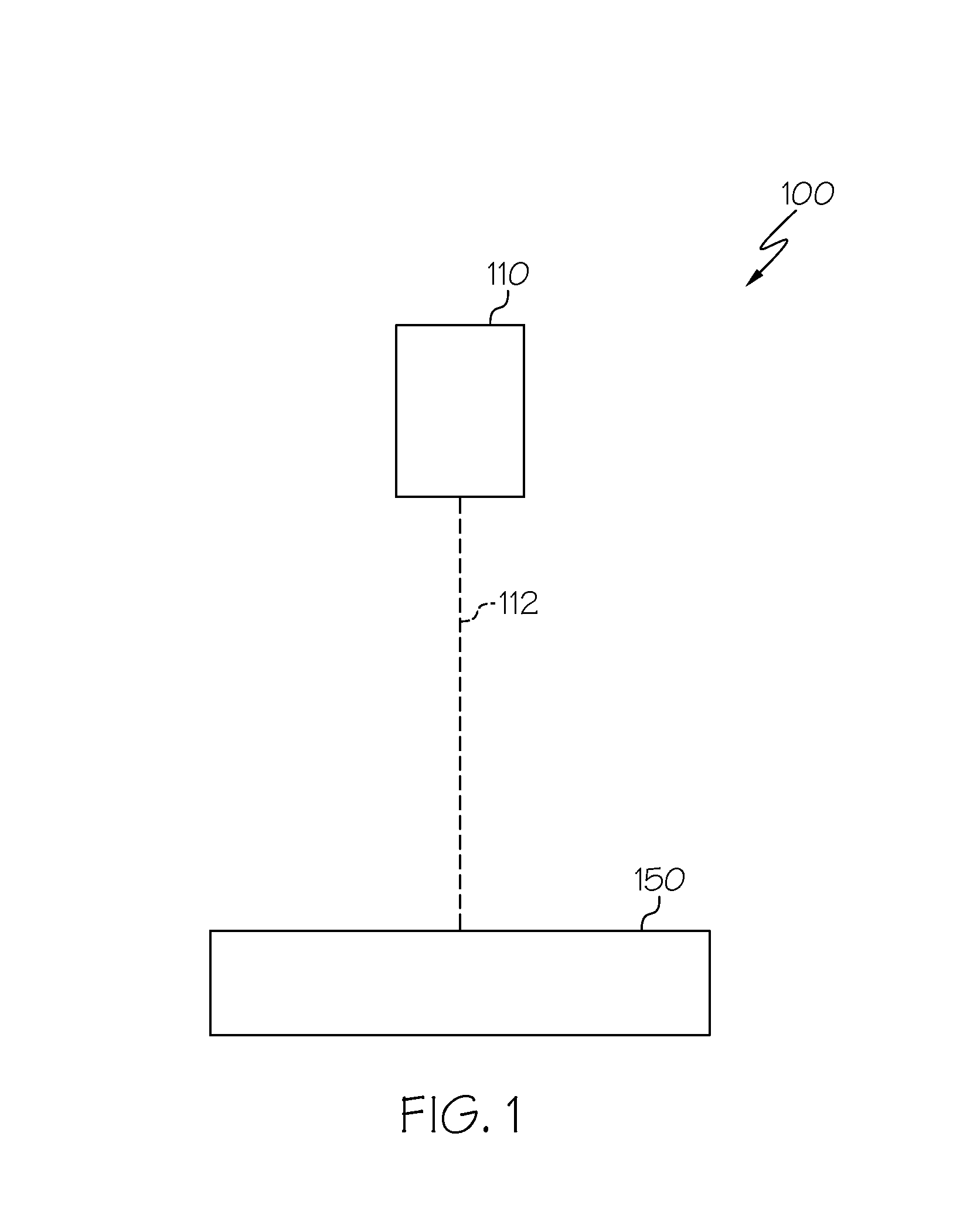

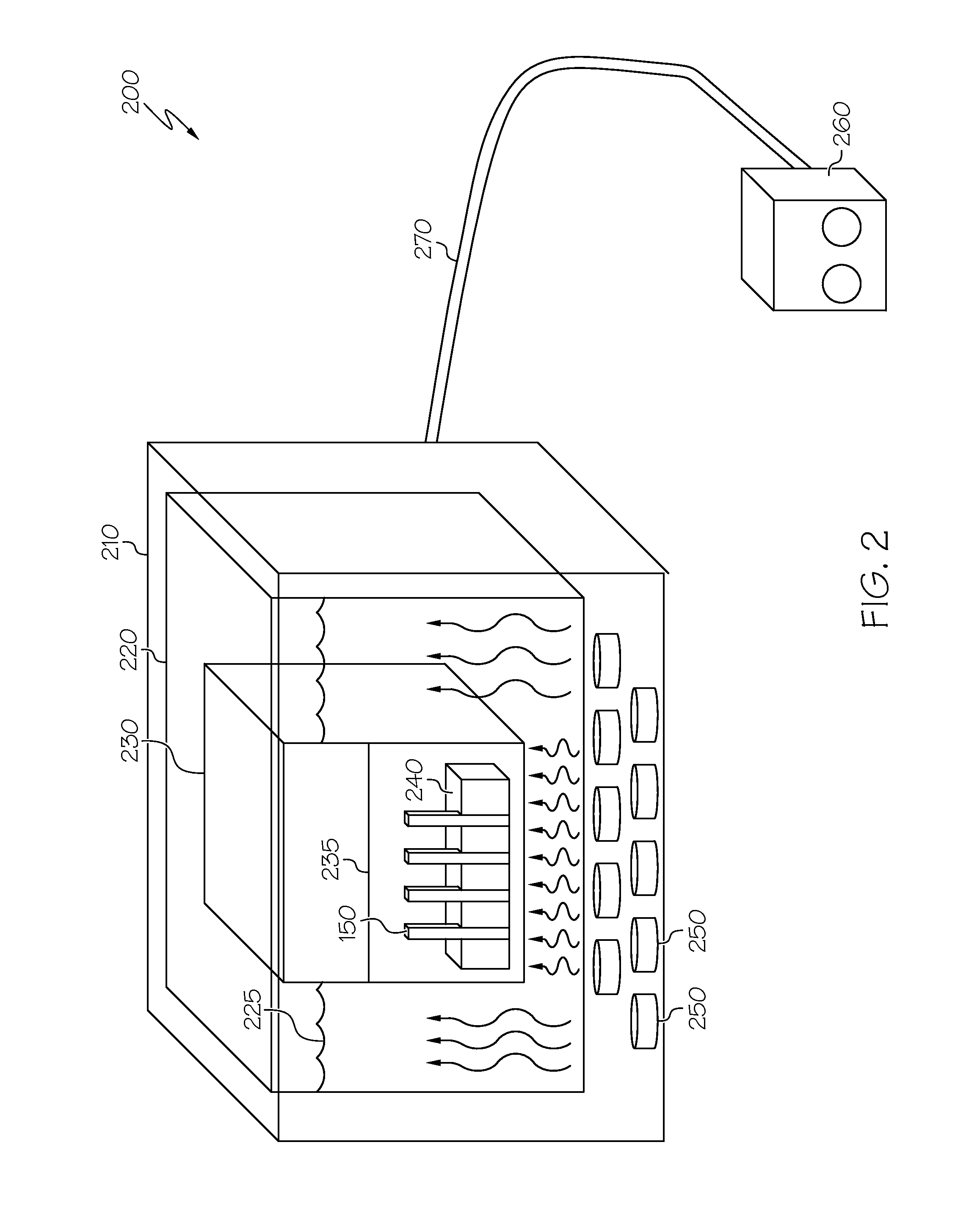

The invention relates to a test device and a method for simulating acid etching crack flow guide capability. The test device consists of a liquid storage tank, a diaphragm pump, a pipeline electric heating sleeve, a flow meter, a flat plate clamping device, a pressure return valve, a condensing pipe, a waste liquid tank, a data collection and control panel and the like, wherein the inner side of the clamping device is provided with a temperature sensor and a pressure sensor, both ends of the lamping device are provided with small liquid inlet holes and small liquid outlet holes, the inside of the clamping device is provided with a liquid inlet piston and a liquid outlet piston, a rock core chamber is arranged between the liquid inlet piston and the liquid outlet piston, the clamping device is connected with a pressure machine, and the diaphragm pump, the pipeline electric heating sleeve, the flow meter, the temperature sensor and the pressure sensor are all connected with the data collection and control panel and a computer. The test method comprises the following steps; cutting the rock into rock core samples conforming to the standard flow guide chamber, and sealing and curing the rock core samples; placing the rock core samples into the rock core chamber; adopting a gasket for simulating the crack width; sequentially opening a clear water storage tank and an acid liquid storage tank; starting the computer, and inputting experiment parameters; and calculating the flow guide capability of the acid etching cracks of the rock core samples. The invention can simulate the real conditions of the underground acid etching crack forms, and can meet the requirements of the acid etching crack flow guide capability test under different environment conditions.

Owner:SOUTHWEST PETROLEUM UNIV

Novel ti-supported lead dioxide electric pole and preparation method thereof

InactiveCN101417831ALow costReduce internal stressWater/sewage treatment by sorptionAcid etchingLead dioxide

The invention relates to a novel titanium substrate lead dioxide electrode and a preparation method thereof, which belong to the field of water treatment technology application. The titanium substrate lead dioxide electrode adopts titanium material as a carrier; after the titanium substrate undergoes acid etching, pyrolytic process is adopted to plate a tin-stibium oxide bottom layer; alkaline solution is then used for electroplating an alpha-PbO2 intermediate layer; acidic composite electroplating solution is used for preparing a fluorine-containing beta-PbO2 surface layer doped with an active metal (such as bismuth, nickel, lanthanum, cerium and erbium) and a particle with high absorption performance (such as powdered activated carbon and chitosan), thus obtaining a novel titanium substrate lead dioxide electrode. The titanium substrate lead dioxide electrode prepared by the method has low cost and long service life. Using the electrode as an anode and applying certain applied voltage can realize efficient removal and mineralization to the organic contaminants in the water. With simple operation and convenient management, the method is applicable to small-scale and dispersible wastewater and feed water treatment.

Owner:BEIJING NORMAL UNIVERSITY

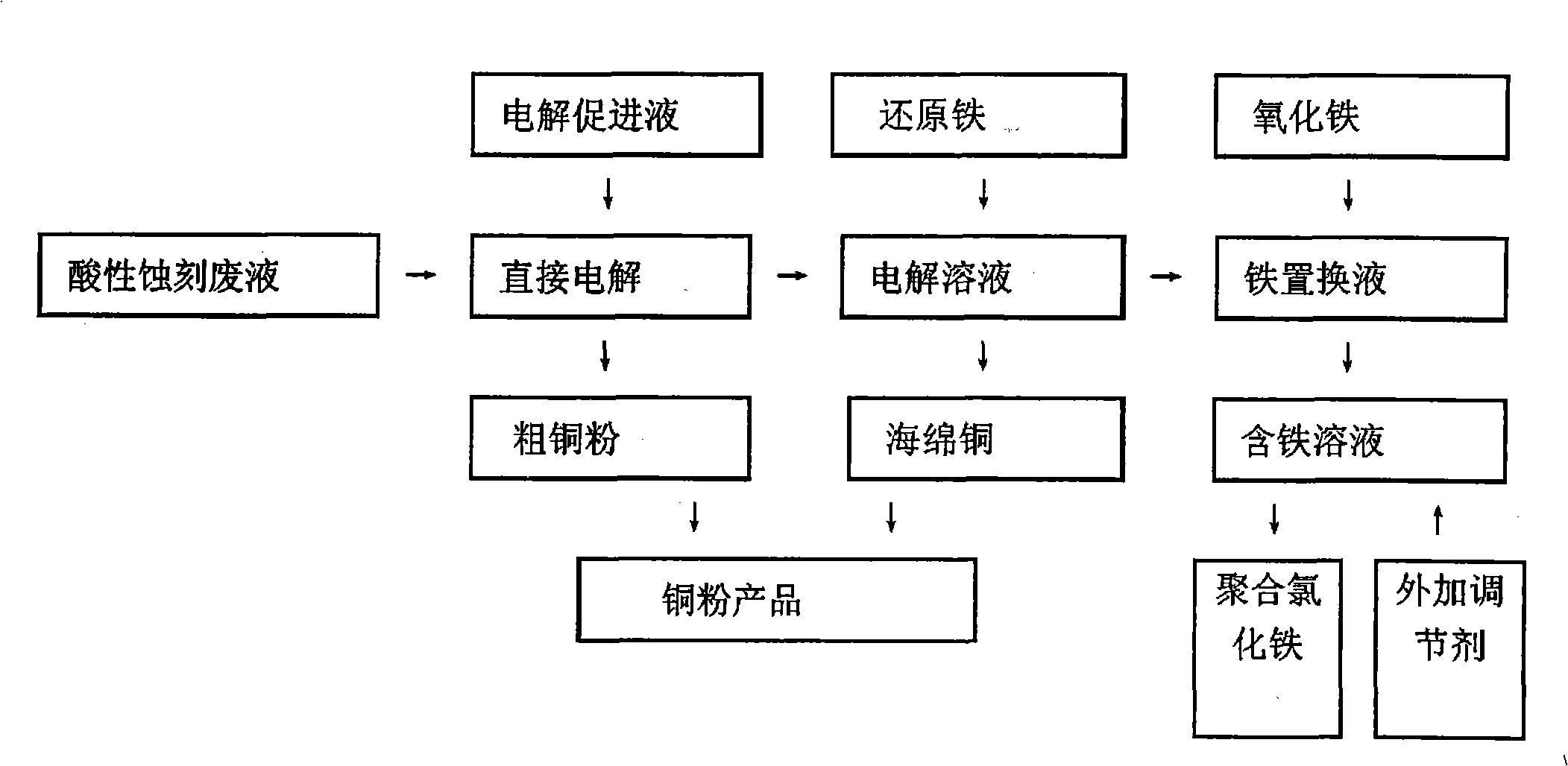

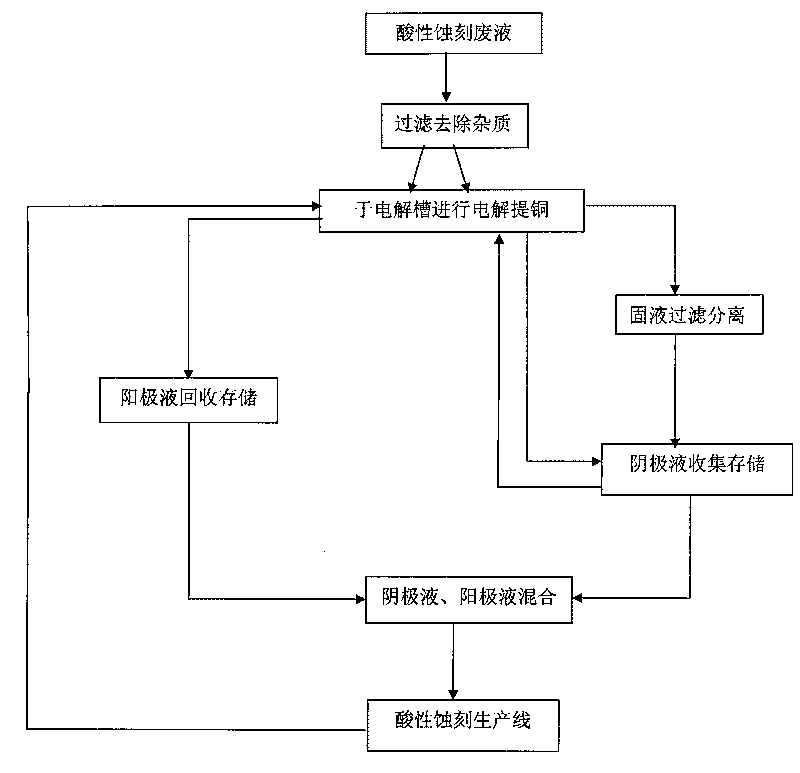

Method for extracting copper from printed circuit board acidic spent etching solution and preparing poly ferric chloride

InactiveCN101353795ASolve the rare problem of recyclingPromote resource recyclingPhotography auxillary processesProcess efficiency improvementAcid etchingElectrolysis

The invention relates to a method for extracting copper of a PCB acid etching waste liquid and preparing polyferric chloride, which comprises the following steps: the PCB acid etching waste liquid is electrolyzed directly and copper powder precipitated by electrolysis is reclaimed; reduced iron is added into a mixed solution after the electrolysis and copper sponge precipitated by replacement reaction is reclaimed; claimed crude copper is purified and prepared into copper powder products; the mixed solution after replacement reaction is added with ferric oxide or a substance containing Fe irons; the mixed solution mingled with the Fe irons is added respectively with a polymeric antioxidant and a stabilizer and simultaneously, the pH value of which is regulated with acid or alkali; and finally, the PFC is prepared. The method of the invention completely realizes reclamation and recycling of wastes and water environment treatment and finally 'zero' emission and has good environmental protection, simple preparation process, high economic benefit and wide application scope.

Owner:HUNAN VARY TECH

Acid fracturing process of oil gas well mining temperature control various mucic acid

ActiveCN101353958AReduce fluid lossEasy to form non-uniform etchingFluid removalDrilling compositionAcid etchingMucic acid

The invention relates to an acid fracturing method of a temperature-control and variable-viscosity acid in the exploitation of an oil-gas well, which comprises the steps that: a common chlorohydric acid pickling process is firstly used for removing the pollution of an embrasure; then, the temperature-control and variable-viscosity acid fracturing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing process, or a temperature-control and variable-viscosity acid fracturing enclosed acidizing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing enclosed acidizing process is adopted; the weight ratio of the components of the temperature-control and variable-viscosity acid are as follows: 100 portions of basic acid solution, 0.5 portion to 1.5 portions of the main agent of the temperature-control and variable-viscosity acid, 1 portion to 3 portions of a corrosion inhibitor of the temperature-control and variable-viscosity acid, 0.5 portion to 1 portion of an emulsion breaker, 0.5 portion to 1 portion of a ferric ion stabilizer and 0.5 portion to 1 portion of a high efficient discharge aiding agent; 2-percent KCL clear water is used for displacing the temperature-control and variable-viscosity acid into the stratum. The temperature-control and variable-viscosity acid is easily prepared on site, with low friction drag and strong pumpability, thereby being capable of being applied to high-discharge construction; under the high temperature condition of a storing layer, both the fresh acid and the residue acid have high viscosity, thus increasing the length of acid-etching cracks. After the construction is finished, the viscosity of the residue acid is reduced, which is beneficial to the back discharge of the residue acid.

Owner:PETROCHINA CO LTD

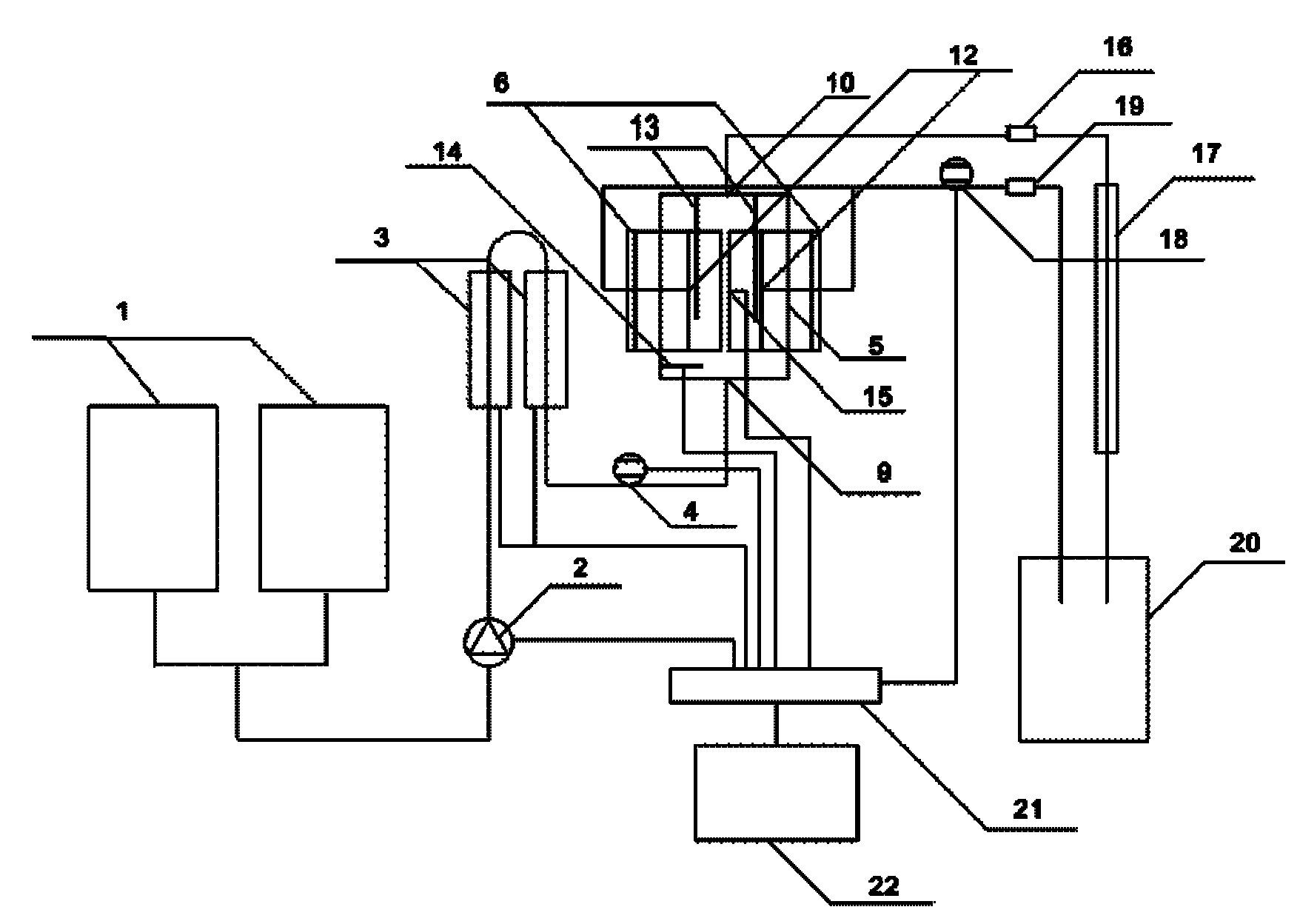

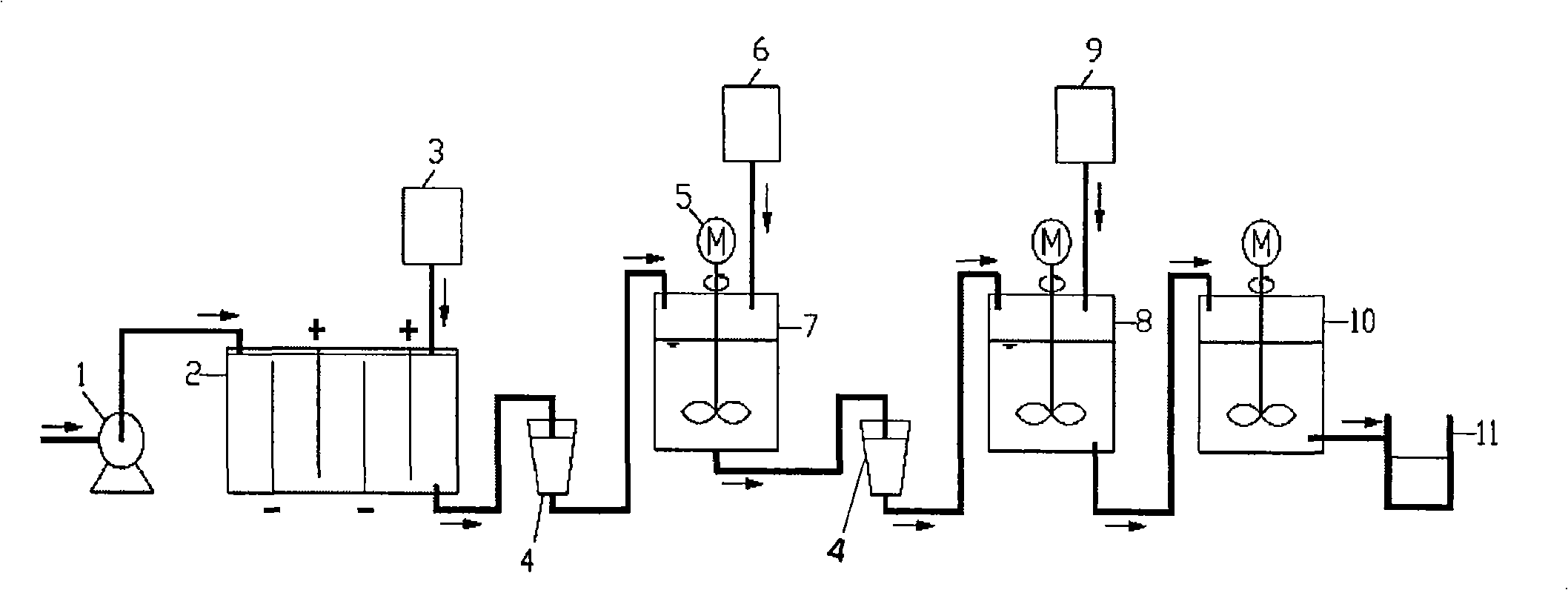

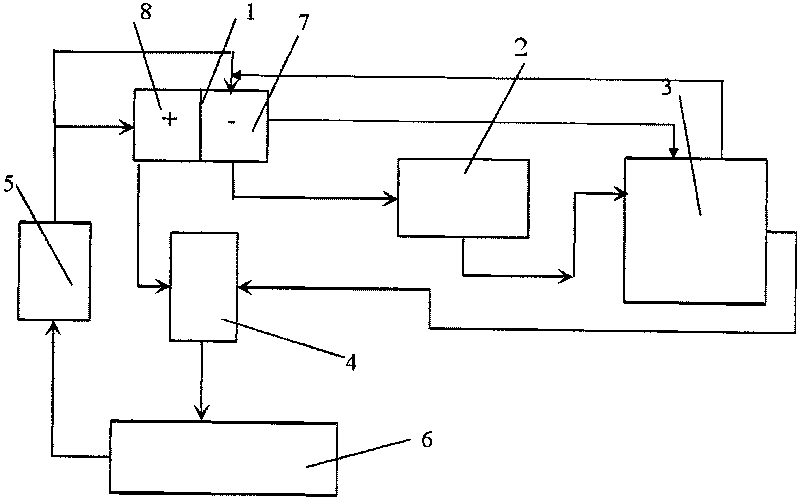

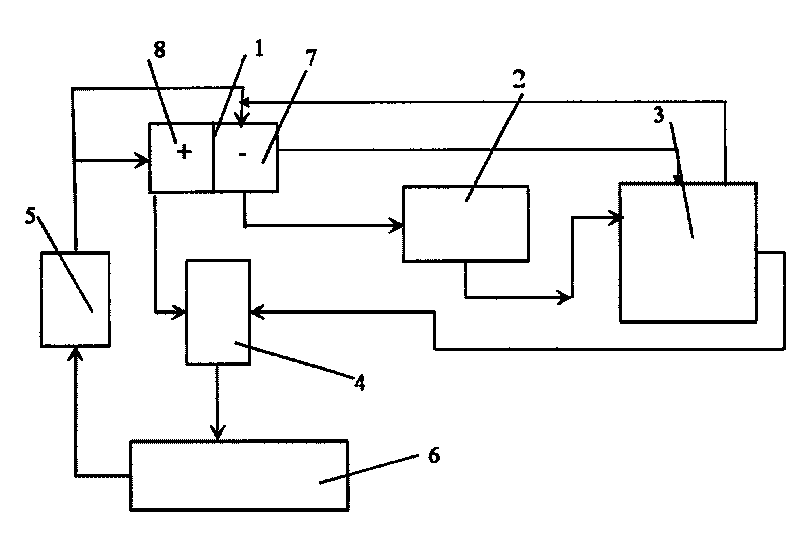

Copper recovery system of printed board acid etching waste solution and etching solution regeneration method

ActiveCN101748430ATo achieve the purpose of recycling copperPhotography auxillary processesProcess efficiency improvementAcid etchingElectrolysis

The invention relates to the field of recovery, in particular to a copper recovery system of printed board acid etching waste solution and an etching solution regeneration method. The system comprises a set of solid-liquid separation device, a current control device and an electrolytic bath, wherein the electrolytic bath is divided into a cathode chamber and an anode chamber by an ion membrane; the insides of the cathode chamber and the anode chamber are respectively provided with a cathode plate and an anode plate; the cathode plate and the anode plate are respectively connected with the current control device; all the bathes are connected with the electrolytic bath by pipelines to form a closed loop, through arranging the ion membrane in the electrolytic bath to divide the electrolytic bath into the cathode chamber and the anode chamber, when waste solution enters the electrolytic bath, the liquid in each chamber has electrolysis reaction under the action of respective polar plate to precipitate copper in the cathode chamber, the copper is recovered by a filter unit, and the bath solution enters a mixing bath for regeneration and reuse. The system reaches the goal of the regeneration of etching solution and recovery of copper.

Owner:江苏地一环保科技有限公司

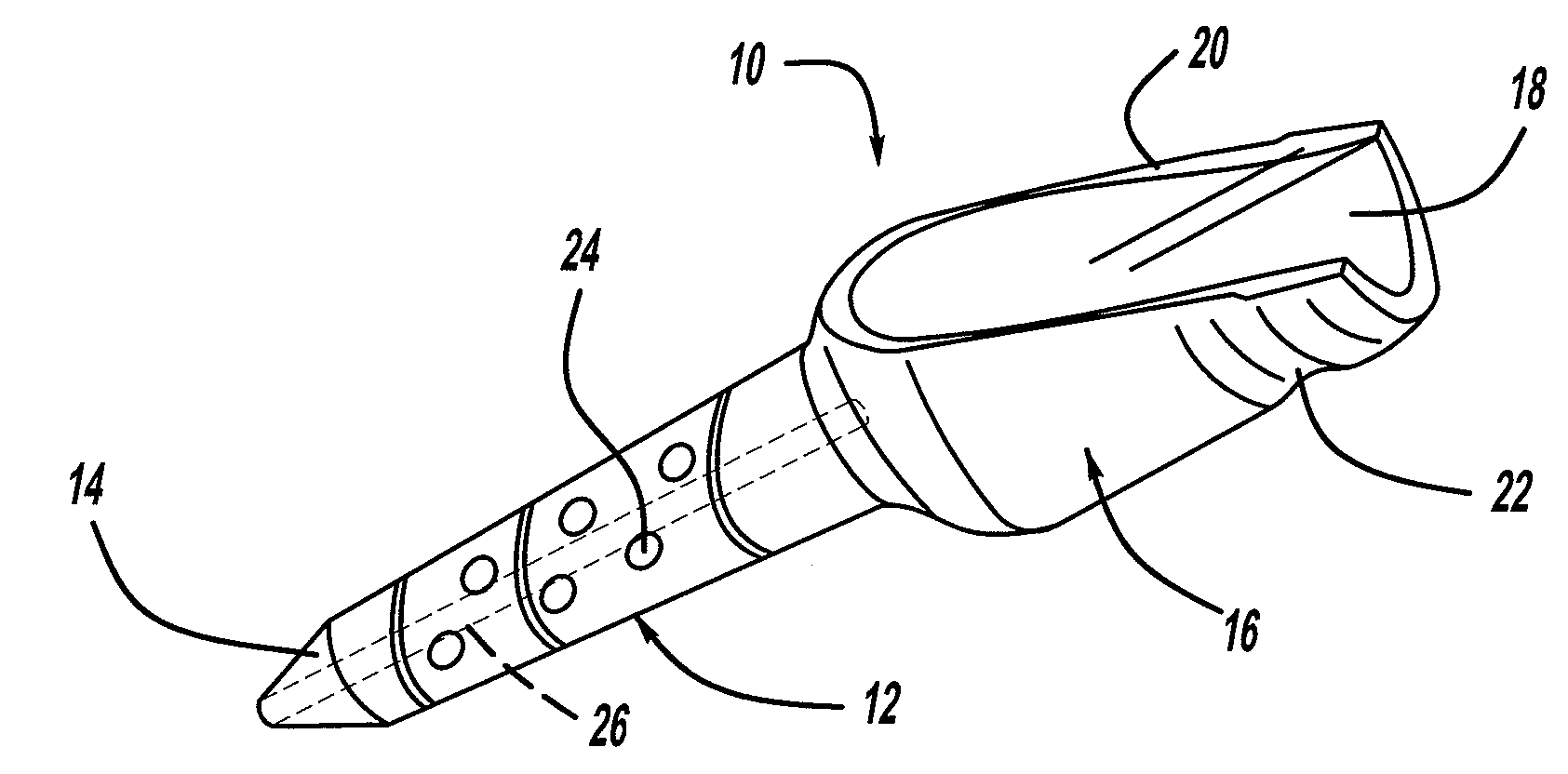

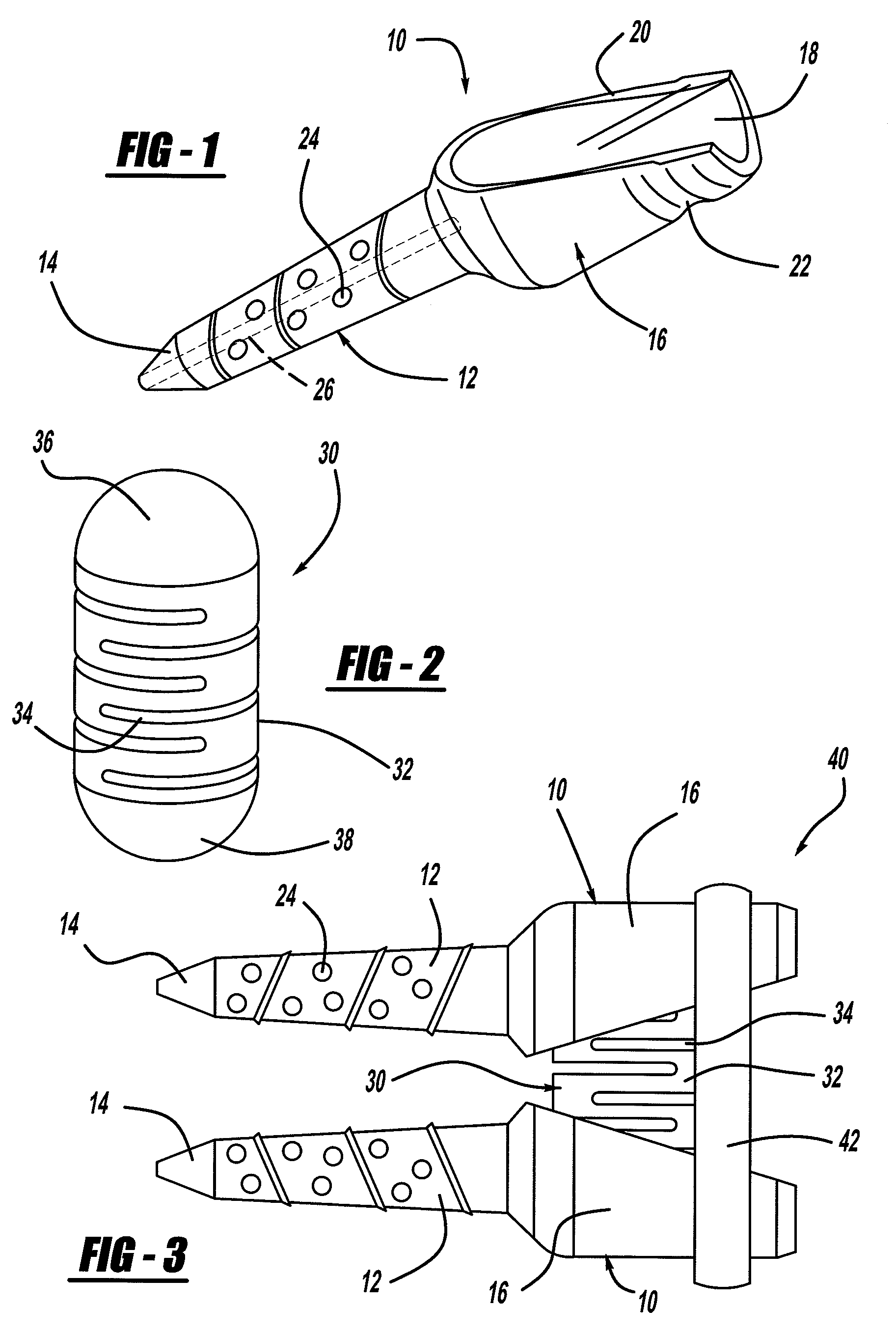

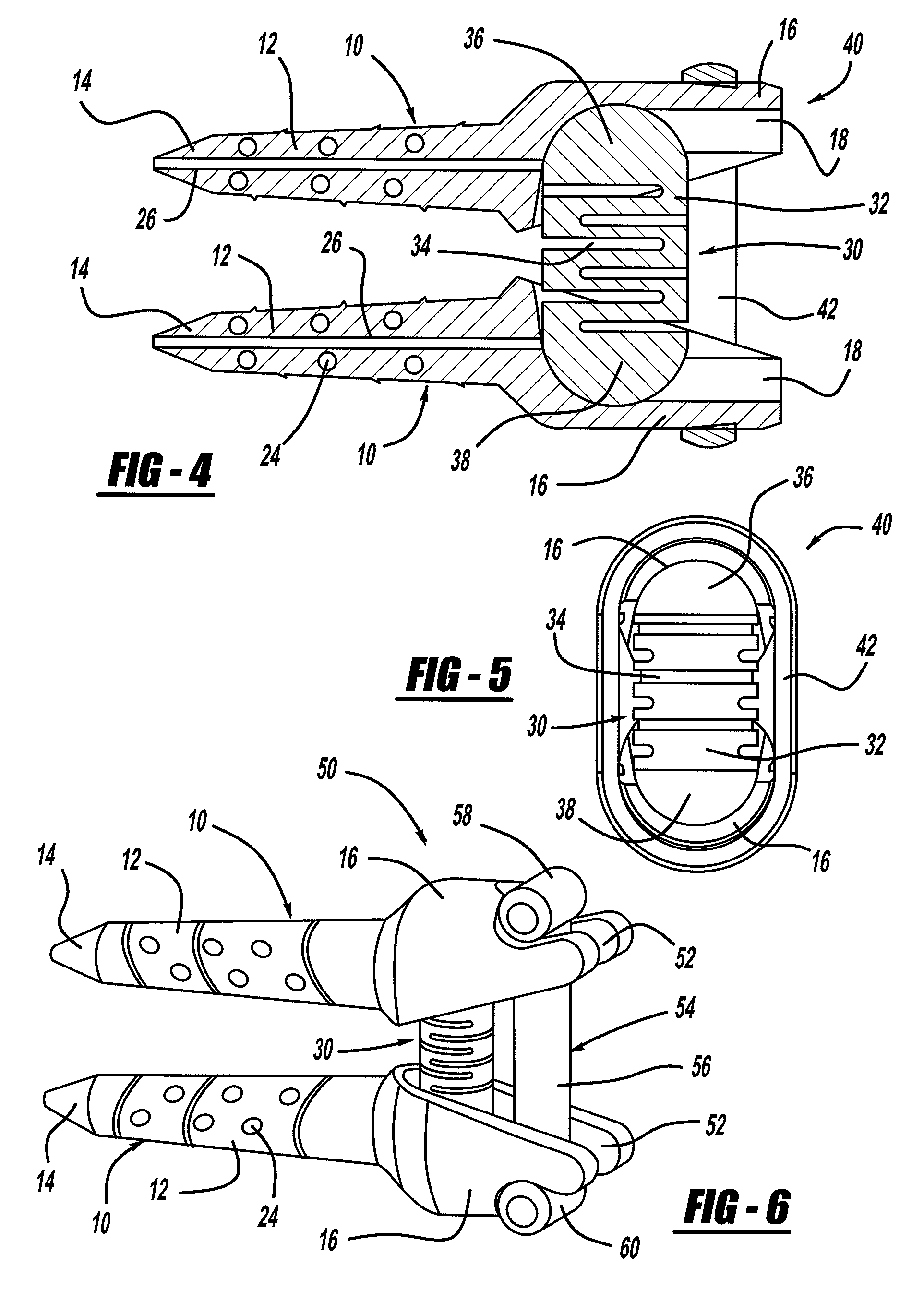

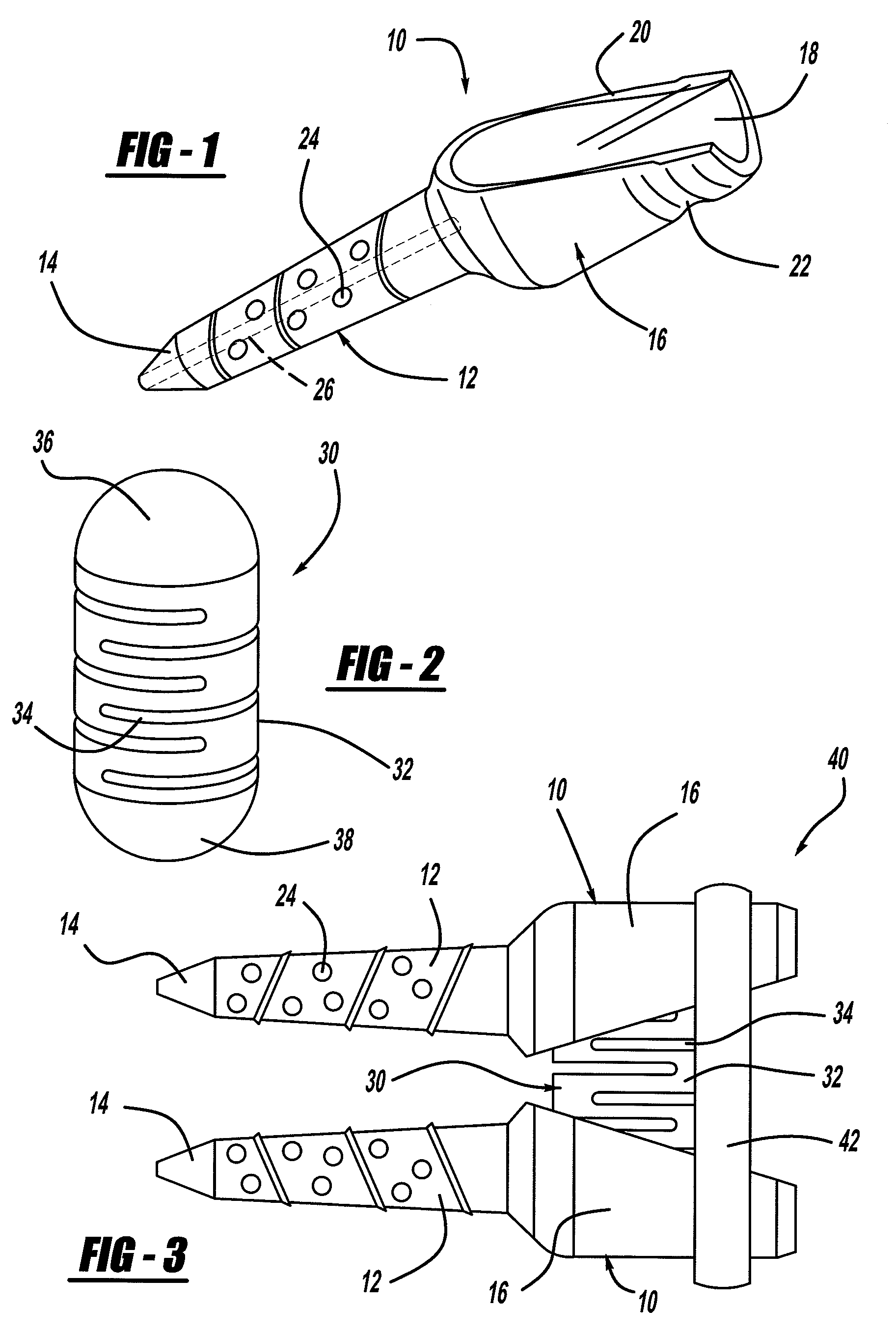

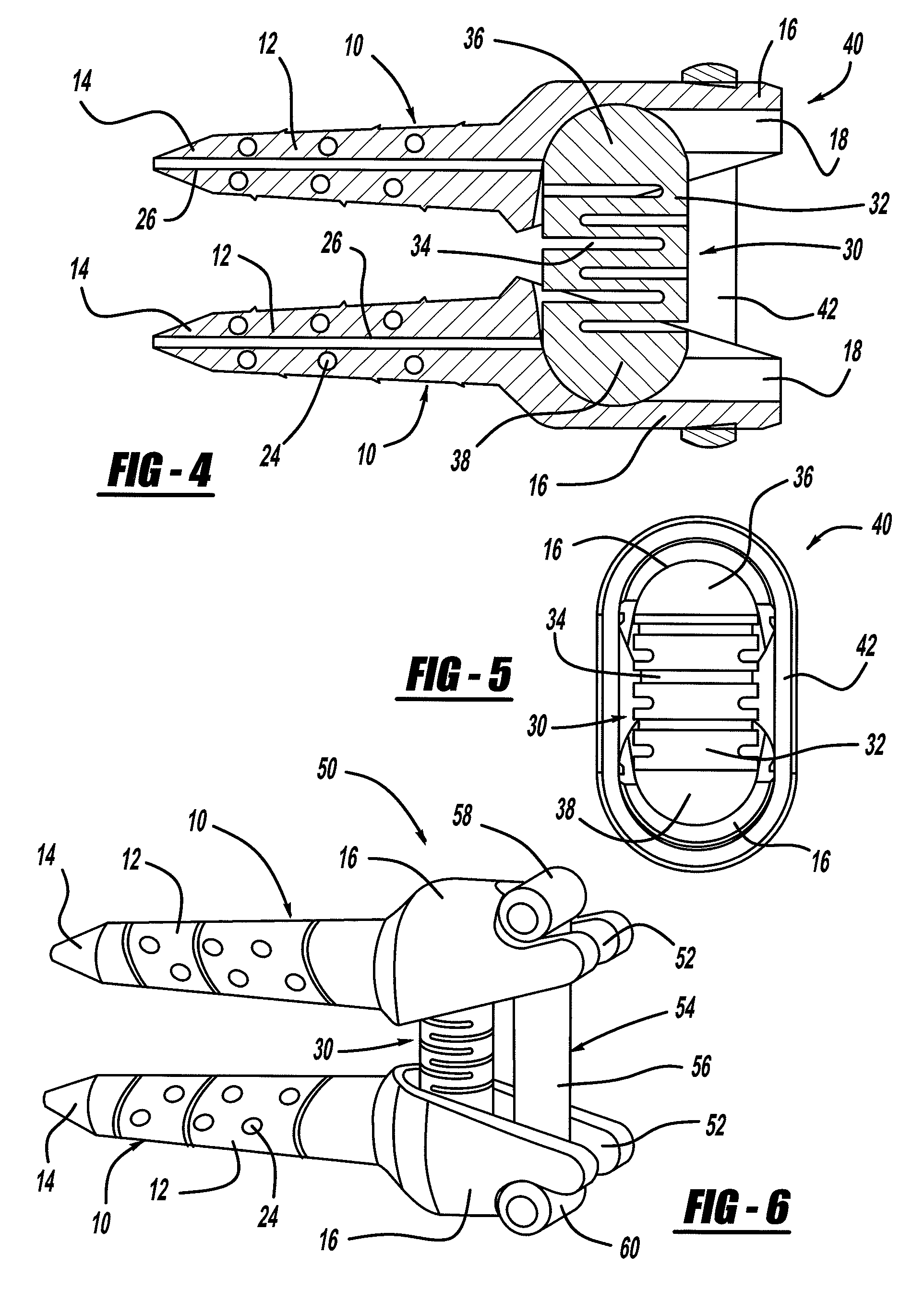

Surgical Screw Including a Body that Facilitates Bone In-Growth

ActiveUS20080177331A1Promote growthPromote bone growthSuture equipmentsInternal osteosythesisAcid etchingCervical fusions

A surgical screw that includes a body portion that facilitates bone in-growth from a bone in which the screw is mounted so as to stabilize the screw in the bone. The body portion can have various configurations for facilitating bone in-growth, such as indentations, a roughened surface, such as by acid etching or abrasive media blasting, specialized coatings, such as hydroxyapetite, sintered beads, machined channels, etc. Because the body portion of the screw facilitates bone growth, the screw will be more firmly mounted to the bone so as to have a greater integrity in response to movement of the bone. The type of surgical screw can be any surgical screw that will benefit from being better anchored in bone, such as pedicle screws, long bone screws, cervical fusion screws, tendon anchoring screws, etc.

Owner:MI4SPINE

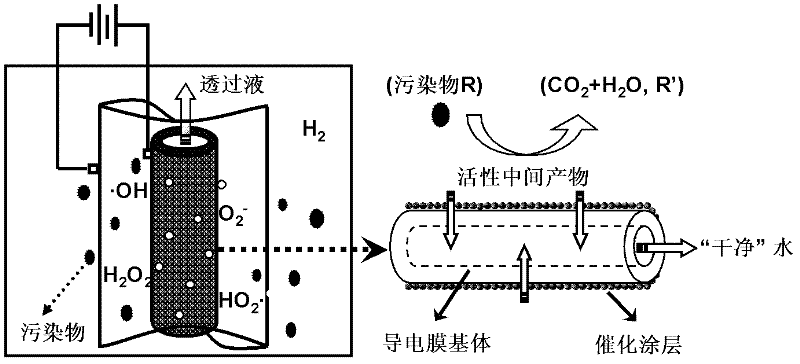

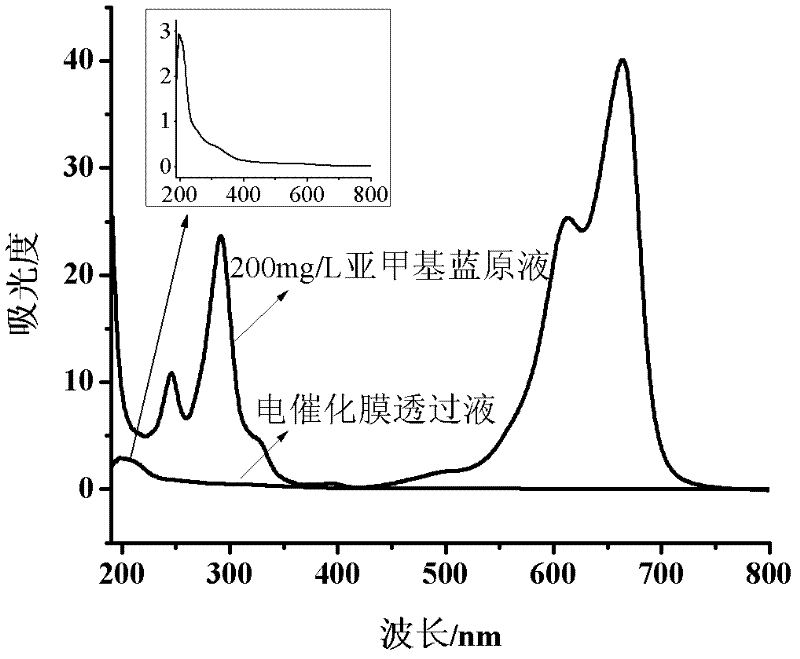

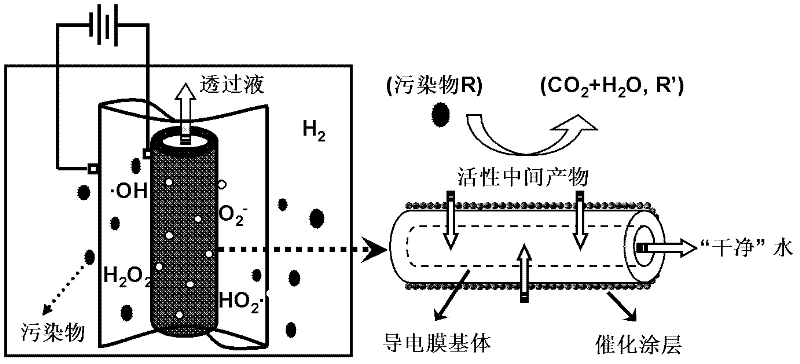

Nano loaded titanium-based electric catalytic film and preparation method thereof

InactiveCN102350228AImprove degradation efficiencyHigh electrode strengthSemi-permeable membranesDispersed particle separationAcid etchingCatalytic oxidation

The invention discloses a nano loaded titanium-based electric catalytic film comprising a conductive microporous separating titanium film matrix and a catalytic coating. Furthermore, the invention also discloses a preparation method of the nano loaded titanium-based electric catalytic film, which comprises the following steps of: (1) preprocessing the titanium film matrix by sand blasting, alkali washing, and acid etching: soaking the matrix after sand blasting in an NaOH solution for 0.5 to 2h, then processing for 1 to 2h in an oxalic acid solution with the mass percent concentration of 10 percent after washing to a neutral state, washing with water and drying at 100 to 120 DEG C; and (2) preparing and loading a catalytic coating: preparing the catalytic coating by adopting a sol-gel method, a thermal decomposition method, an electrodeposition method or a chemical vapor deposition method and loading at the surface of the titanium film matrix and in a hole. Furthermore, the invention also discloses a film reactor comprising the nano loaded titanium-based electric catalytic film. According to the nano loaded titanium-based electric catalytic film, the defects on material strength, range limitation of working voltage, catalytic oxidation efficacy and the like in the prior art are solved.

Owner:SHANGHAI CAS ADVANCED RES INST

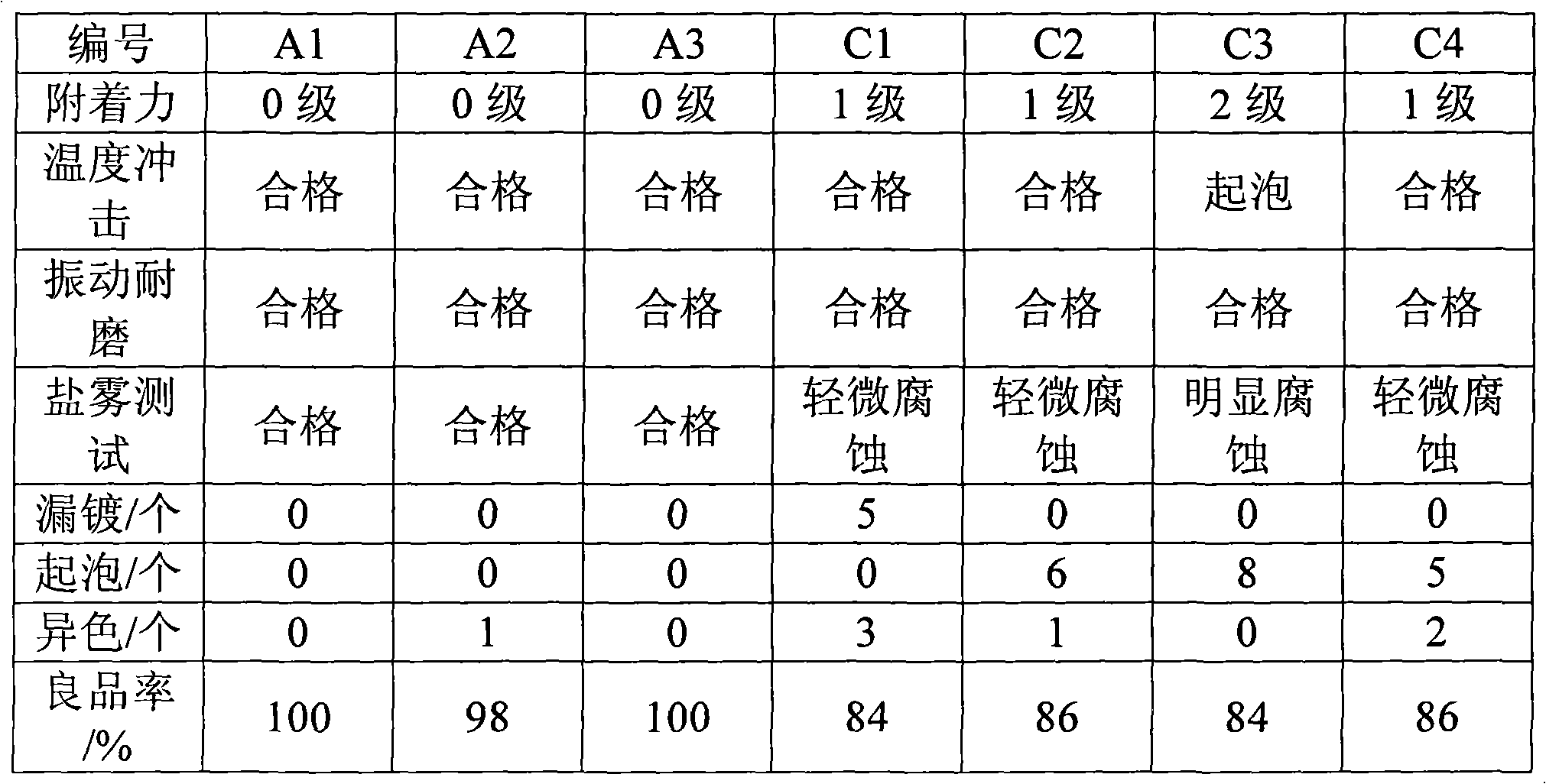

Aluminum alloy surface treatment method

InactiveCN101922010ALess prone to missing platingNot prone to foamingHot-dipping/immersion processesAnodisationAcid etchingLaser etching

The invention provides an aluminum alloy surface treatment method which comprises the steps of sequentially carrying out pretreatment, chemical plating and electroplating on an aluminum alloy matrix, wherein the pretreatment comprises the steps of sequentially carrying out anode oxidation, laser etching, erosion and acid etching on the aluminum alloy matrix. By using the method for forming electroplating texture on the surface of an aluminum alloy, the obtained product has natural texture, is not subject to skip plating, bubbling and discoloration phenomena and has a good decorative effect. Besides, the method has the advantage of simple operation, realizes the unshaded treatment and the convenient maintenance by using the technology of anode oxidation plus electroplating, and facilitates the mass production.

Owner:BYD CO LTD

Touch panel substrate having transparent conductive film

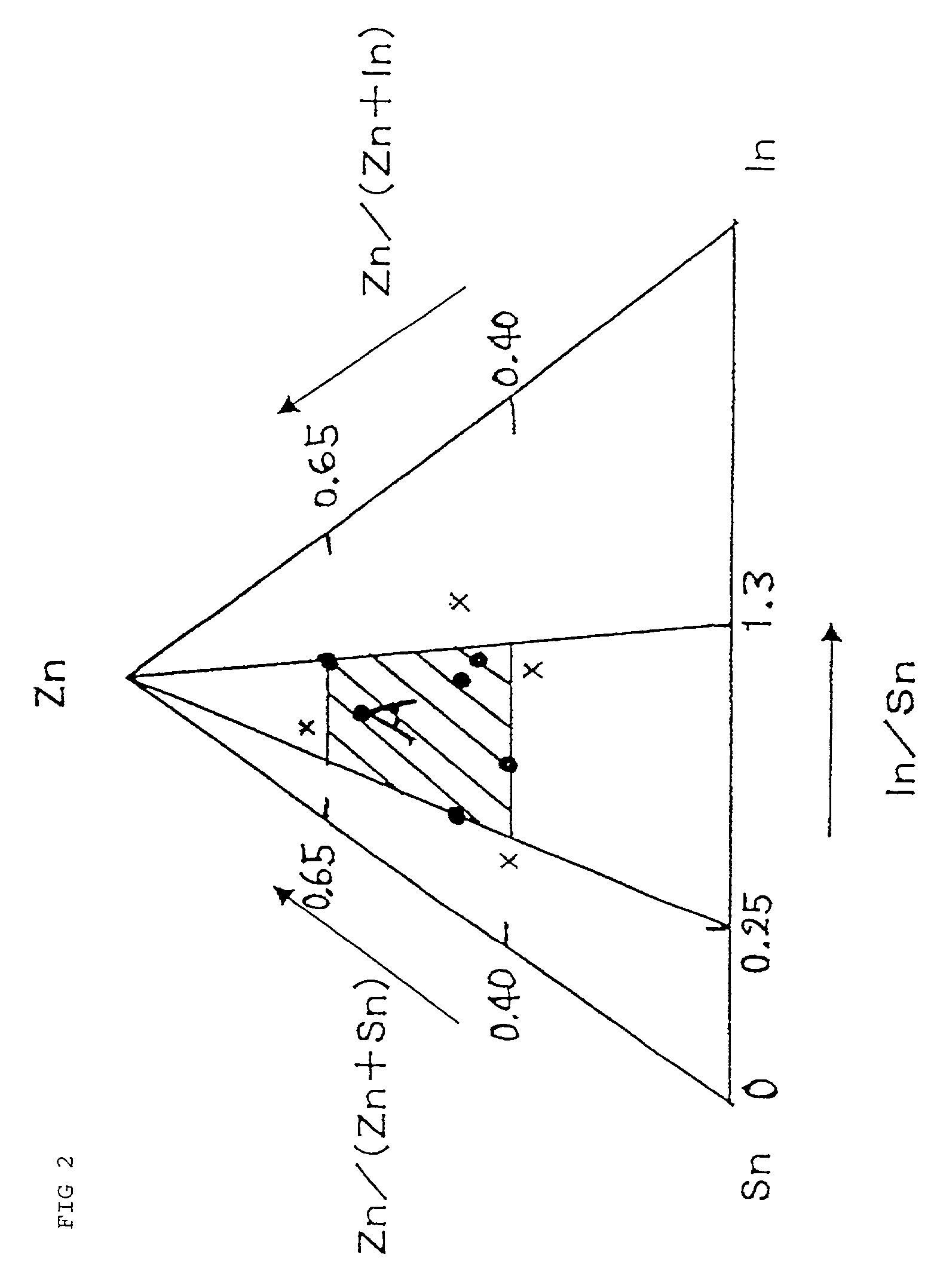

InactiveUS20010040733A1Satisfactory display qualityHigh light transmittanceConductive layers on insulating-supportsVacuum evaporation coatingAcid etchingIndium

A transparent touch panel substrate comprising a transparent substrate and deposited thereon a transparent conductive metal oxide film which contains zinc, indium, and tin as metallic elements and is soluble in acids. The transparent conductive metal oxide film preferably contains zinc in an amount of from 40 to 65 atomic % based on all metals and contains indium in an amount of from 0.25 to 1.3 times the amount of tin on an atomic basis. The film preferably has a thickness of from 100 to 160 nm. Unlike the conventional substrate for resistive film type transparent touch panels which comprises a glass plate coated with a transparent conductive ITO film, the touch panel substrate of the invention combines three properties: high light transmittance; ease of processing in forming a transparent electrode by acid etching; and the transparent conductive film has a moderate sheet resistance of from 500 to 5,000 OMEGA. It therefore realizes a touch panel which combines the three functions of having satisfactory display quality, being of the power-saving type, and enabling touch switch operations to be conducted without fail.

Owner:NIPPON SHEET GLASS CO LTD

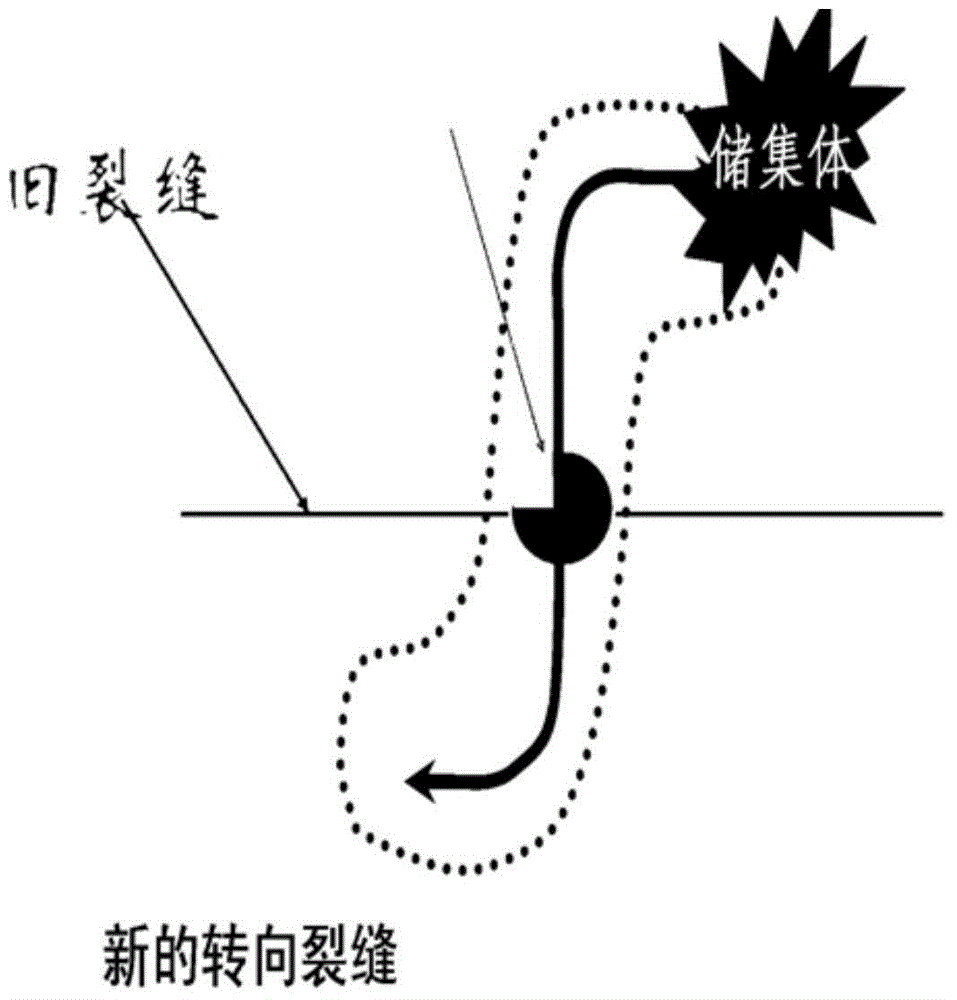

Fractural diverting acid-fracturing method for carbonate oil-gas reservoirs

InactiveCN105041288AImprove acid fracturing efficiencyFluid removalSealing/packingAcid fracturingAcid etching

The invention provides a fractural diverting acid-fracturing method for carbonate oil-gas reservoirs. The method includes the steps of 1, injecting 50-5000 cubic meters of fracturing fluid into a stratum at a displacement speed of 2.0-15.0 m<3> / min; 2, injecting 5-100 cubic meters of material fluid into the stratum at a displacement speed of 1.0-15.0 m<3> / min, and allowing pumping at a displacement speed of 0.5-4.0 m<3> / min after the material fluid enters a preset intra-fracture bridge plug; 3, injecting 50-500 cubic meters of fracturing fluid into the stratum at a displacement speed of 3.0-15.0 m<3> / min to allow forced fractural diverting; 4, injecting 20-300 cubic meters of acid fluid at a speed of 2.0-15.0 m<3> / min to allow modification by acid etching; performing at least one operation of steps from 2 to 4. The method has the advantages that multiple diverted acid-fracturing fractures can be formed after repeated multiple of temporary plugging and fracture forming, temporary plugging material degrades after acid-fracturing construction is complete, low pollution is caused to reservoirs, and the method helps improve acid-fracturing efficiency.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +3

Dental implant and surface treatment method thereof

InactiveCN103654979AStrong oxidation abilityImprove hydrophilicityDental implantsSurface reaction electrolytic coatingAcid etchingDentistry

The invention discloses a dental implant and a surface treatment method thereof. The surface treatment method for the dental implant comprises the following steps of dental implant cleaning, sandblasting, surface acid etching, surface nanocrystallization processing, soaking, calcinating, and cleaning and the like, so that the dental implant adopting a micron and nanometer mixed structure and having the visible-light catalytic activity through nitrogen doping is obtained. The dental implant achieves preferable hydrophilia, protein adsorption capacity and good biological activity.

Owner:广东省口腔医院

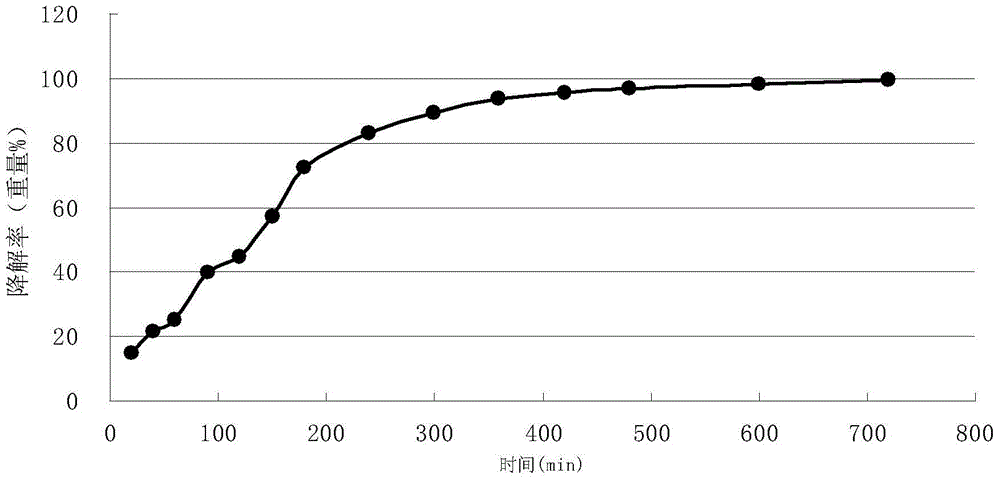

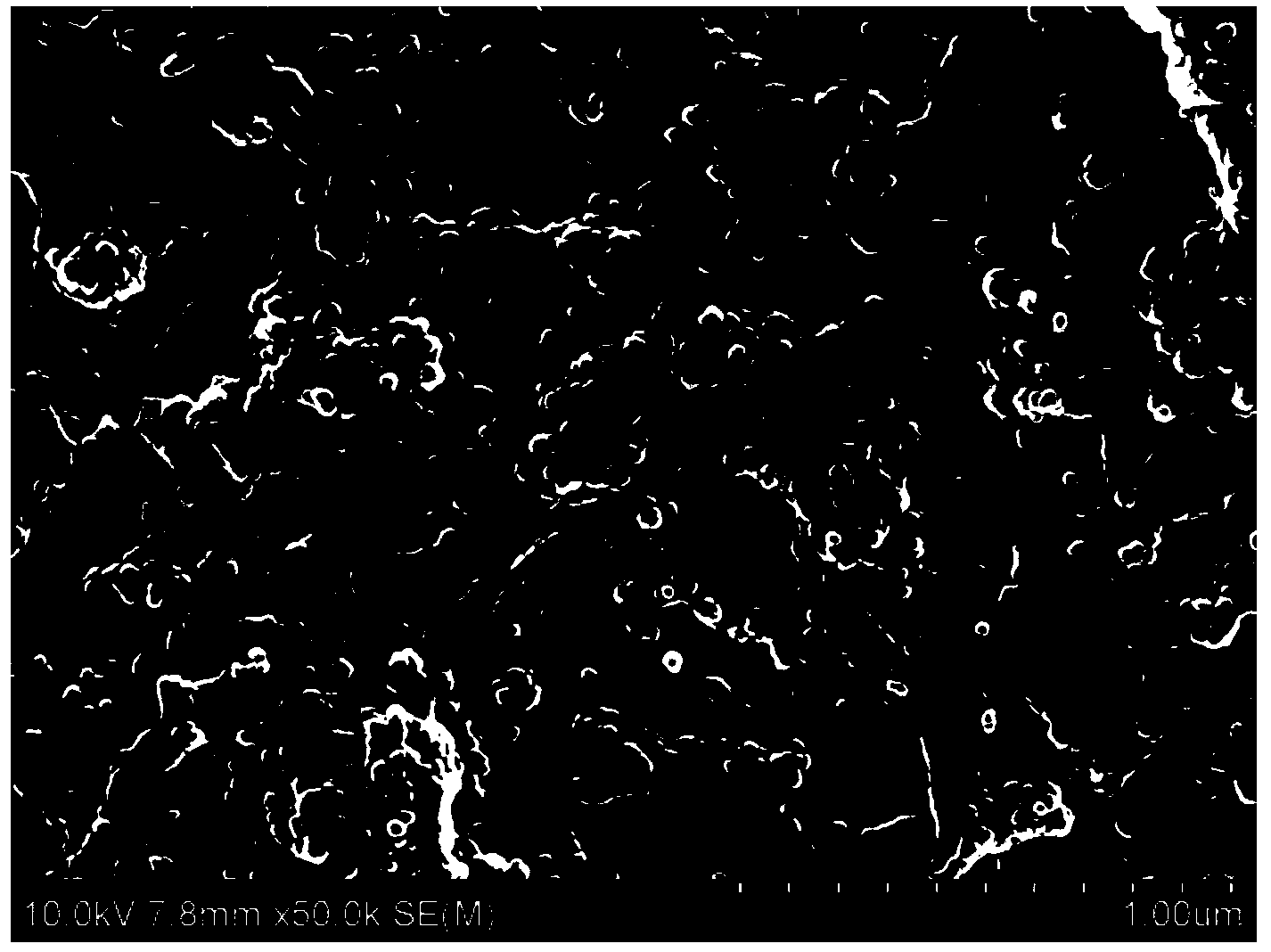

Preparation method of lithium ion battery porous silicon carbon composite negative material

InactiveCN102709565AInhibition of volume changeSmall volume changeCell electrodesAcid etchingCarbon composites

The invention puts forwards a preparation method of a lithium ion battery porous silicon carbon composite negative material. The prepared porous silicon carbon composite material simultaneously has the characteristics of high capacity and excellent circulating stability. Micron silicon and nanometer aluminum powder are promoted to be compounded by utilizing a high-energy ball milling method, a porous silicon material can be formed through acid etching, and through a porous structure, the volume change of silicon in the discharging process is relieved to a great extent. Meanwhile, the stress generated by the volume change of the silicon can be effectively buffered through taking graphite as a dispersion matrix and in combination with a secondary surface amorphous carbon coating technology of the composite material, so that the circulating stability of the material is improved. The preparation method of the material has the advantages of simplicity, low cost and easiness in industrial production.

Owner:力芯(青岛)新能源材料有限公司

Surgical screw including a body that facilitates bone in-growth

ActiveUS7892265B2Promote growthPromote bone growthSuture equipmentsInternal osteosythesisAcid etchingCervical fusions

A surgical screw that includes a body portion that facilitates bone in-growth from a bone in which the screw is mounted so as to stabilize the screw in the bone. The body portion can have various configurations for facilitating bone in-growth, such as indentations, a roughened surface, such as by acid etching or abrasive media blasting, specialized coatings, such as hydroxyapetite, sintered beads, machined channels, etc. Because the body portion of the screw facilitates bone growth, the screw will be more firmly mounted to the bone so as to have a greater integrity in response to movement of the bone. The type of surgical screw can be any surgical screw that will benefit from being better anchored in bone, such as pedicle screws, long bone screws, cervical fusion screws, tendon anchoring screws, etc.

Owner:MI4SPINE

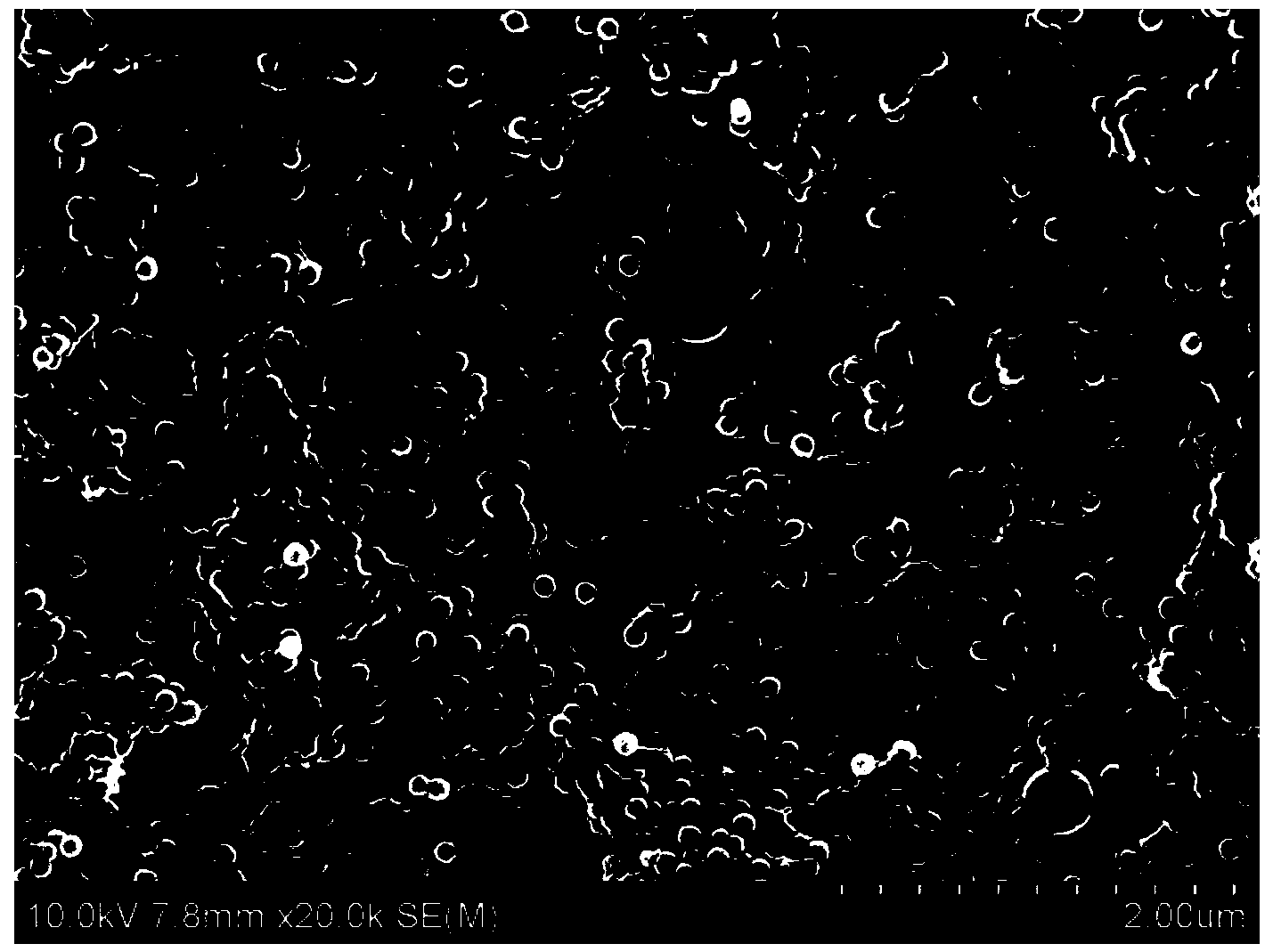

Surface processing technology for dental implant

InactiveCN102232876AGood surface morphologyGood rough surfaceArtificial teethCleaning using liquidsAcid etchingTitanium

The invention discloses a surface processing technology for a pure-titanium dental implant. The technology comprises the following steps: A, removing oil from the dental implant by ultrasonic cleaning; B, sandblasting the dental implant by white corundum to make the surface of the implant to be uniform gray in color and allow a three-dimensional porous structure to be formed on the surface of the dental implant; C, carrying out acid etching on the surface of the sandblasted dental implant with a mixed liquid with a certain concentration and a certain ratio of sulfuric acid to hydrochloric acid to allow gradually decreased multilevel scallops to be formed on the surface of the dental implant; and D, flushing and neutralizing the acid etched dental implant, and removing oil. According to the surface processing technology for the dental implant designed by the invention, the multilevel porous structure with biological activity is formed on the surface of the pure-titanium implant, so the biological activity of the pure-titanium implant is improved, the stability of the implant is improved, the bone combination speed of the dental implant is accelerated, the bone interfacial combination strength of the implant is enhanced, thereby the technology has the advantages of simple and high efficient technology, and low cost.

Owner:JIANGSU TRAUSIM MEDICAL INSTR

Self-etch amphiphilic dental adhesive and preparation method thereof

InactiveCN103622837AHigh bonding strengthDentin bonding effect is goodImpression capsDentistry preparationsAcid etchingAdhesive

The invention discloses a self-etch amphiphilic dental adhesive and a preparation method thereof. The adhesive is a one-component adhesive and comprises the following components in parts by weight: 100 parts of polymerizable monomer, 0.2 to 0.8 part of photoinitiator, 0.1 to 0.5 parts of an accelerating agent, 0.001 to 0.5 parts of a polymerization inhibitor and 1 to 20 parts of filler; the polymerizable monomer comprises the following components in weight percent: 40% to 60% of resinous monomer, 1% to 10% of amphiphilic monomer, 2% to 10% of acidic monomer and 35% to 50% of dilute monomer. The self-etch amphiphilic dental adhesive provided by the invention can be used for acid etching of dentin, has the characteristic of amphipathicity, and is relatively high in bonding strenth; not only does the development of the adhesive update the conventional clinical adhesive, but also the adhesive has a relatively good dentin bonding effect.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

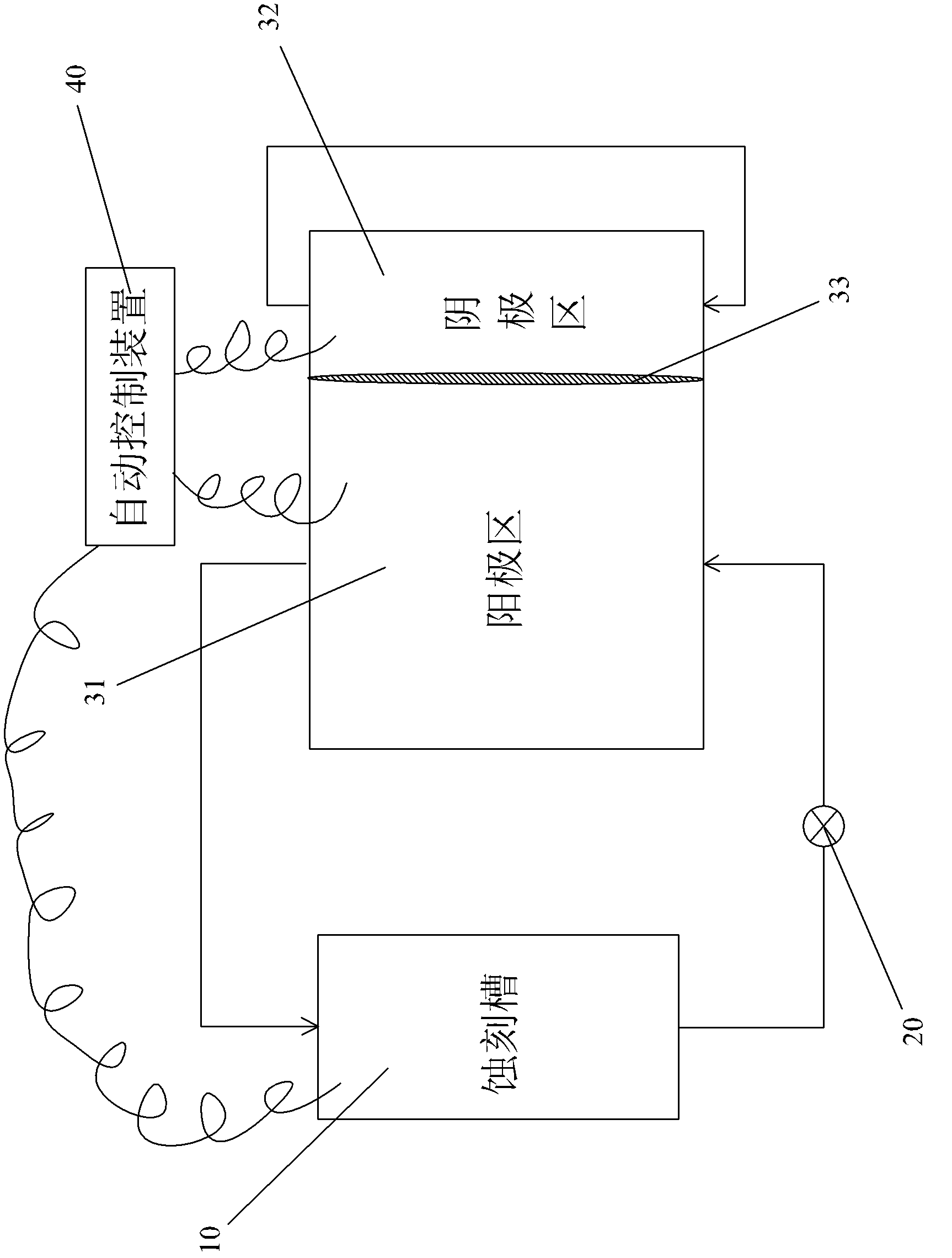

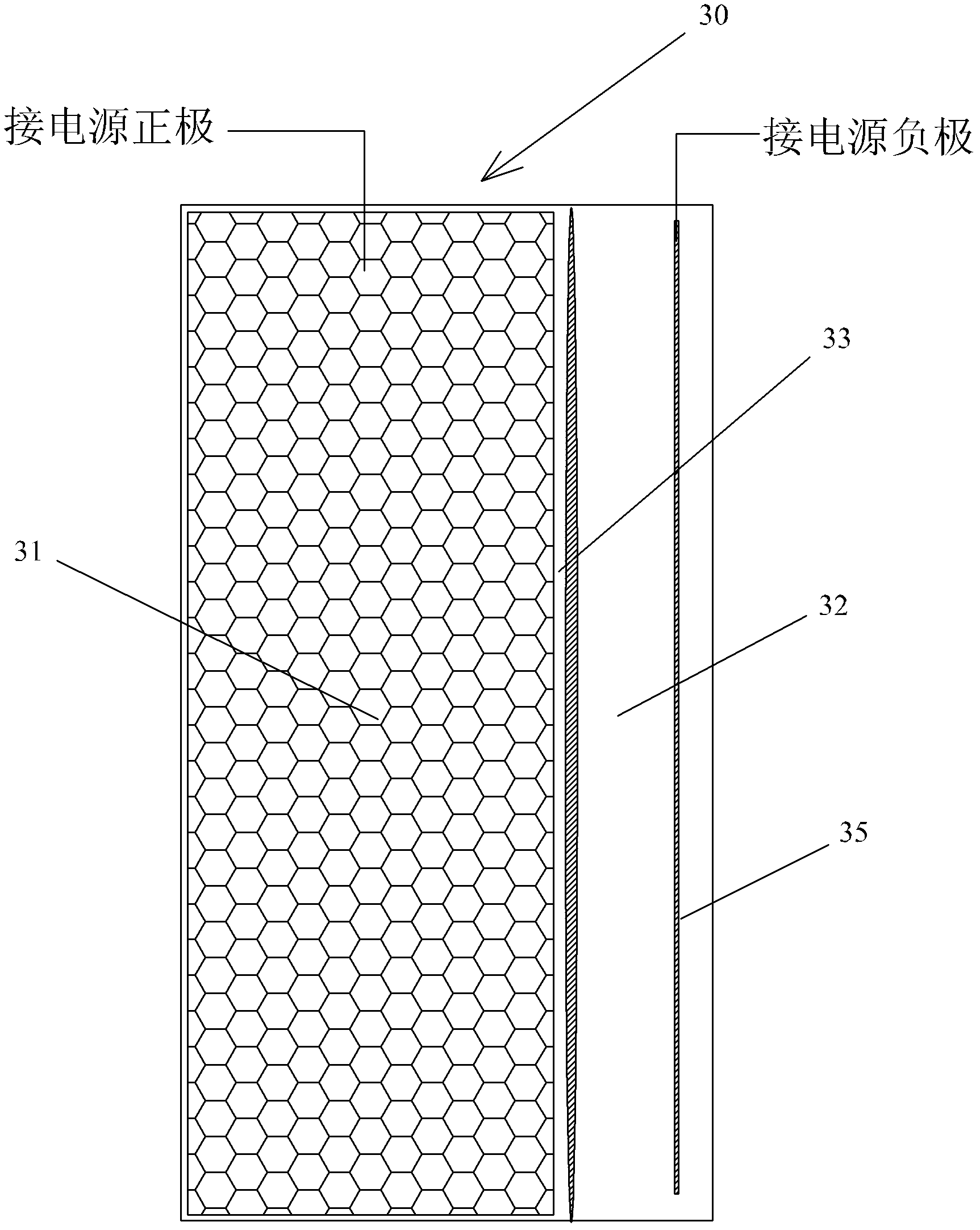

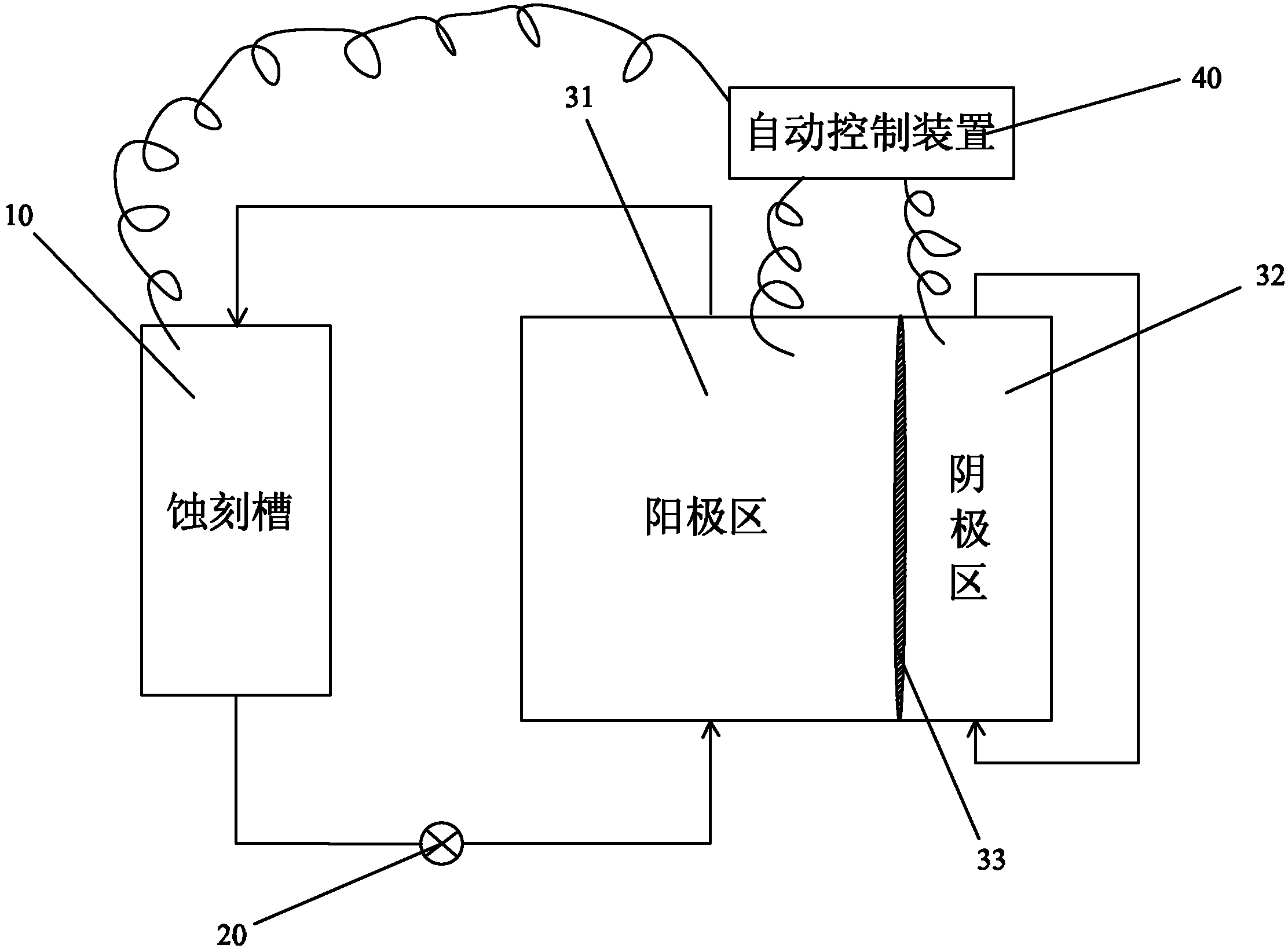

Recycling and regenerating process method and metal copper recovery system of acid chloride etching solution

InactiveCN102321908ASimple structurePracticalElectrolysis componentsPhotography auxillary processesAcid etchingElectrolysis

The invention discloses a recycling and regenerating process method and a metal copper recovery system of an acid chloride etching solution. The system comprises an acid etching bath, a membrane electrolytic bath and an automatic control device, wherein the membrane electrolytic bath is connected to the acid etching bath through a pump, and is divided into a cathode region and an anode region by a separation membrane support, and the anode region adopts an immersion reflow anode; the automatic control device is connected to the membrane electrolytic bath, and is used for pumping the etching solution to the anode region of the membrane electrolytic batch from the etching bath by the pump, and pumping the etching solution after being subjected to electrolytic regeneration treatment to the etching work bath from the anode region by the pump to continue to carry out the etching operation; and when the etching solution is regenerated in the anode region, copper ions permeate an ion-exchange membrane into the cathode region and is deposited on a cathode, so that the electrolytic recovery of copper is realized. In the system, the etching solution is regenerated while the metal copper is recovered, the regenerated etching solution returns to the etching groove to continue working without discharging any waste water, waste gas or waste matter; and the fully automatic control of the whole system is realized.

Owner:GUANGDONG SKYCHEM TECH LTD

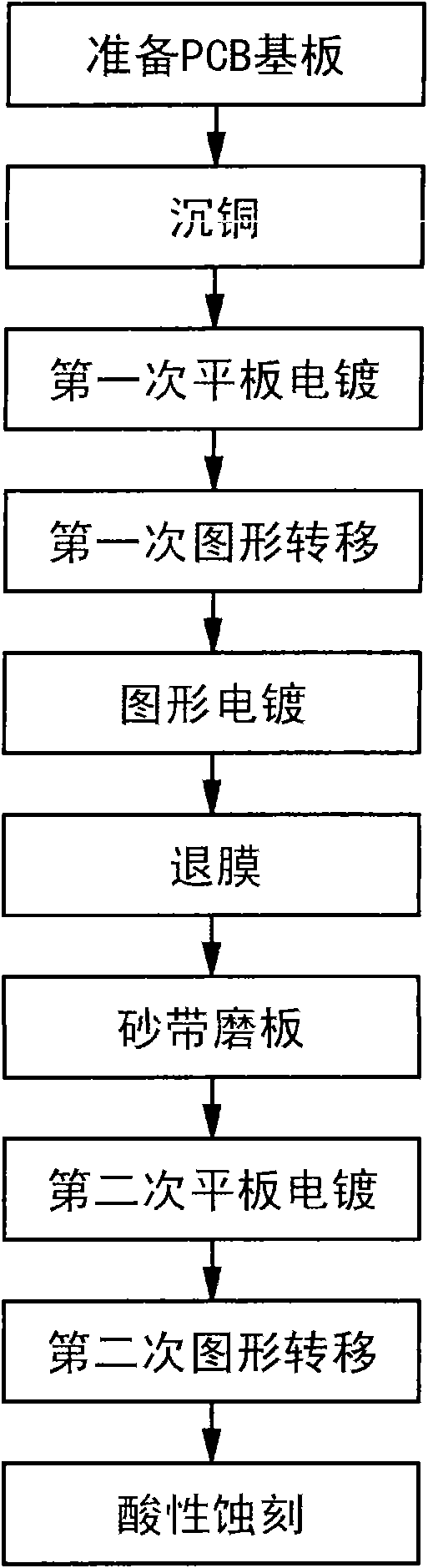

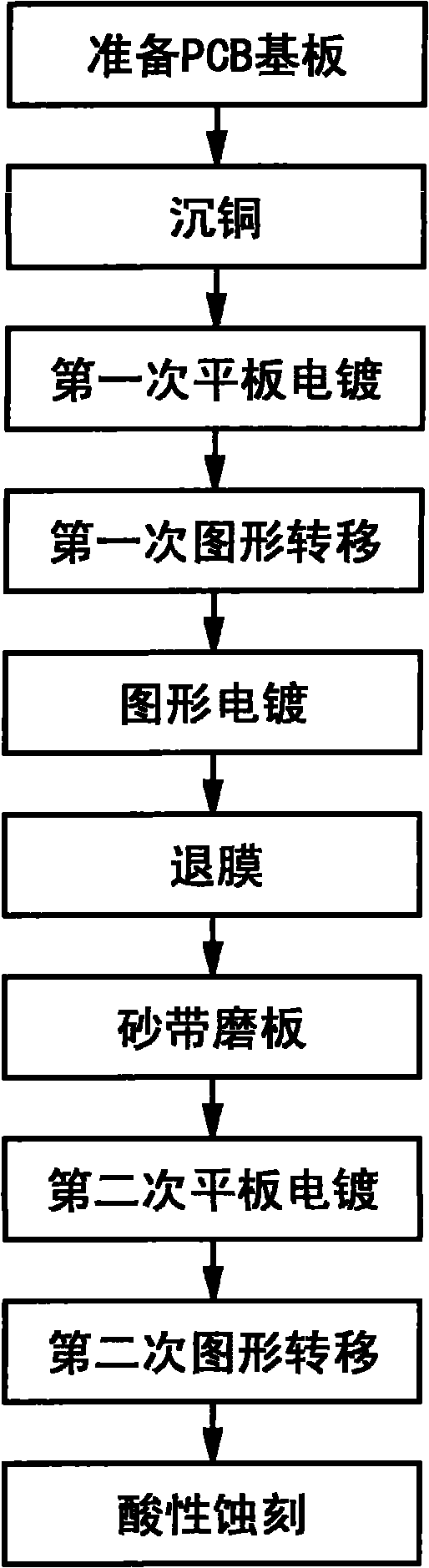

Method for manufacturing high-AR and fine-line PCB

InactiveCN101841972AReduce thicknessEasy to manufacturePrinted circuit manufactureAcid etchingFine line

The invention provides a method for manufacturing a high-AR (aspect ratio) and fine-line PCB (printed circuit board), which comprises the following steps: (1) preparing a PCB substrate; (2) carrying out PTH (plating through hole) process; (3) carrying out primary electroplating process; (4) carrying out primary pattern transfer; (5) carrying out pattern electroplating process; (6) removing dry film; (7) abrading the PCB substrate by an abrasive belt; (8) carrying out secondary electroplating process; (9) carrying out secondary pattern transfer; and (10) carrying out the acid etching process. By adopting the primary electroplating process and the secondary electroplating process and adopting the step for plating holes instead of surfaces with copper, the method of the invention can meet the requirements for the thickness of the hole copper, reduce the thickness of the surface copper and make the etching process easier at the same time, thus favoring for the production of fine-line and small-gap PCBs, being helpful for the fine-line manufacture and meeting the requirements of quality for the reliability of the PCBs.

Owner:CHINA CIRCUIT TECH SHANTOU CORP

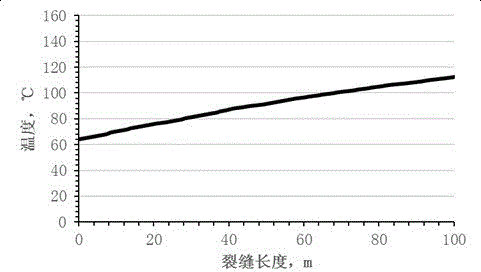

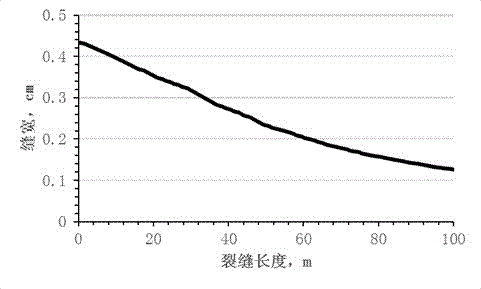

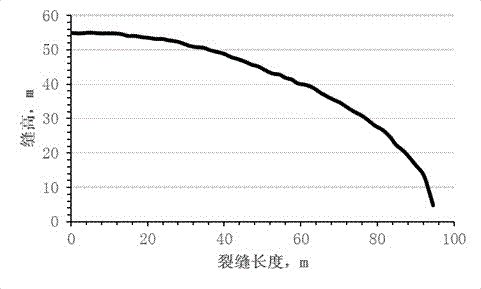

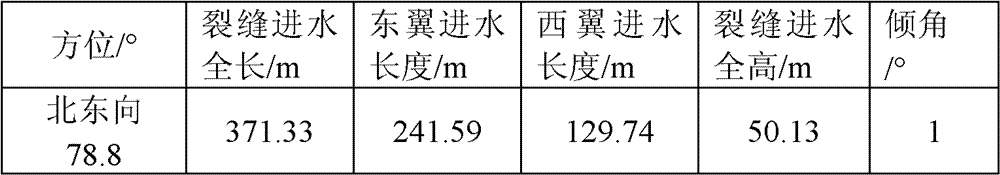

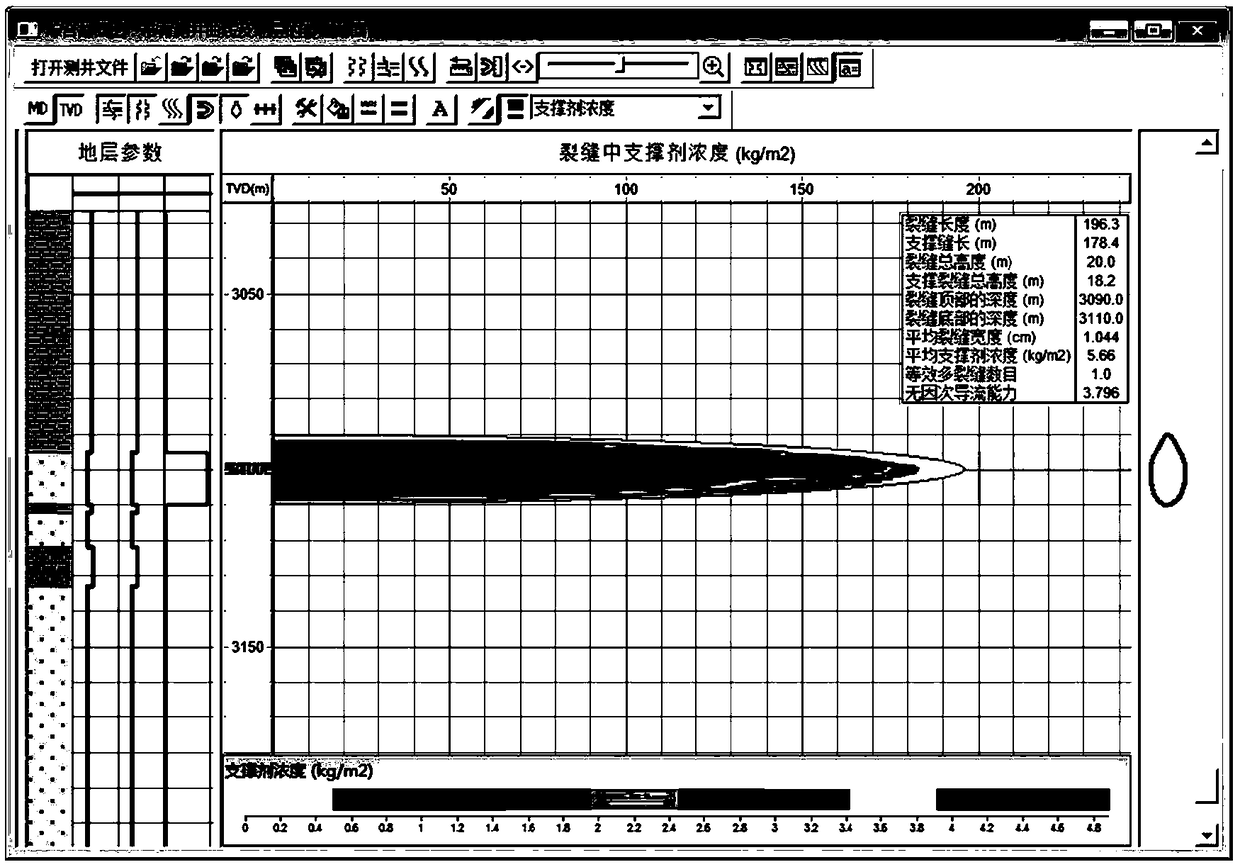

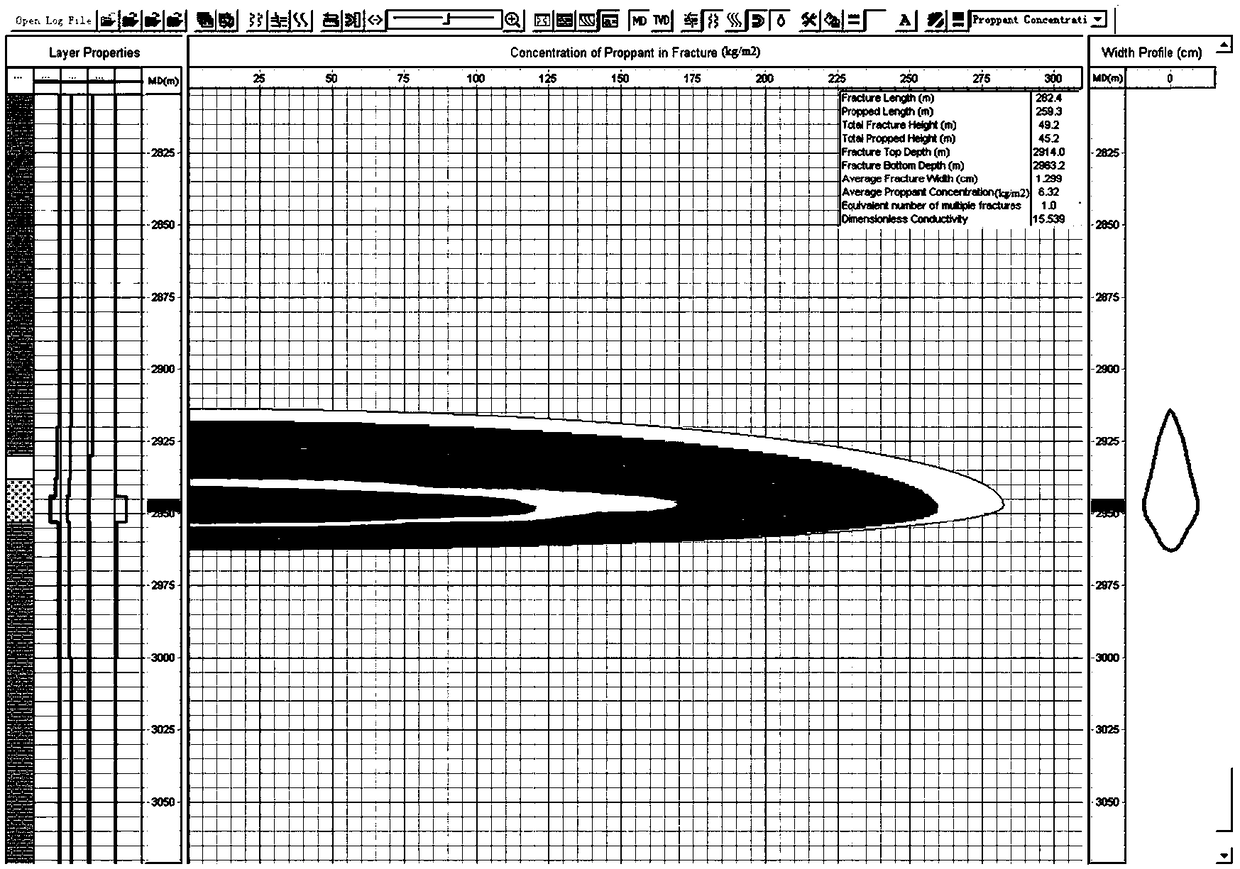

Method for experimentally determining carbonate rock oil and gas reservoir acid fracturing fracture conductivity distribution

ActiveCN106522935AImprove the transformation effectThe distribution of diversion capacity is conducive to real evaluationConstructionsFluid removalAcid fracturingAcid etching

The invention discloses a method for experimentally determining carbonate rock oil and gas reservoir acid fracturing fracture conductivity distribution. The method comprises the steps that an acid fracturing simulator FracproPT is adopted for simulating the down-hole acid fracturing fracture extending and acid etching process during acid fracturing, and fracture width distribution, fracture height distribution, temperature distribution and acid liquor mass concentration distribution data in the hydraulic fracture length direction are obtained; in the hydraulic fracture length direction, fracture width, fracture height and temperature data of total 10 feature points with the acid liquor mass concentration being 100%, 90%, 80%, 70%, 60%, 50%, 40%, 30%, 20%, 10% of the initial mass concentration are selected; acid injection displacement of the oil field site scale is converted into acid injection displacement of the laboratory scale; according to the acid liquor mass concentration data of the 10 feature points, acid liquor used for an experiment is prepared; and the acid etching process is simulated, the conductivity under the condition of reservoir closed pressure is tested experimentally, and a distribution diagram of the acid etching fracture conductivity in the fracture length direction under the reservoir condition is drawn. The method is reliable in principle and simple and convenient to operate and has wide market prospects.

Owner:SOUTHWEST PETROLEUM UNIV

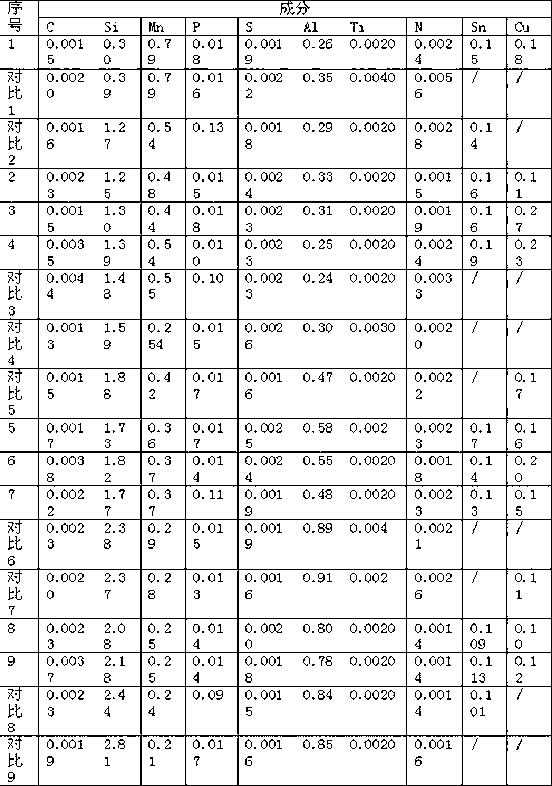

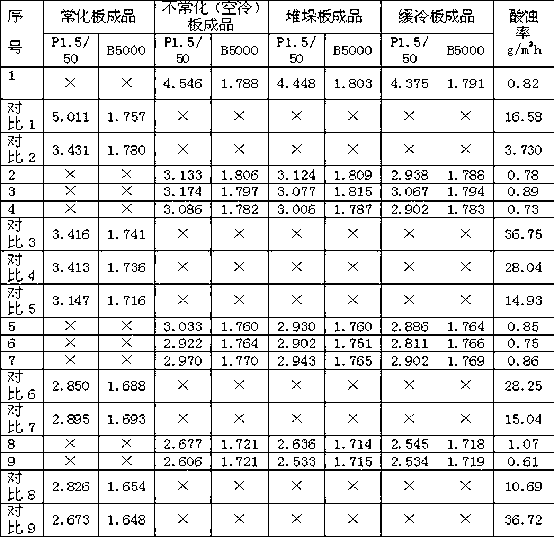

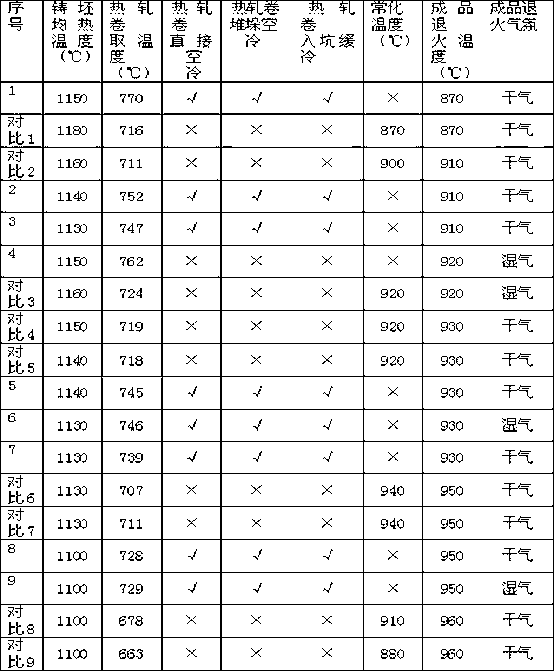

Normalization-free high-magnetic induction low-iron loss acid etching-resistant non-oriented silicon steel and production method thereof

The invention relates to a normalization-free high-magnetic induction low-iron loss acid etching-resistant non-oriented silicon steel and a production method thereof. The normalization-free high-magnetic induction low-iron loss acid etching-resistant non-oriented silicon steel comprises the following components in percentage by weight: C less than or equal to 0.0050%, 0.30-2.50% of Si, 0.15%-0.80% of Mn, 0.25-0.80% of Al, P less than or equal to 0.050%, S less than or equal to 0.0050%, N less than or equal to 0.0050%, Ti less than or equal to 0.0050% and 0.20-0.45% of Sn+Cu, wherein Sn and Cu are not equal to 0.The production method comprises the following steps of: smelting and casting into a blank; heating and soaking the cast blank to 1080-1150 DEG C; carrying out conventional hot rolling; rolling; pickling; carrying out one-time cold rolling to the thickness of a finished product; and annealing. The normalization-free high-magnetic induction low-iron loss acid etching-resistant non-oriented silicon steel disclosed by the invention is low in Si alloying degree, achieves the P 1.5 / 50 to the level of medium-high grade non-oriented silicon steels and the magnetic induction B 5000 higher than that of common non-oriented silicon steels by more than 0.08 T and equivalent to that of high-magnetic induction non-oriented silicon steels with same iron loss grades, is very conductive to enhancing the stability of a motor operated in a harsh environment for a long time and prolonging the service life of the motor and can also reduce the rusting loss in producing, storing, transporting and using processes.

Owner:武汉钢铁有限公司

Cross-linked acid and sand-carrying acid-fracturing method for ground with argillaceous dolomites

ActiveCN103089228AImprove diversion capacityImprove well productivityFluid removalAcid etchingCross-link

The invention discloses a cross-linked acid and sand-carrying acid-fracturing method for a ground with argillaceous dolomites. Cross-linked acid-fracturing for the ground is combined with cross-linked acid sand-carrying acid-fracturing for the ground in the method, and in other words, the cross-linked acid and sand-carrying acid-fracturing method includes performing the cross-linked acid-fracturing in a prepad fluid stage; and performing the cross-linked acid sand-carrying acid-fracturing for the ground in a main sand feeding stage. The cross-linked acid and sand-carrying acid-fracturing method has the advantages that the process is simple, operation is facilitated, and a construction effect is obvious; the method can be widely applied to transformation construction for complex lithologic oil and gas reservoirs with argillaceous dolomites and the like; a deep-penetration prop fracture with durable flow conductivity can be formed to the greatest extent under the combined effect of acid-fracturing and sand-feeding acid-fracturing technologies, acid etching and propping effects are played for the fracture, and the flow conductivity of the artificial fracture and the productivity of an oil well are greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

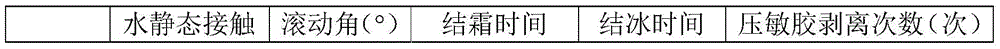

Preparation method of super-hydrophobic coating layer on aluminum surface

ActiveCN105521934AImprove hydrophobicityGood anti-fogPretreated surfacesLiquid/solution decomposition chemical coatingAcid etchingSilanes

The invention discloses a preparation method of a super-hydrophobic coating layer on an aluminum surface. The preparation method mainly comprises the following steps: (1) an aluminum piece is polished by an abrasive paper, is ultrasonically cleaned for 10 minutes by acetone and ethanol, is washed by distilled water to remove oil stains on the surface, and is dried in an oven; (2) the aluminum piece is dip in an acid etching agent for etching to obtain the aluminum surface with a micron rough structure; (3) the micron rough aluminum piece is dip in nanometer TiO2 particle solution, and is treated at high temperature to obtain the aluminum surface with a micron-nanometer composite rough structure; and (4) the aluminum surface with the micron-nanometer composite rough structure is treated by fluorine silane with low surface energy to obtain the aluminum surface with super-hydrophobic performance. The prepared super-hydrophobic aluminum piece is excellent in self-cleaning performance, fog resistance and ice covering resistance, and can be applied to field of ice covering prevention.

Owner:ZHEJIANG UNIV

Embedding unpackaging method for plastic packaged device packaged by flip chip bonding process

InactiveCN102522319AGuaranteed electrical performanceGuaranteed electricitySemiconductor/solid-state device manufacturingAcid etchingDevice material

The invention discloses an embedding unpackaging method for a plastic packaged device packaged by a flip chip bonding process. The method comprises the following steps of: first longitudinally preparing a sample by adopting embedding sample preparation equipment; then grinding off a chip bonding soldering block in the sample to expose a chip bonding salient point by adopting an automatic / manual grinding system; next unpackaging the front surface or back surface of the sample, namely the surface with a chip circuit by adopting an acid etching method, wherein an opening has a size which is less than or equal to that of a chip, and is deep enough to expose the surface of the chip; and finally, immediately washing the acid-unpackaged sample, drying the sample with air and inspecting the dried sample. By the method, a semiconductor device packaged in a flip chip bonding way or a chip size package (CSP) way is unpackaged in a way of combining a mechanical method and the acid etching method, structures such as a bonding structure and the like in the sample can be integrally reserved after the sample is unpackaged, the electrical properties of the sample also can be maintained after the sample is unpackaged, and the requirement of subsequent inspection such as destructive physical analysis, failure analysis and the like on the integrity of the sample is completely met.

Owner:CASIC DEFENSE TECH RES & TEST CENT

Method for displacement chemical silver plating on copper powder

InactiveCN101709461AIncrease profitHigh activityLiquid/solution decomposition chemical coatingAcid etchingSilver plate

The invention discloses a method for displacement chemical silver plating on copper powder. The method comprises the following steps of: cleaning and oil removal, water washing, acid etching, water washing, catalytic liquid treating, chemical silver plating and the like. In the method, a catalytic liquid capable of preplanting catalytic mass points is developed; the surface of the copper powder is preplanted with discretely distributed palladium mass points after the copper powder is treated by the catalytic liquid at a room temperature by controlling components, pH value and treatment time of the catalytic liquid; and the preplanted palladium mass points can catalyze and promote the silver ion reduction to improve precipitation speed and to retard copper-ammonia complex ions to be absorbed on the copper surface so as to obtain a sliver plating layer with good cladding performance in the chemical silver-plating process for the copper powder. Compared with the conventional method of displacement chemical silver plating, the method realizes surface activation of the copper powder by pretreating the catalytic liquid, a silver content of the silver plating copper powder is greatly improved, the problems of poor cladding performance of replacement type chemical silver plating and the like are solved, and the method is simple in process and convenient to operate and has good application prospect.

Owner:GUANGDONG UNIV OF TECH

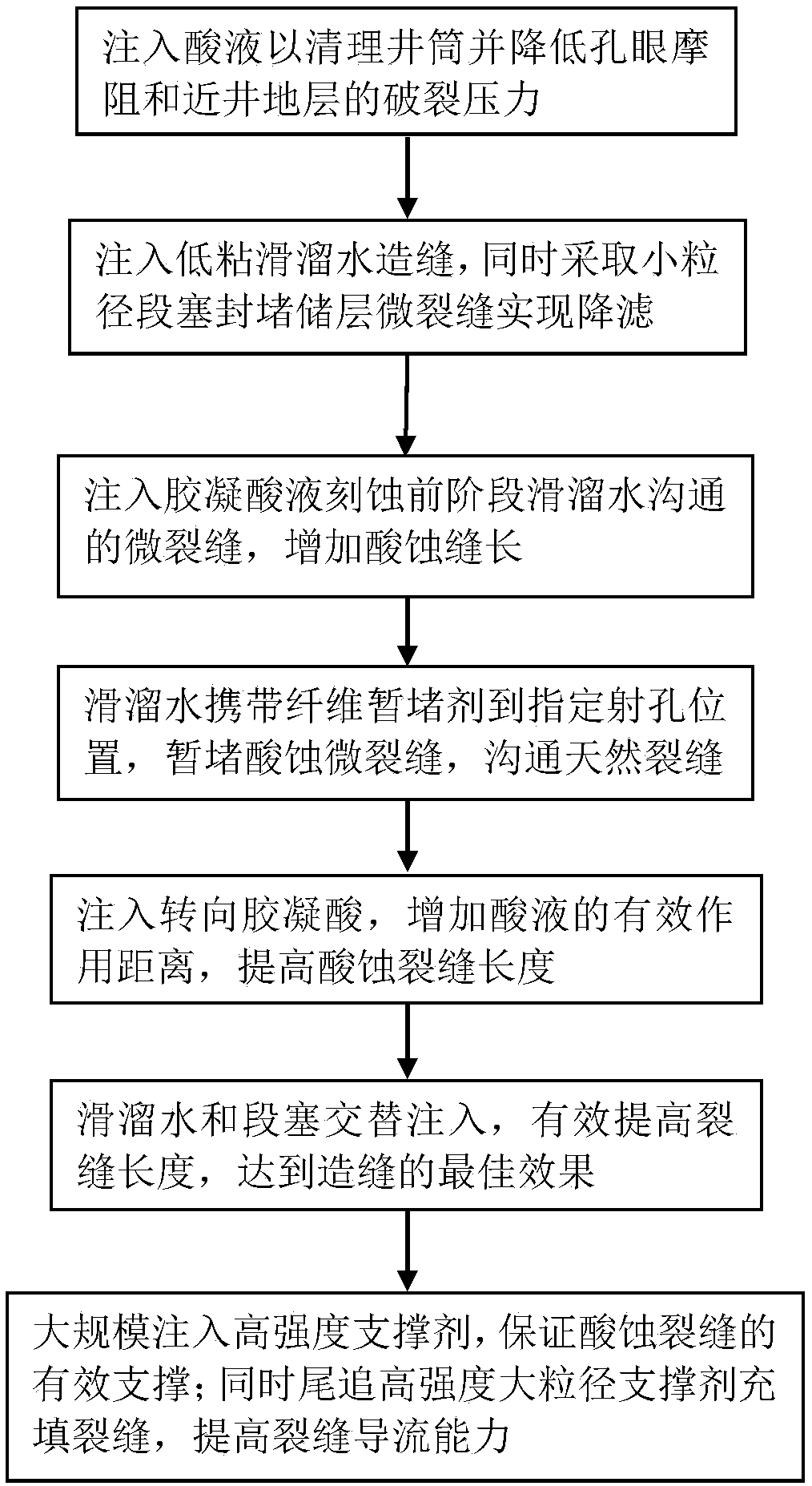

Volume fracturing method for crack net of carbonate reservoir

ActiveCN109296350AImprove diversion capacityReduce shut-in timeFluid removalAcid fracturingAcid etching

The invention relates to a volume fracturing method for a crack net of a carbonate reservoir. The volume fracturing method comprises the following steps that (1) initial crack initiation is conducted,specifically, slickwater is injected into a pretreated formation for crack making, then gel acid is injected for conducting acid etching transformation on cracks, and the crack length is increased; (2) temporary blocking in the cracks is conducted, specifically, microcracks formed by acid etching formation are temporarily blocked through temporary blocking agents carried by the slickwater; (3) turning for acid fracturing is conducted, specifically, gel acid is injected into the temporarily-blocked formation, and after the temporary blocking agents are displaced in place by the gel acid, the gel acid turns to other parts for acid etching transformation; (4) crack making through slickwater is conducted, specifically, slickwater is injected into the formation subjected to acid etching transformation in the step (3) for crack making; and (5) crack-expansion supporting is conducted, specifically, sand-carrying fluid is injected into the formation subjected to crack making in the step (4) for supporting. According to the volume fracturing method for the crack net of the carbonate reservoir, liquid leak-off can be effectively reduced, the effect of 'near-control and far-expansion' is achieved, the abundant secondary cracks can be formed, connectivity with main cracks and natural cracks is improved, and thus the transformation effect of volume fracturing is improved.

Owner:中石化石油工程技术服务有限公司 +1

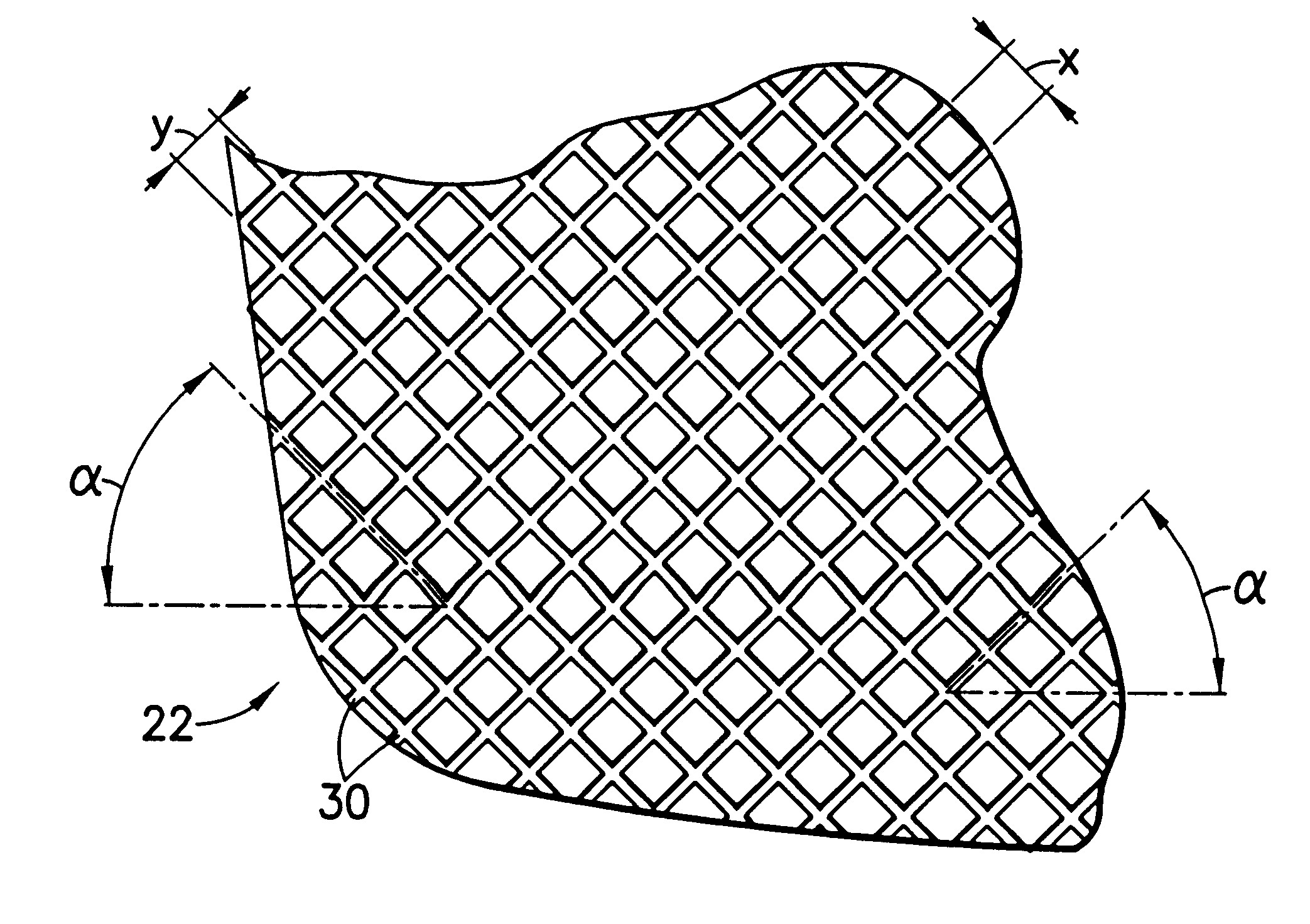

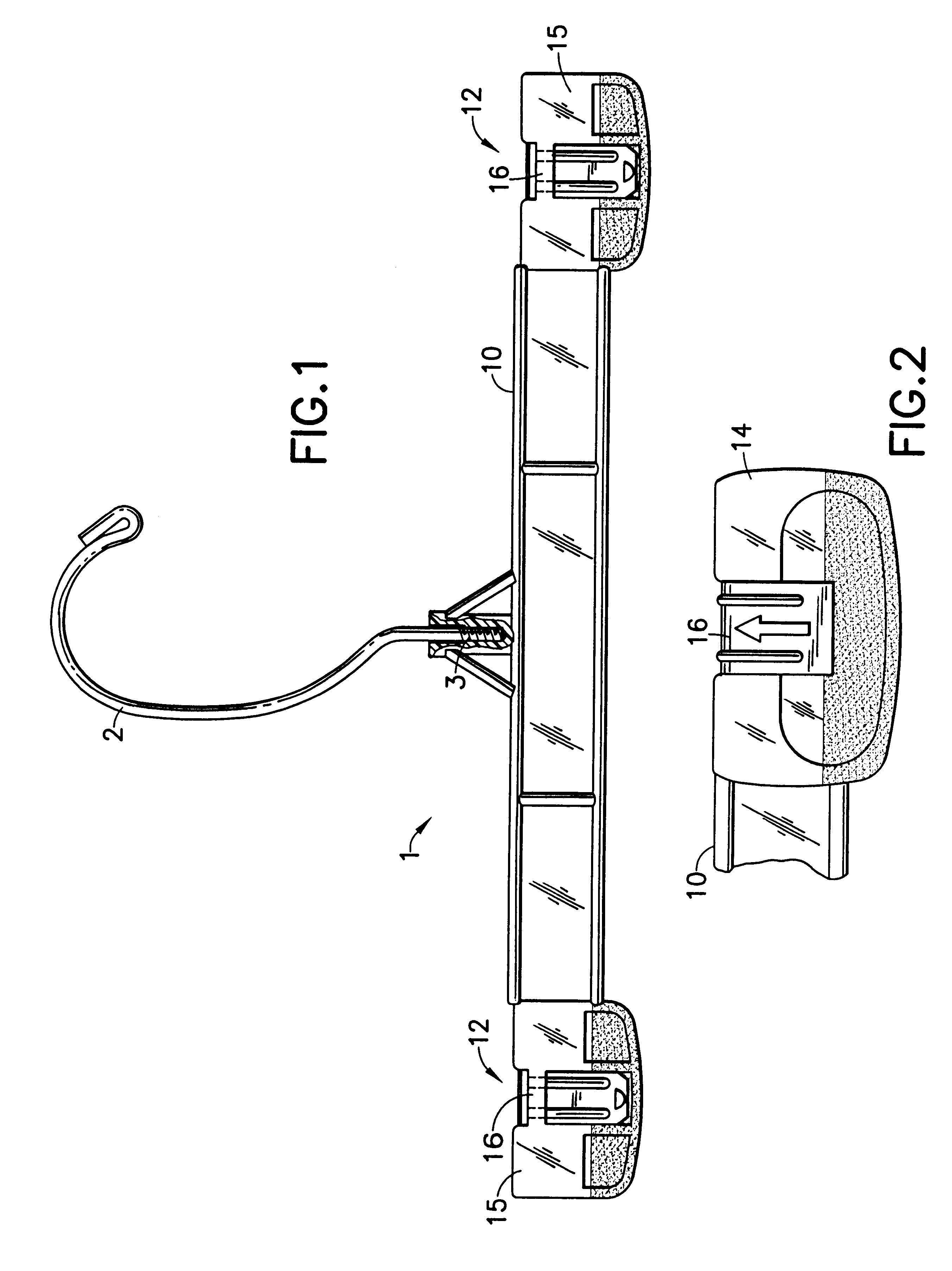

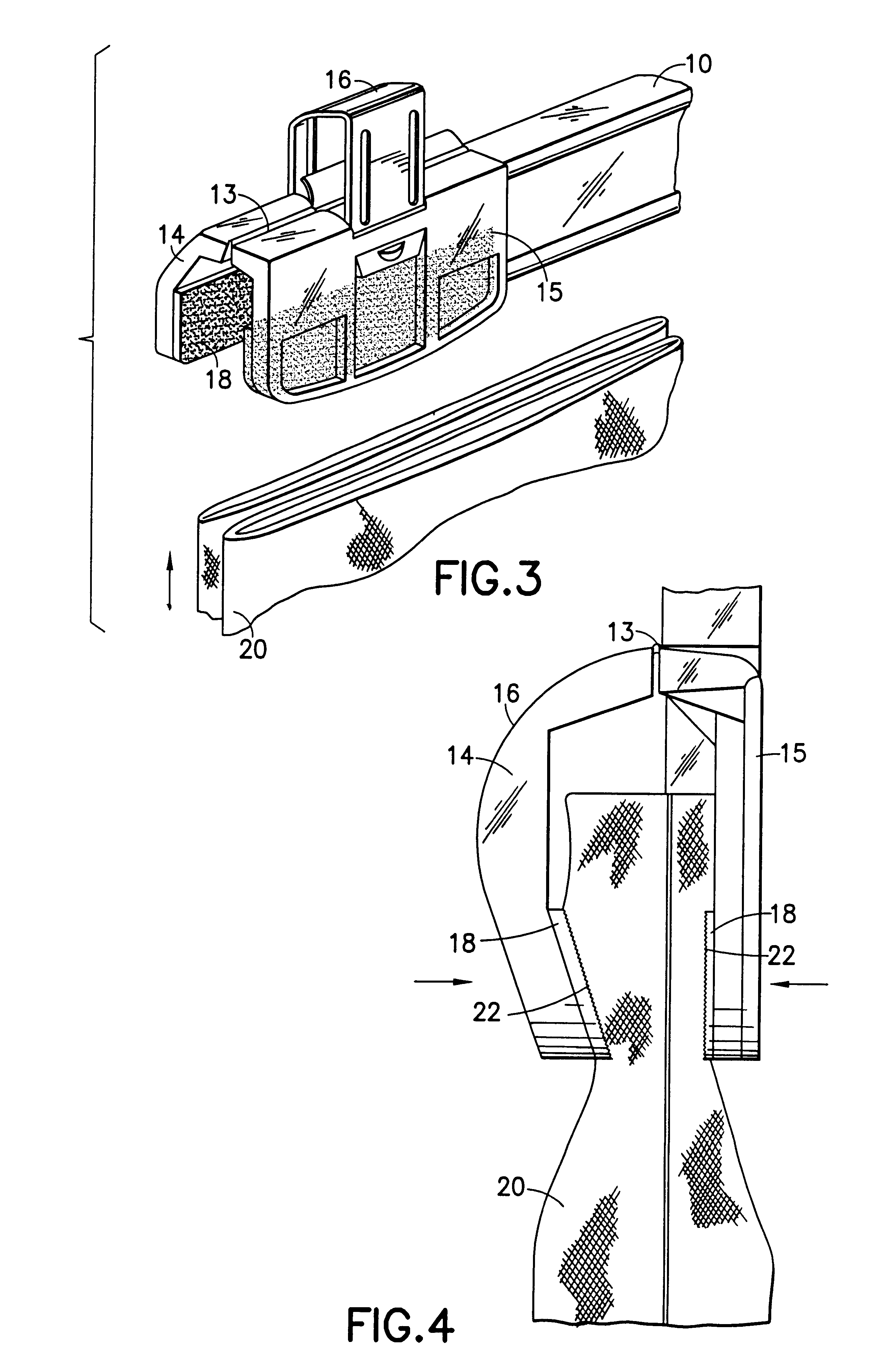

Garment hanger with integral crease-free clamps

A clamp-type garment hanger defined by a pair of opposed jaw members between which a garment is hung. The opposed jaw members have gripping members and opposed non-ribbed gripping surfaces having an enhanced coefficient of friction. The gripping members, opposed gripping surfaces with enhanced coefficient of friction and jaw members are all formed by injection molding in one piece from the same material, which may include either polystyrene, polypropylene, polyethylene, styrene-butadiene copolymers and blends, or polycarbonates. The coefficient of friction is provided to the gripping surface by forming a texture or pattern on the surface with relief structure which does not exceed a maximum elevation, or maximum depth, from the surface. The texture or pattern may be provided by molding, engraving, acid etching, electrical discharge machining, vapor honing, or sandblasting.

Owner:ACCESSORY CORP THE

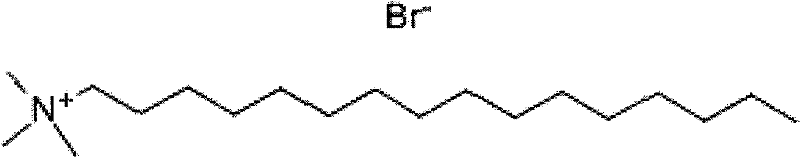

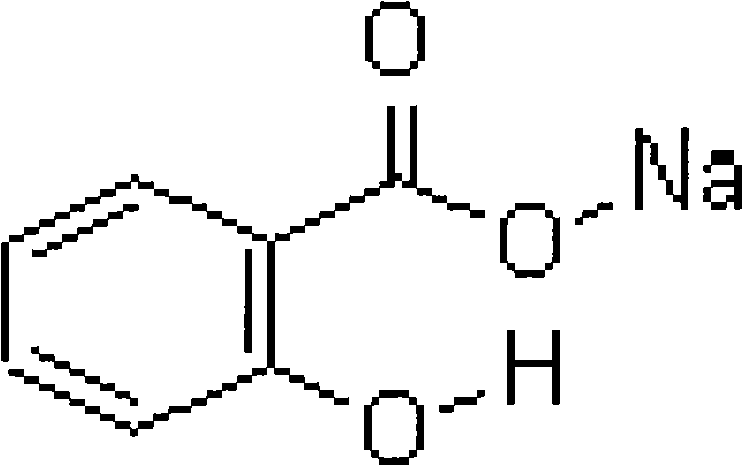

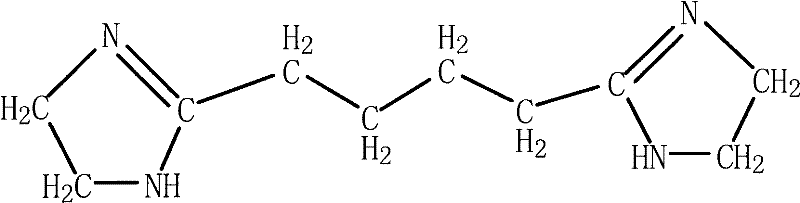

Clean viscous acid for acid fracturing of carbonate reservoir

ActiveCN102453480AGood retarding performanceExtended service lifeDrilling compositionAcid etchingHydrogen-Ion Concentrations

The invention discloses a clean viscous acid for acid fracturing of a carbonate reservoir, which is applied to the technical fields of acidification and acid fracturing of petroleum carbonate reservoirs. The clean viscous acid consists of the following components in percentage by weight: 3-7 percent of hexadecyl trimethyl ammonium bromide, 0.3-0.7 percent of sodium salicylate, 15-28 percent of hydrochloric acid, 0.125-0.25 percent of citric acid or 0.05-0.1 percent of CX-301 or 0.3-0.5 percent of TW-1 serving as an iron ion stabilizing agent, 0.2-0.25 percent of a diimidazoline quaternary ammonium salt and the balance of water. The clean viscous acid has high retardative property, the retarding rate can reach 42-56 percent, the fresh acid viscosity is 25-40 mPa.S, and the acid liquor viscosity rises during acid fracturing of the carbonate reservoir. When the hydrogen ion concentration falls till the pH is more than or equal to 2, the acid liquor viscosity rises for forming viscoelastic gel, the permeation resistance of an acid liquor in a high permeation layer is increased, and the length of an acid etching crack is prolonged. Reacted residual acid gel can undergo gel breaking automatically, is free from residues, is easy for discharging, and has small damage to stratums.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com