Patents

Literature

177results about How to "Guaranteed electricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

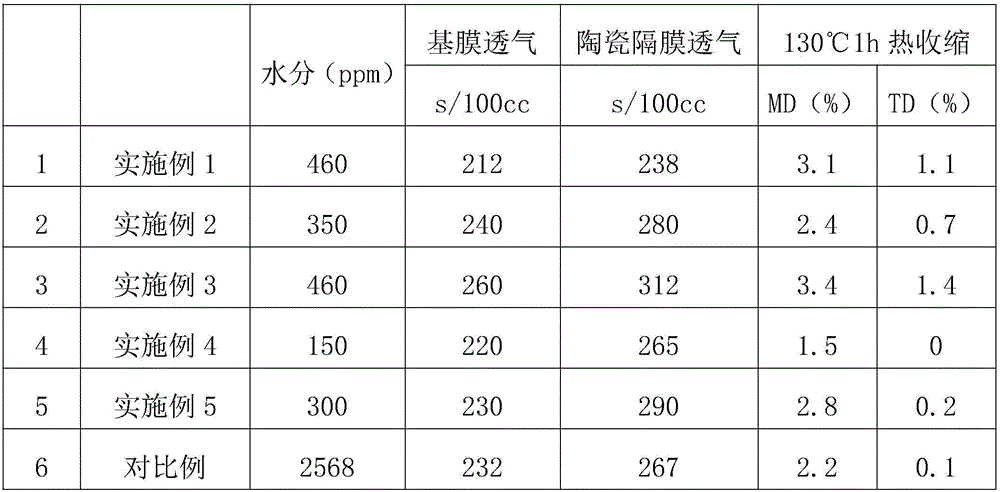

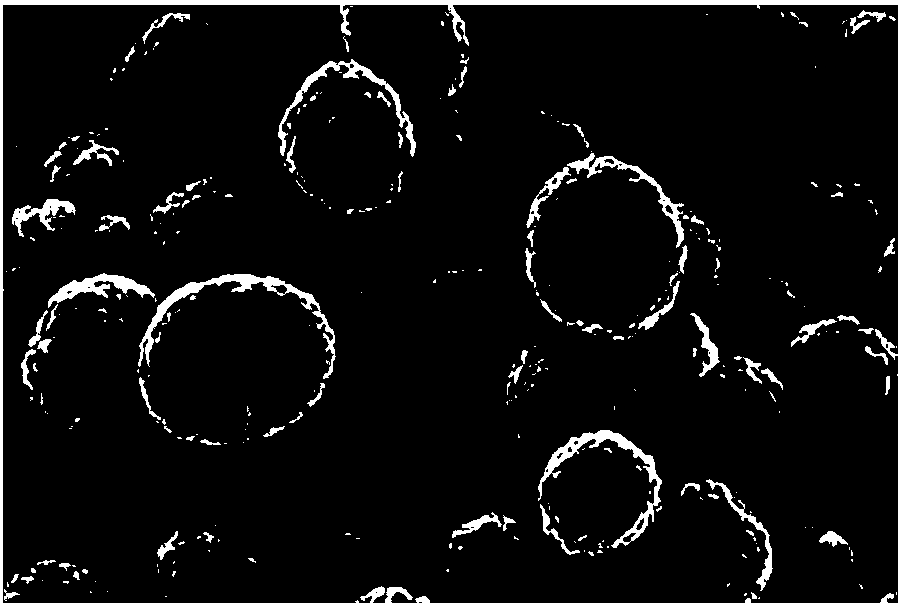

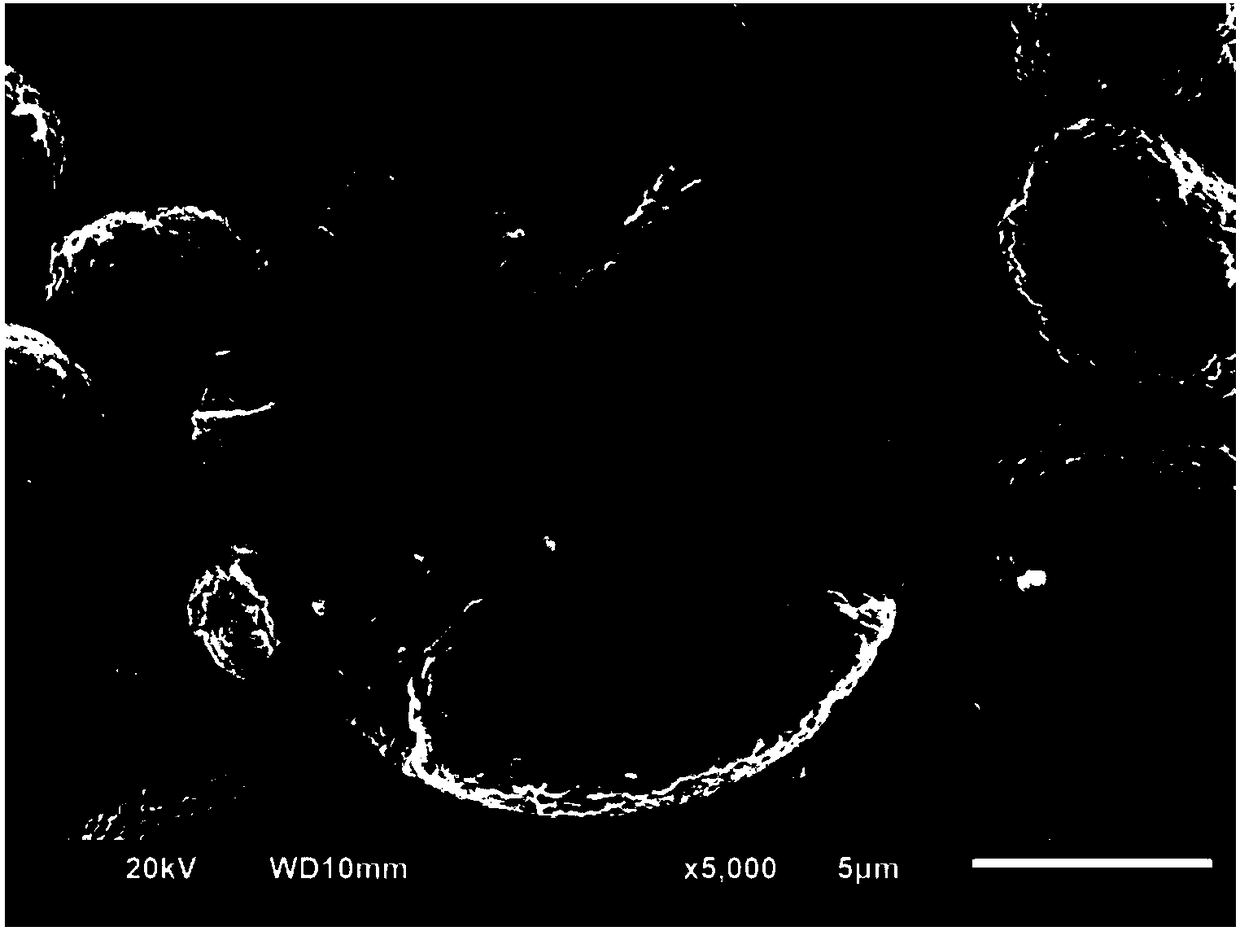

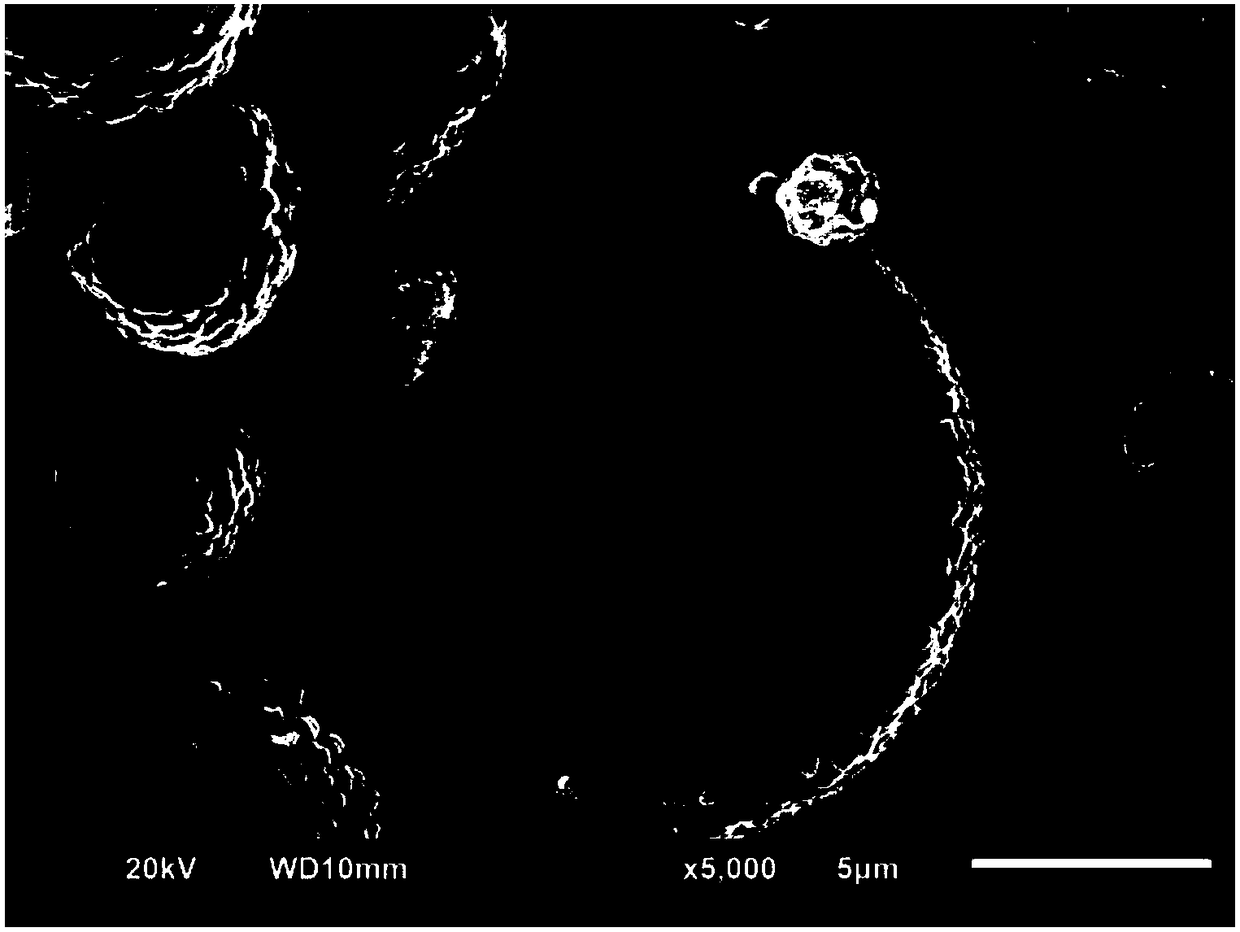

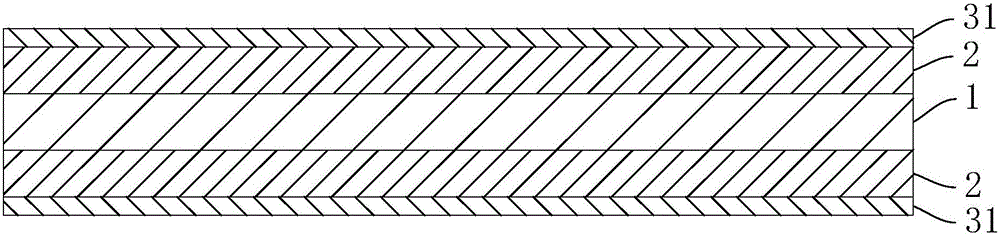

Manufacturing method for ceramic diaphragm with low water absorbency

InactiveCN105957994ASmall water absorptionGuaranteed electricityCell component detailsElectricityOrganic solvent

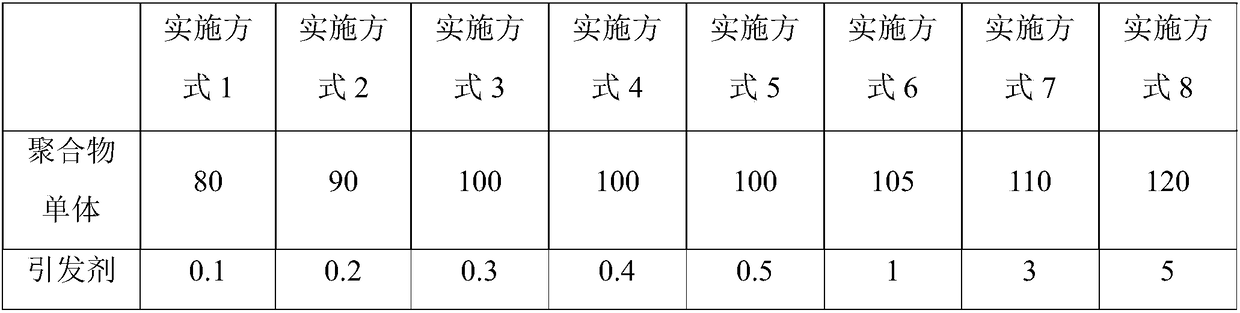

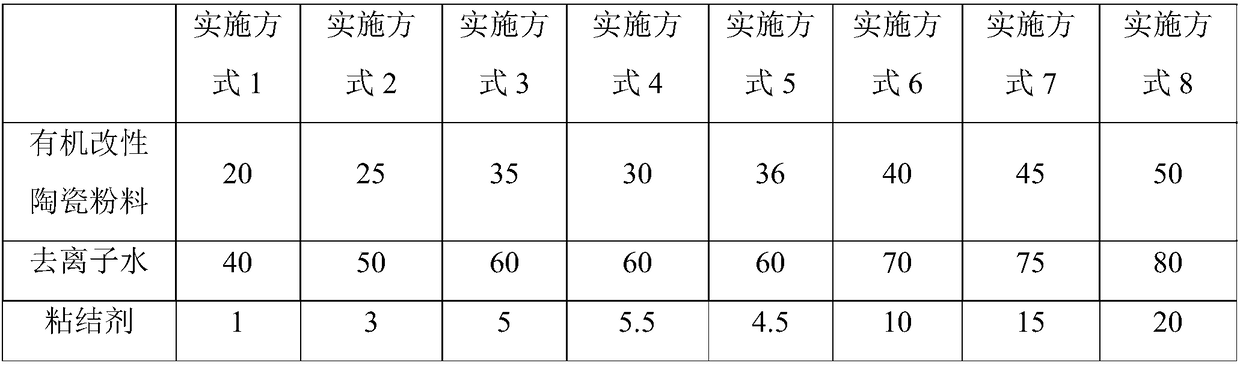

The invention provides a manufacturing method for a ceramic diaphragm with low water absorbency. The manufacturing method comprises the following steps of 1) surface modification of a ceramic powder: enabling the ceramic powder to be mixed into an organic solvent of a coupling agent, reacting for 2-8h at a temperature of 40-80 DEG C to enable the surface of the ceramic powder to be crosslinked with a hydrophobic functional group; and then carrying out vacuum drying to obtain a solid material; 2) preparing the solid material obtained in the step 1) into aqueous paste, wherein the aqueous paste comprises 10-50mass% of the solid material, 1-20mass% of a binder and 50-80mass% of deionized water; and 3) coating the surface of the lithium ion battery diaphragm with the aqueous paste prepared in the step 2), and removing moisture through a baking process to obtain the product. The manufacturing method has the beneficial effects that the water absorbency of the surface of the ceramic diaphragm is lowered; meanwhile, it is ensured that the ceramic diaphragm does not adsorb moisture and impurity in the production, transport and use processes; and therefore, the electrical property and the safety performance of the lithium battery are ensured.

Owner:NINGDE ZHUOGAO NEW MATERIAL TECH CO LTD

Embedding unpackaging method for plastic packaged device packaged by flip chip bonding process

InactiveCN102522319AGuaranteed electrical performanceGuaranteed electricitySemiconductor/solid-state device manufacturingAcid etchingDevice material

The invention discloses an embedding unpackaging method for a plastic packaged device packaged by a flip chip bonding process. The method comprises the following steps of: first longitudinally preparing a sample by adopting embedding sample preparation equipment; then grinding off a chip bonding soldering block in the sample to expose a chip bonding salient point by adopting an automatic / manual grinding system; next unpackaging the front surface or back surface of the sample, namely the surface with a chip circuit by adopting an acid etching method, wherein an opening has a size which is less than or equal to that of a chip, and is deep enough to expose the surface of the chip; and finally, immediately washing the acid-unpackaged sample, drying the sample with air and inspecting the dried sample. By the method, a semiconductor device packaged in a flip chip bonding way or a chip size package (CSP) way is unpackaged in a way of combining a mechanical method and the acid etching method, structures such as a bonding structure and the like in the sample can be integrally reserved after the sample is unpackaged, the electrical properties of the sample also can be maintained after the sample is unpackaged, and the requirement of subsequent inspection such as destructive physical analysis, failure analysis and the like on the integrity of the sample is completely met.

Owner:CASIC DEFENSE TECH RES & TEST CENT

Composite cladded lithium ion cathode material, and preparation method thereof

InactiveCN108206276AFast transferImprove uniformity of charge distributionCell electrodesSecondary cellsSolventElectrically conductive

The invention discloses a composite cladded lithium ion cathode material, and a preparation method thereof. According to the composite cladded lithium ion cathode material, Li(NiCoMn)O2 and / or Li(NiCoAl)O2 is taken as a matrix; the surface of the matrix is cladded with an electrically conductive cladding layer; the electrically conductive cladding layer comprises a lithium fast ion conductor material, and optionally comprises an electronic conductor material. The preparation method comprises following steps: 1, the lithium fast ion conductor or raw materials of the lithium fast ion conductor are dispersed in a solvent, and optionally, an electronic conductor material or raw materials of the electronic conductor material are dispersed in the solvent so as to obtain an electrically conductive cladding layer solution; 2, a cathode material is dispersed in the electrically conductive cladding layer, and stirring is carried out so as to obtain a mixed solution; 3, the mixed solution is stirred, and is subjected to distillation with stirring so as to obtain a dried powder; and 4, the dried powder is subjected to annealing, smashing, and sieving successively so as to obtain the compositecladded lithium ion cathode material. The composite cladded lithium ion cathode material possesses following advantages: cracking is not easily caused, the electrical properties are excellent, the preparation method is simple, and is convenient for industrialized production.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

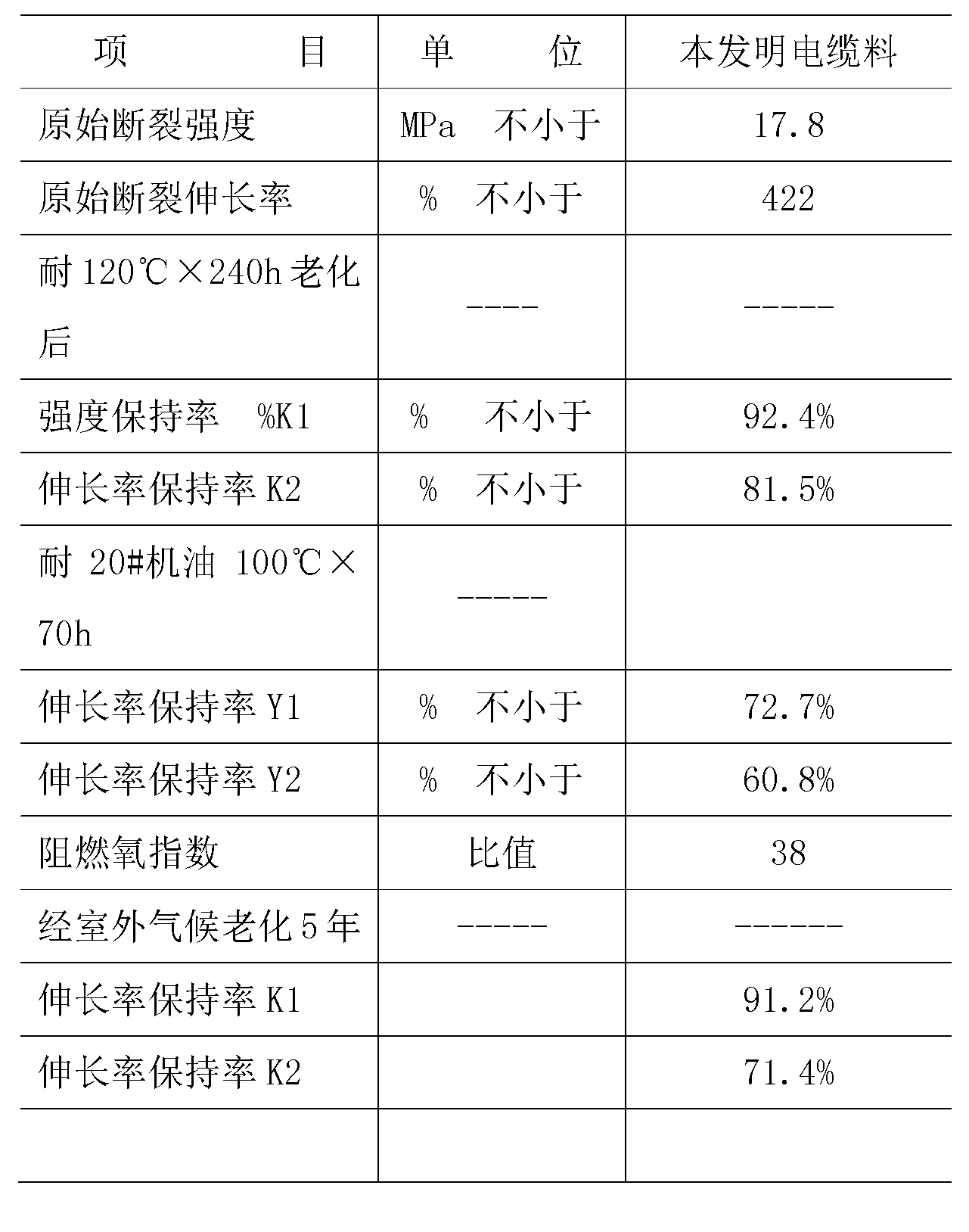

Flame-retardant type cable sheath insulation material and preparation method thereof

InactiveCN103012885ASo as not to damageGuarantee unimpededRubber insulatorsPlastic/resin/waxes insulatorsPolyesterEthylene thiourea

The invention discloses a flame-retardant type cable sheath insulation material and a preparation method thereof. The flame-retardant type cable sheath insulation material comprises the following raw materials in parts by weight: 94-102 parts of neoprene CR121, 16-21 parts of chlorinated polyethylene, 16-22 parts of semi-reinforcing carbon black N774, 2-4 parts of magnesium oxide, 1-2 parts of glass powder, 32-36 parts of mica powder, 1-2 parts of anti-aging agents MB, 1-2 parts of 2-thiol-group benzimidazole, 5-7 parts of polyamide wax micropowder, 1-2 parts of accelerants DM, 0.8-1 part of accelerants TMTD, 18-23 parts of kaolin, 1-3 parts of adipic acid propanediol polyester, 2-4 parts of zinc borate, 4-6 parts of talcum powder, 0.8-1 part of zinc oxide, 2-3 parts of modified calcium carbonate, 5-6 parts of antimony trioxide, 4-6 parts of ethylene thiourea, 4-6 parts of ethylene bis stearamide, 0.7-0.9 part of di-n-octyltin bis(isooctyl thioglycollate) and 0.5-0.8 part of bis(P,P-bis-ethylhexyl diphosphato) ethanediolato titanate. The flame-retardant type cable sheath insulation material disclosed by the invention has characteristics superior to those of common rubber and flame-retardant rubber, namely, the flame-retardant type cable sheath insulation material disclosed by the invention has the property of common silicon rubber at normal temperature, and a rigid shell after is formed being ablated by high temperature flames so as to protect the burnt object not to be damaged.

Owner:安徽文峰电子科技集团有限公司

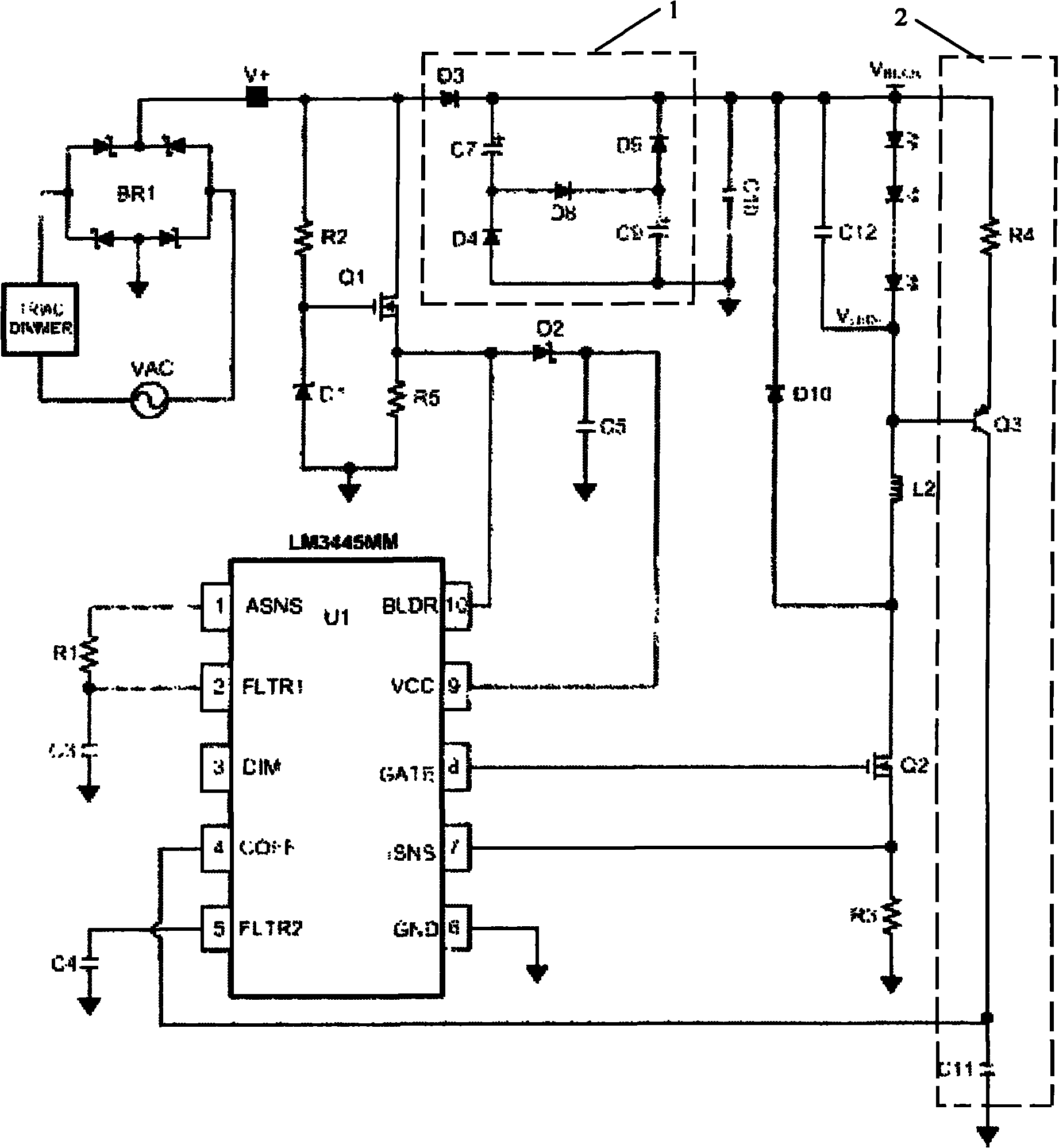

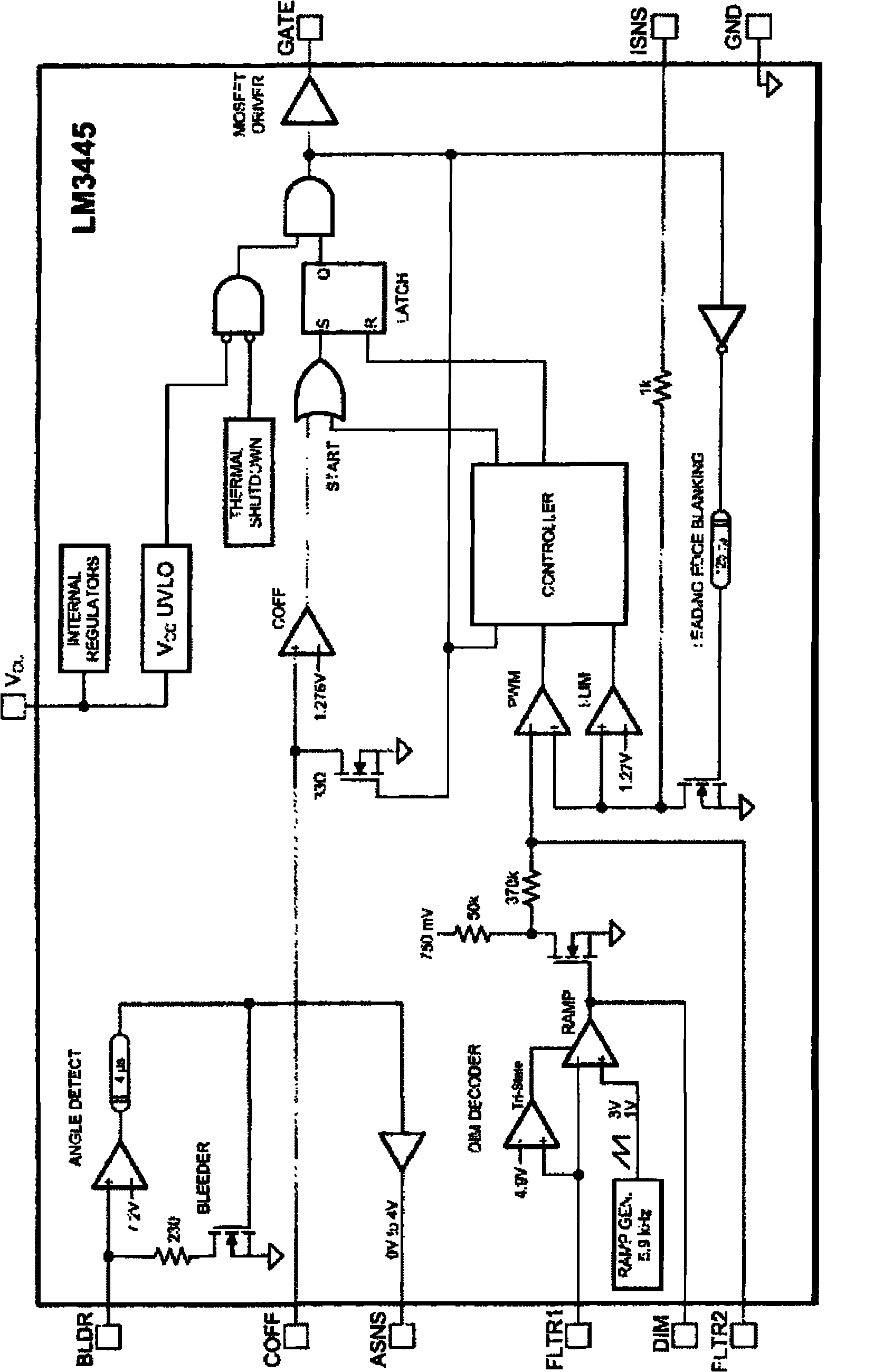

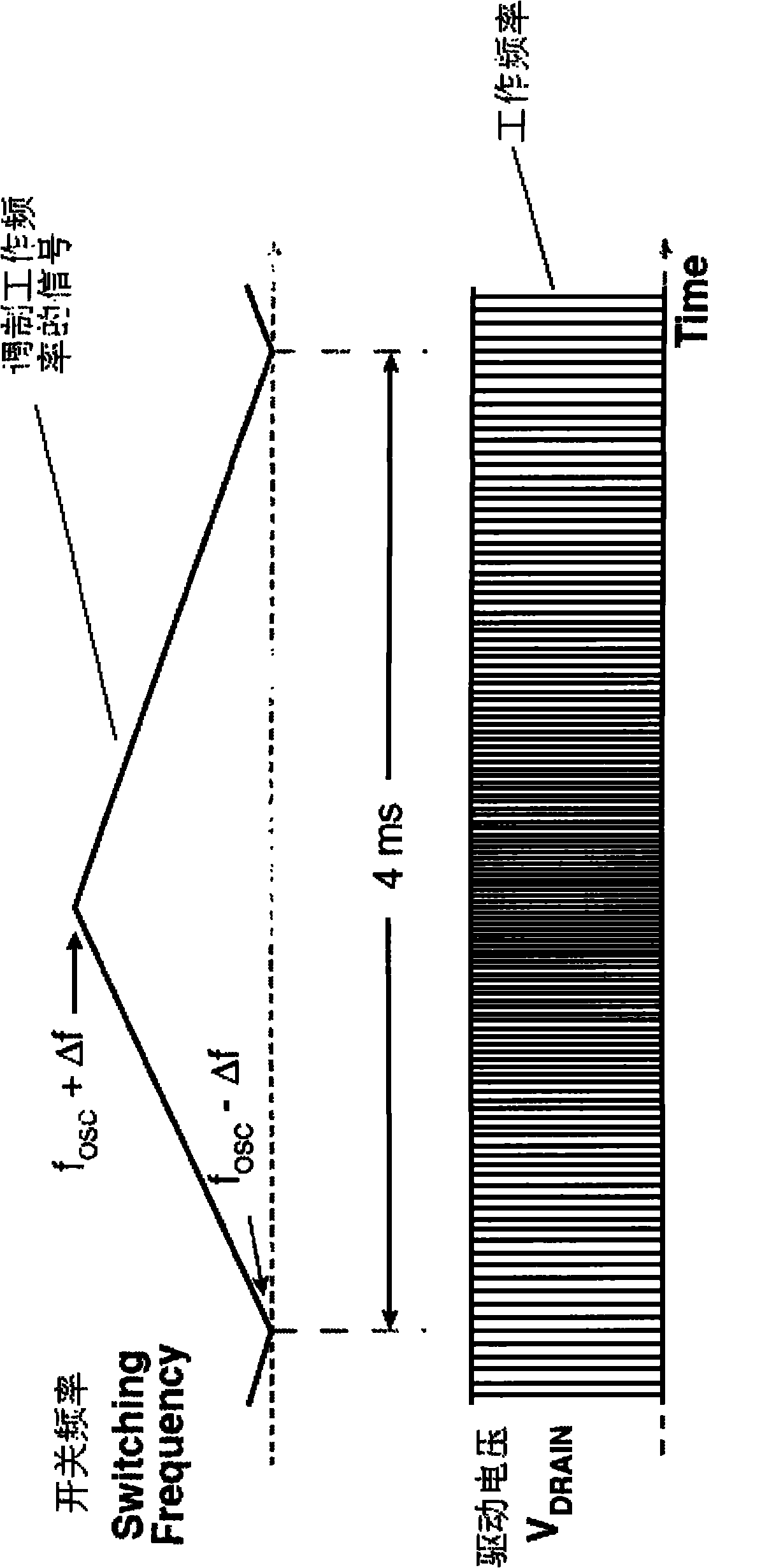

Control method of light emitting diode (LED) constant current power supply and LED constant current power supply circuit

InactiveCN101984732ASimple control circuitLow costElectric light circuit arrangementEnergy saving control techniquesTransformerAlternating current

The invention relates to a control method of a light emitting diode (LED) constant current power supply and an LED constant current power supply circuit. In the invention, the control method of the LED constant current power supply is as follows: extracting an input voltage signal, an input current signal and a feedback voltage signal, then inputting the signals to a control circuit; converting the acquired signals into digital signals by the control circuit, adding a frequency jitter signal; carrying out logical operation to obtain a pulse signal for controlling a switch to work; and isolating the high-frequency alternative current by the high-frequency transformer so as to perform constant current driving on the LED. In the invention, the LED constant current power supply comprises a control circuit, a power supply unit, an input voltage detection unit, an output frequency jitter control unit, an output voltage detection unit, a primary current detection unit, a switch S1, a high frequency transformer and an output filter unit. The circuit of the invention can automatically adapt to the change of load LEDs and eliminate the impact of the circuit parameter change on working condition, thereby ensuring long-term stable work of the circuit.

Owner:王际

Irradiation type ceramic fire-resistant silicone rubber, preparation method of rubber and application to wires and cables

ActiveCN103013129AImprove insulation performanceImprove compactnessInsulated cablesInsulated conductorsPolymer scienceVulcanization

The invention discloses irradiation type ceramic fire-resistant silicone rubber, a preparation method of the rubber and application to wires and cables. The rubber comprises the following components in parts: 100 parts of methyl vinyl silicone rubber, 60-100 parts of white carbon black, 20-50 parts of alumina, 3-10 parts of structure control agent, 3-5 parts of sintering additive, 0.25-1.5 parts of surface treating agent and 1-1.5 parts of sensitizing agent. The preparation method of the silicone rubber comprises the steps that raw methyl vinyl silicone rubber is subjected to roller coating and mixing; white carbon black and alumina that are treated by the surface treating agent, the structure control agent, the treated sintering additive, and the sensitizing agent are added in sequence, and subjected to mixing uniformly; a sizing material after placing is subjected to remixing and plasticity recovery; and the balance of white carbon black is added. The fire-resistant silicone rubber material is subjected to extrusion processing and electron irradiation vulcanization, and has the advantages that the fire-resistant silicone rubber material is compact in ceramic body, stable in structure, stable in fire resistance, good in insulating property, less in environmental pollution, good in crosslinking uniformity and convenient in control measure, and the control measure can be conducted at a room temperature.

Owner:WUXI JIANGNAN CABLE

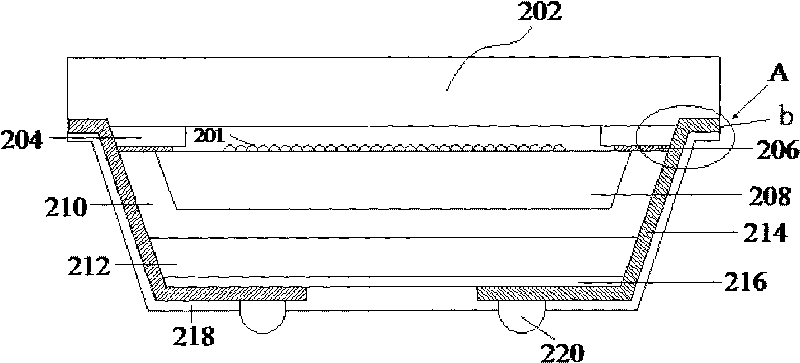

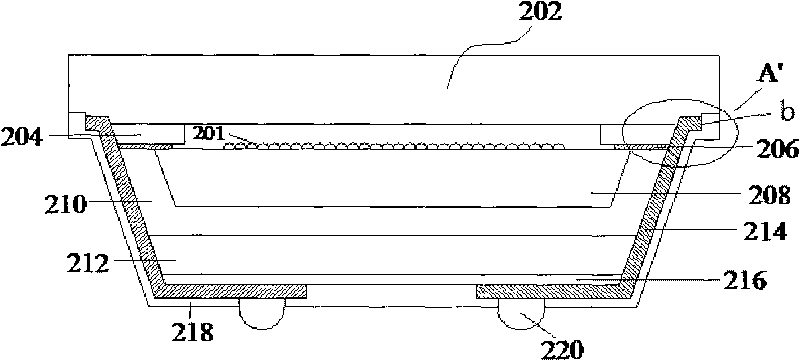

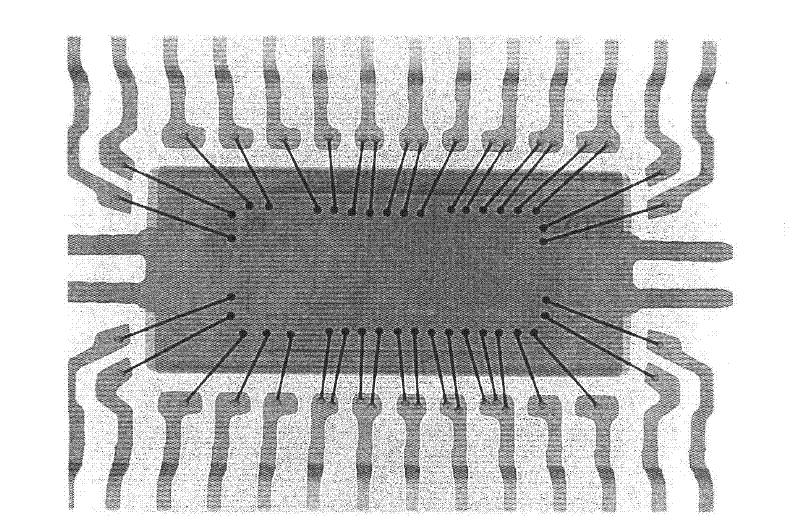

Encapsulating structure of semiconductor chip and manufacturing technology thereof

ActiveCN101710581AImprove stabilityQuality improvementSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologySemiconductor chip

The invention provides an encapsulating structure of a semiconductor chip, comprising an encapsulating body, a chip, a weld pad, a leading wire metal layer and a protecting layer, wherein, the chip is encapsulated into the encapsulating body and comprises a photosensitive element; the weld pad is connected with the chip; the leading wire metal layer is connected with the exposed part of the side surface of the weld pad in a T-shaped connection mode, extends to the back of the encapsulating body from the side wall of the encapsulating body and is connected with a welding bulge; and the protecting layer covers the outer surface of the leading wire metal layer. The encapsulating structure is characterized in that the protecting layer is also used for coating the end surface of the side wall of the encapsulating body on the leading wire metal layer. The encapsulating structure strengthens the stability of a connecting point of the welding side surface and the leading wire metal layer in the encapsulating structure of the semiconductor chip, ensures the electrical property of the connecting point and further improves the quality of a semiconductor chip encapsulating product.

Owner:CHINA WAFER LEVEL CSP

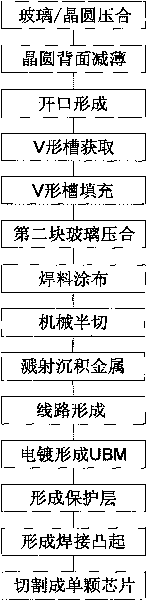

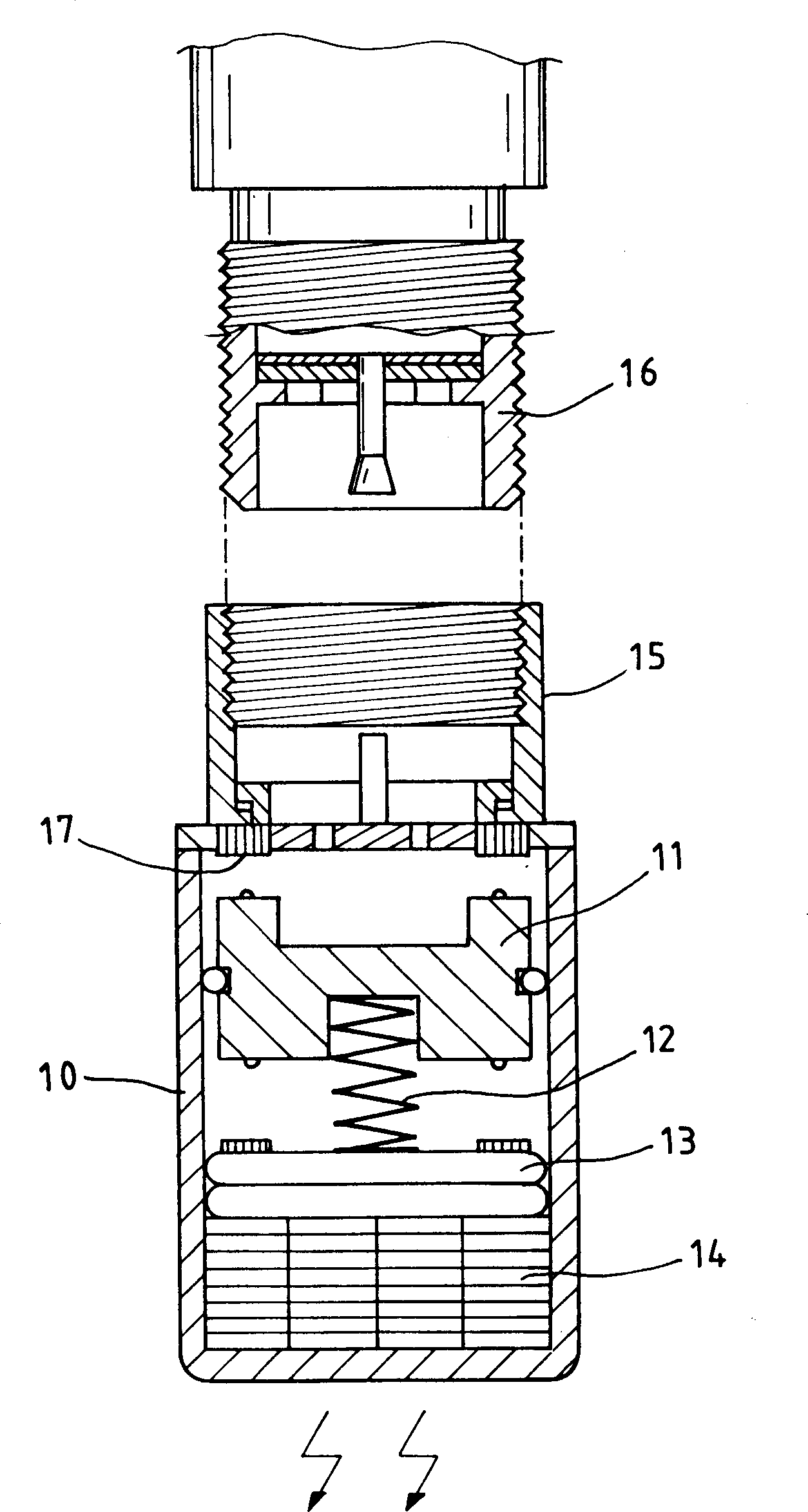

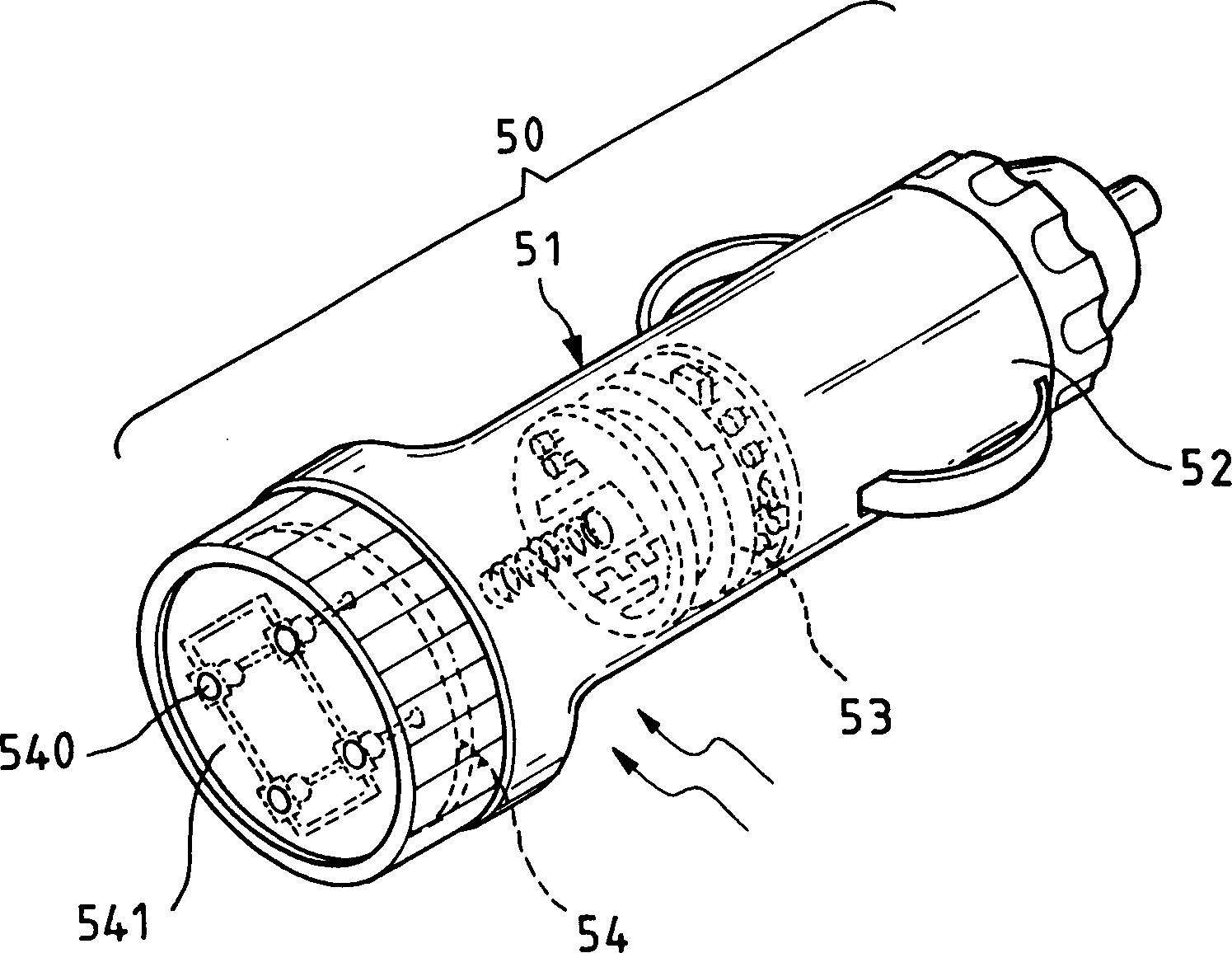

Tyre pressure detecting and warning device

The present invention relates to a tire pressure detection and warning device. It includes a detection unit lock-fixed on the tire valve, a reverse locking unit for preventing said detection unit from being drawn out arbitrarily and a receiving warning unit which can be placed on the electric cigarette lighter for use. Said detection unit is composed of insulating fixed ring, spring sheet, probe and flexible air pressure chamber. Besides, said invention also provides their connection mode and the working principle of said detection and warning device.

Owner:柯月英

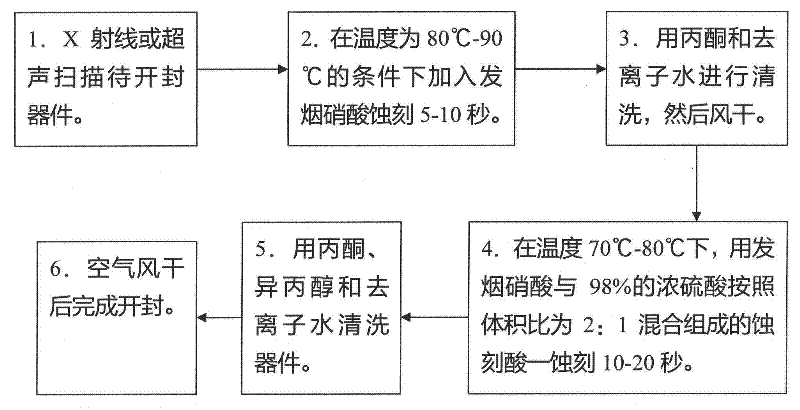

Method for unsealing plastically-packaged apparatus containing un-passivated metal layer structure

ActiveCN102456538AGuaranteed electricityMeet integrity requirementsSemiconductor/solid-state device manufacturingKetoneIntegrated circuit

The invention diswcloses a method for unsealing a plastically-packaged apparatus containing an un-passivated metal layer structure, comprising the following steps of: firstly, etching the plastically-packaged apparatus for 5-10 seconds in an environment at 80-90 DEG C by fuming nitric acid, starting to perform a cleaning process in 30 seconds, cleaning the etched apparatus by acetone and deionized water, and then drying in air; secondly, etching the plastically-packaged apparatus for 10-20 seconds in an environment at 70-80 DEG C by an etching acid I formed by mixing fuming nitric acid with 98% concentrated sulphuric acid in a volume ratio of 2: 1, and immediately cleaning the apparatus by acetone, isopropyl ketone and deionized water after etching; and lastly, drying in air. The plastically-packaged semiconductor integrated circuit with a chip surface made of nickel-copper, nickel-tungsten and the like and produced by a structure which is not protected by a passivation layer is unsealed by a method of precisely controlling unsealing technique parameters and performing an etching process twice, the interior structure of the apparatus can be completely reserved after the apparatus is unsealed, and the apparatus is ensured to be able to keep electrical performance after being unsealed, so that the demand on the integrity of the apparatus by the follow-up inspections of destructive physical analysis, failure analysis and the like is completely satisfied.

Owner:CASIC DEFENSE TECH RES & TEST CENT

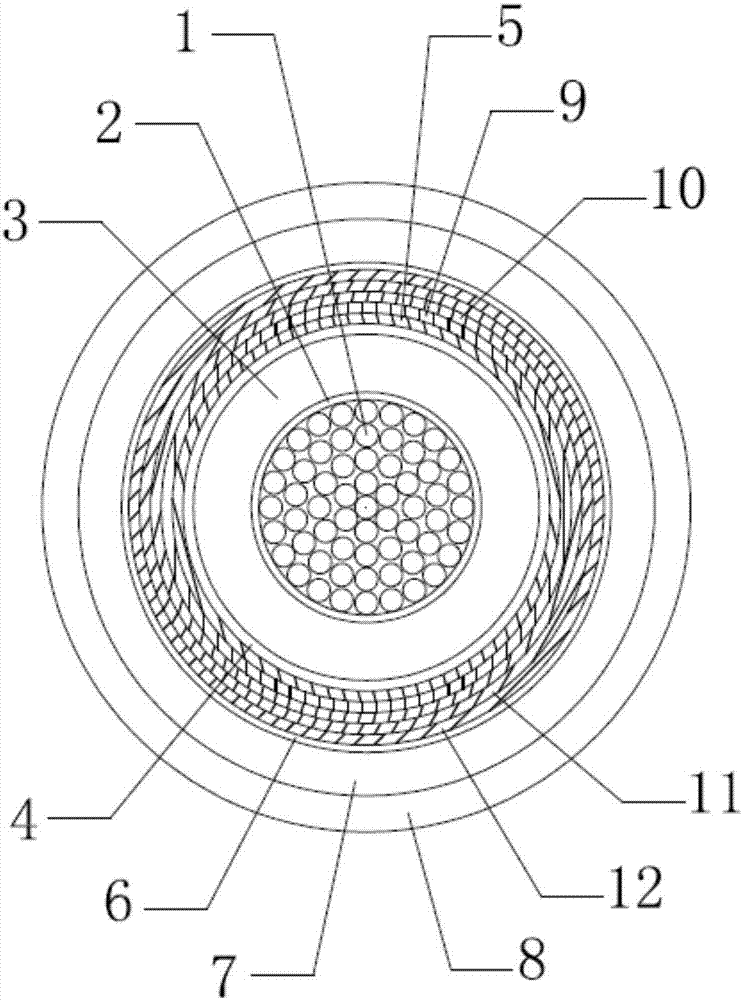

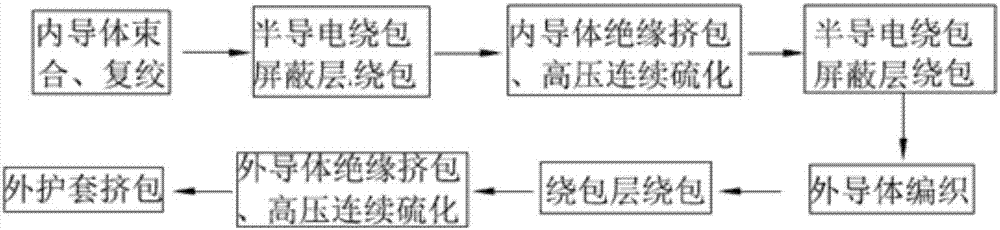

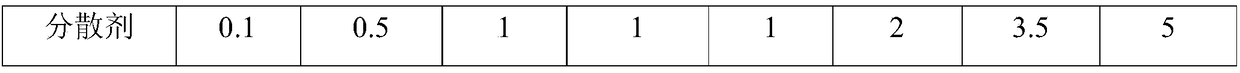

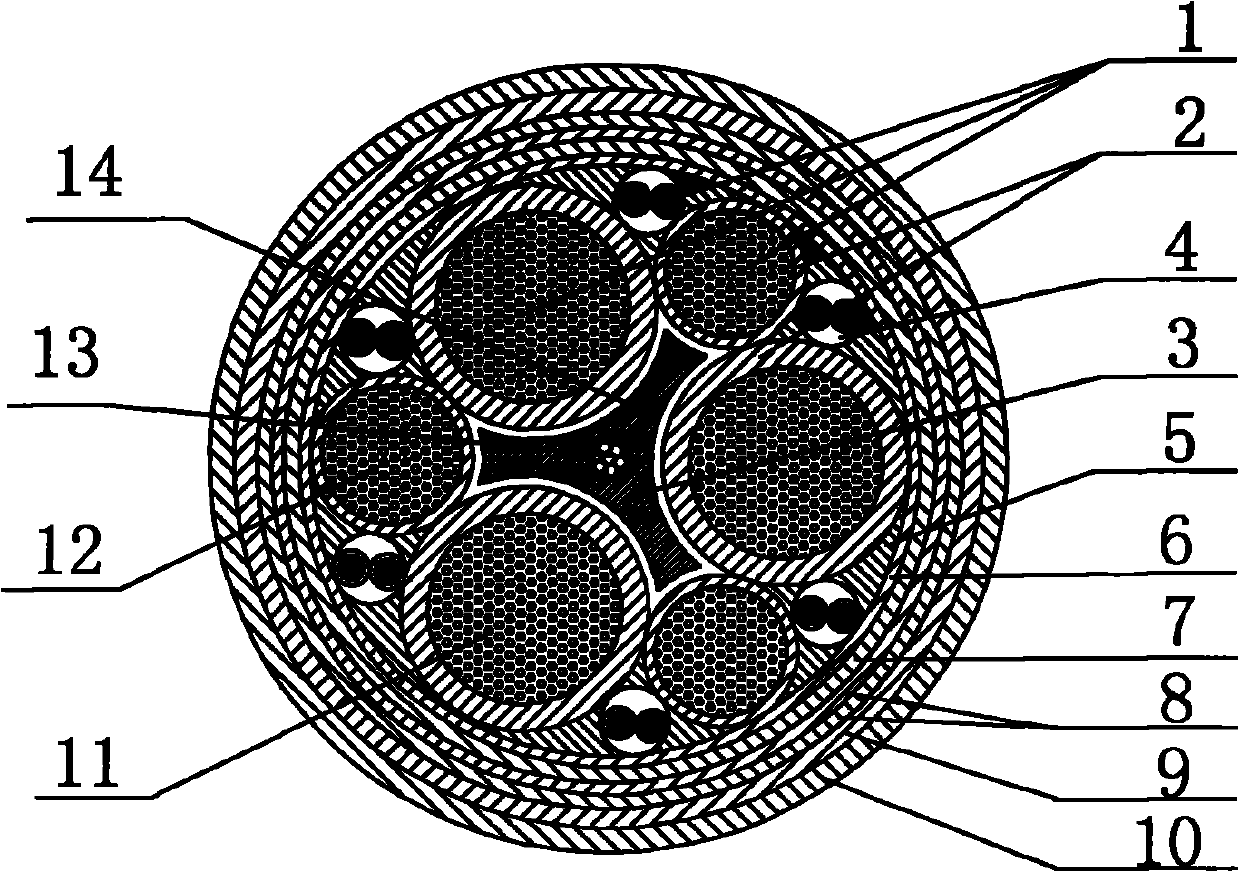

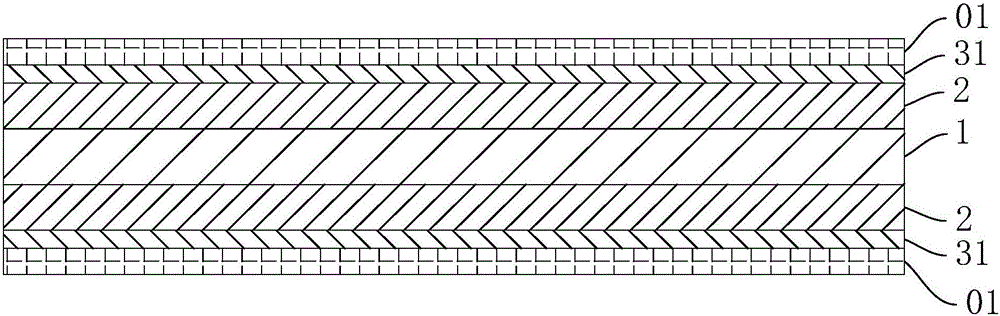

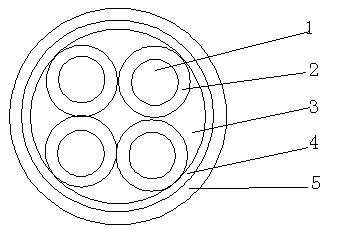

Manufacturing method of cable for high power transmission equipment and cable

InactiveCN107154285ANo damageReduce weightConcentric cablesPower cables with screens/conductive layersReliable transmissionElectrical conductor

A cable for high power transmission equipment, its structure from inside to outside is: inner conductor, first semiconductive wrapping shielding layer, inner conductor insulation, second semiconducting wrapping shielding layer, outer conductor, wrapping layer, Outer conductor insulation and outer sheath. The insulating layer of the inner conductor is made of silicon rubber; the outer conductor is braided with one or more layers of tinned copper wire; the insulating layer of the outer conductor is made of silicon rubber; the outer sheath layer is made of polyurethane. The manufacturing method of the cable comprises: 1) manufacturing the inner conductor; 2) manufacturing the first semiconductive wrapping shielding layer; 3) manufacturing the inner conductor insulating layer; 4) manufacturing the second semiconductive wrapping shielding layer; 5) manufacturing 6) manufacturing the wrapping layer; 7) manufacturing the insulating layer of the outer conductor; 8) manufacturing the outer sheath layer. In each step, a specific process method is adopted, so that the electrical and mechanical properties of the cable prepared by this method can meet or exceed the detection requirements, so that the cable for high-power transmission equipment can transmit high power safely and reliably, and has the advantages of light weight. , miniaturization, low temperature resistance, good flexibility, small bending radius and other excellent performances, suitable for high electric energy technical equipment.

Owner:JIANGSUSNGSHANG CABLE GROUP

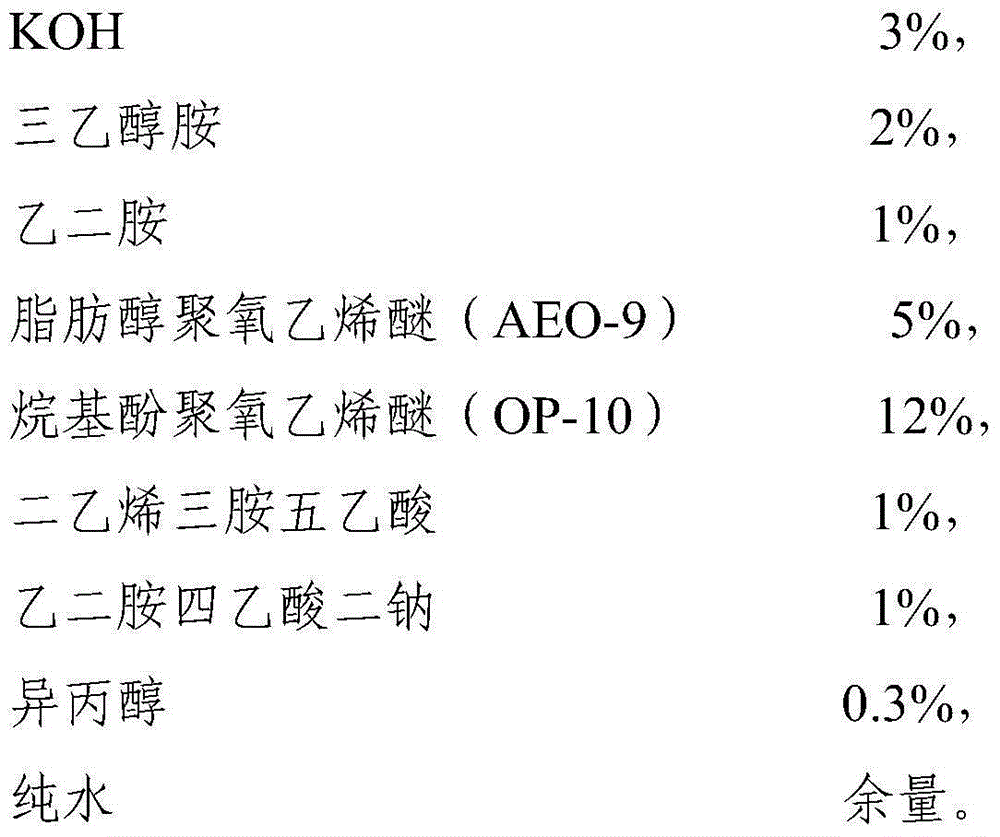

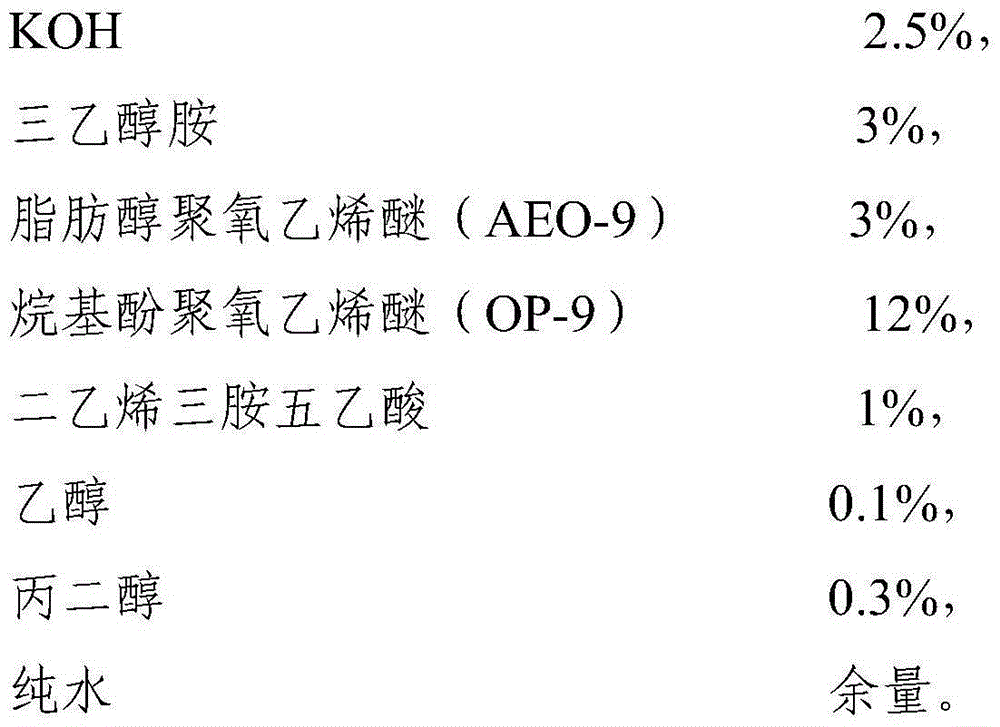

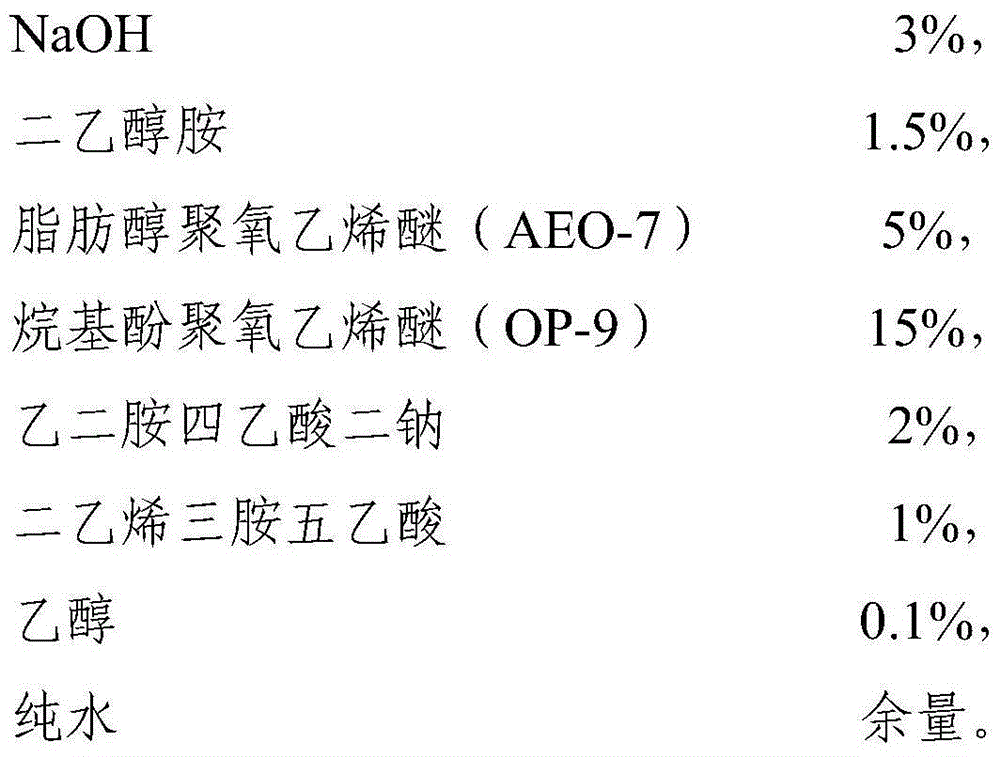

Special cleaning solution for high-performance photovoltaic silicon chips

InactiveCN103525573AReliable safety and health qualityNot corrosiveOrganic detergent compounding agentsNon-ionic surface-active compoundsSilicon chipChemistry

The invention discloses a special cleaning solution for high-performance photovoltaic silicon chips, which is composed of high-polymer carboxylic acid, organic amine, a surfactant, a complexing agent, a corrosion inhibitor, other assistants and water. The cleaning solution has the advantages of excellent cleaning performance, high use safety and environmental protection.

Owner:SHANGHAI YUSHIRO CHEM IND

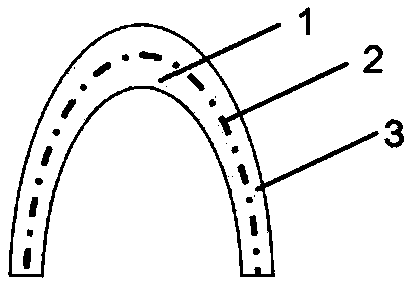

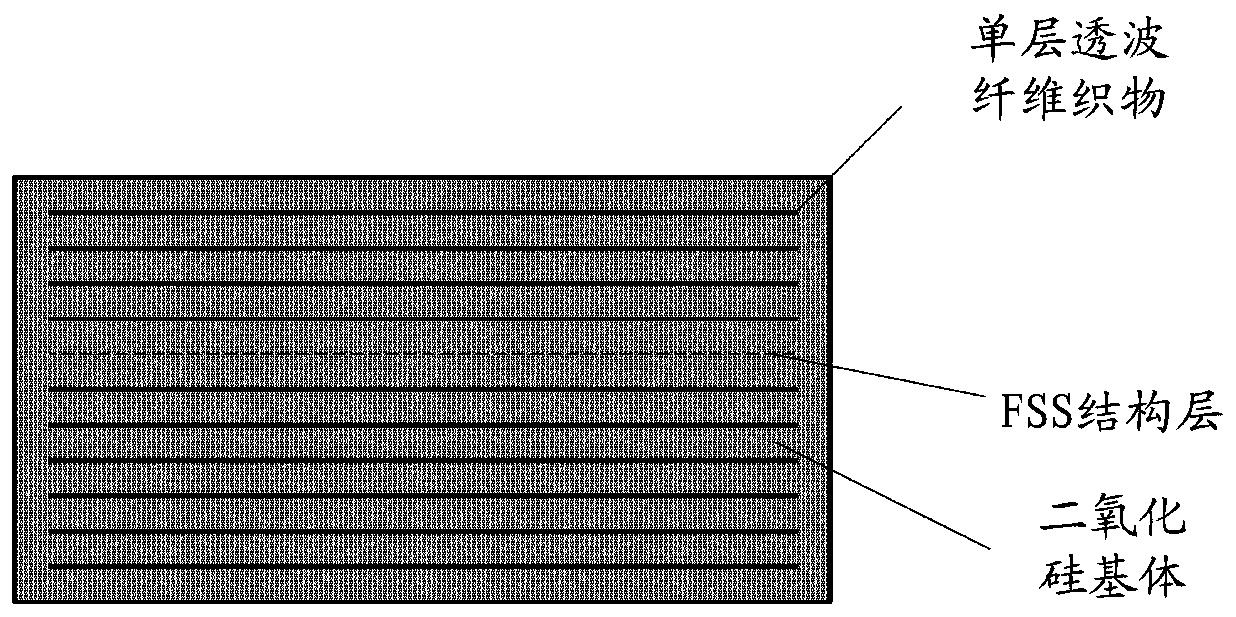

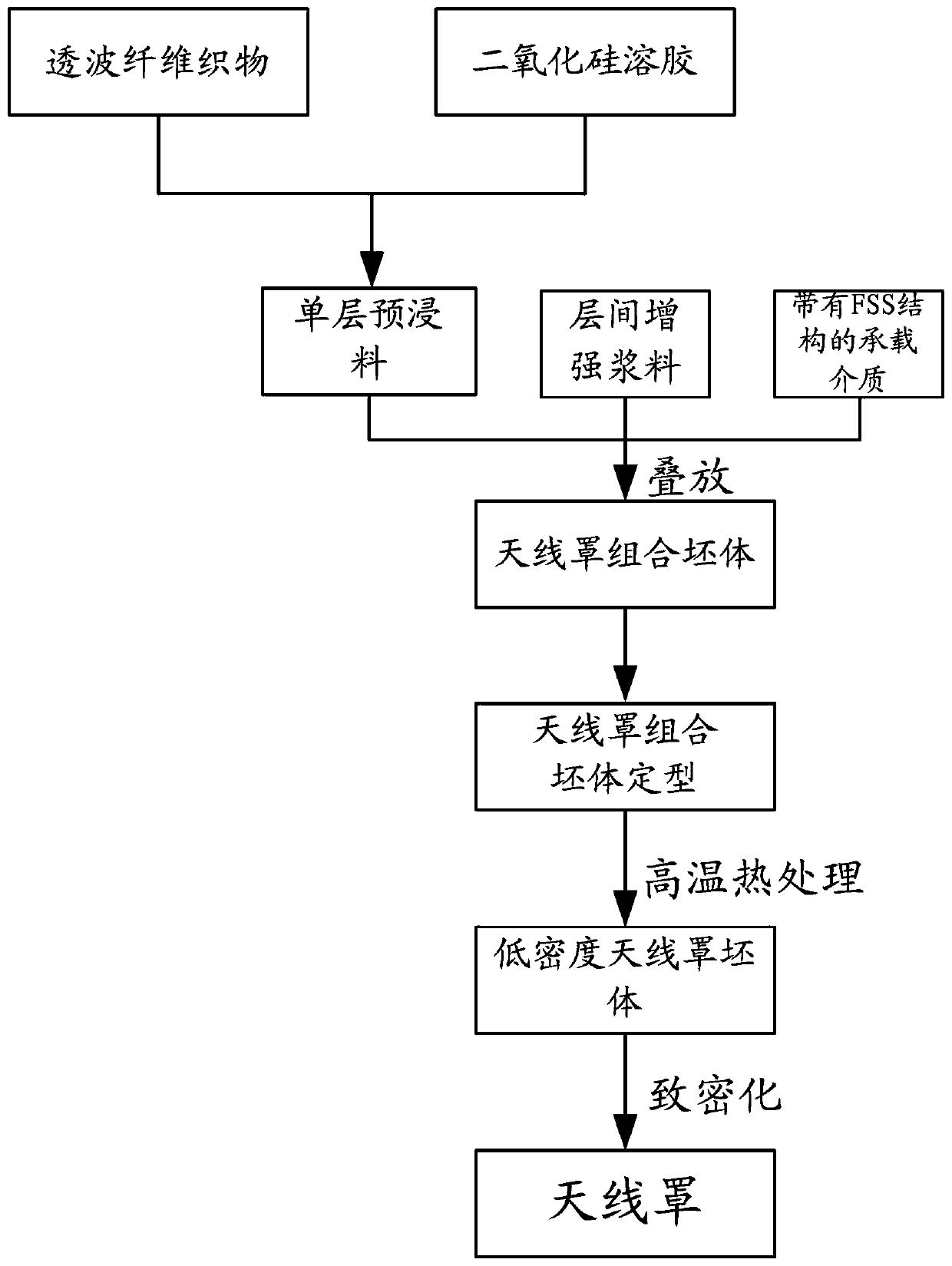

High-temperature-resistant frequency selective surface antenna cover and preparation method thereof

ActiveCN109786961AStable structureImprove adaptabilityRadiating element housingsEngineeringSilicon dioxide

The invention provides a high-temperature-resistant frequency selective surface antenna cover and a preparation method thereof, a layered structure is adopted, the antenna cover is composed of a bearing layer, at least one layer of FSS (frequency selective surface) structural layer and an anti-ablation / washing layer, the bearing layer and the anti-ablation / washing layer are a plurality of layers of 2D and / or 2.5D fabric reinforced silicon dioxide-based ceramic materials, and the FSS structural layer, the bearing layer and the anti-ablation / washing layer are integrally formed by adopting a gluedipping-gel technology. According to the antenna cover and the preparation method in the invention, a single-layer or multi-layer FSS structure is prepared inside the fiber-reinforced silicon dioxide-based ceramic material, the FSS structure is stable, the FSS structure is good in environmental adaptability under the protection of the fiber-reinforced silicon dioxide-based ceramic material, the application field is wider, and engineering application of the technology is facilitated.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

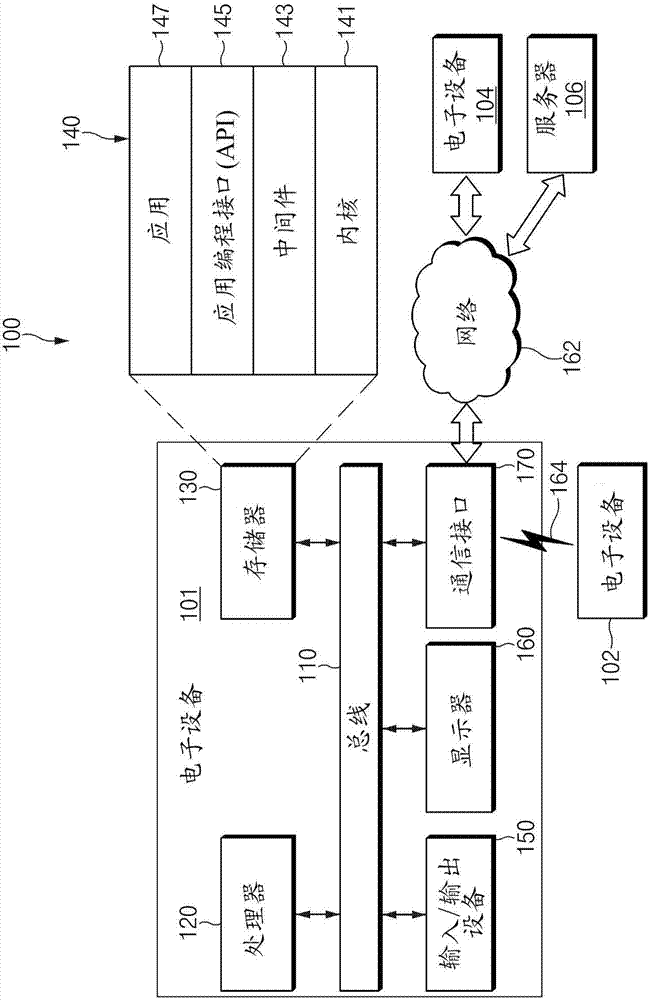

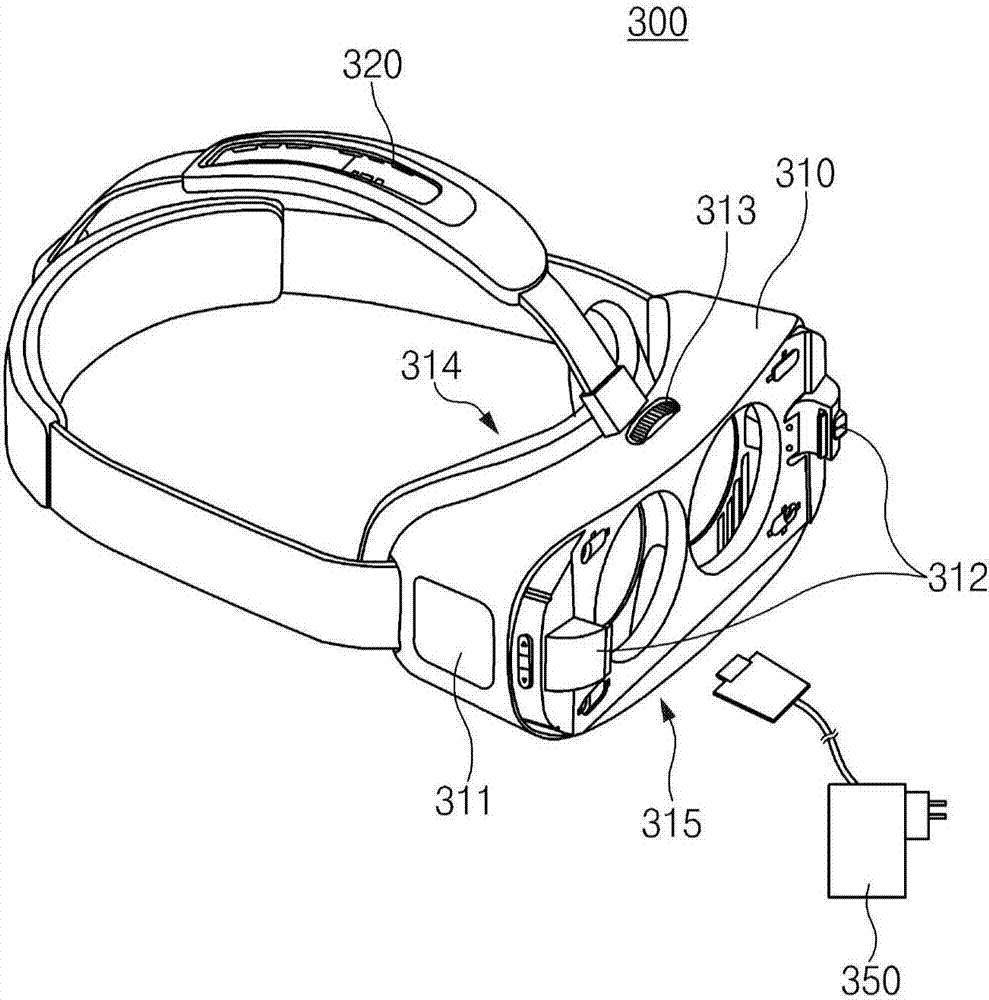

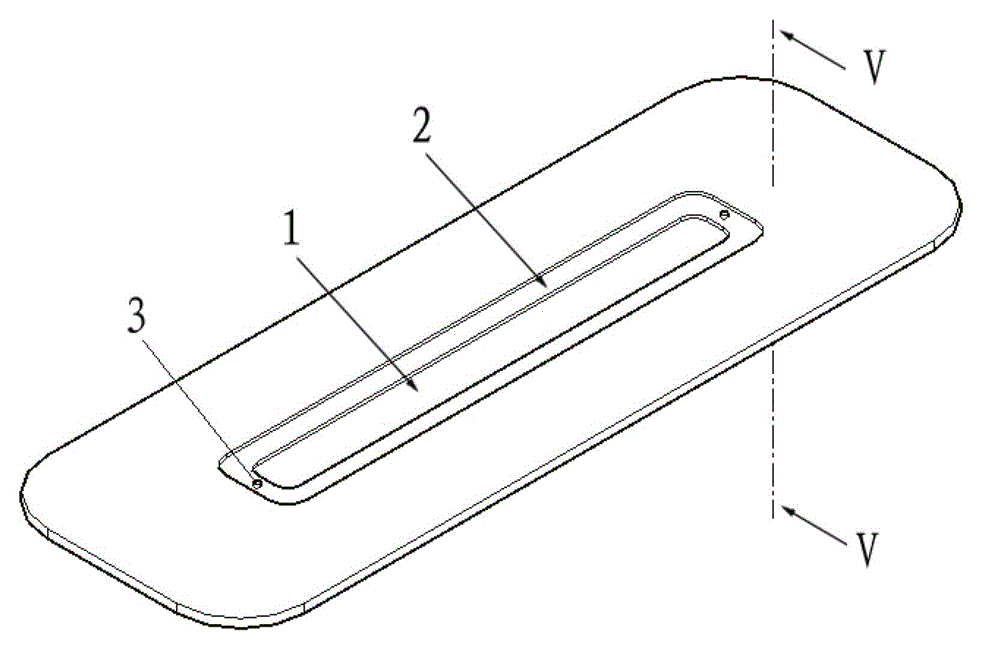

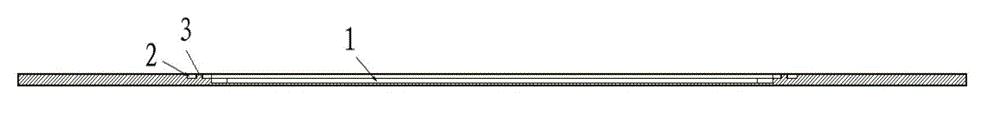

Electronic device and method for controlling power thereof

ActiveCN106997097AGuaranteed electricityCoupling contact membersPower supply for data processingControl powerEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

Cleaning agent used for solar grade silicon wafers and preparing method thereof

ActiveCN105039006ASimple recipeEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSurface-active agentsCleansing Agents

The invention discloses a cleaning agent used for solar grade silicon wafers and a preparing method thereof. One hundred parts of the cleaning agents comprise, by weight, 2 parts to 5 parts of inorganic base, 10 parts to 20 parts of surface active agents, 1 part to 5 parts of corrosion inhibitors, 1 part to 5 parts of complex agents, 0.1 part to 0.5 part of assistants and the balance water. The preparing method of the cleaning agent includes the following steps: the water and the surface active agents are firstly mixed, the inorganic base is slowly added in a multi-time and small-amount mode under the condition that stirring is carried out at the rotating speed of 300-500 turns per minute, stirring is continuously carried out for 10-20 minutes, the complex agents, the corrosion inhibitors and the assistants are finally added and stirred to be completely dissolved, and the cleaning agent is obtained. By means of the cleaning agent used for the solar grade silicon wafers, metal ions and various organic pollutants on the surfaces of the silicon wafers can be effectively removed, damage to the silicon wafers is small, the amount of cleaning foam is small, and the cleaning efficiency is high.

Owner:SHAANXI TECHN INST OF DEFENSE IND

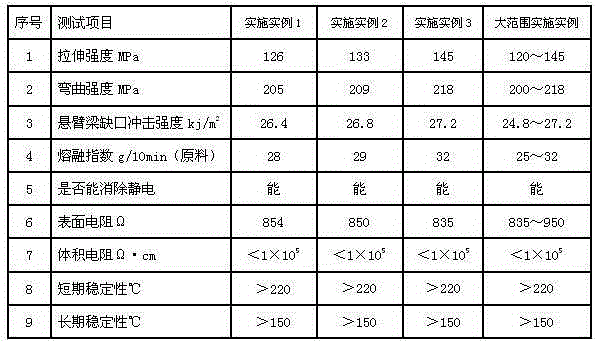

Semi-conductive nylon strap for cable shielding and preparation method thereof

The invention belongs to the technical field of materials and discloses a semi-conductive nylon strap for cable shielding. The semi-conductive nylon strap is prepared from the following raw materials in parts by weight: 40-80 parts of nylon 11 resin, 10-20 parts of nylon 1010 resin, 5-10 parts of nylon 6 resin, 10-20 parts of linear low density polyethylene, 8-16 parts of maleic anhydride grafted polyethylene, 0.6-0.8 part of a coupling agent, 18-25 parts of a filler, 0.4-0.6 parts of an antioxidant, 2-6 parts of a flame retardant, 10-15 parts of a conducting matter, 20-25 parts of reinforcing fibers and 10-18 parts of a surface modifier, wherein the ratio of the nylon 11 resin to the nylon 1010 resin to the nylon 6 resin to the linear low density polyethylene to the maleic anhydride grafted polyethylene is 8:2:1:2:1.6. The semi-conductive nylon strap disclosed by the invention has the beneficial technical effects of high tensile / bending / cantilever notch impact strength, small electric resistance, good high temperature stability, easy processing and the like, and is capable of eliminating static electricity.

Owner:青岛云塑高分子材料科技有限公司

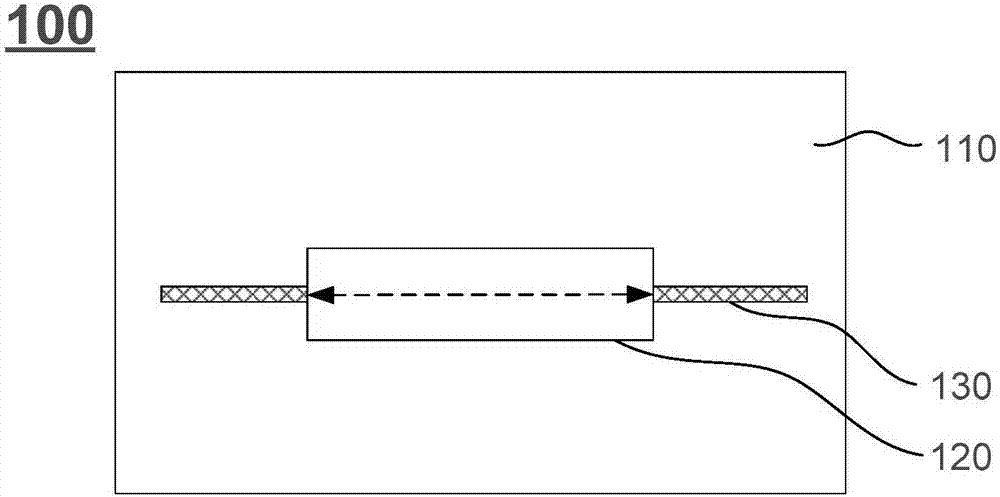

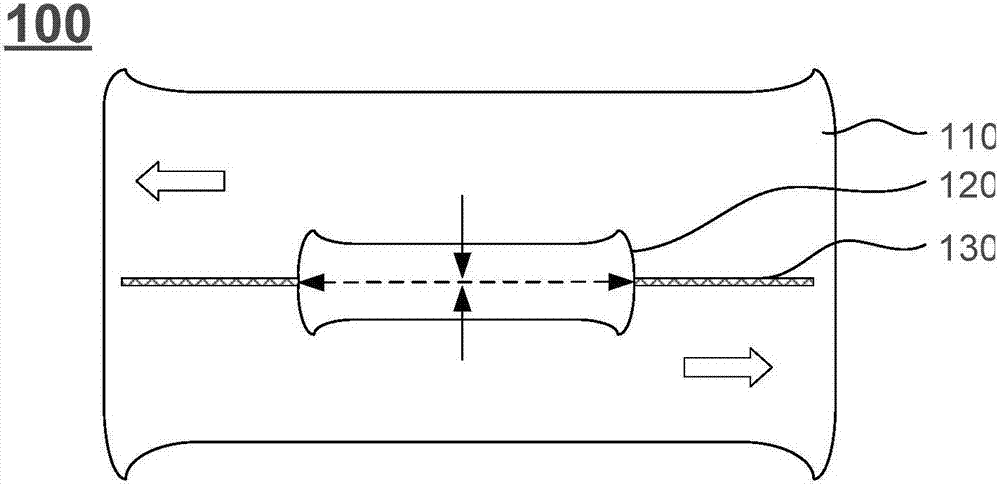

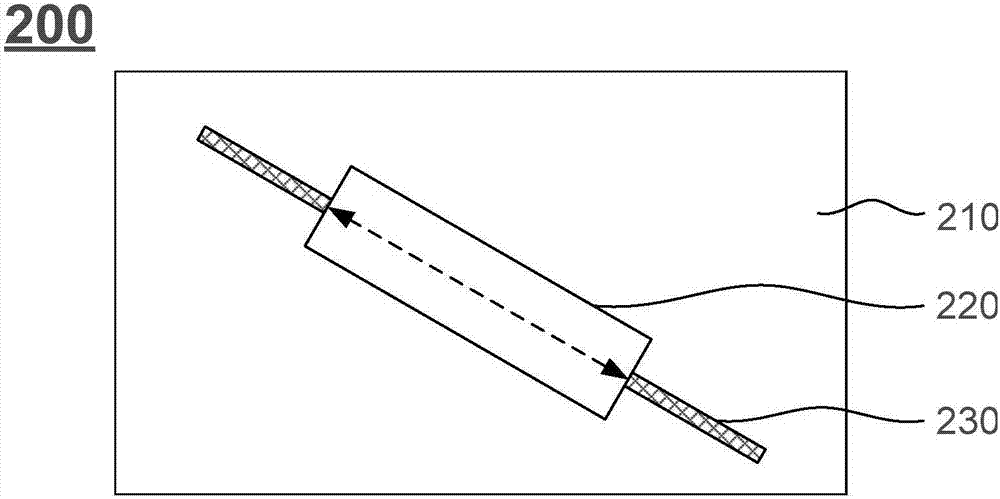

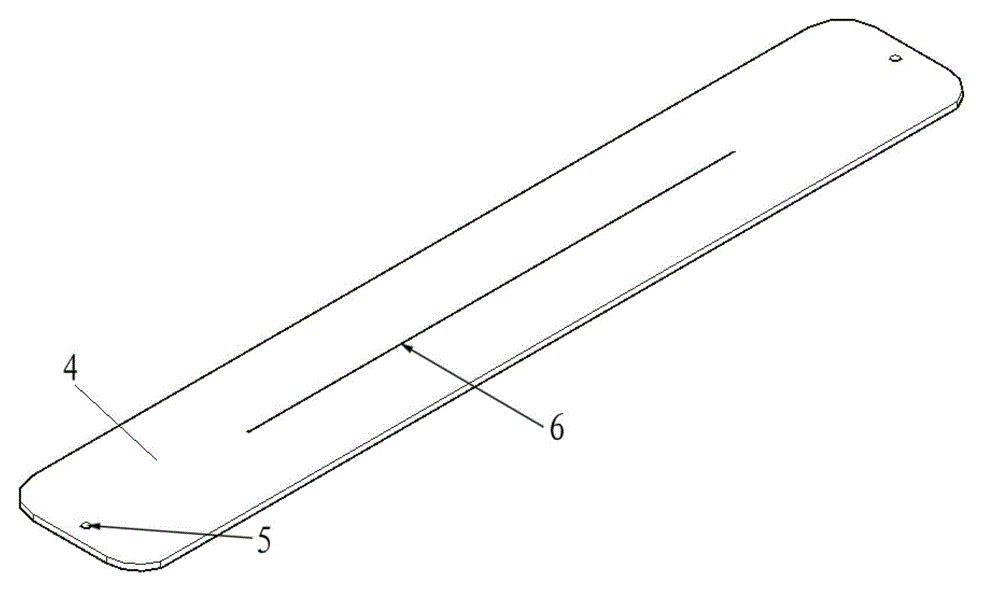

Flexible electronic device and manufacturing method therefor

ActiveCN107204342AGuaranteed electrical performanceGuaranteed rubbing resistanceFinal product manufactureDigital data processing detailsFlexible electronicsElectricity

The invention provides a flexible electronic device and a manufacturing method therefor. The electronic device comprises a flexible substrate and a device layer formed on the flexible substrate. The device comprises a semiconductor structure and a wire structure, which are connected with each other. The extending direction of the wire structure is consistent with the trench direction of the semiconductor structure. The extending direction of a first wire structure and the stretching direction of the flexible substrate form an inclined angle which is less than 90 degrees. According to the invention, the impact on the semiconductor structure and the first wire structure from stress is reduced to the minimum value through the adjustment of the trench direction of the semiconductor structure and the extending direction of the first wire structure, thereby guaranteeing the electrical performances and anti-kneading performances of the flexible electronic device.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

A method for prepare a low moisture ceramic separator for lithium battery, an aqueous slurry, and a ceramic separator

ActiveCN109167008AGuaranteed electricityEnsure safetySecondary cellsCell component detailsMetallurgySlurry

The invention belongs to the technical field of preparation of a lithium battery separator, in particular to a preparation method of a low-moisture ceramic separator for lithium battery, an aqueous slurry and a low-moisture ceramic separator. The preparation method of the low-moisture ceramic separator for the lithium battery comprises the following steps: step S1, preparing an organic modified ceramic powder; 2, prepare an aqueous slurry from that organic modified ceramic powder; And step S3, coating an aqueous slurry on the surface of the lithium ion battery separator and baking to remove water to form a ceramic separator so as to reduce the water absorption of the ceramic separator.

Owner:JIANGSU ANREDA NEW MATERIAL

High-efficiency energy-saving environmental-protection fireproof flexible soft cable used for intelligent electric network

InactiveCN101794643ASmall bending radiusEasy to moveRubber insulatorsBraided wire conductorsPower cableCopper wire

The invention provides a high-efficiency energy-saving environmental-protection fireproof flexible soft cable used for an intelligent electric network, relates to the field of the manufacture of cables and comprises an insulated cable core, wherein the insulated cable core comprises a power cable core, a control cable core and a signal shielding cable core. A high-flame-retardant glass fibre belt wrapping layer, a copper belt wrapping and shielding layer, a double-layer copper wire weaving and shielding layer, a shielding and wrapping layer and a ceramic fireproof silicon rubber sheath layer are sequentially arranged outside the insulated cable core from inside to outside, a filling material is arranged in a clearance between the insulated cable core and the high-flame-retardant glass fibre belt wrapping layer, and a heterogenic halogen-free filling framework is arranged between a power cable and a control cable; and by the arrangement, the cable can have the capability of resisting strong electromagnetic interference and strong static interference and also has stronger capabilities of high-temperature resistance and fire prevention.

Owner:YANGZHOU YAGUANG CABLE

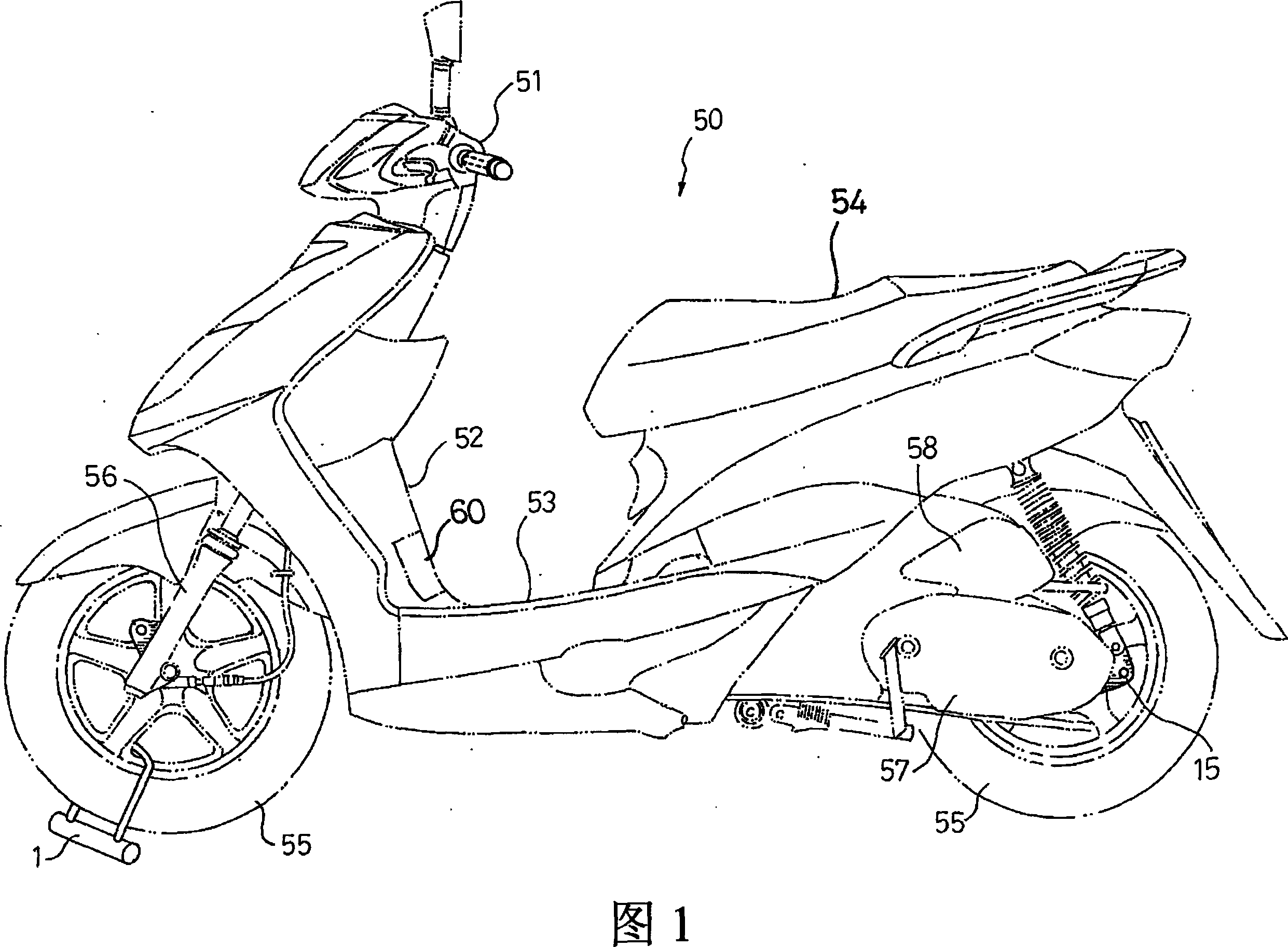

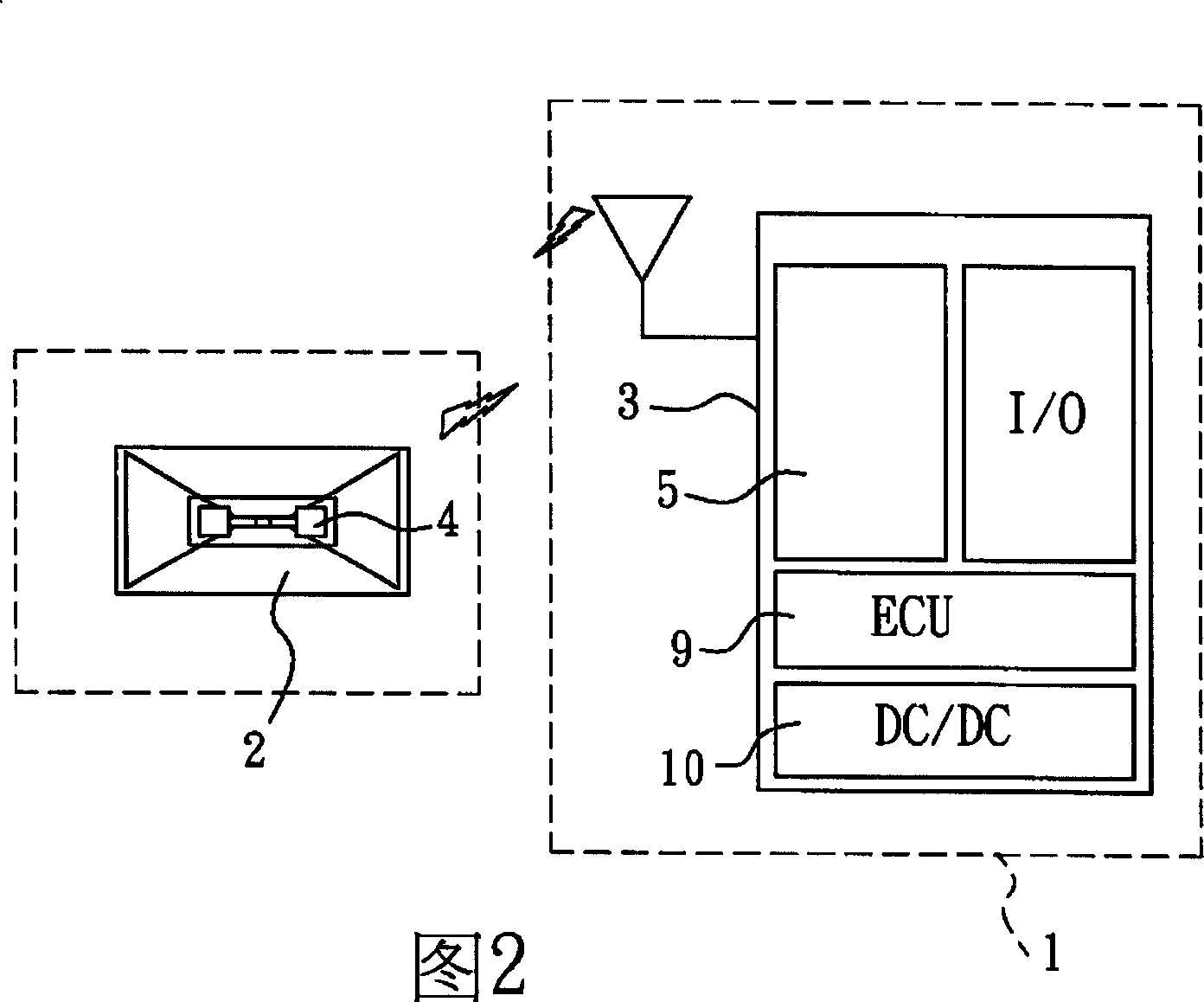

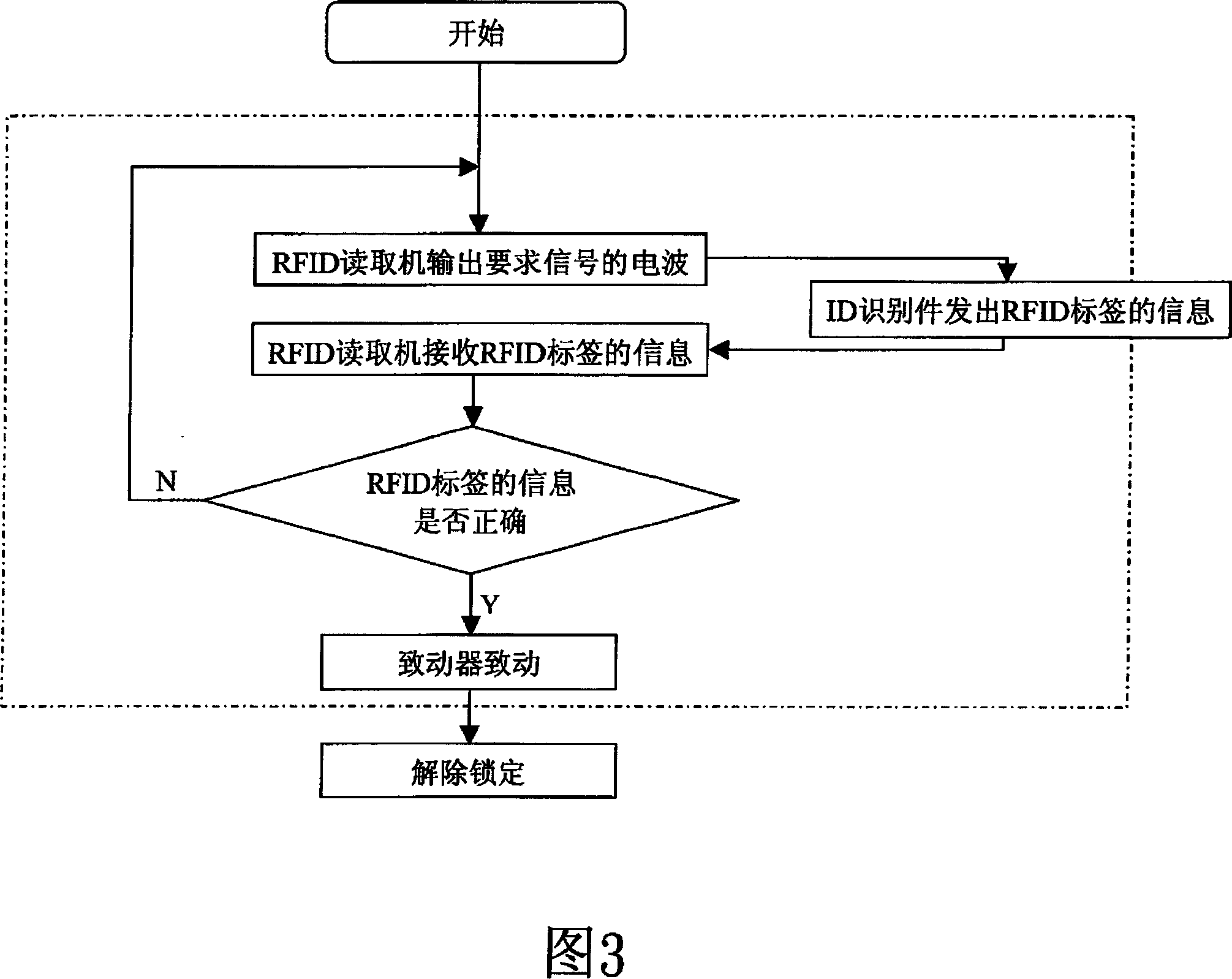

Induction type locomotive lock

InactiveCN101145249AEasy to useReduce power consumptionElectric permutation locksSensing record carriersRadio frequencyEngineering

The invention aims at providing an inductive locomotive locker can be unlocked with a RFID (wireless radio frequency identification) system rather than by rotating a key inserted into the key hole. The inductive locomotive locker of the invention comprises an ID identifying part which comprises a RFID tag; a catcher; and a locker body which comprises a RFID reader able for reading the information coming from the RFID tag, a locking member able for locking the catcher, an actuator able to actuate the locking component, a central micro-processor and a power supply part, wherein the central micro-processor controls the actuator to free the lock of the locking component to the catcher according to the information from the RFID tag read by the RFID reader.

Owner:YAMAHA MOTOR CO LTD

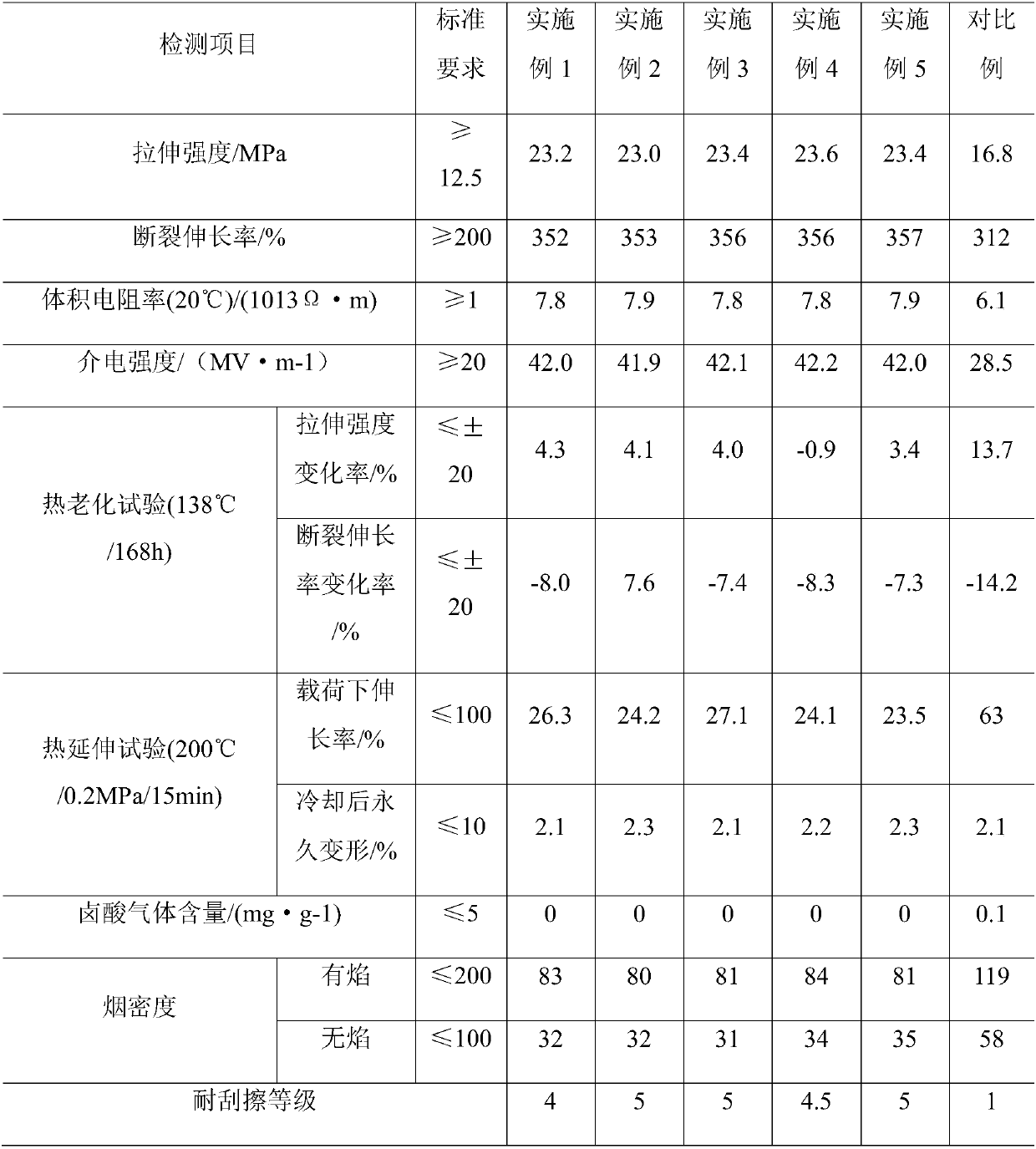

Environment-friendly cable insulation layer, and preparation method thereof

InactiveCN107722439AHas flame retardant propertiesImprove scratch resistancePlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethylenePolyolefin

The invention discloses an environment-friendly cable insulation layer, and belongs to the field of wire cable. The environment-friendly cable insulation layer comprises an internal insulation layer and an external insulation layer; a double layer co-extrusion insulation layer is composed of the internal insulation layer and the external insulation layer; the internal insulation layer is preparedfrom an irradiation crosslinked polyethylene insulation material; the external insulation layer is prepared from a low-smoke halogen-free flame-resistant irradiation crosslinked polyolefin insulationlayer; the external insulation layer comprises, by weight, 43 to 65 parts of an ethylene-vinyl acetate copolymer, 40 to 60 parts of linear low density polyethylene, 35 to 47 parts of ethylene propylene diene monomer, 54 to 75 parts of a scratch-resistant agent, 25 to 30 parts of a sensitizing agent, 48 to 60 parts of a silicon nitrogen flame retardant, 25 to 35 parts of a composite anti-aging agent, 12 to 20 parts of a reinforcing filler, and 25 to 35 parts of a composite compatilizer. The environment-friendly cable insulation layer, is friendly to the environment, and is capable of improvingthe scratch resistance of cables greatly.

Owner:南京创贝高速传动机械有限公司

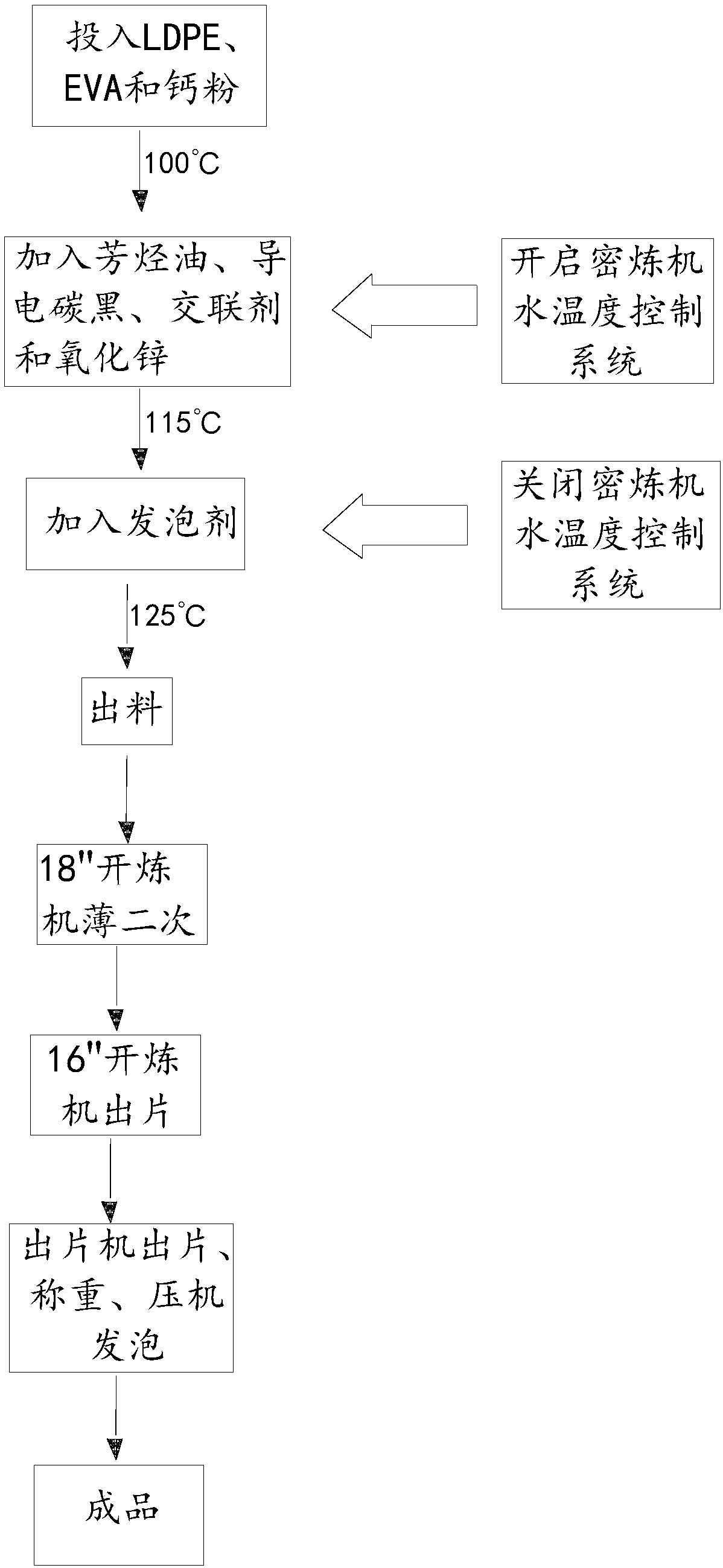

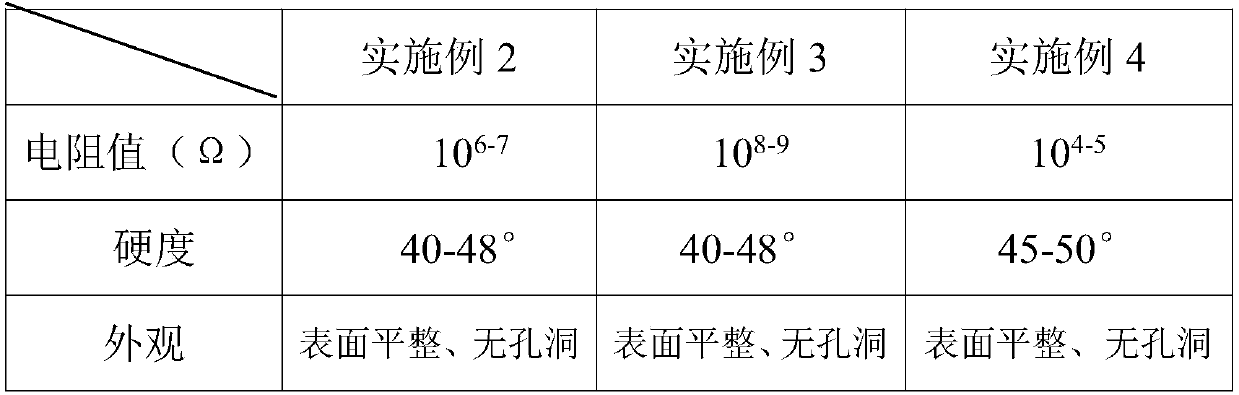

Preparation method for permanently antistatic and conductive EVA

The invention provides a preparation method for permanently antistatic and conductive EVA. The preparation method comprises the following concrete steps: (1) adding LDPE, EVA and calcium powder into an internal mixer, then carrying out stirring, carrying out heating to 95 to 105 DEG C, and opening a water temperature control system of the internal mixer; (2) maintaining a temperature in a range of95 to 105 DEG C, adding conductive carbon black, aromatic oil, a cross-linking agent and zinc oxide into the internal mixer, continuing stirring, and heating the internal mixer to 110 to 120 DEG C; (3) maintaining the temperature in a range of 110 to 120 DEG C, adding a foaming agent into the internal mixer, closing the water temperature control system of the internal mixer, continuing stirring,and carrying out heating to 125 DEG C; and (4) discharging a material, placing the material into an open mill with a size of 18'', allowing the material to pass through rollers two times, allowing anobtained material to enter an open mill with a size of 16'' so as to obtain sheets, and carrying out foaming through a pressing machine so as to obtain a finished product. The product prepared by using the preparation method provided by the invention is permanently antistatic and permanently conductive, and has the advantages of good surface controllability, smooth surface and no pores at the sametime.

Owner:广州市欧橡隔热材料有限公司

Manufacturing method of ultra-thin printed circuit board and ultra-thin printed circuit board

The invention discloses a manufacturing method of an ultra-thin printed circuit board. According to the manufacturing method of the ultra-thin printed circuit board disclosed by the invention, conductive circuits are electroplated and bonding sheets and copper foils are laminated on a support plate provided with metal layers and first copper foils to achieve layer addition; and the copper foils and the bonding sheets, which are relatively small in electroplating thickness and relatively small in lamination thickness are carried through the support plate, so that the whole hardness of an electroplating layer (namely a first conductive circuit layer) and a lamination layer (namely second copper foils, third copper foils and fourth copper foils) is improved; the limitation of equipment on the thickness of the board in production is effectively avoided; the board blocking phenomenon of the relatively thin electroplating layer and the relatively thin lamination layer in the horizontal equipment treatment process is avoided; deformation (for example, warping, bending, tiny wrinkles and the like) of the electroplating layer and the lamination layer is avoided; and the problems that the printed circuit board is scrapped and is low in yield due to the deformation are further solved.

Owner:SHANGHAI MEADVILLE ELECTRONICS +1

Ceramic fireproof fire-resistant silicon rubber wire and cable

InactiveCN103489510ASo as not to damageGuarantee unimpededInsulated cablesInsulated conductorsElectrical conductorFire - disasters

The invention relates to a ceramic fireproof fire-resistant silicon rubber wire and cable. The wire and cable comprise a plurality of conductors, each conductor is wrapped by a ceramic silicon rubber insulating layer in an extruding mode to form a wire core, multiple wire cores are wrapped by a wrapping tape layer to form a cable core, padding is arranged in the cable core, and a ceramic silicon rubber outer sheath is arranged outside the cable core. The ceramic fireproof fire-resistant silicon rubber wire and cable have characteristics batter than those of a common rubber cable and a flame retardant rubber cable and form a hard shell after being ablated by high-temperature flames to protect a burned article from being damaged, and the hard shell formed after ablation protects the wire and cable, so that unblocked electric power and communication are ensured, and precious time are won for personnel evacuation and rescue under the fire disaster condition.

Owner:江苏金枫达科技有限公司

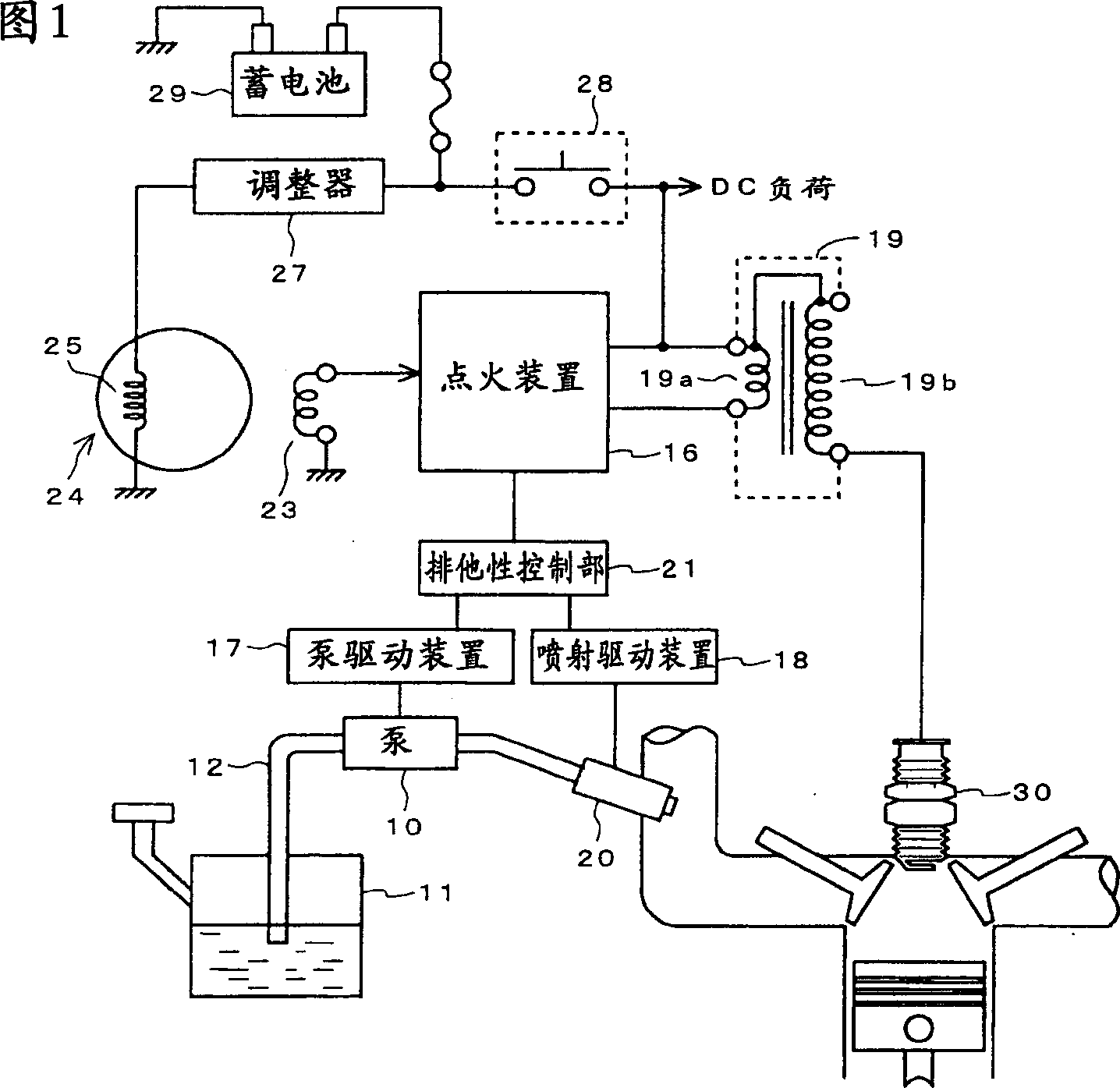

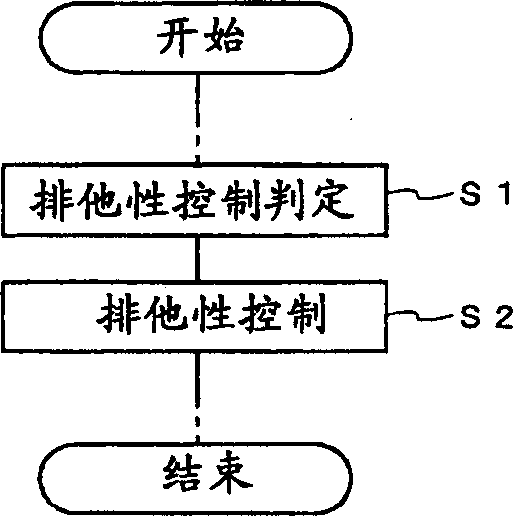

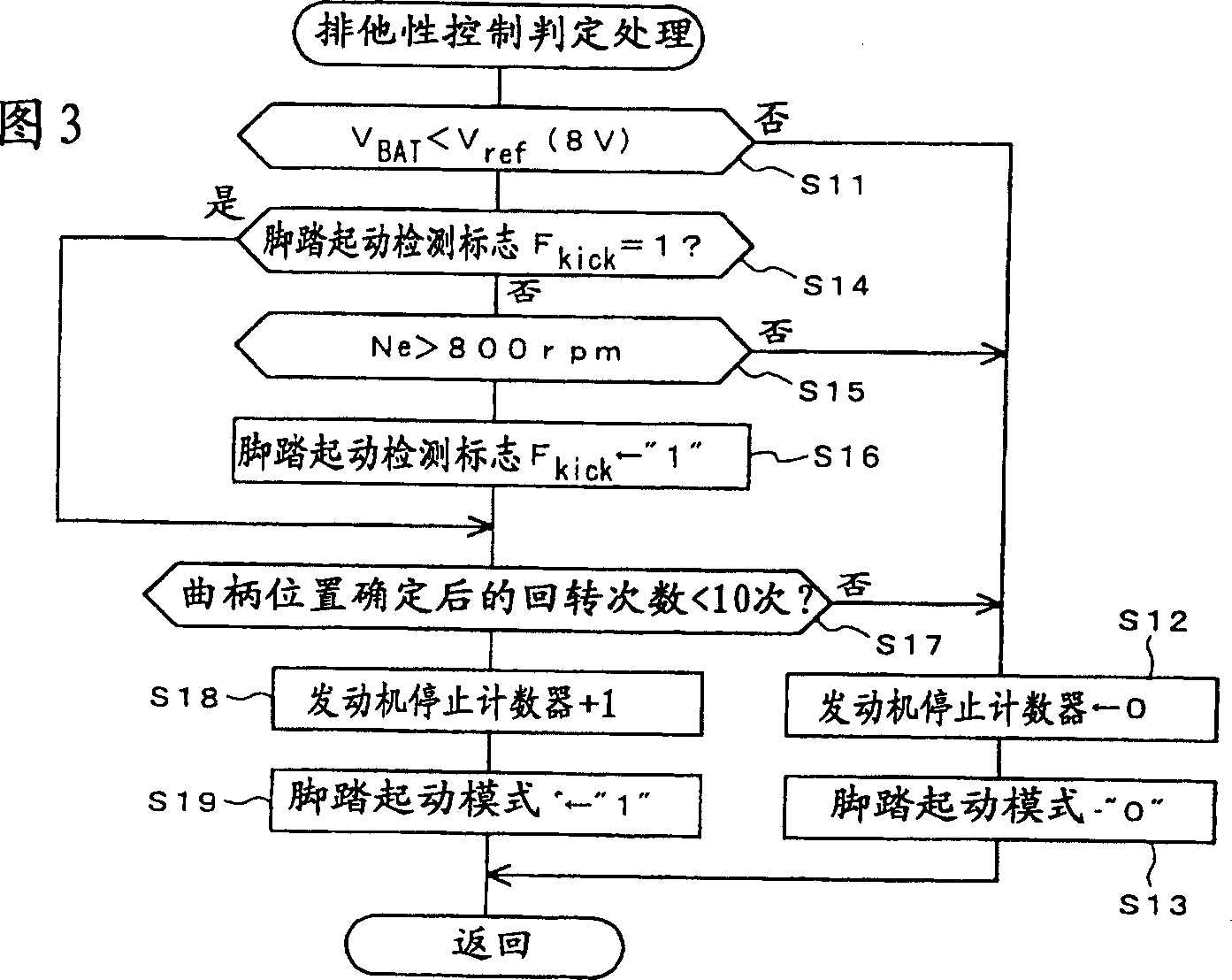

Start controller for engine

InactiveCN1333423AImprove starting performanceGuaranteed electricityElectrical controlInternal combustion piston enginesPower flowEngineering

A starting control device of engine capable is provided. An exclusive control part 21 controls an energization to each system such that at least one of a pump system including a fuel pump 10, an injection system including an injector 20 and an ignition system including an ignition unit 16 is timely divided or is exclusively driven regarding at least one of another system.In this way, by ensuring a current fed to respective devices by exclusively driving a device unnecessary for being always simultaneously driven at the time of starting the engine, can further improve a starting property of the engine.

Owner:HONDA MOTOR CO LTD

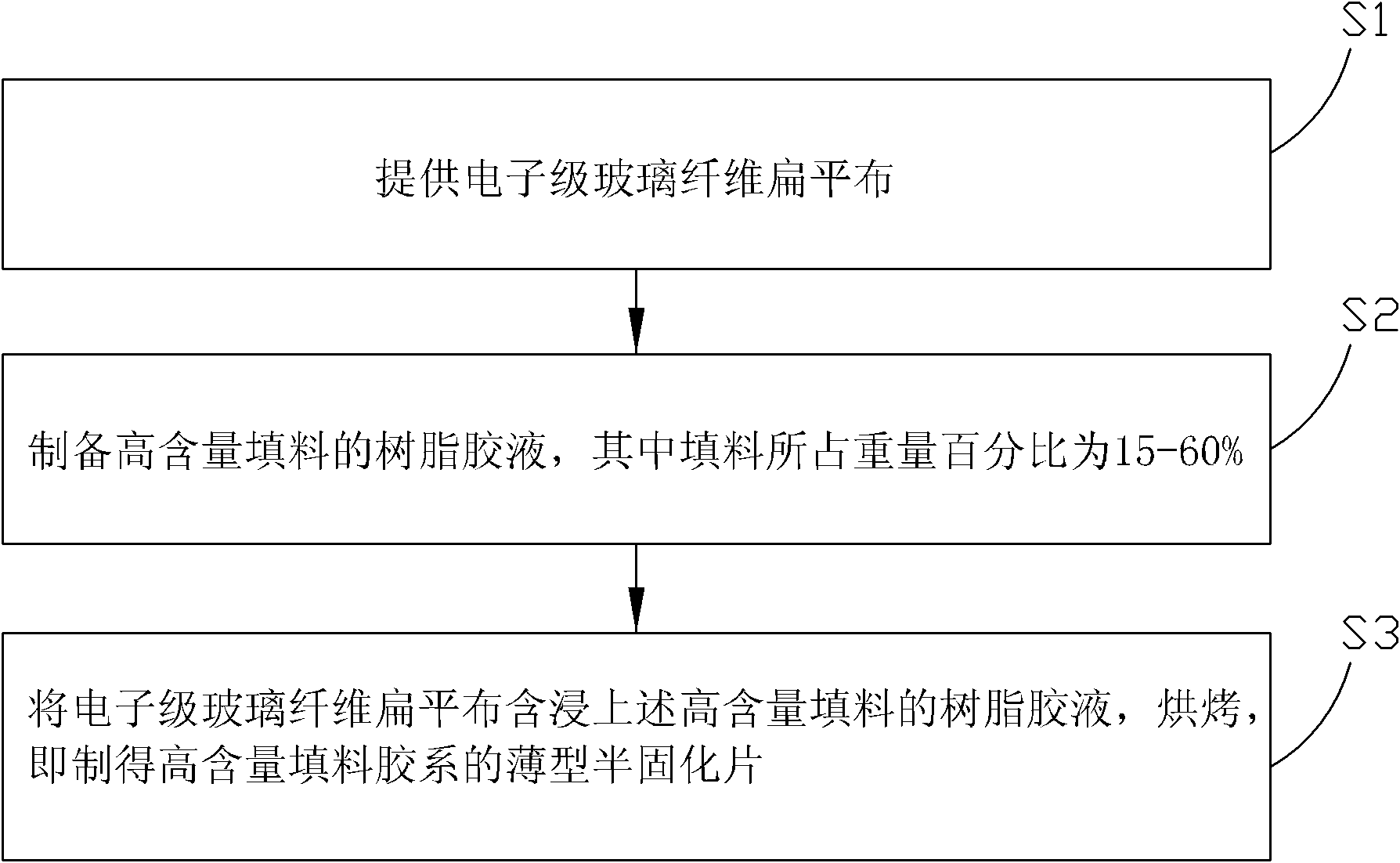

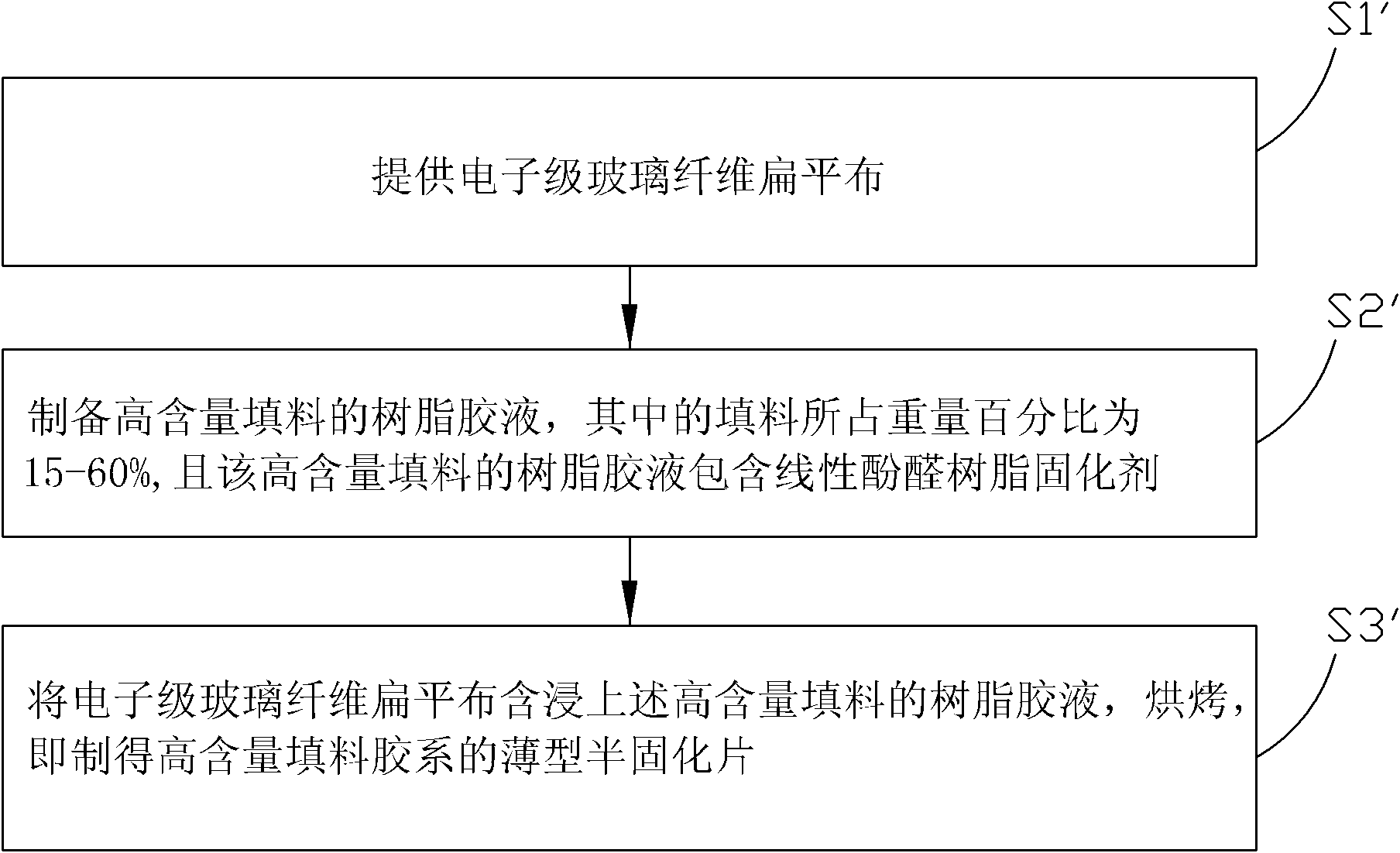

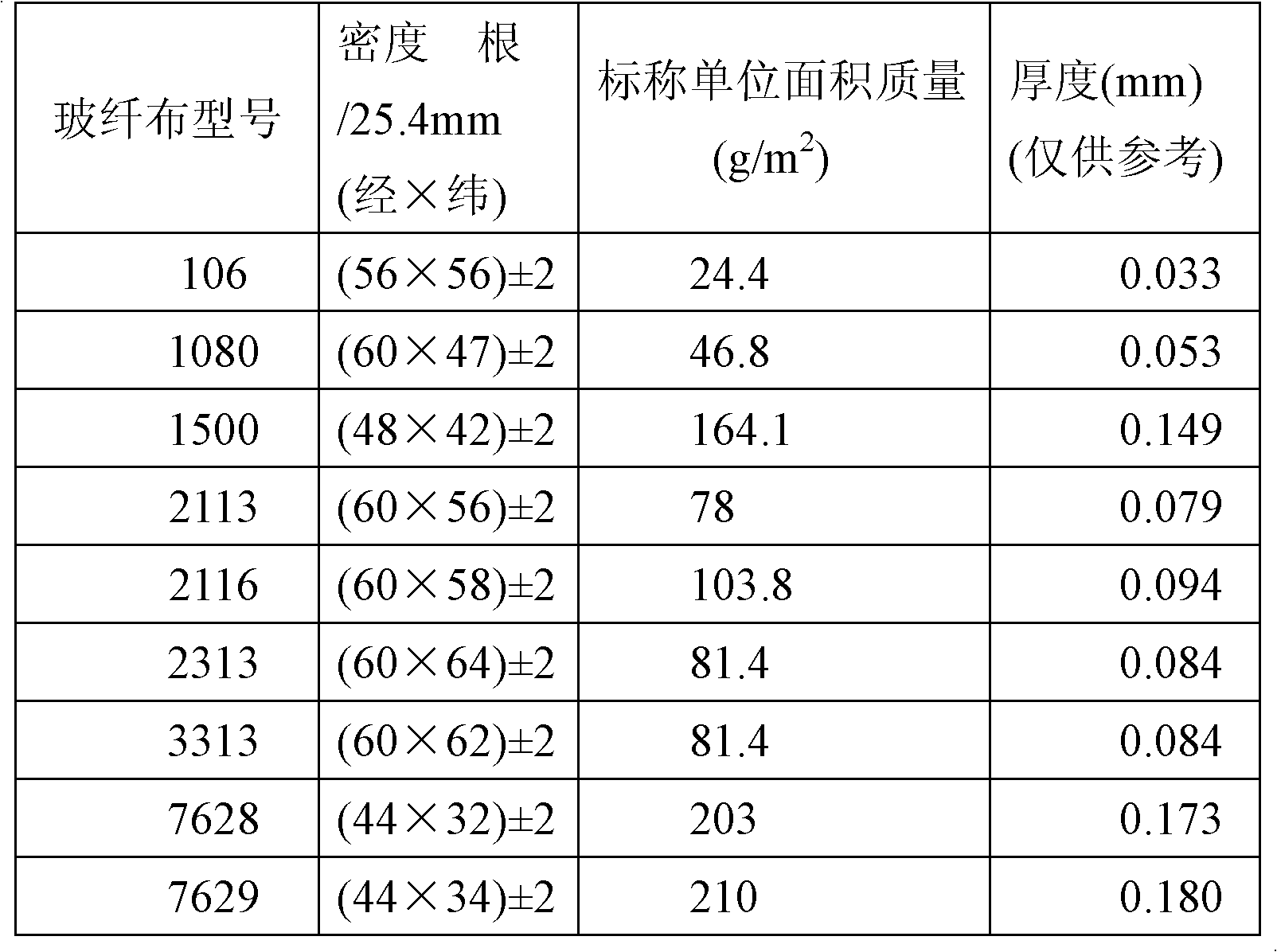

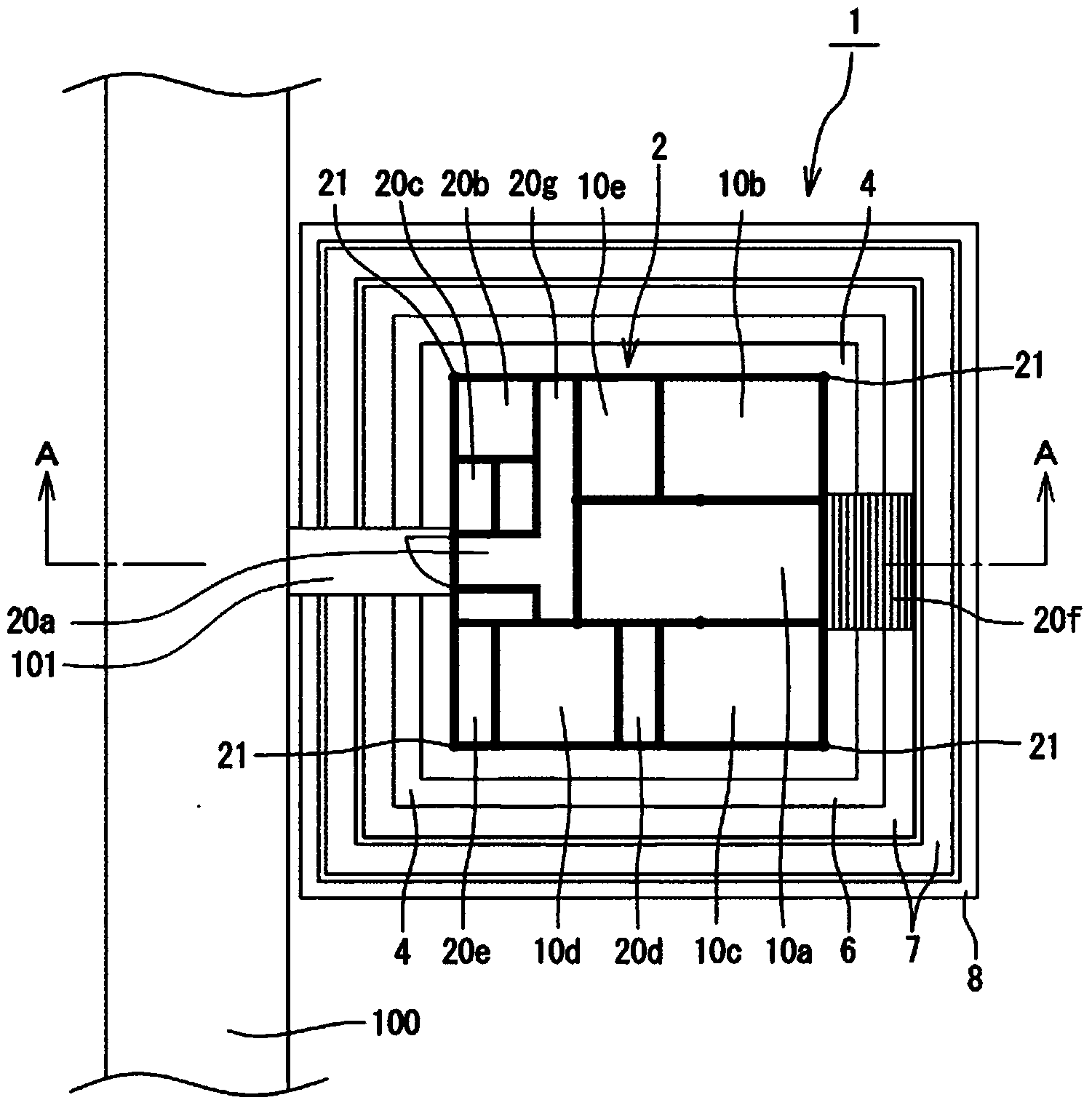

Production method of thin prepreg with high-content filler adhesive system

ActiveCN102031008AAddresses apparent pinhole defectsGuaranteed electricityCircuit susbtrate materialsMetal layered productsGlass fiberElectricity

The invention relates to a production method of thin prepreg with a high-content filler adhesive system, comprising the following steps: step 1, providing an electronic-grade fiberglass flat cloth, wherein the nominal mass per unit of the electronic-grade fiberglass flat cloth is 15-50g / m<2>, and the weft clearance area is 0-0.01mm<2>; step 2, preparing a resin adhesive solution containing a high-content filler, wherein the filler accounts for 15-60% by weight; and step 3, impregnating the electronic-grade fiberglass flat cloth in the resin adhesive solution containing a high-content filler, and baking to obtain the thin prepreg with a high-content filler adhesive system. The production method of the thin prepreg with a high-content filler adhesive system provided by the invention effectively solves the apparent pinhole defect of the thin prepreg, improves the percent of pass, and ensures the electrical property and reliability of a copper-clad plate made from the thin prepreg, thereby ensuring the electrical insulation property of a printed circuit board (PCB) and improving the quality of products.

Owner:GUANGDONG SHENGYI SCI TECH

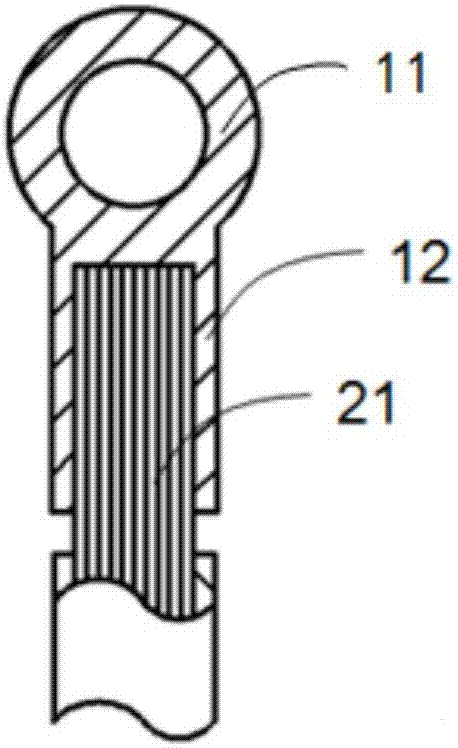

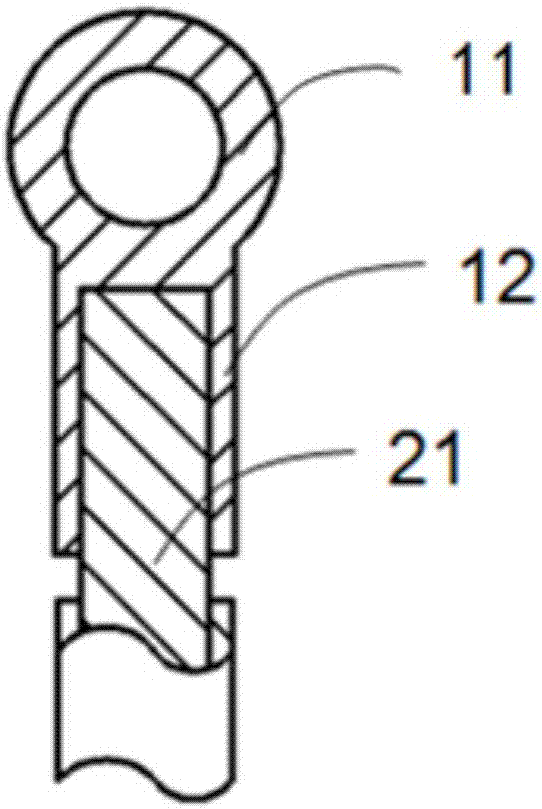

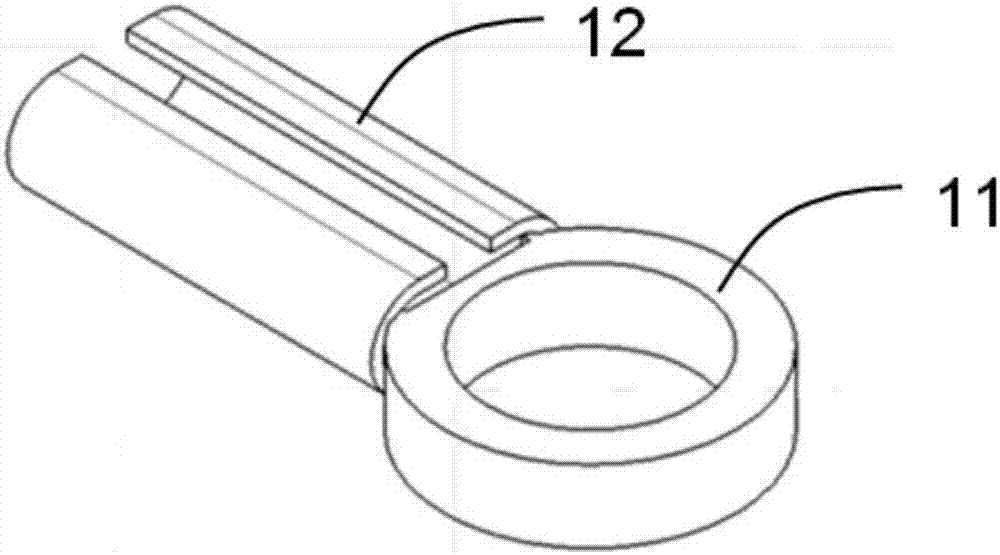

Copper terminal and aluminum wire joint and magnetic induction welding method thereof

ActiveCN107123867AGood welding effectAvoid harmElectric connection structural associationsSoldered/welded connectionsElectrical performanceCopper

The invention discloses a copper terminal and aluminum wire joint and a magnetic induction welding method thereof. The copper terminal of the joint is divided into a connector and a functional part connected with the connector. The aluminum guide core of the aluminum wire is connected with the connector of the copper terminal. The aluminum guide core extends or does not extend to the functional part. The magnetic induction welding method comprises the steps that S1 the aluminum guide core after insulating layer stripping and the connector of the copper terminal are assembled; and S2 the welding end of the aluminum wire and the connector of the copper terminal are welded together through magnetic induction welding. According to the technical scheme, copper and aluminum are welded; the electrical performance and the mechanical performance are better; terminals of terminal connectors of different shapes are connected with the aluminum wire; and the preparation efficiency and quality are improved.

Owner:JILIN ZHONG YING HIGH TECH CO LTD

Inner electrode of glass-ceramic stacked capacitor and preparation method of the inner electrode

InactiveCN102568818AGuaranteed electricityLower sintering temperatureFixed capacitor electrodesFixed capacitor dielectricSilver pasteGlass-ceramic

The invention discloses an inner electrode of a glass-ceramic stacked capacitor and a preparation method of the inner electrode in the technical field of functional materials. The inner electrode structurally comprises glass-ceramic dielectric layers and silver paste electrode layers which are stacked, wherein an inner electrode transition layer is arranged between one glass-ceramic dielectric layer and one silver paste electrode layer which are adjacent to each other. The preparation process of the inner electrode comprises the steps of: firstly plating a metal film on each of the two surfaces of each glass-ceramic dielectric single sheet to serve as the inner electrode transition layer; and then coating a low-temperature silver paste electrode on the surface of each of the plated metal film layers, stacking multiple layers and later, conducting sintering. According to the invention, the structure and the preparation method of the inner electrode which is used for the glass-ceramic stacked capacitor and can be sintered at low temperature are found out, so that the sintering temperature is lowered by over 300 DEG C, the self-owned electrical property of a glass-ceramic dielectric material is maintained, the dielectric constant is kept at 176 approximately and the direct-current breakdown field strength is increased to about 33kV / mm. The preparation method is very suitable for preparing the high-voltage-resistant inner electrode of the glass-ceramic stacked capacitor.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

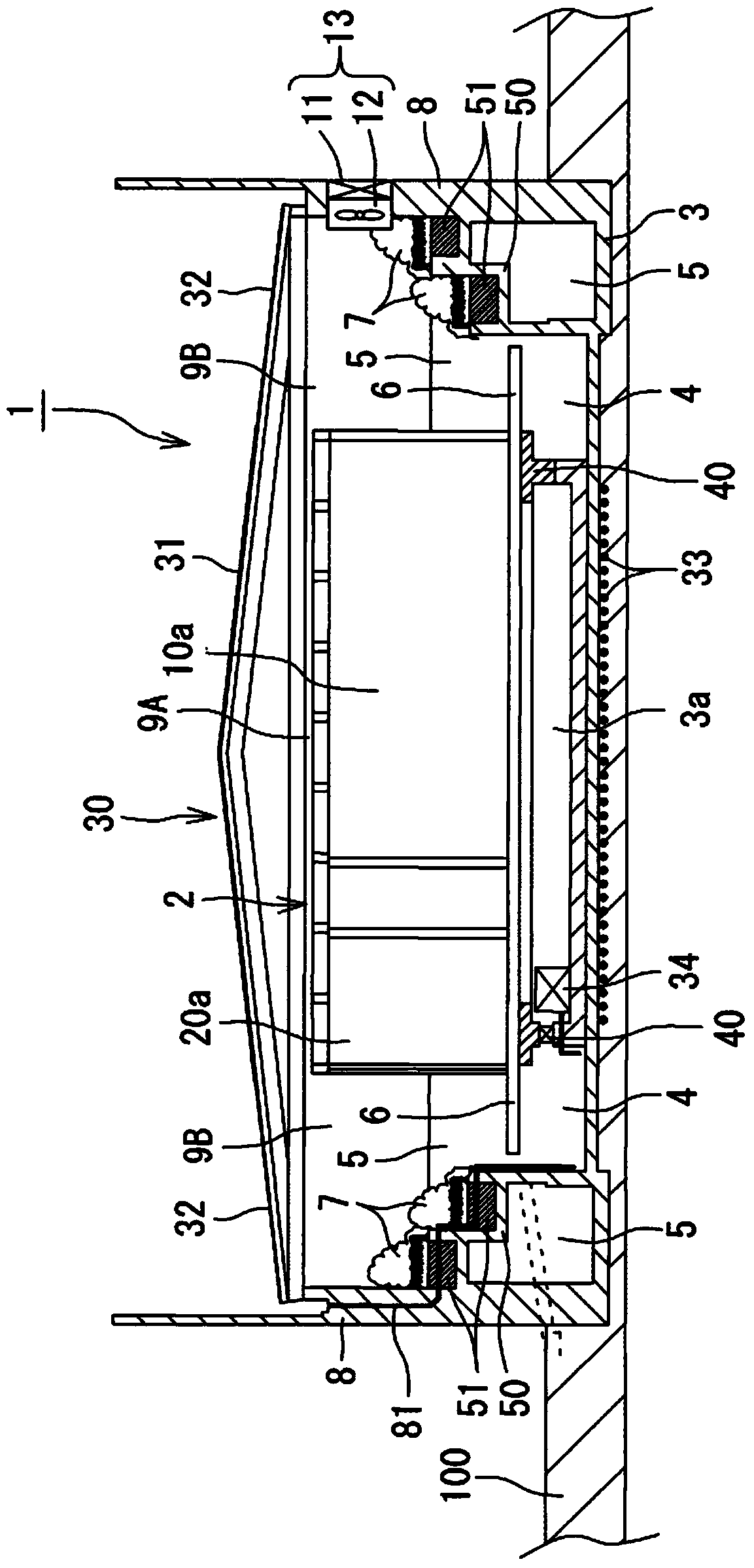

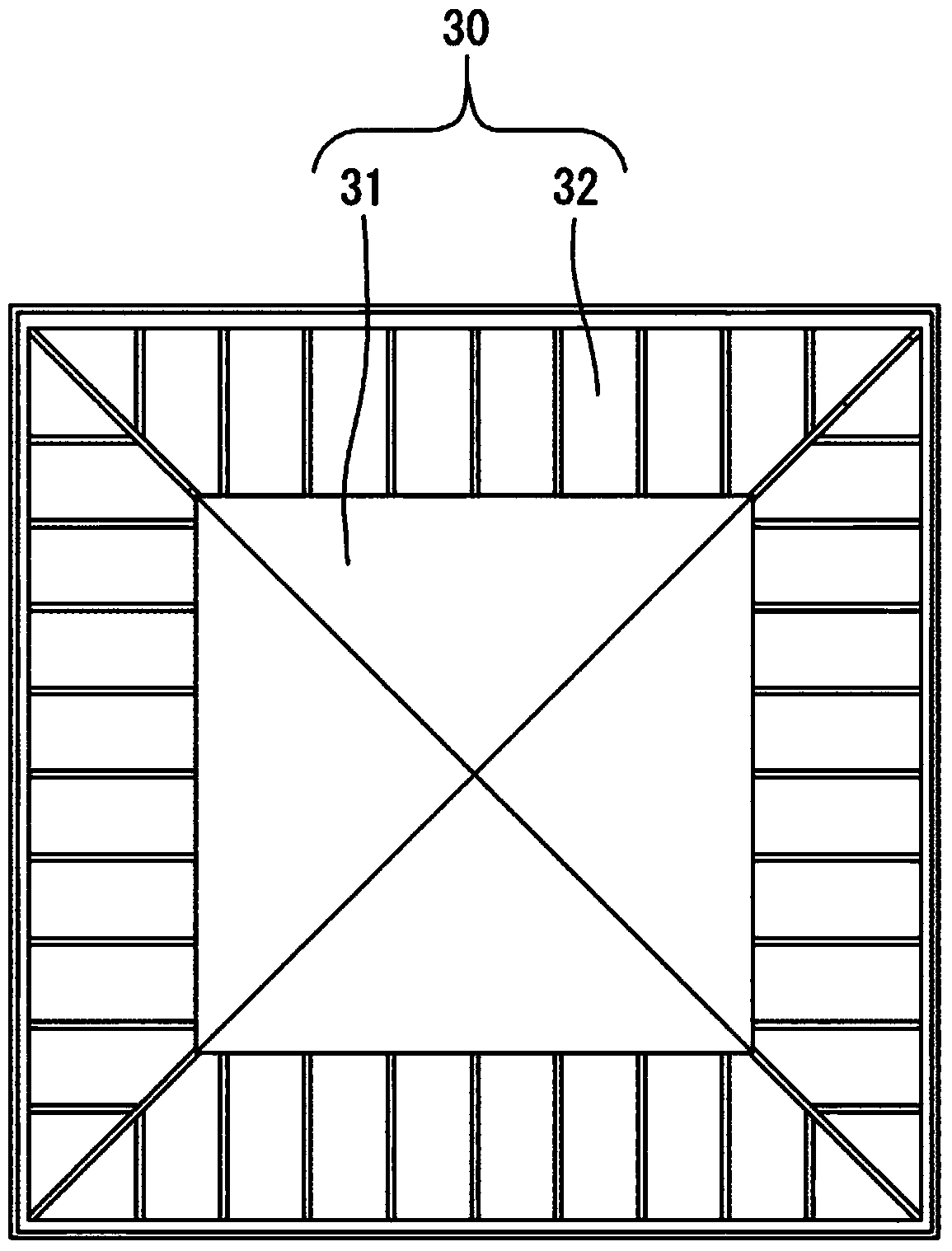

Architectural structure

ActiveCN103842598AEnsure safetyUnaffected by crosswindsMechanical apparatusLighting and heating apparatusInterior spaceWalling

Provided is an architectural structure which has improved safety, comfortableness, and economic efficiency by achieving an enclosed structure and isolation from the outside. An architectural structure is characterized by being provided with: a foundation (3); a wall (8) which is erected around the foundation (3) so as to be integrated with the foundation (3); a house part (2) which is disposed in the middle of the foundation (3) and serves as an indoor space; a roof (30) which covers an interior space surrounded by the wall (8), the roof (30) being supported by the wall (8) and not structurally connected to the house part (2), and a seismic isolation mechanism (40) which suppresses vibrations of the house part (2) during an earthquake, and characterized by making it possible to make the interior thereof an enclosed space by the foundation (3), the wall (8), and the roof (30).

Owner:室井纮

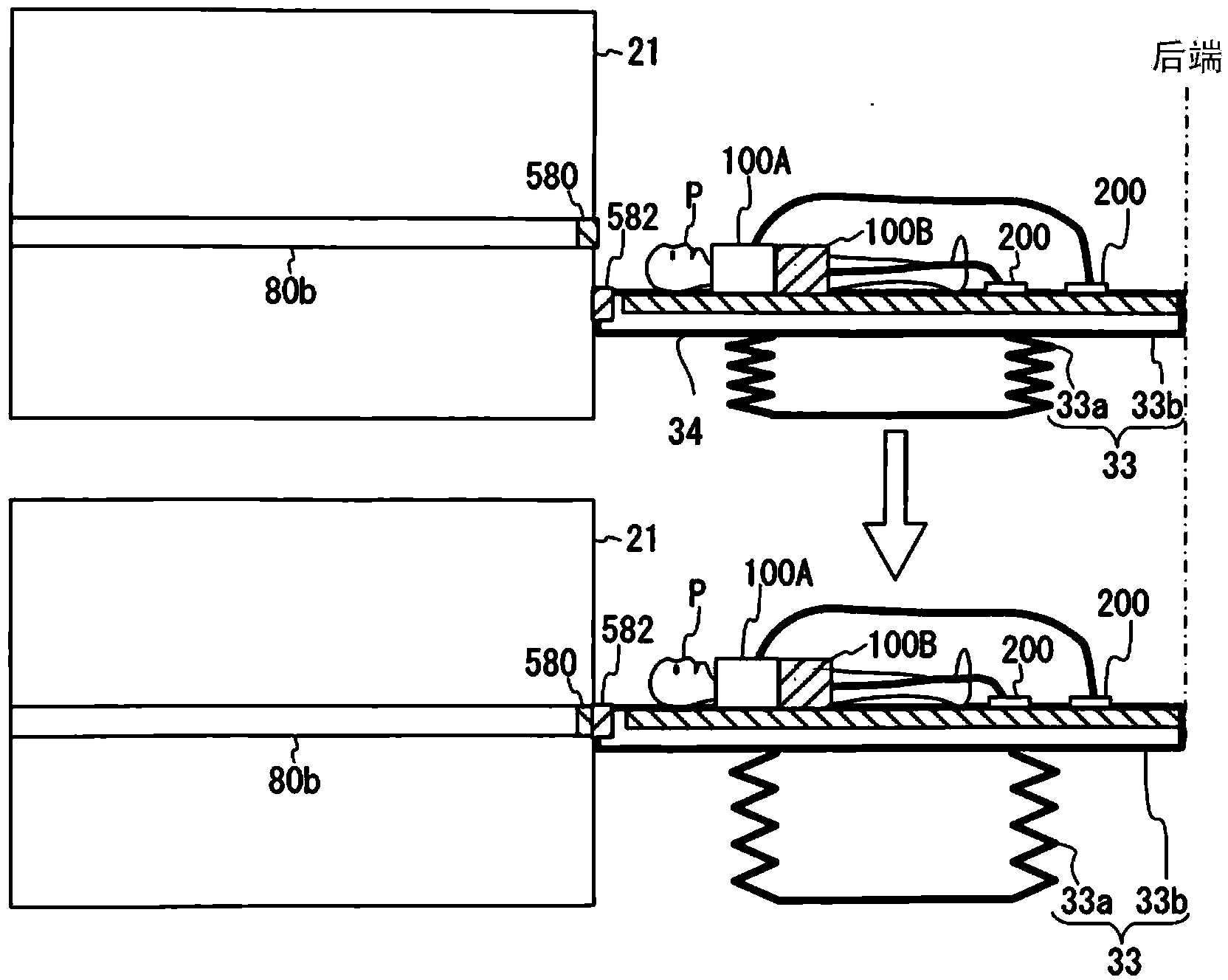

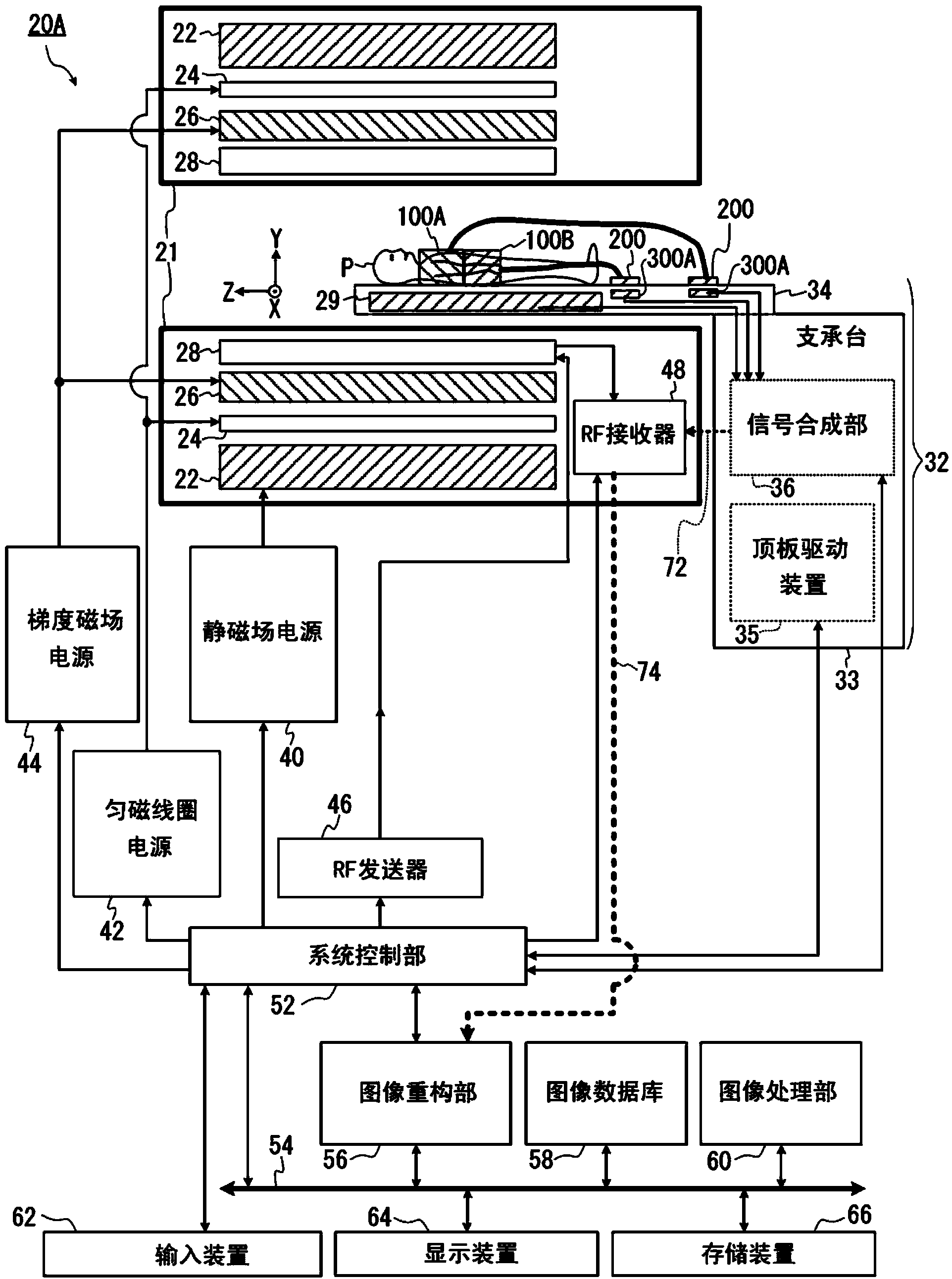

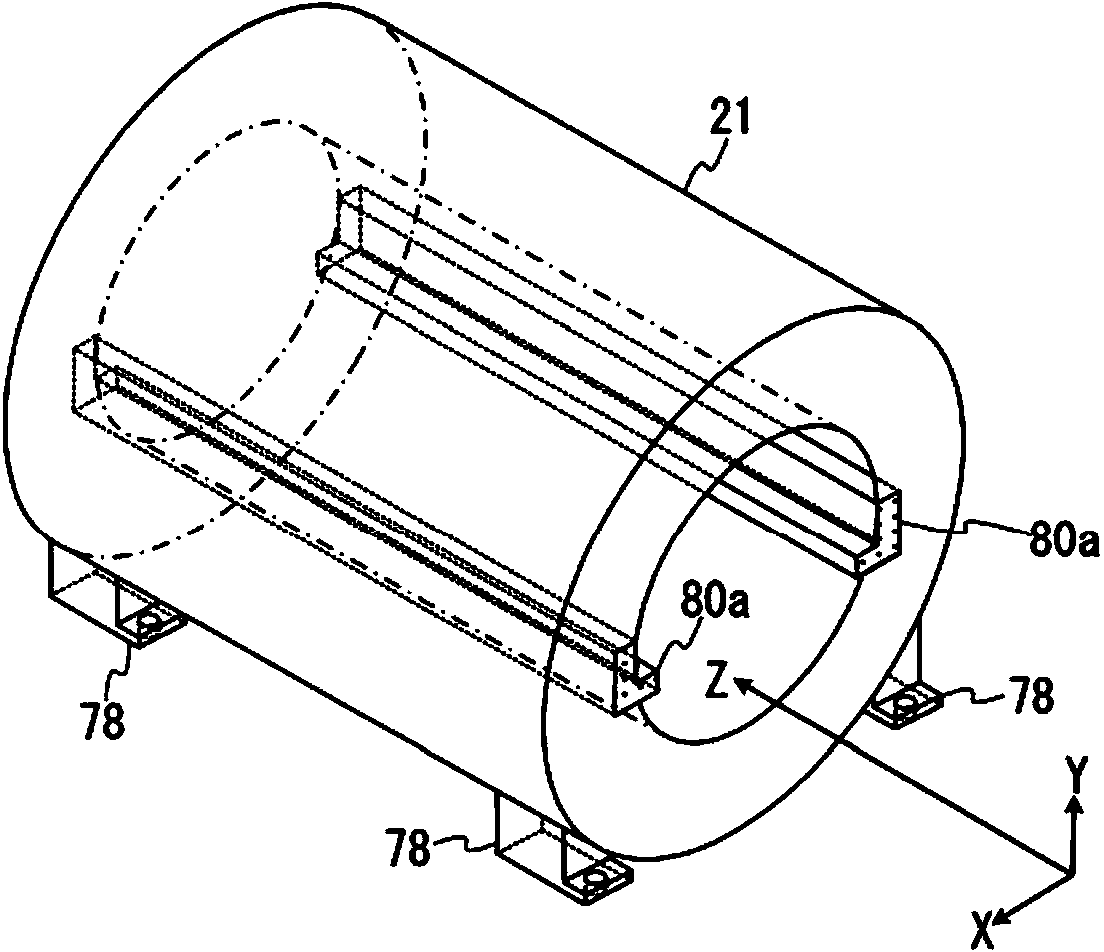

Magnetic resonance imaging apparatus and bed device

ActiveCN103857333AGuaranteed electricityDiagnostic recording/measuringSensorsCommunication unitResonance

Owner:TOSHIBA MEDICAL SYST CORP

Methods for vacuum brazing, assembling and locating radio fuse antenna radiator

ActiveCN102717167AGuarantee welding qualityGuaranteed electrical performance and electrical parametersSoldering auxillary devicesSolderingElectricity

The invention discloses methods for vacuum brazing, assembling and locating a radio fuse antenna radiator, which comprise the following steps that (1) a locating pin is utilized to preliminarily locate; and (2) at the welding line of a cover plate and a cavity body, burrs are generated through the nailing of a burr positioning tool, so precision locating is carried out. The method for locating is utilized, a soldering flake can be well enabled not to dislocate during the assembling process, the seam in the cover plate is enabled not to deviate, and the molten soldering flux is enabled to uniformly and fully filled, and does not flow into the cavity. The cavity and the cover plate can be tightly, uniformly and smoothly fit with each other, accordingly, the welding strength, air tightness and surface appearance quality are well ensured, the electrical property is enabled to be qualified, and finally, the welding quality can be enabled to satisfy the requirements of technical conditions. The methods for assembling and locating are utilized, the consumption of manpower and material resources is reduced, and the average assembling time for each set is 33 minutes, so the assembling efficiency is improved.

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com