Environment-friendly cable insulation layer, and preparation method thereof

A cable insulation and environment-friendly technology, which is applied in the direction of insulated conductors, insulated cables, organic insulators, etc., can solve the problems of poor scratch resistance, friction whitening, and influence on the appearance of wires, etc., and achieve good scratch resistance and scratch resistance Stable and reliable effect of improved performance, insulation performance and anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] 1. Preparation of inner insulating layer:

[0043] S1. Put the raw materials for preparing the inner insulating layer into a high-speed mixer according to the ratio, mix at a speed of 1400rpm for 5min, and then discharge at a speed of 600rpm;

[0044] S2. Put the raw materials mixed in step S1 into a twin-screw extruder to extrude and granulate. The speed of the extruder is 400r / min. The temperature is 150°C, and the head temperature is 125°C;

[0045] S3. The extruded material obtained in step S2 is irradiated and cross-linked by an electron accelerator to obtain an irradiated cross-linked polyethylene insulating material, and the irradiation dose is 16MRad;

[0046] Second, the preparation of the outer insulating layer:

[0047] (1) The EPDM rubber, scratch-resistant agent, sensitizer, silicon nitrogen flame retardant, compound anti-aging agent, reinforcing filler and compound compatibilizer used in the preparation of the inner insulating layer Mix in the mixer for...

Embodiment 1

[0057] An environment-friendly cable insulation layer, including an inner insulation layer and an outer insulation layer, the inner insulation layer and the outer insulation layer are double-layer co-extruded insulation layers, the inner insulation layer is made of irradiated cross-linked polyethylene insulation material, and the outer insulation layer It is made of low-smoke, halogen-free, flame-retardant radiation cross-linked polyolefin insulation material.

[0058] The outer insulation consists of the following components:

[0059] Ethylene-vinyl acetate copolymer 86kg

[0060] Linear Low Density Polyethylene 80kg

[0061] EPDM rubber 70kg

[0062] Pentaerythritol Stearate 36kg

[0063] Erucamide 14.4kg

[0064] Silicone masterbatch 21.6kg

[0065] Polyethylene wax 14.4kg

[0066] High molecular weight polysiloxane 21.6kg

[0067] Trimethylolpropane trimethacrylate 50kg

[0068] Silicon nitrogen flame retardant 96kg

[0069] Antioxidant PNX102 30kg

[0070] Antio...

Embodiment 2

[0083] An environment-friendly cable insulation layer, the difference between this embodiment and Embodiment 1 is:

[0084] The outer insulation consists of the following components:

[0085] Ethylene-vinyl acetate copolymer 97kg

[0086] Linear Low Density Polyethylene 90kg

[0087] EPDM rubber 76kg

[0088] Pentaerythritol Stearate 39.5kg

[0089] Erucamide 15.8kg

[0090] Silicone masterbatch 23.7kg

[0091] Polyethylene wax 15.8kg

[0092] High molecular weight polysiloxane 23.7kg

[0093] Trimethylolpropane trimethacrylate 52.5kg

[0094] Silicon nitrogen flame retardant 102kg

[0095] Antioxidant PNX102 33kg

[0096] Antioxidant 168 11kg

[0097] Antioxidant PS800 11kg

[0098] Silica 15.4kg

[0099] Superfine talcum powder 12.6kg

[0100] Maleic anhydride grafted ethylene-vinyl acetate copolymer 24.75kg

[0101] Maleic anhydride grafted polyethylene 19.25kg

[0102] Maleic anhydride grafted polyolefin 11kg.

[0103] The inner insulating layer consists of...

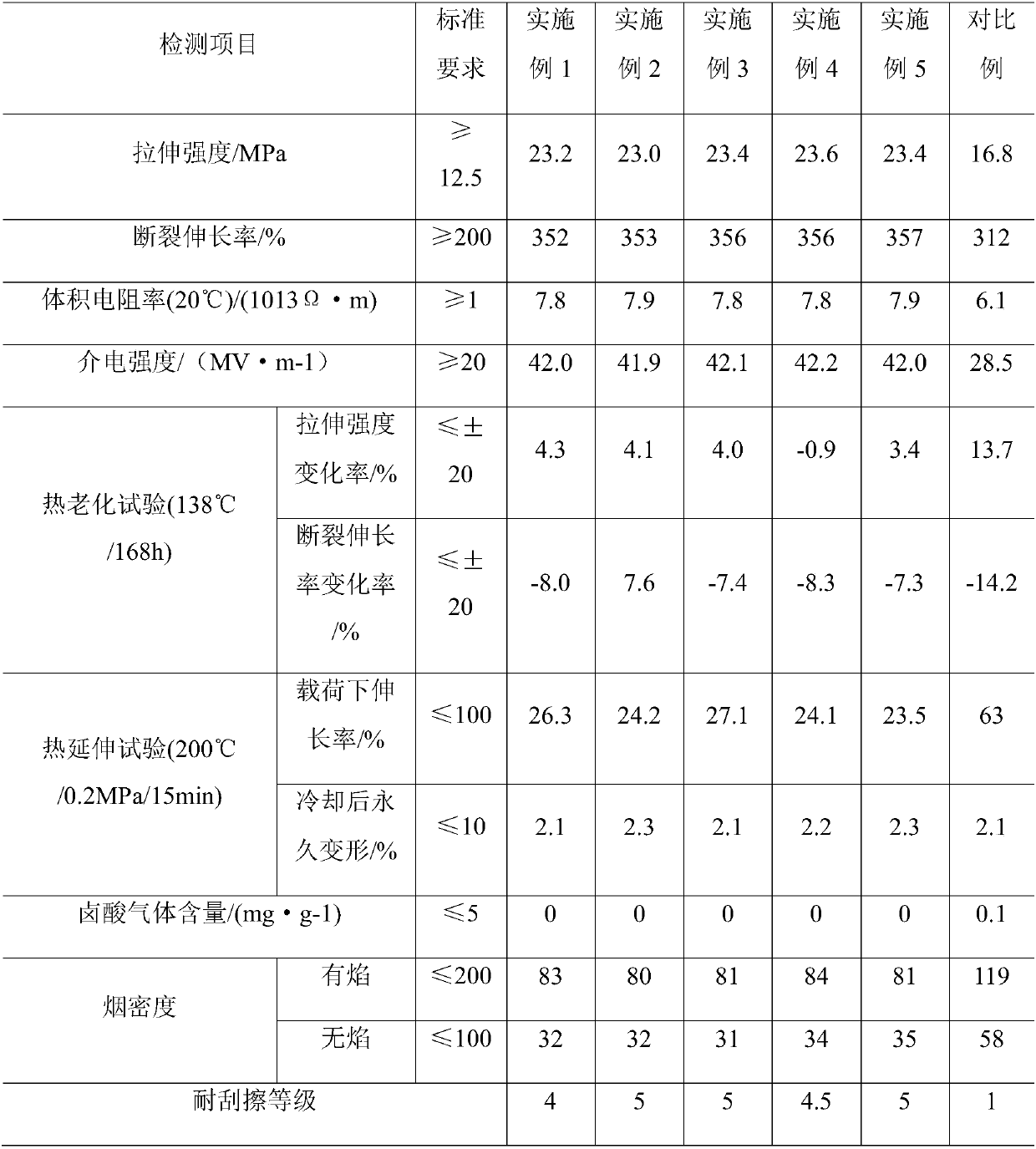

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com