Double-component polyester polystyrene foam with inflaming retarding property and preparation method thereof

A two-component polyurethane and foamed adhesive technology, applied in the field of construction adhesives, can solve the problems of poor safety performance, low adhesion, flammability, etc., and achieve high construction efficiency, improved flame retardancy, high shear the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

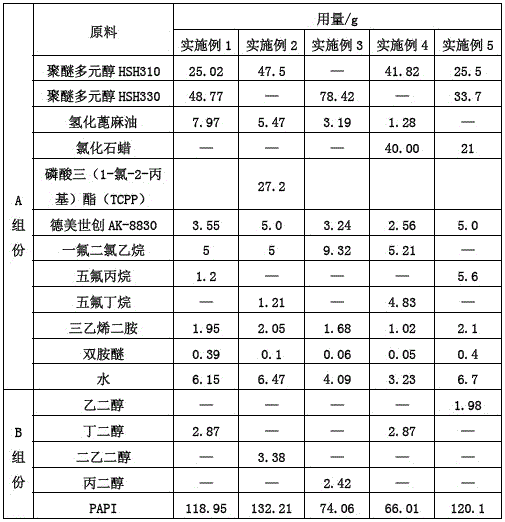

[0035] A two-component polyurethane foam with flame-retardant properties and its preparation method according to the present invention will be further described in conjunction with specific examples. The specific composition is listed in Table 1. It is necessary to point out that this embodiment is only for illustration, and the protection scope of the present invention is not limited to the scope of illustration.

[0036] The specific preparation process of the embodiment is as follows.

[0037] Component A: First, add polyether polyol, foam stabilizer, thixotropic agent and flame retardant into a four-neck bottle and mix evenly, heat to 120ºC, stir for 30min, then cool down to below 80ºC, add catalyst and foaming agent And water, after mixing evenly, it can be used with component B.

[0038] Component B: Dehydrate the polyol until the water content is less than 0.5%, add PAPI under the protection of nitrogen, slowly raise the temperature to 80ºC (5ºC / min), stir and keep war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com