Yarn fire retardant and processing technology of fire-retardant yarn

A technology of flame retardant and compounding agent, which is applied in the fields of biochemical fiber treatment, textile and paper making, fiber treatment, etc. It can solve problems such as inability to endow wool with functions, achieve good economic and social benefits, improve flame retardant performance, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Take a small amount of water, dissolve 5% Pyrovatex CP New, 1% JFC fatty alcohol polyoxyethylene ether, and 1% hydrophilic softener in water to prepare solution 1;

[0024] 2) Take the remaining amount of water, mix 1% industrial phosphoric acid, 0.5% formic acid, 0.5% citric acid, 50% disodium hydrogen phosphate / sodium dihydrogen phosphate buffer; then add transglutamate according to the amount of 60U / g fabric Amidase (MTG), configured as solution 2;

[0025] 3) Put solution 2 in the dye vat, add wool yarn containing 100% wool, the weight bath ratio of yarn to solution 2 is 1:30, and soak for 5-10 minutes at room temperature;

[0026] 4) Add solution 1 into the dye vat and mix well, continue soaking at room temperature for 120 minutes, then heat the liquid in the dye vat to 65°C at a rate of less than 2°C per minute, keep it warm for 30 minutes, drain the liquid, and rinse with water More than two times, dehydration and drying can be done.

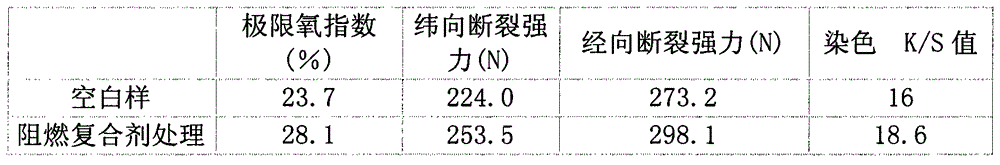

[0027] The samples arr...

Embodiment 2

[0030] 1) Take a small amount of water, mix 8% DS-101, 2% BS-12 dodecyl dimethyl betaine, 1% stearamidopropyl dimethylamine and bis (2-chloroethyl) ether The softener synthesized according to the molar ratio of 2:1 is dissolved in water to form solution 1;

[0031] 2) Take the remaining amount of water, mix 2% industrial phosphoric acid, 1% formic acid, 1% citric acid, 50% boric acid / borax buffer solution, and 1% nonionic antistatic agent; Glutaminase (MTG), configured as solution 2;

[0032] 3) Put the solution 2 in the dye vat, add 70% wool and 20% nylon. Wool blended yarn with 10% cotton yarn, the weight-to-bath ratio of yarn and solution 2 is 1:20, soaked at room temperature for 5-10 minutes;

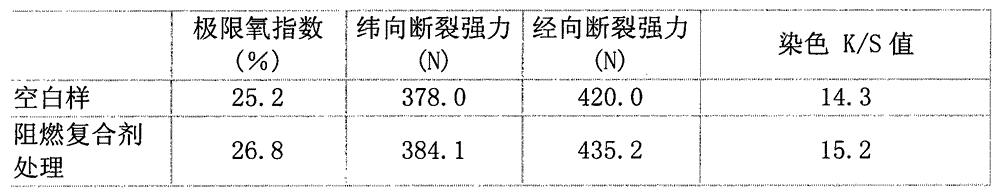

[0033] 4) Add solution 1 into the dye vat and mix well, continue soaking at 35°C for 60 minutes, stir during the process, then heat the liquid in the dye vat to 65°C at a speed of less than 2°C per minute, and keep it warm for 30 minutes , Drain the liquid, rinse with water for m...

Embodiment 3

[0037] 1) Take a small amount of water, and synthesize 8% of trimethylolpropane, trimethyl phosphite, and trimethyl phosphate in a molar ratio of 1:1:1 to obtain a flame retardant, 3% BS-12 dodecyl Dimethyl betaine, 1% hydrophilic softener, dissolved in water to form solution 1;

[0038] 2) Take the remaining amount of water, mix 3% industrial phosphoric acid, 1% formic acid, 1% citric acid, 50% disodium hydrogen phosphate / potassium dihydrogen phosphate buffer, and 1% nonionic antistatic agent; Add transglutaminase (MTG) to the amount of g fabric to configure solution 2;

[0039] 3) Put the solution 2 in the dye vat, add 30% wool and 20% nylon. Wool blended yarn with 20% polyester and 10% cotton yarn, the weight-to-bath ratio of yarn to solution 2 is 1:20, soaked at room temperature for 5-10 minutes;

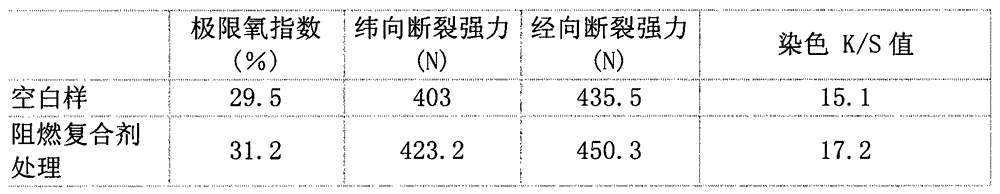

[0040] 4) Add solution 1 into the dye vat and mix well, continue soaking at room temperature for 90 minutes, then heat the liquid in the dye vat to 65°C at a speed of less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com