Patents

Literature

544 results about "Diphenyl phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

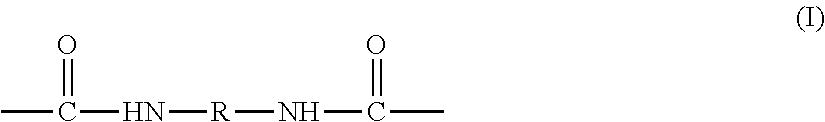

Halogen-Free, Flame Retardant TPU Composite

Halogen-free TPU compositions comprise in weight percent based on the weight of the composition: A. 1 to 99% thermoplastic polyurethane (TPU), B. 1 to 50% tris(2-butoxyethyl)phosphate (TBEP), C. 1 to 70% metal hydrate, and D. 1 to 70% organic phosphate ester other than tris(2-butoxyethyl)phosphate. These compositions exhibit better smoke suppression as compared with conventional organic phosphate flame retardant TPU compositions such as those based on resorcinol bis(diphenyl phosphate) (RDP) and bisphenol-A bis(diphenyl phosphate) (BPADP) in the absence of TBEP.

Owner:DOW GLOBAL TECH LLC

PET (polyethylene glycol terephthalate) fiber/teflon fiber composite sound absorbing cotton and preparation method of PET fiber/teflon fiber composite sound absorbing cotton

InactiveCN102965843AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsNon-woven fabricsDiphenyl phosphatePolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / teflon fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of teflon fibers, 10 to 15 parts of emulsifying agents OP-30, 5 to 10 parts of peregal O-20, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of HIPS (high impact polystyrene), 15 to 20 parts of activated clay, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of dioctyl adipate, 4 to 6 parts of cresyl diphenyl phosphate, 2 to 3 parts of liquid paraffin, 1 to 2 parts of 3-aminopropyltrimethoxysilane, 2 to 3 parts of calcium stearate, 1 to 2 parts of barium stearate, 0.5 to 1.5 parts of anti-aging agents RD and 1 to 2 parts of antioxidants DLTP (dilauryl thiodipropionate). The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

CMR-grade high-flame-retardation polyvinyl chloride cable jacket material and preparation method of same

ActiveCN102382401AReduce dosageImprove flame retardant performanceInsulated cablesInsulated conductorsDiphenyl phosphatePlasticizer

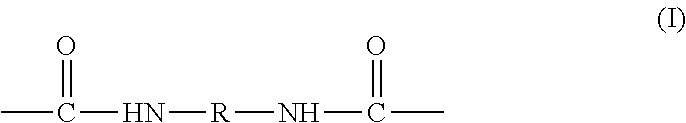

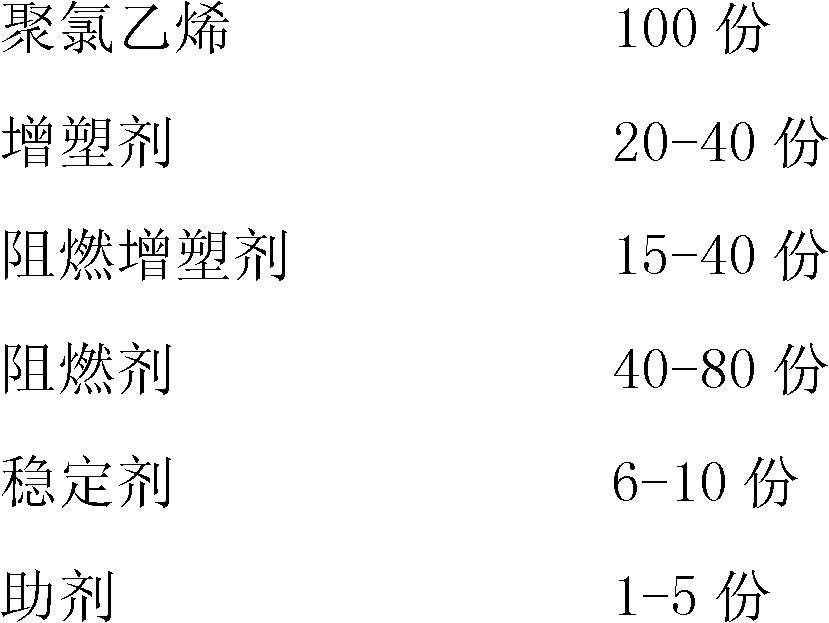

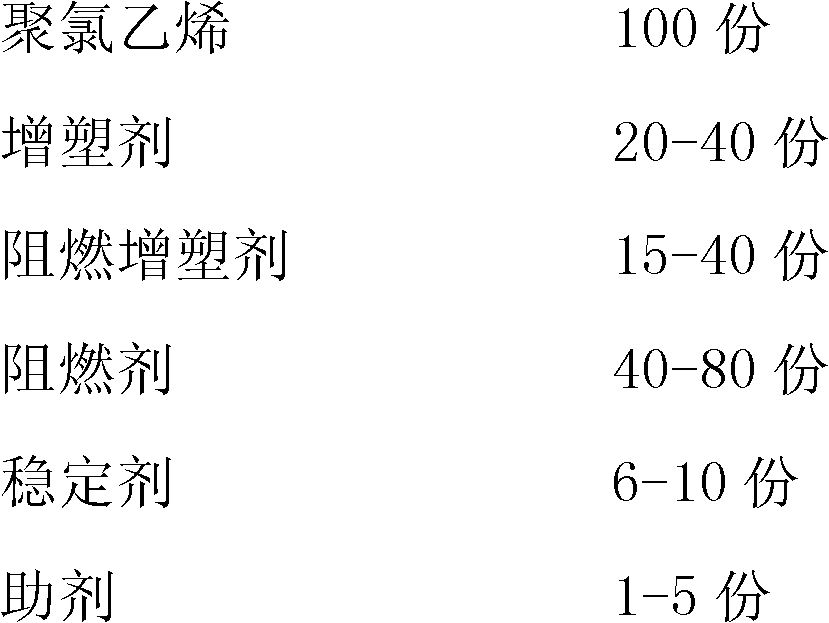

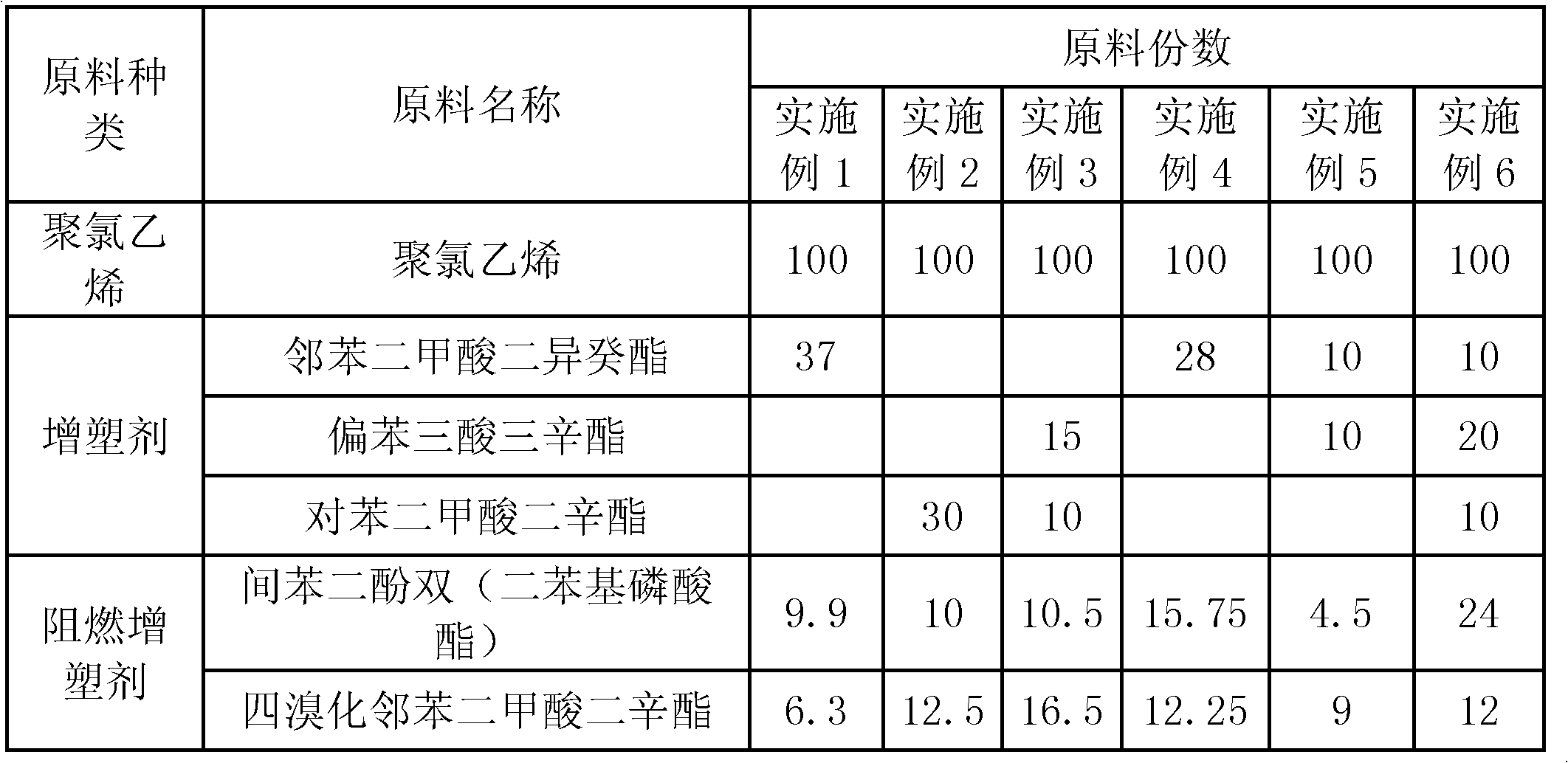

The invention provides a CMR-grade high-flame-retardation polyvinyl chloride cable jacket material including the materials in parts by weight as follows: 100 parts of polyvinyl chloride, 20-40 parts of plasticizer, 15-40 parts of flame retardant plasticizer, 40-80 parts of flame retardant, 6-10 parts of stabilizer and 1-5 of additives, wherein the flame retardant plasticizer is a mixture of resorcinol bis(diphenyl phosphate), tetrabromide phthalate dioctyl and phosphate tris(2,3-dichloropropyl) in weight ratio of 3-6:3-6:1. The invention also provides a preparation method of the jacket material. In the cable jacket material, the usage of common plasticizer can be reduced greatly and simultaneously the flame retardation property of the product is improved effectively, therefore the optimalcombination of processability and flame retardation is achieved.

Owner:江西一舟数据技术有限公司

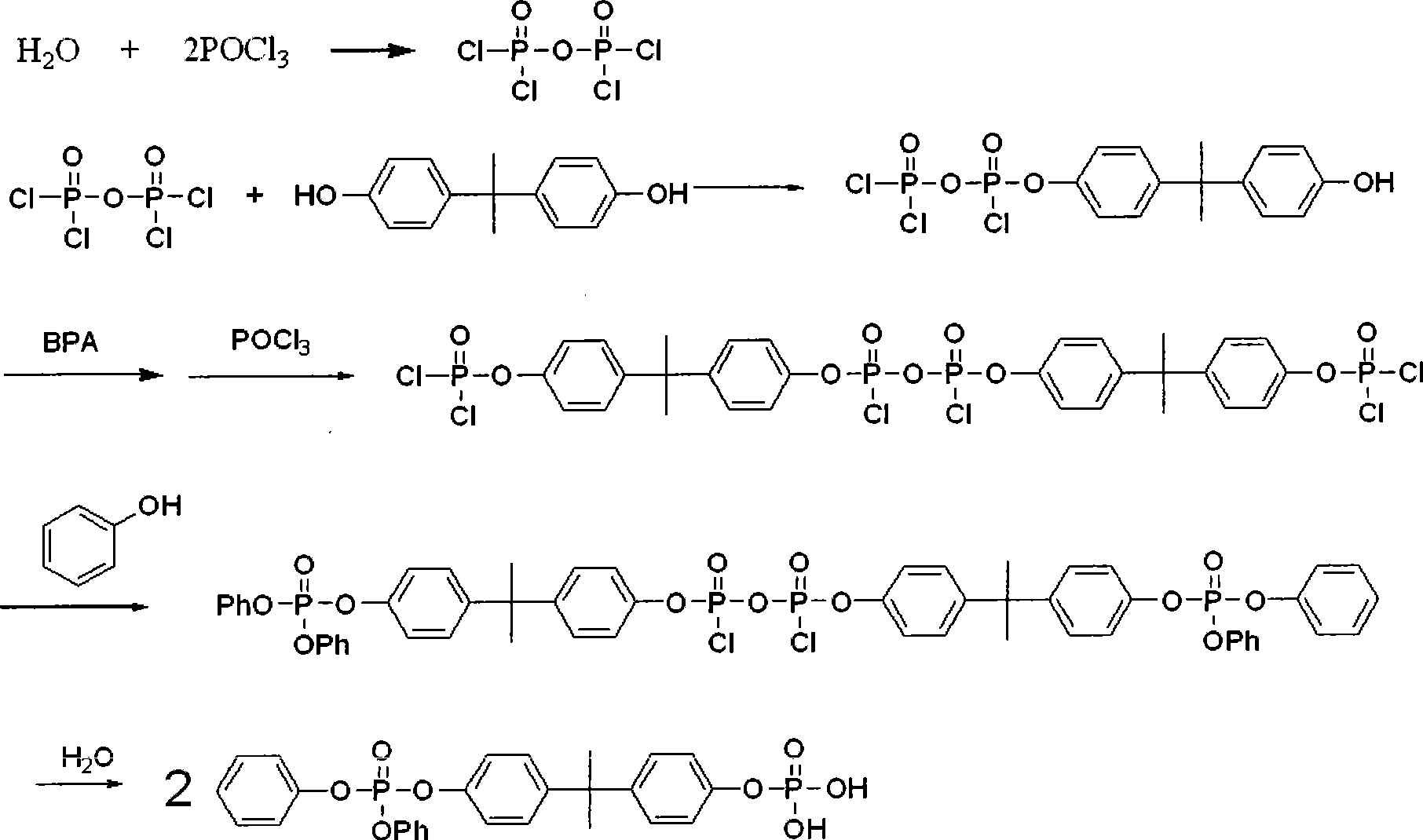

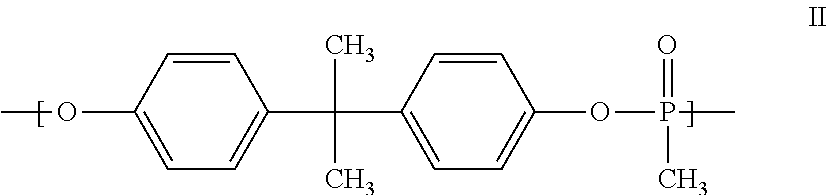

Method for preparing combustion inhibitor bisphenol A bis(diphenyl phosphate)

ActiveCN101456879ASignificant progressSignificant positive effectGroup 5/15 element organic compoundsPhenolBisphenol

The invention relates to a preparation method for flame retardant bisphenol A bi(diphenyl phosphate). The preparation method comprises the following steps: taking phosphorus oxychloride, bisphenol A and phenol as raw materials, adopting anhydrous zinc chloride or anhydrous aluminum chloride as a main catalyst, and adopting anhydrous calcium chloride or calcium phosphate as a promoter; adding the phosphorus oxychloride, the main catalyst and the promoter into a reactor for intensive stirring, when the materials are heated up to 73 to 78 DEG C, continuously adding bisphenol A, after the addition of bisphenol A is completed within 2.5 to 3 hours, heating up to and maintaining the temperature of 110 to 115 DEG C, and continuing the reaction for 1.5 to 2 hours; leaking out excessive phosphorus oxychloride under the normal and reduced pressure; and cooling down the intermediate product to 100 DEG C, continuous dropping phenol into the intermediate product, heating up to 140 DEG C 2 hours later, carrying out the reaction for 3 to 4 hours, monitoring the content of phenol through the liquid chromatography, and complementing phenol till the phenol content in the crude product is less than 0.5 percent. The yield reaches 98 percent; the content of triphenyl phosphate is less than 1.5 percent; and the acid number is 0.03mgKOH / g.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

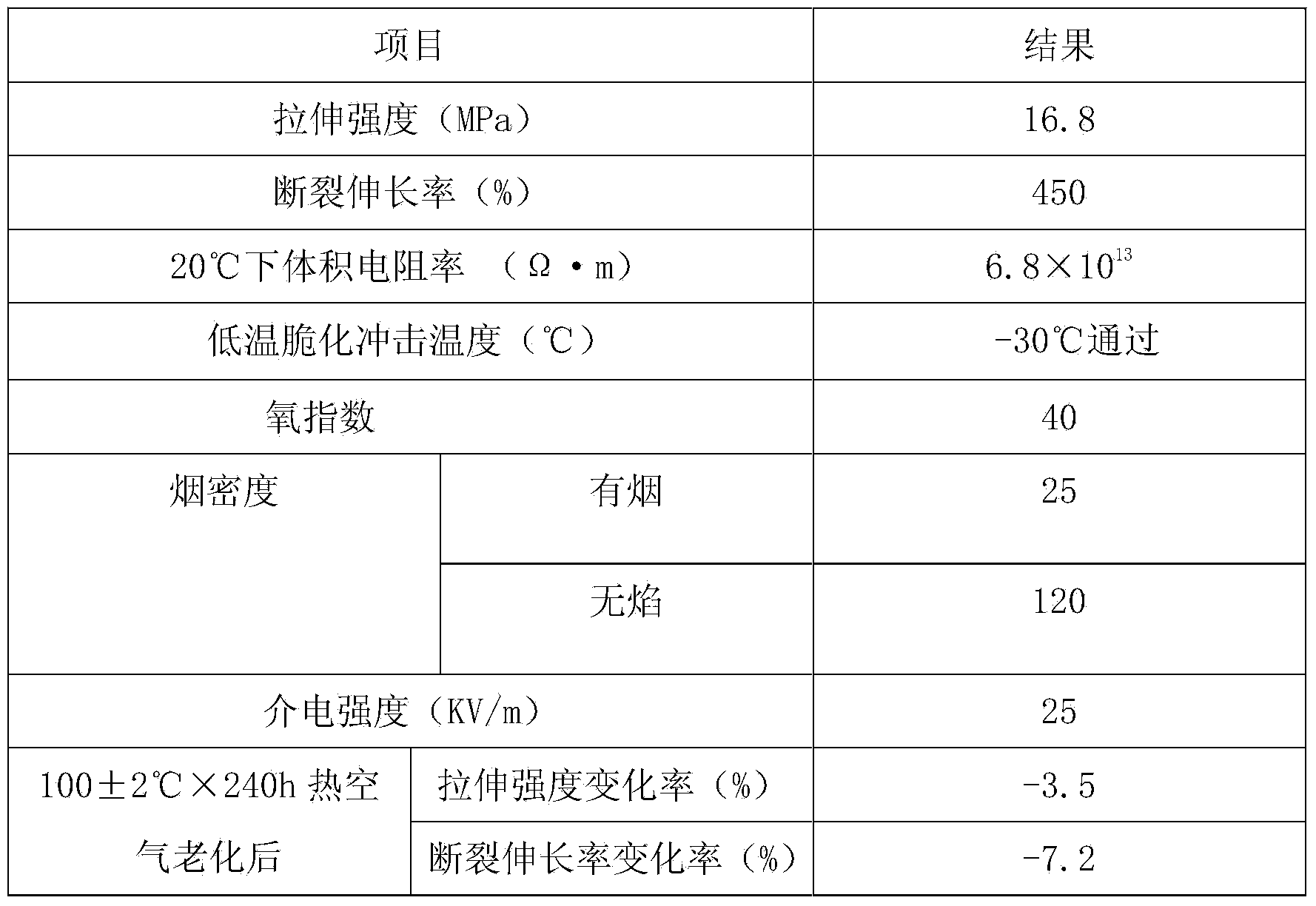

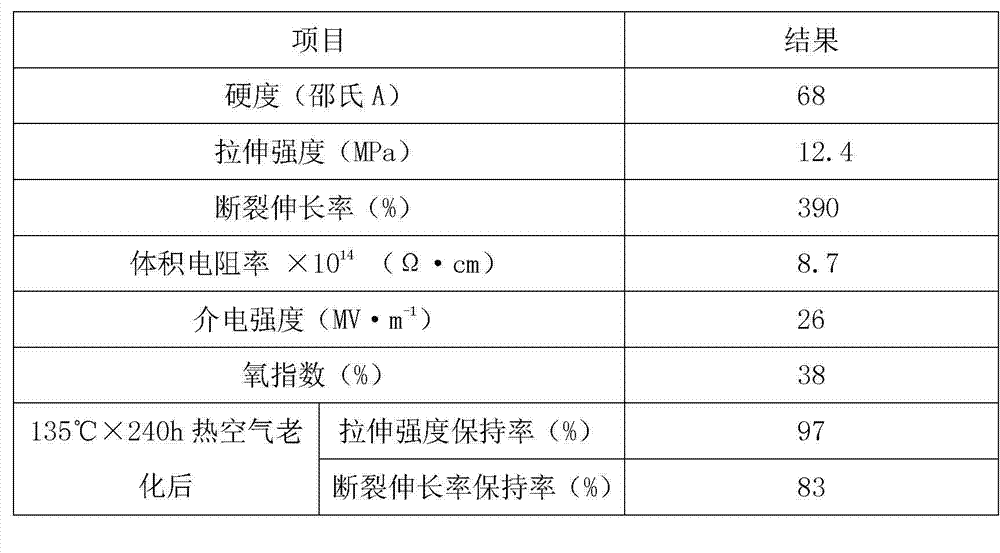

Flame-retardant oil-resistant aging-resistant thermoplastic elastomer cable material

ActiveCN103524913AFlame retardant hasFlame retardant and oil resistantPlastic/resin/waxes insulatorsInsulated cablesCalcium silicatePolyvinyl chloride

The invention provides a flame-retardant oil-resistant aging-resistant thermoplastic elastomer cable material prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride SG-3, 10-20 parts of nitrile rubber N26, 10-15 parts of polycarbonate, 10-15 parts of poly(ethylene terephthalateco-1,4-cylclohexylenedimethylene terephthalate), 15-20 parts of a silane coupling agent, 30-40 parts of bisphenol-A bis(diphenyl phosphate), 20-30 parts of calcium carbonate, 1-2 parts of calcium silicate, 30-50 parts of barium stearate, 10-15 parts of cresyl diphenyl phosphate, 3-4 parts of glycerol trioleate, 2-3 parts of a crosslinking agent TAIC, 2-3 parts of stearic acid, 1-2 parts of N,N'-m-phenylenedimaleimide, 5-8 parts of alcohol ester-12, 0.5-1.0 part of PE wax, 1-2 parts of aluminum nitride powder, 1-2 parts of jade powder, and 8-10 parts of a modified filler. The flame-retardant oil-resistant aging-resistant thermoplastic elastomer cable material has the characteristics of flame retardancy, oil resistance, aging resistance, and acid and alkali resistance, and has lower specific density and low manufacture cost.

Owner:滁州君越高分子新材料有限公司

Preparation of bisphenol A bis(diphenyl phosphoester )

ActiveCN101348500AEasy accessNot easy to produceGroup 5/15 element organic compoundsDiphenyl phosphateSocial benefits

The invention provides a method for preparing bisphenol A bi-(diphenyl phosphate). The method is characterized in that the proper amount of bisphenol A and phosphorus oxychloride is added in a reactor, and subjected to heating and stirring until bisphenol A is completely dissolved, and dissolved materials are obtained; the proper amount of Lewis acid and phosphorus oxychloride is added in a reactor provided with a chlorine hydride absorption device and subjected to quick heating, the dissolved materials are added in the reactor, the excessive phosphorus oxychloride is distilled off after the reaction finishes, and the proper amount of phenol is added, the temperature is adjusted until the reaction finishes, and the finished product is obtained after washing and debenzolization. The product prepared by the process of the invention has the advantages of having good product quality, lowering labor intensity, improving working environment and having better economic and social benefits.

Owner:山东旭锐新材股份有限公司

Low-smoke halogen-free flame-retardant cable material

InactiveCN105037899ASoft textureHigh tensile strengthPlastic/resin/waxes insulatorsInsulated cablesEpoxyAntioxidant

The invention discloses a low-smoke halogen-free flame-retardant cable material, and belongs to the field of materials. The low-smoke halogen-free flame-retardant cable material solves the problem that an existing cable material is poor in mechanical property and electrical property. The low-smoke halogen-free flame-retardant cable material is composed of 50-60 parts of high density polyethylene, 20-30 parts of ethylene-ethyl acrylate copolymers, 20-30 parts of methyl vinyl silicone rubber resin, 1-3 parts of magnesium stearate, 2-5 parts of novolac epoxy resin, 15-25 parts of isopropyl phenyl diphenyl phosphate, 1-2 parts of dilauryl thiodipropionate, 10-20 parts of dimellitate, 1-2 parts of antioxidants 1010, 1-1.5 parts of antioxidants CA, 10-20 parts of maleic anhydride grafting ethylene-octylene copolymers, 5-10 parts of polysiloxane, 20-30 parts of nano magnesium hydroxide, 13-18 parts of nano clay, 3-7 parts of zinc oxide, 5-10 parts of polyethylene wax and 3-8 parts of calcium stearate. The low-smoke halogen-free flame-retardant cable material can be widely used as insulation and sheathing materials of various electric wires and cables.

Owner:国网山东莒南县供电公司 +2

Impact-resistant high-adhesive-force inflaming-retarding modified bisphenol A epoxy resin paint

InactiveCN104293107AImprove impact resistanceImprove adhesionFireproof paintsChloropene polymer coatingsTitanium nitrideKetone

The invention discloses an impact-resistant high-adhesive-force inflaming-retarding modified bisphenol A epoxy resin paint which comprises the following raw materials in parts by weight: 66-69 parts of modified bisphenol A epoxy resin, 12-15 parts of glycerin alkyd resin, 13-16 parts of aldehyde ketone resin KR-130, 22-26 parts of graphene, 4-6 parts of titanium nitride, 5-8 parts of nano-magnesium hydroxide, 0.8-1.2 parts of a silane coupling agent KH-550, 2.4-2.8 parts of diphenyl phosphate ester, 1.6-1.9 parts of zinc borate, 1-2 parts of antimony trioxide, 0.6-0.9 part of a defoaming agent, 0.5-0.8 part of a smoothing agent, 0.4-0.7 part a mildew preventive, 1.2-1.5 parts of pigment and 50-53 parts of a solvent. The impact-resistant high-adhesive-force inflaming-retarding modified bisphenol A epoxy resin paint is strong in impact resistance, good in adhesive force and excellent in inflaming retarding performance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

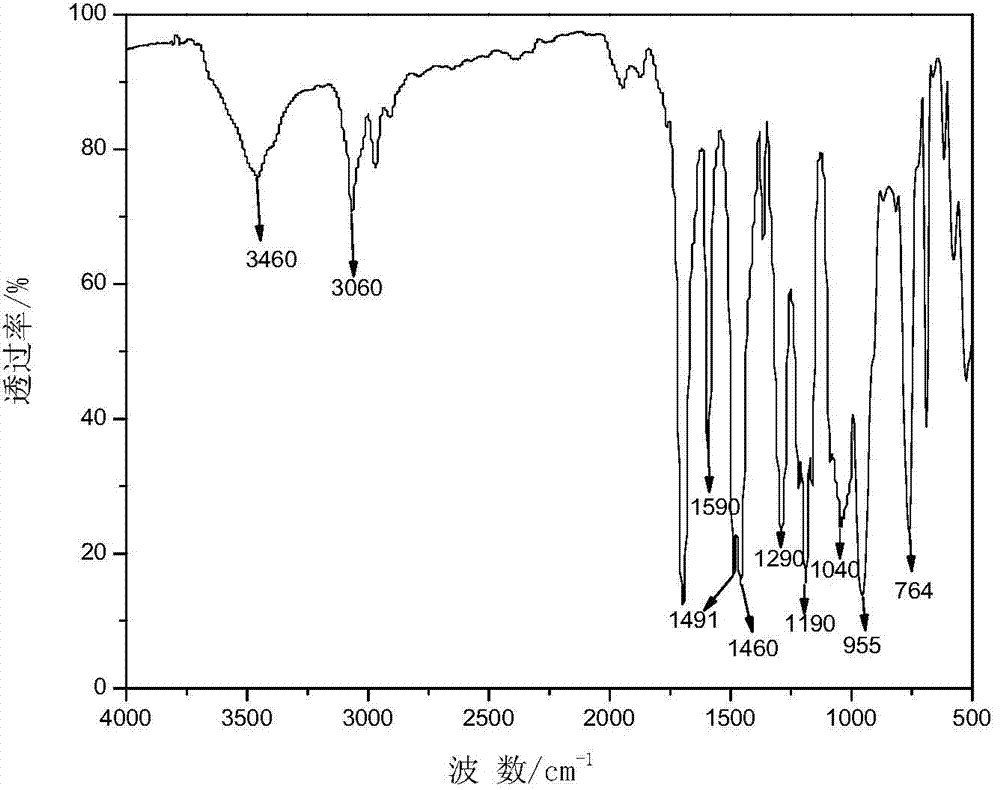

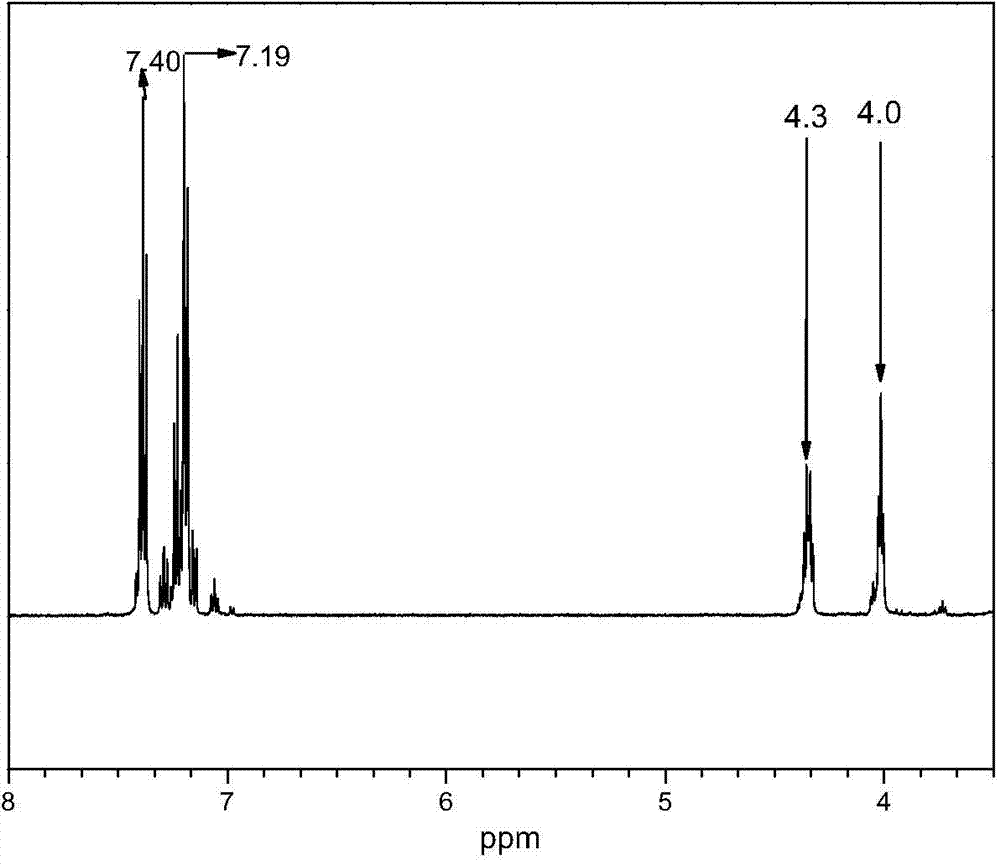

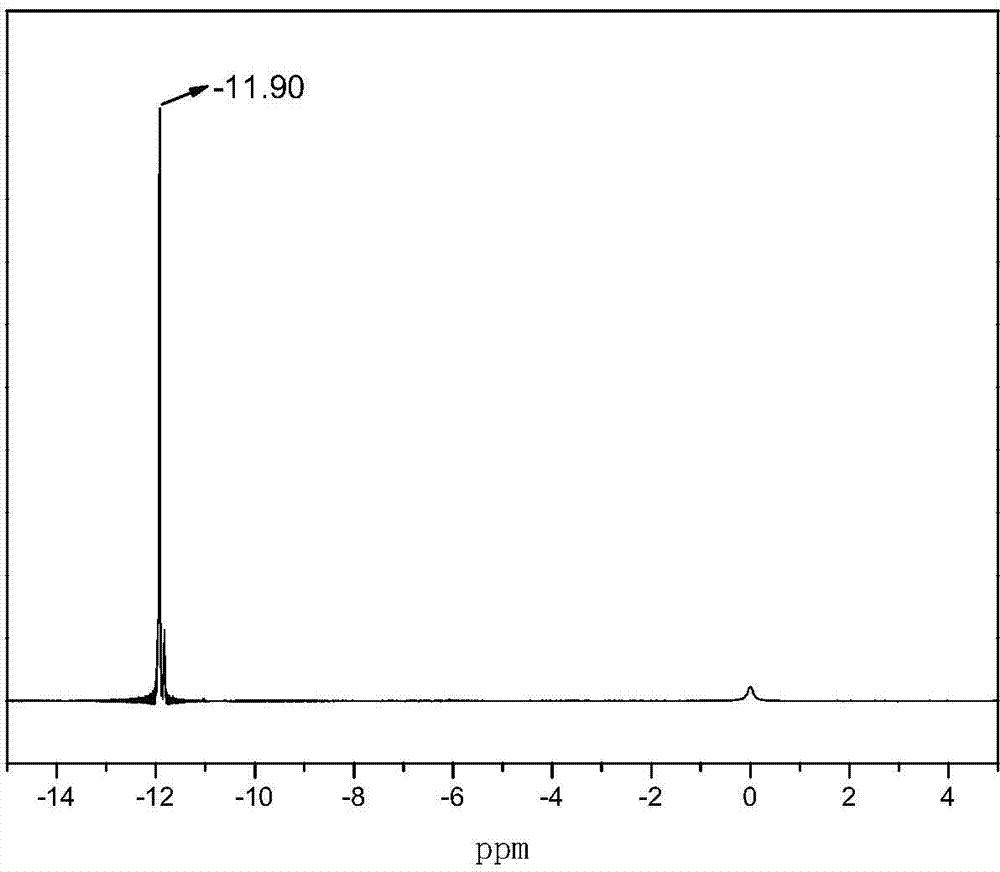

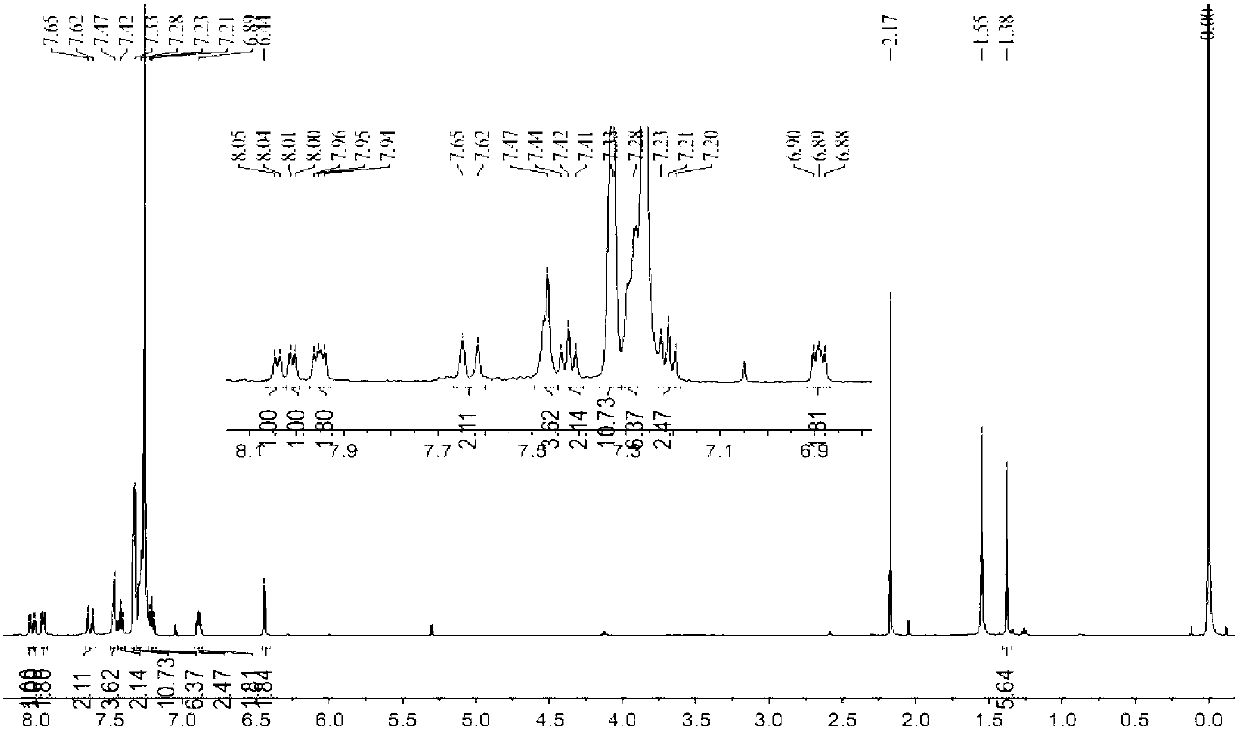

Triazine exciplex material based on phosphine oxide and carbazole, and preparation method and application thereof

ActiveCN106883268AIncrease varietyImprove luminous efficiencyGroup 5/15 element organic compoundsSolid-state devicesDiphenyl phosphateCarbazole

The invention relates to a triazine exciplex material based on phosphine oxide and carbazole, and a preparation method and application thereof, which solve the technical problems of fewer existing blue light exciplex receptor materials. The structure of the triazine exciplex material based on the phosphine oxide and the carbazole is as follows (shown in the description). The preparation method comprises the following steps: adding monobromotrityl-based triazine, a carbazole compound, anhydrous K2CO3 and CuI into 1,3-dimethyl-2-imidazolone to react, and purifying to obtain an intermediate compound; and then enabling the intermediate compound to react with diphenyl phosphate and palladium acetate in anhydrous DMF, and then purifying to obtain the triazine-type exciplex material. The material can be applied to TADF (thermal activation delayed fluorescence) and phosphorescence organic electroluminescence devices.

Owner:HEILONGJIANG UNIV

Flame-retardant PVC (polyvinyl chloride) artificial leather and preparation process thereof

InactiveCN103951913AGood component compatibilityGood mechanical propertiesSynthetic resin layered productsTextiles and paperMelamine phosphatePolyvinyl chloride

The invention provides flame-retardant PVC (polyvinyl chloride) artificial leather and a preparation process thereof. The flame-retardant PVC artificial leather comprises the following components in parts by weight: 70-120 parts of PVC resin powder, 30-50 parts of DOP (dioctyl-phthalate) plasticizer, 15-25 parts of halogen-free phosphate plasticizer, 3-6 parts of heat stabilizer, 8-12 parts of wollastonite, 30-50 parts of isopropyl phenyl diphenyl phosphate, 8-12 parts of melamine phosphate, 15-25 parts of melamine cyanurate, 20-30 parts of antimonous oxide, 15-25 parts of zinc borate, 15-30 parts of activity aluminum hydroxide, 3-8 parts of calcium carbonate, 3-8 parts of AC (activated carbon) foaming agent. The preparation process of the flame-retardant PVC artificial leather is as follows: weighing materials, high-speed stirring, banburying, refining (initial plasticizing), extruding and forming, refining (strengthened plasticizing), four-roll rolling, adhering with fireproof cloth, PVC foaming, surface-treating and obtaining products. The flame-retardant PVC artificial leather disclosed by the invention is good in flame retardant performance.

Owner:FOSHAN GAOMING JUNTENG PLASTICS

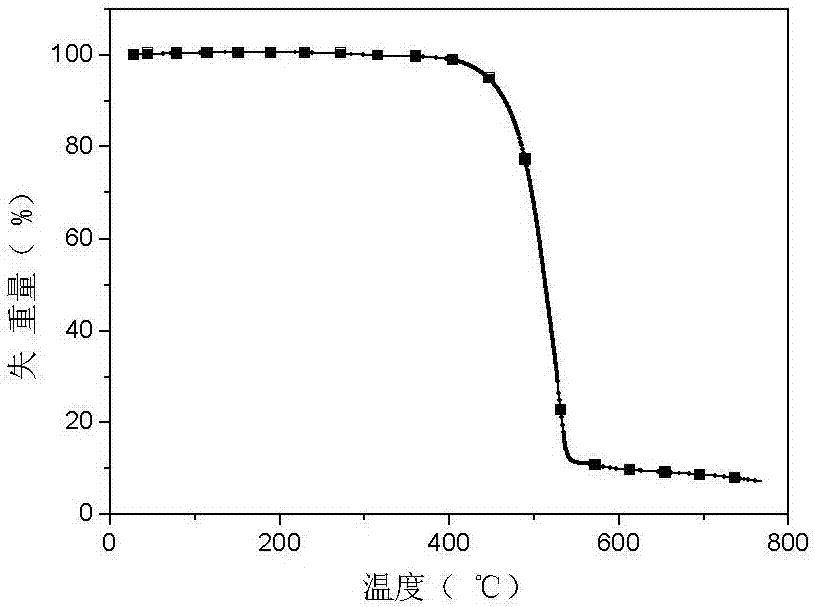

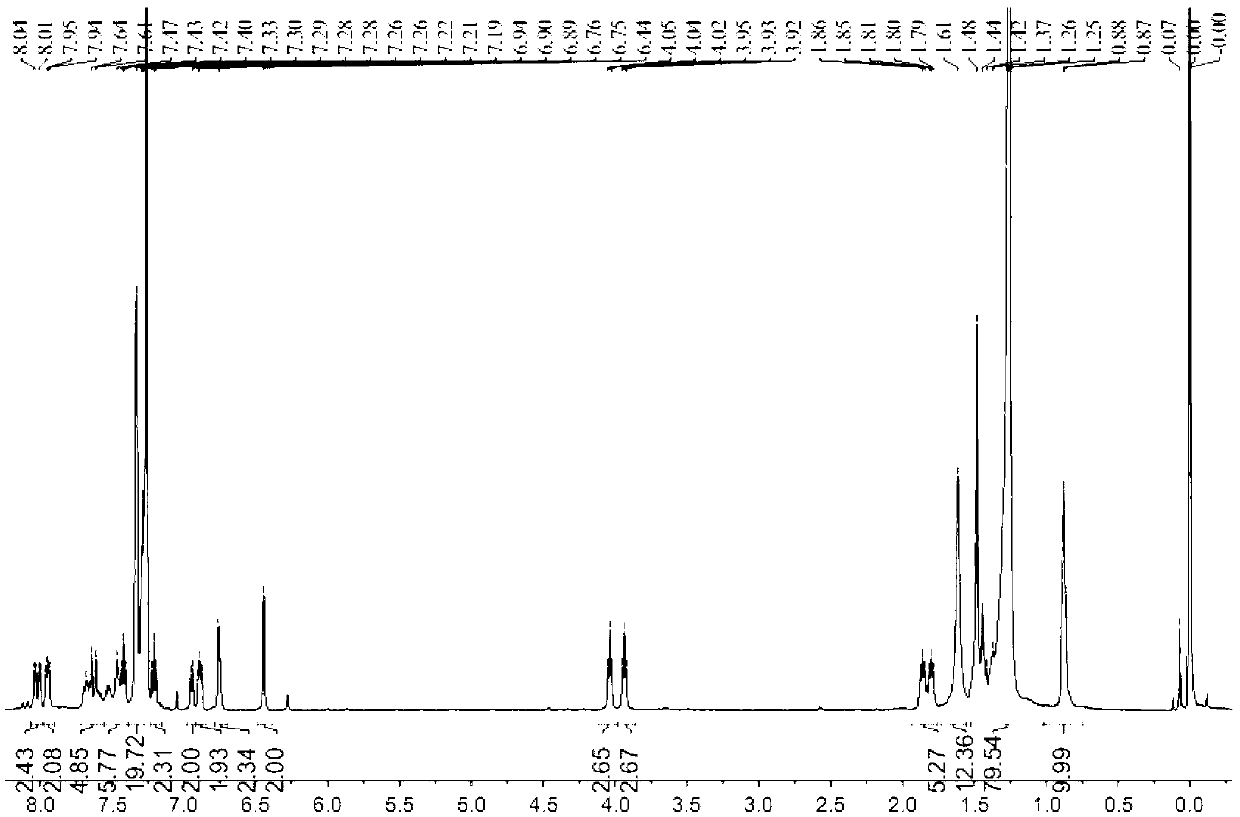

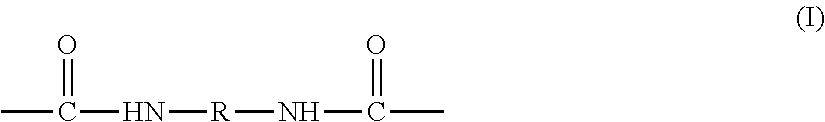

Triazine ring hexaphenyl phosphate-containing flame retardant and preparation method thereof

ActiveCN103923347AEasy to operateReduce energy consumptionGroup 5/15 element organic compoundsDiphenyl phosphateOrganic solvent

The invention discloses a triazine ring hexaphenyl phosphate-containing flame retardant and a preparation method thereof, relating to the technical field of preparing halogen-free flame retardant. According to the method, the mole ratio of tri(2-hydroxylethyl)isocyanurate to diphenyl chlorophosphate is 1:(3-3.2) under the condition of an organic solvent, the preparation method comprises the following steps of: sequentially adding tri(2-hydroxylethyl)isocyanurate, solvent, acid-binding agent and a catalyst, dropwise adding diphenyl chlorophosphate solution at -10DEG C to 5DEG C, heating to 20DEG C-25DEG C after the dropwise addition is completed, preserving heat for 2h-8h, after the reaction is finished, decompression-steaming the solvent, then sequentially washing with water and 5wt% sodium carbonate solution, and finally performing vacuum drying. The triazine ring hexaphenyl phosphate-containing synthetic method provided by the invention is simple to operate, low in cost and less in energy consumption; the decomposition temperature of the prepared flame retardant is at 280DEG C-438DEG C, and the prepared flame retardant has better thermal stability and better carbon forming capability.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

High-elasticity wear-resisting flame-retardant rubber material

The invention discloses a high-elasticity wear-resisting flame-retardant rubber material. The high-elasticity wear-resisting flame-retardant rubber material is prepared from the following raw materials in parts by weight: 40-45 parts of butadiene styrene rubber, 30-36 parts of polyurethane elastomer, 10-18 parts of chloroprene rubber, 2-3 parts of vulcanizing agent BPO (benzoyl peroxide), 1.2-1.8 parts of sulphur, 2-4 parts of accelerant DM (2,2'-dibenzothiazoledisulfde), 20-25 parts of modified titanium dioxide, 10-14 parts of calcite powder, 6-10 parts of brucite powder, 4-9 parts of aluminum nitride, 14-15 parts of carbon black N660, 2-5 parts of quartz powder, 5-8 parts of zinc oxide, 9-12 parts of magnesium hydrate, 1-4 parts of single alkoxyl pyrophosphate titanate coupling agent, 2-5 parts of diphenyl phosphate, 1-4 parts of melamine, 1-3 parts of stearic acid, 1-1.3 parts of anti-aging agent 264, and 2-4 parts of anti-aging agent MB (2-mercaptobenzimidazole). The high-elasticity wear-resisting flame-retardant rubber material has high elasticity, good abrasion resistance and excellent flame retardant effect.

Owner:ANHUI HONGYI CABLE GROUP

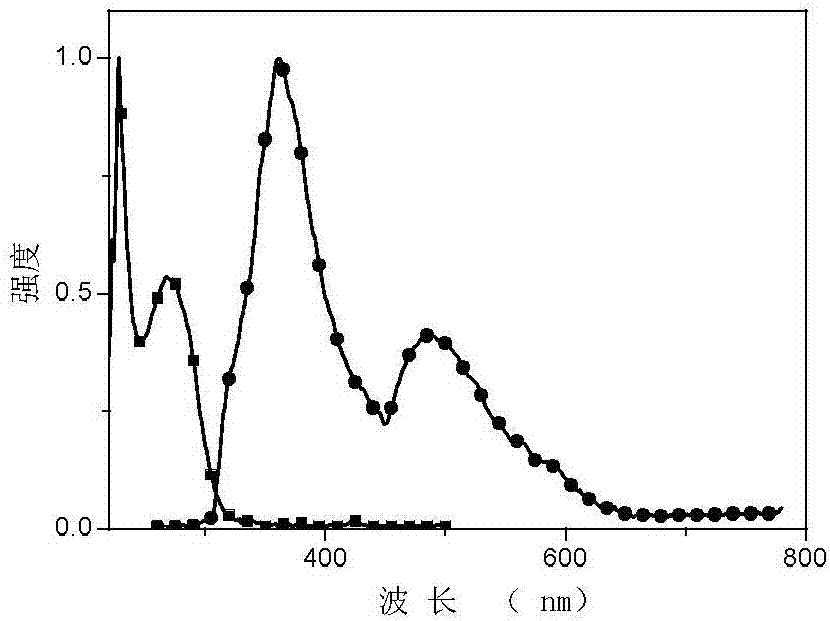

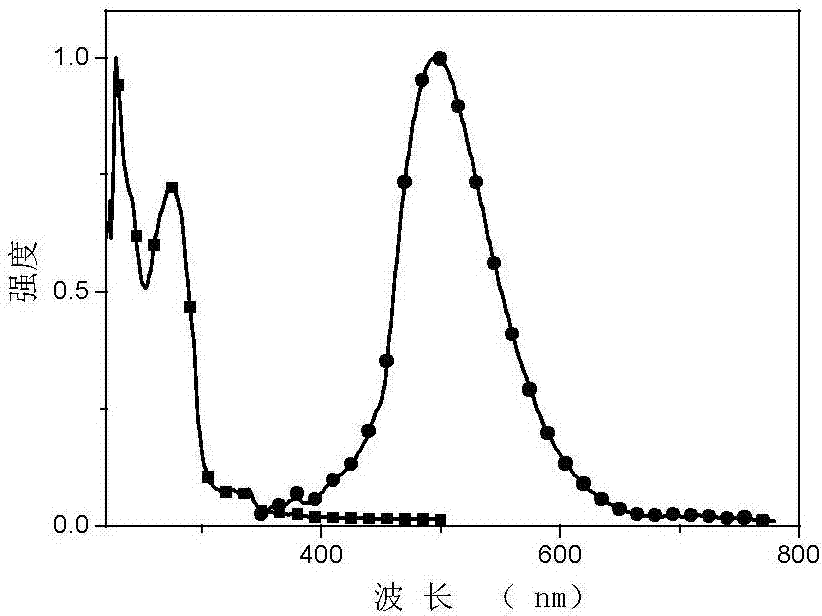

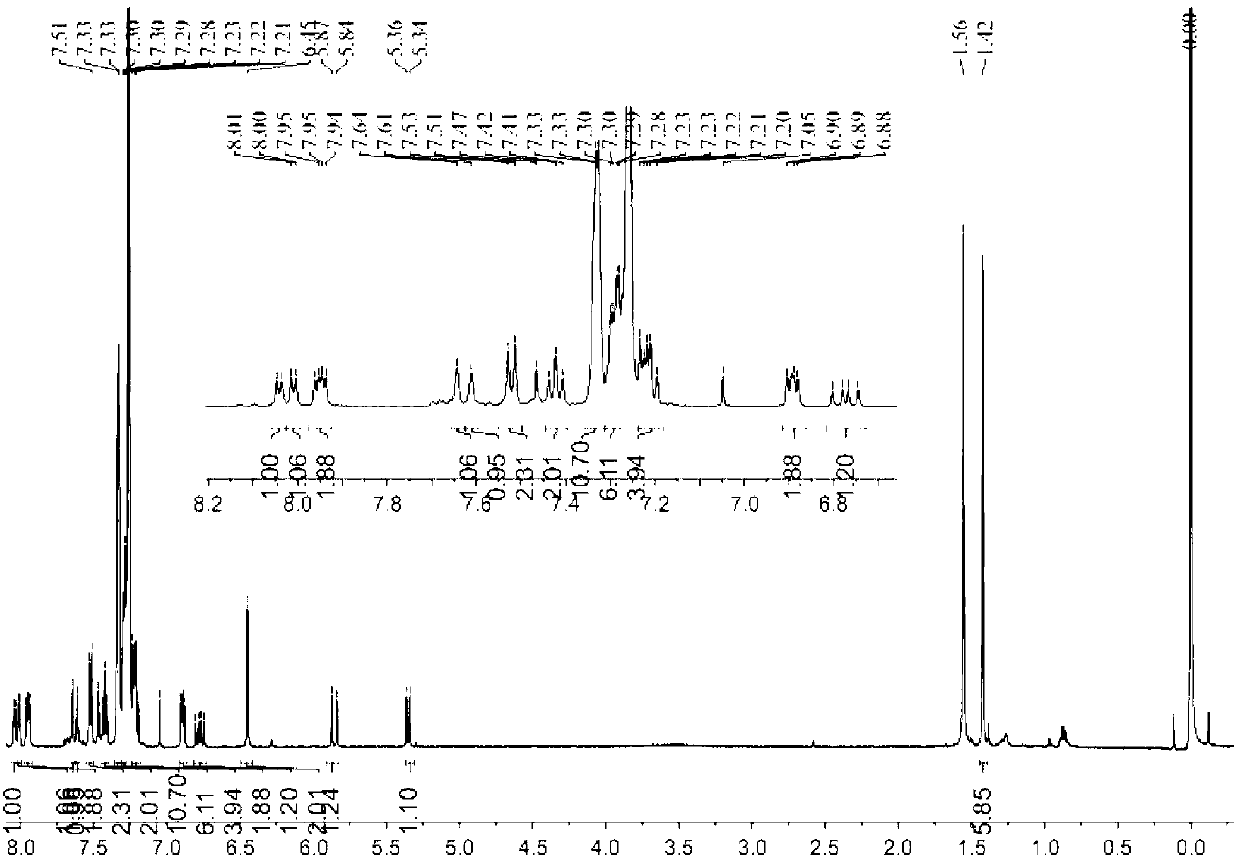

Near infrared BODIPY (Boron Dipyrromethene Compounds) hydroxyl radical probes and synthesis method and usage thereof

InactiveCN103342720AEfficient detectionEfficient detection and detectionGroup 5/15 element organic compoundsBiological testingInfraredDiphenyl phosphate

The invention discloses a kind of near infrared boron dipyrromethene compounds (BODIPY) based on duplex thiophene pyrrole groups. The near infrared boron dipyrromethene compounds have the following structure: FORMULA, wherein the group at meso site is changed to obtain a series of hydroxyl radical probes. The BODIPY hydroxyl radical probes based on 3,5-(diphenyl phosphate styryl) are synthesized for the first time in the invention, the 3,5 site groups of the BODIPY are introduced into the group, so that the absorption spectrum red shift of the probe reaches 630nm, the emission peak reaches 650nm and is located within the range (650-900nm) of a biological window, and meanwhile, the fluorescence quantum efficiency of the probe is high. Moreover, the kind of probes can be used for efficiently and quickly detecting hydroxyl radicals and can be successfully applied in biological imaging. Therefore, the probes have a brilliant application prospect of detecting the hydroxyl radicals in biological systems.

Owner:NANJING UNIV

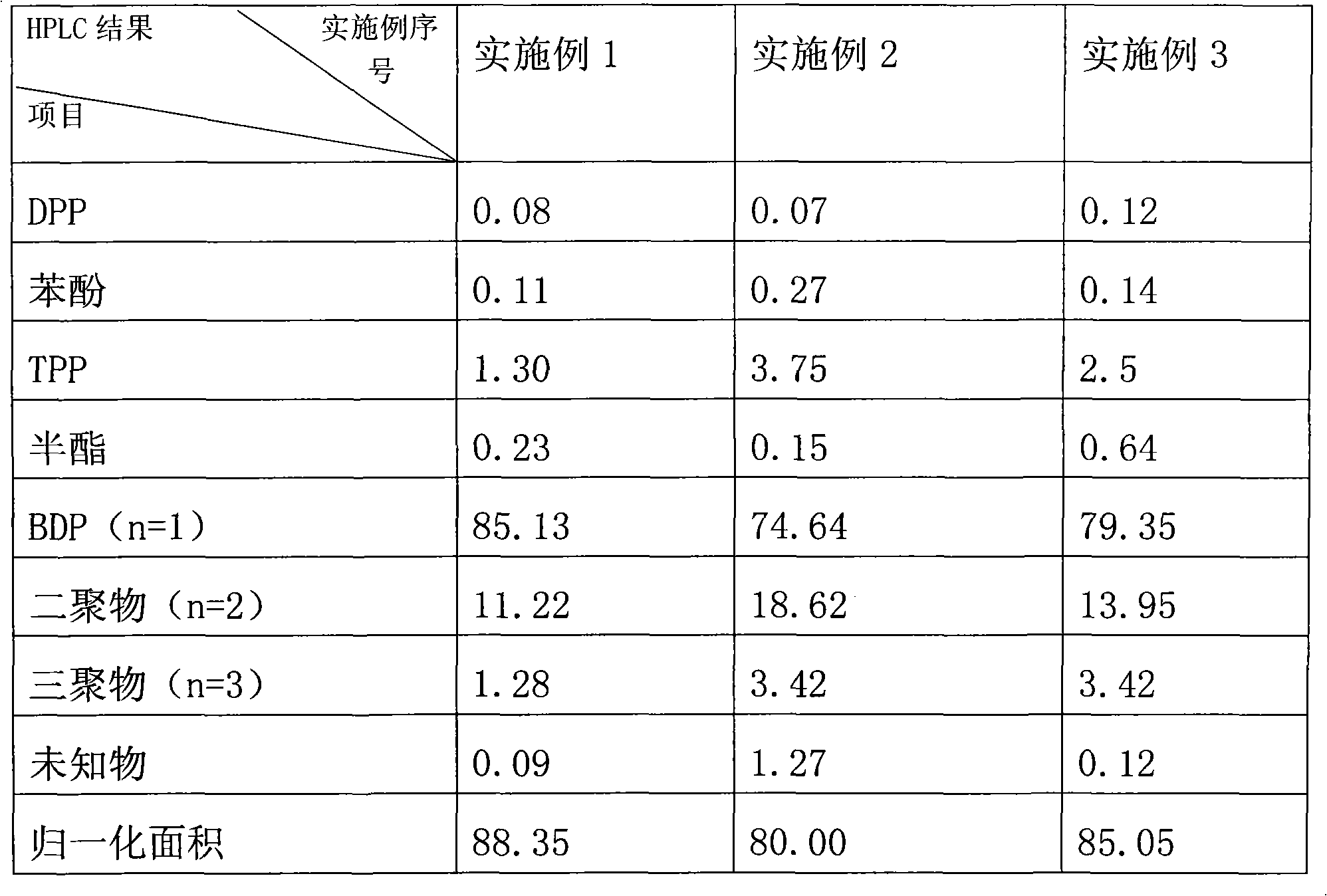

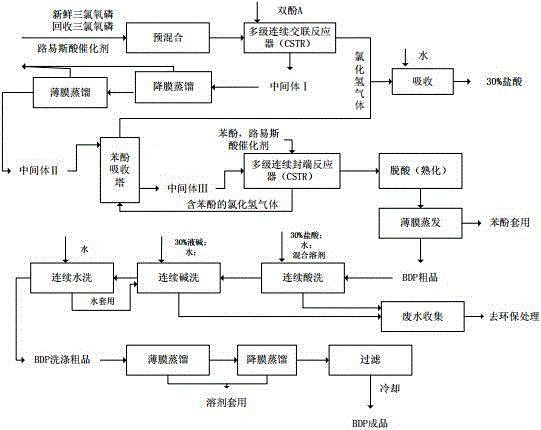

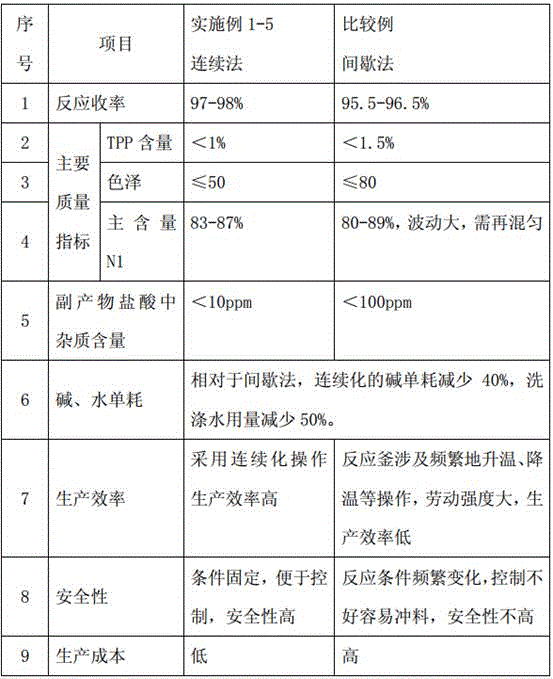

Continuous preparation method for bisphenol A-di(diphenyl phosphate)

ActiveCN106496264AReduce labor intensityMeets requirementsGroup 5/15 element organic compoundsCustomer requirementsDiphenyl phosphate

The invention discloses a continuous preparation method for bisphenol A-di(diphenyl phosphate). The continuous preparation method for the bisphenol A-di(diphenyl phosphate) comprises a multistage crosslinking reaction process, a continuous phosphorus oxychloride recycling process, a continuous multistage end capping reaction and phenol recycling process, a continuous crude product refining process, and a continuous solvent recycling and filtering process. The BDP is prepared by the continuous processes, the production cost is reduced, the labor intensity of operators is greatly reduced, the labor efficiency is improved, and the product yield is greatly improved, so the lot production quality is stable, and the production is safe and environment-friendly. The yield is improved by 1-1.5%, the color number is improved below 50, and the TPP is controlled to be 1%, and is reduced by 50% compared by an original intermittence device. The high-end customer requirement is satisfied, and the quality index fluctuation of each product is small.

Owner:ZHEJIANG WANSHENG

Nano-kieselguhr modified chlorosulfonated polyethylene rubber cable material

ActiveCN102964705AImprove flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsDiphenyl phosphatePolymer science

The invention discloses a nano-kieselguhr modified chlorosulfonated polyethylene rubber cable material. The cable material is prepared from the following raw materials in parts by weight: 100-120 parts of chlorosulfonated polyethylene rubber CSM2305, 20-30 parts of duprene rubber CR322, 10-20 parts of ethylene-vinyl acetate rubber, 5-10 parts of di-n-hexyl adipate, 5-10 parts of isopropylphenyl diphenyl phosphate, 4-6 parts of di(2-Ethylhexyl)-4,5-epoxytetrahydrophthalate, 1-2 parts of nonsoluble sulfur, 4-6 parts of butyl perbenzoate, and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Low-silver copper-base conductive ink and preparation method thereof

The invention discloses a low-silver copper-base conductive ink and a preparation method thereof. The conductive ink is prepared from the following components in parts by weight: nano copper wires, silver nitrate, indium powder, titanium dioxide powder, bismuth tungstate powder, 500-mesh tourmaline powder acidified carbon fibers, an epoxy resin, sodium hypophosphite, trimethylamine borane, polyoxypropylene glycerol ether, diphenyl phosphite, ethylene bis stearamide, sodium methylene bis-naphthalene sulfonate, polydimethylsiloxane, dipropylene glycol, isopropanol and acetone. The conductive ink has low silver content, thereby greatly lowering the manufacturing and use cost; the conductive ink has the advantages of favorable conductivity and favorable adhesive force, and thus, can be widely used in solar electromagnetic devices, thin film switches, flexible printed circuits and other electronic devices; and therefore, the conductive ink has huge use and application values.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

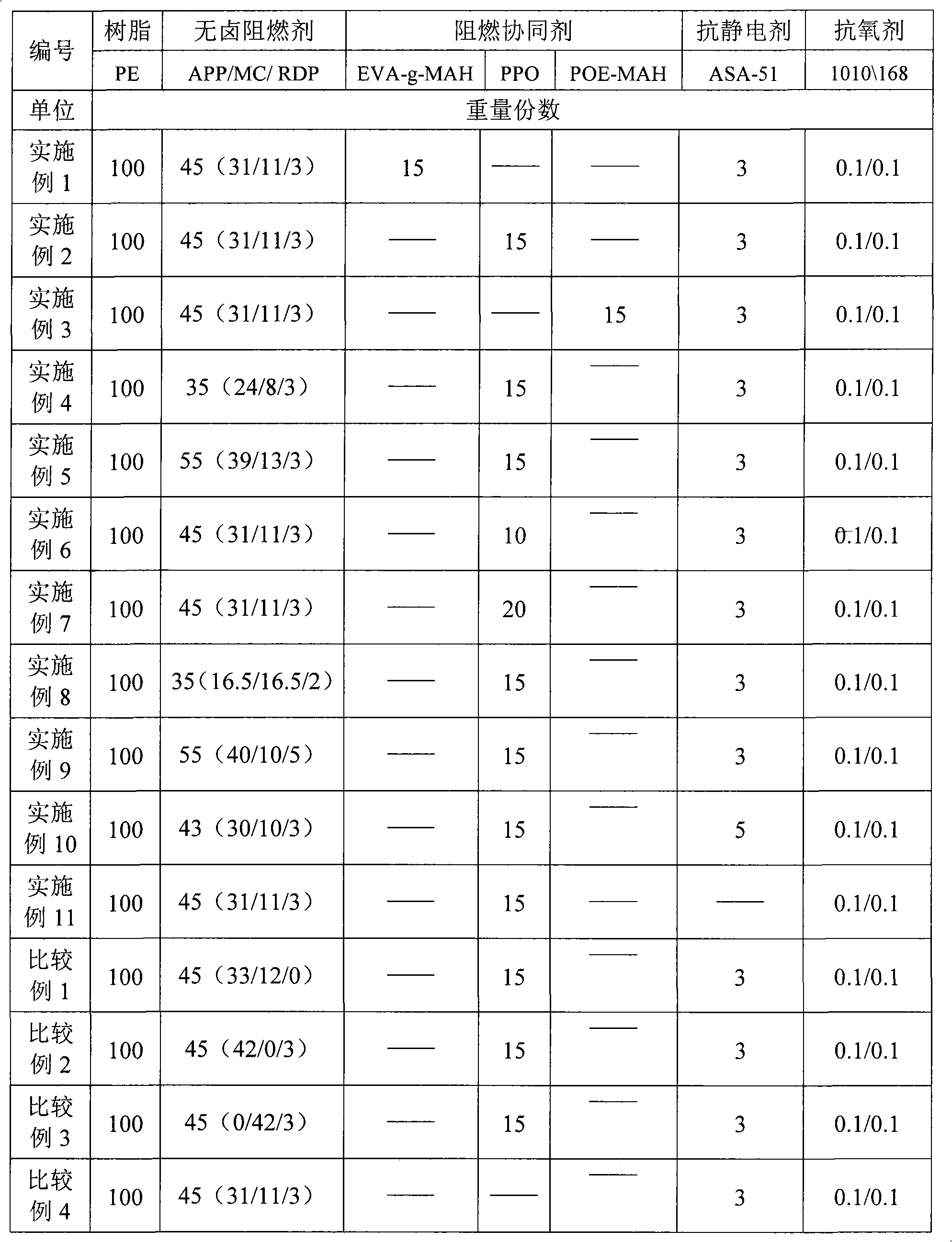

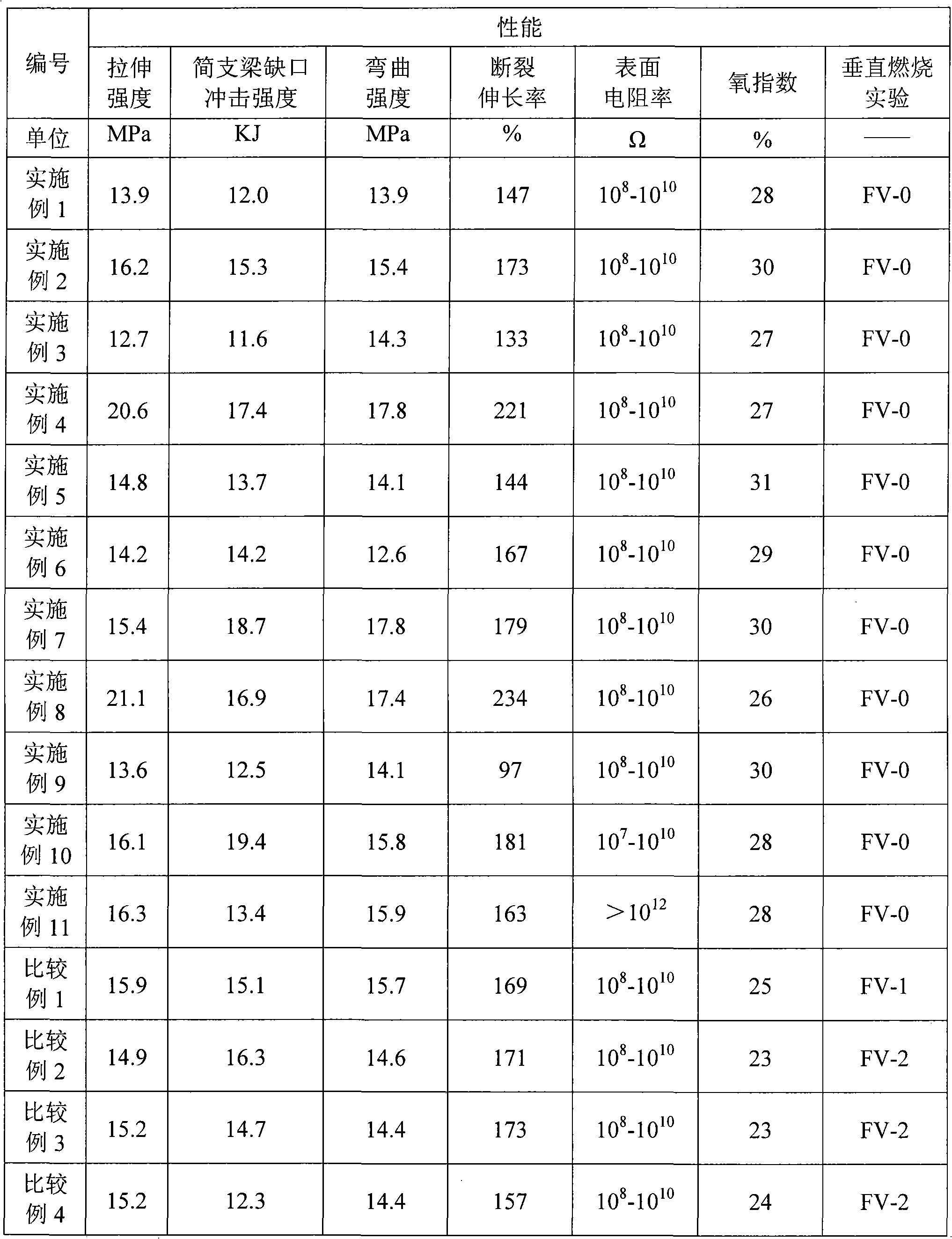

Non-halogen flame-proof polyvinyl composite and method of producing the same

The invention provides a non-halogen flame-retardant polyethylene composition and a preparation method thereof, which relates to the field of the flame-retardance modification of resins. The composition contains 100pbw (parts by weight) of polyethylene resin, 35 parts to 55 parts of non-halogen fire retardants and 8 parts to 20 parts of flame-retardant synergists. The non-halogen fire retardant is compounded by ammonium polyphosphate, melamine cyan urate and hydroxyphenol (diphenyl phosphate), wherein, the total amount of the ammonium polyphosphate and the melamine cyan urate accounts for 32pbw to 50pbw, and the weight ratio of the ammonium polyphosphate and the hydroxyphenol is 1:1 to 4:1; the hydroxyphenol (Diphenyl phosphate) accounts for 3pbw to 5pbw. The flame-retardant synergist can be graft copolymer of vinyl acetic ester and maleic anhydride, or graft copolymer of maleic anhydride and ethylene / octane, or ethylene / octane copolymer or polyphenyl ether. All components are mixed according to the parts by weight and then melted to obtain the polyethylene composition. Under the condition that FV-0 grade is ensured to reached, the polyethylene composition has high flame-retardant efficiency, generates no molten drop, creates small volume of smoke during burning and has good comprehensive mechanical properties.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

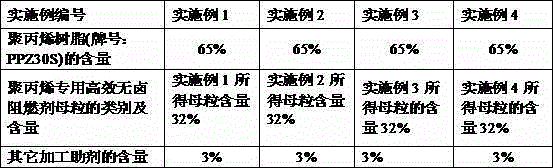

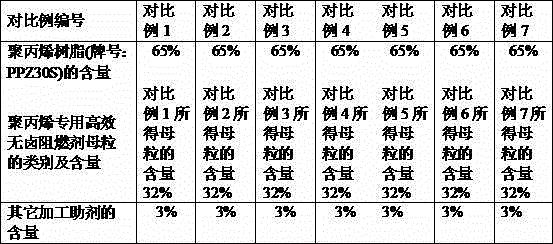

Efficient halogen-free flame retardant master batches special for polypropylene as well as preparation method and application of efficient halogen-free flame retardant master batches

ActiveCN105255016AAdd lessReduce the impact of physical and mechanical propertiesDiphenyl phosphatePolymer science

The invention provides efficient halogen-free flame retardant master batches special for polypropylene. The efficient halogen-free flame retardant master batches consist of the following raw materials in percentage by weight: 30-40% of ammonium polyphosphate, 10-20% of pentaerythritol octahydrogen tetraphosphate, 15-25% of melamine, 5-15% of bisphenol-A bis(diphenyl phosphate), 10-30% of microporous polypropylene, 0.1-1% of pentaerythritol stearate, 0.1-0.5% of an antioxidant 1010 and 0.1-0.5% of an antioxidant 168, wherein the microporous polypropylene is a particle with the size of 3-5mm, the size of cells on surfaces of the particles is 10-100 microns, and the cell density is more than 10<5> / cm<3>. The efficient halogen-free flame retardant master batches special for polypropylene have the characteristics of easy dispersing, easy processing, high flame-retardant efficiency and low production cost, and can be widely applied to production of a flame-retardant polypropylene material for extrusion molding, injection molding and membrane blowing.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

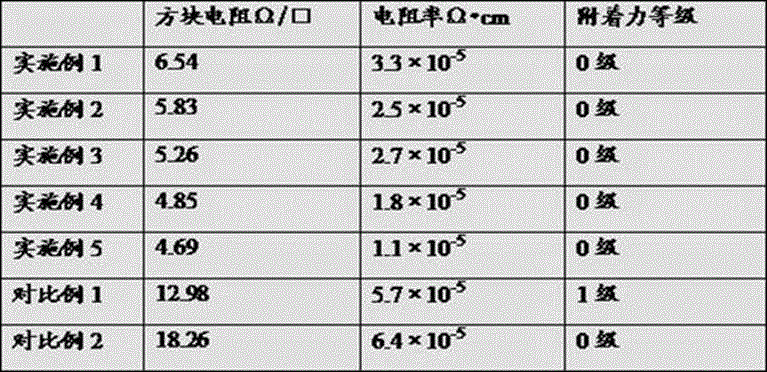

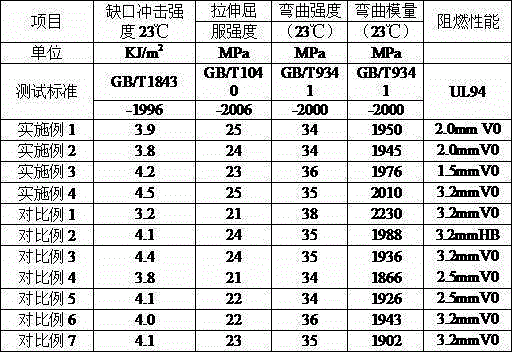

Flame-retardant PC (Poly Carbonate)/ABC composite material capable of shielding high-frequency electromagnetic wave and preparation method thereof

The invention relates to the technical filed of PC (Poly Carbonate) / ABC composite materials and particularly relates to a flame-retardant PC / ABC composite material capable of shielding high-frequency electromagnetic wave and a preparation method thereof. The flame-retardant PC / ABC composite material capable of shielding high-frequency electromagnetic wave comprises PC, ABS, a surface-treated silver-coated copper fiber, a carbon fiber, conductive carbon black, bromotriazine, bisphenol A bis(diphenyl phosphate), polytetrafluoroethylene, an antioxidant 168, an antioxidant 1076, pentaerythritol stearate, an ethylene vinyl acetate copolymer, a silicone-acrylic copolymer toughening agent and gamma-aminopropyl triethoxysilane. Due to the silver-coated copper fiber, the disadvantages that not only the copper fiber is easily oxidized but also silver powder is relatively expensive are avoided, the same effect is achieved and the cost is reduced; the conductivity and the shielding effectiveness are more stable and the flame retardancy is significantly improved. The preparation method disclosed by the invention is simple and mature and high in production efficiency and is conducive to being universally popularized and applied.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

Heatproof high-strength cable

The invention discloses a heatproof high-strength cable which comprises a conductor, an insulating layer, a high-temperature-resistant layer and an outer sheath insulating layer which are made of a modified polyvinyl chloride material. The modified polyvinyl chloride material comprises polyvinyl chloride, nylon, maleic anhydride grafted polyphenyl ether, bisphenol-A polycarbonate, stearic acid pentaerythritol ester, trioctyl trimellitate, stearic acid, isopropyl phenyl diphenyl phosphate, calcined kaolin, modified nano-calcium carbonate, maleic acid modified hydrotalcite, modified graphene oxide, carbon nanofibers, diethyl dithiocarbamate neodymium, calcium adipate, glyzinc, beta-diketone, pentaerythritol, ethylene-vinyl alcohol and antioxidant. The heatproof high-strength cable is high in intensity, good in heat resistance and long in service life.

Owner:ANHUI LAND GRP

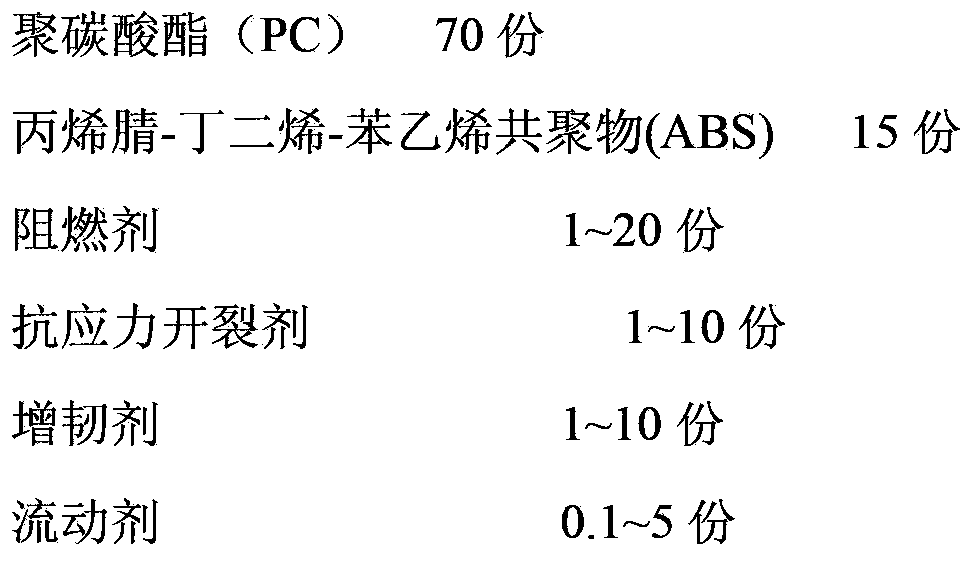

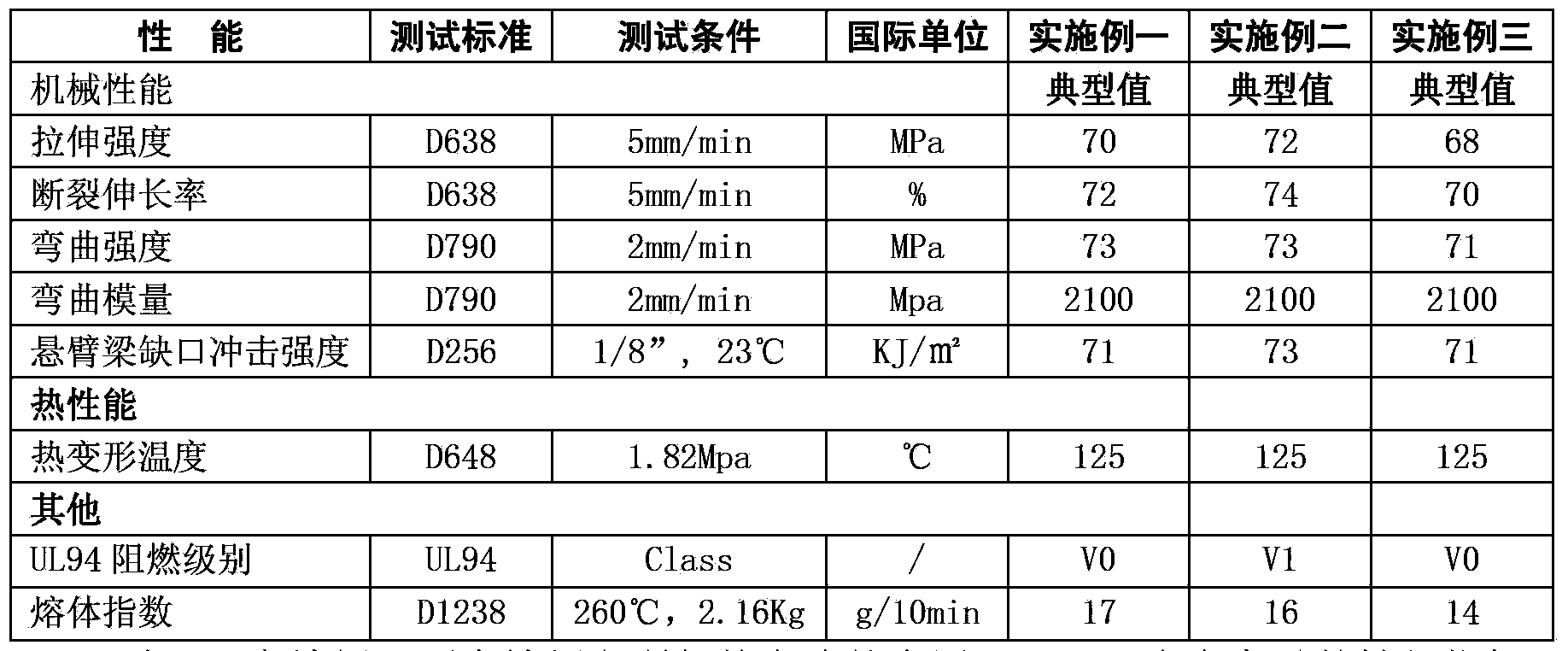

PC-ABS alloy for computer housing

A PC-ABS (Acrylonitrile Butadiene Styrene) alloy for a computer housing is characterized by comprising the following constitutes in parts by weight: 70 parts of PC polycarbonate, 15 parts of ABS copolymer, 1-20 parts of flame retardant, 1-10 parts of stress cracking resisting agent, 1-10 parts of flexibilizer, 0.1-5 parts of flowable agent, wherein the flame retardant is at least one selected from triphenyl phosphate, tricresyl phosphate, bisphenol A diphosphonate cresyl diphenyl phosphate; the stress cracking resisting agent is at least one selected from ethyl- hydrogenised nitrile-acrylate ternary co-polymerized graft, and acrylic acid grafted polyolefin elastomer copolymer; the flexibilizer is at least one selected from ethylene-octane copolymer, ethylene-butane copolymer, ethylene-propene copolymer, and phenethylene-butadiene copolymer. The PC- ABS alloy improves gap impact strength performance and reduces complexity of the operation control.

Owner:SHENZHEN XINGSHENGDI NEW MATERIALS

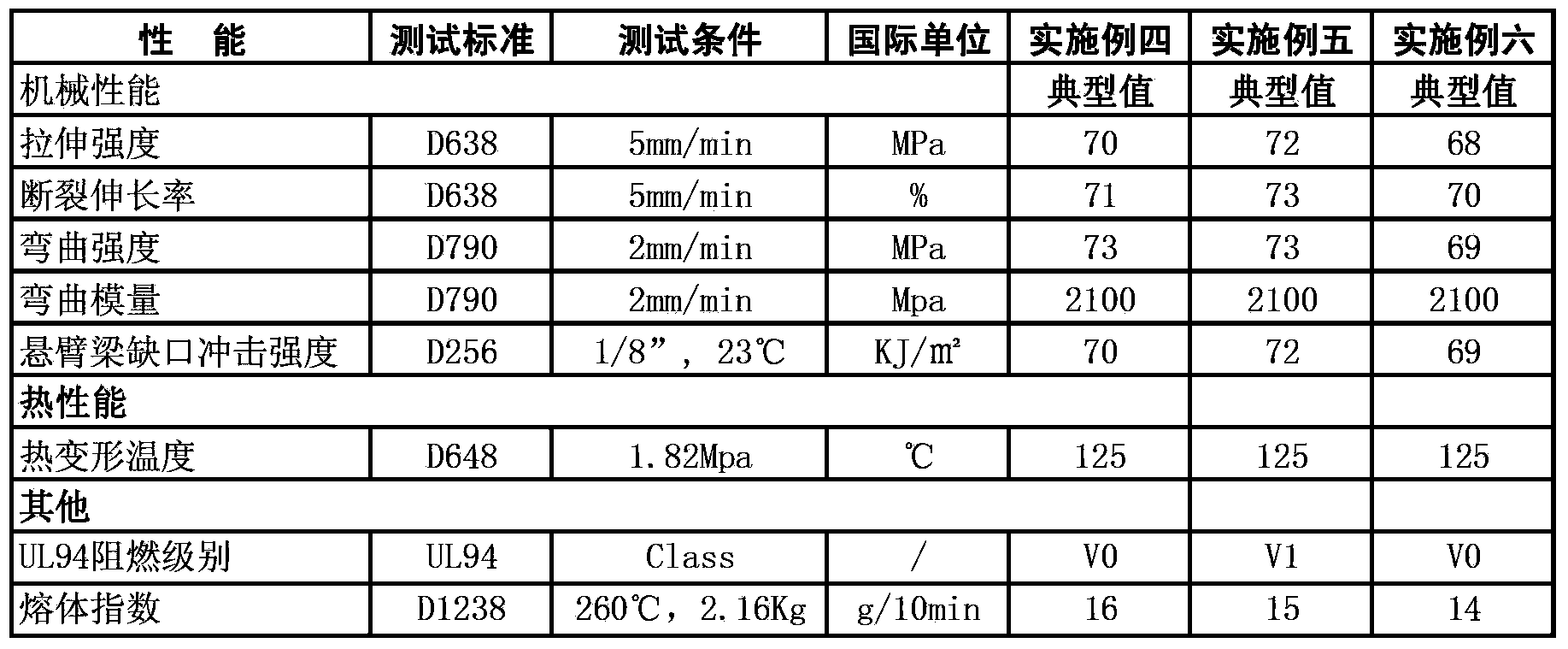

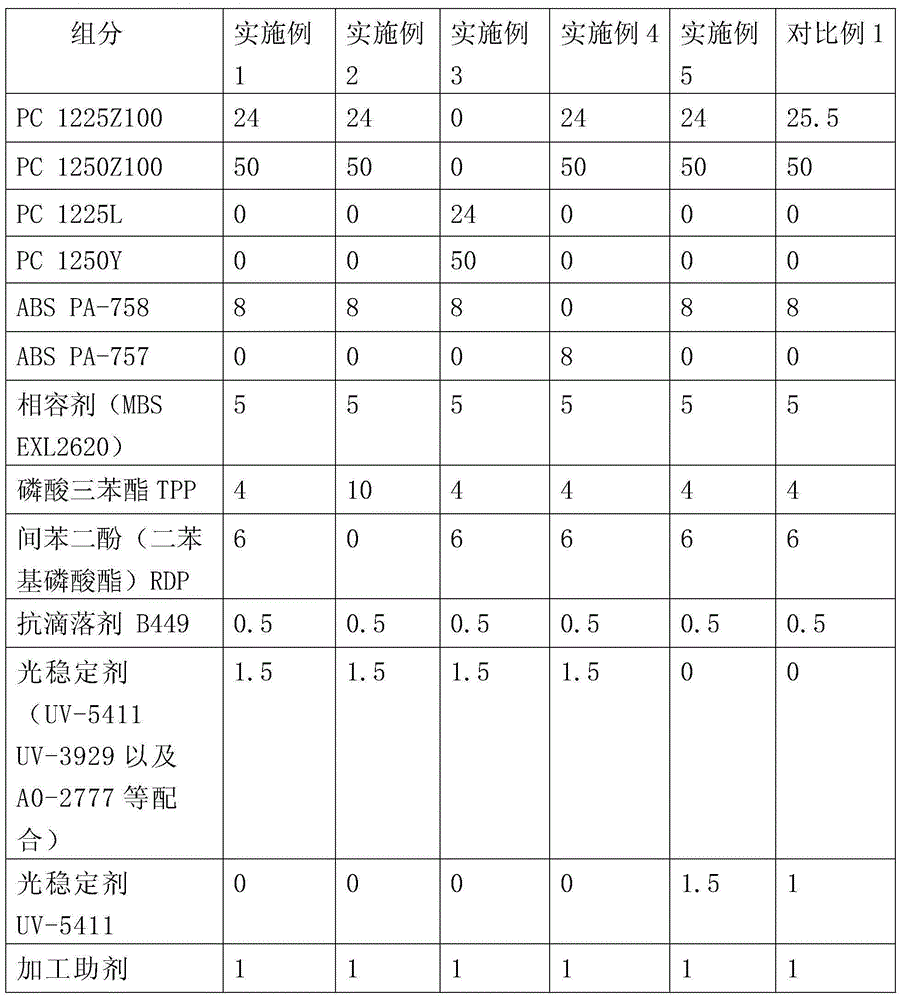

High weather resistant, halogen-free and flame retardant PC/ABS alloy material special for outdoor telecommunication box and preparation method thereof

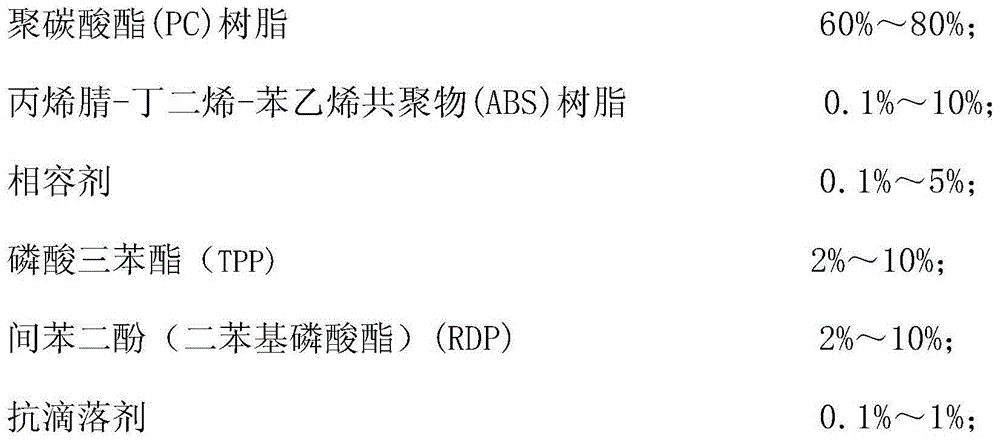

The invention discloses a high weather resistant, halogen-free and flame retardant PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy material special for an outdoor telecommunication box and a preparation method thereof. The PC / ABS alloy material is prepared from the following raw materials by weight percentage: 60%-80% of polycarbonate resin; 0.1%-10% of acrylonitrile-butadiene-styrene resin; 0.1%-5% of a compatibilizer; 2%-10% of triphenyl phosphate; 2%-10% of resorcinol (diphenyl phosphate); 0.1%-1% of an anti-dripping agent; 0.1%-2% of a light stabilizer; and 0.1%-2% of assistants. According to the invention, the PC and ABS resin with good weather resistance are adopted as the matrix, and through synergy of the compatilizer, the halogen-free flame retardants and the light stabilizer, the halogen-free and flame retardant PC / ABS alloy material with high heat resistance and high performance can be obtained, and can be widely used in the communications industry, the automobile industry, building materials, decoration materials, cables and the electrical industry. The preparation method of the alloy material adopts existing equipment, is simple to operate, and is suitable for industrialized production.

Owner:SHANGHAI AUSELL CHEM TECH

Pest control formulation

InactiveUS20060264402A1Reduce stimulationReduce synthesisBiocidePhosphorous compound active ingredientsDiphenyl phosphateEar tag

The present invention relates to a pest control system which includes a pest control active ingredient and isodecyl diphenyl phosphate as a carrier for the active ingredient. The system releases the active ingredient efficiently and uniformly. The pest control system is less irritating to the animal's skin as compared to prior art systems. The system is useful for making animal collars, ear tags, pest strips, liquid spot-on treatments, and the like.

Owner:REDLINE

Halogen free, flame retardant compositions for wire and cable applications

Owner:DOW GLOBAL TECH LLC

High-strength impact resistance oil paint

InactiveCN105255353AOvercoming impact resistanceOvercome the problem of large shrinkage during curingFireproof paintsPolyurea/polyurethane coatingsAcrylic resinPolyethylene glycol

The invention discloses high-strength impact resistance oil paint. The high-strength impact resistance oil paint is prepared from polyurethane acrylic resin, epoxy-acrylic resin, bisphenol A epoxy resin, ethylene diglycidyl ether, polyethylene glycol, 2-propenoic acid,1,1'-[(1-methyl-1,2-ethanediyl)bis[oxy(methyl-2,1-ethanediyl)]]ester, pentaerythritol triacrylate, azodiisobutyronitrile, 1-hydroxycyclohexylphenylketone, triarylsulfonium hexafluoroantimonate salt, carbon black, graphene oxide, carbon nanotubes, cresyl diphenyl phosphate, a flatting agent, an antifoaming agent, a thickening agent, a silane coupling agent, phenolic epoxy acrylate, solvent and corrosion inhibitor. The high-strength impact resistance oil paint is good in impact resistance, excellent in anti-static property, high in strength, high in adhesive force with a base material and not prone to be disengaged in the using process.

Owner:安徽嘉年华漆业有限公司

Halogen-Free, Flame Retardant Compositions for Wire and Cable Applications

ActiveUS20120244305A1Plastic/resin/waxes insulatorsLayered productsDiphenyl phosphatePolymer science

A halogen-free, flame retardant composition comprises thermoplastic polyurethane, olefin block copolymer, carbonyl-containing olefin polymer compatibilizer, and flame retardant package comprising bisphenol-A bis(diphenyl phosphate) and / or resorcinol bis(diphenyl phosphate), a nitrogen / phosphorus based, halogen-free flame retardant, and epoxidized novolac. The composition that will not only be processed easily to make a wire or cable sheath but also pass both the VW-1 flame retardancy test and the UL1581 heat deformation test at 150° C. exhibits good tensile and flexibility properties.

Owner:DOW GLOBAL TECH LLC

Anti-flaming aging-resistant rubber material

The invention discloses an anti-flaming aging-resistant rubber material which comprises the following constituents in parts by weight: 40 parts to 45 parts of butadiene styrene rubber, 30 parts to 36 parts of polyurethane elastomer, 10 parts to 15 parts of chlorinated butyl rubber, 2 parts to 3 parts of vulcanizing agent BPO, 1.2 parts to 1.8 parts of sulphur, 2 parts to 4 parts of divinyl carboxylic acid sodium, 20 parts to 30 parts of calcite powder, 9 parts to 11 parts of kieselguhr, 5 parts to 7 parts of aluminum silicate, 14 parts to 15 parts of carbon black N660, 14 parts to 15 parts of carbon black N330, 10 parts to 12 parts of magnesium hydroxide, 3 parts to 5 parts of quartz powder, 5 parts to 7 parts of zinc oxide, 2 parts to 4 parts of calcium stearate, 5 parts to 8 parts of barium stearate, 5 parts to 7 parts of diphenyl phosphate ester, 2 parts to 4 parts of melamine, and 1.5 parts to 2.5 parts of silane coupling agent KH450. The anti-flaming aging-resistant rubber material has an excellent anti-flaming aging-resistant performance, so that smog is effectively prevented from generating during a combustion process; besides, the ozone resistance and the weather resistance of the anti-flaming aging-resistant rubber material are excellent; moreover, the anti-flaming aging-resistant rubber material further has the advantages of high elasticity, high hardness and high strength.

Owner:南通鹏达体育用品有限公司

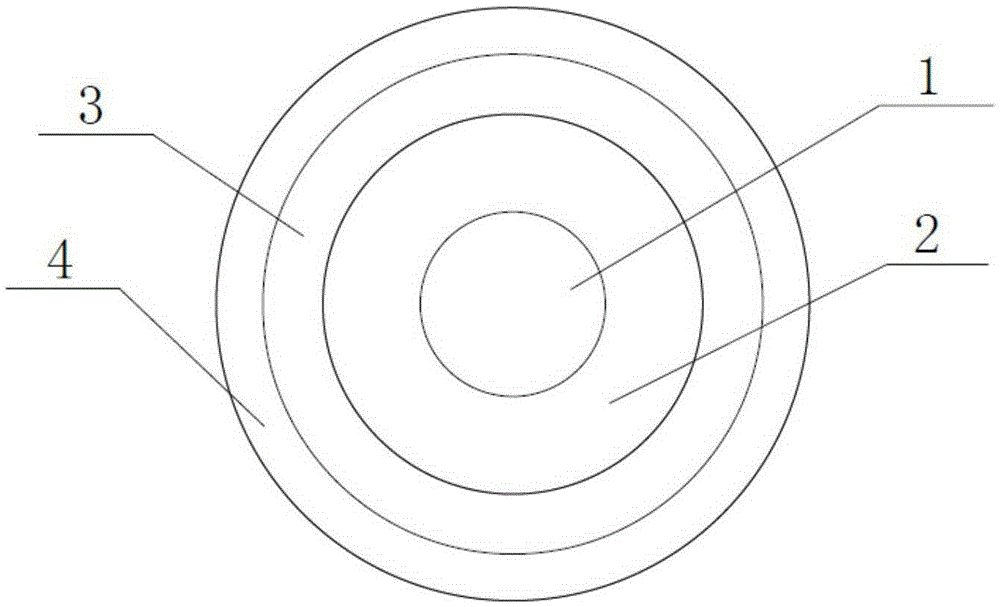

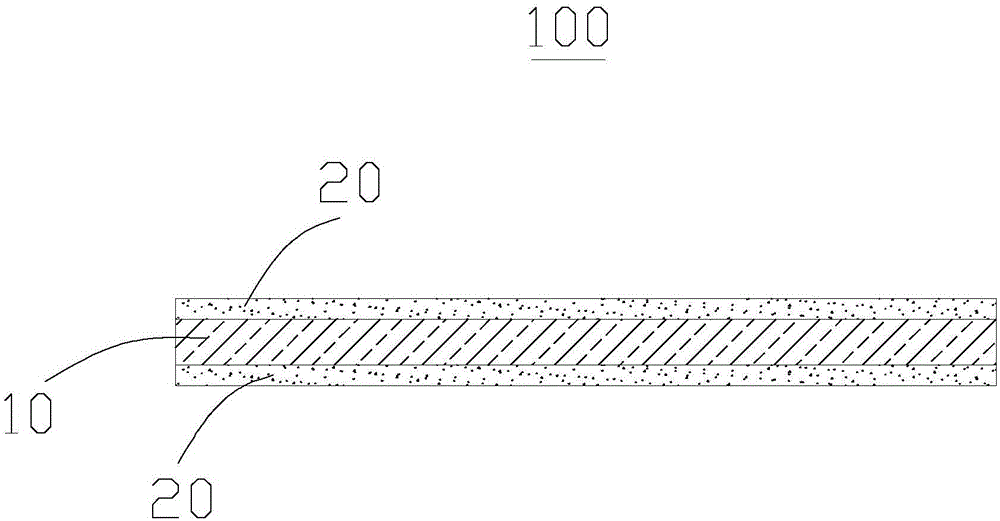

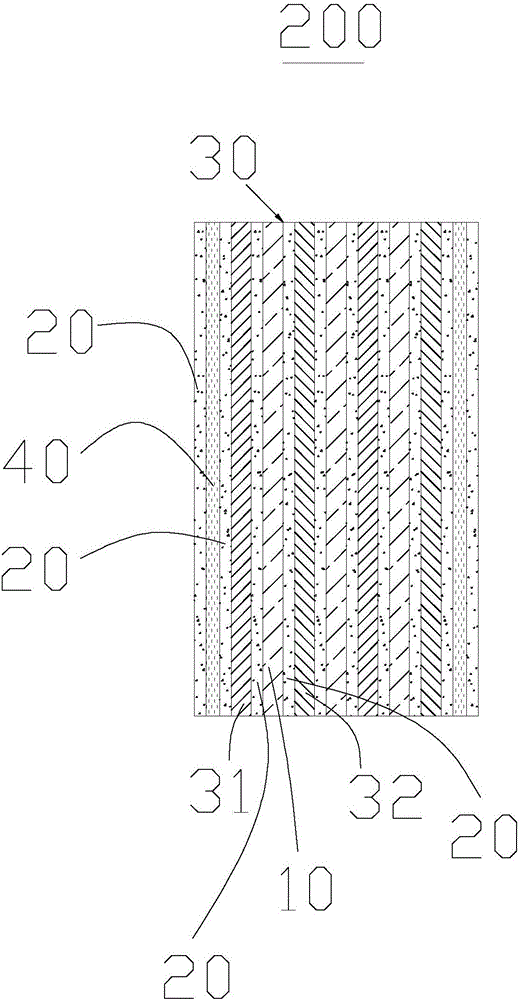

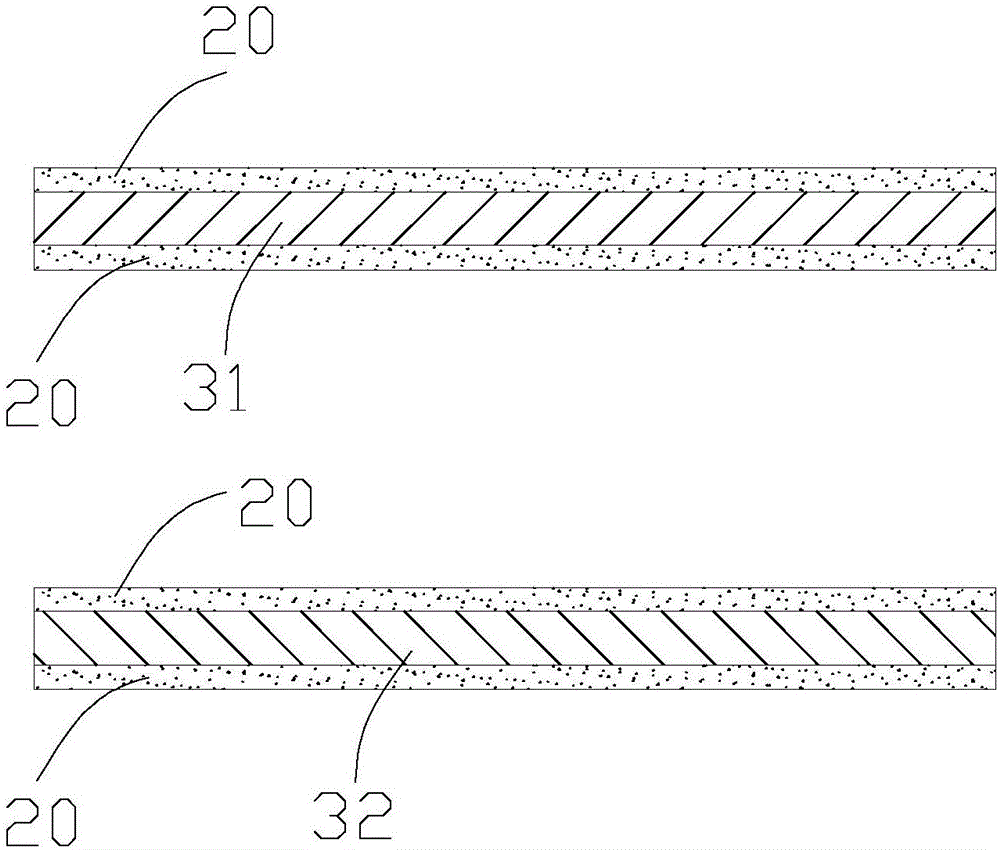

Ceramic diaphragm, lithium ion battery and preparation methods for ceramic diaphragm and lithium ion battery

InactiveCN106684289AImprove securityExtend your lifeFinal product manufactureSecondary cellsPolyetherimideDimethylsilane

The invention discloses ceramic diaphragm with high safety performance, a lithium ion battery and preparation methods for the ceramic diaphragm and lithium ion battery. The ceramic diaphragm comprises a diaphragm substrate and ceramic film coated outside of the diaphragm substrate. The diaphragm substrate comprises an inorganic filler, an organic binder and a hot-melt organism. The inorganic filler is selected from one or more of nano aluminium hydroxide, aluminium oxide, barium sulfate, magnesium hydroxide and calcium carbonate inorganic materials. The organic binder is selected from one or more of polyvinylidene fluoride, polytetrafluoroethylene and polyoxyethylene macromolecule materials. The hot-melt organism is selected from one or more of tri(beta-chloroethyl) phosphate, cresyl diphenyl phosphate, trioctyl phosphate, triphenyl phosphate, tricresyl phosphate, polydimethylsiloxane, organic silicones , polystyrene containing silicon copolymers, polyetherimide, bisphenol F polycarbonate, polyurethane and polymethyl methacrylate.

Owner:OPTIMUM BATTERY CO LTD

High-strength plastic pipe

The invention discloses a high-strength plastic pipe. The high-strength plastic pipe is prepared from the following raw materials in parts by weight: 80 to 140 parts of modified filler, 150 to 160 parts of PVC (Polyvinyl Chloride) resin powder, 1 to 2 parts of stearoyl-rac-glycerol, 18 to 22 parts of zinc borate, 1.2 to 3.4 parts of silane coupling agent KH570, 1 to 3 parts of melamine, 6 to 8 parts of chlorcosane, 10 to 20 parts of calcium carbonate, 2 to 3 parts of hydrogenated castor oil, 1.5 to 2.5 parts of ultraviolet stabilizer UV-2908, 2 to 3 parts of ammonium polyphosphate, 1 to 2 parts of graphene, 1 to 2 parts of tricresyl phosphate, and 1 to 2 parts of cresyl diphenyl phosphate. According to the high-strength plastic pipe, the modified filler is added, so that the strength is high; zinc borate added realizes high fire resistance; and the ultraviolet stabilizer added brings good effect of resisting illumination and ultraviolet ray; and therefore, the high-strength plastic pipe is applicable to various environments.

Owner:安徽玉发塑业有限公司

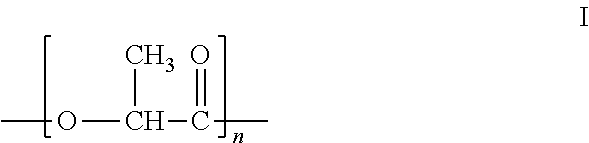

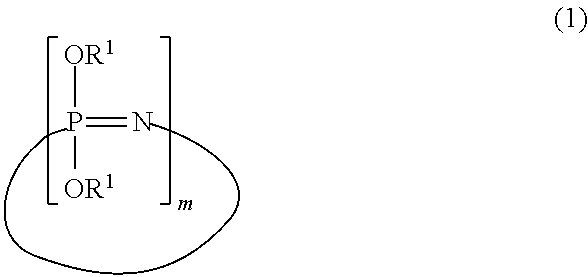

Flame retardant polylactic acid compounds

Owner:POLYONE CORPORATION

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com